Patents

Literature

325 results about "Sintered alloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sintered aluminum powder alloys have properties quite different from those of material fabricated by conventional techniques. The oxide that forms immediately on the surface of aluminum is not reduced back to metal during sintering and the resulting powder product contains a substantial amount of oxide.

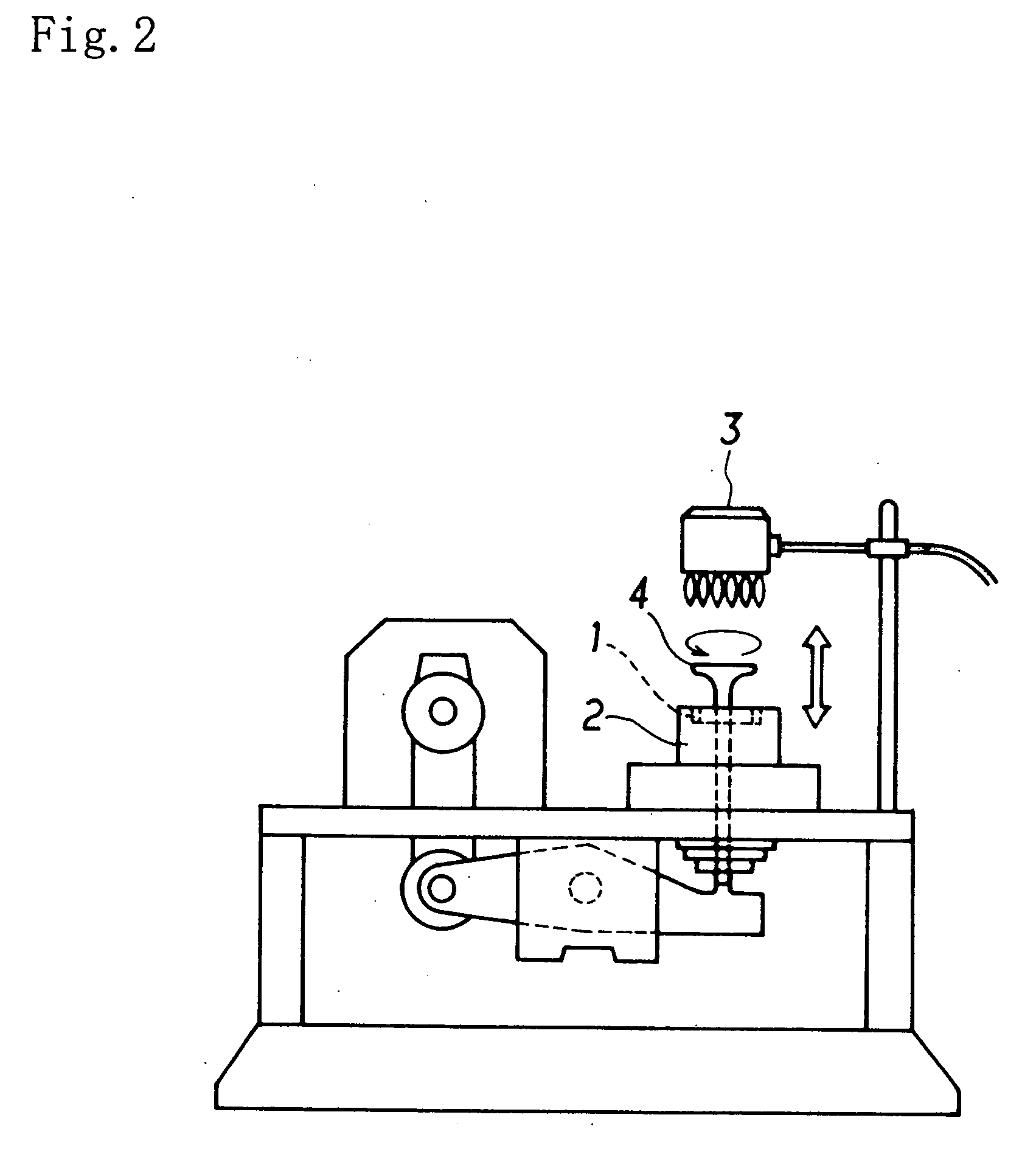

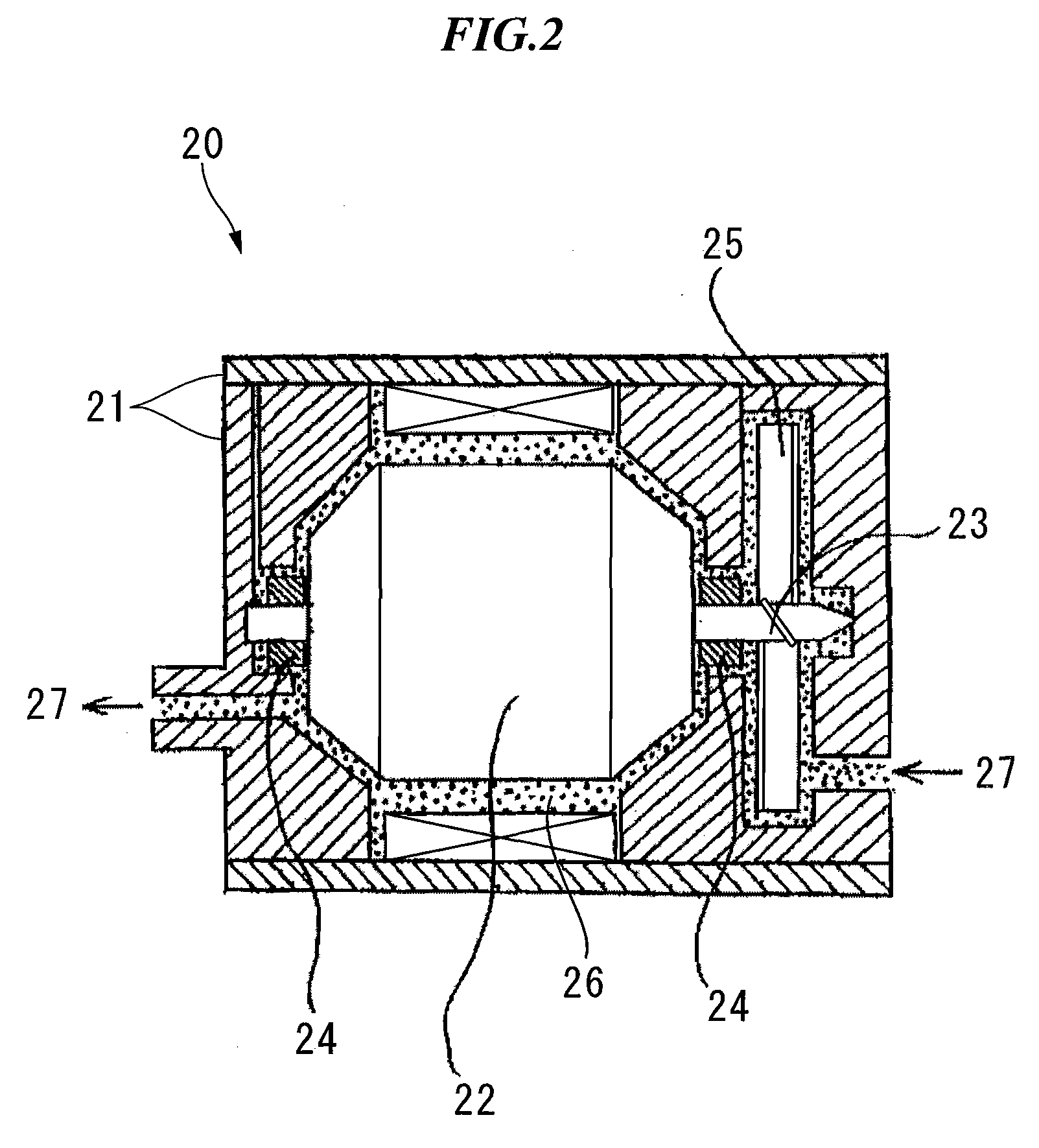

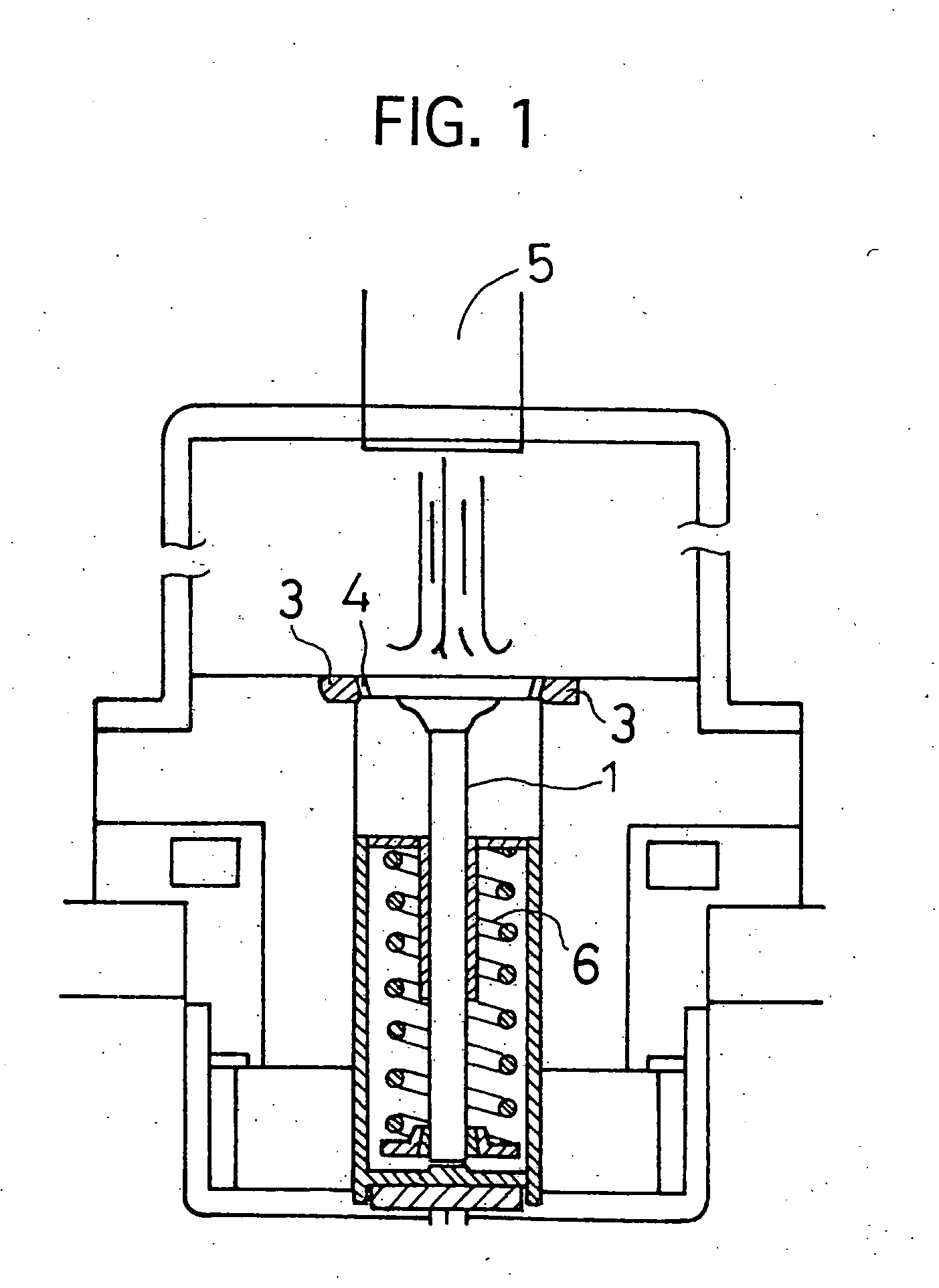

Electrically powered steering device

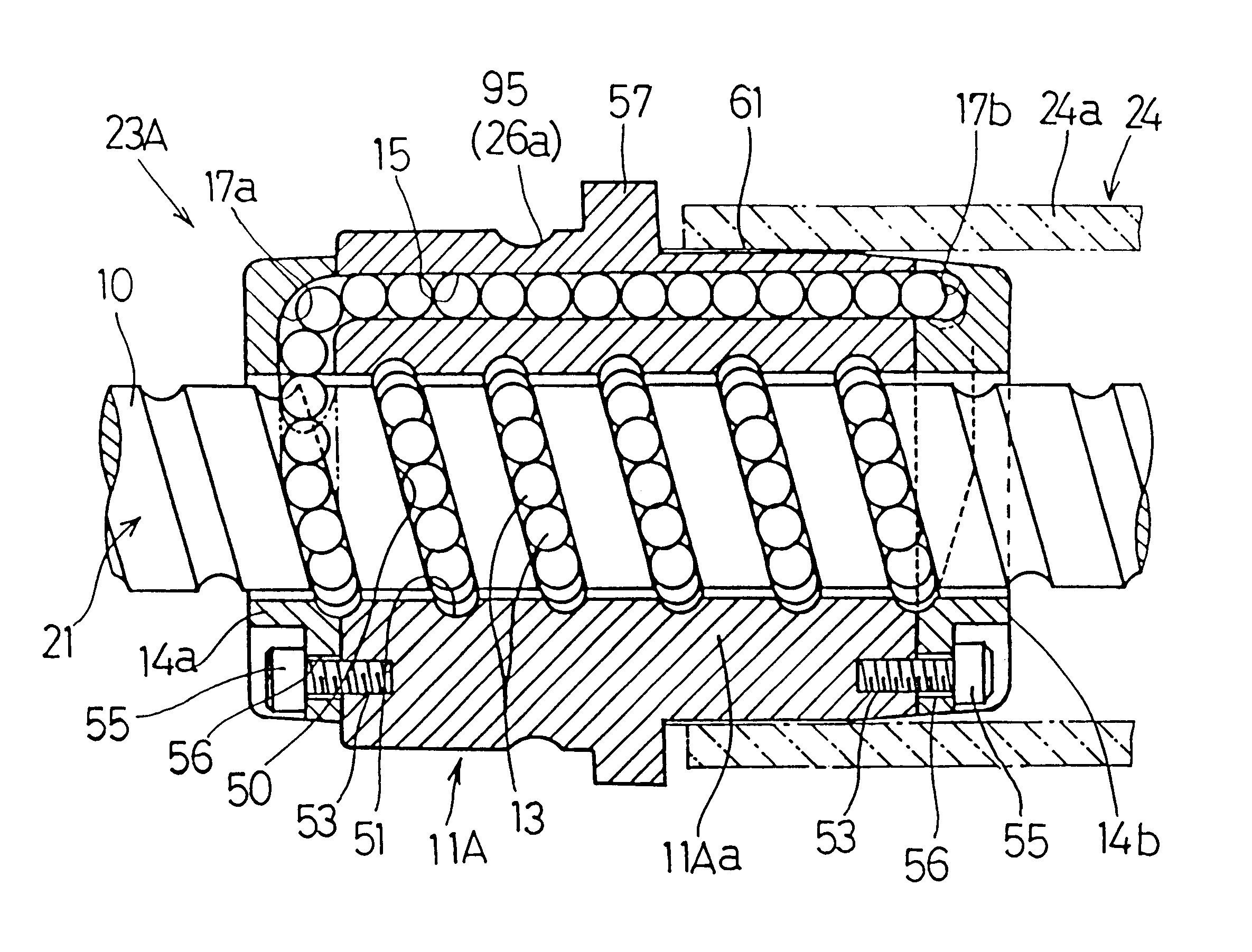

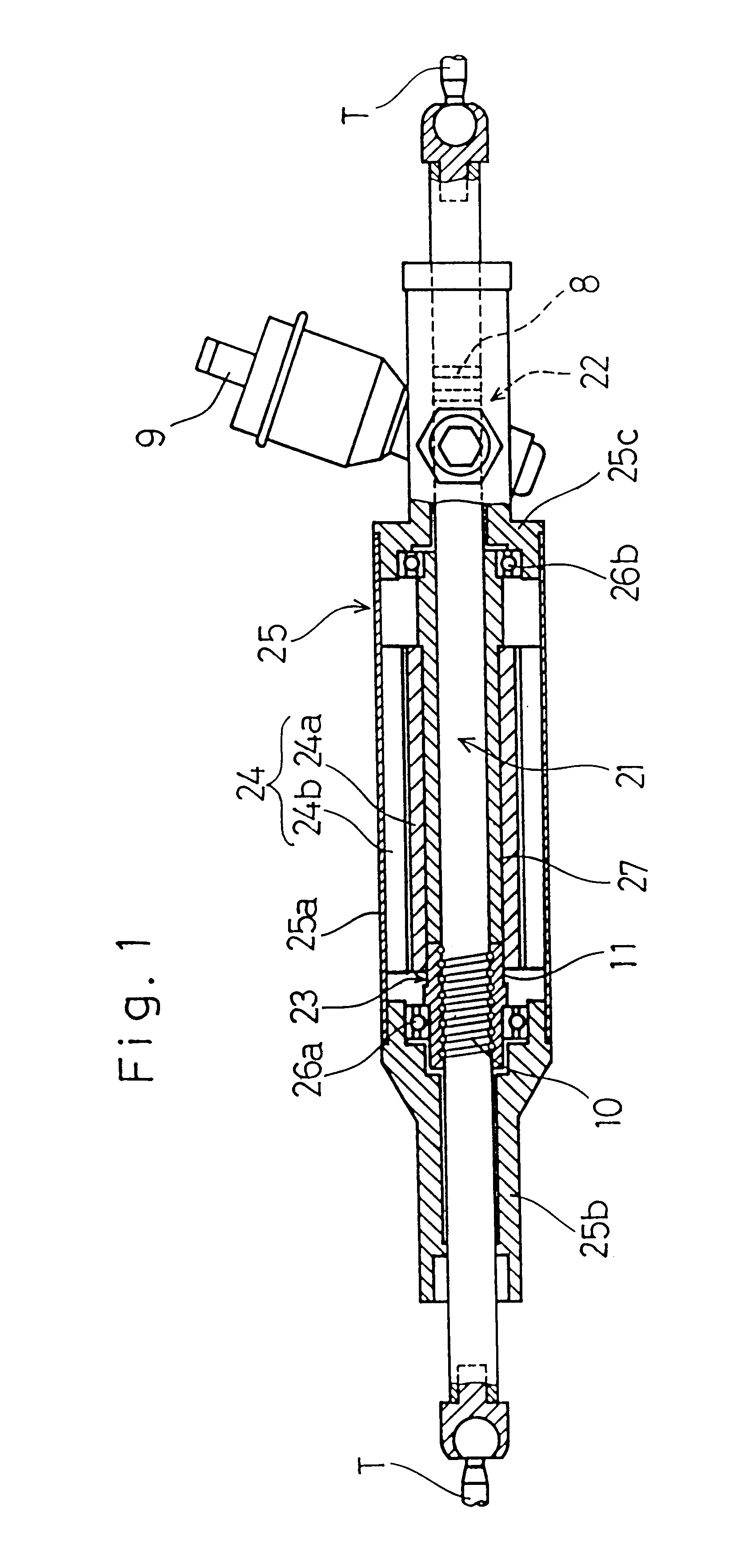

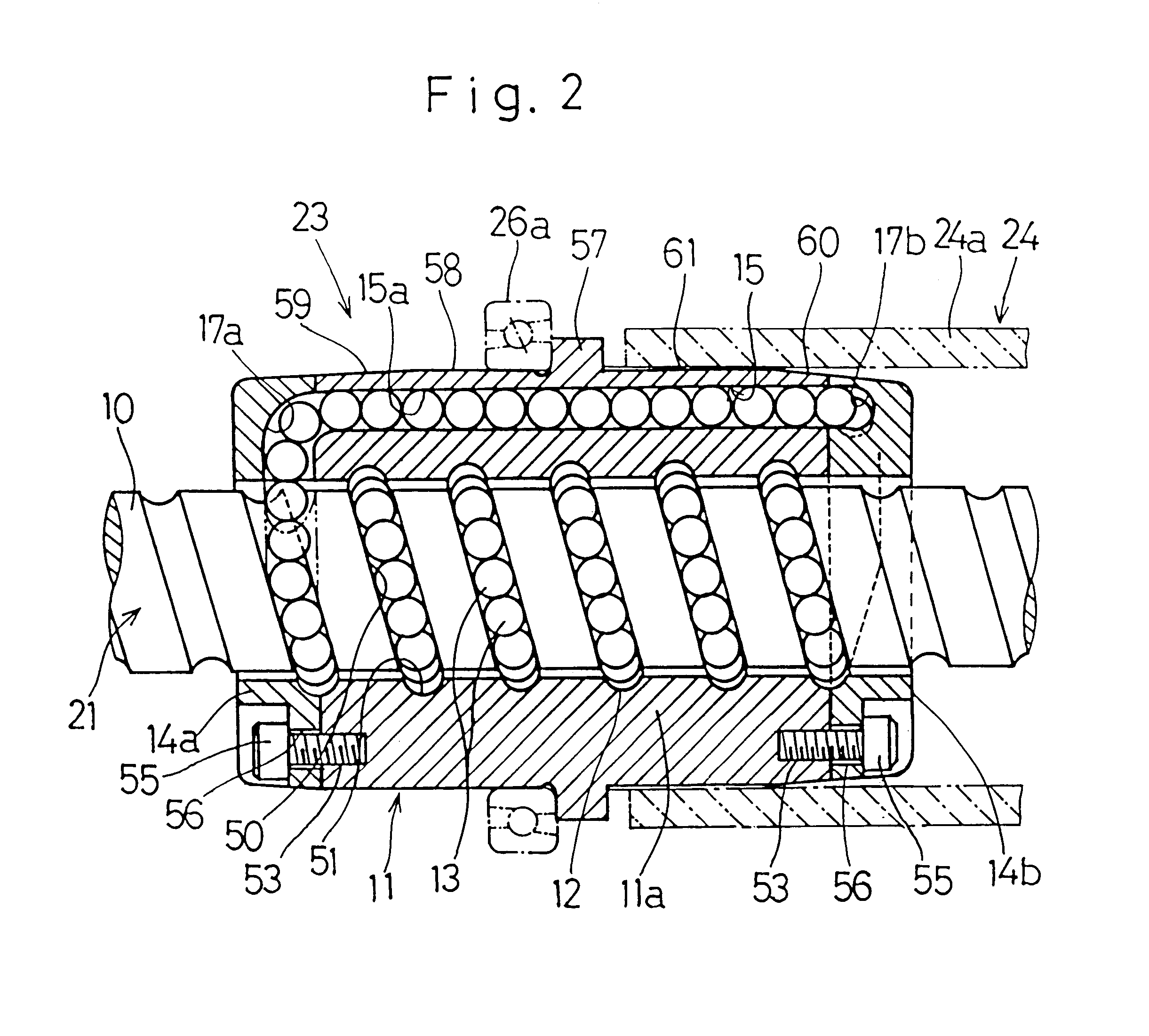

An electrically powered steering device comprises a ball screw mechanism for transmitting a steering force from a steering wheel to steerable vehicle wheels. The ball screw mechanism includes a rotary nut 11 having a nut body 11a in which a circulating passage 15 is formed so as to extend axially thereof, and end caps 14a and 14b secured respectively to opposite ends of the nut body 11a. Each of the end caps 14a and 14b has defined therein respective guideways 17a and 17b for balls 13 that communicate opposite ends of the circulating tunnel 14 with a ball rolling passage 12. The end caps 14a and 14b and the nut body 11a are made of a sintered alloy. The nut body 11a has an outer periphery of one end thereof that is axially progressively reduced in diameter to define a tapered surface.

Owner:NTN CORP

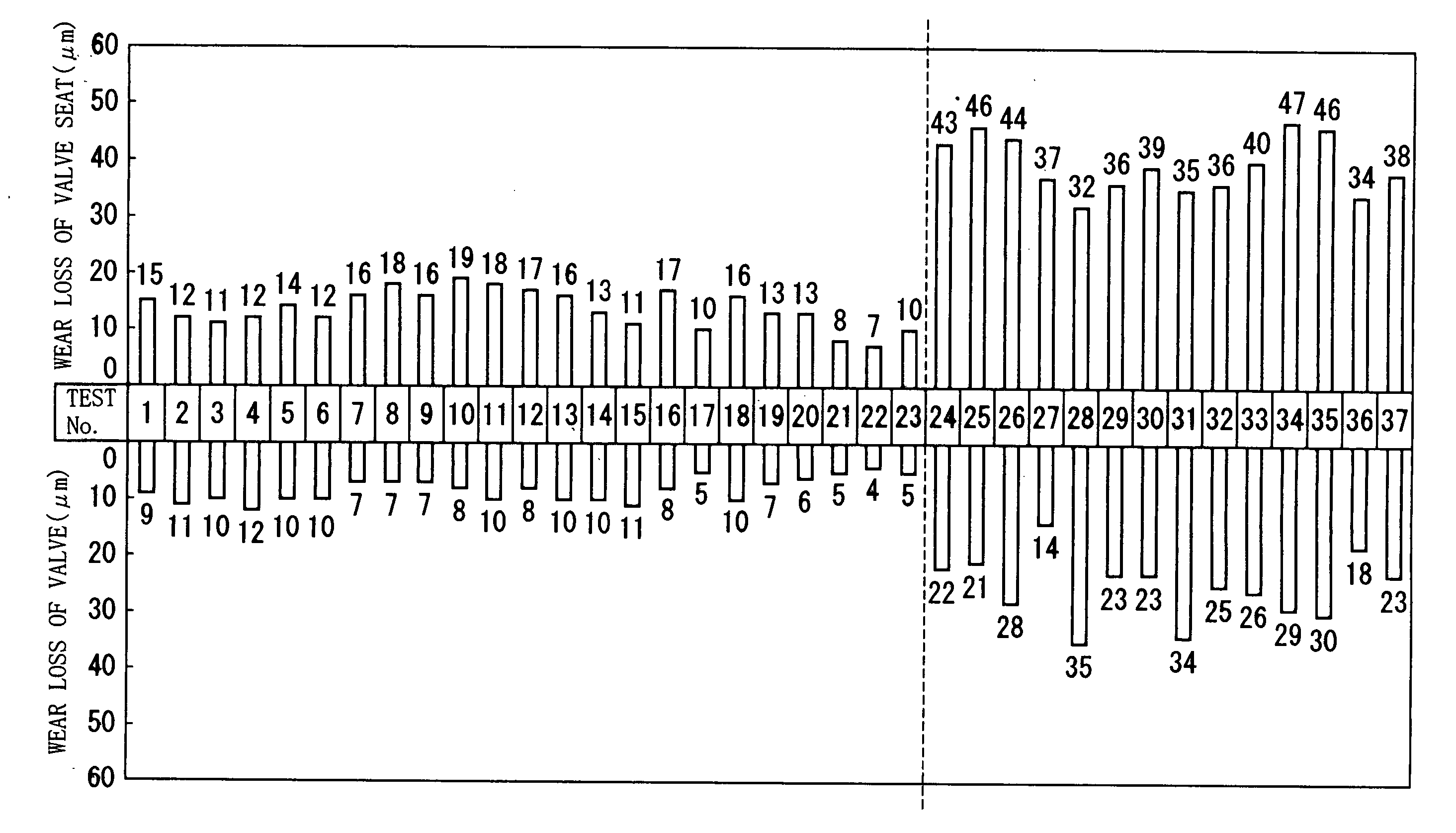

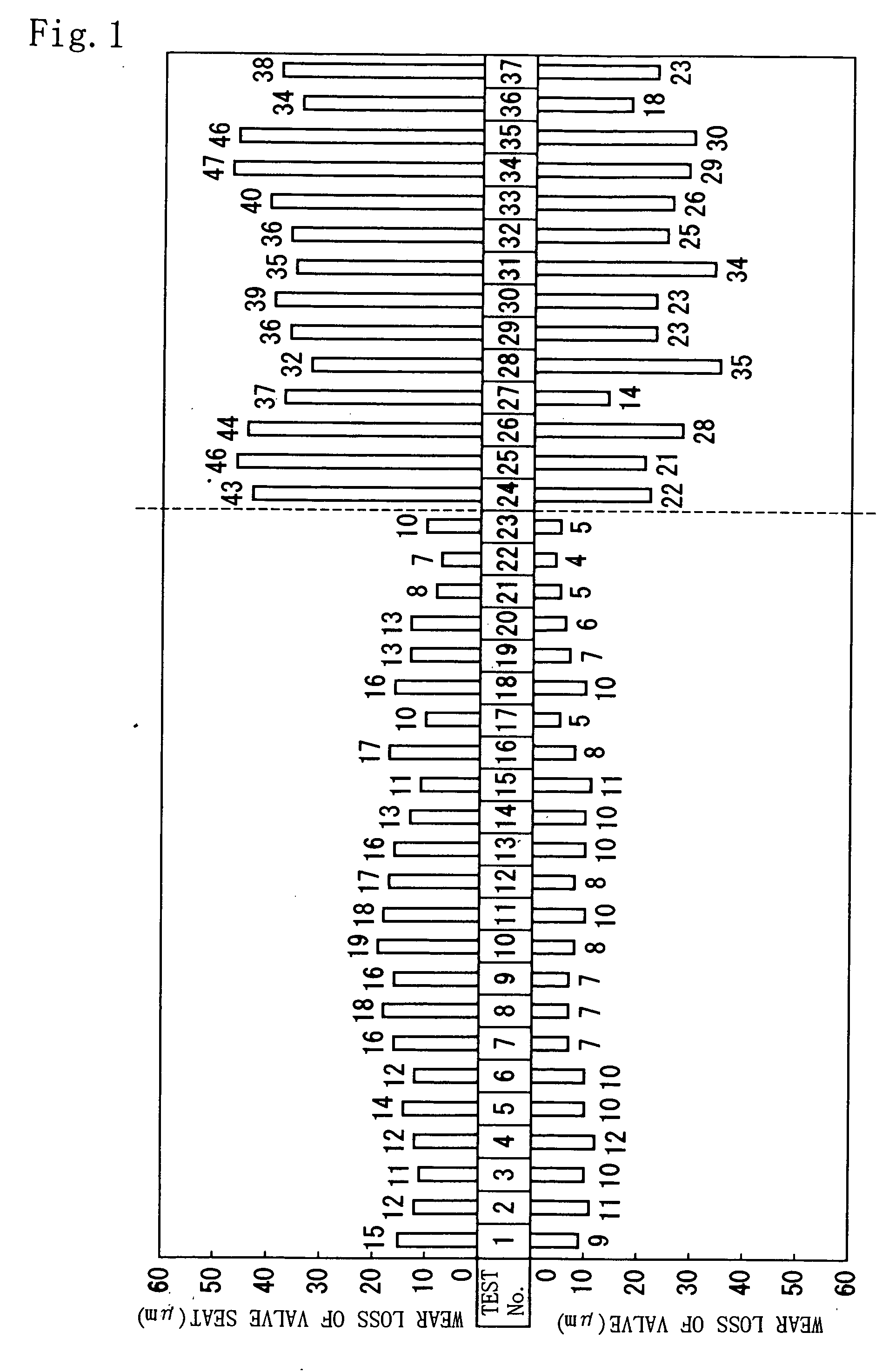

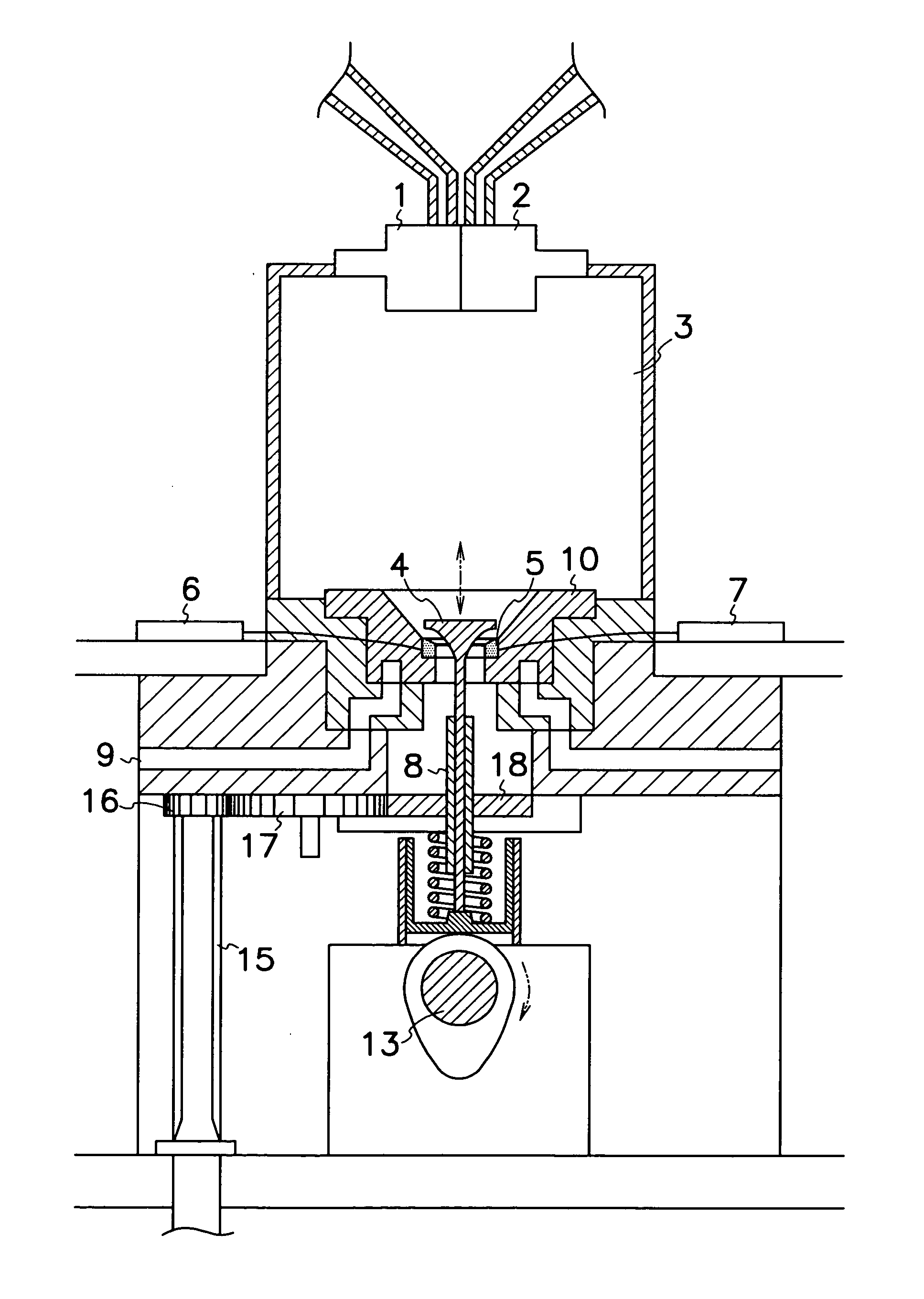

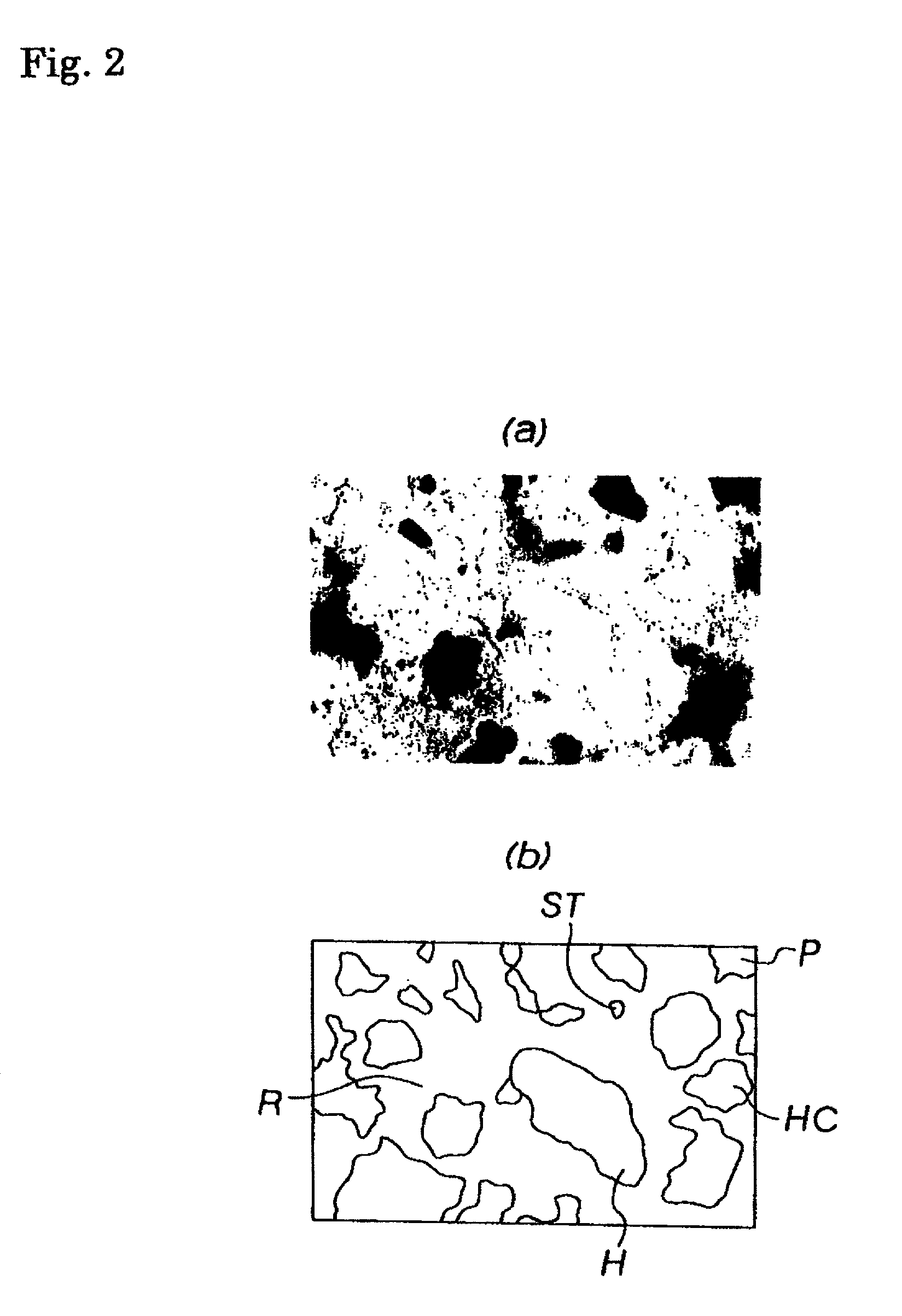

Abrasion resistant iron base sintered alloy material for valve seat and valve seat made of iron base sintered alloy

InactiveUS6139599AAbrasion resistance of the sintered alloy material is remarkably increasedIncrease resistanceMachines/enginesSlide valveCarbideHardness

A valve seat made of an iron base sintered alloy for internal combustion engines comprises of hard particles of hardness 700-1300 Hv dispersed by 3-20% by volume in a matrix phase comprising comprising of a 5-40% psarlite phase, a 20-60% fine carbide dispersed phase, and a 5-20% high alloy diffusd phase. The hard paricles are preferably selected from a group of Mo-Ni-Cr-Si-Co intermetallic compound particles, Cr-Mo-Co intermetallic compound particles, and Fe-Mo alloy particles. The iron base sinteed alloy is conpised of, by weight, C: 0.2-2.0%, Cr: 1.0-9.0%, Mo: 1.0-9.0%, Si: 0.1-1.0%, W: 1.0-50%, V: 0.2-3.0%, one or more Cu, Co and Ni of 0.5-10.0% in total, and the remainder substantial Fe.

Owner:NIPPON PISTONRING CO LTD

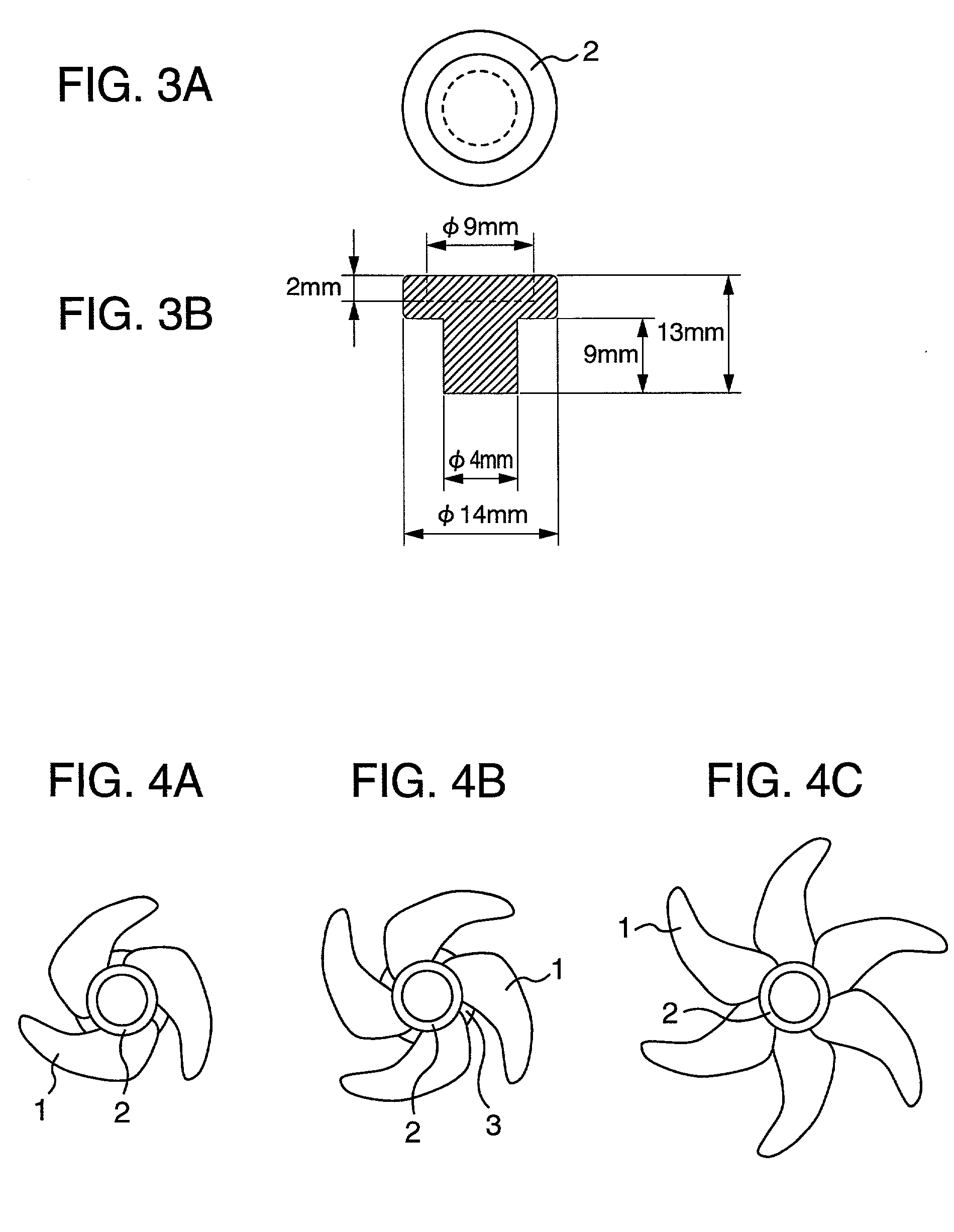

Electrode of a vacuum valve, a producing method thereof, a vacuum valve, a vacuum circuit-breaker and a contact point of the electrode

InactiveUS20020144977A1Improve circuit performanceWell formedContact materialsContact member manufacturingHigh conductivityMetal

The inventive electric contact point of a vacuum valve is made of a sintered alloy containing a heat-resistant metal and a high-conductivity metal. The contact point has at least three slit grooves which extend from the central region to the peripheral region of the contact point, and is soldered to an electrode rod which is connected to the contact point. The contact point includes at least three radially extending vane type contact point members each made of a sintered alloy containing a heat-resistant metal and a high-conductivity metal, and soldered to the electrode rod.

Owner:HITACHI LTD

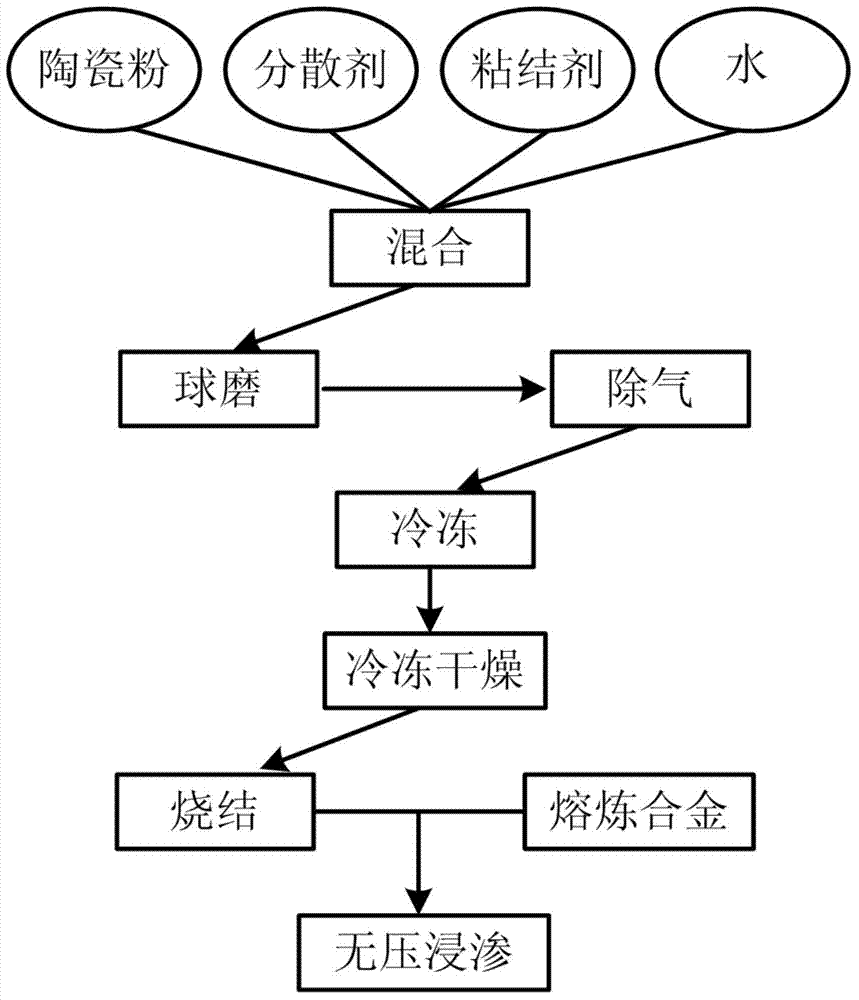

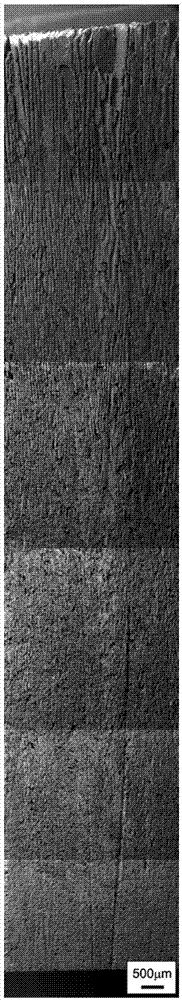

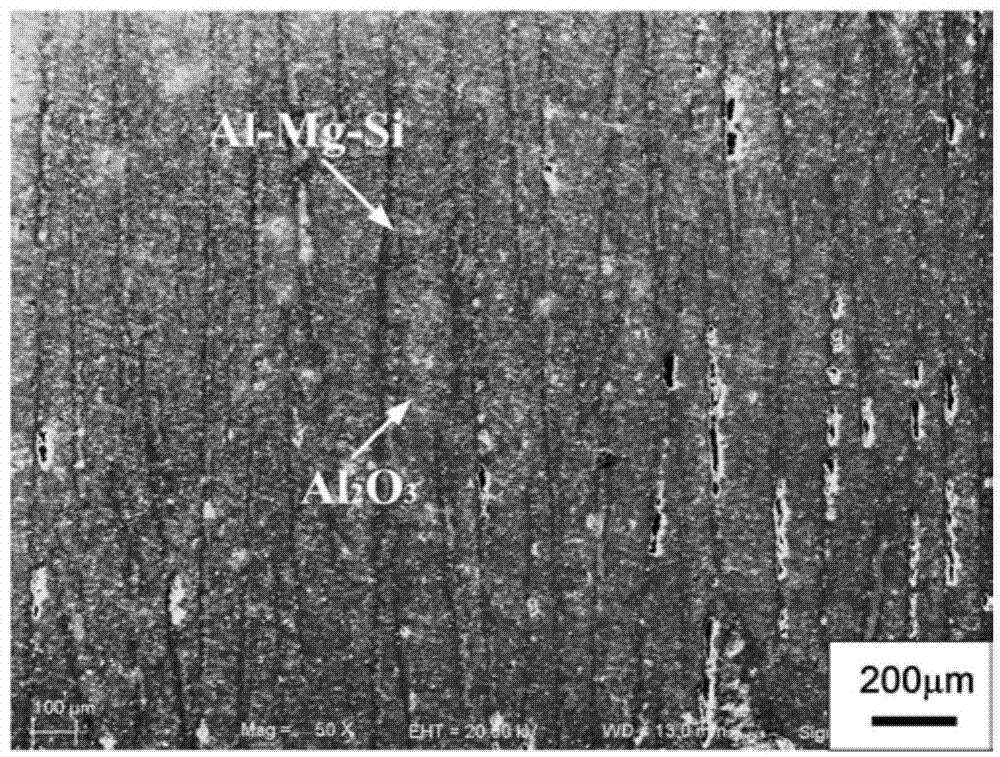

High-strength lamellar Al-based metal ceramic composite material and preparation method thereof

InactiveCN103895285ANot easy to sinterEasy to manufactureCeramicwareMetal layered productsWater basedMass ratio

The invention discloses a high-strength lamellar Al-based metal ceramic composite material and a preparation method thereof, aiming at solving the problems of high preparation cost, complex operation, single type of reinforcement ceramic and low strength. The high-strength lamellar Al-based metal ceramic composite material, i.e., high-strength lamellar structure Al-Si-Mg / (Al2O3, SiC, TiC) composite material comprises ceramic powder and Al-Si-Mg alloy. The volume fraction of ceramic powder is 20%-40vol%; the volume fraction of Al-Si-Mg alloy is 80%-60vol%; the mass ratio of aluminum in the Al-Si-Mg alloy is 75-84wt%; the mass ratio of silicon is 10-15wt%; the mass ratio of magnesium is 6-10wt%. The preparation method of the high-strength lamellar Al-based metal ceramic composite material comprises the following steps: preparation of water-based ceramic slurry; directional solidification; freezing and drying; sintering of blanks; smelting of alloy; and non-pressure infiltration.

Owner:JILIN UNIV

Rare earth alloy sintered compact and method of making the same

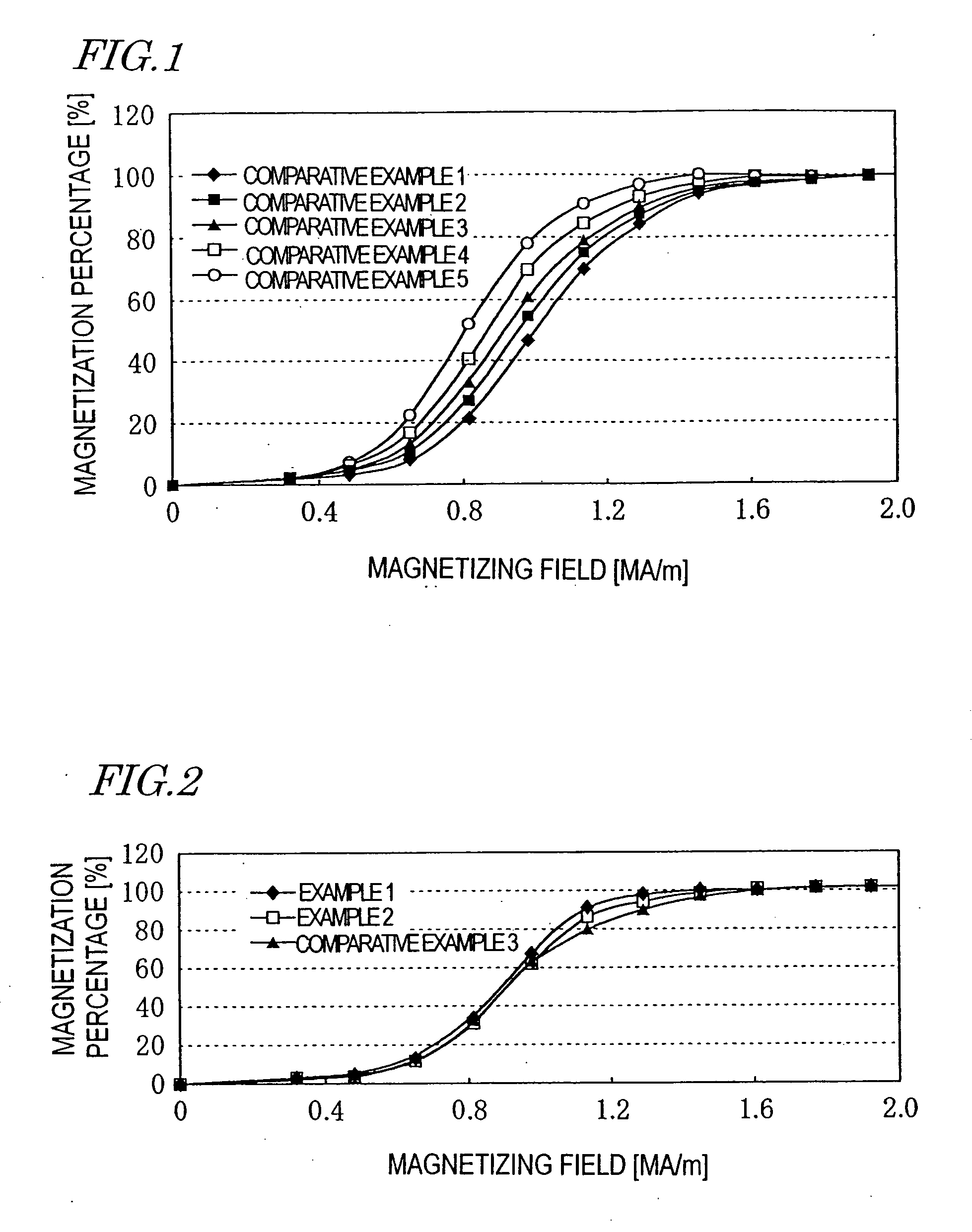

InactiveUS20050098238A1Fully magnetizedLower magnetizing fieldInductances/transformers/magnets manufactureMagnetic materialsRare-earth elementBoron

A rare earth alloy sintered compact includes a main phase represented by (LR1-xHRx)2T14A, where T is Fe with or without non-Fe transition metal element(s); A is boron with or without carbon; LR is a light rare earth element; HR is a heavy rare earth element; and 0<x<1. The sintered compact is produced by preparing multiple types of rare earth alloy materials including respective main phases having different HR mole fractions, mixing the alloy materials so that the sintered compact will include a main phase having an average composition represented by (LR1-xHRx)2T14A, thereby obtaining a mixed powder, and sintering the mixed powder. The alloy materials include first and second rare earth alloy materials represented by (LR1-uHRu)2T14A (where 0≦u<x) and (LR1-vHRv)2T14A (where x<v≦1) and including a rare earth element R(=LR+HR) at R1 and R2 (at %), respectively. ΔR=|R1−R2| is about 20% or less of (R1+R2) / 2.

Owner:HITACHI METALS LTD

Pb-free bearing used for fuel-injection pump

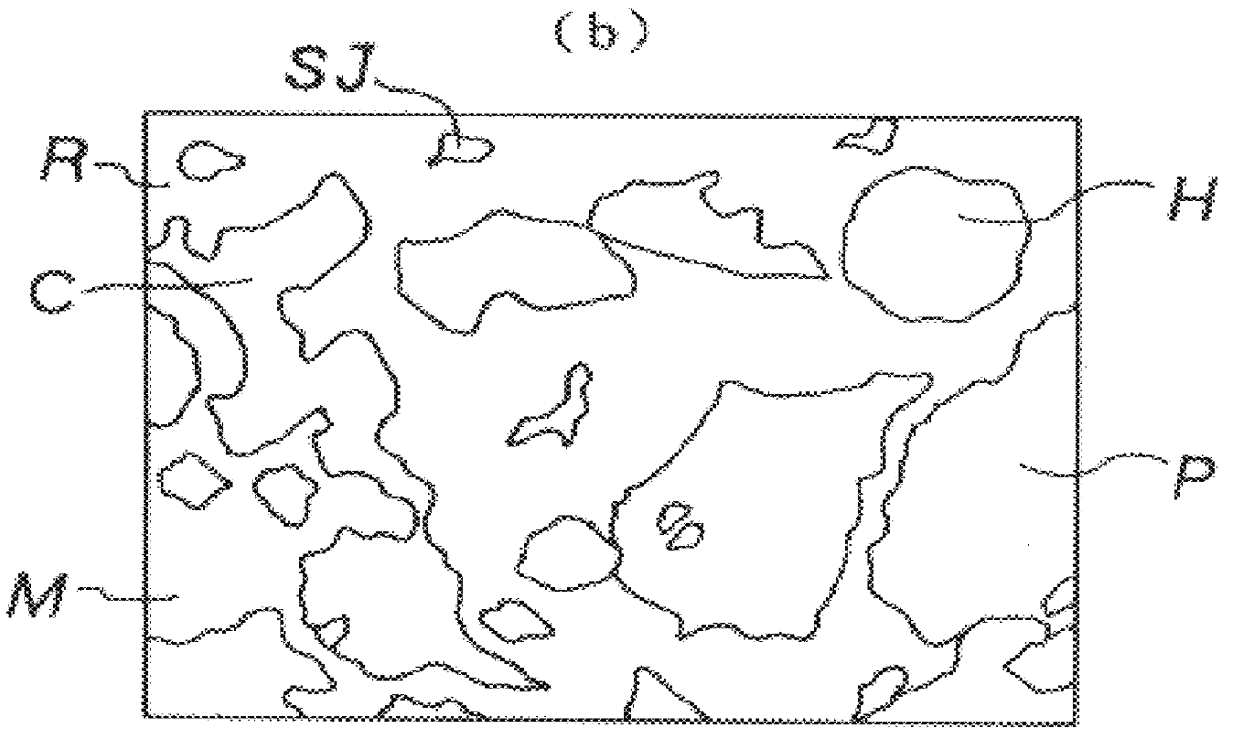

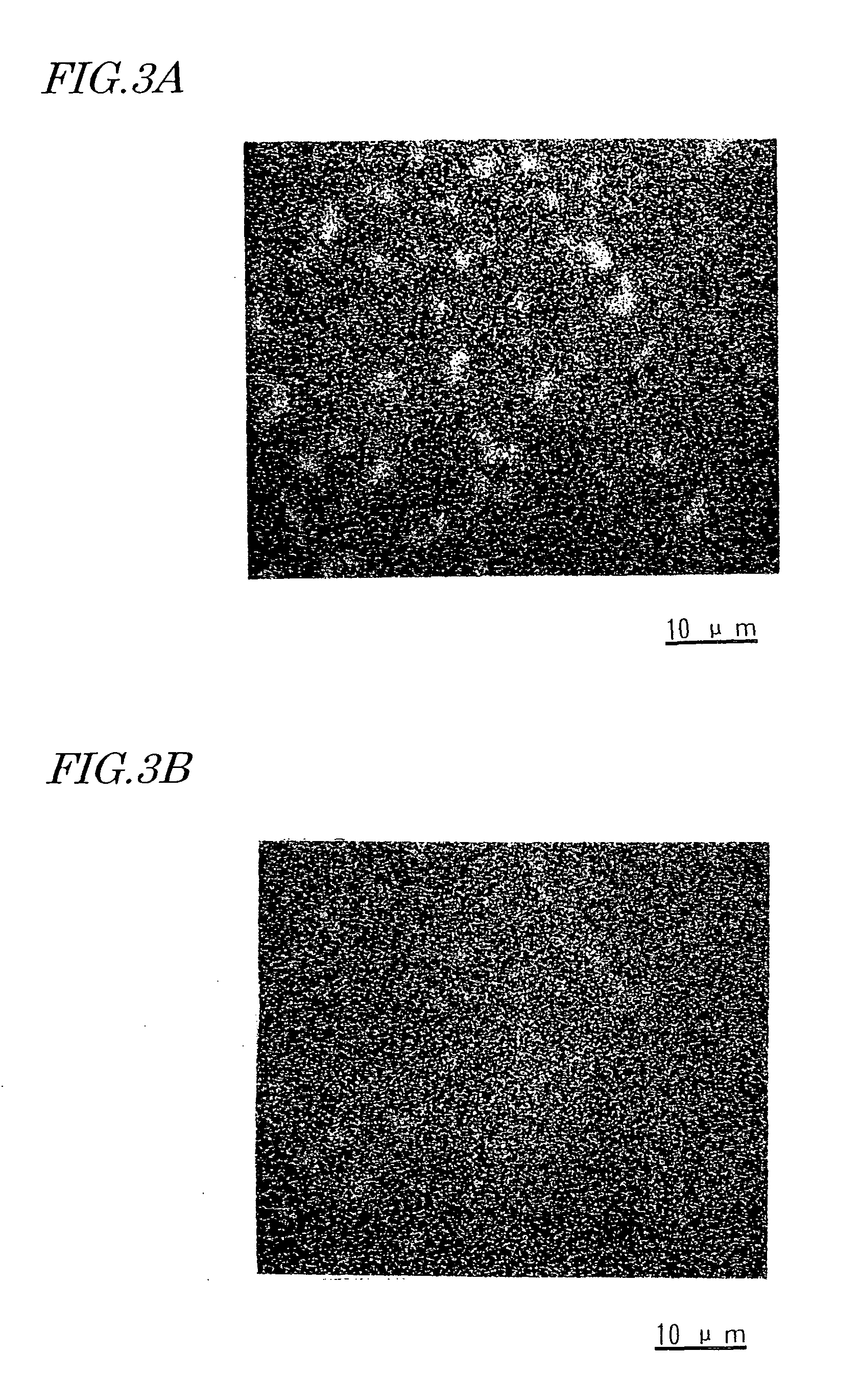

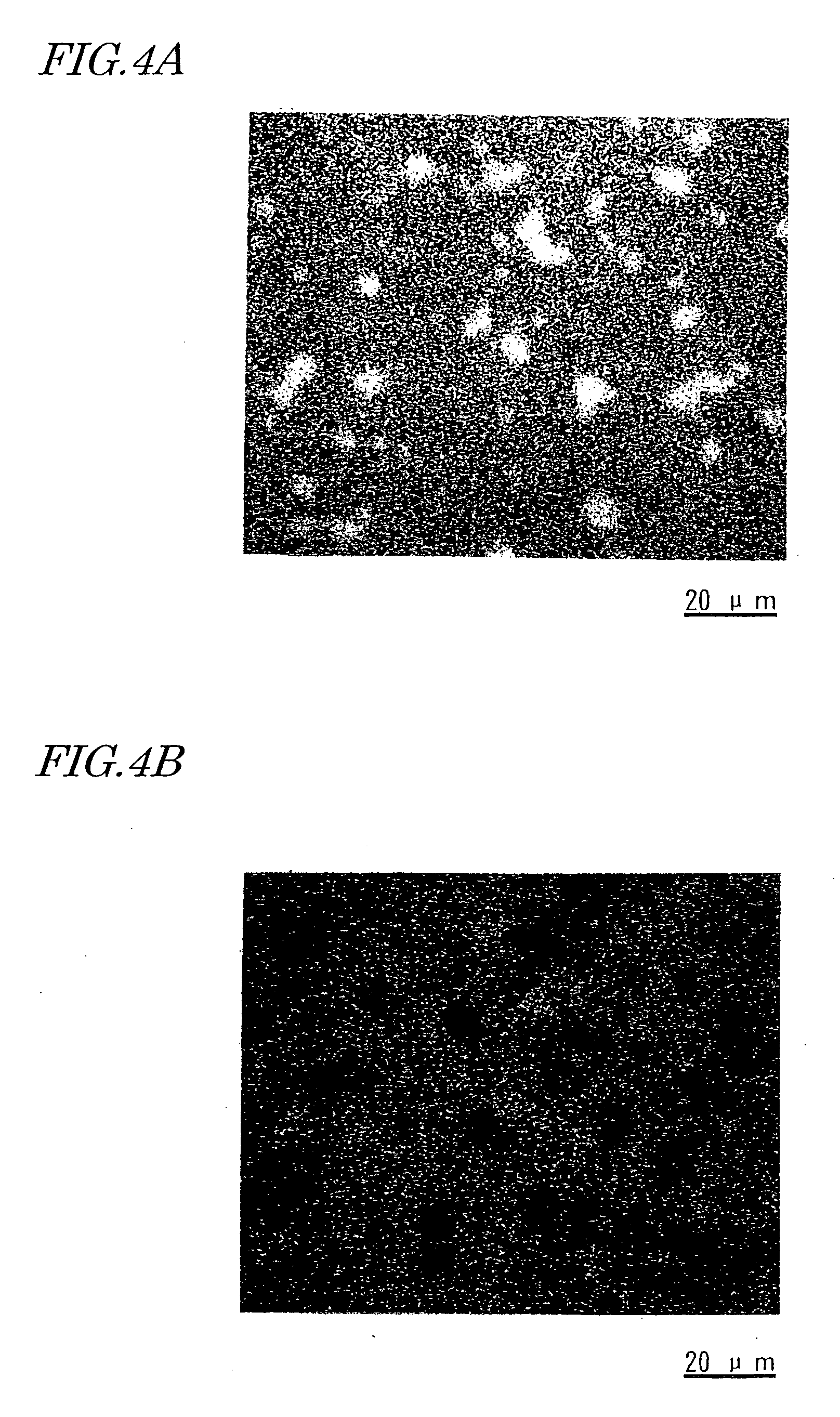

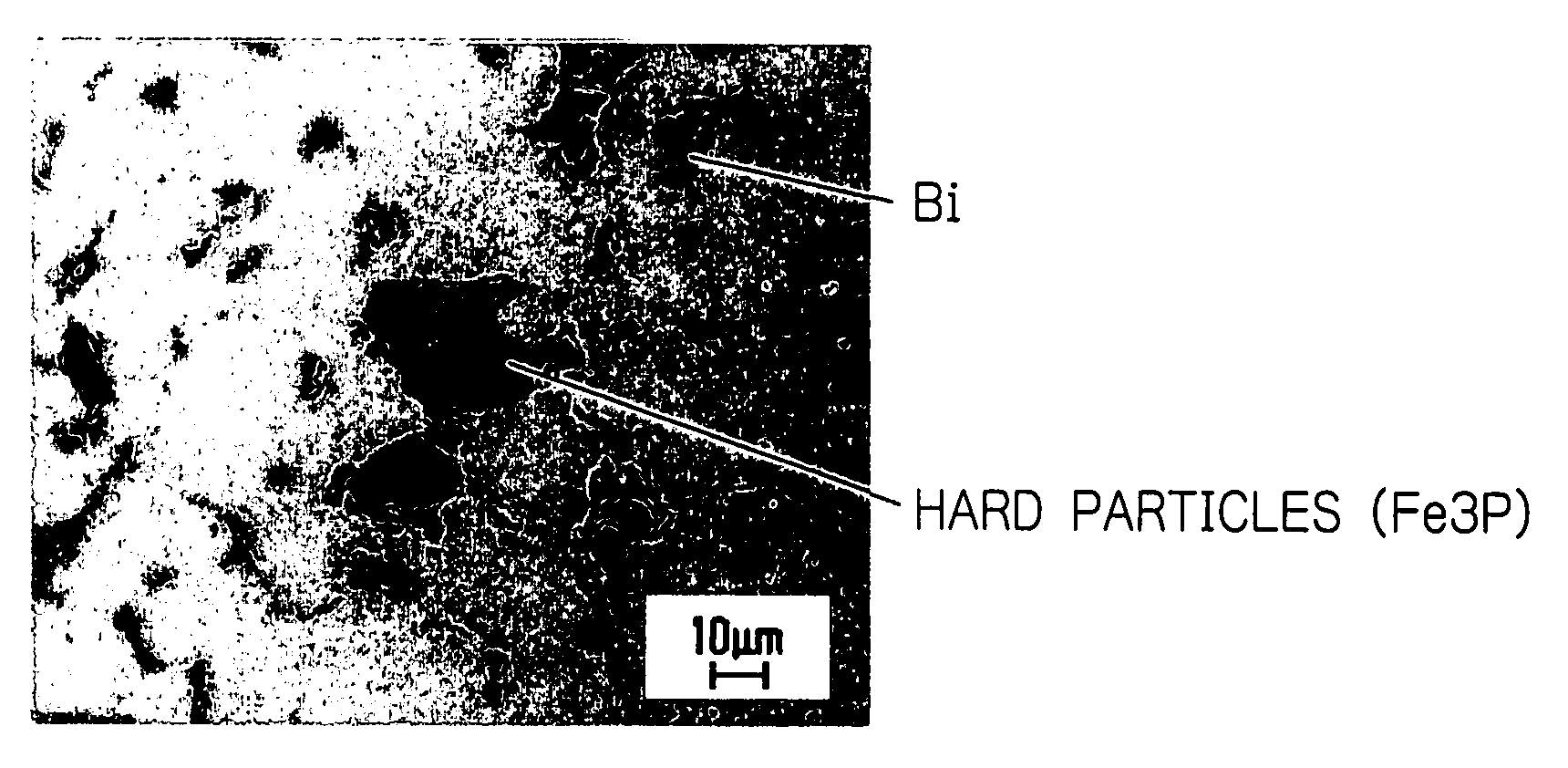

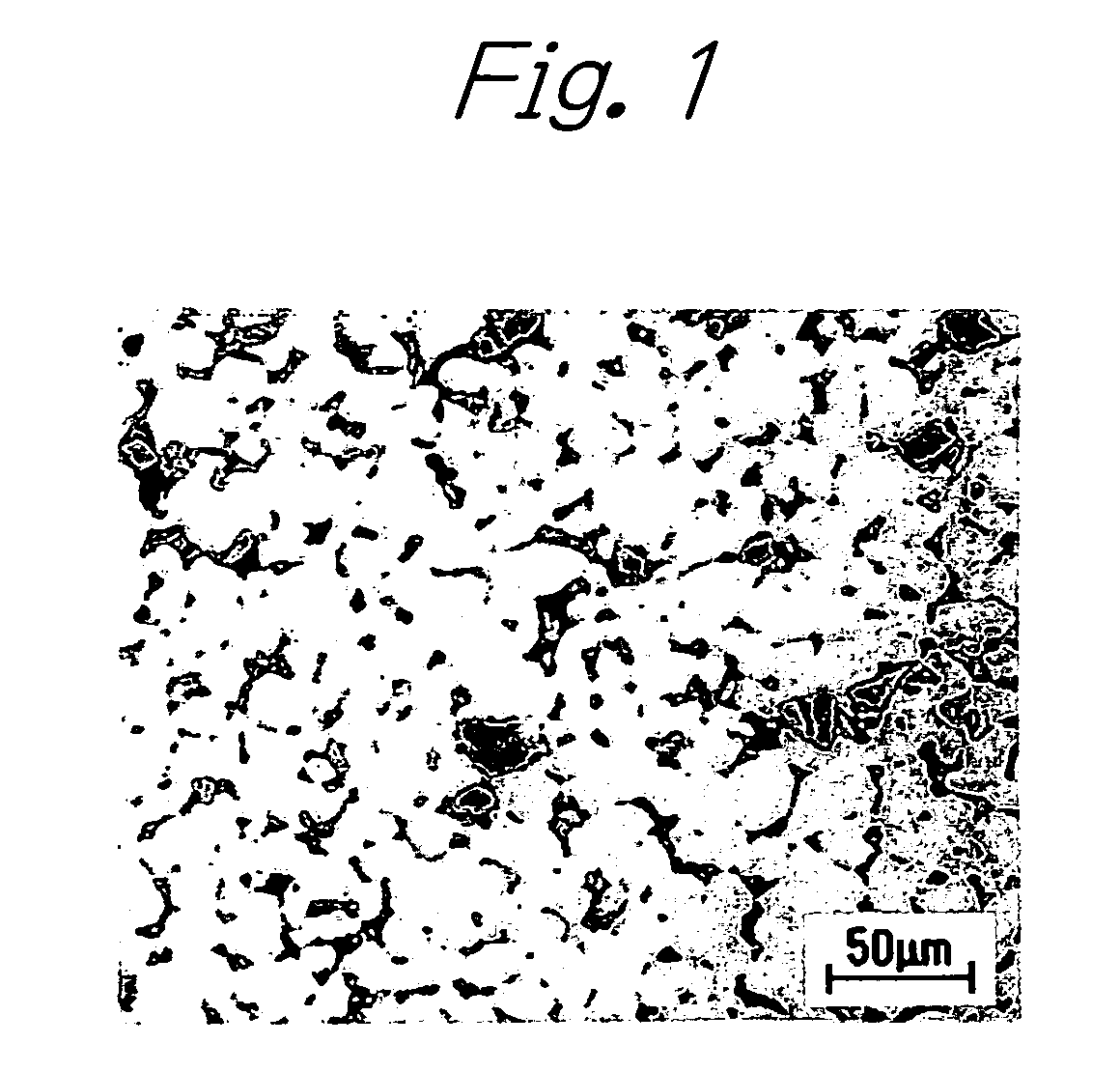

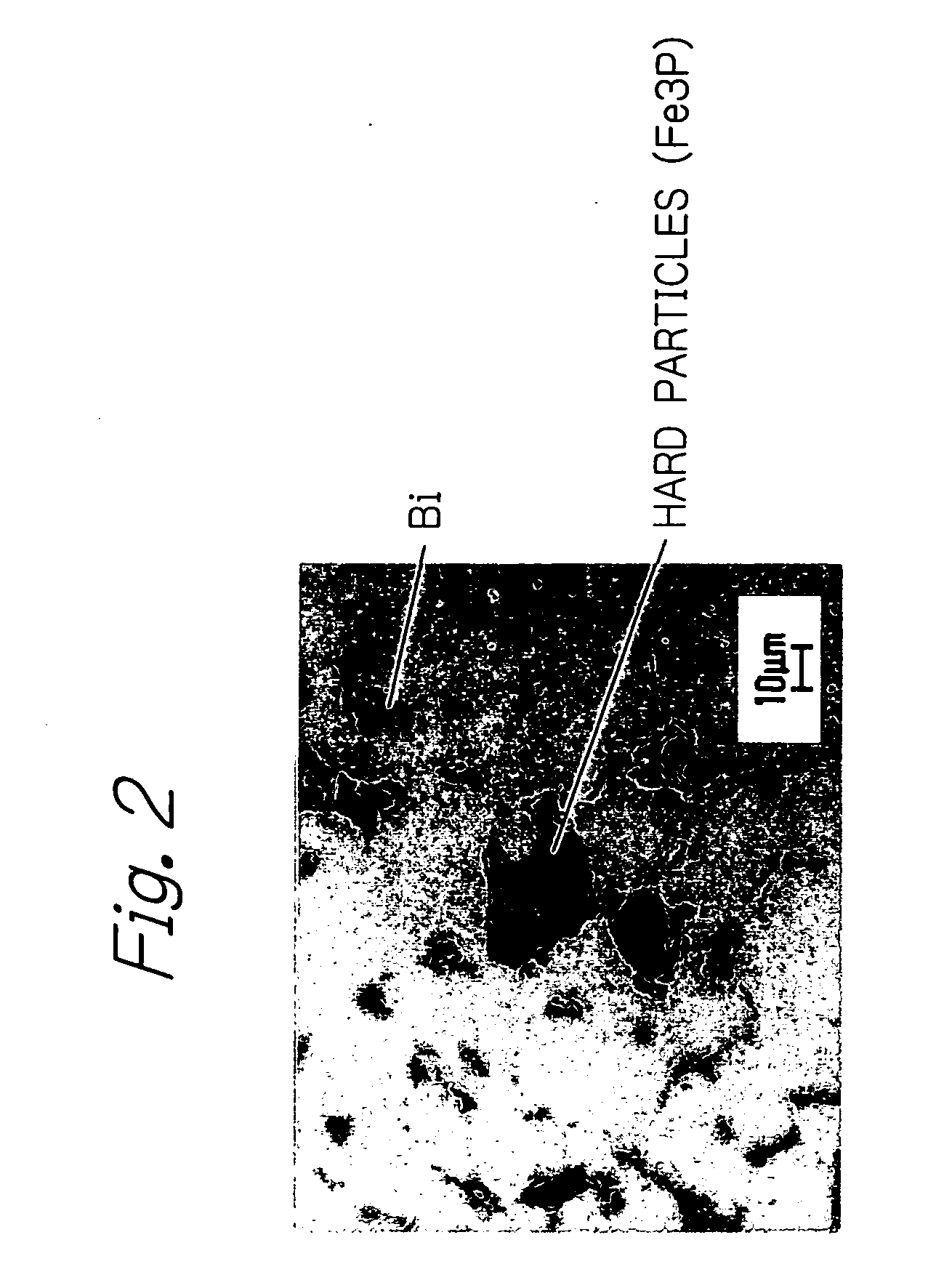

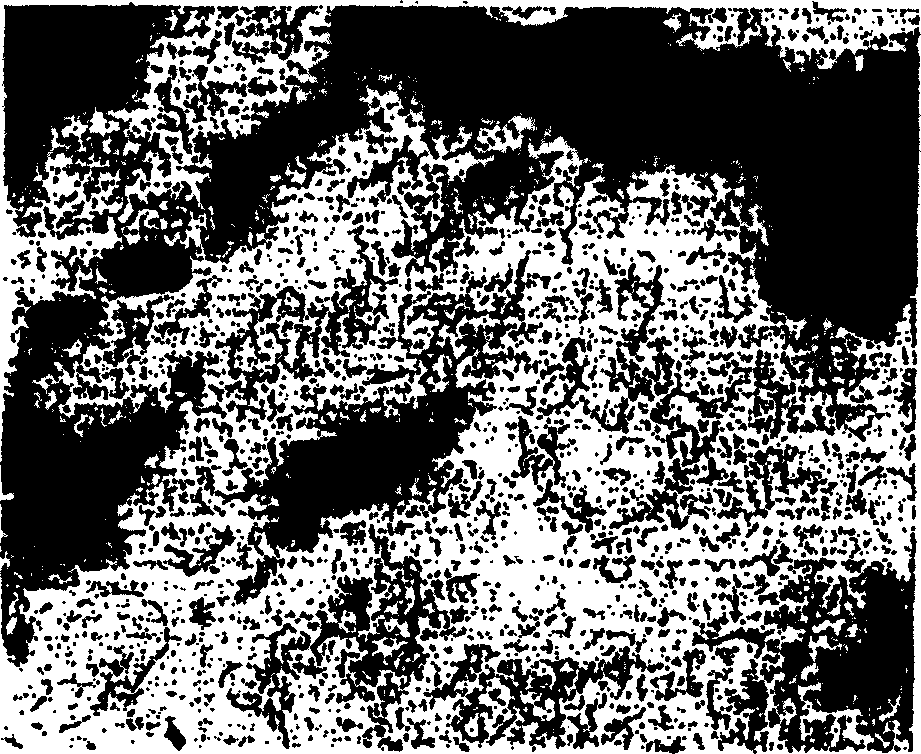

In a Cu—Bi based sintered alloy, to which hard particles, such as Fe3P, are added, the main constituent components of the microstructure are a Cu matrix, Bi phase and the hard particles. In the sintering method of the present invention, the flow of the Bi phase is suppressed to as low level as possible. The novel structure is that the contact between the Bi phase and hard particles is kept to a low ratio. A lead-free bearing used for a fuel injection pump according to the present invention contains from 1 to 30 mass % of Bi and from 0.1 to 10 mass % of hard particles having from 10 to 50 μm of the average particle diameter, the balance being Cu and unavoidable impurities. The properties of the main component phases are utilized at a high level such that the sliding properties are equivalent to those of a Pb containing Cu-based sintered alloy.

Owner:TAIHO INDUSTRIES CO LTD +1

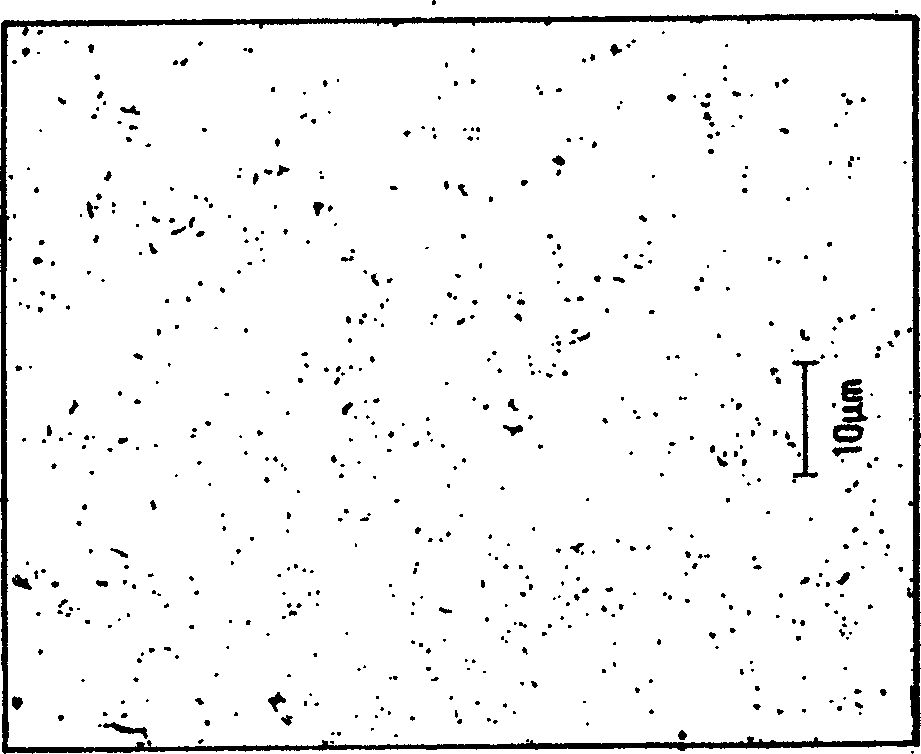

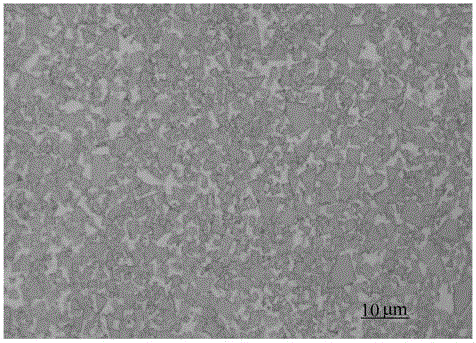

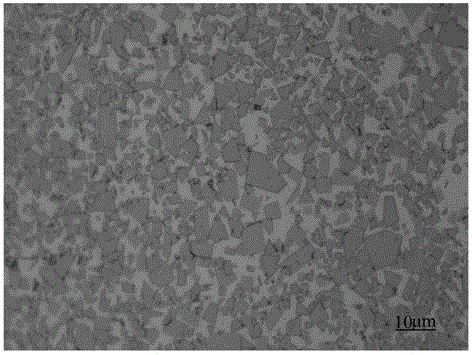

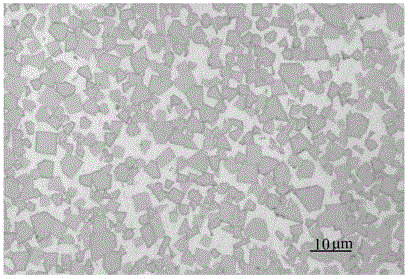

Submicron grain Ti(C, N)-base cermet and its prepn process

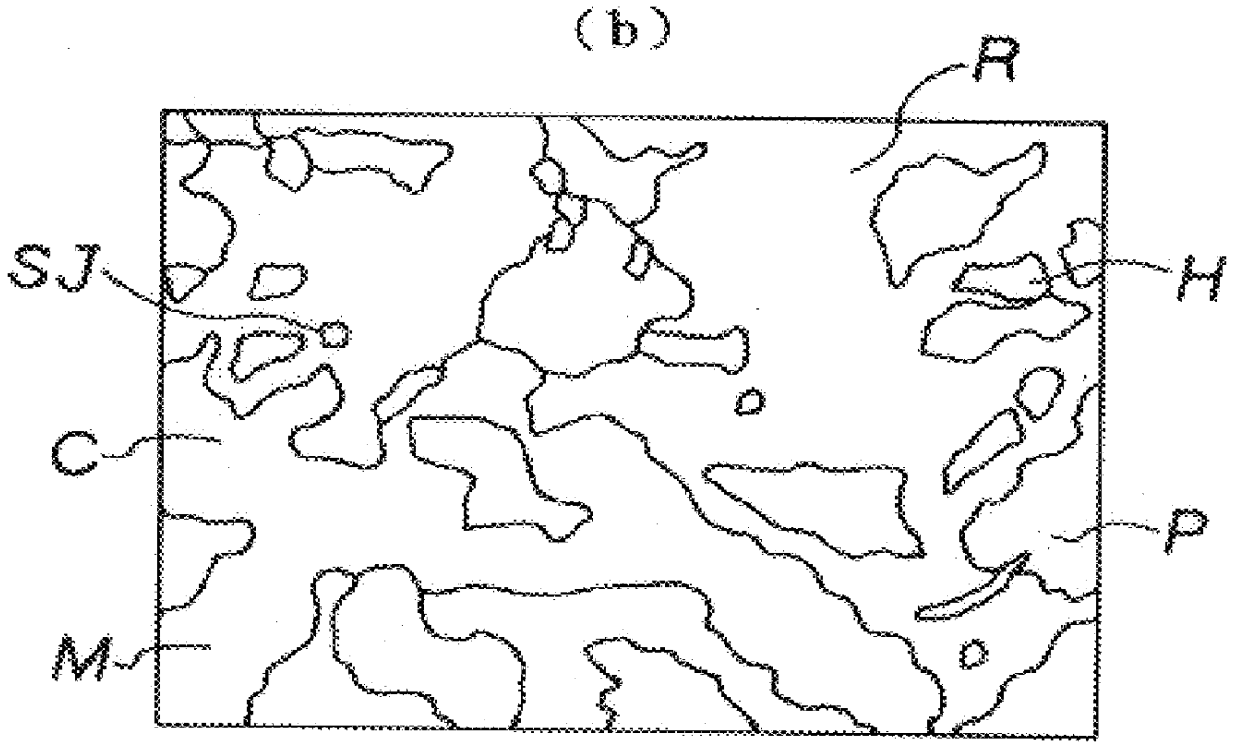

The present invention relates to the preparation of cermet material, and the sintered alloy has submicron crystal grain structure, and high hardness, toughness and strength. The cermet is prepared through mixing IVB, VB, VIB, Ti, one or more metal carbide, nitride or complex solid solution carbide-nitride ceramic powder and iron family element Ni, Co, etc.; high-energy ball milling, drying, pressing to form, vacuum sintering, hot isostatic pressing and other steps. The cermet has hard crystal phase reaches submicron granularity of 0.6-1.0 micron. Under scanning electronic microscope, four kinds of metal structure may be observed including black core phase, white core phase, gray ring phase and white adhesion phase. Compared with available cermet, the present invention has obviously improved hardness and toughness, and may be used in cutter and other wear resistant parts.

Owner:HUAZHONG UNIV OF SCI & TECH

Sintered alloy valve seat and its manufacturing method

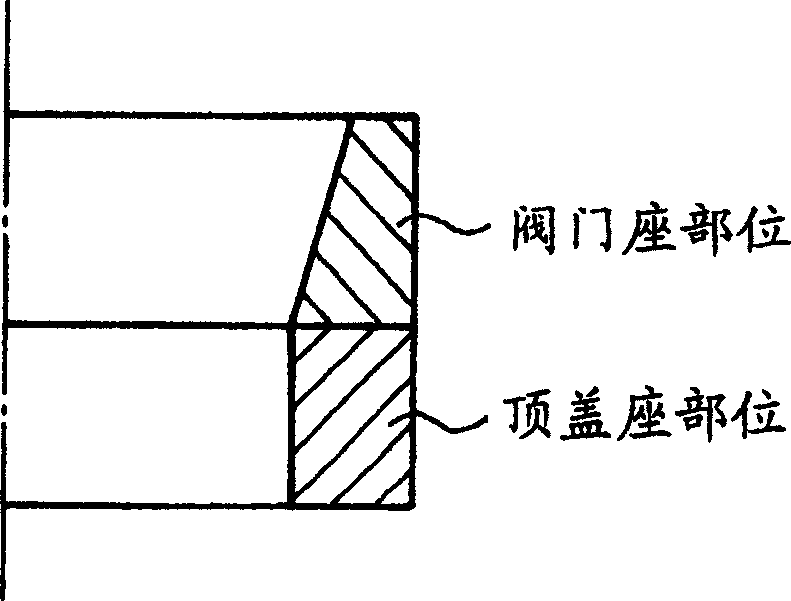

A valve seat, press-fitted into a cylinder head of an internal combustion engine, containing an iron-based sintered alloy, includes a valve-seating section and a head-seating section. The valve-seating section and the head-seating section are monolithically formed by a sintering process and form a double layer structure. The valve-seating section includes a first iron-based sintered alloy member that has a porosity of 10 to 25 percent by volume and a sintered density of 6.1 to 7.1 g / cm<3> and contains hard particles dispersed in a matrix. The head-seating section includes a second iron-based sintered alloy member that has a porosity of 10 to 20 percent by volume and a sintered density of 6.4 to 7.1 g / cm <3>.

Owner:NIPPON PISTONRING CO LTD +1

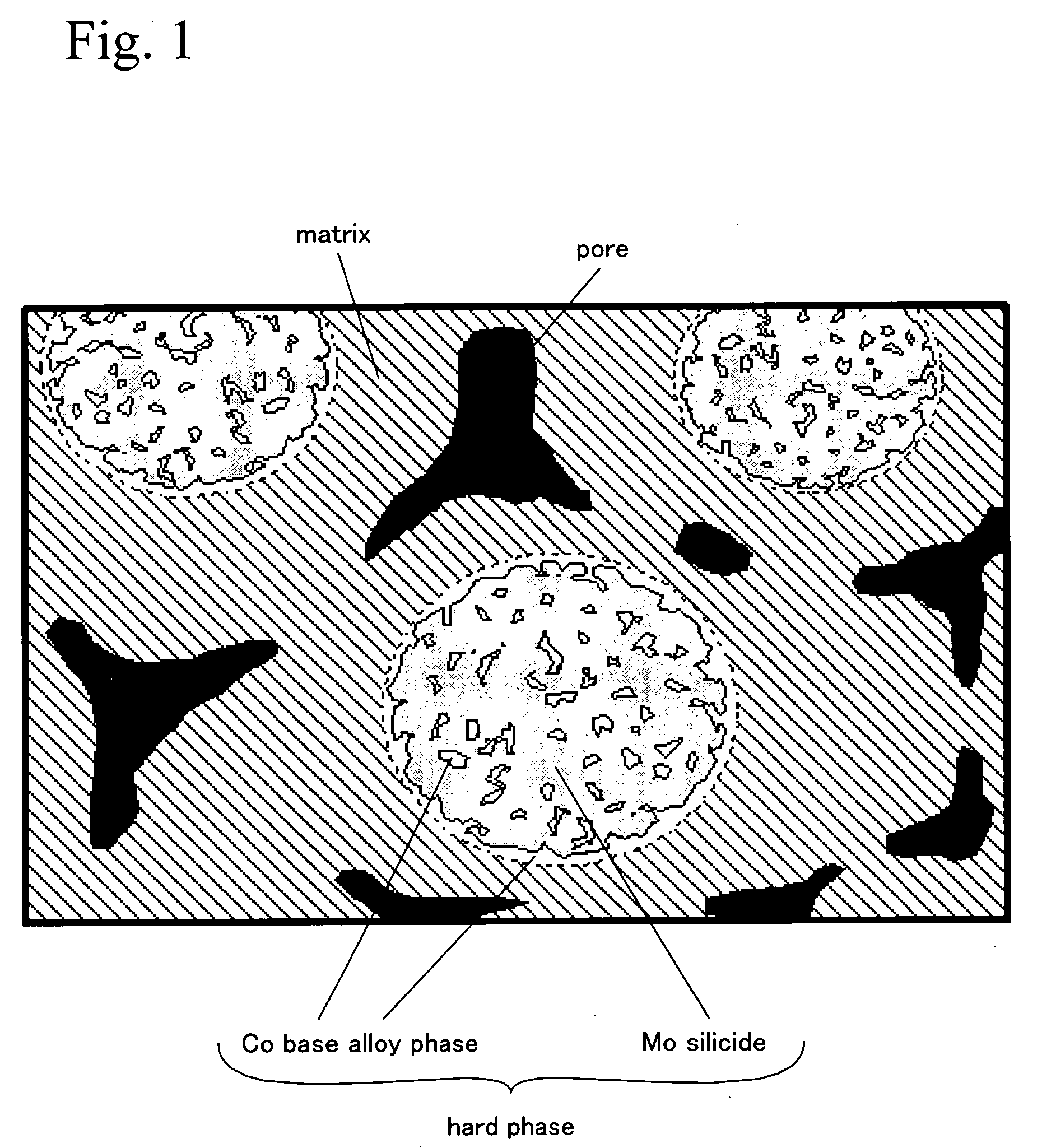

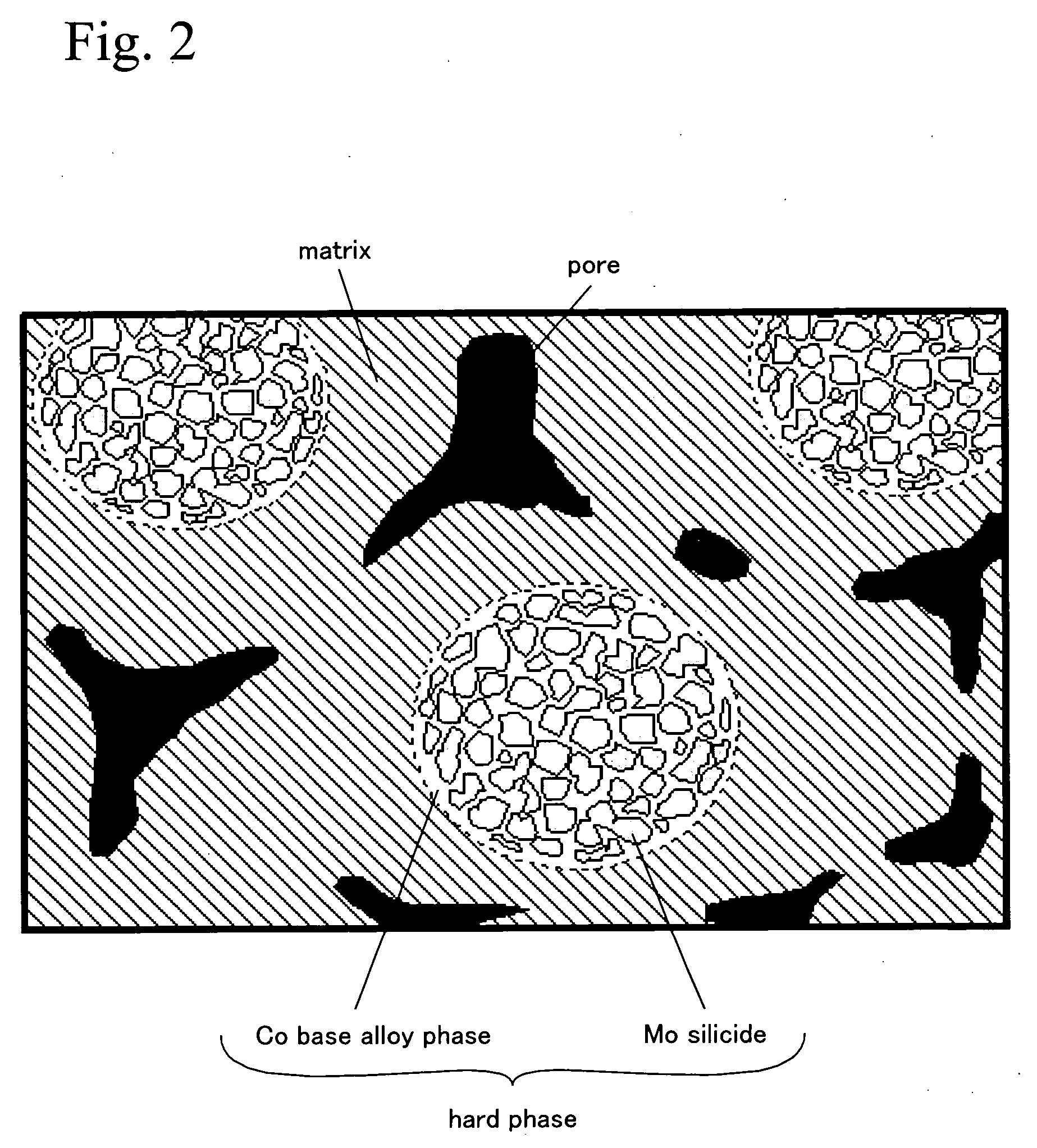

Alloy powder for forming hard phase and ferriferous mixed powder using the same, and manufacturing method for wear resistant sintered alloy and wear resistant sintered alloy

ActiveUS20050132842A1Good high temperature wear resistanceReduce pointsMachines/enginesLift valveWear resistantWear resistance

Alloy powder for forming a hard phase for a valve seat material having excellent high temperature wear resistance. The overall composition is consisted of Mo: 48 to 60 mass %, Cr: 3 to 12 mass % and Si: 1 to 5 mass %, and the balance of Co and inevitable impurities.

Owner:HITACHI POWDERED METALS COMPANY

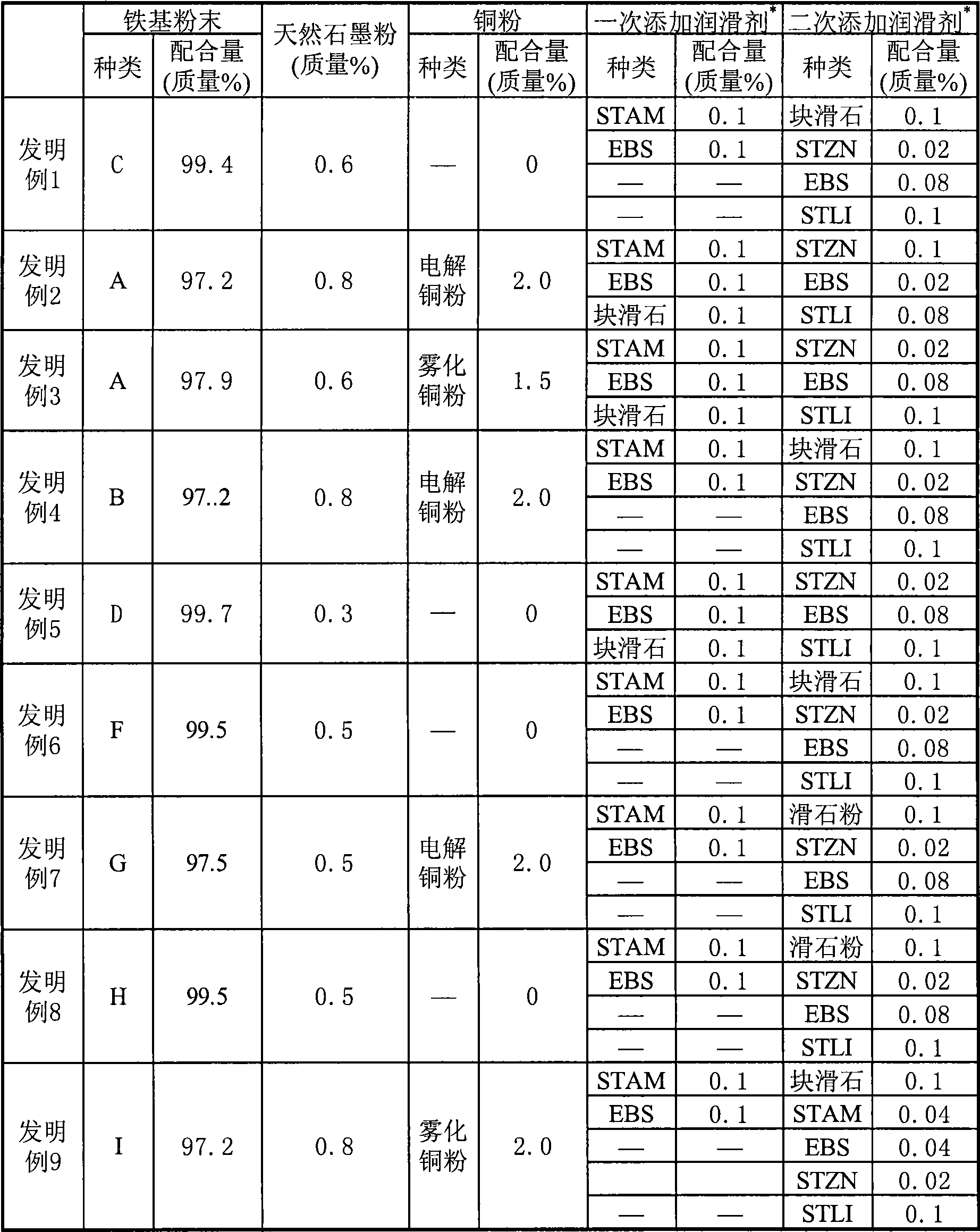

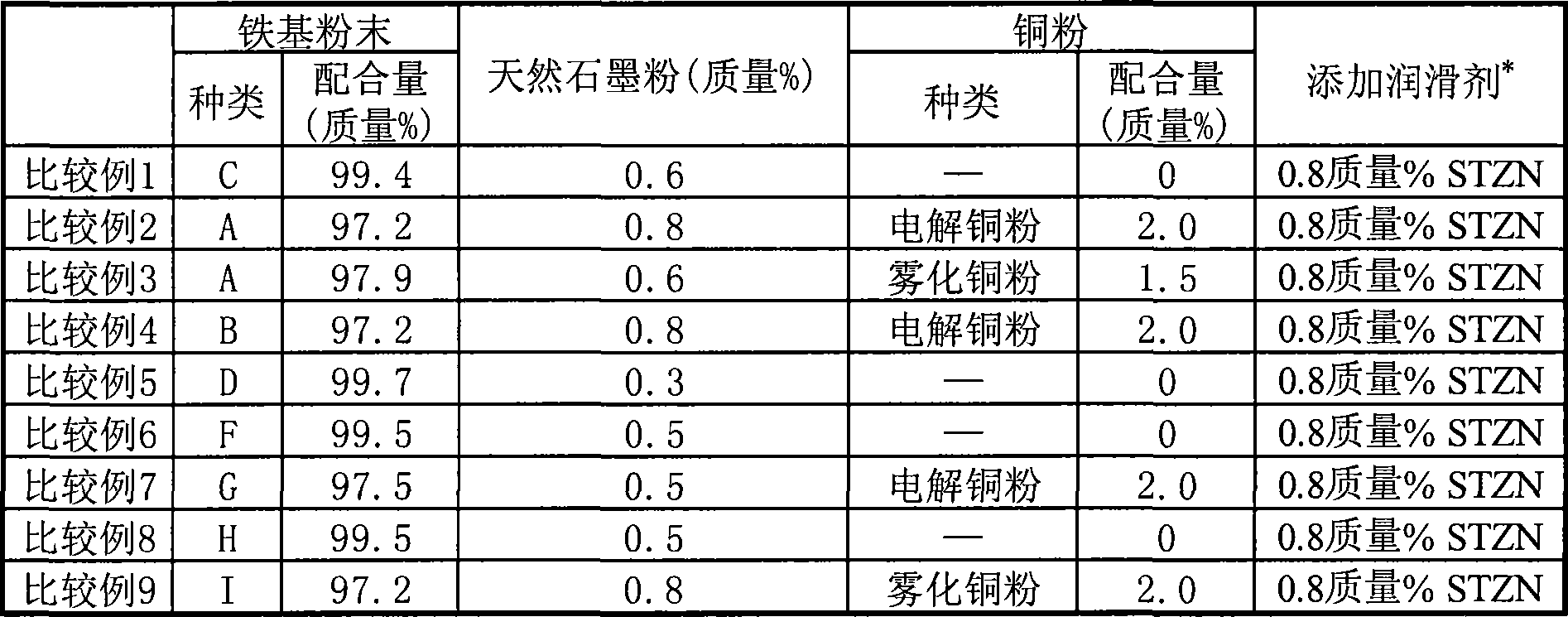

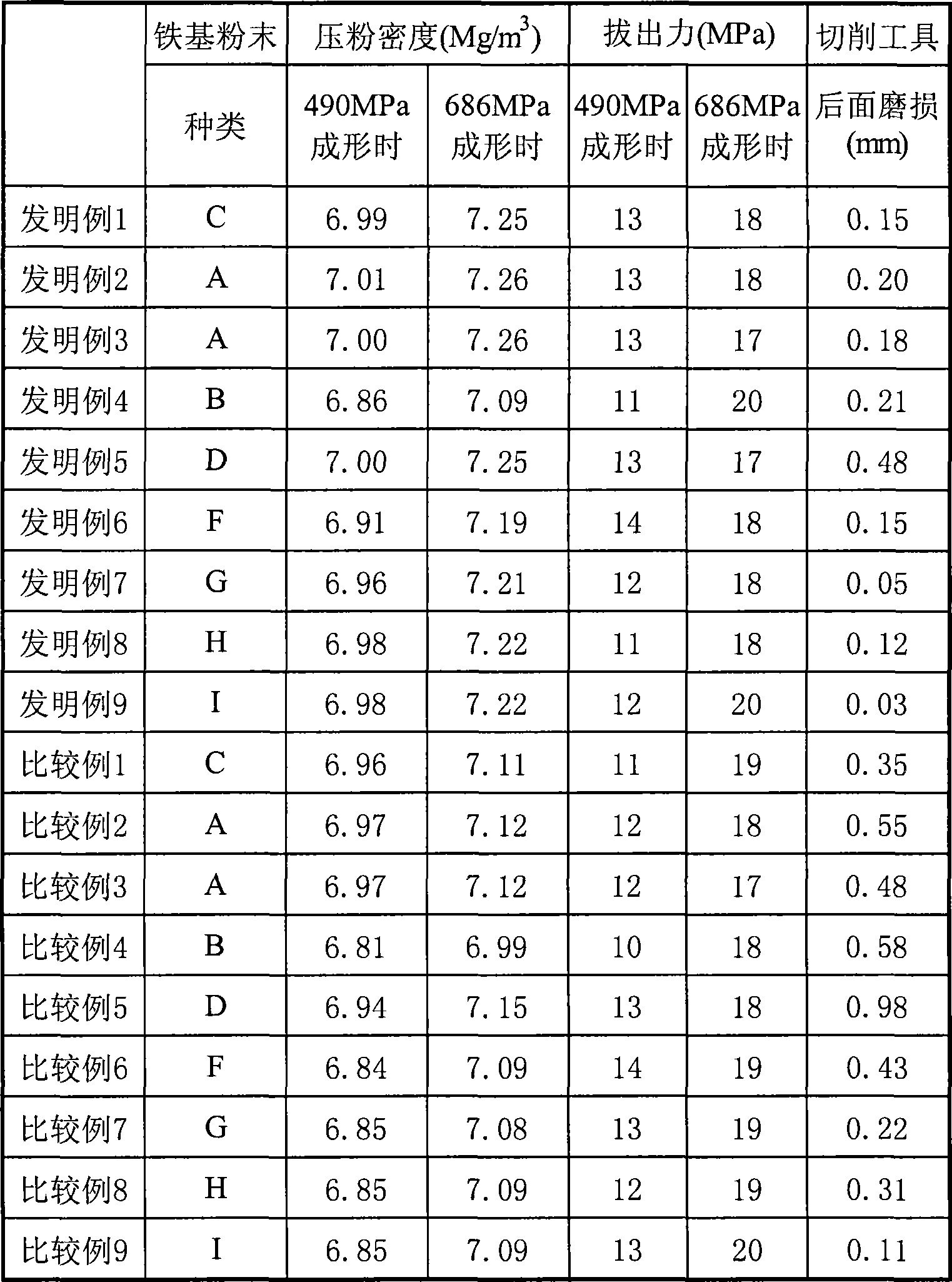

Iron-based powder mixture, and method of manufacturing iron-based compacted body and iron-based sintered body

ActiveCN101384387AGood formabilityHigh densityTransportation and packagingMetal-working apparatusPowder mixtureTalc

An iron-base mixed powder for powder metallurgy which comprises an iron-base powder and at least one member selected from between talc and steatite and preferably further contains a metal soap.This mixed powder does not produce adverse effect on furnace atmosphere in sintering a compact of the powder and exhibits excellent compactibility even in a low-temperature region of below 100 DEG C and the sintered compact made from the powder is favorably excellent in machinability.

Owner:JFE STEEL CORP

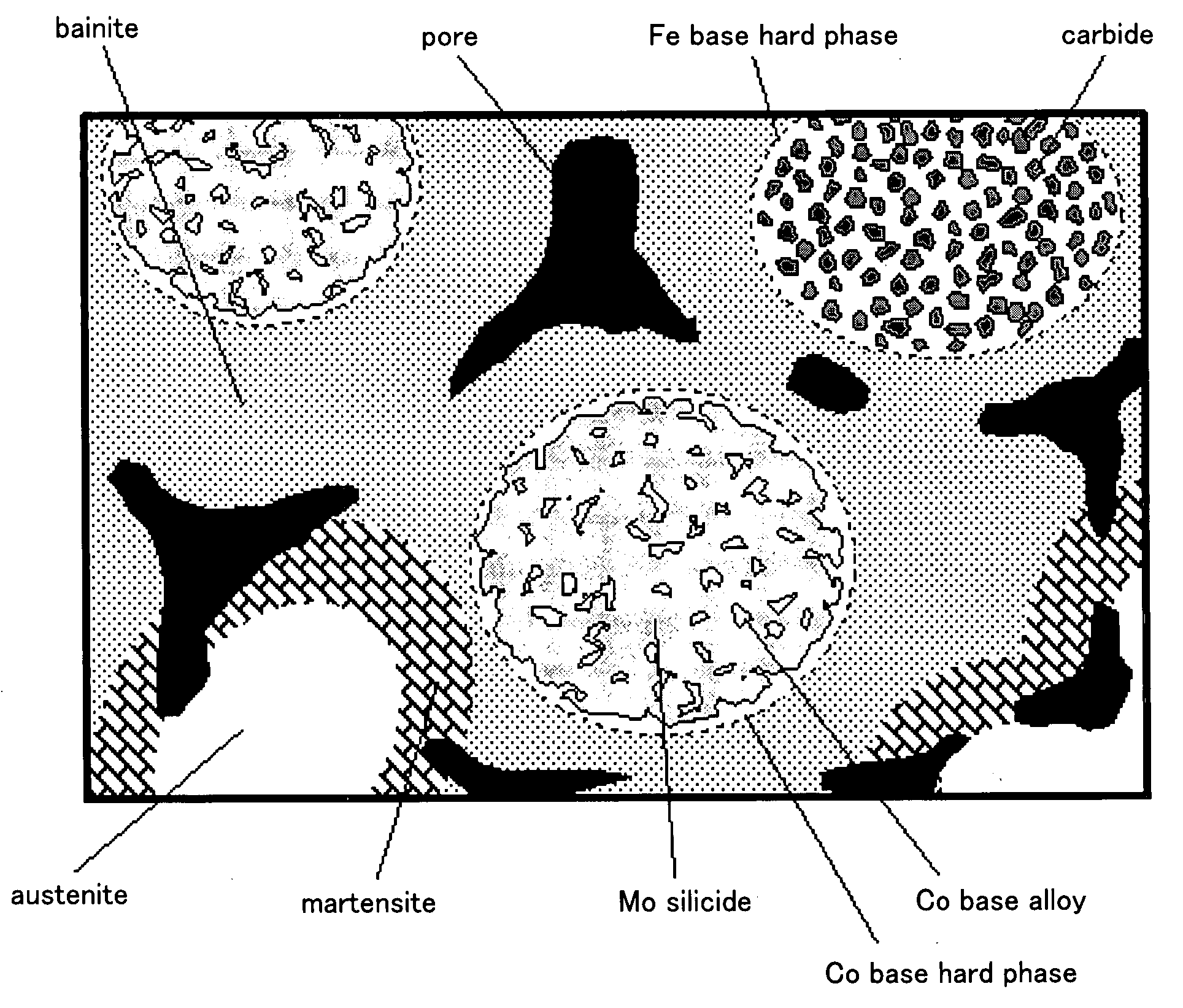

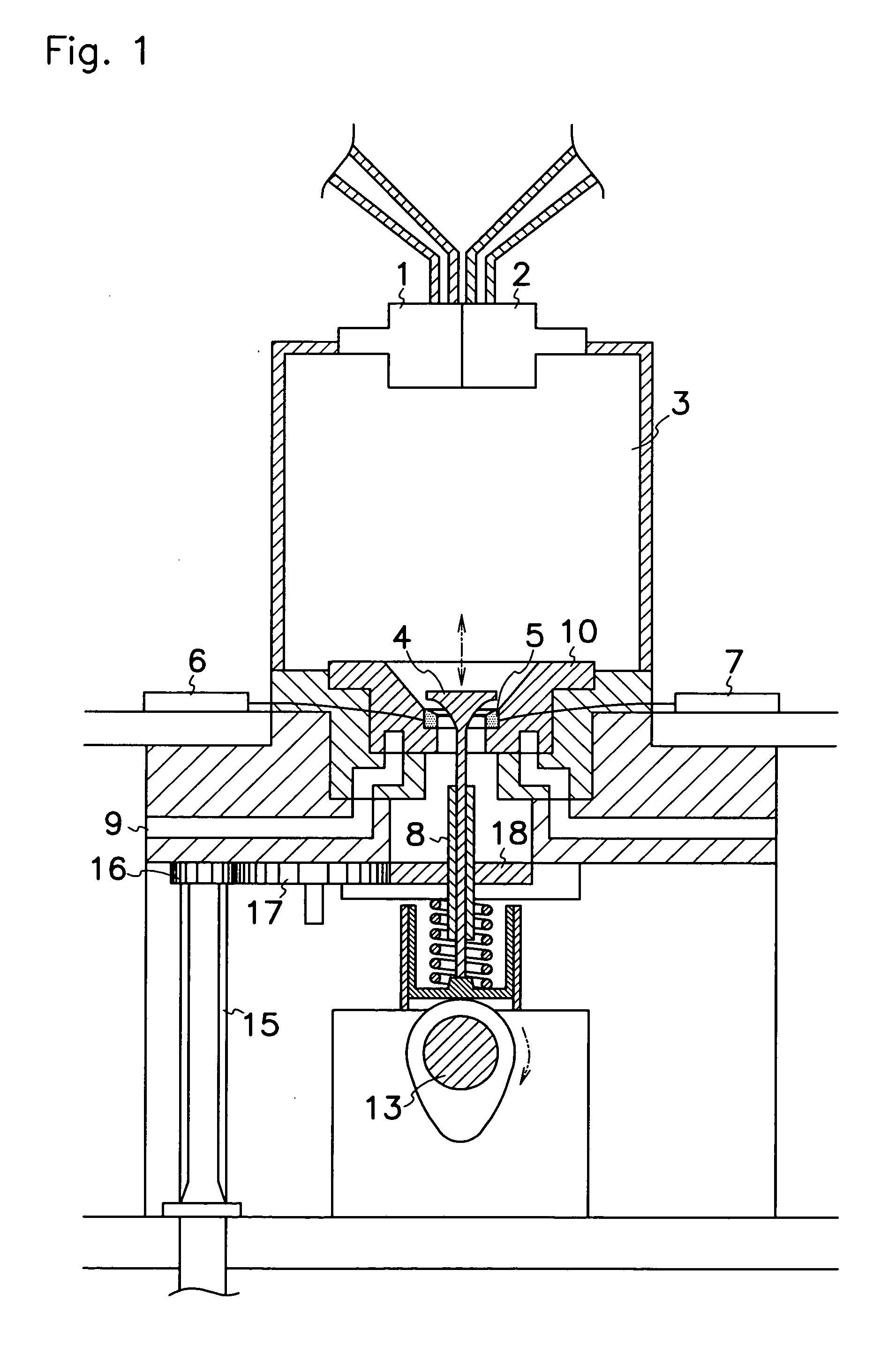

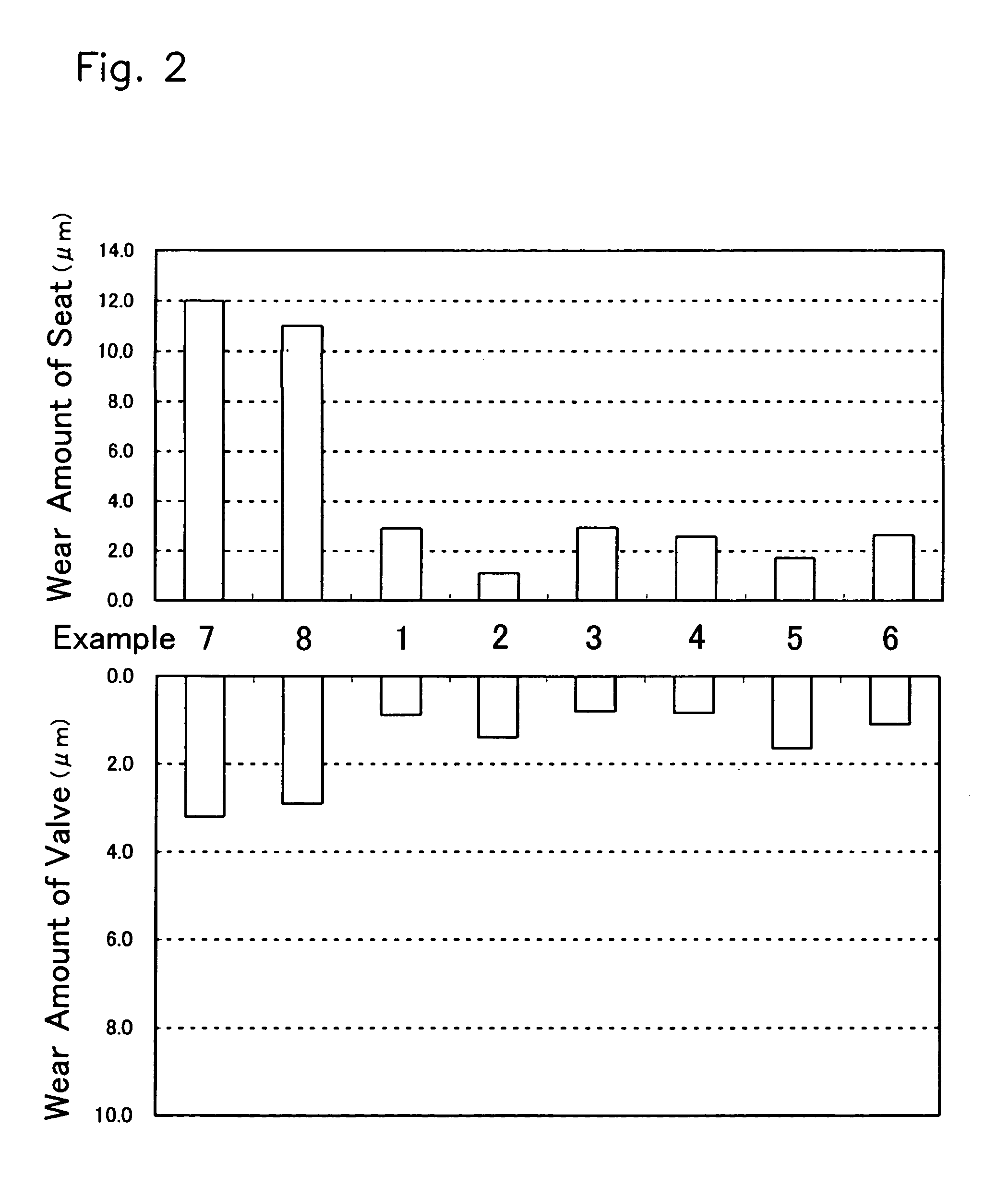

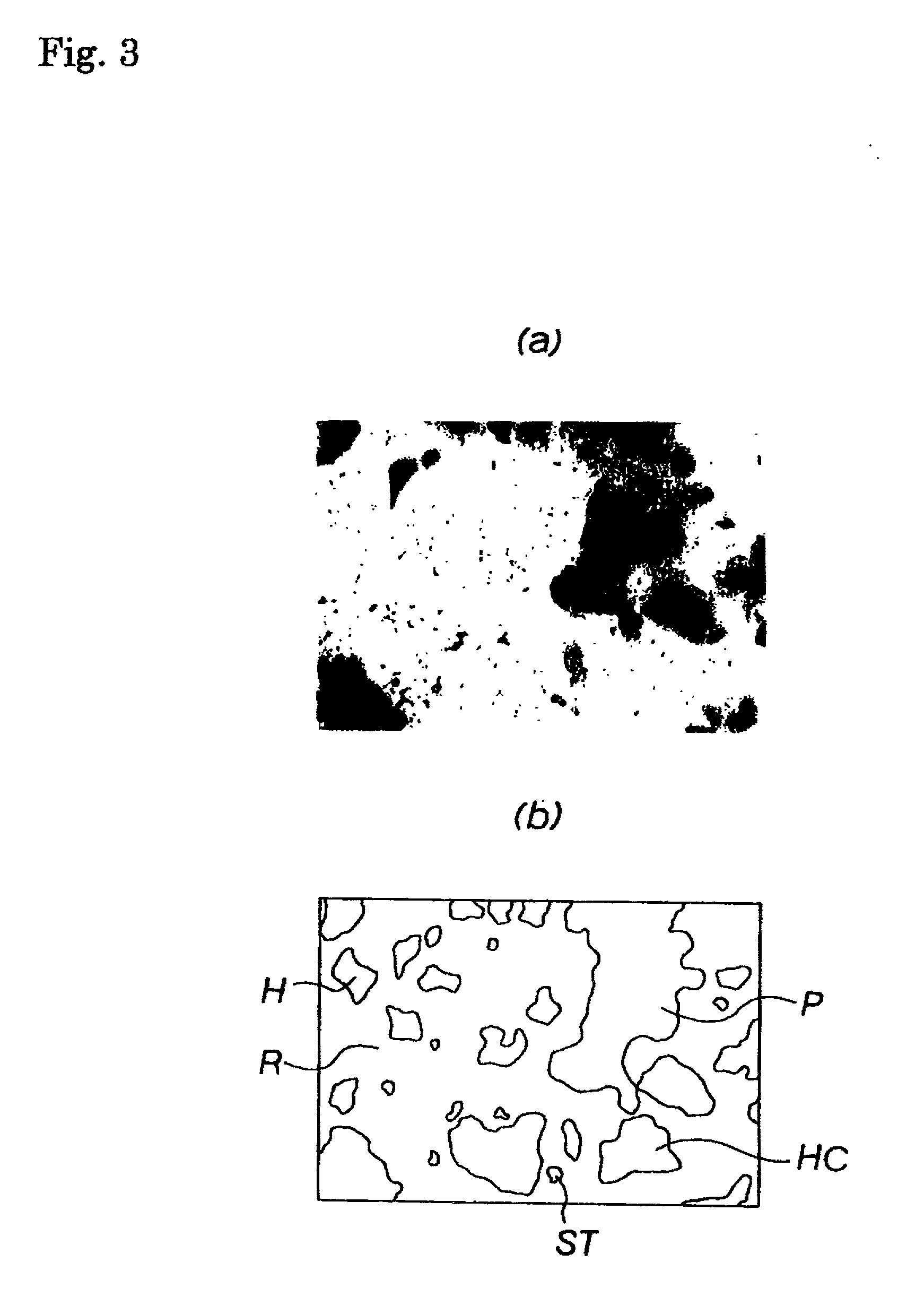

Iron-based sintered alloy material for valve seat

InactiveUS20050193861A1Improve wear resistanceReduced opposite aggressibilityMachines/enginesLift valveHardnessCobalt

An iron-based sintered alloy material for a valve seat having improved wear resistance and reduced opposite aggressibility to a mating valve. The iron-based sintered alloy material contains 10% to 20% by area of first hard particles and 15% to 35% by area of second hard particles dispersed in a base matrix phase, the first and the second hard particles accounting for 25% to 55% by area in total. The first hard particles are composed of a cobalt-based intermetallic compound and have a size of 10 to 150 μm and a hardness of at least 500HV0.1 and less than 800HV0.1. The second hard particles are composed of a cobalt-based intermetallic compound and have a size of 10 to 150 μm and a hardness of at least 800HV0.1 and less than 1100HV0.1. Solid lubricant particles may also be dispersed in the base matrix phase.

Owner:NIPPON PISTONRING CO LTD +1

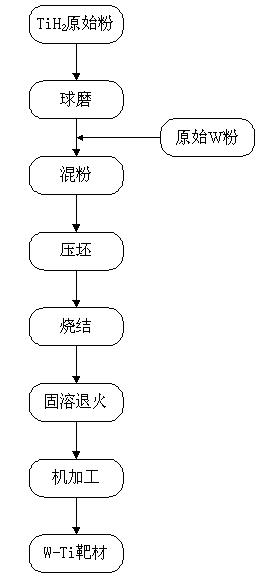

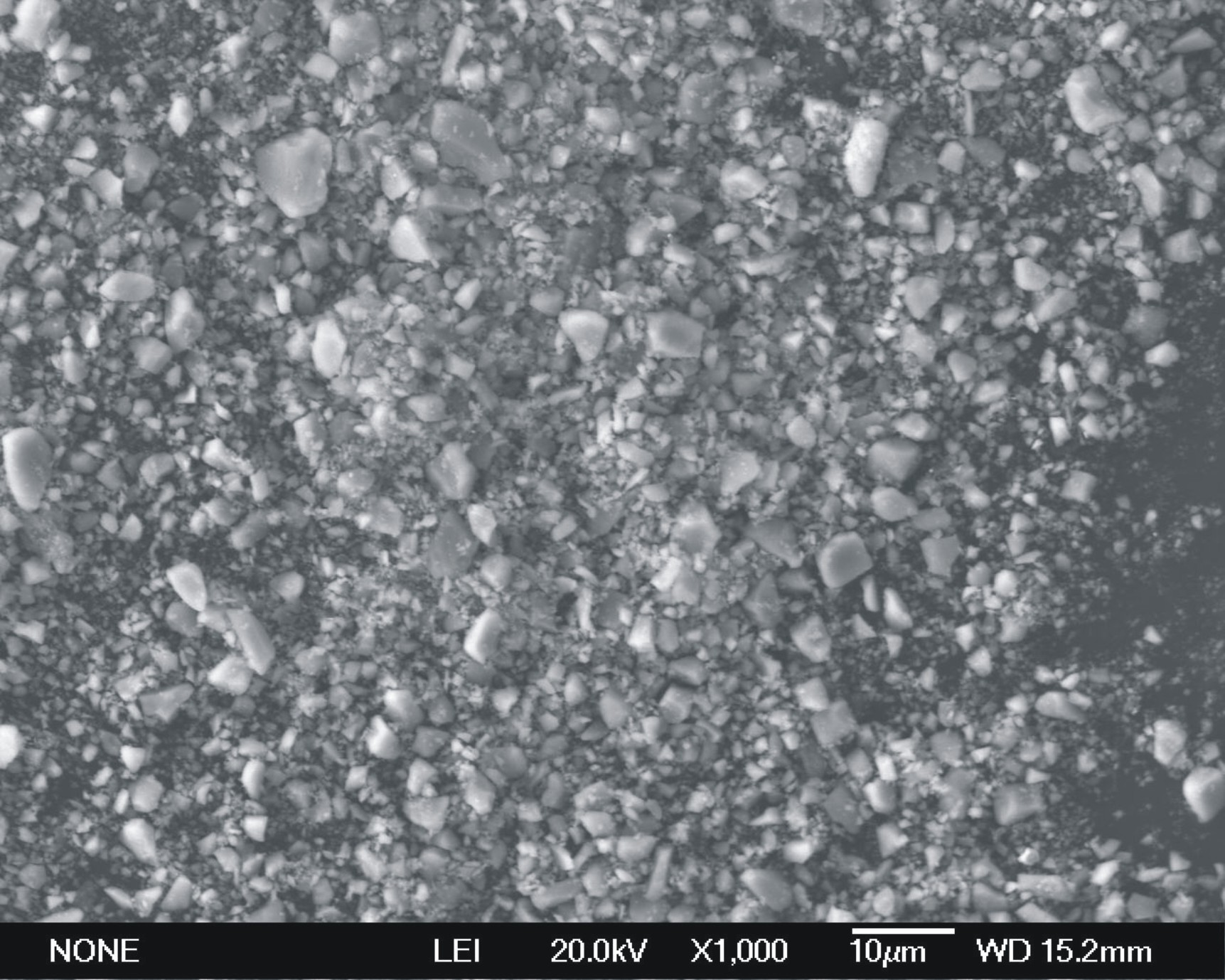

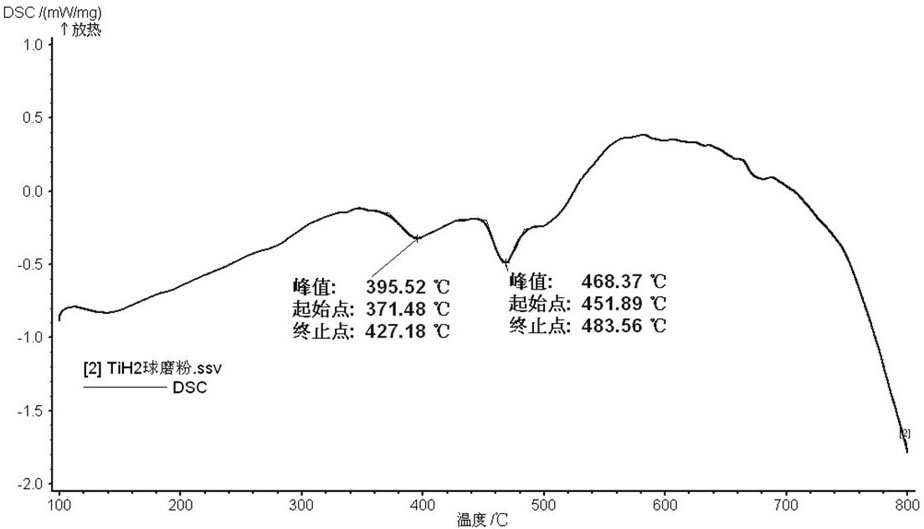

Method for preparing W-Ti alloy target material

InactiveCN101928850AUniform alloy structureHigh densityVacuum evaporation coatingSputtering coatingPressureless sinteringSintered alloy

The invention discloses a method for manufacturing a W-Ti alloy target material. In the method, W powder with purity higher than 99.9 percent and TiH2 powder with purity higher than 96.7 percent are used as raw materials, the TiH2 powder is subjected to high-energy ball milling and then is mixed with the W powder; then, the powder is compacted for 3 to 6 minutes at the pressure of between 250 and 280MPa, and the compact blank is subjected to vacuum loose sintering, and the sintered alloy is subjected to solution annealing and quenching; and finally, machining the W-Ti alloy to obtain the target finished product. Compared with the prior art, the method has low sintering temperature and does not have pressure in the sintering process, and the prepared alloy target material has the advantages of uniform tissue, high compactness and large controllable size.

Owner:XIAN UNIV OF TECH

Carbon fiber reinforced copper-based composite material and preparation method thereof

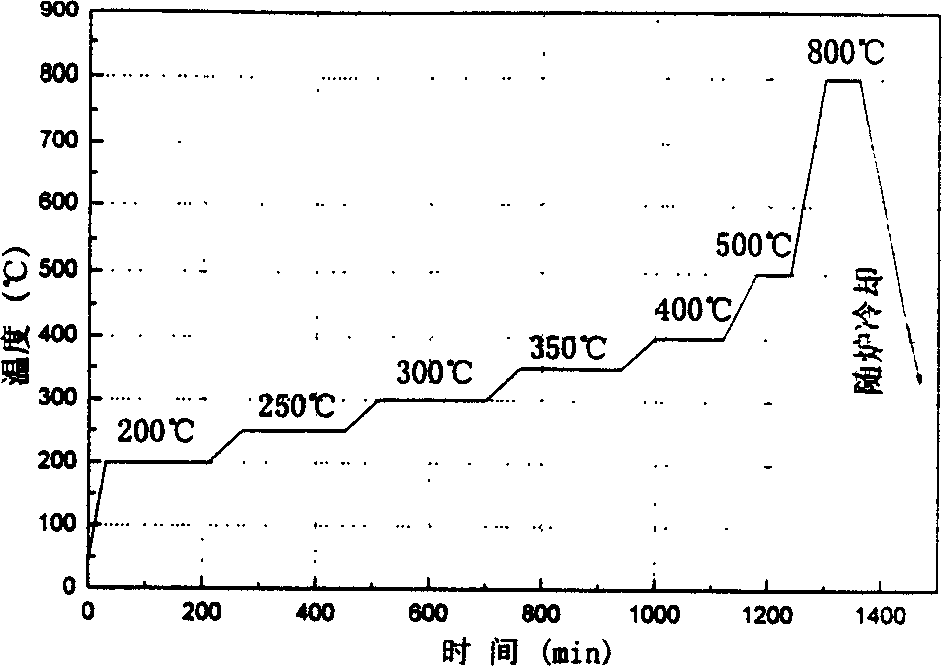

The invention discloses a preparation method of a carbon fiber reinforced copper-based composite material. The preparation method comprises the following steps: I, weighing ingredients and carrying out ball-milling mixing for 3 hours, thereby obtaining a mixed material, and wrapping the surface of carbon fiber by a nickel layer, wherein the particle size of graphite powder is 50mu m, the graphite powder is subjected to chemical plating technical treatment, and a copper layer is plated on the surface of the graphite powder; II, pressing the mixed material prepared in the step I under the pressure of 700MPa, thereby obtaining a blank; III, performing secondary sintering on the blank prepared in the step II, thereby obtaining a sintered alloy block; and IV, performing thermal treatment on the alloy block treated in the step III, thereby obtaining the carbon fiber reinforced copper-based composite material. The carbon fiber reinforced copper-based composite material disclosed by the invention not only has excellent self-lubrication property, but also is particularly excellent in wearing resistance and mechanical property.

Owner:宁波新睦科技有限公司

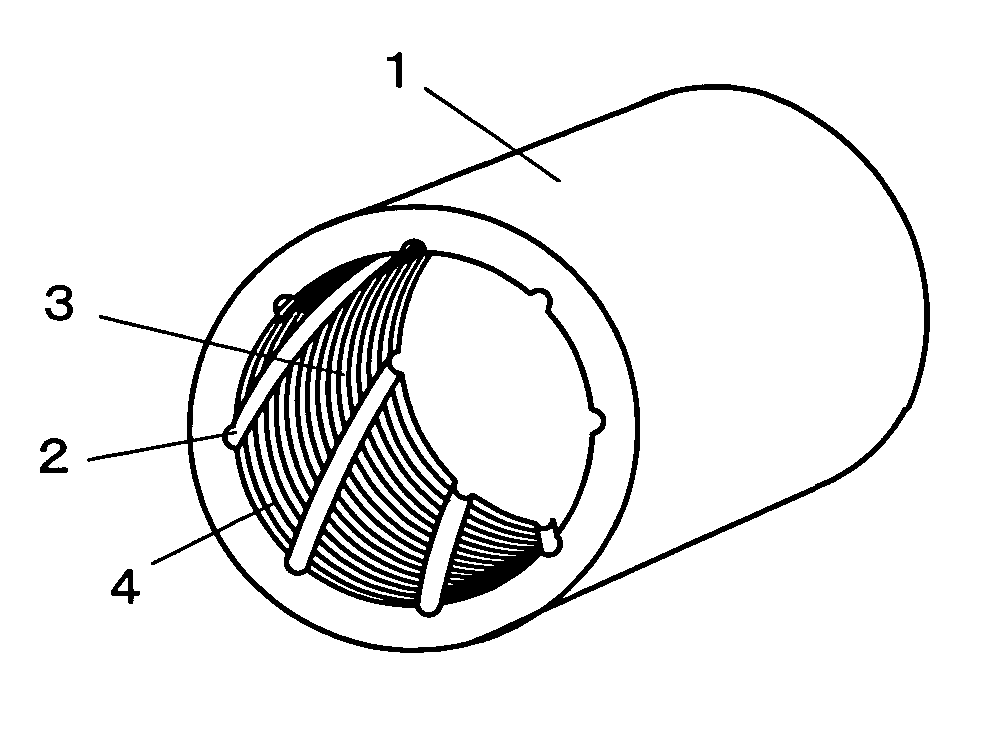

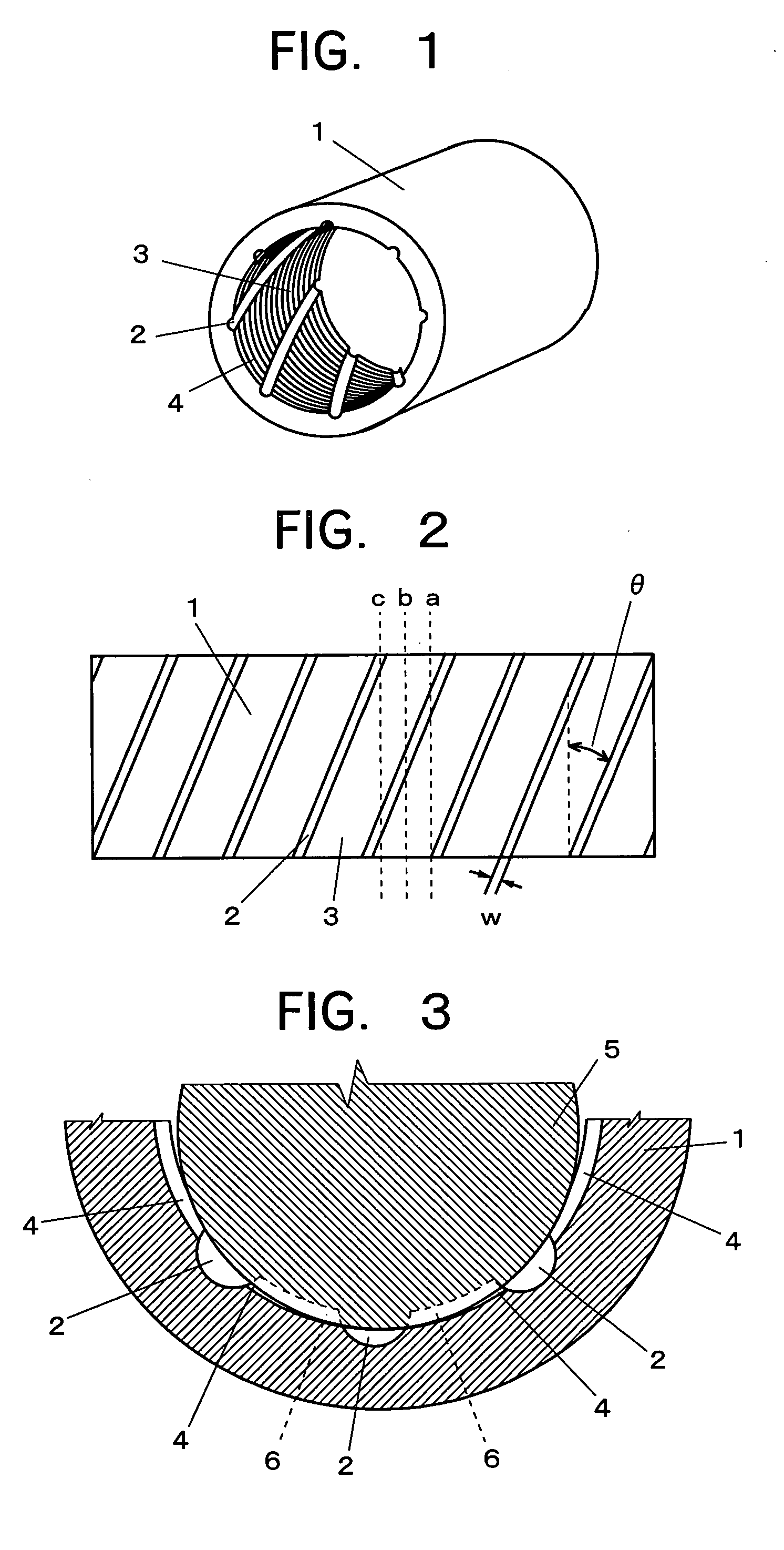

Sliding bearing for use under high load

InactiveUS20050286822A1Avoid large quantitiesImprove wear resistanceShaftsBearing componentsHigh loadBearing surface

A sliding bearing which is suitable for and durable in the use under high load of sliding in rocking motion, and the structure of bearing is not complicated so as to facilitate the manufacturing. The alloy used for making the bearing is composed of iron-based sintered alloy having quenched structure, and the bearing surface is provided with inclined grooves of an inclination angle of 10 to 40° relative to the direction perpendicular to the sliding direction and a width of 2 to 8 mm and the area of inclined grooves is 50% or less of the total inner bearing surface and an imaginary line perpendicular to the sliding direction crosses both the inclined groove and the bearing surface at any position of the inner surface of bearing. When the bearing is used, at least the inclined grooves are impregnated with a lubricant.

Owner:HITACHI POWDERED METALS COMPANY

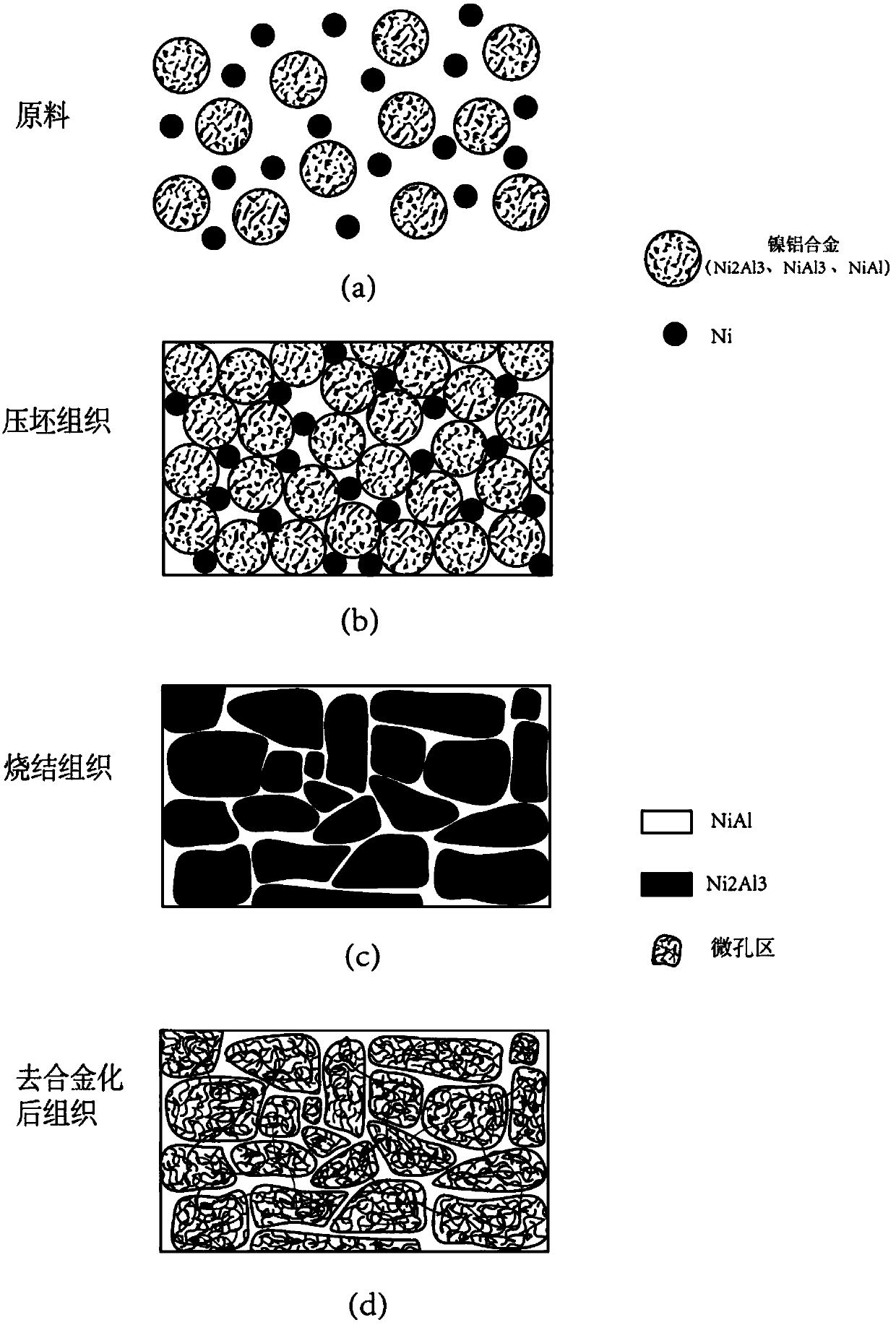

Preparation method of high-strength nano-porous nickel film

The invention discloses a preparation method of a high-strength nano-porous nickel film, and belongs to the technical field of a nano-porous metal film material, in particular discloses a method for preparing a high-strength nano-porous metal film material combining a micron-sized reinforcing framework and nano-sized pores through mixing alloy and metal powder, implementing powder metallurgy to obtain an alloy sheet, and further dealloying the sintered alloy sheet. The preparation method, through preparing a film precursor by powder metallurgy and selective corrosion in junction with dealloying, can increase the number of pores, and simultaneously keep high strength; aperture of the nano-porous metal film is adjustable from 0.5nm to 100nm when controlling various reaction conditions and parameters. The entire process, which is implemented in a stable environment, is safe, reliable, pollution-free, simple, low in cost and up to industrial demand, so that the prepared nano-porous metal film material is applicable to such aspects as biological medicine, organic synthesis, organic solvent micro and nano-filtration, catalysis and the like.

Owner:TIANJIN POLYTECHNIC UNIV

Bearing for motorized fuel pump

ActiveUS20090011268A1Excellent abrasion resistanceImprove corrosion resistanceBearing componentsThin material handlingPorosityGraphite

Owner:AISAN IND CO LTD +1

Coating for high bonding phase cemented carbide sintering

The invention discloses a coating for high bonding phase cemented carbide sintering. The coating comprises the following components in percentage by mass: 55-69.5 percent of metal oxide powder, 2.85-6.1 percent of carbon black, 0.15-3.5 percent of water soluble adhesive (powder) and 27.5-38 percent of distilled water. When the coating prepared by utilizing the components is painted on a graphite sintering boat, the coating can effectively separate the direct contact between a high bonding phase cemented carbide sintering product and the graphite boat, prevent the occurrence of diffusion and migration of liquid phase and carbon between the sintered alloy and the graphite boat under the liquid phase sintering temperature and achieve the purposes of anti-bonding and anti-carburizing. The coating has the advantages of low cost, simple preparation and no pollution on a sintering furnace, no toxicity for an operator, no dust harm and easy cleaning and is an ideal coating for high bonding phase cemented carbide sintering.

Owner:ZIGONG CEMENTED CARBIDE CORP

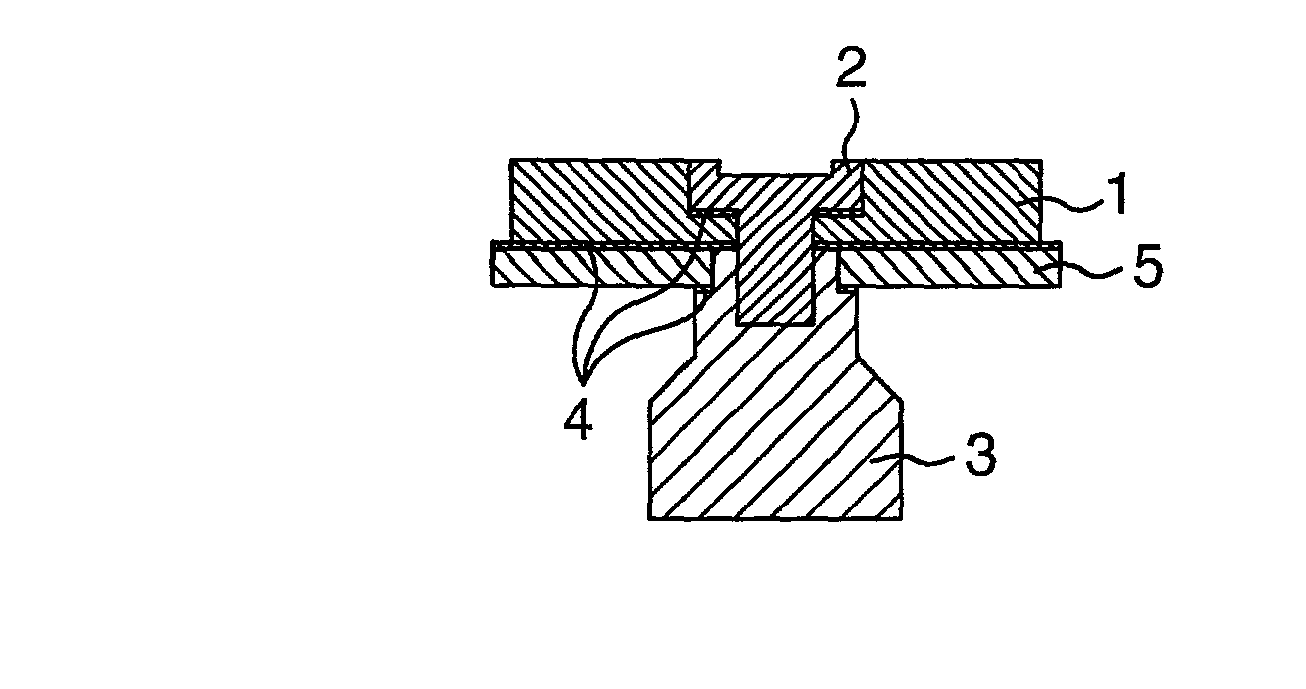

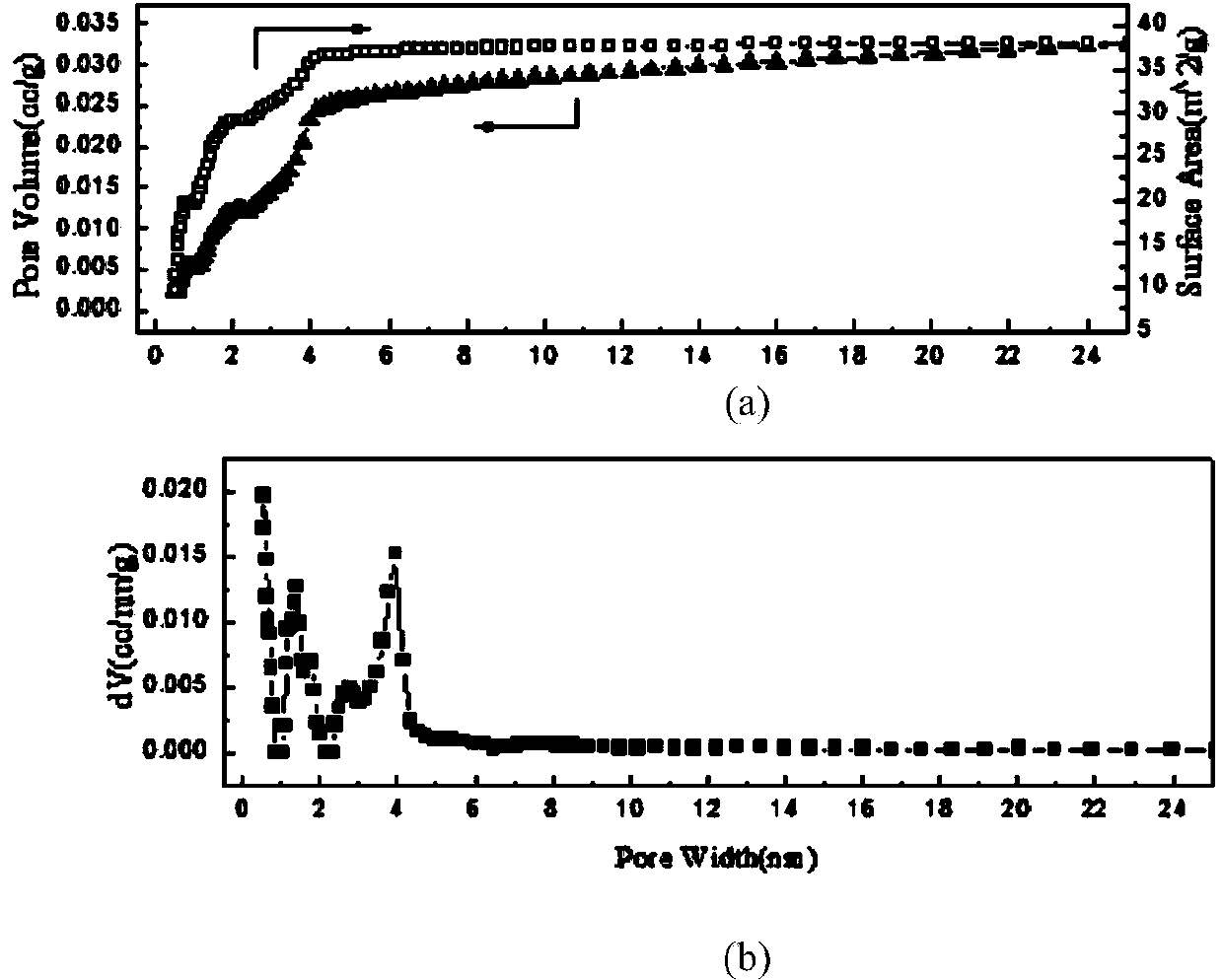

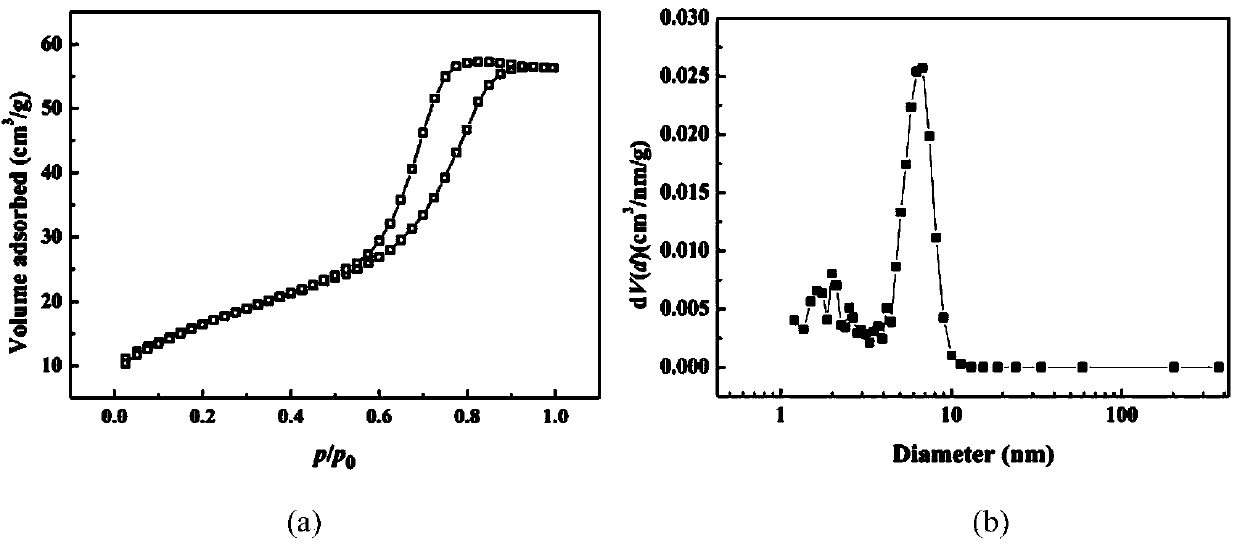

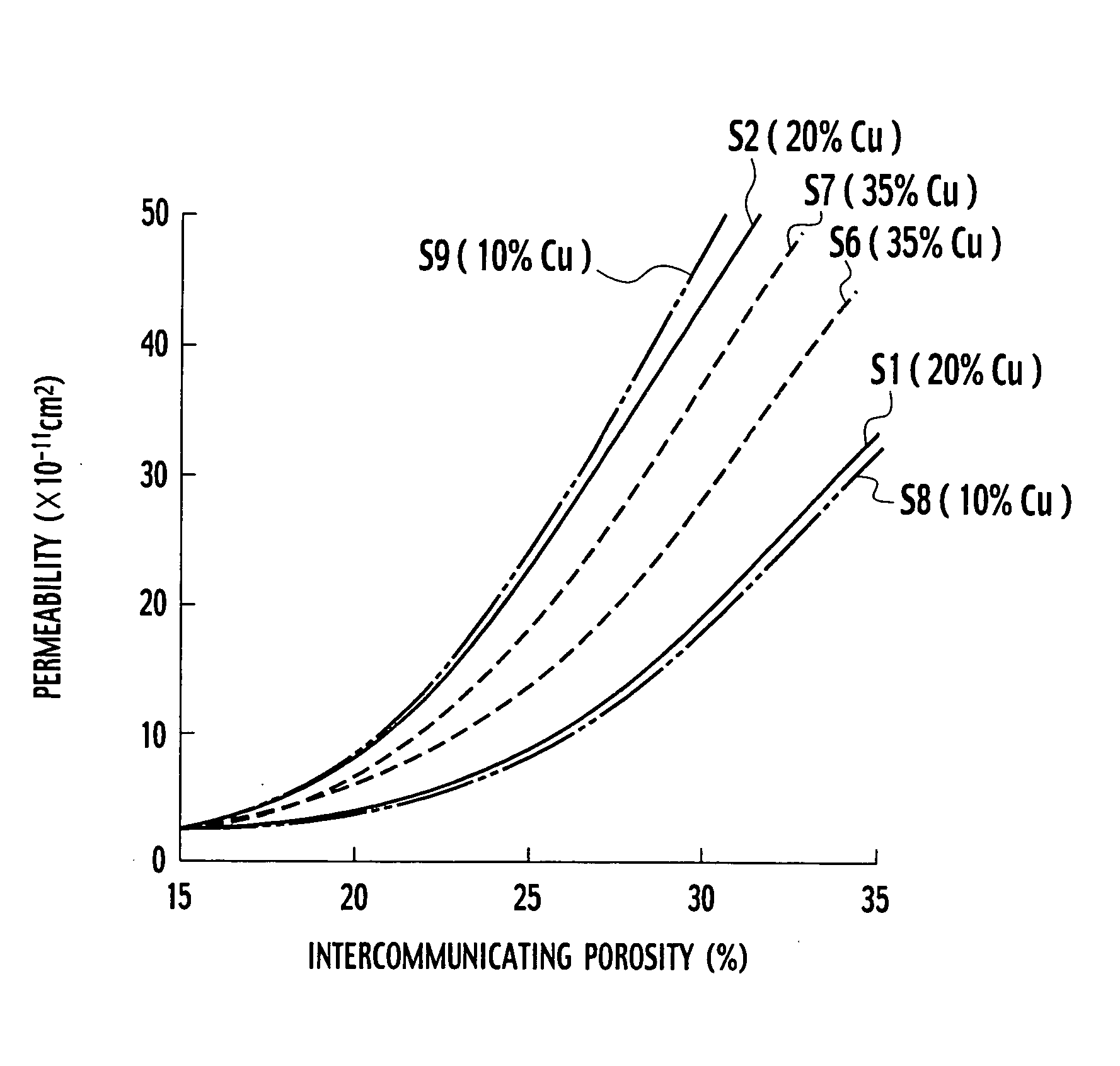

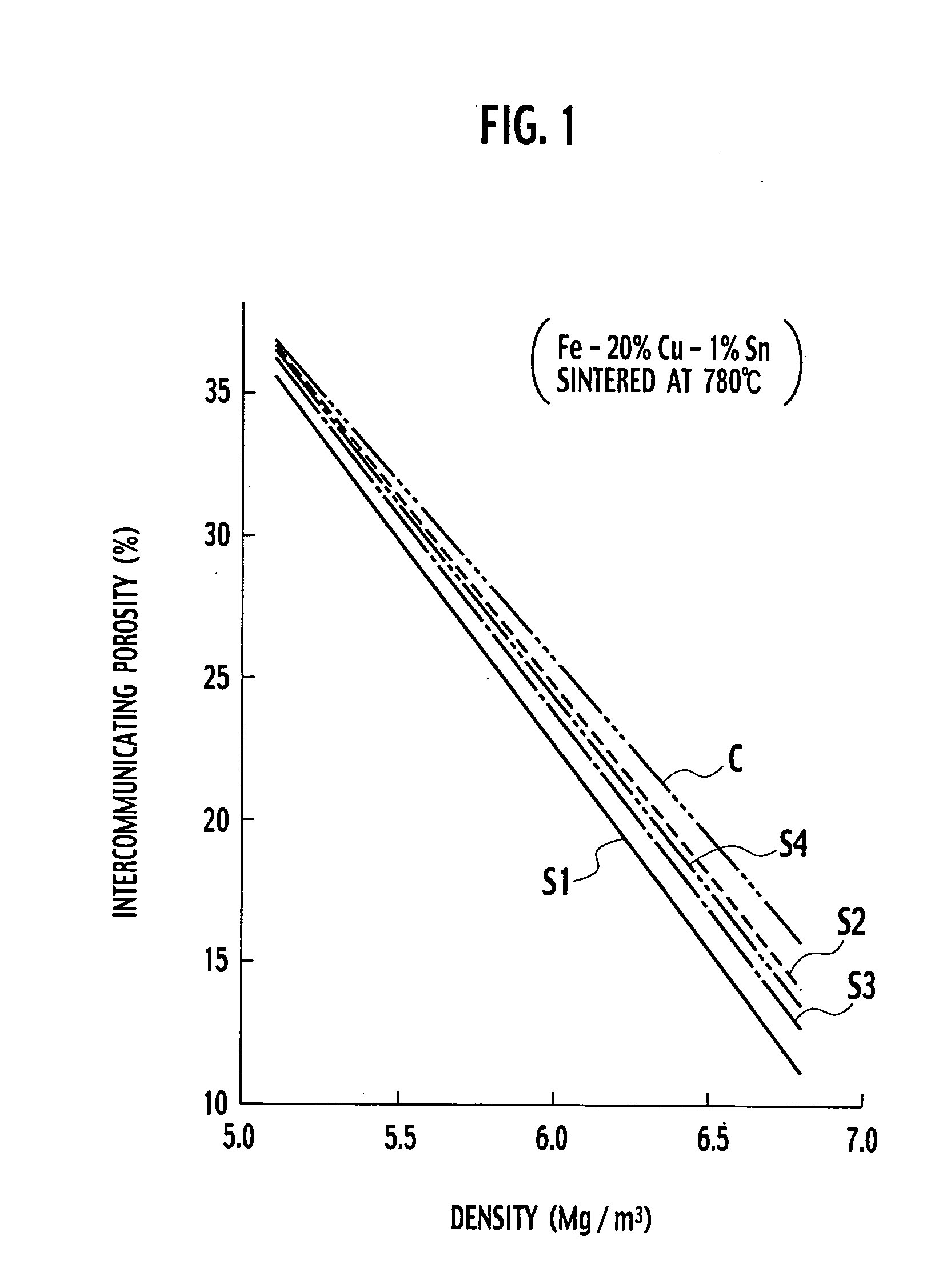

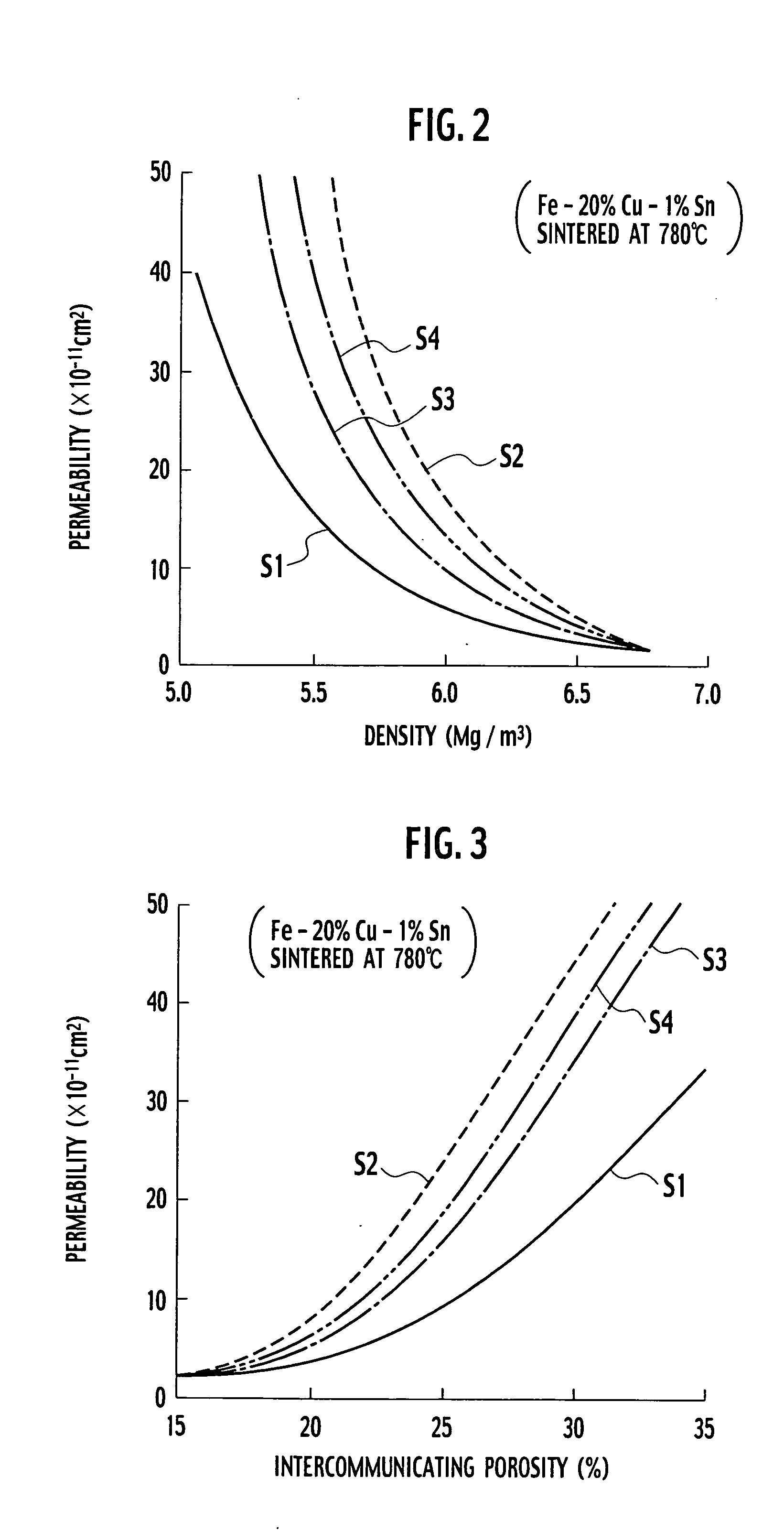

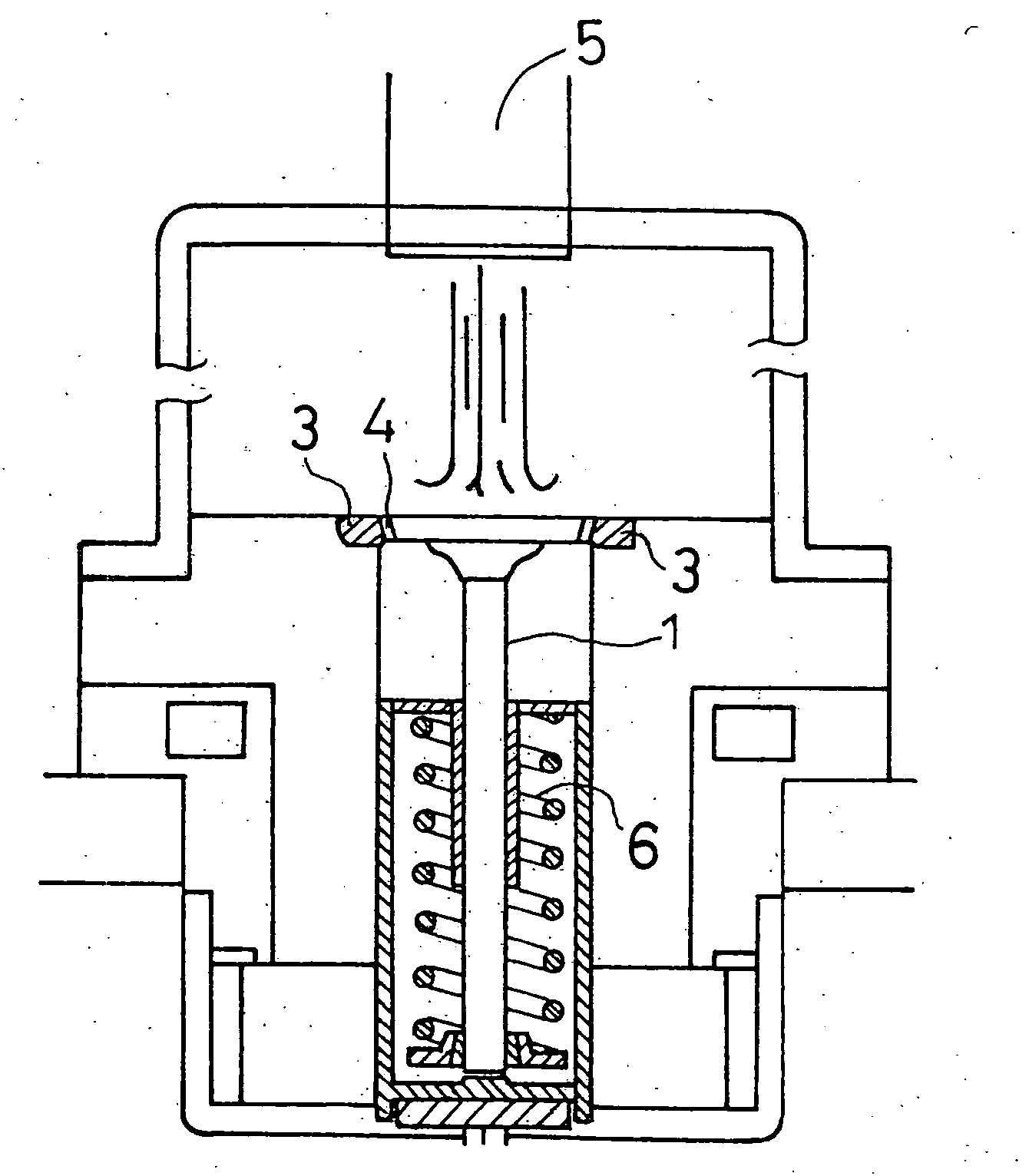

Manufacturing processes of sintered alloy and oil-impregnated sintered bearing

Disclosed is a manufacturing process of a sintered iron-copper base porous alloy and of an oil-impregnated sintered bearings, having the steps of: preparing a mixed powder comprising an iron powder, and at least one of a copper powder and a copper alloy powder; forming the mixed powder into a green compact; and sintering the green compact to obtain a sintered iron-copper base porous alloy. The iron powder contains a porous iron powder which has a particle size of 177 microns or less and a specific surface area of 110 to 500 m2 / kg according to a gas adsorption method. The sintered compact has high intercommunicating porosity and low permeability, and it is sized to prepare the sintered bearing into which a lubricating oil is impregnated.

Owner:HITACHI POWDERED METALS COMPANY

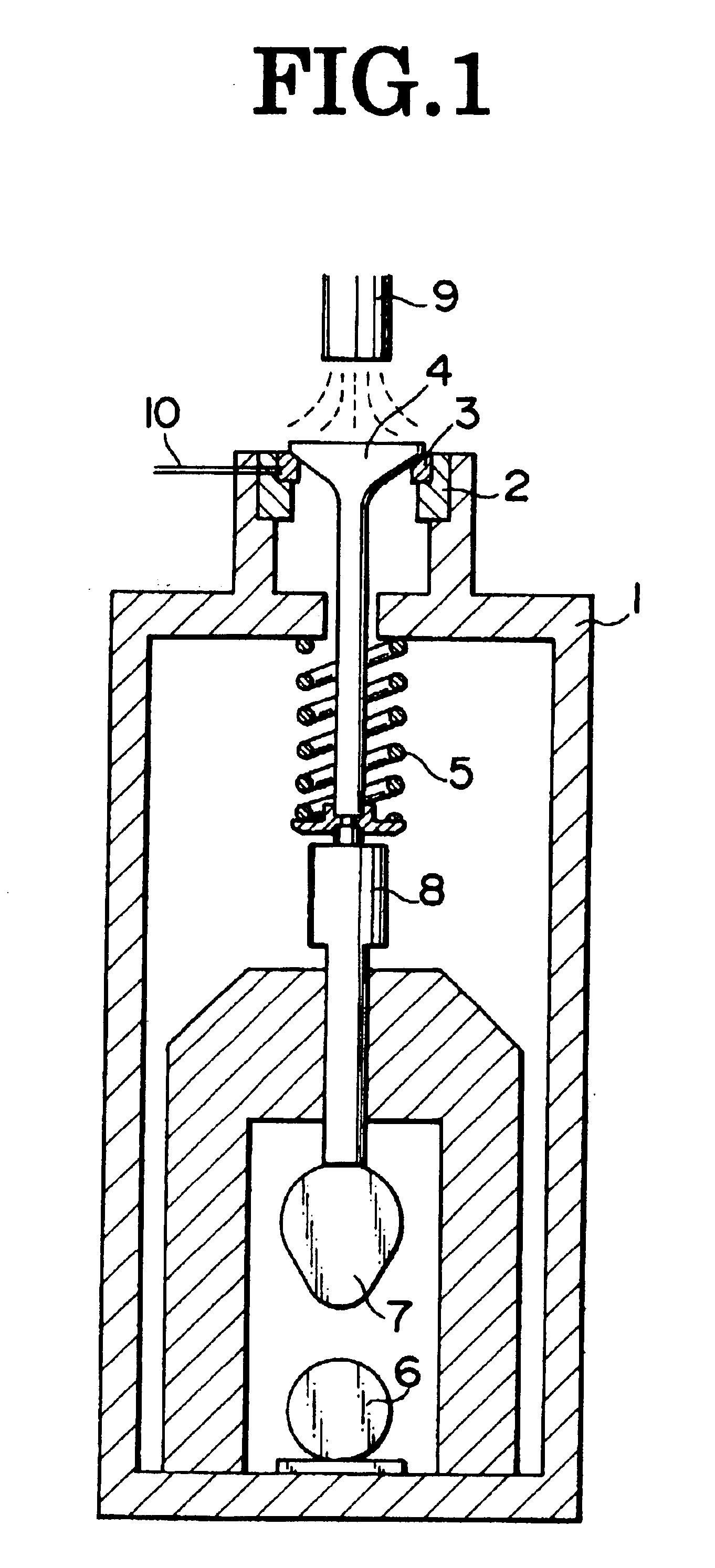

Sintered alloy, method for production thereof and valve sheet

InactiveUS20040194576A1Solve the lack of wear resistanceImprove wear resistanceMachines/enginesLift valveWear resistanceMaterials science

To provide a sintered alloy capable of showing wear resistance and a process for producing the same as well as a valve seat of good wear resistance. A sintered alloy comprising 4-30% by weight Mo, 0.2-3% by weight C, 1-30% by weight Ni, 0.5-10% by weight Mn, 2-40% by weight Co, and the balance of inevitable impurities and Fe when the entirety is taken as 100% by weight. Aprocess for producing a sintered alloy in which a green compact of a raw mixture powder including hard particles is sintered, thereby producing said sintered alloy. A valve seat comprising said sintered alloy.

Owner:TOYOTA JIDOSHA KK +1

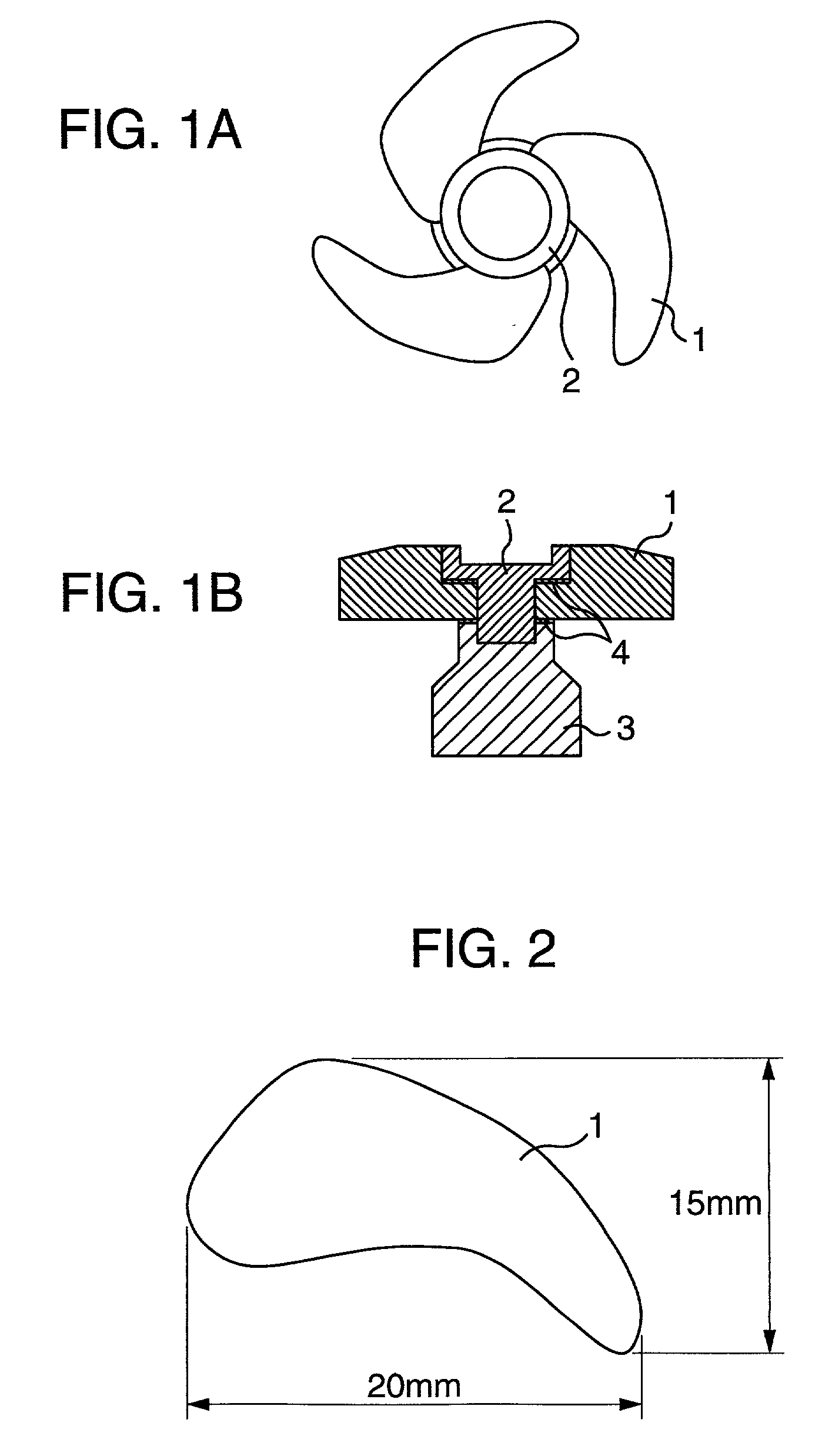

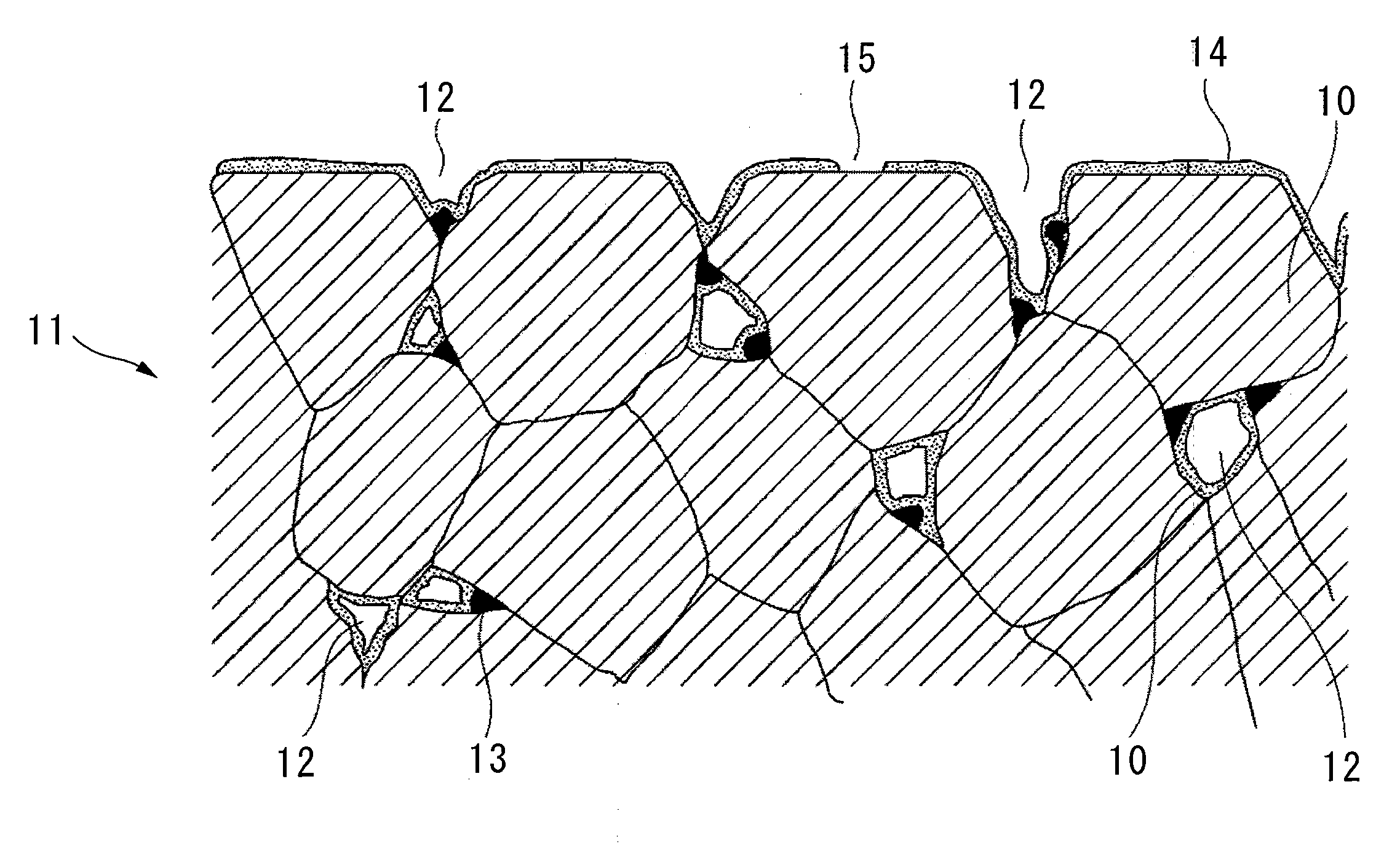

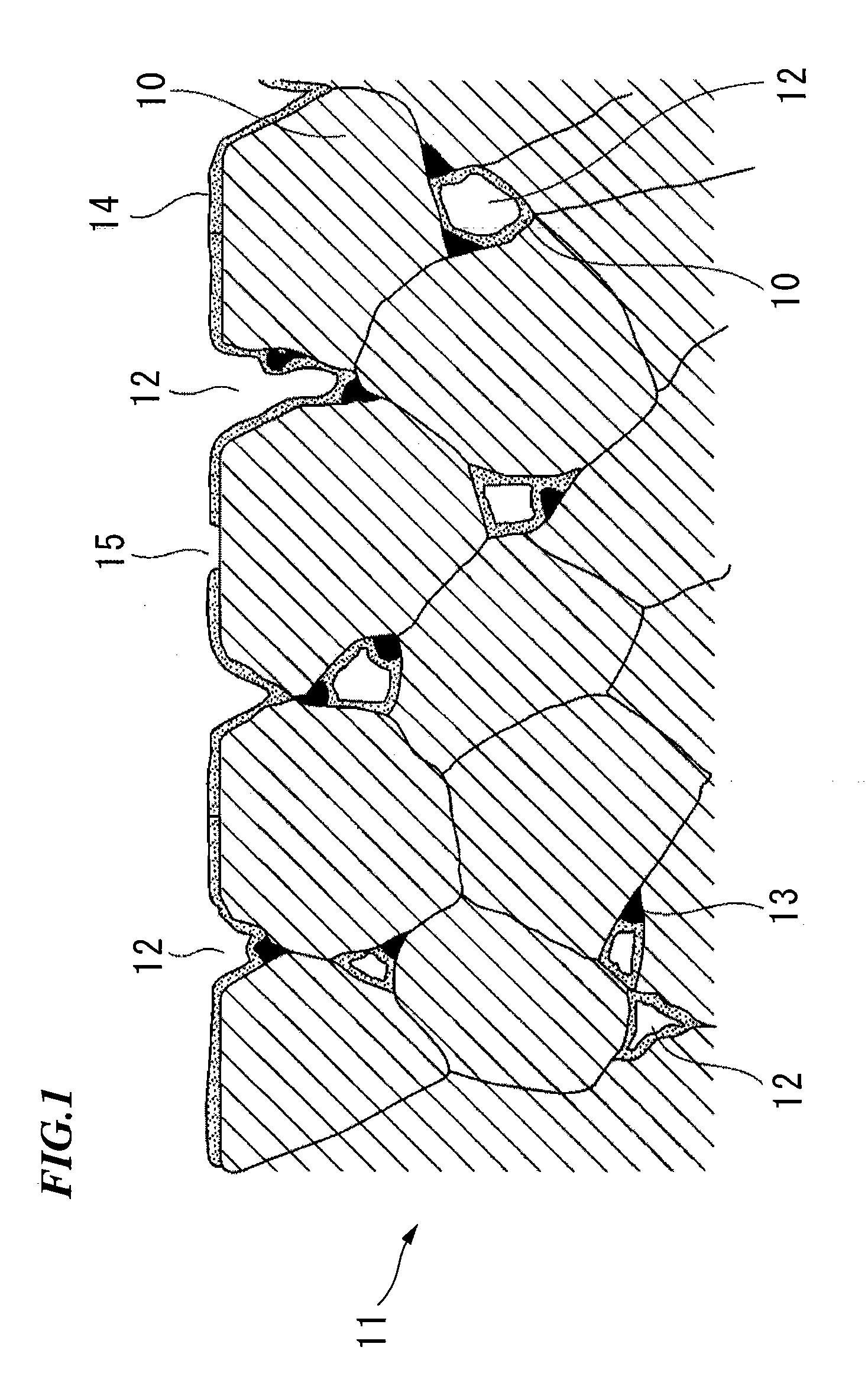

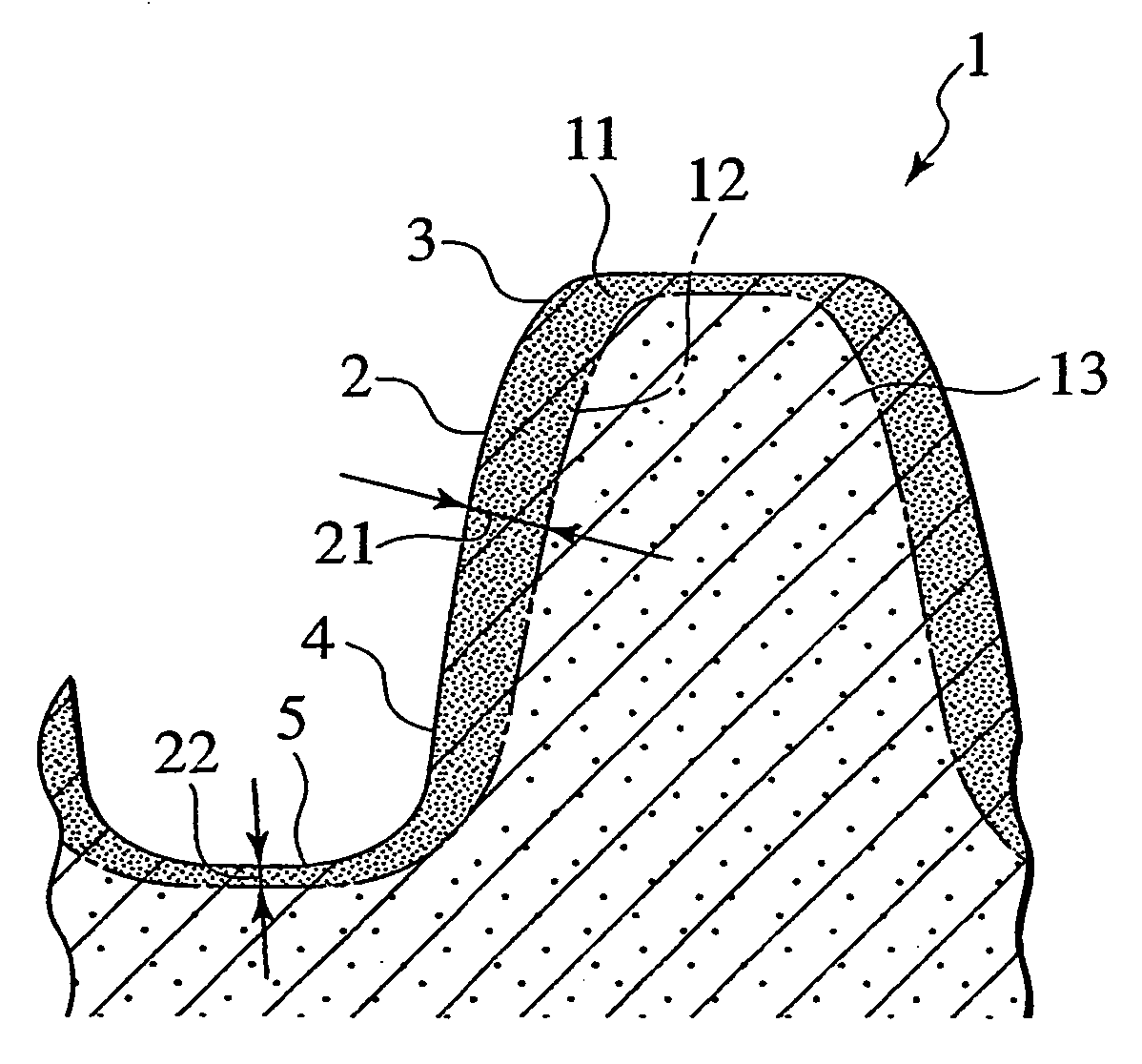

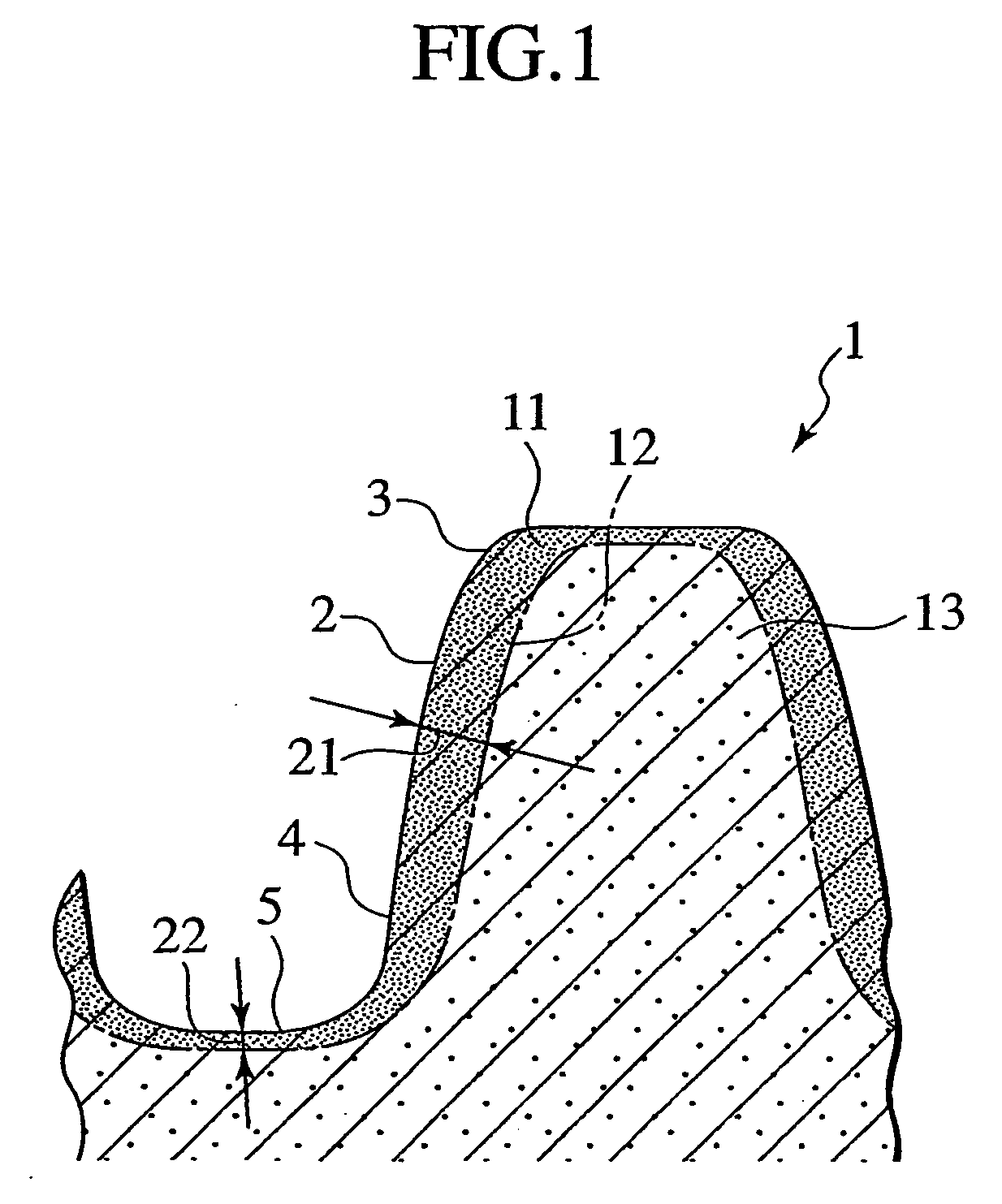

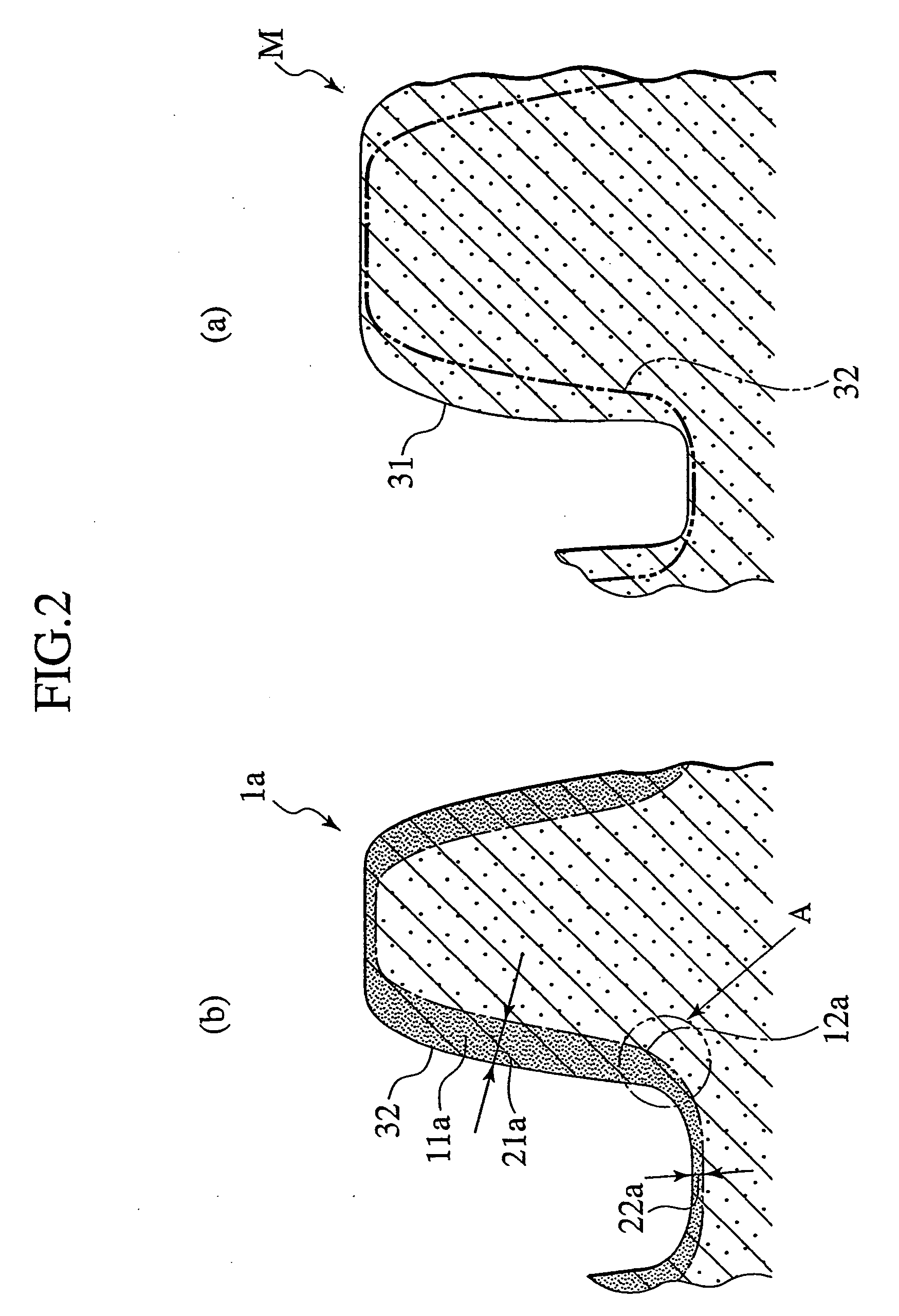

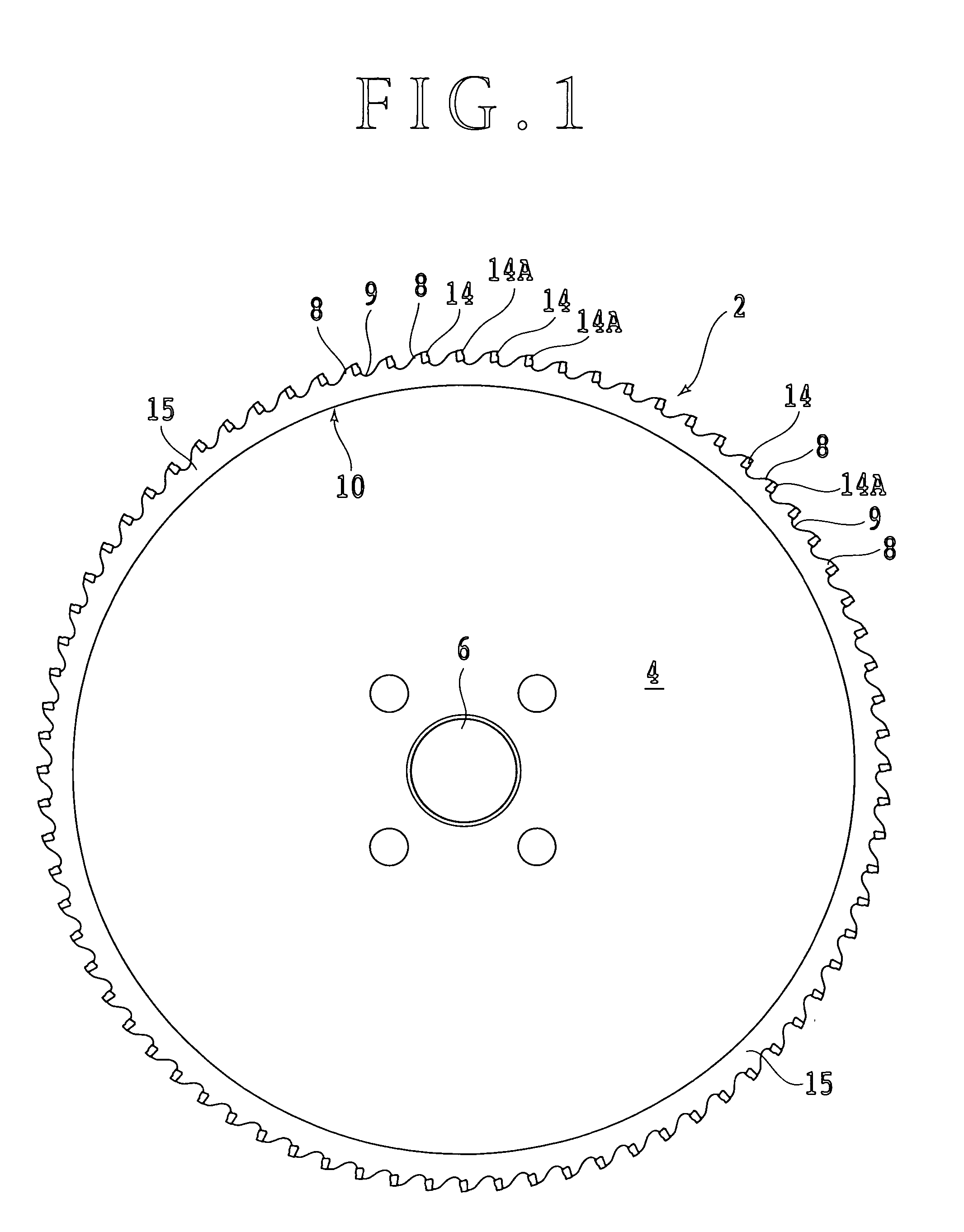

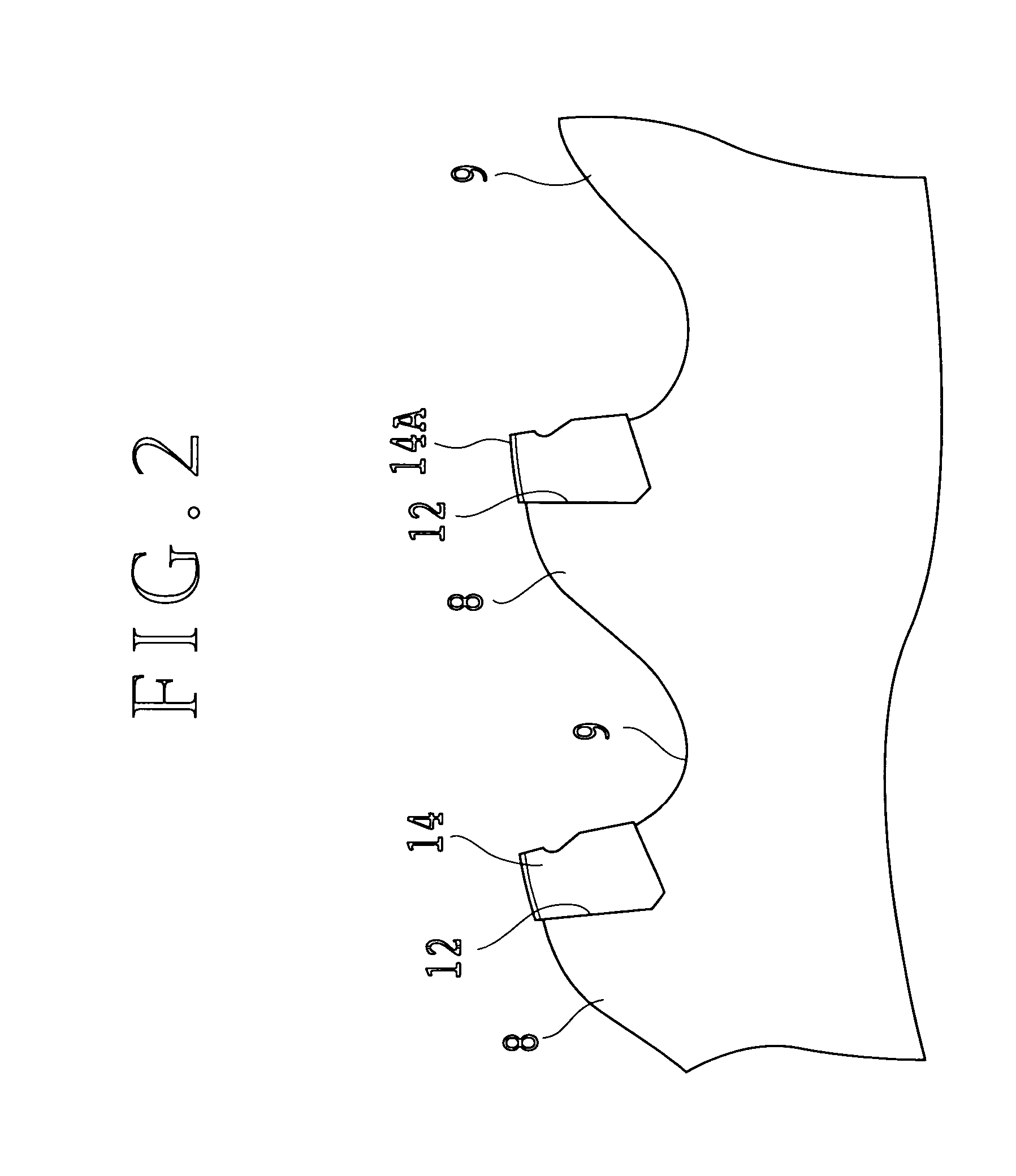

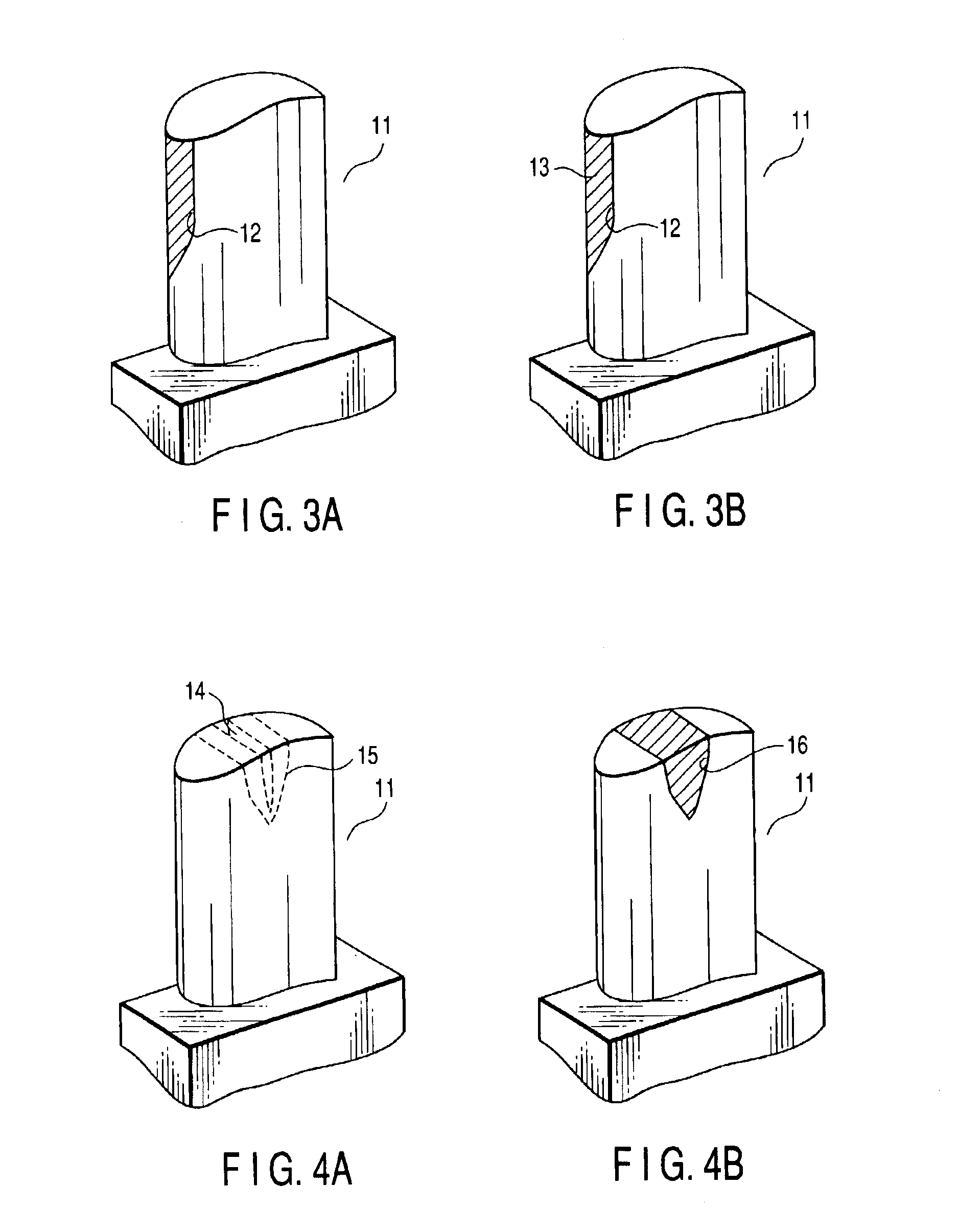

Sintered gear

Disclosed is a sintered gear composed of a sintered alloy having a metal matrix and pores. The tooth surface (2, 3, 4) of the tooth and the bottom land (5) have a densified layer (11) in which the porosity is reduced to 10% or less from the sintered alloy. The densified layer at the tooth surface is formed with a thickness of 300 to 1,000 microns, and the densified layer at the bottom land is formed with a thickness of 10 to 300 microns. The boundary surface of the densified layer is continuous from the tooth surface side to the bottom land side so as not to have a substantial level difference.

Owner:HITACHI POWDERED METALS COMPANY +1

Sintered alloy for valve seats, valve seat and manufacturing method thereof

A sintered alloy for valve seats is comprised of carbon at 1 to 2 percent by weight, chromium at 3.5 to 4.7 percent by weight, molybdenum at 4.5 to 6.5 percent by weight, tungsten at 5.2 to 7.0 percent by weight, vanadium at 1.5 to 3.2 percent by weight, and the remainder of iron and unavoidable impurities. Enstatite particles at 1 to 3 percent by weight, hard alloy particles (A) with a Vickers hardness of 500 to 900 at 15 to 25 percent by weight, and hard alloy particles (B) with a Vickers hardness of 1000 or more at 5 to 15 percent by weight (A+B=35 percent by weight or less) are dispersed in the matrix of the sintered alloy skeleton distributed with carbide. Copper or copper alloy at 15 to 20 percent by weight is infiltrated into pores of the skeleton.

Owner:TEIKOKU PISTON RING CO LTD

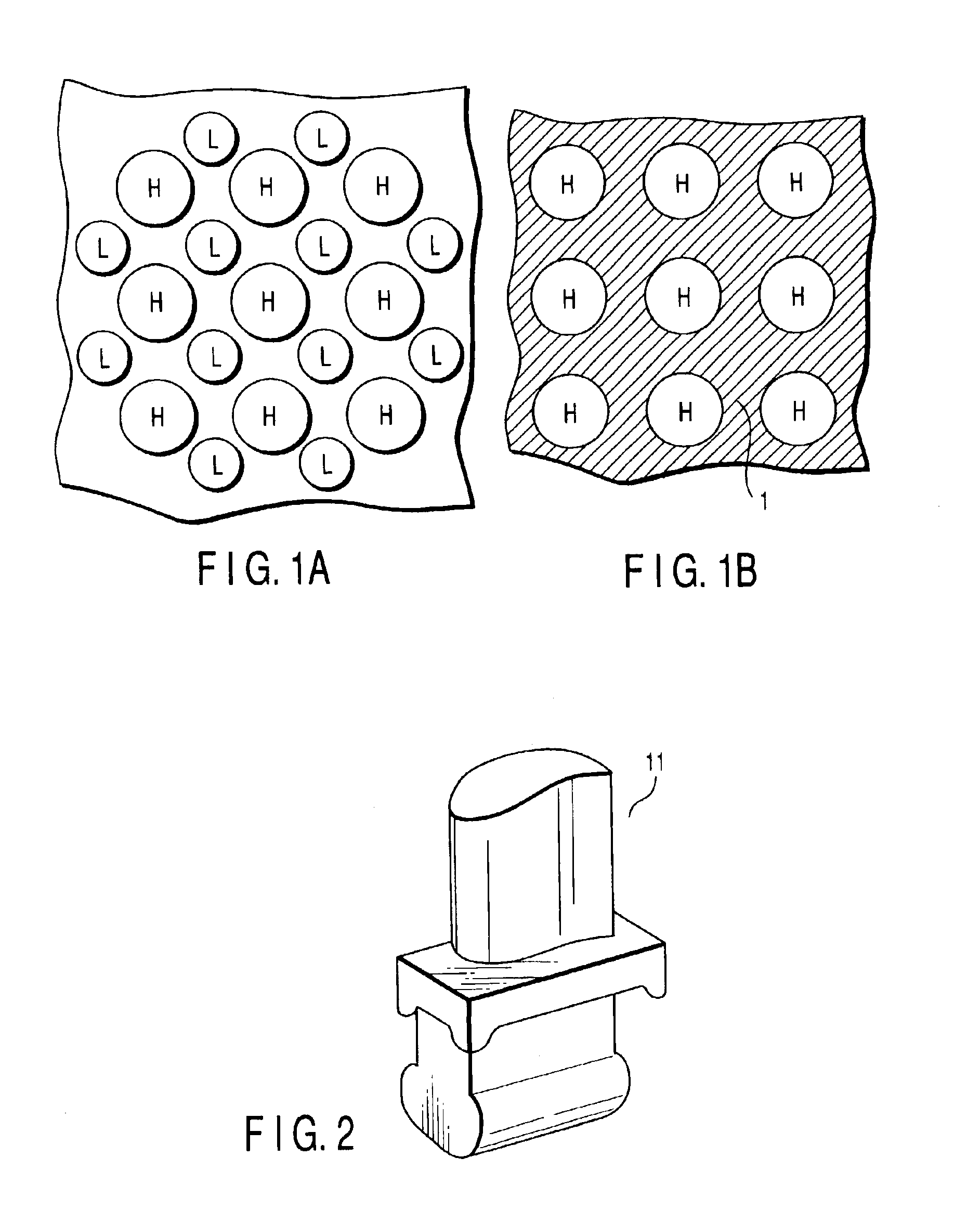

Iron-based sintered alloy with dispersed hard particles

An iron-based sintered alloy having improved thermal and mechanical strength is provided. The iron-based sintered alloy with dispersed hard particles comprises: a matrix comprising, by weight, 0.4 to 2% silicon (Si), 2 to 12% nickel (Ni), 3 to 12% molybdenum (Mo), 0.5 to 5% chromium (Cr), 0.6 to 4% vanadium (V), 0.1 to 3% niobium (Nb), 0.5 to 2% carbon (C), and the reminder of iron (Fe); and hard particles comprising 60 to 70% molybdenum (Mo), 0.3 to 1% boron (B), 0.1% or less carbon (C), and the reminder of iron (Fe). The hard particles are dispersed in the matrix in an amount in the range of 3 to 20% based on the entire alloy. They are sintered to produce the iron-based sintered alloy. Addition of boron into the ferromolybdenum hard particles enhances the wettability of the ferromolybdenum hard particles to prevent the hard particles from falling off the matrix. Thus, the adhesive property between the matrix and the hard particles is improved, thereby enhancing the thermal and mechanical strength of the iron-based sintered alloy.

Owner:RIKEN CO LTD

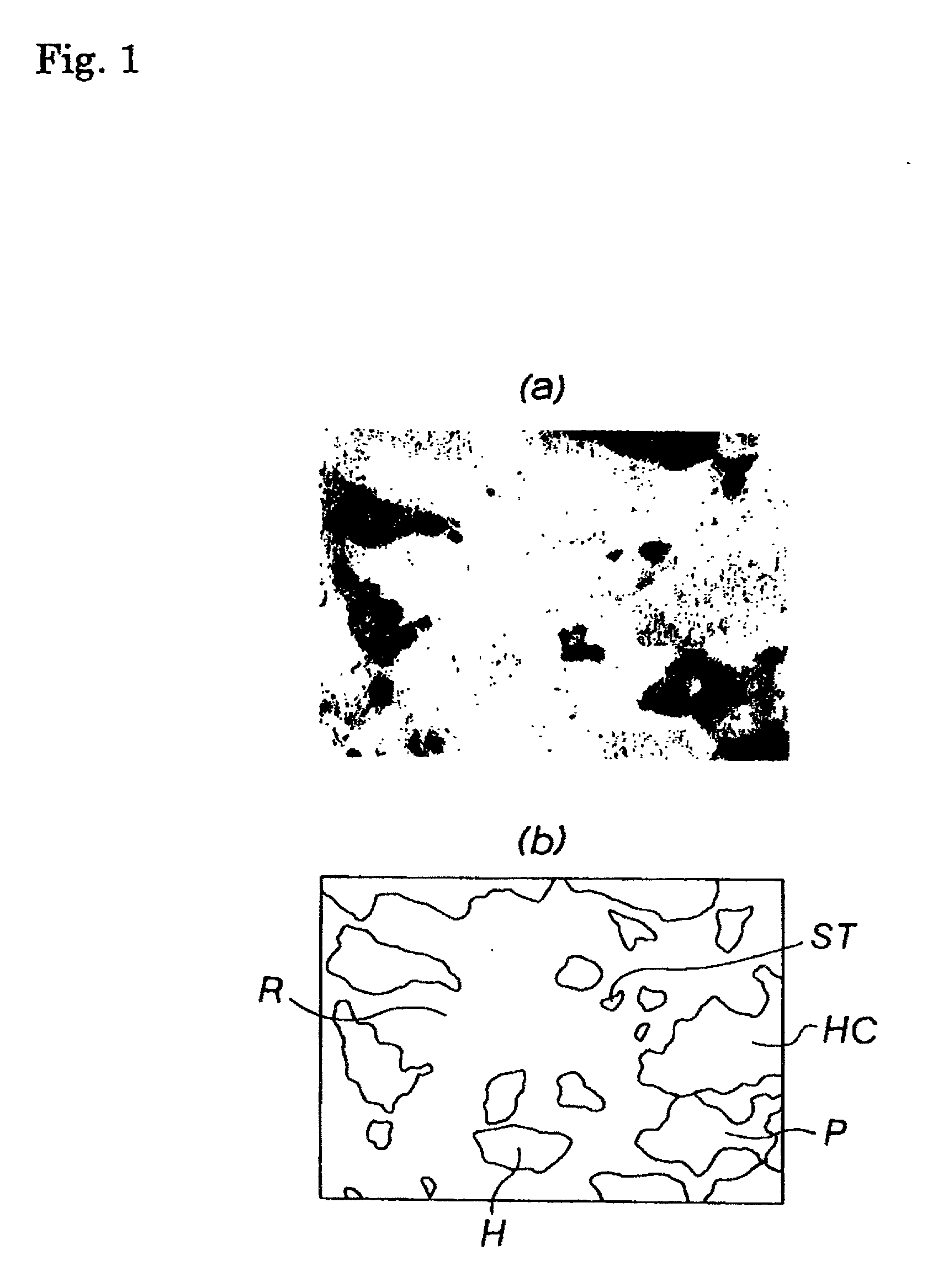

Iron-based sintered alloy material for valve seat and valve seat made of iron-based sintered alloy

InactiveUS20020084004A1Increase resistanceImprove toughnessMachines/enginesLift valveCarbideHardness

An iron-based sintered alloy material for a valve seat, in which hard particles are dispersed in a base matrix phase, is characterized in that the base matrix phase is comprised of 5 to 40 vol. % of a pearlite phase and 10 to 40 vol. % of a high-alloy diffused phase and particles having hardness of Hv 600 to 1300 and particle diameter of 10 to 150 mum are dispersed as the hard particles, by the amount of 10 to 30 vol. %, in the base matrix phase. The hard particles are preferably at least one type of particles selected from the group consisting of intermetallic compound particles of Mo-Ni-Cr-Si-Co; intermetallic compound particles of Cr-Mo-Co; Fe-Mo alloy particles; and carbide-precipitated particles.

Owner:NIPPON PISTONRING CO LTD

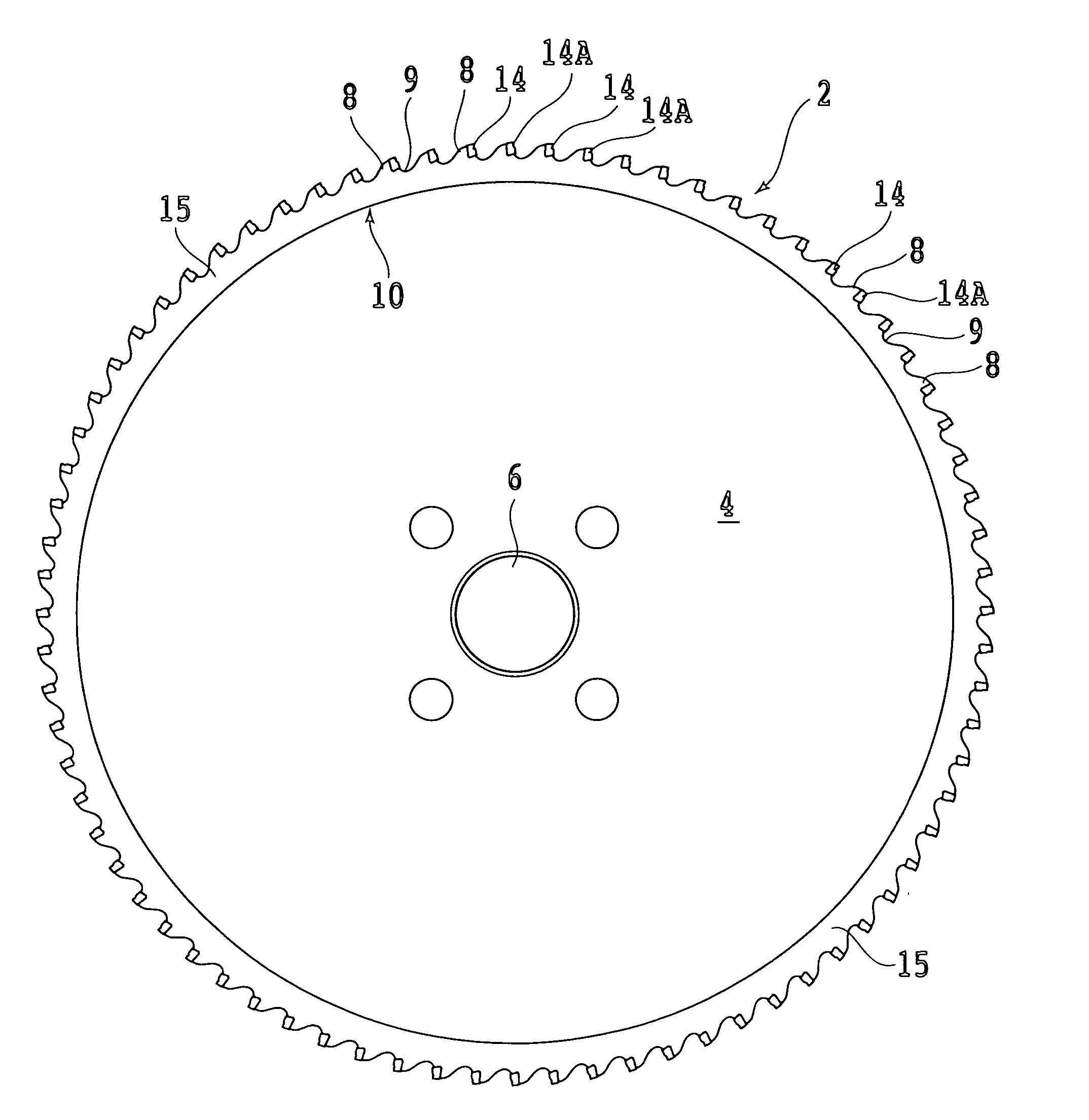

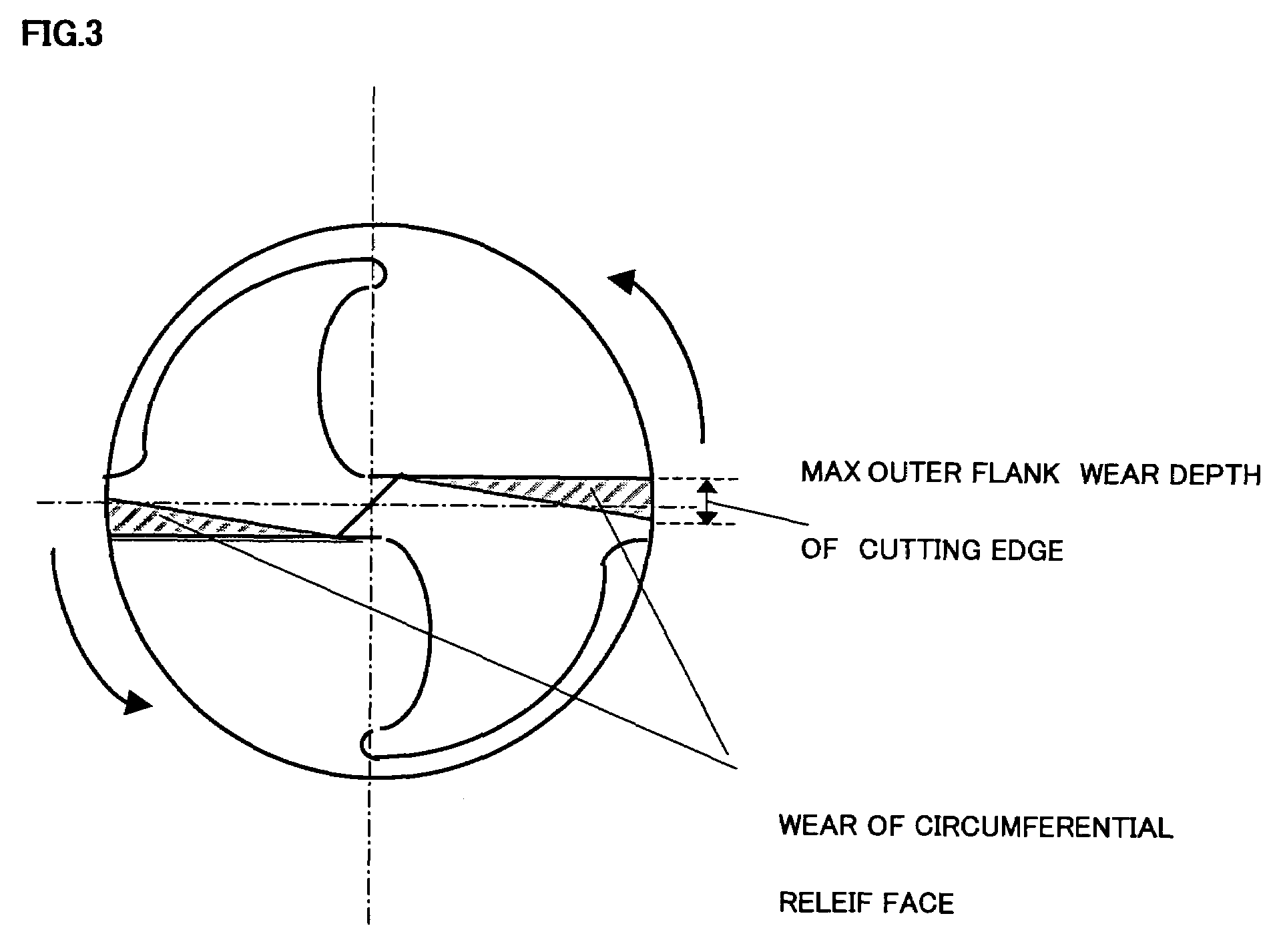

Disk cutter having tip inserts coated with a hard material

InactiveUS20060225553A1Improve adhesionProlong lifeMetal sawing devicesMetal sawing toolsCircular discMetallurgy

A disk cutter including an annular disk-shaped base adapted to be driven about an axis of rotation, a plurality of tip supports formed along the outer circumference of the base integrally therewith so that a gullet is defined between adjacent ones of the tip supports, a plurality of tip inserts respectively fixed to the tip supports, and a TiAlN coating formed on the surface of each tip insert. Each tip insert is formed of a sintered alloy composed of 98 to 90 w % of WC powder having a particle size of 0.1 to 0.8 μm and 2 to 10 w % of Co powder. The TiAlN coating has a thickness of 1 to 5 μm.

Owner:TENRYU SAW MFG

Hard alloy mold material for fastener formed through cold upsetting and preparation method of hard alloy mold material

Owner:SHAREATE TOOLS

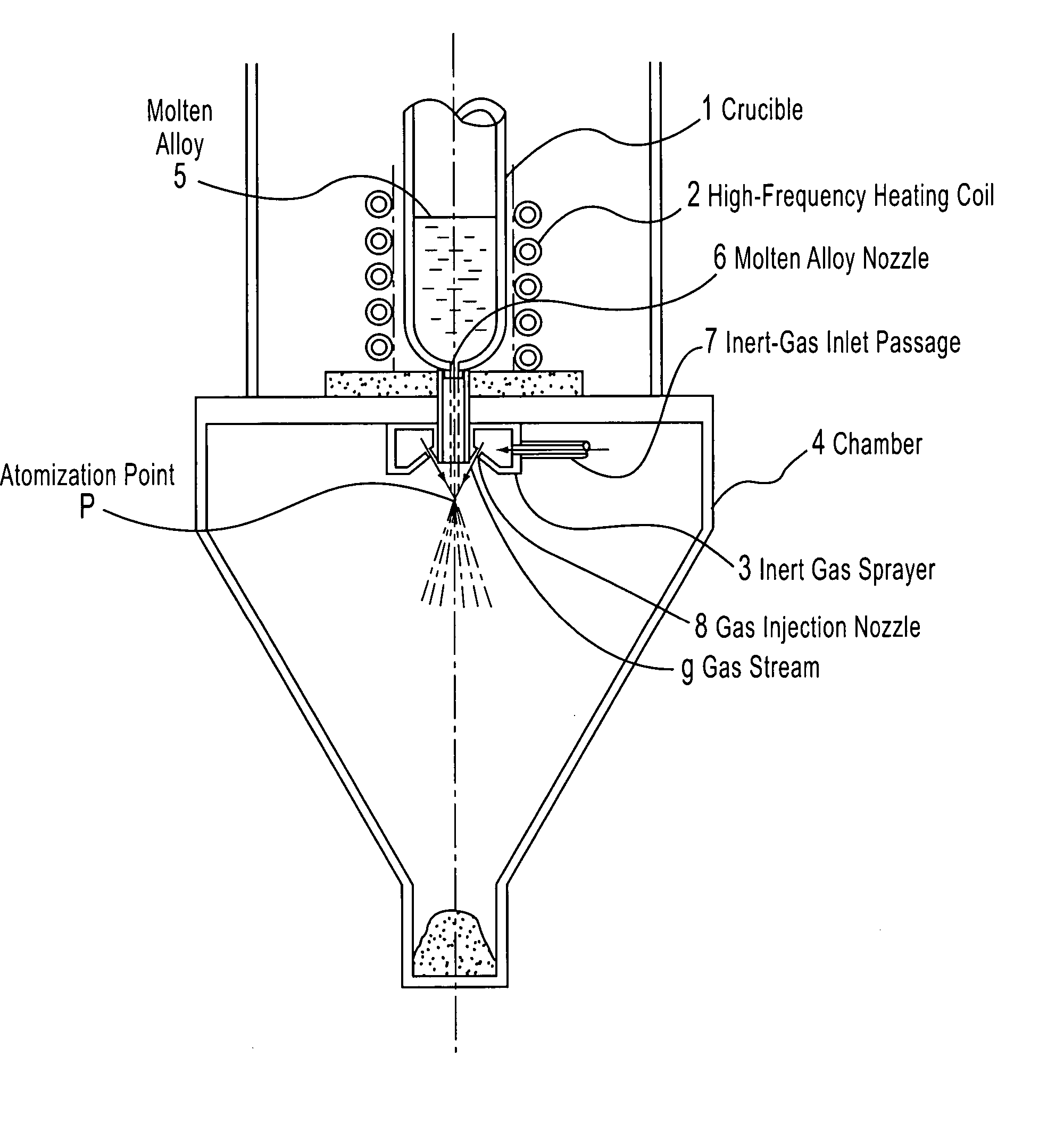

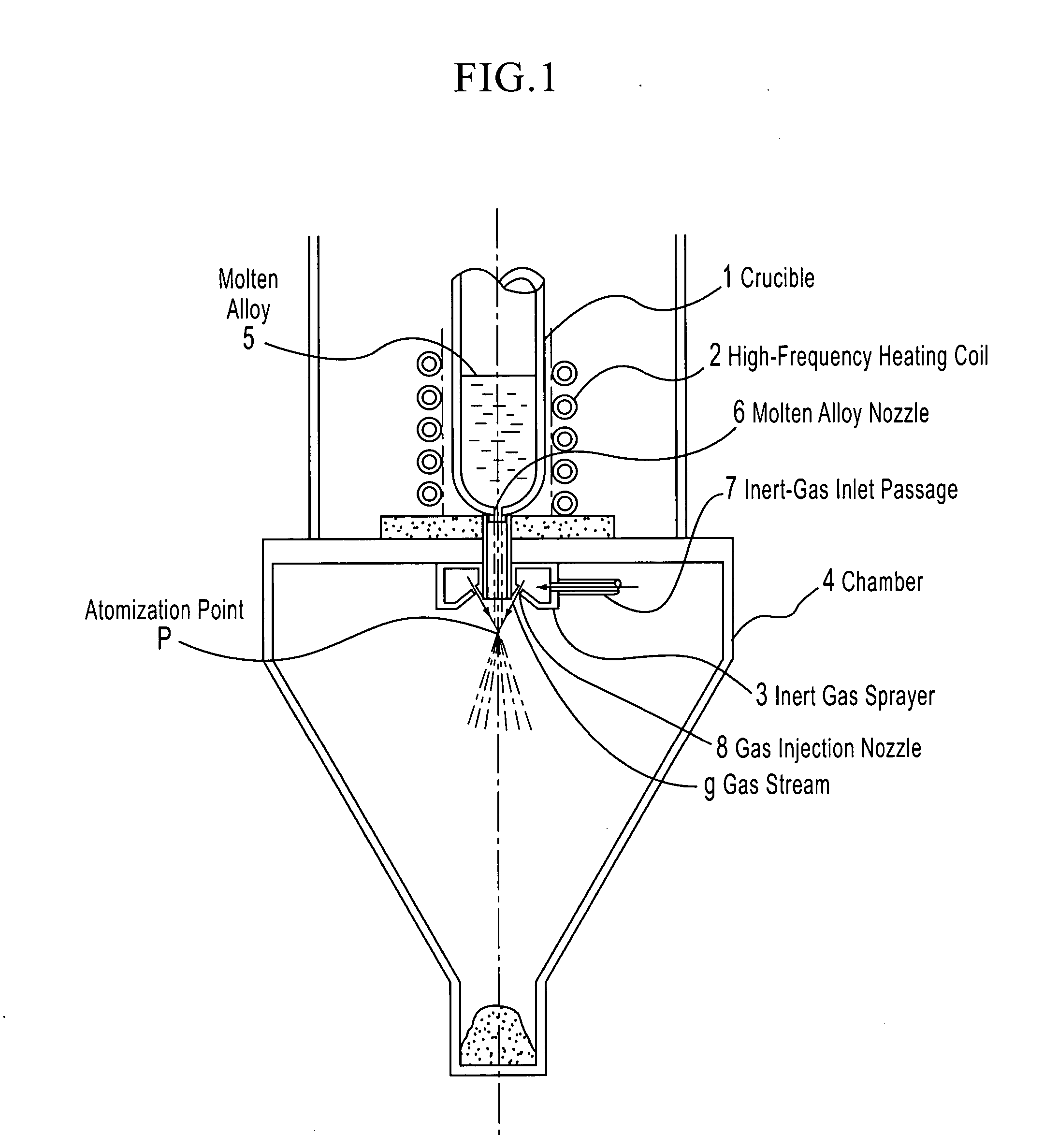

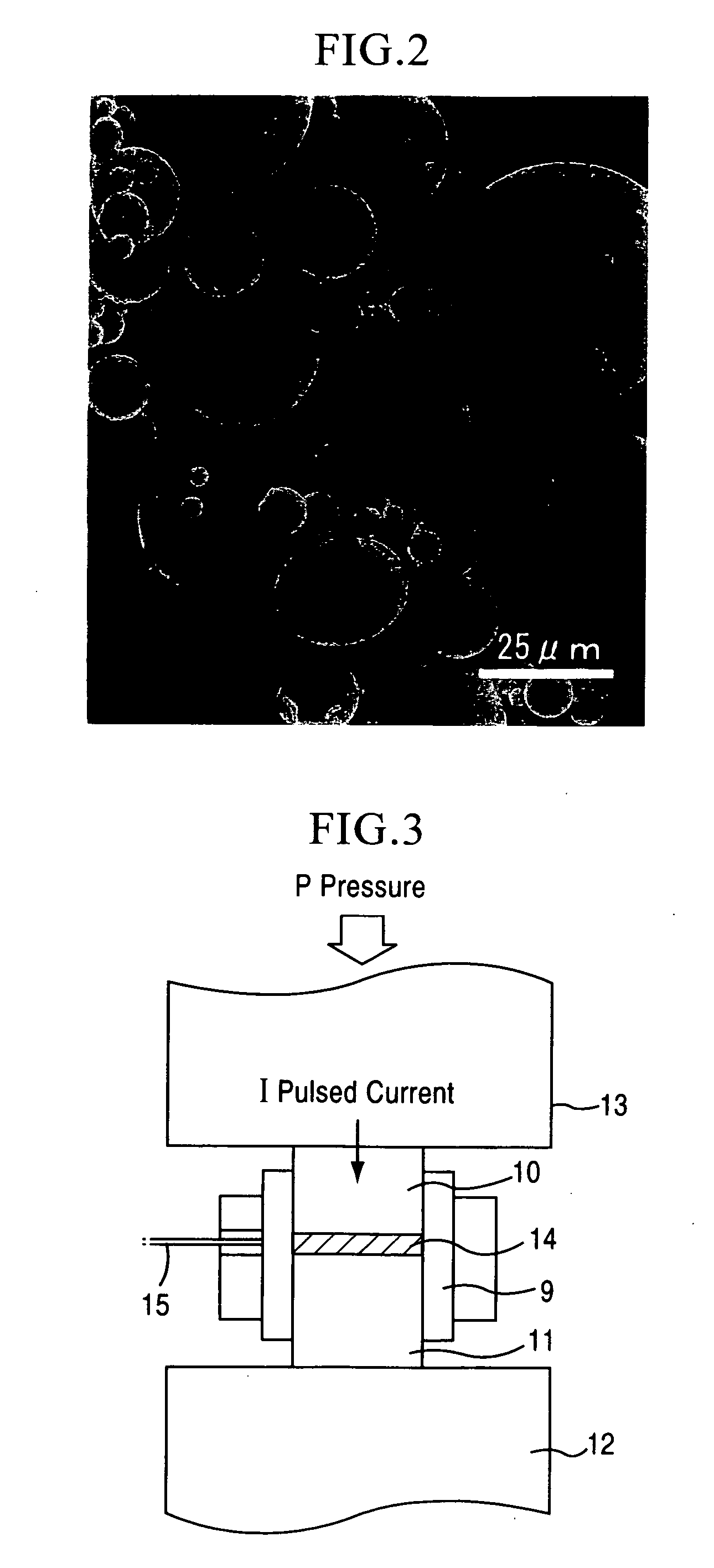

Spherical particles of fe base metallic glass alloy, fe base sintered alloy soft magnetic material in bulk form produced by sintering the same, and method for their production

InactiveUS20060254386A1High amorphous-alloy forming abilityExcellent soft magnetic propertiesTransportation and packagingMetal-working apparatusTransformerSpherical shaped

Disclosed is a Fe—Ga—P—C—B—Si based metallic glass alloy particle prepared by a gas atomizing process, which has an approximately complete spherical shape, a relatively large particle size and a high crystallization temperature (Tx). The plurality of particles may be subjected to a spark plasma sintering process at the crystallization temperature or less under a compression pressure of 200 MPa or more, to provide a bulk Fe-based sintered metal soft magnetic material of metallic glass, which has a high density, a single phase structure of metallic glass in an as-sintered state, excellent soft magnetic characteristics applicable to a core of a magnetic head, a transformer or a motor, and a high specific resistance.

Owner:JAPAN SCI & TECH CORP

Method for manufacturing co-base sintered alloy sputtering target for formation of magnetic recording film which is less likely to generate partricles, and co-base sintered alloy sputtering target for formation of magnetic recording film

InactiveUS20100270146A1Inhibition formationCellsVacuum evaporation coatingBinary alloyChemical composition

A method for manufacturing a Co-base sintered alloy sputtering target for the formation of a magnetic recording film including providing a Cr—Co alloy powder consisting of 50 to 70 atomic % of Cr and remaining Co, a Pt powder, a non-magnetic oxide powder, and a Co powder, blending and mixing the powders together so as to give the chemical composition consisting of 2 to 15 mol % of a non-magnetic oxide, 3 to 20 mol % of Cr, and 5 to 30 mol % of Pt and a remainder containing Co, and sintering the mixture under pressure. Or alternatively providing a Pt—Cr binary alloy powder consisting of 10 to 90 atomic % of Pt and remaining Cr, a Pt powder, a non-magnetic oxide powder, and a Co powder, blending and mixing the powders so as to give the chemical composition above, and then sintering the mixture under pressure.

Owner:MITSUBISHI MATERIALS CORP

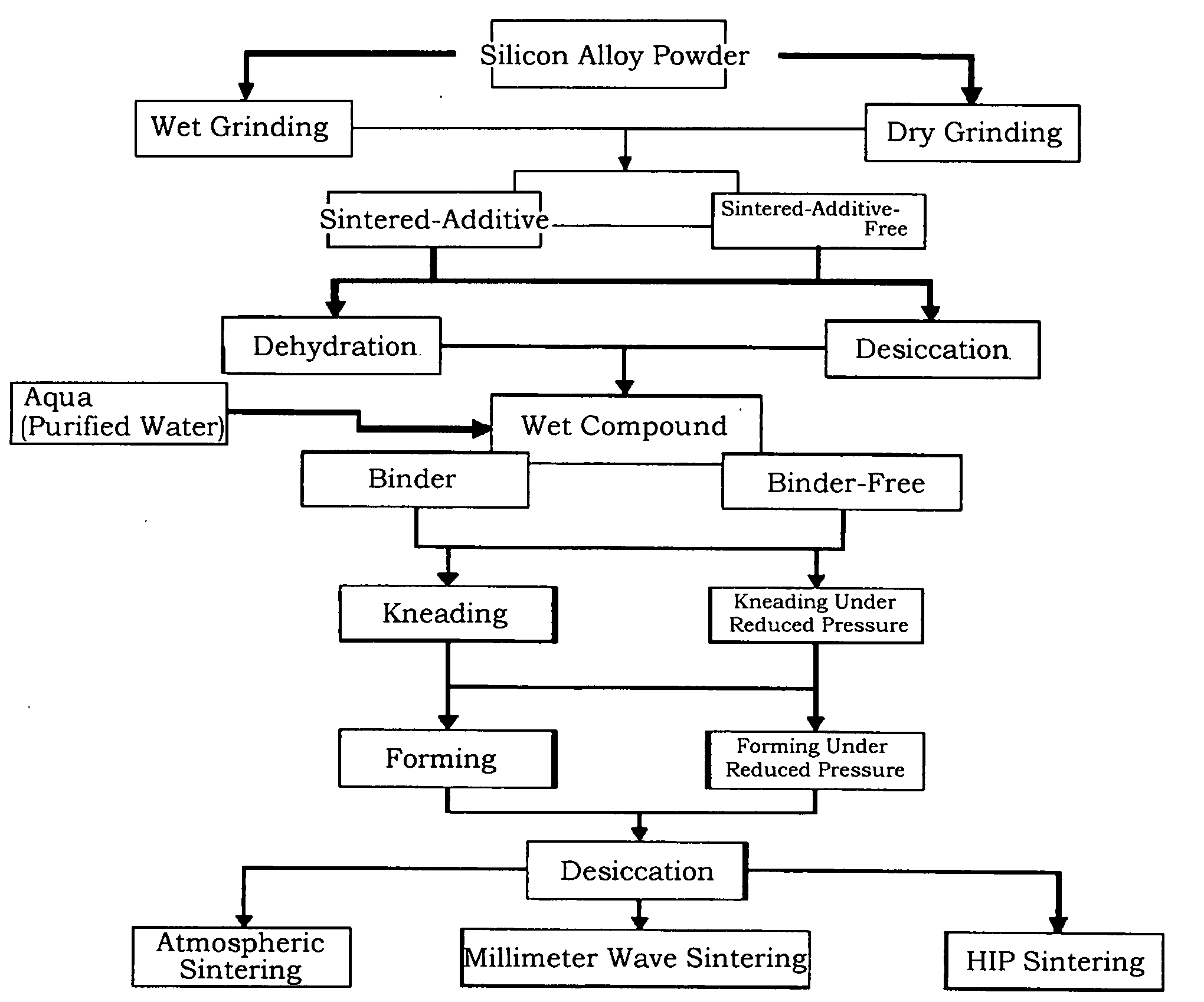

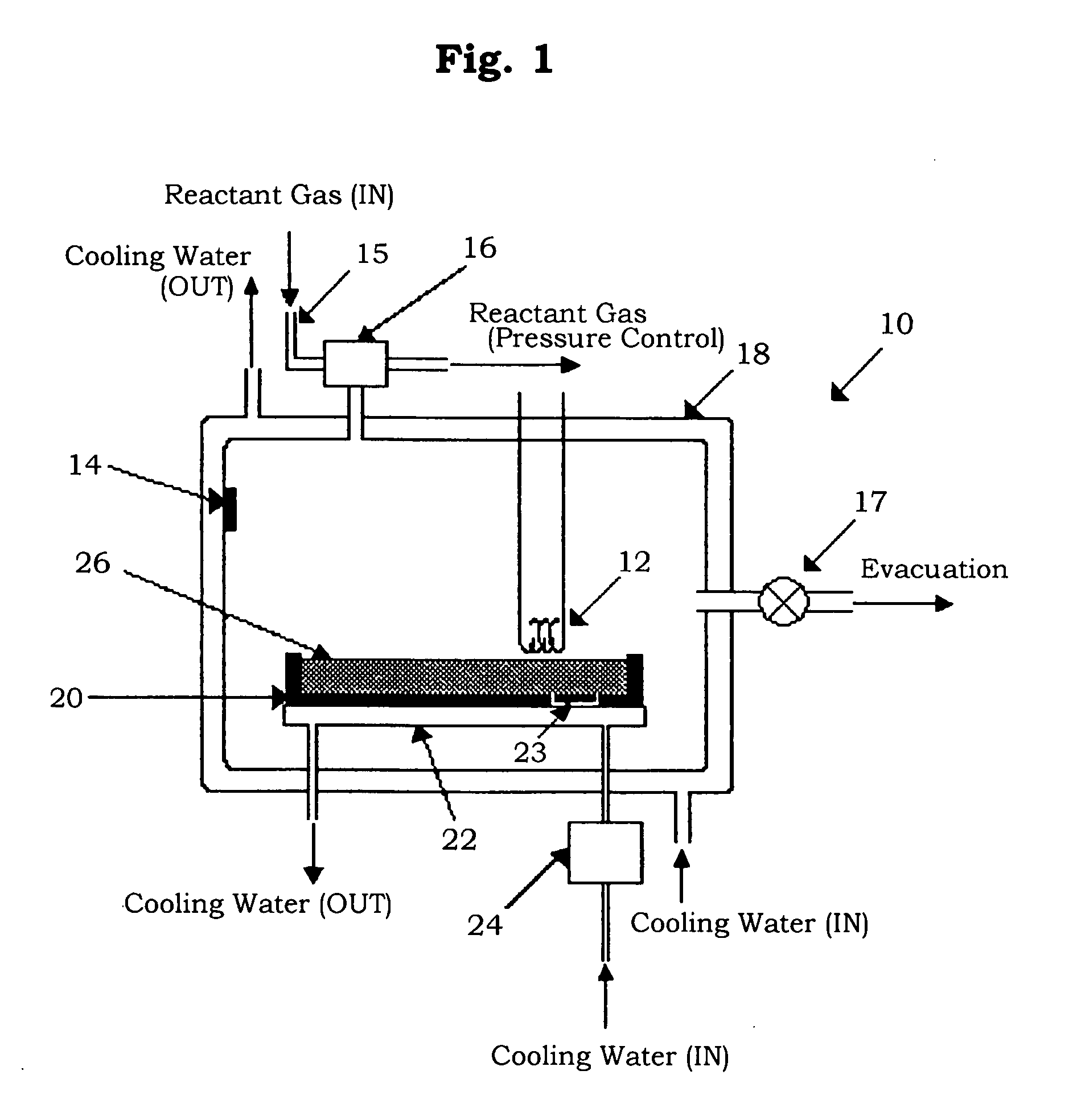

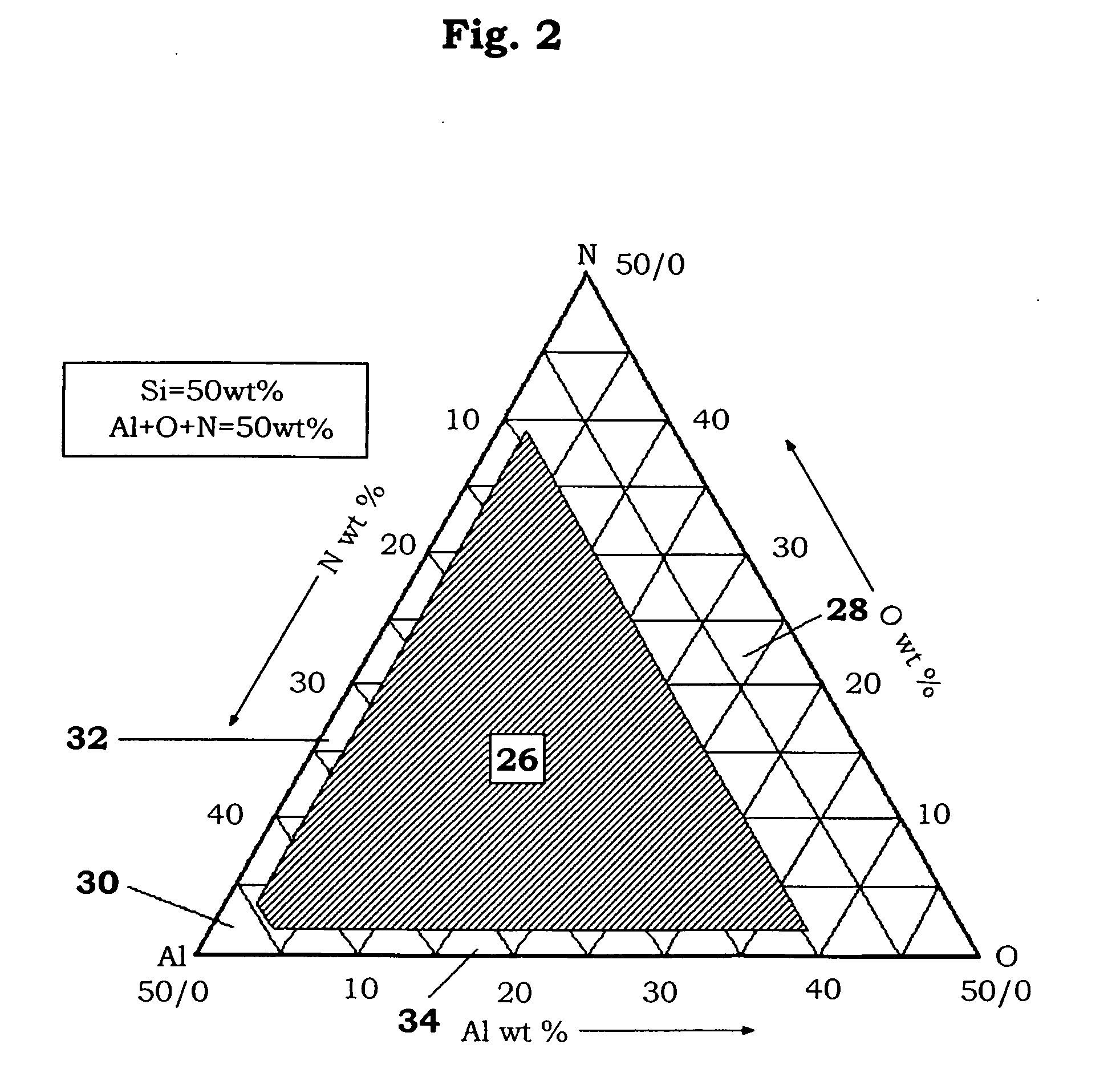

Silicon alloy, alloy powder thereof, manufacturing apparatus, manufacturing process and sintered alloy thereof

InactiveUS20080159905A1Heat treatment process controlNitrogen and non-metal compoundsBack burnsSilicon alloy

A controlled combustion synthesis apparatus comprises an ignition system, a pressure sensor for detecting internal pressure, a nitrogen supply, a gas pressure control valve for feeding nitrogen and exhausting reaction gas, means for detecting the internal temperature of the reaction container, a water cooled jacket, and a cooling plate. A temperature control system controls the temperature of the reaction container by controlling the flow of cooling water supplied to the jacket and the cooling plate in response to the detected temperature. By combustion synthesizing, while controlling the internal pressure and temperature, the apparatus can synthesize a silicon alloy including 30-70 wt. % silicon, 10-45 wt. % nitrogen, 1-40 wt. % aluminum, and 1-40 wt % oxygen.

Owner:ISMAN J CORP

Ni-based sintered alloy

InactiveUS6884275B2Avoid it happening againOvercome in mechanical strengthBlade accessoriesGas turbine plantsMelting temperatureAtmosphere

Disclosed is a Ni-based sintered alloy used for preparing a high temperature part utilized under a high temperature gas atmosphere, characterized in that the Ni-based sintered alloy is prepared by mixing and heating two kinds of Ni alloy powders differing from each other in the melting point.

Owner:MITSUBISHI HITACHIPOWER SYST LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com