Ferritic stainless steel sheet excellent in surface gloss and corrosion resistance and method for producing same

a technology of which is applied in the direction of heat treatment equipment, heating/cooling devices, furnaces, etc., can solve the problems of not studying the effect of surface glossiness at all, and it is difficult to say that sus430lx and sus430j1l will have economic sufficient in the future, so as to achieve excellent surface gloss and corrosion resistance, not increase in alloy cost or manufacturing cost, and excellent economic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

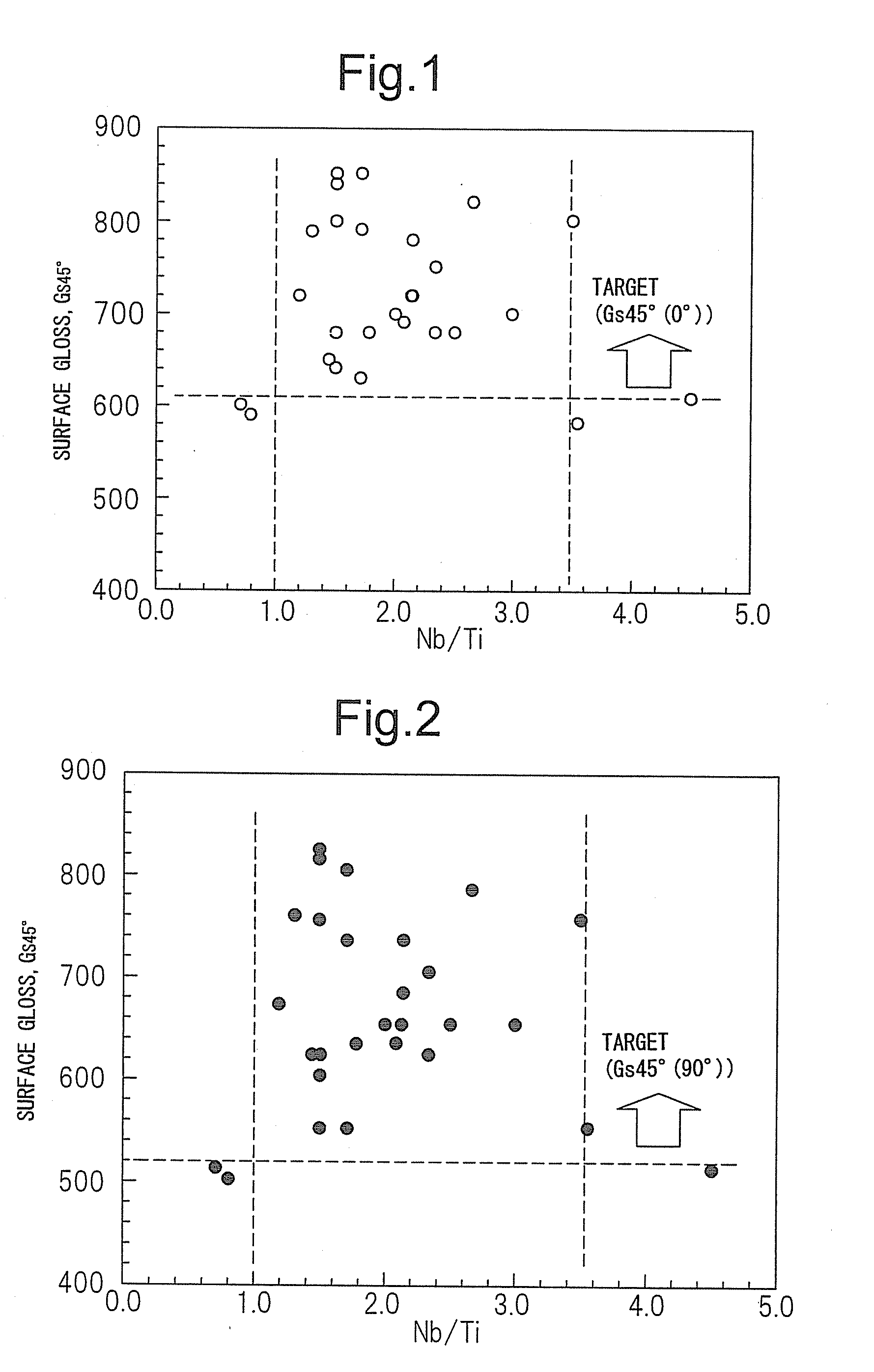

[0050]Examples of the present invention will be explained as follows.

[0051]A ferritic stainless steel which has the ingredients of Table 1 was smelted, hot rolled by an extraction temperature of 1150 to 1220° C., and coiled by a coiling temperature of 480 to 750° C. to obtain hot rolled steel sheet of a thickness of 4.0 to 6.0 mm. The hot rolled steel sheet was annealed, or not, and was cold rolled once or twice interspaced by process annealing to produce 0.4 to 1.0 mm thick cold rolled steel sheet. The obtained cold rolled steel sheet was treated by finish annealing at a temperature of completion of recrystallization of 870 to 1020° C. and was treated by ordinary pickling to obtain the No. 2B product in surface specifications prescribed in JIS G 4307. For the ordinary pickling, for example, dipping in an alkali salt bath (430° C.), then treatment by neutral salt electrolysis (50° C., Na2SO4) may be used.

For the ingredients of the steel, both of the ranges prescribed by the present ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com