Patents

Literature

23177results about How to "Improve water resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

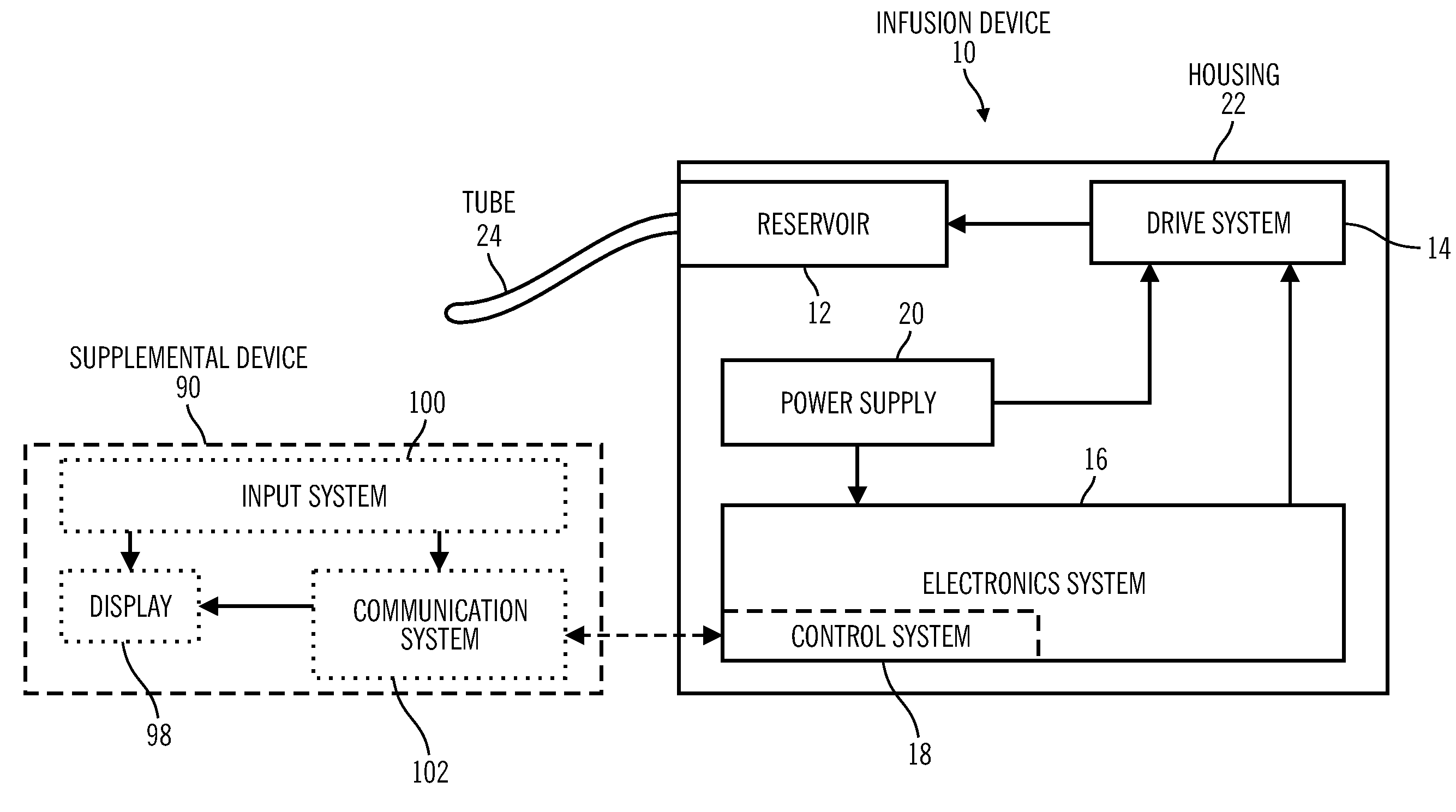

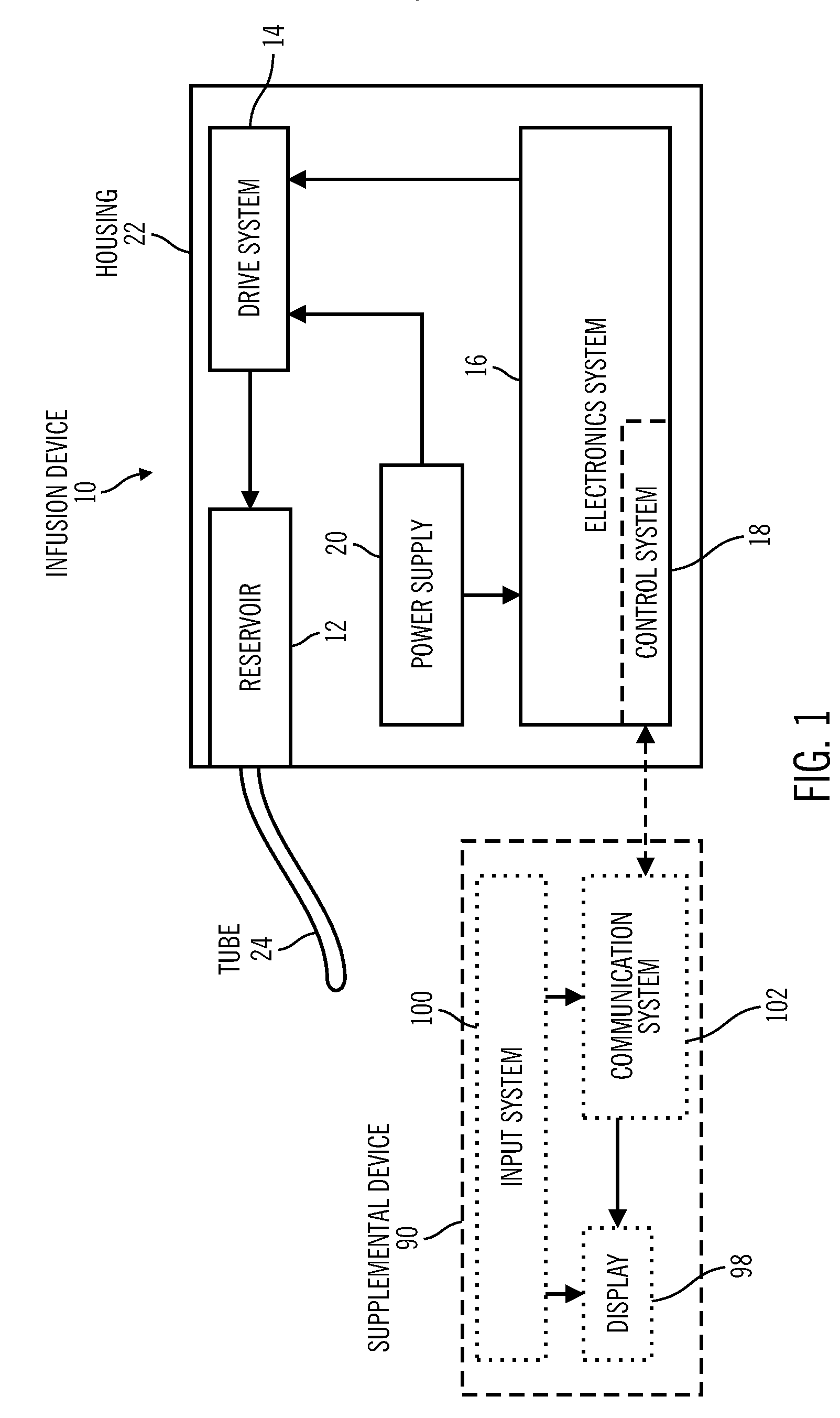

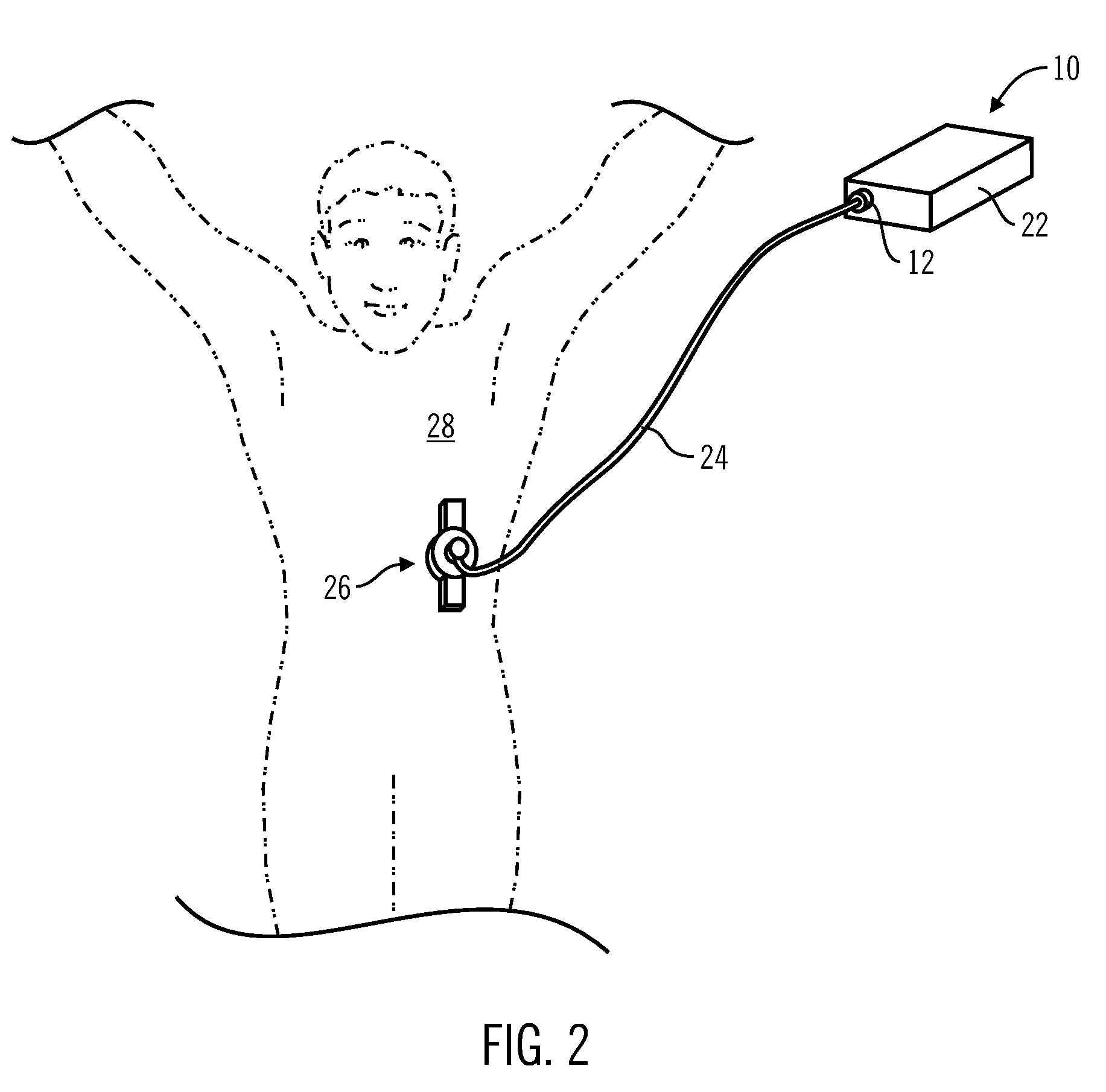

Control Tabs for Infusion Devices and Methods of Using the Same

InactiveUS20100160861A1Improve water resistanceImprove the immunityOther blood circulation devicesMedical devicesBiomedical engineeringElectrical element

An external infusion device that infuses a fluid into an individual's body includes a housing, a reservoir, a drive system, a power supply, electrical elements, and a tab. The reservoir contains the fluid, and the drive system forces the fluid from the reservoir. The electrical elements control the power to the drive system to regulate the rate that fluid is forced from the reservoir. The tab mates with the housing, and contains at least one electrical element. The tab is removable, and may be replaced with a different tab. The different tab may change the rate fluid is forced from the reservoir. A tab may be removed from one external infusion device and installed in a different external infusion device. The tab may be limited to use in a predetermined number of external infusion devices and may include a power supply.

Owner:MEDTRONIC MIMIMED INC

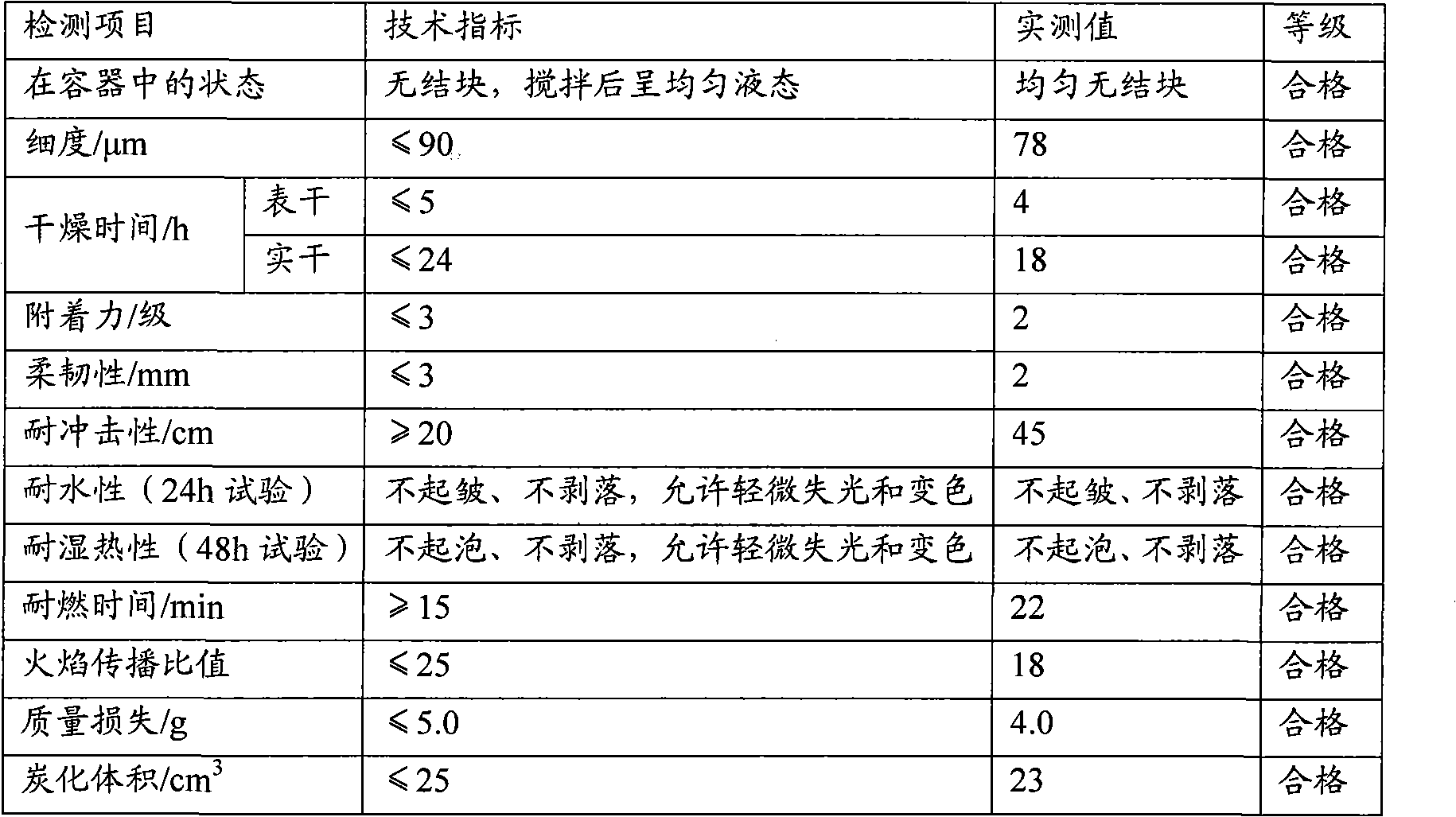

Solvent-free expansion type fire-proof epoxy coating and its preparation method

The invention discloses the inflatable fire-resisting paint, comprising A and B. The A comprises epoxide resin, modified resin, catalyst, foamable agent, fire retarding agent, fluxing agent, color filler and smog inhibiting agent, and the B comprises color filler, curing agent and auxiliary agent. The fire-resisting paint has the advantages of good heat-insulating property, adhesion force and intensity. The coating has good water resistance, acid- alkali resistance, corrosion resistance and tenacity, and is not easy to drop. The paint can be used in rolled steel and aluminum products, especially the fireproof situation of oil factories.

Owner:MARINE CHEM RES INST

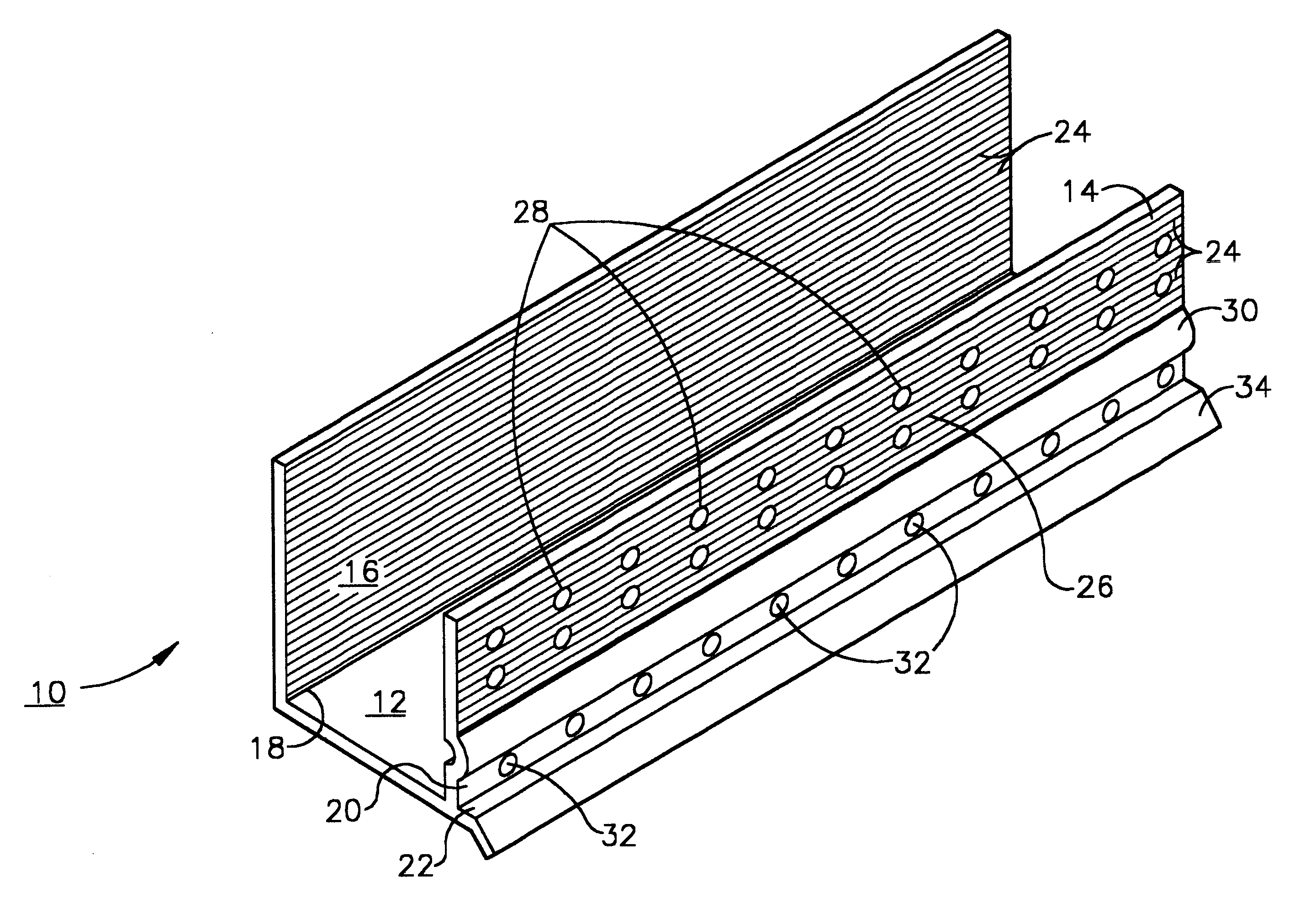

Moisture management system

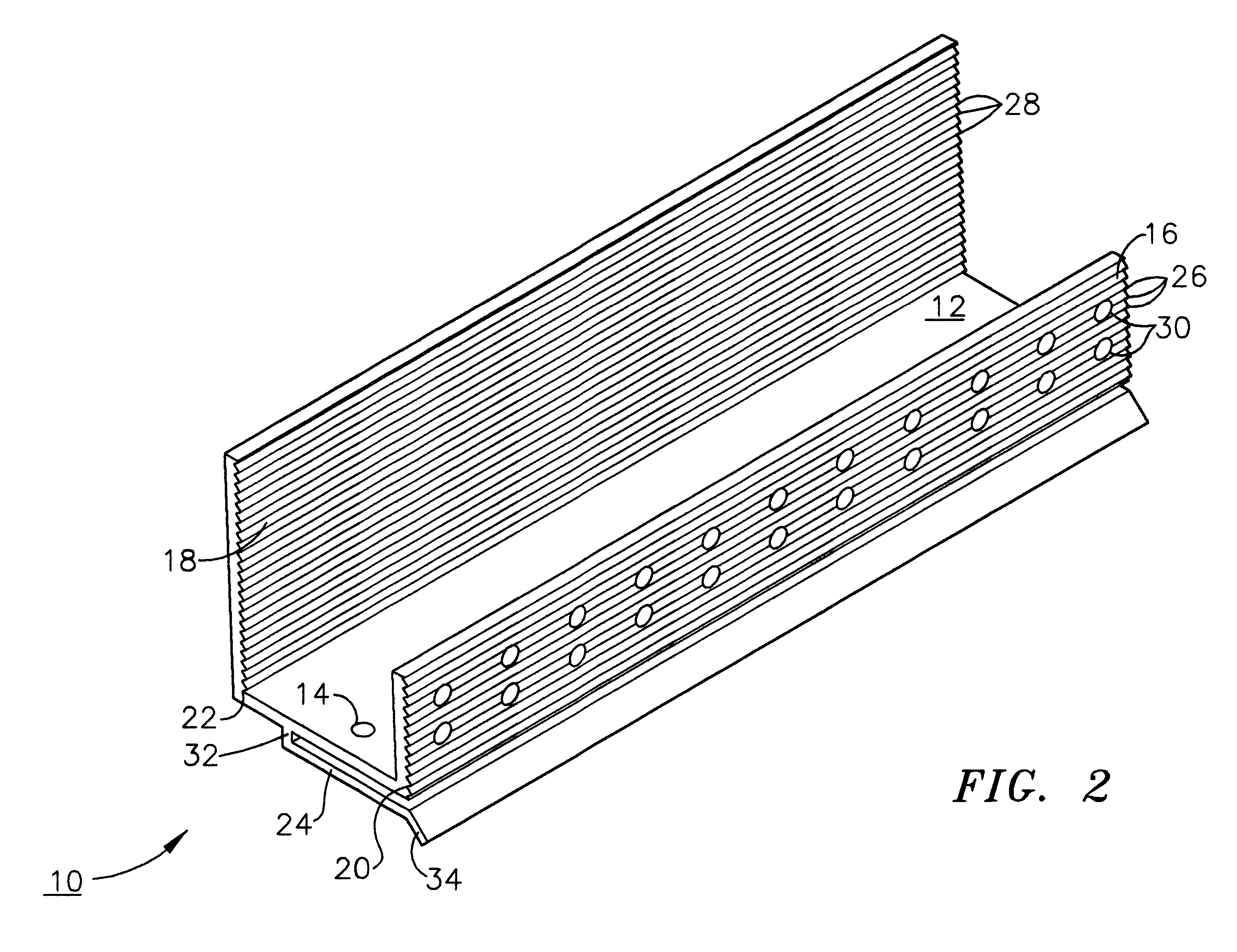

InactiveUS6470638B1Improve adhesionImprove moisture managementBuilding roofsRoof covering using slabs/sheetsAdhesiveEngineering

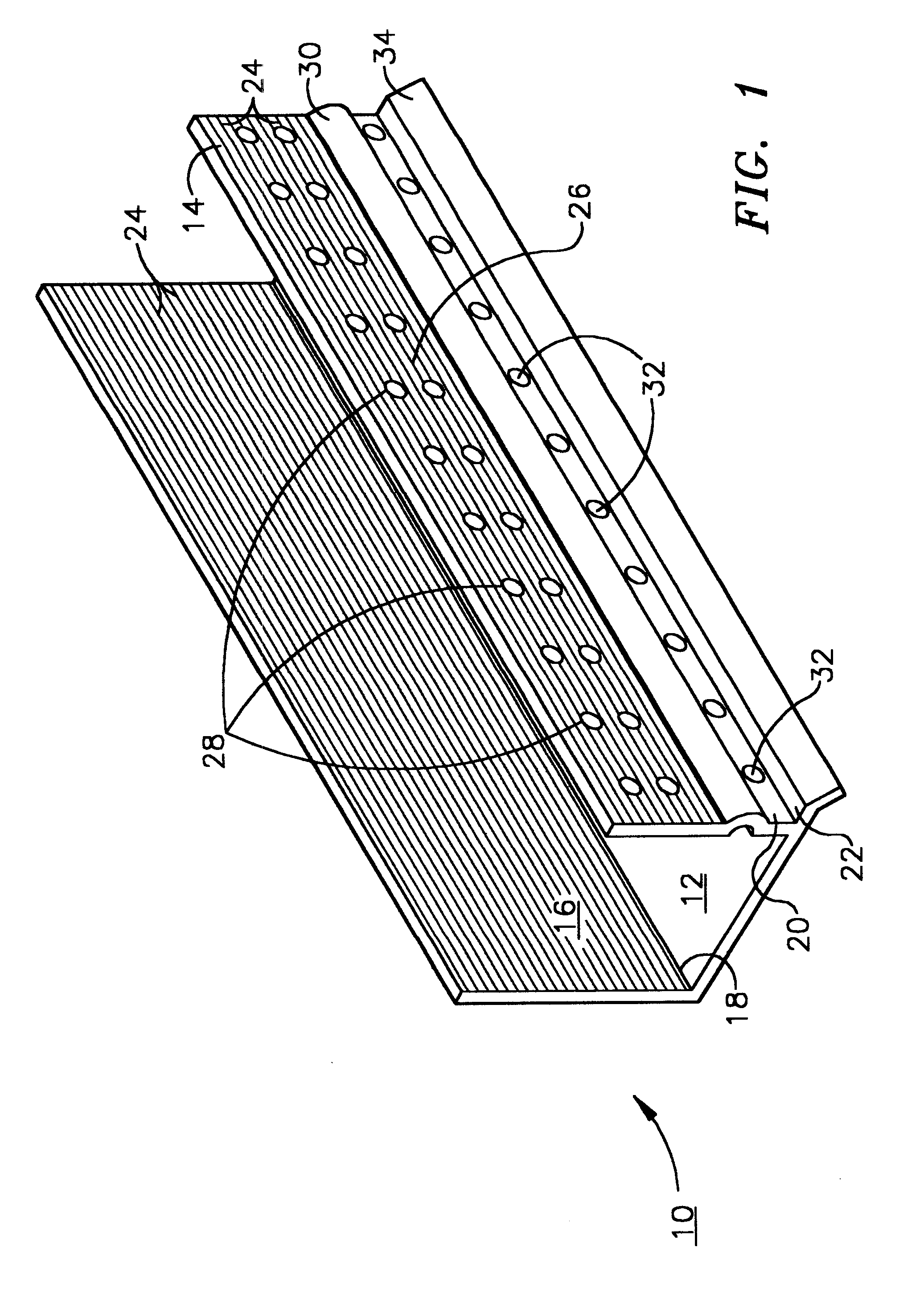

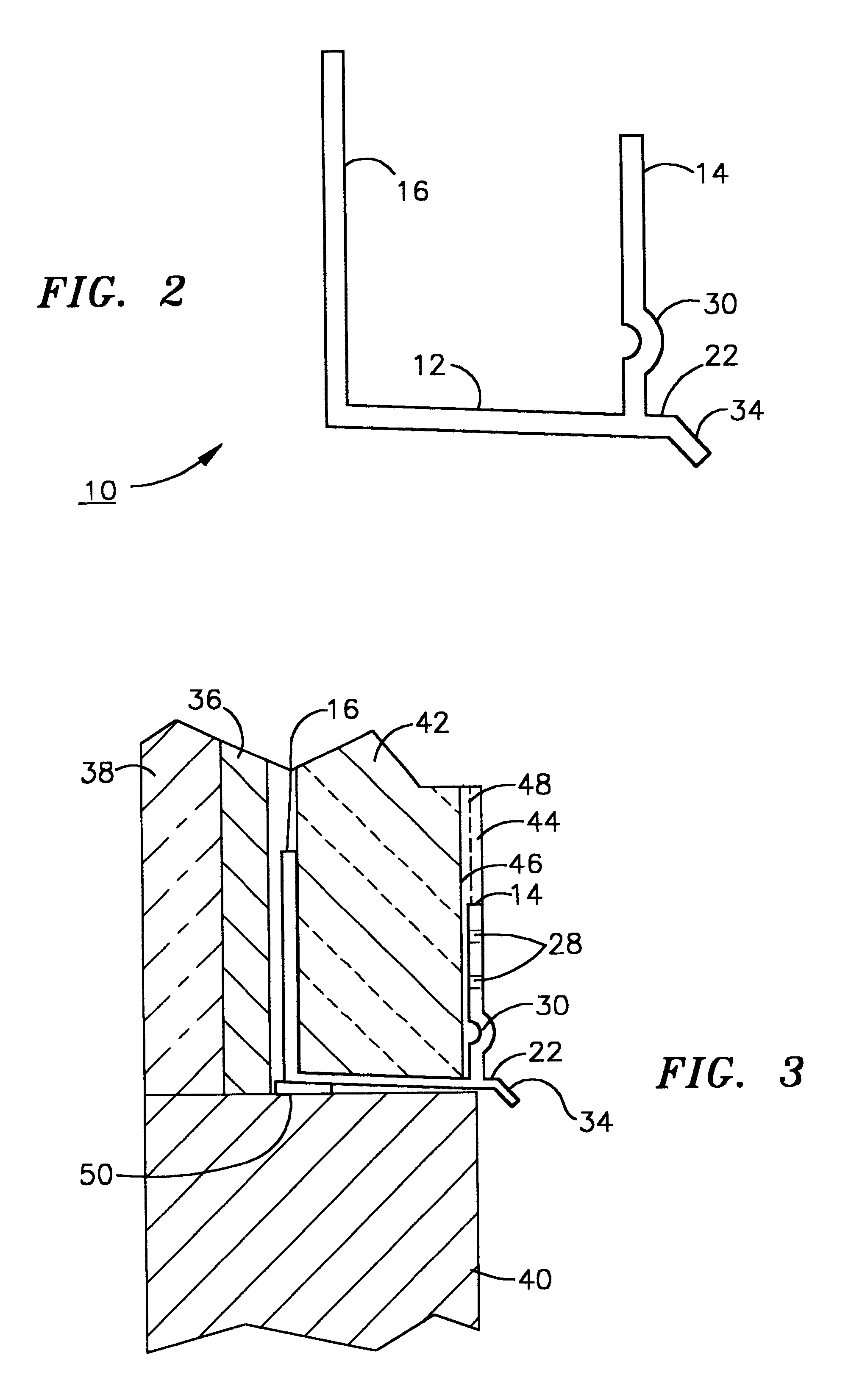

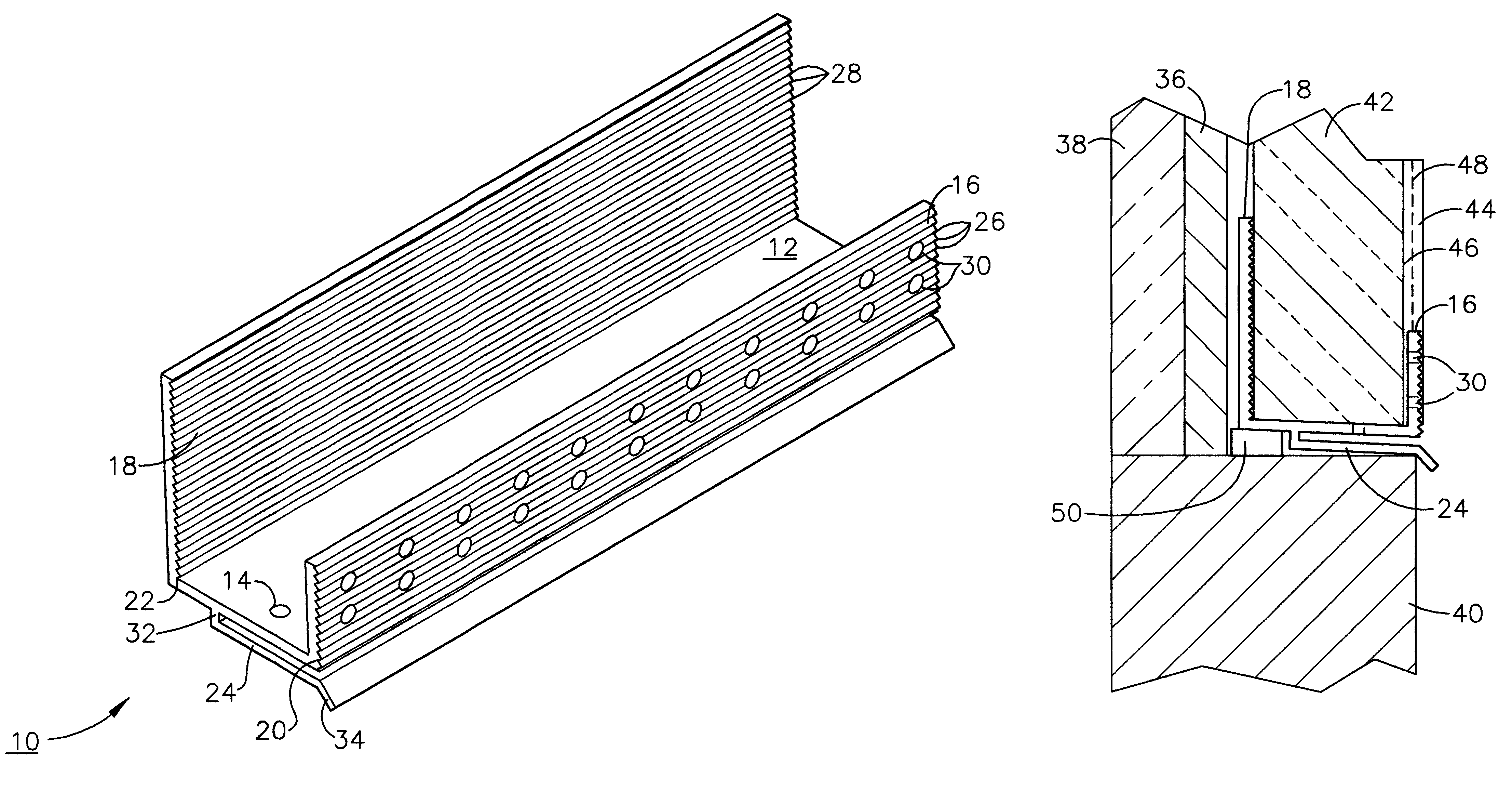

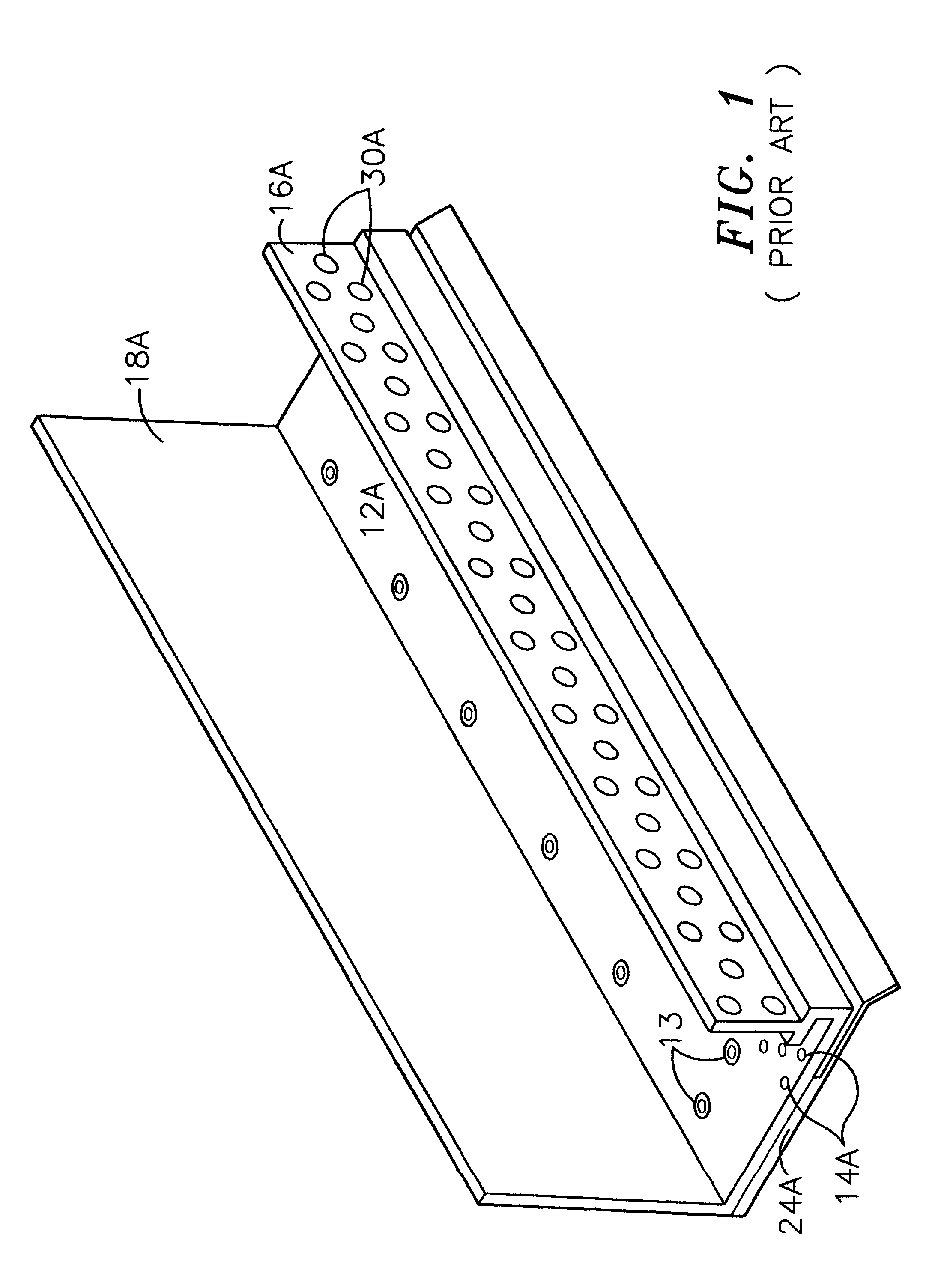

An improved moisture management system for installation over doors and windows in buildings that included exterior, stucco-covered, curtain walls comprising an integrally formed, three sided, elongated track including a base, an upright front wall that includes at its base weep holes for the removal of entrained moisture as well as a longitudinal forward extending finish stop above the weep holes, and an upright rear wall at opposing elongated edges of the base, and, extending angularly downward from the outside of the base, and integrally formed therewith, a drip plate that permits ready drainage of water exiting the moisture management system through the weep holes in the upright front wall. Preferably, elongated striations in the front faces of both the front and rear upright walls as well as holes in the upright front wall above the finish stop provide improved adherence of sealants and adhesives used in the installation process.

Owner:PLASTIC COMPONENTS

Moisture management system

InactiveUS6293064B1Improve water resistanceImprove featuresRoof covering using slabs/sheetsRoof covering using tiles/slatesAdhesiveEngineering

A moisture management system for installation over doors and windows in buildings that included exterior, stucco-covered, curtain walls comprising an integrally formed, three sided, elongated track including a base having weep holes therein, an upright front wall and an upright rear wall at opposing elongated edges of the base, and, extending angularly downward from the outside of the base, and integrally formed therewith, a drip plate that permits ready drainage of water entering the moisture management system through the weep holes in the base. Elongated striations in the front faces of both the front and rear upright walls as well as holes in the front upright wall provide adherence of sealants and adhesives used in the installation process.

Owner:PLASTIC COMPONENTS

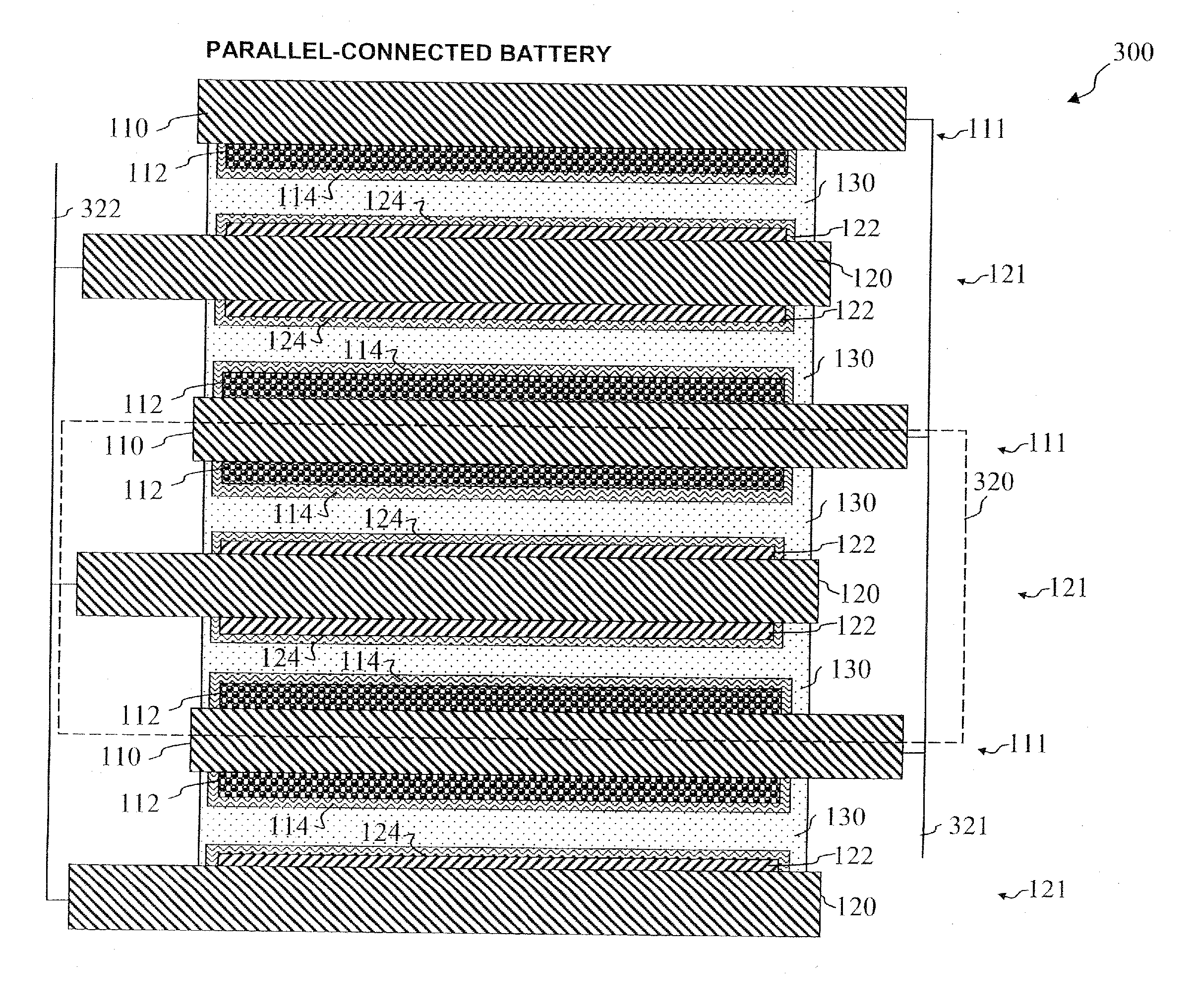

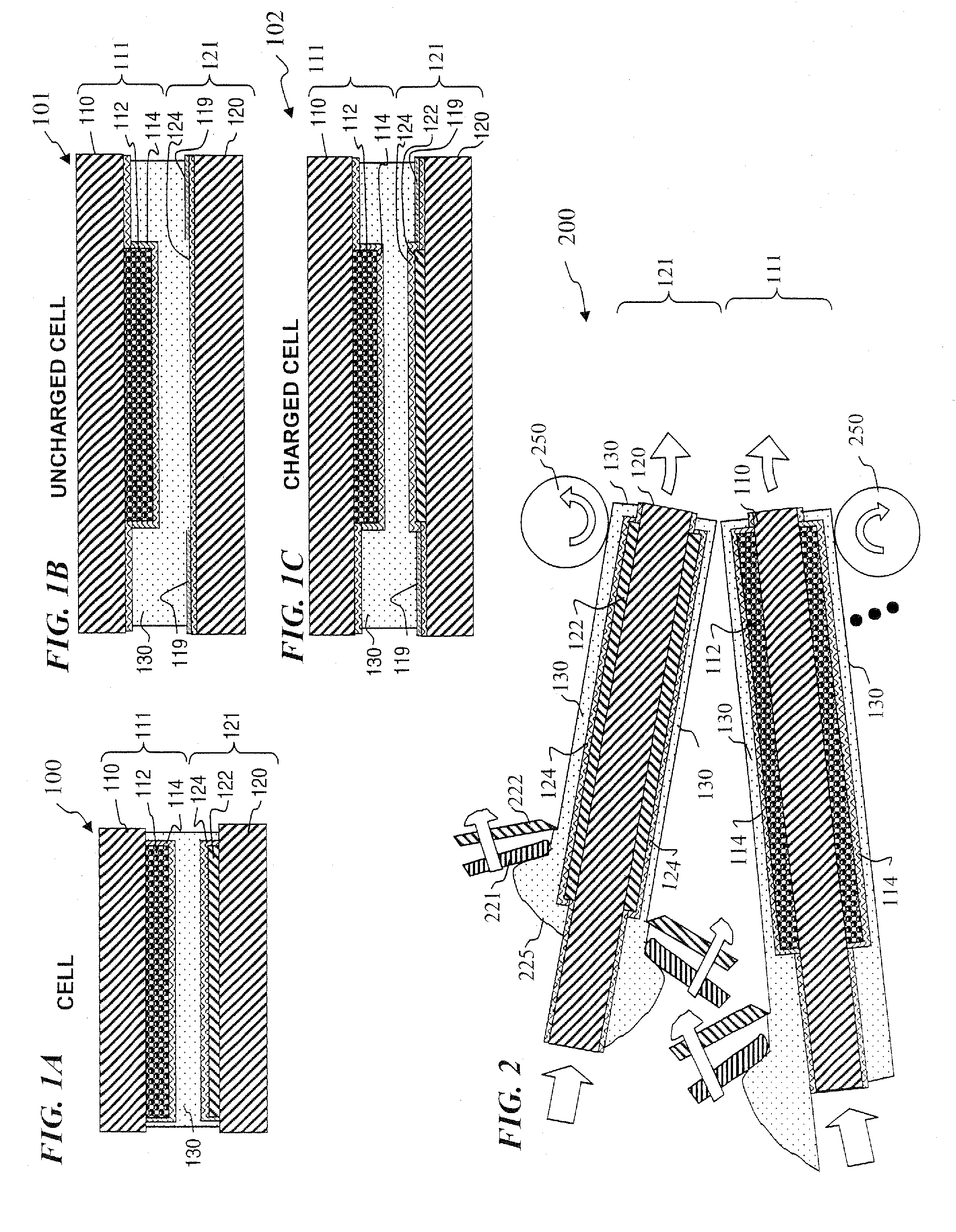

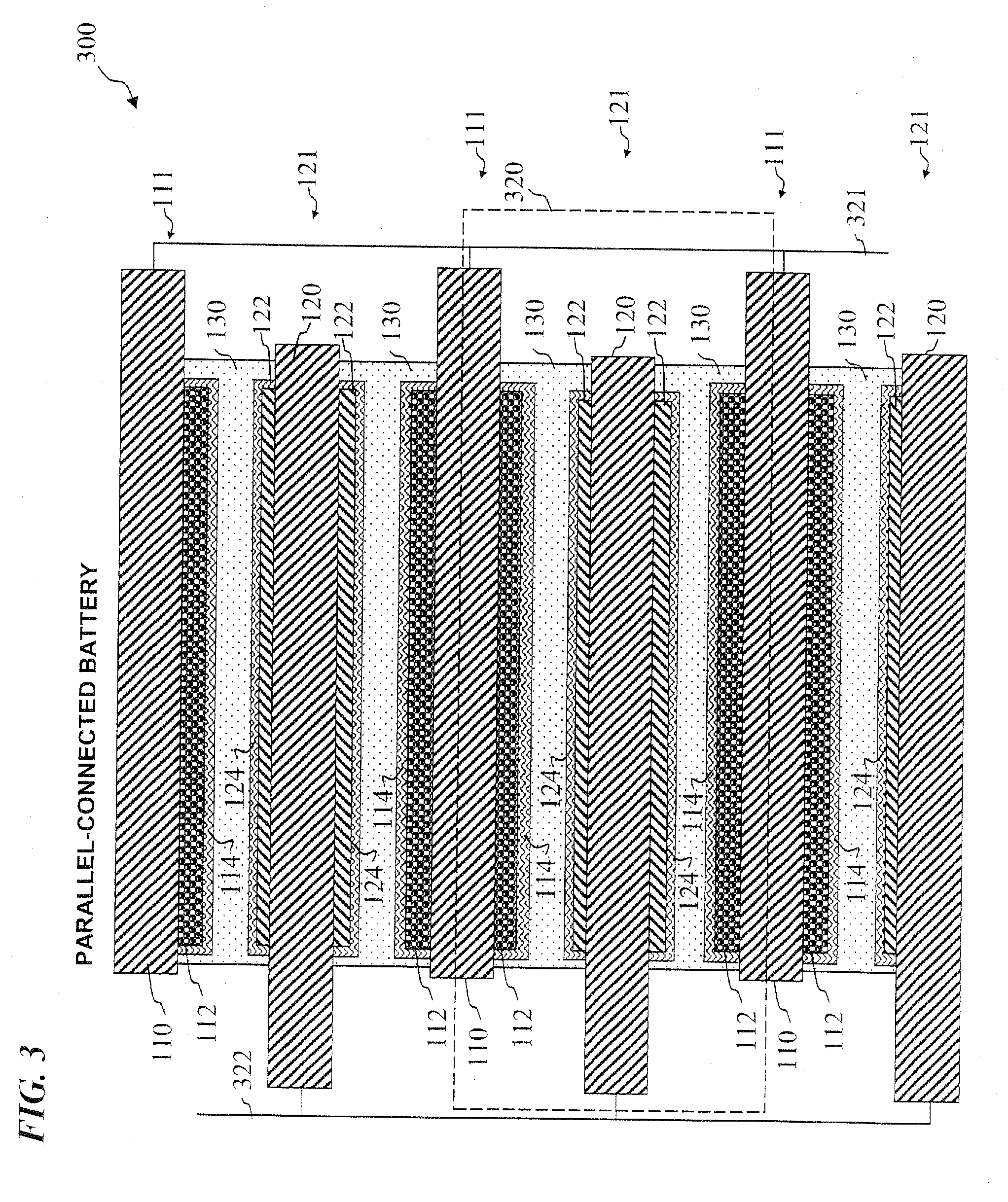

THIN-FILM BATTERIES WITH POLYMER AND LiPON ELECTROLYTE LAYERS AND METHOD

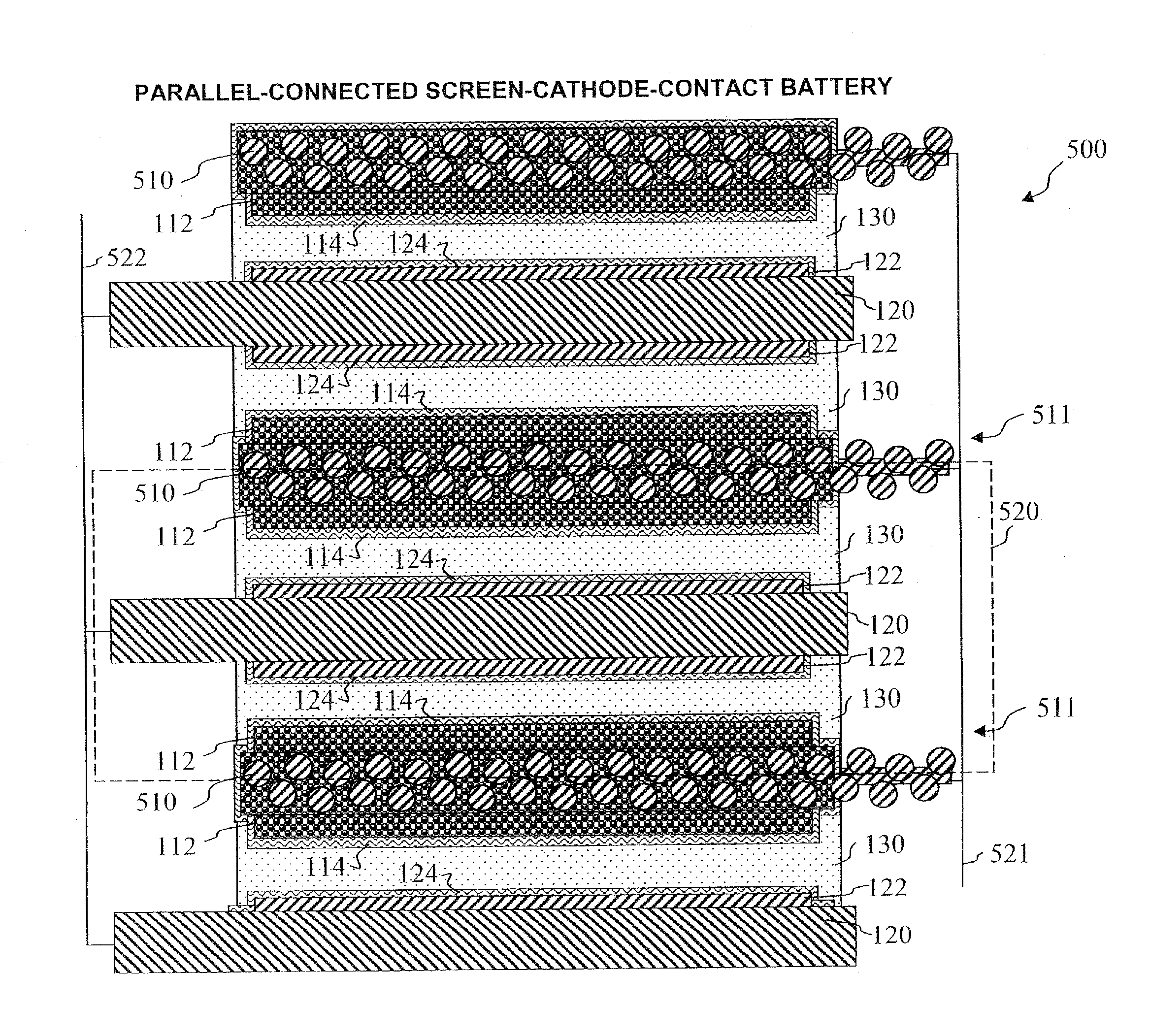

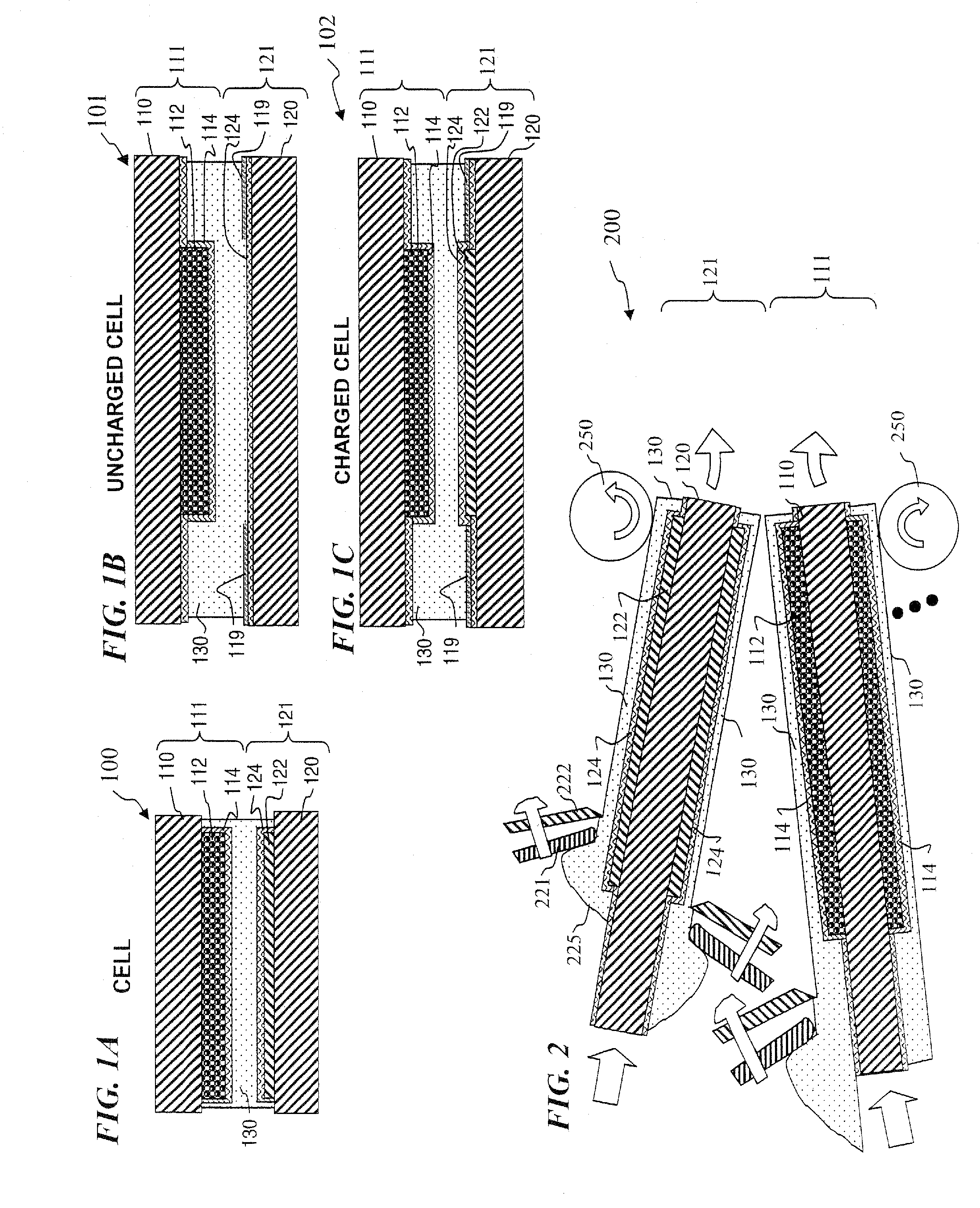

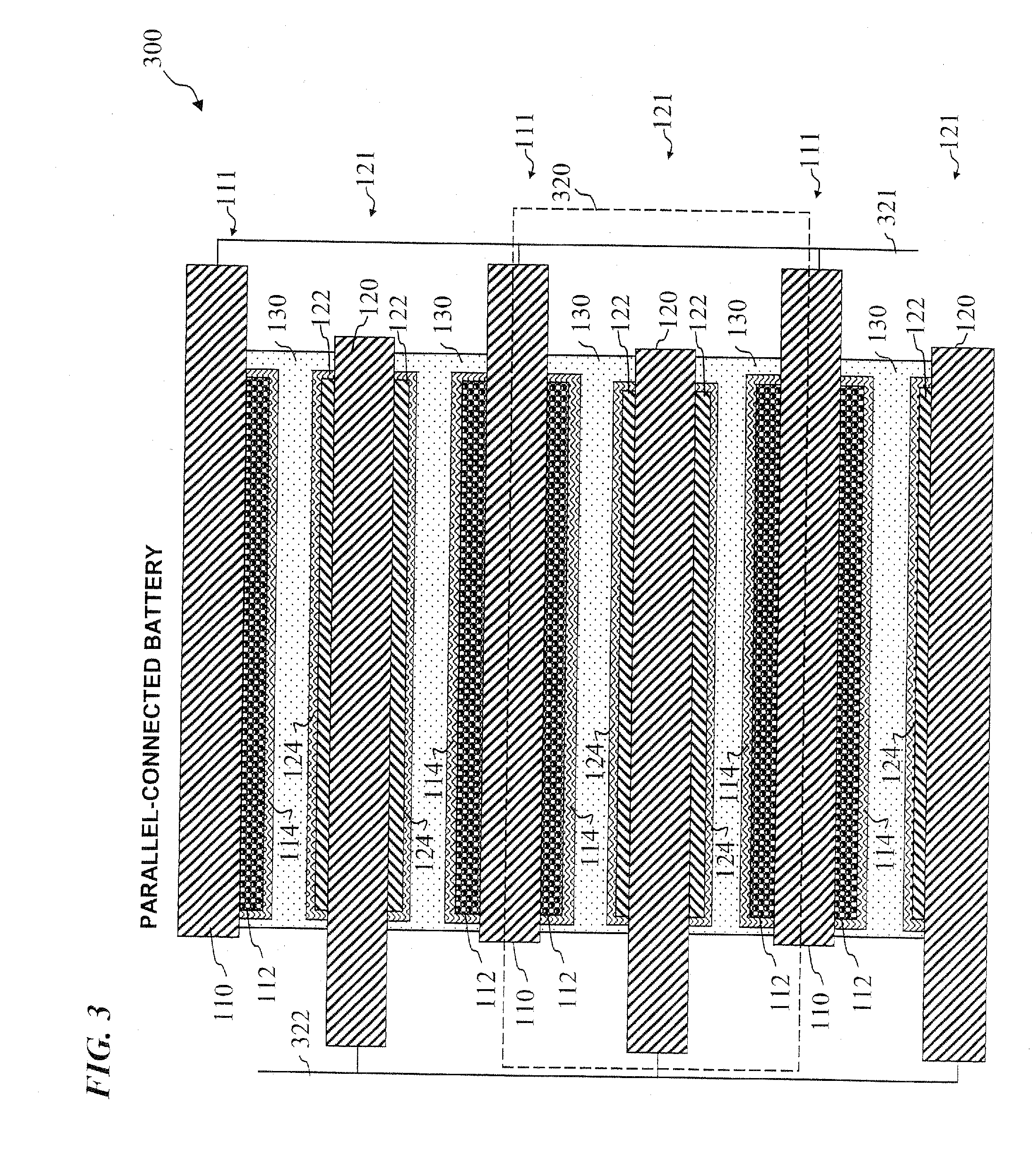

InactiveUS20070015061A1Improve environmental resistanceInhibition formationFinal product manufactureElectrode carriers/collectorsLithium metalPolymer gel

A method and apparatus for making thin-film batteries having composite multi-layered electrolytes with soft electrolyte between hard electrolyte covering the negative and / or positive electrode, and the resulting batteries. In some embodiments, foil-core cathode sheets each having a cathode material (e.g., LiCoO2) covered by a hard electrolyte on both sides, and foil-core anode sheets having an anode material (e.g., lithium metal) covered by a hard electrolyte on both sides, are laminated using a soft (e.g., polymer gel) electrolyte sandwiched between alternating cathode and anode sheets. A hard glass-like electrolyte layer obtains a smooth hard positive-electrode lithium-metal layer upon charging, but when very thin, have randomly spaced pinholes / defects. When the hard layers are formed on both the positive and negative electrodes, one electrode's dendrite-short-causing defects on are not aligned with the other electrode's defects. The soft electrolyte layer both conducts ions across the gap between hard electrolyte layers and fills pinholes.

Owner:CYMBET CORP

Thin-film batteries with soft and hard electrolyte layers and method

InactiveUS20070015060A1Improve environmental resistanceInhibition formationFinal product manufactureConductive materialLithium metalPolymer gel

A method and apparatus for making thin-film batteries having composite multi-layered electrolytes with soft electrolyte between hard electrolyte covering the negative and / or positive electrode, and the resulting batteries. In some embodiments, foil-core cathode sheets each having a cathode material (e.g., LiCoO2) covered by a hard electrolyte on both sides, and foil-core anode sheets having an anode material (e.g., lithium metal) covered by a hard electrolyte on both sides, are laminated using a soft (e.g., polymer gel) electrolyte sandwiched between alternating cathode and anode sheets. A hard glass-like electrolyte layer obtains a smooth hard positive-electrode lithium-metal layer upon charging, but when very thin, have randomly spaced pinholes / defects. When the hard layers are formed on both the positive and negative electrodes, one electrode's dendrite-short-causing defects on are not aligned with the other electrode's defects. The soft electrolyte layer both conducts ions across the gap between hard electrolyte layers and fills pinholes.

Owner:CYMBET CORP

Gypsum wood fiber product having improved water resistance

InactiveUS6010596AImprove water resistanceHigh strengthNon-fibrous pulp additionNatural cellulose pulp/paperFiberWax

An improved water resistant gypsum board is made by adding an aqueous wax emulsion containing a cationic surfactant to an aqueous slurry containing calcium sulfate and host particles at a slurry temperature which maintains calcium sulfate hemihydrate crystals. The wax emulsion is stable at the temperature of slurry which maintains the calcium sulfate hemihydrate. The slurry is then dewatered and rehydrated to form a gypsum board and dried at a temperature to melt the wax.

Owner:UNITED STATES GYPSUM CO

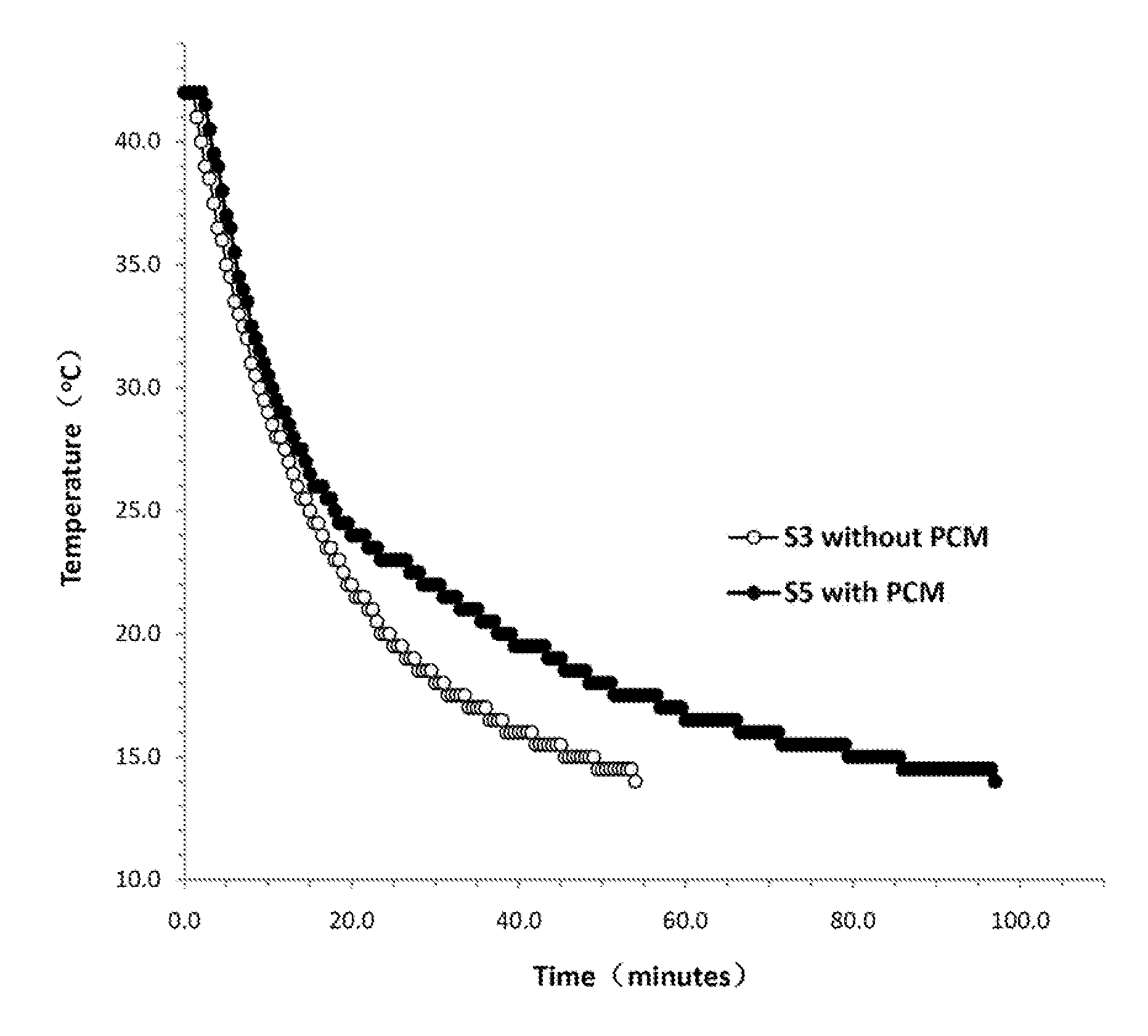

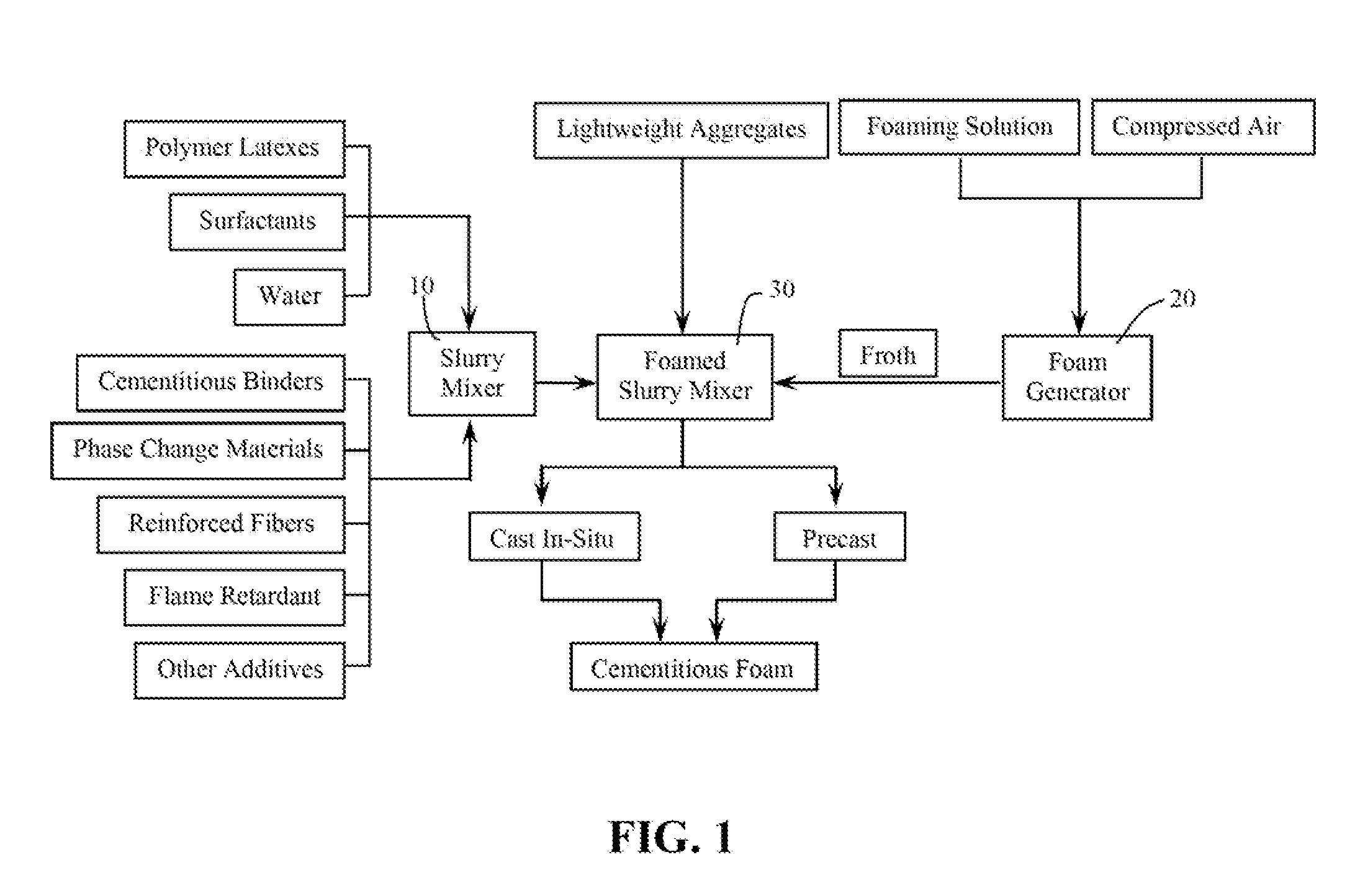

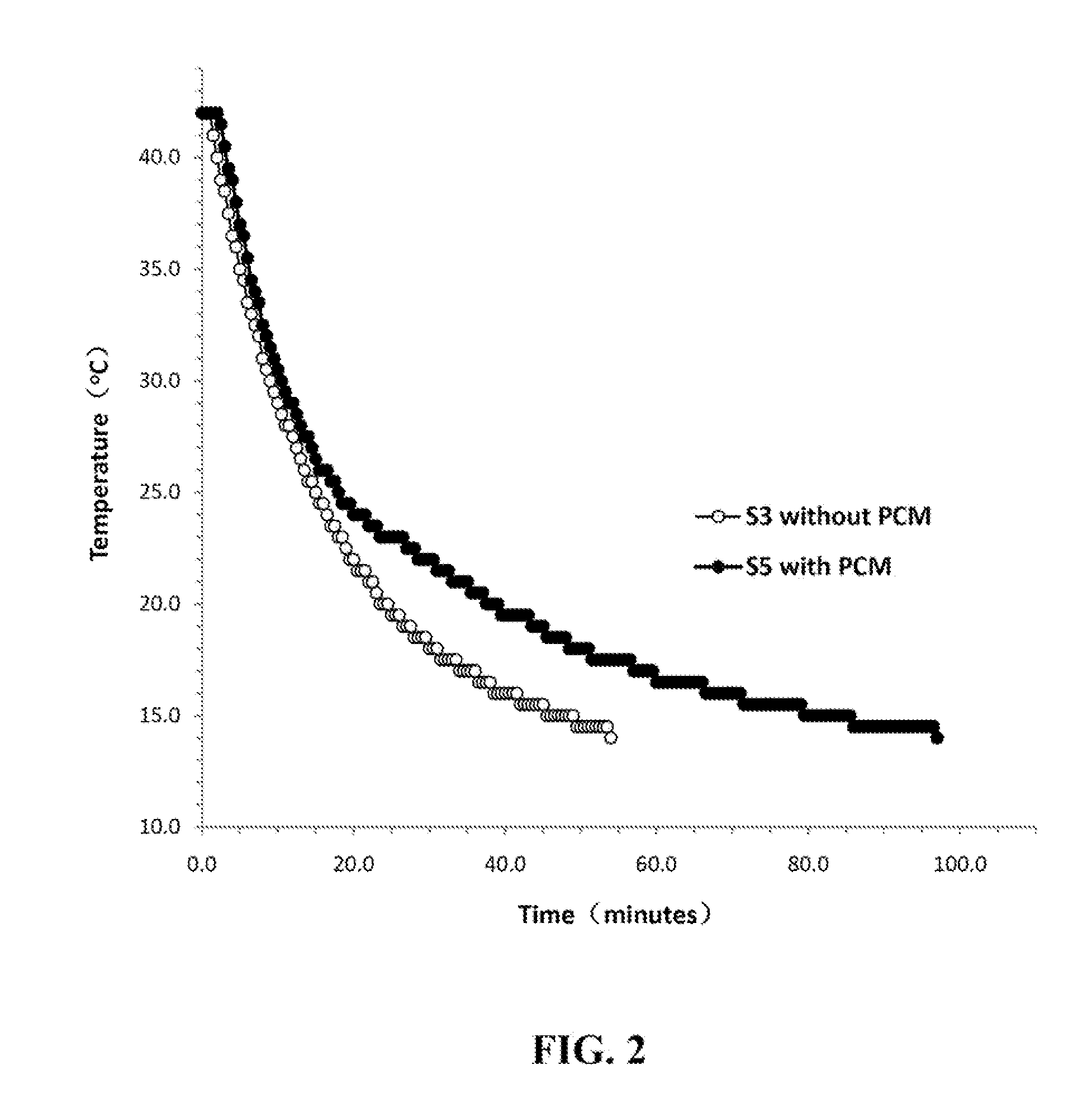

Fireproof insulating cementitious foam comprising phase change materials

ActiveUS8070876B1Improve fire resistanceImprove high temperature resistanceSolid waste managementSynthetic resin layered productsThermal energyThermal energy storage

A fireproof insulating foamed cementitious composition with thermal energy storage capacity is provided for use in producing wall insulation boards, fireproof claddings for steel structures, inner cores of fire resistant wall or door panels, and the like. The composition demonstrates improved energy efficiency in which phase change materials, such as microencapsulates, are used in conjunction with a cementitious mixture of calcined gypsum and hydraulic cement, lightweight aggregates, a polymer latex, and a foaming solution to create stable air bubbles inside the cementitious matrix. The calcined gypsum and the hydraulic cement are present in a weight ratio range from about 1:3 to about 3:1. The composition may further include reinforced fibers, surfactants, inorganic flame retardants, and other additives. The presence of the phase change material not only increases energy efficiency of the cured cementitious foam material, but also improves compatibility between calcined gypsum and cement during slurry mixing and hardening.

Owner:JIANG HAIHONG

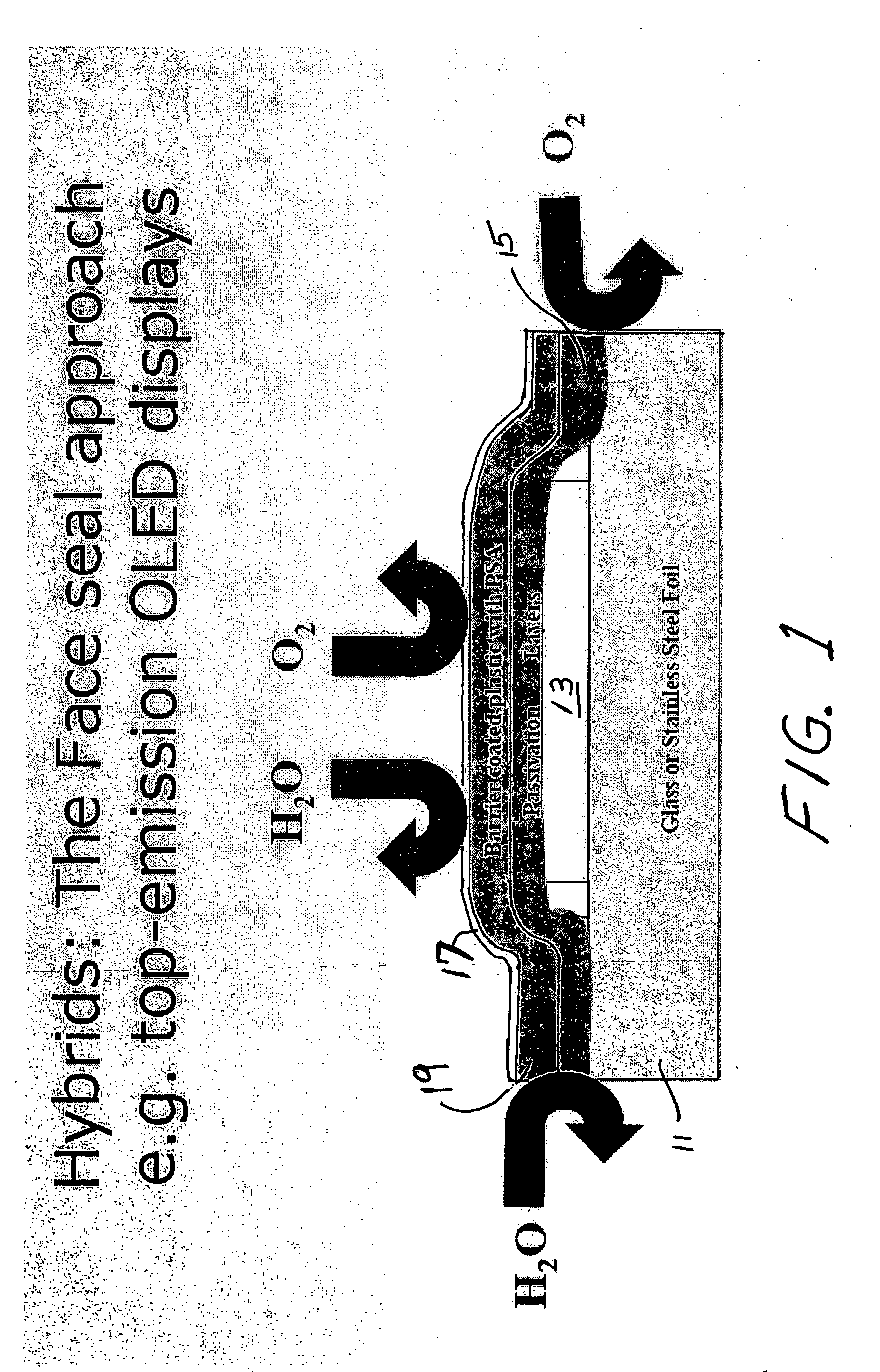

Gas barrier

InactiveUS20070135552A1Improved resistance to water vapor transmissionSmall sizeMaterial nanotechnologyPolymer scienceSealant

Nanoparticles of amorphous aluminum oxynitride or silicon oxynitride having a very high aspect ratio are used to fill polymeric materials to provide products that have an extremely low WVTR / OTR. Such products are particularly effective for incorporation into organic light-emitting devices or the like which are susceptible to degradation from moisture and / or oxygen. Pressure sensitive and / or thermosetting adhesives filled with such particles create excellent sealants. Polymeric sheets or films made from resin in which these nanoparticles are dispersed, or intimately associated with, before extrusion exhibit very low WVTR / OTR.

Owner:GENERAL ATOMICS

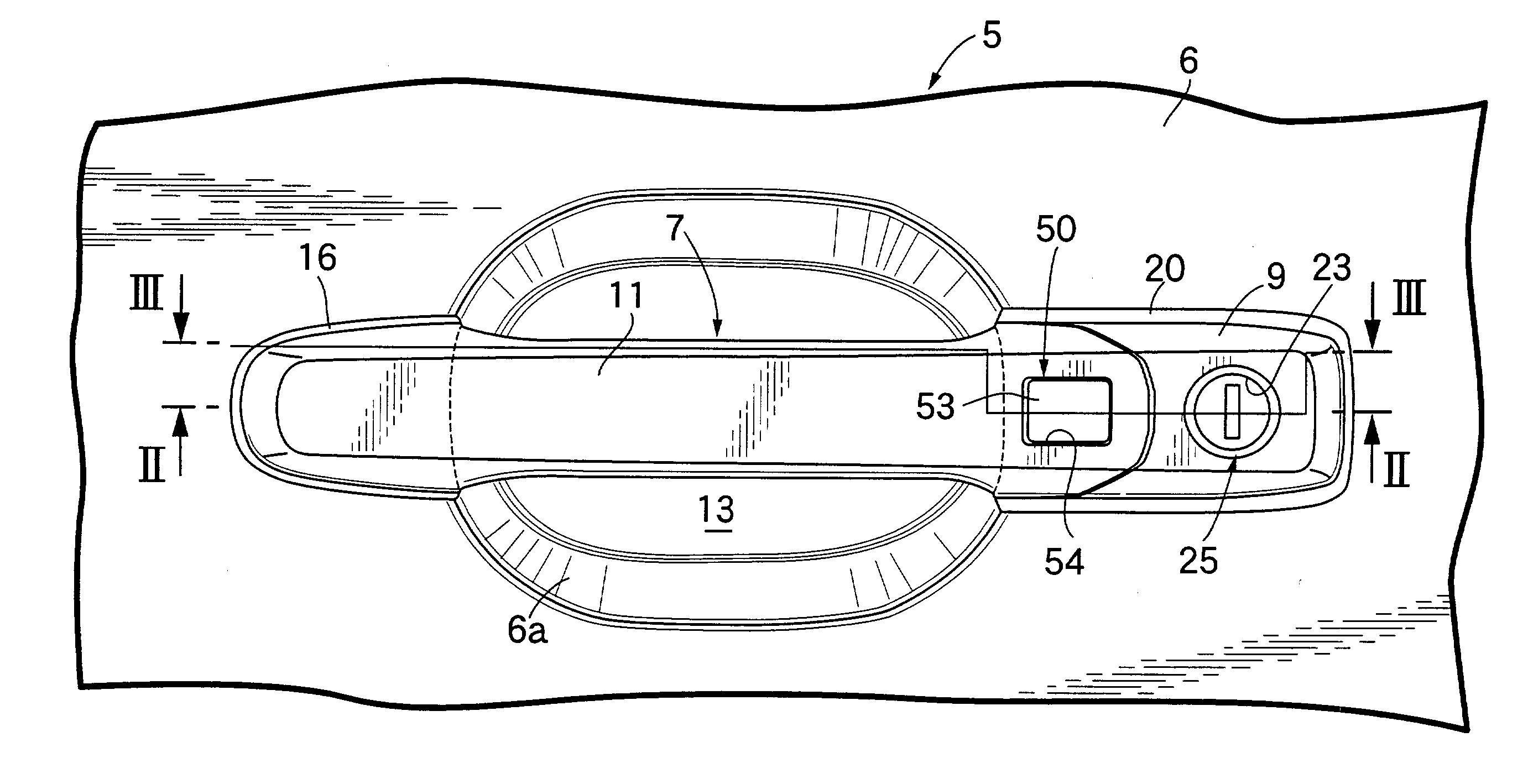

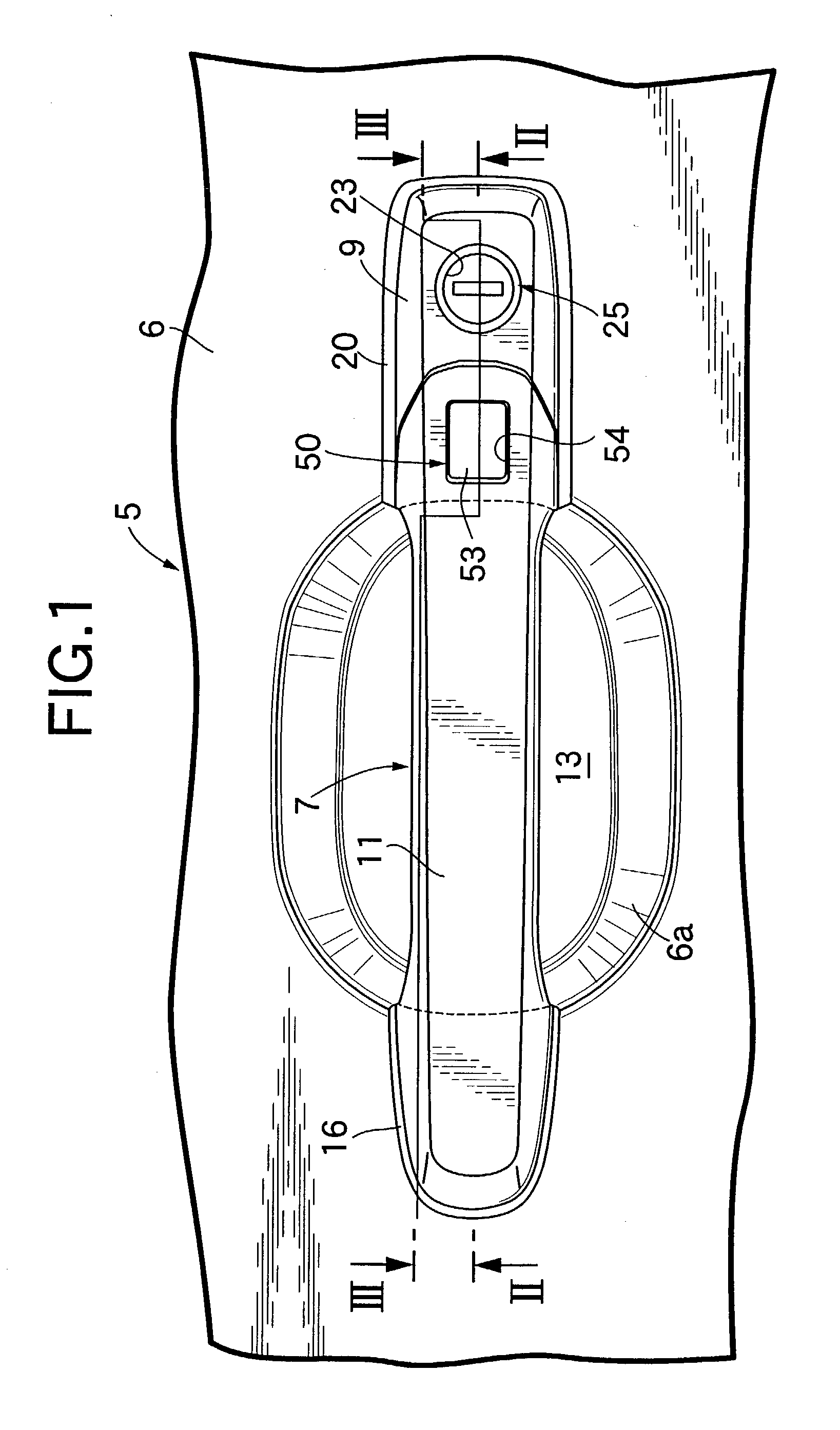

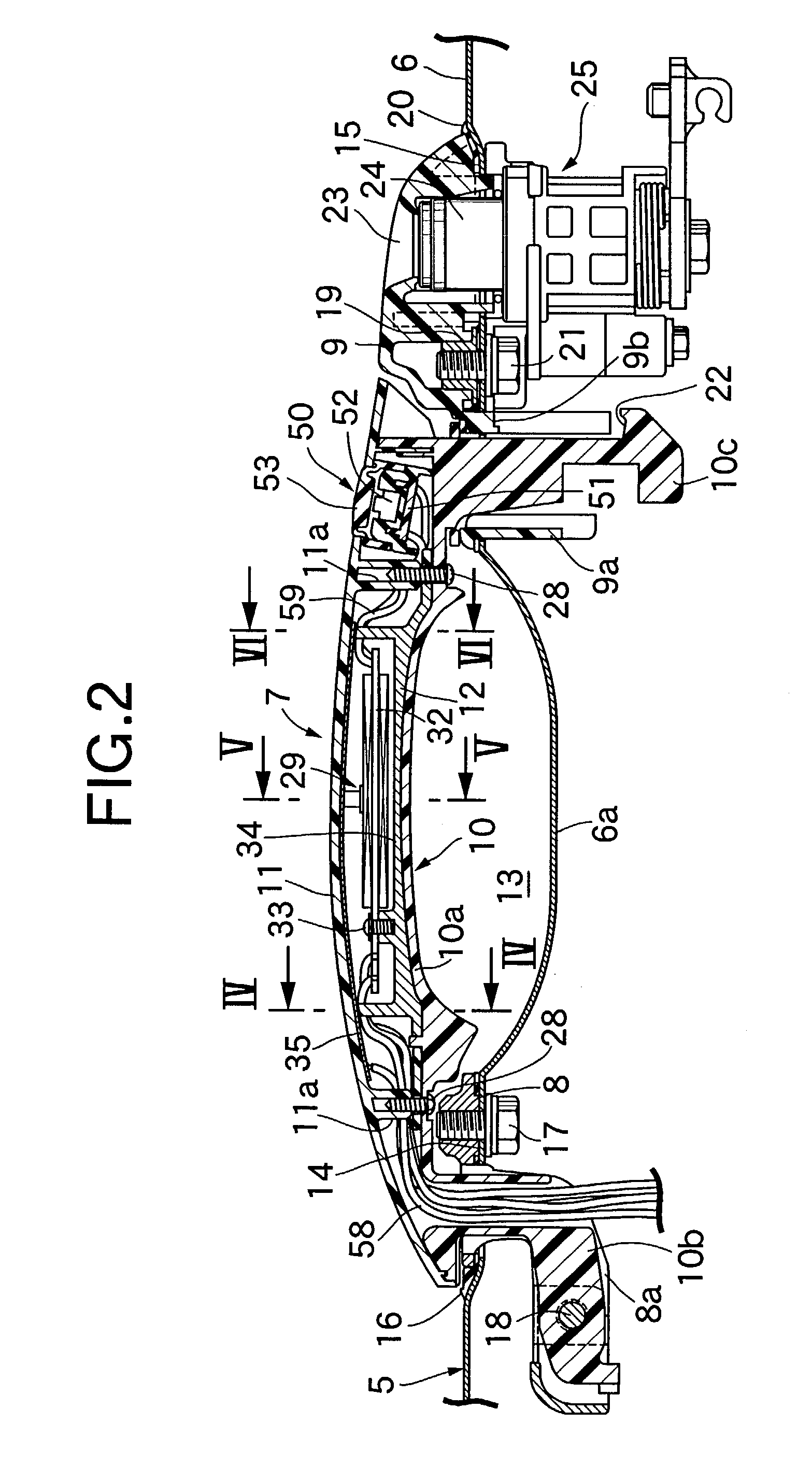

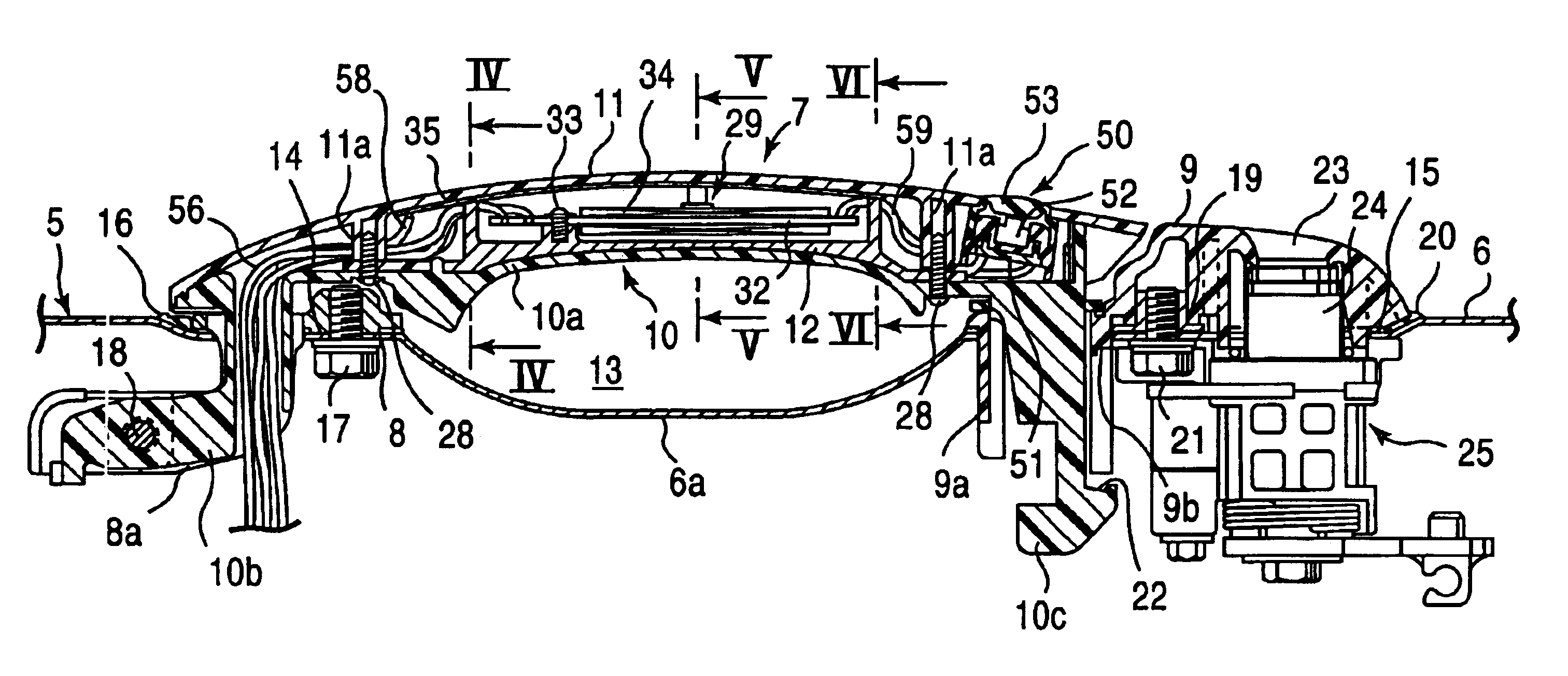

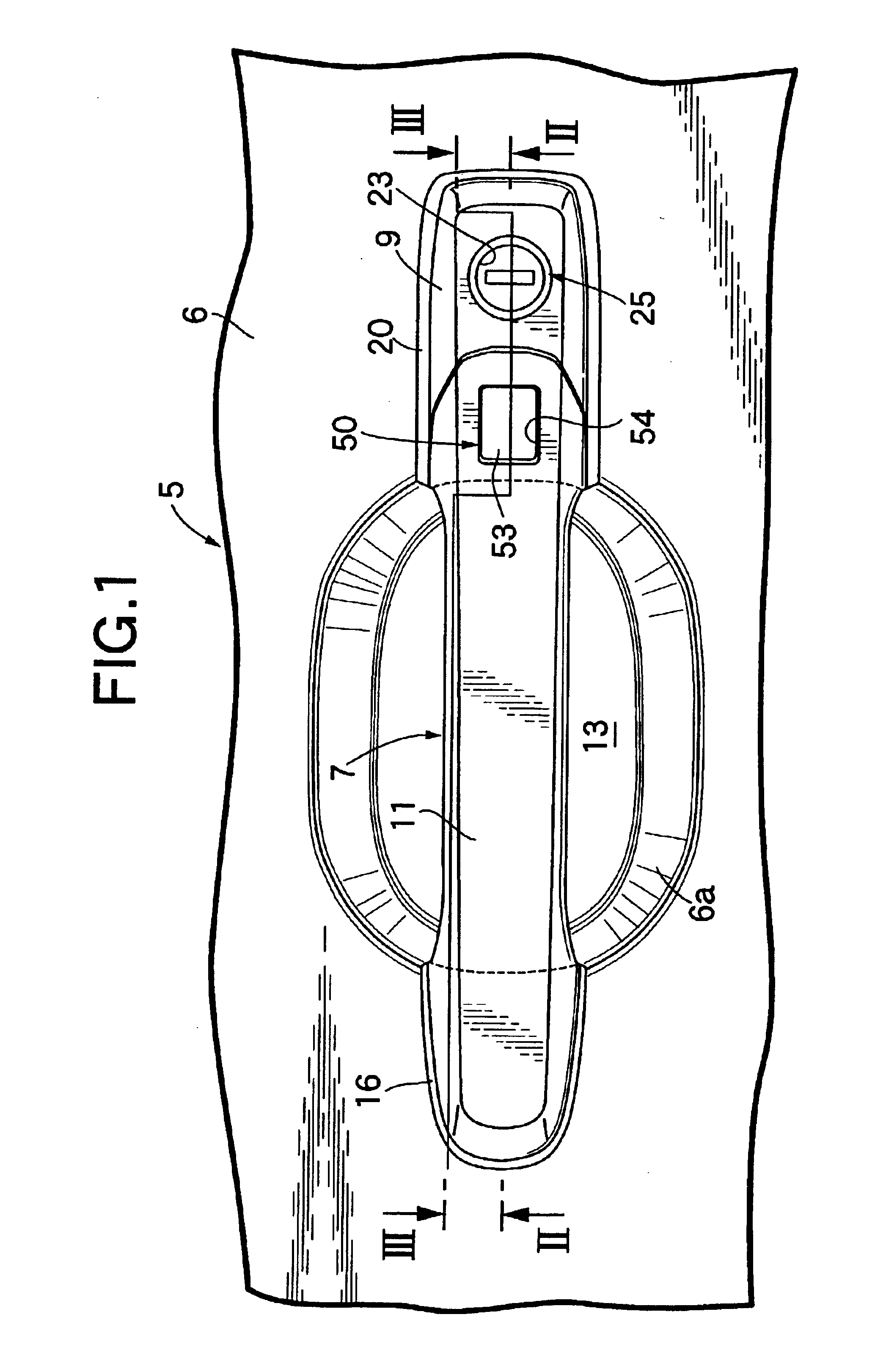

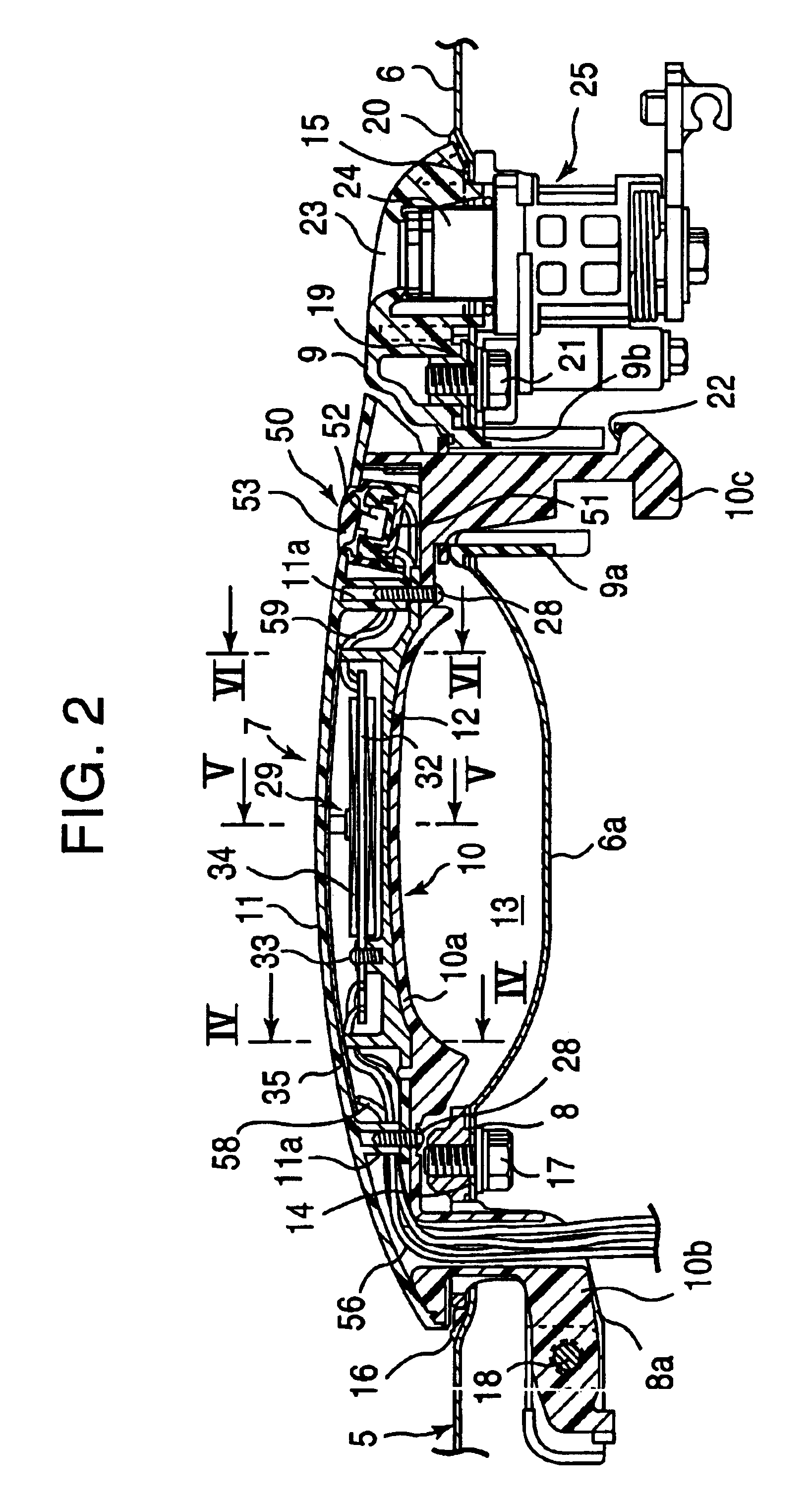

Vehicle door handle system

InactiveUS20030122556A1Accurate identificationEasy to installWing handlesResistance/reactance/impedenceCapacitanceEngineering

A vehicle door handle system includes a pair of electrodes disposed within an operating handle located on the outer surface side of a door along the longitudinal direction of the vehicle. A detection circuit for detecting a change in capacitance between the two electrodes is connected to the two electrodes.

Owner:HONDA LOCK MFG CO LTD +1

Wood adhesive and method of preparing thereof

InactiveUS20100258033A1Drying rate of adhesiveLow pour pointProtein waste adhesivesStarch adhesivesHigh densityAdhesive

A wood adhesive having a) 100 weight parts of water; b) between 3 and 45 weight parts of a proteinaceous material; c) between 0.01 and 15 weight parts of an acidity regulator; d) between 0.01 and 15 weight parts of an aromatic compound; e) between 0.01 and 15 weight parts of a curing agent; f) between 0.01 and 15 weight parts of a preservative; g) between 0 and 15 weight parts of a viscosity modifier; h) between 0 and 10 weight parts of a filler; and i) between 0 and 15 weight parts of a drier. The wood adhesive can be used for preparation of plywood, blockboard, oriented strand board (OSB), flakeboard, fiberboard, veneer plywood, middle density fibreboard, high density fibreboard, hardboard, flooring substrate, LVL, and so on. A method for preparing the wood adhesive is also provided.

Owner:YANG GUANG +1

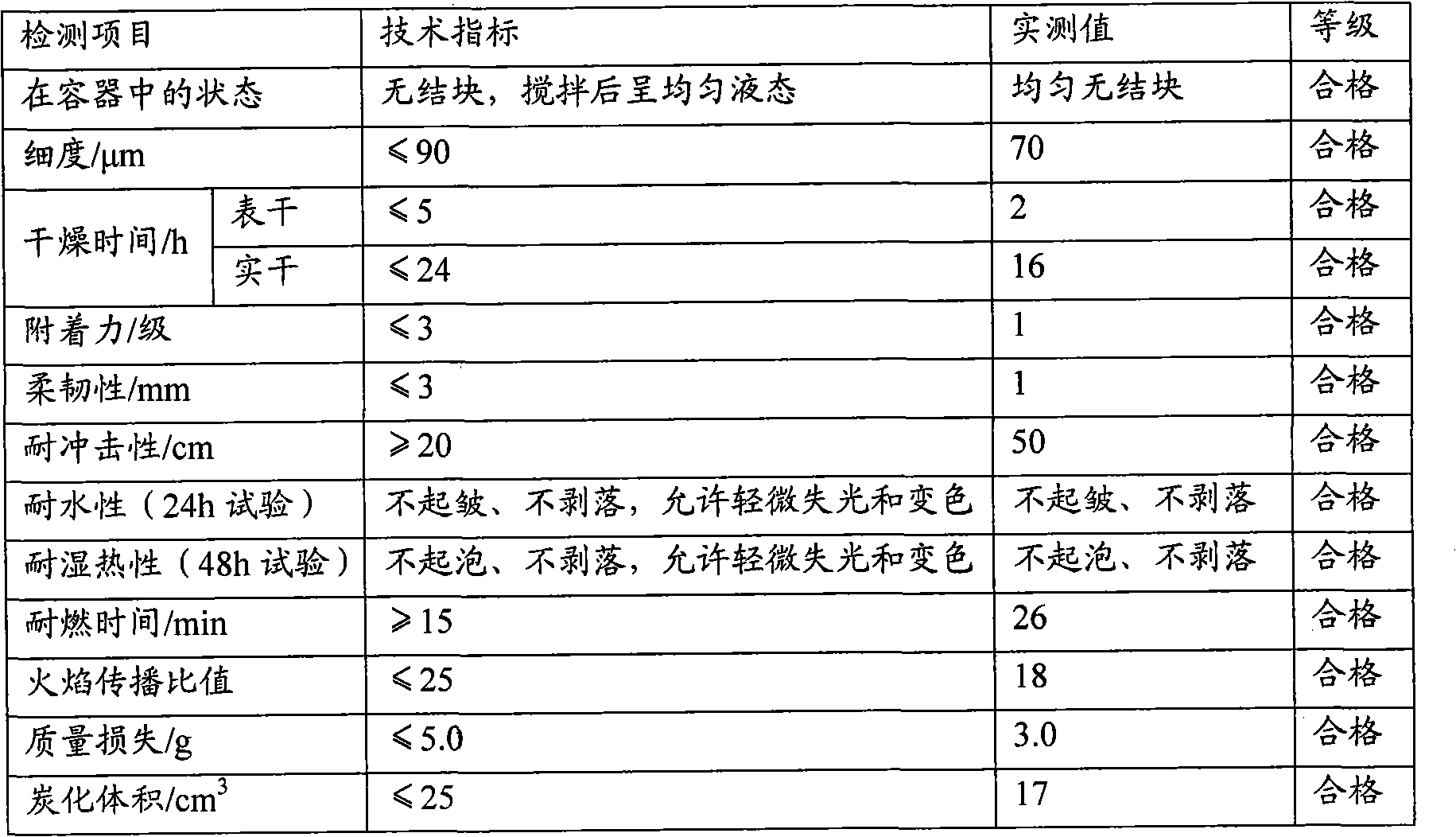

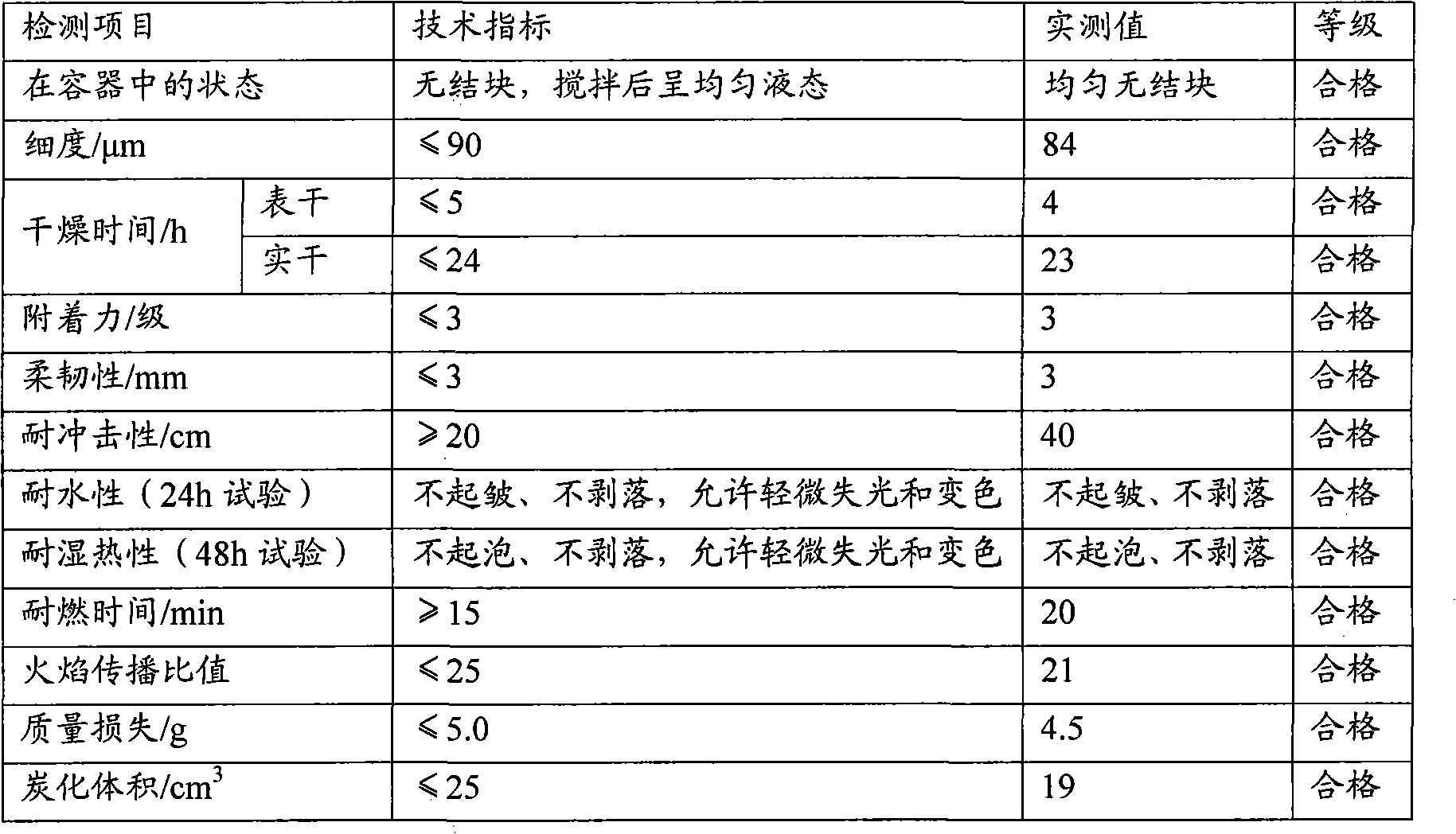

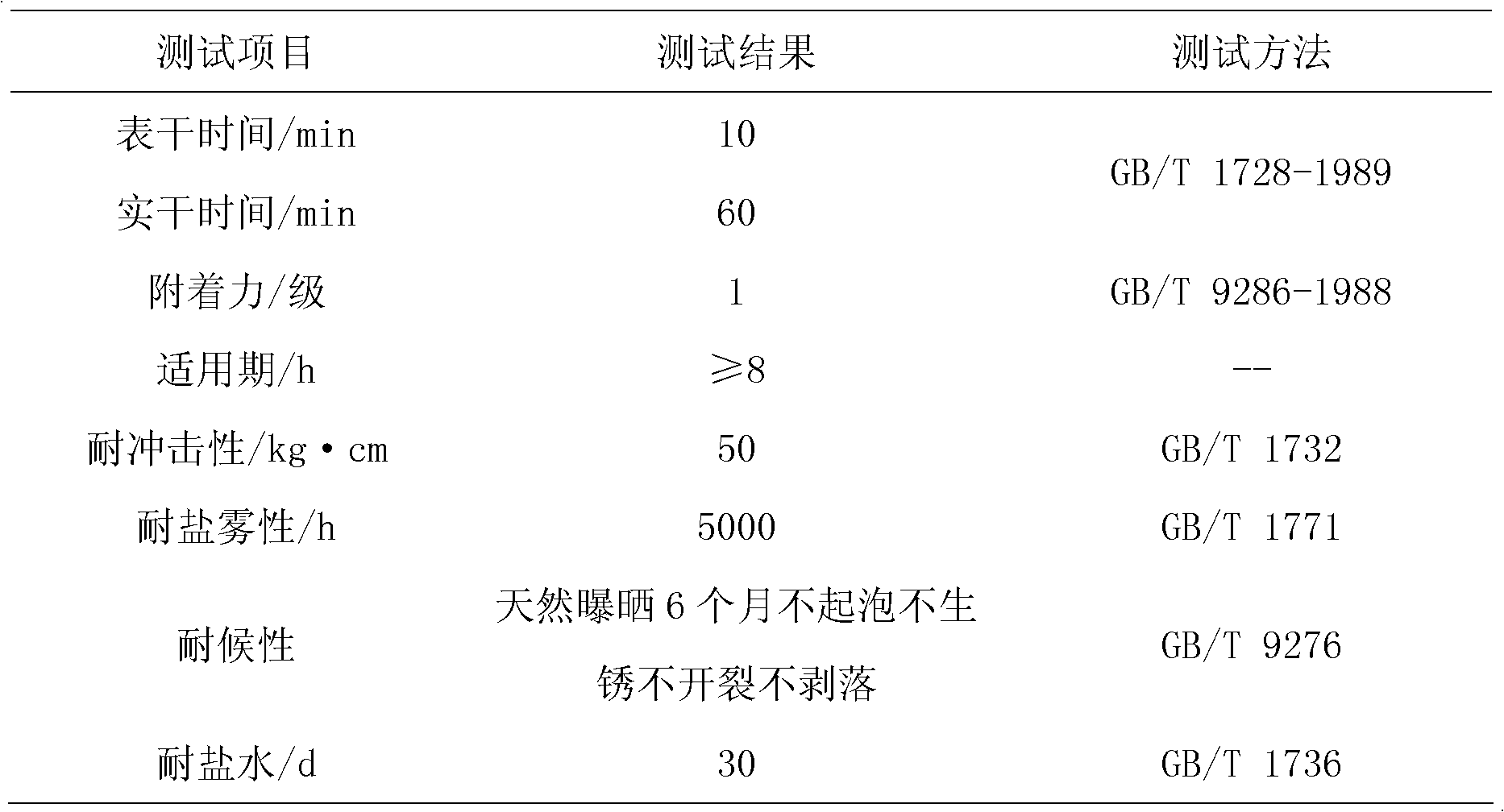

Expanded type fireproof coating and preparation method thereof

ActiveCN101659823AReduce usageLow costFireproof paintsPolyurea/polyurethane coatingsSolventAnti ageing

The invention discloses an expanded type fireproof coating and a preparation method thereof, which are characterized by comprising the steps of grinding and dispersing 15-35 percent of microcapsule flame retardants, 5-10 percent of fillers and 10-30 percent of solvent according to the percentage of the total mass of the coating after preparation until the fineness thereof is less than 90 microns;then adding and dispersing coating matrixes and additives which respectively take up 20-40 percent and 1-5 percent of the total mass of the coating after preparation until the system is uniform; and alternatively adding flame retardant synergist agents which account for 0-10 percent of the total mass of the coating after preparation before grinding. The obtained expanded type fireproof coating hasgood stability, overcomes the defects of poor high-temperature resistance, poor anti-aging performance, poor water resistance and the like in the traditional organic expanded type fireproof coating,lowers the use amount and cost of the flame-retardant additives which all realize non-halogenation, does not cause larger impact on the environment, and has very good application prospects.

Owner:UNIV OF SCI & TECH OF CHINA

Vehicle door handle system

InactiveUS6740834B2Accurate identificationEasy to installWing handlesAnti-theft devicesCapacitanceEngineering

Owner:HONDA LOCK MFG CO LTD +1

Hydrophobic granule and preparation method thereof, and waterproof breathable structure and forming method thereof

ActiveCN101838116AImprove hydrophobicityImprove water resistanceSolid waste managementSoil conditioning compositionsEpoxyPolyresin

The invention relates to a hydrophobic granule and a preparation method thereof, and a waterproof breathable structure and a forming method thereof. The hydrophobic granule comprises aggregate and a hydrophobic resin film coated on the aggregate, wherein the aggregate size is 6-300 meshes, and the hydrophobic resin film is made of one or a plurality of hydrophobic epoxy resin, bakelite, polyurethane resin and silicone resin, and coated on the aggregate. The preparation method of the hydrophobic granule comprises the following steps: heating the aggregate to 50-400 DEG C; adding the hydrophobic resin, evenly stirring so that a film is coated on the aggregate surface; and cooling, crushing and screening to obtain the hydrophobic granules. The hydrophobic granule can be widely used as a waterproof breathable layer in desert planting, lake bottom seepage-proofing, river course seepage-proofing, landscape water system bottom seepage-proofing, and has favorable waterproof and breathable properties.

Owner:北京仁创科技发展有限公司

Modified magnesium oxy-sulfur cement

InactiveCN102924038AImprove mechanical propertiesImprove water resistanceAqueous solutionMaterials science

The invention relates to modified magnesium oxy-sulfur cement. The cement consists of the following raw materials in parts by weight: 100 parts of magnesium oxide, 0.05-10 parts of additive, 50-200 parts of 10%-30% magnesium sulfate aqueous solution and 0-300 parts of filler. The modified magnesium oxy-sulfur cement has excellent mechanical property and water resistance, is temperature-resistant, does not crack, can be used for substituting for a magnesium oxy-chloride cement and can be used for producing materials of mortar, concrete, slabs, crafts and the like.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

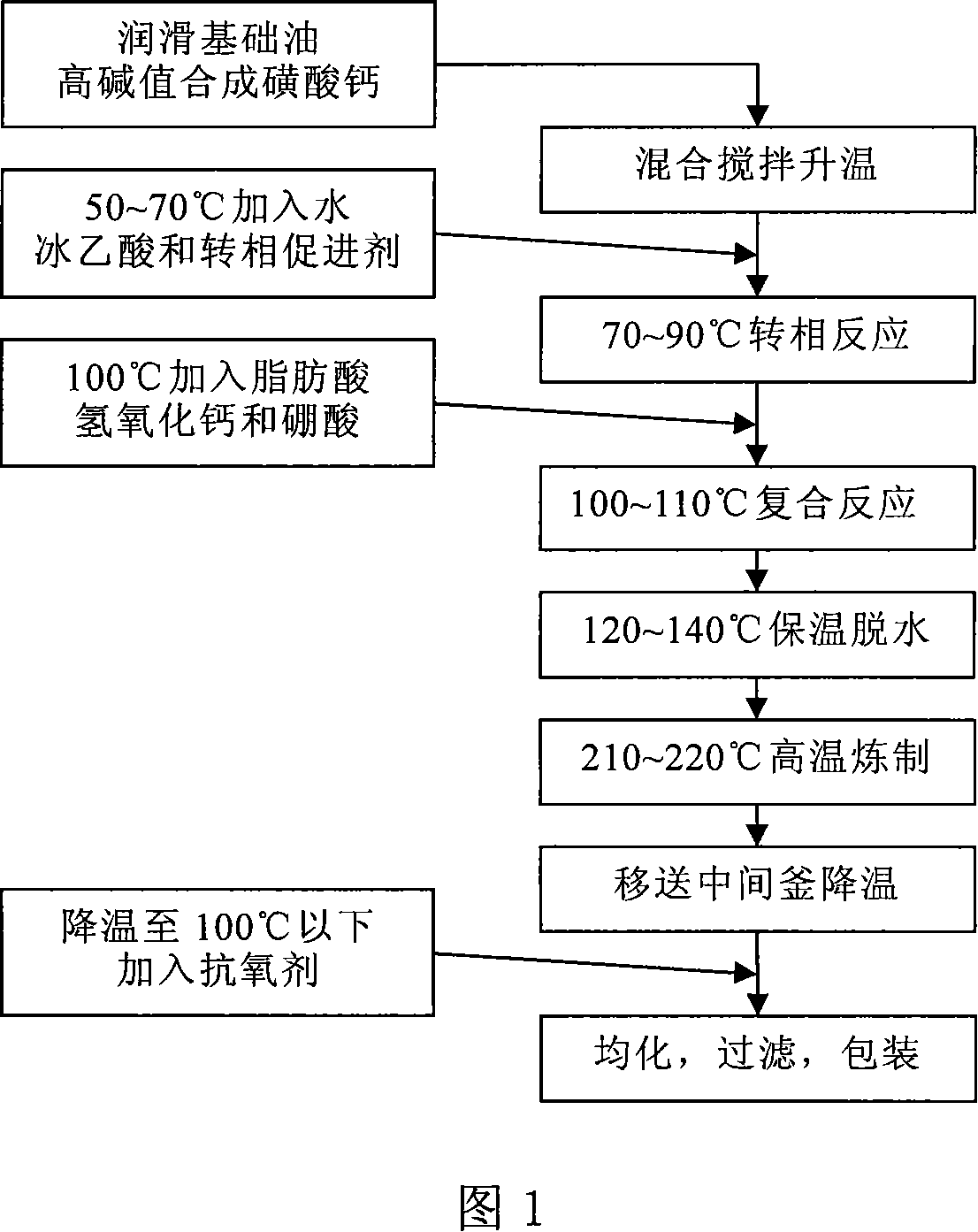

Compound sulphonic acid albany grease and method for producing the same

ActiveCN101153239AImprove performanceImprove water resistanceLubricant compositionAntioxidantManufacturing enterprises

The invention relates to calcium sulfonate complex grease and a manufacture method thereof, in particular to grease producing the thickening agent by synthetic reaction with super-high base value. At first, the lubricating base oil and the calcium sulfonate are added into an opening reaction kettle to be stirred, the phase inversion promoter, the glacial acetic acid and the water are added into the kettle to boost the temperature to make the insulating reaction until the materials are thickened, then the calcium hydroxide, the aliphatic acid and the boric acid are added into make an insulating reaction, a temperature rise, an insulating dehydration and a refining in turn, then the materials are moved into an intermediate kettle, the antioxidant is added to disperse and homogenize, and the finished product is produced after the filtering. The invention has excellent anti-spray performance, excellent high temperature performance, good extreme pressure anti-abrasion performance, prominent anti-shear performance, good pumping performance, anti-rust performance and water adding shear stability; has apparent phase inversion effect and good product performance, decreases the grease exchange times under the same working condition and increases the service life of the equipment, which is proved by the trial applications of a plurality of appliance manufacture enterprises, steel works, paper mills and so on.

Owner:无锡中石油润滑脂有限责任公司

High-abrasion resistant ultraviolet light solidifying fingerprint resistant coating

InactiveCN101701129AGood hardness and wear resistanceMeet wear resistancePolyurea/polyurethane coatingsSolventFingerprint

The invention relates to a light solidifying high-abrasion resistant fingerprint resistant coating which is used for the surfaces of plastic shells of portable electronic products, such as mobile phones, MP3, digital cameras, handheld computers, and the like and comprises the following components: 10-35 percent of high-functionality urethane acrylate, 5-25 percent of bifunctional urethane acrylate, 0.01-20 percent of acrylic ester monomer, 5-20 percent of high-functionality acrylic ester, 5-40 percent of fluorin-contained acrylic ester, 0.01-10 percent of nano inorganic powder filler, 1-5 percent of light initiating agent, 0.01-5 percent of auxiliary agent and 5-30 percent of solvent. The invention improves the fingerprint resistant capability of a coating film by the enrichment and microphase separation of a fluorin-contained group added into the coating on the surface of a coating surface, provides excellent abrasion resistance and hardness by using the polyurethane structure in the coating and the added nano abrasion resistant filler and meets the requirements of abrasion resistance, scratch resistance and fingerprint resistance of the portable electronic products.

Owner:武汉嘉特利佰联创科技有限公司

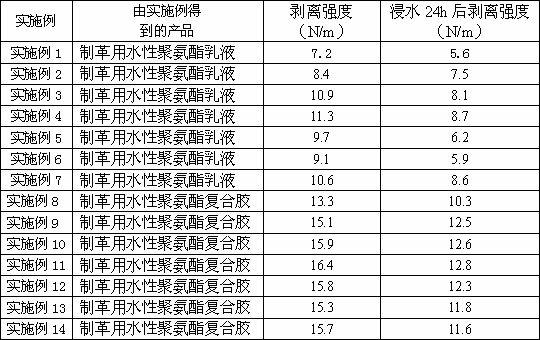

Water-based polyurethane composite adhesive for tanning and preparation method and application of composite adhesive

InactiveCN102618202ATroubleshoot MigrationOvercome the problem that the performance cannot fully meet the requirements of useNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePolyol

The invention discloses water-based polyurethane composite adhesive for tanning and a preparation method and application of the composite adhesive, belongs to the technical field of water-based polyurethane composite adhesive preparation methods, and in particular relates to a method for preparing composite adhesive in the fields of artificial leather and synthetic leather. The method for preparing the water-based polyurethane composite adhesive for tanning is characterized by comprising the following steps of: reacting polyol polymer and isocyanate, adding chain extender, hydrophilic chain extender, cross linker, catalyst and solvent, reacting, cooling and emulsifying, to obtain emulsion; and mixing the emulsion, curing agent, wetting agent, tackifier, adsorbent and thickening agent uniformly, and thus obtaining the hot-melt adhesive for artificial leather adhesive layers. The water-based polyurethane composite adhesive for tanning is used for compounding polyvinyl chloride (PVC) / cloth for artificial leather of luggage and clothes. The prepared water-based polyurethane composite adhesive for tanning has high adhesive fastness and good water and solvent resistance, and can be applied to processes of knife coating, roll coating and the like of binding materials of middle layers of artificial leather and synthetic leather in the fields of textiles, leather processing and the like.

Owner:江阴市诺科生物新材料科技有限公司

Bi-component polyurethane coating and preparation method thereof

ActiveCN102757722AGuaranteed viscosityGuaranteed mechanical propertiesPolyurea/polyurethane coatingsPlasticizerShock resistance

The invention relates to a bi-component polyurethane coating which is prepared from a component A and a component B in a weight ratio of 1:(1-3), wherein the component A comprises the following materials in parts by weight: 40-80 parts of polylol, 20-50 parts of polyisocyanates, 1-10 parts of plasticizer and 0-5 parts of storage stabilizing agent; and the component B comprises the following materials in parts by weight: 10-40 parts of polylol, 10-40 parts of liquid filler, 5-10 parts of crosslinking agent, 30-60 parts of solid filler, 3-15 parts of plasticizer, 0.1-8 parts of thixotropic agent, 0-5 parts of pigment and 0.2-5 parts of additive. The bi-component polyurethane coating is suitable for water prevention, permeability resistance, corrosion resistance and protection of a horizontal plane, can be thickly coated and constructed (>3mm / turn) on complex parts such as a vertical surface and an incline, does not generate sagging and bubble phenomena in a construction process, is full in color, and has the advantages of excellent mechanical property, shock resistance, water resistance and corrosion resistance.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Waterborne room-temperature self-curing inorganic zinc rich coating

ActiveCN102146225AStrong adhesionHigh modulusAlkali metal silicate coatingsAnti-corrosive paintsEnvironmental resistanceMaterials science

The invention discloses waterborne room-temperature self-curing inorganic zinc rich coating. The coating is prepared by uniformly mixing a prepared base stock and powder in a mass ratio of 1:1.5-3.5, wherein the process of preparing the base stock comprises the following steps of: adding 5 to 10 parts of water into alkali metal silicates solution with the mode number of 2.5 to 3.7 and stirring the mixture at low speed; then adding silica sol drops with the grain diameter of 7 to 20nm and the solid content of 25 to 32 percent, dripping 1 to 10 parts of silane coupling agent and adding 0.5 to 2parts of stabilizing agent; and filtering out precipitates to obtain the transparent base stock. The inorganic zinc rich coating has high drying speed and good early-period waterproofness and can resist to washing with certain pressure after being dried for 20 minutes, has good salt spray corrosion resistance due to the adoption of multiple anticorrosion mechanisms and can resist to the high temperature of 400 DEG C. Meanwhile, the constructability of the conventional waterborne inorganic zinc rich coating is greatly improved; and the corrosion resistance year limit can reach over 15 years. The paint is prepared at normal temperature under normal pressure and has low production cost. The environmental protection requirement is met.

Owner:SOUTH CHINA UNIV OF TECH +1

Preparation of graft modification protein-based adhesive

InactiveCN101302410ASolve application problemsIncrease added valueGraft polymer adhesivesAdhesiveRedox

The invention relates to a method for preparing graft modification protein adhesives, belonging to the adhesive technical field. The method obtains the graft modification protein adhesives by adopting redox system initiator to react for a period of time at a certain temperature and linking vinyl monomer branched chains on a protein trunk chain. During the production and use processes, substances such as formaldehydes and so on are not released, thereby the method is favorable for environmental protection; and simultaneously the method can increase the added value of protein products and has important economic value. Because more hydrophobic groups are linked on the protein trunk chain, the interaction between the graft modification protein adhesives obtained and molecular groups on the wood surface is stronger and the adhesives are difficult to damage by water molecules, thereby the graft modification protein adhesives have good bonding strength and superior water resistance. The method widens the application environment and solves the problem which disturbs actual application of the protein adhesives for a long time, consequently having obvious technical advance.

Owner:JIANGNAN UNIV

Organic silicon modified aqueous polyurethane

InactiveCN1854165AImprove water resistanceFeel goodFibre treatmentPolyureas/polyurethane adhesivesWater basedCross-link

An organic silicon modified water-based polyurethane and its production are disclosed.The polyurethane consists of low-polymer polybasic alcohol, vulcabond and chain extender. The production is carried out by dispersing pre-polymer in water, adding ammonia silane coupling agent into system, synthesizing pre-polymer, reacting amine base with residual vulcabond base, chain extending for pre-polymer while hydrolytic condensation polymerizing, cross-linked reacting and obtaining final product. It has better water resistance and handle, less surface performance and wider temperature range. It can be used for pigment, leather finishing agent and adhesive.

Owner:广州宏昌胶粘带厂

Gelatinization material gypsum-cement and producing method thereof

The invention relates to a gypsum-cement binding material and a production method thereof. The material contains gypsum binding material, active admixture, alkaline excitant, oagulation accelerator, lime, water-reducing agent, early-strength agent and gypsum hemihydrate. The weight proportions of the components are as follows: 40%-80% of gypsum binding material, 10%-45% of active admixture, 4%-15% of alkaline excitant, 0-6% of coagulation accelerator, 0-1% of early-strength agent, 0-1% of water-reducing agent, 0-5% of lime and 0-10% of gypsum hemihydrate. The production method comprises the following steps: weighing raw materials at the given ratio, mixing all raw materials, and packaging. The inventive gypsum-cement material has high strength, good water resistance and good volume stability; and can be used as masonry cement, cement mortar, gypsum plaster, jointing gypsum and heat-insulating mortar.

Owner:长沙归一新材料科技股份有限公司

Preparation method and application of modified polyurethane aqueous dispersions of polyisocyanate curing agents

InactiveCN101696262ASimple processEasy to operatePolyurea/polyurethane coatingsLeather surface finishingPolyesterSolvent

The invention discloses a preparation method and application of modified polyurethane aqueous dispersions of polyisocyanate curing agents. The preparation method comprises the following steps of: carrying out prepolymerization reaction by using polyester polyol, vulcabond monomer and a polyisocyanate curing agent; reacting with a hydrophilic chain-extending agent and a micro-molecule chain-extending agent to obtain polyurethane prepolymer containing hydrophilic groups (carboxyl or sulfonic groups) and isocyanate(NCO)-terminated groups; neutralizing the polymer into salt, and then dispersing the salt into water; and preparing the modified polyurethane aqueous dispersions of the polyisocyanate curing agents by the chain extending of a polyamine chain-extending agent. The modified polyurethane aqueous dispersions of the polyisocyanate curing agents have self-crosslinking function at room temperature, and the self-crosslinking density is over 85%. Compared with non-modified polyurethane aqueous dispersions prepared under the same condition, the modified polyurethane aqueous dispersions have superior film forming property, water resistance, alcohol resistance, pollution resistance, cold resistance, dry / wet rubbing resistance and chemical solvent resistance; and coating films have especially high drying speed, high hardness increment speed and high final hardness.

Owner:SOUTH CHINA UNIV OF TECH

Sludge curing agent and application thereof

ActiveCN101081718AGood boardIncreased durabilitySludge treatment by de-watering/drying/thickeningSolid waste managementSludgeSlag

The present invention is sludge curing agent and its application, and belongs to the field of soil treating chemicals technology. The sludge curing agent includes powdered components and liquid components, the powdered components include cement clinker 30-60 weight portions, slag 30-60 weight portions, lime 3-8 weight portions, gypsum 1-7 weight portions and other sulfates 1-7 weight portions; and the liquid components include polyacrylamide 5-30 weight portions, polyaluminum chloride 0-20 weight portions, mannitol 0-30 weight portions, lignosulfonate 20-80 weight portions, lignosulfonate-iron or chromium ion complex 0-30 weight portions, alkylphenol ethoxylate 0.2-2 weight portions, tannin 0-10 weight portions, humate 0-10 weight portions, and alpa-olefin sulfonate 0.2-2.5 weight portions. The sludge curing agent has low cost, small consumption, high cumulate strength and high cumulate water tolerance, and may be applied widely.

Owner:BEIJING ZHONGYONGJI FIRMING AGENT TECH DEV

Environmental-friendly waterproof polymer mortar

InactiveCN101560084AImprove adhesionStrong bondSolid waste managementSilicate CementConstruction aggregate

The invention relates to environmental-friendly waterproof polymer mortar, which comprises the following components in portion by weight: 50 to 230 portions of low-clinker silicate cement, 200 to 450 portions of quartz sand, 80 to 120 portions of fly ash, 1 to 18 portions of re-dispersible polyethylene vinyl acetate latex powder, 1 to 10 portions of dispersible polyvinyl acetate vinyl versatate latex powder, 0.2 to 0.6 portion of water reducing agent, 0.05 to 0.3 portion of antifoaming agent, and 0.25 to 2.25 portions of polypropylene fibers. A gel material prepared from steel slag, tailings and the fly ash replaces silicate cement and partial aggregate in the prior mortar; the modified waterproof polymer mortar has the advantages of excellent impermeability, good mechanical property and construction property, simple production technology, and easy manufacture, greatly consumes industrial and mining wastes, controls the ecological environment, and lowers the cost; and the product has reliable quality and wide market; and the environmental-friendly waterproof polymer mortar can be popularized and applied in large area.

Owner:黑龙江省学府环艺雕塑有限公司

Preparation method of double-layer coated water-based aluminum pigment

The invention discloses a preparation method of a double-layer coated water-based aluminum pigment, which comprises the following steps: coating ethyl orthosilicate on lamellar aluminum powder to form a single-layer coated aluminum pigment; and under the action of an azo initiator, coating a hydrophilic ester monomer on the single-layer coated aluminum pigment to form the double-layer coated water-based aluminum pigment. The double-layer coated water-based aluminum pigment prepared by the method provided by the invention has the advantages of high coating tightness and favorable water resistance, and the coating layer can not be easily damaged. The organic layer on the outer layer is easily compatible with high-molecular rein in the paint, has favorable dispersity in the paint, and is mainly used in various water-based paints and water-based inks.

Owner:HEFEI SUNRISE PIGMENTS

Ultraviolet light curing printing ink for digital printing and dyeing preparation thereof

UV solidified printing ink for digital code printing and dyeing is composed of polyurethane acrylate, prepolymer, activity monomer, dyestuff, light initiator, dispersant agent and other addition agents. The prepolymer has the character of low viscosity and good flexibility. The ink doesn't contain organic solvent and has wide material adaptation, storage stability and softness.

Owner:DONGHUA UNIV

Aldehyde-free vegetable protein-based wood adhesive as well as preparation and application methods thereof

InactiveCN104610909AOvercome water resistanceOvercome strengthNon-macromolecular adhesive additivesProtein adhesivesCross-linkAdhesive

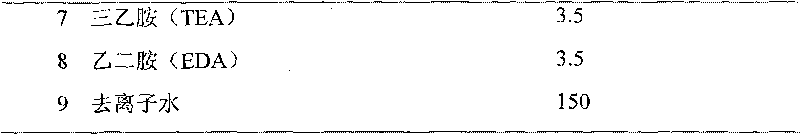

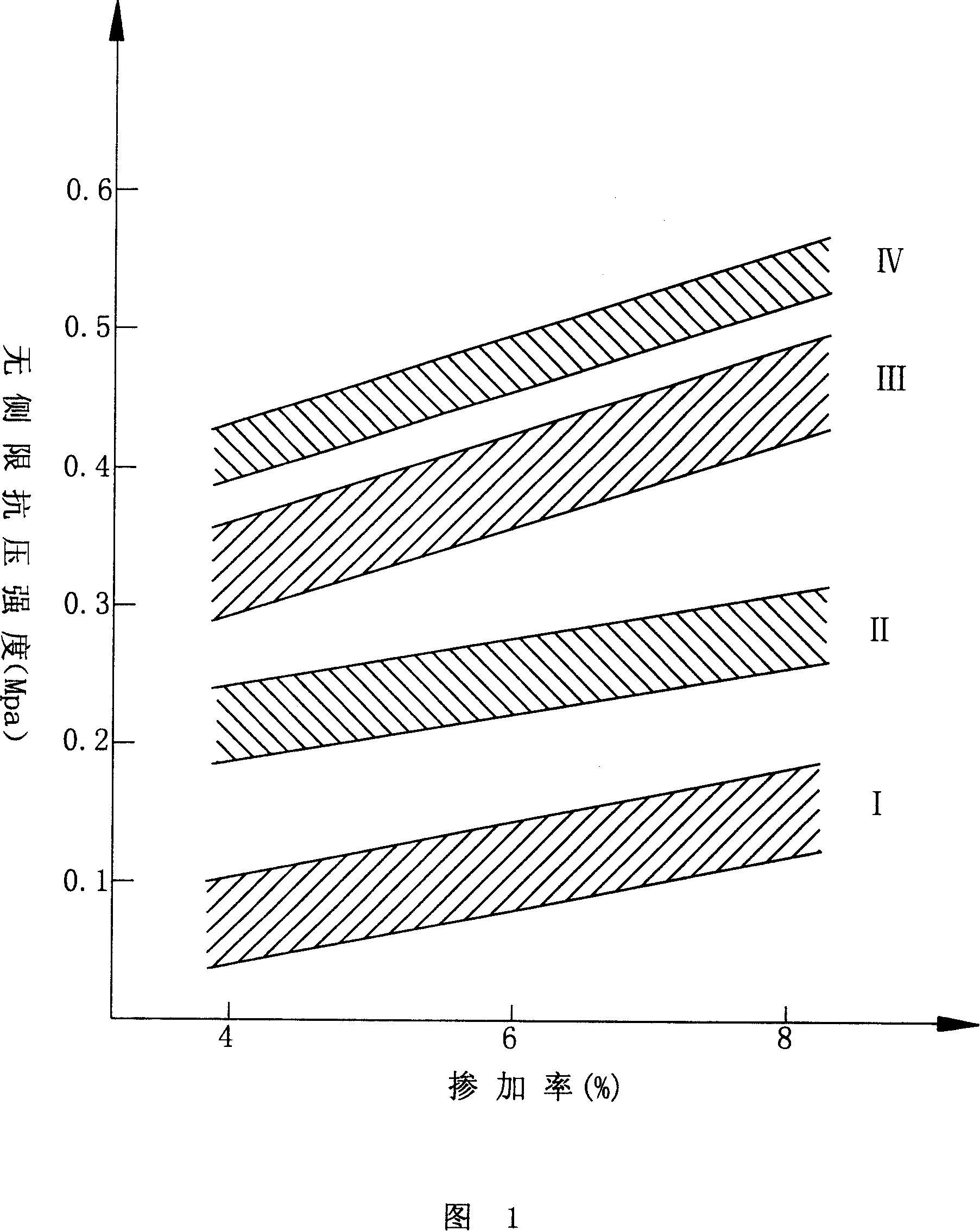

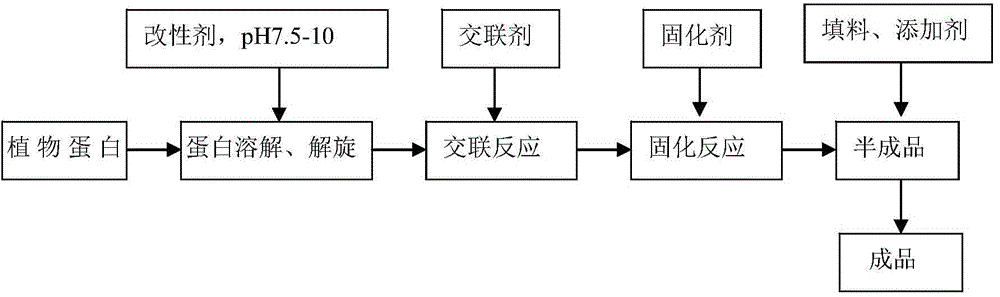

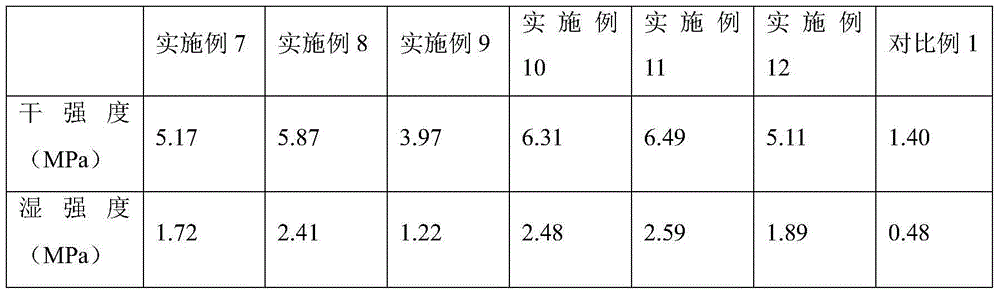

The invention belongs to the technical field of design, research and development of environment-friendly chemical materials and specifically relates to an aldehyde-free vegetable protein-based wood adhesive as well as preparation and application methods thereof. The aldehyde-free vegetable protein-based wood adhesive is prepared from the following components in parts by mass: 100 parts of water, 20-40 parts of vegetable protein, 0.1-5 parts of modifier, 20-40 parts of cross-linking agent, 2-20 parts of curing agent, 1-5 parts of packing and 0-3 parts of additive. The finished product is formed by virtue of vegetation protein dissolution, a cross-linking reaction and a curing reaction. The adhesive is mainly applied to a wood material in such a manner of roll coating, scraper coating, curtain coating or spraying, and then a composite wood artificial board can be obtained by virtue of aging, cold pressing and hot pressing.

Owner:乌鲁木齐奥森碳环生物能源有限公司

Doped multi-layer core-shell silicon-based composite material for lithium ion battery and preparation method thereof

ActiveCN109599551AInhibits and buffers swellingPrevent partial failureMaterial nanotechnologySecondary cellsCarbon filmComposite film

The present invention relates to a doped multi-layer core-shell silicon-based composite material for a lithium ion battery, and a preparation method thereof. Other than being doped with a necessary lithium element, the material is also doped with at least a non-metallic element and a metal element; the material has a structure in which a silicon oxide particle doped with elements is taken as a core, and a multilayer composite film which is tightly coated on the surface of the core particle is taken as a shell; the core particle contains uniformly dispersed monoplasmatic silicon nanoparticles,the content of doping elements gradually decreases from the outside to the inside without a clear interface, and a dense lithium silicate compound is formed on the surface of the core particle by embedding and doping the lithium element; and the multilayer composite film is a carbon film layer and a doped composite film layer composed of the carbon film layer and other elemental components. The doped multi-layer core-shell silicon-based composite material provided by the present invention has a high capacity, good rate performance, high coulombic efficiency, good cycle performance, a low expansion rate, and other electrochemical characteristics when the material is used for the negative electrode of lithium ion battery.

Owner:BERZELIUS (NANJING) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com