Method for preparing aluminum oxynitride transparent ceramic through gel casting

A technology of gel injection molding and aluminum oxynitride, which is applied in the field of preparation of transparent ceramics, can solve the problems of oxygen inhibition, toxic monomers, limited application of gel injection molding, etc., and achieves low cost, simple operation, and molding. Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] (1) Preparation of aluminum oxynitride powder

[0030] Aluminum oxynitride powder can be prepared by solid phase reaction method, aluminothermic reduction method, carbothermal reduction method and / or combined method by ball milling and sieving or by spray granulation to obtain aluminum oxynitride powder with high uniform particles. Taking the carbothermal reduction method as an example, refer to the method disclosed by the inventor in Chinese patent CN101928150A.

[0031] (2) Anti-hydration treatment of aluminum oxynitride powder

[0032] Before the anti-hydration treatment, the synthesized AlON powder, sintering aid, and absolute ethanol can be mixed for ball milling, grinding, and sieving (for example, through a 200-mesh sieve). For example, a planetary ball mill can be used, with alumina balls as the ball milling medium, the ball milling speed is 100-300 rpm, and the ball milling time is more than 12 hours, preferably 20-30 hours. Sintering aid can use Y 2 o 3 an...

Embodiment 1

[0043] 1) Synthesis of AlON powder: high-purity alumina and carbon black are uniformly mixed at a mass ratio of 95:5, and then kept at 1550°C for one hour in a nitrogen atmosphere, and then kept at 1750°C for 2 hours, and finally single-phase AlON is obtained Powder;

[0044] 2) Mix 20g of AlON powder synthesized with 30ml of absolute ethanol and 150g of high-purity alumina balls and ball mill for 20h at a ball milling speed of 250rpm, dry the milled AlON powder at 60°C for 24h, and then pass through a 200-mesh sieve;

[0045] 3) Take 100g of AlON powder sieved in step 2), add 0.1g of dispersant polyacrylic acid and 50ml of absolute ethanol, mix ball mill for 1 hour, add 2g of isocyanate, and filter out the slurry after ball milling for 10 minutes, add Siya to the slurry Ethylpentamine 1.3g and stirred for 2h, then dried at 50°C for 20h and passed through a 200-mesh sieve;

[0046] 4) Mix 50g of AlON powder after anti-hydration treatment in step 3, 100g of water, and 0.5g of ...

Embodiment 2

[0050] 1) Same as step 1 in Example 1);

[0051] 2) Same as step 2 in Example 1);

[0052] 3) Same as step 3 in Example 1);

[0053] 4) Mix 60g of AlON powder after anti-hydration treatment in step 3, 100g of water, and 0.5g of water-soluble isobutylene polymer by ball milling for 2 hours. The obtained water-based slurry is first degassed under vacuum for 20 minutes, and then Pour into the mold. Cured at 40°C for 2 hours. After demoulding, the ceramic green body is first dried at a temperature of 40-50°C for 48 hours; then pre-fired in a muffle furnace to remove organic matter: the heating rate is 5°C / min, and the pre-fired temperature is 500°C , holding time is 8h;

[0054] 5) Sinter the pre-fired ceramic green body in step 4) in a nitrogen atmosphere furnace at a sintering temperature of 1900°C for 20 hours;

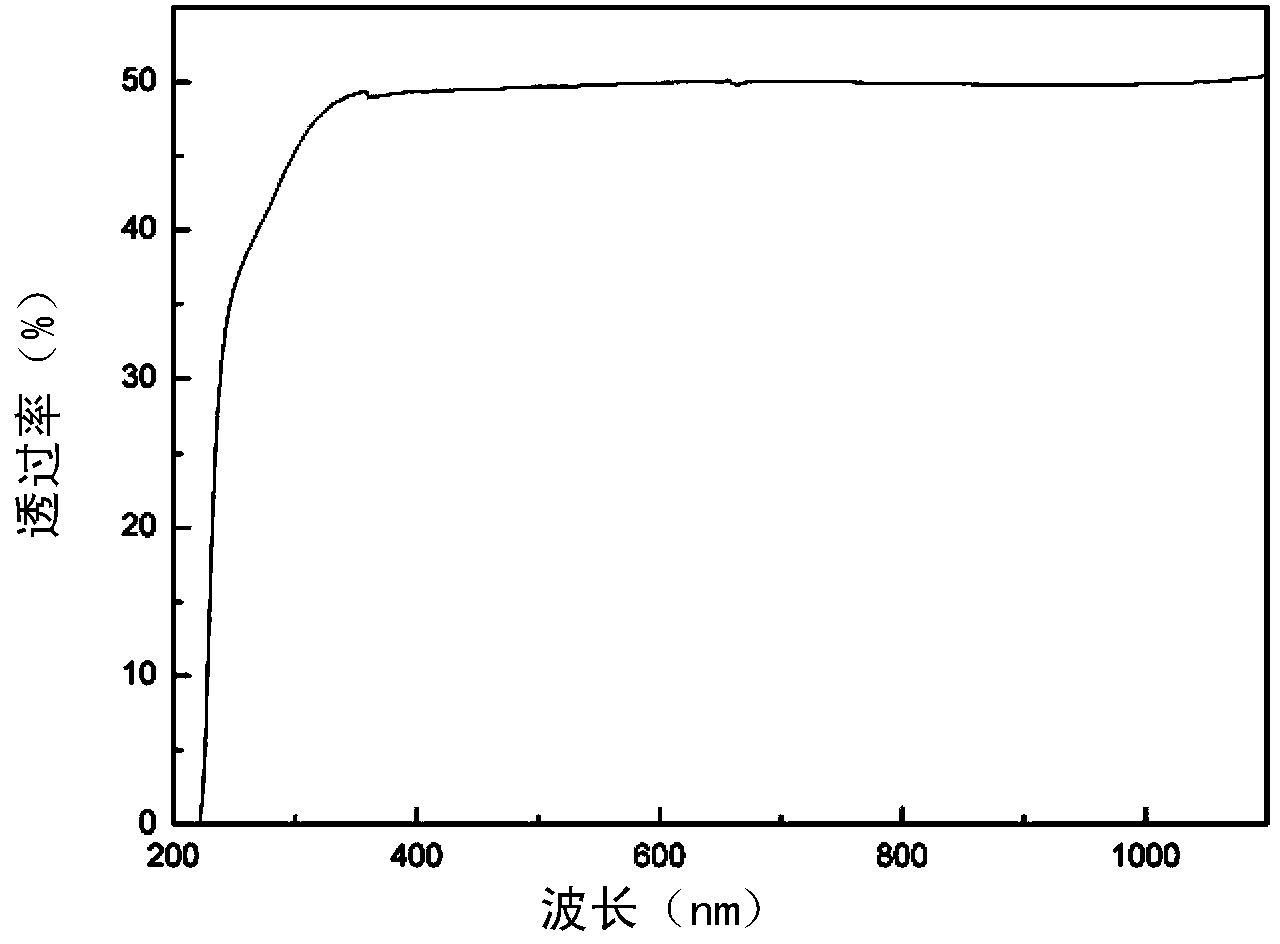

[0055] 6) The ceramic sample sintered in step 5) is processed and polished to 2 mm with a surface grinder and diamond grinding paste, and the sample transmittance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com