Atomic layer deposition equipment and cleaning method thereof

A technology of atomic layer deposition and equipment, applied in coating, metal material coating process, gaseous chemical plating, etc., can solve the problems of unsatisfactory process, shedding of crystal particles, long maintenance time, etc., to shorten cleaning time, The effect of avoiding open cavity maintenance and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

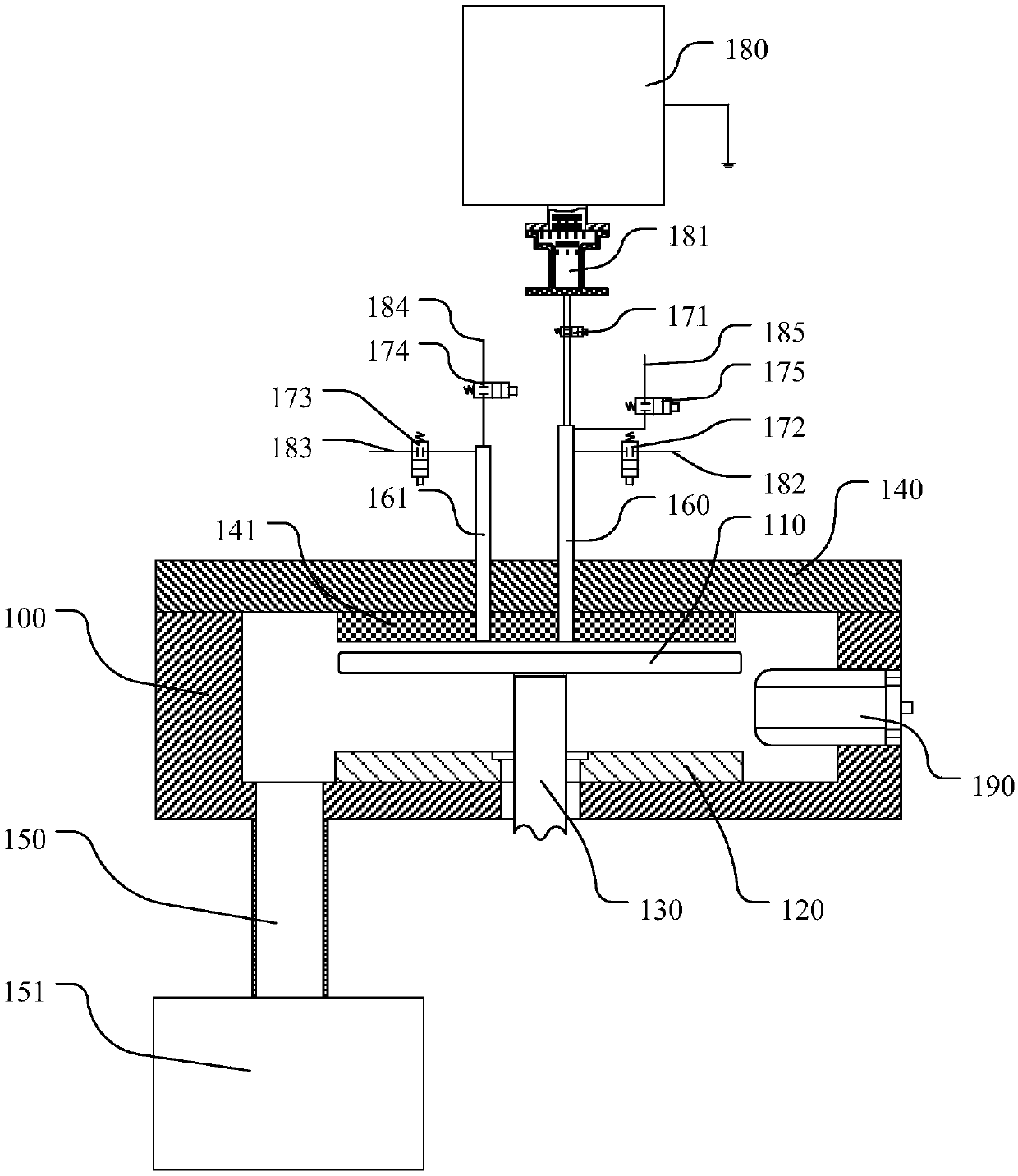

[0048] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

[0049] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

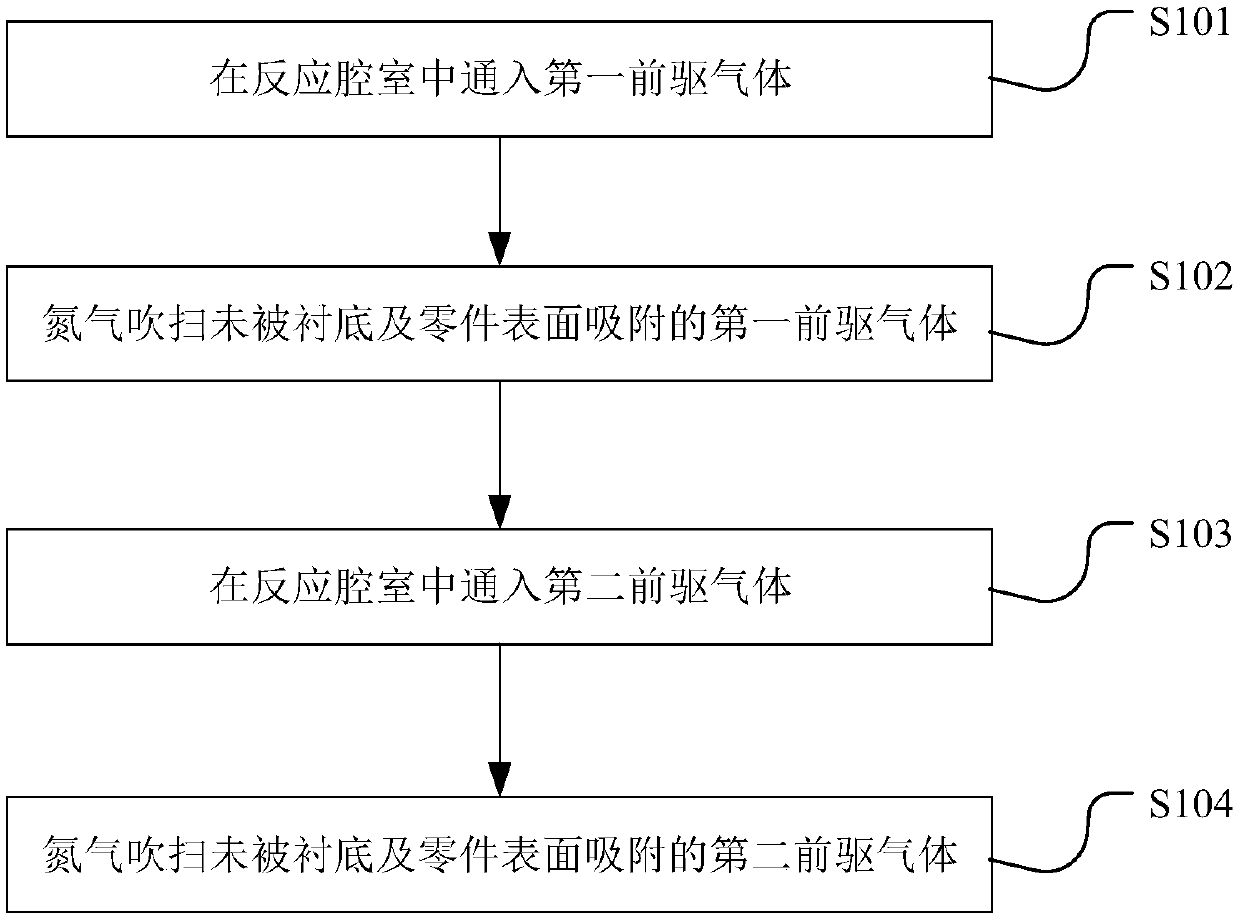

[0050] figure 1 A flow diagram of atomic layer deposition according to the prior art is shown.

[0051] Such as figure 1 As shown, in the prior art, in step S101, a first precursor gas is introduced into the reaction chamber, so that the first precursor gas is adsorbed on the substrate. In step S102, nitrogen gas is introduced into the reaction chamber to purge the first precursor gas not adsorbed by the substrate. In step S103, a second precursor gas is introduced into the reaction chamber to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com