Waterborne room-temperature self-curing inorganic zinc rich coating

An inorganic zinc-rich coating and self-curing technology, which is applied in the direction of anti-corrosion coatings, alkali metal silicate coatings, coatings, etc., can solve the problems of increased preparation costs, unstable storage of silicate resins, and high cost, and achieve improved Effects of early water resistance and adhesion, improvement of final film-forming performance, and improvement of anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

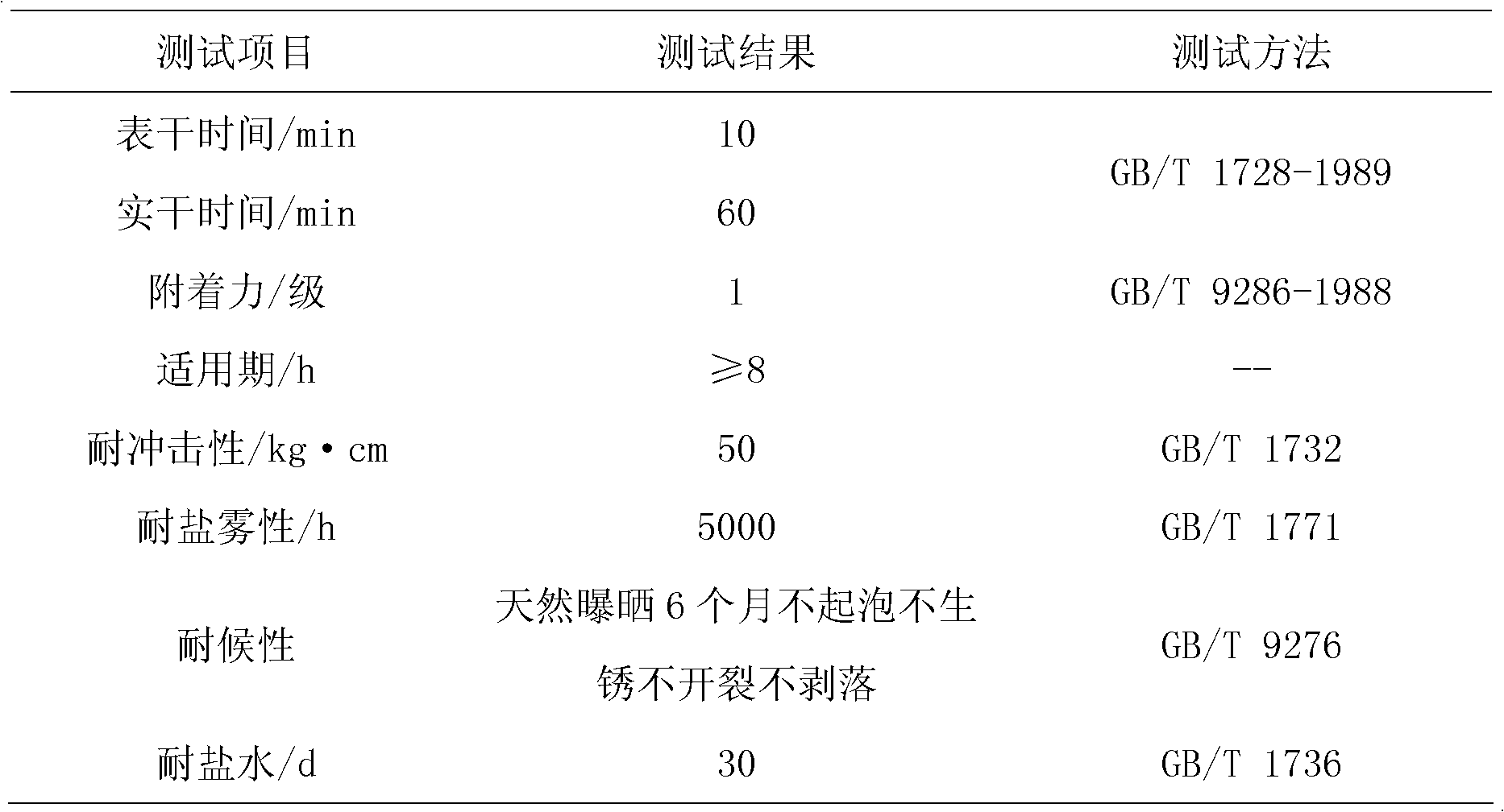

Embodiment 1

[0030] A water-based room-temperature self-curing inorganic zinc-rich coating comprises a base material and a powder; wherein the base material is prepared by the following steps:

[0031] 1) Take 18.78kg of potassium silicate solution with a modulus of 3.6 and a solid content of 28% by weight and pour it into a container with a stirring device, add 2.58kg of water, start stirring at a low speed of 400r / min for 10 Minutes to mix the potassium silicate solution evenly.

[0032] 2) Increase the rotation speed to 1500r / min, weigh 5.61kg of silica sol with a particle size of 7nm and a solid content of about 30%, slowly drop it into the container, and keep a stable vortex for about 30min, at this time the solution turns from white to translucent viscous solution.

[0033] 3) Add 2.22 kg of water while stirring, so that the viscosity of the obtained solution is moderate, and the pH is about 11 at this time.

[0034] 4) Slowly add a total amount of 0.3 kg of methyltrimethoxysilane ...

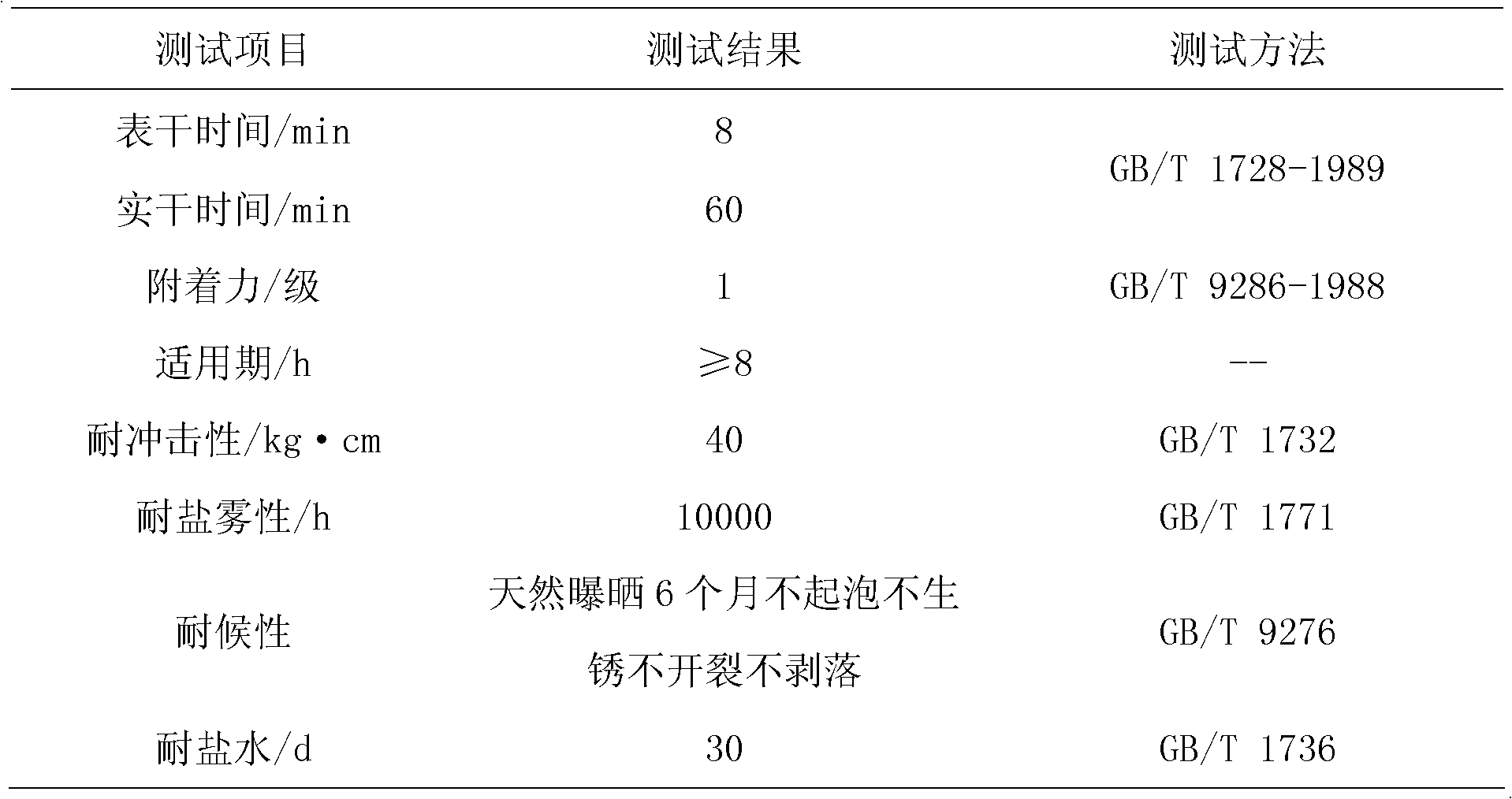

Embodiment 2

[0042] A water-based room temperature self-curing inorganic zinc-rich coating, comprising a base material and a powder; wherein, the preparation process of the base material is as follows:

[0043] 1) Take 12kg of lithium silicate solution with a modulus of 3.3 and a solid content of 25% and pour it into a container with a stirring device, add 2.58kg of water, stir at a low speed of 300r / min, and continue for 15 minutes to make the lithium silicate solution well mixed.

[0044] 2) Increase the rotating speed to 1500r / min, weigh 9kg of silica sol with a particle size of 10nm and a solid content of about 30%, slowly drop it into the container, and keep a stable vortex for about 30min. At this time, the solution changes from white to translucent viscous thick solution.

[0045] 3) Add 2.82 kg of water while stirring, so that the viscosity of the obtained solution is moderate, and the pH is about 11 at this time, and stir for 10 minutes.

[0046] 4) Slowly add 3 kg of methyltrie...

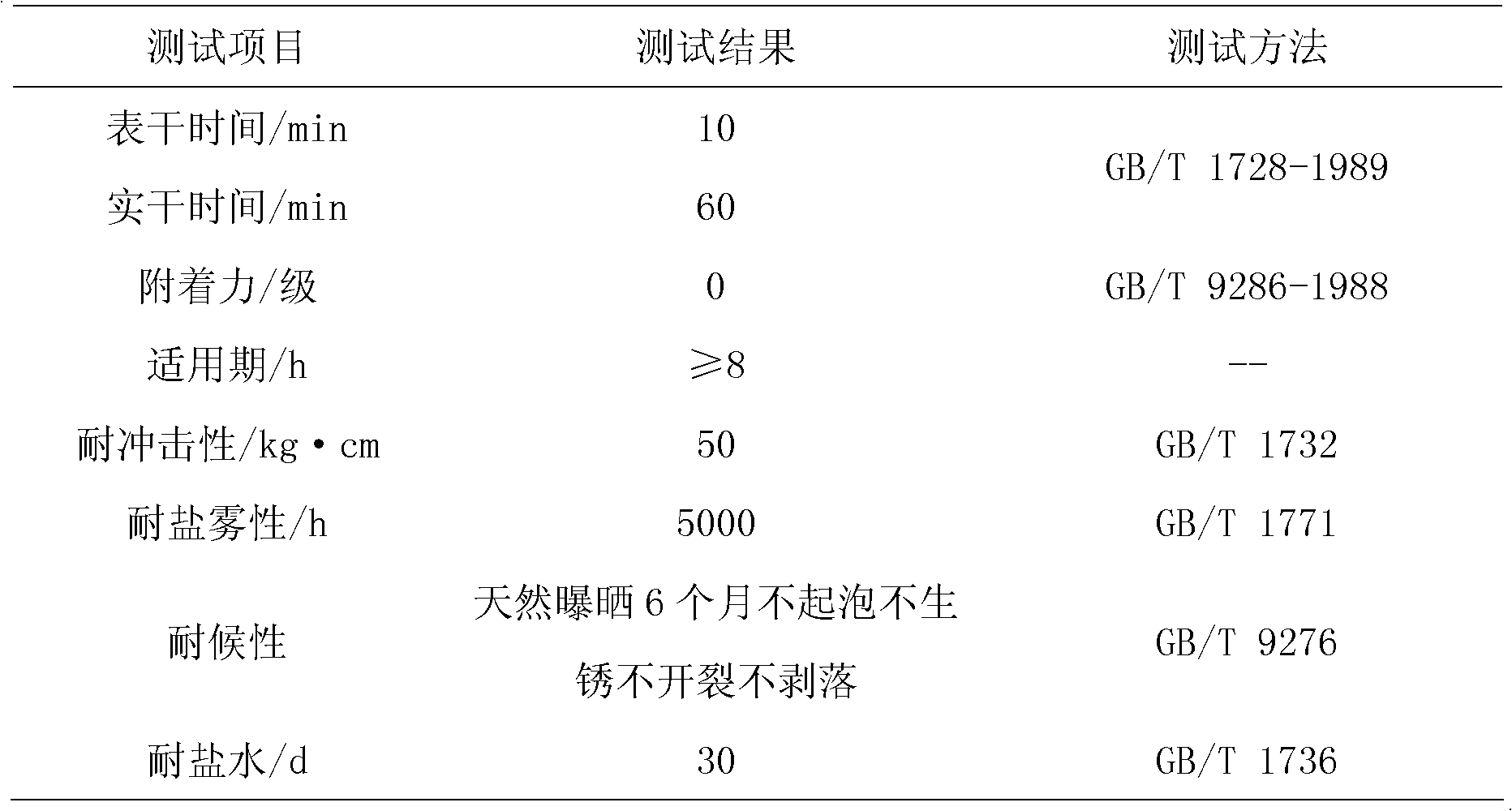

Embodiment 3

[0054] A water-based room temperature self-curing inorganic zinc-rich coating, comprising a base material and a powder; wherein, the preparation process of the base material is as follows:

[0055] 1) Take 15kg of sodium silicate solution with a modulus of 2.8 and a solid content of 28% and pour it into a container with a stirring device, add 2.5kg of water, start stirring at a low speed of 500r / min for 10 minutes to mix the potassium silicate solution uniform.

[0056] 2) Increase the rotation speed to 1200r / min, weigh 7.8kg of silica sol with a particle size of 20nm and a solid content of about 30%, slowly drop it into the container, and keep a stable vortex for about 30min, at this time the solution turns from white to translucent viscous solution.

[0057] 3) Add 3.26 kg of water while stirring, so that the viscosity of the obtained solution is moderate, and the pH is about 11 at this time, and stir for 10 minutes.

[0058] 4) Slowly add 1.2kg of methyltrimethoxysilane d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com