Two-phase automobile steel plate with low yield-strength ratio and high strength and production method of two-phase automobile steel plate

A technology with low yield strength ratio and production method, applied in the field of low yield strength ratio and high strength automotive dual-phase steel plate and production, can solve the problems of decreased yield strength elongation, increased yield strength ratio, and steel plate cracking, etc. The effect of good elongation, high tensile strength, low yield strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] This embodiment is mainly aimed at the development of continuous annealed steel sheets for automobiles, and the test process simulates the pretreatment and continuous annealing process of cold-rolled steel sheets. But the process is also suitable for medium and thick plates, profiles and rods and wires.

[0059] Steel smelting:

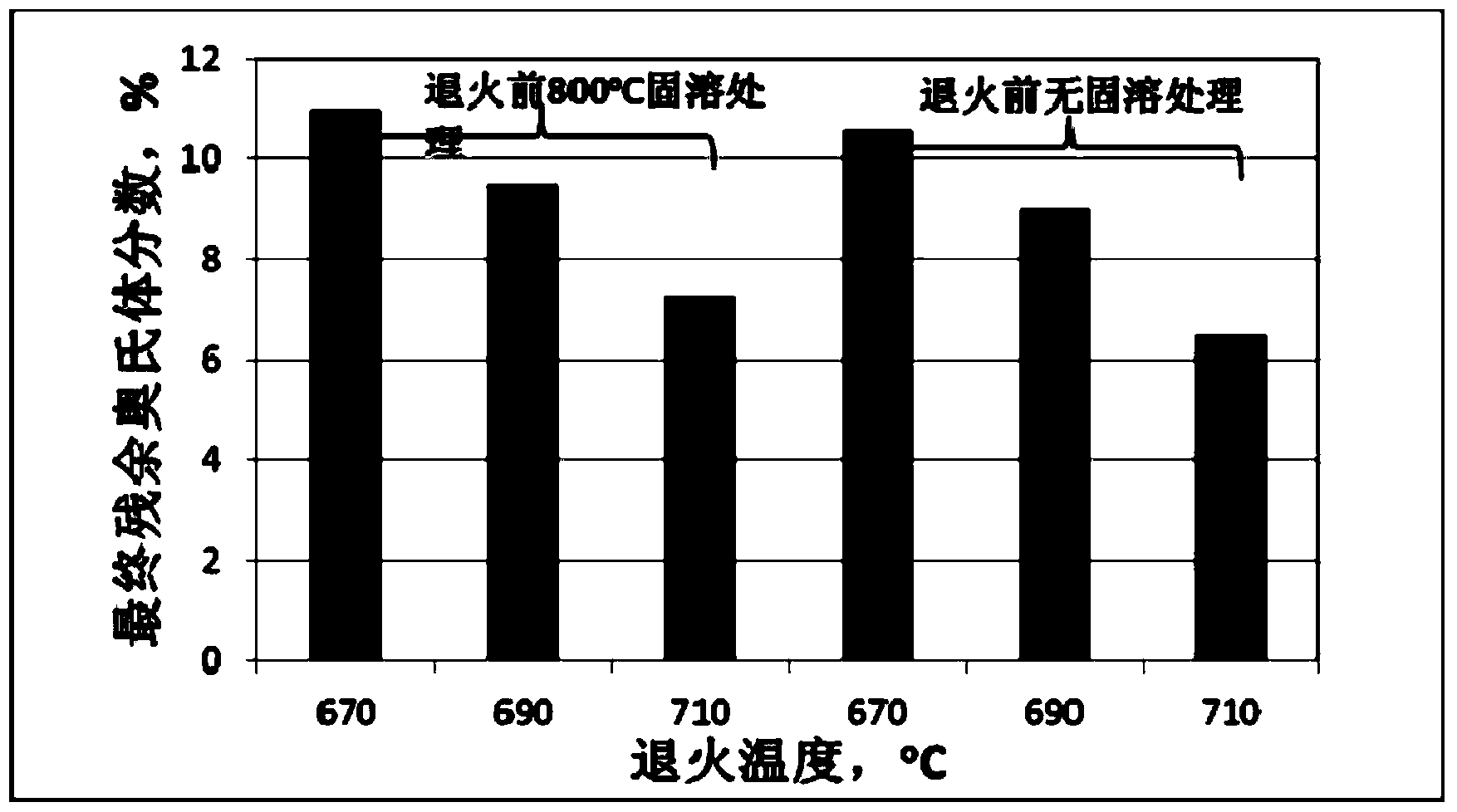

[0060] The steel of the present invention can be smelted by a converter with the chemical composition shown in Table 5, cast a continuous casting slab of about 200-220mm through a continuous casting machine, and roll it into a hot-rolled coil of 3mm through a hot rolling mill. Rolled to 1.6mm. Subsequent annealing of the cold-rolled sheet is done on an annealing simulator in the laboratory. The cold-rolled steel plates are divided into two batches, (A) after solid solution at 850°C for half an hour, then air-cooled after being taken out; (B) without solid solution treatment. Then this cold-rolled steel plate is rapidly heated to 670-710 and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com