Iron-based powder mixture, and method of manufacturing iron-based compacted body and iron-based sintered body

A technology of mixed powder and iron-based powder, which is applied in the field of press-formed mixed powder, iron-based powder sintered body, and mixed powder for powder metallurgy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

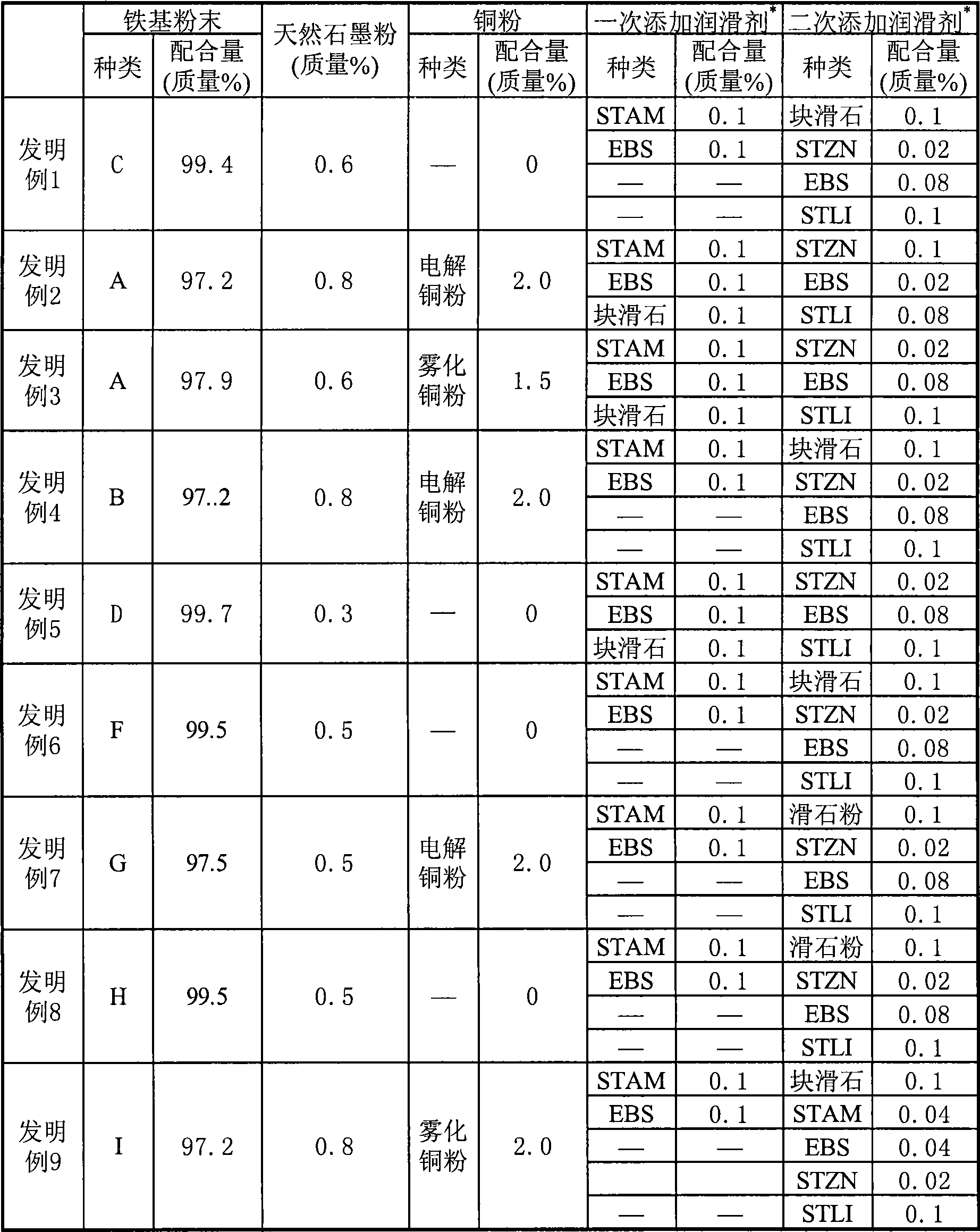

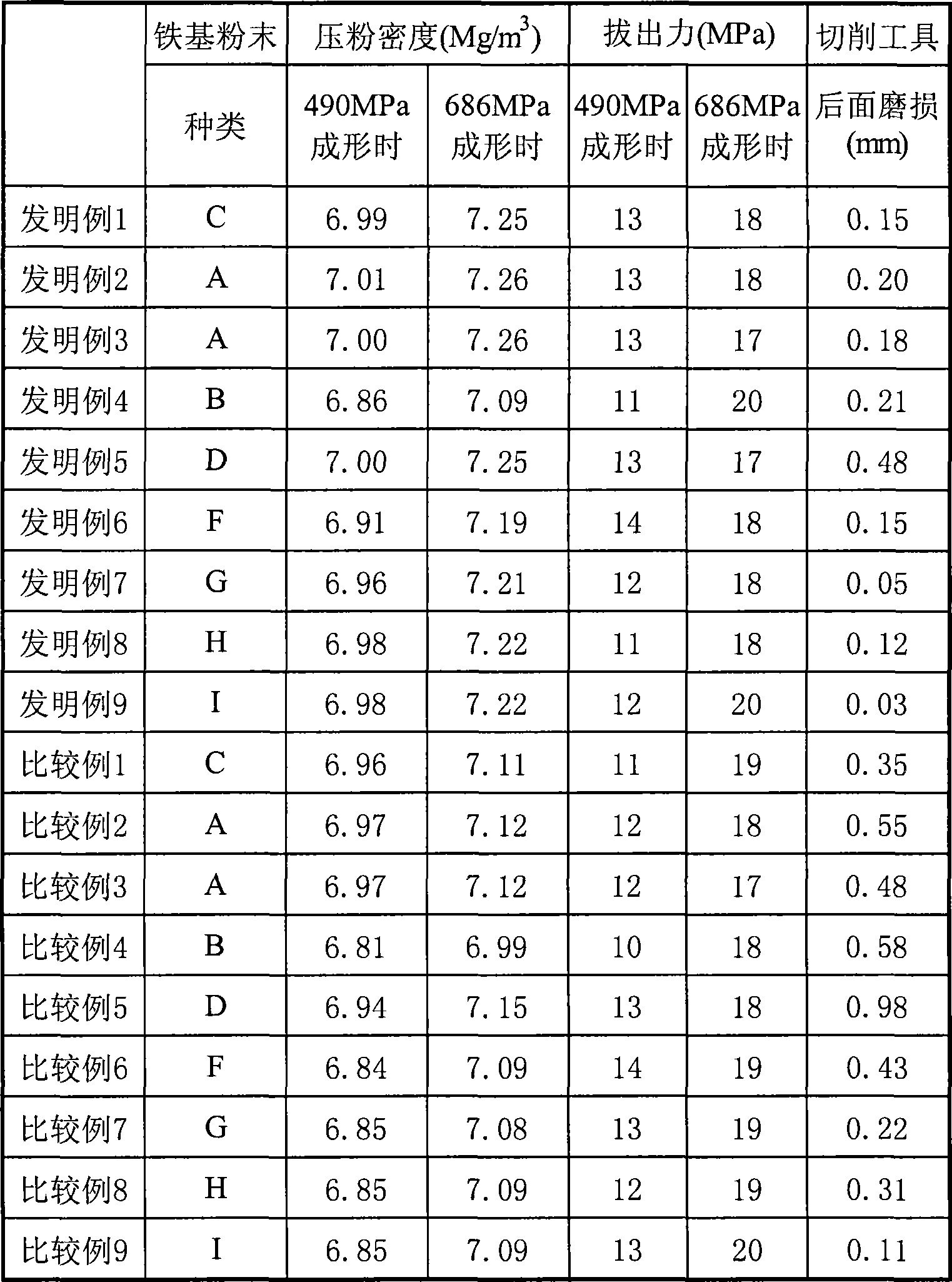

[0108] Add various lubricant powders (primary additives) to various iron-based powders, natural graphite powders (average particle size: 5 μm) and / or copper powders (average particle size: 25 μm) shown in Table 2, and stir with a high-speed bottom After heating to 140°C while mixing in a type mixer, cool to below 60°C, add various lubricant powders (secondary additives), stir at 500rpm for 1 minute, and discharge the mixed powder from the mixer. The types and compounding quantities of the primary and secondary additives are recorded in Table 2 together. The added amount (parts by mass) of the lubricating material represents the ratio of the iron-based powder, natural graphite powder, and copper powder to the total mass 100% in outer numbers, and is approximately the same as the numerical value expressed in inner numbers. In addition, the average particle diameters of the talc powder and steatite powder were 6 μm and 4 μm, respectively.

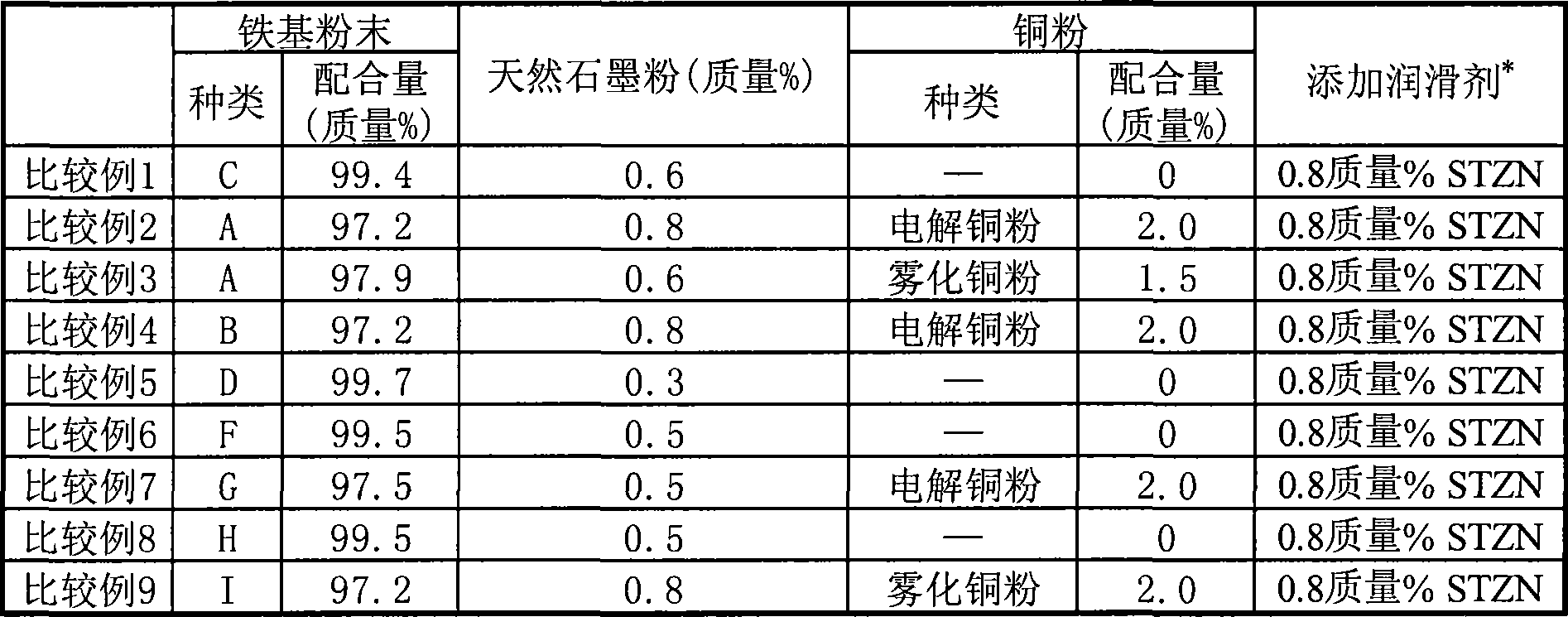

[0109] In addition, for comparison, a ...

Embodiment 2

[0123] Add various lubricants (primary additives) to various iron-based powders, natural graphite powders and / or copper powders shown in Table 5, heat to 140°C while mixing with a high-speed bottom mixer, and cool to Below 60°C, add various lubricants (secondary additives), stir at 500rpm for 1 minute, and discharge the mixed powder from the mixer. The types and compounding quantities of the primary and secondary additives are recorded in Table 5 together. The raw materials used are those described in Table 1 as in Example 1.

[0124] In addition, for comparison, it is prepared to add 0.6% by mass of ethylene bisstearamide to the powder of the same iron-based powder, natural graphite powder and / or steel powder composition as above and mix it with a V-shaped container rotary mixer to obtain mixed powder (comparison material).

[0125] Next, each iron-based mixed powder obtained at room temperature was filled into a superhard flat mold with an inner diameter of 11 mm heated in...

Embodiment 3

[0137] Add various lubricants (primary additives) to various iron-based powders, natural graphite and / or copper powders shown in Table 7, heat to 140°C while mixing with a high-speed bottom mixer, and cool to 60°C. Below ℃, add various lubricants (secondary additives), stir at 500rpm for 1 minute, and discharge the mixed powder from the mixer. The types and compounding quantities of the primary and secondary additives are recorded in Table 7. The raw materials used are the same as in Example 1.

[0138] And, for comparison, mixed powders in which ethylene bisstearamide was added by weight and mixed with a V-shaped container rotary mixer were produced.

[0139] Next, each of the obtained iron-based mixed powders was heated to 60°C, and then filled into a superhard flat plate with an inner diameter of 11 mm that was preheated so that the temperature of the wall surface of the chamber was 80°C and coated with lithium stearate powder. In the mold, press molding was performed at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com