Polymer chemically-modified asphalt composition capable of being stably stored at high temperature and preparation method thereof

A technology of polymer chemistry and modified asphalt, used in building structures, building insulation materials, building components, etc. High and low temperature performance, the effect of preventing asphalt curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

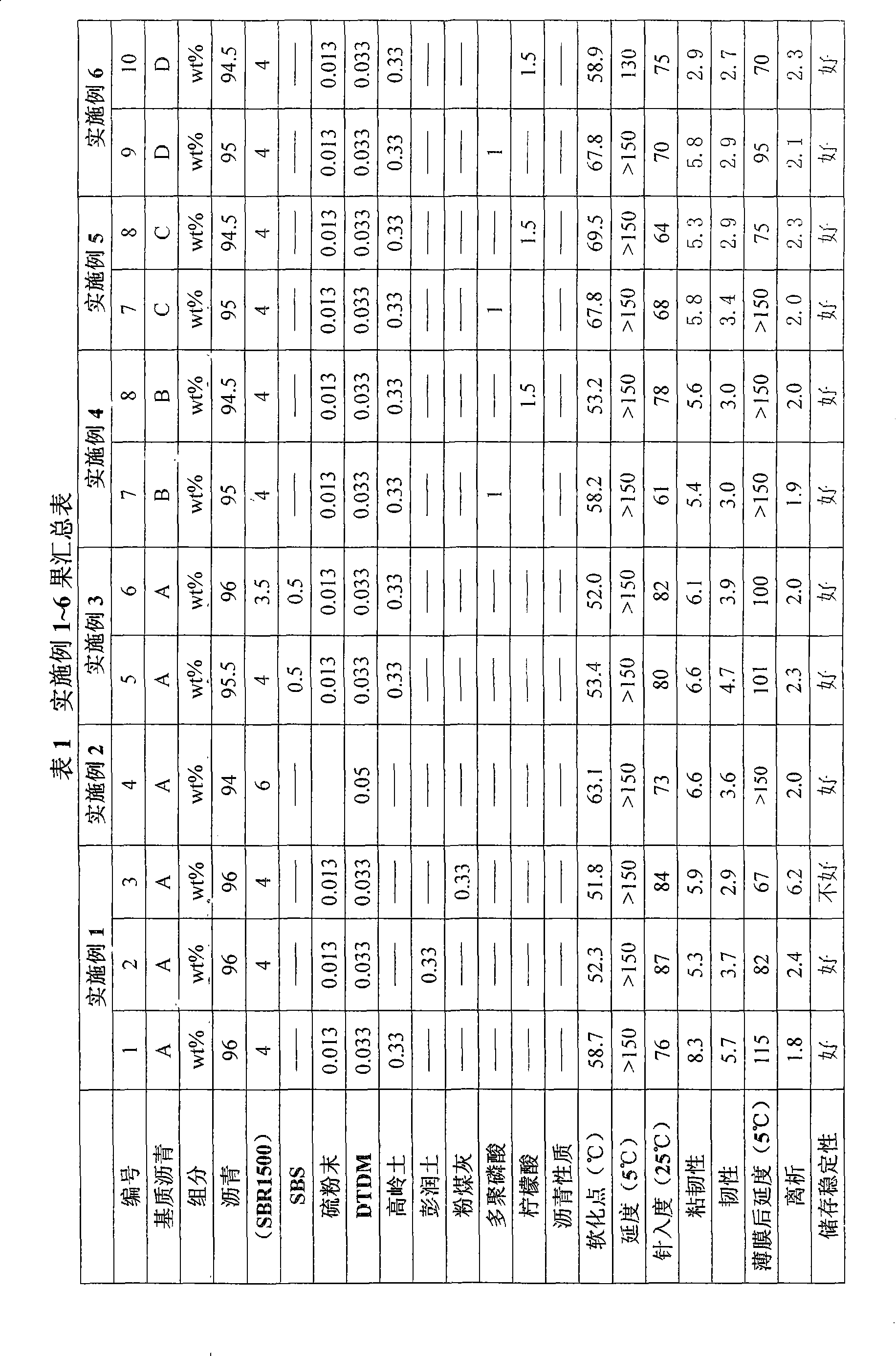

Examples

Embodiment 1

[0054] This is an embodiment of the present invention.

[0055] Heat asphalt A to 170±10°C, add 4wt% styrene-butadiene rubber (SBR1500), stir and disperse with a high-speed shear mixer for 30-60 minutes, add 0.02-0.03wt% vulcanizing agent, and then add 0.3-0.4 Wt% additives and fillers, continue to stir and disperse for 30-60 minutes, the mixture is uniform, and the storage stability is good.

Embodiment 2

[0057] This is an embodiment of the present invention.

[0058] Heat asphalt A to 170±10°C, add 6wt% styrene-butadiene rubber (SBR1500), stir and disperse with a high-speed shear mixer for 30-60 minutes, add 0.04-0.05wt% vulcanizing agent, continue stirring and dispersing for 30- After 60 minutes, the mixture is uniform and has good storage stability.

Embodiment 3

[0060] This is an embodiment of the present invention.

[0061] Heat asphalt A to 170±10°C, add 4-5wt% styrene-butadiene rubber (SBR1500) and styrene-butadiene-styrene block copolymer (SBS), stir and disperse with a high-speed shear mixer for 30- After 60 minutes, add 0.04-0.05wt% of sulfur-containing compounds, then add 0.3-0.4wt% of additives and fillers, continue stirring and dispersing for 30-60 minutes, the mixture is uniform, and the storage stability is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com