Internally and externally heated pyrolysis reactor

A pyrolysis reactor, internal and external heating technology, applied in the direction of direct heating dry distillation, biofuels, coke ovens, etc., can solve the problems of inability to large-scale, poor material adaptability, expensive equipment, etc., to achieve the effect of prolonging residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

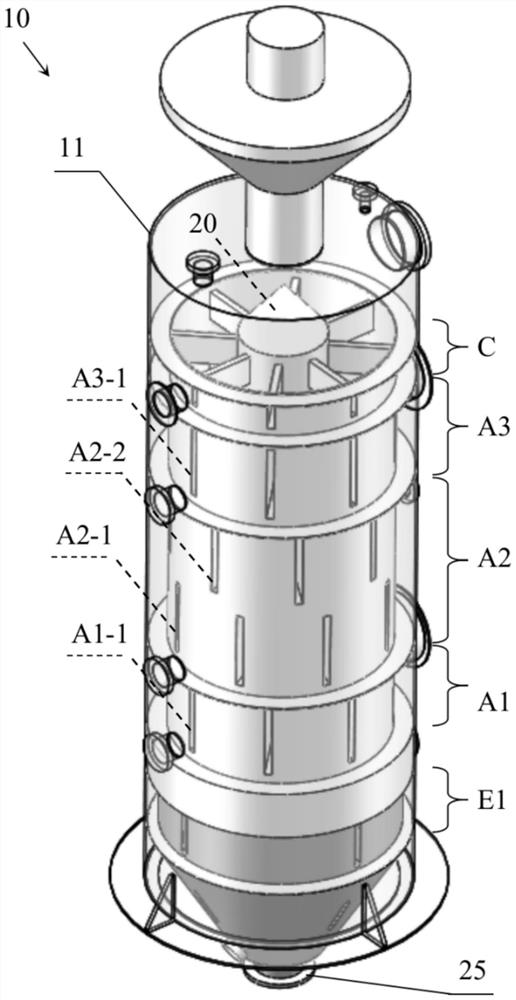

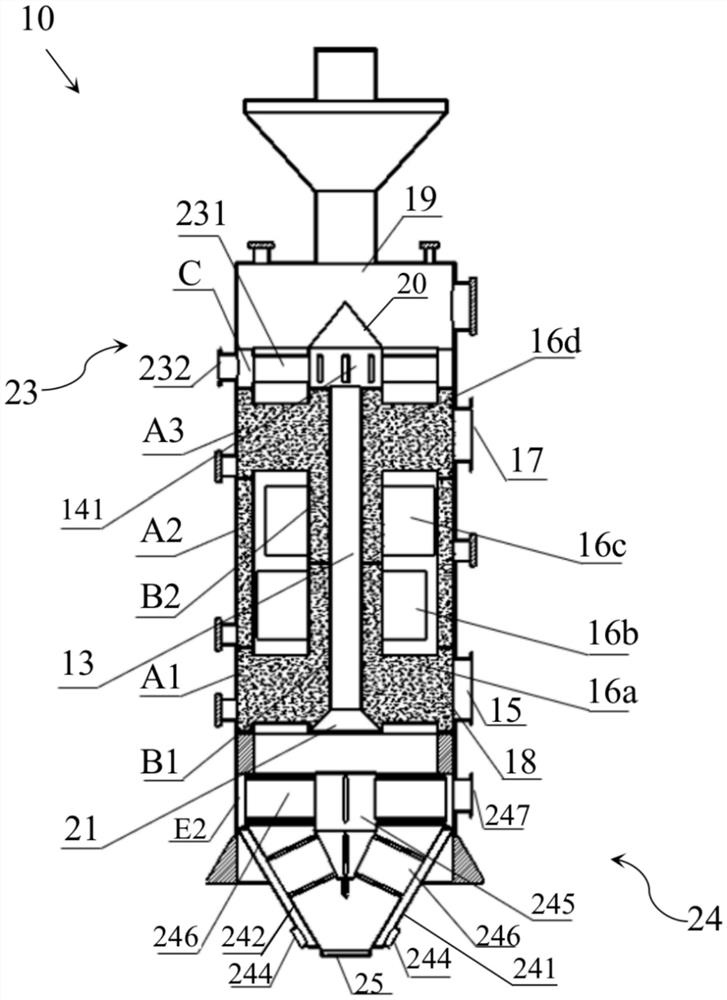

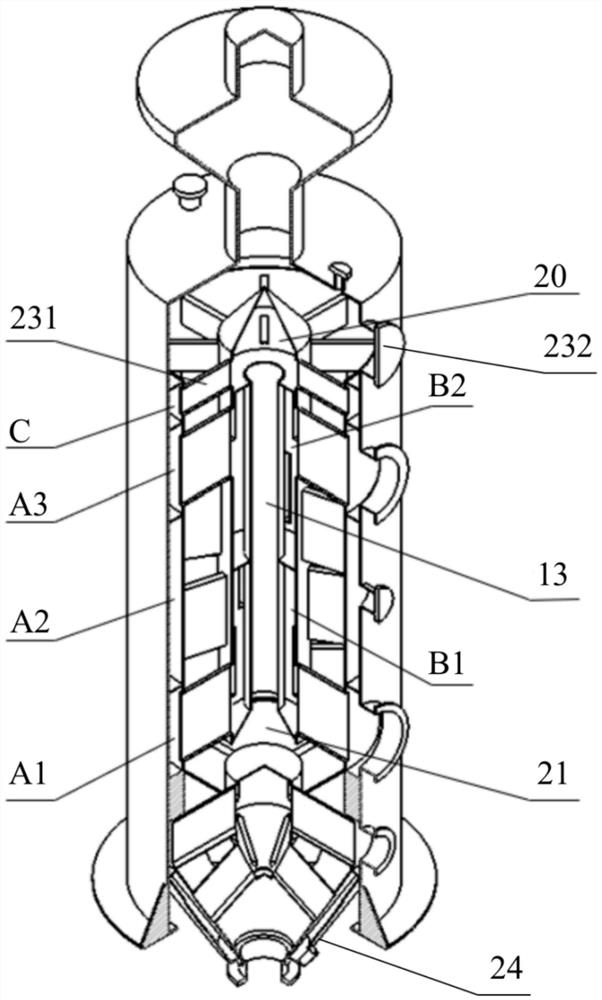

[0031] The internal and external heating pyrolysis reactor involved in the present invention will be described in detail below with reference to the accompanying drawings.

[0032]

[0033] Such as Figure 1-10 As shown, the main part of the internal and external heating pyrolysis reactor 10 is in the shape of a vertical cylinder, including an outer shell 11, an outer partition 12, a central air pipe 13, an inner partition 14, a high-temperature fluid inlet 15, an air passage 16, and a high-temperature fluid Outlet 17, heat storage part 18, feed part 19, material blocking cone 20, pyrolysis gas collection port 21, pyrolysis gas partition 22, pyrolysis gas discharge part 23, cooling part 24 and pyrolysis residual solid outlet 25 .

[0034] The outer partition part 12 is located in the outer casing 11, and includes an outer partition cylinder 121 and four outer partition rings 122-1-122-4. The outer partition cylinder 121 is arranged at a certain distance from the outer casi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com