3D mold overlaying intelligent robot

An intelligent robot and mold technology, applied in welding equipment, manufacturing tools, auxiliary welding equipment, etc., can solve problems such as low work efficiency, inability to guarantee process stability, and inability to guarantee the performance of welding materials, so as to improve welding quality and guarantee process. Stability, the effect of ensuring flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

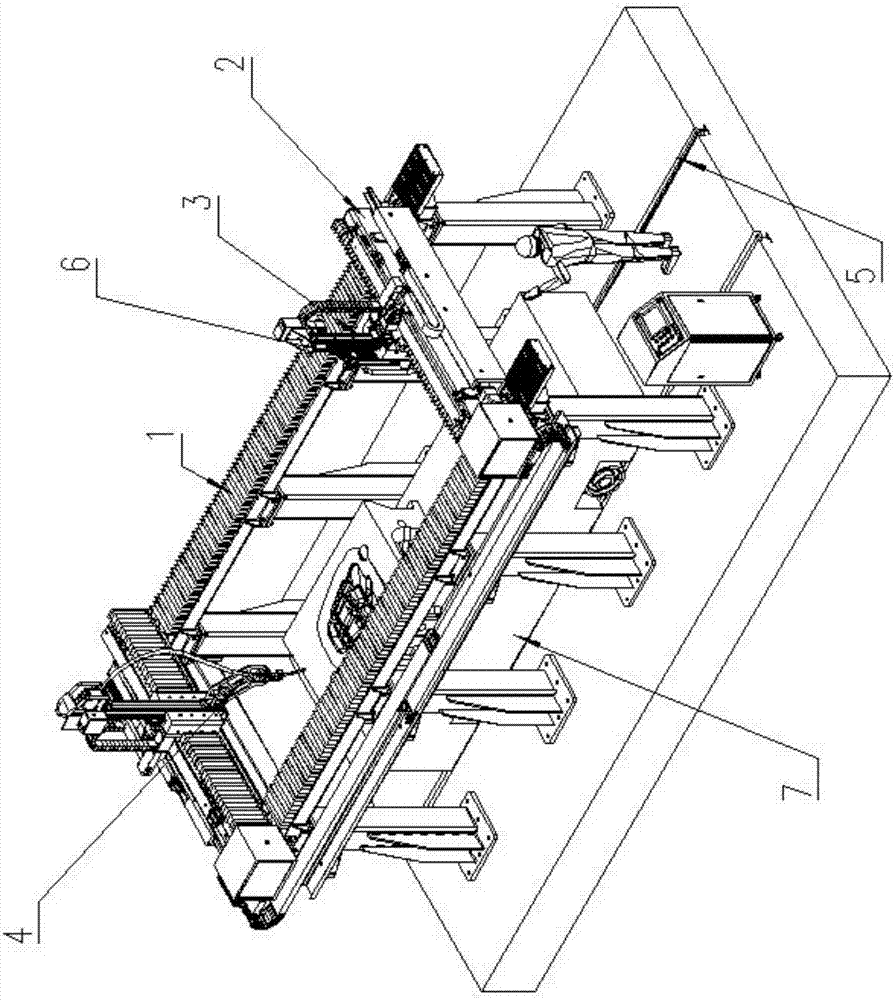

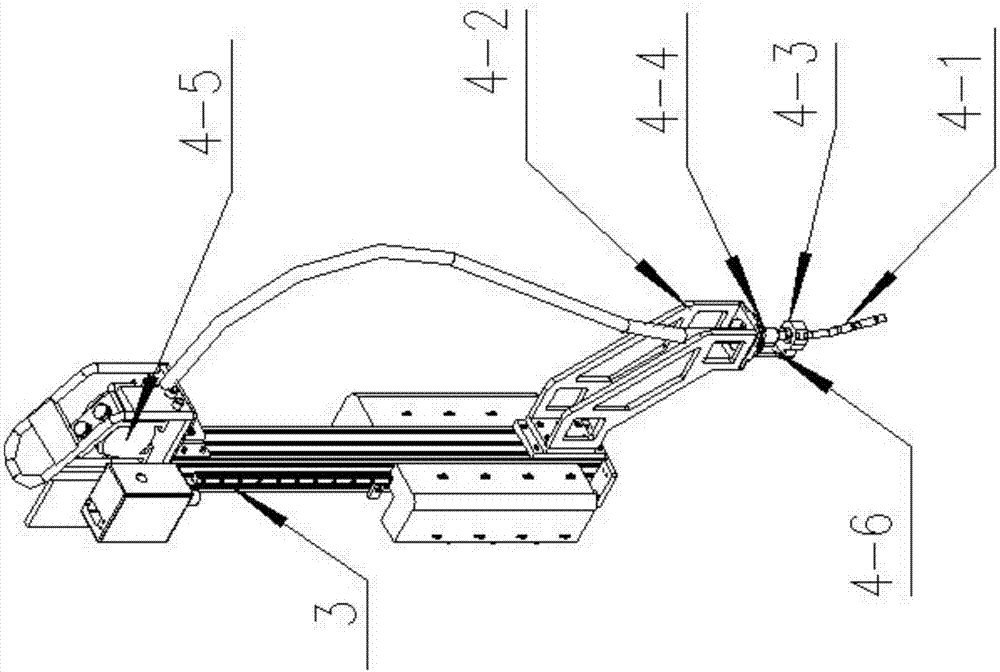

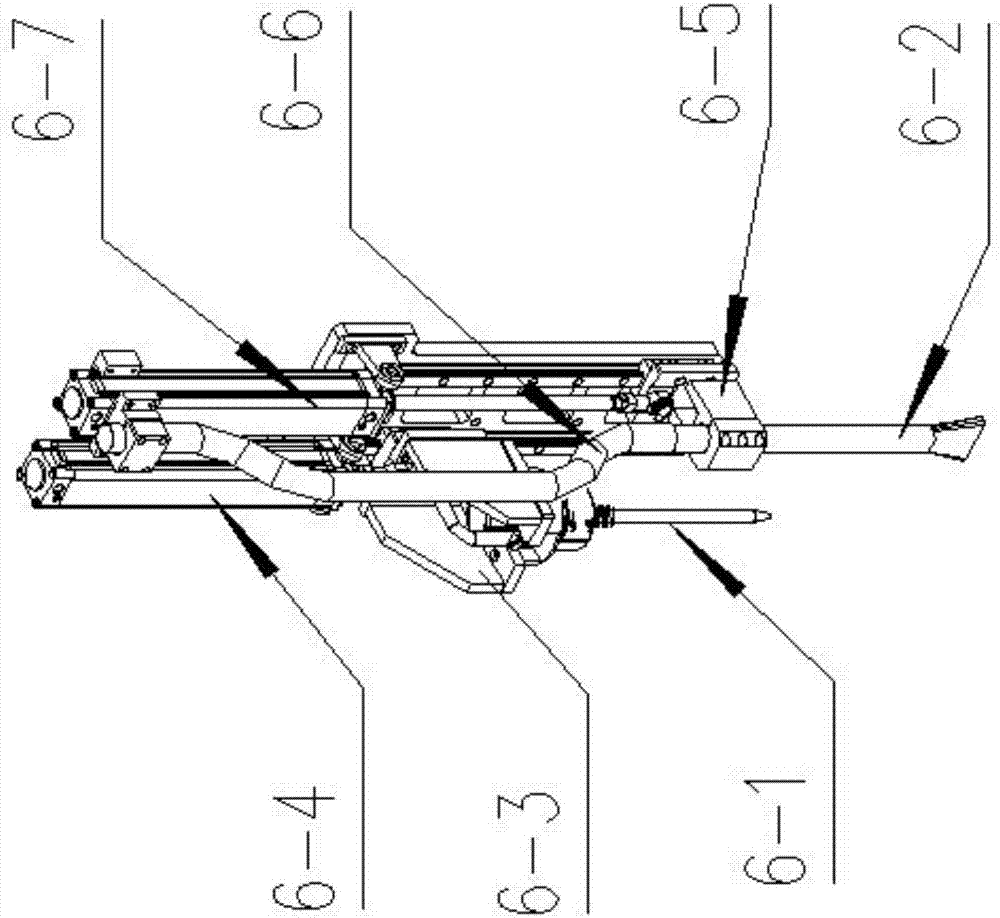

[0018] Example 1, such as Figure 1-3 Shown: the mold 3D surfacing intelligent robot of the present invention consists of X-axis beam 1, Y-axis beam 2, Z-axis vertical guide rail 3, welding head 4, flat car guide rail 5, welding stress relief device 6, electric flat car 7, The mold is composed of a constant temperature heating device.

[0019] There are two X-axis beams 1, and the two X-axis beams 1 are arranged in parallel. The two X-axis beams 1 are installed on the ground or the base through columns, and two Y-axis beams 2 are installed between the top surfaces of the two X-axis beams 1. , the two Y-axis beams 2 are driven by independent transmission devices to move along the X-axis beam 1. Specifically, a rack is laid on the top surface of the X-axis beam 1, and a gear is installed on the Y-axis beam 2, and the gear meshes with the rack. The Y-axis crossbeam 2 is controlled to move on the X-axis crossbeam 1 through a servo motor and a rack and pinion transmission system t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com