Model cleaning device based on photocuring 3D printing

A 3D printing and cleaning device technology, applied to 3D object support structures, metal processing equipment, manufacturing tools, etc., can solve the problems of cumbersome manual cleaning process, influence of model accuracy, pollution of operators and operating environment, etc., and achieve cleaning process Convenient and fast, ensure the overall accuracy, and prevent the effect of alcohol splash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

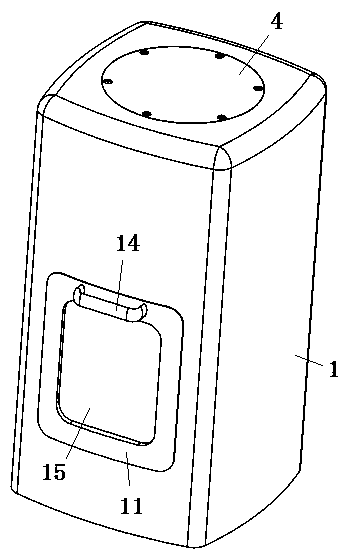

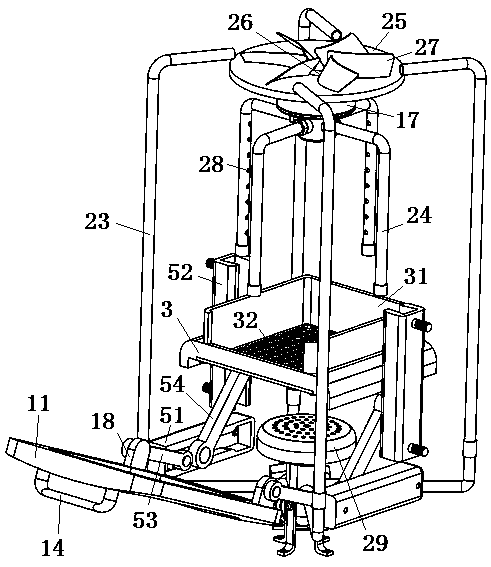

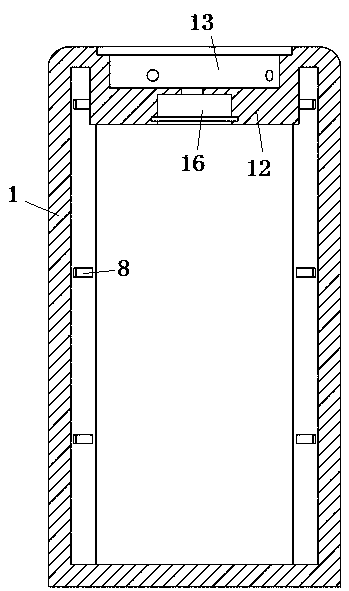

[0039] Embodiment 1: as Figure 1-5As shown, a model cleaning device based on light-curing 3D printing includes a housing 1, a cleaning mechanism 2, and a loading table 3; The top end extends downwards to form an installation part 12, and an installation groove 13 is provided above the installation part 12; the cleaning mechanism 2 includes a water pump 21, a flow divider 22, a liquid inlet pipe 23, a liquid outlet pipe 24 and an impeller 25; the water pump 21 The bottom end of the housing 1 is fixedly connected by bolts. The lower part of the flow divider 22 is fixedly connected with four brackets by bolts. The brackets are fixedly connected to the bottom end of the housing 1 by bolts. To the inner bottom of the housing 1, the liquid outlet of the water pump 21 is fixedly connected to the joint at the bottom of the flow divider 22 through a pipeline. In this embodiment, the water pump 21 can be used for diving, and its model is HQB-2200; The interior of the installation groo...

Embodiment 2

[0045] Embodiment 2: This embodiment is different from Embodiment 1. The difference is that in Embodiment 1, when cleaning the model, only the surroundings and the top of the model can be cleaned, but the bottom of the model cannot be cleaned; while in this embodiment , can avoid the above defects, specifically:

[0046] The cleaning mechanism 2 also includes a shower head 29; the shower head 29 is screwed to the top of the flow divider 22, and is located below the material placement platform 3, and the material placement platform 3 is provided with several through holes 32; When the present embodiment is working, the alcohol branch is sprayed upwards from the shower head 29 at the bottom of the material placing table 3, so as to achieve the purpose of all-round cleaning.

[0047] Apart from this, this embodiment is completely the same as Embodiment 1, which will not be repeated here.

Embodiment 3

[0048] Embodiment 3: This embodiment is a further improvement of Embodiment 2. The main improvement is that when placing the model in Embodiment 2, the model is likely to interfere with the drain pipe, which is troublesome to use; and in this embodiment, The above drawbacks can be avoided, specifically:

[0049] It also includes a lifting mechanism 5; the lifting mechanism 5 includes symmetrically arranged slideways I51, slideways II52, connecting rods I53, connecting rods II54, sliders I55 and sliders II56, and the slideways I51 are laterally fixedly connected by bolts The lower part of the inner wall of the housing 1 on both sides adjacent to the door 11, the slideway II52 is vertically fixedly connected to the inner wall of the housing 1 above the slideway I51 by bolts, and the slider I55 and the slider II56 are slidably connected to the slideway I51 and the slideway I51 respectively. In the inner chute of track II52, the size of slider I55 and slider II56 is smaller than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com