Patents

Literature

242 results about "Windrow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A windrow is a row of cut (mown) hay or small grain crop. It is allowed to dry before being baled, combined, or rolled. For hay, the windrow is often formed by a hay rake, which rakes hay that has been cut by a mowing machine or by scythe into a row, or it may naturally form as the hay is mown. For small grain crops which are to be harvested, the windrow is formed by a swather which both cuts the crop and forms the windrow.

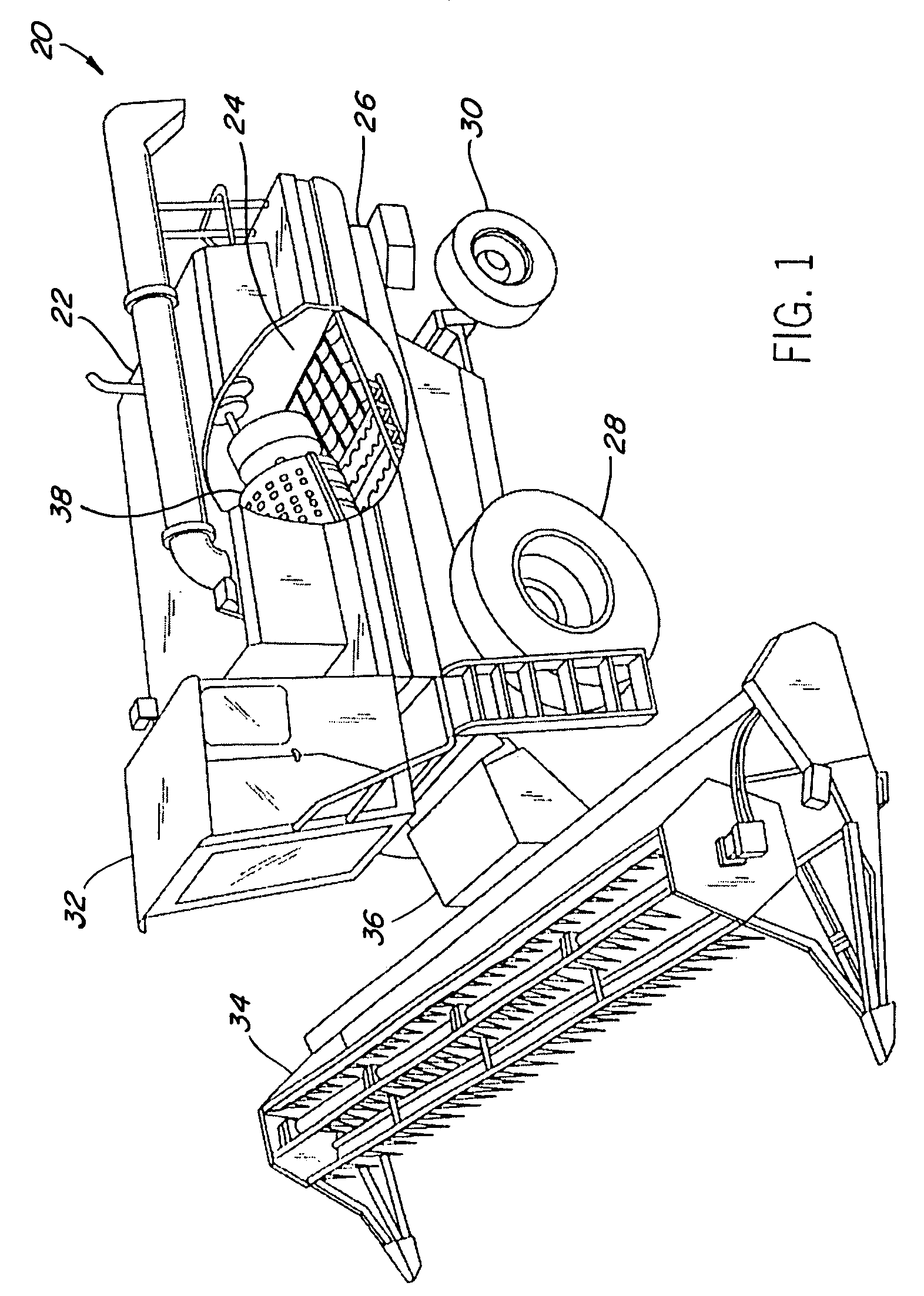

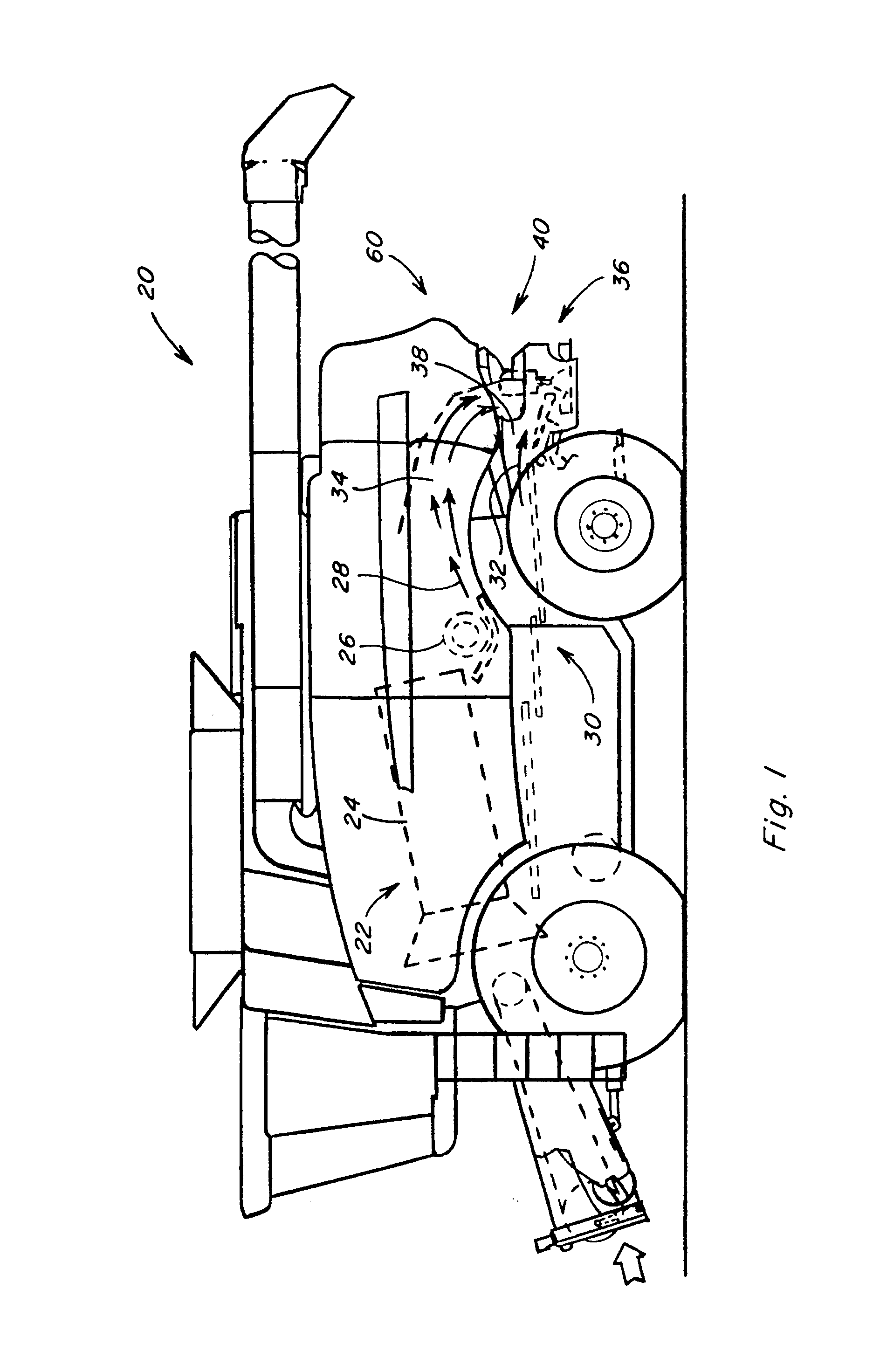

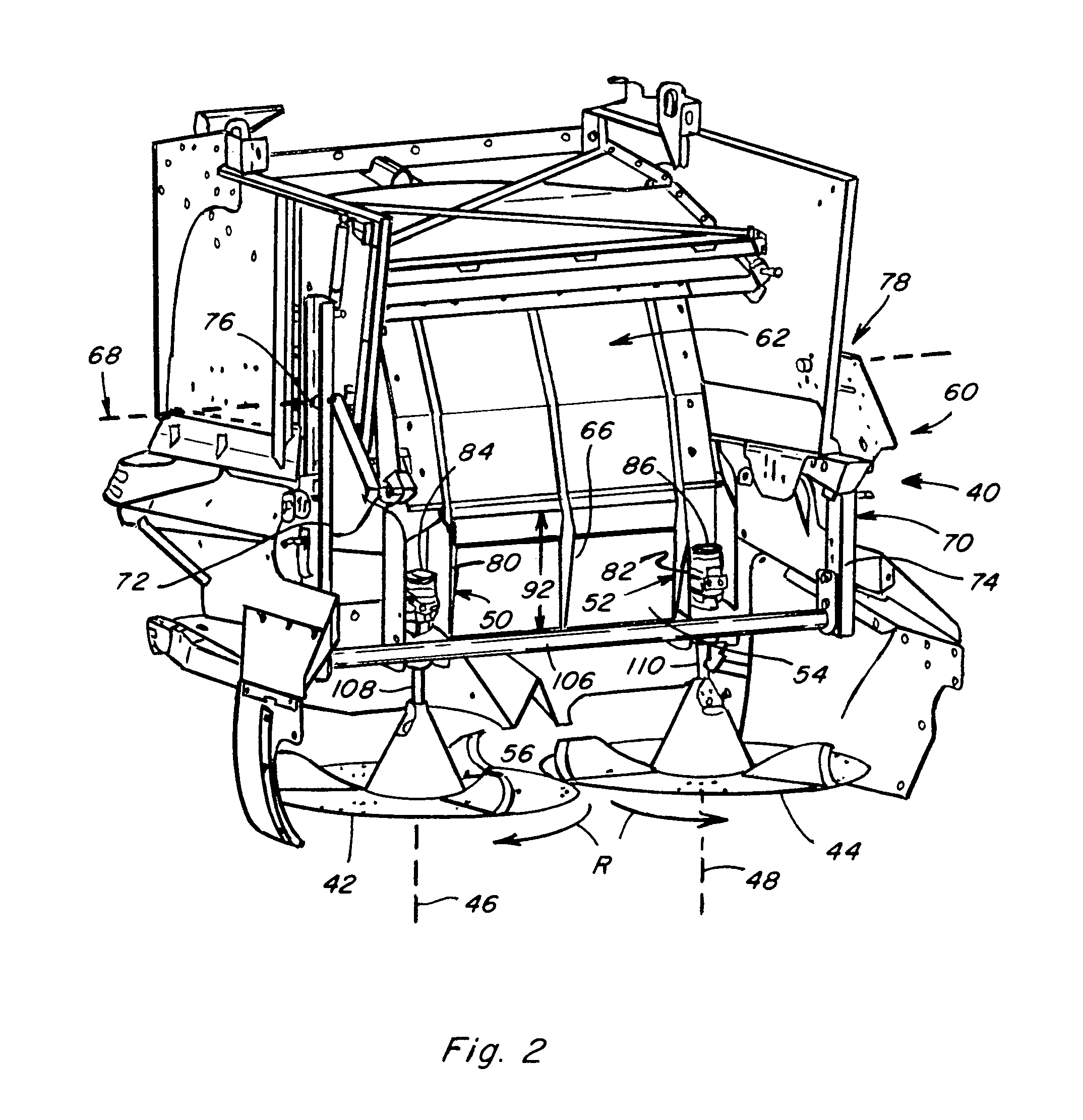

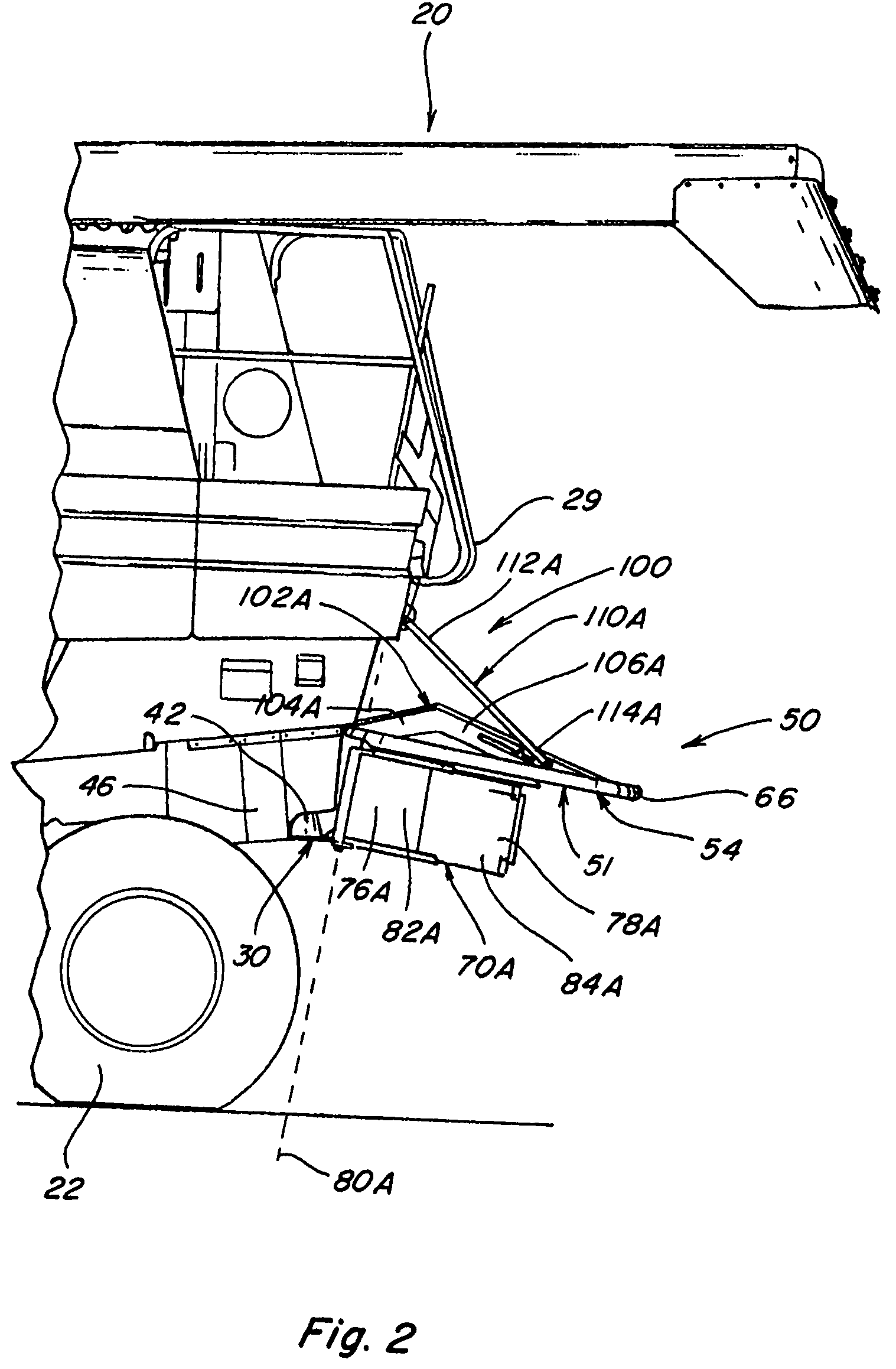

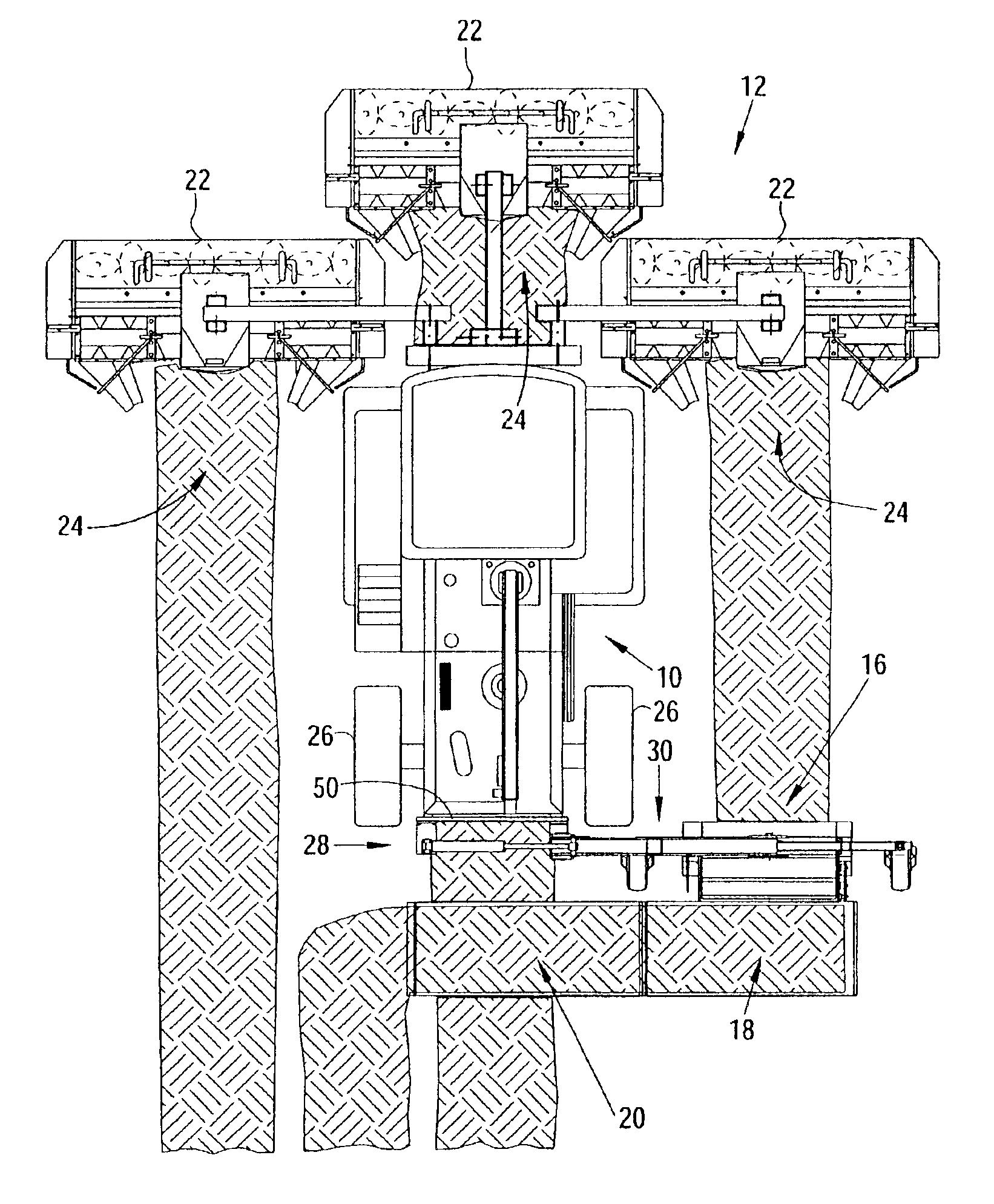

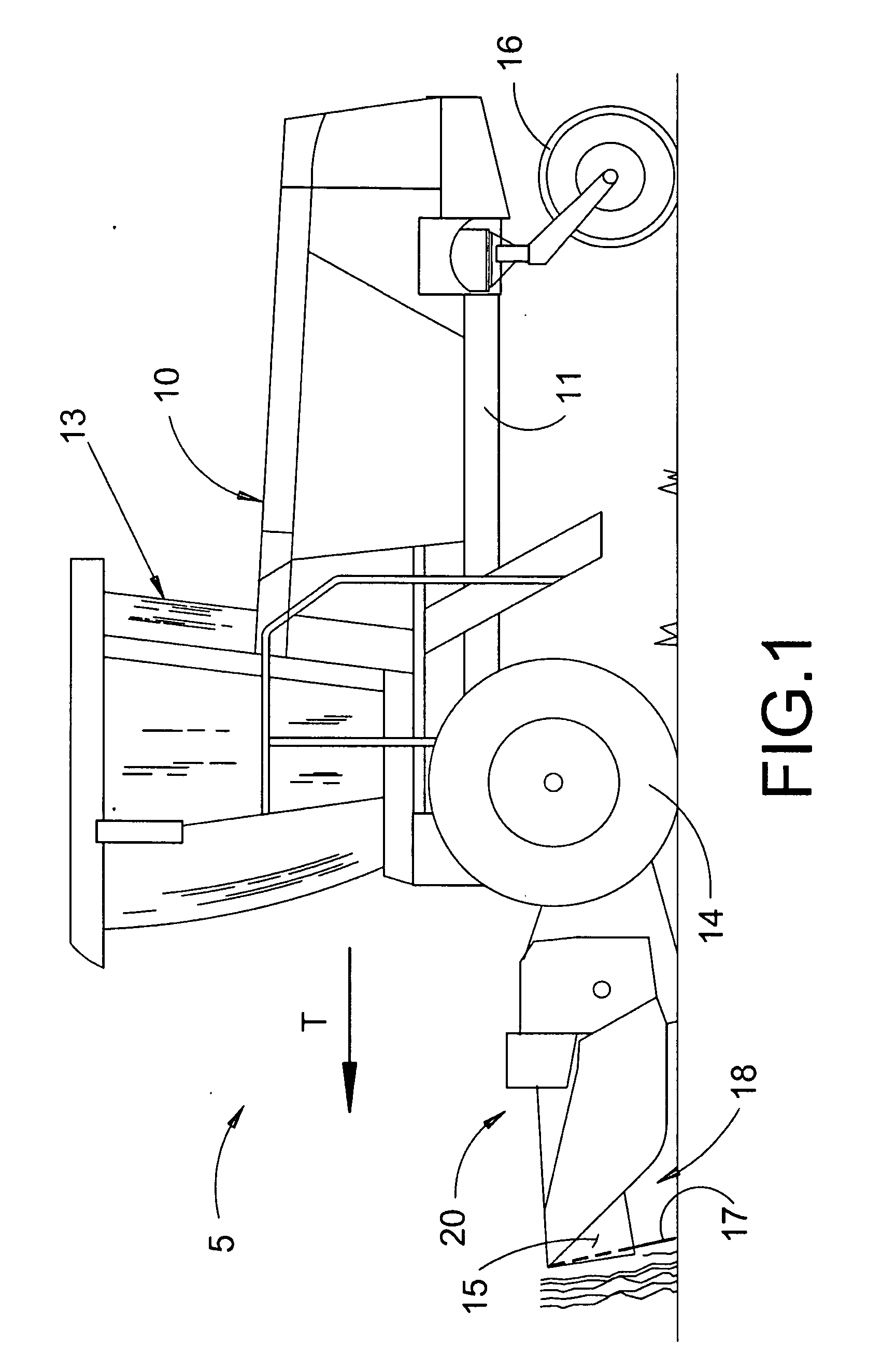

System and method for positively discharging crop residue from a combine

ActiveUS7066810B2Precise, efficient, and consistent crop residue dischargeDifferent typeMowersThreshersChaffEngineering

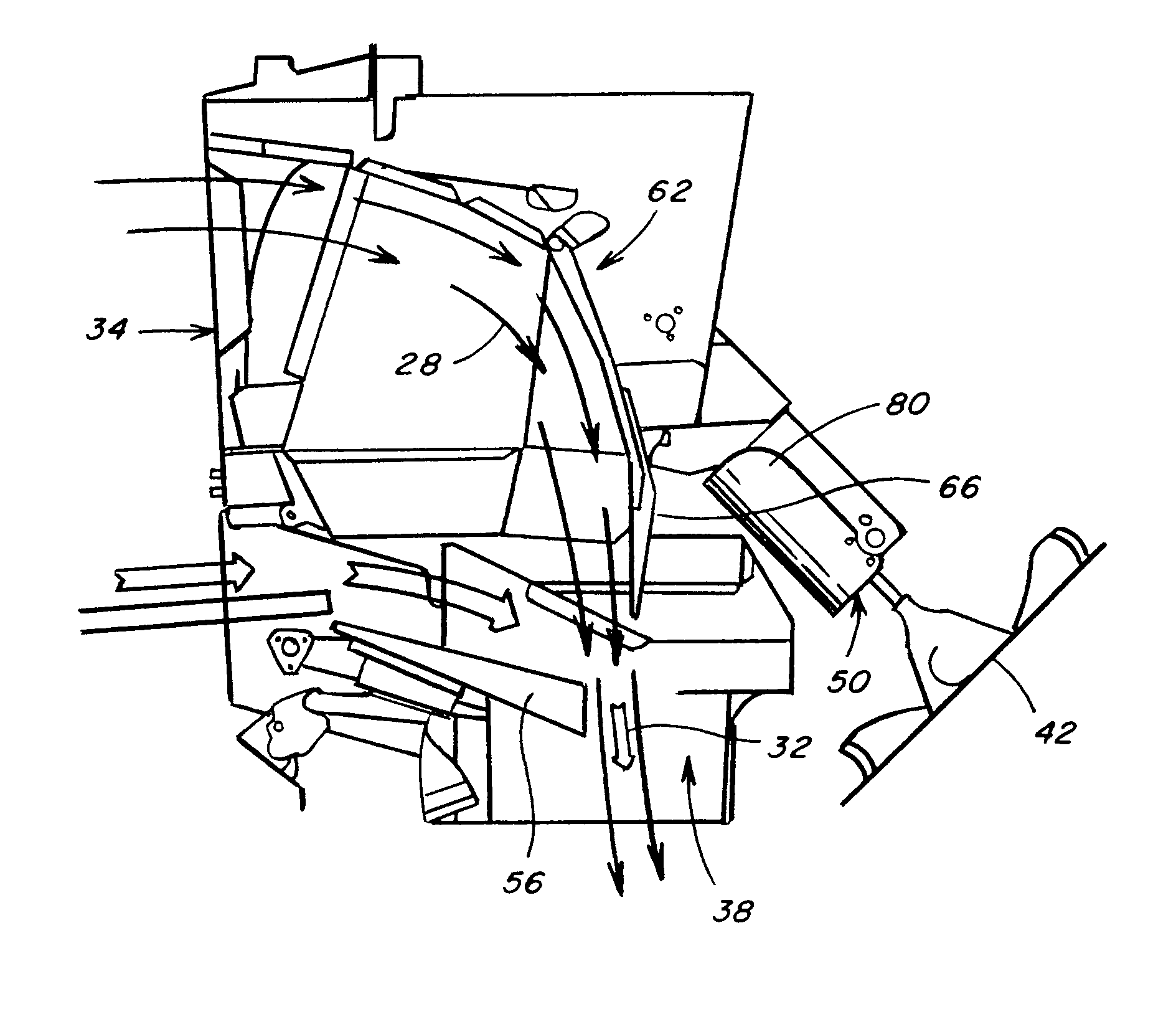

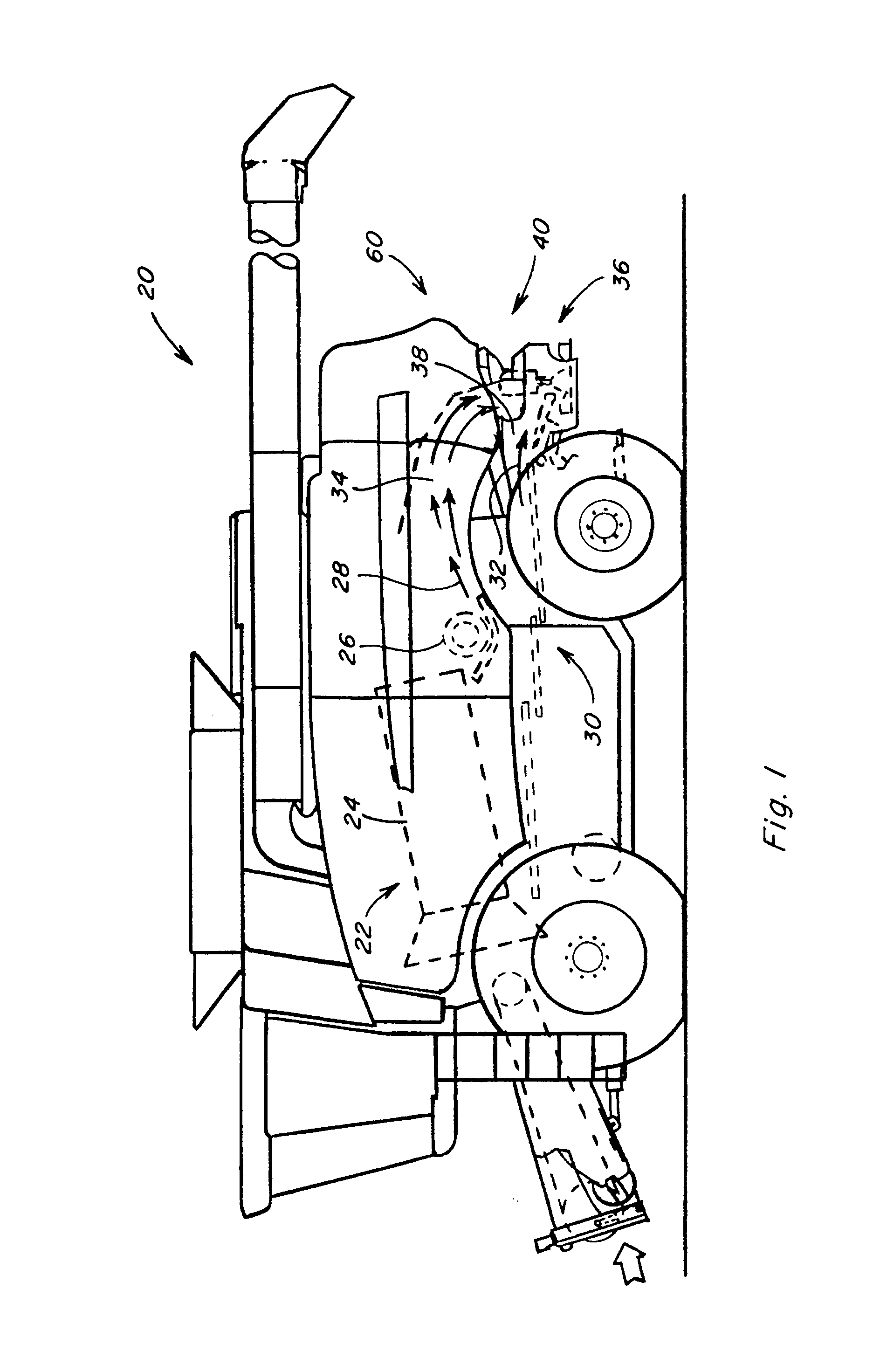

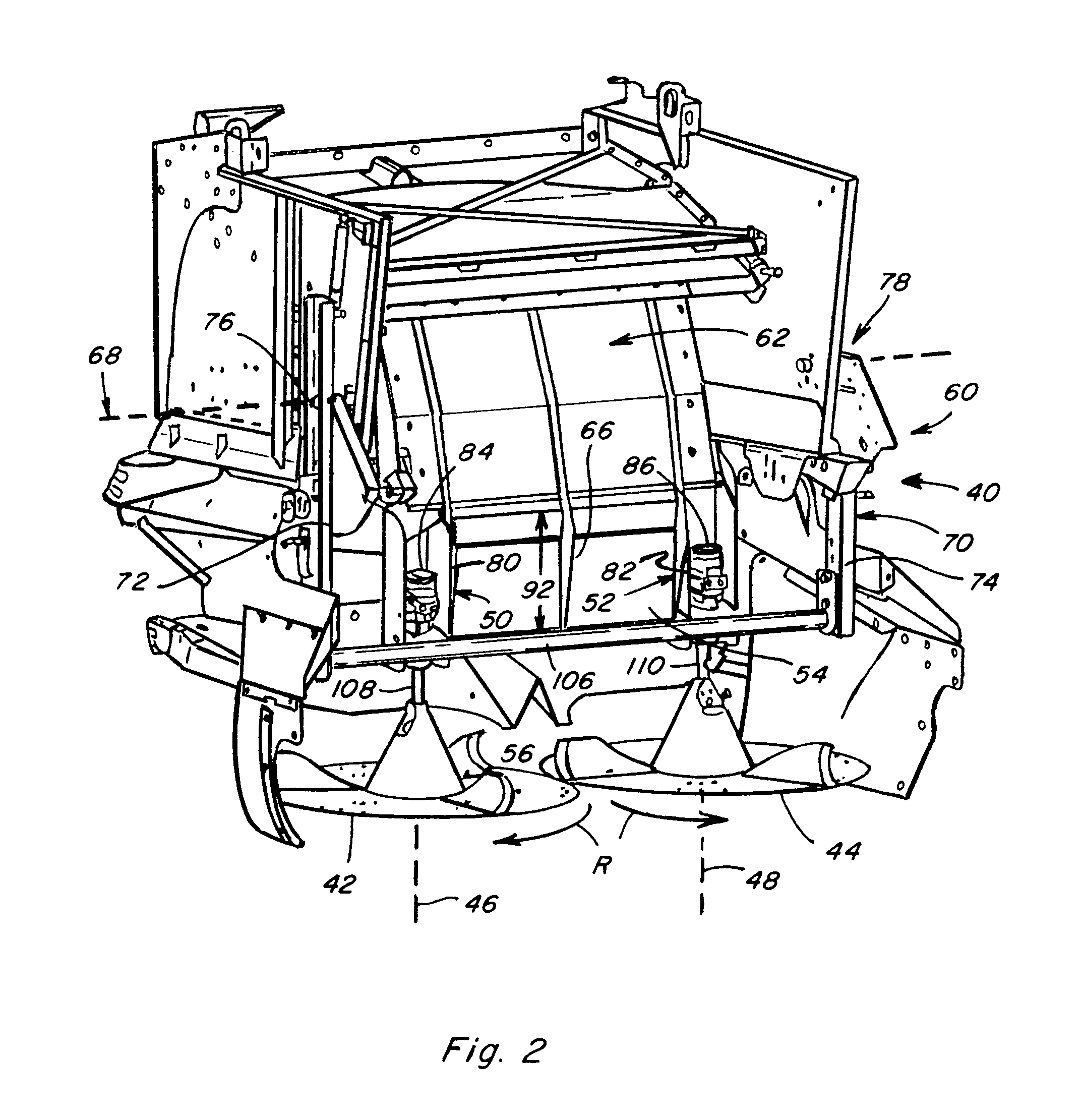

A system and method for positively discharging crop residue from a combine for precisely and consistently delivering crop residue from the threshing and separating area of a combine to the combine's residue handling system or outwardly from the rear of the combine and onto the harvested field below as a windrow. The present invention can include, or operate in cooperation with, a discharge mechanism, such as a conventional discharge beater, which delivers at least some of the crop residue to a conveying mechanism of the system. The system also includes a guide mechanism including a door arrangement configurable in several alternative configurations for receiving and merging and regulating crop residue flow from the discharge mechanism and the conveying mechanism, and directing the merged flow to a desired processing mechanism, such as, but not limited to, a chaff spreader, a straw chopper and / or spreader, etc.

Owner:BLUE LEAF I P INC

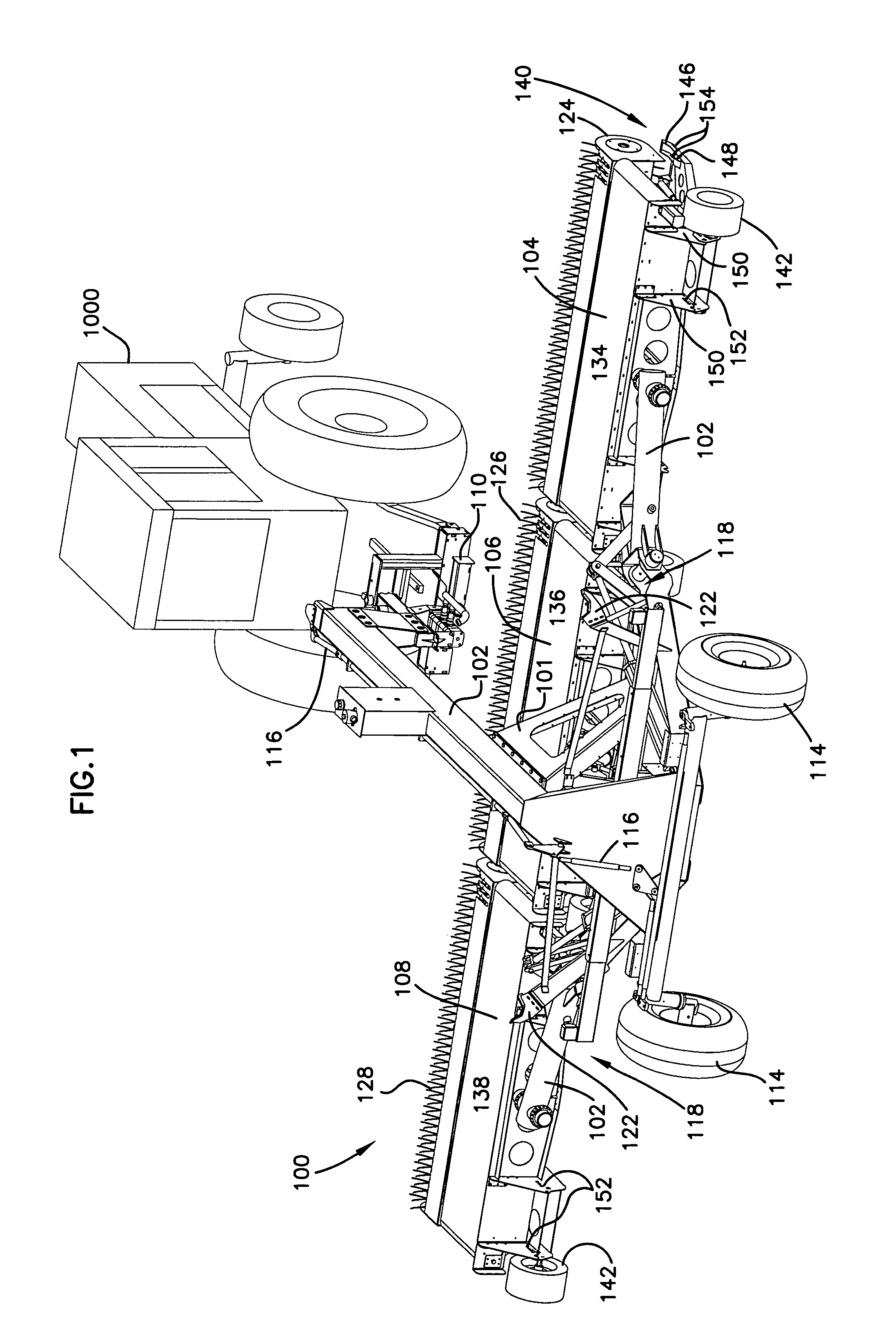

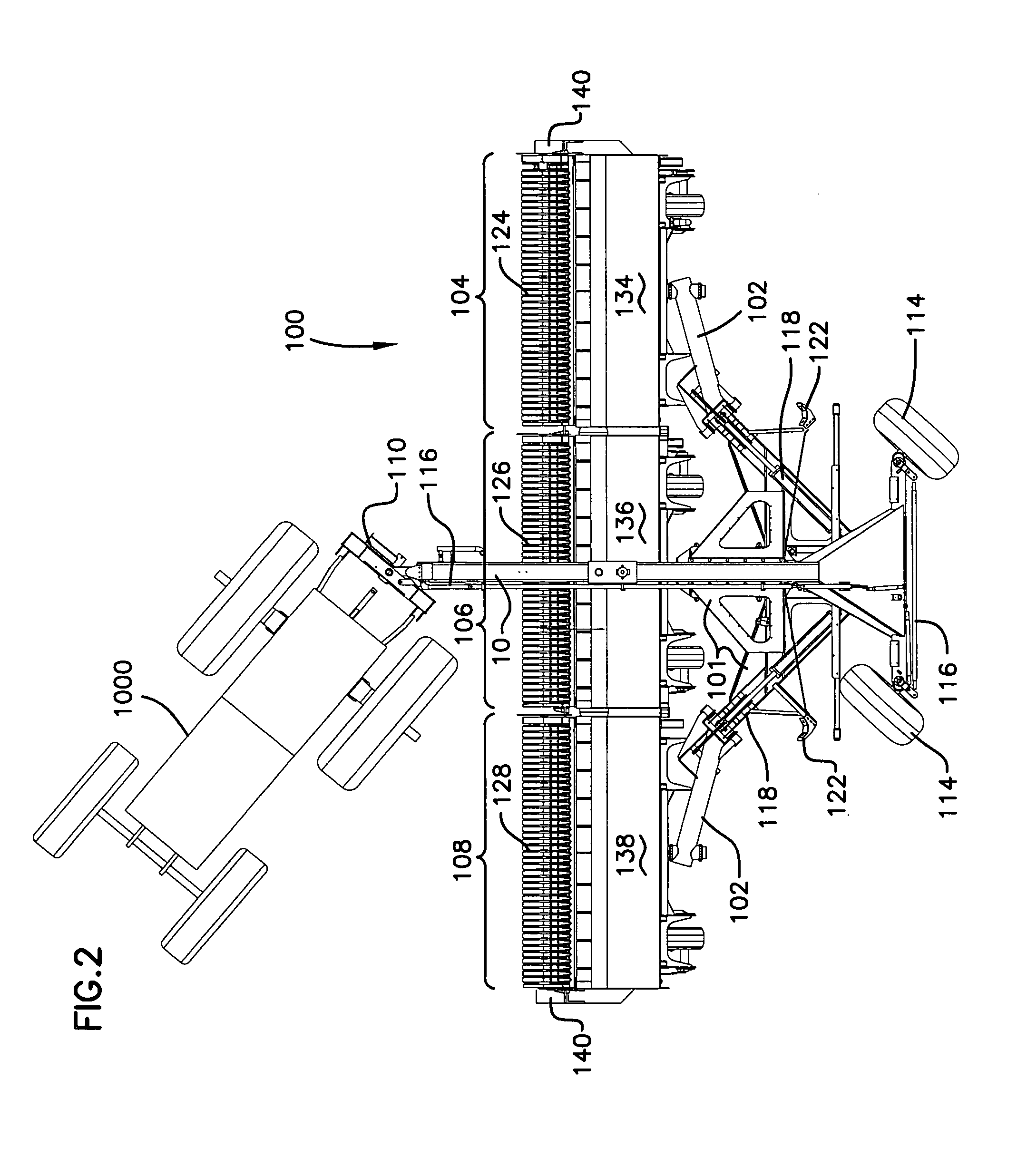

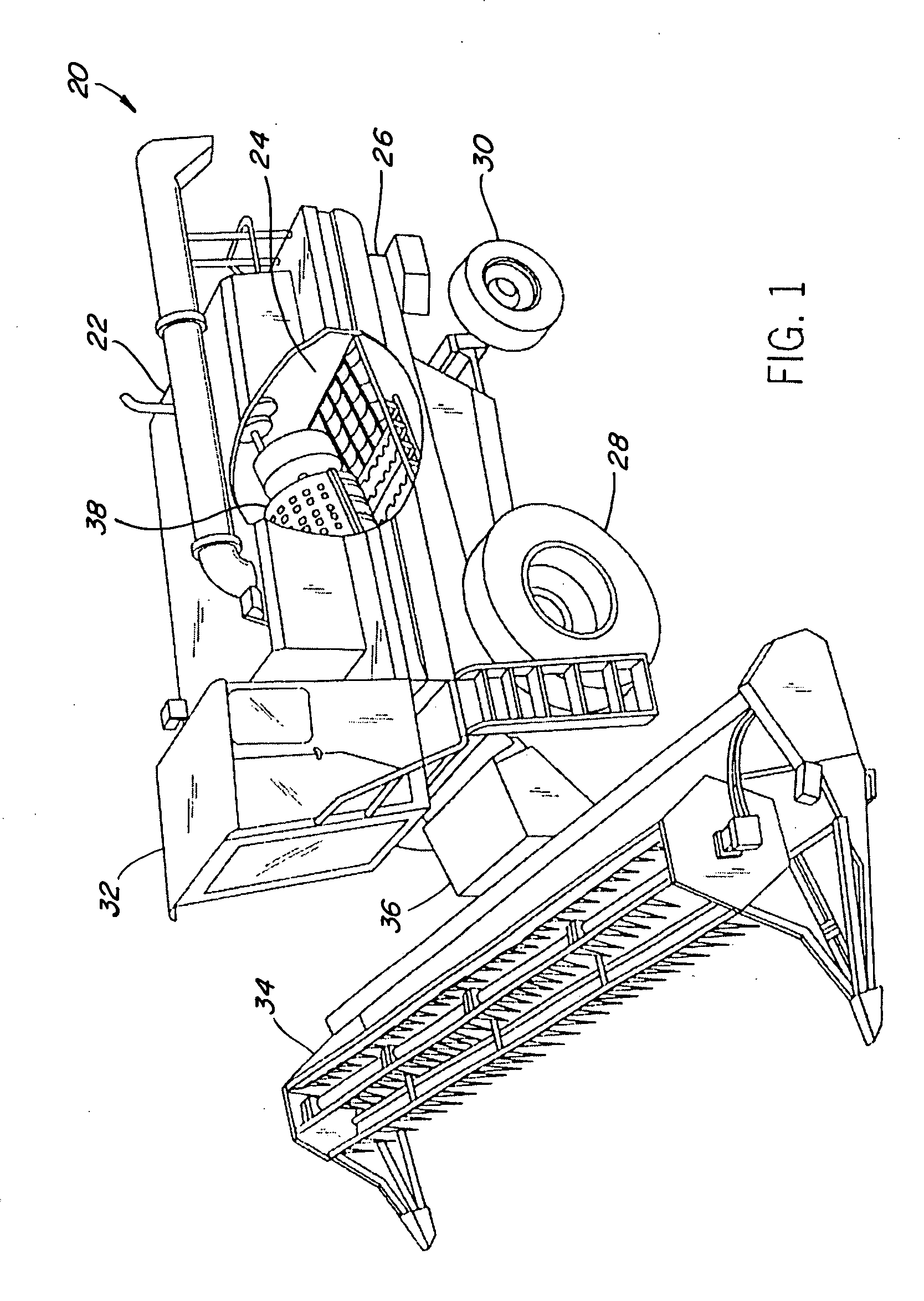

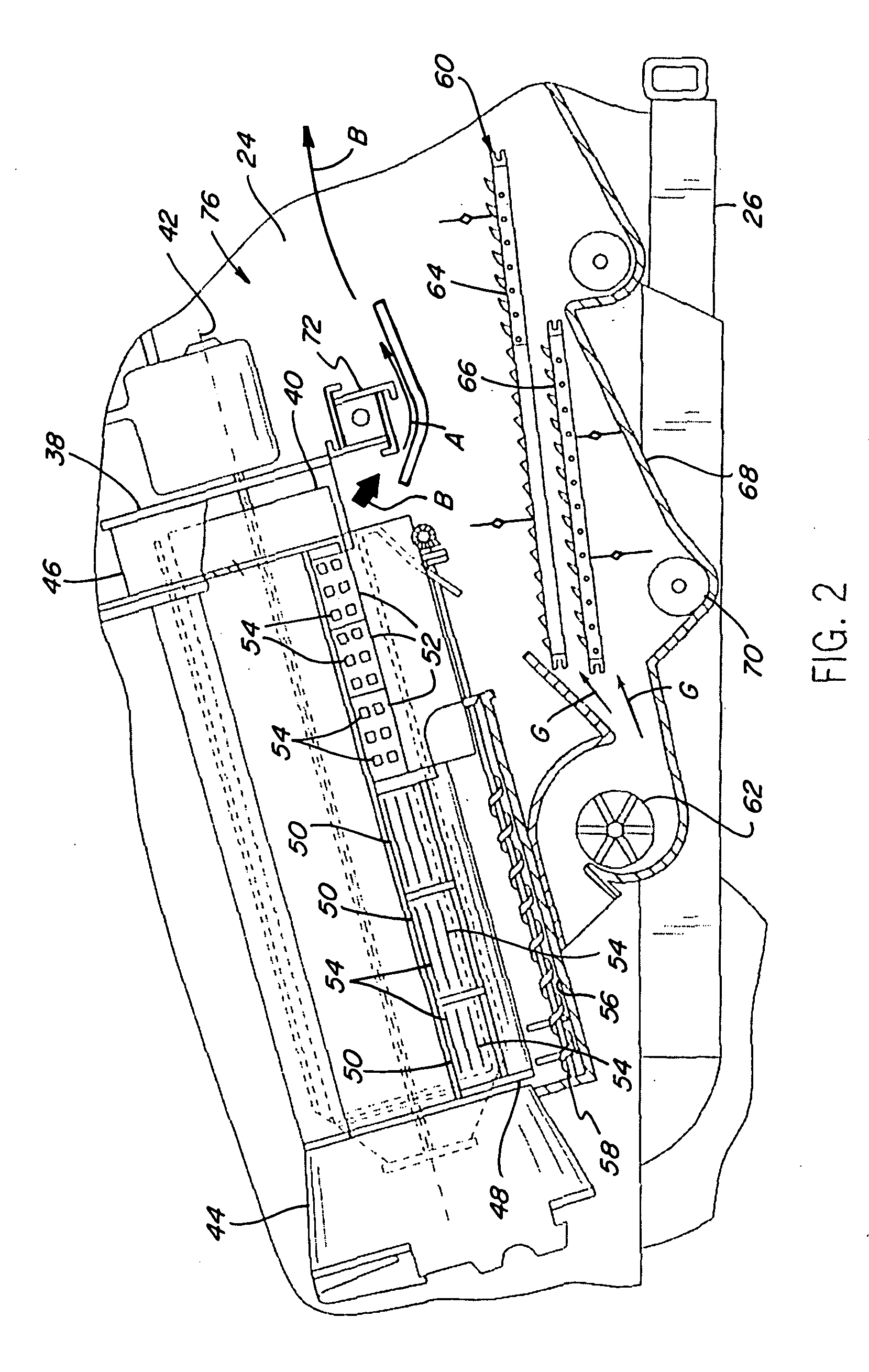

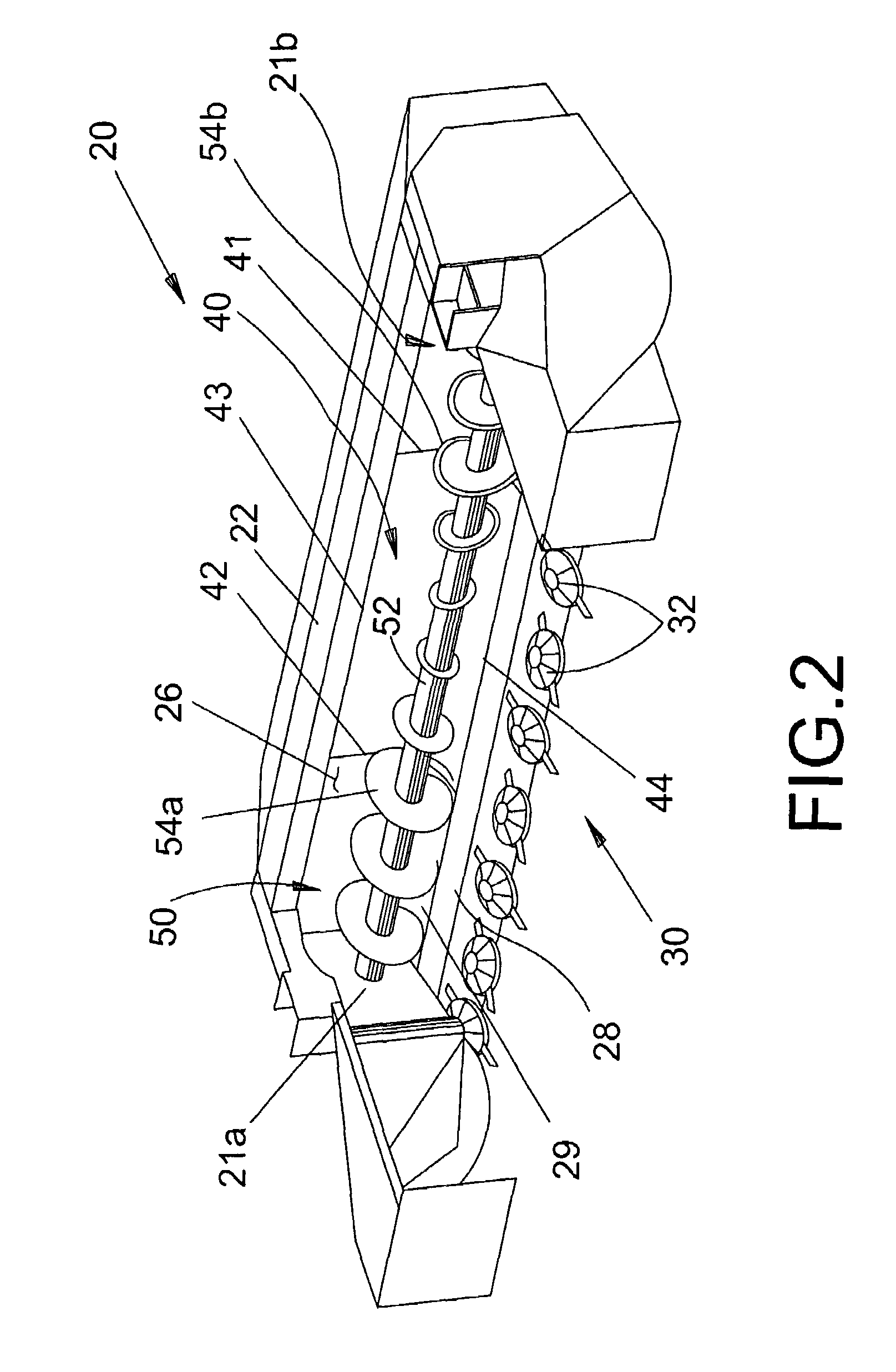

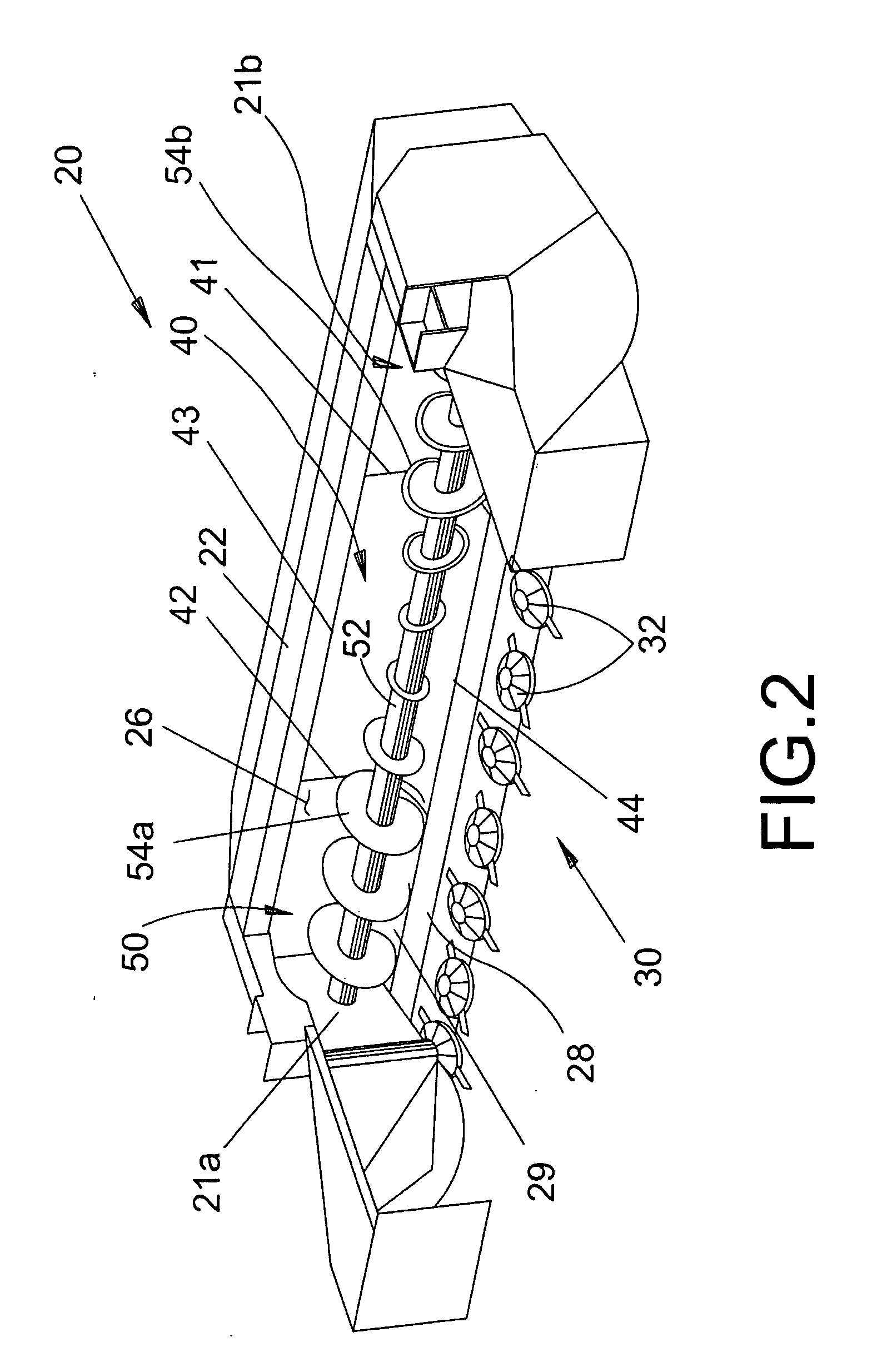

Windrow merging apparatus

InactiveUS7310929B2Reduce weightSpadesAgricultural machinesPickup Device ComponentMechanical engineering

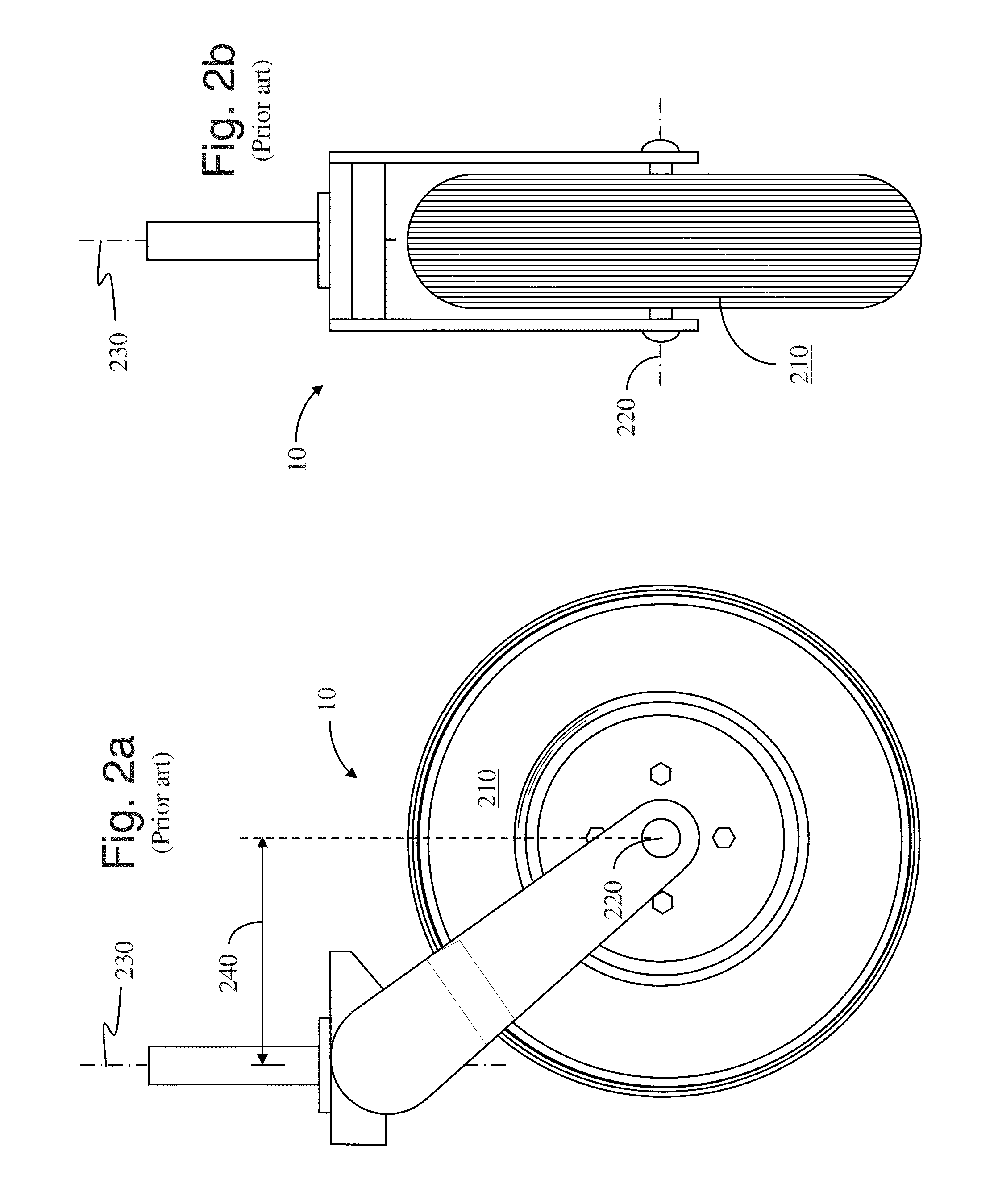

A windrow merger has a frame supporting first, second and third pickup assemblies, with the two outside pickup assemblies foldable between an extended use position and a retracted travel position. Each of the pickup assemblies includes a reversible conveyor providing multiple windrow merging configurations. The pickup assemblies are interchangeable and aligned to define an unobstructed pickup face.

Owner:OXBO INT CORP

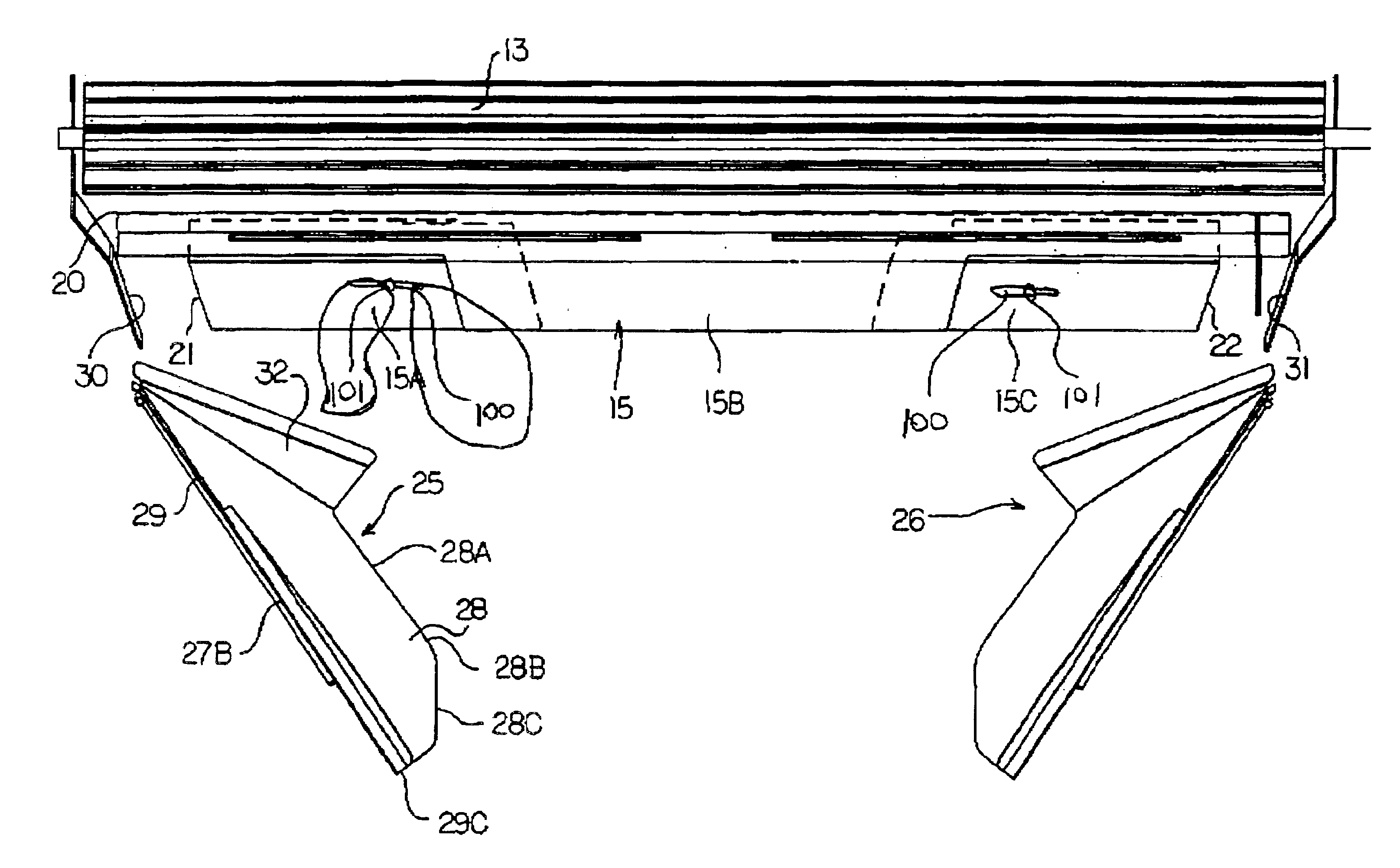

Windrow forming system for a crop harvesting header

A windrow is formed by discharging the crop rearwardly from a crop conditioner, engaging a center part of the web with a center deflector panel which is adjustable in width so as to direct that portion of the web, selected to match the intended width of the windrow, in contact with the center deflector panel downwardly toward the ground leaving two side portions which are not deflected and thus move to a height above the center portion, and engaging each of the side portions with a side deflector panel so that the side portion is redirected from a position at one side of the center portion and above the center portion to a position on top of the center portion.

Owner:MACDON INDS

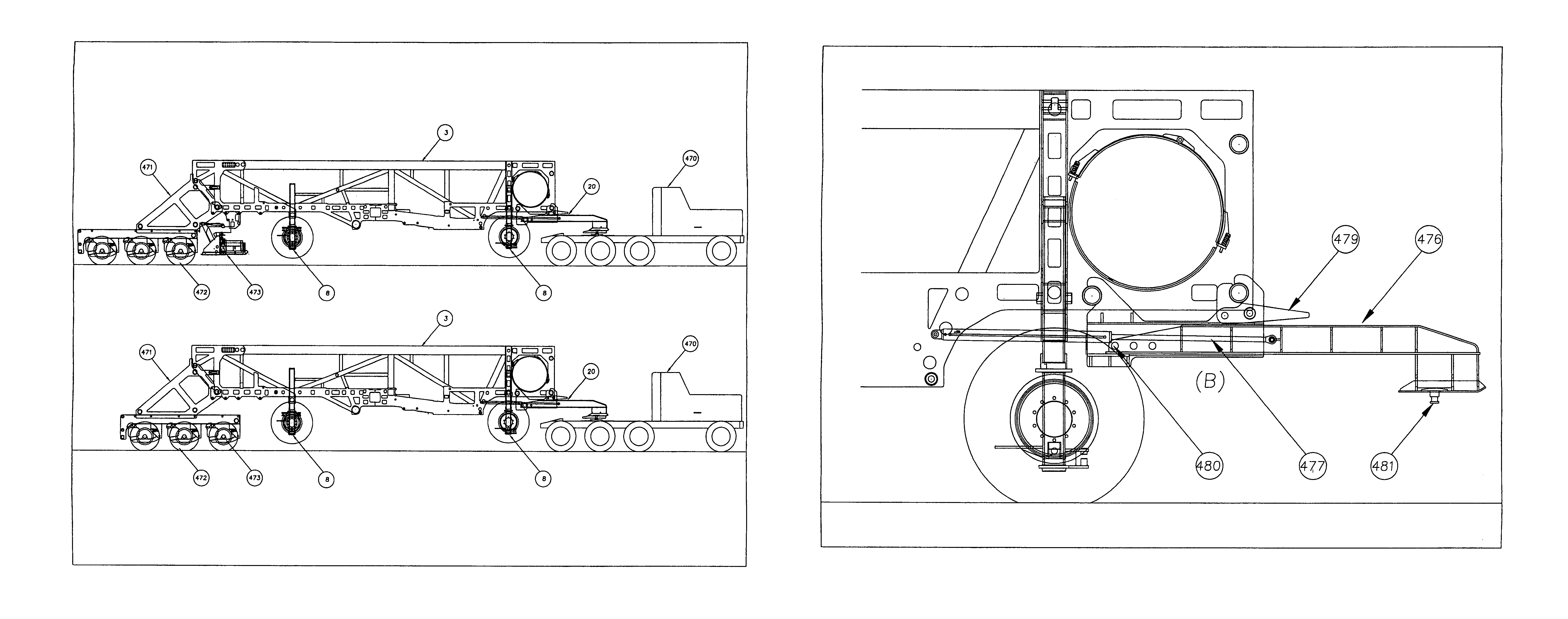

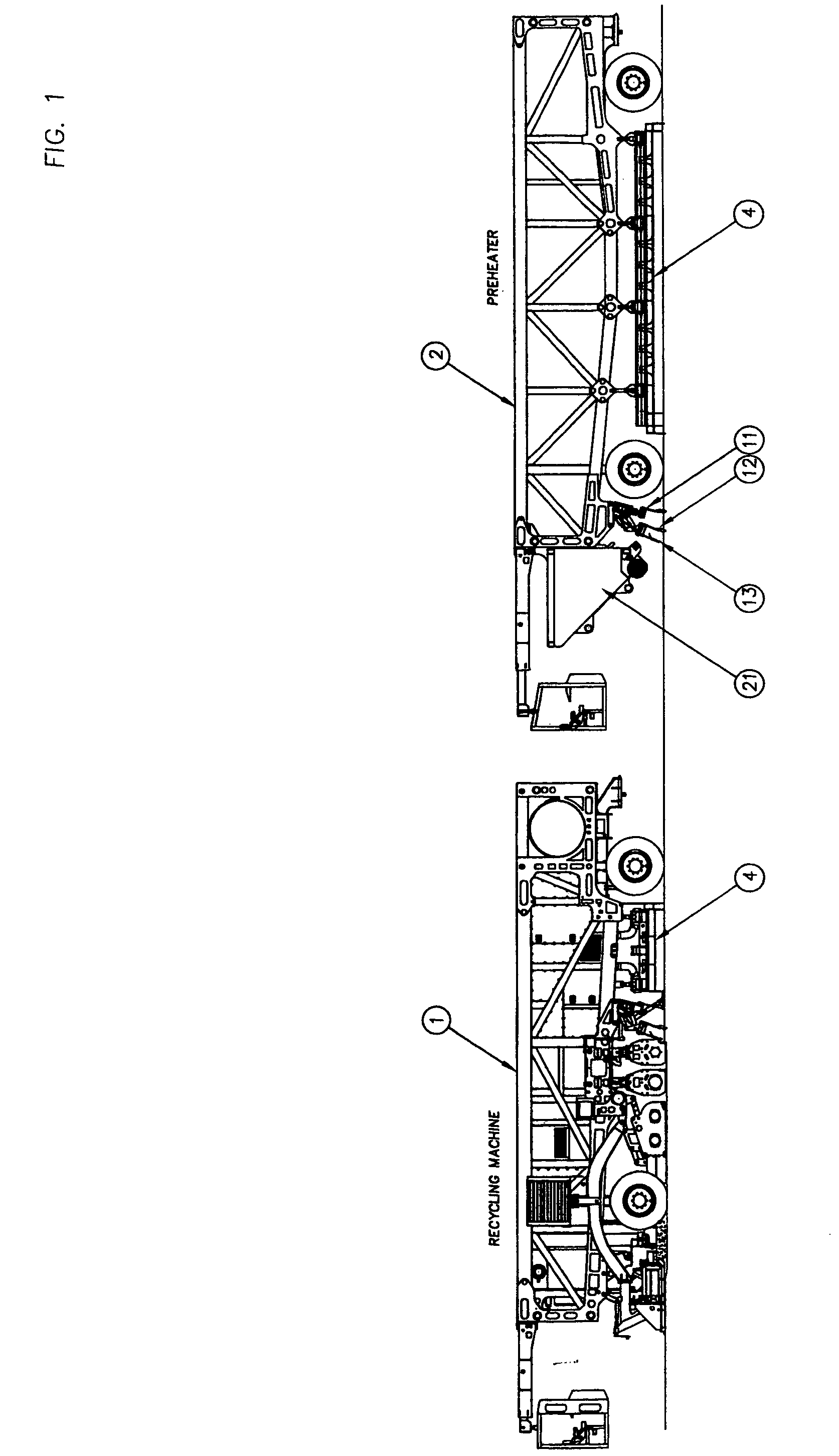

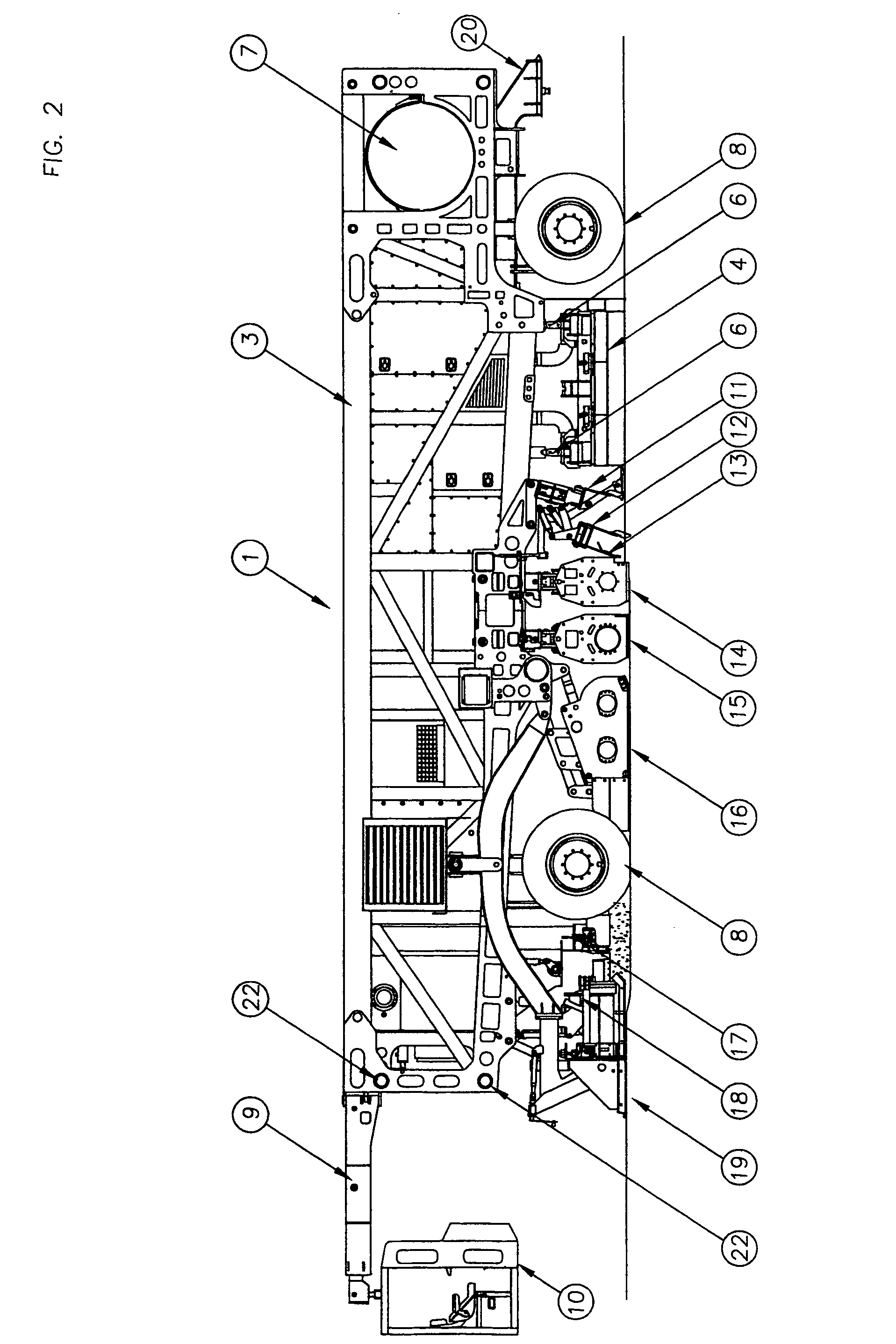

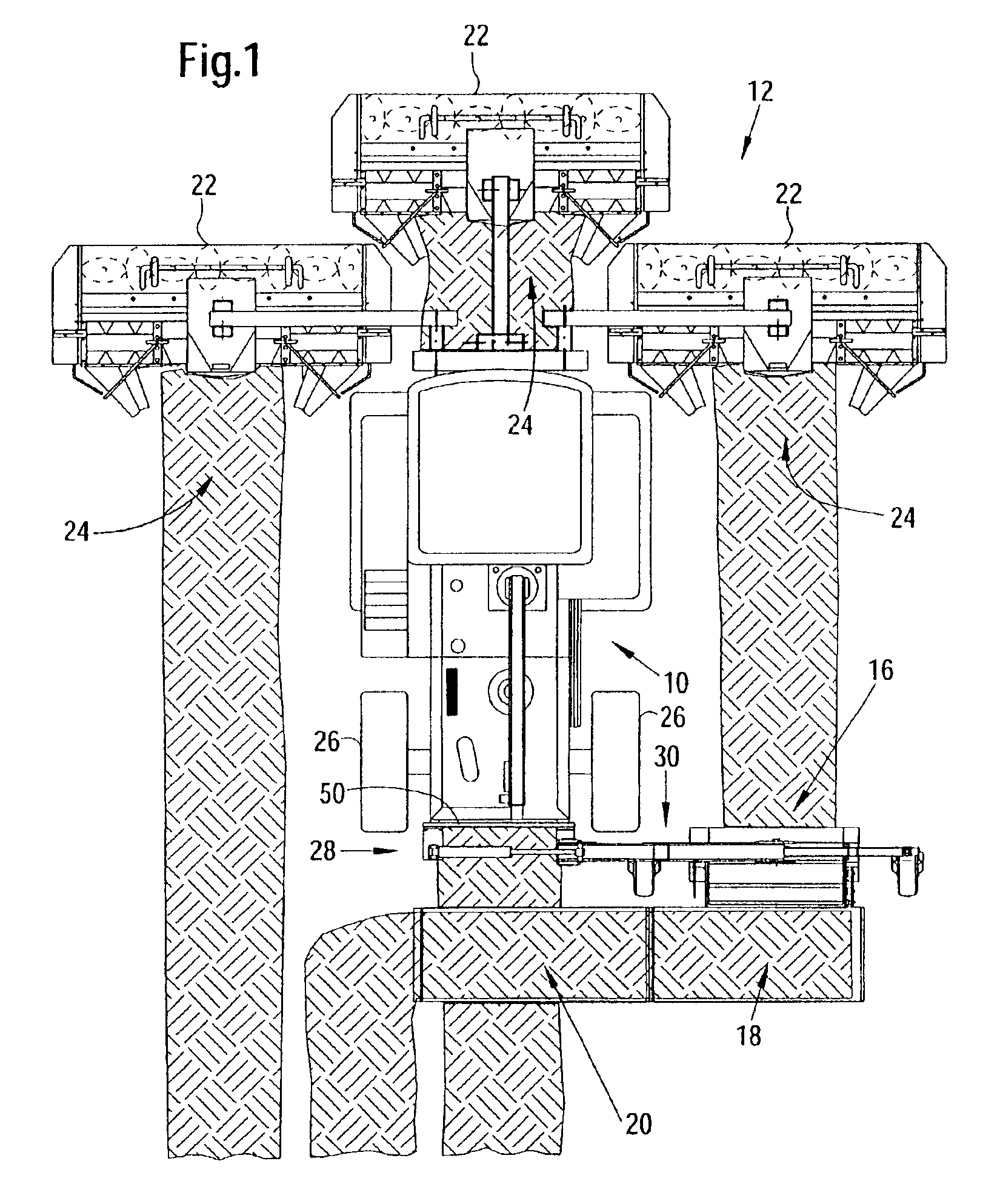

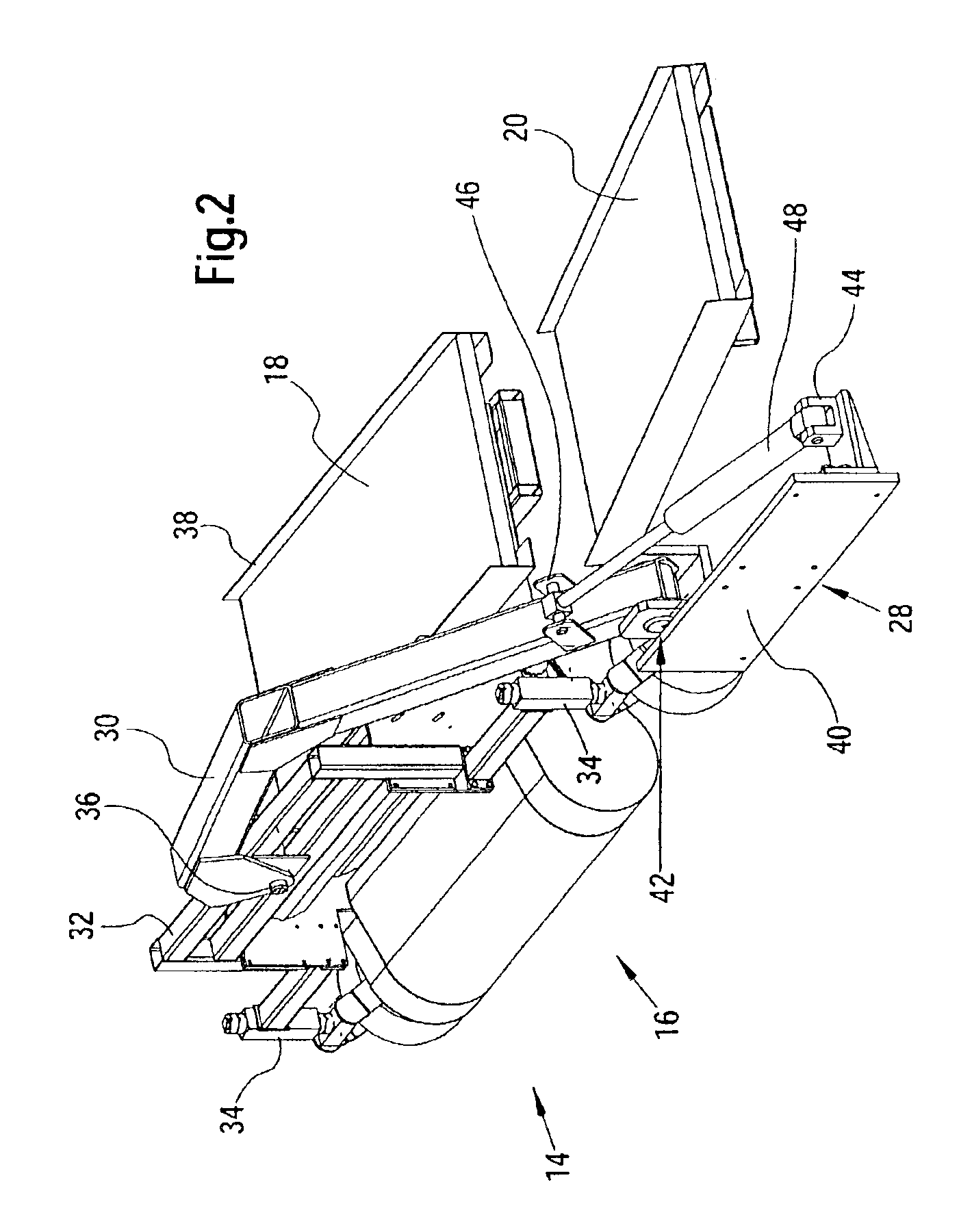

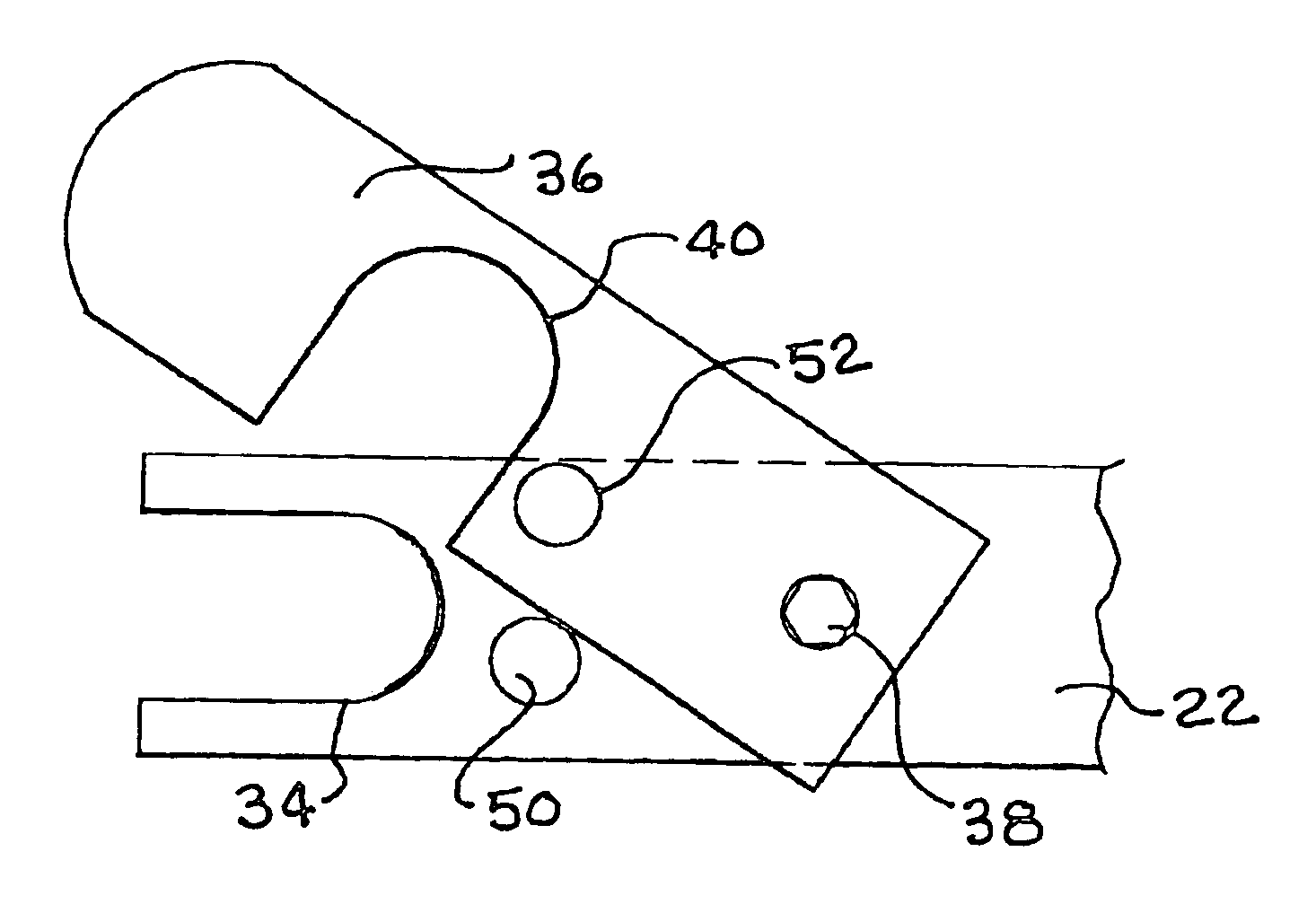

Hot in-place asphalt recycling machine

InactiveUS7077601B2Improve performanceIncrease flexibilityIn situ pavingsUnderstructuresScreedRoad surface

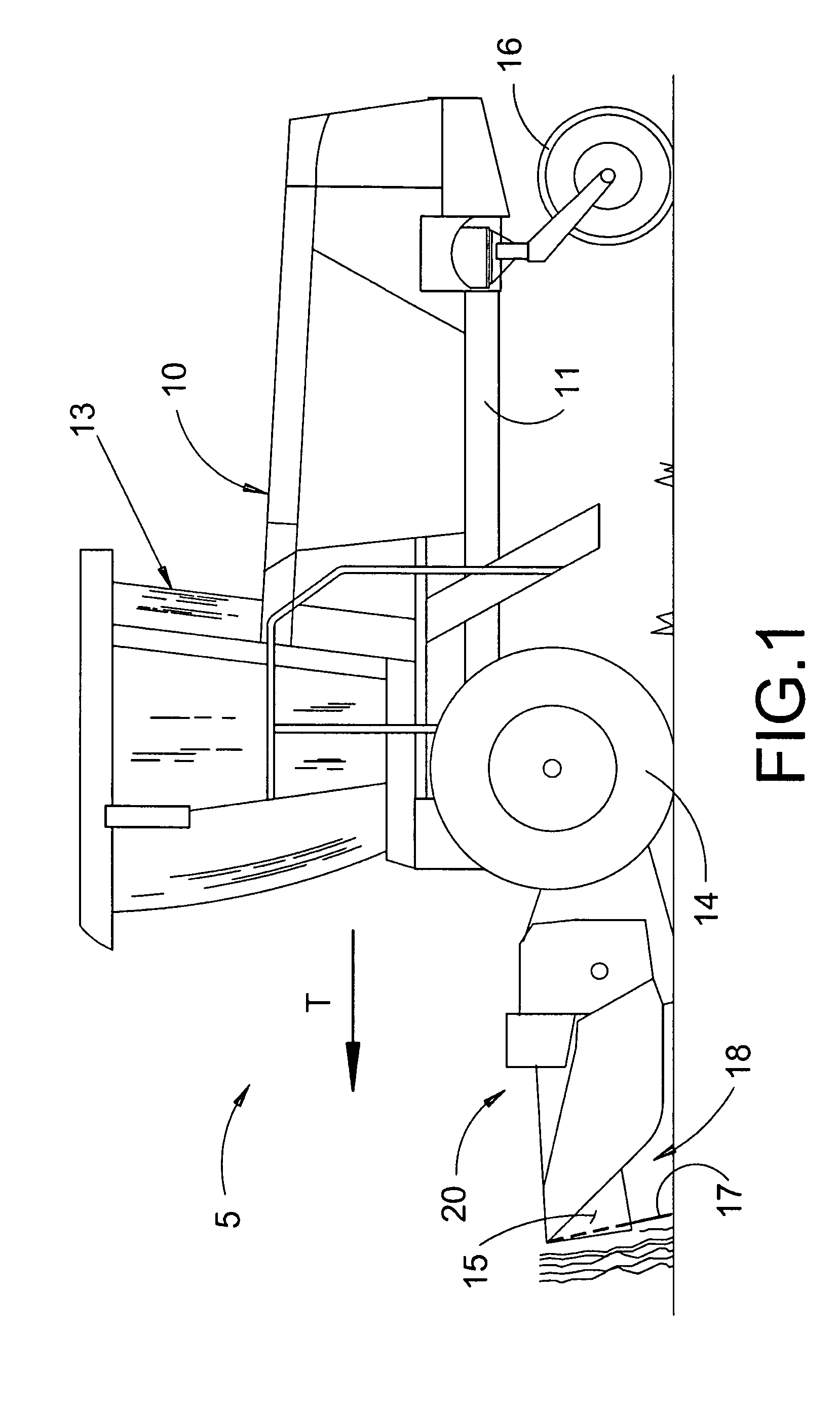

A machine for providing hot-in-place recycling and repaving of an existing asphalt-based pavement, in which the pavement is first heated. Using this machine the heated pavement surface is then scarified, and new aggregate is dispensed onto it, to form a recycled, preheated asphalt and aggregate mixture. This mixture is again heated and scarified to premix it, and a new pavement surface is now milled to grade and width by applying this mixture using a plurality of extension mills having a main frame. The pavement surface is then remilled to grade using a main mill. Rejuvenator fluid is introduced in the main mill of the machine, and mixed with the recycled asphalt and aggregate mxiture. Rejuvenator fluid is also introduced into a pug mill of the machine and again mixed with the recycled asphalt and aggregate mixture. The rejuvenator-enriched, recycled asphalt and aggregate windrow thus formed is then laid to grade using one or more screeds.

Owner:ENVIRO PAVE

Method for preparing organic fertilizer by using plant residues as raw material

InactiveCN104261911AAccelerates decay and degradationImprove decomposition abilityBio-organic fraction processingExcrement fertilisersMicrobial agentDecomposition

The invention relates to a method for preparing an organic fertilizer by using plant residues as a raw material. The method comprises the following steps: crushing the raw material to below 20mm, stirring and mixing the broken material with animal wastes or an inorganic fertilizer; controlling the C / N ratio of the mixed materials to be (15-35) to 1 and the pH to be 6-9; adding water, so that the moisture content in the mixed materials in the step (2) is 55-70wt%; adding a first composite microbial agent to ferment; after once fermentation, raising the temperature of windrows to above 50 DEG C; and spraying a water-dispersed second composite microbial agent to ferment for the second time. With plant residues heap corruption (composting) as a biological process for succession of a microbial community, through inoculation of exogenous complex microbial agents, efficient decomposition on agricultural wastes is facilitated; different composite microbial agents are respectively added at different composting stages; and a small amount of additives (animal wastes, urea, ammonium nitrate and the like) are added, so that the composting speed is increased, and the quality of the product organic fertilizer is really improved.

Owner:烟台中正新技术有限公司

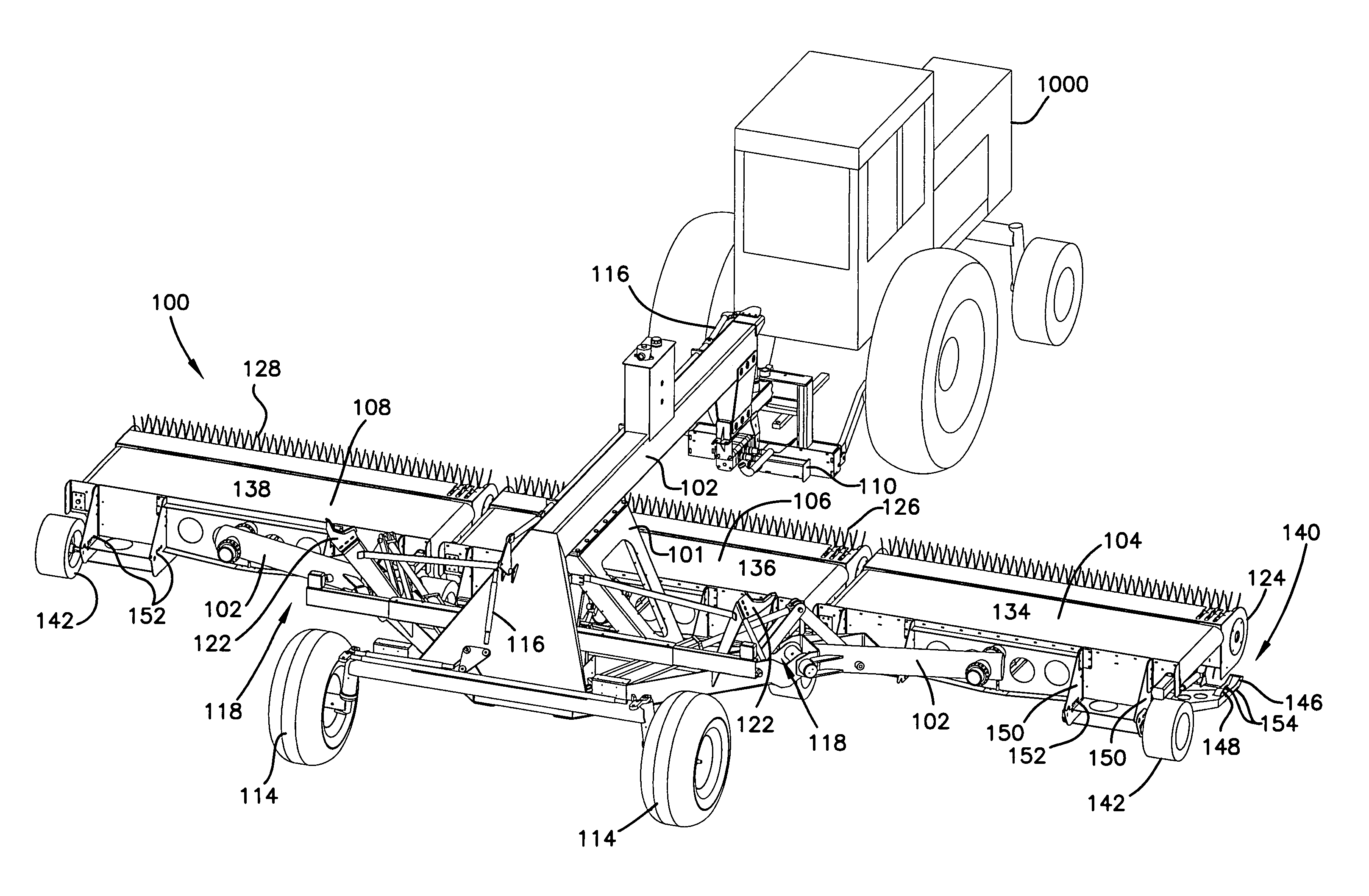

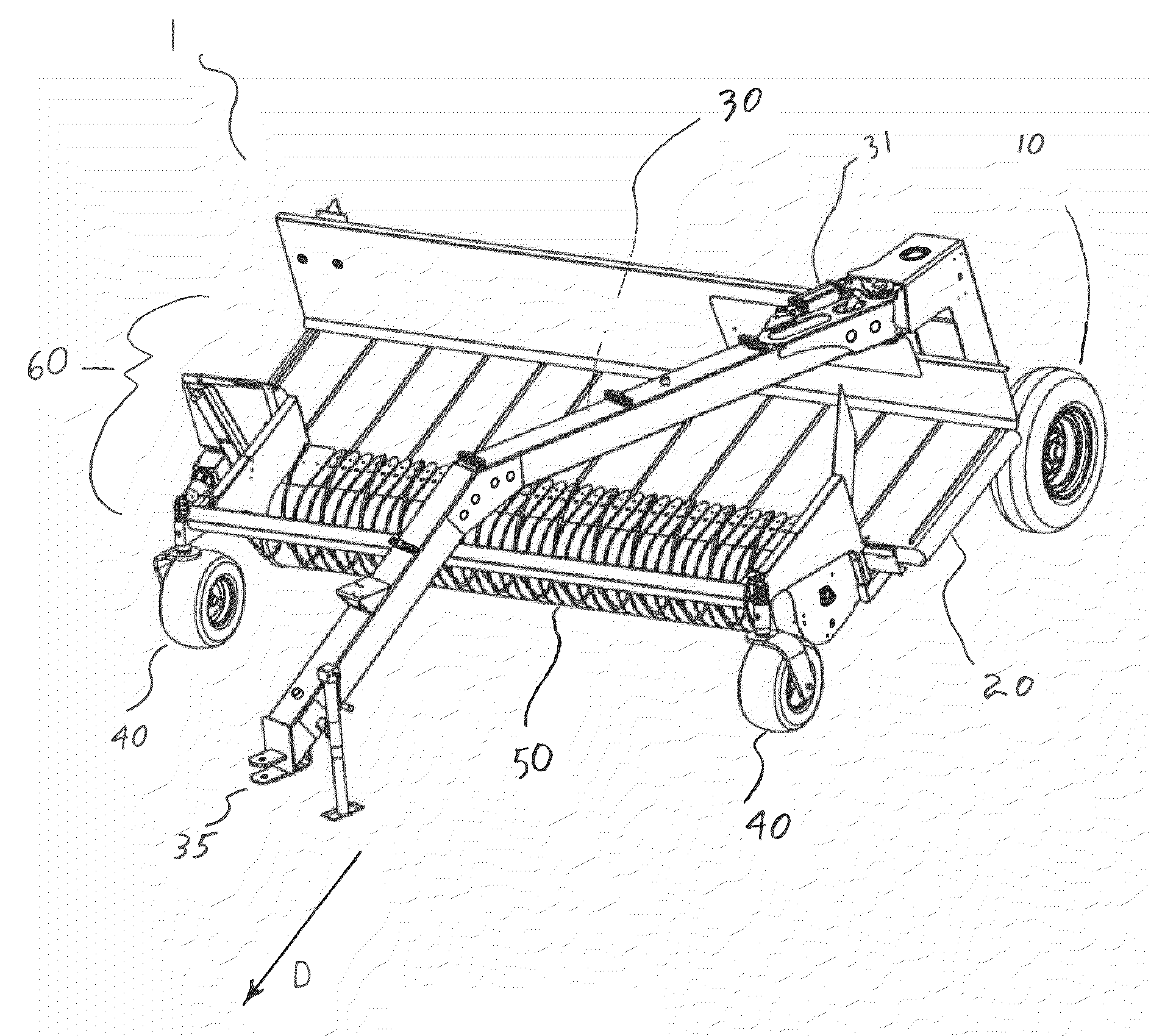

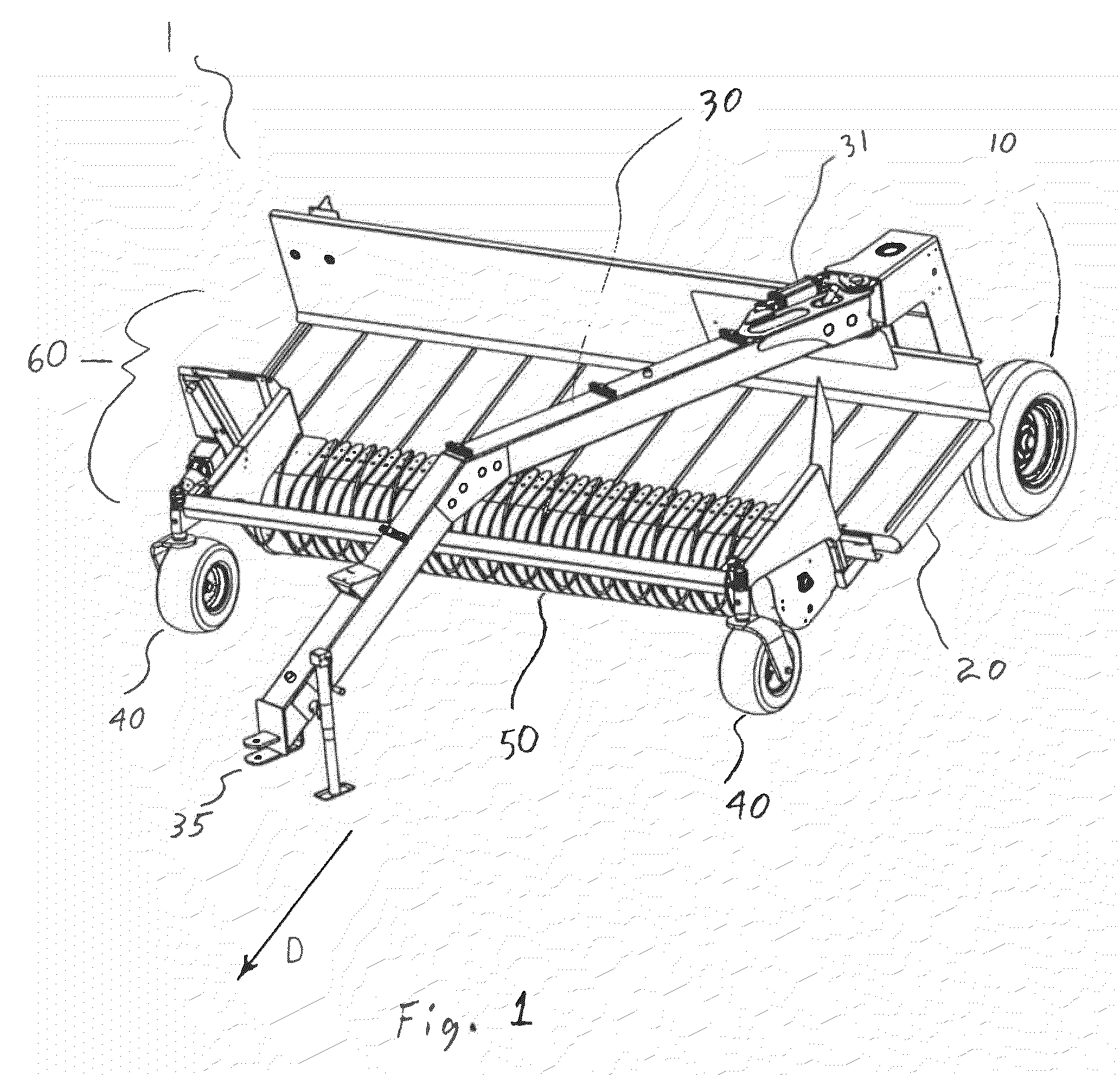

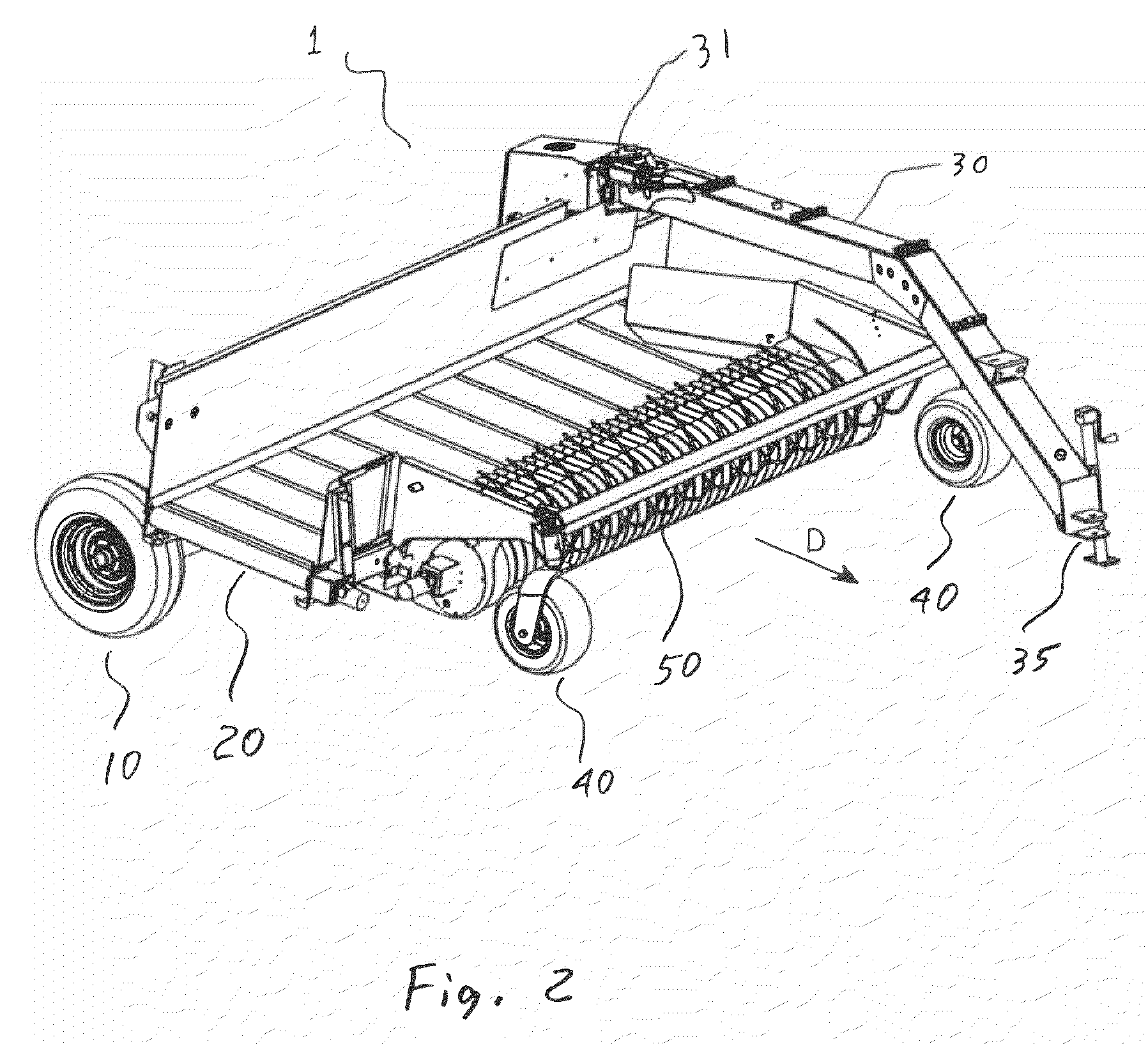

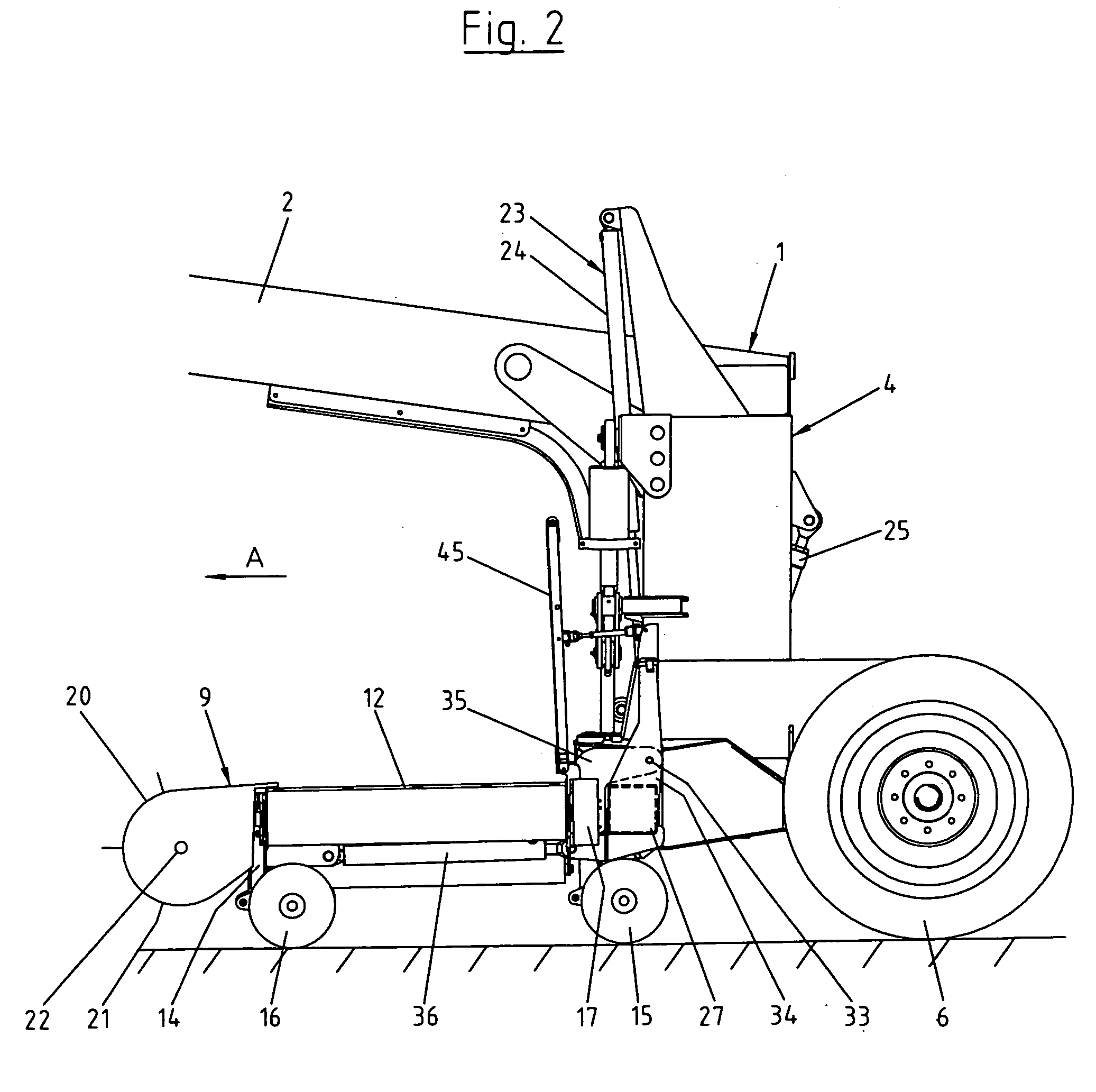

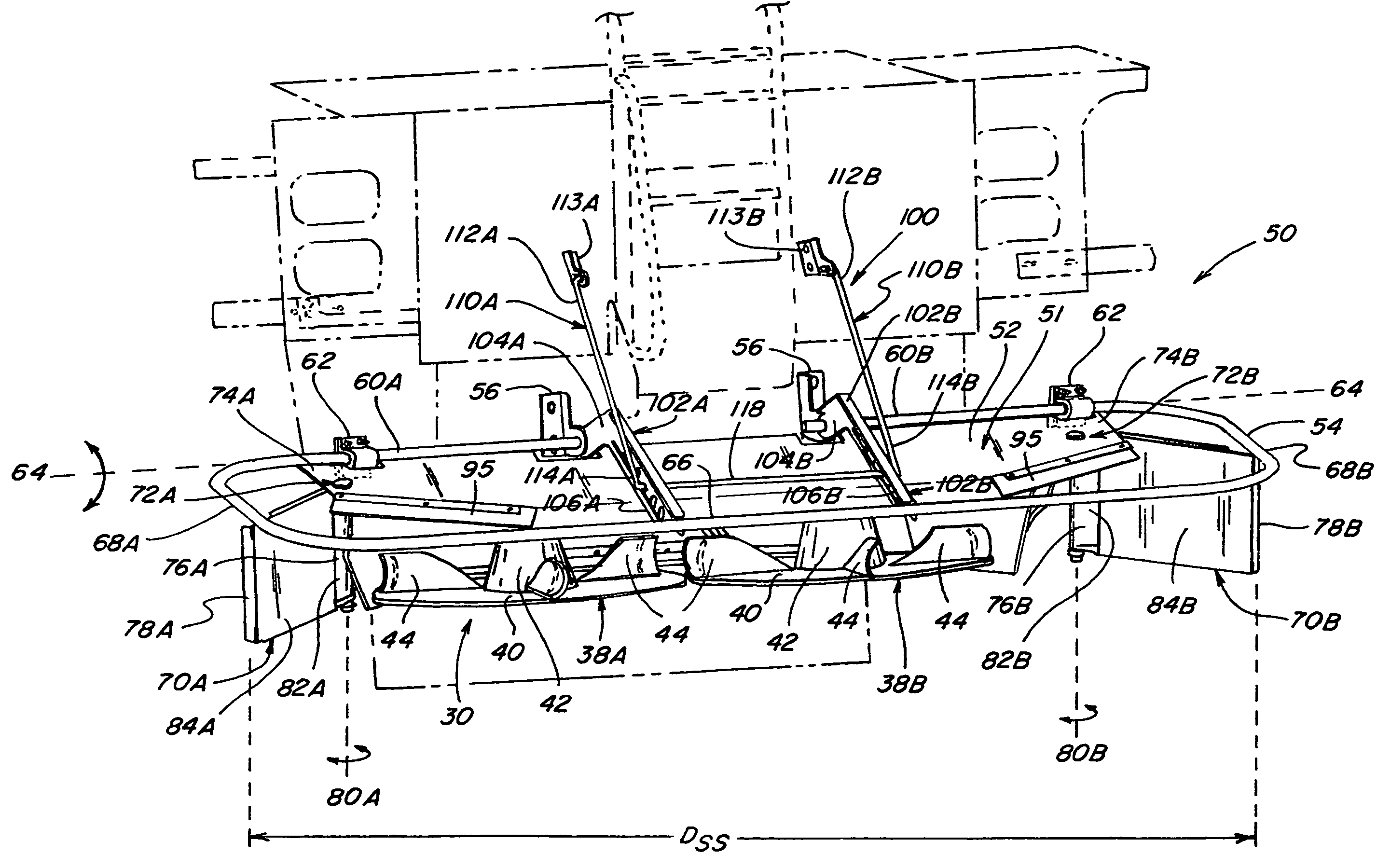

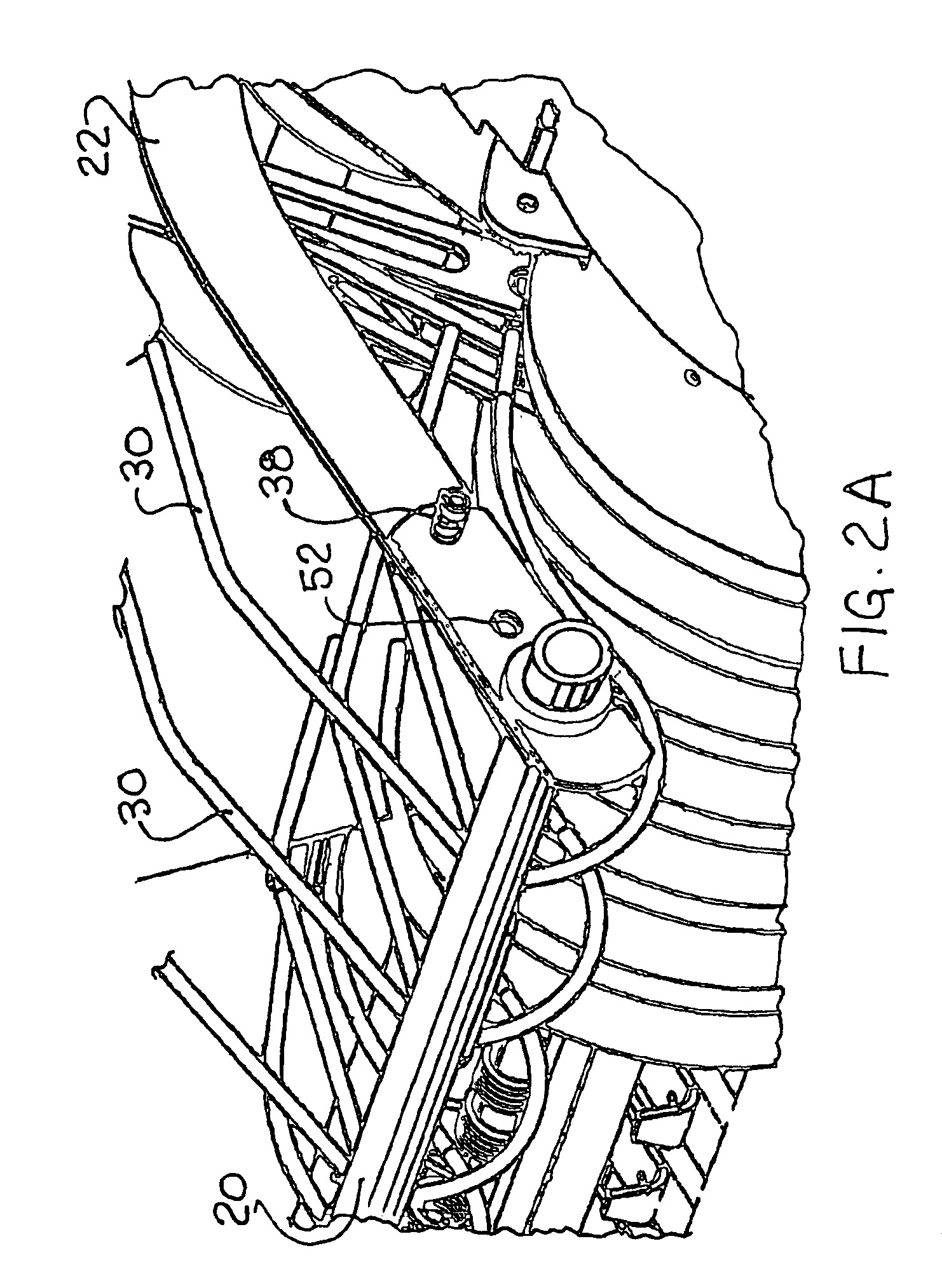

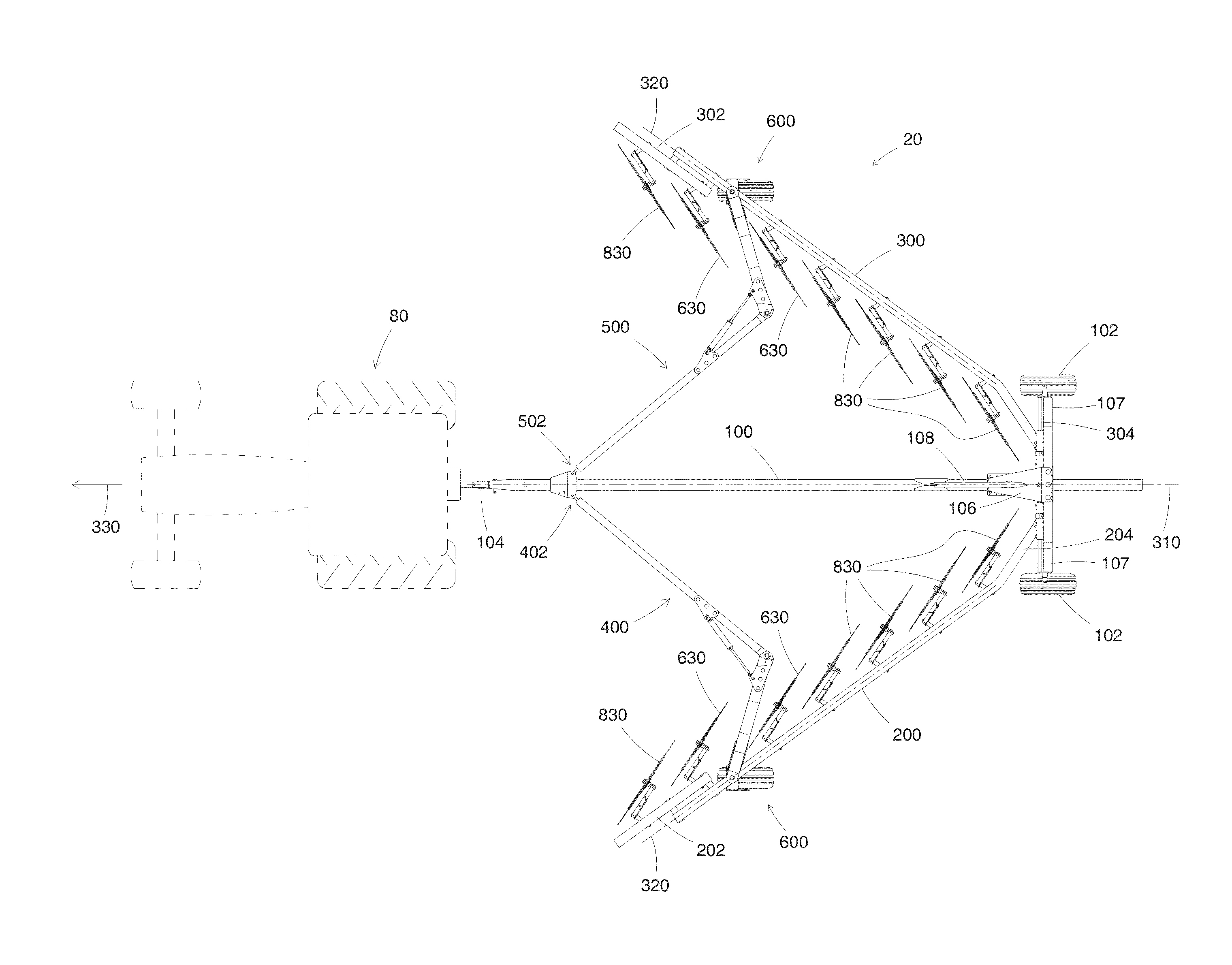

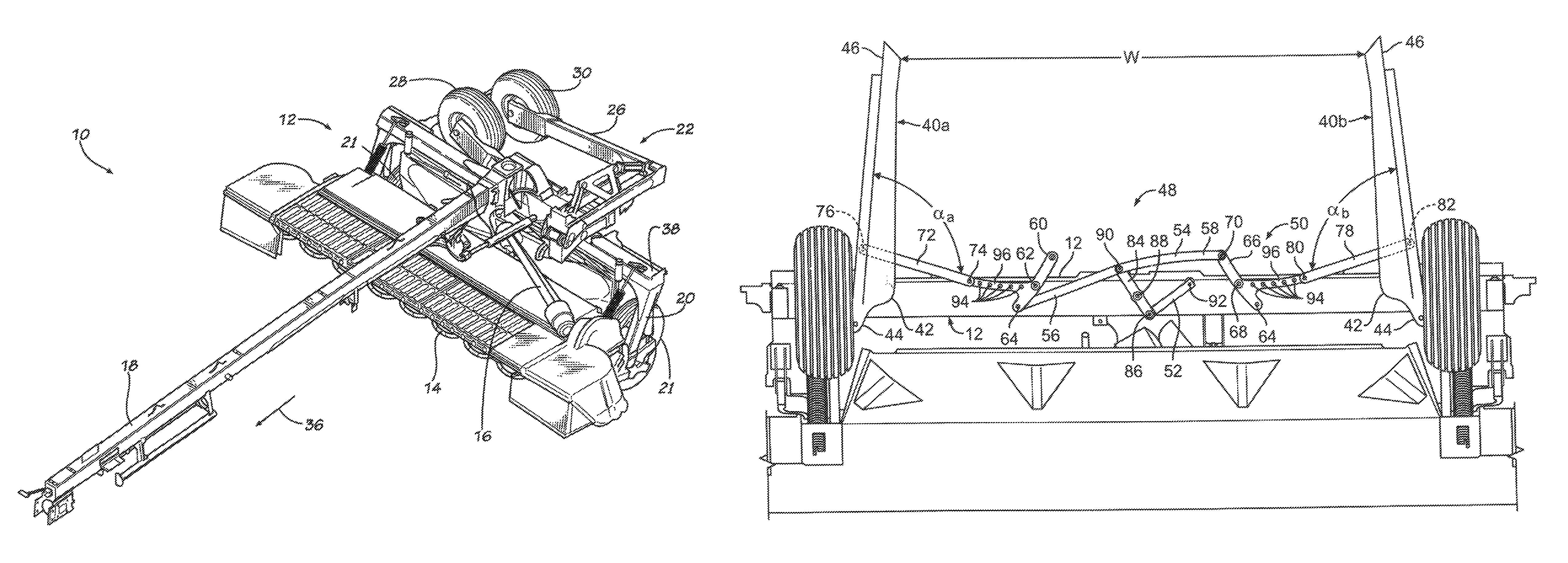

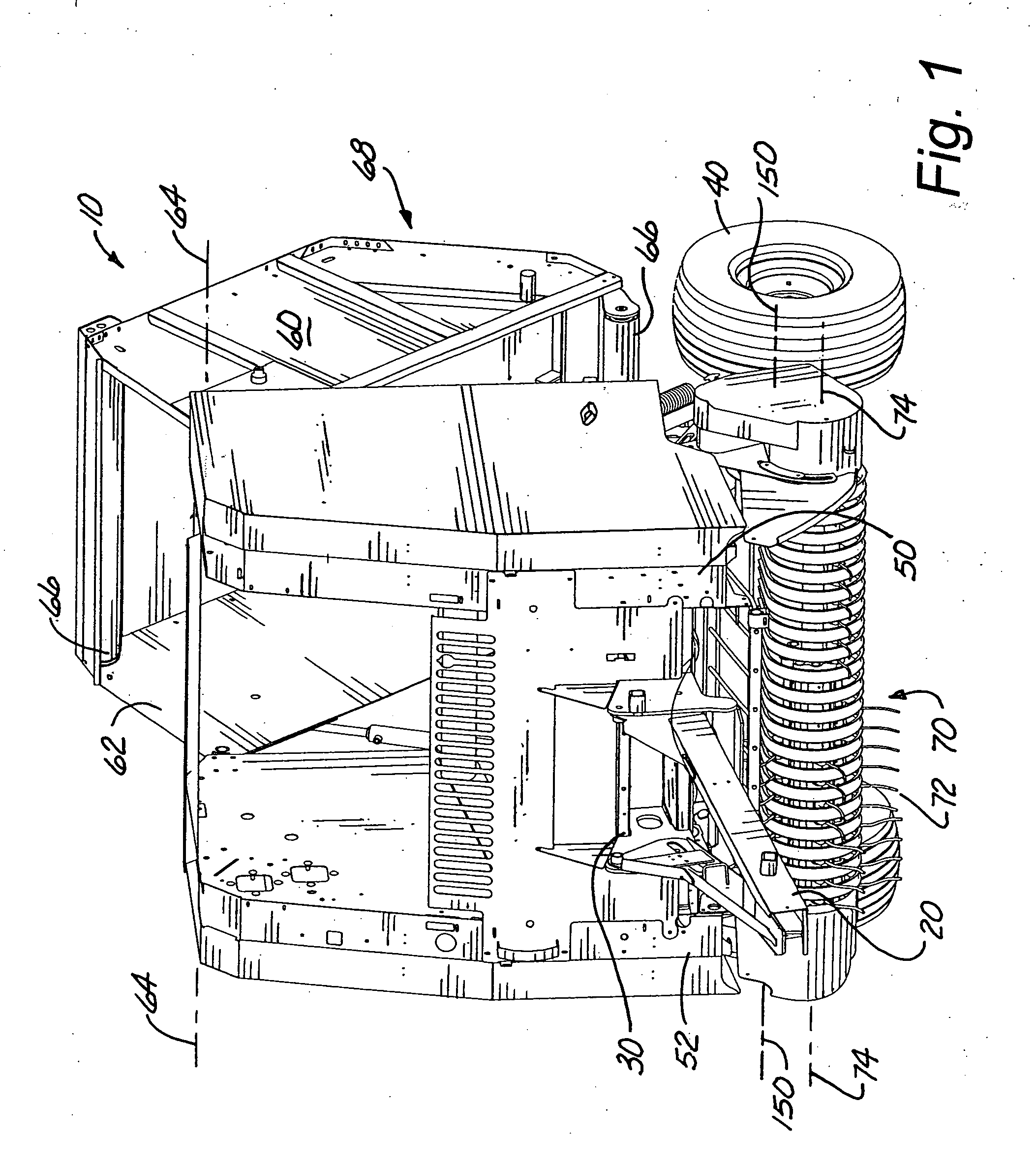

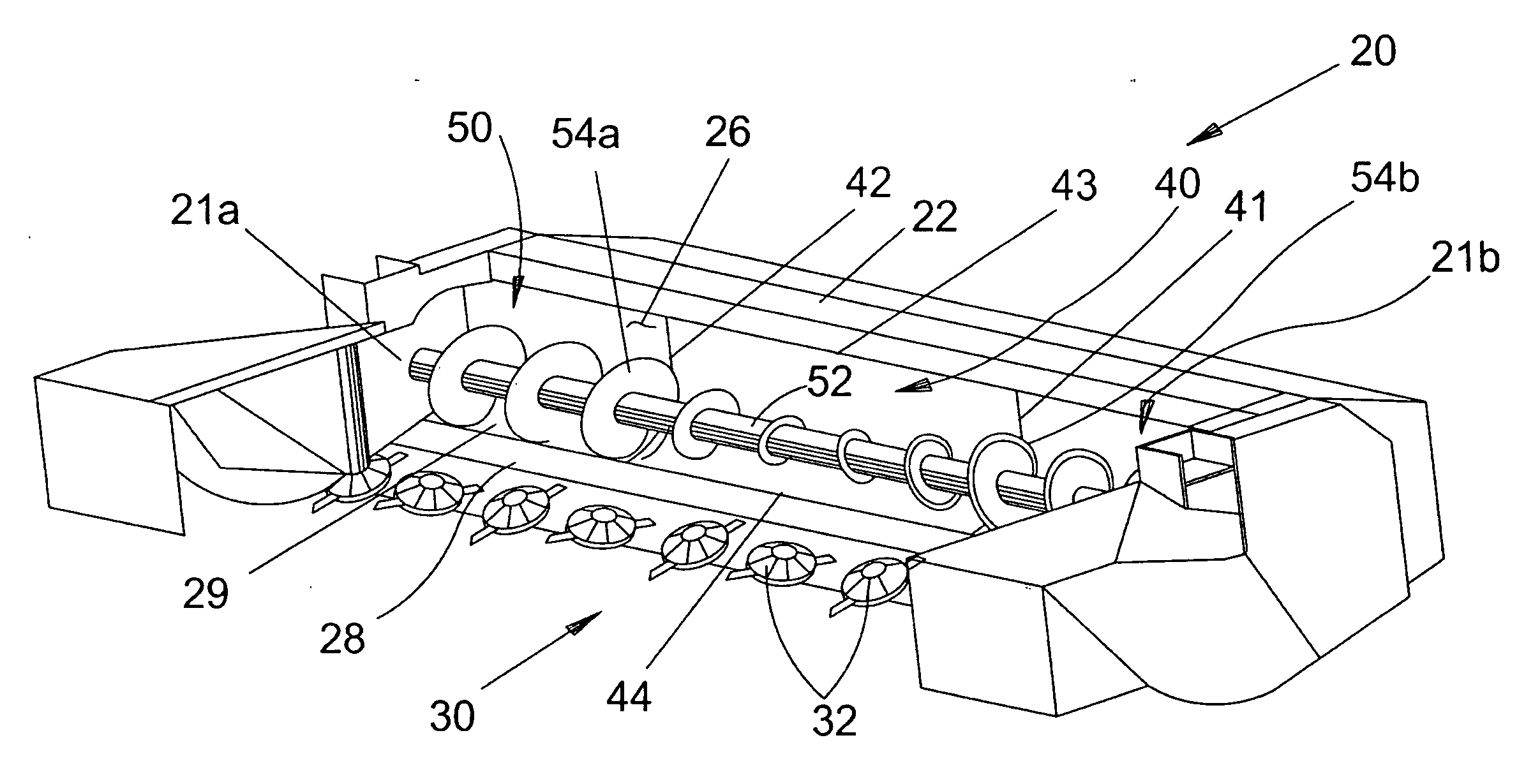

Multi-axis floating merger suspension

A crop merging machine includes a trailer frame, a drawbar assembly coupled to an axle, and a header assembly including a frame and a wheel. The merging machine further includes a pick-up assembly coupled to the header frame and a cross-conveyor assembly coupled to the header frame adjacent to the pick-up assembly. The pick-up and cross-conveyor assemblies are configured to cooperate to lift crop materials off the field surface and move the crop materials laterally to discharge onto the field surface to form a windrow. The merging machine includes a suspension assembly disposed between the trailer frame and header assembly, the suspension assembly being coupled to the header assembly and trailer frame and configured to allow the header assembly to pivot, relative to the trailer frame, about a first axis of rotation and to pivot about a second, distinct axis of rotation to follow a contour of the field surface.

Owner:KUHN NORTH AMERICA

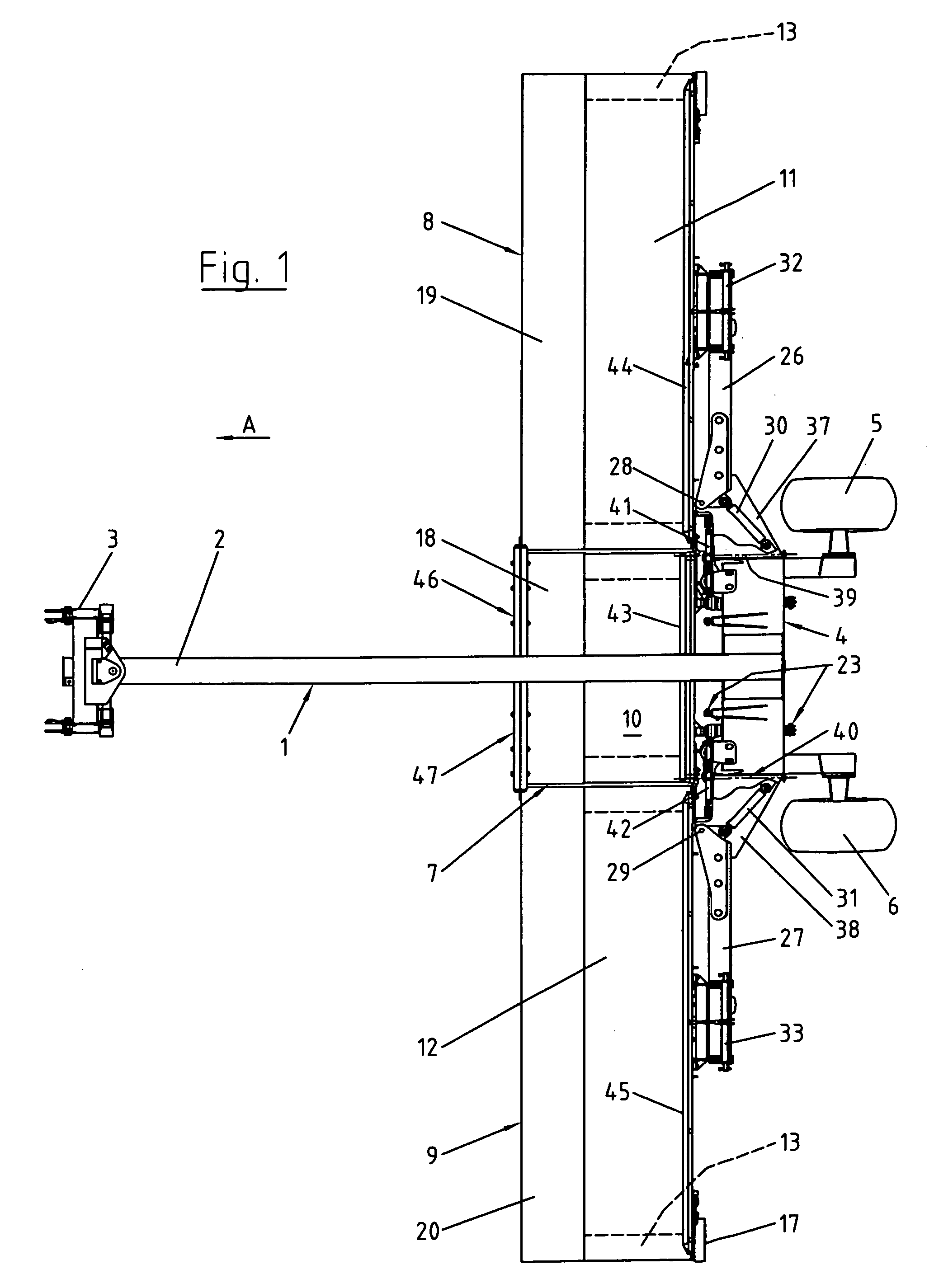

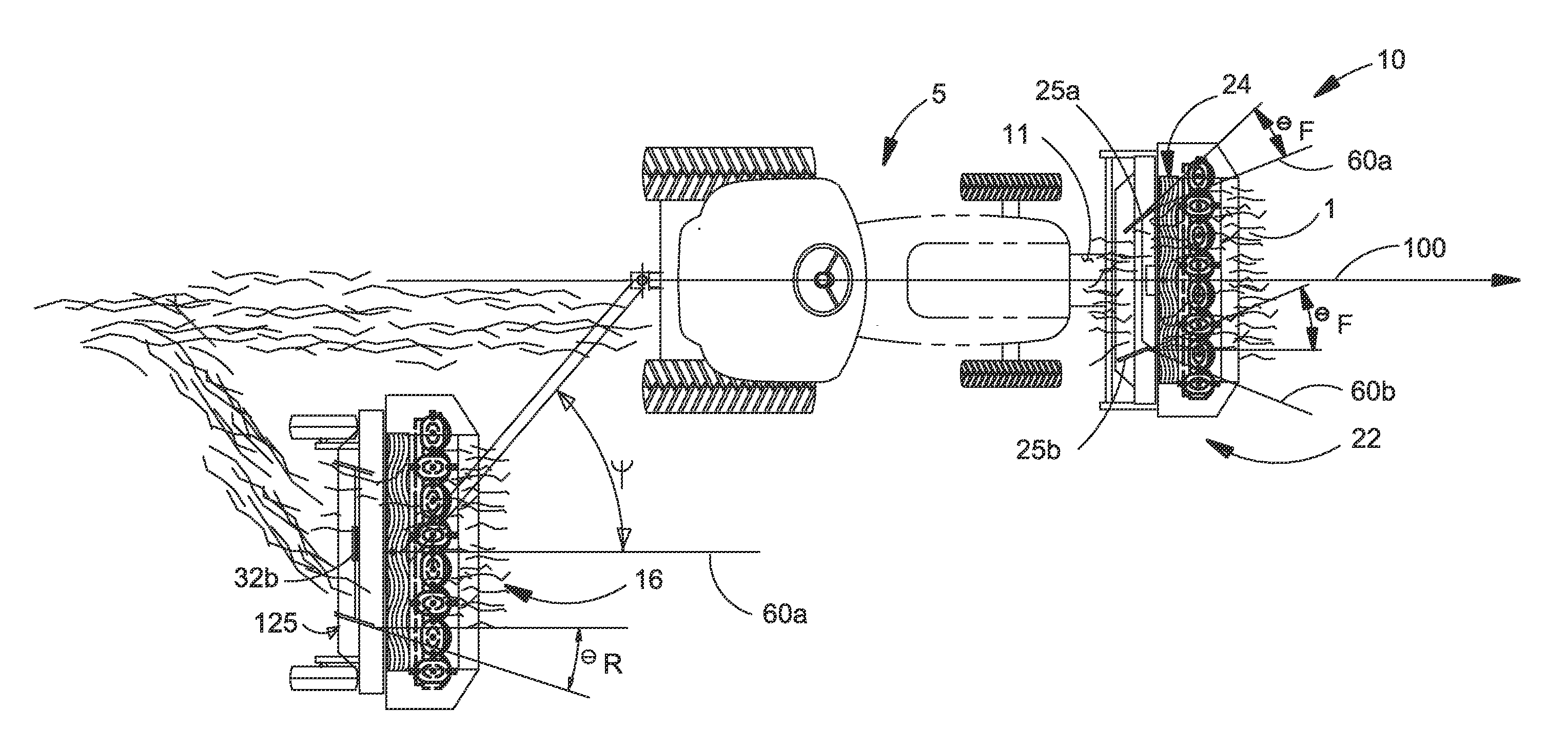

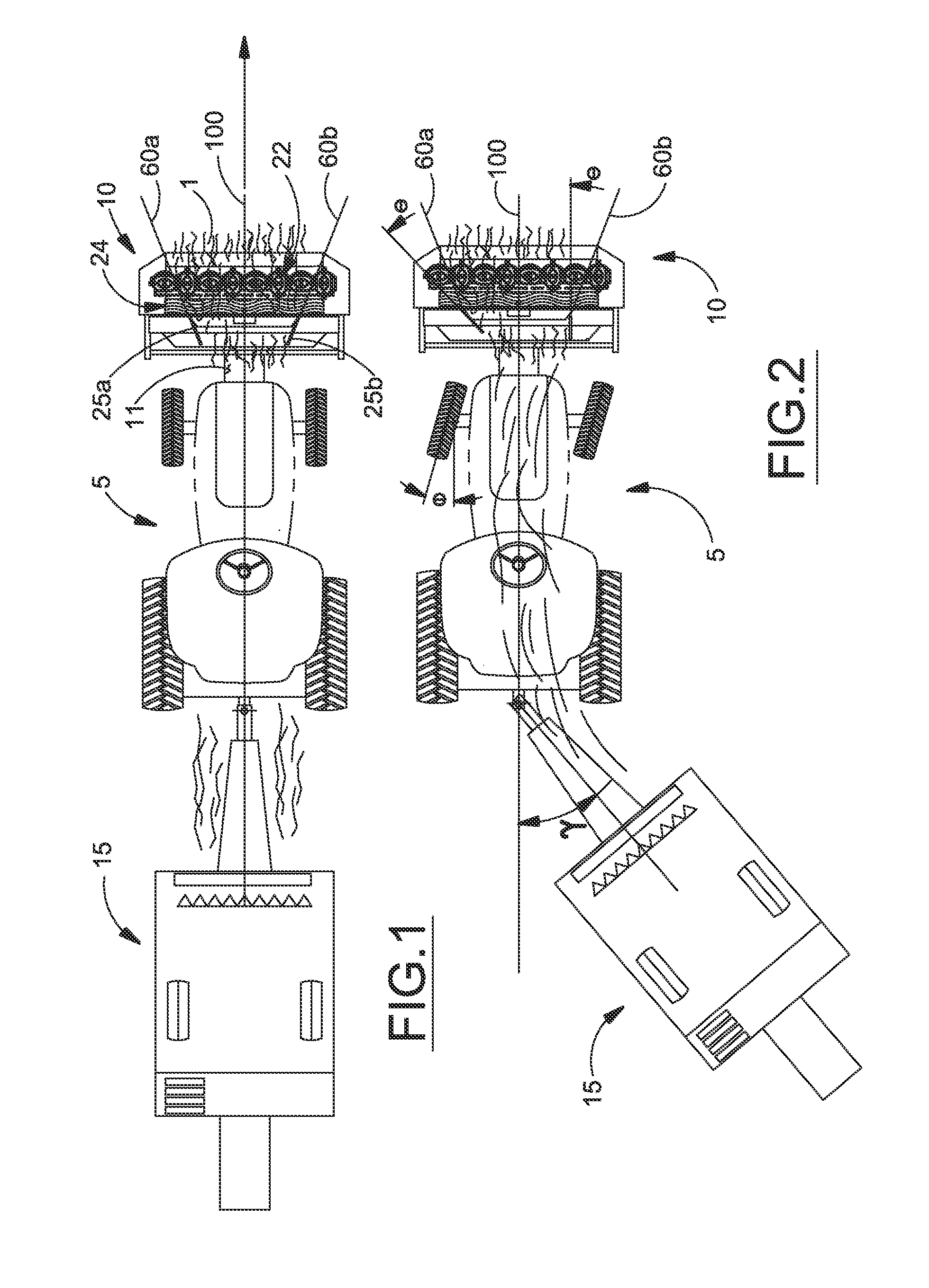

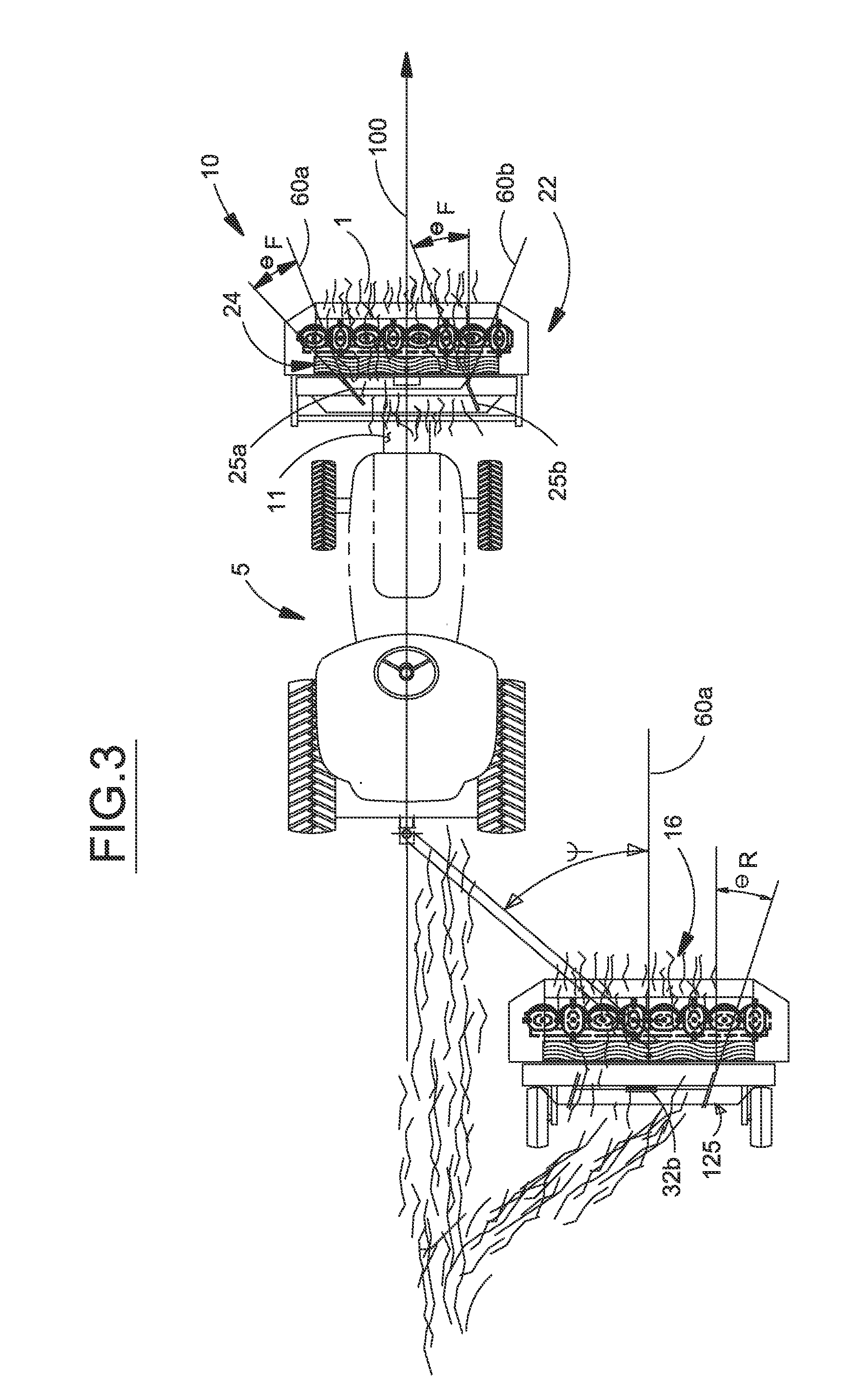

Agricultural machine for swathing products lying on the ground

ActiveUS20060254244A1Improve stabilityReduce widthAgricultural machinesMowersHorizontal axisEngineering

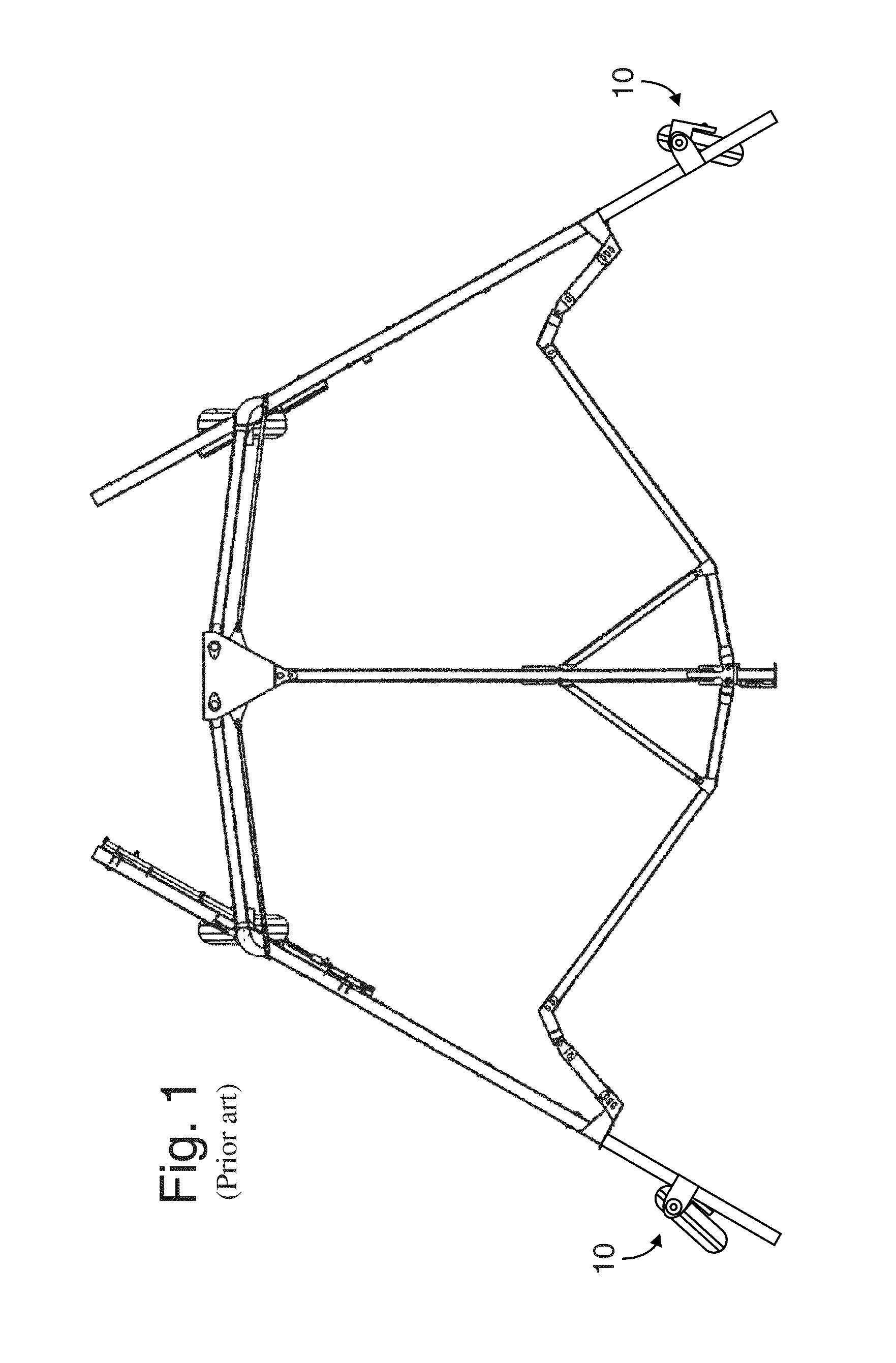

An agricultural machine for grouping windrows together or for windrowing products lying on the ground, comprising in particular a main frame supporting a central gathering and windrowing device and two side gathering and windrowing devices connected to support arms that extend laterally during work, each of said side support arms being articulated relative to the main frame on a substantially vertical axis about which it is foldable at an angle of approximately 90° for transport and each of said side gathering and windrowing device being articulated on its support arm by means of a substantially horizontal axis about which it is foldable upwards at an angle of approximately 90° to obtain a reduced machine width for transport.

Owner:KUHN SA

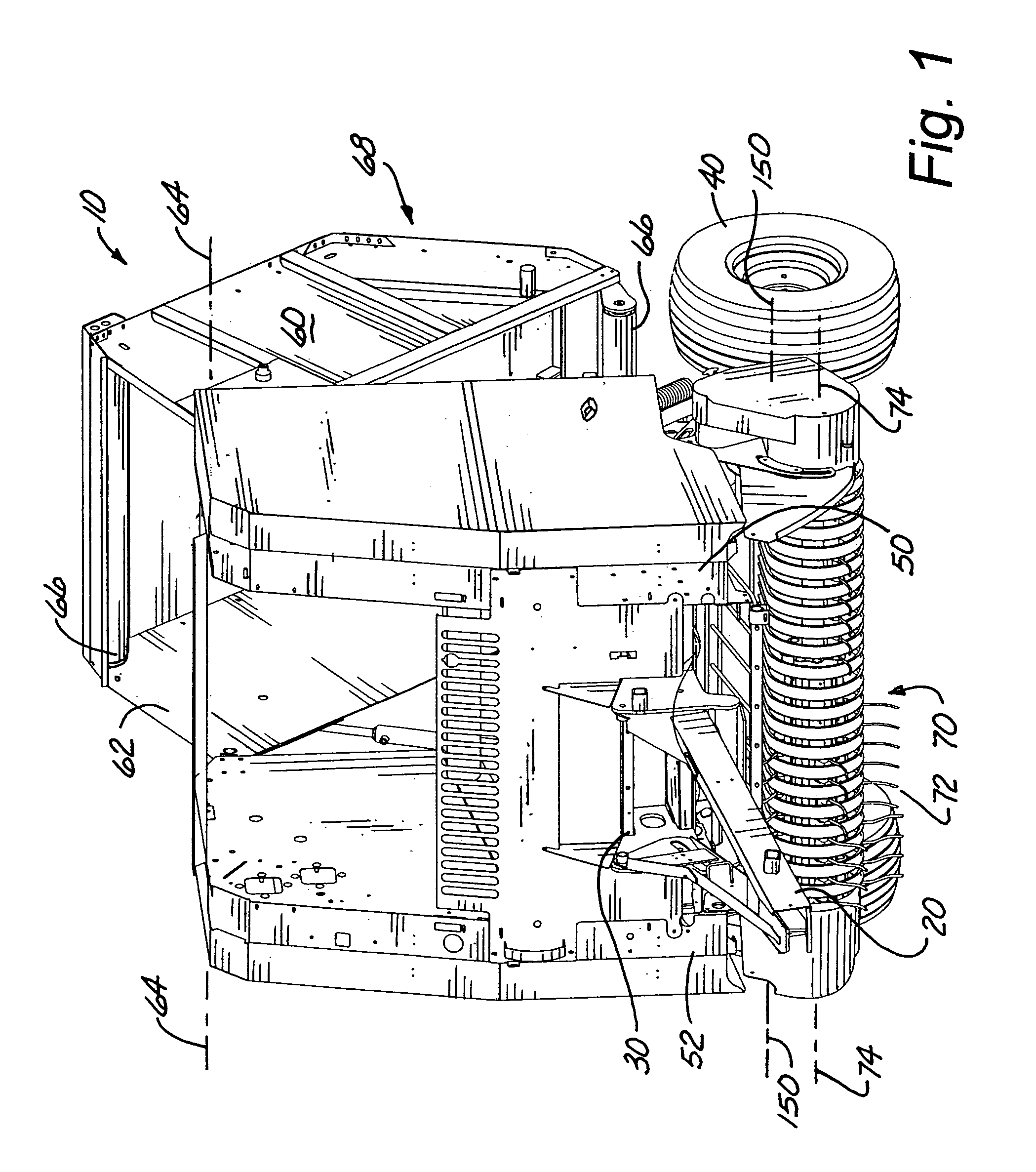

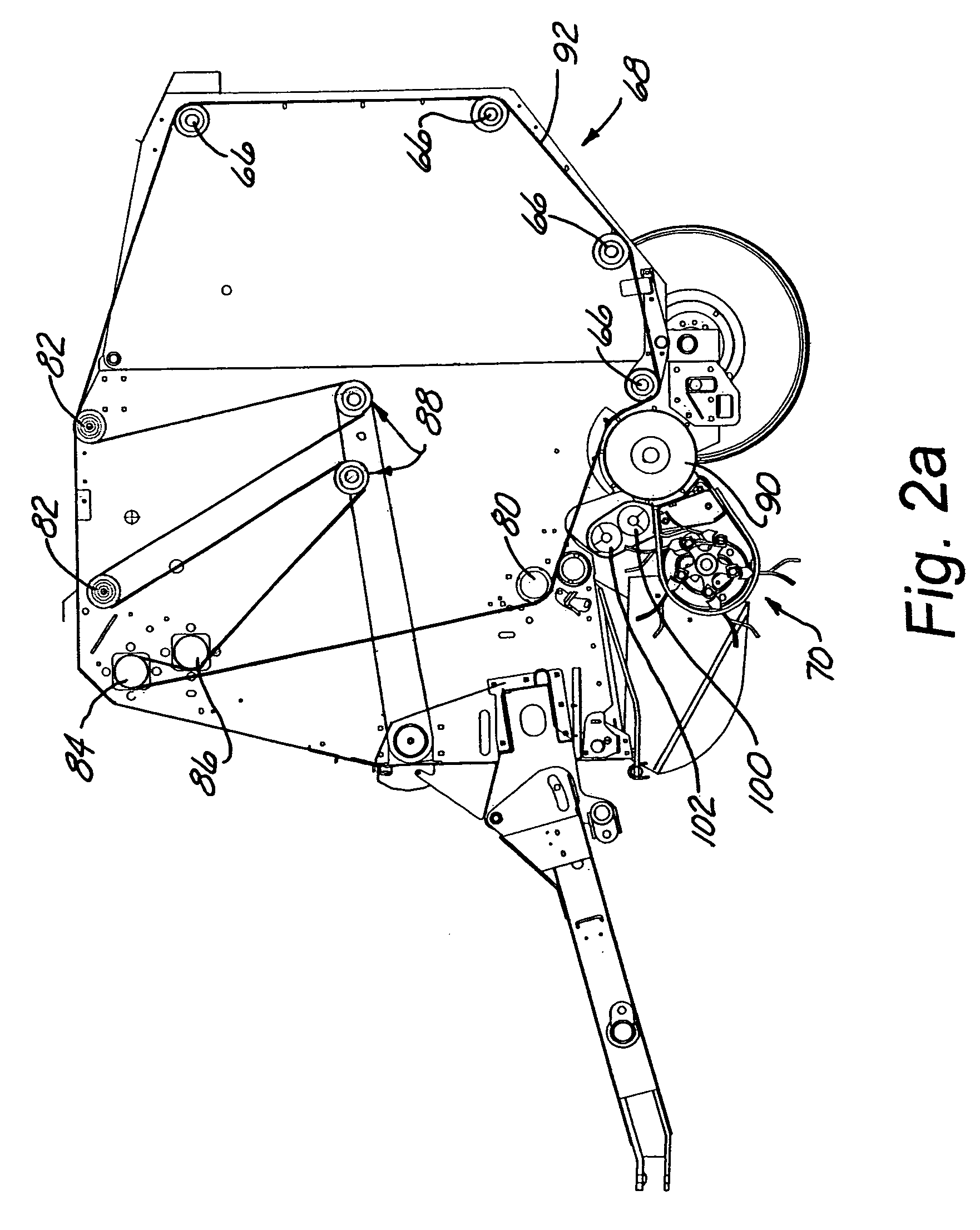

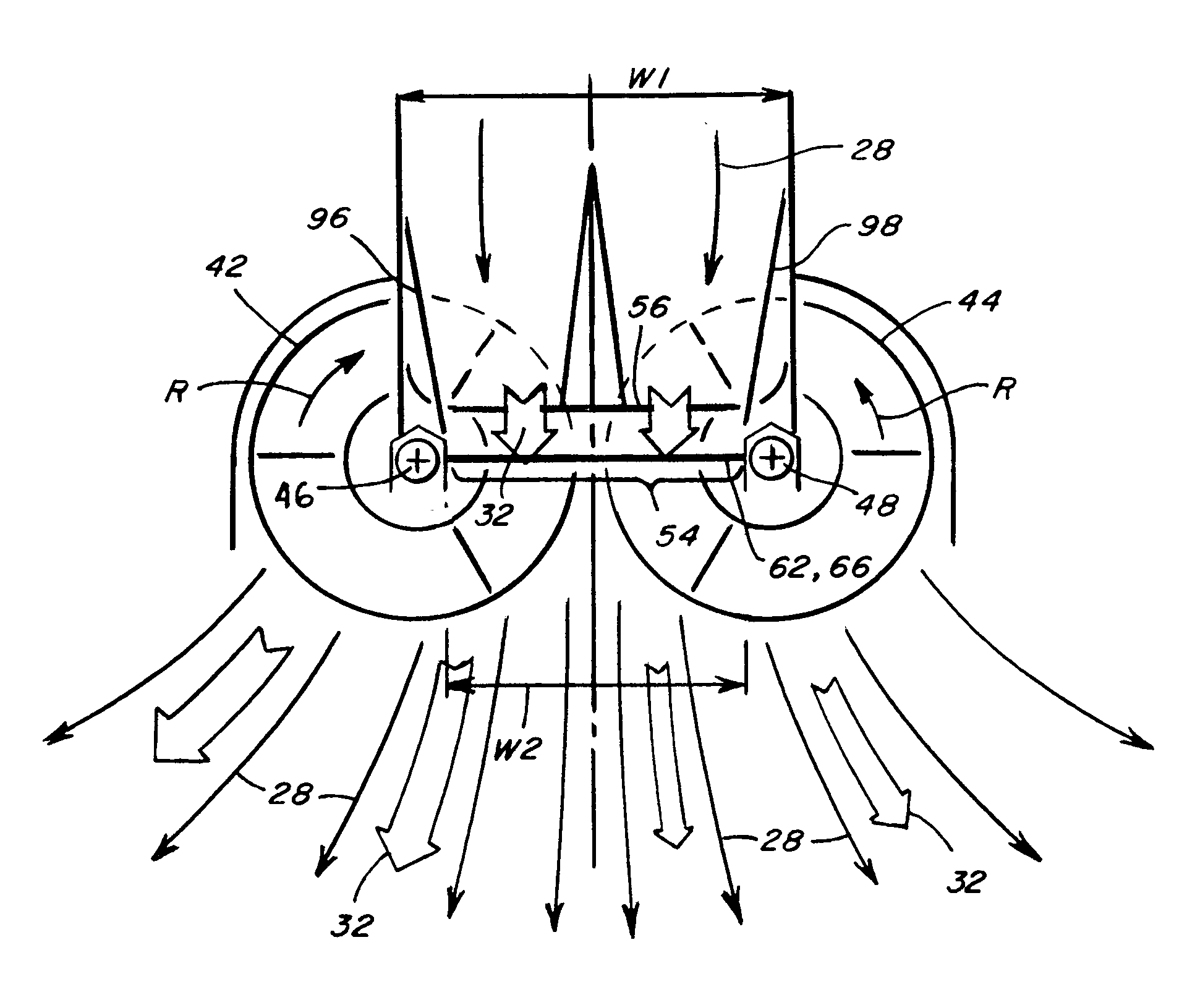

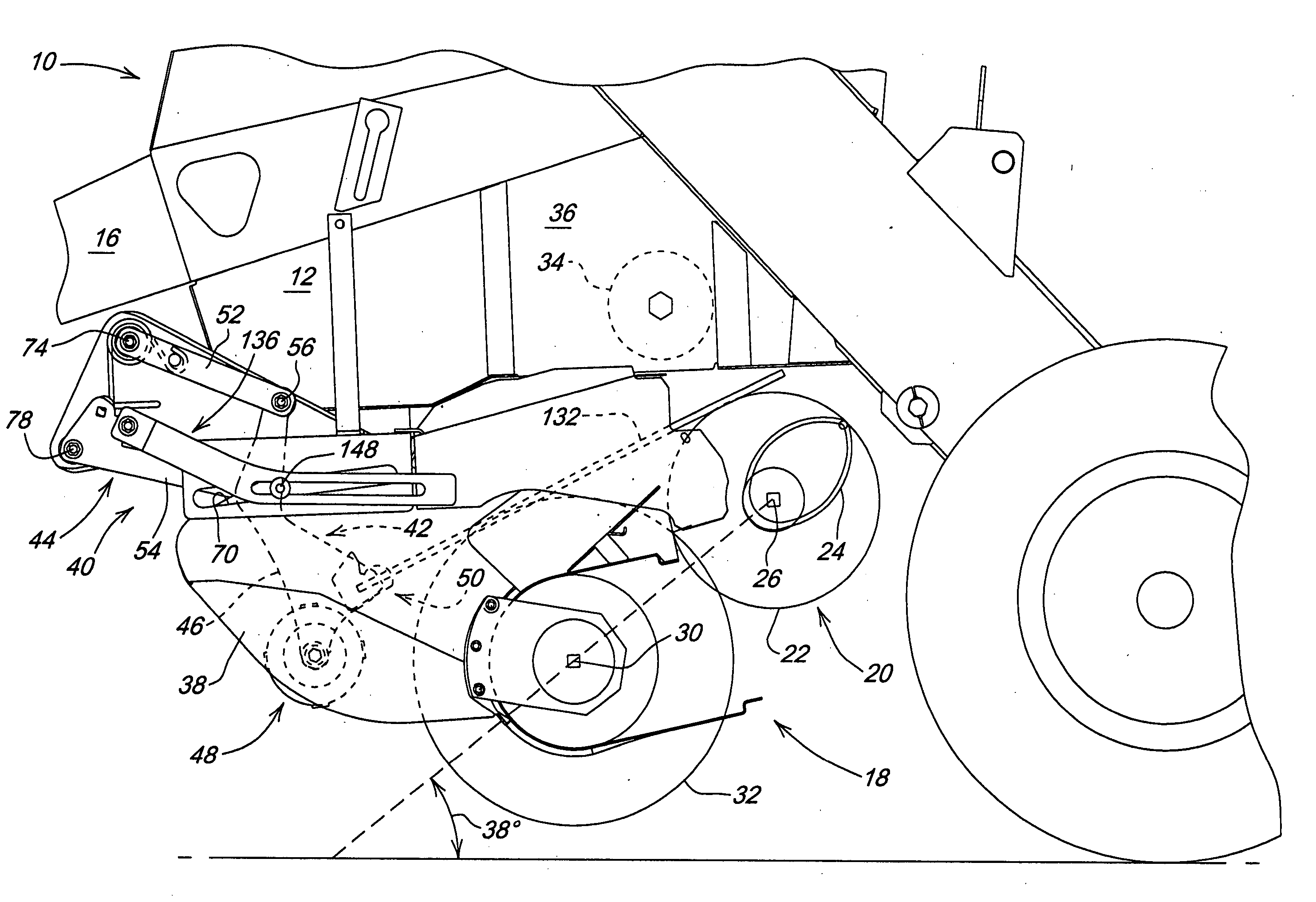

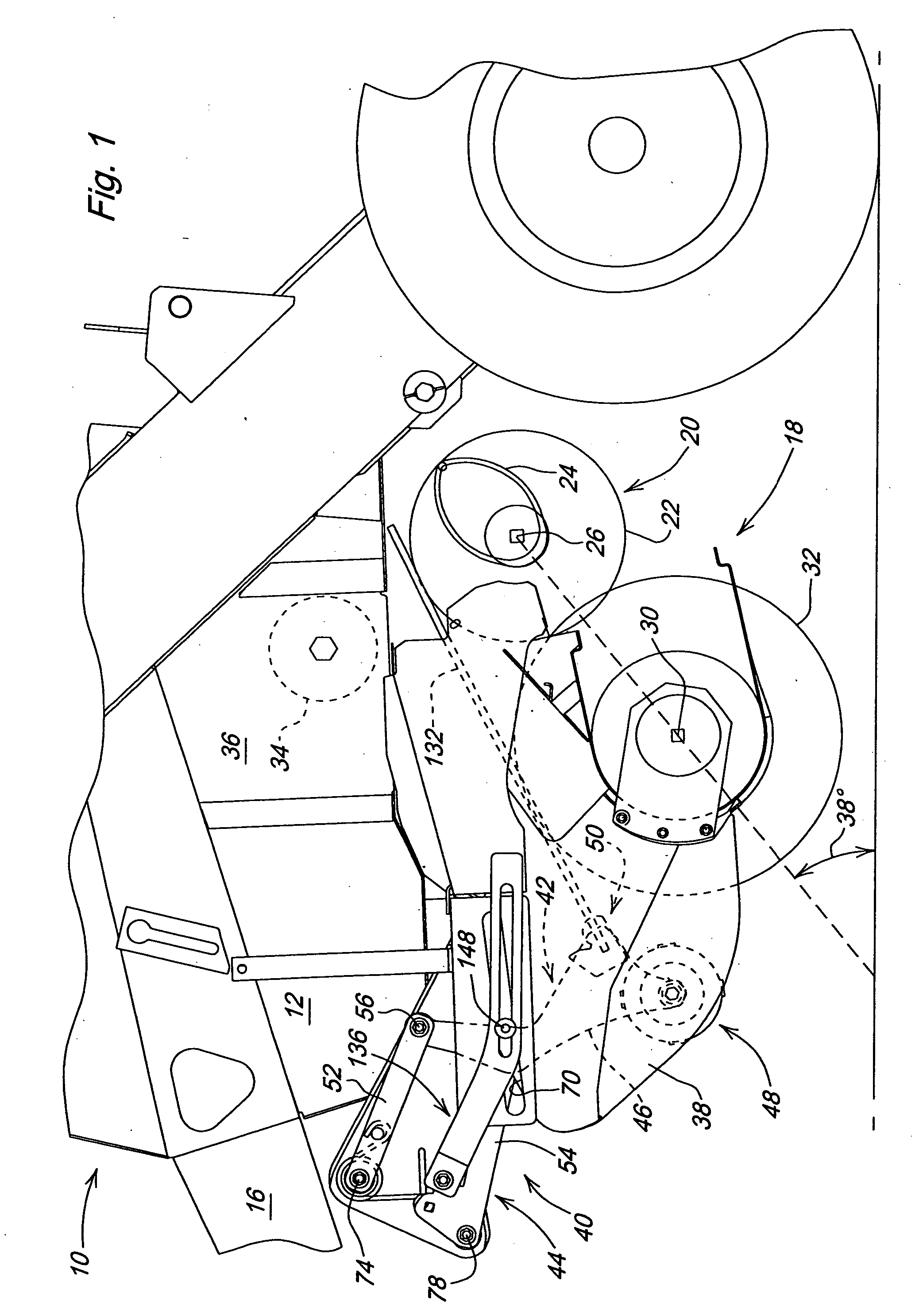

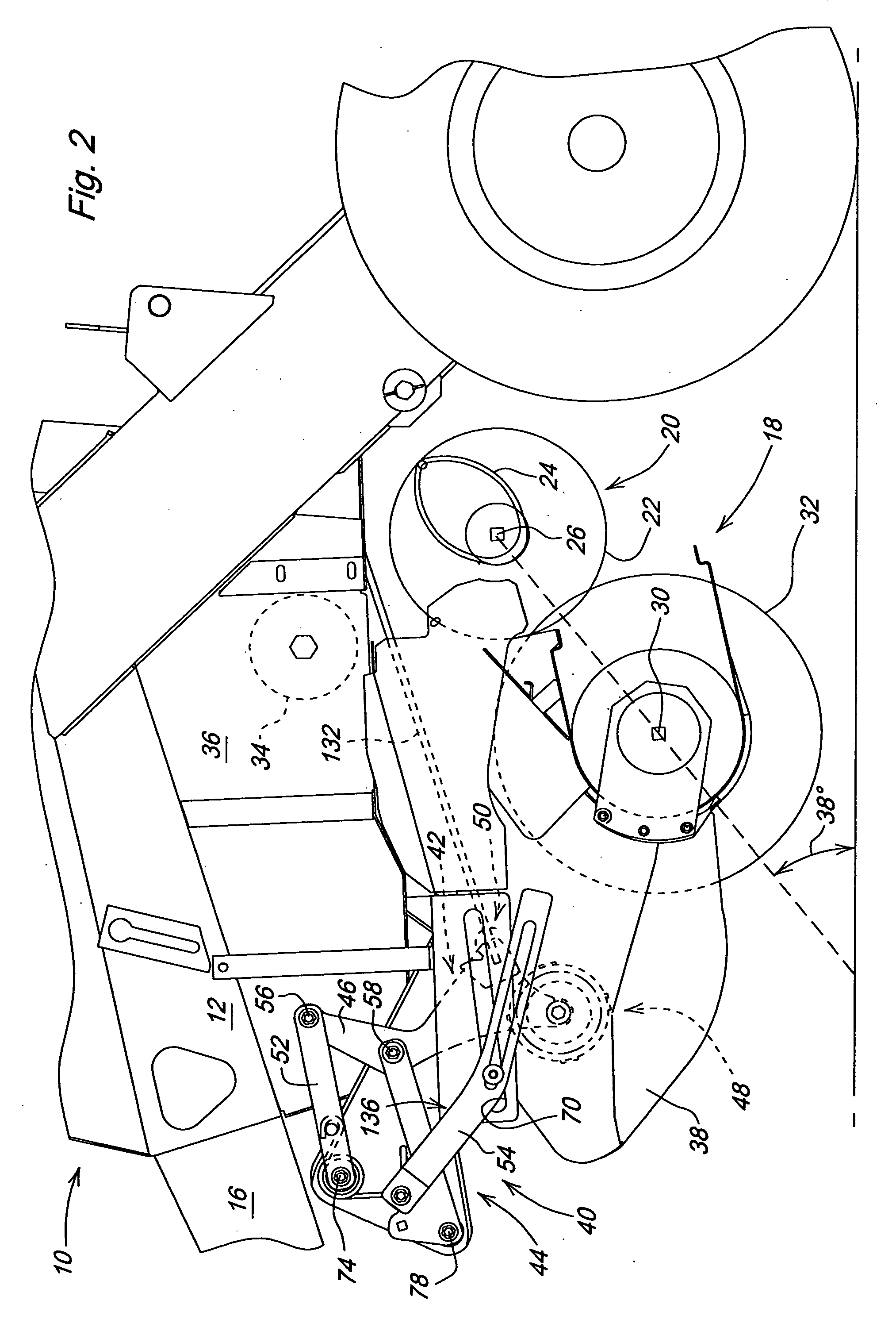

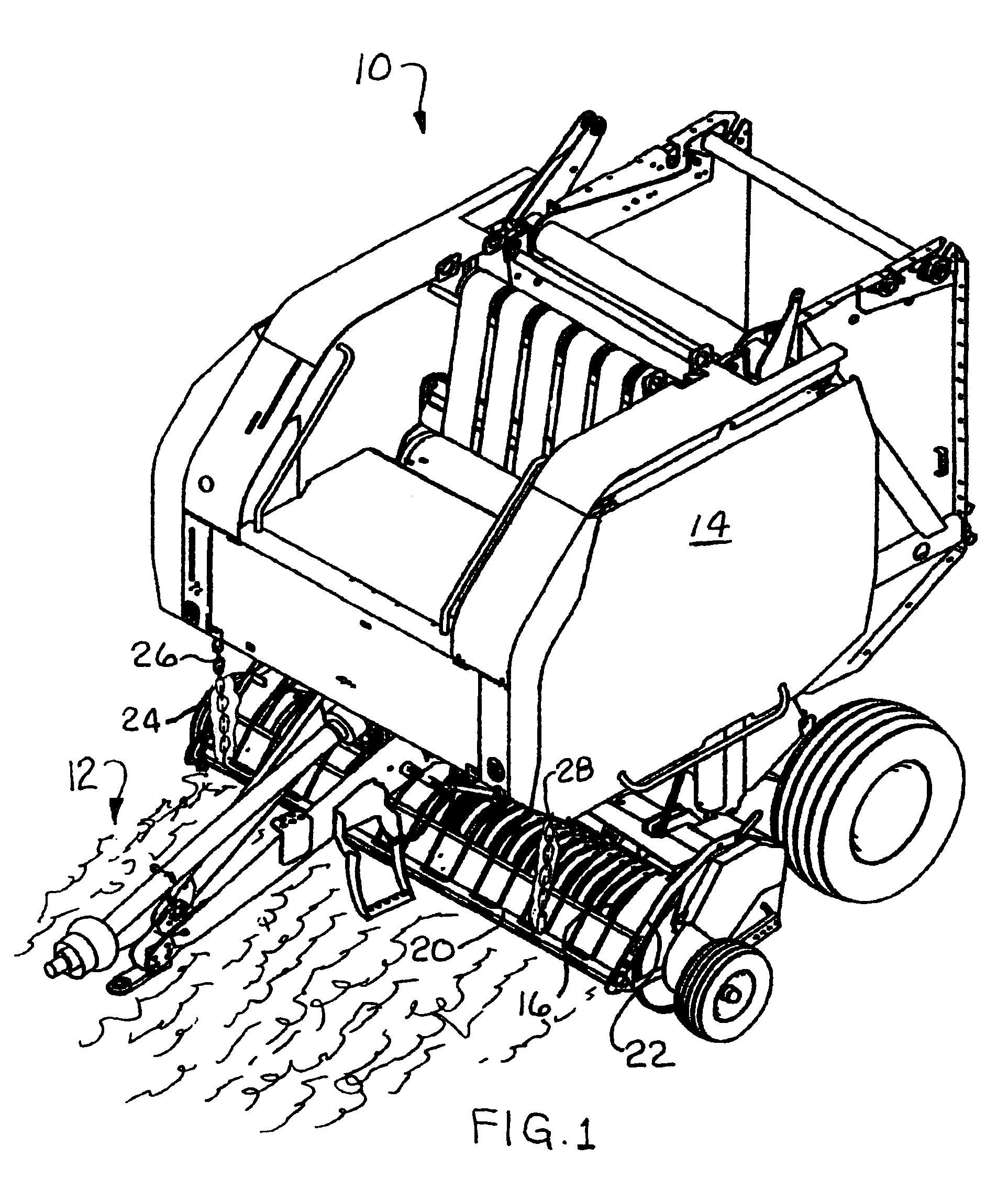

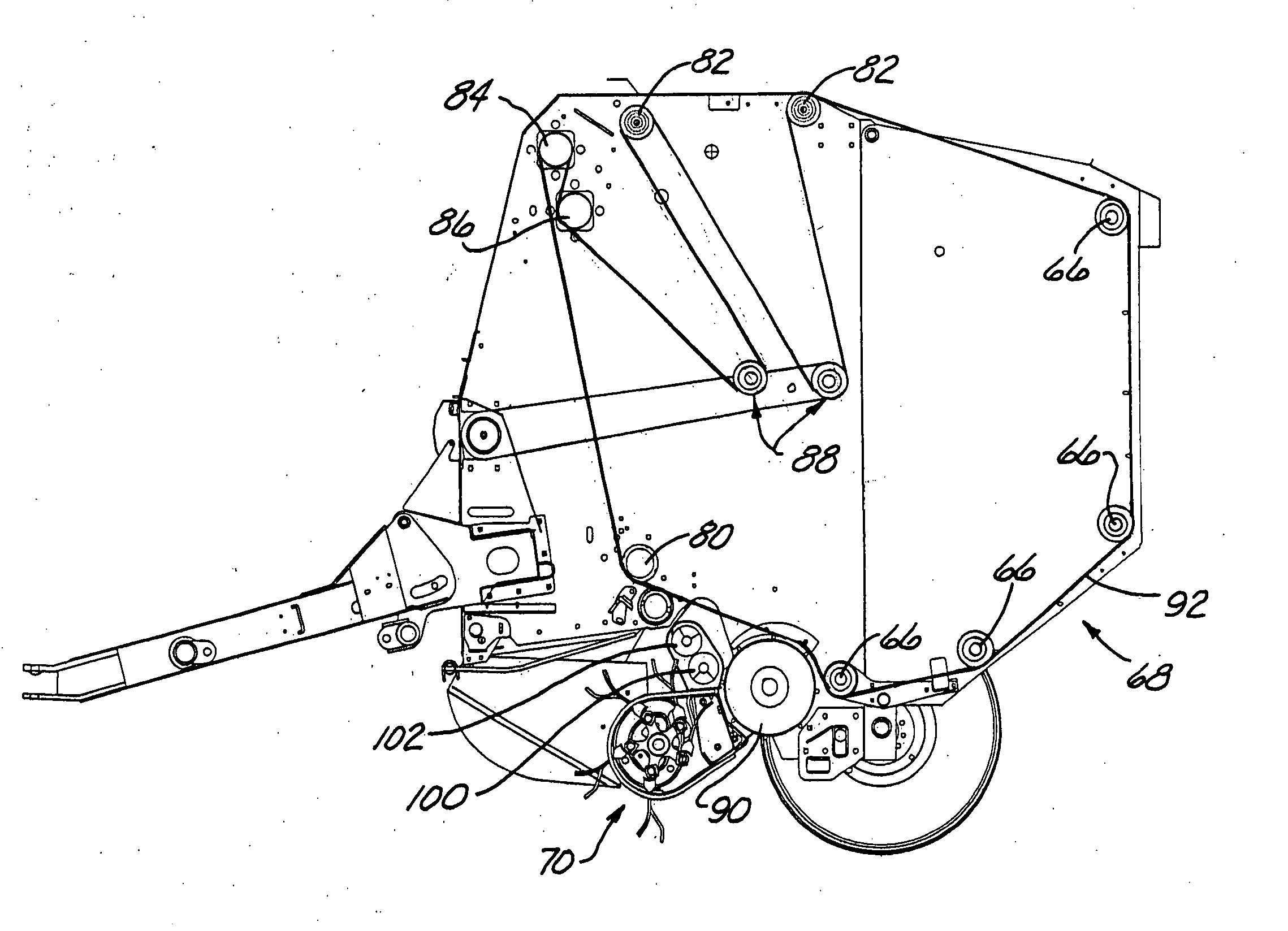

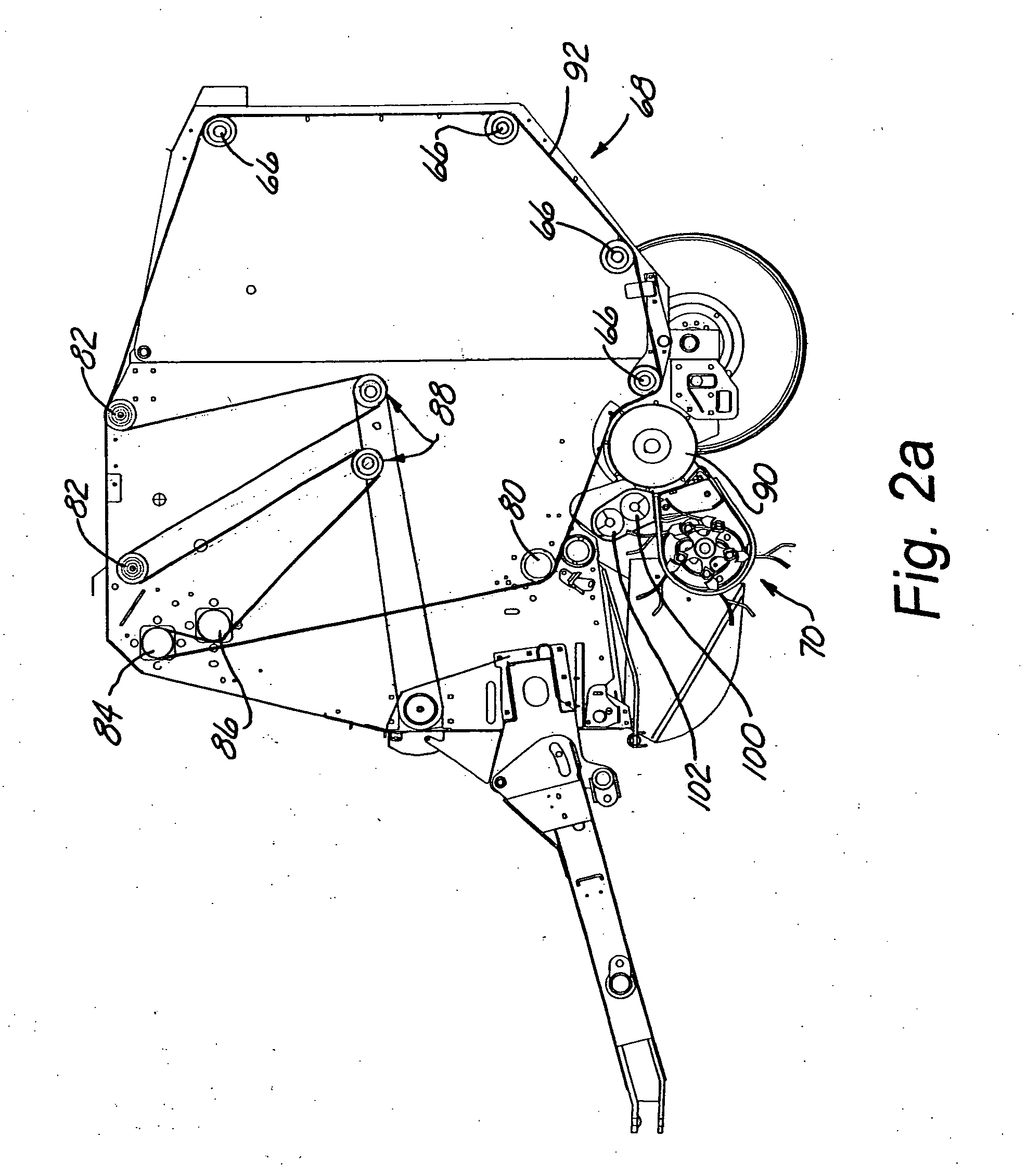

Wide pickup header for a round baler

When harvesting forage in the form of a large round bale, for instance, there are times in which a windrow of forage material lies outside the side boundaries of the bale-forming chamber. This may be due to the windrow being made wide by machinery having driven through it, or by wind, or because of the need to turn the forage harvesting equipment tightly. A wide pickup, notably wider than the width of the bale-forming chamber, provides a solution to this common problem. Dual augers at each end of the wide pickup provide the force to direct the forage into a narrower path, to enter the bale-forming chamber. The orientation and size of the augers permits the pickup header to reside in the same location it would if it was not wider than the baler. Tines or teeth of various rigidities and shapes are provided in the pickup for more effective pickup of the forage.

Owner:VERMEER MFG CO

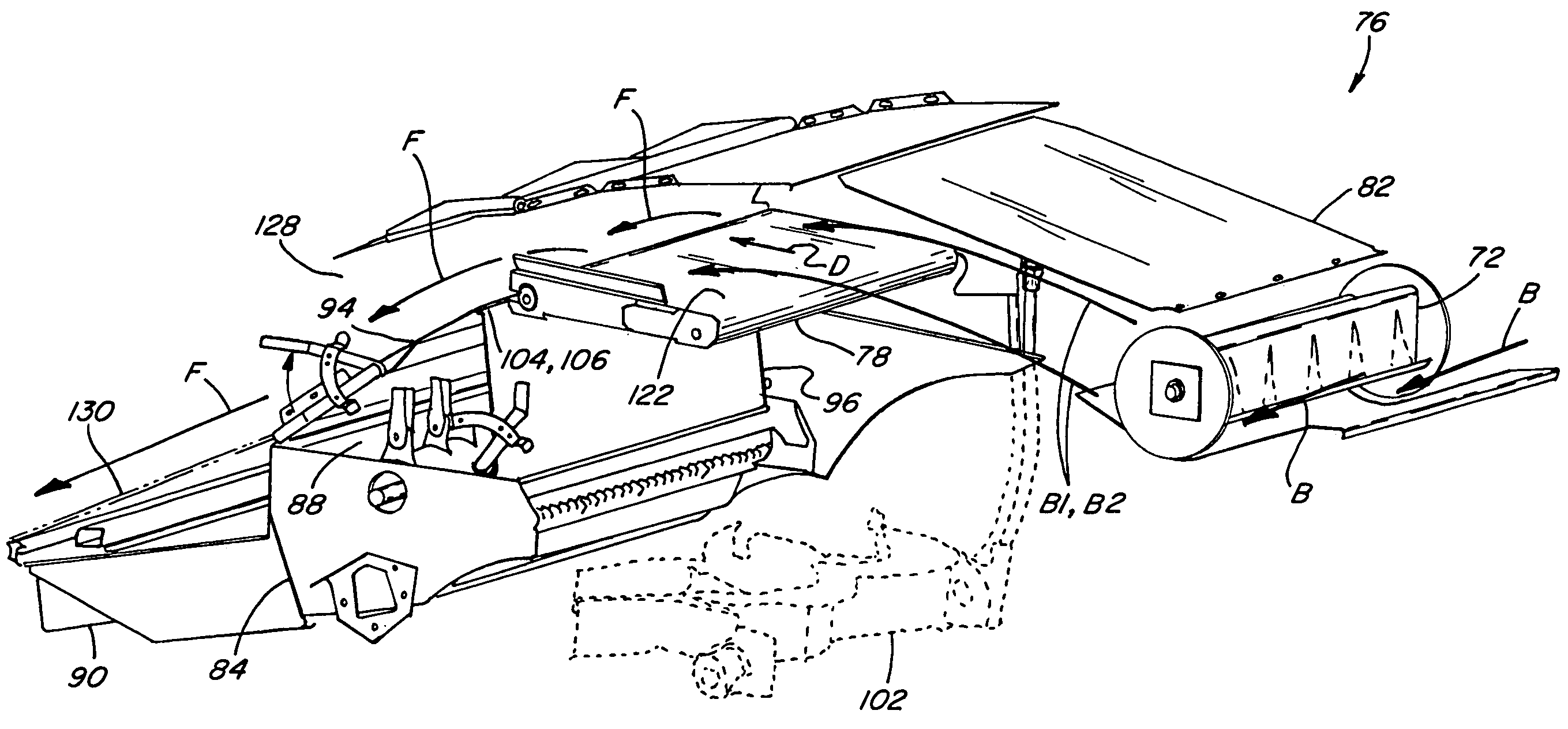

Crop residue distribution apparatus and system with cooperatively movable deflector door and spreader assembly

The crop residue distribution apparatus and system use a horizontal crop spreader assembly and deflector door independently relatively positionable to be configurable in a straw windrowing and chaff spreading configuration in which straw flow is directed through an aperture between drive units of the spreader assembly while the chaff is directed to the spreader disposed in a lower opening; in a straw and chaff spreading configuration wherein the door closes the aperture and both straw and chaff are directed to the spreader; and in a straw and chaff windrowing configuration wherein the spreader is withdrawn from the lower opening such that the straw and chaff are both discharged therethrough to form a windrow without requiring removing disks of the spreader.

Owner:BLUE LEAF I P INC

Rotary platform having converging elements for specialty crops

A rotary platform is provided for the harvest of specialty crops such as grass seed. In particular the conditioning rolls are removed from the header to reduce seed shatter and converging elements are added inside the conditioner opening on both sides and to the rear of the cutterbar to feed the crop around the conditioner opening corner and to the rear of the platform. Additional converging elements are provided behind the first converging elements at a angle less then 90 DEG. to the ground so as to form the top of the windrow so that there is minimal seed loss. The converging elements may or may not be powered and the angle of the second converging element can be adjustable. The rotary knives perform the cutting function more efficiently than a sickle cutterbar, and the converging elements move the crop toward the center to form a windrow with less disturbance.

Owner:DEERE & CO

Crop residue distribution apparatus and system with cooperatively movable deflector door and spreader assembly

ActiveUS8585475B2Avoid flowSimple and economical meanMowersThreshersCrop residueMechanical engineering

The crop residue distribution apparatus and system use a horizontal crop spreader assembly and deflector door independently relatively positionable to be configurable in a straw windrowing and chaff spreading configuration in which straw flow is directed through an aperture between drive units of the spreader assembly while the chaff is directed to the spreader disposed in a lower opening; in a straw and chaff spreading configuration wherein the door closes the aperture and both straw and chaff are directed to the spreader; and in a straw and chaff windrowing configuration wherein the spreader is withdrawn from the lower opening such that the straw and chaff are both discharged therethrough to form a windrow without requiring removing disks of the spreader.

Owner:BLUE LEAF I P INC

Windrow forming construction

A windrow forming construction mountable at the rear of a combine above the level of a spreader assembly, such construction extending rearwardly from the combine to beyond the rear extent of the spreader assembly footprint and laterally across the expanse of the spreader assembly footprint and being adjustably positionable to vary the inclination thereof relative to the ground surface, the construction including side deflectors disposed at opposite sides of the construction so as to control to some extent the sidewardly distribution of the crop residue, which side deflectors are laterally pivotable about generally vertical axes to vary the spacing between the free ends thereof and are also longitudinally extendable so as to channel to some extent the crop residue towards the space between the free ends, and a positioning mechanism operable to vary the inclination of such construction relative to the ground surface so as to control to some extent the degree with which the crop residue is directed into the stubble remaining on the field and to support the construction in such position.

Owner:BLUE LEAF I P INC

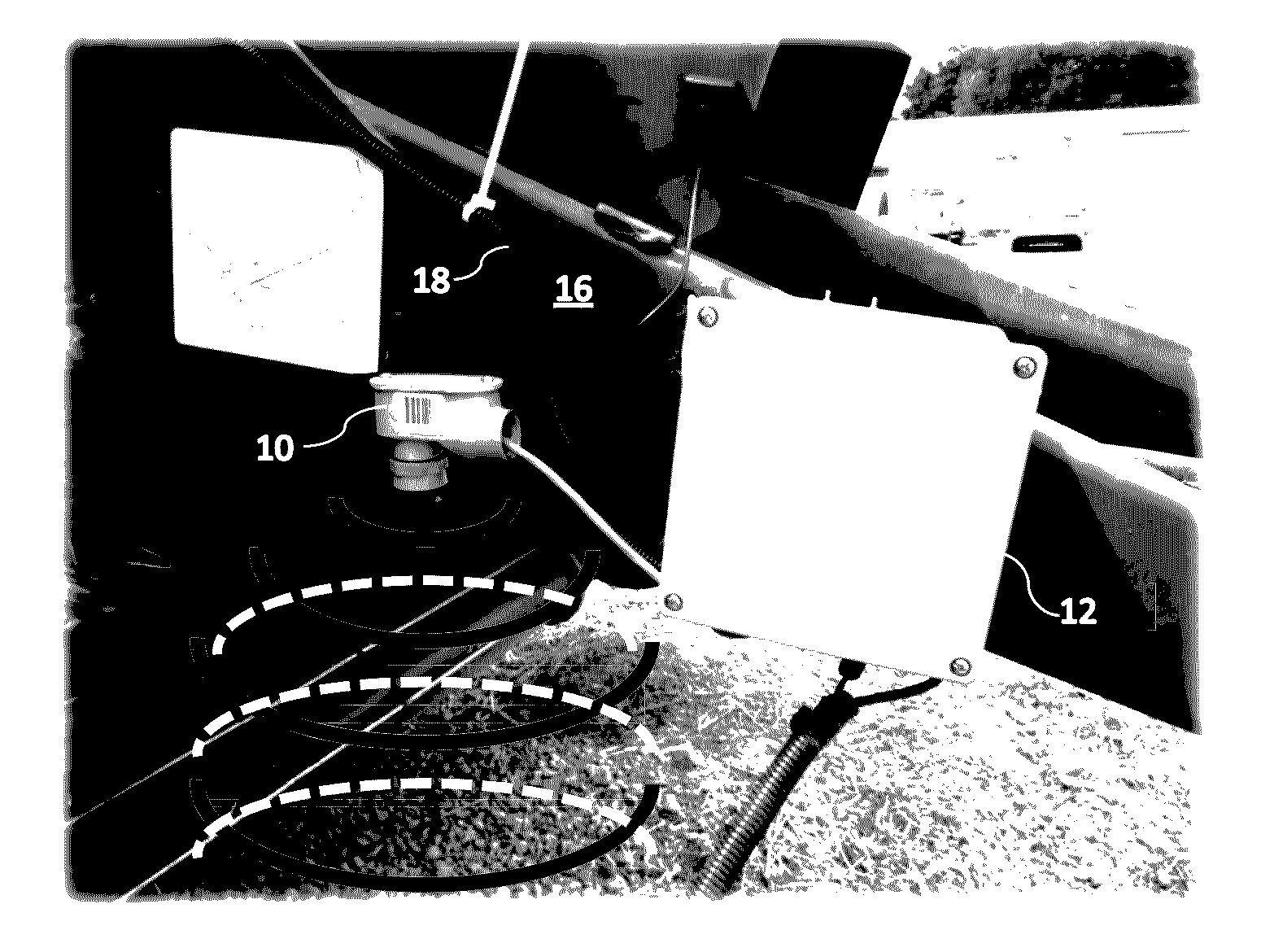

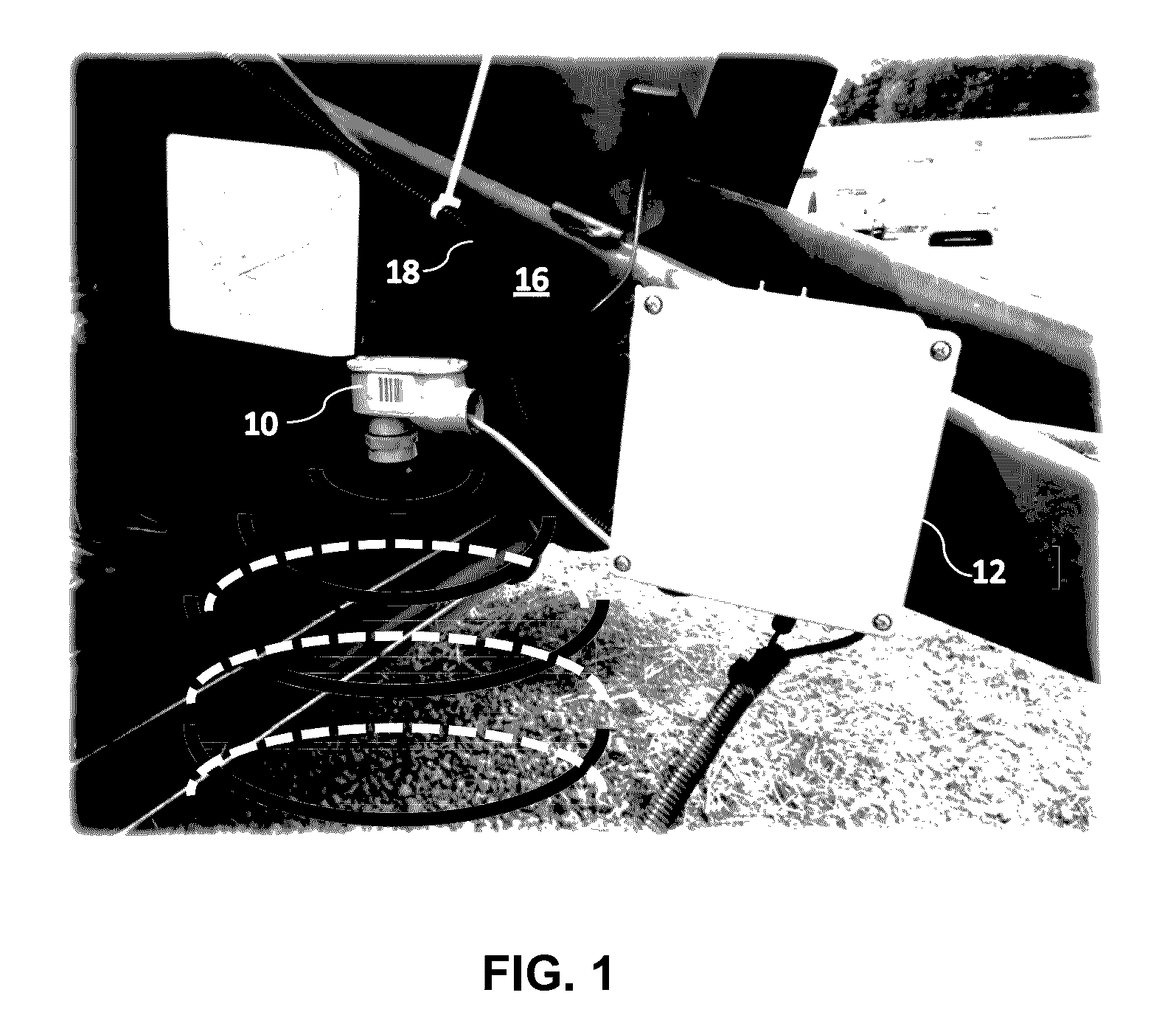

Yield Monitor for Windrow-Collected Materials

Disclosed are methods and systems for determining the amount of material contained in a windrow. In particular embodiments, the methods and systems are applicable to agricultural applications, and in particular to hay yield monitoring. Systems include a remote sensing technology to determine windrow height. Remote sensing methods can include ultrasonic sensors, optical sensors, and the like. Systems can provide real time yield data.

Owner:CLEMSON UNIV RES FOUND

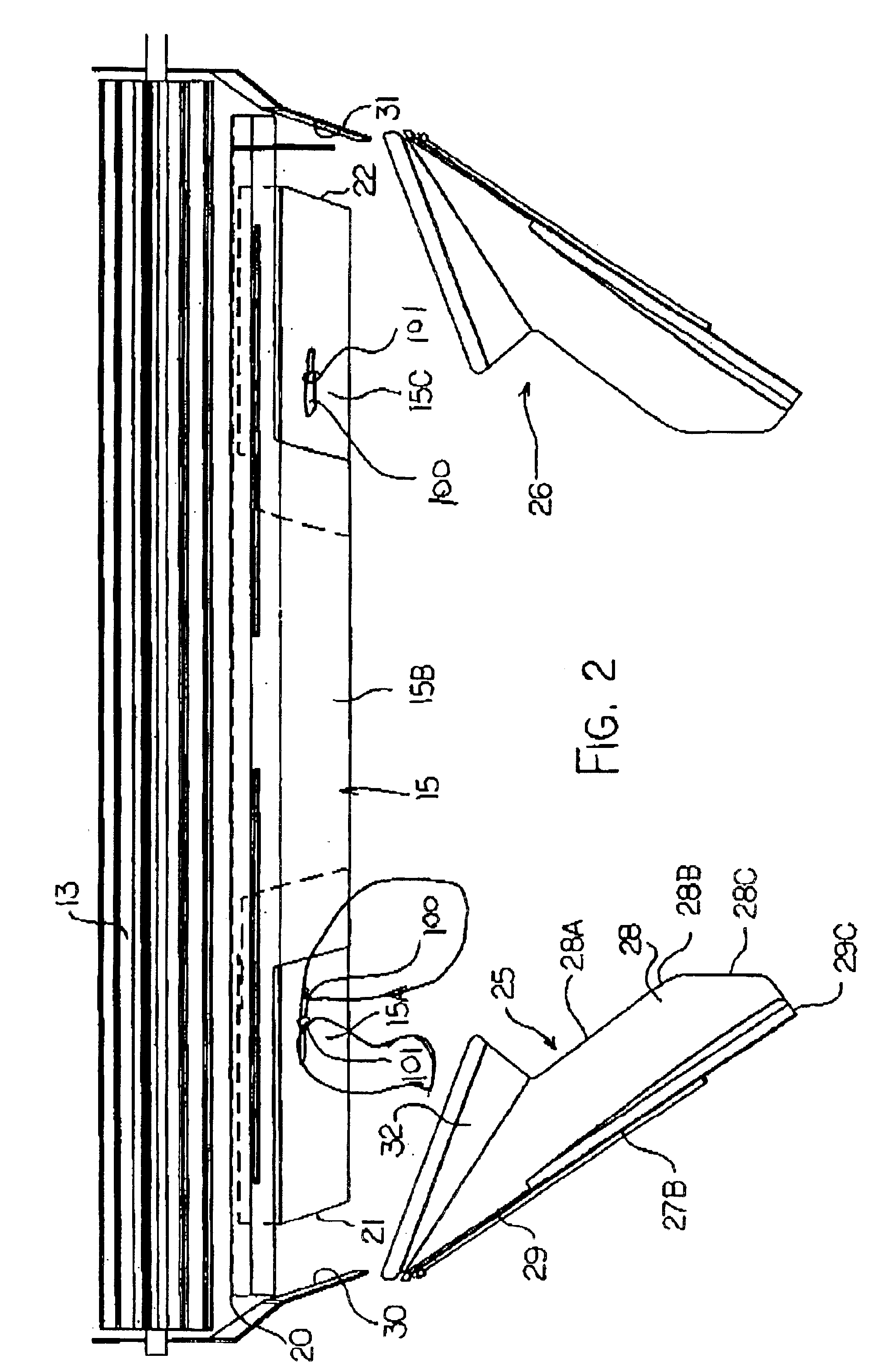

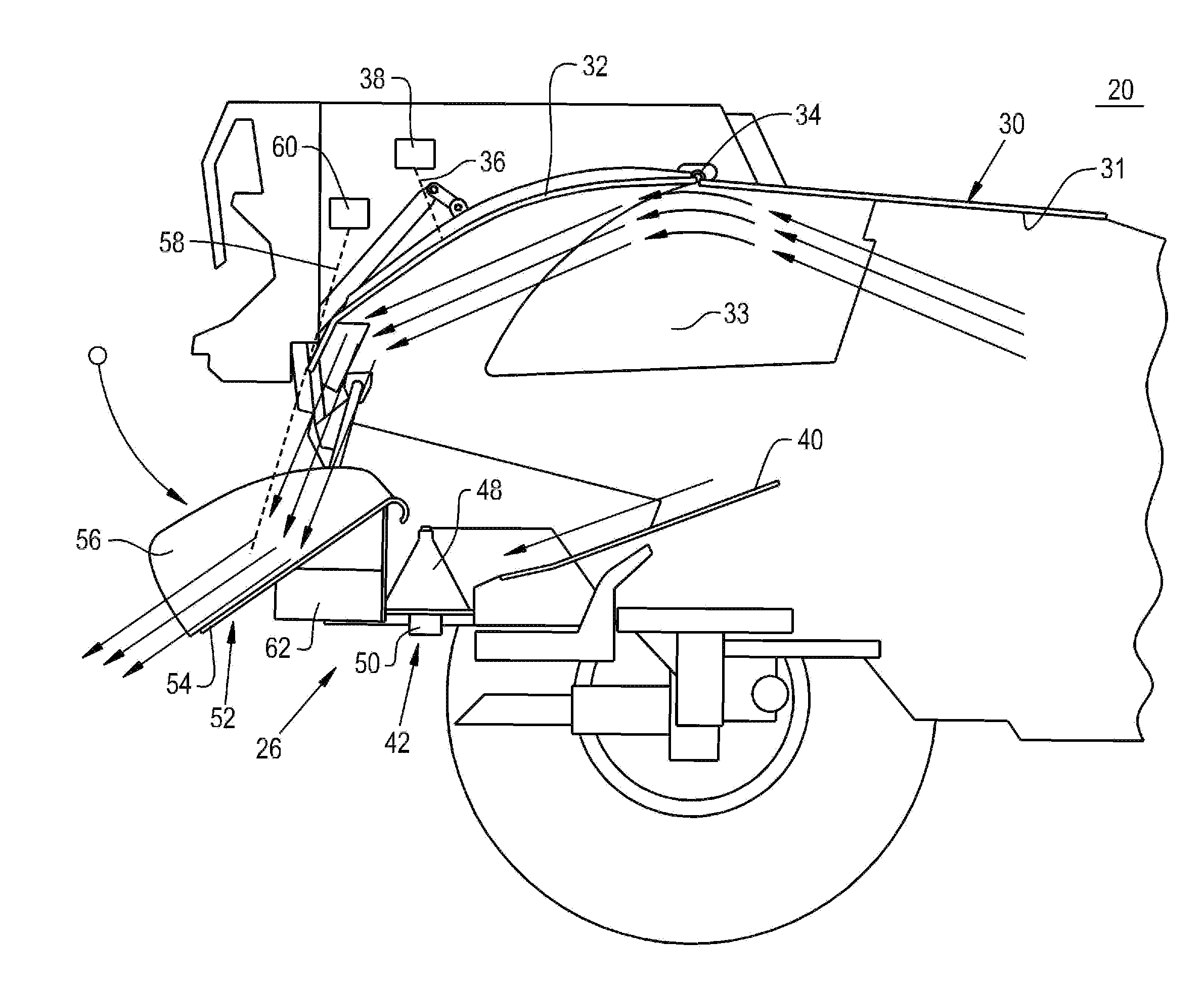

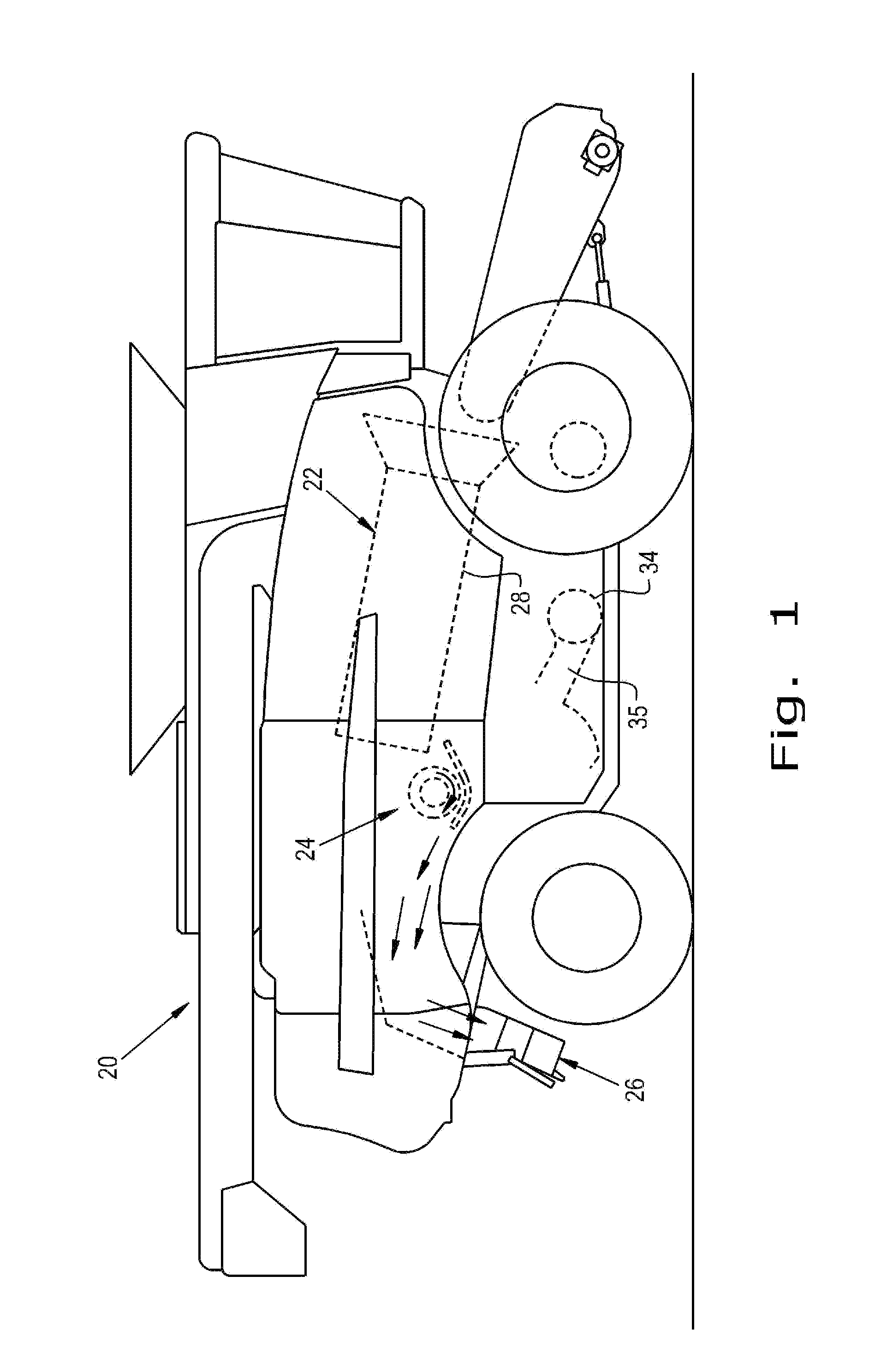

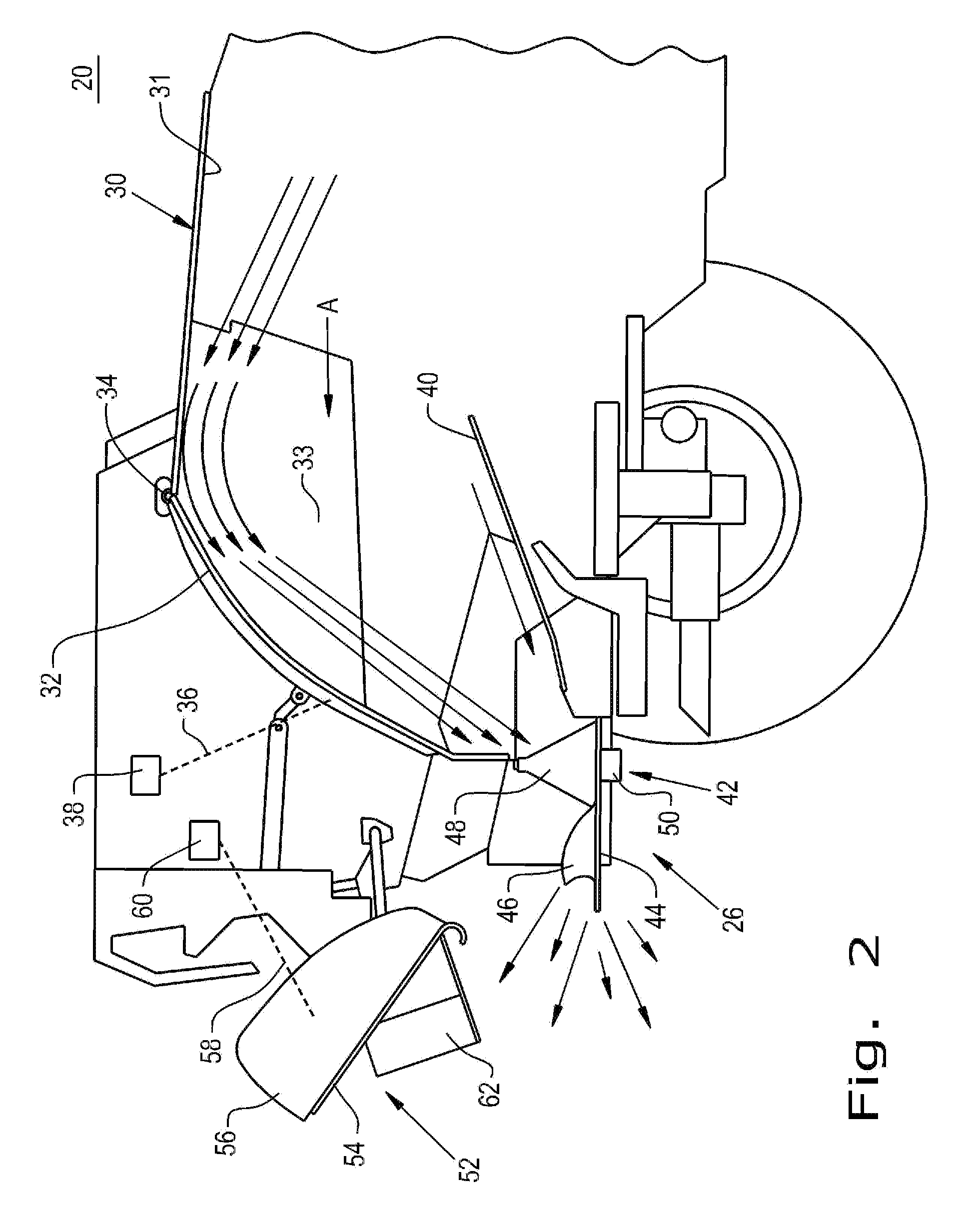

System and method for positively discharging crop residue from a combine

A system and method for positively discharging crop residue from a combine for precisely and consistently delivering crop residue from the threshing and separating area of a combine to the combine's residue handling system or outwardly from the rear of the combine and onto the harvested field below as a windrow. The present invention can include, or operate in cooperation with, a discharge mechanism, such as a conventional discharge beater, which delivers at least some of the crop residue to a conveying mechanism of the system. The system also includes a guide mechanism including a door arrangement configurable in several alternative configurations for receiving and merging and regulating crop residue flow from the discharge mechanism and the conveying mechanism, and directing the merged flow to a desired processing mechanism, such as, but not limited to, a chaff spreader, a straw chopper and / or spreader, etc.

Owner:BLUE LEAF I P

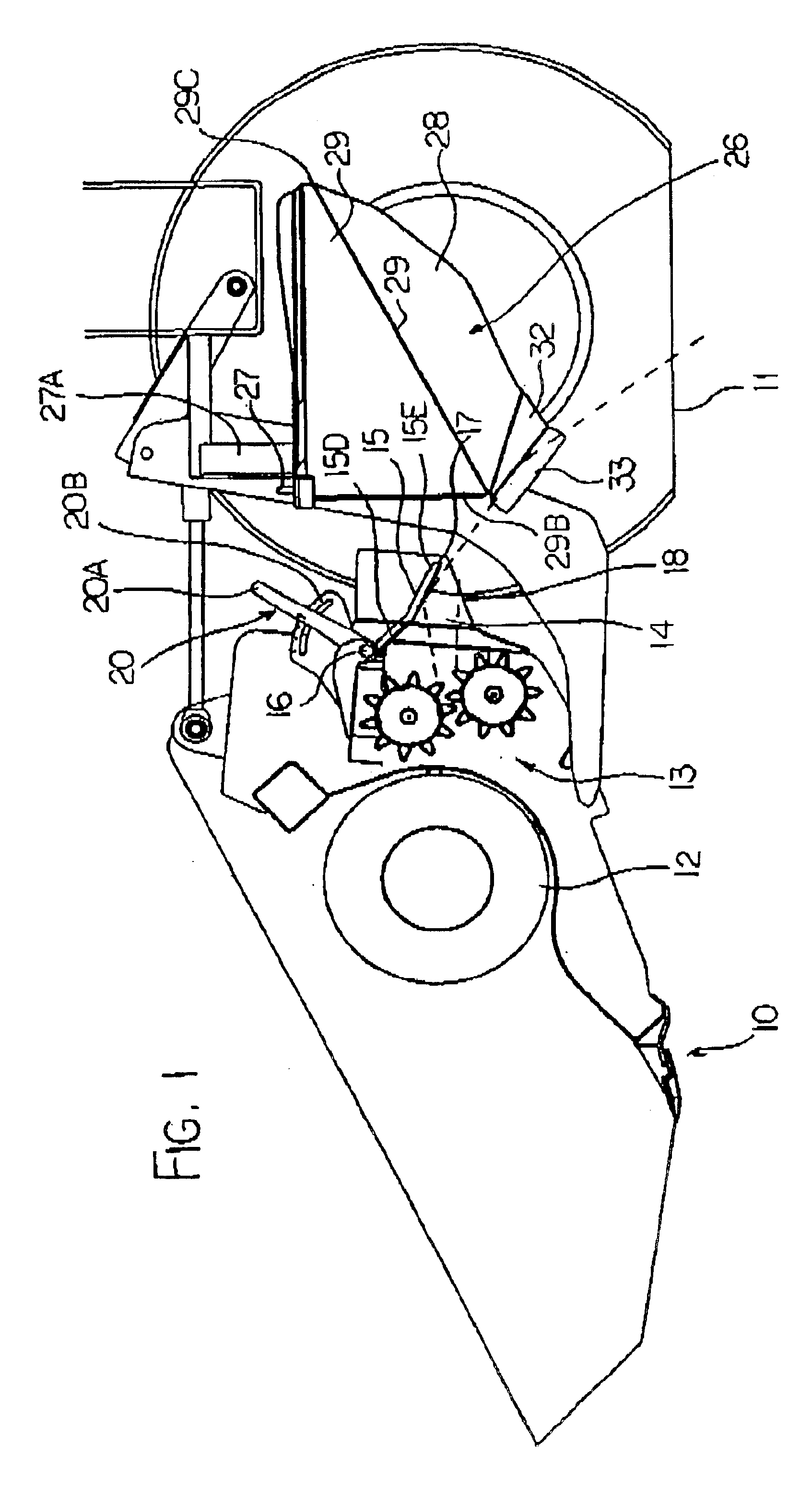

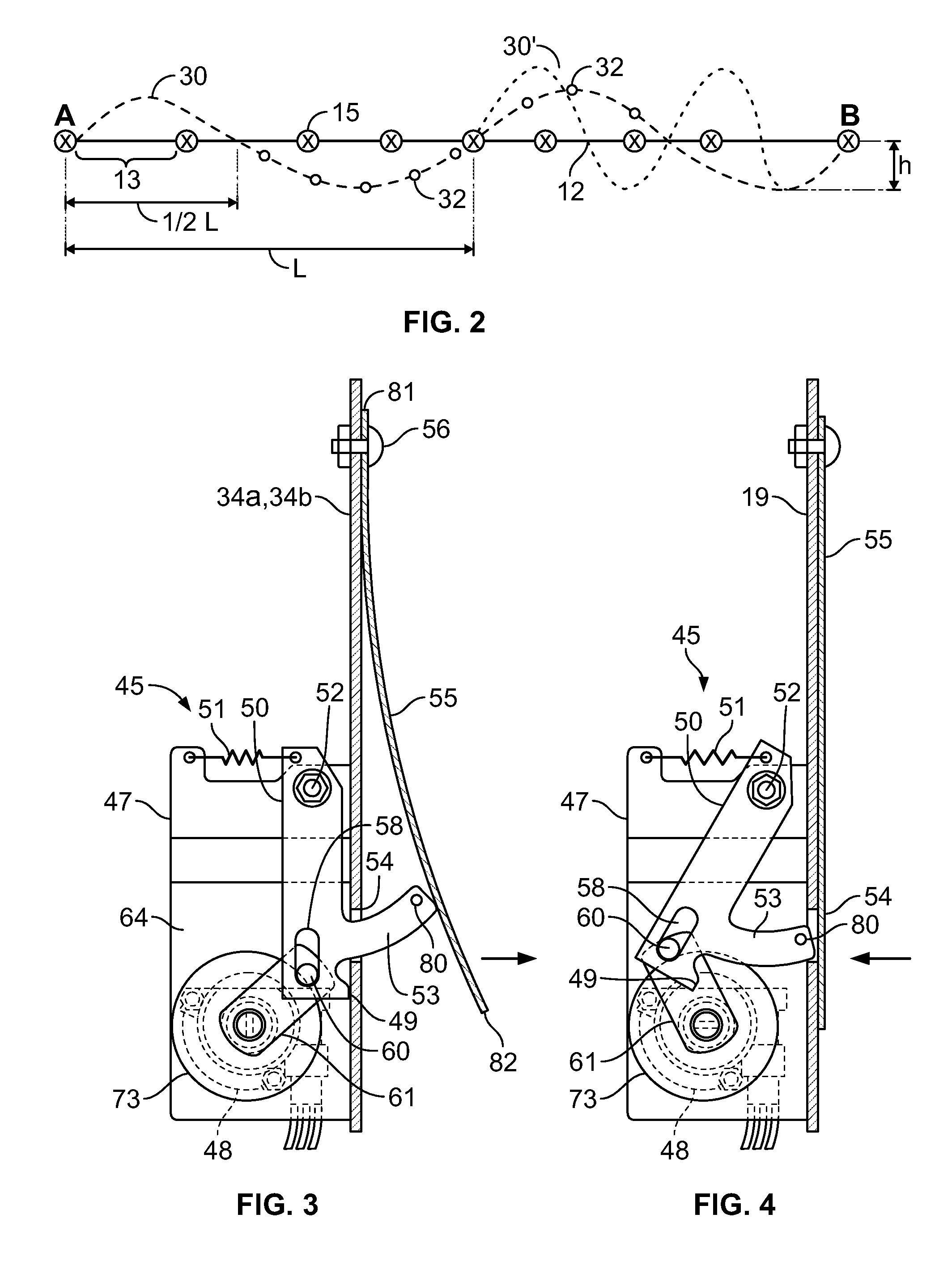

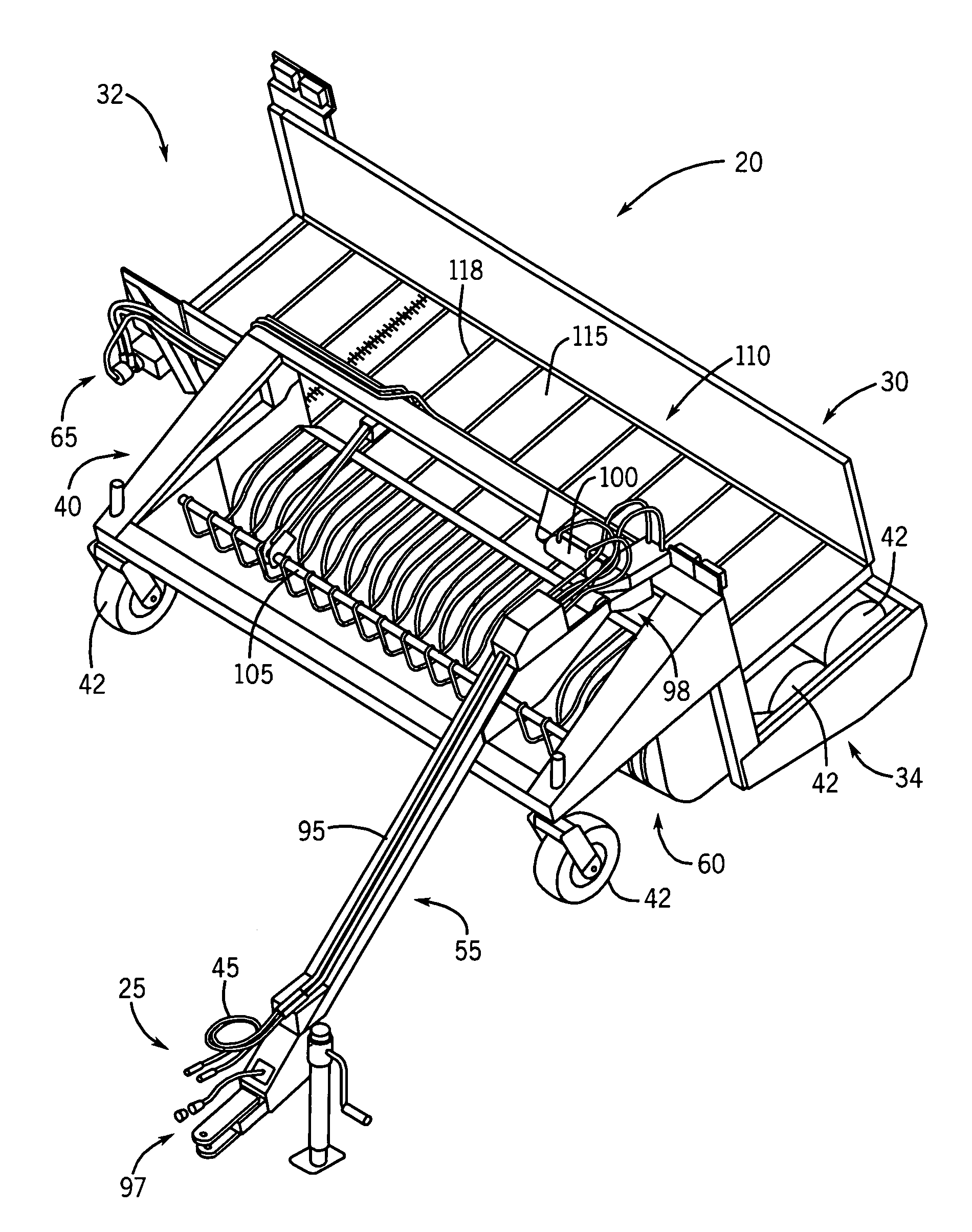

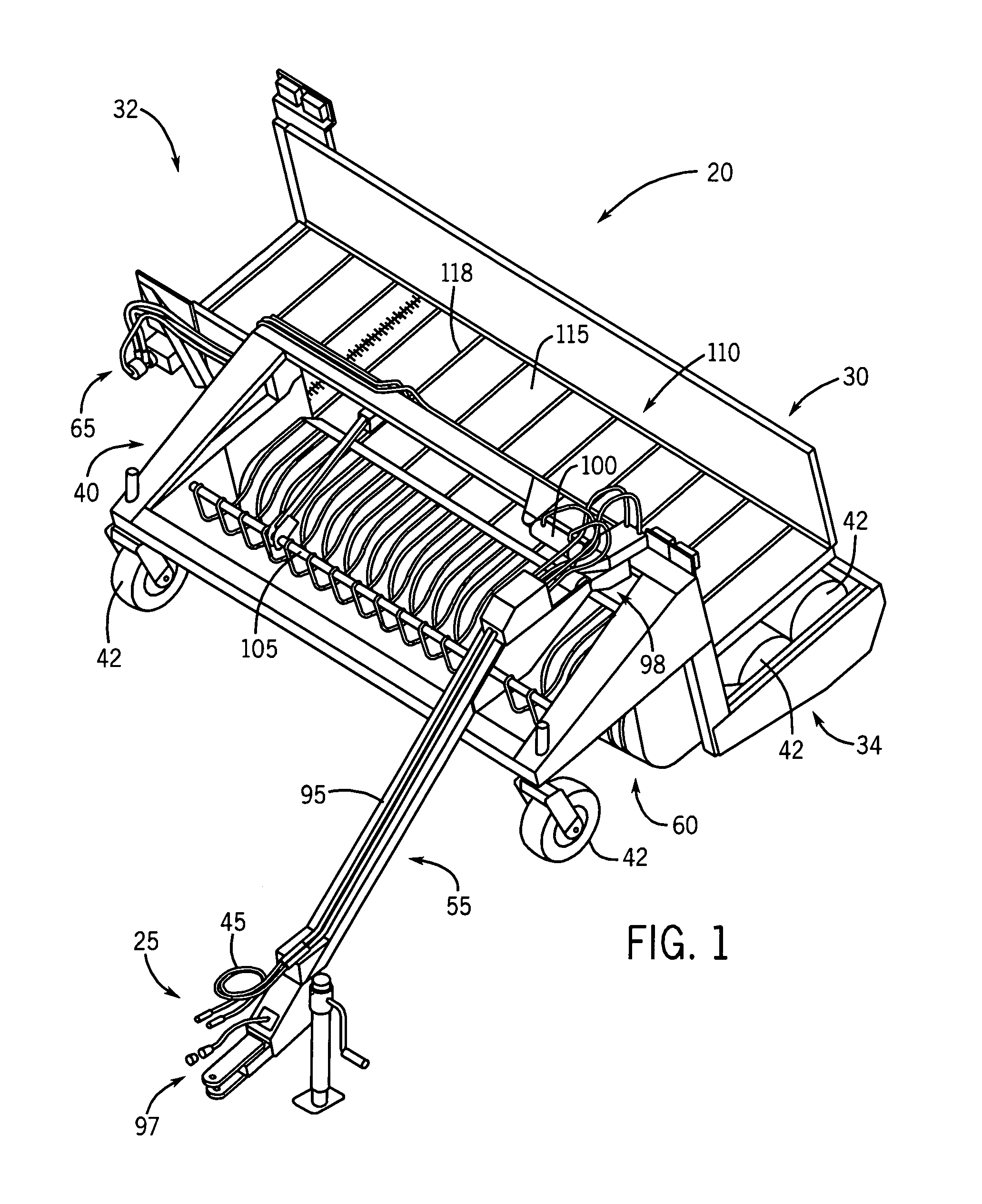

Integrated crop baffle and hold-down assembly used with baler pick-up and suspension for same

A large round baler includes a crop pick-up having a tined reel for lifting a windrow of crop to a secondary feeder which moves the crop into the baling chamber. Crop feeding is aided by an integrated crop baffle and hold-down assembly suspended from the baler frame for vertical floating movement by a trailing four-bar linkage arrangement. The baffle is located ahead of the pick-up tine reel, and the compressor rods extending rearwardly over the reel from a location close to an upper rear region of the baffle to a region beneath a bale starter roll. The linkage arrangement controls the movement of the integrated crop baffle and hold-down assembly such that the assembly quickly adjusts to varying windrow thickness, and so that interference between the starter roll and the rear sections of the crop hold-down compressor is avoided.

Owner:DEERE & CO

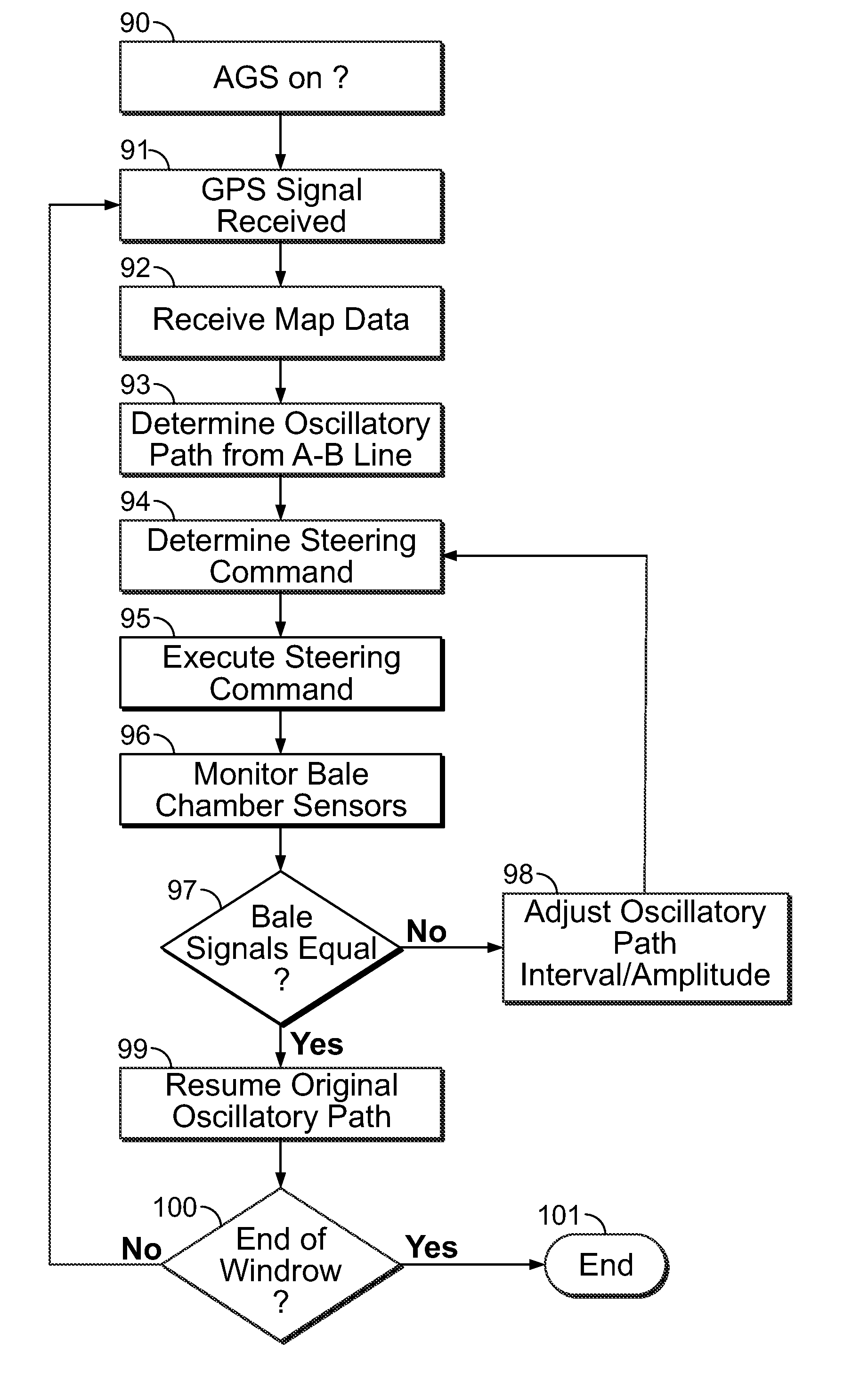

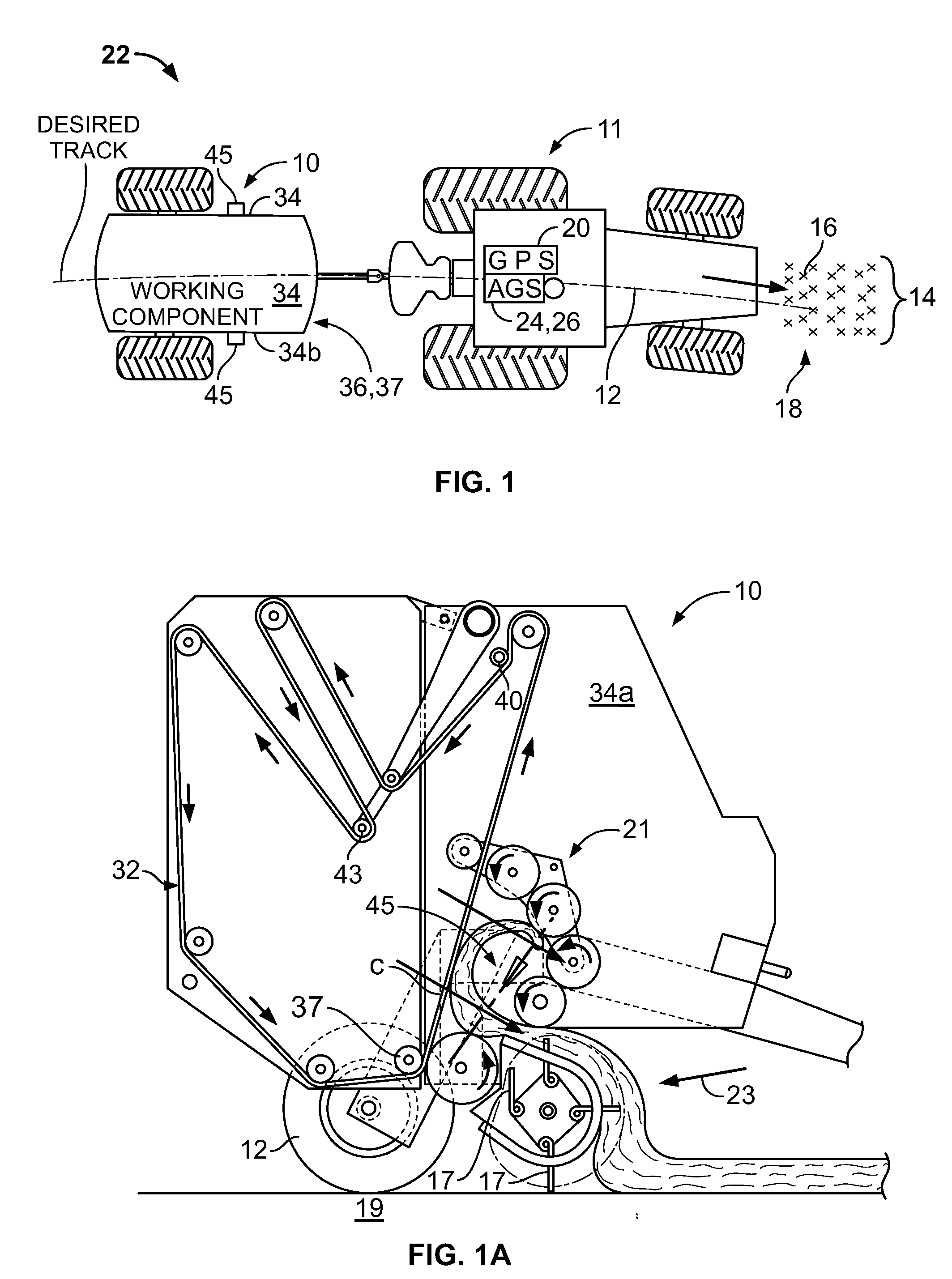

Guidance method for agricultural vehicle

An automated method and system includes an automatic guidance system (AGS) and swath pattern. The AGS steers a vehicle towing a rotary baler in an “S”, or oscillatory pattern around a predetermined approximate centerline of the swath path. The oscillatory pattern may be user defined. By steering the vehicle in an oscillatory pattern referenced to the A-B line, a windrow of crop material may be distributed into an even and optimal bale size and density by the baler. Bale chamber sensors detect an imbalance of crop density and in response, AGS adjusts an interval or amplitude of oscillatory pattern

Owner:BLUE LEAF I P INC

Active steering windrow shields

A system for positioning crop windrow guide shields projecting generally rearwardly alongside the crop discharge stream as it exits an agricultural mower. The shields are coupled for simultaneous, coordinated movement and repositioned by a powered actuator in response to either a manual input by a vehicle operator or automatically by a controller based on a steering angle deflection between a tractor and a towed implement. The system may be adapted for use with a single implement being operated on a side hill to control windrow drifting. The system may also be used with simultaneously operated front-mounted and pull-behind mowers to direct the crop discharge streams into a merged windrow.

Owner:CNH IND AMERICA LLC

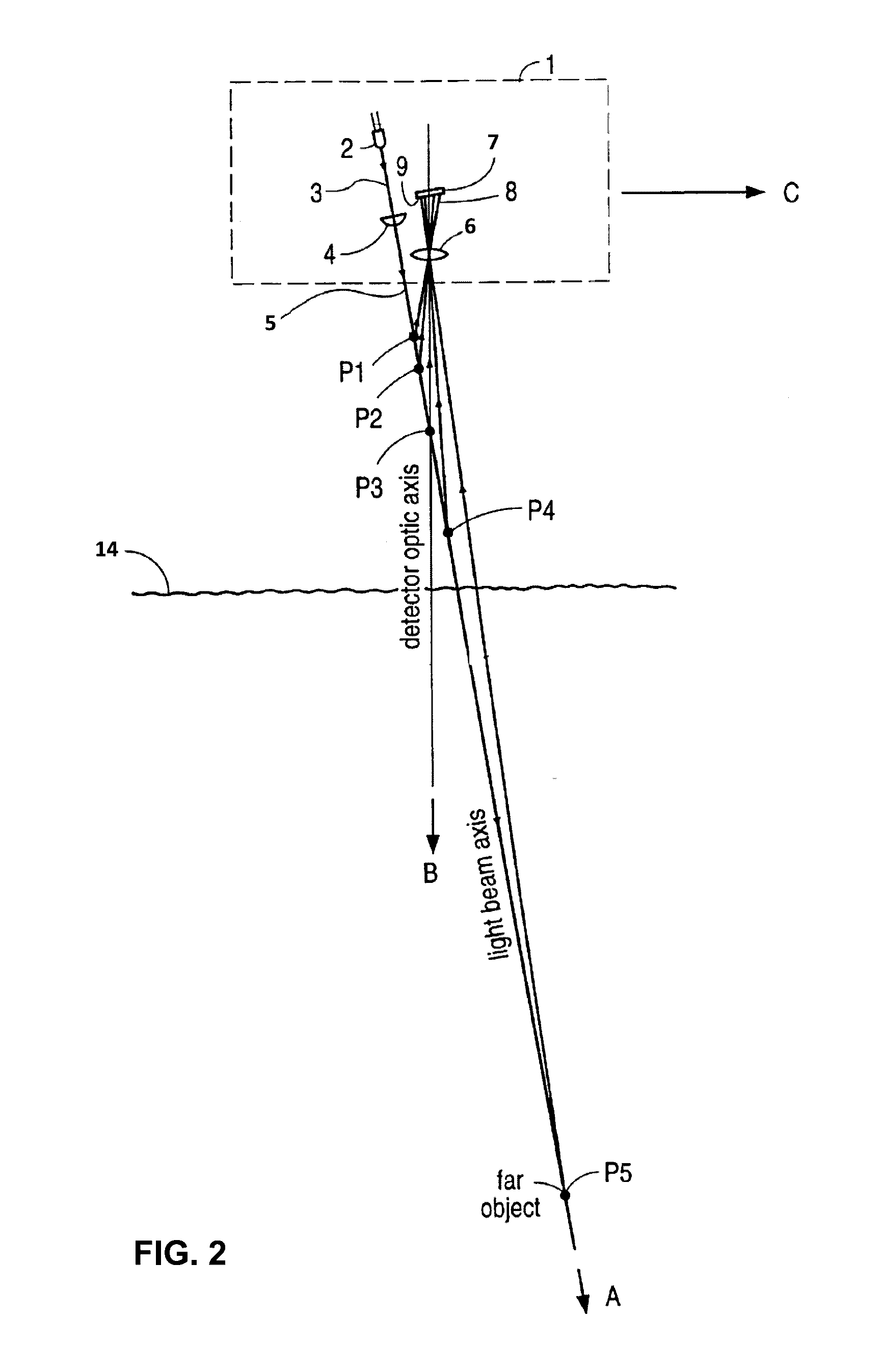

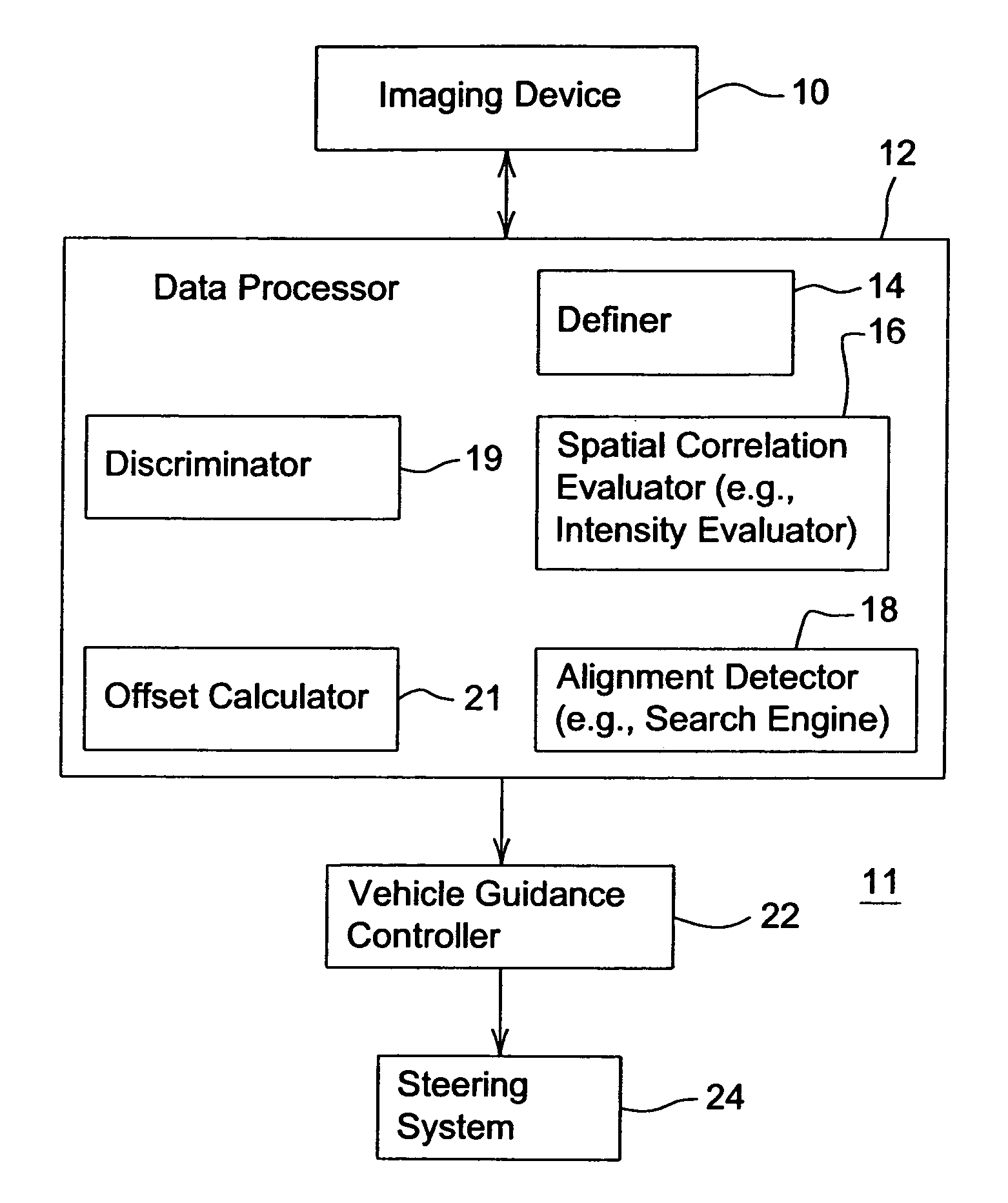

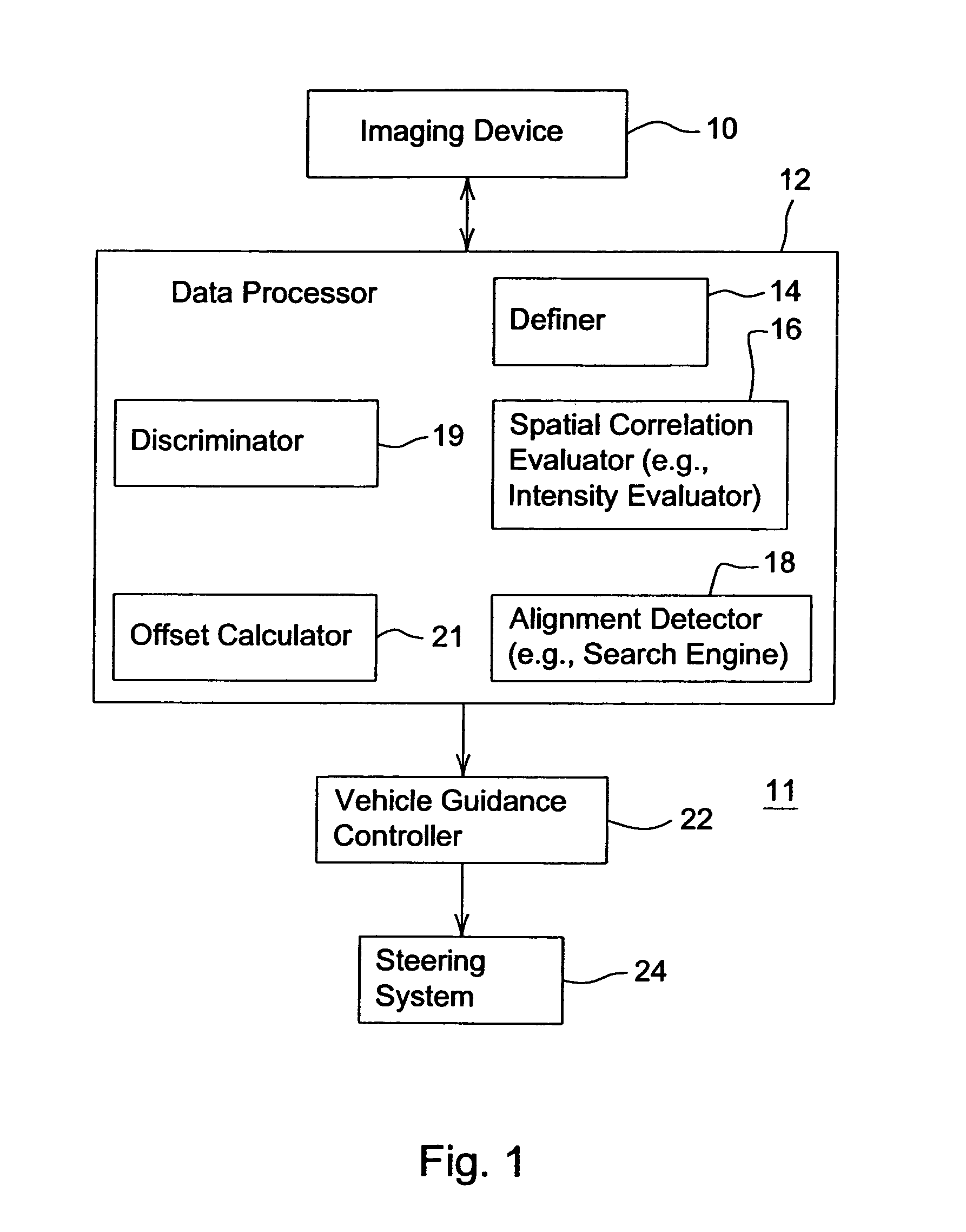

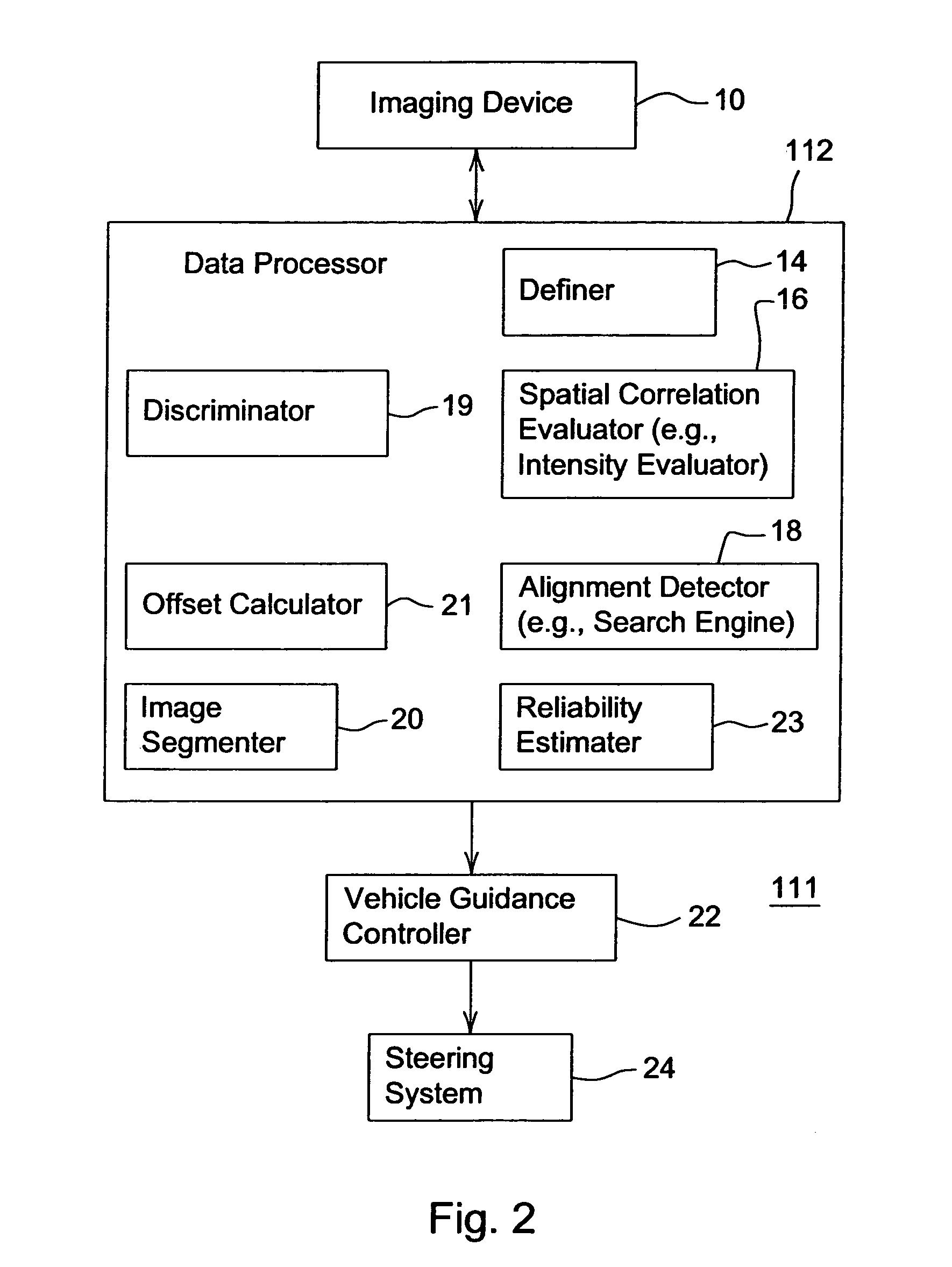

System for vehicular guidance with respect to harvested crop

ActiveUS8185275B2Analogue computers for trafficAnti-collision systemsSpatial correlationDiscriminator

A discriminator identifies windrow pixels associated with a windrow within a collected image. A definer defines a search space with respect to a vehicle. An evaluator determines respective spatial correlations between the defined search space and the windrow pixels for different angular displacements of the search space. An alignment detector or search engine determining a desired vehicular heading as a preferential angular displacement associated with a generally maximum spatial correlation between the defined search space and the windrow pixels. An offset calculator estimates an offset of the vehicle to a central point of the windrow or a depth axis to achieve the desired vehicle heading and desired position of the vehicle with respect to the windrow.

Owner:DEERE & CO

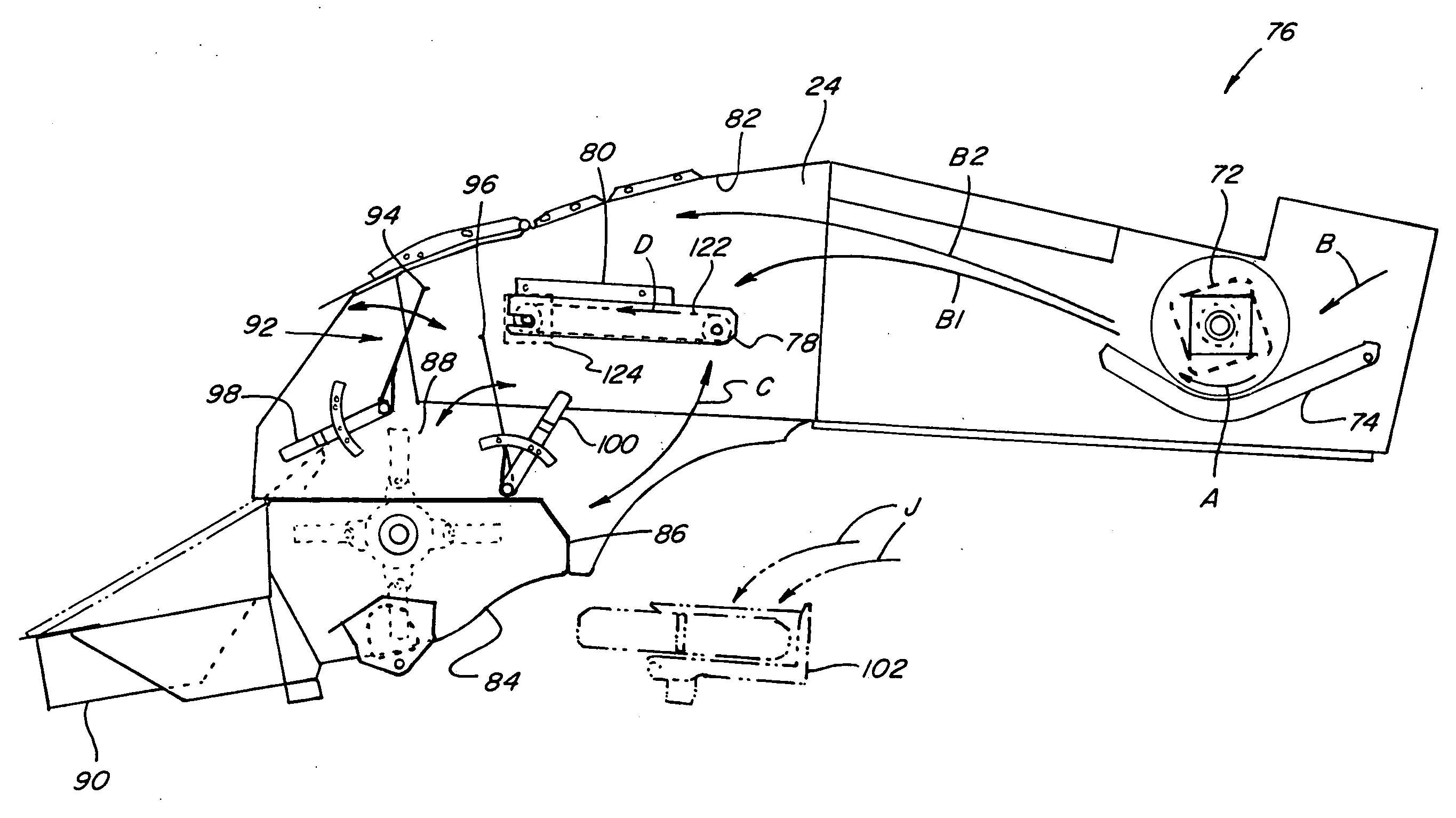

Windrow merging attachment

A windrow merging implement with a pick-up, a conveyor and a connecting hitch or structure is provided in combination with a mowing vehicle, with the connecting hitch being releasably secured to a rear end of the vehicle chassis. The mowing vehicle is operative to form windrows of crop in one or more of three locations, namely, a central location passing longitudinally between the wheels of the vehicle and one on each side of the vehicle. The windrow merging implement may be positioned at either side of the vehicle for picking up the windrow deposited there, and includes a conveyor structure for either depositing the picked up windrow upon or alongside the centrally deposited windrow. Also disclosed is an embodiment where the windrow merging implement picks up and displaces transversely the centrally deposited windrow. A further embodiment discloses two windrow merging implements which respectively pick up the windrows at the opposite sides of the vehicle and convey them inwardly so as to be combined with the centrally located windrow.

Owner:DEERE & CO

Wind guard latch retainer

ActiveUS6935094B1Reliable constructionReduce manufacturing costLoadersMowersEngineeringAgricultural crops

Owner:CNH IND AMERICA LLC +1

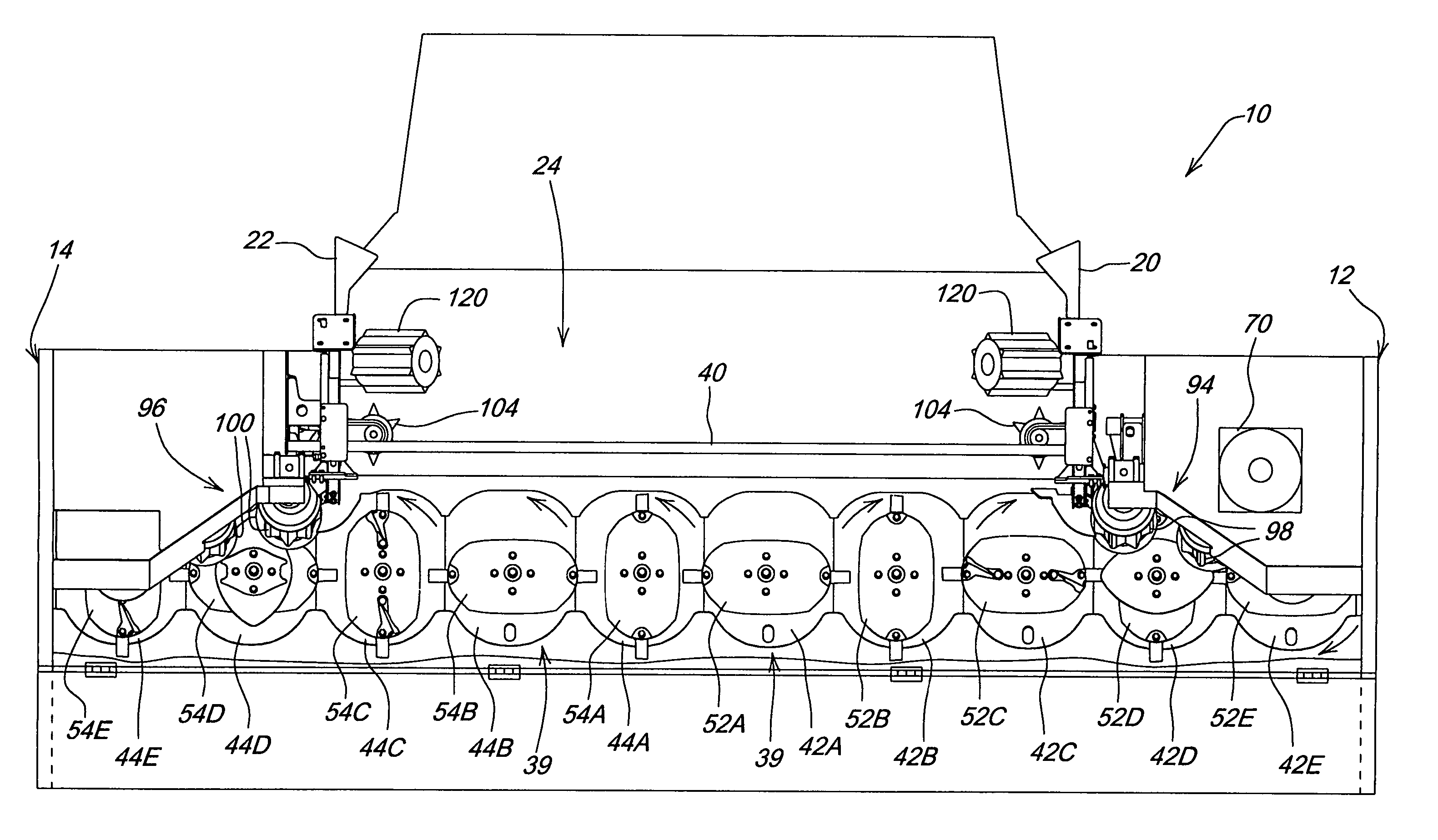

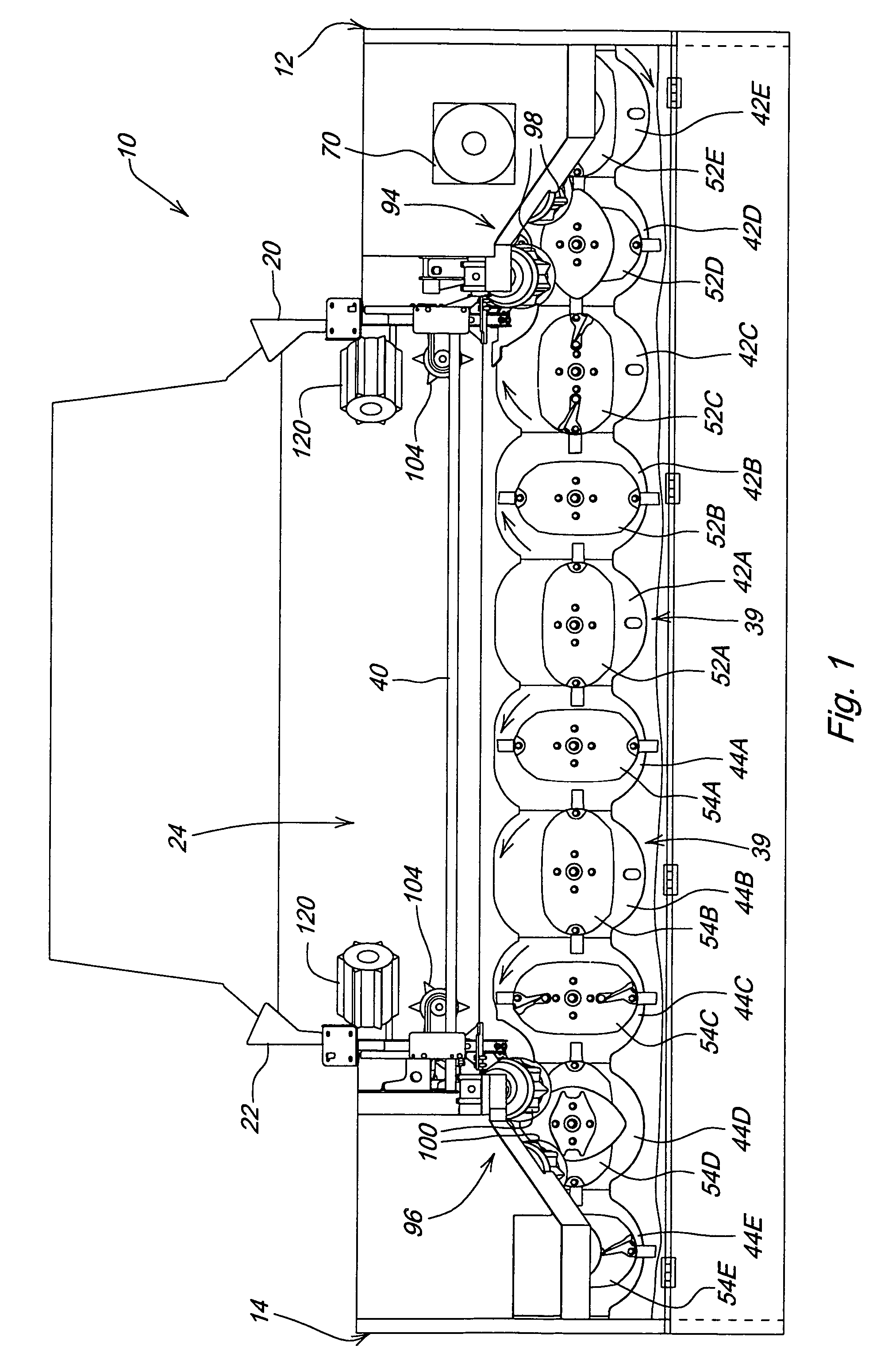

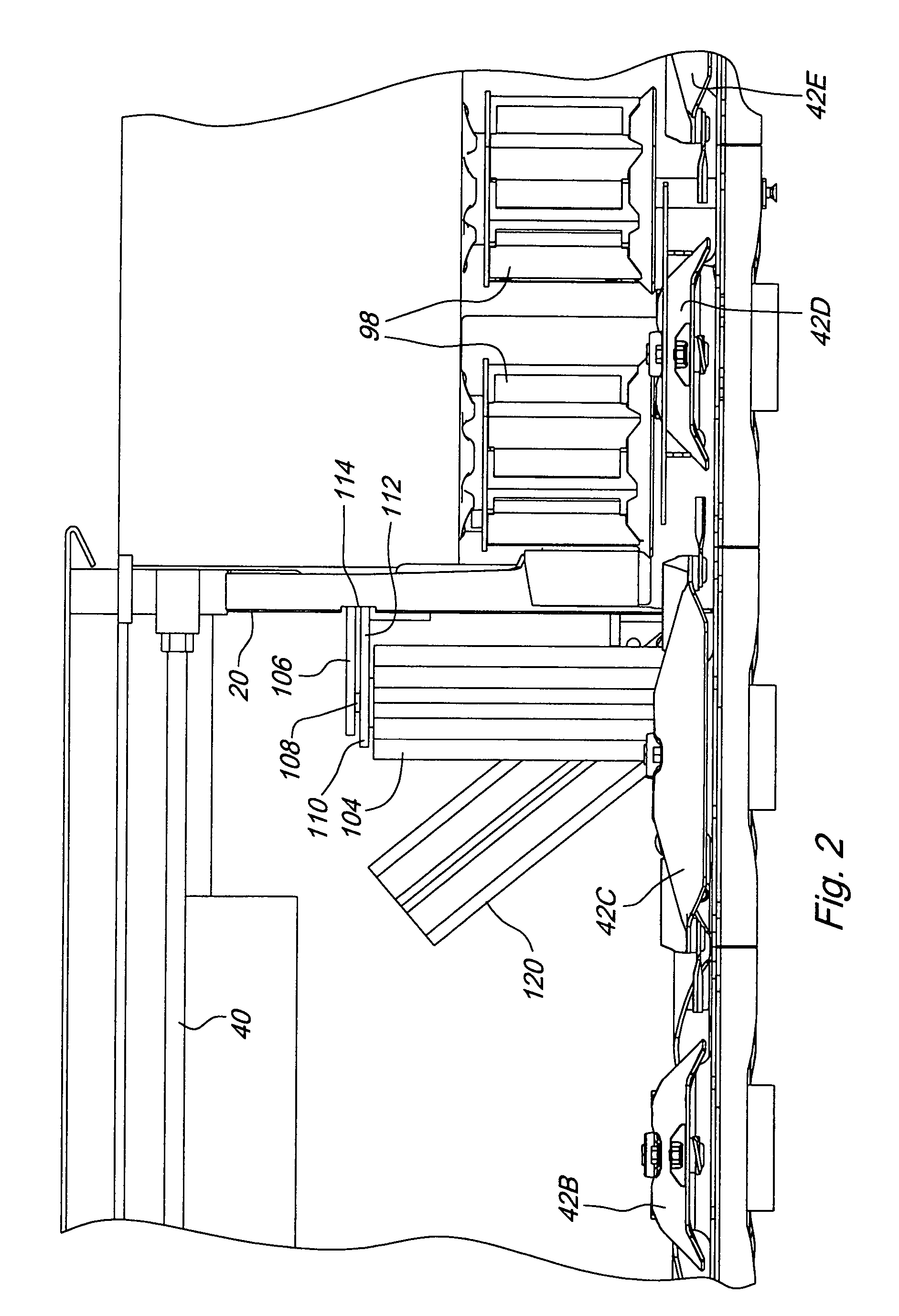

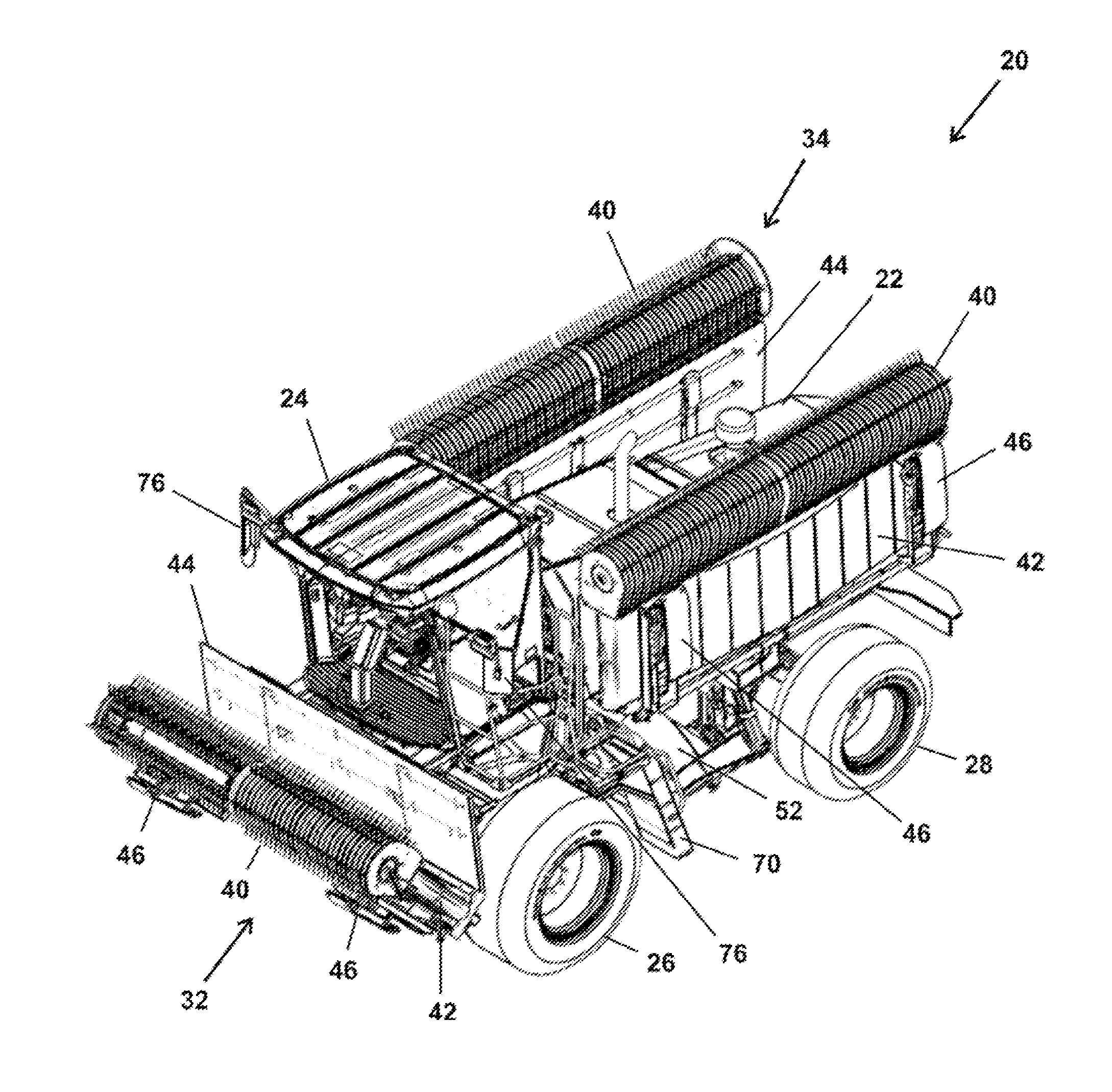

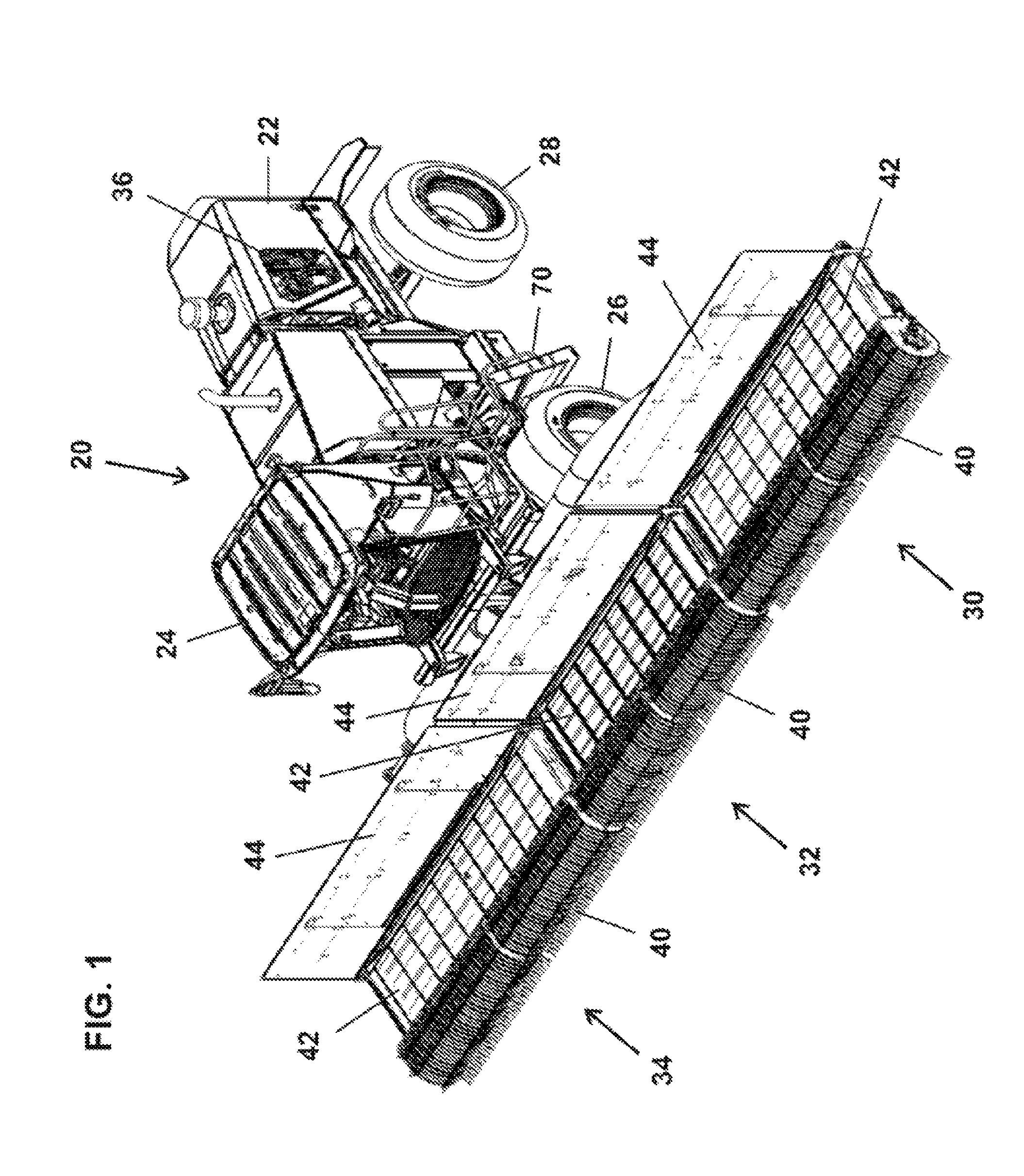

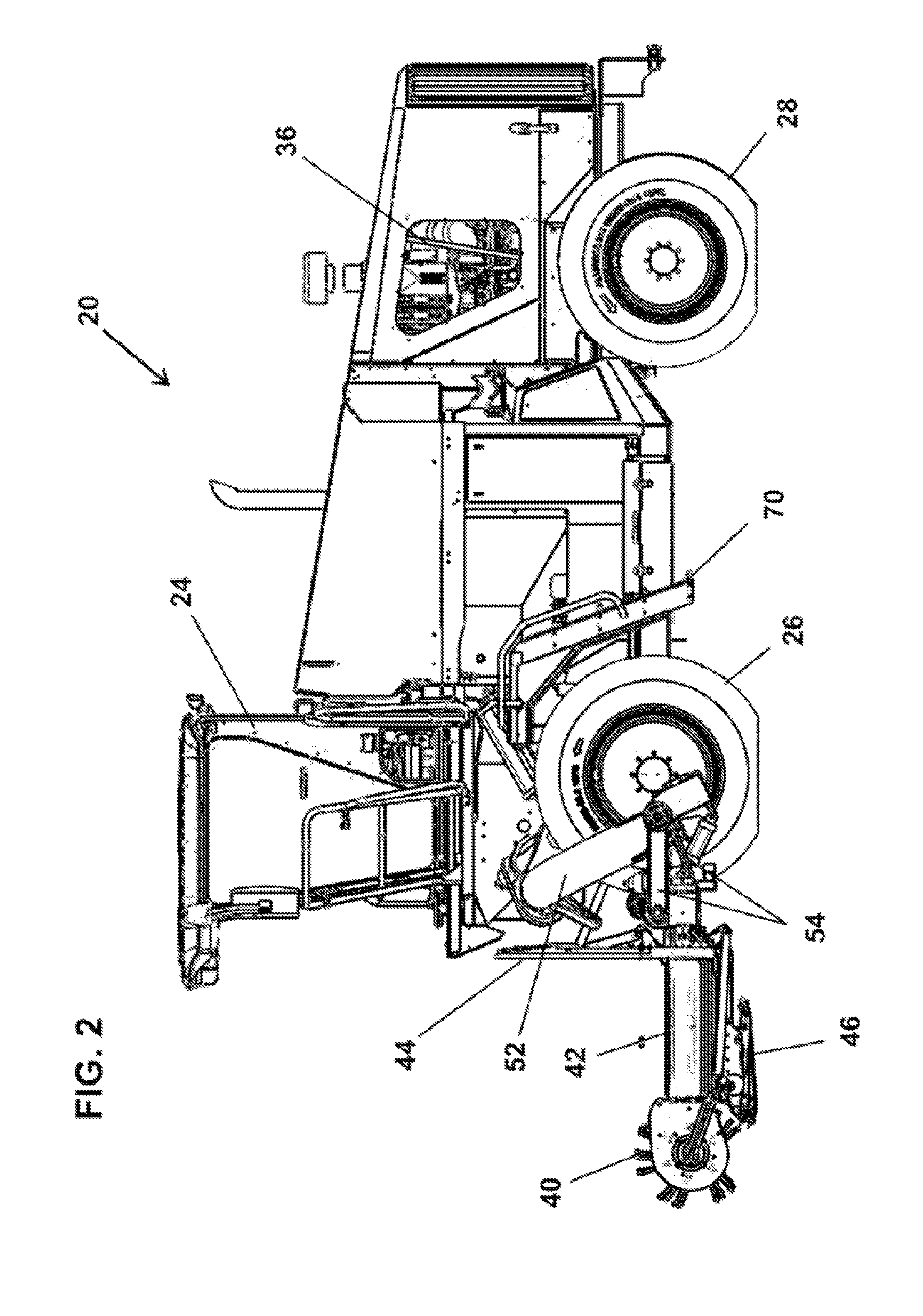

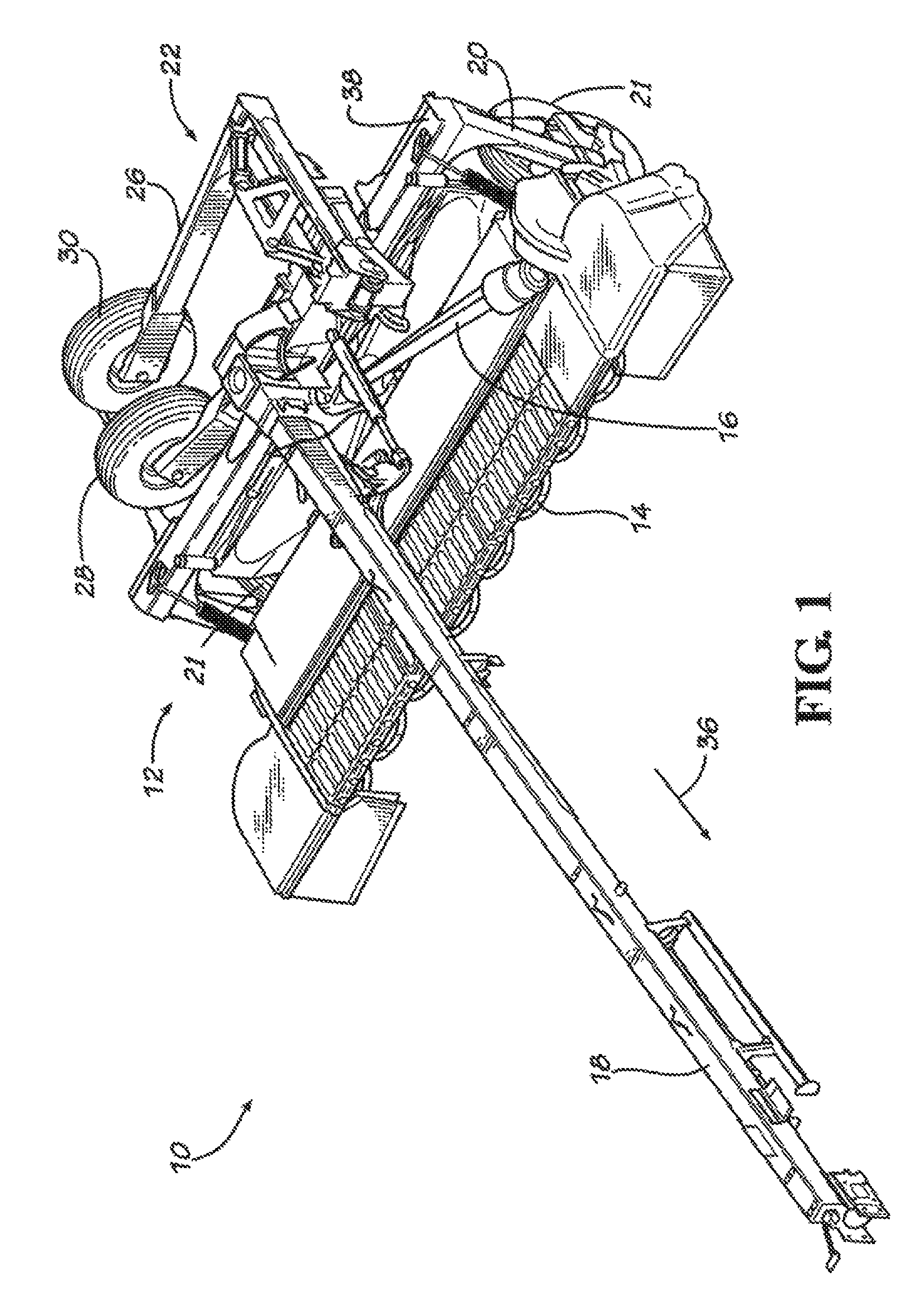

Self-propelled windrow merger

A self-propelled windrow merger includes a motor and a chassis. At the front of the merger are a first pickup and transfer assembly, a second pickup and transfer assembly and a third pickup and transfer assembly. A cab is above and behind the second pickup and transfer assembly. A folding mechanism for moves each of the pickup and transfer assemblies between a first position wherein the first, second and third pickup and transfer assemblies are laterally aligned and a second position wherein the first and third pickup and transfer assemblies are positioned rear of the cab.

Owner:OXBO INT CORP

System for flexible crop residue management

An agricultural harvester with a flexible crop residue management system. A pivotal swath door and displaceable windrow chute are coordinated to be displaced between positions in which all of crop residue is spread laterally and another position in which straw in the crop residue is directed in a windrow by a windrow chute and the chaff is directed laterally.

Owner:BLUE LEAF I P

Folding frame for an agricultural implement

ActiveUS8657025B2Narrow widthHigh strengthSpadesAgricultural machinesAgricultural engineeringWindrow

A folding frame for an agricultural implement such as a wheel rake. The frame includes ground engaging wheels and two toolbars foldable for operation and for transport. The folding frame is provided flexibility to conform to uneven surfaces, yet stability against the torques and forces of operation. A slidable tongue provides folding action between the transport position and the operating position. A spacing between rear ends of the two toolbars may be altered hydraulically for wider or narrower windrows. A novel caster wheel provides support for the toolbars and is located so that the implement's transport position is narrower than the prior art's.

Owner:VERMEER MFG CO

Auger with tapered flighting

ActiveUS7621113B2Efficient collectionEfficient preparationMowersPackagingMechanical engineeringWindrow

Owner:BLUE LEAF I P INC

Windrow shield control system for a header of an agricultural harvester

An agricultural harvester is provided which includes a chassis and harvesting wheels, transport wheels and windrow shields connected to the chassis. The transport wheels are deployed in concert with the windrow shields in order to avoid damage to the windrow shields during placement of the transport wheels into an operative, ground contacting position. A first actuator opens and closes the windrow shields for field and transport operations and windrow shield positioning mechanisms are configured to dispose the windrow shields in a plurality of cut crop opening widths when the windrow shields are in an open position. The first actuator is operated remotely in-cab to eliminate need for the harvester operator to dismount the harvester and open and close the windrow shields for field and road transport operations. The windrow shield positioning mechanisms may be manually adjusted or automatically adjusted in-cab.

Owner:BLUE LEAF I P INC

Cultivation material composition for producing high-quality agaricus blazei and manure-free rice straw raw material cultivation method

InactiveCN102138441AReduce the problem of heavy metal cadmium content exceeding the standardGuaranteed breathabilityCultivating equipmentsSoilless cultivationPhosphoric acidMaterials processing

The invention discloses a cultivation material composition for producing high-quality agaricus blazei and a manure-free rice straw raw material cultivation method. The invention is characterized in that: the cultivation material composition comprises the following raw materials in part by weight: 1,000 to 1,500 parts of rice straw, 33 to 45 parts of ammonium bicarbonate, 35 to 45 parts of calciumsuperphosphate, 35 to 40 parts of gypsum and 34 to 50 parts of lime; and the rice straw raw material cultivation method comprises: raw material preparation and processing, namely primary fermentationof windrow, mushroom house selection and disinfection, secondary fermentation of culture materials on beds in the house, inoculation and culture, earthing and fruiting management, wherein the step ofraw material processing, namely primary fermentation, also comprises special pre-piling, pile building and pile turning. The method helps to effectively solve the problem that the content of heavy metals such as cadmium in the agaricus blazei exceeds a standard. Ammonium bicarbonate is used as a nitrogen source fertilizer in the cultivation materials, so damage caused by ammonia is prevented; theprocess is simple; the management is work-saving and labor-saving; the anlages of the agaricus blazei mushrooms is uniform and the mushroom shape is desirable; the yield and quality of the agaricus blazei mushrooms are high; and the artificial cultivation scale of the agaricus blazei can be enlarged.

Owner:INST OF SOIL & FERTILIZER FUJIAN ACADEMY OF AGRI SCI

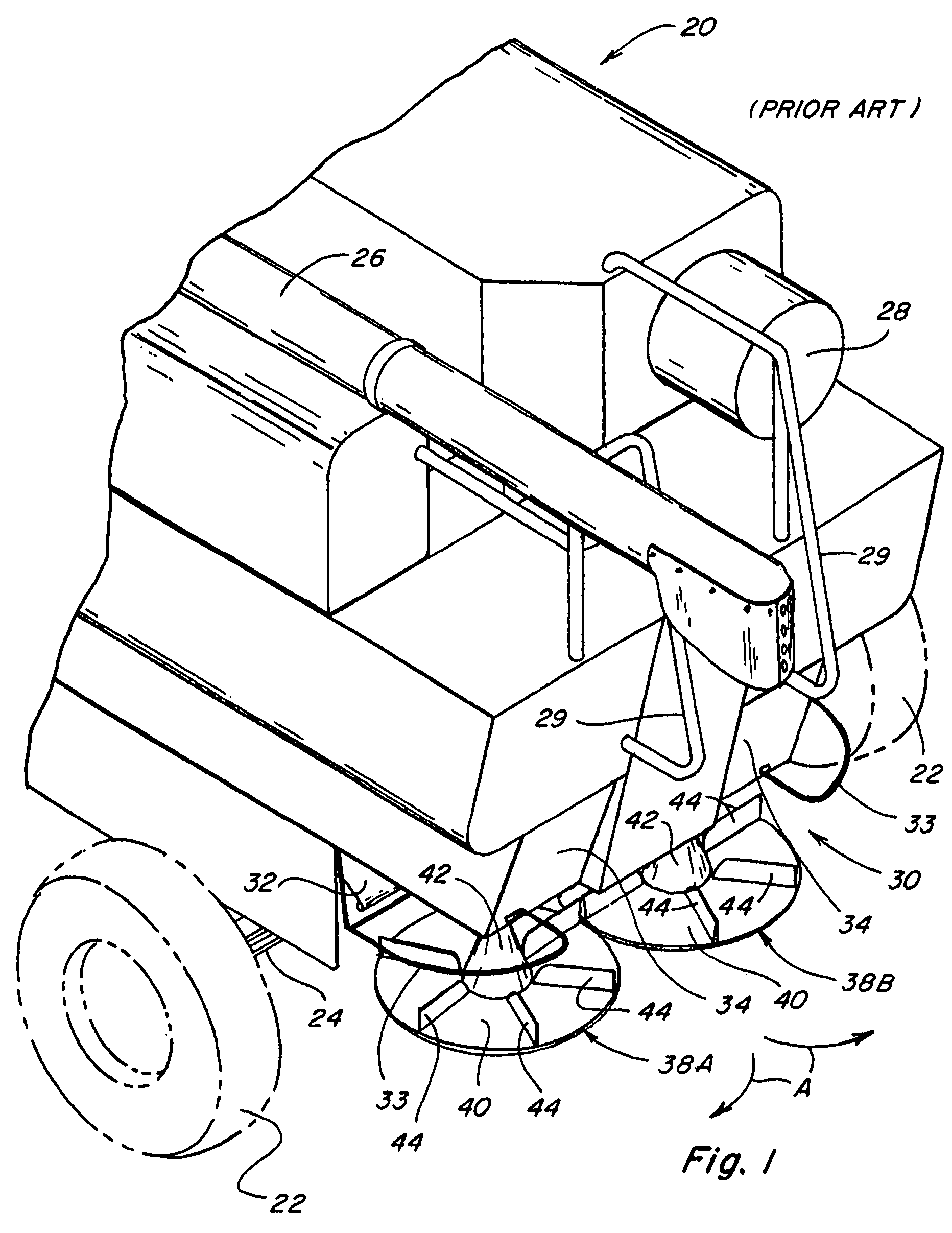

Wide pickup header for a round baler

When harvesting forage in the form of a large round bale, for instance, there are times in which a windrow of forage material lies outside the side boundaries of the bale-forming chamber. This may be due to the windrow being made wide by machinery having driven through it, or by wind, or because of the need to turn the forage harvesting equipment tightly. A wide pickup, notably wider than the width of the bale-forming chamber, provides a solution to this common problem. Dual augers at each end of the wide pickup provide the force to direct the forage into a narrower path, to enter the bale-forming chamber. The orientation and size of the augers permits the pickup header to reside in the same location it would if it was not wider than the baler. Tines or teeth of various rigidities and shapes are provided in the pickup for more effective pickup of the forage.

Owner:VERMEER MFG CO

Auger with tapered flighting

ActiveUS20090250317A1Efficient collectionEfficient preparationMowersPackagingMechanical engineeringWindrow

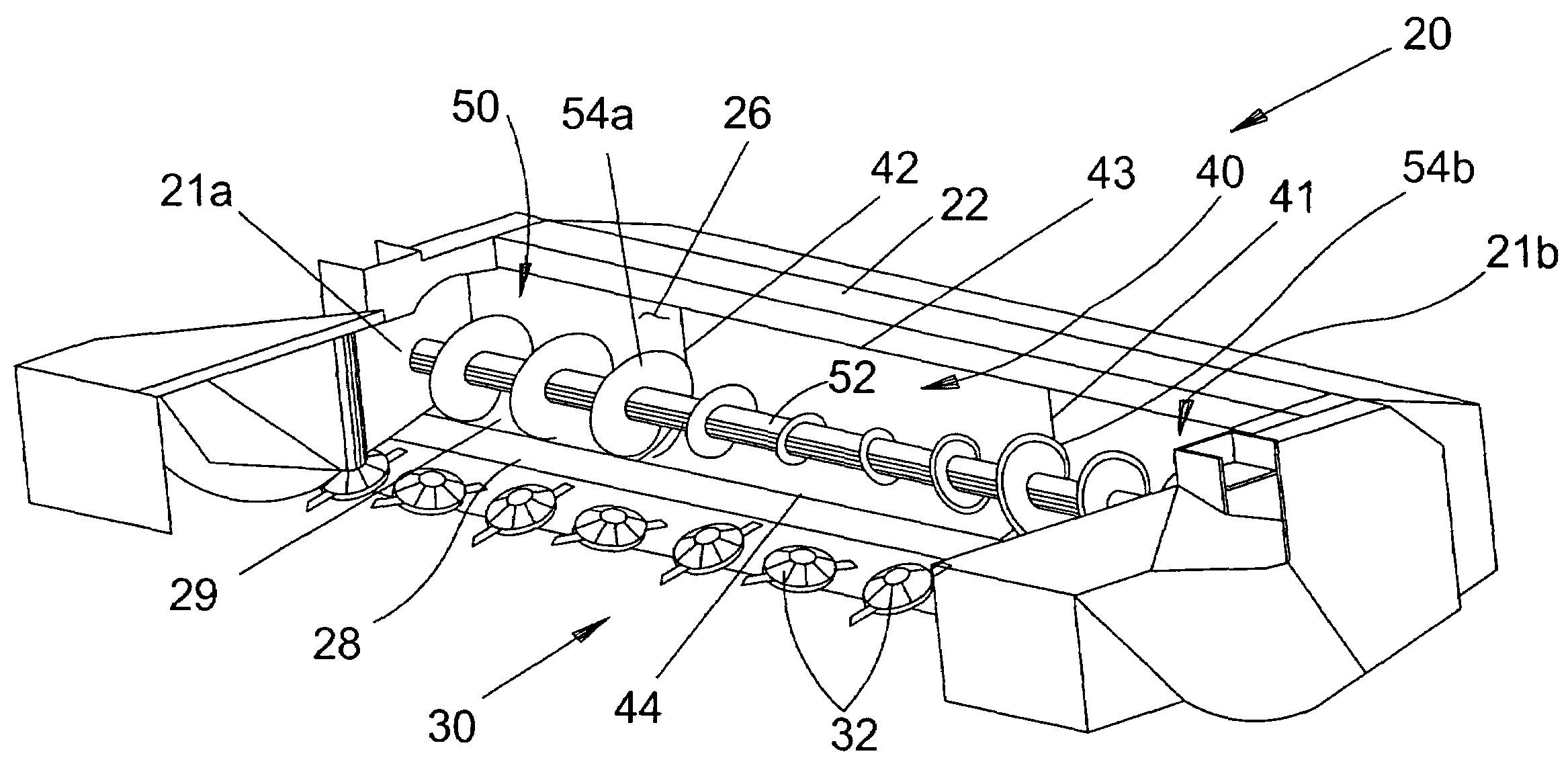

A crop conveying apparatus for laterally urging crop from outboard ends of a cutting header on an agricultural harvester toward an interior discharge zone for formation of a windrow or for feed to a subsequent crop processing apparatus. Helical flighting extending radially from a transversely disposed, rotatable central core defines a first profile for the auger apparatus adjacent each outboard end of the header and extending inwardly to a position near, but not co-extensive with the width of a crop discharge zone in the header. Auger flighting in the central portion of the header co-extensive with the width of the discharge zone opening features a variable profile that tapers from the first profile to a minimum profile centrally located between the side edges of the discharge zone opening to provide optimal movement of severed crop material into the discharge opening, resist entanglement and clogging of the crop material, and minimize the loss of seed from the crop stem.

Owner:BLUE LEAF I P

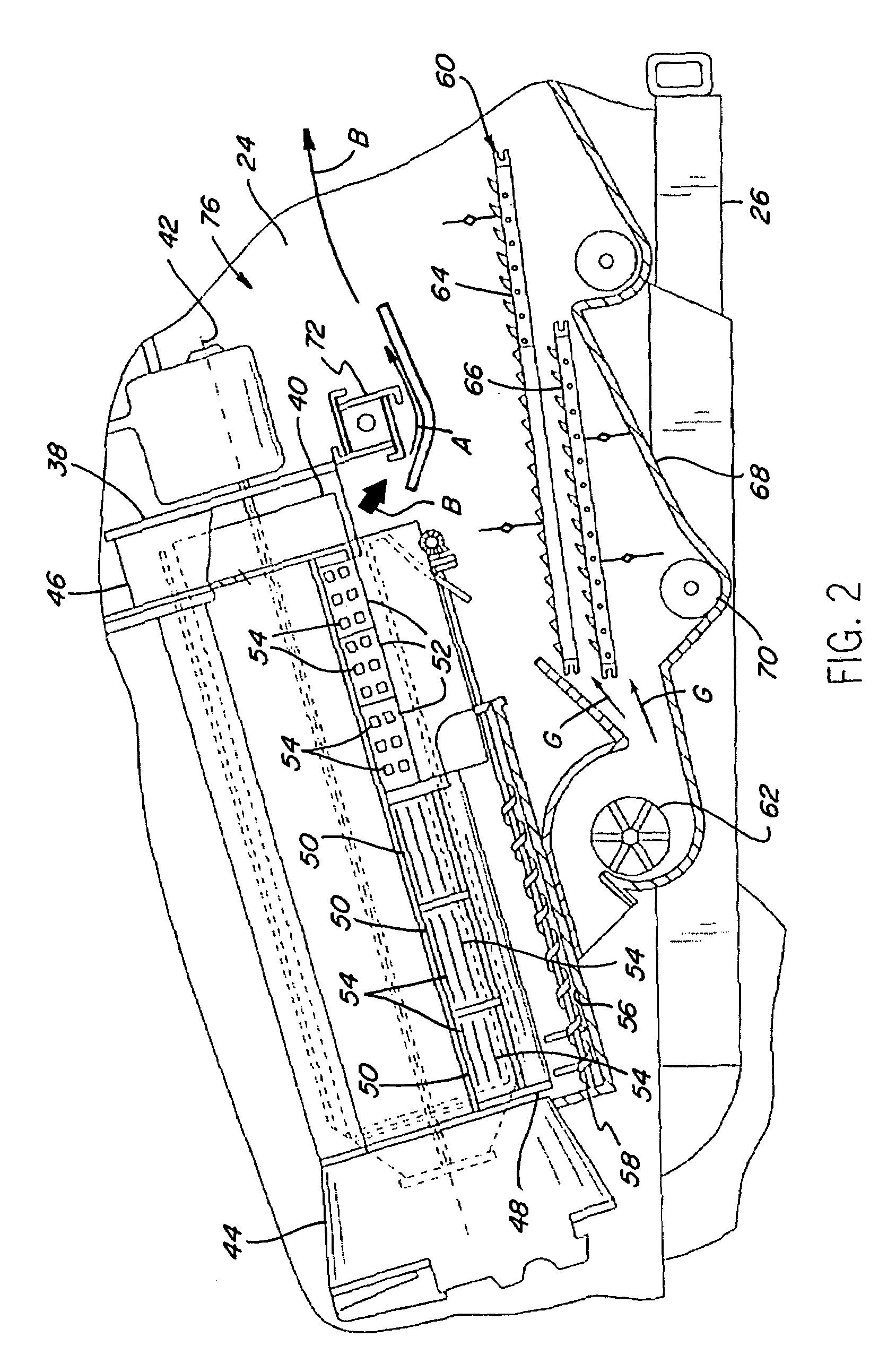

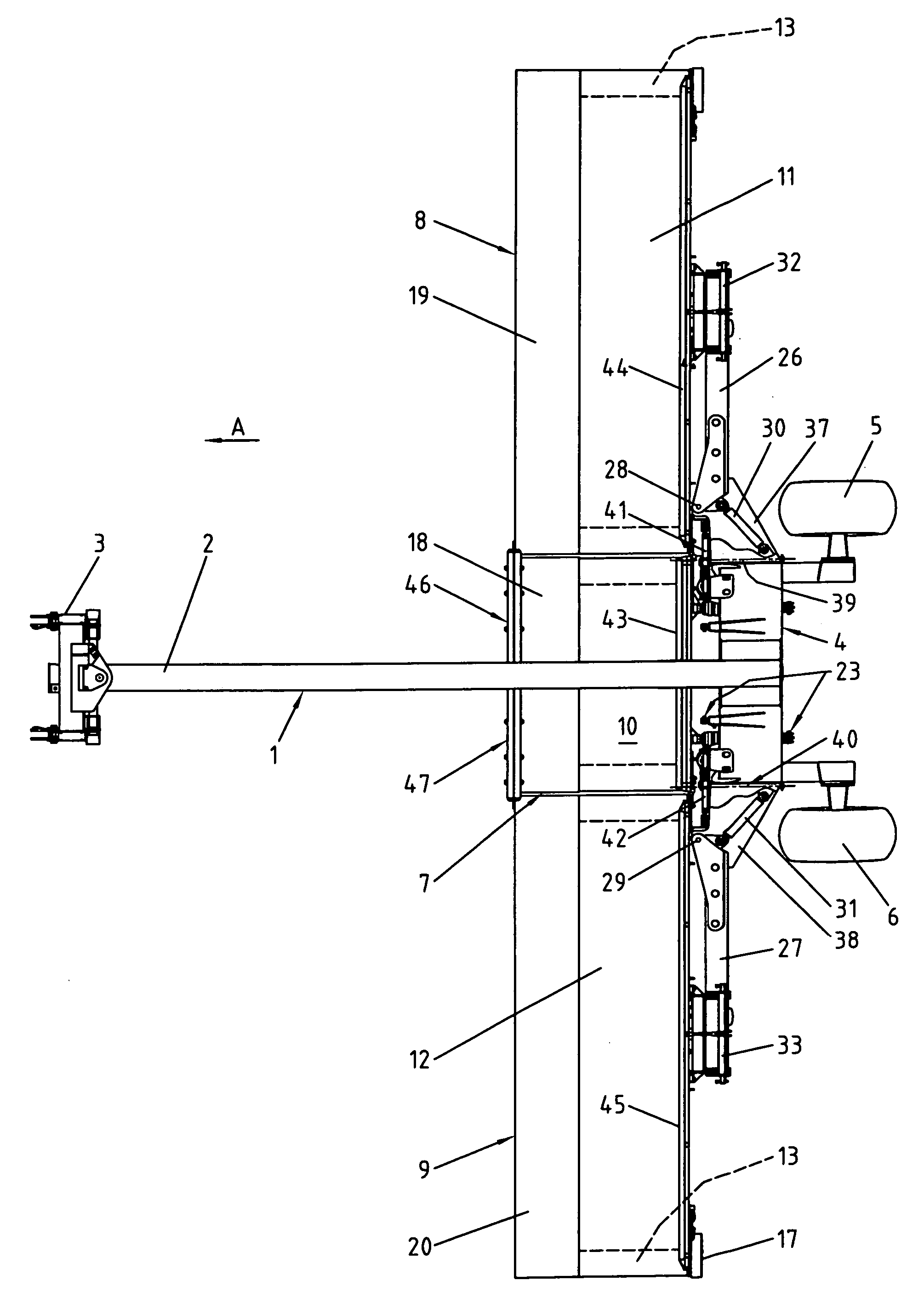

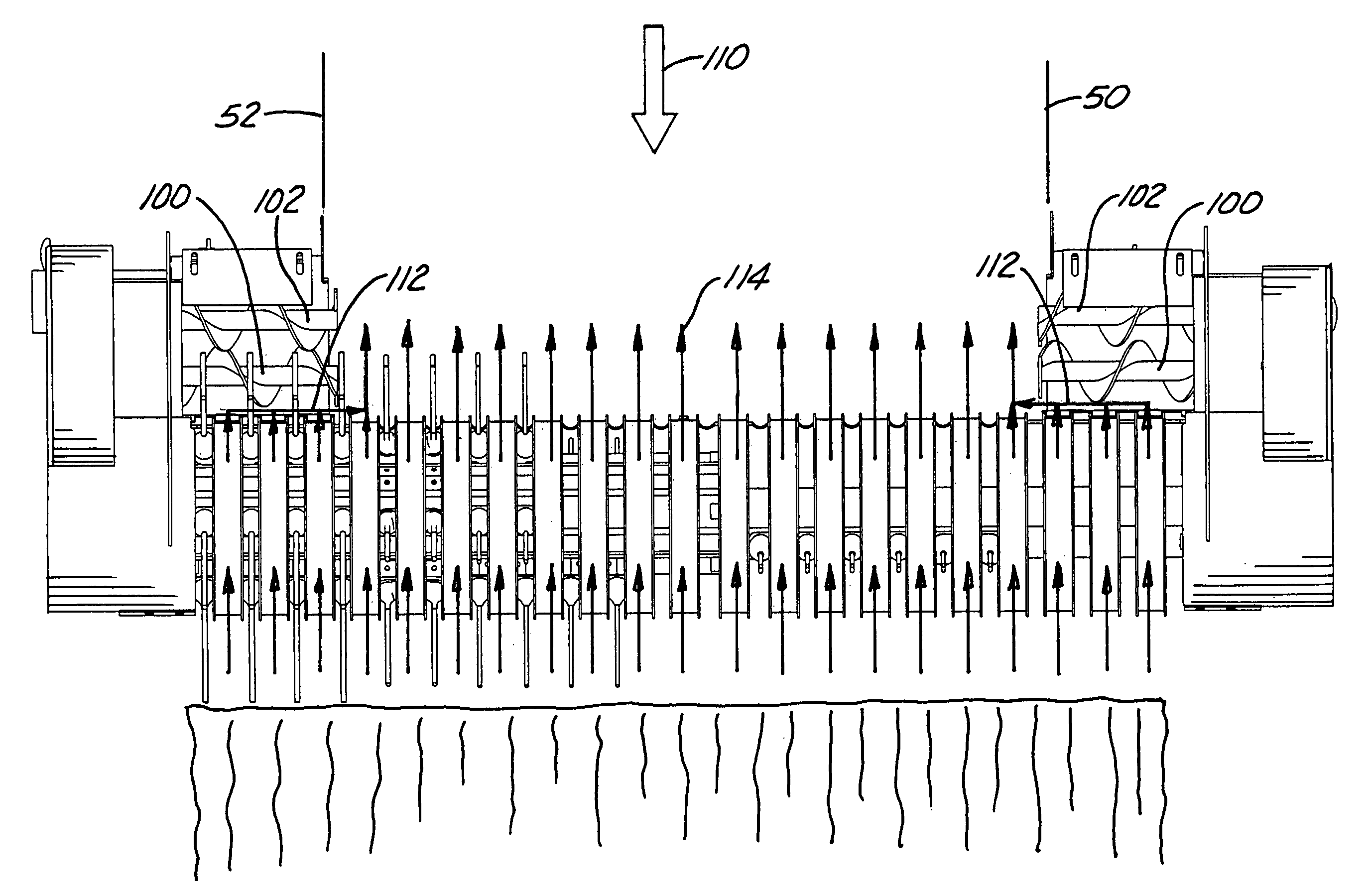

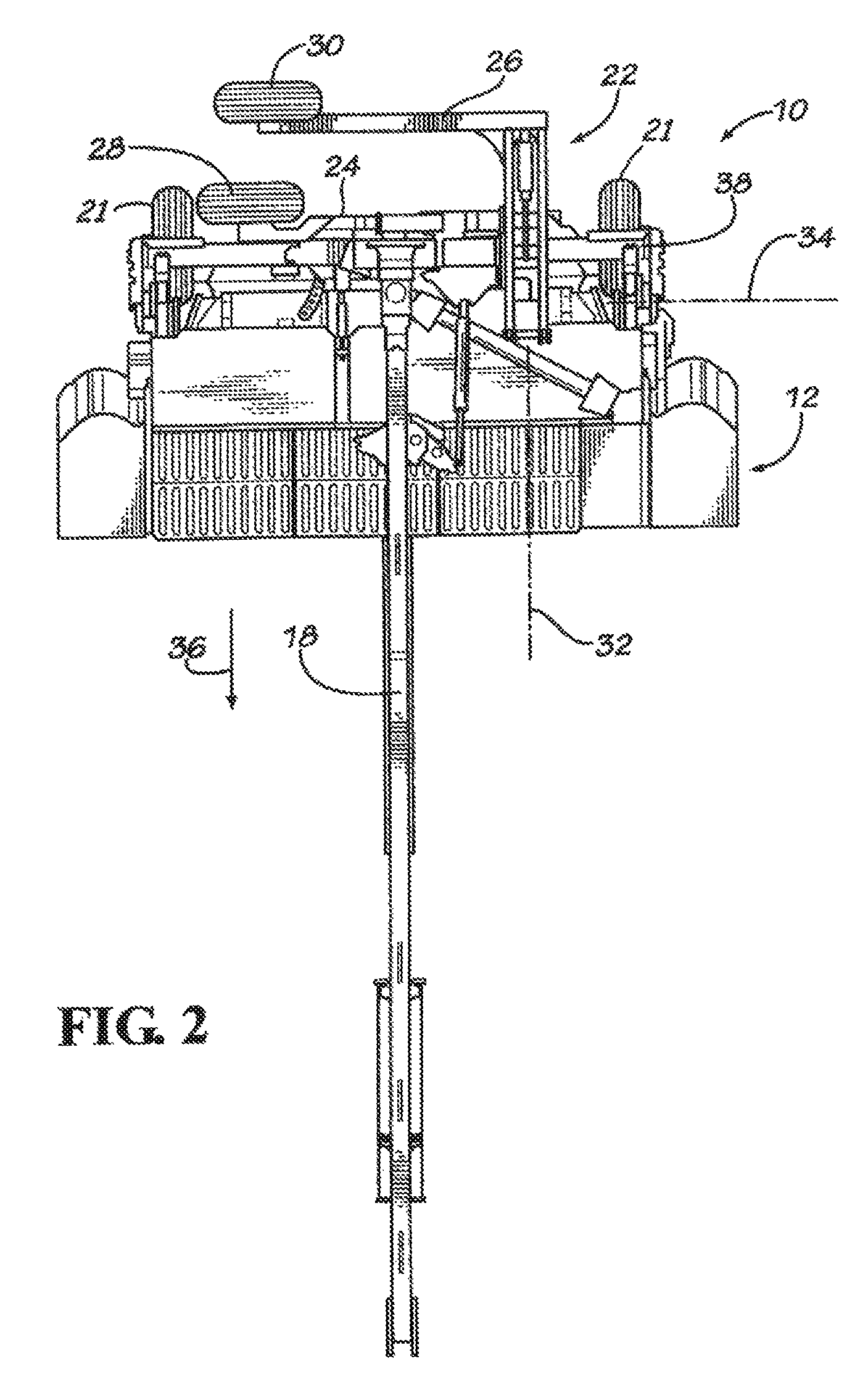

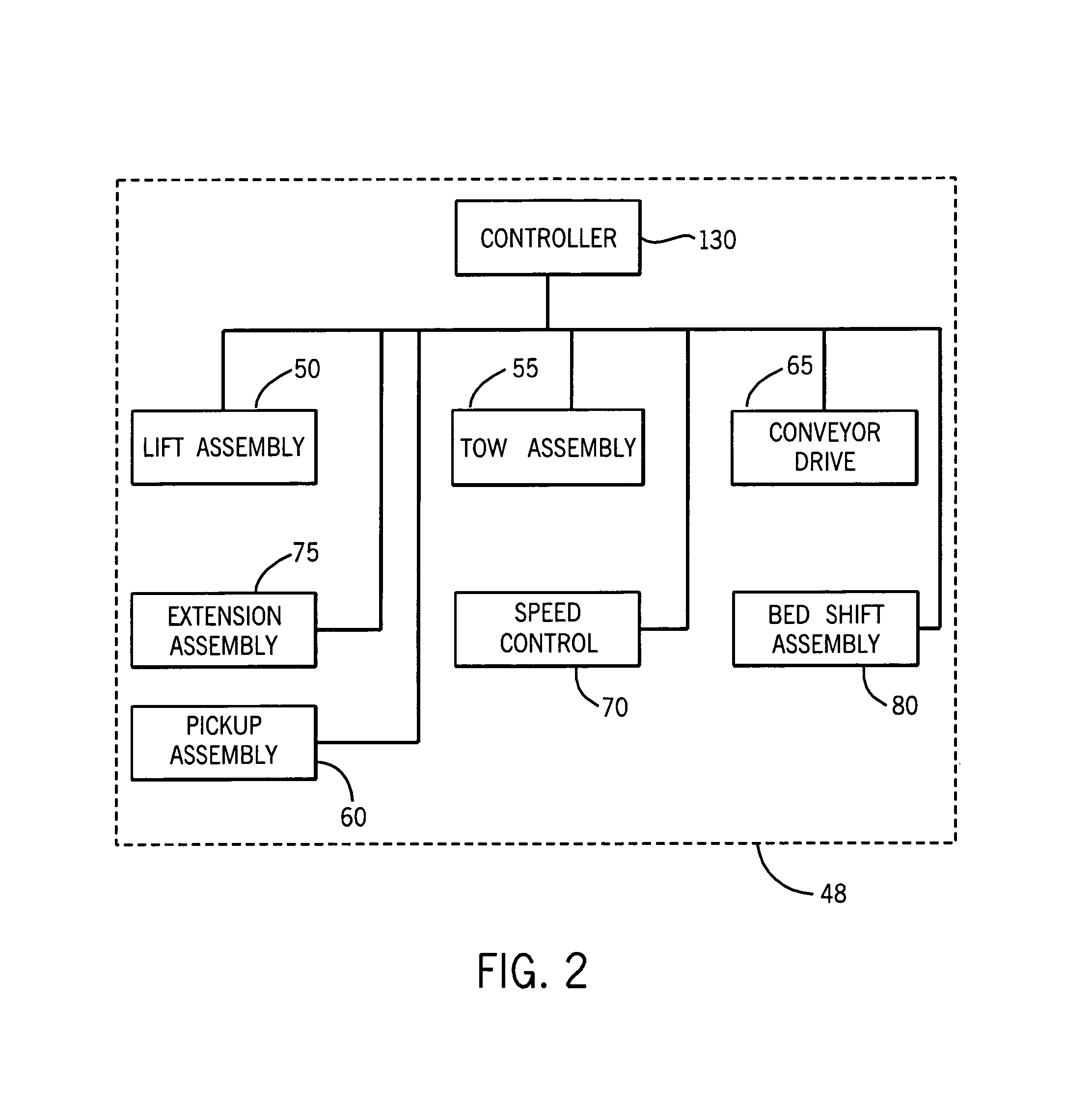

Control arrangement for a pull-type windrow merger

InactiveUS6971225B1Accelerated dryingGood conditionHaymakersHarvestersControl signalBiological activation

A control arrangement is configured to remotely control operation of a windrow merger pulled by a tow vehicle. The windrow merger includes a plurality of functional systems or assemblies configured to selectively collect and discharge crop material, and that can be adjusted to alter the operating characteristics or parameters of the windrow merger. The control arrangement includes a controller, a housing, and a harness configured to communicate control signals from the controller to the number of functional assemblies. The control arrangement further includes a manifold assembly configured to the control signals from the controller to respective control valves operable to control operation of the number of functional assemblies. Thereby, the controller allows the operator to regulate operation and activation of each of the number of functional assemblies from the operator's cab of the tow vehicle.

Owner:GHEL CO

Method for production of organic fertilizer by utilizing pig manure

InactiveCN103964942AAccelerated ripeningIncrease humification factorBio-organic fraction processingOrganic fertiliser preparationOxygenOrganic content

The invention discloses a method for production of an organic fertilizer by utilizing pig manure. The method comprises the following steps: A, pretreatment of raw material: the pig manure is used as raw material, the carbon-nitrogen ratio is adjusted to 28, the moisture content of the raw material is reduced to 60 percent, and EM strains are added; B, compost fermentation: compost fermentation is performed by adopting an aerobiotic windrow type composting technology; C, postprocessing of compost products: the moisture is reduced to be below 30 percent, particles can pass through a sieve with 60 mesh, and microelements or functional microorganisms are add for adjustment; D, packaging and storing of finished products. The organic fertilizer produced with the method is excellent in product quality, and is in strict conformance with the national standards and industrial standards of the commercial organic fertilizer: the organic content is not less than 45 percent, the total nutrient content is not less than 5 percent, the moisture content is not greater than 30 percent, and the pH value is 5.5-8.5; the death rate of ova of roundworms is not less than 98 percent, and the number of manure coli-group is not greater than 50 unit / g; in the produced organic fertilizer, in per kilogram of dry matters, the heavy metal content standards of the product are as follows: As is not greater than 30, Hg is not greater than 5, Pb is not greater than 100, Cd is not greater than 3 and Cr is not greater than 300.

Owner:MUYUAN FOODS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com