Method and apparatus for maldi analysis

a laser desorption and ionization mass spectrometry technology, applied in the field of matrix assisted laser desorption/ionization mass spectrometry, to achieve the effect of broadening the tof peak width and increasing the residence tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

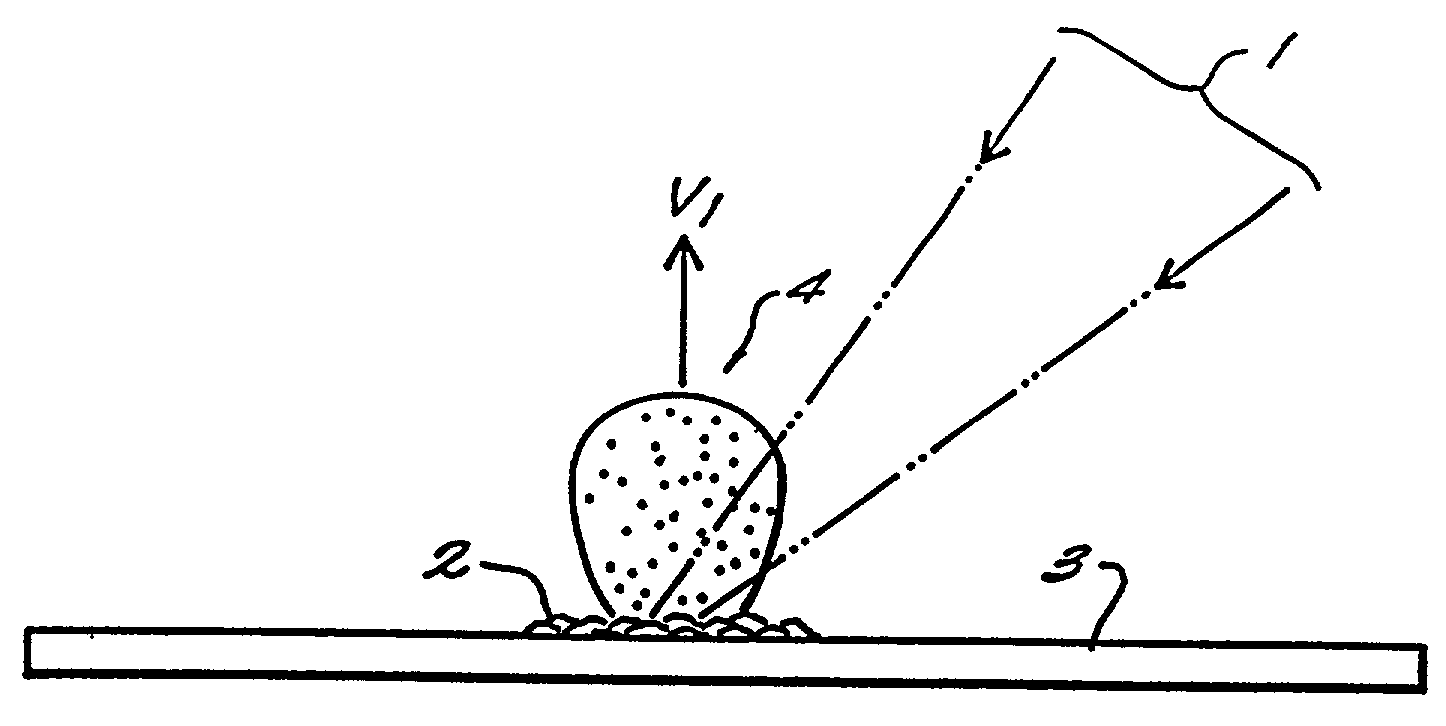

[0030] FIG. 1 shows a representative prior art set up for the matrix assisted laser desorption and ionization of a specimen such as a large molecule compound having a molecular weight, for example, in the range of 500 to 100,000 daltons or more. As shown, a substrate 3 such as a sheet of metal foil or a glass slide, bears a sample 2 in a region on its surface. As discussed above, sample 2 is generally deposited as a solution of a relatively low molecular weight laser-absorbent material with a minor amount of the large molecule analyte contained therein, and it is allowed to dry in place to form a thin layer of solid material which may for example consist of a granular or continuous bed of crystals. In special cases a solvent, stable in vaccuo is used such as glycerol. The sample 2 then forms a thin liquid layer or droplet on substrate 3. A laser beam 1 is directed at the sample 2 causing a plume 4 of material to be desorbed therefrom. In general, the matrix material is taken to be a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| velocity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com