Patents

Literature

201 results about "Aluminum oxynitride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

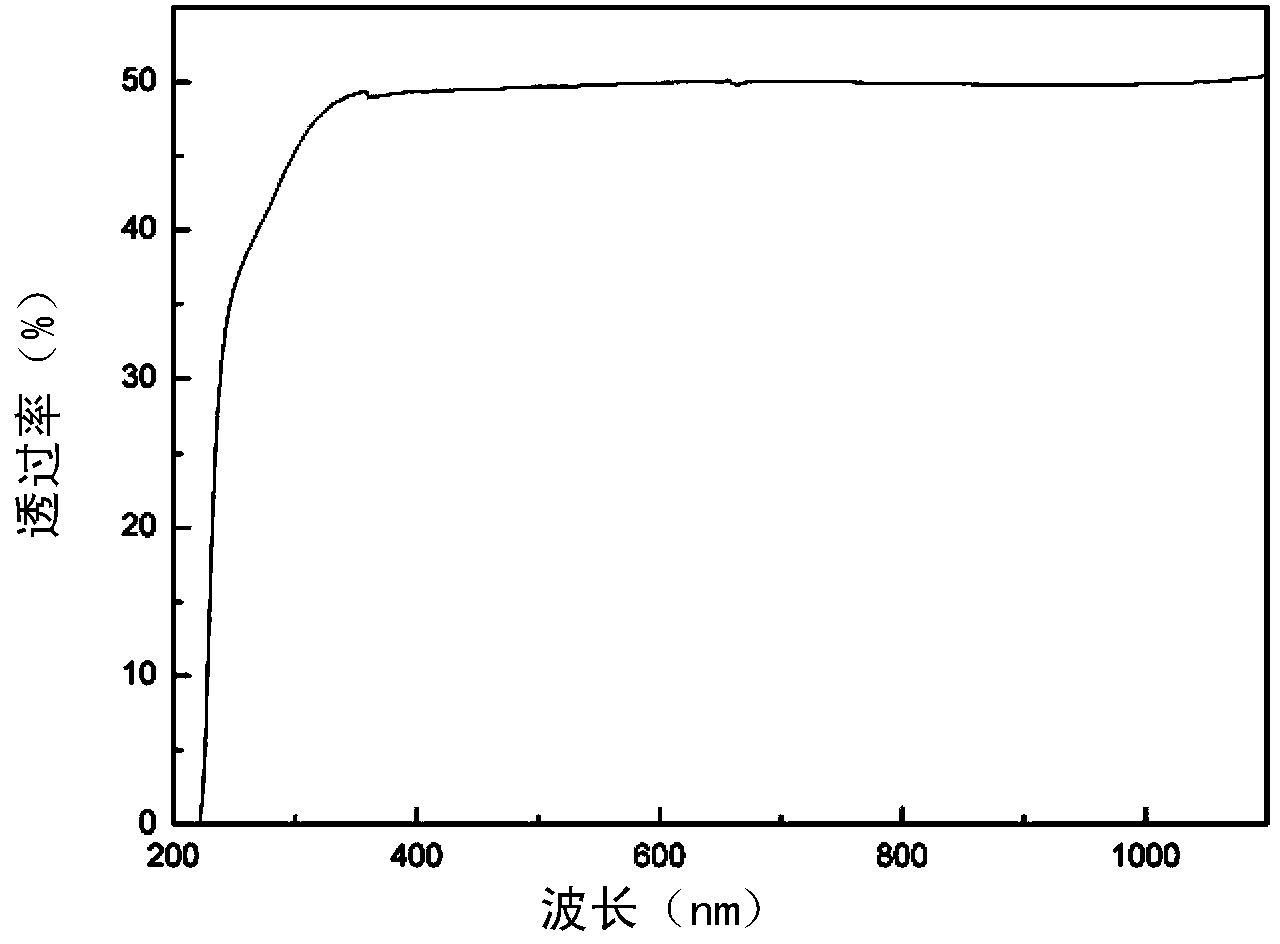

Aluminium oxynitride or AlON is a ceramic composed of aluminium, oxygen and nitrogen. It is marketed under the name ALON by Surmet Corporation. AlON is optically transparent (≥80%) in the near-ultraviolet, visible and midwave-infrared regions of the electromagnetic spectrum.

Method of forming mixed rare earth oxynitride and aluminum oxynitride films by atomic layer deposition

InactiveUS20070237699A1Aluminium compoundsSemiconductor/solid-state device manufacturingGate dielectricRare earth

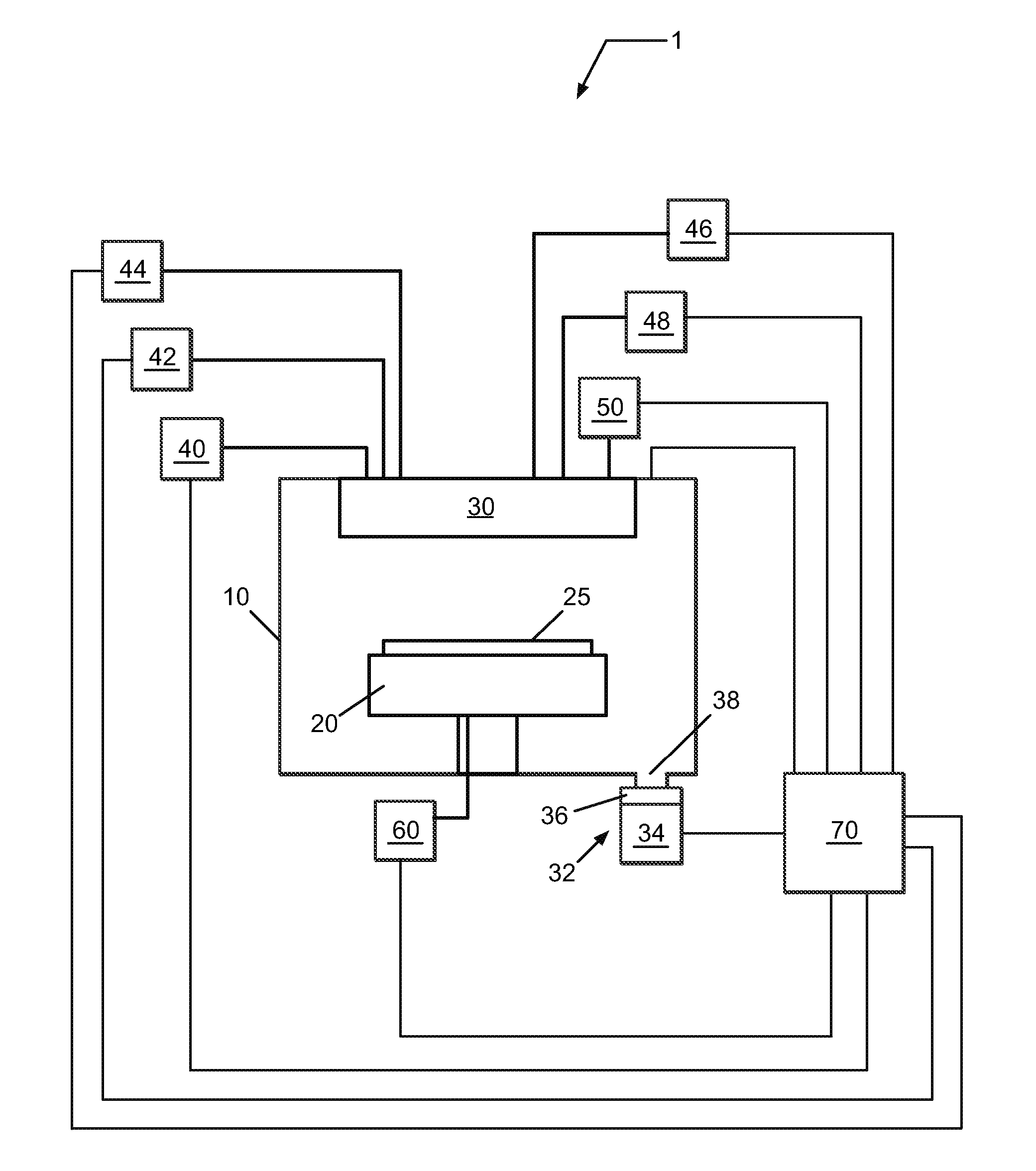

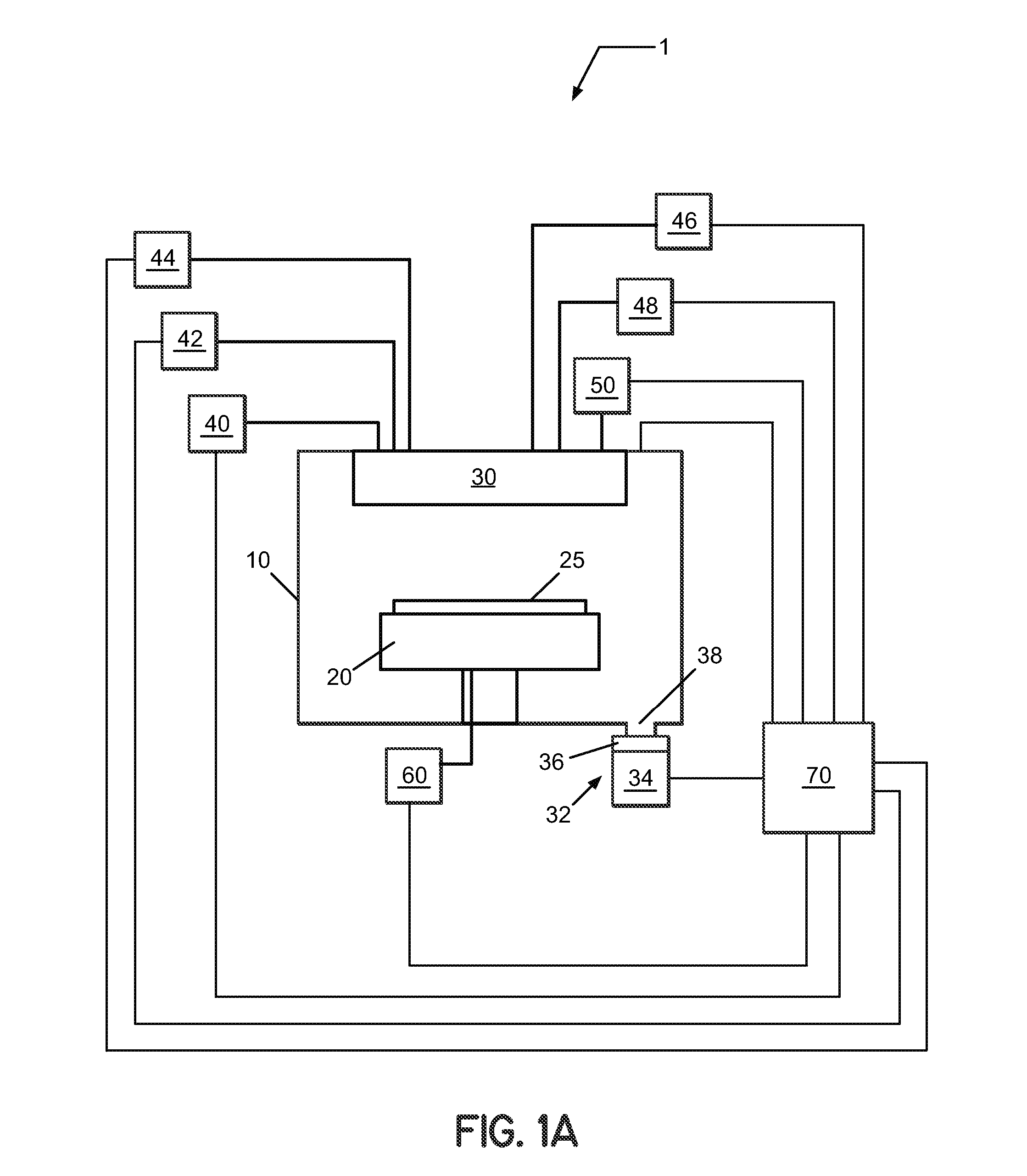

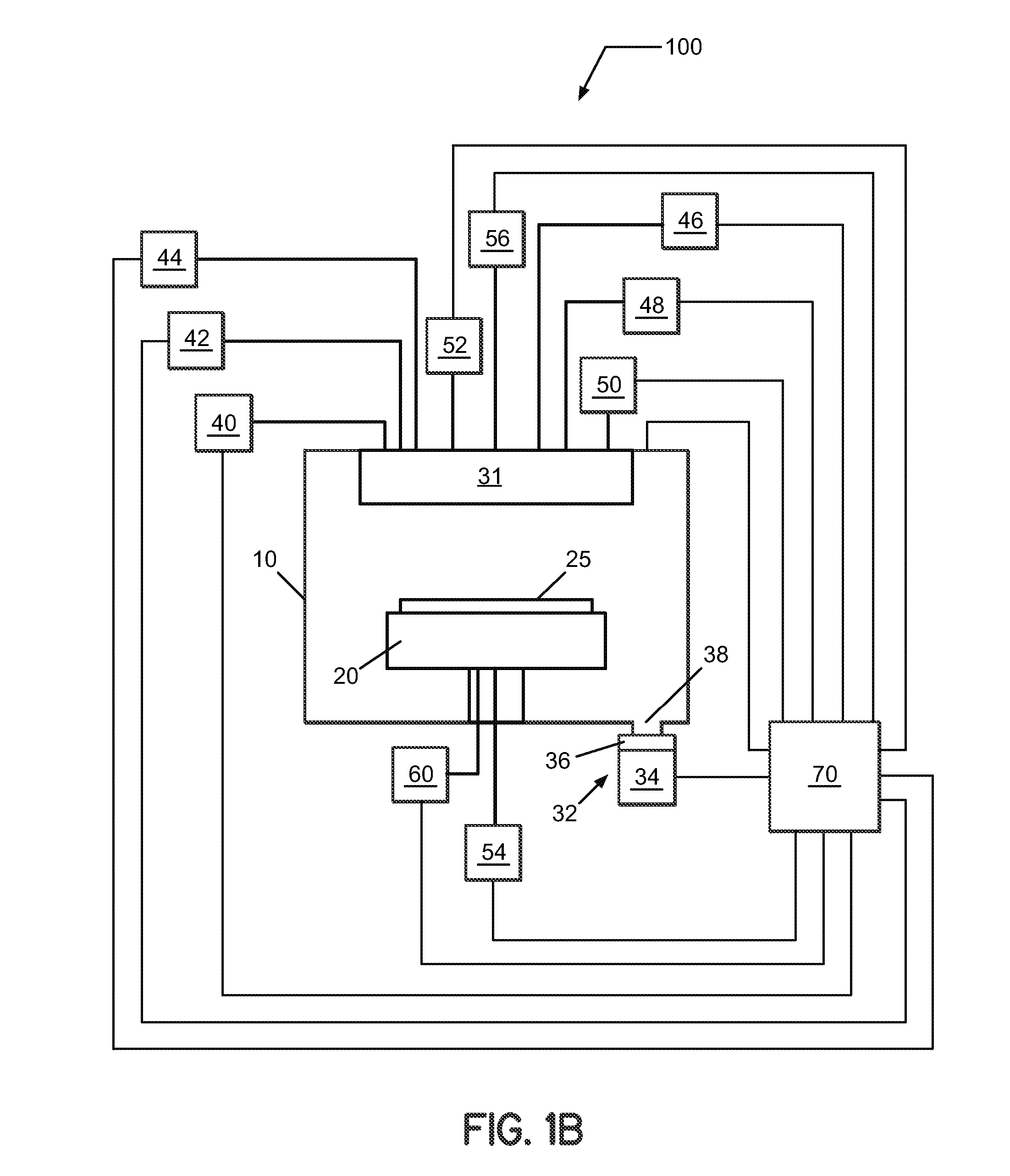

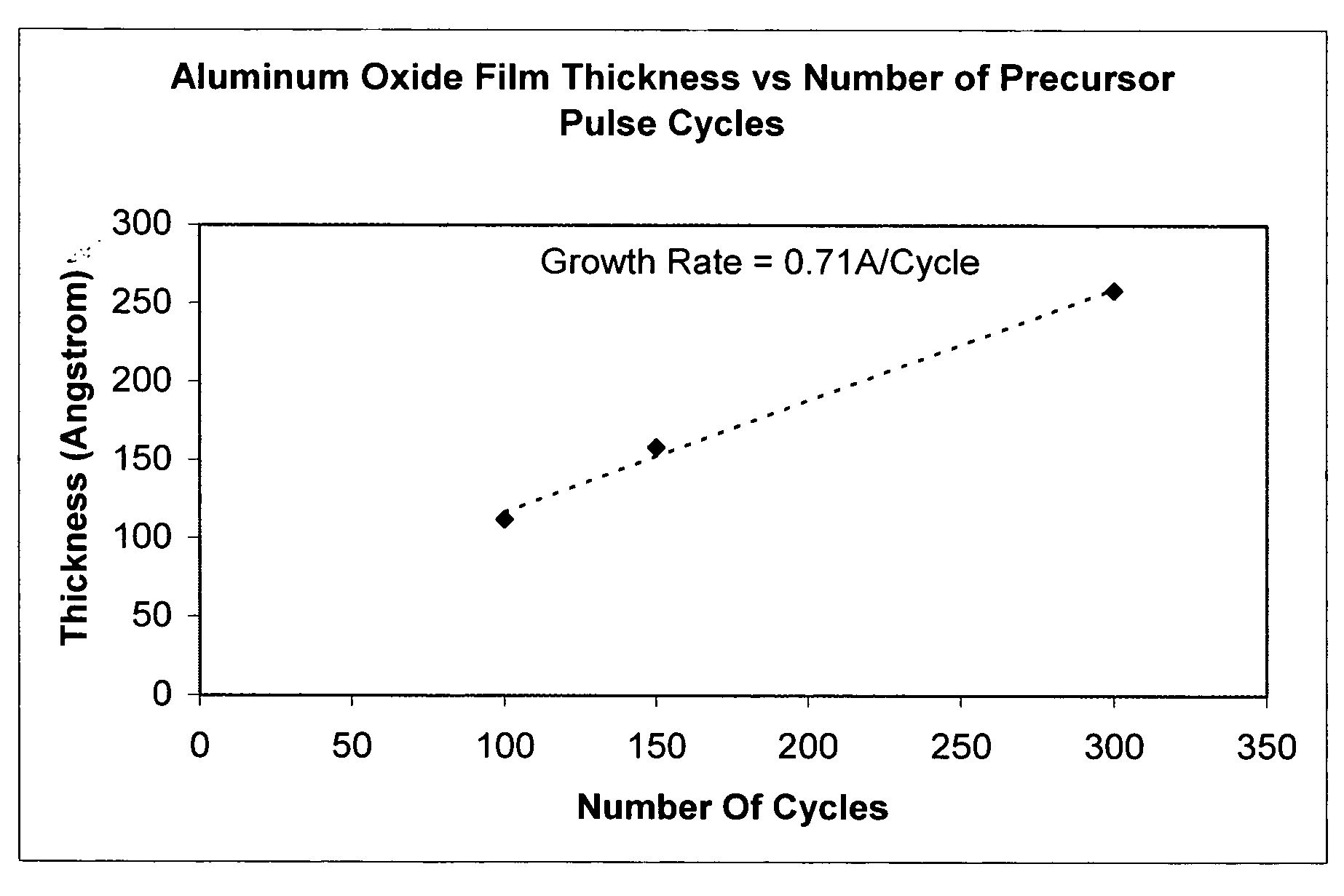

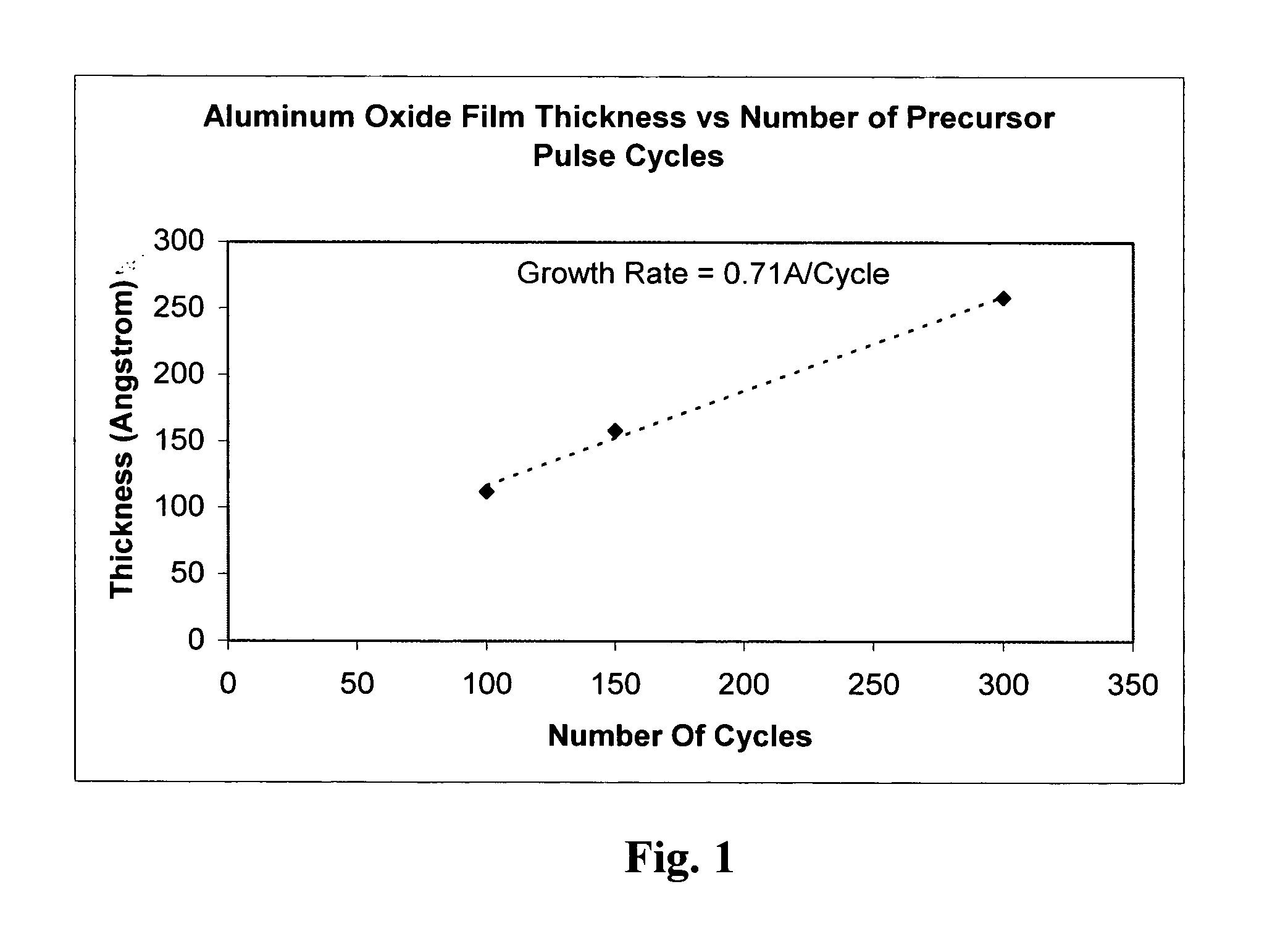

A method is provided for depositing a gate dielectric that includes at least two rare earth metal elements in the form of an oxynitride or an aluminum oxynitride. The method includes disposing a substrate in a process chamber and exposing the substrate to a gas pulse containing a first rare earth precursor and to a gas pulse containing a second rare earth precursor. The substrate may also optionally be exposed to a gas pulse containing an aluminum precursor. Sequentially after each precursor gas pulse, the substrate is exposed to a gas pulse of an oxygen-containing gas, nitrogen-containing gas or an oxygen- and nitrogen-containing gas. In alternative embodiments, the first and second rare earth precursors may be pulsed together, and either or both may be pulsed together with the aluminum precursor. The first and second rare earth precursors comprise a different rare earth metal element. The sequential exposing steps may be repeated to deposit a mixed rare earth oxynitride or aluminum oxynitride layer with a desired thickness. Purge or evacuation steps may also be performed after each gas pulse.

Owner:TOKYO ELECTRON LTD

Methods for forming aluminum containing films utilizing amino aluminum precursors

ActiveUS20050003662A1Security benefitsSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChemical structureHydrogen

A method of forming an aluminum containing film on a substrate includes providing a precursor having the chemical structure: Al(NR1R2)(NR3R4)(NR5R6); where each of R1, R2, R3, R4, R5 and R6 is independently selected from the group consisting of hydrogen and an alkyl group including at least two carbon atoms. The precursor is utilized to form a film on the substrate including at least one of aluminum oxide, aluminum nitride and aluminum oxy-nitride. Each of the R1-R6 groups can be the same or different and can by straight or branched chain alkyls. An exemplary precursor that has is useful in forming aluminum containing films is tris diethylamino aluminum.

Owner:AIR LIQUIDE AMERICA INC

Deposition of charge trapping layers

ActiveUS20180122959A1Solid-state devicesSemiconductor/solid-state device manufacturingTrappingAluminum oxynitride

A semiconductor device and method for manufacturing the semiconductor device are disclosed. Specifically, the semiconductor device may include a charge trapping layer with improved retention and speed for VNAND applications. The charge trapping layer may comprise an aluminum nitride (AlN) or aluminum oxynitride (AlON) layer.

Owner:ASM IP HLDG BV

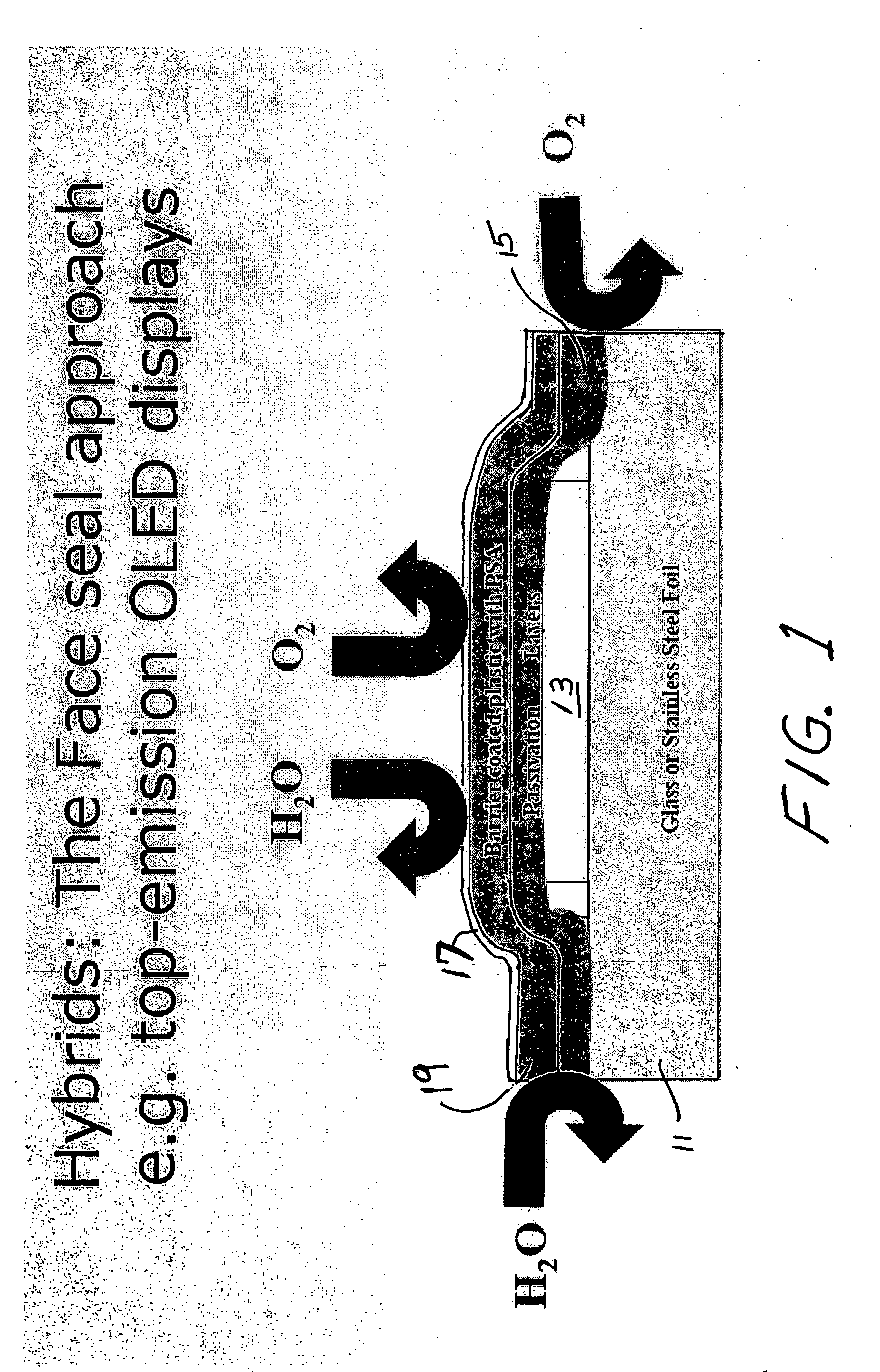

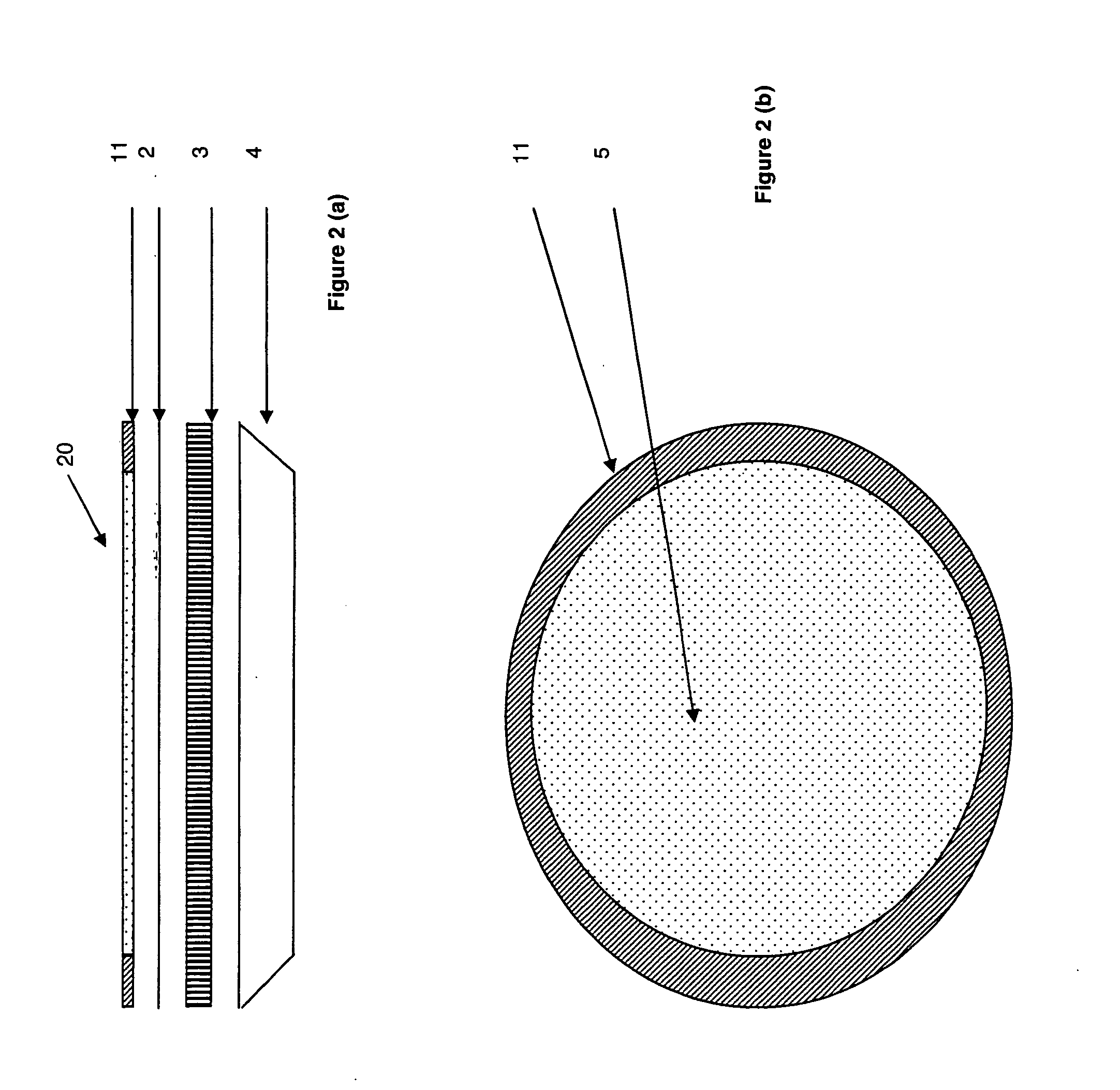

Gas barrier

InactiveUS20070135552A1Improved resistance to water vapor transmissionSmall sizeMaterial nanotechnologyPolymer scienceSealant

Nanoparticles of amorphous aluminum oxynitride or silicon oxynitride having a very high aspect ratio are used to fill polymeric materials to provide products that have an extremely low WVTR / OTR. Such products are particularly effective for incorporation into organic light-emitting devices or the like which are susceptible to degradation from moisture and / or oxygen. Pressure sensitive and / or thermosetting adhesives filled with such particles create excellent sealants. Polymeric sheets or films made from resin in which these nanoparticles are dispersed, or intimately associated with, before extrusion exhibit very low WVTR / OTR.

Owner:GENERAL ATOMICS

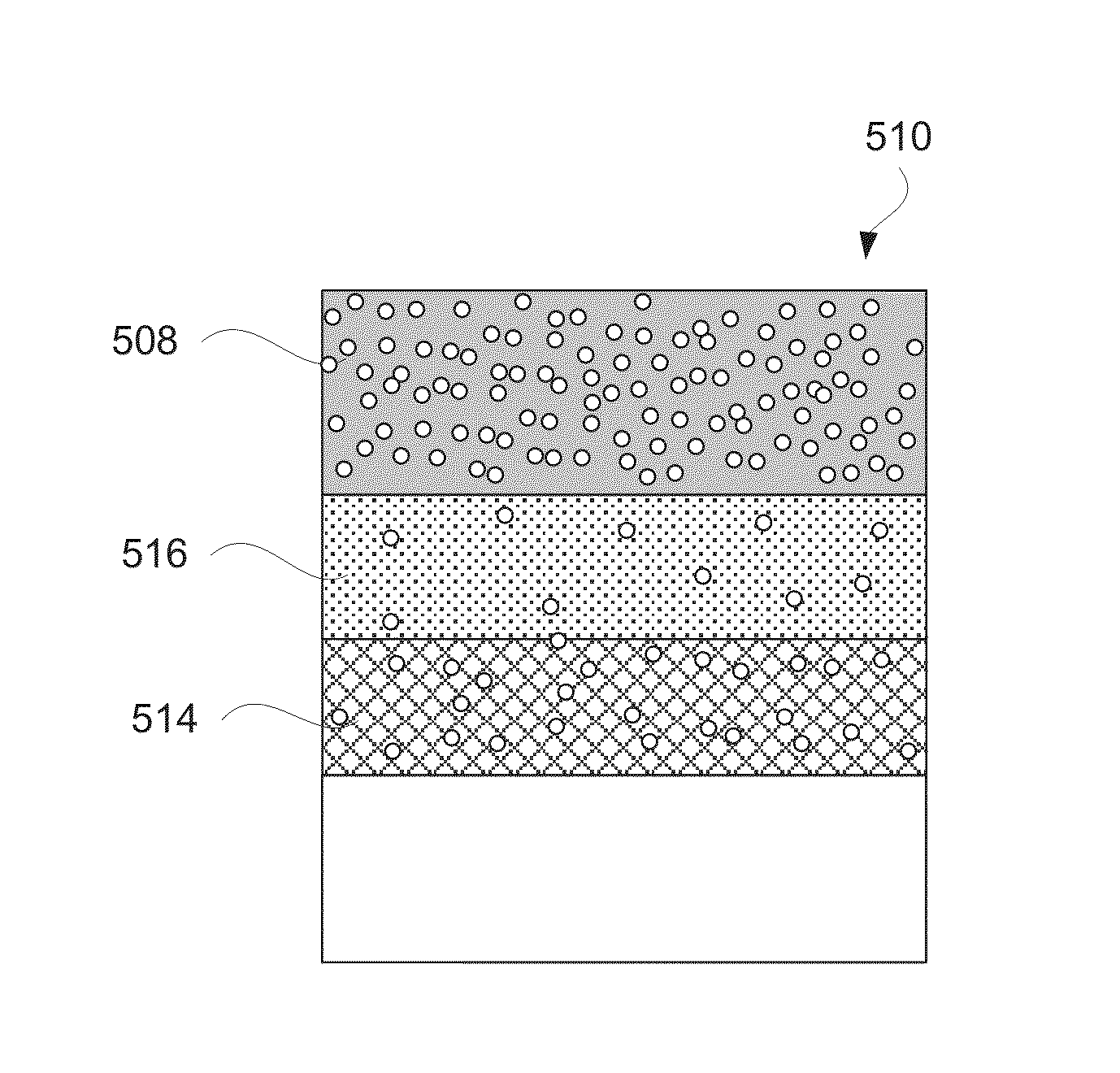

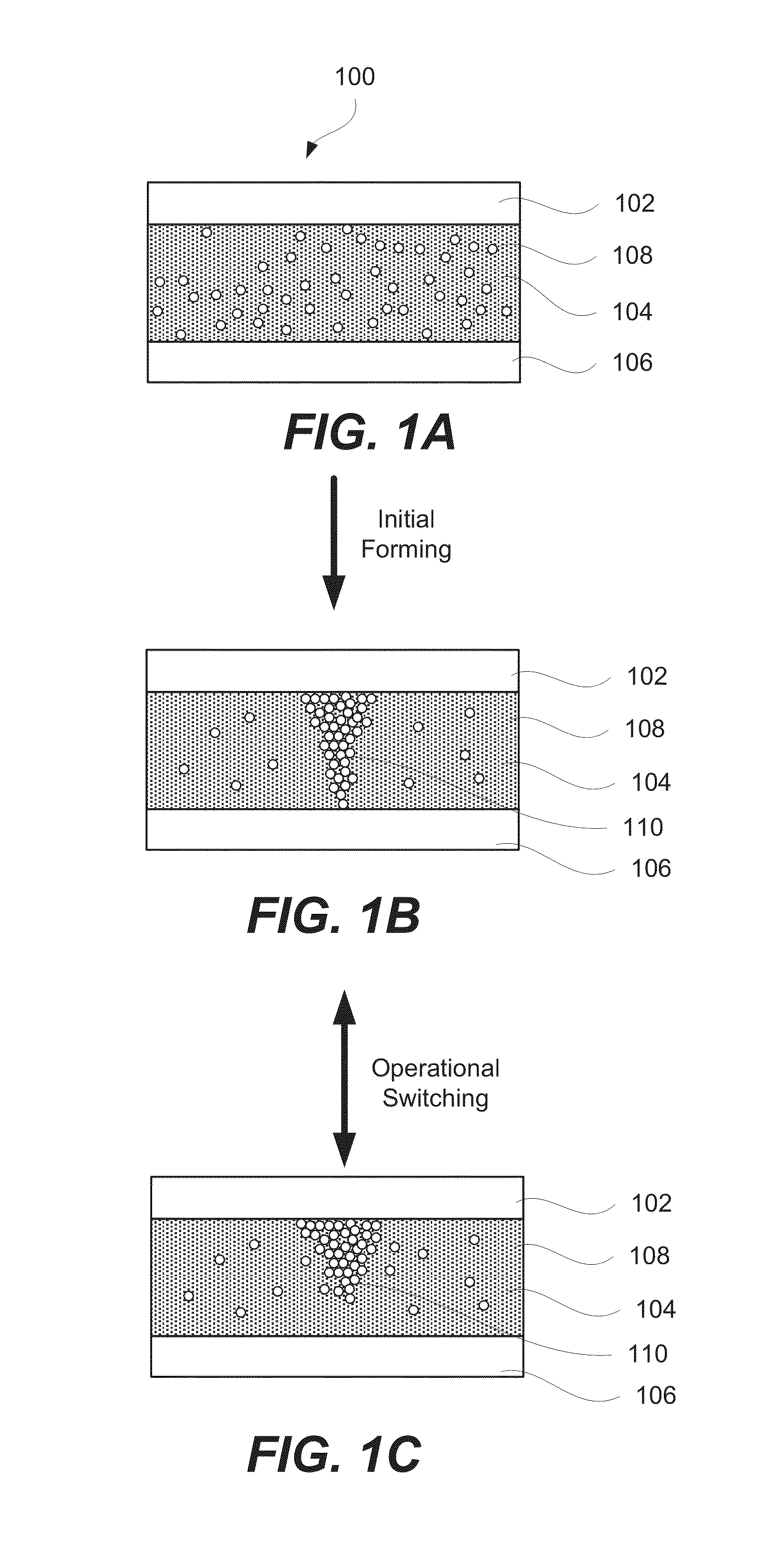

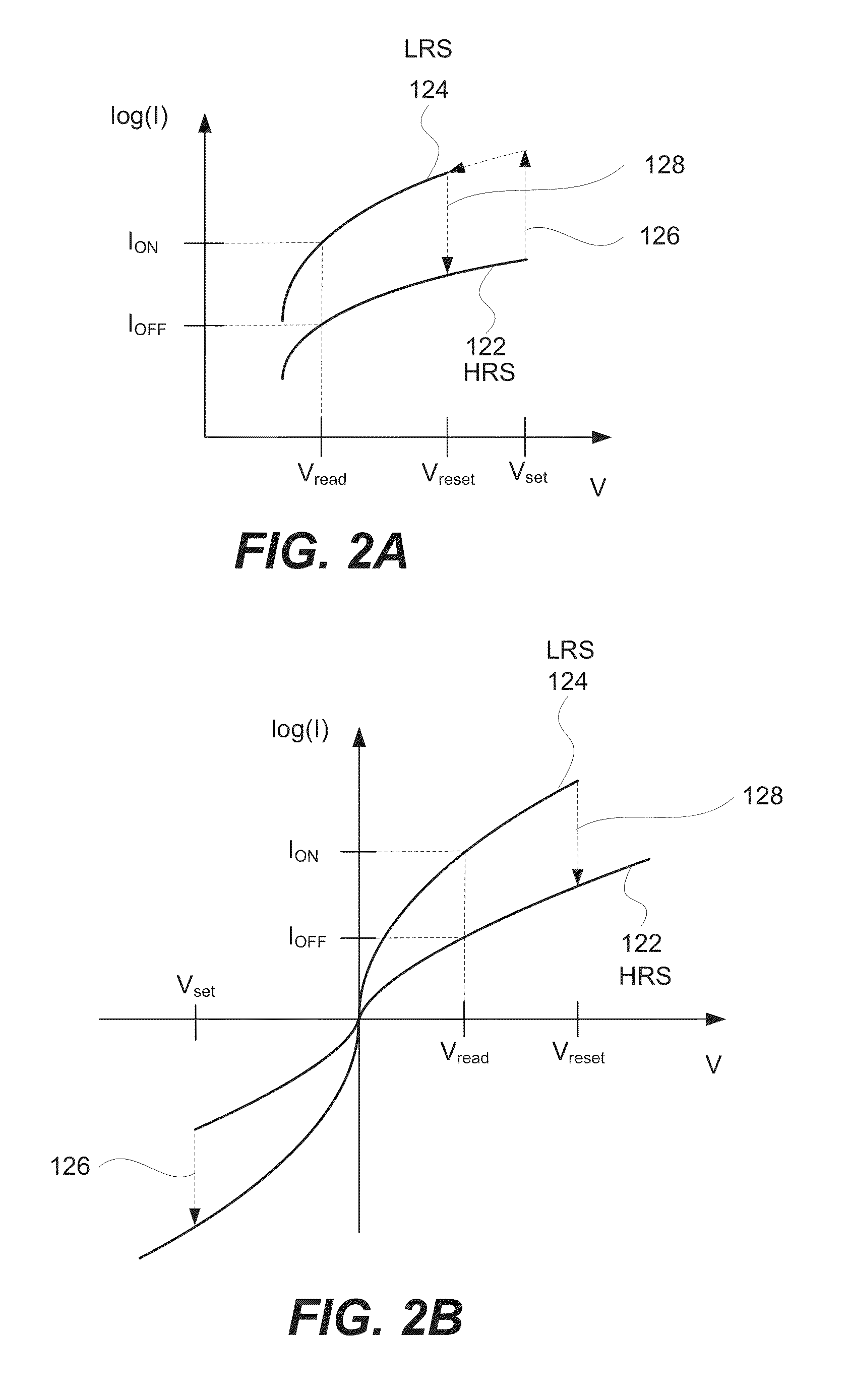

Confined Defect Profiling within Resistive Random Memory Access Cells

ActiveUS20150034898A1Improvement of resistive switching characteristicDigital storageBulk negative resistance effect devicesTitanium nitrideResistive switching

Provided are resistive random access memory (ReRAM) cells and methods of fabricating thereof. A stack including a defect source layer, a defect blocking layer, and a defect acceptor layer disposed between the defect source layer and the defect blocking layer may be subjected to annealing. During the annealing, defects are transferred in a controllable manner from the defect source layer to the defect acceptor layer. At the same time, the defects are not transferred into the defect blocking layer thereby creating a lowest concentration zone within the defect acceptor layer. This zone is responsible for resistive switching. The precise control over the size of the zone and the defect concentration within the zone allows substantially improvement of resistive switching characteristics of the ReRAM cell. In some embodiments, the defect source layer includes aluminum oxynitride, the defect blocking layer includes titanium nitride, and the defect acceptor layer includes aluminum oxide.

Owner:SANDISK TECH LLC

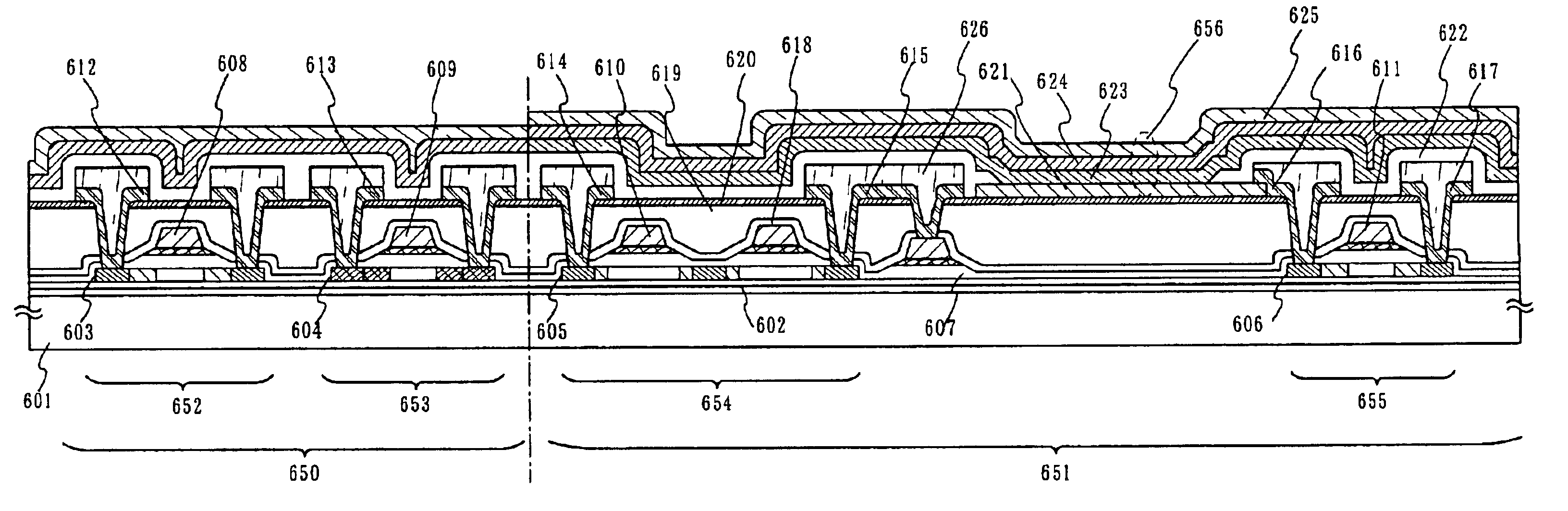

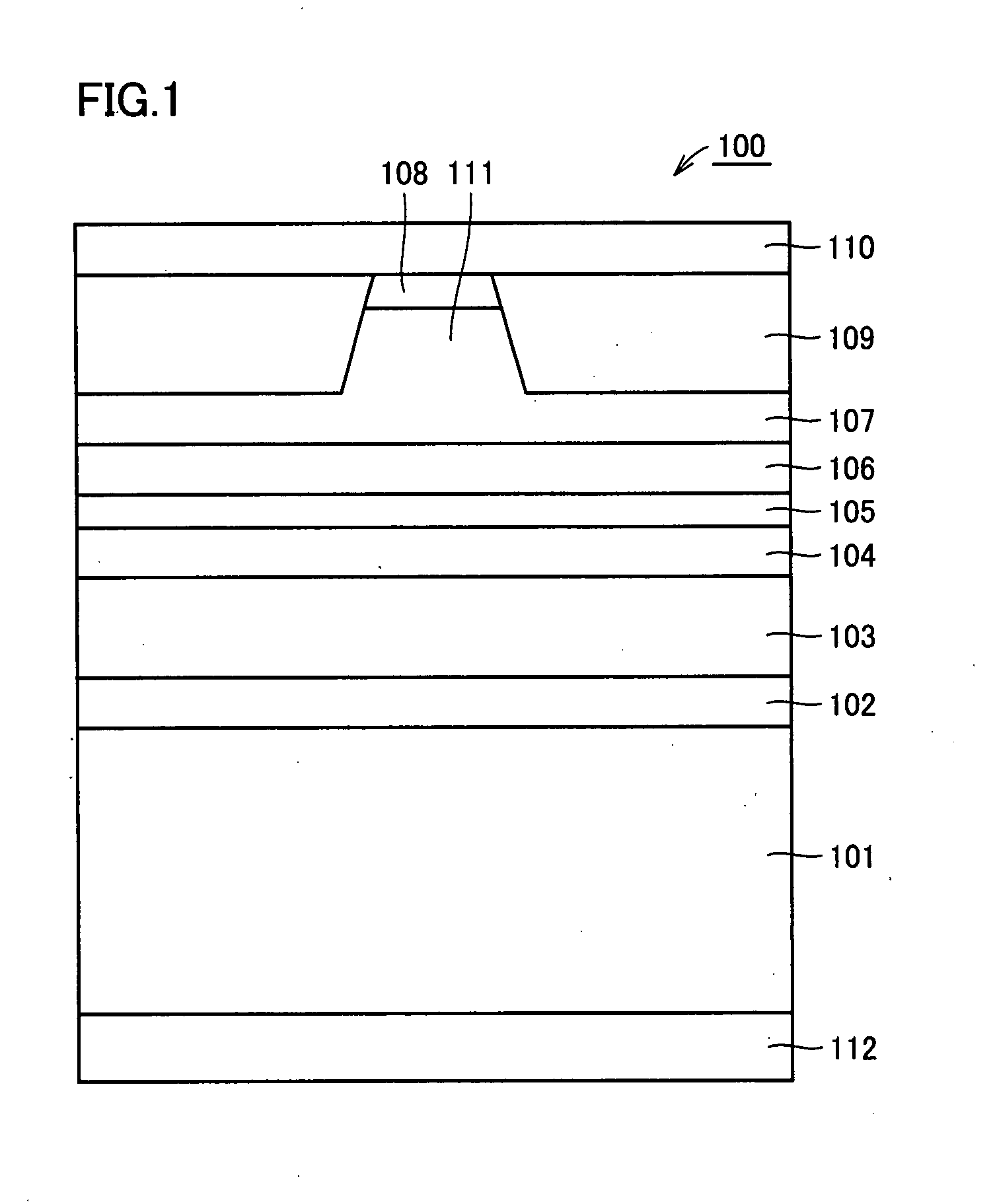

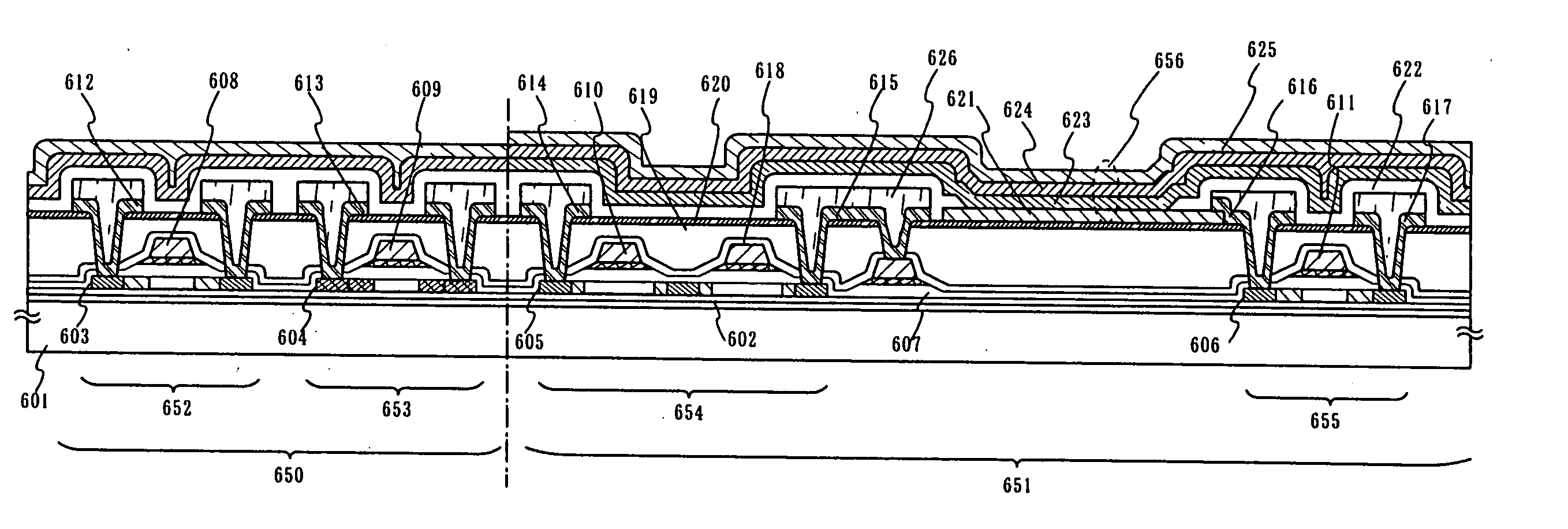

Light emitting device

InactiveUS20030146439A1Avoid contaminationPrevent penetrationFinal product manufactureElectroluminescent light sourcesStructuring elementAluminum oxynitride

An objective is to increase the reliability of a light emitting device structured by combining TFTs and organic light emitting elements. A TFT (1201) and an organic light emitting element (1202) are formed on the same substrate (1203) as structuring elements of a light emitting device (1200). A first insulating film (1205) which functions as a blocking layer is formed on the substrate (1203) side of the TFT (1201), and a second insulating film (1206) is formed on the opposite upper layer side as a protective film. In addition, a third insulating film (1207) which functions as a barrier film is formed on the lower layer side of the organic light emitting element (1202). The third insulating film (1207) is formed by an inorganic insulating film such as a silicon nitride film, a silicon oxynitride film, an aluminum nitride film, an aluminum oxide film, or an aluminum oxynitride film. A fourth insulating film (1208) and a partitioning layer (1209) formed on the upper layer side of the organic light emitting element (1202) are formed using similar inorganic insulating films.

Owner:SEMICON ENERGY LAB CO LTD

Light emitting device

InactiveUS6852997B2Improve reliabilityInhibit deteriorationFinal product manufactureElectroluminescent light sourcesStructuring elementAluminum oxynitride

An objective is to increase the reliability of a light emitting device structured by combining TFTs and organic light emitting elements. A TFT (1201) and an organic light emitting element (1202) are formed on the same substrate (1203) as structuring elements of a light emitting device (1200). A first insulating film (1205) which functions as a blocking layer is formed on the substrate (1203) side of the TFT (1201), and a second insulating film (1206) is formed on the opposite upper layer side as a protective film. In addition, a third insulating film (1207) which functions as a barrier film is formed on the lower layer side of the organic light emitting element (1202). The third insulating film (1207) is formed by an inorganic insulating film such as a silicon nitride film, a silicon oxynitride film, an aluminum nitride film, an aluminum oxide film, or an aluminum oxynitride film. A fourth insulating film (1208) and a partitioning layer (1209) formed on the upper layer side of the organic light emitting element (1202) are formed using similar inorganic insulating films.

Owner:SEMICON ENERGY LAB CO LTD

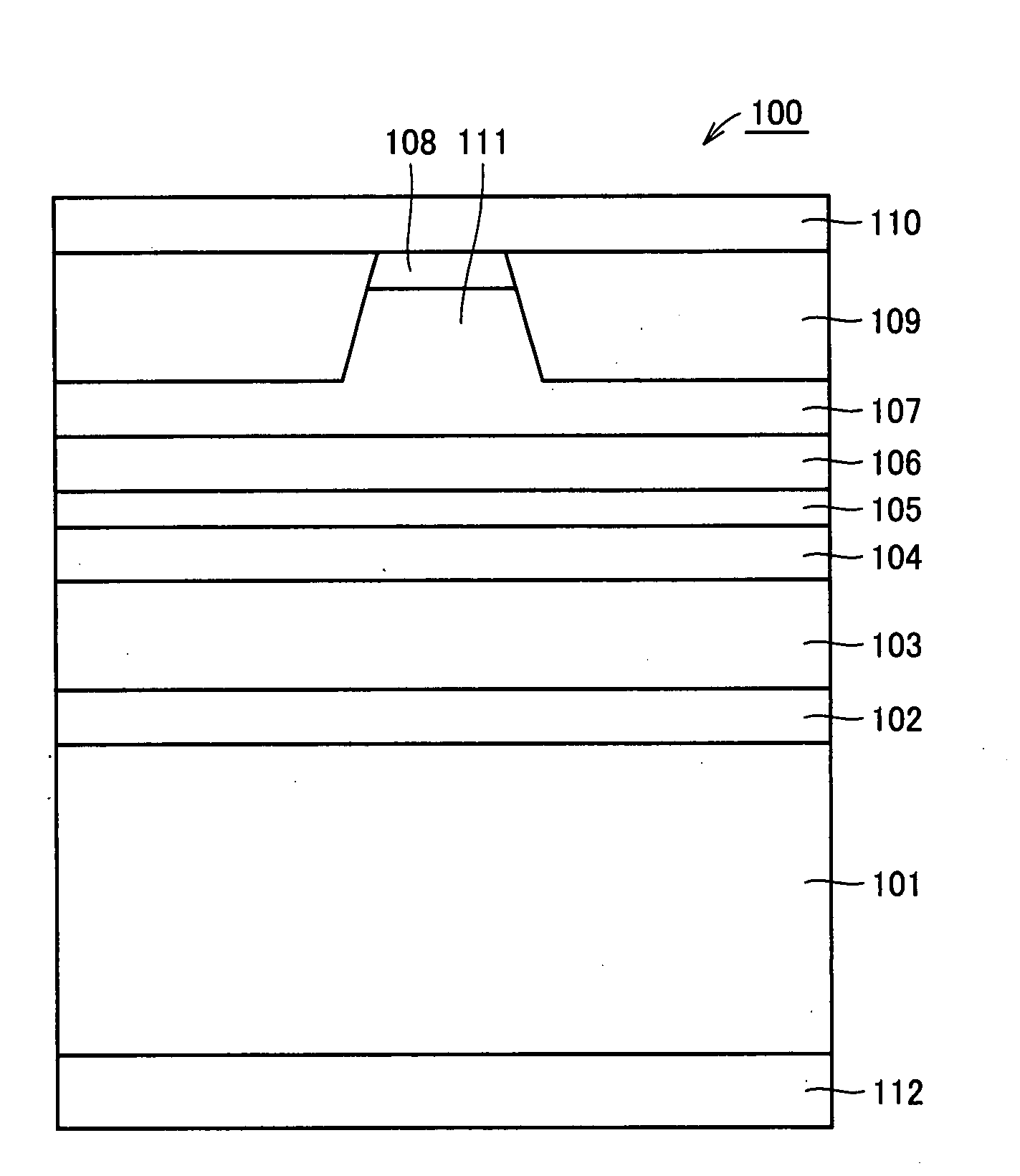

Nitride semiconductor light emitting device

ActiveUS20070210324A1Improve reliabilityIncrease powerLaser detailsNanoopticsAluminum oxynitrideLight emitting device

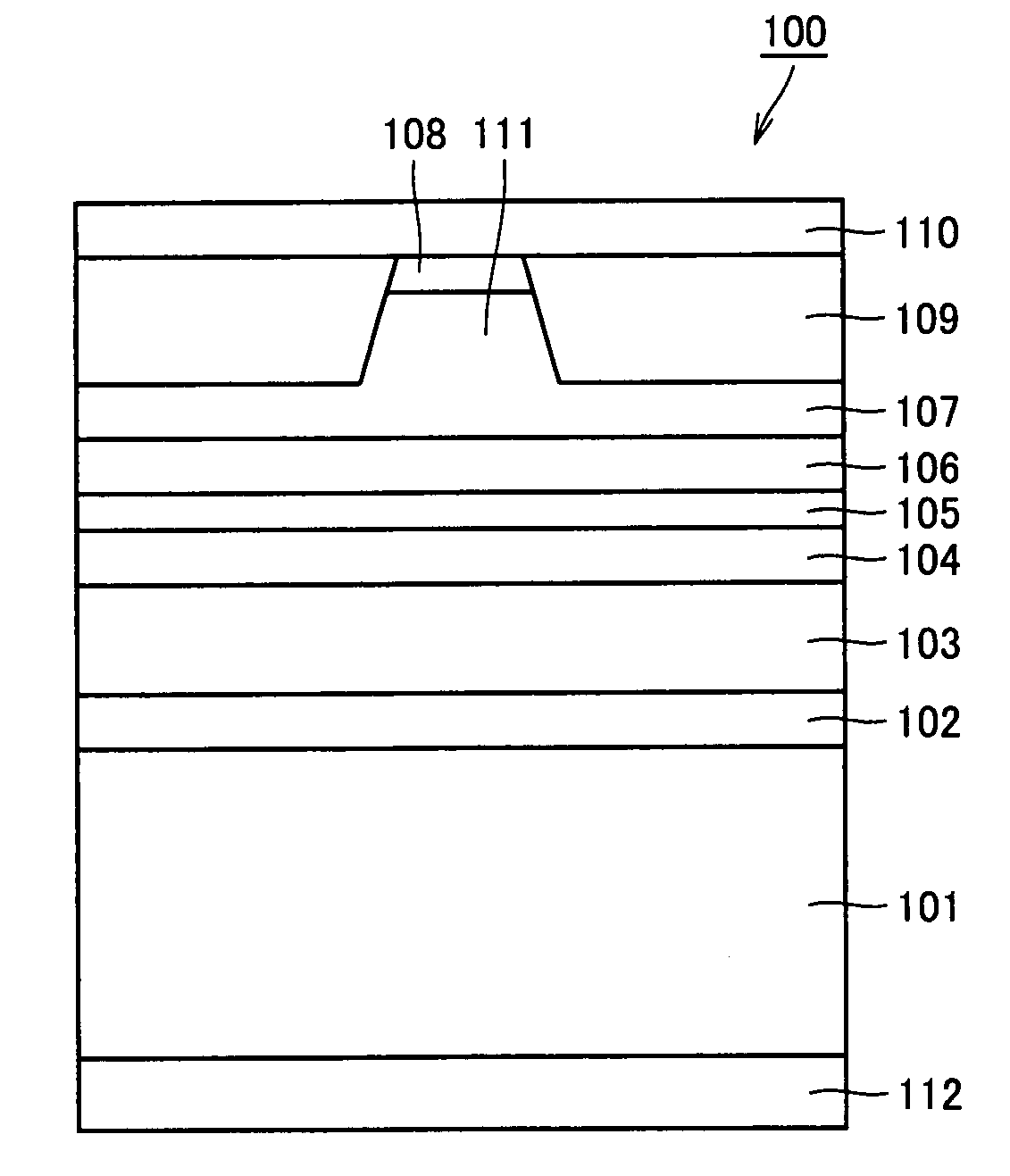

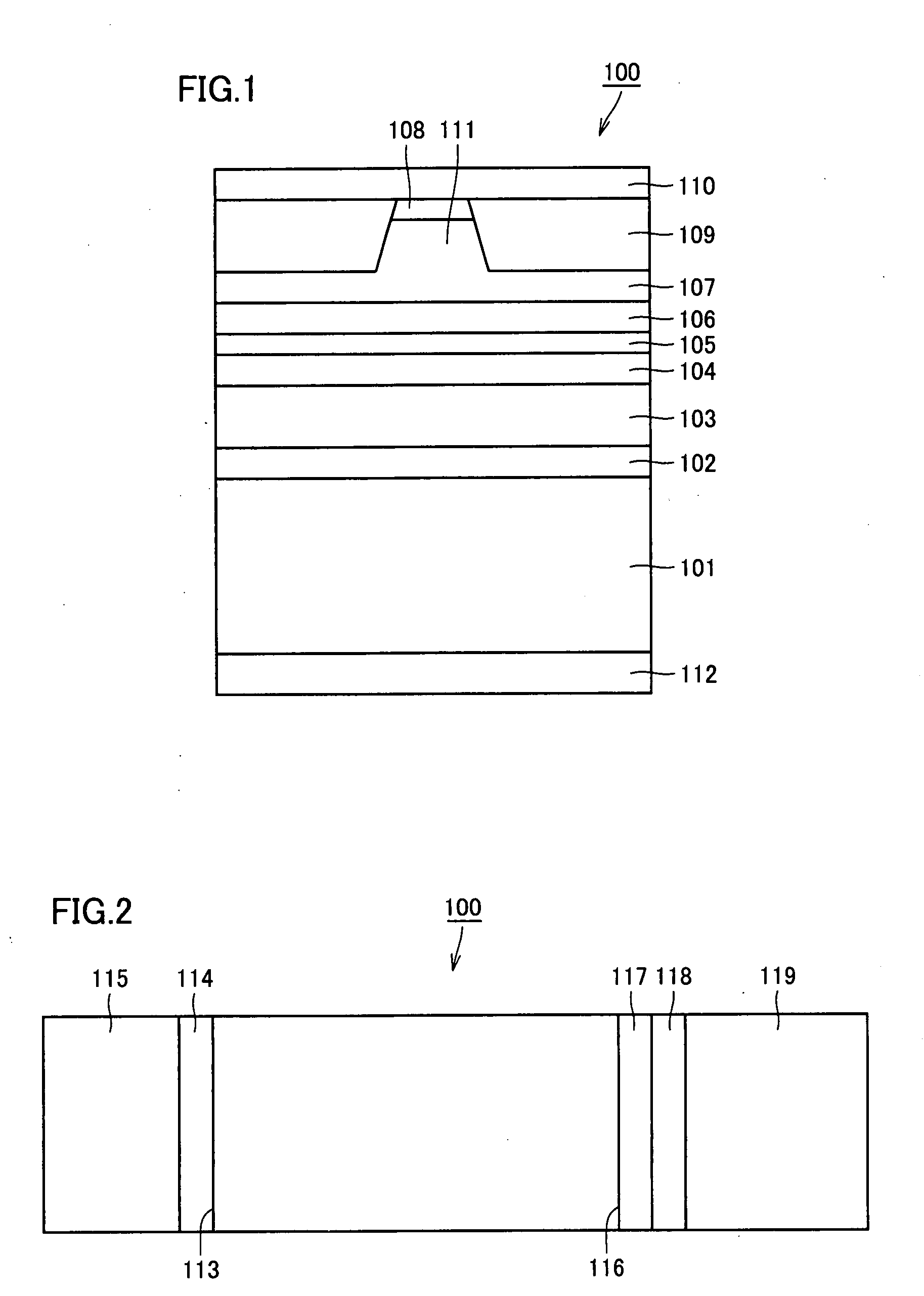

A nitride semiconductor light emitting device includes a first coat film of aluminum nitride or aluminum oxynitride formed at a light emitting portion and a second coat film of aluminum oxide formed on the first coat film. The thickness of the second coat film is at least 80nm and at most 1000nm. Here, the thickness of the first coat film is preferably at least 6nm and at most 200nm.

Owner:SHARP FUKUYAMA LASER CO LTD

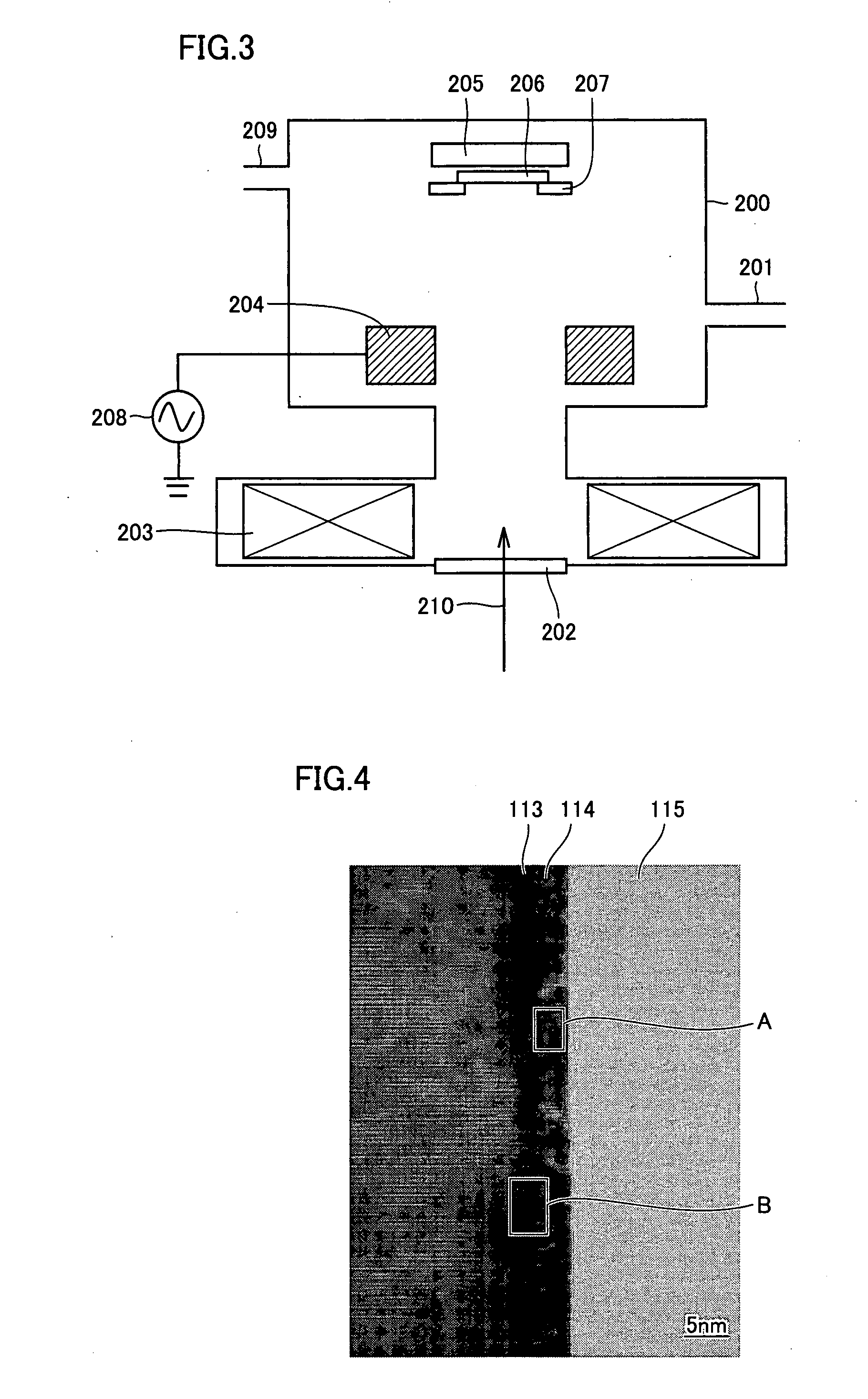

Nitride semiconductor light emitting device, method of manufacturing nitride semiconductor light emitting device, and nitride semiconductor transistor device

ActiveUS20070205424A1Reliability is deterioratedImprove reliabilityOptical wave guidanceLaser detailsAluminum oxynitrideLight emitting device

Provided are a nitride semiconductor light emitting device including a coat film formed at a light emitting portion and including an aluminum nitride crystal or an aluminum oxynitride crystal, and a method of manufacturing the nitride semiconductor light emitting device. Also provided is a nitride semiconductor transistor device including a nitride semiconductor layer and a gate insulating film which is in contact with the nitride semiconductor layer and includes an aluminium nitride crystal or an aluminum oxynitride crystal.

Owner:SHARP FUKUYAMA LASER CO LTD

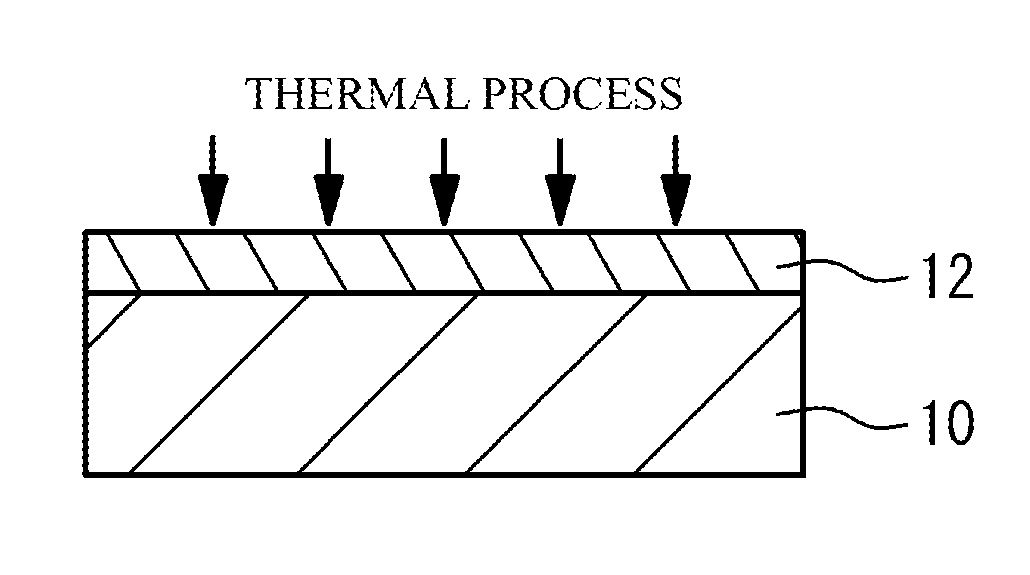

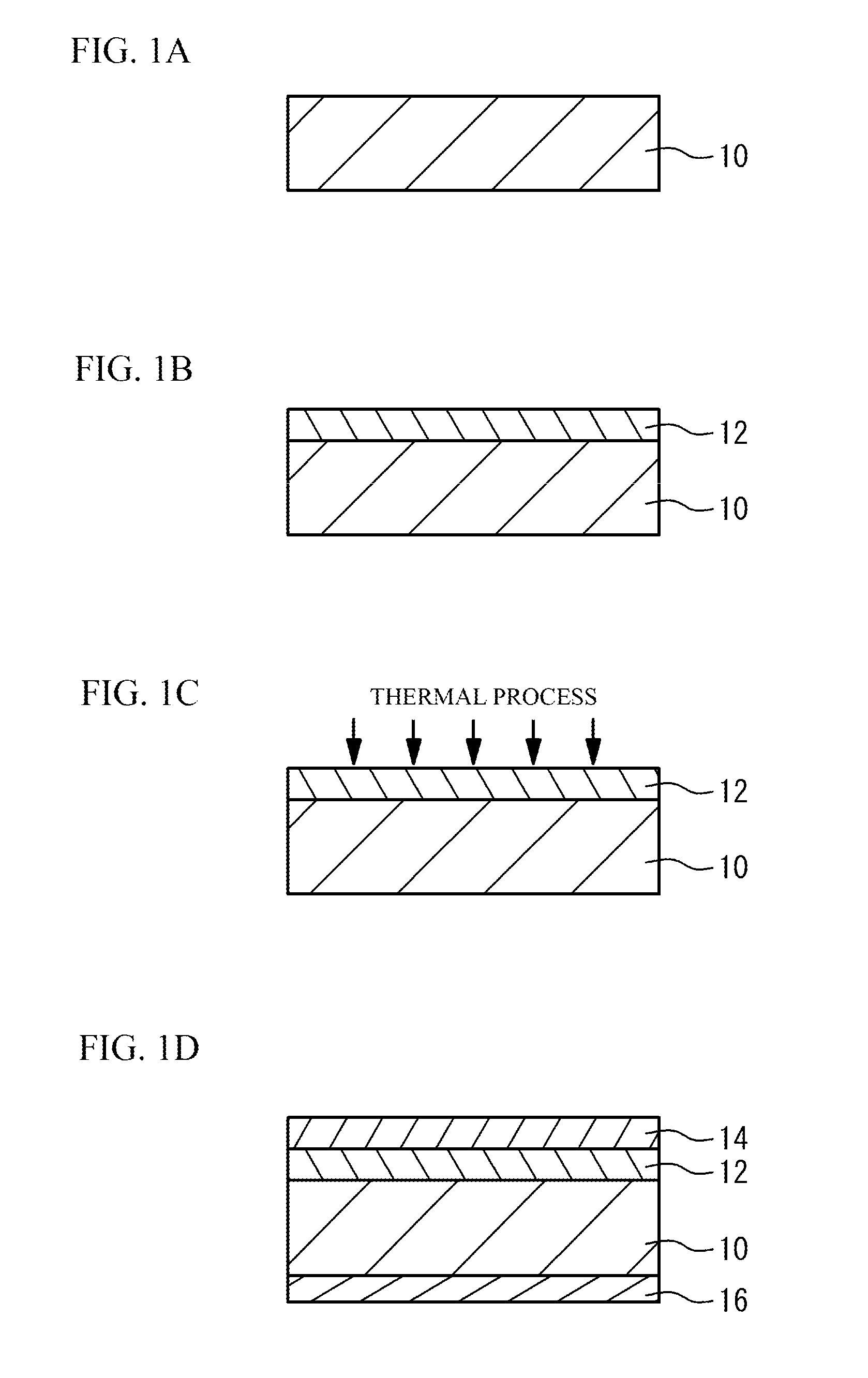

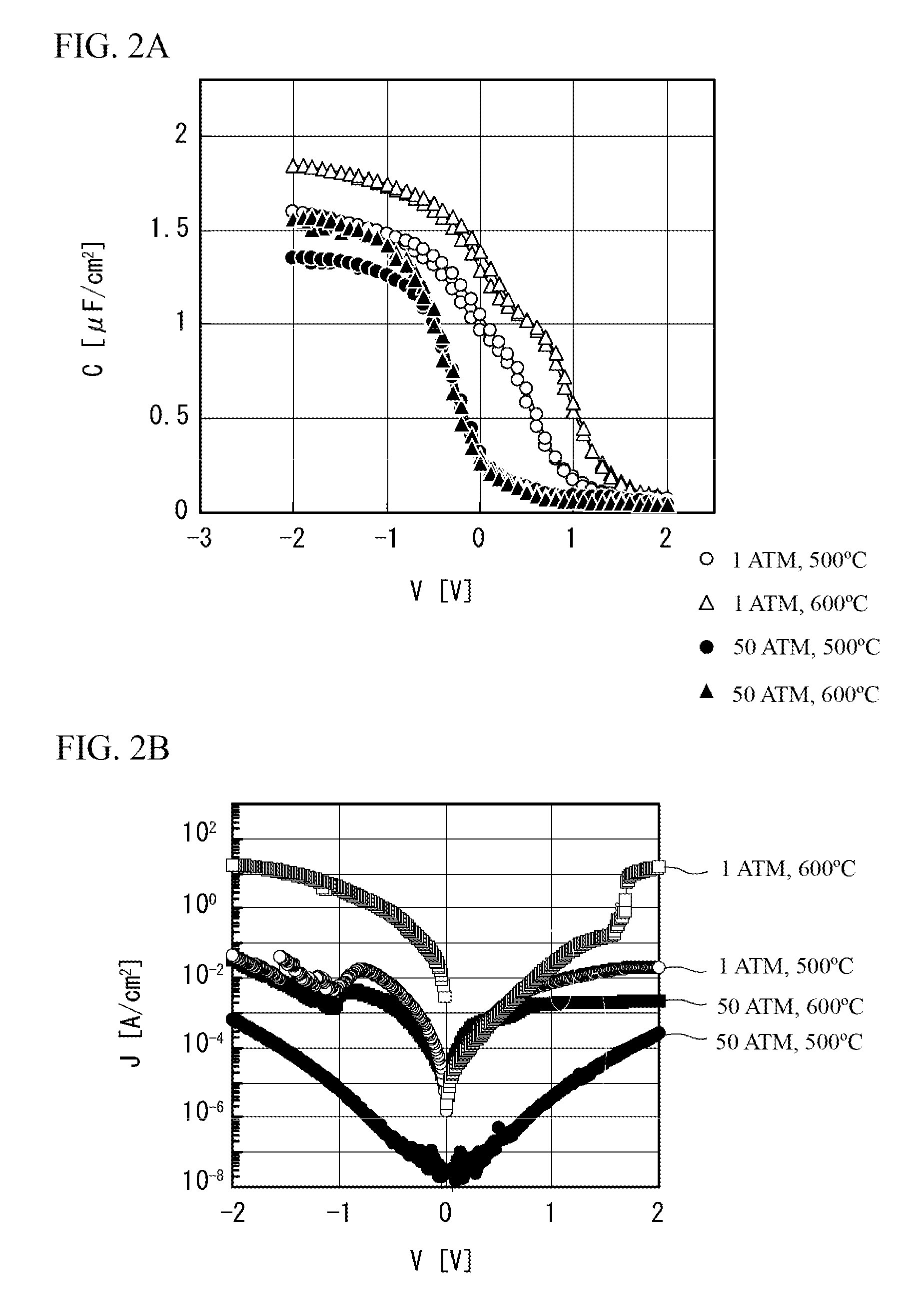

Semiconductor structure having aluminum oxynitride film on germanium layer and method of fabricating the same

ActiveUS9306026B2Reduce interfaceSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceSemiconductor structure

A semiconductor structure includes: a germanium layer 30; and an aluminum oxynitride film 32 that is formed on the germanium layer, wherein: an EOT of the aluminum oxynitride film is 2 nm or less; Cit / Cacc is 0.4 or less; on a presumption that Au acting as a metal film is formed on the aluminum oxynitride film, the Cit is a capacitance value between the germanium layer and the metal film at a frequency of 1 MHz in a case where a voltage of the metal film with respect to the germanium layer is applied to an inversion region side by 0.5 V; and the Cacc is a capacitance value between the germanium layer and the metal film in an accumulation region.

Owner:JAPAN SCI & TECH CORP

Pyrolytic layer of aluminium oxynitride and glazing comprising same

InactiveUS6838179B1Improve wear resistanceGlass/slag layered productsNatural mineral layered productsRainbowGas phase

The invention concerns glass panels comprising thin layers in particular for providing them with solar protective or low-emissive properties, and also comprising other thin layers for correcting rainbow effects induced by the former. The invention is characterized in that said glass panels comprise a glass substrate coated with an aluminum oxynitride layer, deposited by gas phase pyrolysis, and whereof the characteristics of thickness and refractive index are selected so as to attenuate colors reflected by the layer providing the glass panel with low-emissive and / or solar protective properties, layer which is deposited on the aluminum oxynitride layer.

Owner:GLAVERBEL SA

Nitride semiconductor light-emitting device and method of manufacturing nitride semiconductor light-emitting device

ActiveUS20070246720A1Reduce the valueLower mirror lossLaser detailsSolid-state devicesAluminum oxynitrideLight emitting device

A nitride semiconductor light-emitting device including a coating film and a reflectance control film successively formed on a light-emitting portion, in which the light-emitting portion is formed of a nitride semiconductor, the coating film is formed of an aluminum oxynitride film or an aluminum nitride film, and the reflectance control film is formed of an oxide film, as well as a method of manufacturing the nitride semiconductor light-emitting device are provided.

Owner:SHARP FUKUYAMA LASER CO LTD

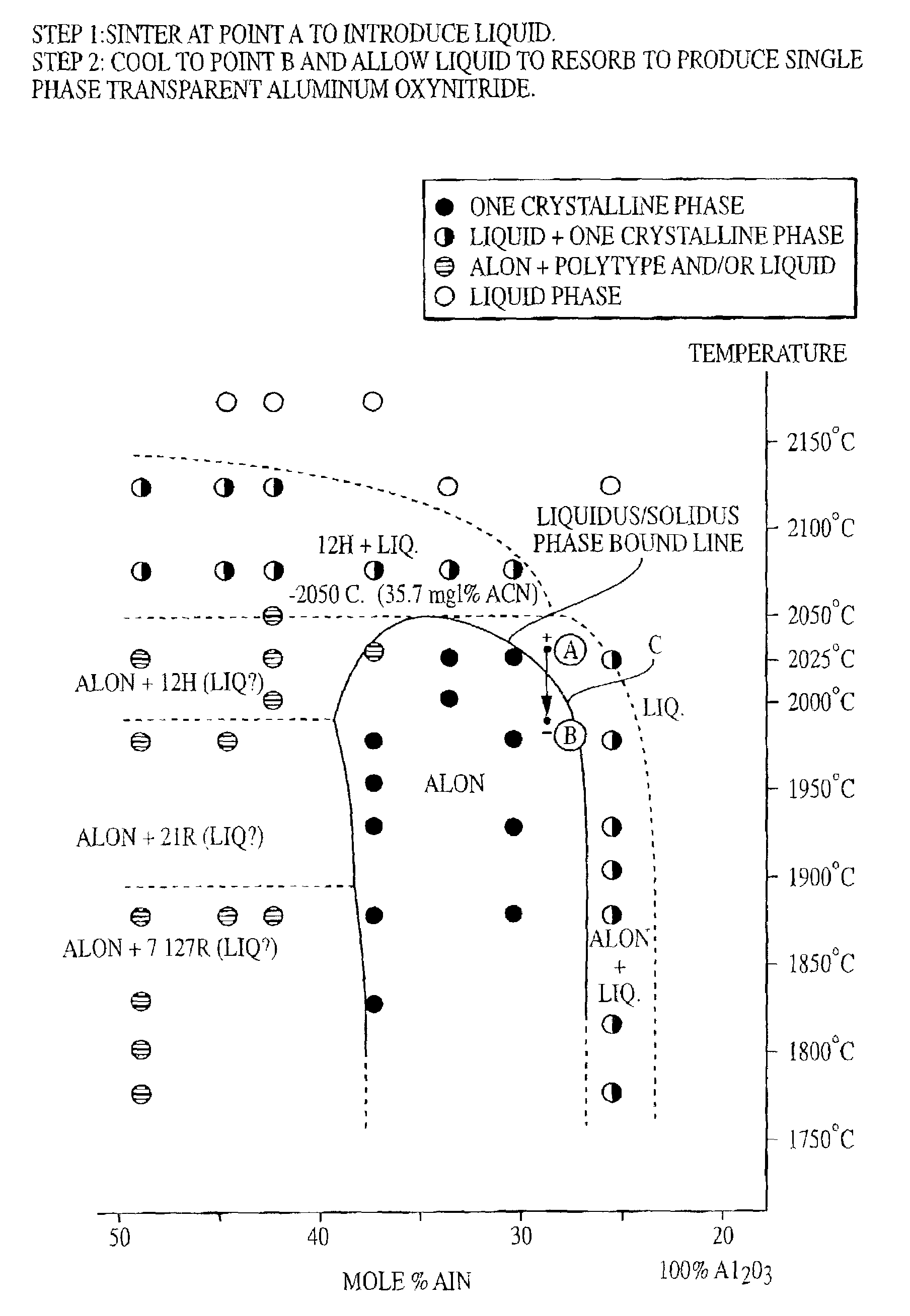

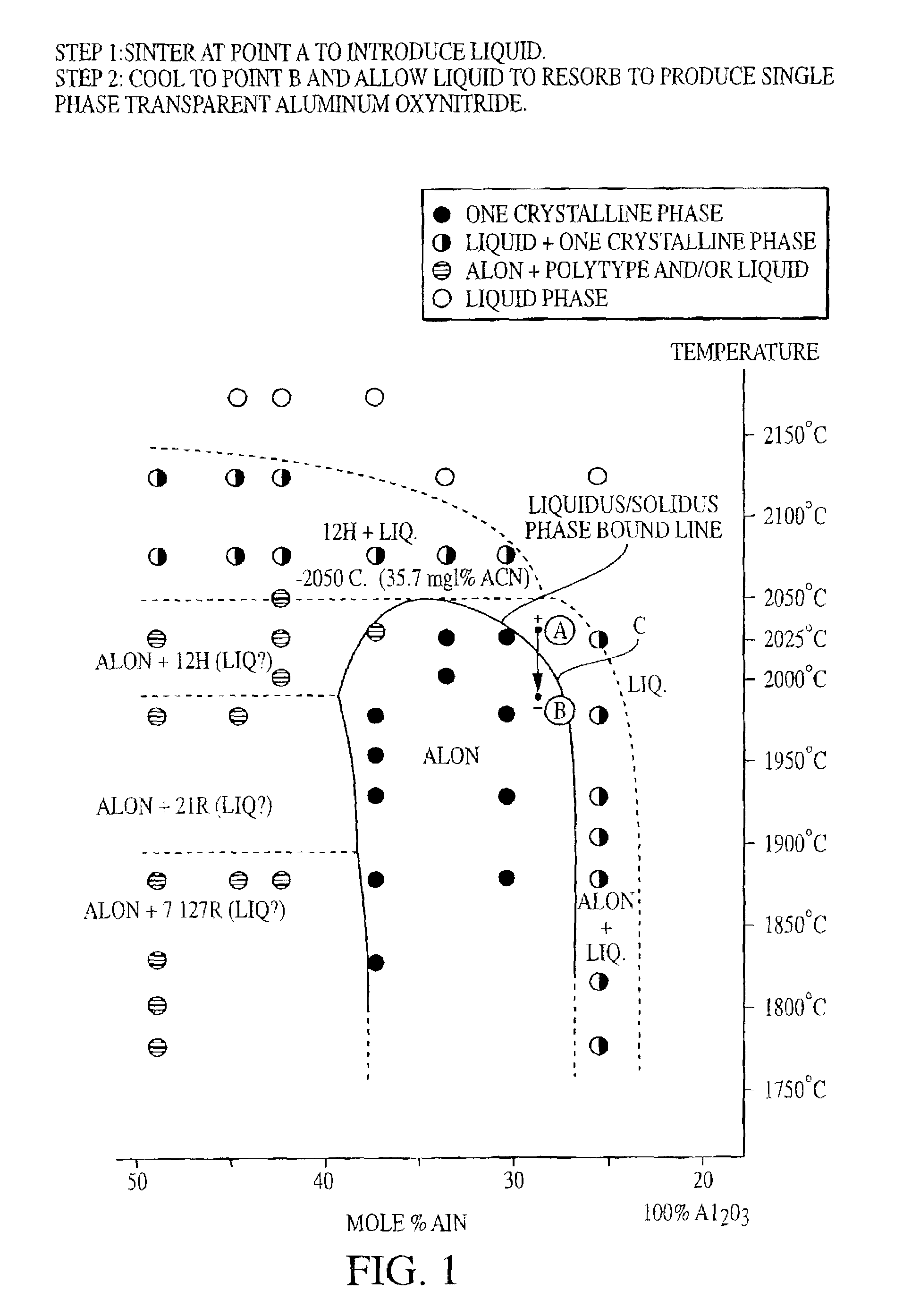

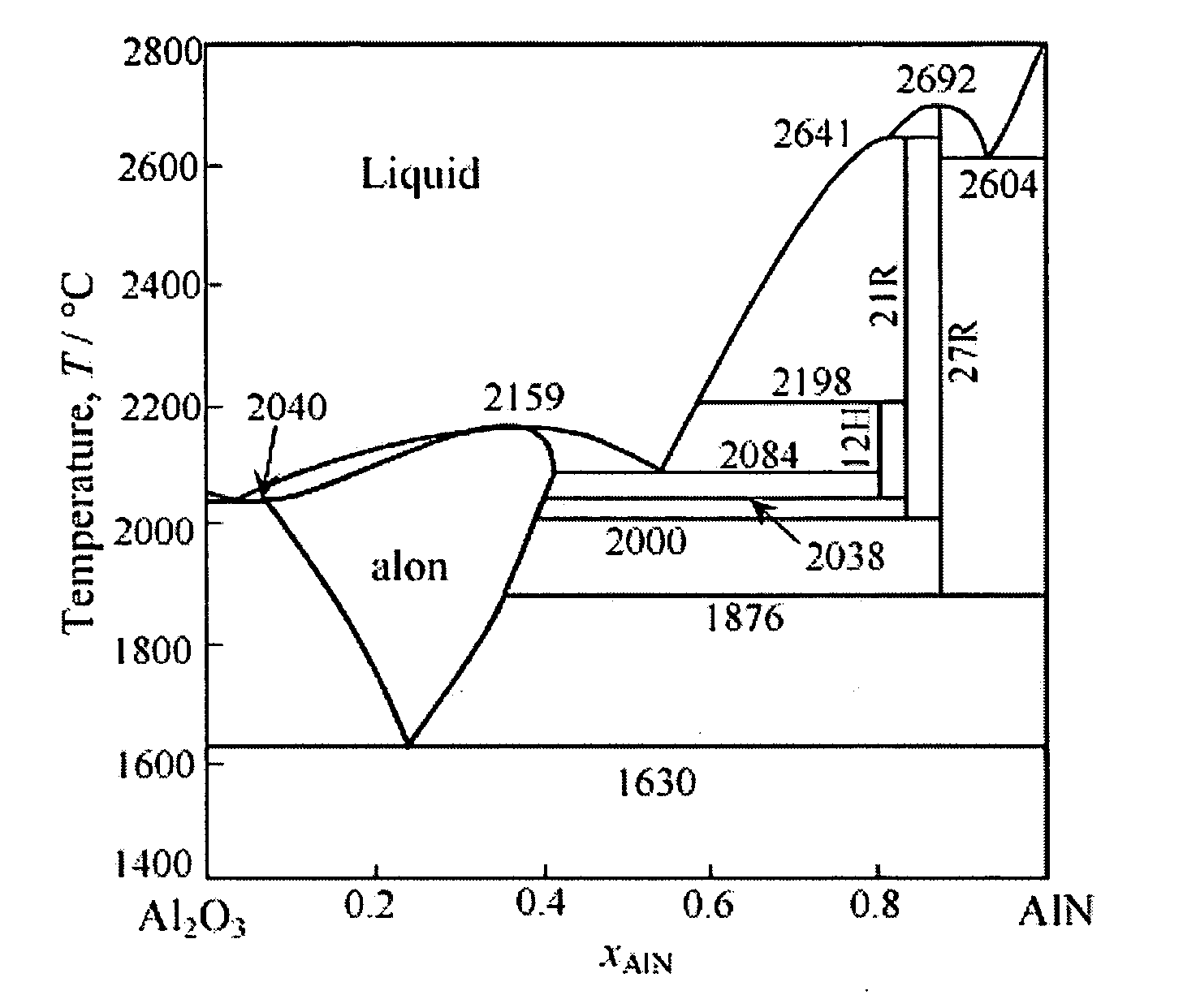

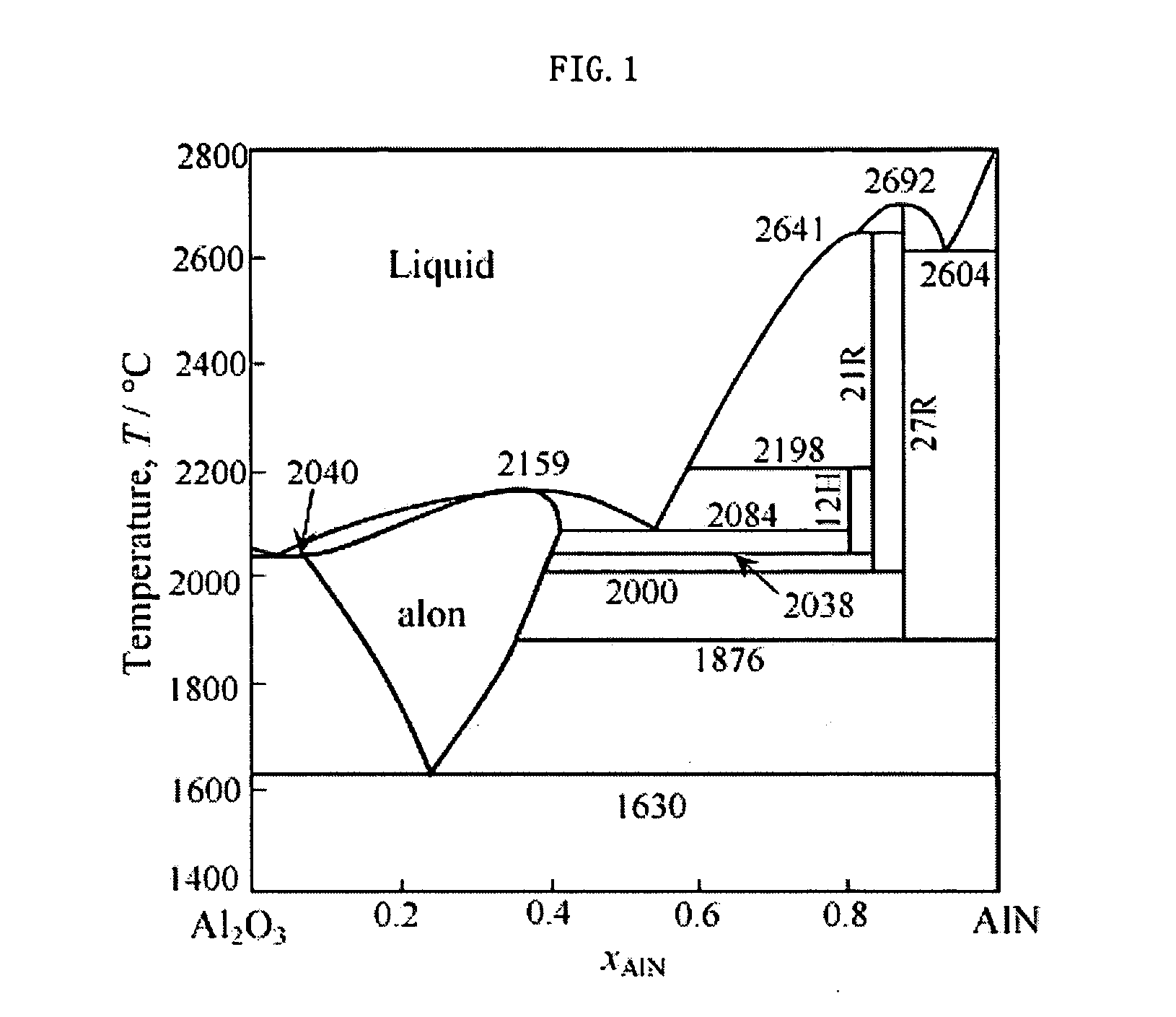

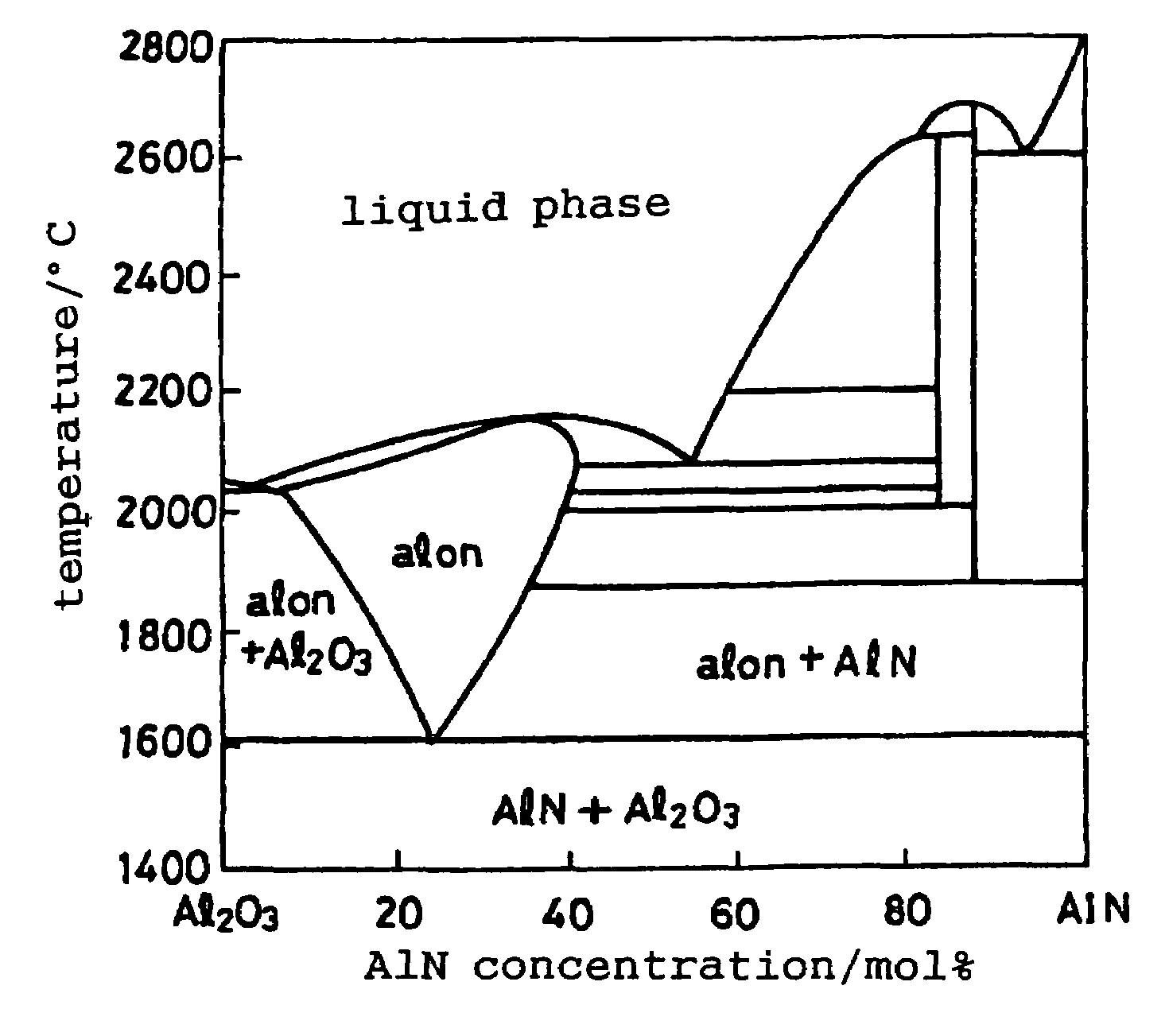

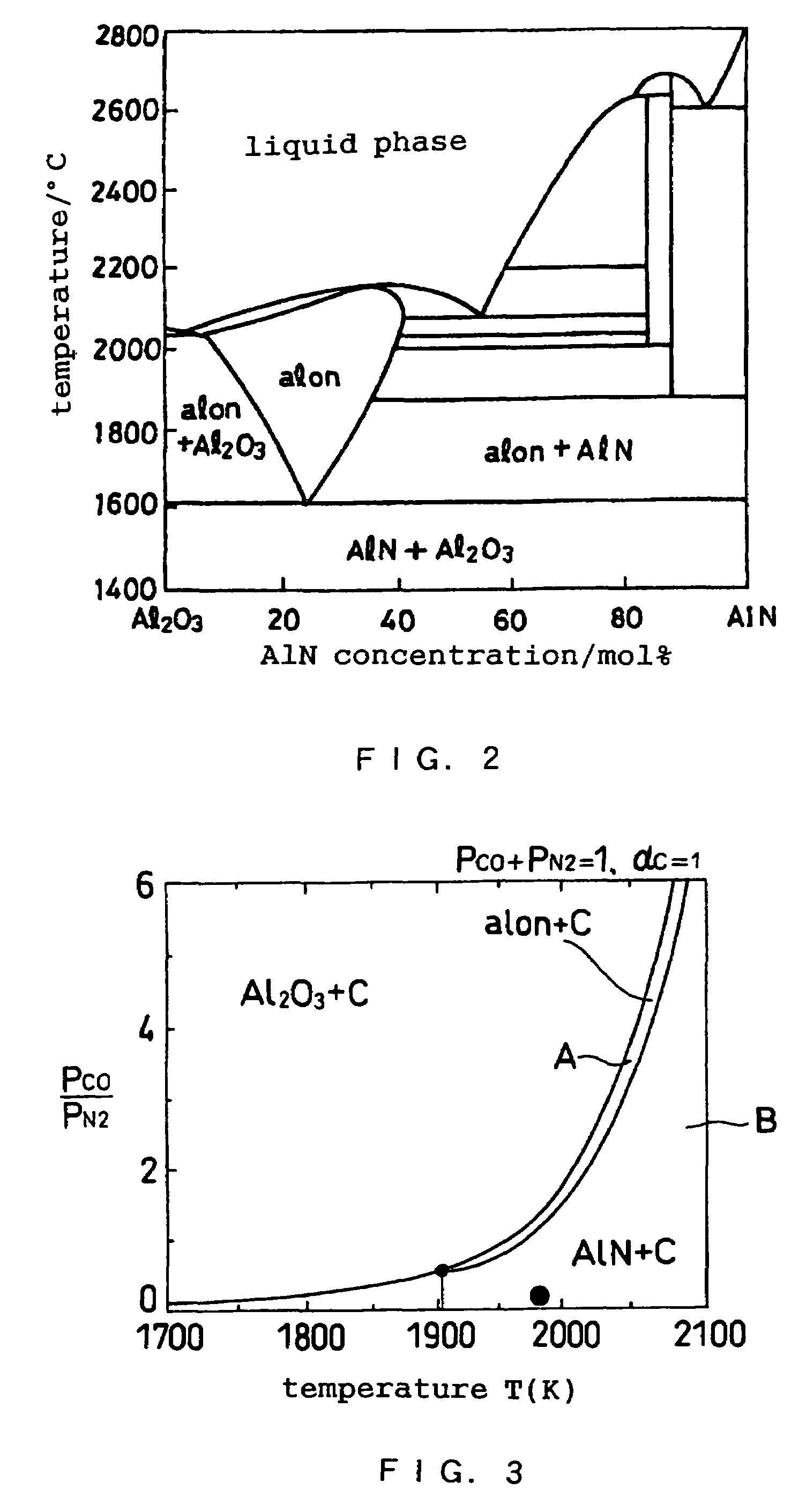

Transient liquid phase reactive sintering of aluminum oxynitride (AlON)

InactiveUS7045091B1Low production costShorten the sintering timeAmmonium nitratesNitrogen compoundsSolid regionAluminum oxynitride

A transparent aluminum oxynitride product is produced by a first heat treating step wherein a combination of Al2O3 and AlN at a temperature within the solid-liquid phase and a second step of sintering the heat treated combination at a temperature at least 50° C. less than the heat treating temperature. The method introduces a small fraction of liquid that aids in pore elimination and densification. In a single step, the material is shifted from the liquid / solid region into a solid AlON solution region, wherein the liquid is fully reacted with the solid AlON phase, with further sintering occurring. The procedure is sufficient to eliminate voids and other imperfections which often result in a reduction in optical clarity.

Owner:ARMY UNITED STATES OF THE AMERICAS AS REPRESENTED BY THE SEC OF THE

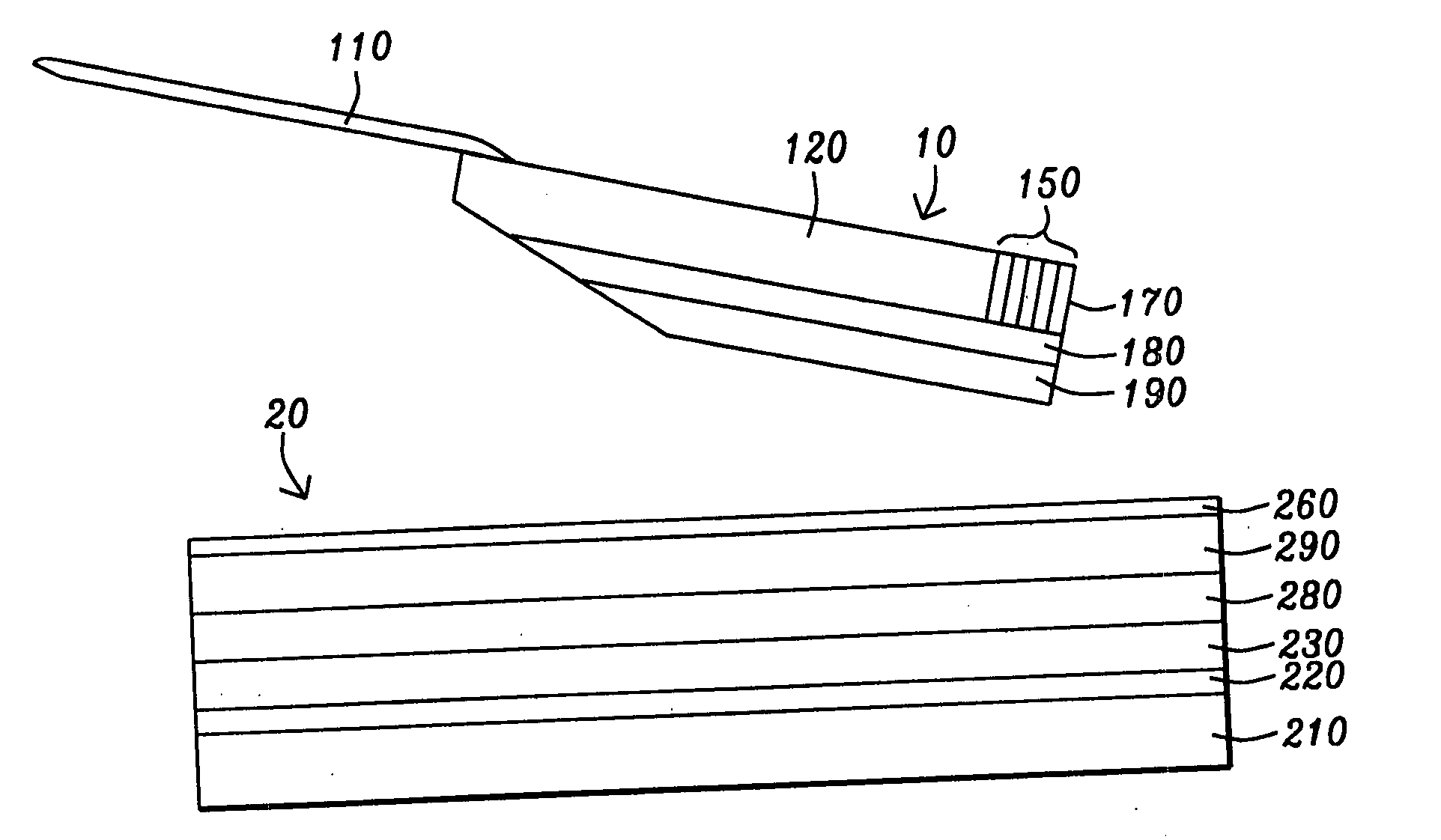

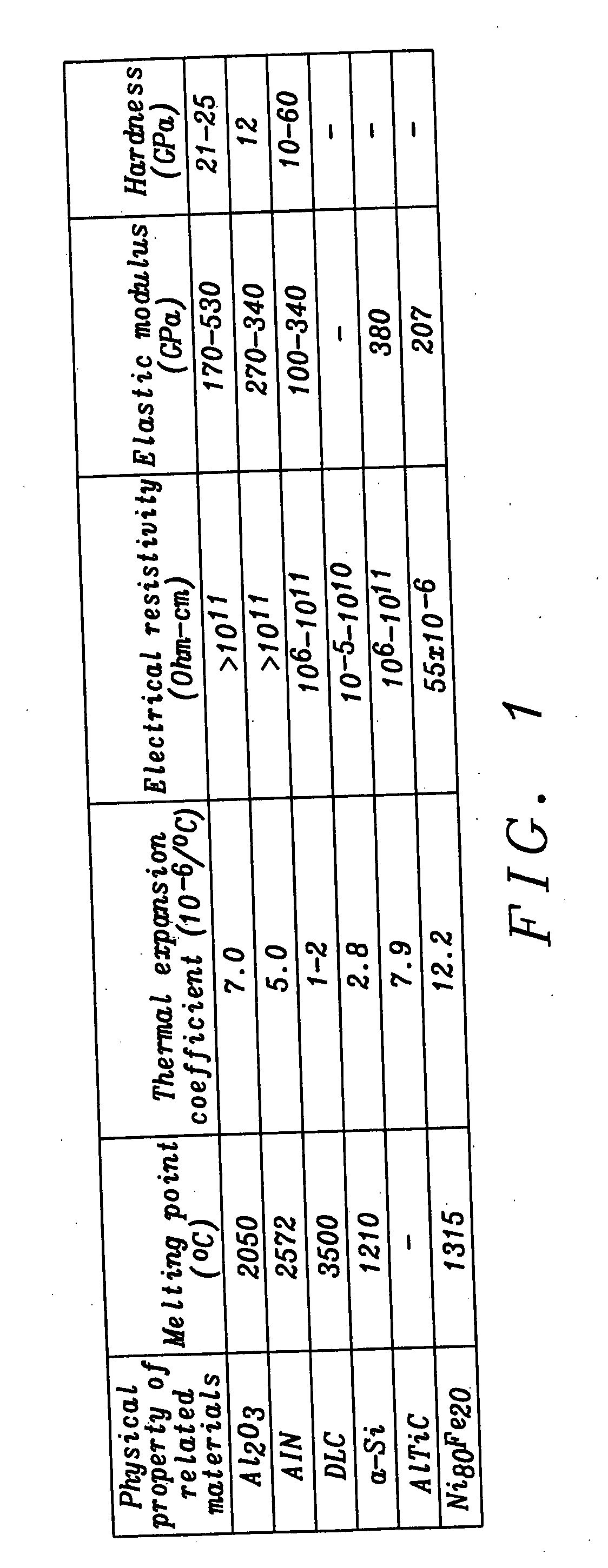

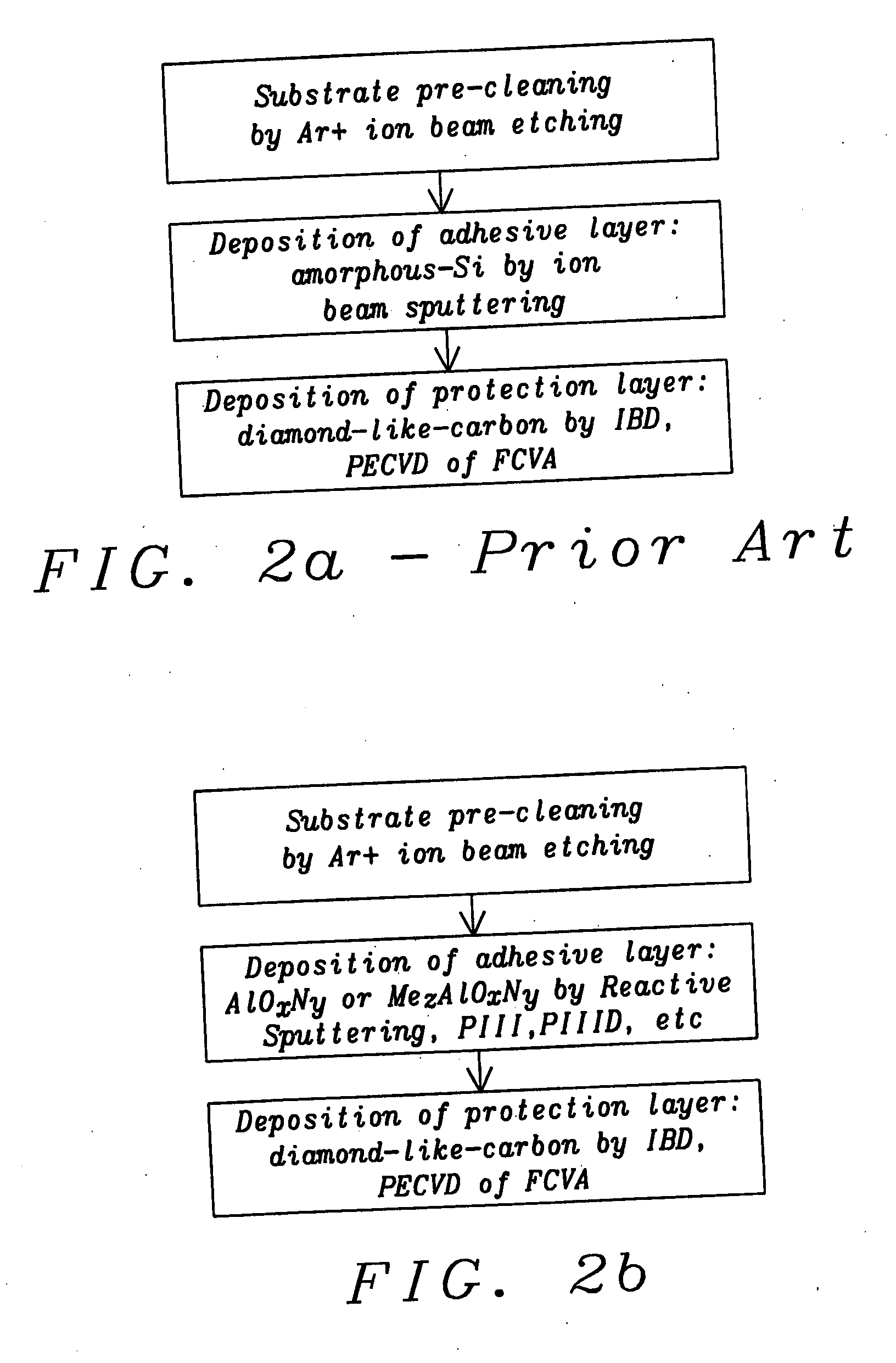

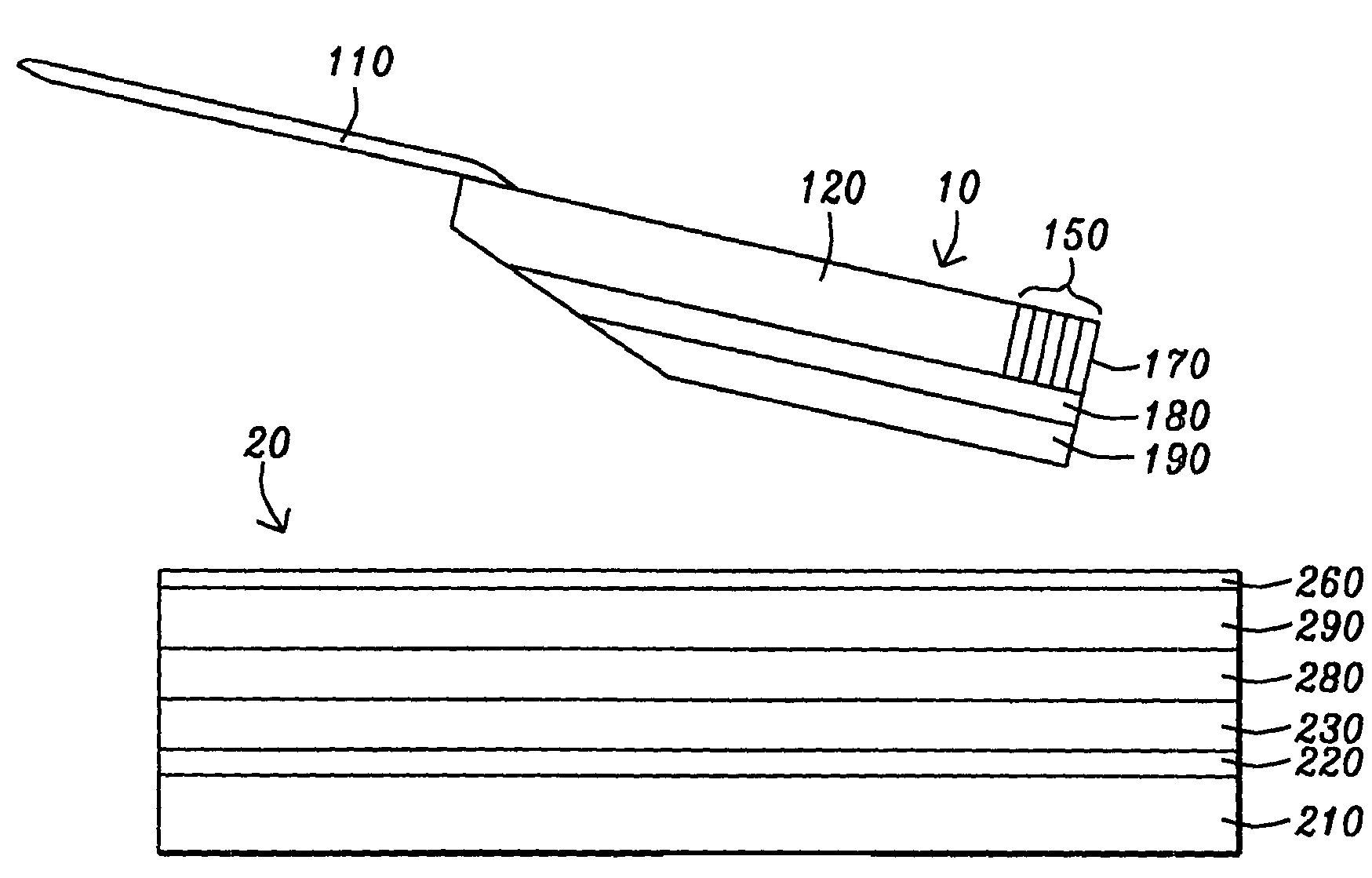

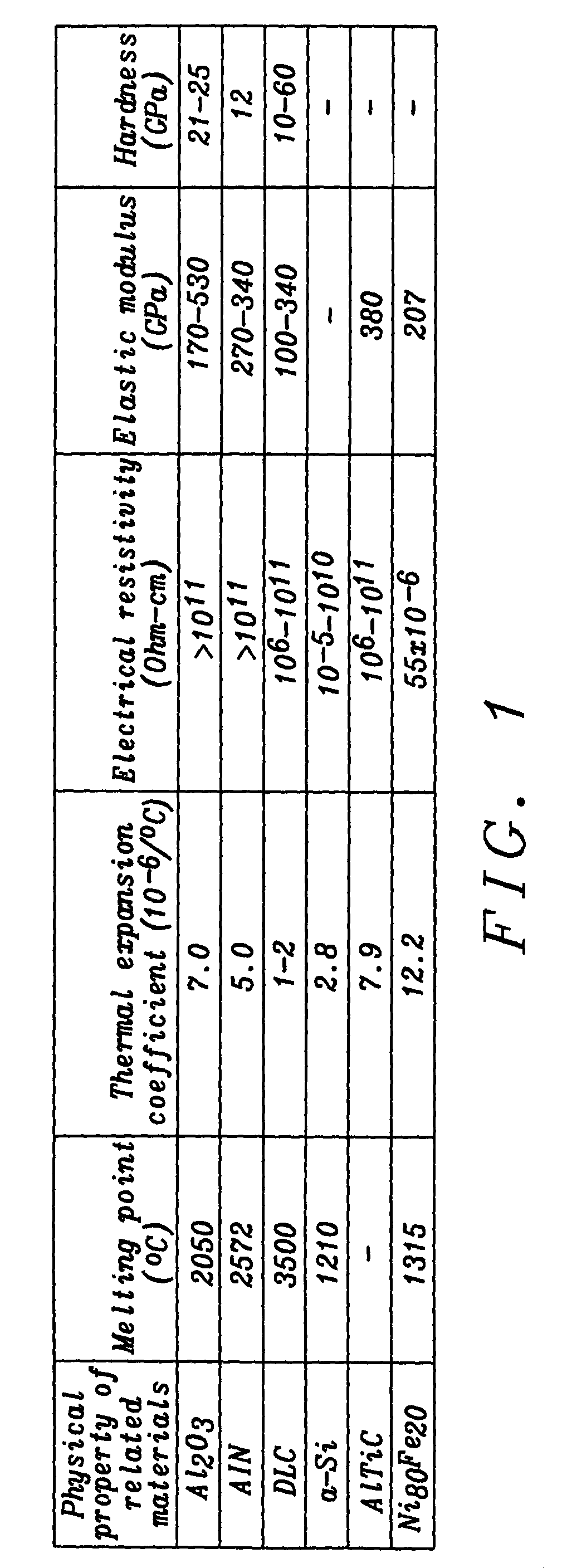

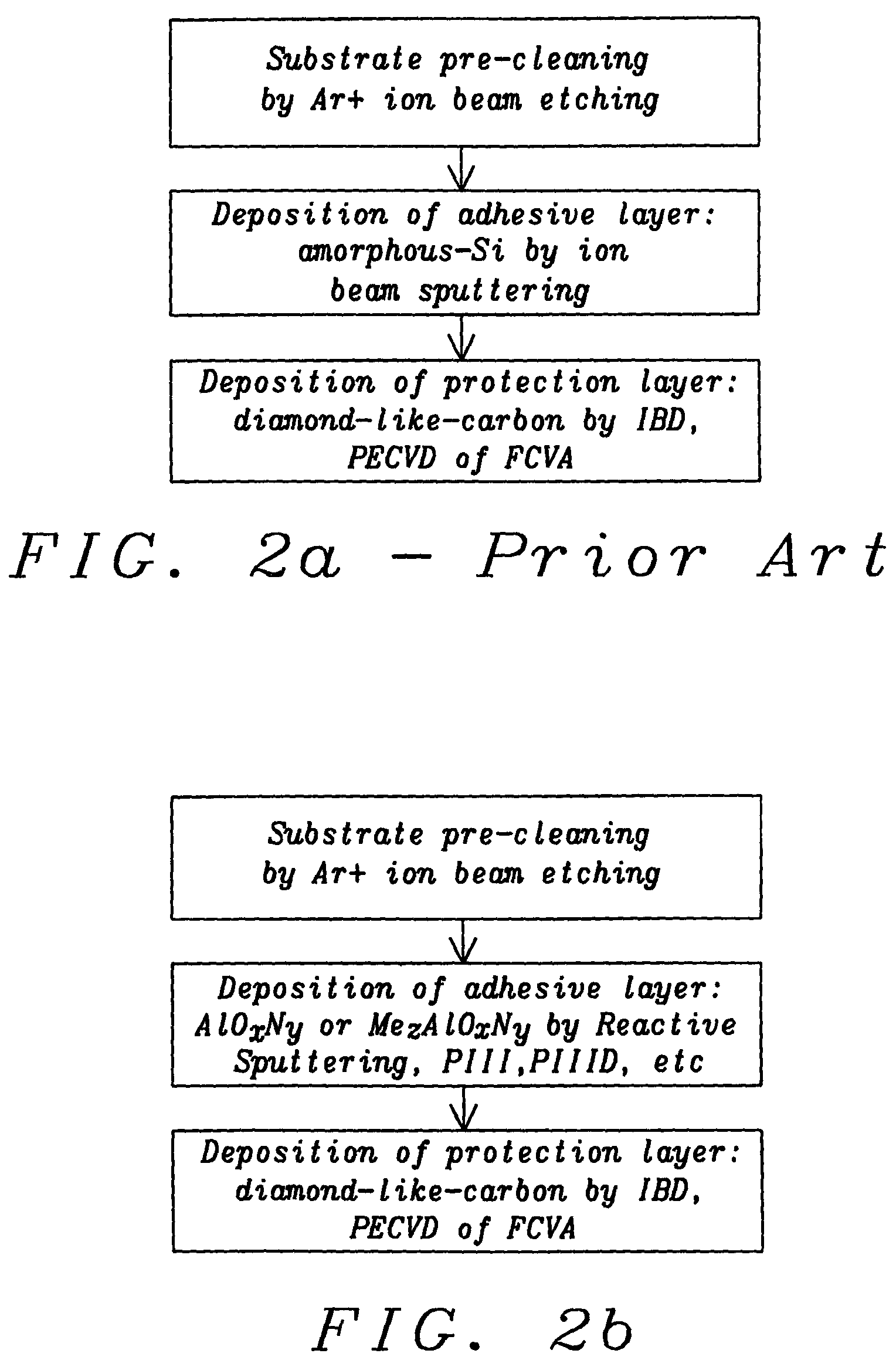

Magnetic recording head and media comprising aluminum oxynitride underlayer and a diamond-like carbon overcoat

ActiveUS20080176108A1Protective layerProvide wear resistanceElectric discharge heatingVacuum evaporation coatingDiamond-like carbonAlloy

A method for forming a protective bilayer on a magnetic read / write head or magnetic disk. The bilayer is formed as an adhesion enhancing underlayer and a protective diamond-like carbon (DLC) overlayer. The underlayer is formed of an aluminum or alloyed aluminum oxynitride, having the general formula AlOxNy or MezAlOxNy where Mez symbolizes Tiz, Siz or Crz and where x, y and z can be varied within the formation process. By adjusting the values of x and y the adhesion underlayer contributes to such qualities of the protective bilayer as stress compensation, chemical and mechanical stability and low electrical conductivity. Various methods of forming the underlayer are provided, including reactive ion sputtering, plasma assisted chemical vapor deposition, pulsed laser deposition and plasma immersion ion implantation.

Owner:SAE MAGNETICS (HK) LTD

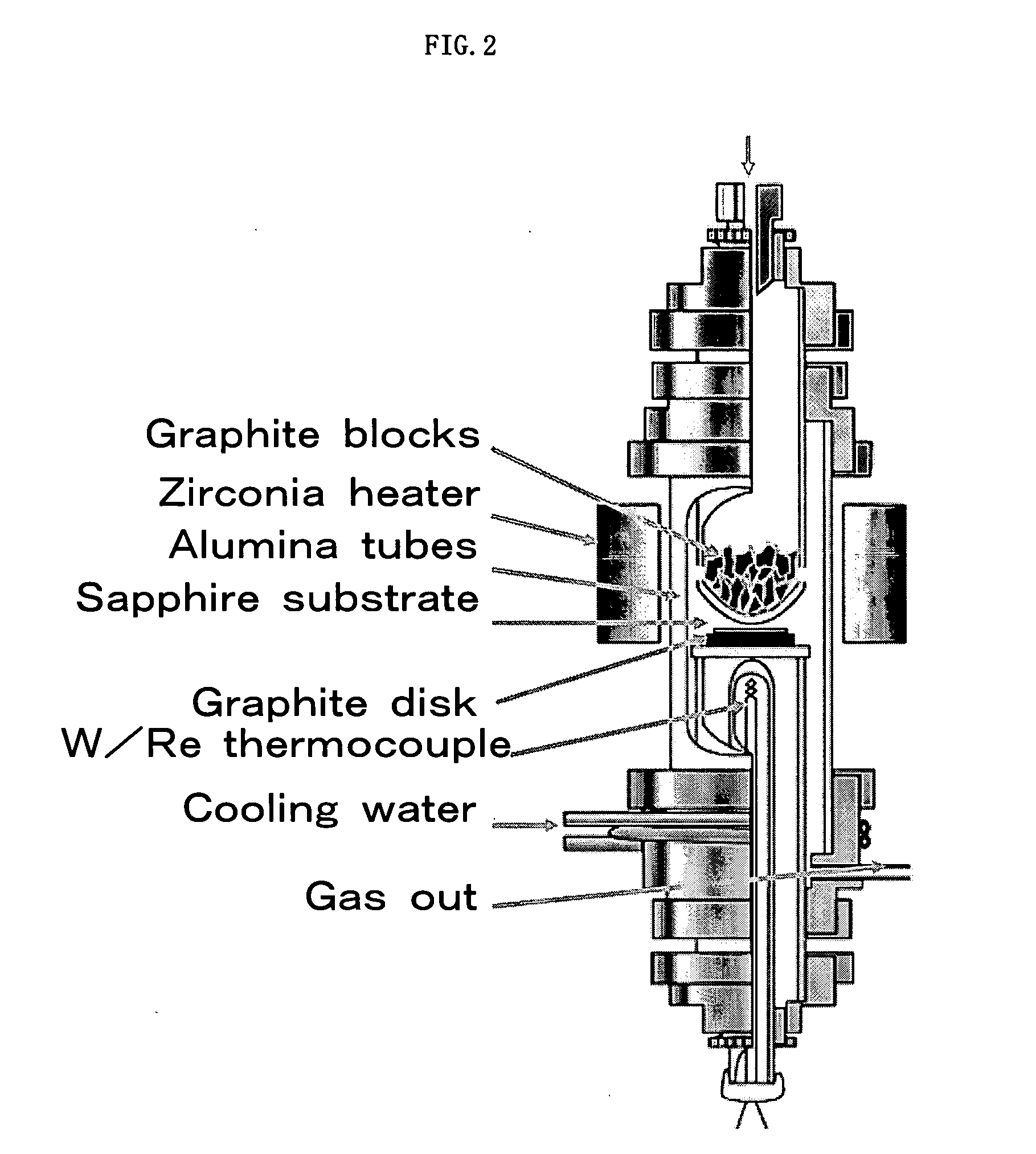

Highly crystalline aluminum nitride multi-layered substrate and production process thereof

InactiveUS20050059257A1Reduce dislocation densityHigh crystallinityPolycrystalline material growthAfter-treatment detailsRocking curveCrystal orientation

A highly crystalline aluminum nitride multi-layered substrate comprising a single-crystal α-alumina substrate, an aluminum oxynitride layer and a highly crystalline aluminum nitride film as the outermost layer which are formed in the mentioned order, wherein the aluminum oxynitride layer has a threading dislocation density of 6.3×107 / cm2 or less and a crystal orientation expressed by the half-value width of its rocking curve of 4,320 arcsec or less; and a production process thereof.

Owner:TOKYO INST OF TECH +1

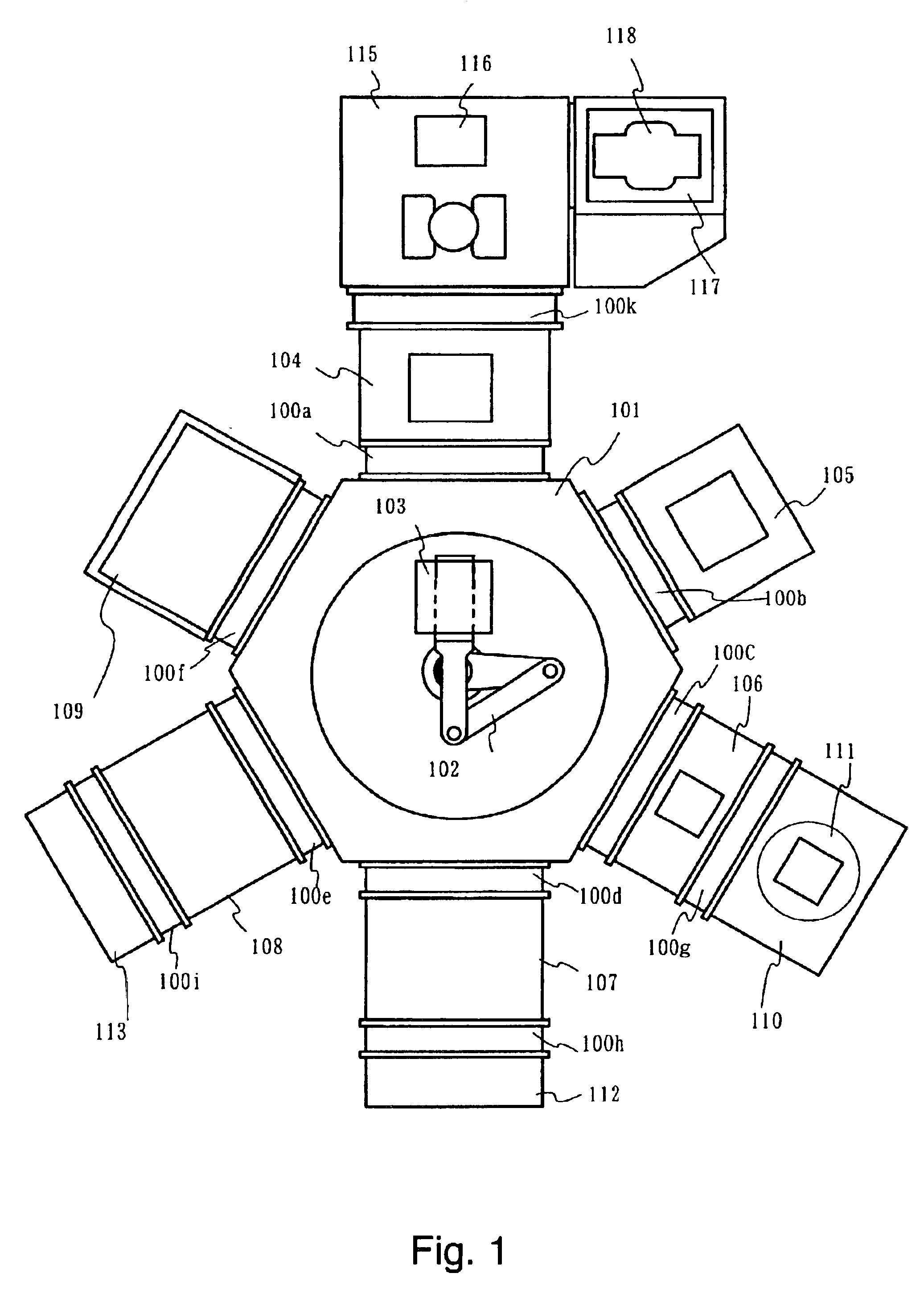

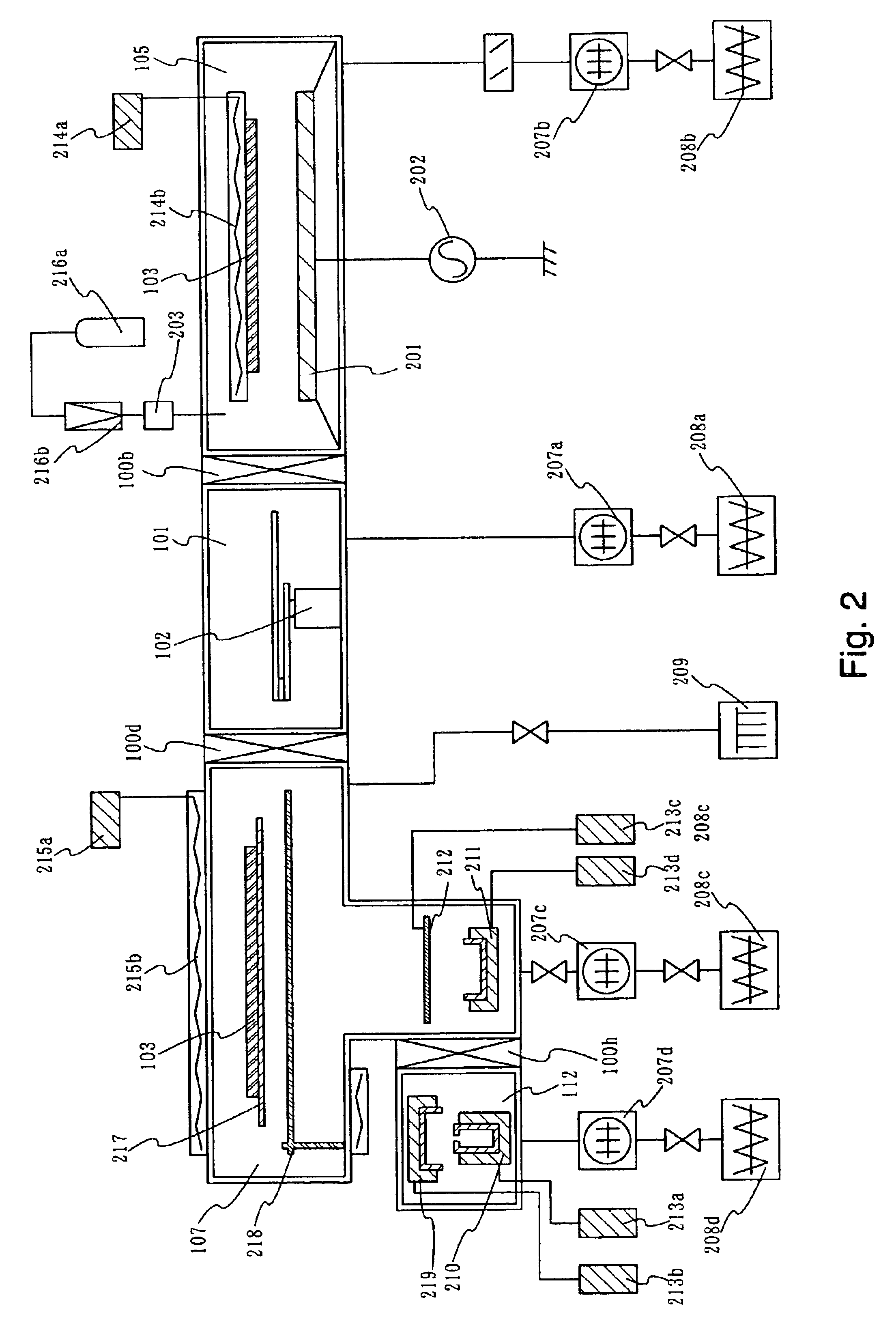

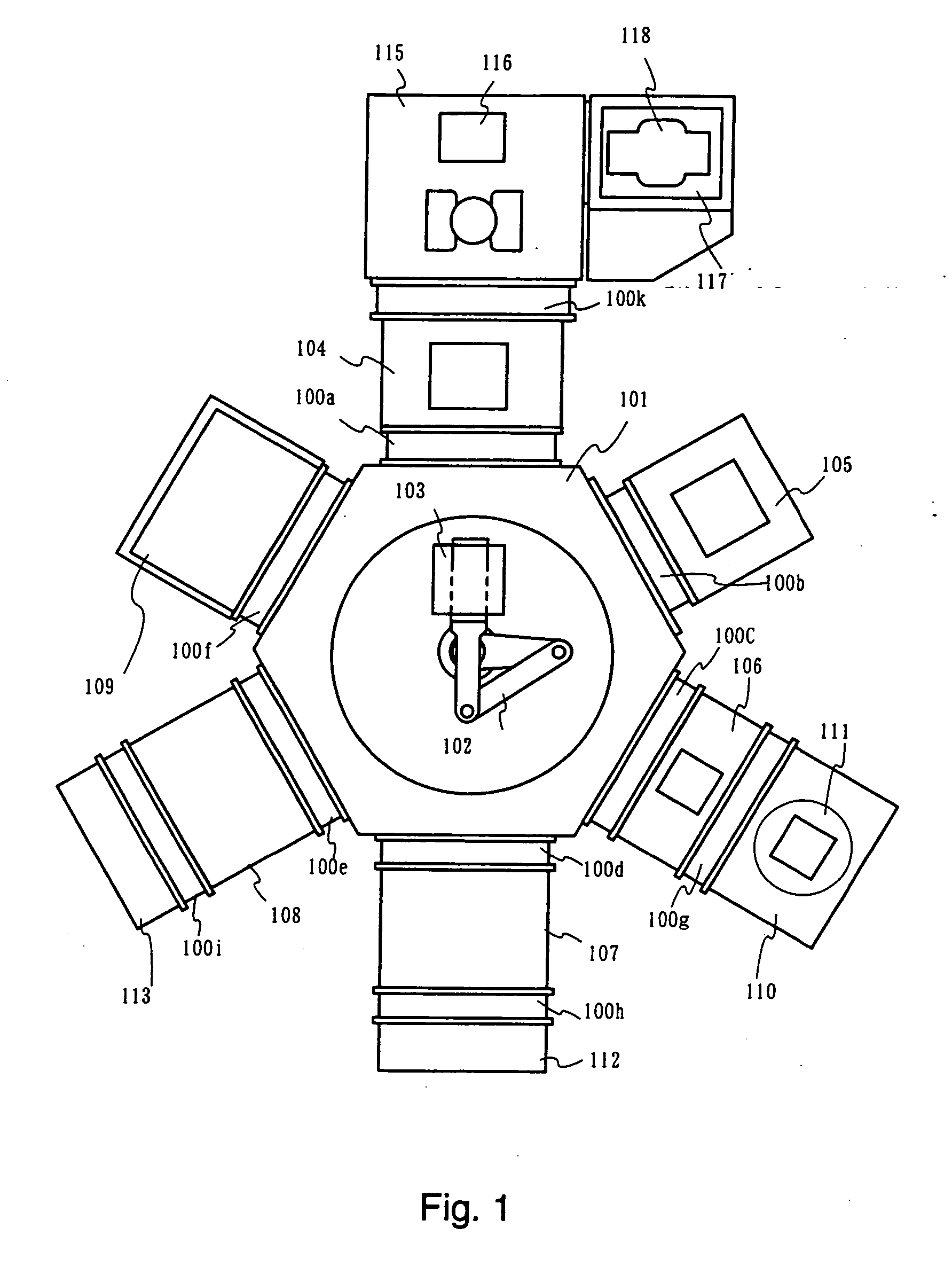

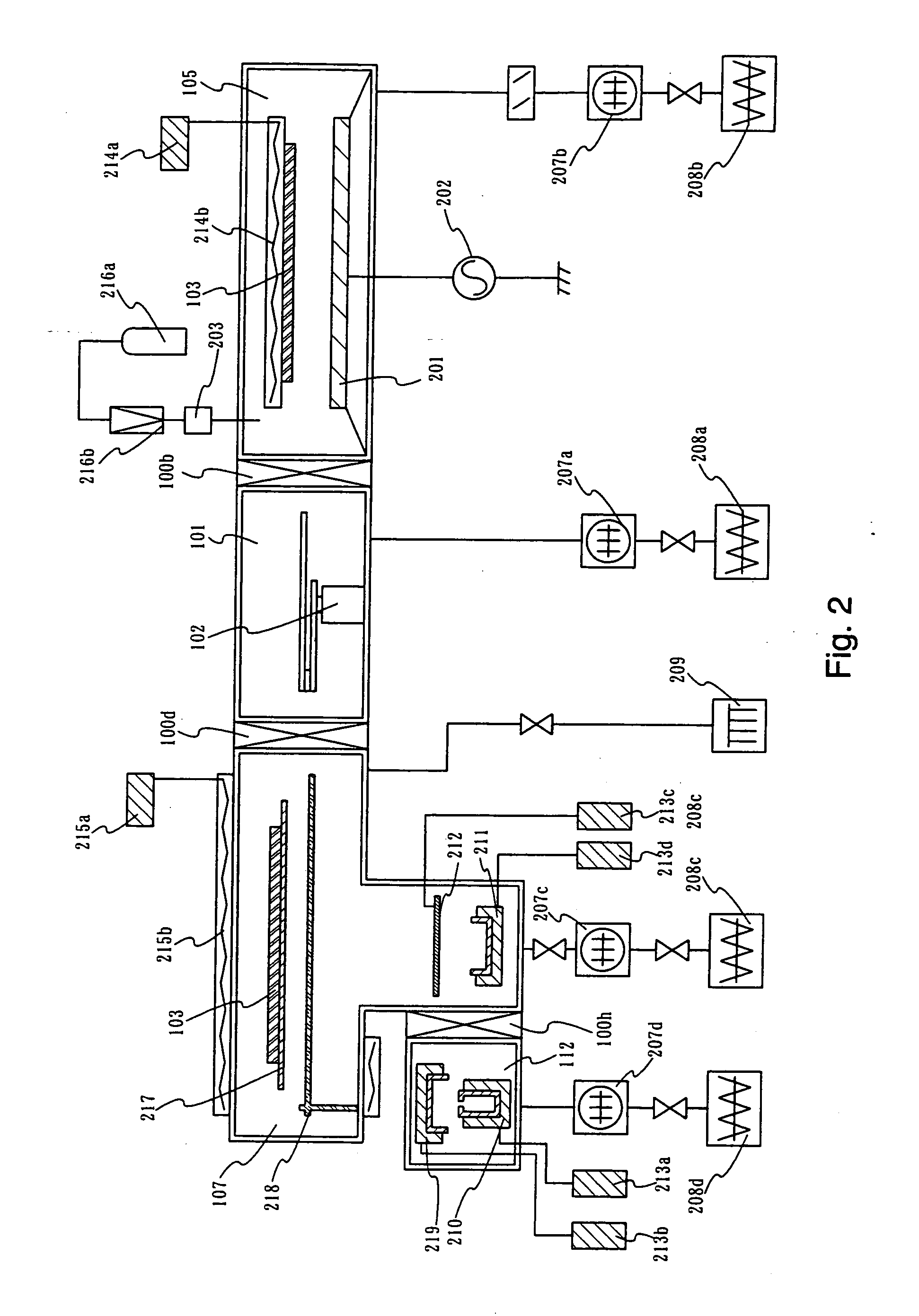

Clamp for use in processing semiconductor workpieces

ActiveUS20060171094A1Increase clamping forceReduce leakageSemiconductor/solid-state device manufacturingDielectricEngineering

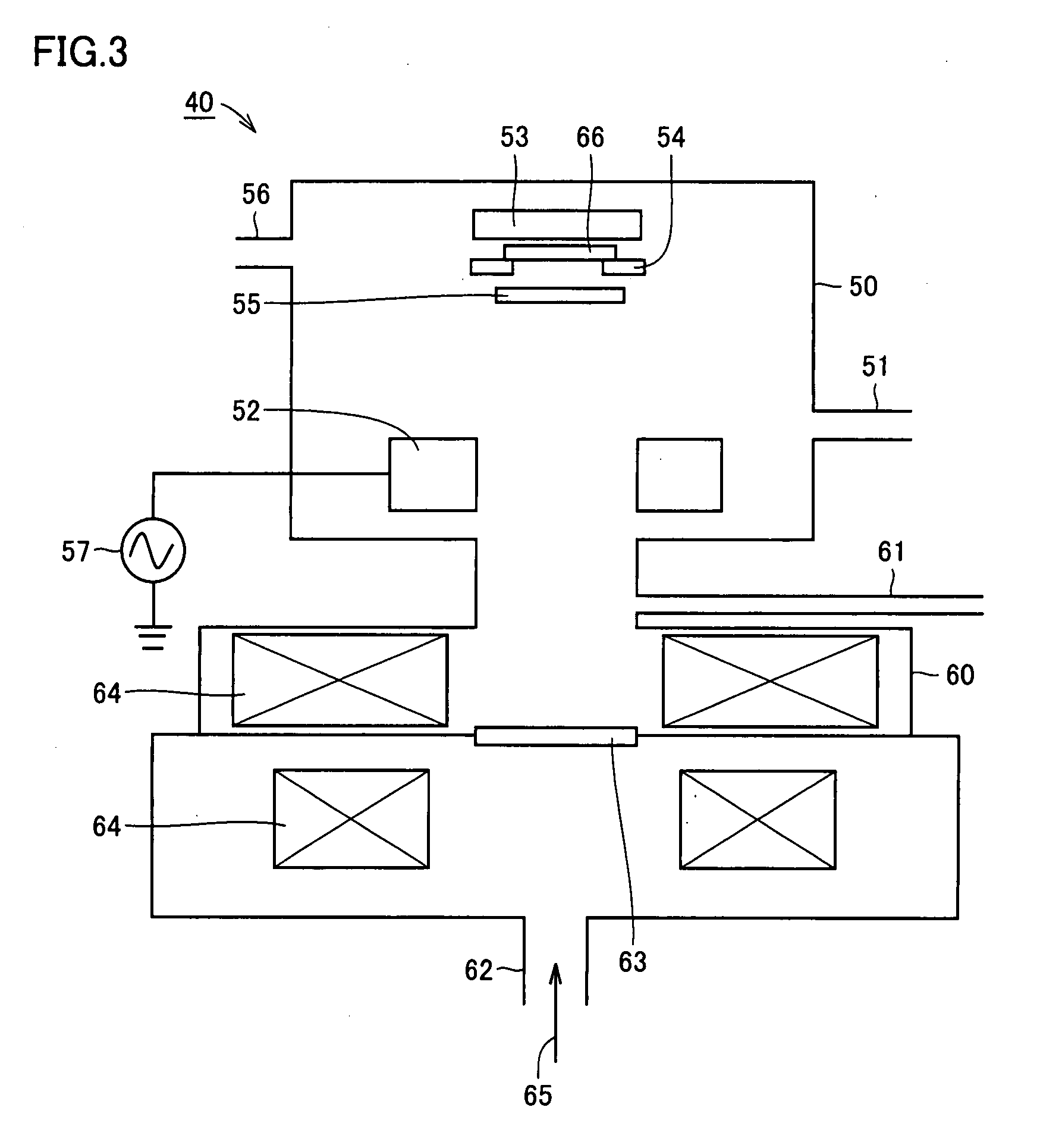

An apparatus is provided to improve clamping of a work piece to a support surface. The apparatus includes a support base, an insulator layer disposed on the support base, an electrode layer disposed on the insulator layer, and a clamping layer comprising aluminum oxynitride disposed on the electrode layer wherein the workpiece is clamped to the surface of the clamping layer. The apparatus provides a higher clamping force for the workpiece while reducing gas leakage and particle levels in addition to maintaining a declamping time suitable for high throughput processing. The apparatus may further provide a raised surface geometry or embossments on the dielectric or a dielectric comprising an outer ring a center cavity for reducing particle contamination to the backside of the workpiece. Also, a thin wall sleeve may be provided between the base and the insulator and alternating current may be applied to opposite ones of interdigitated electrode pairs to reduce particle contamination and improve the implantation uniformity.

Owner:VARIAN SEMICON EQUIP ASSOC INC

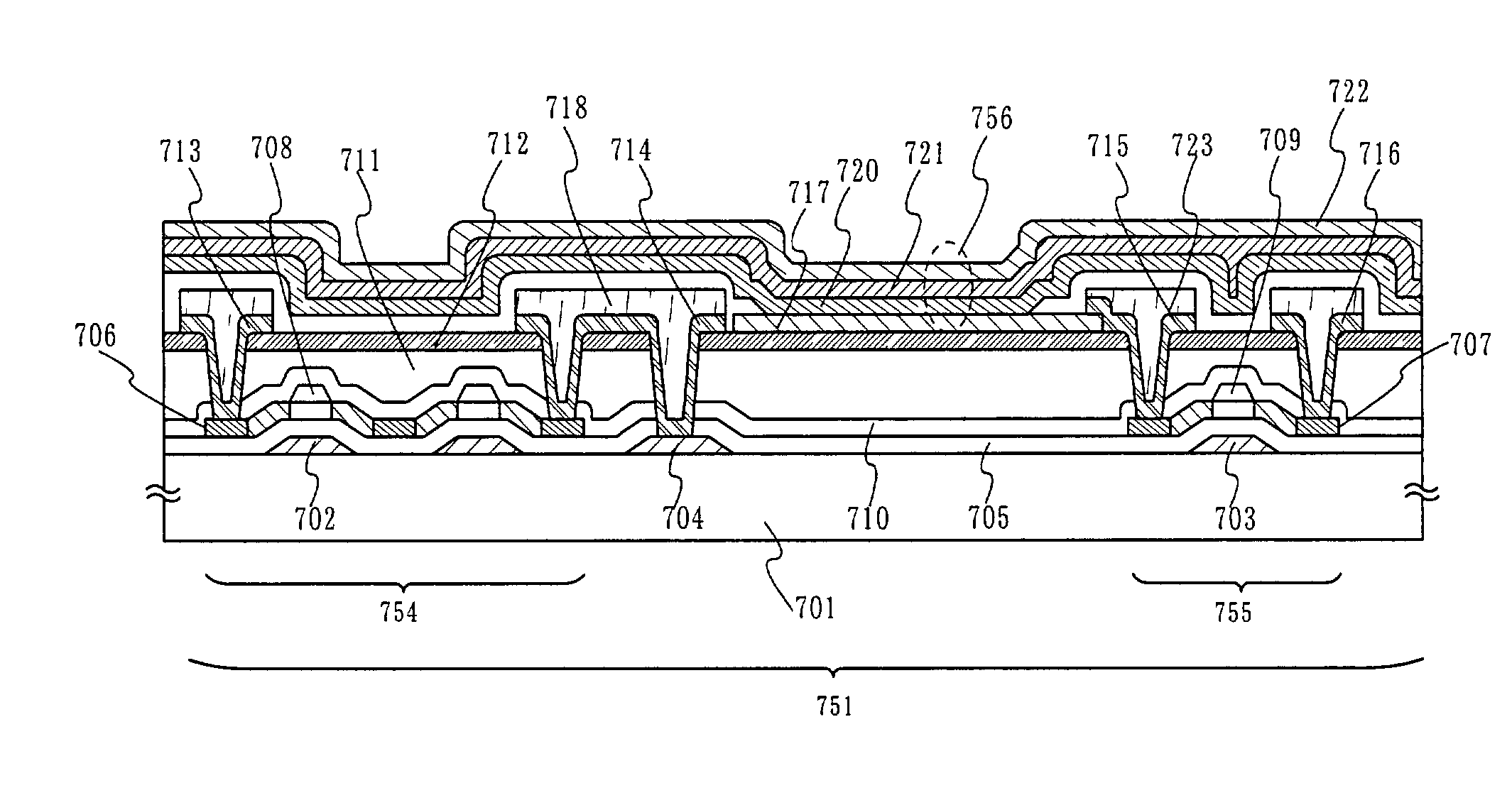

Light emitting device

InactiveUS20050224803A1Improve reliabilityAvoid lightFinal product manufactureElectroluminescent light sourcesAluminum oxynitrideLight emitting device

An objective is to increase the reliability of a light emitting device structured by combining TFTs and organic light emitting elements. A TFT (1201) and an organic light emitting element (1202) are formed on the same substrate (1203) as structuring elements of a light emitting device (1200). A first insulating film (1205) which functions as a blocking layer is formed on the substrate (1203) side of the TFT (1201), and a second insulating film (1206) is formed on the opposite upper layer side as a protective film. In addition, a third insulating film (1207) which functions as a barrier film is formed on the lower layer side of the organic light emitting element (1202). The third insulating film (1207) is formed by an inorganic insulating film such as a silicon nitride film, a silicon oxynitride film, an aluminum nitride film, an aluminum oxide film, or an aluminum oxynitride film. A fourth insulating film (1208) and a partitioning layer (1209) formed on the upper layer side of the organic light emitting element (1202) are formed using similar inorganic insulating films.

Owner:SEMICON ENERGY LAB CO LTD

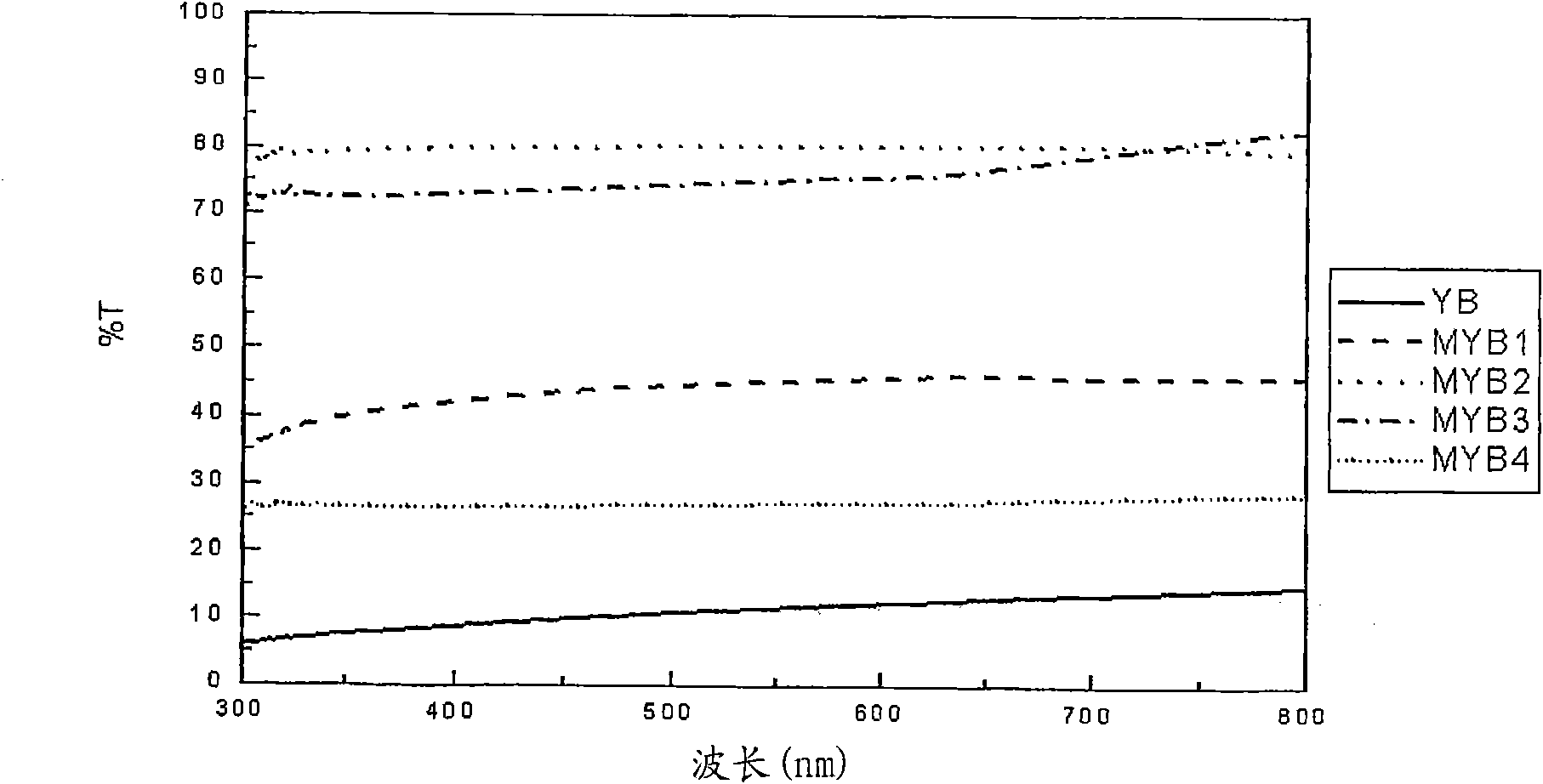

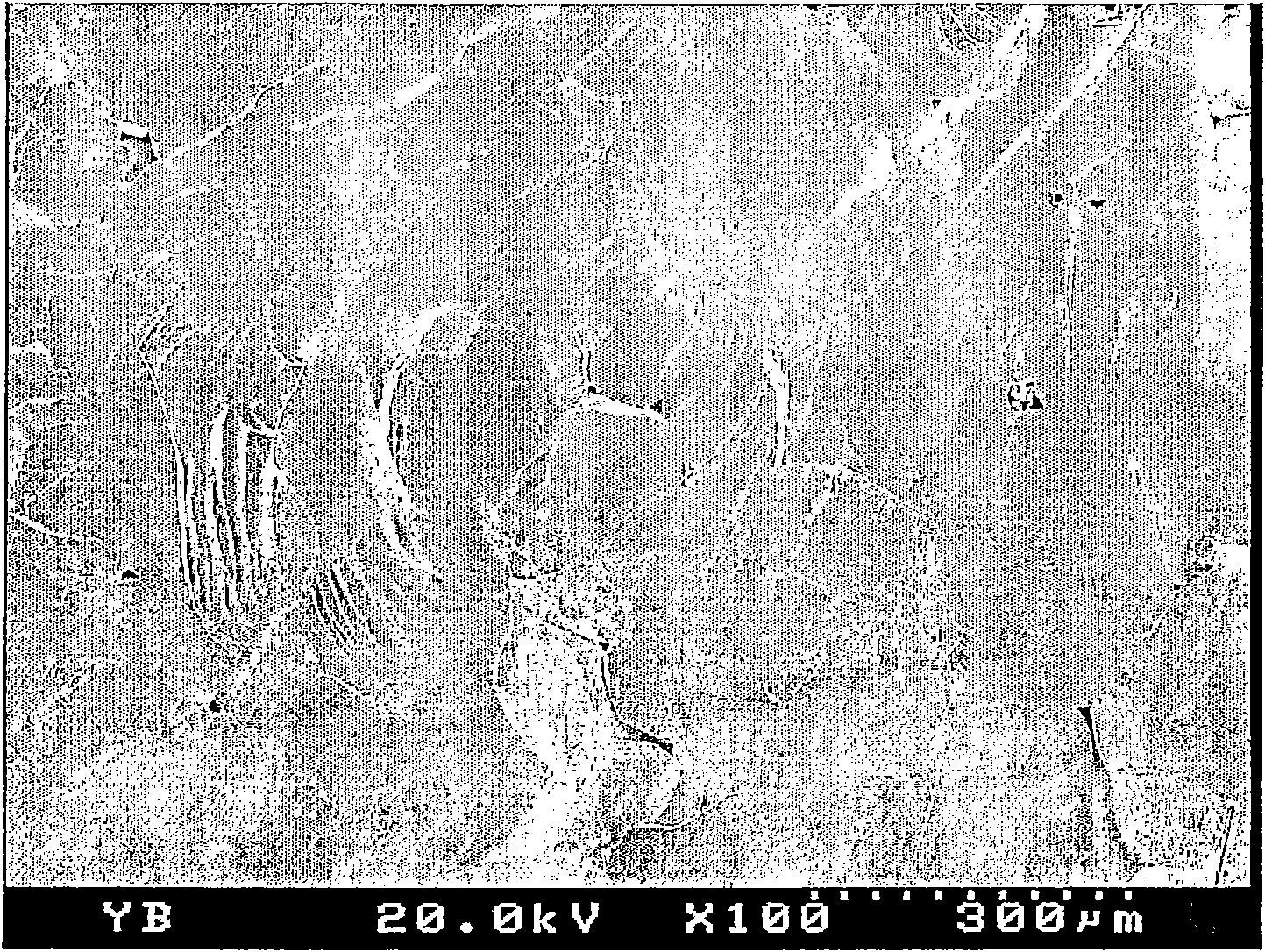

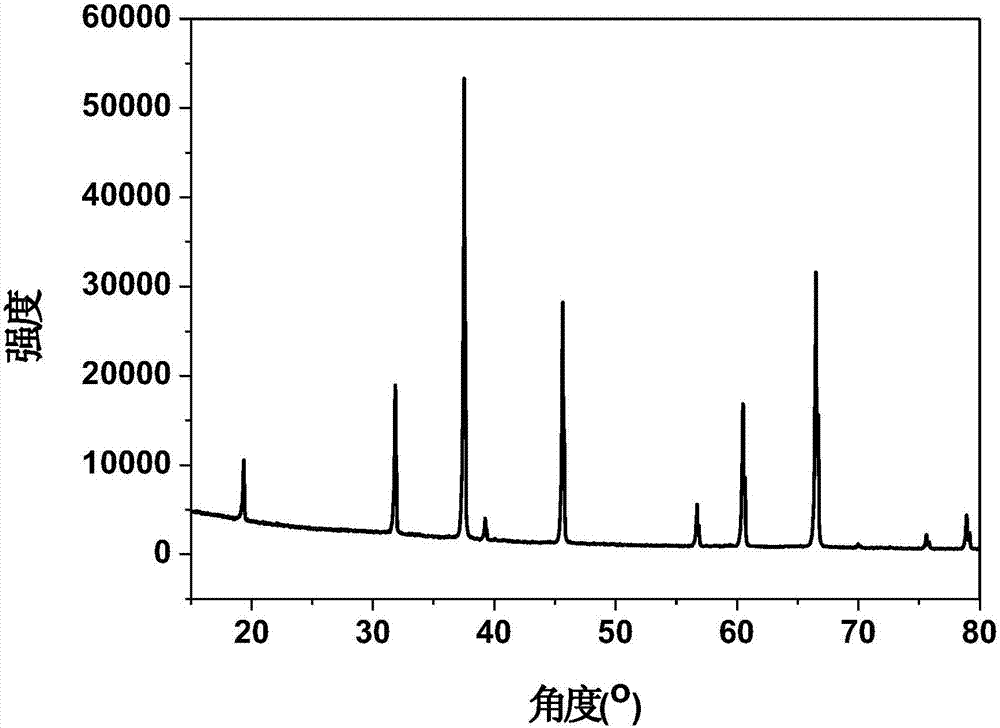

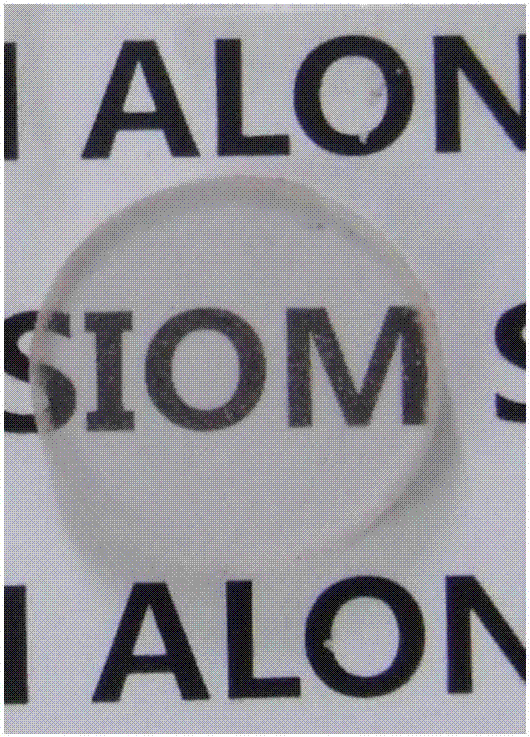

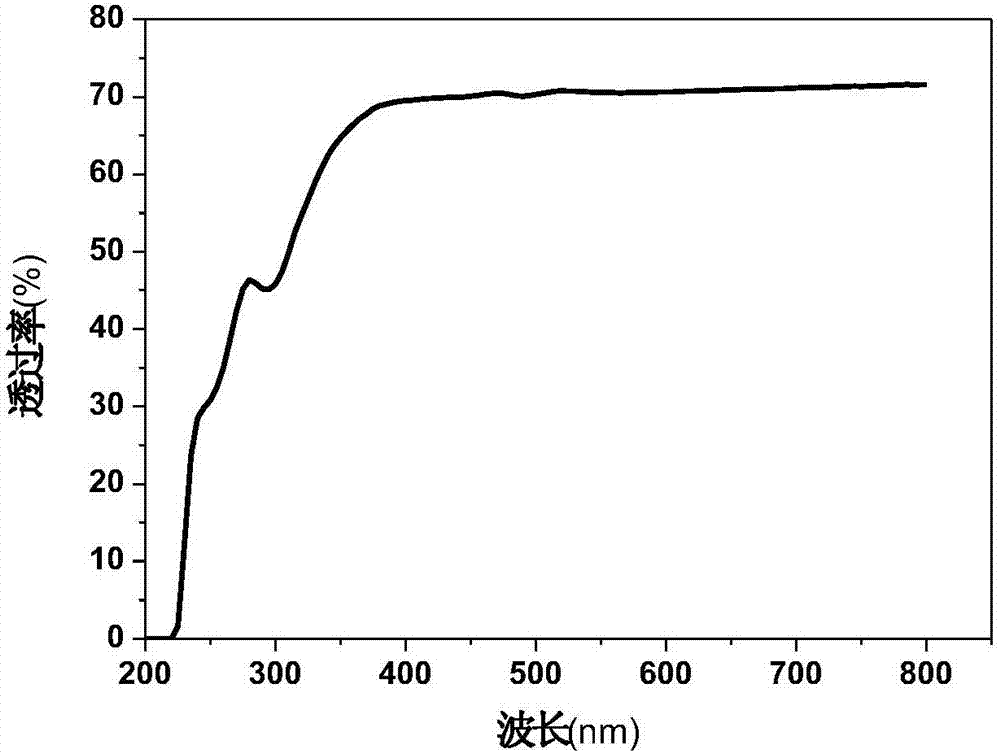

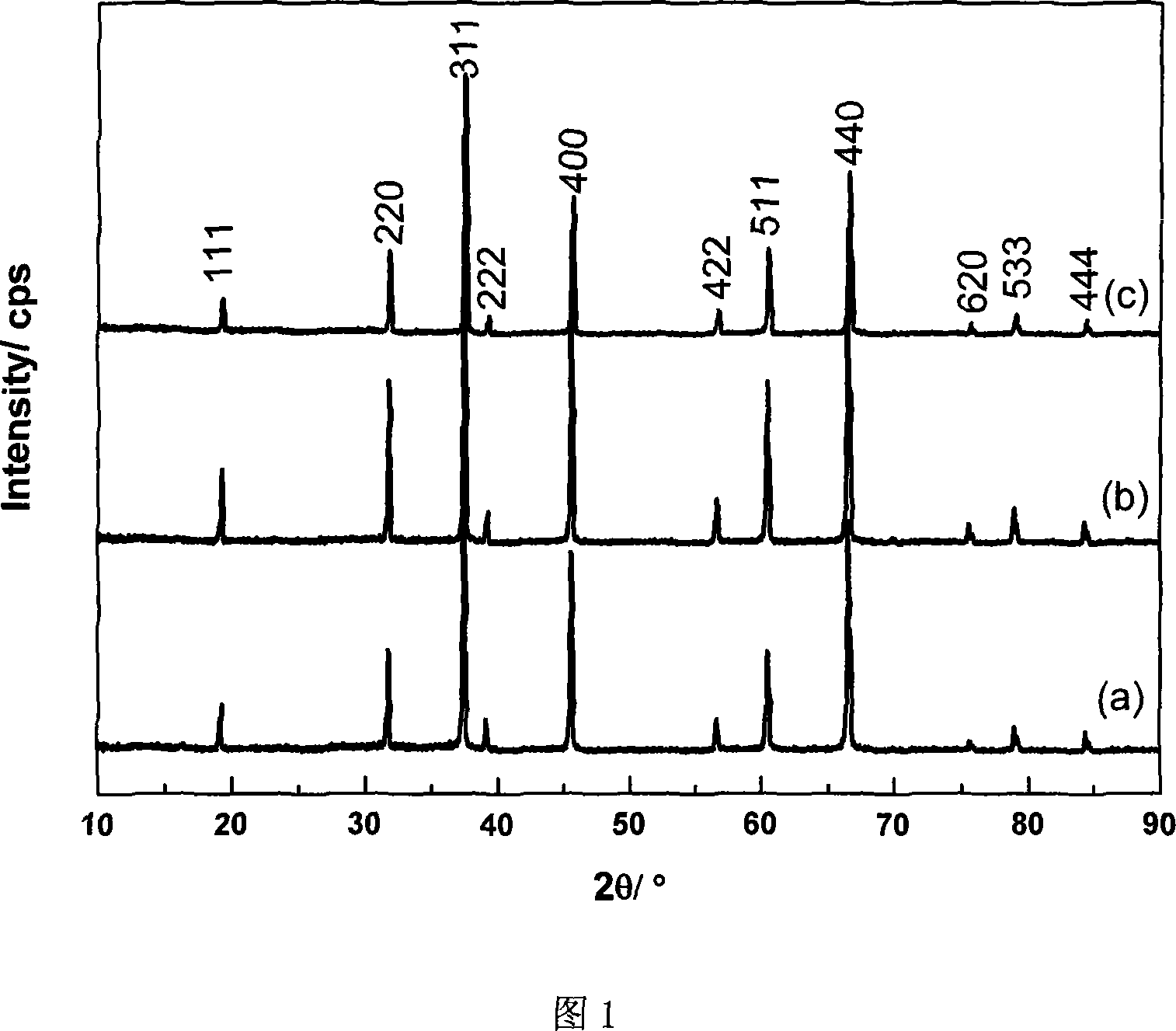

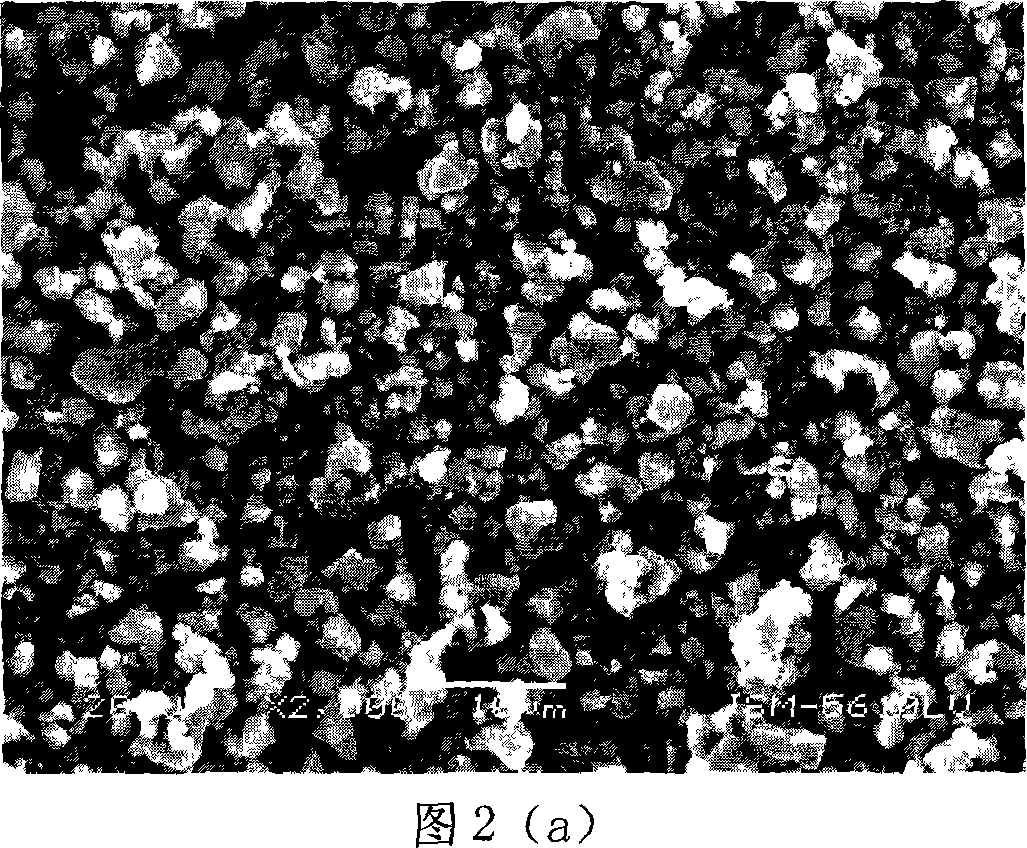

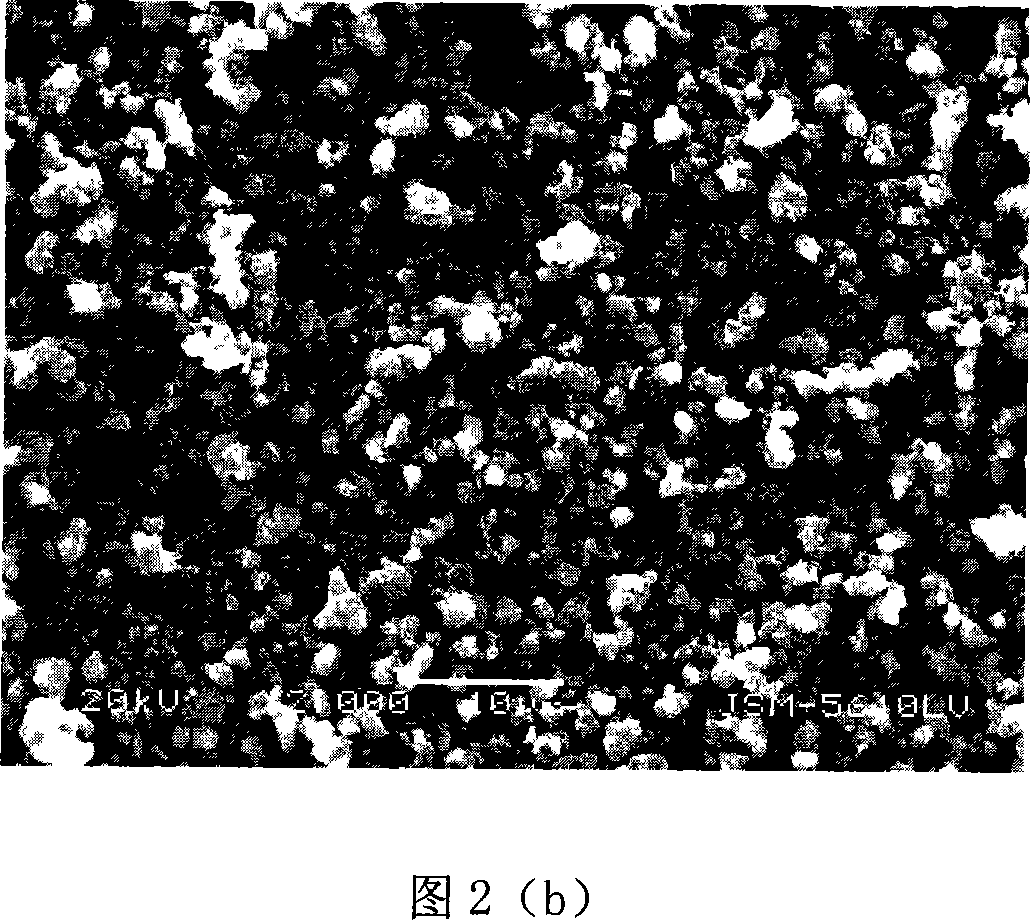

Method for manufacturing transparent polycrystalline aluminum oxynitride

The present invention relates to a method of manufacturing a transparent polycrystalline aluminum oxynitride. Aluminum oxynitride manufactured by prior art methods has a great number of porosities therein and thus has low transparency. The present invention is directed to solving such a problem. In the method of manufacturing aluminum oxynitride of the present invention, a sintering additive added to a source powder includes less than 0.5wt.% MgO. Further, the source powder is presintered at 1550 DEG C to 1750 DEG C so that a relative density becomes 95% or more and is then resintered at 1900 DEG C or more so that a relative density higher than that of presintering can be accomplished. According to the present invention, a cubic-phased polycrystalline aluminum oxynitride ceramic can be obtained, wherein porosities therein are nearly eliminated and its substantial transparency becomes 95% or more.

Owner:RES COOPERATION FOUND OF YEUNGNAM UNIV

Technique for preparing transparent aluminum oxynitride ceramic

InactiveCN101033139AReduce equipment conditionLow reaction temperatureNitrogen gasAluminum oxynitride

This invention relates to a preparation method for transparent nitrogen alumina ceramics including mixing raw materials, molding blanks and sintering characterizing in mixing Al2O3 in the weight ratio of 80-95% and AlN of 5-20%, adding sintering aids in 0.1-9% of the mixture weight to be ball-milled and dried then pressed and molded, then to get the blank in equal static pressure, then biscuit firing the blank by rising the temperature to 800-1200deg.C for 0.5-3h, then lowering the temperature and firing the second time by sintering at normal pressure under N atmosphere and rises the temperature to 1800-1900deg.C for 0.5-8h to get a transparent nitrogen alumina ceramic material.

Owner:SHANDONG UNIV OF TECH

Method for making dense polycrystalline aluminum oxynitride

InactiveUS7163656B1Consistently and uniformly dense and economically producedReduce wearCeramic shaping apparatusClaywaresPolycrystalline aluminumPowder mixture

A dense polycrystalline aluminum oxynitride body is produced. According the method of production, aluminum oxide (alumina) powder and 26 to 40 mole % aluminum nitride powder is mixed to form a very fine powder mixture. The powder mixture is shaped and hot pressed at a moderate temperature, preferably about 1600° C., which is below the temperature of aluminum oxynitride (AlON) formation to produce a dense intermediate body. The dense intermediate body is reacted to produce a highly dense polycrystalline aluminum oxynitride body. The dense body is particularly useful for ballistic armor.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Low loss visible-IR transmitting glass-aluminum oxynitride composites and process

InactiveUS20070087203A1Reduce polishing costsFacilitate transmissionGlass/slag layered productsMetal layered productsTransmittanceMid infrared

This invention pertains to a composite of AlON and a germanate glass, and to a process for bonding AlON to the glass. The composite includes AlON and glass bonded together and having transmission in the visible and mid-infrared wavelength region. The process includes the step of heating them together above the softening temperature of the glass, the composite having excellent, i.e., typically in excess of about 60%, transmission in the 0.4-5 wavelength region.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Method for preparing aluminum oxynitride transparent ceramic through gel casting

The invention relates to a method for preparing an aluminum oxynitride transparent ceramic through gel casting. The method comprises the following steps: (1) ball-milling and mixing aluminum oxynitride powder, a dispersing agent and absolute ethyl alcohol, adding a hydration-resisting agent, performing hydration-resisting treatment, drying and sieving to obtain aluminum oxynitride powder processed by the hydration-resisting treatment, wherein the mass ratio of the aluminum oxynitride powder, the dispersing agent and the hydration-resisting agent is 100:(0.1-5):(0.1-5); (2) mixing the aluminum oxynitride powder processed by the hydration-resisting treatment, a water-soluble isobutene polymer and water to obtain a water-base slurry, wherein the mass ratio of the aluminum oxynitride powder processed by the hydration-resisting treatment, the water-soluble isobutene polymer and the water is (10-80):(0.1-5):100; (3) performing vacuum degassing on the base-base slurry, injecting the degassed base-base slurry into a mold, performing self-gel curing to obtain a biscuit, and drying the biscuit; (4) presintering the dried biscuit, and performing pressure-less sintering to obtain the aluminum oxynitride transparent ceramic.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Method for manufacturing aluminum oxynitride (AlON) powder and other nitrogen-containing powders

InactiveUS6955798B2Low costLess expensiveNitrogen-metal/silicon/boron binary compoundsAluminium oxynitridesHeating timeNitrogen

A method of preparing substantially homogeneous aluminum oxynitride powder and other nitrogen-containing powders is provided. Particularly with respect to the AlON powder, the method comprises the steps of milling a mixture of aluminum and aluminum oxide in a nitrogen-containing atmosphere until a milled powder composed of aluminum-nitrogen solid solution and aluminum oxide forms. The next step is heating the milled powder in the presence of an inert gas and keeping it at sufficient temperature for a sufficient heating time to form the substantially homogenous aluminum oxynitride powder. This method is extended to the preparation of other powders by employing appropriate starting materials. The resultant powders are also claimed as part of the instant invention.

Owner:NANOMAT

Magnetic recording head and media comprising aluminum oxynitride underlayer and a diamond-like carbon overcoat

ActiveUS7782569B2Provide wear resistanceProtective layerElectric discharge heatingVacuum evaporation coatingDiamond-like carbonAlloy

A method for forming a protective bilayer on a magnetic read / write head or magnetic disk. The bilayer is formed as an adhesion enhancing underlayer and a protective diamond-like carbon (DLC) overlayer. The underlayer is formed of an aluminum or alloyed aluminum oxynitride, having the general formula AlOxNy or MezAlOxNy where Mez symbolizes Tiz, Siz or Crz and where x, y and z can be varied within the formation process. By adjusting the values of x and y the adhesion underlayer contributes to such qualities of the protective bilayer as stress compensation, chemical and mechanical stability and low electrical conductivity. Various methods of forming the underlayer are provided, including reactive ion sputtering, plasma assisted chemical vapor deposition, pulsed laser deposition and plasma immersion ion implantation.

Owner:SAE MAGNETICS (HK) LTD

Method for preparing aluminum oxynitride transparent ceramic

The invention discloses a method for preparing aluminum oxynitride transparent ceramic. The method comprises the following steps: performing ball-milling mixing of aluminum oxide powder, aluminum nitride powder and a sintering aid, and then drying and sieving to obtain mixed powder; putting the mixed powder in a graphite mould; spark plasma sintering: putting the prepared mould in a SPS sintering furnace and sintering quickly; putting AlON ceramic in a graphite sintering furnace; preserving heat for 2-4 hours at sintering temperature of 1,650-1,800 DEG C in a nitrogen atmosphere; removing carbon permeating in SPS to further improve the transmittance of AlON. According to the method disclosed by the invention, AlON transparent ceramic with high transmittance is obtained when the sintering temperature is lower than that of a common pressureless sintering technology.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI +1

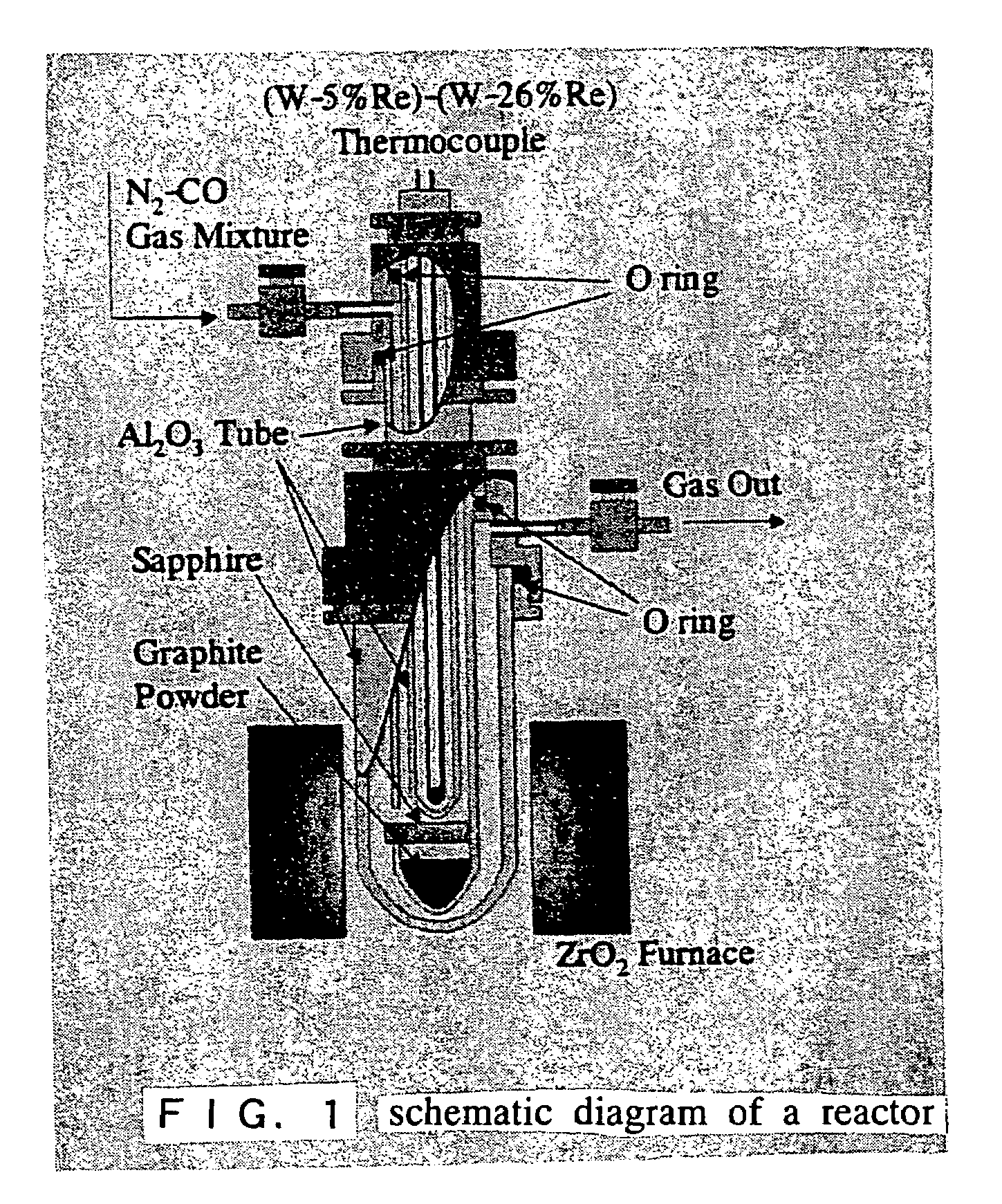

Method for quickly preparing gamma aluminum nitride oxygen transparent ceramic powder

A process for fast preparing the transparent gamma-aluminum oxynitride ceramic powder includes such steps as proportionally mixing aluminum nitride powder with alpha-Al2O3 powder, drying, loading it into a graphite reactor containing N2 or N contained gas mixture, high-current heating to 1600-1850 deg.C at 50-500 deg.C / min, holding the temp for 0-60 min, and grinding.

Owner:WUHAN UNIV OF TECH

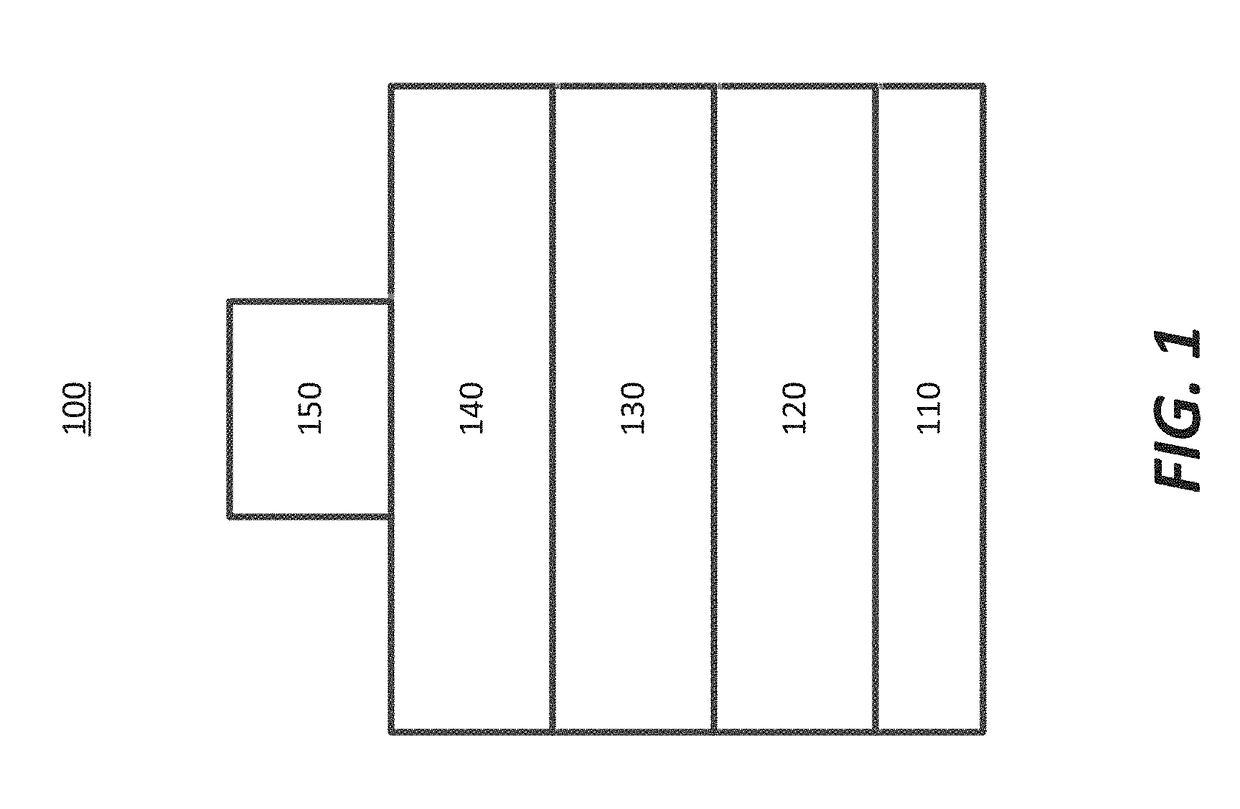

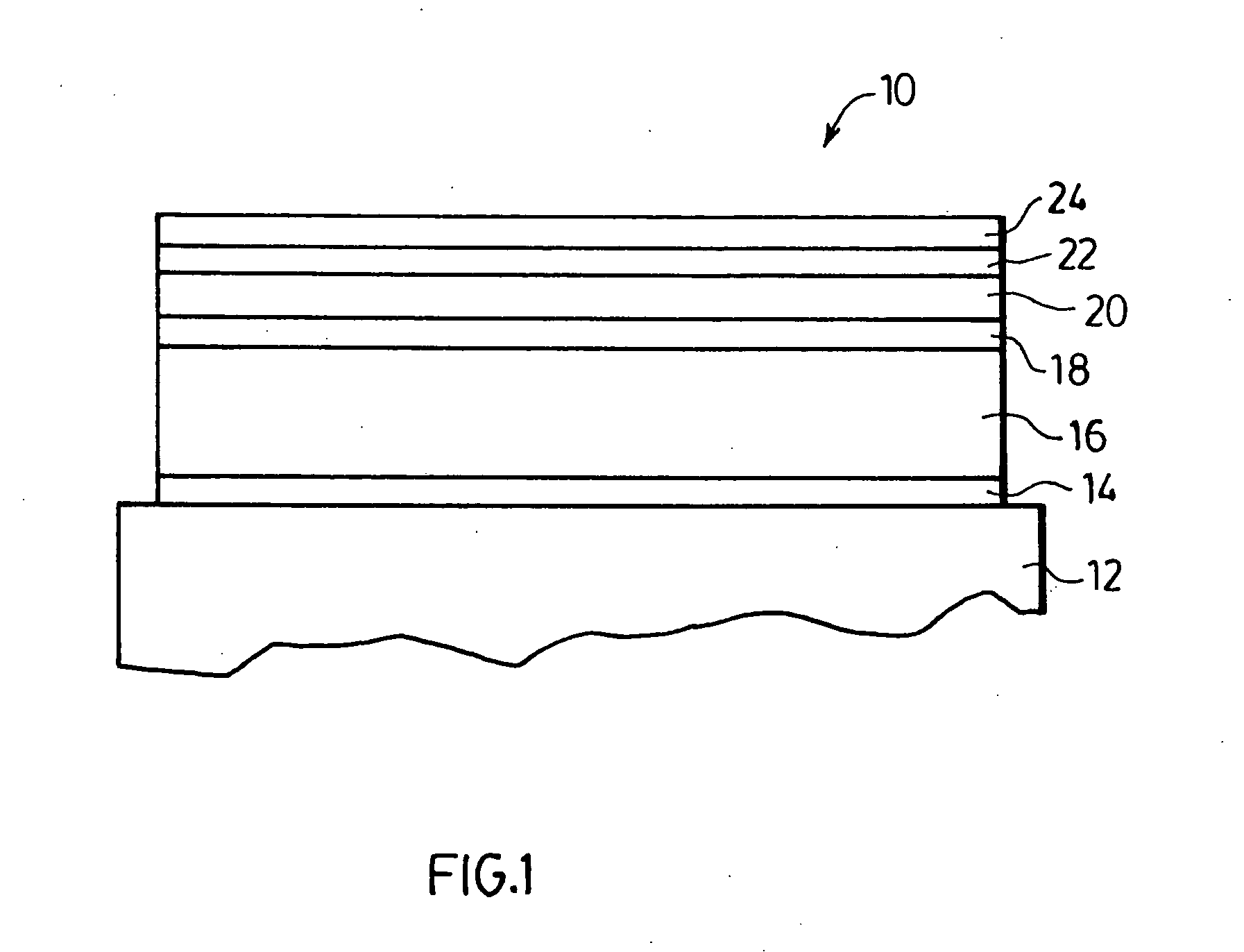

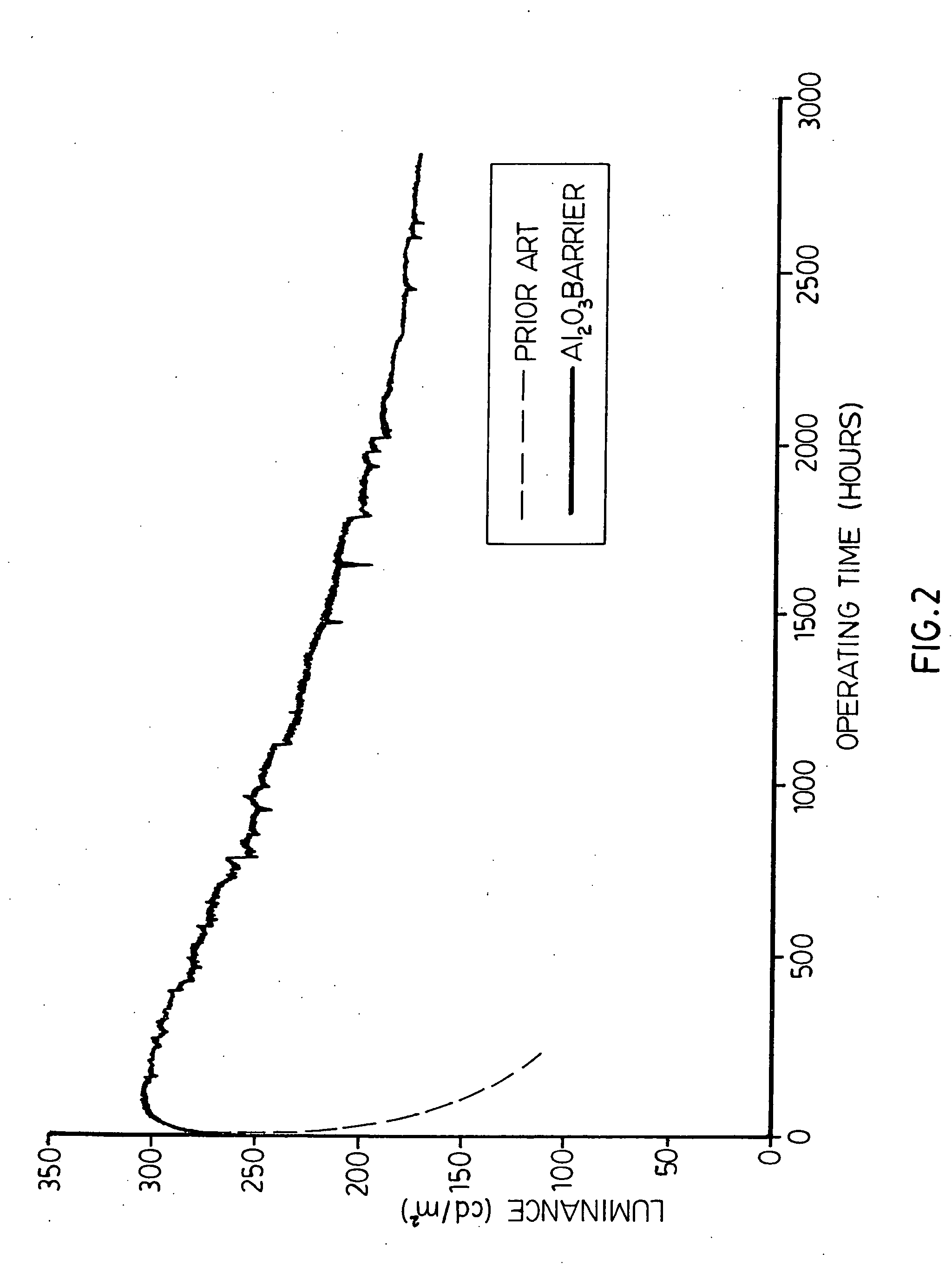

Aluminum oxide and aluminum oxynitride layers for use with phosphors for electroluminescent displays

InactiveUS20060017381A1Extended service lifeImproves luminance and operating lifeDischarge tube luminescnet screensElectroluminescent light sourcesPhosphorRare earth

A novel laminate is provided to improve the operating stability of thioaluminate based phosphors used in ac thick film dielectric electroluminescent displays. The novel structure comprises a rare earth activated alkaline earth thioaluminate phosphor thin film layer and an aluminum oxide or aluminum oxynitride layer provided directly adjacent and in contact with the bottom of the phosphor thin film layer. The invention is particularly applicable to phosphors used in electroluminescent displays that employ thick dielectric layers subject to high processing temperatures to form and activate the phosphor films.

Owner:SANYO ELECTRIC CO LTD +1

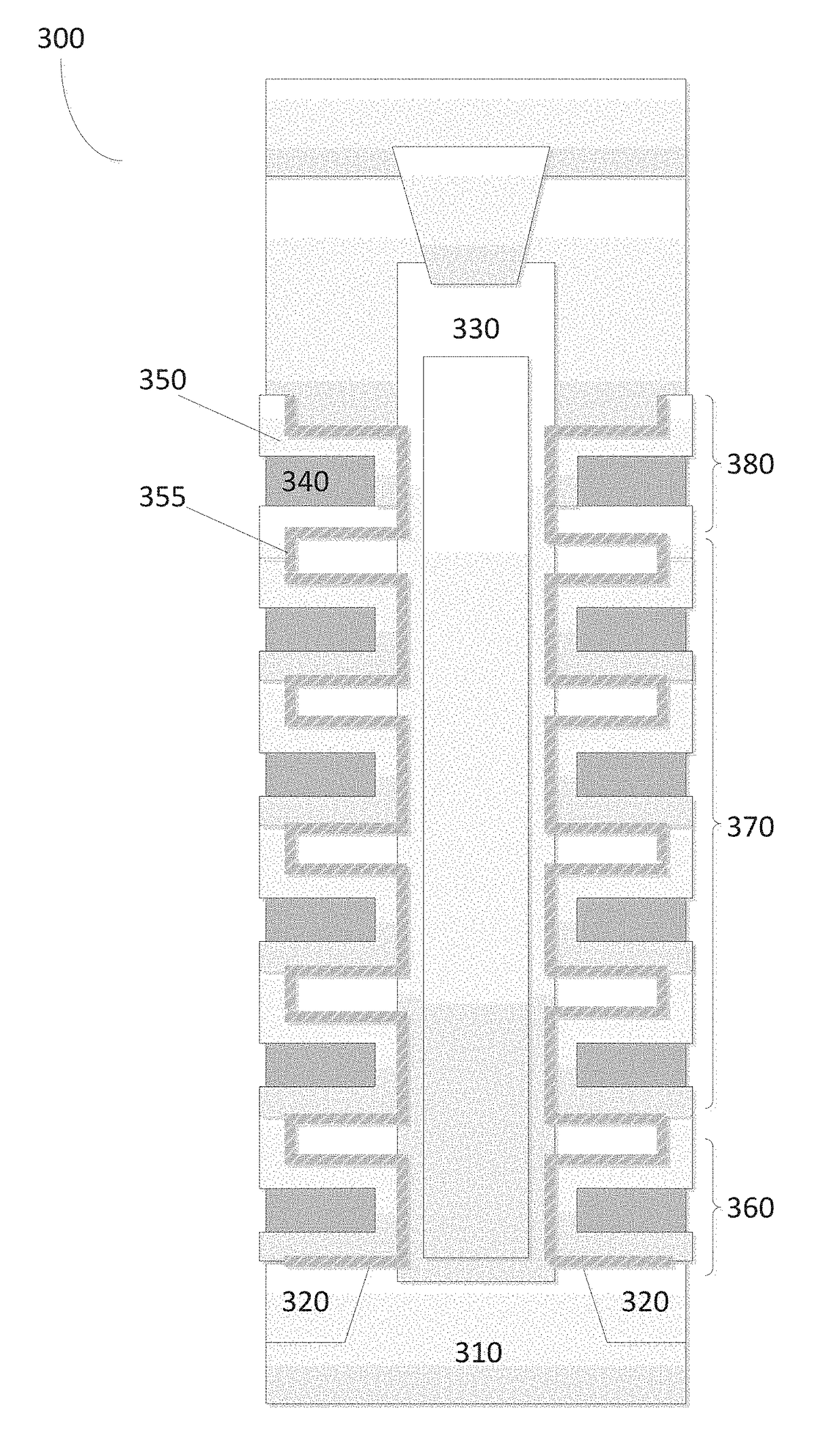

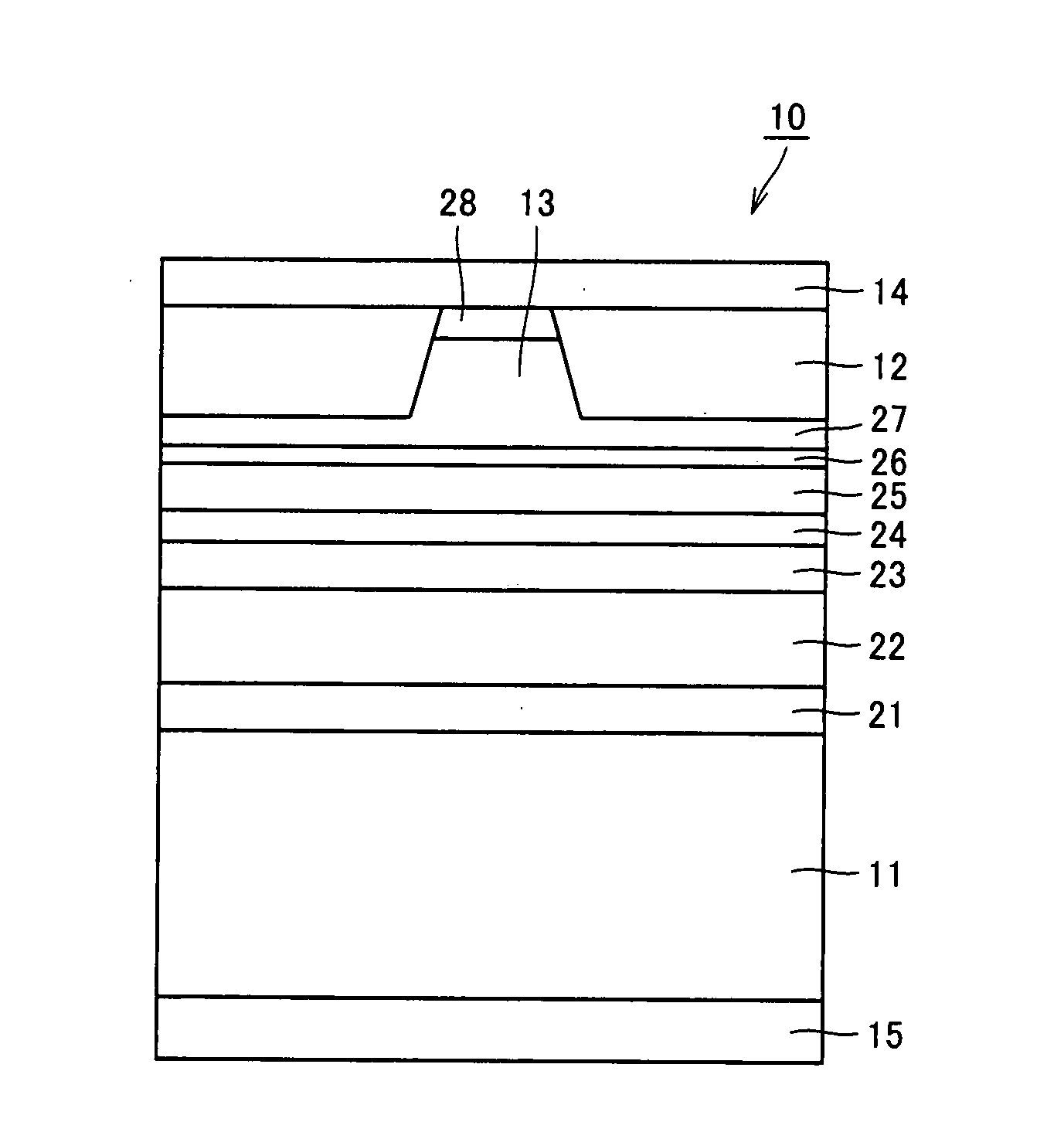

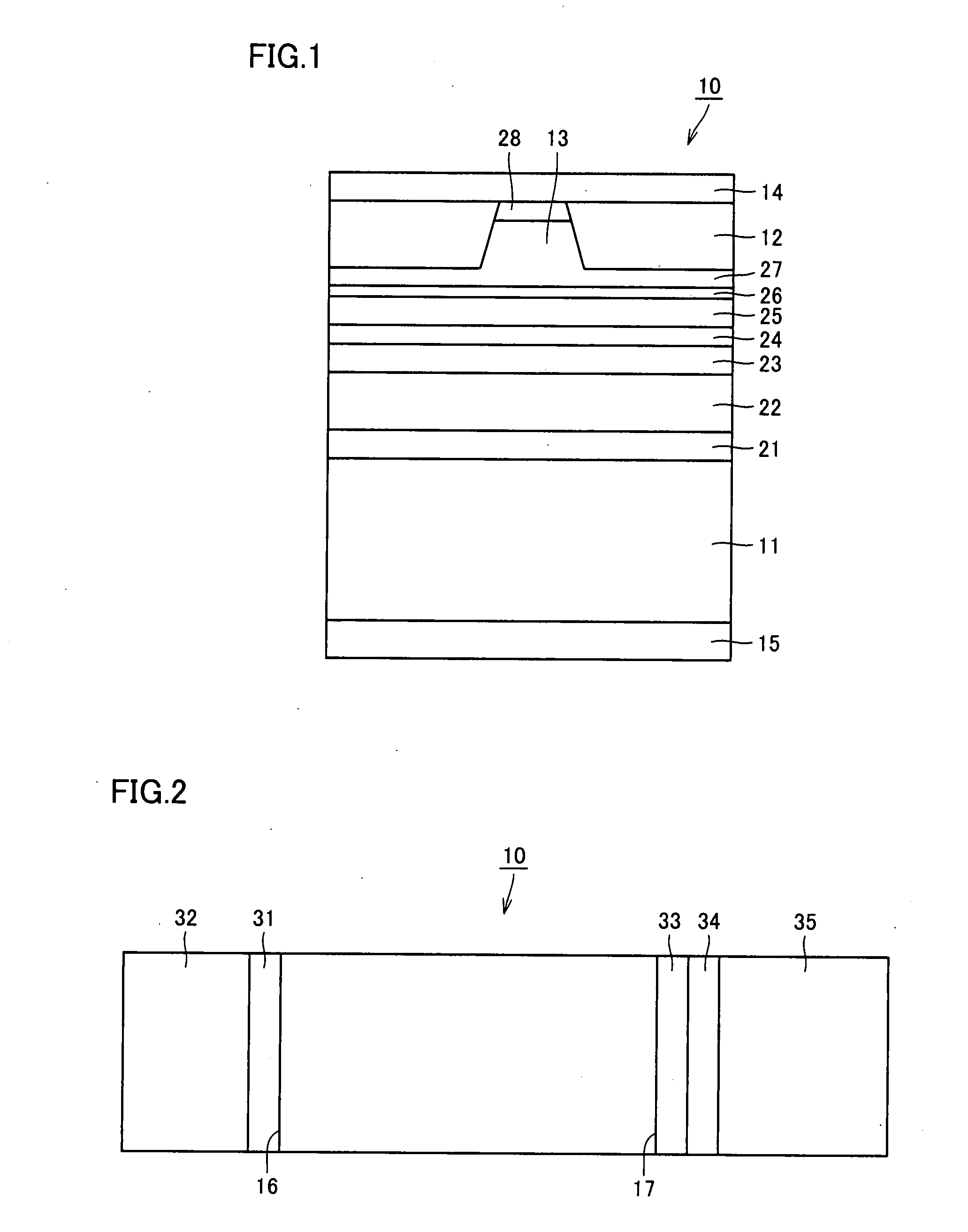

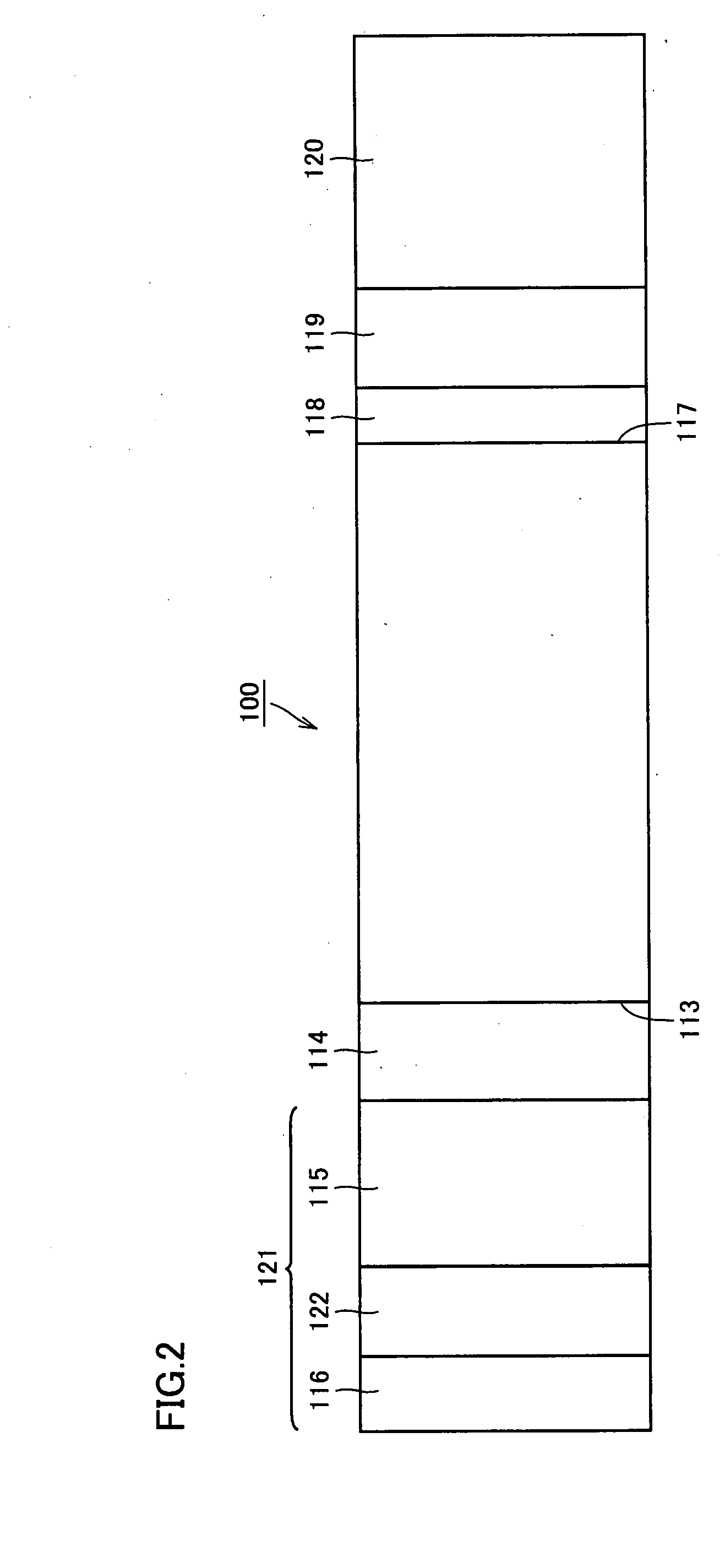

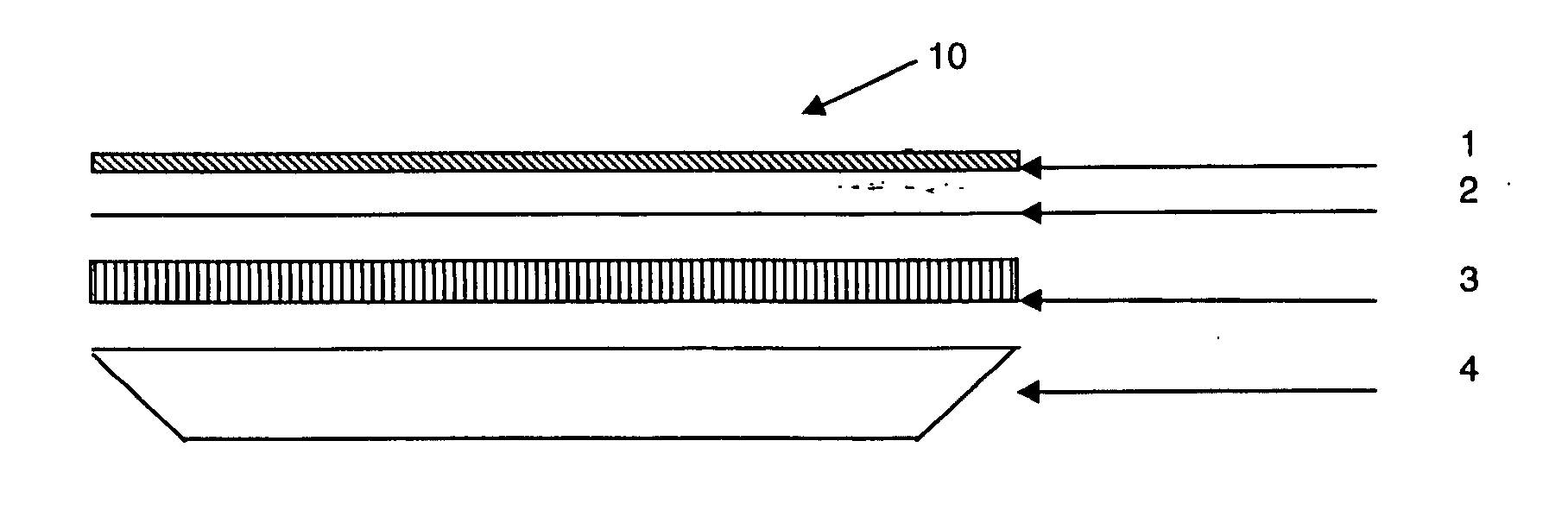

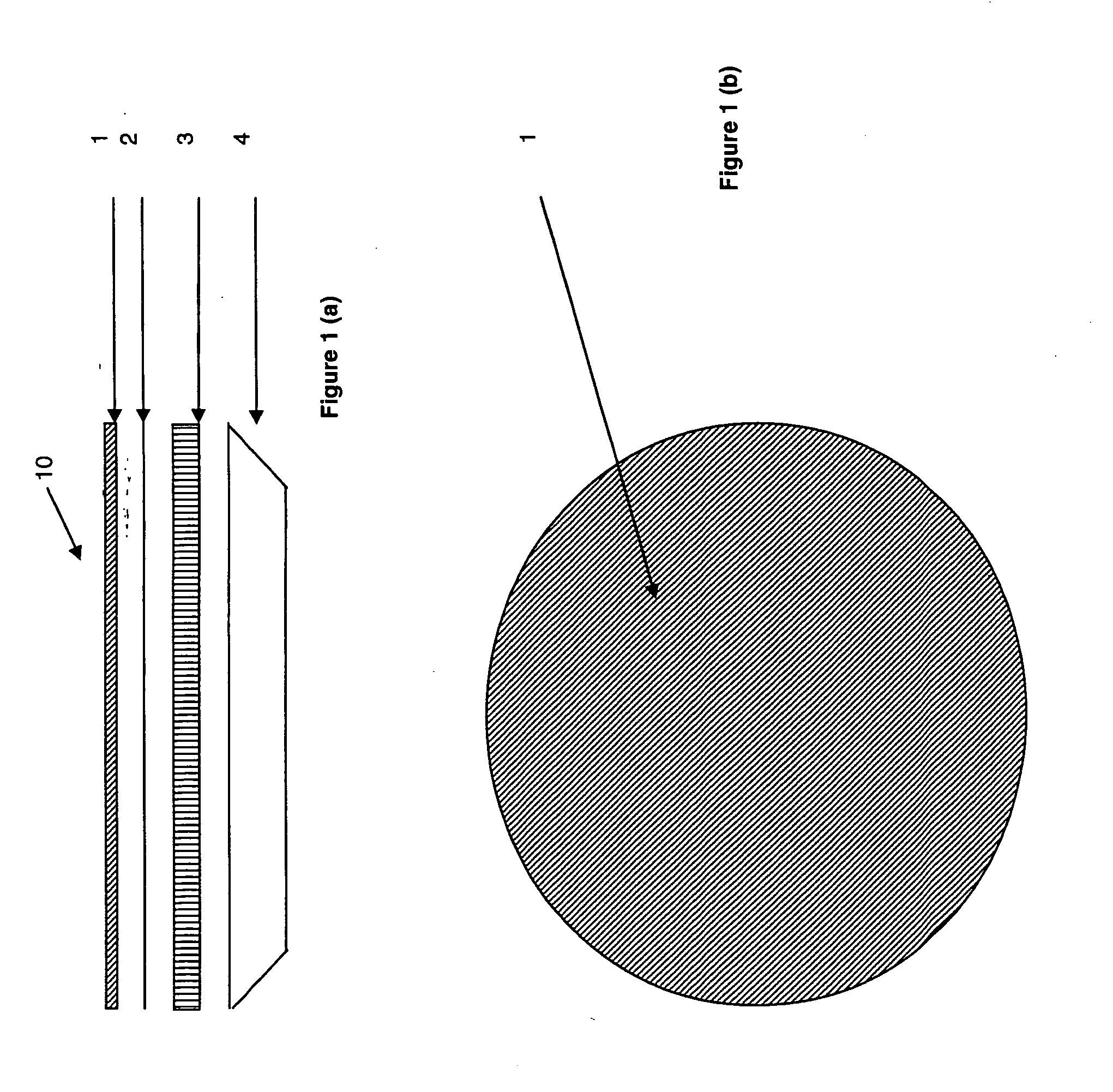

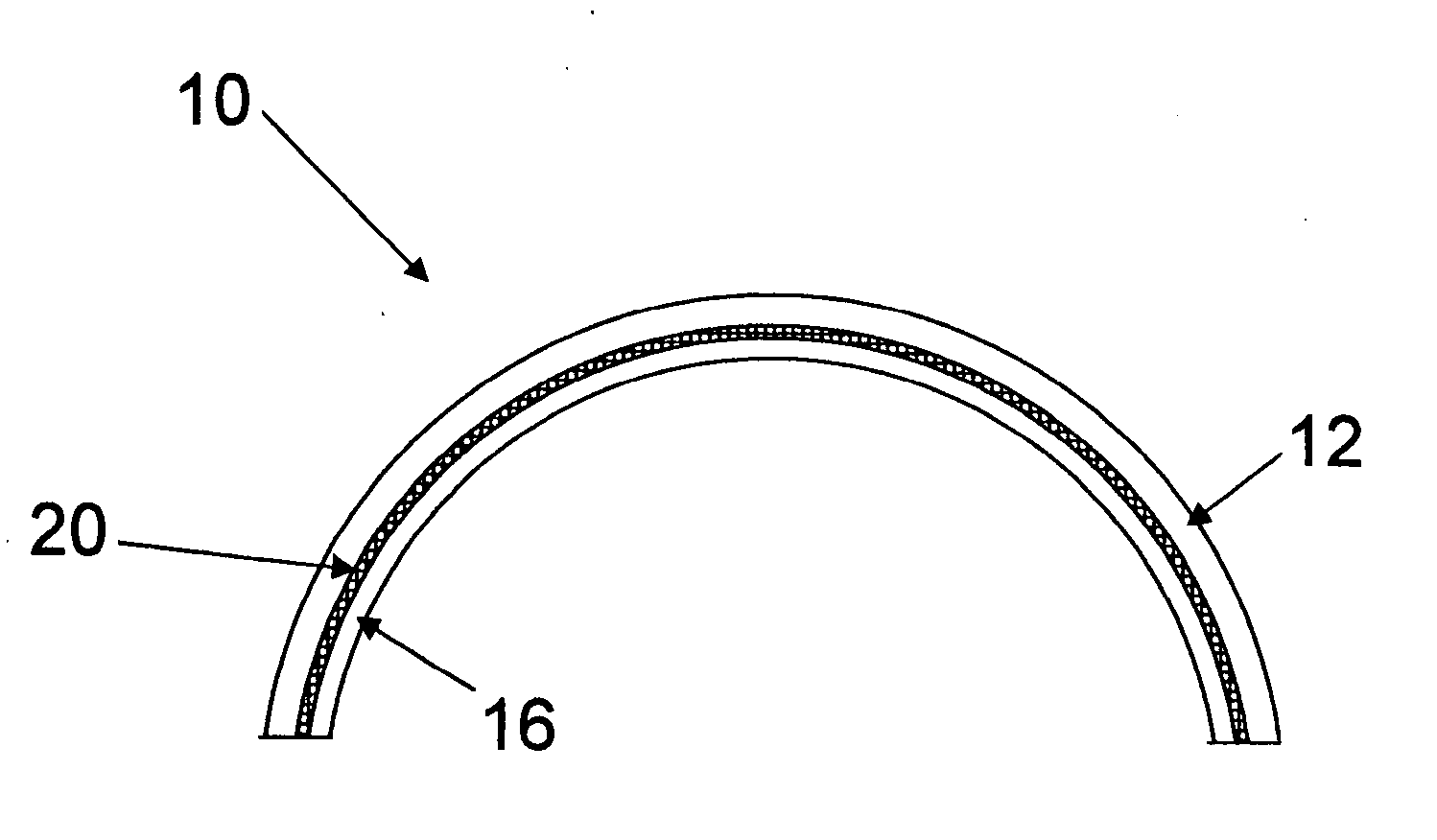

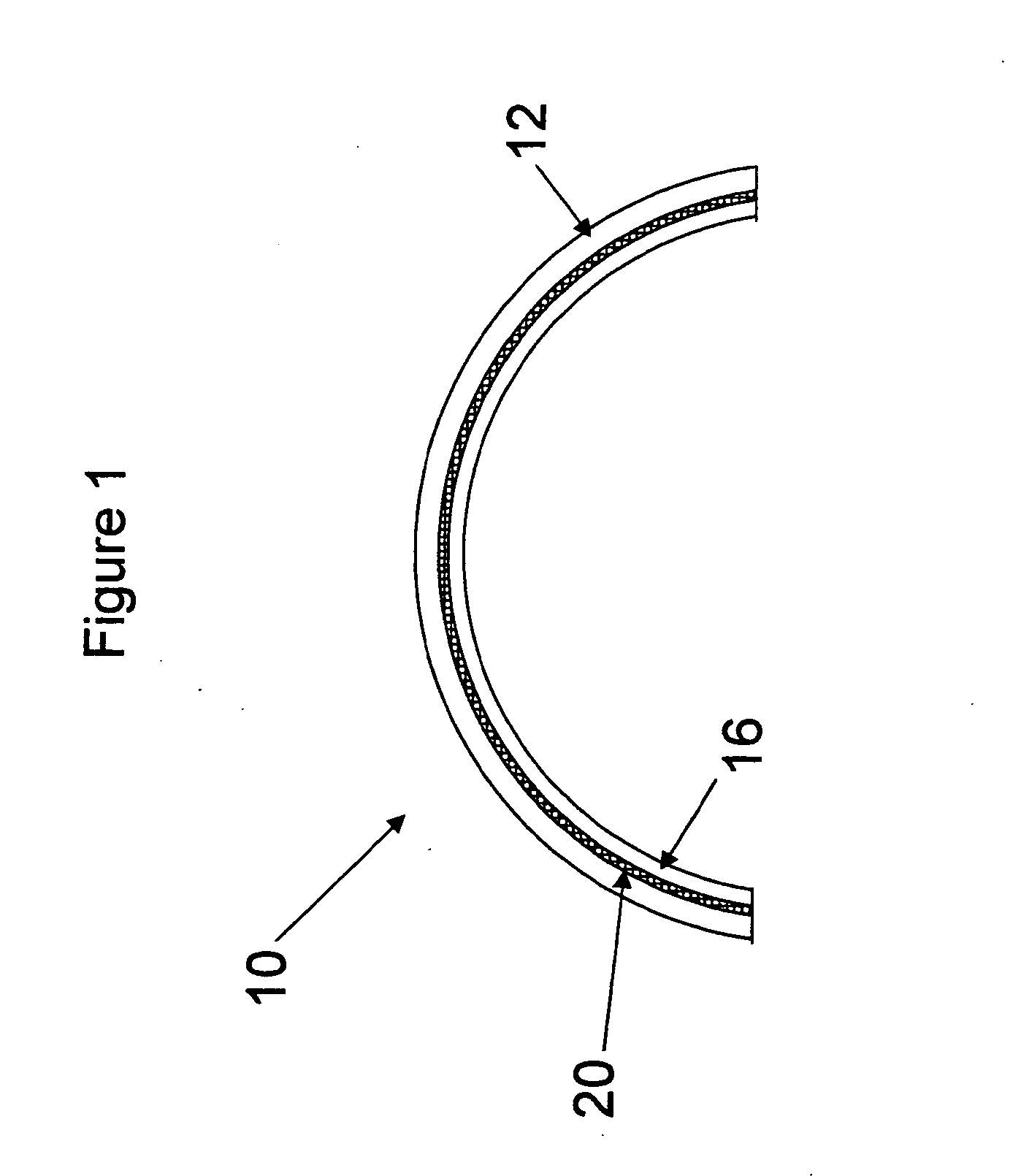

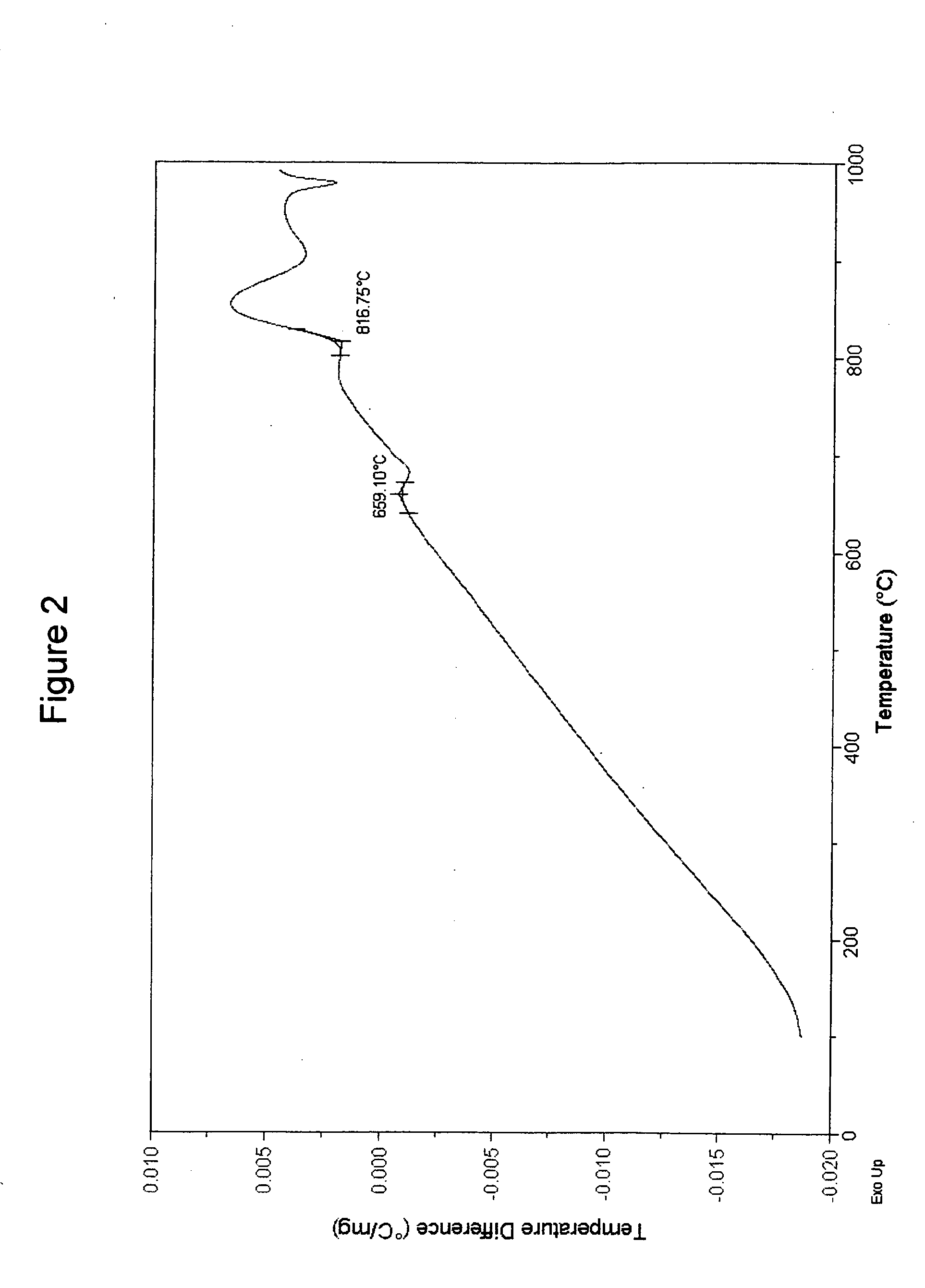

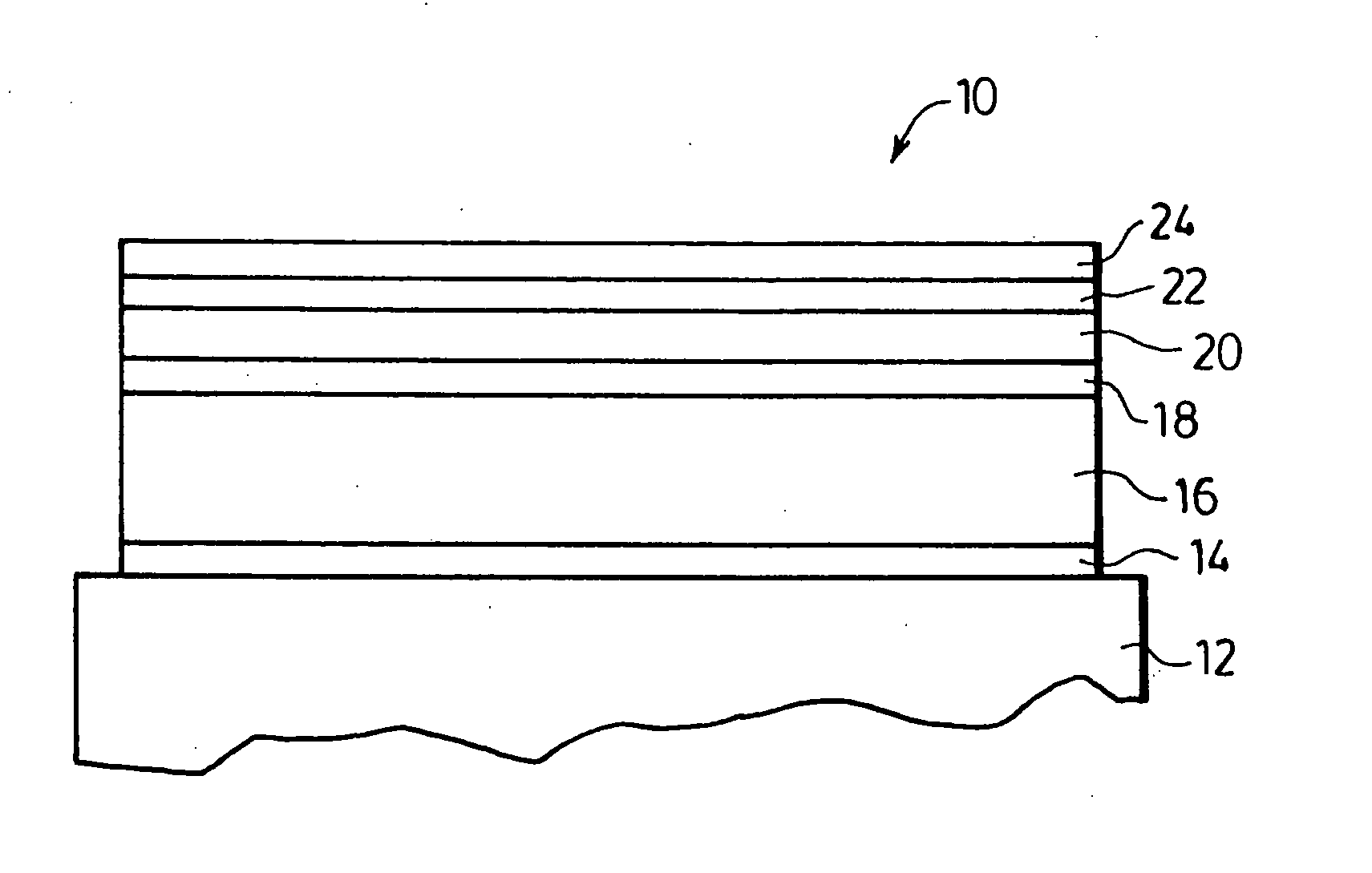

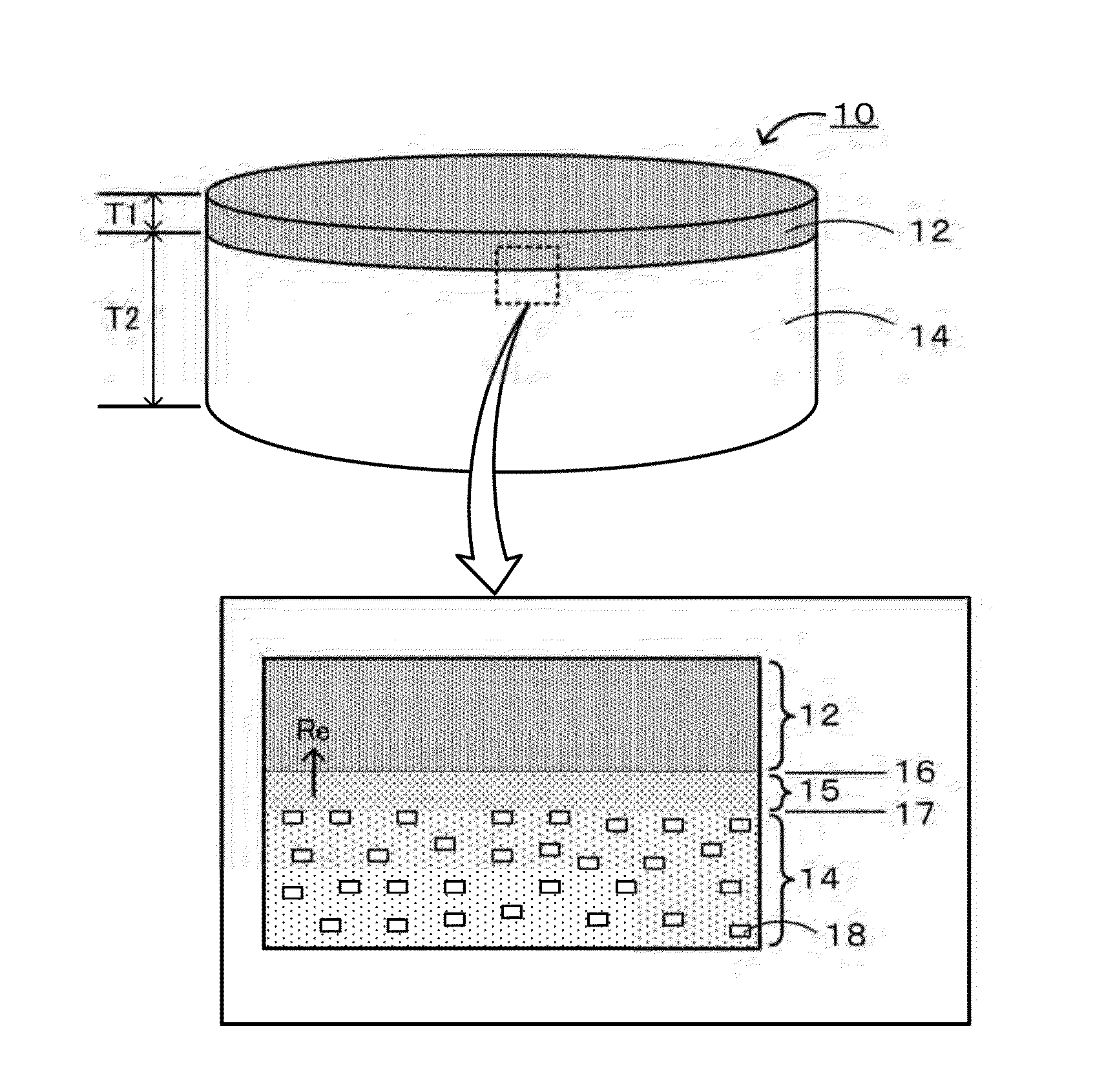

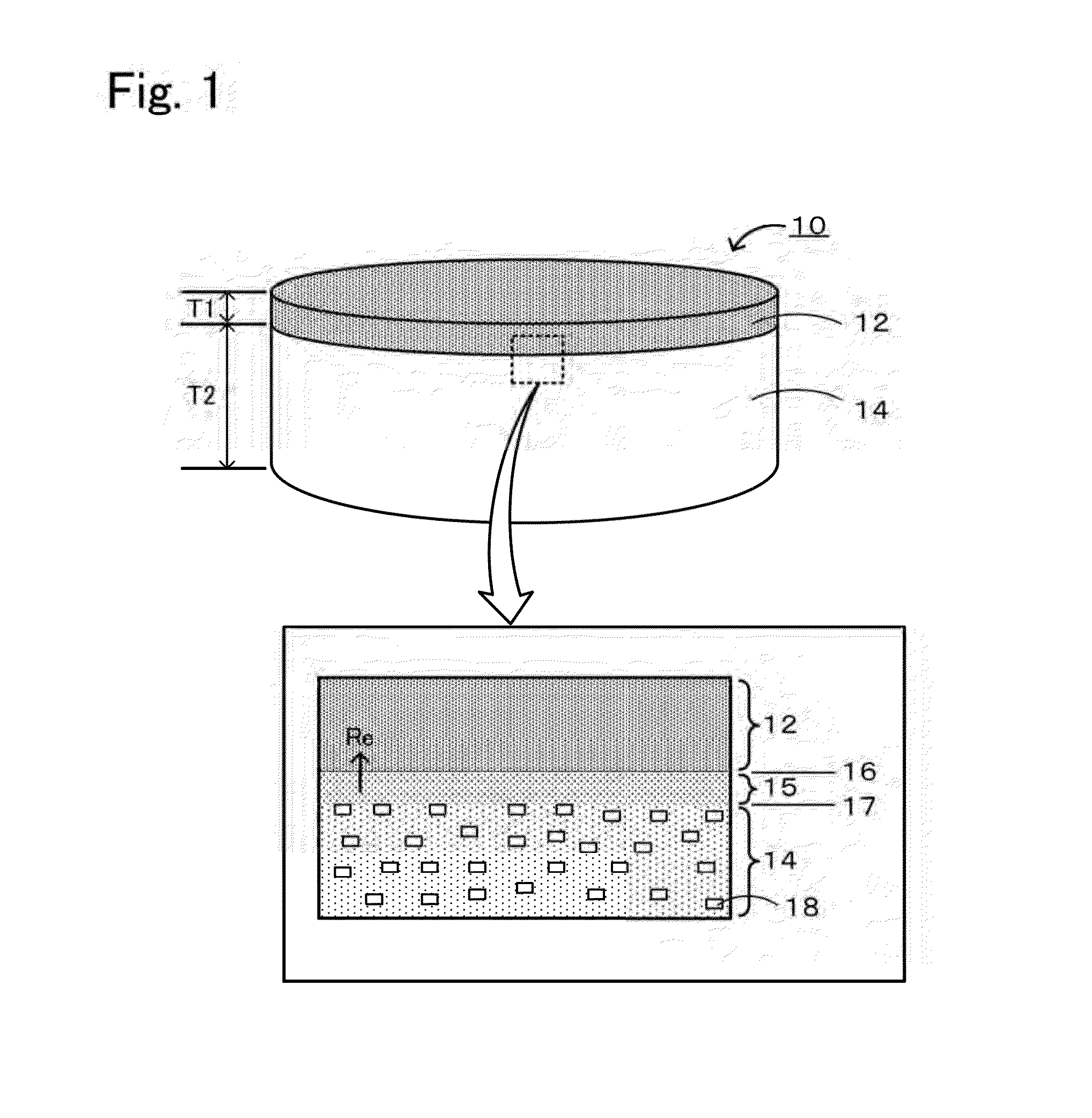

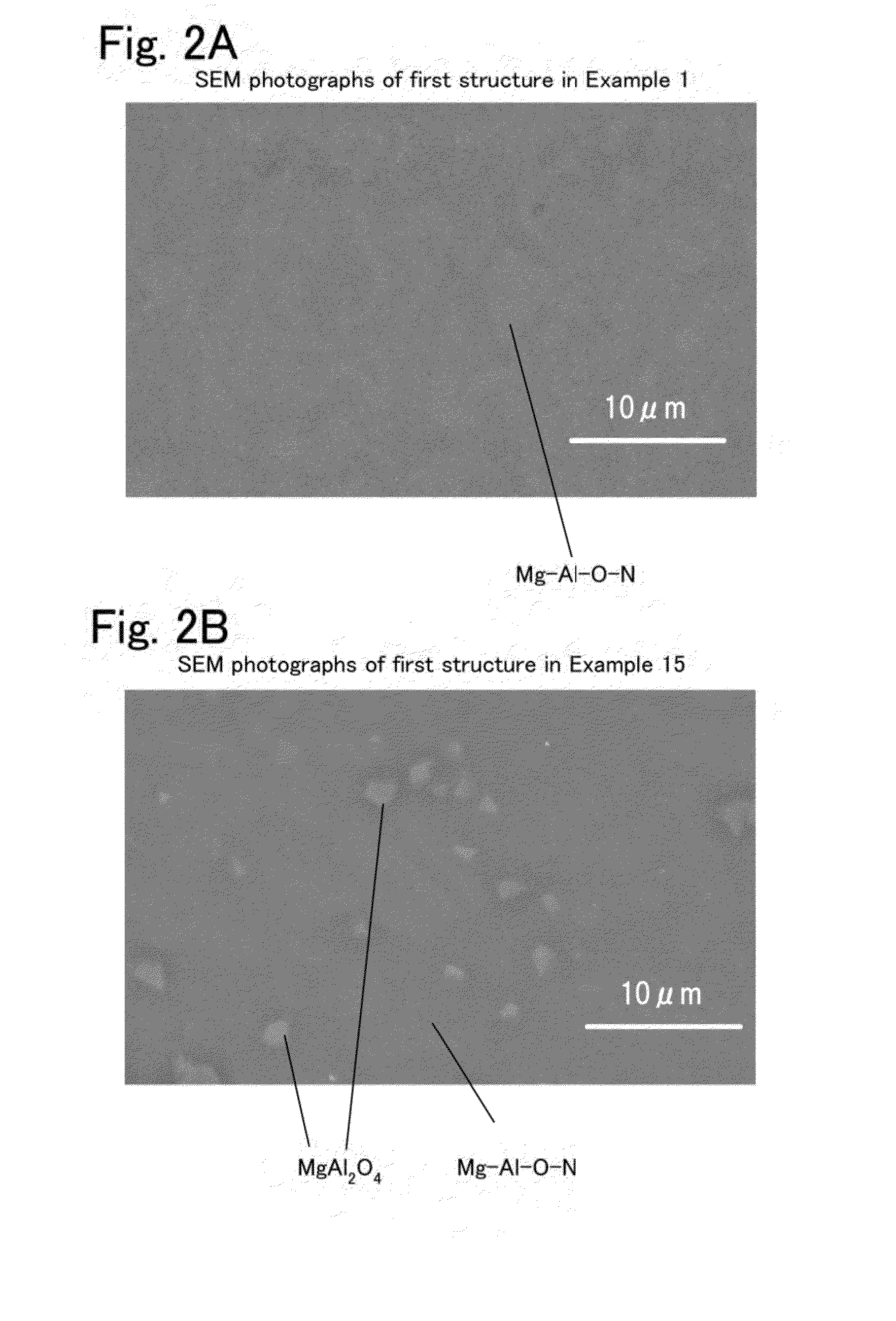

Laminated structure, member for semiconductor manufacturing apparatus, and method for producing laminated structure

ActiveUS20140079946A1Reduce generationReduce defectsElectric discharge tubesLaminationReaction layerRare earth

A laminated structure 10 includes a first structure 12 containing a main phase of magnesium-aluminum oxynitride, a second structure 14 containing a main phase of aluminum nitride and grain boundary phases of a rare-earth aluminum composite oxide having a garnet-type crystal structure, and a reaction layer 15 formed between the first structure 12 and the second structure 14. The reaction layer 15 is an aluminum nitride layer containing a smaller amount of grain boundary phases 18 of the rare-earth aluminum composite oxide than the second structure 14. The reaction layer 15 of the laminated structure 10 has a thickness of 150 μm or less. The reaction layer 15 is formed during the sintering by diffusing the grain boundary phases 18 into the first structure 12.

Owner:NGK INSULATORS LTD

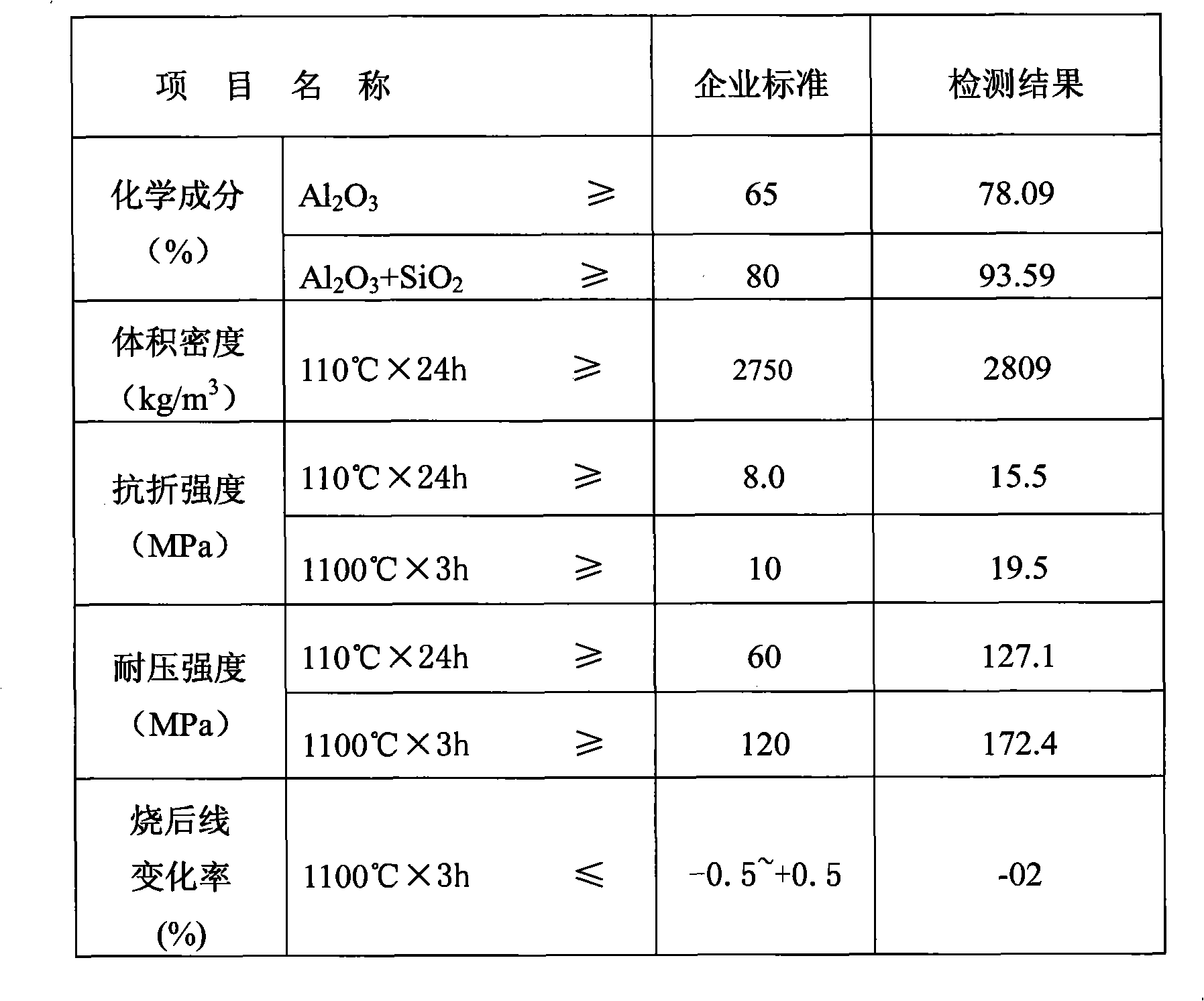

Flame-proof pouring material special for tertiary air tube shut-off device

ActiveCN101492303AGood chemical resistanceImproved thermal shock stabilityMulliteTemperature resistance

The invention discloses a refractory castable material special for tertiary air duct gates, comprising the following components according to the weight percentage: 70-75% of mullite M70, 5-10% of aluminum oxynitride (AlON), 6-7% of pure calcium aluminate cement, 3-4% of a-Al2O3, 3-5% of silica fume and 5-7% of water. During preparation, dodecacalcium heptaluminate (C12A7) with mass being 2% of the total mass of the mixed six components is additionally added. The refractory castable material special for tertiary air duct gates of the invention has extremely high wear-resisting property and thermal shock resistance. By adding AlON nano fine powder as an antioxidant, high thermal resistance and high temperature resistance to chemical erosion of products are improved; by increasing low temperature oxide of sodium oxide and reducing the sintering temperature of the castable material, the strength and wear-resisting property of products are improved; by adding C12A7 to adjust stripping time of the castable material, different requirements on the construction time and customers are met.

Owner:ZHEJIANG KINGCRED NEW MATERIAL CO LTD

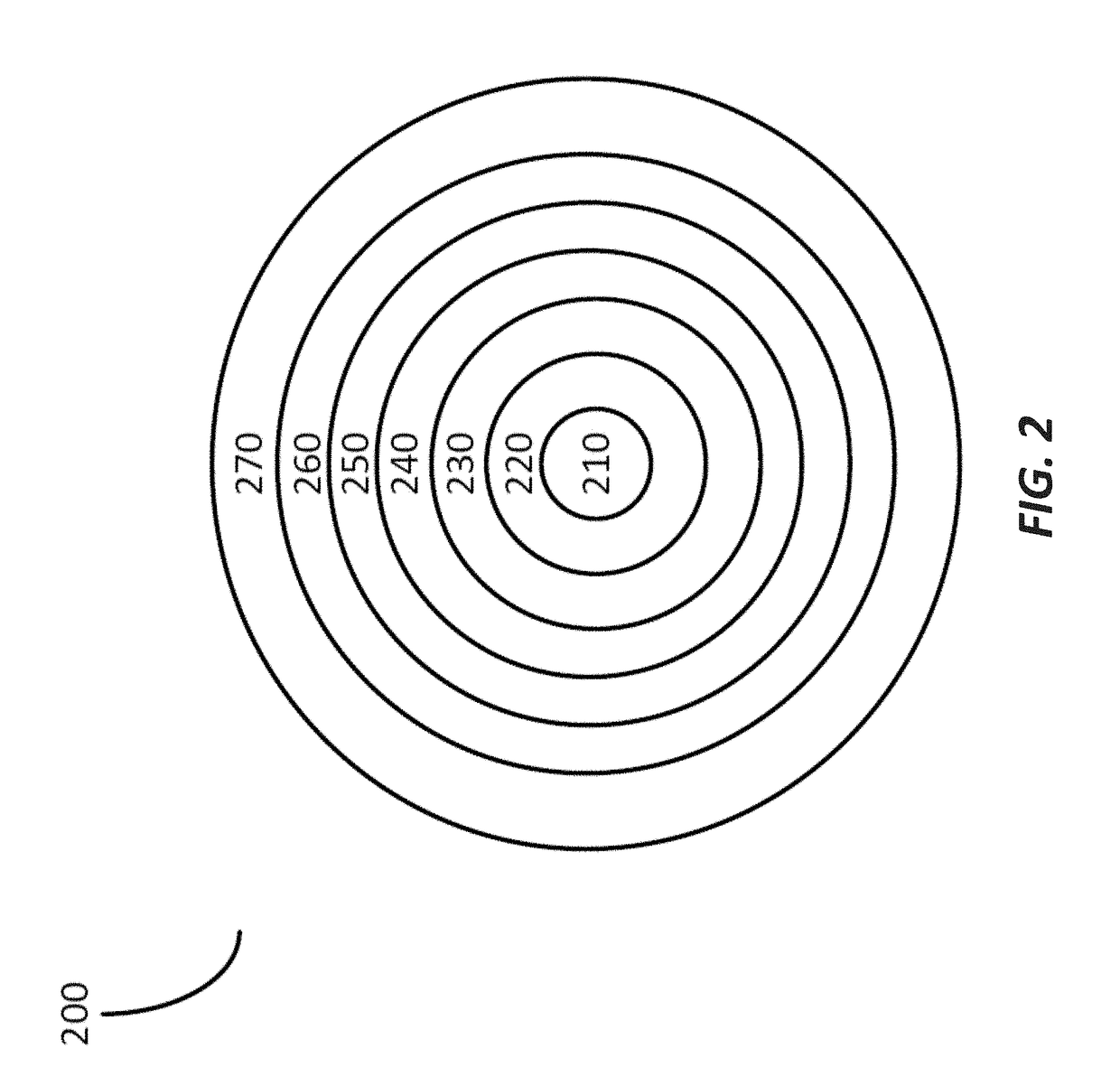

Single crystalline aluminum nitride film, method of forming the same, base substrate for group III element nitride film, light emitting device and surface acoustic wave device

InactiveUS7220314B2Reduce dislocation densityLittle latticePolycrystalline material growthSemiconductor/solid-state device manufacturingNitrogenSurface acoustic wave

A single crystalline aluminum nitride laminated substrate comprising a single crystalline α-Al2O3 substrate such as a sapphire substrate, an aluminum oxynitride layer formed on the substrate and a single crystalline aluminum nitride film as the outermost layer, wherein the dislocation density in the single crystalline aluminum nitride is 108 / cm2 or less.The above single crystalline aluminum nitride laminated substrate is formed by nitriding the substrate by heating in the presence of carbon, nitrogen and carbon monoxide.The above single crystalline aluminum nitride film has a law dislocation density, little lattice mismatching and excellent crystallinity. A Group III element nitride film having excellent luminous efficiency can be formed on this aluminum nitride film. The above laminated substrate is used in a base substrate for a Group III element nitride film, a light emitting device and a surface acoustic wave device.

Owner:TOKYO INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com