Patents

Literature

128results about How to "Ensure process stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

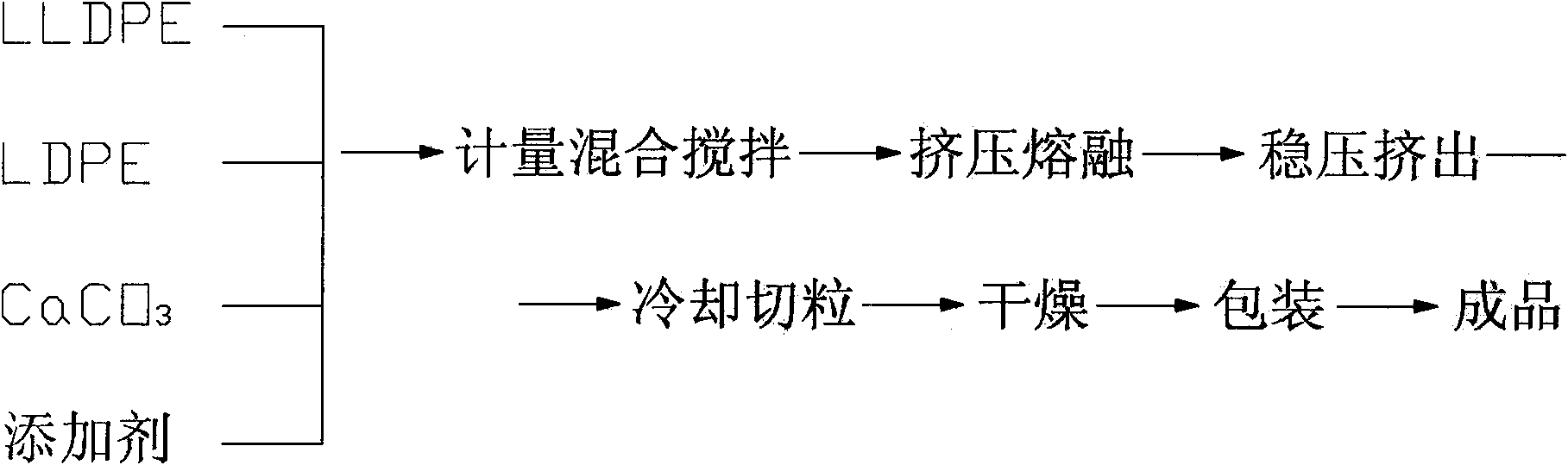

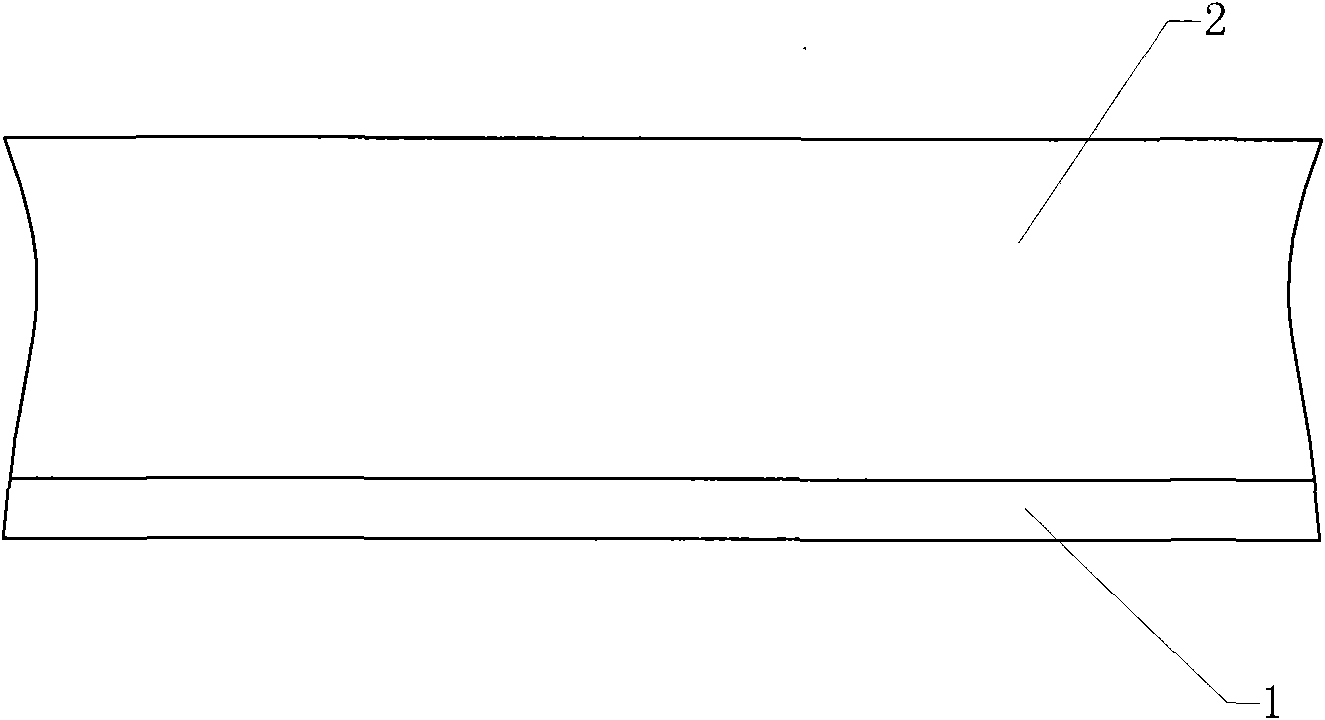

Ultrathin high porosity film and preparation method thereof

The invention discloses an ultrathin high porosity film and a preparation method thereof. The film comprises the following components by weight percent: 40-50% of : PE(LLDPE / LDPE), 45-55% of calcium carbonate and 3-5% of modified additives (plastic additive and film forming additive). The preparation method of the invention comprises the following steps: (1) breathable film master batch process flow and (2) breathable film process flow. The product of the invention can replace imported products, thus reducing the production cost of the breathable film, improving the current dilemma of foreignmonopoly, filling the domestic blank to develop and produce the breathable film material with independent intellectual property rights and having practical and great economic benefit and social benefit.

Owner:ZHEJIANG YUEHAN TECH BREATHABLE MATERIAL

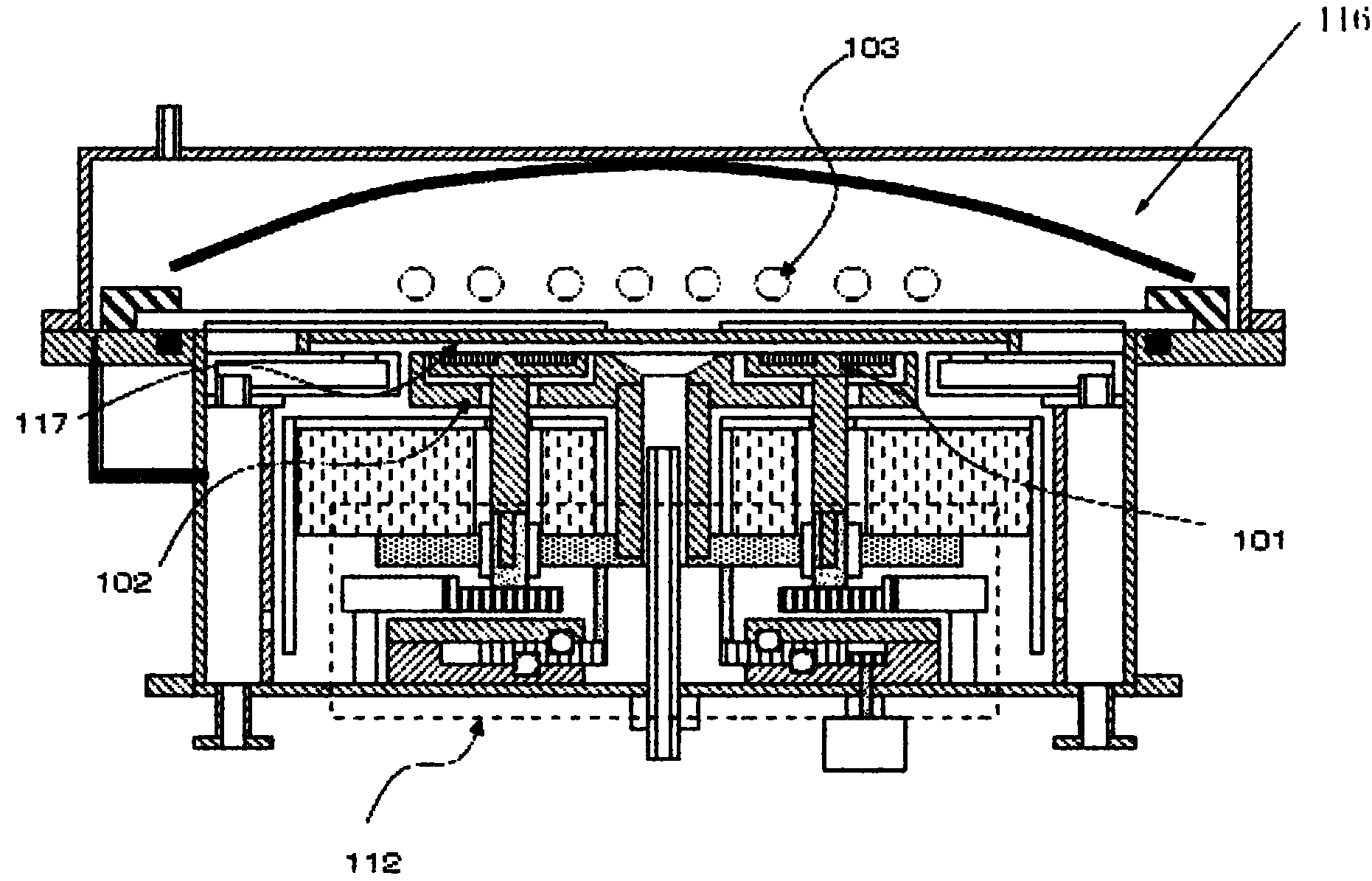

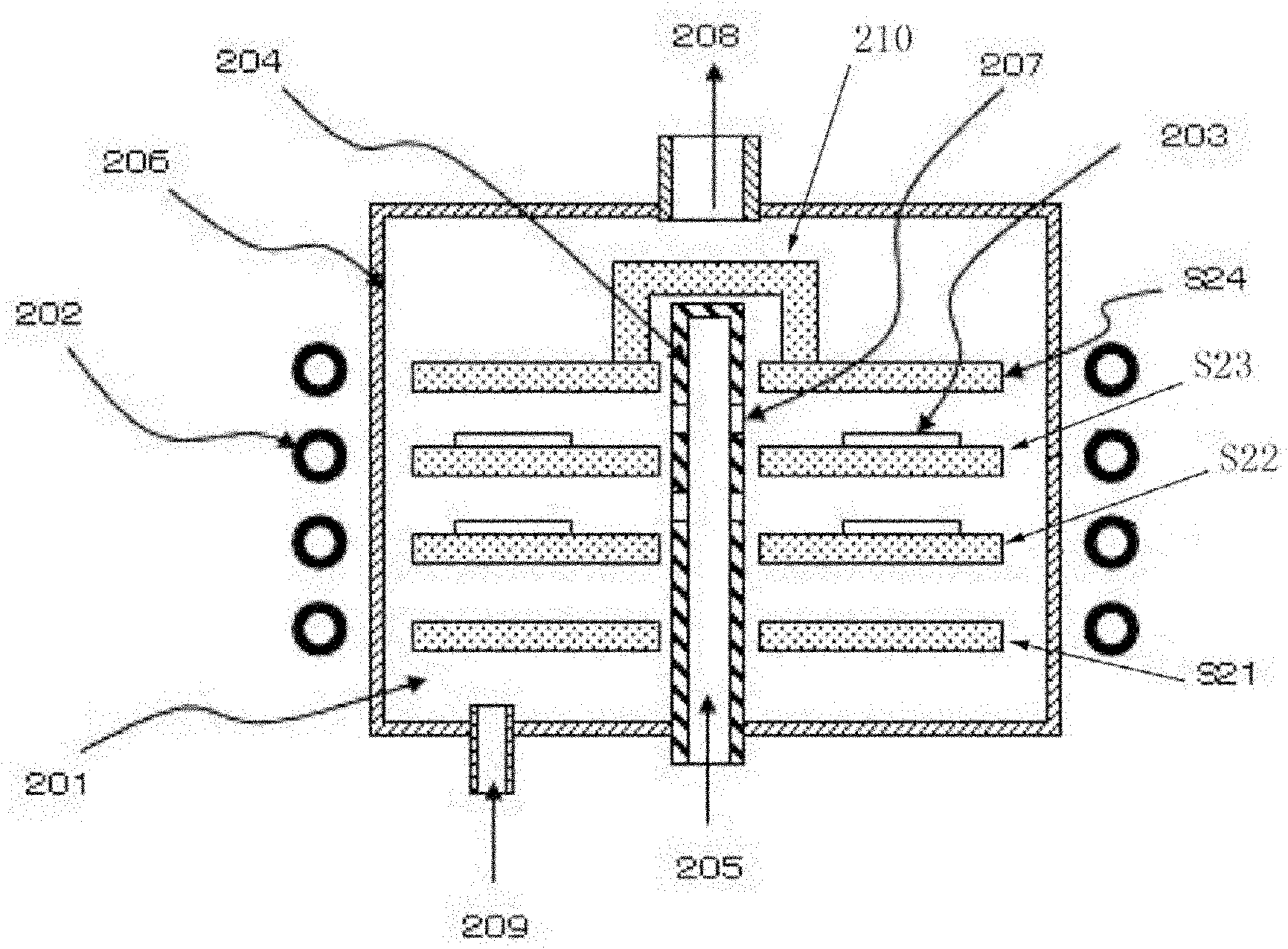

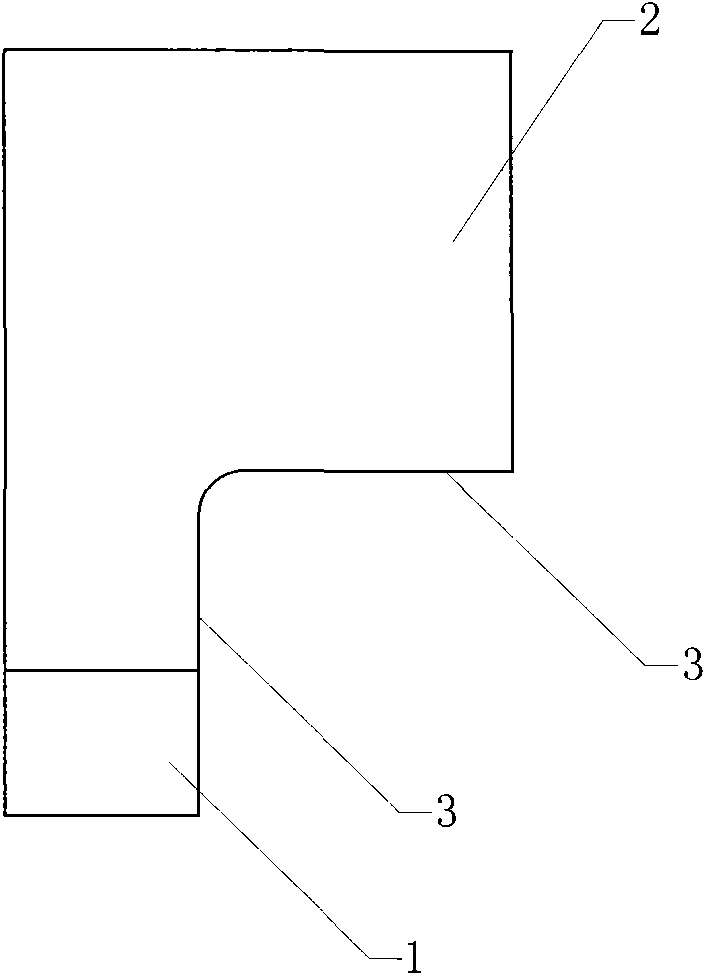

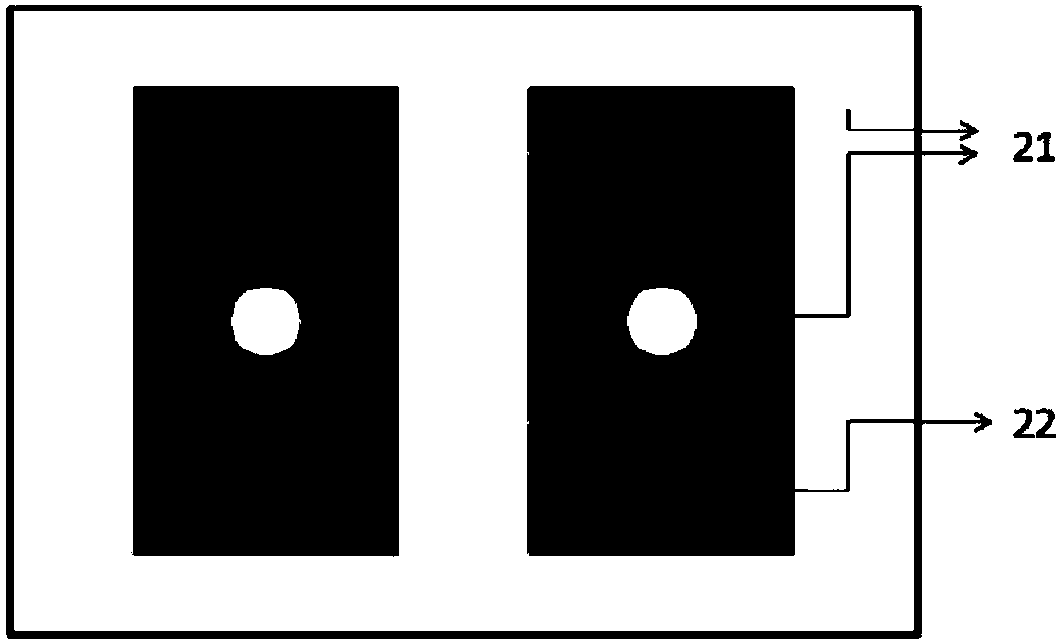

Pallet device and crystallized film growth device

ActiveCN102485953AIncrease production capacityIncrease profitSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringProduct gas

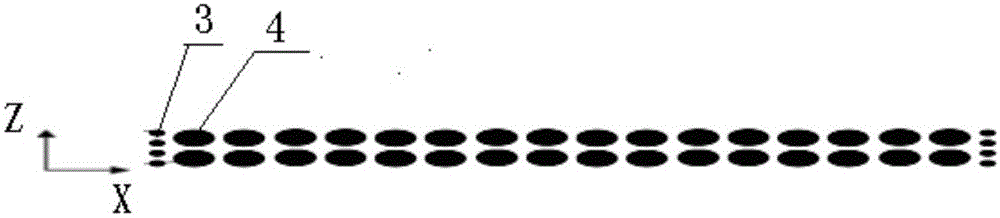

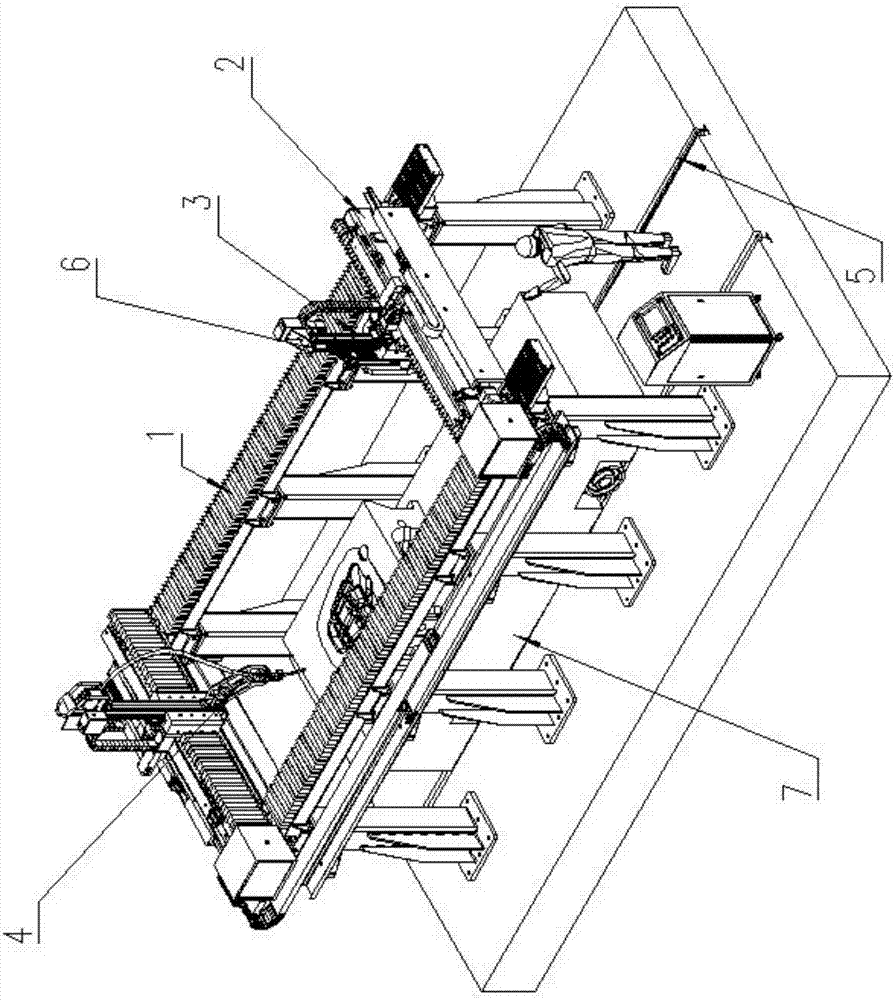

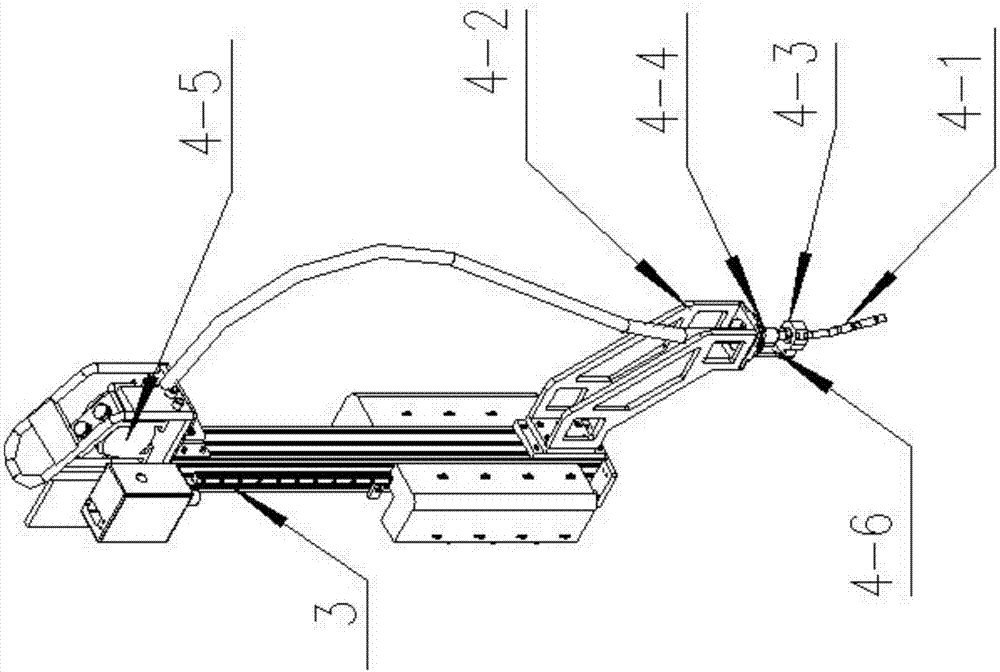

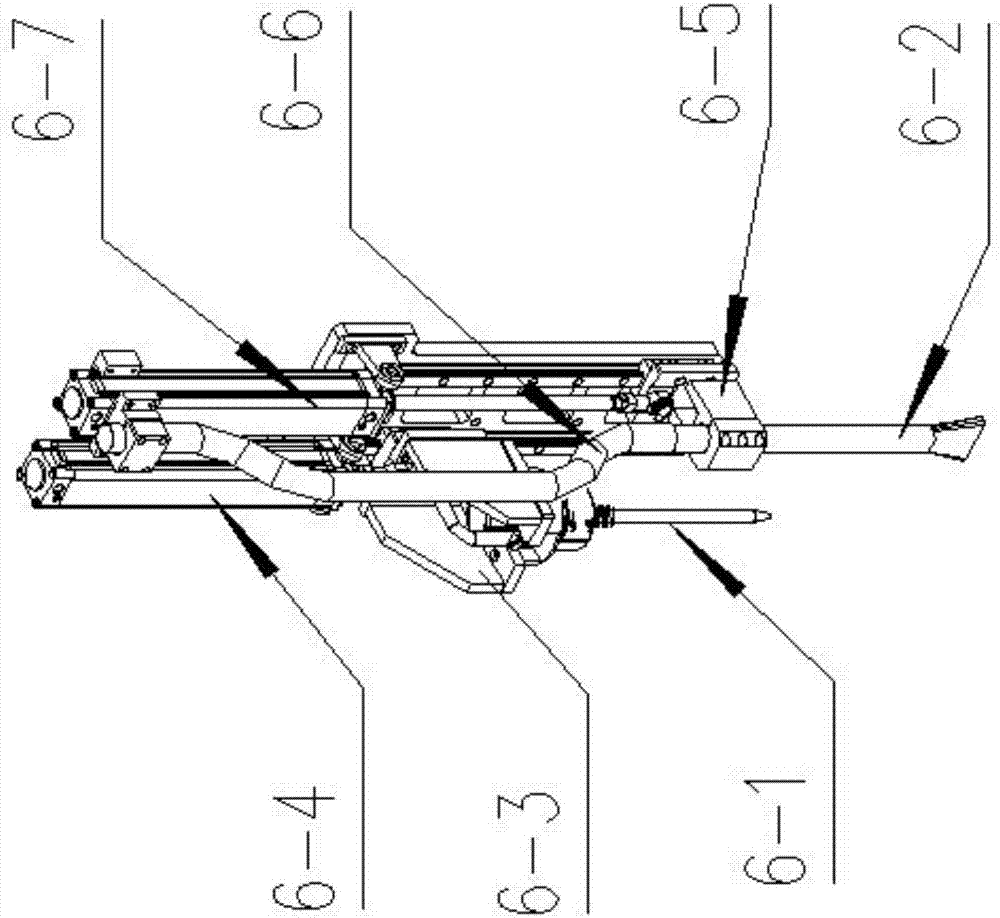

The invention, belonging to the technical field of crystallized film growth, particularly provides a pallet device for bearing processed substrates. The ballet device comprises a plurality of pallets arranged laminatedly along with a length wise direction, and certain space exists between adjacent pallets. In addition, the invention further provides a crystallized film growth device, comprising a process cavity, a process gas conveying system and an exhaust system, wherein the process cavity is provided with the pallet device for bearing the substrates in the process. The pallet device and the crystallized film growth device having the pallet device can increase the number of the substrates processed by the process at every time with low cost and increase the productivity.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

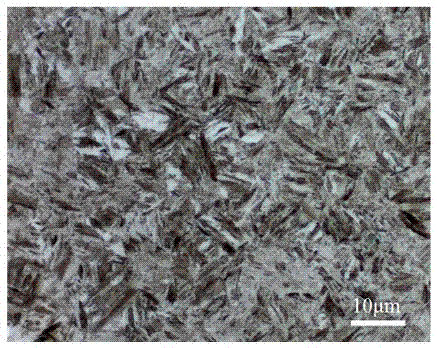

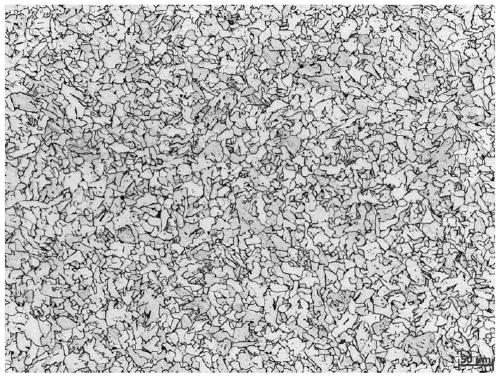

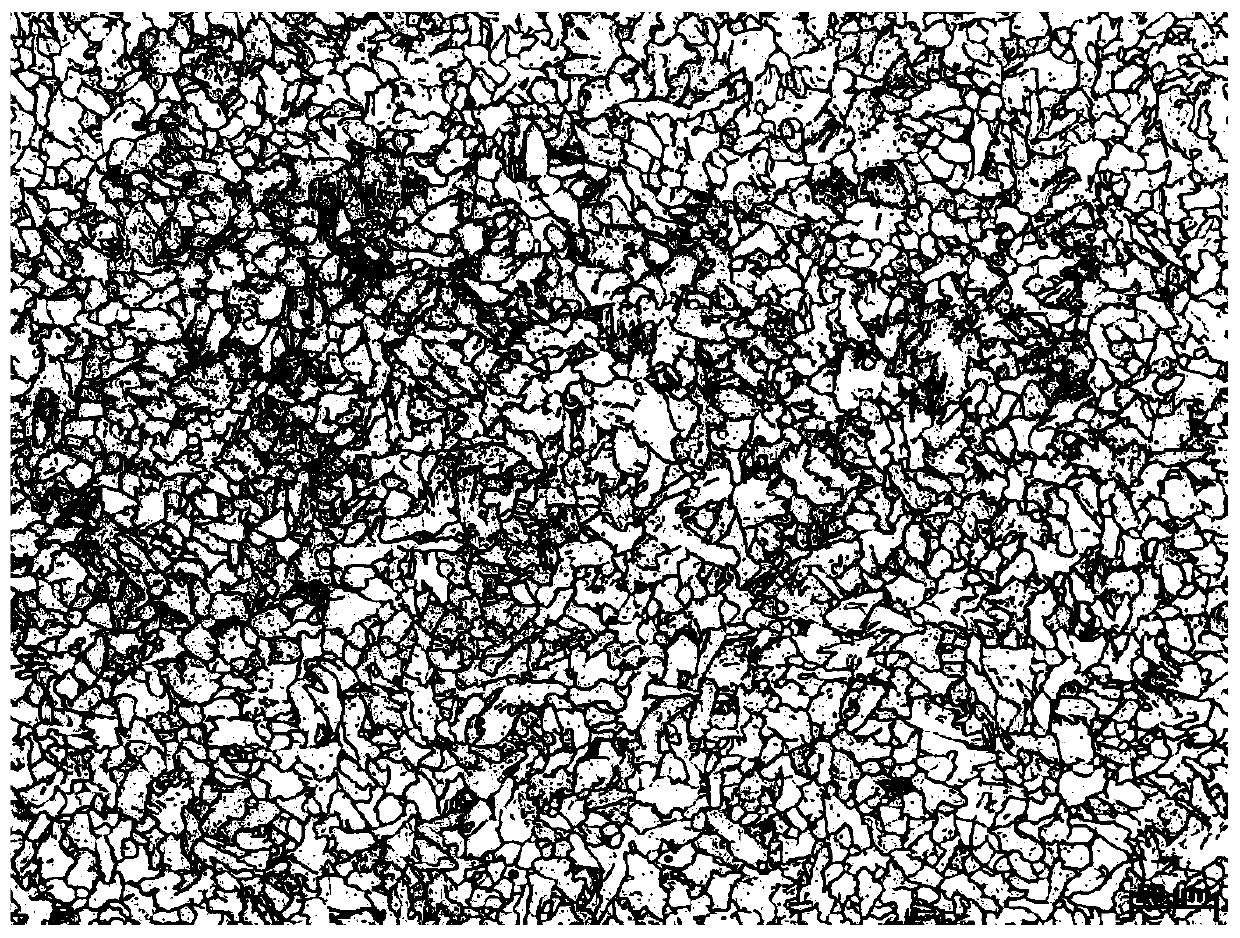

Low-alloy, high-strength and high-toughness composite phase steel and heat treatment method thereof

InactiveCN103045950AGuaranteed uniformityEnsure process stabilityHeat treatment process controlMartensite transformationAlloy

The invention discloses low-alloy, high-strength and high-toughness composite phase steel. The low-alloy, high-strength and high-toughness composite phase steel comprises the following components in mass percentage: 0.40-0.90% of C, 0.5-2.0% of Si, 0.5-3.0% of Mn, 0.5-4.0% of Cr, 2.0-5.0% of Al, less than or equal to 0.01% of S, less than or equal to 0.01% of P and the balance of Fe. The invention further discloses a preparation method of the low-alloy, high-strength and high-toughness composite phase steel, comprising the following steps of: firstly, quickly heating steel to 850-1000 DEG C, and keeping the constant temperature for 2-30min so as to austenitize a workpiece sufficiently; secondly, quickly quenching to -20 to 50 DEG C so as to obtain a partially supersaturated martensite and an austenite without martensitic transformation; thirdly, keeping the constant temperature of the workpiece at 300-600 DEG C for 5-600min for carbon distribution; and finally, quenching to room temperature to obtain the composite phase steel. The preparation method is simple in process; by the preparation method, steel strength is improved, good toughness is ensured, and the low-alloying cost is low; and the preparation method is wide in industrial application prospect.

Owner:ZHONGBEI UNIV

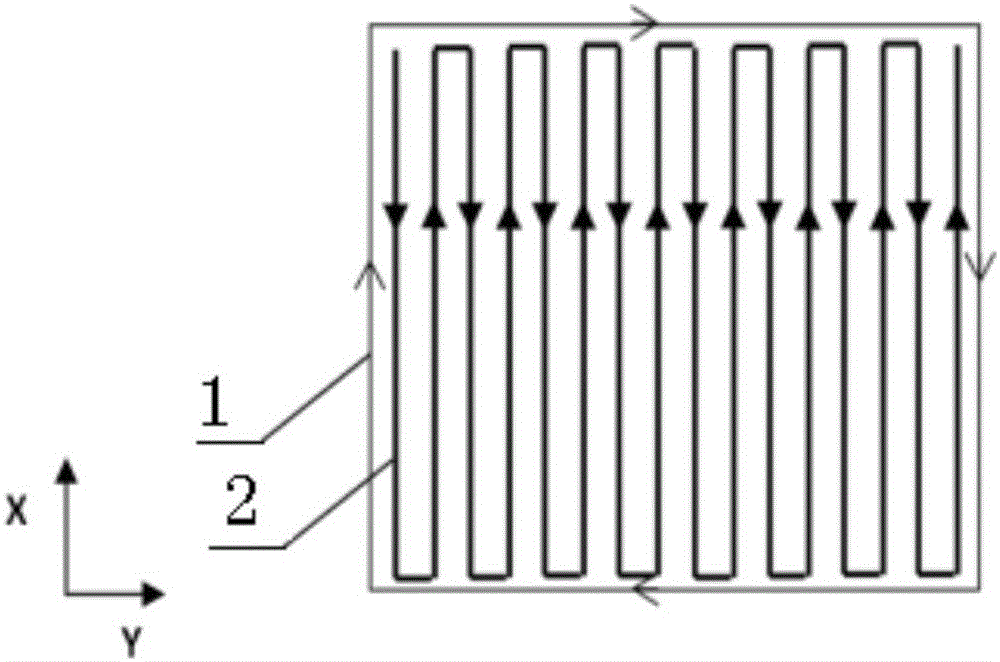

Metal laser selective melting method

InactiveCN105665704AQuick scanEnsure surface refinementAdditive manufacturing apparatusIncreasing energy efficiencyLaser scanningMetal powder

The invention provides a metal laser selective melting method. The metal laser selective melting method is characterized in that two kinds of lasers with different powers are adopted for conducting laser melting on metal powder zones needling to be melted; during melting, the lasers with the low power firstly conduct scanning on outline boundaries of the metal powder zones; then the lasers with the high power conduct scanning on internal zones of the metal powder zones; and during scanning, the thickness of a metal powder layer obtained by scanning with the lasers with the high power one time is integral multiples of the thickness of the metal powder layer obtained by scanning with the lasers with the low power one time. According to the metal laser selective melting method, the efficiency of the laser molding process is improved, and meanwhile, the surface quality of a metal part is guaranteed; and in other words, while the stability and the molding quality of the overall process are guaranteed, the building speed of metal laser selective melting equipment is improved as a whole.

Owner:ANHUI TUO BAO ADDITIVE MFG TECH CO LTD

3D mold overlaying intelligent robot

ActiveCN106994577AReduce the impactGuaranteed temperatureWelding/cutting auxillary devicesAuxillary welding devicesSlagEngineering

The invention discloses a 3D mold overlaying intelligent robot. The 3D mold overlaying intelligent robot comprises two X-axle cross beams; two Y-axle cross beams are mounted between the top surfaces of the two X-axle cross beams, and are driven to move along the X-axle cross beams through respectively independent transmission devices; Z-axle vertical guide rails are respectively mounted on the two Y-axle cross beams, and are driven to move along the Y-axle cross beams through Z-axle transmission devices; a welding head is slidingly mounted on the Z-axle vertical guide rail of one Y-axle cross beam; a welding destressing device is mounted on the Z-axle vertical guide rail of the other Y-axle cross beam, and comprises a high-frequency hammering device and a dust sucking device; and a constant-temperature mold heating device is mounted below the middle of the two X-axle cross beams. The 3D mold overlaying intelligent robot guarantees the temperature in the welding process, improves the welding quality, reduces the influence on the welding precision by higher temperature, adopts the welding destressing device to remove slag to guarantee the flatness after welding, and can be used for repairing a mold and printing a new mold.

Owner:重庆佛思坦智能装备有限公司 +3

Setting Method of Revolutions per Minute on Real Time of Rotatiing Cutting Tool, and Control Device

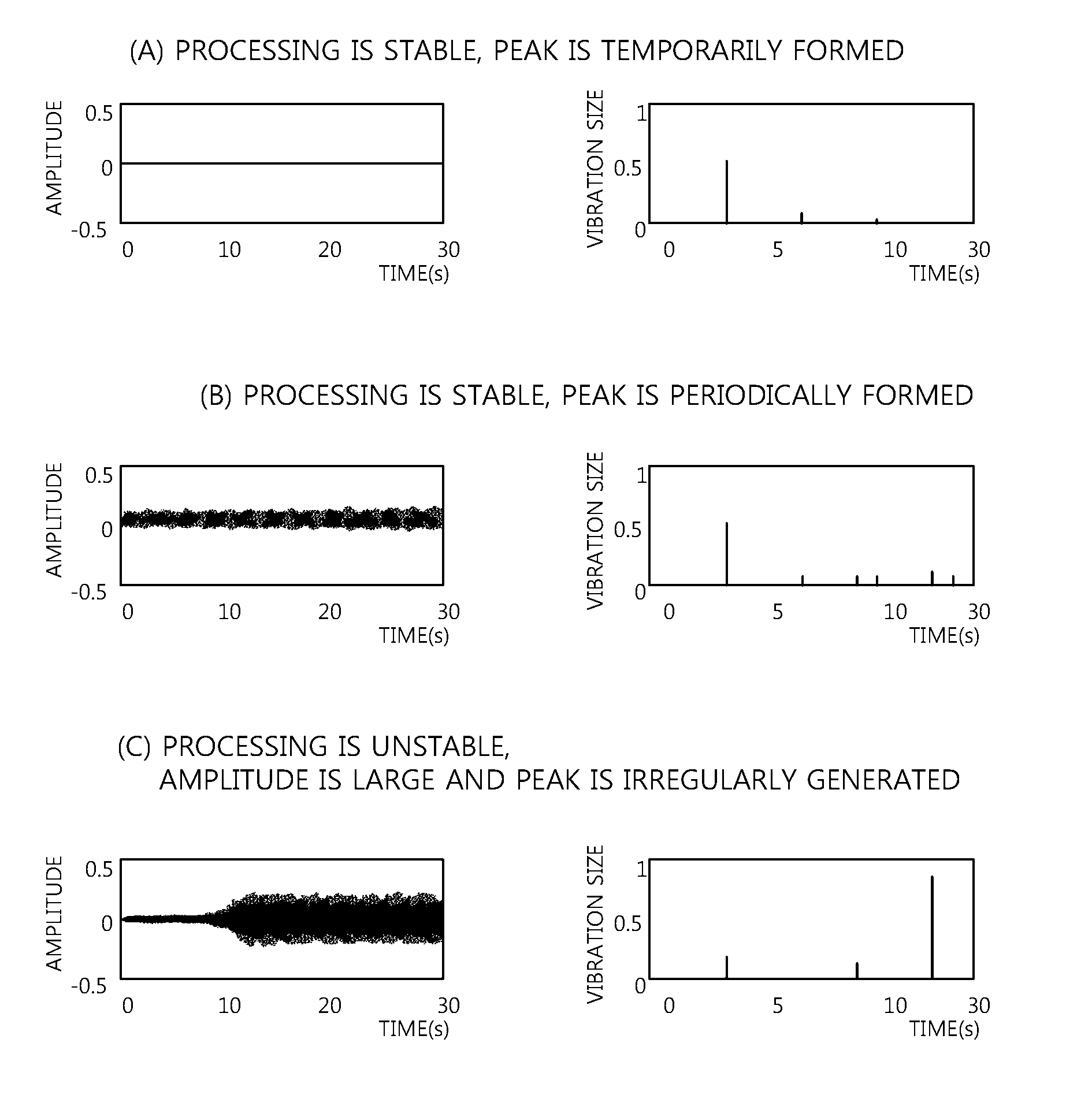

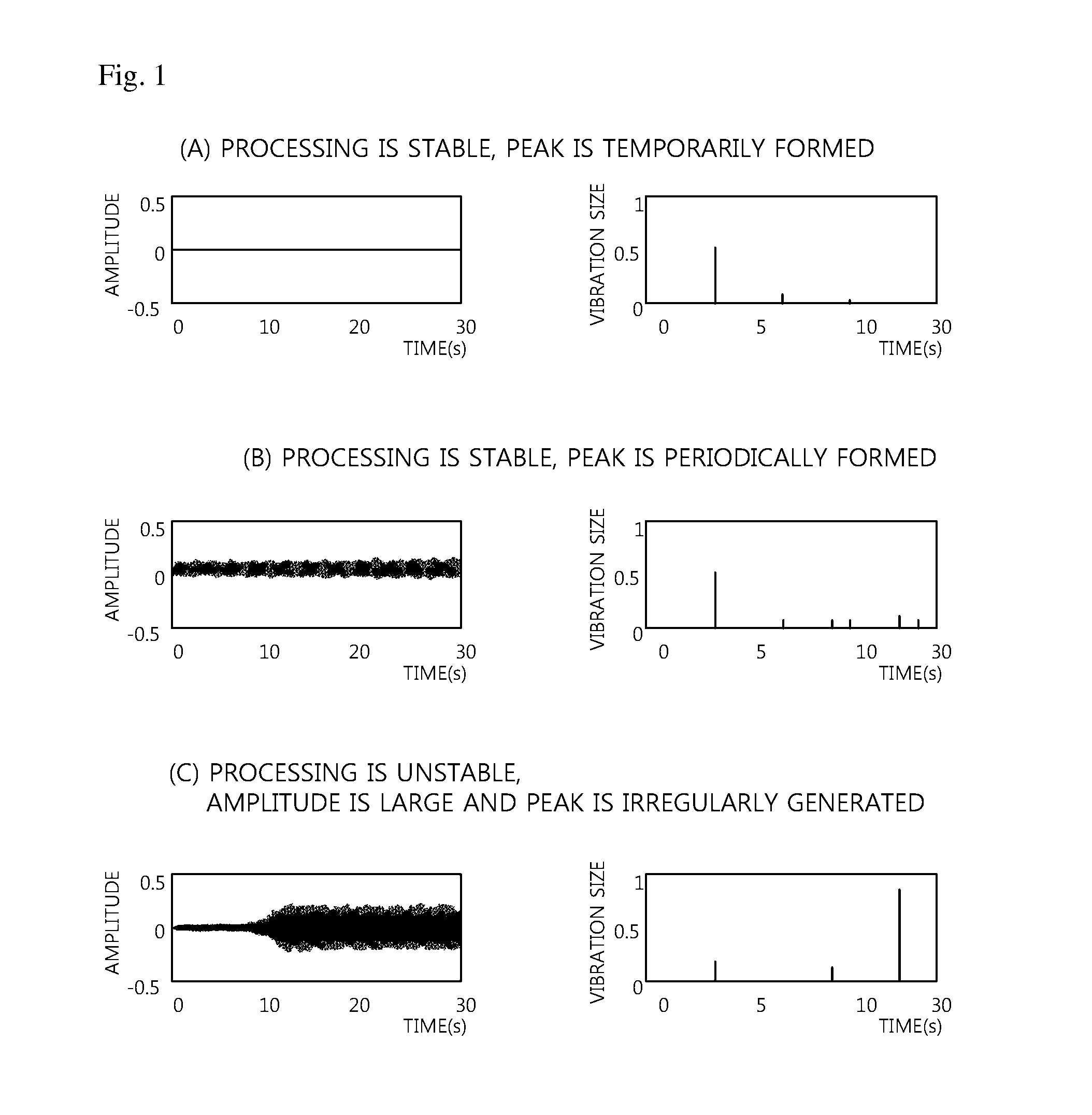

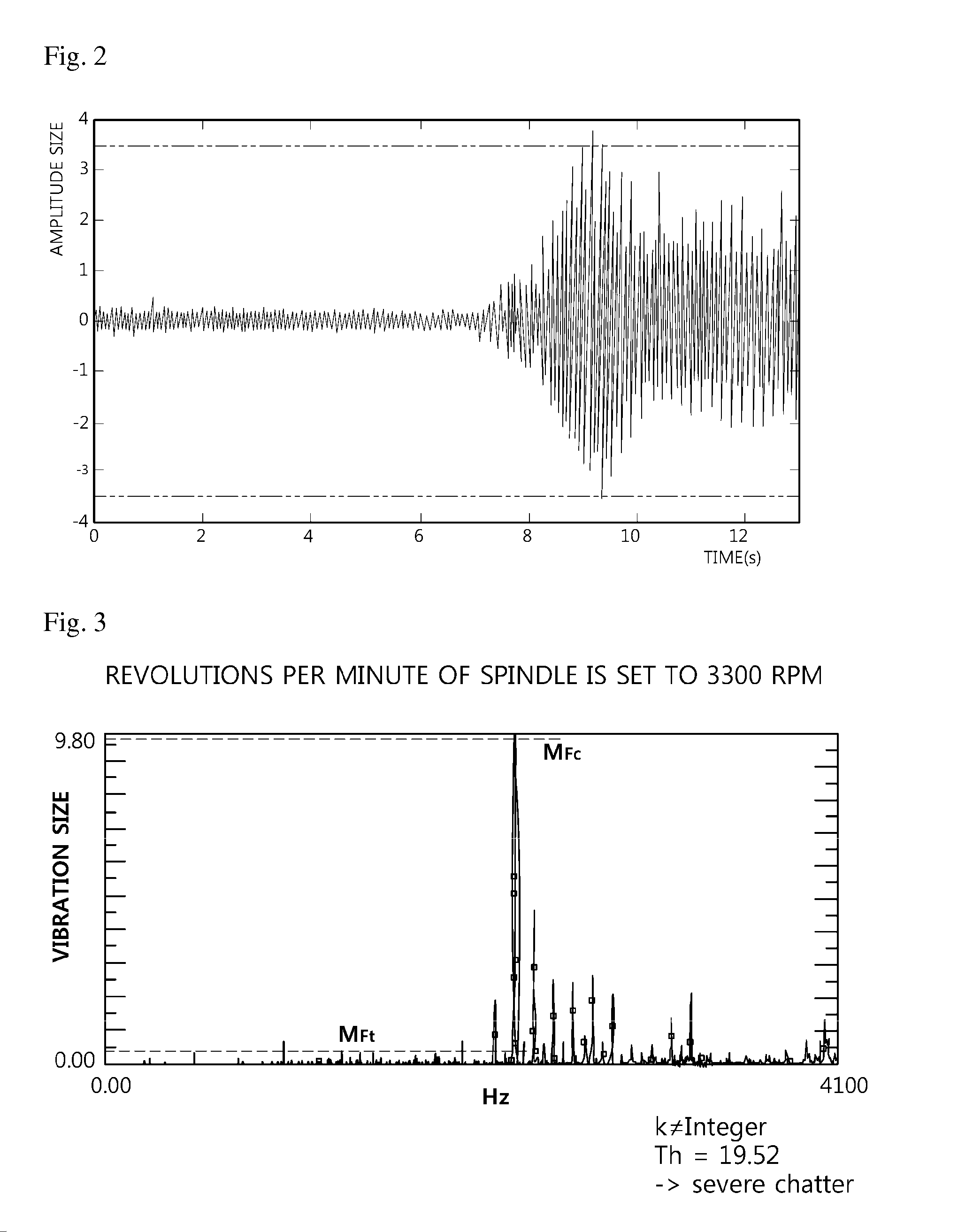

ActiveUS20140364991A1Ensure process stabilityAutomatic control devicesSpecial data processing applicationsRevolutions per minuteEngineering

Disclosed is a setting method of revolutions per minute on a real time of a rotating cutting tool, and a control device, and more particularly, a vibration characteristic is consistently evaluated and analyzed when a cutting process is in progress to suppress and avoid suppression.

Owner:DN SOLUTIONS CO LTD

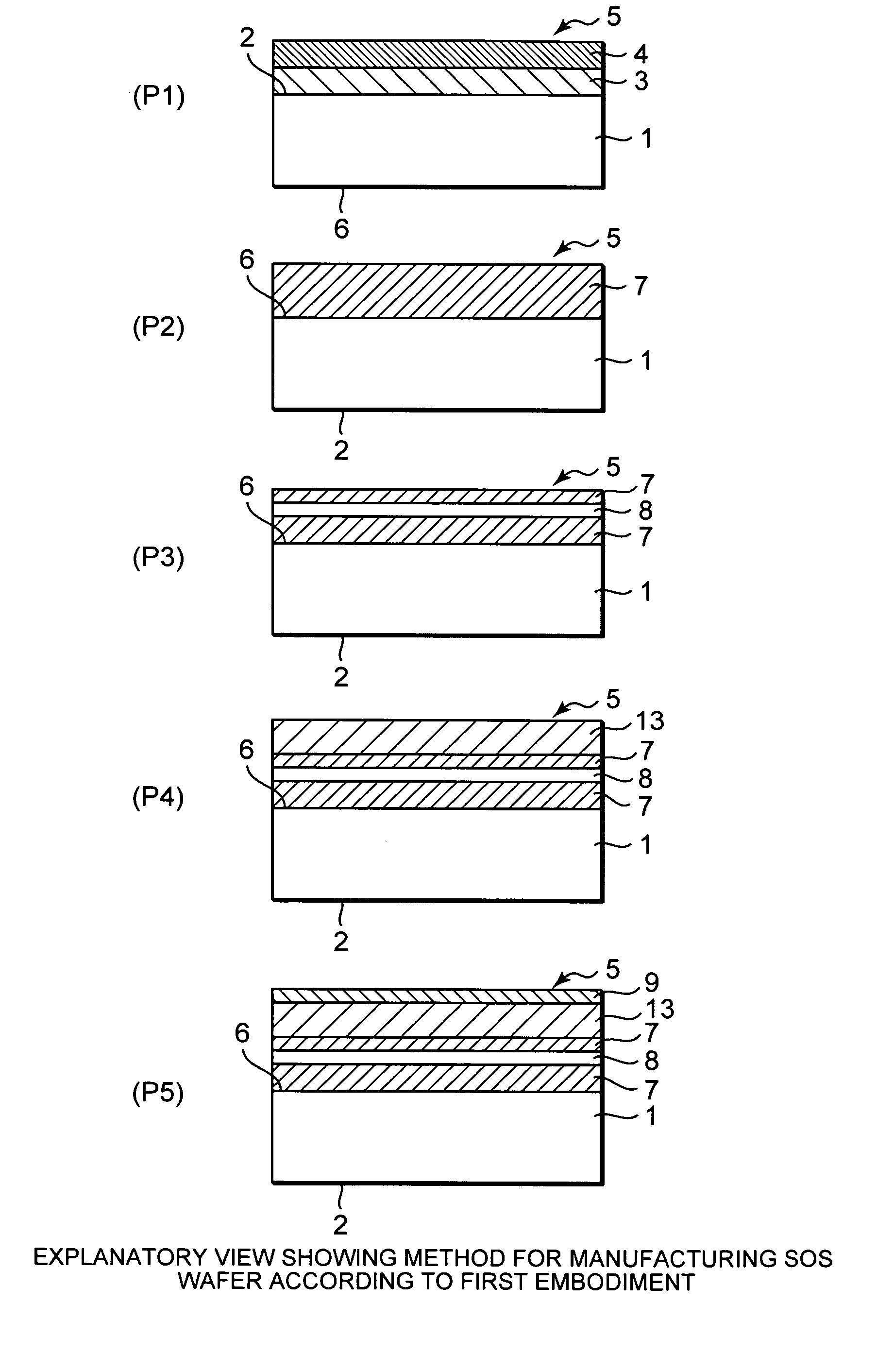

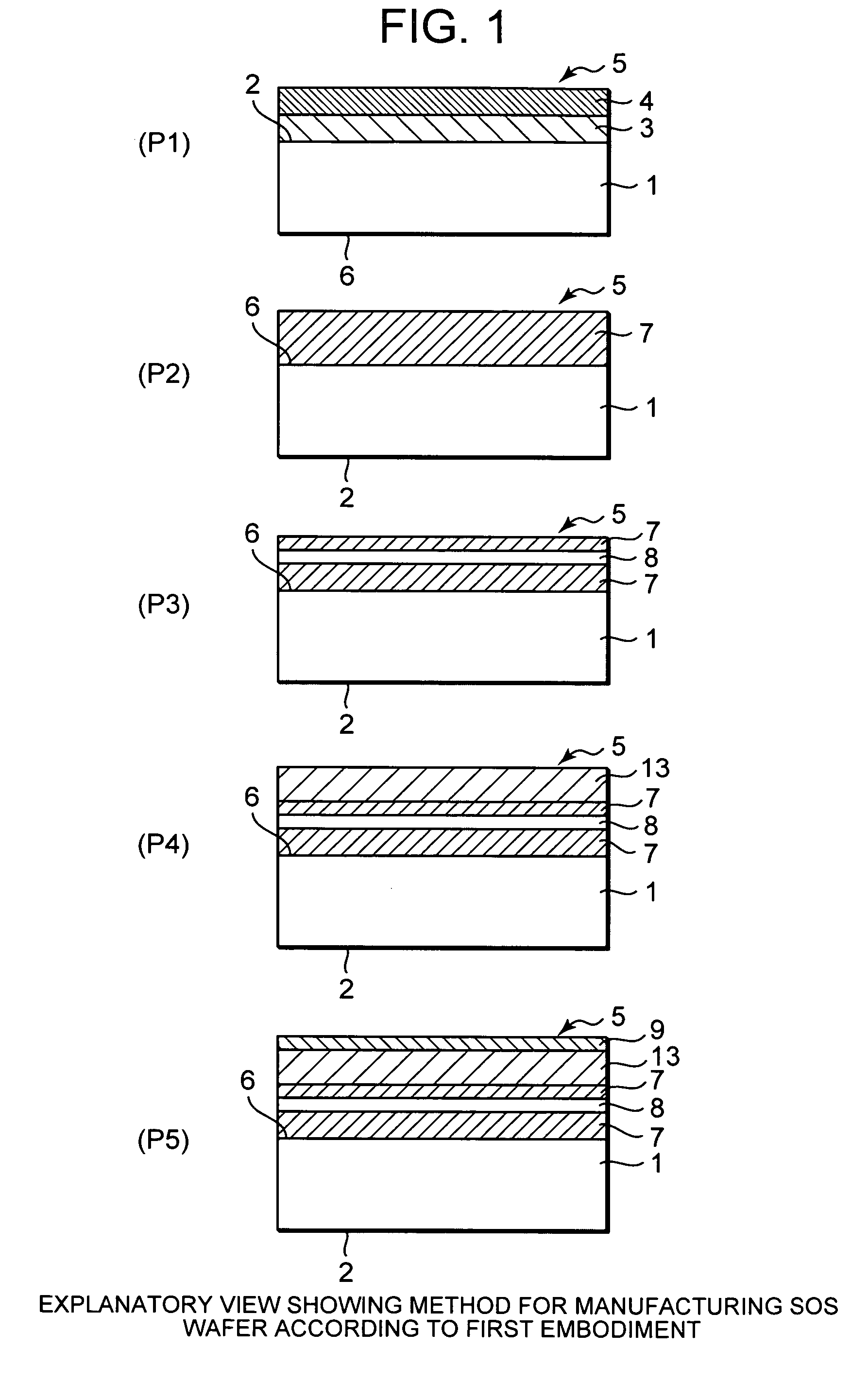

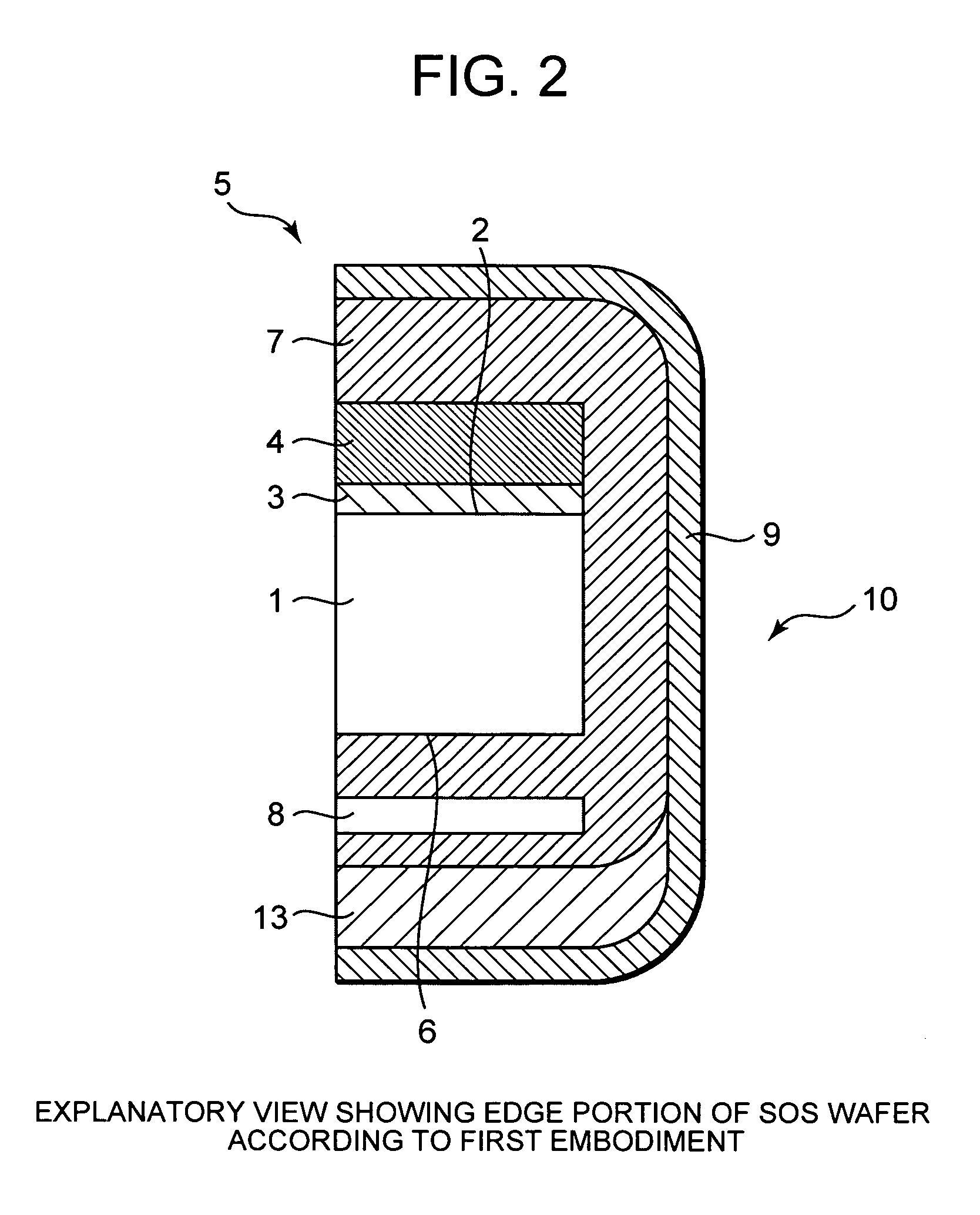

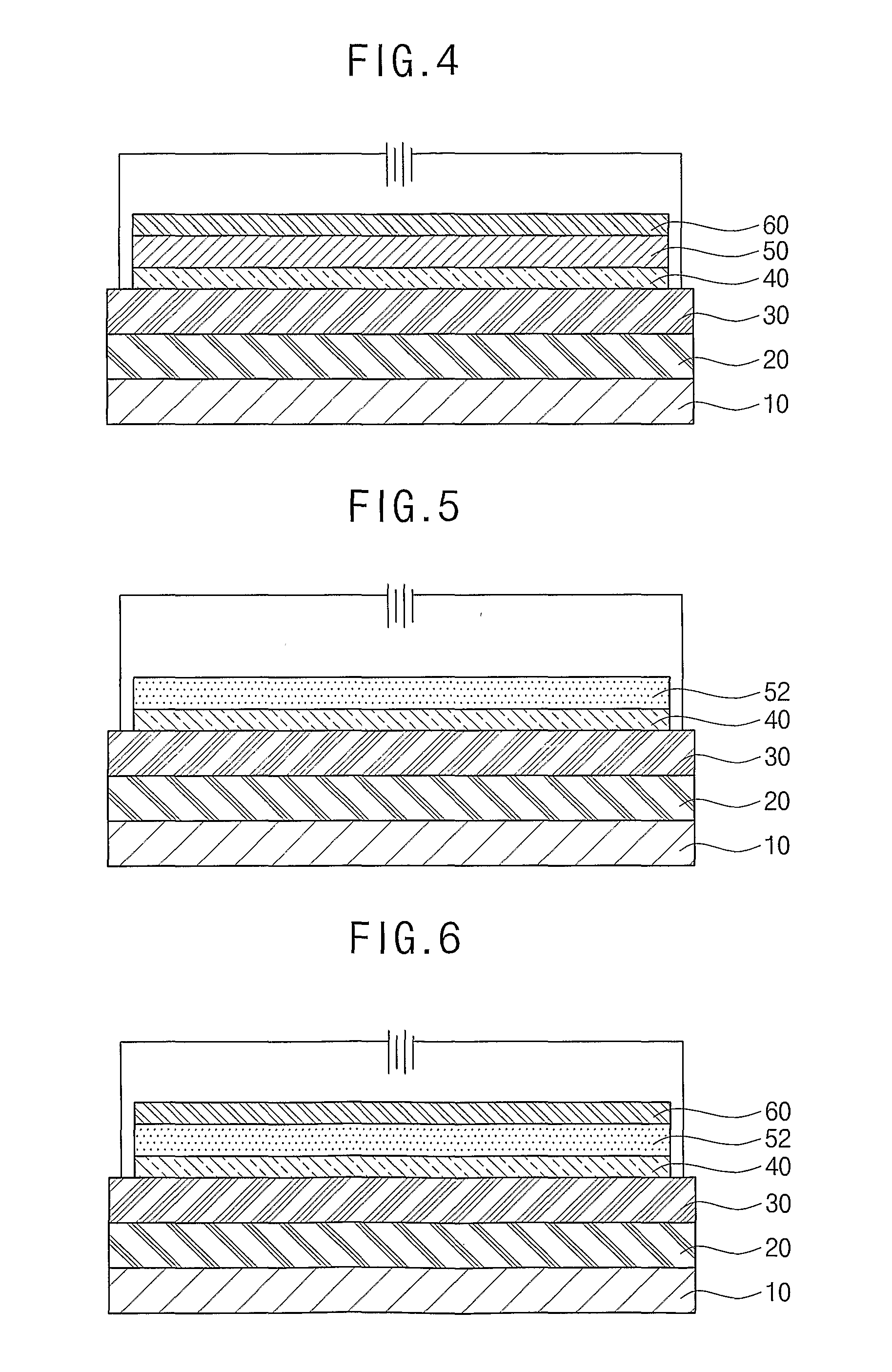

SOS wafer and manufacturing method thereof

InactiveUS20060214230A1Ensure process stabilityGuaranteed smooth progressSemiconductor/solid-state device detailsSolid-state devicesWaferingEngineering

The present invention provides an SOS wafer comprising a non-transparent polysilicon layer provided on a back surface of a sapphire substrate, a silicon nitride layer which protects the polysilicon layer, and a stress relaxing film which cancels stress produced in the silicon nitride layer, wherein the silicon nitride layer and the stress relaxing film are provided on the back surface side.

Owner:LAPIS SEMICON CO LTD

Bragg raster hydrogen sensor and its preparing process

InactiveCN1587993AAvoid the process of fine processingLittle impact on performanceMaterial analysis by electric/magnetic meansColor/spectral properties measurementsFiberGrating

A Prague raster hydrogen sensor and its manufacture technology are used in automatic control field. In Prague raster hydrogen sensor, structure id formed by palladium film sticking on substrate nickel film, whose one end is fixed on Cu base and another to be cantilever beam, optical fiber probe with Prague raster impending end of cantilever beam and fiber-tail is contact. Its manufacture technology includes: rendering by Cr / Cu on monocrystalline silicon substrate; electroplating Cu film; magnetism control hydrogen sensitive film; coating photoresist; photoetching; electroplating Ni film and clearing photoresist; corrasion palladium with Ni film; corrasion copper film with Ni film; manufacturing Prague raster by choosing Prague wavelength and molecule laser writing method; optical fiber probe with Prague raster on its end is sticking on cantilever beam and another end fiber-tail of optical fiber is contact. The invention has increased axial driving force of raster, solved the problem of easy to be destroyed brought by increasing film thickness for raising sensitiveness.

Owner:SHANGHAI JIAO TONG UNIV

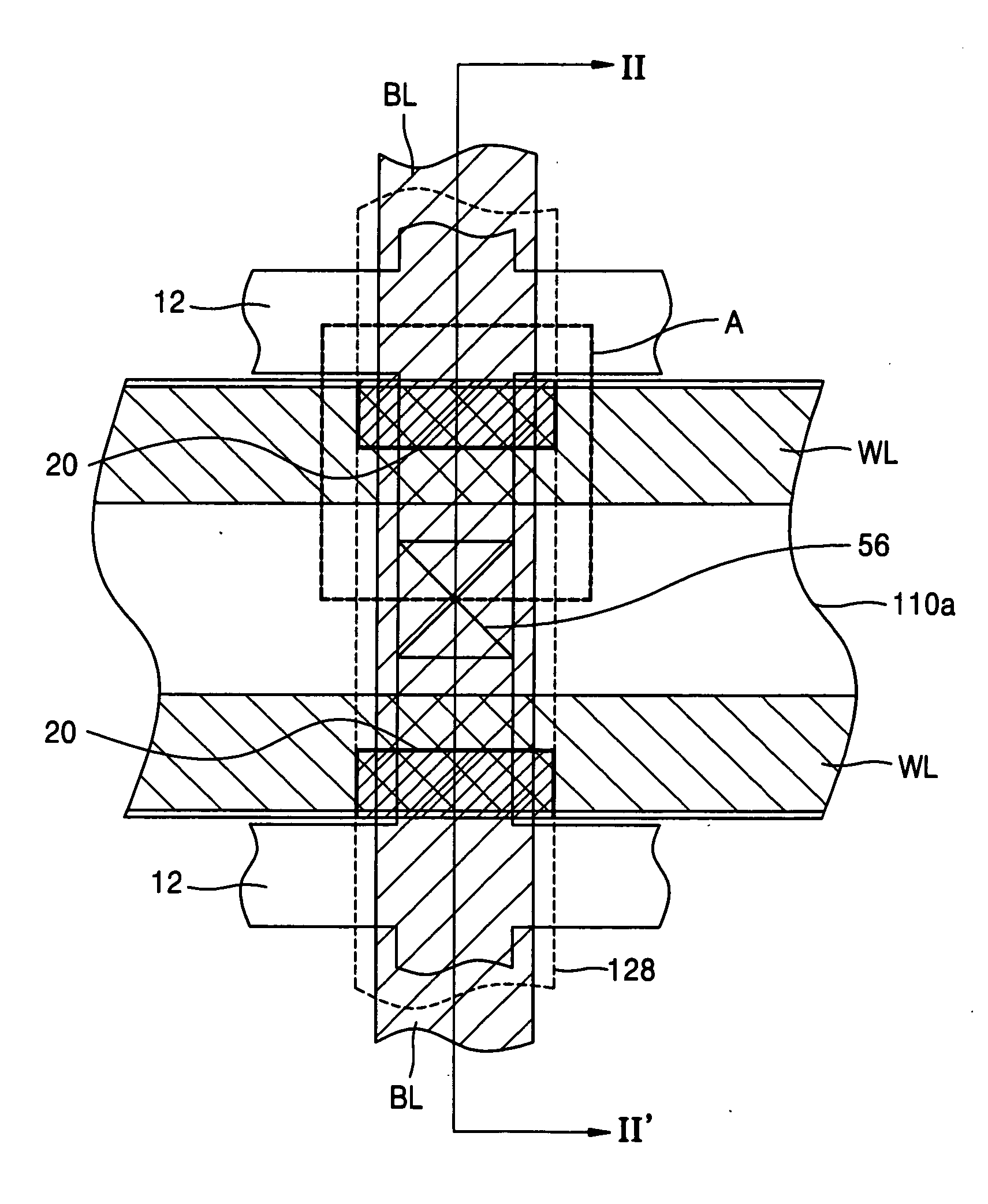

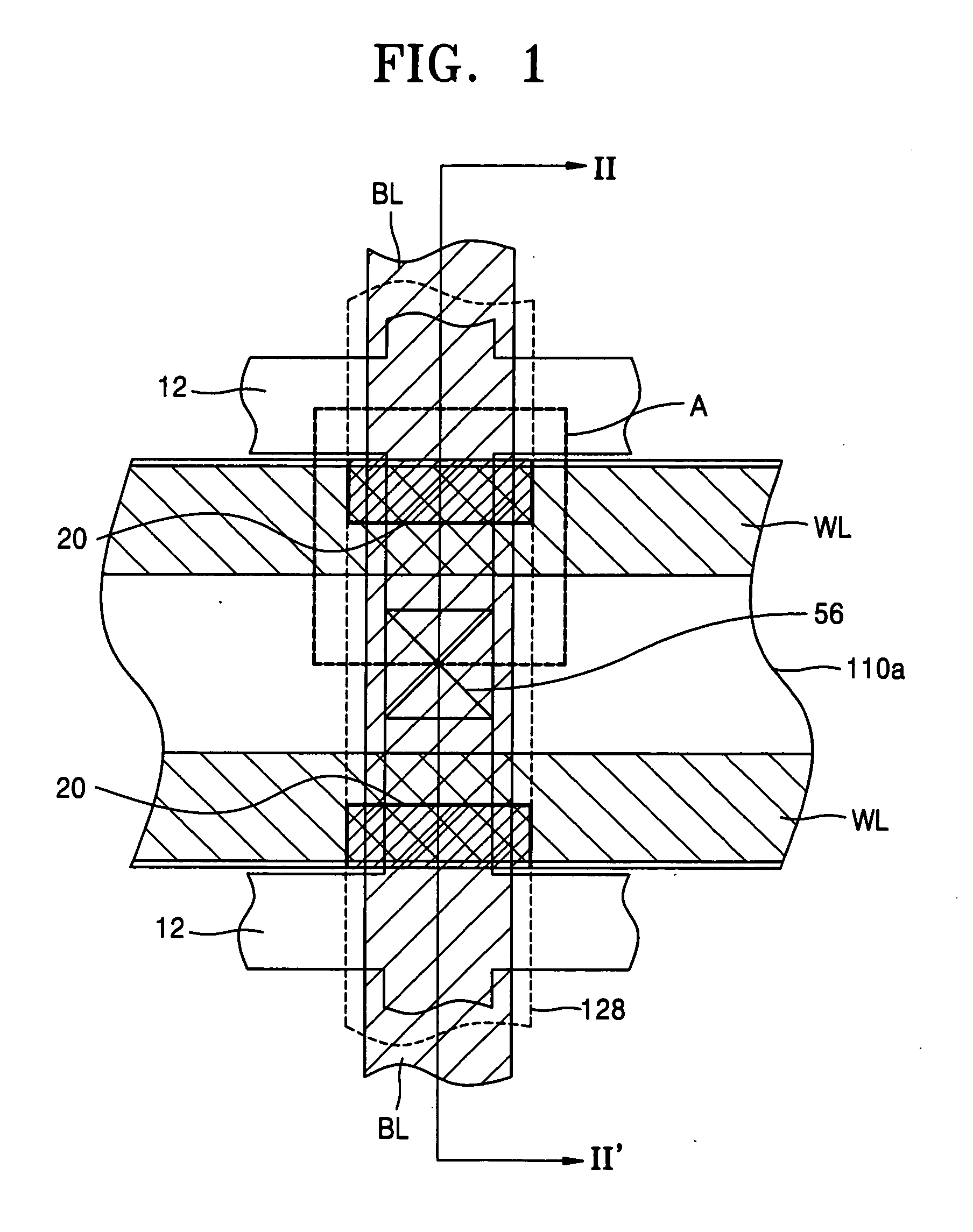

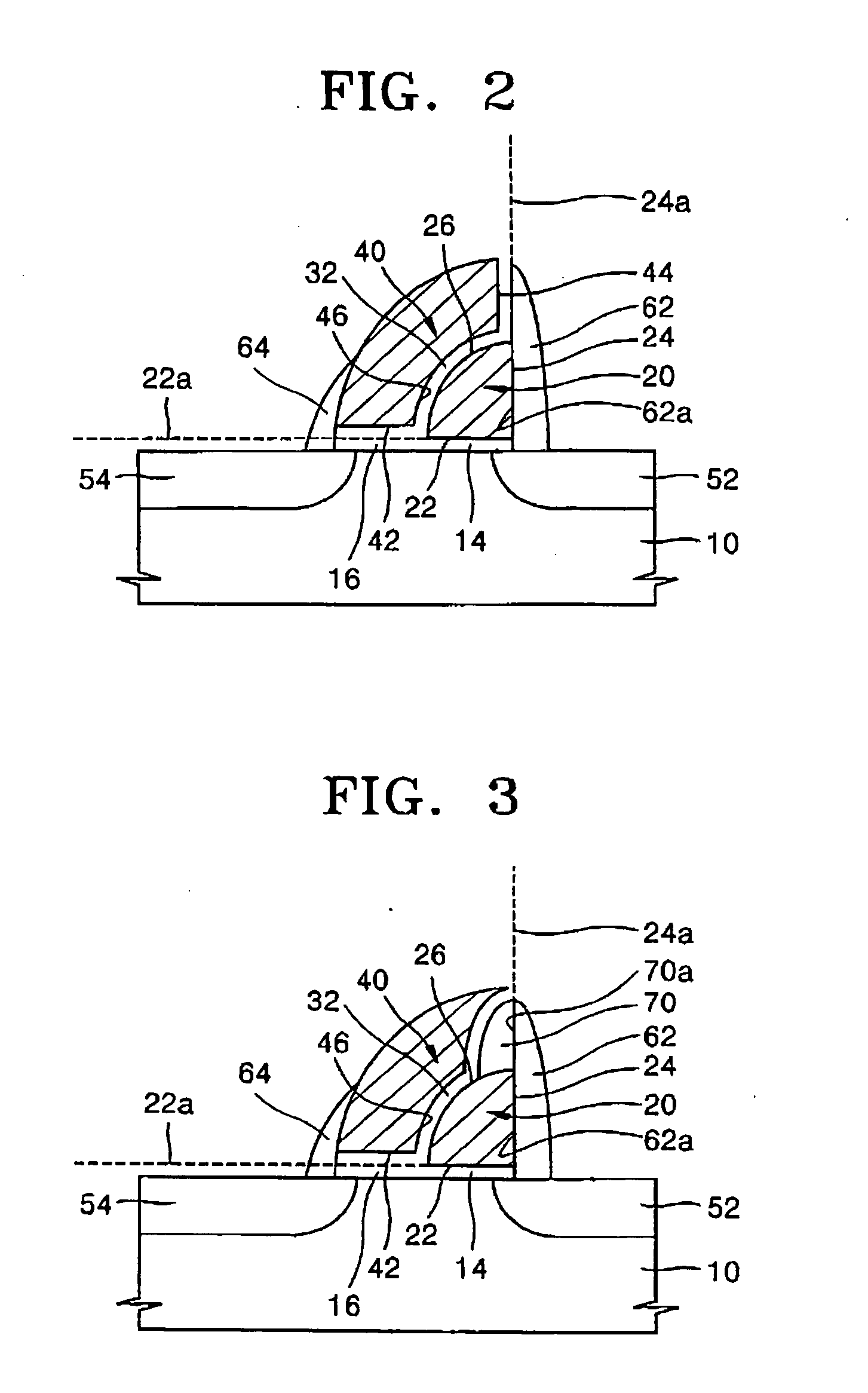

Split gate type flash memory device and method of manufacturing the same

InactiveUS20060001077A1Limited resolutionEnsure stability of processTransistorSolid-state devicesElectrical and Electronics engineeringSemiconductor

In a split gate type flash memory device, and a method of manufacturing the same, the device includes a memory cell array having a memory cell uniquely determined by a contact of a corresponding bit line and a corresponding word line, a floating gate formed on a semiconductor substrate to constitute the memory cell, the floating gate having a horizontal surface parallel to a main surface of the substrate, a vertical surface perpendicular to the main surface of the substrate, and a curved surface extending between the horizontal and vertical surfaces, a control gate formed over the curved surface of the floating gate in an area defined by an angle range of less than 90° between an extension line of the horizontal surface and an extension line of the vertical surface, and source and drain regions formed in an active region of the substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

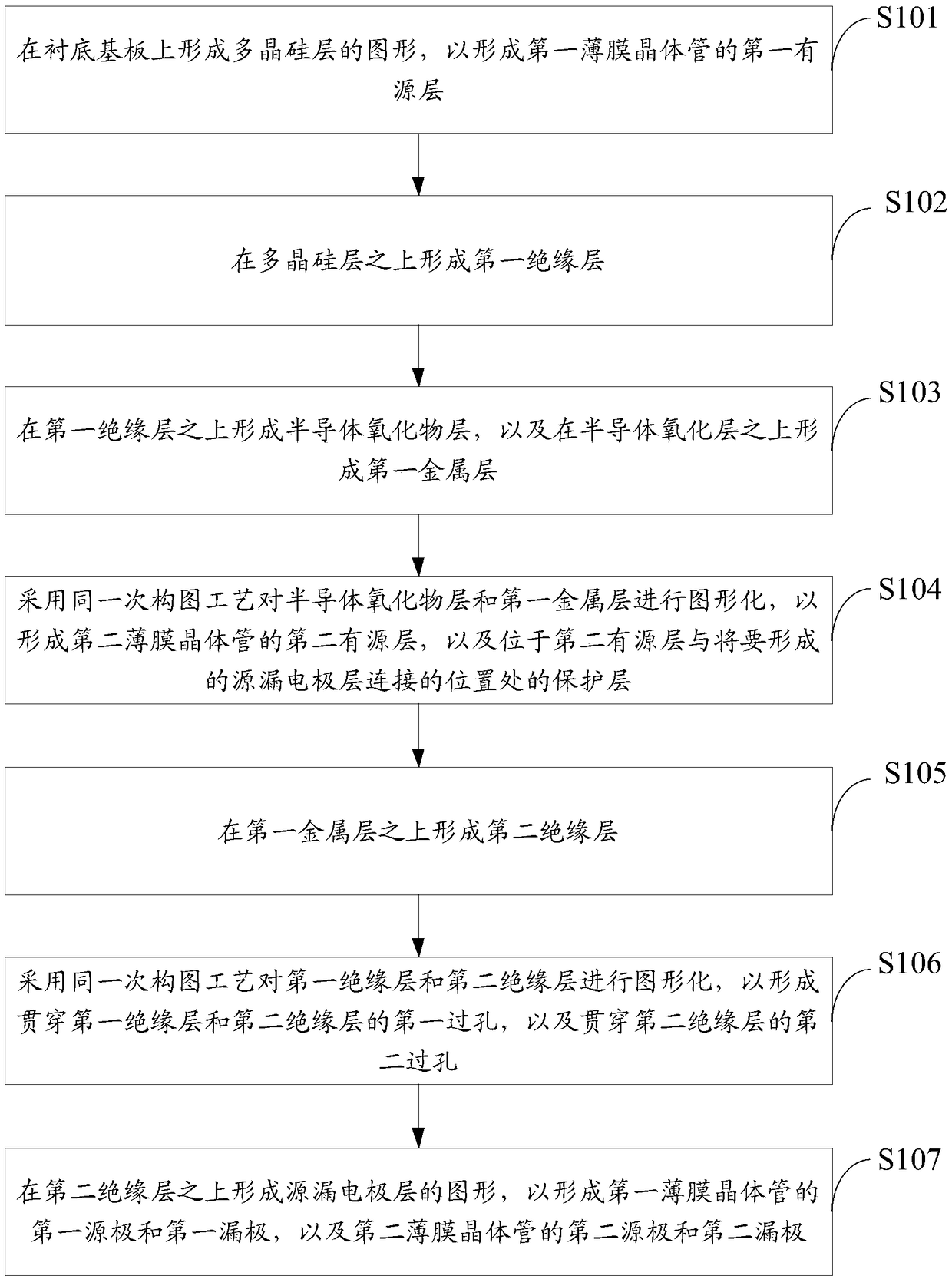

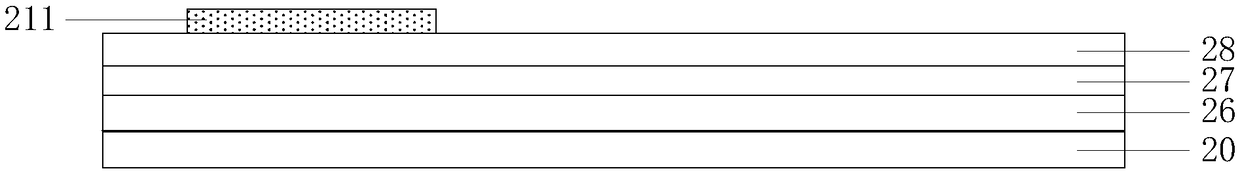

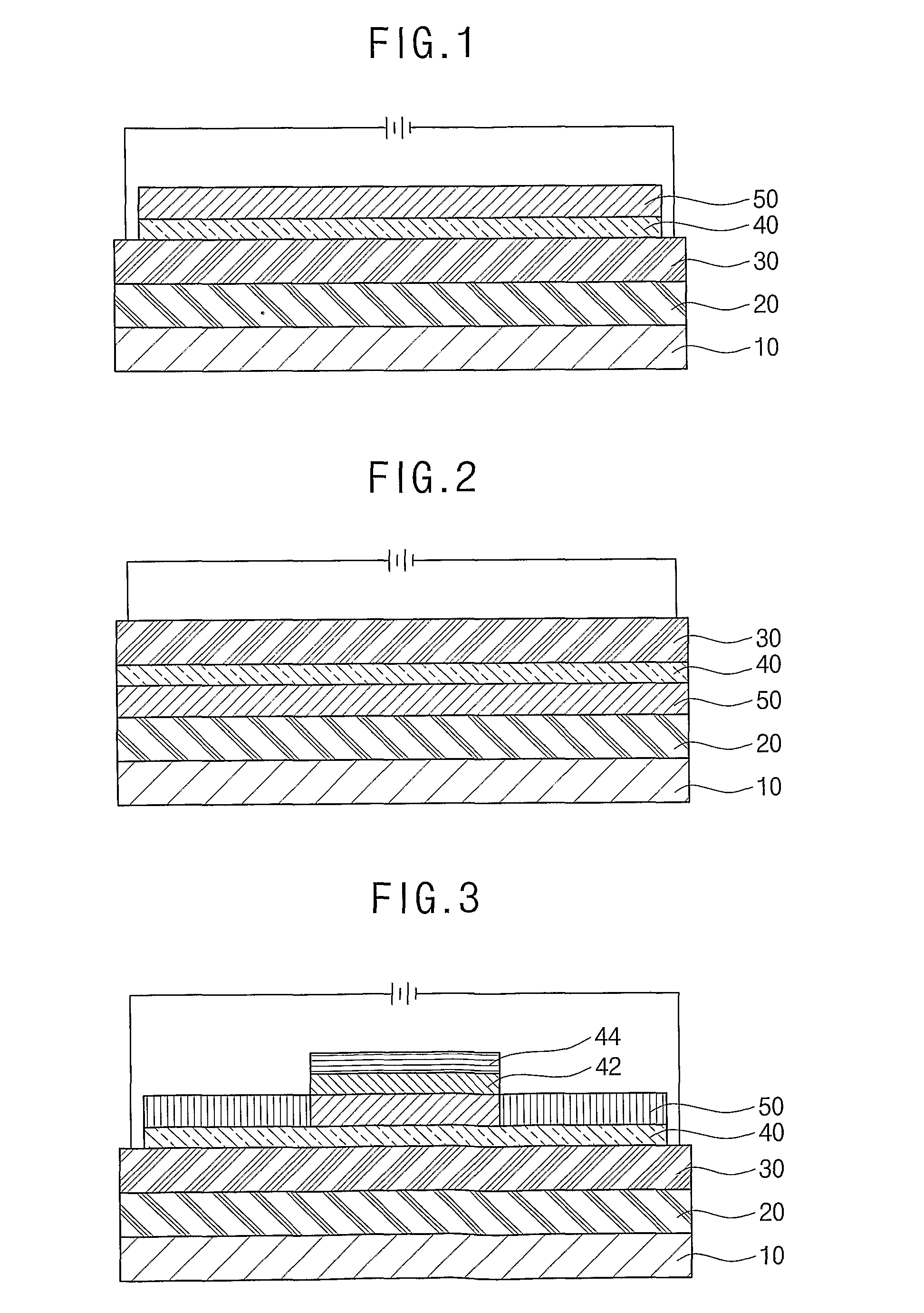

Display panel, manufacturing method thereof, and display device

ActiveCN109273409AReduce the number of timesReduce in quantitySolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceSemiconductor

The invention discloses a display panel, a manufacturing method and a display device thereof. The manufacturing method comprises the following steps: forming a pattern of a polysilicon layer on a substrate; Forming a first insulating layer over the polysilicon layer; Forming a semiconductor oxide layer over the first insulating layer and forming a first metal layer over the semiconductor oxide layer; patterning The semiconductor oxide layer and the first metal layer by the same patterning process; Forming a second insulating layer over the first metal layer; patterning The first insulating layer and the second insulating layer by the same patterning process; forming A pattern of source and drain electrode layers over the second insulating layer. By providing a protective layer, the secondactive layer exposed at the second via hole can be protected, so that the first via hole and the second via hole can be fabricated by the same patterning process, the primary patterning process is saved, the process stability is ensured, the number of patterning processes and the number of mask plates are reduced, and the manufacturing cost is reduced.

Owner:BOE TECH GRP CO LTD

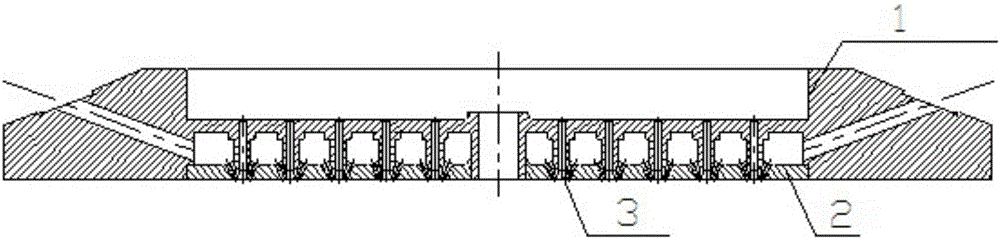

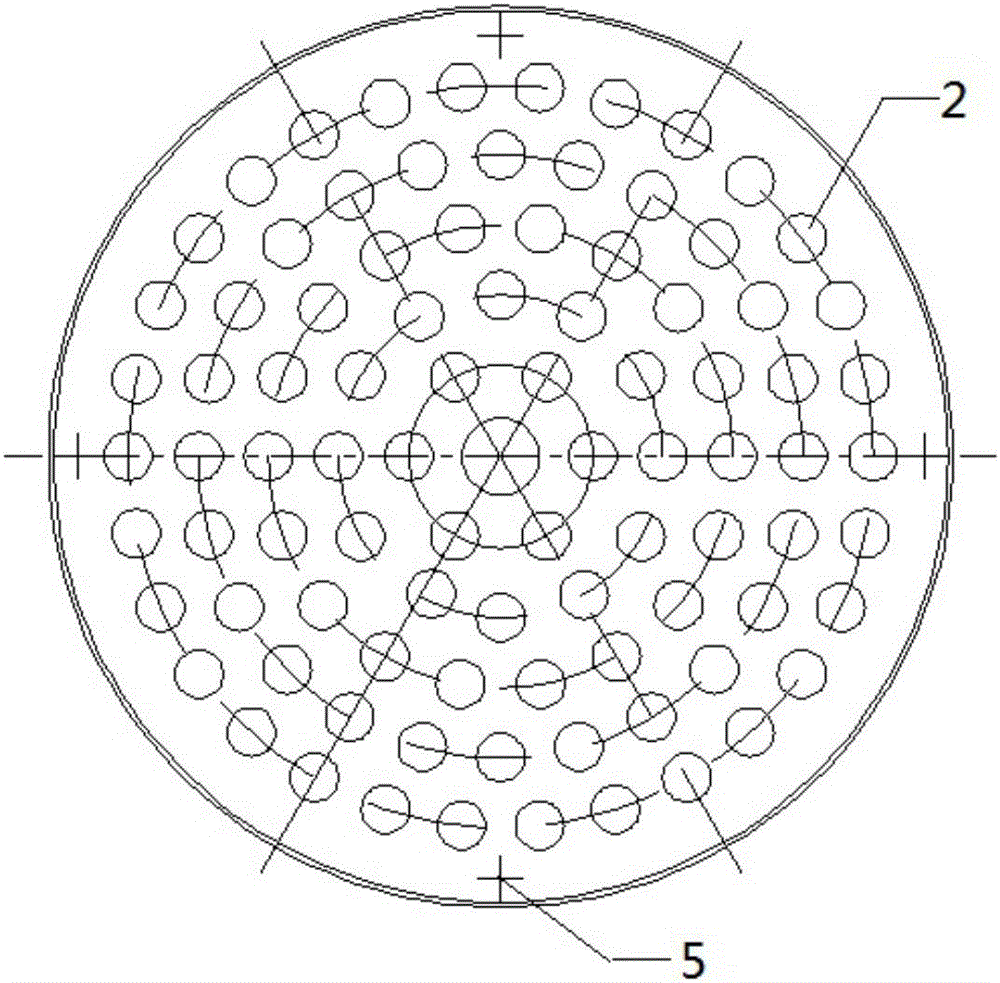

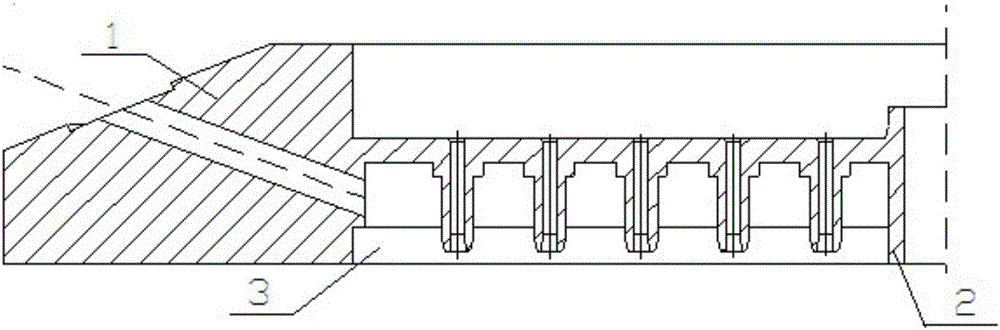

Welding method for multi-part structure of head injector in thrust chamber of liquid-propellant rocket engine

InactiveCN106735829AImprove reliabilityImprove welding qualityElectron beam welding apparatusThrust chamberPre treatment

The invention discloses a welding method for a multi-part structure of a head injector in a thrust chamber of a liquid-propellant rocket engine. According to the method, welding for the head injector in the thrust chamber of the liquid-propellant rocket engine is completed through welded part machining, welding reference machining for nozzle units, welded part pre-treatment, welded part assembly, welded part welding, nozzle unit welding, welding joint detection and drying. According to the method disclosed by the invention, a welding process method for a complex injector structure is optimized to be vacuum electron beam welding adopting a welding method which is more advanced, higher in reliability, higher in welding quality and lower in welding risk from traditional braze welding; and moreover, repair welding is hardly carried out once the traditional braze welding is failed, and local repair welding can be carried out in the vacuum electron beam welding, so that the product scrap risk is lowered.

Owner:湖北三江航天江北机械工程有限公司

Q&P steel with gradient structure and manufacturing method thereof

InactiveCN105463307AIncreased strength and plasticityEnsure process stabilitySolid state diffusion coatingCarburizingAustenite

The invention discloses Q&P steel with a gradient structure. The Q&P steel comprises, by weight percent, 0.14-0.29% of C, 1.1-2.8% of Si, 1.8-3.0% of Mn, 0.5-1.9% of Cr, 1.5-3.1% of Al, smaller than or equal to 0.01% of S, smaller than 0.01% of P and the balance Fe. A manufacturing method of the Q&P steel includes the steps of austenitizing, carburizing, quenching, tempered carbon distributing and quenching. According to the Q&P steel and the manufacturing of the Q&P steel, technology stability and organization gradient can be ensured in production of large-size products, strength of the steel is improved, good toughness of the steel is also ensured, and low alloying cost is low.

Owner:ZHONGBEI UNIV

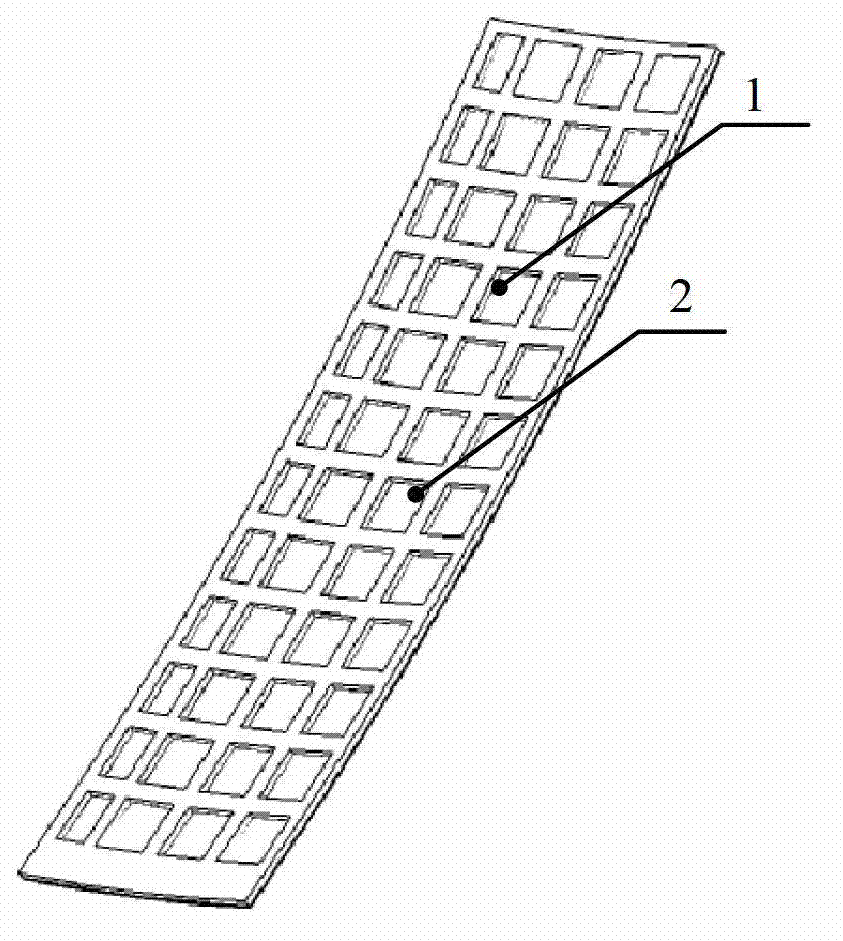

Pole piece cutting method

InactiveCN101612691AEnsure process stabilityQuality improvementElectrode manufacturing processesElectrode carriers/collectorsEngineeringPole piece

The invention provides a pole piece cutting method, which uses laser for cutting a pole piece along a predetermined cutting route. The invention adopts the cutting mode of non-physical contact; dust does not exist in the cutting process; after cutting, the fracture position of the pole piece does not have burr; the cutting method is particularly suitable for the cutting of the pole piece, the fracture of which takes on irregularly shape; the pole piece in the cutting process is not acted by mechanical force; the interior of the pole piece does not generate mechanical stress, and the crystalline phase organization of the pole piece also does not change; and the cutting method of the invention can ensure the process stability of the pole piece cutting and is beneficial to increase the quality of an electrical core and the percent of pass of a battery.

Owner:SHENZHEN GEESUN INTELLIGENT TECHNOLOGY CO LTD

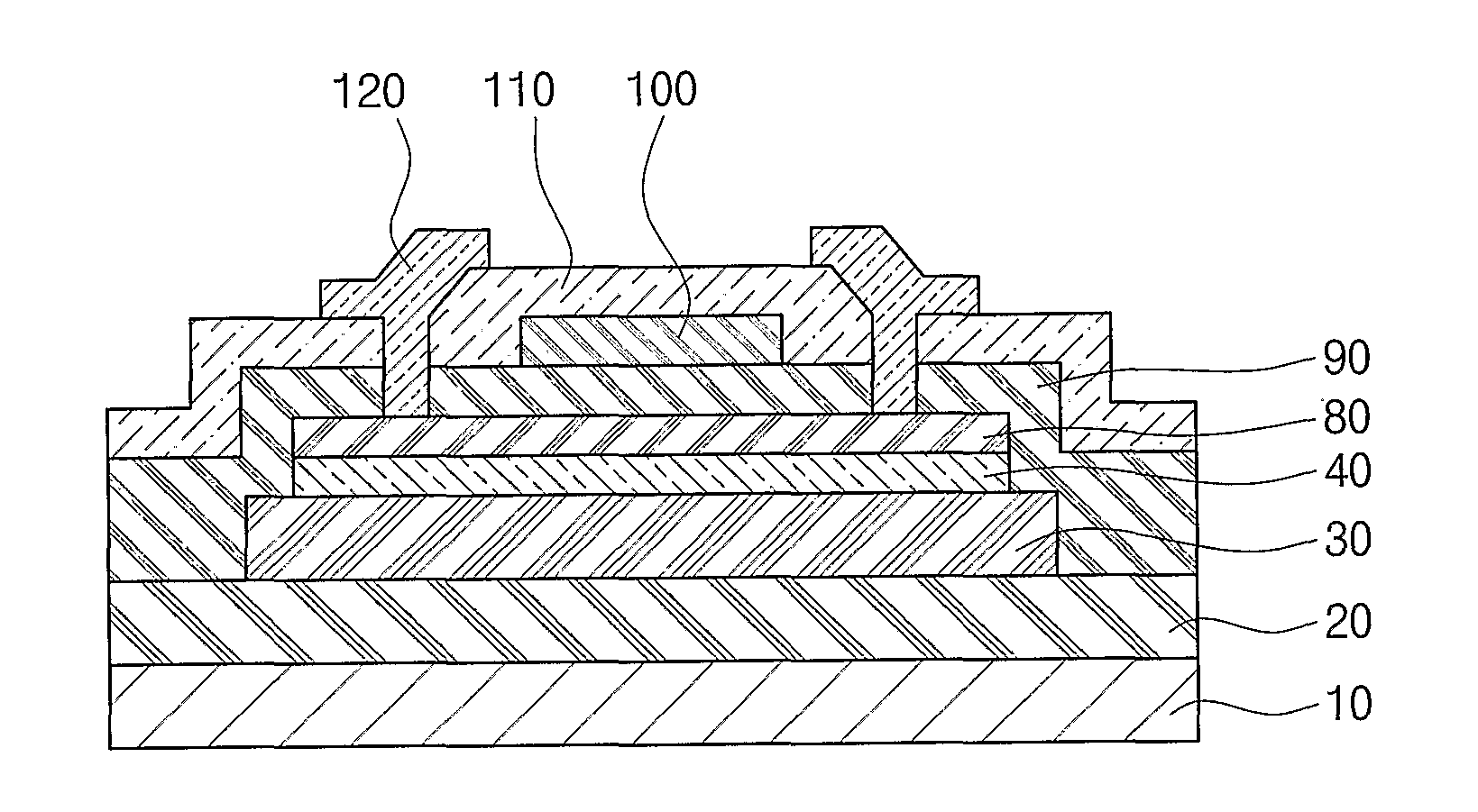

Fabricating method of polycrystalline silicon thin film, polycrystalline silicon thin film fabricated using the same

InactiveUS20100270558A1Reduce processing timeHigh crystallinityTransistorSolid-state devicesMetal alloyAmorphous silicon

Provided are a method of fabricating a polycrystalline silicon thin film using high temperature heat generated by Joule heating induced by application of an electrical field to a conductive layer, which can ensure process stability at high temperature and thus processing time can be reduced and a polycrystalline silicon thin film having excellent crystallinity can be obtained, a polycrystalline thin film using the method and a thin film transistor including the polycrystalline thin film. The method includes providing a substrate, forming a metal or metal alloy layer having a melting point of 13000 C or more on the substrate, forming an insulating layer on the metal or metal alloy layer, forming an amorphous silicon (a-Si) thin film, an amorphous / polycrystalline composite silicon thin film, or a poly-Si thin film on the insulating layer, and applying an electrical filed to the metal or metal alloy layer to induce Joule heating and generate high temperature heat, and crystallizing and annealing the amorphous silicon (a-Si) thin film, the amorphous / polycrystalline composite silicon thin film, or the poly-Si thin film using the high temperature heat.

Owner:ENSIL TECH CO LTD

Method for pre-stretch bending of metal thick slab and numerical control machining forming of high-rib wallboard with curvature

The invention relates to a method for pre-stretch bending of a metal thick slab and numerical control machining forming of a high-rib wallboard with curvature, and mainly solves the problems that residual stress is high, the streamline of a molded surface is poor, deviation between an actual curved surface shape and a theoretical shape is large and the like in the conventional forming method. The method mainly comprises the following steps of: the pre-stretch bending of the metal thick slab, and the numerical control machining forming of the high-rib wallboard with the curvature. The method aims to greatly reduce the workload of the subsequent assembly process, improve production efficiency and whole quality and prolong service life. The residual stress in the slab is controlled by stretching and bending deformation modes in the pre-stretch bending process, so that the shape of the slab is approximate to the curved surface shape of the wallboard; the release process of the residual stress is controlled, and new residual stress is not generated or a little new residual stress is generated by controlling numerical control machining environment, process and parameters in the wallboard forming process, so that the forming quality of the wallboard is ensured; and numerical control machining is used as the final process of wallboard production in the method, so that product quality and process stability can be ensured to a great extent, and the designed theoretical shape of the wallboard can be ensured to the greatest extent.

Owner:SHENYANG AEROSPACE UNIVERSITY

Preparation method of ceramic-based electronic circuit

ActiveCN108558413AAvoid damageHigh dimensional accuracyCircuit susbtrate materialsLaser beam welding apparatusChemical platingMetallurgy

The invention discloses a preparation method of a ceramic-based electronic circuit, comprising the following steps: firstly, a ceramic matrix is prepared by using a conventional ceramic powder; then,a surface protective layer is deposited on the surface of the ceramic matrix; and a three-dimensional shape of the electronic circuit is engraved on the surface of the ceramic matrix by using a laserdevice; the ceramic matrix is immersed in a surface modifier liquid colloid to completely remove the residual surface protective layer; and finally, the electronic circuit itself is prepared by a conventional chemical plating and / or electroplating process. By optimizing combinational design of laser output power, laser engraving line spacing, engraving times and the engraving pattern, the surfaceof the ceramic matrix in the laser engraving area is roughened, thus being beneficial to interface bonding of the electronic circuit and the ceramic matrix and simultaneously reducing chippings generated during the engraving process to the maximum.

Owner:SHANGHAI AMPHENOL AIRWAVE COMM ELECTRONICS CO LTD

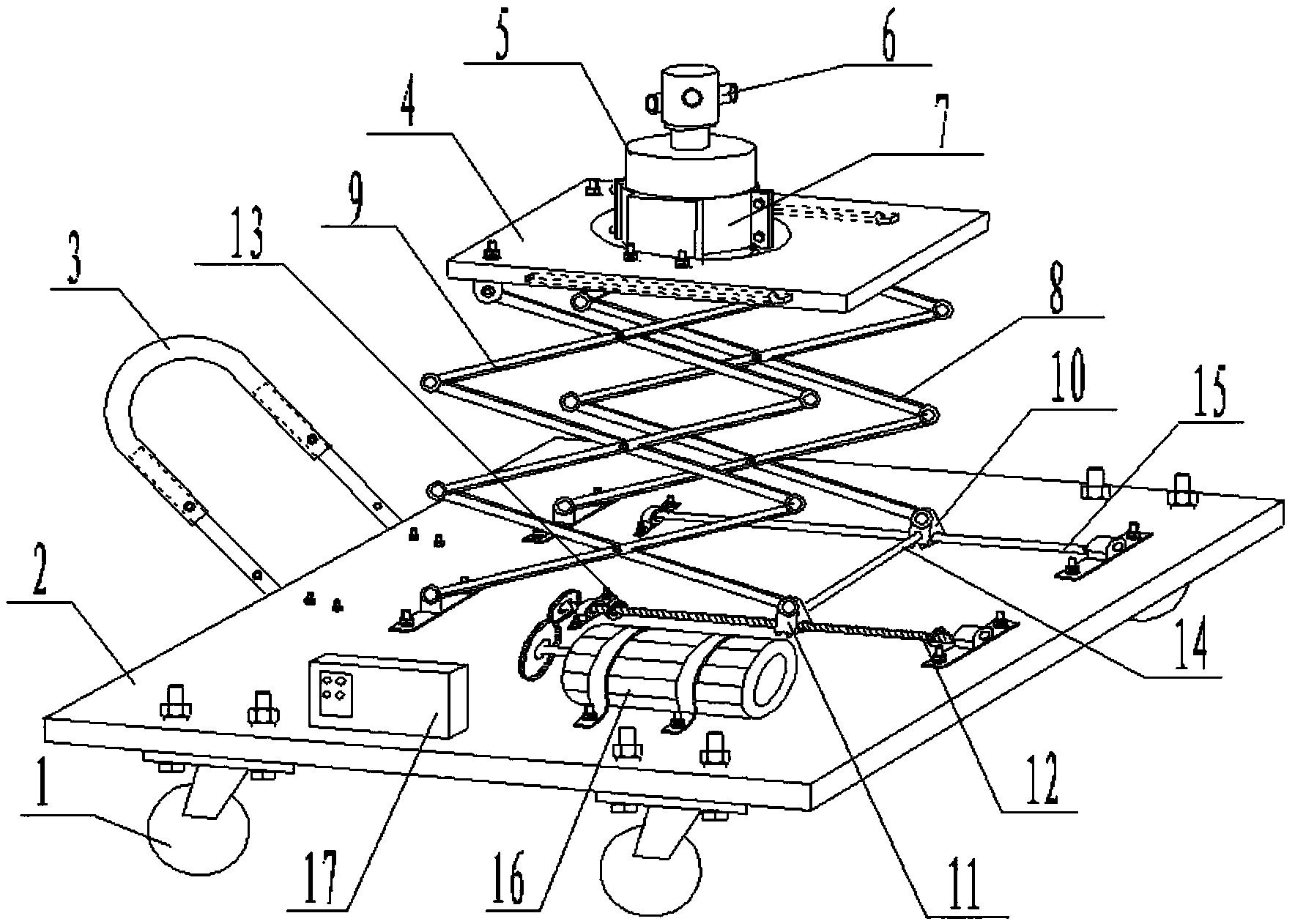

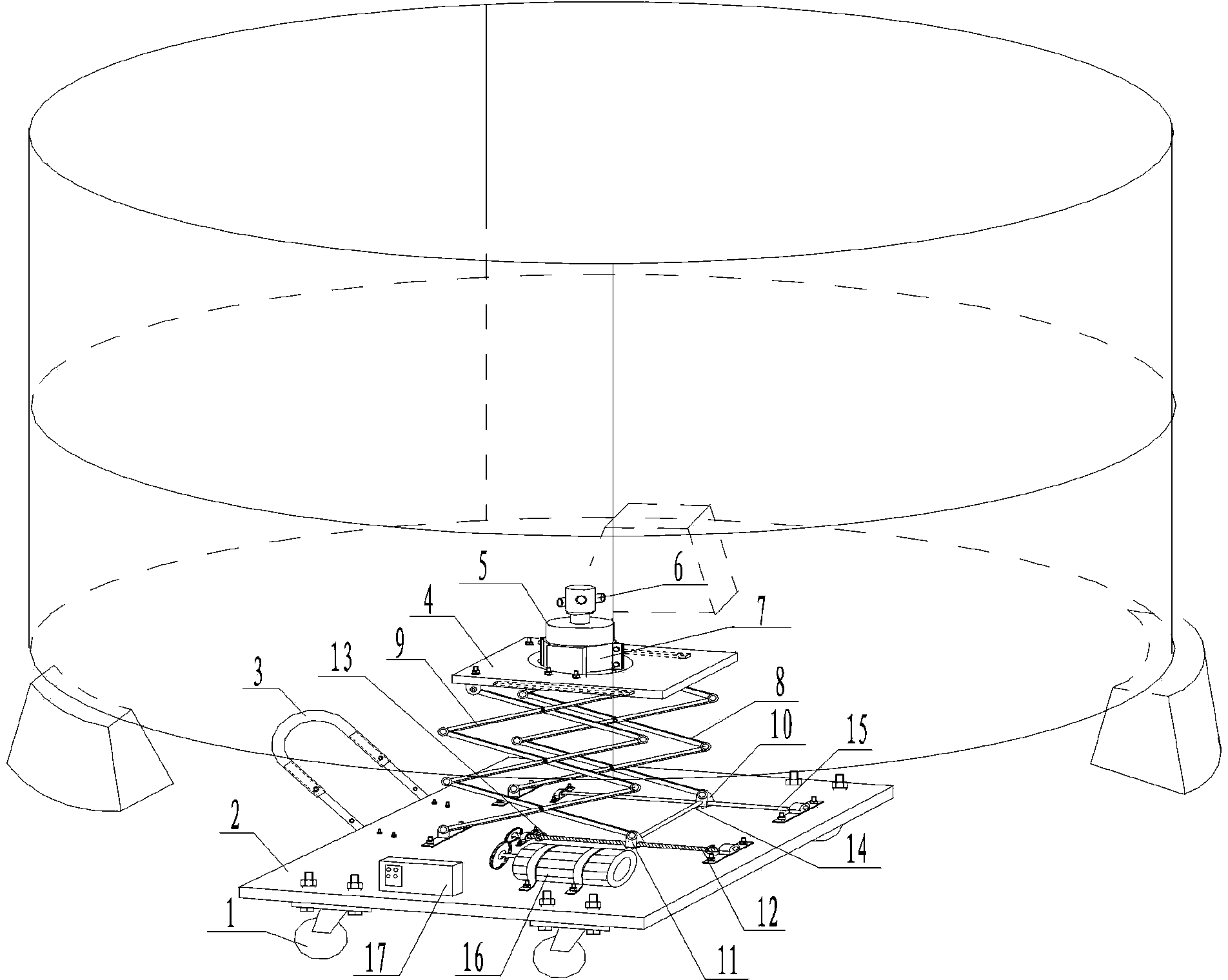

X-ray detection device with laser positioning function

InactiveCN104237260AEnsure process stabilityShort detection cycleMaterial analysis using wave/particle radiationSteering wheelX-ray

The invention provides an X-ray detection device with a laser positioning function. A laser positioner is mounted at a pipe head at the upper end of a circumferential X-ray emitter which is fixed on a lifting table through a ray emitter clamping mechanism by a semicircular structural pressing ring; fixed legs and movable legs at the upper ends of telescopic hinges are connected with the lifting table; fixed legs at the lower ends of the telescopic hinges are connected with a mounting base, and movable legs at the lower ends of the telescopic hinges are connected with a rolling shaft screw rod and a sliding rail on the mounting base; a connection rod mounted between the rolling shaft screw rod and the sliding rail is used for connecting the movable legs at the lower ends of the telescopic hinges; a mobile limiting block is mounted on the rolling shaft screw rod; a driving motor drives the rolling shaft screw rod to rotate through a gear; a steering wheel, a pushing handle, the driving motor and a control box are fixed on the mounting base. According to the X-ray detection device with a laser positioning function, the problems that a conventional circumferential X-ray detection device is heavy in structure and short in effective travel and the problems that annular ray beams are easily shaded and are hard to position are successfully solved; the X-ray detection efficiency and detection quality of the X-ray detection device are effectively improved.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

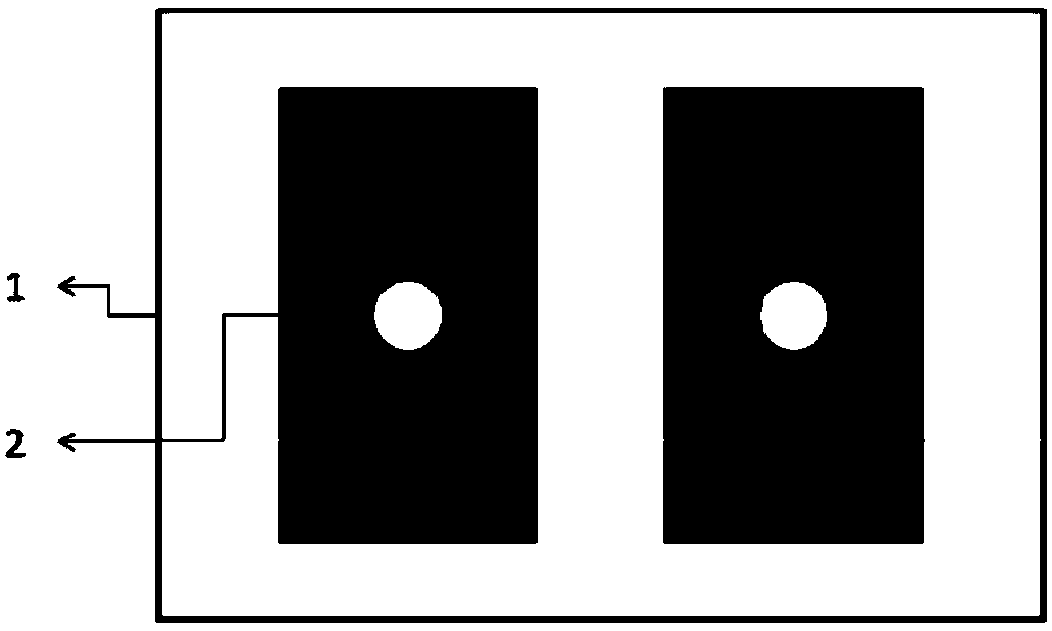

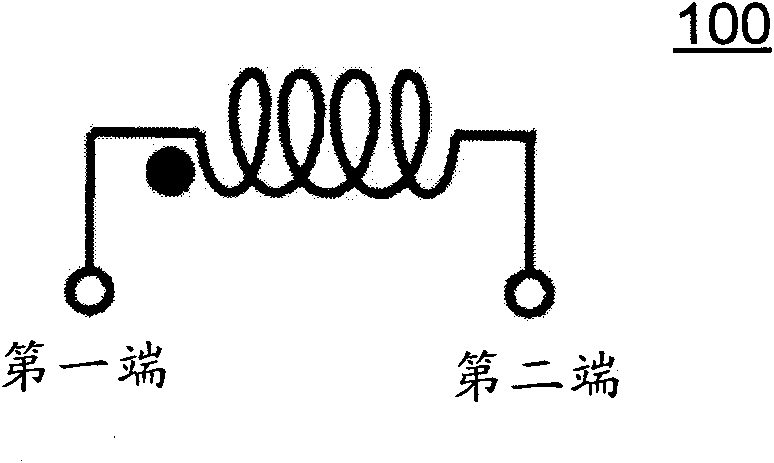

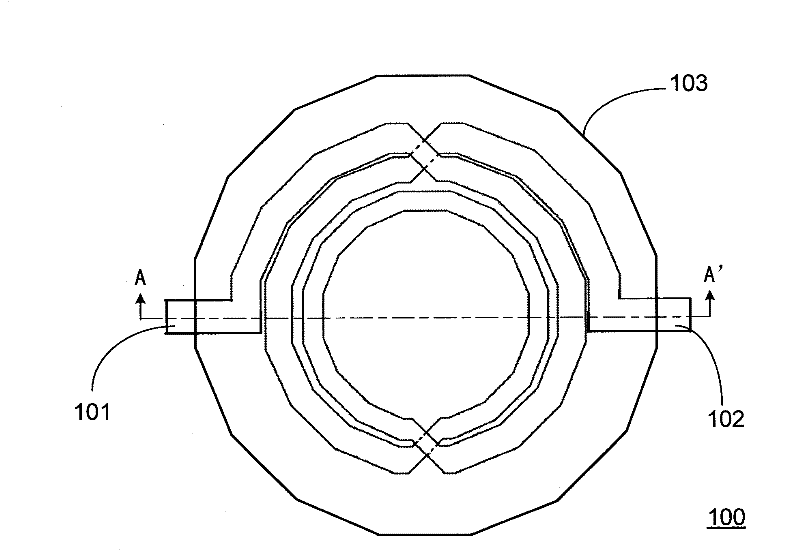

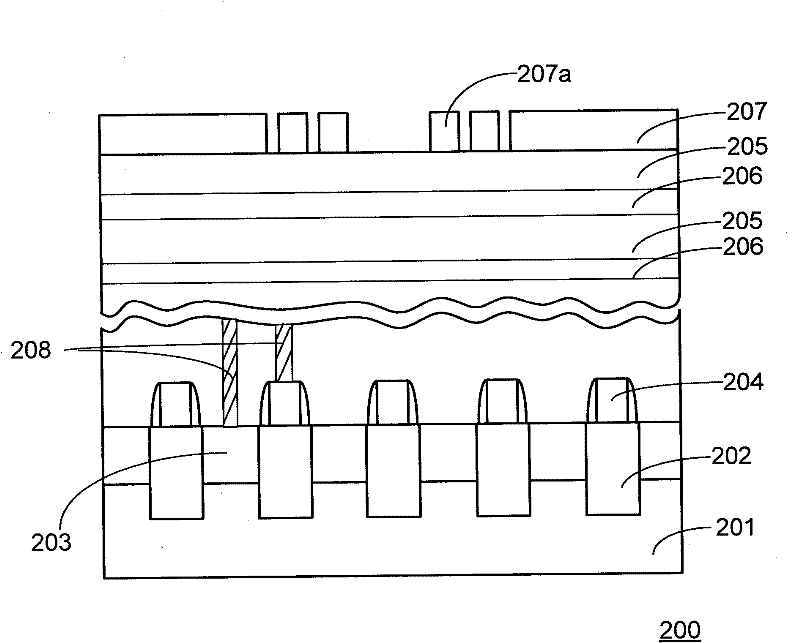

Semiconductor device

ActiveCN102194817AHigh quality factorGood patterning densitySolid-state devicesSemiconductor devicesPower semiconductor deviceEngineering

The invention provides a semiconductor device, which comprises a substrate, a plurality of shallow isolation grooves, a plurality of active regions, a polycrystalline silicon layer, a plurality of interlayer dielectric layers, a first metal layer, a second metal layer and a patterned grounding shielding layer, wherein the plurality of shallow isolation grooves are formed in the substrate; the plurality of active regions are formed in the substrate; adjacent active regions are spaced through the plurality of shallow isolation grooves; the polycrystalline silicon layer is formed on the plurality of shallow isolation grooves; the plurality of interlayer dielectric layers are formed in the active regions and on the polycrystalline silicon layer; the first metal layer is sandwiched between adjacent interlayer dielectric layers; the second metal layer is formed on the interlayer dielectric layers which are positioned on a top layer and is used for forming planar induction; and the patterned grounding shielding layer is formed by grounding the active regions and the polycrystalline silicon layer through contact holes which are formed in the interlayer dielectric layers. According to the device, compared with planar induction without the patterned grounding shielding layer, the planar induction inserted into the patterned grounding shielding layer provides comparability or better Q performance, and the influence of induced substrate coupled noise on a circuit can be reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

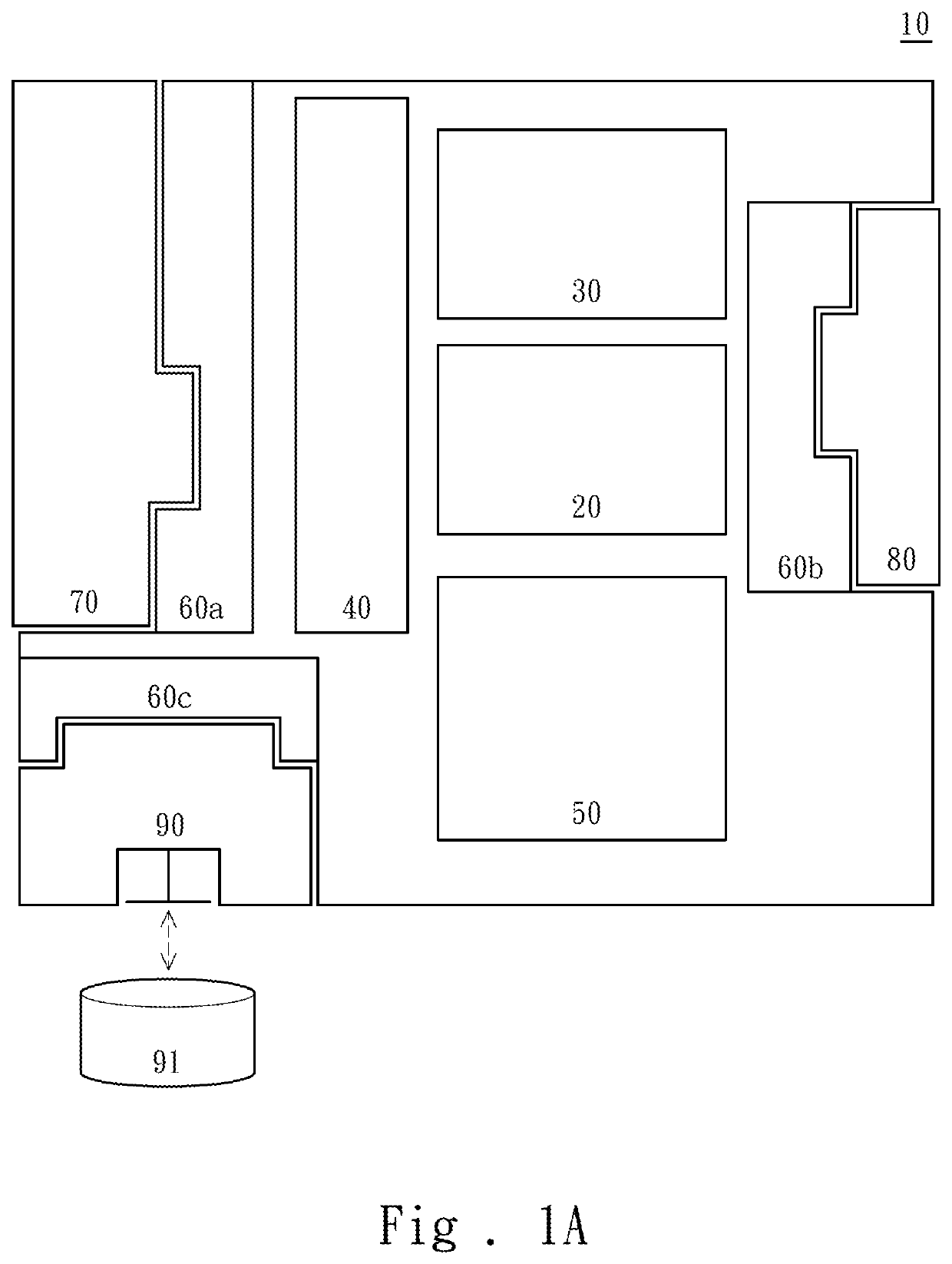

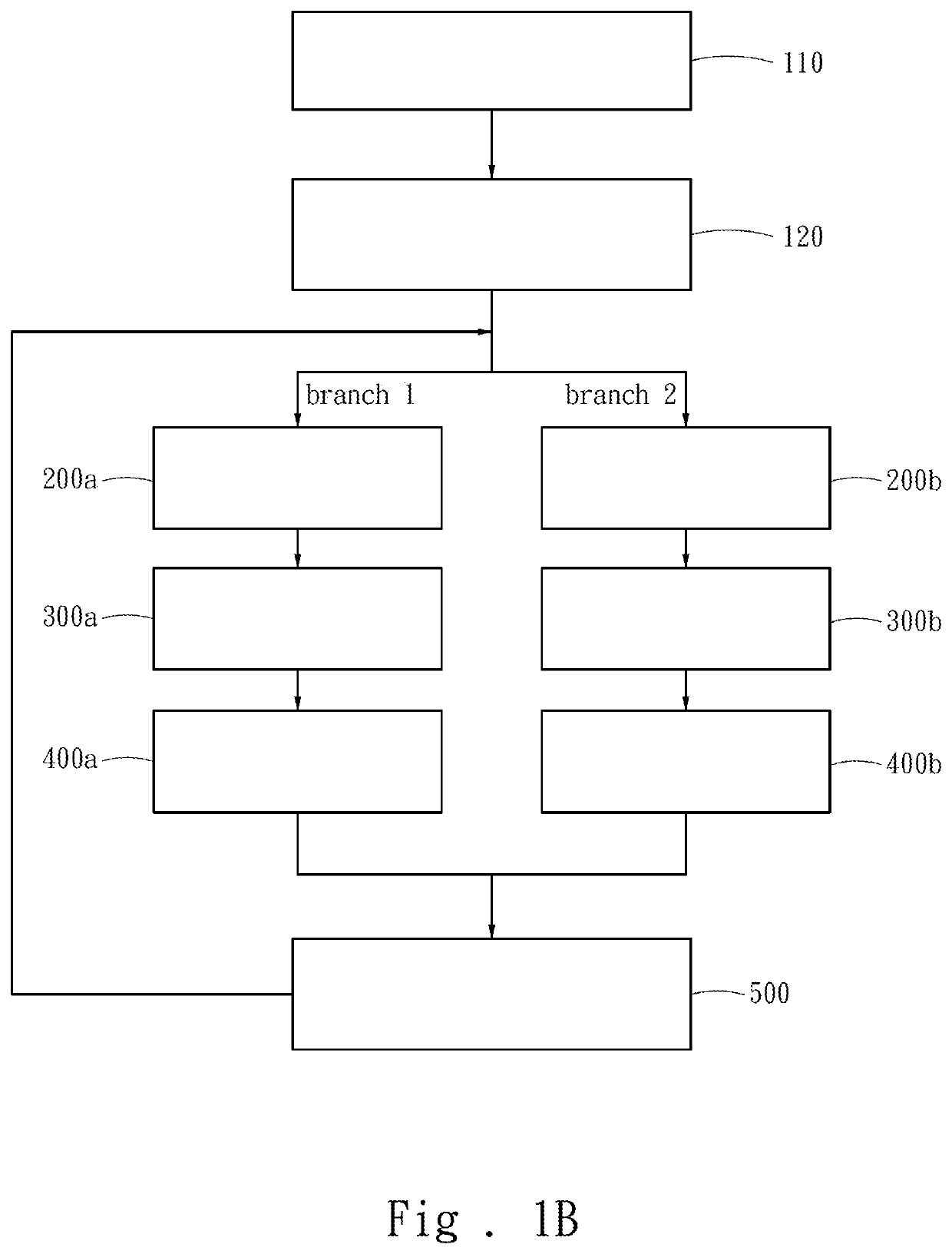

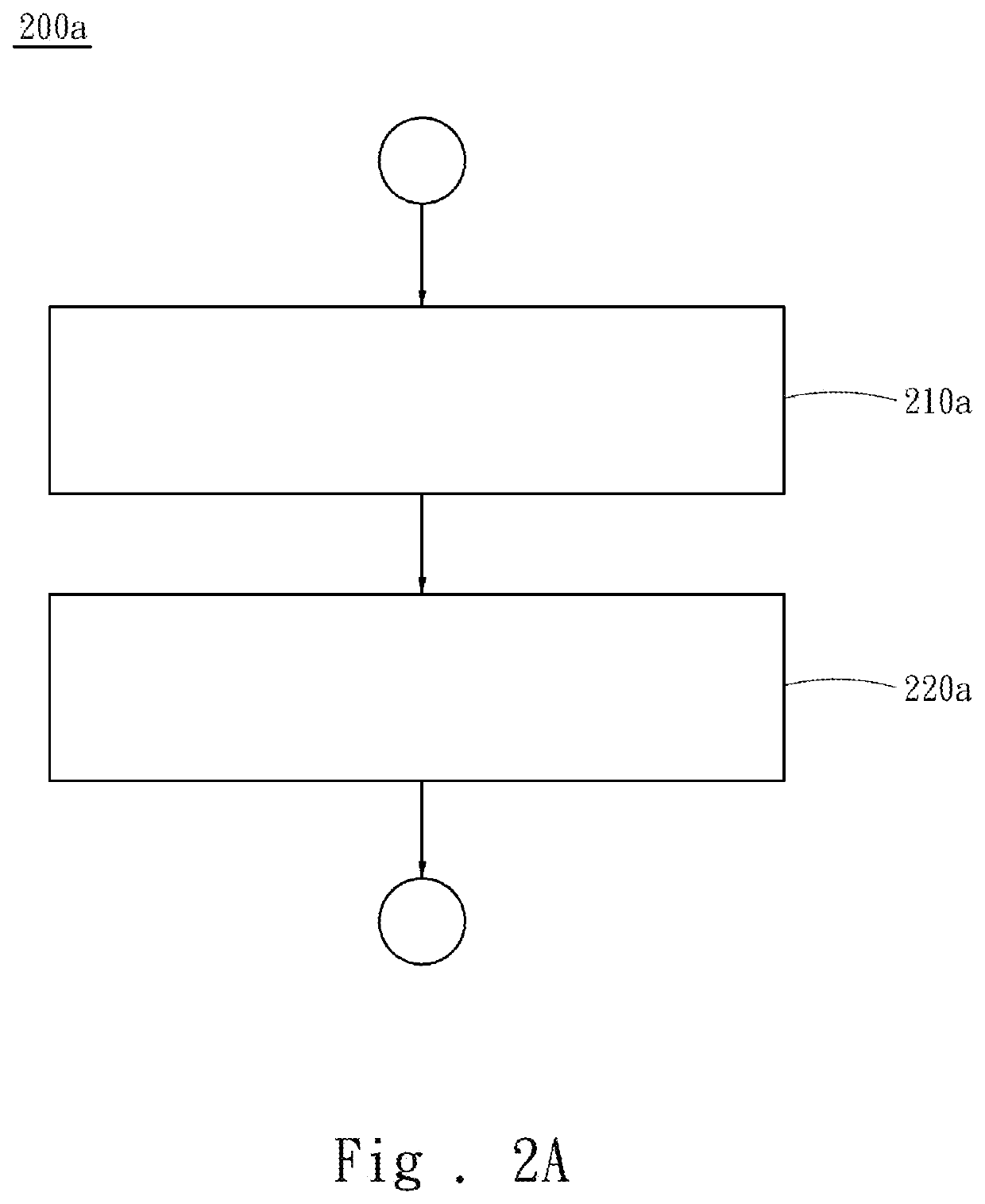

Modeling method for smart prognostics and health management system and computer program product thereof

InactiveUS20200250584A1Ensure process stabilityIncrease production capacityMathematical modelsEnsemble learningAdaptive optimizationModelSim

The present invention provides a modeling method for a smart prognostics and health management system. The method comprises a new tree establishing step, a dual-branch modeling step, and a model adaptive optimization step. As monitoring data increases, a golden model can be selected as a benchmark for optimization decision from prediction hypothesis models constructed by the dual-branch modeling step. This benchmark is used for next prediction. A prediction result of the system is caused to meet an expected target value. The present invention provides a computer program product for the smart prognostics and health management system at the same time. The above-described modeling method for the smart prognostics and health management system is completed when the computer program product is executed.

Owner:MARKETECH INT

Production method for hot rolling acid pickling automobile plate

The invention discloses a production method for a hot rolling acid pickling automobile plate. The hot rolling acid pickling automobile plate comprises chemical elements including, by weight, 0.02-0.04% of C, smaller than or equal to 0.05% of Si, 0.20%-0.30% of Mn, smaller than or equal to 0.020% of P, smaller than or equal to 0.020% of S, 0.010%-0.020% of Nb, 0.030-0.050% of Als, smaller than or equal to 0.008% of N and the balance Fe and inevitable impurities. The preparing method for the hot rolling acid pickling automobile plate sequentially includes the following steps of molten iron pre-desulfuration treatment, converter steelmaking, steel ladle LF refining, continuous casting, casting blank heating, rough rolling, finish rolling, laminar cooling, high-temperature coiling, flattening,acid pickling, rinsing, oil smearing and coiling. By means of the production method for the low-carbon, low-manganese and low-silicon component design is adopted, the carton equivalent is reduced onone hand, and the steel plate welding performance is improved; on the other hand, ferrous silicate which is hardly subjected to acid pickling is prevented from being formed on the surface of a steel plate in the hot rolling process, and the surface quality of the steel plate is improved; a proper amount of Nb alloys are added, so that the strengthening effect of the Nb alloys is sufficiently achieved, and low-cost component design is achieved; and high-temperature coiling is adopted, the laminar cooling control difficulty is lowered, the steel roll through roll technology is stability, and thesteel roll plate shape quality and the through roll performance stability are improved.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

Sintered flux for filament swinging submerged arc surfacing of continuous casting roller and preparation method for sintered flux

ActiveCN102416533AImprove conductivityEnsure process stabilityWelding/cutting media/materialsSoldering mediaNitrogenMetal

The invention relates to a sintered flux for filament swinging submerged arc surfacing of a continuous casting roller and a preparation method for the sintered flux. The preparation method comprises the following steps of: screening each ingredient by using a screen of 20 meshes; adding 15 to 25 percent of MgO, 20 to 30 percent of Al2O3, 25 to 35 percent of CaF2+CaO, 5 to 10 percent of SiO2, 5 percent of ZrO2, 2 to 5 percent of Na3AlF6, 0 to 3 percent of metallic Mn, 0 to 3 percent of Cr2O3, 0 to 4 percent of TiFe, 0 to 4 percent of CaCO3 and 0 to 3 percent of No. 45 SiFe into a powder mixing powder, and mixing; slowly adding neutral potash water glass into the prepared mixed powder, humidifying uniformly, granulating and roasting; and sintering at the temperature of between 800 and 950 DEG C, cooling, and thus obtaining the sintered flux. The sintered flux used for filament swinging submerged arc surfacing by matching a nitrogen alloyed 0Cr13Ni4MoN(414N) flux-cored wire can realize surfacing repair of the continuous casting roller.

Owner:中机焊业科技(福建)有限公司

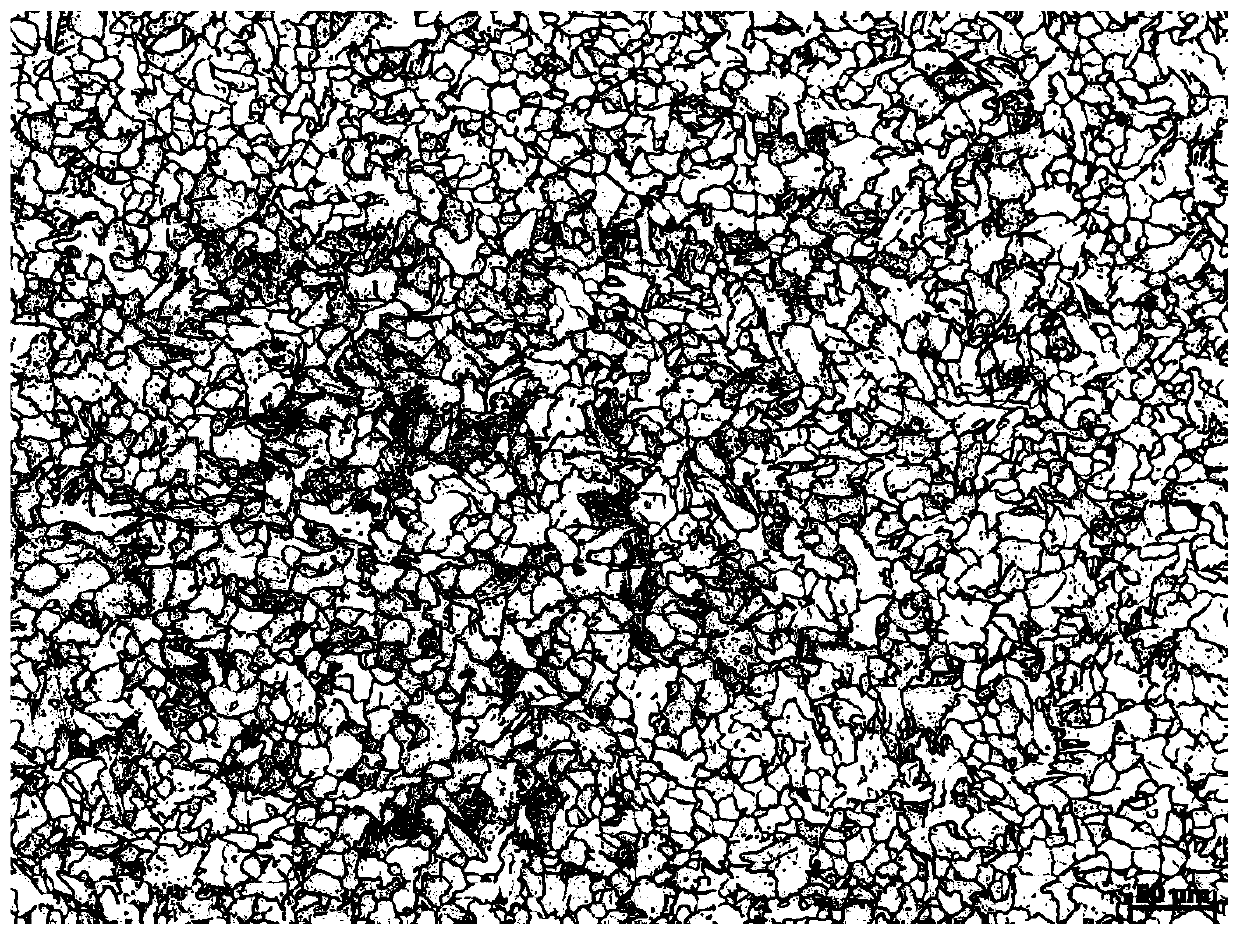

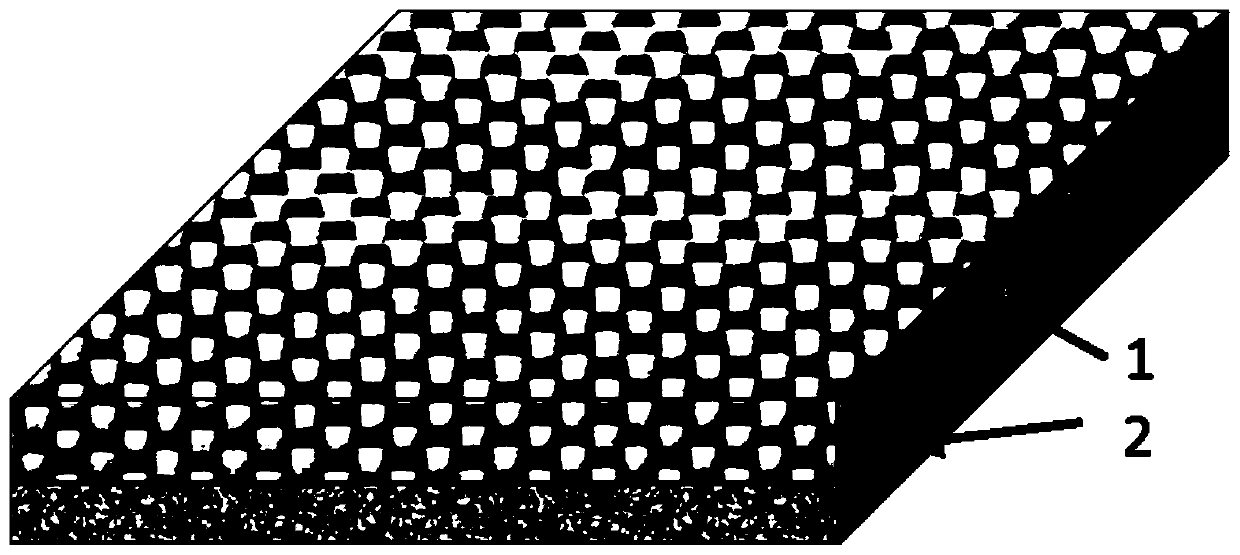

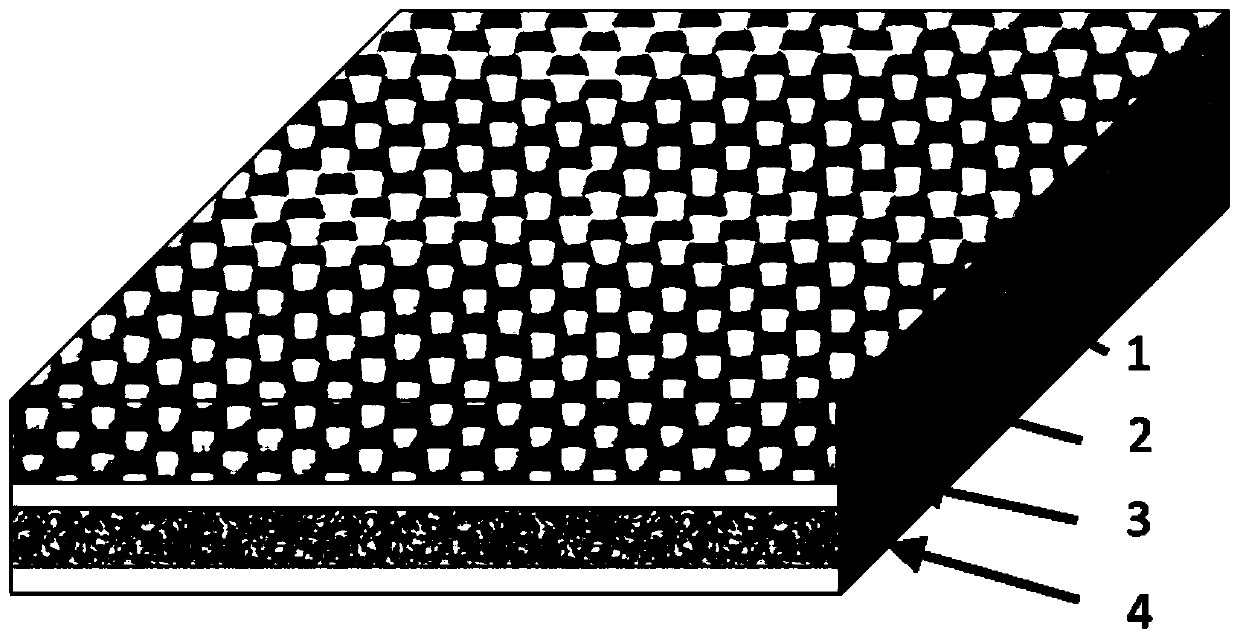

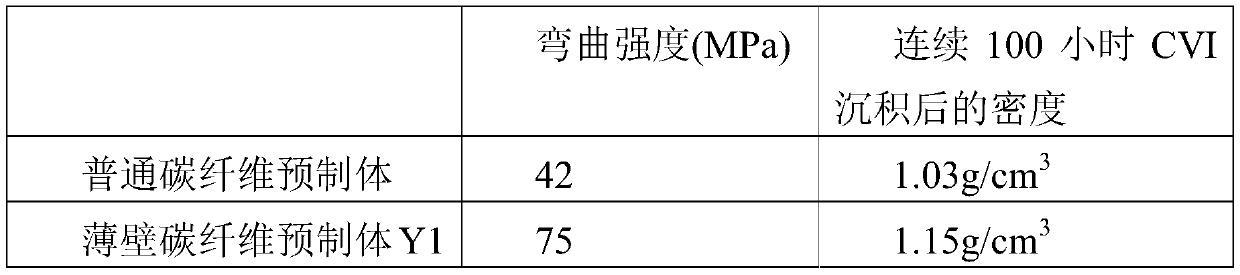

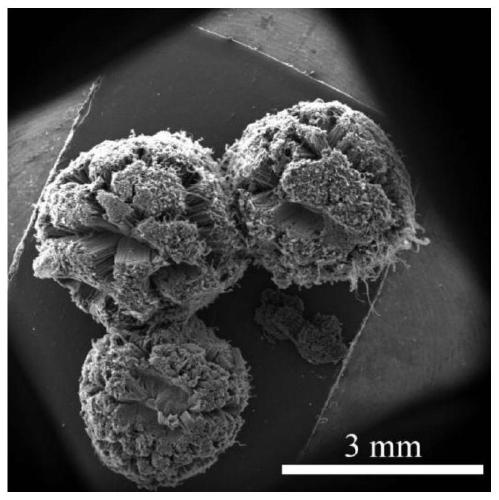

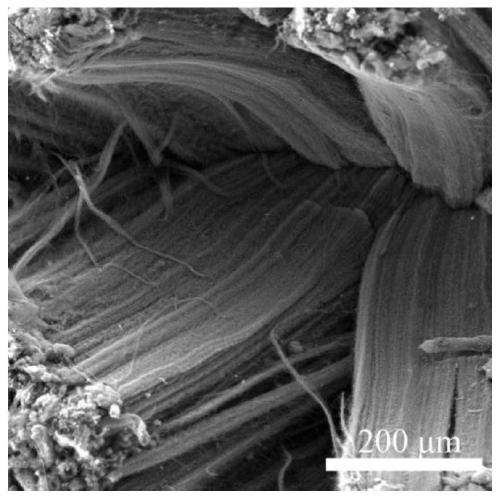

Large thin-wall carbon fiber needling prefabricated body and preparation method thereof

The invention discloses a large thin-wall carbon fiber prefabricated body. Resin exists in prefabricated body structural unit layers or among the prefabricated body structural unit layers; the unit layer structures serve as the structural unit layers formed by sequentially superposing and then needling carbon fiber net tires, resin films and carbon cloth; or the unit layer structures serve as thestructural unit layers formed by sequentially superposing and then needling carbon fiber / resin fiber net tires and carbon fiber / resin fiber mixed fabric; and the large thin-wall carbon fiber prefabricated body is prepared by superposing the unit structure layers by multiple layers via hot pressing. The prefabricated body has the certain rigidity and the relatively high size accuracy, and has a relatively small influence on the structure of C / C composite substrate carbon, and subsequent CVI technology forming is facilitated.

Owner:JIANGSU TIANNIAO HIGH TECH

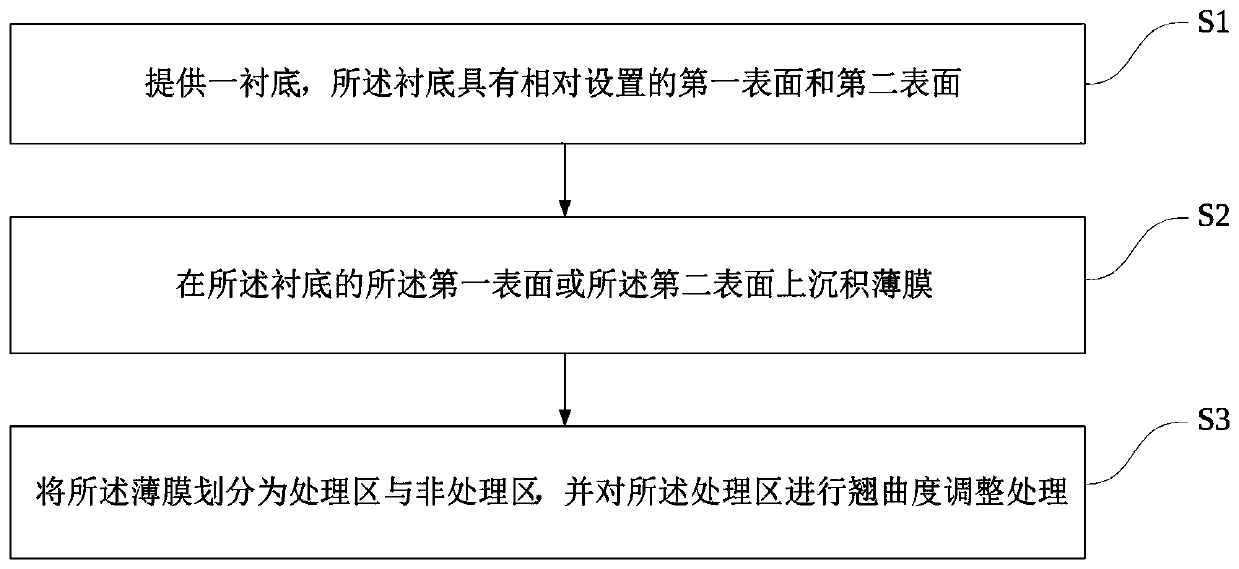

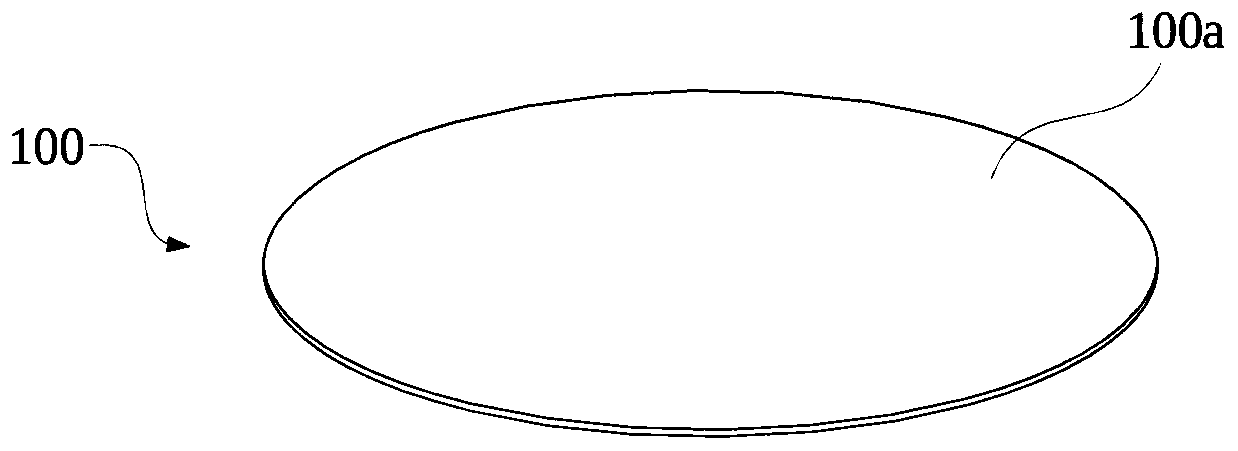

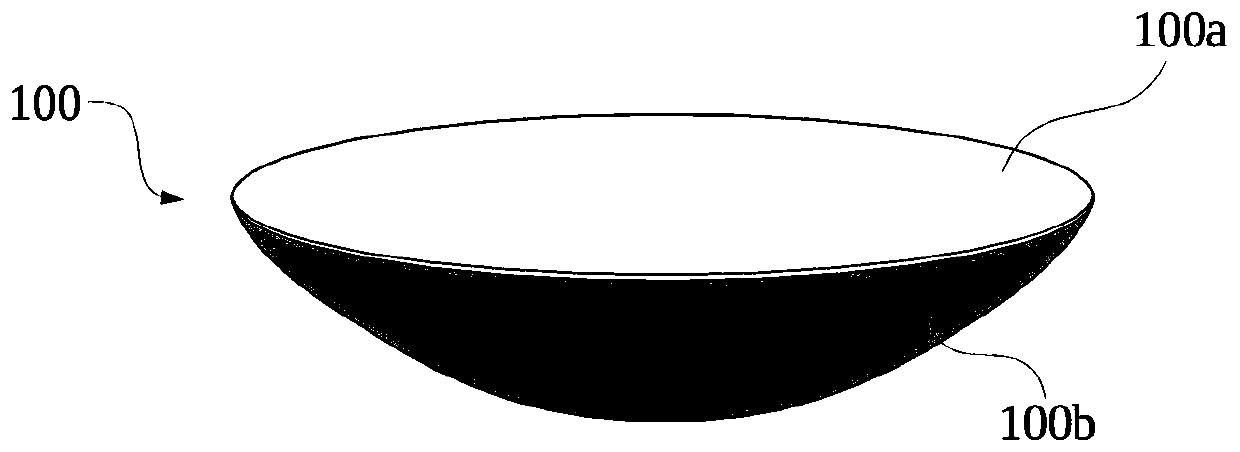

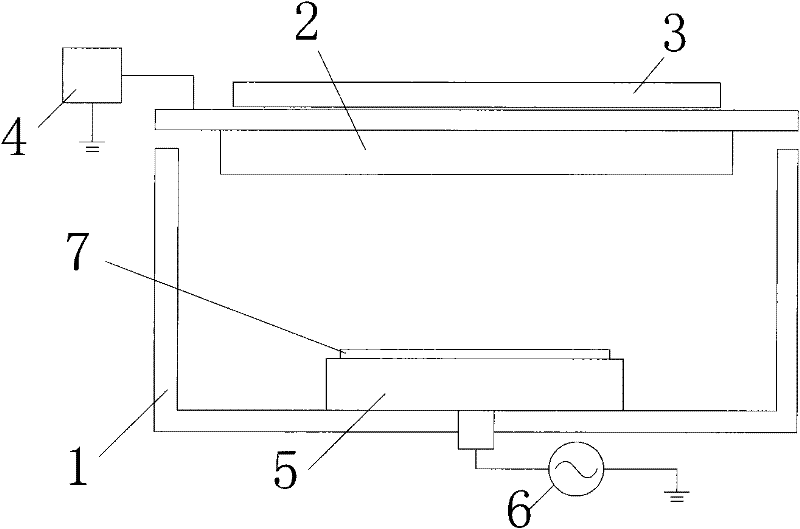

Wafer warpage adjustment method and equipment

InactiveCN110690113AEnsure process stabilityGuaranteed yieldSemiconductor/solid-state device manufacturingWaferThin membrane

The invention provides a wafer warpage adjustment method and equipment. The wafer warpage adjustment method comprises the following steps: providing a wafer having a first surface and a second surfacewhich are oppositely arranged;depositing a thin film on the first surface or the second surface of the wafer; and dividing the thin filminto a treatment area and a non-treatment area and performing warpage adjustment treatment on the treatment area. The warpage degree adjustment treatment is performed on a part of areas of the thin film after the thin film is deposited so that the anisotropic warpage presented by the wafer is adjusted and the surface of the wafer keeps flat and thus the process stability of the manufacturing process and the product yield can be ensured.

Owner:YANGTZE MEMORY TECH CO LTD

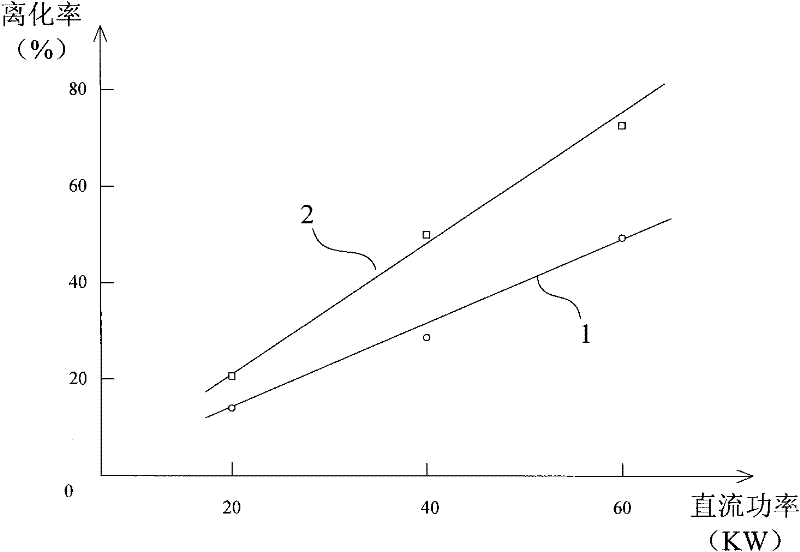

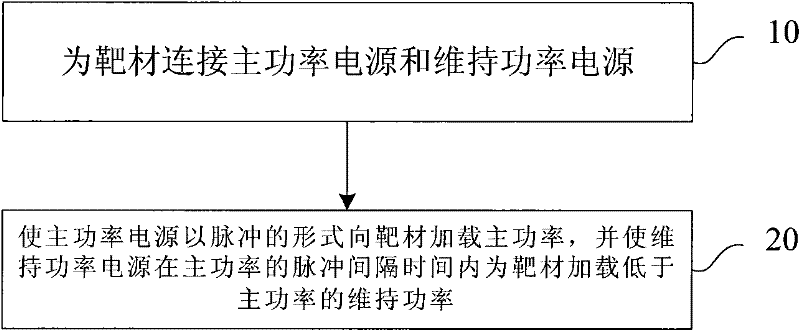

Target power loading method, target power supply and semiconductor processing equipment

InactiveCN102409303AAvoid heat surge problemsMeet the process requirementsElectric discharge tubesVacuum evaporation coatingSputteringComputer module

The invention provides a target power loading method for a magnetic control sputtering process, which comprises the following steps that: (10) a target is respectively connected with a main power supply and a maintenance power supply; and (20) a certain main power is loaded to the target by the main power supply in a pulse form, so that the maintenance power supply at least loads a certain maintenance power to the target during pulse interval time of the main power supply, the maintenance power is less than the main power, and further, the glow discharge process of the sputtering process is maintained during the pulse interval time of the main power. By the target power loading method disclosed by the invention, the stability and the controllability of the process are ensured, simultaneously, the metal ionization is remarkably improved, and further, the process requirements of the technical node are met. In addition, the invention also provides a target power supply which comprises a main power module and a maintenance power module, and semiconductor processing equipment which applies the target power loading method or the target power supply.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

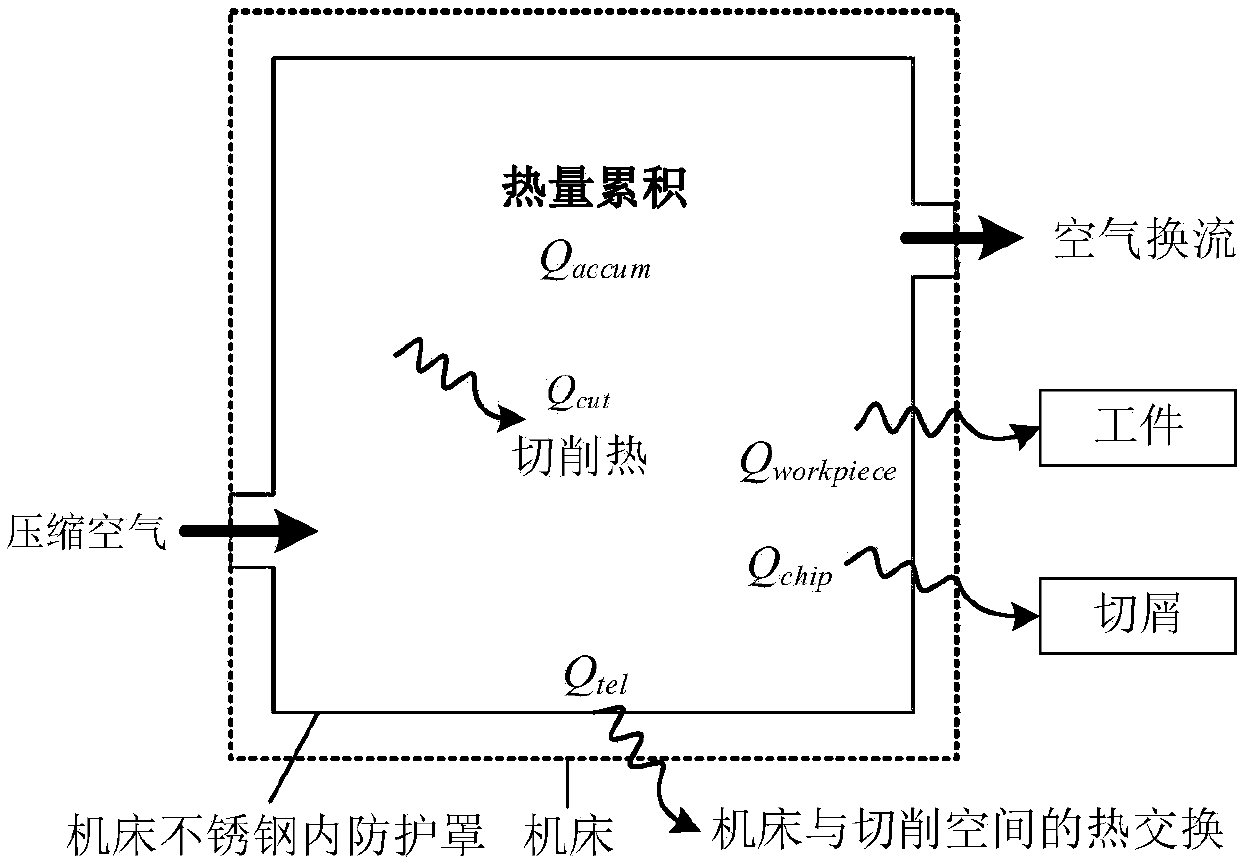

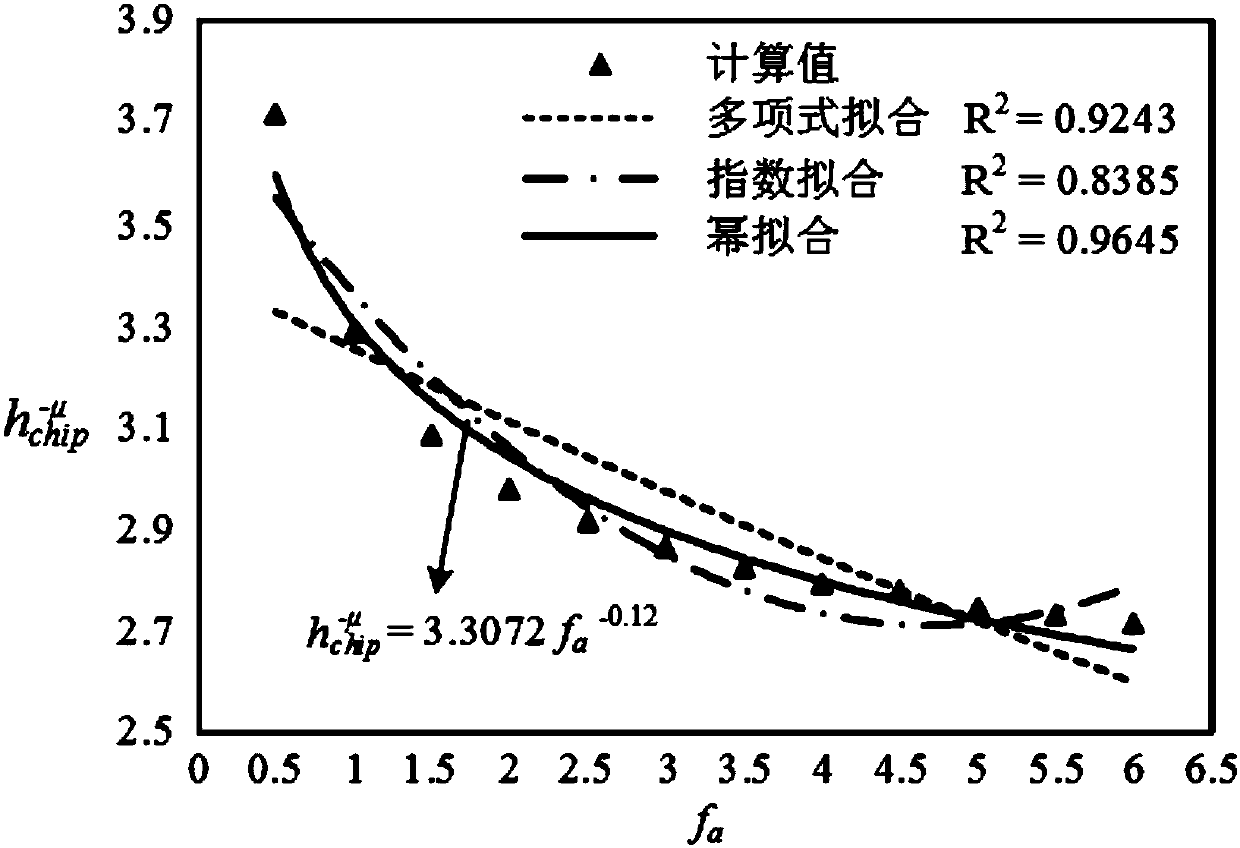

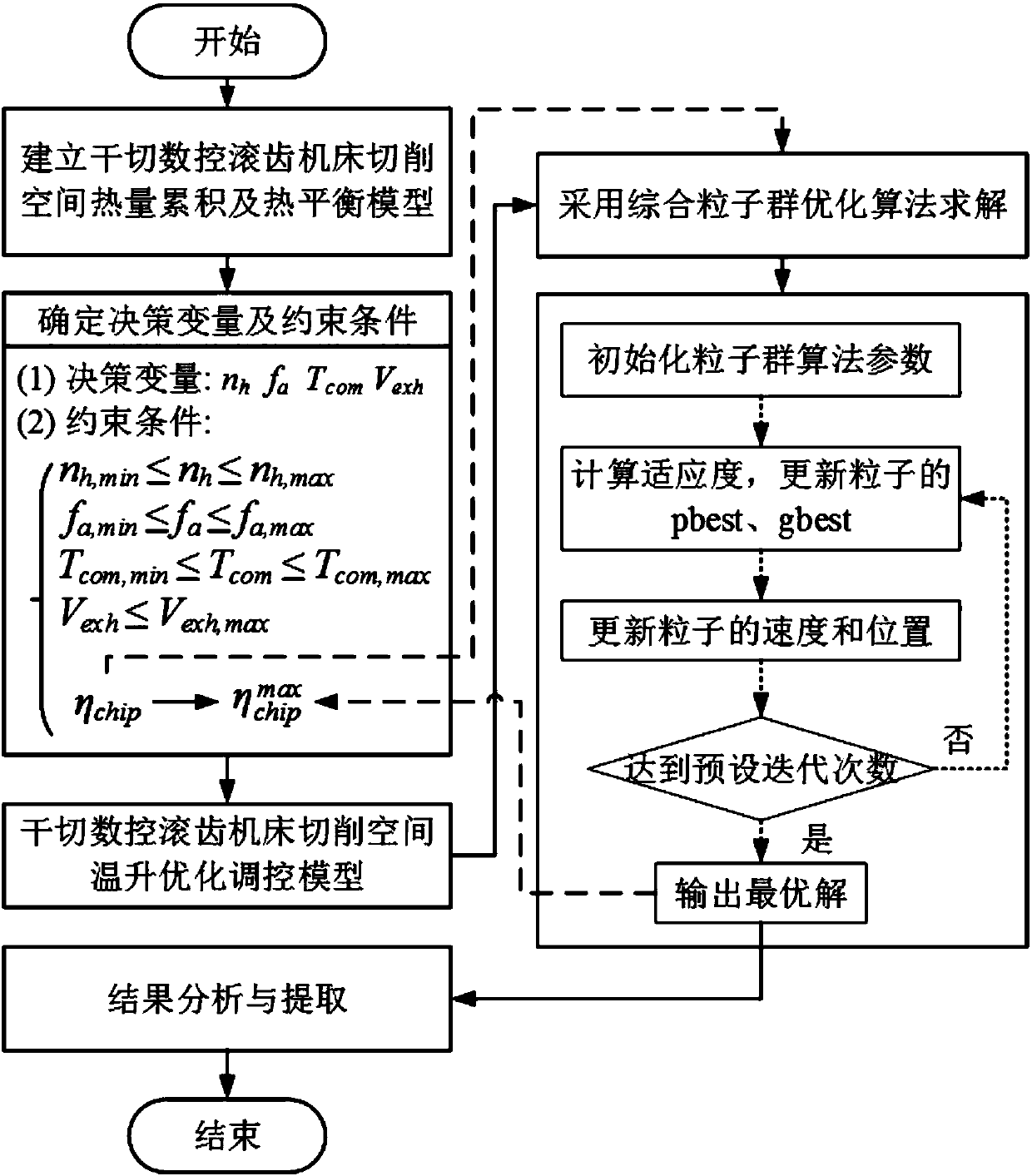

Dry cutting numerical control gear hobbing machine tool cutting space temperature rise optimal regulation method

ActiveCN108037660AImprove machining accuracyEnsure process stabilityAdaptive controlNumerical controlHobbing

The invention discloses a dry cutting numerical control gear hobbing machine tool cutting space temperature rise optimal regulation method. The method mainly comprises the following steps: 1) a dry cutting numerical control gear hobbing machine tool cutting space heat accumulation model and a heat balance model are built; 2) dry cutting numerical control gear hobbing machine tool cutting space temperature rise optimal regulation is carried out; 3) a dry cutting numerical control gear hobbing machine tool cutting space temperature rise optimal regulation model is solved, and thus, values of a hob rotation speed nh, a hob axial feeding amount fa, low-temperature compressed air temperature Tcom and an air commutation device exhaust volume Vexh when Tspace-T1 is the minimum are acquired; and 4) the hob rotation speed nh, the hob axial feeding amount fa, the low-temperature compressed air temperature Tcom and the air commutation device exhaust volume Vexh which are acquired after optimization are used for dry cutting gear hobbing processing.

Owner:CHONGQING UNIV

Processing technology of glass bottle

InactiveCN107151097ABright colorHigh light transmittanceGlass shaping apparatusCoatingsCalciteTransmittance

The invention discloses a processing technology of a glass bottle. The processing technology comprises the following steps: (1) treating broken glass; (2) mixing raw materials: weighing the following raw materials in parts by weight: 50-80 parts of powder particles, 40-60 parts of calcite, 30-40 parts of albite, 10-20 parts of fluorite, 5-10 parts of borax, 2-6 parts of sodium carbonate, 1-5 parts of table salt, 0.1-0.8 part of magnesium sulfate, 0.01-0.05 part of cobalt powder and 0.6-1.8 parts of a compound clarifying agent, and evenly mixing and stirring the weighed raw materials to obtain a mixture; (3) molding by sintering; (4) annealing; (5) performing plate-making and printing; (6) tempering the glass bottle. The processing technology of the glass bottle can eliminate the pressure in a glass bottle body, thus avoiding the phenomenon of bursting caused in a production process and the phenomenon of cracking caused in a later use process; furthermore, the processing technology simplifies a coating operation process and increases the tightness of a coating layer; the glass bottle produced by using the processing technology is bright in color, high in light transmittance and long in service life.

Owner:合肥钢骨玻璃制品有限公司

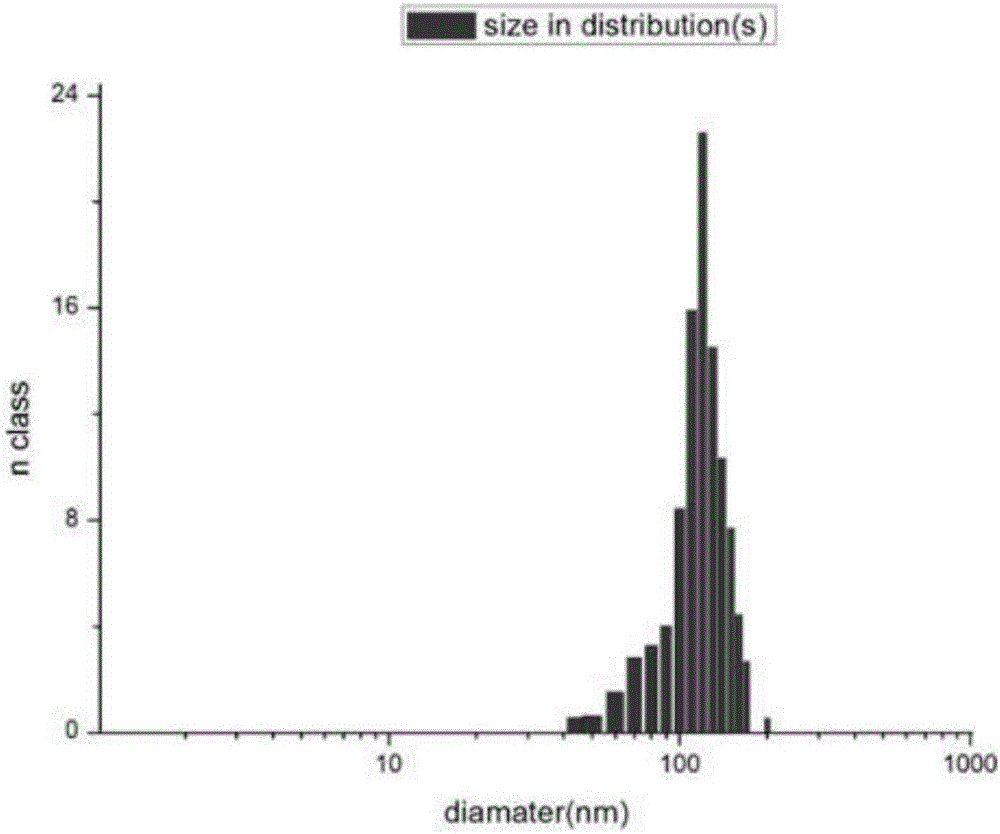

Paclitaxel nanoparticles and preparation method thereof

ActiveCN106265513AReduce intakeSmall toxicityOrganic active ingredientsPharmaceutical non-active ingredientsWater bathsFreeze-drying

The invention discloses a preparation method of paclitaxel nanoparticles. The preparation method comprises the following steps of dissolving PEG-PLA or PEG-PLA and folate-PEG-PLA mixed polymer with tetrahydrofuran; dissolving paclitaxel with dichloromethane; uniformly mixing the solutions; adding 2% polyvinyl alcohol of which the volume is 1.5 times of that of the mixed solution, and performing ultrasonic mixing; dropwise adding the mixed solution into water at a speed of 20-30drop / min, and performing ultrasonic treatment in an ice bath; stirring the obtained emulsion in a water bath at a room temperature under normal pressure, volatilizing an organic solvent, performing centrifugation, collecting precipitates, washing with water, and performing re-hydration; dialyzing a hydration obtained by the re-hydration; adding 2.5wt% of a freeze-drying protective agent F-68 into the dialyzed nano micelle, and performing cryopreservation, thereby obtaining the paclitaxel nanoparticles. The method is simple in operation steps and easy to operate; after the medicament micellar solution is placed at a room temperature for one week, no medicament is released, which further proves that the medicament is wrapped in cores of the nanoparticles and the properties are relatively stable.

Owner:SHANDONG UNIV QILU HOSPITAL

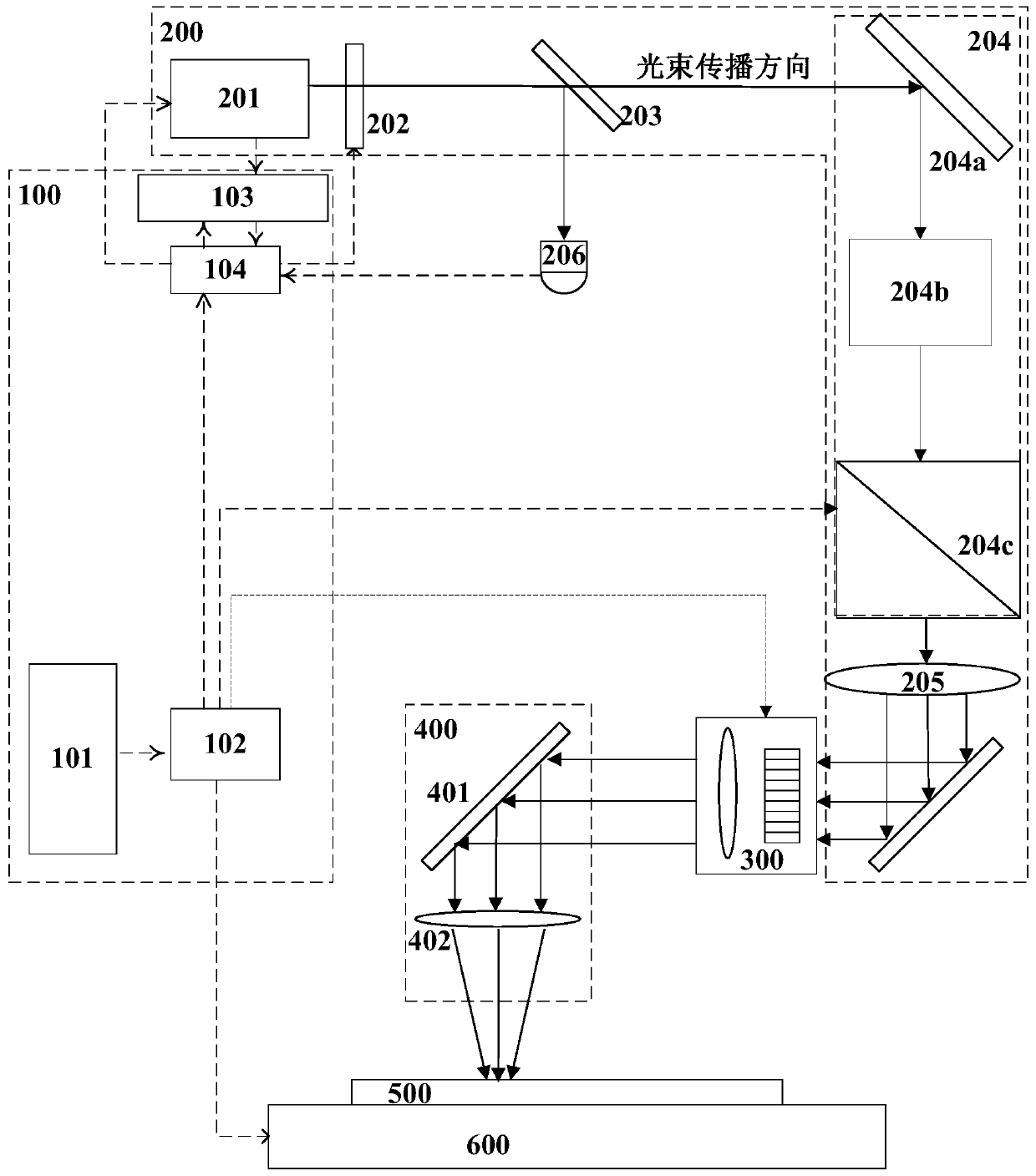

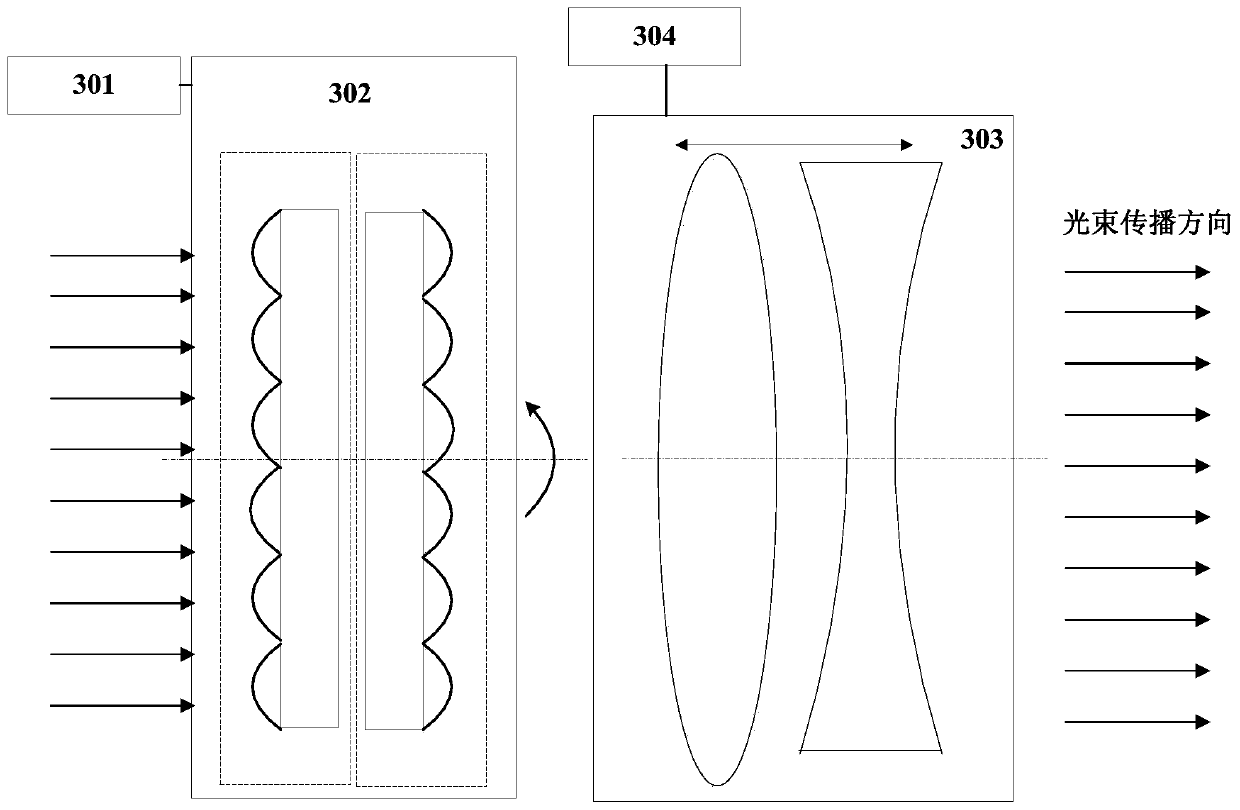

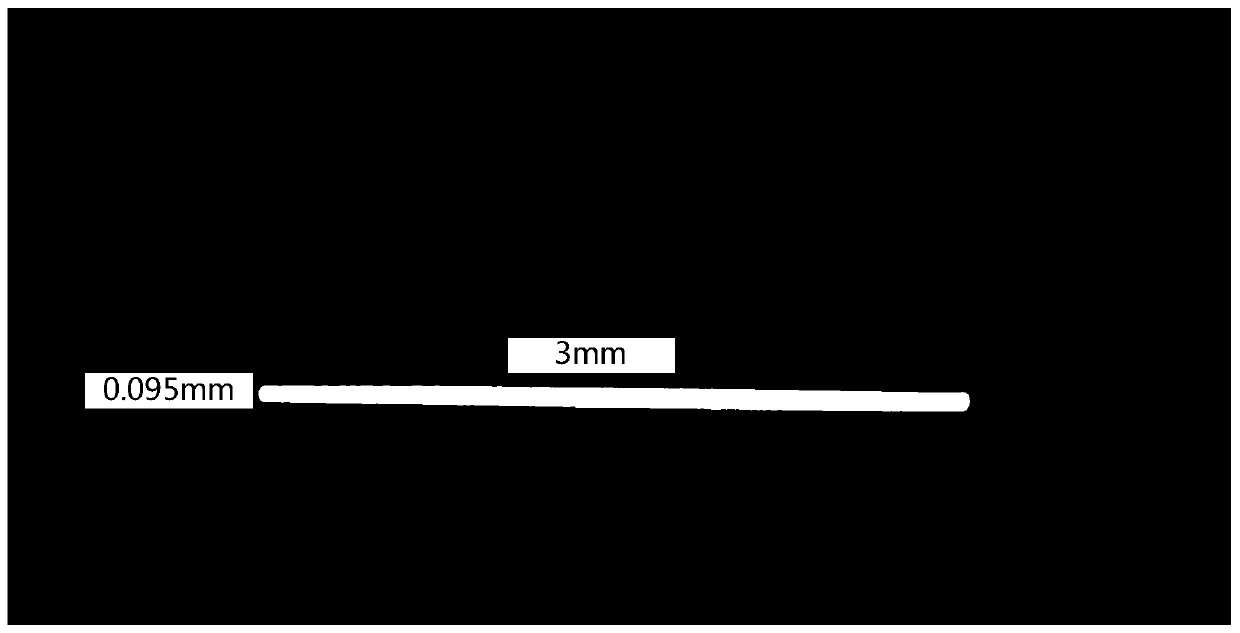

Laser annealing device

ActiveCN110064839AEnsure process stabilityReduce the influence of machine flareSemiconductor/solid-state device manufacturingHeat treatment process controlLaser annealingElectricity

The embodiment of the invention discloses a laser annealing device which comprises a control module, a laser beam generation module, a laser beam adjustment module and an optical module. The laser beam generation module is electrically connected with the control module and is used for producing a first laser beam according to a laser control signal output by the control module; the laser beam adjustment module is electrically connected with the control module and is used for adjusting the laser intensity distribution of the first laser beam so as to convert into a second laser beam according to a movable mechanism parameter output by the control module; and the optical module is used for converging the second laser beam so as to form a light spot corresponding to the laser control signal on a correspondingly arranged substrate. According to the laser annealing device provided by the embodiment of the invention, no matter how the quality of a light beam output by the laser changes, thefirst laser beam cannot be influenced, and uncertain influences cannot bring to the process; and the yield of the laser has no need to be frequently adjusted, so that the maximum utilization of the yield of the laser is ensured.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

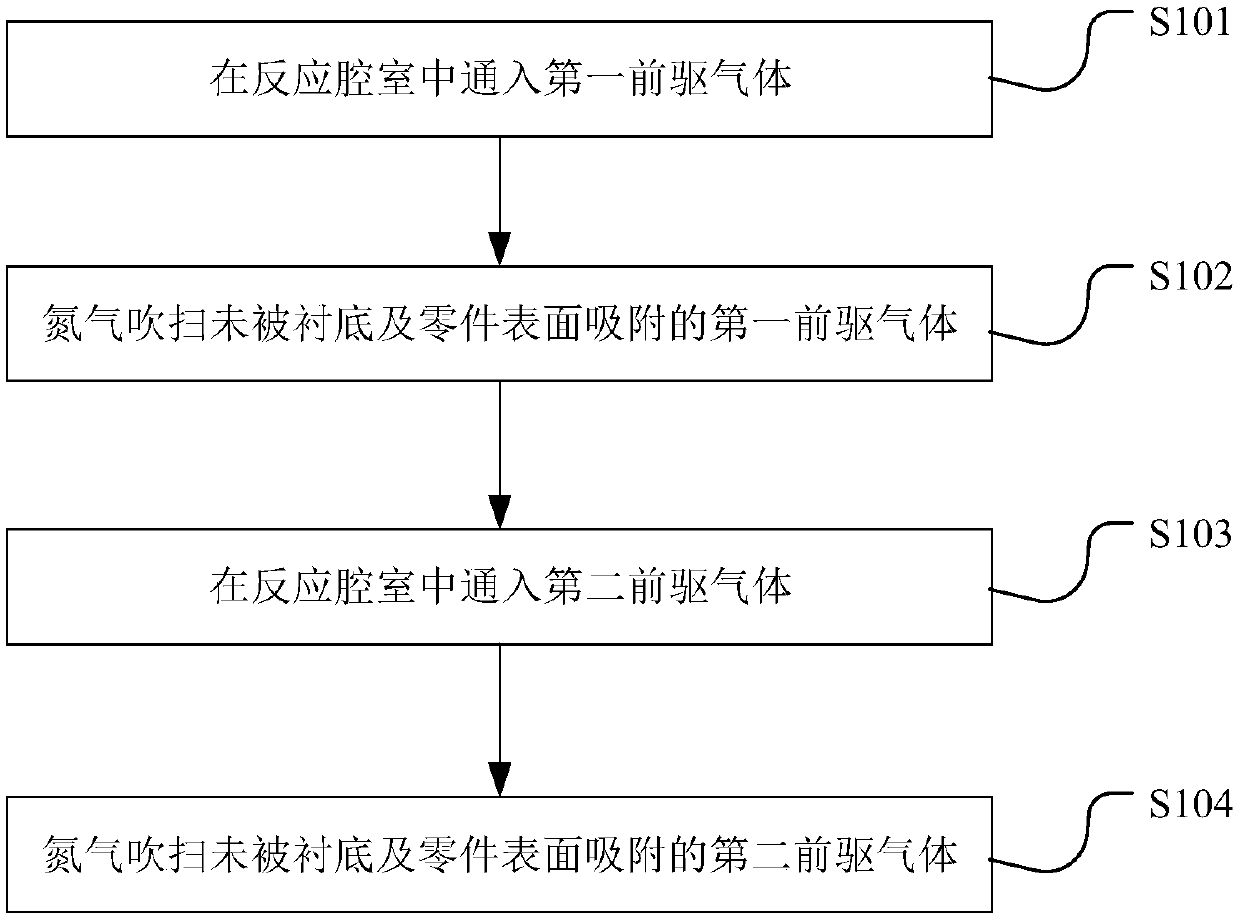

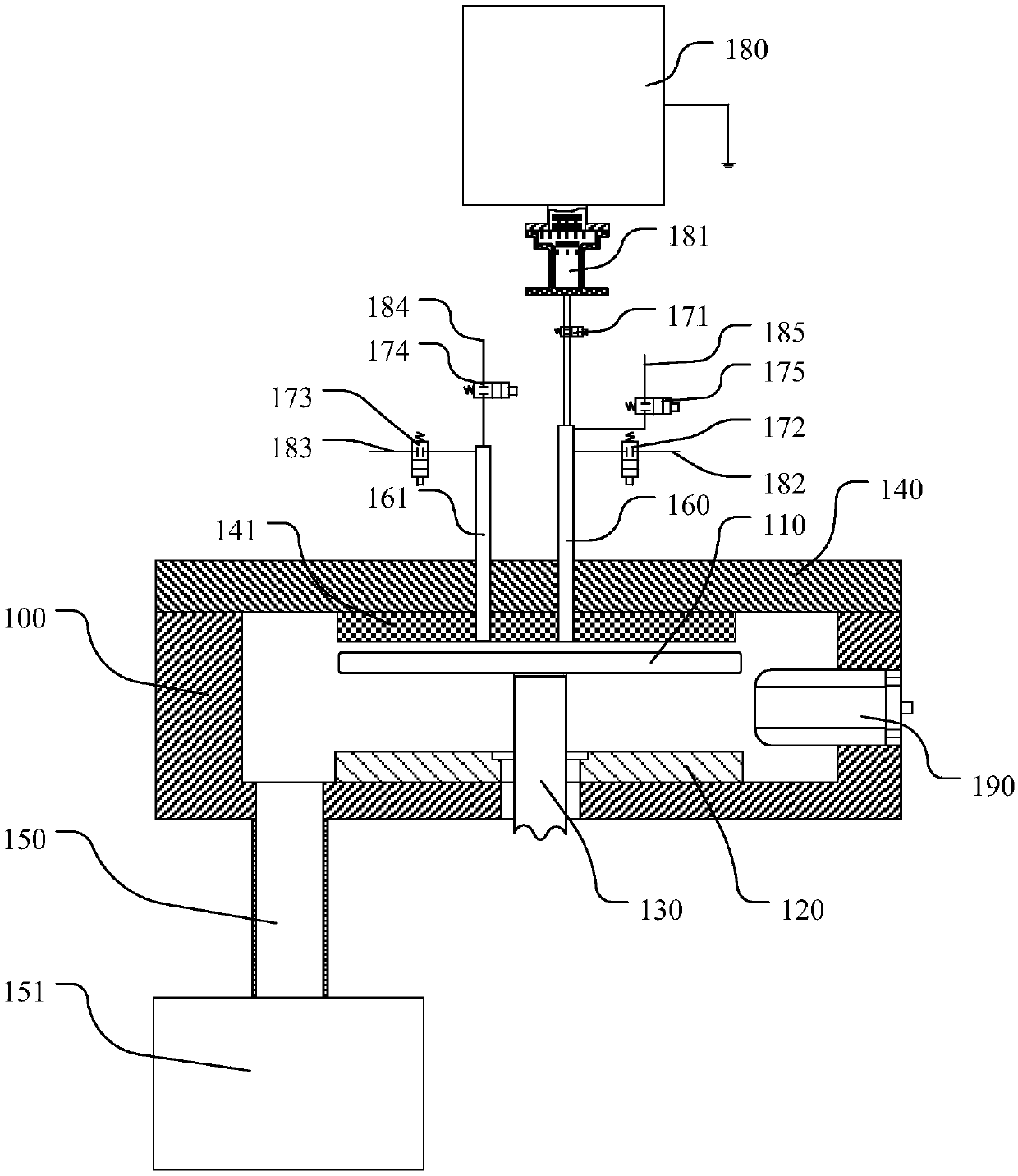

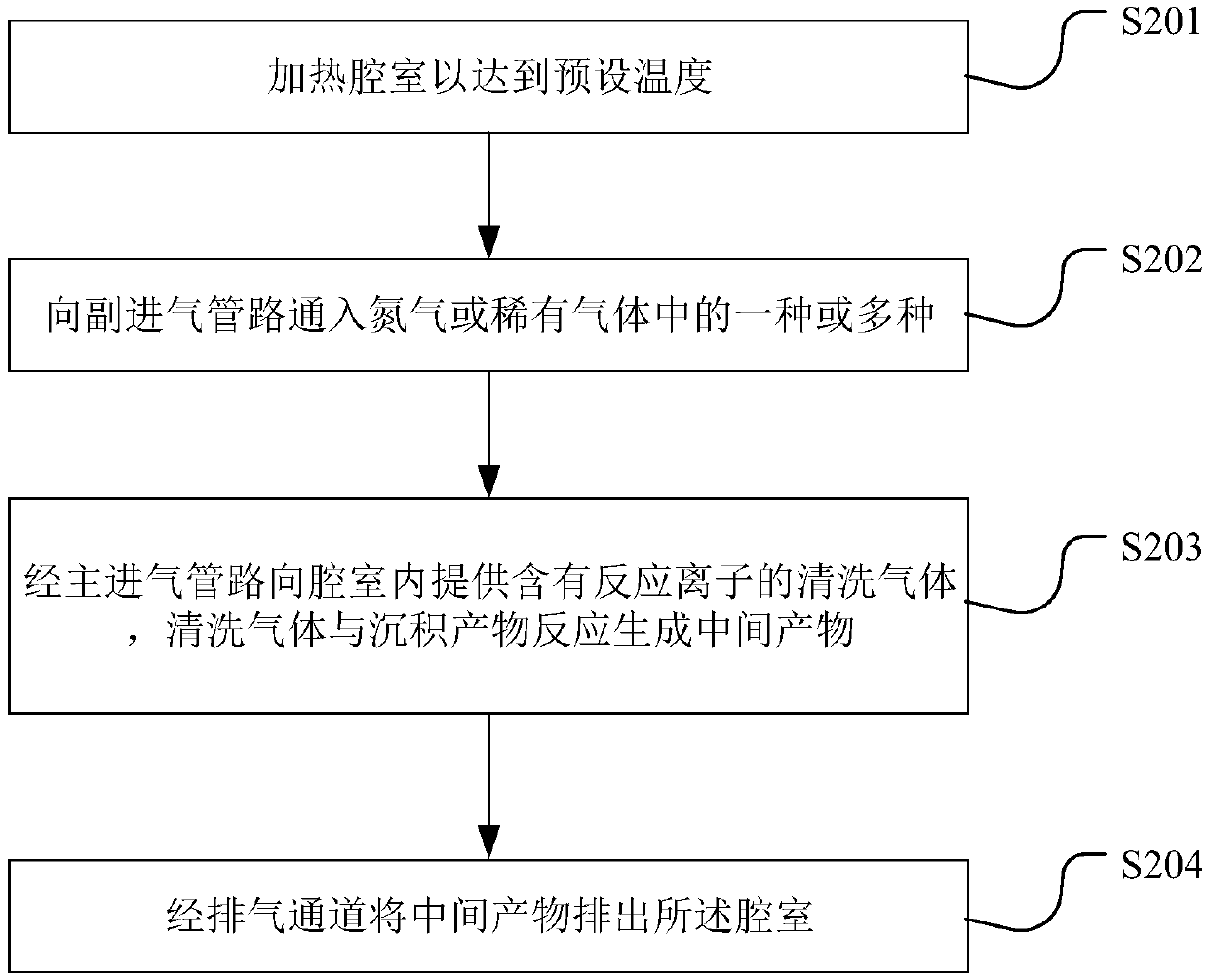

Atomic layer deposition equipment and cleaning method thereof

PendingCN109609930AEnsure process stabilityWith heating functionChemical vapor deposition coatingTemperature controlEngineering

The invention discloses atomic layer deposition equipment and a cleaning method thereof. The atomic layer deposition equipment comprises a chamber, an exhaust pipeline, a gas inlet assembly and a temperature controlling unit; the exhaust pipeline is connected between the chamber and a vacuum pump; the gas inlet assembly is connected to the chamber and used for providing cleaning gas containing reaction ions, and the cleaning gas reacts with a process post-deposition product to generate an intermediate product; and the temperature controlling unit is used for heating the atomic layer depositionequipment, so that the intermediate product is in a gas state. A main gas inlet pipeline of the atomic layer deposition equipment can provide the cleaning gas to the chamber, the chamber is providedwith the temperature controlling unit, the intermediate product is in the gas state, and thus the atomic layer deposition equipment can be effectively cleaned under the condition of not decreasing thetemperature and not detaching equipment parts.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

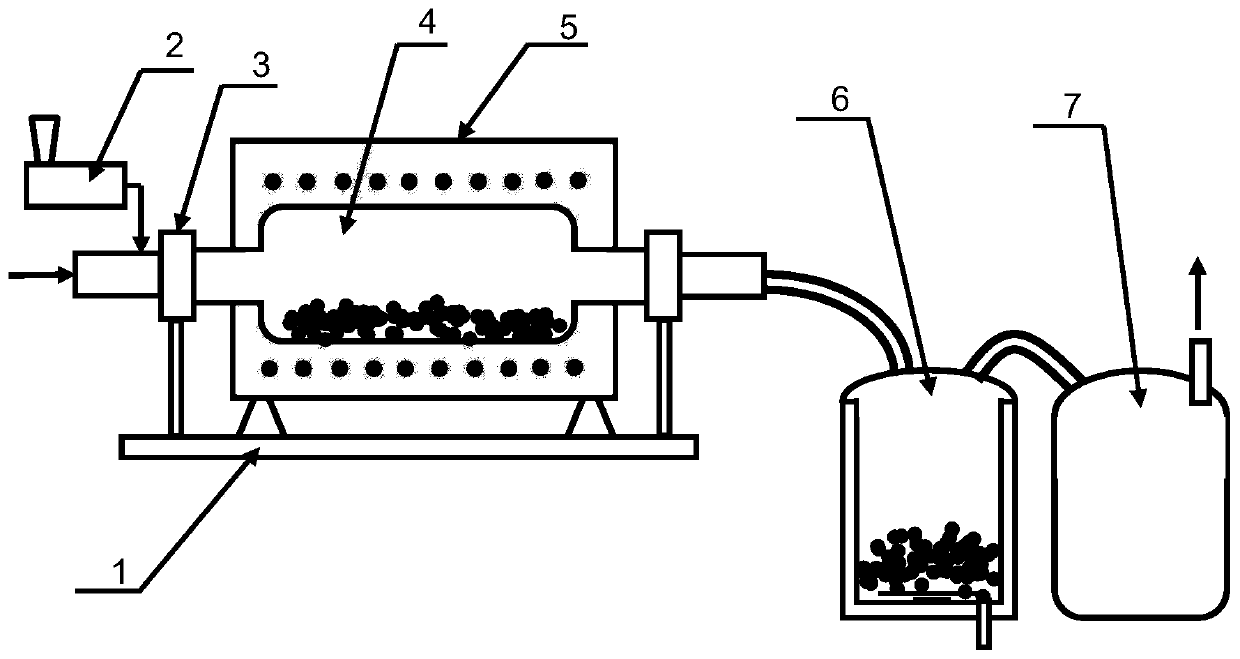

Device and method for preparing carbon nanotubes in batches

ActiveCN110451486AReduce energy consumptionImprove efficiencyCarbon compoundsCarbon sourceBatch production

The invention discloses a device and a method for preparing carbon nanotubes in batches. The device is composed of a tiltable tubular rotary furnace, a solid feeder, a solid powder separator, a powdercollector and an auxiliary system. The device and the method are based on a technology for preparing carbon nanotubes by floating catalytic chemical vapor deposition, inorganic ceramic beads adoptedas a collection carrier are placed in the high temperature zone of the tiltable tubular rotary furnace, and a carbon source and a catalyst are introduced for the growth of the carbon nanotubes; and after the growth is completed, a furnace body is tilted and rotated at the same time, the carbon nanotubes deposited on the tube wall of the rotary furnace are scraped off by the ceramic beads, enter the solid powder separator and are separated, and a carbon nanotube powder is brought into the powder collector by an inert gas current, and is collected to finally obtain the carbon nanotubes. The device and the method can realize continuous batch production of the carbon nanotube, solves the problem that carbon nanotube product is prone to deposit on the tube wall of the furnace under a stable gasfield distribution reaction condition, obtain the high-quality carbon nanotubes, can be easily amplified to realize industrialization, and have great economic values.

Owner:JIANGXI COPPER TECHNOLOGY RESEARCH INSTITUTE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com