Oil tank cleaning robot

A technology for cleaning robots and oil tanks, applied to cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as insufficient safety performance, inability to clean sludge, inconvenient use and operation, etc., and achieve compact structure and convenience Portable and mobile, easy to collect effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

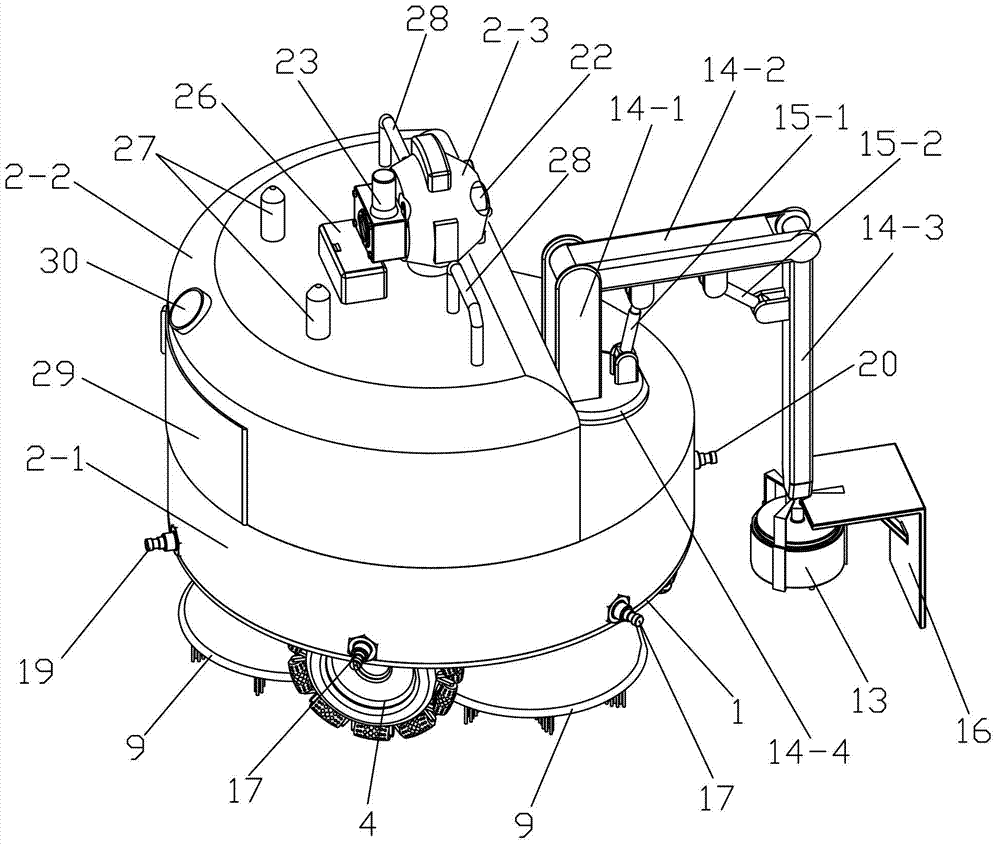

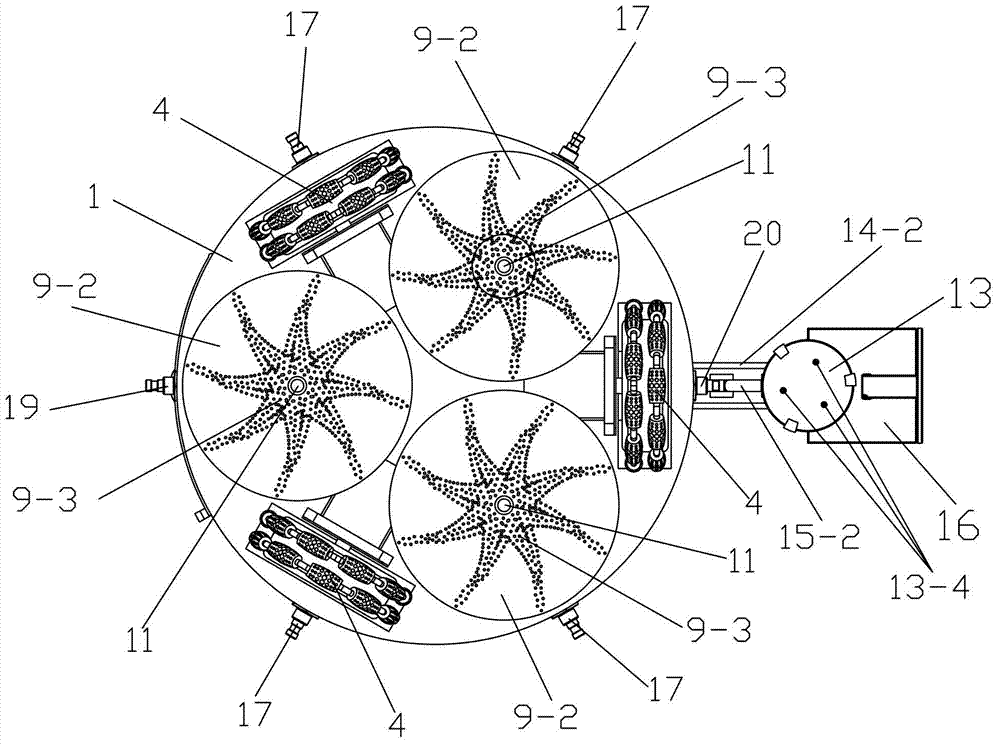

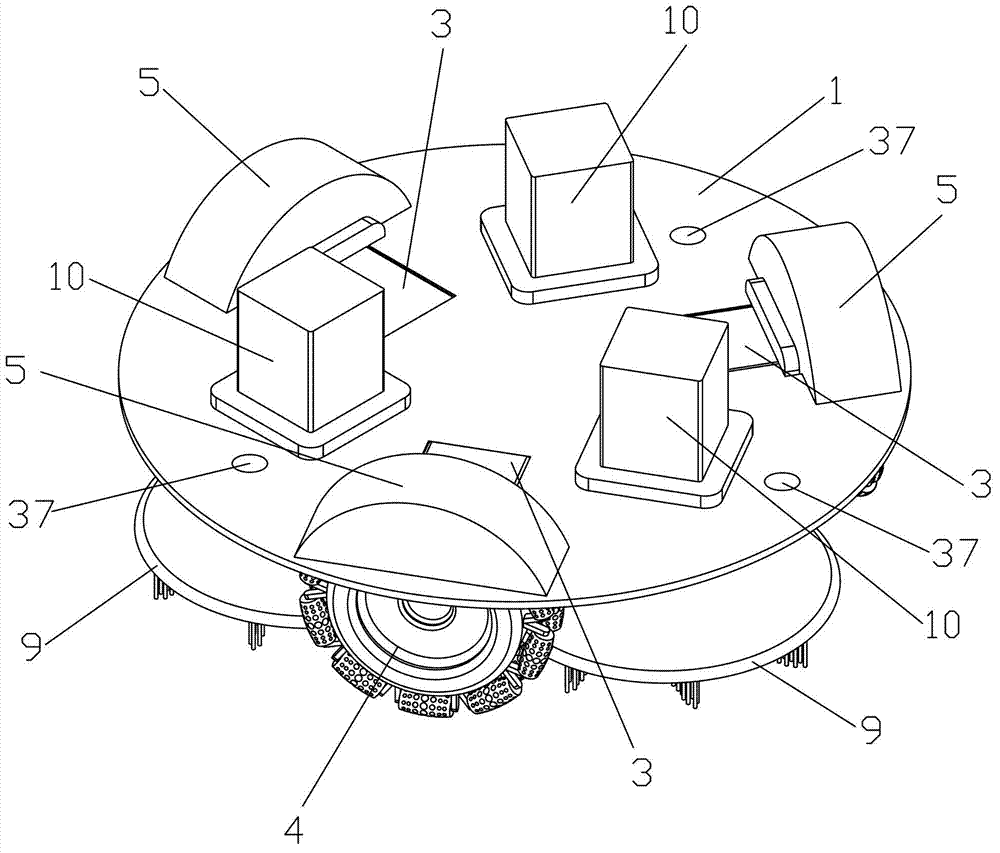

[0081] Such as figure 1 , figure 2 and image 3 As shown, the present invention includes a body, a walking unit, a cleaning unit, a control unit and a sensor communication unit, and a power supply unit for supplying power to the walking unit, cleaning unit, control unit and sensor communication unit;

[0082] The body includes a base plate 1, a lower shell 2-1 fixedly connected above the base plate 1, and an upper shell 2-2 fixedly connected above the lower shell 2-1;

[0083]The walking unit includes three driving wheels 4 and three driving wheel hydraulic motors 3 respectively used to drive the three driving wheels 4, and the three driving wheels 4 are embedded and installed on the base plate 1 in an equilateral triangle shape, The three driving wheel hydraulic motors 3 are arranged on the base plate 1 in an equilateral triangle, the driving wheel 4 is connected to the output shaft of the driving wheel hydraulic motor 3, and the driving wheel 4 is sleeved with The water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com