Patents

Literature

291 results about "Oriented strand board" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oriented strand board (OSB) is a type of engineered wood similar to particle board, formed by adding adhesives and then compressing layers of wood strands (flakes) in specific orientations. It was invented by Armin Elmendorf in California in 1963. OSB may have a rough and variegated surface with the individual strips of around 2.5 cm × 15 cm (1.0 by 5.9 inches), lying unevenly across each other and comes in a variety of types and thicknesses.

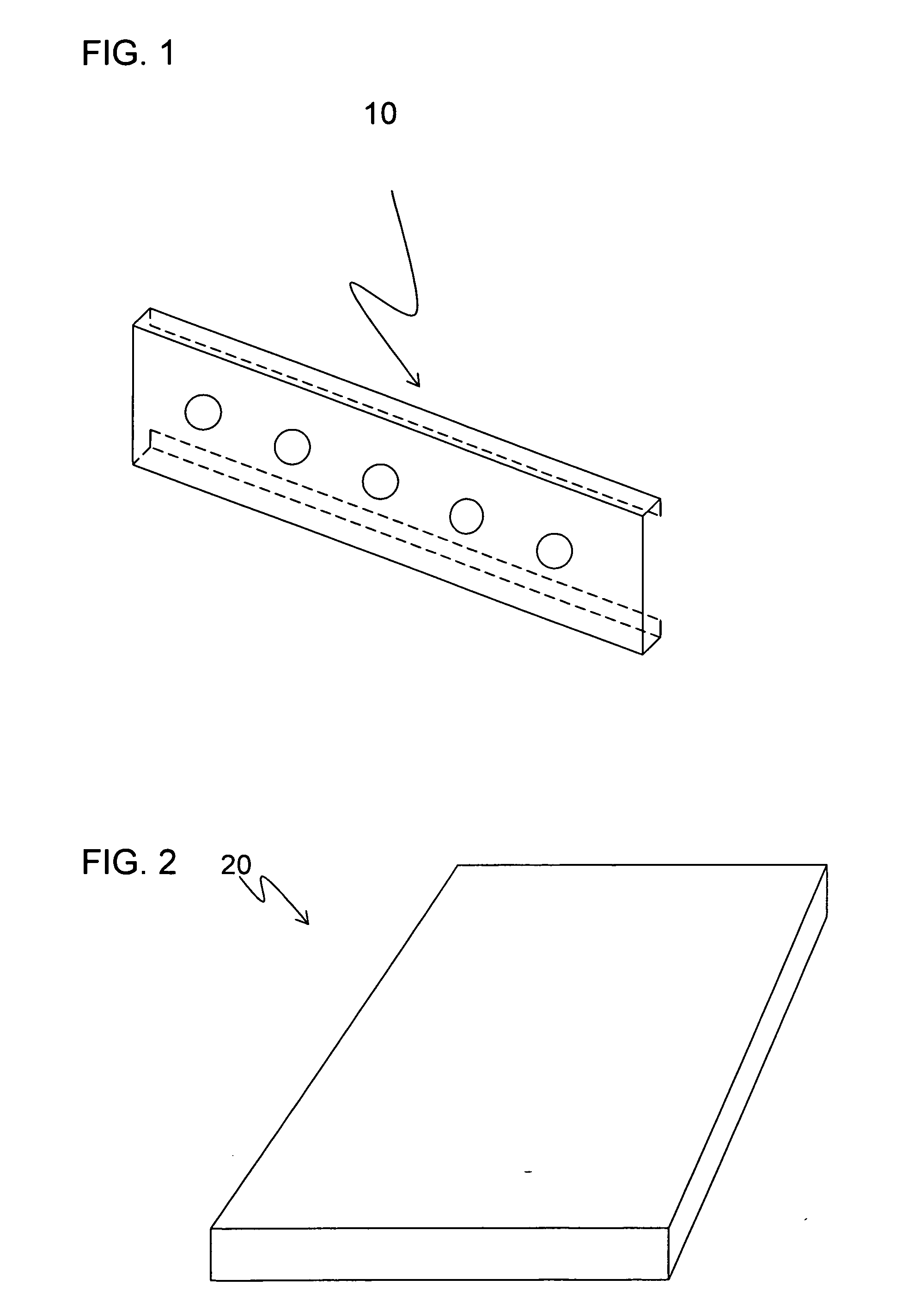

Non-combustible reinforced cementitious lighweight panels and metal frame system for a fire wall and other fire resistive assemblies

ActiveUS20060168906A1Reduce buildReduce capacityBuilding roofsSolid waste managementMicrosphereMetal framework

A fire resistive assembly including metal framing members, for example, C-joists, U-joists, open web joists, HAMBRO or other metal frame systems that support a reinforced, lightweight, dimensionally stable SCP panel. The assembly is non-combustible, water durable, mold and rot resistant, termite resistant and is capable of resisting shear loads equal to or exceeding shear loads provided by plywood or oriented strand board panels. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

Wood adhesive and method of preparing thereof

InactiveUS20100258033A1Drying rate of adhesiveLow pour pointProtein waste adhesivesStarch adhesivesHigh densityAdhesive

A wood adhesive having a) 100 weight parts of water; b) between 3 and 45 weight parts of a proteinaceous material; c) between 0.01 and 15 weight parts of an acidity regulator; d) between 0.01 and 15 weight parts of an aromatic compound; e) between 0.01 and 15 weight parts of a curing agent; f) between 0.01 and 15 weight parts of a preservative; g) between 0 and 15 weight parts of a viscosity modifier; h) between 0 and 10 weight parts of a filler; and i) between 0 and 15 weight parts of a drier. The wood adhesive can be used for preparation of plywood, blockboard, oriented strand board (OSB), flakeboard, fiberboard, veneer plywood, middle density fibreboard, high density fibreboard, hardboard, flooring substrate, LVL, and so on. A method for preparing the wood adhesive is also provided.

Owner:YANG GUANG +1

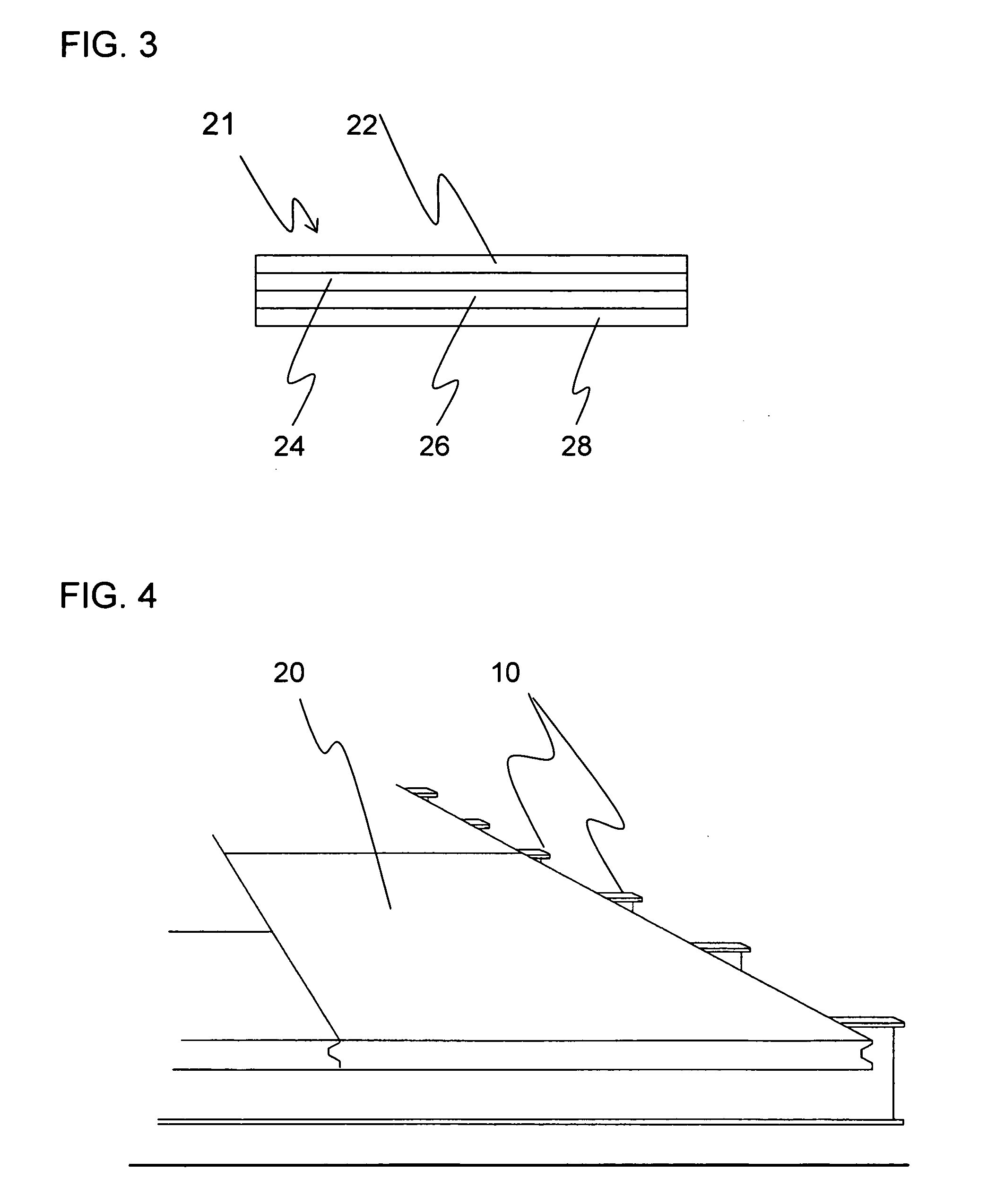

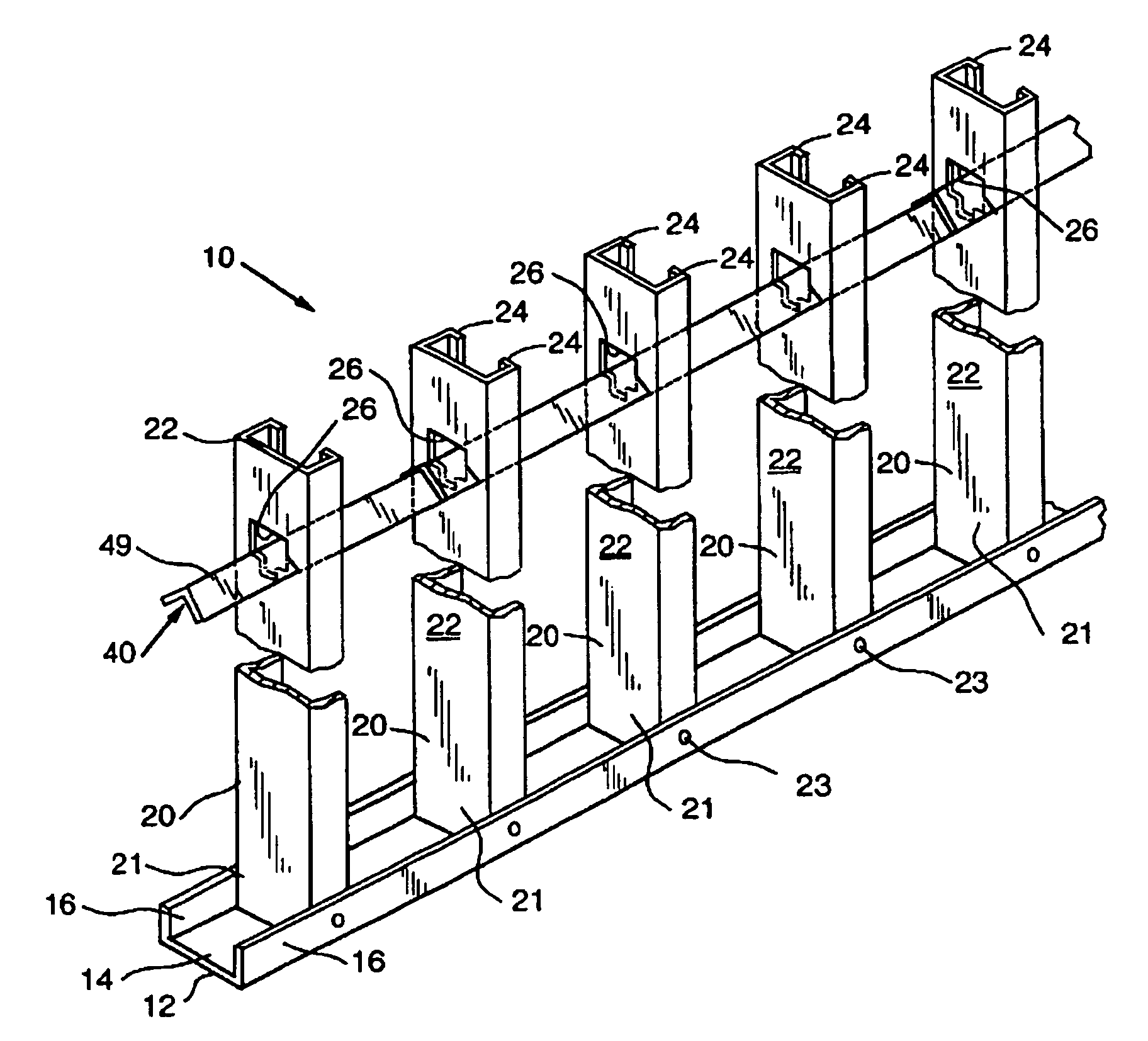

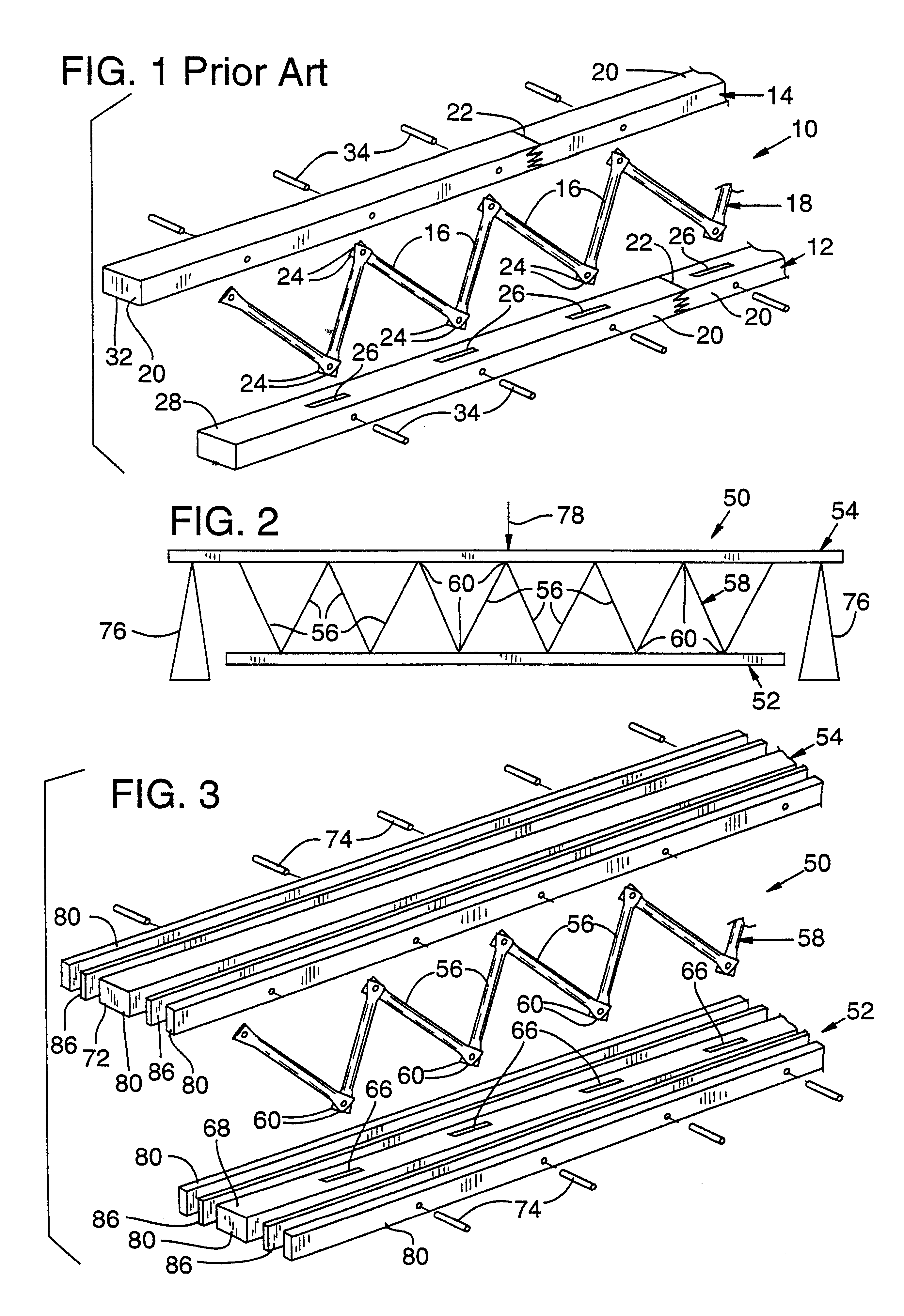

Non-combustible reinforced cementitious lightweight panels and metal frame system for flooring

ActiveUS20060144005A1Easy constructionIncreasing builder productivitySolid waste managementFloorsMicrosphereEngineering

A flooring system including horizontal metal framing members, for example, C-joists, U-joists, open web joists, HAMBRO or other metal frame systems that support a reinforced, lightweight, dimensionally stable SCP panel. The flooring system is non-combustible, water durable, mold and rot resistant, termite resistant and is capable of resisting shear loads equal to or exceeding shear loads provided by plywood or oriented strand board panels. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

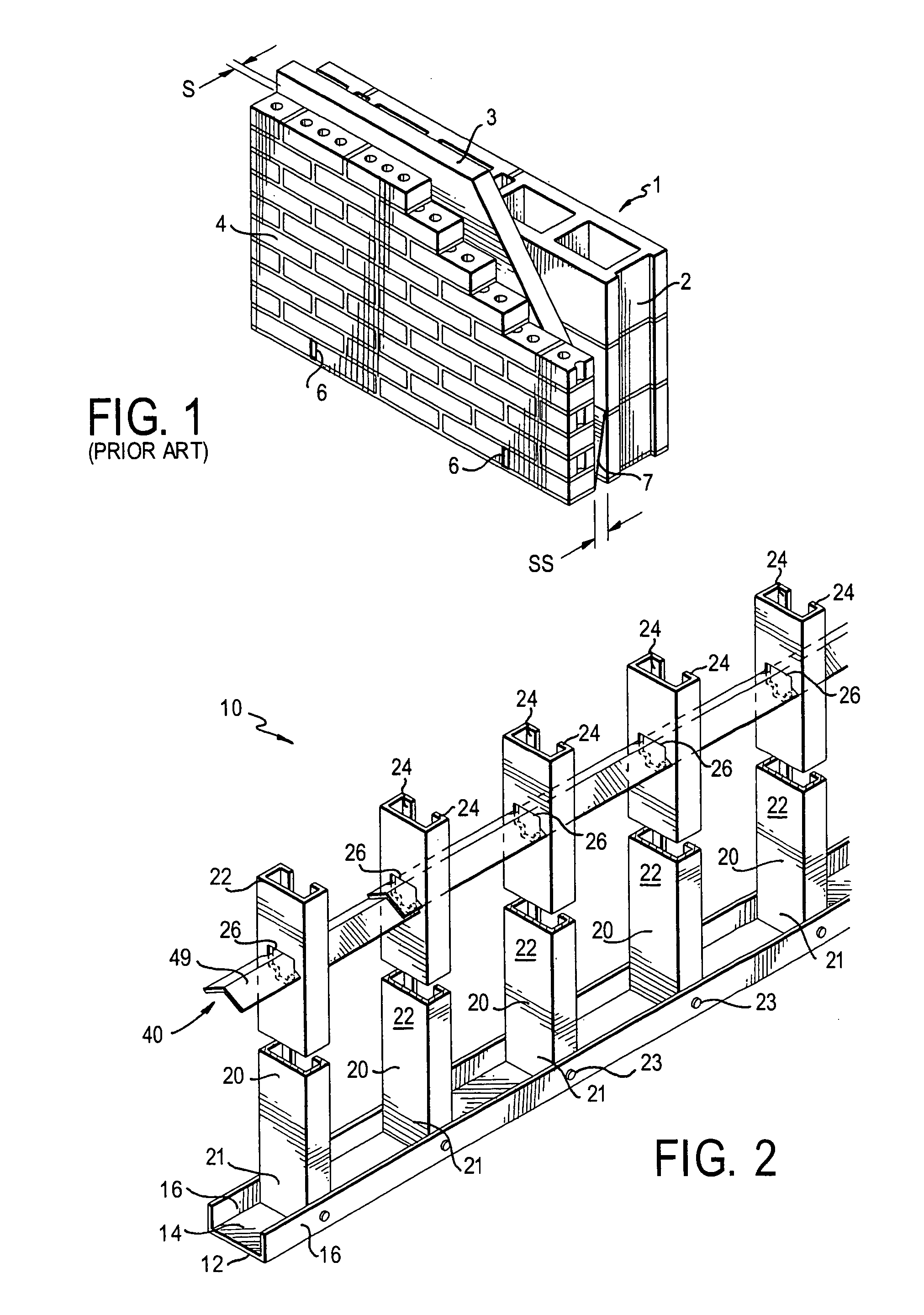

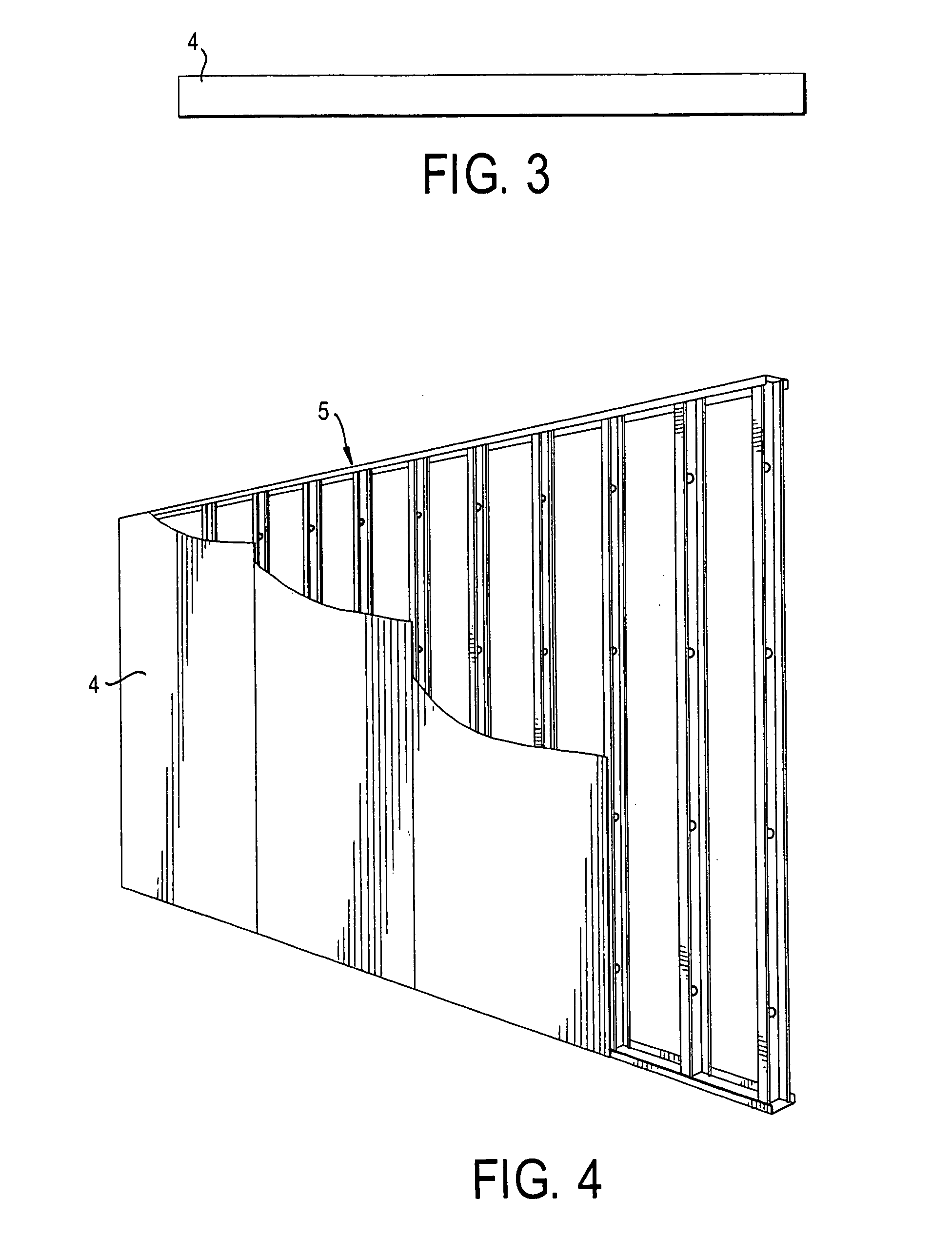

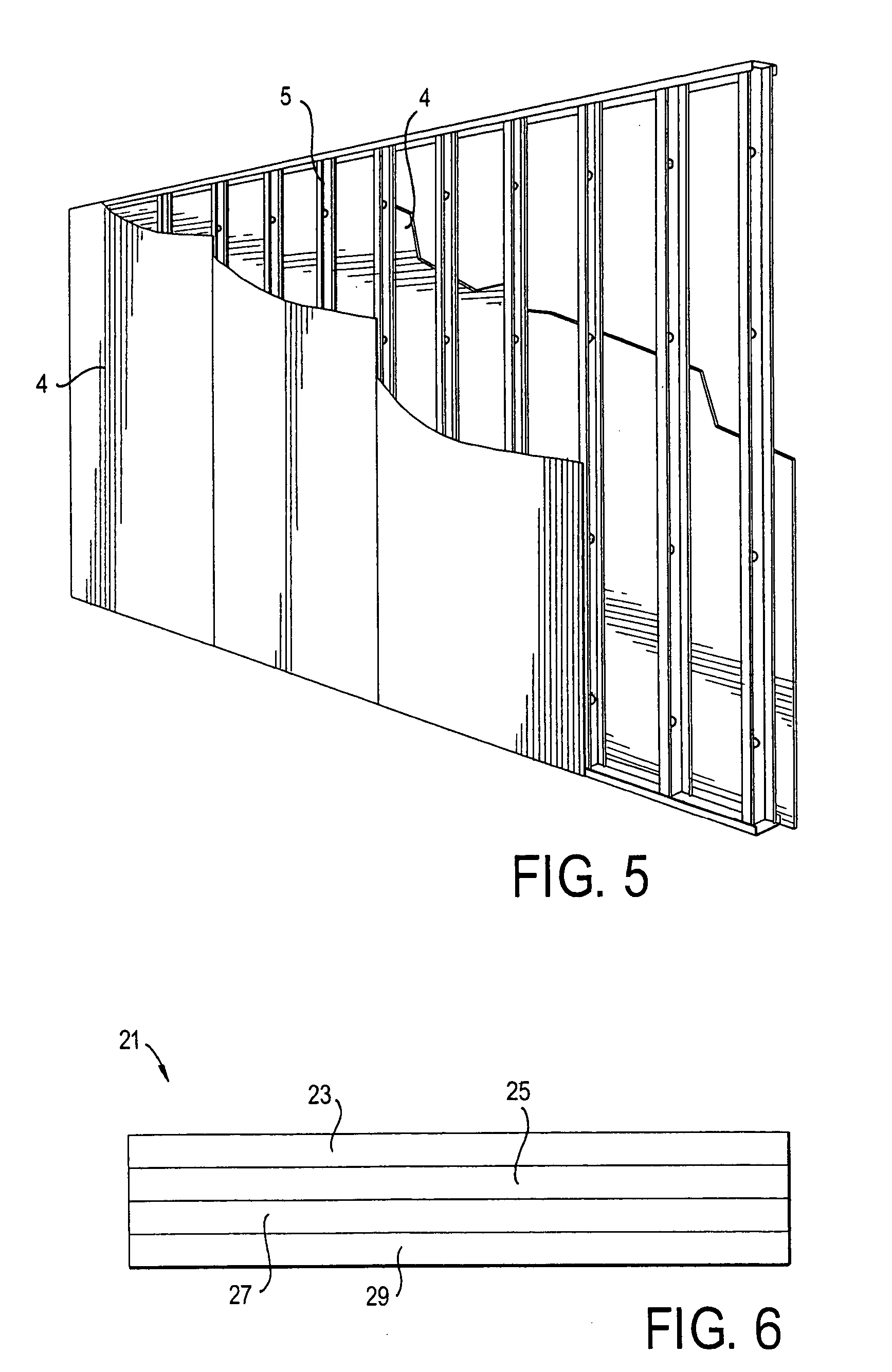

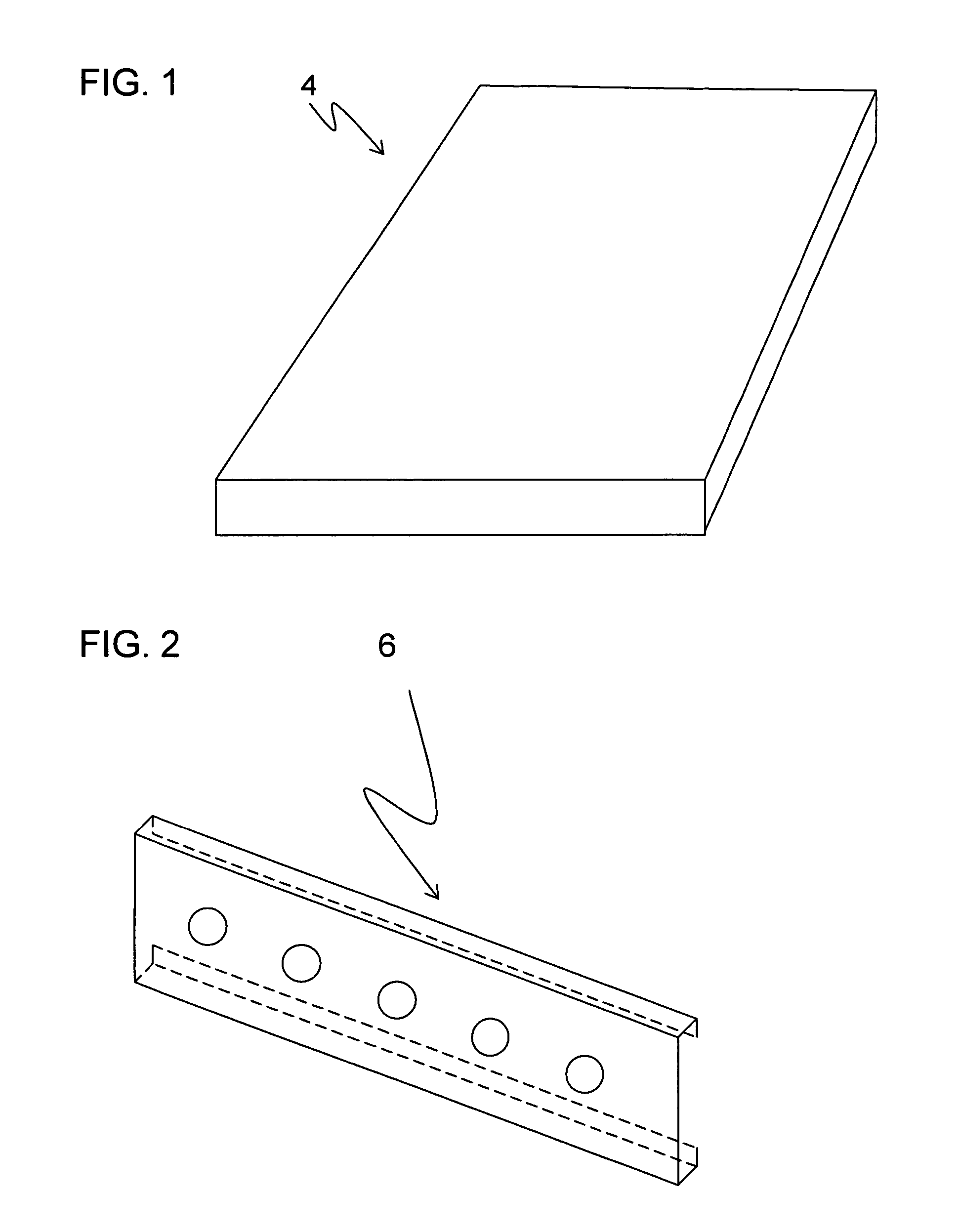

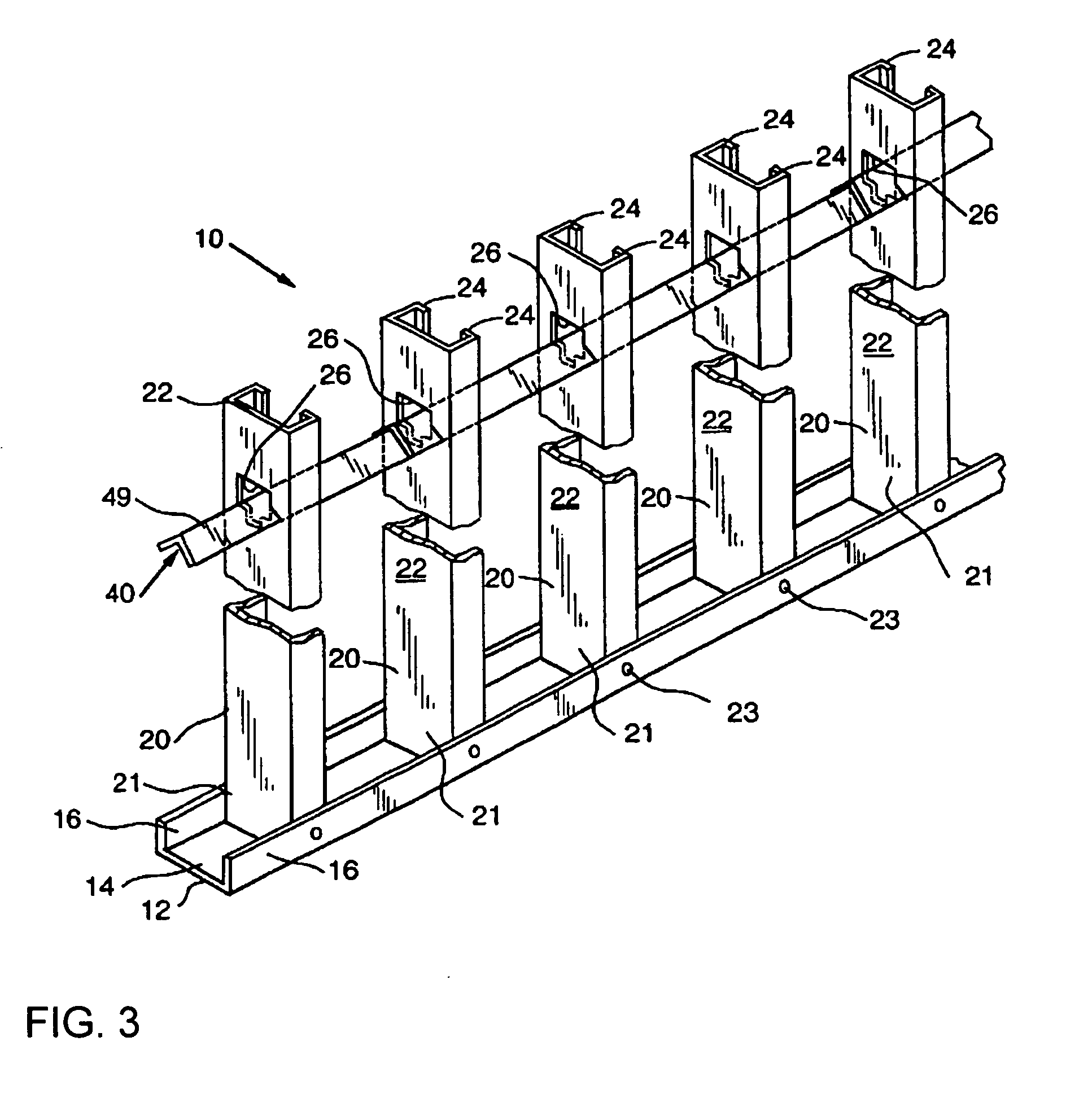

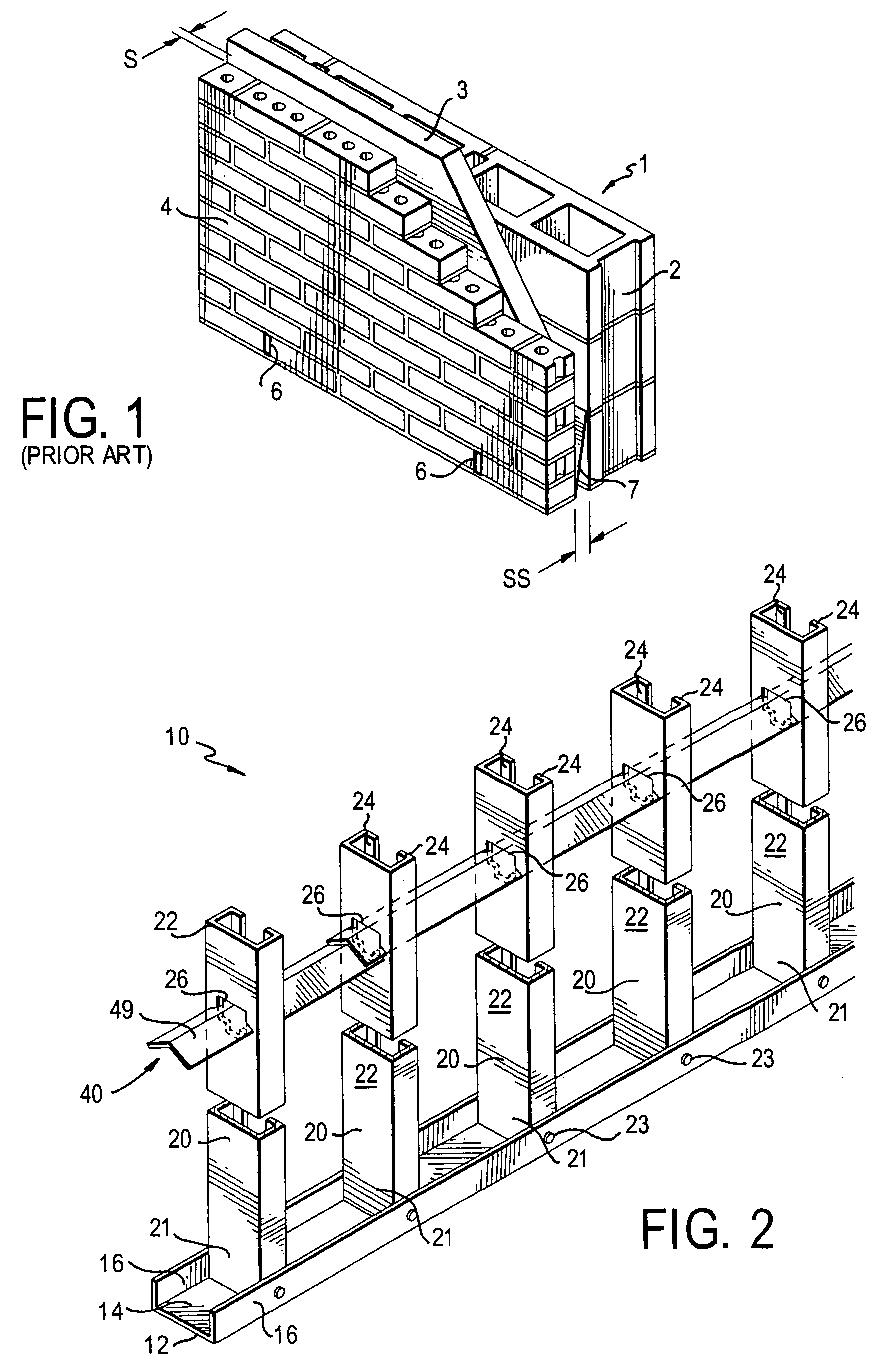

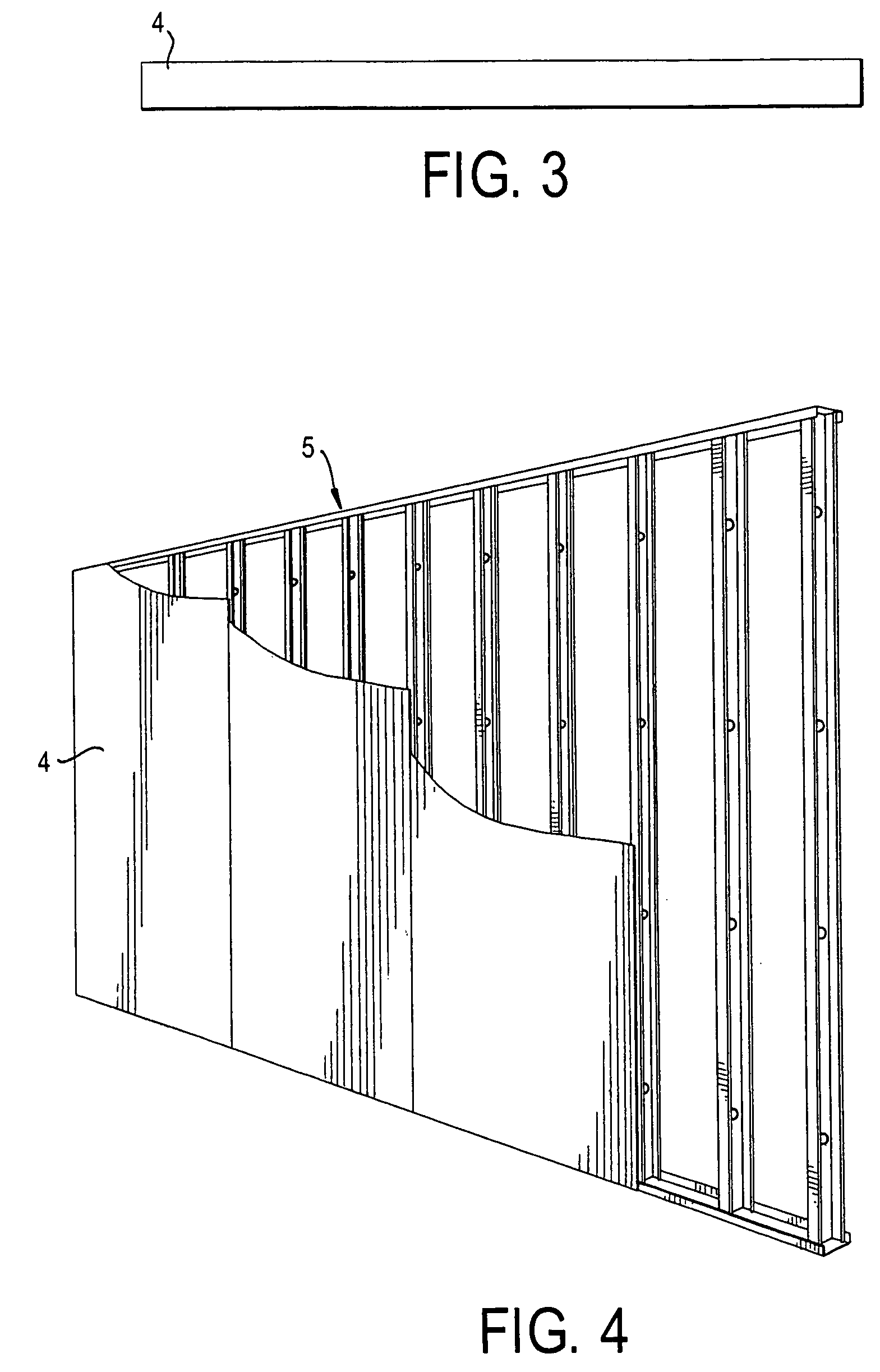

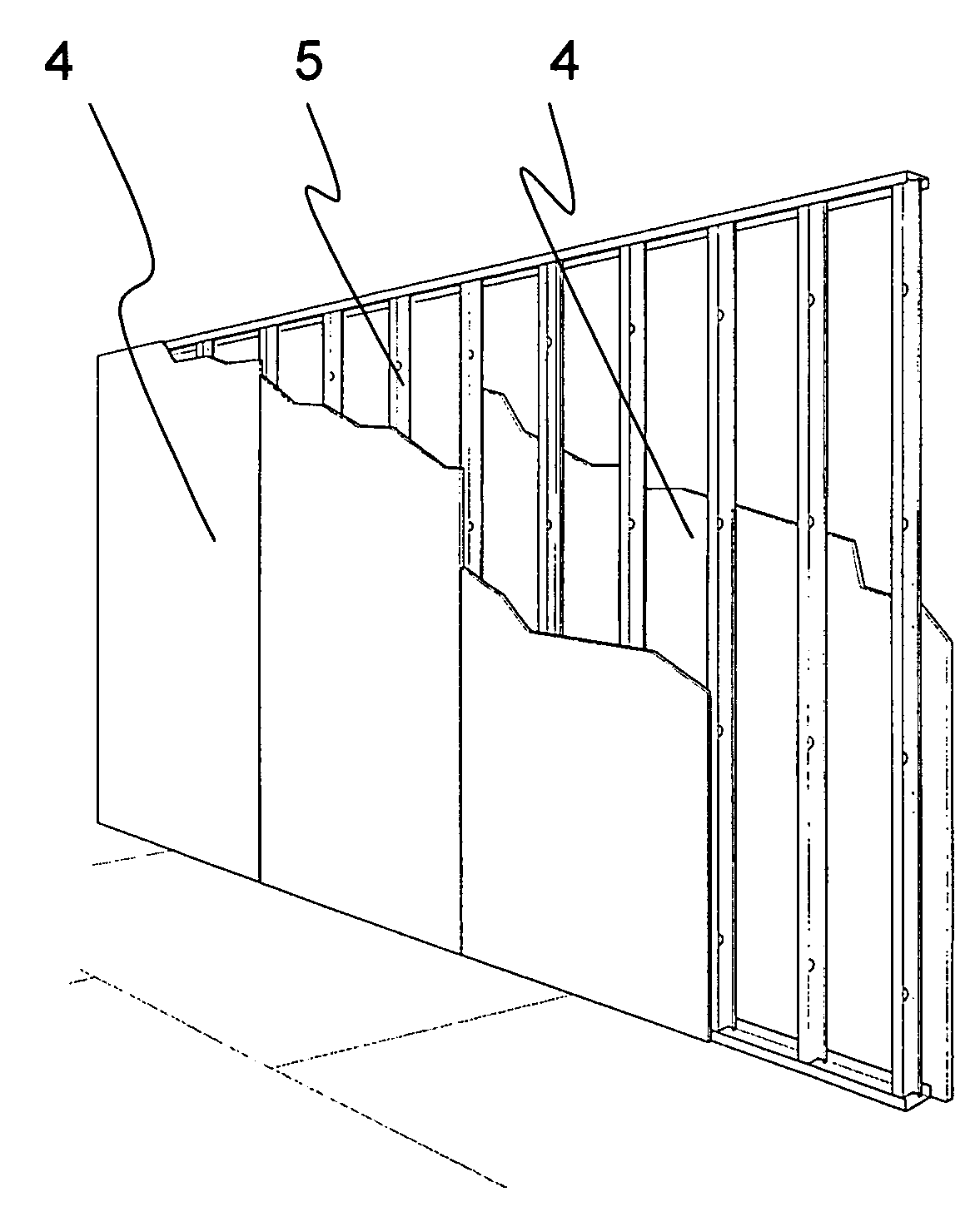

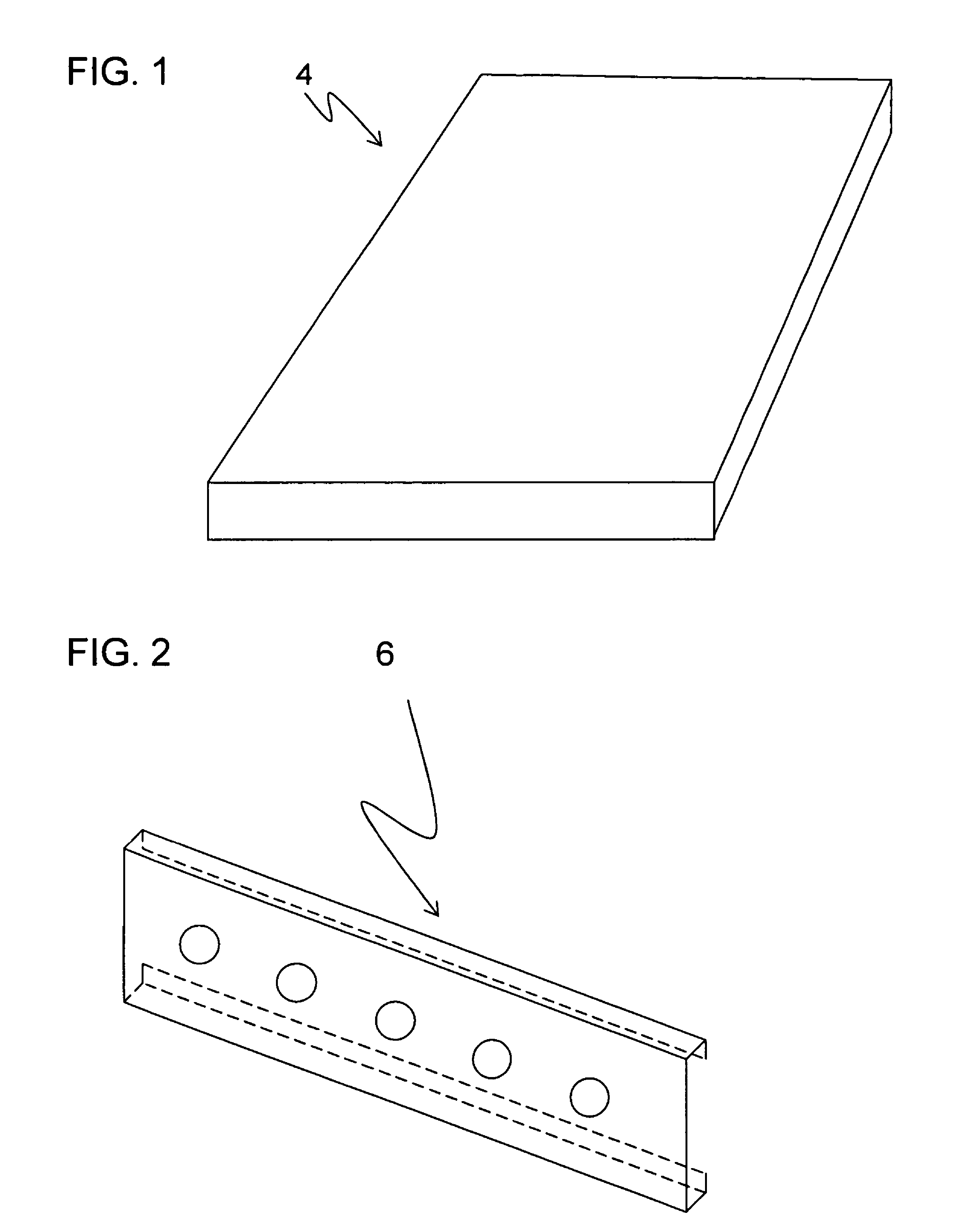

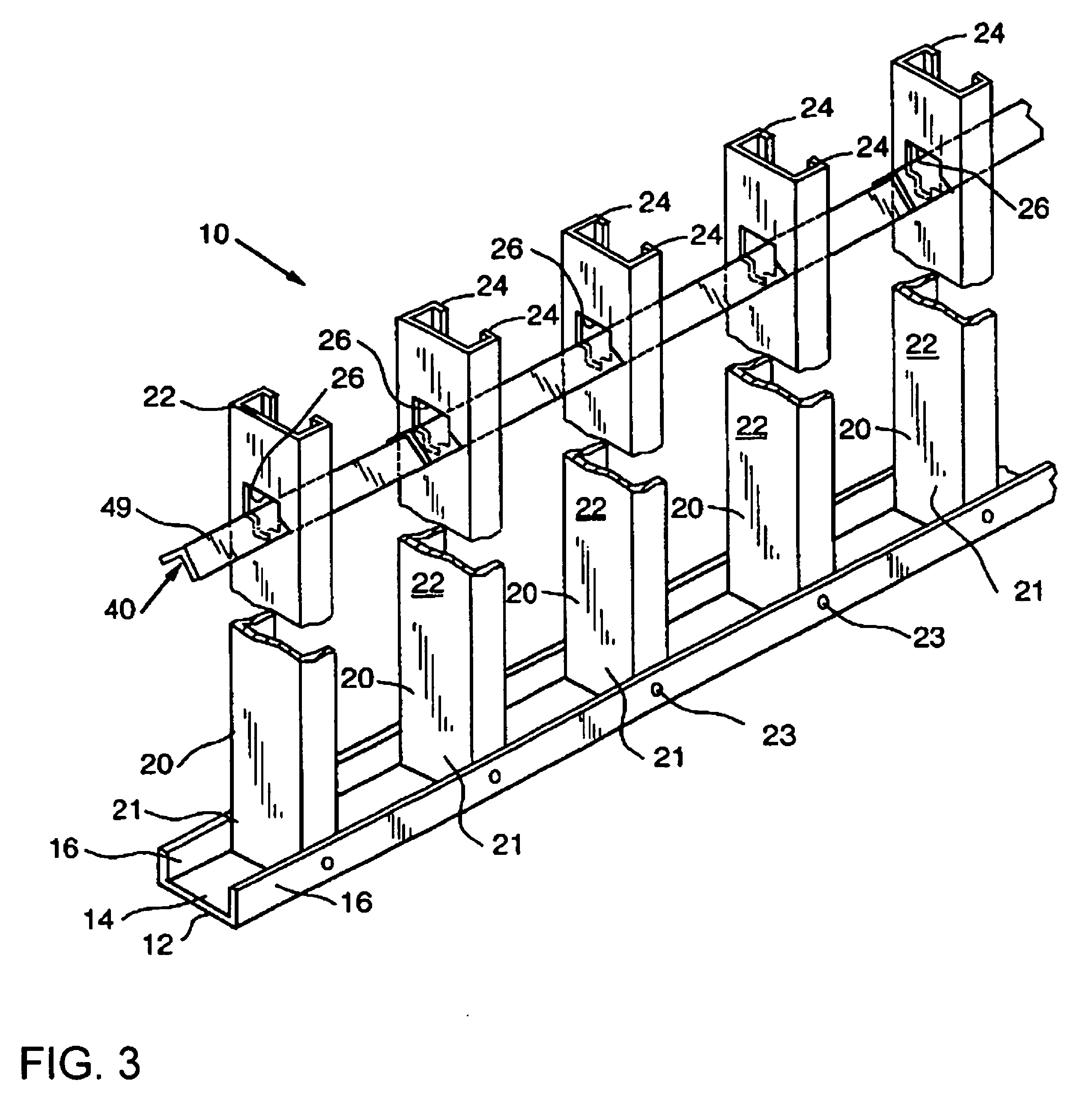

Non-combustible reinforced cementitious lightweight panels and metal frame system for shear walls

ActiveUS20060174572A1Heavy loadMaximization of building volumeSolid waste managementWallsMicrosphereVertical shear

A vertical shear wall system including vertical metal framing members, for example, C-joists, U-joists, open web joists, or other metal frame systems that support a reinforced, lightweight, dimensionally stable SCP panel. The shear wall system is non-combustible, water durable, mold and rot resistant, termite resistant and is capable of resisting shear loads equal to or exceeding shear loads provided by plywood or oriented strand board panels. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

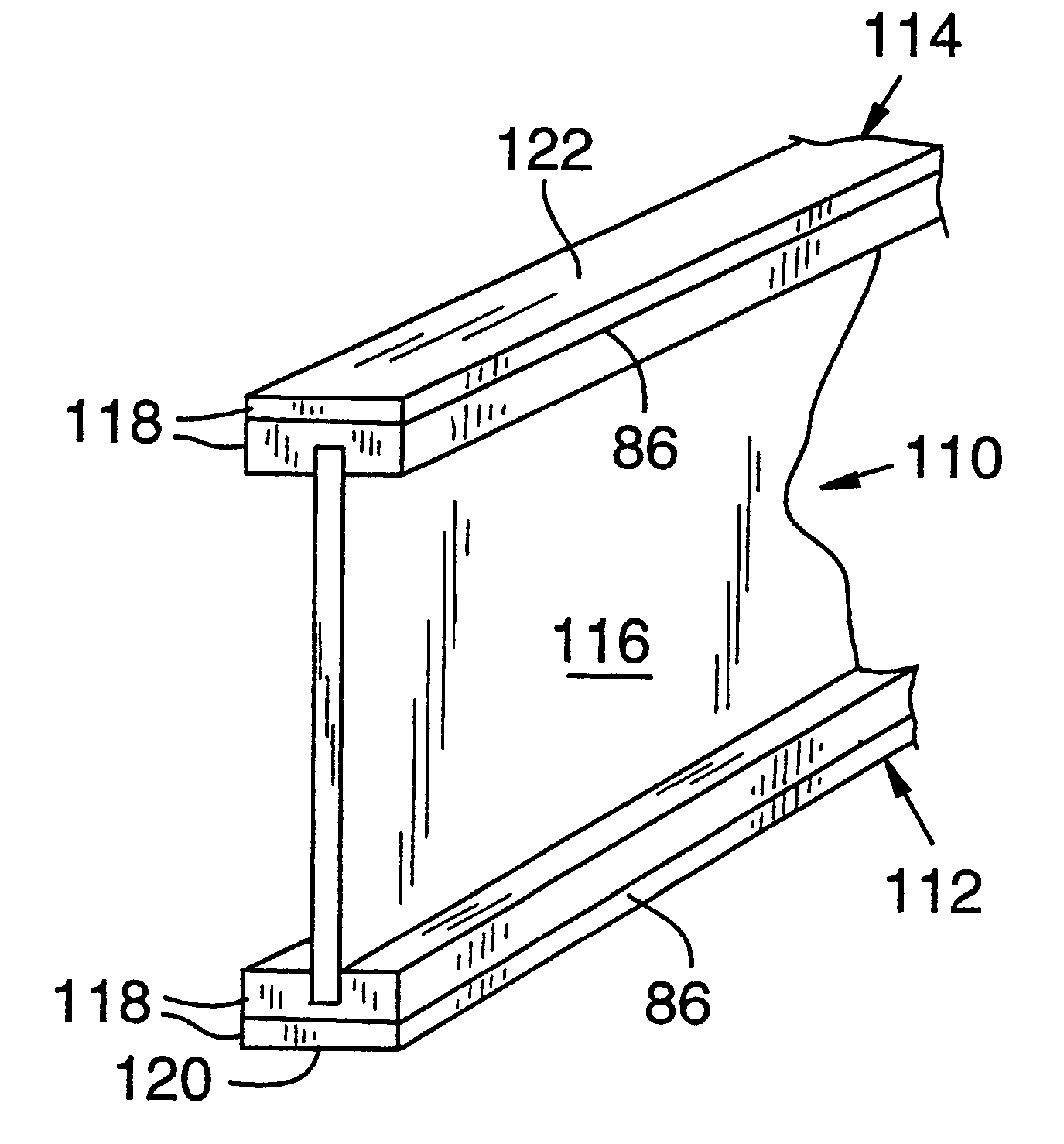

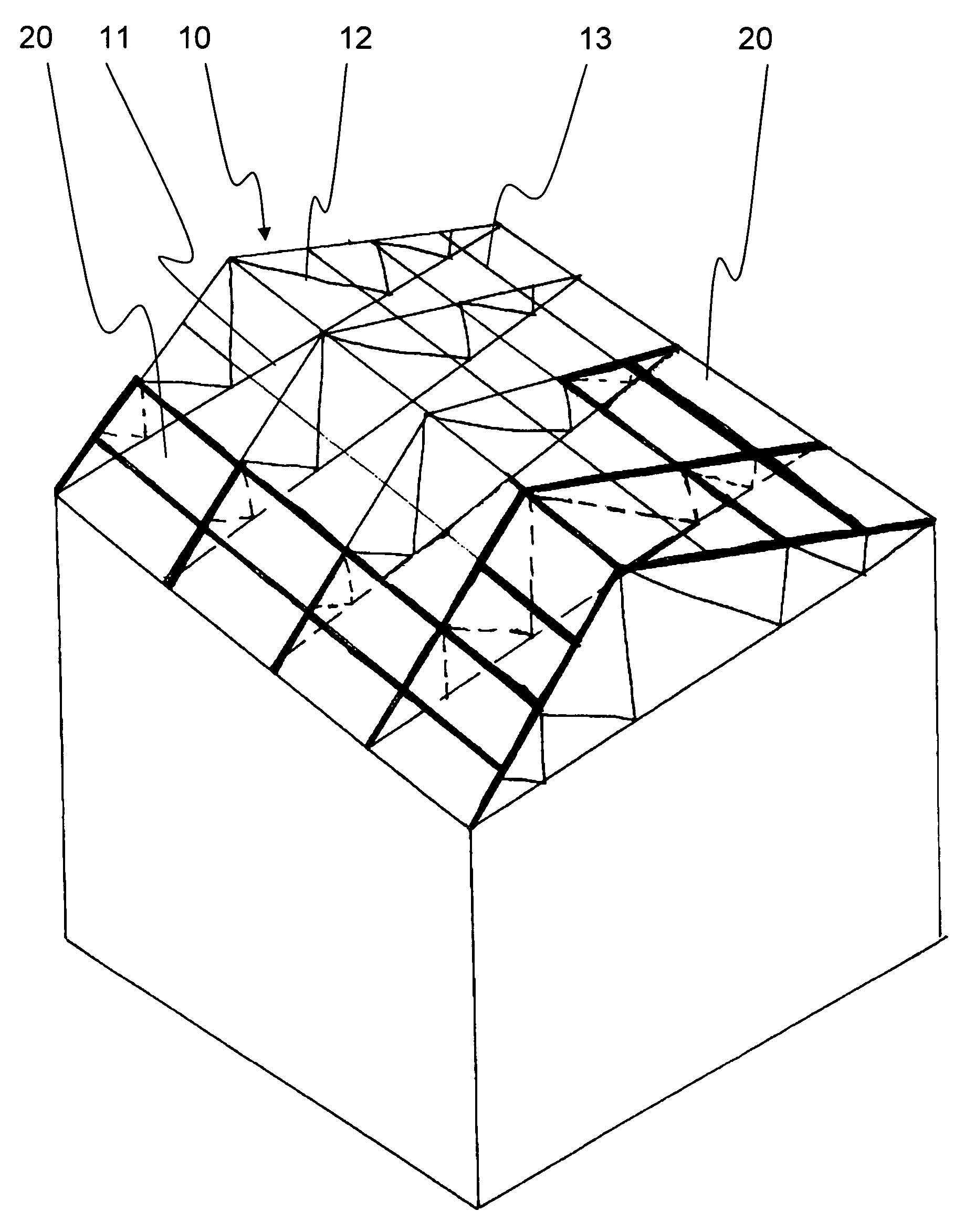

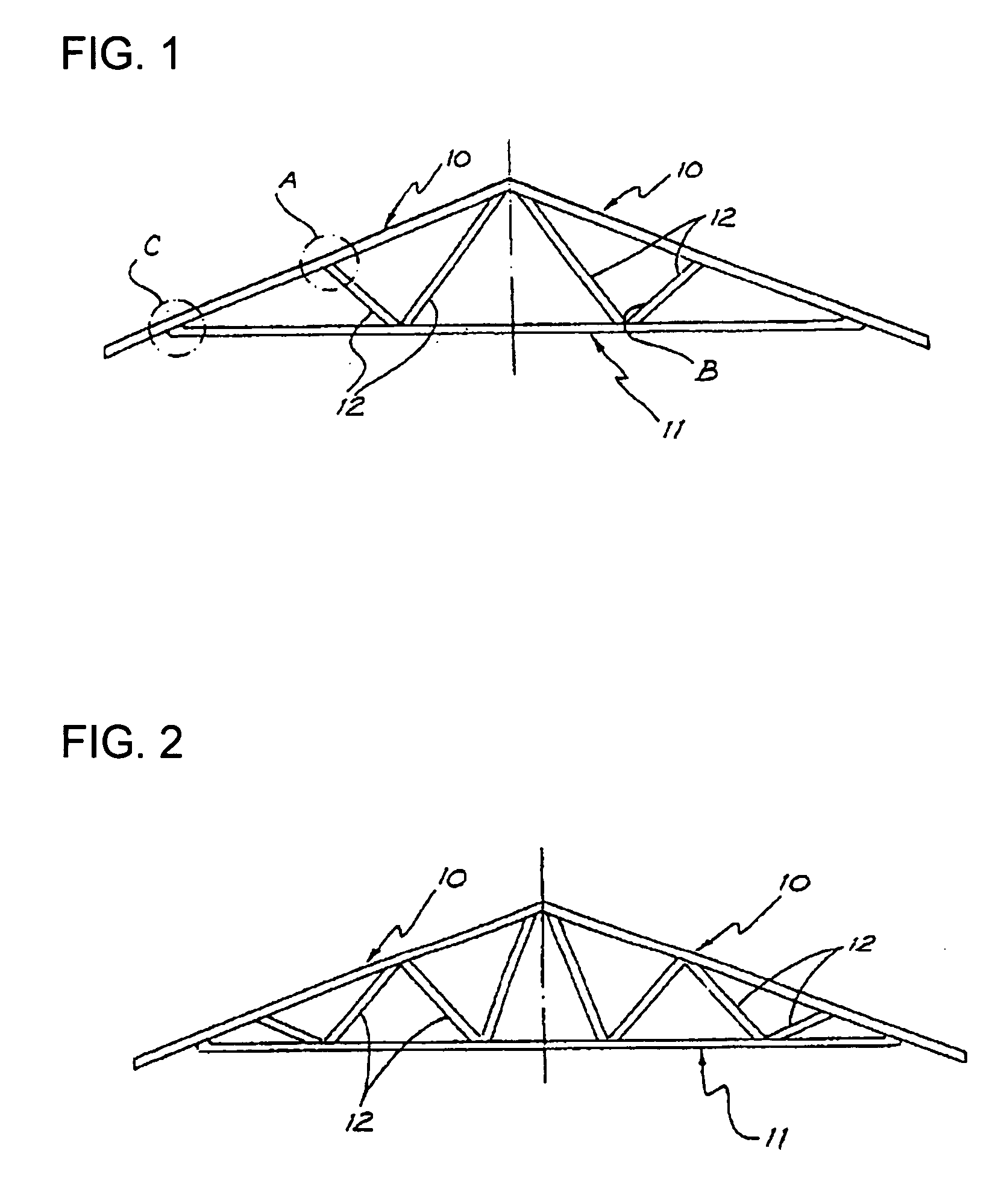

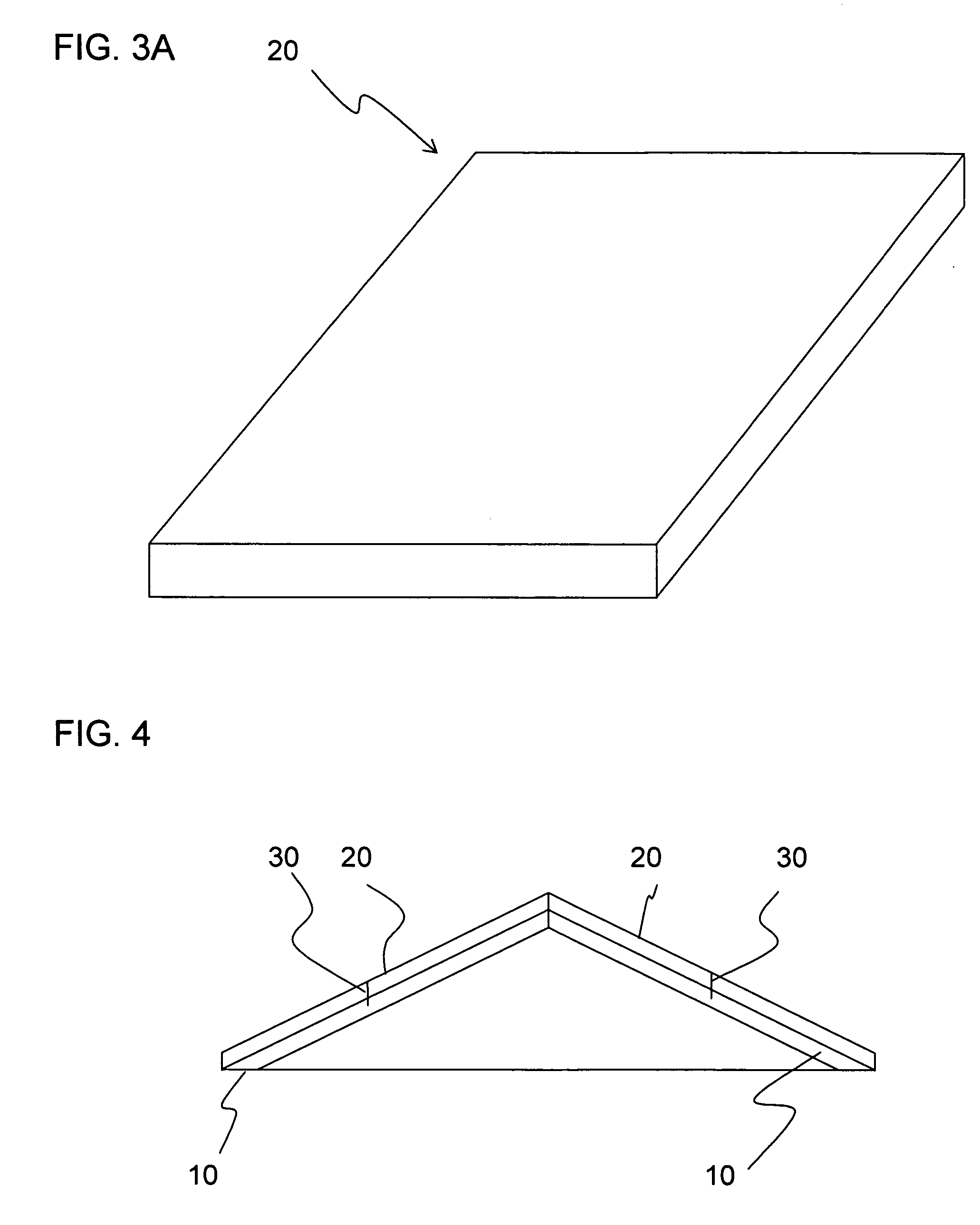

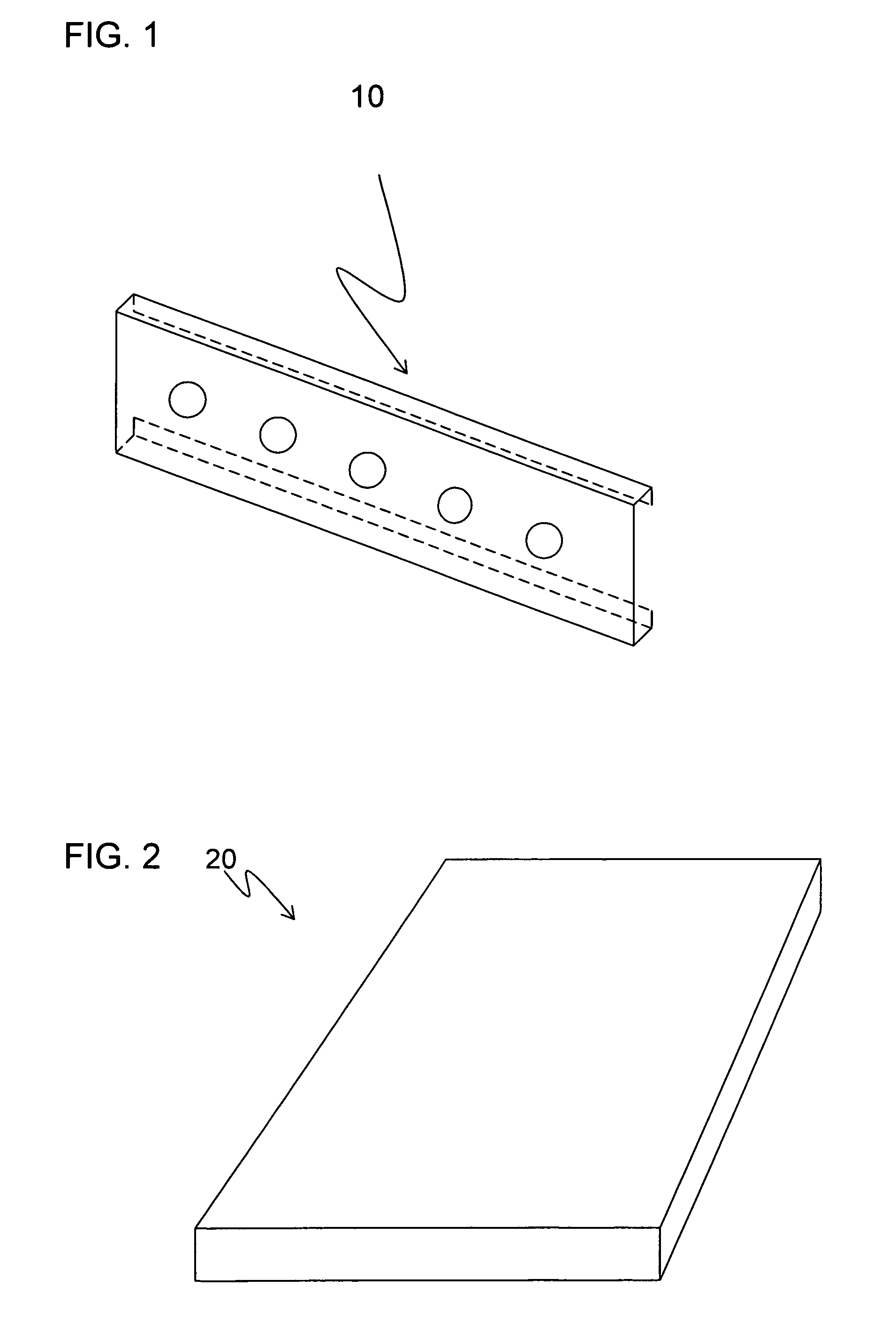

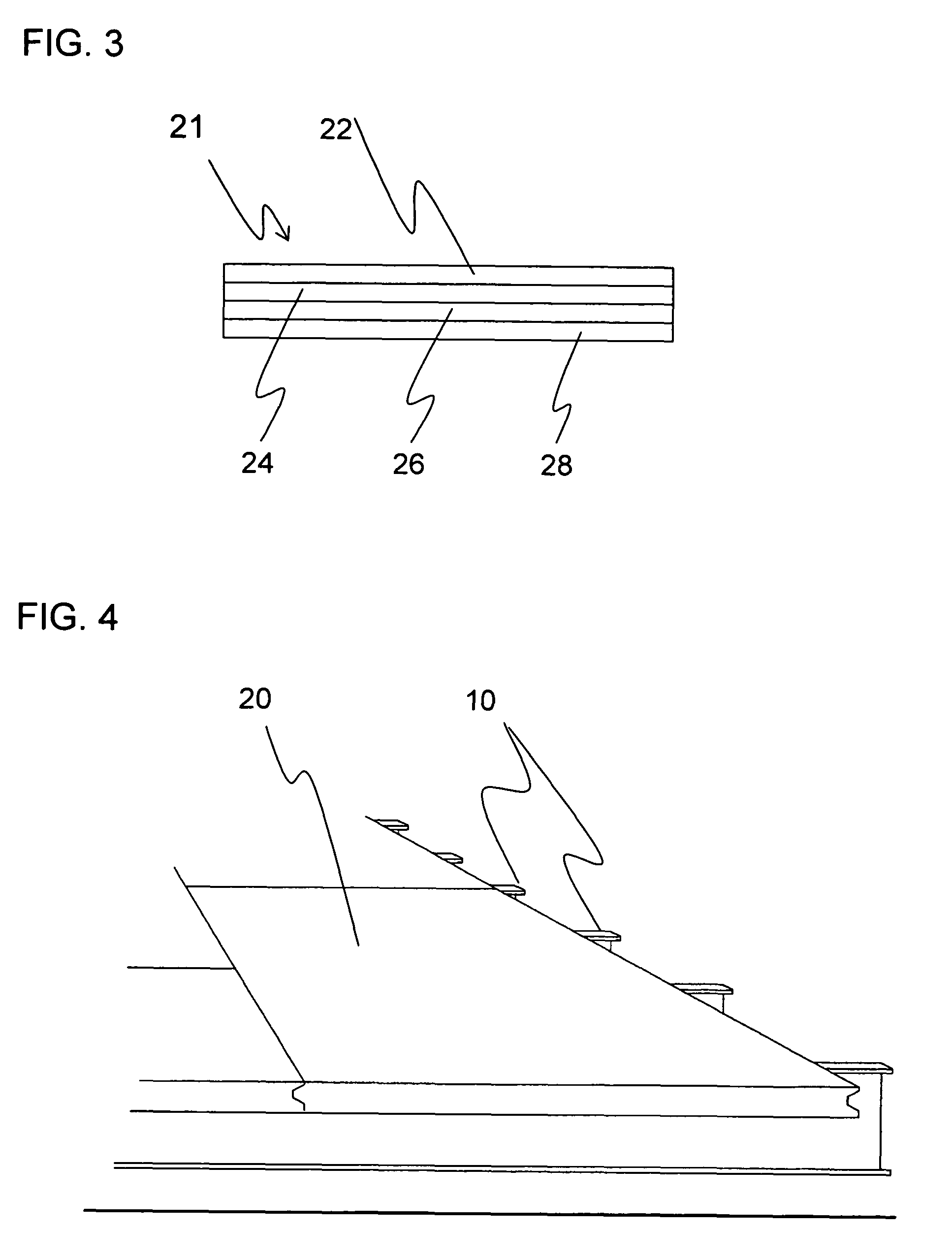

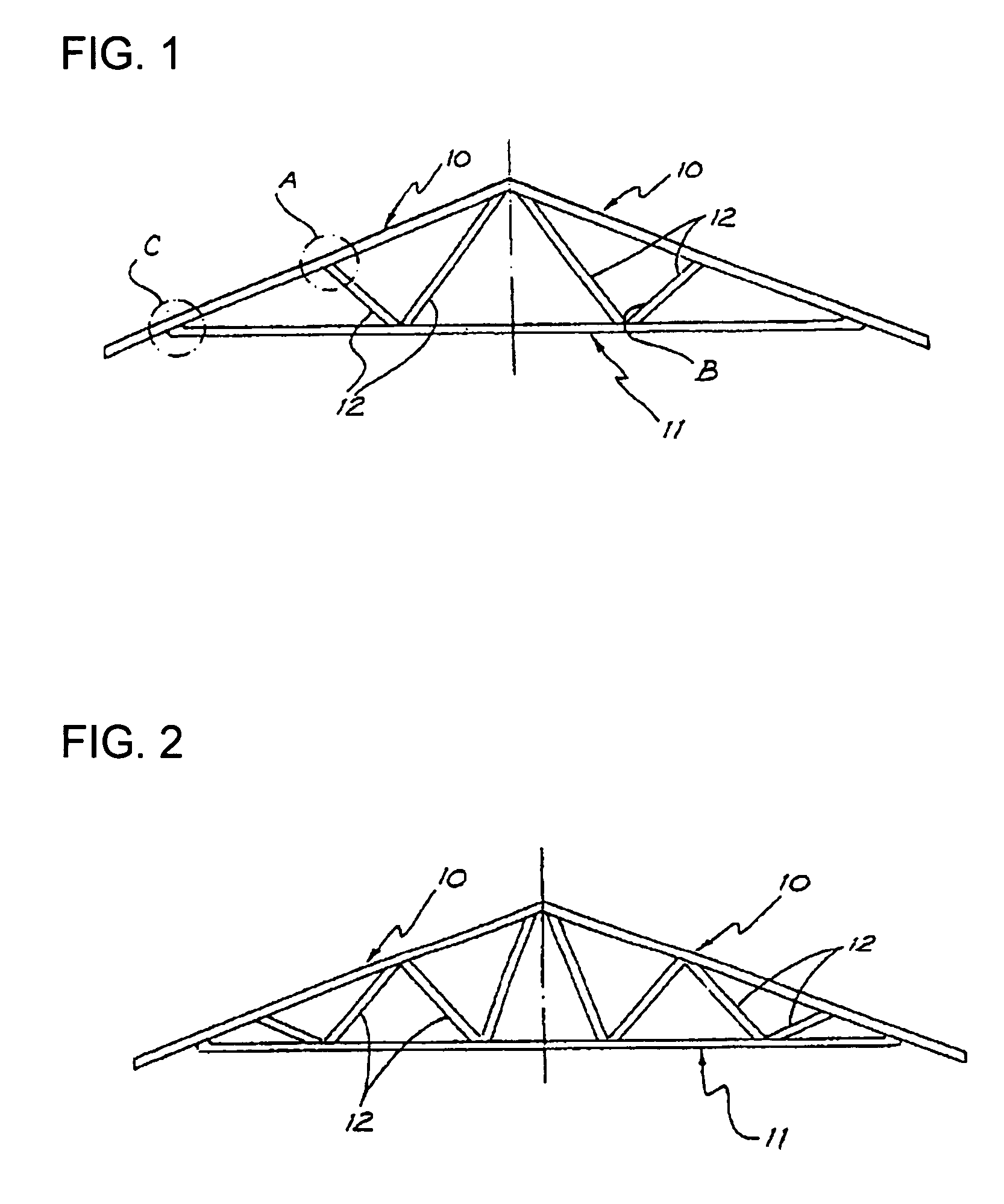

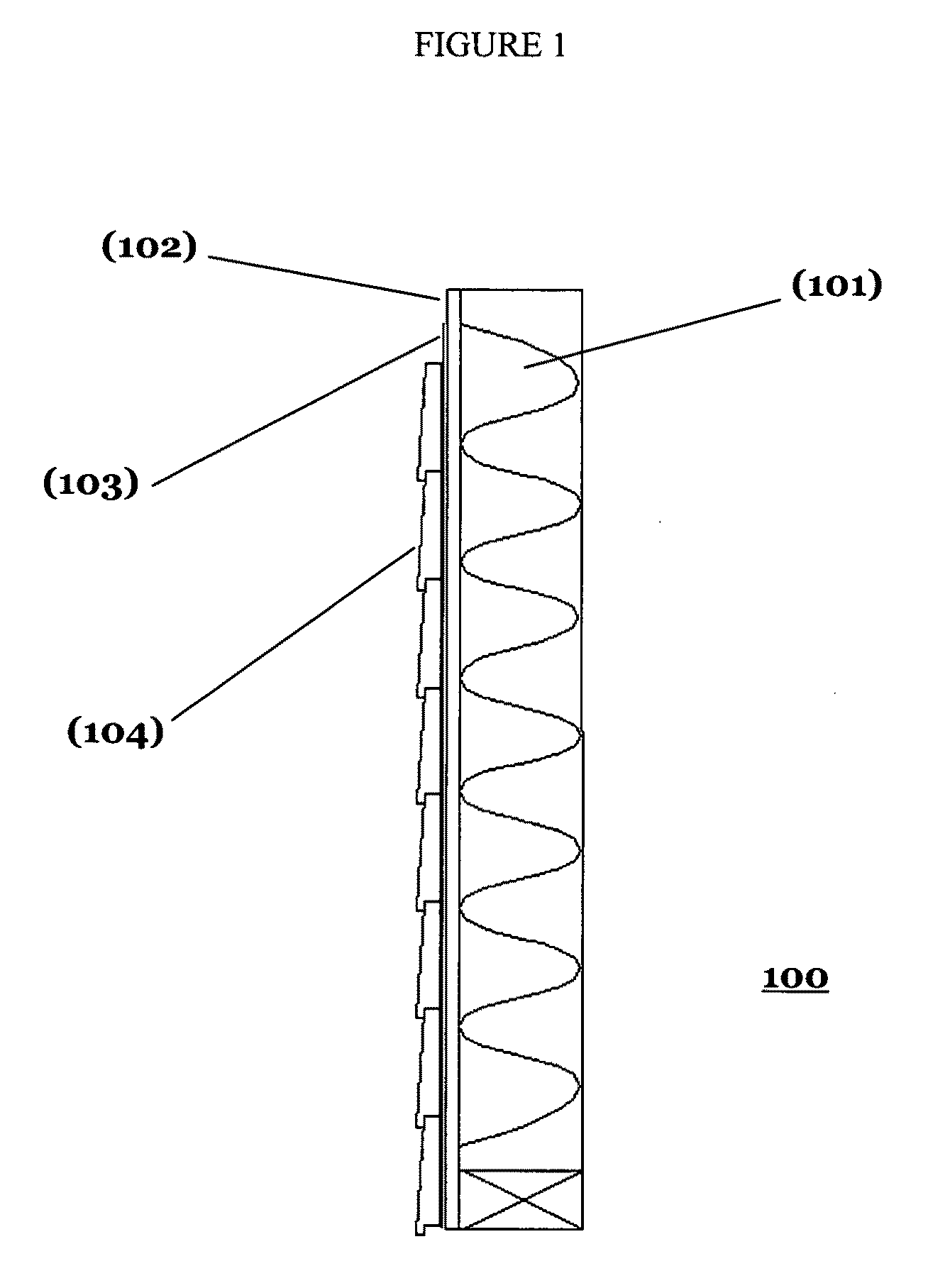

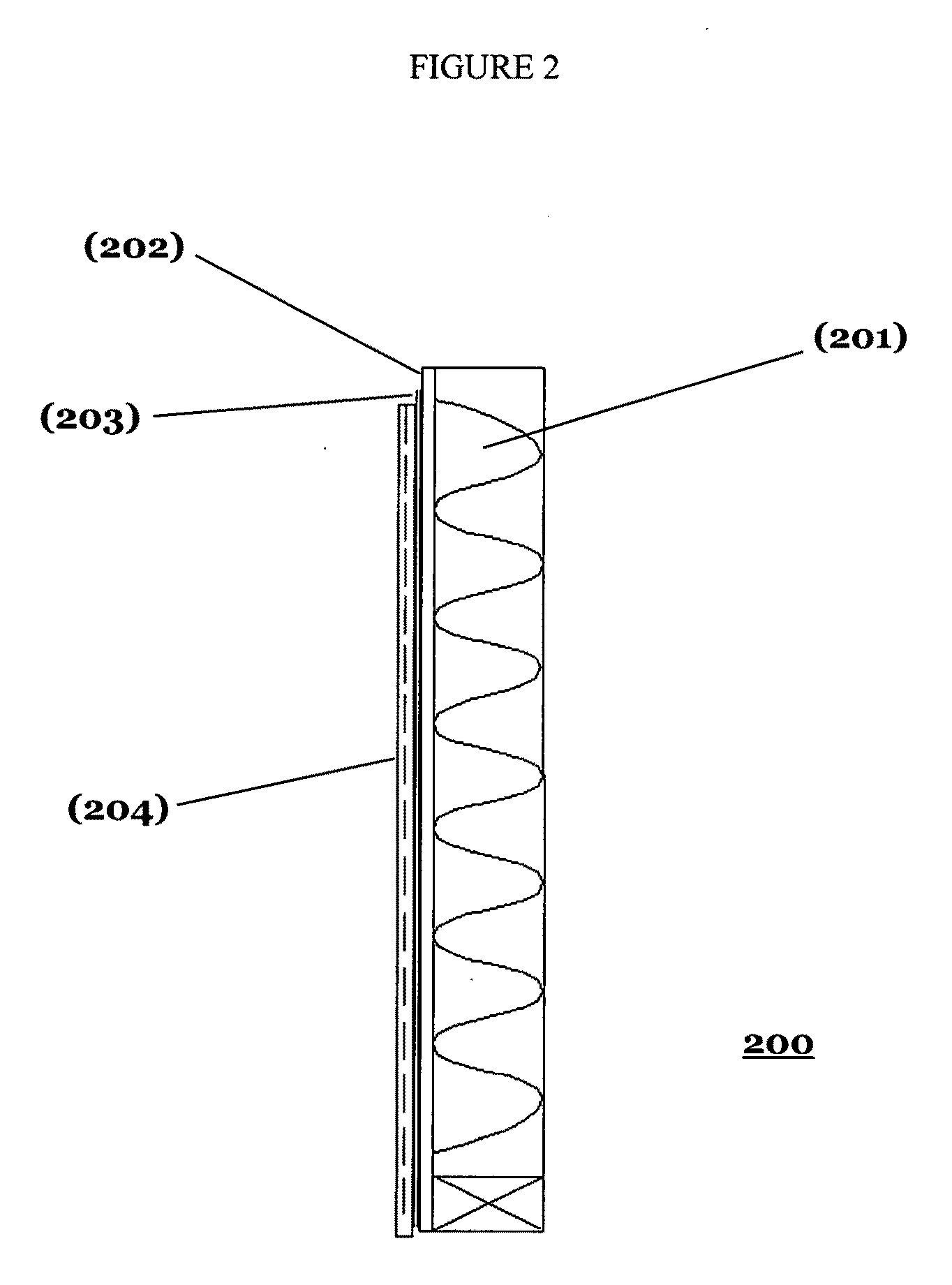

Wood I-beam conditioned reinforcement panel

InactiveUS6173550B1Improve the immunityComparable and great strengthGirdersJoistsResin matrixEngineering

The present invention includes wood I-beams with fiber reinforcement. In a preferred embodiment, a wood I-beam includes an opposed pair of elongated wood flanges and a substantially continuous web positioned between them. In one embodiment, the web includes multiple metal tubes that extend between the wood flanges and form a zig zag pattern. The ends of the metal tubes are flattened parallel to the plane of the metal web so the ends can fit within either slots in the top surface of the bottom wood flange or slots in the bottom surface of the top wood flange. Metal pins pass through the sides of the wood flanges and the flattened ends of the metal tubes to secure the tubular metal web to the flanges. In other embodiments the web includes oriented strand board (OSB) or plywood. Reinforcements are adhered to the wood flanges so that the metal pins also pass through the reinforcements. The reinforcements preferably include multiple fiber strands held within a resin matrix.

Owner:OREGON CASCADES WEST COUNCIL OF GOVERNMENTS

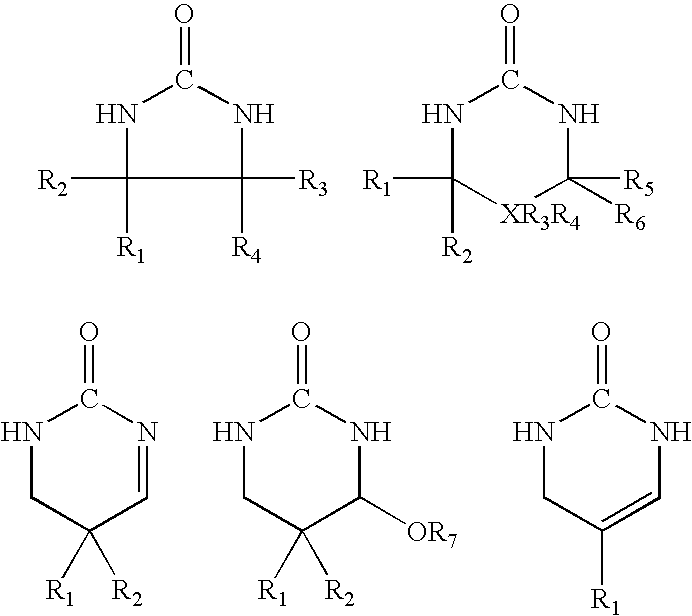

Durable thermoset binder compositions from 5-carbon reducing sugars and use as wood binders

ActiveUS20110263757A1Minimize formaldehyde contentWeaken energyCosmetic preparationsOrganic detergent compounding agentsTris(2-aminoethyl)amineParticle board

The present invention provides thermosetting aqueous binder compositions of (i) one or more diprimary diamine, e.g. lysine, or poly(primary amine), e.g. polyethylenimine and tris(2-aminoethyl)amine, and (ii) one or more 5-carbon reducing sugar, such as xylose. The binders are at least substantially formaldehyde free and cure rapidly at temperatures sufficiently low and with sufficiently little swelling to enable one to provide wood or woody material containing articles, such as particle board, oriented strand board and bamboo boards or articles.

Owner:ROHM & HAAS CO

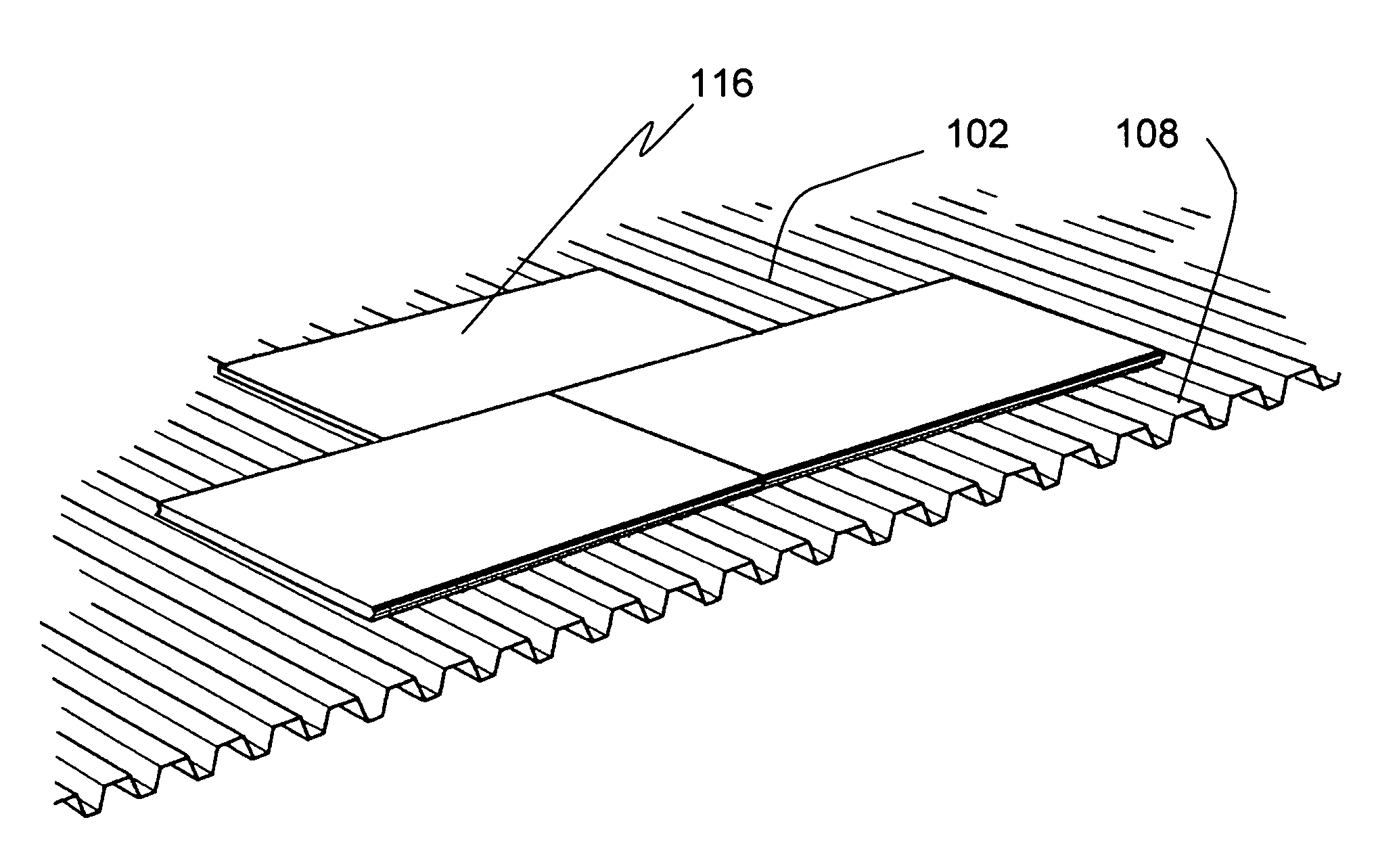

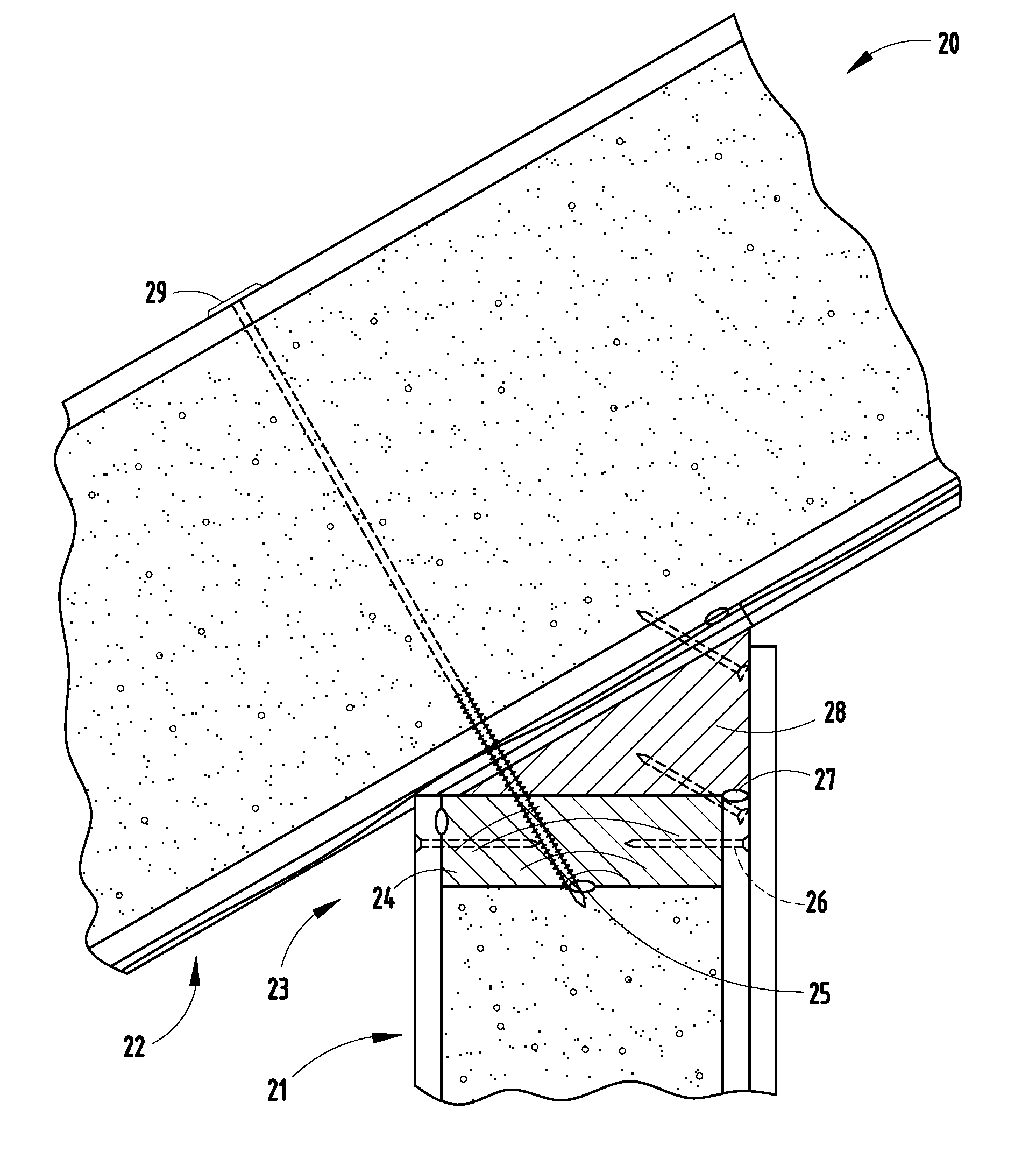

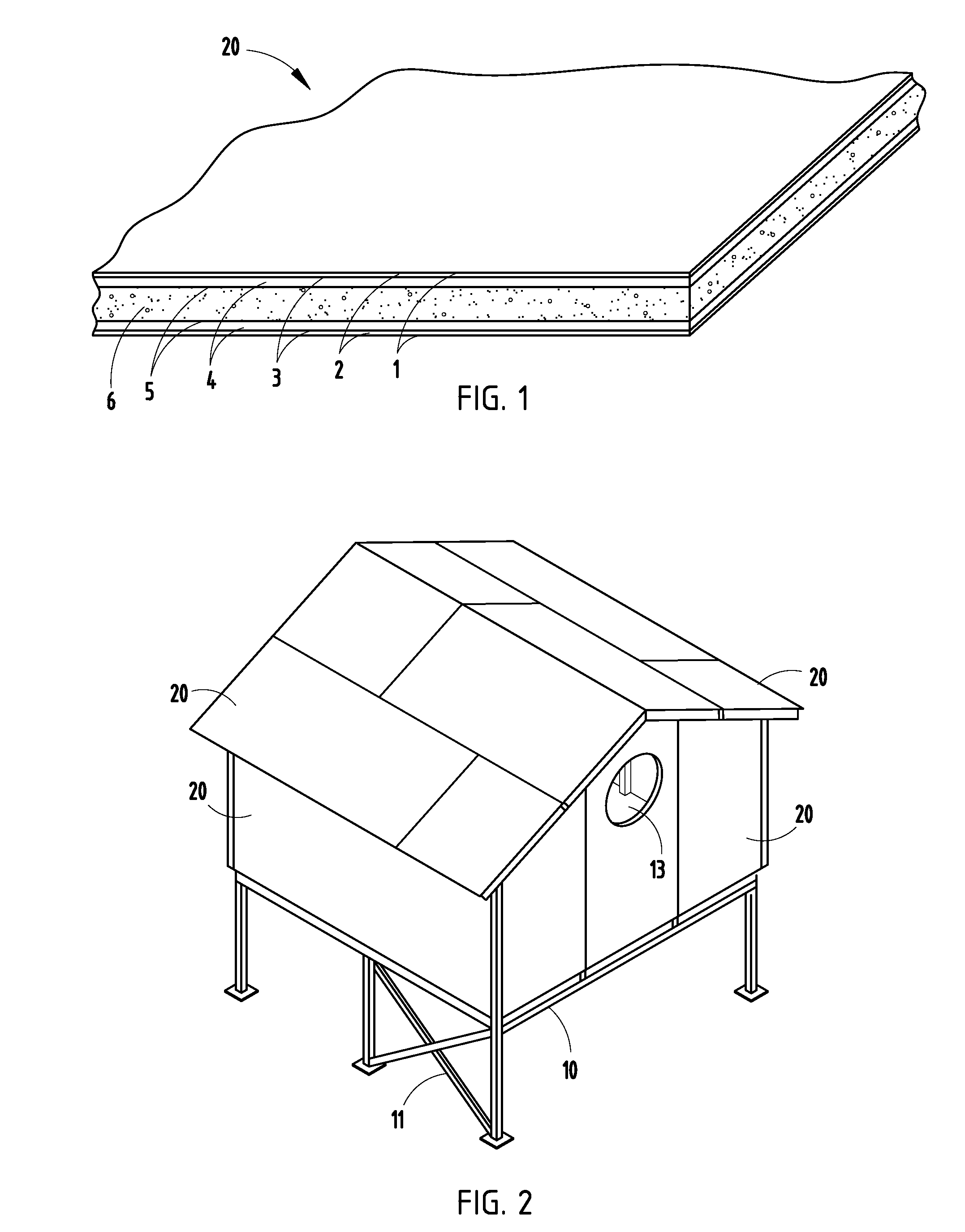

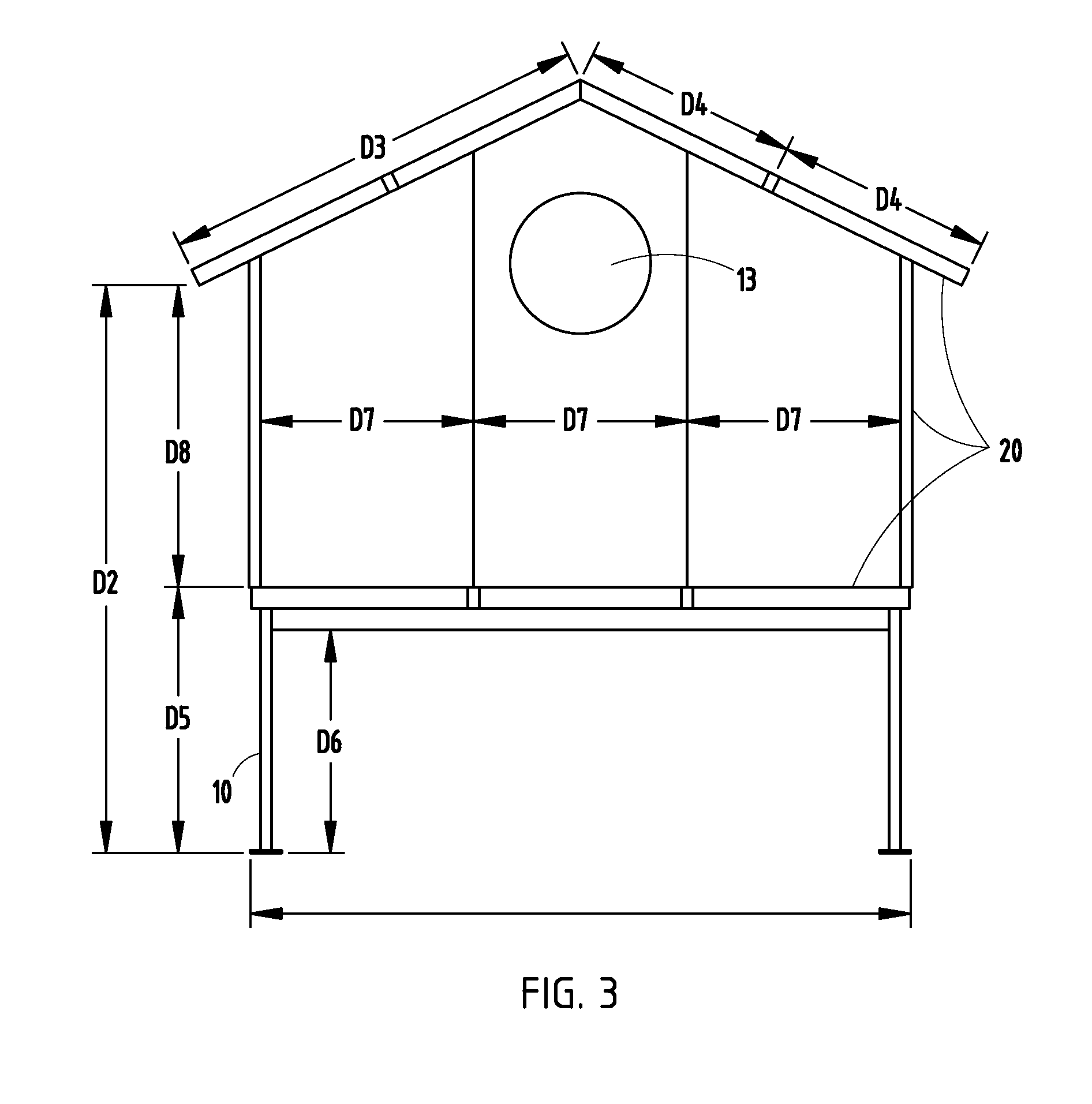

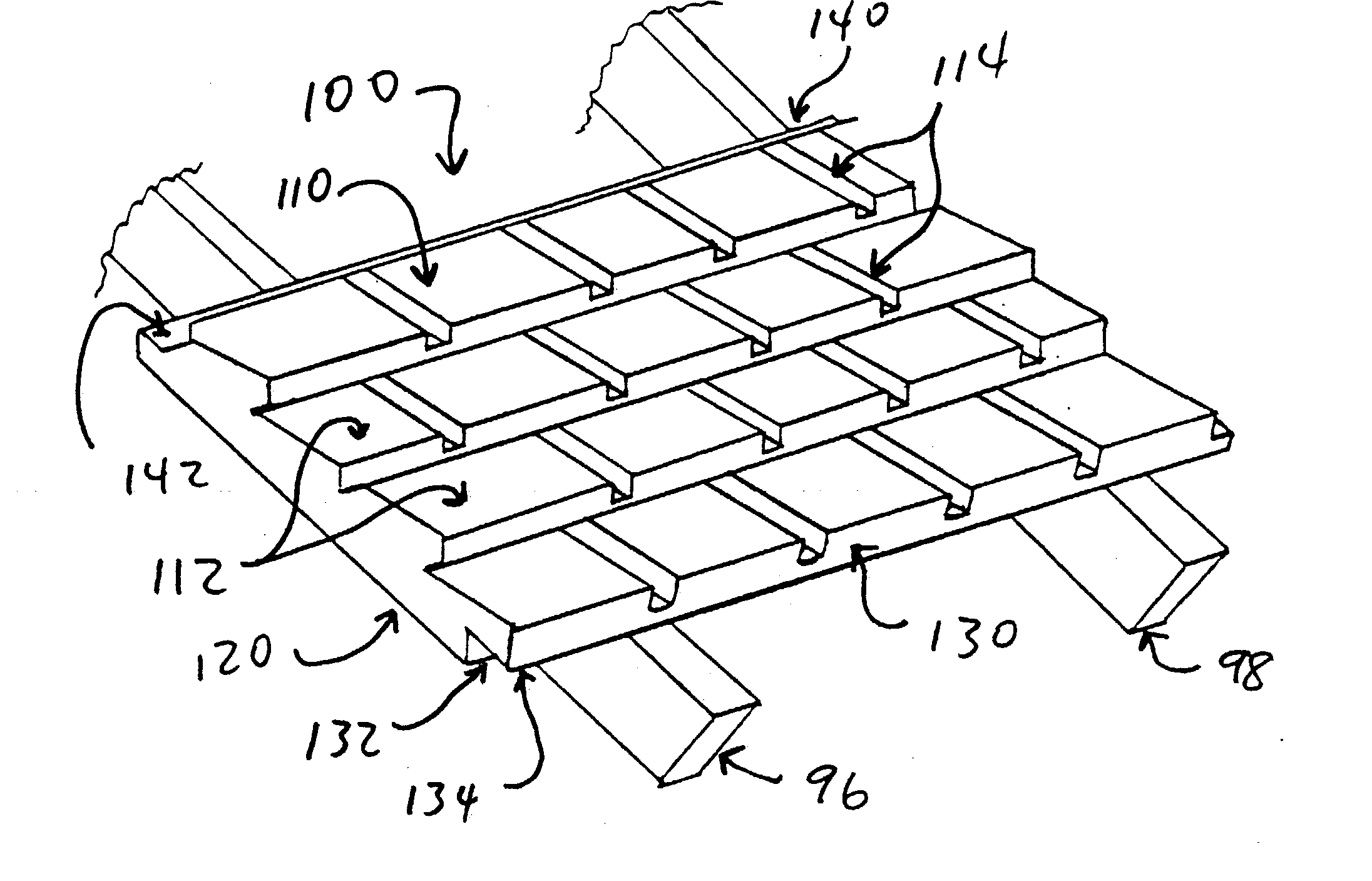

Non-combustible reinforced cementitious lightweight panels and metal frame system for roofing

A roofing system including horizontal or sloped metal framing members, for example, C-joists, U-joists, open web joists, or other metal frame systems that support a reinforced, lightweight, dimensionally stable SCP panel. The roofing system is non-combustible, water durable, mold and rot resistant, termite resistant and is capable of resisting shear loads equal to or exceeding shear loads provided by plywood or oriented strand board panels. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

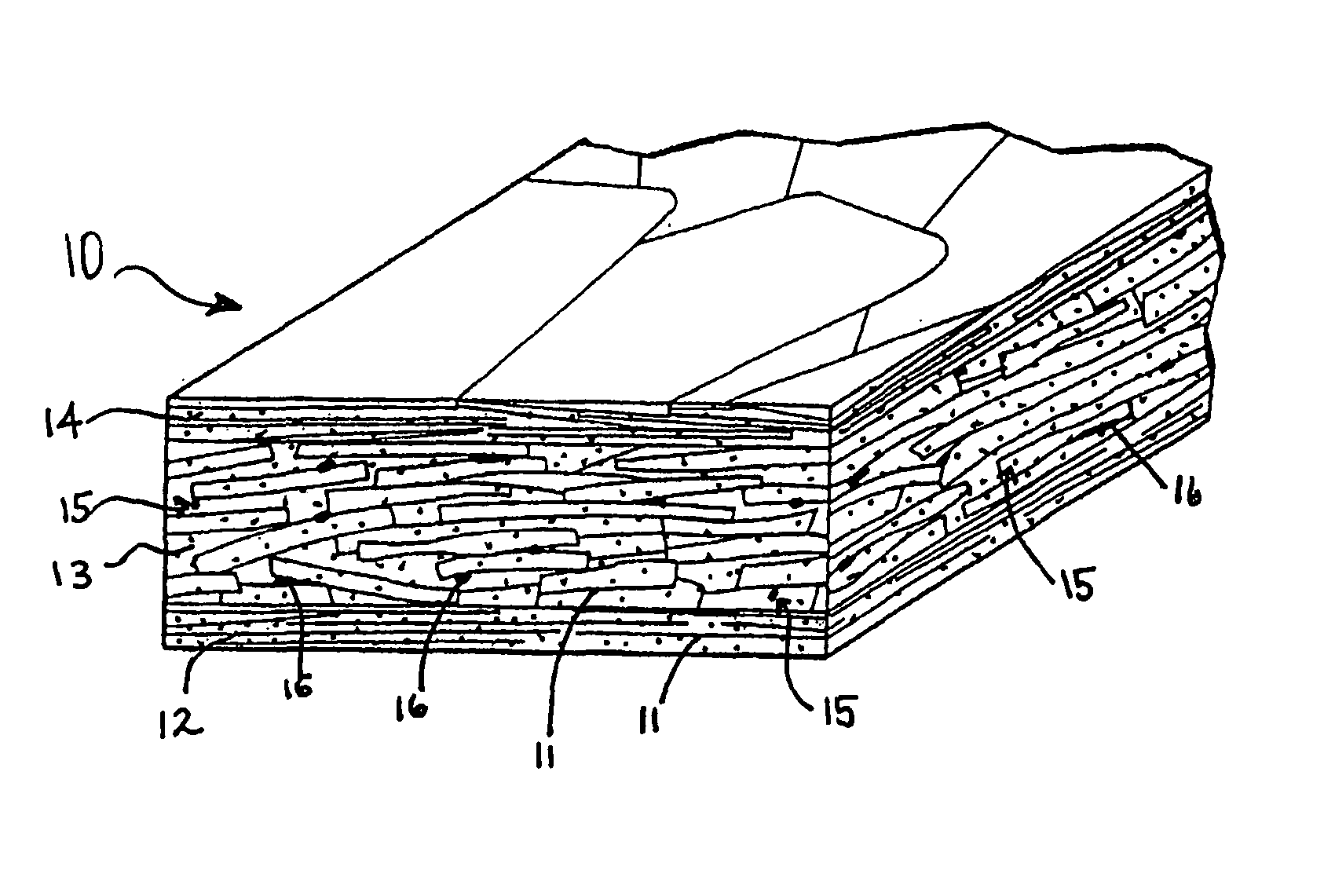

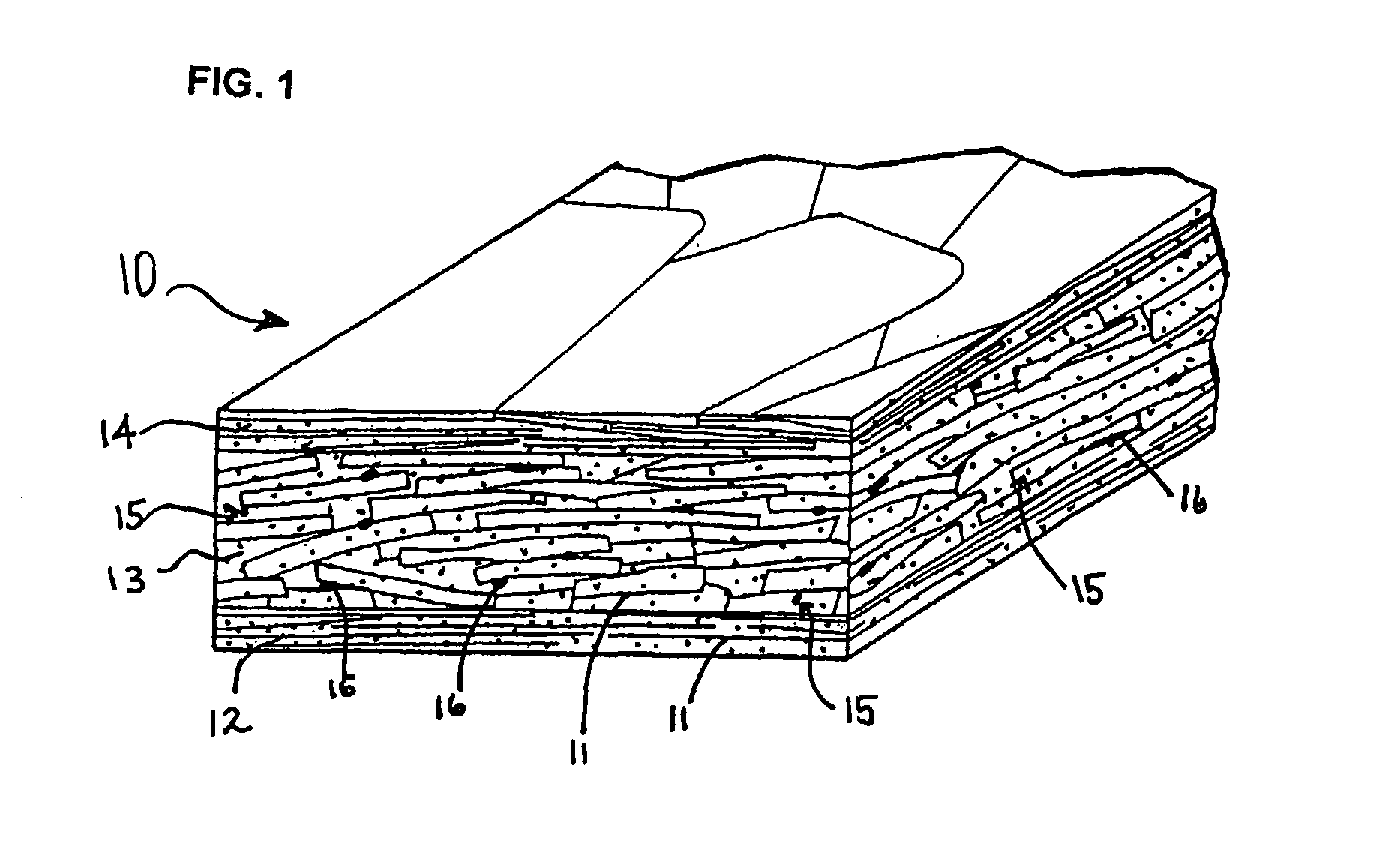

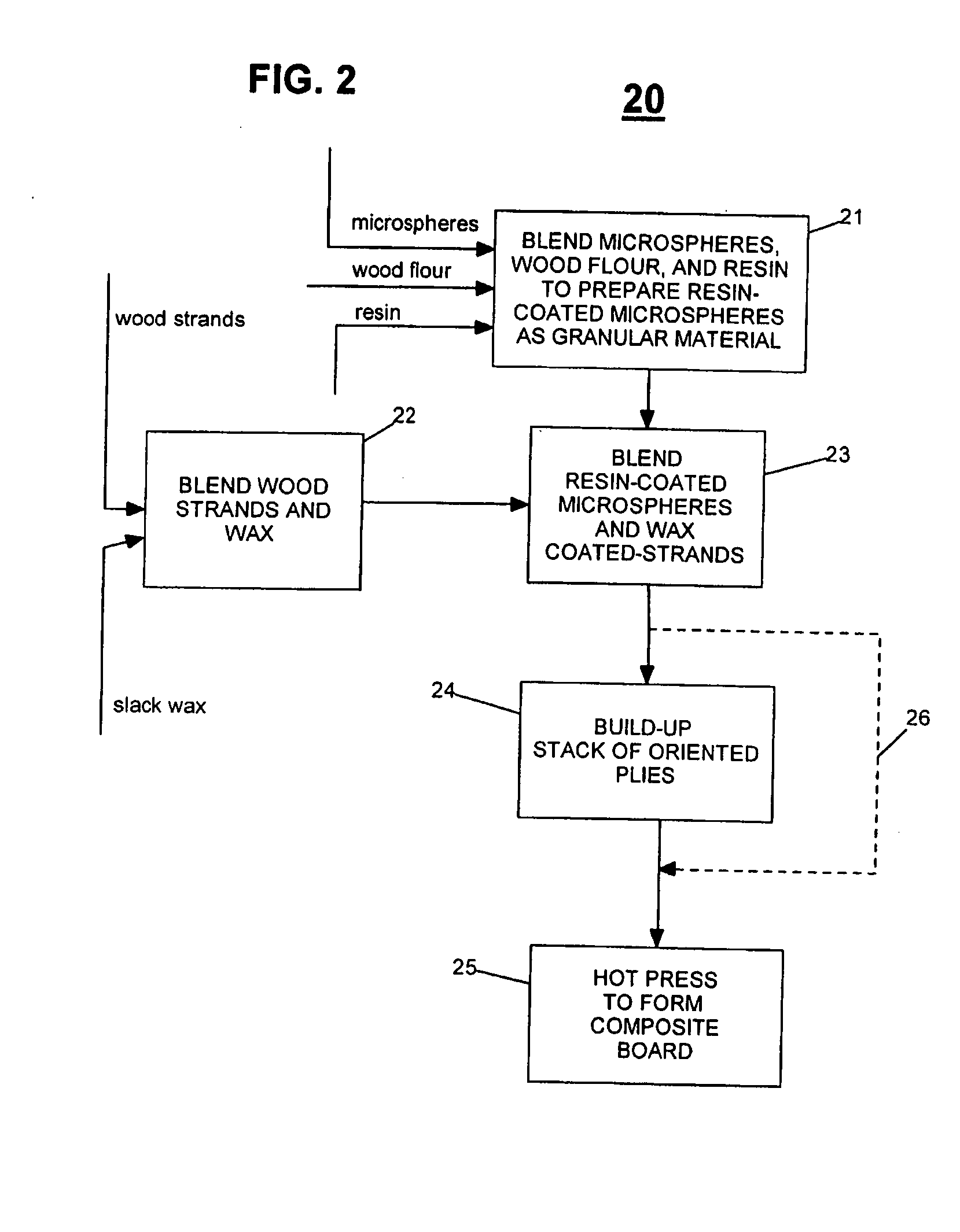

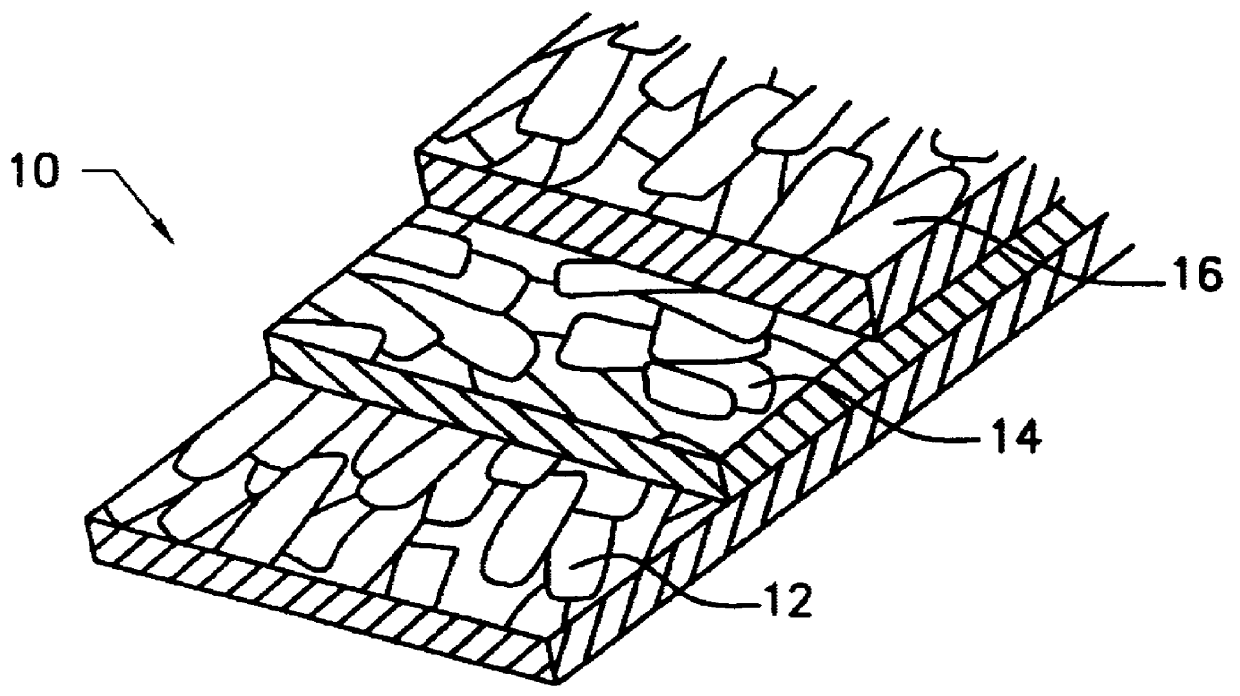

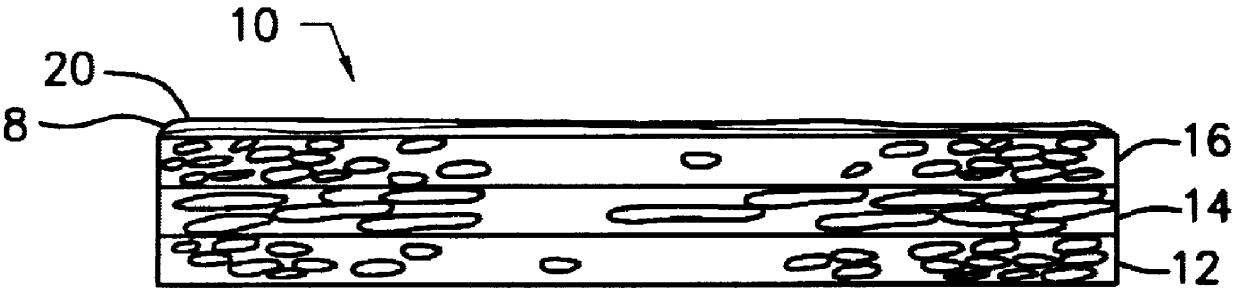

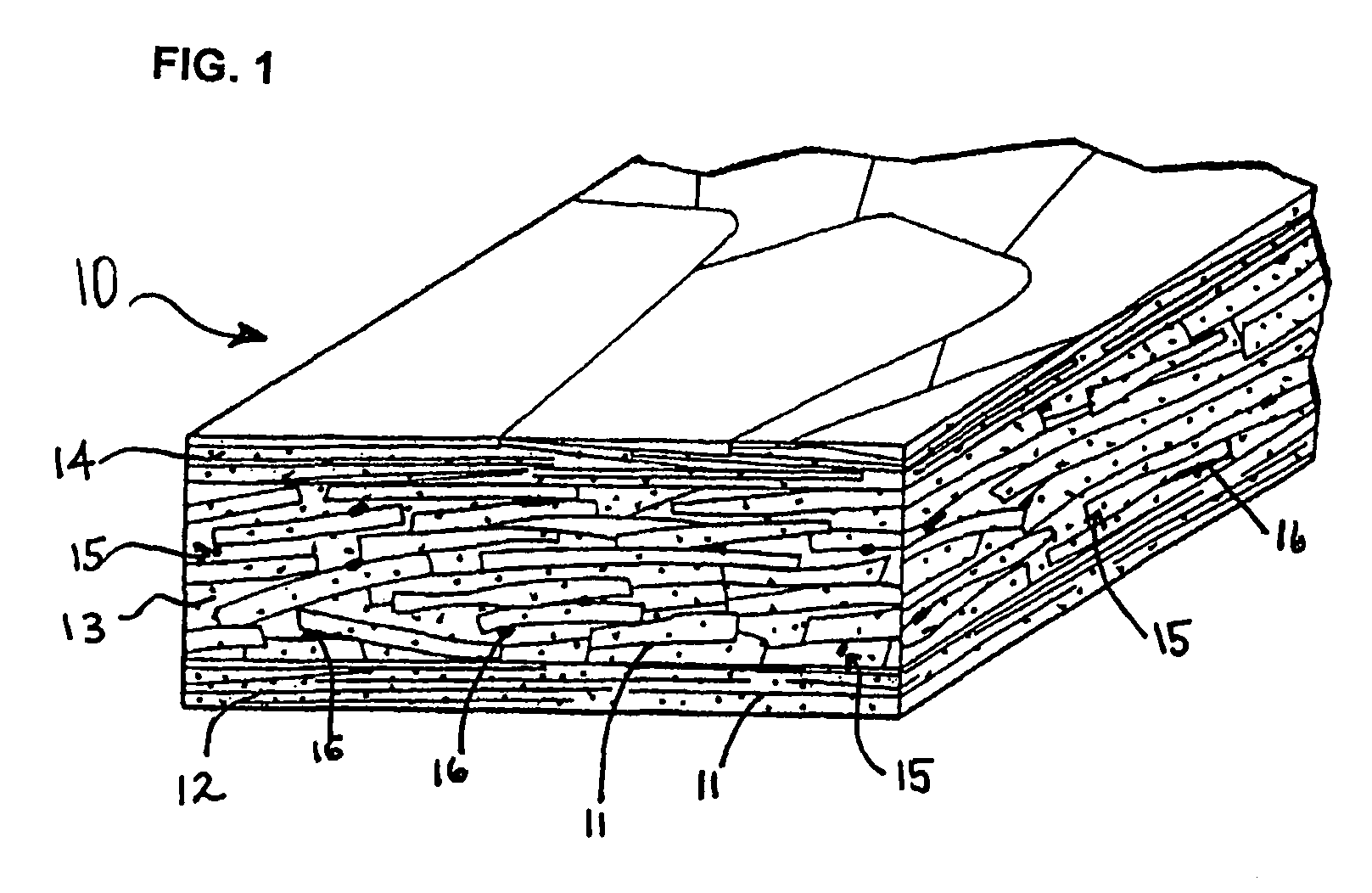

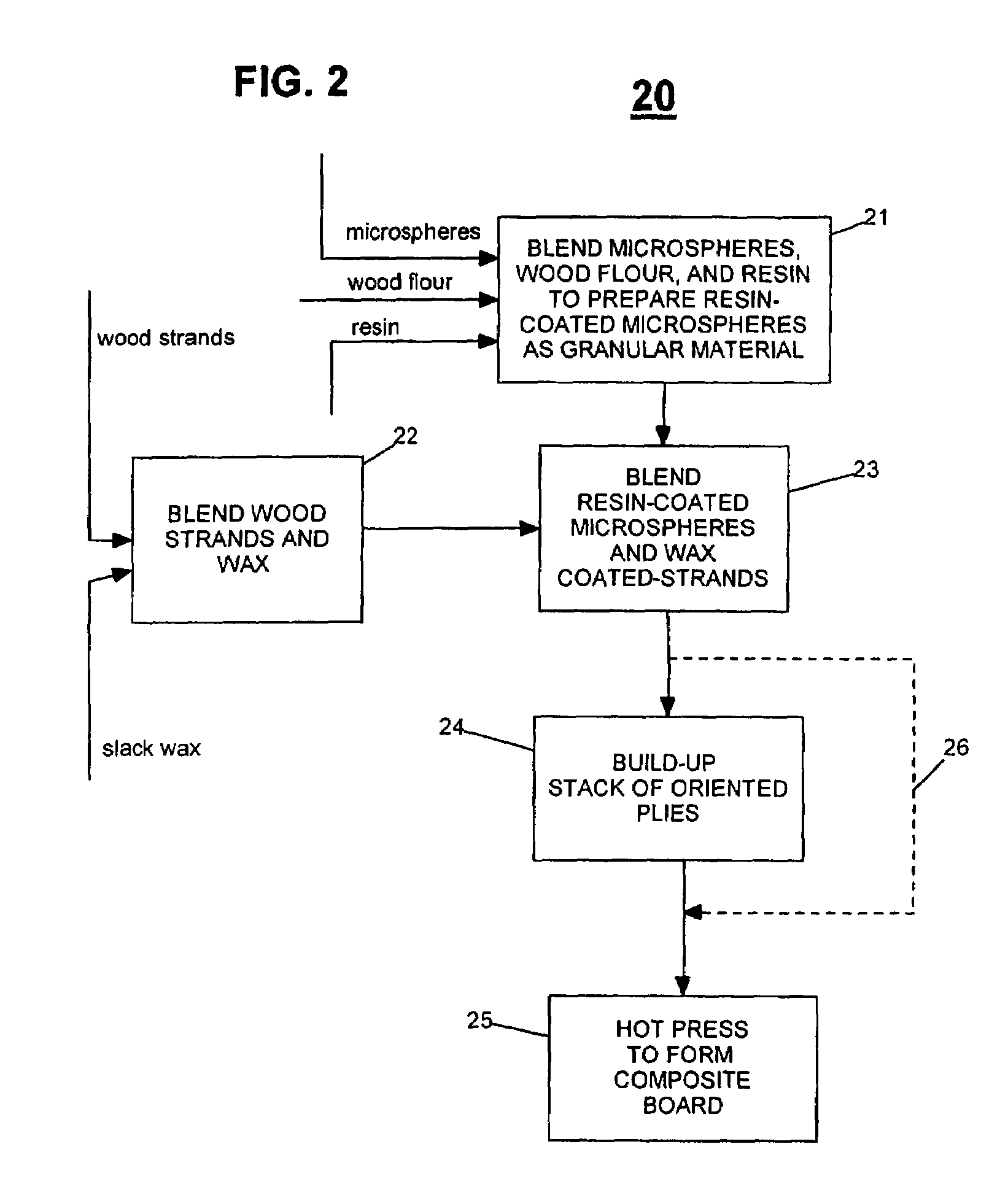

Strength-enhanced, lightweight lignocellulosic composite board materials and methods of their manufacture

InactiveUS20050019548A1Reduced board densityImprove structural strengthSynthetic resin layered productsWood working apparatusCelluloseVolumetric Mass Density

Lighweight lignocellulosic board materials, such as oriented strand board and others, having reduced densities while maintaining suitable mechanical properties, and methods for their manufacture.

Owner:HUBER ENGINEERED WOODS

Surface treatment for wood materials including oriented strand board

Oriented strand board is post-fabrication treated with a polymeric coating which includes isocyanate constituents to produce a construction material which is smooth, has high gloss, and which is resistant to water, vapor, and chemical penetration. The isocyanate constituents are most preferably MDI or PMDI, and may be present in a coating composition alone or in combination with other binder materials such as PEEG or other polyols. Prior to application of the coating composition, the surface of the oriented strand board is pretreated using heat and pressure to compress and densify wood at the surface, and to smooth out minor surface irregularities. The coating composition is then applied to the wood surface, and is cured to form a polymeric coating which bonds to the wood material. The polymeric coating is preferably a polyurethane and functions to prevent water, vapor, and chemical penetration into the oriented strand board, thereby permitting its use as a construction material in a wide variety of applications it heretofore has not achieved commercial acceptance. In addition, the polymeric coating provides the oriented strand board with a smooth surface.

Owner:HUBER ENGINEERED WOODS

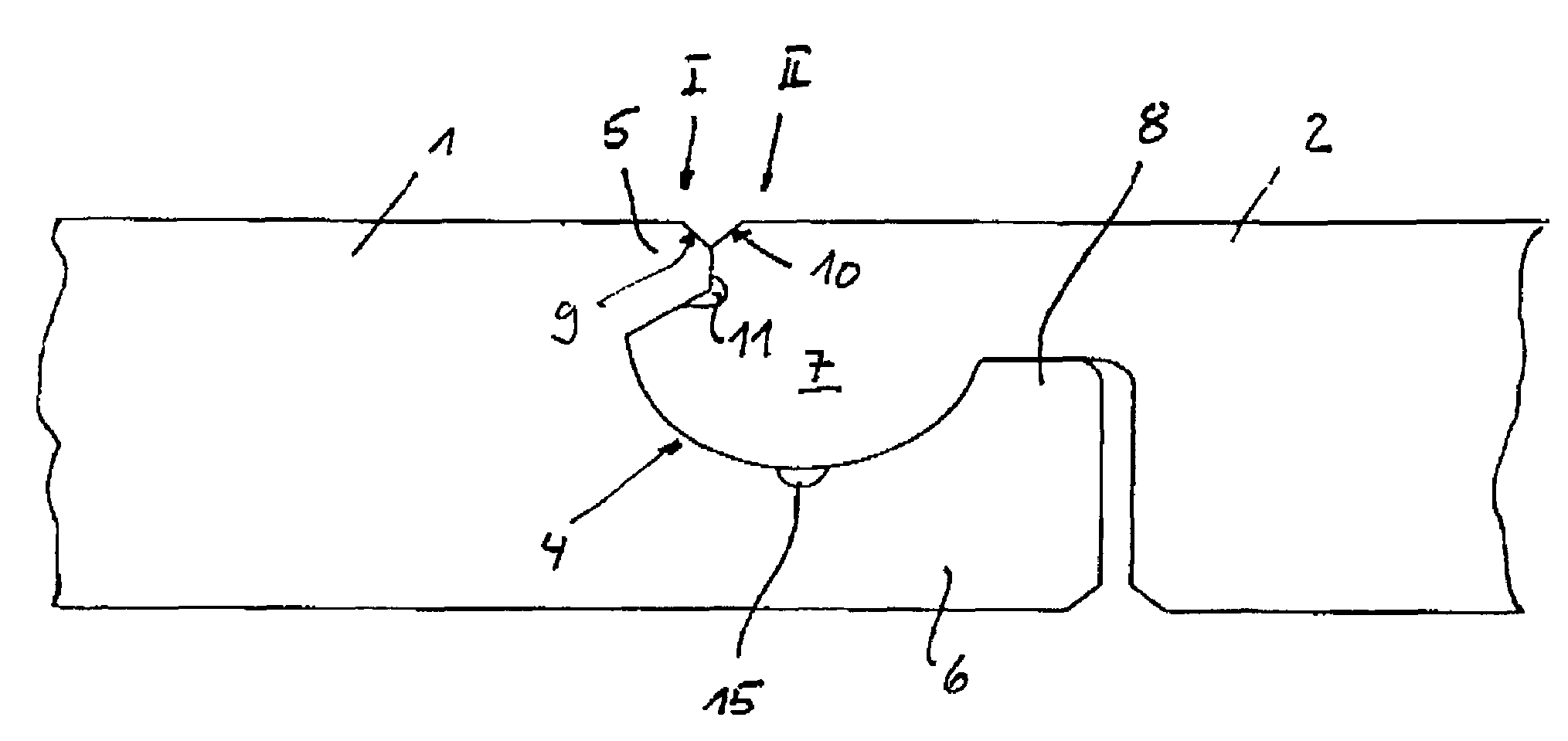

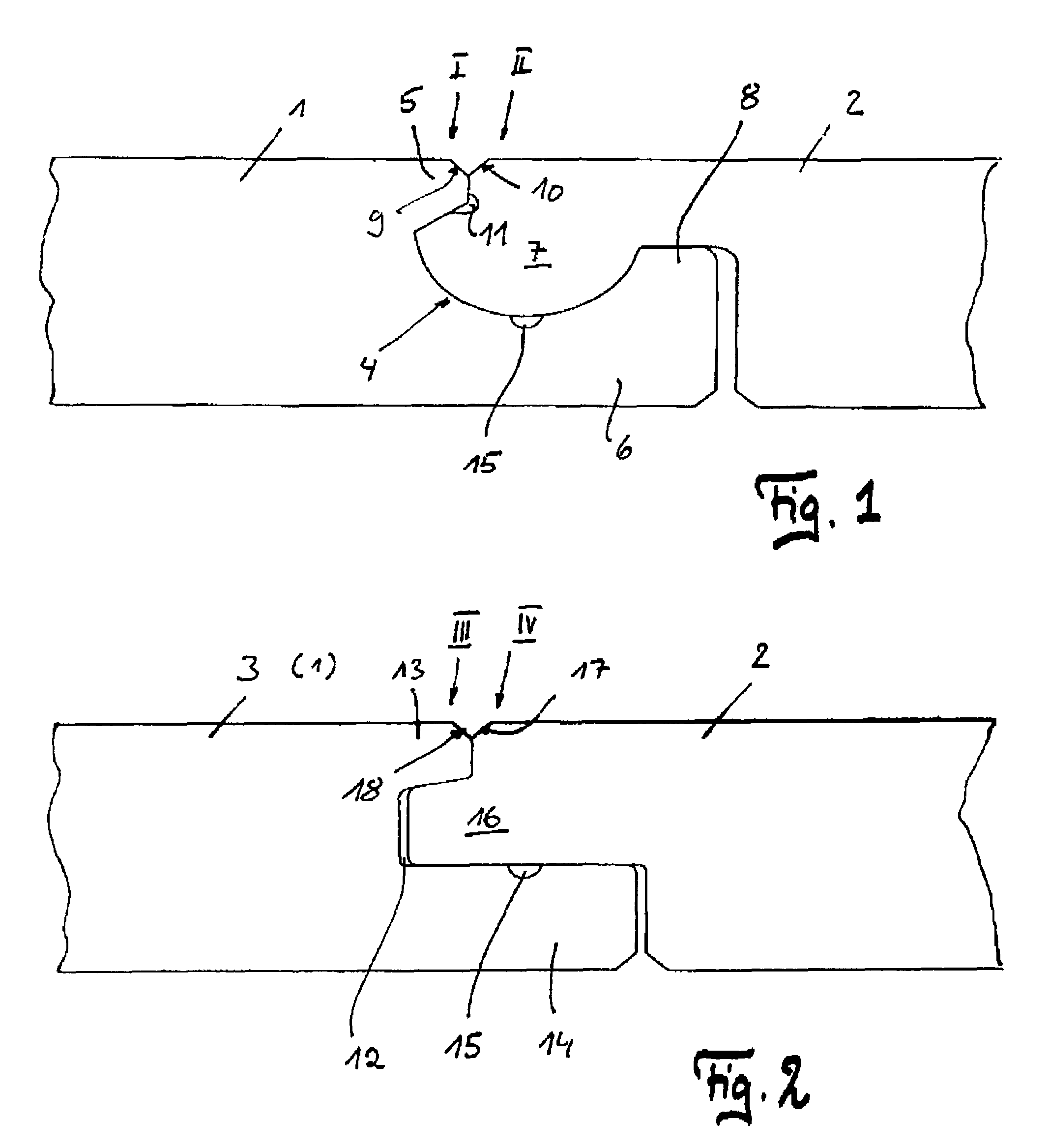

Building board for use in subfloors

A building board made of OSB (oriented strand board) which can be laid on beams, which are spaced apart parallel to one another, in order to form a subfloor in a residential or commercial building and which has two mutually opposite longitudinal edges and two mutually opposite transverse edges running at right angles to the longitudinal edges. One longitudinal edge and one transverse edge in each case has a tongue and the opposite longitudinal edge and transverse edge has a groove corresponding to the tongue, via which a plurality of building boards can be connected to one another and locked in the vertical direction in relation to one another. The tongue and the groove on the longitudinal edge are designed such that two boards which are connected to one another at the longitudinal edges are also locked in a horizontal direction in relation to one another.

Owner:KRONOTEC

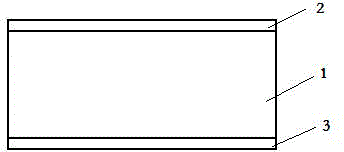

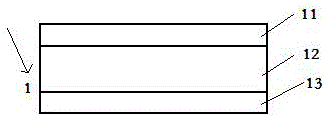

Wood flooring composed of wpl, base and soundproof layer

InactiveUS20060172118A1Improve surface strengthEnhance natural textureCovering/liningsLighting and heating apparatusWood veneerHigh density

Owner:LG CHEM LTD

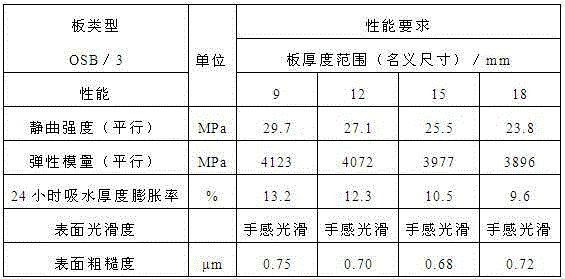

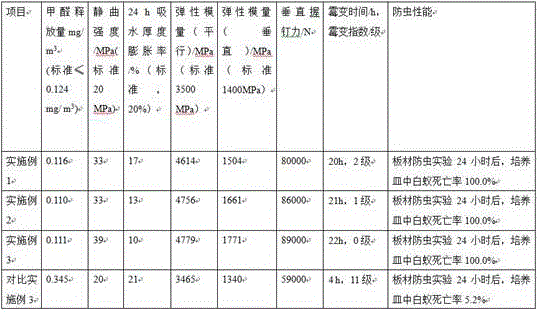

Surface-decorated oriented strand board and preparation process thereof

ActiveCN104626292AHigh strengthGood dimensional stabilityLaminationLamination apparatusFiberParticle board

The invention relates to a surface-decorated oriented strand board and a preparation process of the surface-decorated oriented strand board. The surface-decorated oriented strand board comprises a core layer and a surface layer. Rotary cut veneer leftovers left in the plywood production process are selected as raw materials of the core layer. Sawdust, wood shavings, waste fibers and sanding powder produced in the production process of glued-laminated timber, core-boards, particle boards or medium-density fiberboards are selected as raw materials of the surface layer. The raw materials are subjected to drying, screening, gluing, laying, plate blank sawing and cutting and hot-pressing, and then the surface-decorated oriented strand board can be manufactured. The static bending strength of the oriented strand board in the parallel direction can reach 22-30 MPa, the elasticity modulus of the oriented strand board can reach 3500-4800 MPa, and the surface roughness of the oriented strand board is less than 0.8 micron. The surface-decorated oriented strand board can be directly processed into a decorative surface and can also be widely used for replacing artificial boards such as plywood, the core-boards, the particle boards and the medium-density fiberboards.

Owner:寿光市鲁丽木业股份有限公司

Non-combustible reinforced cementitious lightweight panels and metal frame system for flooring

A flooring system including horizontal metal framing members, for example, C-joists, U-joists, open web joists, HAMBRO or other metal frame systems that support a reinforced, lightweight, dimensionally stable SCP panel. The flooring system is non-combustible, water durable, mold and rot resistant, termite resistant and is capable of resisting shear loads equal to or exceeding shear loads provided by plywood or oriented strand board panels. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

Non-combustible reinforced cementitious lightweight panels and metal frame system for roofing

Owner:UNITED STATES GYPSUM CO

Non-combustible reinforced cementitious lightweight panels and metal frame system for a fire wall and other fire resistive assemblies

A fire resistive assembly including metal framing members, for example, C-joists, U-joists, open web joists, HAMBRO or other metal frame systems that support a reinforced, lightweight, dimensionally stable SCP panel. The assembly is non-combustible, water durable, mold and rot resistant, termite resistant and is capable of resisting shear loads equal to or exceeding shear loads provided by plywood or oriented strand board panels. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

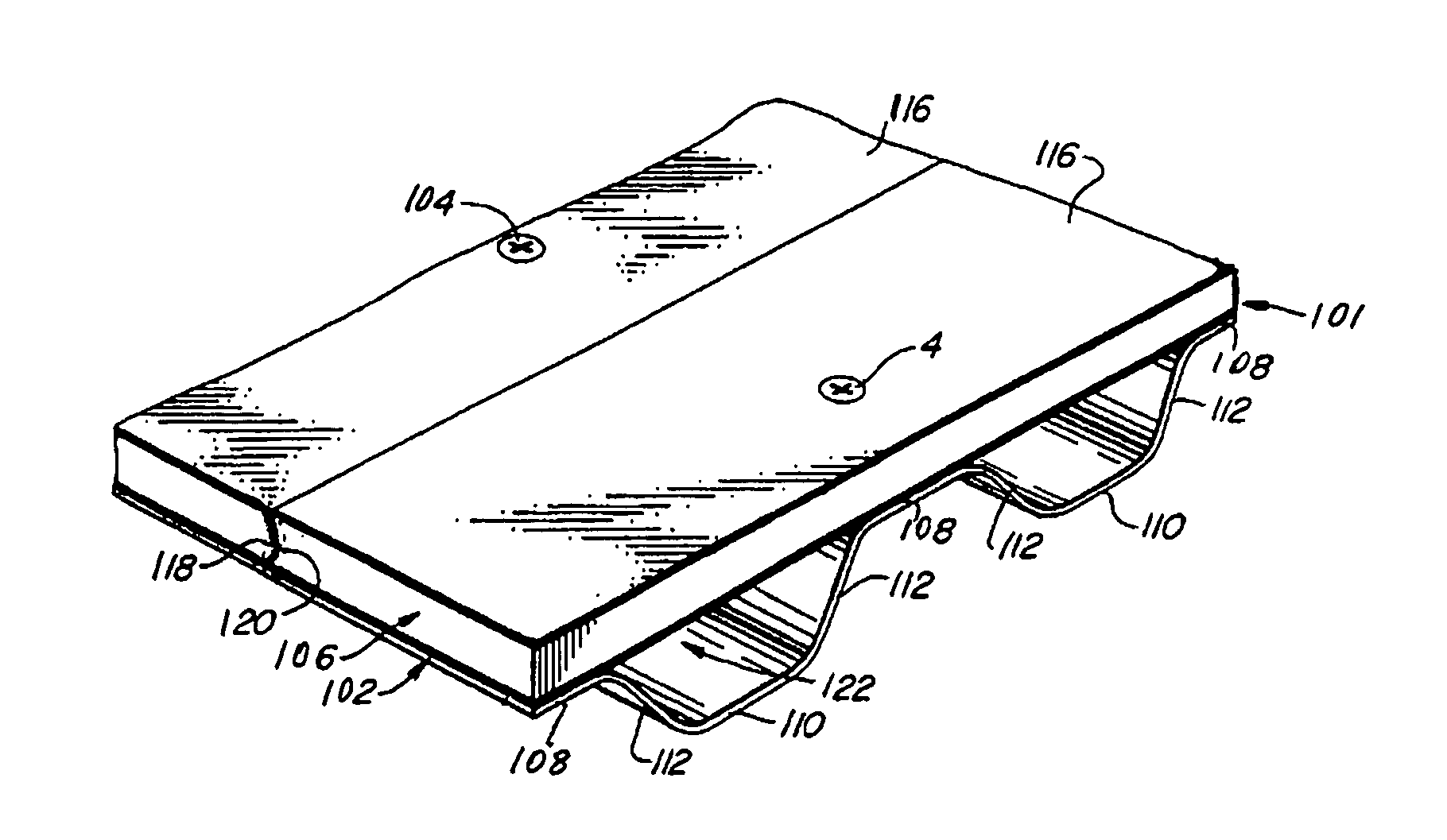

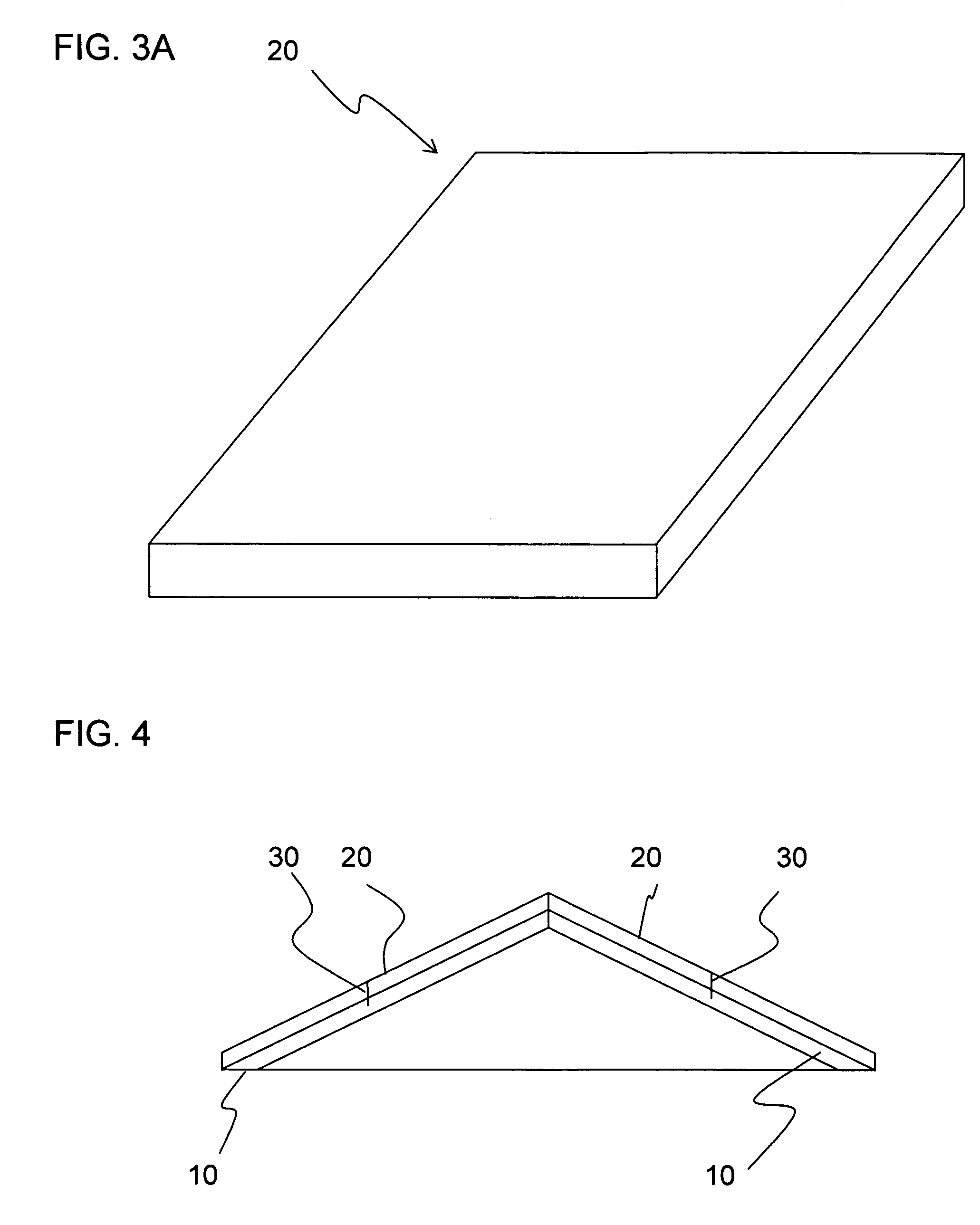

Structural insulated panel for building construction

A structural insulated panel (SIP), such as 8 foot×24 foot, is made with a foam plastic core, oriented strand board on each face, and structural paper on either side of that, all bonded together. The oriented strand board capped with structural paper provides a particularly strong wall structure. Also, the structural paper provides a finished surface as manufactured. SIP-to-SIP joints are created using an insert sandwiched between end portions of in-line-joined SIP panels.

Owner:PORTER WILLIAM H

Wood adhesive and method of preparing thereof

InactiveUS8057892B2Improve waterproof performanceAccelerate the drying rate of an adhesive coatingProtein waste adhesivesLayered productsHigh densityPreservative

A wood adhesive having a) 100 weight parts of water; b) between 3 and 45 weight parts of a proteinaceous material; c) between 0.01 and 15 weight parts of an acidity regulator; d) between 0.01 and 15 weight parts of an aromatic compound; e) between 0.01 and 15 weight parts of a curing agent; f) between 0.01 and 15 weight parts of a preservative; g) between 0 and 15 weight parts of a viscosity modifier; h) between 0 and 10 weight parts of a filler; and i) between 0 and 15 weight parts of a drier. The wood adhesive can be used for preparation of plywood, blockboard, oriented strand board (OSB), flakeboard, fiberboard, veneer plywood, middle density fiberboard, high density fiberboard, hardboard, flooring substrate, LVL, and so on. A method for preparing the wood adhesive is also provided.

Owner:YANG GUANG +1

Non-combustible reinforced cementitious lightweight panels and metal frame system for shear walls

ActiveUS7849649B2Maximization of building volumeEffective volumeSolid waste managementWallsMicrosphereVertical shear

A vertical shear wall system including vertical metal framing members, for example, C-joists, U-joists, open web joists, or other metal frame systems that support a reinforced, lightweight, dimensionally stable SCP panel. The shear wall system is non-combustible, water durable, mold and rot resistant, termite resistant and is capable of resisting shear loads equal to or exceeding shear loads provided by plywood or oriented strand board panels. The panels employ one or more layers of a continuous phase resulting from the curing of an aqueous mixture of inorganic binder, for example, calcium sulfate alpha hemihydrate, hydraulic cement, an active pozzolan and lime. The continuous phase is reinforced with glass fibers and contains lightweight filler particles, for example, ceramic microspheres.

Owner:UNITED STATES GYPSUM CO

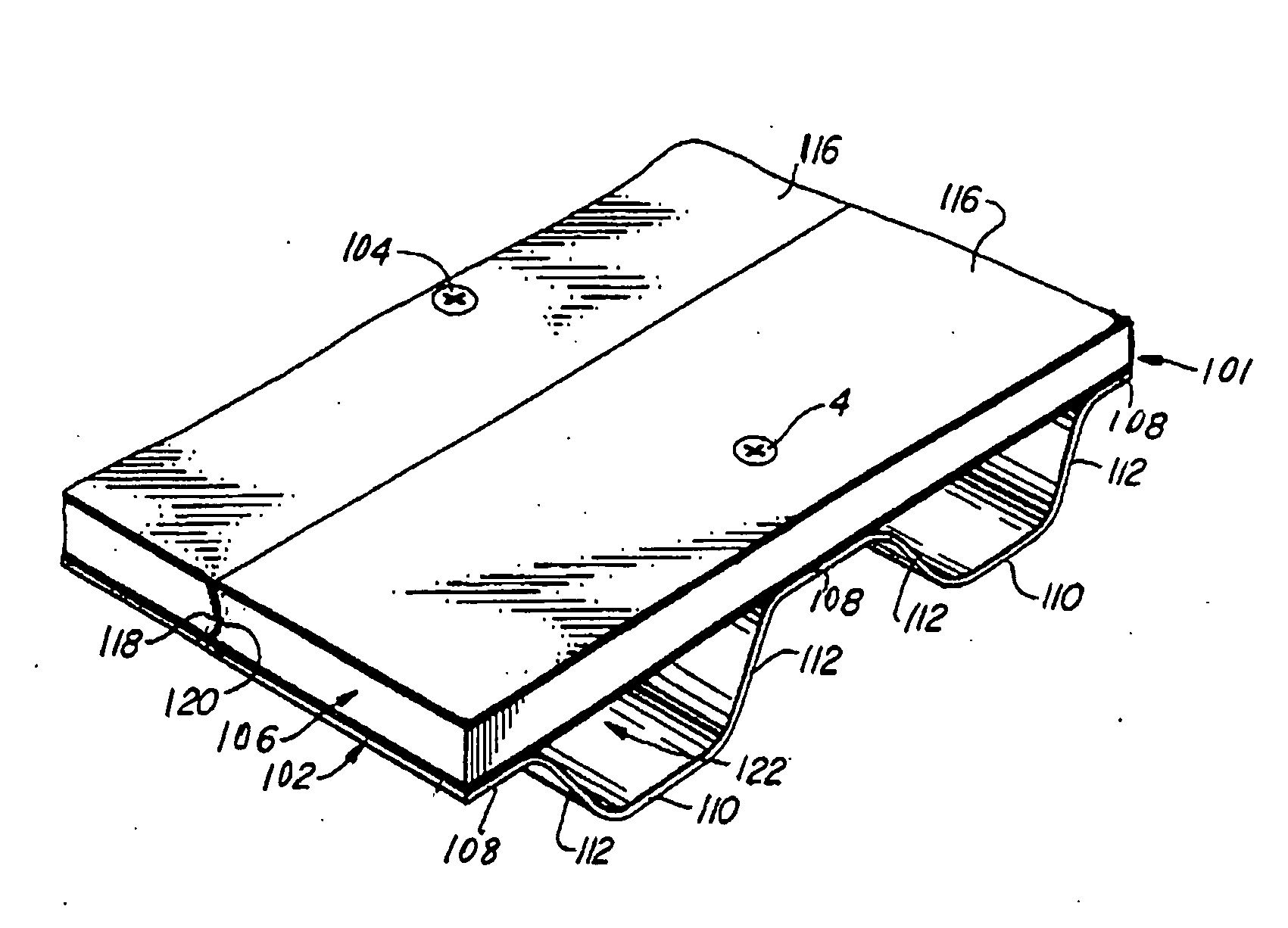

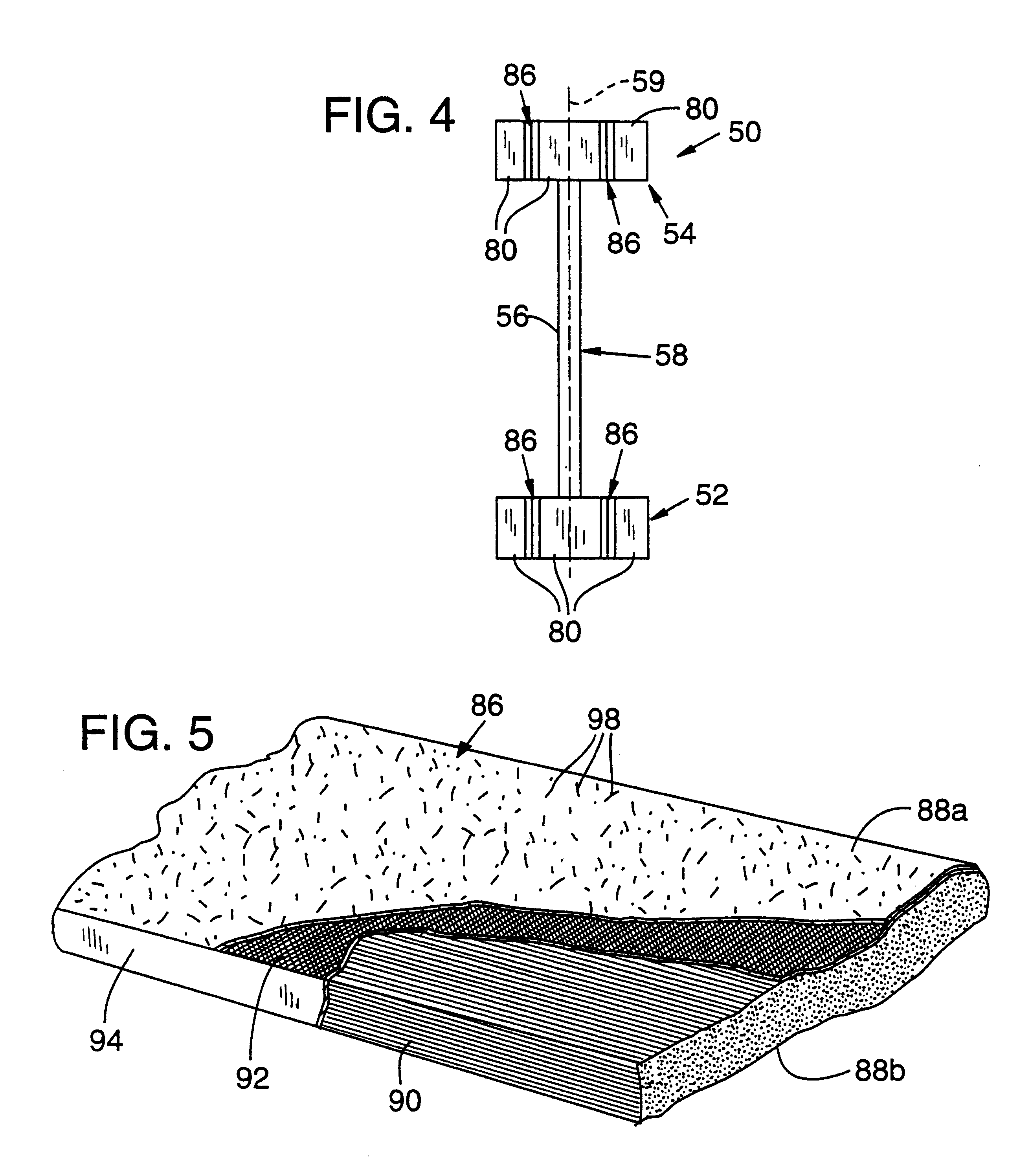

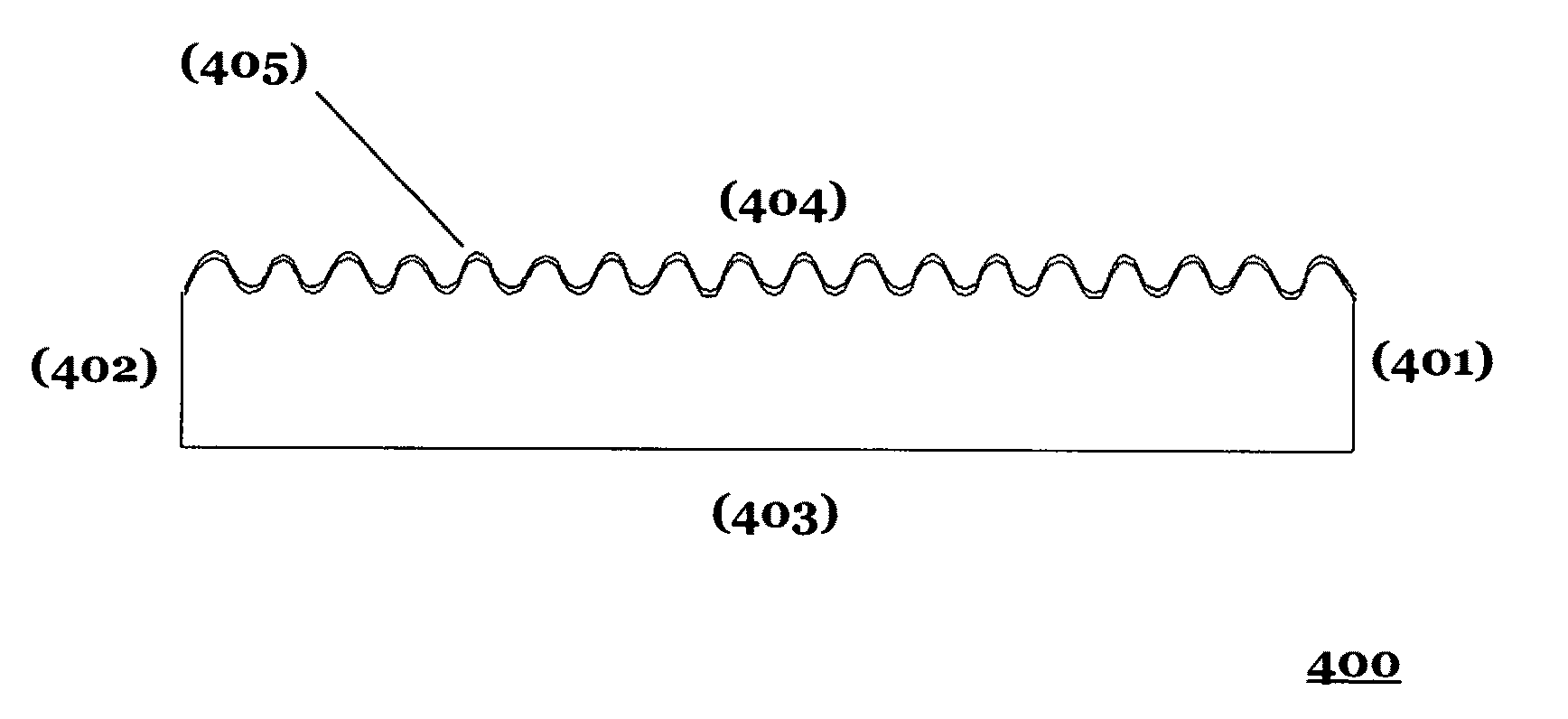

Structural boards having integrated water drainage channels

InactiveUS20090113838A1Improve waterproof performanceCost time be reducedWallsDecorative surface effectsWater trapEngineering

A water resistant structural board suitable for use in a wall system is disclosed. The structural board has water drainage channels on at least one of its surfaces to drain any water trapped behind the sealed wall system. The water drainage channels may be imparted into the structural board during or applied subsequent to a board production process, and the produced board is shipped to the construction site for a wall installation. When desired, the channeled surface of the structural board may be laminated, coated, or sprayed with a water resistant layer to further enhance the water resistant property of the board. A wall system including the disclosed structural board does not require a layer-by-layer installation of a component having water resistant property and a component having water drainage channel structure at a work site; therefore, labor cost and installation time may be reduced significantly. Examples of structural boards are oriented strand board, plywood, particle board, oriented strand lumber, dimensional lumber, fiberboard, wafer board, chipboard, laminated veneer lumber, and any substantially equivalent wood composite board known in art.

Owner:PAULSEN FRITZ G +1

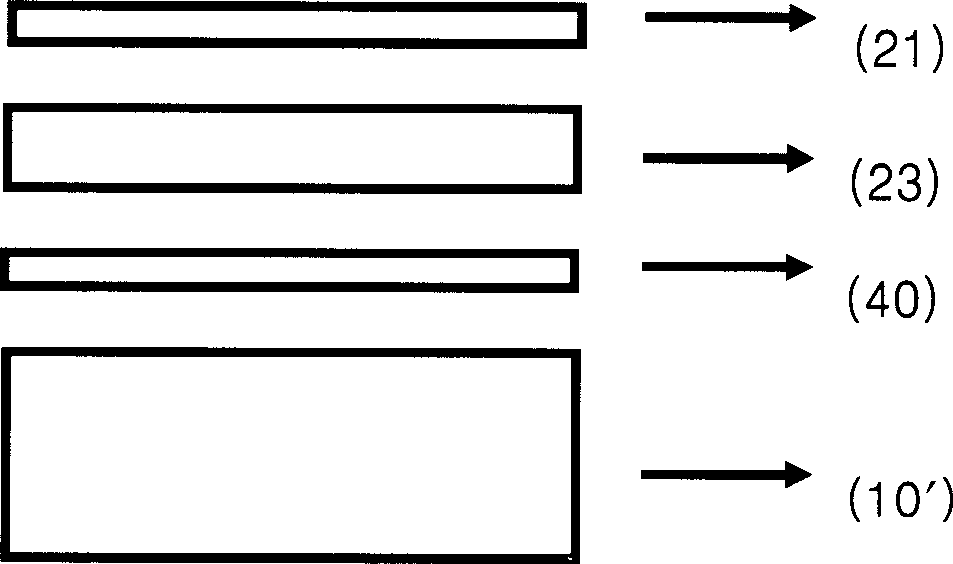

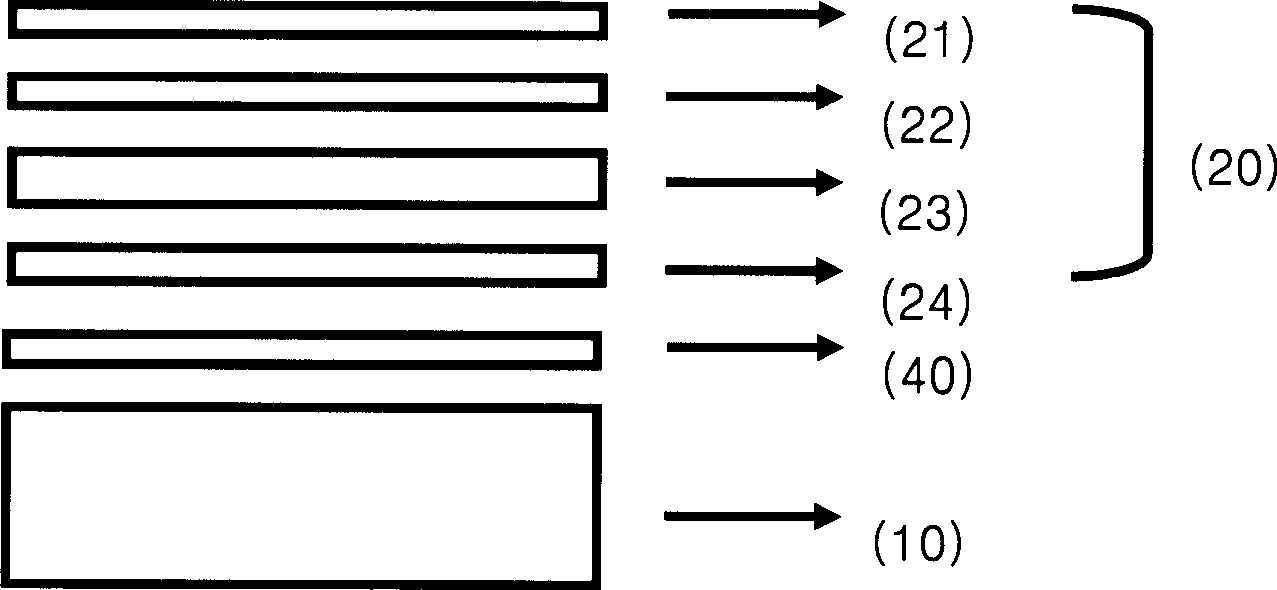

Wood flooring composed of wpl, base and soundproof layer

InactiveCN1735511AImprove sound insulationSynthetic resin layered productsPaper/cardboard layered productsCardboardHigh density

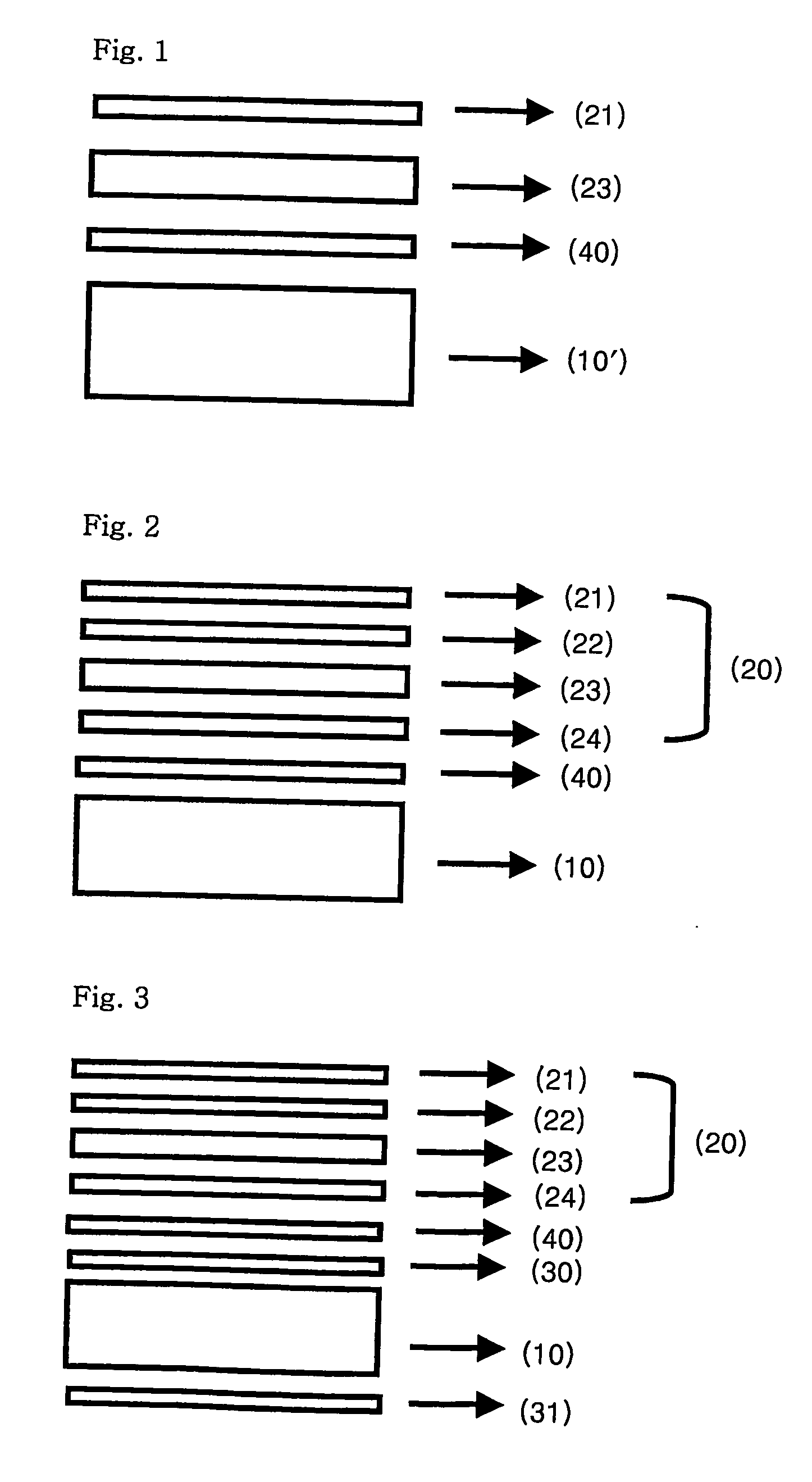

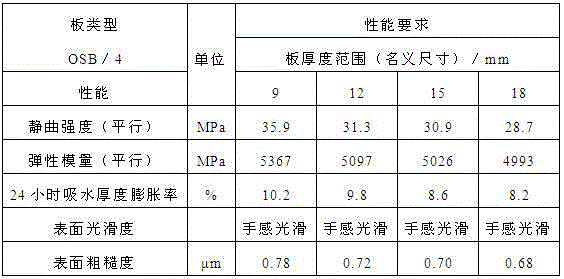

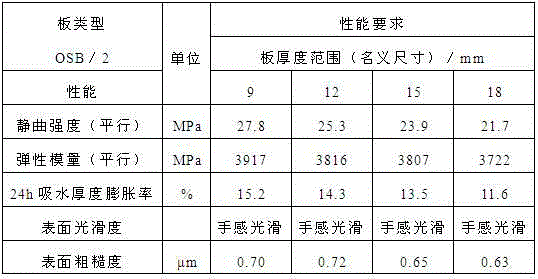

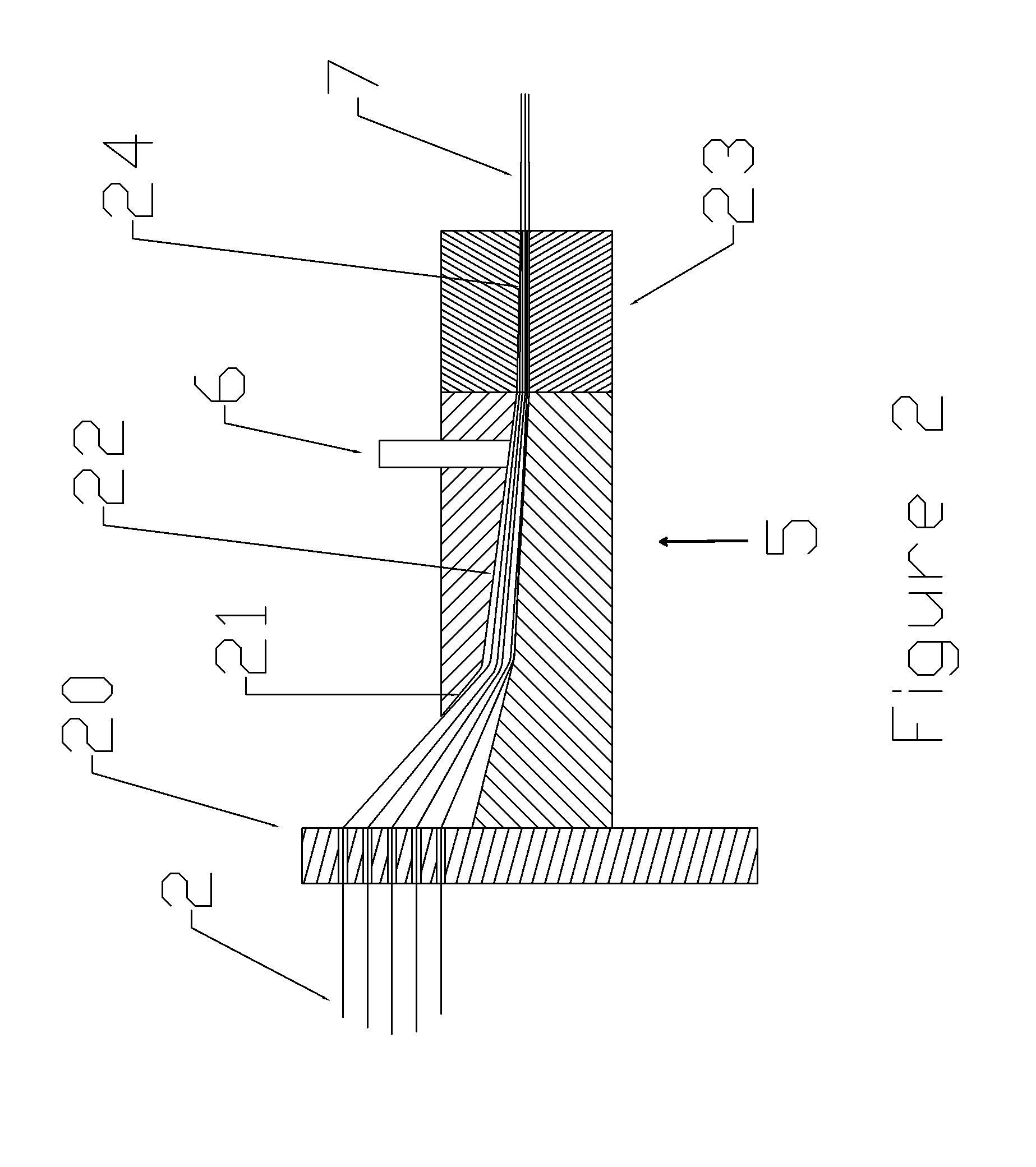

The present invention provides a lamination wood flooring having groove on the back, the WPL of the high pressure resin dipping lamination is laminated on the base selected from the PVC resin layer, oriented strand board(OSB), high density fibreboard (HDF) and waterproof glued board. In particular, the lamination wood flooring having groove on the back includes a WPL 20, an adhesive layer 40, and a base 10 (PVC resin layer, OSB, HDF or waterproof glued board), wherein the WPL 20 includes the base strengthening layer 24 separating by the following order, natural veneer layer 23, the covering layer 22 of the resin dipping and the surface UV coating 21. The lamination wood flooring having groove on the back further shows the excellent sound insulation value.

Owner:LG CHEM LTD

Polymer-aldehyde binding system for manufacture of wood products

InactiveUS20070167561A1Colloidal chemistry detailsUnsaturated alcohol polymer adhesivesFiberCellulose

A formaldehyde-free curable aqueous composition containing a hydroxy-containing polymer, a multi-functional crosslinking agent, and, optionally, a catalyst. The composition is used as a binder for lignocellulosic materials such as plywood, fiber particleboard, medium density fiberboard and oriented strand board.

Owner:DYNEA AUSTRIA

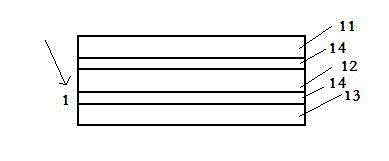

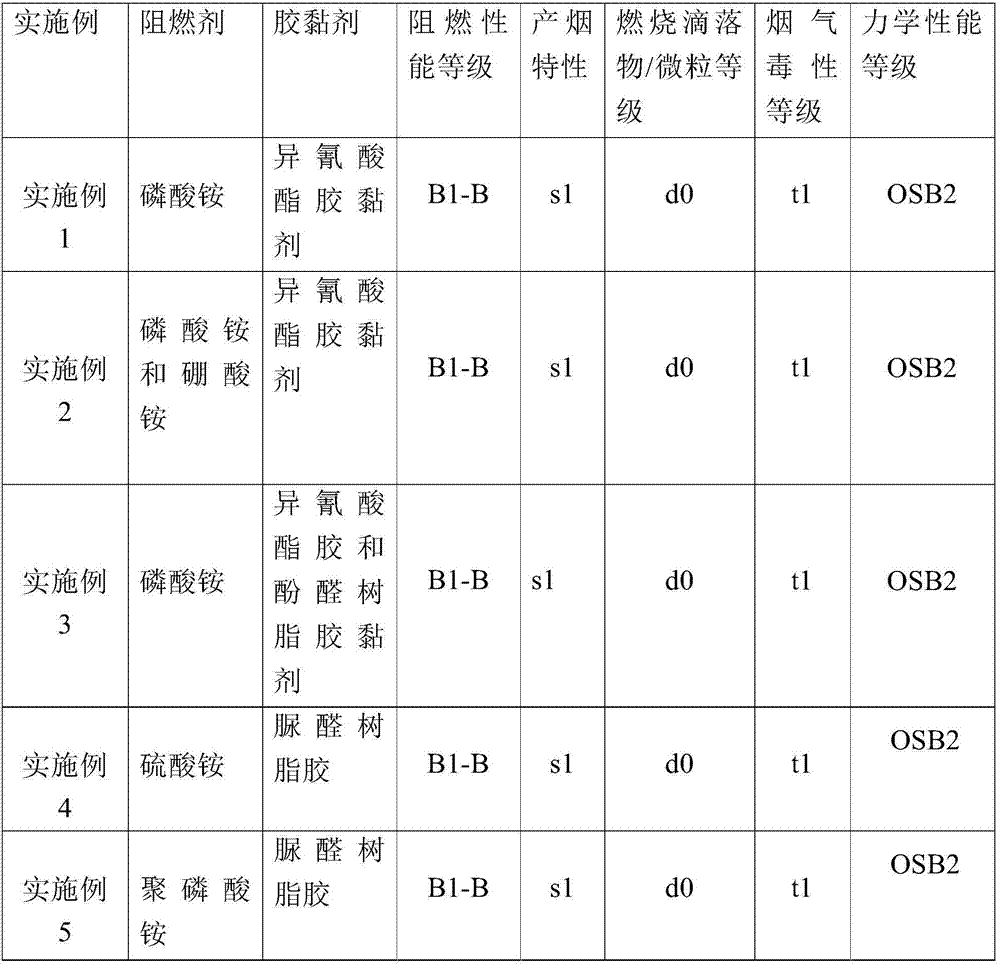

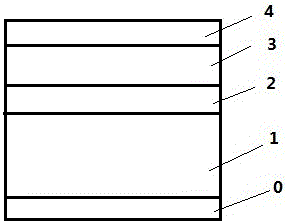

Formaldehyde purification inflaming retarding oriented strand board and manufacturing method thereof

The invention relates to a paint-free decorative overlay fitment board, in particular to a formaldehyde purification inflaming retarding oriented strand board and a manufacturing method thereof, and belongs to the wood processing industry. The formaldehyde purification inflaming retarding oriented strand board comprises a base material layer, an upper surface layer decorative film adhesive layer and a lower surface layer decorative film adhesive layer. The upper surface layer decorative film adhesive layer and / or the lower surface layer decorative film adhesive layer are immersed with an amino resin adhesive solution and a formaldehyde decomposition adhesive solution, the base material layer is an oriented strand board layer, the oriented strand board layer comprises an upper surface layer, a lower surface layer and a core layer shaving layer, wherein the glue mixing wood shavings on the upper and lower surface layers are longitudinally arranged in the fiber direction, the glue mixing wood shavings on the core layer shaving layer are transversely arranged in the fiber direction, an inflaming retarding layer is arranged between the lower surface shaving layer and the core layer shaving layer, and an inflaming retarding layer is arranged between the upper surface shaving layer and the core layer shaving layer. The manufacturing method of the paint-free decorative overlay fitment board comprises the steps of base material sanding, formaldehyde decomposition adhesive solution preparation, decorative film adhesive manufacturing, assembling and pressing and sticking. The formaldehyde purification inflaming retarding oriented strand board is realistic in effect, low in cost and good in formaldehyde purification effect.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

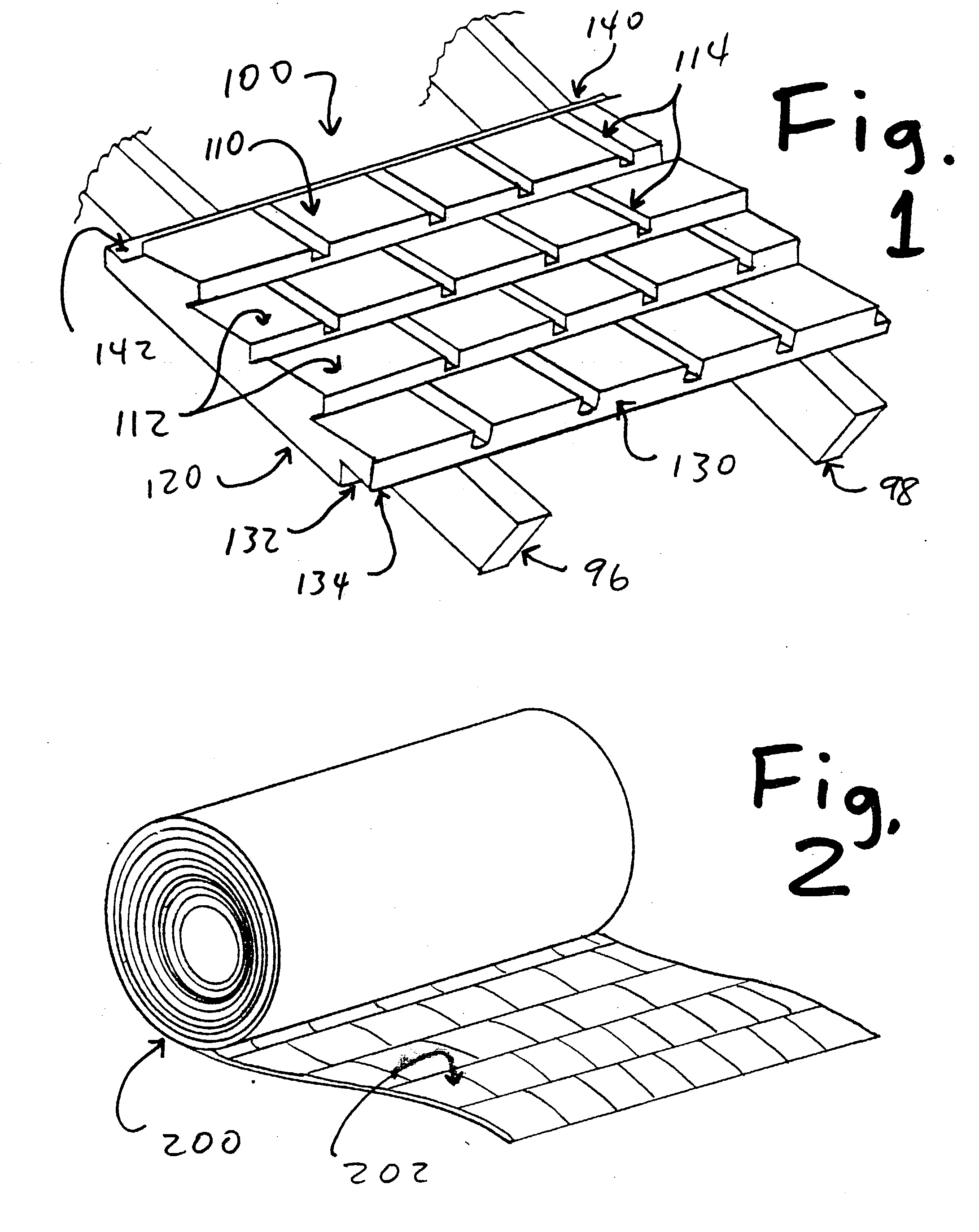

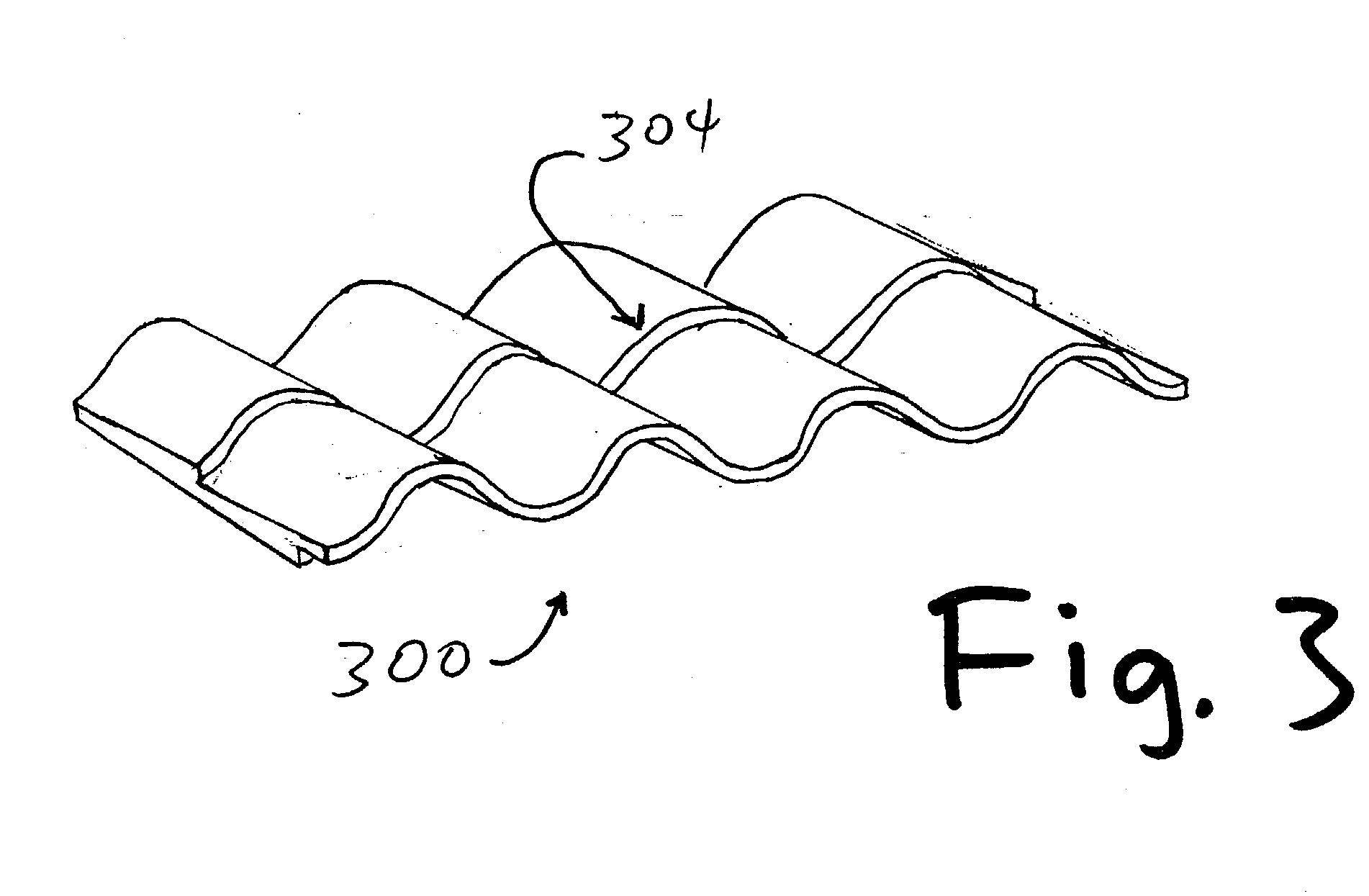

Roofing materials made with nylon fiber composites

InactiveUS20050170141A1Avoid insufficient thicknessSolve the lack of stiffnessLayered productsRecord information storageManufacturing technologyRoof tile

Synthetic nylon fiber composite materials having embossed or molded surfaces that emulate shingles or roofing tiles are disclosed, for providing waterproof, high-strength, durable substitute for shingles or roofing tiles. In one embodiment, these materials can be relatively thin, and designed to rest on supporting sheets of plywood, oriented strand board (OSB), or nylon fiber composite board that have been nailed to rafters. In an alternate embodiment, these materials can be manufactured in sheets with sufficient thickness, stiffness, and strength to allow them to be nailed directly to rafters, thereby eliminating the need for a supporting layer of plywood or OSB. In a third embodiment, these materials can be molded or embossed to emulate Spanish tiles, or to provide enhanced drainage or other useful traits. For improved waterproofing, the lower edge of each segment can be provided with an overhang that will overlap the upper edge of an adjacent sheet on the next lower horizontal row, to provide overlapping material at each juncture between these composite segments. These materials also can be coated or embedded with chemicals that provide increased resistance to water, fire, and ultraviolet damage. They provide excellent thermal insulation, and can reduce heating and air conditioning costs. A preferred manufacturing process uses needle-punched fiber mats, and any combination of nylon-6 and nylon-6,6 fibers can be used.

Owner:BACON FORREST C +2

Strength-enhanced, lightweight lignocellulosic composite board materials and methods of their manufacture

InactiveUS7217458B2Reduced board densityImprove structural strengthSynthetic resin layered productsWood working apparatusCelluloseVolumetric Mass Density

Owner:HUBER ENGINEERED WOODS

Modified flame-retardant oriented strand board and preparation method thereof

InactiveCN107379141AImprove flame retardant performanceImprove stabilityImpregnation spraying apparatusWood treatment detailsPolymer scienceAdhesive

The invention discloses a modified flame-retardant oriented strand board. The modified flame-retardant oriented strand board comprises, by weight, 1-5% of nano silicon dioxide, 10-30% of nitrogen and phosphorus flame retardants, 43-79.5% of wood flakes, 2.5-22% of adhesive and 0.5-3% of an auxiliary agent. The invention further discloses a preparation method of the modified flame-retardant oriented strand board. Compared with a common secondary processing method, a silicon dioxide modified flame retardant and the auxiliary agent are added into a primary shaping technology of the oriented strand board, so that the prepared oriented strand board is better in flame retardant effect and higher in flame retardancy stability. According to the flame-retardant oriented strand board prepared by adopting the preparation method, only simple spraying equipment needs to be additionally arranged in a sizing technology, the device transformation cost is low, a secondary processing device is avoided, and the cost is saved.

Owner:天津北新木业有限公司

Polyurethane laminates made with a double belt press

InactiveUS20130115412A1Excellent Adhesive PropertiesFine surfaceSynthetic resin layered productsPaper/cardboard layered productsComposite laminatesResin matrix

A fiber reinforced composite laminate with fibers generally oriented along two major axes and having a polyurethane resin matrix suitable for reinforcing wood based substrates such as trailer / container flooring, glulams, plywood, particle boards, laminated veneer lumber, and oriented strand board, is provided. The laminate is produced by pulling the fibers through a resin injection box, where a polyurethane resin is injected into the box to wet the fibers. The polyurethane resin wetted fiber layer is then covered with a release media on the top and bottom sides of the layer. The sandwich of fiber, resin and release media is fed to a double belt press capable of applying pressure and heat to consolidate and cure the laminate. The laminate thus made can be thinner than 0.080 inch and provides excellent flatness compared to pultruded thin laminates.

Owner:HAVCO WOOD PRODS

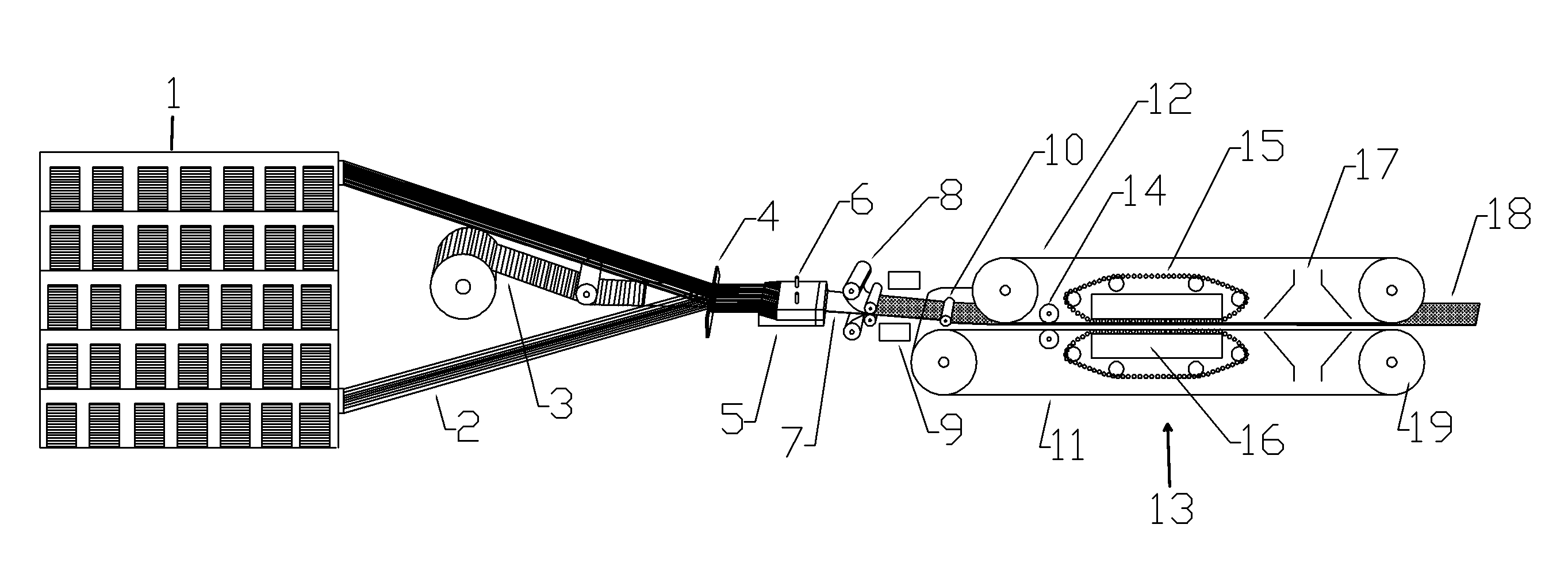

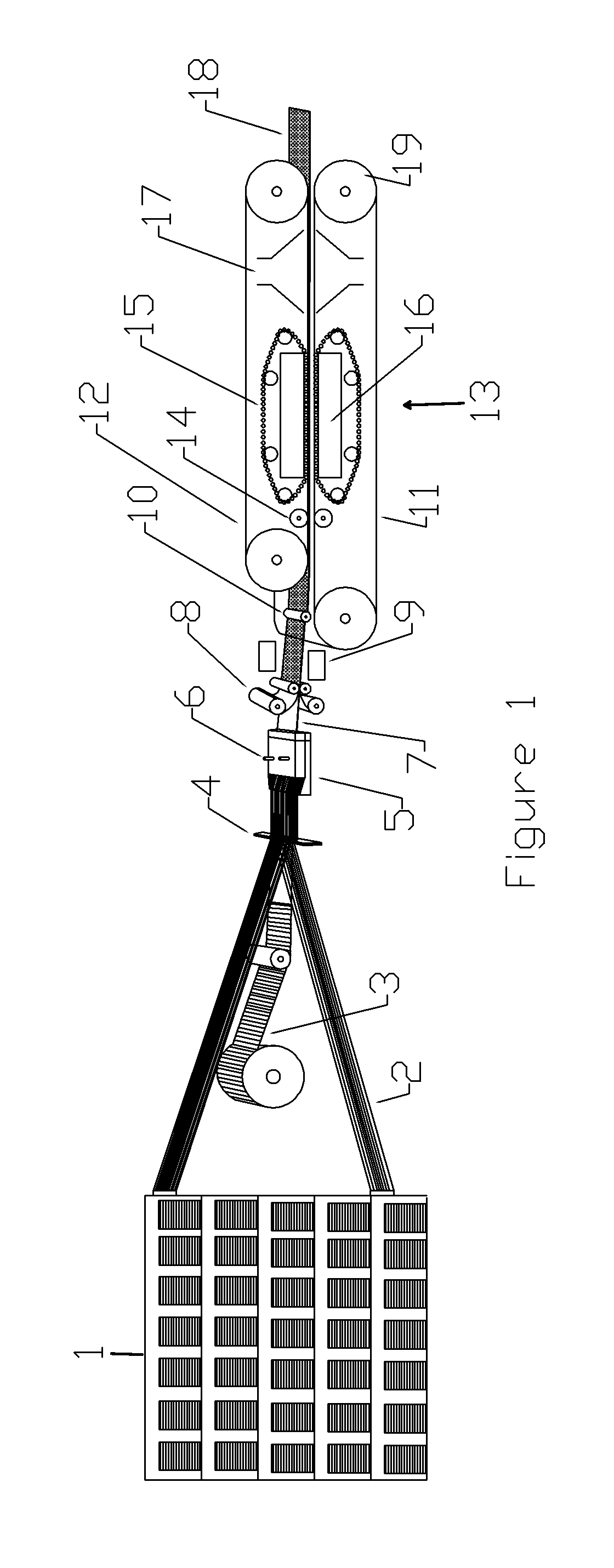

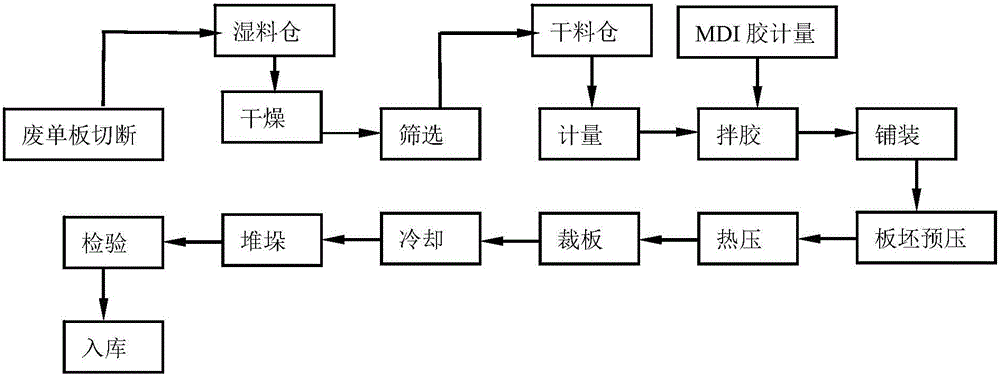

Method for producing oriented strand board by using eucalyptus waste single board

InactiveCN105751345ALow costEasy material selectionFlat articlesDomestic articlesFiberMedium density fiberboard

The invention relates to a method for producing an oriented strand board by using a eucalyptus waste single board. The method comprises the following steps: cutting, humidifying and drying the eucalyptus waste single board serving as a wooden sheet of a basic material, putting the eucalyptus waste single board to be in contact with an MDI formaldehyde-free and insoluble hot-setting adhesive, and performing such processes as oriented spreading and continuous hot press molding. According to the method, the oriented strand board processed by the eucalyptus waste single board with the thickness of 1.50-2.80 mm and the MDI formaldehyde-free and insoluble hot-setting adhesive which serve as raw materials is firm, durable and free of formaldehyde, and is lighter in weight and higher in flatness than furniture made of a moderate-density fiber board.

Owner:广西横县新威林板业有限公司

Termite resistant and fungal resistant oriented strand board and methods for manufacturing

InactiveUS20050037202A1Efficient curingLess expensiveOrganic active ingredientsCosmetic preparationsBotanyOriented strand board

Owner:NORBORD

Method for manufacturing anti-insect and anti-mold oriented strand board with full eucalyptus leftover materials

InactiveCN106346589AWhite colorGood film formingFlat articlesDomestic articlesOptoelectronicsImpurity

The invention discloses a method for manufacturing an anti-insect and anti-mold oriented strand board with full eucalyptus leftover materials. The manufacturing method comprises the following steps of: preparing materials, drying, peeling and removing impurities, sorting and storing, respectively gluing on a surface core layer, hierarchically paving, in advance hot press molding, and sanding wood finishes; an isocyanate sawdust powder hybrid adhesive is coated on the surface, and an anti-insect and anti-mold composite urea-formaldehyde resin adhesive is coated on the core layer; wood shavings on the core layer are divided into three-layer structures, comprising intermediate layer of core layer, upper surface layer of core layer and lower surface layer of core layer; the intermediate layer of the core layer is paved longitudinally, and the upper surface layer of the core layer and the lower surface layer and surface layer of the core layer are paved horizontally. For the oriented strand board prepared by the method, the static bending intensity in a parallel direction is in a scope of 33-39 MPA, the parallel elasticity modulus is in the scope of 4614-4779 MPA, the vertical elasticity modulus is in the scope of 1504-1771 MPA, the thickness swelling rate of water absorption in 24 h is in the scope of 10%-17%, and the vertical nail-holding power reaches up to 89000N. In the manufacturing method, a problem that the board is easy to suffer from erosion of white ants and moths is thoroughly solved by adding an anti-insect and anti-mold additive, and the service life of the board is prolonged.

Owner:广西横县新威林板业有限公司

Photocatalystc composite floor board and production process of photocatalystc composite floor board

InactiveCN104989066ADoes not affect bond strengthAffect bond strengthLaminationLamination apparatusWood shavingsSurface layer

The invention relates to a photocatalystc composite floor board, and belongs to the field of a functional environment-friendly healthy floorboard. The formaldehyde emission content of the composite floorboard is less than 0.3mg / L; the antibacterial rate is higher than or equal to 90 percent; the surface wear-resistant coefficient is less than or equal to 0.08g / 100r; a substrate layer is an oriented shaving board layer; the oriented shaving board layer comprises an upper surface layer and a lower surface layer which are formed by glue mixing wood shavings in longitudinal arrangement according to the fiber direction and a core layer shaving layer formed by glue mixing wood shavings in transverse arrangement according to the fiber direction; and a decoration layer, a wear-resistant primer layer and a photocatalystc antibacterial paint decoration layer are sequentially arranged on the substrate layer. A production process of the photocatalystc composite floor board comprises the steps of shaving board layer sorting, glue preparation, glue distribution and assembling for the first time, cold pressing for the first time, core trimming, glue distribution and assembling for the second time, cold pressing for the second time, hot pressing for the first time, fixed-thickness sanding, edge cutting, puttying, polishing, sorting, reconditioning, glue distribution and veneering, cold pressing for the third time, hot pressing for the second time, multi-blade sawing, sanding, double-end milling, priming, finish paint preparing and finish paint painting. The composite floorboard has the advantages of good antibacterial function, high strength, good wear-resistant performance and comfortable foot feeling.

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com