A kind of water-based environment-friendly vinyl chloride plastic paint and preparation method thereof

A vinyl chloride and plastic paint technology, applied in the field of coatings, can solve the problems of silver powder orientation and poor water resistance, high VOC content of plastic coatings, poor chemical resistance, etc., to achieve smooth and smooth paint film surface, good high temperature storage stability, good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

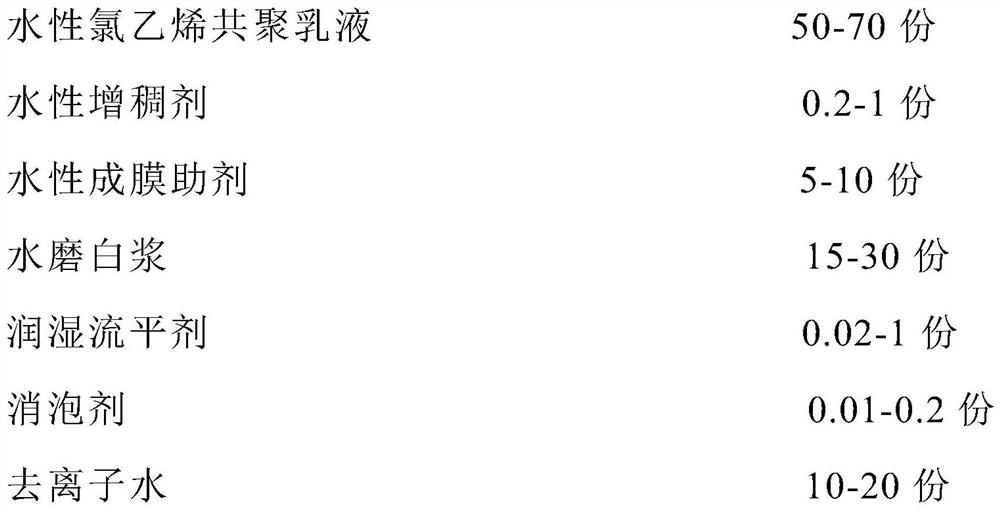

Method used

Image

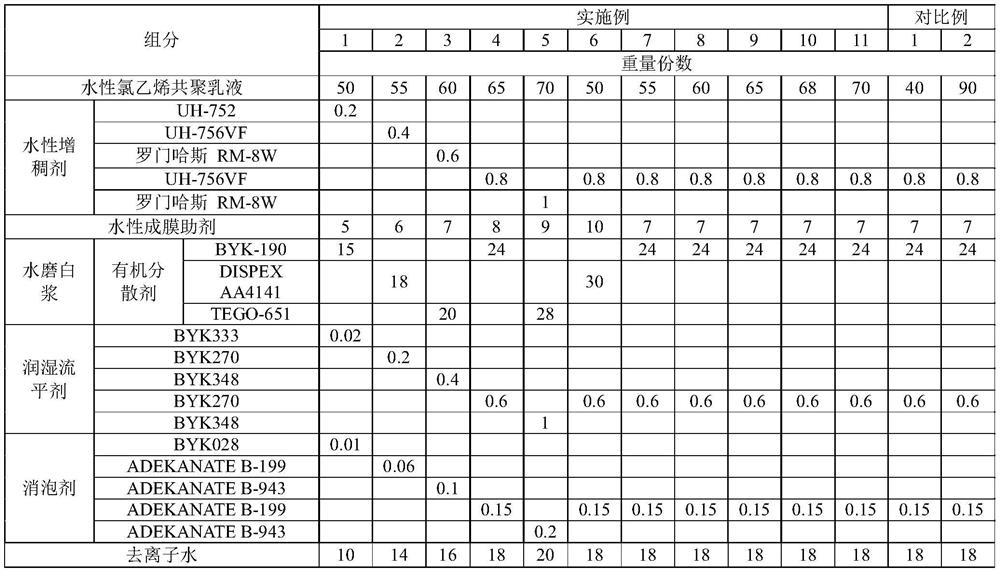

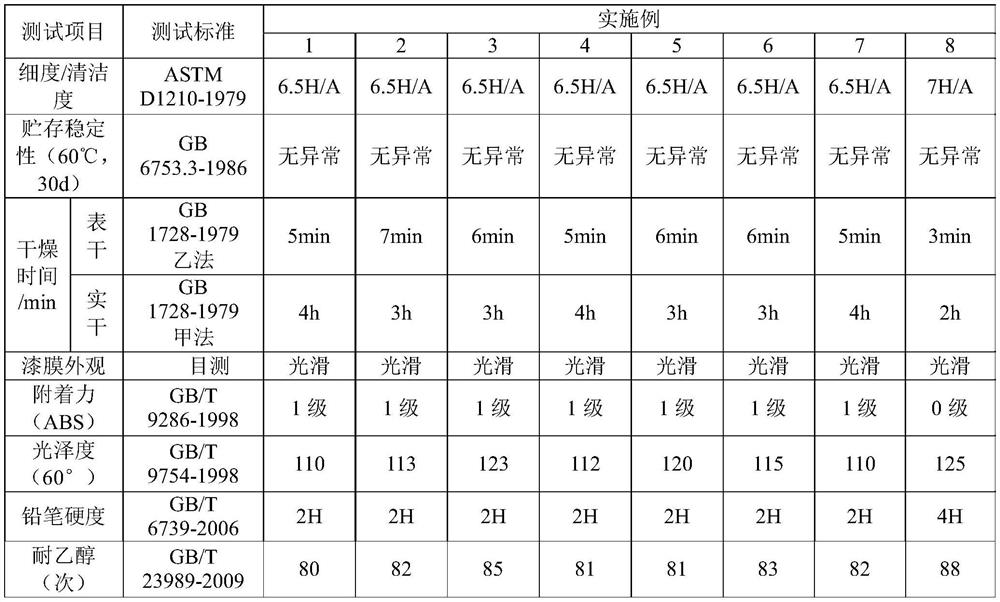

Examples

Embodiment

[0045] (1) Its preparation method of aqueous vinyl chloride copolymer emulsion is as follows:

[0046] (1) monomer pre-emulsification

[0047] Weigh 120 parts of vinyl chloride, 80 parts of acrylate, 20 parts of crosslinking monomer, and 2 parts of nonylphenol polyoxyethylene ether as an emulsifier, put them into a pre-emulsification kettle and stir and emulsify for 2 hours to obtain a pre-emulsified monomer solution;

[0048] (2) Preparation and addition of additives

[0049] Get 160 parts of deionized water, 4 parts of emulsifying agent sodium lauryl sulfate, 1.6 parts of sodium bicarbonate, 1 part of glue-preserving agent polyvinylpyrrolidone and add in the pre-emulsification kettle of step (1) after fully stirring and dissolving; Take initiator 1 part of ammonium persulfate is dissolved in 80 parts of water for subsequent use;

[0050] (3) Polymerization reaction

[0051] Take 1 / 3 volume of the mixed solution in the step (2) pre-emulsification tank and 1 / 4 volume of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com