Patents

Literature

467 results about "Great circle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A great circle, also known as an orthodrome, of a sphere is the intersection of the sphere and a plane that passes through the center point of the sphere. A great circle is the largest circle that can be drawn on any given sphere. Any diameter of any great circle coincides with a diameter of the sphere, and therefore all great circles have the same center and circumference as each other. This special case of a circle of a sphere is in opposition to a small circle, that is, the intersection of the sphere and a plane that does not pass through the center. Every circle in Euclidean 3-space is a great circle of exactly one sphere.

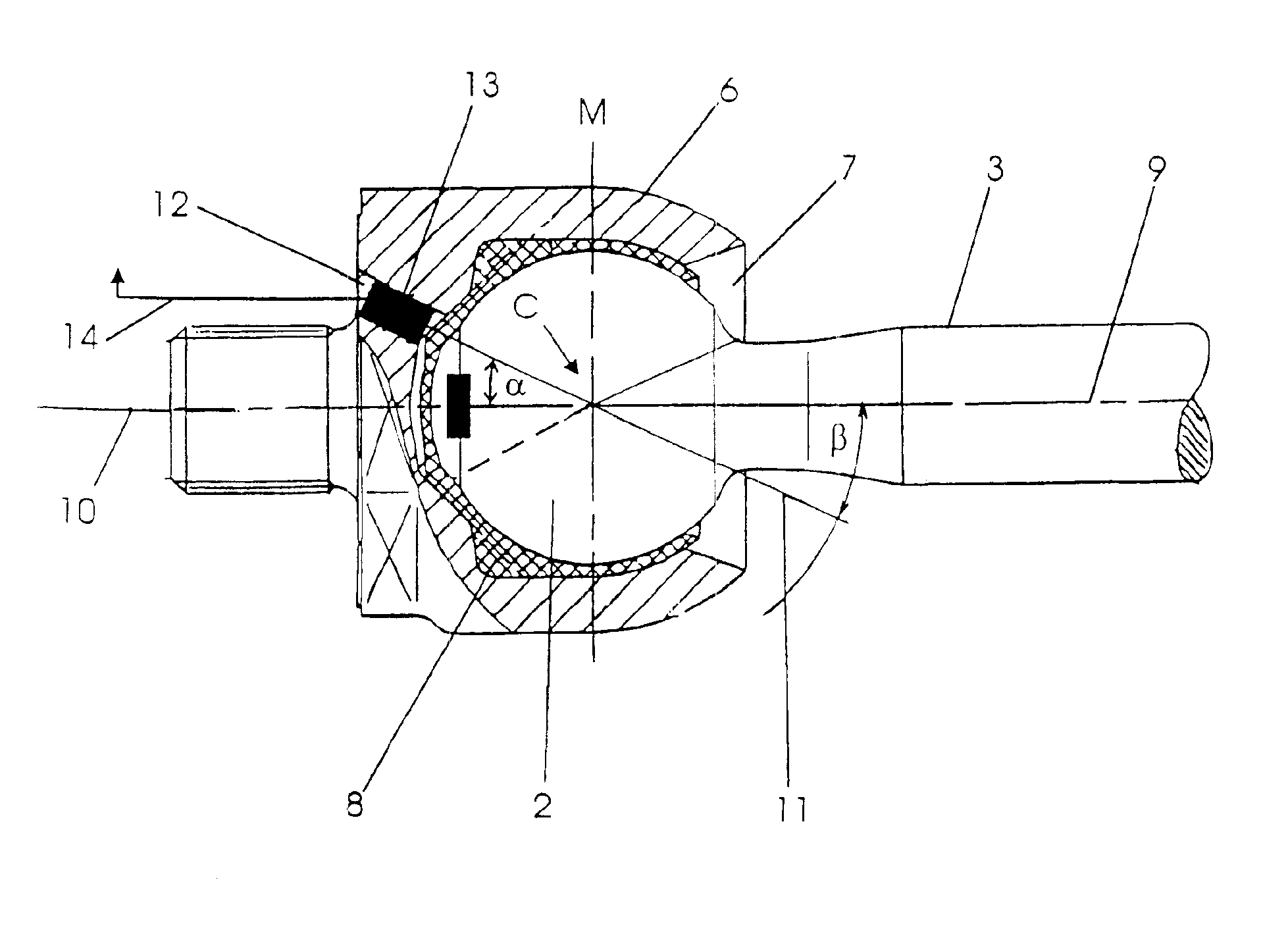

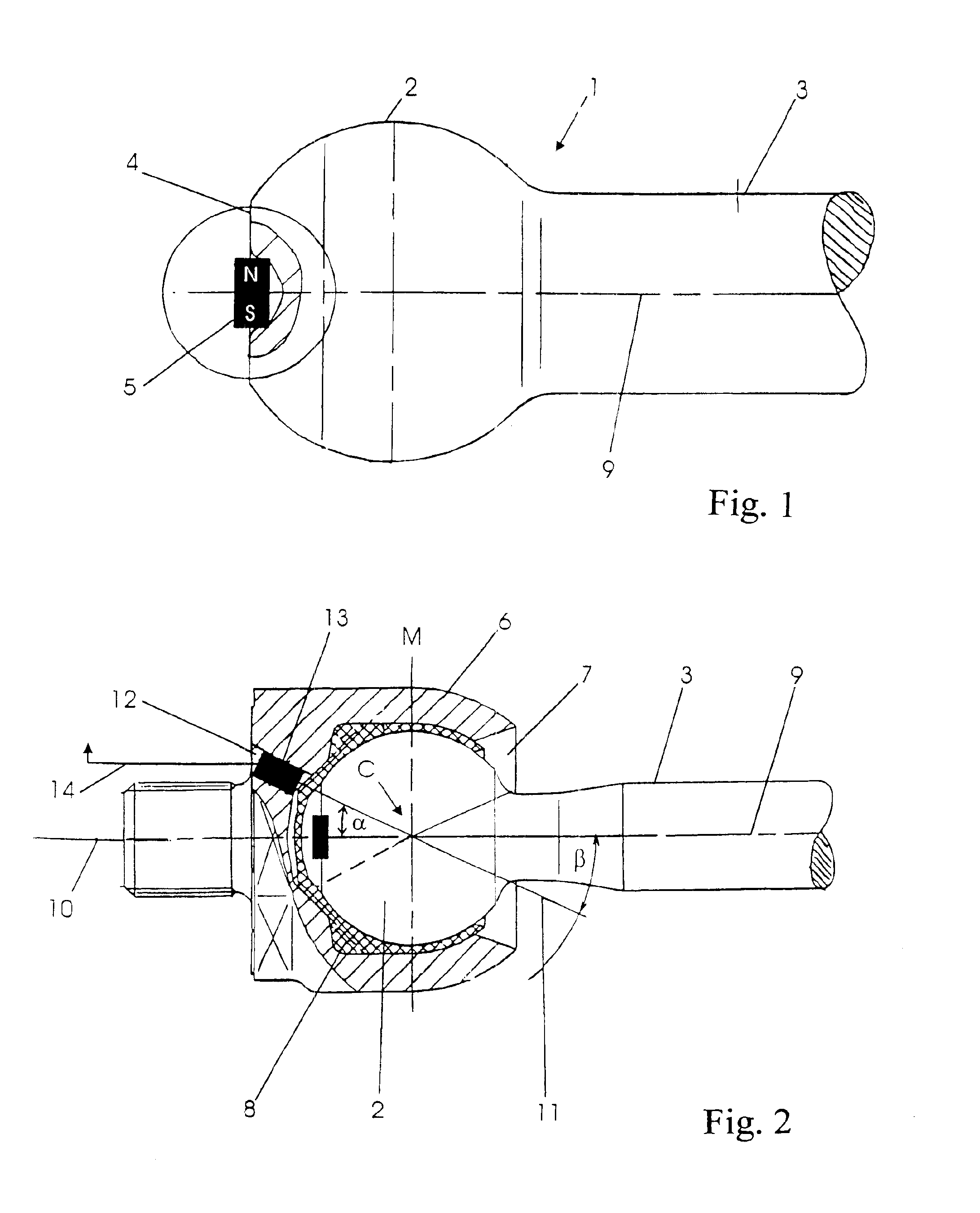

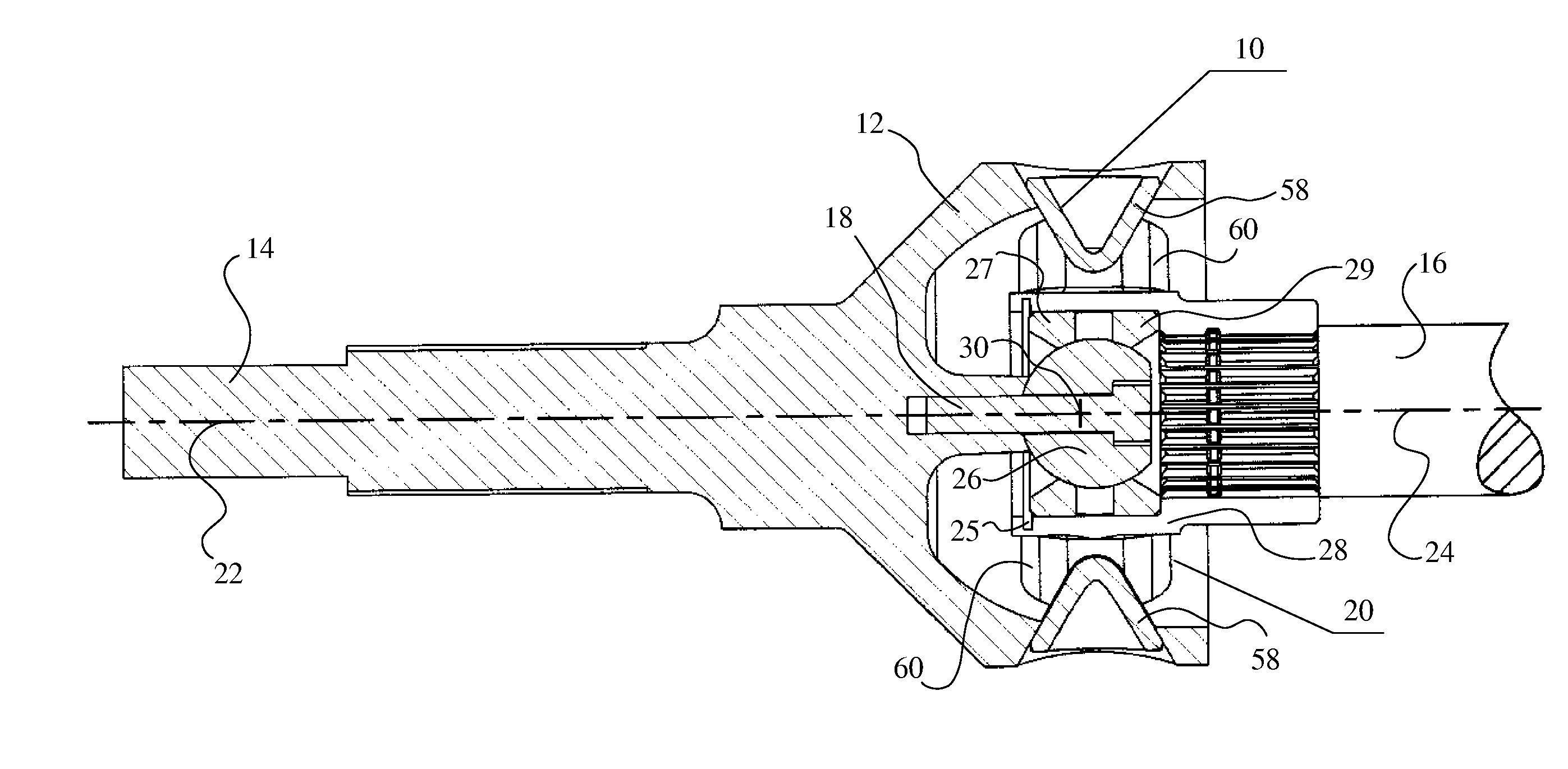

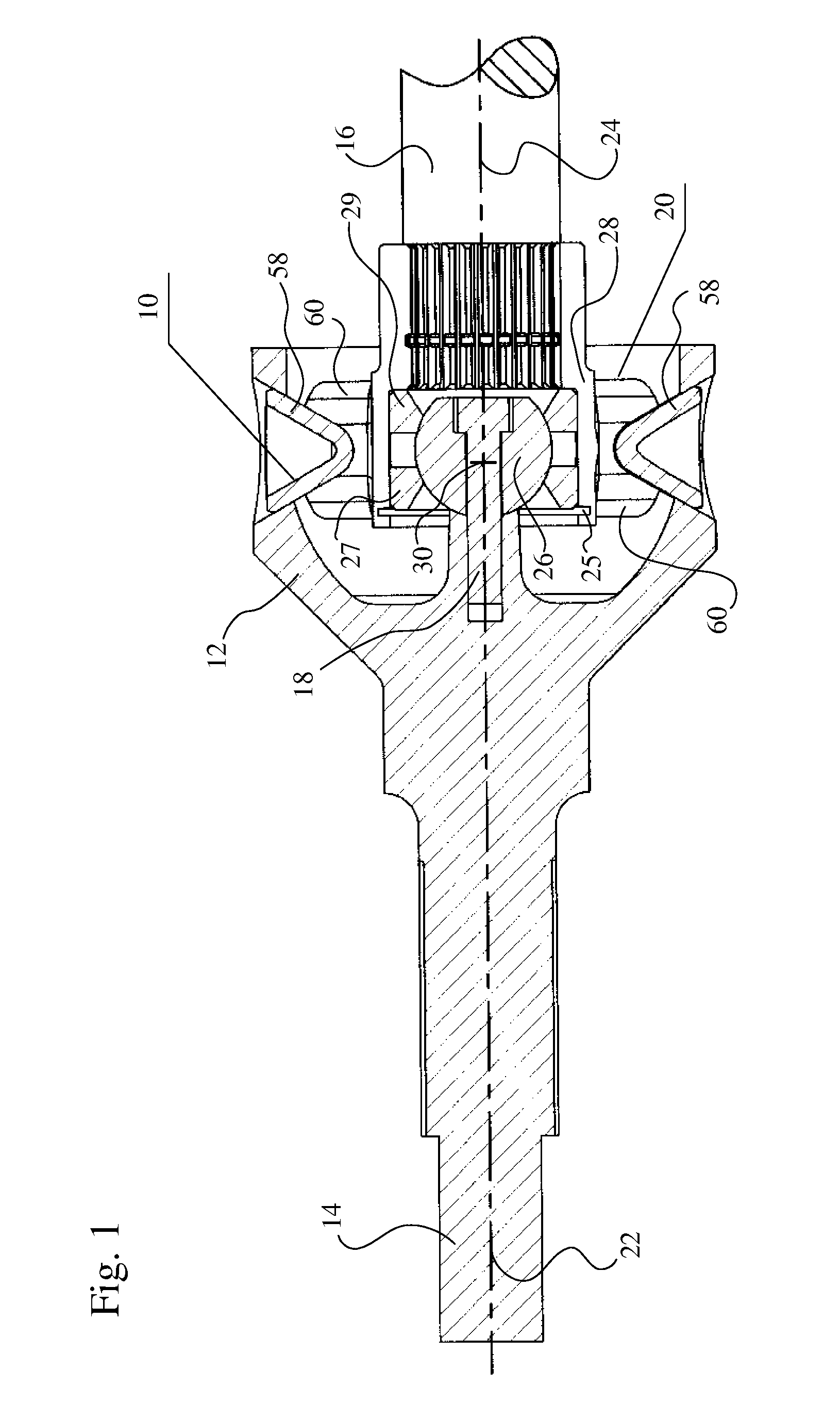

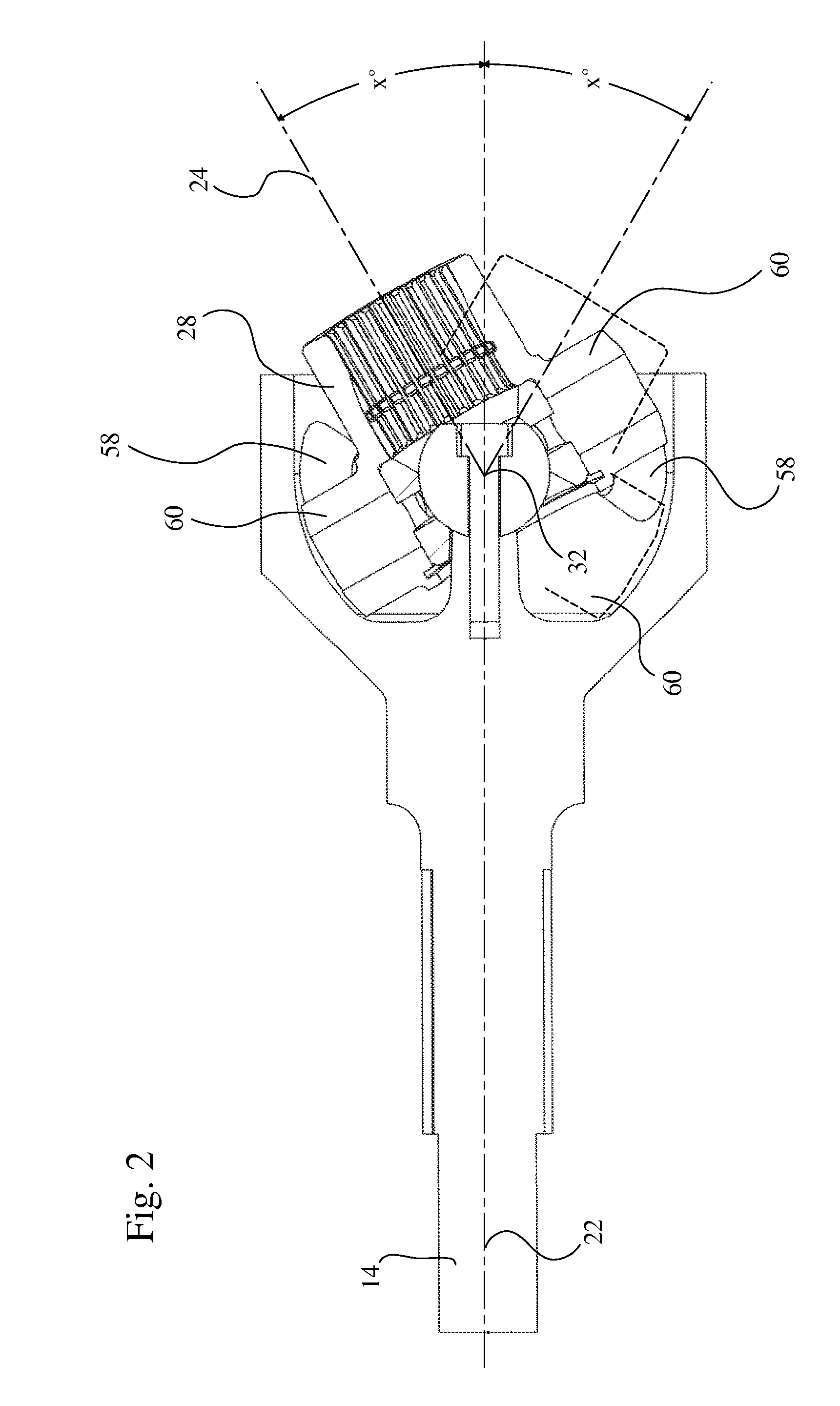

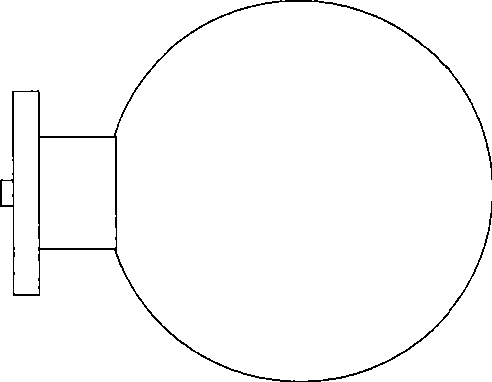

Ball joint with integrated angle sensor

InactiveUS6879240B2Improve accuracyDetect any spatial positionBearing assemblyShaftsTransducerEngineering

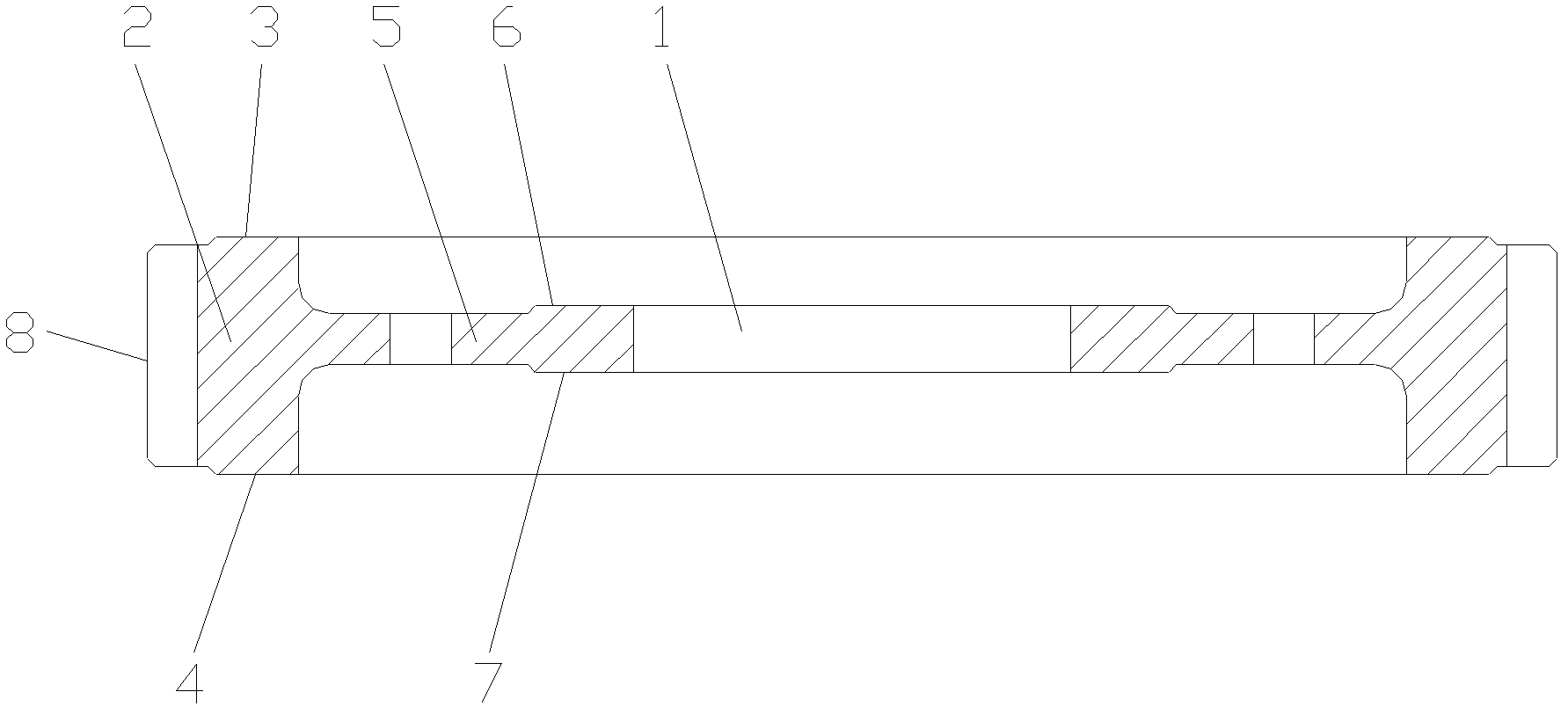

A ball-and-socket joint with integrated angle sensor for a motor vehicle, especially for the chassis of the motor vehicle is created. The ball-and-socket joint has a ball-and-socket joint housing (6) provided with a joint opening (7), a ball pivot (1) having a joint ball (2) and a pin (3), which is mounted, with its joint ball (2), rotatably and pivotably in a hollow-ball-shaped bearing surface in the ball-and-socket joint housing (6), and projects, with its pin (3), through the joint opening (7) out of the ball-and-socket joint housing (6). A two-pole field transducer (5) is provided at the end of the joint ball (2) facing away from the pin (3). The poles of the field transducer (5) are arranged on the ball surface. In this case, at least two field sensors (13) are arranged at a distance from one another with respect to the meridian plane defined by the large circle on the hollow-ball-shaped bearing surface running at right angles to the bearing longitudinal axis in the area or on the ball-and-socket joint housing (6) facing away from the joint opening, and interact with the field produced by the field transducer (5).

Owner:ZF LEMFOERDER METALLWAREN AG

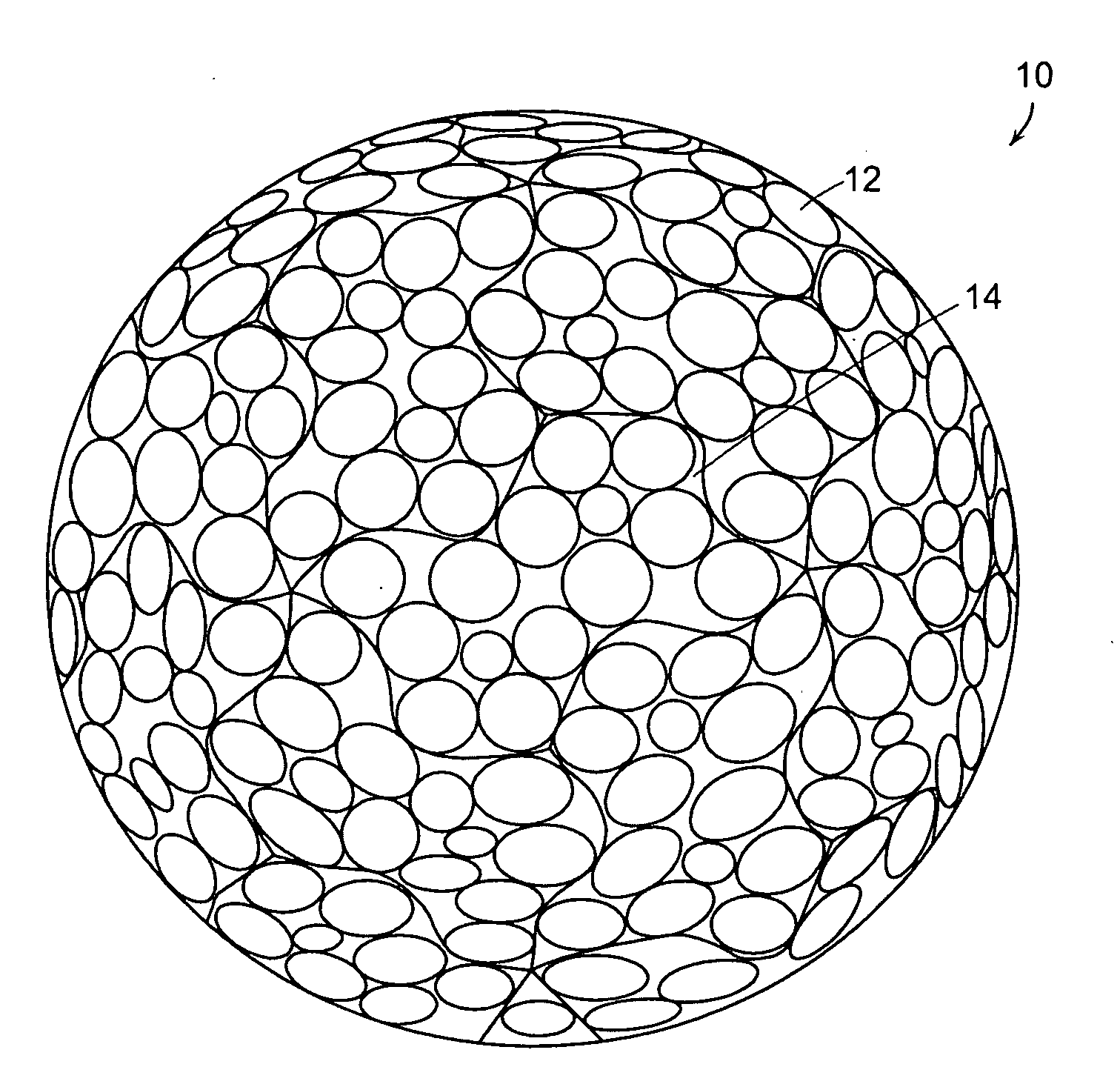

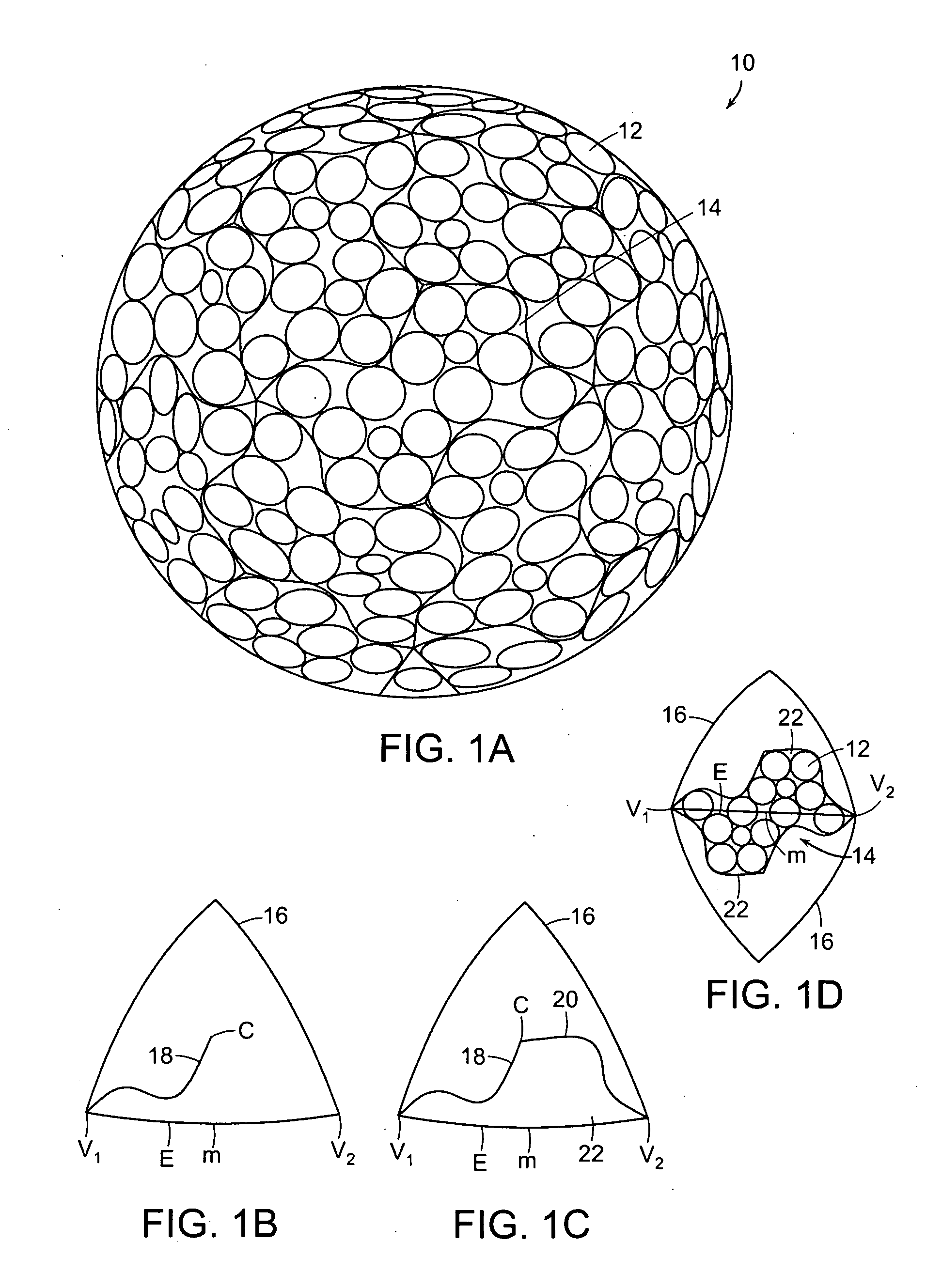

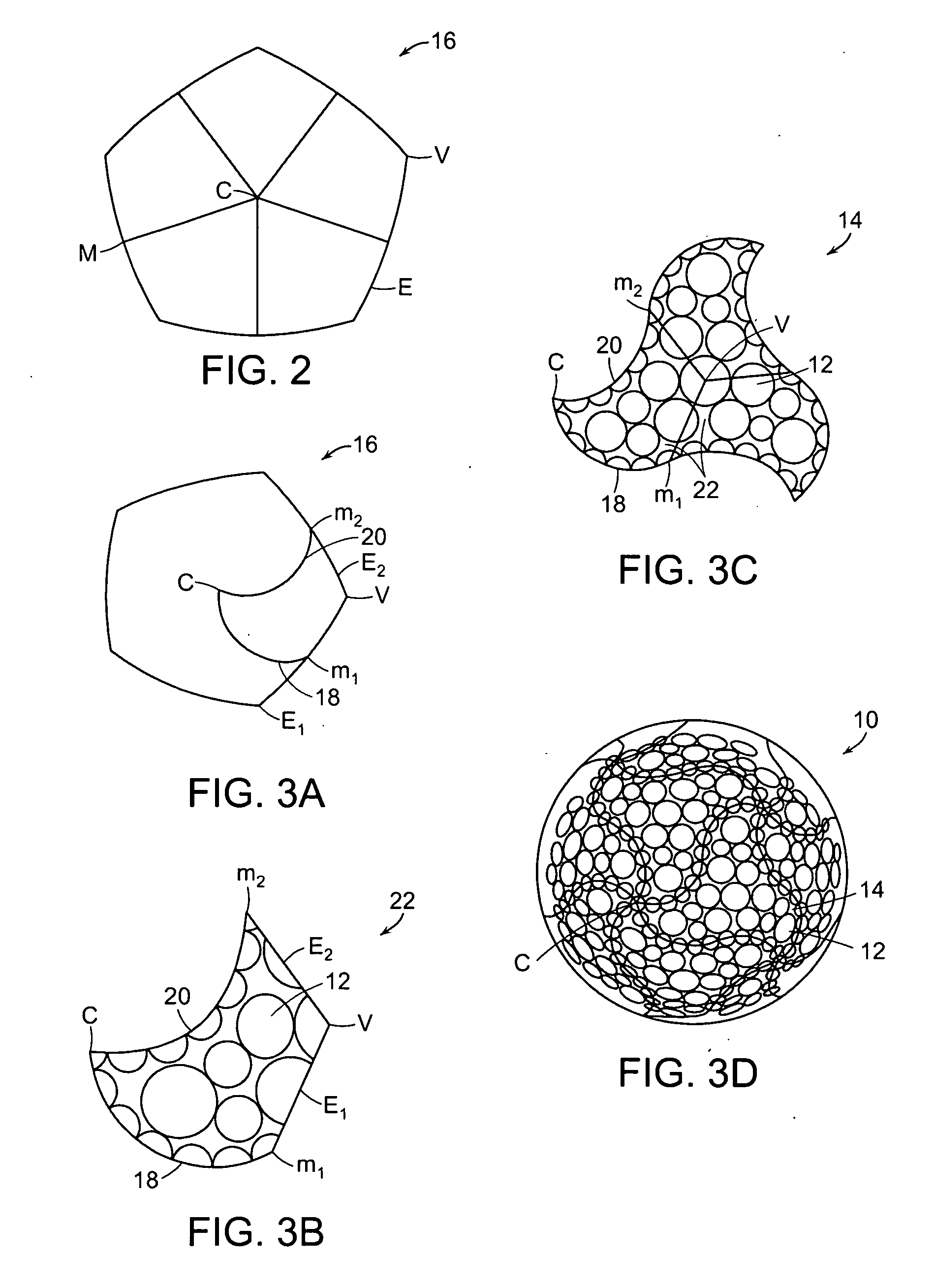

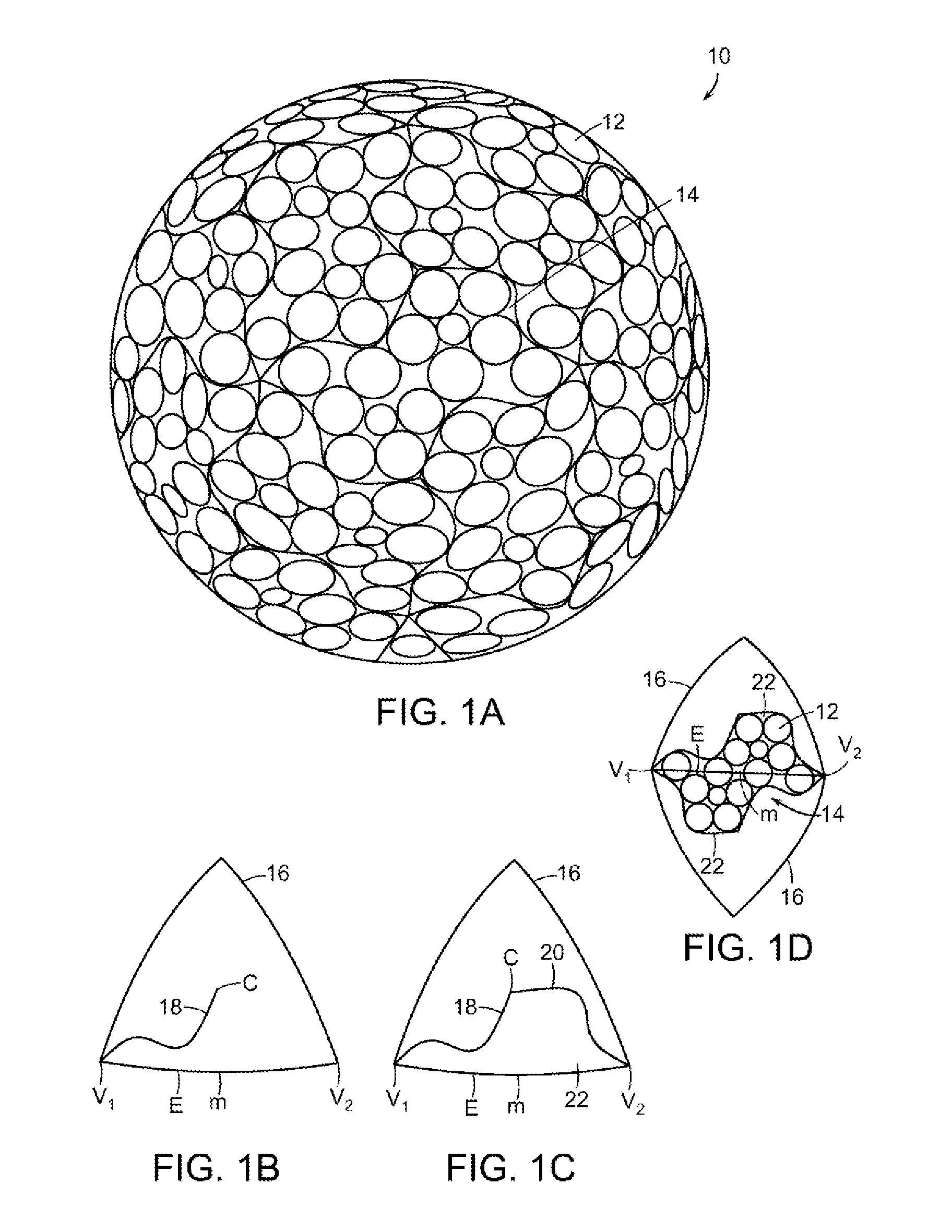

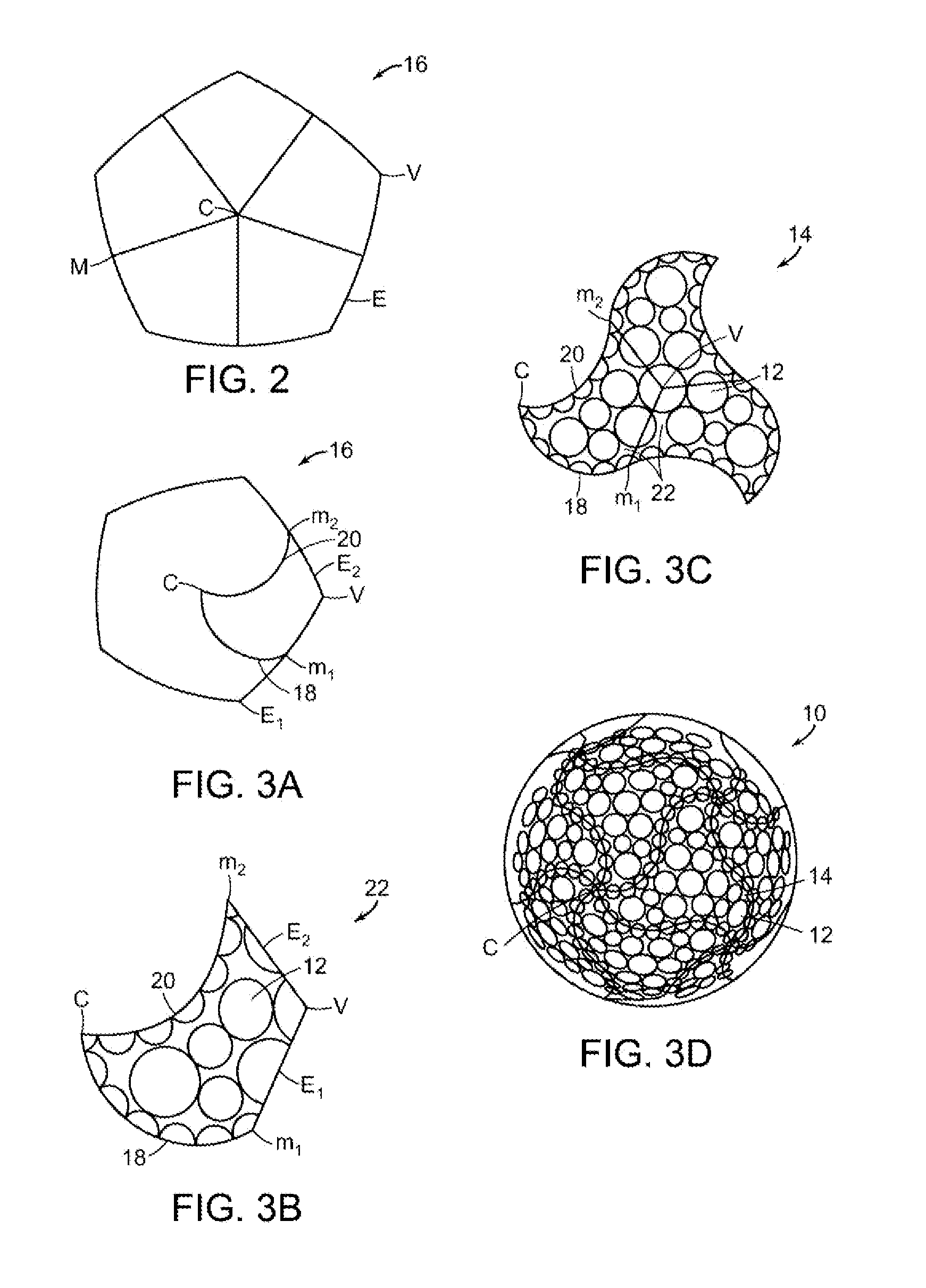

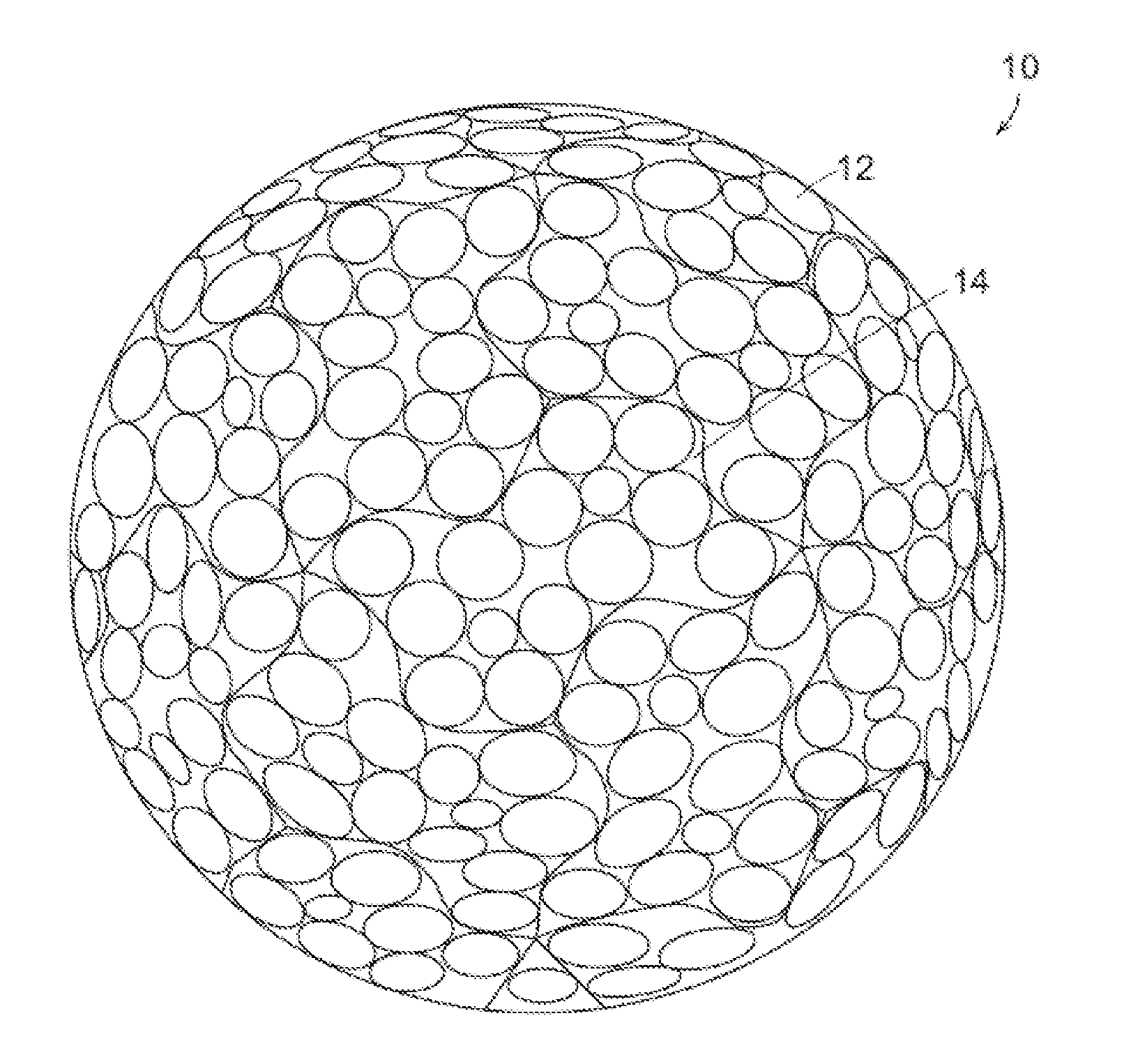

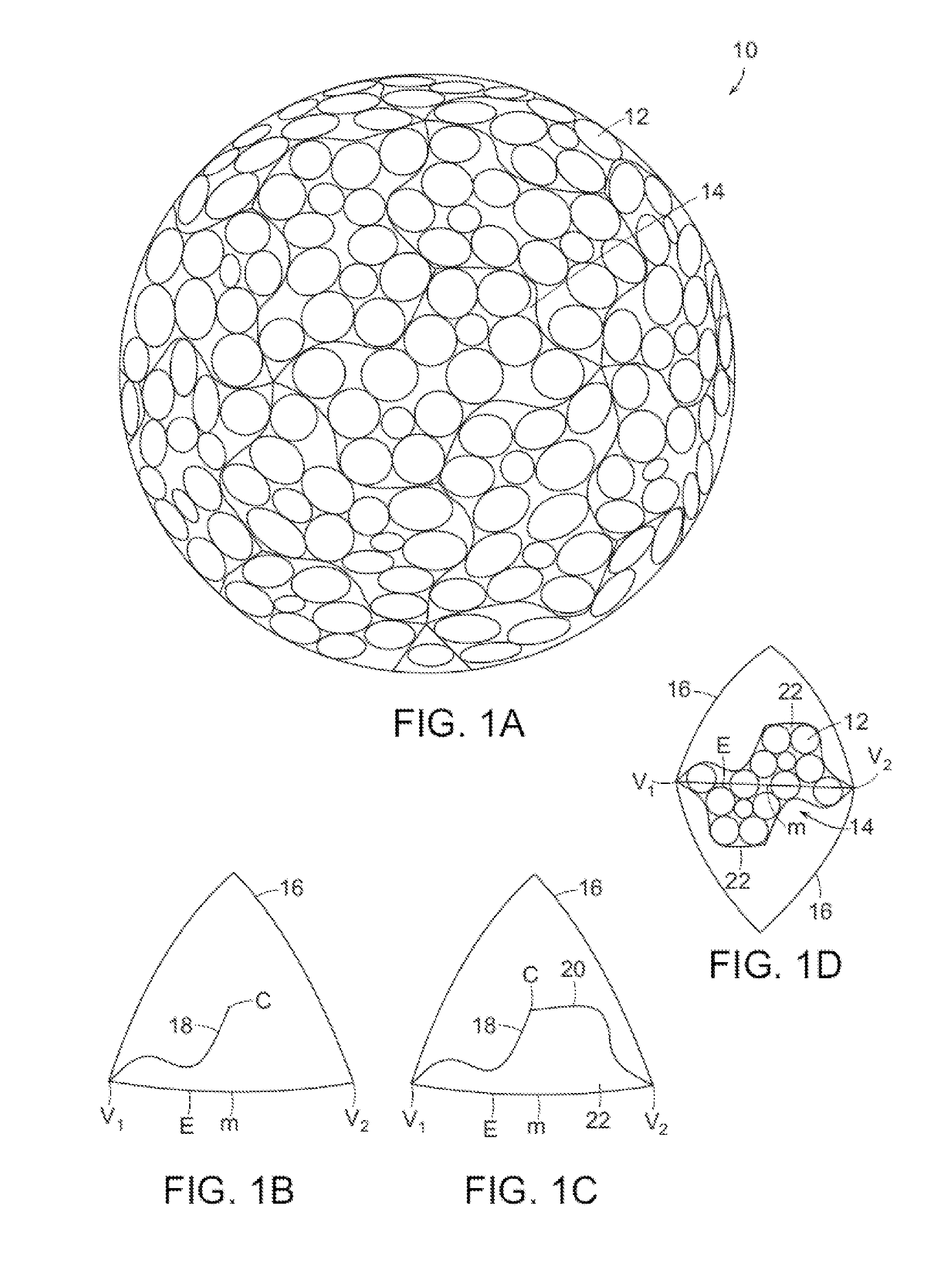

Dimple patterns for golf balls

ActiveUS20100113187A1Improves aerodynamic symmetryMinimize visibilityGolf ballsSolid ballsVisibilityEngineering

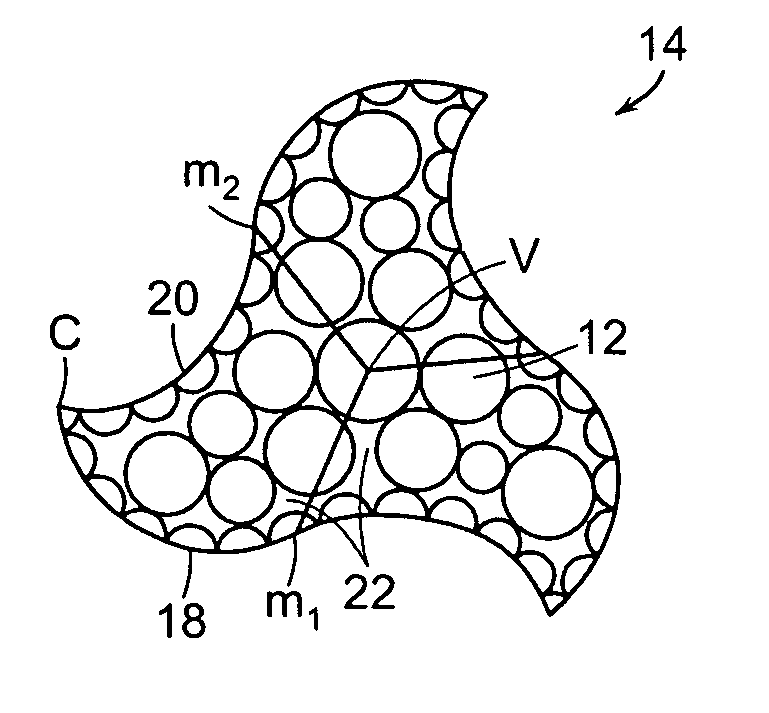

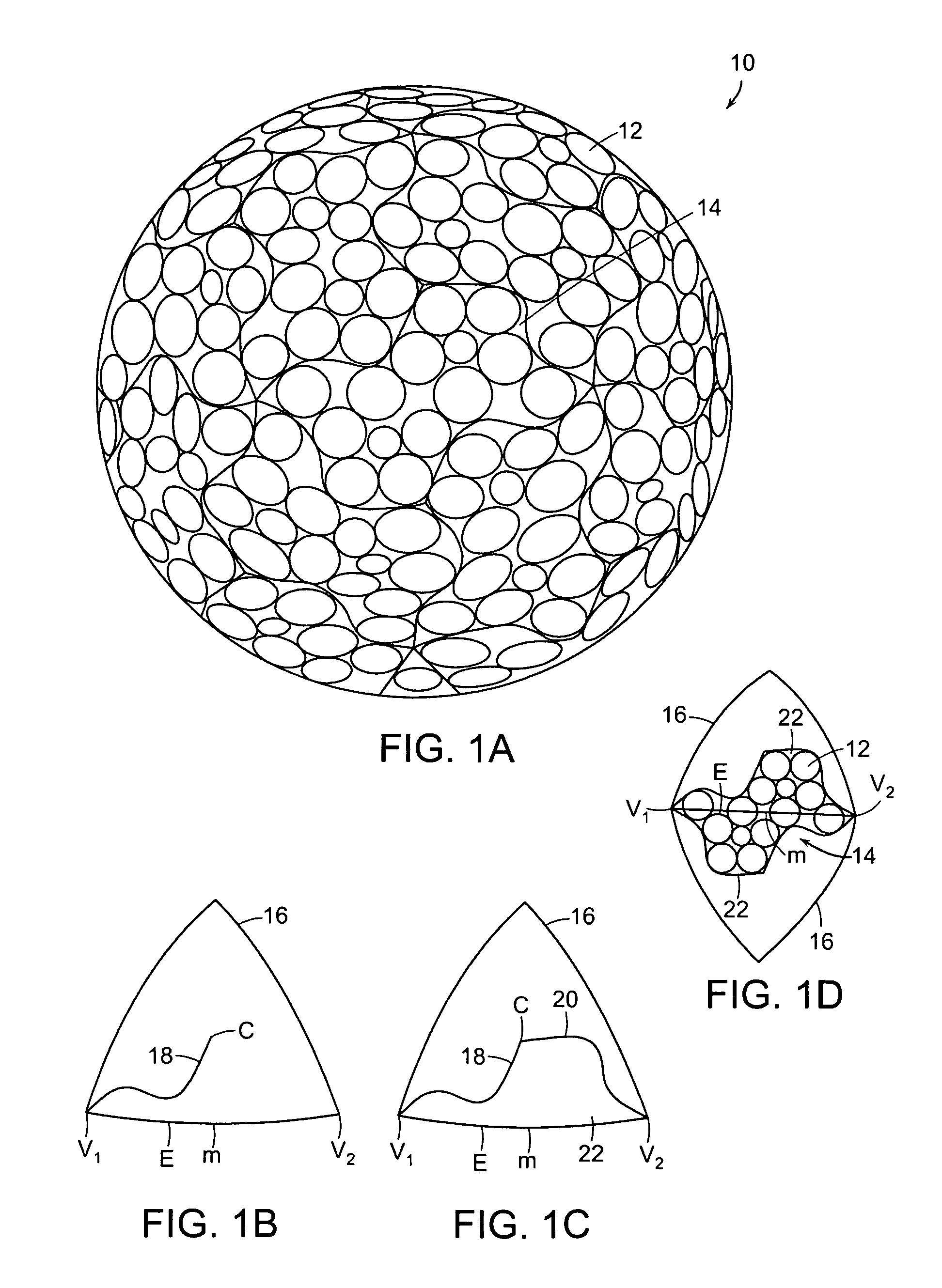

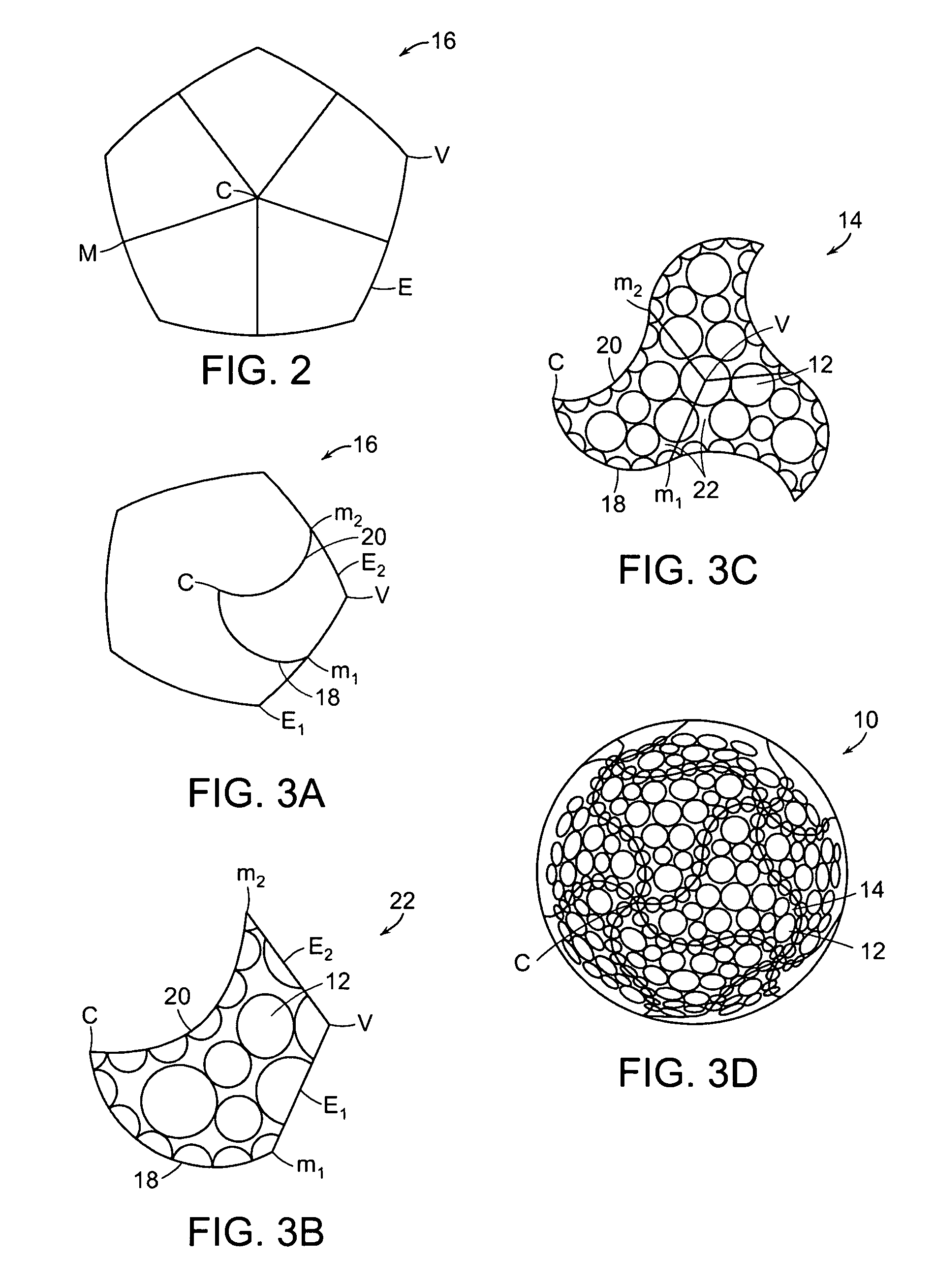

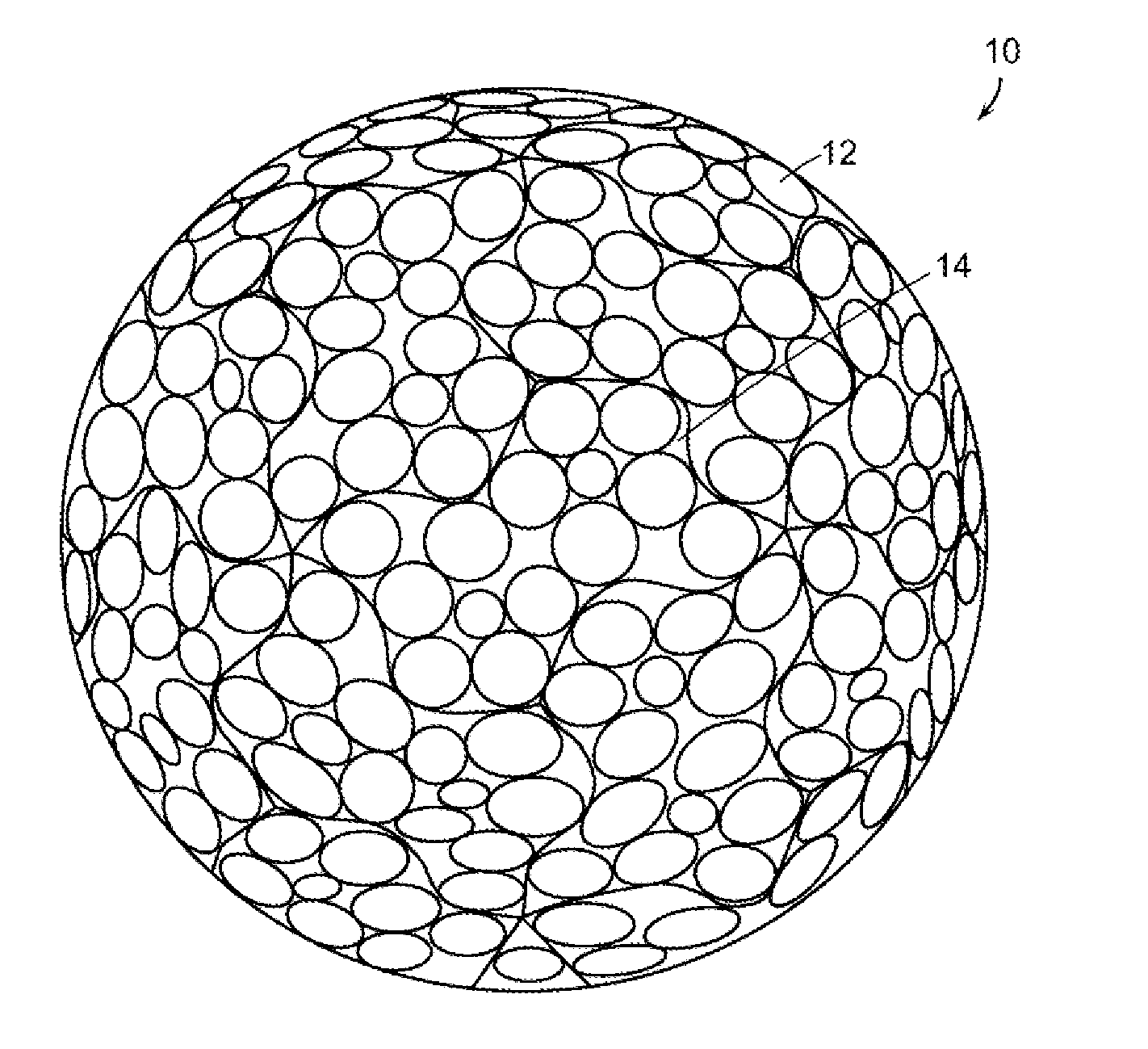

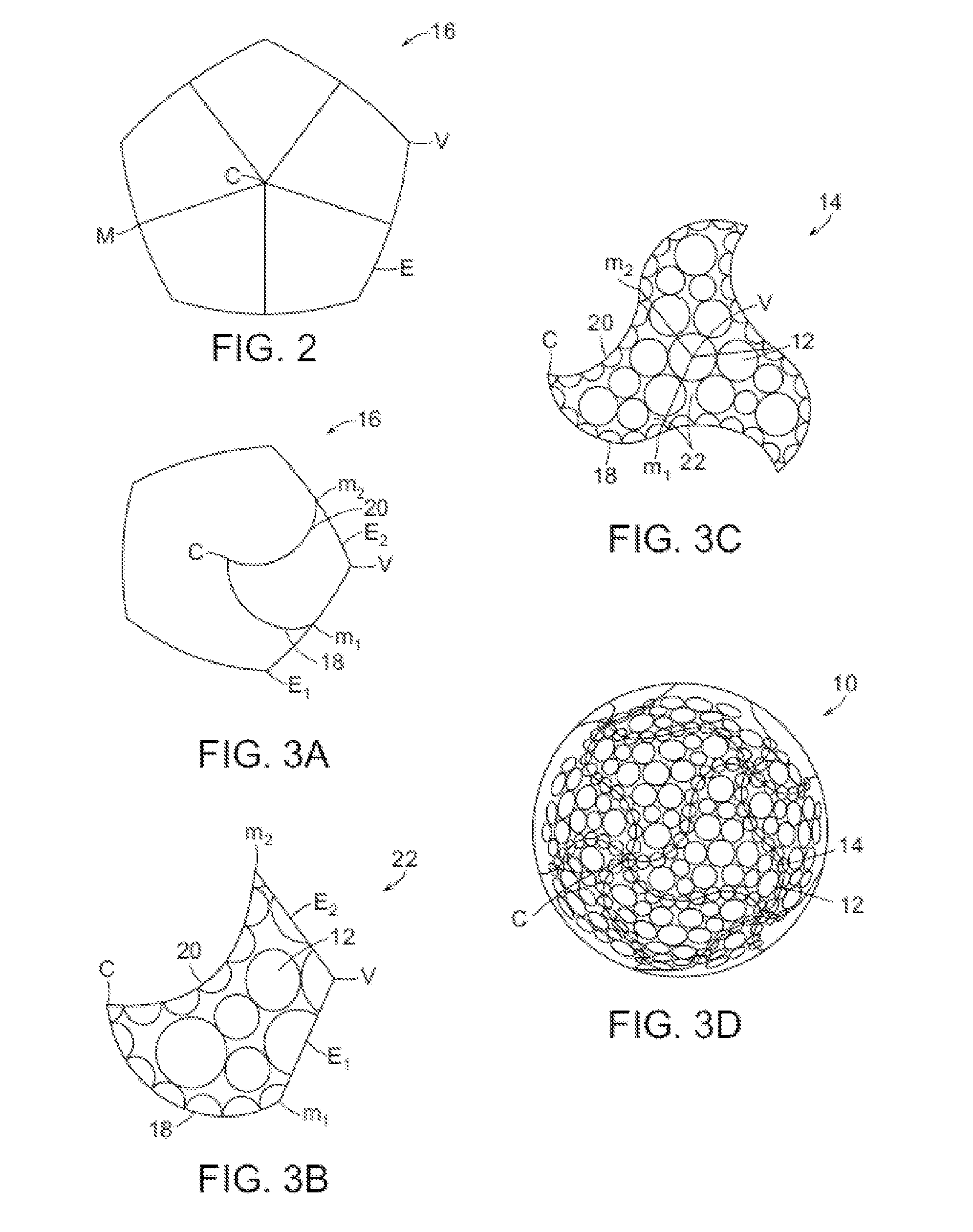

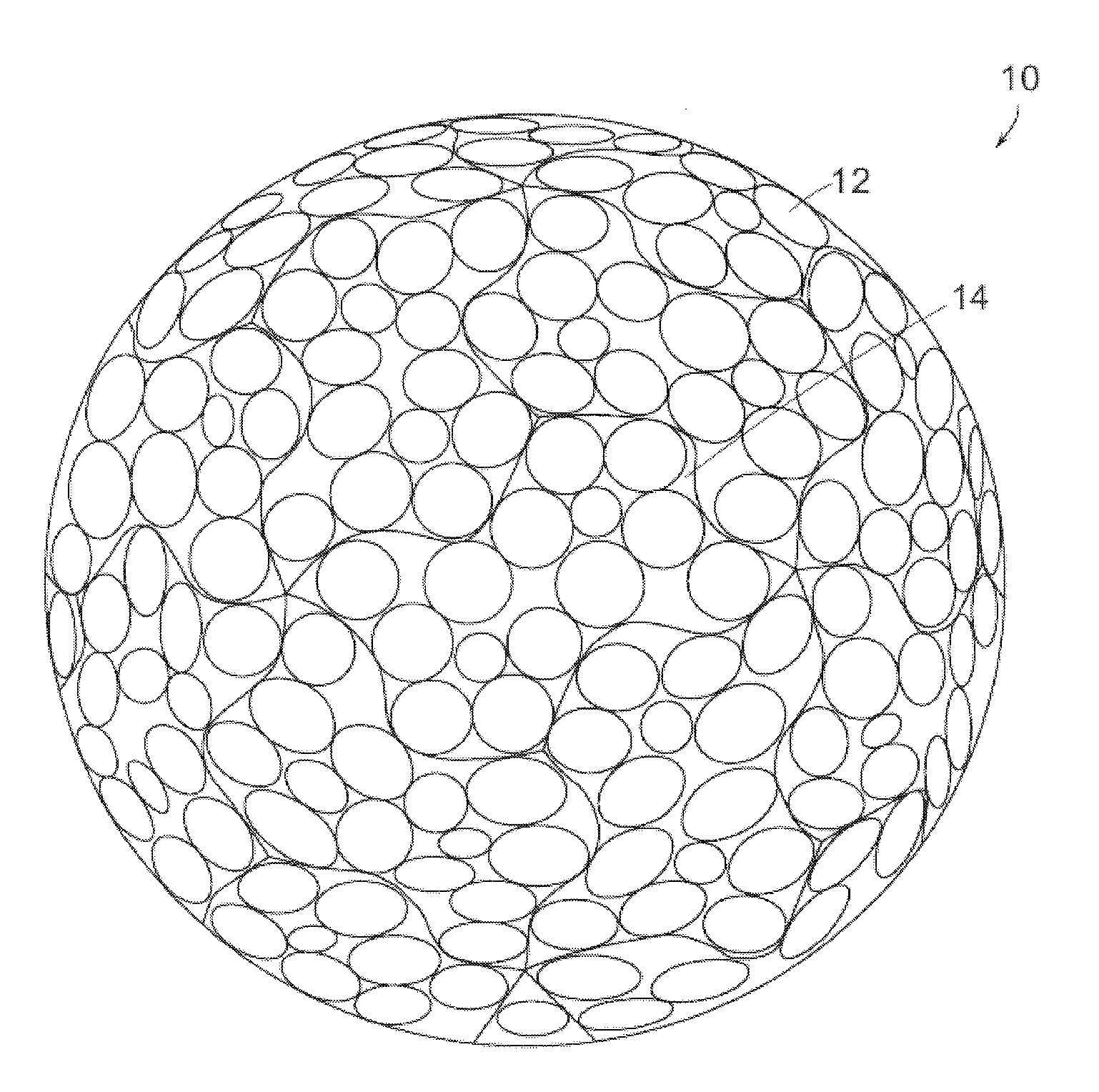

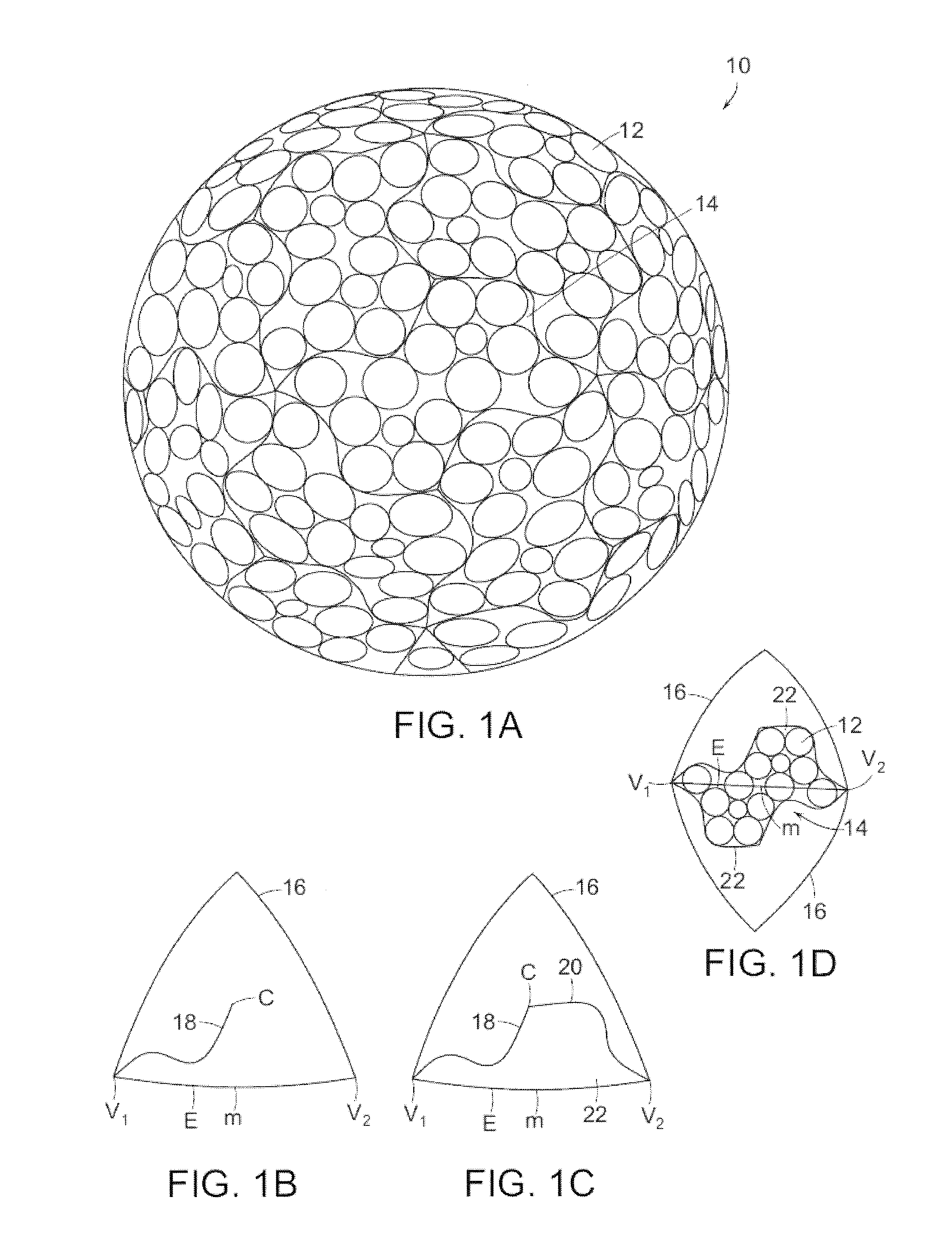

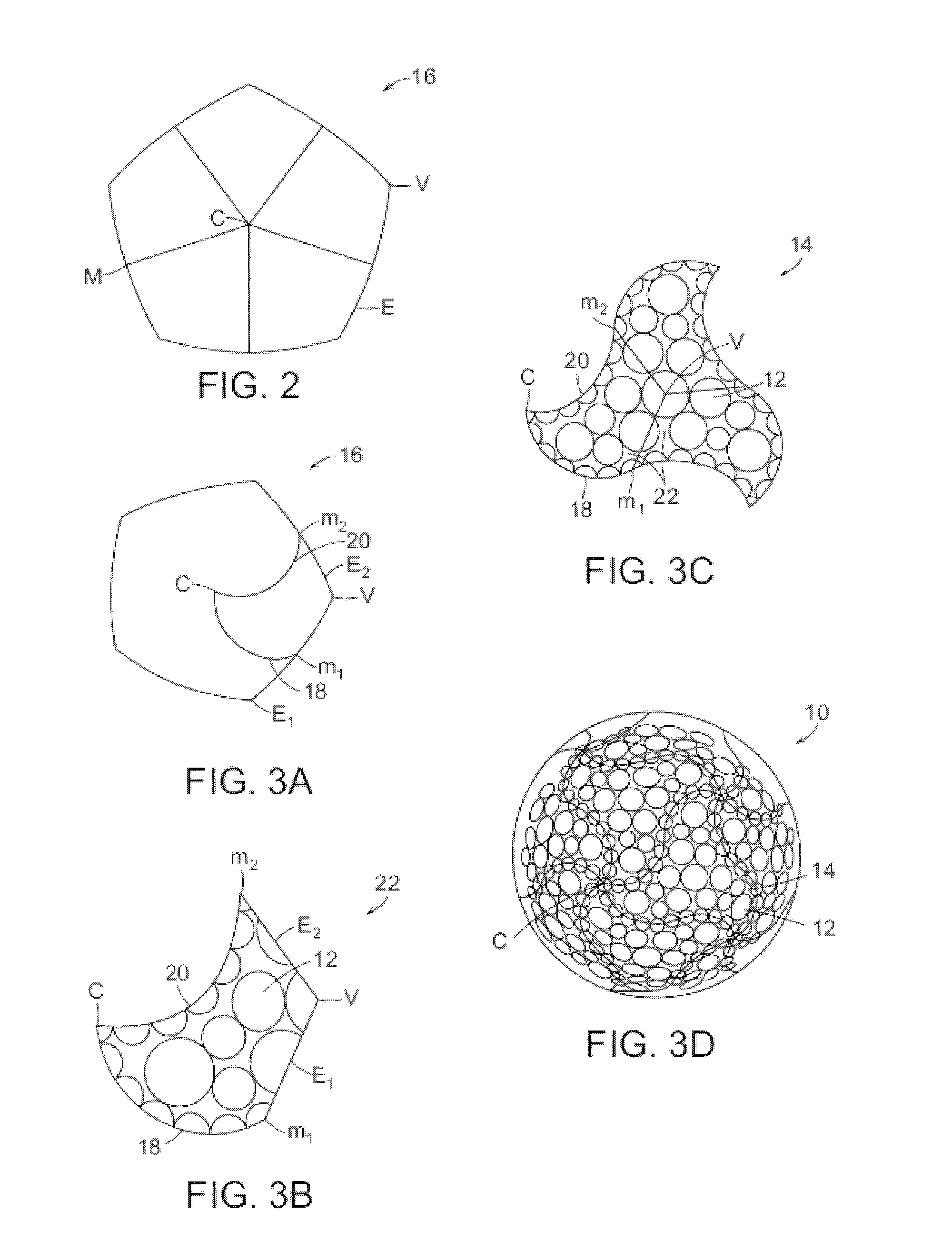

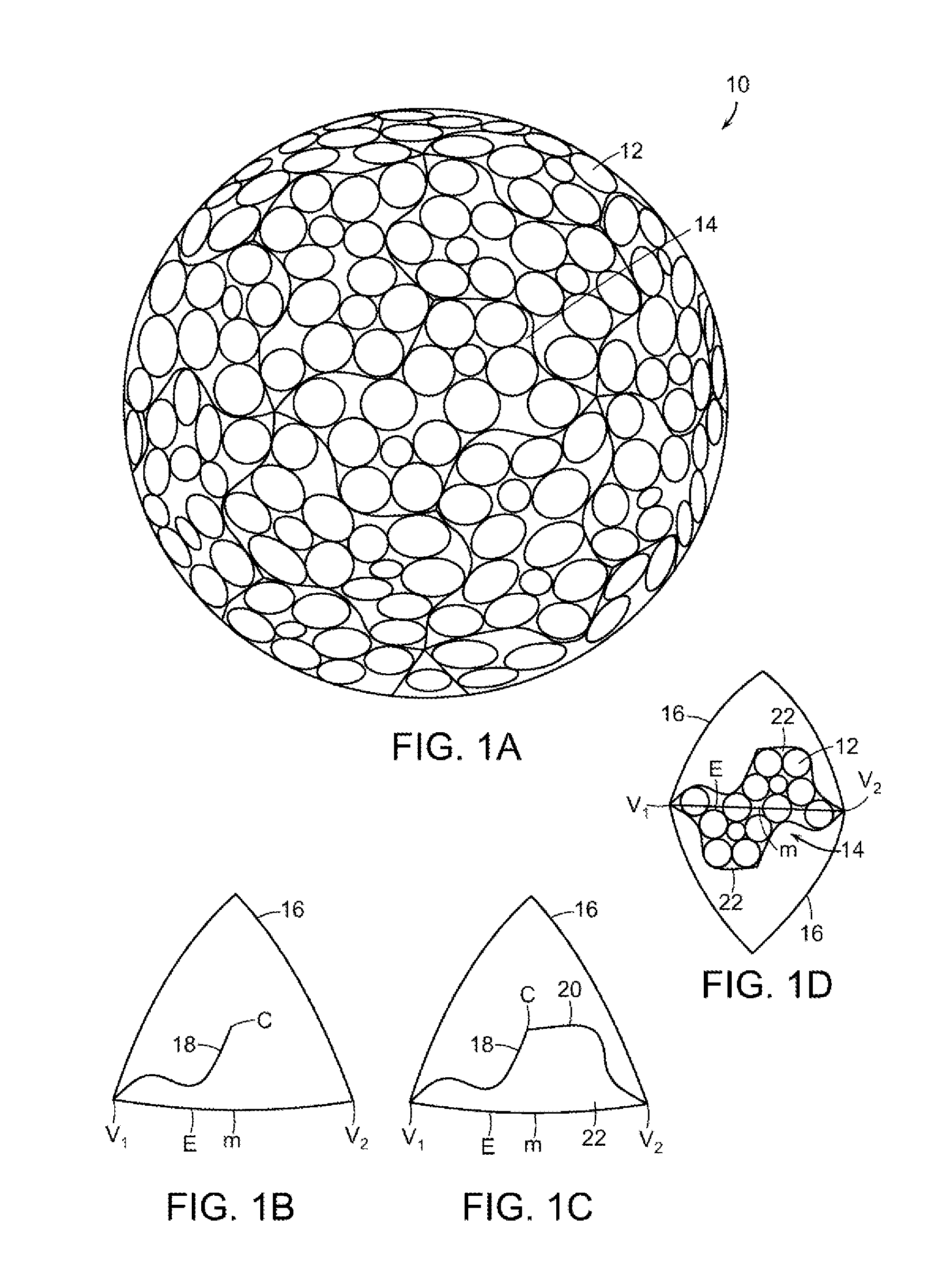

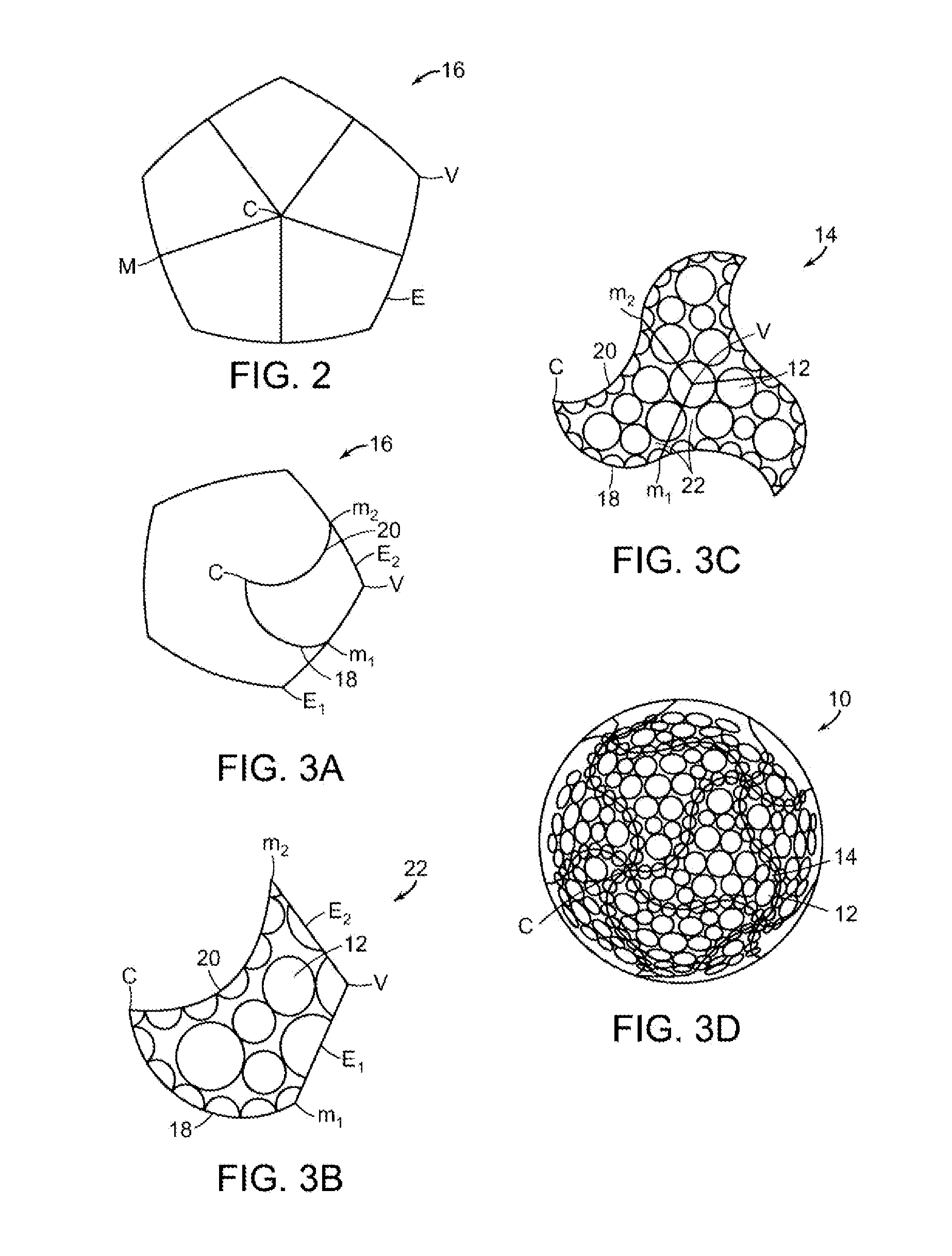

The present invention provides a method for arranging dimples on a golf ball surface that significantly improves aerodynamic symmetry and minimizes parting line visibility by arranging the dimples in a pattern derived from at least one irregular domain generated from a regular or non-regular polyhedron. The method includes choosing control points of a polyhedron, generating an irregular domain based on those control points, packing the irregular domain with dimples, and tessellating the irregular domain to cover the surface of the golf ball. The control points include the center of a polyhedral face, a vertex of the polyhedron, a midpoint or other point on an edge of the polyhedron and others. The method ensures that the symmetry of the underlying polyhedron is preserved while eliminating great circles due to parting lines.

Owner:ACUSHNET CO

Spherical Universal Coupling

InactiveUS20080102966A1Simpler and easy to assembleLess-expensive to manufactureYielding couplingRotary machine partsCouplingGear wheel

A pair of spherical gears connects the intersecting shafts of a CV-joint. One gear has internal teeth, and the other has external teeth. The gear design is based on pitch circles that are great circles on theoretical pitch spheres that are concentric and have identical radii. The gear teeth are preferably straight-sided. Individual smaller construction spheres are arranged in a circle so that the points of tangency between successive smaller spheres are all positioned on the circumference of the identical pitch circles of the gears and are all also positioned on the respective pitch circles of each successive smaller construction sphere. The straight-sided tooth faces of the teeth of the internal gear are preferably cone shaped. The preferred embodiment uses six teeth on each gear, and the gears, while rotating at high speeds under load, can intersect throughout a continuous maximum range of 60° or more.

Owner:TORVEC INC

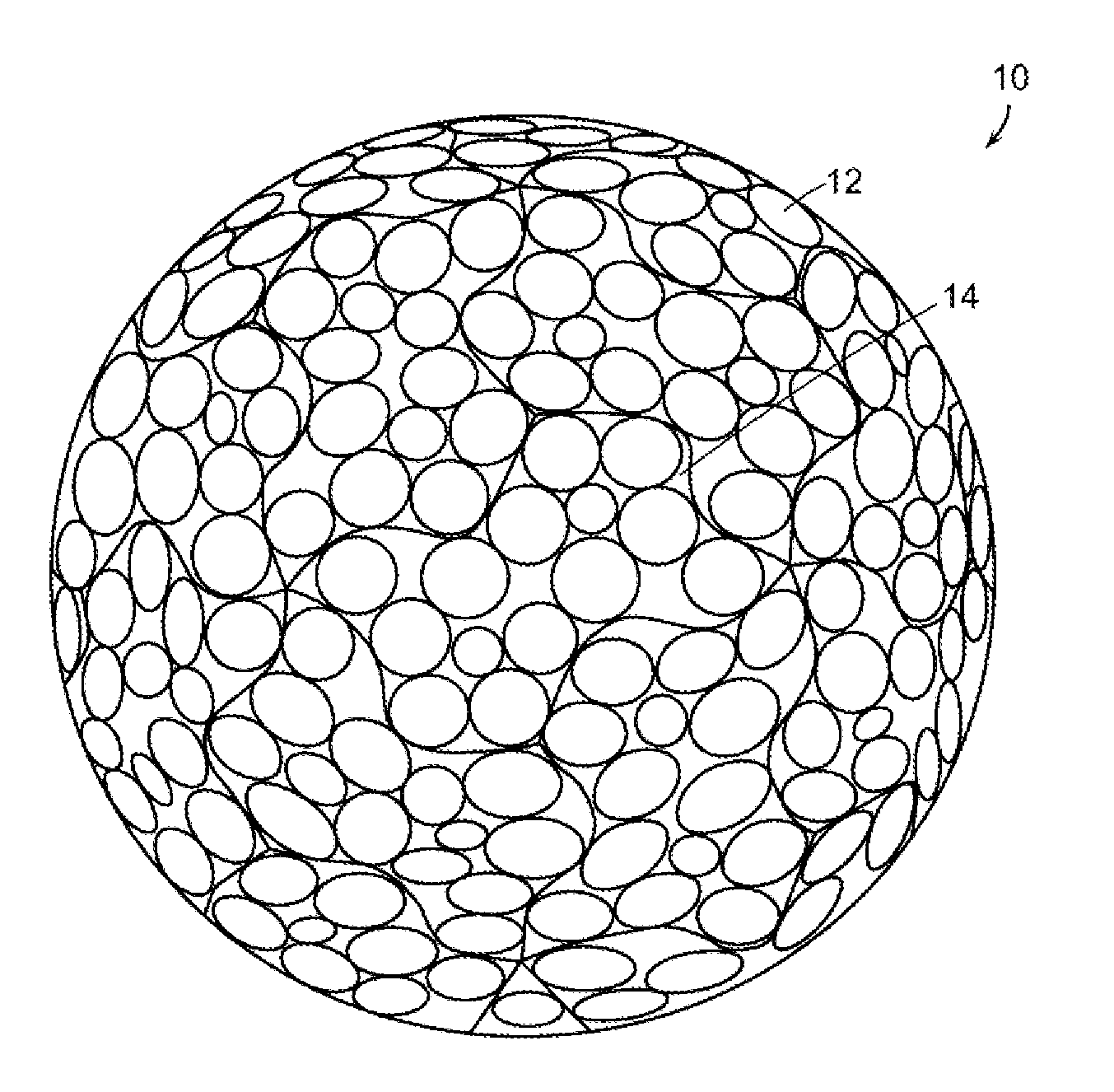

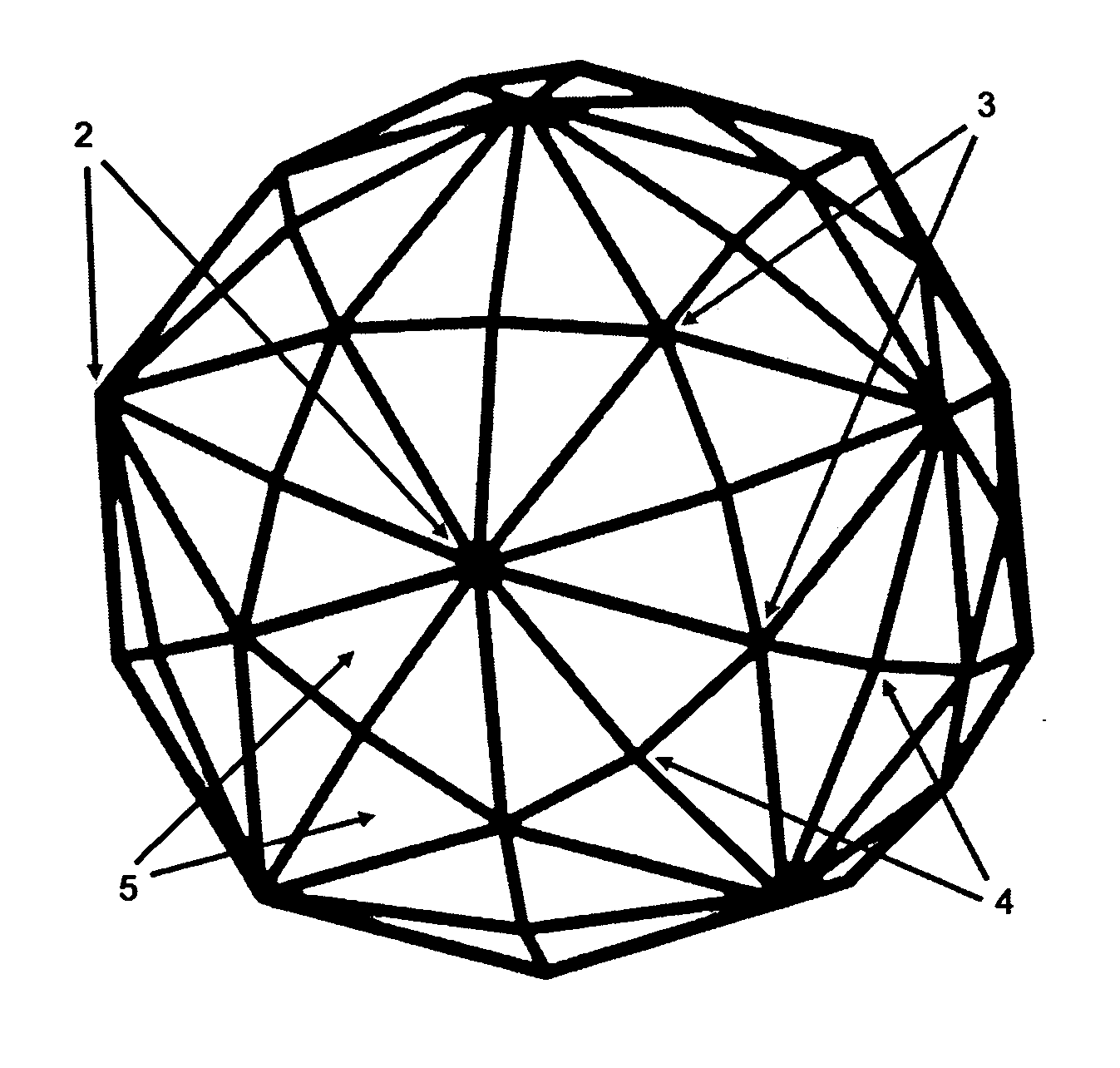

Dimple patterns for golf balls

ActiveUS8029388B2Improves aerodynamic symmetryMinimize visibilityGolf ballsSolid ballsVisibilityEngineering

The present invention provides a method for arranging dimples on a golf ball surface that significantly improves aerodynamic symmetry and minimizes parting line visibility by arranging the dimples in a pattern derived from at least one irregular domain generated from a regular or non-regular polyhedron. The method includes choosing control points of a polyhedron, generating an irregular domain based on those control points, packing the irregular domain with dimples, and tessellating the irregular domain to cover the surface of the golf ball. The control points include the center of a polyhedral face, a vertex of the polyhedron, a midpoint or other point on an edge of the polyhedron and others. The method ensures that the symmetry of the underlying polyhedron is preserved while eliminating great circles due to parting lines.

Owner:ACUSHNET CO

Dimple patterns for golf balls

The present invention provides a method for arranging dimples on a golf ball surface in which the dimples are arranged in a pattern derived from at least one irregular domain generated from a regular or non-regular polyhedron, and particularly a dipyramid. The method includes choosing control points of a polyhedron, generating an irregular domain based on those control points, packing the irregular domain with dimples, and tessellating the irregular domain to cover the surface of the golf ball. The control points include the center of a polyhedral face, a vertex of the polyhedron, a midpoint or other point on an edge of the polyhedron and others. The method ensures that the symmetry of the underlying polyhedron is preserved while minimizing or eliminating great circles due to parting lines.

Owner:ACUSHNET CO

Dimple patterns for golf balls

The present invention provides a method for arranging dimples on a golf ball surface in which the dimples are arranged in a pattern derived from at least one irregular domain generated from a regular or non-regular polyhedron. The method includes choosing control points of a polyhedron, generating an irregular domain based on those control points, packing the irregular domain with dimples, and tessellating the irregular domain to cover the surface of the golf ball. The control points include the center of a polyhedral face, a vertex of the polyhedron, a midpoint or other point on an edge of the polyhedron and others. The method ensures that the symmetry of the underlying polyhedron is preserved while minimizing or eliminating great circles due to parting lines.

Owner:ACUSHNET CO

Dimple patterns for golf balls

The present invention provides a method for arranging dimples on a golf ball surface in which the dimples are arranged in a pattern derived from at least one irregular domain generated from a regular or non-regular polyhedron. The method includes choosing control points of a polyhedron, generating an irregular domain based on those control points, packing the irregular domain with dimples, and tessellating the irregular domain to cover the surface of the golf ball. The control points include the center of a polyhedral face, a vertex of the polyhedron, a midpoint or other point on an edge of the polyhedron and others. The method ensures that the symmetry of the underlying polyhedron is preserved while minimizing or eliminating great circles due to parting lines.

Owner:ACUSHNET CO

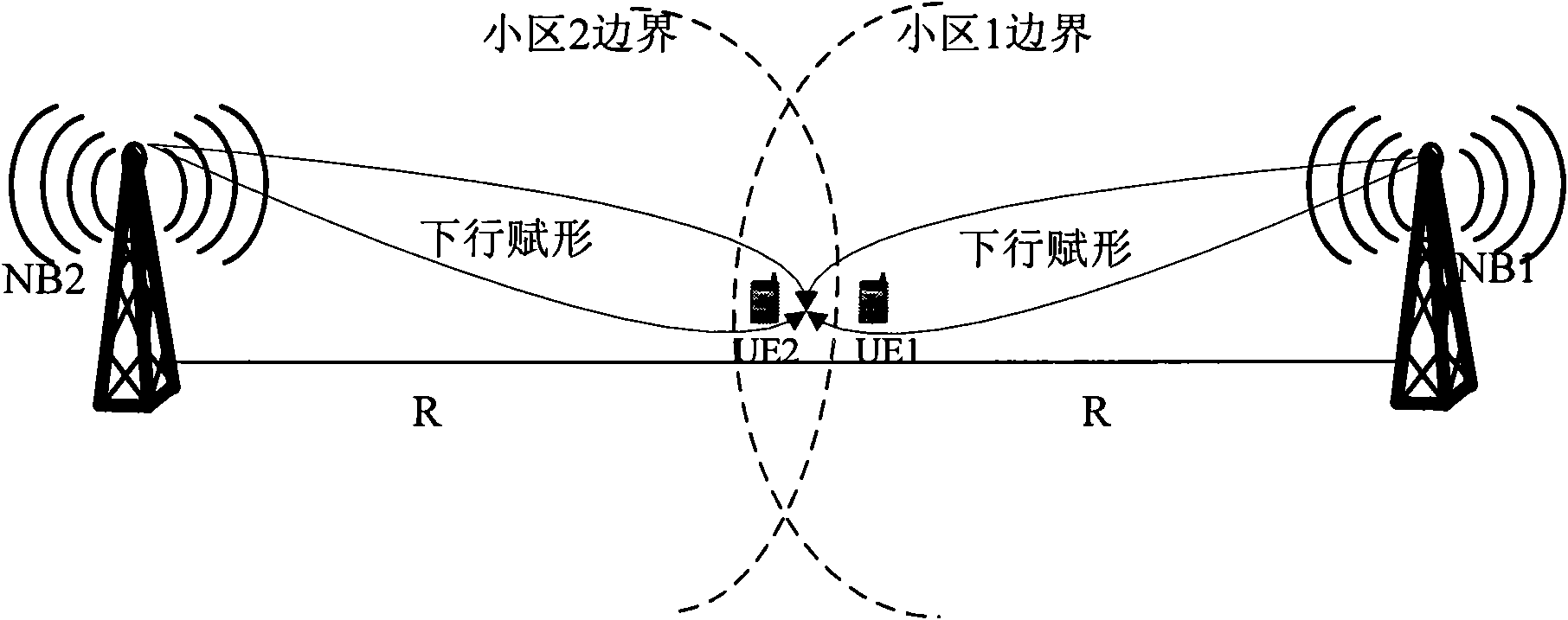

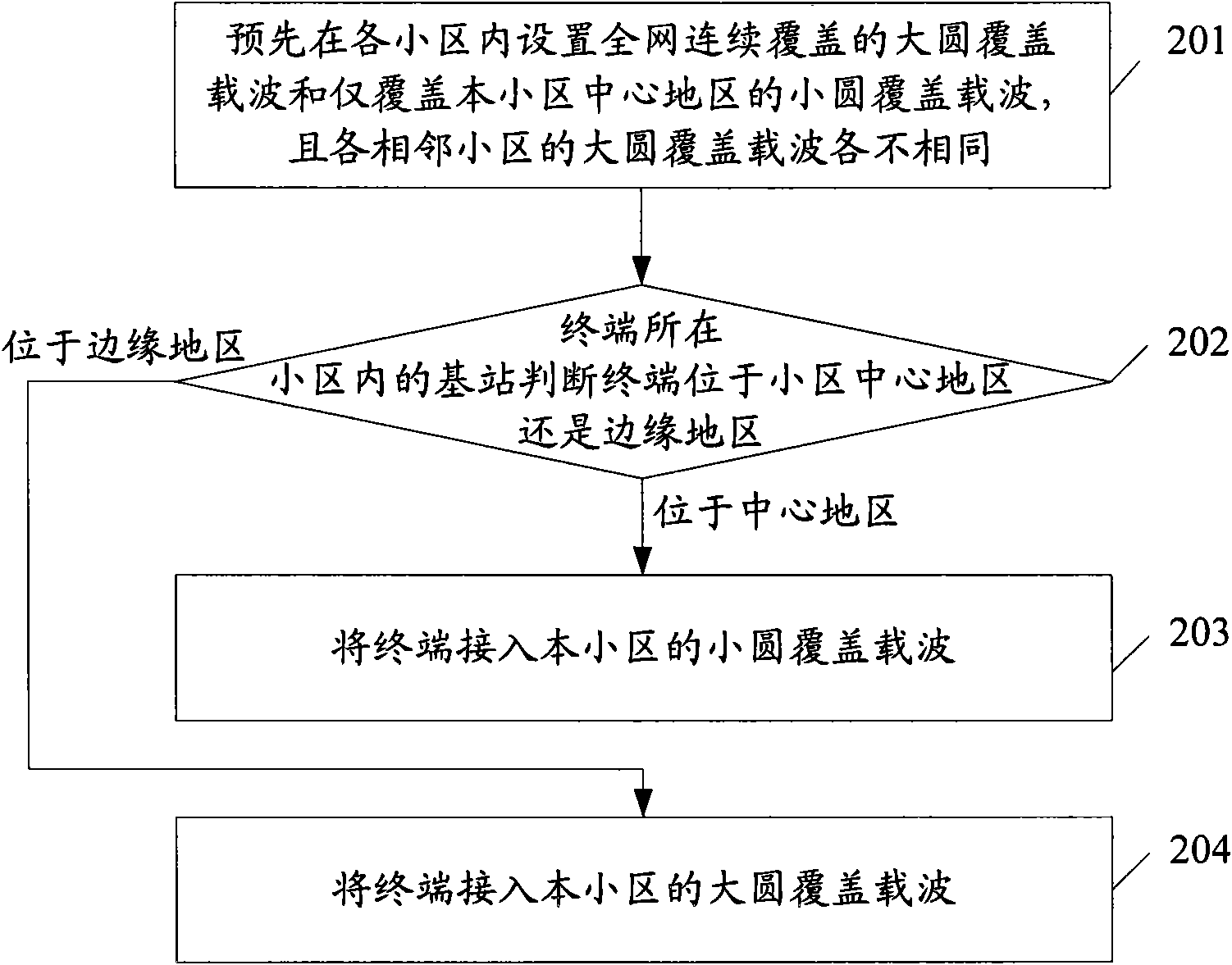

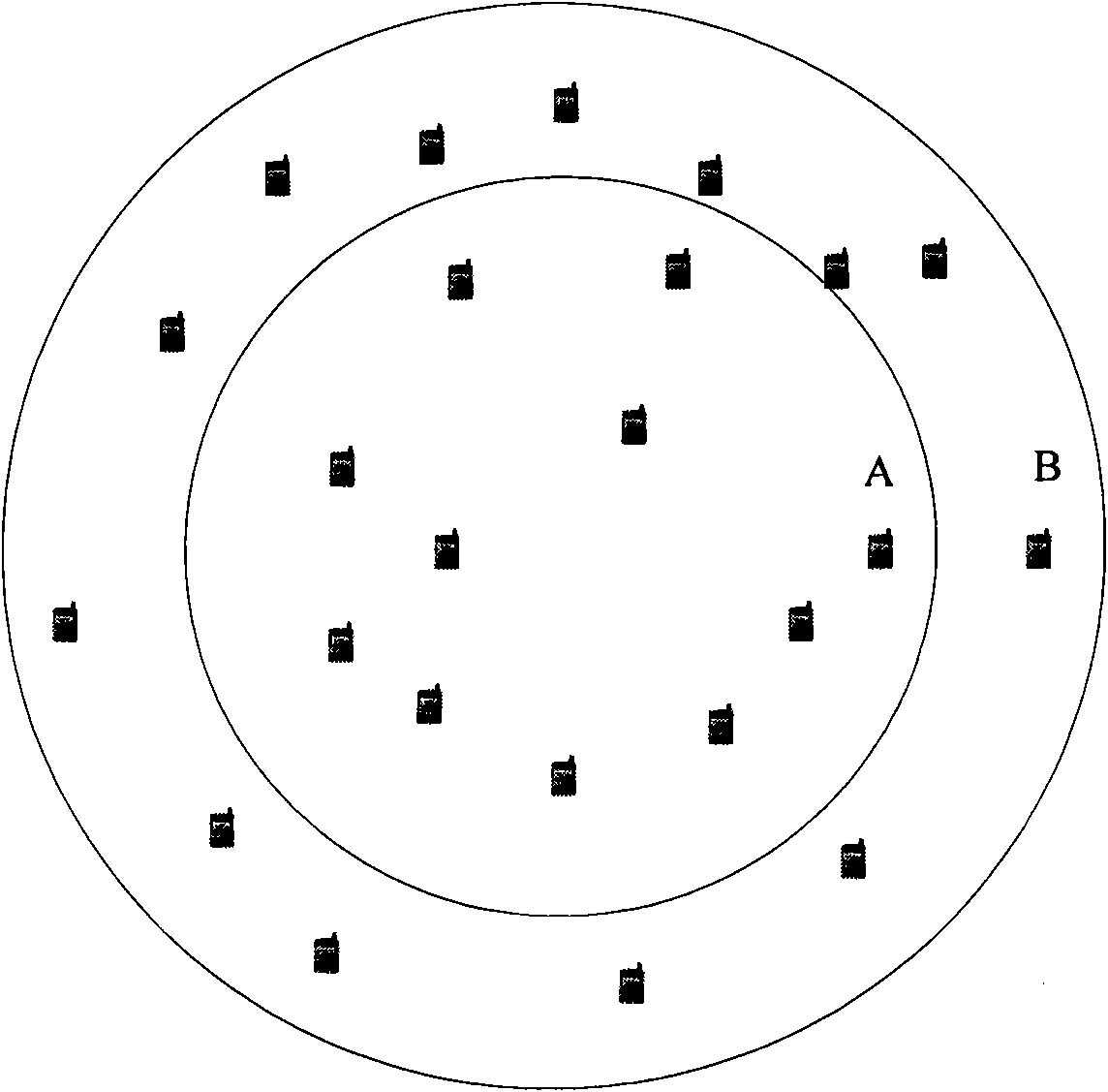

Access method in same frequency network with N frequency points

InactiveCN101674681AAvoid co-channel interferenceRadio transmission for post communicationWireless communicationAccess methodCarrier signal

The invention discloses an access method in a same frequency network with N frequency points, which comprises the following steps: in each district, prearranging a large circle covered carrier wave which continuously covers a whole network and a small circle covered carrier wave which only covers a central area of the district, wherein the large circle covered carrier waves of adjacent districts are different, and each large circle covered carrier wave comprises a main carrier wave of the district; in the terminal access process, when a base station in the district where the terminal is positioned confirms that the terminal is positioned in the central area of the district, accessing the terminal into the small circle covered carrier wave of the district; and when the base station confirmsthat the terminal is positioned in a marginal area of the district, accessing the terminal into the large circle covered carrier wave of the district. By applying the access method, same frequency interference at district boundaries can be avoided.

Owner:TD TECH COMM TECH LTD

Dimple patterns for golf balls

The present invention provides a method for arranging dimples on a golf ball surface in which the dimples are arranged in a pattern derived from at least one irregular domain generated from a regular or non-regular polyhedron. The method includes choosing control points of a polyhedron, generating an irregular domain based on those control points, packing the irregular domain with dimples, and tessellating the irregular domain to cover the surface of the golf ball. The control points include the center of a polyhedral face, a vertex of the polyhedron, a midpoint or other point on an edge of the polyhedron and others. The method ensures that the symmetry of the underlying polyhedron is preserved while minimizing or eliminating great circles due to parting lines.

Owner:ACUSHNET CO

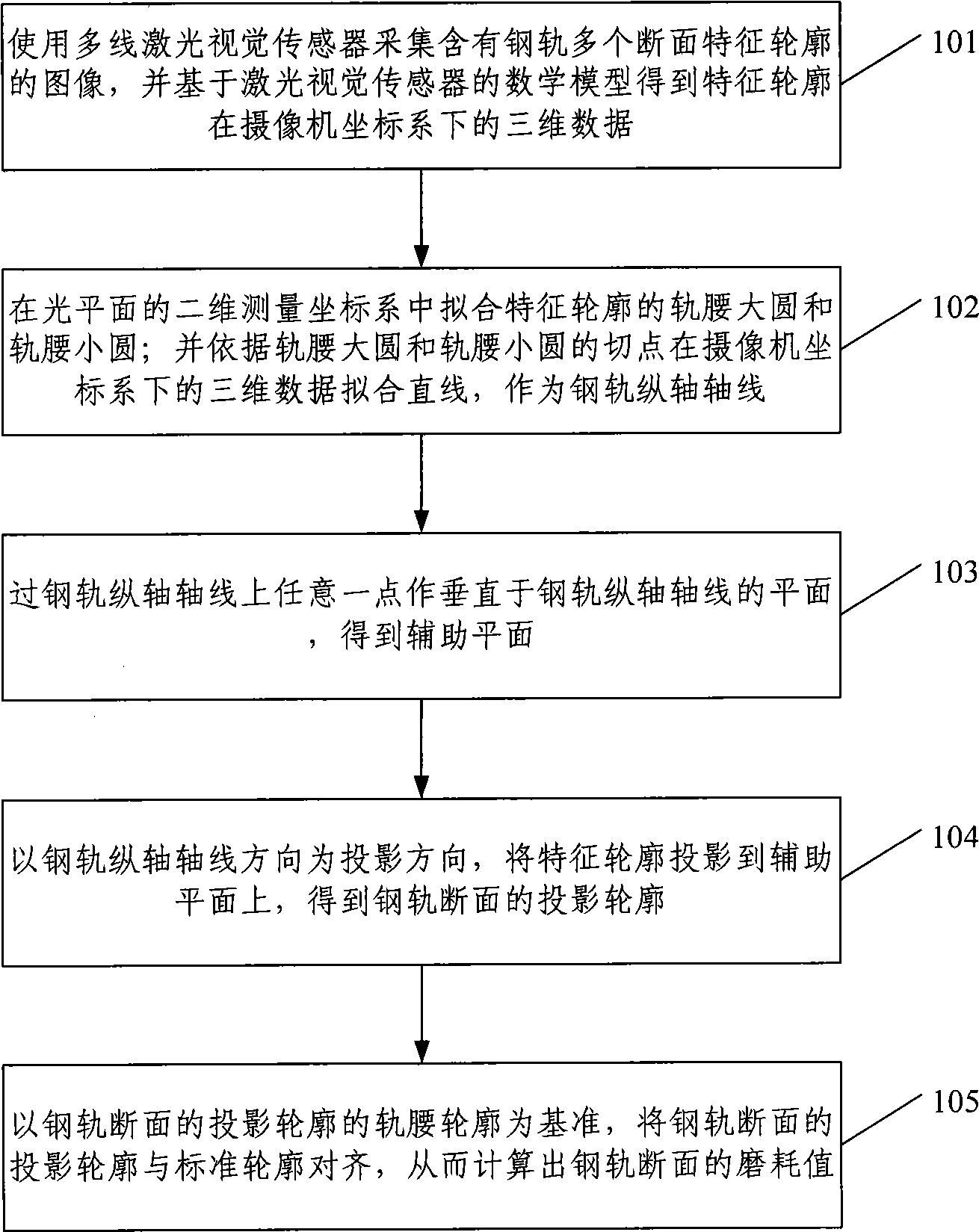

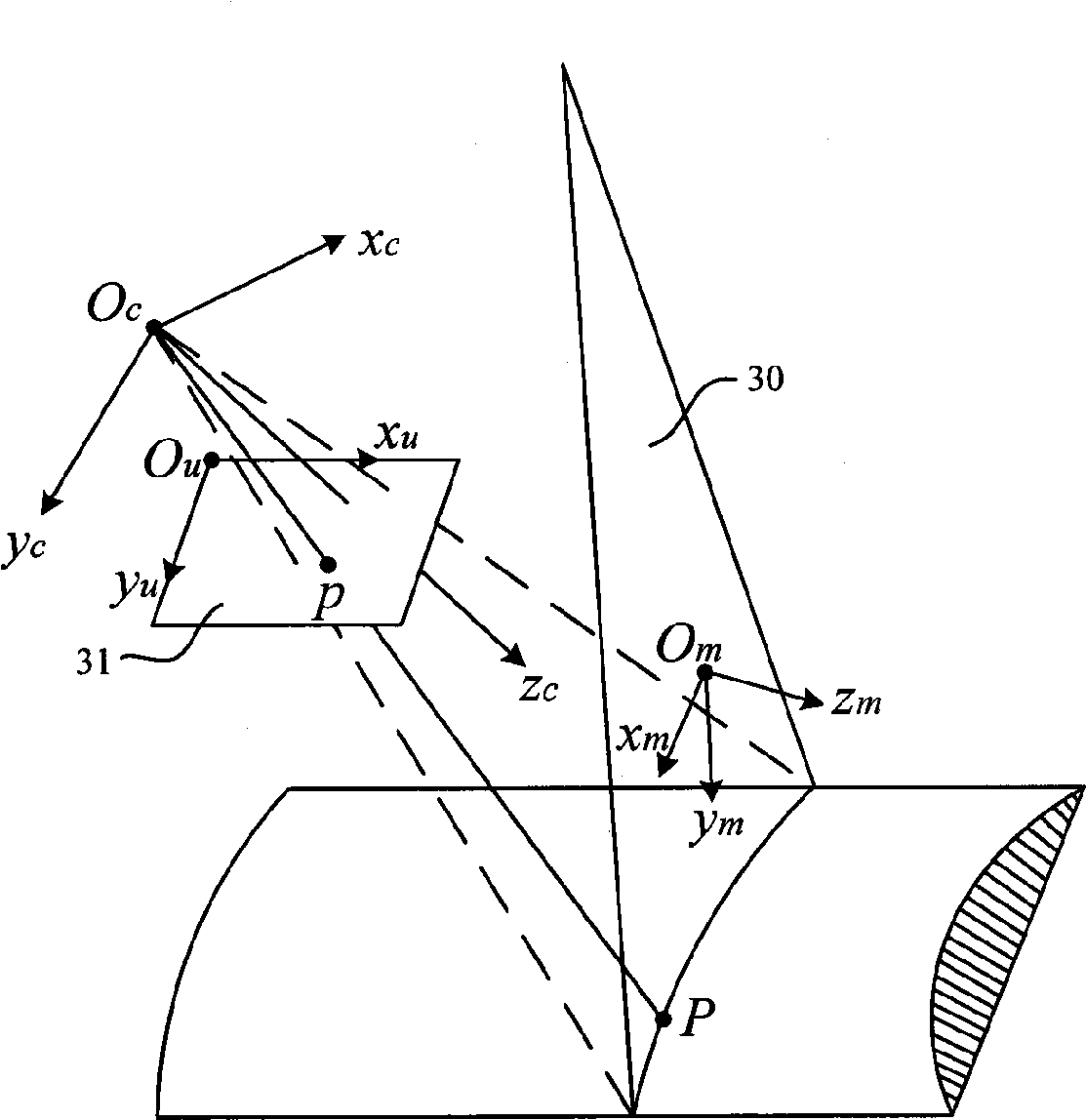

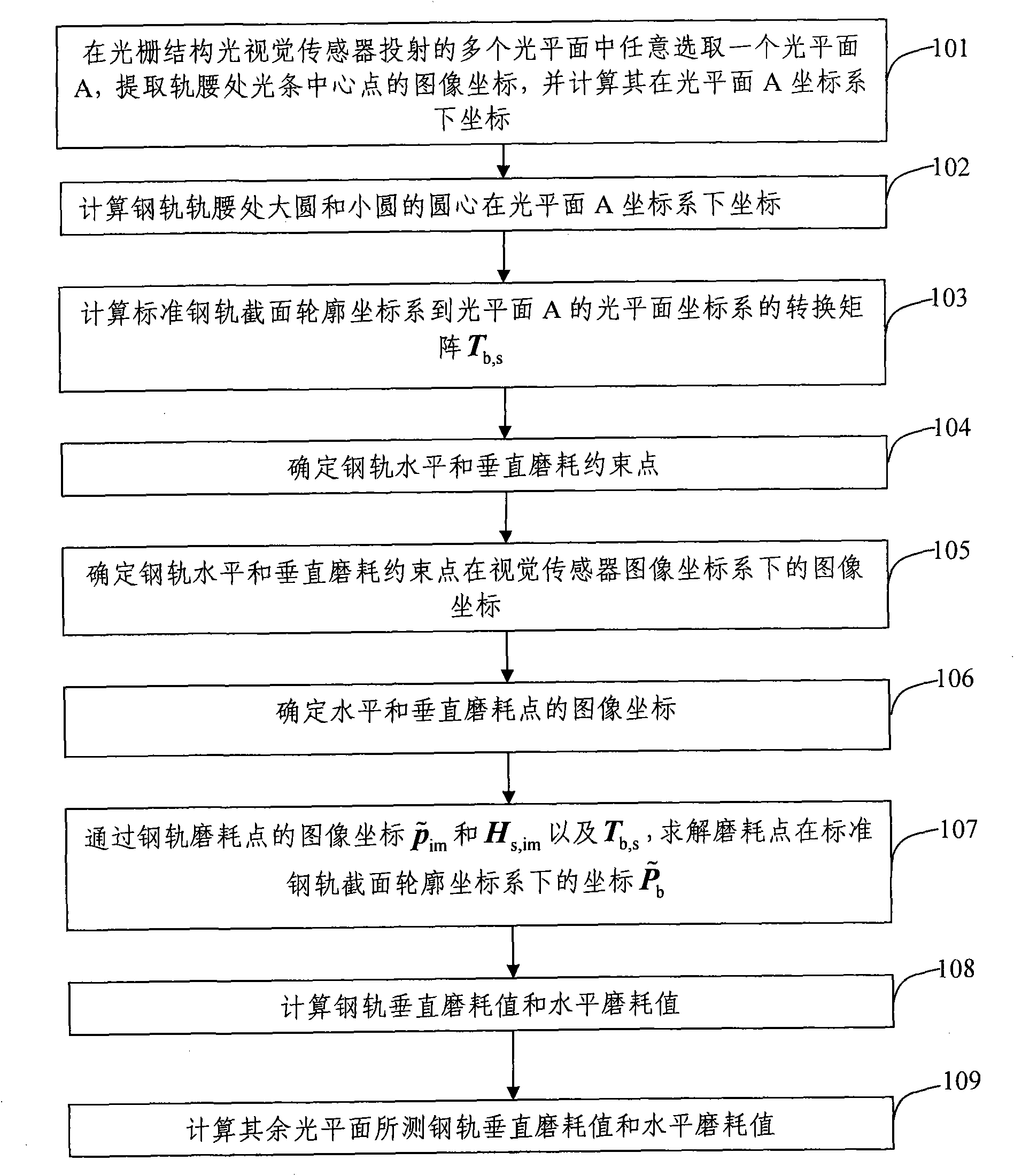

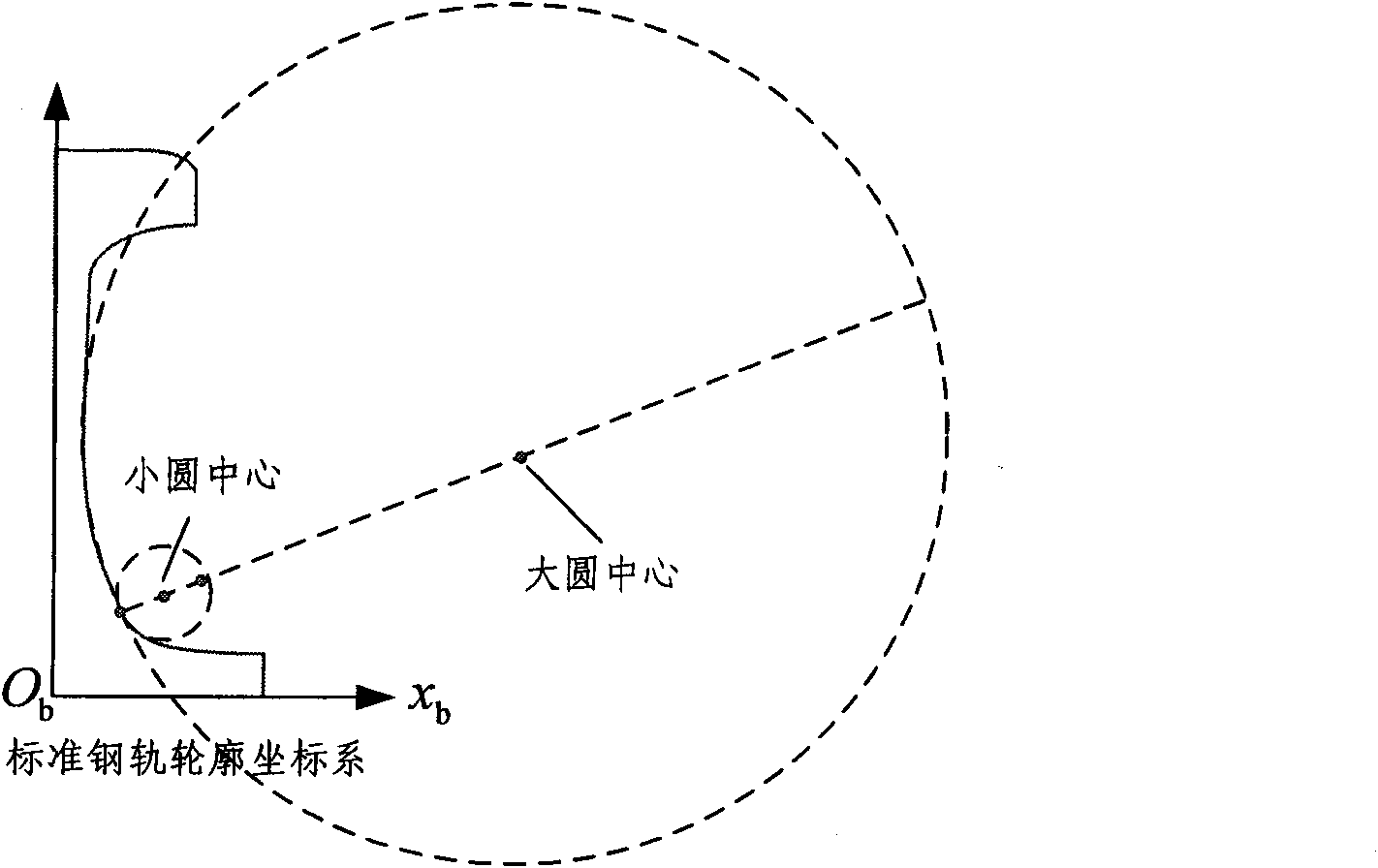

Deviation correction method for measurement of rail wear based on laser vision

InactiveCN101532827AIncrease profitEliminate Wear Measurement ErrorsUsing optical meansObservational errorEngineering

The invention discloses a deviation correction method for measurement of rail wear based on laser vision, comprising the steps of dividing a rail waist profile of a characteristic profile of dividing a cross section of a rail obtained by the measurement by a laser vision sensor into a rail waist big circle and a rail waist small circle; fitting a rail longitudinal shaft line according to a tangent point of the rail waist big circle and the rail waist small circle; projecting the characteristic profile to an auxiliary plane which is vertical to the rail longitudinal shaft line to obtain a projection profile of the cross section of the rail; and calculating the wear value of the cross section of the rail by aligning a standard profile of the cross section of the rail with the projection profile. The measurement error of the rail wear caused by that a light plane projected by the laser vision sensor is not vertical to the rail longitudinal shaft line can be eliminated based on the method.

Owner:BEIHANG UNIV

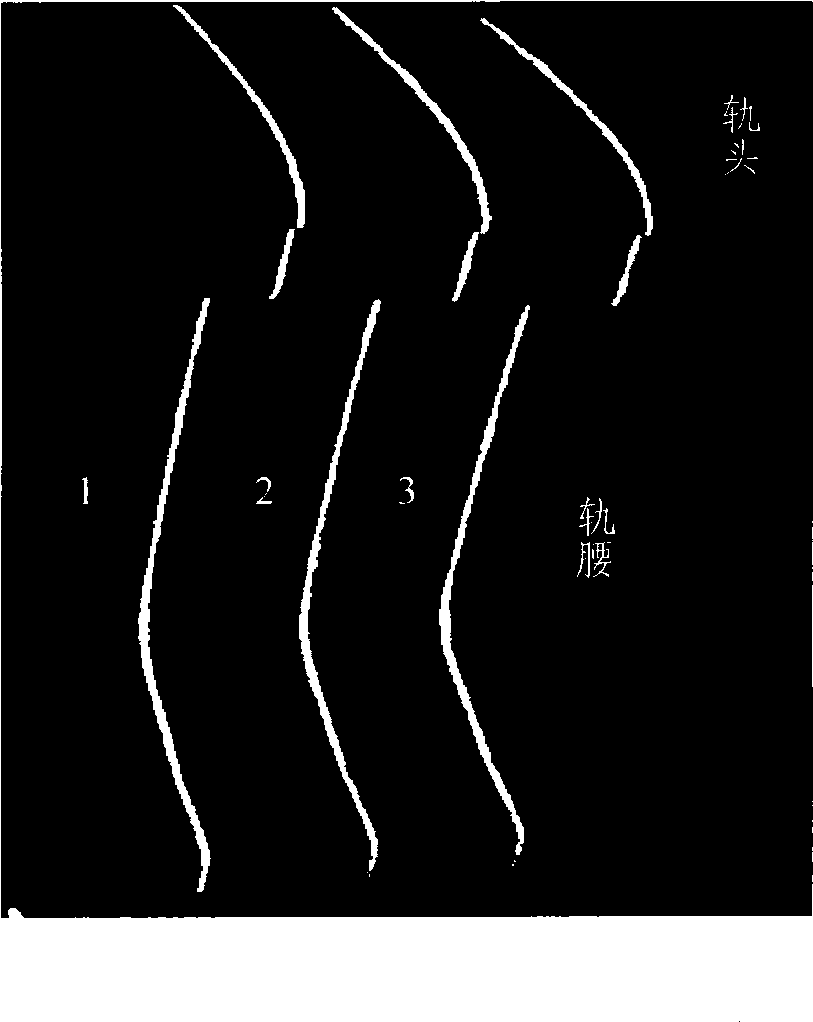

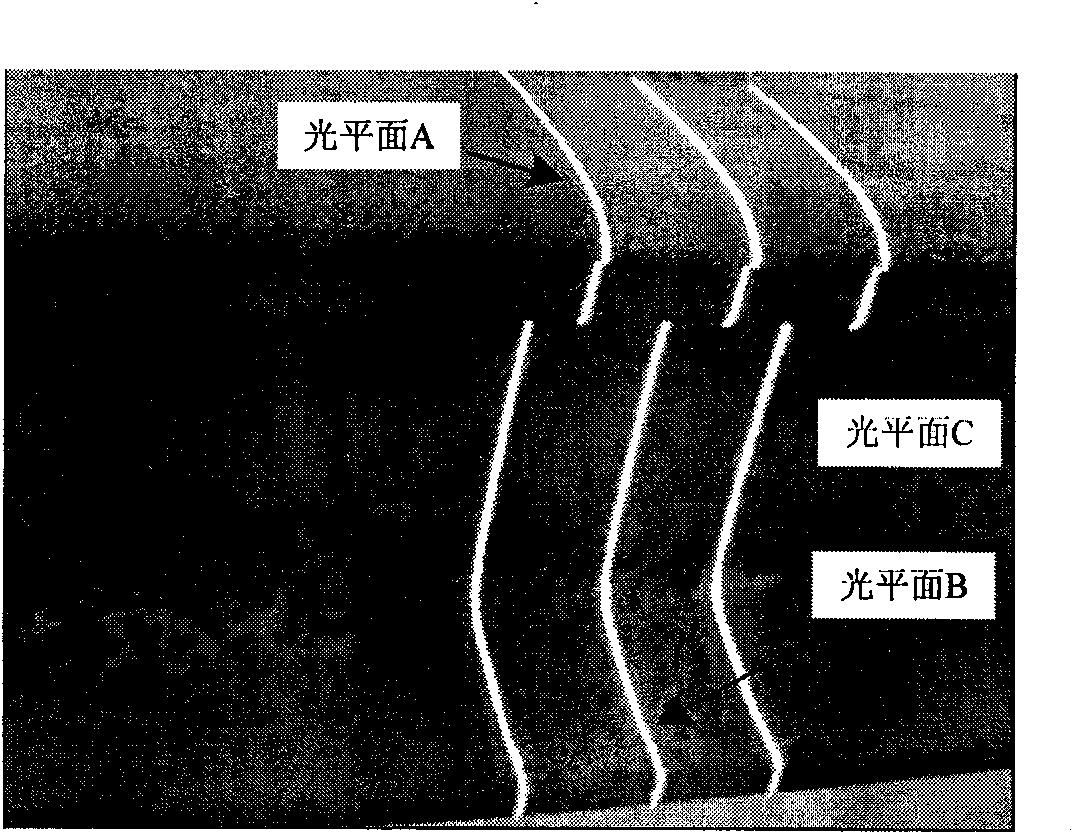

Fast processing method of laser vision image of steel rail wear

InactiveCN101576375ASmall amount of calculationRealize wear value calculationUsing optical meansRailway auxillary equipmentVideo sensorsGreat circle

The invention discloses a fast processing method of a laser vision image of steel rail wear, comprising the following steps of: projecting more than two optical planes which are mutually parallel and vertical to the axial direction of the steel rail, selecting one optical plane and projecting the optical plane to images of the rail waist of the steel rail and an optical strip of the rail head, calculating a coordinate of the center of the optical strip at the rail waist in a coordinate system of the optical plane, and calculating circle center coordinates of large circles and small circles of the rail waist in the coordinate system of the optical plane; calculating a transformation matrix between the coordinate system of the selected optical plane and a profile coordinate system of the section of the standard steel rail; respectively determining intersection points of line segment and the optical strip of the rail head between the constraint points of vertical wear and the constraint points of horizontal wear in the image plane of a video sensor; carrying out inverse transformation on the image coordinate of the vertical wear point and horizontal wear point to the profile coordinate system of the section of the standard steel rail, and determining the coordinate of the vertical wear point and horizontal wear point of the steel rail in the profile coordinate system of the section of the standard steel rail, and the vertical distance and horizontal distance between the vertical wear point and the horizontal wear point of the steel rail and the profile of the standard steel rail, namely the wear value of the measured steel rail. The detection efficiency of the wear value of the steel rail is improved greatly.

Owner:BEIHANG UNIV

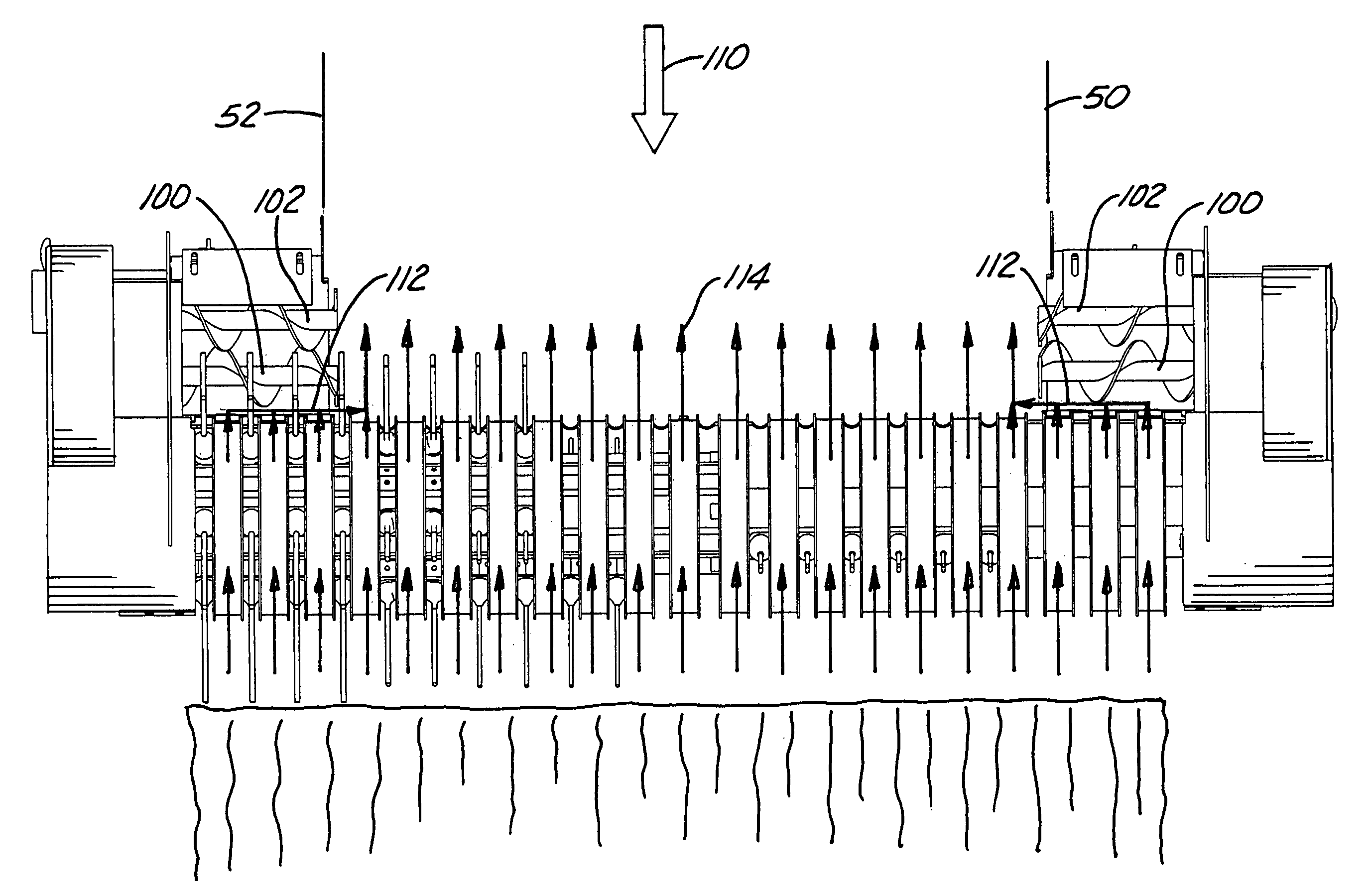

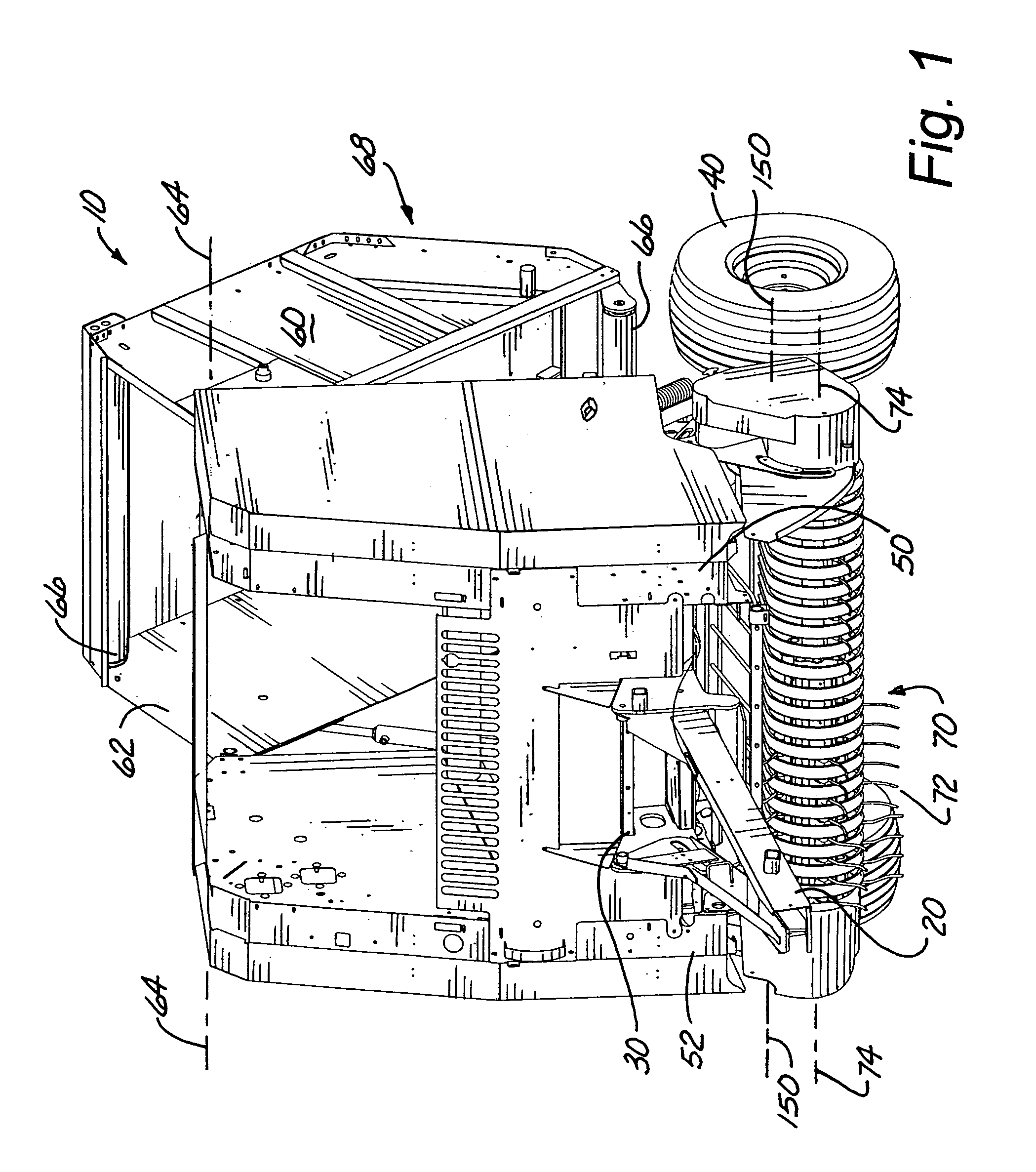

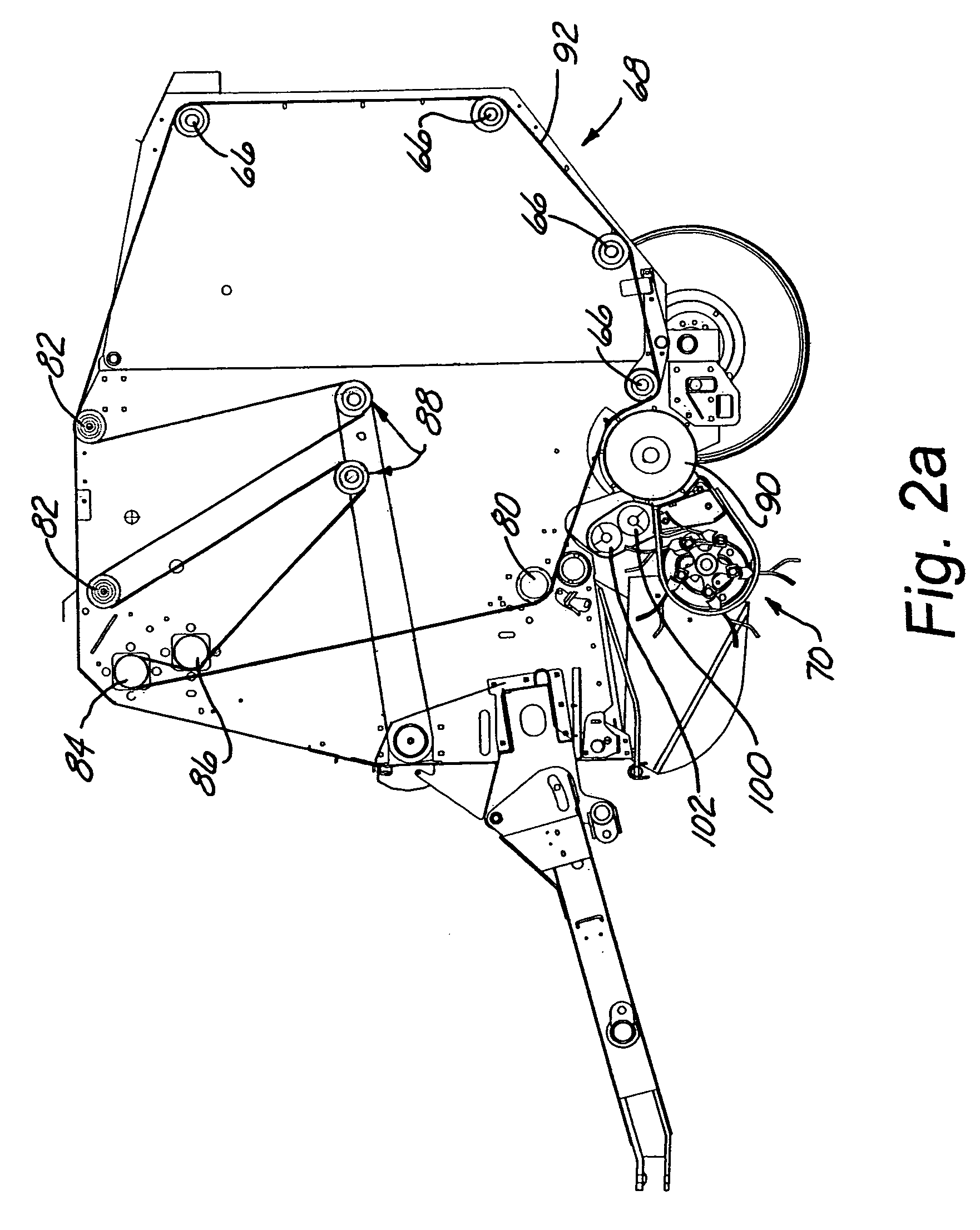

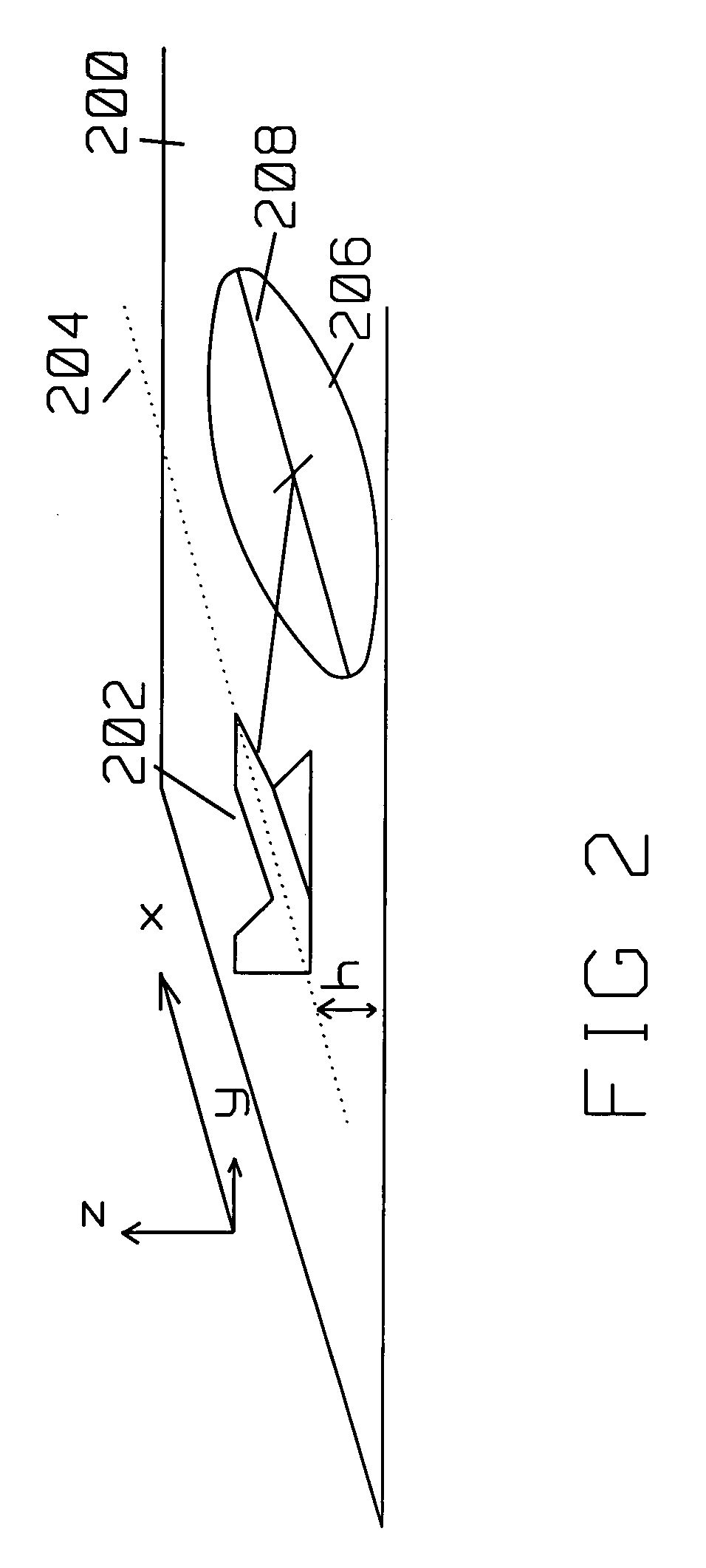

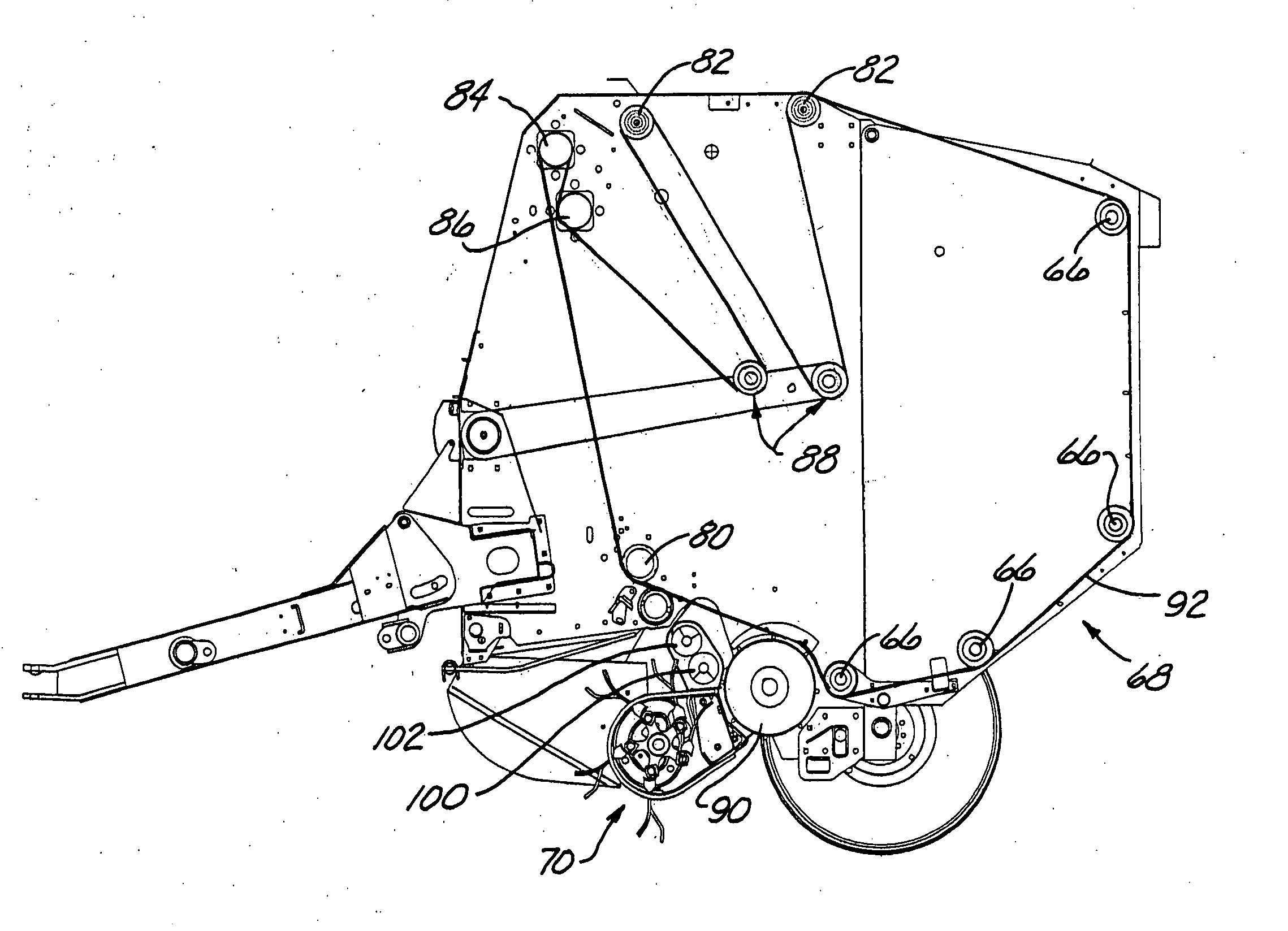

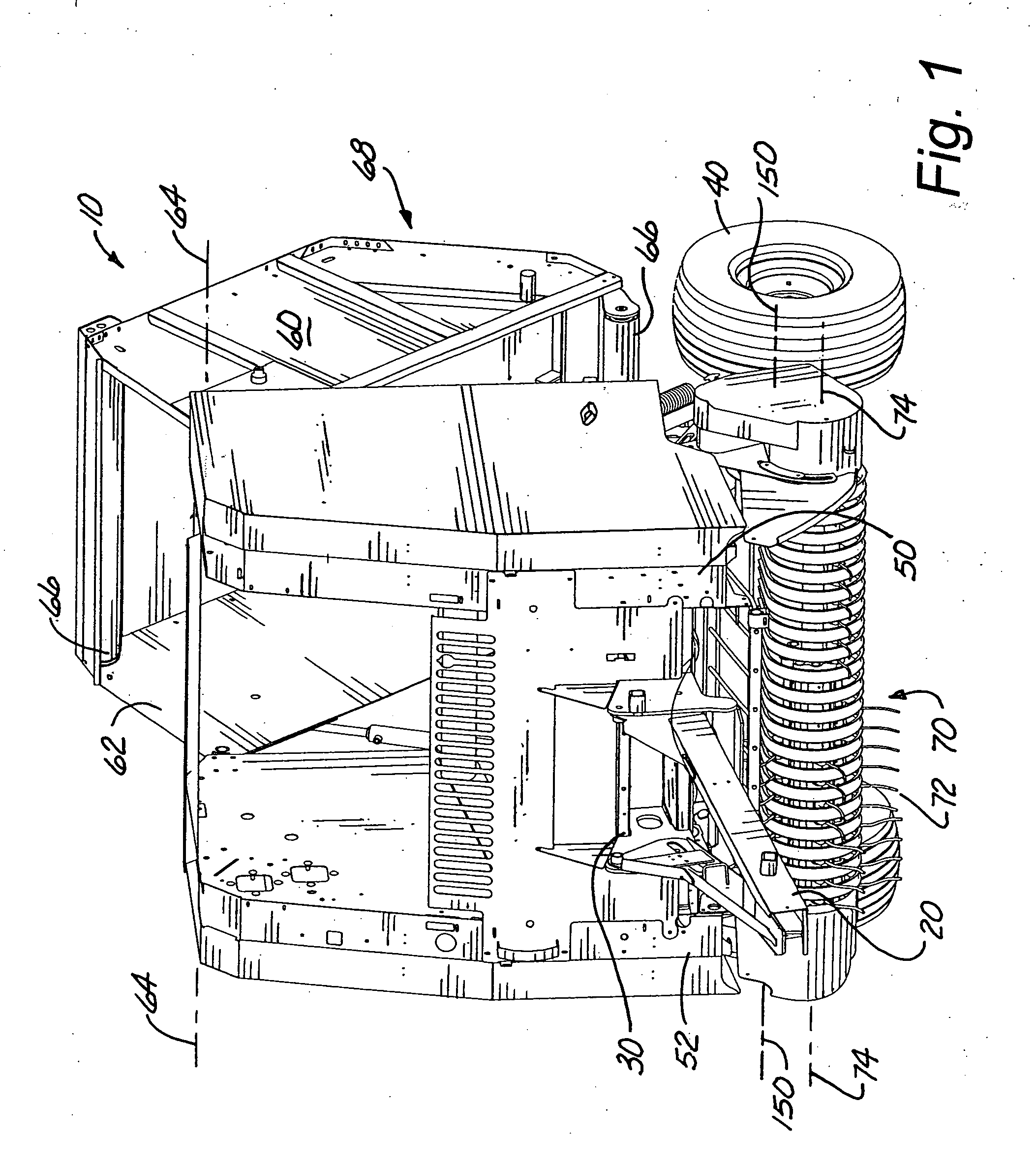

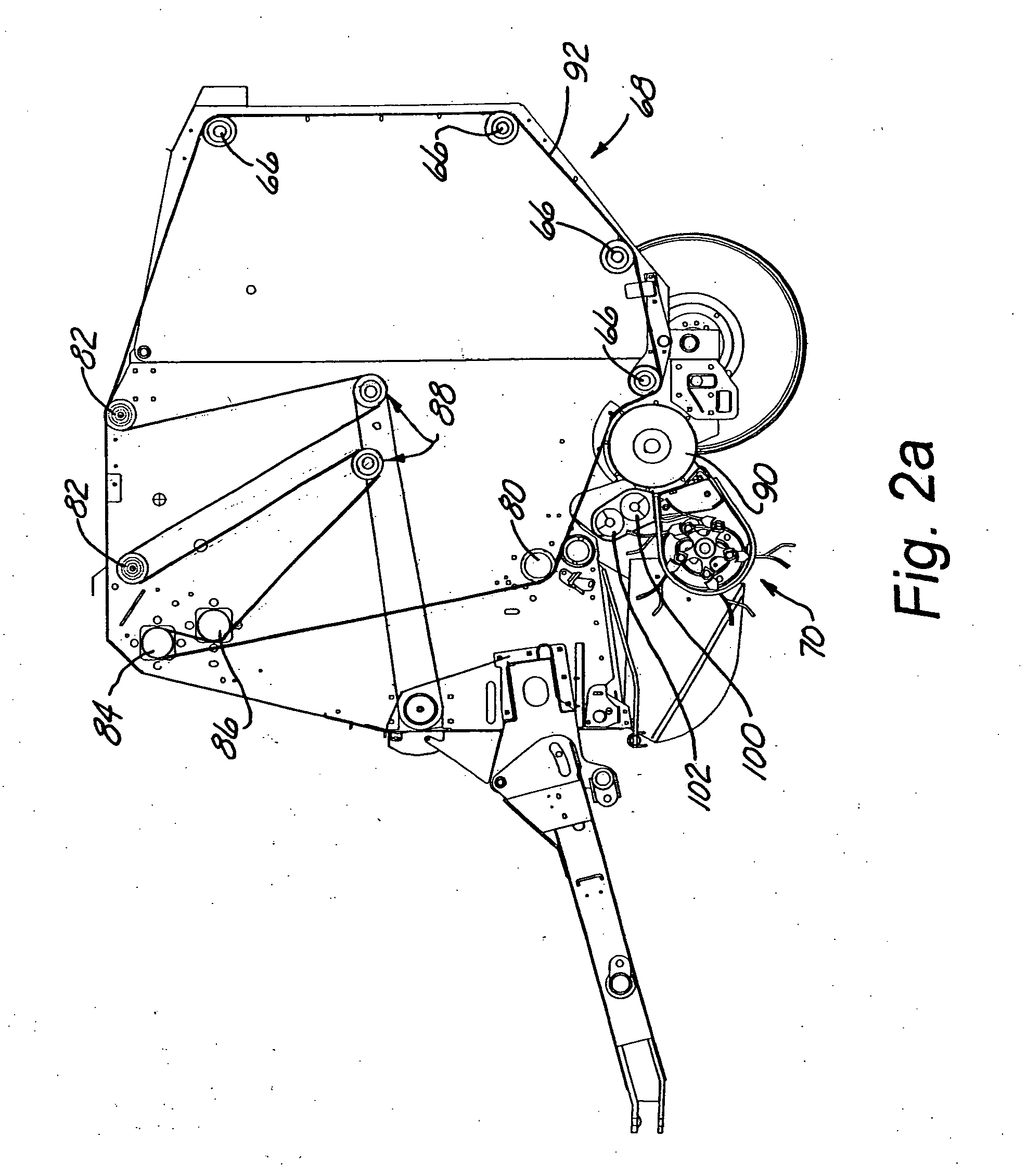

Wide pickup header for a round baler

When harvesting forage in the form of a large round bale, for instance, there are times in which a windrow of forage material lies outside the side boundaries of the bale-forming chamber. This may be due to the windrow being made wide by machinery having driven through it, or by wind, or because of the need to turn the forage harvesting equipment tightly. A wide pickup, notably wider than the width of the bale-forming chamber, provides a solution to this common problem. Dual augers at each end of the wide pickup provide the force to direct the forage into a narrower path, to enter the bale-forming chamber. The orientation and size of the augers permits the pickup header to reside in the same location it would if it was not wider than the baler. Tines or teeth of various rigidities and shapes are provided in the pickup for more effective pickup of the forage.

Owner:VERMEER MFG CO

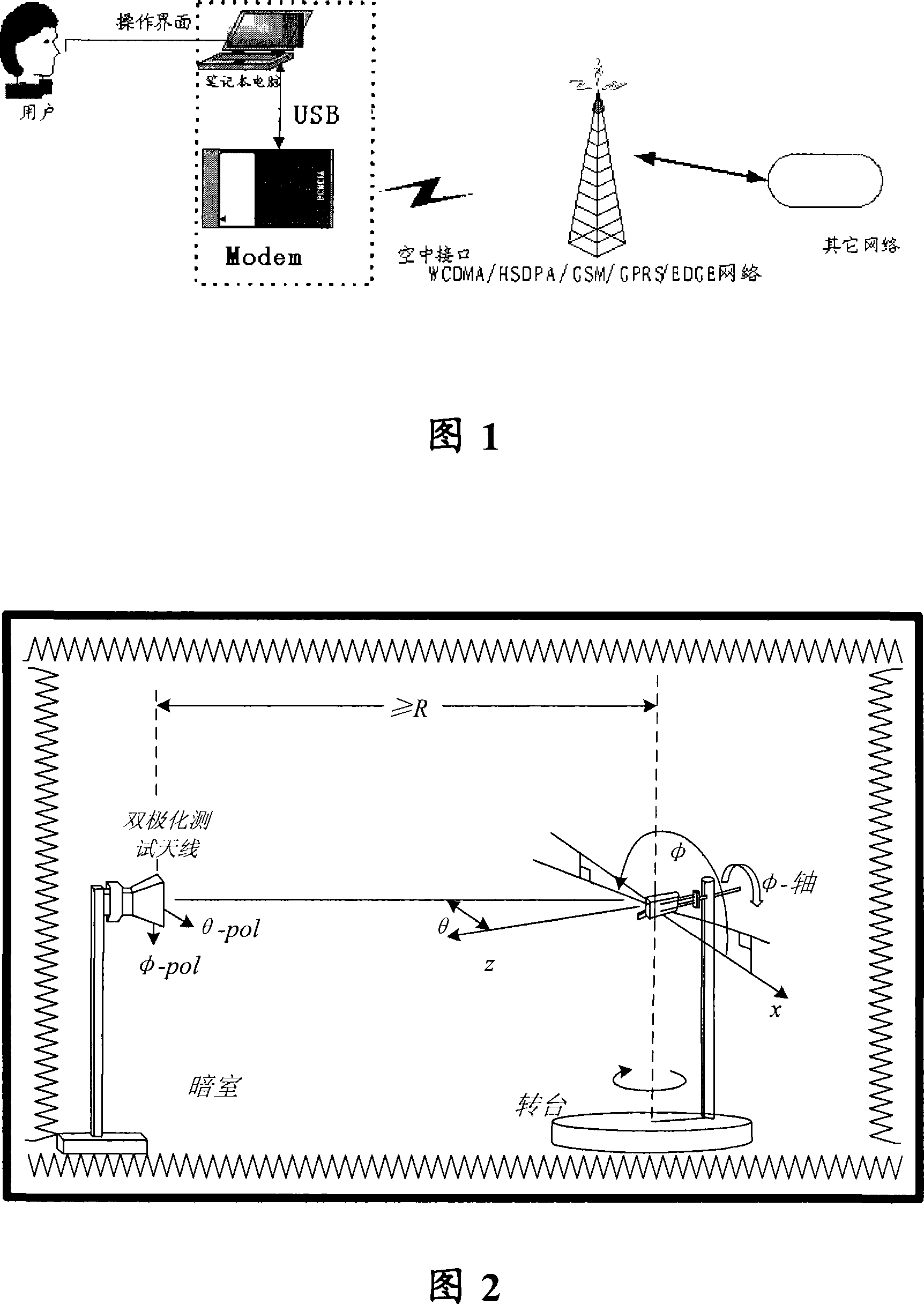

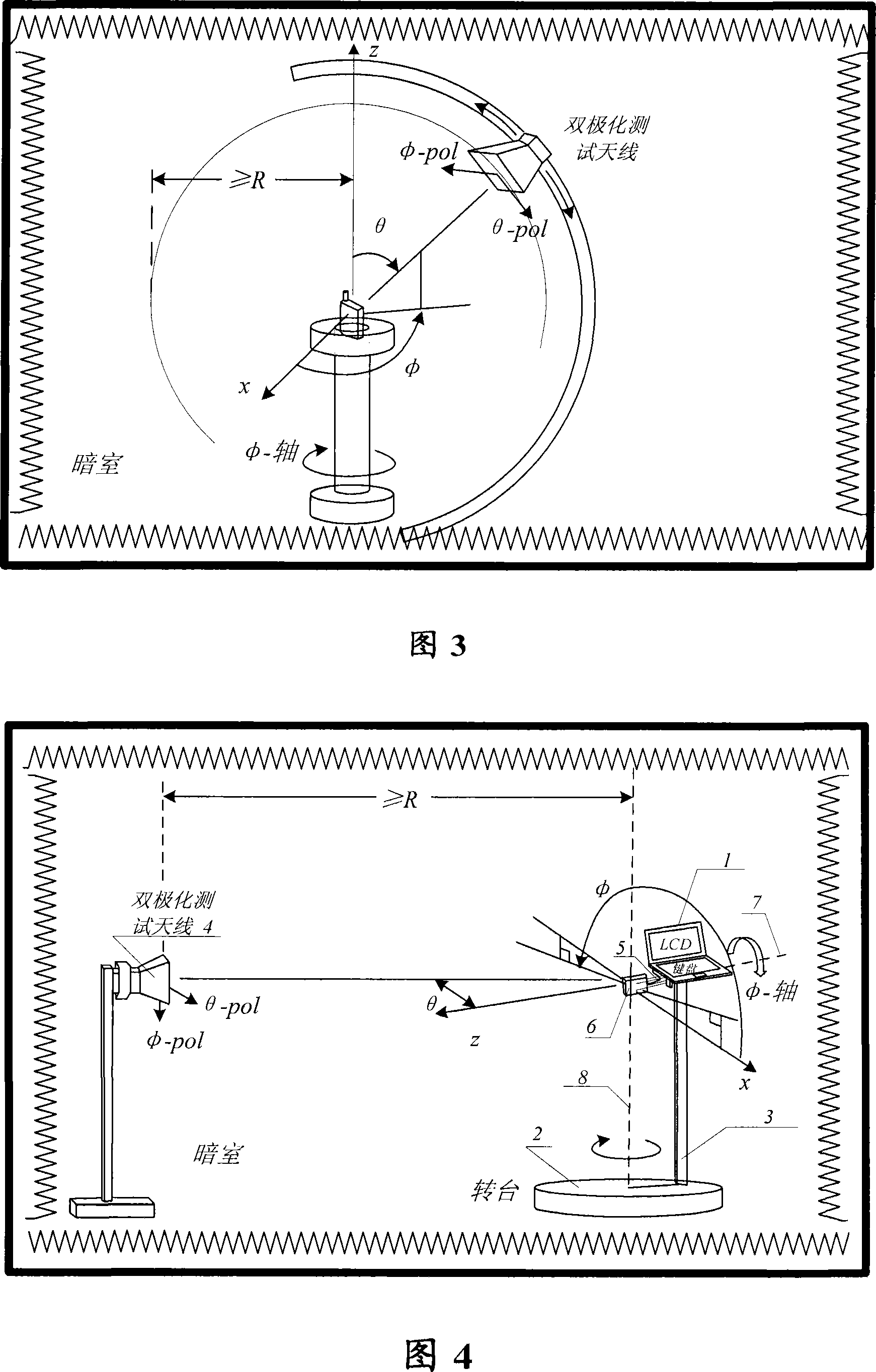

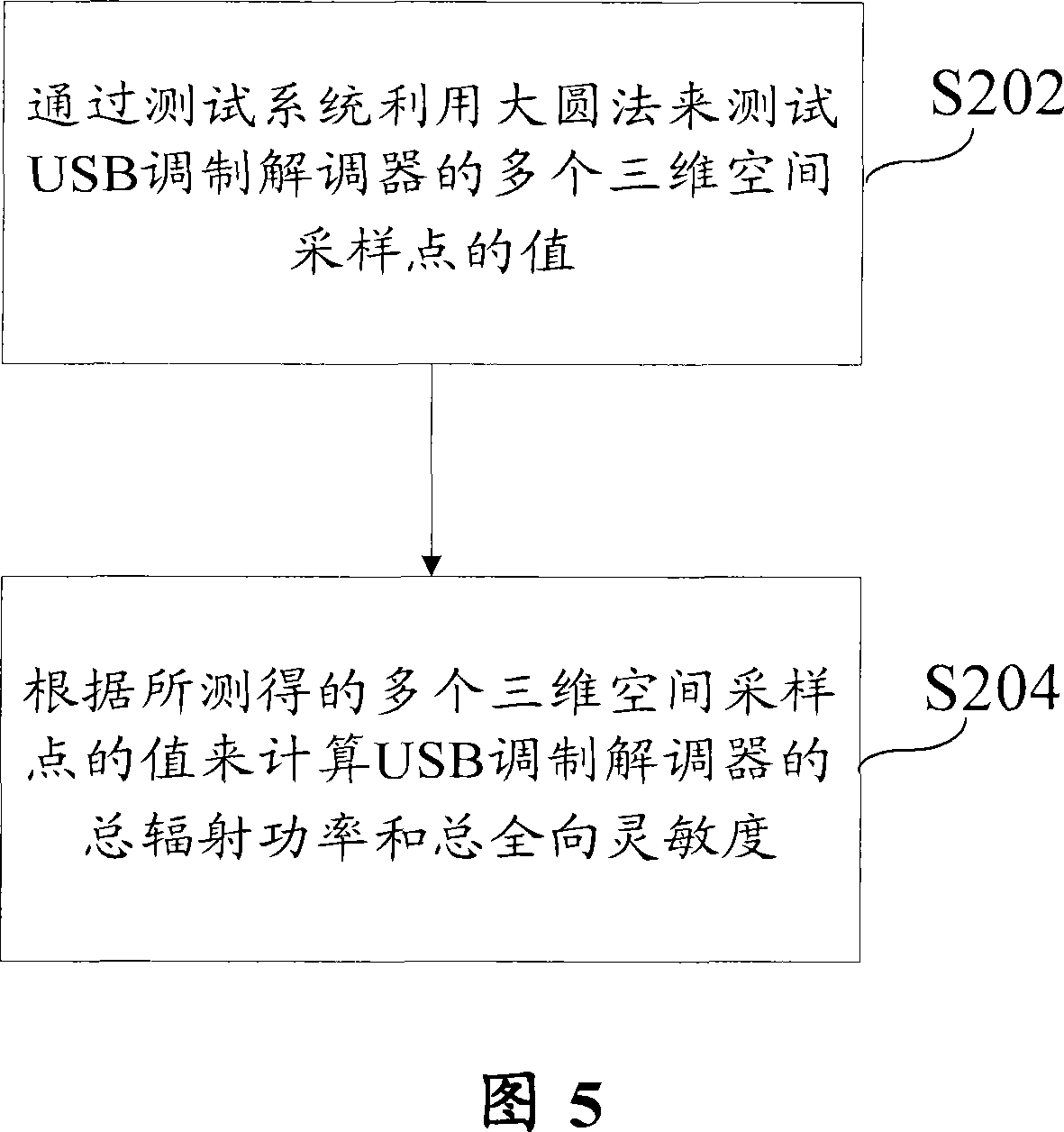

A test system and test method on aerial performance of wireless USB modem

InactiveCN101217322AEfficient use ofRadio/inductive link selection arrangementsTransmission monitoringModem deviceSoftware system

The invention provides a system for testing the aerial performance of a wireless USB modem and comprises a darkroom, a rotating floor that is arranged in the darkroom, a testing antenna and a computer, wherein, the wireless USB modem is connected with the started computer through a USB wire, and the computer is fixed in the top end of a rotating shaft that is vertical to a plane of the rotating floor; the USB modem is arranged in a proper position of the darkroom for implementing the great circle test of the USB modem. The invention further provides a method for testing the aerial performance of the wireless USB modem. Therefore, the invention can better utilize an OTA testing darkroom of existing cellphones, the hardware system of the rotating floor and the software system, and a three-dimensional directivity diagram and TRP and TIS data which are acquired from the testing can reflect the radiation and receiving characteristics of the antenna.

Owner:ZTE CORP

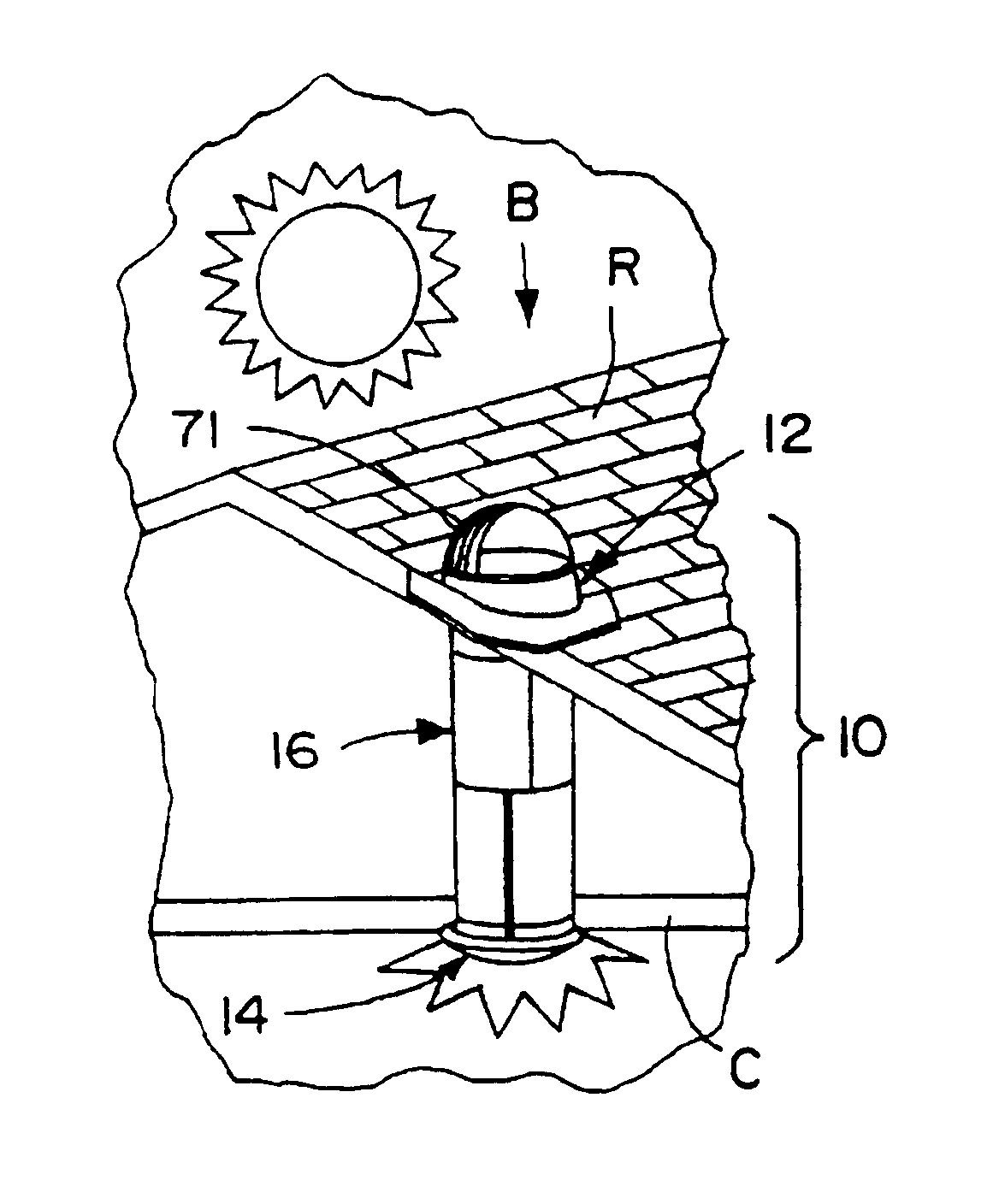

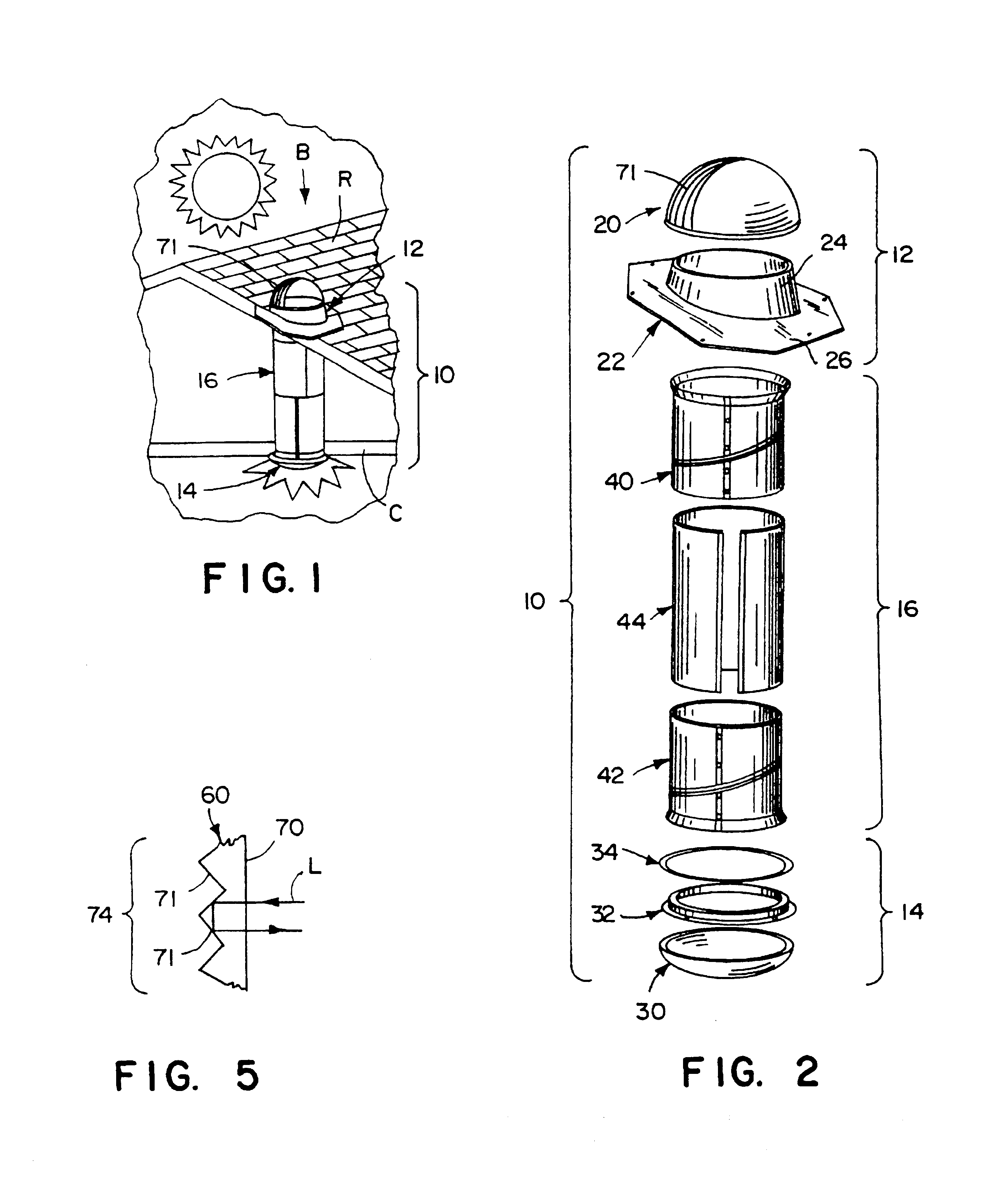

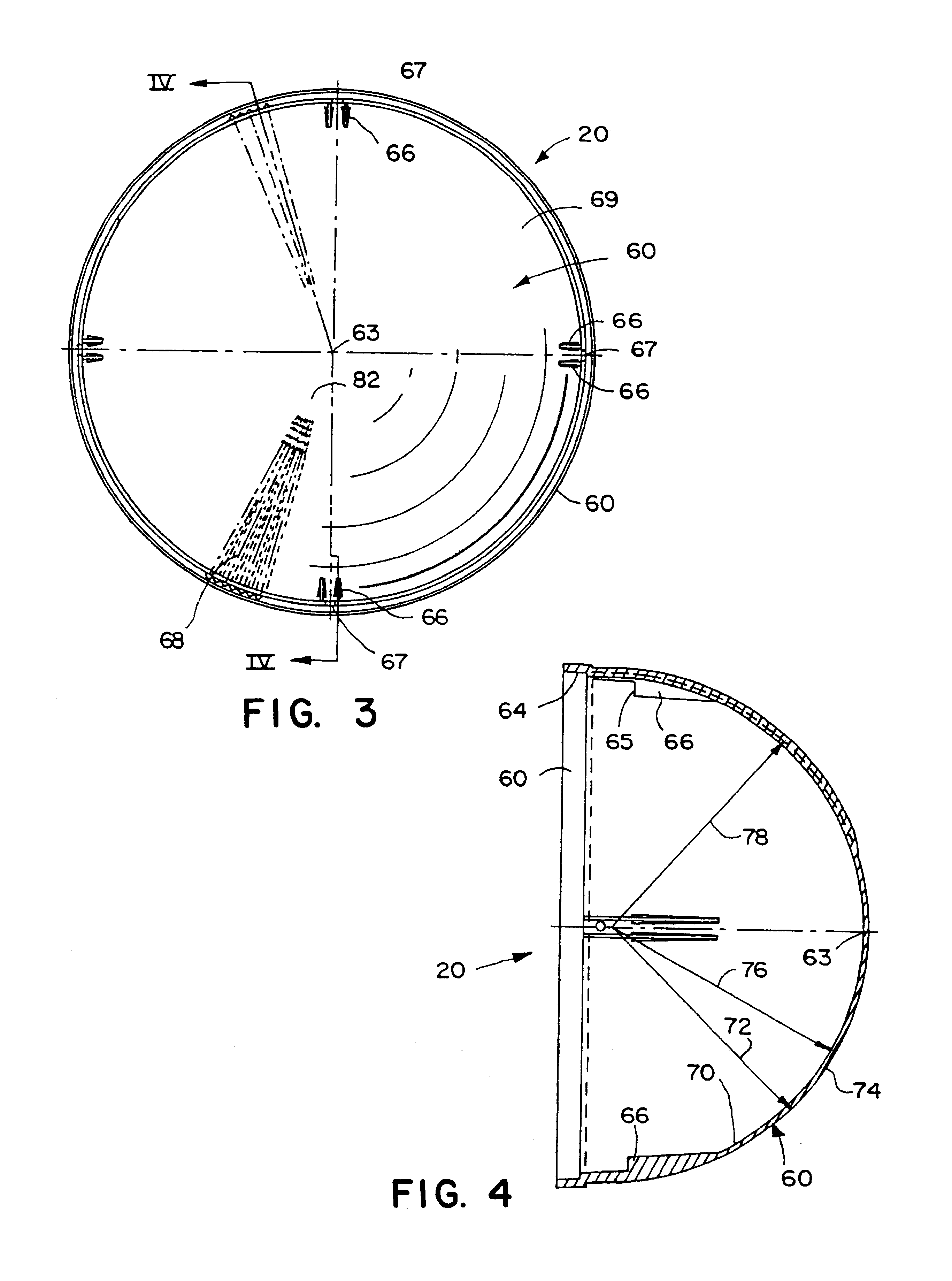

Tubular skylight with improved dome

InactiveUSRE38217E1Increase the amount of lightEffective lightingBuilding roofsPrismsPrism coverEngineering

A tubular skylight having an improved dome improving the efficiency of the skylight. The dome includes an integral prism in a portion of its outer surface to reflect light downwardly through the skylight. The dome is hemispherical, and the prism includes a plurality of grooves extending along great circles that pass through the apex of the dome. The prism covers only an angular segment of the hemispherical dome; and the grooves stop short of the apex of the dome.

Owner:NATURAL LIGHT ENERGY SYST LLC

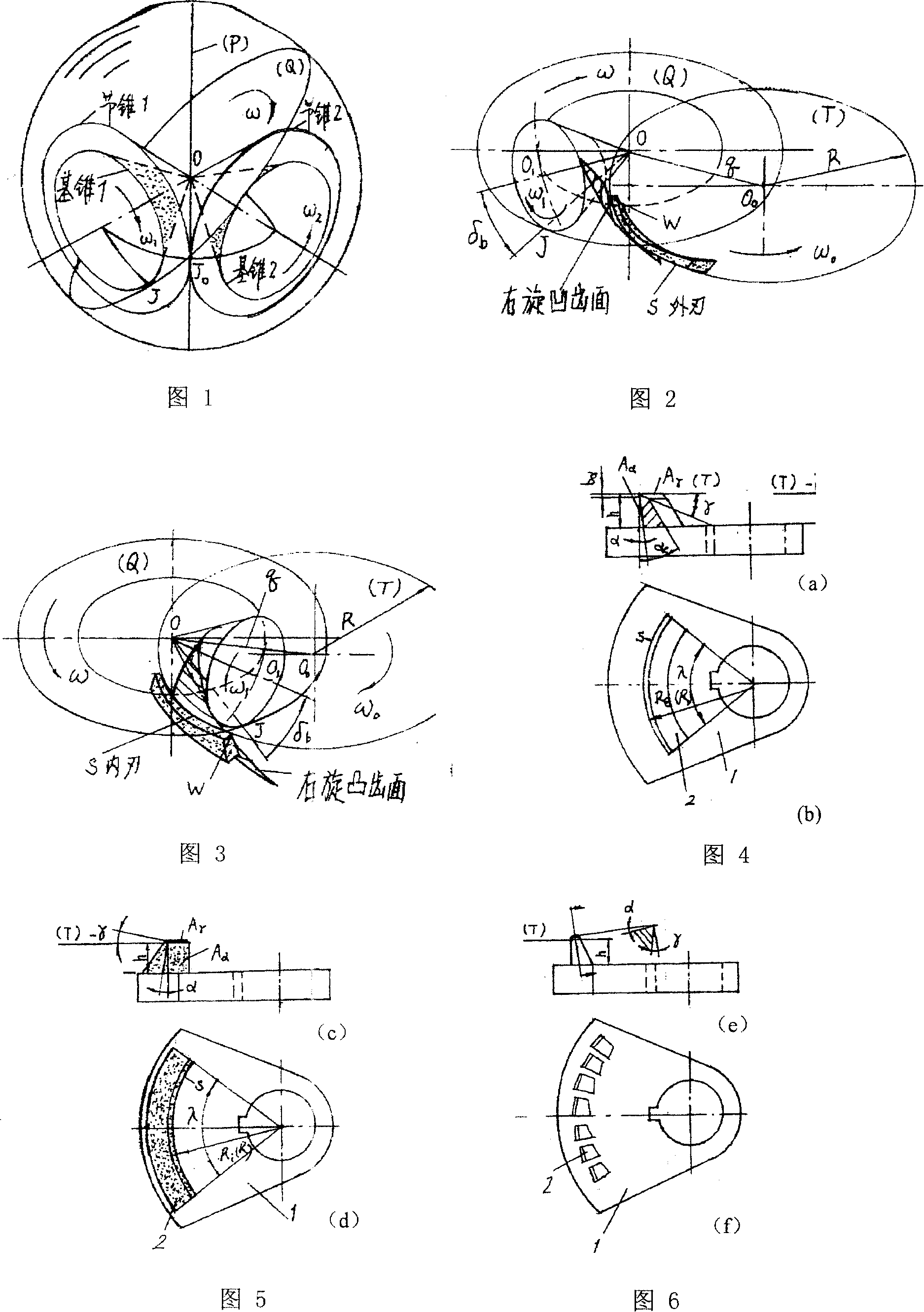

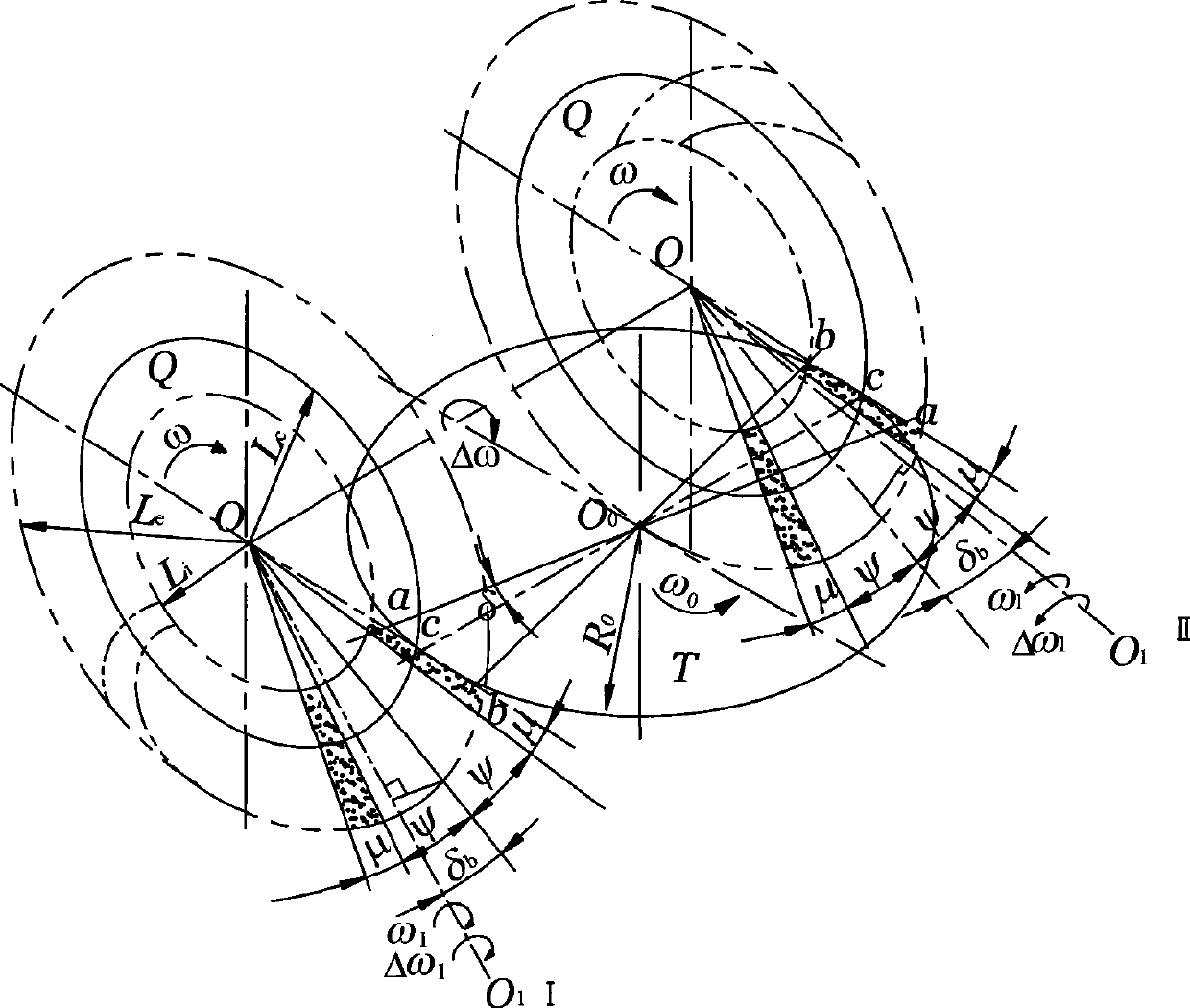

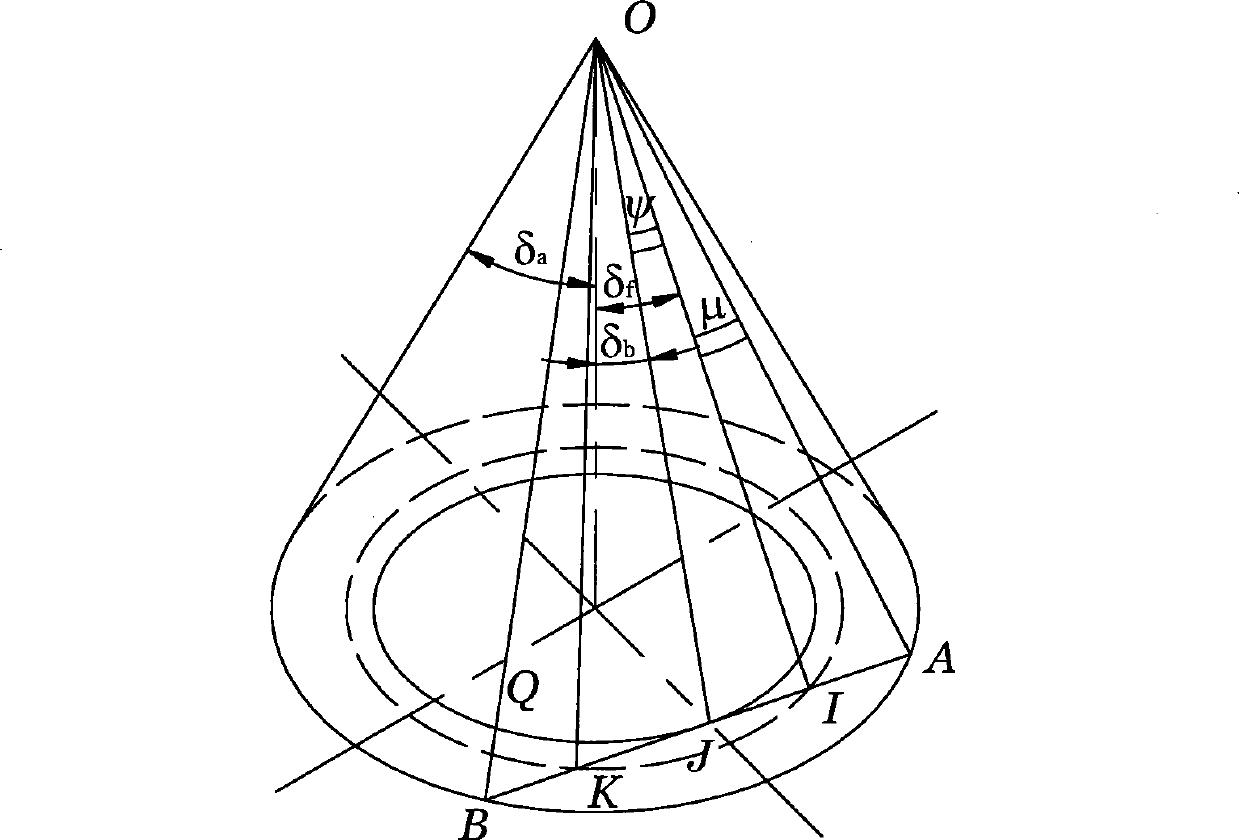

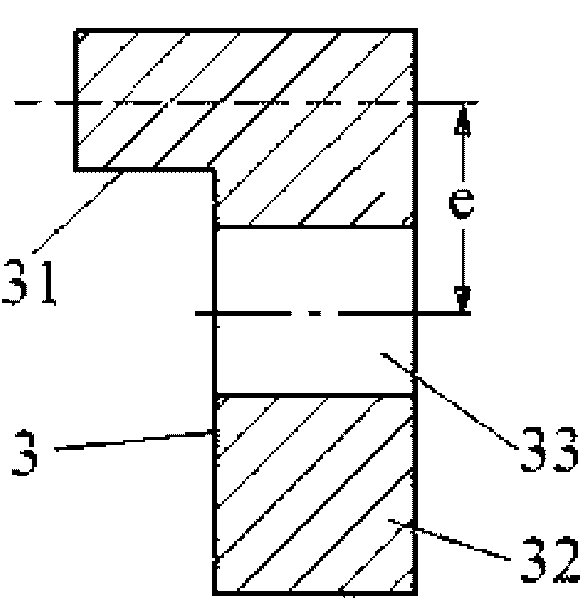

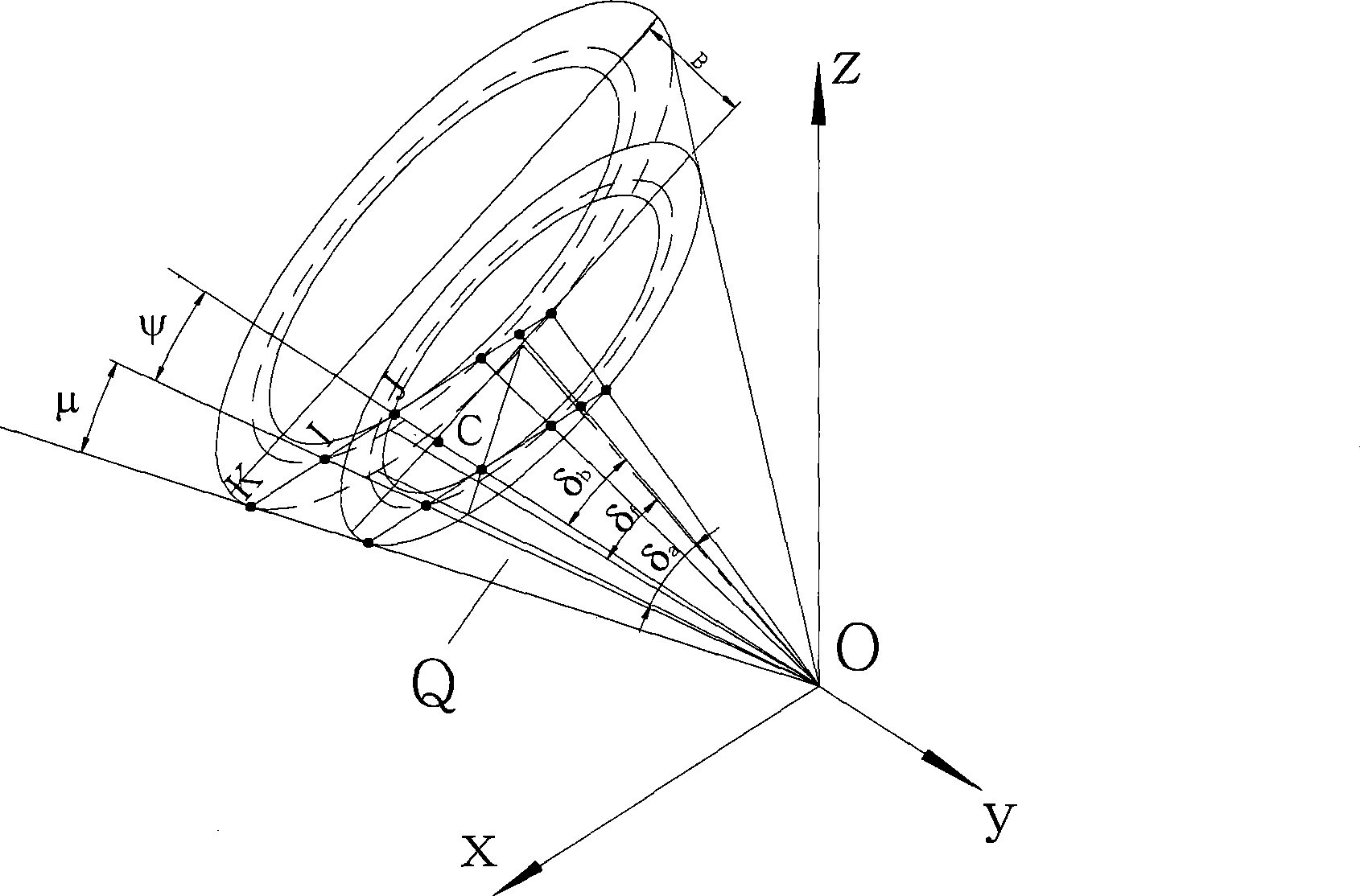

Method for producing cutter teeth of spiral bevel gear with spherical involute profile of tooth tapered tooth

InactiveCN101152677AImprove mesh qualitySimple configurationMilling equipment detailsGear teeth manufacturing toolsGear wheelEngineering

The invention relates to a gear cutting method for manufacture of spiral bevel gear with spherical involute tooth profile shrinkage tooth which is the gear cutting method that an arc-shaped cutting edge skiving cutterhead with turning radius of R on an end surface (T) is adopted for turning of spherical involute tooth profile and the shrinkage tooth is adopted to manufacture the tooth surface of the spiral bevel gear. When in cutting, a tooth casting is tangental to spherical large round plane (Q) represented by machine tool shaking station turning plane and maintains pure rolling according to base cone, rotating speed of every shaft of the machine tool is set up according to following speed ratio relations: when rotating speed of the shaking station is omega, rotating speed of the tooth casting is (1) type, wherein, ZQ is hypothetical tooth number of the shaking station, rotating speed of a cutterheadshaft is (2) type, and omega is opposite to the direction of omega 0; skiving cutterhead knife edge S is tangental to processed tooth surface and tooth surface fine turning process without generation of undercut is finished in the state of large bevel turning. Engaging quality of the cutting gear manufactured with the method is improved, with transient speed ratio constancy and insensitivity of influence of contacting area by transmission included angle alteration, moreover, the gear processed with the method can be exchanged and the invention simplifies the design of the gear and machine tool.

Owner:彭福华

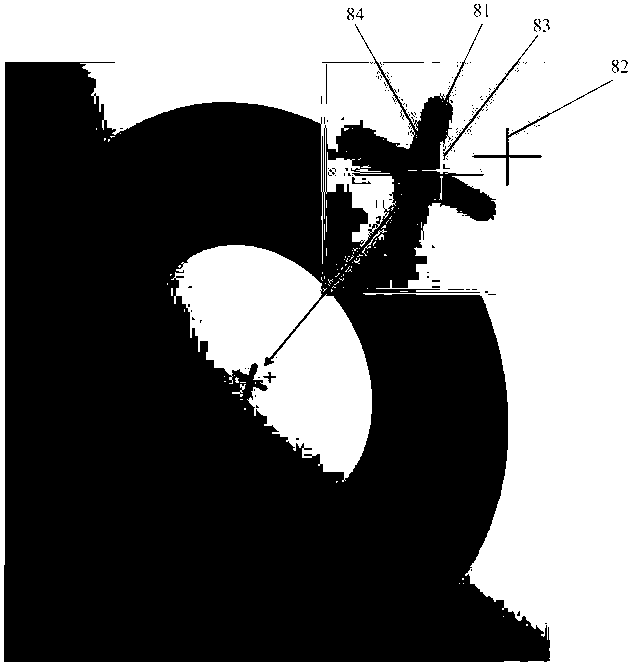

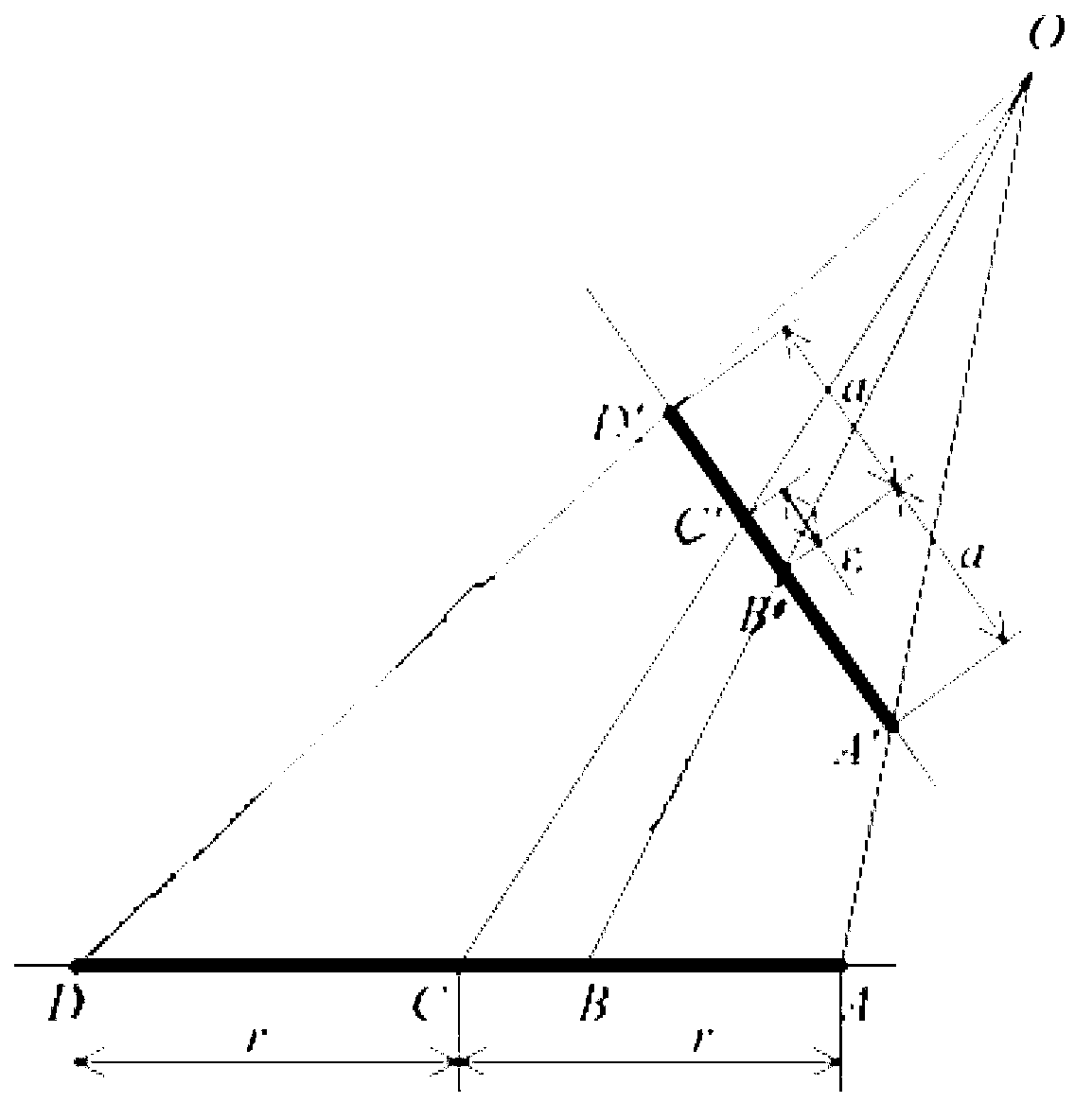

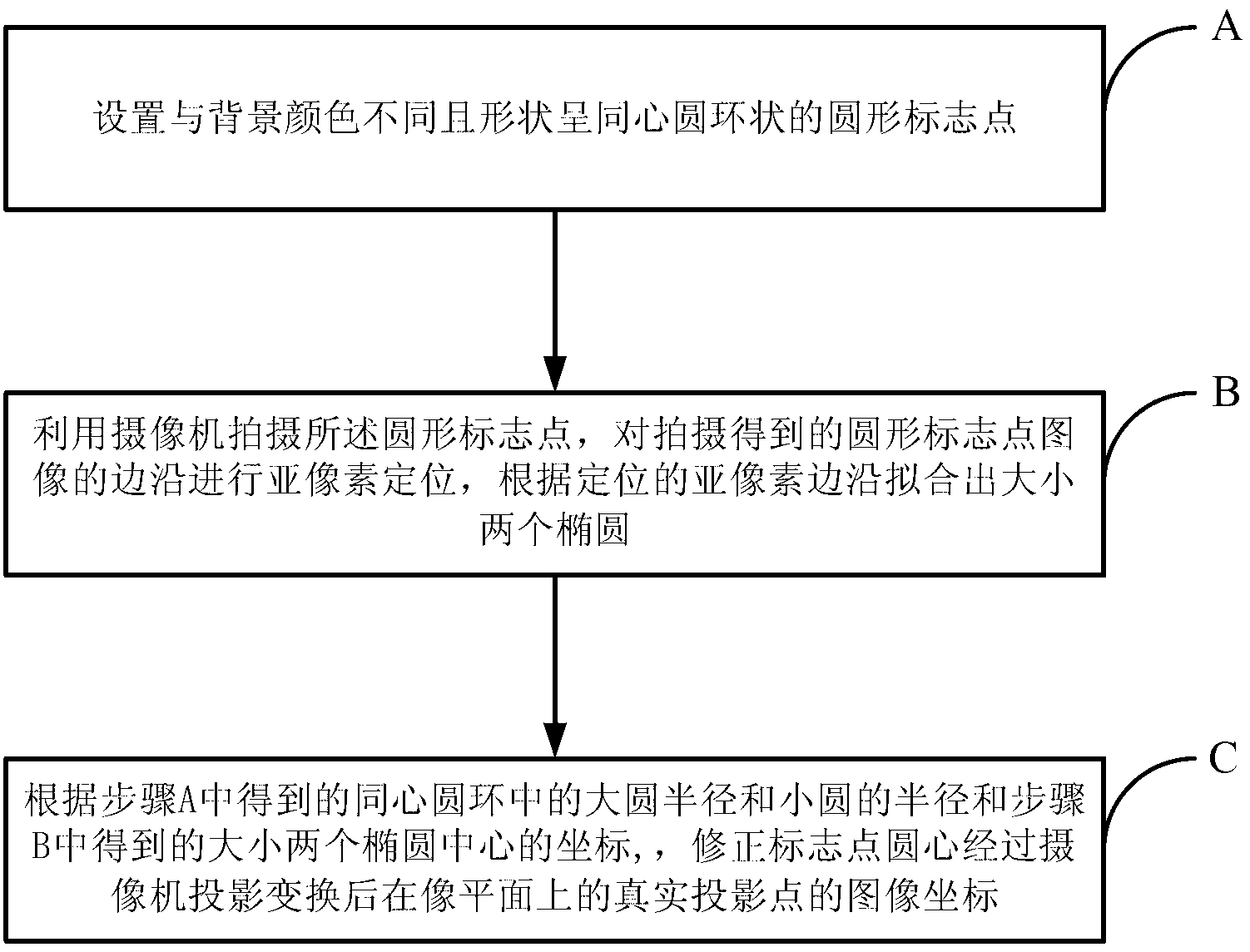

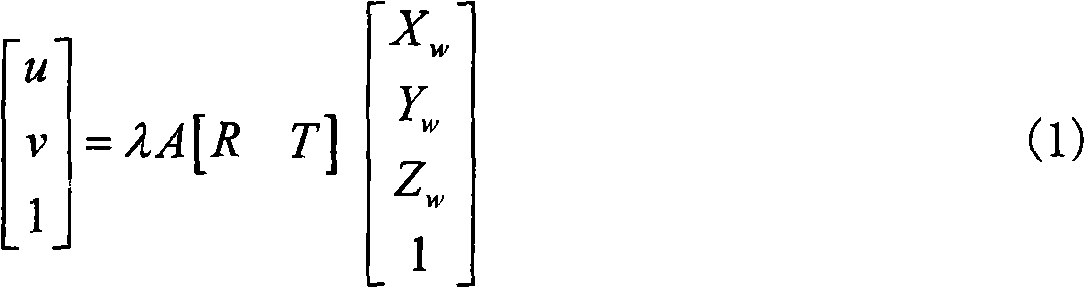

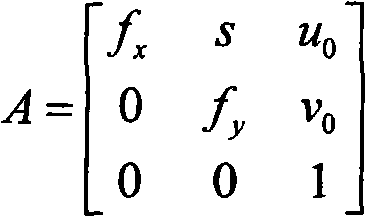

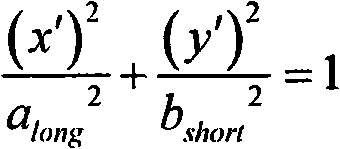

Method and system for correcting circle center deviation of round mark points during camera projection transformation

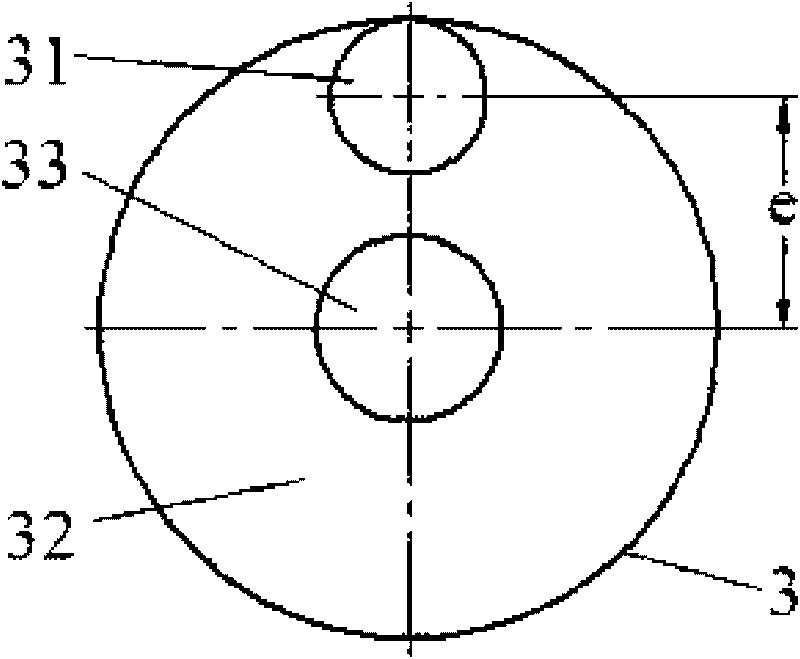

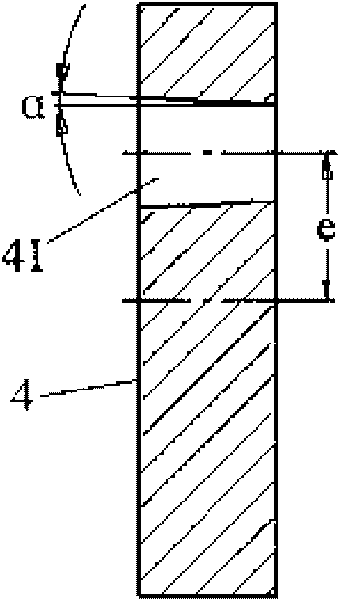

The invention discloses a method and a system for correcting the circle center deviation of round mark points during camera projection transformation. The method for correcting comprises the following steps of: step A, arranging the round mark points which have colors different with a background and have concentric ring shapes; step B, shooting the round mark points by utilizing a camera, carrying out sub-pixel positioning on the edges of the shot image of the round mark points, and fitting a large ellipse and a small ellipse according to the positioned sub-pixel edges; and step C, according to the radiuses r1 and r2 of a large circle and a small circle which are concentric and are obtained in the step A and the center coordinates C1 (muB1, vB1) and C2 (muB2, vB2) of the large ellipse and the small ellipse which are obtained in the step B, correcting the image coordinates of the practical projective points of the circle centers of the round mark points on an image plane after the camera projection transformation. A concentric ring method is adopted, and the linear combination of the large ellipse and the small ellipse is ingeniously utilized to correct the real positions of the circle centers of the manual round mark points on the image plane.

Owner:SHENZHEN ESUN DISPLAY

Means and methods for construction and use of geodesic rhombic triacontahedron

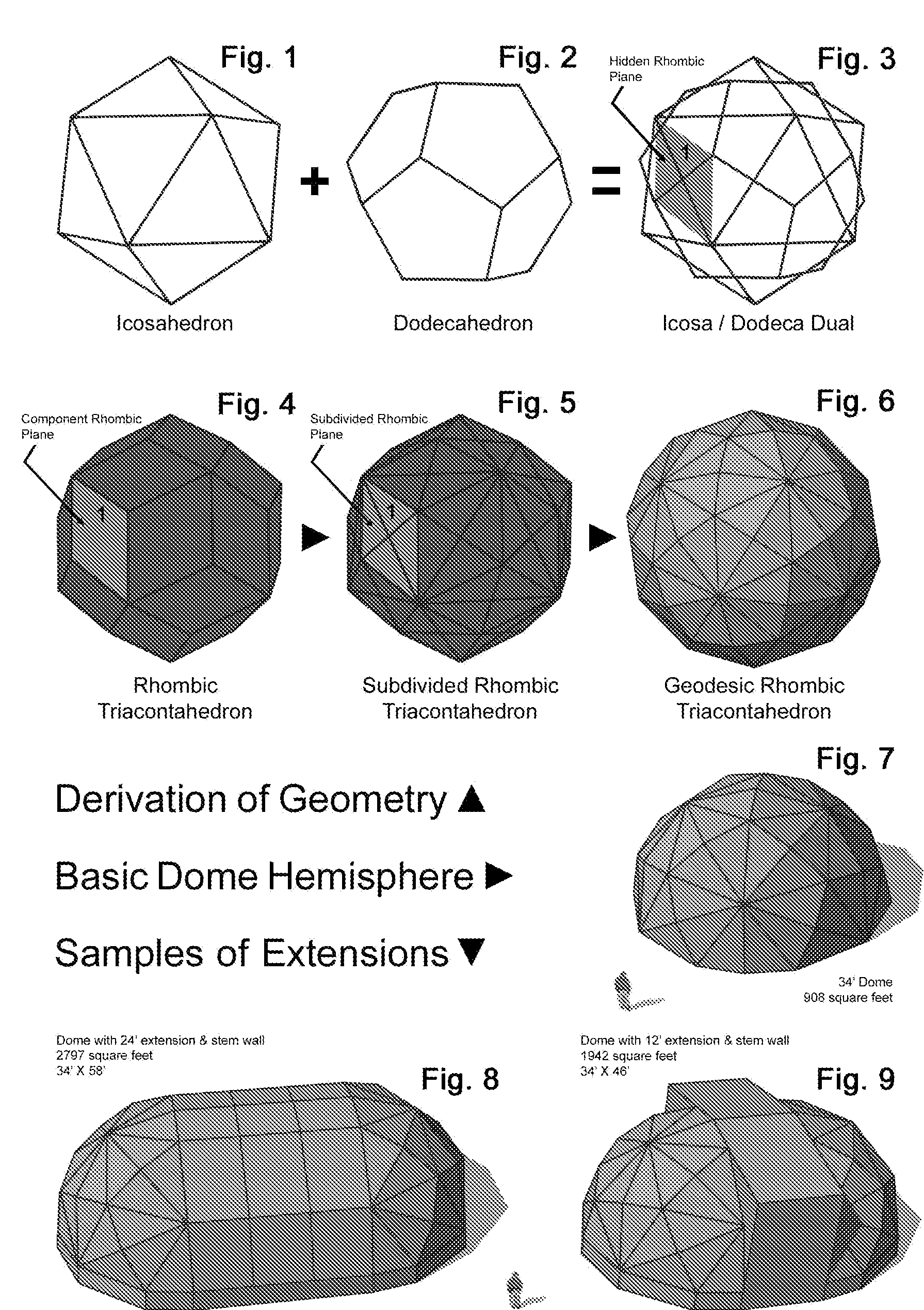

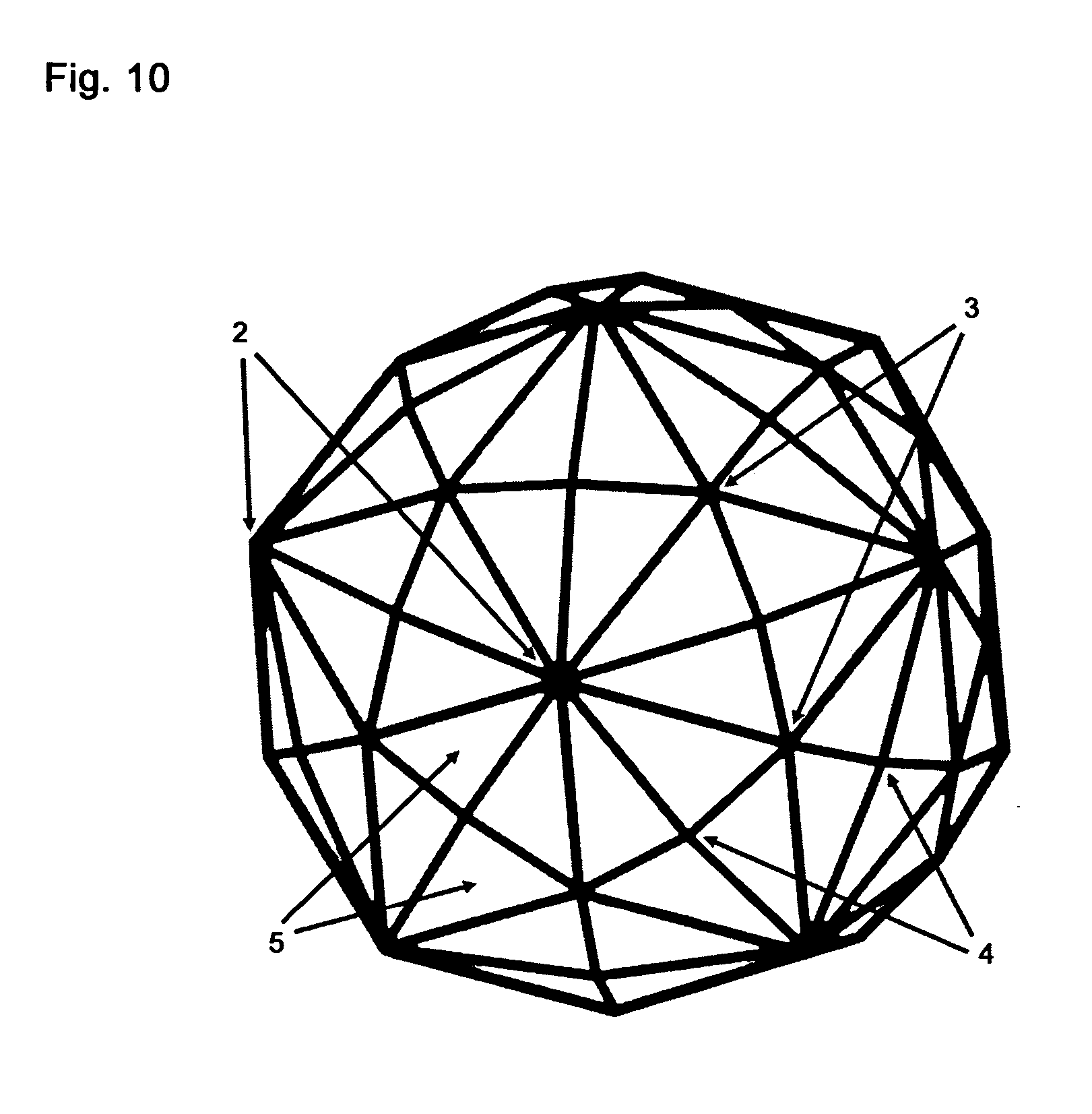

InactiveUS20070163185A1Efficient manufacturingOvercome deficienciesBuilding roofsDiagonalRhombic triacontahedron

A structural system comprising the symmetrical interpenetration of an icosahedron and dodecahedron, further articulated to form a rhombic triacontahedron with each rhombus subdivided by two diagonals at its midpoint. The vertices of the original icosahedron and dodecahedron, and the midpoints of the rhombi, are projected such that a single circumscribed sphere would touch or nearly touch all three sets of resulting vertices. This geometry may used to create a hemispheric geodesic dome. Alternatively, this dome may be subdivided along the hemisphere's great circle segments into two half domes or four quarter domes. Rectangular structural elements may be inserted between the half or quarter domes to increase dome area without increasing dome height and to provide other advantages. The basic triangular components of the disclosed structure may be cut with minimal waste from conventional rectangular construction material such as Structural Insulated Panels. These basic triangular components may be connected with a living hinge.

Owner:MORLEY MICHAEL +1

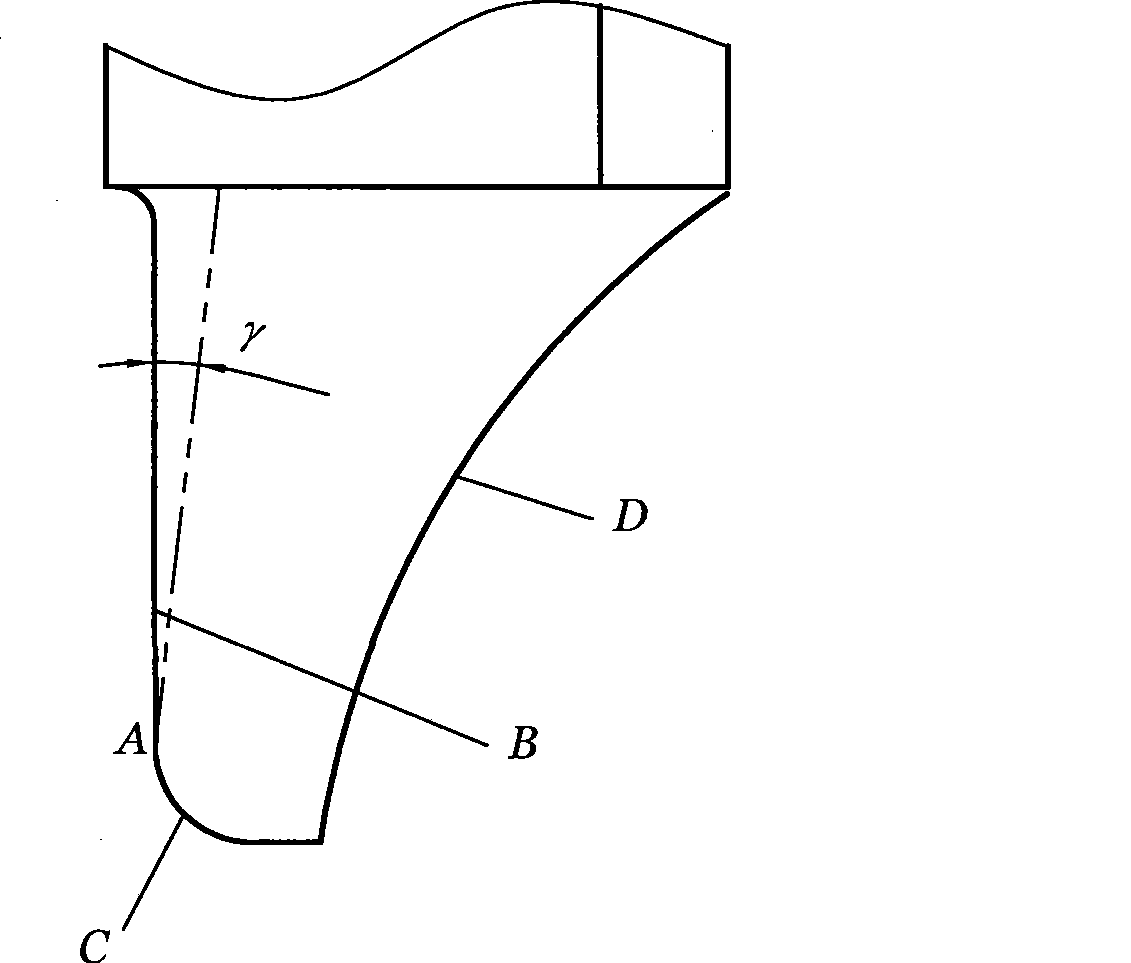

Light rail output bevel wheel machining process

The invention discloses a light rail output bevel wheel machining process which comprises blank making, normalizing, semifinishing, quenching, finish machining and final inspection. The finish machining process comprises a semi-finish turning I, a semi-finish turning II, a finish turning I, a finish turning II, a grinding gear excircle and a grinding gear. By means of the light rail output bevel wheel machining process, semifinishing and finish machining are carried out twice on an end face after quenching treatment is carried out on a teeth blank, when the teeth blank is clamped on a lathe, alignment is carried out according to pitch circle runout, grinding of the end face is replaced by turning, quality of machined gears is improved, and requirements for light rail high power output are met.

Owner:重庆方禾机电设备有限公司

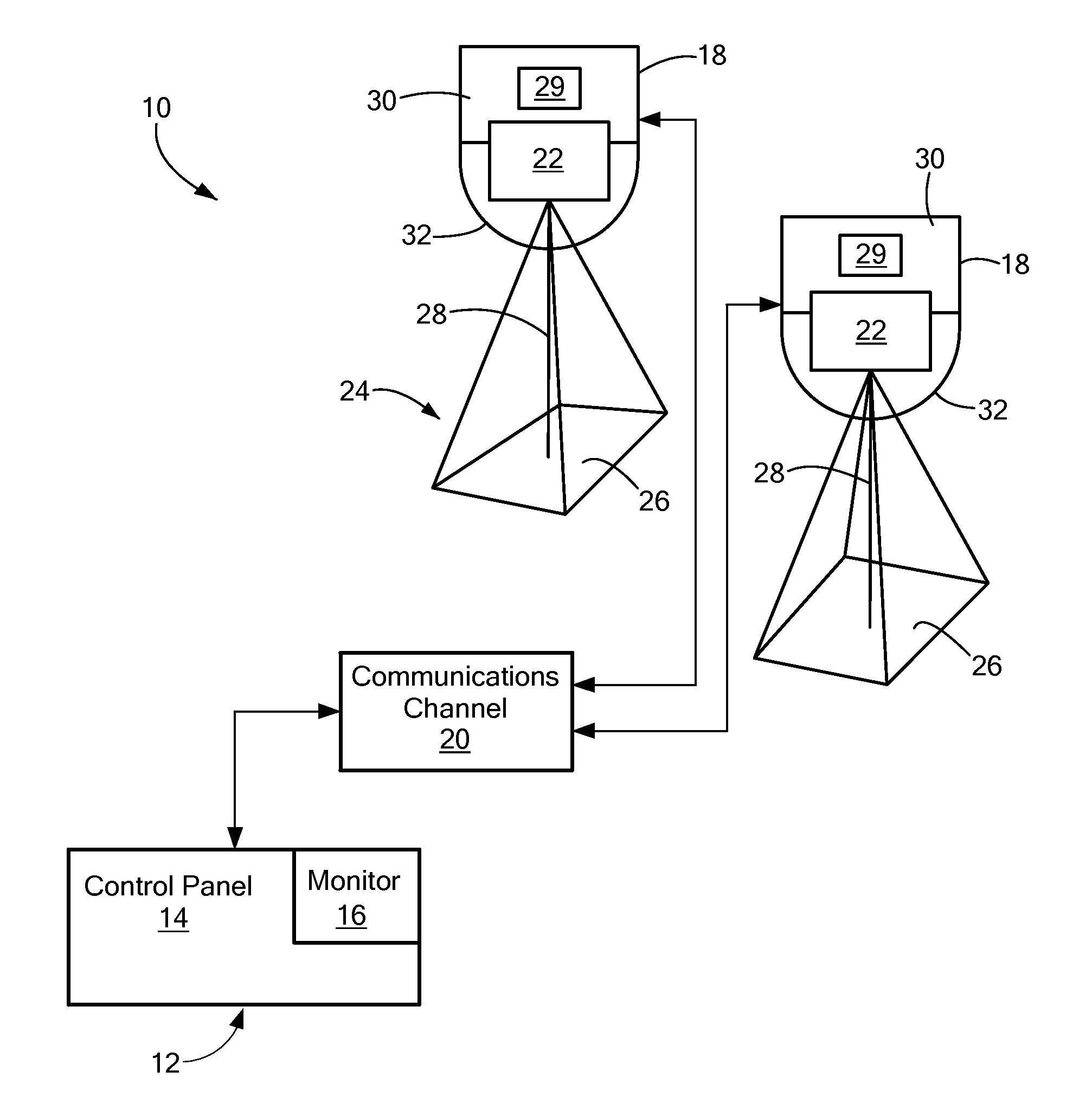

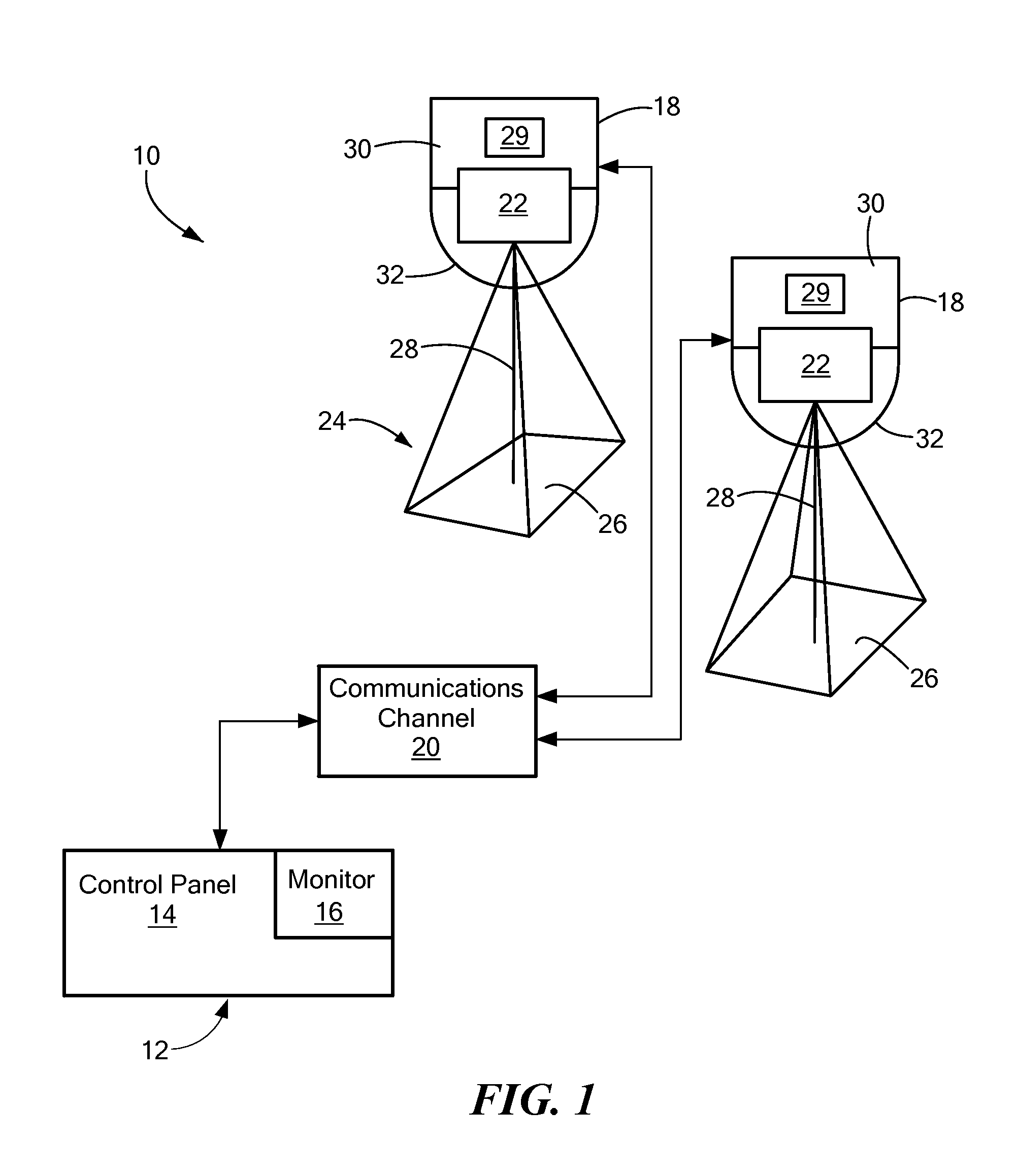

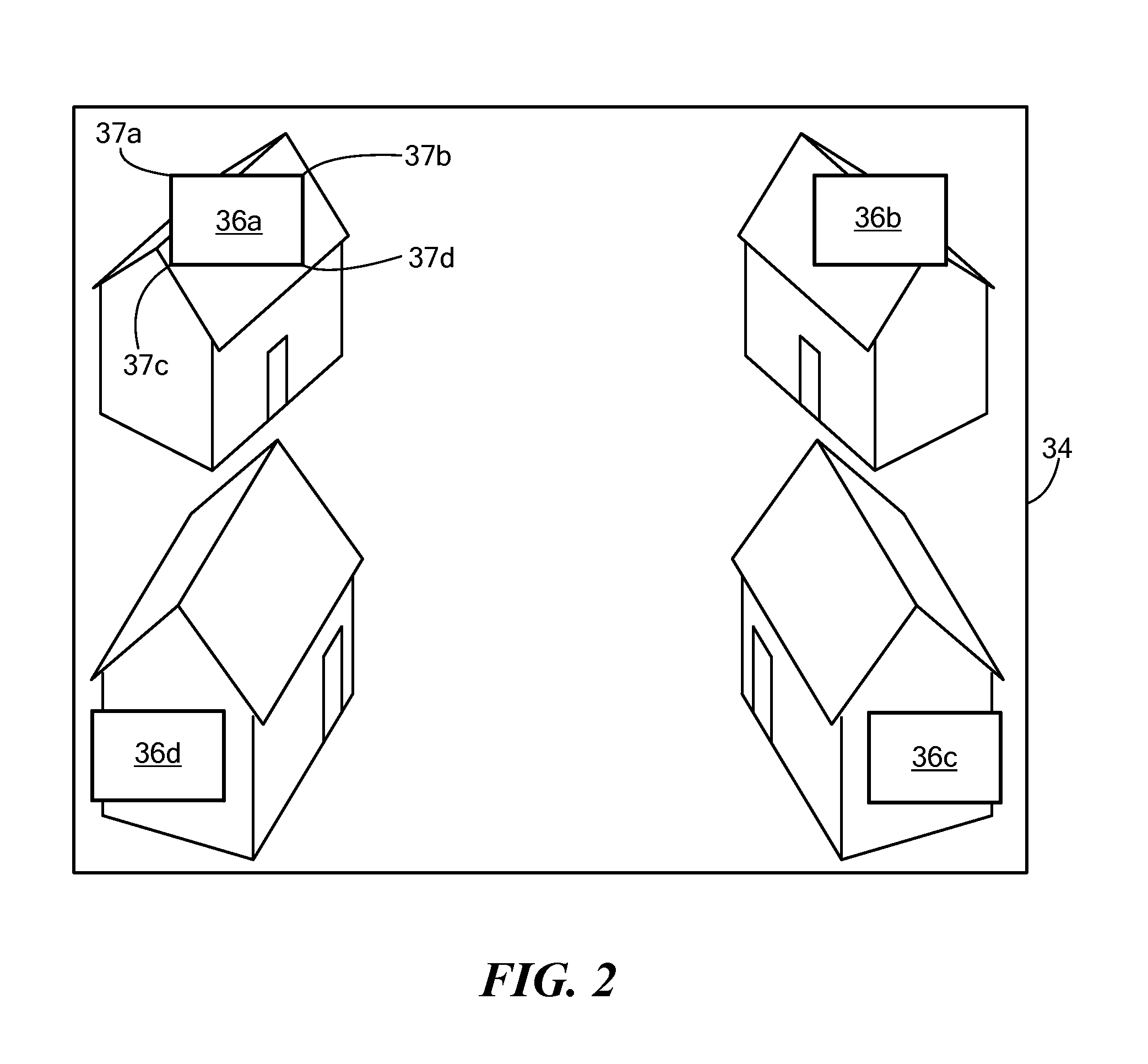

Method and system for converting privacy zone planar images to their corresponding pan/tilt coordinates

ActiveUS20120098965A1Color television detailsClosed circuit television systemsComputer monitorGreat circle

A method and system for converting privacy zone corner points in a still image to PTZ coordinates using the equations for distance along the great circles of a sphere, where the sphere is defined along the pan-tilt axes of a PTZ camera with radius equal to the focal length of the image. The method includes receiving planar coordinate data defining a plurality of privacy zone corner points, the planar coordinate data taken from a still image, converting each privacy zone corner point to corresponding spherical coordinates, converting each of the corresponding spherical coordinates to corresponding PTZ coordinates, and storing the corresponding PTZ coordinates in a storage device. The stored PTZ coordinates may then be transmitted to a computer monitor. The motor of the PTZ camera moves the camera according to the PTZ coordinates until the privacy zone corner points appear at the substantial center of the monitor screen.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

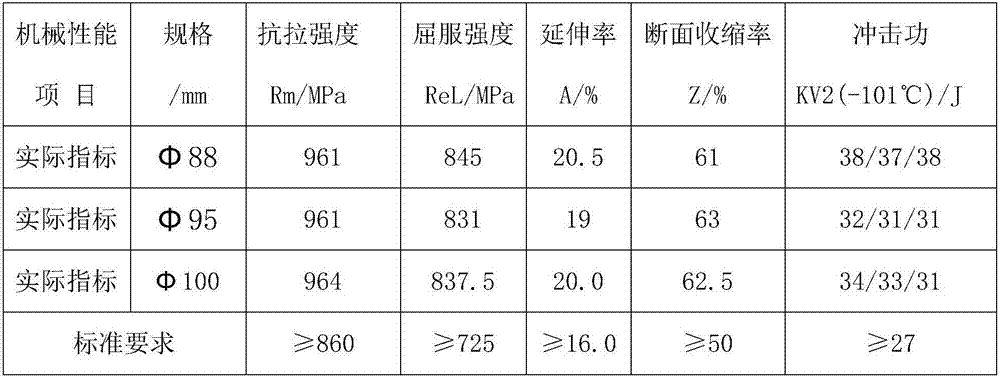

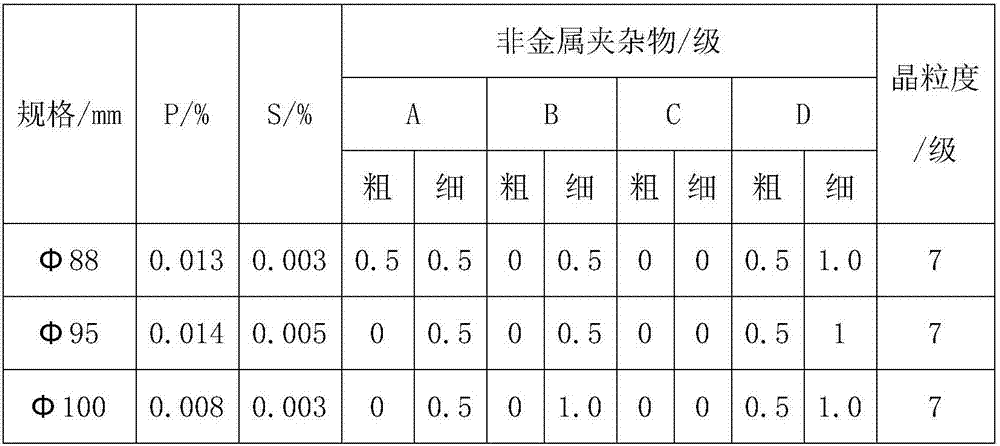

Manufacturing method of ultralow-temperature-impact resistant steel for high-intensity bolt of wind turbine generator set

ActiveCN107299278AImprove uniformityImprove performance indicatorsManufacturing convertersProcess efficiency improvementElectricityPerformance index

A manufacturing method of ultralow-temperature-impact resistant steel for a high-intensity bolt of a wind turbine generator set comprises the following steps: primarily melting by a top-bottom combined blowing basic converter; refining by an LF refining furnace; degassing by a VD vacuum furnace; continuously casting by a round billet arc-shaped continuous casting machine; heating rolled steel; dephosphorizing and oxidizing iron scales; rolling; and drawing into a pit and slowly cooling. According to the method, the development and design are on the basis of three aspects, namely, high toughness, delayed fracture resistance and cold deformability; after the whole round steel is thermally processed, the performance indexes reach that Rm is not less than 950Mpa, Re is not less than 830Mpa, A is not less than 20%, Z is not less than 60%, and KV2 (-101 DEG C) is not less than 30J.

Owner:山东寿光巨能特钢有限公司

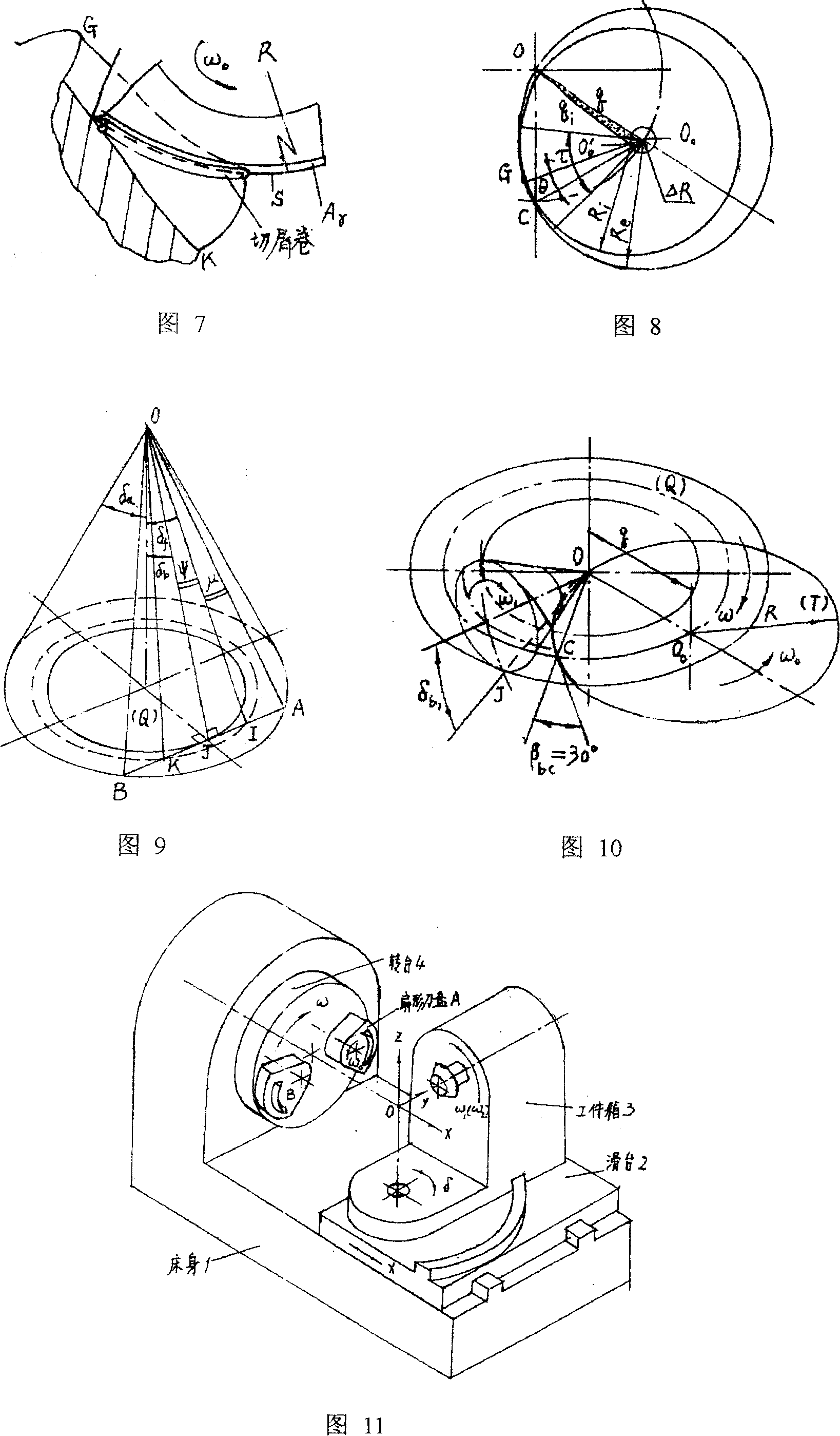

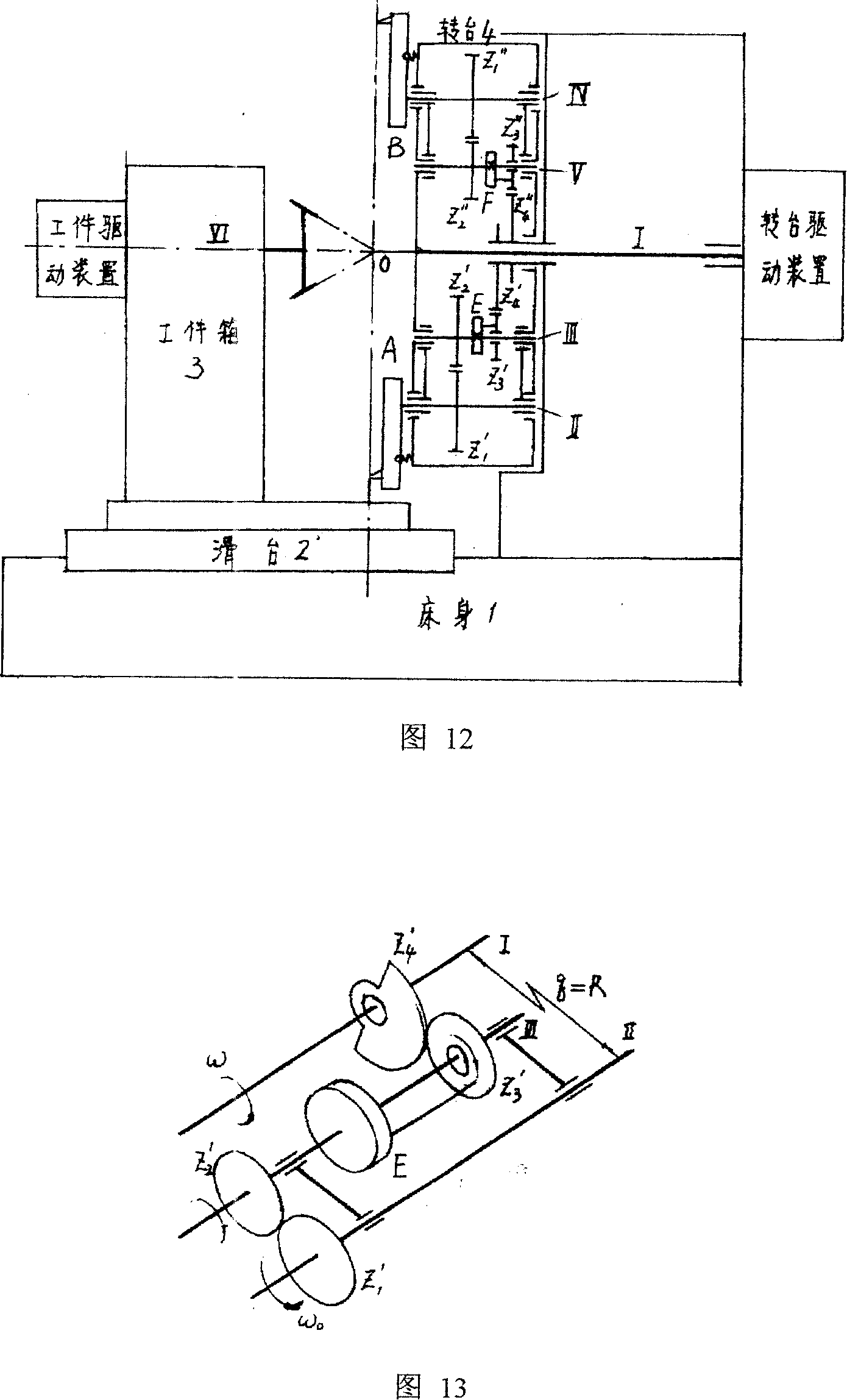

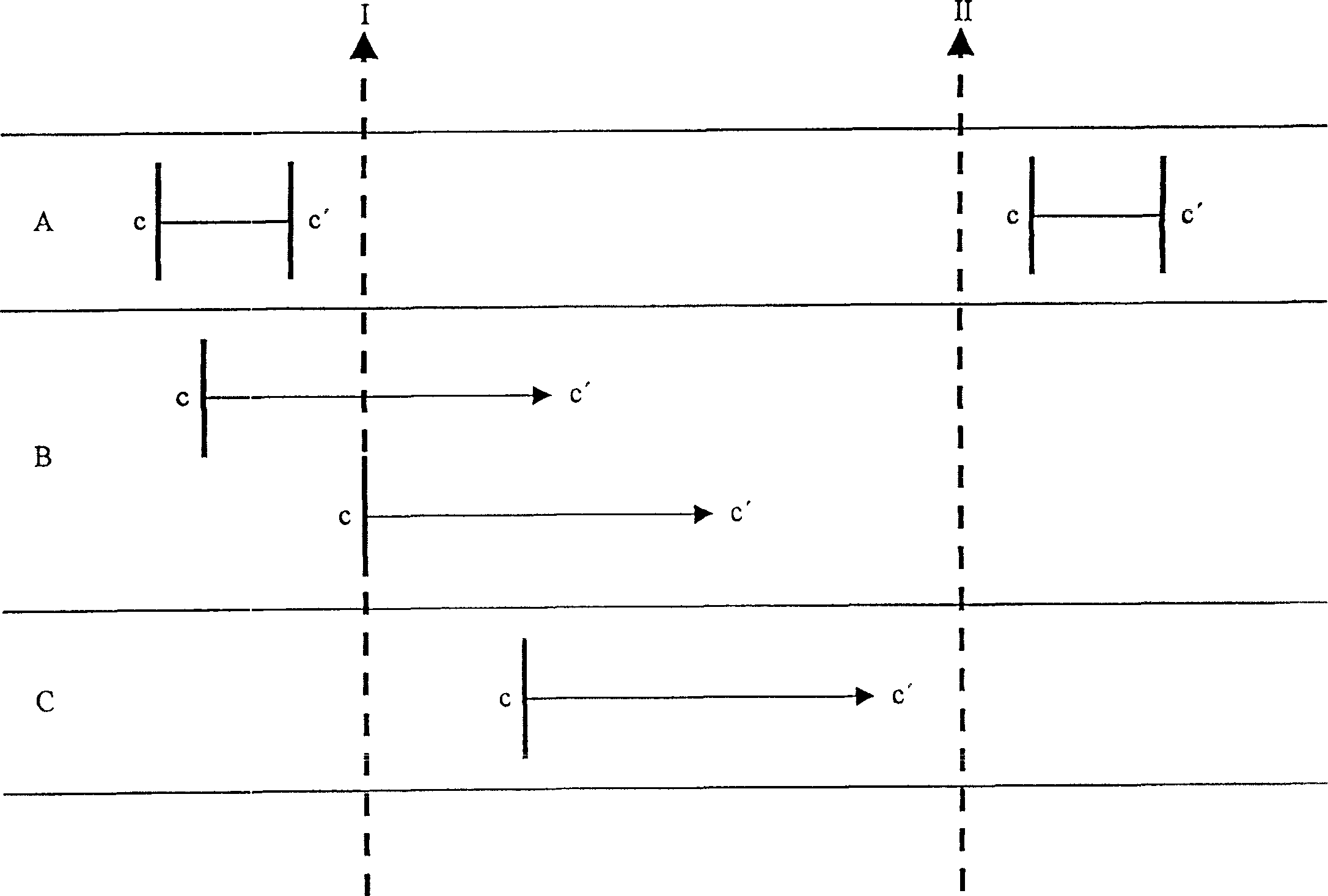

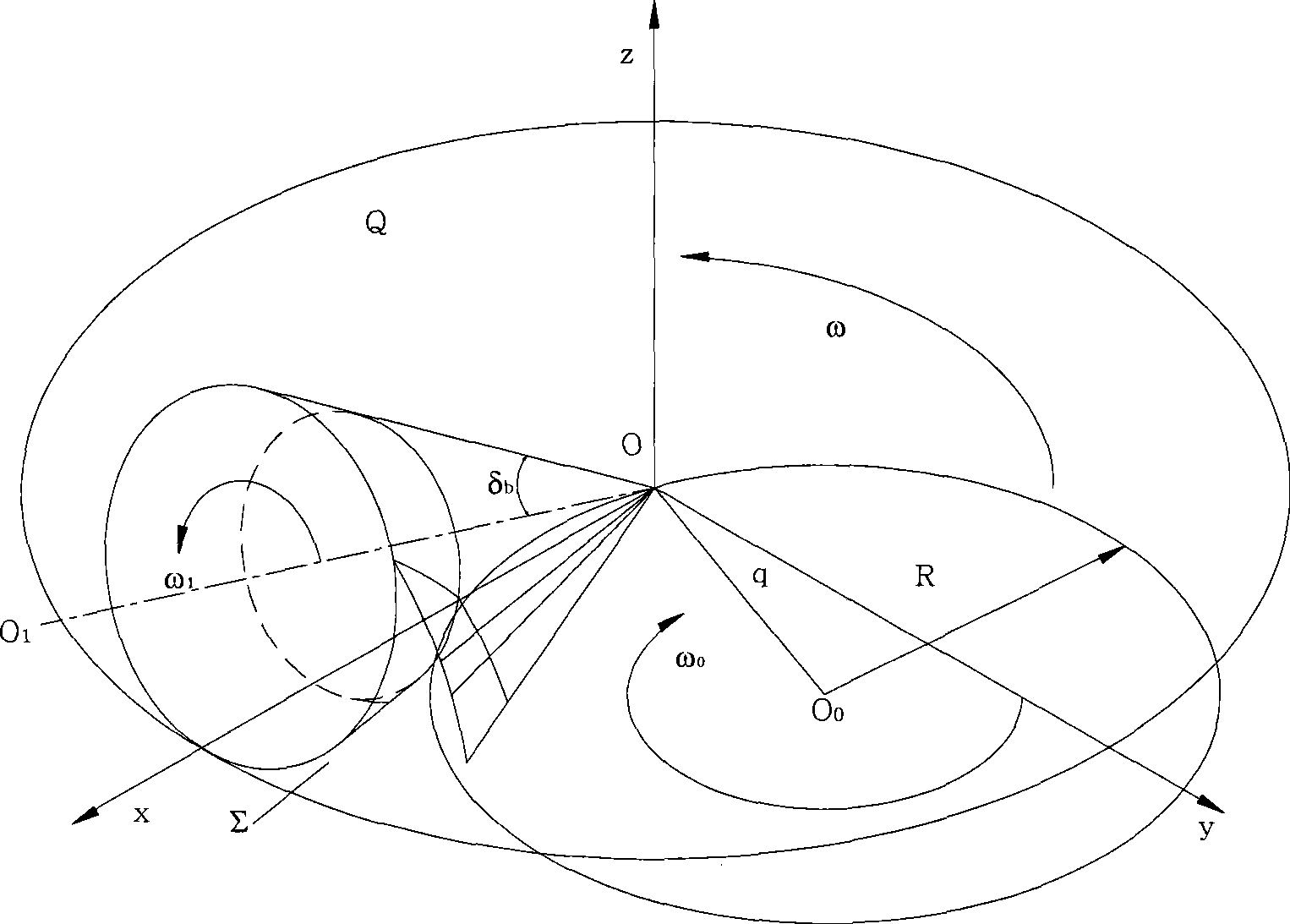

Spherical involute spiral Archimedes spiral bevel gear cutting method and machine tool

InactiveCN101391324AImprove mesh qualityEasy to controlGear teeth manufacturing toolsGear-cutting machinesEngineeringGreat circle

The invention discloses a tooth cutting method for a bevel gear with spherical involute toothed archimedes spiral teeth and a machine tool thereof. The method overcomes the disadvantages that the current tooth cutting method forms principle errors, has complex revision calculation, trial cutting and adjustment of a machine tool, and the like. The tooth cutting method adopts a machine tool with double stations and a single cutter head, which can continuously tooth dividing. When teeth are cut, the I station at one side of the cutter head completes the rough cutting of tooth sockets and the finishing cutting of the concave tooth surfaces of teeth; then the II station at the other side of the cutter head completes the finishing cutting of the convex tooth surfaces of the teeth, each cutter tooth straight edge on a cutting tooth cutter head envelopes and cuts out the side surfaces of the teeth, the circular arc edge of tooth top cuts out the tooth root, and the rough cutting concave edge cuts off the margins of the tooth sockets; and when the teeth are cut, a cutter head shaft and the tooth blank shaft are in a spatial cross position, the rotating end surface of the cutter head is perpendicular to the tangent plane of the gear blank base cone, the cutter head, the gear blank and the big circular plane of an imaginary spherical surface rotate in an uniform speed, the cutter head is in the rotary feed when cutting the teeth, and the continuous hobbling base cone toothed portion is the spiral bevel gear of Archimedes. The invention provides a machine tool, a cutter head and a cutter tooth for realizing the tooth cutting method.

Owner:JILIN UNIV

Round mark point center picture projection point position acquiring method for positioning video camera

InactiveCN101311963ACorrection of center deviationThe result is accurateImage analysisEllipseGreat circle

The invention provides a method for acquiring the position of image projection point of a centre of a circular mark point used in orientation of video camera. The characters include that: the method for setting the circular mark point is: concentric circles are set, and the concentric circles consists of a big circle and a small circle; an inscribed circle which is inscribed in the small circle is arranged in the inner part of the small circle in the concentric circles, and the diameter of the inscribed circle is equal to the radius of the small circle in the concentric circles; the method for acquiring the position of image projection point of the centre of circular mark point is: image is acquired, filtering, division of threshold value, edge checking, profile extraction and ellipse fitting of least square method are carried out on the image for acquiring the line connecting of the centre of the ellipse in the image that the big circular and the small circular in the concentric circles are corresponding to, the line connecting and the edge of the ellipse in the image that the inscribed circle of the small circle in the concentric circles corresponds to intersects at two points, and the point of intersection near to the centre point of the ellipse in the image which the big circle of the concentric circles is corresponding to is the position of the projection point of the centre of the big circle and the small circle in the concentric circles.

Owner:海安江理工技术转移中心有限公司 +1

Free forging method of forge piece of rotary arms

The invention discloses a free forging method of a forge piece of rotary arms, which comprises the steps of: firstly, making a forming die and an upsetting punch; secondly, first forging: heating a steel ingot, tapping and pressing a clamp handle, and removing the clamp handle to obtain desirable blank material of the forge piece; thirdly, second forging: putting a rotary upsetting table on a movable work table, putting the forming die on the rotary upsetting table, putting the desirable blank material of the forge piece into the forming die, putting the upsetting punch at the upper end face of one large circle of the blank material of the forge piece, and forging; and horizontally moving the movable work table to achieve the aim of performing; fourthly, third forging: installing a flat anvil on the end face of the large circle of the blank material of the forge piece, further widening, rolling to be a circle, and furnace filling; and fifthly, fourth forging: overturning the upper surface and the lower surface of the blank material of the forge piece, flatting the other large circle of the blank material of the forge piece, punching, rolling to be a circle, and finishing with many times to obtain a finished product of the forge piece of the rotary arms. The method has simple steps, and guarantees the forging quality.

Owner:MCC SFRE HEAVY IND EQUIP

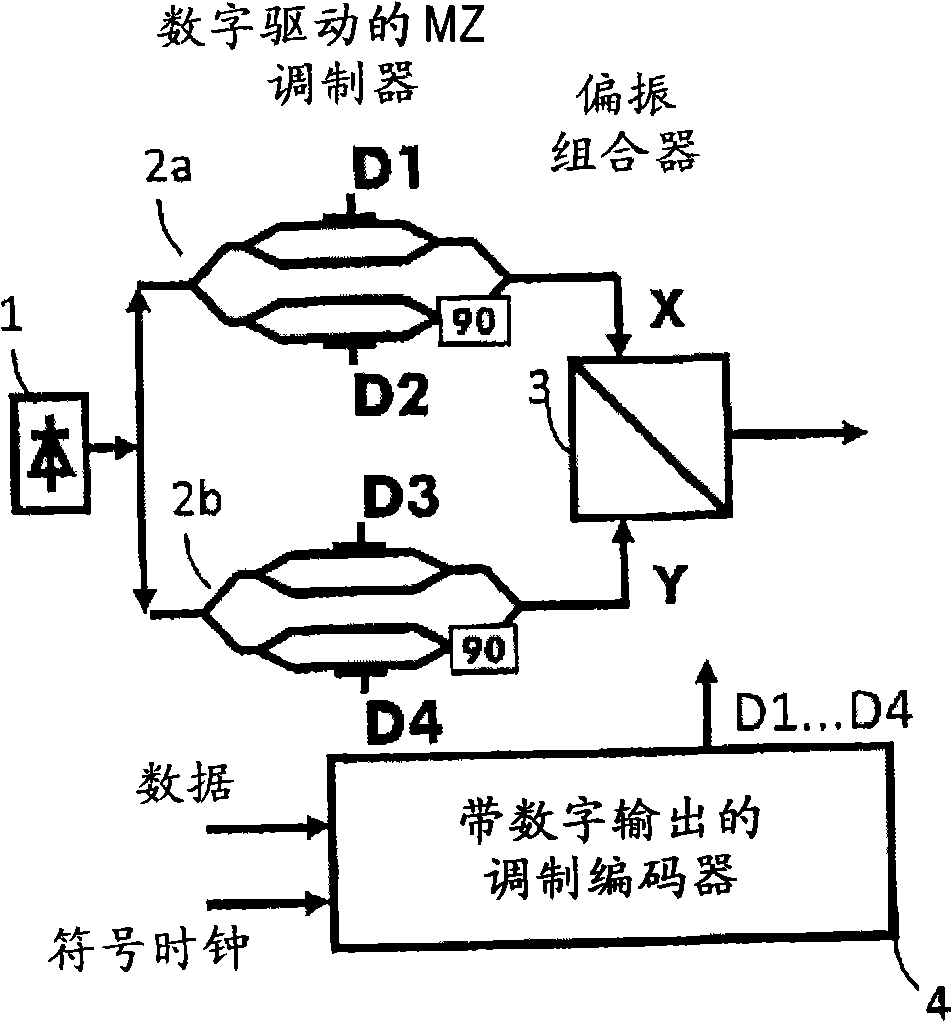

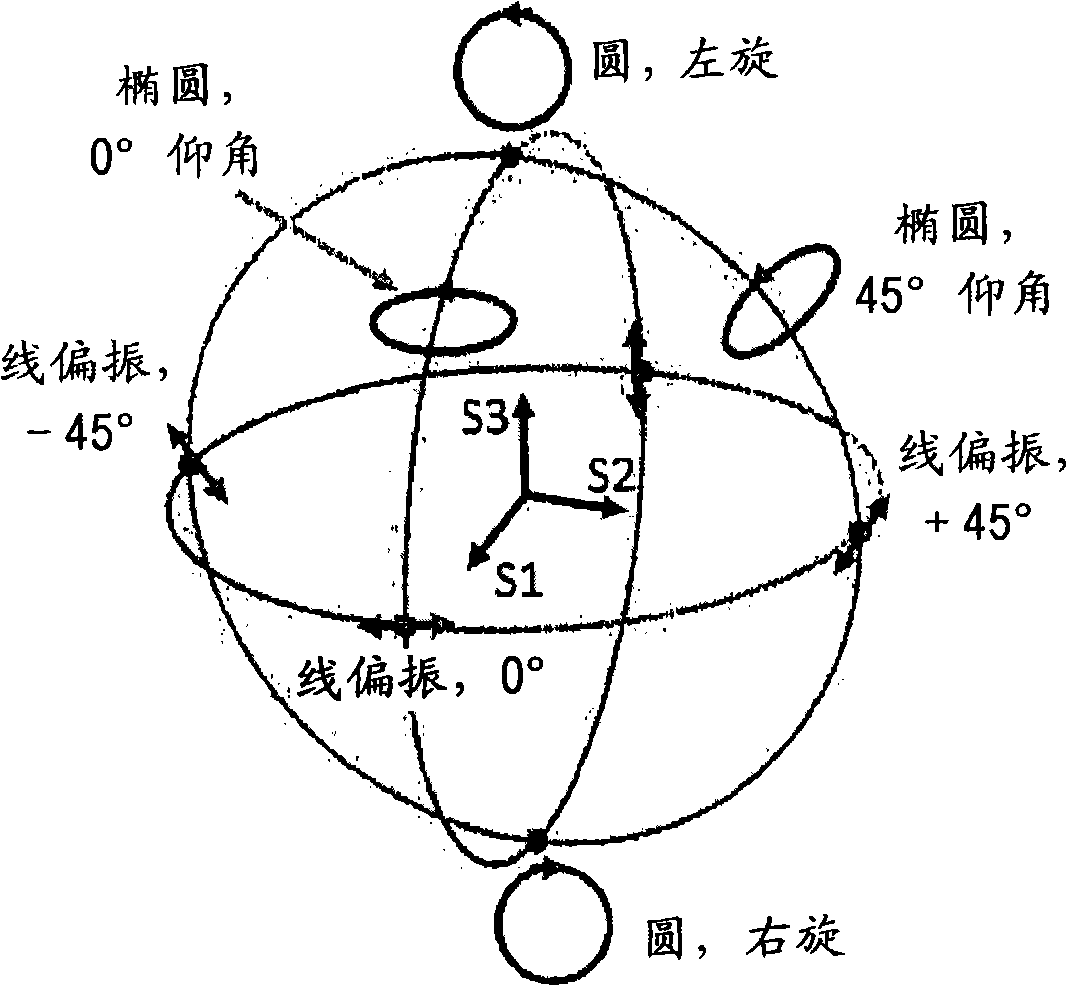

Modulation scheme with increased number of states of polarization

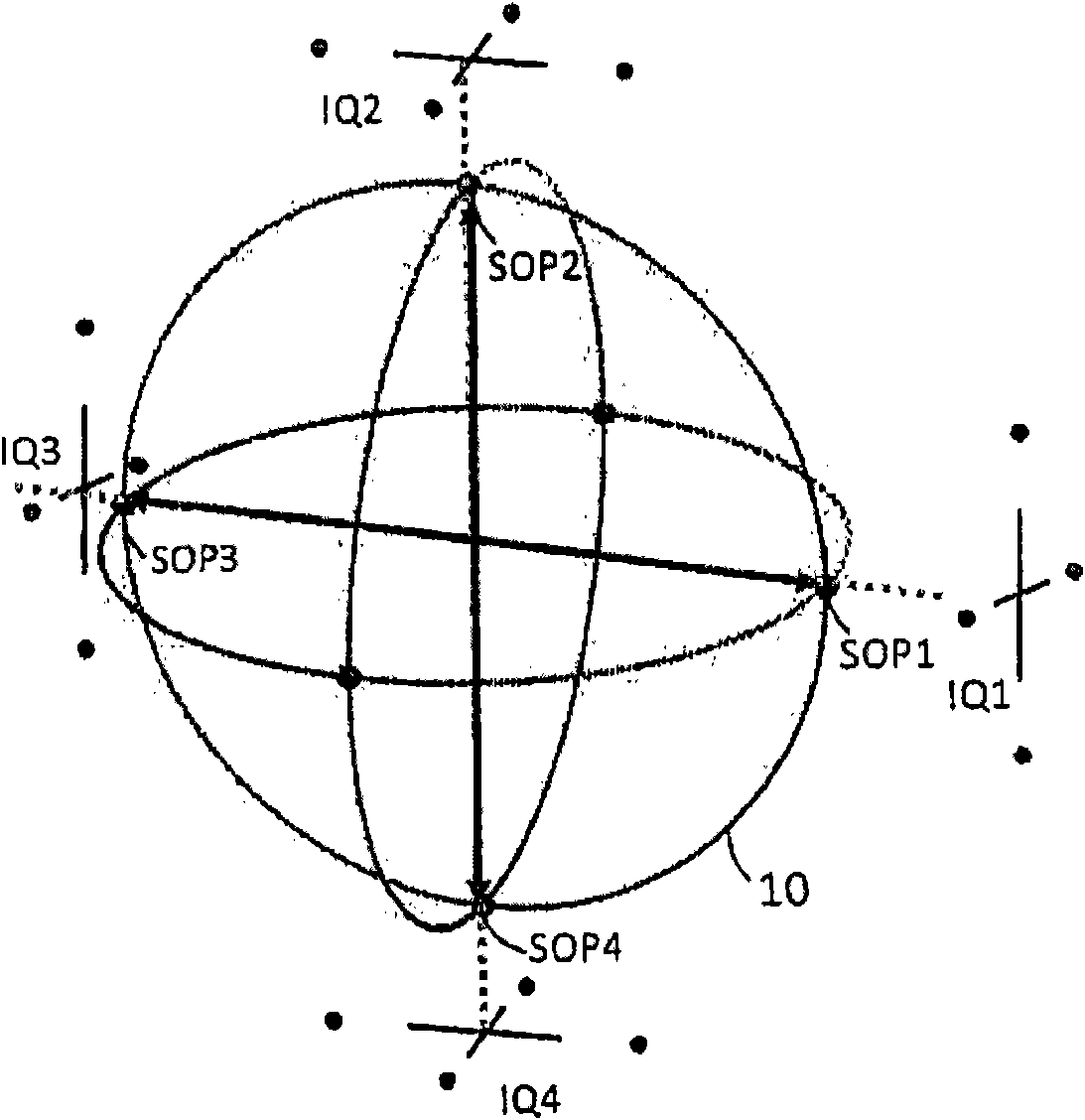

InactiveCN101557260AReduce speed requirementsPolarisation multiplex systemsModulated-carrier systemsPhase stateGreat circle

A modulation method for optical communication comprises the step of generating an optical signal modulated between a plurality of different states of polarization and between different phase states. The plurality of states of polarization comprises first states of polarization (SOP1-4). The first states of polarization (SOP1-4) define a single great circle (10) on the Poincare sphere. The method is characterized in that the plurality of states of polarization further comprise one or more second states of polarization (SOP5-6) located outside the great circle (10). Such additional second statesof polarization increase the symbol alphabet.

Owner:ALCATEL LUCENT SAS

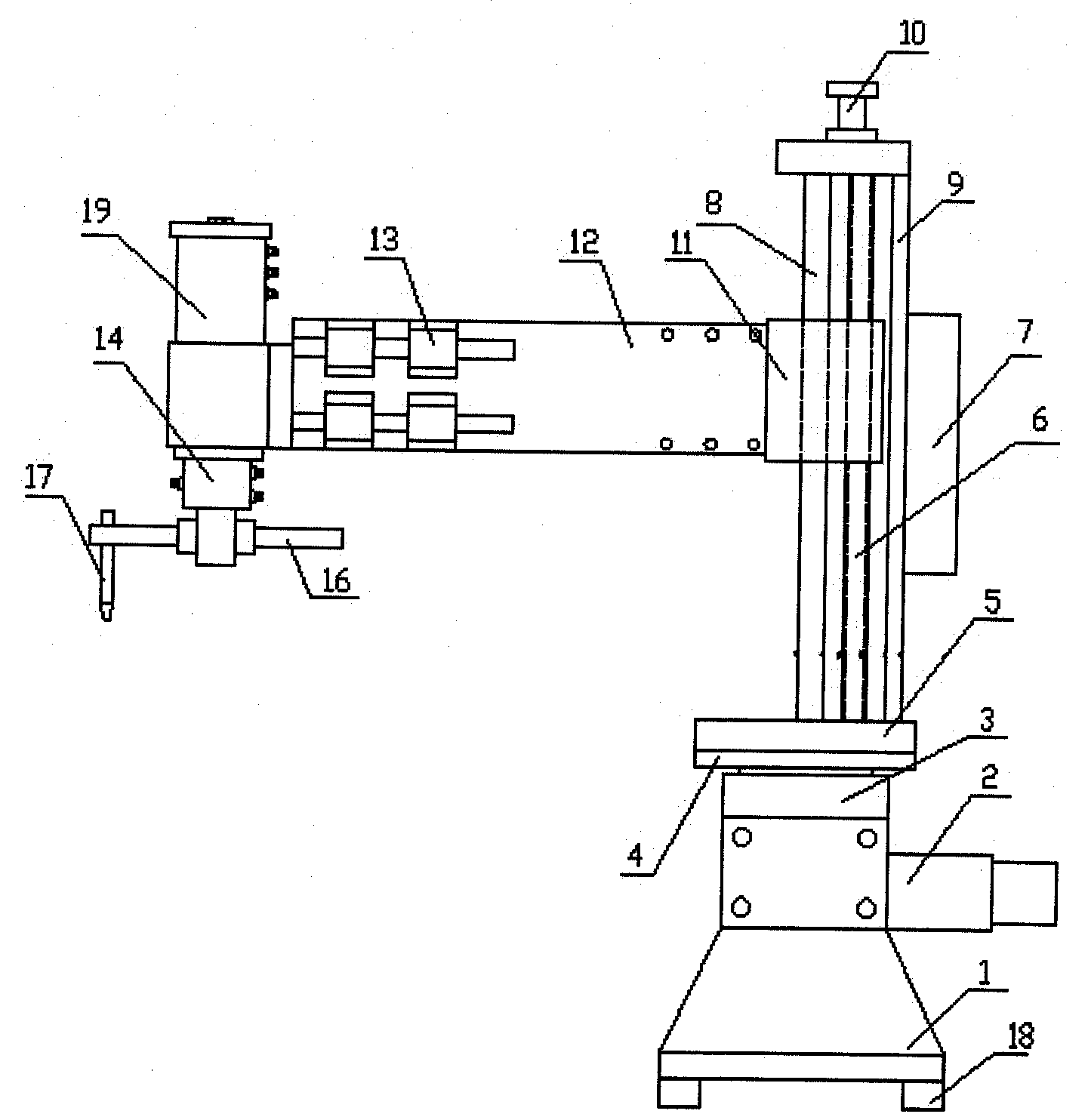

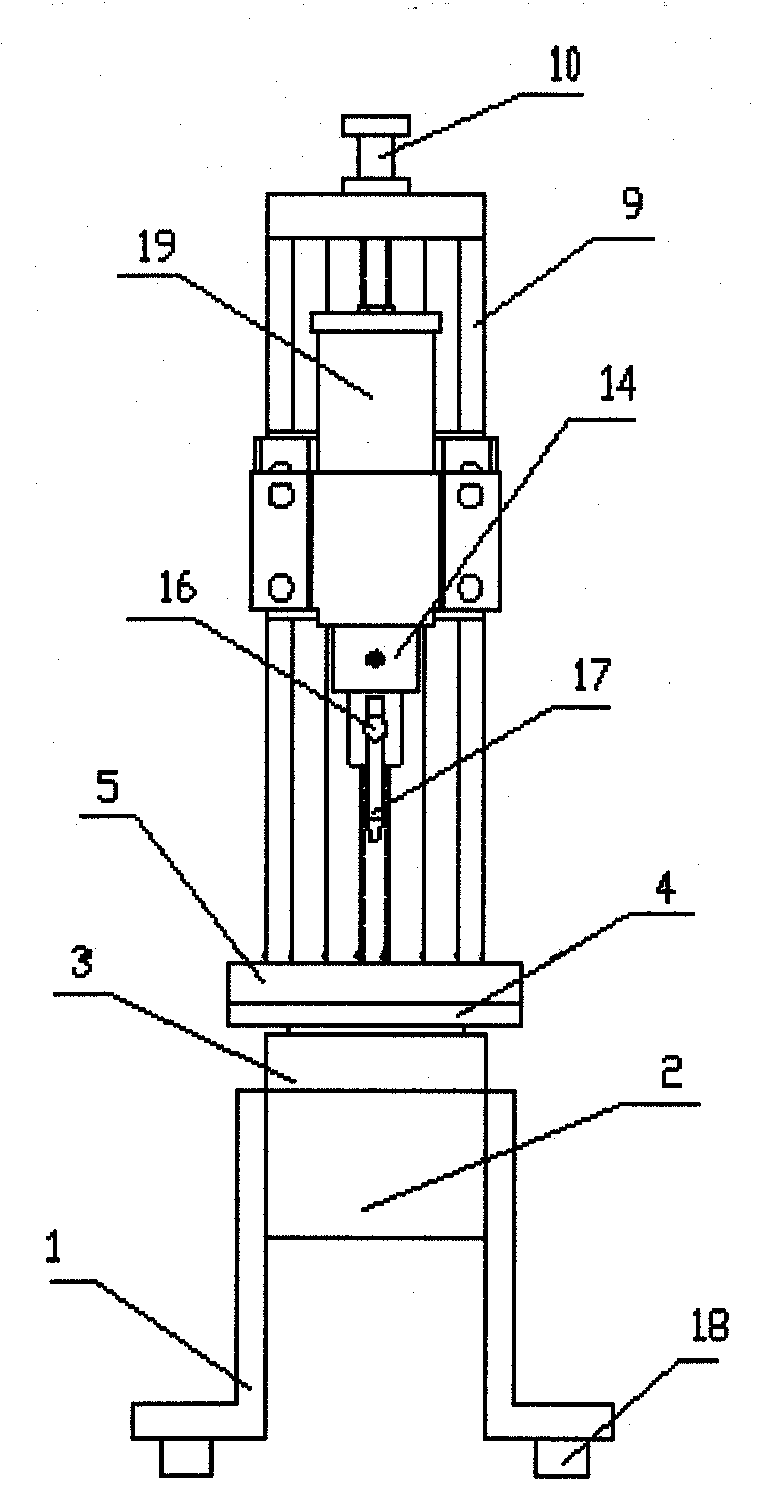

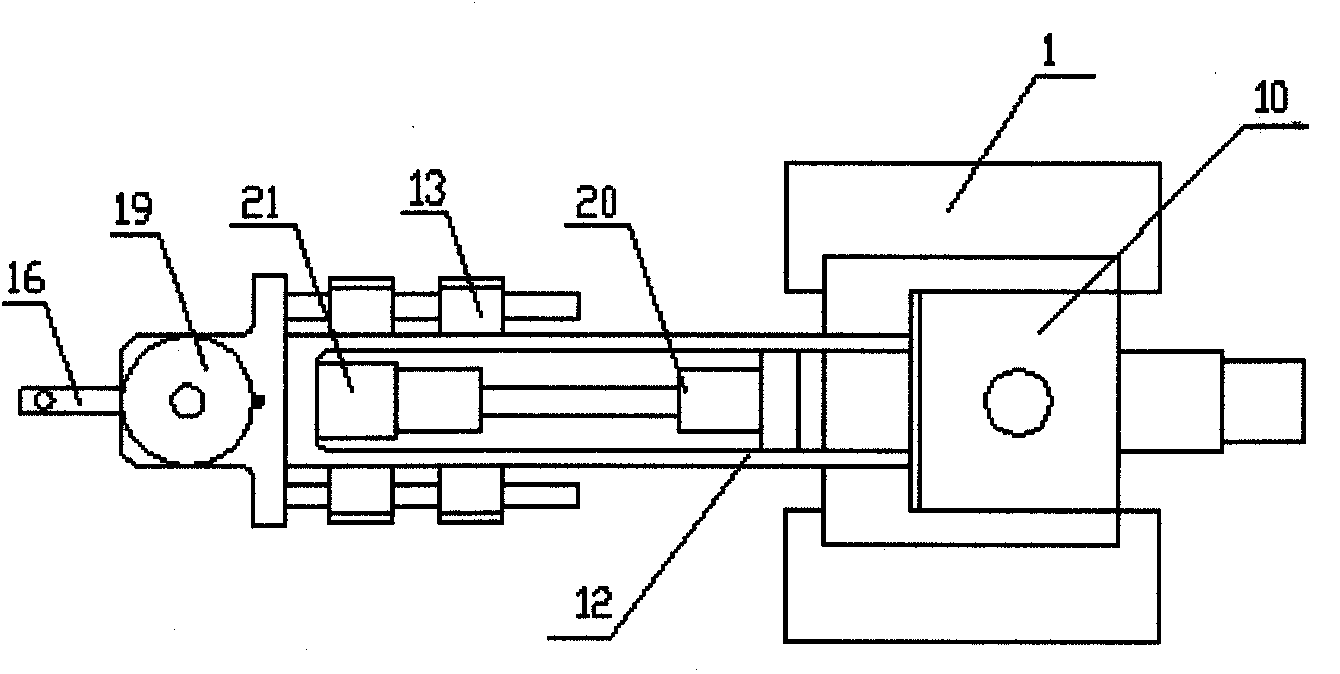

Portable saddle-shaped cutting machine

InactiveCN104028874AWide range of cutting objectsImprove cutting accuracyGas flame welding apparatusChemical industryEngineering

The invention belongs to a cutting machine for cutting circles on arc faces and particularly relates to a portable saddle-shaped cutting machine. The portable saddle-shaped cutting machine comprises a fixed base, a great circle cutting mechanism and a small circle cutting mechanism; the great circle mechanism comprises a great circle cutting spindle arranged on the upper portion of the fixed base, and a lifting sliding table is arranged on the great circle cutting spindle and connected with a lifting arm; the small circle cutting mechanism is arranged at the end, away from the lifting sliding table, of the lifting arm and comprises a telescoping mechanism connected with the lifting arm, and a cutting mouth assembly is arranged at the bottom of a rotary air distribution assembly which is arranged at the end, away from the lifting arm, of the telescoping mechanism. The portable saddle-shaped cutting machine is a perforating machine widely applicable to national defense industry, shipbuilding and ocean engineering, pressure vessels for chemical industry, nuclear power plant equipment and utility boiler industry, and is capable of not only perforating on cylindrical shells and oval shells but also cutting projection round holes on other types of complex spatial curved surfaces and cutting variable-angle double grooves.

Owner:ANHUI SUDONG PETROCHEM POWER EQUIP MFG GRP

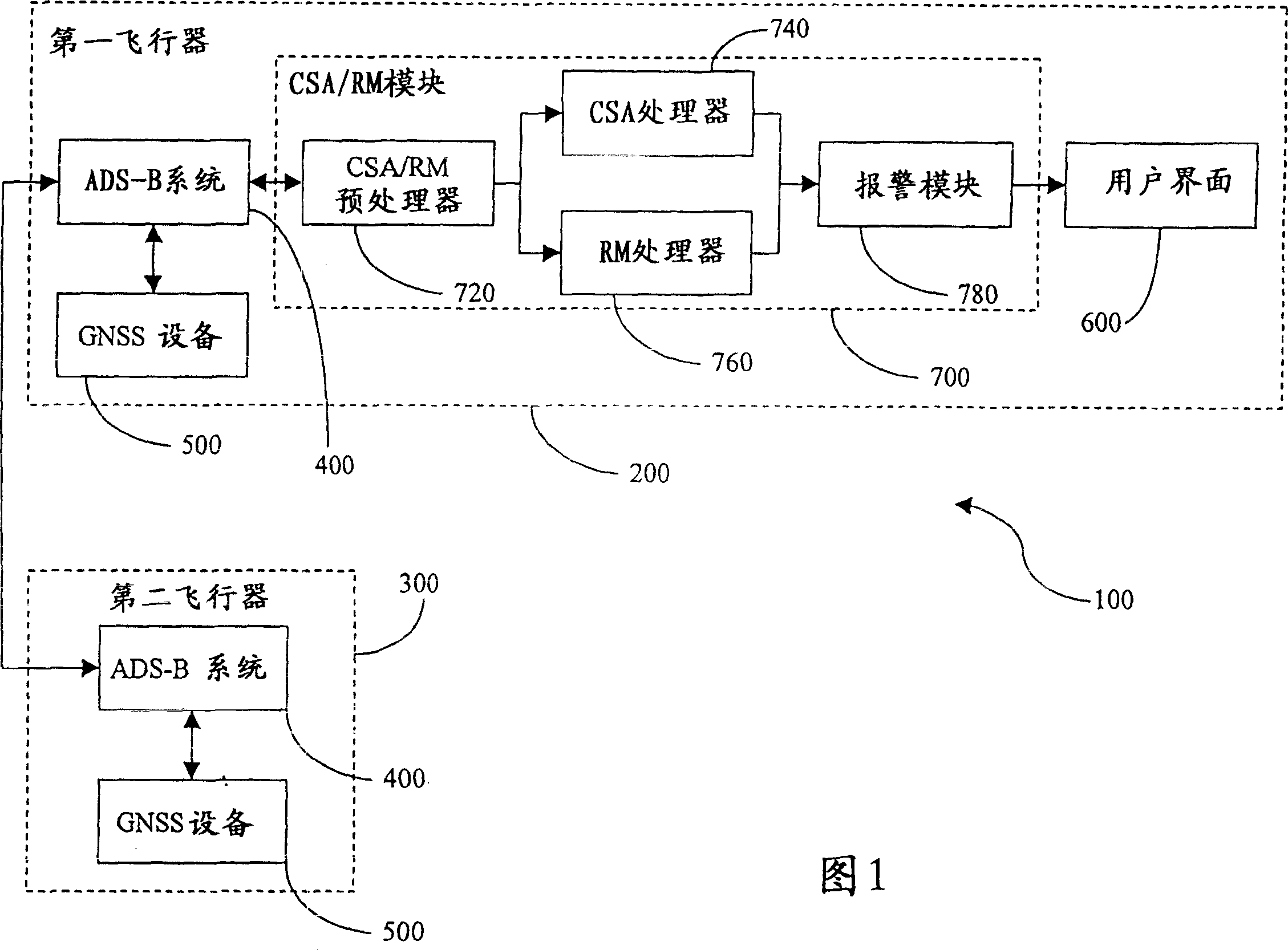

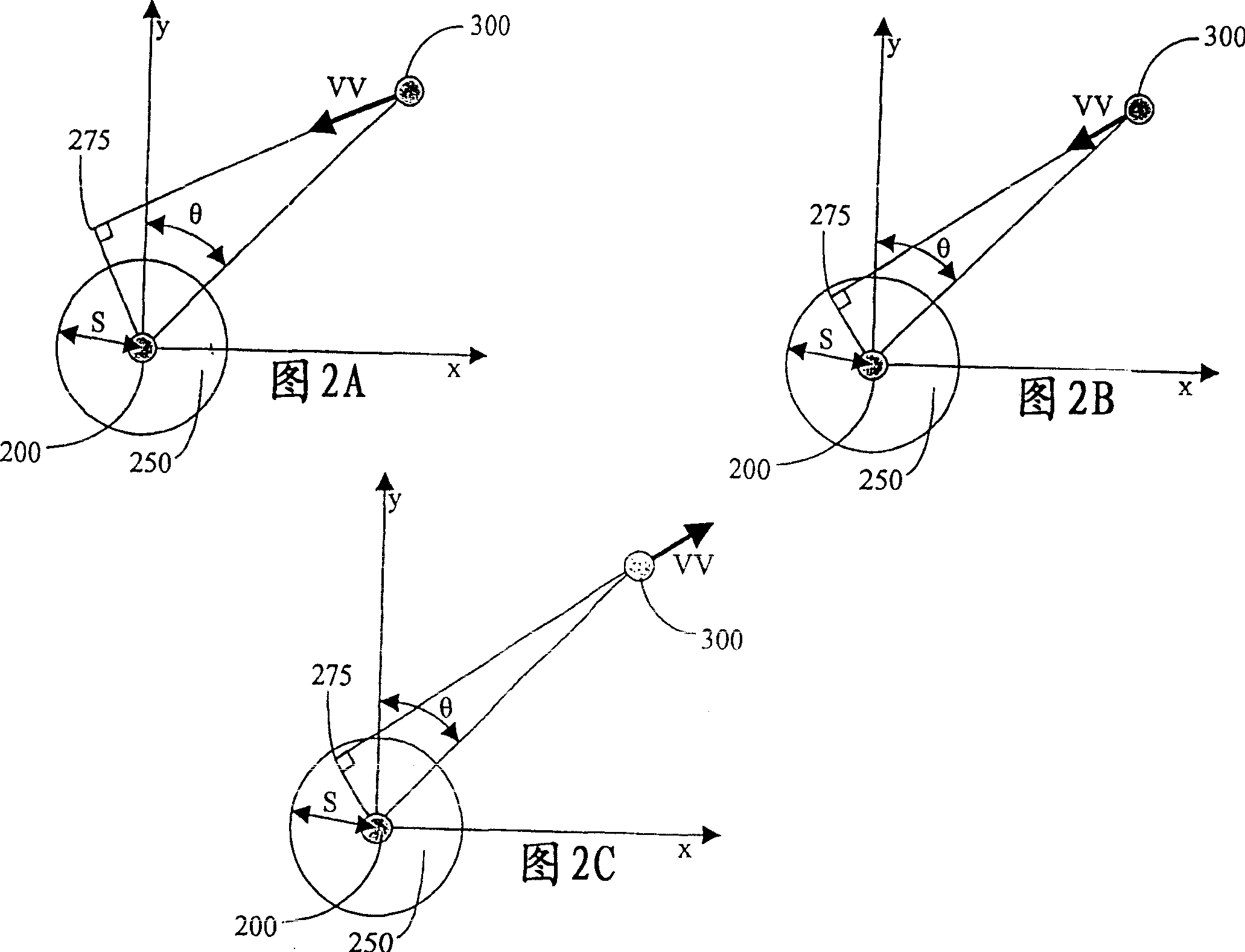

Method for determining conflicting paths between mobile airborne vehicles and associated system and computer software program product

InactiveCN1592919AImprove friendlinessData processing applicationsPosition fixationTime rangeCommunications system

A method of determining conflicting flight paths between a first and a second airborne vehicle is provided, wherein each vehicle comprises an aircraft-to-aircraft navigational communication system having a navigational device. First, a position and a velocity vector are determined for each of the airborne vehicles. A cylindrical volume is then defined about the first airborne vehicle. A separation distance is then determined between the vehicles at a selected time and using a great circle earth model. An accuracy factor is thereafter determined for the position of each vehicle. The separation distance is then modified by the accuracy factor. A determination is then made as to whether the modified separation distance is within the cylindrical volume about the first airborne vehicle during a time range to thereby determine whether conflicting flight paths exist between the vehicles. An associated system and computer software program product are also provided.

Owner:UNITED PARCEL SERVICE OF AMERICAN INC

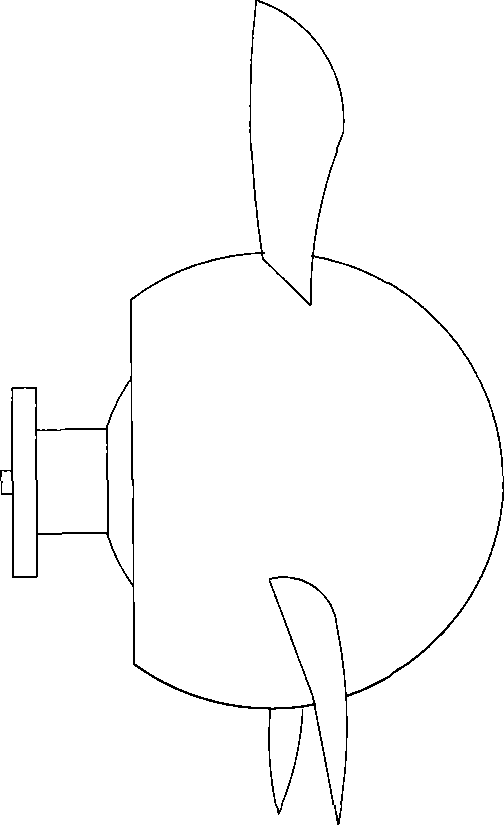

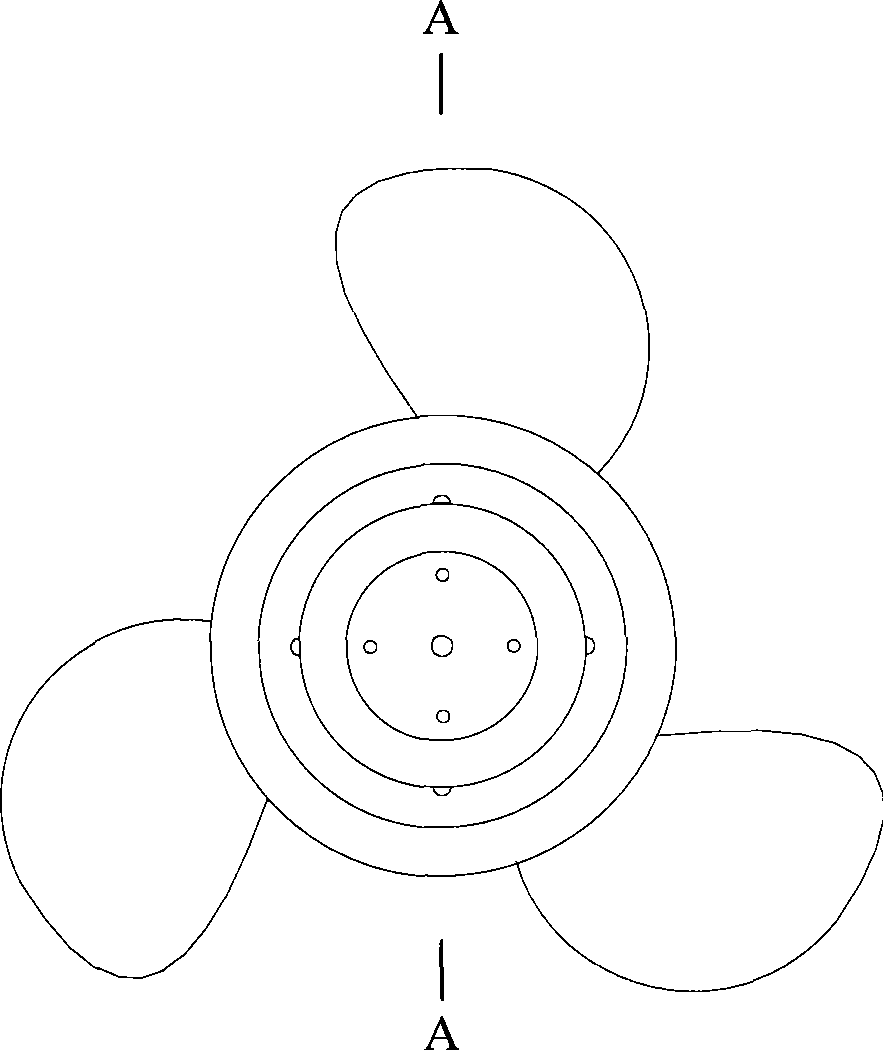

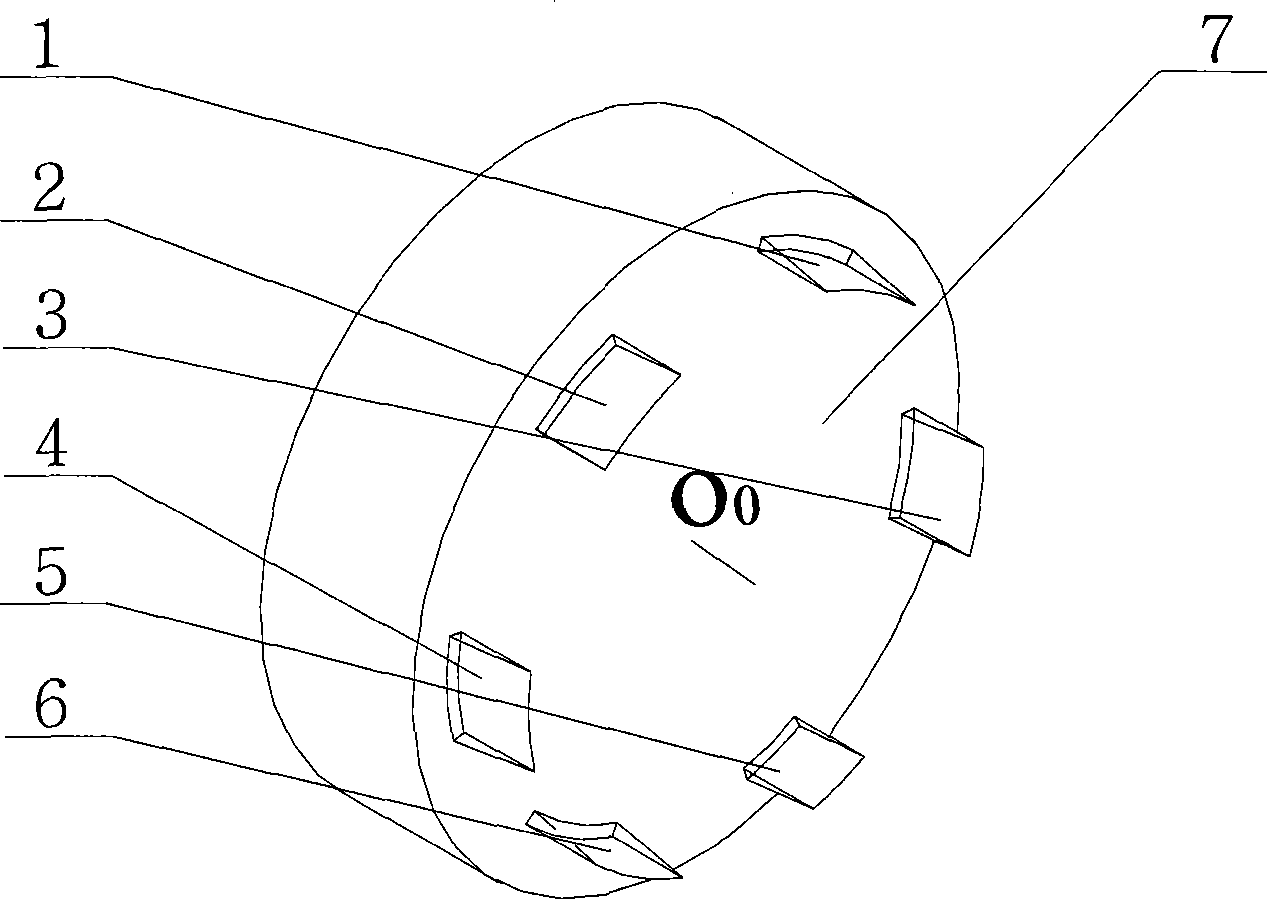

Underwater globular motor propeller

InactiveCN101505076AReduce volumeImprove efficiencyPropulsion power plantsPropulsive elementsEngineeringSpherical shaped

The invention provides an underwater spherical motor propeller. A stator core is in a spherical shape, the surface of the spherical stator core is provided with three grooves which are perpendicular to one another along a big circle, three-phase concentrated windings are placed in the grooves respectively and are pairwise perpendicular, the coils of the three-phase windings are connected to an underwater sealing plug by cables, a spherical sealed shell which is fixed with the stator core wraps the stator core, a spherical shell-shaped outer rotor is sleeved on the sealed shell through rubber bearings, the surface of the rubber bearings are provided with flumes, a rotor core is arranged between two rubber bearings, a slim clearance is reserved between the rotor core and the sealed shell, the rotor core, the rubber bearings and a rotor shell are combined together, and propeller blades are fixed on the rotor shell directly. In the invention, the vectored propulsion of the underwater spherical motor propeller is realized, the performance of the propeller is improved and the mechanical structure of the underwater working device is simplified, the mass and the volume of the underwater working device are reduced; therefore, the underwater working device has better utility and higher reliability.

Owner:如皋市生产力促进中心

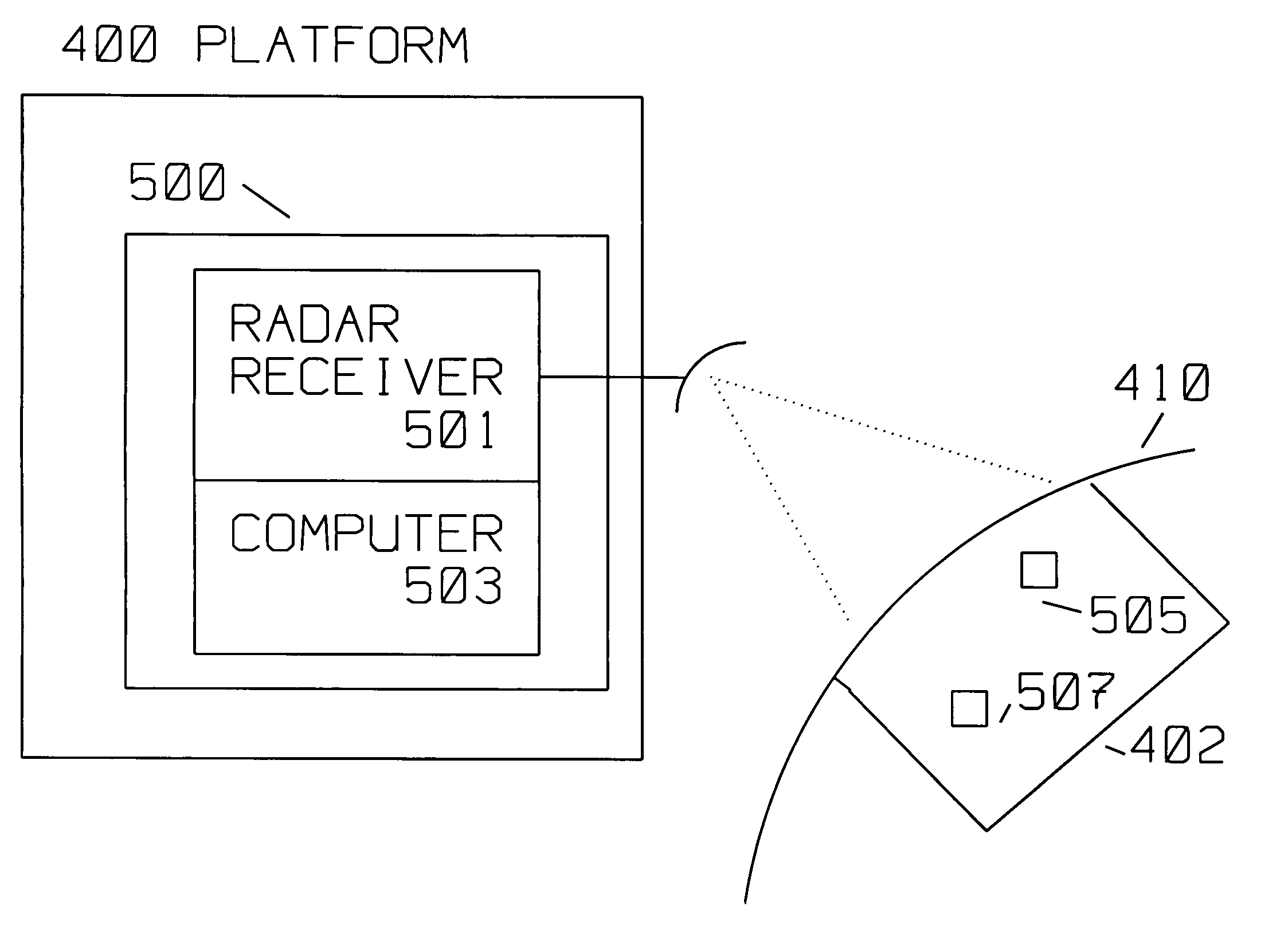

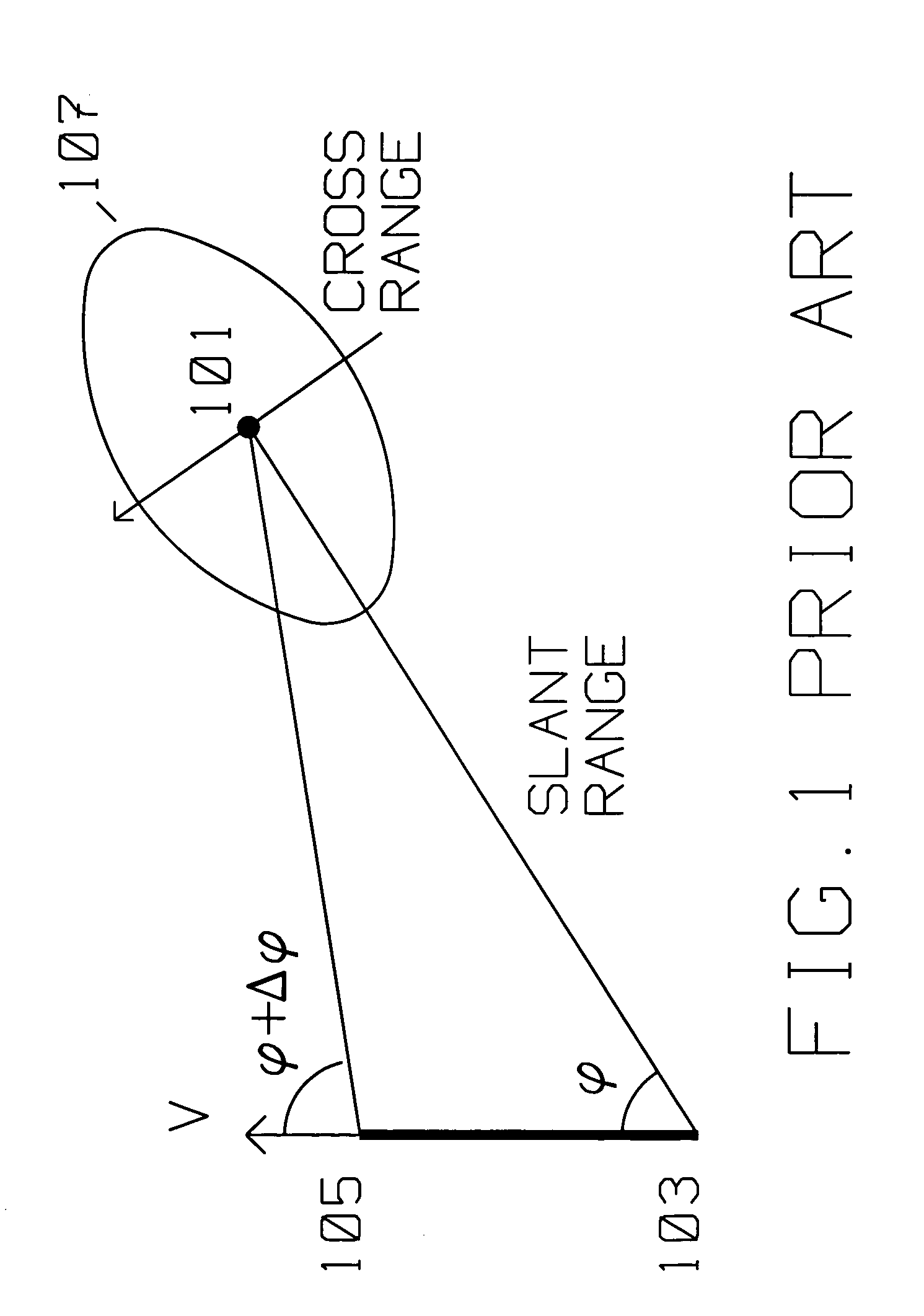

Conformal range migration algorithm (CRMA) "KARMA"

ActiveUS6987479B1Clearer SAR imageIncrease relative motionRadio wave reradiation/reflectionRange migrationClassical mechanics

Motion compensation for coherent combination of pulses facilitates a SAR image of a scene on earth's surface. A great circle (406) is centered with respect to the earth's center, The great circle (406) has an axis (412) perpendicular to a first plane. Axis (412) passes through the earth's center. The first plane contains great circle (406) and includes the earth's center. Great circle (406) has a first center defined by an intersection of the first plane and axis (412). The scene has one or more radar scatterers and is located on a surface (402). The radar system is mounted on a moving platform (400) moving with a component of motion in a direction along great circle (406). The radar comprises a radar receiver for digitizing the radar returns having a phase from scatterers on surface (402), and a computer for focusing the phase of said radar returns from the scatterers on surface (402). The surface (402) is located on a local scene centerline circle (408), the local scene centerline circle (408) defining a second plane. This second plane is parallel to the first plane. The local scene centerline circle (408) is centered on the axis at a second center, where the second center is displaced with respect to the first center along the axis by a distance (414). The phase of the radar returns received from the scene is compensated for the motion of the moving platform (400) using a cylindrical coordinate system referenced with respect to the second center to yield a SAR image.

Owner:RAYTHEON CO

Spherical involute spiral bevel gear cutting method and machine tool

InactiveCN101391322ASimple structureSuitable for the use of numerical control technologyGear teeth manufacturing toolsGear-cutting machinesNumerical controlCircular cone

The invention discloses a cutting method for a bevel gear with spherical involute toothed circular arc teeth and a machine tool thereof. The cutting method comprises a circular arc cutter edge conjugation generating method and an envelope method. A cutter shaft and a gear blank shaft for implementing the circular arc cutter edge conjugation generating method rotate directionally with rotating rates (Omega0) and (Omega1), a cutter edge enters into cutting, a cage chair rotates according to that Omega is equal to Omega1sinaDeltab, the formation of pure rolling of a gear blank base cone and the big circular plane of the spherical surface is guaranteed to complete the processing of spherical involute toothed flank. The cage chair with a real axis is driven to rotate by a servo motor, and for the cage chair without a real axis, the synthesis movement of the y and z directions of a coordinate system forms a cage chair to rotate with the rotating rate (Omega). When the envelope method is implemented, cutter teeth of short arc and even point cutter edge are adopted. Points with the number of k are taken on the circular arc line AC of generating the flank, each cutting can form a spiral line on the flank, the circular arc cutting feed angle Delta Theta of a gear cutter head per cutting is set, and the flank which is composed of spiral lines with the number of k is enveloped and generated by sequentially k-times cutting feed. A third shaft and a forth shaft link a numerical control gear cutting machine to implement the gear cutting method.

Owner:JILIN UNIV

Wide pickup header for a round baler

When harvesting forage in the form of a large round bale, for instance, there are times in which a windrow of forage material lies outside the side boundaries of the bale-forming chamber. This may be due to the windrow being made wide by machinery having driven through it, or by wind, or because of the need to turn the forage harvesting equipment tightly. A wide pickup, notably wider than the width of the bale-forming chamber, provides a solution to this common problem. Dual augers at each end of the wide pickup provide the force to direct the forage into a narrower path, to enter the bale-forming chamber. The orientation and size of the augers permits the pickup header to reside in the same location it would if it was not wider than the baler. Tines or teeth of various rigidities and shapes are provided in the pickup for more effective pickup of the forage.

Owner:VERMEER MFG CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com