Dry cutting numerical control gear hobbing machine tool cutting space temperature rise optimal regulation method

A CNC machine tool and space technology, applied in the direction of control/regulation system, adaptive control, general control system, etc., can solve problems such as the optimal control method of the cutting space temperature rise of dry cutting machine tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

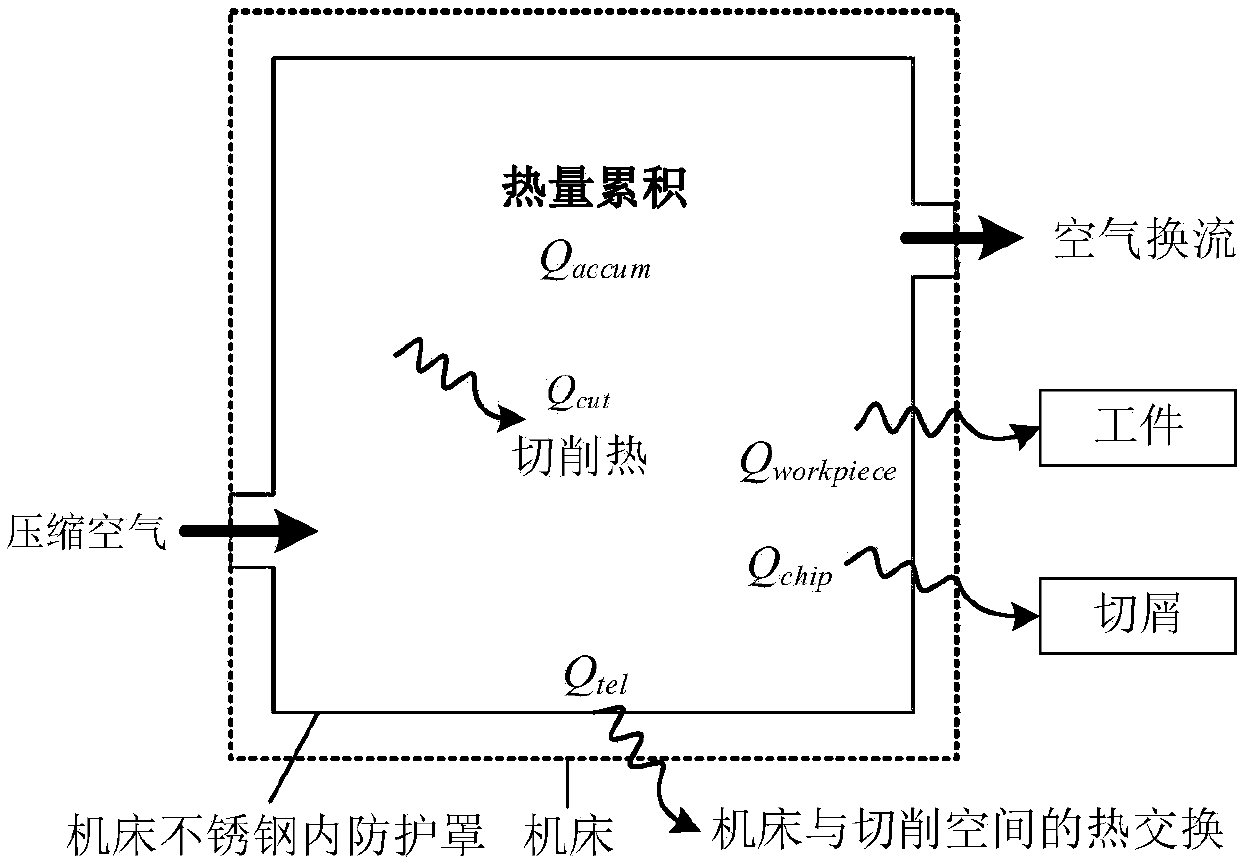

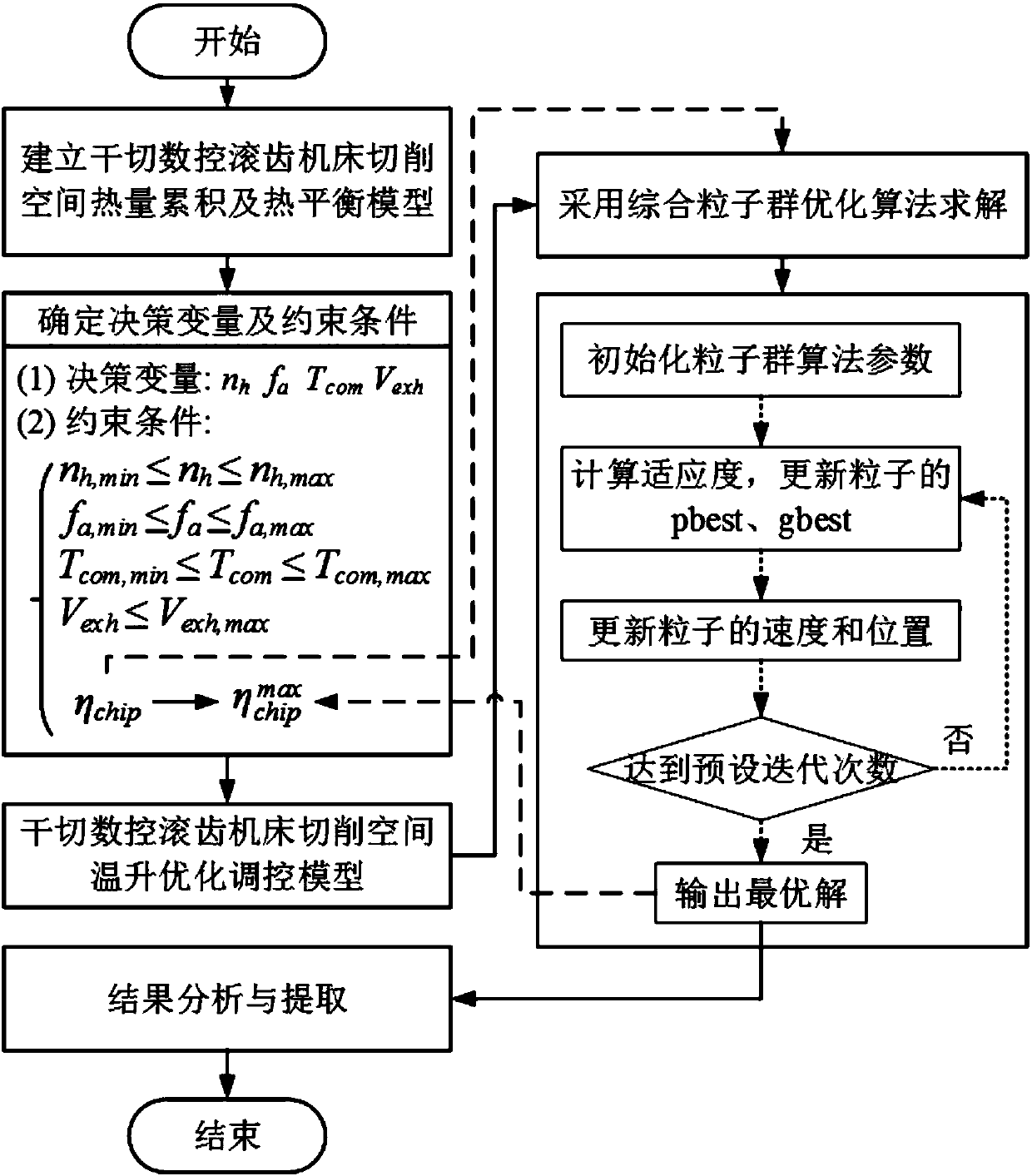

[0091] see Figure 1 to Figure 3 , a dry-cut CNC gear hobbing machine tool cutting space temperature optimization control method, the main steps are as follows:

[0092] 1) Establish the heat accumulation model and heat balance model in the cutting space of the dry cutting CNC gear hobbing machine tool. The main steps are as follows:

[0093] 1.1) According to the law of energy conservation, the heat accumulation model of the cutting space of the dry cutting CNC gear hobbing machine tool during the machining process is established. The heat accumulation model is expressed as follows:

[0094] Q accum =Q cut -(Q chip +Q workpiece +Q comair +Q exhair +Q tel ). (1)

[0095] In the formula, Q accum Heat accumulated in the cutting space. Q cut is the cutting heat generated in the cutting space. Q chip It is the heat taken away by chips when they leave the cutting space. Q workpiece It is the heat taken away by the workpiece when it moves out of the cutting space. ...

Embodiment 2

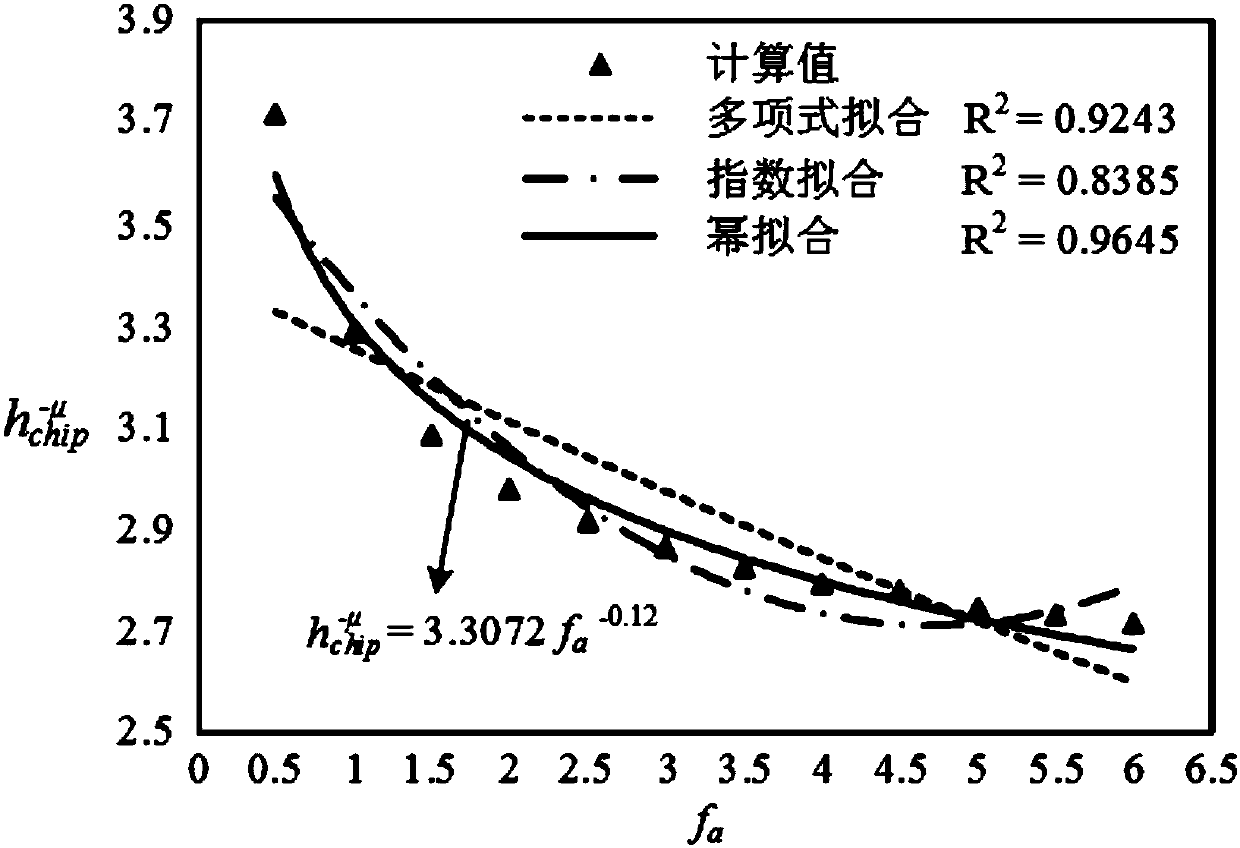

[0169] see Figure 4 to Figure 6 , This embodiment takes the high-speed dry cutting and hobbing machine tool as the object.

[0170] The main steps of optimizing and controlling the temperature rise in the cutting space of the high-speed dry cutting gear hobbing machine are as follows:

[0171] 1) Determine the basic parameters of the high-speed dry cutting gear hobbing machine tool. That is, the hob speed range is 100 ~ 1500r / min, the hob axial feed speed range is 1 ~ 1000mm / min, the rated power of the spindle motor P max 15kW. The maximum displacement of the air exchange device is 1500m 3 / h, and the ambient temperature of the workshop is 21°C. The base material of the dry cutting hob is S390, and the coating material is TiAlN. The normal modulus of the hob is 2.5mm, the number of heads is 2, the number of grooves is 15, the diameter is 80mm, and the helix angle is 1°56'. The number of teeth of the processed gear workpiece is 36, the normal pressure angle is 20°, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com