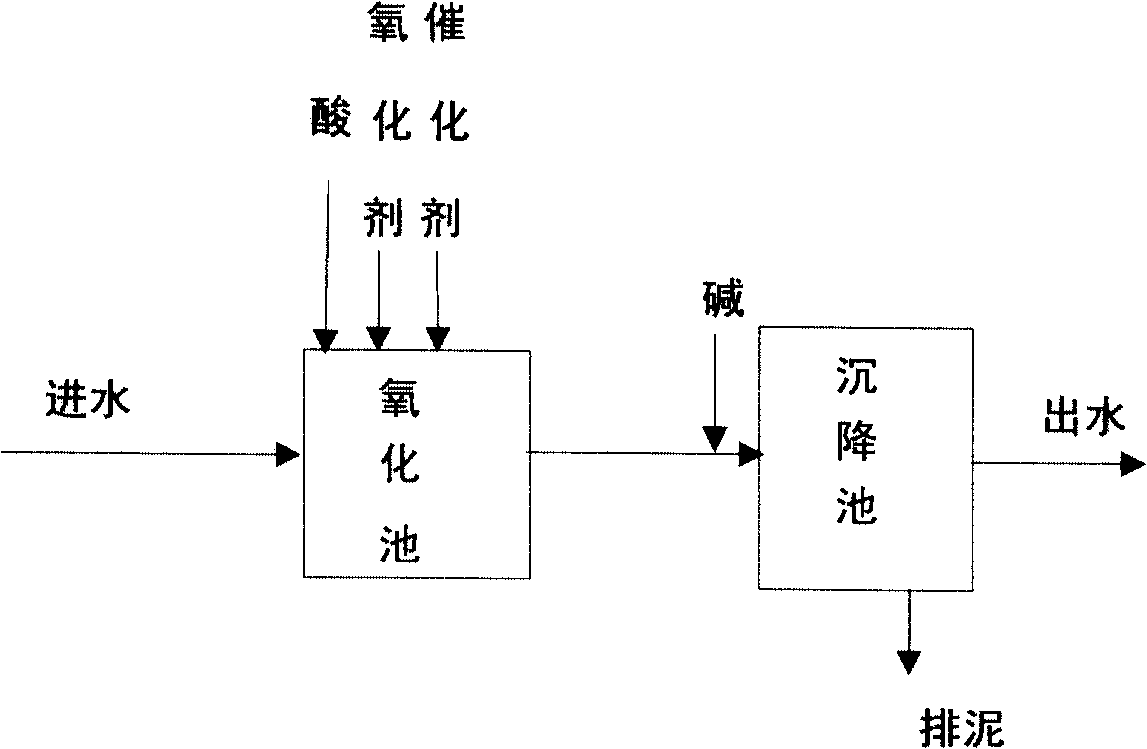

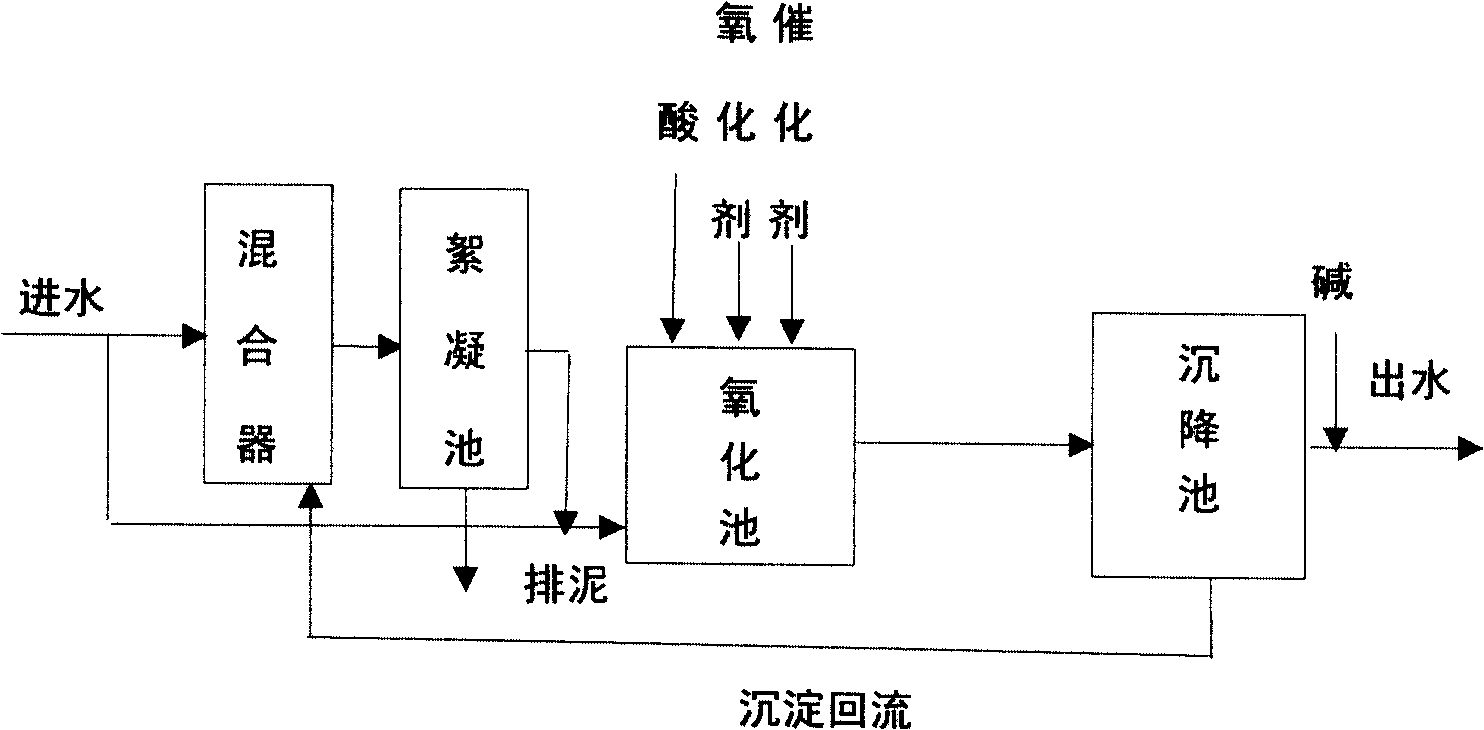

Method for processing waste water by fenton oxidation

A technology for Fenton oxidation and wastewater treatment, which is applied in the fields of oxidized water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] To treat the non-standard effluent of an oil refinery, H 2 o 2 as an oxidizing agent, Fe 2 SO 4 As a catalyst, the acid and base used are concentrated H 2 SO 4 and NaOH. The operating conditions are: H 2 o 2 The ratio to the mass concentration of organic matter (COD) in wastewater is 1:3, H 2 o 2 / Fe 2+ The molar ratio is 1:2, the pH of the oxidation tank is 3, the pH of the effluent is 6.5, the residence time of the oxidation tank is 10 minutes, the residence time of the sedimentation tank is 1 hour, and the residence time of the flocculation tank is 1 hour. Table 1 shows the data comparison between the wastewater treated by the Fenton oxidation treatment method of the present invention and the traditional Fenton oxidation treatment method. The results in Table 1 show that the Fenton oxidation method of the present invention is used to treat non-standard wastewater from refineries, the wastewater treatment effect is improved, and the acid-base consumption is ...

Embodiment 2

[0029] To treat high-concentration wastewater from a chemical plant, H 2 o 2 as an oxidizing agent, Fe 2 SO 4 As a catalyst, the acid and base used are concentrated H 2 SO 4 and NaOH. The operating conditions are determined as: H 2 o 2 The ratio to the mass concentration of organic matter (COD) in wastewater is 1:10, H 2 o 2 / Fe 2+ The molar ratio is 1:1, the pH of the oxidation tank is 3, the pH of the effluent is 6.5, the residence time of the oxidation tank is 10 minutes, the residence time of the sedimentation tank is 1 hour, and the residence time of the flocculation tank is 1 hour. Table 2 shows the data comparison between the wastewater treated by the Fenton oxidation treatment method of the present invention and the traditional Fenton oxidation treatment method.

[0030] The results in Table 2 show that the Fenton oxidation method of the present invention is adopted for the high-concentration wastewater of chemical plants, the wastewater treatment effect is i...

Embodiment 3

[0034] To treat reverse osmosis concentrated water in a factory, H 2 o 2 as an oxidizing agent, Fe 2 SO 4 As a catalyst, the acid and base used are concentrated H 2 SO 4 and NaOH. The operating conditions are determined as: H 2 o 2 The ratio to the mass concentration of organic matter (COD) in wastewater is 1:1, H 2 o 2 / Fe 2+The molar ratio is 1:1.5, the pH of the oxidation tank is 3, the pH of the effluent is 6.5, the residence time of the oxidation tank is 10 minutes, the residence time of the sedimentation tank is 1 hour, and the residence time of the flocculation tank is 1 hour. Table 3 compares the data of wastewater treated by the Fenton oxidation treatment method of the present invention and the traditional Fenton oxidation treatment method. The results in Table 3 show that the Fenton oxidation method of the present invention is used to treat reverse osmosis concentrated water, the wastewater treatment effect is improved, and the acid-base consumption is redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com