Auxiliary heating device and method for increasing oil-gas recovery rate of oil shale in-situ mining

An in-situ mining and auxiliary heating technology, which is applied in the direction of production fluid, earthwork drilling, wellbore/well components, etc., can solve the problems of early condensation of oil and gas, and achieve the effects of reducing early condensation, efficient utilization, and improving recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to avoid obscuring the essence of the present invention, well-known methods, procedures, procedures, components and circuits have not been described in detail.

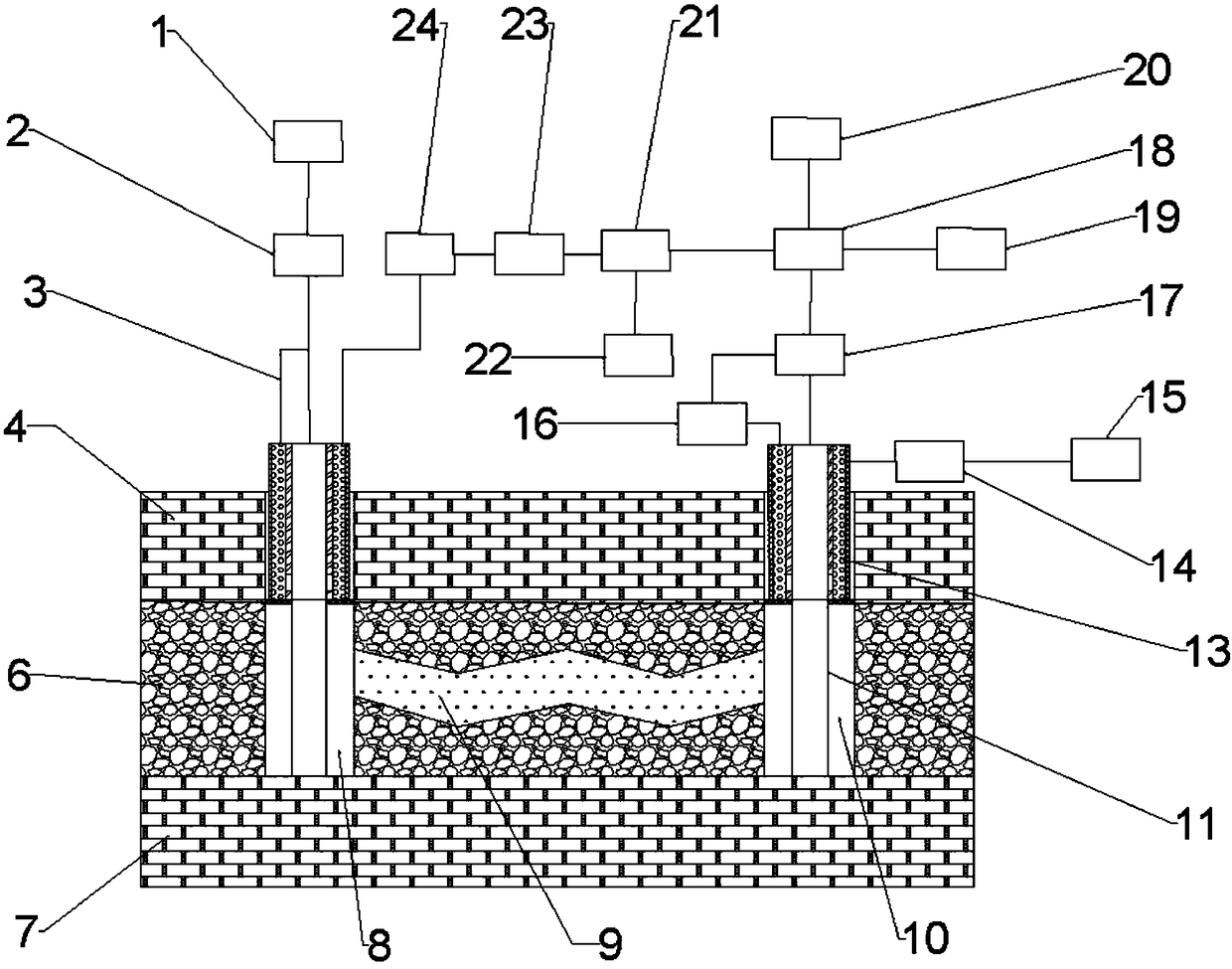

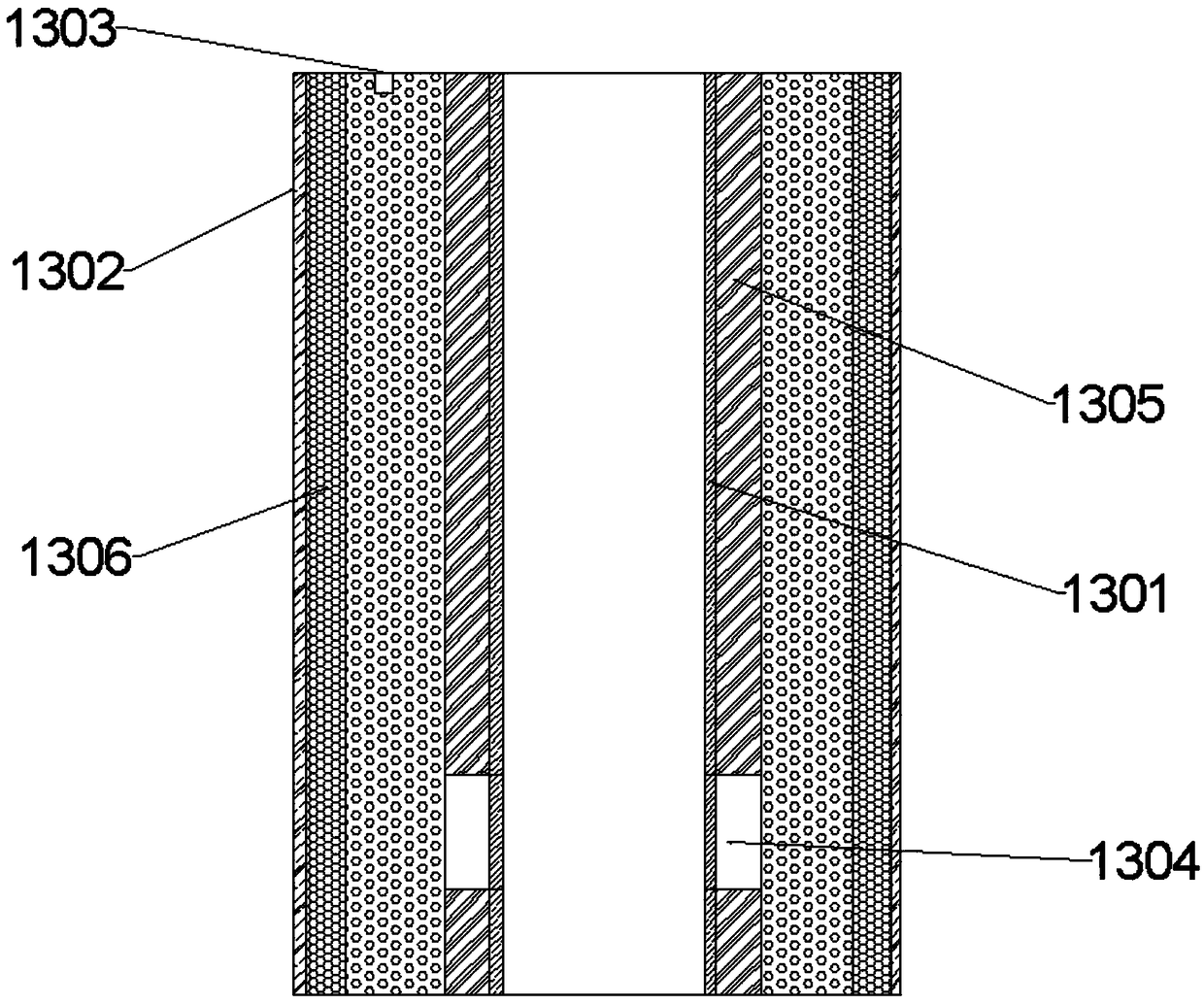

[0031] Such as figure 1 and figure 2As shown, the present invention proposes an auxiliary heating device for improving oil and gas recovery in in-situ mining of oil shale, which is characterized in that it includes an air compressor 1, a ground heat exchanger 2, a heating pipe gas inlet pipeline 3, an oil and gas Transportation channel 9, production well casing 11, heating pipe 13, temperature sensor 14, automatic temperature control device 15, gas pump 16, graded condensation device 17, oil-water separation device 18, wastewater treatment device 19, heavy oil storage tank 20, three Phase separator 21, light oil storage tank 22, gas generator set 23 and combustible gas compressor 24, the inlet end of the ground heat exchanger 2 is connected with the air compressor 1, and the gas outlet ends of the gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com