Excellent-cold-bending-performance steel plate with yield strength larger than 1100 MPa and manufacturing method thereof

A technology of yield strength and cold bending performance, applied in the field of iron and steel metallurgy, can solve the problems of difficult to guarantee ultra-low temperature toughness, difficult to guarantee the cold bending performance of steel plates, and waves at the edge and core of the steel plate, so as to reduce the delayed cracking and bending of the steel plate. The risk of bending cracks, the cost saving of alloys, and the effect of stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

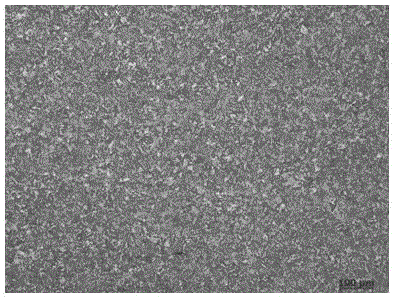

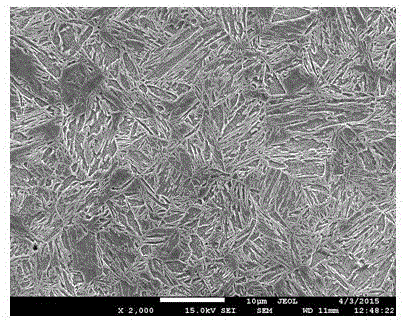

[0062] The thickness of the test steel plate of Example 1 was 5 mm. The plate shape is very good, and the unevenness is ≤3mm / m.

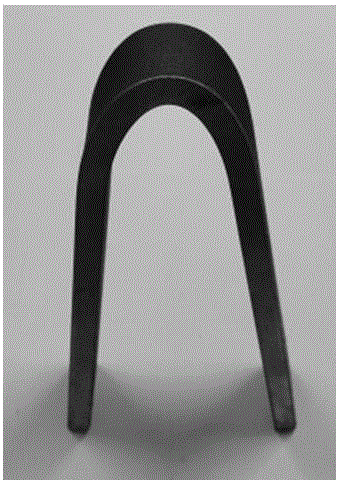

[0063] image 3 It is the appearance of the test steel plate in Example 2 after being bent at 180° according to the national standard GB / T232 laboratory. Bending diameter d=3a. No cracks were observed after bending, and the surface was good.

[0064] Examples 1 and 4 After the test steel is cold-formed at 90°, the steel plate has a width b≥500 mm and a length L=2000 mm. Cold bending radius r=3.0a, where a is the thickness of the steel plate. After cold bending, the surface of the steel plate is good without cracks.

[0065] The invention adopts controlled rolling and controlled cooling and quenching + strong cold straightening technology, and controls from the perspectives of chemical composition design, base metal structure, inclusions, center segregation, quenching temperature and time, etc., to ensure that while achieving ultra-high strength...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com