Patents

Literature

651results about How to "Prevent curing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Jettable compositions

ActiveUS20050171237A1Prevent long-term corrosionReaction is slowAdditive manufacturing apparatusLiquid surface applicatorsMeth-Oligomer

A fully curable jettable composition having a viscosity less than 30 cps at a temperature within the range of 15-180° C., more preferably at a temperature of 15-100° C., e.g. 60-80° C. the composition comprising: (A) at least one low viscosity reactive resin selected from the group consisting of compounds containing an oxetane ring, cycloaliphatic epoxy resins, tetrahydrofurans, hexahydropyrans and mono-functional (meth)acrylates, said resin having a molecular weight of not greater than 300 Daltons, e.g. 250 Daltons or less, and a viscosity at a temperature in the said range of less than 30 cps, e.g. 5 to 15 cps; (B) at least one higher viscosity resin selected from the group consisting of epoxy resins, compounds containing an oxetane ring and acrylates, which resin acts to thicken the low viscosity resin and strengthen a jetted deposit of the composition, the higher viscosity resin having: a viscosity greater than twice that of the low viscosity resin at the said temperature in the range stated above, and a functionality of greater than or equal to 2; (C) at least one curable toughener, preferably having a functionality of at least 2, such as hydroxy, epoxy, acrylic or other reactive functionalised polymer / oligomer (e.g. derived by functionalising poly(tetrahydrofuran), polycaprolactone, polycarbonate diol, or a dendrimeric polyol; (D) at least one initiator for the polymerisation of the resins, and (E) at least one stabiliser for delaying the curing of the resins of the composition; wherein the low viscosity resin is slower to react than the higher viscosity resin and acts to solvate the higher viscosity resin prior to curing and at least partly during curing and wherein at least 30% of the components A and B are cationically curable resins. The composition can be jetted from piezo electric printing heads under the control of a computer program to form a multi-layered article, e.g. a three dimensional article, in which the adjacent droplets merge and are cured homogeneously together.

Owner:3D SYST INC +1

Method for supplementing the diet

InactiveUS6579544B1Increased susceptibilityPrevent diseaseHeavy metal active ingredientsBiocideDietary supplementAlpha-Lipoic Acid

A dietary supplement blend composition is disclosed, the basic formulation of the composition containing vitamins, minerals, and carotenoids. The composition can also contain bioflavonoids, cartilage protectors such as glucosamine or chondroitin, alpha-lipoic acid, coenzyme Q10, and a source of omega-3 fatty acids such as flax seed oil. The composition is beneficial for improving health and preventing disease, particularly for degenerative conditions. A method for supplementing the diet is also disclosed, wherein the quantity of daily rations of the dietary supplement blend composition is determined based on the person's age, body weight, and quality of diet.

Owner:NUTRIEX

Ink composition

The present invention provides an ink composition comprising at least a polymerizable compound, a photo-polymerization initiator and a polymerization accelerator, wherein the polymerizable compound comprises an N-vinyl compound, the photo-polymerization initiator comprises two or more compounds selected from the group consisting of bisacylphosphine oxides, monoacylphosphine oxides and α-amino ketones, and the polymerization accelerator comprises fine particles having a polymerizable functional group. The ink composition of the invention may be a transparent ink composition containing no coloring material. The ink composition of the invention may further contain a fluorescent whitening agent.

Owner:SEIKO EPSON CORP

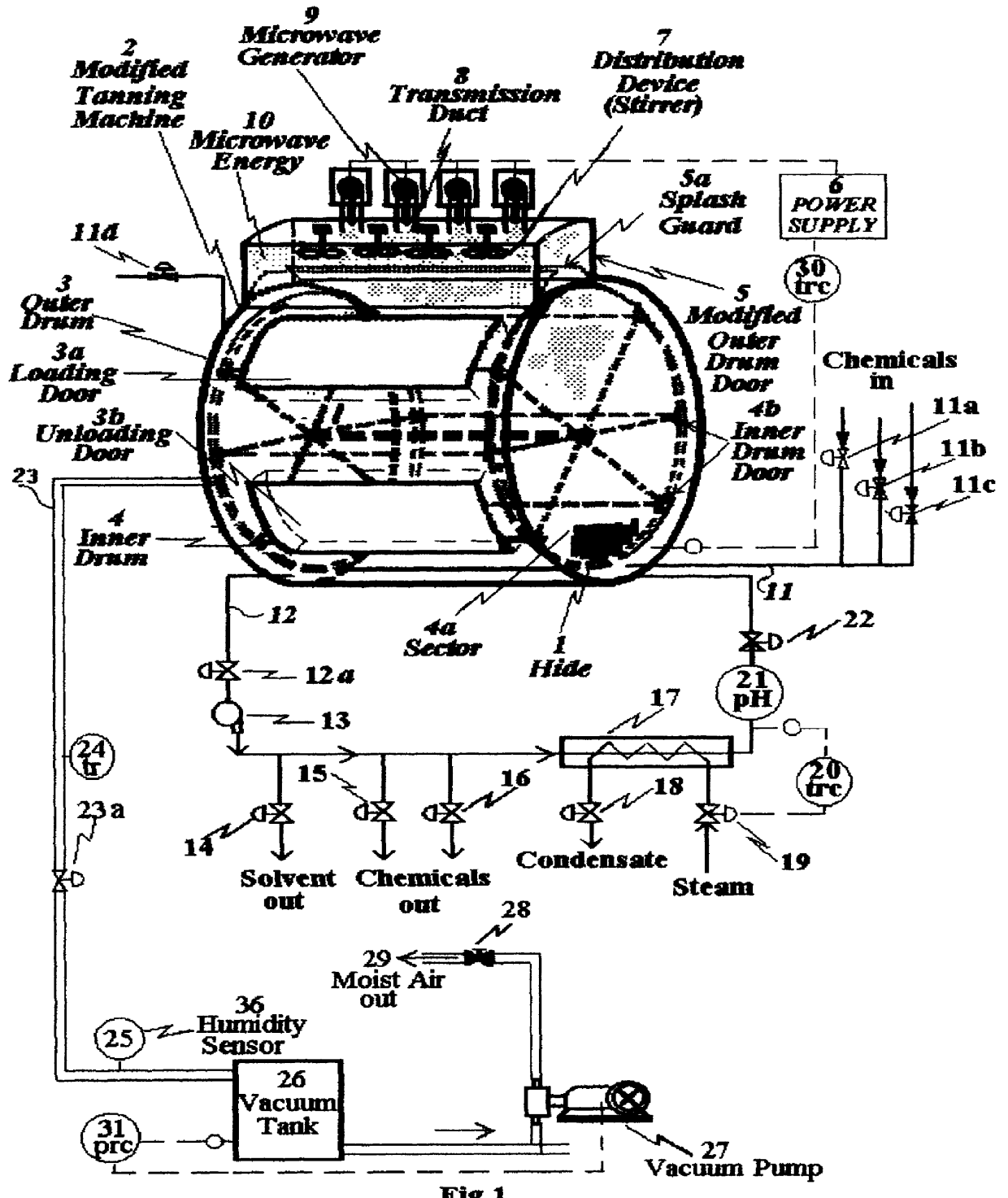

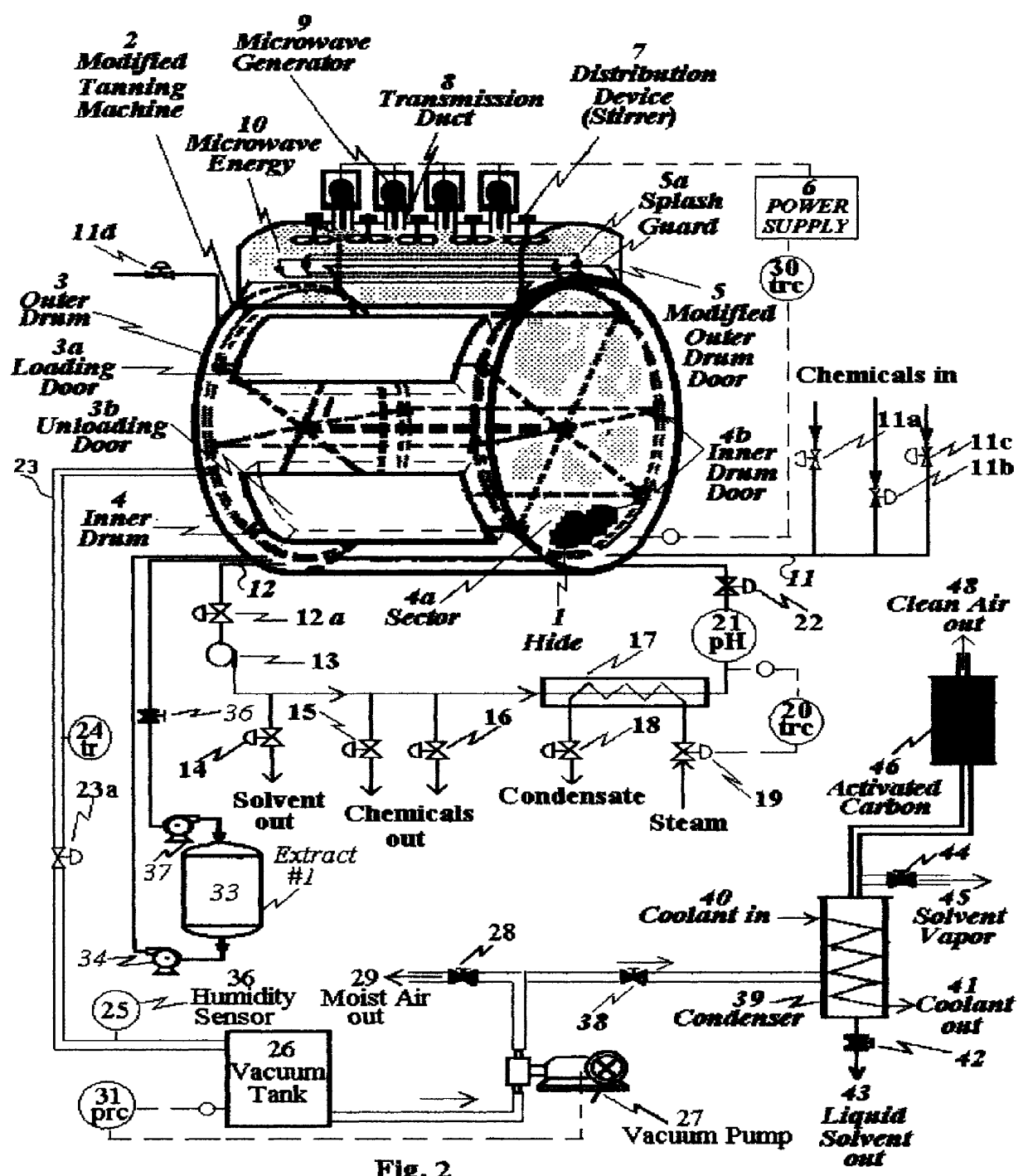

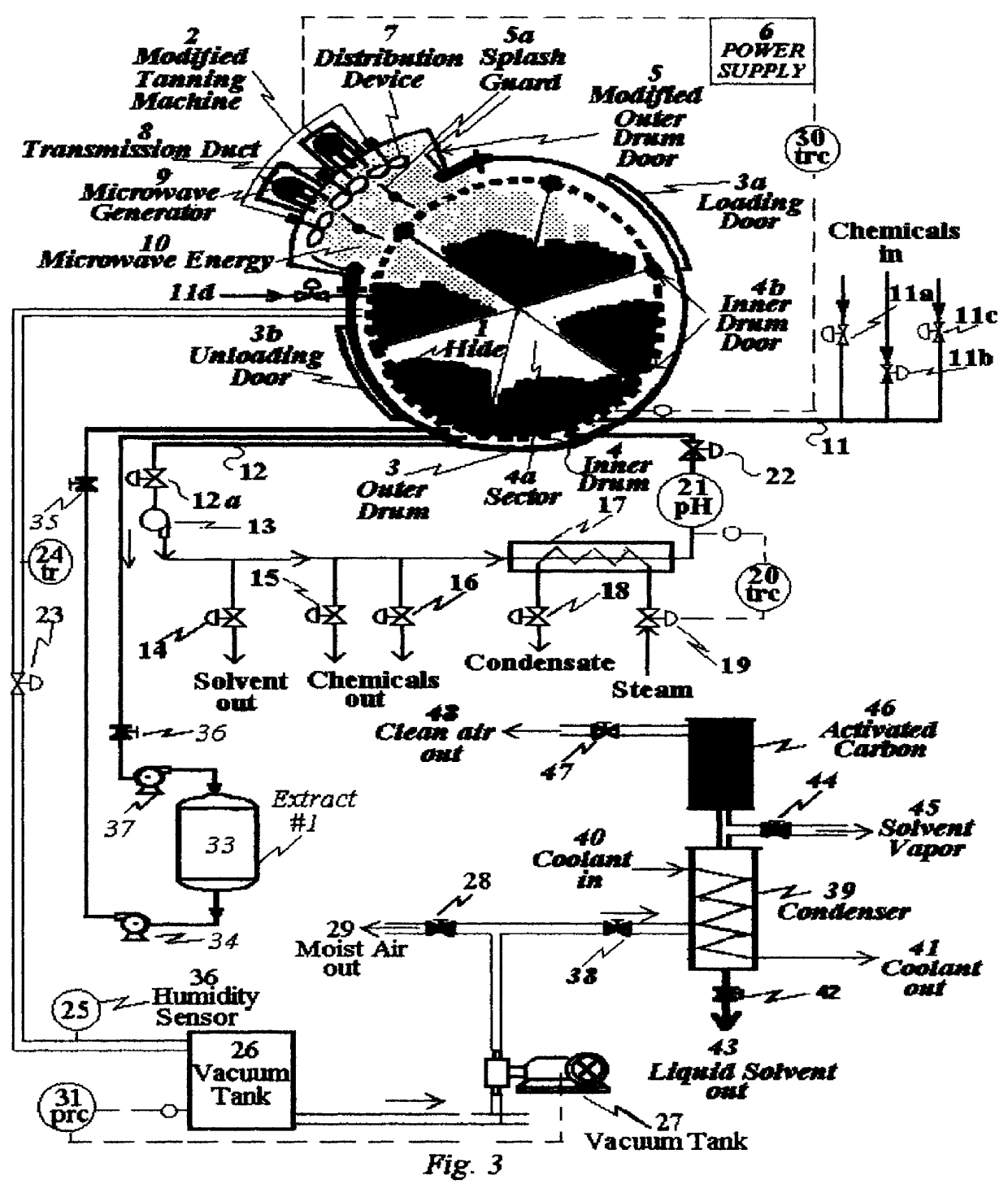

Microwave drying of hides under vacuum in tanning equipment

InactiveUS6092301AHigh market valueQuality improvementDrying solid materials with heatDrying solid materials without heatWater contentSolvent

By providing a hide processor or tanning drum with appropriate equipment for applying vacuum and microwave energy concurrently, these tanning machines become a versatile means of drying to yield dry hides that contain no salt yet store better than salted hides. In this novel process, fresh hides are loaded into the tanning machine where they are washed, demanured and then dried in situ under vacuum with concomitant application of microwave energy. Because the dried hides thus obtained are soft and pliable, they can be mechanically fleshed or shaved to remove the subcutaneous tissues rich in collagen and fat. Alternatively, the hides may be first dried in the tanning machine to below 35% moisture content and degreased using a solvent such as hexane. The solvent remaining in the hides after decantation of the unabsorbed liquid is vaporized at low temperature using vacuum and microwave energy. The hides are then dried in situ to the desired final moisture content. By shaving off the subcutaneous tissues of these hides a dry, fat-free, valuable undenatured collagen product is obtained. If the hides are unhaired before drying, they may be shaved and then accurately split. The process is also suitable for removing hair and fat from hide trimmings to obtain a valuable undenatured collagen product and fat. Furthermore, it can be used to remove fat from connective tissues and other animal offal containing no hair yielding a dry undenatured collagen product.

Owner:KOMANOWSKY MICHAEL

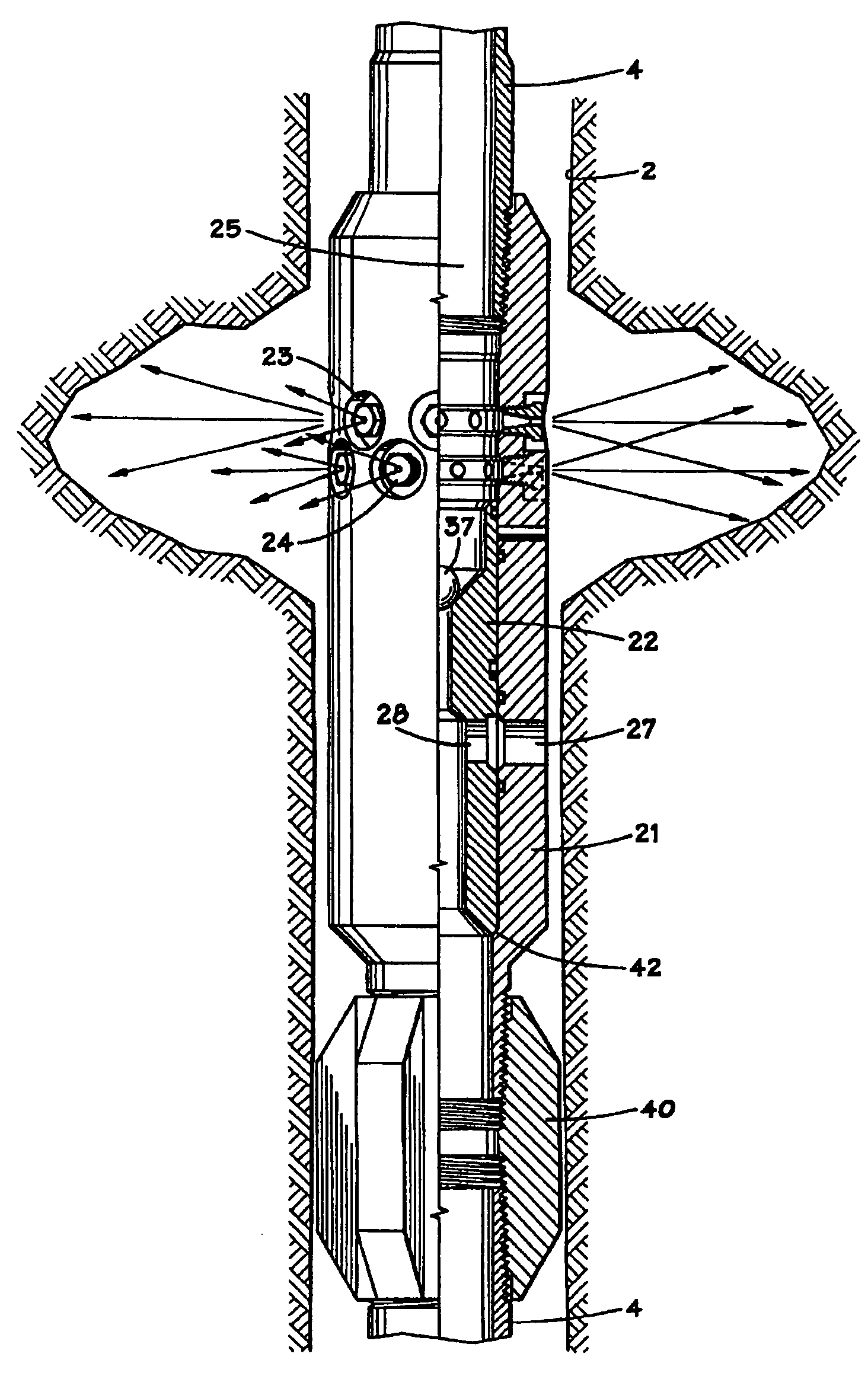

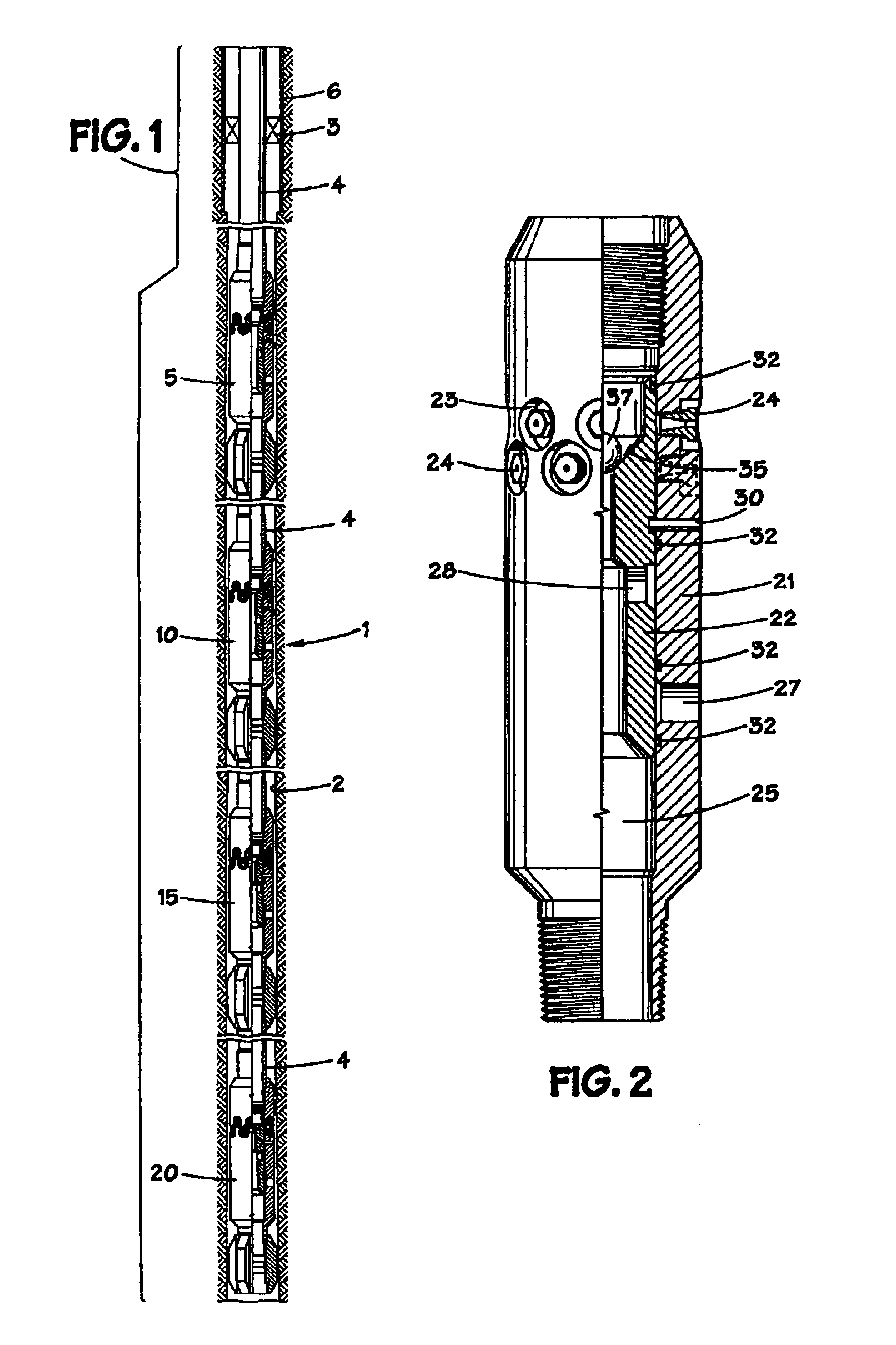

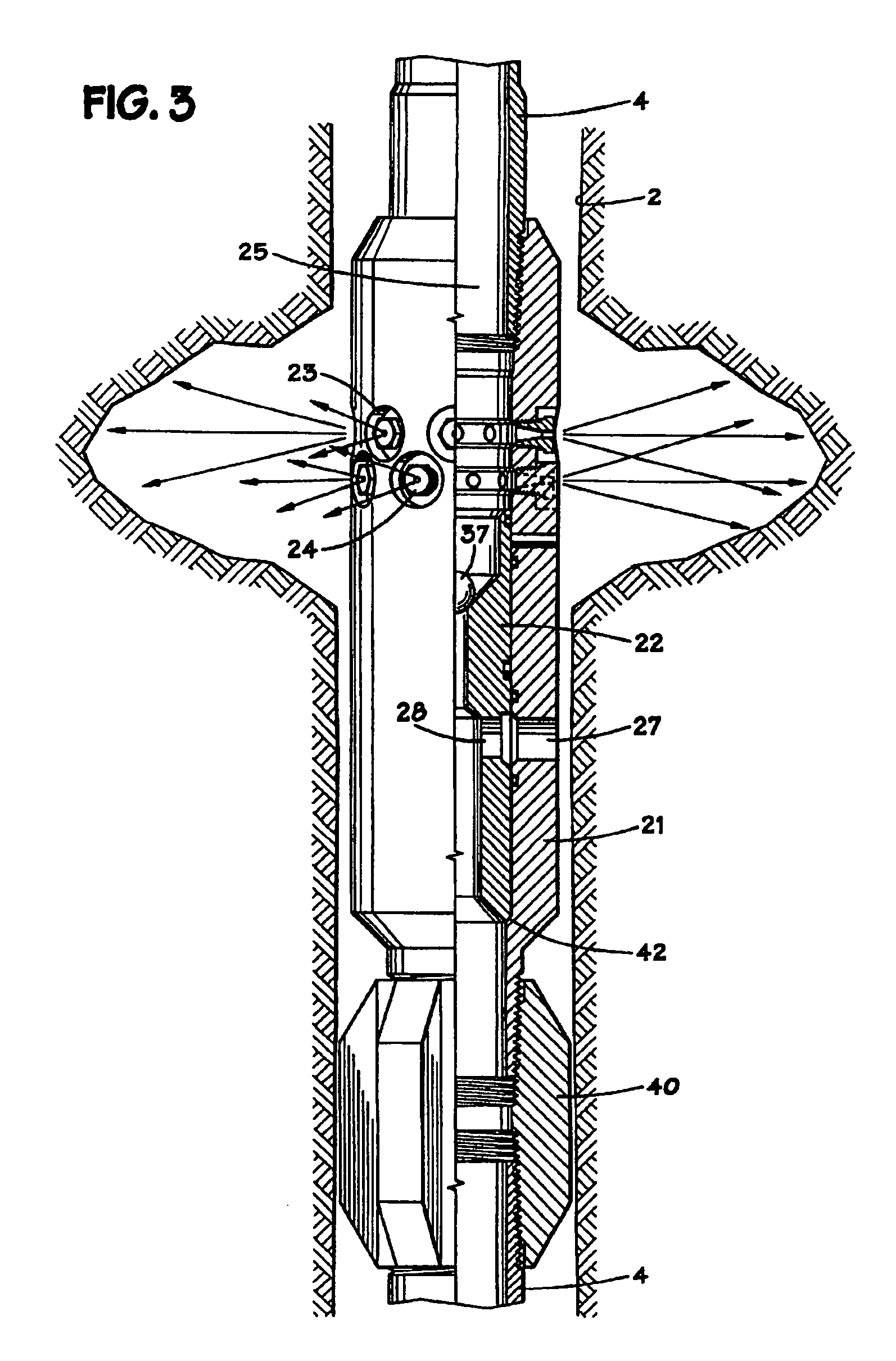

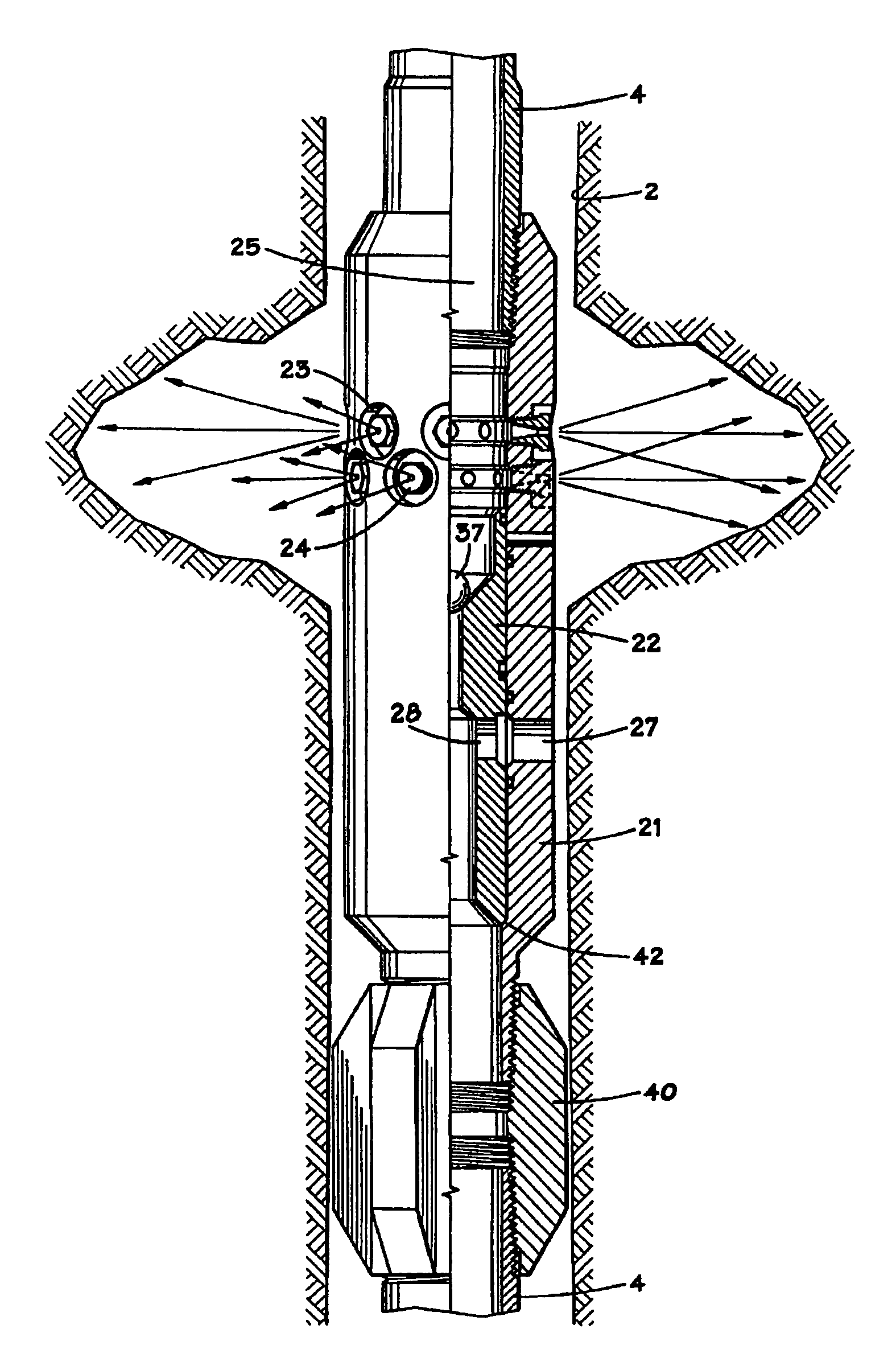

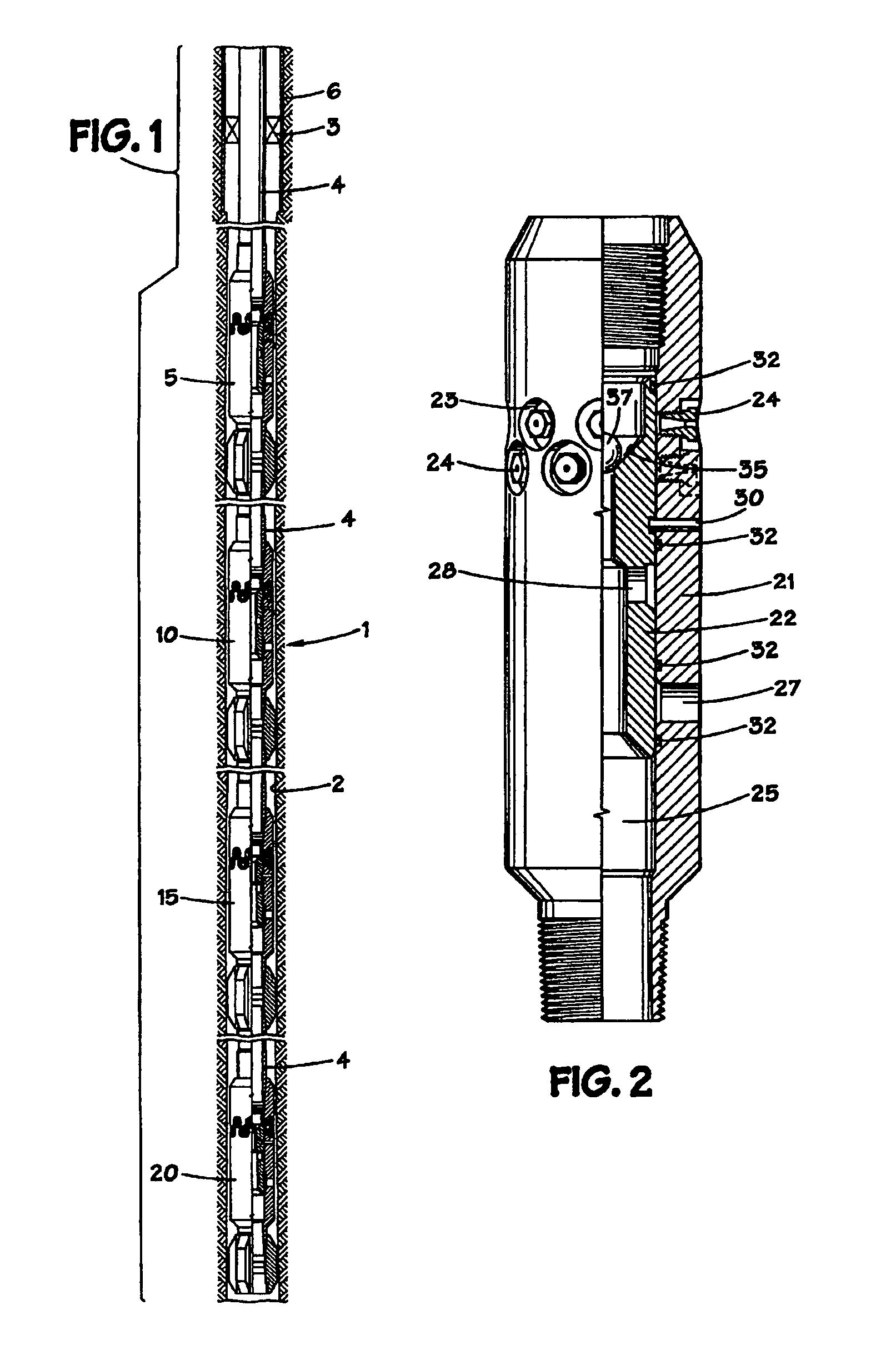

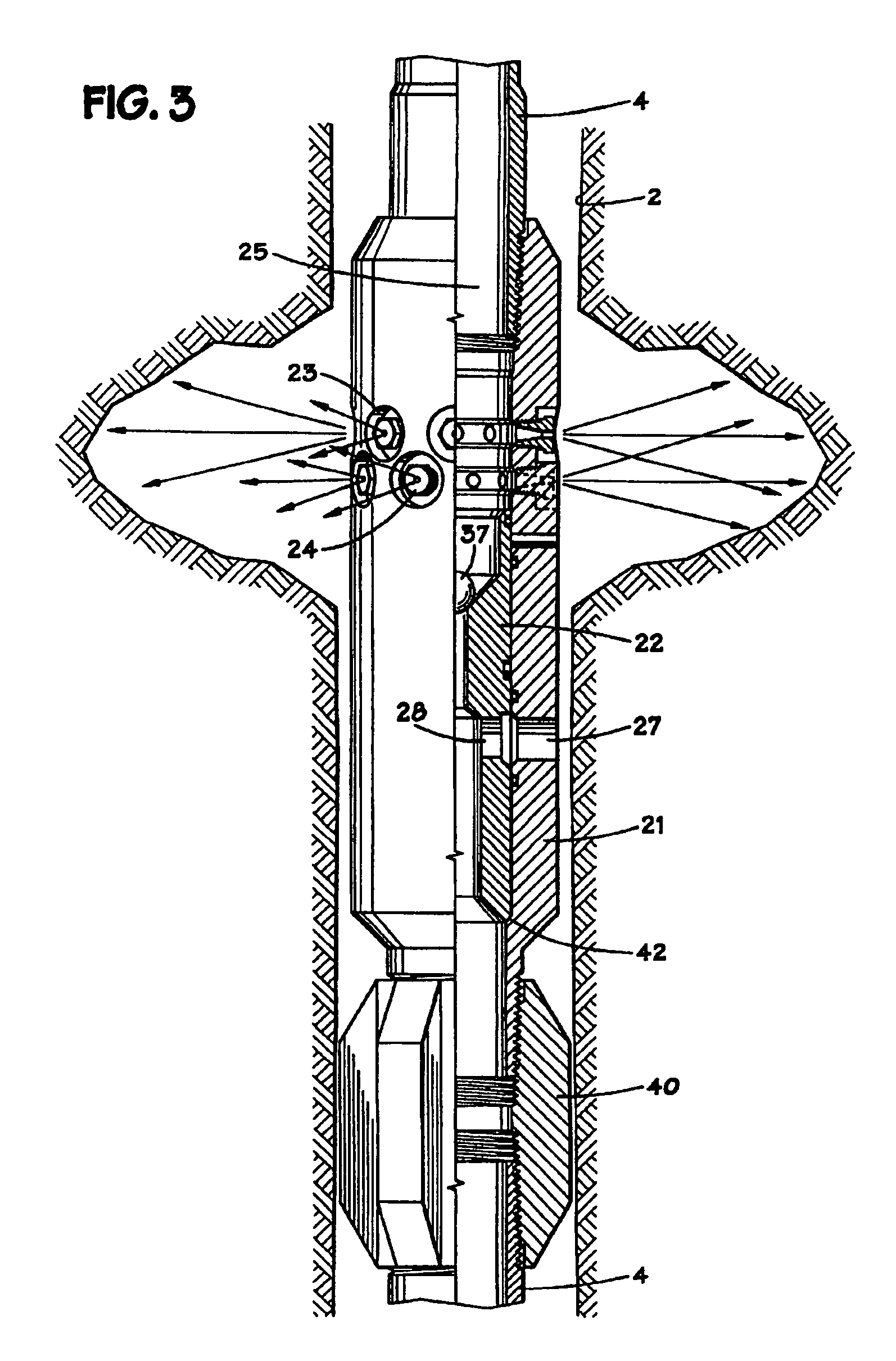

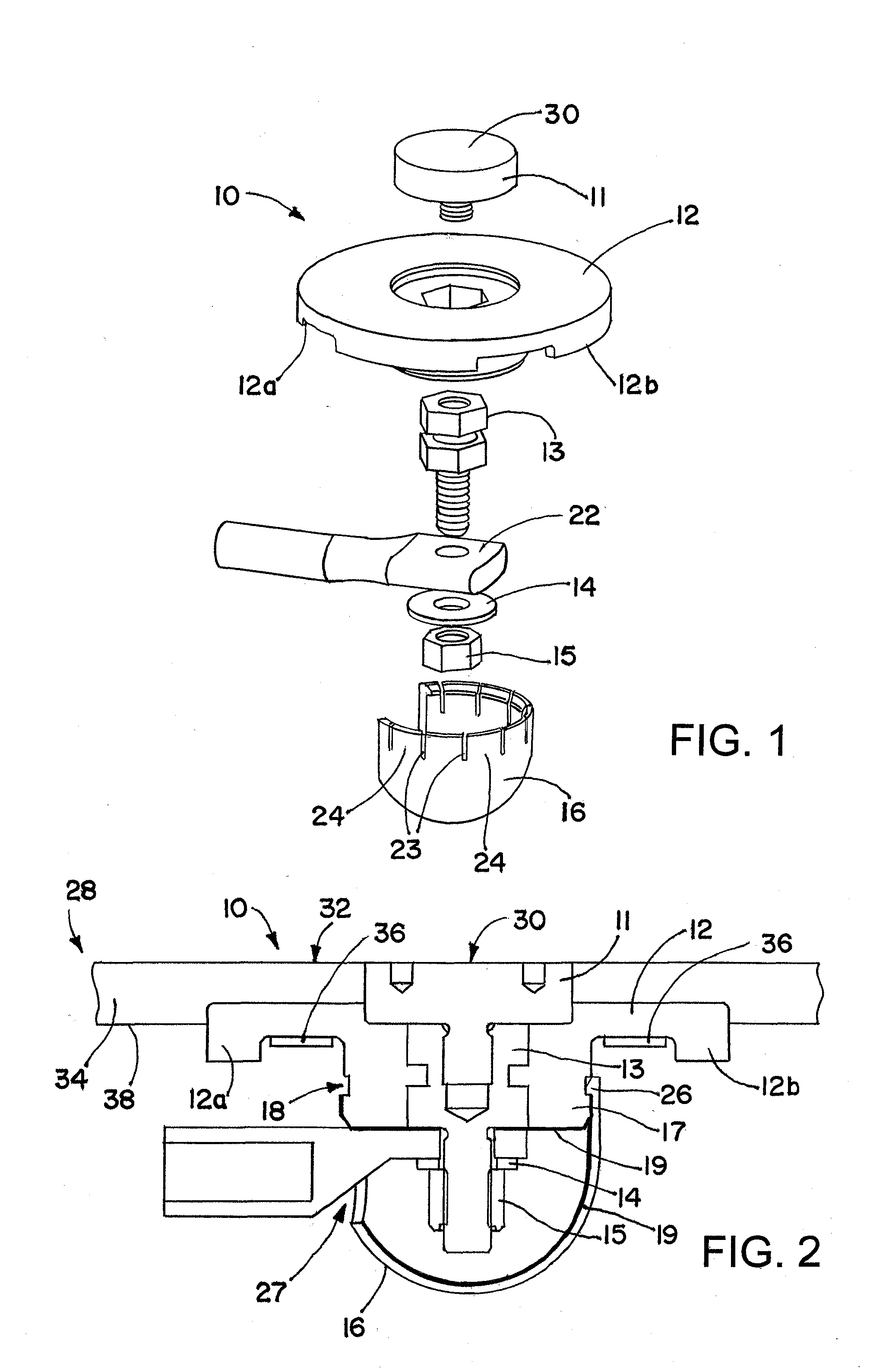

System and method for stimulating multiple production zones in a wellbore

ActiveUS20080210429A1Prevent curingFluid removalWell/borehole valve arrangementsNatural rubberOil well

A system and method for selectively stimulating a plurality of producing zones of a wellbore in oil and gas wells, the system being cemented within the wellbore. The system includes a plurality of modules connected in a string wherein the modules can be selectively actuated to stimulate producing zones adjacent the modules. Each module includes a sleeve shiftable between a closed position and a treating position where a plurality of radial passageways are exposed to the central passageway of the assembly. The system includes a wiper plug that is adapted to pass through ball seats of various sizes in the plurality of modules and an acid solution pumped into the string to break down the cement at the producing zones. The system may include at least one natural rubber wiper ball to remove residual cement from the string.

Owner:BAKER HUGHES INC

Silicone Resin for Protecting a Light Transmitting Surface of an Optoelectronic Device

ActiveUS20090123764A1Improve adhesionPrevent discolorationSpecial surfacesCoatingsOpto electronicElectron

A silicone resin composition and process for coating a light transmitting surface of an optoelectronic device is disclosed. The process involves applying a silicone resin to the light transmitting surface, and causing the silicone resin to cure to form a light transmitting protective coating on the light transmitting surface, the silicone resin having a sufficiently low proportion of organosiloxanes having molecular weights of up to about 1000, such that the protective coating includes less than about 10% of the organosiloxanes having molecular weights of up to about 1000.

Owner:LUMILEDS +1

Non-aqueous electrolyte secondary battery

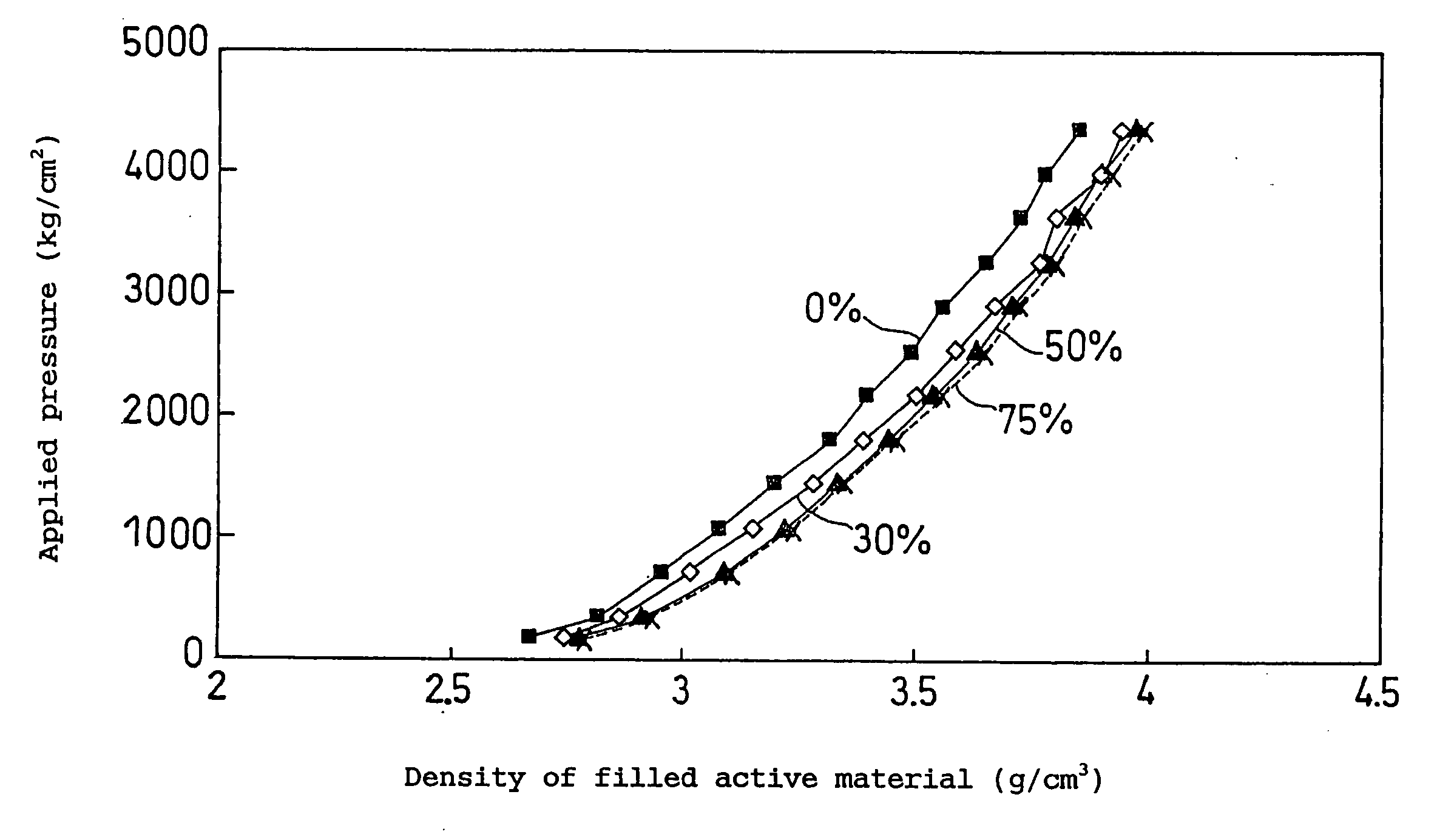

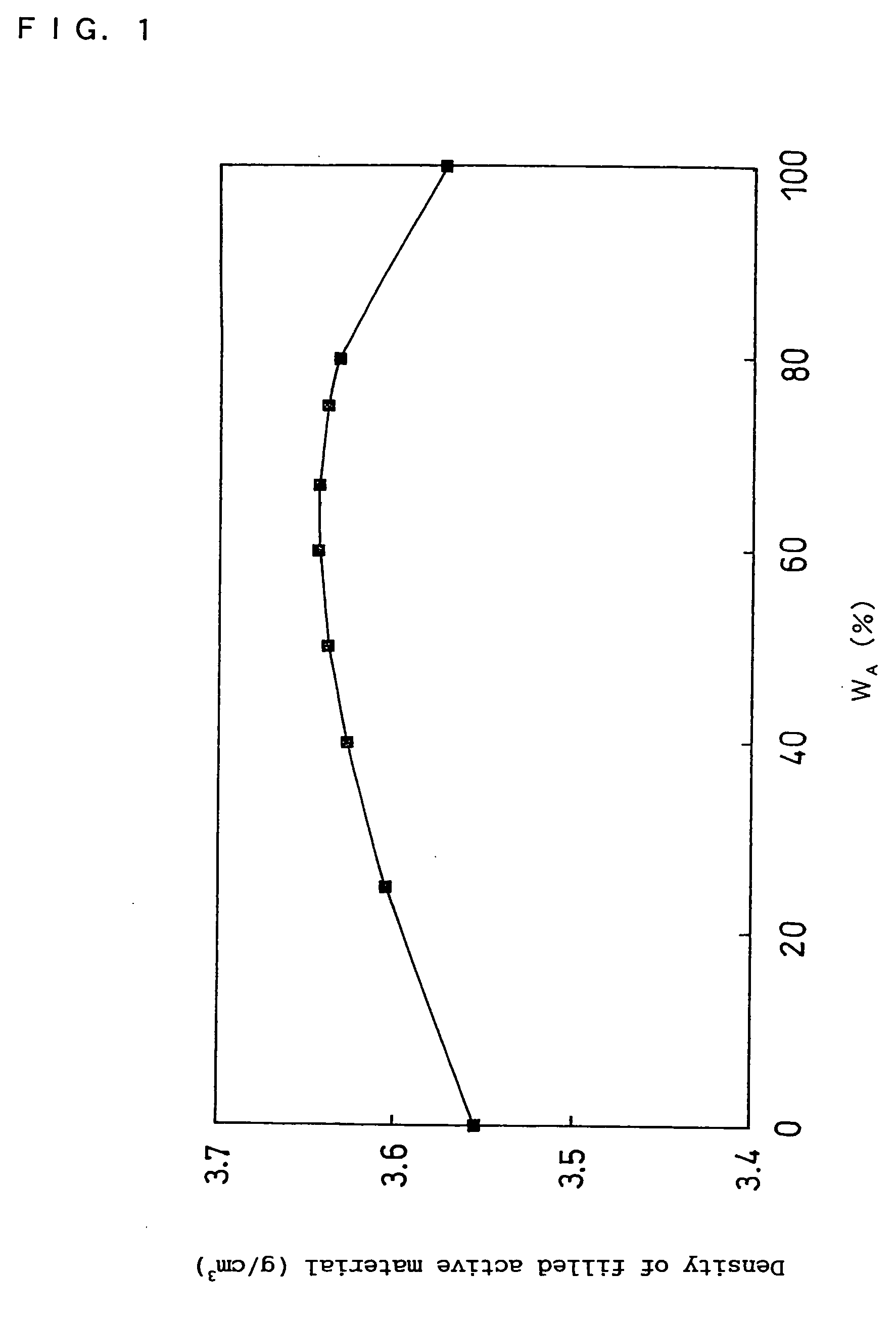

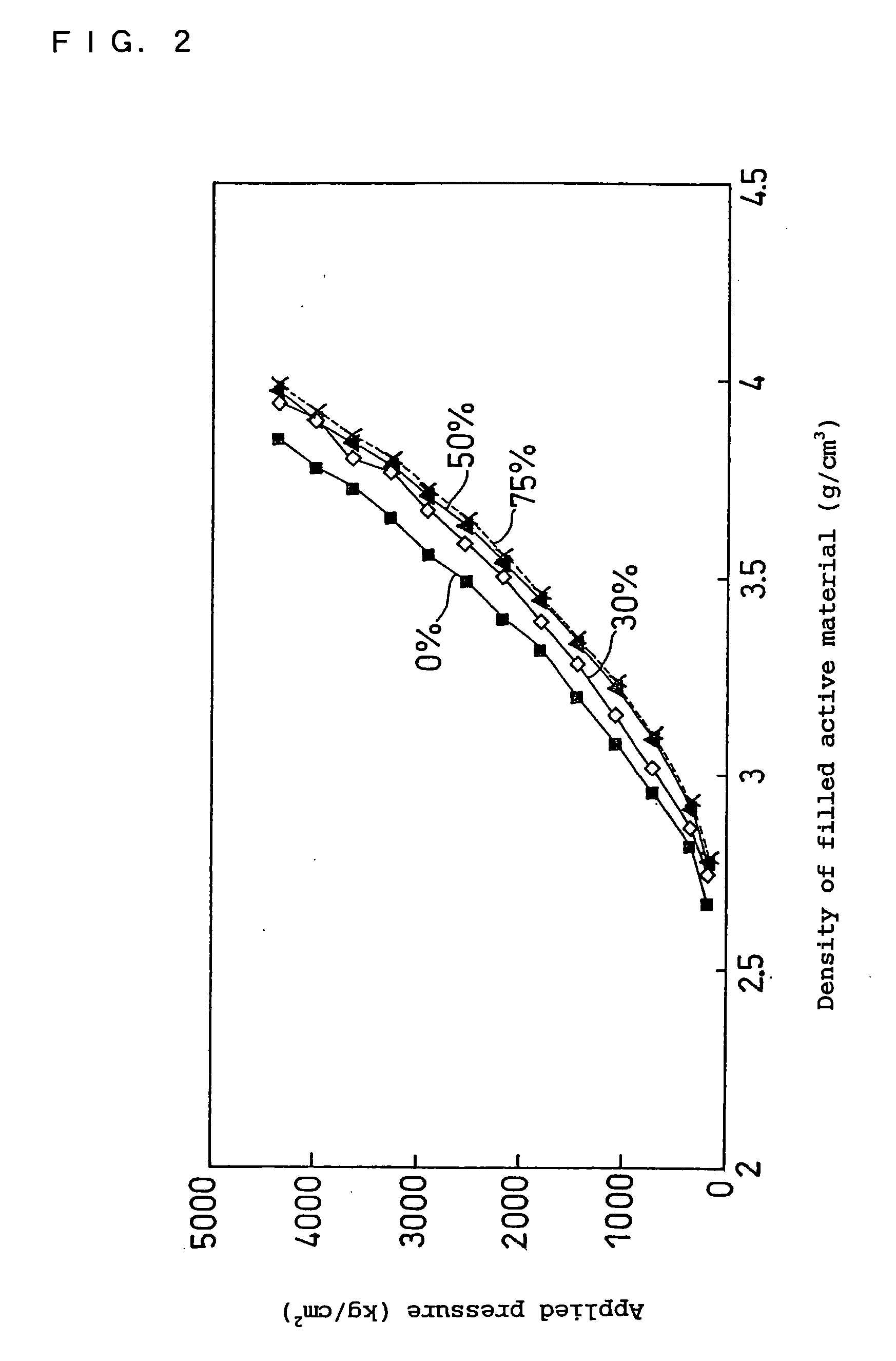

ActiveUS20060115730A1Increase flexibilityPrevent curingFinal product manufactureActive material electrodesParticulatesFluorocarbon

Disclosed is a non-aqueous electrolyte secondary battery having an electrode group in which a positive electrode and a negative electrode are spirally wound with a separator interposed therebetween. The positive electrode contains a positive electrode active material and a binder. The positive electrode active material contains a mixture of two different particulate substances having different average particle sizes. The two different particulate substances are lithium composite metal oxides containing nickel as an essential element. The binder includes fluorocarbon resin and rubber particles. The fluorocarbon resin contains at least a vinylidene fluoride unit. The amount of the rubber particles per 100 parts by weight of the fluorocarbon resin is 1 to 25 parts by weight.

Owner:PANASONIC CORP

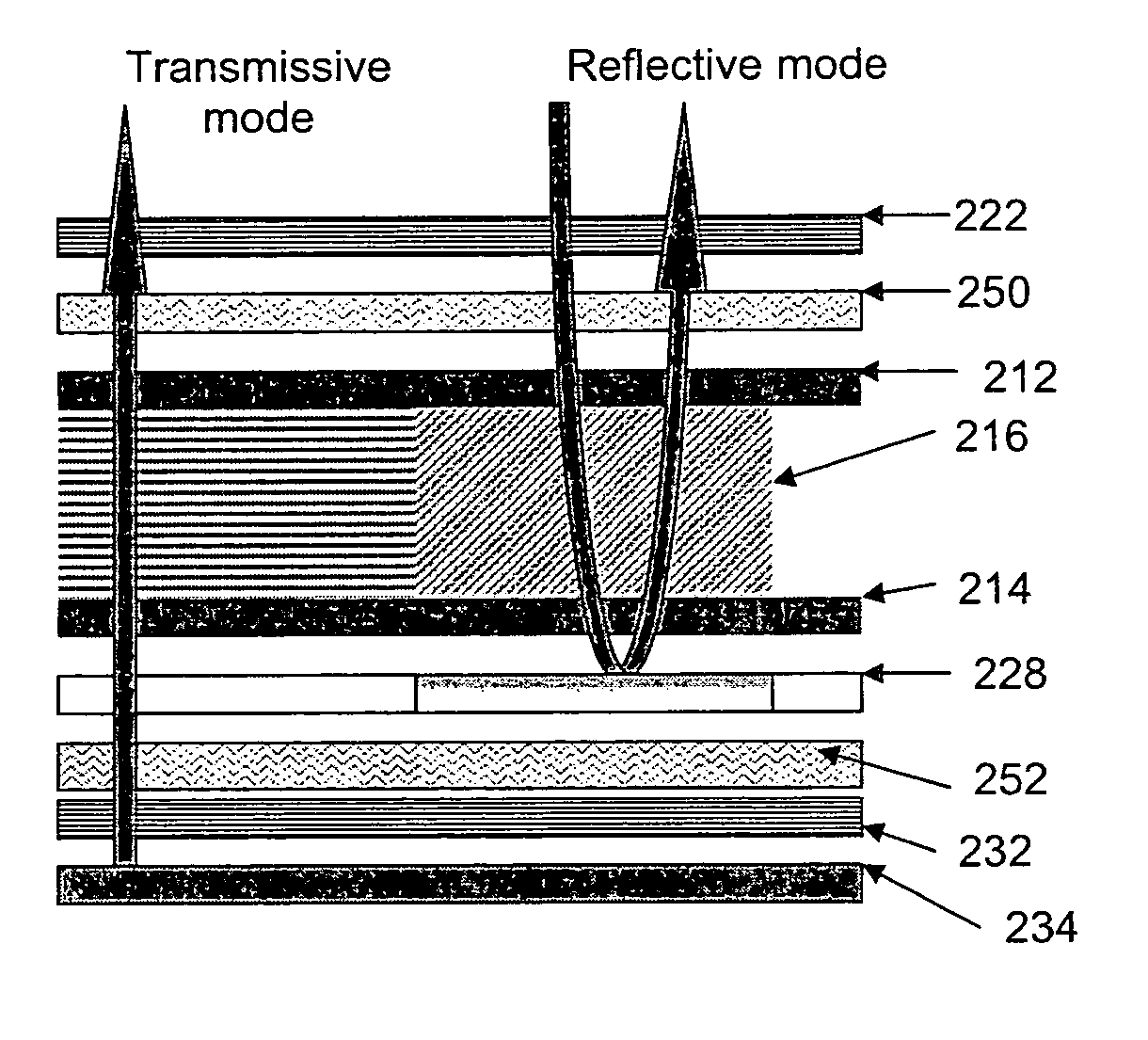

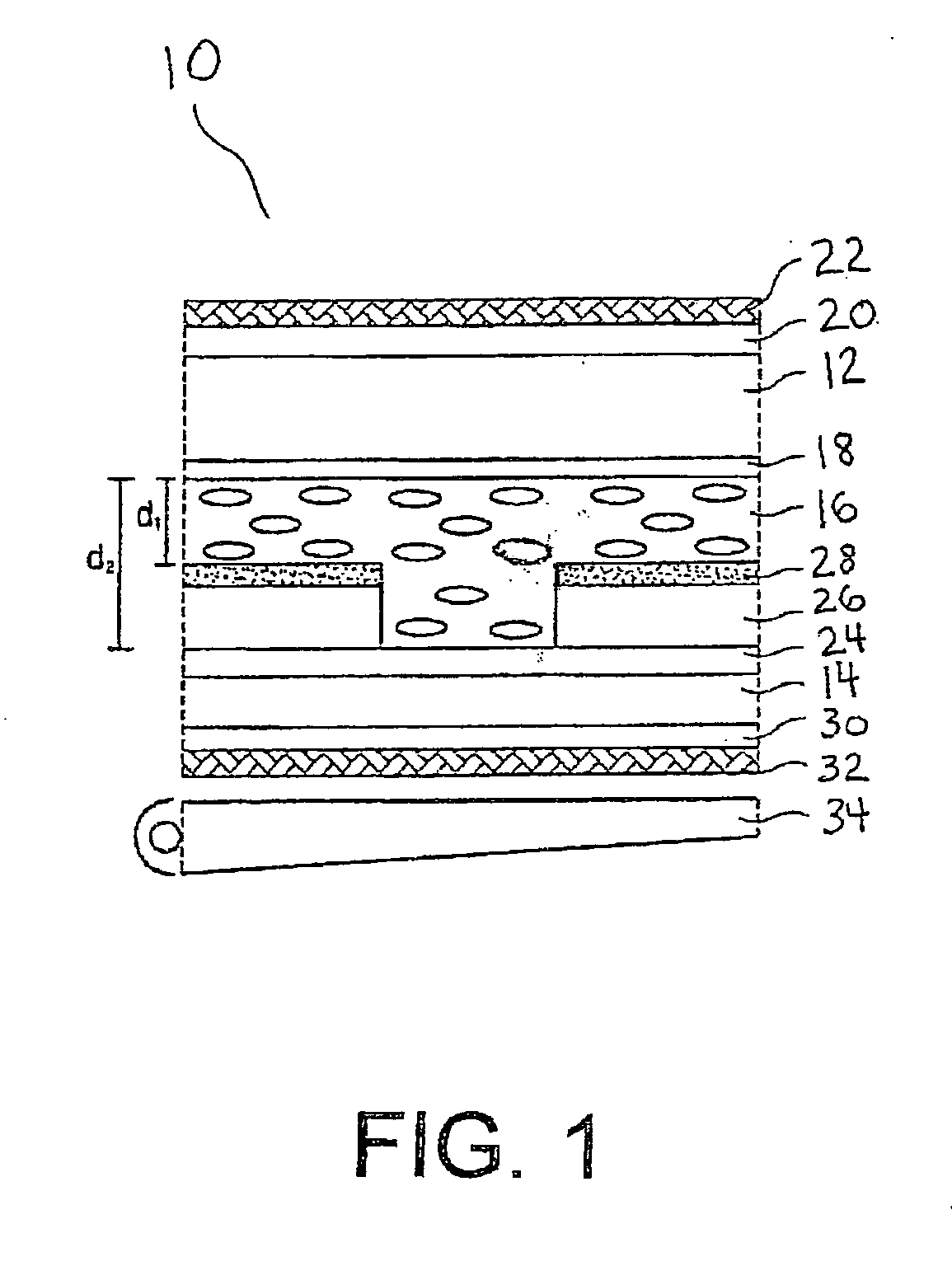

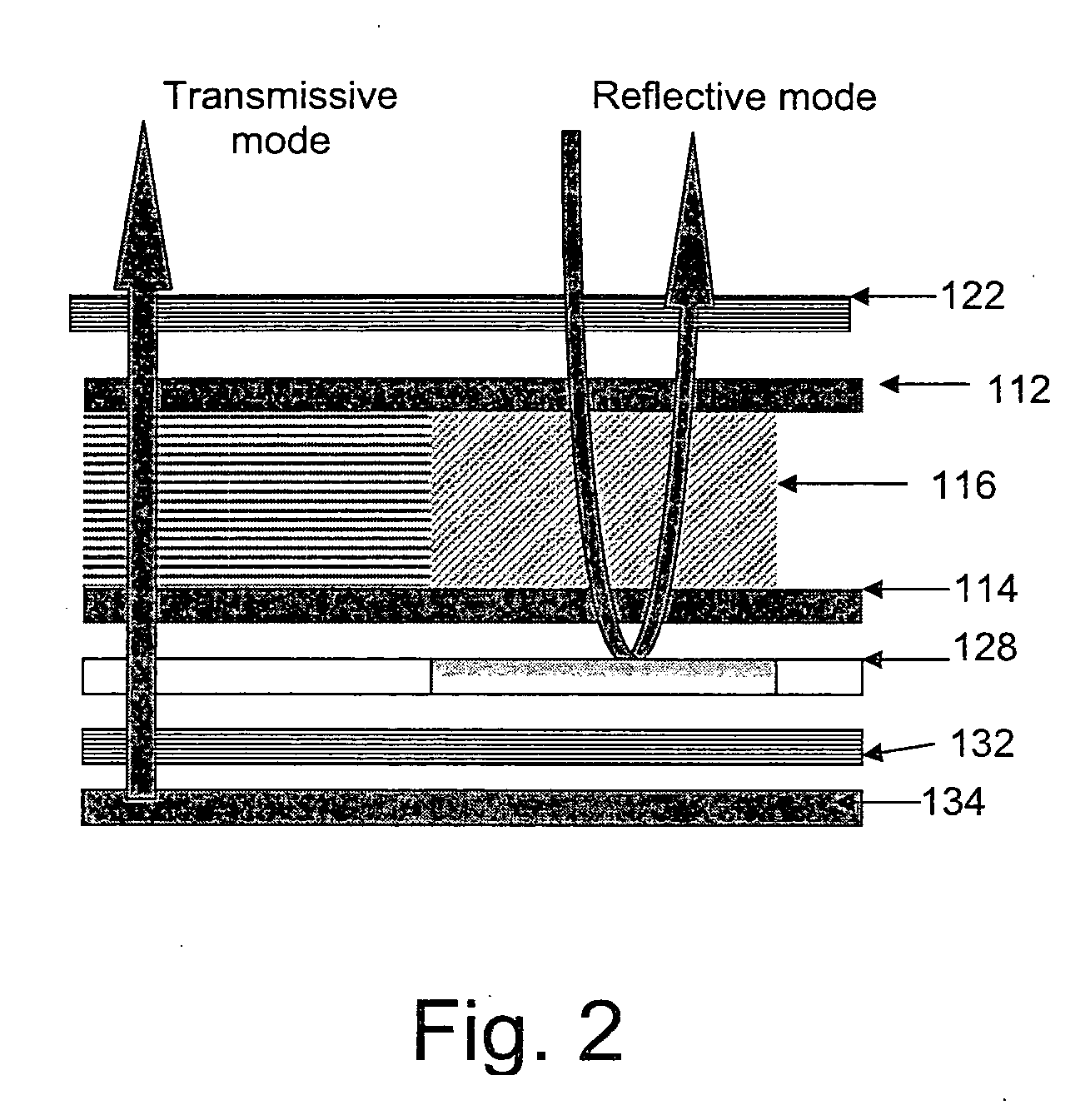

Polymer stabilized electrically controlled birefringence transflective LCD

ActiveUS20060023146A1Improve device stabilityUseful for developmentNon-linear opticsDisplay deviceLiquid crystal

A transreflective display in which the thickness of the liquid crystal layer is the same for both transmissive and reflective modes. The transmissive and reflective pixels are stabilized in two different liquid crystal configurations with different birefringences. The light retardation effect of one path in the transmissive pixels is close to or equals the retardation effect of two paths in the reflective pixels, resulting in synchronization of the two modes.

Owner:KENT STATE UNIV

System and method for stimulating multiple production zones in a wellbore

Owner:BAKER HUGHES INC

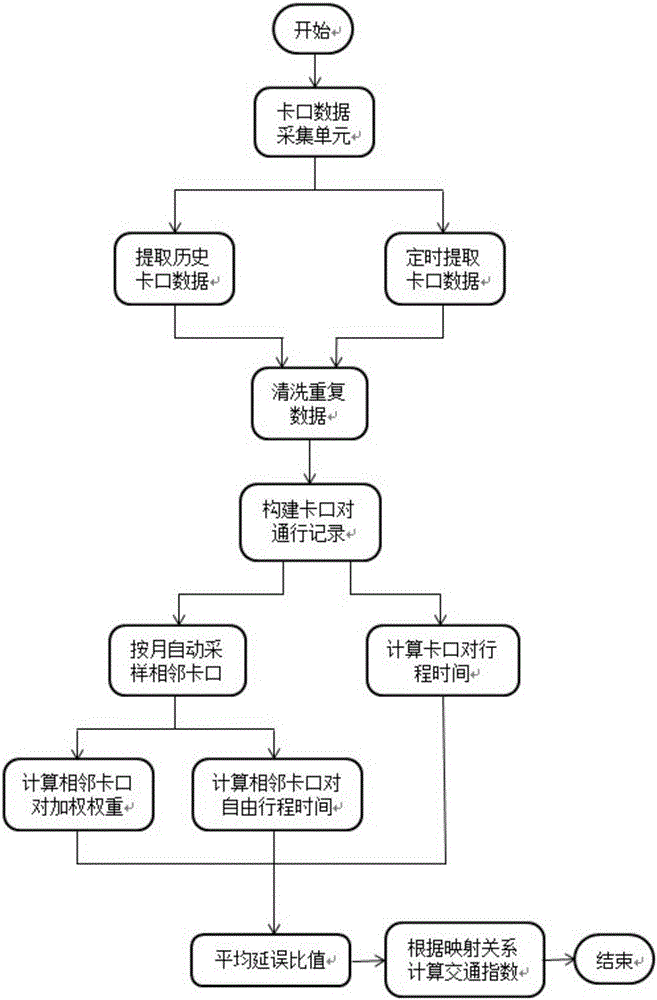

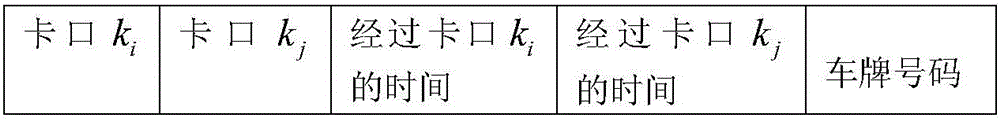

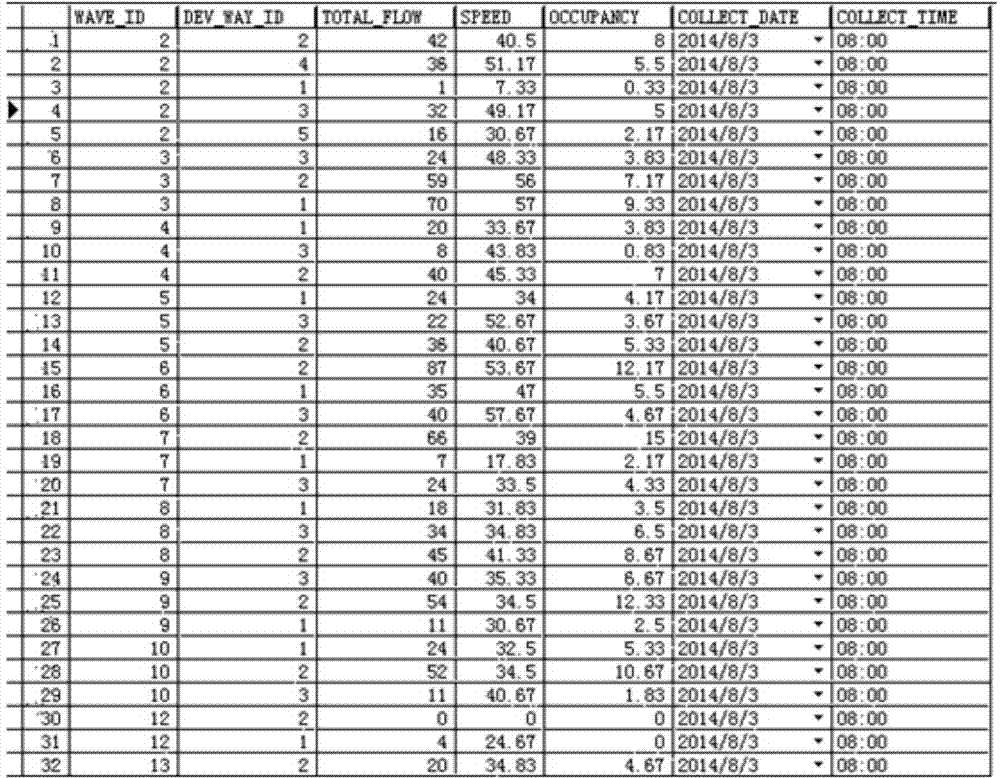

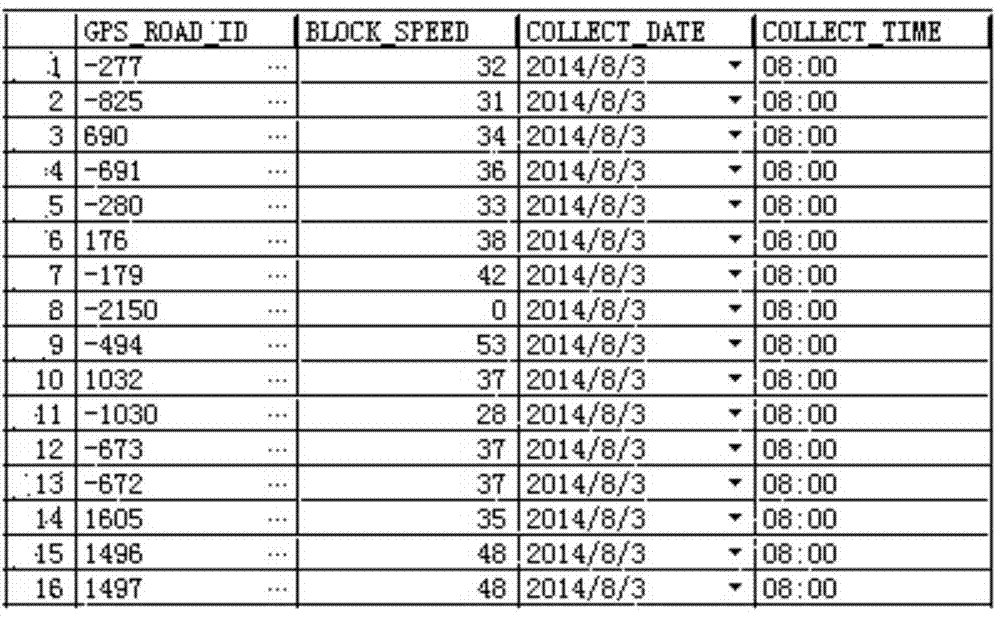

Urban road traffic congestion index calculating method based on checkpoint data

ActiveCN105869405AConsider traffic conditionsCalculation results are objectiveDetection of traffic movementTraffic congestionComputer science

An urban road traffic congestion index calculating method based on checkpoint data comprises steps as follows: step 1, acquiring the checkpoint data; step 2, cleaning the checkpoint data; step 3, building records of vehicle passage checkpoint pairs; step 4, automatically sampling the adjacent checkpoint pairs based on flow direction probability; step 5, calculating free travel time of the adjacent checkpoint pairs; step 6, building a weighting weight set q of road sections where the adjacent checkpoint pairs are located; step 7, acquiring the checkpoint data at regular time according to the statistical cycle; step 8, calculating traffic indexes in the statistical cycle. The urban road traffic congestion index calculating method based on the checkpoint data is better in accuracy, good in flexibility and higher in applicability.

Owner:ENJOYOR COMPANY LIMITED

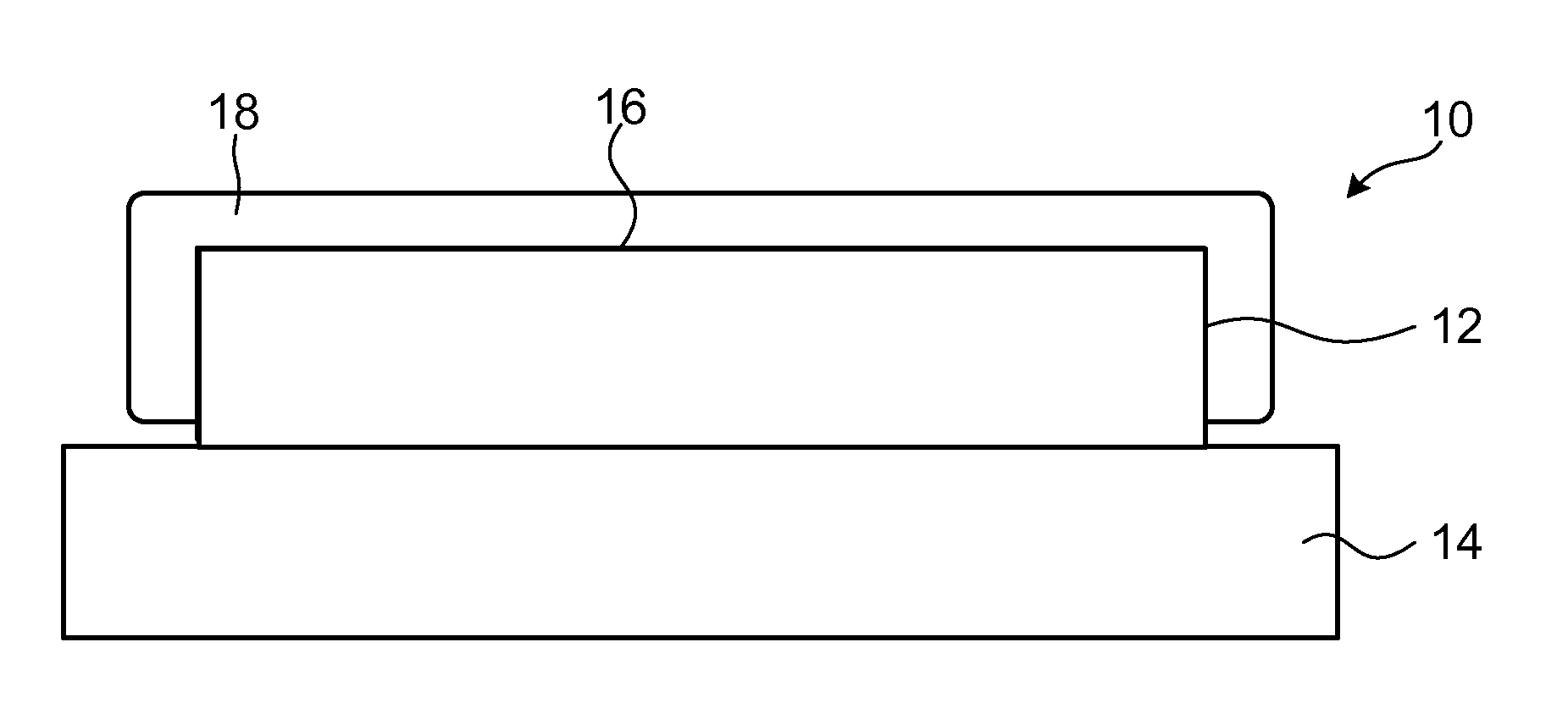

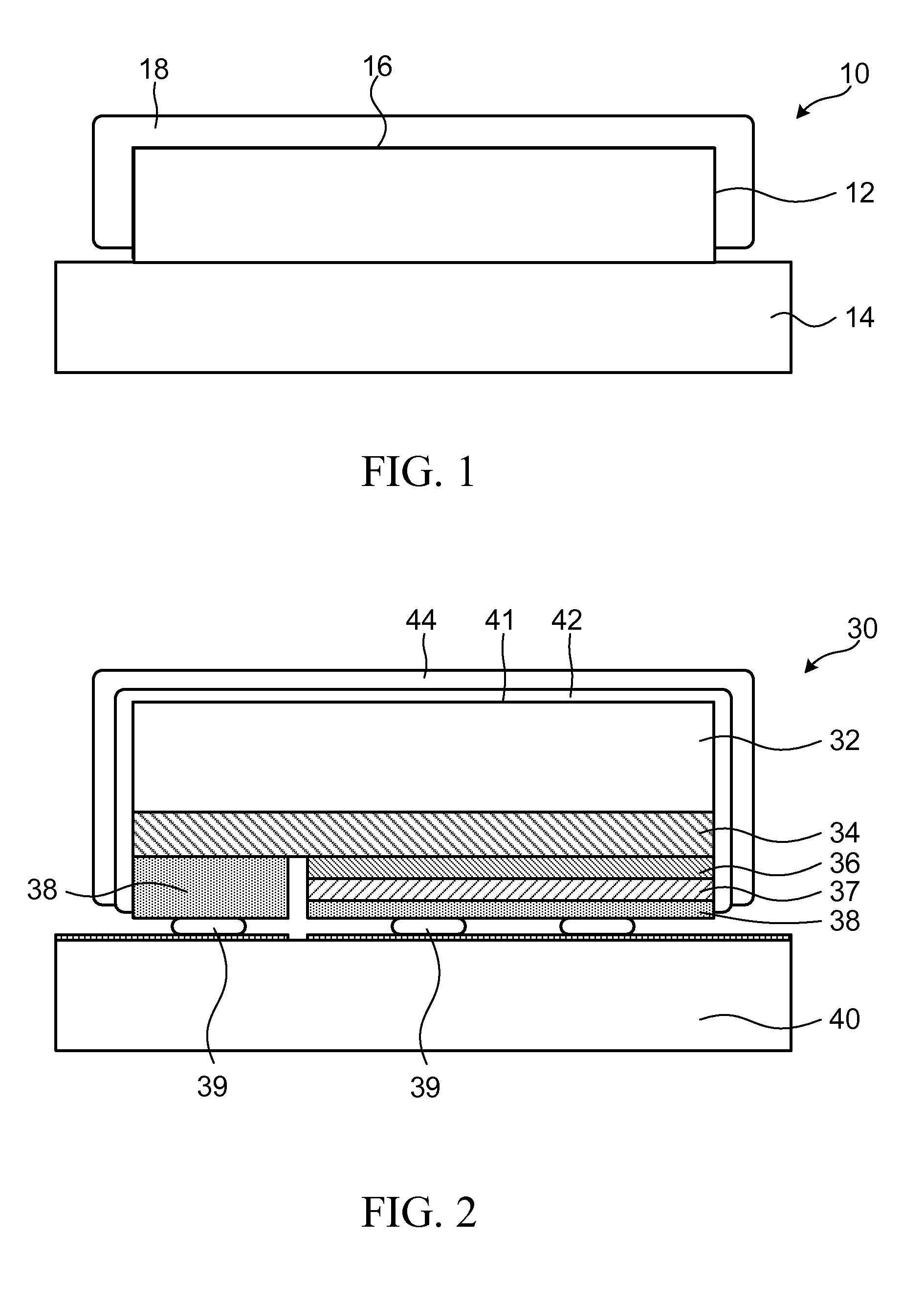

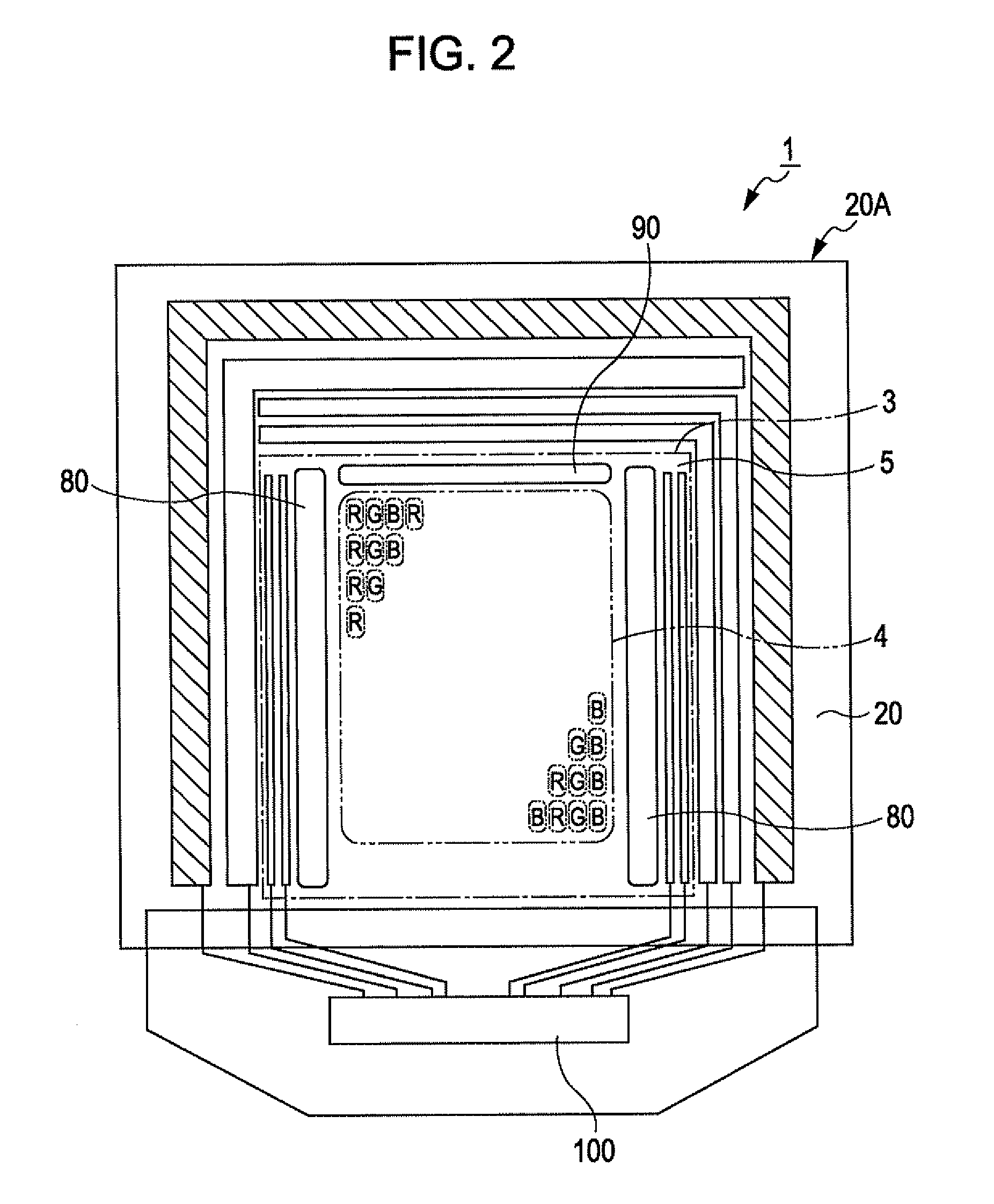

Organic electroluminescent device, method for manufacturing the same, and electronic apparatus including the same

ActiveUS20090051274A1Inhibit deteriorationEfficient extractionDischarge tube luminescnet screensLamp detailsHigh surfaceEngineering

An organic electroluminescent device includes an element substrate including a plurality of light-emitting elements, each including a pair of electrodes with an organic luminescent layer therebetween, and a coating layer covering the light-emitting elements. A sealing substrate is opposed to the element substrate. The sealing substrate includes a plurality of color layers and a light-shielding layer separating the color layers from each other. An outer region sealing layer bonds the outer region of the sealing substrate to the outer region of the element substrate. A filling layer is surrounded by the outer region sealing layer, and bonds the sealing substrate and the element substrate together in the region in which the light-emitting elements and the color layers are arranged. The color layers and the light-shielding layer of the sealing substrate are covered with a surface-modifying layer made of a material having a higher surface energy to the material of the filling layer than the surface energy to the surfaces of the color layers and light-shielding layer.

Owner:SEIKO EPSON CORP

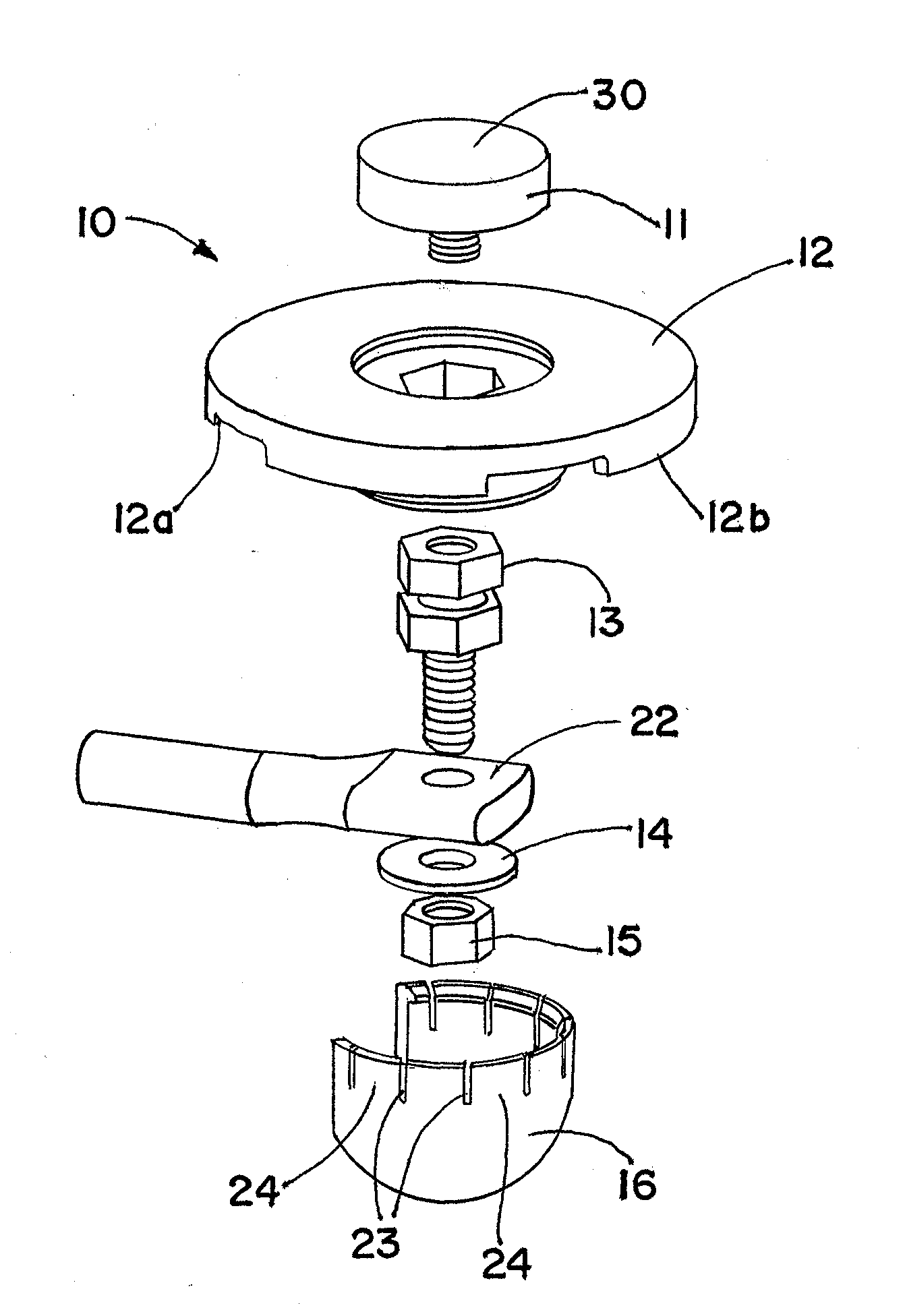

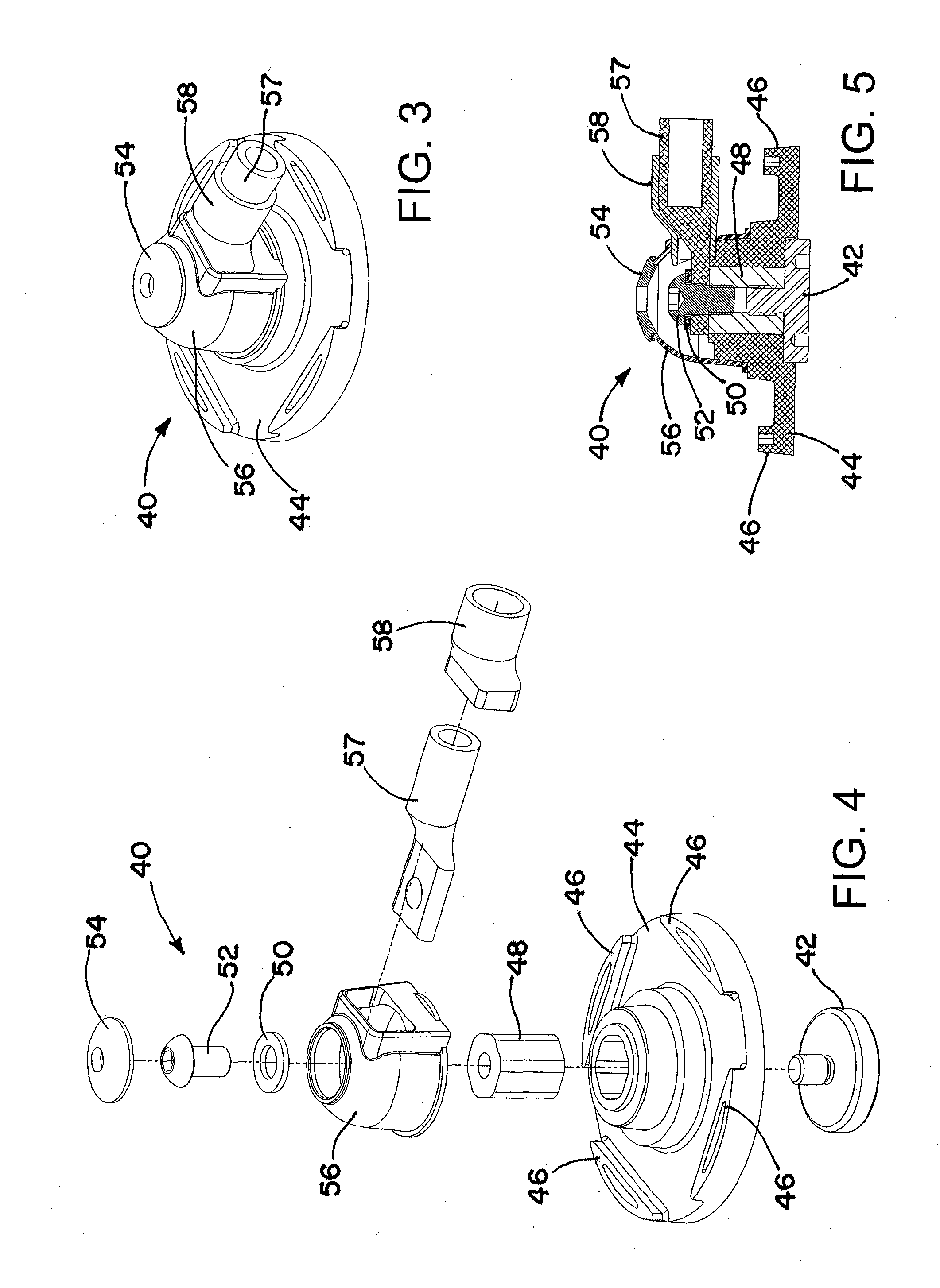

Receptor for wind turbine blade lightning protection

InactiveUS20120020791A1Reduce localized electrical field stressHigh dielectric strengthPropellersConnection to earthElectricityLightning strike

A receptor assembly for lightning protection of an object, such as a wind turbine blade, includes a receptor disk configured to be placed on a surface of the object, a receptor block insulator with an integral receptor block, a cover that engages the receptor block insulator, and a cap that engages the cover. The receptor disk and the receptor block may be made of electrically conductive materials, and the cover, and the cap, and the receptor block insulator may define a chamber among them that is lined with an electrically-conductive coating sandwiched between relatively high dielectric media to electrically isolate and shield internal parts of the receptor assembly from receiving a lightning strike directly.

Owner:ERICO INT

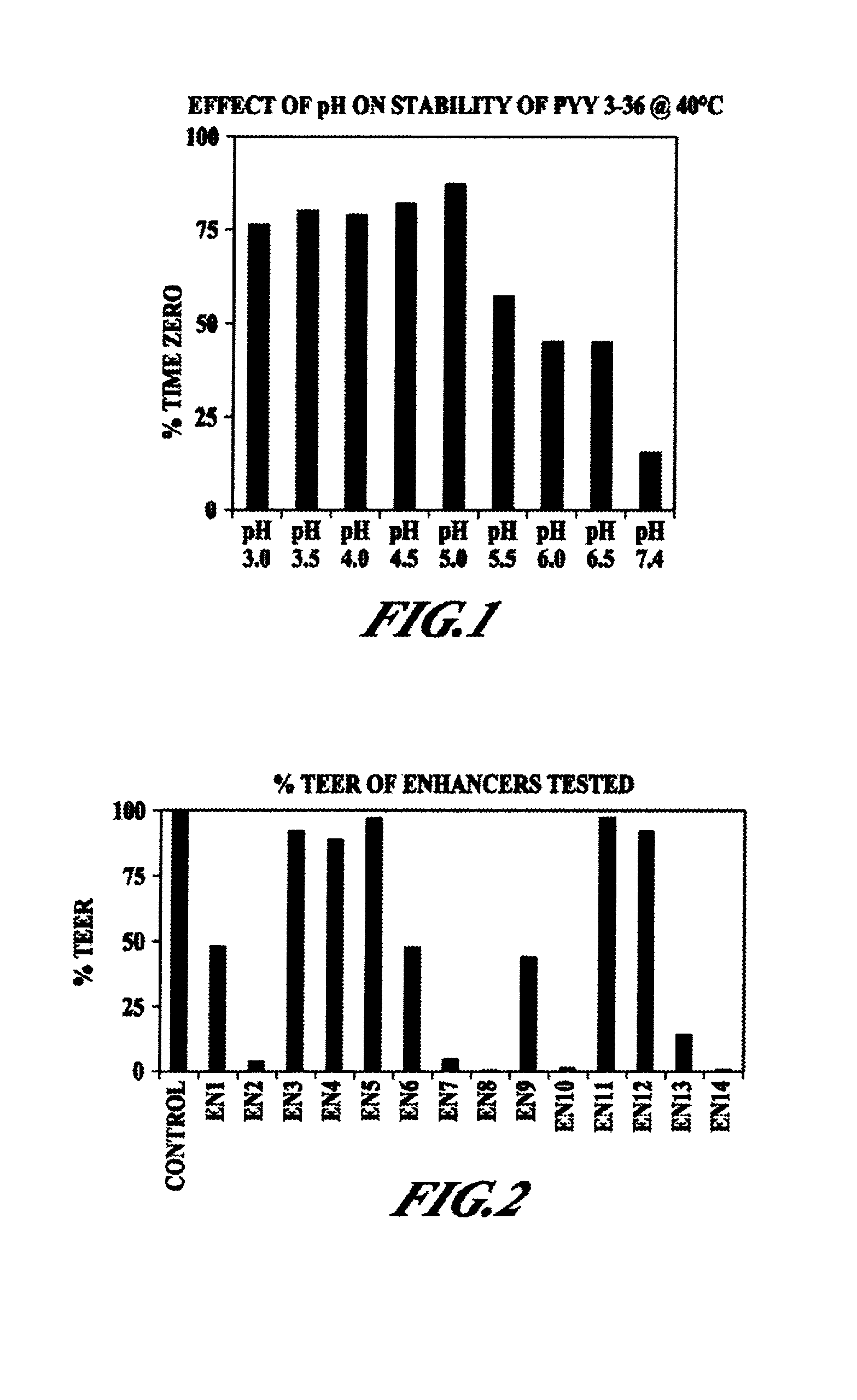

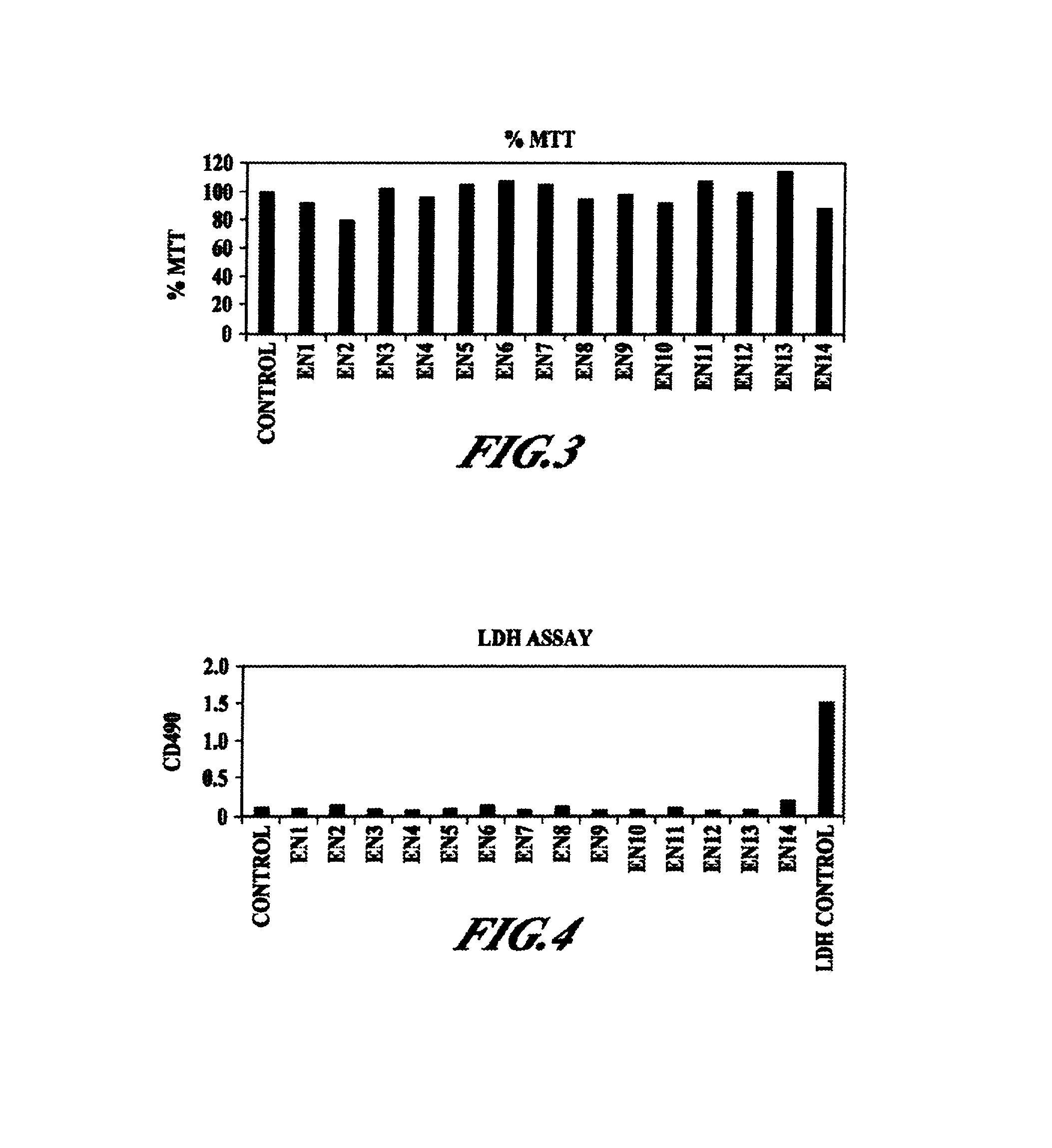

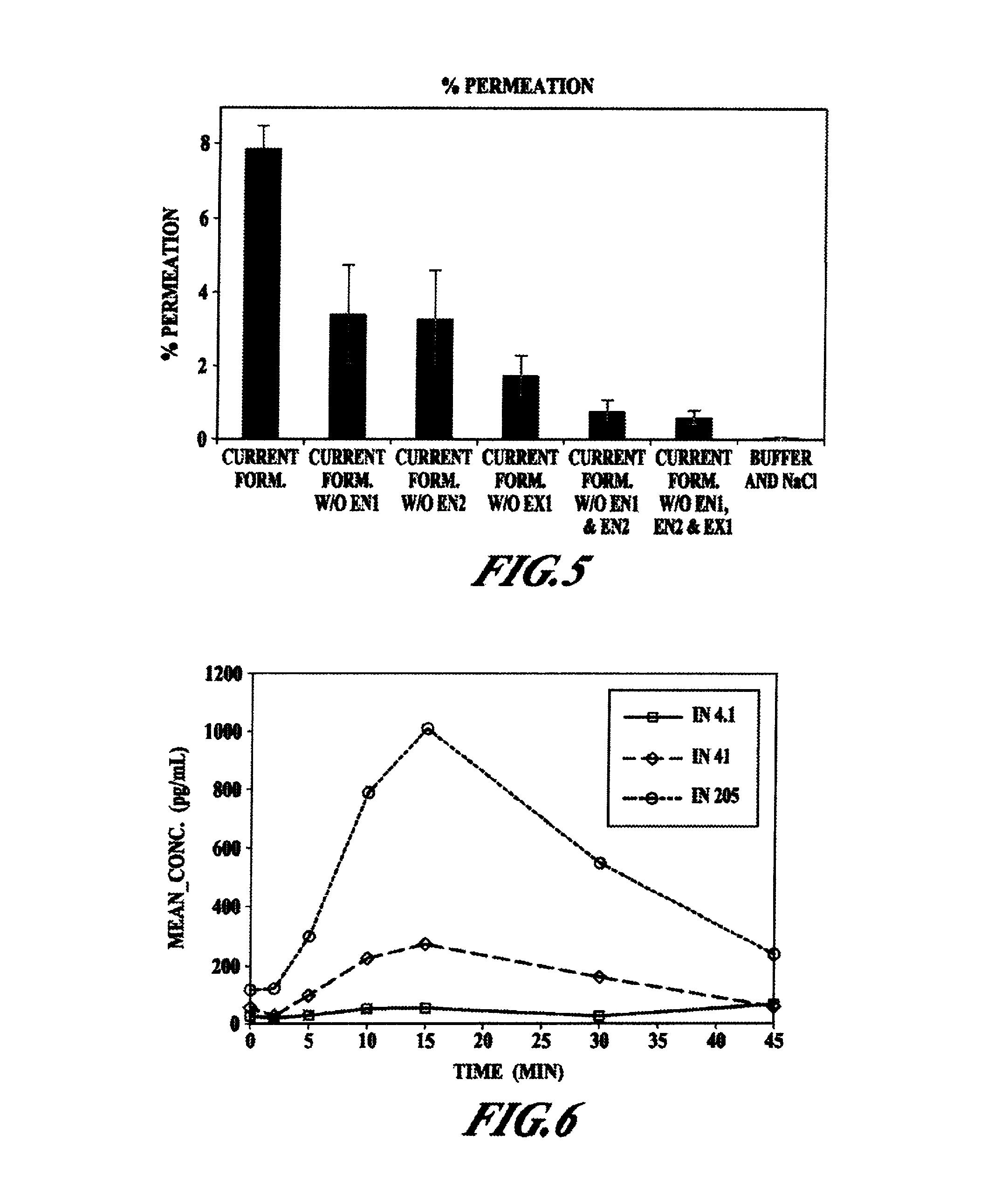

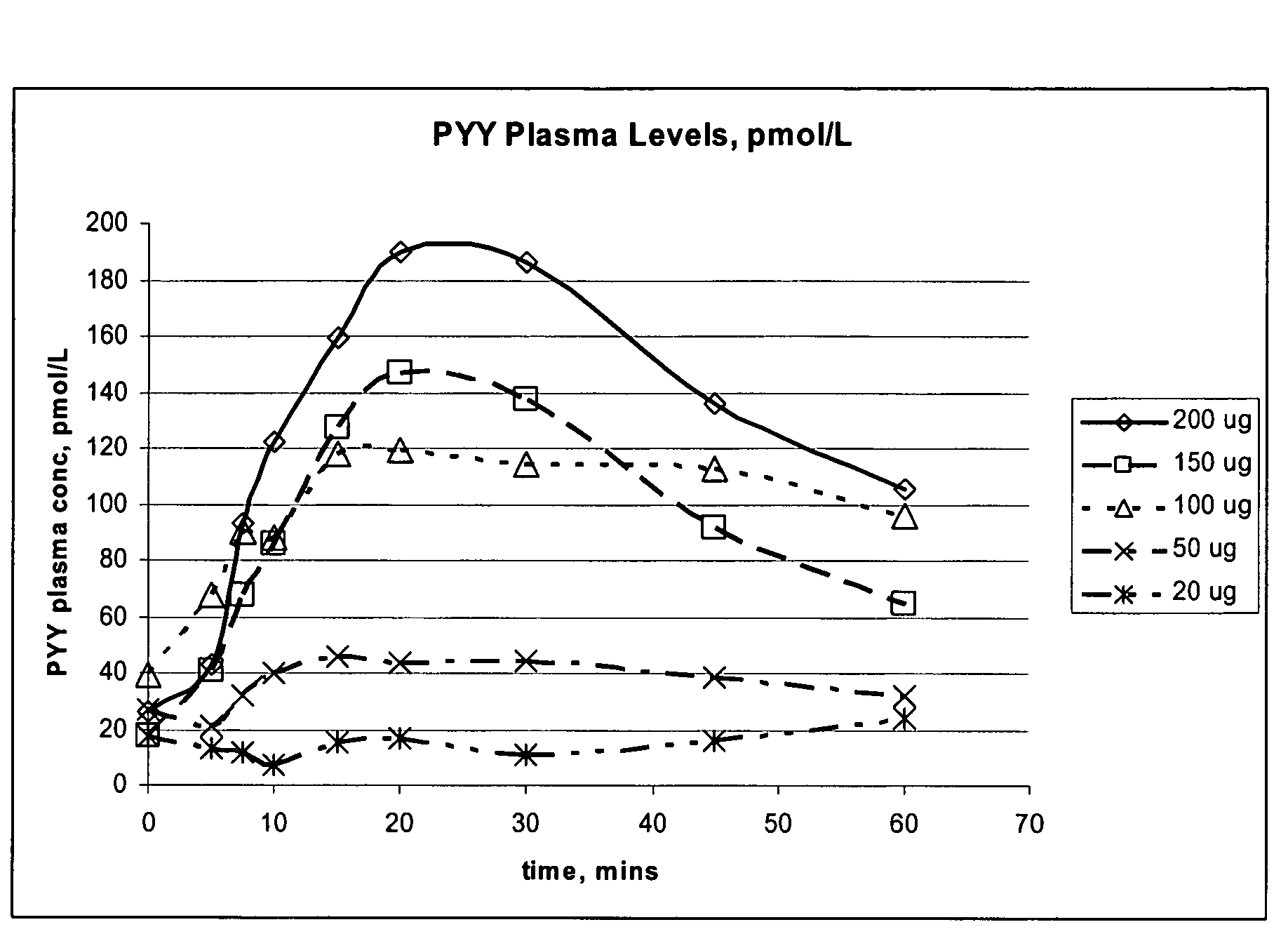

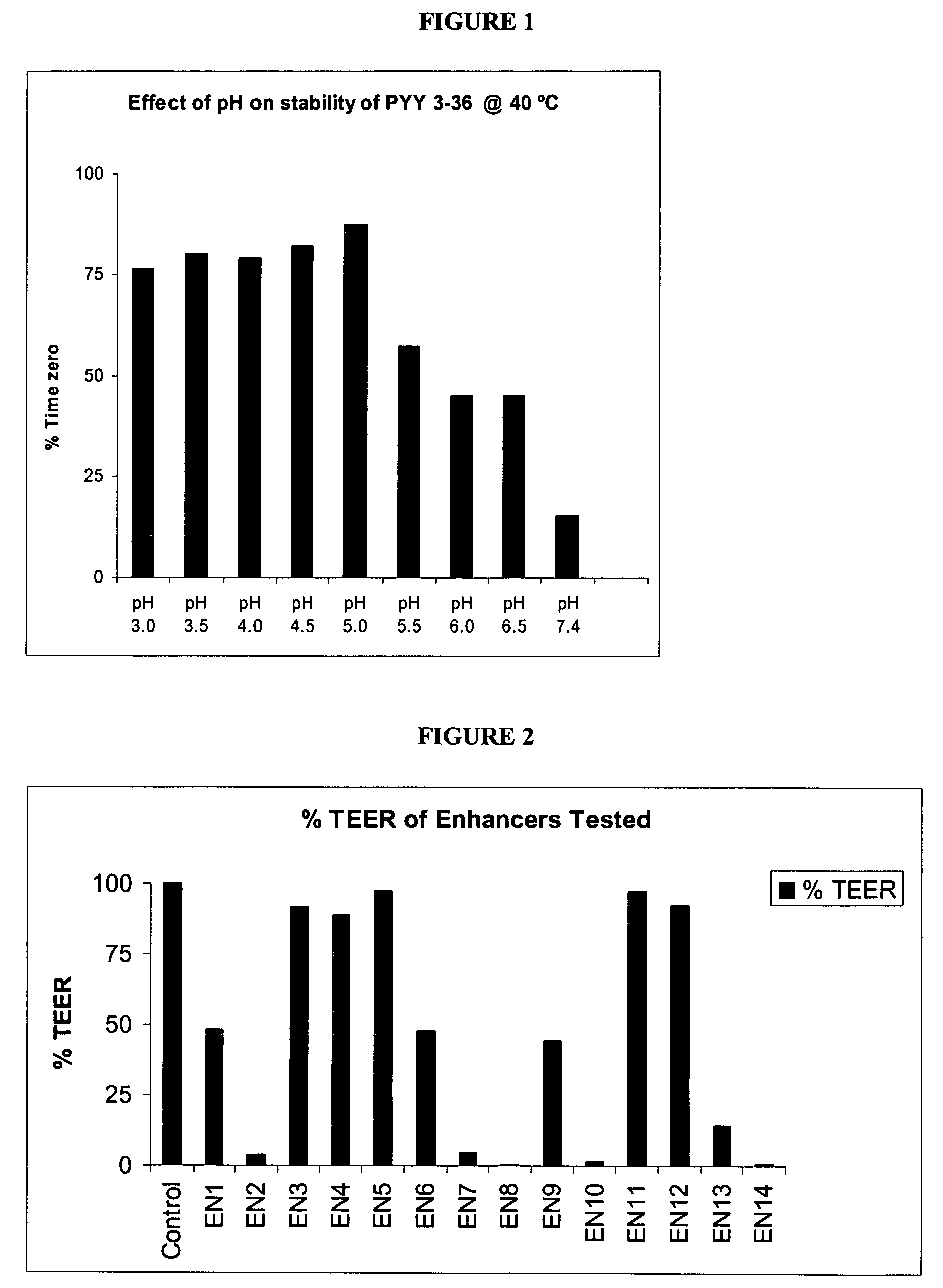

Compositions and methods for enhanced mucosal delivery of Y2 receptor-binding peptides and methods for treating and preventing obesity

InactiveUS7157426B2PromotePrevent and cure diabetesBiocideNervous disorderBinding peptideDense Core Vesicles

Pharmaceutical compositions and methods are described comprising at least one Y2 receptor-binding peptide, such as peptide YY(PYY), Neuropeptide Y (NPY) or Pancreatic Peptide (PP) and one or more mucosal delivery-enhancing agents for enhanced nasal mucosal delivery of the peptide YY, for treating a variety of diseases and conditions in mammalian subjects, including obesity.

Owner:MDRNA

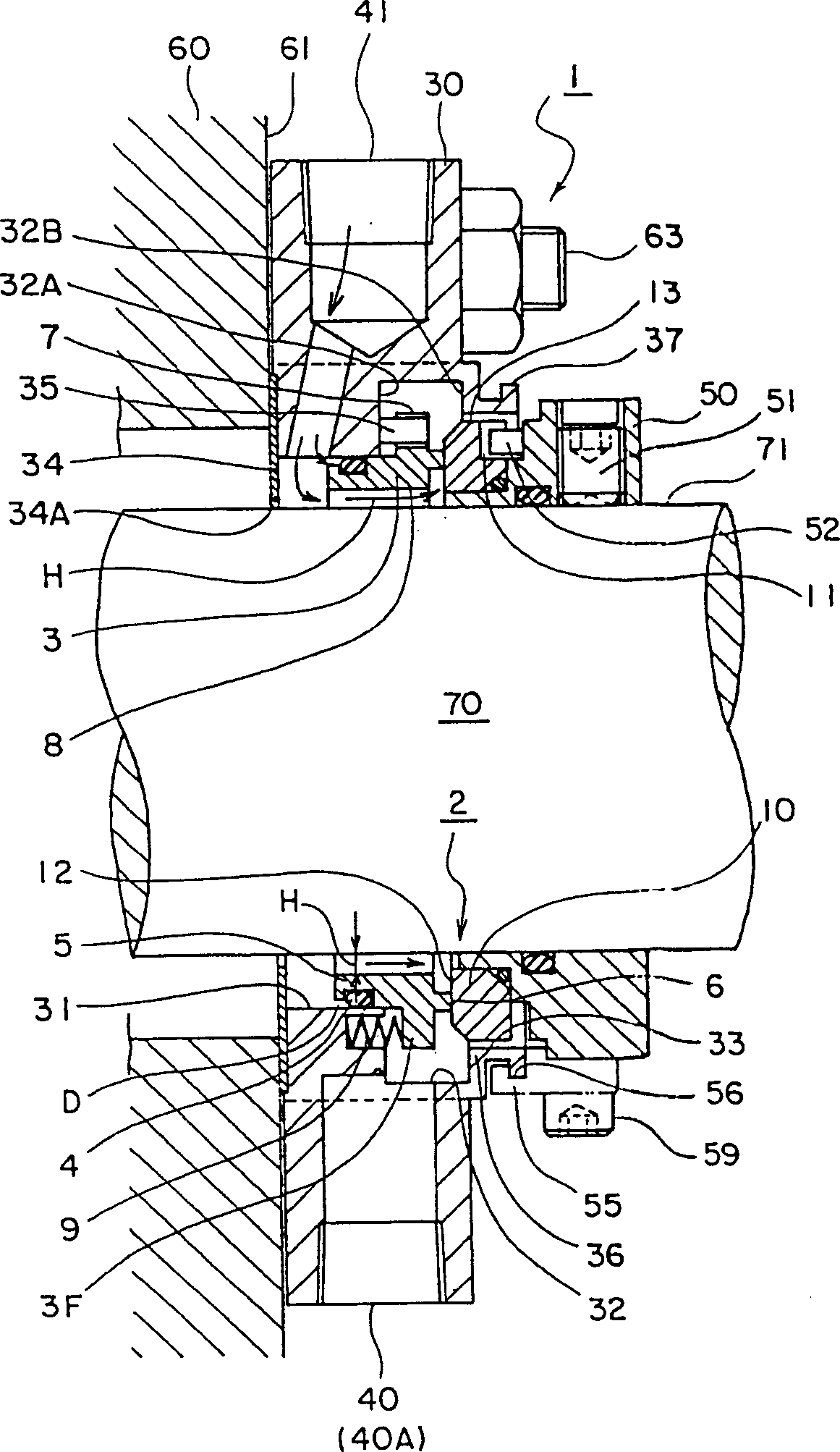

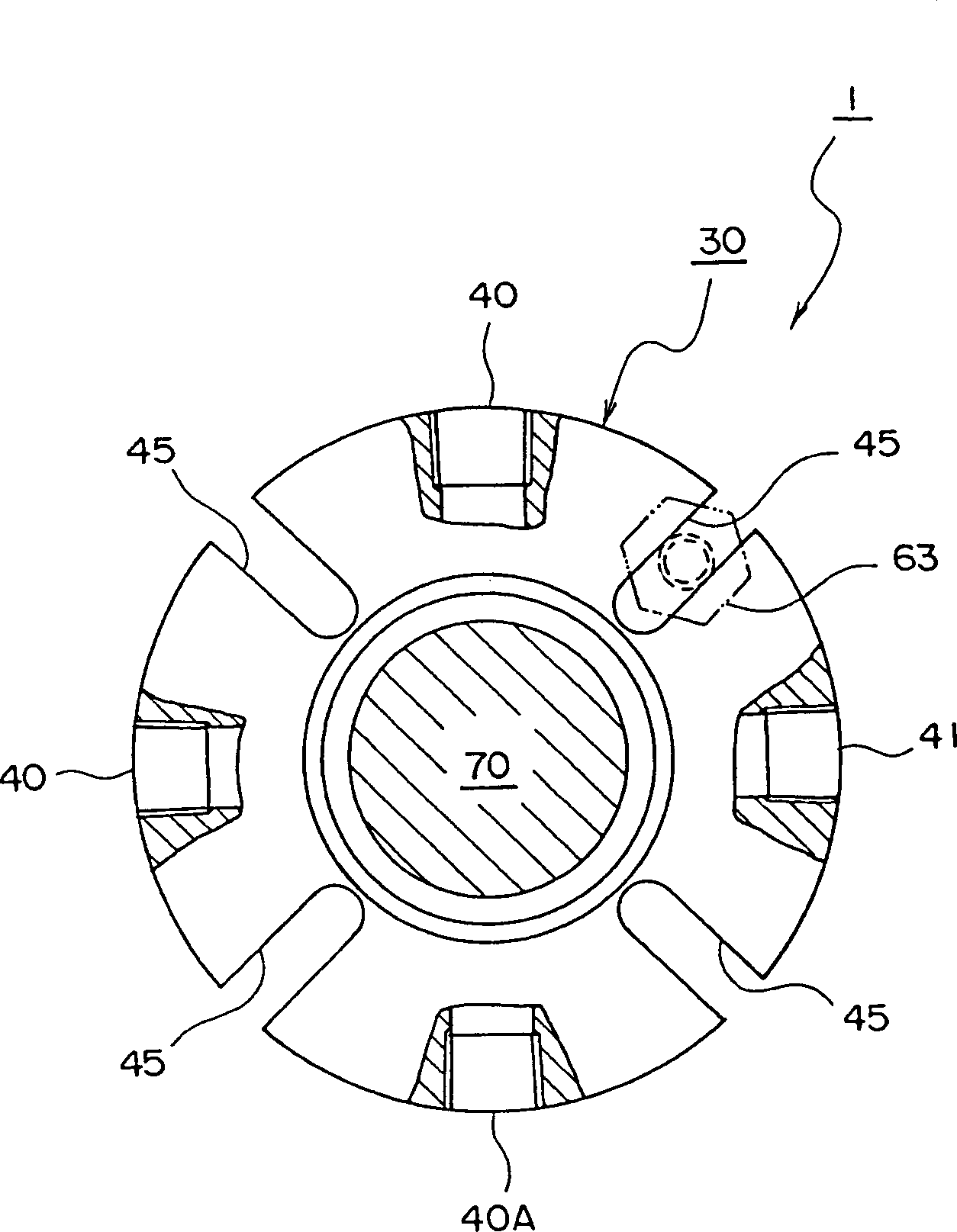

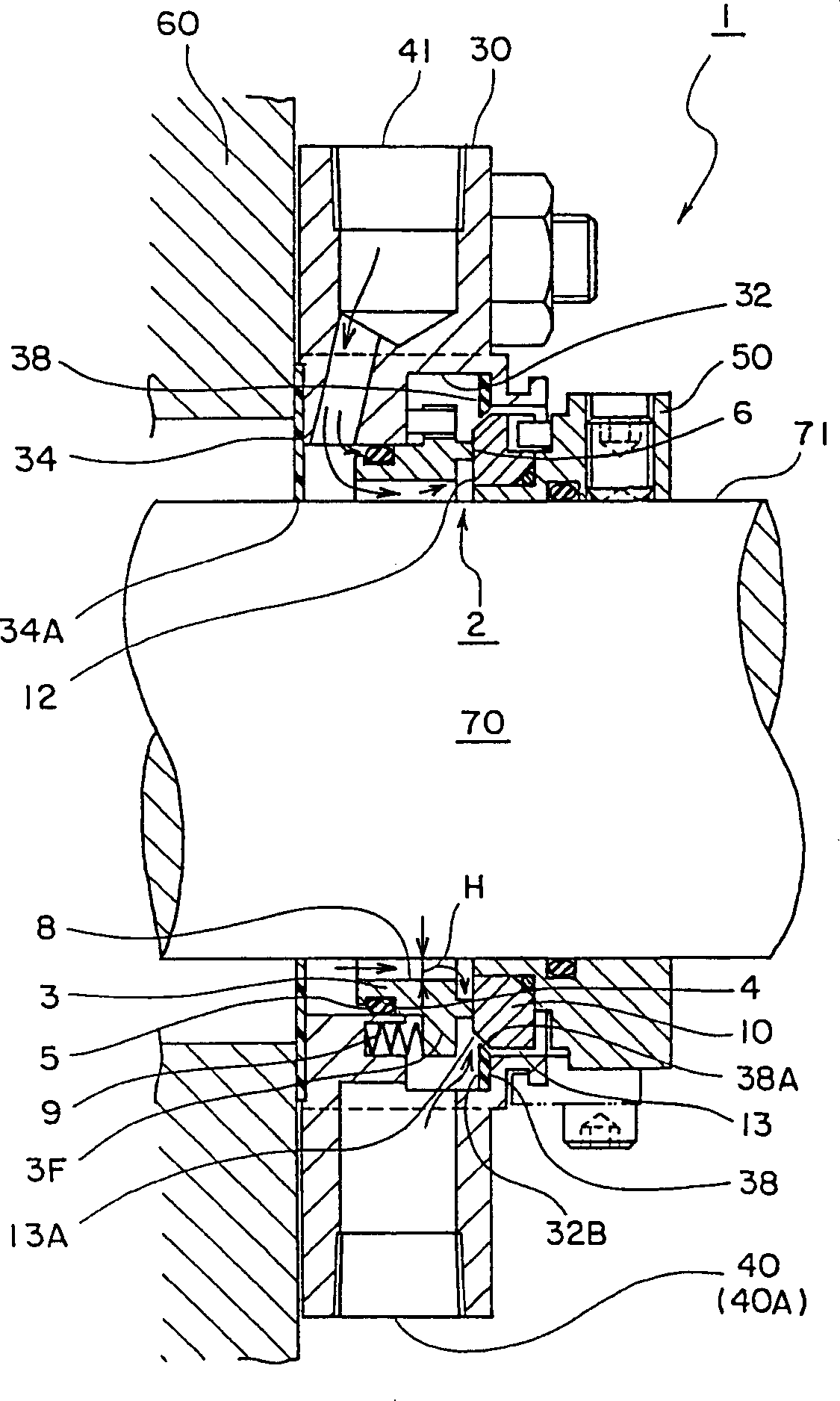

Mechanical seal device

A first seal ring (3) has a clearance H allowing the passage of a sealed fluid, between a shaft (70) and the first seal ring (3) and constituted to communicate a flushing port (41) with the inner peripheral side of the seal face (6) through the clearance (H). A mounting part (30) has a cooling annular groove (32) in the form of covering the seal face (6) of the first seal ring (3) mounted to the inner peripheral surface (8), from the outer diameter side, and the outer throttle face (33) of the cooling annular groove (32) is fitted in proximity to the outer peripheral seal face of a second seal ring (10) while having a cooling fluid passage (40) communicating with the cooling annular groove (32). The invention reduce the sliding heat of a seal face while preventing clogging and sticking of solid matter of a sealed fluid to a mechanical seal externally mounted to a device body.

Owner:EAGLE INDS

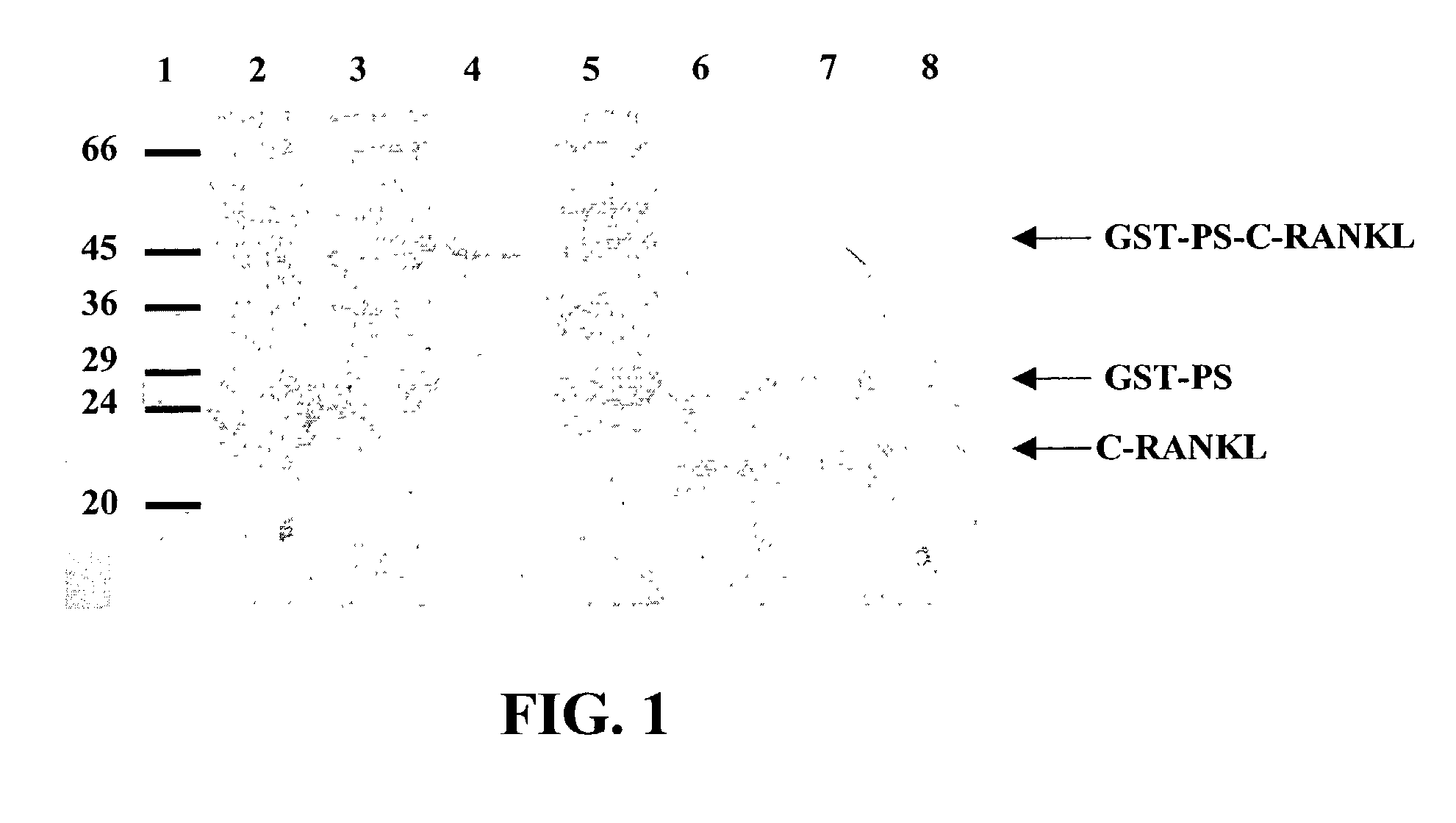

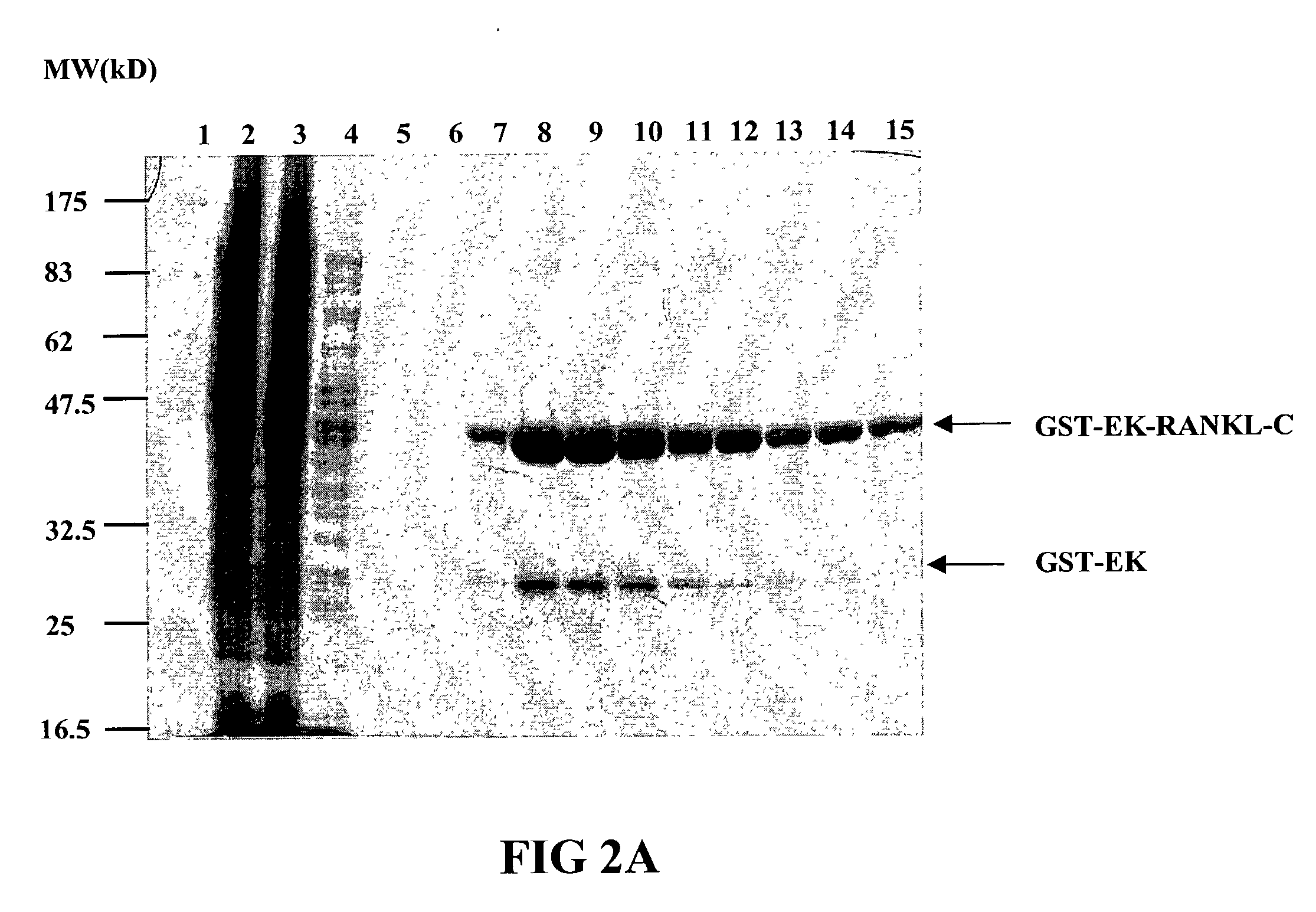

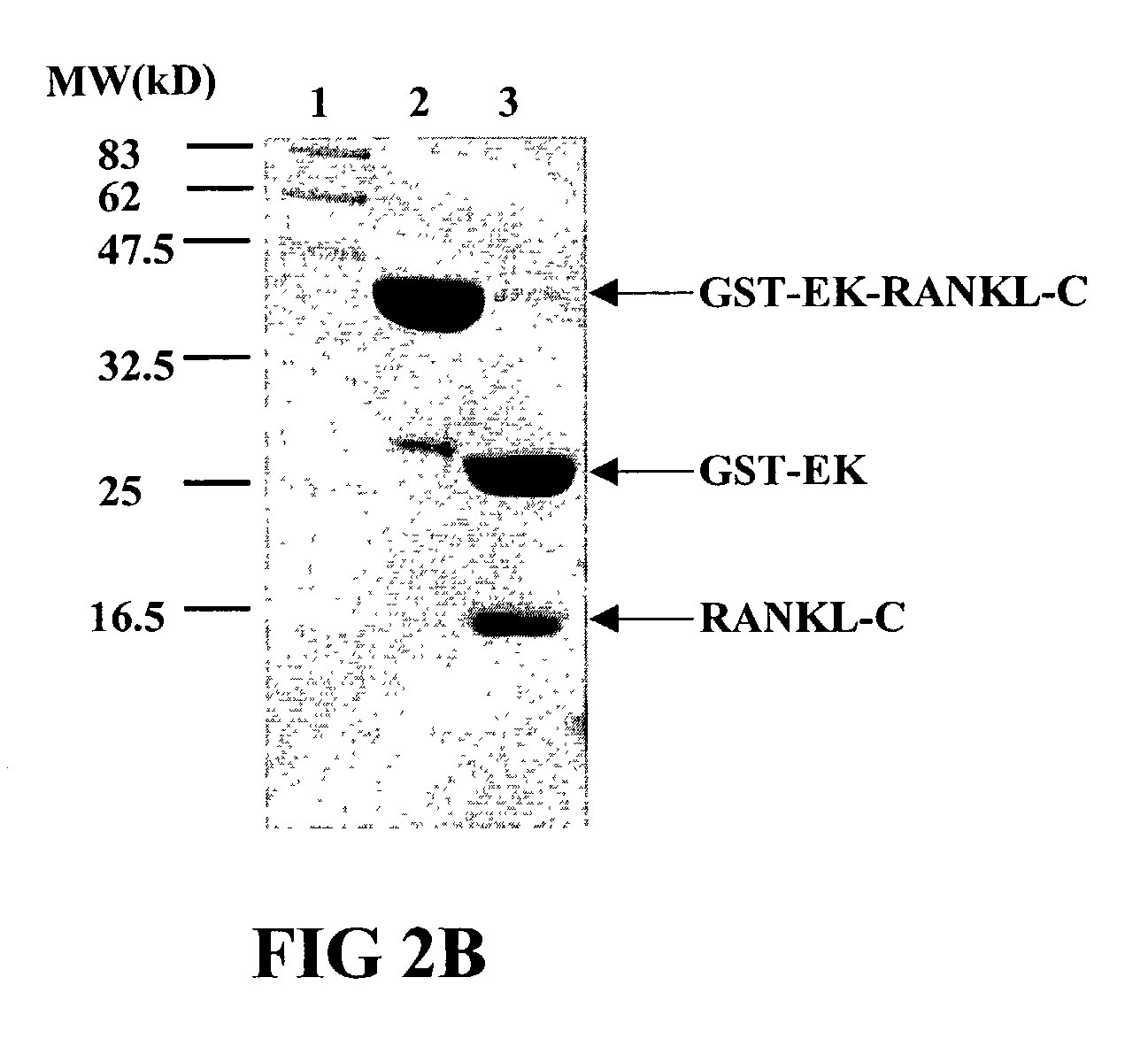

Antigen arrays for treatment of bone disease

InactiveUS7128911B2Induce high titer of anti-RANKLEfficient inductionVirusesPeptide/protein ingredientsDiseaseRANKL Protein

The present invention is related to the fields of molecular biology, virology, immunology and medicine. The invention provides a composition comprising an ordered and repetitive antigen or antigenic determinant array, and in particular a RANKL protein, RANKL fragment or RANKL peptide-VLP-array. More specifically, the invention provides a composition comprising a virus-like particle and at least one RANKL protein, RANKL fragment or RANKL peptide bound thereto. The invention also provides a process for producing the conjugates and the ordered and repetitive arrays, respectively. The compositions of the invention are useful in the production of vaccines for the treatment of bone diseases and as a pharmaccine to prevent or cure bone diseases and to efficiently induce immune responses, in particular antibody responses. Furthermore, the compositions of the invention are particularly useful to efficiently induce self-specific immune responses within the indicated context.

Owner:CYTOS BIOTECHNOLOGY AG

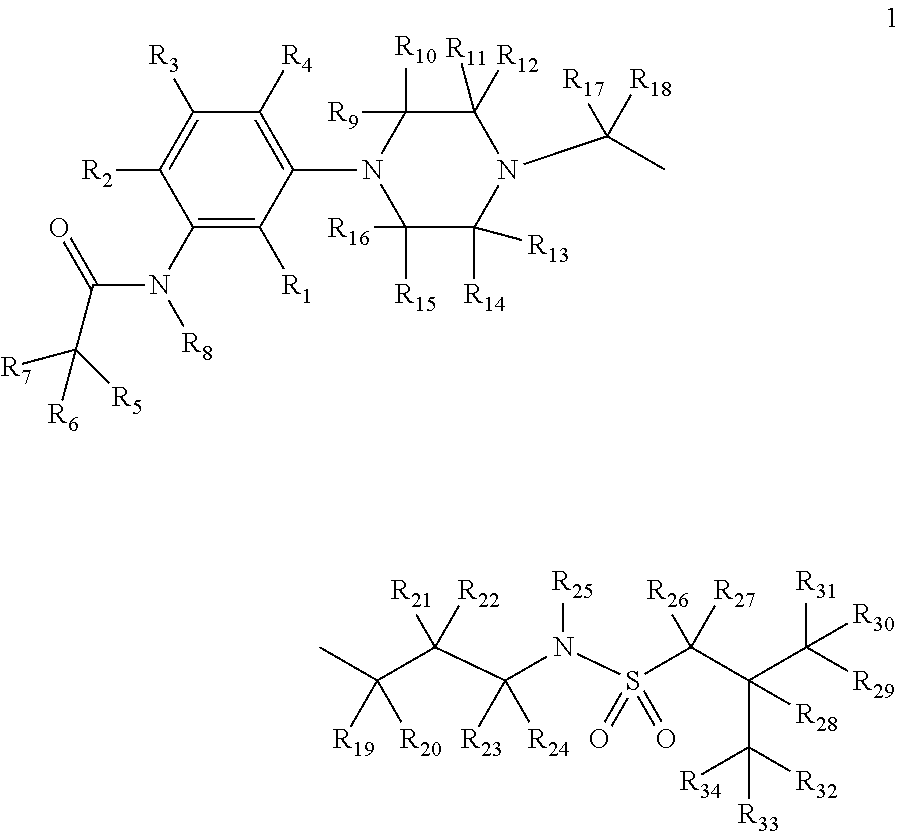

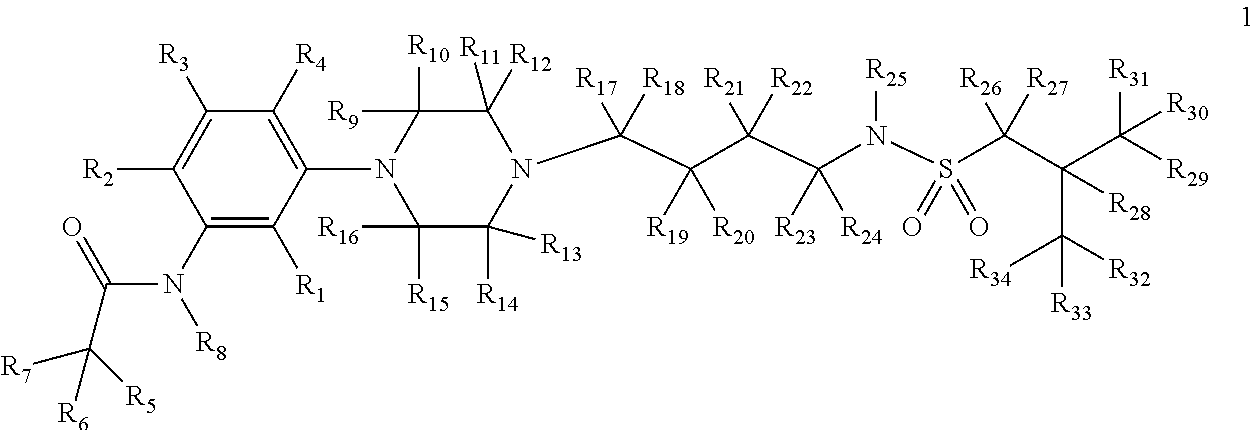

Deuterium-Enriched Alkyl Sulfonamides and Uses Thereof

ActiveUS20140221395A1Reduce appetitePrevent feedback inhibitionOrganic active ingredientsOrganic chemistrySleep disorderDementia

The present invention is concerned with deuterium-enriched sulfonamides of formula 1, their pharmaceutically acceptable salts and methods of use thereof for the treatment of anxiety disorders including, General Anxiety Disorder (GAD), Panic Disorder (PD), Post-Traumatic Stress Disorder (PTSD), Social Phobia (SP), Health Anxiety (Hypochondriasis), depression, major depressive disorders, unipolar depression, bipolar I depression disorder, bipolar II depression disorder, treatment-resistant depression, single episodic and recurrent major depressive disorders, depression in the medically ill, attention deficit hyperactivity disorder (ADHD), attention deficit disorder (ADD), Obsessive-Compulsive Disorder (OCD), Obsessive-Compulsive Personality Disorder (OCPD), Autism Spectrum Disorder (ASD), schizophrenia, psychosis, epilepsy, seizures, hot flashes due to menopause, age-related macular degeneration (AMD), premature ejaculation, male erectile dysfunction, sexual dysfunction, obesity, eating disorders, bulimia nervosa, anorexia nervosa, angina, migraine, pain, nociception, sleep disorders, insomnia, fibromyalgia, alcohol withdrawal, autism, Rett's syndrome, cyclothymic disorder, neural injury, neurodegenerative diseases, Parkinson's disease, Parkinson's disease psychosis, Huntington disease, Alzheimer's disease, frontotemporal dementia, cognitive impairment associated with age-related dementia, Alzheimer's disease, schizophrenia, psychosis, depression, pain or discomfort associated with surgery and pain or discomfort associated with medical illness.

Owner:DHANOA DALJIT SINGH

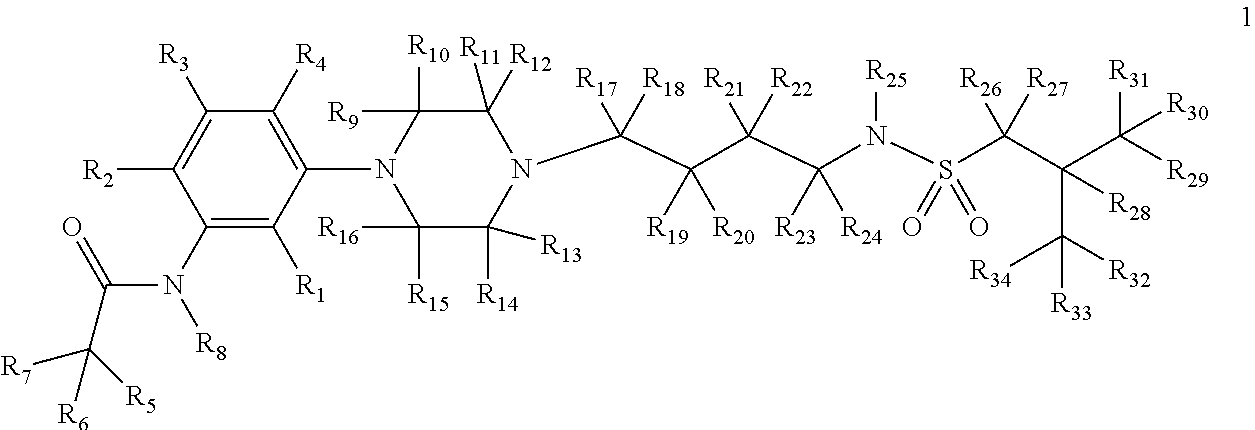

Polymer chemically-modified asphalt composition capable of being stably stored at high temperature and preparation method thereof

InactiveCN101613533AGood storage stability at high temperatureMeet usable requirementsBuilding insulationsElastomerViscous liquid

The invention relates to a high polymer chemically-modified asphalt composition and a preparation method thereof. The preparation method comprises the following steps: chemically modifying rubber, elastomer and base asphalt, and additionally matching stuffing and processing aids; premixing the materials by high polymer processing equipment to prepare the master batch of the modified asphalt; and fully dispersing the master batch into the asphalt by a high-speed shear mixer or by mechanical stirring. Or the modified asphalt material can be prepared by firstly pre-preparing a viscous liquid mixture of modified asphalt and then stirring and mixing the viscous liquid mixture of modified asphalt with the base asphalt. The modified asphalt material prepared by the invention has stable storage performance at high temperature, good performance at high temperature and low temperature, stable processing and preparation and simple and convenient method, and not only can be directly used in factory production but also can be used for road laying sites and in the construction of waterproofing materials.

Owner:NORTHWEST NORMAL UNIVERSITY

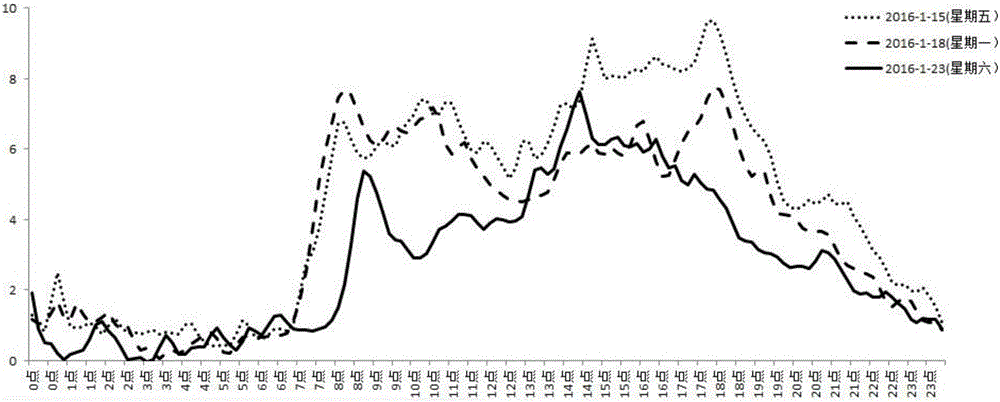

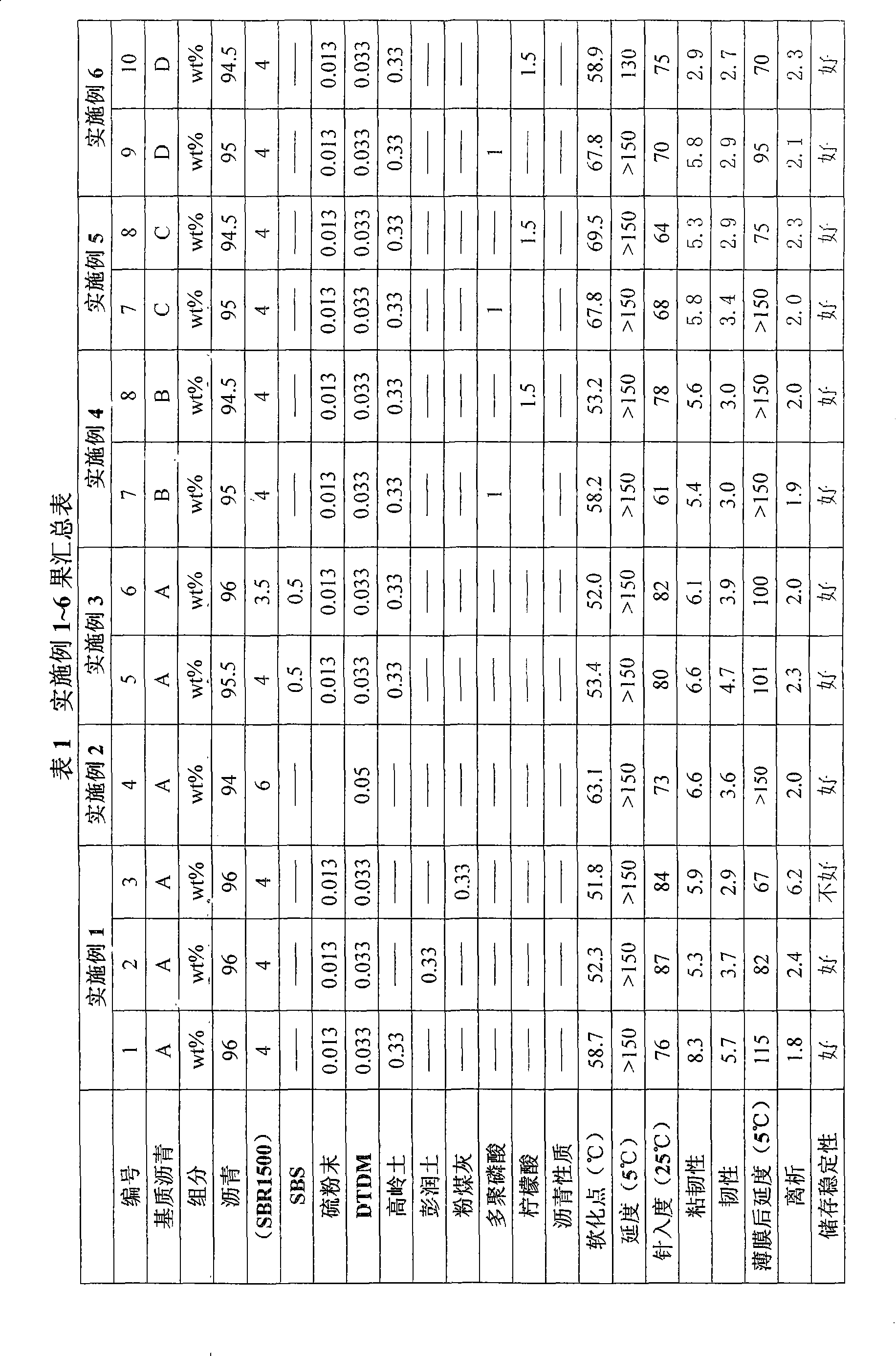

Urban traffic-oriented traffic index calculation method

ActiveCN104715610ACompatible with running speedImprove accuracyDetection of traffic movementSpecial data processing applicationsTraffic capacityMicrowave

The invention relates to an urban traffic-oriented traffic index calculation method. The calculation method is defined by flow and a vehicle speed, and is based on commonly used microwave data and floating car data in urban traffic; and historical or real-time traffic indexes of a road network can be determined by adopting methods such as data fusion, statistical modeling and mathematical modeling. The urban traffic-oriented traffic index calculation method has the characteristics of high accuracy of calculation result, high adaptivity, low cost, high feasibility, simplicity and convenience of calculation process, low time complexity and high operation speed.

Owner:ENJOYOR COMPANY LIMITED

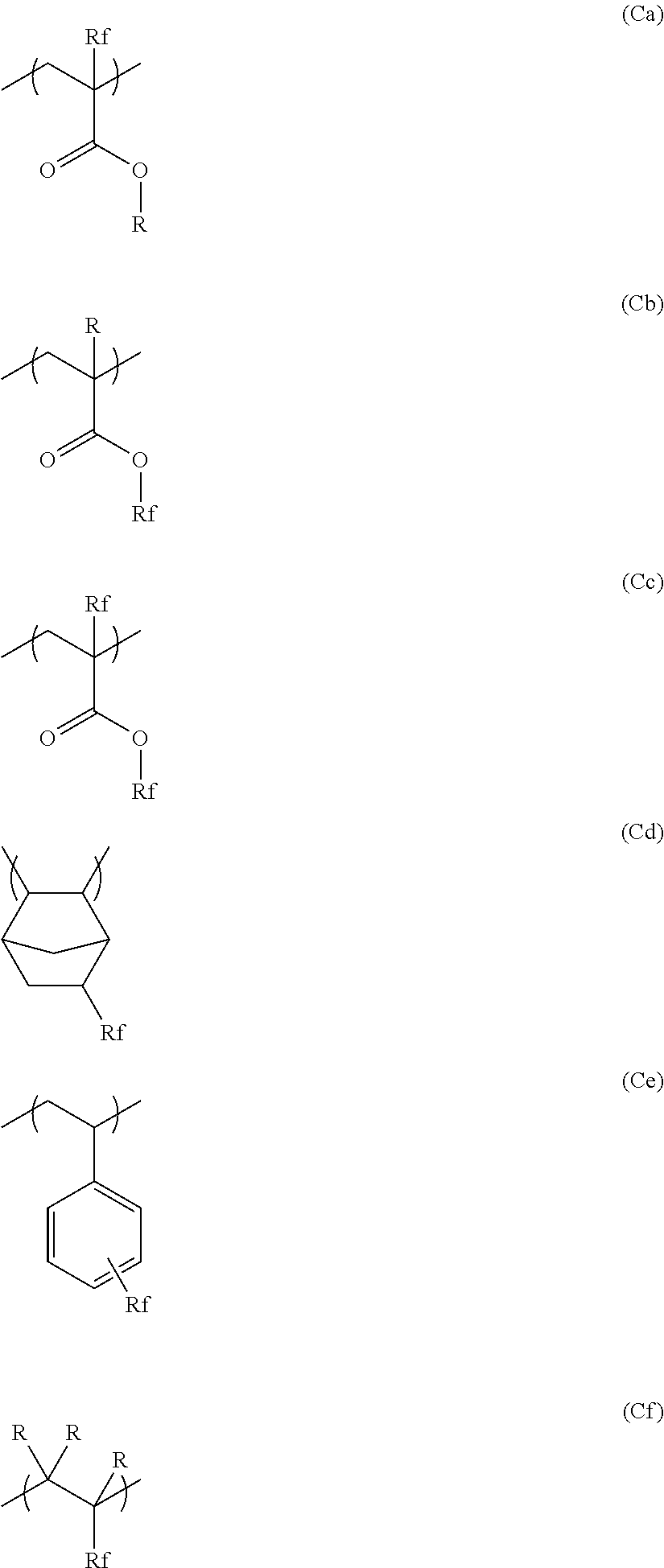

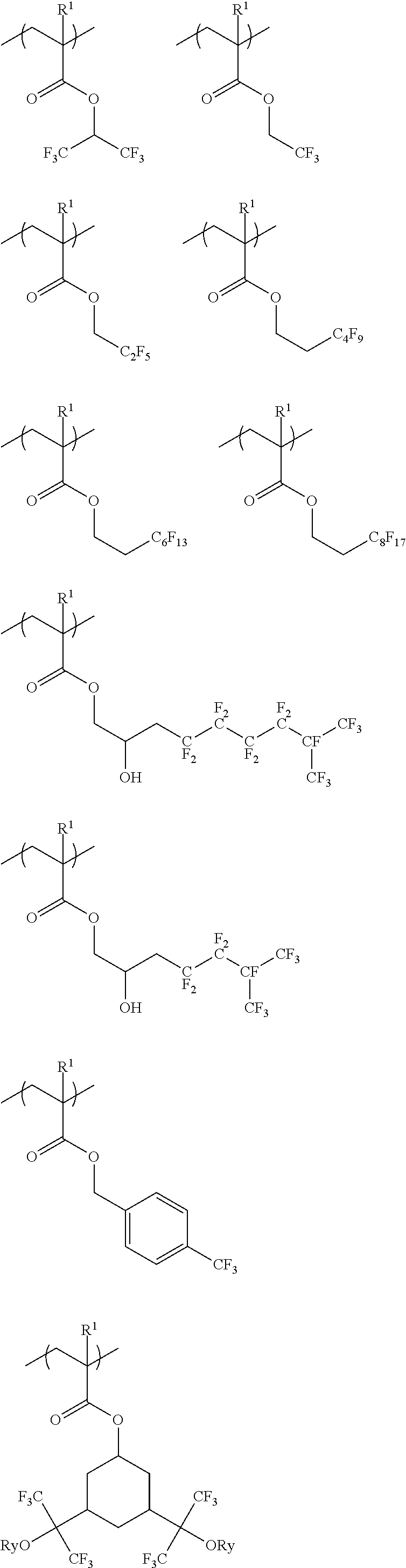

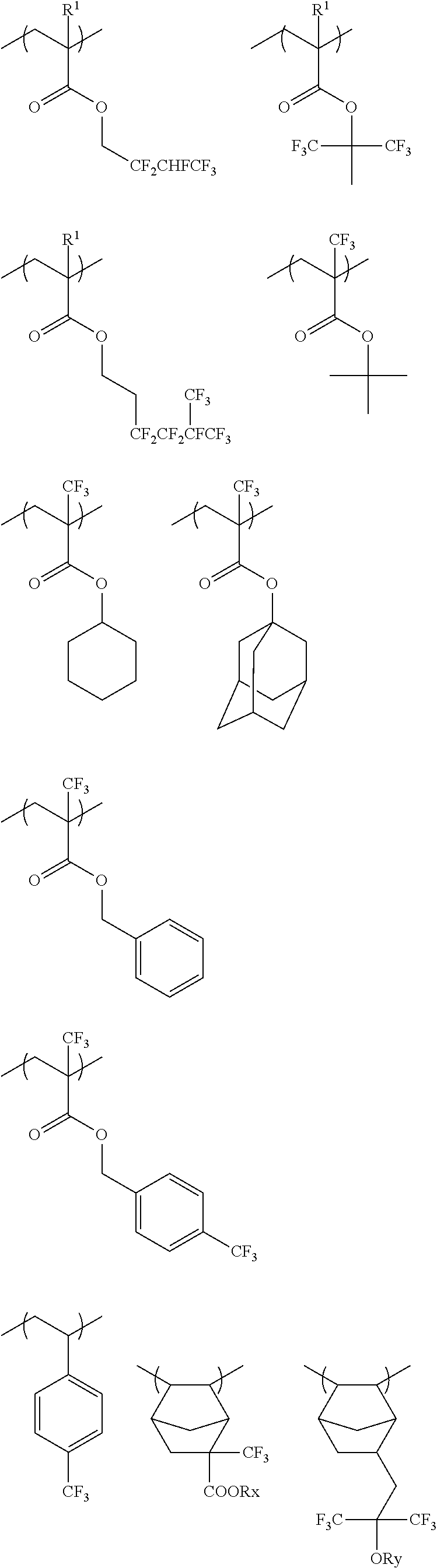

Composition for imprints, pattern and patterning method

InactiveUS20110183127A1Hardly worsening mold transferabilityImprove coating uniformityLayered productsDecorative surface effectsSiliconContamination

A composition for imprints comprising a polymerizable monomer, a photopolymerization initiator, and a polymer having a functional group with at least one of a fluorine atom or a silicon atom and having a polymerizable functional group, wherein the polymer has a weight-average molecular weight of at least 2000 and the amount of the polymer is from 0.01 to 20% by mass relative to the polymerizable monomer, is excellent in patternability and mold releasability, capable of forming good patterns and free from a problem of mold contamination.

Owner:FUJIFILM CORP

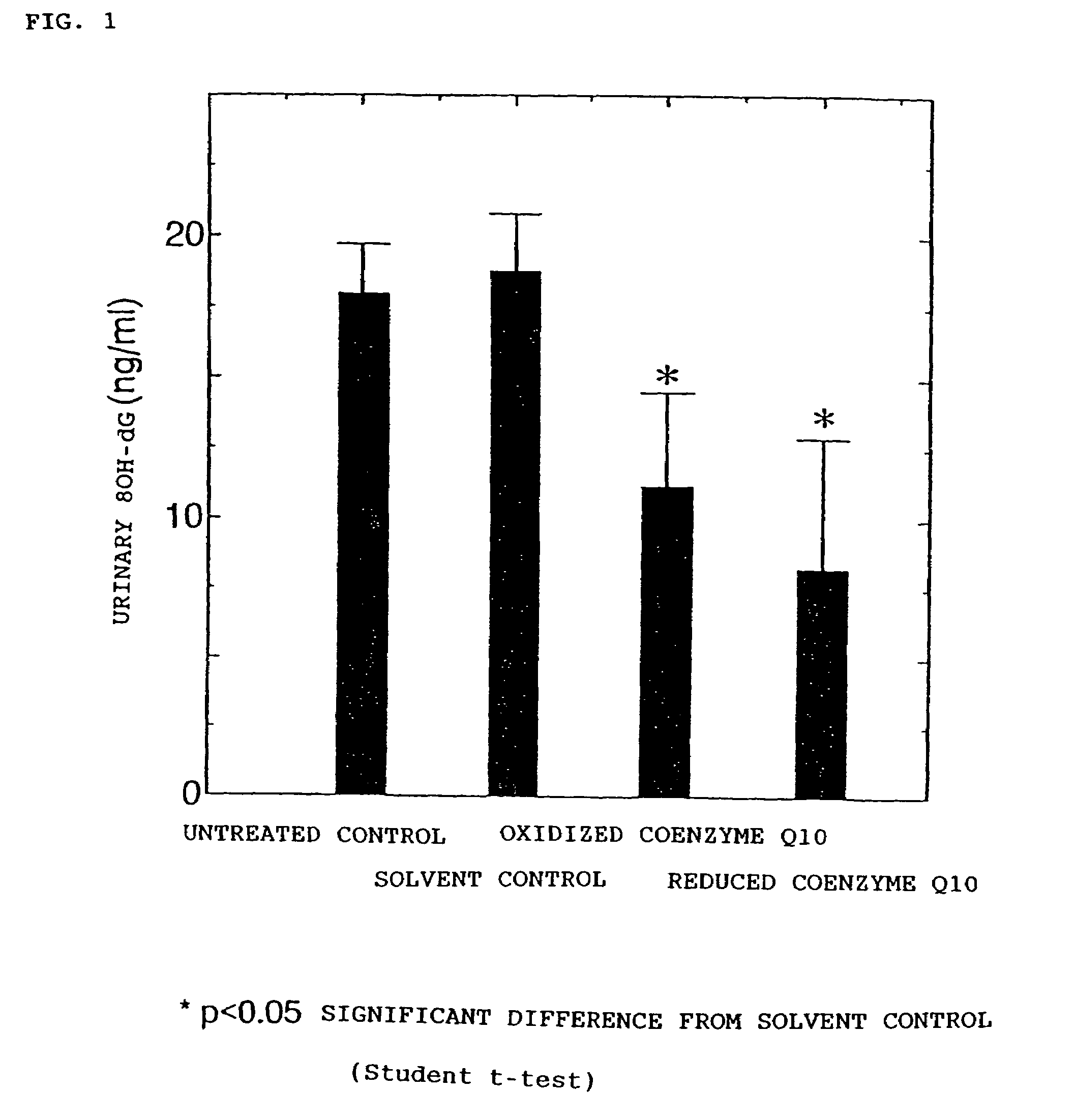

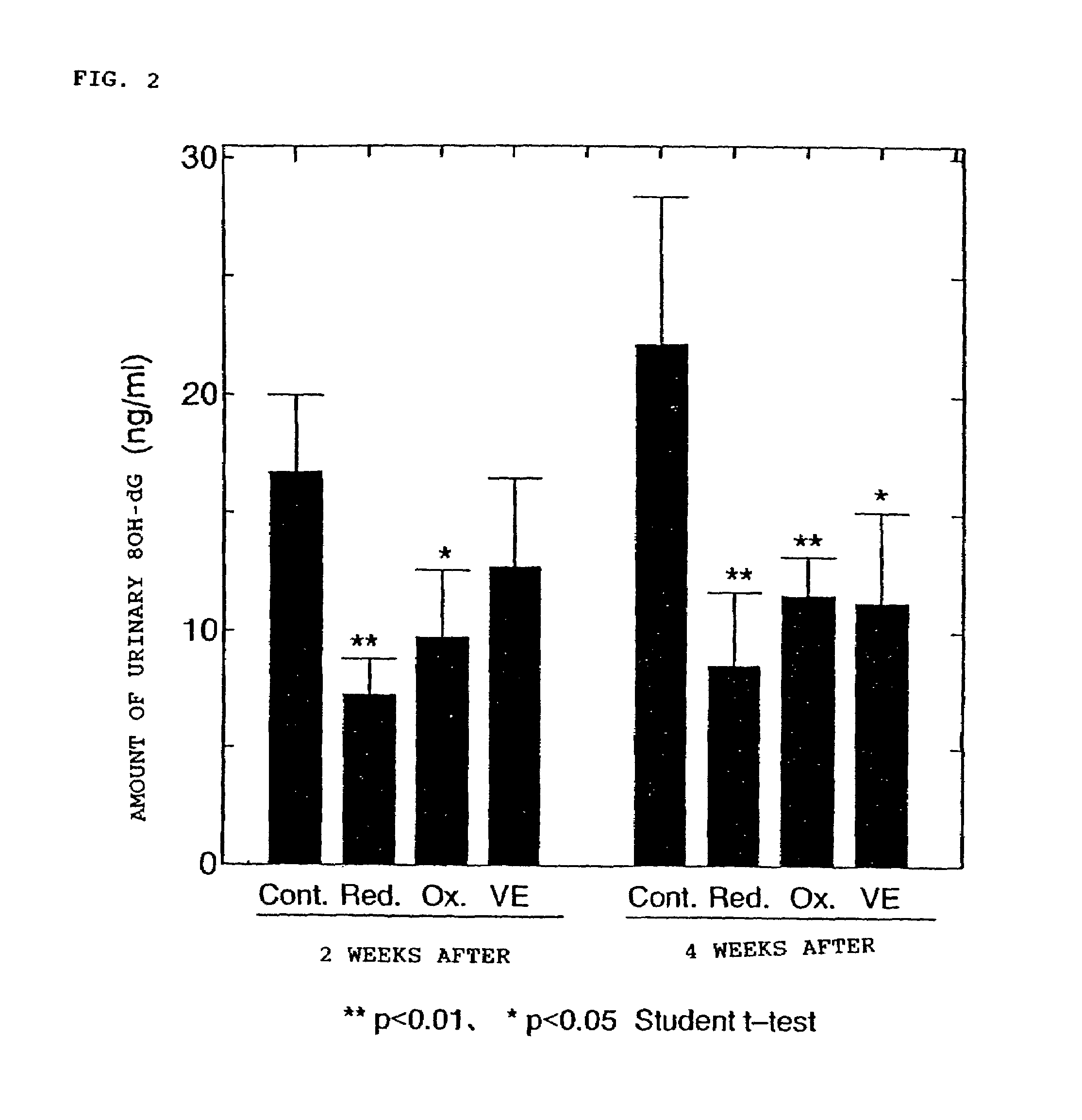

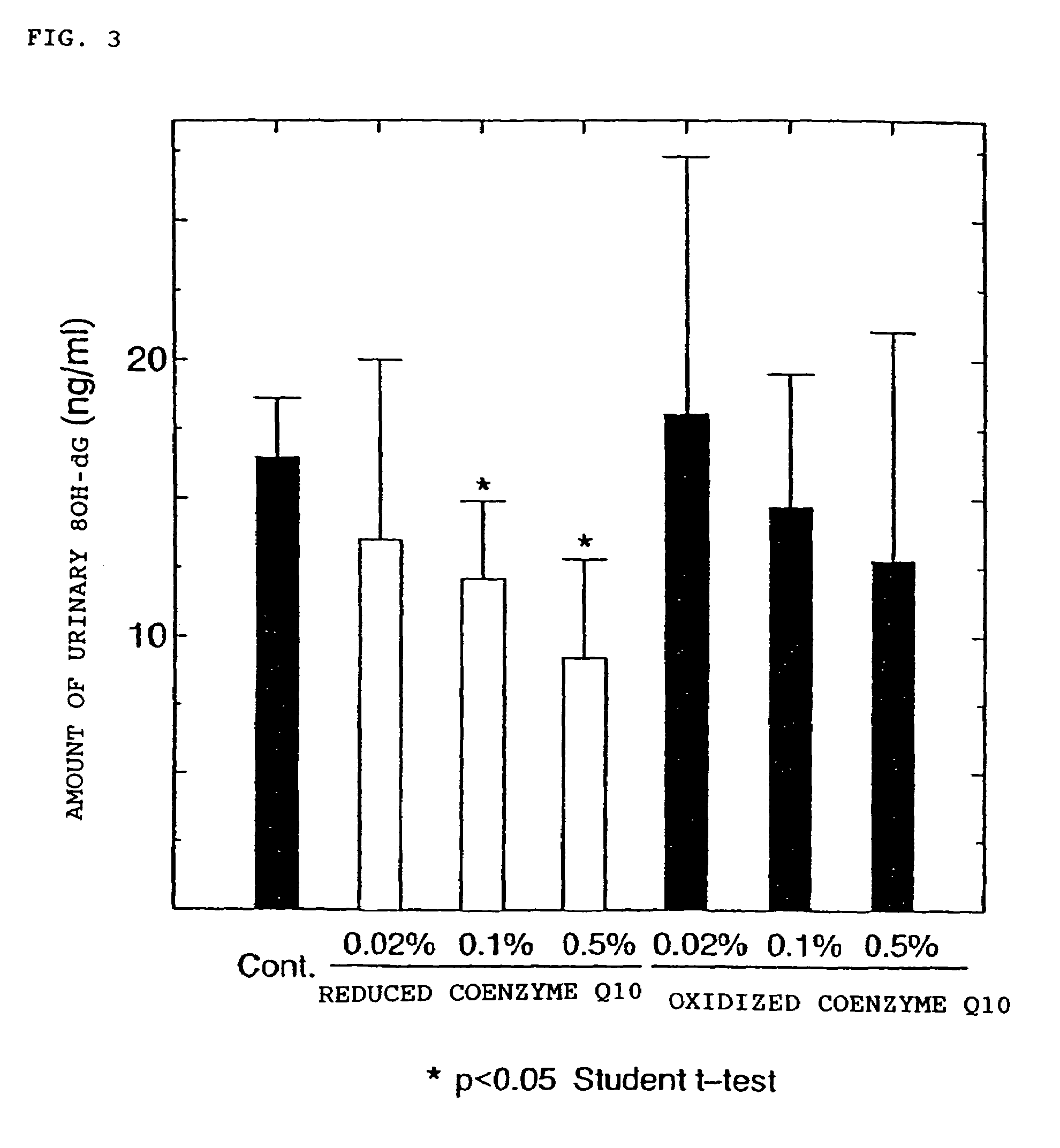

Compositions for lessening oxidative stress

InactiveUS7015252B2Improve securityReduce oxidative stressBiocidePeptide/protein ingredientsDiseaseAdditive ingredient

The present invention provides an antioxidative composition with high safety, which is capable of lessening oxidative stress due to active oxygen species, free radicals, or the like in vivo, thereby preventing the occurrence or worsening of a disease. It was confirmed that by using a composition containing oxidized coenzyme Q and / or reduced coenzyme Q, the amount of urinary 8-hydroxydeoxyquanosine can be decreased in normal or diabetic animals. Also, in histopathological research of the spleens of diabetic rats, it was confirmed that spleen tissue denaturation caused by oxidative stress can be prevented. It was thus found that oxidative stress in vivo can be lessened. According to the present invention, oxidative stress in vivo can be lessened by using a composition containing coenzyme Q as an active ingredient.

Owner:KANEKA CORP

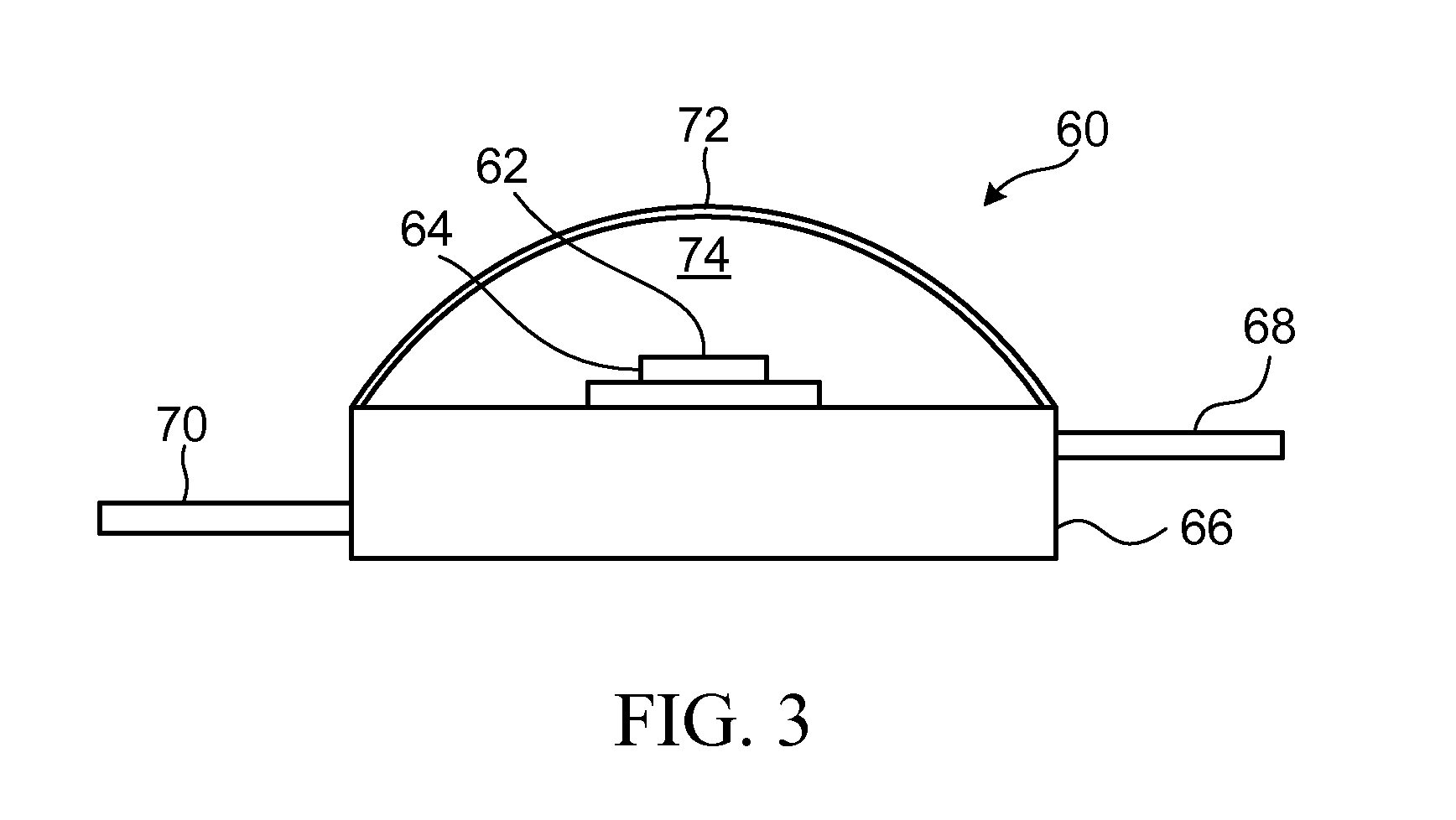

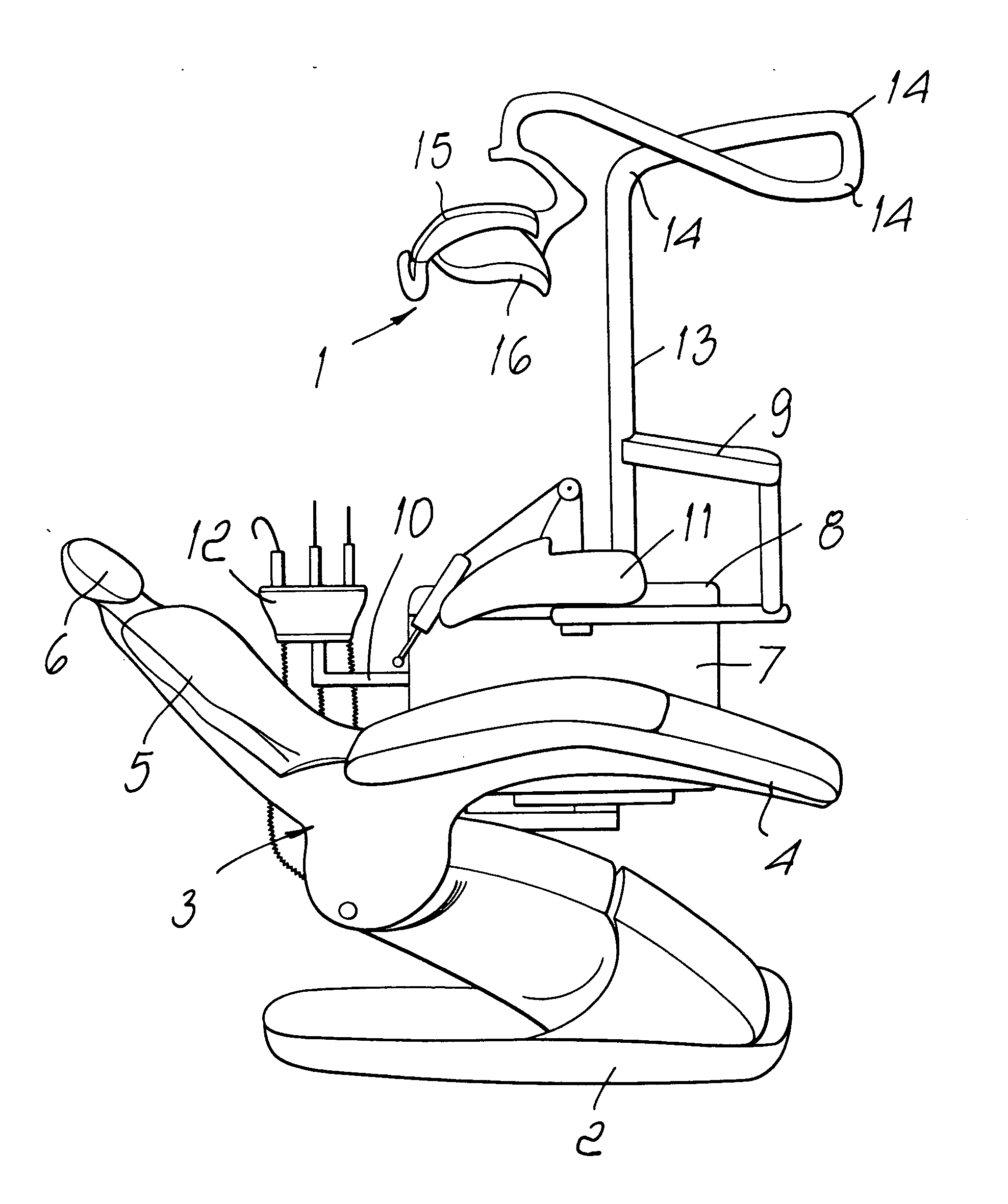

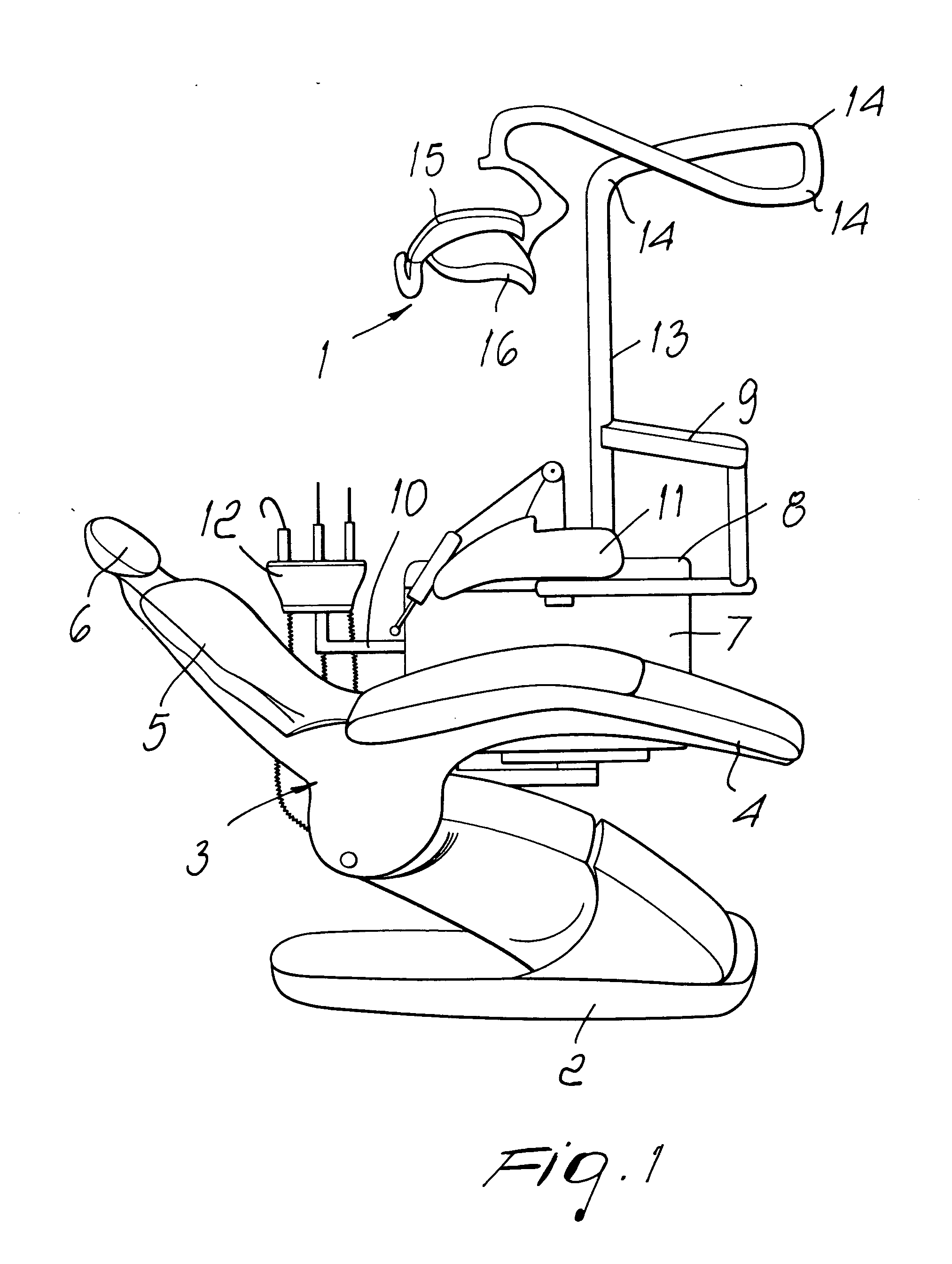

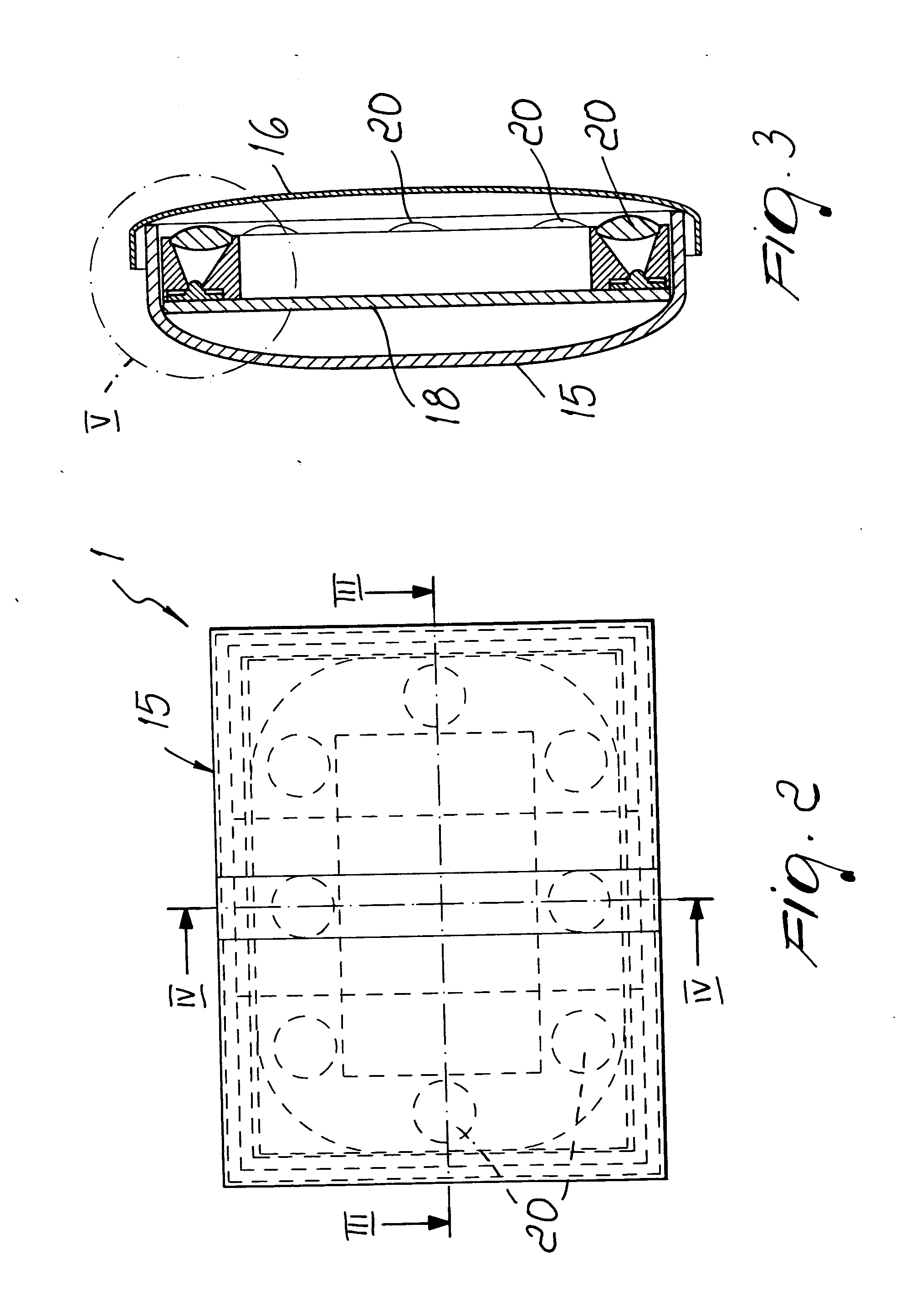

Dental lamp particularly for medical and dental surgeries

InactiveUS20060002135A1Reduce heat emissionsPrevent curingMechanical apparatusSurgeryDental surgeryLight beam

A dental lamp particularly for medical and dental surgeries, comprising an orientable arm that is rigidly coupled at one of its ends to a fixed structure and has the opposite end rotatably associated with a box-like body provided with a screen and a light source. The light source comprises a plurality of luminescent diodes, known as LEDs, which are aligned with respective guides for the emitted light beam, the beam emission directions of all the diodes being substantially convergent.

Owner:EURODENT

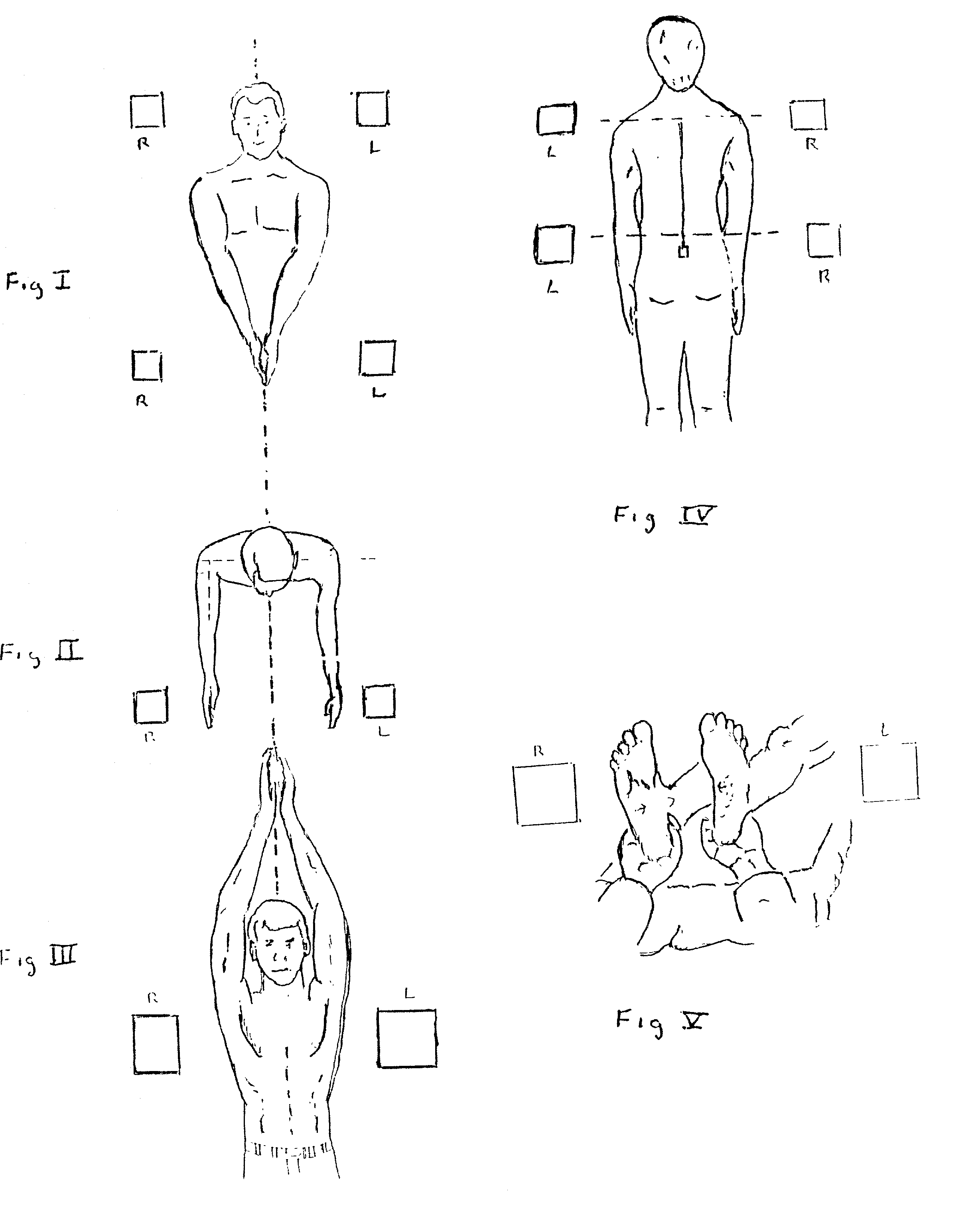

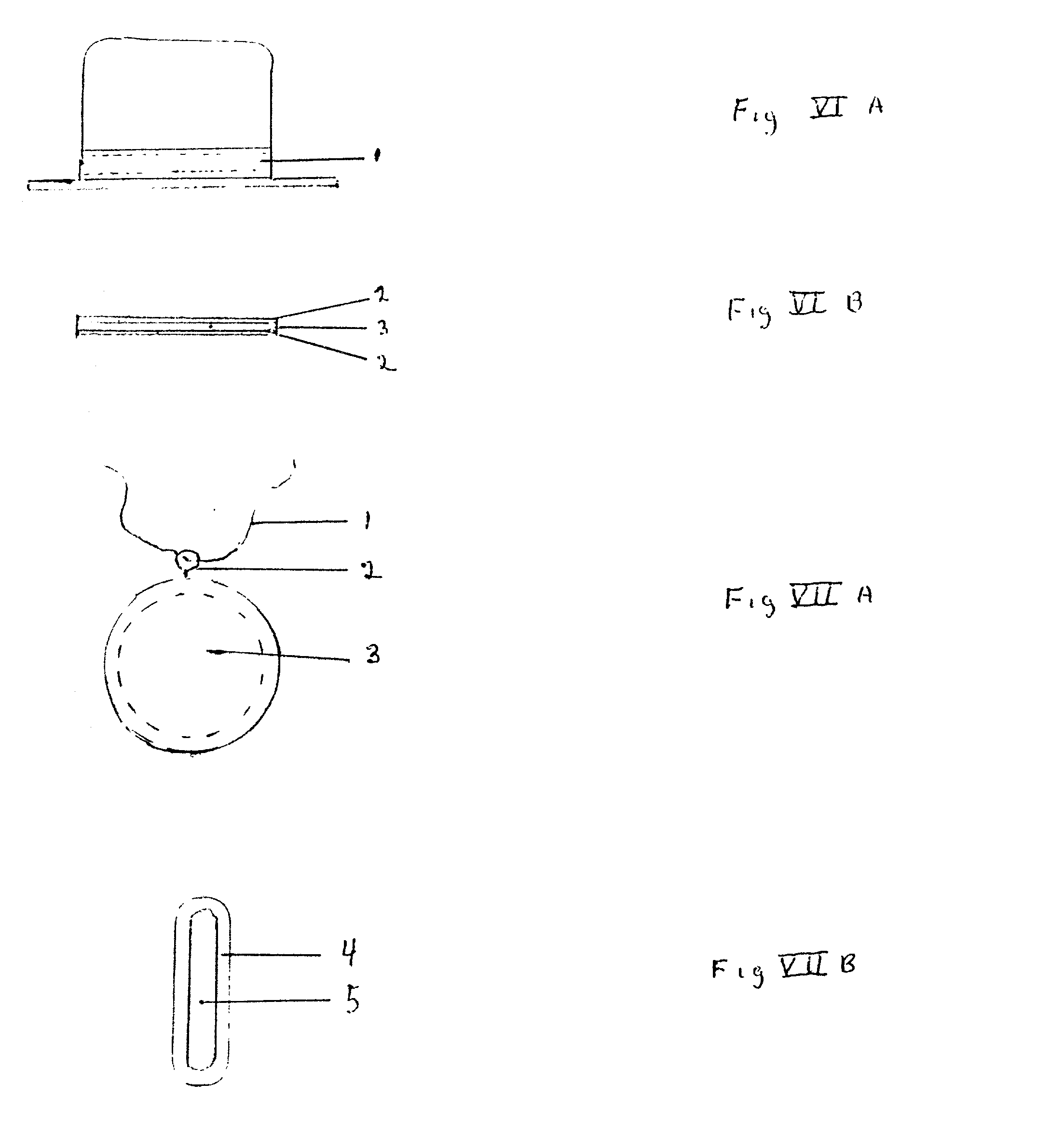

Proprioceptive device that contains nutrients for the treatment of stratural diseases

InactiveUS20020156340A1Preserve integrityDirect contact guaranteeElectrotherapyDiagnosticsDiseaseProprioception

An article such as a locket (sole insert, patch, or other device to hold nutrients in on the body), which incorporates at least one nutrient, which is capable of emitting electromagnetic waves that stimulate proprioceptive zones throughout the body, resulting in a therapeutic effect for the treatment and / or the prevention of problems connected to statural equilibrium.

Owner:BLENDERMANN EDWARD LUDWIG

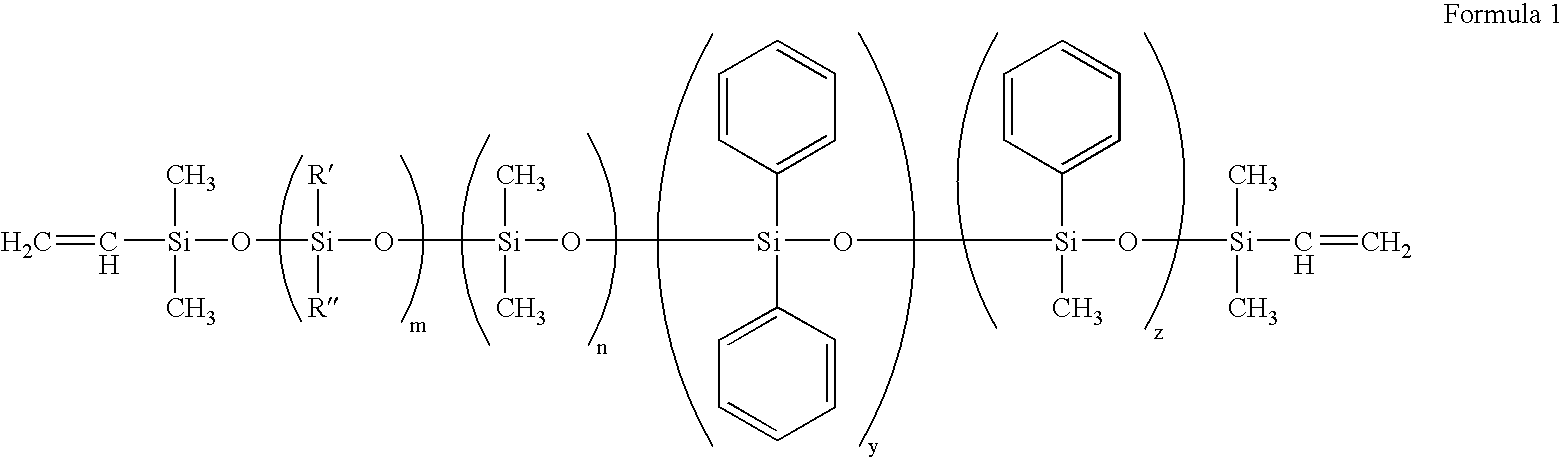

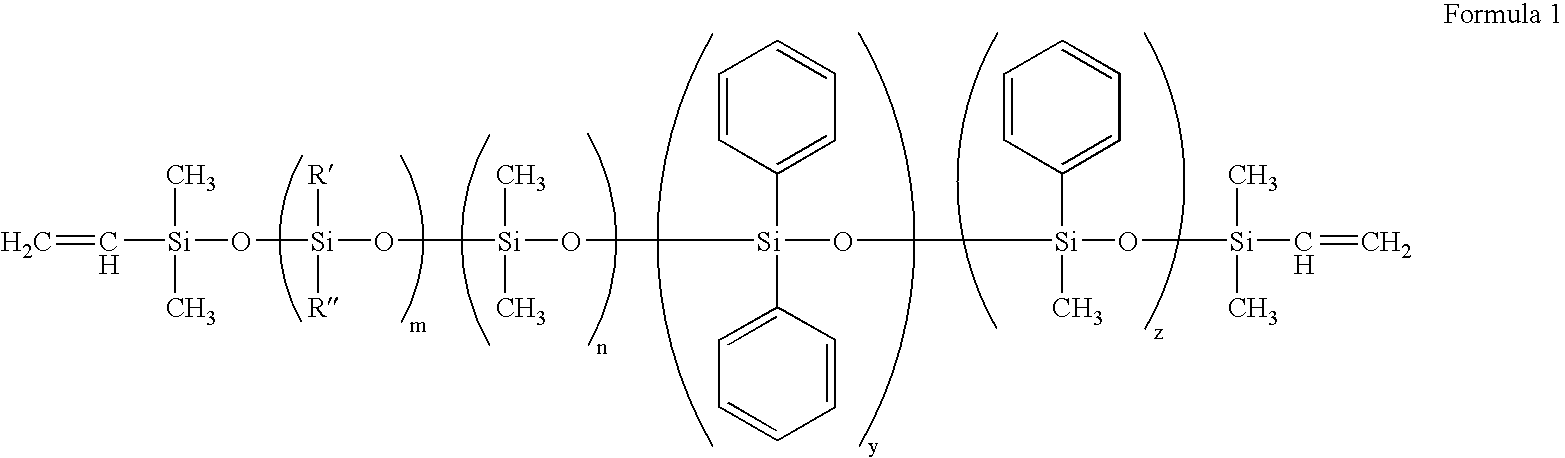

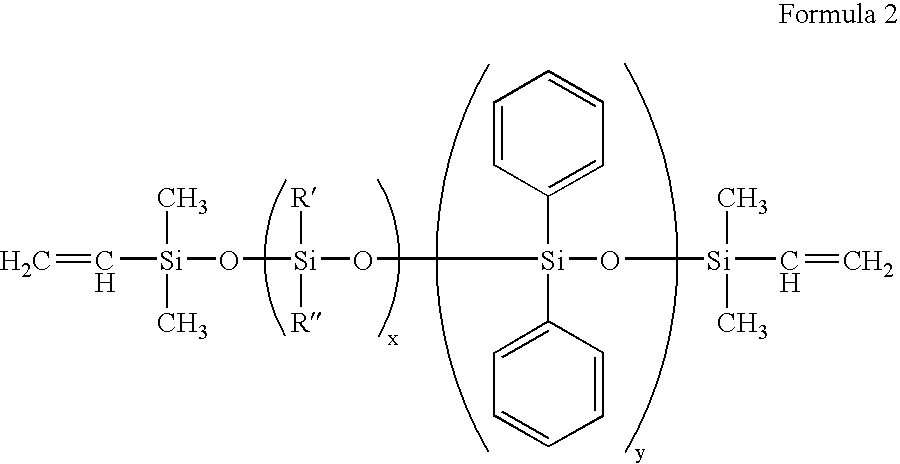

Polymer compositions suitable for intraocular lenses and related methods

ActiveUS20090088839A1Reduces hydride/vinyl ratioPrevent curingTissue regenerationAdhesivesCross-linkPolymer science

A polymeric material with a molecular response time that makes it suitable for use near fragile body tissues. The polymeric material is useful for both low modulus and high modulus applications thereby simplifying the multi-part polymeric article manufacturing process and creating better integrated multi-part polymeric articles. Cross-linked polymers with different moduli may be obtained utilizing the same or similar starting materials but modifying the amount of catalyst, the amount of cross-linking agent, and / or the amount of methyl vinyl cyclics.

Owner:JOHNSON & JOHNSON SURGICAL VISION INC

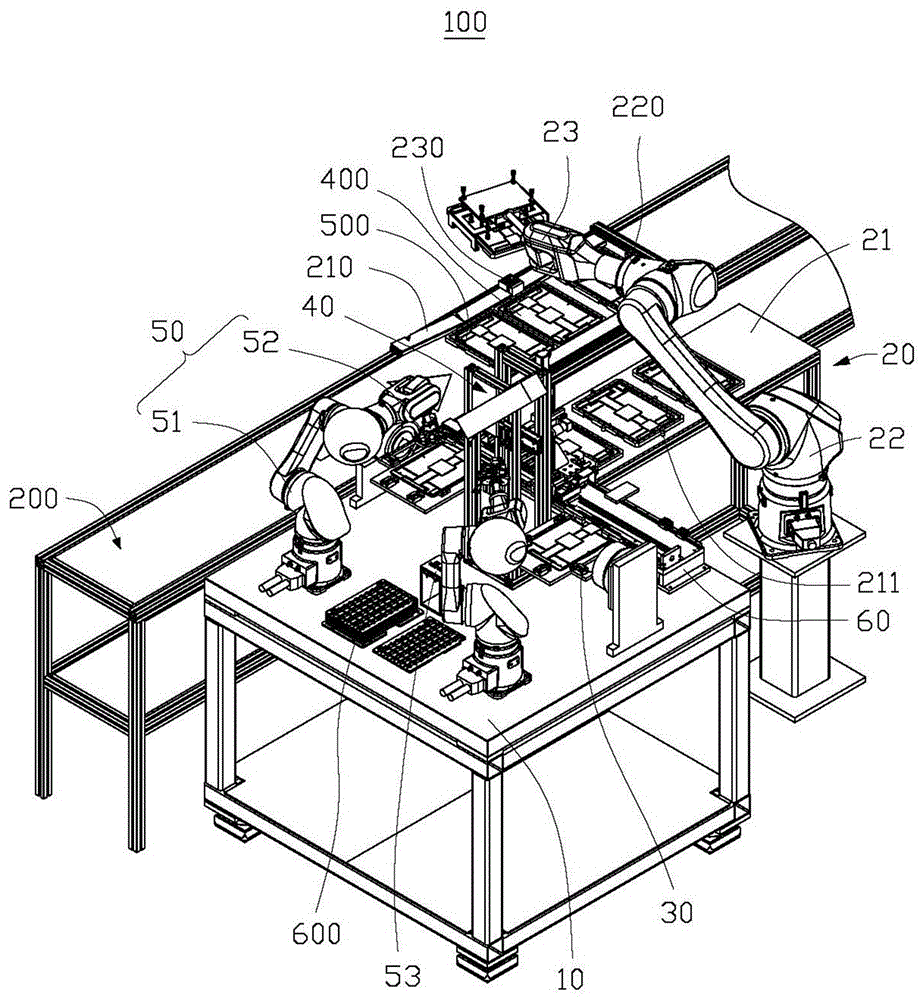

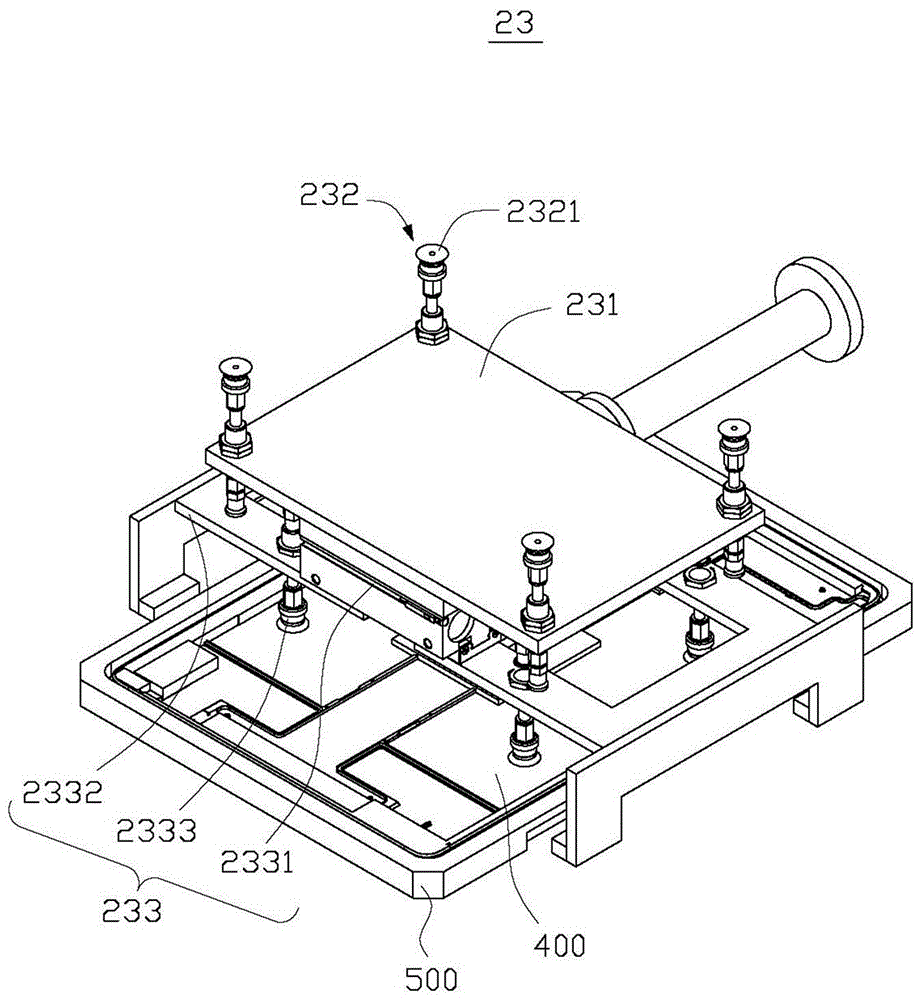

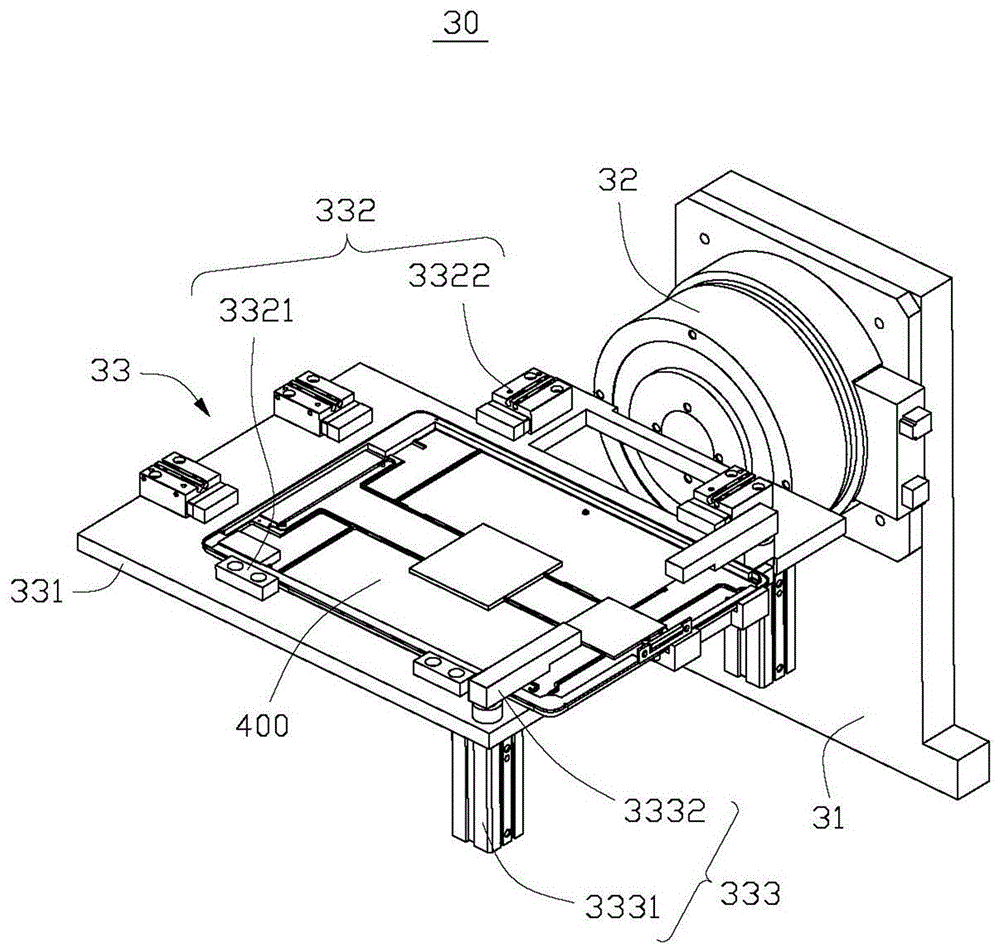

Automatic assembling device

InactiveCN107438357AImprove assembly efficiency and assembly yieldImprove stabilityTotal factory controlElectrical componentsAssembly lineHeating element

The invention provides an automatic assembling device, which is used for being matched with an assembly line to assemble accessories on workpieces. The automatic assembling device comprises a workbench, a loading module, a positioning module, a dispensing module, an assembly module, an electric control module and a detection module fixed on the workbench, wherein the loading module is used for conveying the workpieces to the positioning module; the positioning module, the dispensing module and the assembly module are fixed on the workbench separately; the positioning module is used for positioning the workpieces; the dispensing module is used for carrying out gluing treatment on the accessories; the assembly module is used for mounting the accessories subjected to gluing treatment to the workpieces and comprises a heating element; the heating element is used for carrying out preheating treatment on the accessories; and the detection module comprises two detectors, one detector is used for detecting the deviation when the accessories and the workpieces are assembled and aligned and feeding back the deviation to the assembly module to adjust the assembly positions, and the other detector is used for detecting the offset between the assembled accessories and the corresponding workpieces to screen out unqualified workpieces.

Owner:FU TAI HUA IND SHENZHEN +1

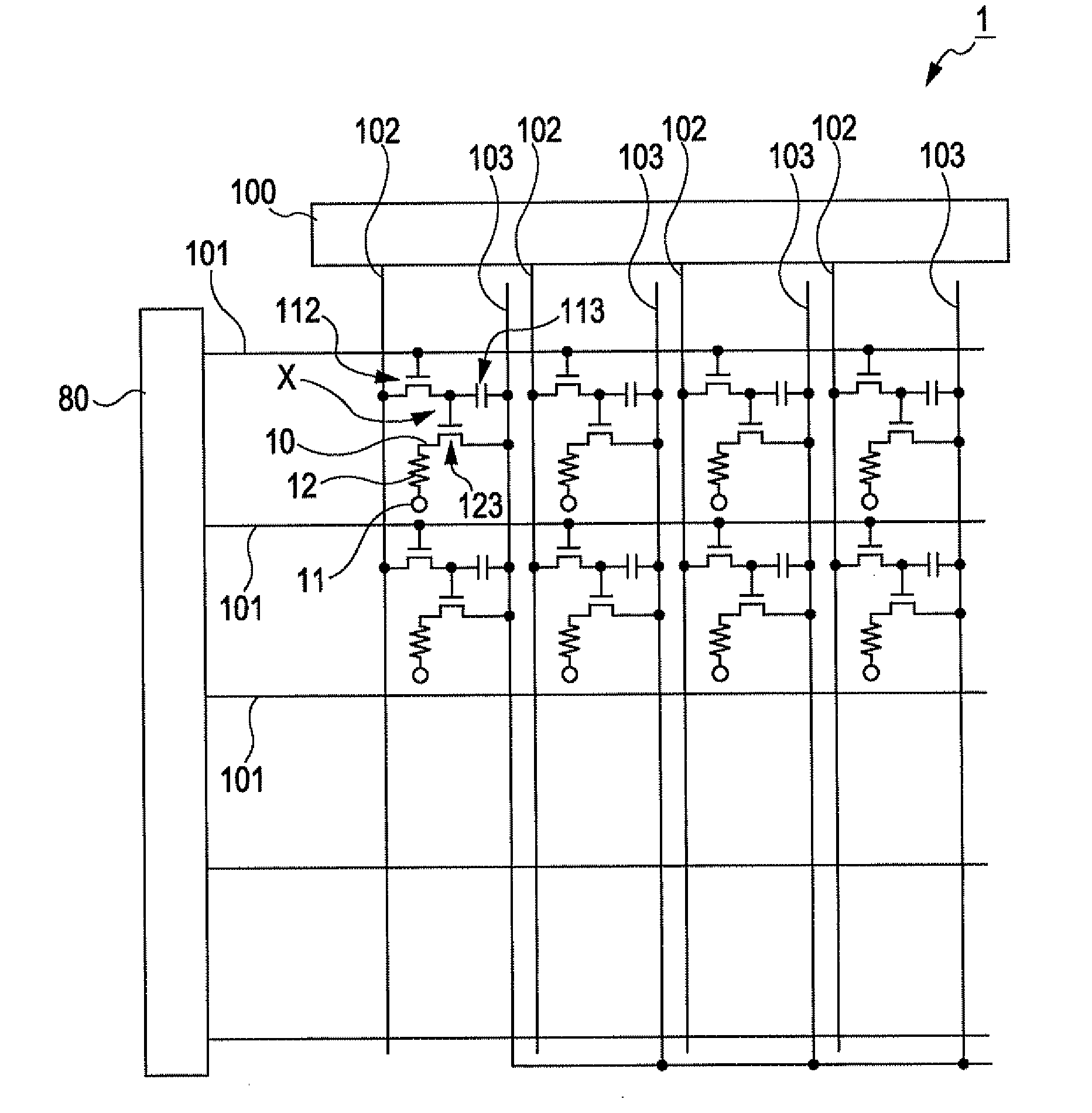

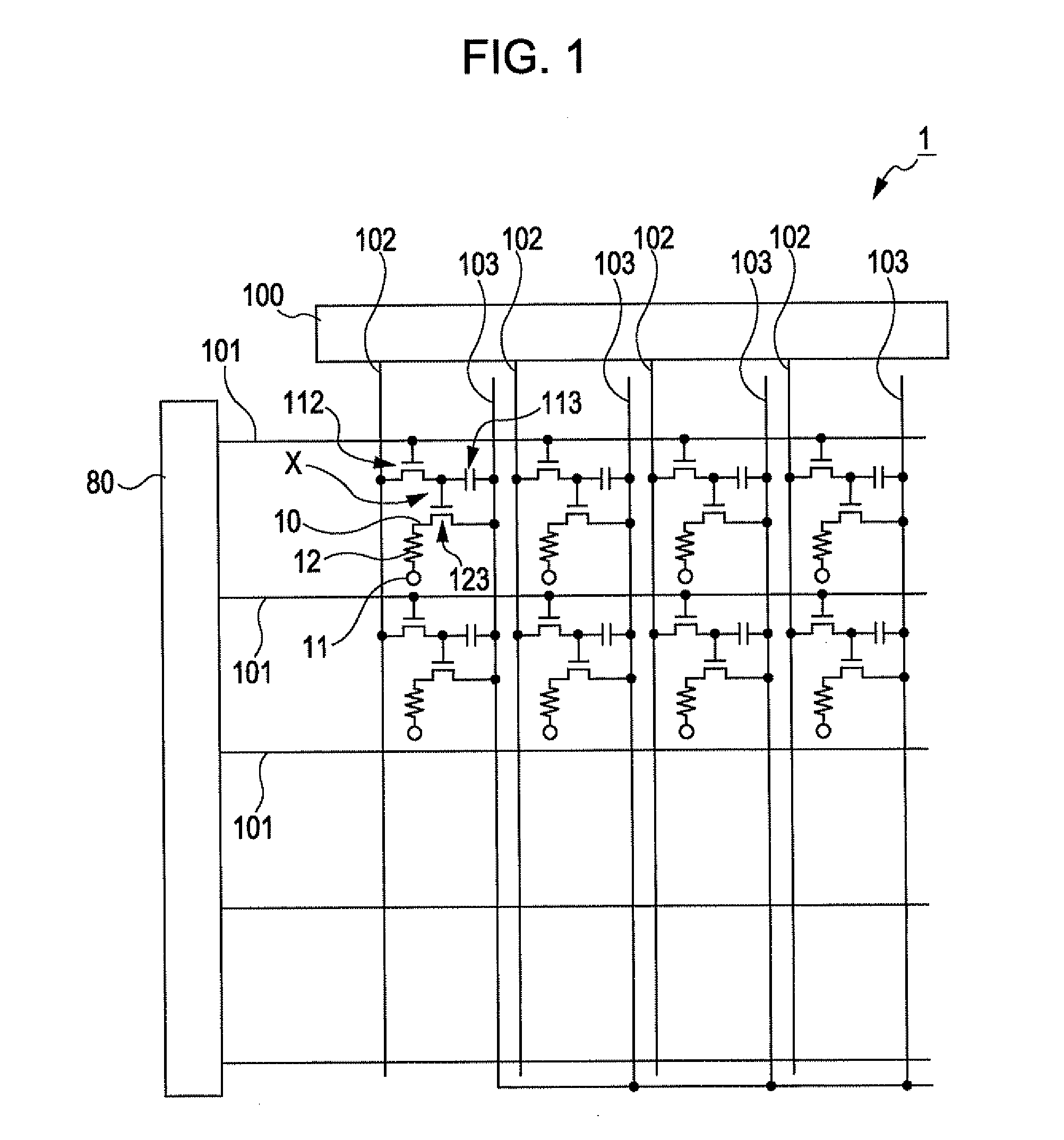

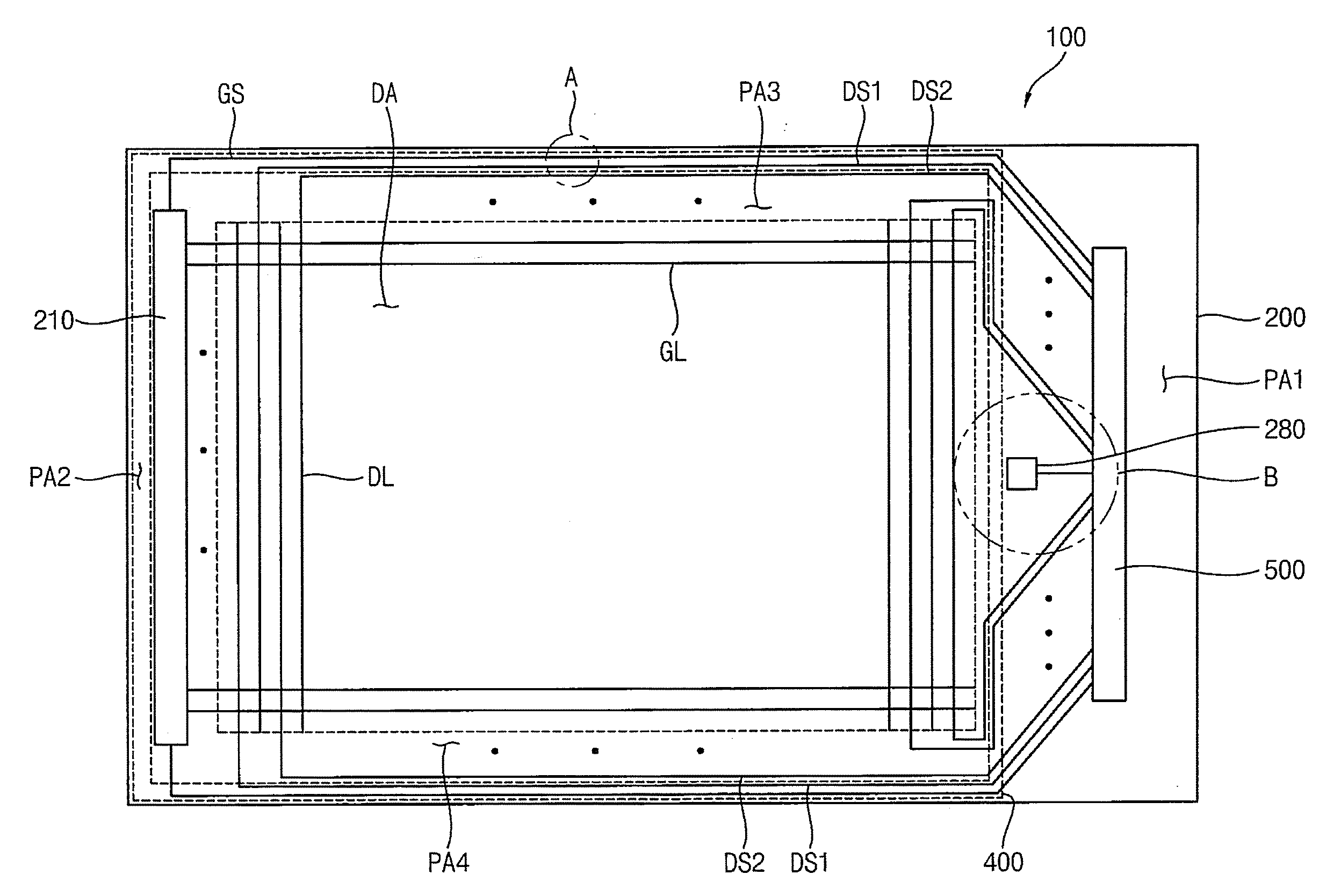

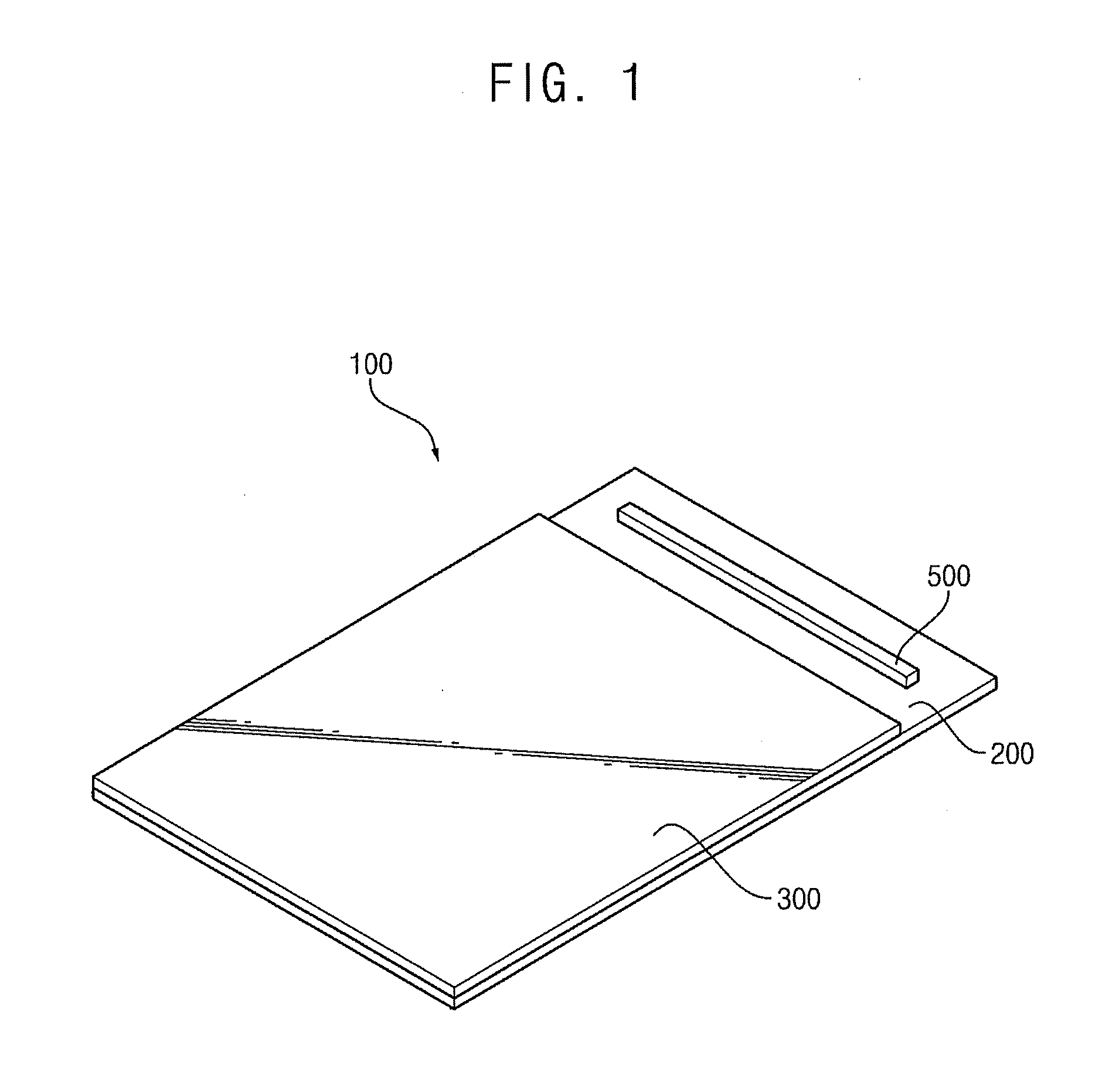

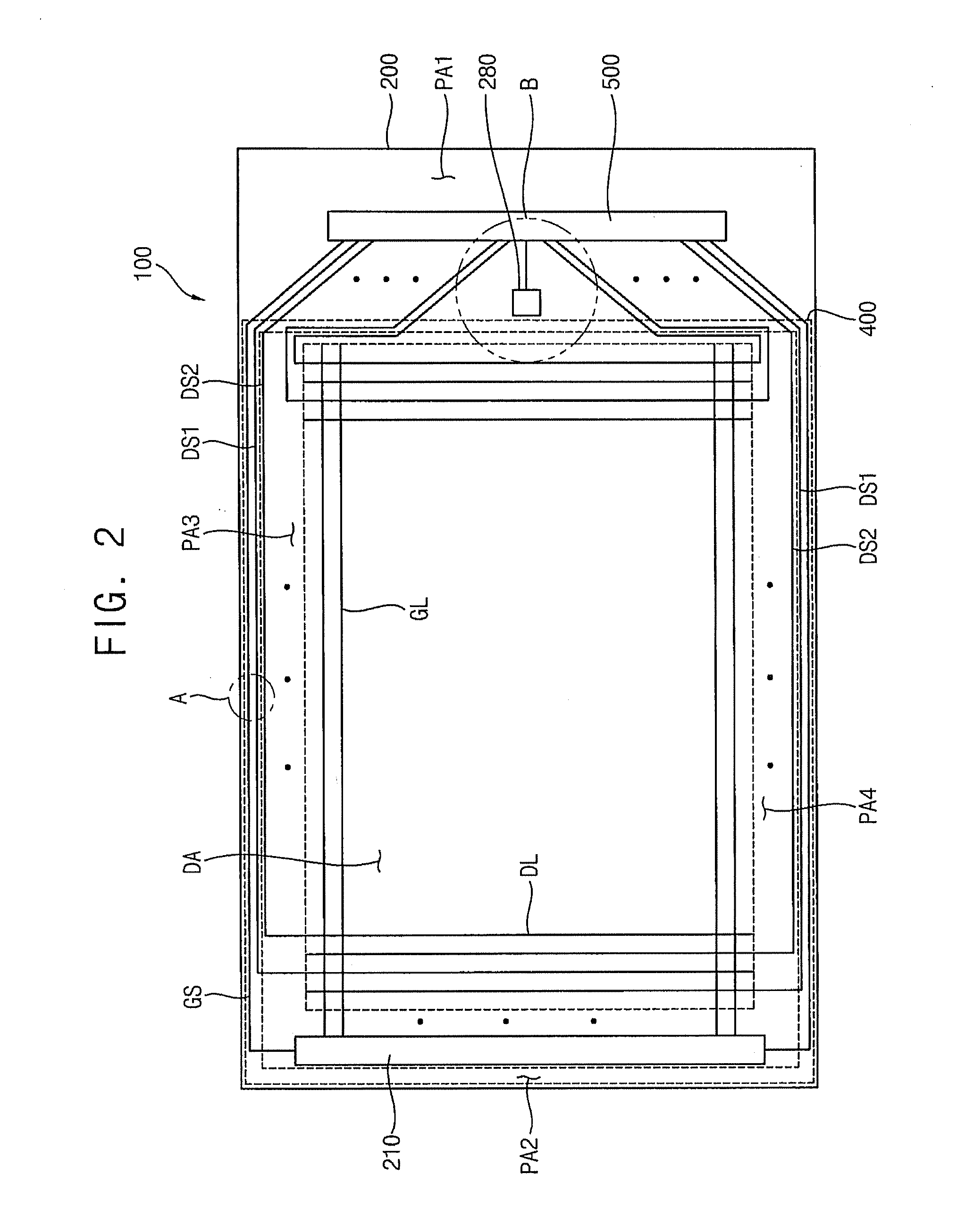

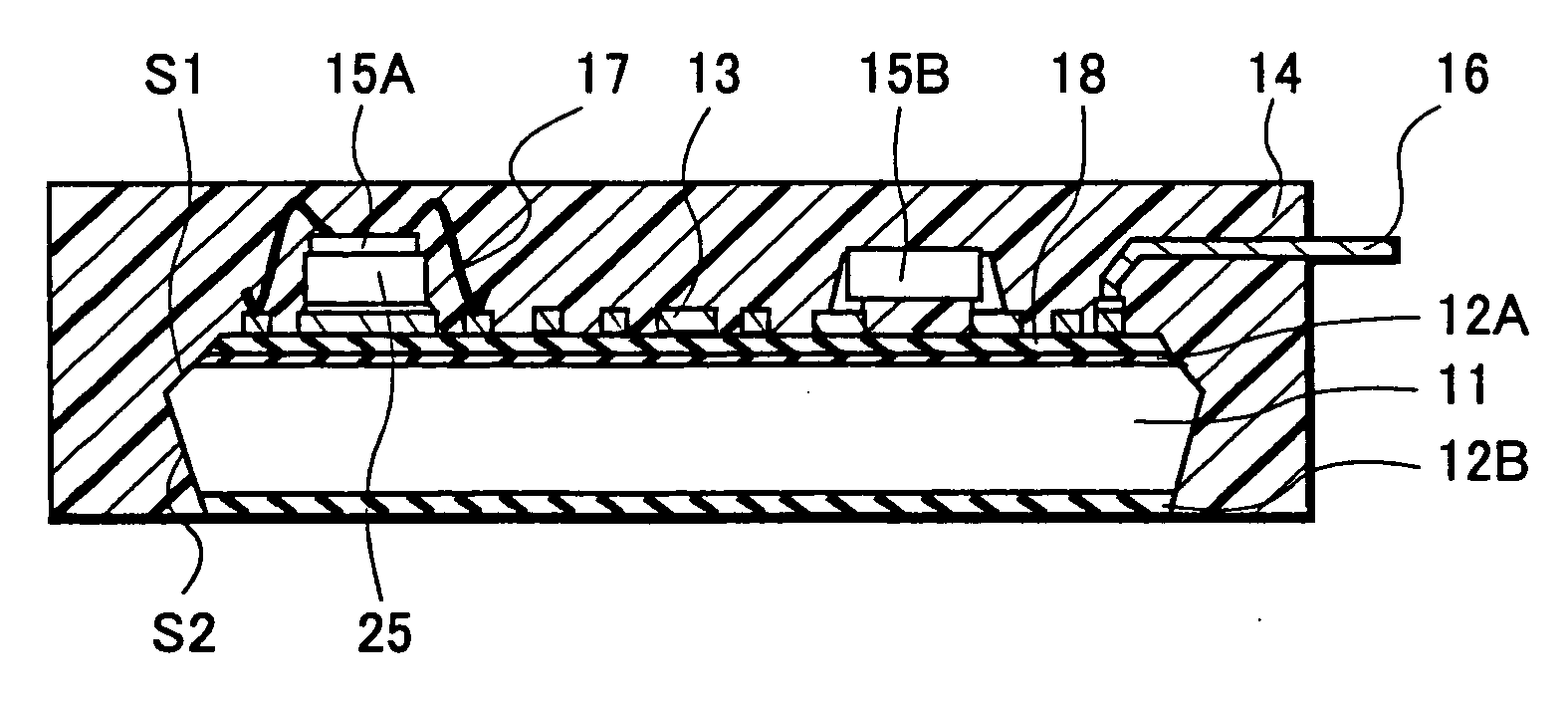

Display apparatus including signal lines arranged for curing a seal line

ActiveUS20080143945A1Incomplete curing can be preventedPrevent curingNon-linear opticsEngineeringSignal lines

A display apparatus includes a display substrate, an opposite substrate, a seal line, a driver chip, a gate insulating layer disposed on the display substrate, a first signal line disposed on a first side of the gate insulating layer, and a second signal line disposed on a second side of the gate insulating layer, wherein portions of the first signal line and the second signal line overlap each other along at least a portion of the seal line.

Owner:SAMSUNG DISPLAY CO LTD

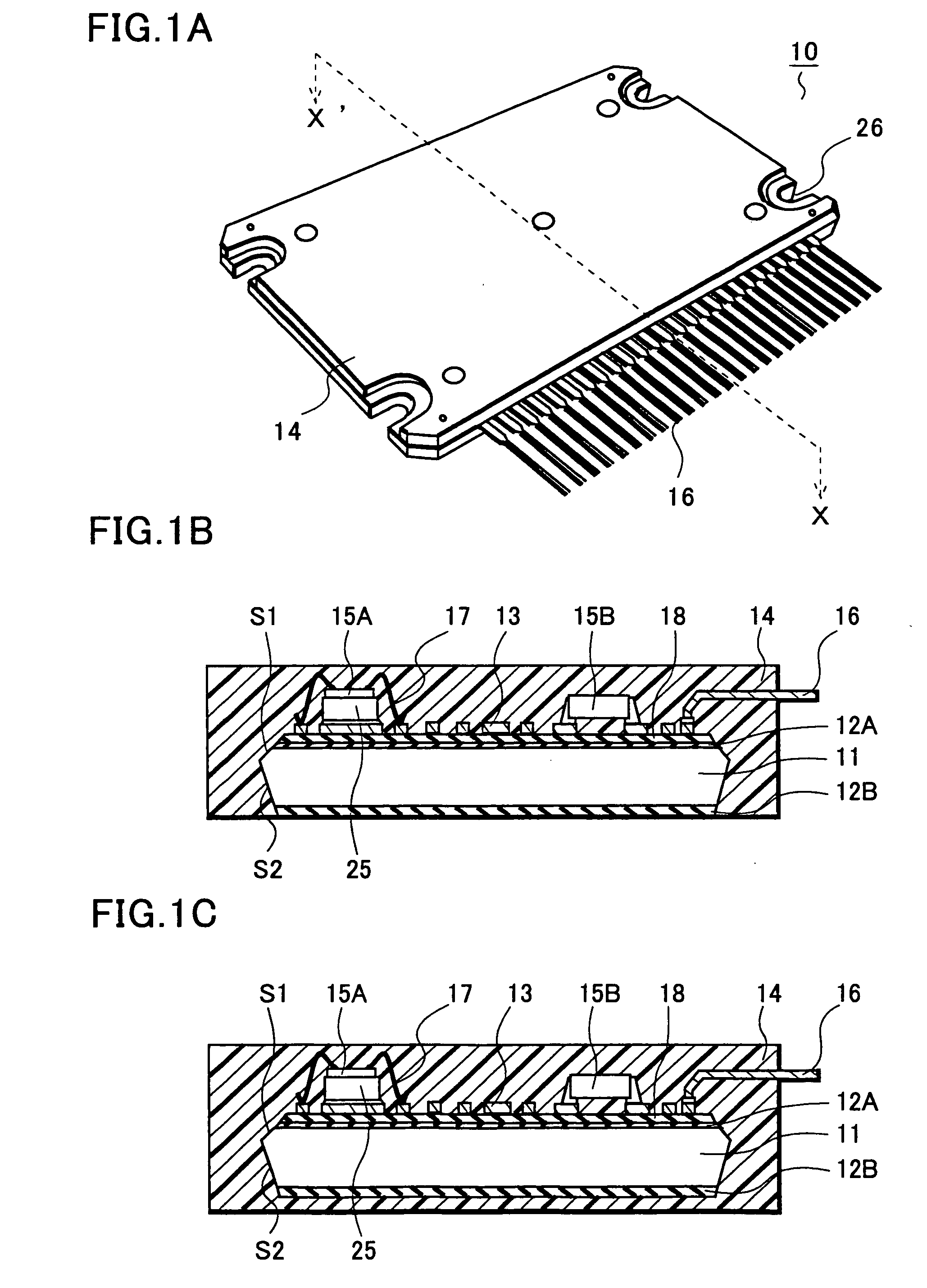

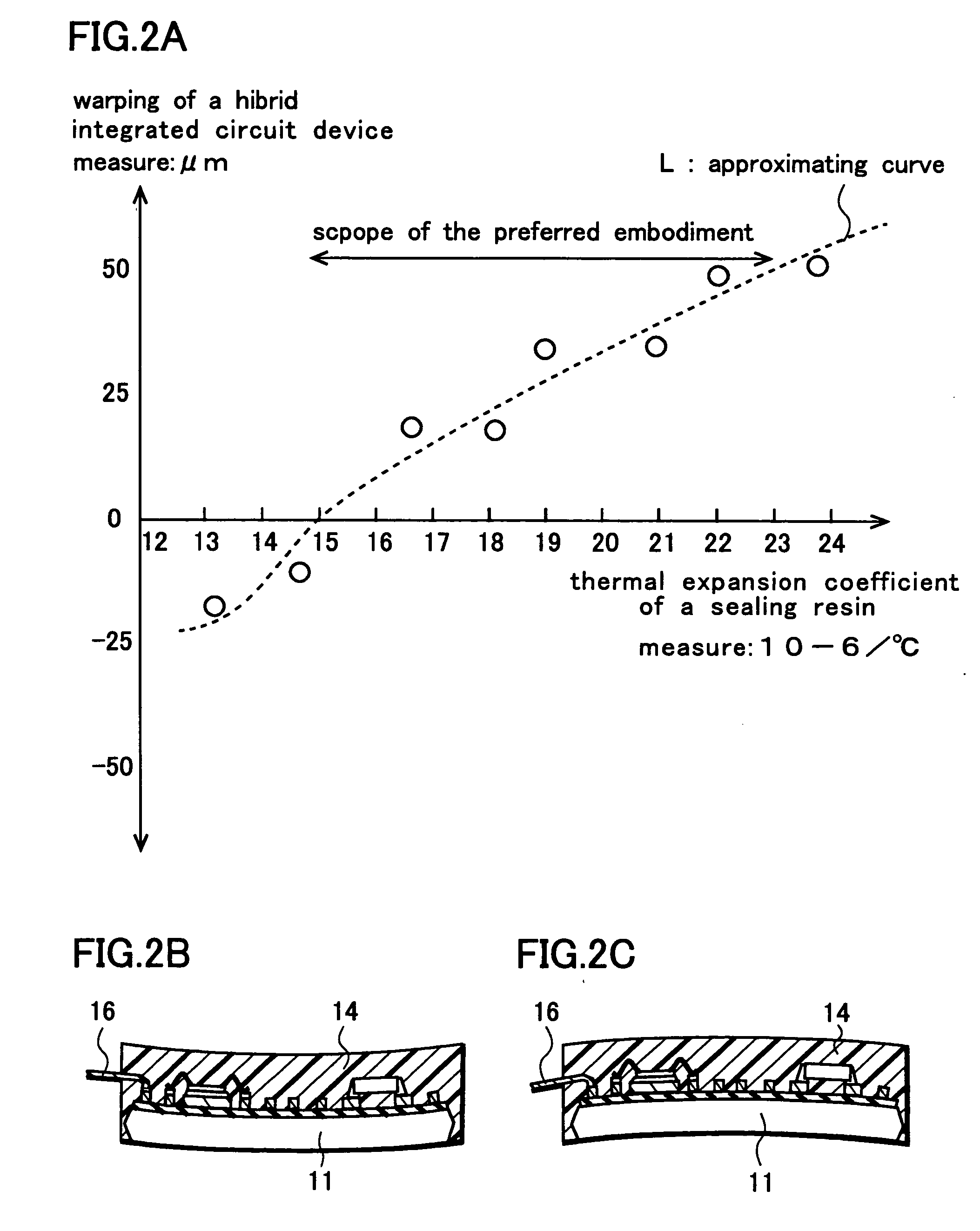

Circuit device and manufacturing method thereof

InactiveUS20060065421A1Cutting curvePrevent curingCooking-vessel materialsSemiconductor/solid-state device detailsThin metalTransfer molding

Warping of a hybrid integrated circuit device 10 due to shrinkage on curing of a sealing resin 14 is suppressed. The hybrid integrated circuit device 10 includes: a conductive pattern 13 provided on a surface of a circuit board 11; circuit elements 15 fixed to the conductive pattern 13; thin metal wires 17 electrically connecting the circuit elements 15 to the conductive pattern; leads 16 which are connected to the conductive pattern 13 to become output or input and extended to the outside; and a sealing resin 14 which is made of a thermosetting resin and covers the circuit board 11 by transfer molding while at least a rear surface of the circuit board is exposed. Here, a thermal expansion coefficient of the sealing resin 14 is set to be smaller than a thermal expansion coefficient of the circuit board 11. Thus, warping of the circuit board 11 in an after cure step can be prevented.

Owner:SANYO ELECTRIC CO LTD +1

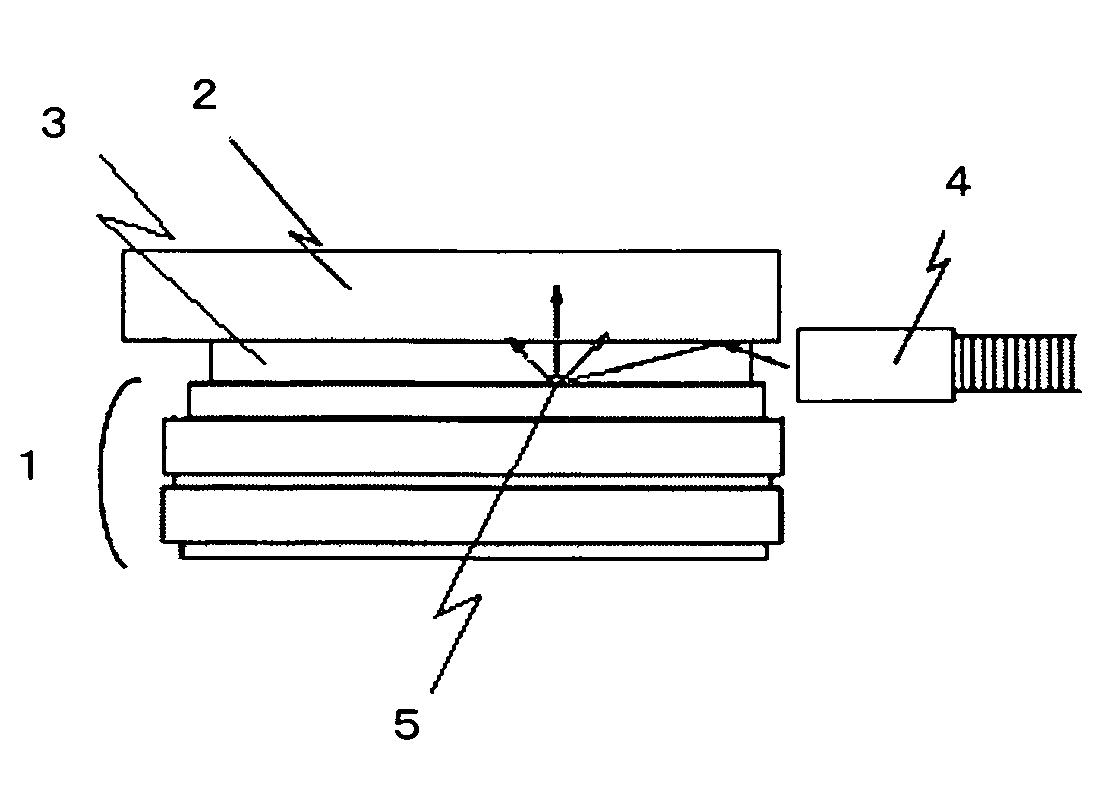

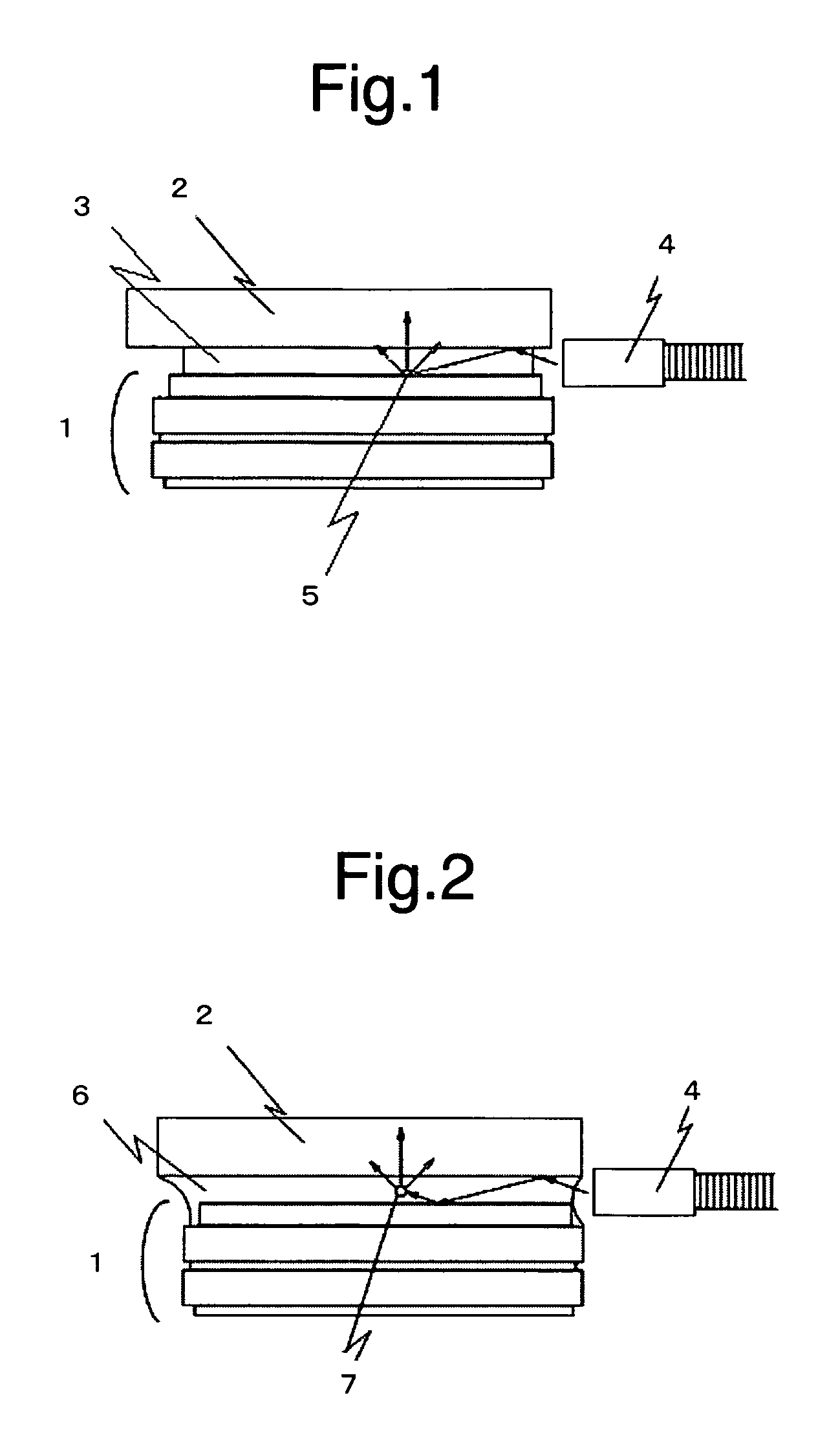

Bonding method and method of manufacturing a display device

InactiveUS7927440B2Prevent curingEasy to disassembleLamination ancillary operationsControlling laminationForeign matterDisplay device

Air bubbles or foreign objects in a transparent adhesive layer that bonds a transparent plate and a plate-like member together in full-surface contact are detected without fail. For the detection, an optical fiber or the like is used to irradiate the adhesive layer with light from a side, the cast light is guided through the adhesive layer, and a state of the adhesive layer is checked with the guided light. A check that discriminates defects in the adhesive layer from defects in the bonded transparent plate is thus made possible.

Owner:DAWNCREST IP LLC

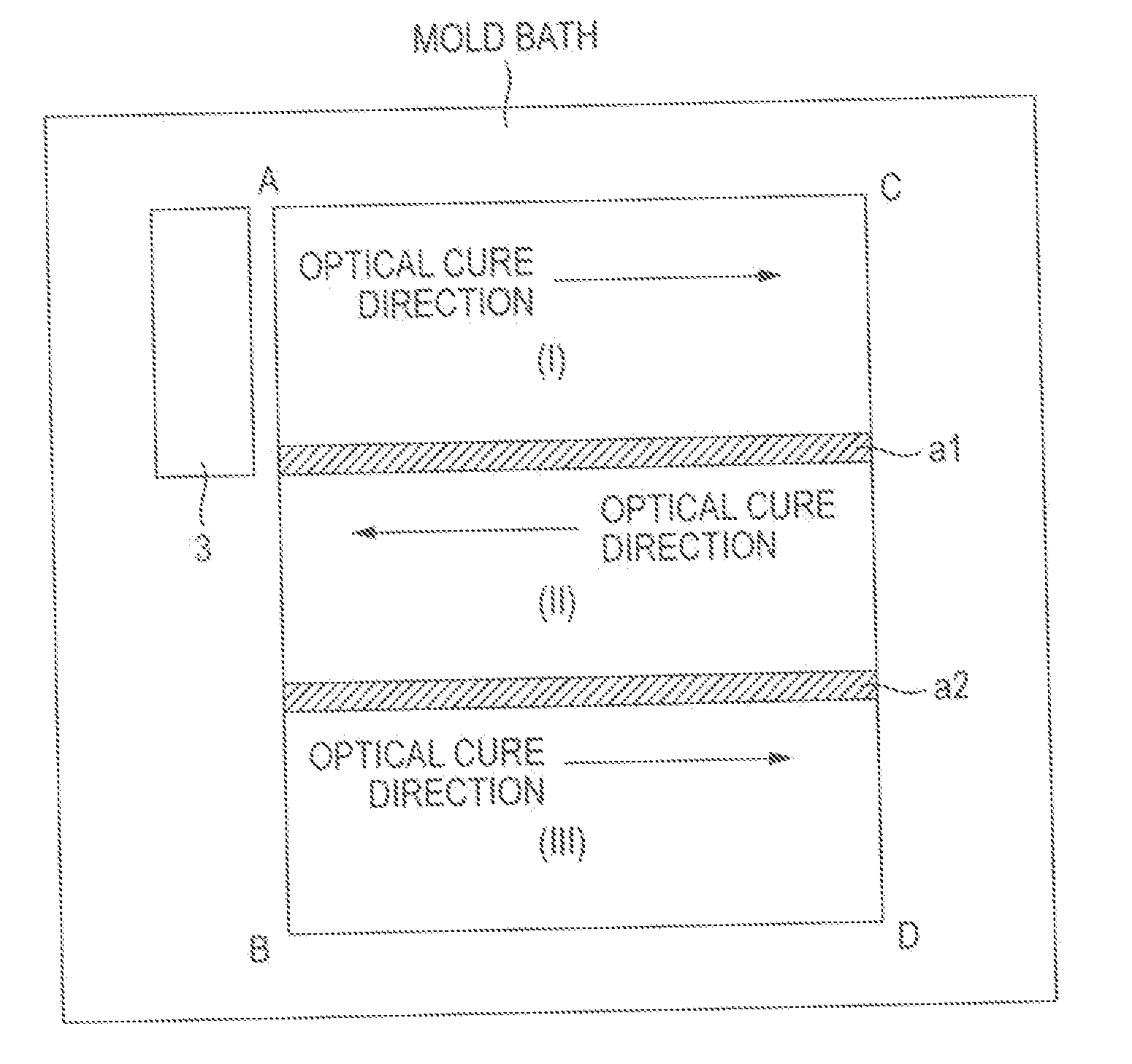

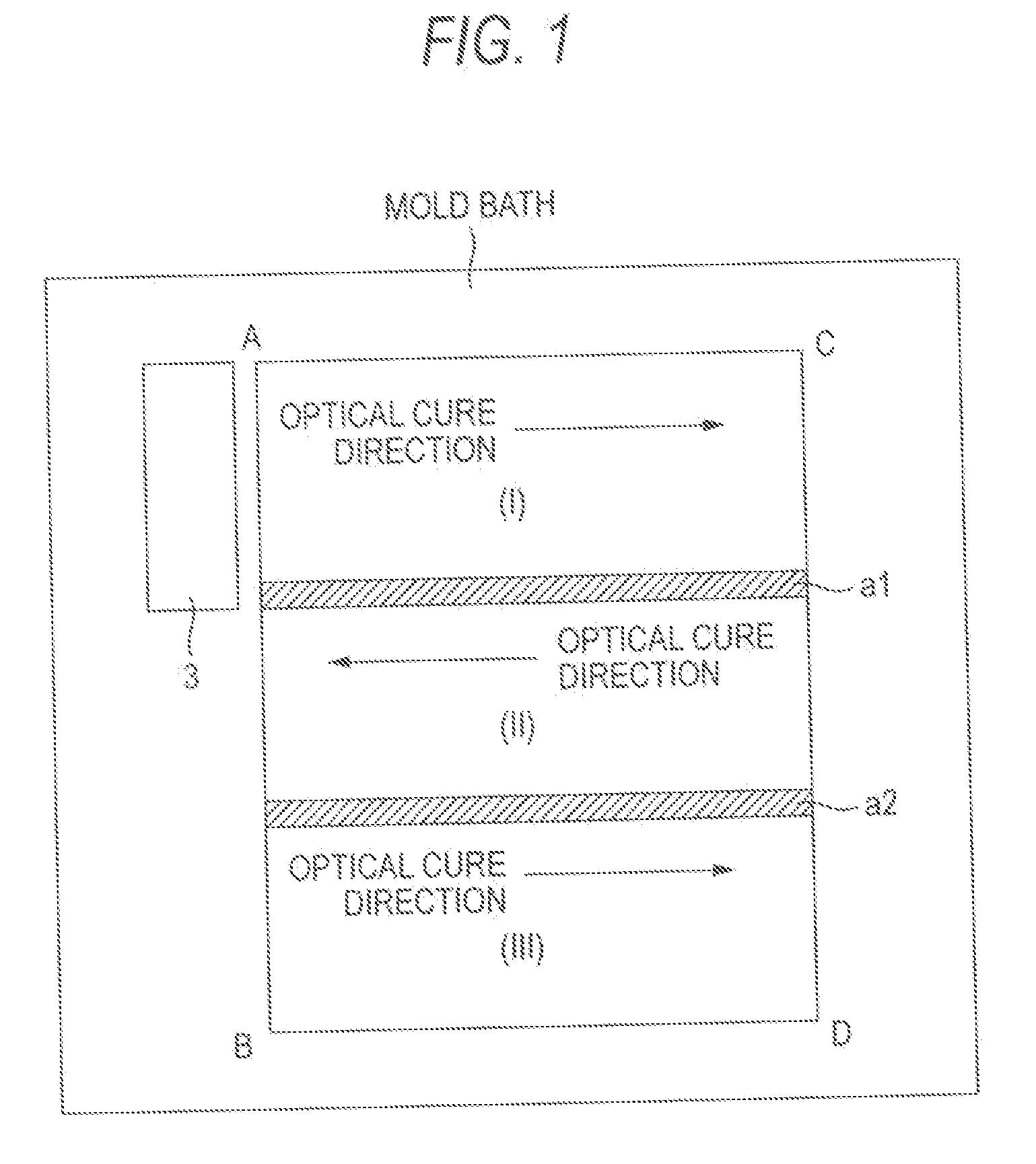

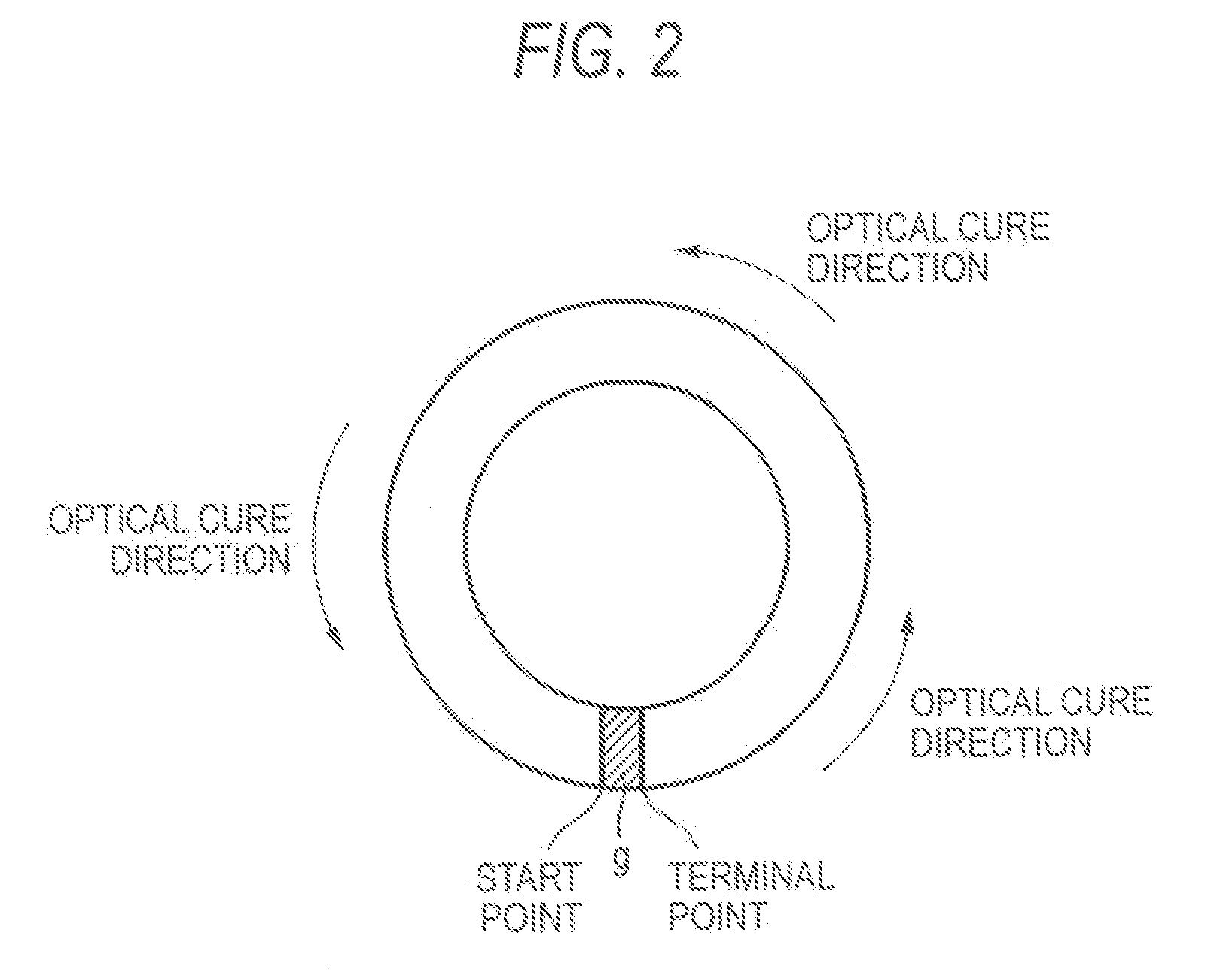

Optical 3-dimensional object formation and device

ActiveUS20070029706A1Superior appearance accuracyHigh dimensional accuracyAdditive manufacturing apparatusAuxillary shaping apparatusSynchronismStereolithography

A method and an apparatus includes using a planar plotting mask which can continuously change a mask image; continuously moving the planar plotting mask with reference to the surface of the photocurable resin composition and exposing the surface of a photocurable resin composition to light by way of the planar plotting mask while continuously changing a mask image of the planar plotting mask in accordance with a cross-sectional profile pattern of an optically-cured resin layer to be formed and in synchronism with movement of the planar plotting mask, to thus form an optically-cured resin layer having a predetermined cross-sectional profile pattern; and performing building operation such that boundary areas among adjacent plotted areas in the optically-cured resin layer become unnoticeable in a finally-obtained stereolithographic three-dimensional object.

Owner:NABLESCO CORP

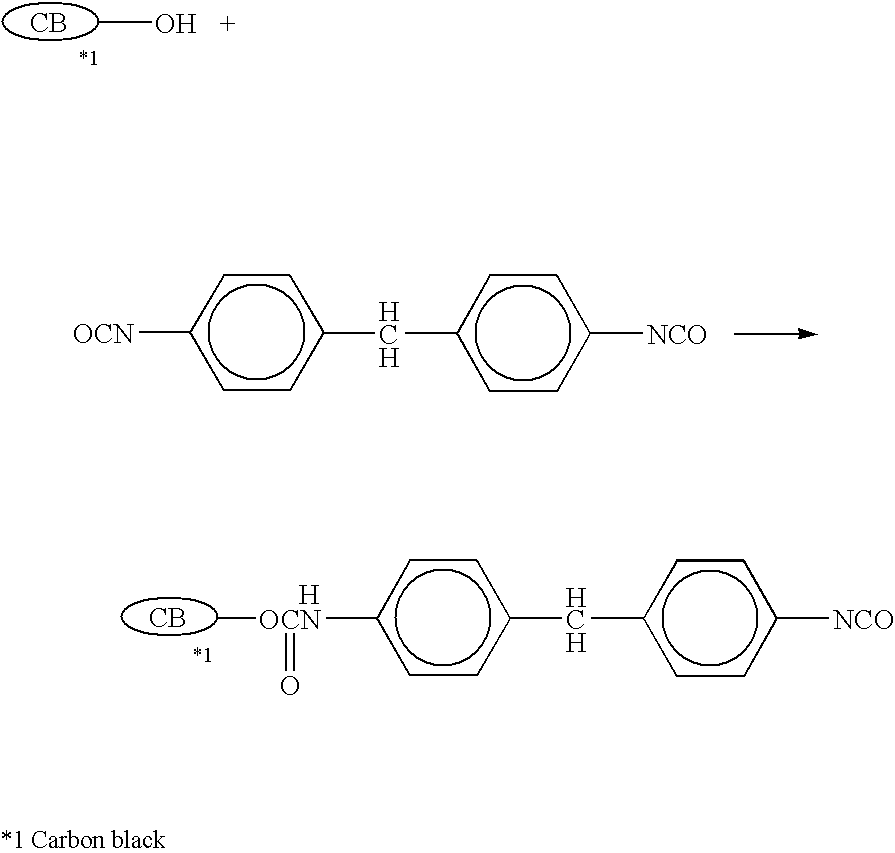

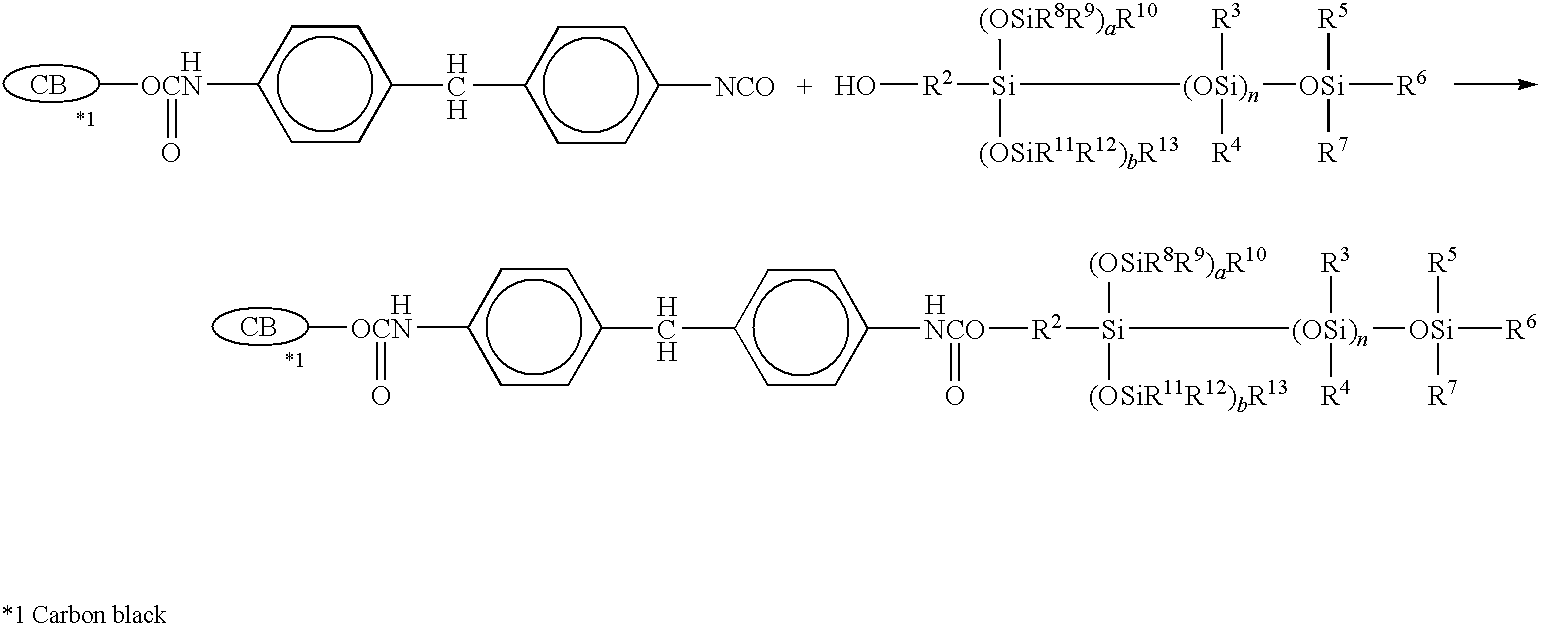

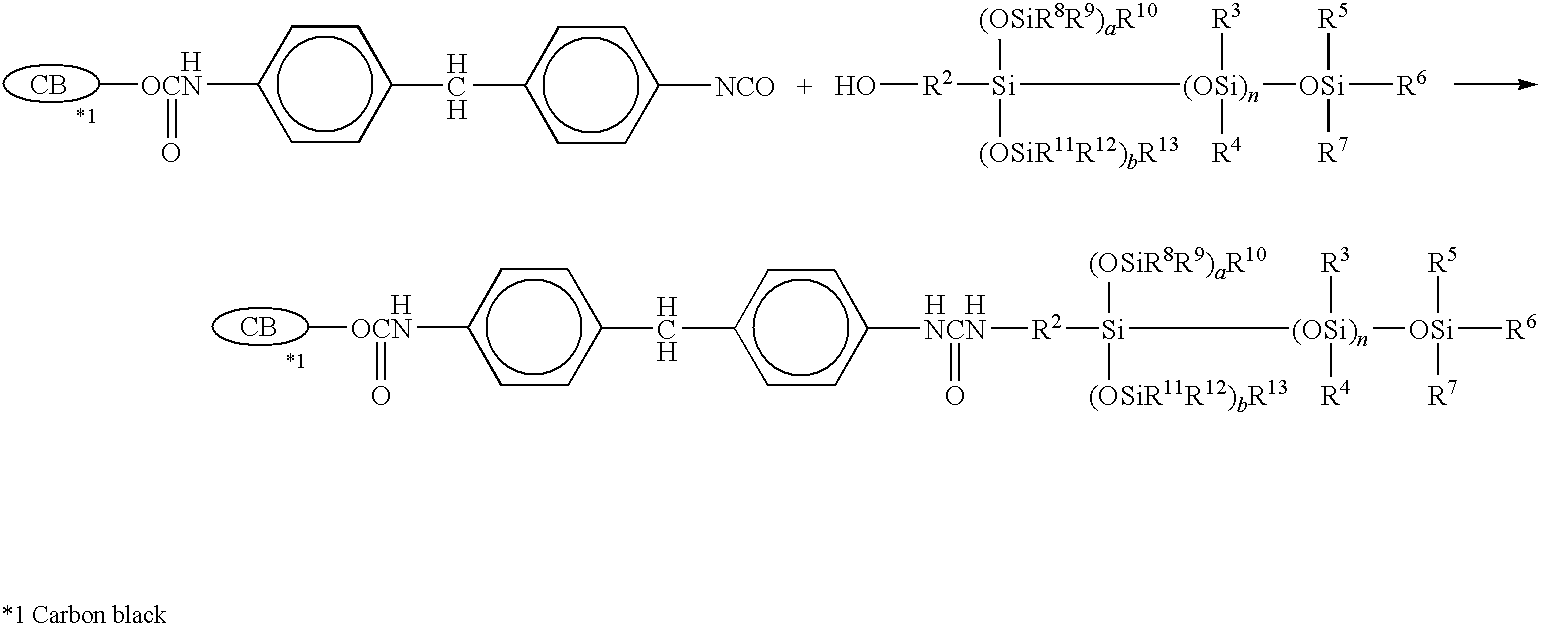

Surface-Modified Carbon Black and Dispersion Thereof

InactiveUS20090137731A1Good dispersionImprove insulation performanceInksCoatingsPolymer scienceSolvent

Surface-modified carbon black which exhibits excellent dispersibility in a silicone oil (non-polar medium) and a dispersion of the surface-modified carbon black are disclosed. The surface-modified carbon black includes an isocyanate compound having isocyanate groups on both ends and chemically bonded to a functional group on the surface of the carbon black, the isocyanate compound being chemically bonded to a reactive silicone polymer. The surface-modified carbon black dispersion is produced by dissolving an isocyanate compound having isocyanate groups on both ends in a solvent, adding carbon black to the solution, mixing the components so that one of the isocyanate groups is bonded to the surface of the carbon black via a urethane bond, removing an unreacted isocyanate compound, dispersing the carbon black in a silicone oil, and adding a reactive silicone polymer to the dispersion, followed by mixing and deaeration.

Owner:TOKAI CARBON CO LTD

Compositions and methods for enhanced mucosal delivery of Y2 receptor-binding peptides and methods for treating and preventing obesity

InactiveUS7229966B2Induce satiety in an individualPromote weight-loss in an individualBiocideNervous disorderDiseasePYY Peptide

Pharmaceutical compositions and methods are described comprising at least one Y2 receptor-binding peptide, such as peptide YY(PYY), Neuropeptide Y (NPY) or Pancreatic Peptide (PP) and one or more mucosal delivery-enhancing agents for enhanced nasal mucosal delivery of the peptide YY, for treating a variety of diseases and conditions in mammalian subjects, including obesity.

Owner:MDRNA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com