Single-component inorganic heat-insulating mortar and preparation method thereof

An inorganic thermal insulation mortar, a single-component technology, applied in the field of building materials and chemistry, can solve the problems of high water absorption rate of inorganic thermal insulation mortar, easily broken inorganic light aggregate, low thermal conductivity, etc., to achieve large-scale popularization and application, various The effect of excellent index and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] One-component inorganic thermal insulation mortar, its raw material components and weight content are as follows: cement 400, fly ash 200, sepiolite fiber 30, gypsum 10, expanded closed-cell perlite 400, redispersible latex powder 10, cellulose ether 2. 1000 parts of water.

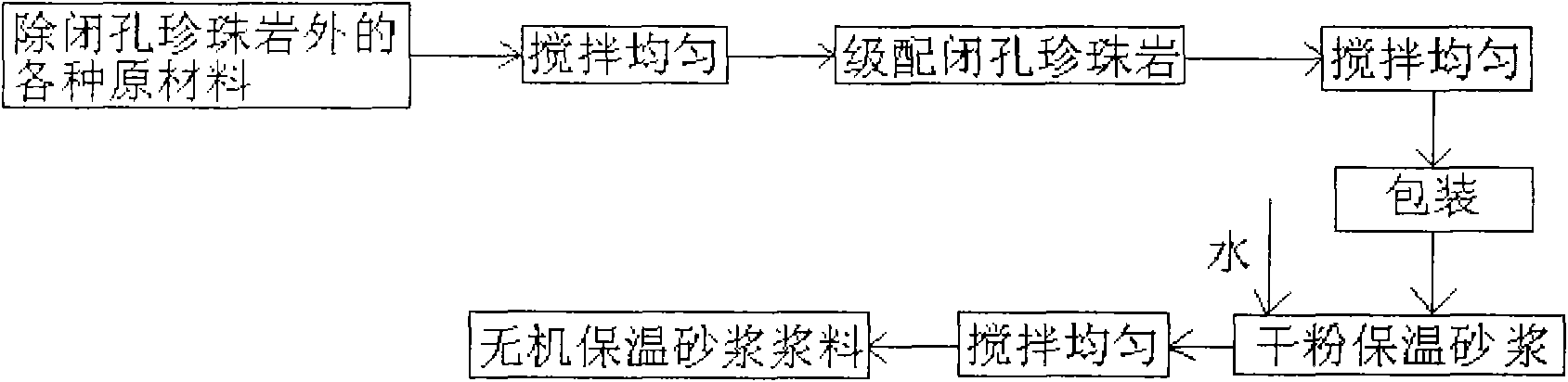

[0028] The method for preparing a one-component inorganic thermal insulation mortar includes the following steps: firstly, cement, fly ash, sepiolite fiber, gypsum, redispersible latex powder and cellulose ether are put into a gravity-free mixer according to the required weight ratio. The stirring spindle stirs at the normal speed of 50 rpm, and the high-speed flying knife is started at 1440 rpm. After 6 minutes of stirring, the high-speed flying knife is stopped, and the speed of the stirring spindle is reduced to 30 rpm and then put into the well-measured gradation expansion closed cell Perlite, continue to mix for 2 minutes, the material can be unloaded. Use an open packaging machine to pack into d...

Embodiment 2

[0030] One-component inorganic thermal insulation mortar, its raw material components and weight content are as follows: cement 450, fly ash 150, sepiolite fiber 20, gypsum 15, expanded closed-cell perlite 420, redispersible latex powder 8, cellulose ether 2. 1100 parts of water.

[0031] The preparation method is the same as in Example 1.

Embodiment 3

[0033] One-component inorganic thermal insulation mortar, its raw material components and weight content are as follows: cement 500, fly ash 100, sepiolite fiber 10, gypsum 20, expanded closed-cell perlite 450, redispersible latex powder 5, cellulose ether 3. 1200 parts of water.

[0034] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| power level | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com