Waste rubber powder modified asphalt functional material and preparation method thereof

A technology of waste rubber powder and modified asphalt, which is applied to building insulation materials, building components, buildings, etc., can solve the problems of poor high-temperature storage stability of polymer-modified asphalt, and achieve poor high-temperature storage stability and easy operation , the effect of facilitating industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a waste rubber powder modified asphalt functional material, which includes 80 parts of base asphalt, 50 parts of activated waste rubber powder, 15 parts of negative ion additives, 8 parts of montmorillonite, 30 parts of recycled rubber powder and silane coupling 8 parts;

[0029] The particle size of the negative ion additive is 15μmμm, the particle size of recycled rubber powder is 20μm; the particle size of the activated waste rubber powder is 20μm; the silane coupling agent is bis-[Y-(triethoxysilyl)propyl] -Tetrasulfide.

[0030] Wherein, the activated waste rubber powder is prepared through the following steps:

[0031] (1) Mix waste rubber powder with release agent and accelerator evenly, grind, and spray the activator in the rubber powder during the grinding process to obtain semi-finished products; the accelerator is ferric chloride; the activator is isopropyl Mercaptan.

[0032] (2) After repeated grinding of the semi-finished product, sievin...

Embodiment 2

[0039] This embodiment provides a waste rubber powder modified asphalt functional material, including 130 parts of base asphalt, 50 parts of activated waste rubber powder, 15 parts of negative ion additives, 8 parts of montmorillonite, 30 parts of regenerated rubber powder and silane coupling Agent 8 parts.

[0040] Among them, the particle size of the negative ion additive is 400μm, the particle size of the recycled rubber powder is 100μm; the particle size of the activated waste rubber powder is 80μm; the silane coupling agent is bis-[γ-(triethoxysilyl)propyl ]-Disulfide.

[0041] Wherein, the activated waste rubber powder is prepared through the following steps:

[0042] (1) Mix the waste rubber powder with the release agent and the accelerator evenly, and grind, and spray the activator in the rubber powder during the grinding process to obtain a semi-finished product;

[0043] (2) After repeated grinding of the semi-finished product, sieving, heating and stirring, to obtain activ...

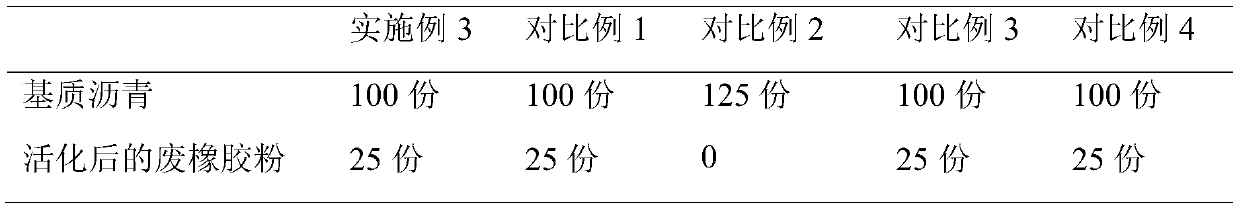

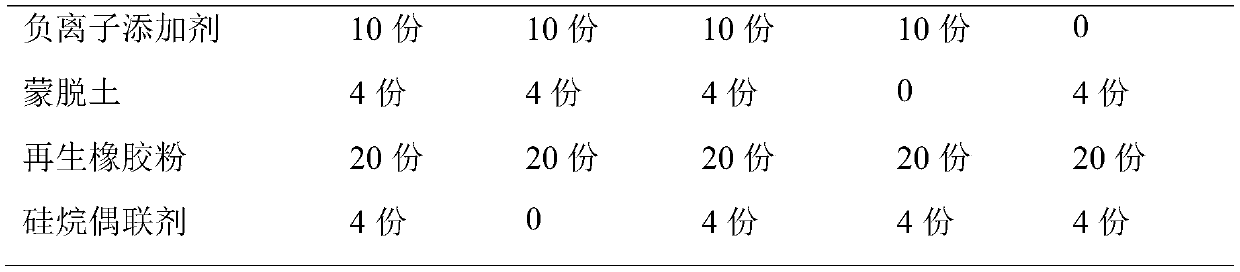

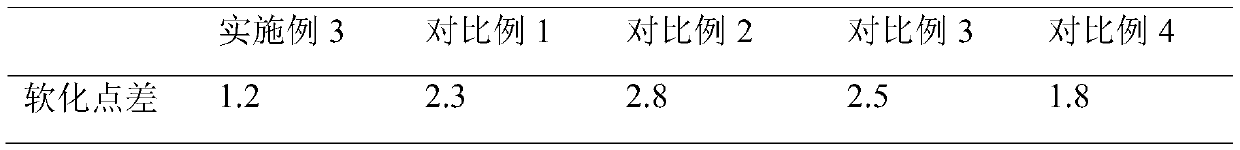

Embodiment 3

[0051] This embodiment provides a waste rubber powder modified asphalt functional material, including 100 parts of base asphalt, 25 parts of activated waste rubber powder, 10 parts of negative ion additives, 4 parts of montmorillonite, 20 parts of recycled rubber powder and silane coupling 4 parts.

[0052] Among them, the particle size of the negative ion additive is 200μm, the particle size of recycled rubber powder is 60μm; the particle size of the activated waste rubber powder is 50μm; the silane coupling agent is bis-[Y-(triethoxysilyl)propyl ]-Tetrasulfide and bis-[γ-(triethoxysilyl)propyl]-disulfide mixture, and the mass ratio is 1:1.

[0053] Wherein, the activated waste rubber powder is prepared through the following steps:

[0054] (1) Mix the waste rubber powder with the release agent and the accelerator evenly, and grind, and spray the activator in the rubber powder during the grinding process to obtain a semi-finished product;

[0055] (2) After repeated grinding of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com