Five-degree of freedom stacking manipulator

A technology of manipulators and degrees of freedom, applied in the direction of manipulators, program-controlled manipulators, conveyor objects, etc., can solve the problems that palletizing manipulators do not have five free manipulators, complex structure, and high cost, so as to improve convenience and reduce production Cost, the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

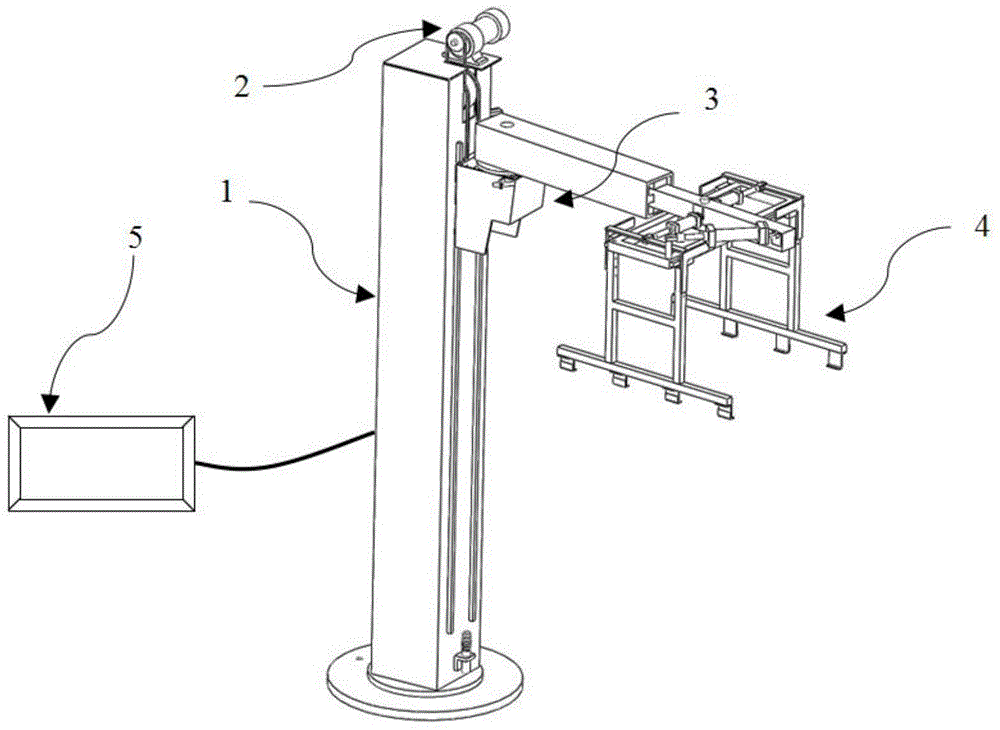

[0031] Such as Figure 1-12 As shown, the five-degree-of-freedom palletizing manipulator of the present invention includes a combined column 1, a lifting component 2, a rotating component 3, a clamping component 4 and a hand-held controller 5;

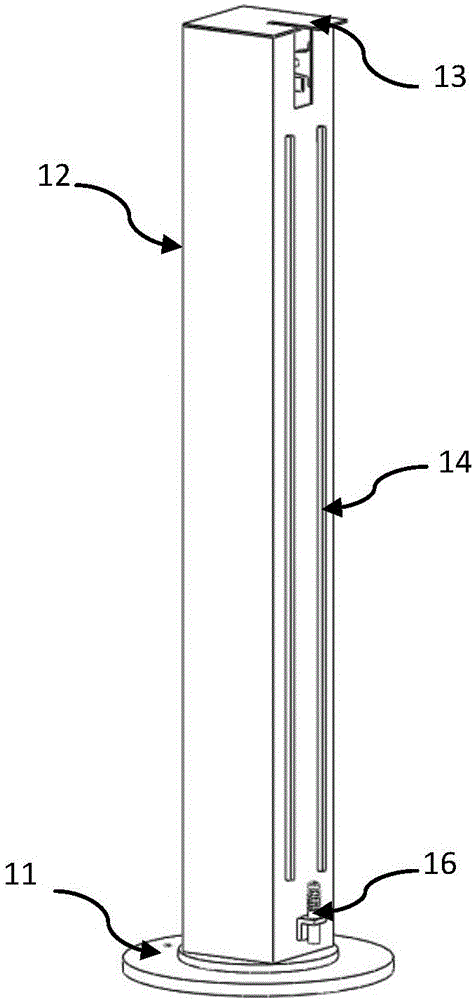

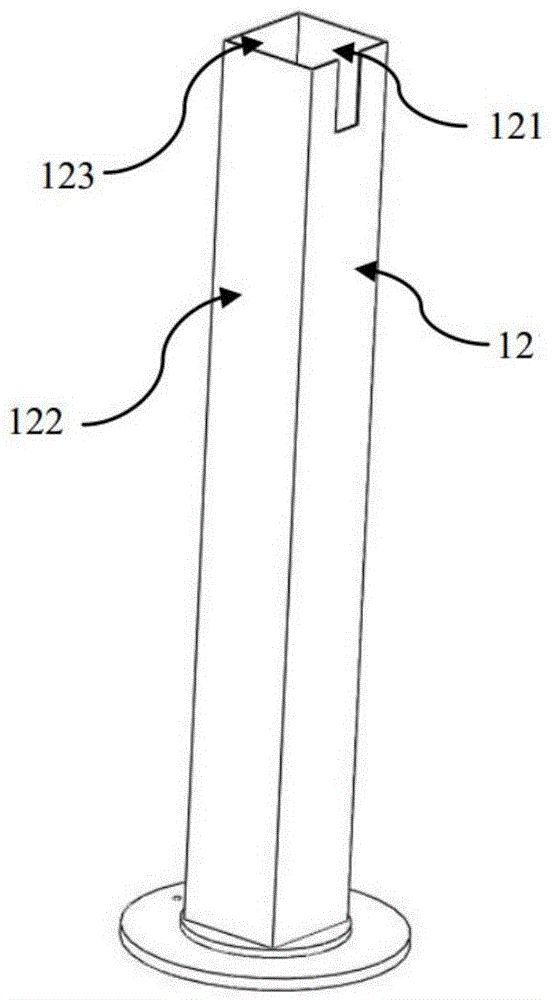

[0032] Wherein, the combined column 1 comprises a circular base 11, a square tube 12 vertically fixedly installed on the circular base 11 and a cover plate 13 horizontally sealed on the top of the square tube 12; on the left side of the square tube 12 The side inner wall 122 and the right side inner wall 121 are respectively vertically provided with a relative semicircular guide rail 15; the front side outer wall of the square tube 12 is vertically provided with a lifting guide rail 14;

[0033]The lifting assembly 2 includes a drive motor 21, a chain wheel set 23, an upper chain 24, a left chain 26, a right chain 25, a traction weight 27 and a sliding housing 28; the drive motor 21 is fixedly installed on the cover plate 13; the sproc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com