Surface-decorated oriented strand board and preparation process thereof

A technology of oriented strand board and preparation process, which is applied in the field of particle board, can solve the problems that the surface layer of oriented strand board cannot meet the dense and delicate quality requirements, and cannot reduce costs, etc., and achieves the effects of low water absorption thickness expansion rate, reduced raw material cost, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1, a decorative oriented strand board, including a core layer and a surface layer, the surface layer includes an upper surface layer and a lower surface layer, the upper surface layer is connected to the upper surface of the core layer, and the lower surface layer is connected to the lower surface of the core layer.

[0041] The shavings of the core layer are arranged horizontally, the shavings of the surface layer are arranged vertically, and the shavings of the surface layer and the core layer form an orientation angle of 60°-90°.

[0042]The core layer accounts for 70%-80% of the total thickness of the oriented strand board, and the surface layer accounts for 30%-20% of the total thickness of the oriented strand board.

[0043] The preparation technology of described oriented strand board comprises the following steps:

[0044] 1) Raw material preparation.

[0045] (1) Preparation of core layer raw materials.

Embodiment 2

[0068] Embodiment 2, a facing oriented strand board, includes a core layer and a surface layer, the surface layer includes an upper surface layer and a lower surface layer, the upper surface layer is connected to the upper surface of the core layer, and the lower surface layer is connected to the lower surface of the core layer.

[0069] The shavings of the core layer are arranged horizontally, the shavings of the surface layer are arranged vertically, and the shavings of the surface layer and the core layer form an orientation angle of 60°-90°.

[0070] The core layer accounts for 70%-80% of the total thickness of the oriented strand board, and the surface layer accounts for 30%-20% of the total thickness of the oriented strand board.

[0071] The preparation technology of described oriented strand board comprises the following steps:

[0072] 1) Raw material preparation.

[0073] (1) Preparation of core layer raw materials.

Embodiment 3

[0096] Embodiment 3, a decorative oriented strand board, including a core layer and a surface layer, the surface layer includes an upper surface layer and a lower surface layer, the upper surface layer is connected to the upper surface of the core layer, and the lower surface layer is connected to the lower surface of the core layer.

[0097] The shavings of the core layer are arranged horizontally, the shavings of the surface layer are arranged vertically, and the shavings of the surface layer and the core layer form an orientation angle of 60°-90°.

[0098] The core layer accounts for 70%-80% of the total thickness of the oriented strand board, and the surface layer accounts for 30%-20% of the total thickness of the oriented strand board.

[0099] The preparation technology of described oriented strand board comprises the following steps:

[0100] 1) Raw material preparation.

[0101] (1) Preparation of core layer raw materials.

[0102] The remaining rotary-cut veneer scr...

PUM

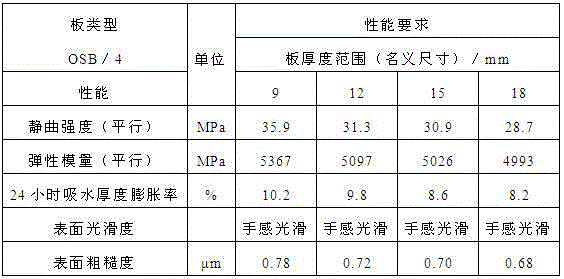

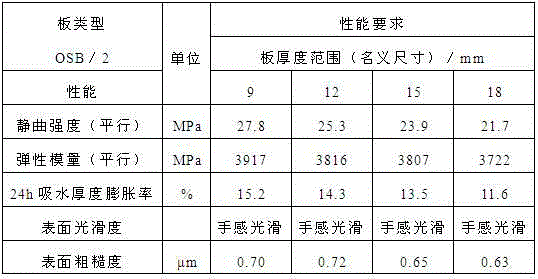

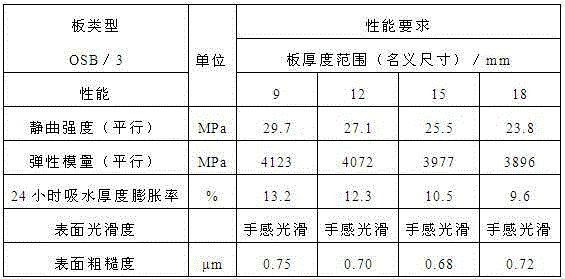

| Property | Measurement | Unit |

|---|---|---|

| Static bending strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com