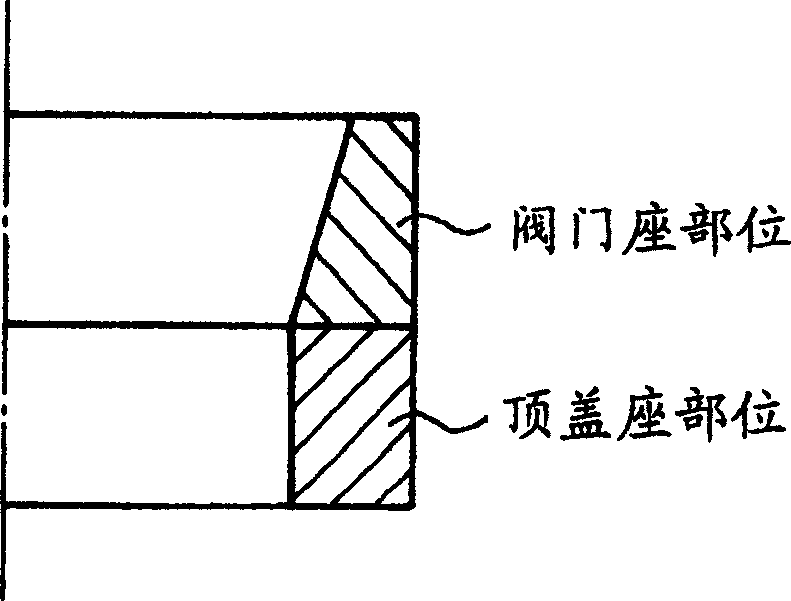

Sintered alloy valve seat and its manufacturing method

A technology of alloy and valve seat, applied in the field of manufacturing this valve seat, can solve the problems of high manufacturing cost, wear of valve and valve seat, complicated steps of increasing density, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0076] Pure iron powder, hard particle powder and iron alloy powder and / or alloy element powder are mixed in the ratio shown in Table 1, and the types of these powders are shown in Table 1. Moreover, a predetermined amount (by weight) of solid lubricant particles is added to 100 parts (by weight) of a mixture of pure iron powder, hard particle powder and iron alloy powder and / or alloy element powder, and the resulting mixture Mix, then knead. Thereby, the first raw material powder for making the valve seat part and the second raw material powder for making the top cover seat part are obtained. In addition to the solid lubricant particle powder, pure iron powder, hard particle powder and iron alloy powder and / or alloy element powder are expressed by mass percentage. Sample 18 is a comparative example without solid lubricant particle powder.

[0077] sample

part

solid lubricant

granular powder

raw briquette...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com