Preparation method of toluylene triazine liquid fluorescent brightener composite

A technology of stilbene triazine and fluorescent whitening agent, applied in the direction of luminescent/fluorescent substance addition, non-polymer organic compound addition, organic chemistry, etc., can solve the problems of low fluorescence intensity and low whiteness, and achieve whiteness High, good whitening effect, the effect of reducing the difficulty of post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

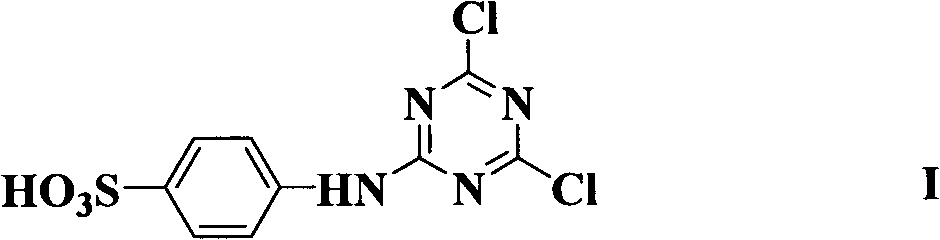

[0037] Step 1 Add 100g of crushed ice to a 500ml beaker, adjust the pH value to about 1.0 with 1.5ml of 30% hydrochloric acid, stir and cool down to 0±2°C, add 25.0g of cyanuric chloride, start stirring, and beat for 1h (keep the pH The value is around 1.0, and the temperature is around 0°C). Add 23.5g of p-aminobenzenesulfonic acid, stir for 20min, adjust pH=3 with 30% NaOH solution, and keep this pH value for 1.5h, then adjust pH=5, and keep this pH value, react until detected by amino reagent Until the amino group disappears, the reaction ends.

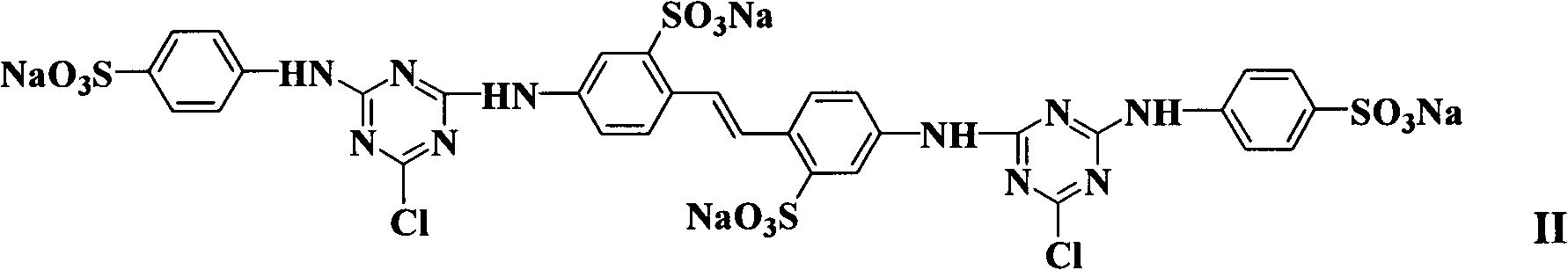

[0038] In the second step, add the aqueous solution prepared by 24.2g of DSD acid to the above reaction solution at a constant speed within 5 to 10 minutes, adjust the pH of the reaction solution to 5.5 to 6 with 30% NaOH solution, and raise the temperature to 50°C, continuously add 30% NaOH The solution was adjusted to ensure that the pH of the reaction solution was 5.5-6.0, and the temperature of the system was kept at 50° C., a...

Embodiment 2

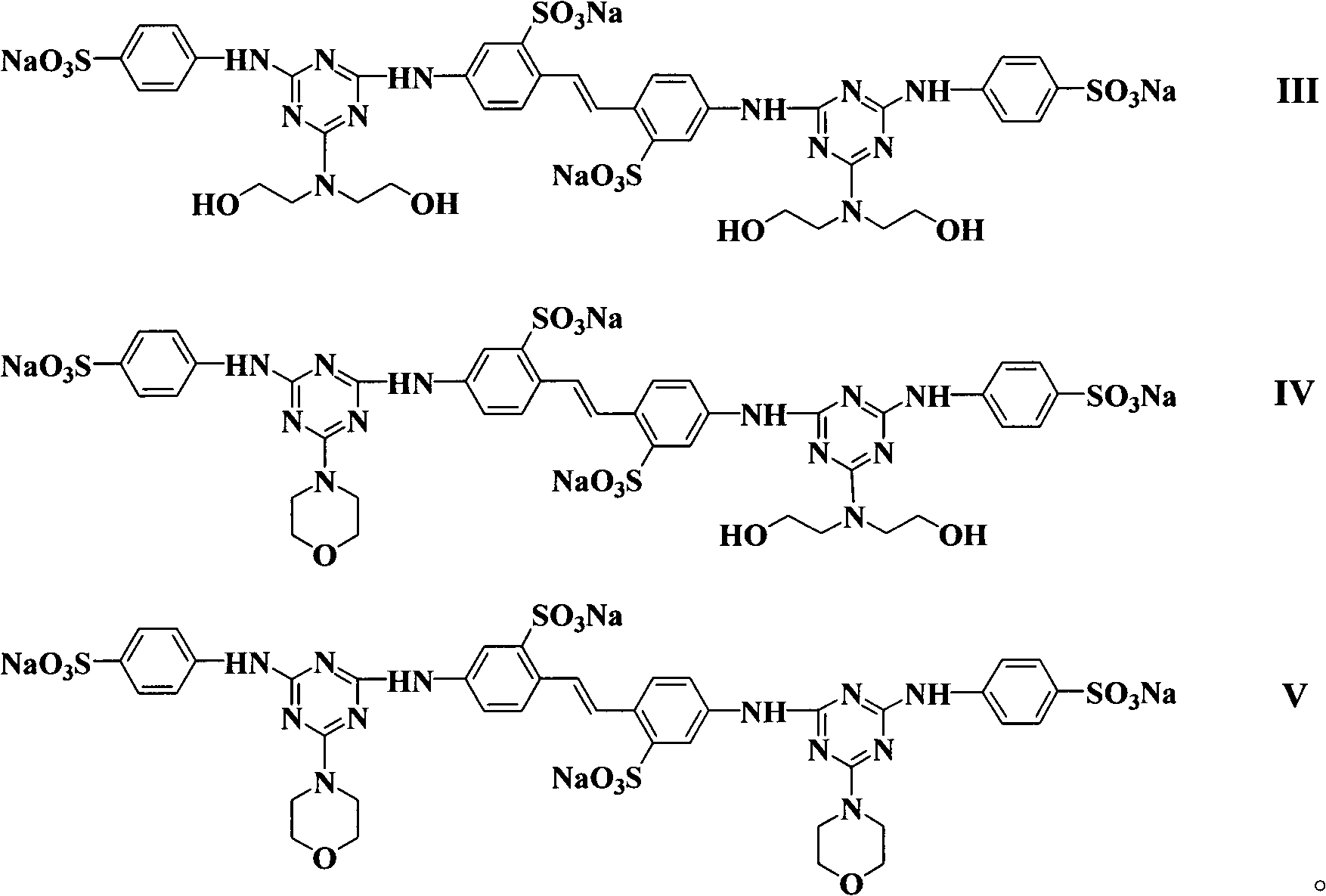

[0046] The 3rd step adds the mixture of 8.66g morpholine and 5.22g diethanolamine, other operation process is the same as embodiment 1. The ratio of each component is determined by high performance liquid chromatography, and the mass ratio of the three components is (III):(IV):(V)=3:6:7.

Embodiment 3

[0048] The 3rd step adds the mixture of 6.5g morpholine and 7.8g diethanolamine, other operation process is the same as embodiment 1. The ratio of each component is determined by high performance liquid chromatography, and the mass ratio of the three components is (III):(IV):(V)=4:5:5.6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com