Means and methods for construction and use of geodesic rhombic triacontahedron

a technology of rhombic triacontahedron and construction method, which is applied in the direction of construction, building roof, building components, etc., can solve the problems of inability to use gavette for dome construction, inability to meet the needs of large-scale construction, etc., to achieve efficient fabrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The following detailed description is directed to certain specific embodiments of the invention. However, the invention can be embodied in a multitude of different ways as defined and covered by the claims. In this description, reference is made to the drawings wherein like parts are designated with like numerals throughout. Unless otherwise noted in this specification or in the claims, all of the terms used in the specification and the claims will have the meanings normally ascribed to these terms by workers in the art.

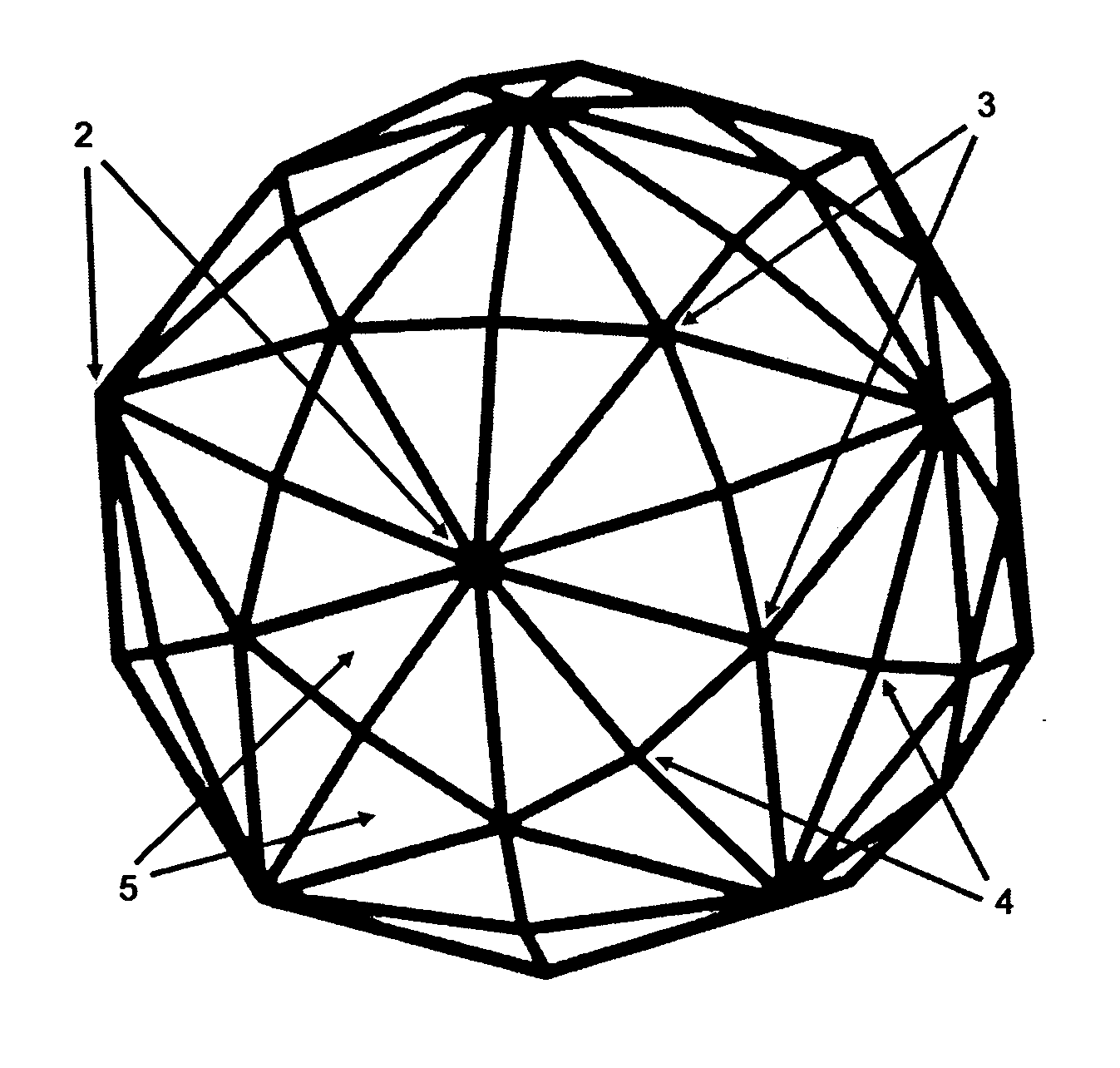

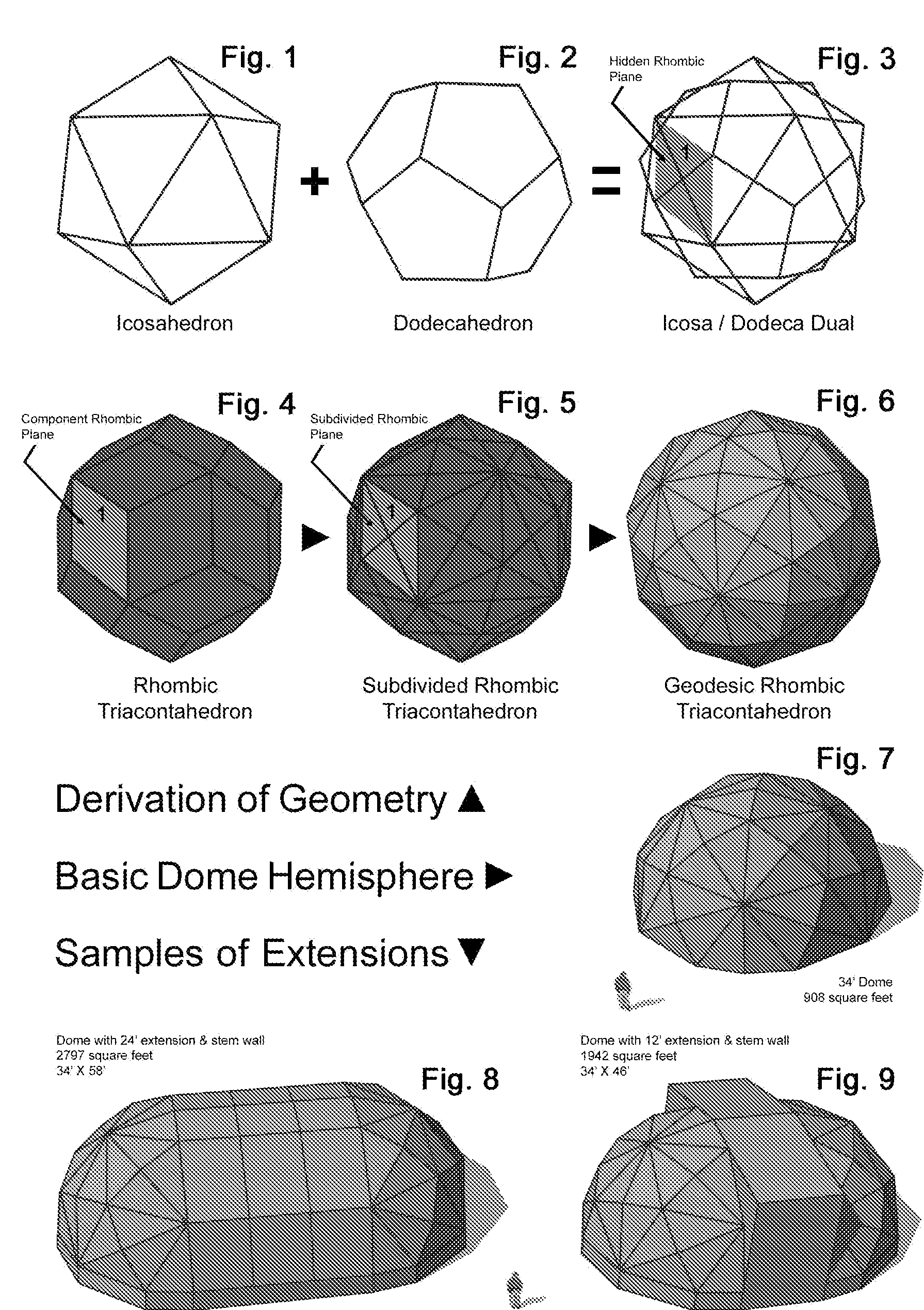

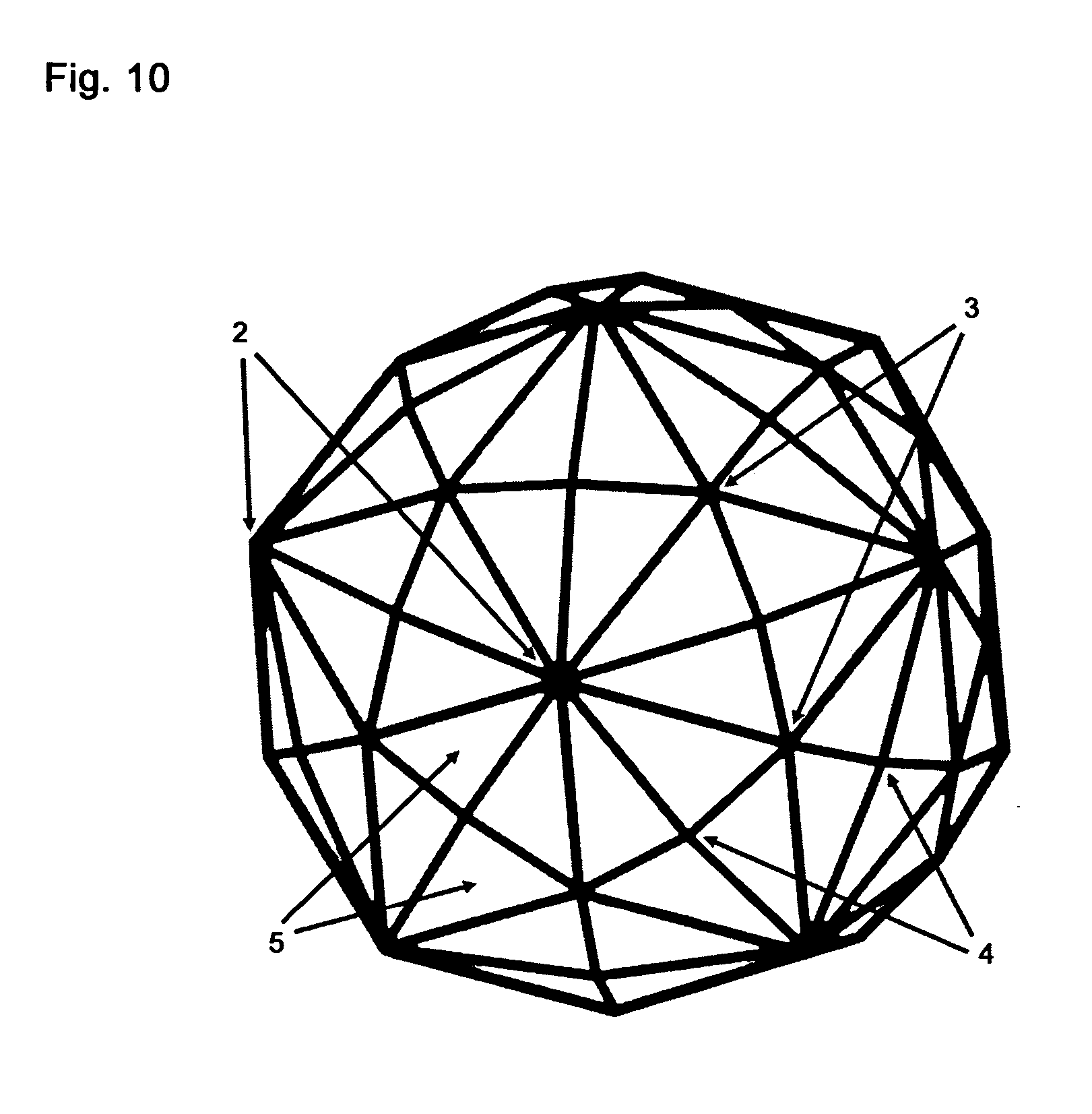

[0050] The Basic Geometry

[0051] Platonic solids are three-dimensional geometries in which each face of the particular solid is identical to all the other faces. In addition, the angles of each face and the length of each face edge are identical. In other words, each platonic solid is symmetrical in every way possible. The platonic solids are the: tetrahedron, octahedron, cube, icosahedron, and dodecahedron.

[0052] Buckminster Fuller used some of the platonic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com