Patents

Literature

769 results about "Pressureless sintering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pressureless sintering. Pressureless sintering is the sintering of a powder compact (sometimes at very high temperatures, depending on the powder) without applied pressure. This avoids density variations in the final component, which occurs with more traditional hot pressing methods.

Ceramic composite material for thin-strip casting side sealing plate and preparation method thereof

The invention provides a ceramic composite material for a thin-strip casting side sealing plate and a preparation method thereof, relating to a ceramic composite material and a preparation method thereof and solving the problems that the traditional side sealing plate has high heat conductivity, serious abrasion, poor seal, high preparation cost and large energy consumption, can not be secondarily processed or reused. The ceramic composite material consists of zirconia, boron nitride and additives. The preparation method comprises the following steps: 1, weighing raw materials; 2, ball milling and mixing the raw materials; 3, drying to obtain uniform mixed powder; and 4, carrying out hot pressed sintering, pressureless sintering, air pressure sintering or hot isostatic pressed sintering on the mixed powder, so as to obtain the ceramic composite material for a thin-strip casting side sealing plate. The compactness of the ceramic composite material is 94%-99%, the bending strength of the ceramic composite material, tested by a three-point bending test at room temperature, is 260-420MPa, and the fracture toughness of the ceramic composite material, tested by a unilateral coped beam method, is 3-8 MPa.m<1 / 2>. The ceramic composite material can be widely applied to the field of side sealing plate materials.

Owner:HARBIN INST OF TECH

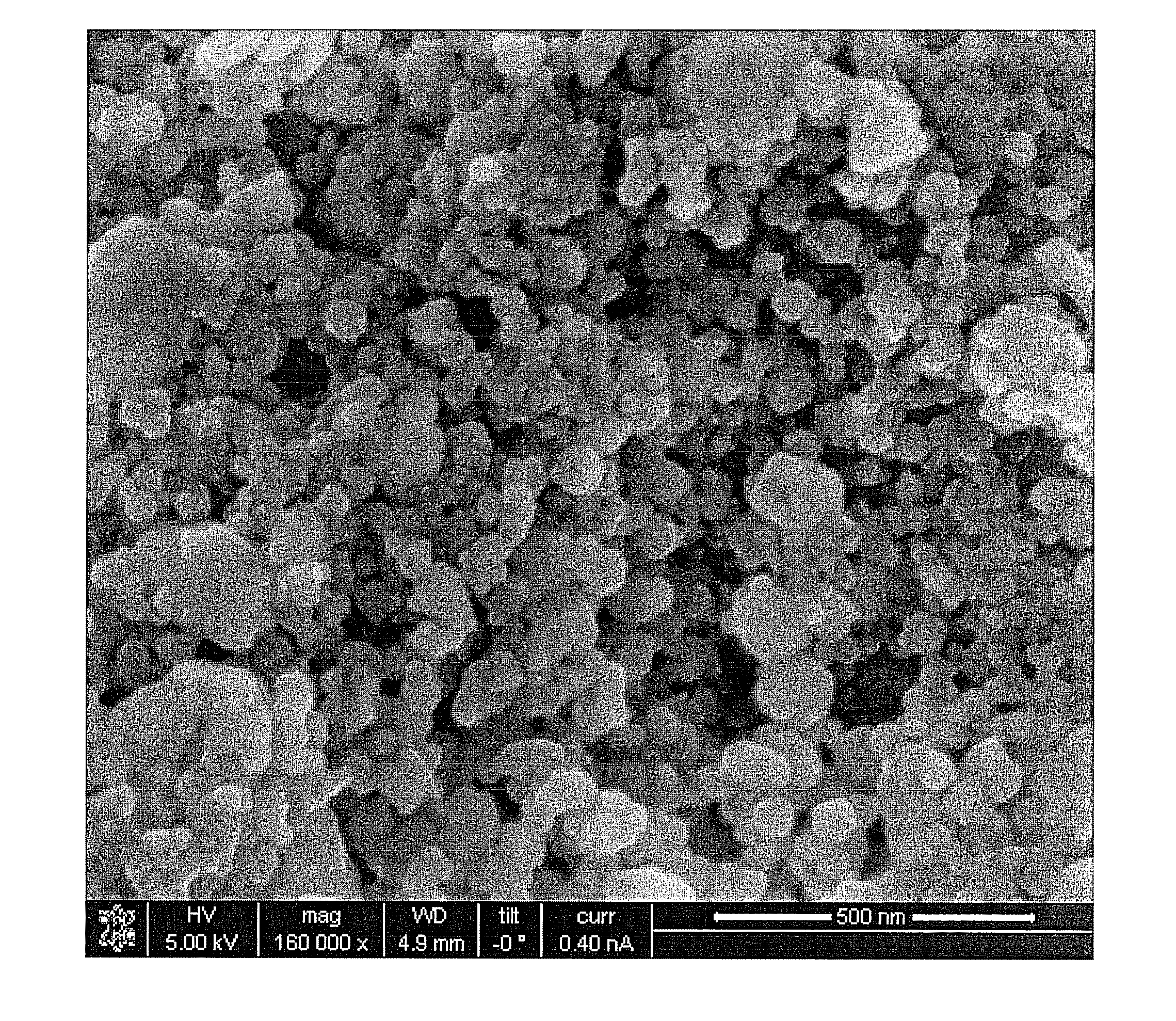

Method of pressureless sintering production of densified ceramic composites

InactiveUS20100130346A1Material nanotechnologySpecial surfacesLiquid-feed flame spray pyrolysisCeramic composite

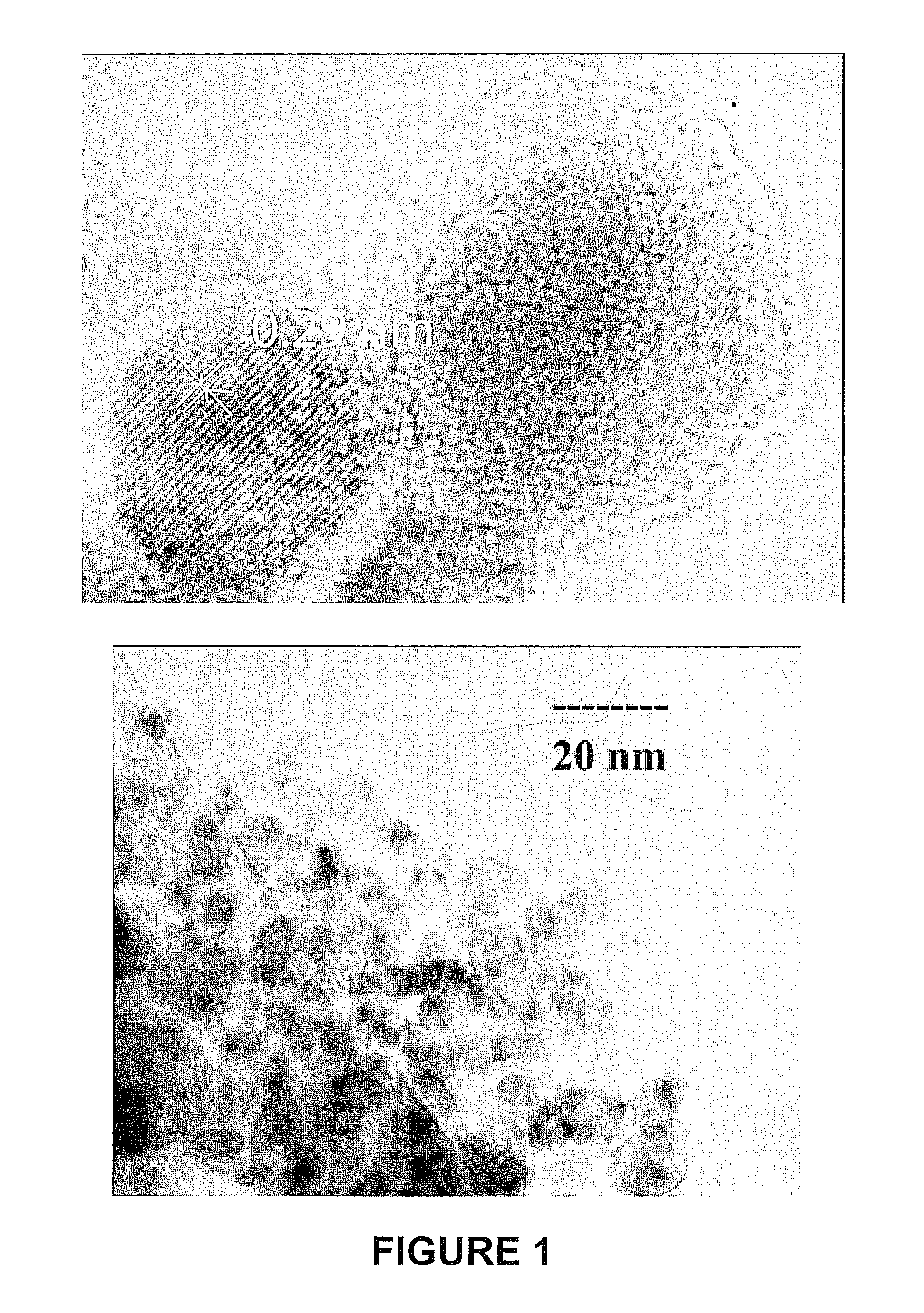

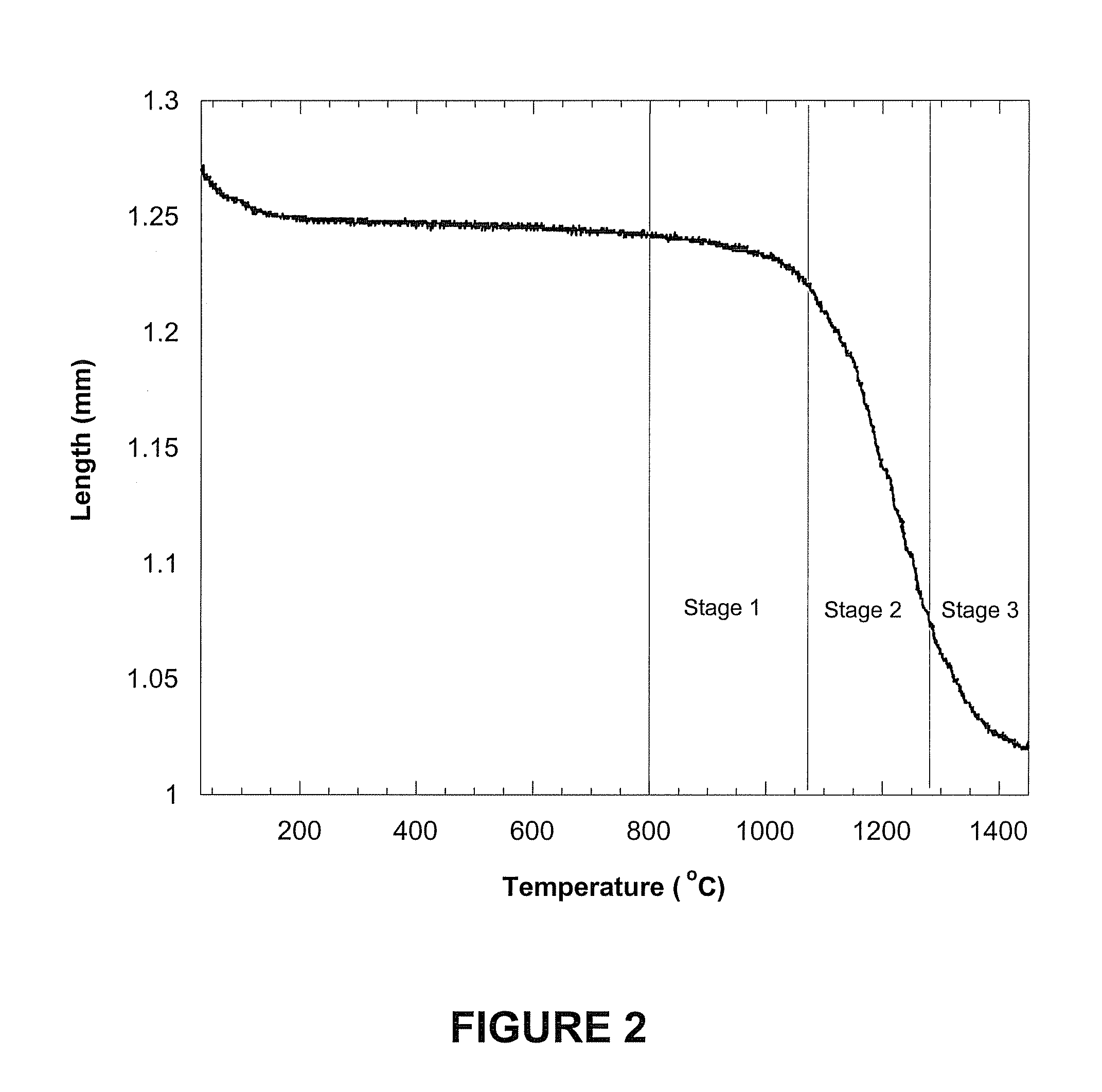

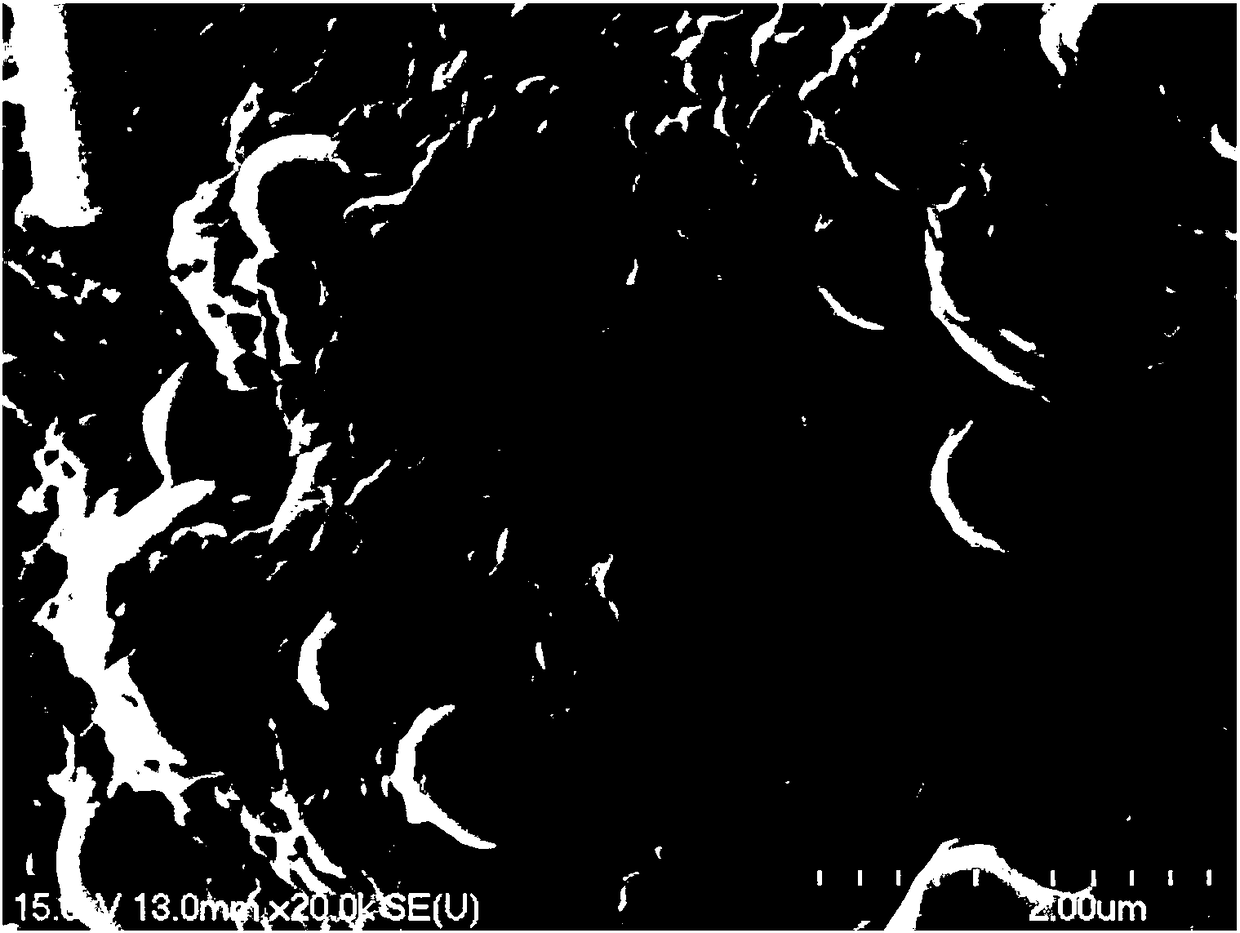

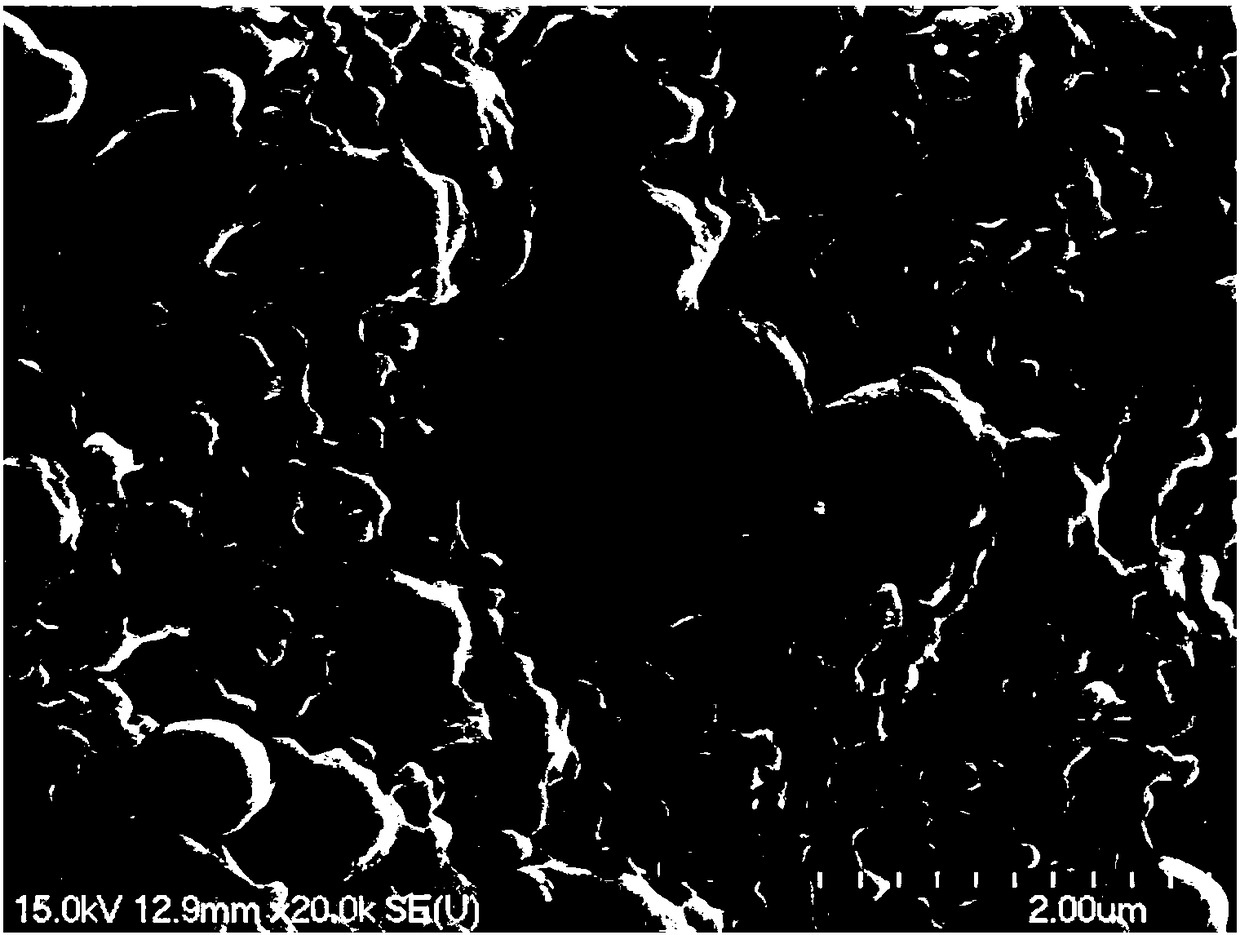

Methods of making and compositions of dense sintered ceramic nano- and micro-composite materials that are highly stable in a variety of conditions and exhibit superior toughness and strength. Liquid feed flame spray pyrolysis techniques form a plurality of nanoparticles (e.g., powder), each having a core region including a first metal oxide composition comprising Ce and / or Zr or other metals and a shell region including a second metal oxide composition comprising Al or other metals. In certain aspects, the core region comprises a partially stabilized tetragonal ZrO2 and the shell region comprises an α-Al2O3 phase. The average actual density of the ceramic after sintering is greater than 50% and up to or exceeding 90% of a theoretical density of the ceramic.

Owner:RGT UNIV OF MICHIGAN

Micro-nano mixed welding paste capable of being used for pressureless sintering and preparation method thereof

ActiveCN108526751AInhibition of violent contractionImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaMicro nanoOrganic solvent

The invention provides a micro-nano mixed welding paste capable of being used for pressureless sintering preparation and a packaging method thereof. The interior of a material is filled with micron-sized spherical particles as a matrix, and the nano-particles are uniformly filled in the material, sintering driving force is provided, so that the whole material is subjected to pressureless sinteringforming at a low temperature. The preparation method comprises the following steps of S1, preparing micron particles with specific sizes and carrying out acid washing and drying; S2, mechanically stirring the micron particle powder with a surfactant, an organic carrier and an organic solvent to obtain a mixture A; S3, fully mixing the metal nano-particles with a dispersing agent, the organic carrier and the organic solvent to obtain a mixture B; and S4, mixing the mixture A and the mixture B to obtain the micro-nano mixed welding paste. According to the micro-nano mixed welding paste capableof being used for pressureless sintering and the preparation method thereof, the welding paste solves problems of volume shrinkage and cracks of the nano welding paste during sintering, the reliability of the welding spots is improved, and the welding paste can be used for packaging and manufacturing for power devices; and according to the scheme, the production process of the welding paste is simplified, the preparation process is green and environment-friendly, the packaging method provided is simple and practical and is beneficial to market popularization.

Owner:深圳市先进连接科技有限公司

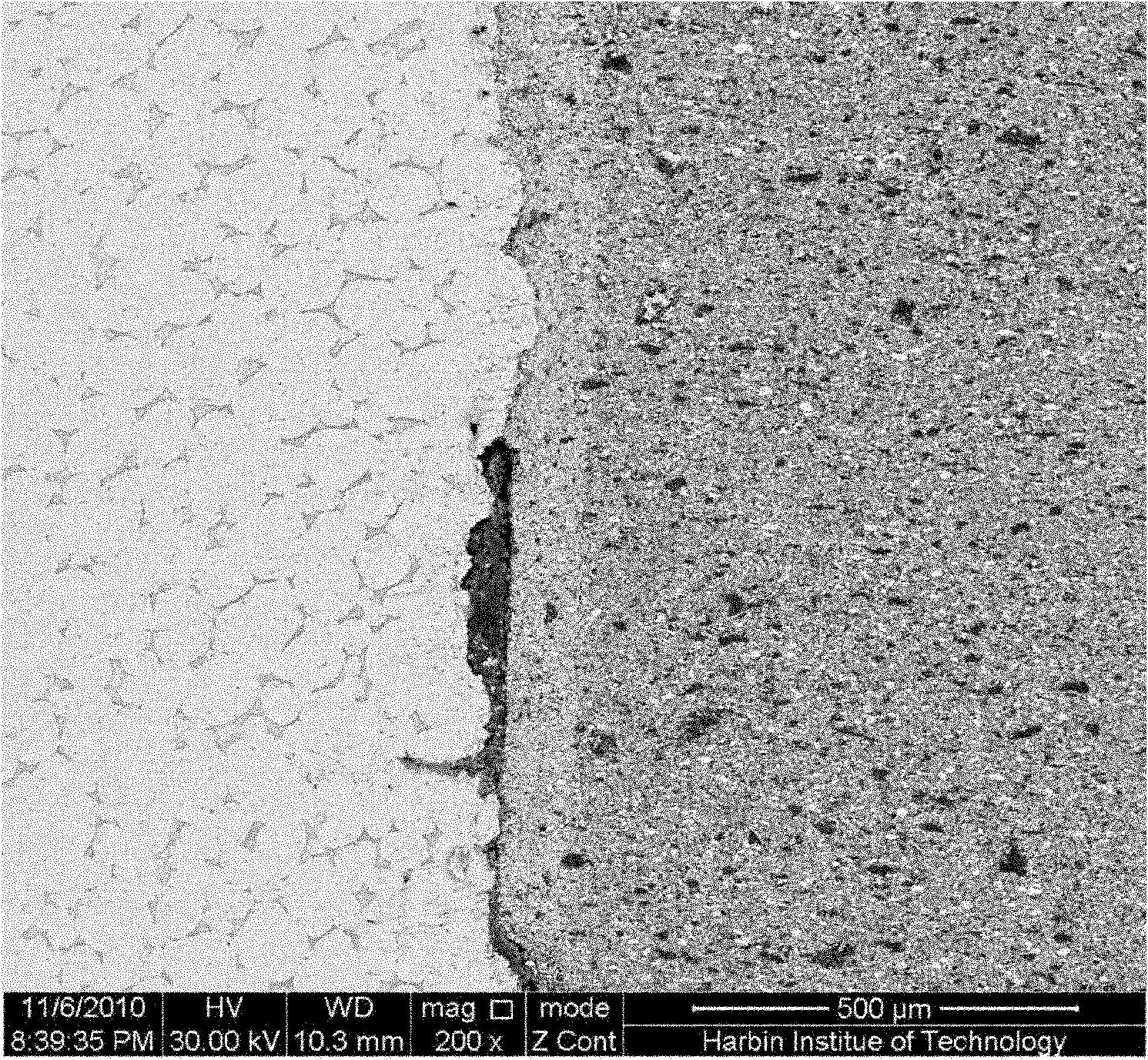

Preparation method of complex phase ceramic material containing zirconium boride

InactiveCN102173813AControlling chemical reaction driving forcesControl the severity of the reactionBorideMaterial defect

The invention relates to a preparation method of a complex phase ceramic material containing zirconium boride, relating to a preparation method of ceramic materials and aiming to overcome the material defects of abnormal crystal grain growth, phase clustering, and the like which are caused by difficult control and overhigh partial temperature in the traditional reaction sintering preparation method and solve the problems of tissue uniformity and comprehensive mechanical property of the complex phase ceramic material. The preparation method comprises the following steps of: 1, placing zirconium oxide and a boron-containing compound or a boron-containing composite into a ball mill to form composite powder; 2, drying the composite powder, then crushing, and screening through a sieve of 200 meshes to obtain uniform mixed powder; 3, carrying out mould pressing or cold isostatic pressing on the mixed powder, and then carrying out pressureless sintering, hot pressing sintering or hot isostatic pressing sintering to obtain the complex phase ceramic material containing the zirconium boride. The complex phase ceramic material containing the zirconium boride has uniform crystal grain size and distribution, the fracture toughness of 3.5-7.5 MPa.m<-1 / 2> and the bending strength of 250-700 MPa and can be used in the field of high-temperature resistant structural members and the like.

Owner:HARBIN INST OF TECH

Hydroxyapatite-zirconium dioxide composite bioceramic material and its preparing method

The invention relates to a kind of hydroxyl apatite - zirconia compound biology ceramic material and its producing method, belonging to biology medical material producing technological field. The invention makes zirconia as substance central layer, on its upper and lower surfaces, respectively spread mix middle layer of zirconia and hydroxyl apatite mixed as per different proportion, on the most outside spread a surface layer of pure hydroxyl apatite, to form a kind of gradient nappe structure; in steel mould, at pressure of 10 - 30 MPa, dry press to molding, then at high temperature of 1500 - 1600 Deg. C, sinter without pressure, then can get hydroxyl apatite - zirconia compound biology ceramic material. The compound material produced by the method of the invention, its anti-bending strength is 900 - 1100 MPa, its fracture toughness (KIC) is 7 - 10 MPaíñm1 / 2, its roughness is 0.5 - 5.0 micron; the compound material has good biology compatibility, so can meet the requirement of load bearing planting body of different parts of human body.

Owner:SHANGHAI UNIV

Preparation method of high-toughness boride-carbide composite ceramic

A preparation method of a high-toughness boride-carbide composite ceramic relates to a preparation method of a boride-carbide composite ceramic and solves the problems that in the conventional preparation of the boride-carbide composite ceramic, due to high sintering temperature and high sintering pressure, the preparation cost is high and the prepared boride-carbide composite ceramic is poor in mechanical property and fracture toughness. The preparation method of the high-toughness boride-carbide composite ceramic comprises the following steps : adding a dispersing medium into boride and carbide; uniformly mixing the dispersing medium, the boride and the carbide; pressing the mixture into a blank material; and sintering the blank material in a two-section pressure-free sintering way at alow temperature and a high temperature sequentially. The sizes and the distribution of grain crystals in the boride-carbide composite ceramic which is prepared under the low-temperature pressure-freeconditions are uniform; the fracture toughness is as high as 5.0-13MPa.m<-1 / 2>; and the bending strength is as high as 400-1000 MPa; the boride-carbide composite ceramic with excellent comprehensive mechanical property can be prepared; the preparation cost is reduced; and the application range is widened.

Owner:吉林长玉特陶新材料技术股份有限公司

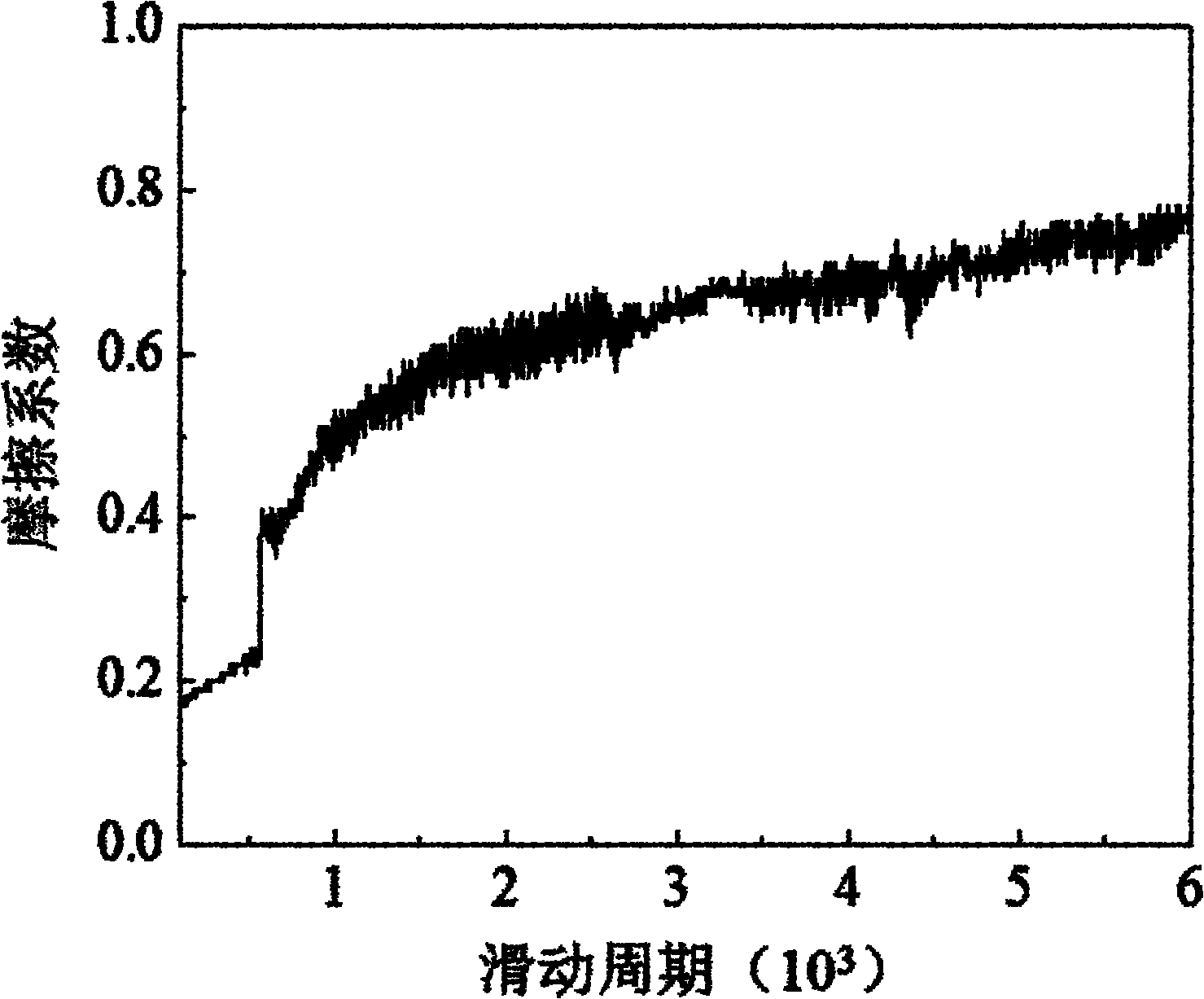

Silicon carbide carbonized complex phase ceramic sealing material and preparation method thereof

InactiveCN101591169AImproved dry friction propertiesGood self-lubricating performanceWater basedHigh density

The invention relates to a silicon carbide carbonized complex phase ceramic sealing material, which comprises the following component in portion by weight: 100 portions of silicon carbide powder, 0.1 to 1 portion of boron carbide, 5 to 30 portions of carbon powder, 0.5 to 3 portions of binding agent PVA, and 0.5 to 1.5 portions of dispersing agent. A preparation method comprises the following steps in turn: (1) blending the raw materials in proportion and then adding the mixture into deionized water, and after ball milling and mixing, preparing the mixture into a water-based silicon carbide composite slurry of which the solid phase weight content is between 40 and 60 percent; (2) adopting a spraying granulating process to perform spray drying on the slurry to obtain silicon carbide granulated powder; (3) adopting a two-step mode of 140 MPa dry pressing pre-compaction and 200 MPa isostatic cool pressing final compaction to carry out forming on the granulated powder to obtain a high-density sealing material blank; and (4) putting the blank into a vacuum pressureless sintering furnace, raising the temperature to between 2,000 and 2,100 DEG C, keeping the temperature for 1 to 1.5 hours, and sintering the blank to obtain the silicon carbide carbonized complex phase ceramic sealing material.

Owner:东新密封有限公司

Tungsten based composite material with granules of double carbide enhanced

A composite carbide particles reinforced W-base composition is prepared from composite carbide particles (10-60 vol.%) and W-base composition through sintering in H2, argon gas, N2, or vacuum at 1900-2300 deg.C. Said composite carbide may be chosen from 4Tac.Zrc, 4Tac.Hfc, TiC.NbC.TaC.HfC, and ZrC.NbC.TaC.HfC. Its advantages are high mechanical performance, and high resistance to oxidizing and ablation.

Owner:HARBIN INST OF TECH

Volume production method of pressureless sintering boron carbide ceramic bullet-proof sheets

InactiveCN104446483AImprove single furnace production capacityHigh degree of automationMicrometerAdhesive

The invention discloses a volume production method of pressureless sintering boron carbide ceramic bullet-proof sheets. The volume production method comprises the following steps: (1) putting various raw materials in material mixing and pulping equipment according to a formula proportion, wherein the raw materials are composed of a solid material A and a liquid material B, the material A comprises the following components in percentage by weight: 75-97wt% of boron carbide powder, 0-15.0wt% of sintering aids, 1.0-12.0wt% of carbon source, 0.5-6.0wt% of adhesive, and 0.5-6.0wt% of dispersant, and the sum of the percentages by weight of the components is 100%; the material B is deionized water; mixed ball milling or high speed stirring is performed on the material A and the material B to prepare a sizing agent, wherein the solid content of the sizing agent is 30-70 wt%; the sintering aids are one or more of nanometer level to micrometer level ZrC, TiC, SiC, AlN and TiB2. The method has the advantages of high yield of a single furnace, high degree of automation, non grinding processing of products, low cost and suitability for mass production, and low-cost and stable mass production is achieved.

Owner:NINGBO VULCAN TECH CO LTD

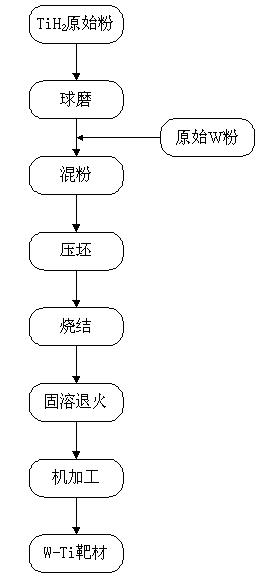

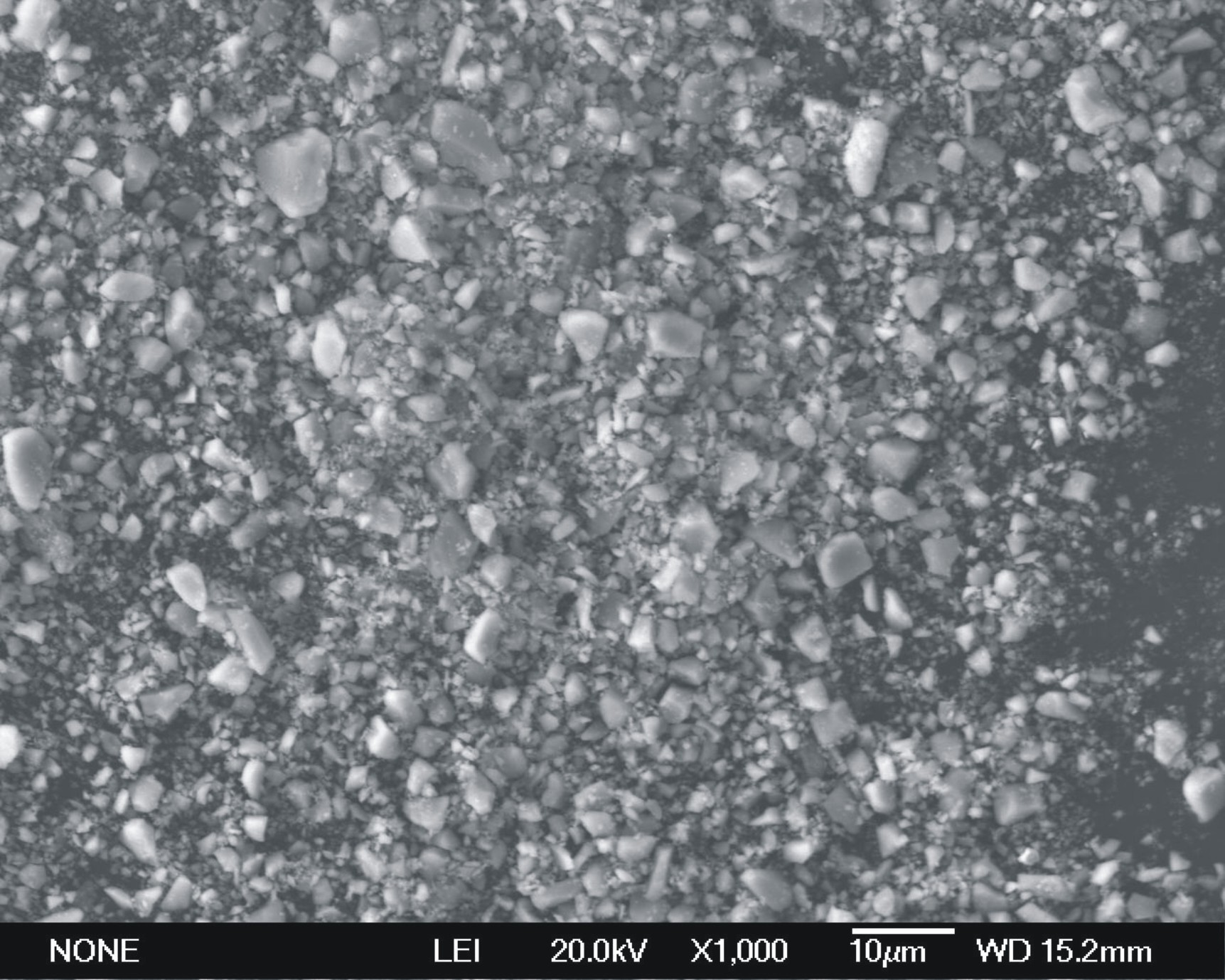

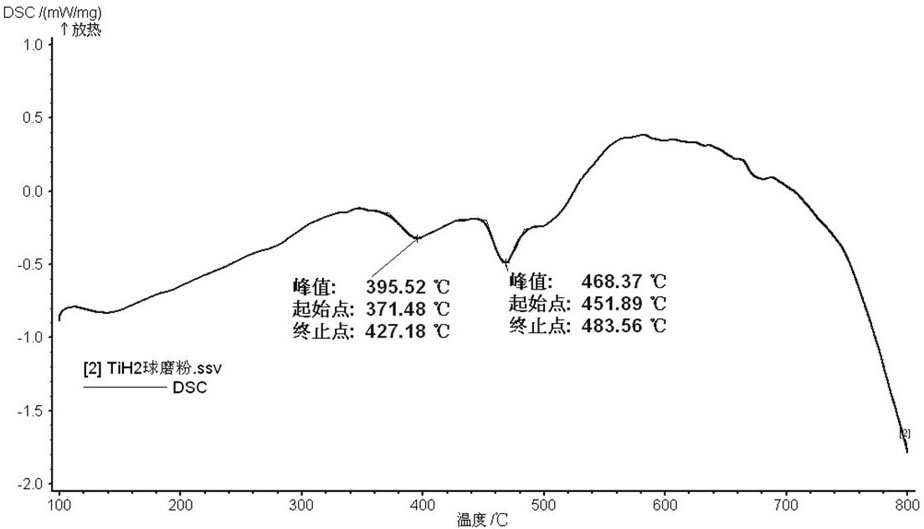

Method for preparing W-Ti alloy target material

InactiveCN101928850AUniform alloy structureHigh densityVacuum evaporation coatingSputtering coatingPressureless sinteringSintered alloy

The invention discloses a method for manufacturing a W-Ti alloy target material. In the method, W powder with purity higher than 99.9 percent and TiH2 powder with purity higher than 96.7 percent are used as raw materials, the TiH2 powder is subjected to high-energy ball milling and then is mixed with the W powder; then, the powder is compacted for 3 to 6 minutes at the pressure of between 250 and 280MPa, and the compact blank is subjected to vacuum loose sintering, and the sintered alloy is subjected to solution annealing and quenching; and finally, machining the W-Ti alloy to obtain the target finished product. Compared with the prior art, the method has low sintering temperature and does not have pressure in the sintering process, and the prepared alloy target material has the advantages of uniform tissue, high compactness and large controllable size.

Owner:XIAN UNIV OF TECH

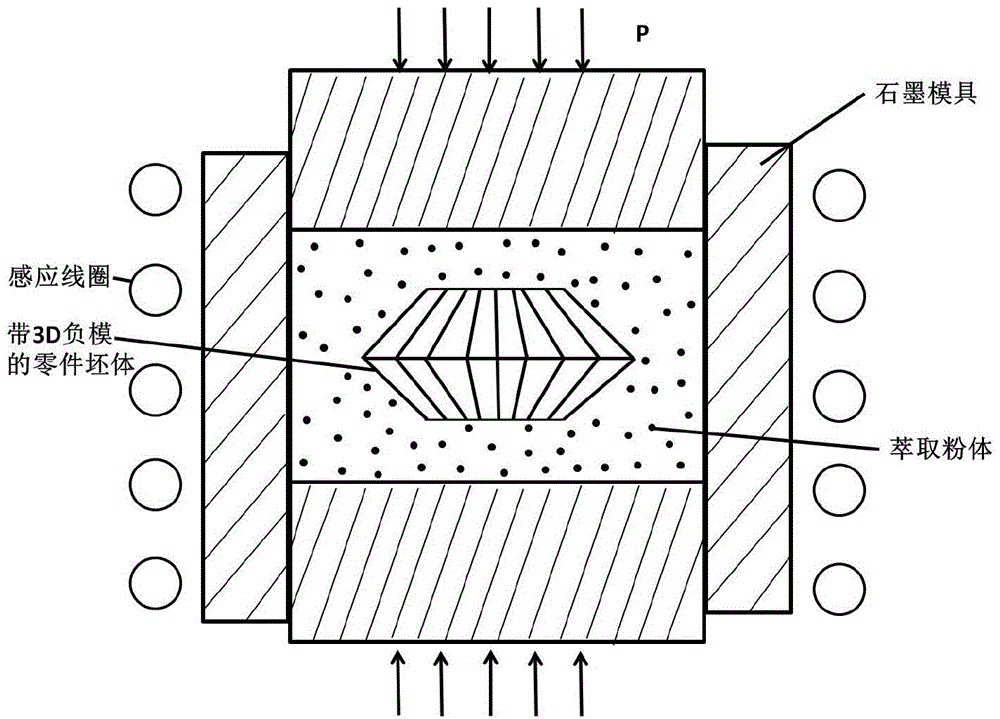

Method for preparing high-density cemented-carbide part with complicated shape and cutter

The invention provides a method for preparing high-density cemented-carbide part with a complicated shape and a cutter. In combination of 3D print technology, slurry injection and extraction of powder pressure, a negative mold of the part with the hollow thin wall can be made via 3D print technology. Slurry containing tungsten-cobalt type alloy is injected into the negative mold of the part and then cured in order to obtain a part blank made by tungsten-cobalt type alloy. By means of extraction of powder pressure and hot-pressed sintering, the high-density cemented-carbide part with the complicated shape and the cutter are made. The method for preparing the high-density cemented-carbide part with the complicated shape and the cutter has following beneficial effects: the method gives full play to advantages of arbitrary forming and high relative density of 3D printing and helps to overcome the defects that the mold (a force-transmitting medium) with the complicated shape by adoption of hot-pressing, cold-isostatically pressing, hot-isostatic pressing is difficult to manufacture and low density and easy cracking and deformation of a blank body by adoption of conventional pressureless sintering and negative pressure sintering; and a high-relative-density cemented-carbide product with arbitrary complicated shapes can be prepared.

Owner:UNIV OF SCI & TECH BEIJING

Low cost process of synthesizing sialon ceramic powder

The method for synthesizing sialon ceramic powder material by low cost is characterized by using metallurgical furnace slag or limestone or fly ash industrial waste material or cheap natural mineral as raw material, adding metal silicon powder, aluminium powder and partial crystal seed through the processes of ball grinding, drying, high-temp. self spreading and other treatment to obtain the invented single-phase alpha-sialon powder material. Said powder material possesses excellent sintering property, can be sintered without pressure at 1600-1800 deg.C, its density is up to 3.07g / se.cm, hardness is 15.53 GPa, and its toughness is 4.72 Mpa.m(1 / 2), as compared with Al2O3, ZrO2 and SiC ceramics its erosion resistance is excellent.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI +1

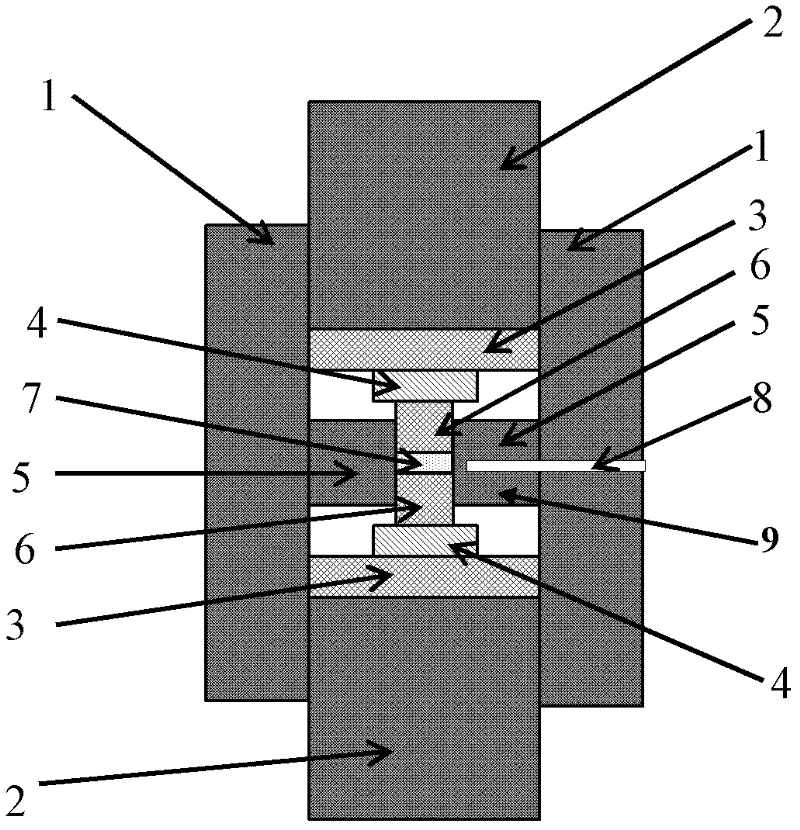

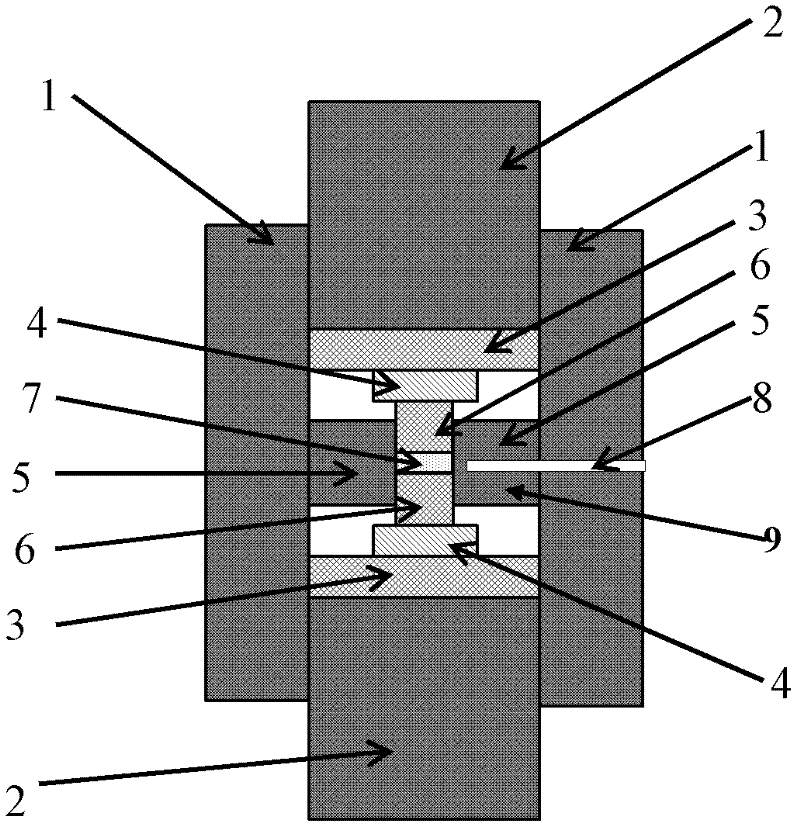

High-pressure sintering combined die and high-pressure rapid sintering method for preparing nanometer ceramic thereof

InactiveCN102390079AAchieve densified sinteringCeramic shaping apparatusInternal pressureHigh pressure

The invention discloses a high-pressure sintering combined die, which comprises a hollow cylindrical outer die, a hollow cylindrical inner die, one pair of cylindrical inner pressure heads, one pair of cylindrical metallic laminations, one pair of cylindrical ceramic laminations and one pair of cylindrical outer pressure heads, wherein the side face of the outer die is provided with a through hole into which a thermocouple is inserted; the hollow cylindrical inner die is arranged in the hollow cavity body of the outer die; the side face of the inner die is provided with a blind hole into which the thermocouple is inserted; the outer die and the inner die are in close fit, and the centre line of the through hole into which the thermocouple is inserted on the side face of the outer die and the centre line of the blind hole into which the thermocouple is inserted on the side face of the inner die coincide; the cylindrical inner pressure heads are half inserted into the upper end and the lower end of the hollow cavity body of the inner die; the inserted inner pressure heads and the hollow cavity body of the inner die form a die cavity; the cylindrical metallic laminations are arranged outside the inner pressure heads; the cylindrical ceramic laminations are arranged outside the cylindrical metallic laminations; the cylindrical outer pressure heads are arranged outside the cylindrical ceramic laminations; and the ceramic laminations and the outer pressure heads are in the close fit with the outer die. The invention also discloses a high-pressure rapid sintering method for preparing a nanometer ceramic by adopting the die. By adopting the die and the sintering method disclosed by the invention, the rapid low-temperature compact sintering can be realized on a nanometer ceramic material.

Owner:XI AN JIAOTONG UNIV

Porous conductive MAX phase ceramics and preparation method and use thereof

InactiveCN101747075APrecise control of porosityPorosity adjustablePhysical/chemical process catalystsCeramicwarePorous ceramicsAtmosphere

The invention relates to a porous conductive ceramics, in particular to a porous conductive MAX phase (Ti3SiC2, Ti3AlC2 or Ti2AlC) ceramics with a through hole structure, and a preparation method and a use thereof. The porosity of the porous ceramics is adjustable within the range of 20-65%, the ceramics comprises a through hole structure, and the openporosity is more than 85%. The preparation method comprises the steps of taking MAX phase ceramic powder as a raw material, molding, carrying out pressureless sintering in an atmosphere furnace, keeping the sintering temperature at 1200-1400 DEG C, and leading the sintering time to be 0.5-3 hours. The MAX phase conductive ceramics with the through hole structure prepared by the pressureless sintering method can be used as a catalyst carrier material for automobile exhaust purification. The invention can solve the problems of liquid phase, a large number of closed pores in the generated hole and the like during the sintering process by optimizing the molding pressure, the sintering temperature and the time precise control of the porosity.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

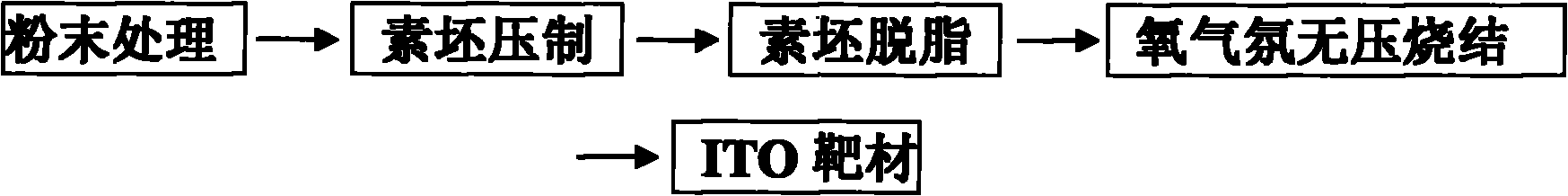

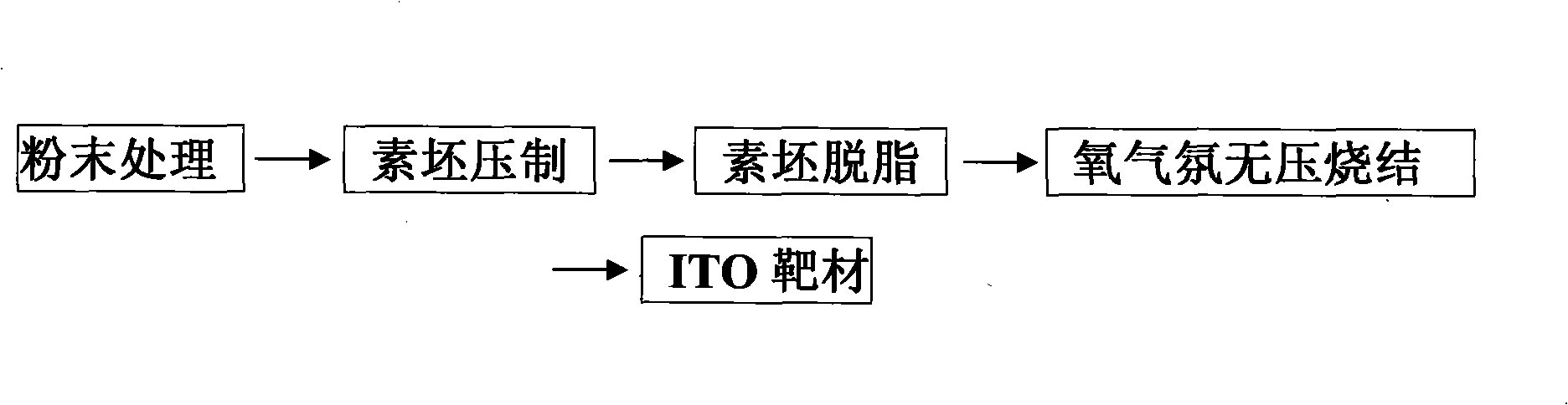

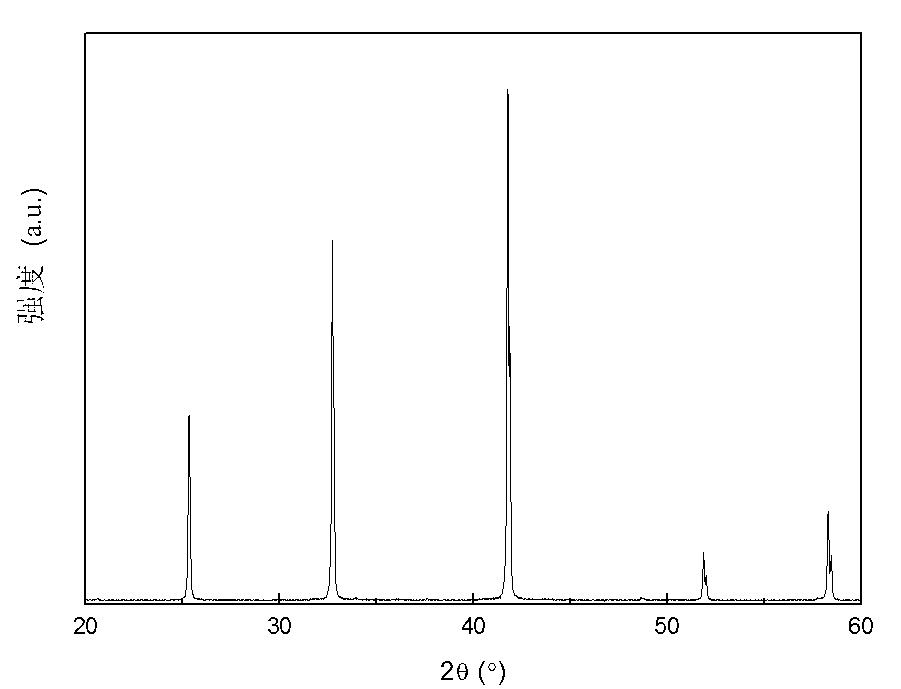

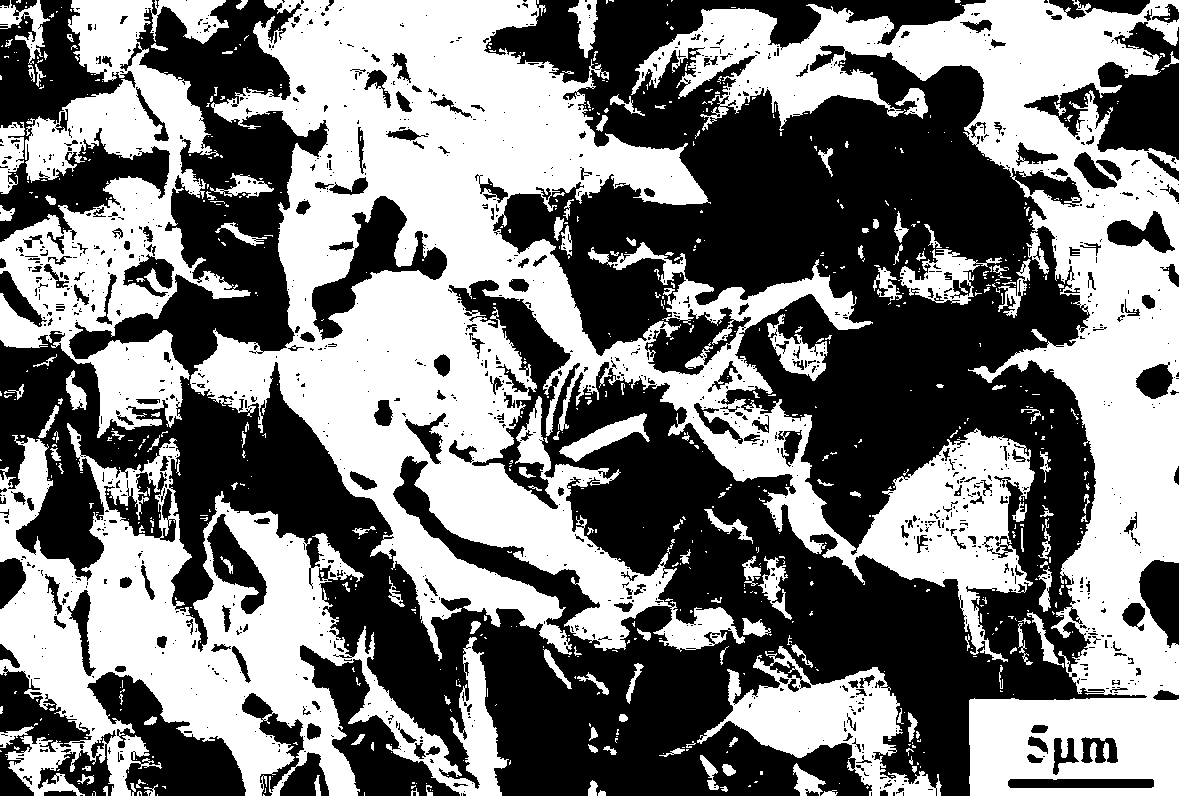

Method of preparing ITO target material by oxygen atmosphere pressureless sintering process

The invention discloses an innovative method of sintering ITO target material, and aims to realize pressureless oxygen atmosphere sintering by optimizing sintering process, and finally to obtain target material having high density and high performance. With sintering method as the basis and according to sintering characteristics of the ITO target material, the method adopts segmented sintering process, and controls oxygen partial pressure of the sintering atmosphere by controlling oxygen flow entering into a hearth to inhibit decomposition of the target material, and to finally obtain the high conductive performance target material, the density of which is more than 99.3%. The oxygen atmosphere pressureless sintering method is a novel ceramic sintering method, and is mainly applied to thesintering of oxide ceramics easy to decompose. Equipment for the method is simple, and products to be sintered are not restricted by size, so large-size ceramics can be produced. It is the first timeto produce the ITO target material by the method, and the ITO target material produced by the method is better than that produced by the commonly used sintering process with hot pressing, sintering process with hot isostatic pressing or common normal pressure sintering process.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of zirconium diboride ceramic with in-situ-introduced boron as additive

InactiveCN103011827AAvoid introducingGood for maintaining excellent performanceArgon atmosphereZirconium dioxide

The invention relates to the field of structural ceramic manufacturing, in particular to a preparation method of zirconium diboride ceramic with in-situ-introduced boron as an additive. The preparation method comprises the following steps: firstly, performing ball milling and mixing zirconium dioxide and elemental boron in a mol ratio of (1: 3.5)-(1: 4.5), and drying to obtain ZrO2 / B mixed powder; secondly, putting the ZrO2 / B mixed powder into a graphite crucible, and performing high-heat treatment at the air pressure of below 200Pa to obtain ZrB2 / B powder; and finally, sieving the obtained ZrB2 / B powder, performing isostatic pressing, putting the ZrB2 / B powder into the graphite crucible, performing pressureless sintering in an argon atmosphere, controlling the sintering temperature at 1800 -2100 DEG C, the heat-preserving time at 1-3 hours and the heating rate at 10-50 DEG C / min, and preserving heat for 0.5 hours at 1500-1700 DEG C to obtain the compact zirconium diboride ceramic. By the preparation method, a ball milling medium is not introduced, the impurity content is reduced, excellent performance of the zirconium diboride ceramic can be maintained easily, and the sintering compactness of the zirconium diboride ceramic is realized at a relatively low temperature (2000 DEG C).

Owner:FUDAN UNIV

Method of preparing compact Ti3AlC2 ceramic by low-temperature non-pressure sintering

This invention relates to a low temperature pressless sintering preparation method for TiAL carbide ceramic, which takes pure Ti, Al and C as the raw materials to weigh and mix them in the mol ration of 3:1:2, then takes the mol volume of Al as the primary standard to add Sn, Si or Al powder of 0.3-0.6mol as the sinter aids, putting the mixed material in a ball mill kettle to be milled for 10-60h, in which, stainless steel balls or horniness alloy balls are applied in the kettle, the weight ratio of the ball material is 10:1-30:1, Ar or N inert gas is filled to the vacuumed kettle and the rate of the ball mill is 200-350rpm to get nanometer level super fine powder then to be ball-milled in ethanol medium for 3h to be dried and added with suitable PVB adhesive to granulate the powder and put into a steel model and pressed to an ingot on a cold equal static press to be sintered in vacuum, Ar or N protection atmosphere for 2-6h under 1250-1500deg.C to get a densed Ti3AlC2 ceramic.

Owner:SHANGHAI UNIV

High purity zirconium boride / hafnium boride and preparation of superhigh temperature ceramic target material

The invention discloses a method for preparing a high-purity ultrahigh-temperature ceramic target material which belongs to the technical field of ceramic target materials, and in particular provides a method for preparing high-purity zirconium / hafnium boride powder and a ceramic target material thereof. The method comprises the steps of taking high-purity Zr powder, Hf powder and high-purity B powder as raw materials, adopting a self-propagating method to prepare high-purity ZrB2 and HfB2 powder respectively and then adopting a high-temperature high-pressure hot-pressing molding process to prepare a high-purity dense zirconium / hafnium boride ultrahigh-temperature ceramic target material, wherein the relative density of the target material reaches 95 to 99 percent. Relative to the prior art, metal powder in the method is slightly excessive when the materials are mixed, so as to make up for the metal loss during self-propagating reaction and further guarantee the component unicity of products. Relative to pressureless sintering, the sintering temperature needed in the method is greatly lowered; in addition, as the hot-pressing process adopts two-stage temperature, blank is uniform in temperature field, so as to ensure that the target material with uniform density can be obtained in the late hot-pressing process.

Owner:有研资源环境技术研究院(北京)有限公司

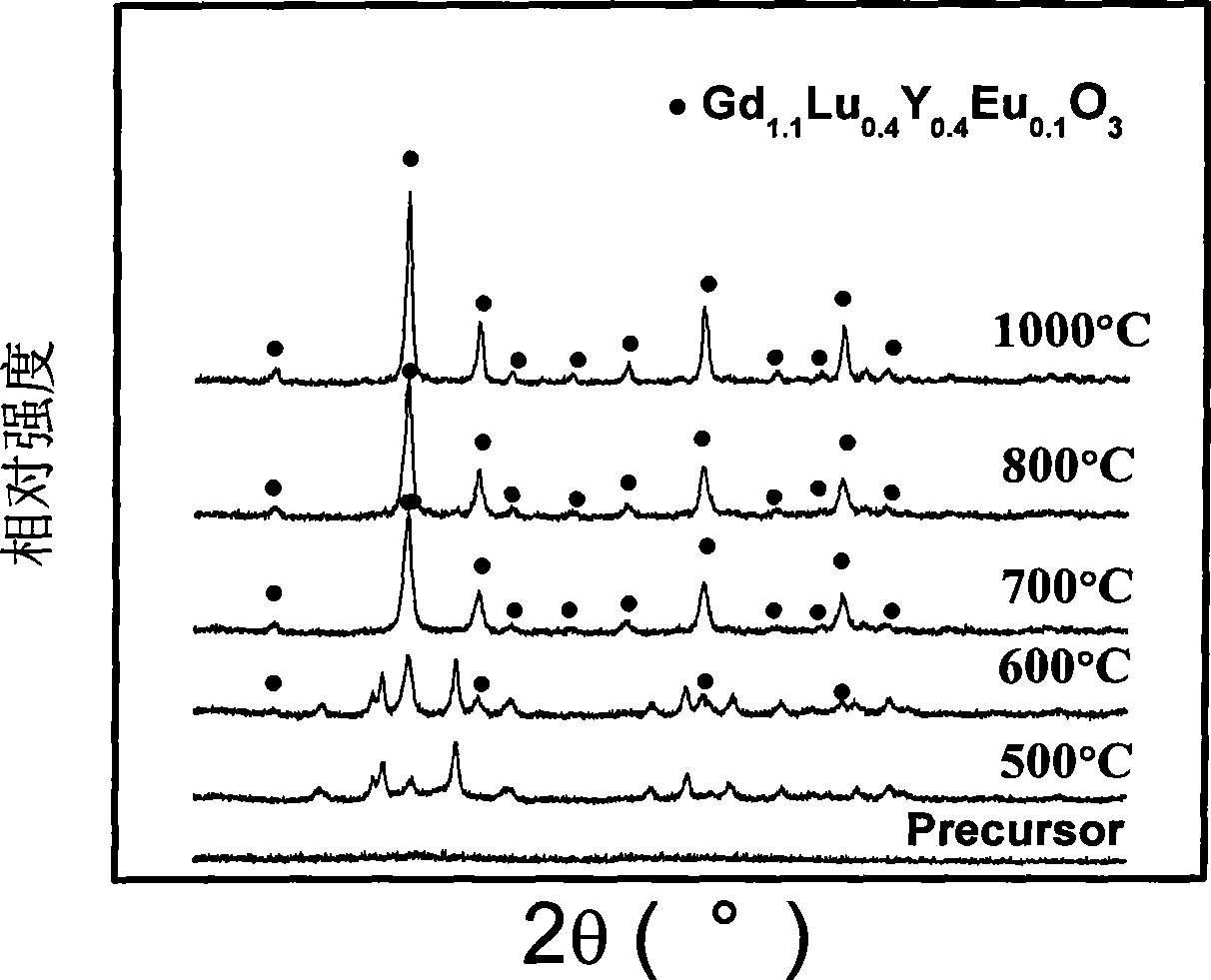

Rare earth oxide solid solution ceramic scintillator and preparation method thereof

The invention discloses a rare earth oxide solid solution ceramic scintillator and a preparation method thereof. The main component of the ceramic scintillator is Gd2xLu2yY2(1-x-y-z)Eu2zO3 (the x is more than or equal to 0.1 and less than or equal to 0.6, the y is more than or equal to 0.1 and is less than or equal to 0.4, and the z is more than or equal to 0.01 and less than or equal to 0.1), and the ceramic scintillator has a crystal structure with a cubic Ia3 point group. Ceramic powder can be synthesized by a chemical coprecipitation method. The coprecipitation method adopts ammonia, ammonium hydrogen carbonate or a mixed solution of the ammonium water and the ammonium hydrogen carbonate as a precipitating agent, titrates the precipitating agent into a solution of gadolinium nitrate, lutecium nitrate, yttrium nitrate and europium nitrate to obtain a precipitate, and then the precipitate is dried and calcined to obtain nano-powder. The obtained powder is pressed into a ceramic blank through an isostatic compaction method, then the pressureless sintering is performed in vacuum or hydrogen atmosphere, the sintering temperature is between 1,600 and 1,900 DEG C, transparent Gd2xLu2yY2(1-x-y-z)Eu2zO3 ceramic can be obtained, a ceramic product with the needed dimension is prepared after the cutting, grinding and polishing, and the transmission rate of the ceramic in a visible region (400-800 nanometers) is more than or equal to 65 percent. The ceramic scintillator emits red light with a main wavelength of 610 nanometers under the excitation of ultraviolet light or X rays, and can be used for scintillating materials of imaging and detection of medical and industrial X rays.

Owner:CHINA JILIANG UNIV

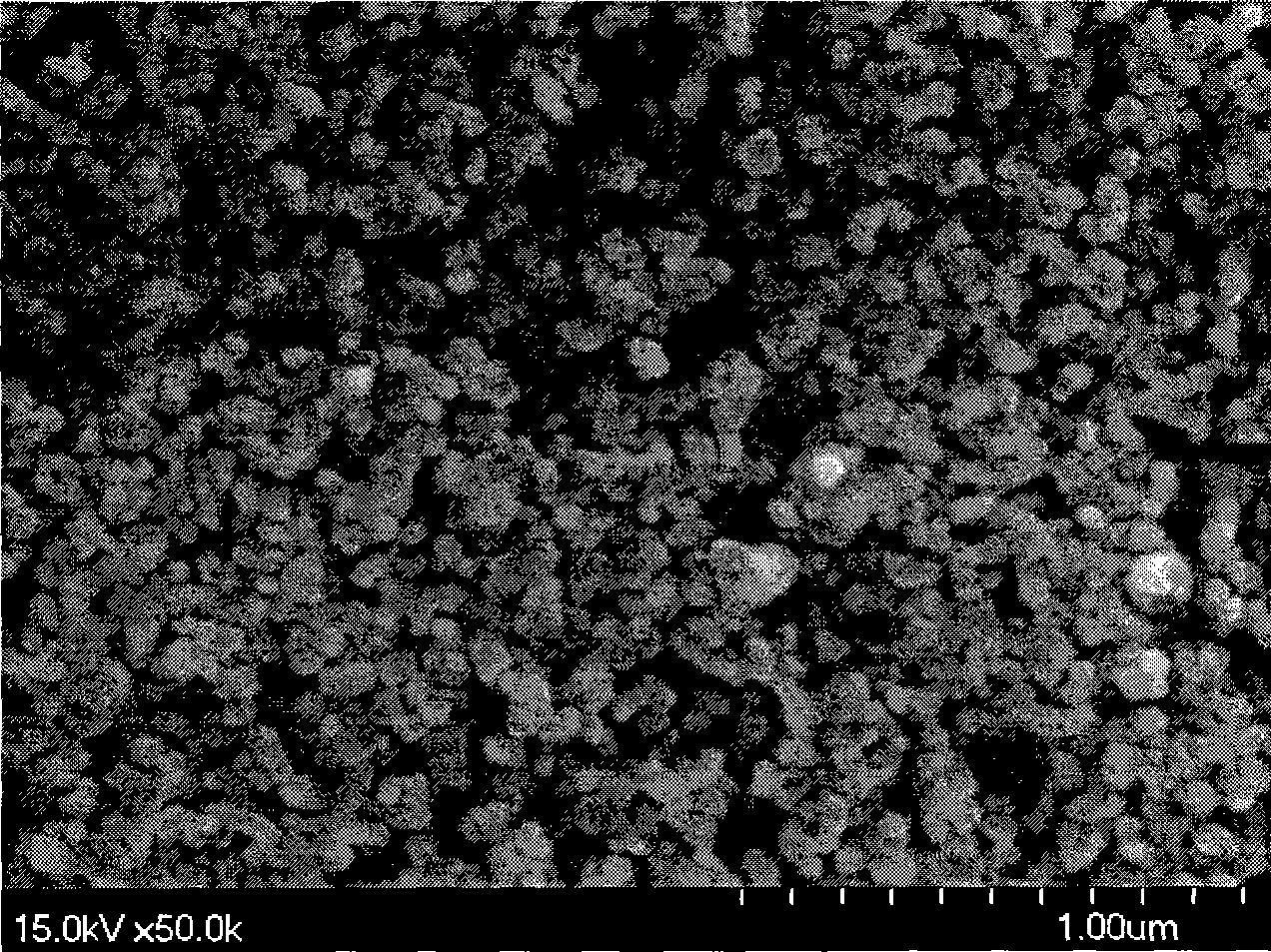

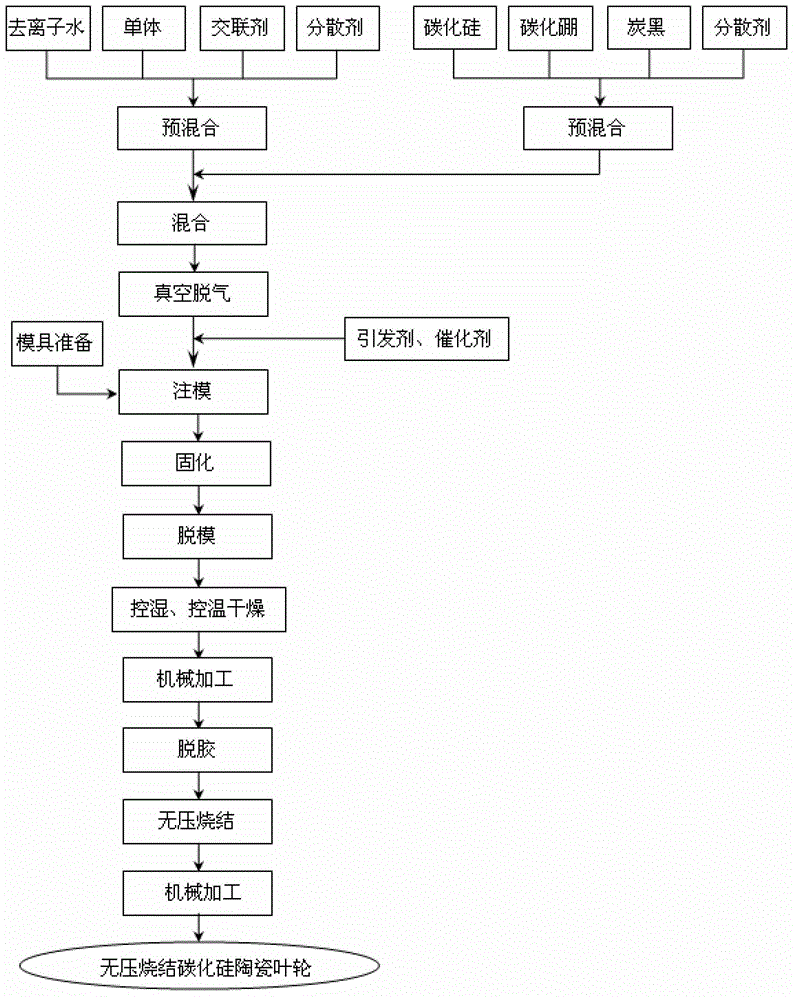

Method for preparing silicon carbide ceramic impeller through gel casting and pressureless sintering

ActiveCN102875150AAvoid uneven dispersionOvercome defects such as uneven curingCarbide siliconGel casting

The invention discloses a method for preparing a silicon carbide ceramic impeller through gel casting and pressureless sintering, and provides a preparation method of a pressureless sintered silicon carbide ceramic impeller with a complex and accurate shape characteristic and an external diameter size capable of reaching over 160 mm. A silicon carbide solid-phase sintering formula system of a boron-containing sintering auxiliary agent and a gel casting and pressureless sintering process are adopted; and the method comprises eight steps of: preparing ceramic slurry; performing injection molding; demolding; drying; machining; degumming; performing pressureless sintering; and machining. According to the method, the technical problems of non-uniform mixing of large-scale ceramic slurry in gel casting, dryness, crack and deformation in a pressureless sintering process and the like are solved, and finally, preparation of the pressureless sintered silicon carbide ceramic impeller is realized. The impeller has good performance such as corrosion resistance, wear resistance, high temperature resistance and the like, and can be widely applied to a centrifugal pump for corrosive liquid conveying of various industries.

Owner:UNIV OF SCI & TECH BEIJING

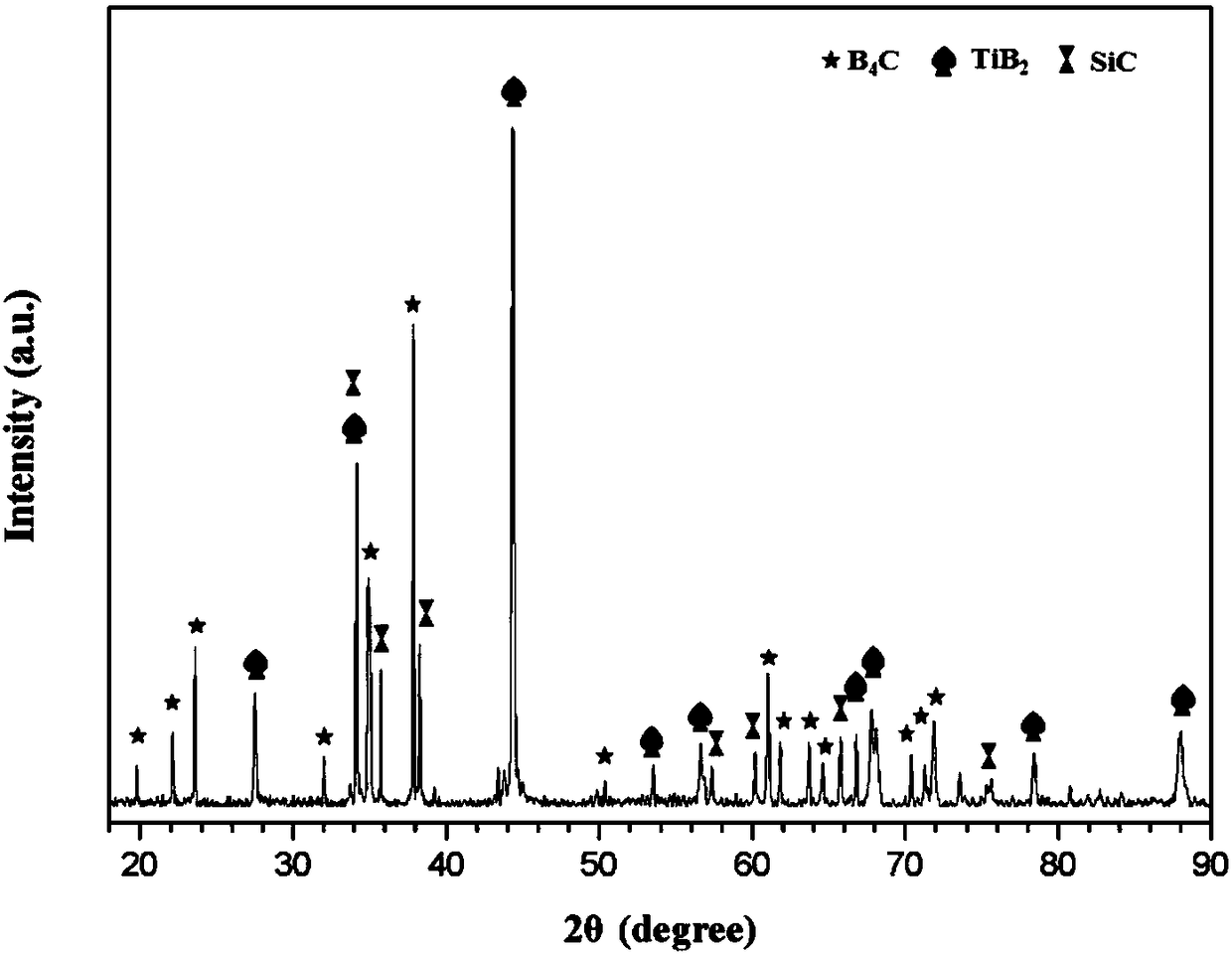

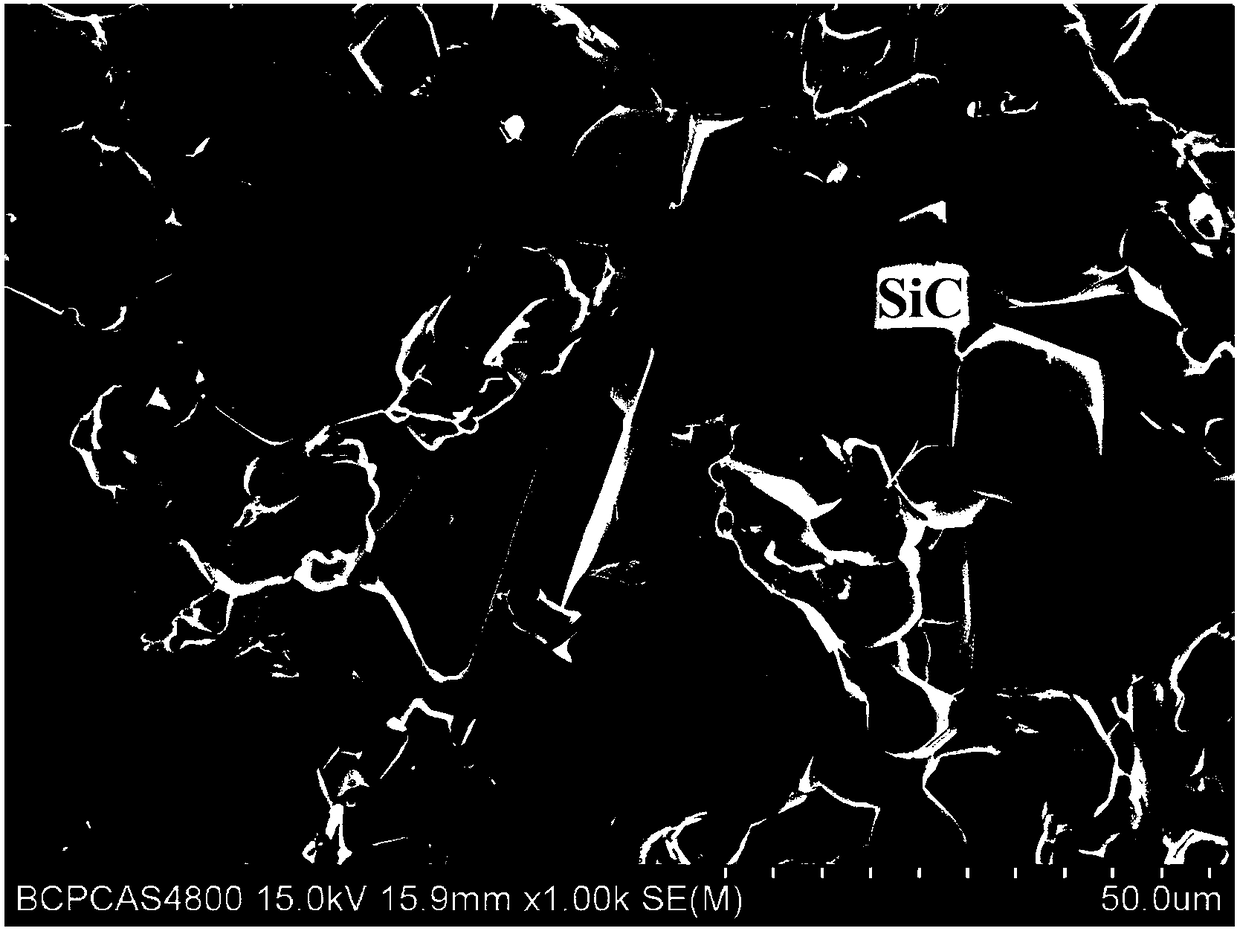

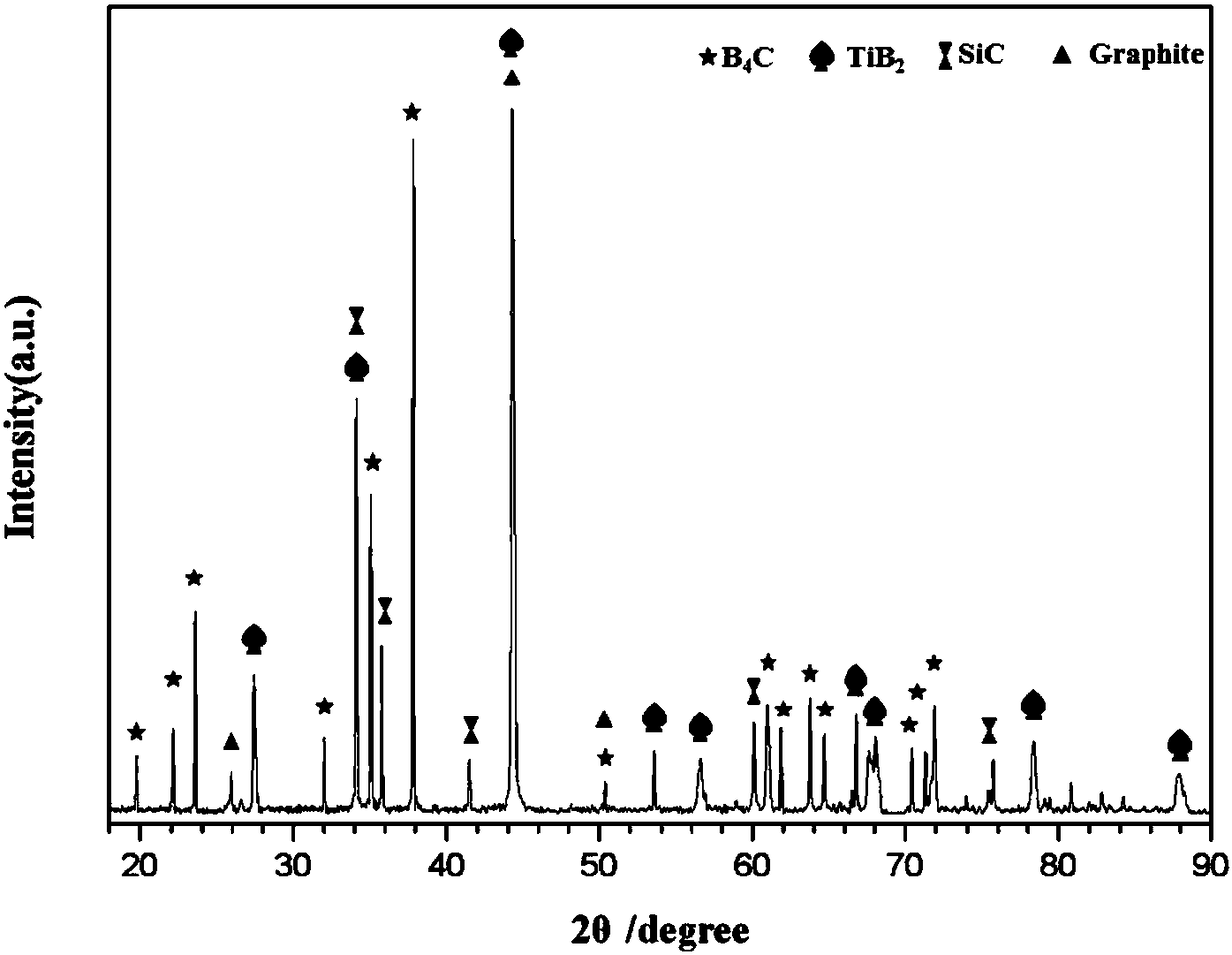

Boron carbide-titanium boride multiphase ceramic material and pressureless sintering preparation method thereof

The invention relates to a boron carbide-titanium boride multiphase ceramic material and a pressureless sintering preparation method thereof, and belongs to the technical field of structural ceramics.Calculated by using total mass of a multiphase ceramic raw material as 100%, the boron carbide-titanium boride multiphase ceramic material is prepared from the following components according to a mass percent: 50%-80% of boron carbide powder, 10%-30% of titanium boride powder, 3%-20% of amorphous carbon powder, and 5%-30% of silicon powder. The method comprises the following steps: mixing raw materials and adding to medium solution, ball-milling and mixing to obtain mixed slurry; after drying the mixed slurry, grinding, sieving to obtain powder; performing compression mould forming on the powder, and performing isostatic cool pressing to obtain a green body; and performing high-temperature pressureless sintering on the green body in vacuum or a protecting gas to obtain the boron carbide-titanium boride multiphase ceramic material. The toughness of the material is apparently improved, the production cost is greatly reduced, and the material can be extensively suitable for the fields ofnuclear power, light armored protection and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

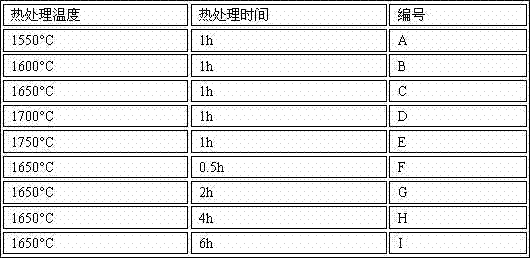

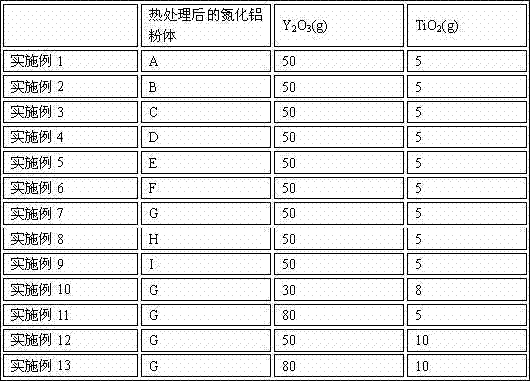

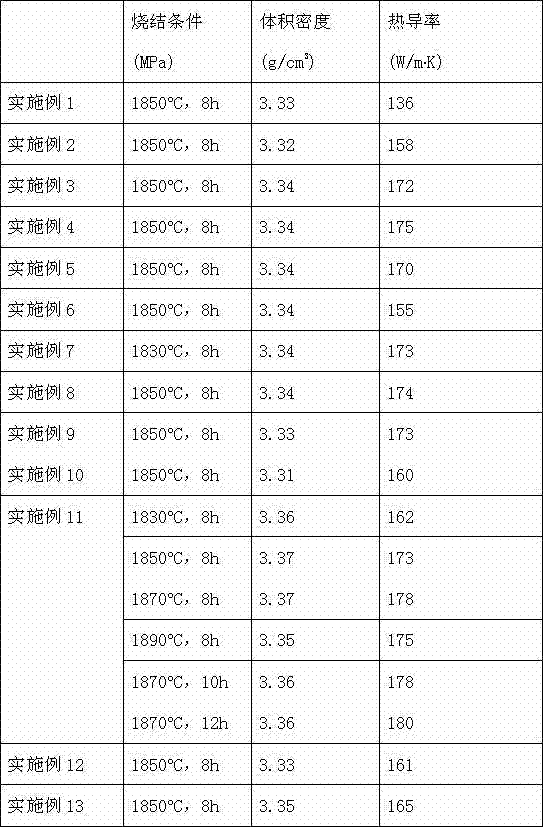

Method for preparing high-heat-conductivity aluminum nitride ceramics by self-propagating powder

The invention relates to the field of preparation of aluminum nitride ceramics and provides a method for preparing high-heat-conductivity aluminum nitride ceramics by self-propagating powder. Heat conductivity of the aluminum nitride ceramics obtained by the method is larger than 160 W / m by K, heat transfer performance is high, and high-power LED packaging requirements can be met. The method includes of thermal pre-treatment of self-propagating powder and preparation of tape casting slurry, tape casting green-ware and ceramic substrates. The thermal-pretreatment of the self-propagating powder includes treating the self-propagating aluminum nitride powder in a graphite oven at the high temperature, the preparation of tape casting slurry includes preparing sintering additives which are Y2O3 and TiO2 composition, the Y2O3 additive amount is 3-8wt%, the TiO2 additive amount is 0.5-1wt%, and the preparation of ceramic substrates adopts high-temperature pressureless sintering.

Owner:FUJIAN HUAQING ELECTRONICS MATERIAL TECH

NiAl intermetallic compound porous material and preparation method thereof

The invention relates to a NiAl intermetallic compound porous material and a preparation method thereof, which belong to the field of inorganic materials. The invention provides a NiAl intermetallic compound porous material with good combination property and a preparation method thereof. The novel NiAl intermetallic compound porous material has communicated three-dimension solid network apertures and the porosity of 30 percent and 55 percent, the biggest pore is from 5 microns and 50 microns; wherein, the atom weight portions of Ni and Al in the material is equal to 60 to 90 : 10 to 40. The preparation method is that Ni and Al powders with a certain granularity are firstly mechanically mixed evenly, and then go through compression molding cold forming, finally the porous material is obtained by a sectional type vacuum pressureless sintering mode. The method has low energy consumption and almost no contamination, and the porous structures can be controlled independently. The NiAl intermetallic compound porous material of the invention has excellent high-temperature mechanical properties, good acid-resistance and alkali-resistance properties, high-temperature oxidation resistance property and excellent filtering quality, and can be used in the fields such as high temperature, separation and the like.

Owner:CHENGDU INTERMENT TECH

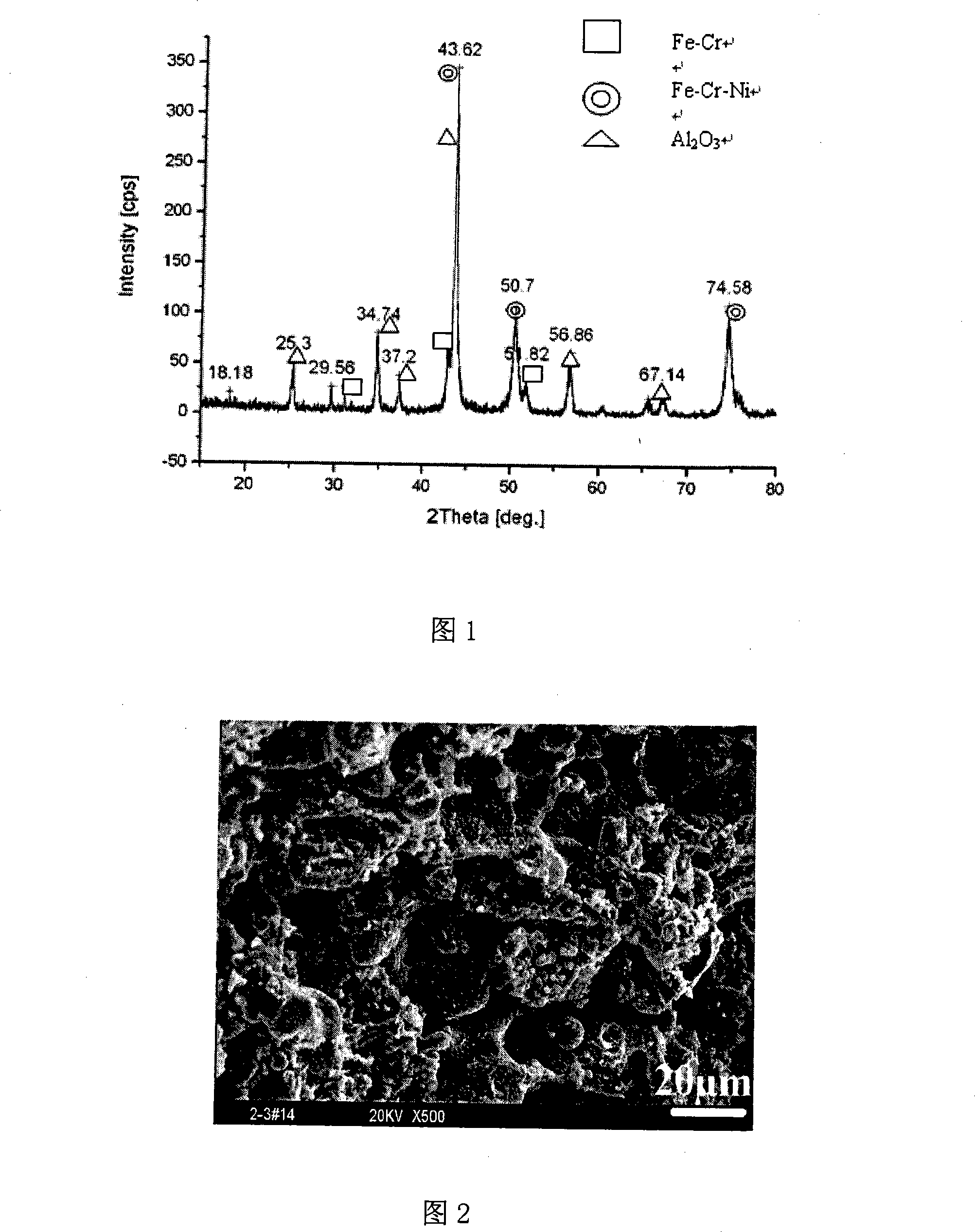

Method for preparing ceramic reinforced metal-based porous composite material

The invention discloses a low-cost low-temperature quick preparation method for nano Al2O3 ceramic original position enforcing Fe-Cr-Ni-base high temperature alloy porous compound material. Initializing powder is prepared in a powder metallurgy mixing component method, nano grade Fe2O3, Cr2O3, Ni2O3 powder and nano grade Al, Ni, Cr, and Fe primitive powder are converted into mass percentage according to the stoichiometric proportion of the reaction formula to be weighed and mixed, and are performed with non-pressure sintering at 800 DEG C under the vacuum condition after being compressed into billet, the whole sintering process is performed through the aluminum thermal reaction method, and minute multi-alloy elements are matched in the component compounding ratio to adjust the air hole rate and to enhance the mechanical property of the material. The method can greatly reduce the preparation temperature, reduce the preparation time, and also reduce the production cost.

Owner:XI AN JIAOTONG UNIV

Method for preparing Ti2AlNb base alloy through powder metallurgy

The invention provides a method for preparing a Ti2AlNb base alloy through a powder metallurgy process, and belongs to the technical field of titanium alloy preparation. The method is characterized bypreparing a Ti2AlNb base intermetallic compound by using alloy powder, prepared by a hydrogenation / dehydrogenation method, through vacuum pressureless sintering, and comprises the following steps: sponge titanium and an aluminum-niobium alloy are added in a hydrogenation furnace for hydrogenation and crushing classification; and then, simple substance aluminum powder is added for self-propagatingdispersion at 700-900 DEG C to form primary prealloying powder. Finally, a high-compactness and large-size Ti2AlNb alloy ingot is prepared through cold isostatic pressing and vacuum pressureless sintering. A Ti2AlNb alloy material is prepared by using low-cost element powder through hydrogenation / dehydrogenation, cold isostatic pressing and vacuum sintering; the process is simple; and the cost islow. The method can prepare the nearly full-compactness Ti2AlNb alloy with the compactness of more than 98%; and the Ti2AlNb alloy is uniform and fine in material organization, excellent in hot working performance and suitable for industrial scale popularization.

Owner:天钛隆(天津)金属材料有限公司

Porous ceramic carrier for high-temperature and high-pressure inorganic filtering membrane and preparation method for porous ceramic carrier

The invention discloses a porous ceramic carrier for a high-temperature and high-pressure inorganic filtering membrane and a preparation method for the porous ceramic carrier. The porous silicon carbide ceramic carrier is prepared by silicon carbide, a binding agent and a pore-forming agent, wherein the mass ratio of the silicon carbide to the binding agent is 80-90:10-20, and the utilization quantity of the pore-forming agent is 35-45% of the sum of the volumes of the silicon carbide, the binding agent and the pore-forming agent. The preparation method includes adding the binding agent and the pore-forming agent in silicon carbide powder; performing ball milling, drying and vacuum heat casting forming; and performing pressureless sintering for a formed blank. Sintering temperature rangesfrom 1250 DEG C to 1350 DEG C, and heat insulation time ranges from 2 hours to 4 hours. As raw materials form main materials by means of fine size grading, the binding agent and the pore-forming agent are added by a special process, technologies such as unique vacuum heat casting forming and the like are adopted, and mechanical strength and porosity of the porous carrier can be improved effectively. The prepared silicon carbide porous ceramic carrier has excellent performances of fine thermal shock resistance, low coefficient of thermal expansion, fine mechanical and chemical stability at high temperature and under high pressure, and the like.

Owner:TSINGHUA UNIV

Preparation method of micro-nano particle reinforced aluminium matrix composite

The invention provides a preparation method of a micro-nano particle reinforced aluminium matrix composite and belongs to the field of an aluminium matrix composite preparation technology. The method comprises the following steps: carrying out high-energy ball milling on powdery aluminium base alloy and reinforcement powder; carrying out vacuum drying on the prepared composite powder after the end of ball milling and sieving; and carrying out supersonic vibration on the dried and sieved composite powder and carrying out pressureless sintering on the dispersible powder by controlling sintering atmosphere so as to prepare a fully-densified powder metallurgy aluminum matrix composite blank, and carrying out hot working such as extrusion, rolling, die forging and the like on the blank so as to obtain the required aluminium matrix composite. By a brand-new activated sintering densification technology, the composite powder directly undergoes supersonic vibration and densification sintering under atmosphere protection without pressing so as to prepare the fully-densified micro-nano particle reinforced aluminium matrix composite blank. The prepared aluminium matrix composite has uniform reinforcement phase distribution and excellent product performance. The method has no limit in size and shape of the product, is low-cost and is suitable for large-scale production.

Owner:天津海力特新材料有限公司

Diamond grinding block and preparation thereof

InactiveCN101407045AReduce heat damageLower sintering temperatureAbrasion apparatusGrinding devicesEpoxyProduction line

The invention provides a method for preparing a diamond grinding block, which belongs to the technical field of powder metallurgy metal base composite material. The method comprises the following steps: using Fe-Cu-Sn superfine prealloyed powder and low grade diamond as raw materials, using a nontoxic gel injection mold forming technology and a low temperature pressureless sintering technology to prepare tool bits, and then adhering the tool bit by using epoxy resin to assemble the tool bits together so as to obtain a high performance diamond grinding block which is applied to the stone materials and ceramics polishing production line. The method has the advantages of no noble metals such as Co, Ni and the like, low cost, low sintering temperature for the tool bits, small thermal damage to the diamond, good grinding and polishing effect, long service life, and good product consistency, environmental protection and no pollution.

Owner:UNIV OF SCI & TECH BEIJING

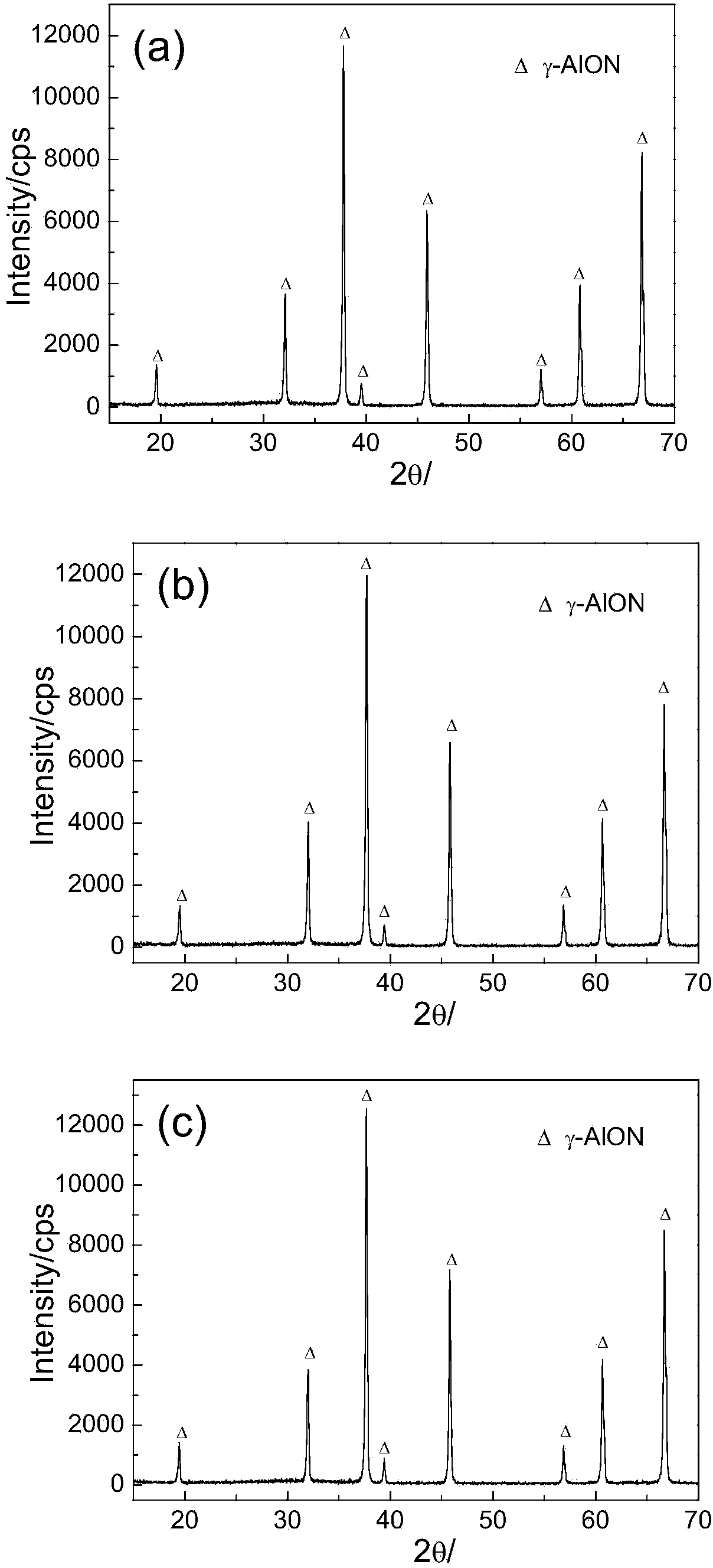

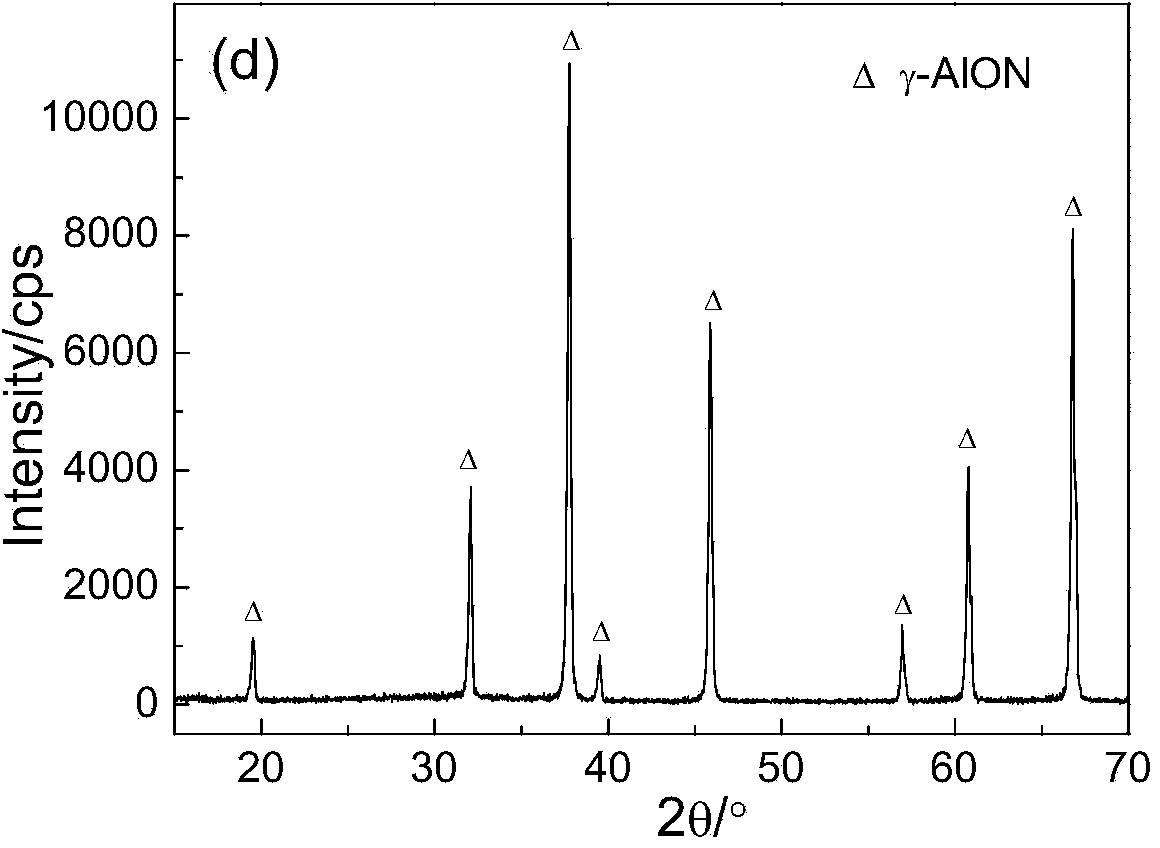

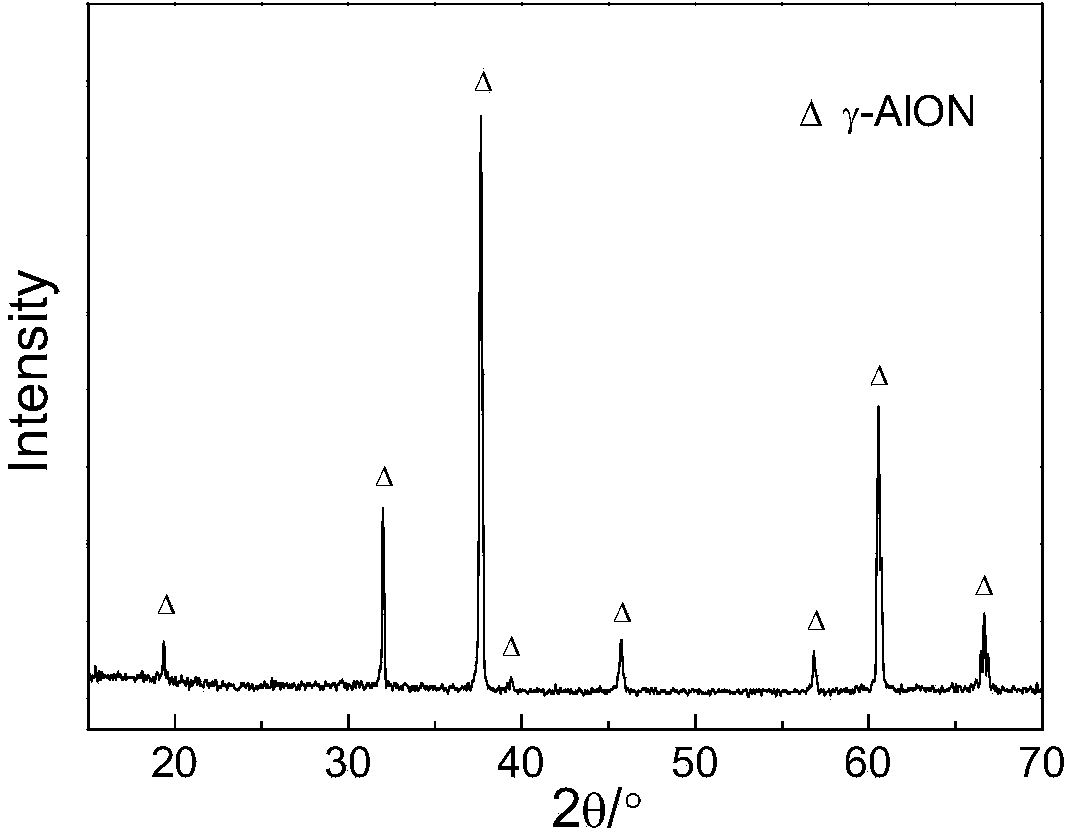

Preparation method for gamma-AlON transparent ceramic powder

The invention relates to a method for preparing pure-phase gamma-AlON transparent ceramic powder by carbothermal reduction of gamma-Al2O3, and belongs to the field of preparation of transparent ceramic materials. According to the preparation method, nano-alpha-Al2O3 and activated carbon are taken as raw materials; powder is filled in a graphite crucible loosely, wherein an aluminum oxide plate is paved at the bottom of the graphite crucible; an air hole which penetrates through the powder is preformed at the aluminum oxide plate; a graphite cover provided with fine and dense air holes is used for covering the hole; the pure-phase gamma-AlON transparent ceramic powder is prepared by adopting a two-step heating process in a flowing nitrogen environment with a micro positive pressure. By the adoption of the preparation method, the vacuumizing difficulty can be effectively reduced, powder is prevented from scattering in a vacuumizing stage, the time required for discharging adsorbed gas can be greatly shortened, the vacuumizing speed is high, and the preparation efficiency of the gamma-AlON powder is greatly improved; the obtained gamma-AlON powder phase has stable and reliable compositions and can be used for pressure-less sintering preparation of AlON transparent ceramics with high transmittance; the process is simple and is easy to operate, and is suitable for industrial production.

Owner:DALIAN MARITIME UNIVERSITY

Aluminium nitride reinforced sibicon carbide ceramic and its preparation method

The invention relates to an aluminum nitride reinforced SiC ceramics, and its weight percentage composition of: SiC 80% ~ 94%, aluminum nitride 5% ~ 19%, yttrium oxide 1% ~ 2%. The invention also open the ceramics production methods, including the following steps : 1) all of the above components as raw added into deionized water, then add the binder, mixture of water-soluble polymer and dispersant, milling 5 ~ 20 hours, then form water-based silicon carbide slurry; 2) use spray granulation process to treat water-based silicon carbide slurry for spray drying, made of SiC powder; 3) using dry-press precompression and cold isostatic pressing final pressure to silicon carbide powder to obtain SiC blank; 4) put the SiC blank into vacuum pressureless sintering furnace, at 1950 ~ 2200 deg for 1 ~ 5 hours, gain enhanced aluminum nitride silicon carbide ceramics. The ceramic made by this method can meet the mechanical seal requirement of special conditions.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com