Patents

Literature

136results about How to "Reduce alloy cost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength X100 pipe line steel hot rolling flat plate and method for manufacturing same

InactiveCN101619416AReduce alloy costLow carbon equivalentTemperature control deviceCooling temperatureHigh intensity

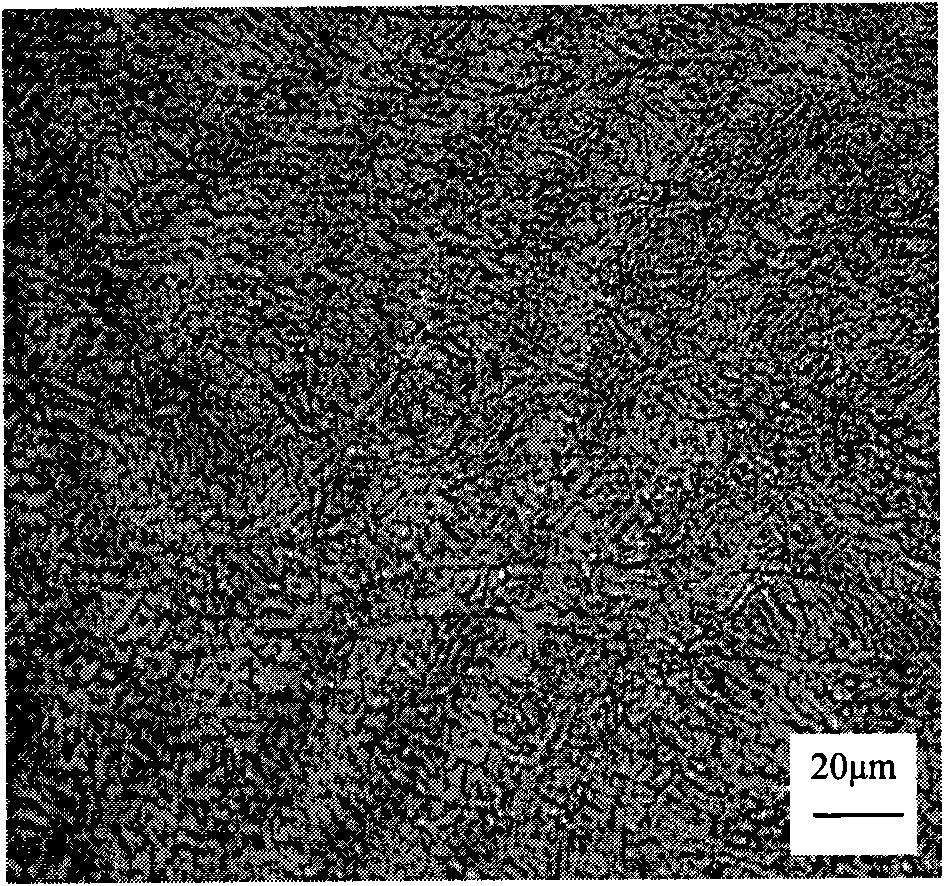

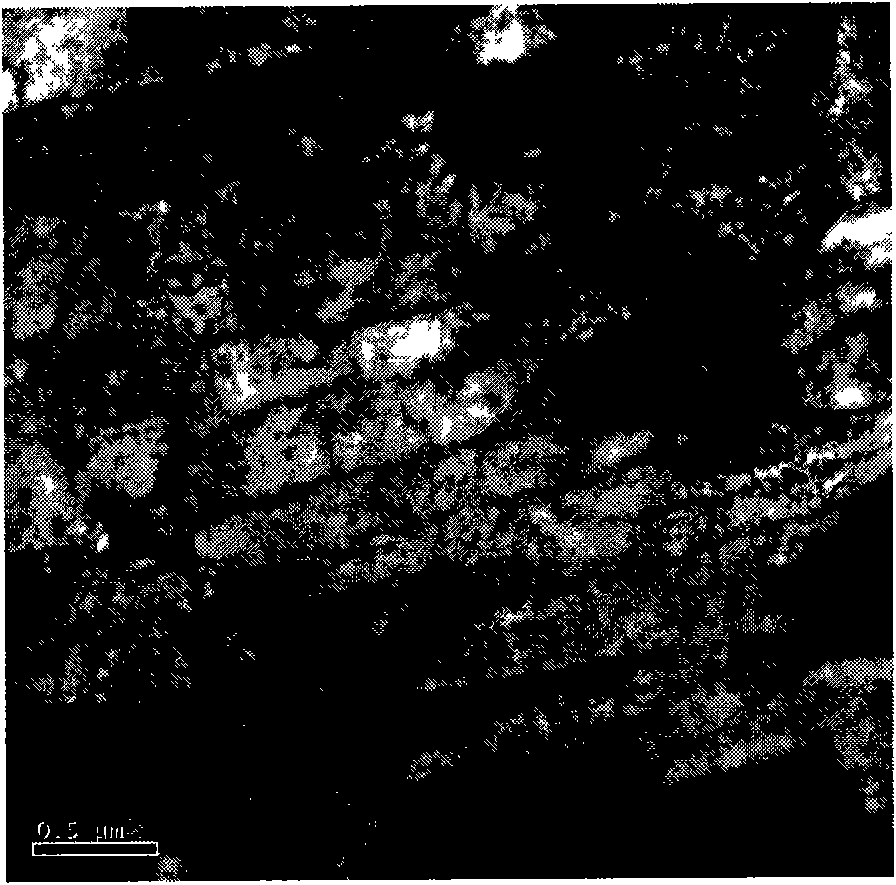

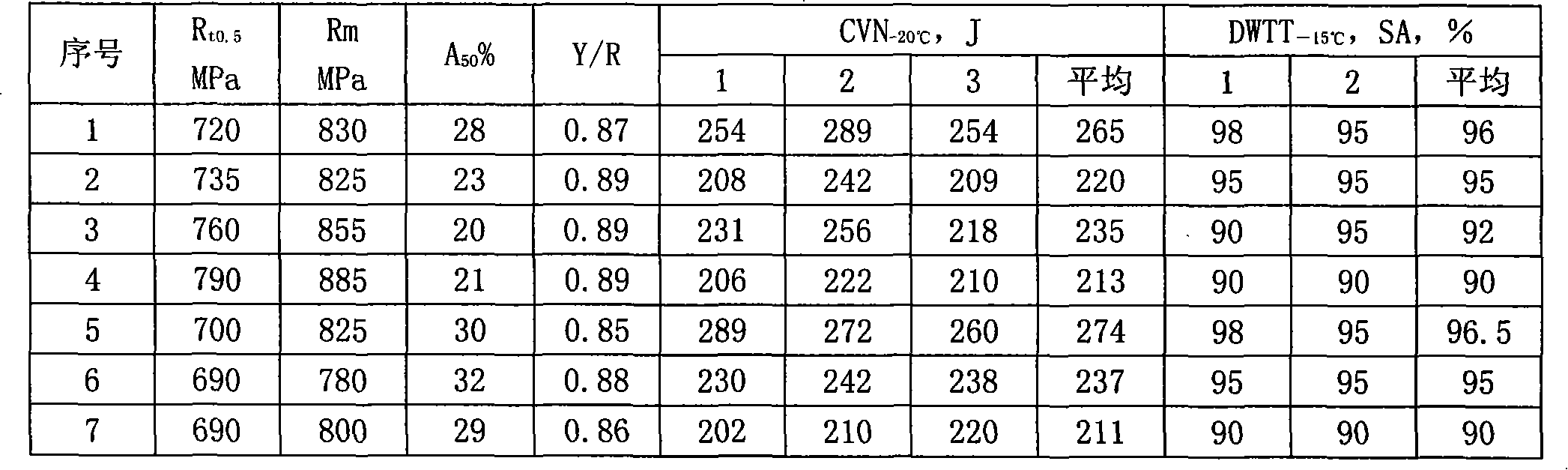

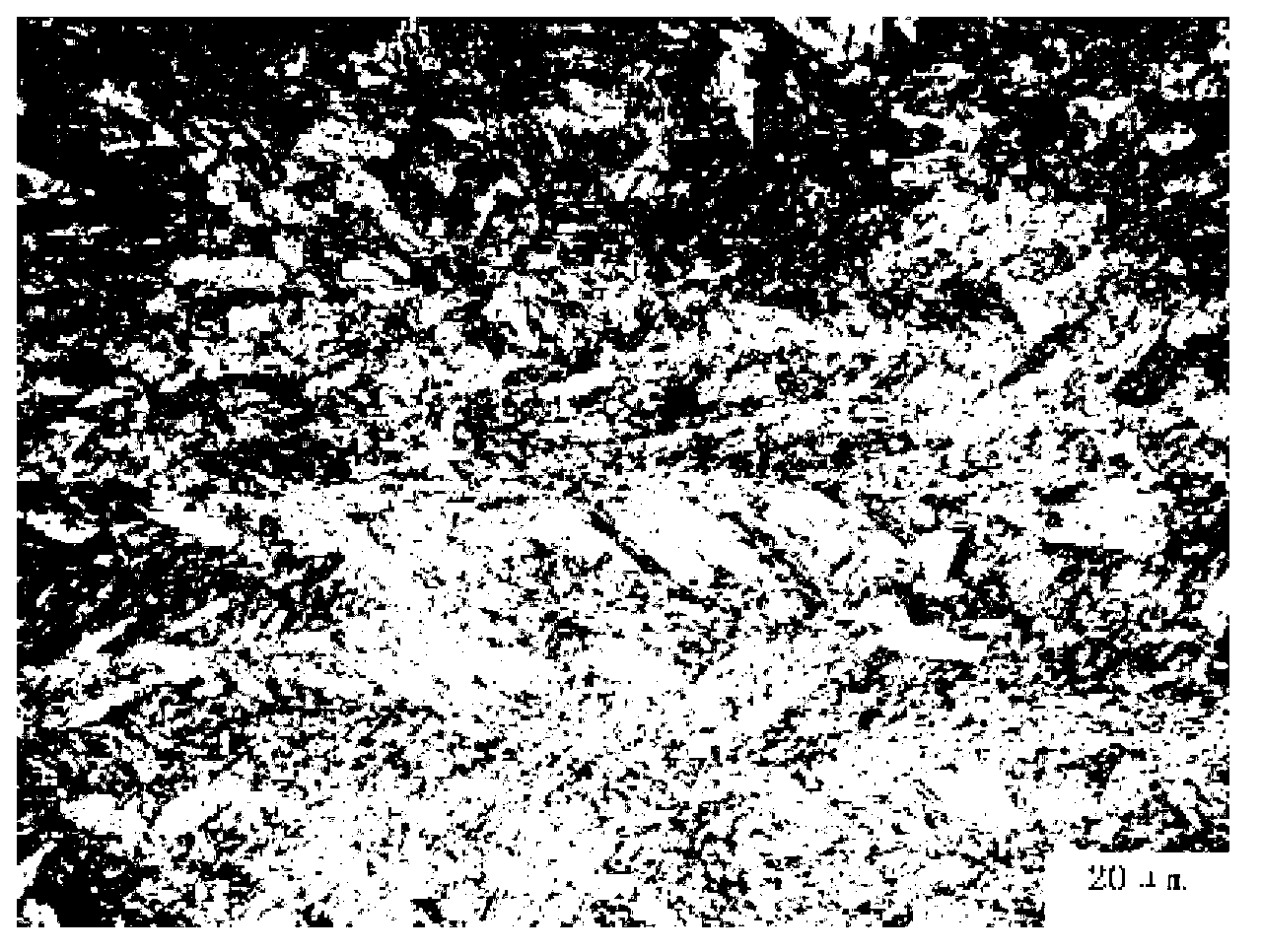

The invention discloses a high-strength X100 pipe line steel hot rolling flat plate and a method for manufacturing the same. The steel comprises the following chemical components in percentage by weight: 0.02 to 0.08 percent of C, 0.10 to 0.35 percent of Si, 1.65 to 2.20 percent of Mn, 0.005 to 0.020 percent of P, less than or equal to 0.003 percent of S, 0.04 to 0.11 percent of Nb, 0.008 to 0.030 percent of Ti, 0.02 to 0.045 percent of Als, one or more of less than or equal to 0.60 percent of Ni, less than or equal to 0.30 percent of Mo and less than or equal to 0.30 percent of Cu, and the balance of Fe and inevitable impurities. The manufacturing method comprises the following steps that: the heating temperature of a plate blank is between 1,160 and 1,280 DEG C, the rough rolling temperature is between 1,070 and 1,150 DEG C, the finish rolling temperature is between 830 and 950 DEG C, the finish cooling temperature is between 300 and 550 DEG C, and the controlled cooling speed is between 15 and 30 DEG C / S. By using the method, a complex phase structure mainly comprising the following bainites can be obtained. By adopting the complex phase structure, the yield strength of the pipe line steel hot rolling flat plate reaches 690 to 825MPa, the tensile strength reaches over 780MPa, the impact energy at a temperature of 20 DEG C below zero is more than or equal to 200J, and the shearing area of DWTT at a temperature of 15 DEG C below zero is more than or equal to 90 percent; and the rolling resistance and the straightening resistance are reduced, and the operating rates of the rolling machine and the straightening machine are improved.

Owner:ANGANG STEEL CO LTD

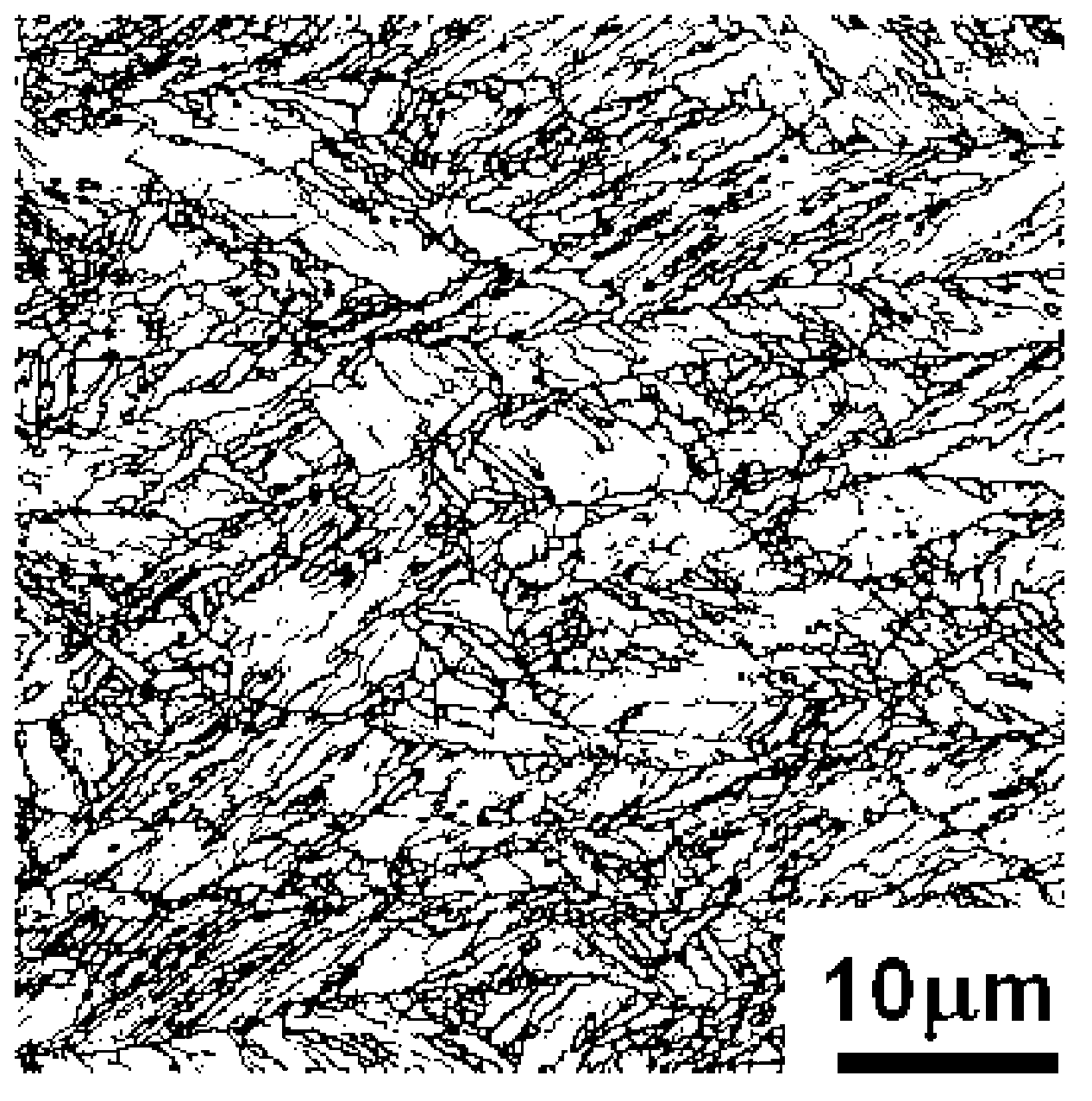

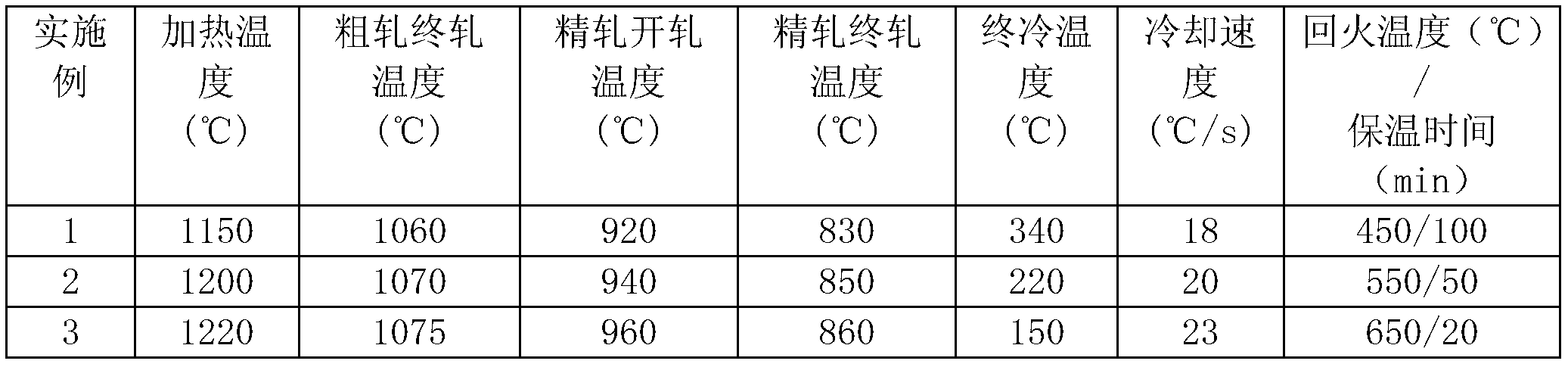

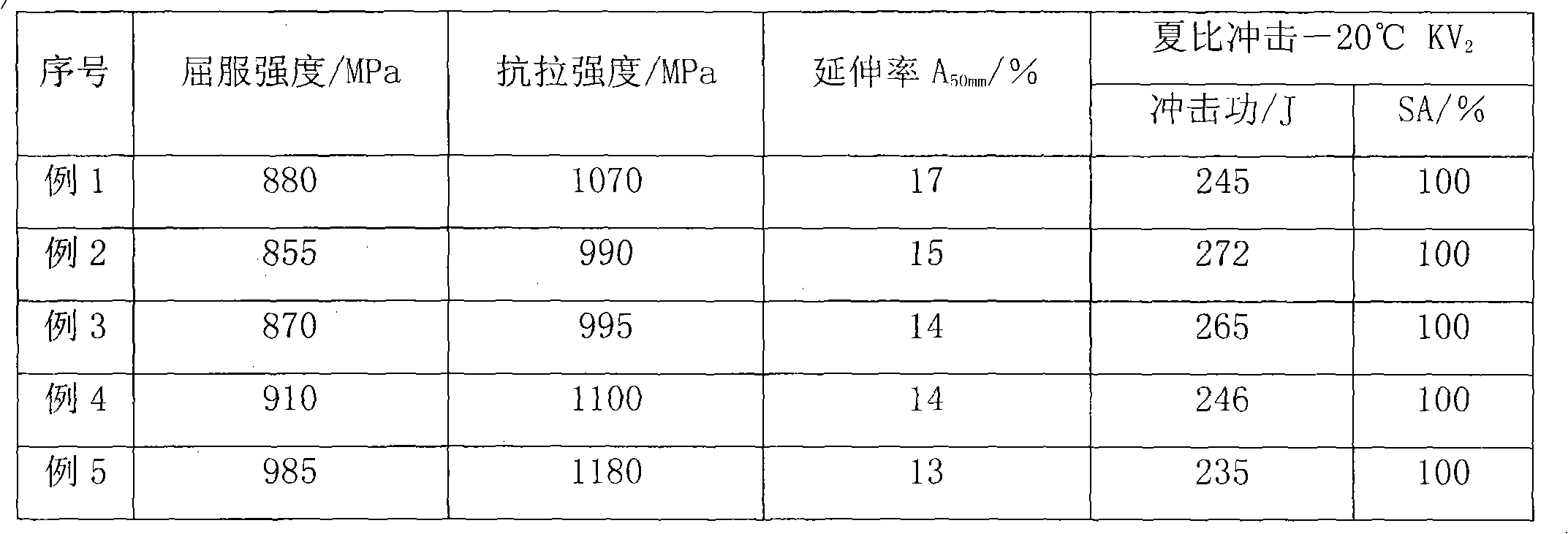

Ultrahigh-strength steel plate steel plate with yield strength of 960MPa-level, and manufacturing method thereof

The invention relates to an ultrahigh-strength steel plate steel plate with yield strength of 960MPa-level, and a manufacturing method thereof. The steel plate comprises the chemical components of: 0.06-0.11% of C, 0.10-0.50% of Si, 1.20-1.60% of Mn, less than 0.015% of P, less than 0.005% of S, 0.20-0.50% of Cr, 0.10-0.30% of Ni, 0.10-0.30% of Mo, 0.02-0.05% of Nb, 0.02-0 .06% of V, 0.008-0.03% of Ti, 0.0005-0.003% of B, 0.02-0.05% of Al, and balance of Fe. According to the invention, through two-stage controlled rolling, and direct quenching and tempering, a refined tempered martensite or lower bainite structure is obtained. Defects such as long process, high energy consumption, large alloy addition amount, and the like of traditional quenching and tempering process are overcome. The obtained steel plate has good toughness and cold bending performance.

Owner:NANJING IRON & STEEL CO LTD +1

X120 pipeline steel with low crack sensitivity and high toughness and manufacturing method thereof

InactiveCN101649425AReduce alloy costLow carbon equivalentTemperature control deviceManufacturing convertersSteel platesSmelting

The invention discloses X120 level pipeline steel with low crack sensitivity and high toughness and a production method. The X120 level pipeline steel comprises the following designed components (wt%): 0.02-0.08wt% of C, 1.5-2.1wt% of Mn, at most 0.5wt% of Si, at most 0.018wt% of P, at most 0.0020wt% of S, 0.01-0.02wt% of Ti, 0.04-0.11wt% of Nb, at most 0.08wt% of V, 0.0030wt% of B, 0.01-0.04wt% of Als, 0.1-0.40wt% of Mo, 0.3-0.5wt% of Ni, at most 0.40wt% of Cu, at most 0.30wt% of Cr and the balance of Fe and unavoidable filth. The invention meets the following formulae: the sum of Mo, Ni, Cuand Cr is smaller than or equal to 1.4 and the sum (Pcm) of C, Si / 30, (Mn+Cu+Cr) / 20, Ni / 60, Mo / 15, V / 10 and 5B is smaller than or equal to 0.23; and the production method comprises the following steps: smelting; heating a continuous casting blank to 1,100-1,250 DEG C; roughly rolling and controlling the finishing temperature at 1,000-1,100 DEG C; finely rolling and controlling the finishing temperature at 800-900 DEG C; resting a steel plate for 10-60 seconds; and cooling with the final coldness temperature of at most 450 DEG C. The invention has little content of the added alloy as well as low cost and crack sensitivity of the steel plate and is beneficial to large-scale production.

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

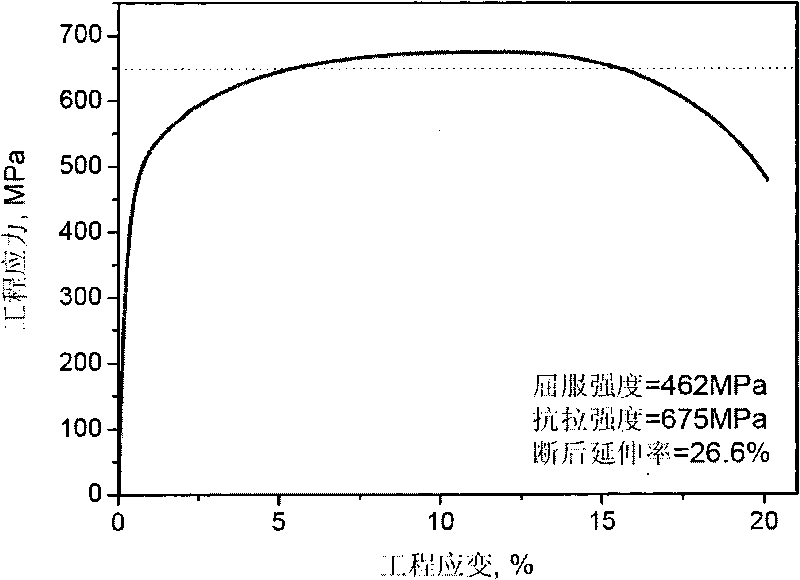

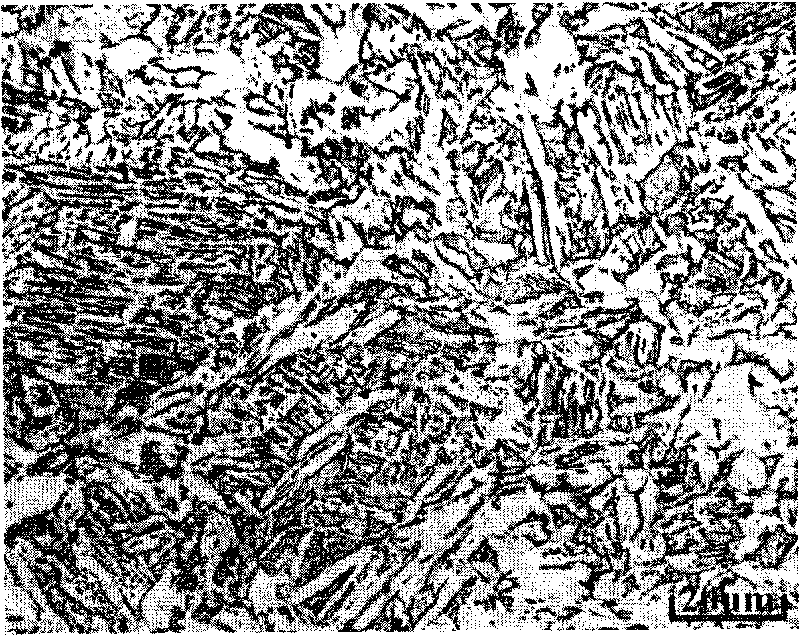

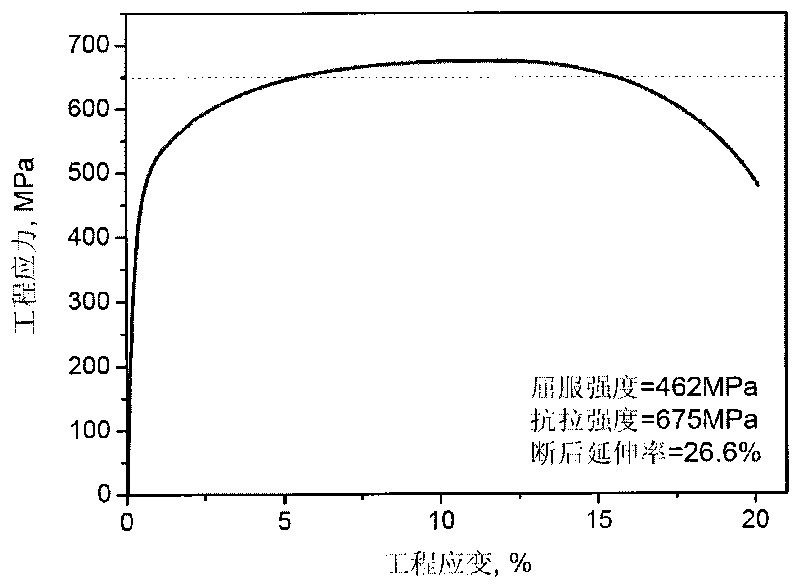

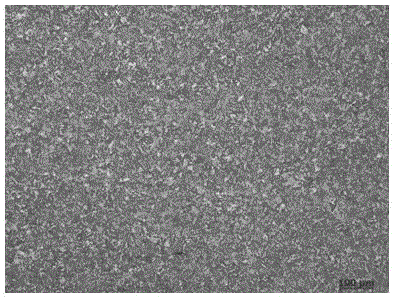

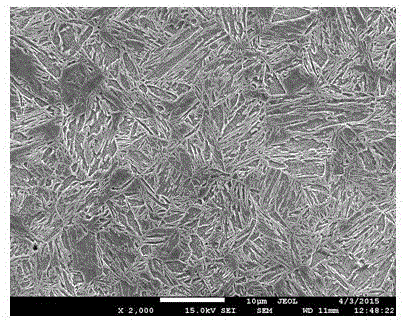

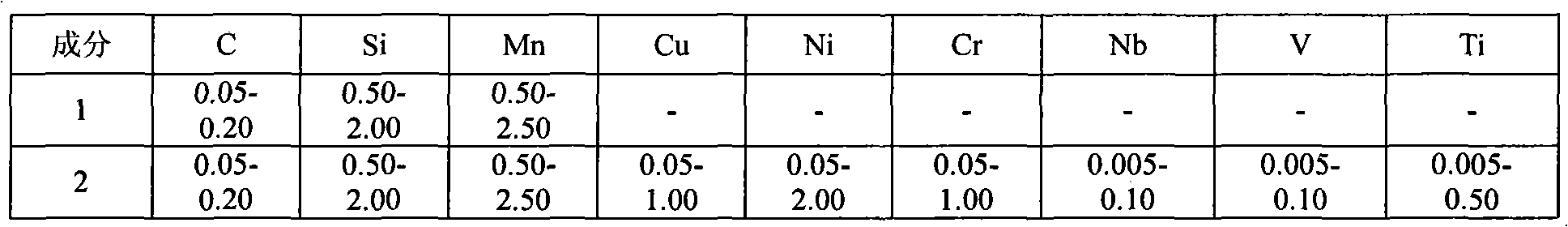

Hot rolled dual phase steel plate with 650MPa of tensile strength and manufacturing method thereof

InactiveCN101717886AReduce alloy costExcellent performanceTemperature control deviceMetal rolling arrangementsSheet steelControllability

The invention relates to a hot rolled dual phase steel plate with 650MPa of the tensile strength and a manufacturing method thereof. The dual phase steel plate contains the ingredients by weight percent of: 0.05-0.12% of C, 0.5-1.2% of Si, 1.0-1.6% of Mn and the balance of Fe and impurities. The manufacturing method of the dual phase steel plate comprises the step: a steel billet containing the same ingredients as the hot rolled dual phase steel plate is sequentially subject to heating, heat insulation, hot rolling and continuous laminar cooling, followed by take-up. The dual phase steel plate according to the invention is designed by adopting common low carbon-silcomanganese steel, has the characteristics of low alloy cost, excellent performance, simple manufacturing process, high production efficiency and great controllability, and is liable to be implemented on traditional continuous hot rolling production line.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Excellent-cold-bending-performance steel plate with yield strength larger than 1100 MPa and manufacturing method thereof

The invention relates to a quenched type ultra-high-strength steel plate with yield strength larger than 1100 MPa. The production technology of the quenched type ultra-high-strength steel plate with the yield strength larger than 1100 MPa comprises the steps of smelting, external refining, vacuum degassing, Ca treatment, continuous casting, dehydrogenation treatment on a casting blank, heating, rolling, cooling, warm straightening, quenching and powerful straightening. According to the quenched type ultra-high-strength steel plate with the yield strength larger than 1100 MPa, the ingredients are economical, the technology is simple, the comprehensive mechanical performance of the steel plate is excellent, the yield strength is over 1100 MPa, the tensile strength is over 1200 MPa, and the Charpy impact energy at the minus 40 DEG C is larger than or equal to 30 J; meanwhile, the performances of the steel plate are uniform, the steel plate is flat, and the waviness of the steel plate is smaller than or equal to 5 mm / m; the cold bending forming performance of the whole steel plate is good, d is equal to 3a, and the result of the 180-degree laboratory GB / T232 cold bending test of the steel plate is qualified; b is larger than or equal to 500 mm, r is equal to 3a, and no crack is generated during 90-degree industrial cold bending forming; and therefore, the machining and use requirements on the ultra-high-strength steel plate of the domestic and overseas large machinery industry are met.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

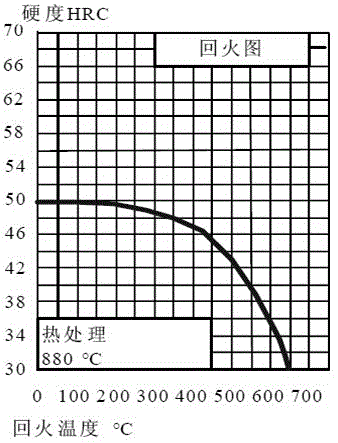

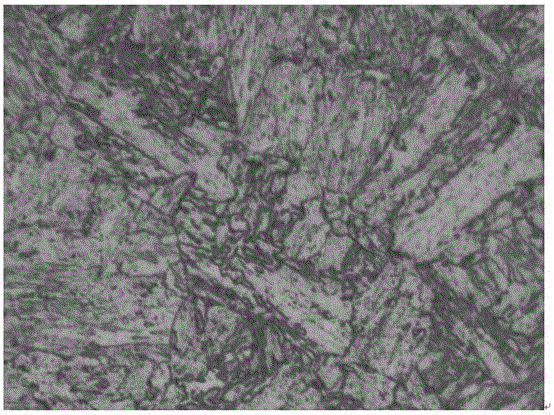

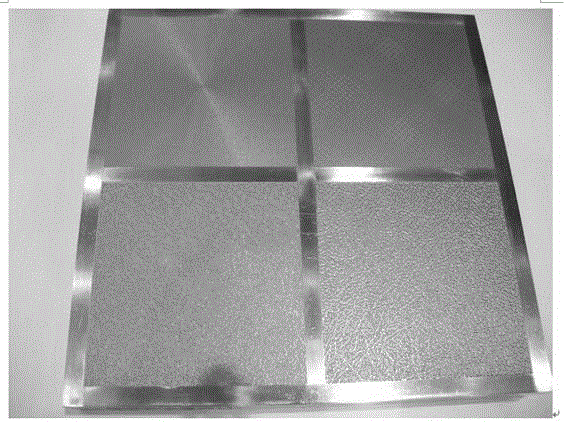

Boron microalloyed die steel and preparation process thereof

The invention relates to boron microalloyed die steel and a preparation process thereof and belongs to the technical field of alloy steel preparation processes. The main alloy elements in alloy chemical components of the die steel comprise, by mass, 0-0.20% of C, 0-0.20% of Si, 1.20-1.60 of Mn, 1.10-1.50% of Cr, 0-0.30% of Ni, 0.20-0.35% of Mo, 0-0.10% of V, less than 0.015% of P, less than 0.005% of S, 0.005-0.01% of B, and the balance Fe. The preparation process of the steel includes the following steps of conducting burdening, smelting, casting and hot delivery; conducting high temperature diffusion heat treatment, multi-directional forging hot working and post-forging hydrogen diffusion tempering treatment; and finally conducting quenching-and-tempering heat treatment so as to obtain a tempered martensite structure with the hardness being 32-38 HRC. The boron microalloyed die steel and the preparation process thereof have the advantages that the prepared die steel has low cost, high hardenability, high hardness, high polishing performance and high skin grain etching performance.

Owner:RUGAO HONGMAO HEAVY FORGING

Yield strength 225MPa-level earthquake-resistant construction steel and production method thereof

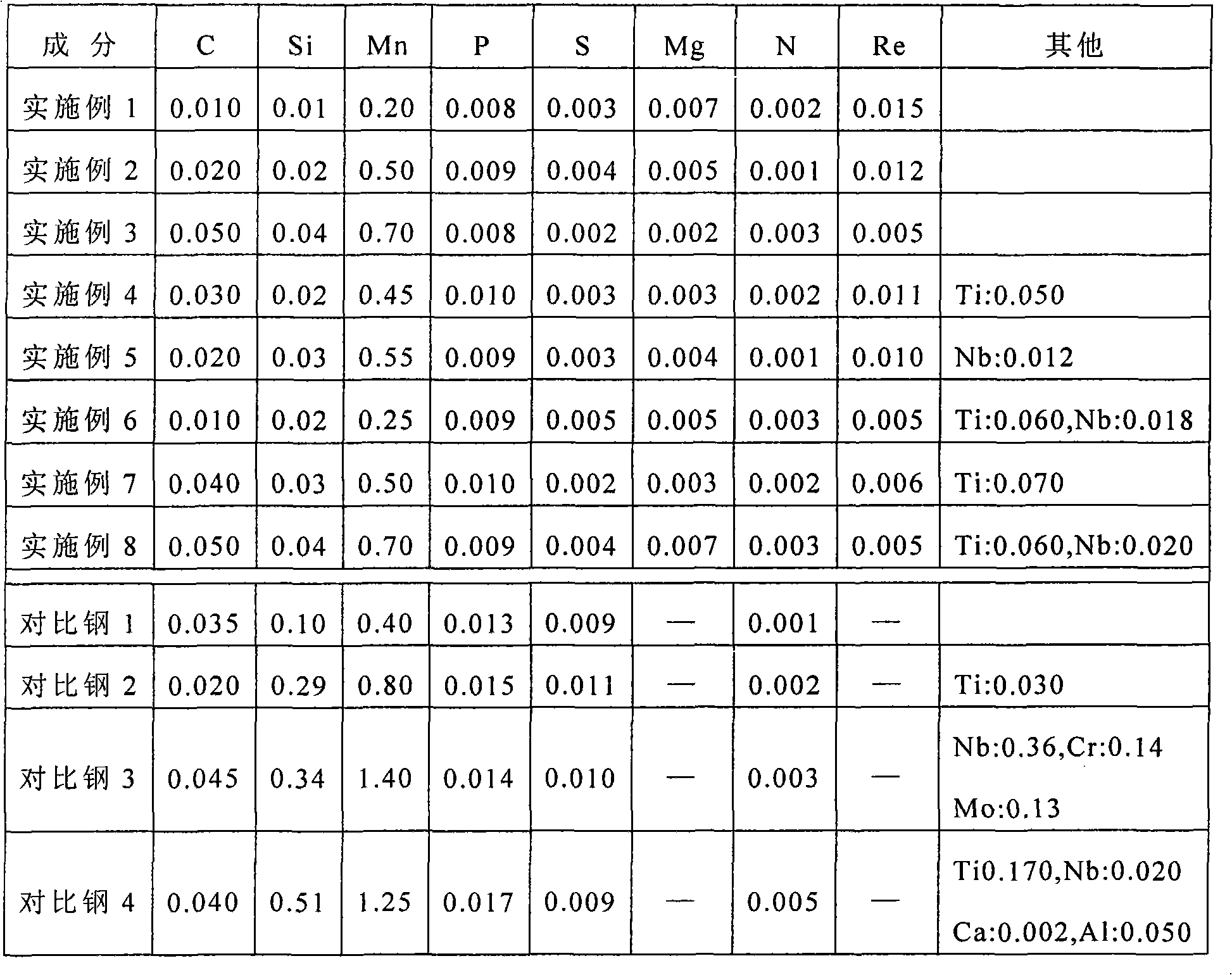

The invention discloses yield strength 225MPa-level earthquake-resistant construction steel and a production method thereof. The steel comprises the following chemical compositions in percentage by weight: 0.01 to 0.05 percent of C, 0.01 to 0.04 percent of Si, 0.20 to 0.70 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.005 percent of S, 0.002 to 0.007 percent of Mg, 0.001 to 0.003 percent of N, 0.005 to 0.015 percent of Re, less than or equal to 0.070 percent of Ti, less than or equal to 0.020 percent of Nb, less than or equal to 0.0520 percent of Al, and the balance of Fe and inevitable impurities. The production method for the earthquake-resistant construction steel comprises the following steps of hot metal desulphurization, converter blowing, vacuum treatment, continuous casting, hot rolling, cooling, and the like. When the yield strength of the steel products exceeds 245MPa, a step of annealing treatment is added after the cooling step. Experiments prove that the yield strength 225MPa-level earthquake-resistant construction steel has the characteristics of low yield strength, high elongation and excellent impact toughness, and the production method has the advantages of simple process and low production cost.

Owner:武钢集团有限公司

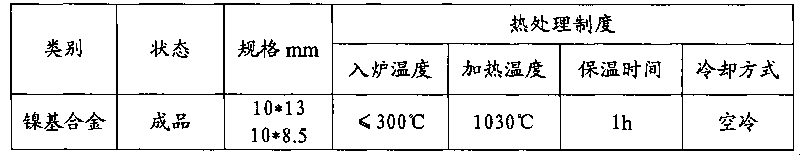

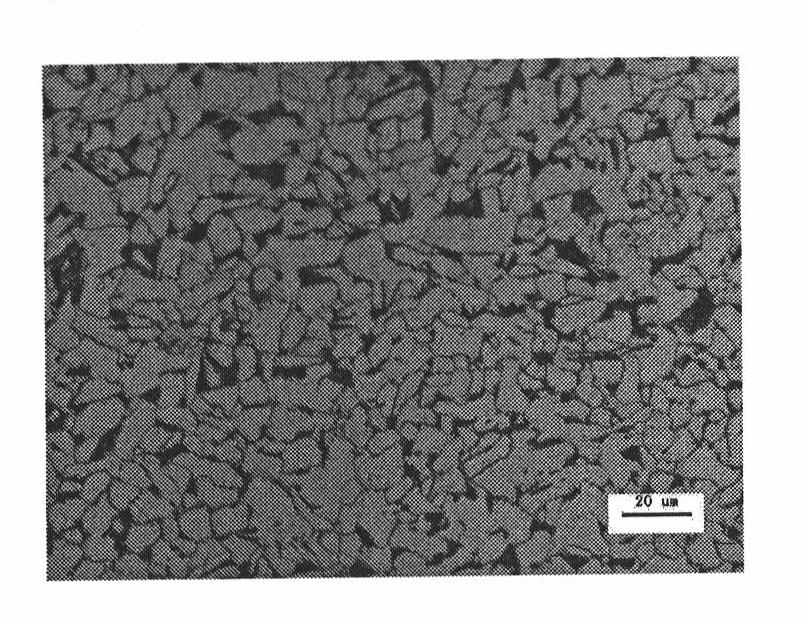

Nickel-based alloy of nuclear power steam generator

The invention relates to a nickel-based alloy of a nuclear power steam generator. The invention can maintain or increase the alloy performance while reducing the alloy cost. The specific scheme of the invention is as follows: 1. a defined amount of rare earth elements are added in steel to have purification and metamorphism functions of deoxidizing, desulfurizing, changing the shape of inclusion and the like, have microalloy function in the alloy and finally increase the oxidation resistance, high temperature strength and plasticity, fatigue life, corrosion resistance, crack resistance and the like of the steel; 2. in view of the production cost, the content of the precious element nickel is needed to be as low as the lower limit under the premise of ensuring the processability and ensuring that the alloy can form the desired metallographic structure; 3. the content of chromium element is increased properly so as to increase the high temperature oxidation resistance and corrosion resistance of alloy; 4. the content of silicon element is adjusted so as to increase the tensile strength and corrosion resistance of alloy while the plasticity of alloy is ensured; and 5. the content of carbon is controlled and titanium element is added at the same time so as to further increase the oxidation resistance and corrosion resistance of steel.

Owner:江苏龙鑫特殊钢实业总公司

Slurry feed line steel with good low-temperature toughness and manufacturing method thereof

InactiveCN102400039AGood welding performanceImprove low temperature impact toughnessTemperature control deviceSlurryPearlite

The invention provides slurry feed line steel with good low-temperature toughness and a manufacturing method thereof. The slurry feed line steel with good low-temperature toughness comprises 0.10 to 0.20% of C, 0.10 to 0.30% of Si, 0.80 to 1.50% of Mn, less than or equal to 0.018% of P, less than or equal to 0.004% of S, 0.010 to 0.035% of Ti, 0.02 to 0.05% of Als, less than or equal to 0.006% of N and the balance Fe. The manufacturing method of the slurry feed line steel with good low-temperature toughness comprises smelting, continuous casting and hot rolling. When a plate blank is heated to a temperature of 1160 to 1300 DEG C, the plate blank is subjected to a first-stage controlled rolling and a second-stage controlled rolling, wherein an initial temperature of the first-stage controlled rolling is in a range of 1130 to 1200 DEG C; an end temperature of the first-stage controlled rolling is above 1020 DEG C; an initial temperature of the second-stage controlled rolling is below 1000 DEG C; and an end temperature of the second-stage controlled rolling is in a range of 780 to 880 DEG C. The plate blank subjected to the first-stage controlled rolling and the second-stage controlled rolling is cooled at a speed of 5 to 20 DEG C per second and then is reeled at a temperature of 550 to 680 DEG C. The manufacturing method of the slurry feed line steel with good low-temperature toughness has the advantages that the slurry feed line steel with good low-temperature toughness does not contain precious alloy elements such as Nb, Mo, V and the like so that an alloy cost is low; S content and P content are controlled strictly so that good low-temperature toughness of steel is guaranteed effectively; and a controlled rolling and controlled cooling technology is utilized for crystal particle refinement so that a pearlite microstructure is uniformly distributed and good steel strength matching with toughness is guaranteed.

Owner:ANGANG STEEL CO LTD

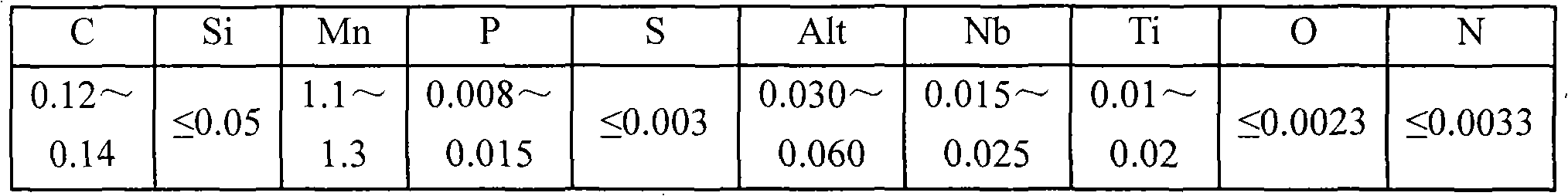

High-strength long-fatigue life wheel steel used for heavy truck and manufacturing method thereof

InactiveCN102127706ALight weightReduce alloy costTemperature control deviceManufacturing convertersHigh intensityPre treatment

The invention relates to a high-strength long-fatigue life wheel steel used for a heavy truck and a manufacturing method thereof, belonging to the technical field of high-strength stamping wheel steel for the heavy truck. The wheel steel comprises the following components: 0.12-0.14% of C, less than or equal to 0.05% of Si, 1.1-1.3% of Mn, 0.008-0.015% of P, less than or equal to 0.003% of S, 0.030-0.060% of Al, 0.015-0.025% of Nb, 0.01-0.02% of Ti, less than or equal to 23ppm of O, less than or equal to 33ppm of N and the balance of Fe and inevitable impurities. The manufacturing process comprises the following steps of: molten iron pretreatment to remove sulphur, top and bottom-blown converter smelting, LF (low frequency) furnace refining, slab casting, hot rolling to obtain the finished product. The wheel steel provided by the invention has the advantages that: compared with the traditional wheel steel, the tensile strength can reach more than 500MPa, the elongation percentage is more than 30%, the flexible life of a manufactured steel ring is more than 500000 times, the radial fatigue life is more than 1450000 times, and the weight of the wheel is reduced by 12-15%. The self weight of a car body is effectively reduced, and the oil consumption is reduced, thus the wheel steel is an ideal plate used for producing wheel rims and wheel arms of the heavy truck.

Owner:SHOUGANG CORPORATION

High-strength steel for automotive wheels and manufacture method thereof

InactiveCN101831585AHigh strengthHigh fatigueManufacturing convertersMetal rolling arrangementsSheet steelHigh intensity

The invention relates to high-strength steel for automotive wheels and a manufacture method thereof, belonging to the technical field of high-strength stamping steel. The steel for automotive wheels comprises the following components in percentage by weight: 0.07-0.12 percent of C, 0.01-0.1 percent of Si, 1.0-1.2 percent of Mn, 0.008-0.015 percent of P, not more than 0.008 of S, 0.020-0.040 percent of Al and the balance of Fe and other impurity elements. The manufacture method has the processes of: molten iron preprocessing for desulfurization, processing by a top-and-bottom combined blown converter, refining treatment by an LF furnace, continuous casting of plate blanks, thermal rolling and finished product obtaining. Compared with traditional steel for wheels, the invention has the advantages that the tensile strength can reach 380-480 MPa, and the elongation rate is 26.0-43.0 percent under the condition that noble metals, such as Nb, and the like are not added. The steel plate with high strength, high fatigue resistance and high stamping performance can be obtained with low alloying cost to effectively lighten the self weight of an automobile and reduce the oil consumption; and therefore, the high-strength steel is an ideal steel plate for producing automobile wheel rims and spokes.

Owner:SHOUGANG CORPORATION +1

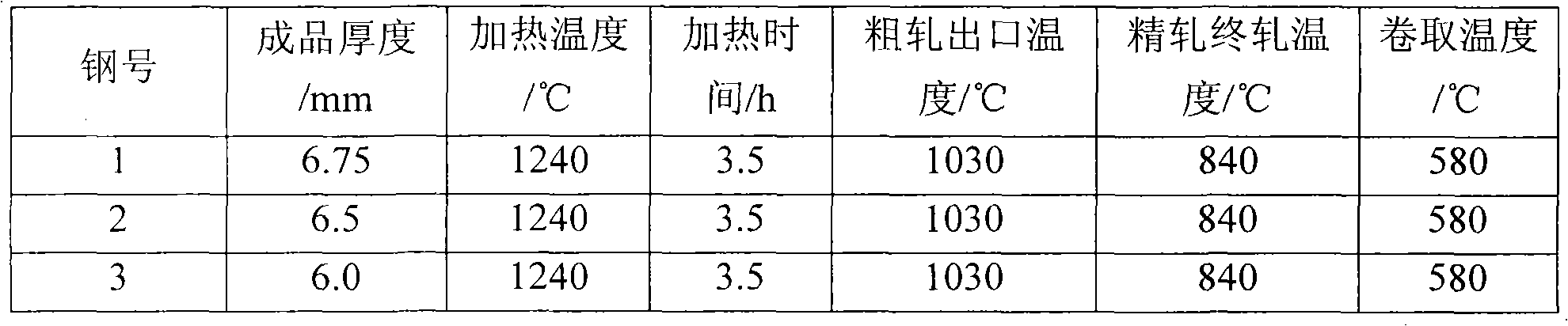

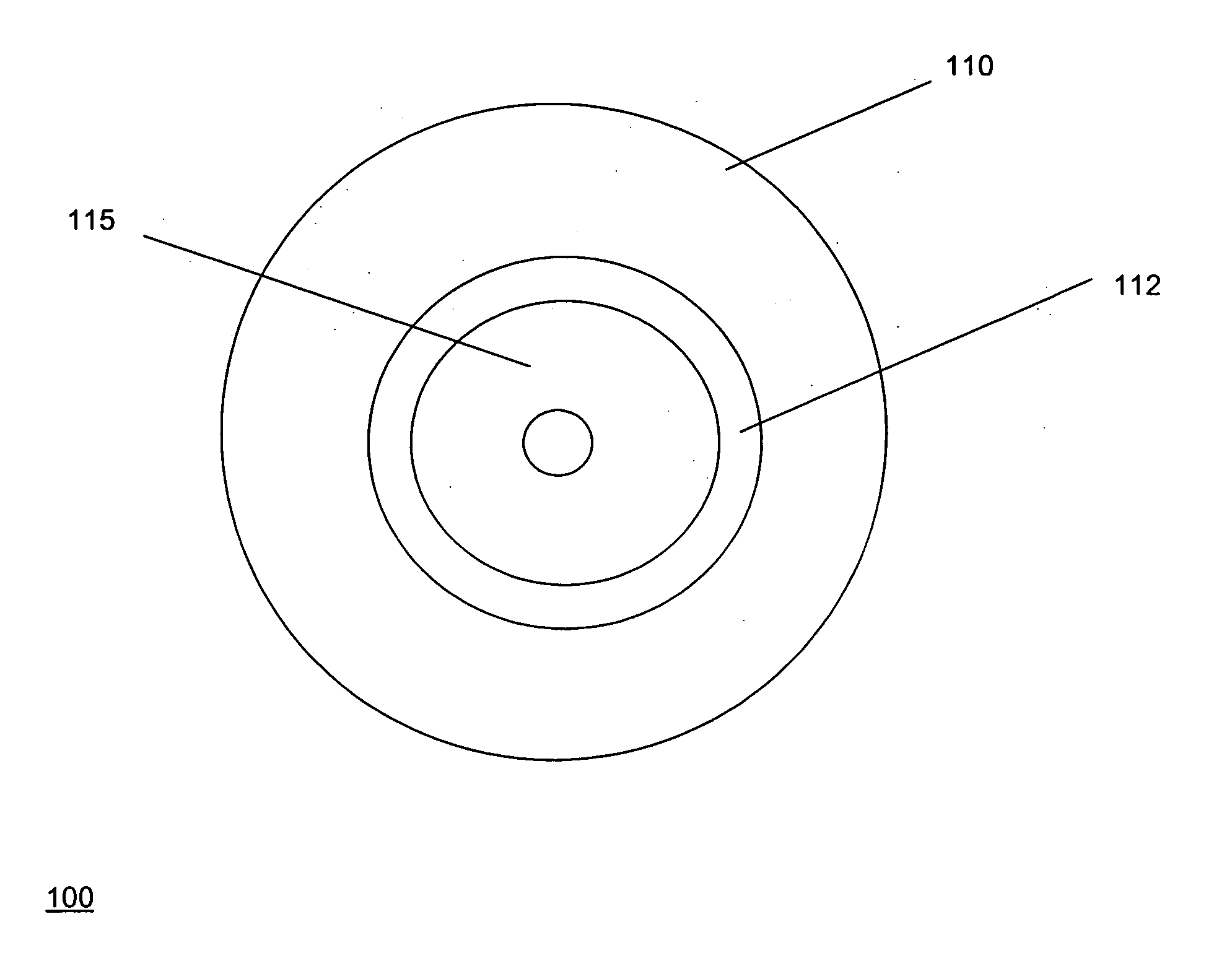

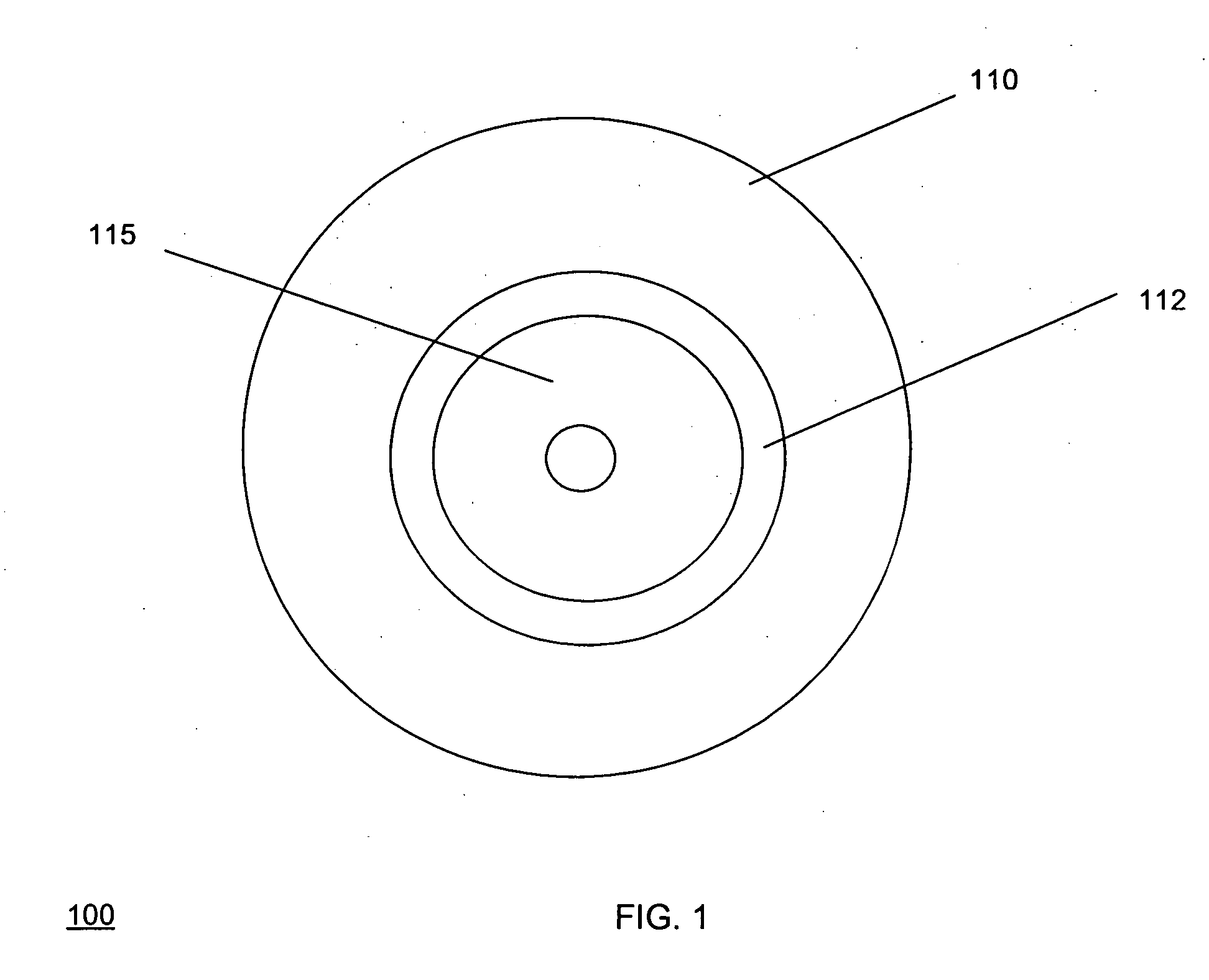

Composite gas turbine discs for increased performance and reduced cost

ActiveUS20060008352A1Reduce manufacturing difficultyReduce alloy costTurbinesBlade accessoriesNickel alloyTurbine

A composite turbine disc includes a high nickel rim section and a steel bore section. The rim section is formed from a high nickel alloy which provides a higher melting point as compared to the material used for the bore section. A plating or forged welding enhanced agent layer is disposed between the bore section and rim section. Composite disc can be formed by forging the rim and bore material together, or by welding the rim and bore material together.

Owner:SIEMENS ENERGY INC

High-niobium Q460-grade fire-resistant steel and manufacturing method thereof

InactiveCN103614638AReduce alloy costShort production processTemperature control deviceMetallurgyMaterials science

The invention relates to high-niobium Q460-grade fire-resistant steel and a manufacturing method thereof. The high-niobium Q460-grade fire-resistant steel comprises the following components in percentage by weight: 0.01 to 0.20 percent of C, 0.1 to 0.4 percent of Si, 0.5 to 1.5 percent of Mn, 0.1 to 1.0 percent of Cr, 0.01 to 0.2 percent of Mo, 0.05 to 0.15 percent of Nb, 0.01 to 0.05 percent of Ti, and the balance of Fe. The manufacturing method comprises the steps of heating a steel billet to 1150 to 1250 DEG C, thermally preserving the steel billet for 120min to 200min, and cooling the steel billet in the air, wherein the coarse rolling finished-rolling temperature is 1000 to 1050 DEG C, and the reduction rate is 2 to 5; the precision rolling starting-rolling temperature is 900 to 1000 DEG C, and the precision rolling finished-rolling temperature is 800 to 900 DEG C; and the re-reddening temperature is 350 to 550 DEG C, and the cooling rate is 10 to 25 DEG C / S. By adopting the manufacturing method, the grade of the finished product steel is improved while the additive amount of heavy metal Mo is reduced.

Owner:NANJING IRON & STEEL CO LTD

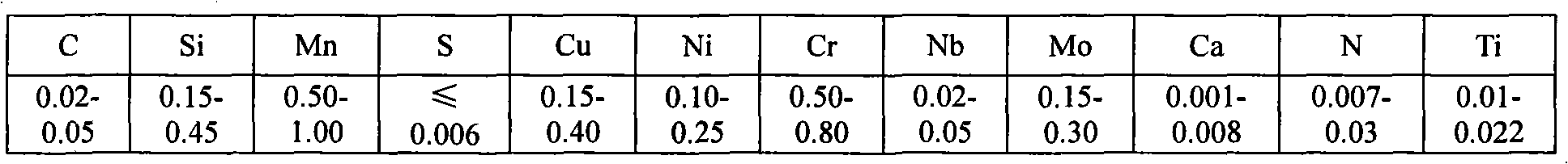

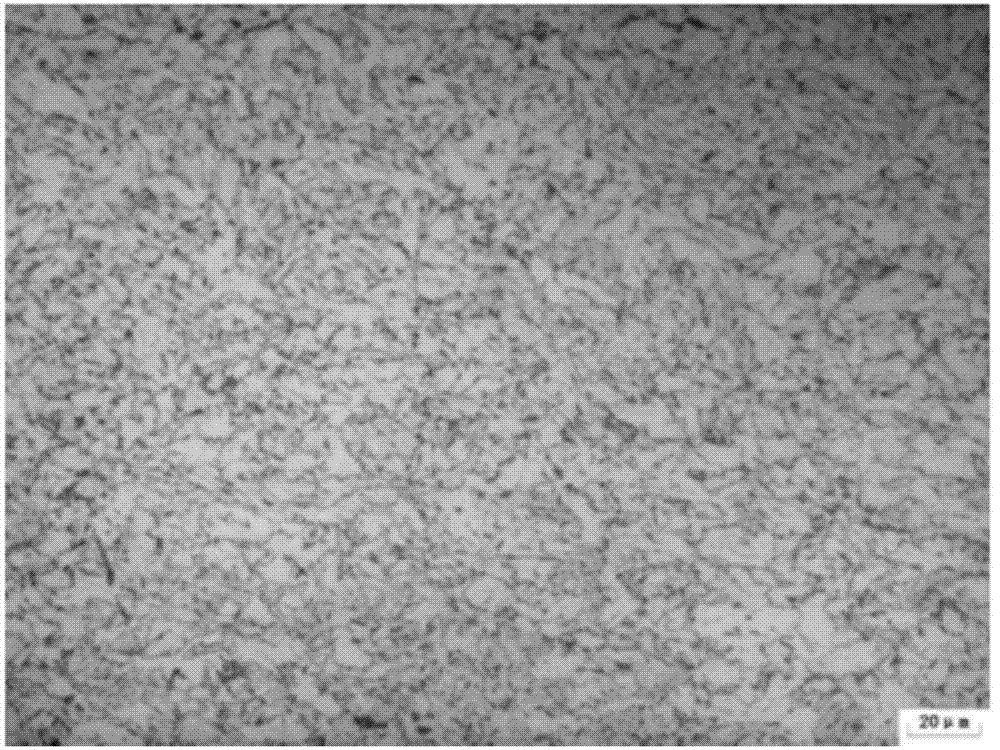

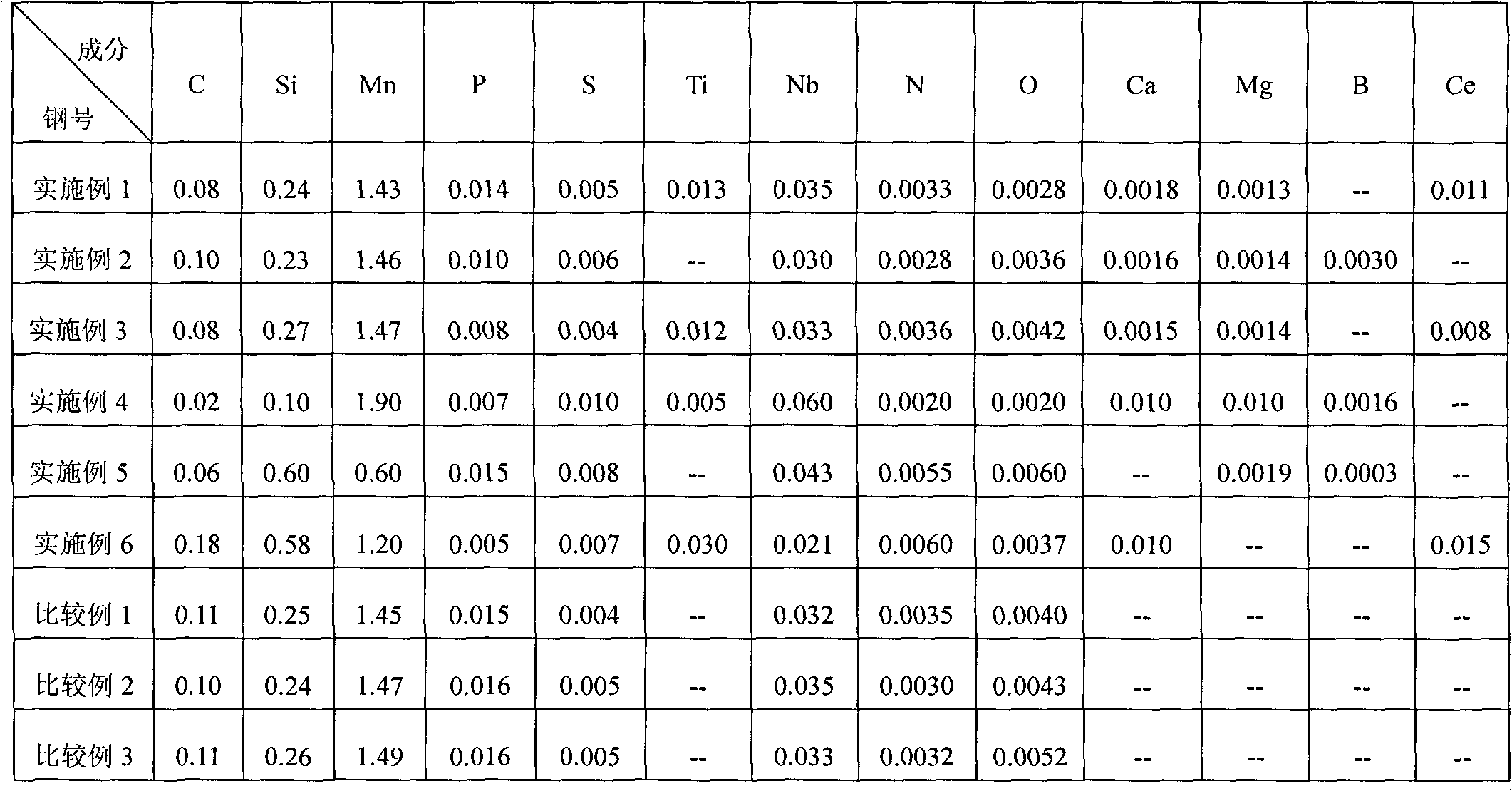

Ultra-large linear energy input welding high-strength steel and production method thereof

InactiveCN101818304AImprove mechanical propertiesImprove toughnessRoll mill control devicesMetal rolling arrangementsSheet steelChemical composition

The invention discloses ultra-large linear energy input welding high-strength steel and a production method thereof, and solves the problems of high alloying cost, poor welding performance of steel plates and low HAZ impact toughness of the conventional large linear energy input welding high-strength steel. The steel comprises the following chemical compositions in percentage by weight: 0.02 to 0.18 percent of C, 0.10 to 0.60 percent of Si, 0.60 to 1.90 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.010 percent of S, less than or equal to 0.060 percent of Nb, 0.0020 to 0.0060 percent of N, 0.0020 to 0.0060 percent of O, and at least two of 0.005 to 0.030 percent of Ti, less than or equal to 0.010 percent of Ca, less than or equal to 0.010 percent of Mg, 0.0003 to 0.003 percent of B, and 0.008 to 0.015 percent of Ce, and the balance of Fe and inevitable impurities. In addition, the chemical compositions meet the following conditions: (1) 4.0C+Mn is less than or equal to 2.1; (2) the carbon equivalent CE is equal to C+Si / 24+Mn / 6+Ni / 40+Cr / 5+Mo / 4+V / 14 and is less than or equal to 0.39. A casting blank with the compositions is prepared through hot metal desulphurization, converter top and bottom blowing, vacuum deep treatment and fine adjustment of the compositions, the casting blank subjected to controlled rolling is air-cooled to room temperature, and the high-strength strong-toughness and excellent-match steel is obtained. The steel has the advantages of high strength, excellent low temperature toughness, and high Z-direction performance, and can bear ultra-large linear energy input (more than or equal to 500kJ / cm) welding.

Owner:武钢集团有限公司

Low-cost, high-strength and high-plasticity metastable beta titanium alloy and preparation method thereof

The invention discloses a low-cost, high-strength and high-plasticity metastable beta titanium alloy and a preparation method thereof. The titanium alloy comprises the following components in percentage by weight: 3-7% of Fe, 4-7.75% of Al, 3-5% of V, O not more than 0.2%, C not more than 0.08%, N not more than 0.05%, and the balance of titanium and inevitable impurities. The preparation method comprises the following steps: sponge titanium, an Al-V intermediate alloy, pure Al and pure Fe are weighed according to ratios; the raw materials are mixed to press as an electrode; a Ti-Al-Fe-V alloy cast blank is prepared by secondary smelting; the cogging and the primary forging are performed to obtain a large-scale forging; the secondary forging is performed to obtain a larger-size rod; the ternary forging is performed to obtain a small-size rod; the solid-solution treatment and the air cooling are performed; and then, the aging treatment and the air cooling are performed to obtain the low-cost, high-strength and high-plasticity metastable beta titanium alloy. The titanium alloy contains higher-content beta elements and stable elements Fe, and has such advantages as low cost, high strength and high plasticity.

Owner:CENT SOUTH UNIV

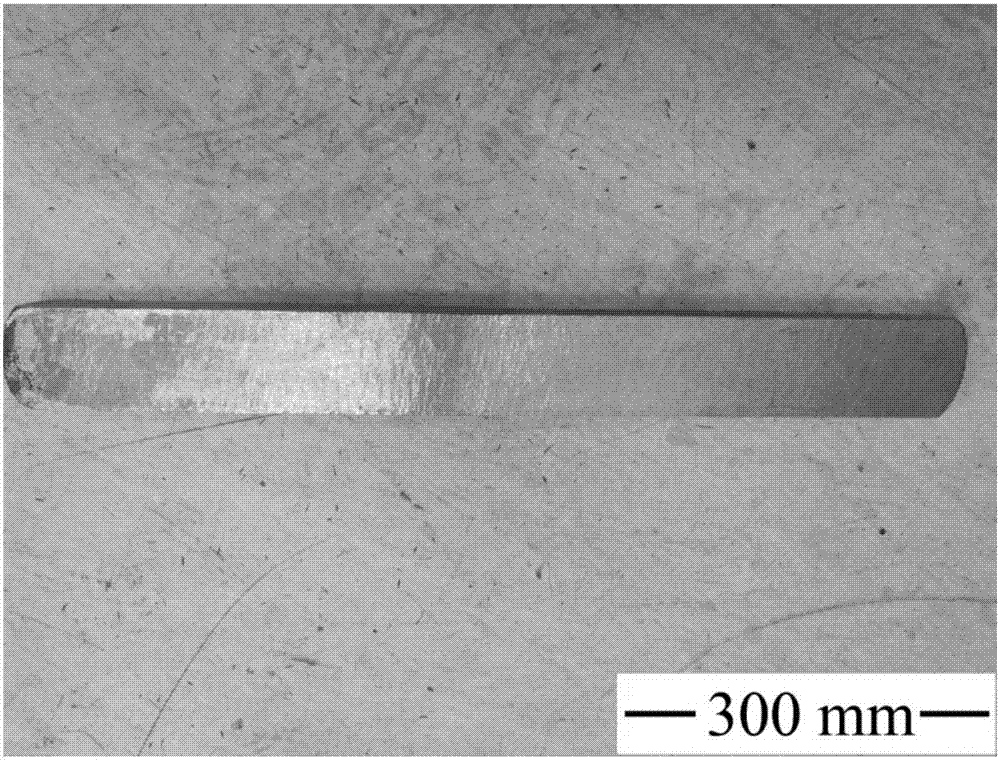

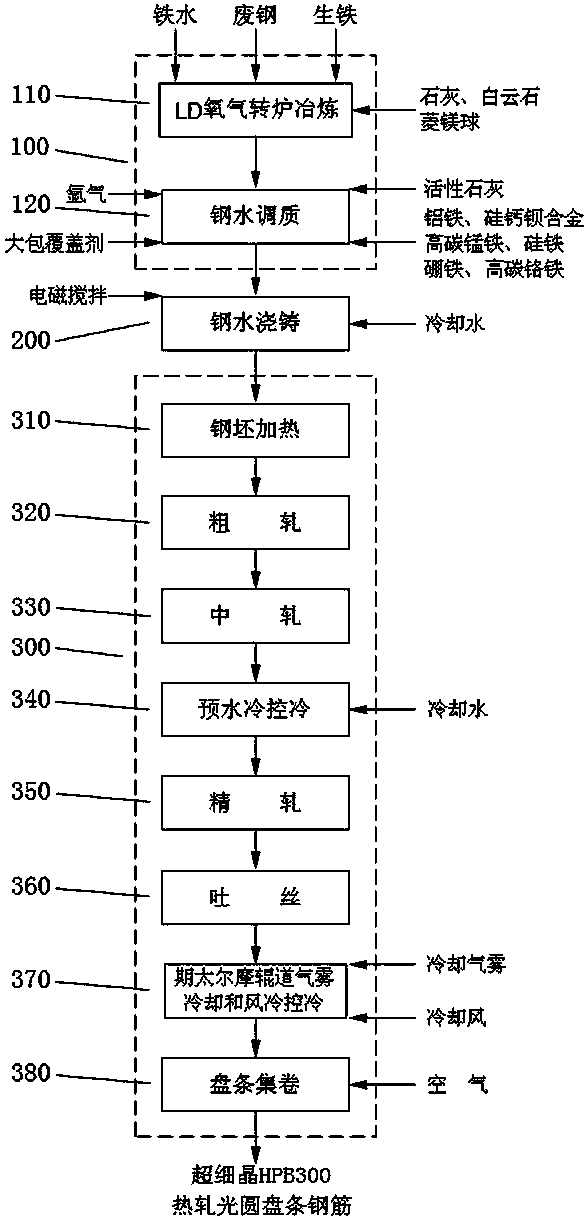

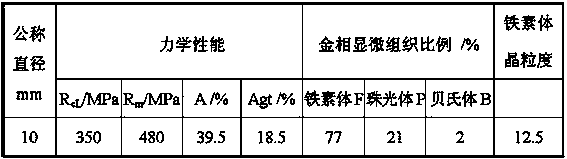

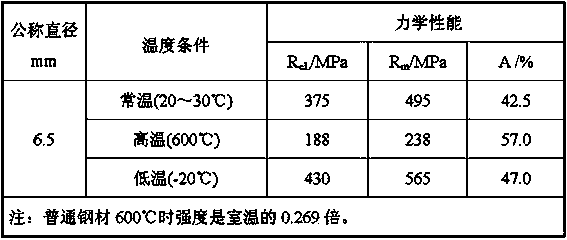

Ultra-fine grained HPB300 hot-rolling optical disc stripe reinforcing steel bar and preparation method thereof

The invention discloses an ultra-fine grained HPB300 hot-rolling optical disc stripe reinforcing steel bar and a preparation method thereof. The ultra-fine grained HPB300 hot-rolling optical disc stripe reinforcing steel bar comprises the following components in percentage by weight: 0.15-0.18% of C, 0.10-0.16% of Si, 0.16-0.28% of Mn, 0.080-0.120% of Cr, 0.0010-0.0020% of B, less than 0.030% of S, less than 0.045% of P and the balance of Fe. The reinforcing steel bar is prepared from molten iron, steel scrap and pig iron through steps of molten steel smelting, molten steel pouring and billet controlled rolling and controlled cooling. According to the reinforcing steel bar, a small amount of ferromanganese, ferroboron and high carbon ferro-chrome alloy into the steel-making step, so that the alloying cost is remarkably lowered. By adopting low-temperature controlled rolling before spinning and a stelmor roller aerial fog cooling process after spinning, the reinforcing steel bar has the advantages of low cost, good toughness, excellent high- and low-temperature performance, low stress time-validity and the like.

Owner:WUKUN STEEL

Method for producing high-strength steel with yield strength of 600MPa level

InactiveCN101538680ASimple metallurgical compositionReduce alloy costTemperature control deviceThin slabLaminar cooling

The invention belongs to the technical field of high-strength steel production, and relates to a method for producing high-strength steel with yield strength of 600MPa level. The high-strength steel is smelted by a converter or an electric furnace; and after the molten steel components are qualified, the molten steel components are delivered to an LF furnace to carry out refining for the molten steel and fine adjustment for the components, wherein the steel comprises the following components in percentage by mass: 0.03 to 0.08 percent of C, 0.20 to 0.50 percent of Si, 1.0 to 1.5 percent of Mn, 0.06 to 0.10 percent of Ti, 0.02 to 0.08 percent of Nb, 0.02 to 0.06 percent of Al, less than or equal to 0.008 percent of limited element S, less than or equal to 0.008 percent of N, less than or equal to 0.04 percent of P, and the balance of Fe. The method adopts a thin slab blank to continuously cast the steel, the charging temperature of a casting blank is between 950 and 1,050 DEG C, the heating temperature is more than or equal to 1,150 DEG C, the discharging temperature is between 1,080 and 1,160 DEG C, the final rolling temperature is between 820 and 920 DEG C, and after laminar cooling, the rolling temperature is between 550 and 650 DEG C. The yield strength of the high-strength steel produced by the method is in a range of 590MPa to 660MPa, the high-strength steel has good forming property and welding property at the same time, and the thickness of a plate is in a range of 1.4 to 9.0 millimeters. By applying the method, the metallurgical components of the steel are simple, the alloying cost is low, and the process is simple and easy to control.

Owner:湖南华菱涟源钢铁有限公司 +1

Production method of HRB500E high-strength and anti-seismic rebar

ActiveCN109554613AAvoid frequent switching operationsAvoid idle waits for operationsChemical compositionRebar

The invention provides a production method of an HRB500E high-strength and anti-seismic rebar. The production method comprises the step that a billet is manufactured. The billet is prepared from the components in percentage: 0.20%-0.25% of C, 0.40%-0.70% of Si, 1.30%-1.60% of Mn, less than or equal to 0.045% of P, less than or equal to 0.045% of S, 0.020%-0.050% of V, 0.0050%-0.0120% of N, and thebalance of Fe and inevitable impurities; the components are basically the same as component formulas used in the production of HRB400 and HRB400E, steel has multiple stages, namely, by adjusting rolling processes, the production of HRB500E and HRB400E can be realized with the same chemical composition formula. Therefore, according to the production method of the HRB500E high-strength and anti-seismic rebar, a unified production technique can be adopted in the preparation of raw materials and blank, the production efficiency is improved favourably, the frequencies of adjusting preparation parameters such as temperature and the proportion of the components are reduced, the stability of products is improved, and the production efficiency is improved favourably.

Owner:SHANDONG SHIHENG SPECIAL STEEL GROUP

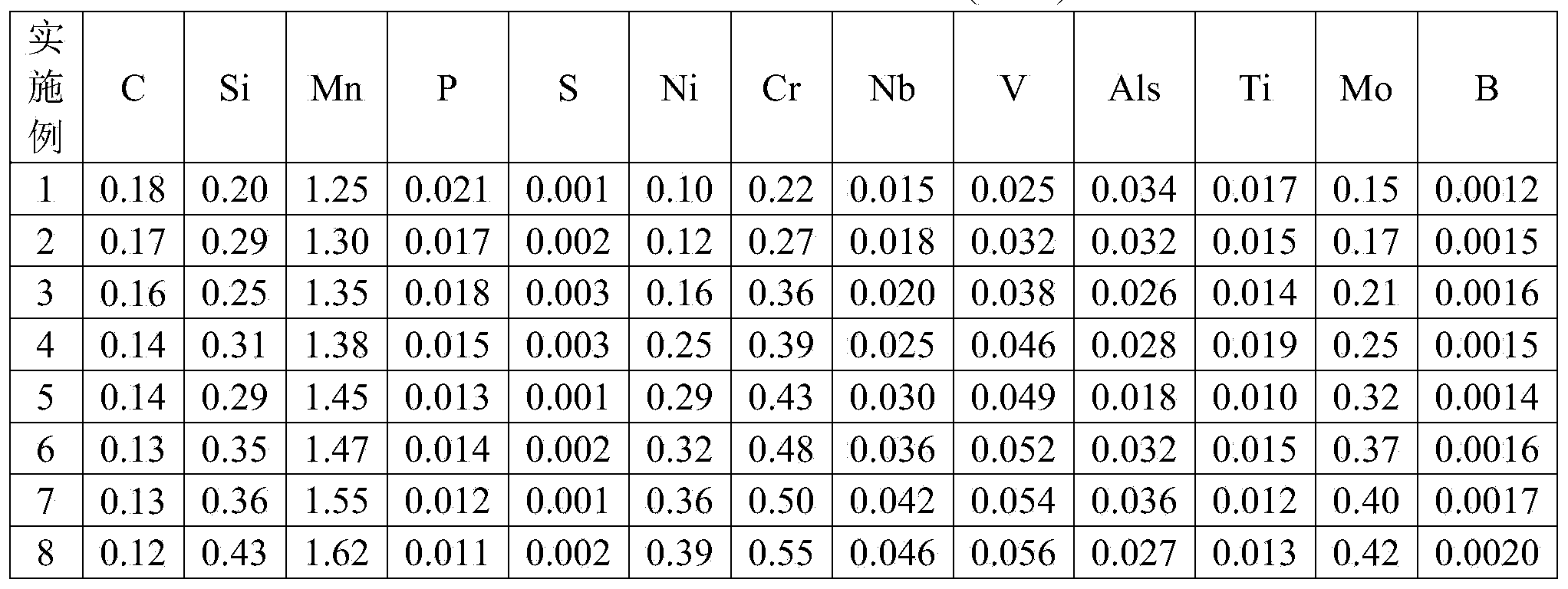

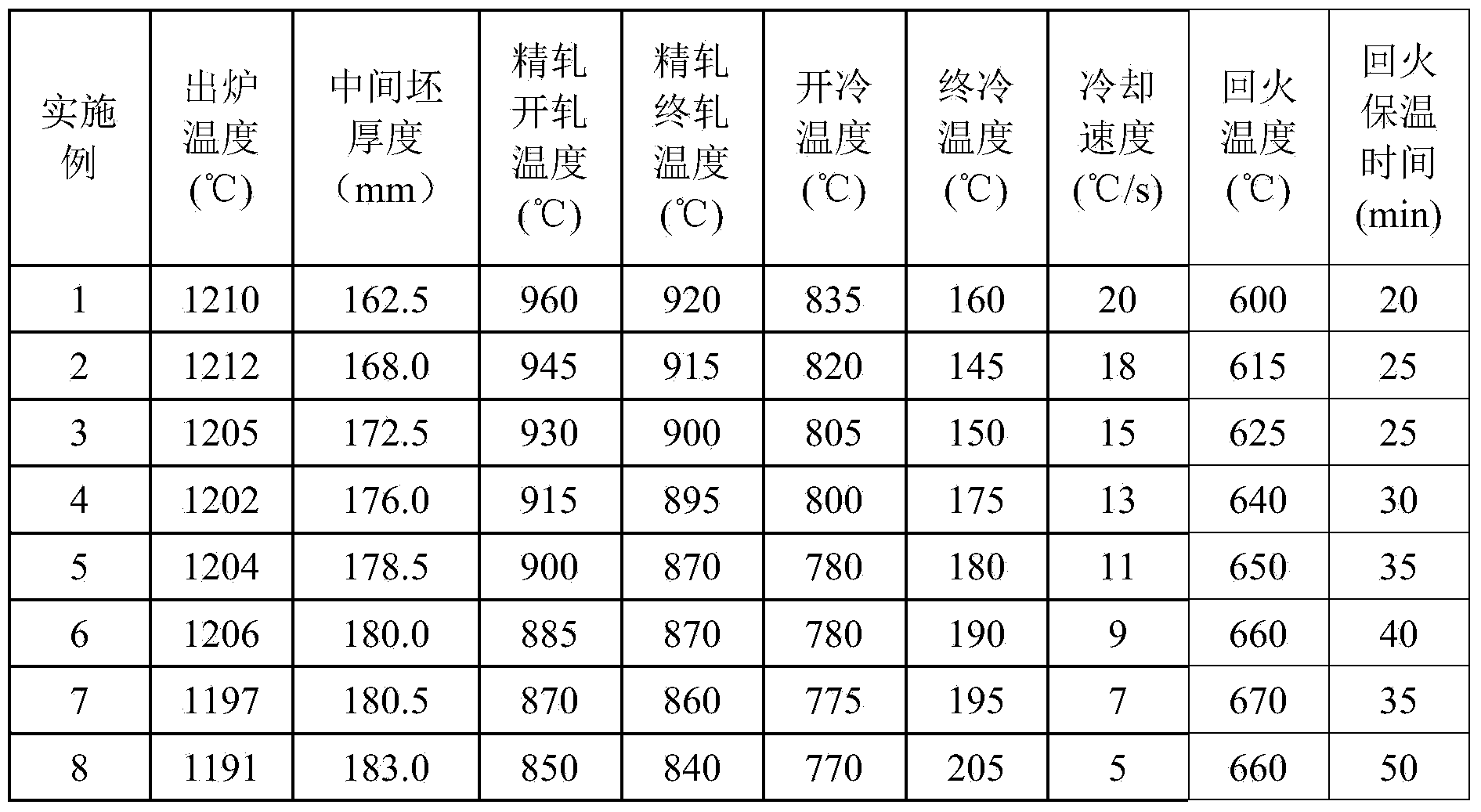

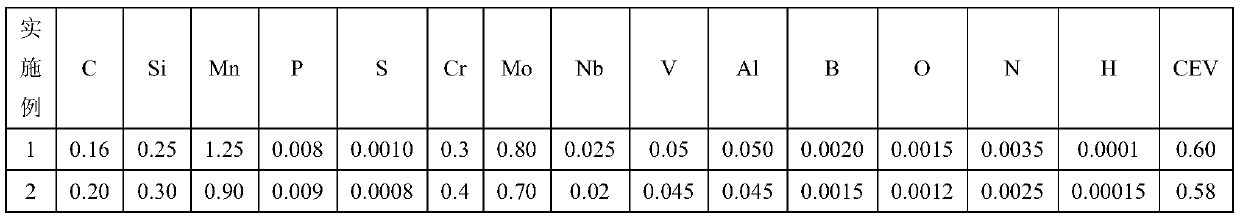

Steel plate with thickness of larger than 60mm and yield strength of 690MPa and preparation method of steel plate

The invention belongs to the fields of steel and iron and particularly relates to a steel plate with the thickness of larger than 60mm and the yield strength of 690MPa. The steel plate contains the following chemical components in percentage by weight: 0.10-0.20% of C, 0.15-0.50% of Si, 1.20-1.70% of Mn, 0.10-0.40% of Ni, 0.20-0.60% of Cr, 0.01-0.05% of Nb, 0.02-0.06% of V, 0.015-0.050% of Als, 0.008-0.025% of Ti, 0.15-0.45% of Mo, 0.0008-0.0030% of B, less than or equal to 0.025% of P, less than or equal to 0.008% of S, less than or equal to 40ppm of N, less than or equal to 20ppm of O, less than or equal to 2ppm of H and the balance of Fe and unavoidable impurities. The steel plate provided by the invention has favorable mechanical properties, plasticity and toughness, has the yield strength of larger than or equal to 690MPa, and can be applied to manufacture of large engineering machines or steel structures such as hydraulic supports for coal mines, heavy engineering machines, ocean platforms and the like.

Owner:SHANDONG IRON & STEEL CO LTD

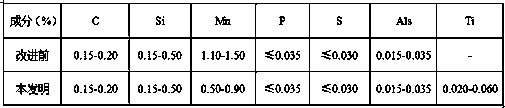

Low-cost manufacturing method of flaw-detection-ensured Q345B stage steel plate

The invention discloses a low-cost manufacturing method of a flaw-detection-ensured Q345B stage steel plate. The steel plate comprises, by mass percent, 0.15 to 0.20% of C, 0.15 to 0.50% of Si, 0.50 to 0.90% of Mn, not larger than 0.035% of P, not larger than 0.025% of S, 0.020 to 0.060% of Ti, 0.015 to 0.035% of Als, and the balance Fe and inevitable impurities. During preparing, molten iron is subject to KR desulfurization treatment firstly, the molten iron obtained after desulfurization treatment is subject to slag removal, the molten iron is converted into a converter to be smelted, outputmolten steel is subject to continuous casting and rolling, finally, the rolled steel plate is subject to stacking for slow-cooling for 24 to 72 hours, and then sampling inspection is carried out; thechemical components and the production process of the prepared Q345B stage steel plate are simple, the production cost is low, the flaw detection property is good, and the method has the good application and popularization prospects.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

High-strength hydrogen-sulfide environmental corrosion-resistant seamless petroleum casing pipe and manufacturing method thereof

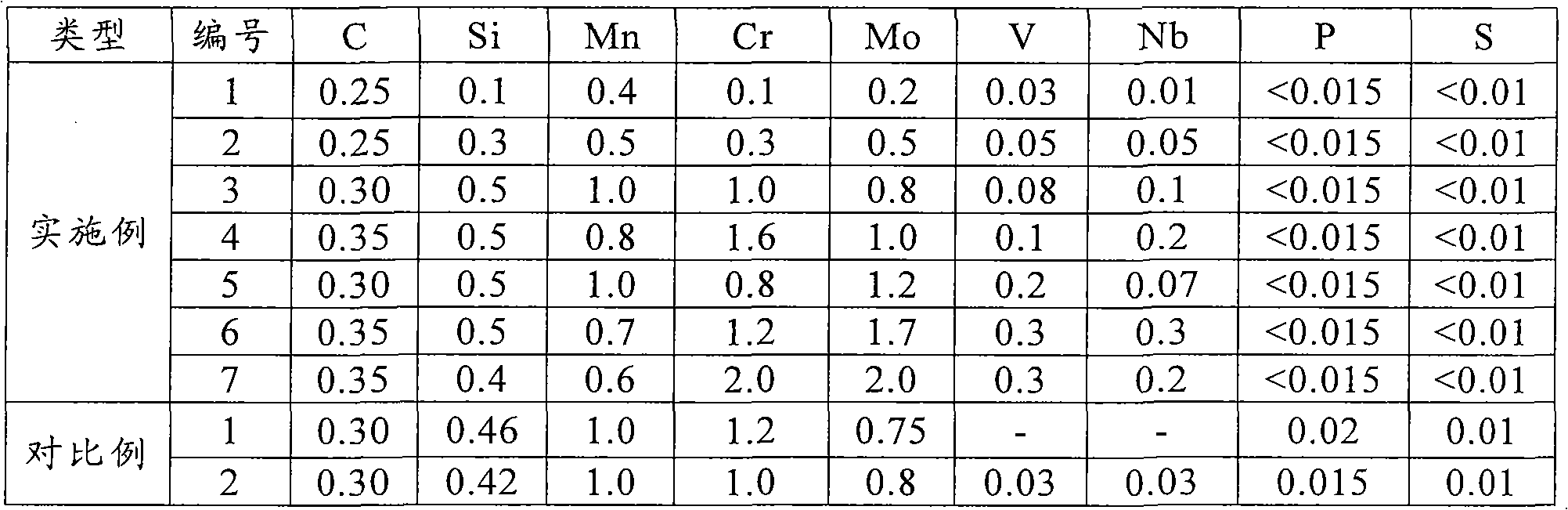

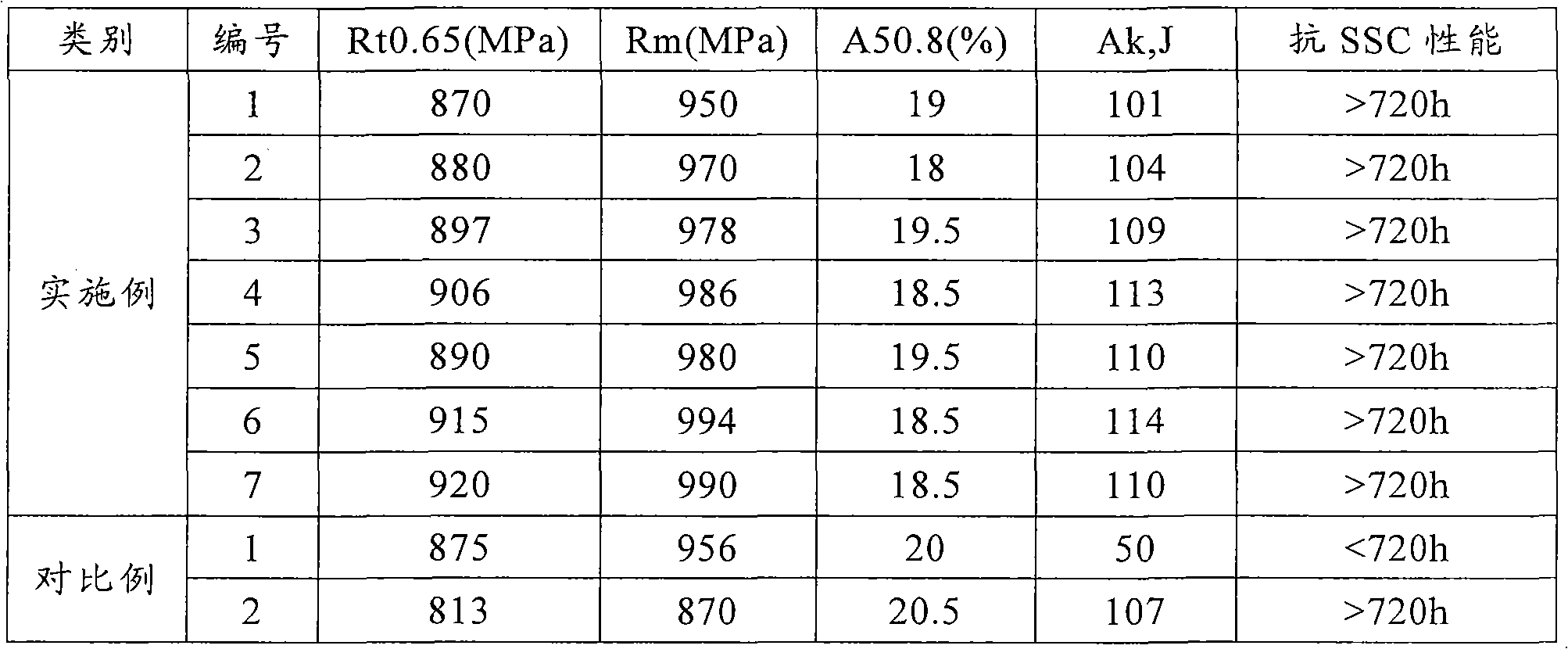

InactiveCN101929313AImprove hardenabilityImprove temper resistanceDrilling rodsDrilling casingsWell drillingHigh intensity

The invention discloses a high-strength hydrogen-sulfide environmental corrosion-resistant seamless petroleum casing pipe which conforms to a 125ksi steel grade and comprises the following components in mass percentage: 0.25-0.35 percent of C, 0.1-0.5 percent of Si, 0.4-1.0 percent of Mn, 0.1-2.0 percent of Cr, 0.2-2.0 percent of Mo, 0.03-0.3 percent of V, 0.01-0.3 percent of Nb, less than 0.015 percent of P, less than 0.010 percent of S and the balance of Fe and inevitable impurities. The seamless petroleum casing pipe can be widely applied to sulfur-contained deep-well and ultradeep-well drilling and mining operations and has quite broad application prospect. The invention also discloses a manufacturing method of the seamless petroleum casing pipe.

Owner:BAOSHAN IRON & STEEL CO LTD

Abrasion-resistant steel good in surface quality and preparation method thereof

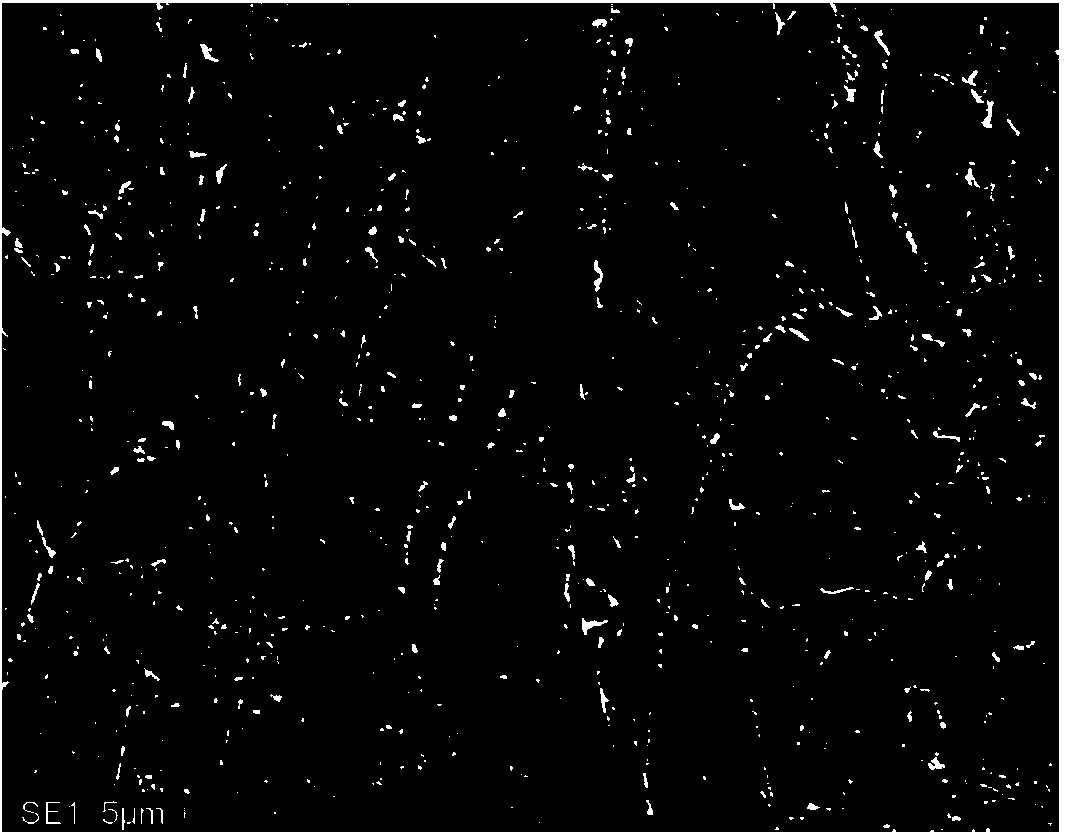

ActiveCN110499456AReduce alloy costLow susceptibility to weld cracksFurnace typesHeat treatment furnacesSteelmakingToughness

The invention relates to abrasion-resistant steel good in surface quality. The abrasion-resistant steel comprises the components of 0.12-0.20% of C, 0-0.1% of Si, 0.6-1.20% of Mn, 0.010-0.040% of Nb,0-0.01% of V, 0.010-0.030% of Ti, 0-0.04% of Al, 0-0.1% of Ni, 0-0.1% of Cu, 0.10-0.40% of Cr, 0-0.1% of Mo, 0.001-0.005% of B, 0.0010-0.0050% of Ca, 0-0.010% of P, 0-0.0015% of S, 0-0.0012% of O, 0-0.0035% of N, 0-0.0002% of H and the balance Fe; and the carbon equivalent CEV is smaller than or equal to 0.4, and PCM is smaller than or equal to 0.25. The production technological process comprisesthe steps of converter steelmaking, LF refining, VD or RH high vacuum degassing, continuous casting, heating, rolling, shot blasting treatment, quenching and tempering. The abrasion-resistant steel has the better surface quality and is free of gas pits, inclusion, pockmarks, press-in scales and other surface defects. The depth of surface mottles caused by scale disengagement is smaller than or equal to 0.1 mm, and steel plate surface coping can be not conducted. Based on element design, preheating-free welding and excellent toughness can be further achieved.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Quake-proof construction steel with yield strength of 160MPa and production method thereof

InactiveCN101775541AImprove purityHigh strengthTemperature control deviceFurnace typesProof constructionChemical composition

The invention discloses quake-proof construction steel with the yield strength of 160MPa and a production method thereof. The steel comprises the following chemical components in percentage by weight: 0.002 to 0.005 percent of C, less than or equal to 0.03 percent of Si, 0.10 to 0.50 percent of Mn, less than or equal to 0.010 percent of P, less than or equal to 0.005 percent of S, 0.002 to 0.007 percent of Mg, 0.020 to 0.070 percent of Ti, 0.010 to 0.030 percent of Nb, 0.001 to 0.003 percent of N, less than or equal to 0.050 percent of Al, and the balance of Fe and inevitable impurities. The production method thereof comprises the steps of desulfuration of molten iron, converter blowing, vacuum treatment, continuous casting, hot rolling, cooling and the like. When the yield strength of steel products exceeds 180Mpa, an annealing treatment step is added after the cooling step. Experiments prove that the quake-proof construction steel with the yield strength of 160MPa has the characteristics of low yield strength, high elongation and excellent impact toughness; and the production method of the steel has the advantages of simple process flow and low production cost.

Owner:武钢集团有限公司

Composite gas turbine discs for increased performance and reduced cost

A composite turbine disc includes a high nickel rim section and a steel bore section. The rim section is formed from a high nickel alloy which provides a higher melting point as compared to the material used for the bore section. A plating or forged welding enhanced agent layer is disposed between the bore section and rim section. Composite disc can be formed by forging the rim and bore material together, or by welding the rim and bore material together.

Owner:SIEMENS ENERGY INC

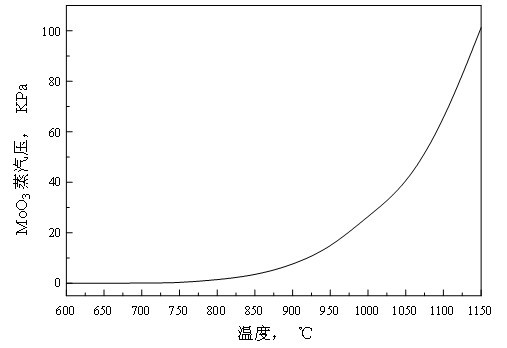

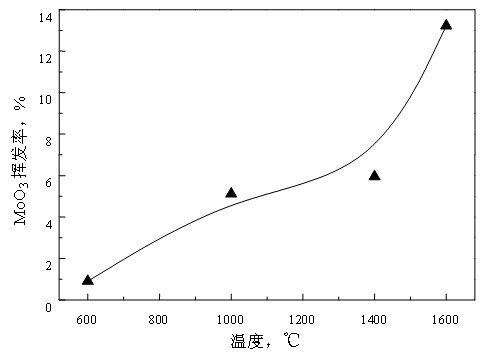

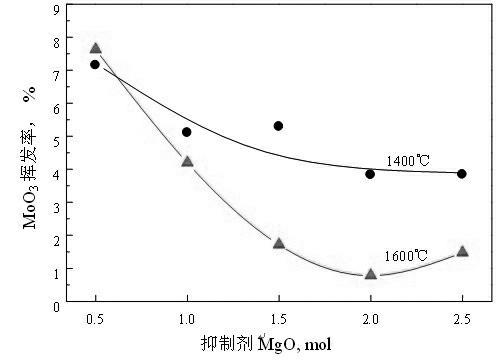

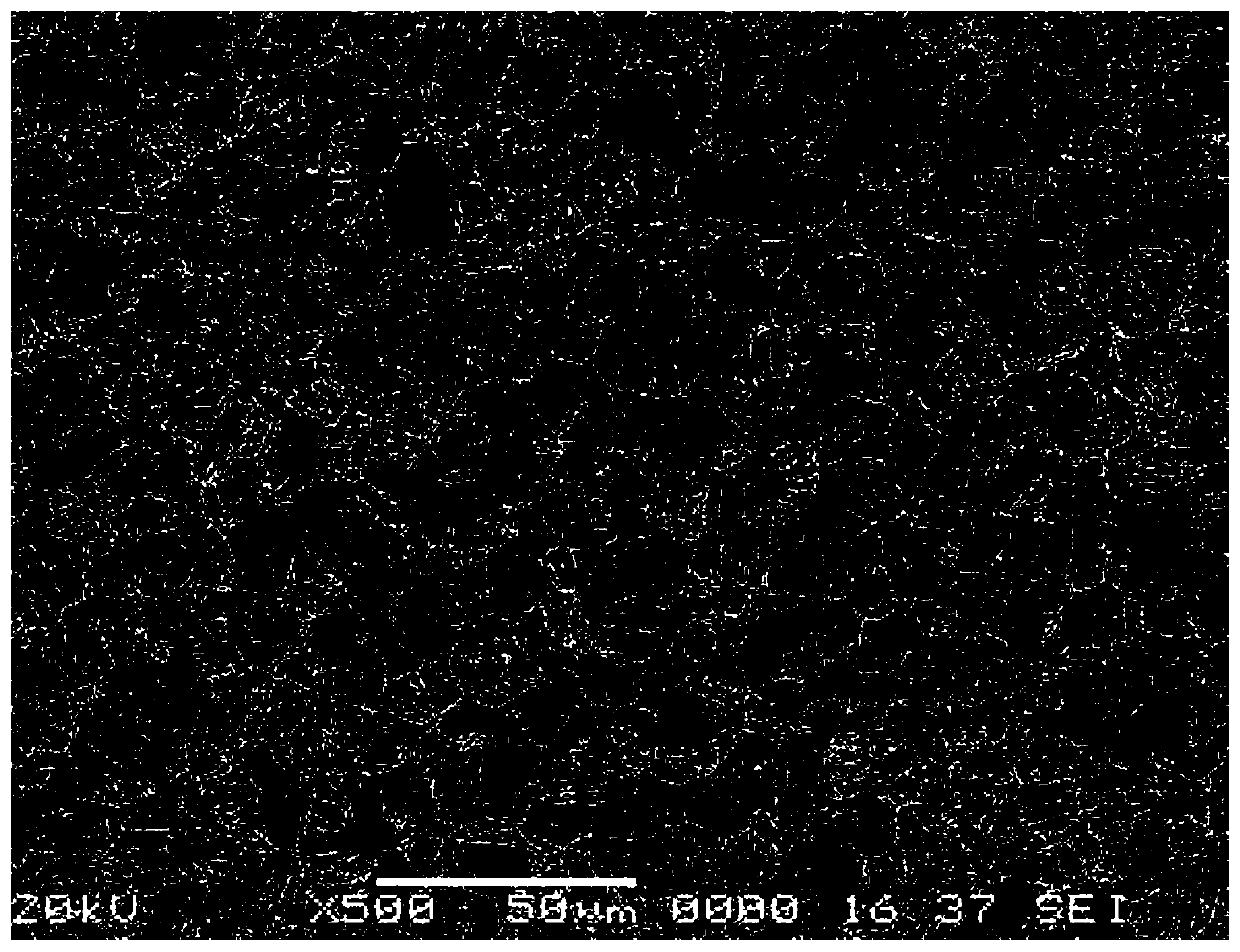

Manufacturing method of molybdenum or vanadium oxide briquetting for steelmaking alloying

The invention discloses a manufacturing method of molybdenum or vanadium oxide briquetting for steelmaking alloying, which comprises the following steps of: adding an inhibitor, a fluxing agent and a reducing agent into molybdenum or vanadium oxide; uniformly mixing the raw materials; wetting the mixture by a water-soluble adhesive; and pressing the wet mixture into a block, wherein the inhibitoris magnesia, the fluxing agent is fluorite and the reducing agent is ferrosilicon powder or carborundum powder. In the oxide briquetting, MgO contained in the magnesia is in tightly contact with MoO3or V2O5 to generate magnesium molybdate or vanadium molybdate difficult to volatilize by the solid-phase reaction, and the volatilization of MoO3 or V2O5 can be effectively inhibited; and meanwhile, the magnesia is difficult to hydrate and a water soluble compound (water glass, brine, urea-formaldehyde resin or the like) can be used as the adhesive. The method is simple and easy to operate, has high yield of directly alloying elements and can be popularized and applied in steel and iron works. Not only can the energy be greatly saved, the CO2 emission is reduced and the environmental load is reduced, but also the alloying cost of molten steel can be greatly reduced.

Owner:SHIJIAZHUANG IRON & STEEL +1

High-temperature-resistant 400 HB wearproof steel plate and production method thereof

The invention relates to a high-temperature-resistant 400 HB wearproof steel plate. The high-temperature-resistant 400 HB wearproof steel plate is prepared from chemical components including 0.15%-0.25% of C, 0.10%-0.40% of Si, 0.8%-1.30% of Mn, 0.010%-0.040% of Nb, 0.030%-0.060% of V, smaller than or equal to 0.010% of Ti, 0.03%-0.06% of Al, smaller than or equal to 0.1% of Ni, smaller than or equal to 0.1% of Cu, 0.10%-0.50% of Cr, 0.50%-1.00% of Mo, 0.001%-0.005% of B, 0.0010%-0.0050% of Ca, smaller than or equal to 0.010% of P, smaller than or equal to 0.0015% of S, smaller than or equal to 0.0015% of O, smaller than or equal to 0.0035% of N, smaller than or equal to 0.0002% of H, larger than or equal to 0.55 or smaller than or equal to 0.65 of the carbon equivalent CEV and the balanceFe and inevitable impurity elements, wherein CEV=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. In a production process, controlled cooling is carried out after rolling is completed, grains are refined, and fine Martensite lathes are obtained for following offline quenching. High-temperature tempering is adopted after quenching is completed, under the combined effect of Cr / Mo / V precipitates, it is guaranteed that the microstructure of the high-performance performance finished steel plate of the steel plate is uniform tempered sorbite, and the grains are fine; and the size is smaller than or equal to 20 micrometers, fine uniform precipitates are dispersed on a ferrite matrix, and the precipitates are carbide.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

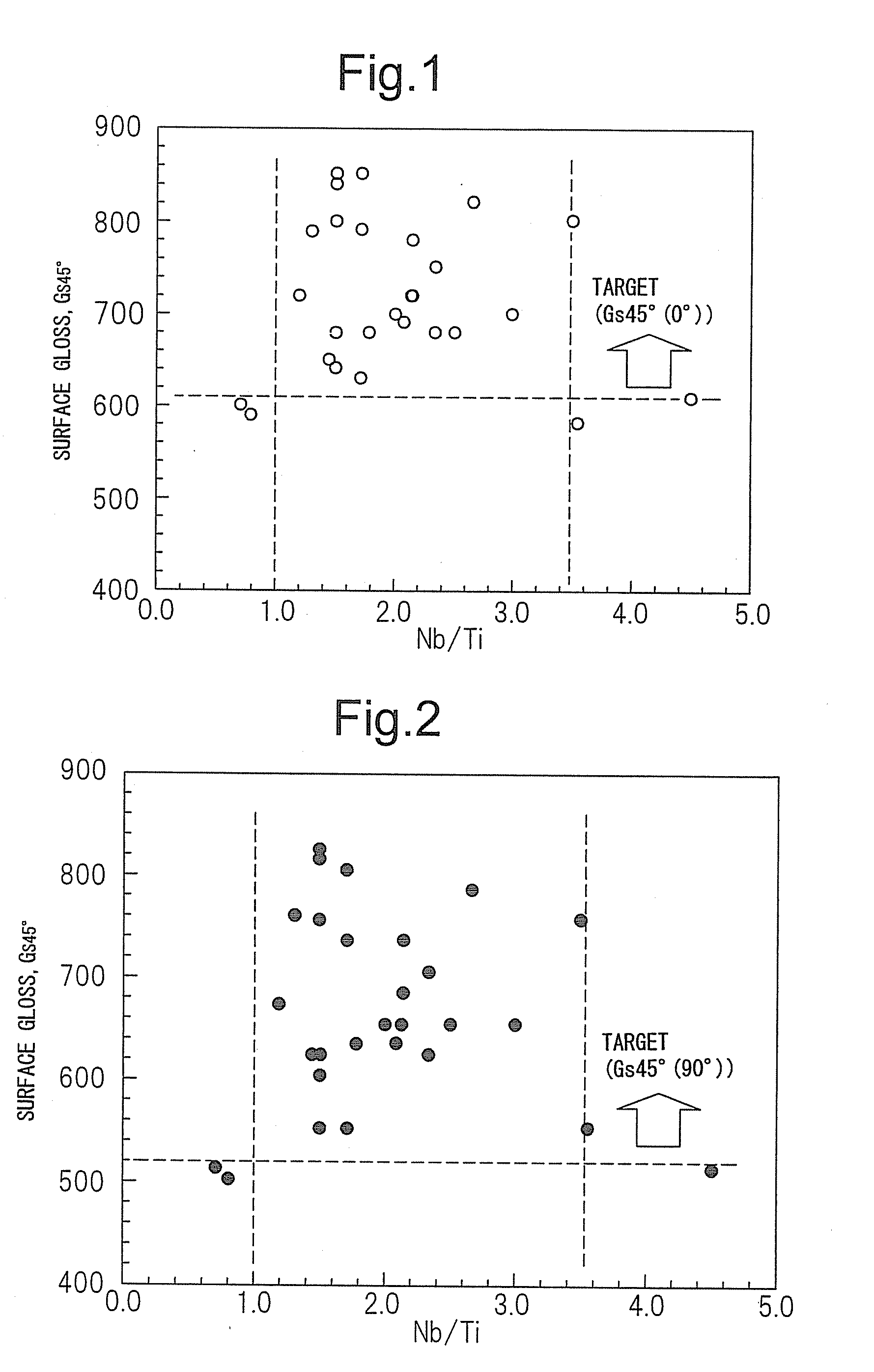

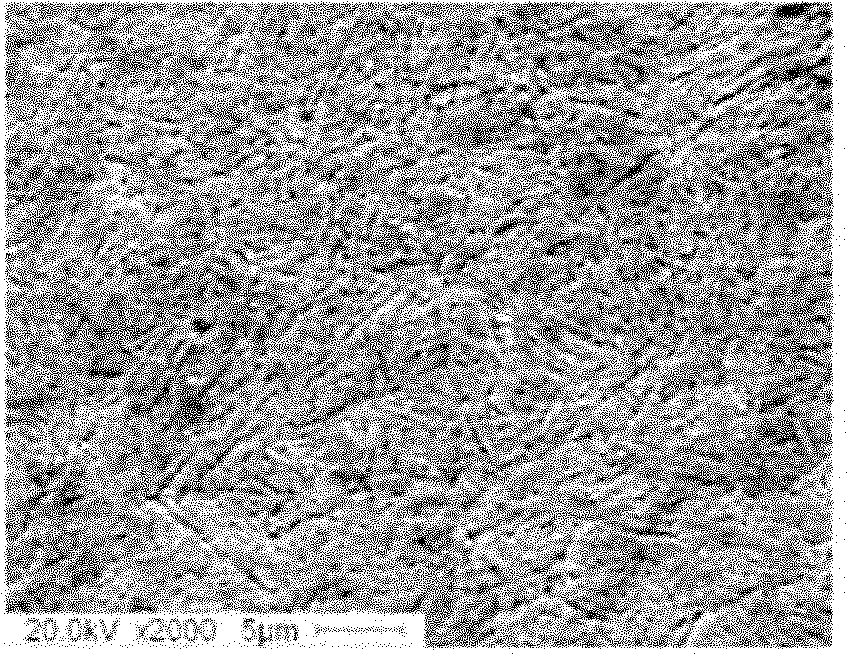

Ferritic stainless steel sheet excellent in surface gloss and corrosion resistance and method for producing same

InactiveUS20130017116A1Improve corrosion resistanceExcellent in surface glossinessFurnace typesHeating/cooling devicesImpurityHot rolled

The stainless steel sheet according to the present invention is a ferritic stainless steel which is comprised of, by mass %, C: 0.001 to 0.03%, Si: 0.01 to 1.0%, Mn: 0.01 to 1.5%, P: 0.005 to 0.05%, S: 0.0001 to 0.01%, Cr: 12 to 16%, N: 0.001 to 0.03%, Nb: 0.05 to 0.3%, Ti: 0.03 to 0.15%, Al: 0.005 to 0.5%, Sn: 0.01 to 1.0%, and has the remainder of Fe and unavoidable impurities and satisfies the relationship of 1≦Nb / Ti≦3.5. The method comprises heating a slab of stainless steel which contains the above steel ingredients, setting the extraction temperature 1080 to 1190° C., and setting the coiling temperature after the end of hot rolling 500 to 700° C. After hot rolling, the method comprises annealing the hot rolled sheet, which can be omitted, cold rolling once or cold rolling twice or more which includes processing annealing, and finish annealing the steel sheet at 850 to 980° C.

Owner:NIPPON STEEL & SUMIKIN STAINLESS STEEL CORP

High-silicon high-manganese hot-work die steel and preparation method thereof

The invention discloses a high-silicon high-manganese hot-work die steel, comprising the chemical elements in percentage by mass: 0.3-0.4% of C, 1.2-1.8% of Si, 0.6-1.5% of Mn, 3.5-4.5% of Cr, 0.8-1.0% of Mo, 0.3-0.5% of V, less than or equal to 0.03% of P, less than or equal to 0.03% of S, and the balance of Fe and other inevitable impurities. Correspondingly, the invention also discloses a preparation method of the high-silicon high-manganese hot-work die steel. The high-silicon high-manganese hot-work die steel not only has high tempering resistance and good impact toughness, but also can become a low-cost economic type hot-work die steel due to reduction of the content of noble alloy elements such as chromium, molybdenum and the like.

Owner:宝武特种冶金有限公司

Q&P steel with gradient structure and manufacturing method thereof

InactiveCN105463307AIncreased strength and plasticityEnsure process stabilitySolid state diffusion coatingCarburizingAustenite

The invention discloses Q&P steel with a gradient structure. The Q&P steel comprises, by weight percent, 0.14-0.29% of C, 1.1-2.8% of Si, 1.8-3.0% of Mn, 0.5-1.9% of Cr, 1.5-3.1% of Al, smaller than or equal to 0.01% of S, smaller than 0.01% of P and the balance Fe. A manufacturing method of the Q&P steel includes the steps of austenitizing, carburizing, quenching, tempered carbon distributing and quenching. According to the Q&P steel and the manufacturing of the Q&P steel, technology stability and organization gradient can be ensured in production of large-size products, strength of the steel is improved, good toughness of the steel is also ensured, and low alloying cost is low.

Owner:ZHONGBEI UNIV

Steel plate for polar ocean engineering and preparation method of steel plate

ActiveCN112048665AGood welding performanceLow costManufacturing convertersFurnace typesSlow coolingCorrosion resistant

The invention discloses a steel plate for polar ocean engineering and a preparation method of the steel plate. The steel plate is prepared from the components in percentage by mass: 0.06%-0.09% of C,0.20%-0.35% of Si, 1.48%-1.63% of Mn, 0.020%-0.035% of Nb, 0.010%-0.020% of Ti, 0.020%-0.035% of V, 0.08%-0.17% of Ni, 0.015%-0.040% of Als, less than or equal to 0.013% of P and less than or equal to0.005% of S. The preparation method of the steel plate comprises the steps: primarily smelting, refining and casting are conducted, a casting blank is obtained, and then slow cooling is conducted; the slowly-cooled casting blank is heated and then rolled, and the steel plate is obtained; and the steel plate is cooled. The type of steel has excellent comprehensive properties such as high strength,low temperature resistance, easy welding, corrosion resistance and the like, and is good in low-temperature aging impact toughness.

Owner:LAIWU STEEL YINSHAN SECTION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com