Patents

Literature

579results about How to "Excellent indicators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

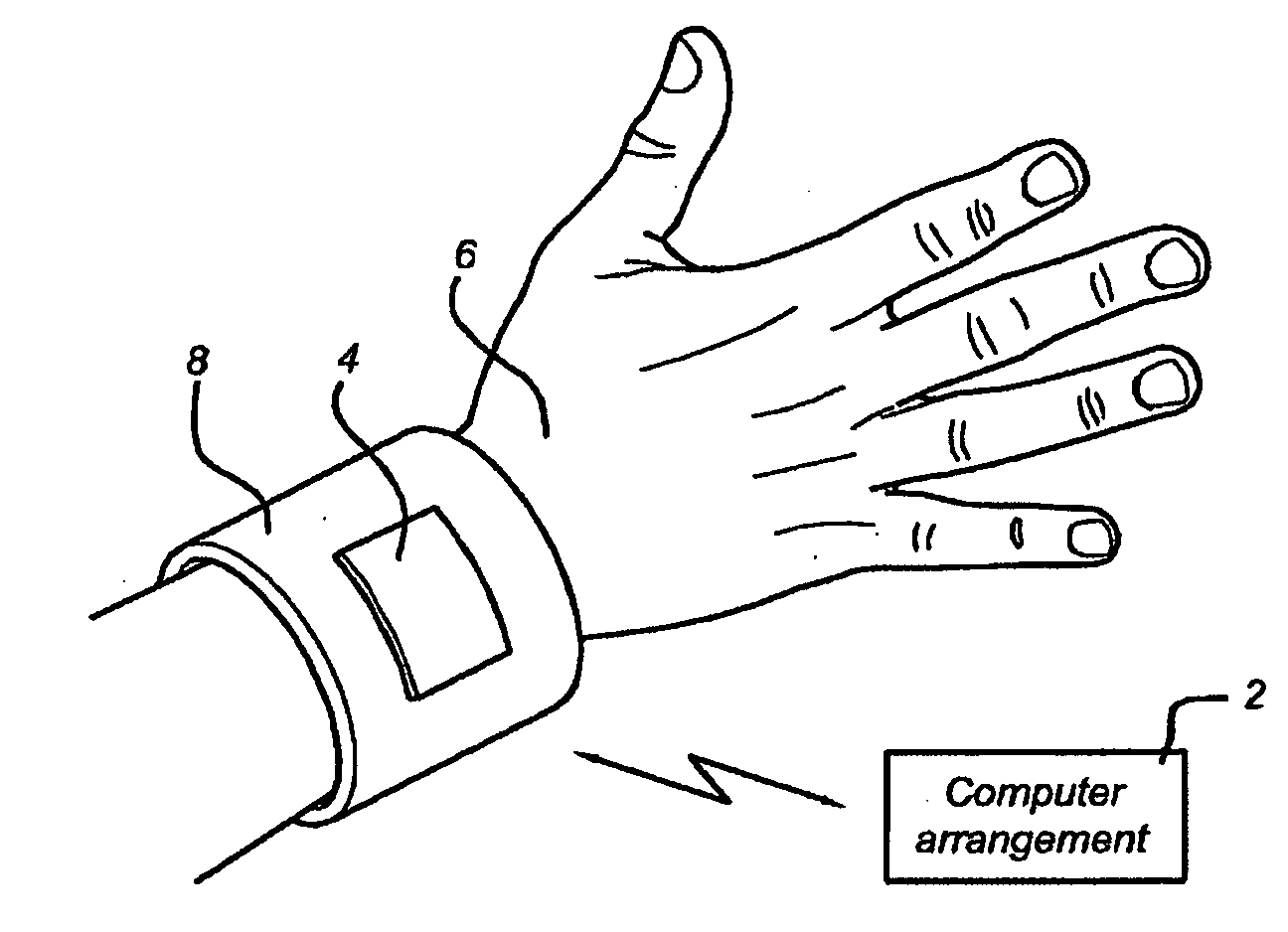

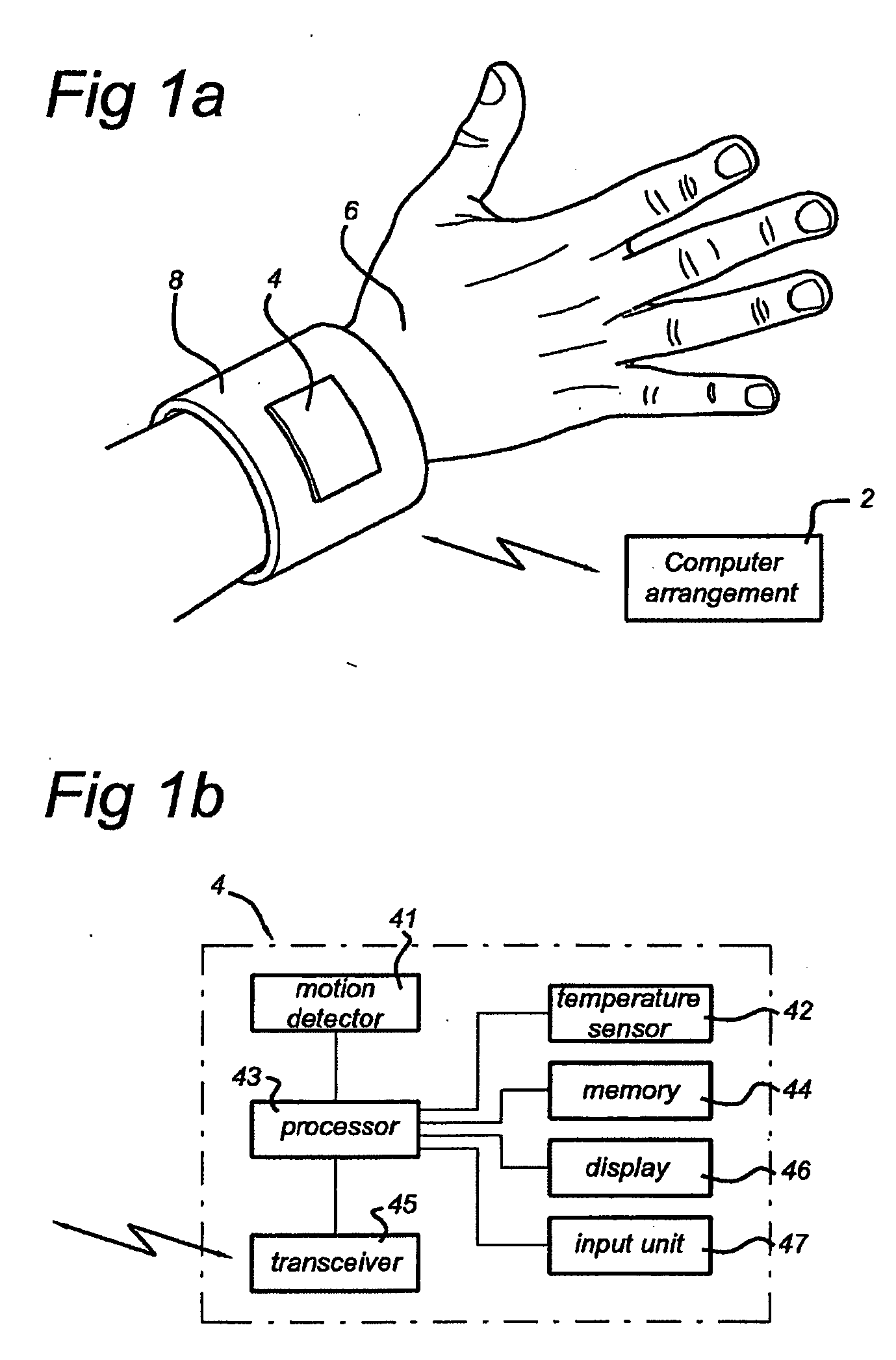

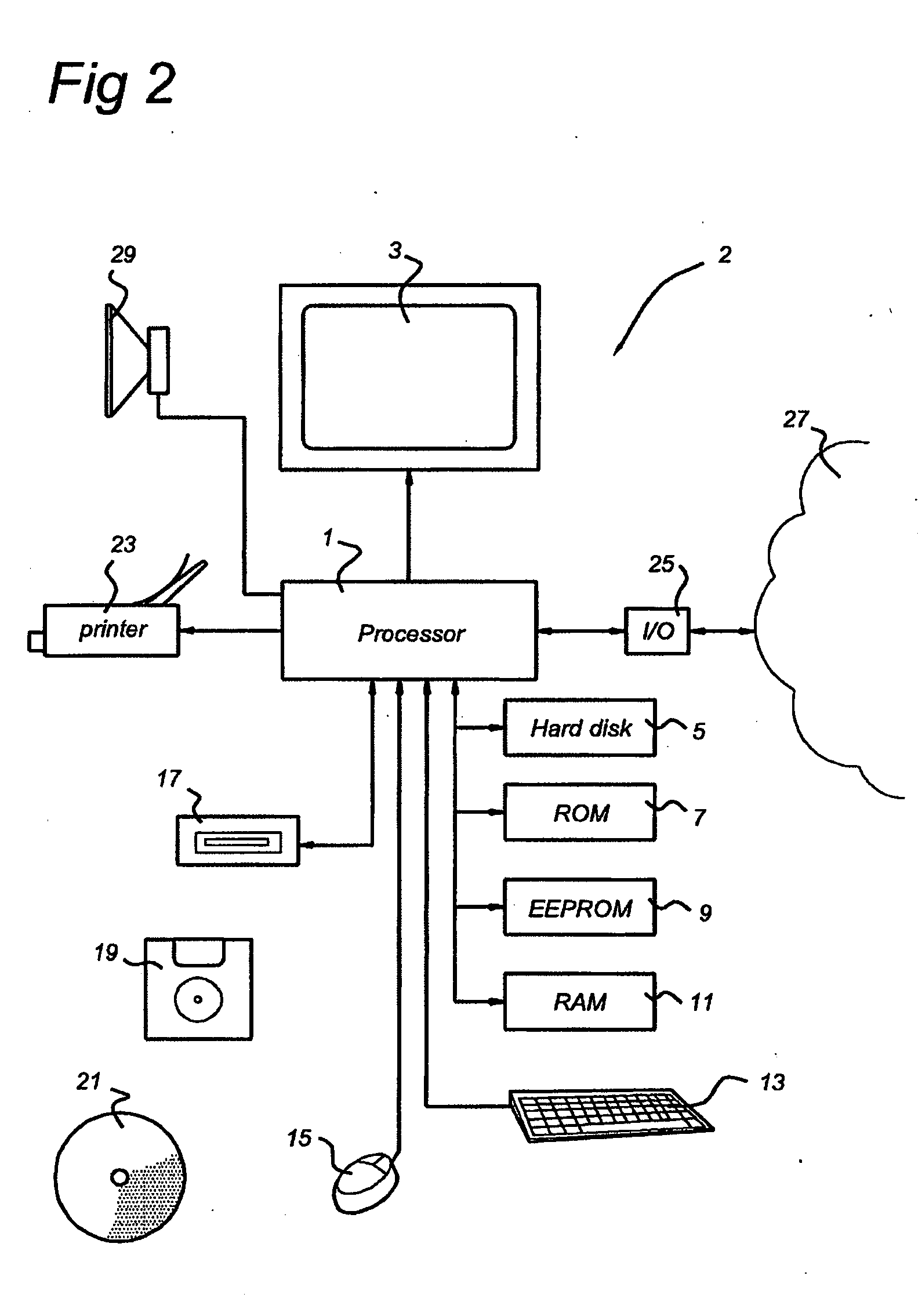

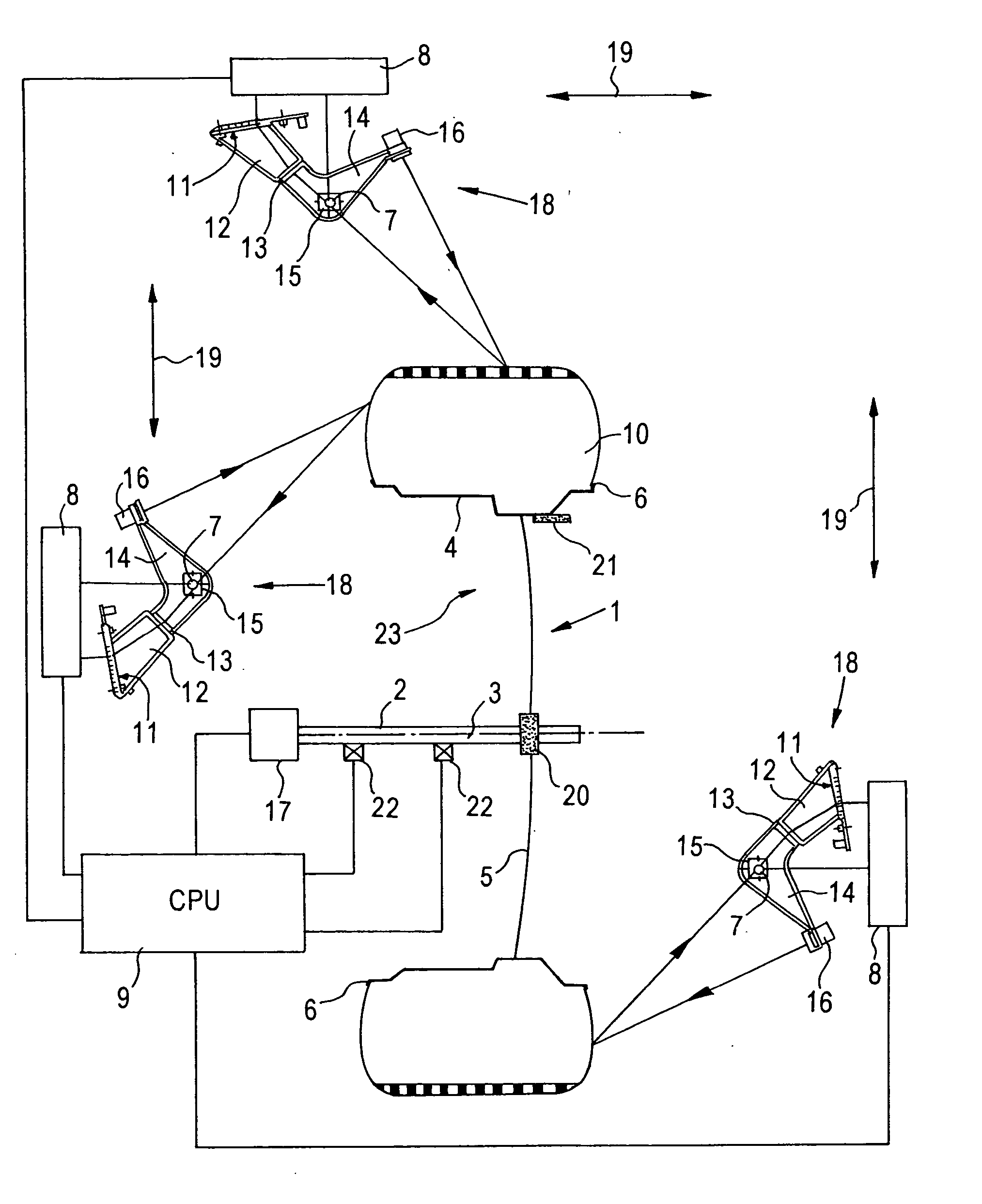

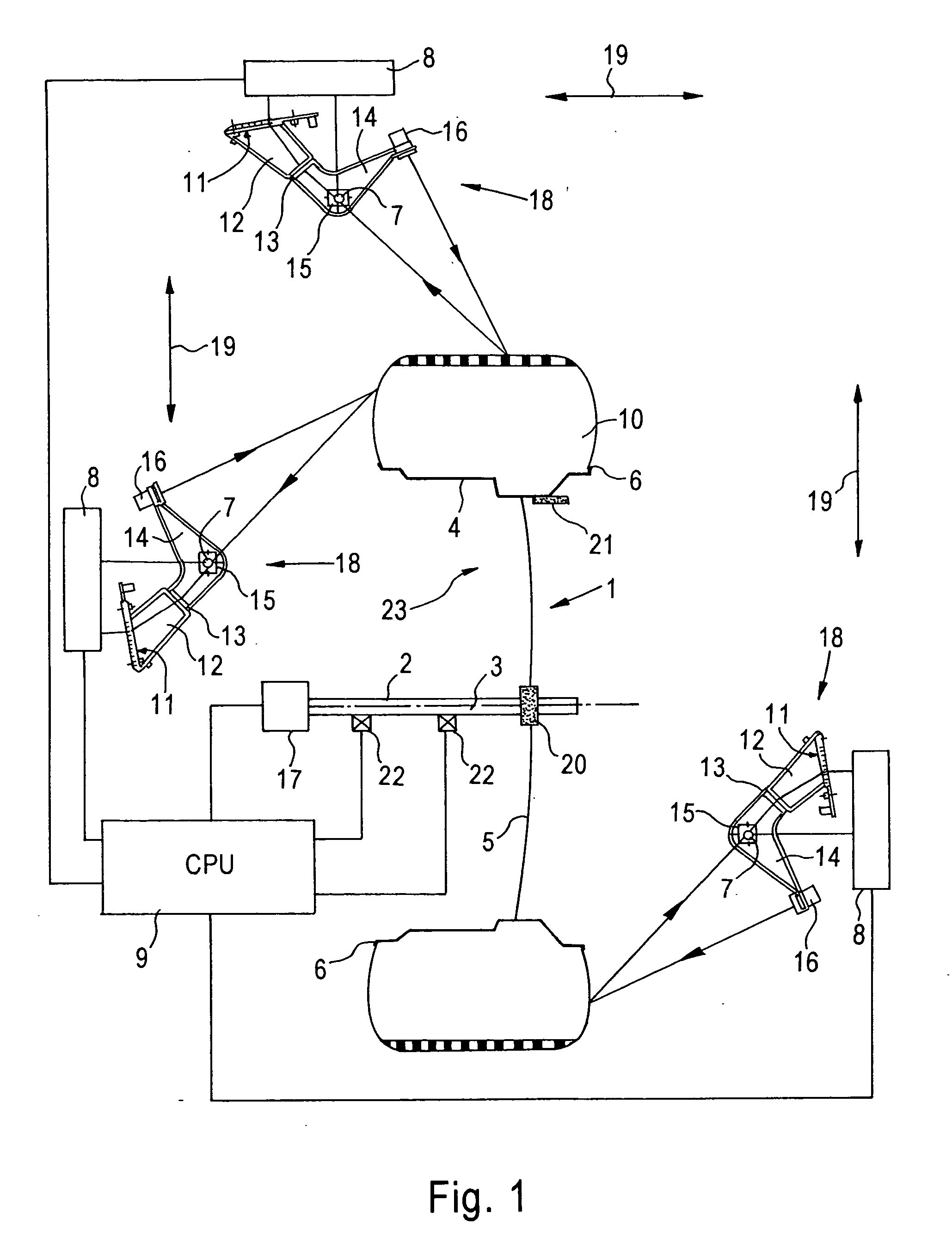

Skin Temperature Measurement in Monitoring and Control of Sleep and Alertness

InactiveUS20100100004A1Easy to useExcellent indicatorsElectroencephalographyElectro-oculographyMedicineMonitoring and control

Method of an arrangement for monitoring sleep in a subject by measuring within a prescribed interval skin temperature of a predetermined region of the subject's body and a motion sensor for sensing motion of the subject, comparing the measured skin temperature of the predetermined region with a predetermined temperature threshold, and classifying the subject as being asleep or awake based on whether the skin temperature of the predetermined region is above or below the temperature threshold and on the motion data. In alternative aspects the invention relates to methods of and arrangements for manipulating sleep, as well as monitoring or manipulating alertness.

Owner:KONINK NEDERLANDSE AKADE VAN WETENSCHAPPEN

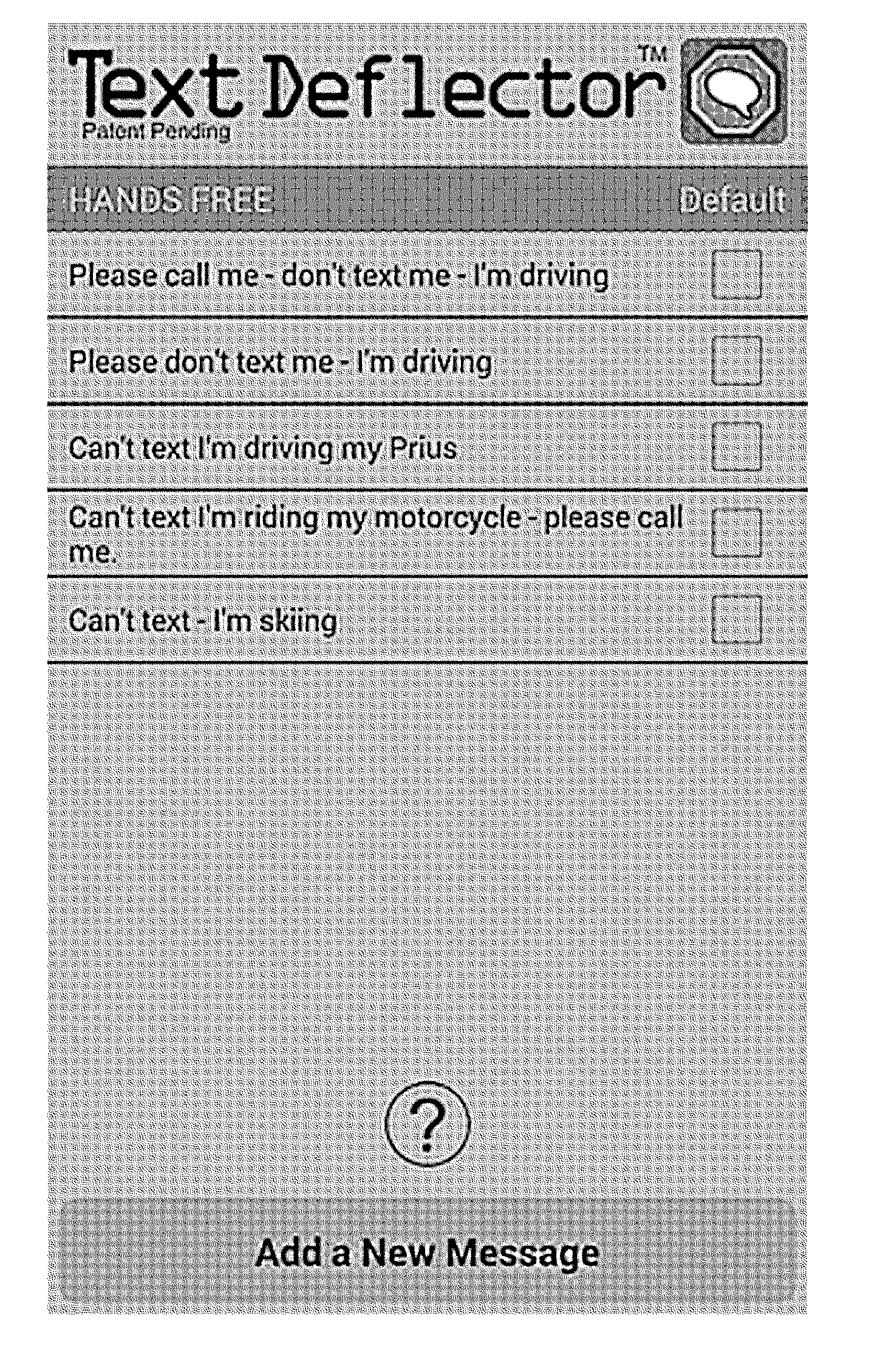

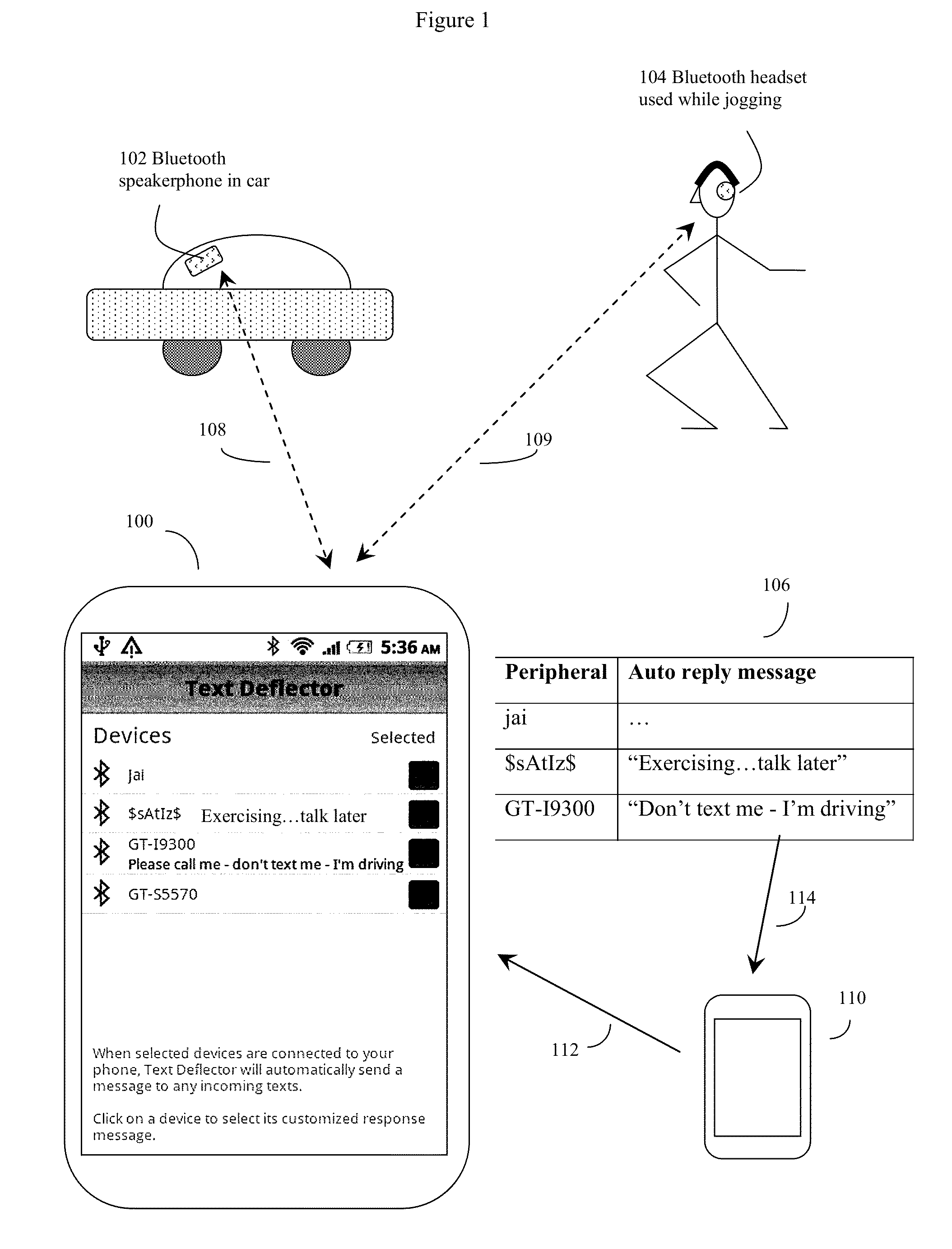

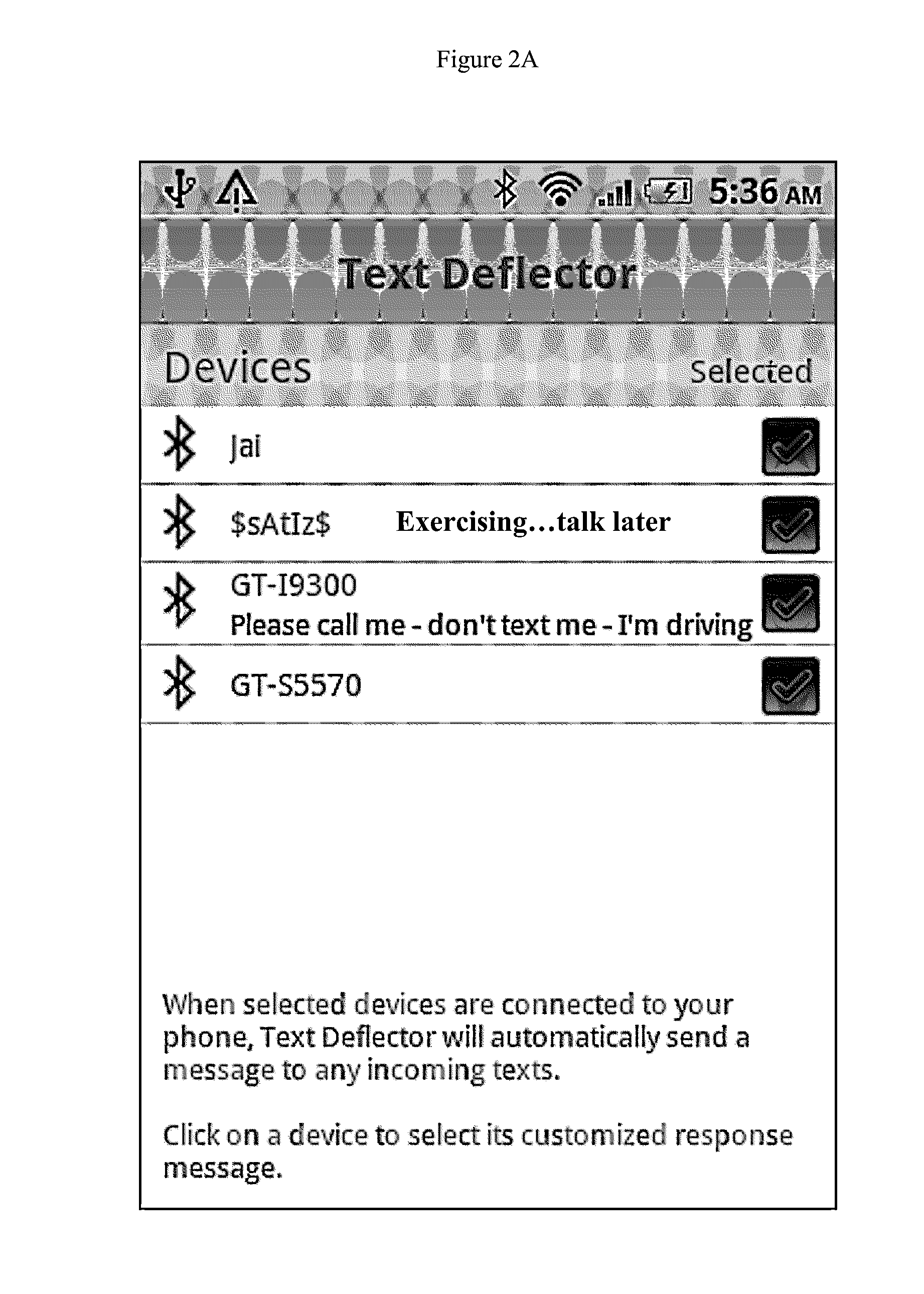

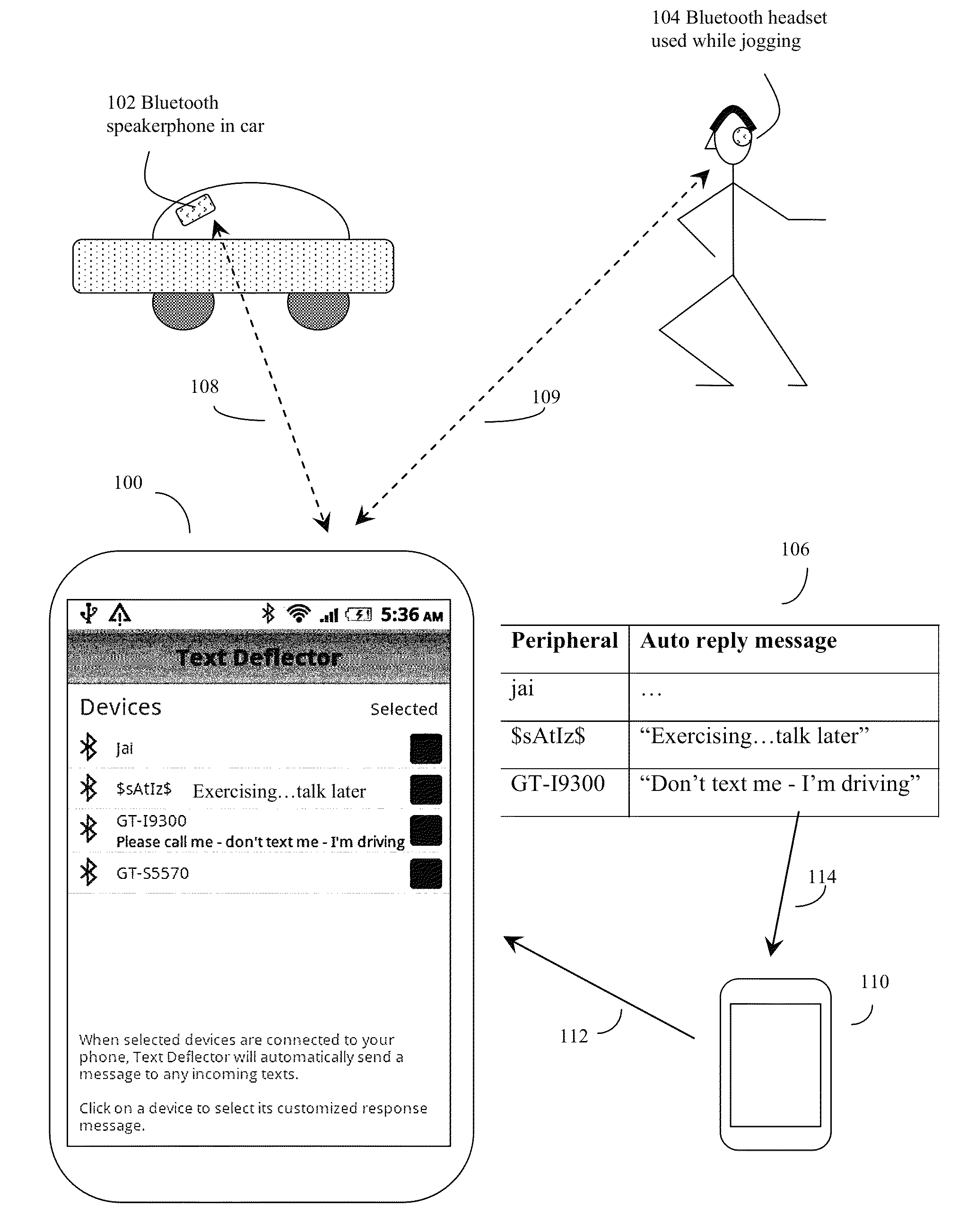

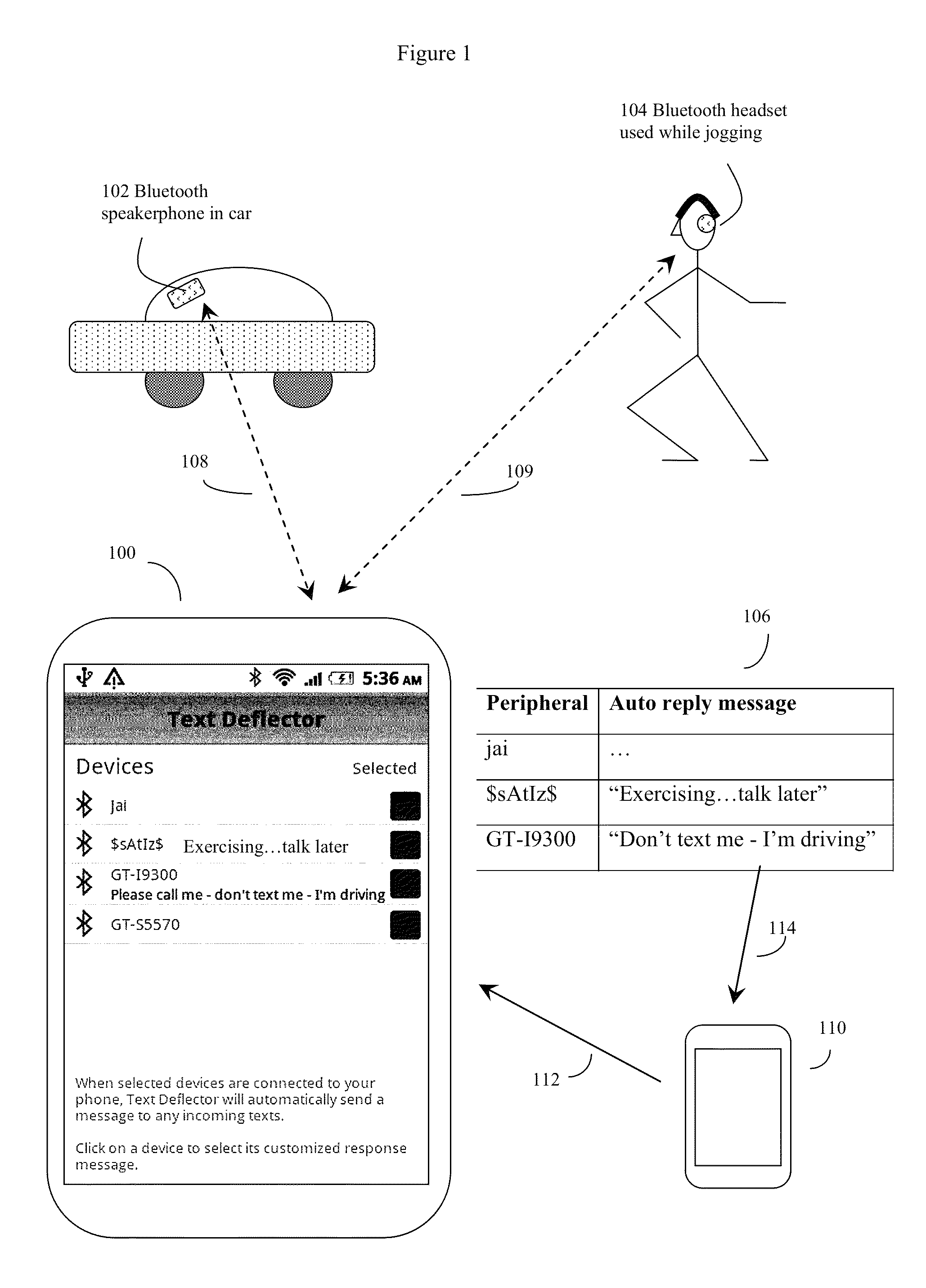

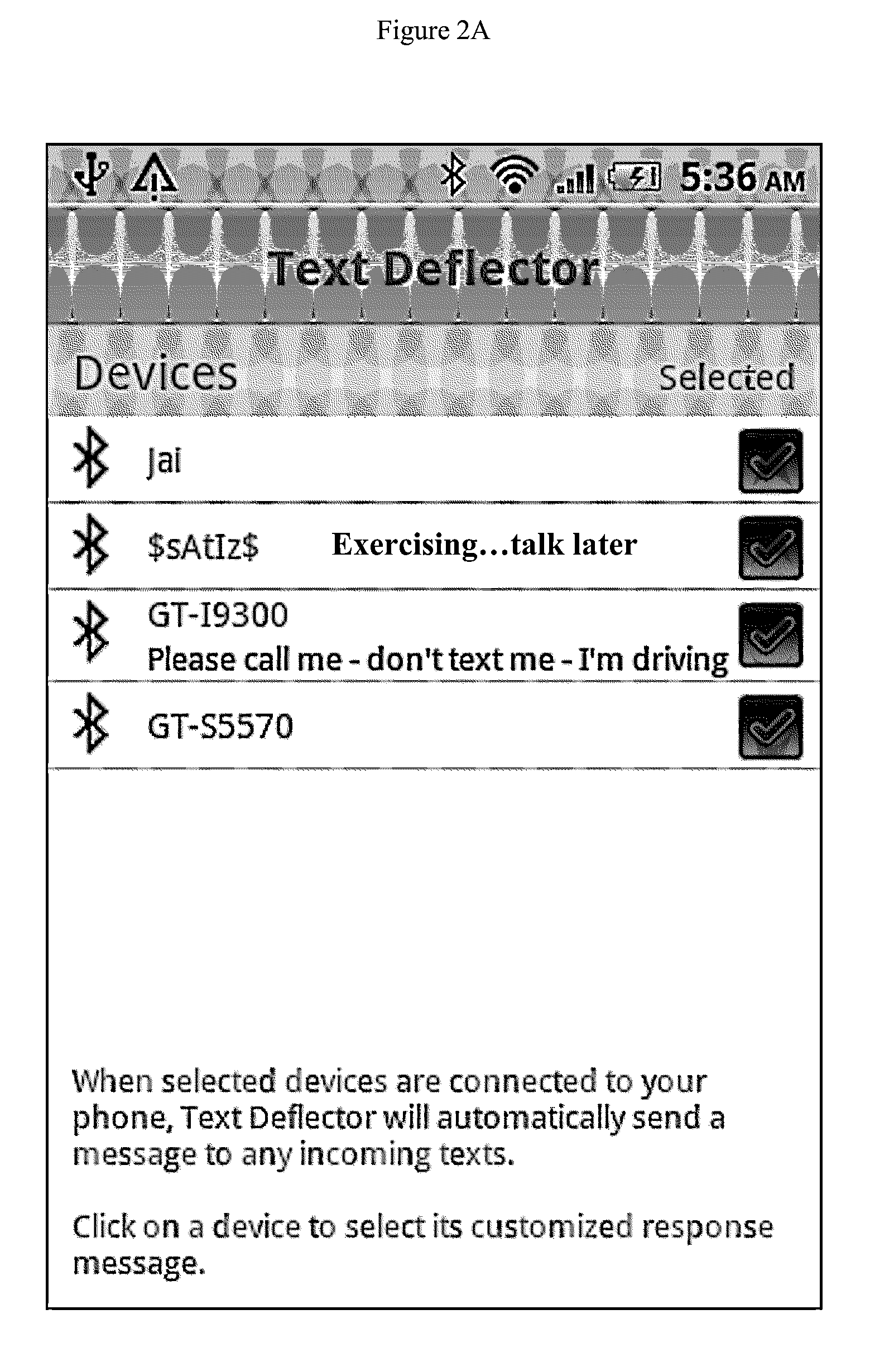

Peripheral specific selection of automated response messages

ActiveUS20140342762A1Preventing distracted drivingExcellent indicatorsAutomatic call-answering/message-recording/conversation-recordingDevices with bluetooth interfacesDistracted drivingBluetooth

Software and computer processor implemented system and method of providing customized automated responses to different types of incoming electronic messages from various contact sources, particularly useful for preventing distracted driving. Here the invention's software, often in the form of an app, runs on a smartphone or other computerized device configured to automatically connect to various peripherals, such as automobile associated Bluetooth peripherals. When operating, the app causes connected peripherals to automatically trigger auto response mode in response to incoming messages. Optionally, different automated responses to be assigned to different peripheral identification codes or different incoming message originators. Various prioritization schemes, such as last peripheral connected dominates, and various ways in which different contact specific automated responses may interact with various peripheral specific automated responses, are also discussed.

Owner:HAJDU LORALEE +1

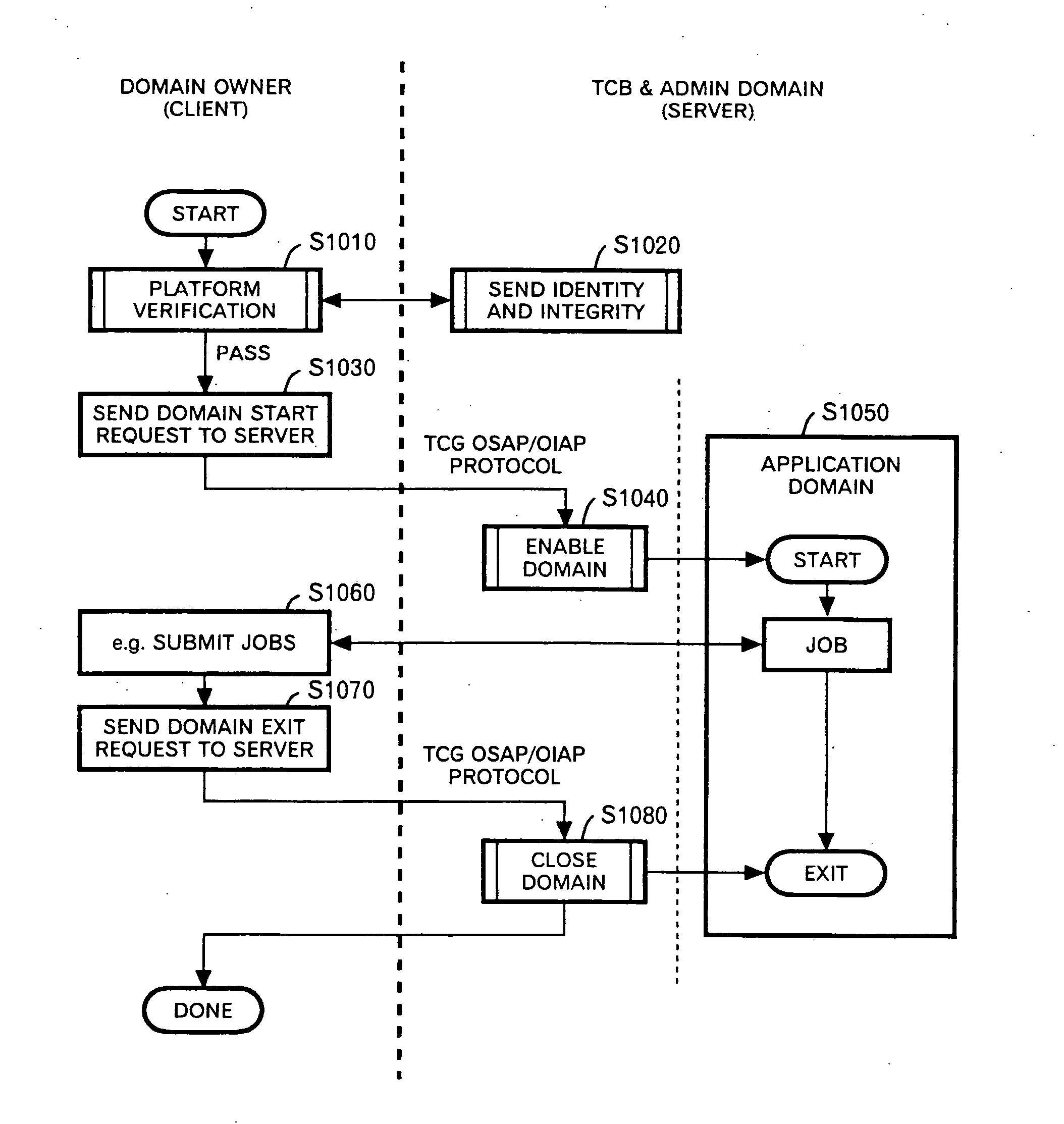

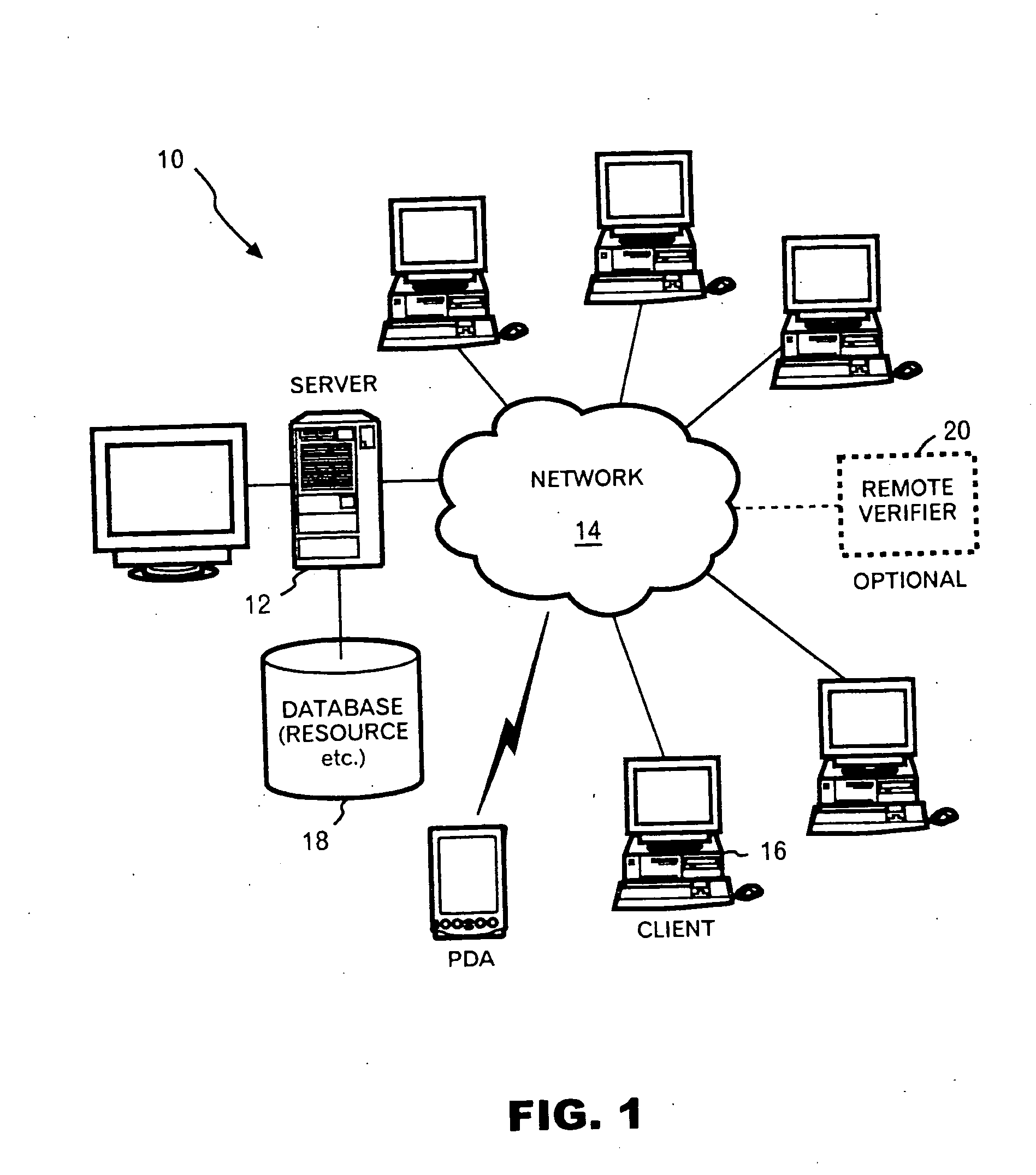

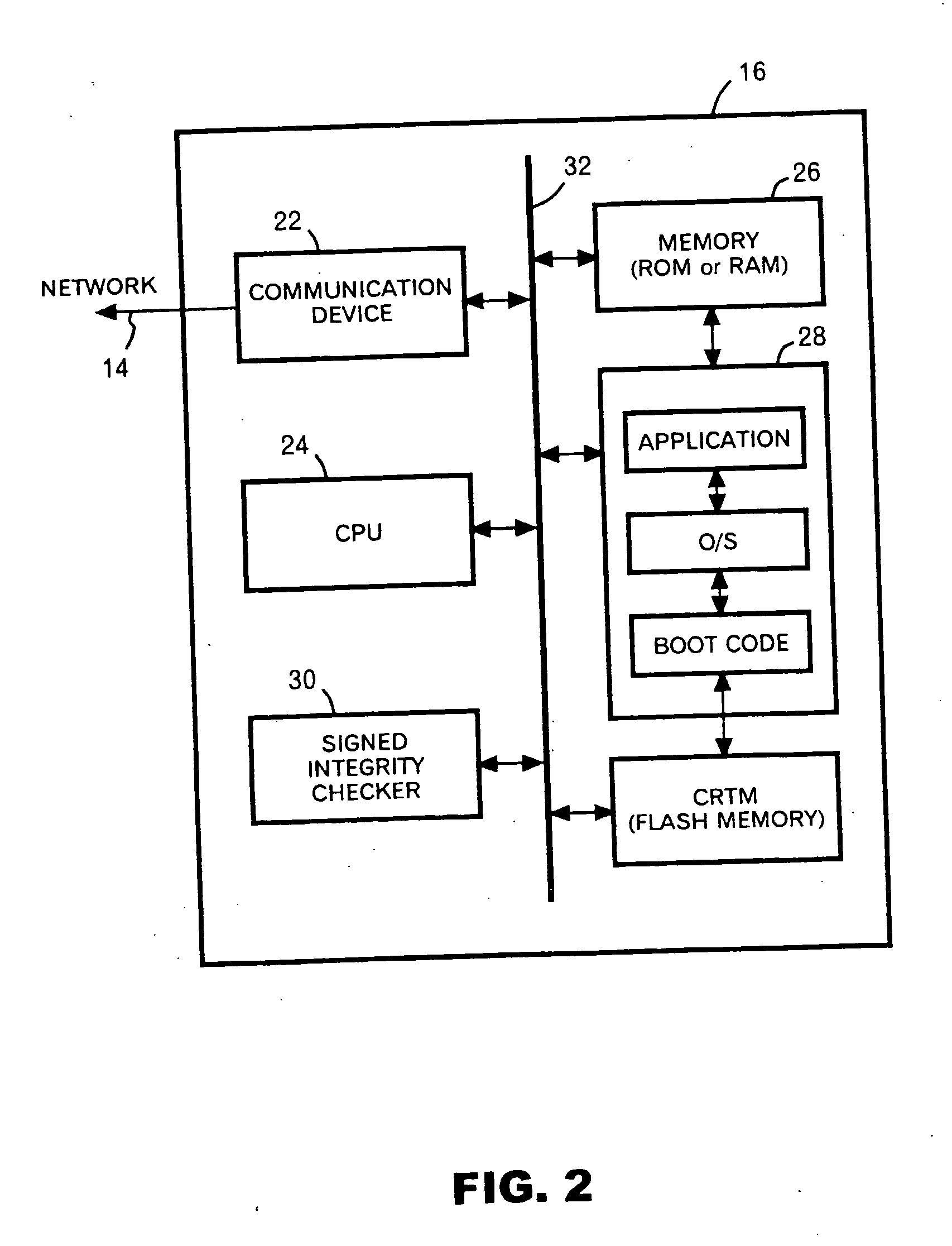

Information processing apparatus, a server apparatus, a method of an information processing apparatus, a method of a server apparatus, and an apparatus executable process

InactiveUS20050120219A1Excellent indicatorsUser identity/authority verificationDigital computer detailsThird partyComputer hardware

To provide an information processing apparatus, a server apparatus, a method of an information processing apparatus, a method of a server apparatus, and an apparatus executable program. An information processing apparatus uses signed integrity values unique to software configuration and asserting integrity of initial codes of a networked server. The server apparatus generates keys used for certifying the server apparatus(S810, S820, S830). One of the keys are certified by a third party to generate a digital signature (S840). The digital signature is attached to the integrity values and the signed integrity values are transmitted to the information processing apparatus for allowing the information processing apparatus to have secure services through the network (S850, S860).

Owner:IBM CORP

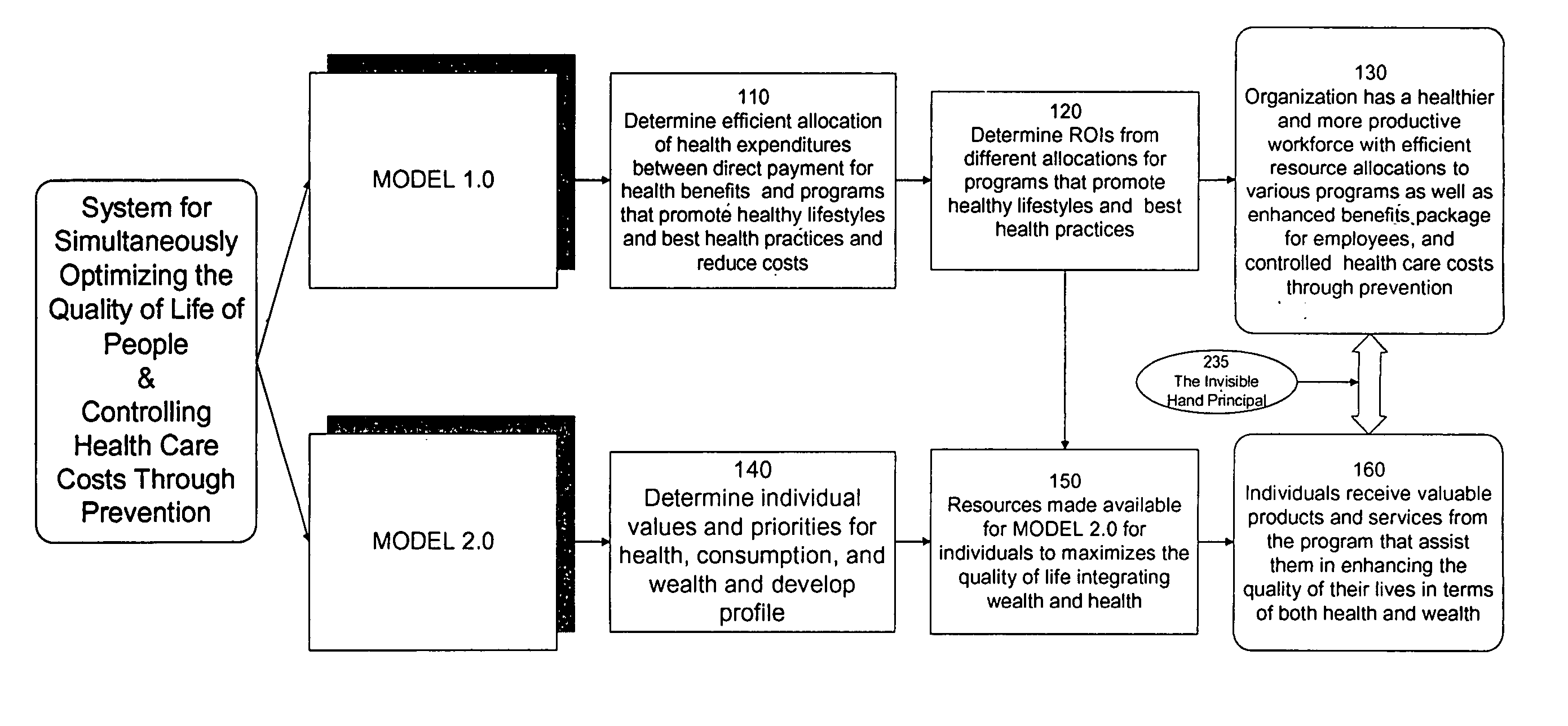

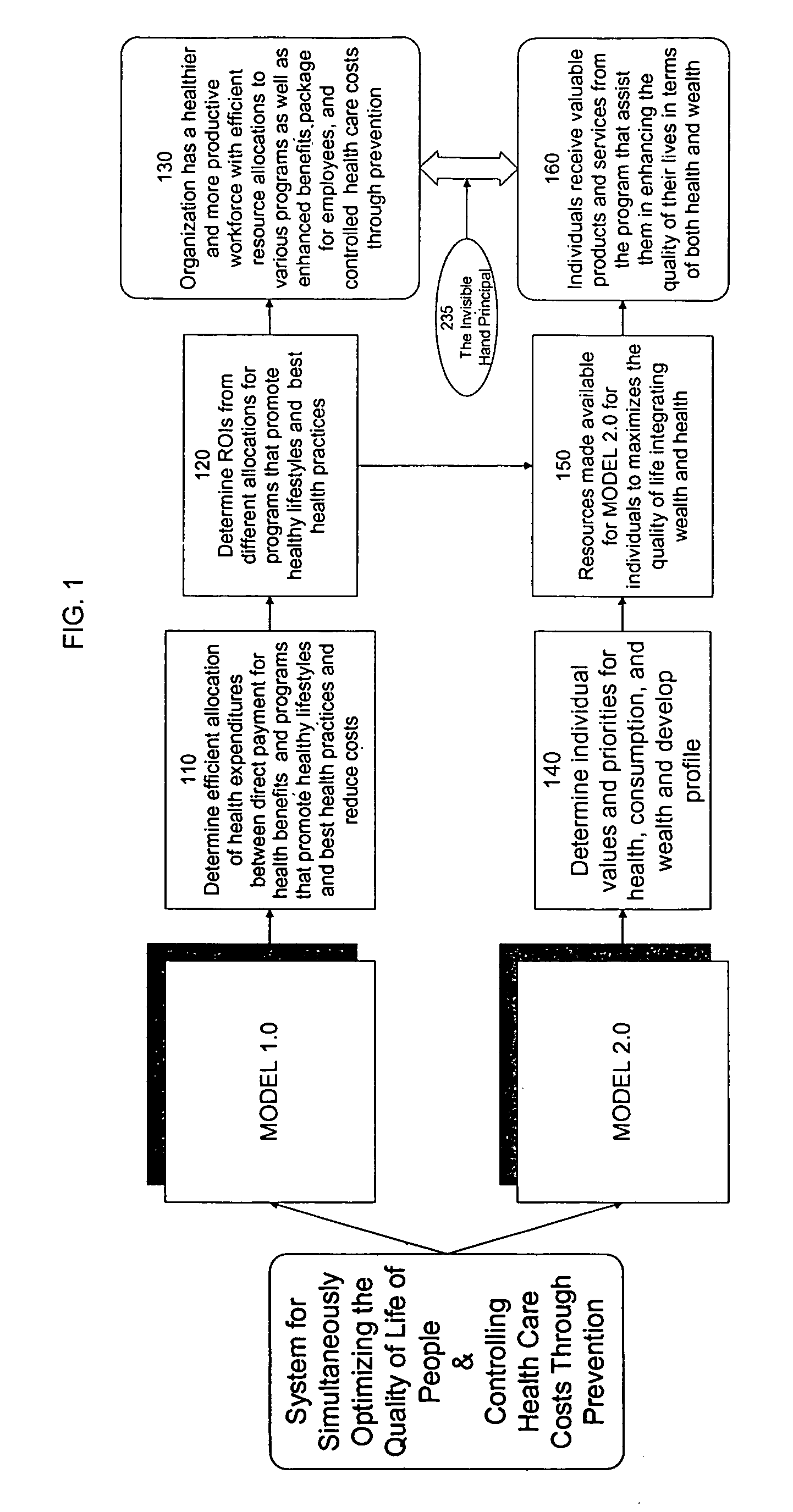

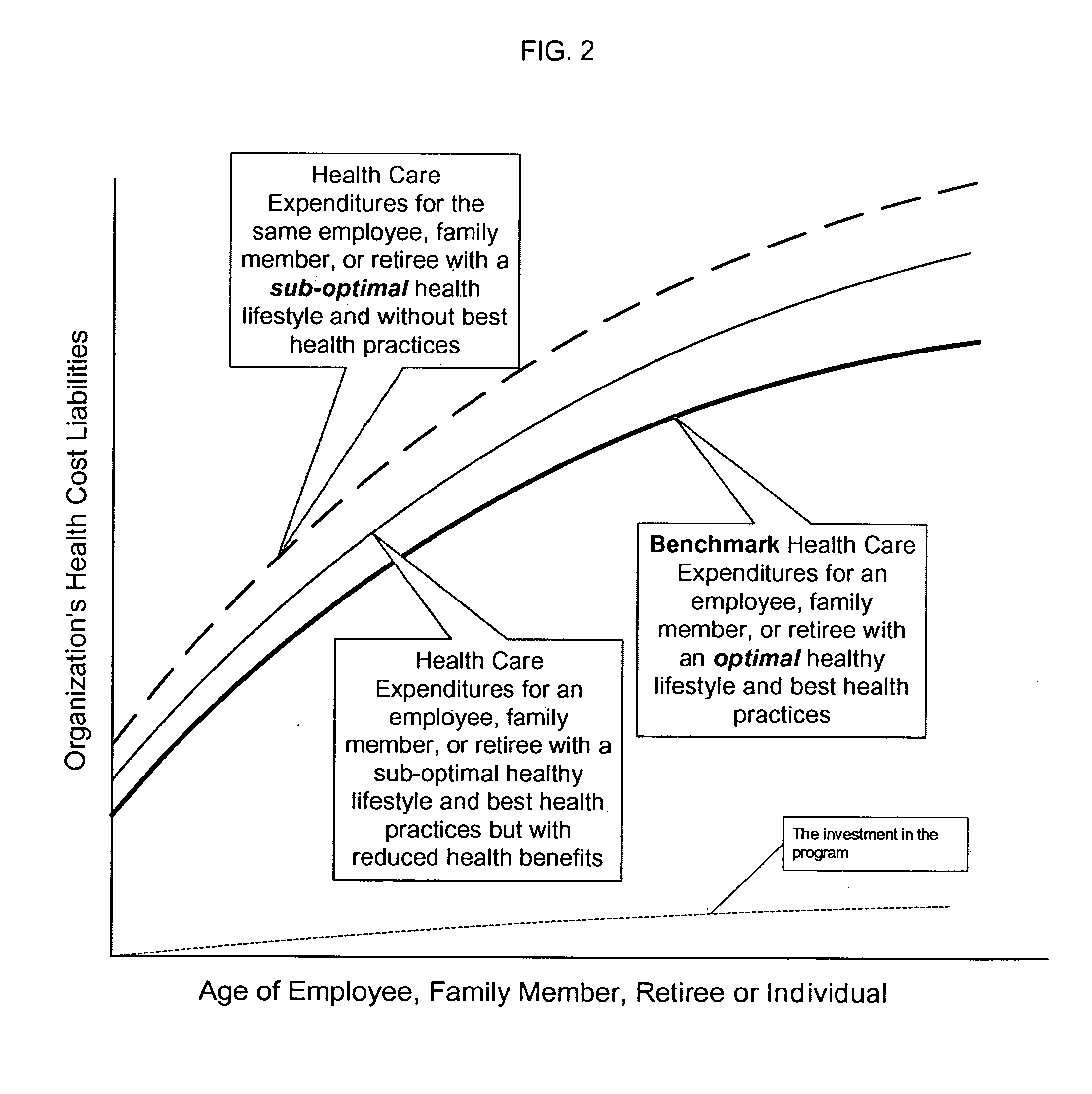

System and method for simultaneously optimizing the quality of life and controlling health care costs

InactiveUS20060026036A1Quality improvementImprove the quality of lifeFinanceHealth-index calculationCost evaluationProgram planning

A method and system for optimizing health expenditure by an organization including developing a Cohort-based personnel model for the organization; determining lifecycle health costs based on the personnel model; evaluating impact of a lifestyle program, a best health practices program, and an employee benefits program on the life cycle health costs for a first scenario; and measuring project evaluation criteria for the lifestyle, best health practices, and employee benefits programs. A method and system for integrating health and wealth of an individual including developing a profile regarding health and wealth, and quality of life specifications for the individual; determining a quality of life index based on wealth, best health practices and lifestyle of the individual, wherein the quality of life index includes both health and wealth information; and measuring impacts of the profile, wealth, best health practices and lifestyle of the individual on the quality of life index.

Owner:MAHMOOD SYYED TARIQ

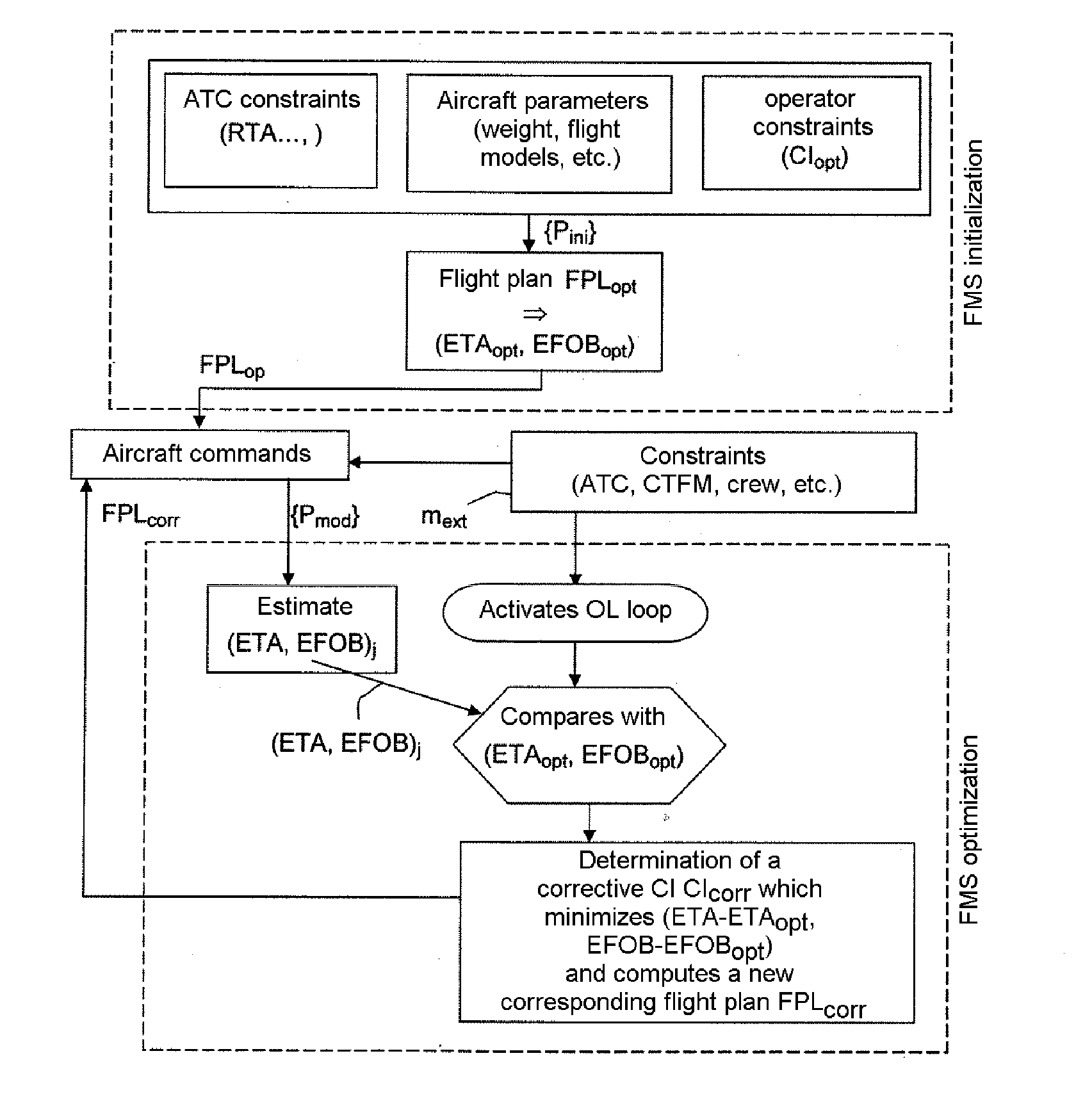

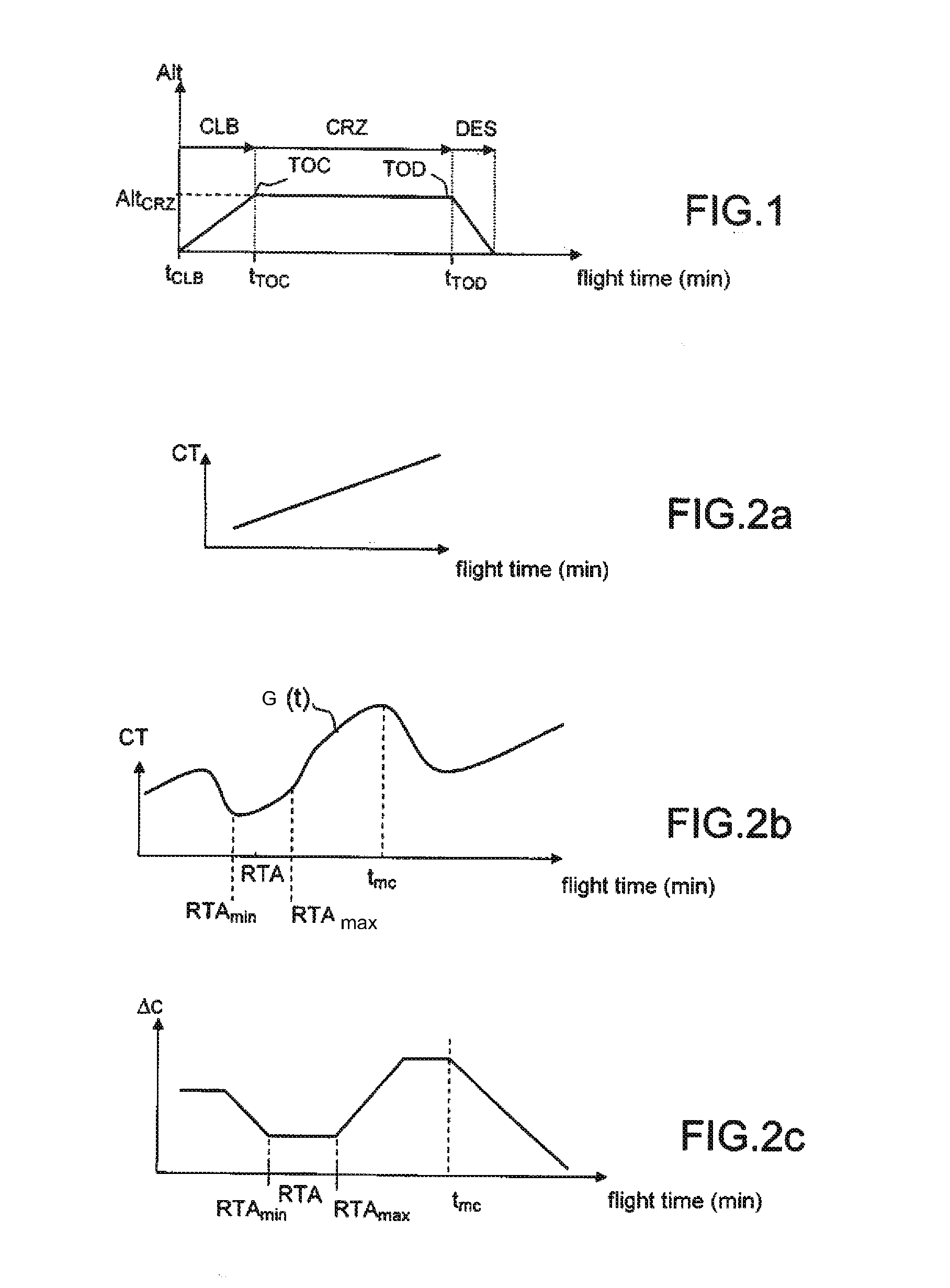

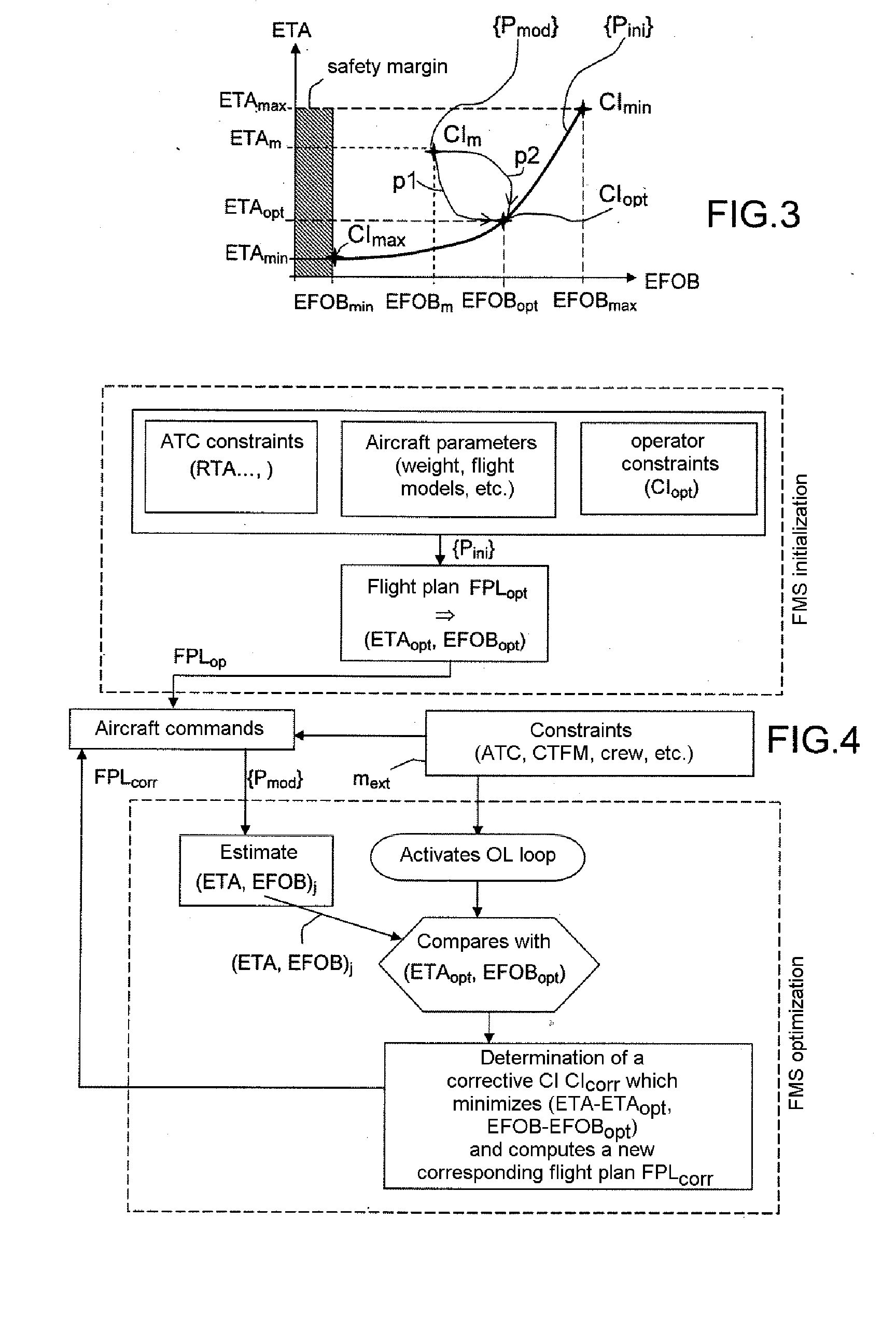

Method of optimizing a flight plan

InactiveUS20080300738A1Excellent indicatorsEnergy saving arrangementsNavigational calculation instrumentsCost indexFlight management system

A method of optimizing a flight plan of an aircraft used in a flight management system of an aircraft is disclosed. This method makes it possible to constrain the real cost index of the mission executed to the optimal cost index CIopt predetermined by the aircraft operator, by acting on objectives ETAopt and EFOBopt of values of ETA and of EFOB to be achieved. Objectives are linked to this optimal cost index, in order to make the system return from a cost index CIm to the optimal cost index CIopt, while taking account of various constraints imposed by the ATC or the CTFM. Both constraints mext influence the cost index and constraints which limit the field of possible solutions.

Owner:THALES SA

Peripheral specific selection of automated response messages

ActiveUS9432499B2Excellent indicatorsPreventing distracted drivingAutomatic call-answering/message-recording/conversation-recordingDevices with bluetooth interfacesDistracted drivingApplication software

Software and computer processor implemented system and method of providing customized automated responses to different types of incoming electronic messages from various contact sources, particularly useful for preventing distracted driving. Here the invention's software, often in the form of an app, runs on a smartphone or other computerized device configured to automatically connect to various peripherals, such as automobile associated Bluetooth peripherals. When operating, the app causes connected peripherals to automatically trigger auto response mode in response to incoming messages. Optionally, different automated responses to be assigned to different peripheral identification codes or different incoming message originators. Various prioritization schemes, such as last peripheral connected dominates, and various ways in which different contact specific automated responses may interact with various peripheral specific automated responses, are also discussed.

Owner:HAJDU LORALEE +1

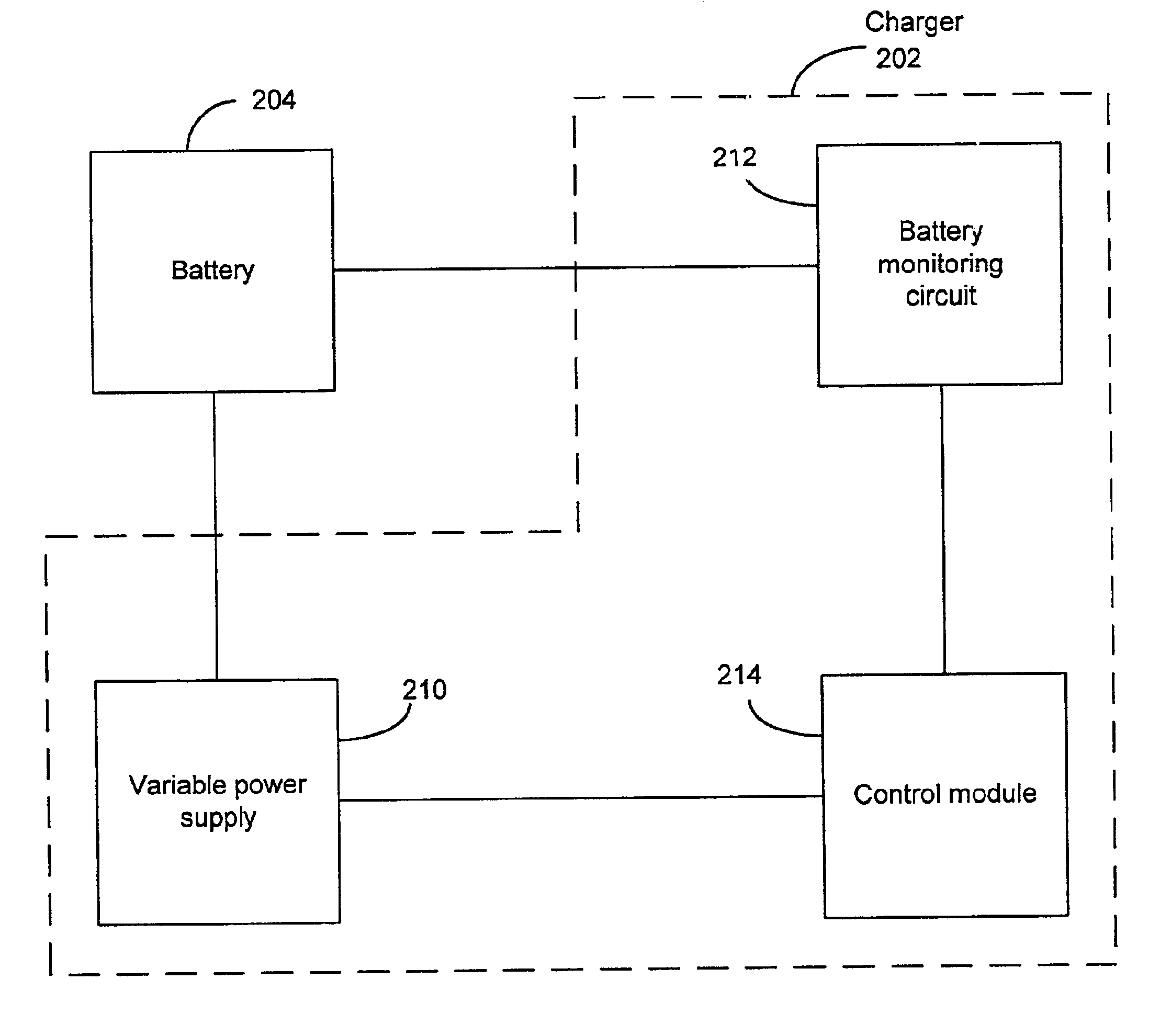

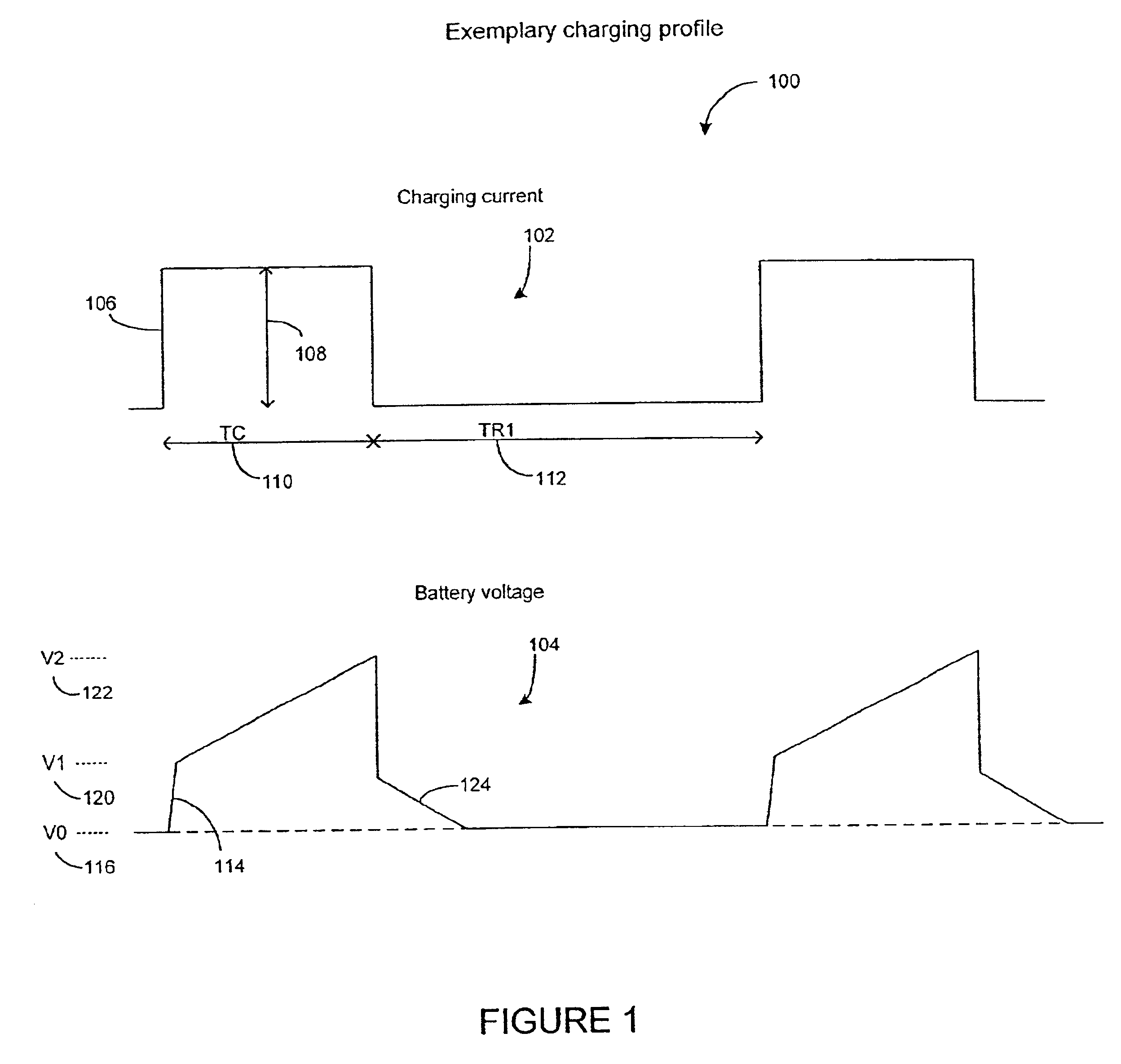

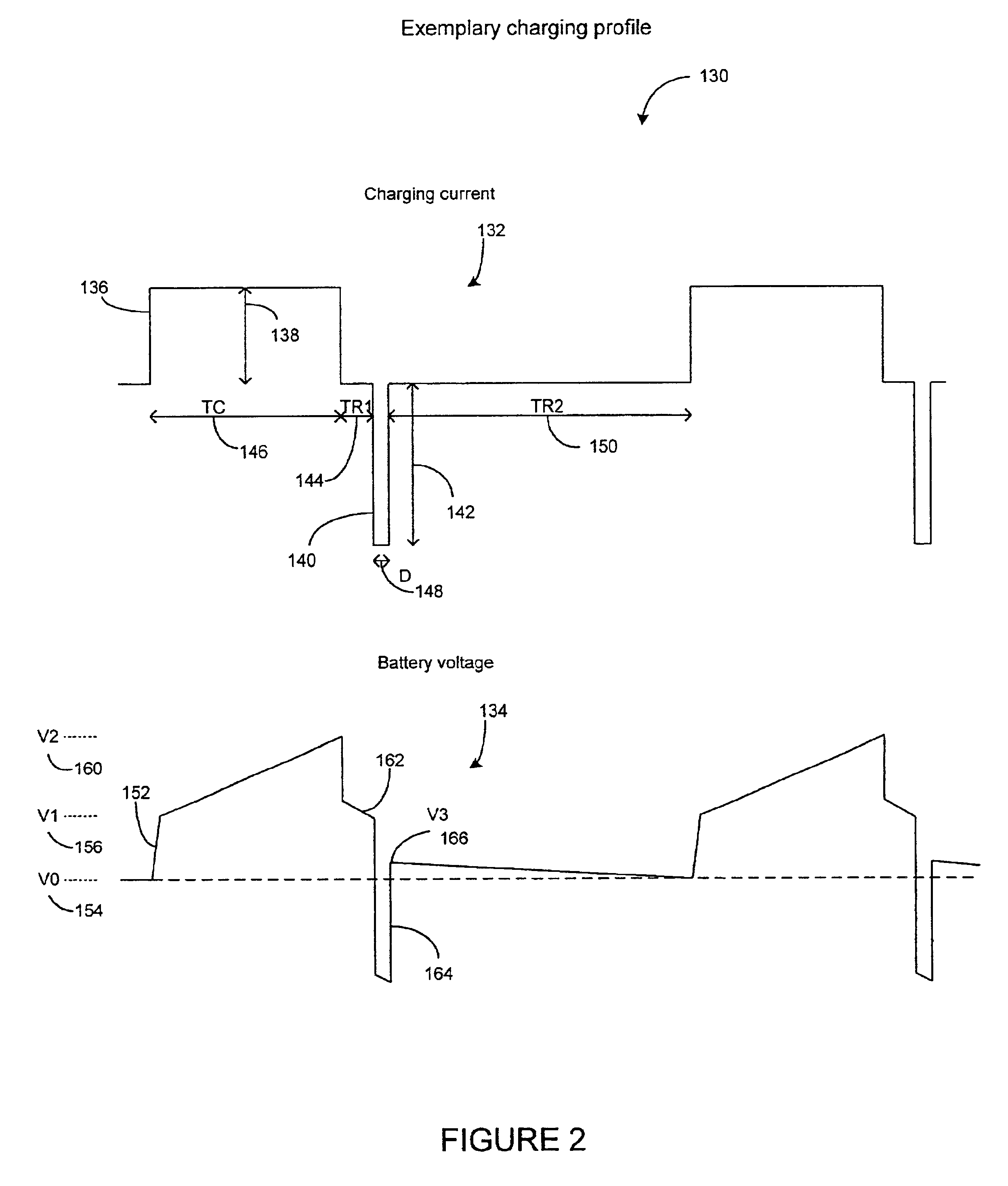

Battery charging method

InactiveUS6841974B2Reduces pulse amplitudeExcellent indicatorsBatteries circuit arrangementsElectric powerHigh rateTerminal voltage

A battery charger that adjusts and applies charging pulses to a battery such that one or more battery parameter is regulated. Terminal voltage of the battery, relative to the battery's quiescent voltage, during the charge application is one such battery parameter indicative of the battery's charge absorption rate. Maintaining the charging voltage at a predetermined value during the charging process is achieved by adjusting the charging pulse both amplitude-wise and temporally. The adjustment of the charging pulse is performed such that a high rate of charge input into the battery is maintained during the charging process.

Owner:HDM SYST

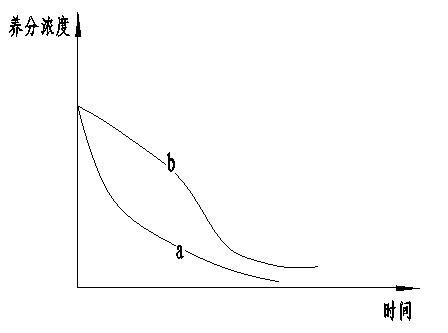

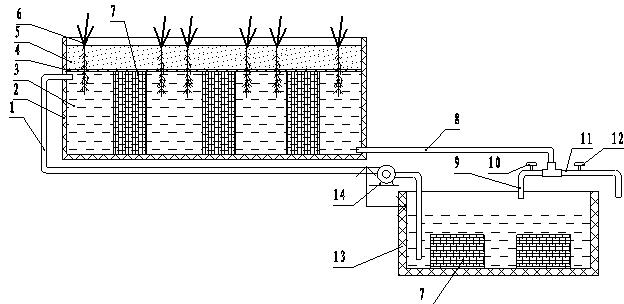

Small soilless culture method and device

ActiveCN102119651AIncrease the concentration of inputFewer deliveriesAgriculture gas emission reductionCultivating equipmentsSlagPeat

The invention relates to a small soilless culture method and device. A nutrient solution is contained in a culture disk or a nutrient solution storage pool; crops are planted into the nutrient solution; a soil copy material is added into the nutrient solution; the soil copy material comprises the following raw materials in parts by weight: 20-90 parts of organic matter and 2-80 parts of nonmetal mineral substance, wherein the organic matter is one or mixture of peat, fermented straw, fermented bagasse and fermented livestock and poultry manure; the nonmetal mineral substance is one or mixtureof coal ash, steel slag, zeolite, bentonite, opal, attapulgite mineral soil, pearlite, vermiculite, rectorite clay, sepiolite clay and kieselguhr; and the proportion of the nutrient solution to the soil copy material is (5-2):1. By adding the soil copy material into the nutrient solution, the nutrient charge concentration can be improved, the nutrient charge frequency is reduced, and the labor cost is reduced; meanwhile, when the concentration is reduced due to the absorption of the nutrients, the concentration reduction range is slower, and a deficiency symptom caused by lacking nutrients ofplants is lightened; in addition, trace elements needed by plants can be also supplemented.

Owner:杜友萍

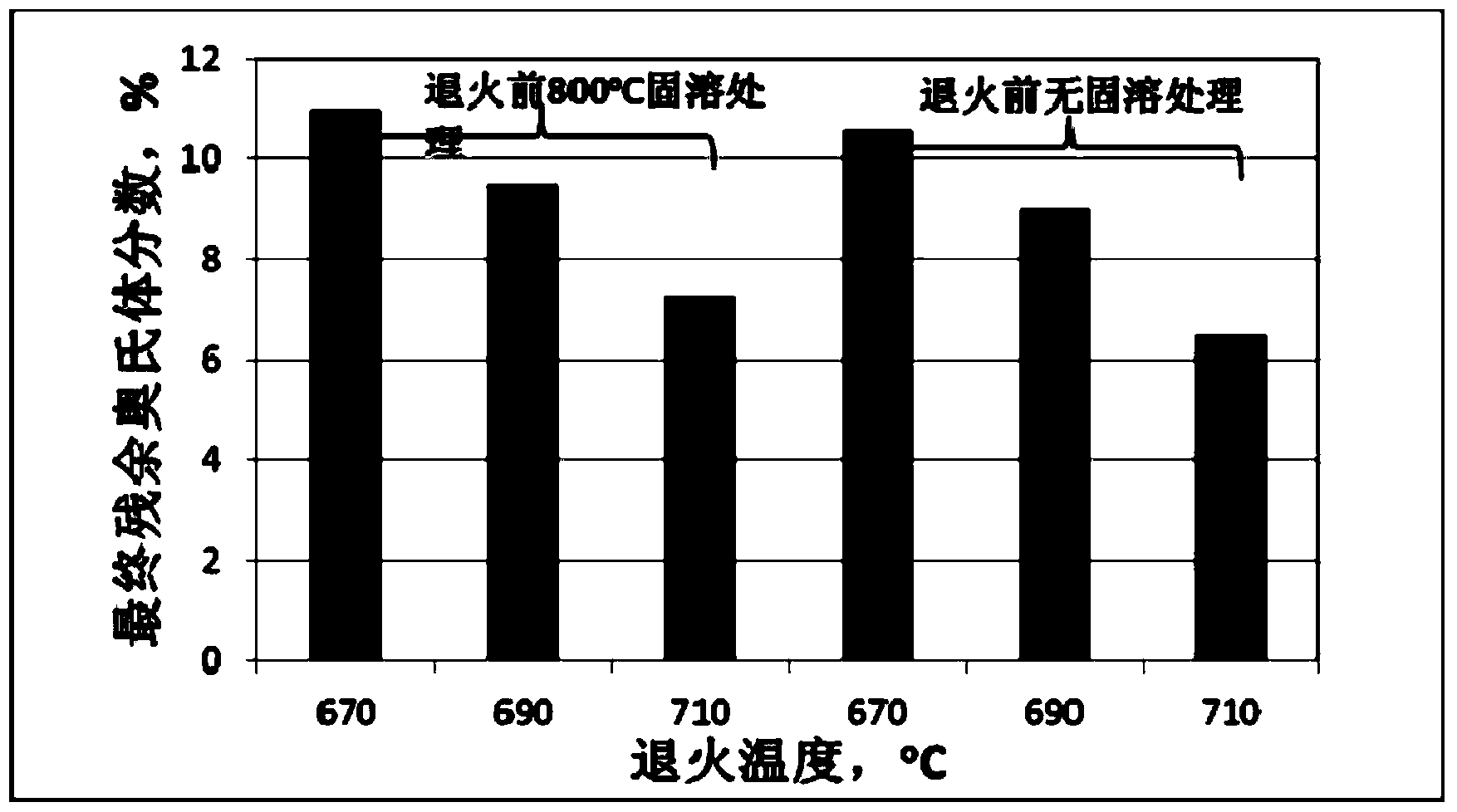

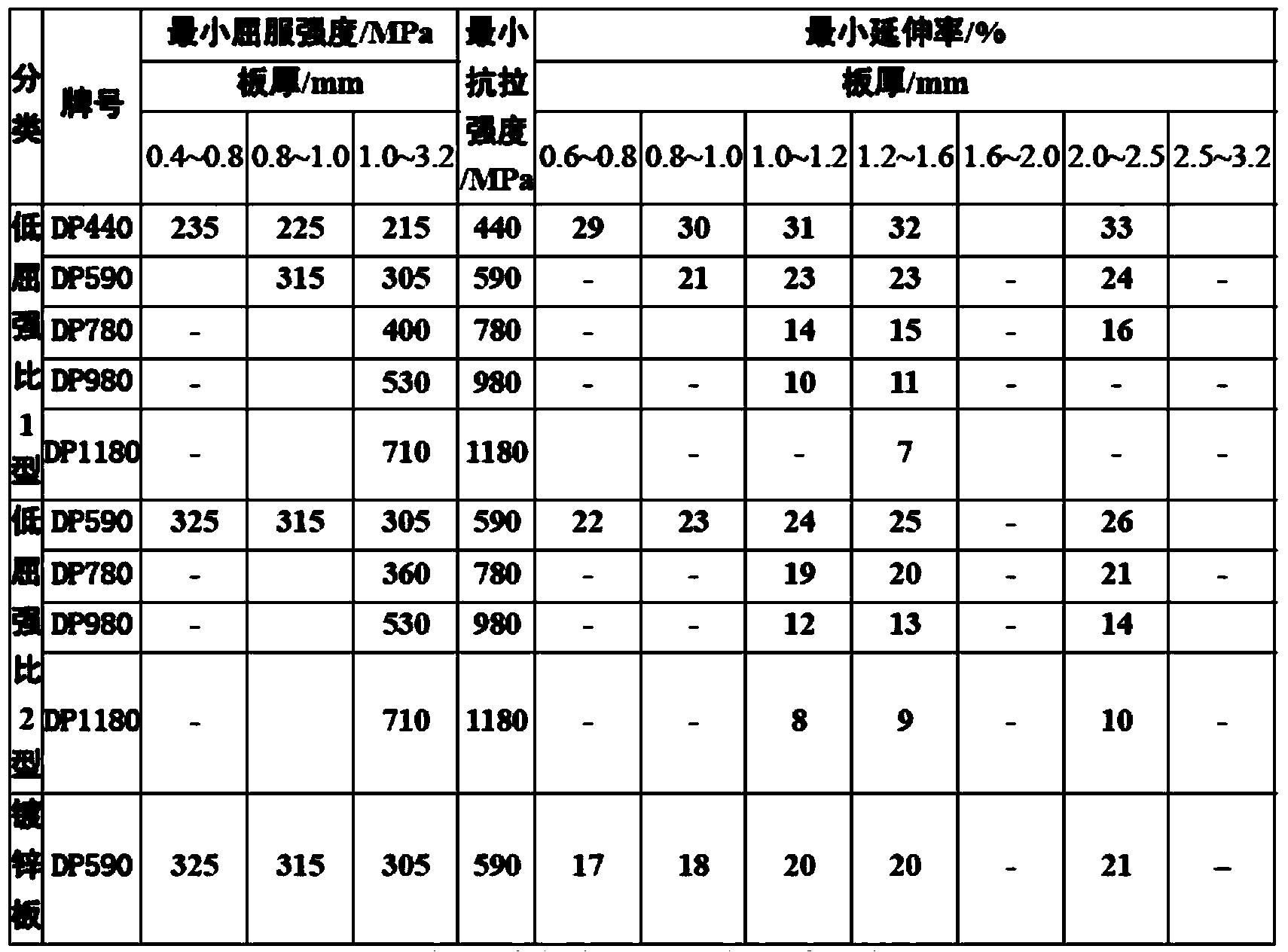

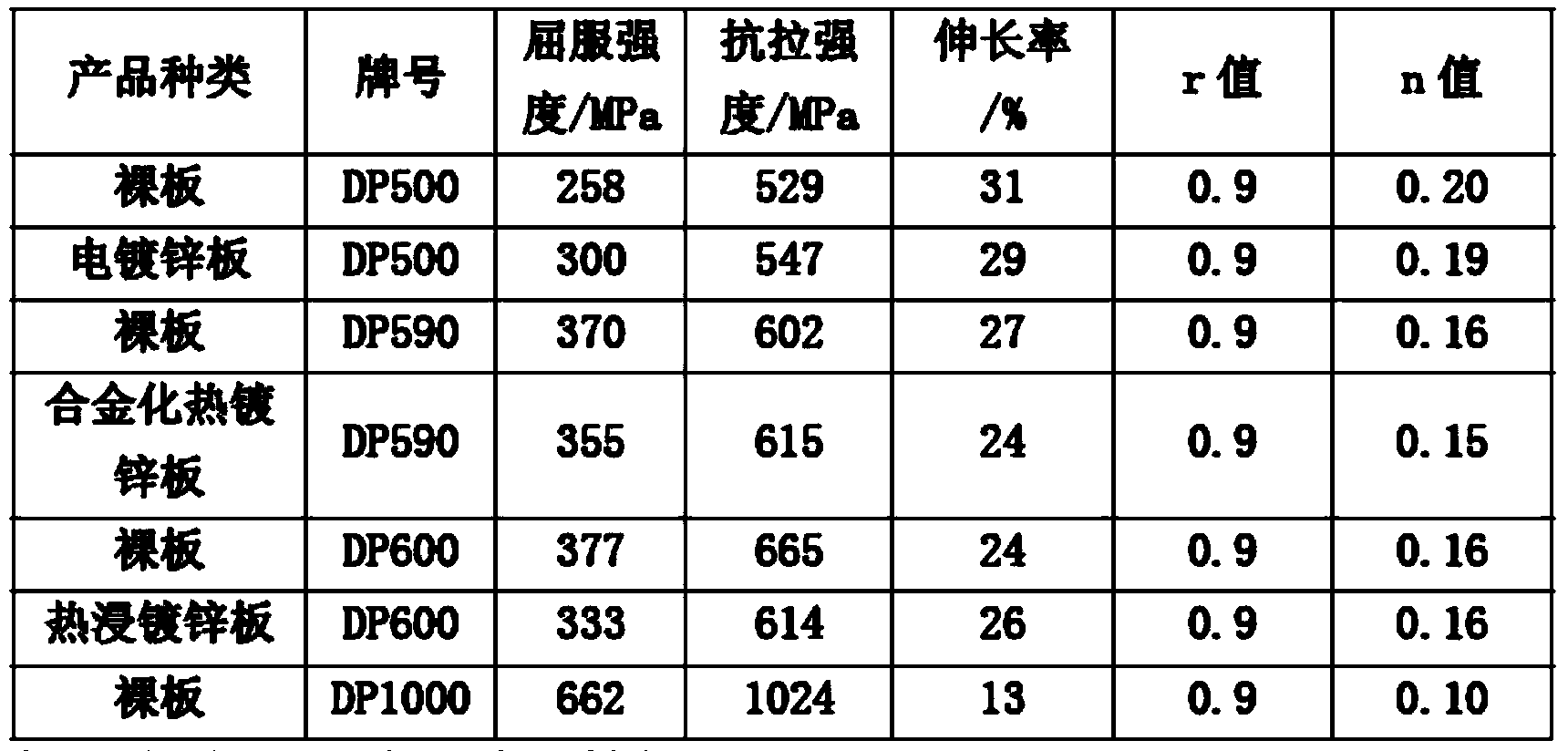

Two-phase automobile steel plate with low yield-strength ratio and high strength and production method of two-phase automobile steel plate

The invention discloses a two-phase automobile steel plate with low yield-strength ratio and high strength and a production method of the two-phase automobile steel plate, belonging to the technical field of steel for automobiles. The two-phase automobile steel plate comprises the following chemical components: 0.1-0.40wt% of C, 3.0-8.0wt% of Mn, less than or equal to 0.020wt% of P and less than or equal to 0.02wt% of S; on the basis, the two-phase automobile steel plate can be additionally provided with one or more of the following elements: 0.1-3.0wt% of Ni, 0.2-3.0wt% of Cr, 0.1-0.8wt% of Mo, 0.3-2.3wt% of Si, 0.5-2.0wt% of Cu, 0.0005-0.005wt% of B, 0.02-0.10wt% of Nb, 0.002-0.25wt% of [N], 0.05-0.25wt% of Ti, 0.02-0.25wt% of V, 0.015-0.060wt% of Al, 0.002-0.005wt% of RE (Rare Earth) and 0.005-0.03wt% of Ca. The two-phase automobile steel plate has the advantages that the two-phase automobile steel plate with low yield strength, high tension strength and favorable elongation can be produced through annealing within short time; the performance indexes of the two-phase automobile steel plate are as follows: two-phase steel with the tension strength of 980MPa has the yield-strength ratio of not larger than 0.55 and the elongation of larger than 22%, and two-phase steel with the tension strength of 1180MPa has the yield-strength ratio of not larger than 0.55 and the elongation of larger than 17%.

Owner:CENT IRON & STEEL RES INST

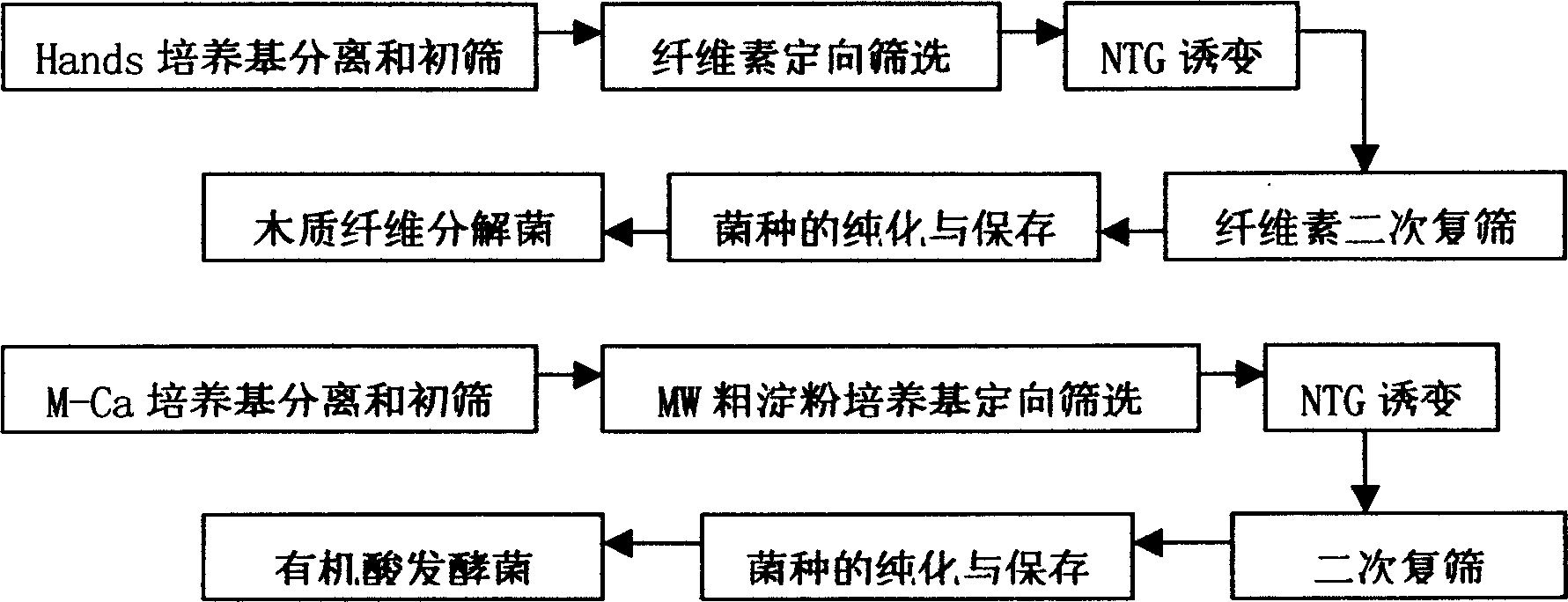

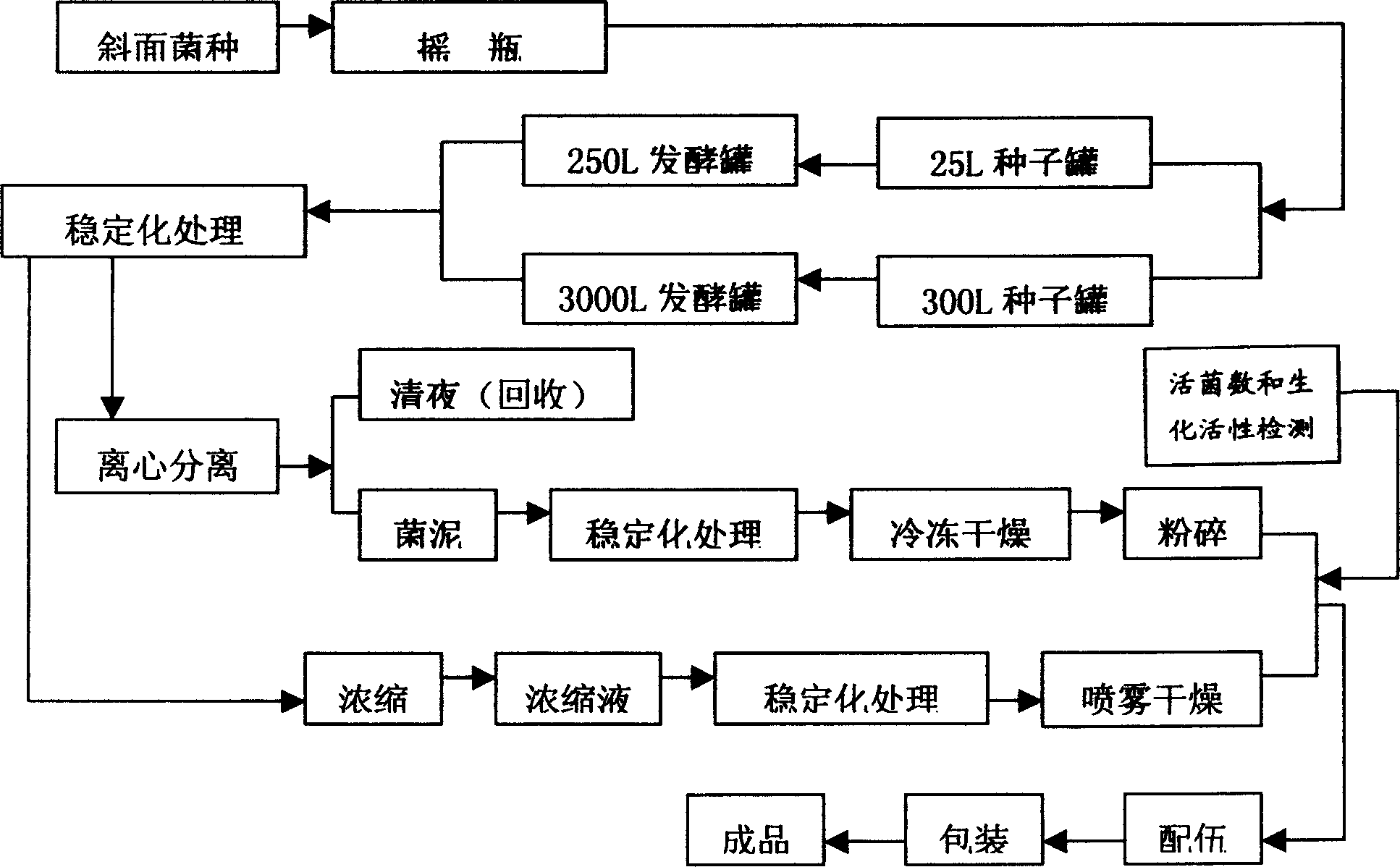

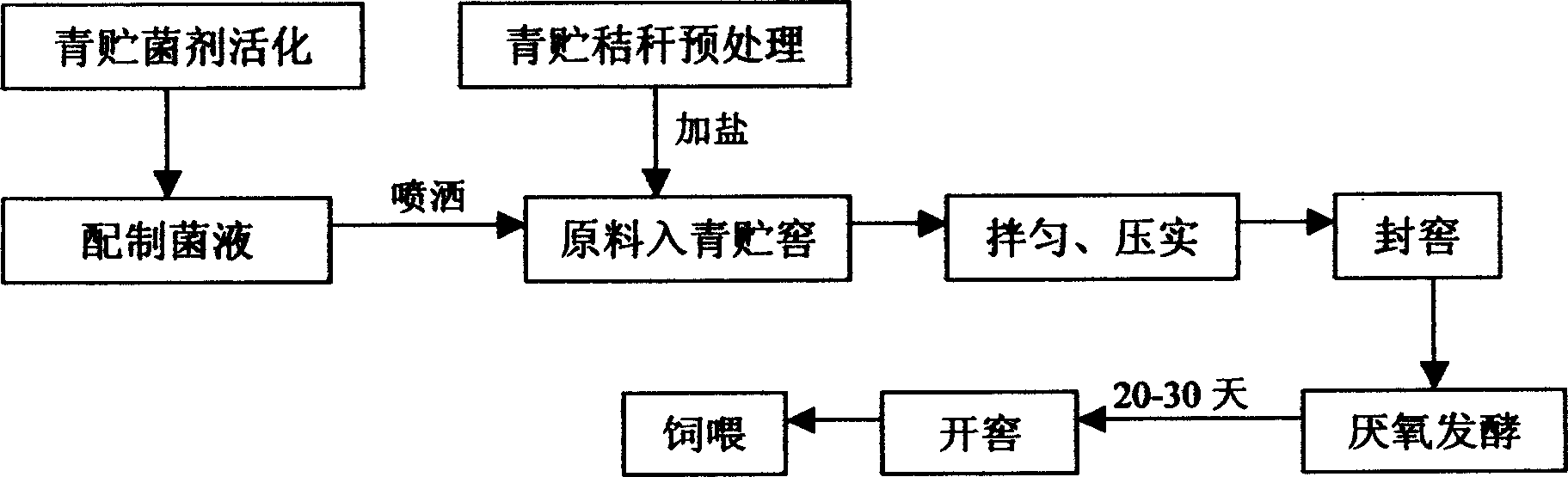

Microbial ensiling strain and composite fungus, method for producing silage

A high-activity composite microbial product for ensilage is composed of the streptococcus lactis and other 3 bacterial strains. After it is added to the raw materials of ensilage, such as corn plant, alfalfa, straw, stalk and pasturage, their pH value can be quickly lowered and the cellulose and semi-cellulose can be decomposed to obtain excellent feed.

Owner:THE INST OF MICROBIOLOGY XINJIANG ACADEMY OF AGRI SCI +1

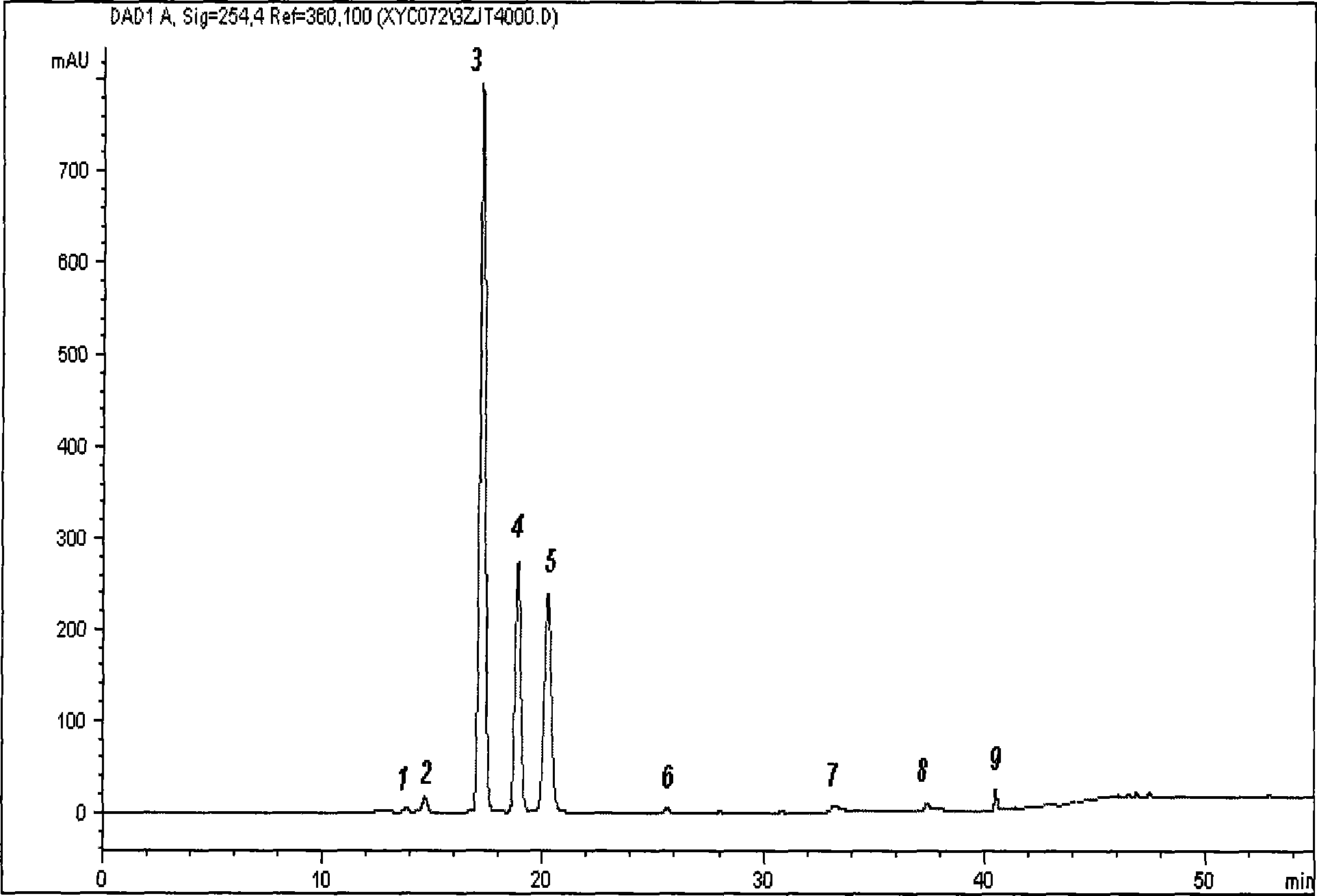

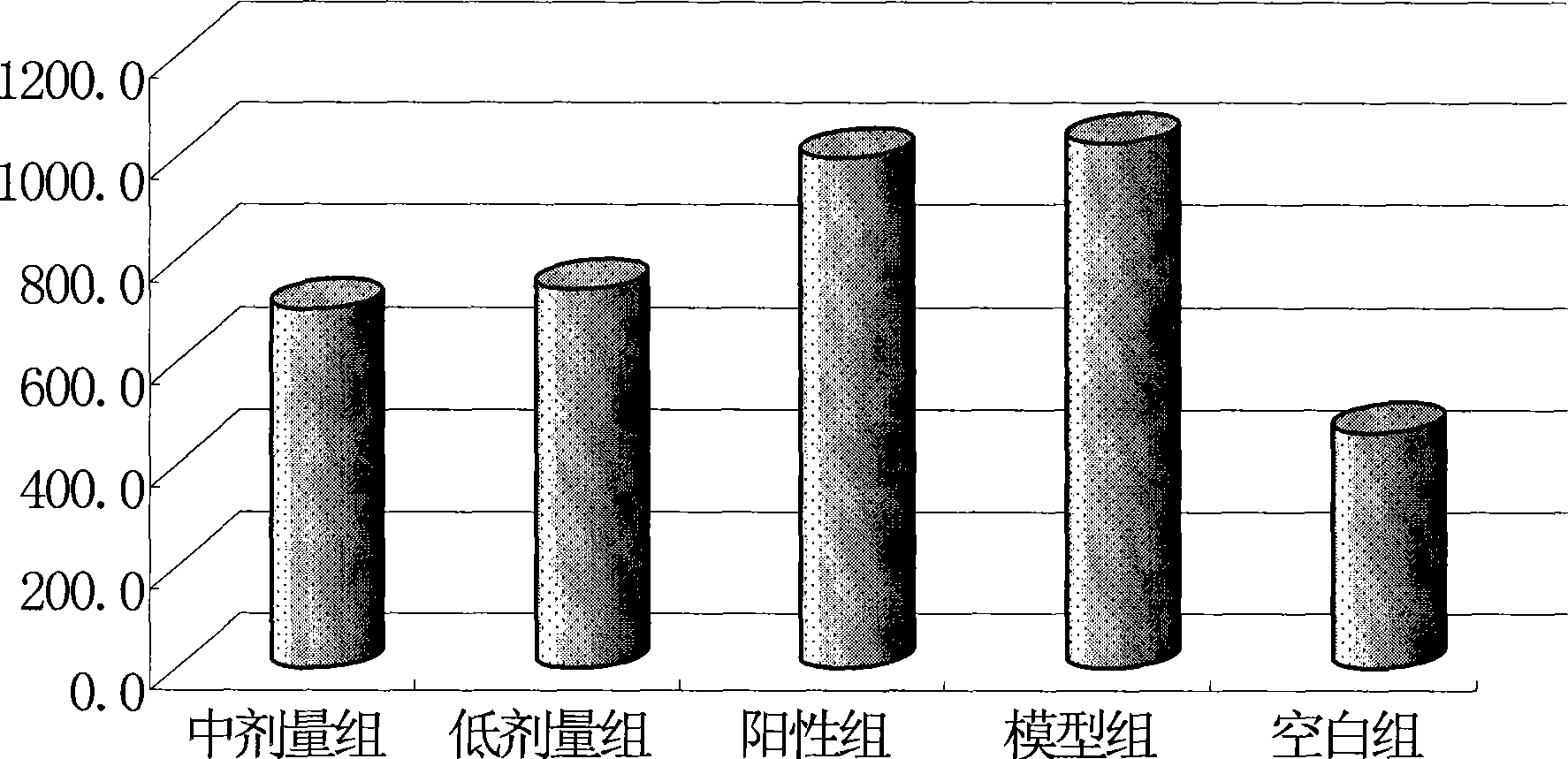

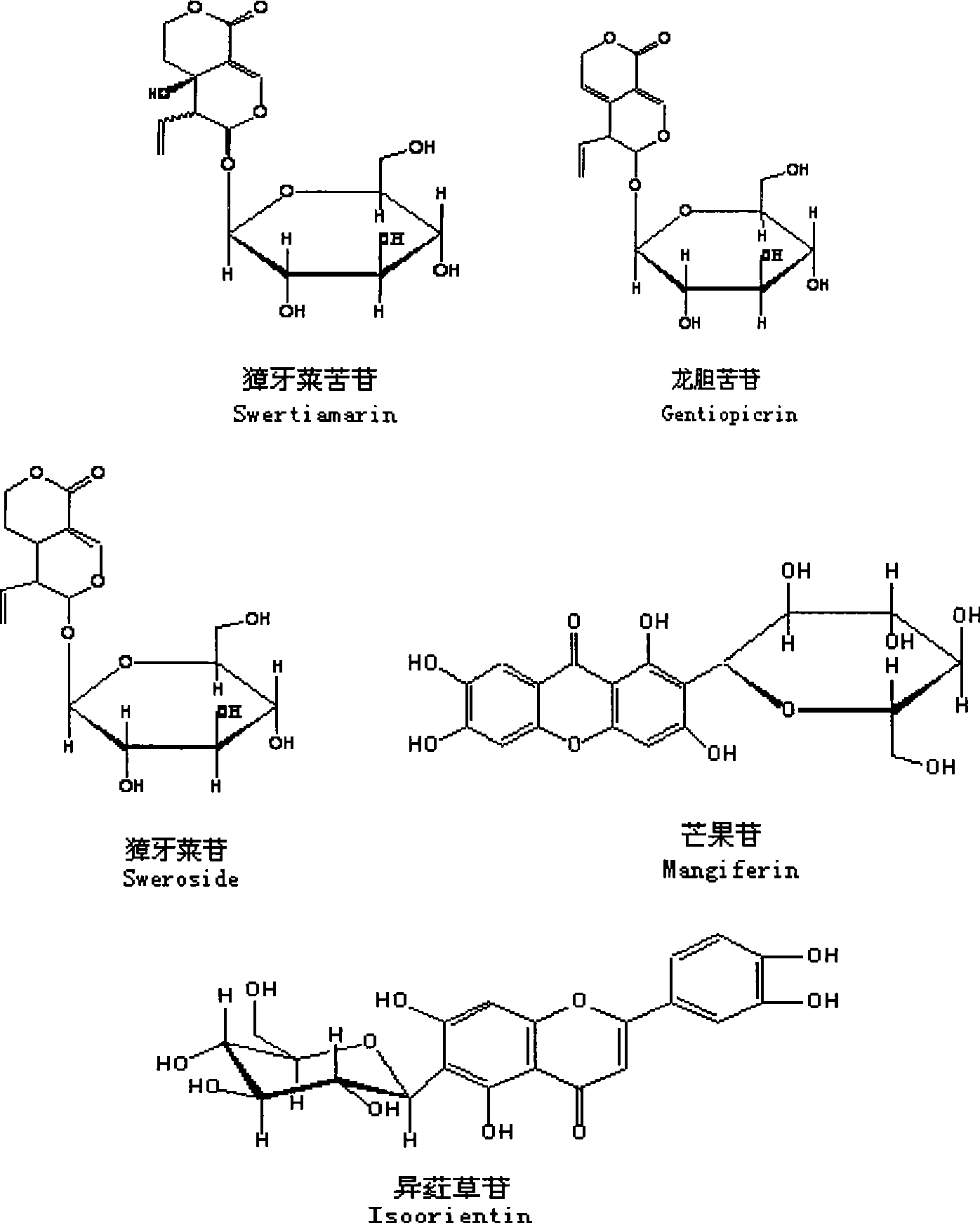

Tibetan capillary extract and preparation method, medicine composition and use thereof

ActiveCN101396428AReduce qualityExcellent indicatorsSugar derivativesDigestive systemAdditive ingredientTraditional medicine

The invention provides a Tibetan virgate wormwood herb extract containing swertiamain, gentiopicroside, sweroside, mangiferin and isoorientin, and the weight ratio of the five ingredients is (0.04-0.71): (20-40): (1-15): (1.6-26): (0.01-0.16). The invention further provides a preparation method of the Tibetan virgate wormwood herb extract, a pharmaceutical composition containing the Tibetan virgate wormwood herb extract and a medical use of the Tibetan virgate wormwood herb extract. The Tibetan virgate wormwood herb extract can improve various indicators caused by liver injury, promote the reversal of the liver fibrosis process and better prevent liver cirrhosis.

Owner:CHINA ACAD OF SCI NORTHWEST HIGHLAND BIOLOGY INST +1

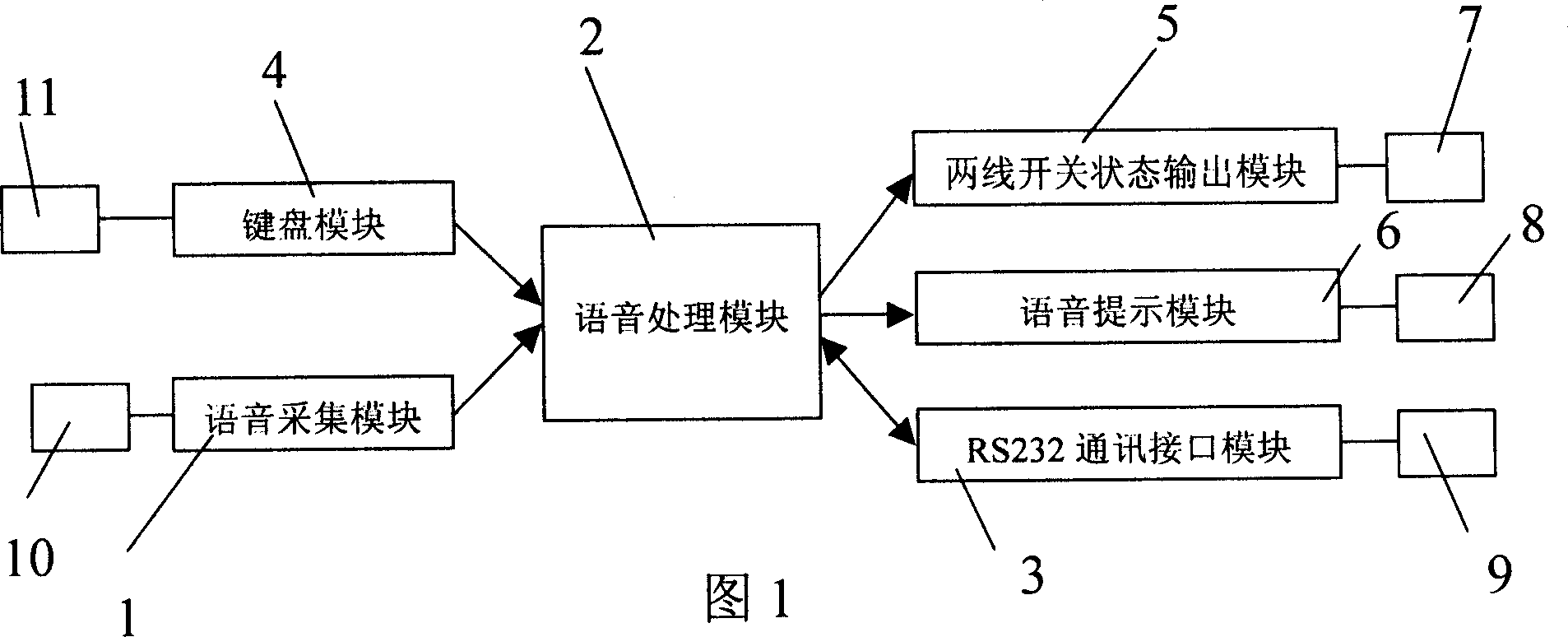

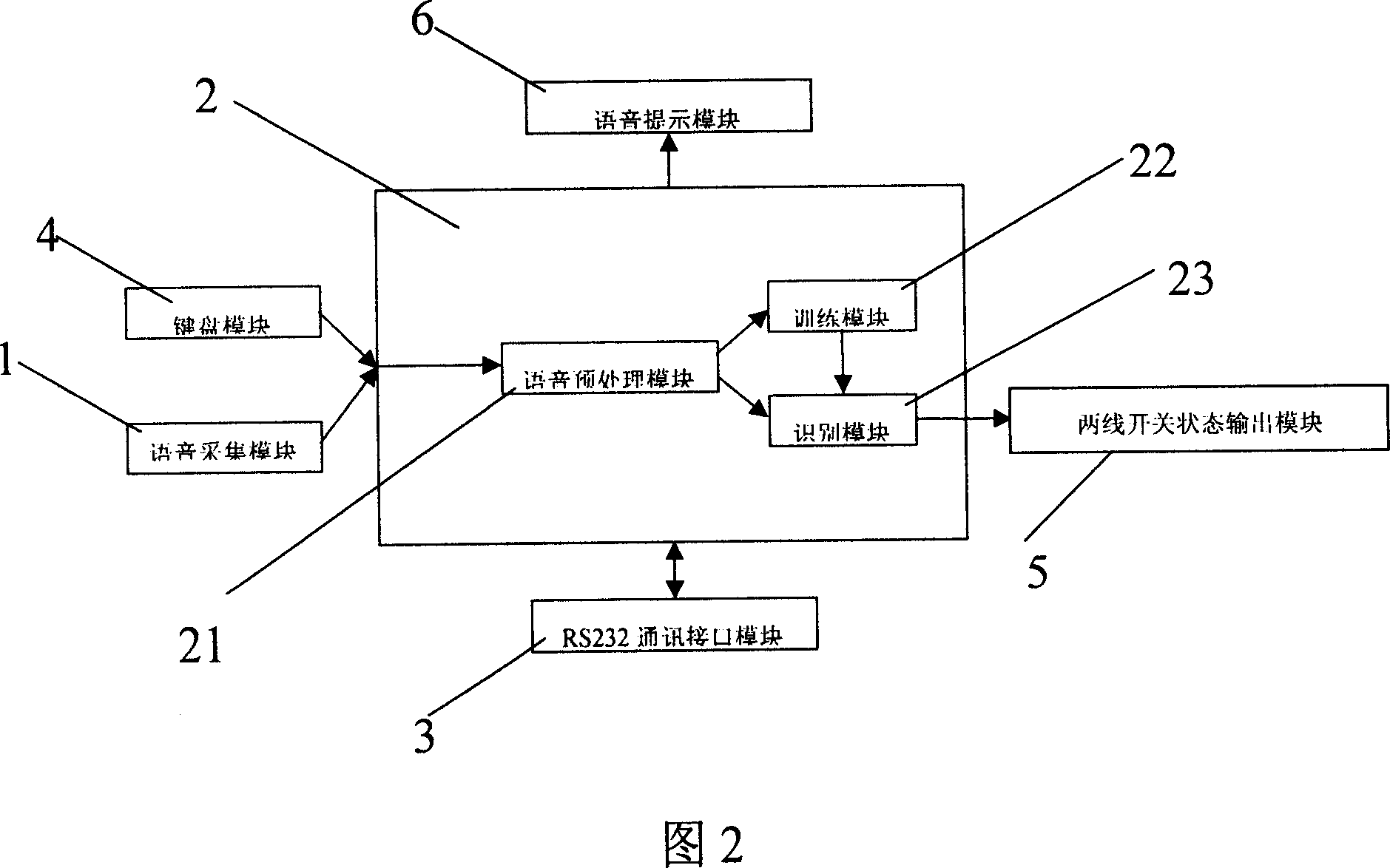

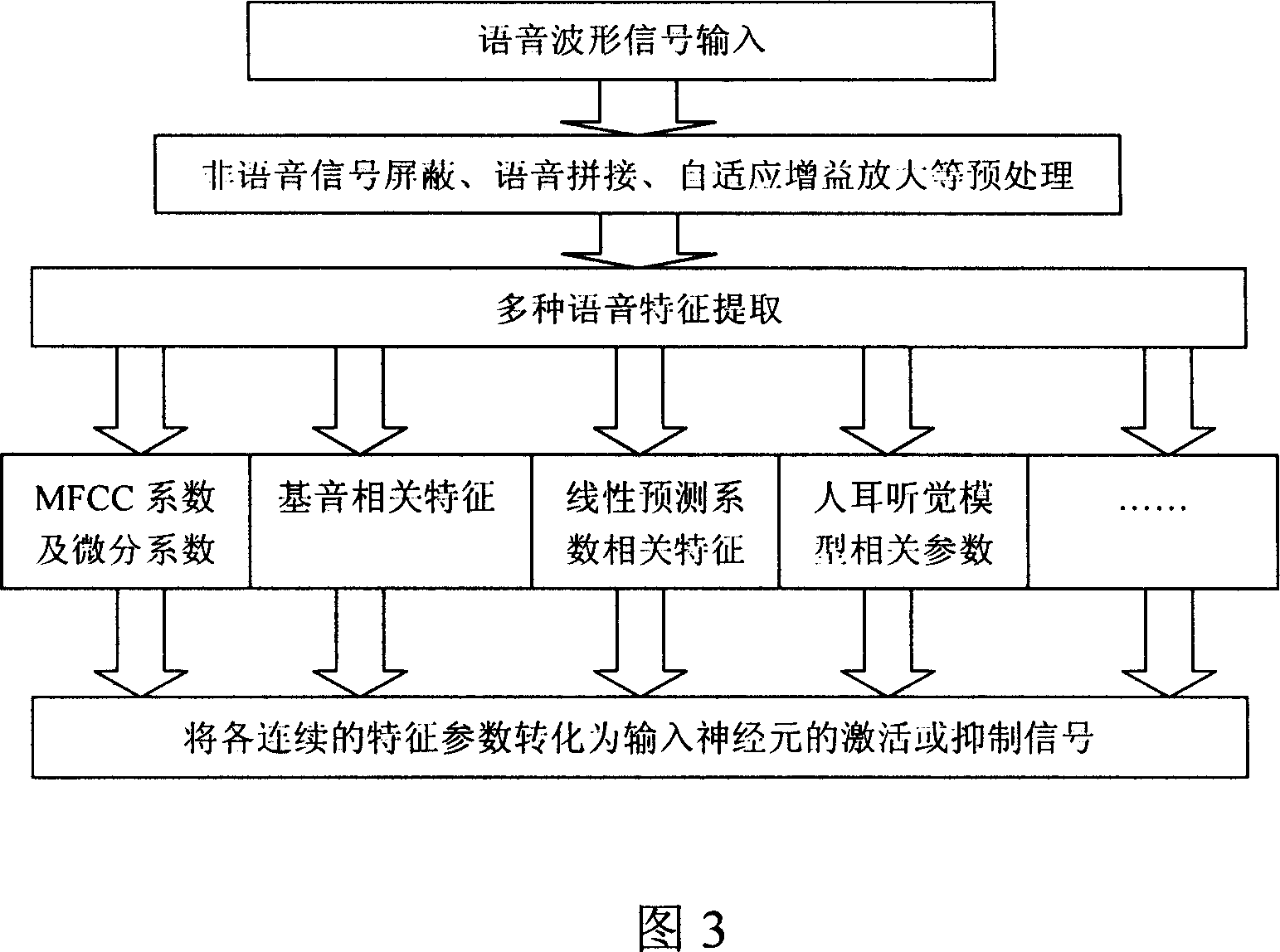

Soundwave discriminating unlocking module and unlocking method for interactive device at gate of building

InactiveCN1941080AImprove securityReduce false recognition rateElectric permutation locksSpeech recognitionComputer moduleSpeech sound

This invention is a voice identification lock module and its working method. The module is composed by a keyboard, voice collecting module, voice processing module, switch status output module, voice notice module and RS232 communication port. The lock key is based on identification of individual voice character. Error rate is less than 1%.

Owner:上海优浪信息科技有限公司

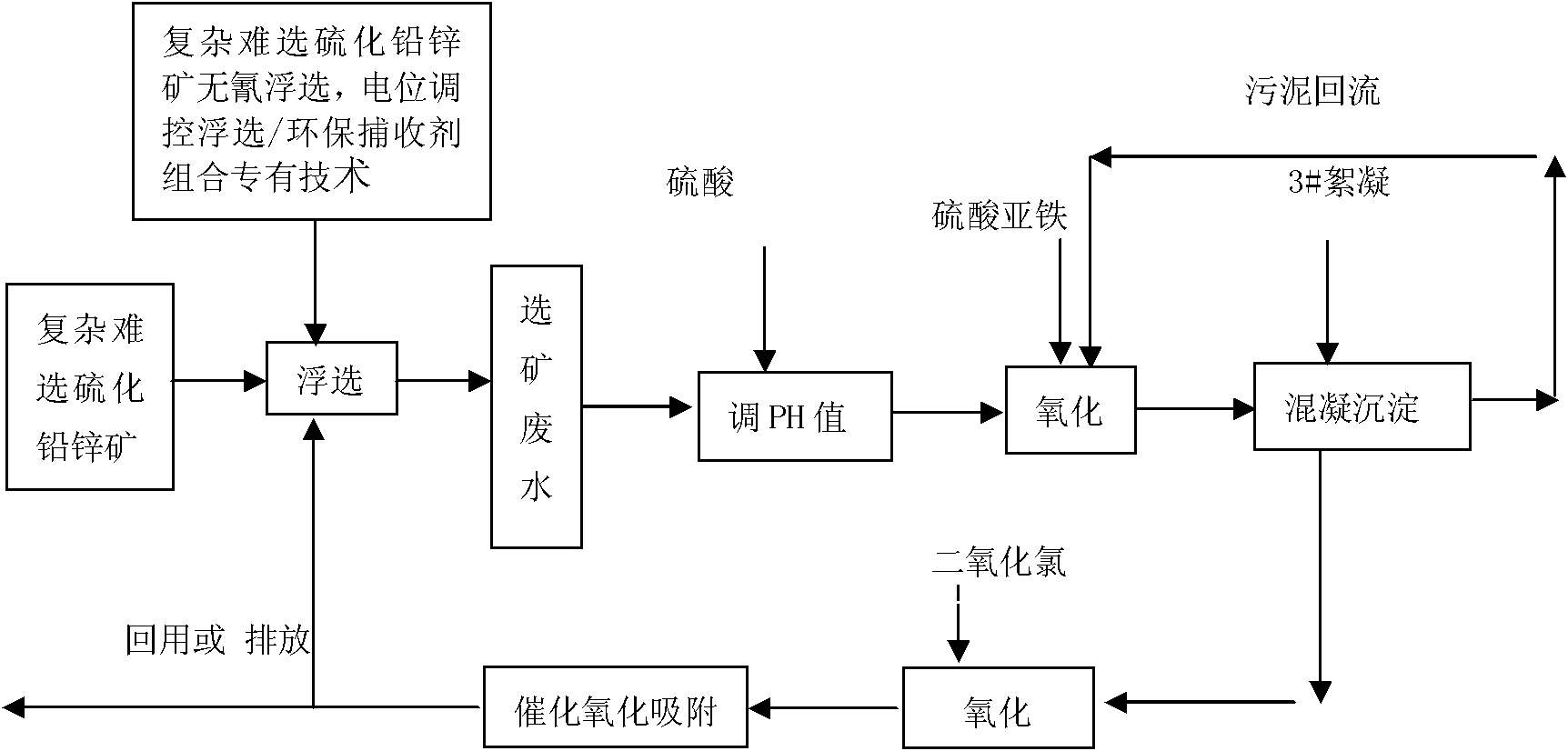

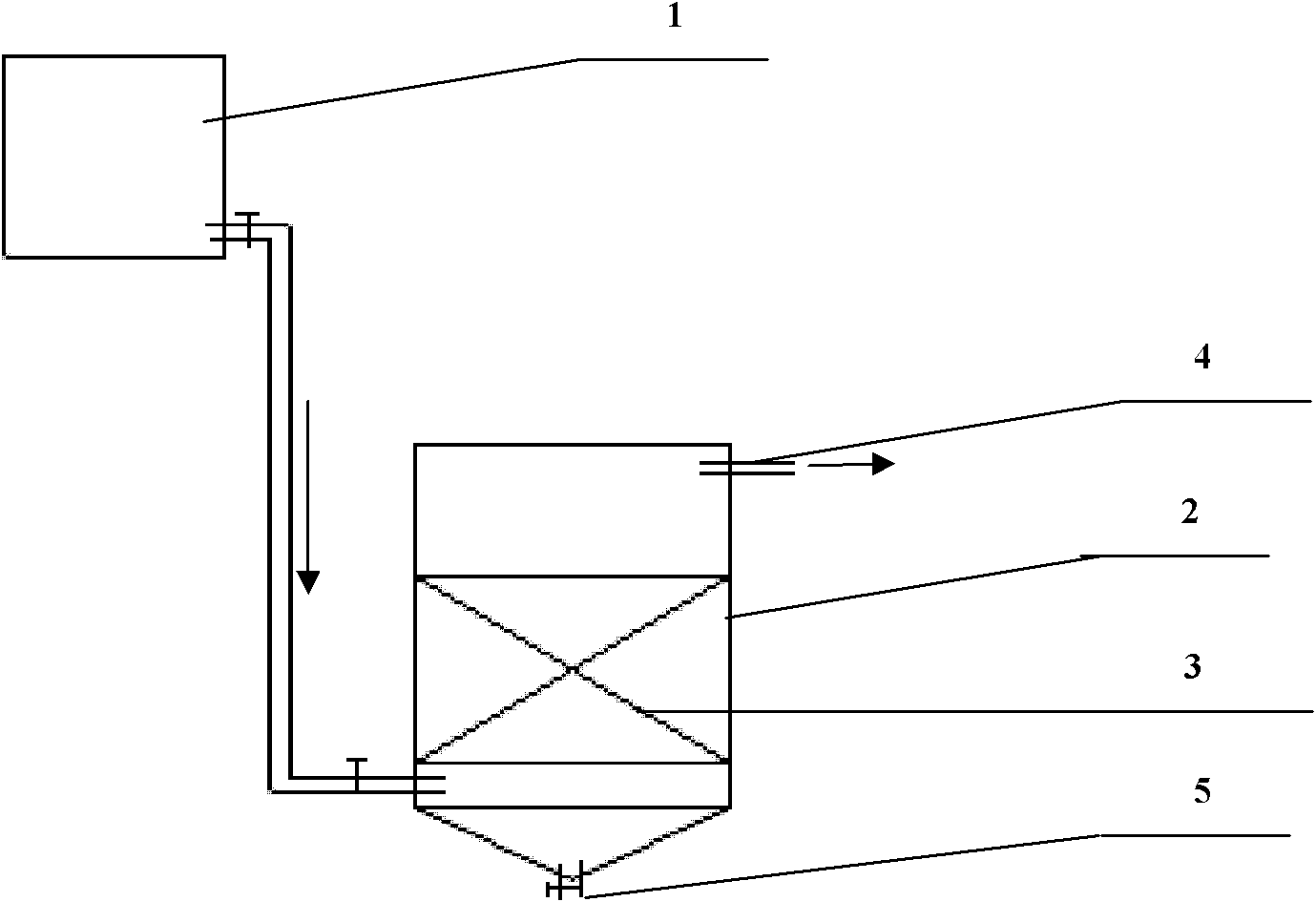

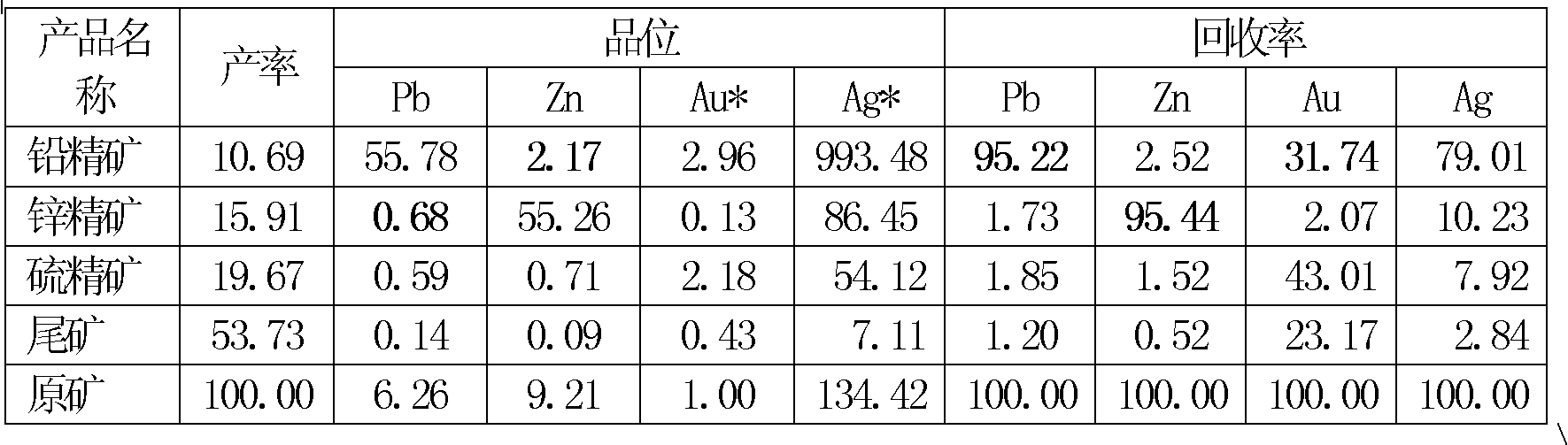

Method for treating and recycling lead-zinc sulfide ore dressing wastewater

ActiveCN101913720AEliminate the effects ofExtended service lifeWaste water treatment from quariesMultistage water/sewage treatmentActive carbonNovel technique

The invention provides a technique for treating and recycling lead-zinc ore dressing wastewater and aims to solve the problems of influence on the ore dressing index due to the recycling of the ore dressing wastewater for production and environmental pollution caused by drainage. The novel technique for treating and recycling the lead-zinc sulfide ore dressing wastewater comprises the steps of: adjusting the pH value of the total wastewater of an ore dressing plant; adding ferrous sulfate and flocculant into the wastewater to perform oxidation-coagulation treatment; and oxidizing the treated water by using chlorine dioxide, and performing catalytic oxidation and adsorption by using an active carbon bed, so that the treated water reaches the relevant discharge standard of China; and totally recycling the treated water by adopting the combined application of potential-controlled flotation and an environmental-protection collector. Compared with the field process technique, the method saves the cyanide flotation process and improves the recovery rates of lead, zinc and gold. The method provides whole technical integration of the combined application technique of the potential-controlled flotation and the environmental-protection collector and the wastewater treatment technique for the treatment and recycling of the lead-zinc ore dressing wastewater, and realizes recycling of the ore dressing wastewater.

Owner:HUNAN HERMES SAFE ENVIRONMENT PROTECTION SCI

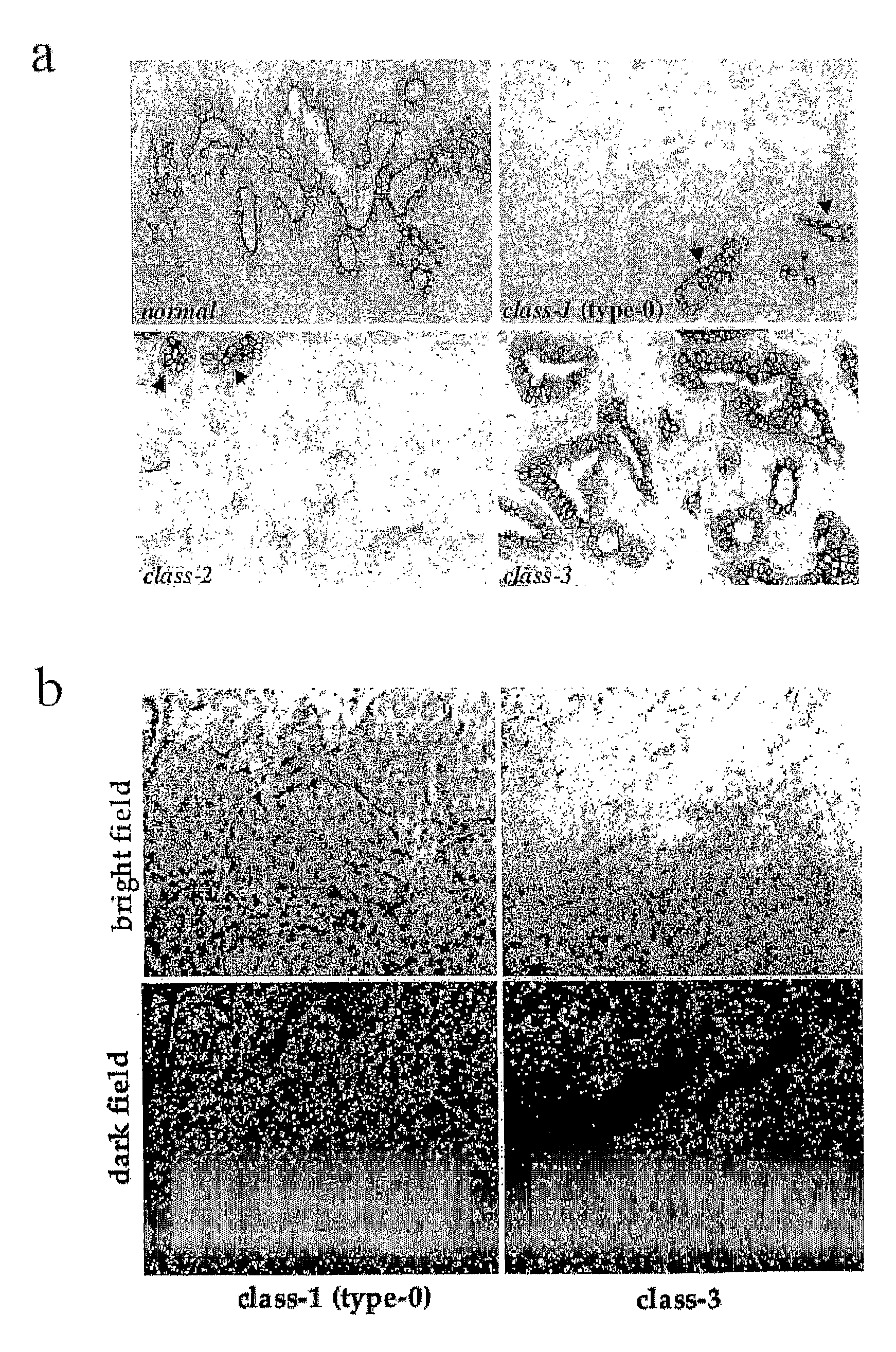

Cancer Markers

InactiveUS20080188405A1Prognosis is dramatically affected by Numb statusImproved prognosisPeptide/protein ingredientsMicrobiological testing/measurementImmunologyCancer marker

Owner:IFOM FOND INST FIRC DI ONCOLOGIA MOLECOLARE

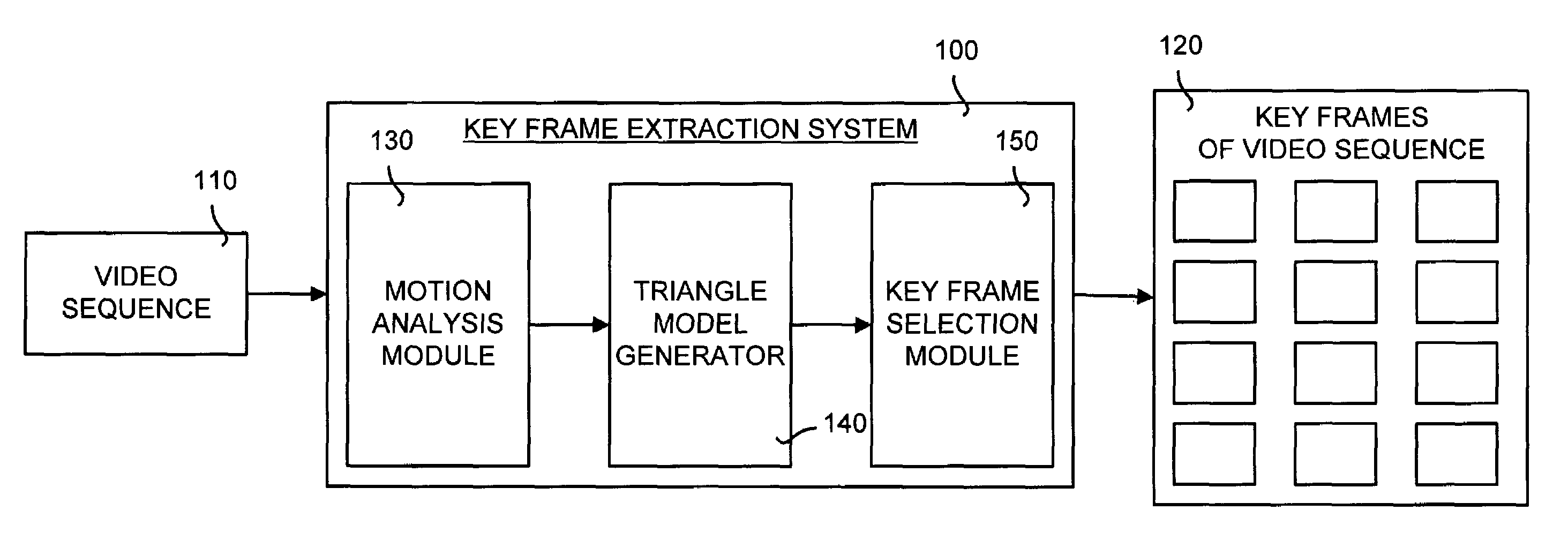

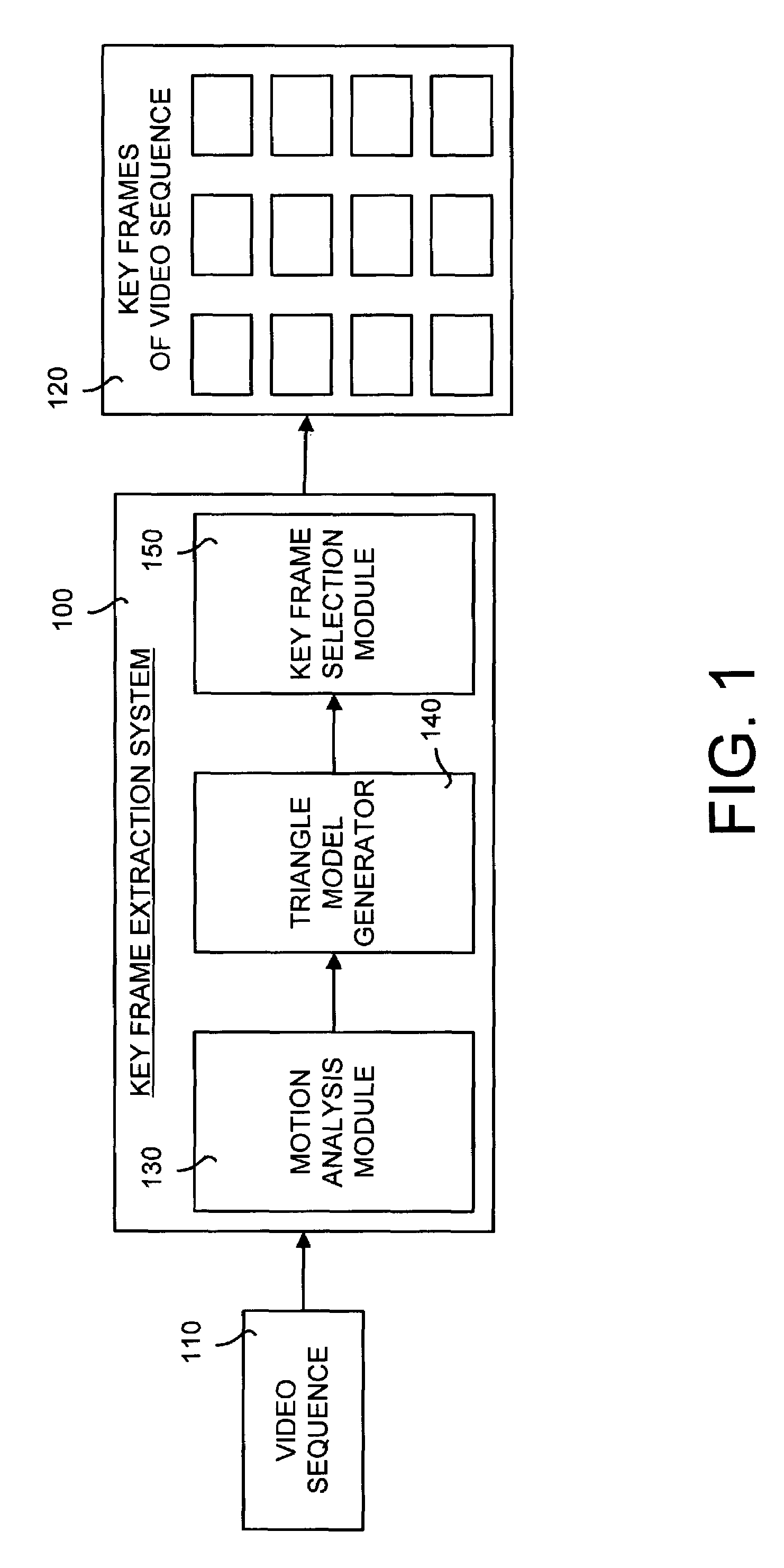

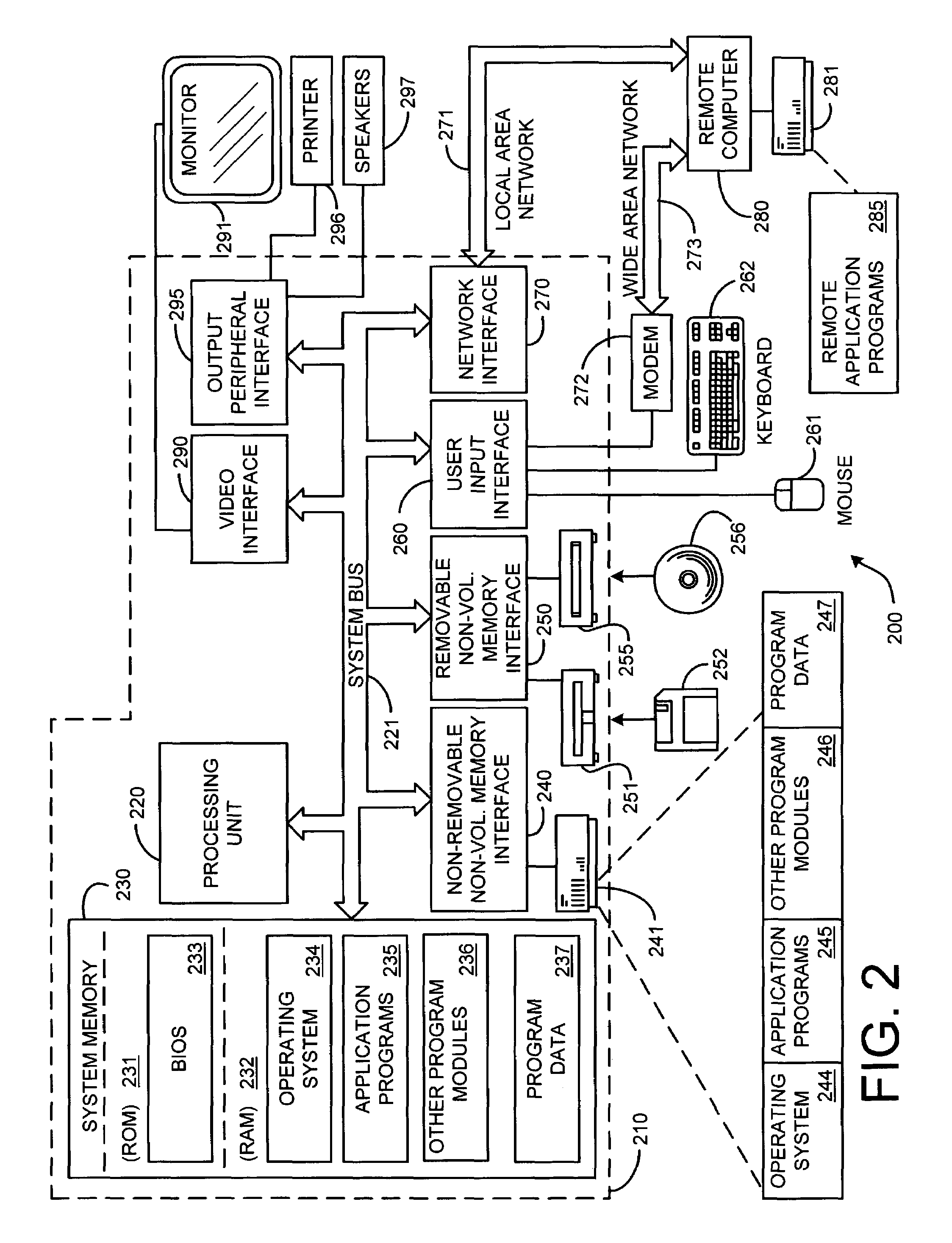

Method and system for extracting key frames from video using a triangle model of motion based on perceived motion energy

InactiveUS7027513B2Weaken energyExcellent indicatorsTelevision system detailsPicture reproducers using cathode ray tubesSubject matterVideo sequence

The present invention includes a key frame extraction system and method for extracting key frames from a video based on motion analysis of frames within the video. Key frames are highlight frames that are effective in summarizing a video sequence. This allows a user to quickly find a desired spot in a video is long and contains differing subject matter. The key frame extraction system and method uses a triangle model of the motion energy in each frame and extracts key frames based on this model. More specifically, motion analysis is performed on the video frames in order to identify motion acceleration and motion deceleration points within the frames. A triangle model of motion then is constructed based on results of the motion analysis. The apex of the triangle represents a turning point between motion acceleration and motion deceleration. Frames corresponding to this apex are selected as key frames.

Owner:MICROSOFT TECH LICENSING LLC

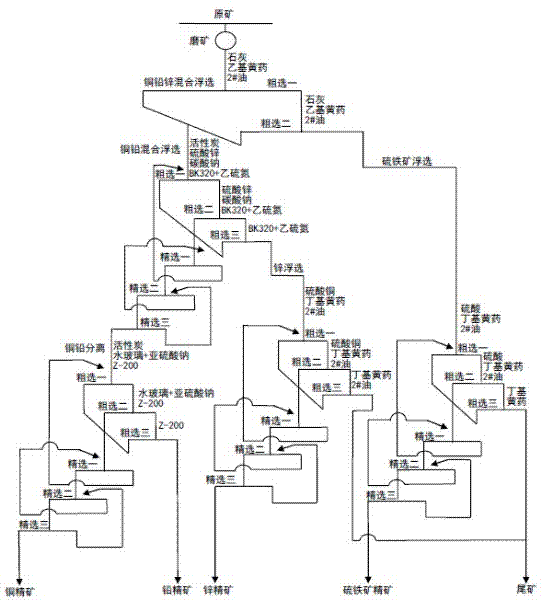

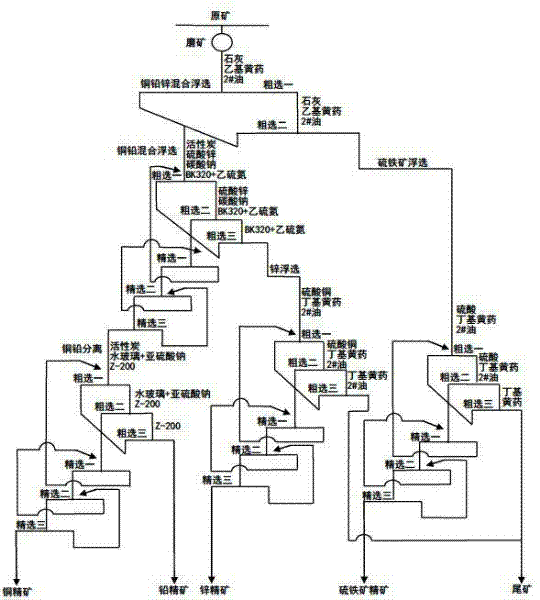

Mineral dressing method for separating Cu-Pb-Zn-Fe multi-metal sulfide mineral

The invention discloses a mineral dressing method for separating a Cu-Pb-Zn-Fe multi-metal sulfide mineral, which comprises the following steps: selecting a raw mineral, grinding the mineral, carrying out mixed flotation to Cu, Pb and Zn, carrying out mixed flotation to Cu and Pb, separating Cu and Pb, carrying out Zn flotation and pyrite flotation, and finally obtaining a Cu, Pb, Zn and pyrite concentrate. The method has the advantages of good metal sulfide mineral effect and high metal recovery rate, is simple to operate and is suitable to popularize and apply.

Owner:KUNMING UNIV OF SCI & TECH

Method of matching a vehicle wheel

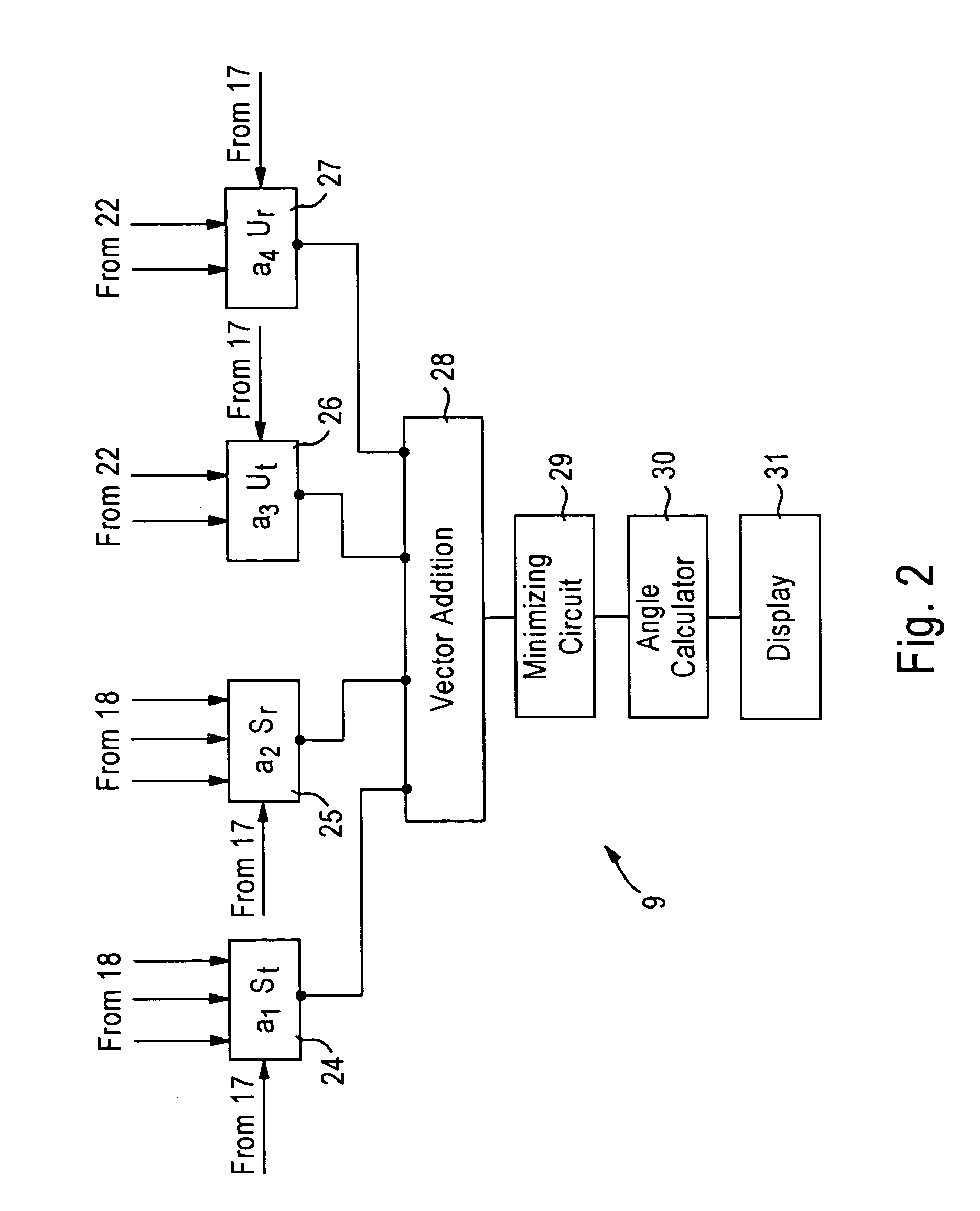

ActiveUS20050055153A1Improve operational fluencyOptimizes index vectorStatic/dynamic balance measurementComplex mathematical operationsEngineeringAutomotive engineering

Owner:SNAP ON EQUIP

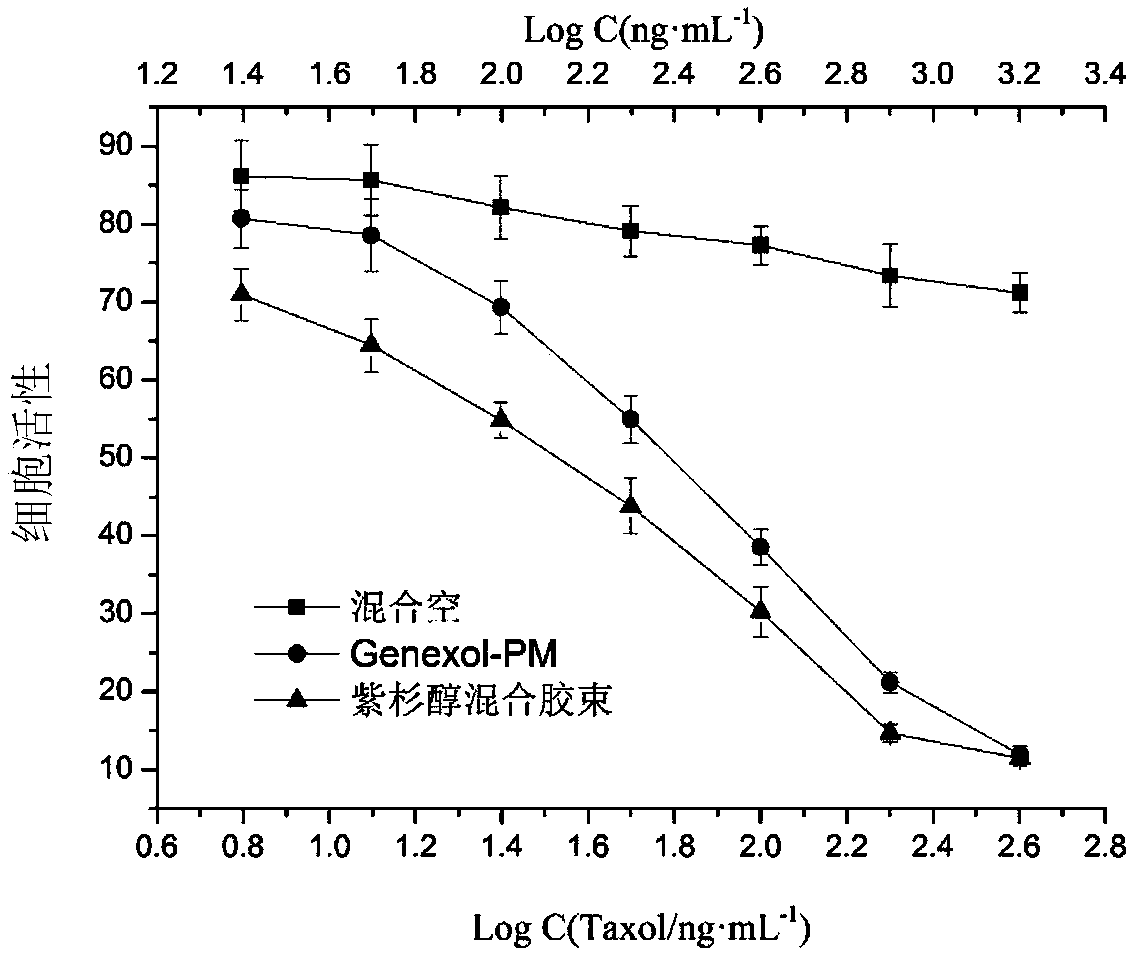

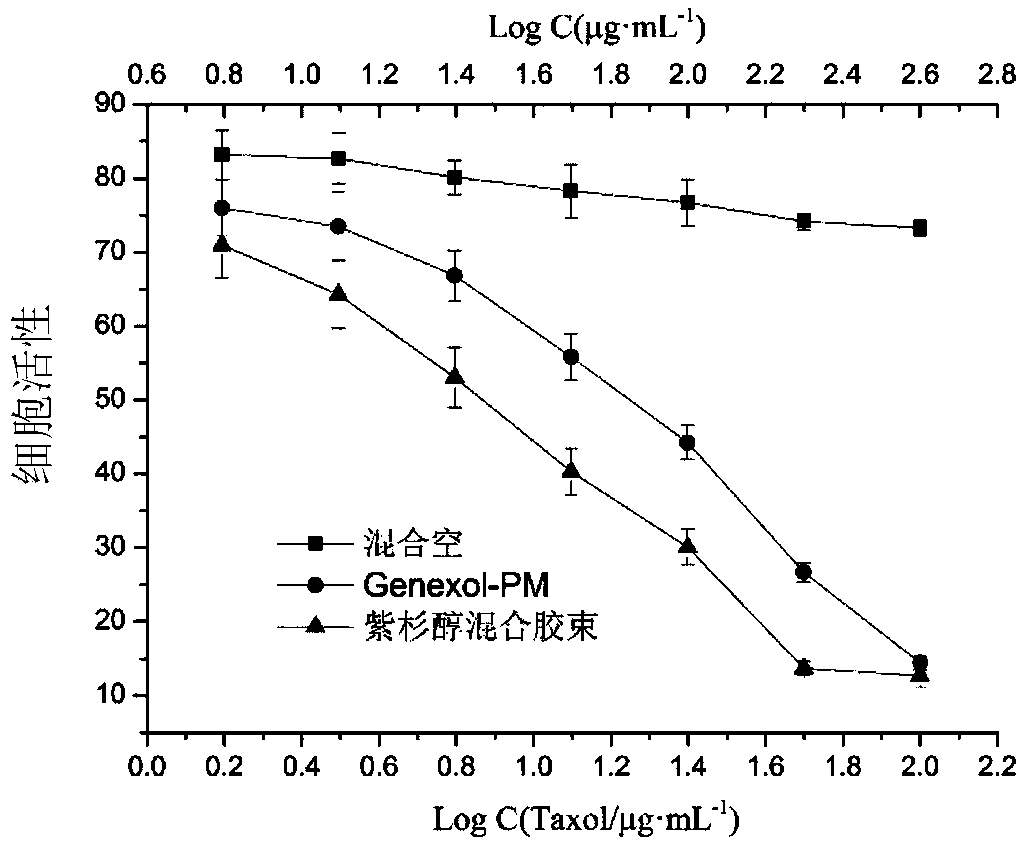

Blank mixed micelle, and preparation method and applications thereof

ActiveCN108420793AImprove uniformityReliable uniformityOrganic active ingredientsCosmetic preparationsMixed micelleCurative effect

The invention discloses blank mixed micelle, and a preparation method and applications thereof. The blank mixed micelle comprises an amphiphilic copolymer and ginsenoside represented by formula I, ishigh in efficiency, is safe, is stable, is high in targeting performance, is excellent in homogeneity, is stable in quality, is convention in preparation technology, can be used for coating one or a plurality of active substances in drugs or cosmetics and health care substances, and is capable of forming mixed micelle containing loaded active substances. Compared with conventional nanometer micelle, the blank mixed micelle possesses following advantages: the mixed micelle loaded with active substances is excellent in drug forming performance, multiple drug resistance, stability, homogeneity, and safety performance, and is small in particle size; and the curative effect of loaded active drugs on drug resistant cells is better.

Owner:XIAMEN GINPOSOME PHARM CO LTD

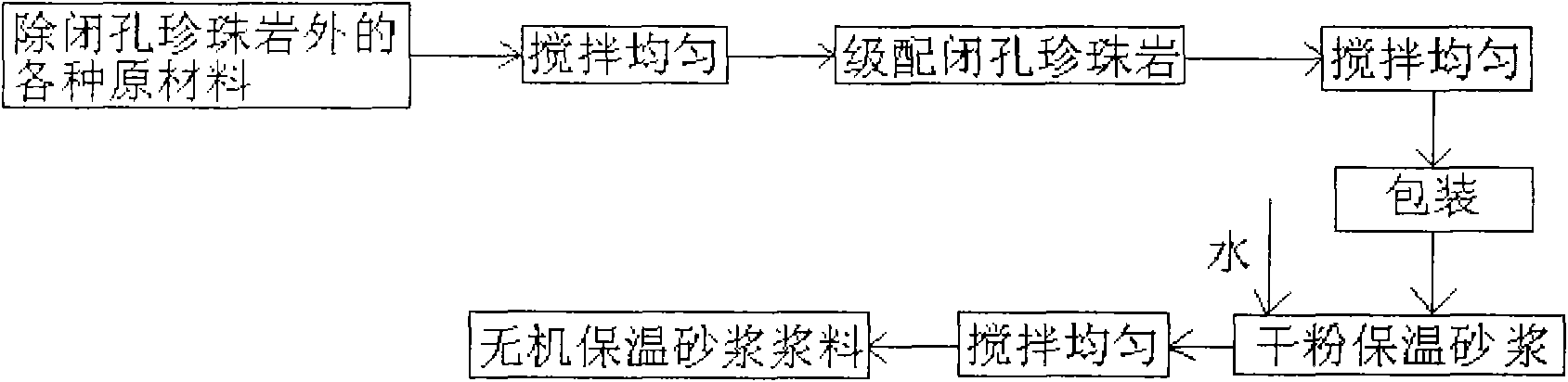

Single-component inorganic heat-insulating mortar and preparation method thereof

The invention relates to single-component inorganic heat-insulating mortar which is prepared from the following components in parts by weight: 400-500 parts of cement, 400-450 parts of expanded closed cell perlite, 100-200 parts of fly ash, 5-10 parts of redispersible emulsion powder, 10-30 parts of sepiolite fiber, 2-3 parts of cellulose ether, 10-20 parts of gypsum and 1000-1200 parts of water. The inorganic heat-insulating mortar has low heat conduction coefficient, good thermal insulation performance, high compressive strength and bonding strength, excellent mechanical performance, good construction workability, simple operation and high construction efficiency; and single-component production is carried out by adopting the process of the invention, the quality is easy to control, and the invention is beneficial to on-site civilized construction.

Owner:武汉威尔博科技发展有限公司

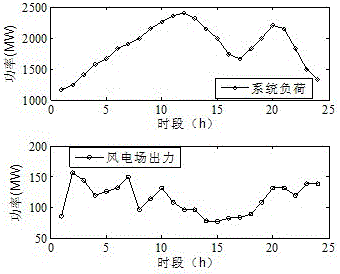

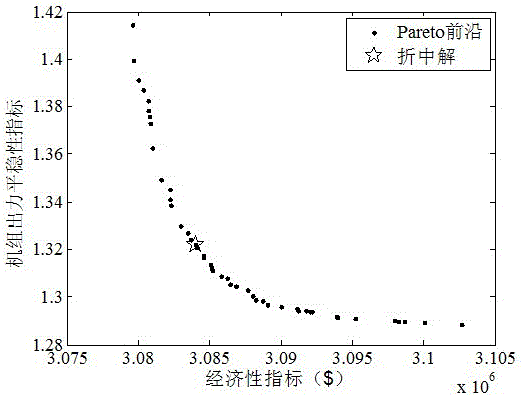

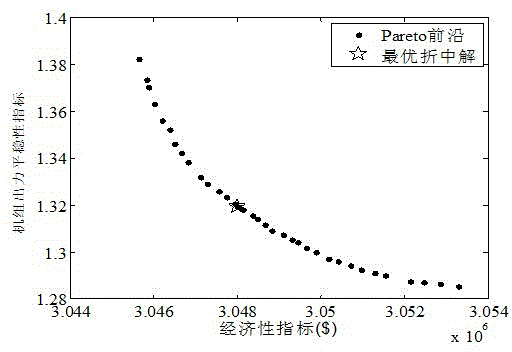

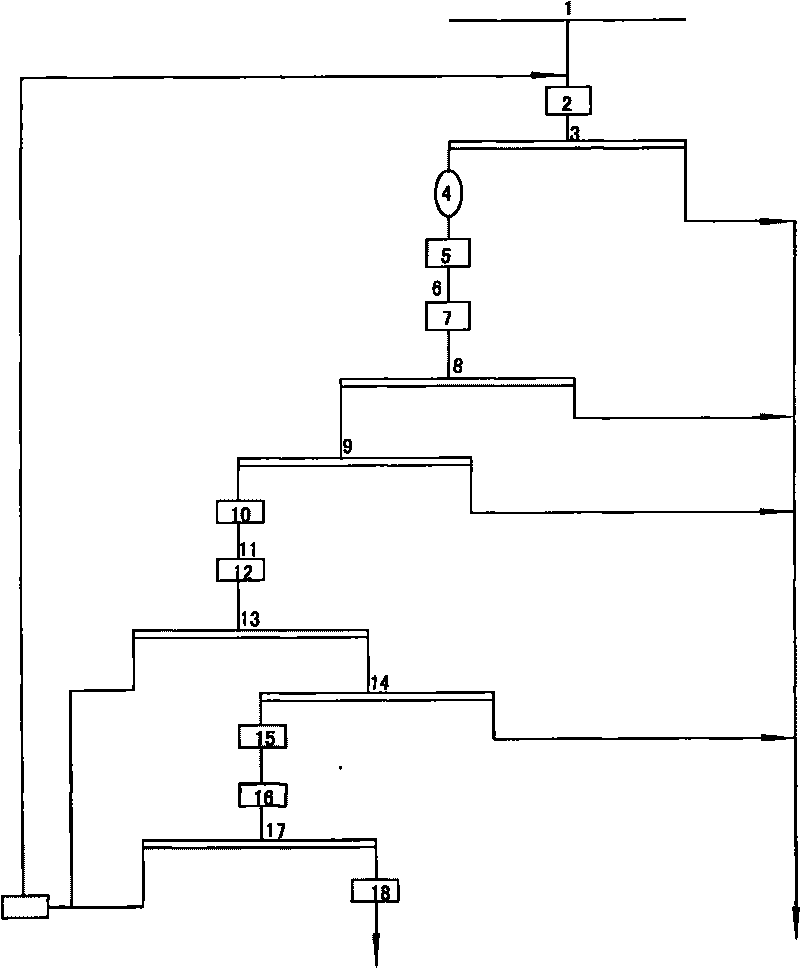

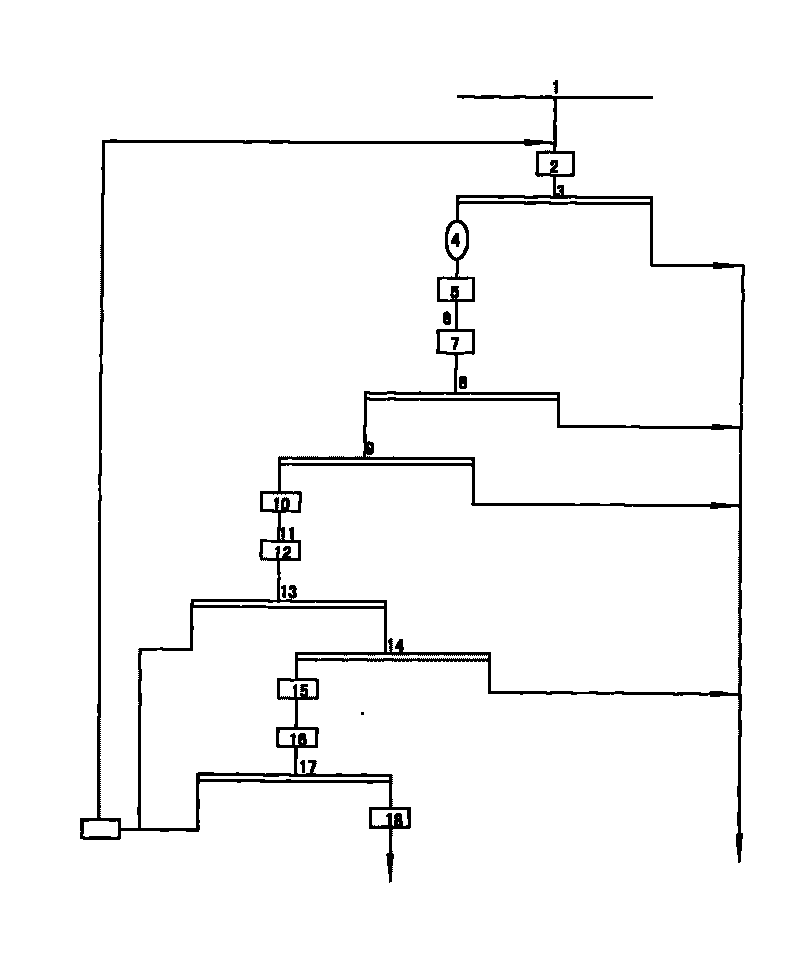

Environmental economy power generation dispatching method

InactiveCN104009494AExcellent indicatorsReduced service lifeSingle network parallel feeding arrangementsForecastingLeading edgeComputer science

The invention provides an environmental economy power generation dispatching method. The environmental economy power generation dispatching method comprises the steps of establishing a multi-target scheduling model taking power output stability of a thermal power generating unit and a hydroelectric generating set into consideration, wherein the multi-target scheduling model comprises an objective function and a constraint condition; inputting preset a real-time system expected loss of a load; solving the Pareto optimality leading edge of environmental economy scheduling based on the multi-target particle swarm optimization to obtain the historical Pareto optimality solution set; calculating the satisfaction degree of Pareto optimality solutions and selecting the optimality solution with the highest satisfaction degree as the needed environmental economy power generation dispatching result. The environmental economy power generation dispatching method can provide a wind-fire-water coordinated optimized scheme containing operational risks, and is reasonable and practical.

Owner:WUHAN UNIV

New method for recycling iron minerals in magnetic separated gangues

The invention belongs to the technical field of mineral separation in iron and steel metallurgy industry, and particularly relates to a new method for recycling iron minerals in magnetic separated gangues, which adopts a method for recycling the magnetic separated gangues through staged magnetic separation, regrinding, fine screening and a magnetic separation column process: sending the magnetic separated gangues recycled by a recycling machine to a concentrated low-intensity magnetic separator; feeding the separated iron minerals into a ball mill for ball milling and discharging, and sendingthe minerals to a first segment of dehydration tank by a pump through a pump box; sending the dehydrated concentrate to a second segment of magnetic separator; sending the selected concentrate to a high frequency vibrating screen, returning substances on the screen to a feeding box of the concentrated low-intensity magnetic separator, and feeding the products under the screen into a third segmentof magnetic separator; sending the magnetic separated concentrate into a feeding box of a magnetic separation column to cause the concentrate to automatically flow to the magnetic separation column; and returning the gangues in each segment of magnetic separator to the gangue recycling machine. The concentrate at the magnetic separation column is the final concentrate, and the gangue at the firstsegment of magnetic separation recycling machine is the final gangue. The invention has reasonable process flow, can improve the grade of the reclaimed iron minerals in the magnetic separated ganguesthrough reasonable separation, fully utilize mineral resources, reduce the waste and loss of metals, obtain good indexes and simultaneously obtain remarkable economic benefit.

Owner:ANSTEEL GRP MINING CO LTD

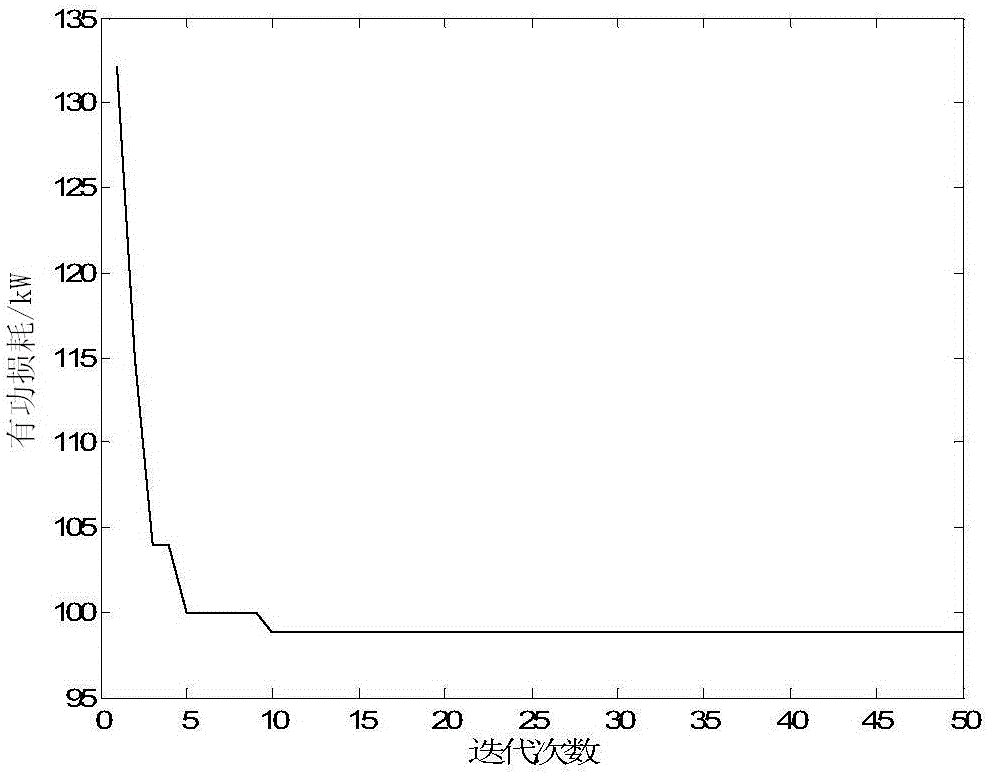

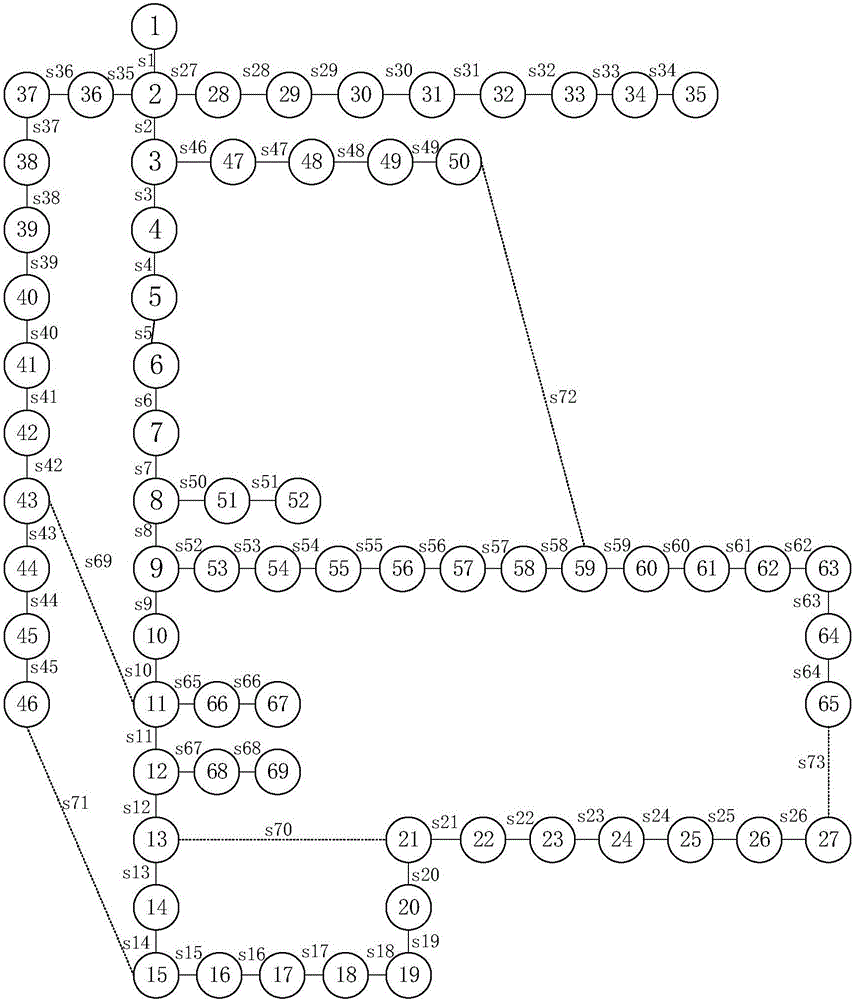

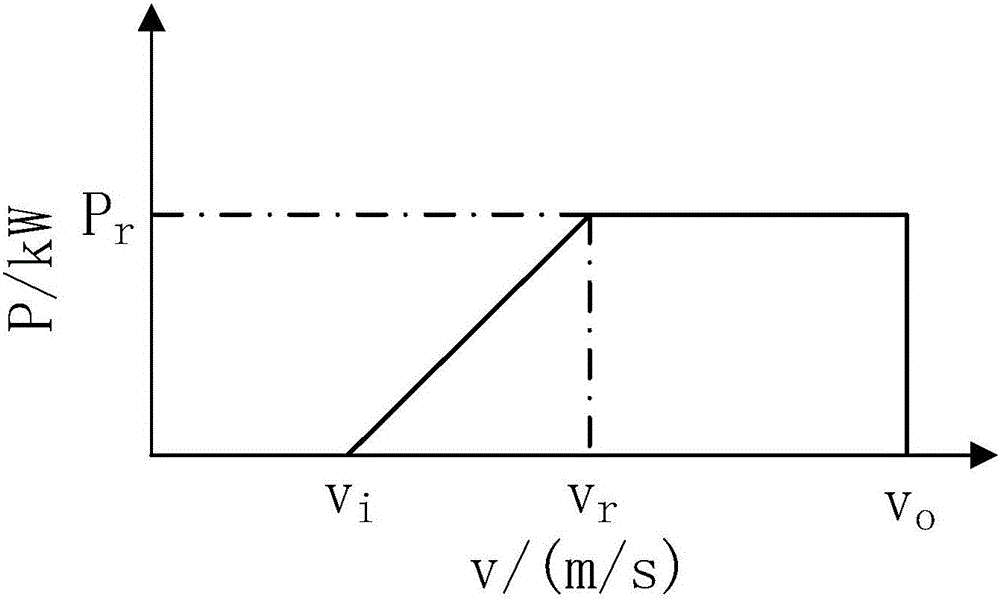

Multi-target distribution network reconstruction method considering distributed generation and load uncertainty

ActiveCN105741193AExcellent indicatorsGuaranteed production efficiencyData processing applicationsAc network circuit arrangementsBiogeographySimulation

The invention discloses a multi-target distribution network reconstruction method considering distributed generation and load uncertainty. Wind power output force, photovoltaic power generation and load uncertainty are taken into consideration in the method. The three most important evaluation indexes, of optimized operation of a distribution network, including active loss, minimal voltage value of nodes and load balancing degree, namely three optimizing reconstruction targets, are given. Wind power output force, photovoltaic power output force and load uncertainty factors are processed through a scene analytical method. The final reconstruction scheme is obtained through multi-target disturbance biogeographic algorithm and fuzzy set theory. A multi-target reconstruction decision solution can be rapidly found, and high searching efficiency is ensured. Under an absorbing distributed power supply condition, various indexes of a network can be improved substantially through network reconstruction, so that the reconstruction is more adaptable to a real decision-making process.

Owner:HOHAI UNIV

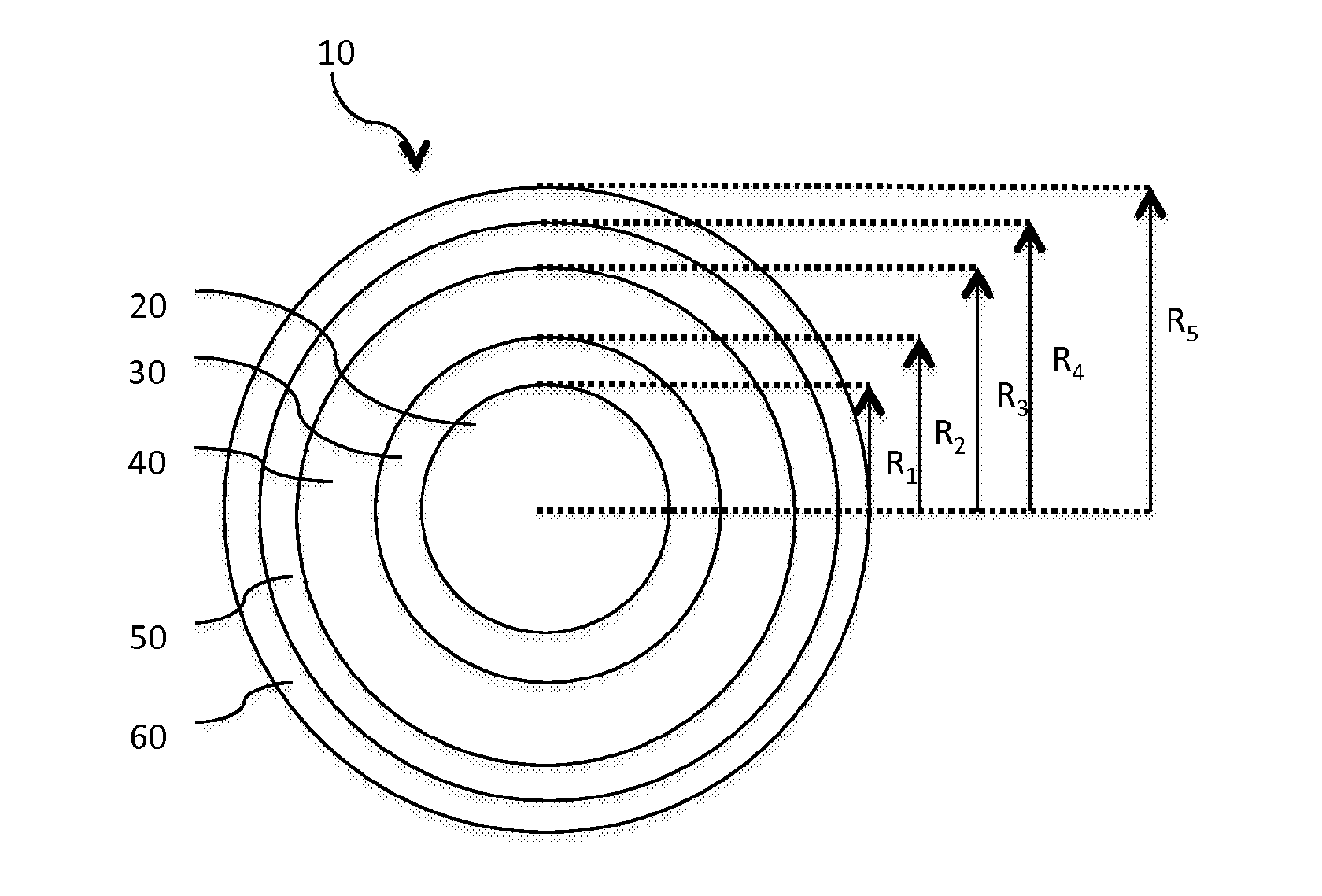

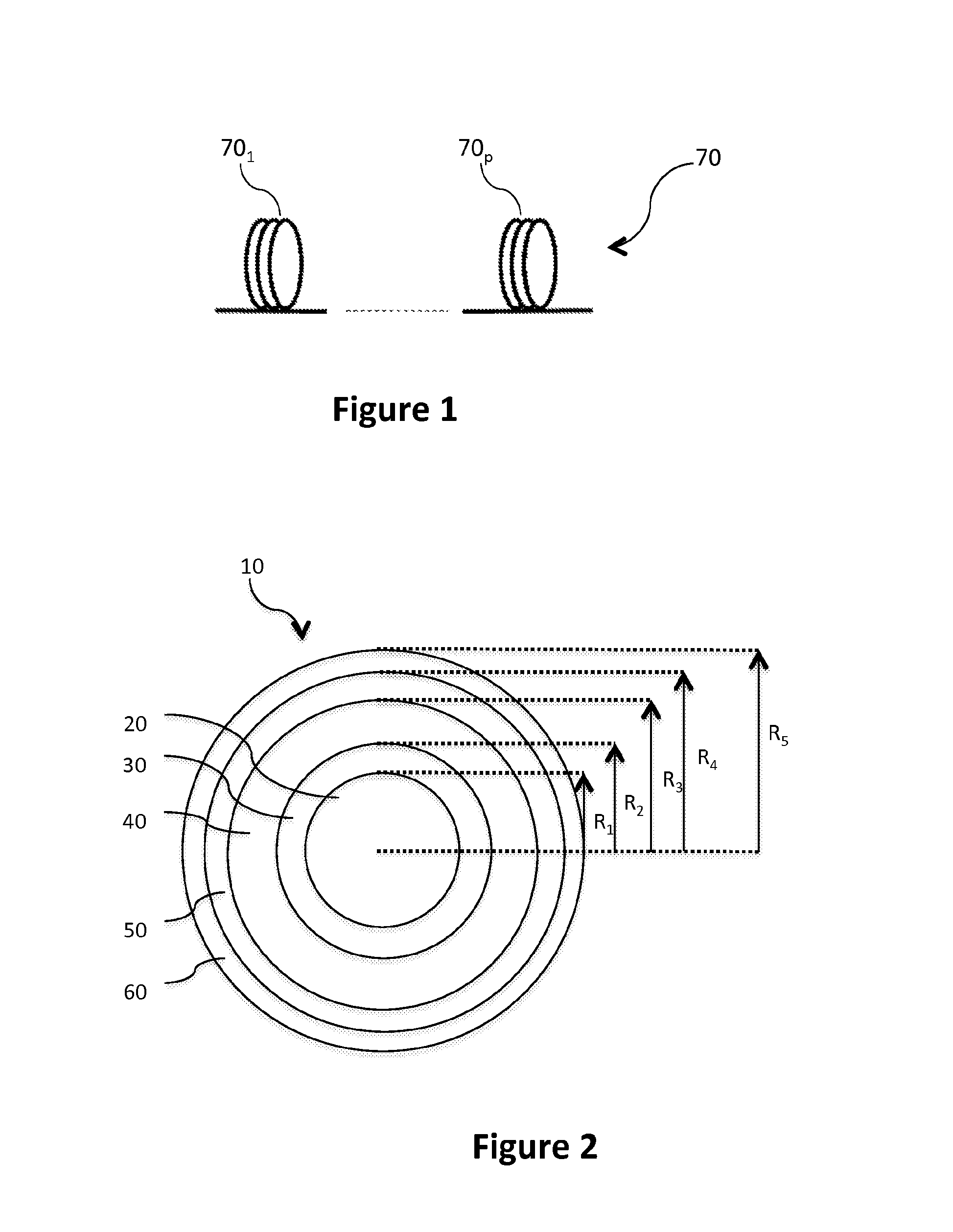

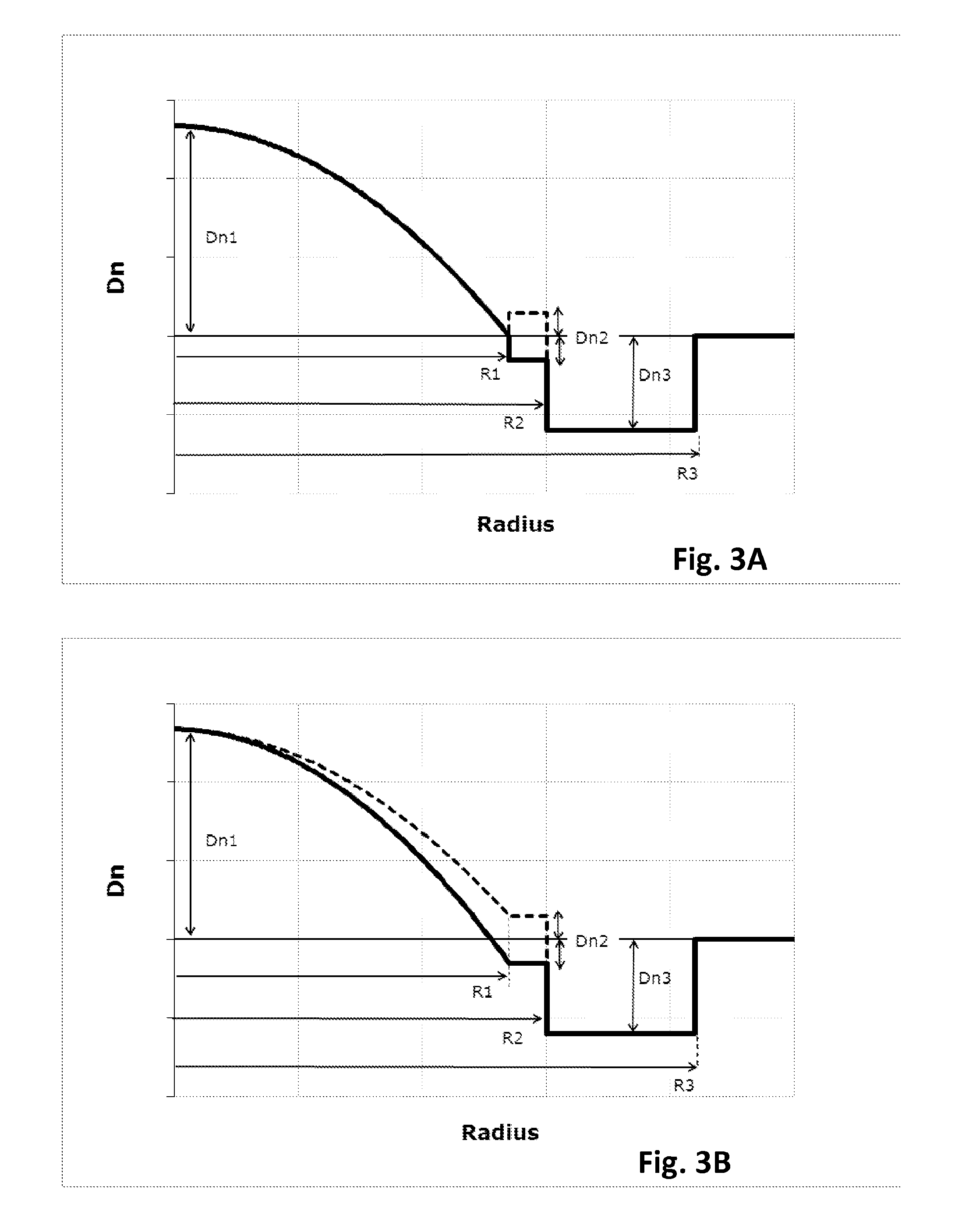

Few mode optical fiber links for space division multiplexing

ActiveUS20160231503A1Easy to manufactureLow costOptical fibre with graded refractive index core/claddingOptical fibre with multilayer core/claddingFiberTime-division multiplexing

The invention relates to an optical link comprising N optical fibers, with N≧2. Each optical fiber comprises an optical core and an optical cladding surrounding the optical core, the optical core having a single αi graded-index profile with αi≧1, and the optical core having a radius R1i, where i E [1; N] is an index designating said optical fiber. Said optical cladding comprises a region of depressed refractive index ntrenchi, called a trench, surrounding the optical core. According to embodiments of the invention, for all optical fibers in said link, said optical core radius R1i and said length Li are chosen such that R1i≧13.5 μm and so as to satisfy a criterion C of quality. Thus, the invention provides a few-mode optical fiber link, which allow guiding an increased number of LP modes as compared to prior art FMF links, while reaching low Differential Mode Group Delay.

Owner:DRAKA COMTEQ BV

Preparation method of composite vegetable protein peptide

InactiveCN110037163ARaise the gradeImprove market competitivenessMulti-step food processesVegetable proteins working-upBiotechnologyHeart cells

The invention discloses a preparation method of a composite vegetable protein peptide. Soybean protein, walnut protein, sesame protein, wheat protein and corn protein are mixed according to a certainproportion to prepare a solution, and then enzymolysis is carried out to prepare the composite vegetable protein peptide. After enzymolysis, the vegetable proteins have different biological activities: the soybean peptide provides continuous nutritional power for heart cells and removes blood fat in cardiovascular blood vessels; the corn oligopeptide protects liver cells from being damaged; the wheat oligopeptide has good effect on spleen deficiency; the walnut peptide has the function of clearing lung; and the sesame peptide can nourish the kidney.

Owner:王书敏

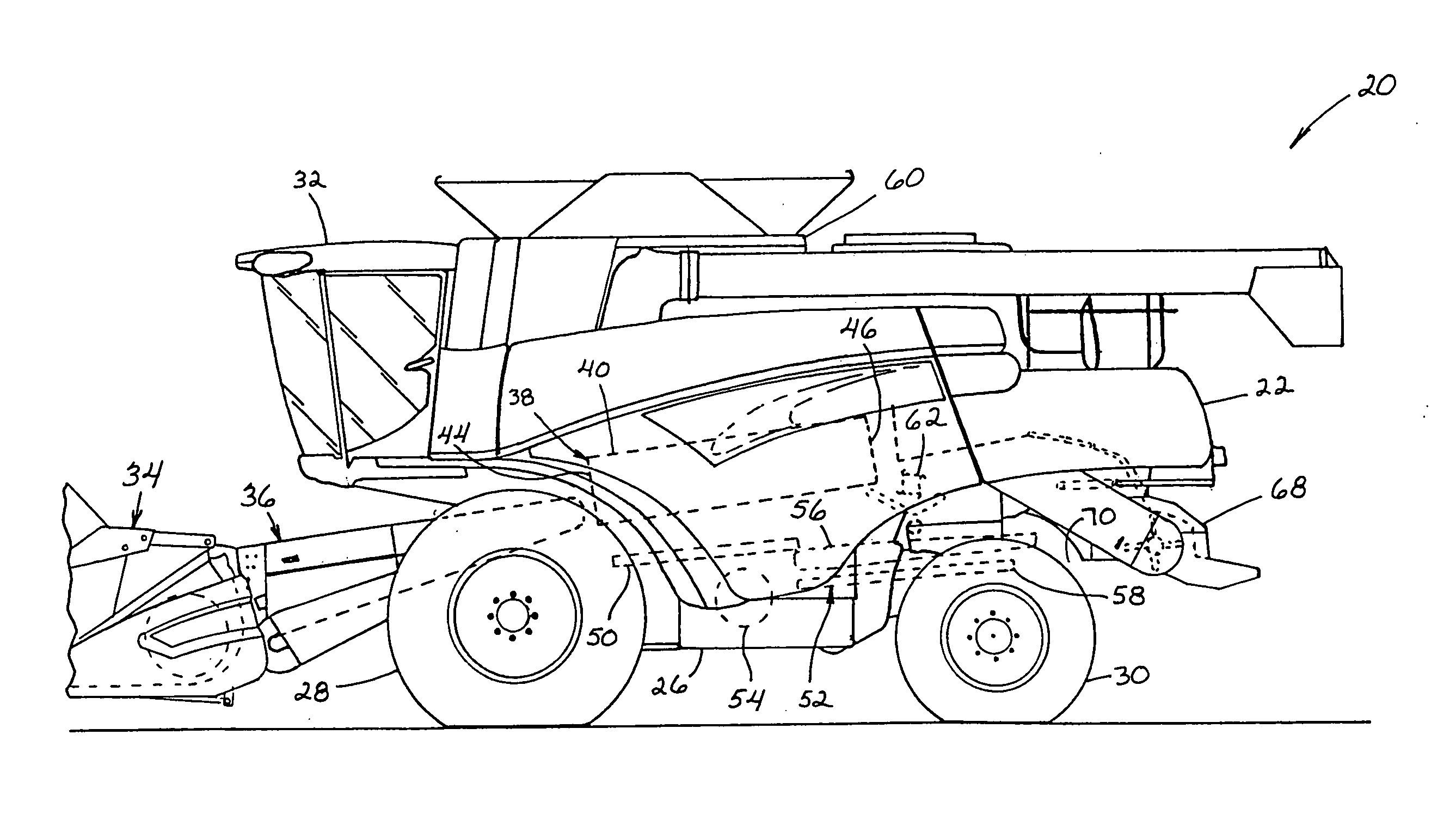

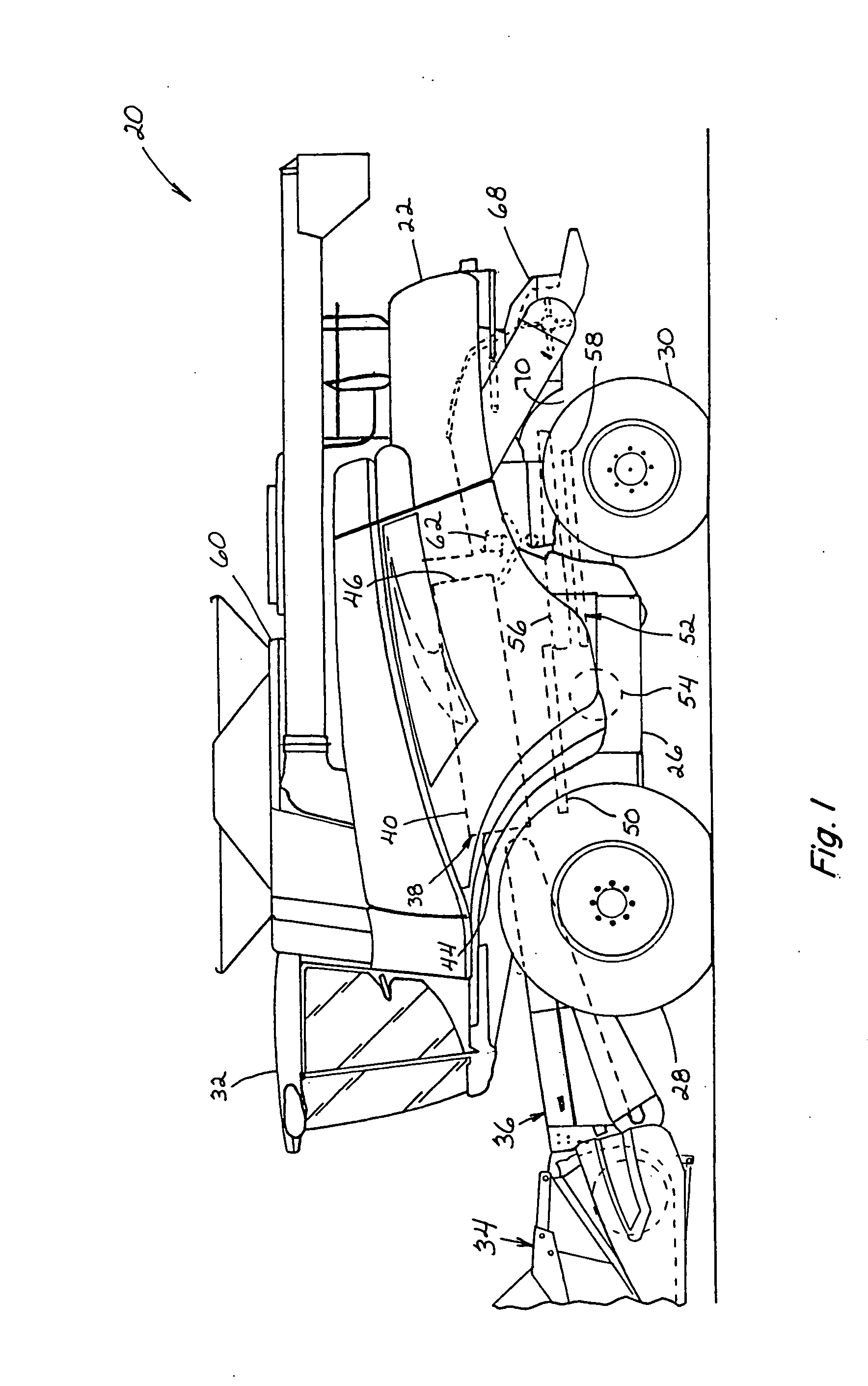

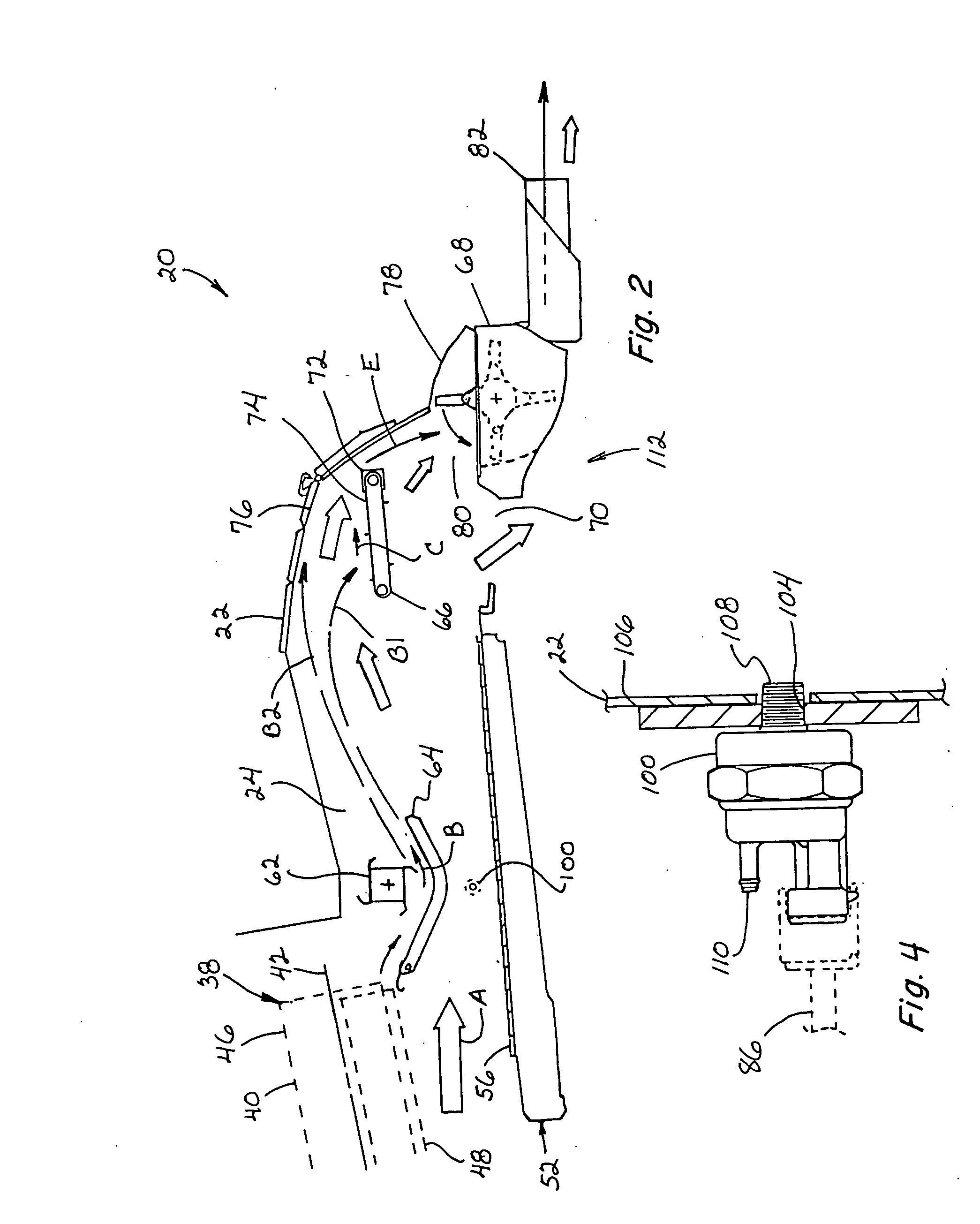

System and method for detecting a condition indicative of plugging of a discharge path of an agricultural combine

A system and method for detecting a condition indicative of onset of plugging or actual plugging of a discharge of an agricultural combine, utilizing a pressure sensor disposed at a location within the combine spaced from the discharge and operable for sensing an air pressure condition relating to a flow indicative of a reduced crop residue flow condition toward or in the discharge.

Owner:BLUE LEAF I P

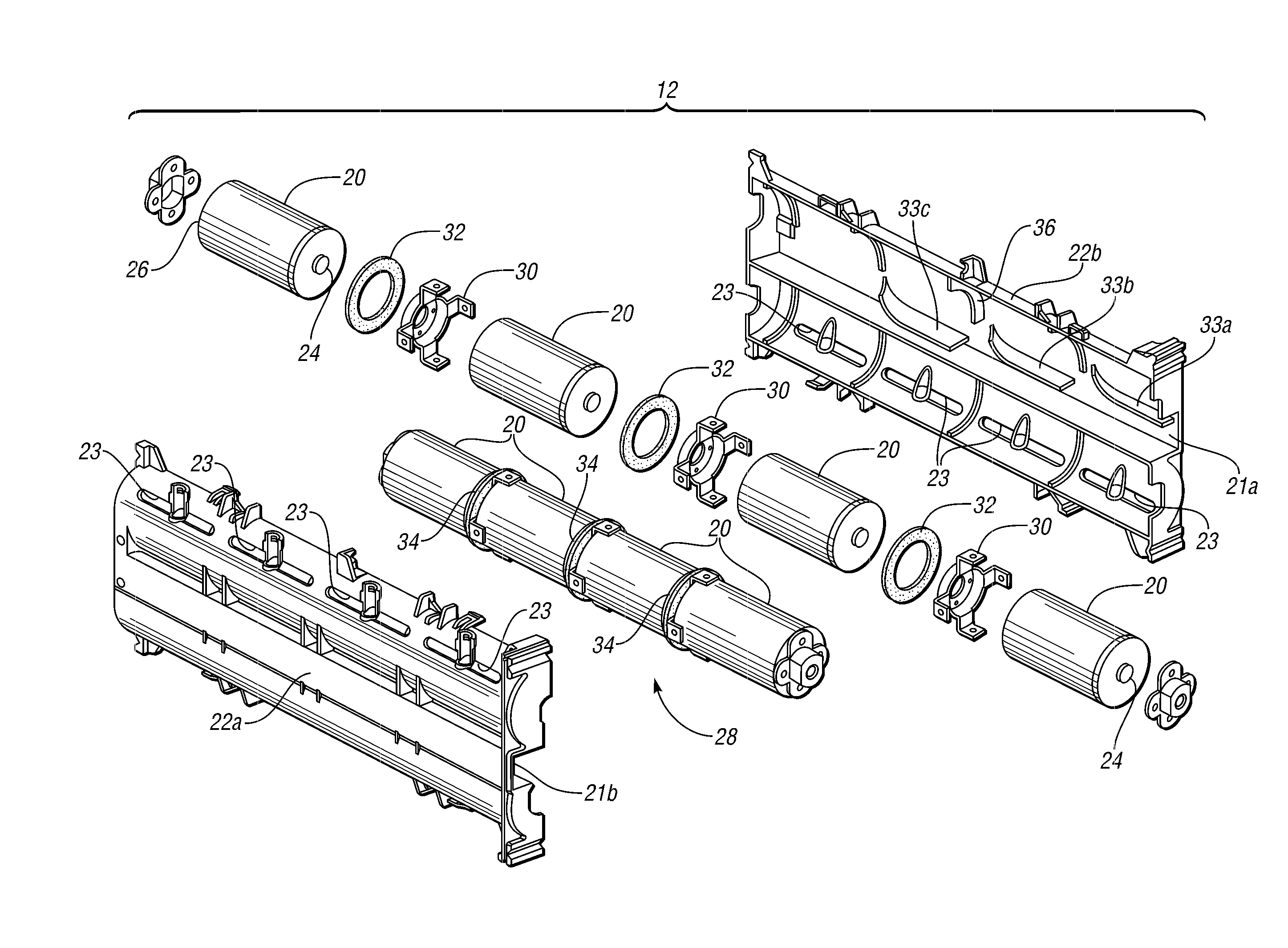

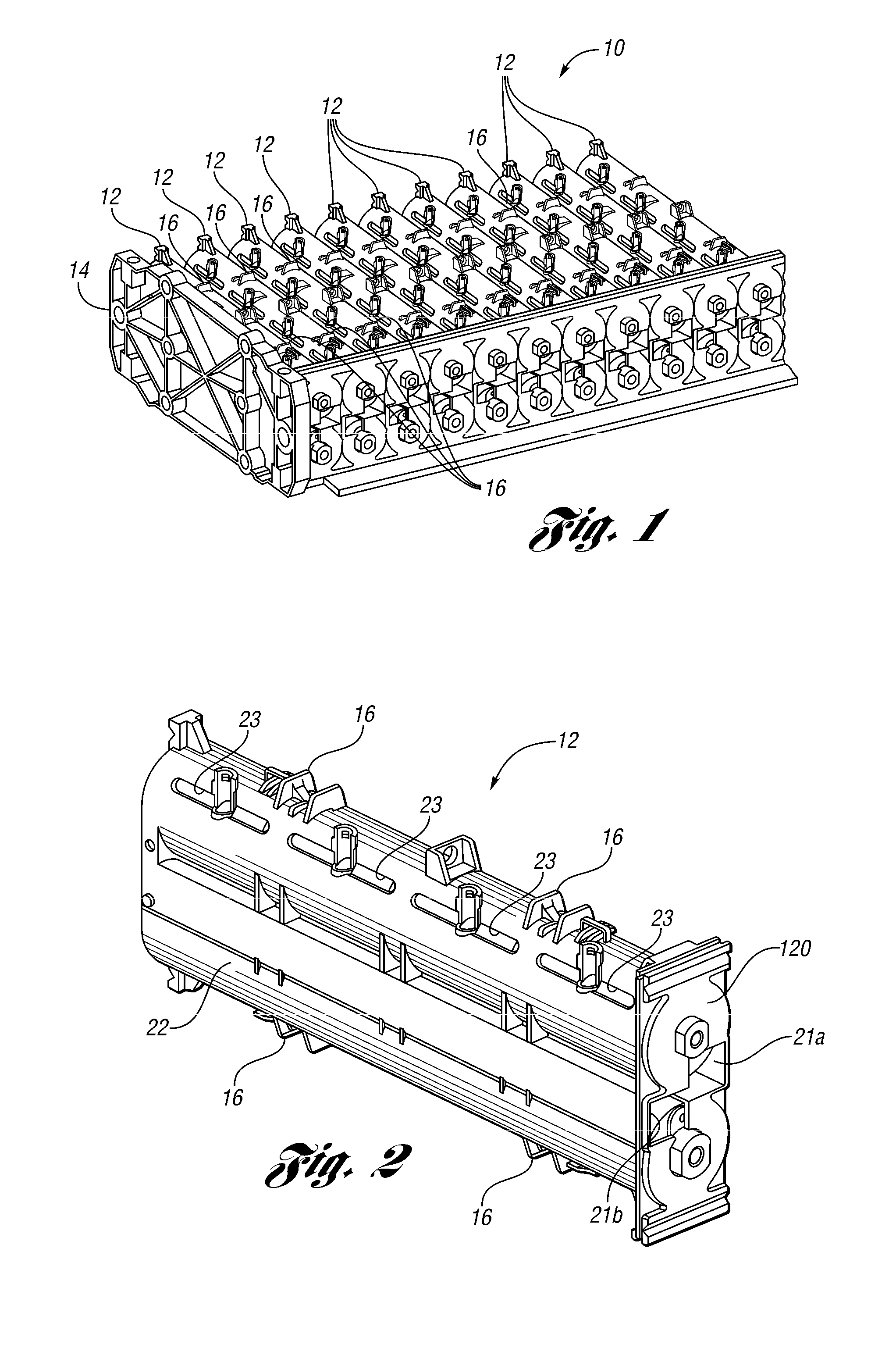

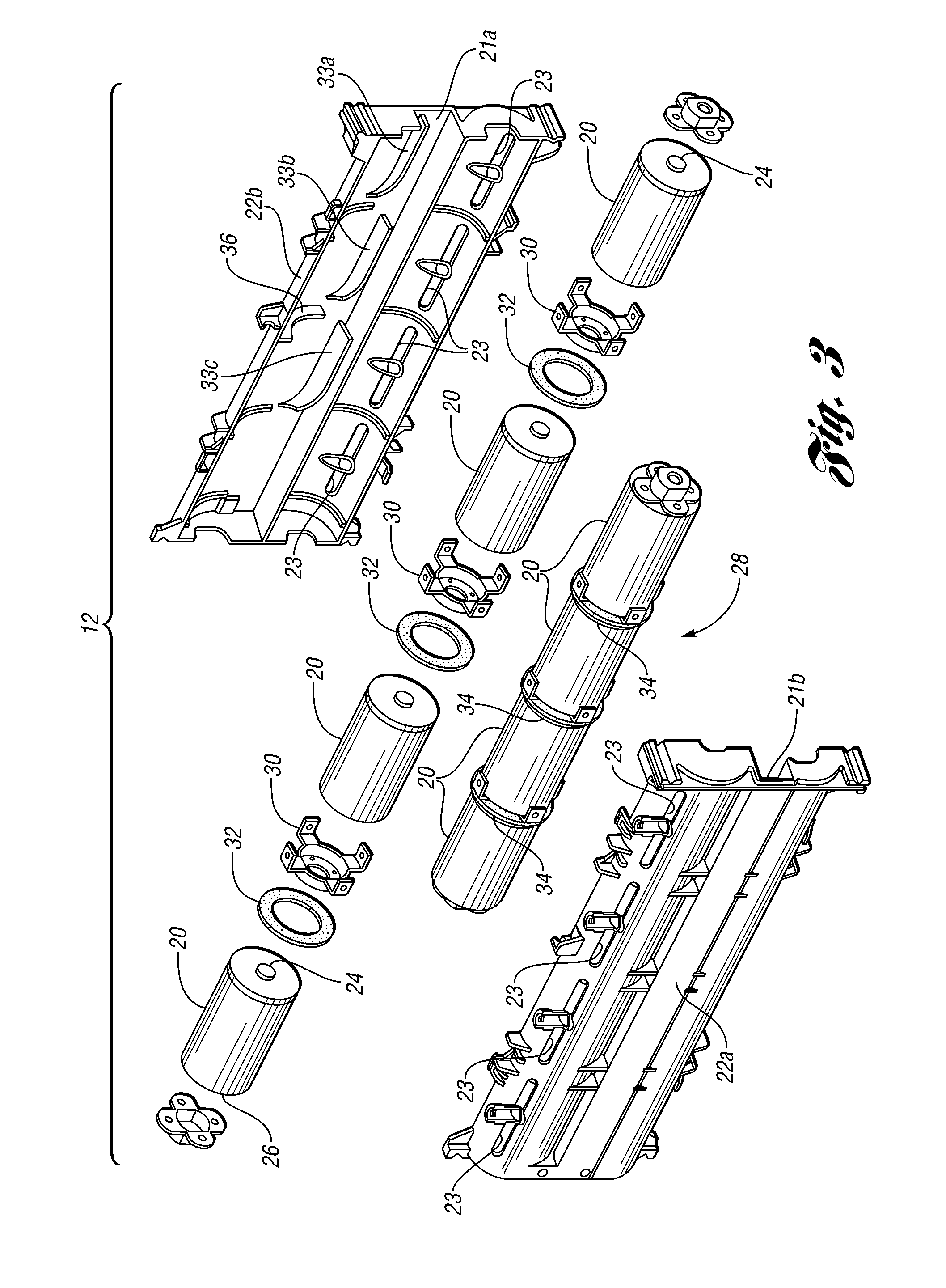

Battery cover assembly

ActiveUS20110177376A1Avoid breakingEasy to shapePrimary cell to battery groupingSmall-sized cells cases/jacketsInterconnectorEngineering

An end-to-end cell connection system for a battery assembly uses a conductive interconnector with an inner portion welded to an end of one cell, a standoff portion contiguous with the ring portion, tabs extending from the standoff portion, with the tabs welded to an end of another cell. By placing an insulator between the interconnector and the one cell, an electrical short is prevented in the event that a longitudinally coupled cell group is jostled. At the cell connections, there is a recess. To hold the cell group in place, the housing has a tab extending into the recess. The tab is at the center so that any dimensional variations are accommodated on each side of the tab. The interconnector also may include a receptacle for a thermistor to obtain a measure of battery assembly temperature. Diverter ribs may be provided in the housing to distribute flow to all cells.

Owner:FORD GLOBAL TECH LLC

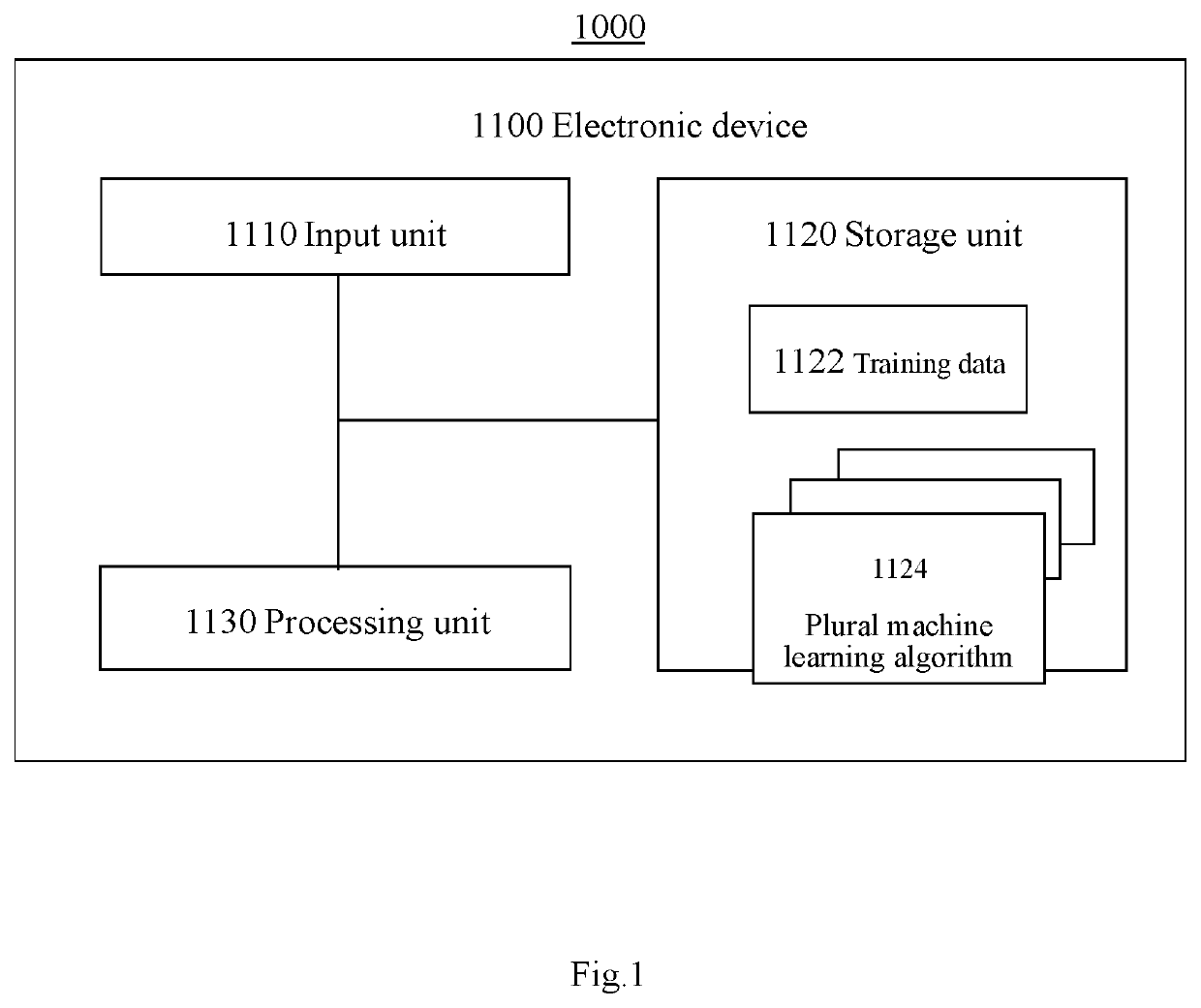

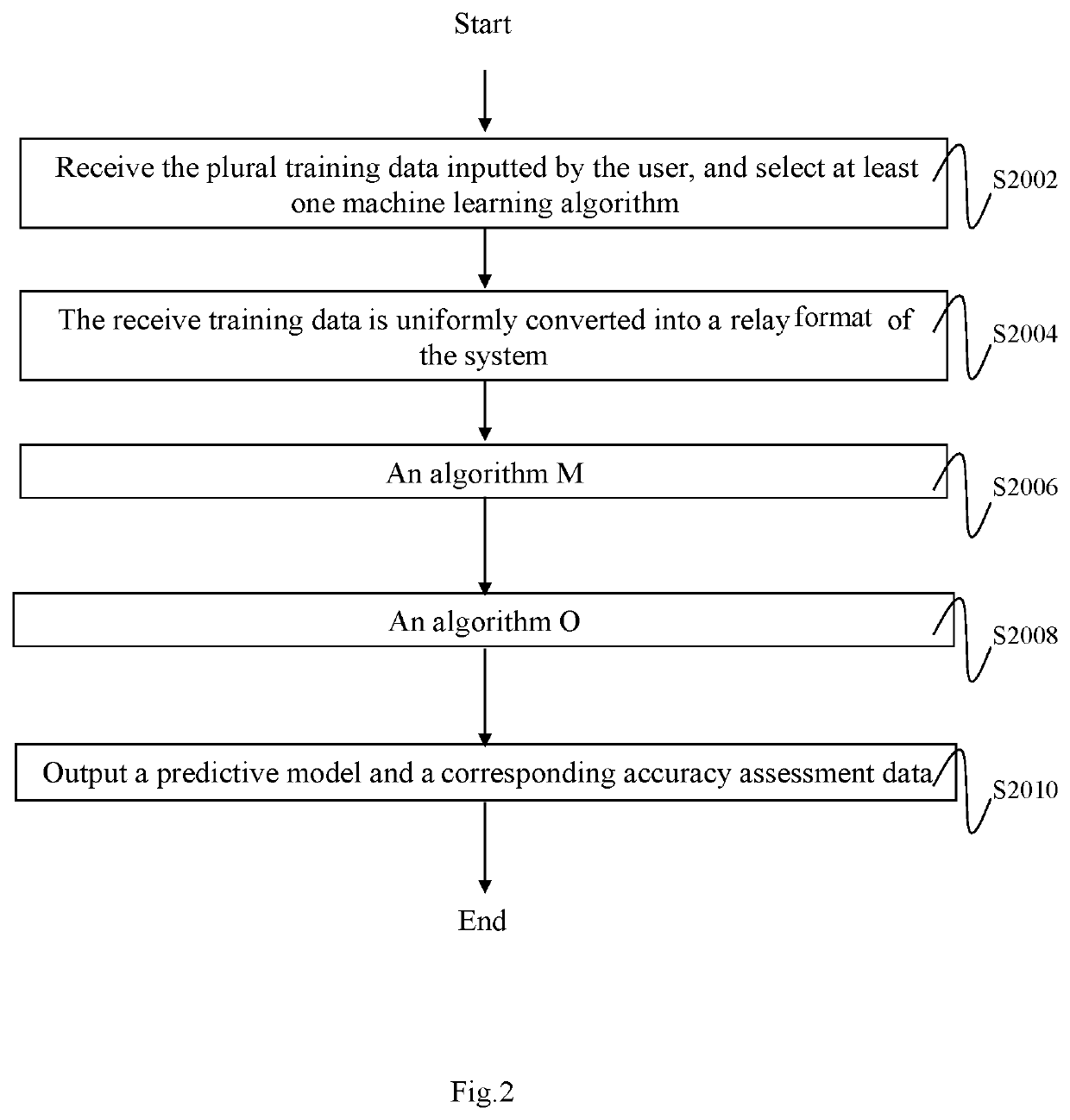

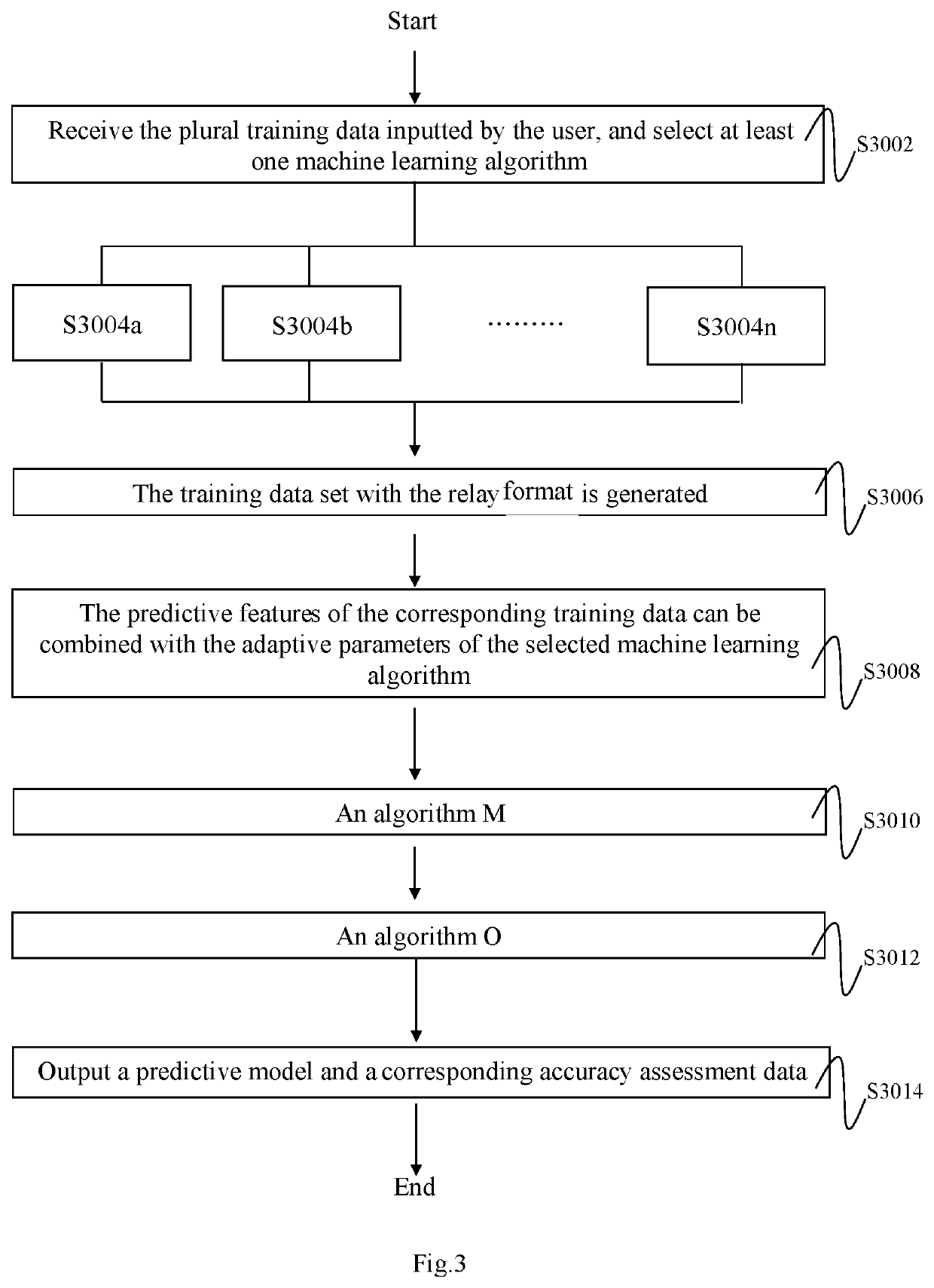

Systems and Methods for Creating an Optimal Prediction Model and Obtaining Optimal Prediction Results Based on Machine Learning

InactiveUS20200074325A1Excellent indicatorsMathematical modelsEnsemble learningEngineeringArtificial intelligence

The present invention provides Systems and Methods for Creating an Optimal Prediction Model and Obtaining Optimal Prediction Results Based on Machine Learning. In the method for creating an optimal prediction model, the steps are first to input a plural training data and at least one of machine learning algorithms, then convert the training data into a relay format. The method is further to select the automated predictive features, optimize the machine learning algorithm parameter, and then optimize the iterative prediction model. After that, a prediction model and an accuracy assessment data are outputted. In the process of obtaining the prediction result, the data to be predicted is converted into a relay format, and an automated program is used for iterative prediction to generate and output the prediction result and accuracy evaluation data.

Owner:NAT CHIAO TUNG UNIV

Environment protection type single-component polyurethane binder, production and use method of the same

ActiveCN101130680AWon't happenExcellent indicatorsUnspecified rubber coatingsPolyureas/polyurethane adhesivesPolyurethane adhesivePolyol

The invention discloses an environment-friendly type monocomponent polyurethane adhesive to pave gas permeable playground, which comprises the following parts: isocyanate, polyether polyol, age resister, ultraviolet absorbent, dimorpholine ether catalyst and polymerization inhibitor, wherein the polyether polyol is polypropene oxide polyol, which is selected from one or more components of DL-2000, DL-3000, MN-3050 or 330N; the isocyanate is diphenyl methane diisocyanate; the adhesive and rubber particle are blended evenly with weight rate at 15-20: 100 to be paved and solidified (dried). The invention is superior to international index of runway, which is especially for paving indoor playground.

Owner:SHANDONG INOV POLYURETHANE

Magnesium binder used for pellet and preparation method and addition method thereof

InactiveCN102719662AIncrease the content of MgOImprove metallurgical performance indicatorsPass rateUltimate tensile strength

The invention provides a magnesium binder used for a pellet and a preparation method and an addition method thereof. The preparation method comprises: adding 30-35% of magnesite powder having a passing rate more than 80% through a 320 mesh, 40-55% of bentonite and 12-15% of active lime into a mixer; mixing a mixture above while adding 3-5% of sodium carbonate; and pulling the mixture out and airing the mixture for 7-9h to get a finished product. The addition method comprises adding the binder to a surface of a pellet mixture on a material conveying belt according to a preset weight of the binder that should be conveyed of a unit time and a unit length and based on a ratio by weight from 2.5% to 4.5%. Pellet MgO can be improved by 1-2%, mechanical strength of the pellet can be improved by 1-2%, and an initial softening temperature can be improved by 100-150 DEG C with the magnesium binder added into the pellet mixture. Blast furnace output can be improved by about 5% and coke ratio can be reduced by 10 kg by the pellet using the binder in the invention.

Owner:ANGANG STEEL CO LTD

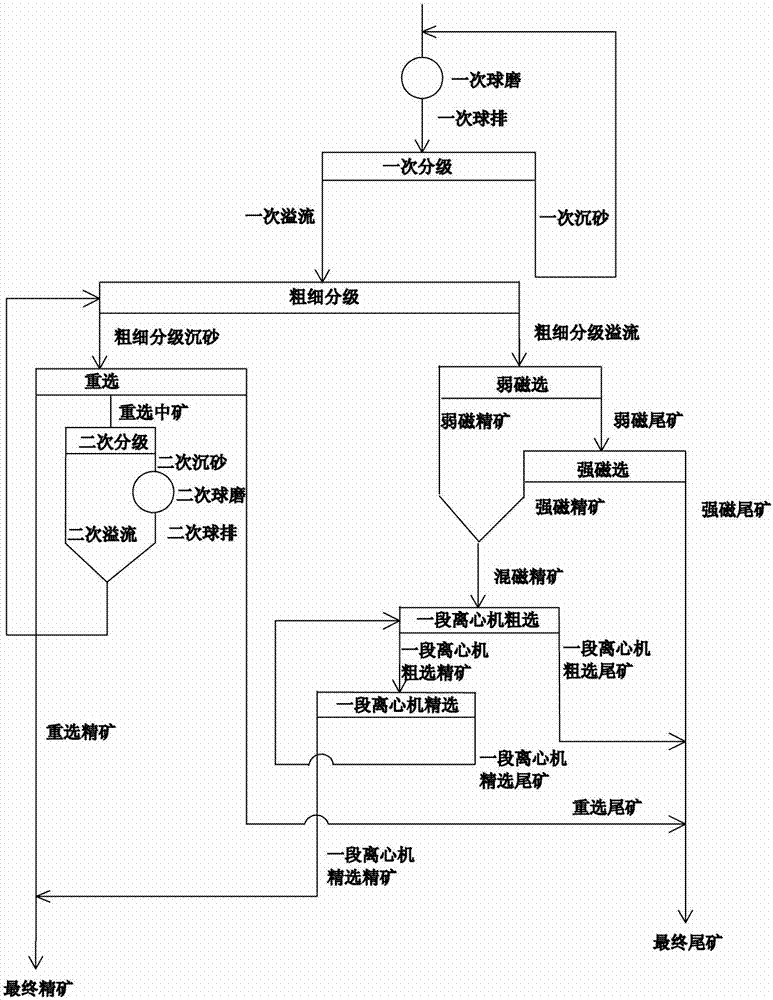

Lean hematite processing technology

InactiveCN102921540ASimple production processShort processWet separationEngineeringReverse flotation

The invention belongs to the technical field of lean hematite processing, in particular to a lean hematite processing technology which comprises the steps of stage grinding, coarse-fine separation, coarse fraction gravity separation, fine-fraction magnetic separation and centrifuge beneficiation. The lean hematite processing technology disclosed by the invention adopts centrifuge beneficiation to replace reverse flotation beneficiation in the original technology, so that the whole production technological flow is optimized and becomes shorter, and the loss of fine fraction high-grade hematite particles in tailings is reduced; besides, the technological course is more adaptive to properties of the hematite, so that the influence of over-high content of iron carbonate over reverse flotation in the original technological course is effectively solved; and furthermore, due to the adoption of centrifuge beneficiation, reagents does not need to be used and hematite pulp does not need to be heated, so that expenses of reagents and coal are effectively saved and the hematite processing cost is reduced.

Owner:ANSTEEL GRP MINING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com