Patents

Literature

2000 results about "Poultry manure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

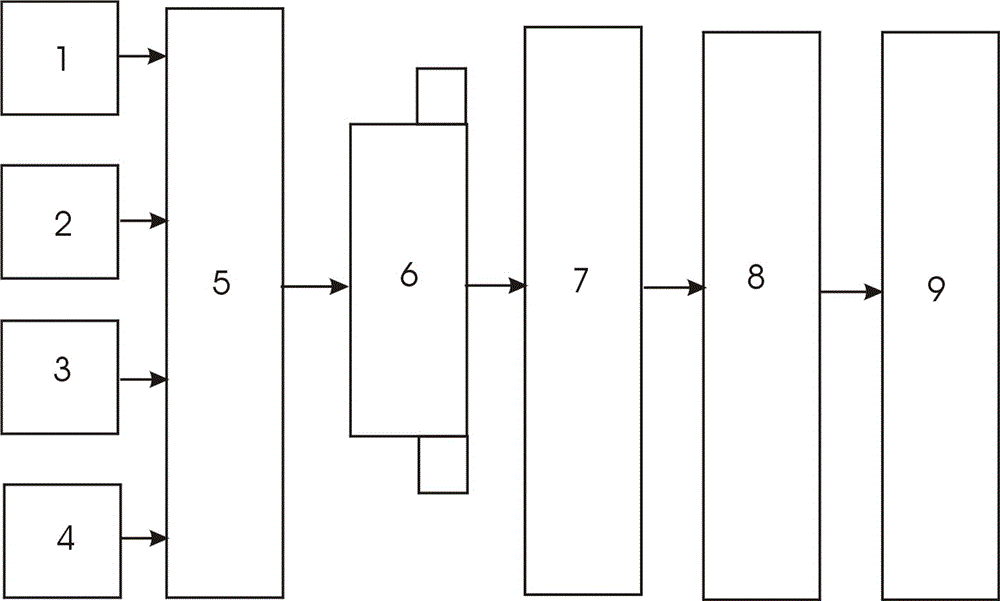

Poultry manure is the organic waste material from poultry consisting of animal feces and urine. Poultry litter refers to the manure mixed with some of the bedding material or litter (wood shavings or sawdust) and feathers (Figure 1). This publication deals with litter.

Organic fertilizer with livestock and poultry manure and preparation method thereof

InactiveCN103145463ANo pollution in the processImprove fertilizer efficiencyBio-organic fraction processingOrganic fertiliser preparationEffective microorganismMixed materials

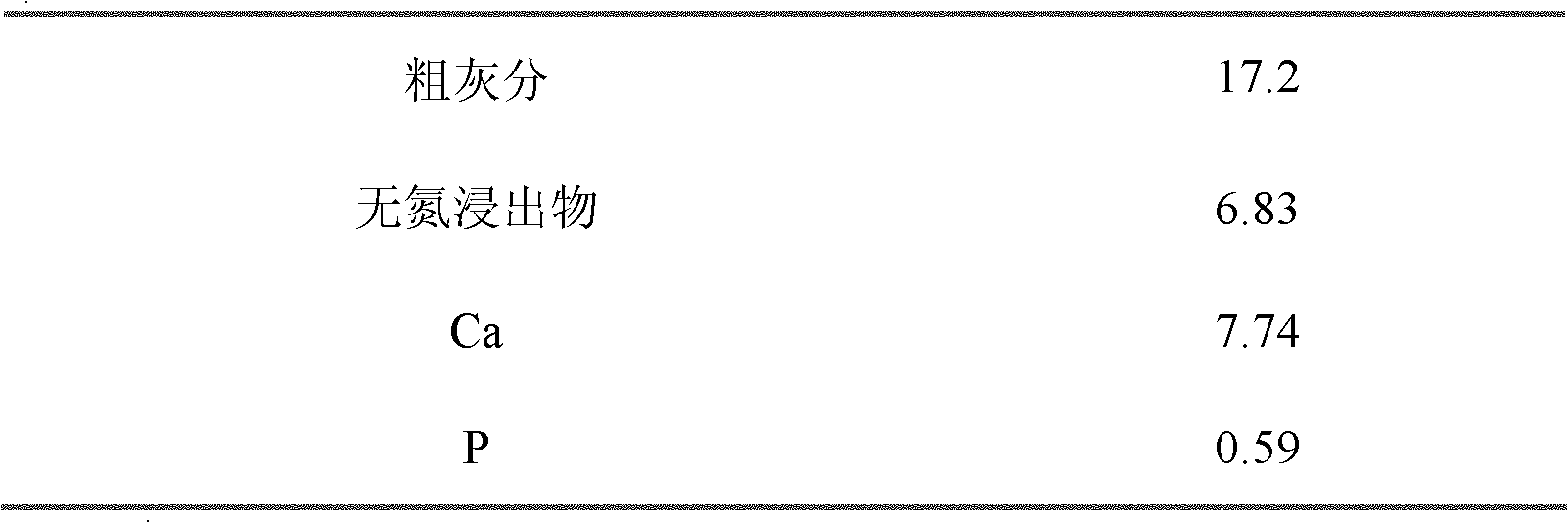

The invention provides an organic fertilizer with livestock and poultry manure and a preparation method thereof. The organic fertilizer comprises cow manure, edible mushroom dregs, pig manure, chicken manure, maize straw powder and an Em (effective microorganisms) stock solution. The specific formula of the organic fertilizer comprises 19.7 percent of edible mushroom dregs, 10 percent of pig manure, 10 percent of chicken manure, 20 percent of maize straw powder, 0.3 percent of Em stock solution, and the balance of cow manure. The preparation method of the organic fertilizer is characterized in that a production technology of the organic fertilizer with the livestock and poultry manure mainly adopts a shallow pool type fermentation technology, namely the cow manure, the pig manure, the chicken manure, the edible mushroom dregs, the maize straw powder and the Em stock solution are poured into a mixer in proportion and are evenly mixed and stirred, the evenly mixed and stirred materials are sent into a shallow layer pool type fermentation pool, and the organic fertilizer fermentation environment temperature is controlled to be above 15 DEG C. Firstly, various raw materials including the livestock and poultry manure, the edible mushroom dregs, the straw powder and a fermentation bactericide are mixed, and then the mixed materials are put into a mixing and stirring machine to be evenly stirred, are sent into the material fermentation pool to be fermented for 8 days and are discharged from the pool to enter a secondary aerobic fermentation procedure. The organic fertilizer has the advantages of low cost and high yield and can improve the quality of crops.

Owner:郑晓华

Special organic-inorganic composite biological pesticide-fertilizer for flowers and preparation method thereof

The invention provides a special organic-inorganic composite biological pesticide-fertilizer for flowers. The special organic-inorganic composite biological pesticide-fertilizer for flowers comprises the following raw materials in parts by weight: 80-90 parts of municipal sludge, 10-20 parts of fruit peel, 10-20 parts of fallen leaves, 10-15 parts of poultry manure, 10-14 parts of bagasse, 20-30 parts of iron ore slag, 10-12 parts of animal feathers, 10-15 parts of tree ash, 10-15 parts of monoammonium phosphate, 20-25 parts of urea, 10-12 parts of ammonia sulfate, 8-10 parts of ammonium hydrogen carbonate, 8-10 parts of potassium chloride, 5-7 parts of carboxymethyl chitosan, 20-30 parts of modified bentonite, 5-8 parts of lignite, 2-4 parts of black dye tree, 9-11 parts of celastrus angulatus, 9-11 parts of common carpesium fruit, 9-11 parts of radix sophorae flavescentis, 4-6 parts of lilac daphne flower bud, 3-5 parts of coptis root, 10-12 parts of powder of root of stellera chamaejasme, 2-4 parts of vegetable oil, 1-3 parts of zinc sulfate, 3-4 parts of ferrous sulfate, 0.8-1.2 parts of borax, 20-26 parts of potassium fulvate and 0.3-0.4 part of EM (effective microorganism) strain. The pesticide-fertilizer disclosed by the invention has the advantages of scientific ratio of nitrogen, phosphorus and potassium, easiness in absorption by crops, obvious yield-increasing benefit and the like. By applying the pesticide-fertilizer, the nutrient absorption of plants can be balanced, the quality of flowers can be effectively improved, plants are green in leaves and bright in flower, and the flowering phase is also prolonged.

Owner:东至县神山化肥有限责任公司 +1

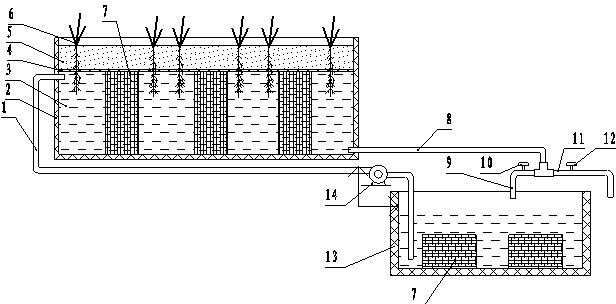

Small soilless culture method and device

ActiveCN102119651AIncrease the concentration of inputFewer deliveriesAgriculture gas emission reductionCultivating equipmentsSlagPeat

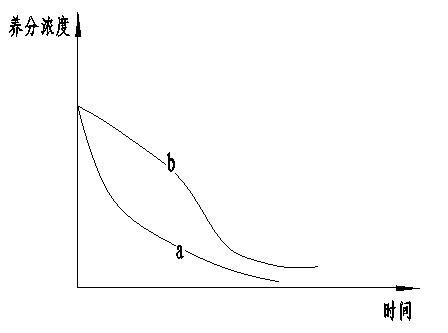

The invention relates to a small soilless culture method and device. A nutrient solution is contained in a culture disk or a nutrient solution storage pool; crops are planted into the nutrient solution; a soil copy material is added into the nutrient solution; the soil copy material comprises the following raw materials in parts by weight: 20-90 parts of organic matter and 2-80 parts of nonmetal mineral substance, wherein the organic matter is one or mixture of peat, fermented straw, fermented bagasse and fermented livestock and poultry manure; the nonmetal mineral substance is one or mixtureof coal ash, steel slag, zeolite, bentonite, opal, attapulgite mineral soil, pearlite, vermiculite, rectorite clay, sepiolite clay and kieselguhr; and the proportion of the nutrient solution to the soil copy material is (5-2):1. By adding the soil copy material into the nutrient solution, the nutrient charge concentration can be improved, the nutrient charge frequency is reduced, and the labor cost is reduced; meanwhile, when the concentration is reduced due to the absorption of the nutrients, the concentration reduction range is slower, and a deficiency symptom caused by lacking nutrients ofplants is lightened; in addition, trace elements needed by plants can be also supplemented.

Owner:杜友萍

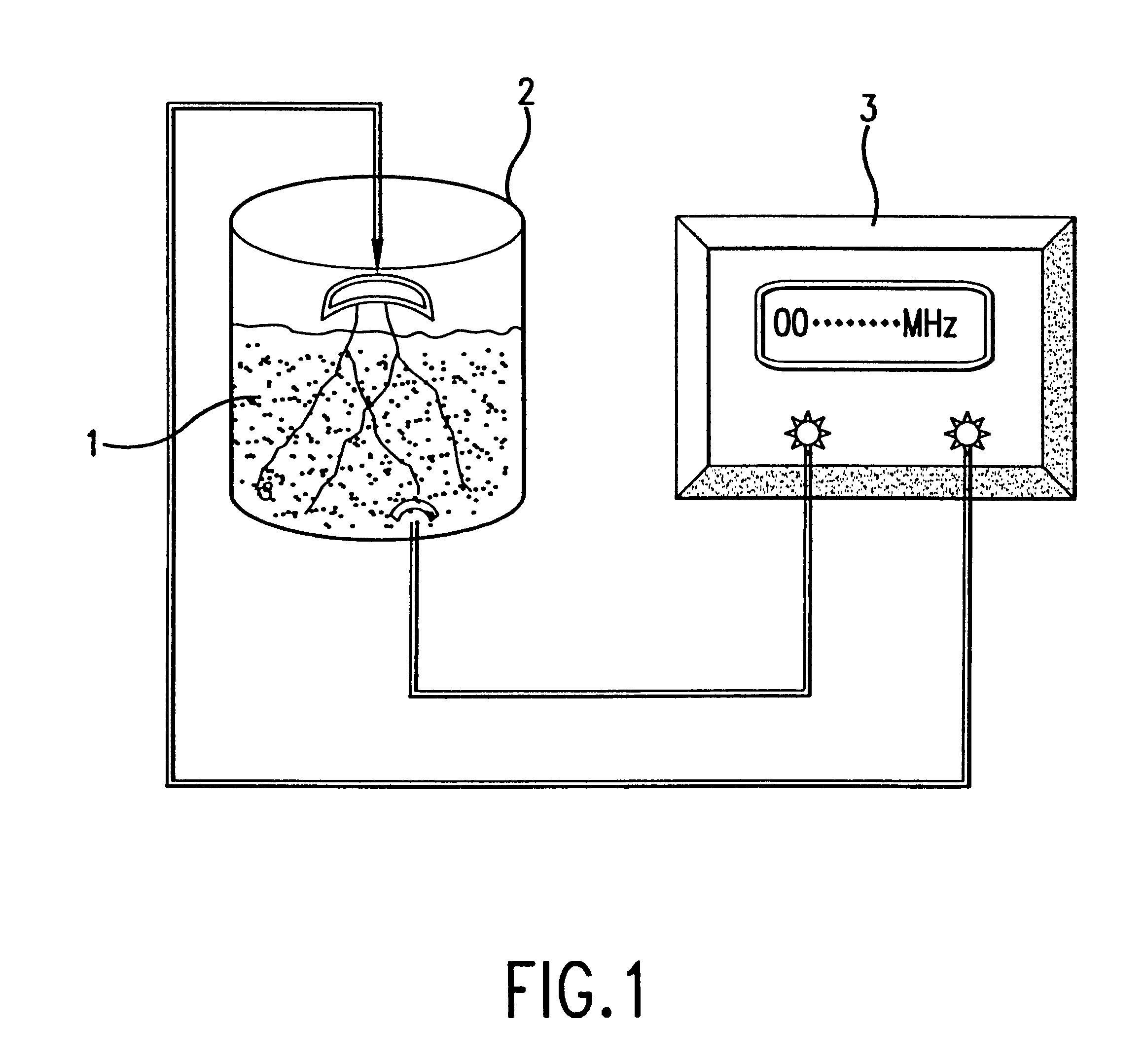

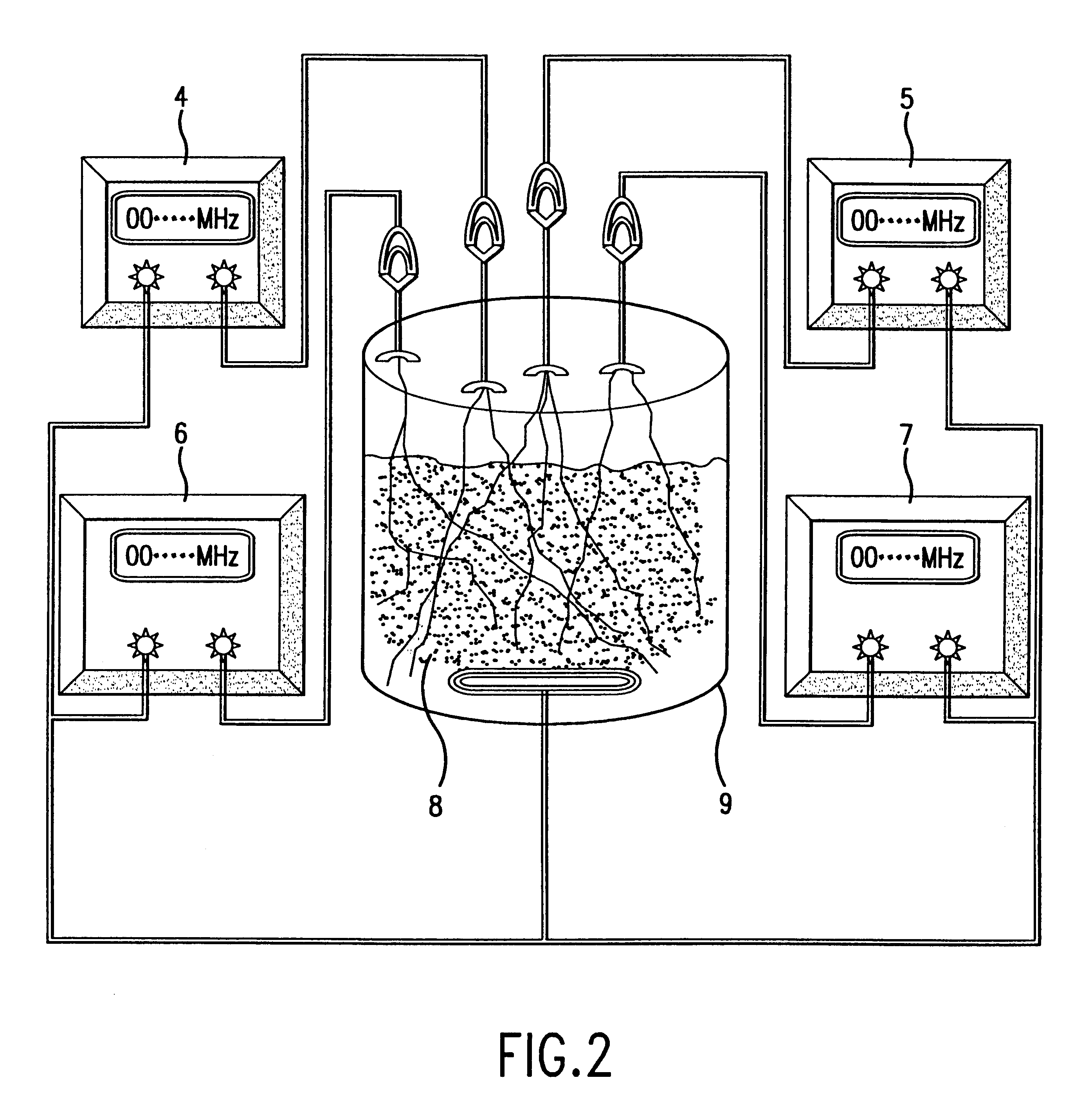

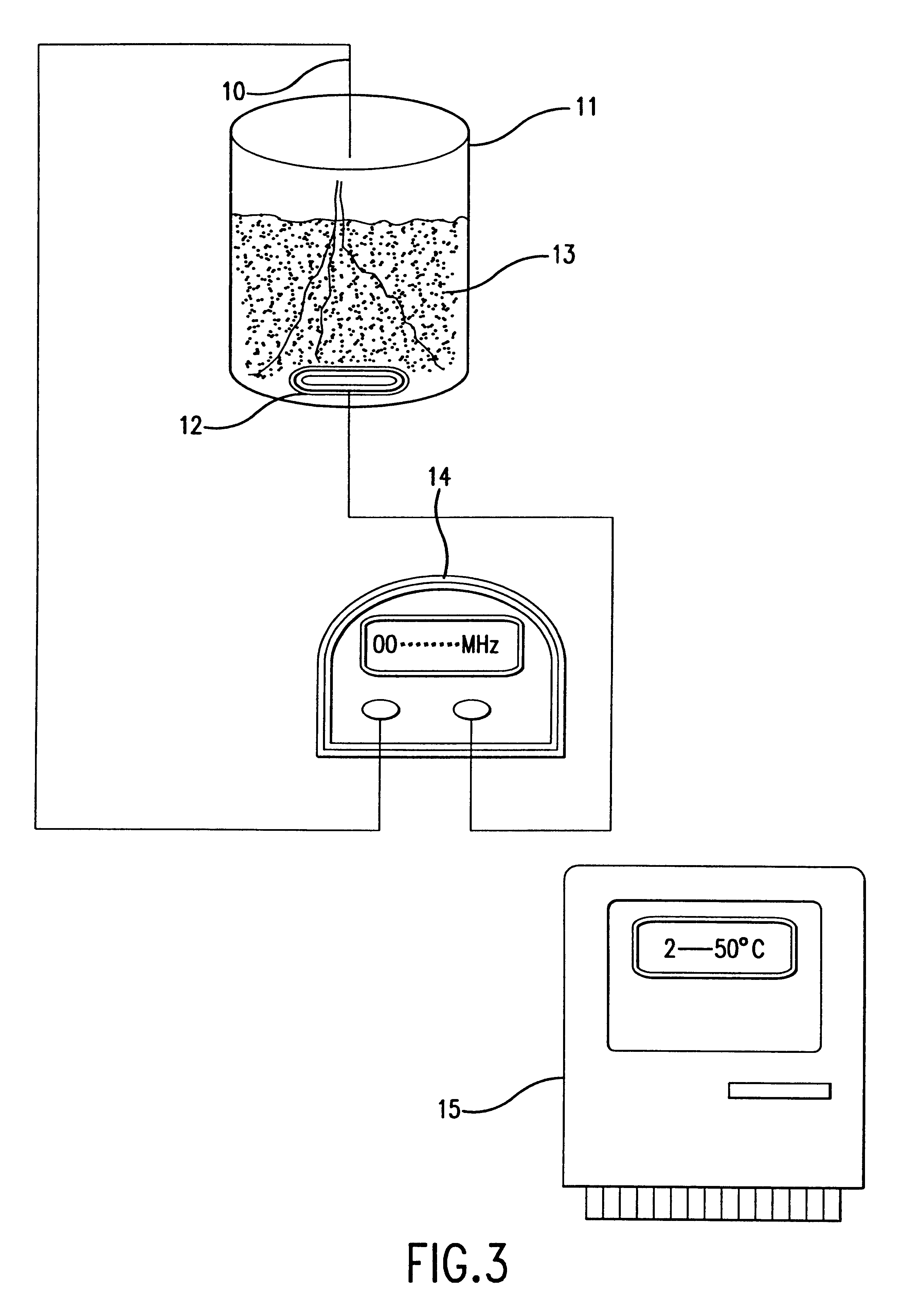

Biological fertilizer compositions comprising poultry manure

InactiveUS6596272B2Reduce odorEasy to solveBiocideBioreactor/fermenter combinationsPotassiumPoultry manure

The present invention provides biological fertilizer compositions that comprise yeast cells and poultry manure. The yeast cells of the invention have an enhanced ability to fix atmospheric nitrogen, decompose phosphorus minerals and compounds, decompose potassium minerals and compounds, decompose complex carbon compounds, overproduce growth factors, overproduce ATP, decompose undesirable chemicals, suppress growth of pathogenic microorganisms, or reduce undesirable odor. The biological fertilizer composition of the invention can replace mineral fertilizers in supplying nitrogen, phosphorus, and potassium to crop plants. Methods of manufacturing biological fertilizer compositions, and methods of uses are also encompassed.

Owner:ULTRA BIOTECH

Microbial ecological organic fertilizer and preparation method thereof

InactiveCN105218254AWide variety of sourcesSimple structureBio-organic fraction processingOrganic fertiliser preparationHigh absorptionMicrobial agent

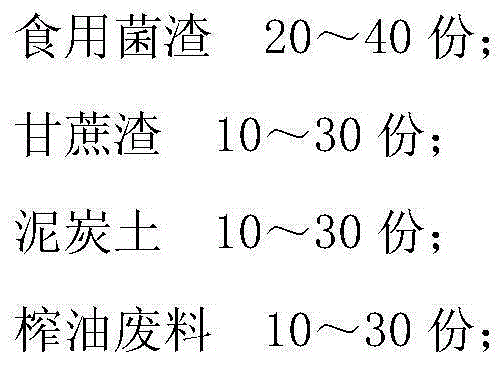

The invention discloses microbial ecological organic fertilizer and a preparation method thereof. The organic chemical fertilizer comprises the following components: edible mushroom dregs, sugarcane dregs, peat soil, oil squeezed waste, filter sludge, livestock and poultry manure and a microbial agent, wherein the microbial agent comprises bacillus subtilis, saccharomycetes, aspergillus niger, guanyloribonuclease, trichoderma, lactobacillus, photosynthetic bacteria, actinomycetes and streptomyces microflavus. The prepared organic fertilizer has advantages of wide raw material source, low cost, high absorption utilization rate, comprehensive nutrients, low dosage, no odor, fast fertilizer effect, various bacteria types, high content, capability of preventing injurious pests, simple preparation method and the like.

Owner:广西多得乐生物科技有限公司

Fruit tree special-purpose fertilizer and preparation method thereof

InactiveCN103524270AAvoid pollutionSolve problems such as pollutionFertilizer mixturesPhosphateAgricultural engineering

The invention discloses a fruit tree special-purpose fertilizer which is prepared from the raw materials of, by weight: 300-340 parts of live stock and poultry manure, 200-230 parts of soybean stalk, 100-120 parts of bagasse, 100-120 parts of air-dried sludge, 50-55 parts of beer grains, 30-35 parts of ox blood powder, 20-24 parts of cooked soybean, 60-65 parts of rock phosphate powder, 14-18 parts of bamboo charcoal, 10-12 parts of maifanite powder, 12-15 parts of zeolite powder, 30-35 parts of urea, 50-55 parts of mono-ammonium phosphate, 20-23 parts of ammonium sulfate, 6-9 parts of an EM inoculant, 10-15 parts of a soil conditioner, and proper amount of water. According to the fruit tree special-purpose fertilizer, wastes such as live stock and poultry manure, soybean stalk, bagasse, air-dried sludge, and the like are adopted as main raw materials, such that resource is saved, and problems such as environment pollution are solved. The raw materials are convenient to obtain, and are cheap, such that good environmental and economic benefits are provided. The fertilizer provided by the invention has the advantages that: with the fertilizer, beneficial microbe number and activity are improved, soil physiochemical traits are improved, soil nutrients are increased and balanced, and pesticide and chemical fertilizer residue and other harmful substances in soil can be degraded.

Owner:ANHUI WANLI ECOLOGICAL LANDSCAPE

Comprehensive utilization method of livestock and poultry manures and crop straw resources

InactiveCN103204718ASave energyFermentation temperature can be adjustedBio-organic fraction processingWaste based fuelFecesSlurry

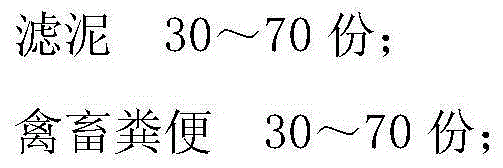

The invention discloses a comprehensive utilization method of livestock and poultry manures and crop straw resources, which comprises the following steps of: (1) anaerobic fermentation: mixing livestock and poultry manures and crushed straw, adjusting the solid content of the obtained mixture to 15-40%, and adding an anaerobic fermentation inoculum into the mixture to carry out anaerobic fermentation so that biogas is produced and a biogas residue and biogas slurry mixture is obtained; (2) biogas utilization: purifying the biogas obtained in the step (1), and taking the purified biogas as boiler gas; (3) utilization of biogas residue and biogas slurry: not carrying out solid-liquid separation on the biogas residue and biogas slurry mixture obtained in the step (1), but directly taking the biogas residue and biogas slurry mixture as a mixed aerobic composting raw material; and (4) aerobic composting mixing: mixing the biogas residue and biogas slurry mixture obtained in the step (1), crushed straw and part of manures, and after the moisture content of the obtained mixture is adjusted to be 50-60%, carrying out aerobic composting. According to the invention, the biogas obtained through anaerobic fermentation is converted into a heat source of mixed aerobic composting, and the biogas residue and biogas slurry mixture is used for producing bio-organic compound fertilizers.

Owner:么向和

Method and apparatus for fermentation production of sludge gas with mixed stalk raw material

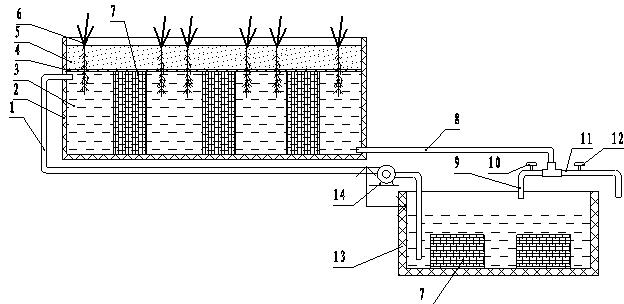

InactiveCN101429480AIncrease profitAchieve pollutionBioreactor/fermenter combinationsBiological substance pretreatmentsCelluloseThermal insulation

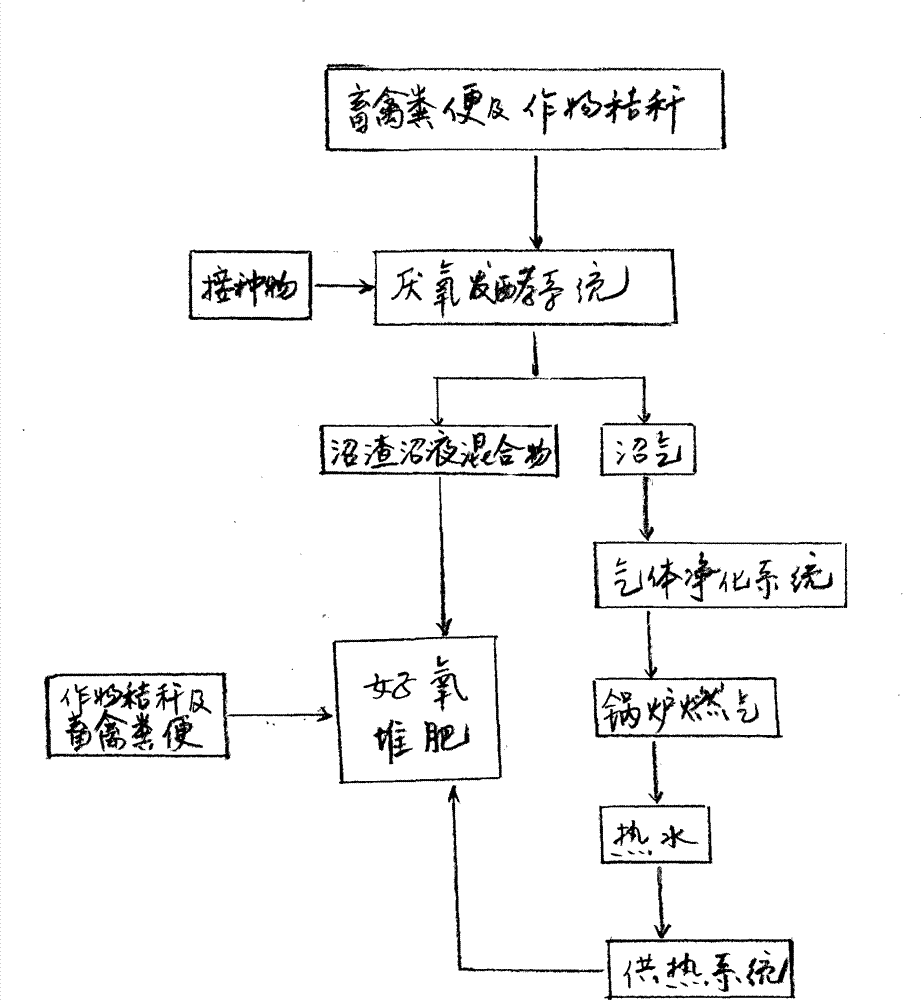

The invention relates to a method for producing biogas through the fermentation of a straw mixed raw material and a device thereof, in particular to a method for producing the biogas through second-stage middle temperature fermentation treatment to a mixed raw material of cellulose of plant straws, kitchen household garbage, livestock and poultry manure and sewage, and a device thereof. The device is suitable for the comprehensive utilization of crop straws, kitchen household garbage, livestock and poultry manure and so on, and belongs to equipment needed by environmental engineering. The method comprises the following steps: through three pretreatment modes, the three raw materials are pretreated and then are mixed according to the proportion of 1 to 1 to 3; the mixing ratio of each raw material can be 10 to 20 percent more or less; the carbon-nitrogen mol ratio is controlled to be between 25 to 1 and 30 to 1; the raw materials enter a main anaerobic fermentation tank and an auxiliary anaerobic fermentation tank after the mixing; the volume ratio of the main tank and the auxiliary tank is 1 to 1.5; the main anaerobic fermentation tank is provided with a thermal insulation layer; and a zymocyte bed, a stirring device, a temperature control device, and a circulating hot water heating device are arranged in the main anaerobic fermentation tank. The device can synchronously treat the plant straws, the kitchen household garbage, and the livestock and poultry manure and sewage, realize the automatic thermostatic control and second-stage fermentation, and has high biogas yield.

Owner:新疆西域牧歌农业科技有限公司 +1

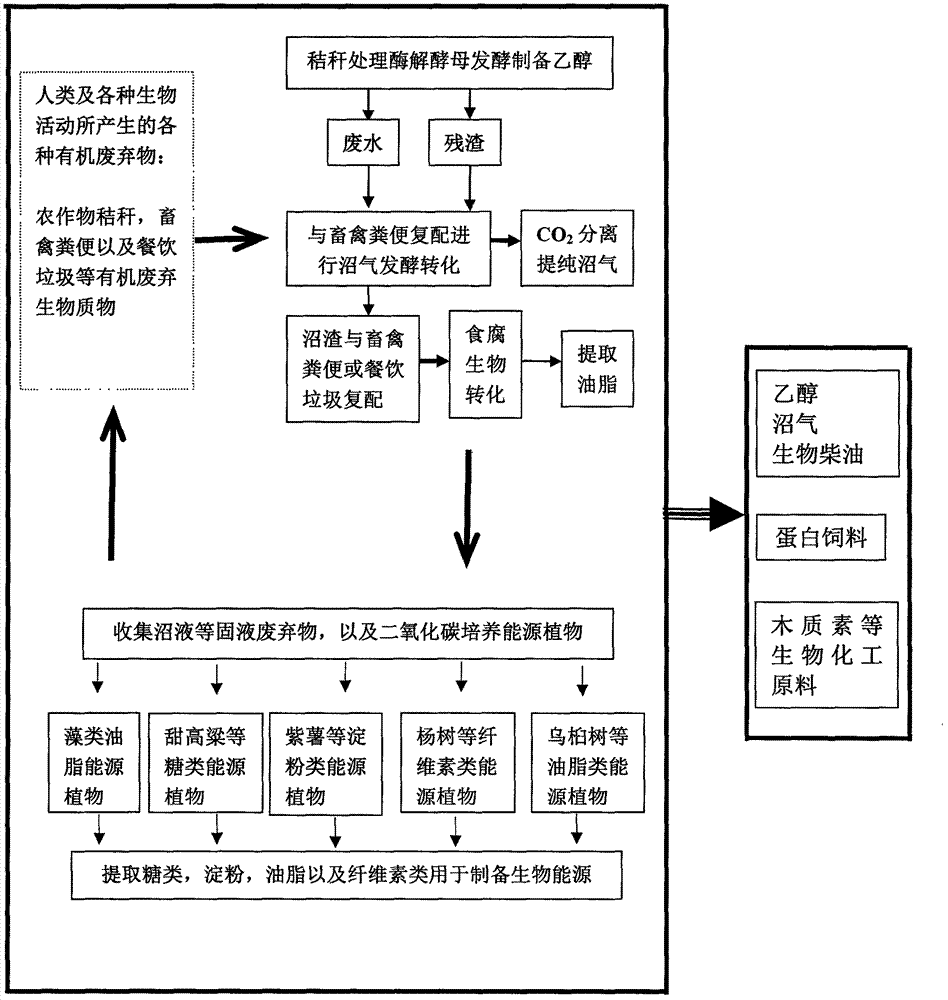

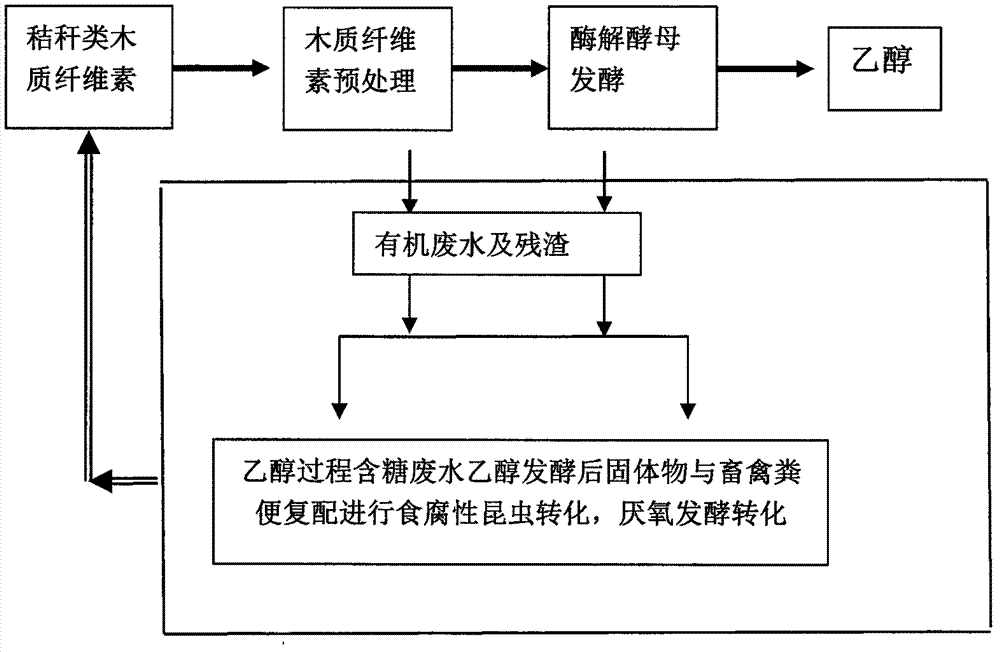

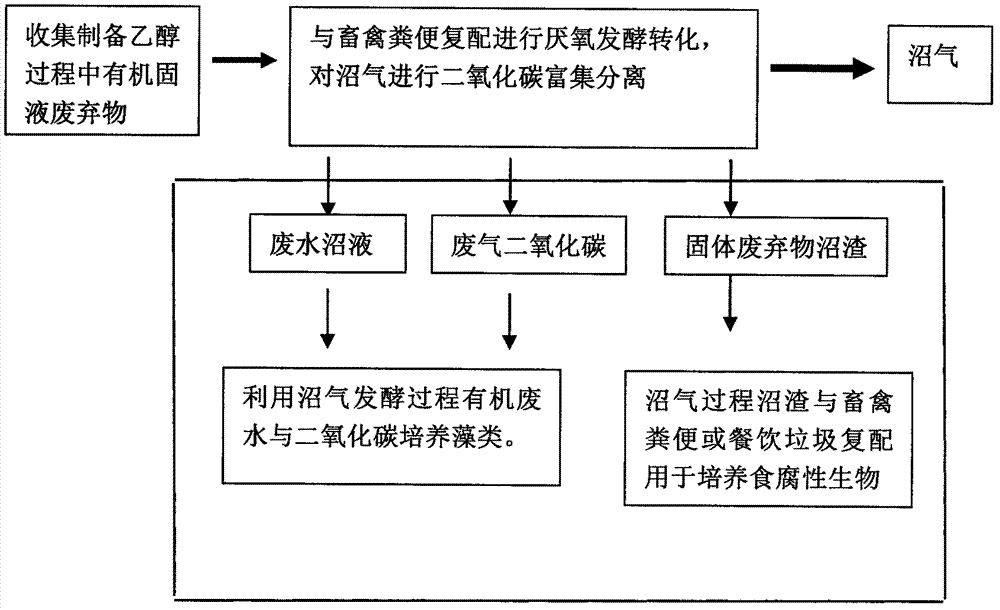

Co-production method for preparing ethanol, biogas and biodiesel by using organic waste

ActiveCN103923948AHigh yieldAbundant raw materialsBio-organic fraction processingClimate change adaptationCelluloseBiodiesel

The present invention provides a method for co-producing ethanol, biodiesel, biogas and other biological energy sources by using organic waste as a raw material. The method comprises that: a lignocellulose raw material is pretreated, enzymolysis sugar production and ethanol fermentation are performed, livestock and poultry manure is added to the enzymolysis residue, anaerobic fermentation is performed to produce biogas, the biogas residue is converted through saprophagous insects, organic wastewater is adopted to culture microalgae, and the insects and the microalgae are adopted to prepare the biodiesel; and an energy source plant conversion and utilization system is adopted to collect the process wastewater, the biogas liquid, the waste gas, the biogas residue and other solids and separate and enrich the biogas process carbon dioxide so as to be used for culture of sweet sorghum, sugar cane and other sugar-containing energy source plants, purple sweet potato and other starch-containing energy source plants, aspen and other cellulose-containing energy source plants, and sapium sebiferum and other grease-containing energy source plants, and the biomass produced by the energy source plants can further be used for extracting sugar sources, starch, fat and cellulose for biological energy source production.

Owner:HUAZHONG AGRI UNIV +1

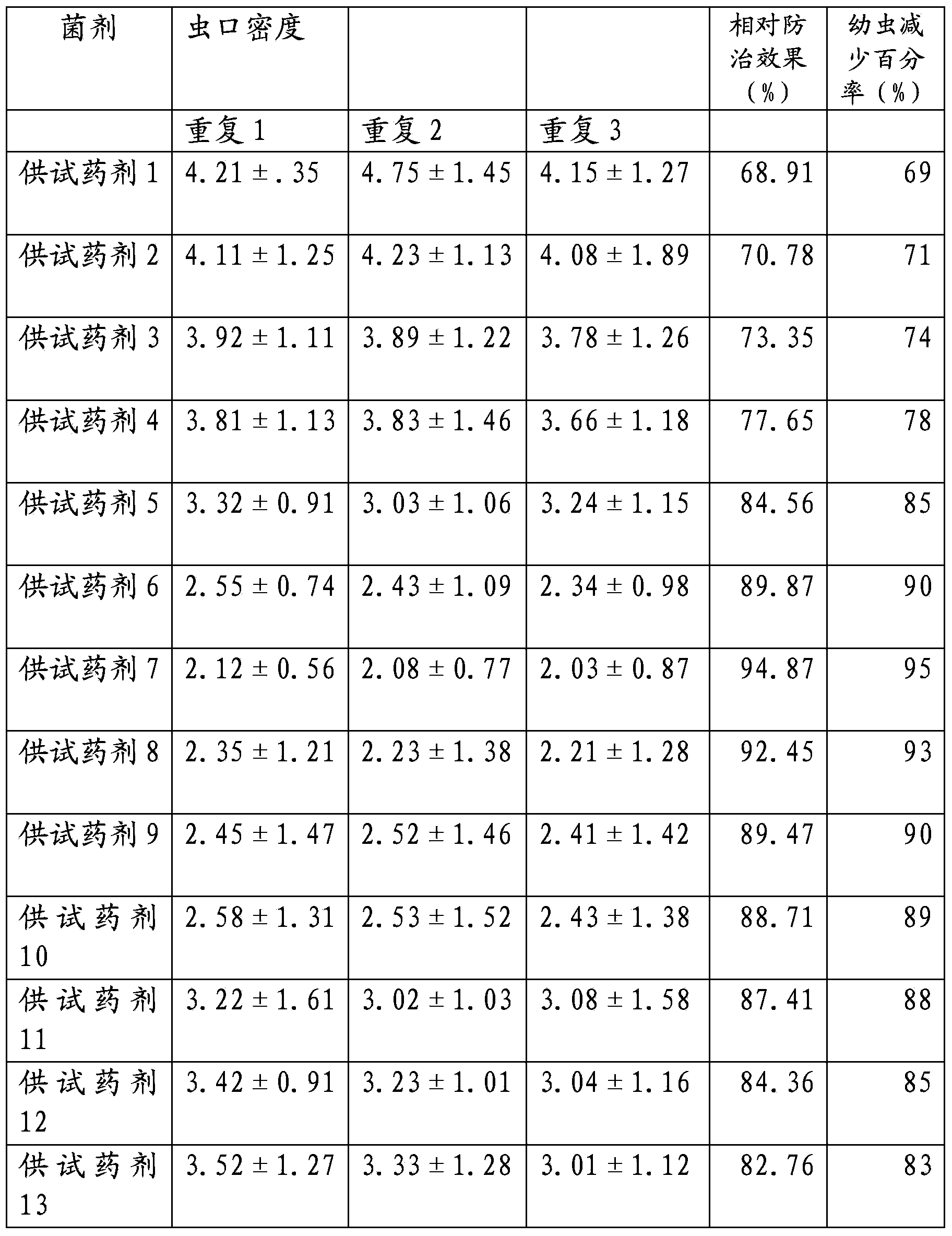

Bio-organic fertilizer and method for preparing bio-organic fertilizer which prevents and treats soil insects

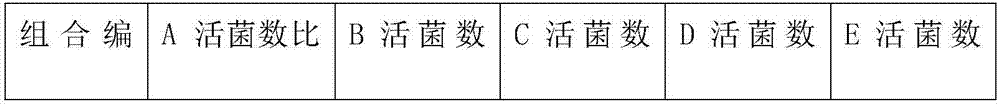

The invention relates to a bio-organic fertilizer and a method for preparing the bio-organic fertilizer which prevents and treatments soil insects. The bio-organic fertilizer is added with active bacteria and other nutrition bacterial genus, wherein the active bacteria and other nutrition bacterial genuses can prevent and treat soil insects. The bio-organic fertilizer comprises biological agents and organic fertilizers, wherein the microbial agents comprise bacterial colonies of Japanese beetle bacilli, withered grass bacilli, enormous bacilli, jelly-formed bacilli, brown ball nitrogen-fixing bacteria and bacillus licheniformis. The Japanese beetle bacilli are the main type of bacterium which prevents and treats soil insects and other types of bacteria are mainly used for fixing nitrogen, decomposing phosphorus, decomposing potassium, and preventing and treating soil-borne diseases. The organic fertilizer comprises livestock and poultry manure and edible mushroom dregs. The livestock and poultry manure and the edible mushroom dregs are mixed, ferment and are thoroughly decomposed, the microbial agents are added and the bio-organic fertilizer is prepared. The bio-organic fertilizer and the method for preparing the bio-organic fertilizer which prevents and treatments soil insects can effectively kill larvas of soil insects. Bacterial colonies of microorganisms grow by fixing nitrogen, decomposing phosphorus and decomposing potassium, the structure of soil is improved, the organic content of soil is improved, the quality of crops is improved and the crop yield is improved.

Owner:成都天星农业科技有限公司

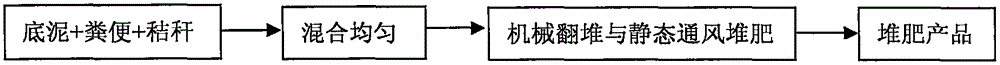

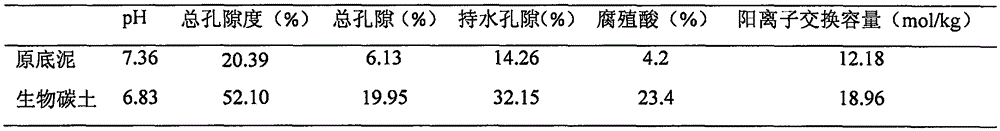

Engineering method for producing biochar soil from dredging sediment

InactiveCN105646064ABiocarbon soil has high added valuePromote aromatizationBio-organic fraction processingSewage/sludge fertilisersResource utilizationPoultry manure

The present invention relates to an engineering method for producing biochar soil from dredging sediment, and belongs to the field of solid waste resource utilization. The biochar soil is prepared by uniformly mixing the raw materials of dredging sediments, poultry manure and dry straw according to a certain weight proportion, adjusting the C / N ratio and moisture content of the mixture, adding a certain proportion of a nitrogen retention and water-retaining agent; carrying out windrow composting by a mechanical turning and static forced ventilation combined manner for about 30 days, maintaining the pile at 55-65 DEG C for 10-12 days until the full maturity of the compost products. The biochar soil is utilized according to actual need. The invention realizes large-scale engineering treatment of dredging sediment, poultry manure and crops straws, provides an ecological way to solve the non-point source pollution caused by dredging sediment and poultry manure, and air problem caused by crops straws burning; and the compost products can be used for ecological engineering construction, so as to organically combine environmental benefits, economic benefits and ecological benefits.

Owner:BEIJING FORESTRY UNIVERSITY

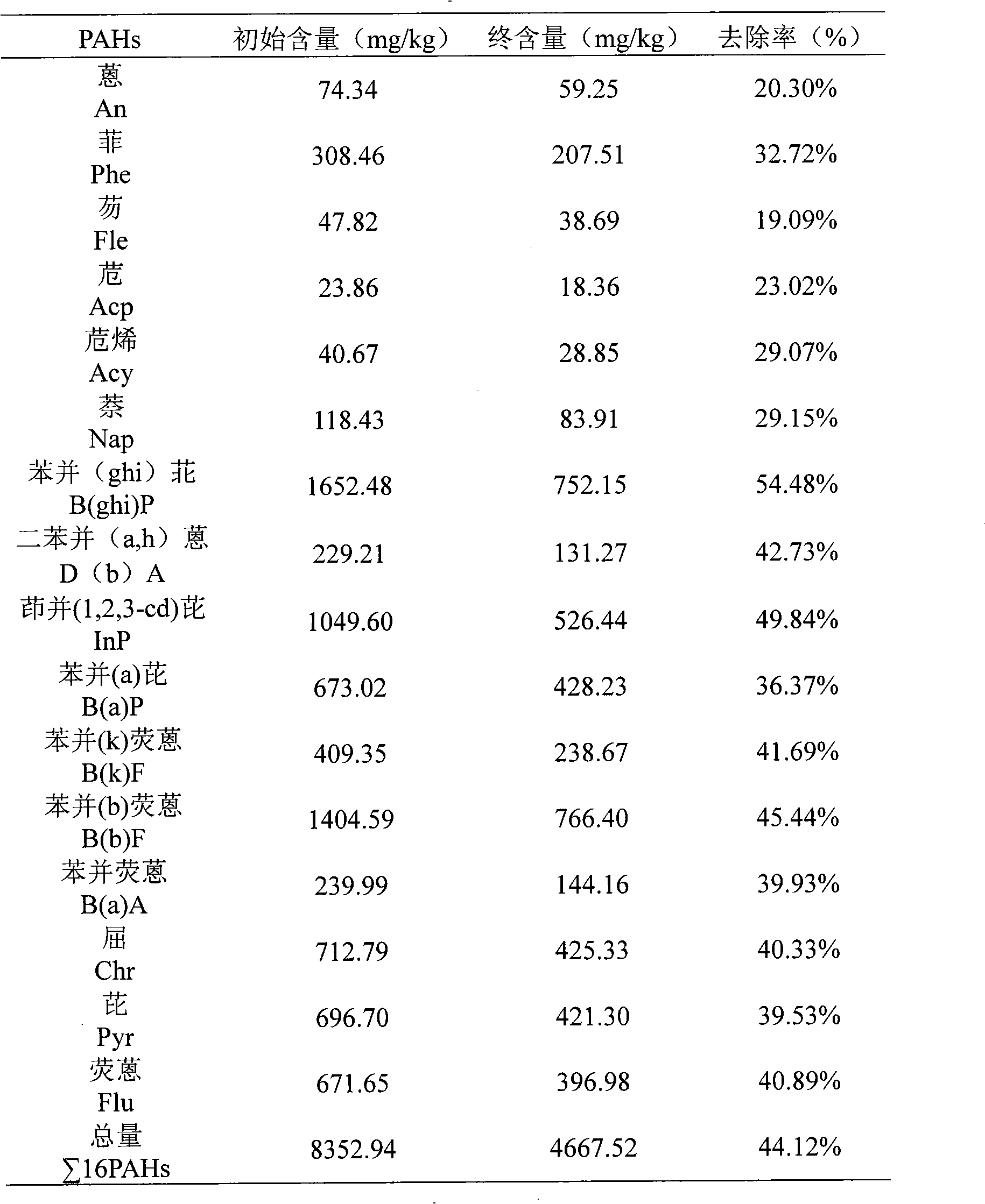

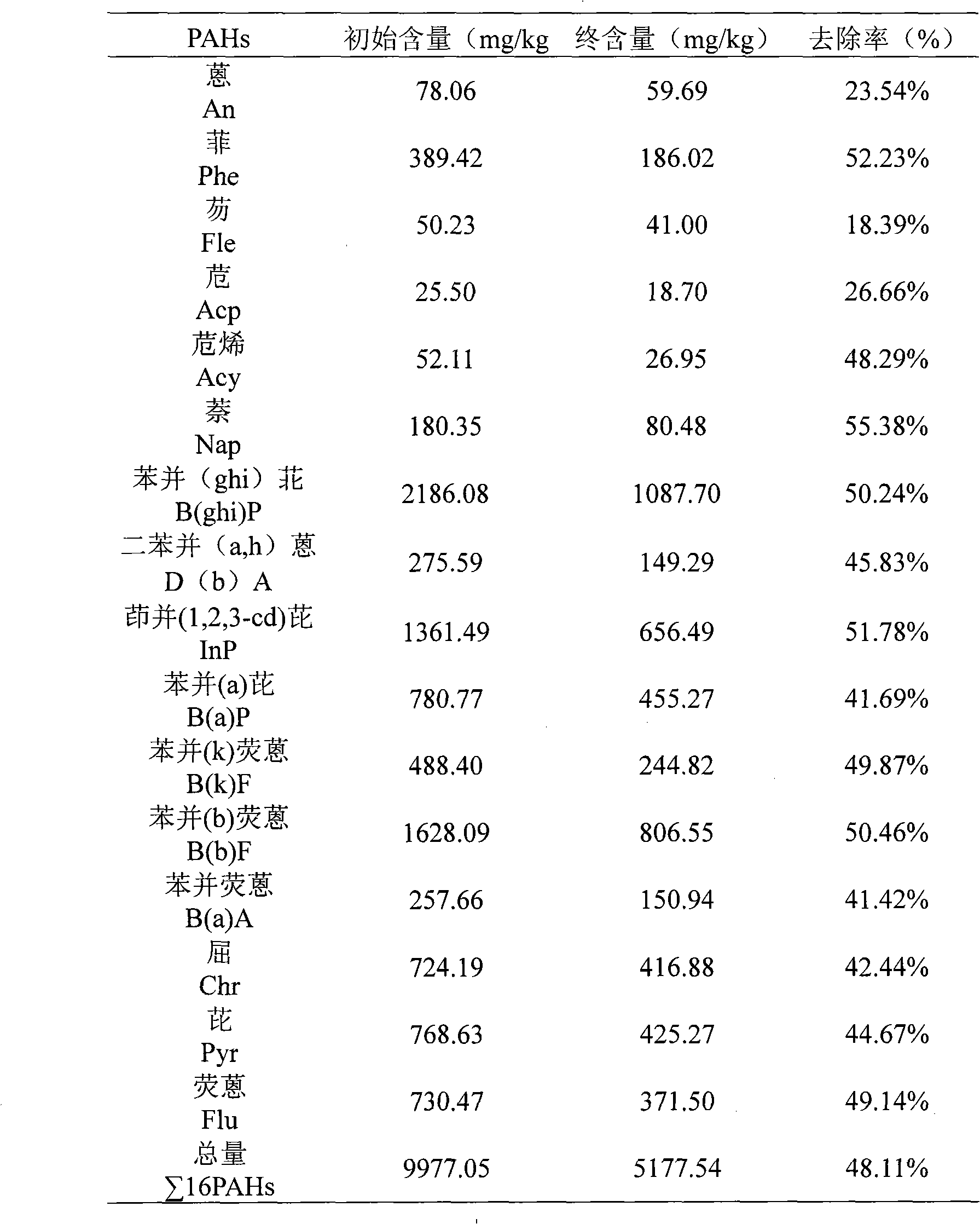

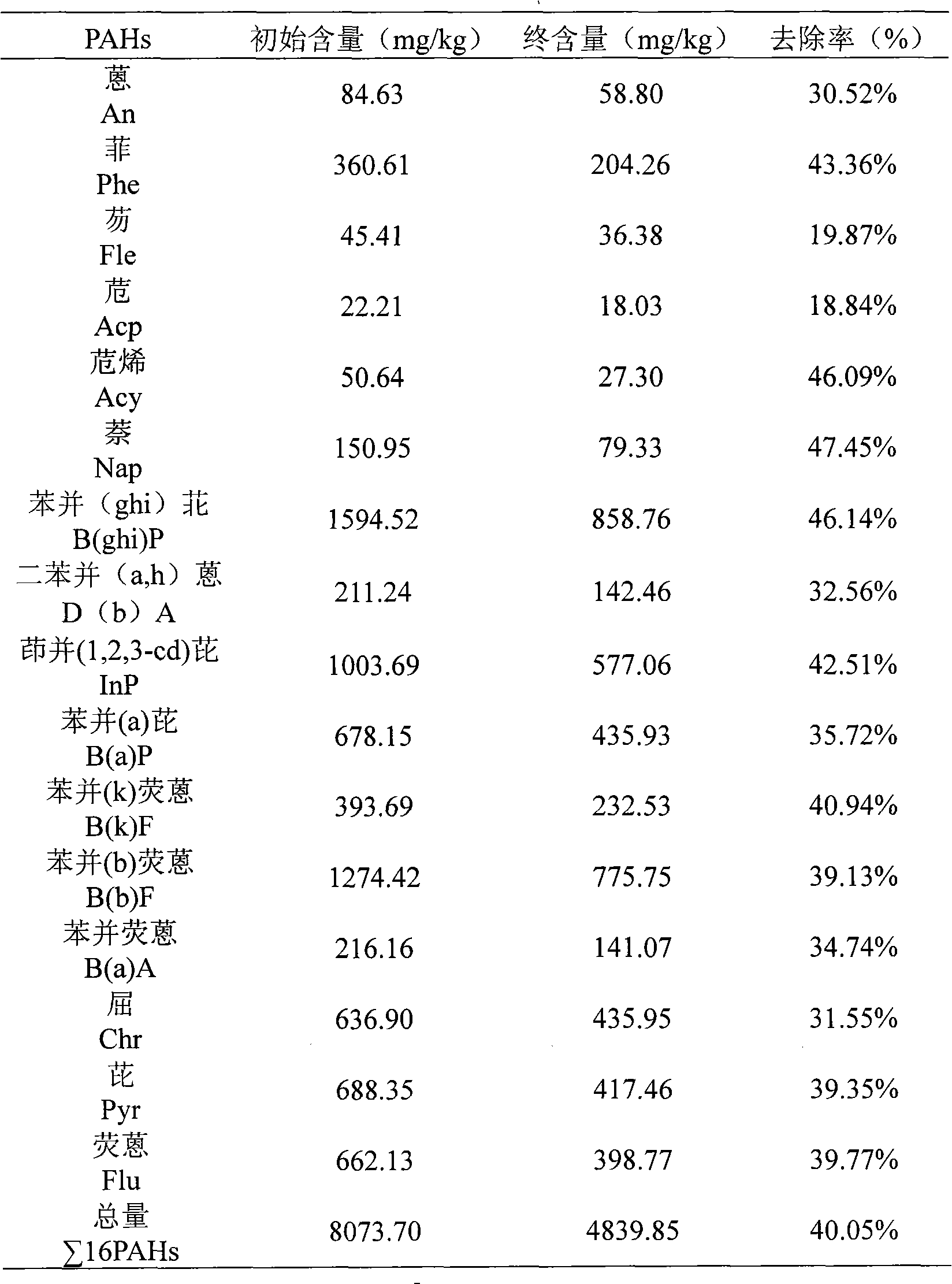

Method for restoring polycyclic aromatic hydrocarbon contaminated soil by charcoal

InactiveCN101618394ARealize resourcesWide variety of sourcesContaminated soil reclamationPolycyclic aromatic hydrocarbonPollution soil

The invention discloses a method for restoring polycyclic aromatic (PAHs) polluted soil by charcoal which is prepared by livestock and poultry manure and belongs to the field of polluted soil restoration. The method comprises the following steps: preparing charcoal by using livestock and poultry manure output by a livestock and poultry plant by a thermal cracking method under the conditions of oxygen deficiency and high temperature of 350-600 DEG C; crushing the prepared charcoal into grains of 2-8mm; mixing the charcoal and polluted soil sufficiently in proportion of 0.5-10 percent; maintaining the water content of soil from 10 to 17 percent; and processing the mixture for 30-300 days to remove various PAHs in the soil. The method for restoring polycyclic aromatic (PAHs) polluted soil by charcoal not only can be used for processing PAHs polluted soil in different places, but also can be used for restoring the land on site.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

Activated carbons from animal manure

Activated carbons may be produced by carbonization of poultry manure, followed by activation of carbonized manure. Carbons produced from poultry manure by the method described herein exhibit enhanced activity for metal ion adsorption.

Owner:UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF AGRI THE

Composite conditioner for remediation of farmland heavy metal contaminated soil and preparation method thereof

InactiveCN106734123AConducive to cultivationImprove adsorption and passivation abilityContaminated soil reclamationPhosphateSoil remediation

The invention relates to the field of soil remediation, particularly to a composite conditioner for remediation of farmland heavy metal contaminated soil and a preparation method thereof. The composite conditioner comprises the following substances in parts by mass: 40 to 55 parts of modified biological carbon, 15 to 25 parts of poultry manure, 15 to 25 parts of modified clay, 5 to 8 parts of phosphate and 5 to 12 parts of quick lime. Through combined utilization of organic modified substances, inorganic modified substances and other effective components, the composite conditioner achieves the good effect of multi-action synergetic remediation, and has the characteristics that the cost is low, the effect is good, the stability is high, the soil cultivability can be improved, and increase of crop yield and income is facilitated.

Owner:东莞中科土壤科技开发有限公司

Bio-organic fertilizer and preparation method thereof

InactiveCN106748524ASolve pollutionRealize resource utilizationBio-organic fraction processingExcrement fertilisersLivestock manurePotassium

The invention discloses a bio-organic fertilizer. The bio-organic fertilizer comprises the following raw materials in parts by weight: 80-100 parts of livestock manure, 30-50 parts of rice bran, 50-80 parts of manioc waste, 10-30 parts of filter mud, 5-10 parts of plant ash, 5-10 parts of decoction residue, 1-5 parts of potassium fulvic acid, 1-5 parts of biological bacterium, 5-10 parts of zymophyte, and 1-5 parts of compound additive. According to the bio-organic fertilizer, livestock manure, rice bran, manioc waste, filter mud and other agricultural wastes are fermented twice to obtain the bio-organic fertilizer, thus the recycling is achieved, the wastes are turned into treasure, and the problem of organic matter caused environmental pollution can be solved. The invention further provides a preparation method of the bio-organic fertilizer. The preparation method is characterized in that the raw materials are uniformly mixed and then subjected to first fermenting and second fermenting; oxygen is charged during the first fermenting, so that the fermenting is sped up, and the fermenting time is reduced; the bio-organic fertilizer prepared by twice full fermenting is outstanding in effect, does not cause soil hardening, and is environmentally friendly.

Owner:广西南宁奥浦森肥业有限公司

Long-acting synergistic controlled release fertilizer

InactiveCN103787798ANo pollution in the processSimple processAgriculture gas emission reductionFertilizer mixturesNitrification inhibitorsPoultry manure

The invention discloses a long-acting synergistic controlled release fertilizer, which mainly comprises a nitrogen fertilizer, a phosphate fertilizer, a potash fertilizer, a biological inoculant, a urease inhibitor, a nitrification inhibitor and poly(aspartic acid). Specifically, in terms of weight percentage, the nitrogen fertilizer accounts for 10-60, the phosphate fertilizer accounts for 10-60, the potash fertilizer accounts for 10-60, an organic biological multielement compound agent accounts for 5-50, wherein the biological inoculant accounts for 6-8, a liquid binder accounts for 3-5, a filling material accounts for 10-20, livestock and poultry manure or humic acid accounts for 50-80, the urease inhibitor accounts for 0.1-0.15, the nitrification inhibitor accounts for 0.15-0.2, and the poly(aspartic acid) accounts for 6-20. The invention aims to overcome the defects in the prior art, ordinary fertilizers have the disadvantages of short effective period, unreasonable nutrient proportion, unscientific and unbalanced nutrient supply, especially the nitrogen fertilizer conflict is more prominent. The long-acting synergistic controlled release fertilizer is released along with the absorption rate of crops, fertilizer loss can be effectively reduced, and saving, yield increase, synergia, convenience, environmental protection and multiple objectives can be achieved, and agricultural sustainable development can be realized. The long-acting synergistic controlled release fertilizer is simple and feasible in application, and is suitable for China's actual conditions, thus being an inevitable course for the world fertilizer development in the 21st century.

Owner:李明

Harmless extraction process for poultry manure prepared agricultural biochemical fulvic acid

ActiveCN102816332ATo achieve the extraction effect of separationEliminate hidden dangersOrganic chemistryFertilizer mixturesBiotechnologyAcid dissolution

The invention relates to a harmless extraction process for poultry manure prepared agricultural biochemical fulvic acid. The process includes an acid dissolution extraction technology of fulvic acid and a Fenton oxidative degradation technology. The acid dissolution extraction technology of fulvic acid consists of: making a suspending solution from a group A acid dissolution extracting agent that has a pH value of less than or equal to 2 and contains 0.1%-2.5% of ferrous sulfate as well as 1%-2.5% of sulfuric acid and fermented poultry manure in a ratio of 1:5-15, and conducting stirring for 30min-60min at room temperature, thus obtaining dissolved fulvic acid containing a chelate of an organic acid and ferrous ions. The Fenton oxidative degradation technology consists of: mixing a material subjected to the acid dissolution extraction with a group B acid dissolution extracting agent that has a pH value of less than or equal to 2 and contains 15% of hydrogen peroxide and 1%-2.5% of sulfuric acid, controlling the content of hydrogen peroxide in the material at 0.5%-3.0%, when the two groups of materials are mixed, catalyzing the hydrogen peroxide with the ferrous ions, thus generating a Fenton oxidative degradation reaction. Therefore, residual antibiotics, hormones, pesticides and pathogenic bacteria, rot-causing bacteria and helminth eggs can be rapidly degraded and their hazards can be eliminated, thereby reaching a harmless extraction effect.

Owner:FUJIAN CHAODA GROUP

An organic fertilizer manufacturing process through dual processing with microbial strains and earthworms

InactiveCN104529571AImprove fertilityEasy to produceBio-organic fraction processingExcrement fertilisersFiberMicroorganism

An organic fertilizer manufacturing process through dual processing with microbial strains and earthworms is provided. An organic fertilizer is manufactured from plant fiber, poultry manure, the microbial strains and the earthworms. The produced organic fertilizer is capable of obviously improving soil fertility and loosening soil, is simple and convenient in a production process and low in cost, and brings farmers with the earthworms, and other by-products.

Owner:PUDING HEYE BIOLOGICAL ORGANIC FERTILIZER

Cotton seedling raising transplantation method

InactiveCN101379919ALow costImprove structural performanceCultivating equipmentsSoilless cultivationFungicideAntitranspirant

The invention relates to a method for transplanting cotton seedlings. The method comprises three steps of preparation of a matrix, sowing and transplanting sequentially. Step 1, cotton stalks, rape stalks, corn stalks, soybean stalks or wheat straws are crushed, added with a nitrogenous fertilizer, and mixed with human excrement or livestock and poultry manure bio-fertilizer or other fertilizers to obtain a mixture which is treated to obtain a prepared material, then the prepared material is sun-dried or baked, added with a fungicide and bagged for spare use; step 2, the prepared cotton stalk matrix or the matrixes prepared from other stalks are filled in a seedling raising aperture disk or flatly spread on a plastic film laid on the ground as a seedbed, seeds are sown, watered and covered with an agricultural film, and seedlings are raised under heat insulation condition; step 3, an antitranspirant and a rooting agent are applied before transplanting; the taken seedlings are bound, put in the watered rooting agent solution for root soaking, and then taken out and put in a watered gel containing a water retention agent to dip the roots; when in transplantation, the water retention agent is applied to planting furrows; after transplantation, the seedlings are covered with soil, and irrigated with adequate water for fixing the roots. The method is characterized by high seedling survival rate, stable effect, short rejuvenation period, low cost and environmental protection.

Owner:操宇琳

Method for building orchard via building soil at bare purple rock sloping fields

InactiveCN102172156AConducive to changing barrennessConducive to changing the economyCultivating equipmentsHorticultureFruit treeSoil science

A method for building orchard via building soil at bare purple rock sloping fields comprises the following steps of: (1) selecting purple shale interbedding bare rock or purple shale bare rock gentle sloping fields with gradients of less than 15 degrees at the southeast slope of purple rock hillock to be used as the object for orchard soilbuilding; (2) delimiting explosion lines and shot hole points at the selected soilbuilding sloping fields along the contour line; (3) performing two times of layered directional explosions in spring, and stacking thin layers to form ditches, connecting the ditches with drainage ditches; (4) stirring the gravels in thin piles 1-2 times in high temperature seasons like summer and autumn; (5) backfilling the weathered broken gravels and half-weathered materials and weathered materials in next autumn, and filling organic fertilizers; (6) building horizontal ladder soils at the same height; (7) importing new soil and fertilizing according to standards, and importing fine granular soils; (8) after fruit trees are planted, turning over the surface soil layer; (9) interplanting crops, increasing the soil fertility, wherein watermelon and leguminous crops are planted in the first two years for improving soil fertility; and 1000-1500 kg of livestock and poultry manures are applied in every 667m<2> for interplanting watermelon. By adopting the invention, soils can be built in the bare purple rock sloping fields, and orchard is built; the purpose of recycling and highly-efficient utilization of the lands difficult to use in purple rock areas is realized.

Owner:谢庭生

Compound fertilizer having growth promotion and high slow-release properties and used for rice planting as well as preparation method of compound fertilizer

InactiveCN106396982AIncrease productionQuality improvementCalcareous fertilisersMagnesium fertilisersCalcitePoultry manure

The invention discloses compound fertilizer having growth promotion and high slow-release properties and used for rice planting. The compound fertilizer is prepared from raw materials as follows: ammonium nitrate, monopotassium phosphate, urea, urea phosphate, calcium superphosphate, ammonium dihydrogen phosphate, potassium sulfate, magnesium sulfate, potassium nitrate, amino sodium dicarboxylate, Trichoderma, yeast powder, straw fermentation bacteria, cellulase, potassium mineral powder, rare earth, low-rank coal, silico-calcium powder, turf powder, fly ash, pine sawdust, kaolin, rice hull powder, poultry manure, maize straw, blue-green alga powder, dolomite, diatomite, calcite, humic acid, lignin, EDTA (ethylene diamine tetraacetic acid) chelate zinc, amino acid chelated molybdenum, dicyandiamide, phosphoric triamide and a modified slow-release agent. The invention further discloses a preparation method of the compound fertilizer having growth promotion and high slow-release properties and used for rice planting. The compound organic fertilizer has outstanding slow-release performance and can effectively increase the rice yield and improve the rice quality.

Owner:袁家和

Method and ecological recirculating culture method for treating livestock and poultry manure by using Hermetia illucens

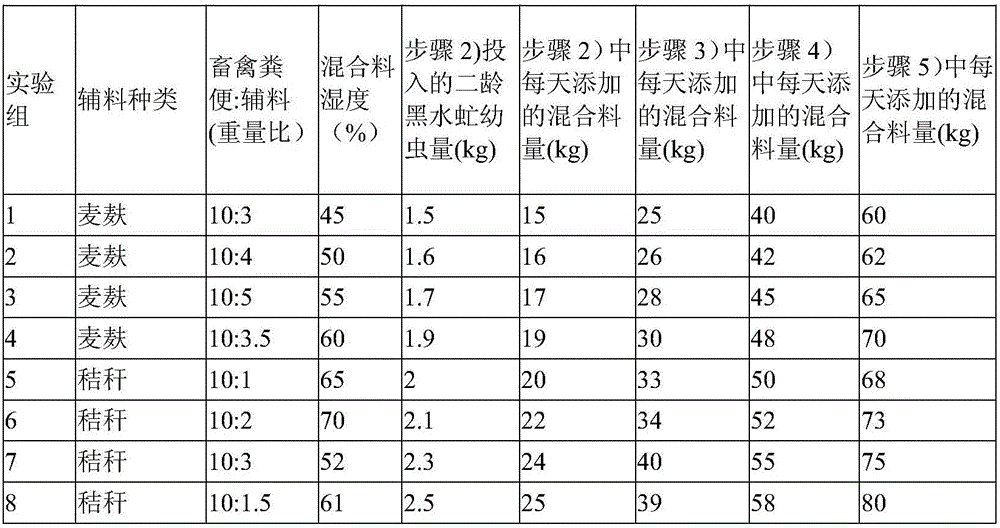

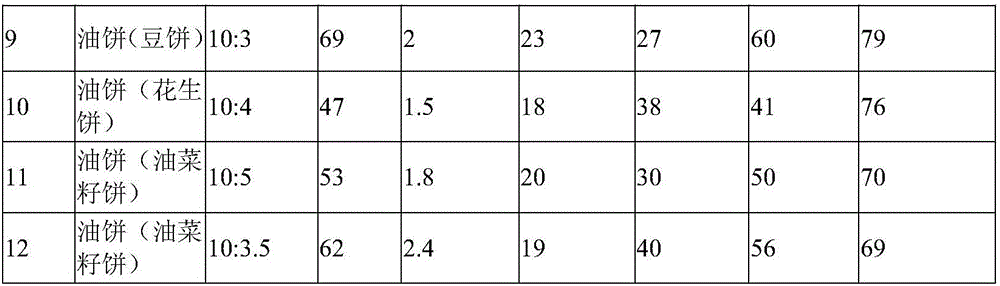

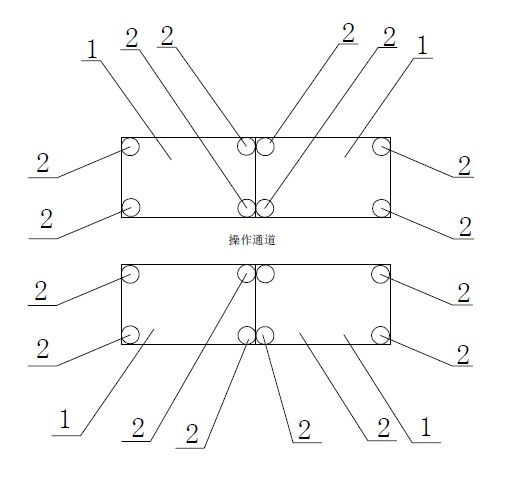

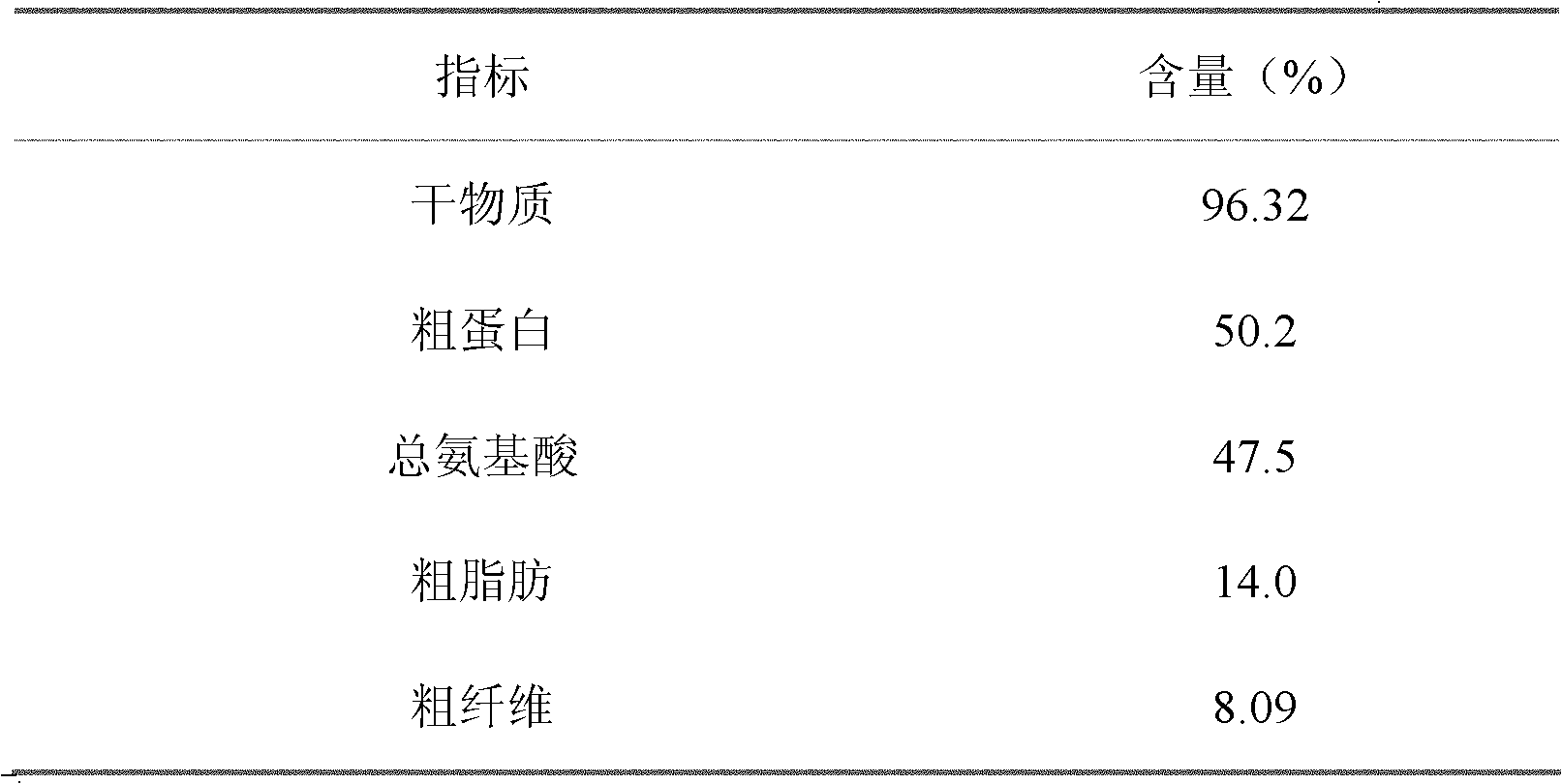

The invention discloses a method for treating livestock and poultry manure by using Hermetia illucens; the method comprises the steps of 1) mixing well livestock and poultry manure, an auxiliary material and livestock and poultry urine, wherein the mixture has humidity of 45-70%, the auxiliaries include wheat bran, straws or oil cake, the weight ratio of the livestock and poultry manure to the auxiliary material, to be specific, the livestock and poultry manure to wheat bran or oil cake, is 10:(3-5), or the weight ratio of the livestock and poultry manure to straws is 10:(1-3); 2) adding larvae of Hermetia illucens, adding the mixture, and feeding to third instar; 3) adding 25-40 kg of the mixture each day for feeding; 4) adding 40-60 kg of the mixture each day for feeding; 5) adding 60-80 kg of the mixture each day for feeding until a six-instar prepupal stage. An ecological recirculating culture method for treating livestock and poultry manure by using Hermetia illucens is also disclosed; Hermetia illucens is used as a feed in poultry or aquatic culture, the excrement of Hermetia illucens is used in earthworm culture, earthworms is used as a feed, poultry excrement is treated with Hermetia illucens, and the excrement of earthworms is made into fertilizer for planting industry.

Owner:北京申城生物科技集团有限公司

Method for producing insect protein feed through treating livestock and poultry manure by utilizing ptecticus aurife

InactiveCN102058039ASolve the pollution of the environmentTake advantage ofAnimal feeding stuffFecesPoultry manure

The invention discloses a method for producing an insect protein feed through treating livestock and poultry manures by utilizing ptecticus aurife, comprising the following steps of: (1) placing a cultivated 3-year larva of ptecticus aurife into wet livestock and poultry manures for sub-culturing and growing; and (2) when the 3-year larva of ptecticus aurife grows into a mature larva, collecting mature larva, firstly treating the mature larva with hot water or steam, then drying in the sun, drying in the air or drying and pulverizing to obtain a high quality insect protein feed. The method for producing the insect protein feed through treating the livestock and poultry manures by utilizing the ptecticus aurife promotes the effective utilization of insect protein on the animal husbandry and aquaculture and becomes one way to solve the shortage of protein feed resources in China and also solve the problem of serious pollution of the livestock and poultry manures.

Owner:AGRI BIO TECH INST GUANGDONG ACADEMY OF AGRI SCI +3

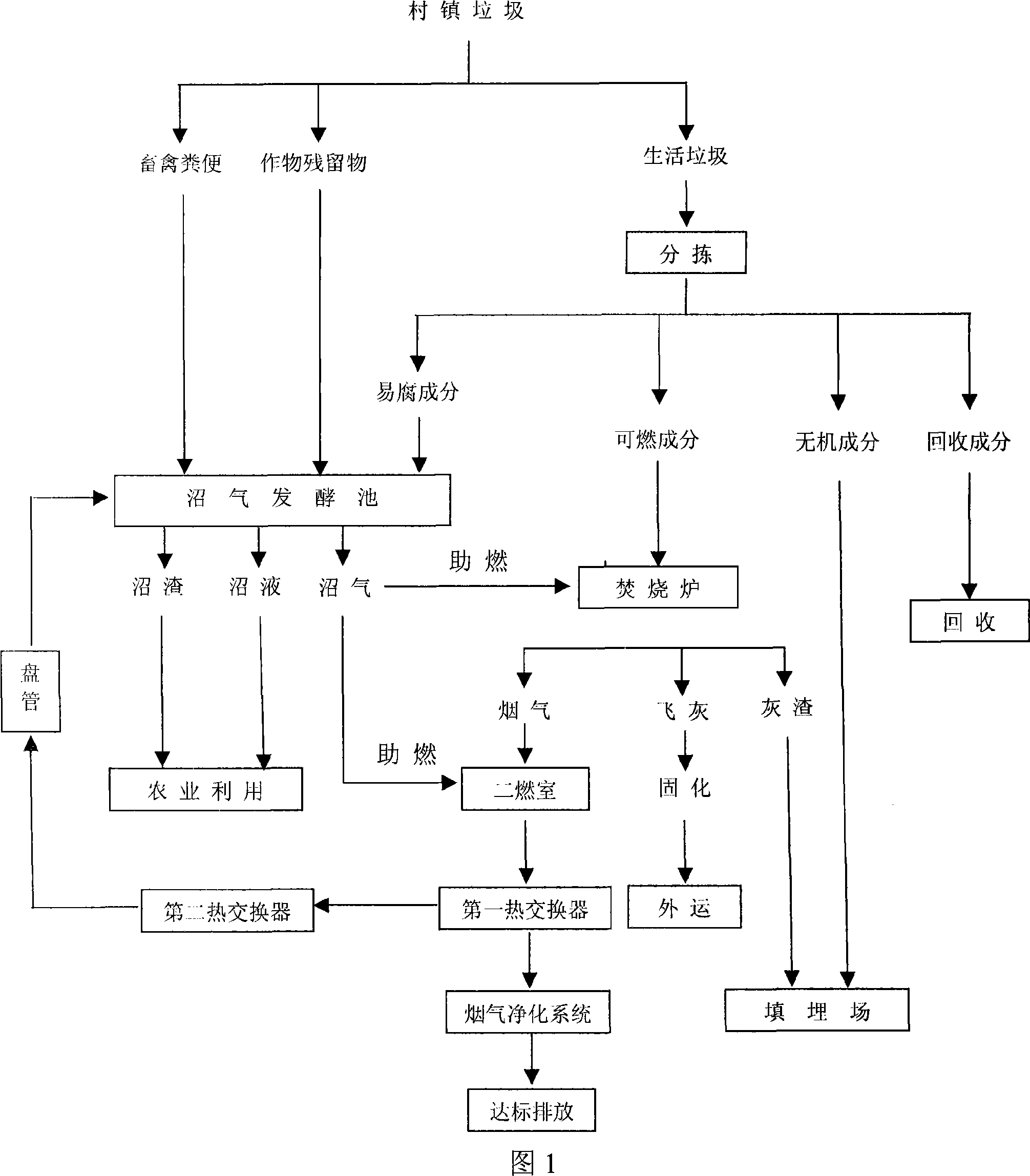

Rubbish comprehensive processing method adapted for village and small town

InactiveCN101062825AIncineration harmlessIncineration reductionBio-organic fraction processingChemical industryThermal energyResource utilization

The invention discloses a garbage comprehensive treatment method for village, which comprises the following steps: sorting life garbage of village to perishable element, combustible constituent, reclaiming element; inorganic element; allocating the perishable element, residues of crop, animal and poultry manure and water with mass ratio at 0. 8-1. 2:0. 8-1. 2:8; proceeding anaerobic fermentation under the insulation action of burning lose heat; generating marsh gas; burning the combustible constituent with combustion-supporting marsh gas completely; getting high temperature smoke gas; recovering thermal energy through the first and second heat exchanger; maintaining the temperature of marsh gas fermenting tank; obtaining resource utilization of marsh liquid or slag, marsh gas and reclaiming component; health-filling the inorganic element and burning ash slag. This invention can prevent twice pollution of the burning smoke gas, which can increase the efficiency and output of mash gas.

Owner:ZHEJIANG UNIV

Superhigh-temperature composting method for livestock and poultry manure

InactiveCN107162656AAvoid pollutionEasy to storeBio-organic fraction processingExcrement fertilisersDecompositionAnimal feces

The invention discloses a superhigh-temperature composting method for livestock and poultry manure. The method comprises the following steps: adjusting the water content of livestock and poultry manure to 45 to 60% by using a conditioning agent and then adding a decomposition bacterial strain for organic materials; then heating a mixed material, allowing the temperature of the mixed material to rise to 80 to 85 DEG C within 1 to 2 h and maintaining the superhigh temperature for 16 to 24 h to accomplish composting fermentation, wherein a high-pressure fan carries out aeration or stirring on the material for oxygen supply during fermentation; and after completion of fermentation, allowing the water content of an obtained composting product to fall to 20 to 30%, wherein the composting product allows the germination rate of seeds to reach 95% or above. The composting method provided by the invention can realize rapid decomposition of livestock and poultry manure, and the prepared composting product is thorough in inactivation of pathogenic organisms and low in loss of carbon and nitrogen and has substantially better fertilizer efficiency compared with traditional composting products.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Special organic-inorganic compound biological medicine fertilizer for sweet potatoes, and preparation method thereof

The invention provides a special organic-inorganic compound biological medicine fertilizer for sweet potatoes, which comprises the following raw materials in parts by weight: 50-60 parts of sweet potato vines, 10-20 parts of deciduous leaves, 10-12 parts of bone meal, 15-17 parts of poultry droppings, 18-22 parts of sodium humate, 14-16 parts of chicken feathers, 10-12 parts of monoammonium phosphate, 18-20 parts of concentrated superphosphate, 10-12 parts of ammonium bicarbonate, 8-10 parts of potassium sulphate, 10-16 parts of silkworm faeces, 8-10 parts of sepiolite, 2-3 parts of cnidium fruit, 2-3 parts of aloe, 3-4 parts of buckeye, 2-3 parts of pharbitis seed, 4-6 parts of cinnamomum burmannii, 0.02-0.04 part of sodium molybdate, 1.5-2.0 parts of magnesium sulfate, 3-5 parts of potassium chloride, 0.2-0.3 part of ferrous sulfate and 1-2 parts of EM(effective microorganisms) strain. After various organic wastes are mixed and fermented to produce the green organic fertilizer, the environmental pollution is reduced, the fermented organic matter is mixed with the inorganic fertilizer, the Chinese herbal medicine juice (gauleheria) with insecticide properties is added, the nutrition is more comprehensive, and the bactericidal effect is increased; the fertilizer has the advantages of obviously improved fertilizer utilization ratio, single time of application, effective slow release, reduced fertilization frequency, reduced fertilizer cost and improved economic benefit; and after the application of the fertilizer, the quality of the sweet potatoes can be effectively improved, and the yield is can be improved.

Owner:ANHUI CHENGXIANG FERTILIZER

Preparation method of red-layer sandstone slope wounded surface artificial soil

InactiveCN101390468AImprove water and fertilizer retention performanceIncrease physical and chemical propertiesCultivating equipmentsSoilless cultivationPeatPoultry manure

The invention provides a redbed sandstone slope raw surface artificial soil preparation method, which prepares the artificial soil with raw material components including redbed sandstone rock, redbed shale rock, compound containing silkworm excrement and / or wormcast and / or algae residue, peat, straw, livestock and poultry manure, cement, lignosulfonate, high water-absorbent resin and fertilizer which are effectively mixed under certain conditions. The preparation method has significant effects in speeding up the formation of redbed sandstone slope raw surface artificial soil aggregate structure, increasing the water and fertilizer-keeping performances of the soil, improving the physical and chemical properties of the soil and promoting the plant growth and development.

Owner:SICHUAN UNIV

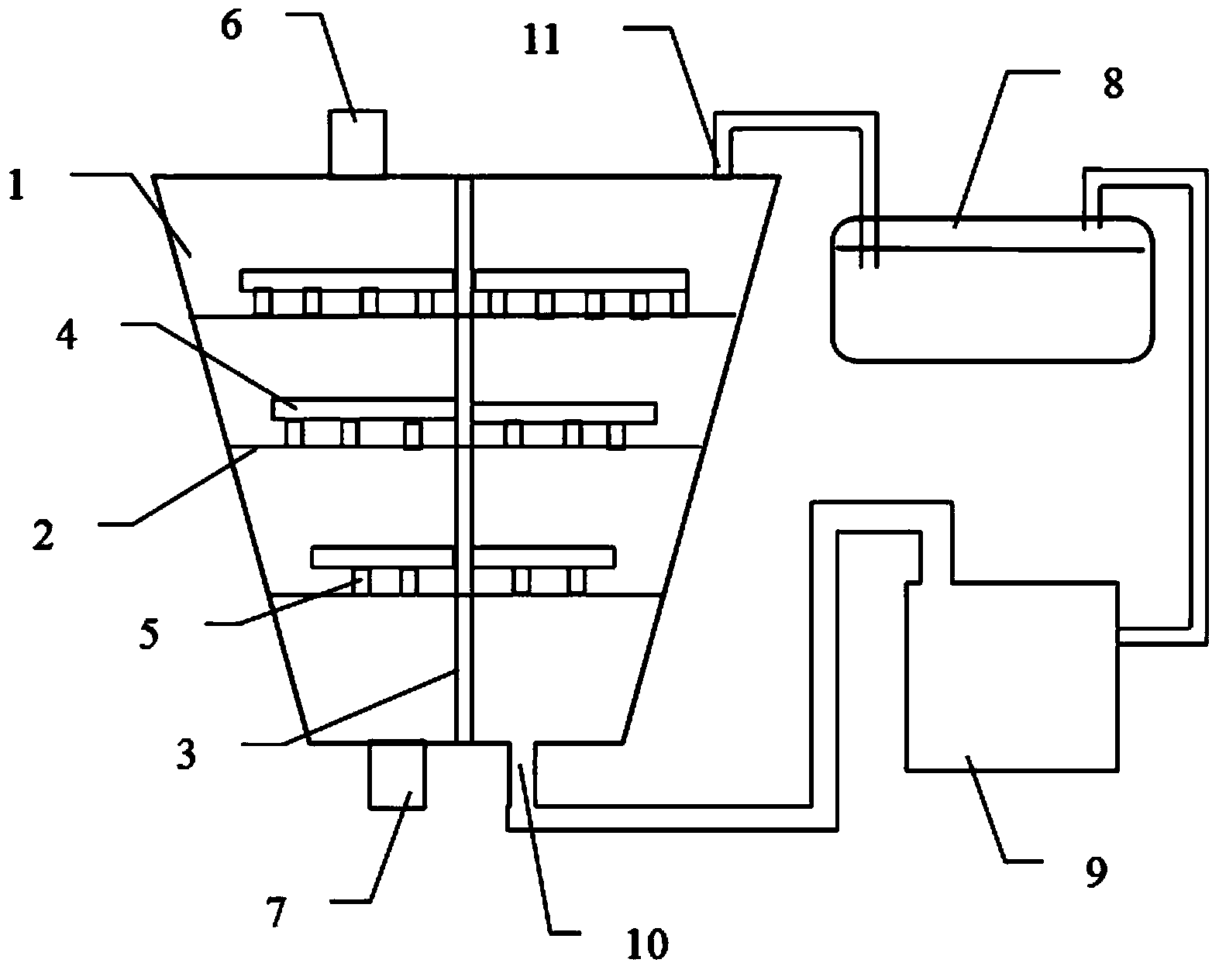

Poultry manure treatment device

ActiveCN104341176AStir wellAvoid cloggingClimate change adaptationExcrement fertilisersFecesEngineering

The invention discloses a poultry manure treatment device. According to the poultry manure treatment device, multiple layers of filtering grilles, of which the sizes of meshes decrease, are sequentially arranged inside the treatment device from top to bottom, and the edges of stirring paddles are comb-tooth-shaped, so that poultry manure is effectively subjected to impurity removal treatment; the filtering grilles are not prone to blockage, and the poultry manure to be treated can be uniformly stirred; in addition, high-temperature steam is introduced inside the treatment device by a steam circulating system, so that the poultry manure to be treated and the high-temperature steam are in full contact, the aims of high-temperature disinfection and sterilization are effectively achieved, the harmfulness of the poultry manure is eliminated, an environment-friendly and efficient organic fertilizer is obtained, the raw materials are obtained locally, and the waste is changed into the valuable.

Owner:广西华兴食品集团有限公司

Organic biofertilizer with additive and preparation method thereof

InactiveCN101928184ANutritional balanceImprove qualityBio-organic fraction processingOrganic fertiliser preparationAdditive ingredientSlag

The invention discloses an organic biofertilizer with an additive and a preparation method thereof. The organic biofertilizer comprises the following ingredients: 40 percent of human manures, poultry manures and animal slurry, 30 percent of waste material slags and 30 percent of crop straws serving as raw materials; and one part of the additive (in an account which is 0.1 percent based on the total weight of the raw materials) is added, which comprises 50 percent of composite bacterial preparation NSC-7, 2 percent of bacillus subtilis, 2 percent of bacillus cereus, 30 percent of lactobacillus, 10 percent of polyaspartic acid, 3 percent of alpha-naphthylacetic acid and 3 percent of indolylacetic acid. The preparation method comprises the following steps of: mixing the raw materials and the additive, stacking in a cement tank, fermenting for 24 hours, adding the rest additive, stirring, and continuously stacking for 2 hours; and granulating and packaging by using the technology for granulating the organic fertilizer. The organic biofertilizer with the additive has the advantages of easy material acquirement, low cost, improvement of the soil, balanced nutrition of the soil, improvement of the quality of crops, yield increase, improvement of the gain for farmers, contribution to environmental protection, wide market prospect and positive effect on the development of enterprises and agriculture.

Owner:郑新民

Organic fertilizer and its preparing process

InactiveCN101012136AImprove breathabilityGood water permeabilityBio-organic fraction processingClimate change adaptationSlagOrganic manure

The invention discloses an organic fertilizer and making method, which comprises the following parts: 40-70% poultry manure, 15-30% peanut slag and 15-30% peat. The making method comprises the following steps: (1) blending each raw material evenly; (2) fermenting under 25-30 deg.c for 3-10d; drying.

Owner:凌文武

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com