Patents

Literature

17081results about How to "Reduce work intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

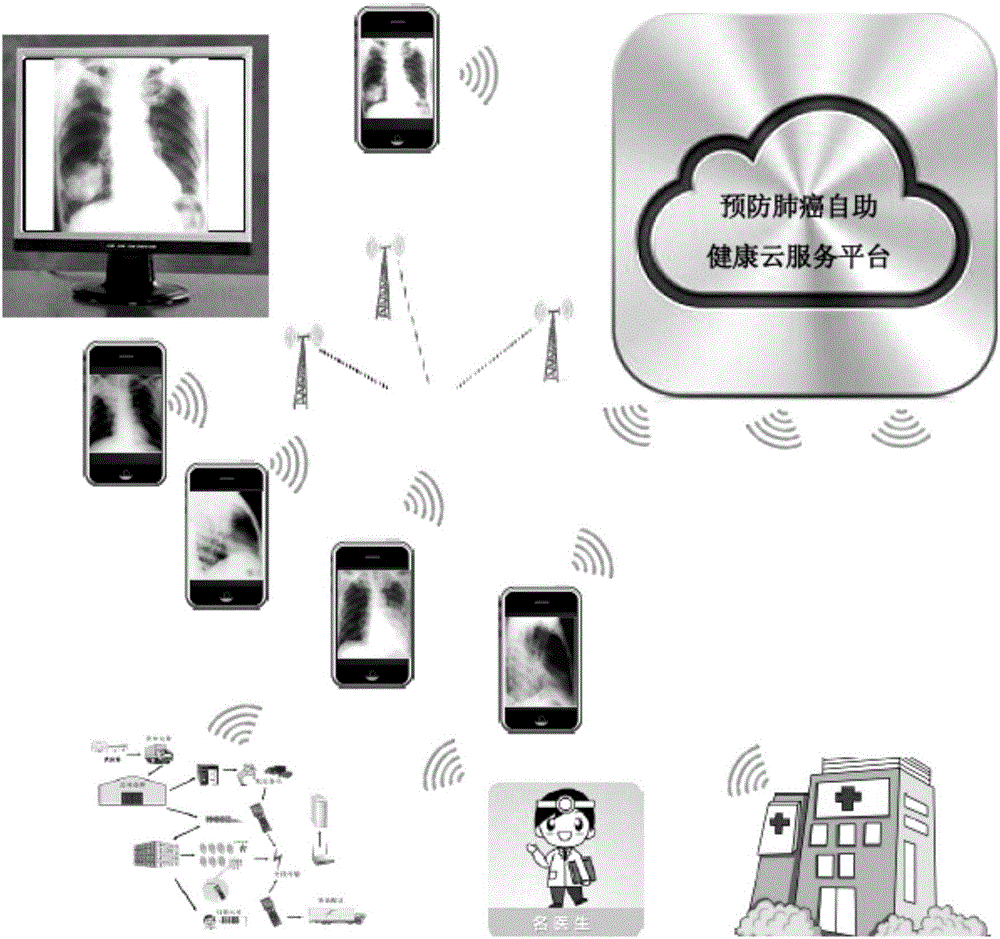

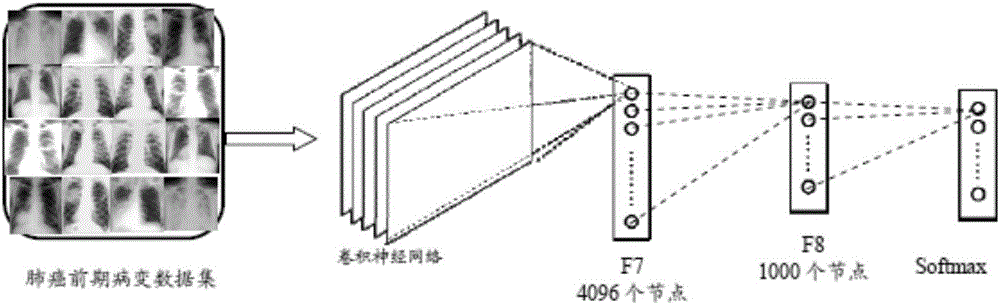

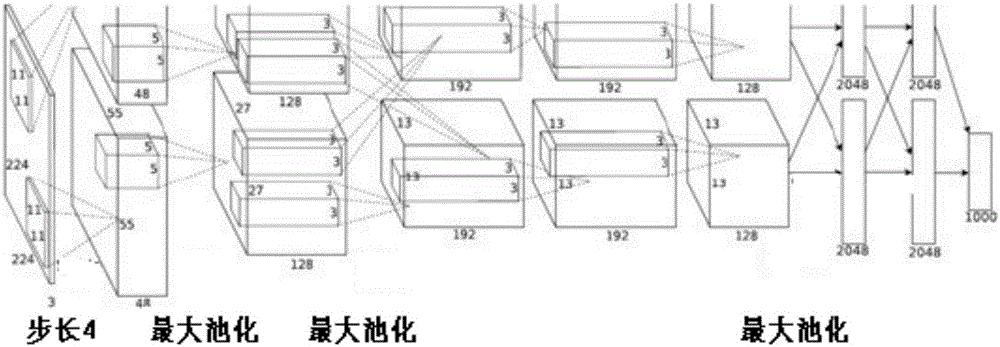

Deep convolutional neural network-based lung cancer preventing self-service health cloud service system

ActiveCN106372390AImprove informatizationIncrease health awarenessSpecial data processing applicationsNerve networkSuspected lung cancer

Owner:汤一平

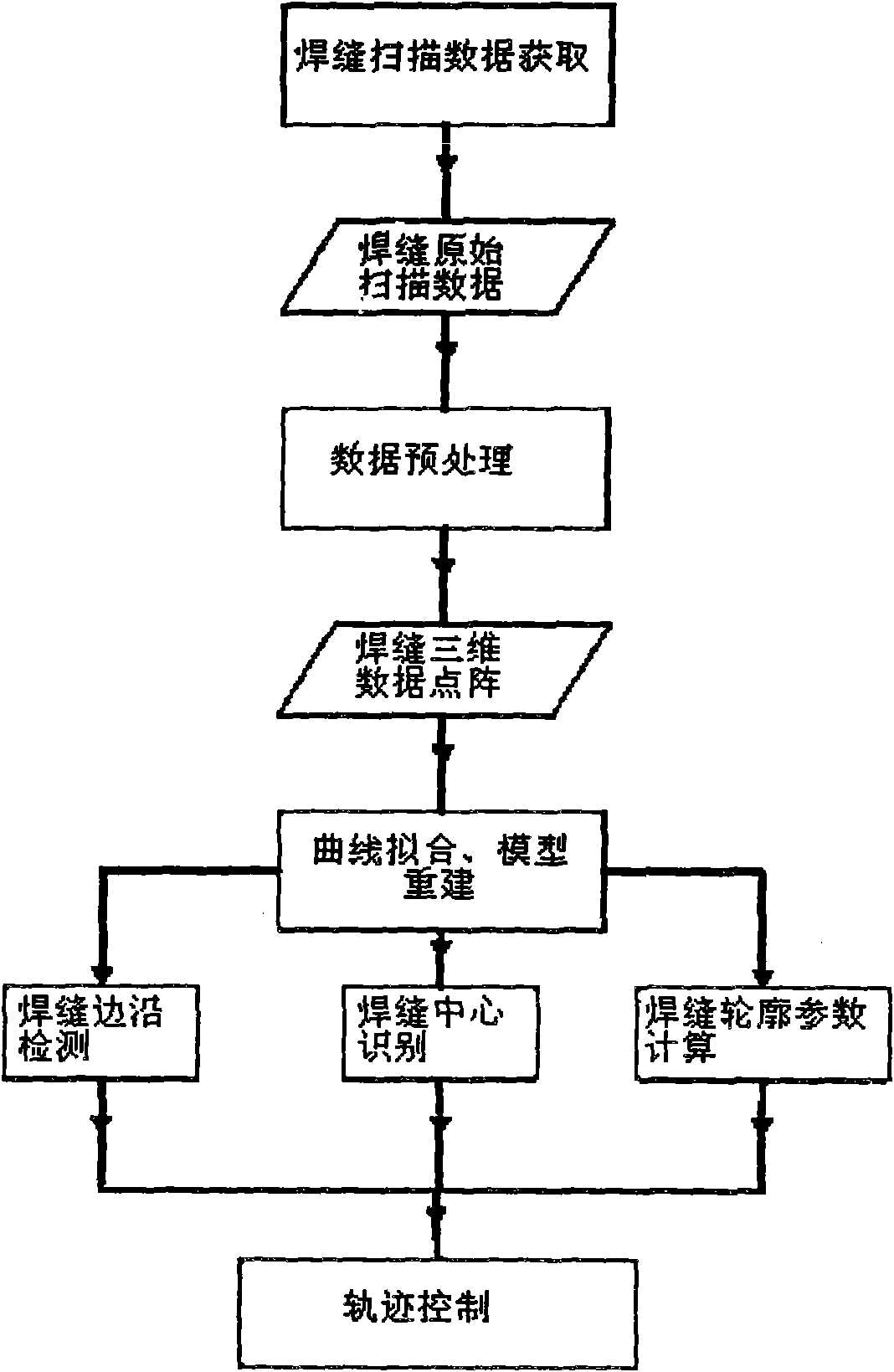

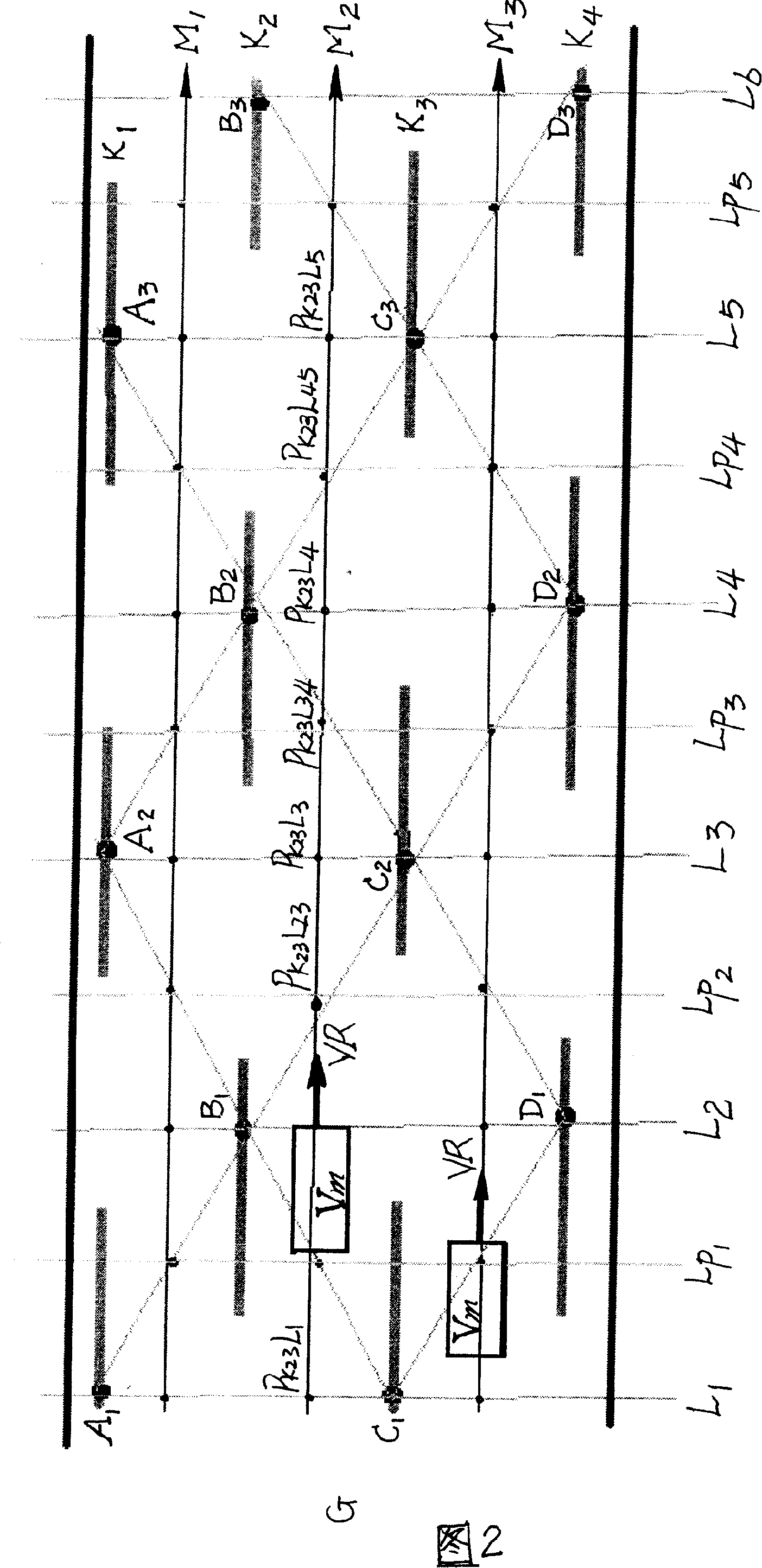

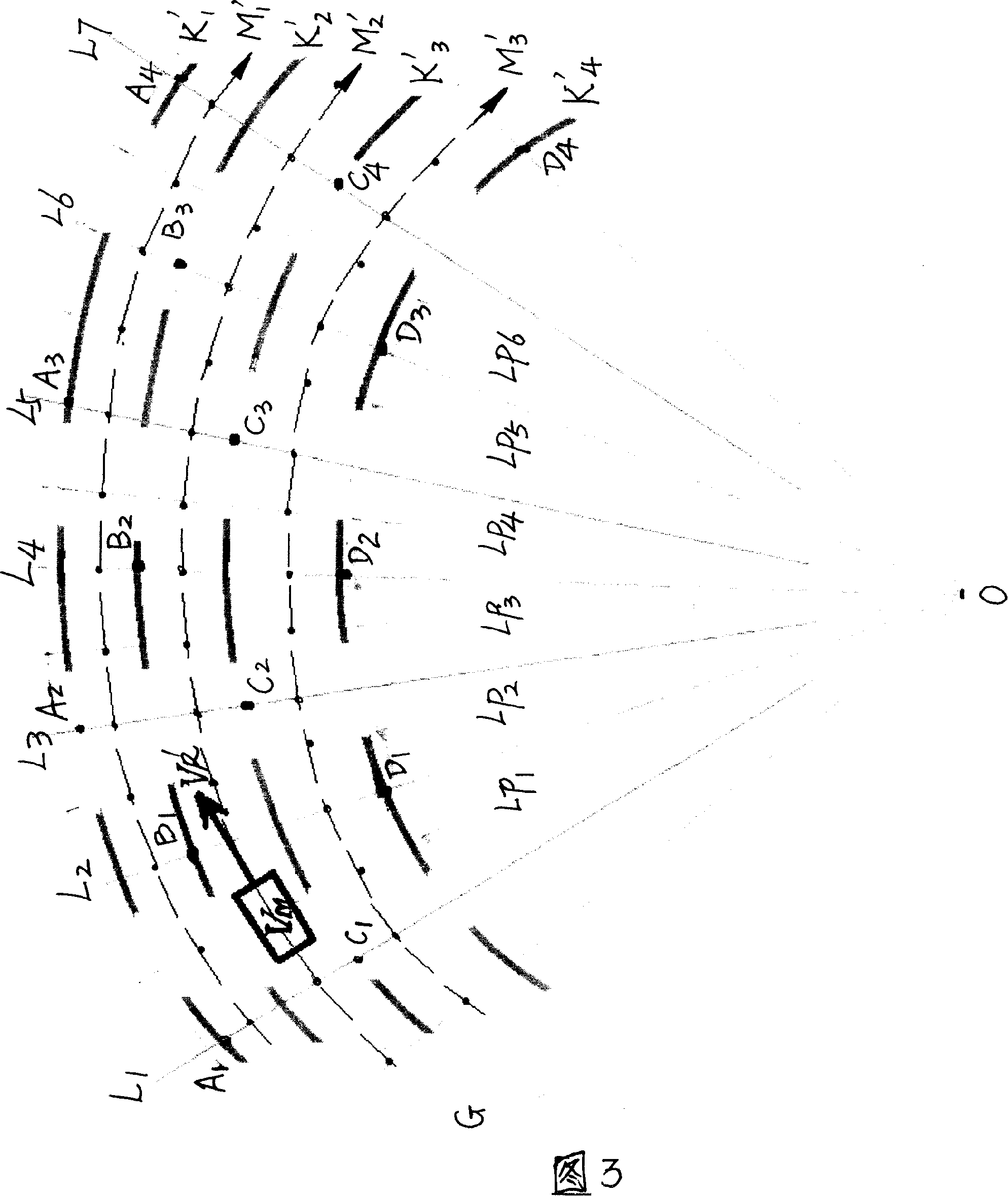

Welding track detection and control method of plate butt weld based on laser ranging

InactiveCN101559512ATo achieve the purpose of seam trackingTo achieve the purpose of trackingArc welding apparatusNumerical controlLaser rangingField tests

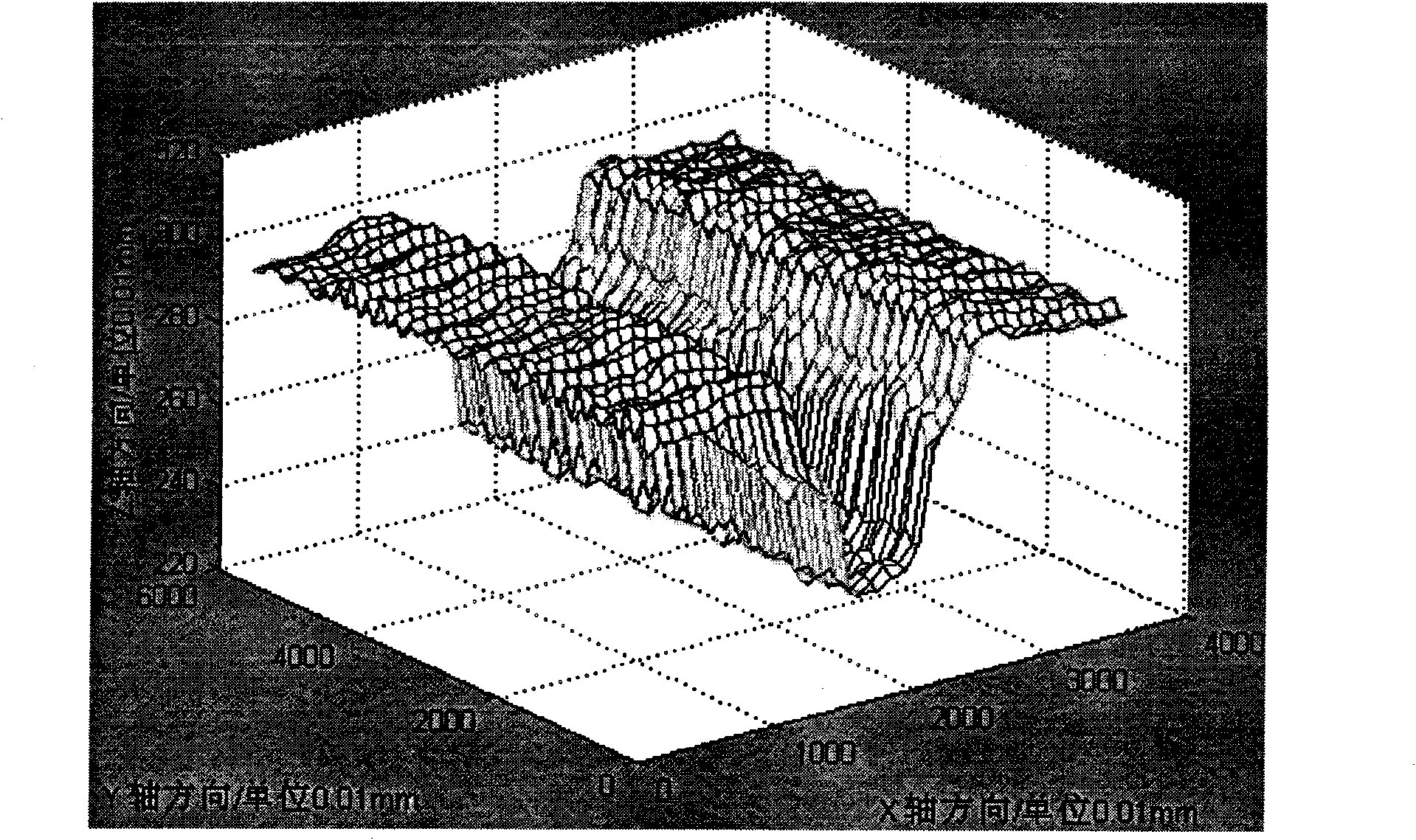

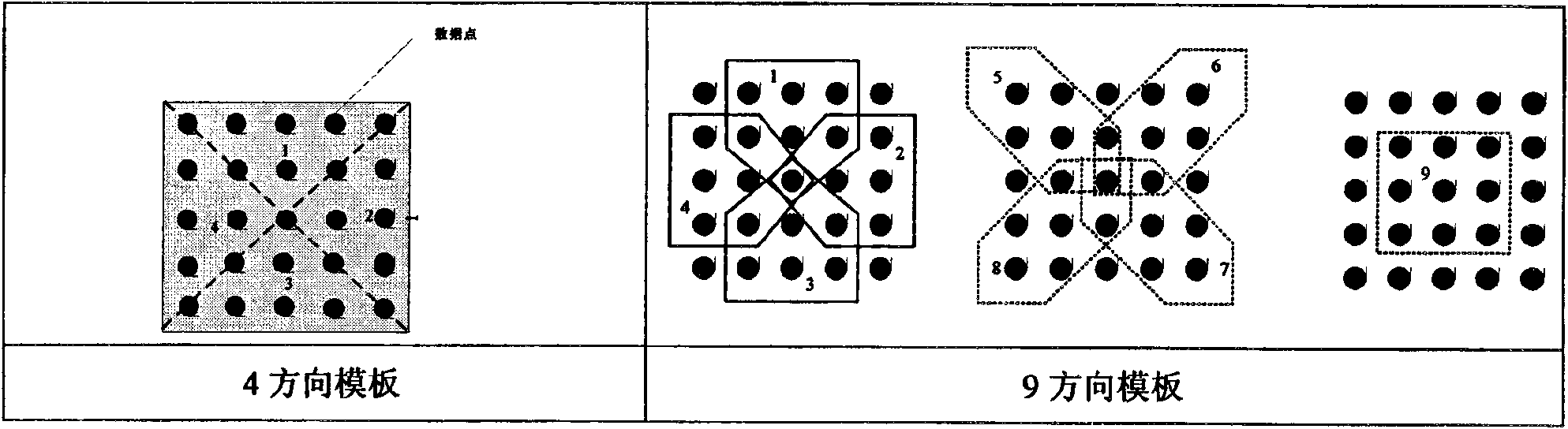

The invention relates to a welding track detection and control method of plate butt weld based on laser ranging, including the following steps: A. track detection is carried out; B. track identification and extraction are carried out; C. track control is carried out; D. the relative position relation between a welding gun and a welding seam is adjusted at last by performing mechanism actions. In the invention, the information of welding seam profile is obtained by transverse scanning of a laser sensor, and welding seam is rebuilt after effective wave filtering treatment to realize three-dimensional detection of the welding seam; simultaneously, the welding track curve is obtained by fit while detecting welding seam by using dynamic B spline fit algorithm, and the track control is carried out in combination with constant speed B spline track interpolation algorithm, thereby fundamentally solving the problem of track detection and control in automatic welding of plate butt weld. By using the method in the invention, the field test welding has welding profile identification precision of 0.15mm and welding track identification precision of 0.2mm, and the welding speed is more than four times of common manual welding.

Owner:SHANDONG UNIV

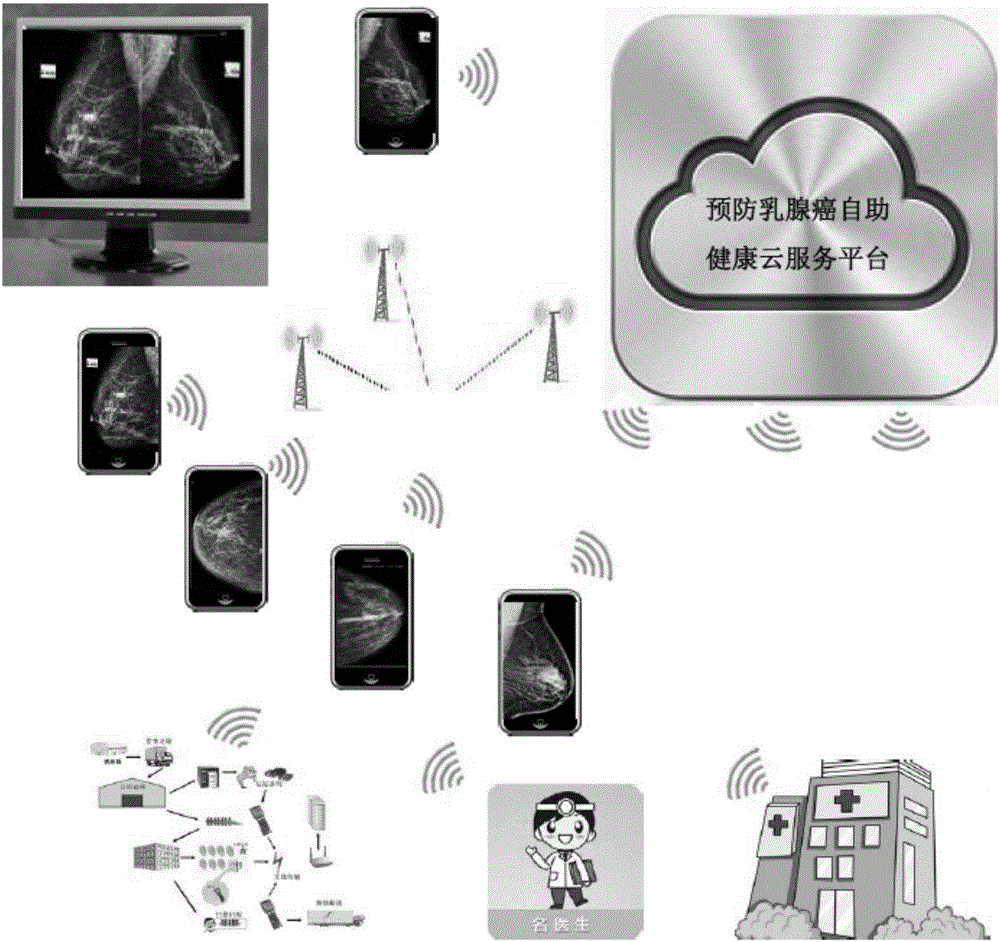

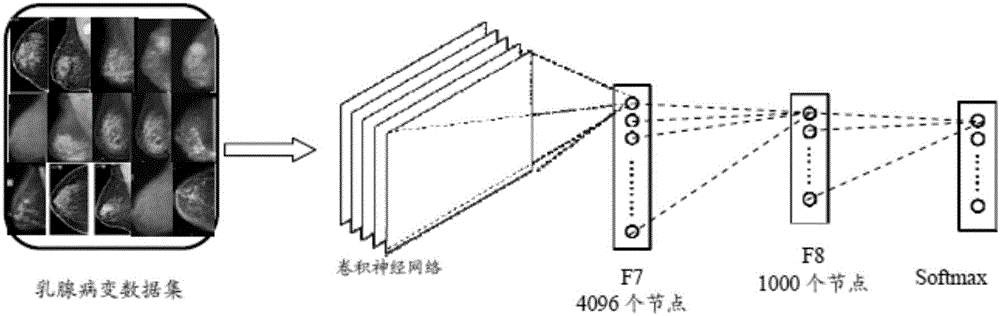

Breast cancer prevention self-service health cloud service system based on deep convolutional neural network

ActiveCN106339591AImprove informatizationIncrease health awarenessCharacter and pattern recognitionSpecial data processing applicationsImage basedMammary gland

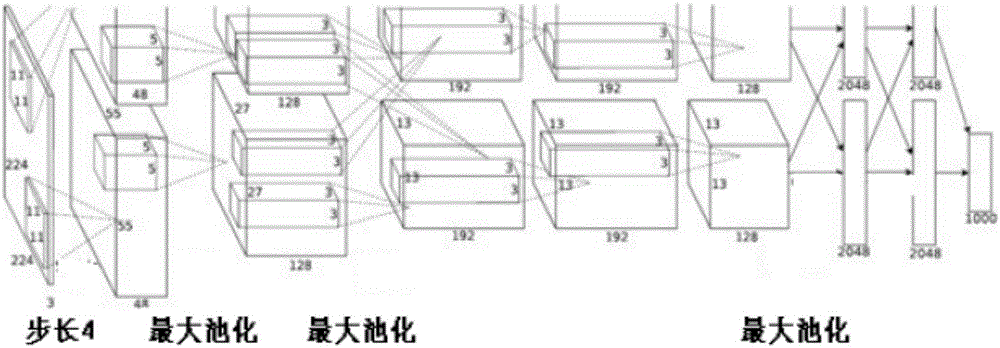

The invention discloses a breast cancer prevention self-service health cloud service system based on a deep convolutional neural network. The self-service health cloud service system mainly comprises a convolutional neural network applied to deep learning and training recognition, a partitioning module which is used for partitioning a breast area from a mammary gland molybdenum target radiography image based on a full-convolutional neural network, the deep convolutional neural network which is applied to BI-RADS classification and evaluation, and a self-service health cloud service platform which is applied to early preventing and treating breast cancer according to a recognized mammary gland inner structure, tumor and calcification types. The self-service health cloud service system can effectively improve the automatic and intelligent level of breast cancer screening based on a mobile internet, enable more women to know and participate in self-service health detection, evaluation and guidance, further improve the health consciousness of the public, and improve self health management capacity.

Owner:汤一平

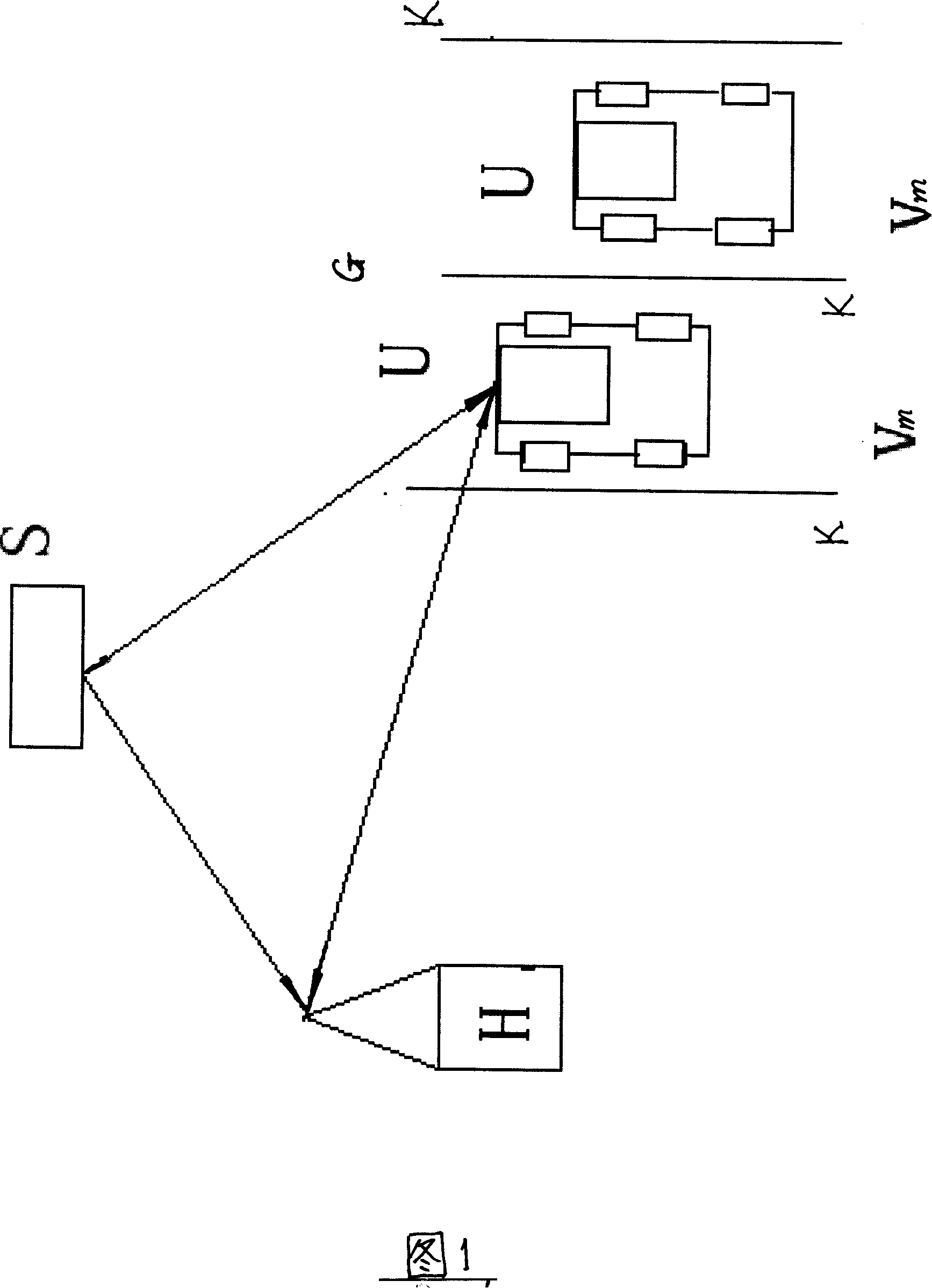

Intelligent traffic dispatching and commanding and information service method and system based on dynamic information

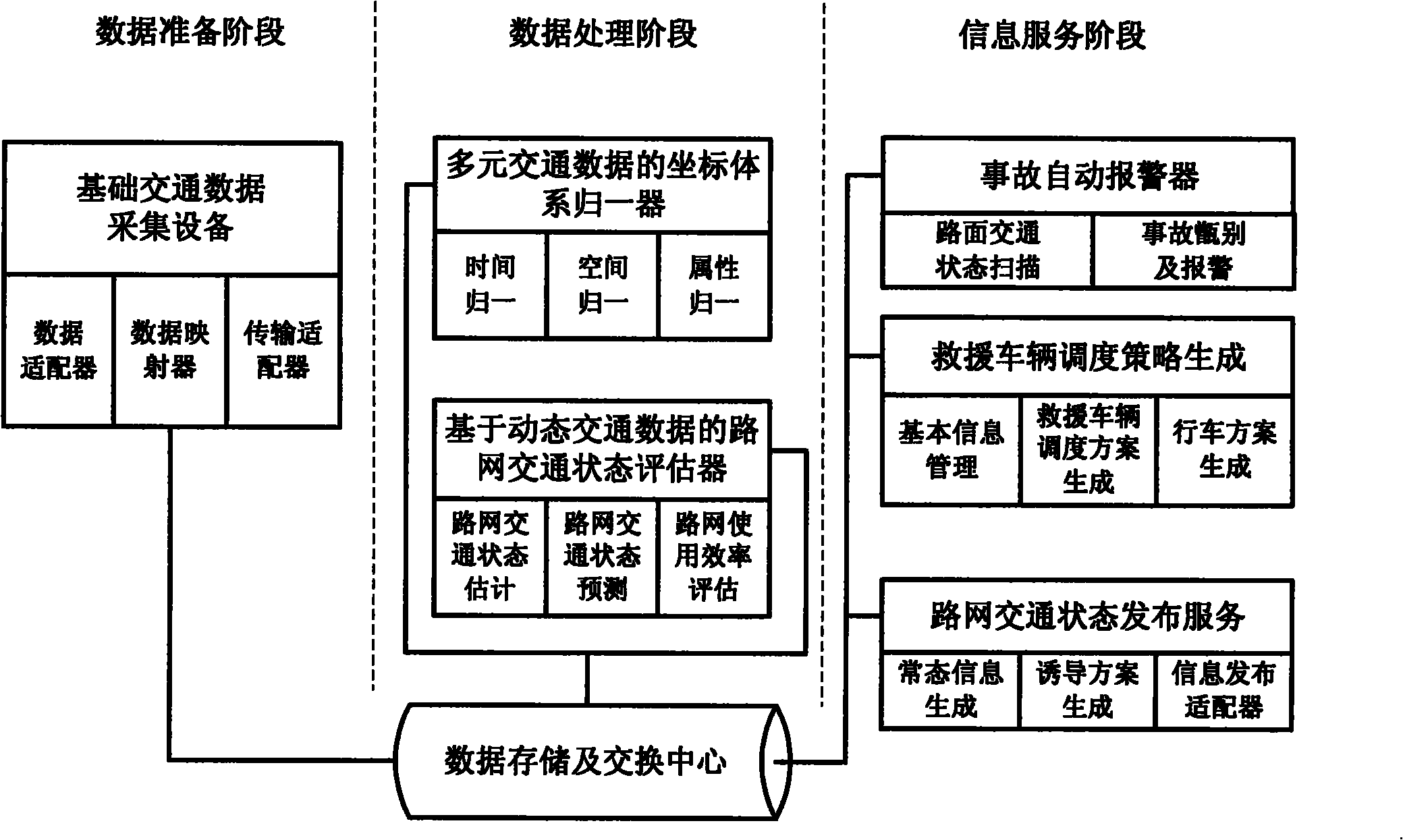

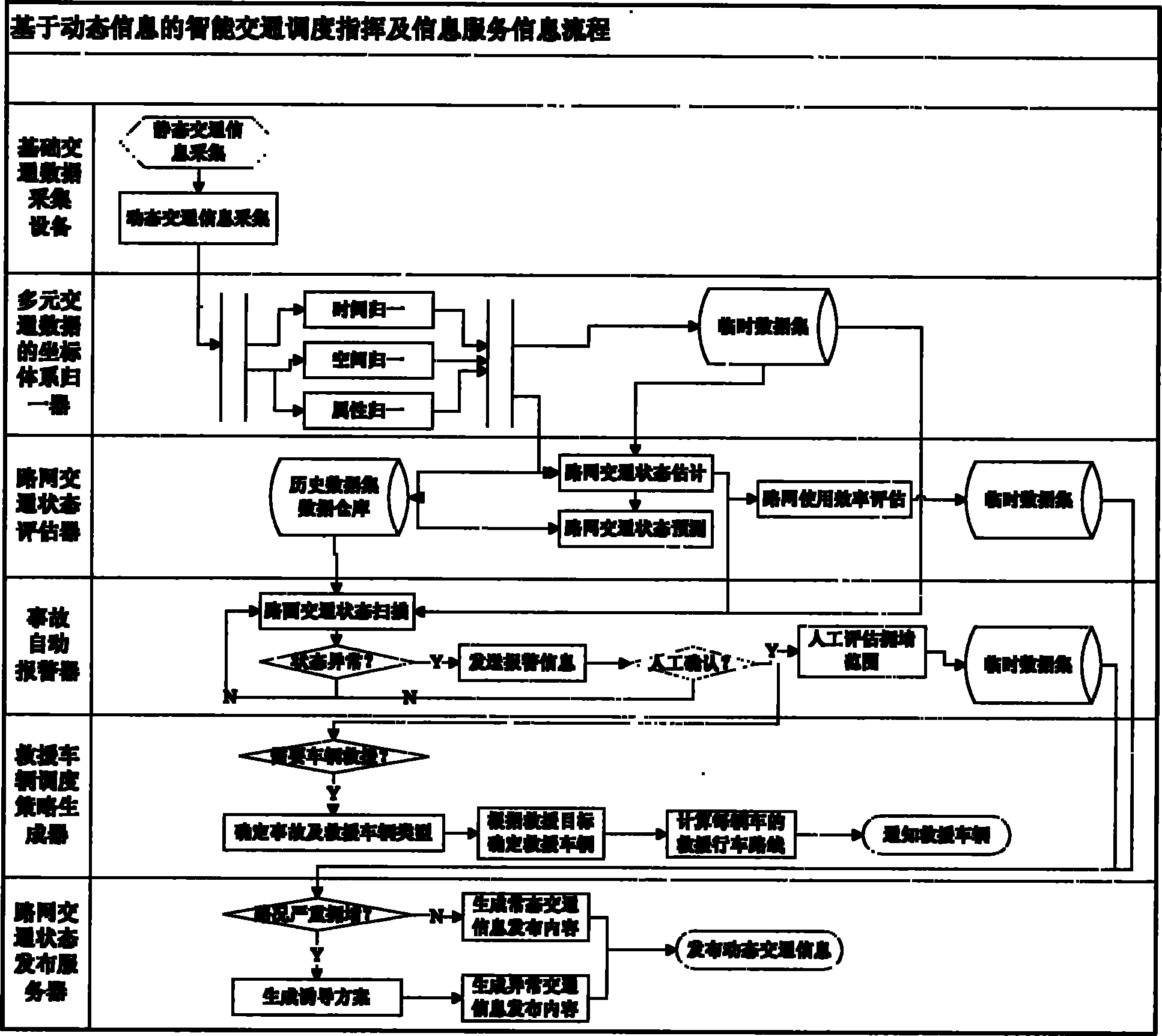

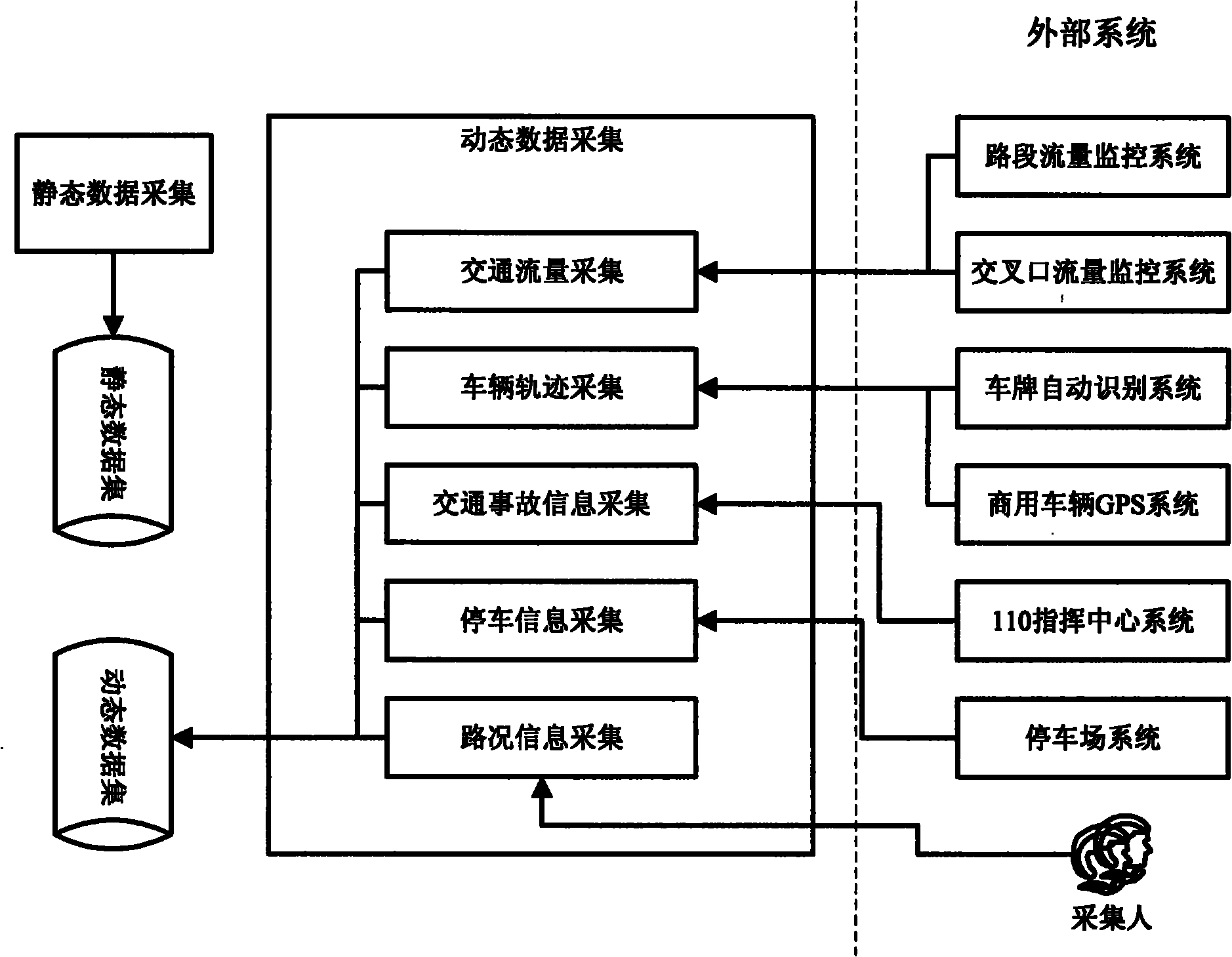

ActiveCN101901546AIncrease profitReduce work intensityDetection of traffic movementSimulationRoad networks

The invention discloses intelligent traffic dispatching and commanding and information service method and system based on dynamic information. The method comprises the following steps of: collecting basic traffic data; normalizing the time, the space and the attributes of the basic traffic data; periodically evaluating and predicting the traffic state of the entire road network; periodically comparing the traffic state evaluation results and the historical data of the road network, and sending a warning prompt to a commander in case of exceeding a certain threshold; responding to a confirmed warning prompt, and creating a breakdown lorry dispatching scheme; and responding to the confirmed warning prompt and the evaluated and predicted road network traffic state, judging whether a serious traffic jam occurs, and creating and releasing abnormal traffic information or normal traffic information. The invention can increase the utilization ratio of the basic traffic data, can enhance the contact between the urban traffic command center and the 110 command center, and can improve the working efficiency of personnel in the command centers and the travelling efficiency of travelers.

Owner:迪爱斯信息技术股份有限公司

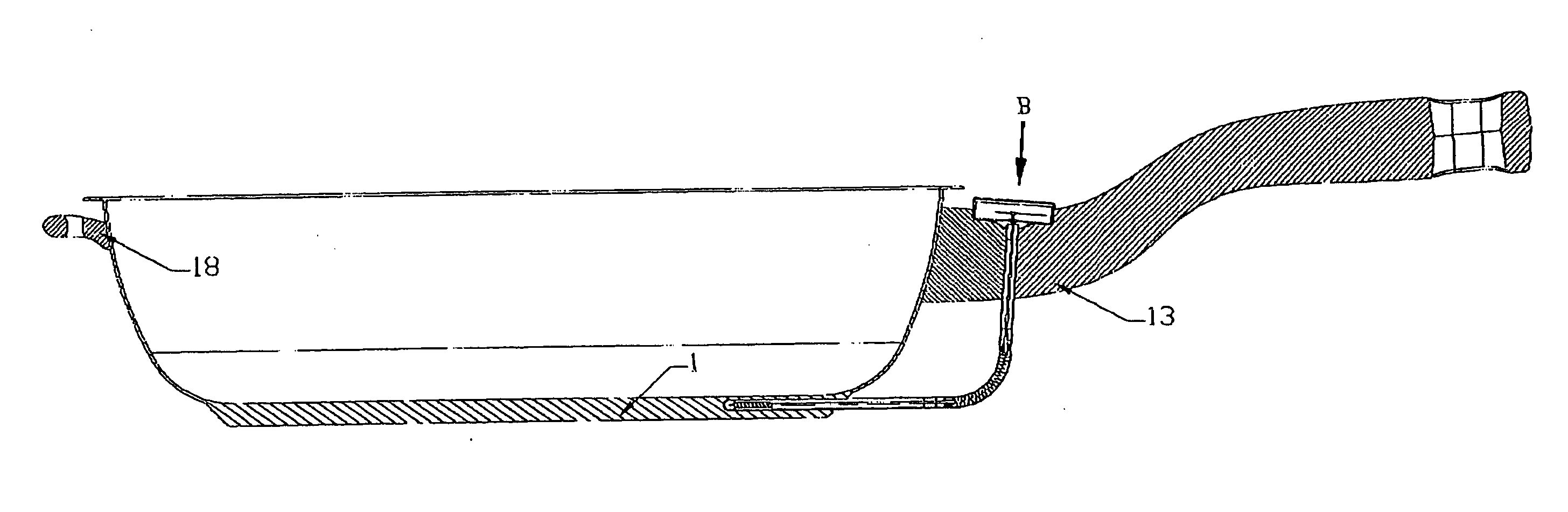

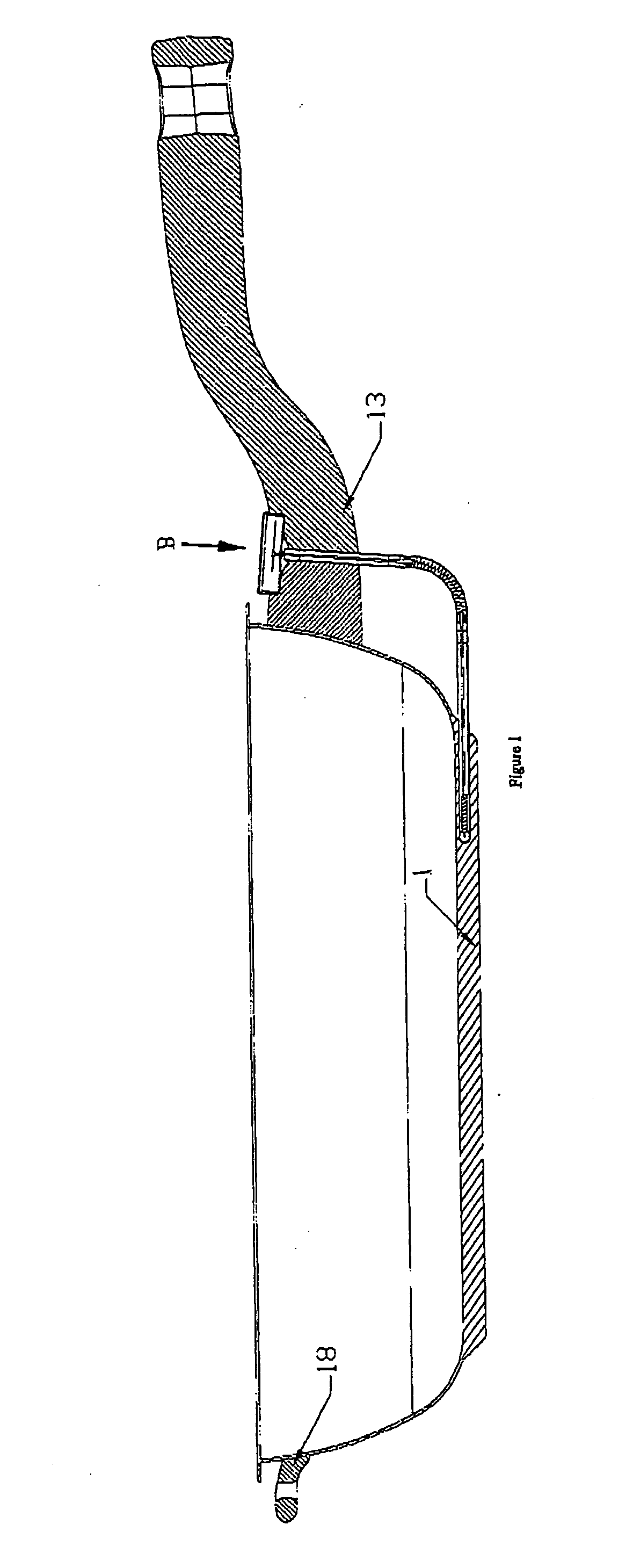

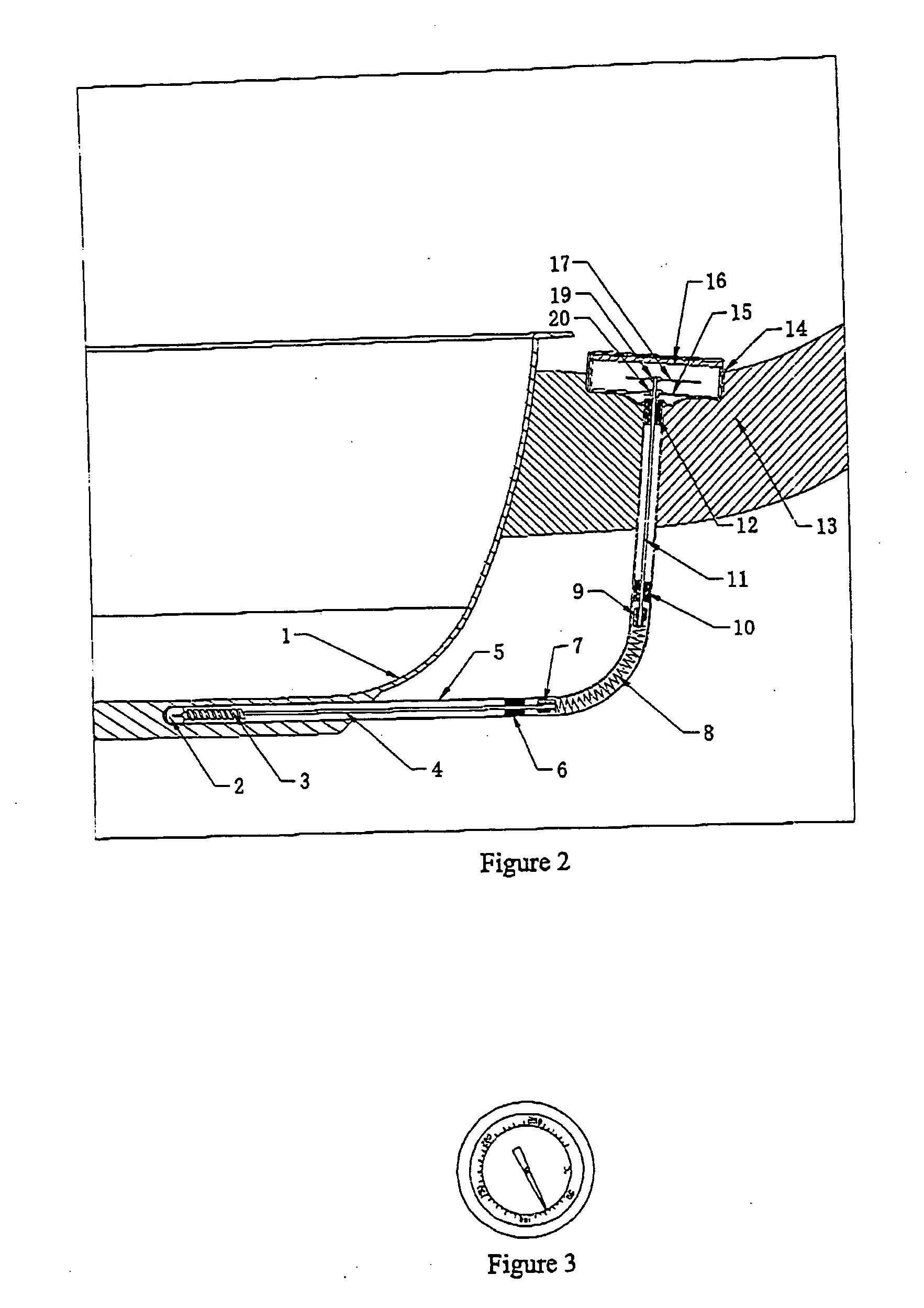

Pan with temperature displaying

InactiveUS20070095215A1Simple structureEasy to useThermometer detailsFrying pansBiochemical engineeringCooking process

The invention discloses a pan with temperature displaying including a pan body and a handle, a temperature-sensing bimetal element being provided in the bottom of the pan body, a display means being provided in the handle, and the temperature-sensing bimetal element being connected with the display means. The invention can rapidly and precisely indicate the temperature of the pan bottom of the pan so that the user can control the cooking level during cooking. The pan according to the invention is of a simple structure, is convenient to use and is easy to popularize.

Owner:MINGLE DEV (SHENZHEN) CO LTD

Automatic pilot system for road vehicle

InactiveCN101131588ARealize autonomous drivingPracticalPosition/course control in two dimensionsPilot systemAutomatic control

This invention relates to an automatic driving system of a road vehicle, especially to a system which providing automatic driving information indication for traveling vehicles and realizing vehicle automatic driving through the vehicle automatic control system, which is characterized by comprising: fixing markers at interval along a road travelling line, receiving information feedback by the fixed markers through a set relay information station and forming the vehicle and road information on the road, and constantly supplying the road and vehicle information of the road where the vehicle is to a vehicle automatic receiving processor after the received GPS(Global Position System) information and the vehicle and road information on the road are overall treated, installing an automatic driving software in a vehicle-mounted computer which can receive and treat relevant information of the relay information station at any time, constantly sending operation instructions to a vehicle automatic controller so as to keep the vehicle travelling information direction line consistent with the vehicle driving speed direction line, and sending instructions to the vehicle automatic controller according to the selected mode by a driver so as to realize vehicle automatic driving.

Owner:吴体福

Whole-nutrition biological flushing and spreading fertilizer and preparation method thereof

InactiveCN101037369ASolve the single nutrientSolve solubilityClimate change adaptationAlkali orthophosphate fertiliserMicroorganismNicotiana tabacum

A full nutrition fertilizer of biology type and its producing method belongs to organic complex fertilizer field in biology type. The components of the full nutrition fertilizer is 20-50% of organic waste liquid, 10-30% of urea, 8-15% of diammomium phosphate, 10-25% of potassium sulfate, 5-20% of medium trace element, 1-5% of microbial inoculum, 0-0.2% of root-promoting agent; 0-2% of solutizer, effective viable count content of the microbial inoculum of more than 1010 / g. The fertilizer is produced by adding the urea, diammomium phosphate, potassium sulfate, medium trace element, root-promoting agent, solutizer into organic waste liquid and blending uniformly, then adding microbial inoculum. The invention uses the wastes to produce fertilizer with a low cost a high availability and a good prospect in the fertilizer industry. The fertilizer can be widely applied to the vegetables, melon and fruits, food, tobacco, forests and different commercial crops.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

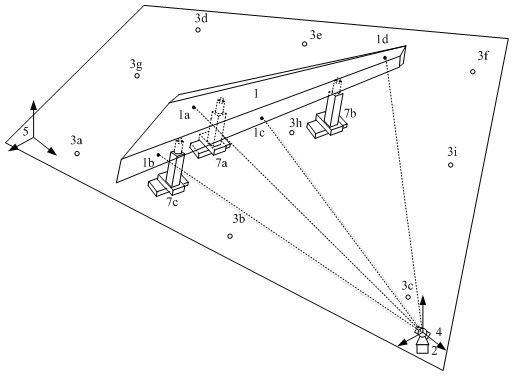

Method for measuring positioning points based on laser tracker in docking process of airplane parts

InactiveCN102519441AImprove assembly measurement accuracyReduce work intensitySurveying instrumentsUsing optical meansJet aeroplaneObservation point

The invention discloses a method for measuring positioning points based on a laser tracker in a docking process of airplane parts. The method provided by the invention comprises the following steps of 1, establishing a model of transformation between an airplane global coordinate system and a laser tracker measure coordinate system according to common observation points, 2, acquiring current calculating positions of positioning measure points of airplane parts according to a process joint sphere centre position, and 3, controlling and driving a laser tracker to search current accurate positions of the positioning measure points of the airplane parts from the current calculating positions according to a cross helical search method and to carry out automatic measure. The method provided by the invention has the advantages that 1, an advanced laser measure technology is adopted so that the airplane assembling measure precision is improved; and 2, a measure process does not need artificial light introduction and full automatic search measure of a docking assembling process is realized according to an algorithm so that working efficiency and measure precision are greatly improved and working strength of workers is reduced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

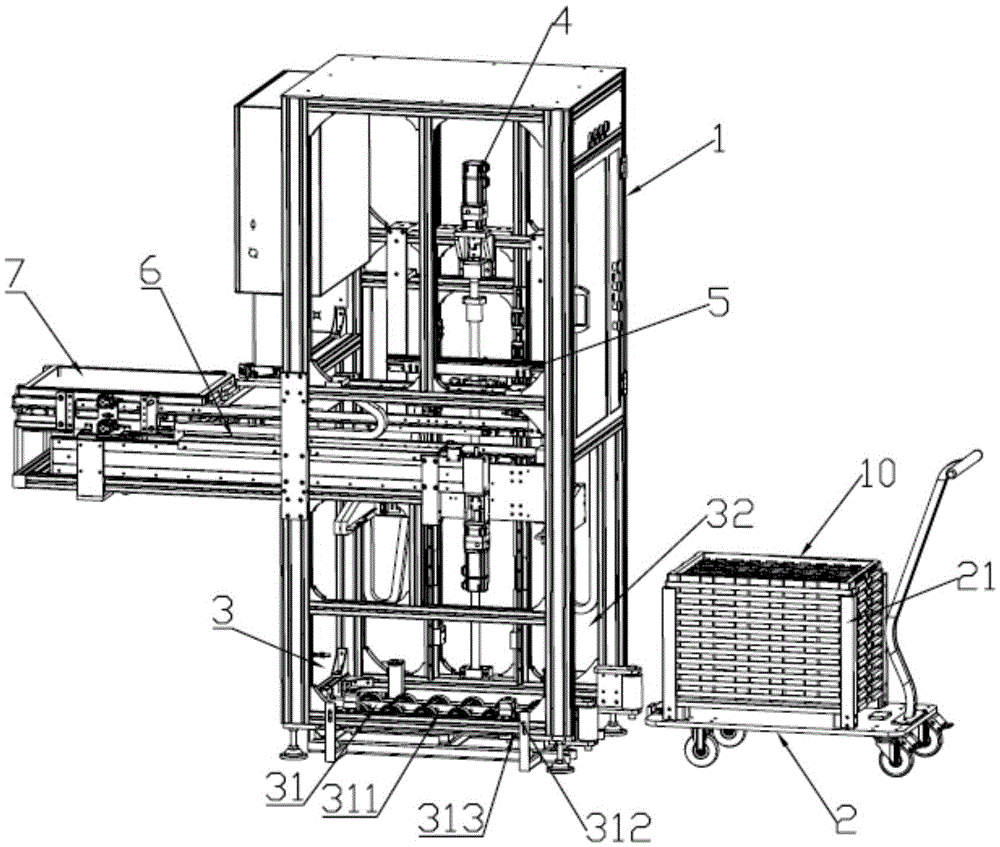

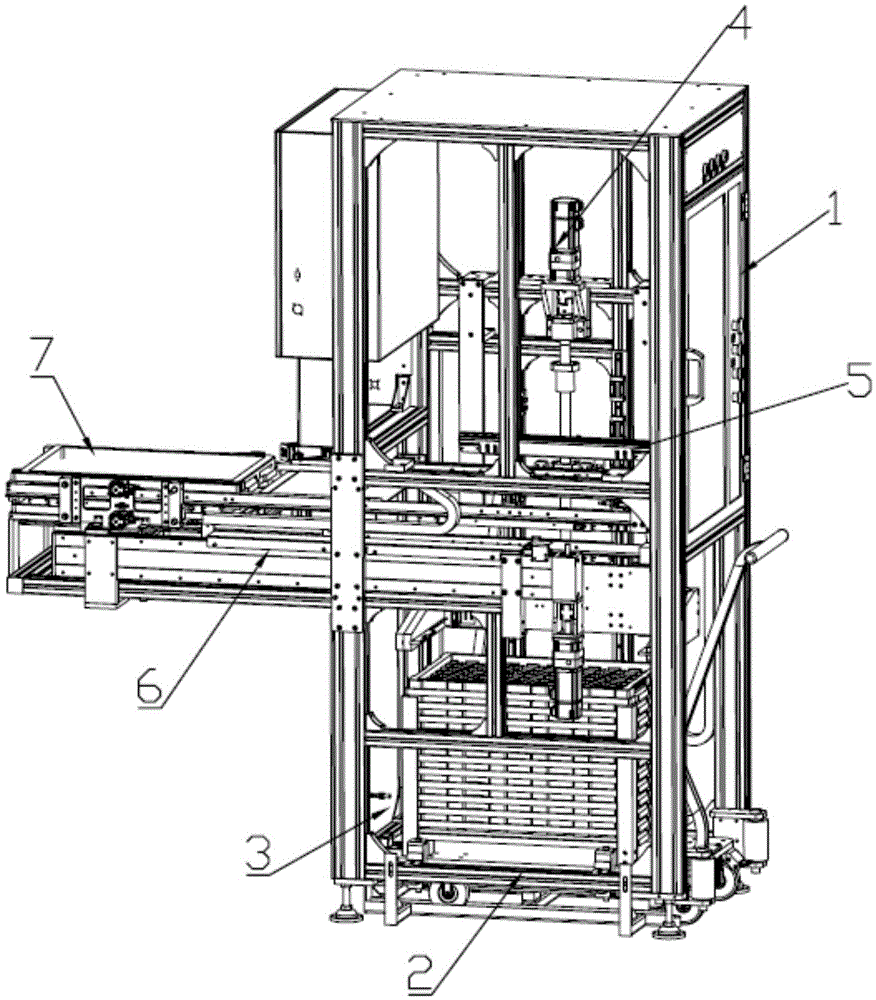

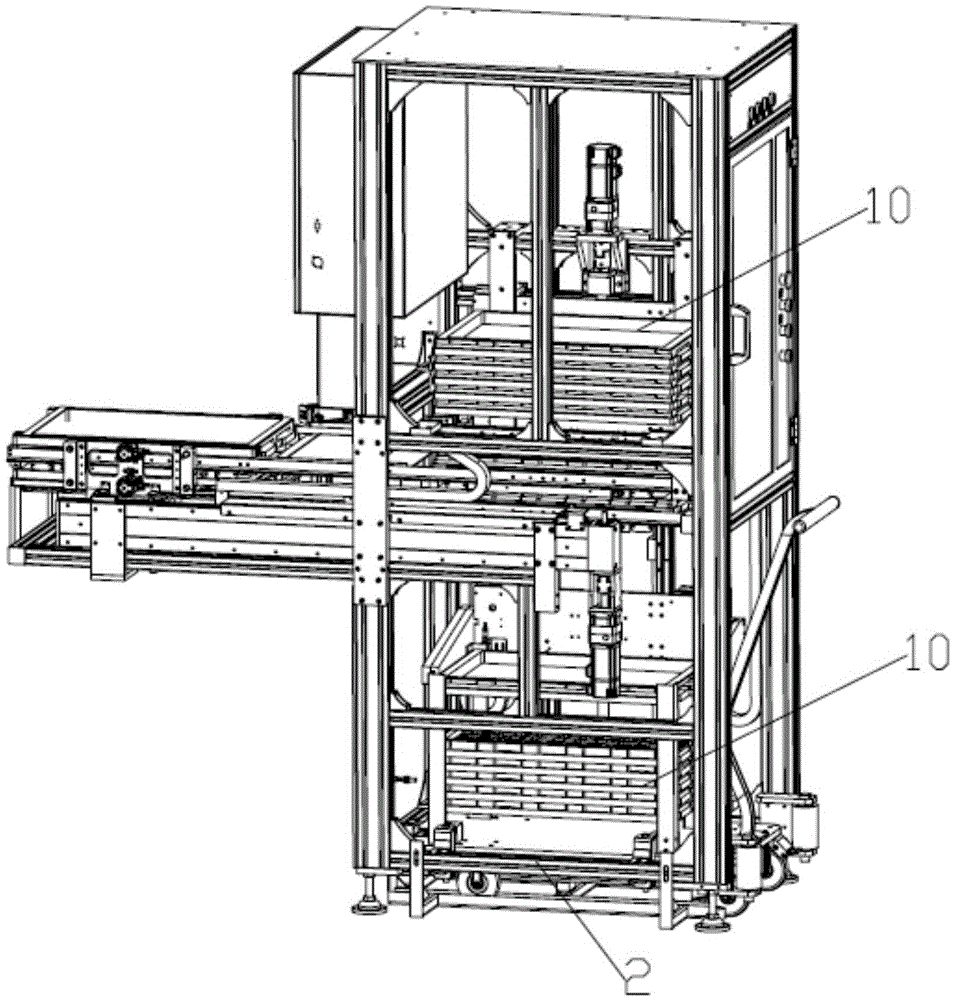

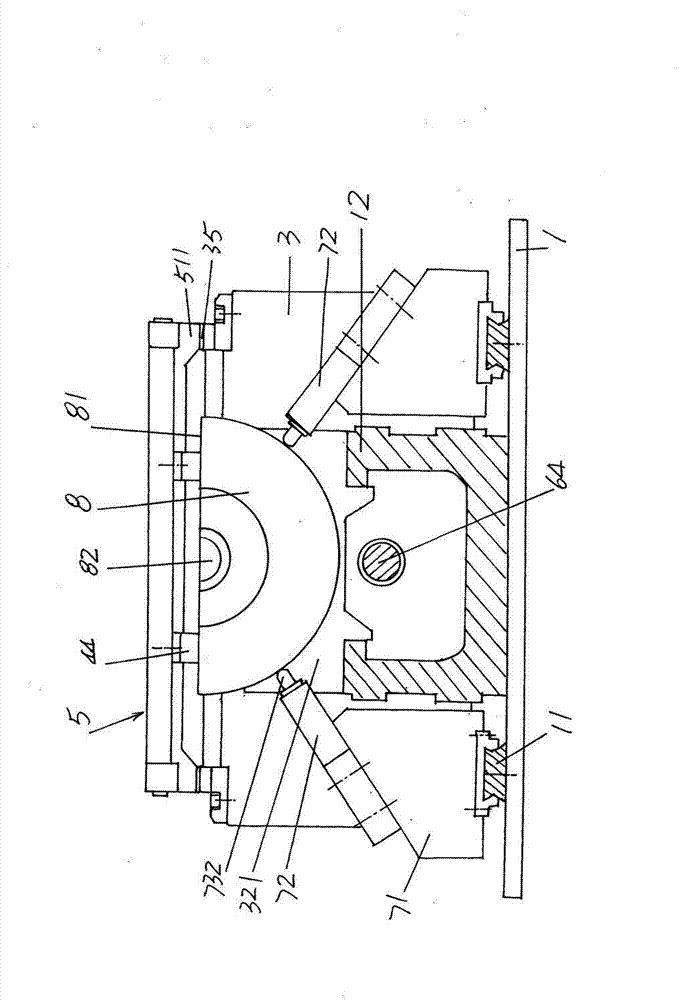

Tray type automatic supply and retraction equipment

InactiveCN105621110AFully automatedRealize intelligenceConveyorsStacking articlesButt jointEngineering

The invention discloses tray type automatic supply and retraction equipment. The equipment comprises a frame and multiple supply cars; a loading area is formed under the frame; a car positioning mechanism is arranged in the loading area; a supply car feed port is formed in one side surface of the loading area in the X direction; and after the support cars enter the loading area from the supply car feed port, the car positioning mechanism locks and positions the supply cars. The frame is provided with a tray hoisting mechanism in the Z direction in an area above the loading area; three layers of tray lifting mechanisms are symmetrically spaced on two sides of the Y direction of the middle part of the frame; a tray carrying mechanism in the X direction is arranged corresponding to two layers of tray lifting mechanisms on the lower side; and a butt joint equipment taking area is formed on the outer side of the tray carrying mechanism. The tray type automatic supply and retraction equipment divides a tray into a mother tray and son trays; for materials with different shapes, only the corresponding son trays need to be replaced, so that the replacement is convenient, and the resource is saved; and a robot is matched to clamp the materials so as to realize the material supply automation and intelligence more efficiently, more accurately and more quickly.

Owner:KUNSHAN BAIAO INTELLIGENT EQUIP CO LTD

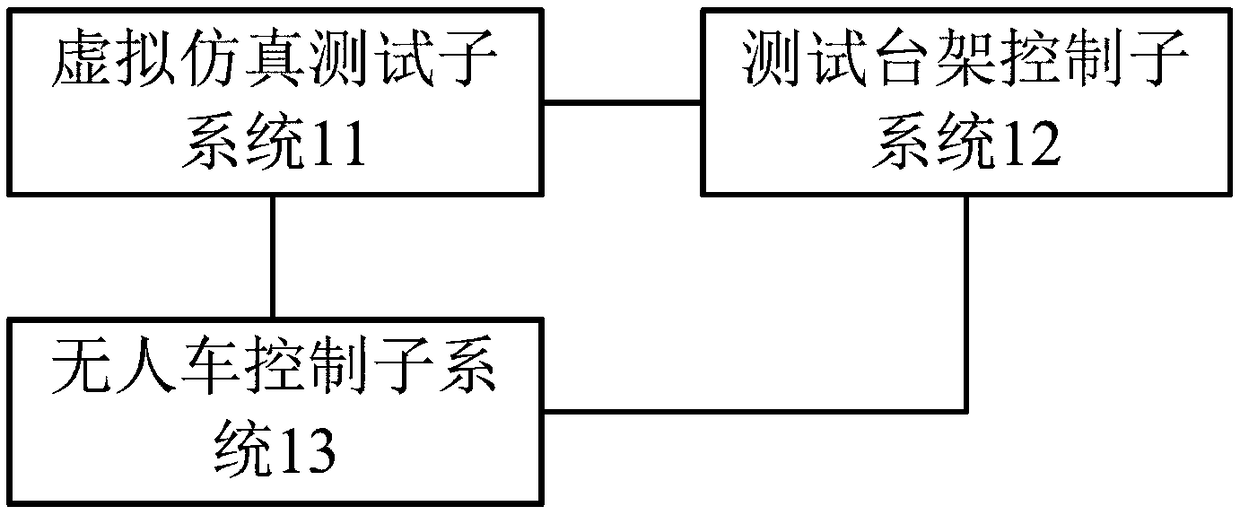

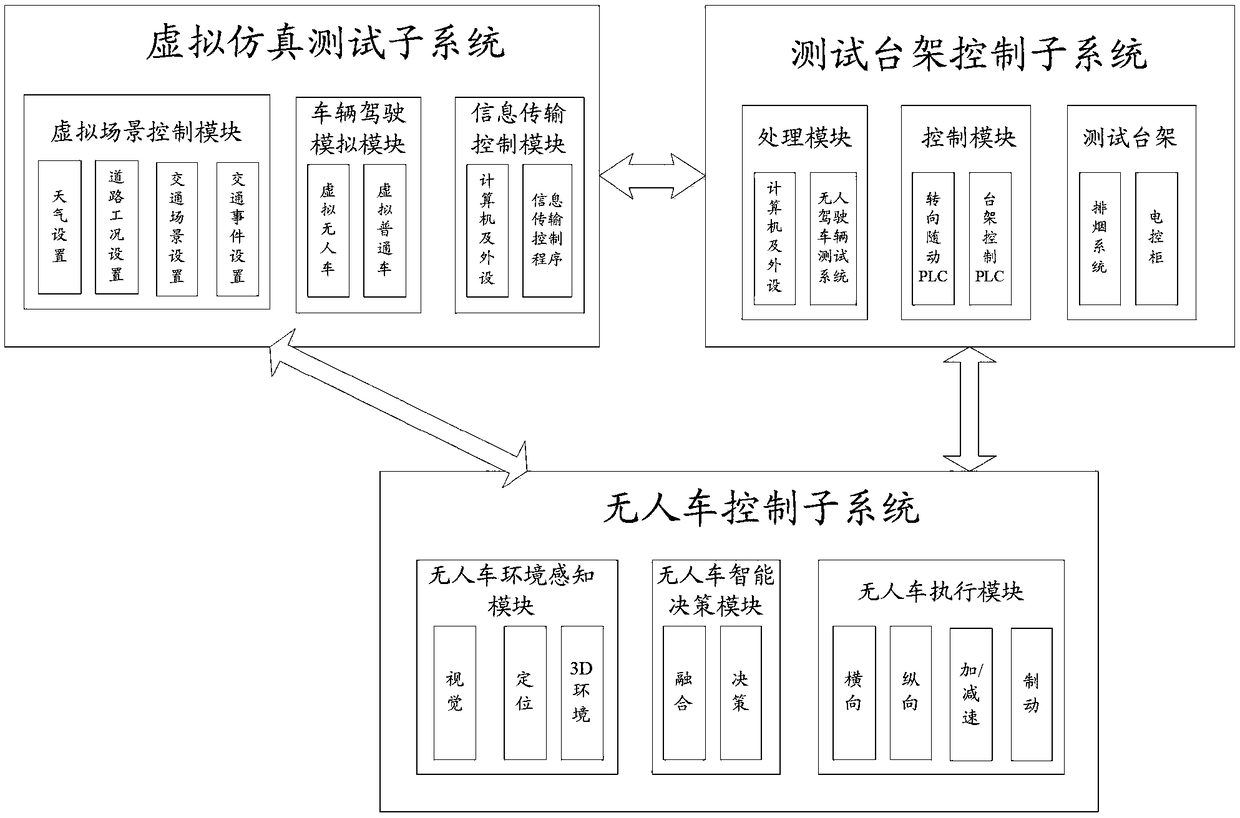

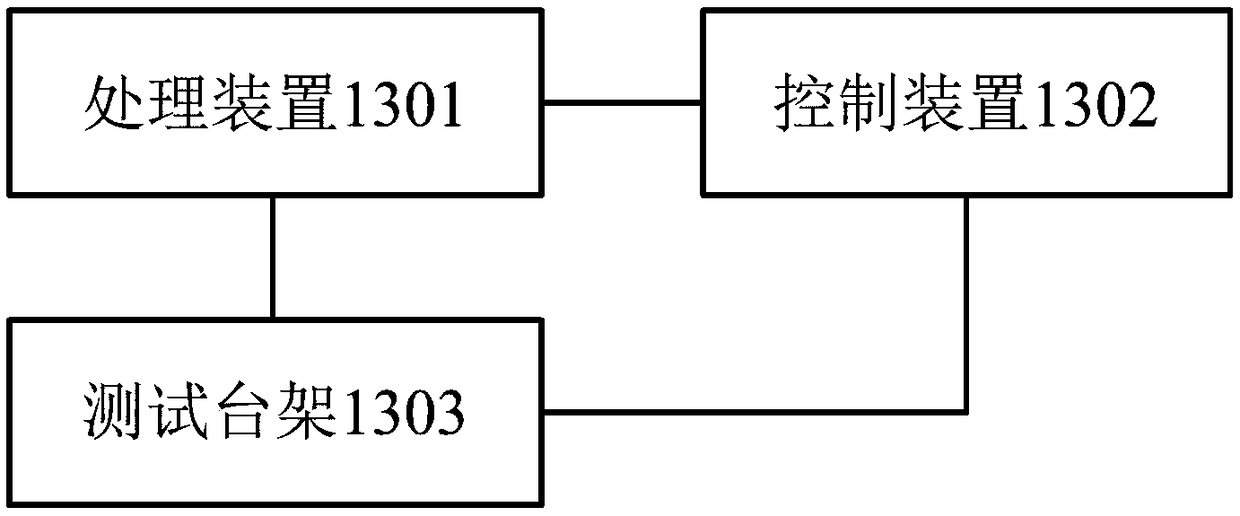

In-loop rapid simulation test system and method of unmanned vehicle

ActiveCN109100155AEnsure safetyGuaranteed reliabilityVehicle testingElectric testing/monitoringRoad surfaceHardware-in-the-loop simulation

The embodiment of the invention provides an in-loop rapid simulation test system of an unmanned vehicle. The system comprises: a virtual simulation test subsystem used for generating a virtual test scene and transmitting a pavement state control instruction to a test bench control subsystem; the test bench control subsystem used for simulating a pavement state, as well as estimating the driving performance of the unmanned vehicle according to driving parameters of the unmanned vehicle; and an unmanned vehicle control subsystem used for performing driving control on the unmanned vehicle according to the virtual test scene. The above system adopts the simulation test mode of combining the virtual reality technology with the hardware in-loop, so that a controllable, repeatable and effective in-loop rapid simulation test of the unmanned vehicle can be achieved indoors; and furthermore, all extreme or special road conditions are exhausted as much as possible, so that the safety and the reliability of the unmanned vehicle before start off can be fully guaranteed. The embodiment of the invention further provides an in-loop rapid simulation test method of the unmanned vehicle.

Owner:CHANGAN UNIV

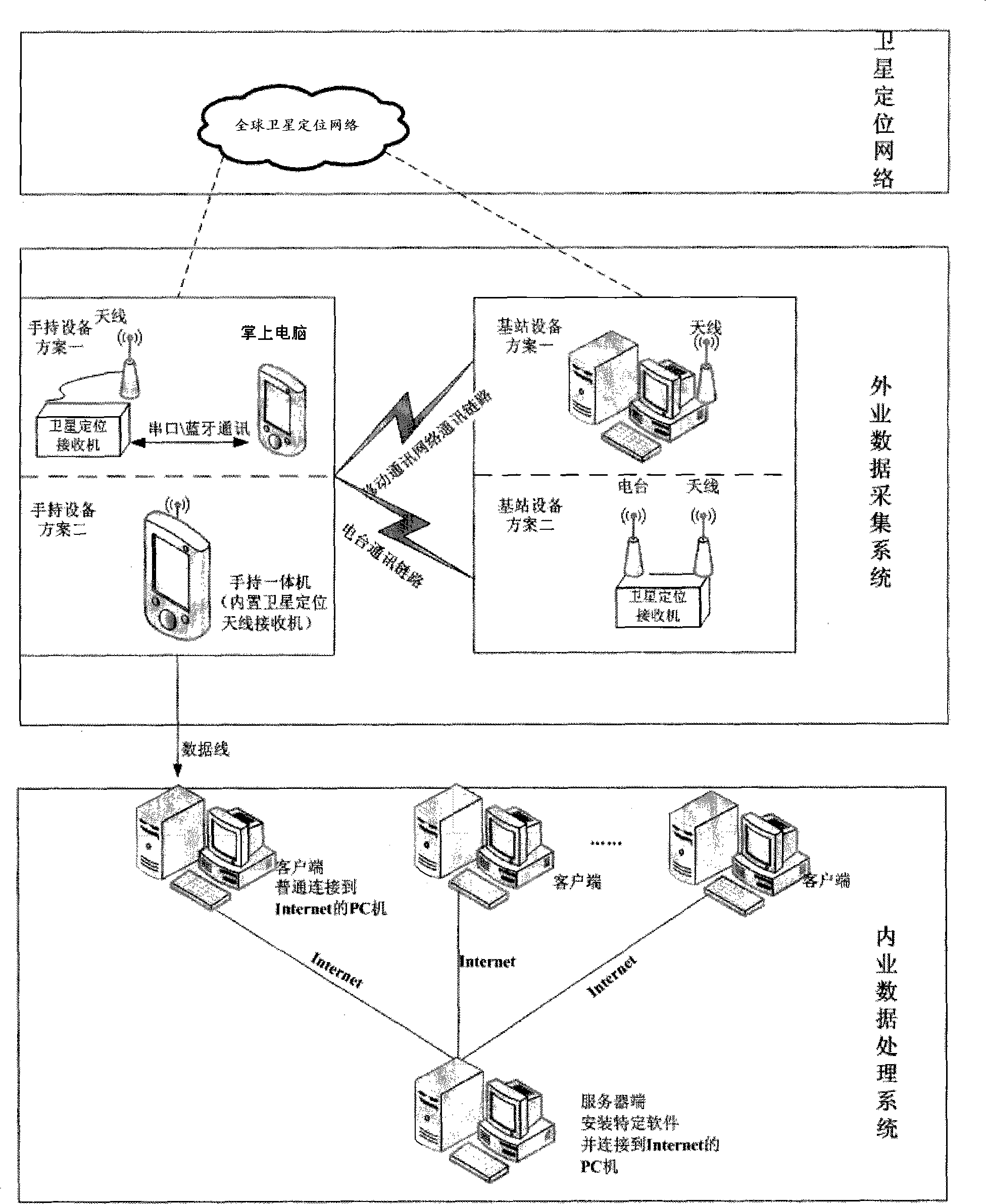

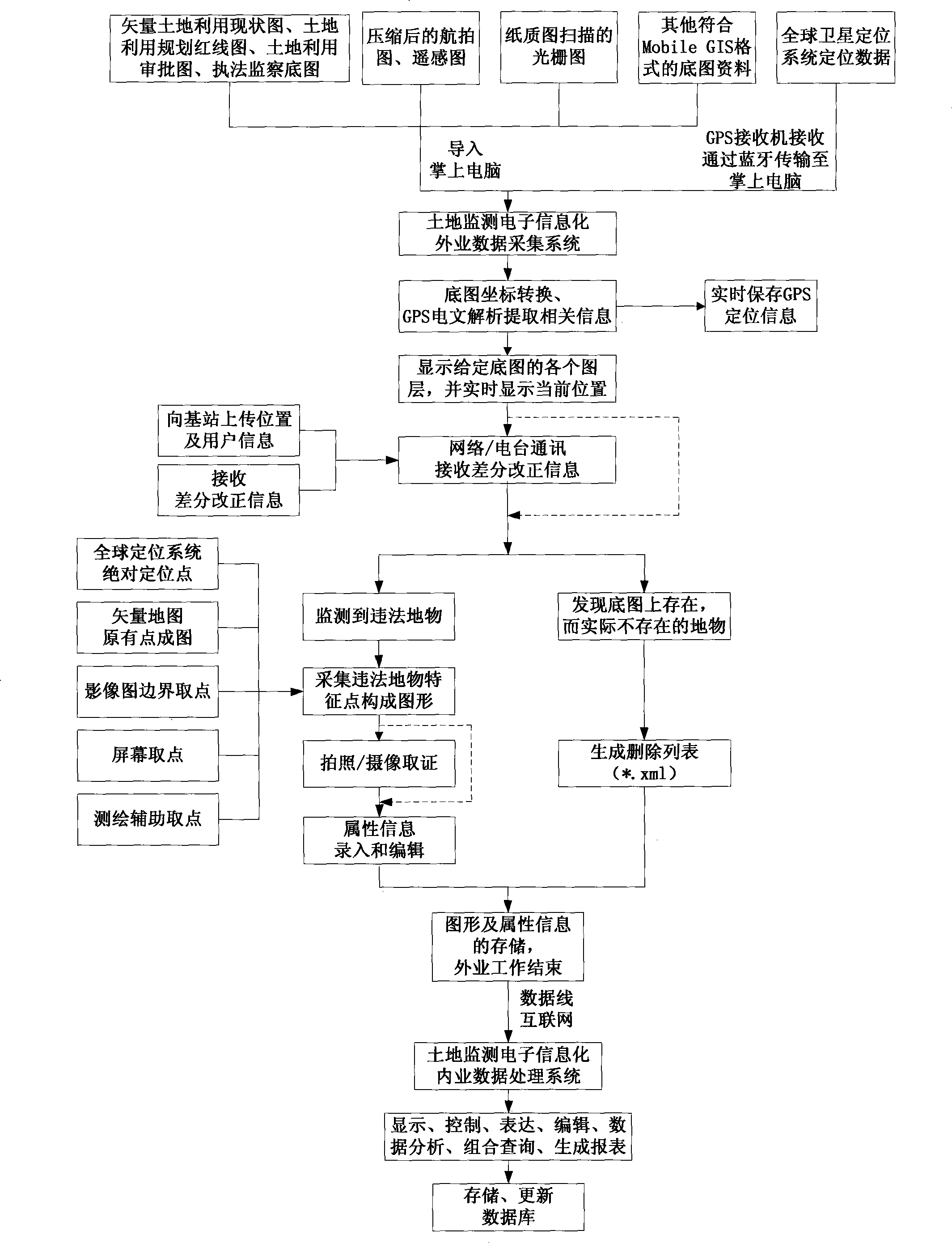

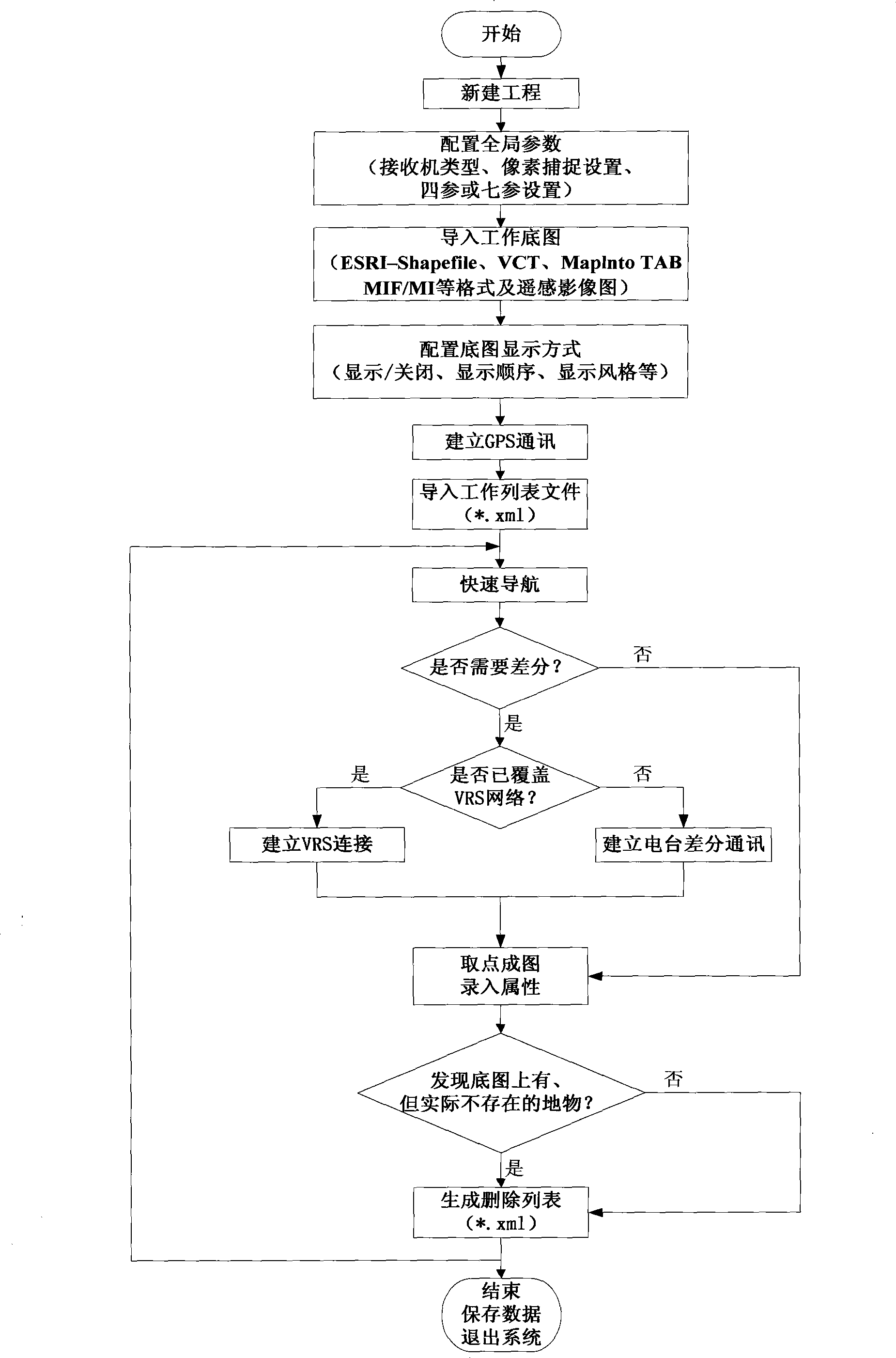

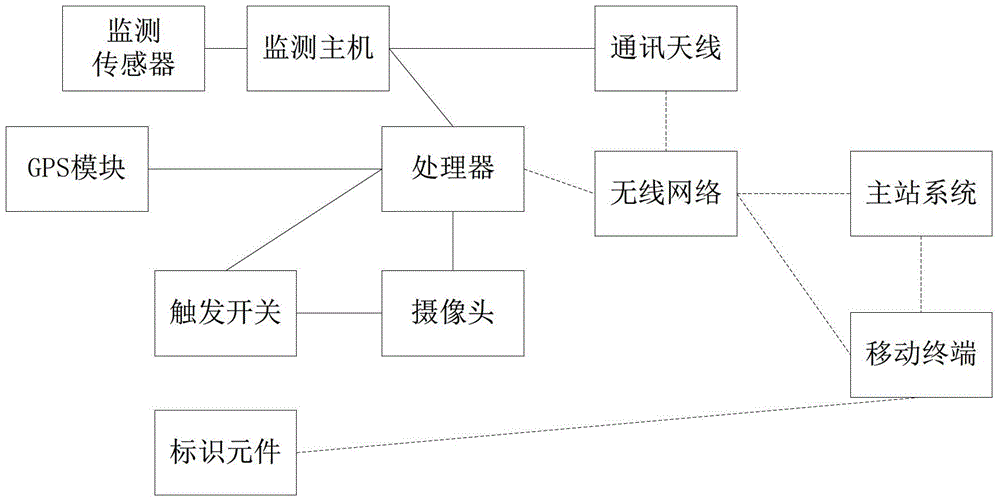

Electronic information system for earth monitor and method thereof

InactiveCN101452072AMeet real needsGuaranteed real-time updatesPosition fixationSatellite radio beaconingTerrainData acquisition

The present invention provides an electronic information system and a method thereof, and constructs two sets of subsystems of field data collecting and indoor data processing. The field data collecting system is based on a Mobile GIS platform and is combined with GPS positioning, GPRS network, bluetooth communication, etc. The field data collecting system realizes high-precision positioning of earth monitoring, uses different methods for executing difference positioning, digital information collecting, eraser list constructing, photograph taking / camera shooting evidence obtaining and terrain hyperlinking for realizing electronic information of field land surveying at the state with / without VRS network. The indoor data processing system is based on SuperMap GIS developing platform and Browser / Server structure, and is combined with XML data interchange, spatial geographical coordinate projection switching, overlapping analyzing, etc. The indoor data processing system realizes multiple functions of indoor multi-source map data expression and operation, combined inquiry, report generation, land monitoring database updating, property formwork customizing, etc., and realizes electronic information of indoor land monitoring operation.

Owner:SOUTHEAST UNIV

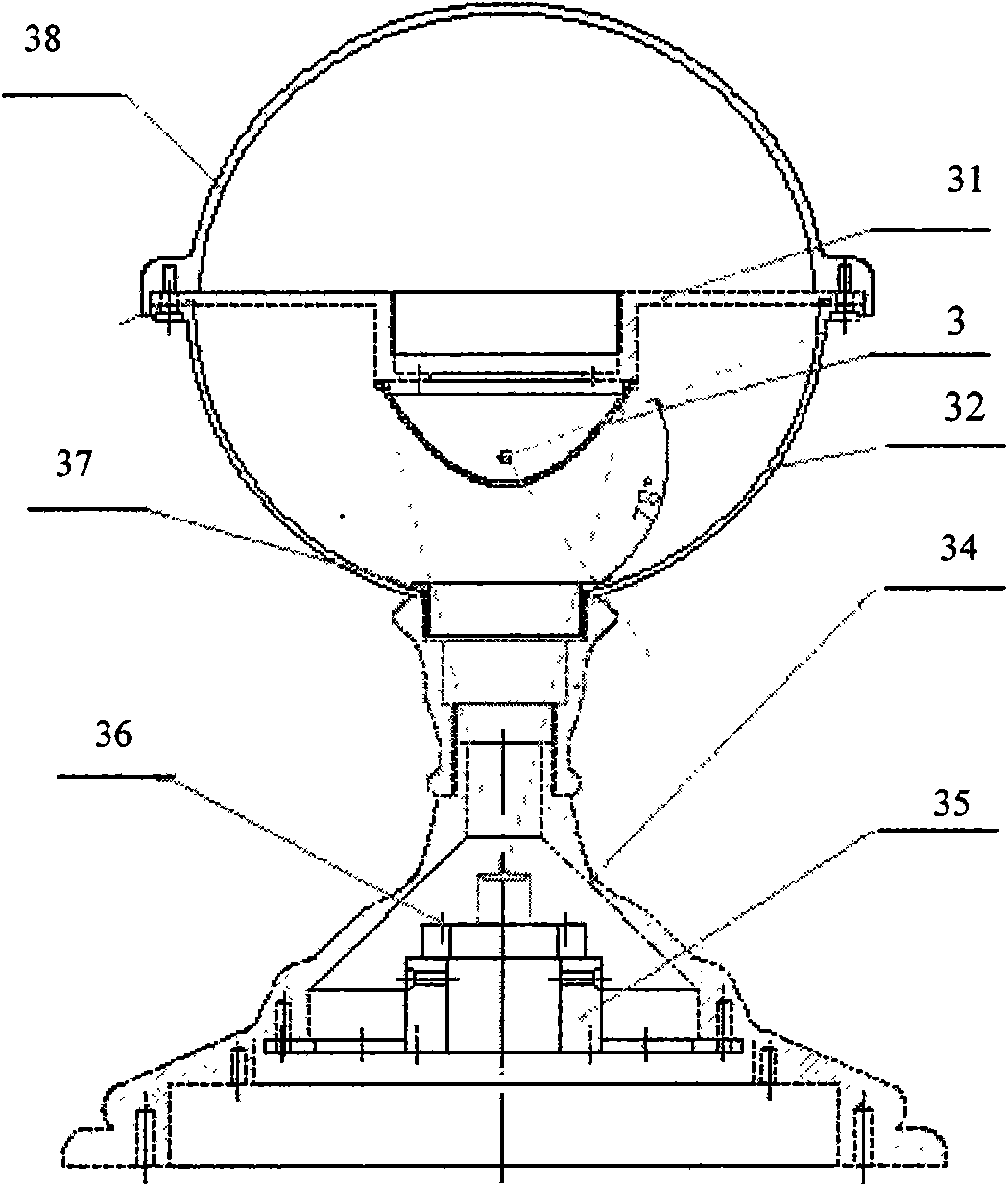

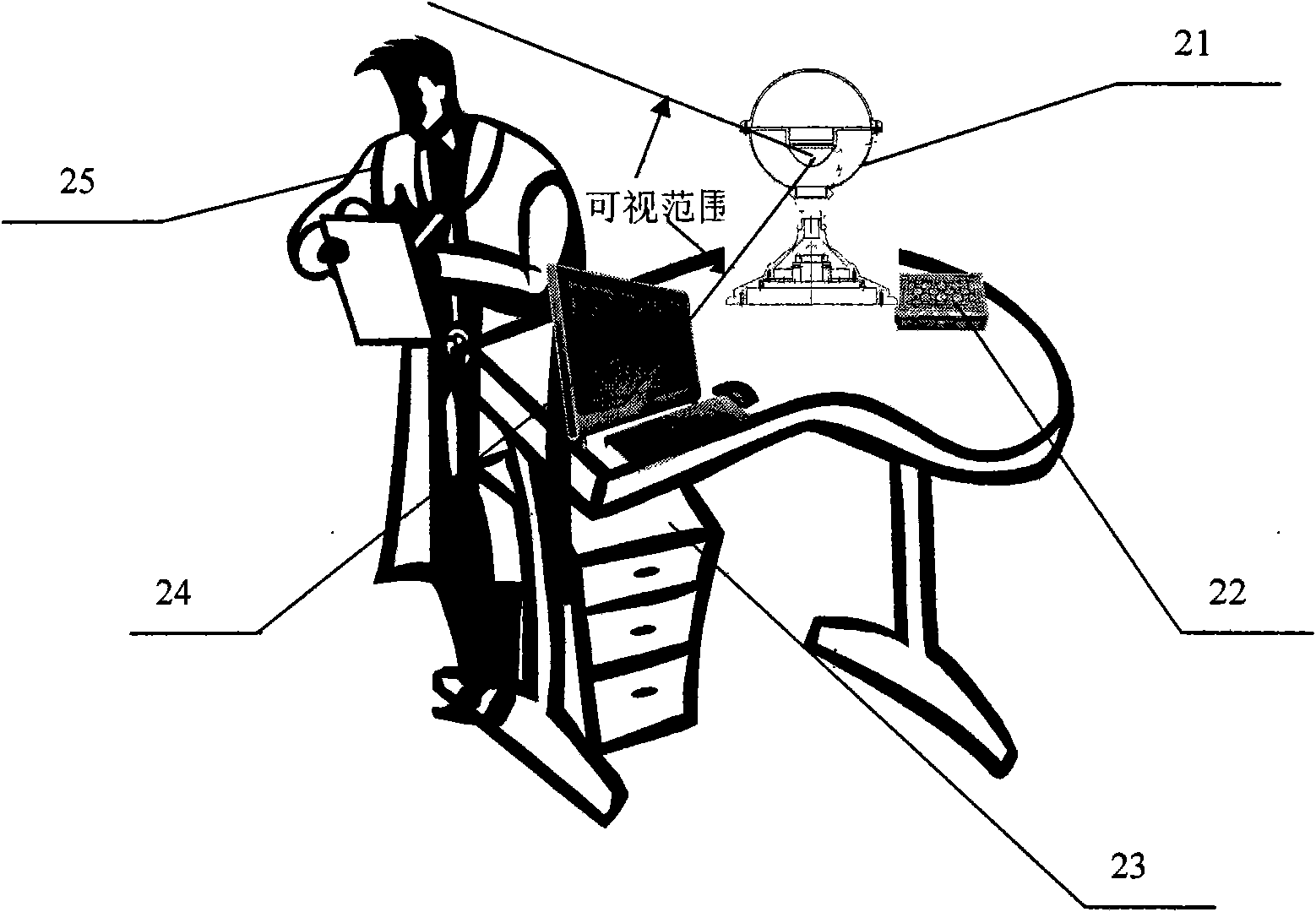

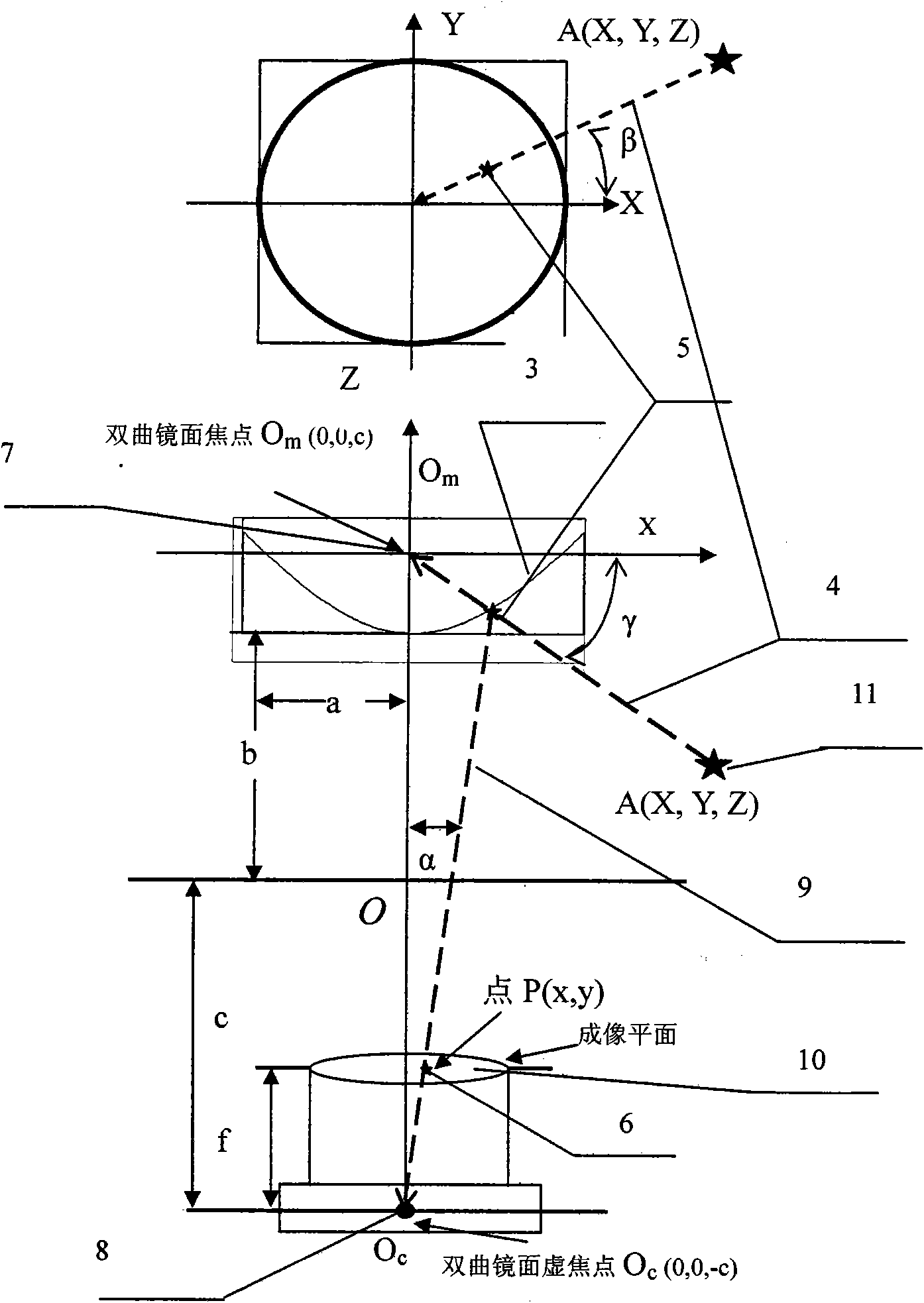

Biometrics-based device for detecting indentity of people and identification

InactiveCN101669824AReduce work intensityReduce error ratePerson identificationCharacter and pattern recognitionFace detectionProcess module

The invention discloses a biometrics-based device for detecting identity of people and identification, which comprises an omni-directional vision sensor used for acquiring the facial image of an ID card holder, an ID card reader used for reading the photograph information in a bulit-in chip of the second-generation ID card and a microprocessor used for comparing whether the facial photograph imagestored in the built-in chip of the second-genration ID card and the facial images acquired by the omni-directional vision sensor are consistent or not, wherein the microprocessor comprises a data module used for reading photograph image in the ID card, a first facial detecting module, a first facial feature extraction module, a panoramicpicture reading module, a second facial detecting module, animage expanding module, a second facial feature extraction module, an identity detecting module for the biological feature of people and the ID card and a decision-layer voting and processing module.The device adopts biometrics identification technology, can greatly improve the efficiency for validating the ID card, and reduce the working strength and error rate of office personnels.

Owner:ZHEJIANG UNIV OF TECH

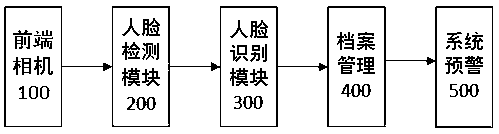

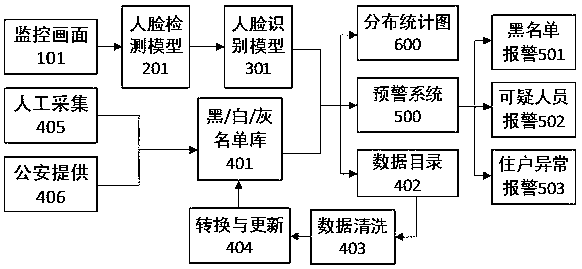

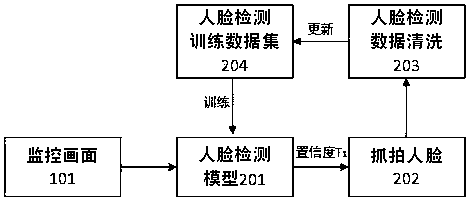

Community personnel file intelligent management method

ActiveCN108052925AImprove securityReduce work intensityCharacter and pattern recognitionCommunity managementIntelligent management

The invention relates to the field of community management, and provides a community personnel file intelligent management method. The method comprises the steps that faces are detected by using a deep learning model, and list database comparison is conducted; management and classification of community personnel are conducted by adopting a mechanism of black, white, and gray lists to achieve real-time alert of special personnel; cleaning of acquired image data is conducted to optimize and train the deep learning model; entry and exit time of the community personnel are analyzed to achieve advance warning of abnormal events; archive information of list database personnel is used for forming relevant statistical data and charts of the community. By means of a community management system, specification management of the community personnel and timely warning of the special personnel and the abnormal events are achieved to reduce work load of security personnel and effectively improve safety coefficient of the community, and community management is more intelligent.

Owner:GOSUN GUARD SECURITY SERVICE TECH

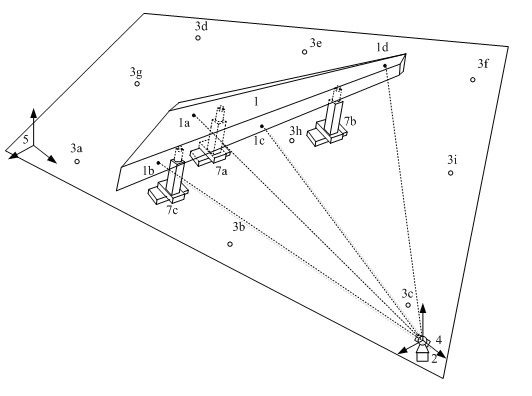

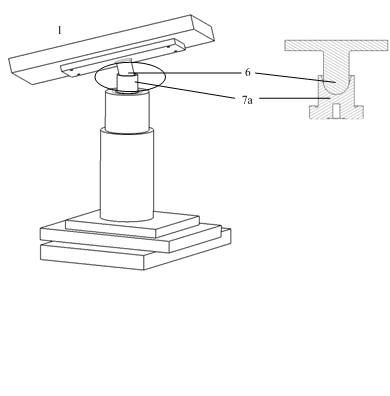

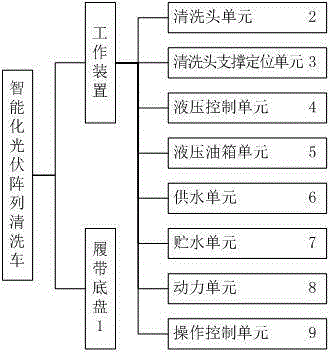

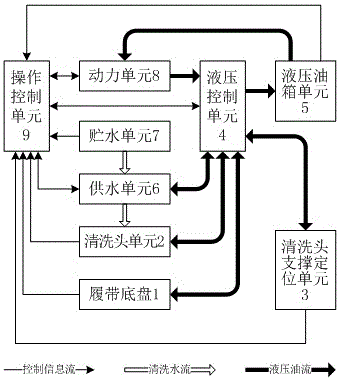

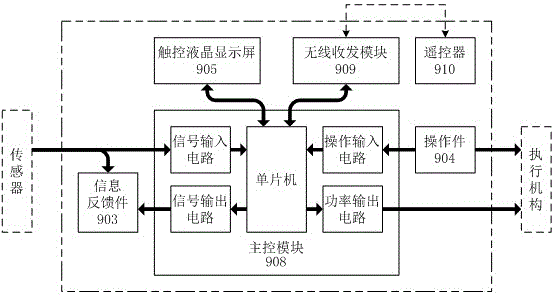

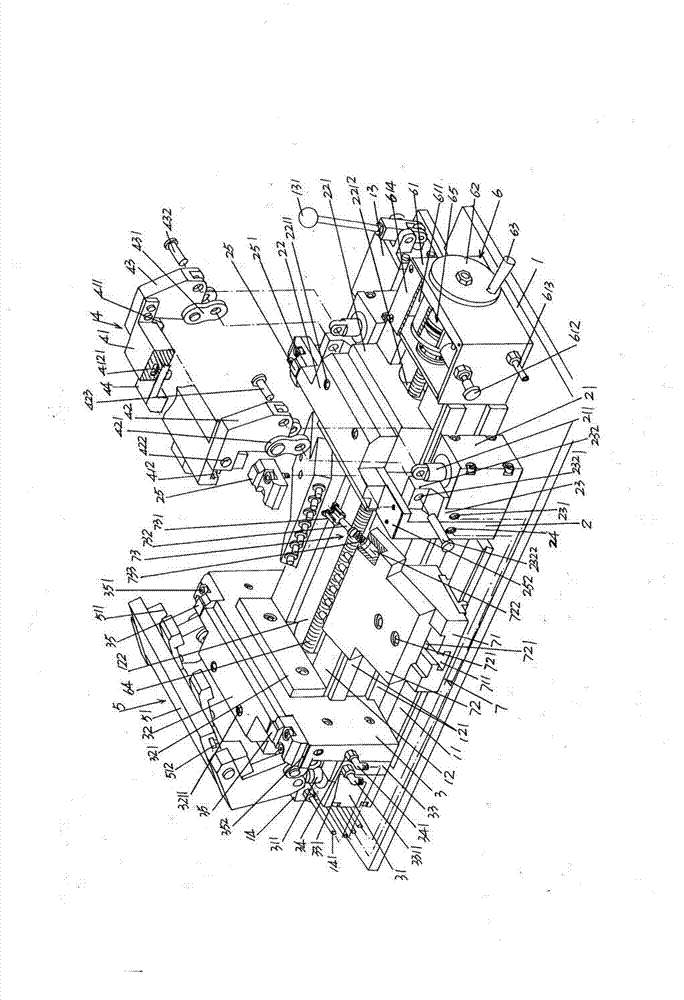

Intelligent photovoltaic array washing car

ActiveCN105107772AFunction increaseRegular shapeCleaning using toolsCleaning using liquidsWater storageHydraulic control unit

The invention provides an intelligent photovoltaic array washing car used for washing photovoltaic arrays of a large-scale ground photovoltaic power station. A washing head supporting and locating unit and a power unit are arranged on the head portion and the tail portion of a crawler base respectively, a water storage unit is arranged adjacent to the power unit, and a washing head unit is provided with range finder sensors used for measuring the distance between the washing head unit and solar cell panels; the washing head supporting and locating unit comprises a movable base capable of rotating and transversely moving and a working arm set provided with a main arm and an end arm, wherein the main arm and the end arm can pitch respectively; a water pump of a water supply unit is driven by a hydraulic motor; a computer is used as a control kernel of a main control module of an operation control unit; a pair of proportional directional valves of the hydraulic control unit controls two base crawler traveling motors, and other directional valves are electromagnetic directional valves controlled by the main control module. According to the intelligent photovoltaic array washing car, the position and the posture of the washing head unit relative to photovoltaic array panels and the position and the posture of a car body relative to the photovoltaic arrays can be automatically controlled, and the intelligent photovoltaic array washing car is intelligent, efficient, flexible in operation, high in adaptability, easy and convenient to operate, concise in structure and good in washing effect.

Owner:CSIC HAIWEI ZHENGZHOU HIGH TECH CO LTD

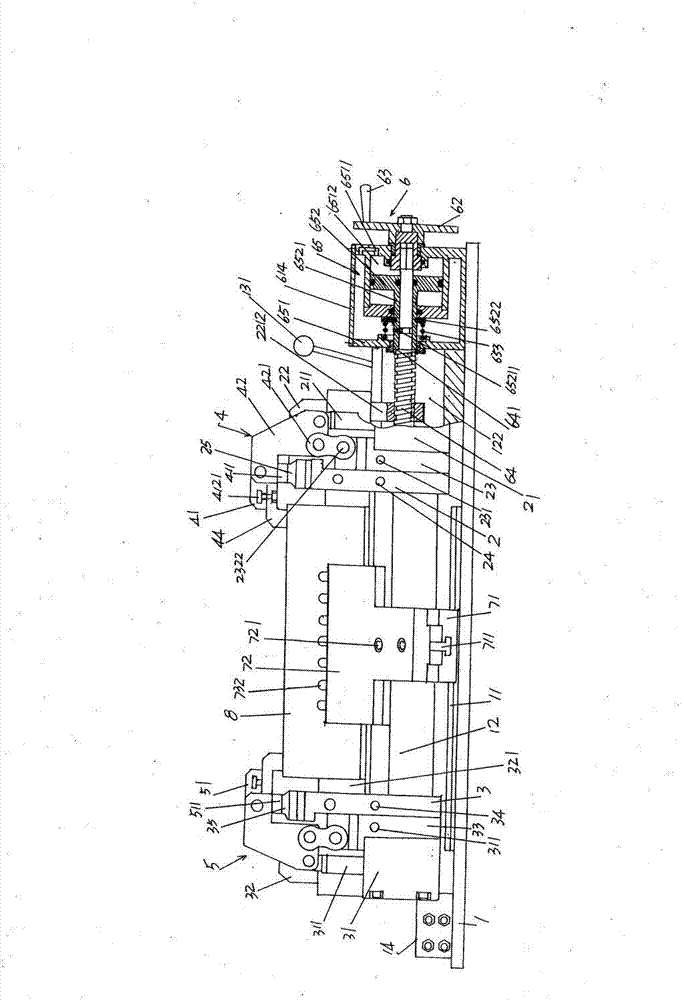

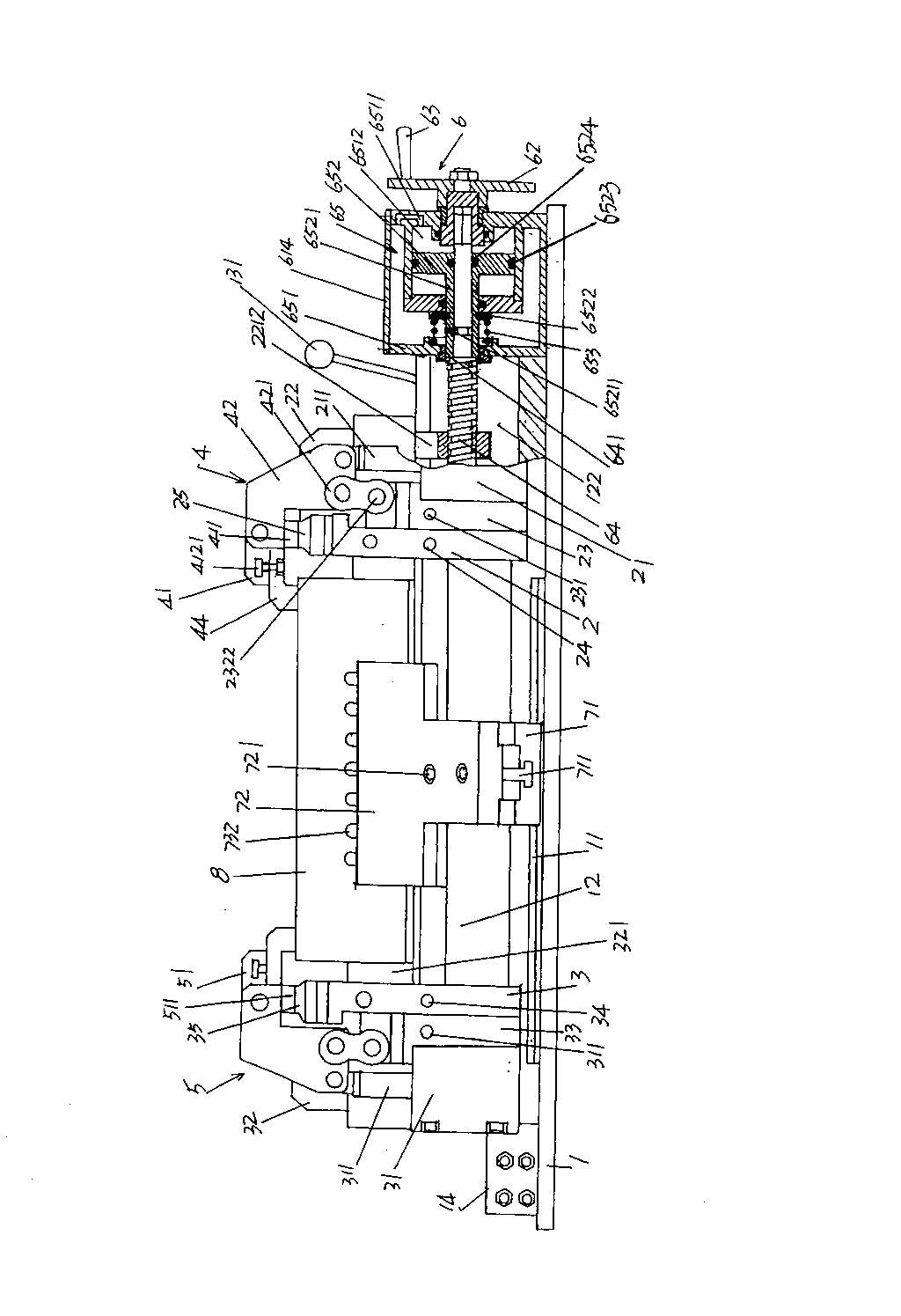

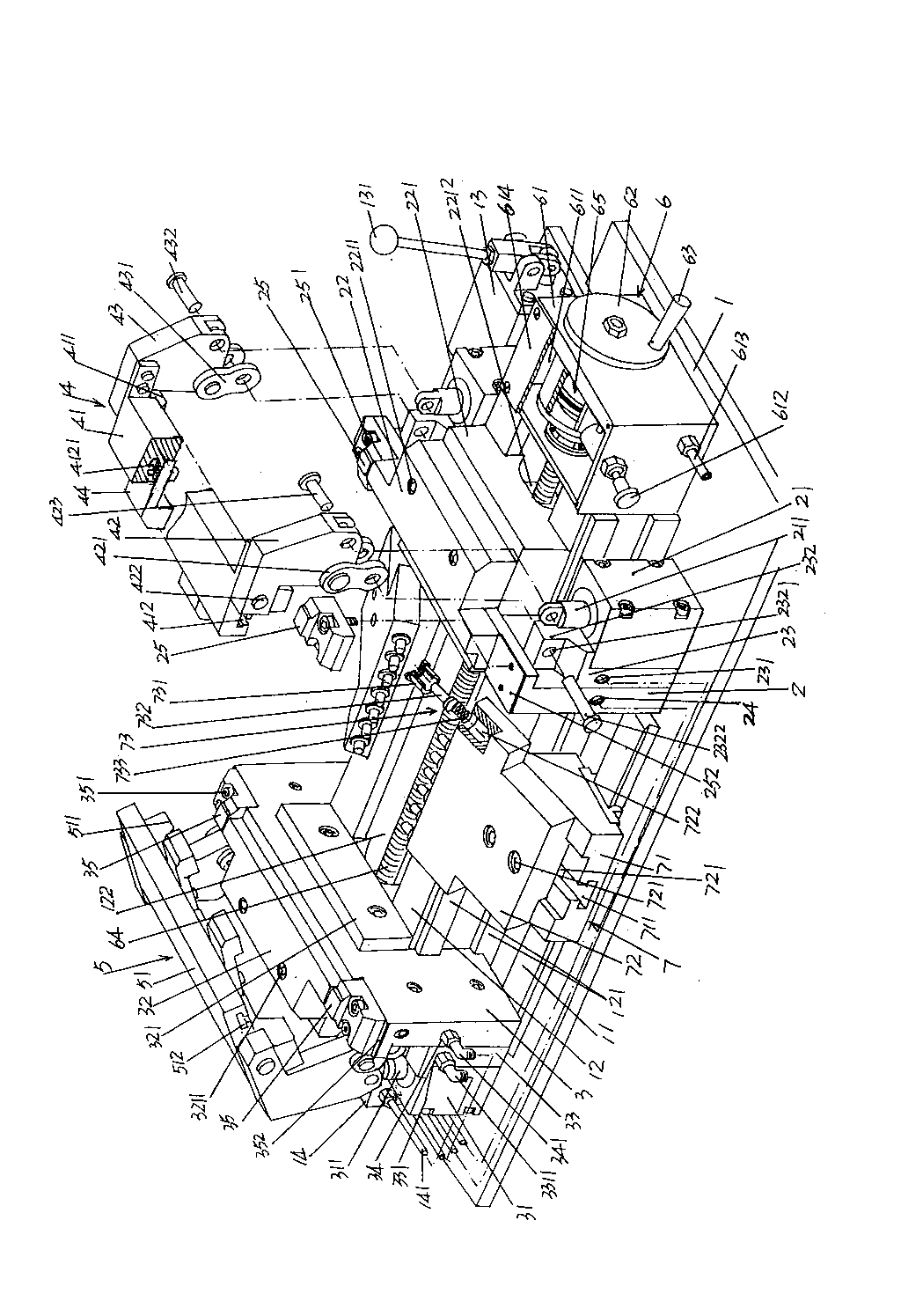

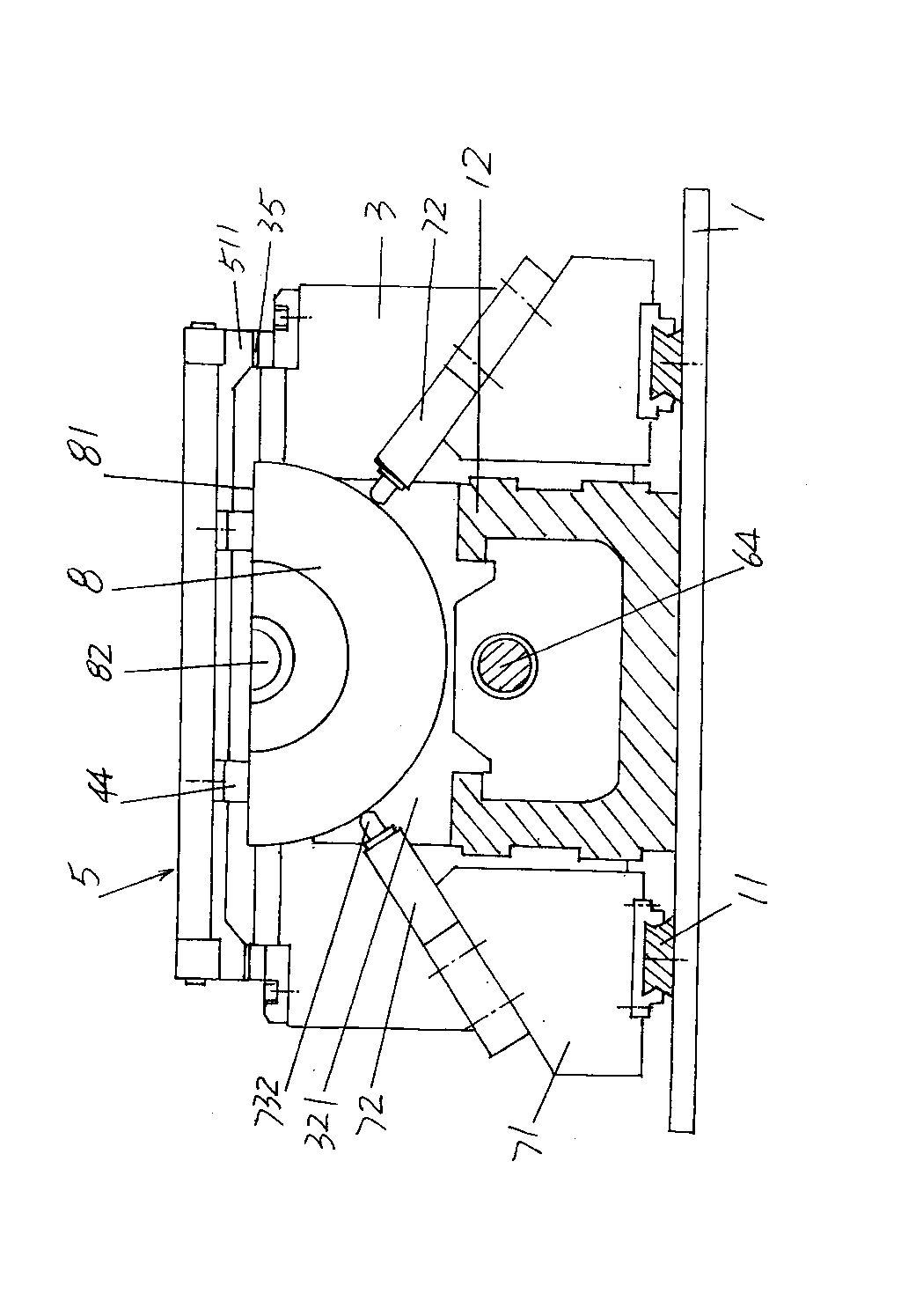

Fixture device for processing glass moulds

ActiveCN102380777BReduce work intensityImprove processing efficiencyPositioning apparatusMetal-working holdersEngineeringMechanical engineering

A fixture device for processing glass moulds belongs to the technical field of work fixtures and comprises a base, a first vice bench holder, a second vice bench holder, a first mould horizontal adjustment mechanism, a second mould horizontal adjustment mechanism, a vice bench driving mechanism and a pair of horizontal adjustment mechanisms. Guide rail bars are arranged on two sides of the base, a vice bench holder sliding seat is arranged between the guide rail bars, a pair of guide rails and a vice bench moving cavity are formed on the vice bench holder sliding seat, a first acting cylinderand a second acting cylinder are fixed to two ends of each of the first vice bench holder and the second vice bench holder respectively, a first vice bench fixing seat and a second vice bench fixing seat are fixed to the middles of the first vice bench holder and the second vice bench holder respectively, a first vice bench and a second vice bench are fixed to the first vice bench fixing seat andthe second vice bench fixing seat respectively, the first mould horizontal adjustment mechanism and the second mould horizontal adjustment mechanism are arranged on the first vice bench holder and the second vice bench holder respectively, the vice bench driving mechanism is arranged on the base, one horizontal adjustment mechanism is fittingly arranged on one of the two guide rail bars, and the other horizontal adjustment mechanism is fittingly arranged on the other guide rail bar. The fixture device has the advantages that one-step clamping is realized, the operating intensity of workers can be relieved, processing efficiency is improved, and processing quality is guaranteed.

Owner:CHANGSHU JIANHUA MOLD TECH

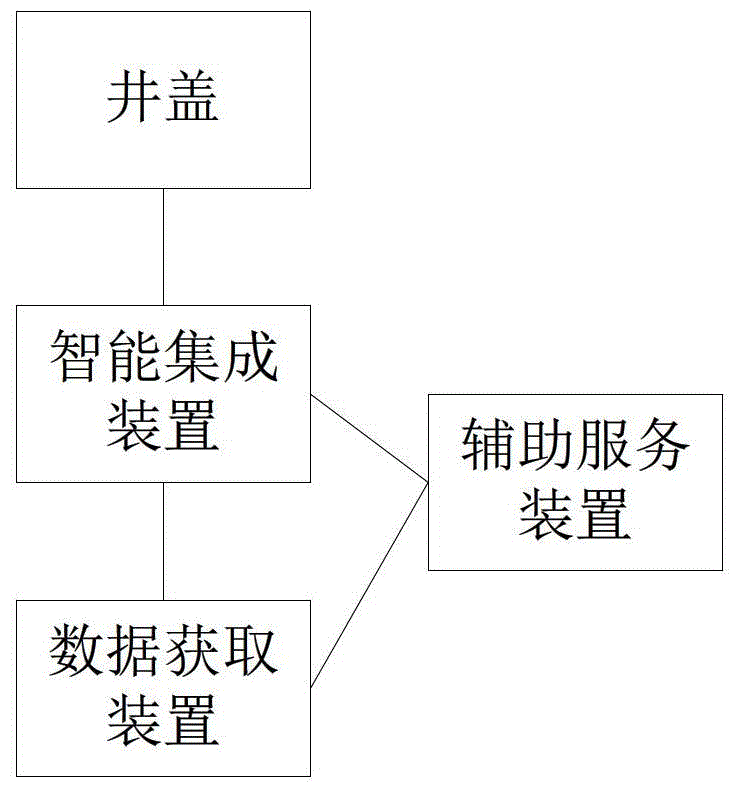

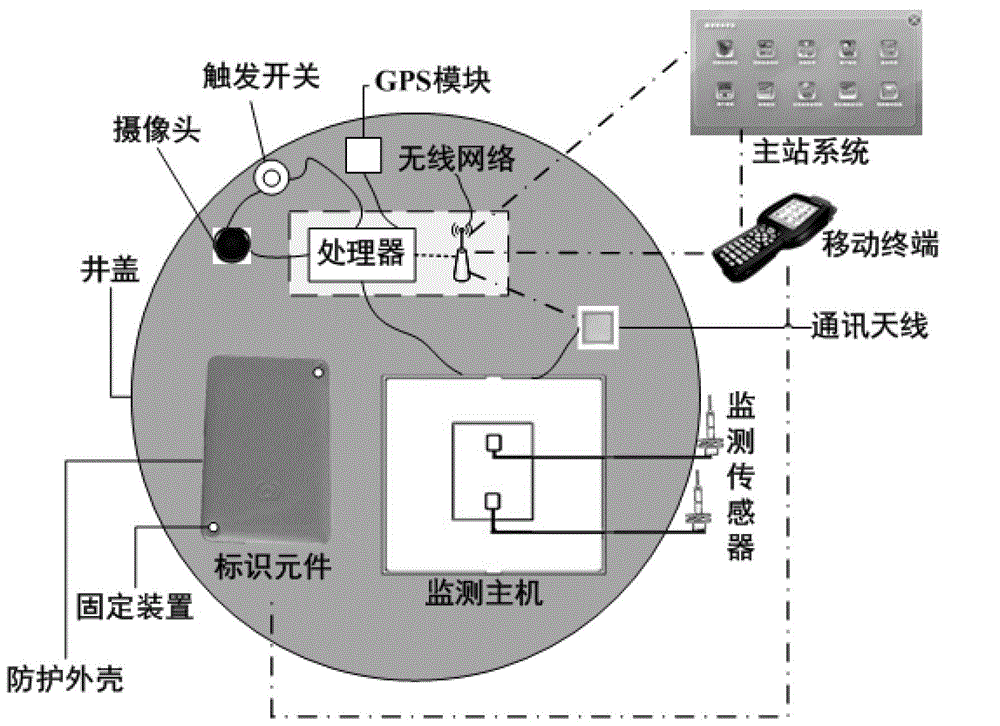

Multi-functional intelligent well cover system

InactiveCN104420482AThe collection is less affected by the environmentImprove reading speedArtificial islandsUnderwater structuresRelevant informationCovering system

The invention discloses a multi-functional intelligent well cover system. The multi-functional intelligent well cover system is characterized by comprising a well cover, an intelligent integration device for performing intelligent processing on the well cover, an information acquisition device for obtaining relevant information of the well cover, and an auxiliary service device for providing application service to the intelligent integration device and the information acquisition device. The multi-functional intelligent well cover system can perform positioning, unique identification, alarm and monitoring on the well cover.

Owner:北京清控人居环境研究院有限公司

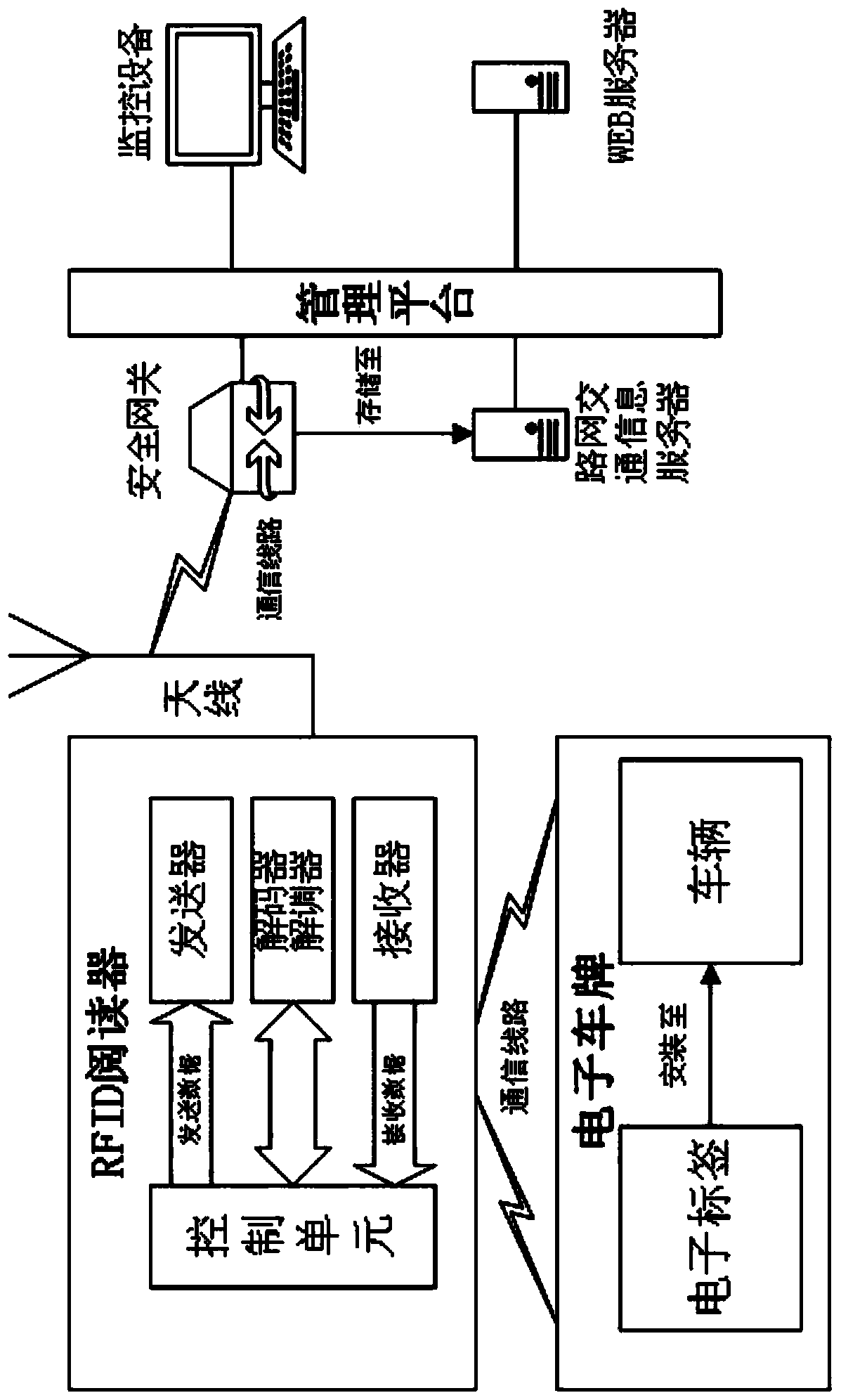

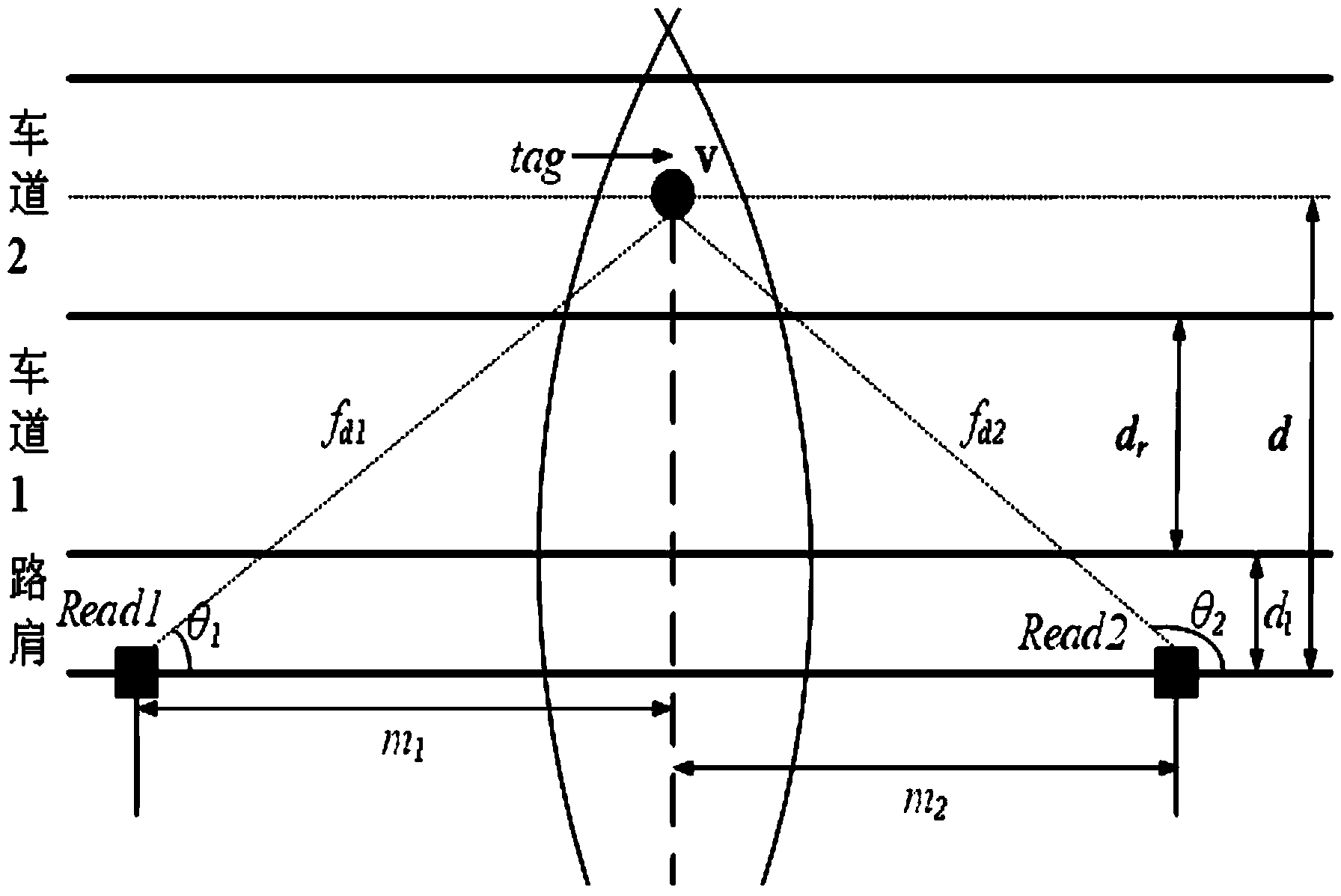

Vehicle peccancy monitoring and tracking positioning system of applying electronic license plate

ActiveCN104064031AReduce violationsReduce work intensityRoad vehicles traffic controlRoad networksEngineering

The present invention relates to the vehicle and traffic monitor technology field, and discloses a vehicle peccancy monitoring and tracking positioning system of applying an electronic license plate. The vehicle peccancy monitoring and tracking positioning system of applying the electronic license plate is characterized by comprising a vehicle equipped with a passive RFID electronic label, an RFID reader laid on a road shoulder and a server arranged in a command center, wherein the RFID reader laid on the road shoulder reads the RFID electronic label in the vehicle passing the position and the traffic data of the vehicle and sends the read vehicle information and traffic data to the server arranged in the command center, and the server arranged in the command center determines whether the vehicle breaks rules and regulations, wherein the static parameters of the vehicle are recorded in the RFID electronic label on the vehicle, and the traffic data of the vehicle is the dynamic parameter of the passing vehicle. By using the electronic license plate as the only identification of the vehicle in a road network, and providing a data processing flow of the vehicle travel path survey, the rationality and feasibility of the total framework structure and the design idea of the system are proved.

Owner:丁宏飞 +9

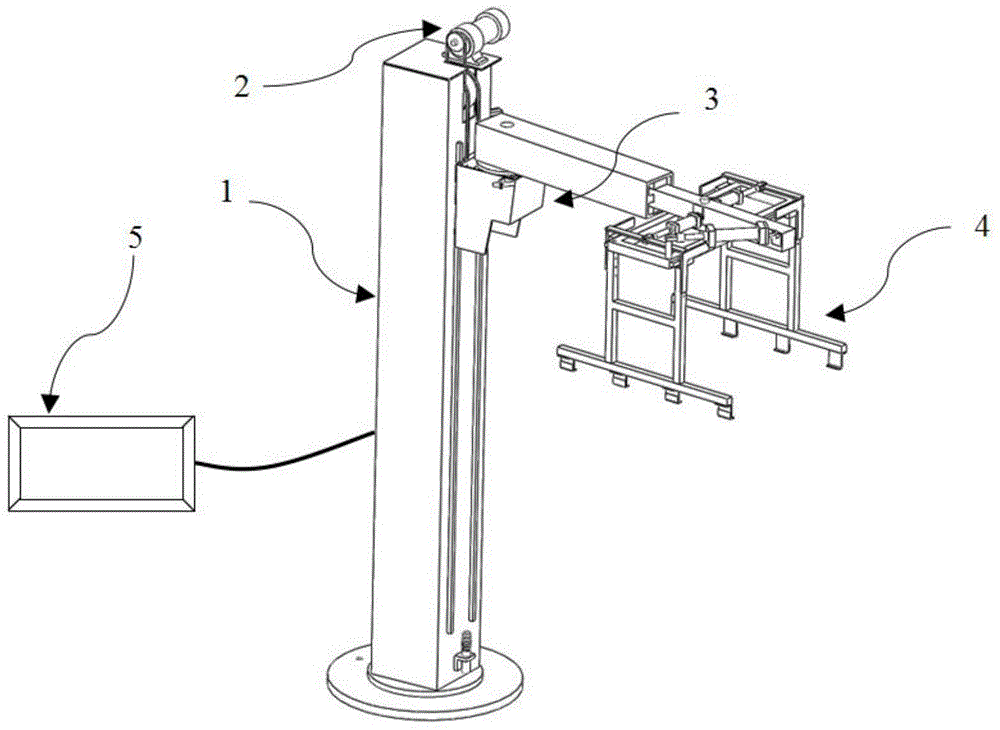

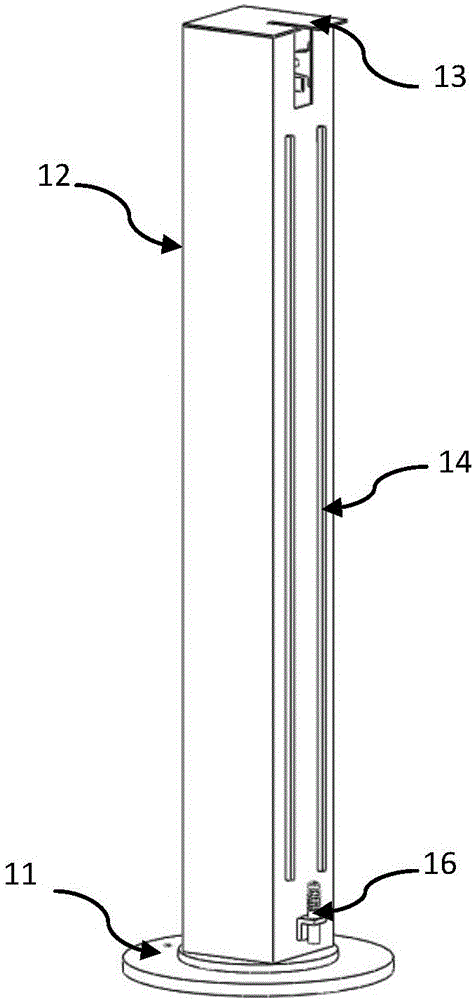

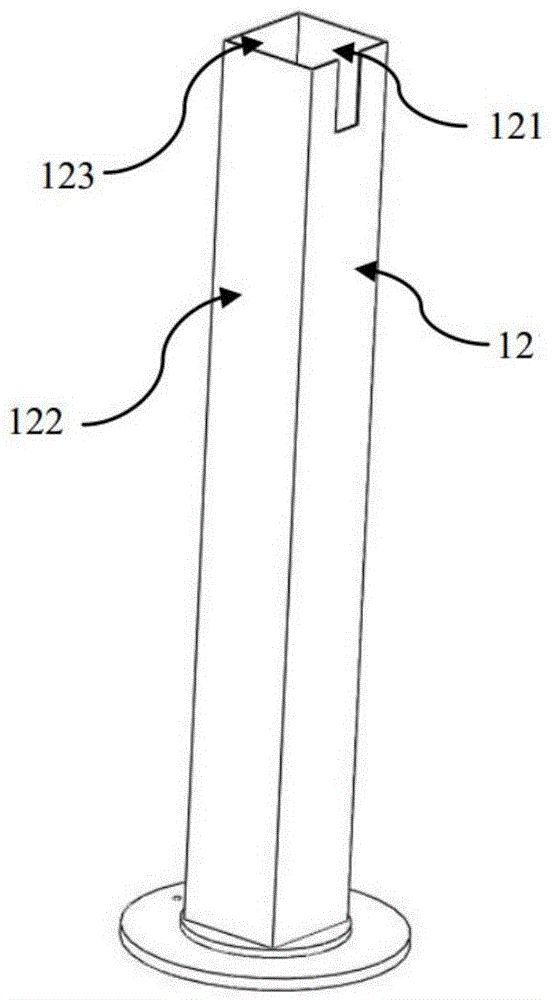

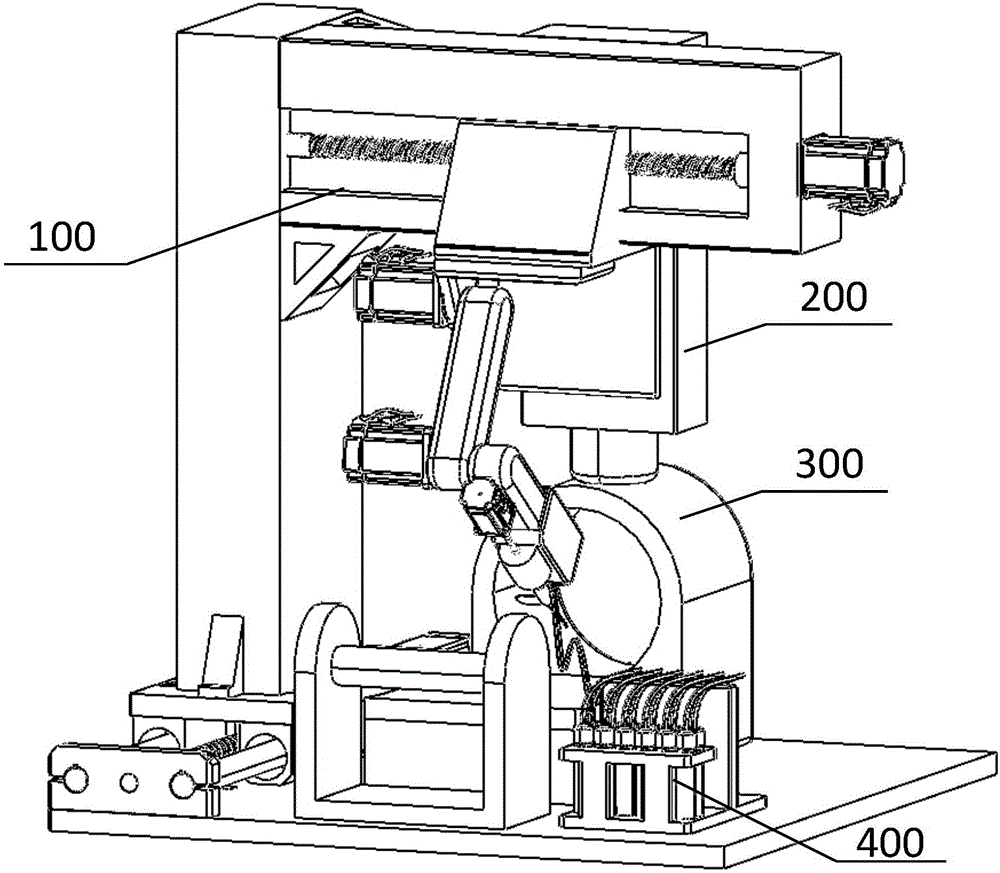

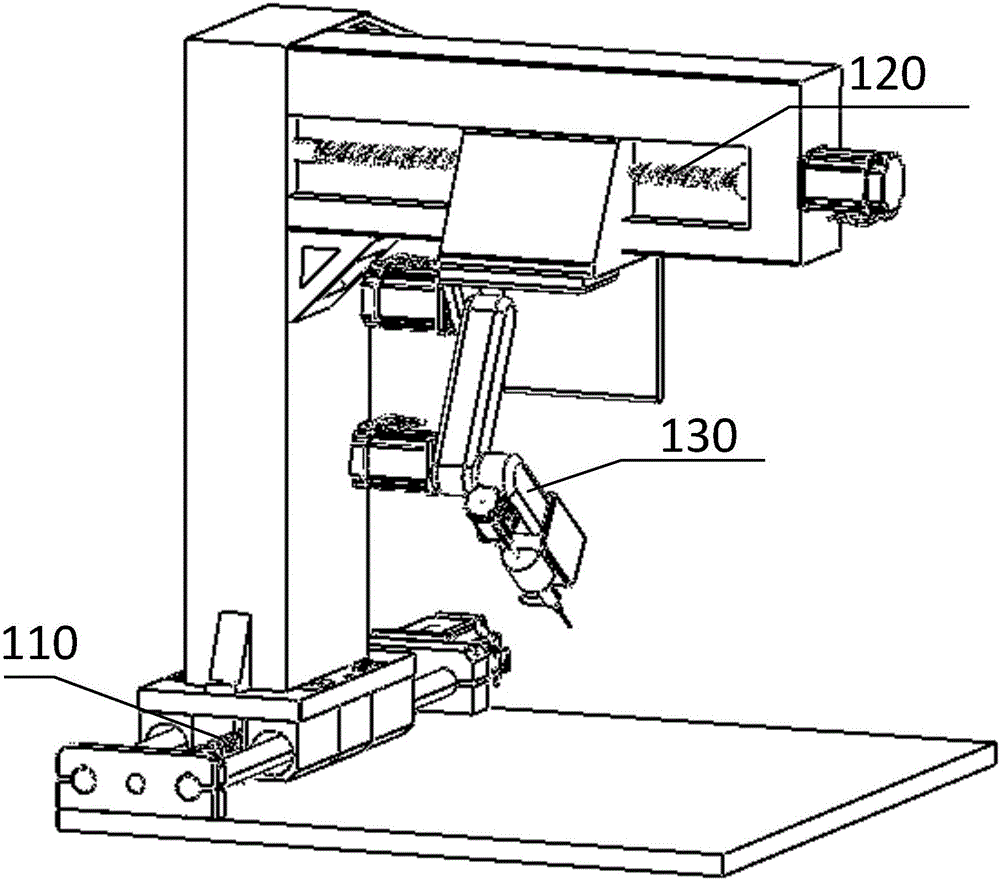

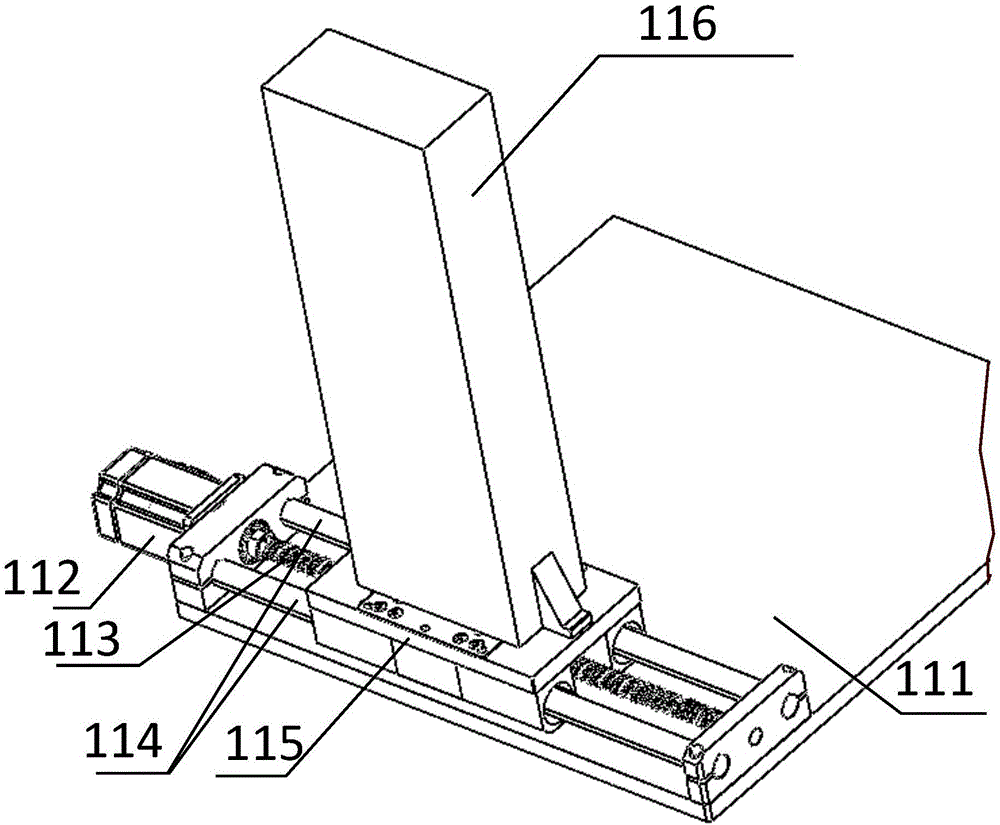

Five-degree of freedom stacking manipulator

ActiveCN104555421AReduce work intensityWon't shakeProgramme-controlled manipulatorConveyor partsEngineeringDegrees of freedom

The invention discloses a five-degree of freedom stacking manipulator and belongs to the field of robot application. The five-degree of freedom stacking manipulator comprises a combined stand column, a lifting module, a rotating module, a clamping module and a handheld controller. During stacking, the handheld controller can control the lifting module to bear the rotating module and the clamping module to together move up and down along the combined stand column; the rotating module drives the clamping module to swing horizontally relative to the combined stand column; the clamping module is used for completing workpiece clamping during stacking. The five-degree of freedom stacking manipulator is rapid in clamping, low in manufacturing cost, small in space occupation and simple in control and can complete tasks in different heights within a certain range.

Owner:NANJING COLLEGE OF INFORMATION TECH

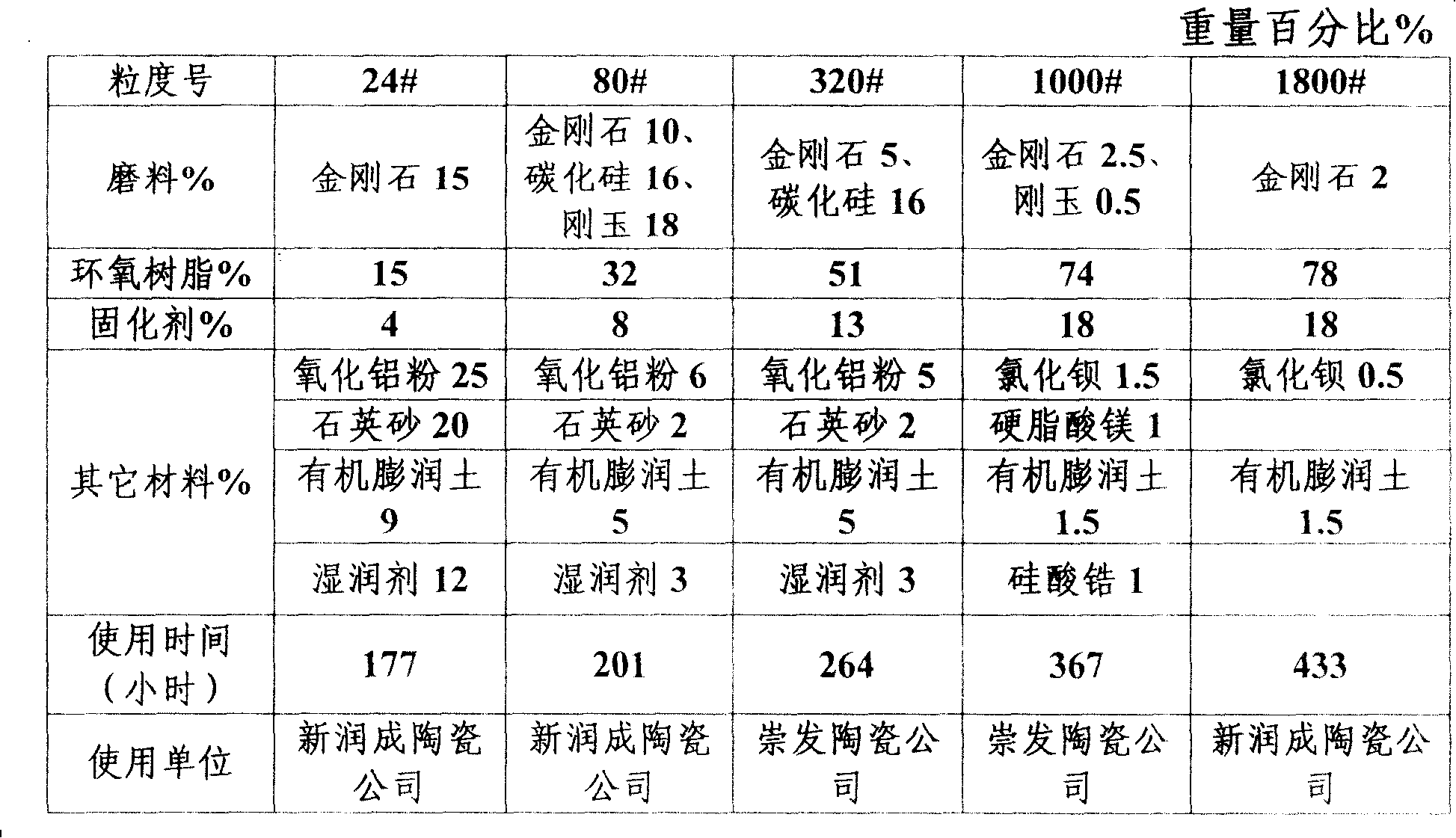

Abrasive tool of epoxy resin combined with compounded abrasive

Disclosed is an abrasive tool made of epoxy resin-bonded compound abrasive material, which comprises epoxy resin, abrasive material and curing agent. The weight percentages are as follow: the epoxy resin is 15 to 78 percent, the abrasive material is 2 to 44 percent and the curing agent is 4 to 18 percent. Wherein, the abrasive material comprises one of diamond, silicon carbide or corundum or the combination of more than one material. The curing agent comprises one of 4.4`-methylenedianil, solid diaminodiphenyl methane or liquid modified diaminodiphenyl methane or the combination of more than one material. The component of the abrasive tool also comprises the other auxiliary material, which comprises one of alumina, barium chloride, sodium chloride, quartz sand, organobentonite, wetting agent, zirconium silicate, calcium carbonate, graphite powder, garnet, magnesium sulfate, phenolic resin, zinc stearate and magnesium stearate, or the combination of more than one material. The product can be made into any shape the same with the present product, which can be applied in various grinding and polishing equipment with wide application scope.

Owner:广东奔朗新材料股份有限公司

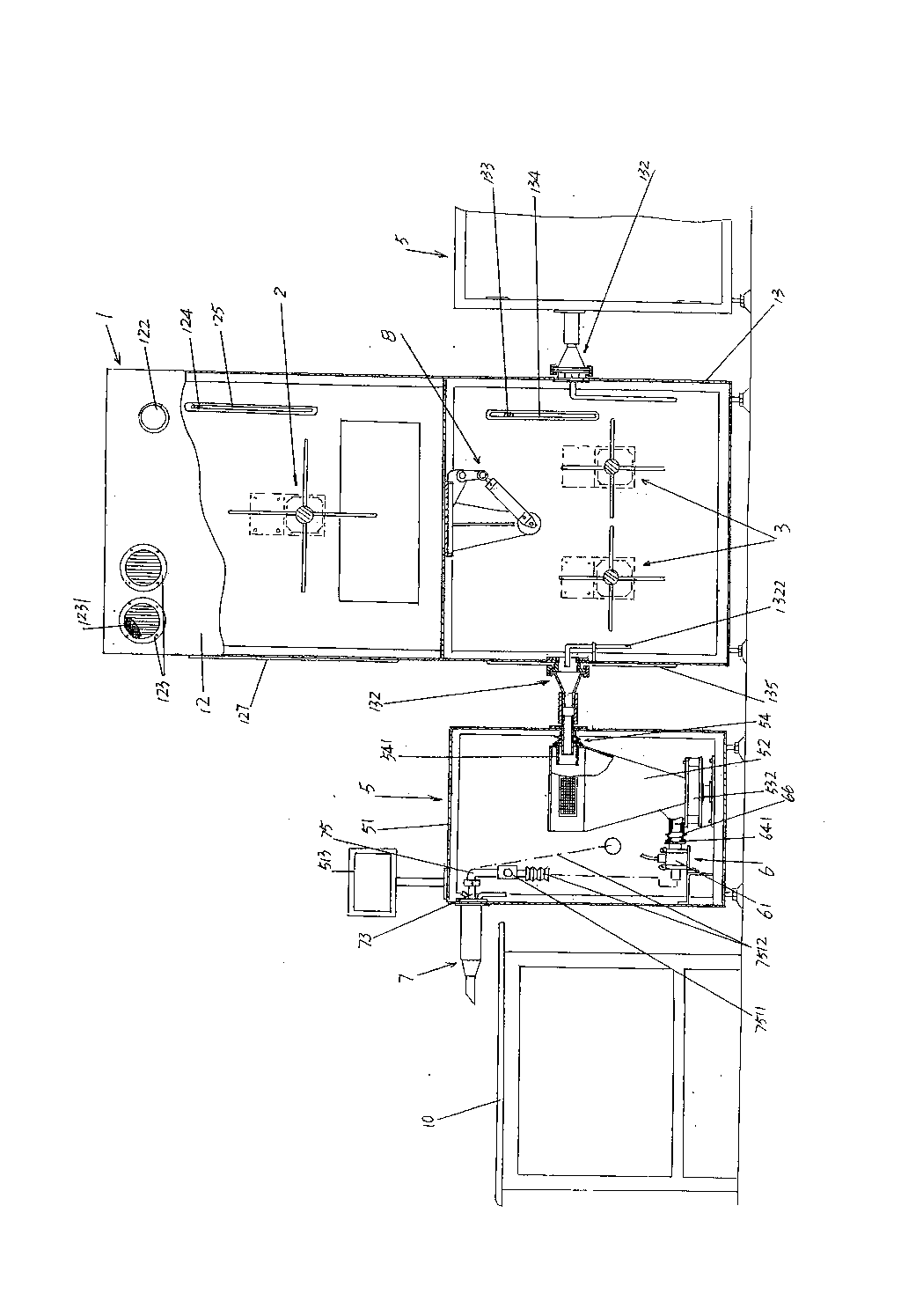

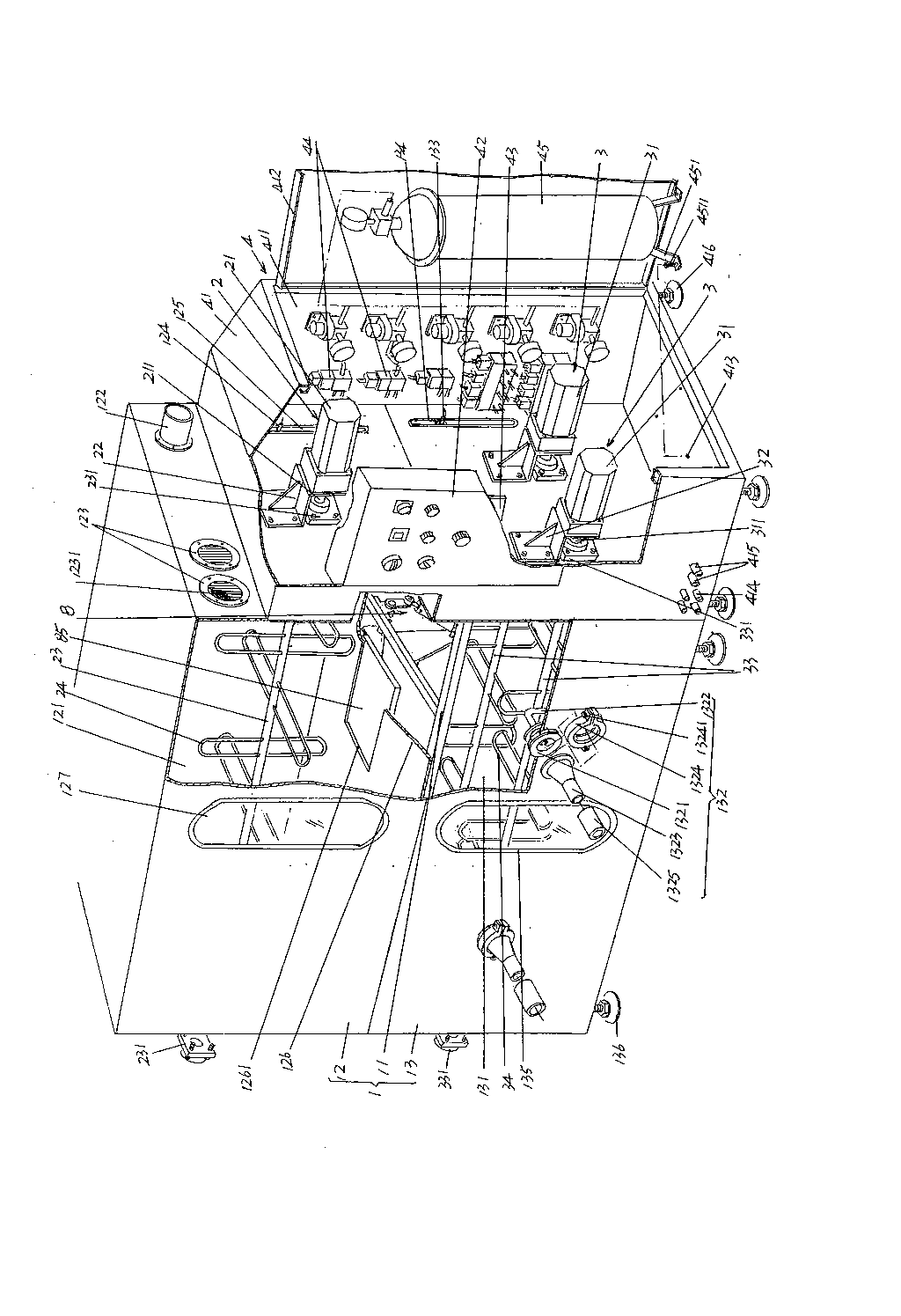

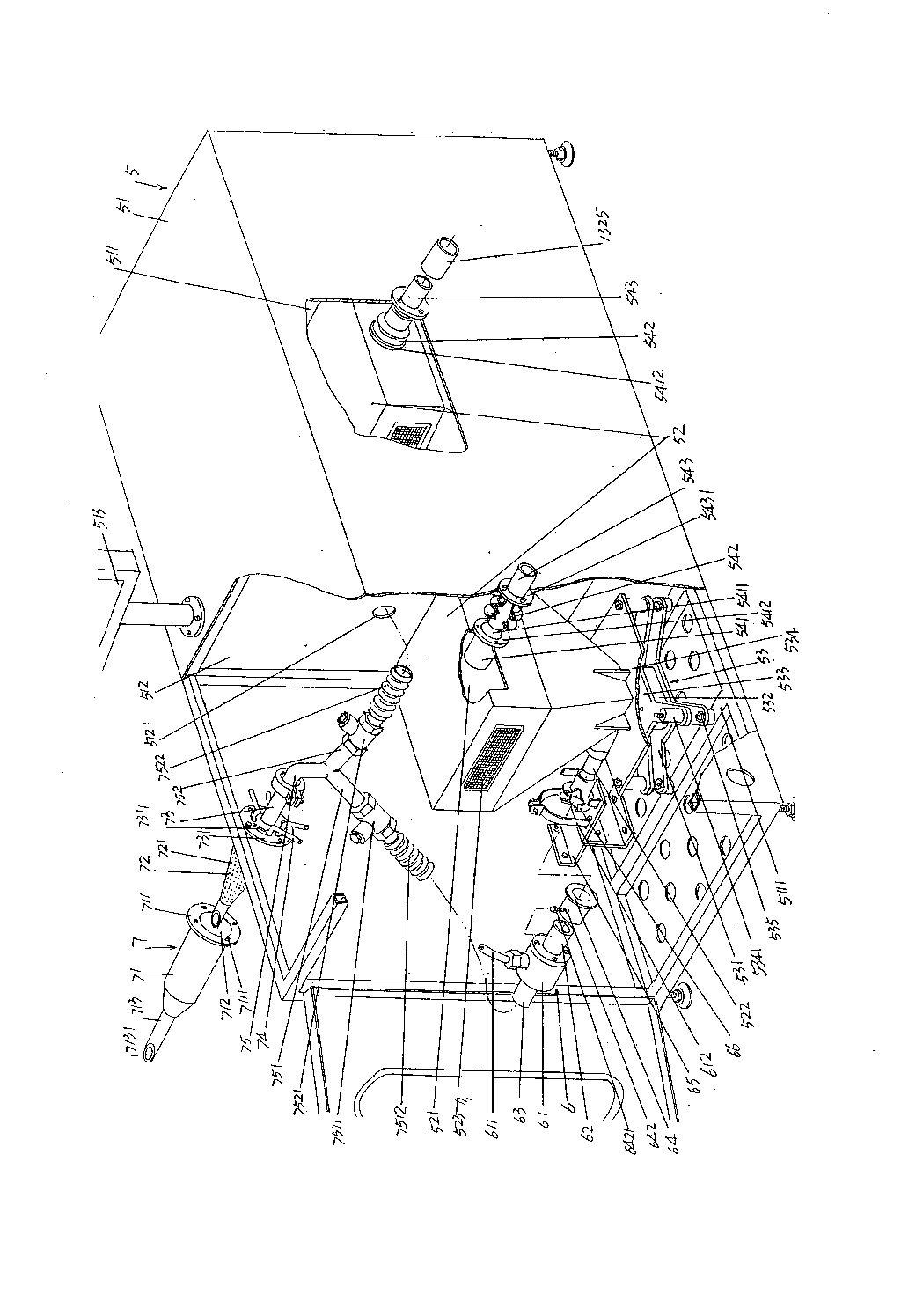

Automatic down filling machine

ActiveCN103101871AReduce escapeNo escapeUpholstery manufactureClothes making applicancesMagnetic valveEngineering

The invention discloses an automatic down filling machine, and belongs to the technical filed of a stowage unit for down and feather filled products. The automatic down filling machine comprises a box body, a first down stirring mechanism, a second down stirring mechanism, an electrical automatic control mechanism, a pair of weighing metering mechanisms, a pair of down output mechanisms, a pair of down filling heads and a box cavity channel start-and-stop mechanism. The box body comprises a box frame, a down storage box and a down delivering box. The first down stirring mechanism is used for stirring down in a down storage box cavity, and the second down stirring mechanism is used for stirring down in a down delivering box cavity. The pair of weighing metering mechanisms is connected with a pair of down leading out connector pipelines on two sides of the down delivering box, the pair of down output mechanisms is connected with the pair of weighing metering mechanisms, the pair of down filling heads is connected with the pair of down output mechanisms in a matched mode, and the box cavity channel start-and-stop mechanism is placed on the box frame. The electrical automatic control mechanism is provided with an electrical box body, a control panel, a programmable controller, a group of magnetic valves and a high-pressure air storage tank. The automatic down filling machine has the advantages of showing rhythmic continuity of down supplying, being capable of providing guarantee for subsequent continuously weighing and down filling, showing good down filling efficiency, reducing operation intensity of workers, eradicating down wasting and showing good automatic control effect.

Owner:苏州比阳特服装设备有限公司

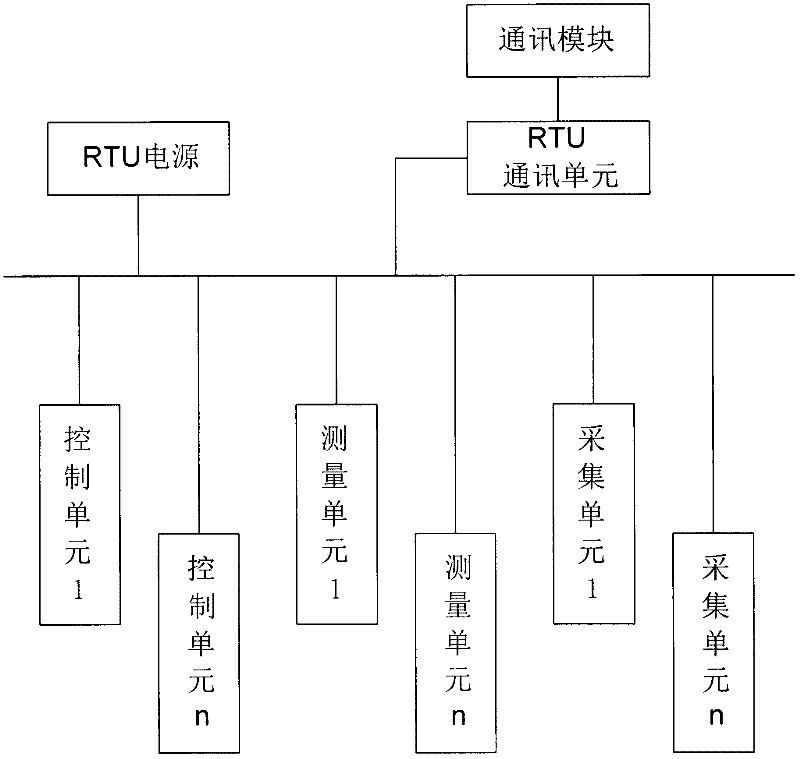

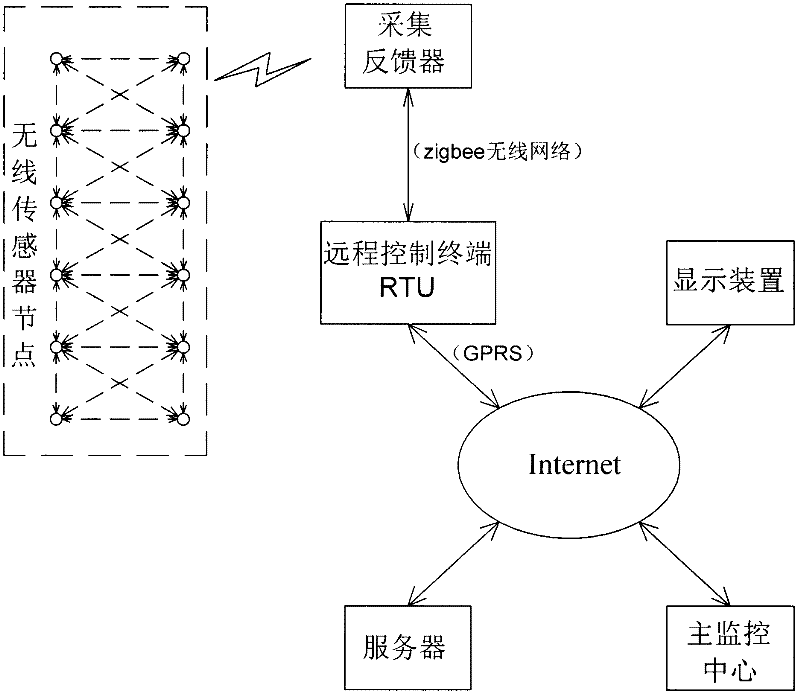

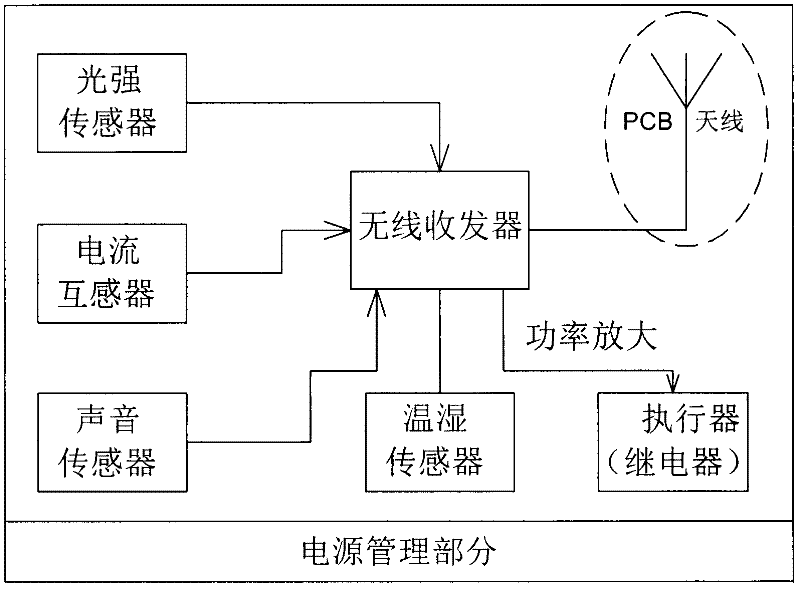

Street lamp energy-saving and managing system based on internet of things

InactiveCN102413611ALow construction costShort cycleEnergy efficient ICTNetwork topologiesGeneral Packet Radio ServiceTransformer

The invention belongs to the technical field of street lamp illumination, and in particular mainly relates to a street lamp energy-saving and managing system based on internet of things. The system mainly consists of a main monitoring center, a remote terminal unit (RTU) and wireless sensor nodes, wherein the wireless sensor node which is responsible for detecting and controlling single lamp street to operate and executing a lamping switching-on and switching-off operation by receiving an instruction sent by the RTU is arranged on each street lamp, the wireless sensor nodes are connected with the RTU through a GPRS (General Packet Radio Service) module, and the RTU arranged at a transformer workstation is respectively connected with the main monitoring center, a server and a display device through Internet. The street lamp energy-saving and managing system disclosed by the invention can realize illumination as required, high efficiency and energy saving and fine management, solves the problems generally existing in the current street lamp monitoring management system and has the advantages of wide application range and suitability for popularization.

Owner:成都智汇科技有限公司

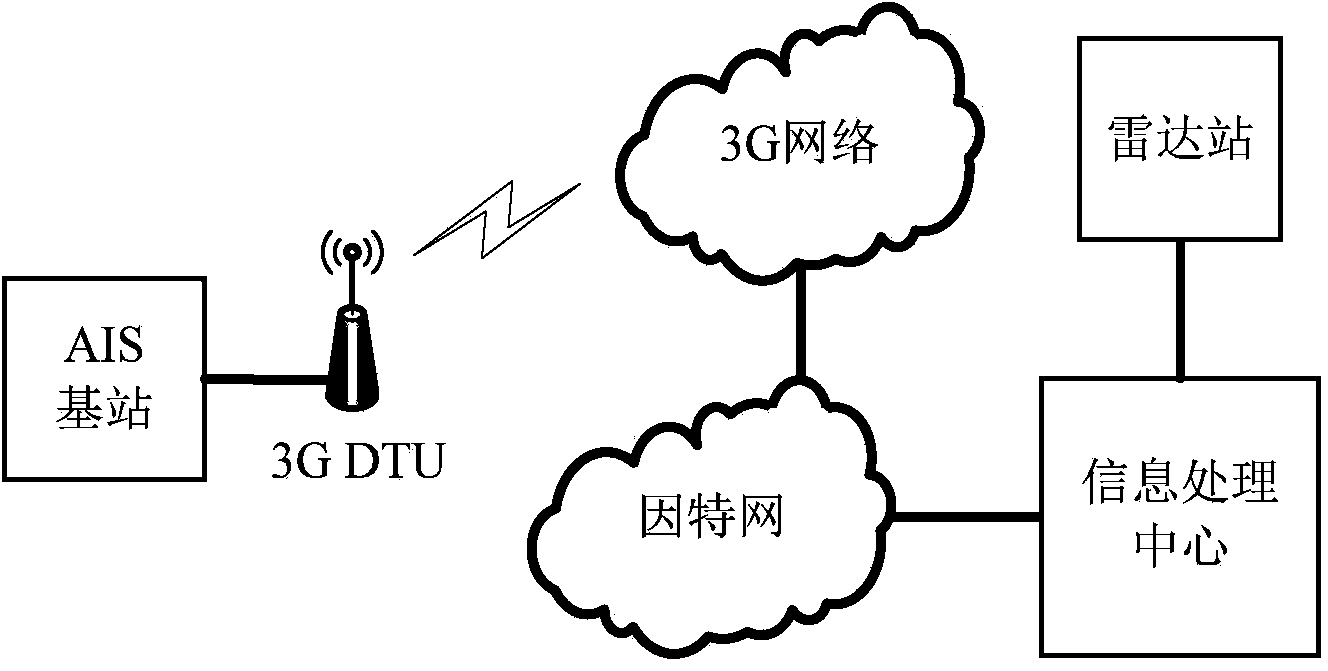

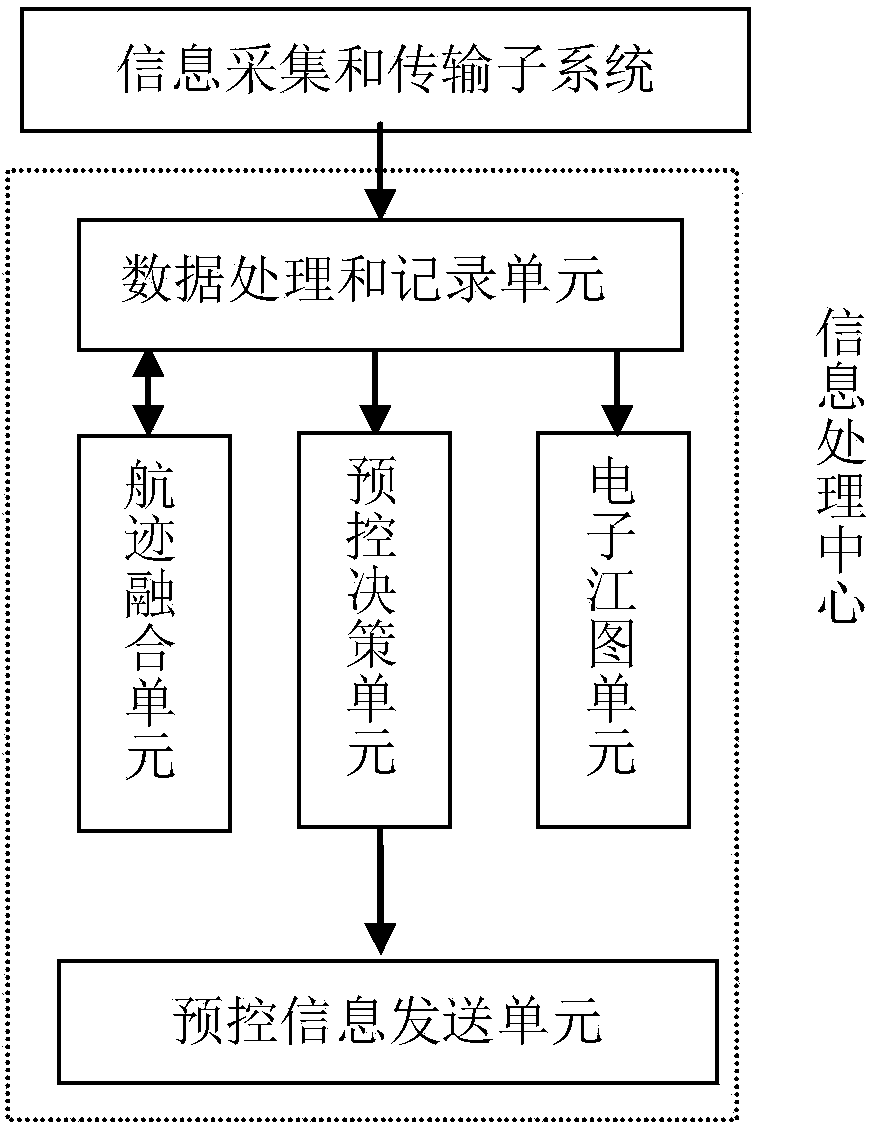

Inland river bridge area ship safe navigation precontrol system

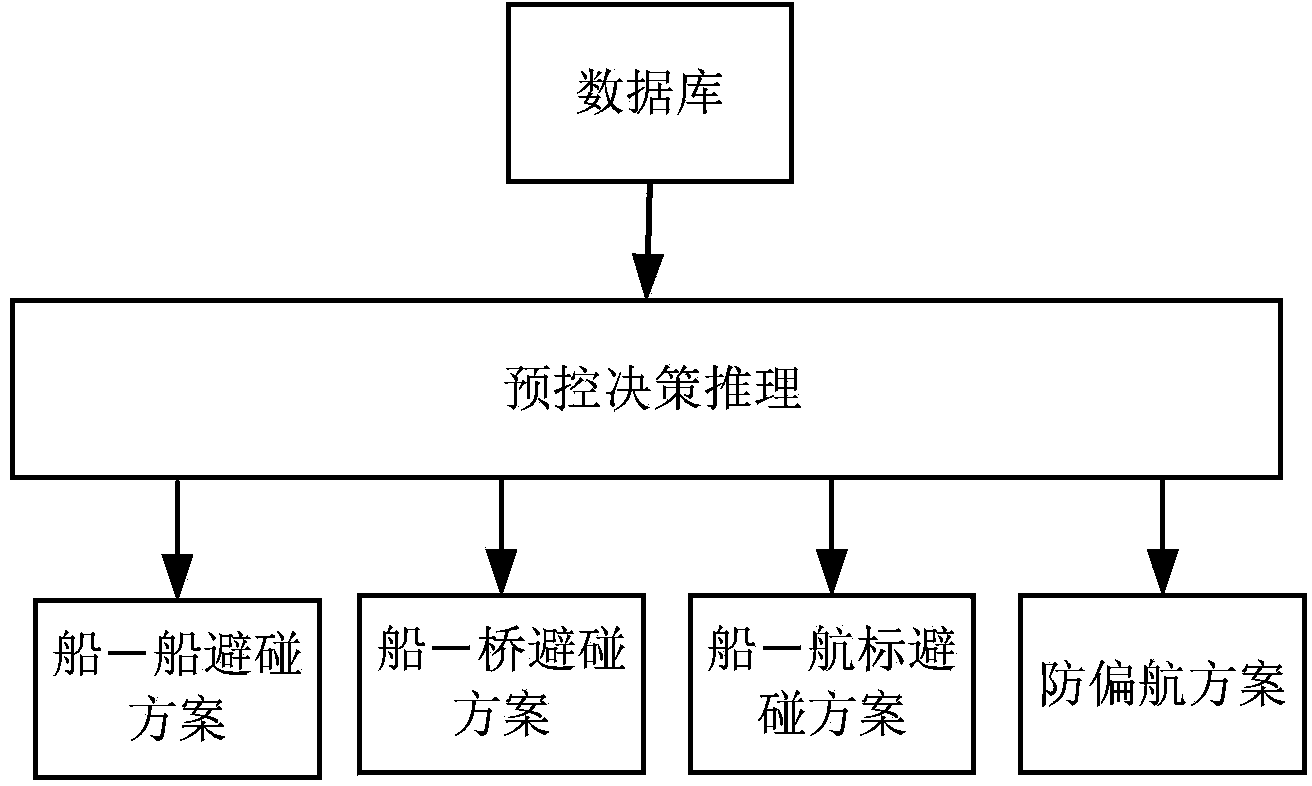

InactiveCN103714718AAddress riskReduce work intensityMarine craft traffic controlInformation processingRadar

The invention relates to an inland river bridge area ship safe navigation precontrol system which comprises a radar station, an information processing center and an AIS base station. The radar station and the AIS base station are respectively in communication connection with the information processing center. The information processing center comprises a data processing and recording unit, a track fusion unit, an electronic river map unit, a precontrol decision-making unit and a precontrol information sending unit, wherein the data processing and recording unit obtains data from the radar station or / and the AIS base station and processes and records the data, the track fusion unit carries out fusion on the obtained radar or / and AIS data to obtain ship tracks, the precontrol decision-making unit carries out prediction according to the data processed and recorded by the data processing and recording unit and judges whether alarm instructions are sent out or not, and the precontrol information sending unit controls the AIS base station to send out alarms according to the instructions sent out by the precontrol decision-making unit. According to real-time traffic situations, the inland river bridge area ship safe navigation precontrol system can automatically identify navigation risks of the ships, automatically carry out early warning on the ships, guide the ships to pass through a bridge area safely, and reduce accident risks.

Owner:WUHAN UNIV OF TECH

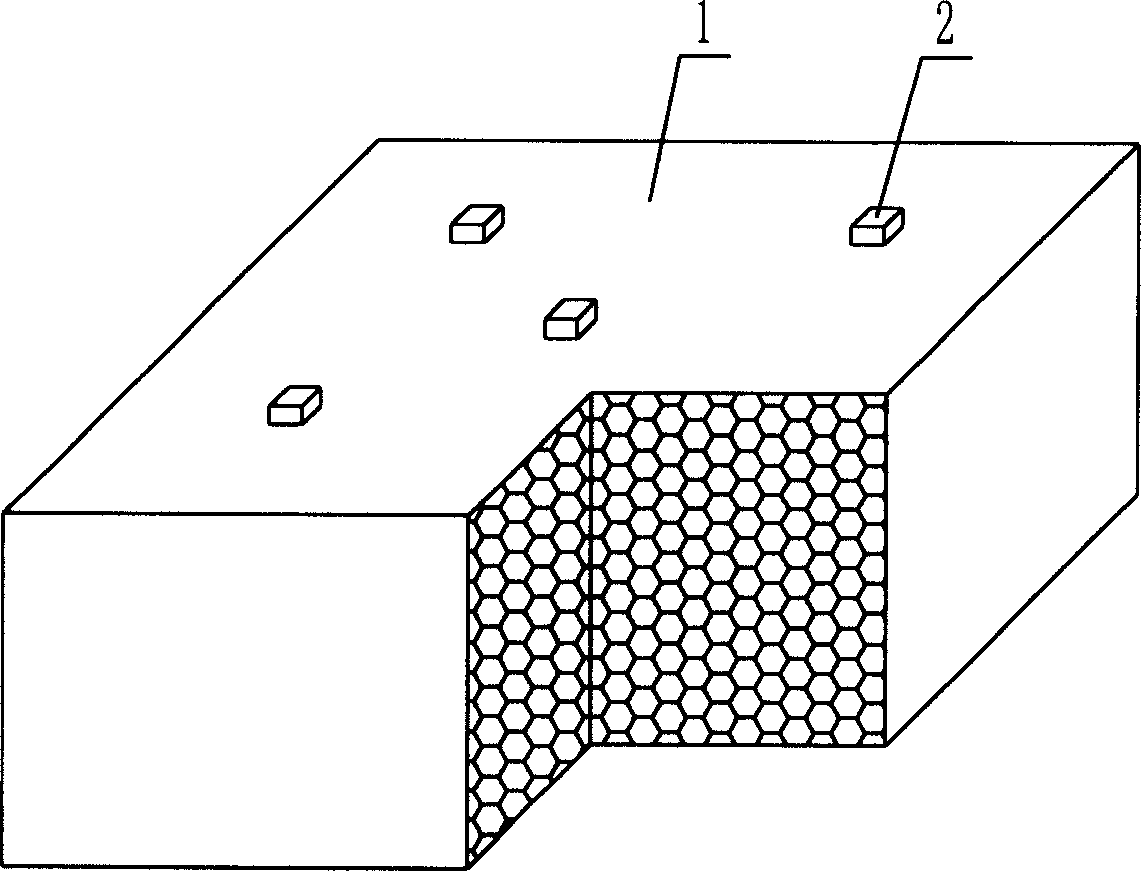

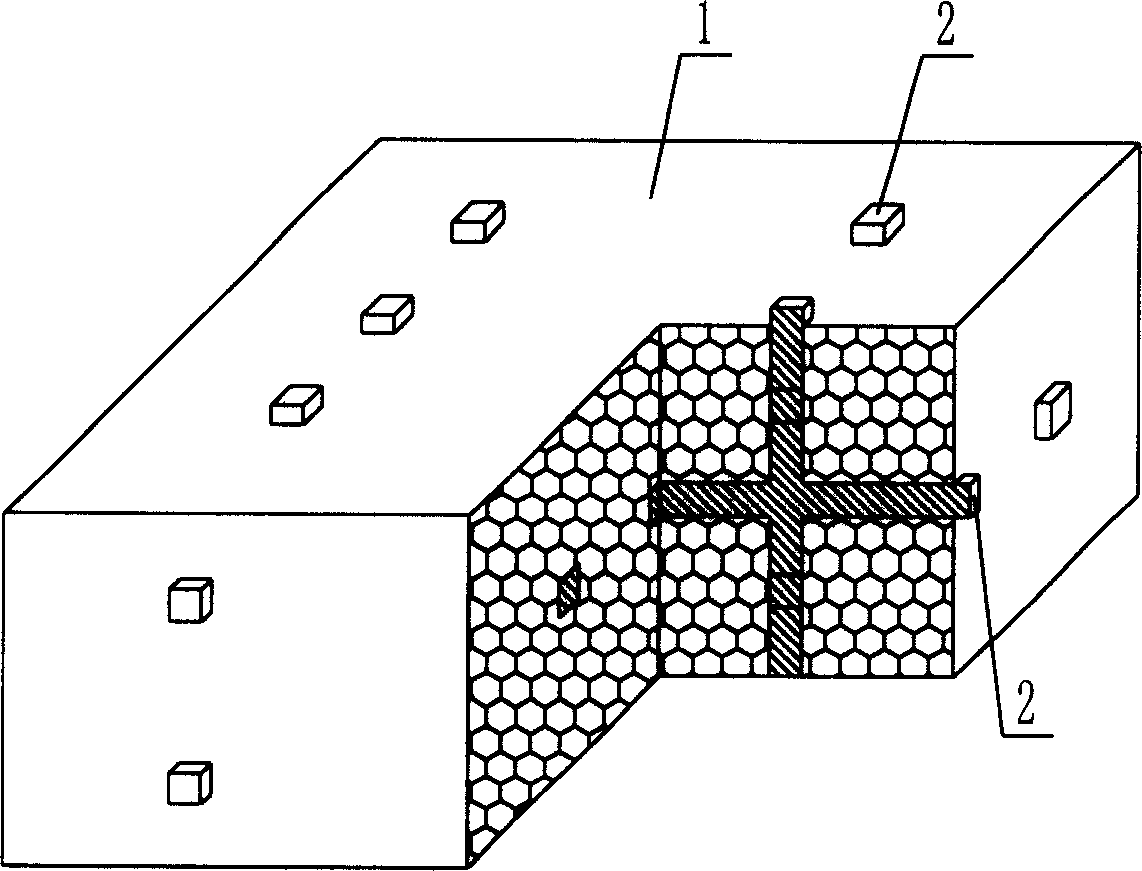

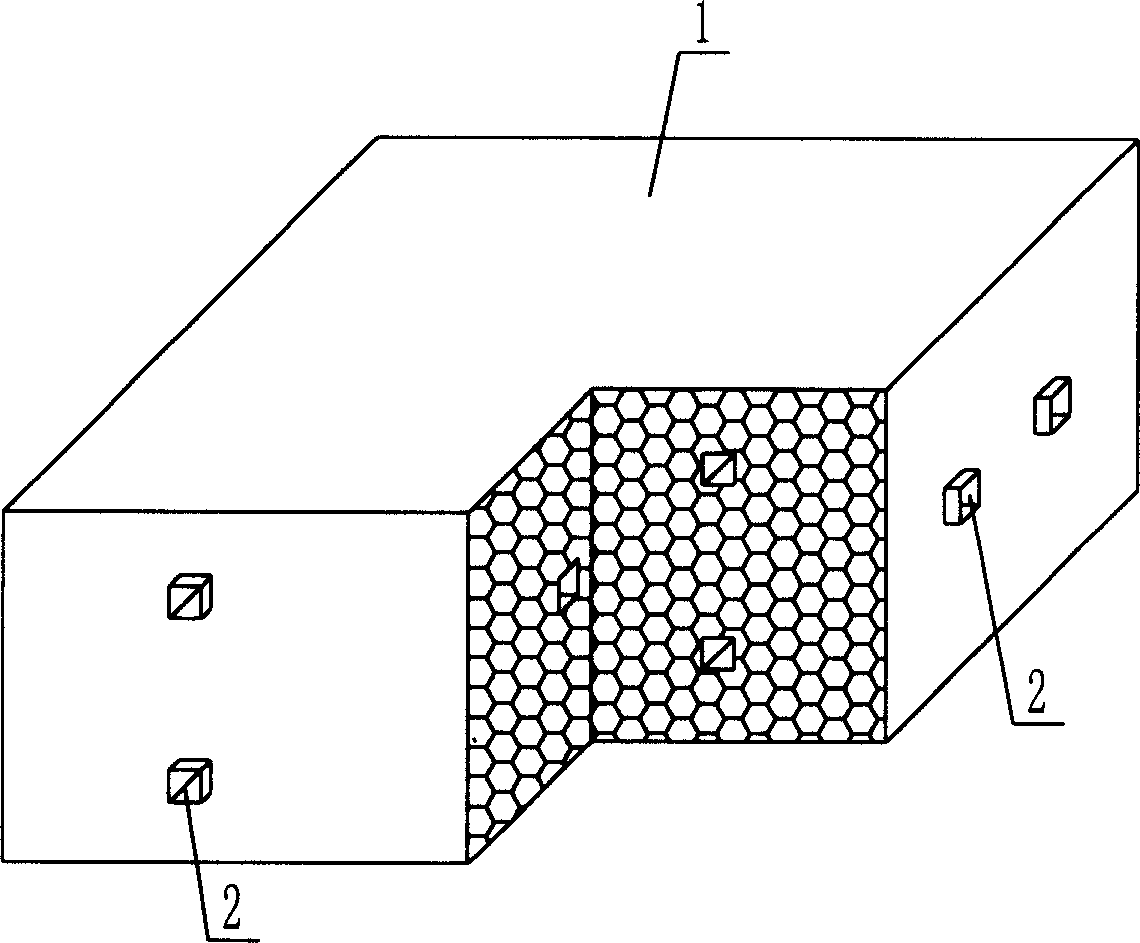

Component of light stuffing mould for concrete poured-in-situ

InactiveCN1598205AIt is convenient to obtain materials nearbyReduce manufacturing costFloorsSolid lightPre stress

A light mould component for concreting, which includes a polyhedron solid light material component, its character lies in: the mentioned polyhedron solid light material component contains at least one strengthening pole. Because of the strengthening pole, the intensity of the component is high, the rigidity is large, and it is not apt to be damaged; additionally, it has characters of simple structure, high intensity, deformation and vibration resisting, easy producing, low cost, and convenient construction. And the applications of the component are wide.

Owner:湖南邱则有专利战略策划有限公司

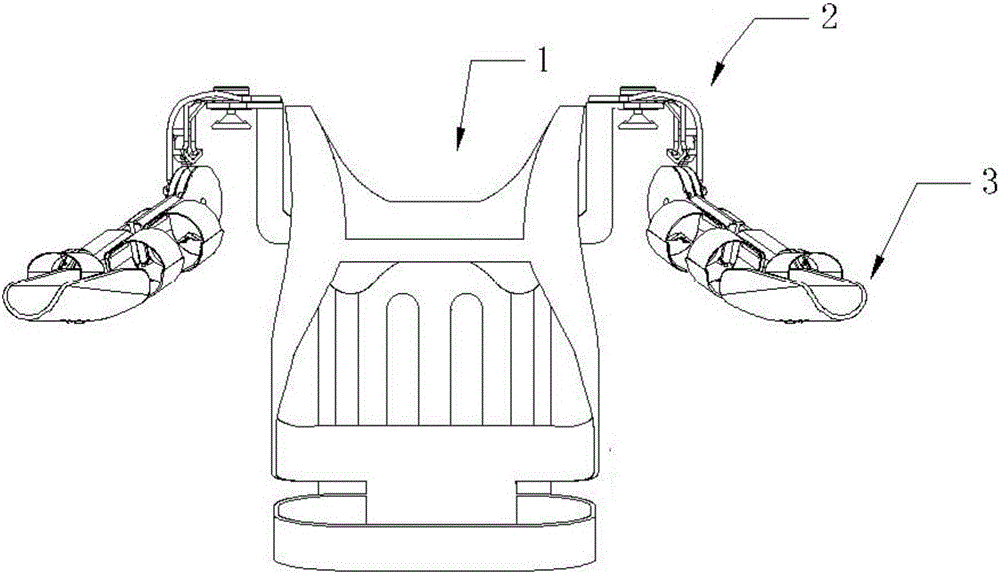

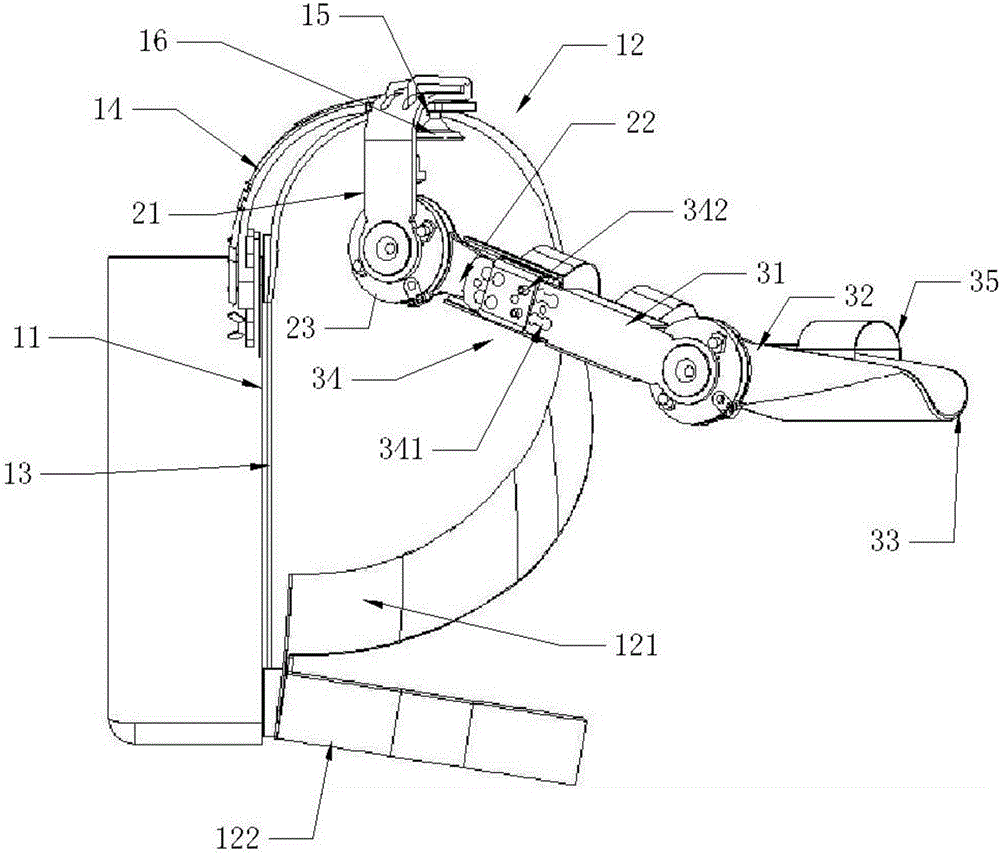

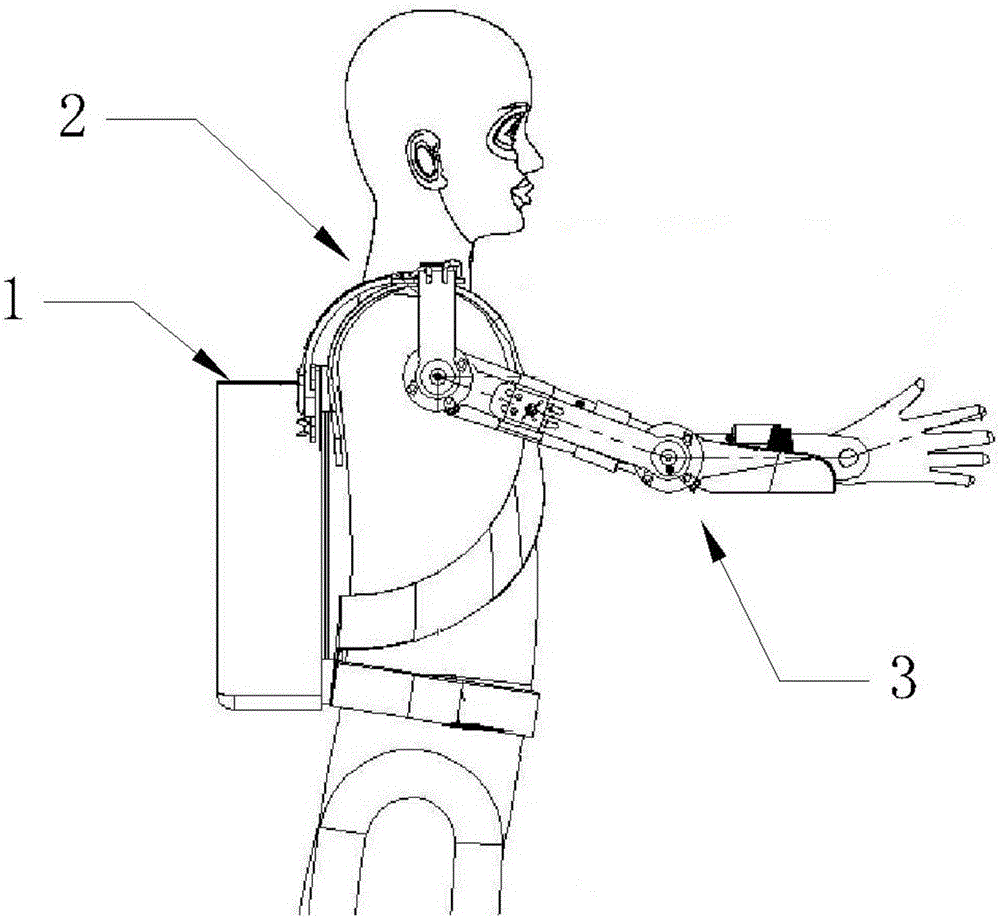

Portable and wearable exoskeleton upper limb robot

InactiveCN105963103ARealize bearerReduce work intensityProgramme-controlled manipulatorChiropractic devicesPower componentSacroiliac joint

The invention discloses a portable wearable exoskeleton upper limb robot, which has the following characteristics, including: a back module, which is used to carry a control system and a battery power component, and is used to realize the carrying function; two shoulder modules, The two shoulder modules are respectively arranged on the left and right sides of the back module, and each shoulder module is used to realize abduction or adduction at a certain angle in the horizontal plane of the human shoulder joint, and flexion or abduction at a certain angle in the sagittal plane. Stretching function: two elbow modules, the two elbow modules are respectively connected with the two shoulder modules, each of the elbow modules is used to realize the bending or extension of the human elbow joint at a certain angle. Using the portable wearable exoskeleton upper limb robot of the present invention can effectively reduce the cost, improve the environmental adaptability of the equipment, reduce the work intensity of the rehabilitation physician and improve the work efficiency, thereby ensuring the reliability of the equipment.

Owner:SHANGHAI ELECTRICGROUP CORP

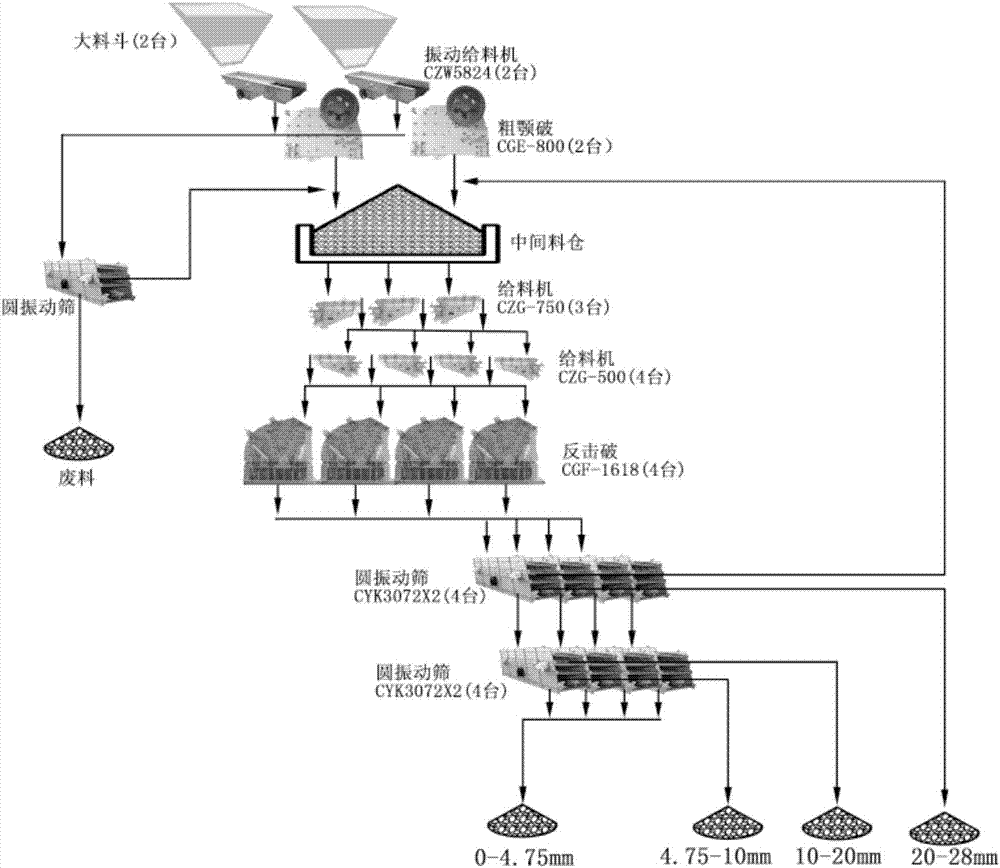

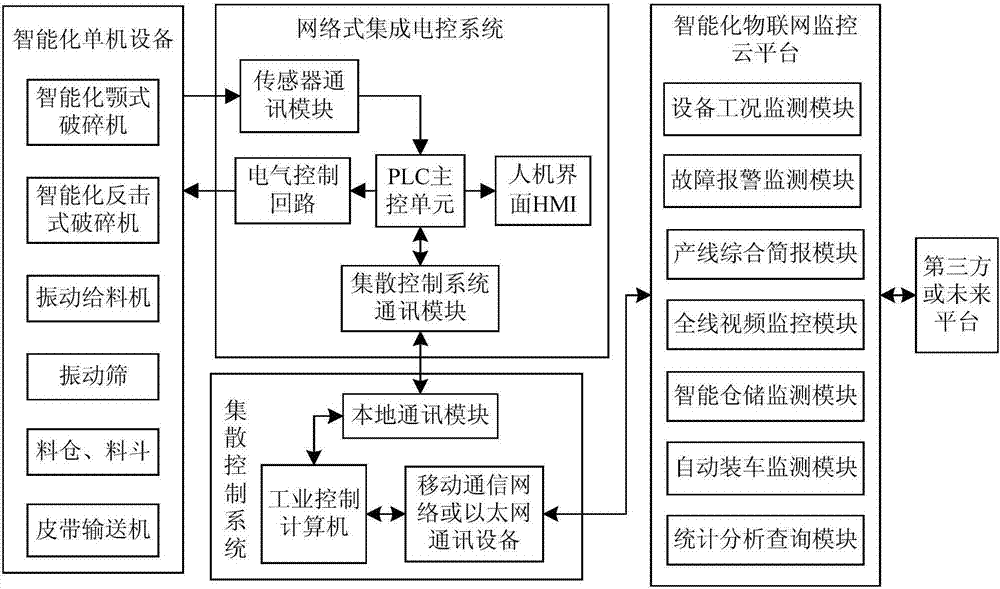

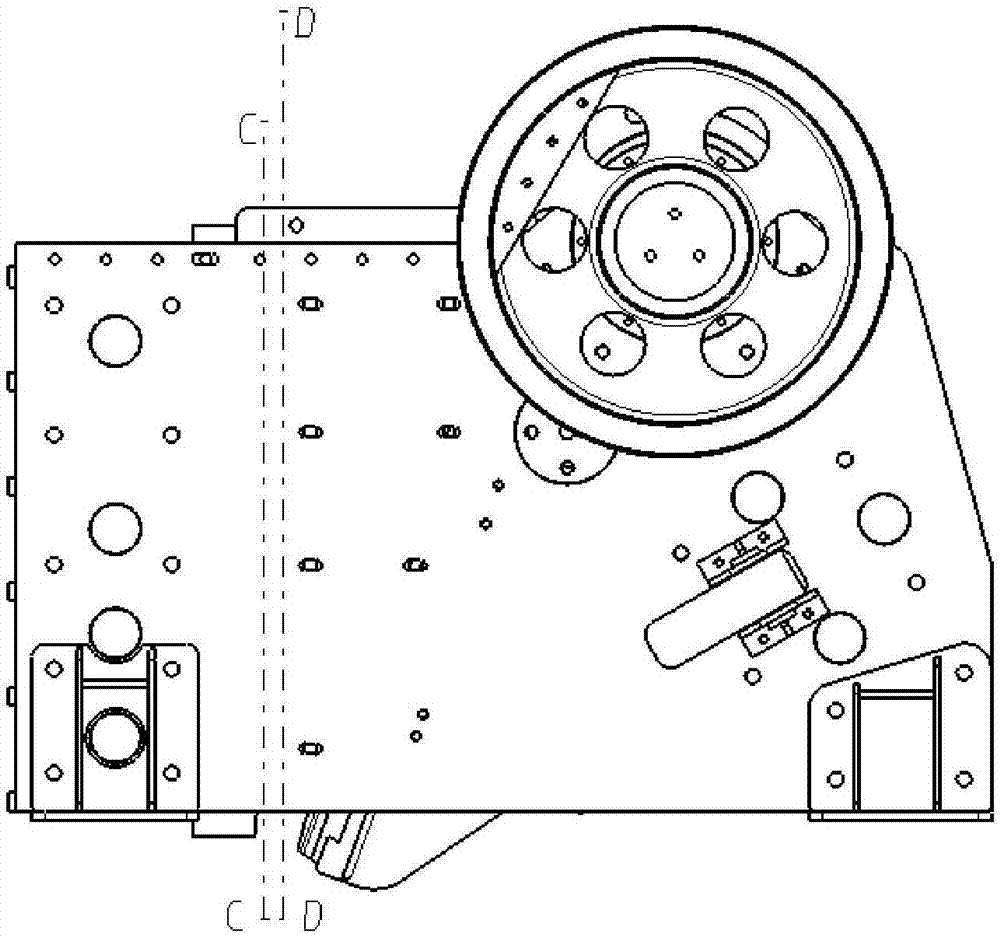

Intelligent gravel aggregate production line

ActiveCN107153410AIncrease the level of automationReduce work intensityTotal factory controlProgramme total factory controlProduction lineDowntime

The invention provides an intelligent gravel aggregate production line, and relates to the technical field of gravel aggregate production. The intelligent gravel aggregate production line comprises an intelligent jaw type crusher, an intelligent impact type crusher, a vibrating screen, a vibrating feeder, a material bin, a hopper, a belt conveyor, a control-related network type integrated electric control system, a distributed control system and an intelligent internet of things monitoring cloud platform, wherein various sensors are additionally arranged on the basis of an original crushing screening production line; sensor information is transmitted to the distributed control system through the network type integrated electric control system, so that automatic regulation and control on the production process is realized, and therefore, the sensor information is transmitted to the intelligent internet of things monitoring cloud platform; and production data storage and safety are managed in a unified mode on the basis of classifying and combing through cloud computation. The intelligent gravel aggregate production line has a fault early-warning function and a real-time alarm function, and quickly increases response speed; internet of things intelligent control and remote monitoring are introduced, the production process is automatically regulated and control, operation is performed with optimal load, the yield is increased, and downtime maintenance is reduced.

Owner:SHANGHAI UNITRUSTON INTELLIGENT TECH CO LTD

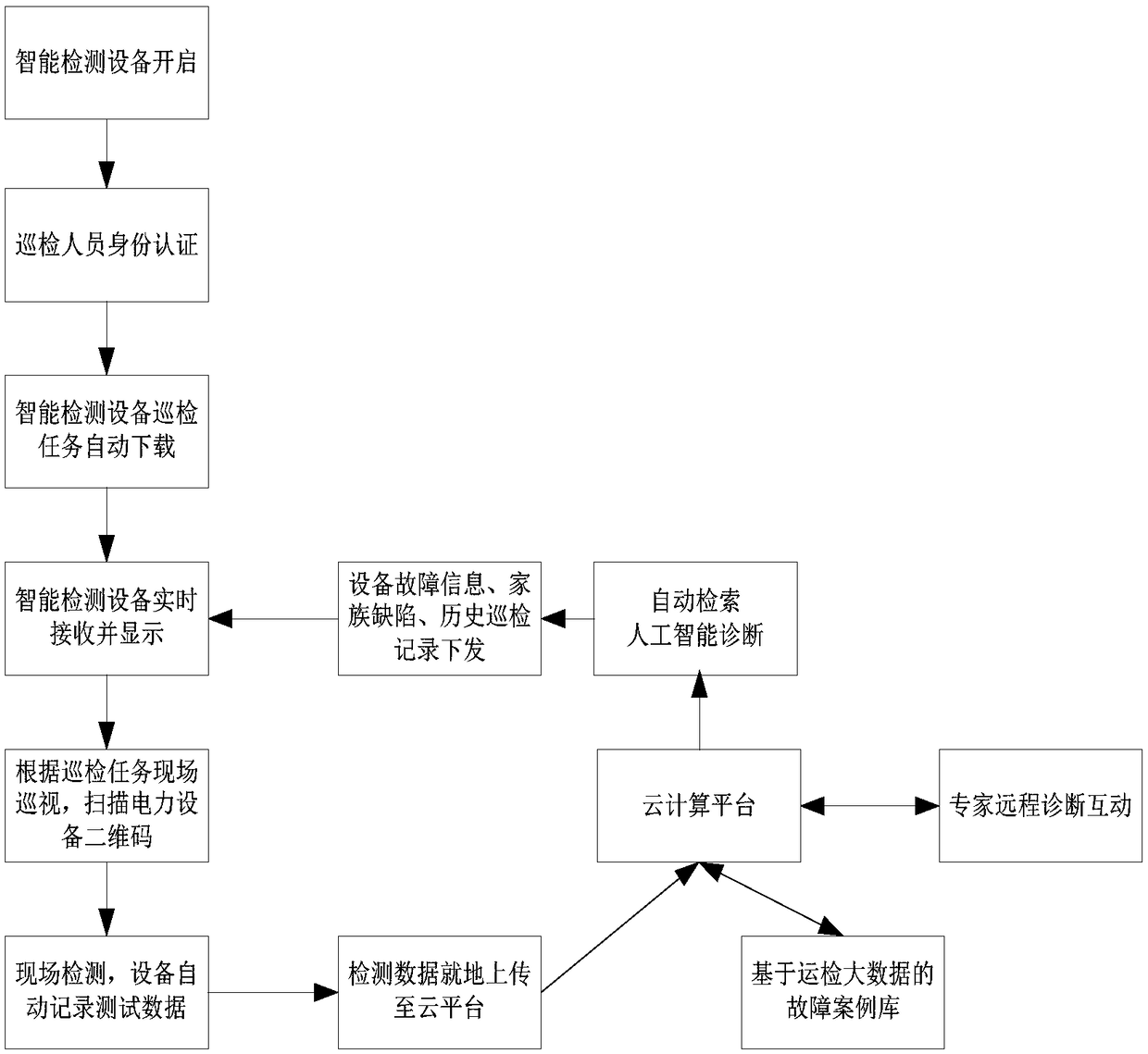

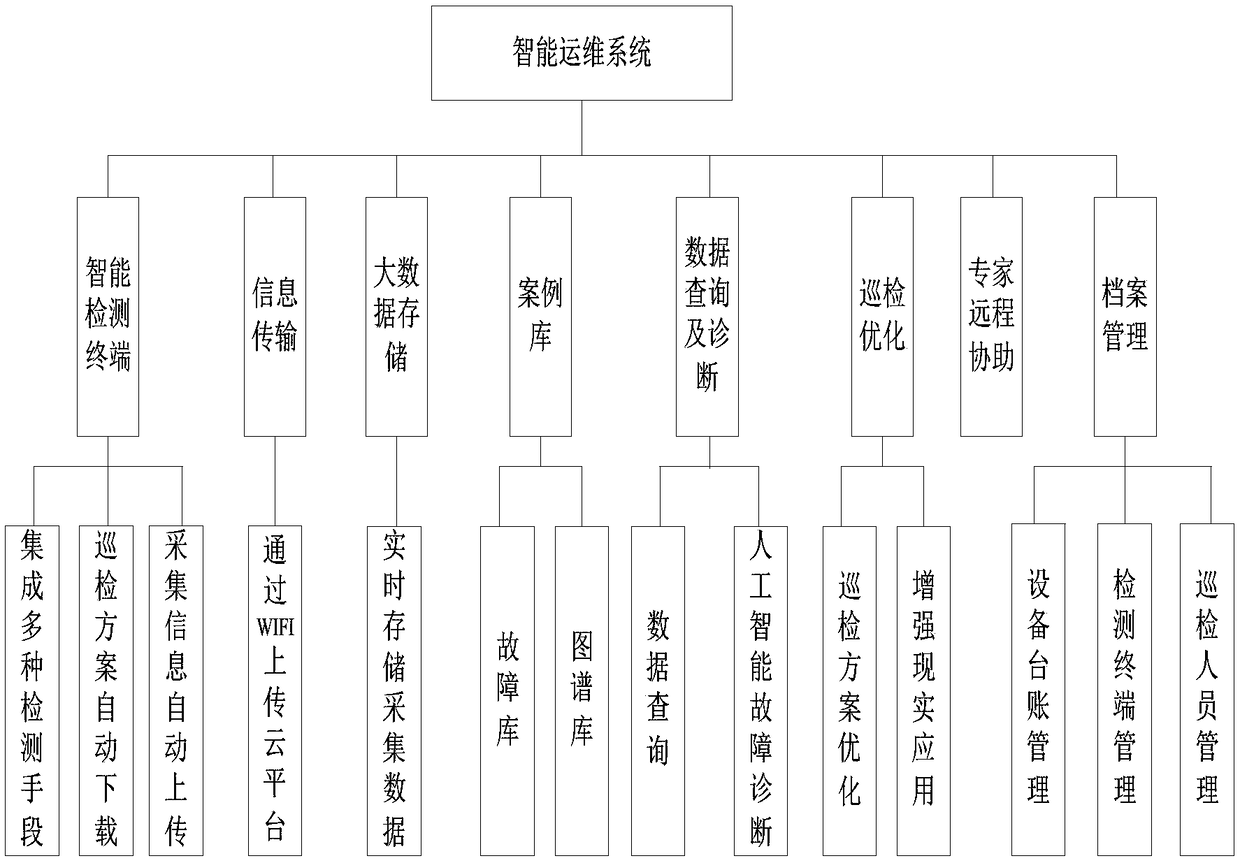

Intelligent maintenance system and method based on wearable augmented reality display terminal and cloud platform

InactiveCN108879440ARealize remote assistanceImprove predictive abilityCircuit arrangementsSustainable buildingsSimulationPower grid

The invention discloses an intelligent maintenance system and method based on a wearable augmented reality display terminal and a cloud platform. According to the intelligent maintenance system and method, an augmented reality technology-based infrared image intelligent identification, video collection and uploading of personnel operation scenarios and real-time conversation with a monitoring center on the scene are achieved, thereby guiding maintenance personnel to implement standard and normalized work process; an intelligent maintenance platform based on big data and artificial intelligenceis built to carry out inspection optimization, defect identification and fault diagnosis; and auxiliary information is transmitted to an intelligent terminal of site operation personnel to display inreal time through an augmented reality technology, so that the operation efficiency is improved, misoperation is avoided and the intelligent maintenance system and method can be applied to multiple power grid operation and maintenance scenarios.

Owner:JINING POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

Full-automatic venous blood sampling device

InactiveCN106510731ARelieve painLow experience requirementOrgan movement/changes detectionDiagnostics using spectroscopyThree degrees of freedomBlood sampling

The invention discloses a full-automatic venous blood sampling device which comprises a syringe needle positioning mechanism, a blood sampling point identifying and treating mechanism connected to the syringe needle positioning mechanism, and an arm fixing positioning mechanism and a needle replacing mechanism arranged on the syringe needle positioning mechanism. The syringe needle positioning mechanism comprises a lead screw transmission assembly, a ballscrew assembly and a three-degree-of-freedom mechanical arm. The lead screw transmission assembly comprises a fixed support and a stand column connected to the fixed support in a sliding mode. The ballscrew assembly is connected to the stand column and the three-degree-of-freedom mechanical arm, and used for driving the three-degree-of-freedom mechanical arm to move left and right. The three-degree-of-freedom mechanical arm comprises a fixing plate, a second mechanical arm body, a first mechanical arm body and a slide block, wherein the two ends of the first mechanical arm body are rotatably connected with the fixing plate and the second mechanical arm body correspondingly, the slide block is connected to the second mechanical arm body in a sliding mode, and a syringe needle is arranged on the slide block.

Owner:XIEHE HOSPITAL ATTACHED TO TONGJI MEDICAL COLLEGE HUAZHONG SCI & TECH UNIV +1

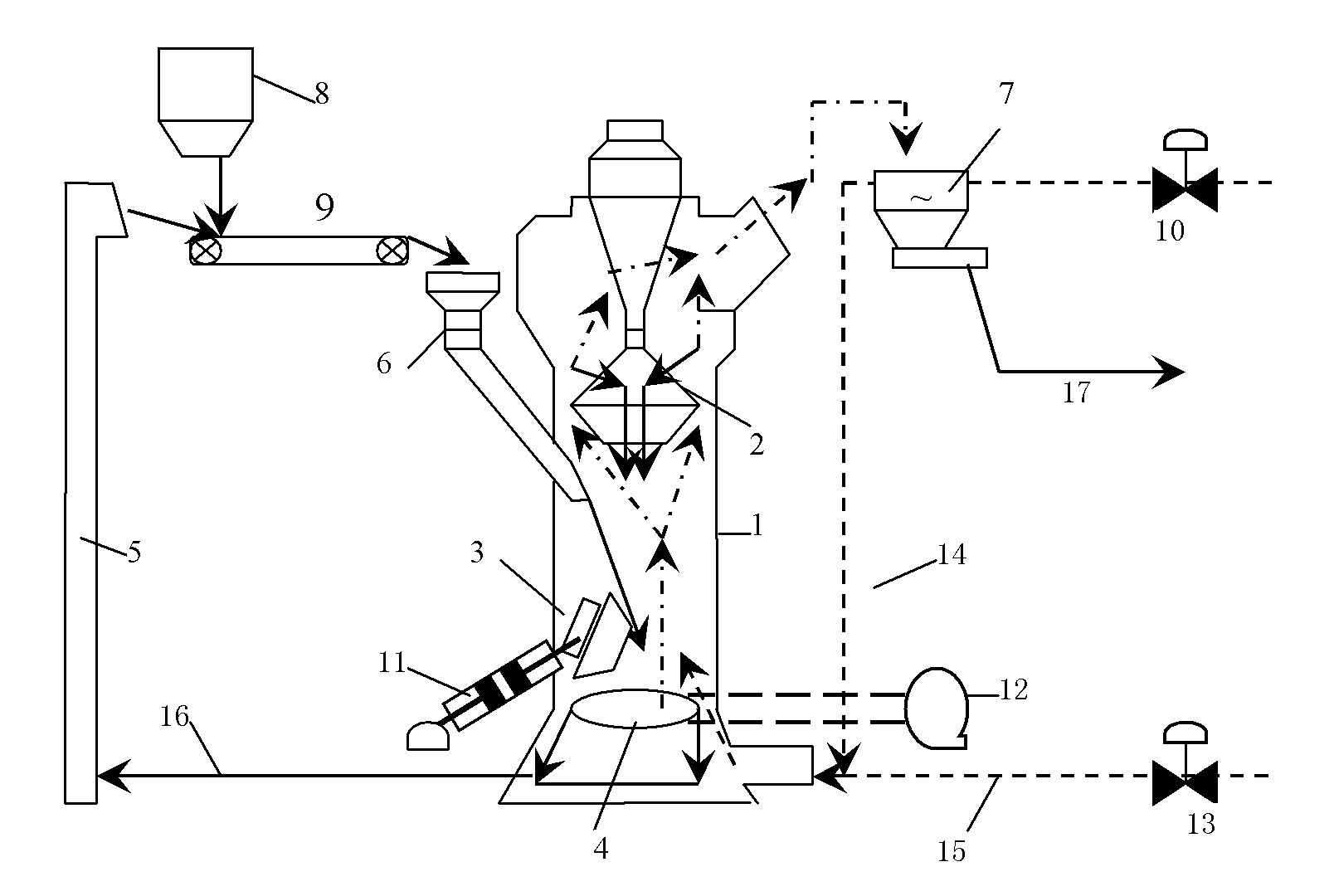

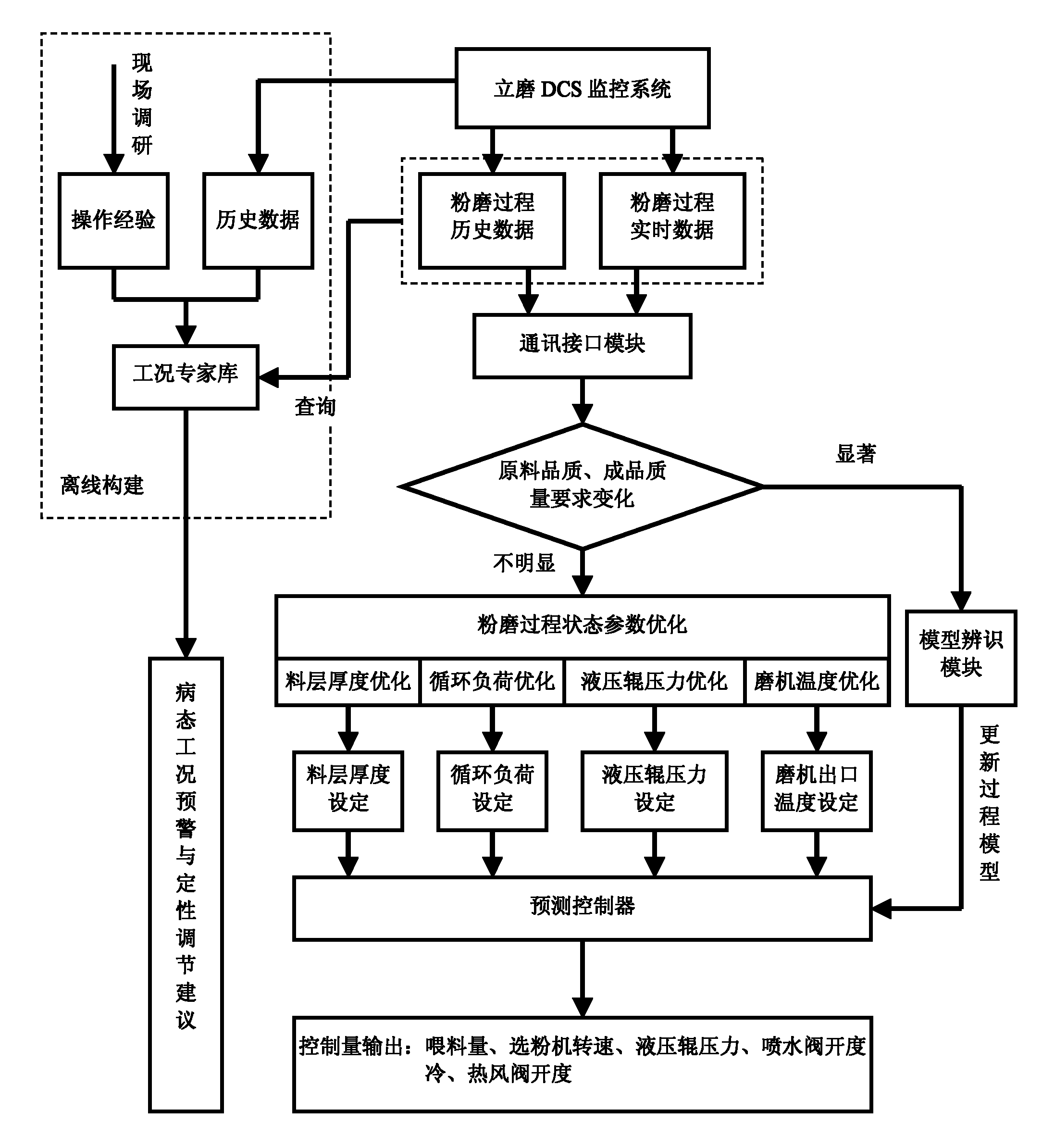

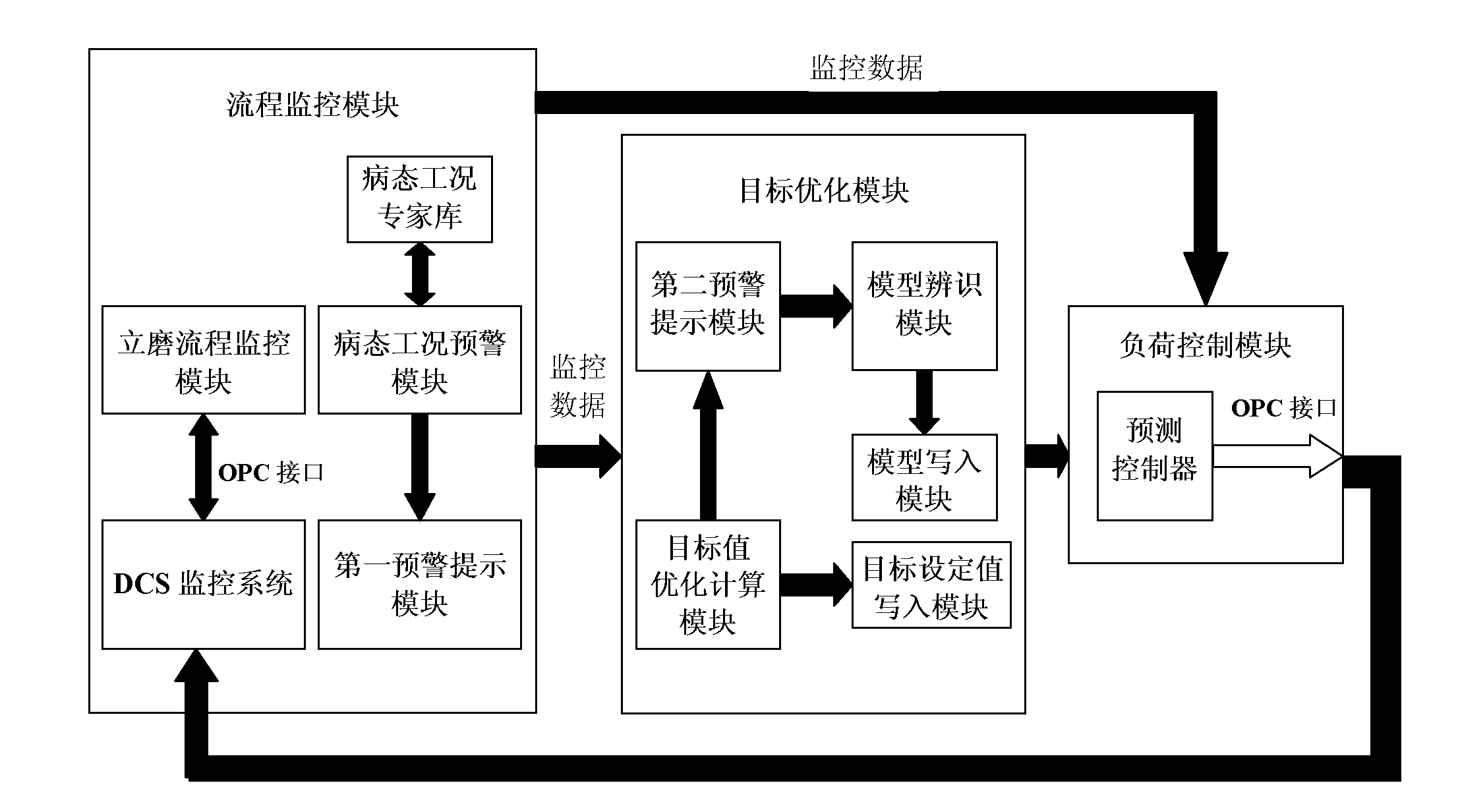

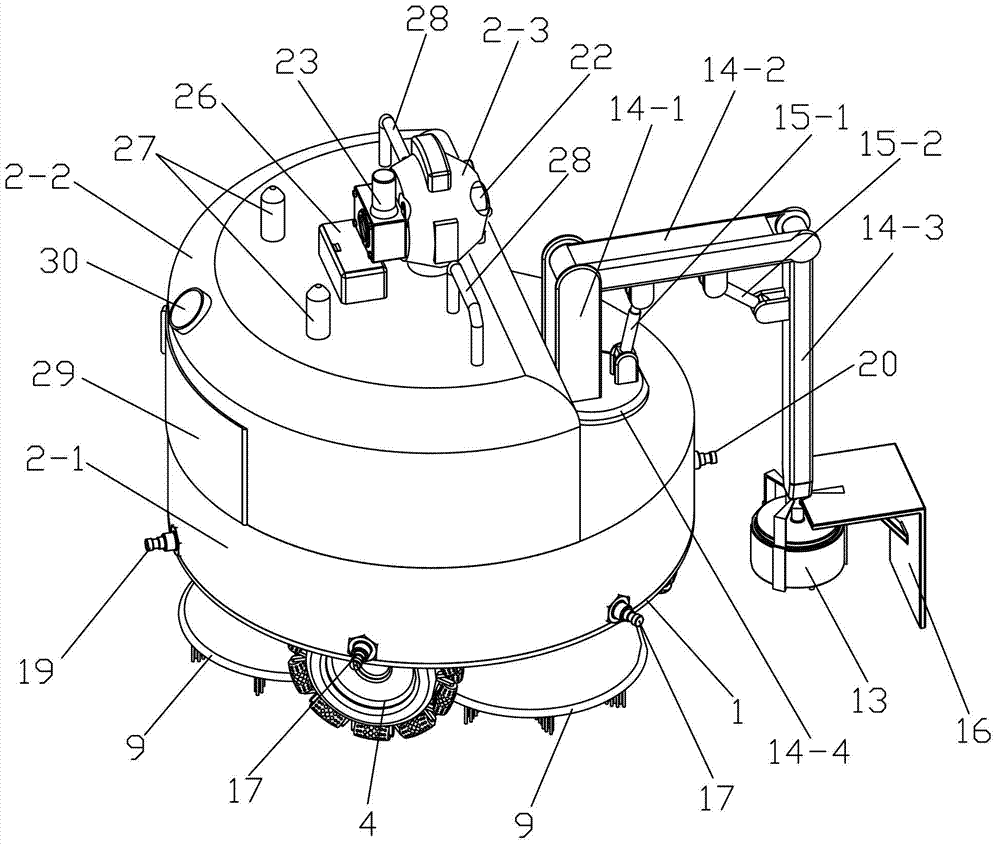

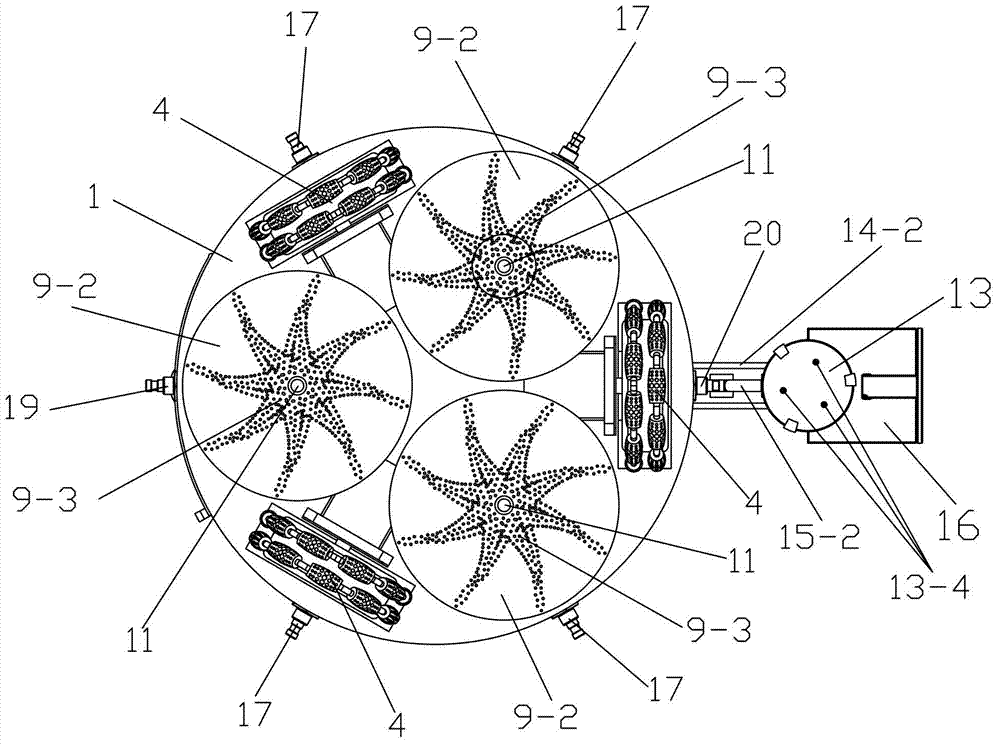

Advanced control method and system for vertical mill based on model identification and predictive control

InactiveCN102151605AIncrease the level of automationQuality improvementCement grindingCement productionMathematical modelOptimal control

The invention relates to raw material grinding in the field of cement process industries, and aims to provide an advanced control method and system for a vertical mill based on model identification and predictive control. The method comprises the following steps of: acquiring real-time data from a distributed control system (DCS) monitoring system; analyzing a variation trend of the operation and technology parameters, and then invoking a pathological working condition expert database for performing trend matching; if a pathological working condition appears, issuing early warning display and giving qualitative adjustment suggestion remind; giving an optimal target set value according to the basic operation condition of the vertical mill and the variation situation of the product quality requirement, and writing into a predictive controller; setting an optimal controlled quantity output according to the optimal target set value, and outputting to the DCS monitoring system to control a field actuator to take action. By adopting the invention, the qualitative adjustment suggestion can be precisely given; a mathematical model of the grinding process of the vertical mill is established and updated in real time; the steady-state error of the control system is reduced; and the grinding process of the vertical mill is instructed, so that the mill can operate stably for long term at a maximum efficiency point, and stable margin is maintained.

Owner:ZHEJIANG UNIV

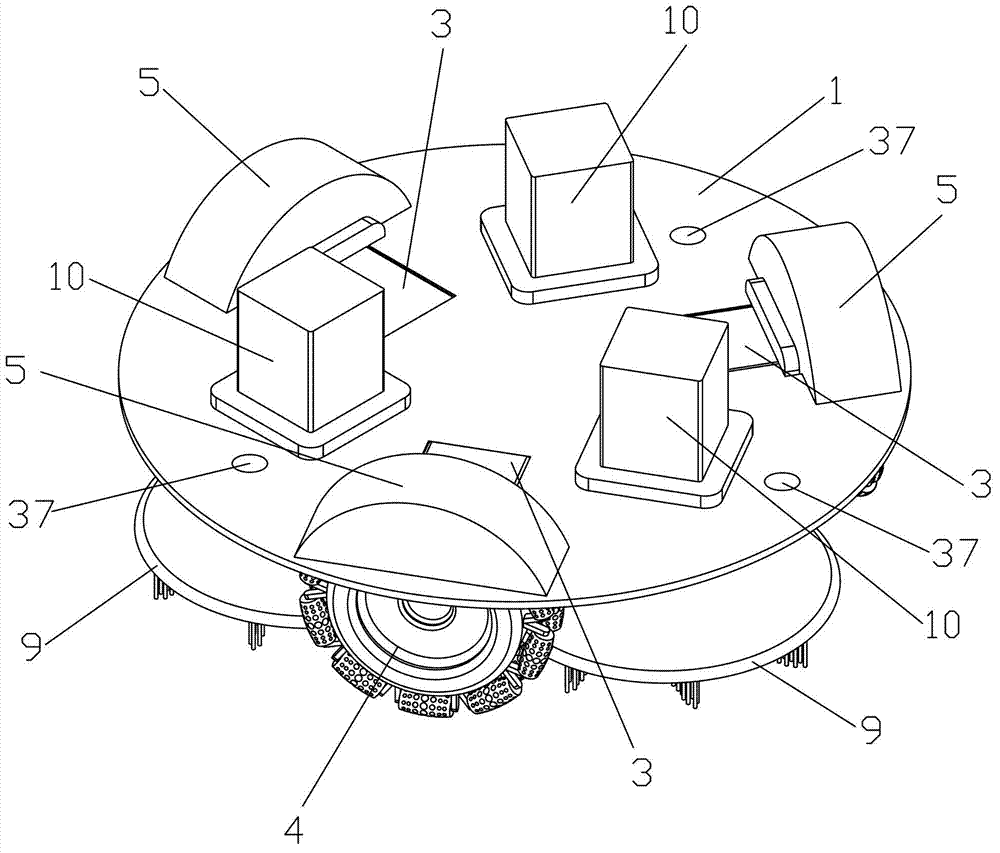

Oil tank cleaning robot

InactiveCN102764750ARealize all-round cleaningCompact structureHollow article cleaningDrive wheelUltrasonic sensor

The invention discloses an oil tank cleaning robot. The robot comprises a robot body, a walking unit, a cleaning unit, a control unit, a sensing communication unit and a power supply unit, wherein the robot body comprises a base plate, a lower casing and an upper casing, the walking unit comprises three driving wheels and three driving wheel hydraulic motors, the cleaning unit comprises a cleaning device and a self-excitation pulse device, the cleaning device comprises three cleaning disk brushes and three cleaning disk brush hydraulic motors, the self-excitation pulse device comprises a pulse device hydraulic motor, a retractable beam assembly and a self-excitation oscillating pulse nozzle, the control unit is composed of a remote control portion and a robot body control portion, and the sensing communication unit comprises a pressure sensor, a temperature sensor, an infrared sensor, an ultrasonic sensor, a horizontal attitude sensor, a turbidity sensor, a camera and an oil-gas concentration monitor. The robot is novel in design, high in intelligent degree, high in working reliability, good in safety performance, energy-saving, environment-friendly, high in practicability, high in popularization and application value and capable of achieving omni-directional cleaning.

Owner:周利坤

Clamp device with improved structure for processing glass mould

ActiveCN102350651BGuaranteed locking effectReduce work intensityPositioning apparatusMetal working apparatusEngineeringMechanical engineering

The invention discloses a clamp device with an improved structure for processing a glass mould, and belongs to the technical field of tooling clamps. The clamp device comprises a base, a first clamp platform fixed mount, a second clamp platform fixed mount, a first mould horizontal adjusting mechanism, a second horizontal adjusting mechanism, a clamp platform driving mechanism and a pair of horizontal adjusting mechanisms, wherein guide rail bars are arranged on two sides of the base respectively, a clamp platform fixed mount sliding seat is arranged between the guide rail bars, and a pair ofguide rails and a clamp platform moving chamber are formed on the clamp platform fixed mount sliding seat respectively; the first clamp platform fixed mount and the second clamp platform fixed mount are positioned on the base, a first acting cylinder and a second acting cylinder are fixed at two ends of the first clamp platform fixed mount and the second clamp platform fixed mount respectively, afirst clamp platform fixed seat and a second clamp platform fixed seat are fixed in the middle parts of the first clamp platform fixed mount and the second clamp platform fixed mount respectively, and a first clamp platform and a second clamp platform are fixed on the first clamp platform fixed seat and the second clamp platform fixed seat respectively; the first mould horizontal adjusting mechanism and the second mould horizontal adjusting mechanism are arranged on the first clamp platform fixed mount and the second clamp platform fixed mount; the clamp platform driving mechanism is arrangedon the base; the two horizontal adjusting mechanisms are arranged on a pair of guide rail bars; and the clamp platform driving mechanism comprises a box body, a handle plate, a handle, a screw rod and a clamp platform locking device. The clamp device has the advantages that: once clamping is embodied, the operating strength is reduced, and the working efficiency is improved.

Owner:CHANGSHU JIANHUA MOLD TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com