Supporting structure for selective laser melting forming and generating method thereof

A support structure, laser melting technology, applied in the direction of process efficiency improvement, processing and manufacturing, solid material additive processing, etc., can solve the problems of increased post-processing difficulty, powder cannot be removed, material waste, etc., to shorten the forming time, reduce Post-processing difficulty and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

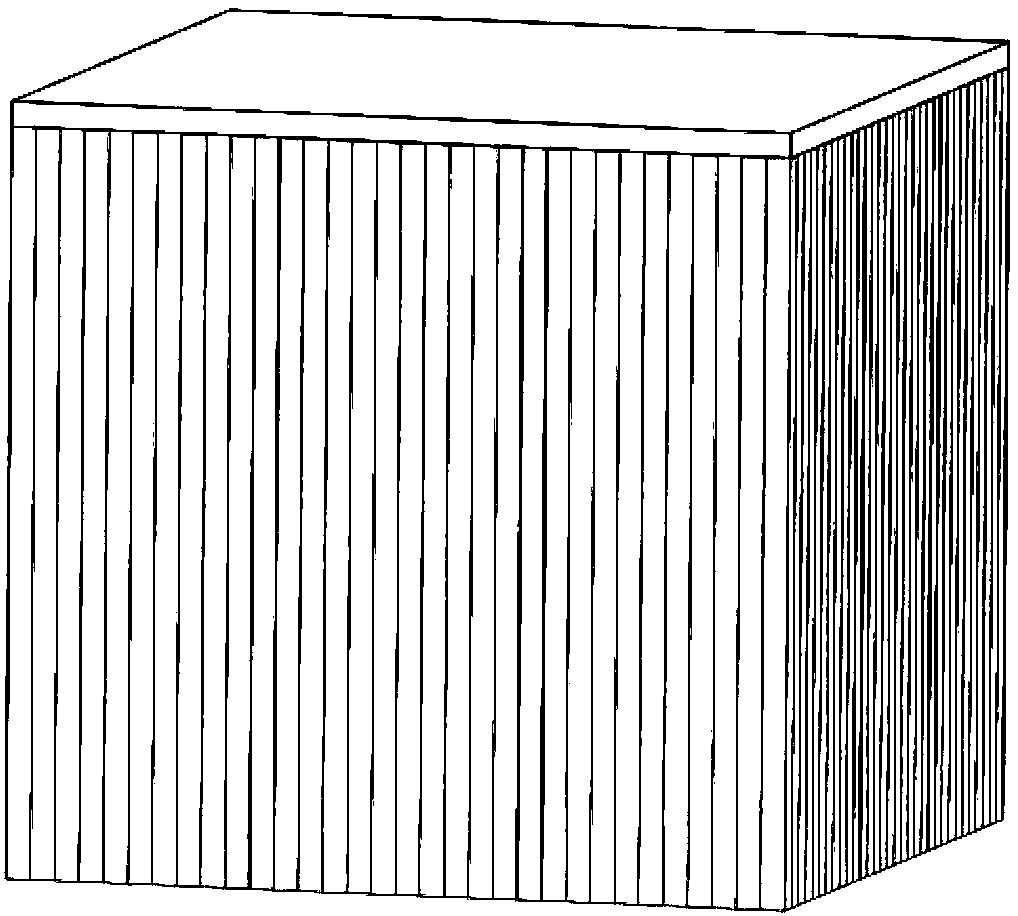

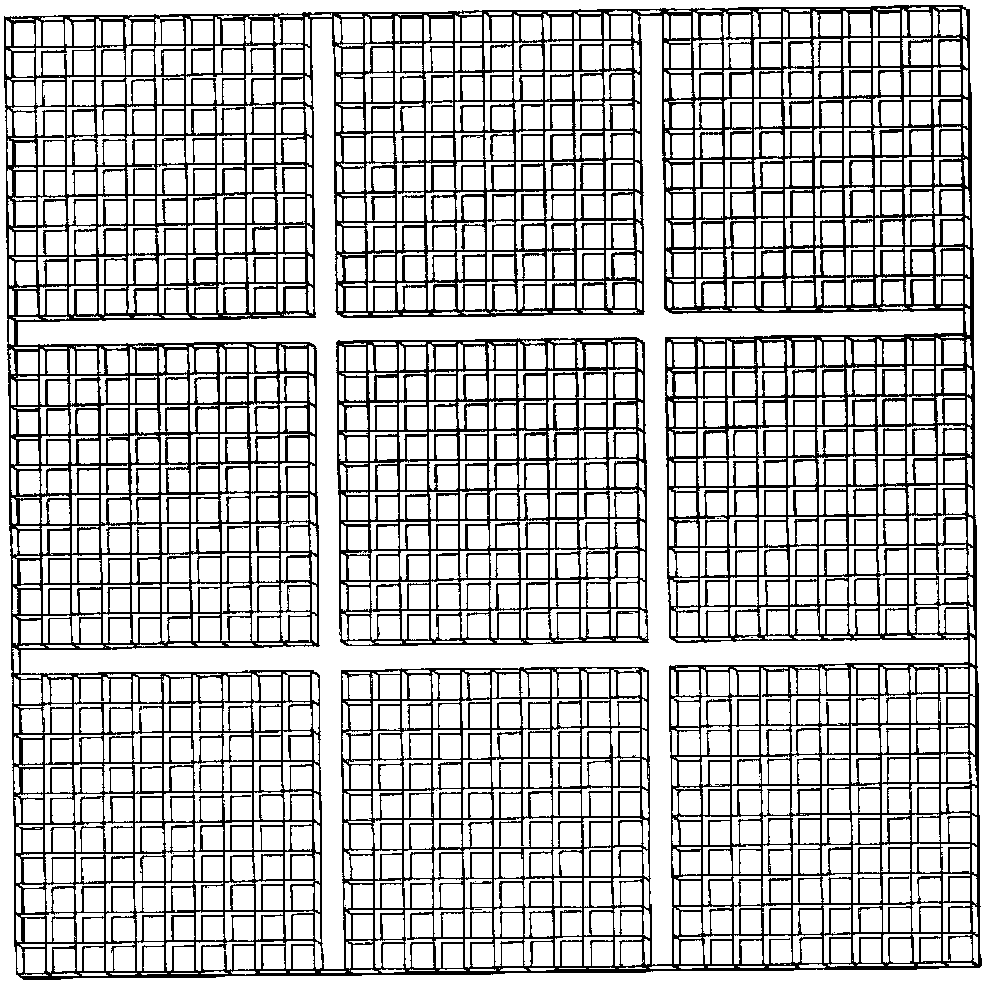

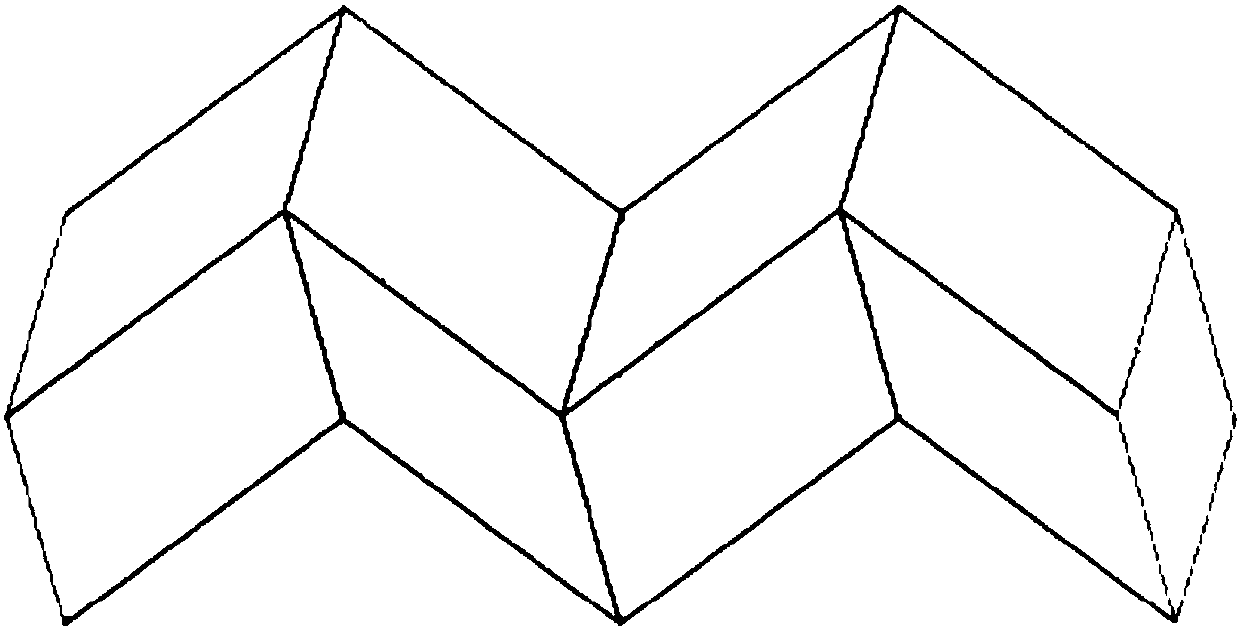

[0030] The supporting structure of the present invention, such as image 3 , Figure 4 , Figure 5 , Image 6 and Figure 7 As shown, it includes several support units 1 arranged in an array on the same plane; each support unit 1 includes several support units 2, and the support units 2 are empty tube structures arranged in the horizontal direction, with the length of the empty tube The direction is the X direction, and several support units 2 are arranged in an array in the Y direction and the Z direction. The adjacent support units 1 are connected to each other through the empty pipe wall to form the support unit 1, and the empty pipe forms the lateral outlet of the support unit 1. powder channel. Empty pipe can be set to broken line shape, and the direction of broken line can be set t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com