Patents

Literature

32 results about "Glued laminated timber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glued laminated timber, also abbreviated glulam, is a type of structural engineered wood product constituted by layers of dimensional lumber bonded together with durable, moisture-resistant structural adhesives. In North America, the material providing the laminations is termed laminating stock or lamstock.

Carbonization wood finger-joint glued-laminated timber and its manufacturing method

InactiveCN101104282AChange part chemistryChange physical propertiesWood veneer joiningWood layered productsCarbonizationFinger joint

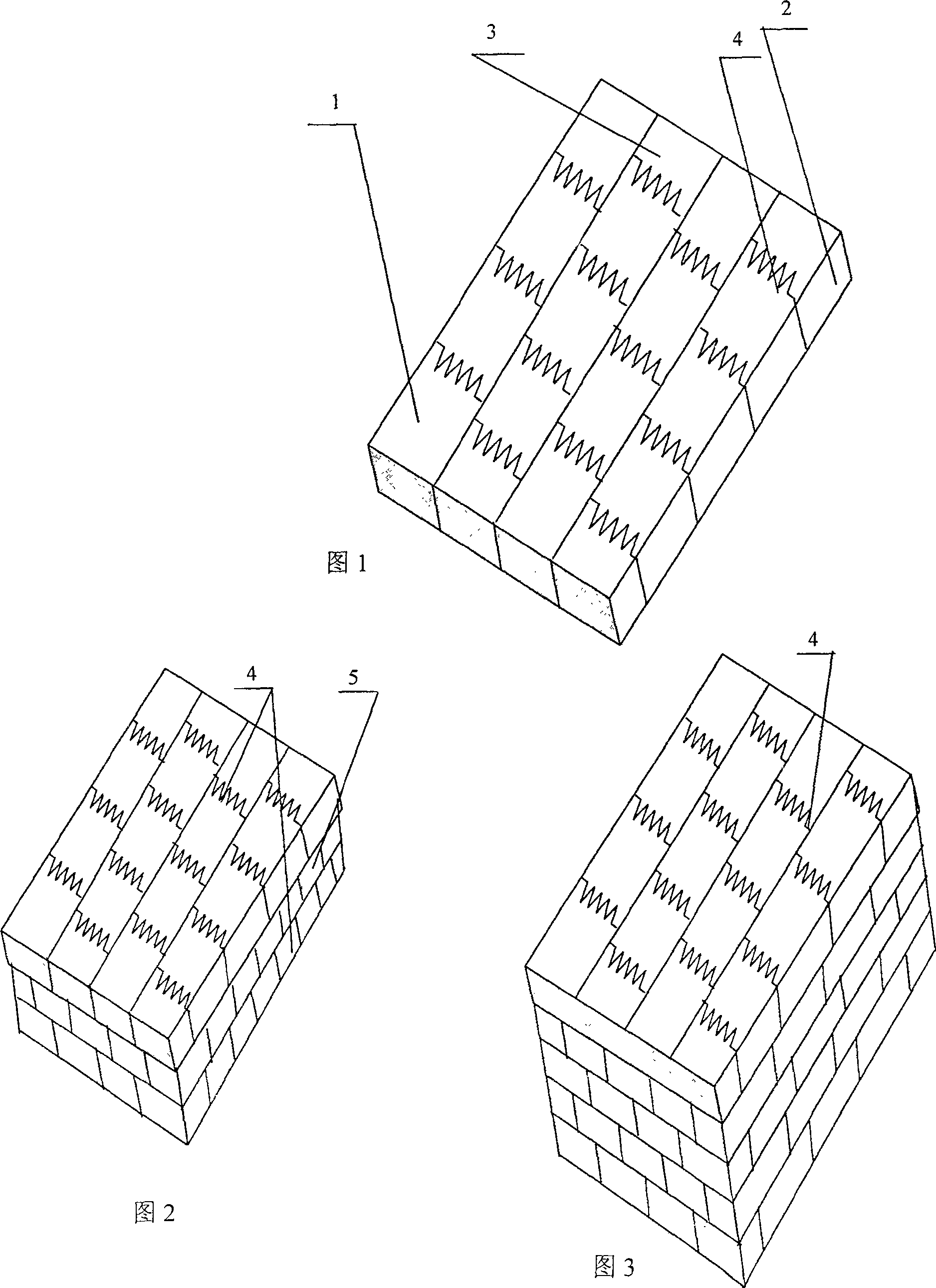

The invention relates to a carbonized figure jointed glulam lumber and a manufacturing method. The carbonized figure jointed glulam lumber is a one-layer integrated board, or one or several layers of lateral battens laying in the sandwich layer and the integrated board with more than two layers is glued in parallel in the direction of thickness. Each layer of the integrated board is made of standard battens formed by gluing many short battens through finger-jointing and tenoning, and then the standard width is formed by gelatinizing on the side of the batten and gluing and joining in parallel. The process of the method includes: log truncation, sawing, carbonization, chopping, finger-jointing, repairing, sanding and repairing; second glue jointing: gelatinizing; testing, warehousing. The advantages are that part of the chemical and physical properties of wood are changed permanently; hydrophilic property of the lumber is reduced and the inner stress is eliminated completely; the color of the wood is darkened and the wood texture is clear; the contained resin inside the wood is removed so that the wood can be glued and finished; the drying operation is substituted by the high temperature carbonization technique; the carbonized figure jointed glulam lumber is of stable size and shape, of no craze and resin and of clear texture and good durability.

Owner:NANJING FORESTRY UNIV +1

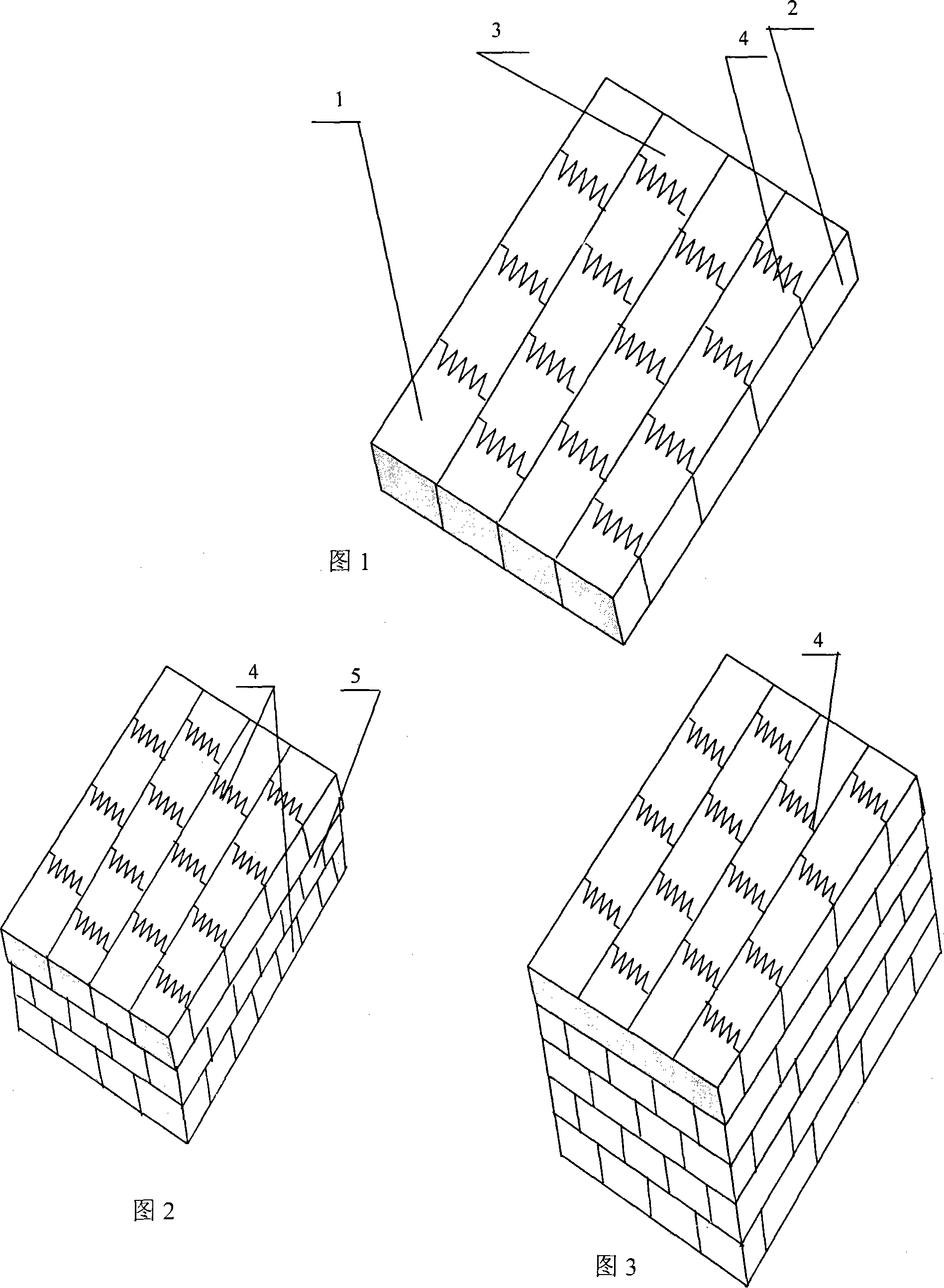

Surface-decorated oriented strand board and preparation process thereof

ActiveCN104626292AHigh strengthGood dimensional stabilityLaminationLamination apparatusFiberParticle board

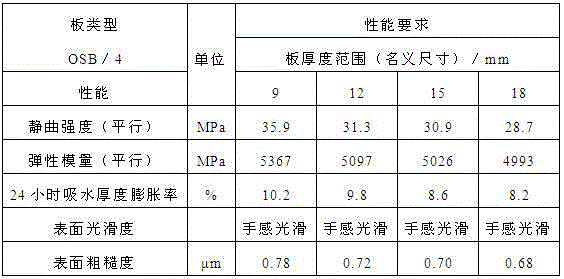

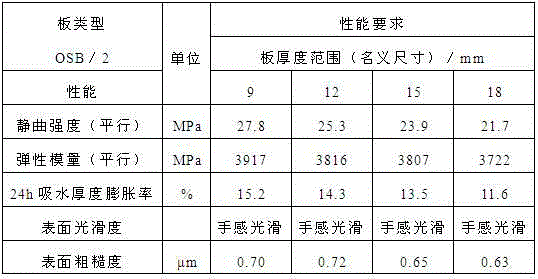

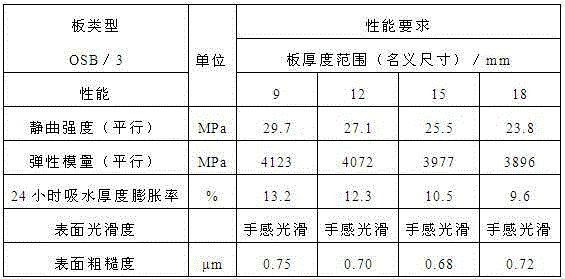

The invention relates to a surface-decorated oriented strand board and a preparation process of the surface-decorated oriented strand board. The surface-decorated oriented strand board comprises a core layer and a surface layer. Rotary cut veneer leftovers left in the plywood production process are selected as raw materials of the core layer. Sawdust, wood shavings, waste fibers and sanding powder produced in the production process of glued-laminated timber, core-boards, particle boards or medium-density fiberboards are selected as raw materials of the surface layer. The raw materials are subjected to drying, screening, gluing, laying, plate blank sawing and cutting and hot-pressing, and then the surface-decorated oriented strand board can be manufactured. The static bending strength of the oriented strand board in the parallel direction can reach 22-30 MPa, the elasticity modulus of the oriented strand board can reach 3500-4800 MPa, and the surface roughness of the oriented strand board is less than 0.8 micron. The surface-decorated oriented strand board can be directly processed into a decorative surface and can also be widely used for replacing artificial boards such as plywood, the core-boards, the particle boards and the medium-density fiberboards.

Owner:寿光市鲁丽木业股份有限公司

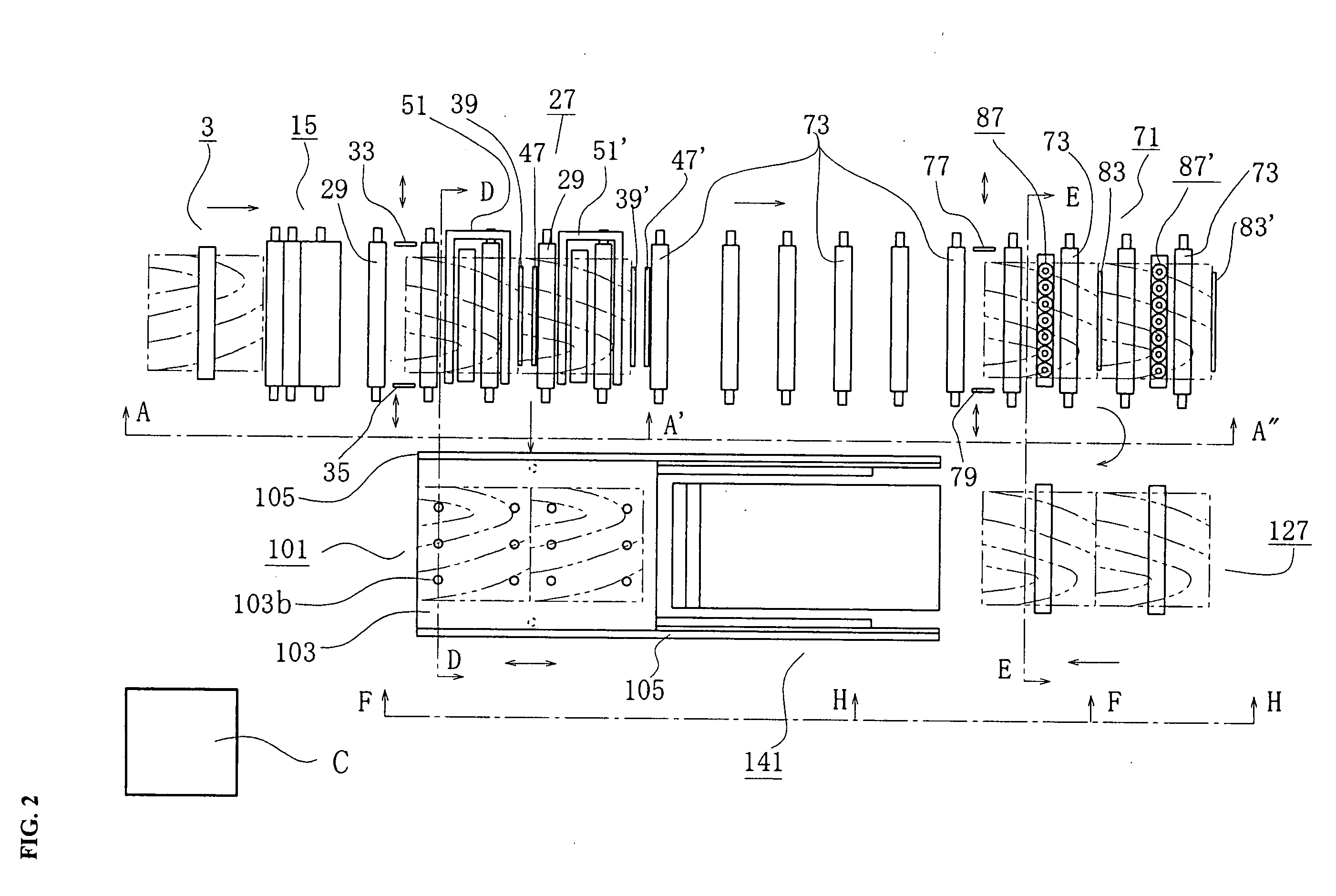

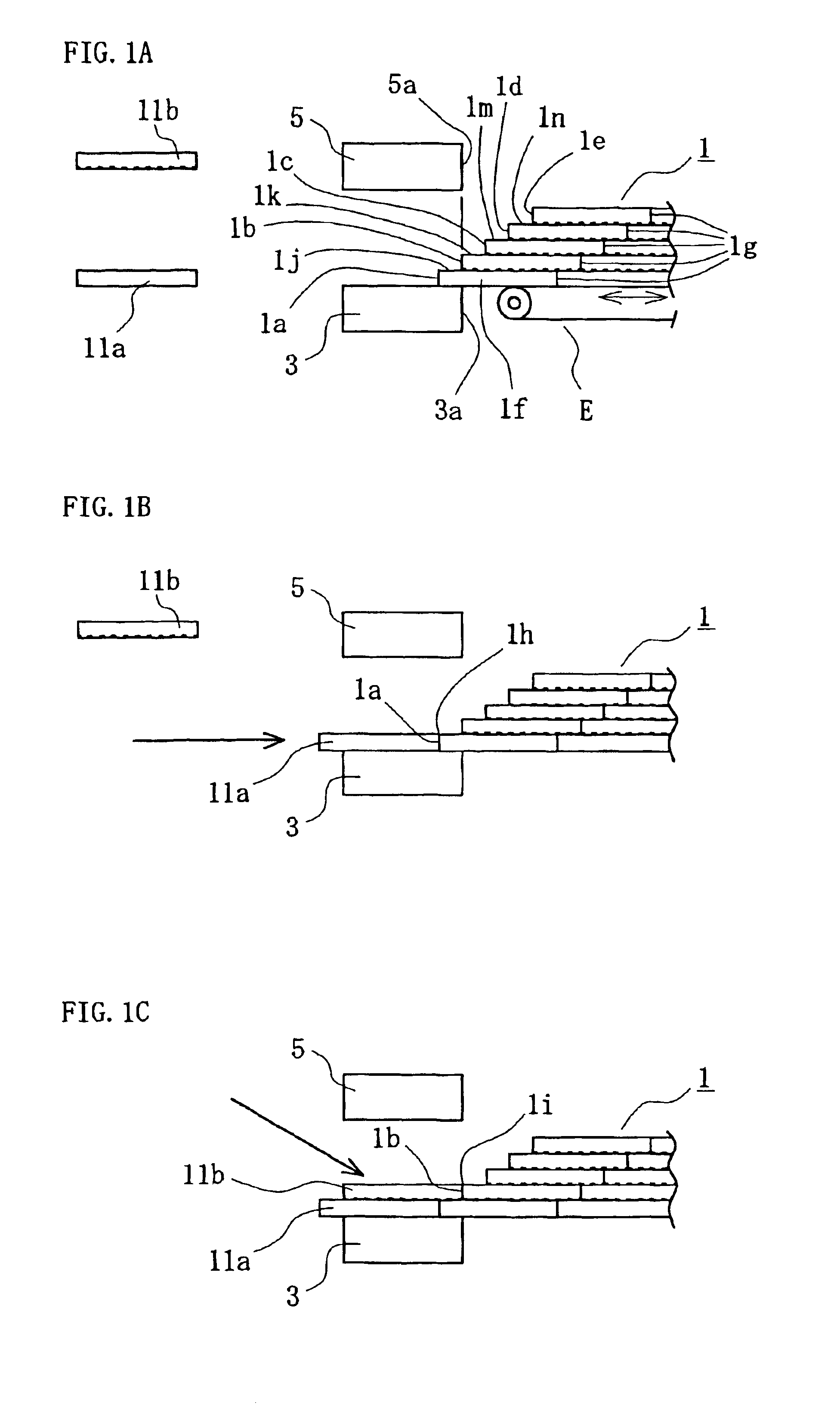

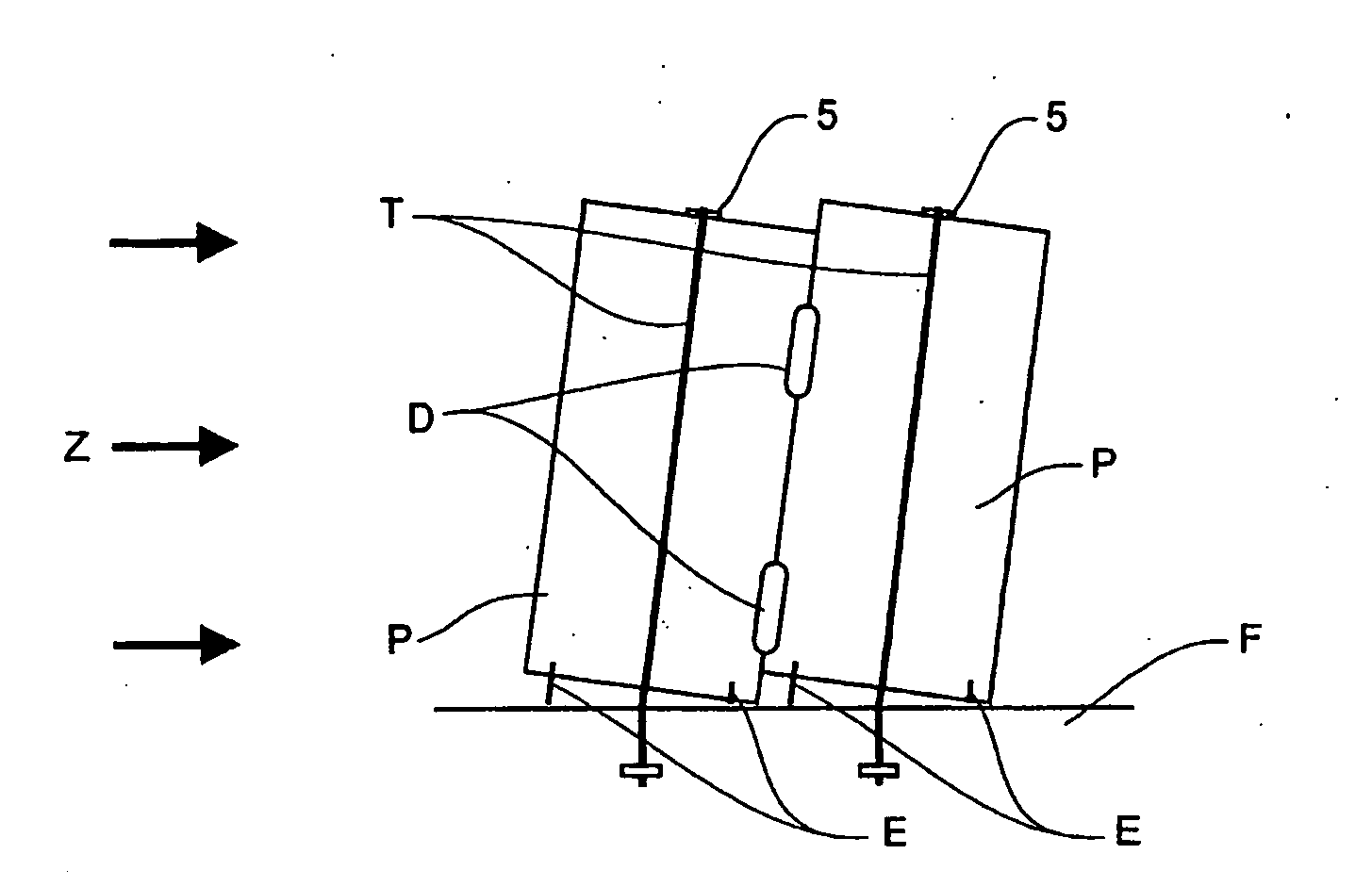

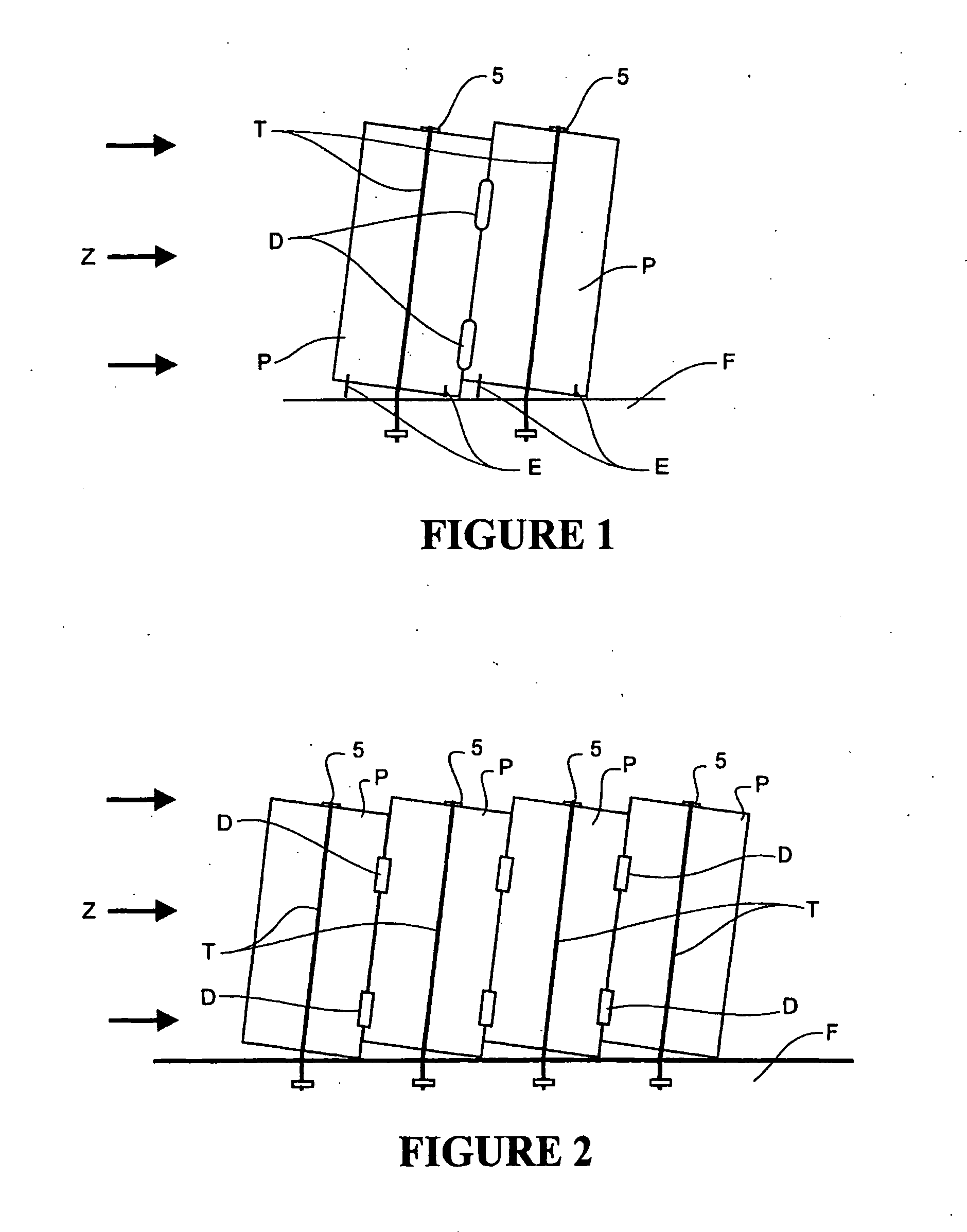

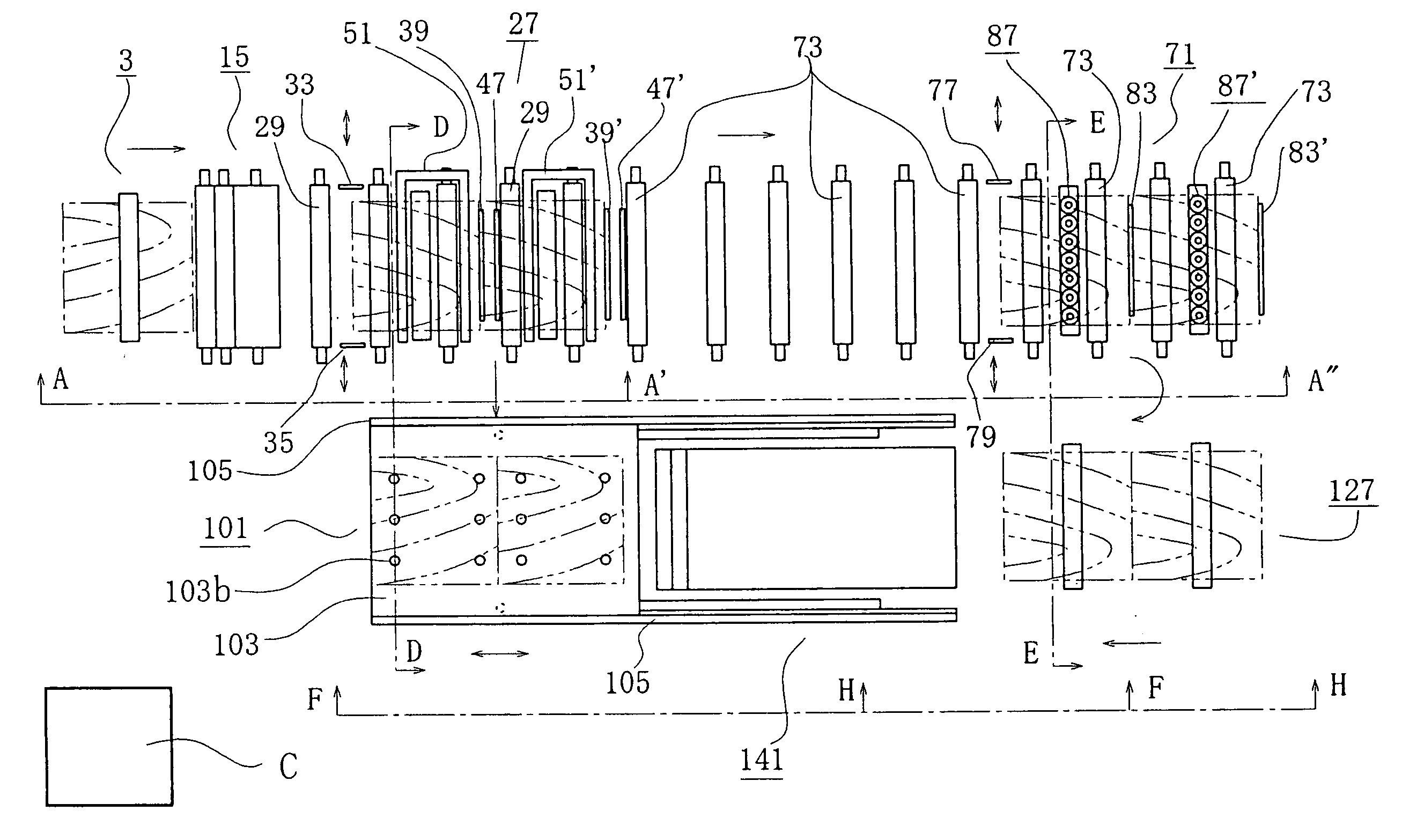

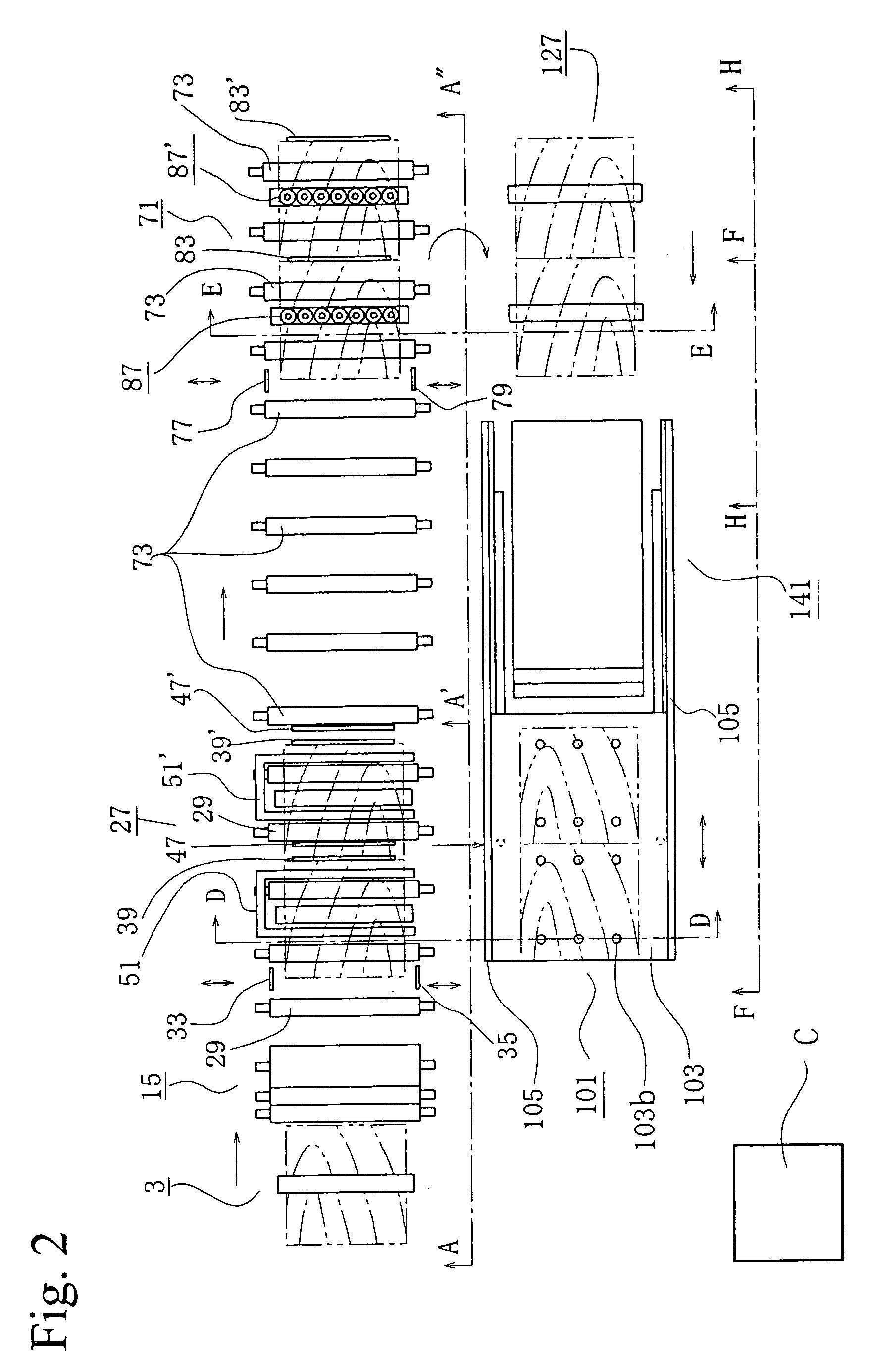

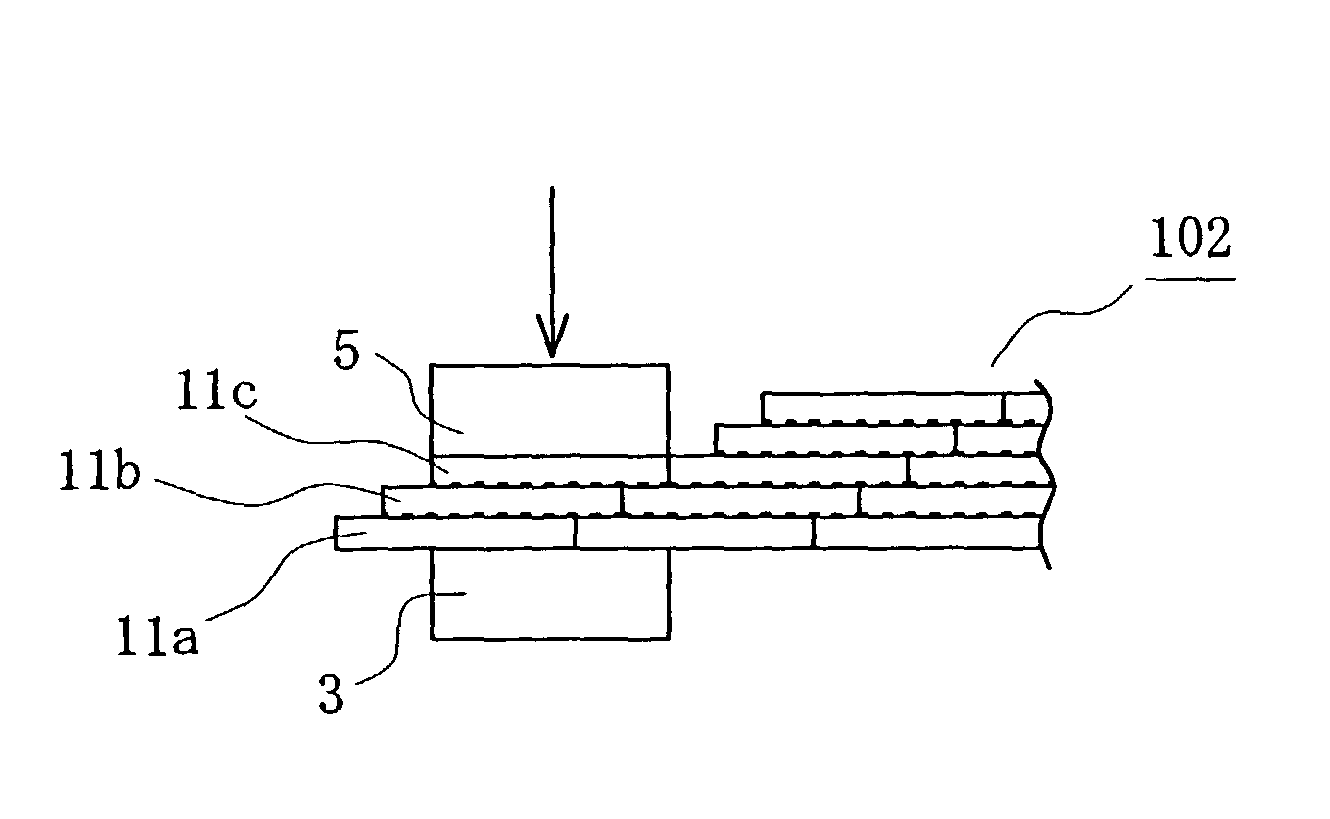

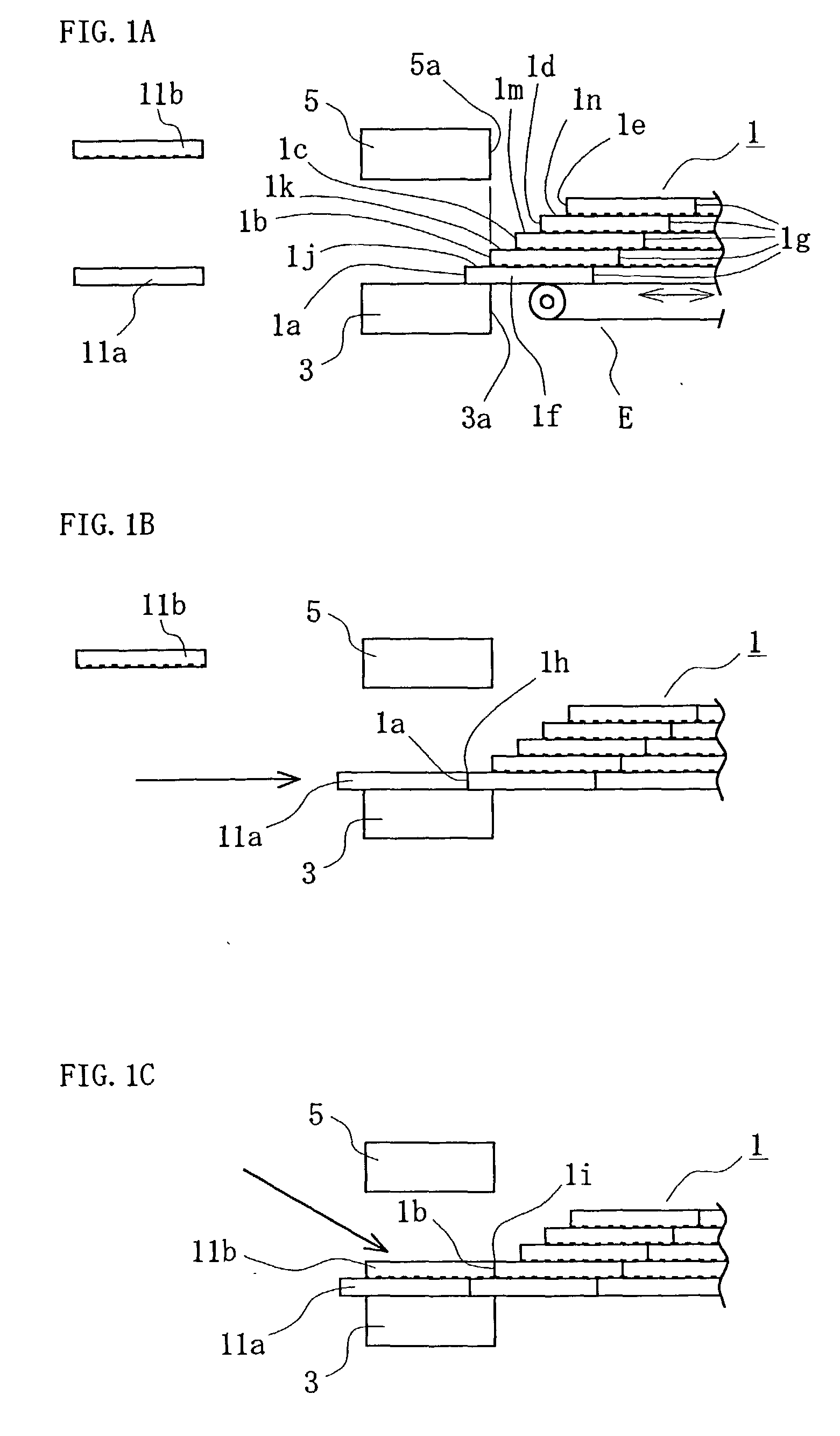

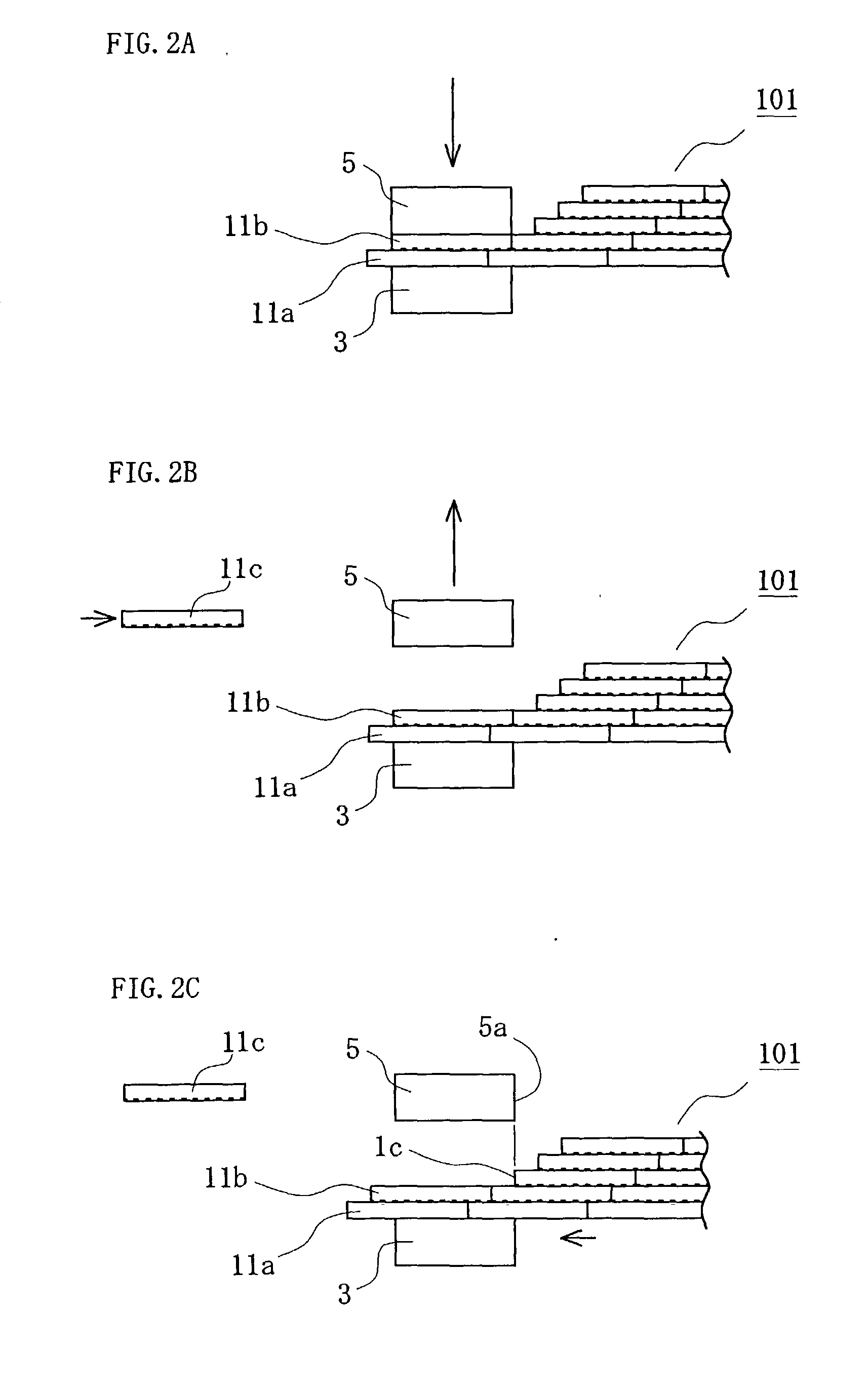

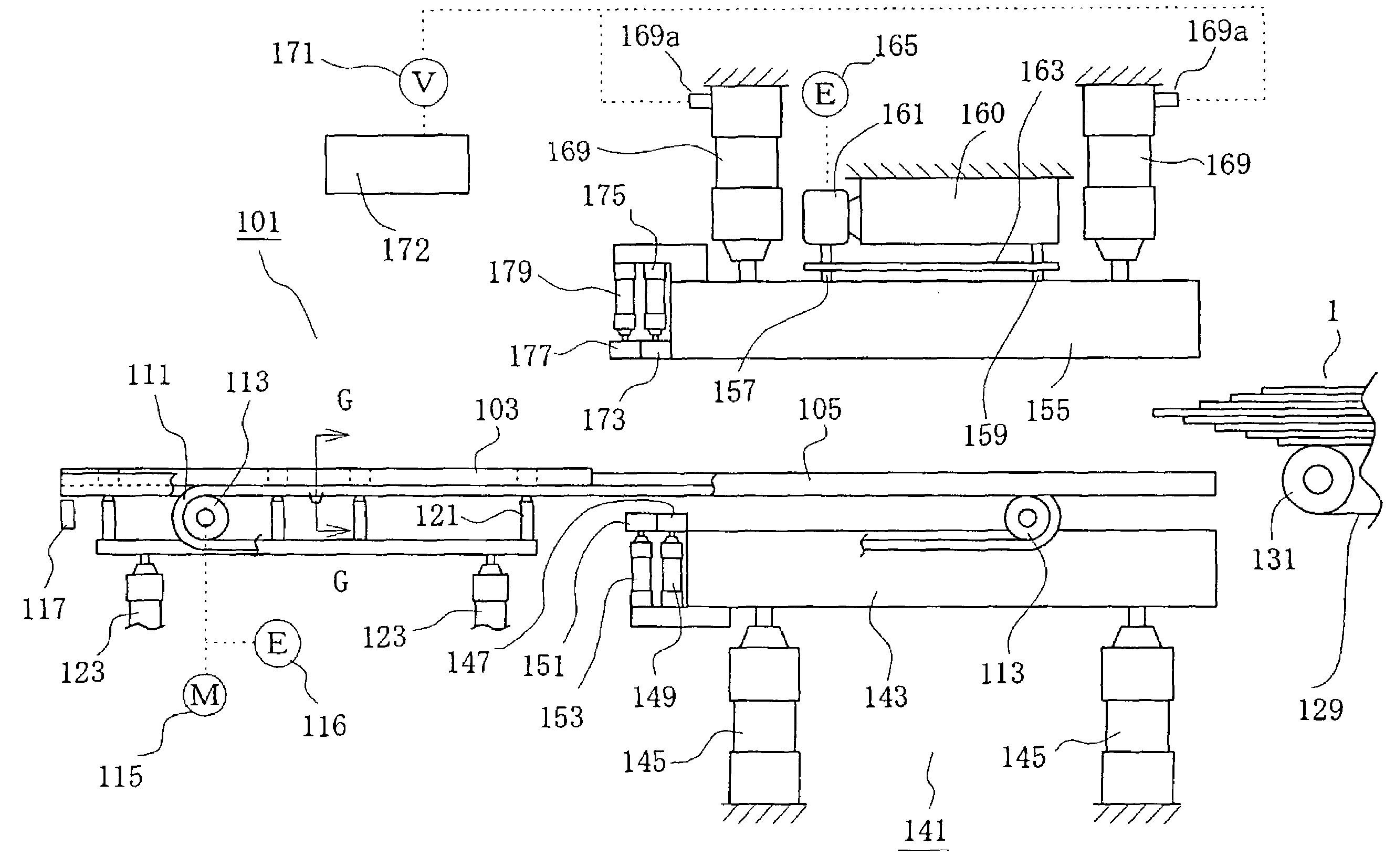

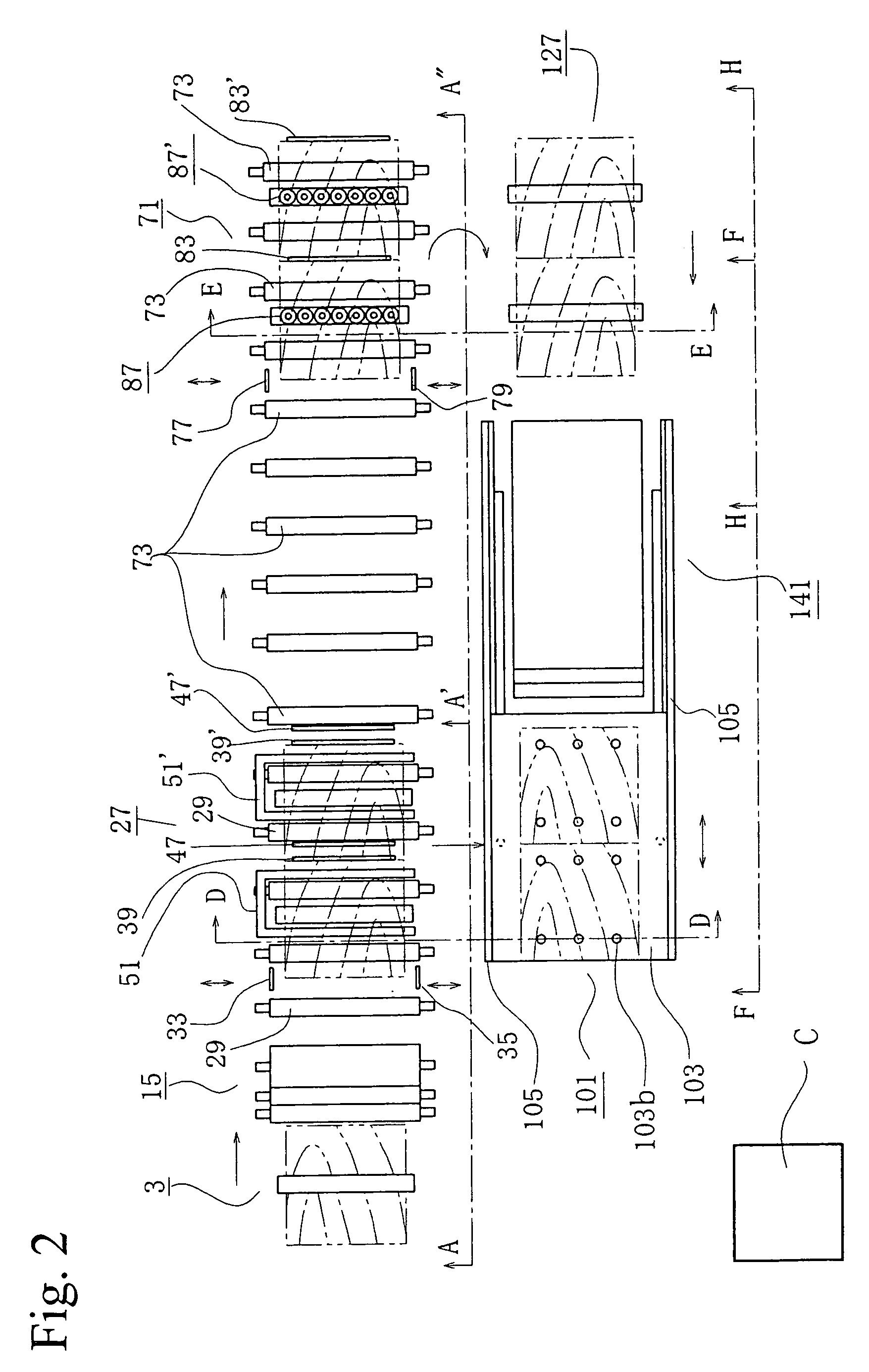

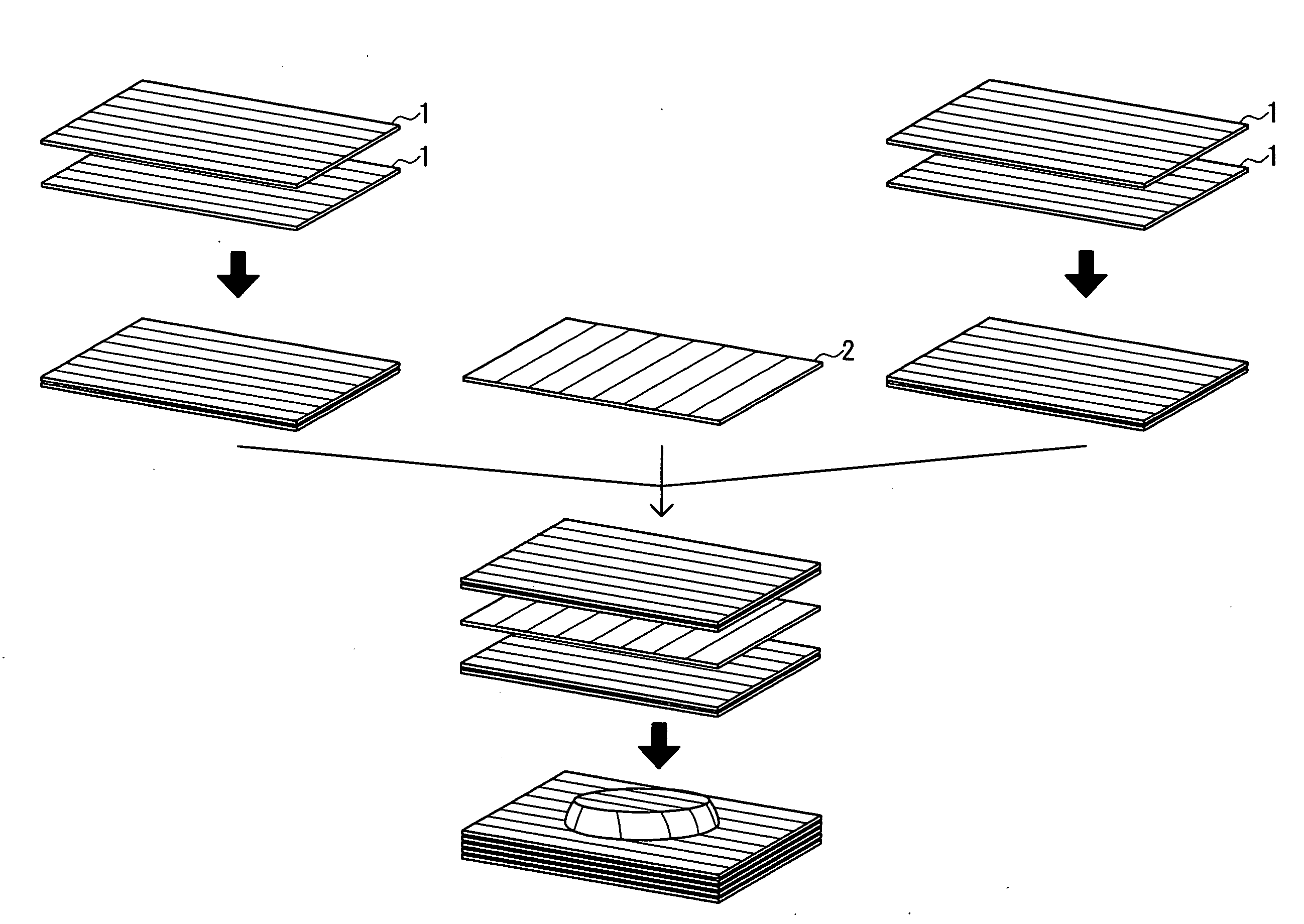

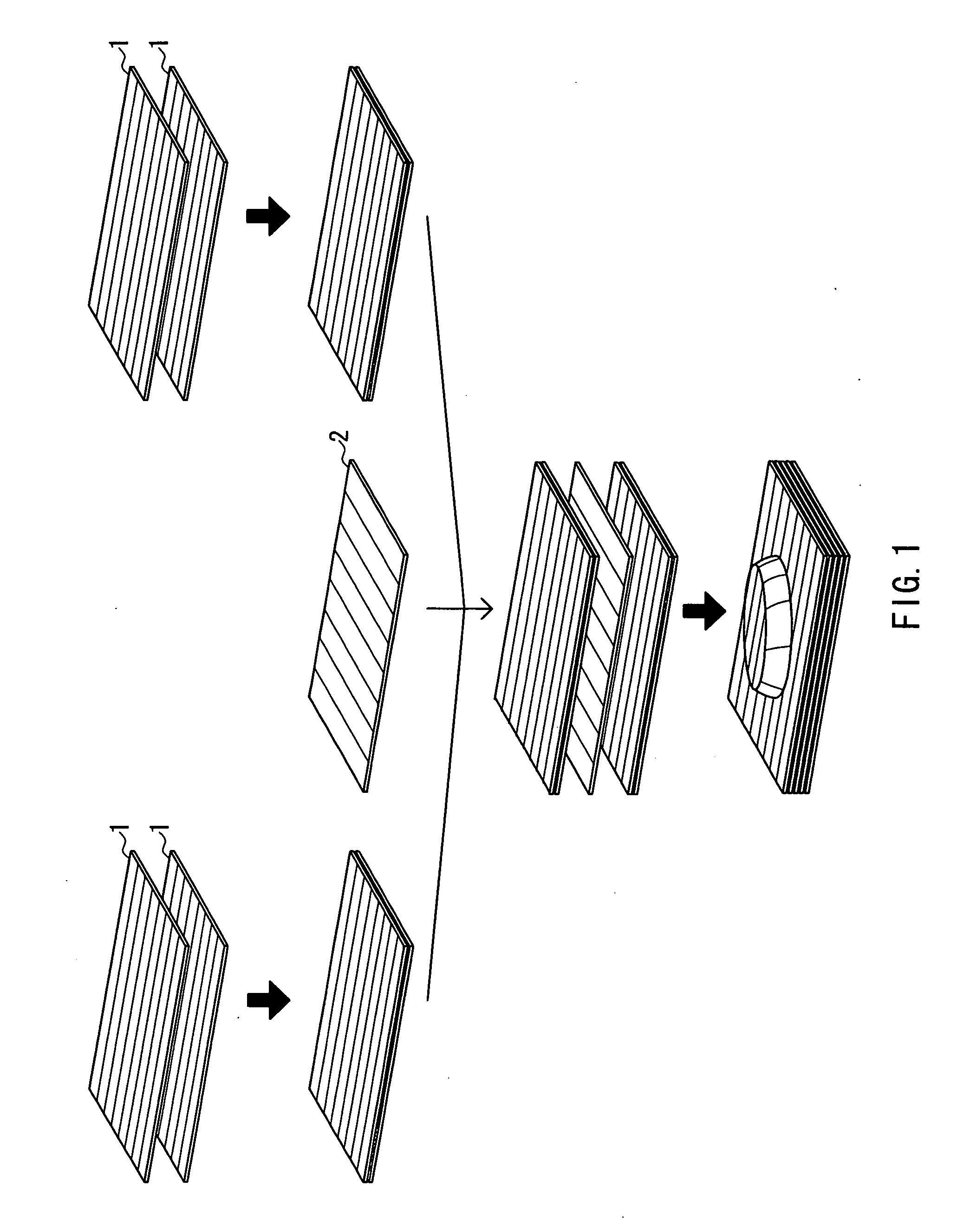

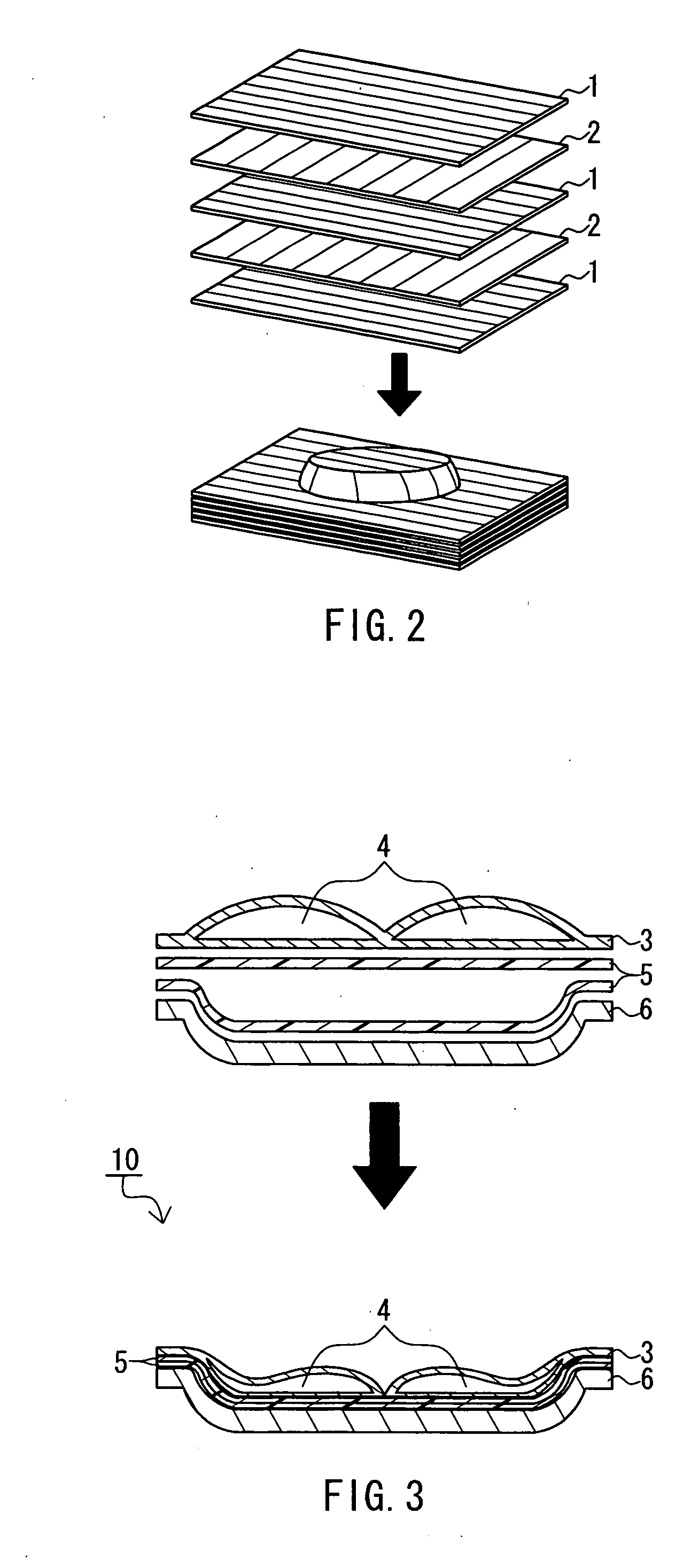

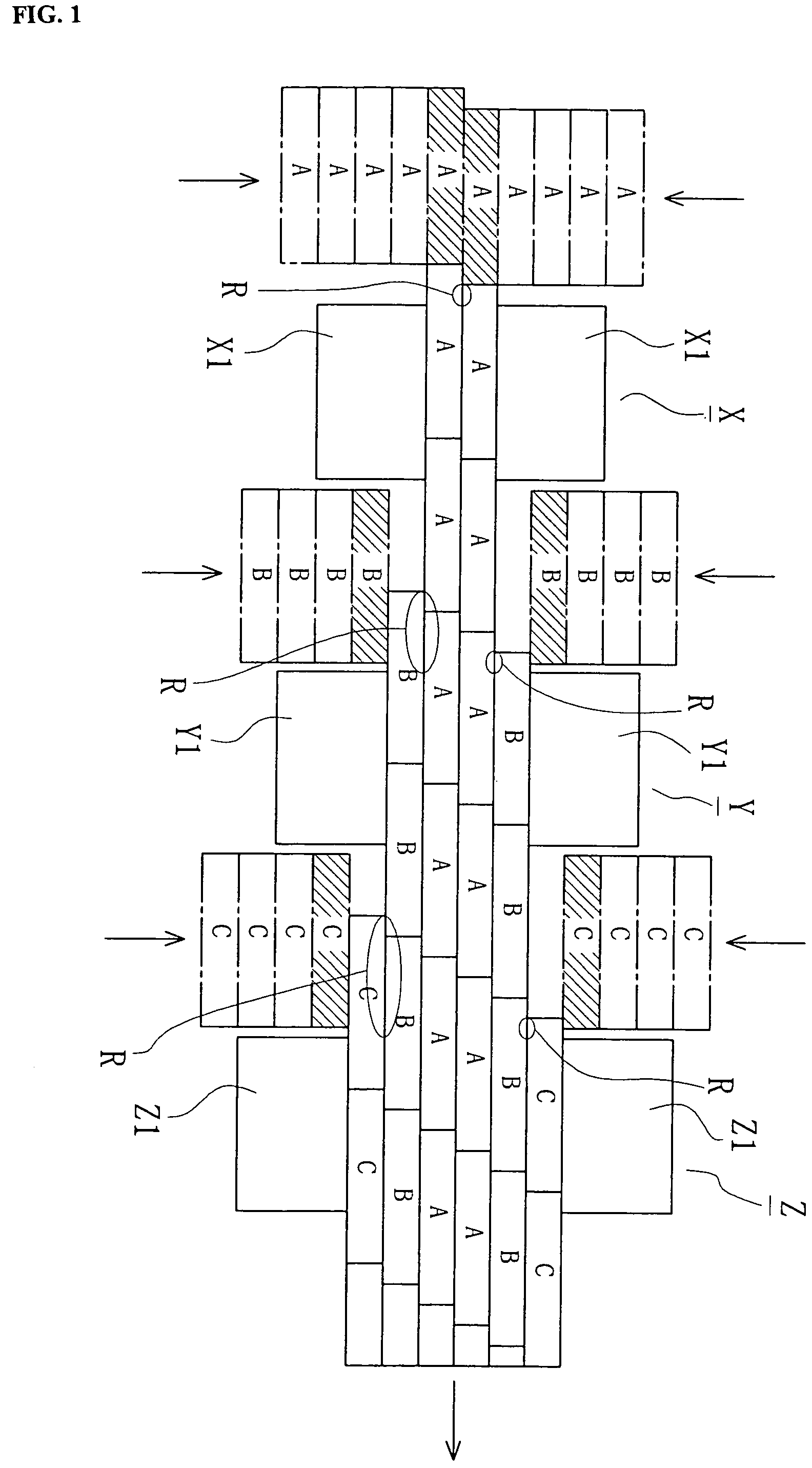

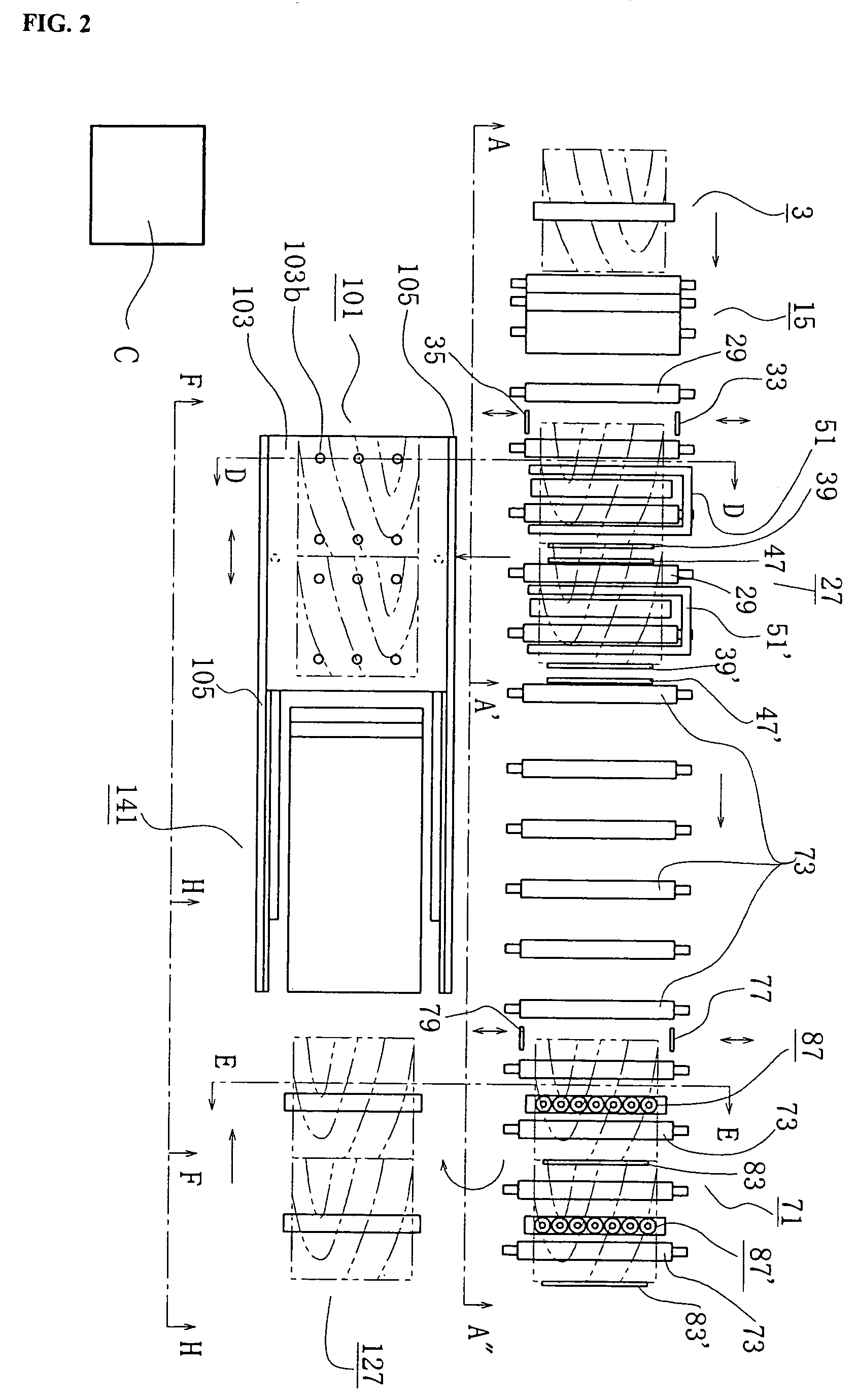

Method and apparatus of manufacturing glued laminated wood

A method and apparatus of manufacturing glued laminated wood such as laminated veneer lumber (LVL) are disclosed. The glued laminated wood is made of a number of wood sheets such as veneer sheets which are laminated together by a hot press with a thermosetting adhesive into a continuous length of multiple-layered board of the glued laminated wood wherein wood sheets in each layer of the multiple-layered board are arranged in a staggered relation in the lengthwise direction of the board to wood sheets in an adjacent layer. The hot press has a pair of heating plates arranged substantially in facing relation to each other and an auxiliary heating plate disposed adjacent to one end of each heating plate. The auxiliary heating plate is adapted to press part of wood sheet which extends out beyond the above end of the heating plate.

Owner:MEINAN MASCH WORKS INC

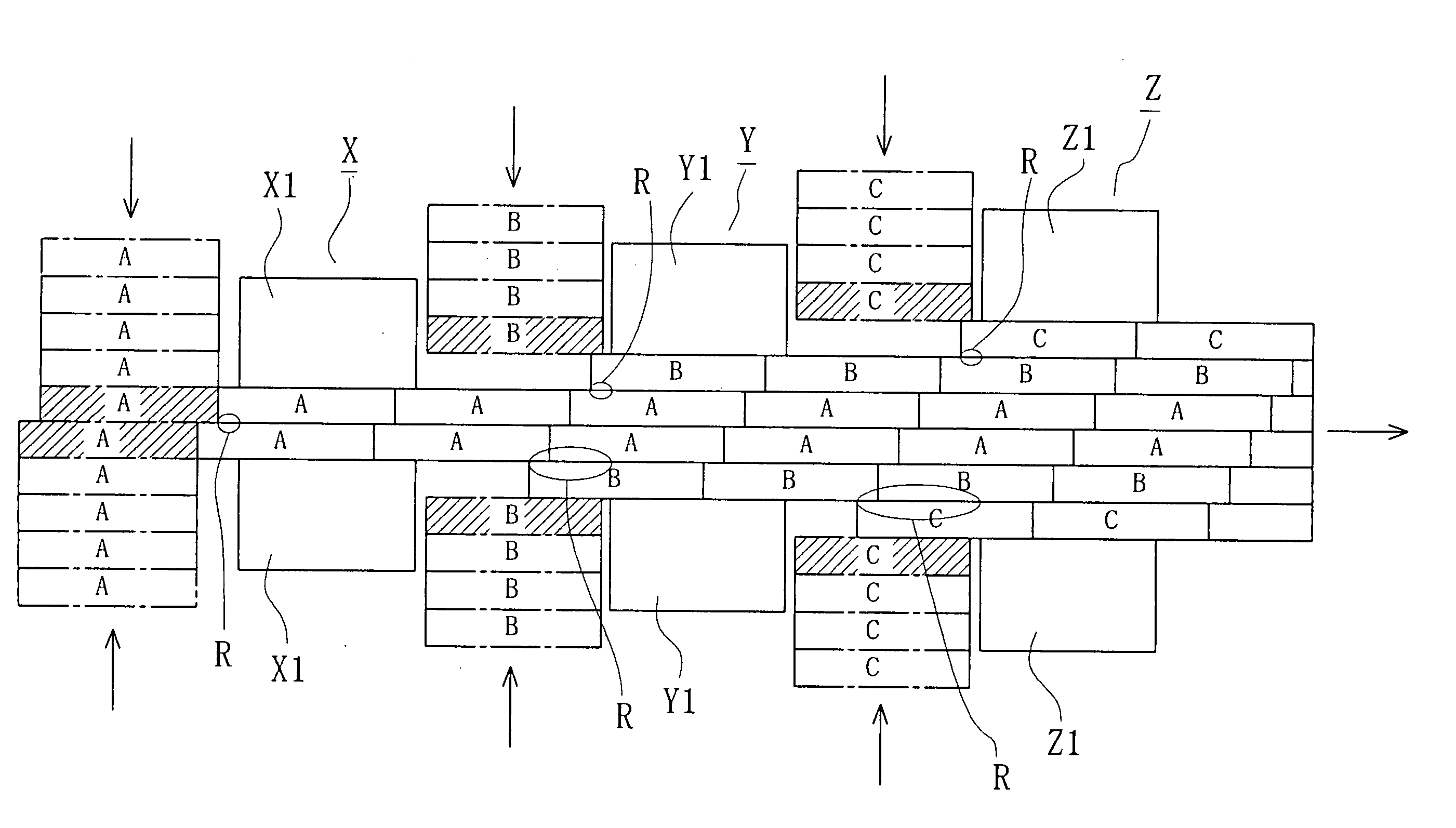

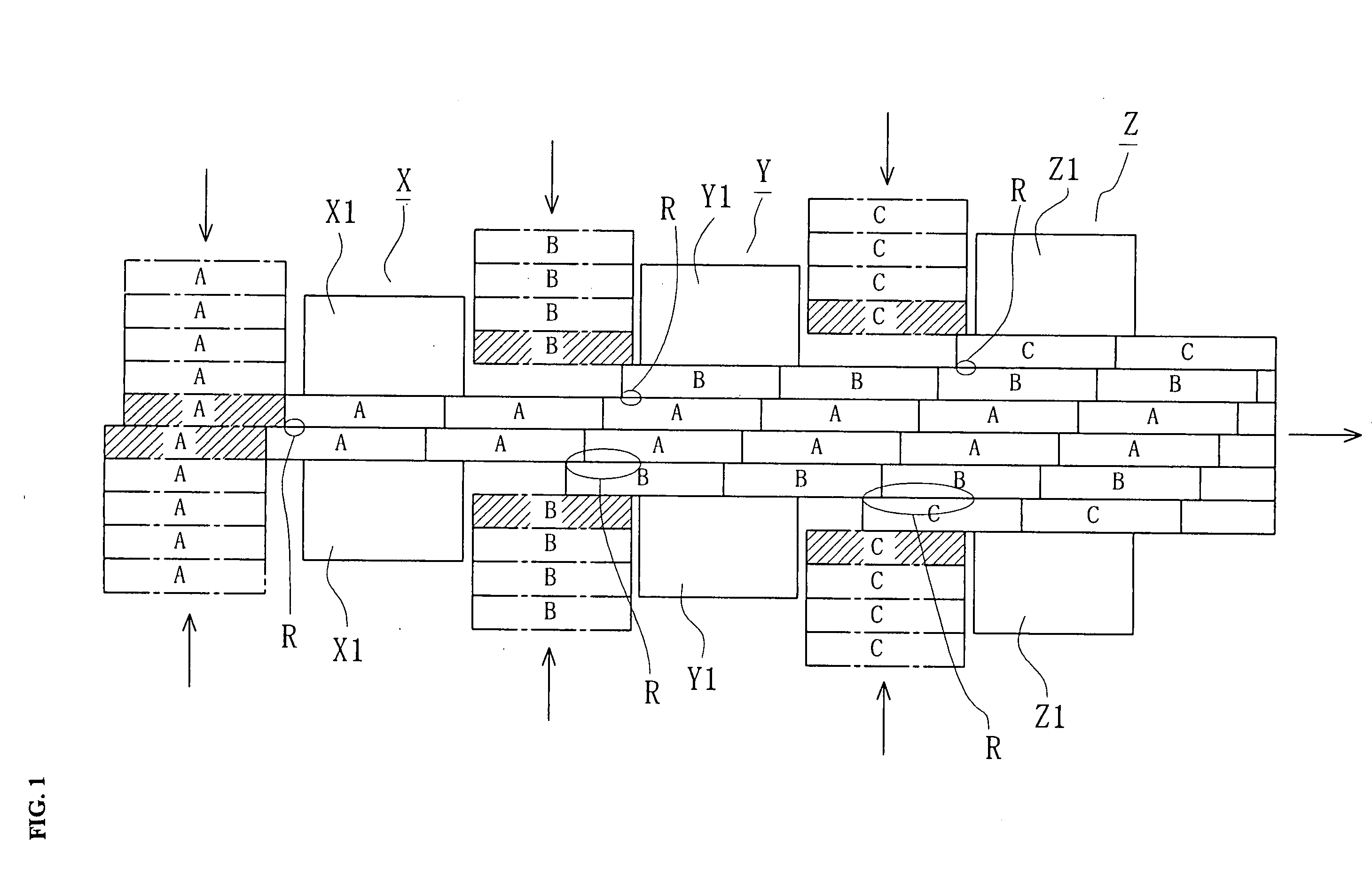

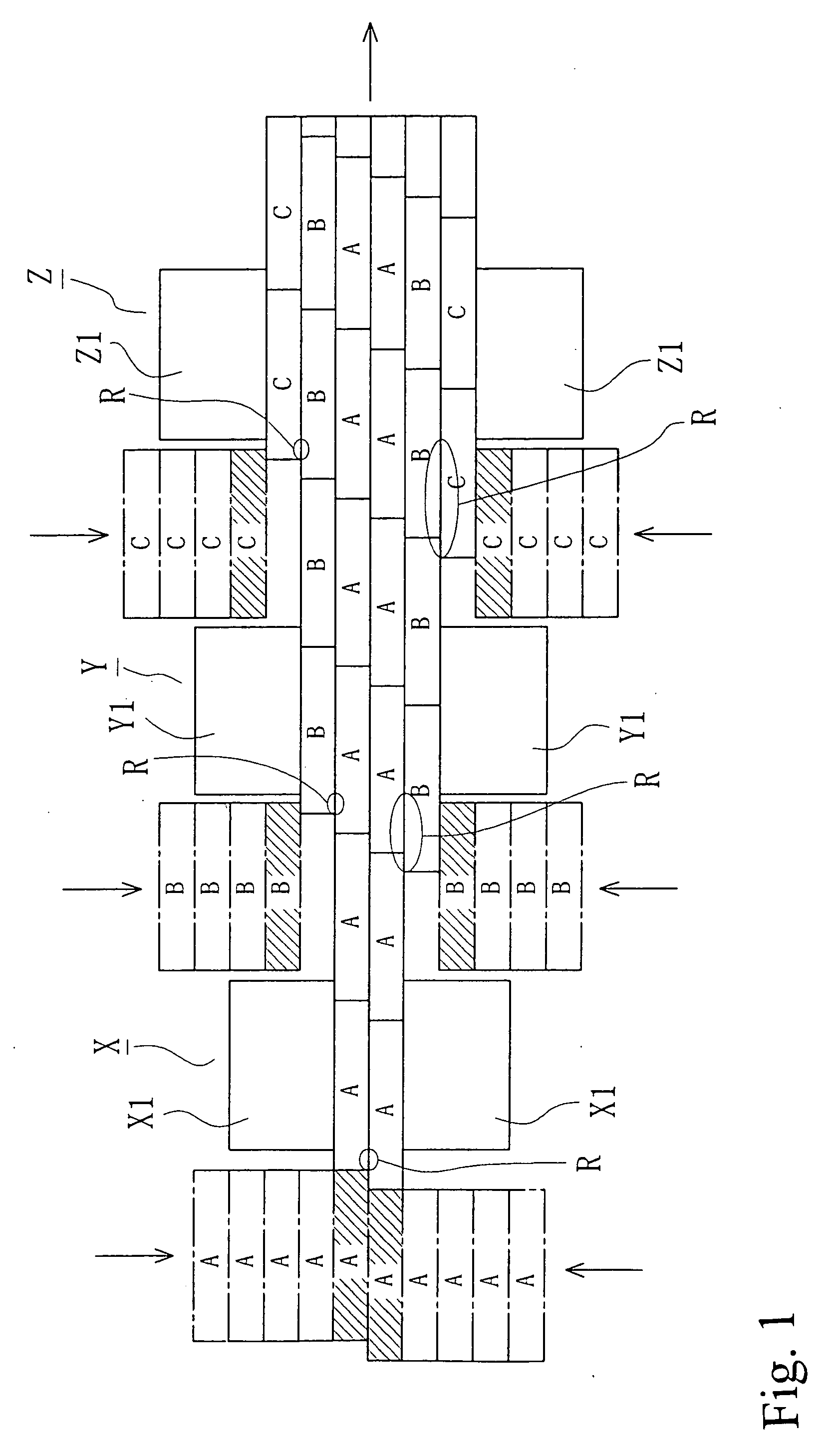

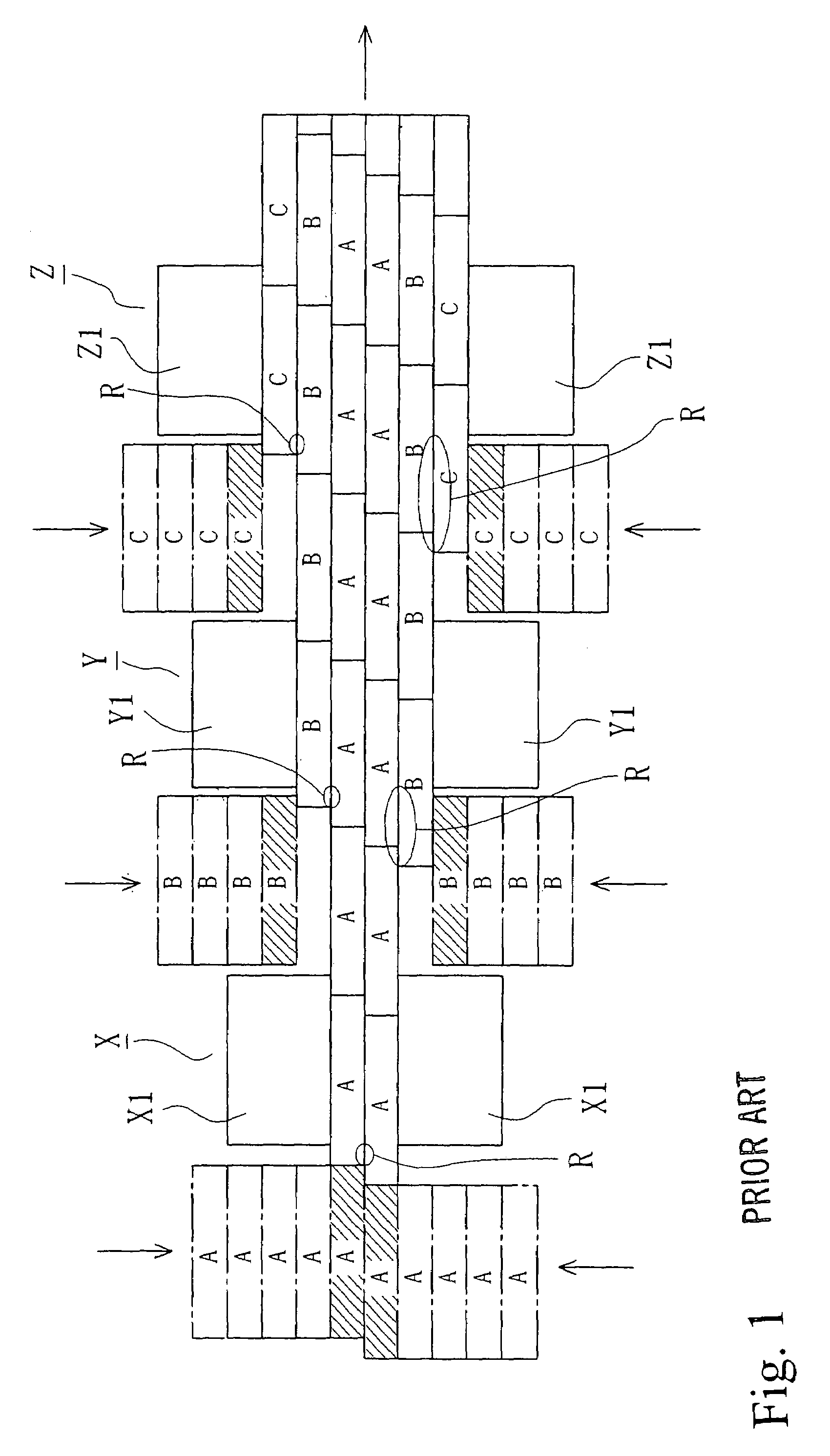

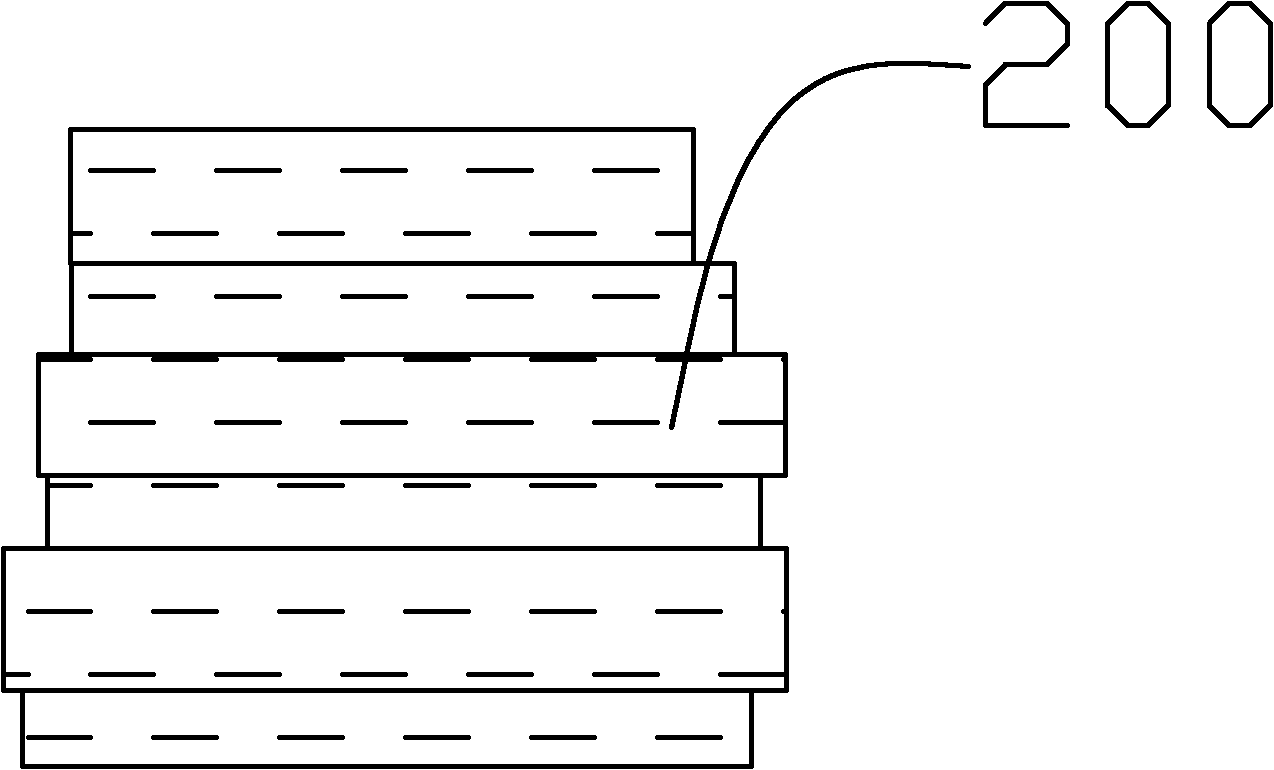

Method of manufacturing glued laminated wood

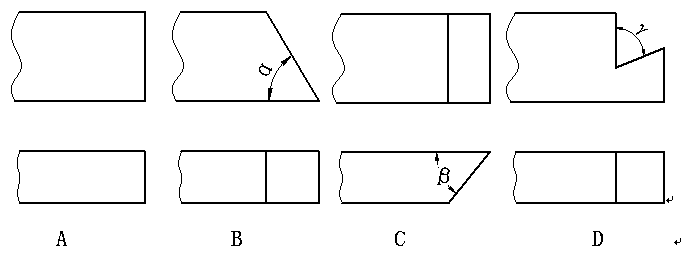

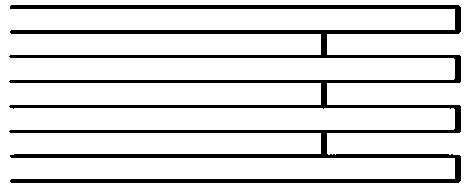

A method of manufacturing glued laminated wood such as laminated veneer lumber (LVL) is disclosed. The glued laminated wood is made of a number of wood sheets such as veneer sheets which are laminated together by a hot press with a thermosetting adhesive into a continuous length of multiple-layered board wherein the end joints of the wood sheets are disposed in a staggered array. There is provided an initial base material having an end which is shaped in the form of a flight of steps including a series of alternate horizontal surface having a lengthwise dimension smaller than the length of the wood sheet and a vertical surface having a height corresponding to the wood sheet thickness, and the glued laminated wood board is formed extending from the end of such initial base material. The hot press includes a pair of heat plates each having an effective pressing area capable of covering the entire surface of the wood sheet. In hot pressing a wood sheet having on one surface thereof coated with adhesive, a board of the glued laminated wood in progress is placed and maintained for a predetermined length of time at a position where the entire top surface of the wood sheet is kept to be pressed from the top by one of the plates while the entire lower surface of the wood sheet is supported from the bottom by the other plate.

Owner:MEINAN MASCH WORKS INC

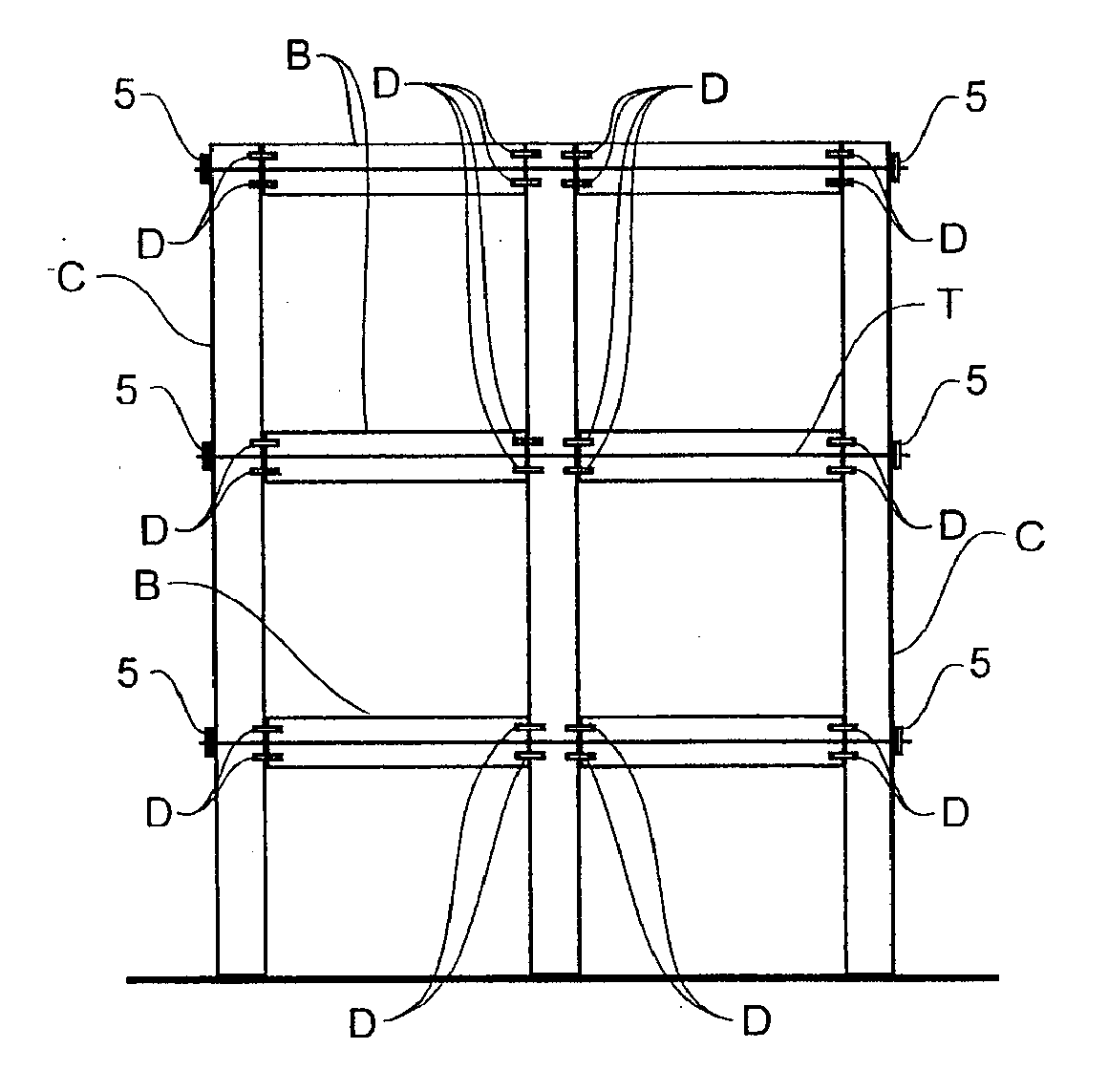

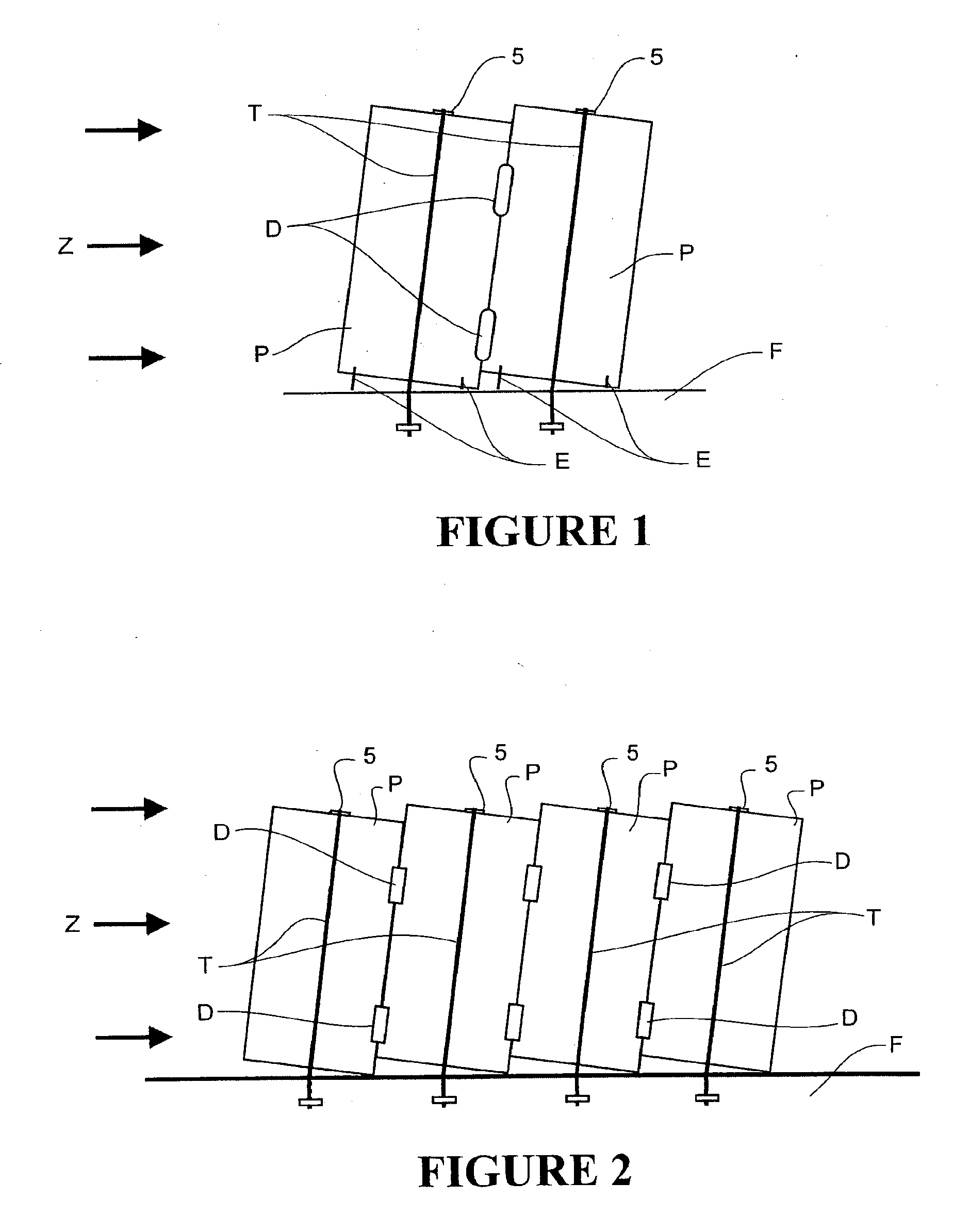

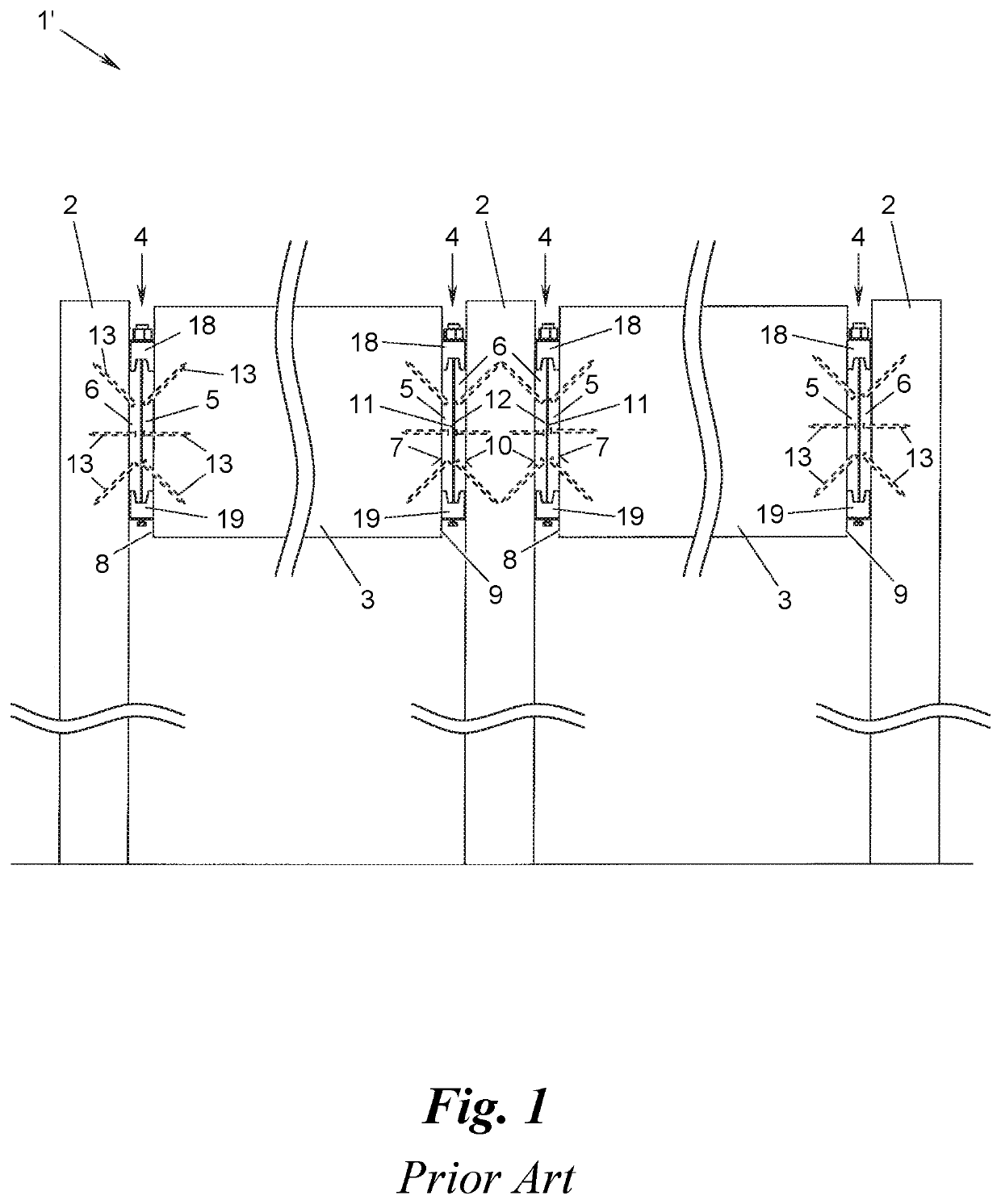

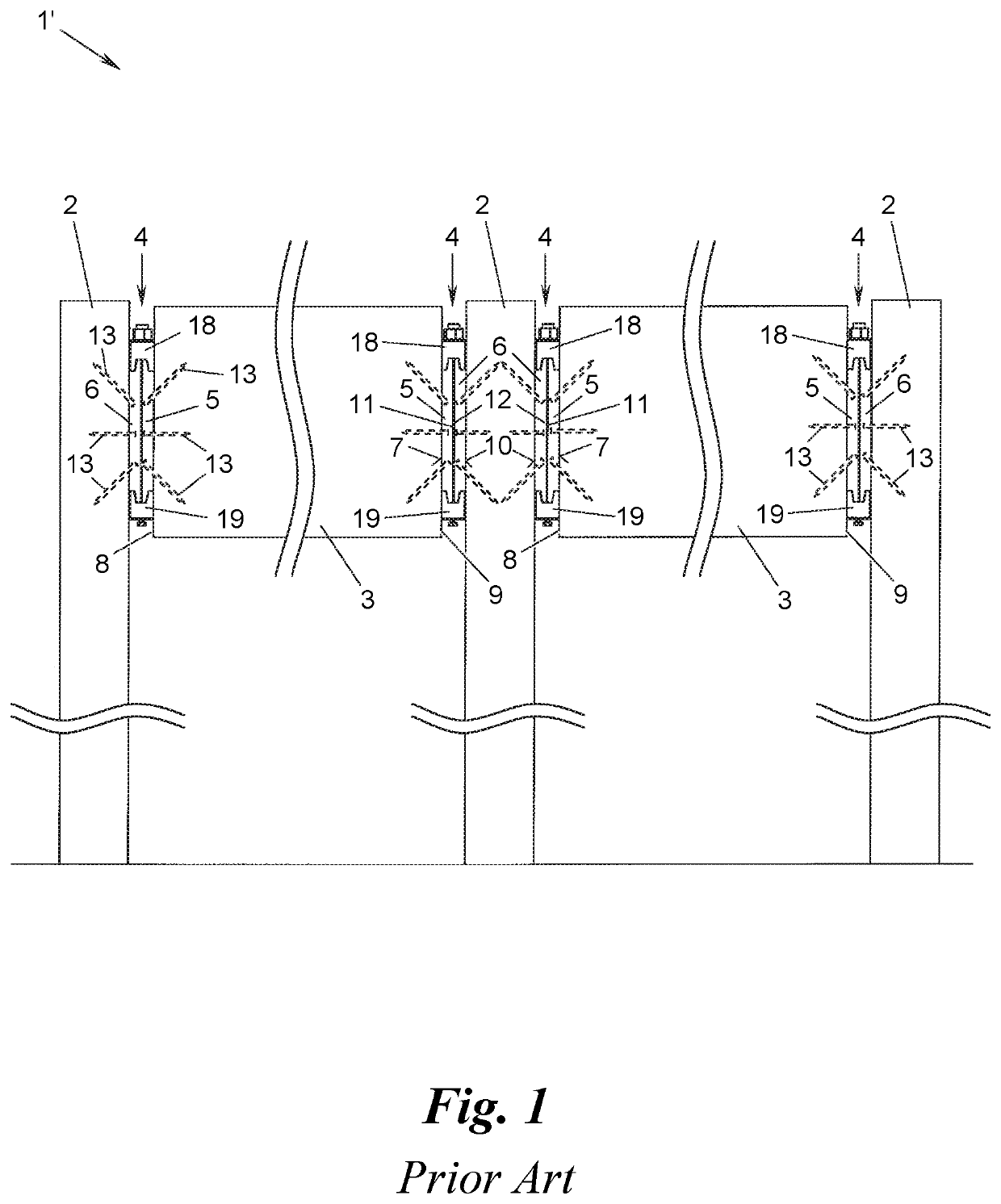

Engineered Wood Construction System for High Performance Structures

InactiveUS20100186316A1Avoiding and minimising structural damagePublic buildingsSpecial buildingStructural systemGlued laminated timber

A building includes a connection between an engineered wood load bearing element of the building such as a column, beam, or load bearing panel, and another load bearing element or a foundation of the building. At least one tendon ties the load bearing elements or the load bearing element and the foundation together. One or more energy dissipaters, replacably connected between the load bearing element and / or the foundation, absorb energy when a loading event causes relative movement of the connection. The engineered wood element maybe a laminated veneer lumber element, a parallel strand lumber element, or a glue laminated timber element, for example. Typically all of the load bearing elements of the building will be engineered wood elements. The building may be single or multi-storey. The building system enables lightweight low cost buildings, with energy dissipaters which may be replaced after extreme loading. The building may be prefabricated

Owner:PRESTRESSED TIMBER LTD

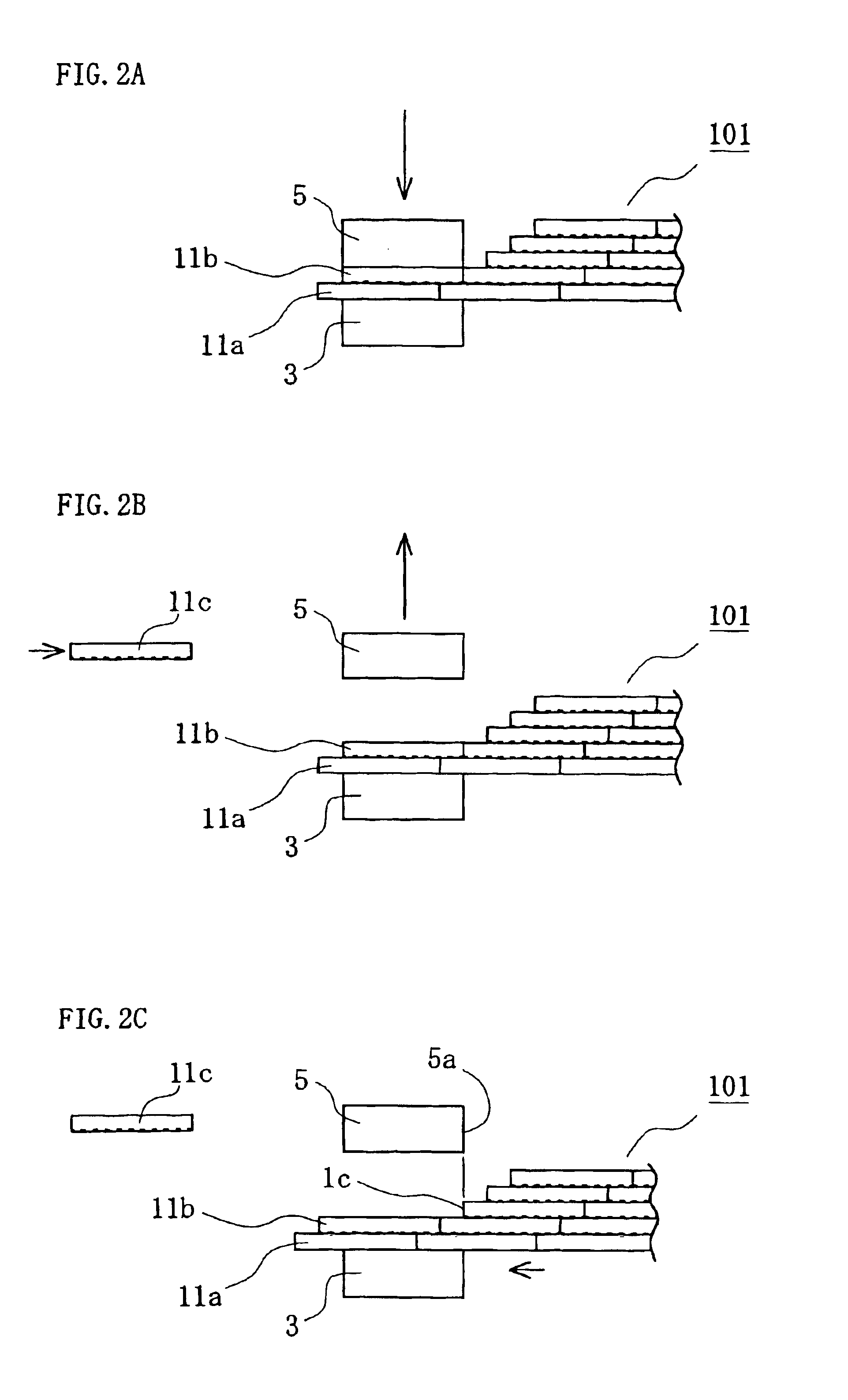

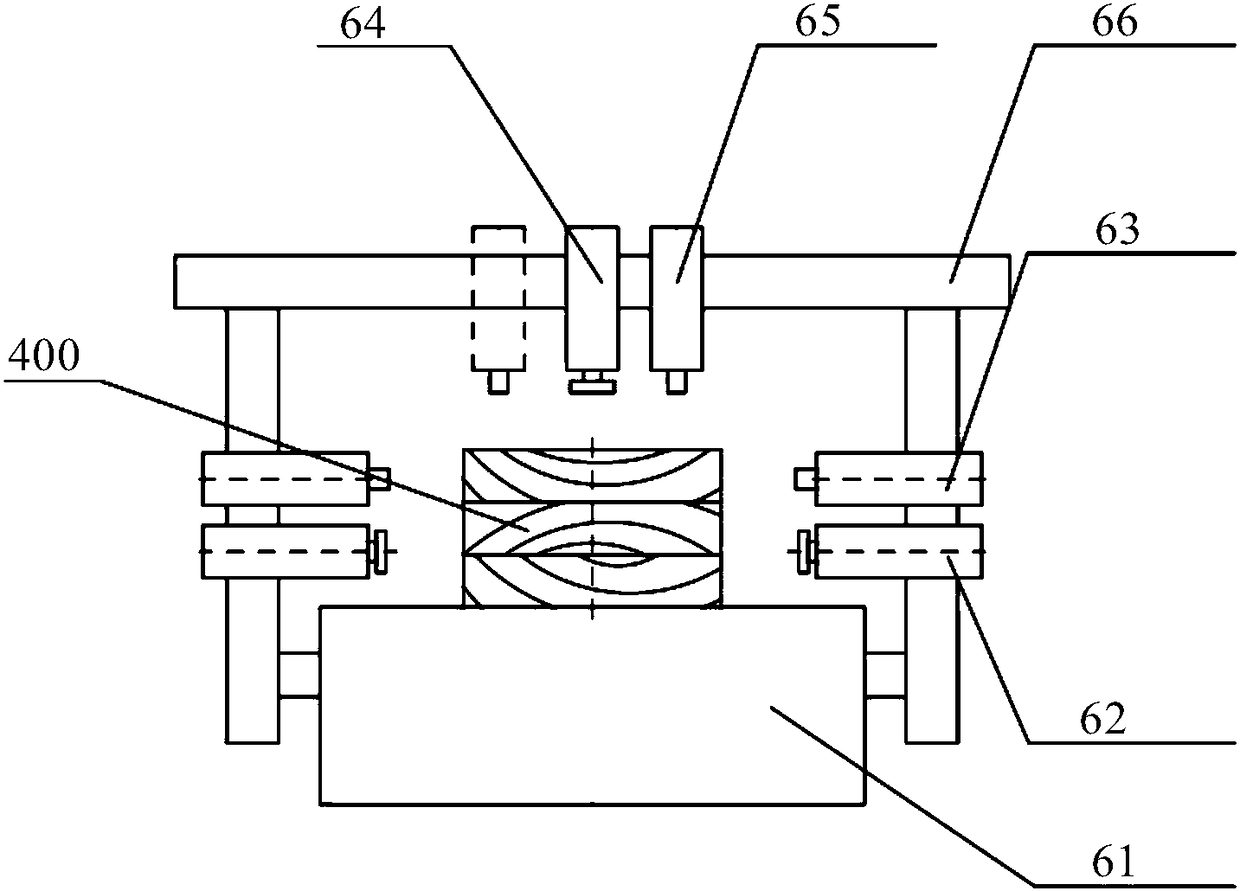

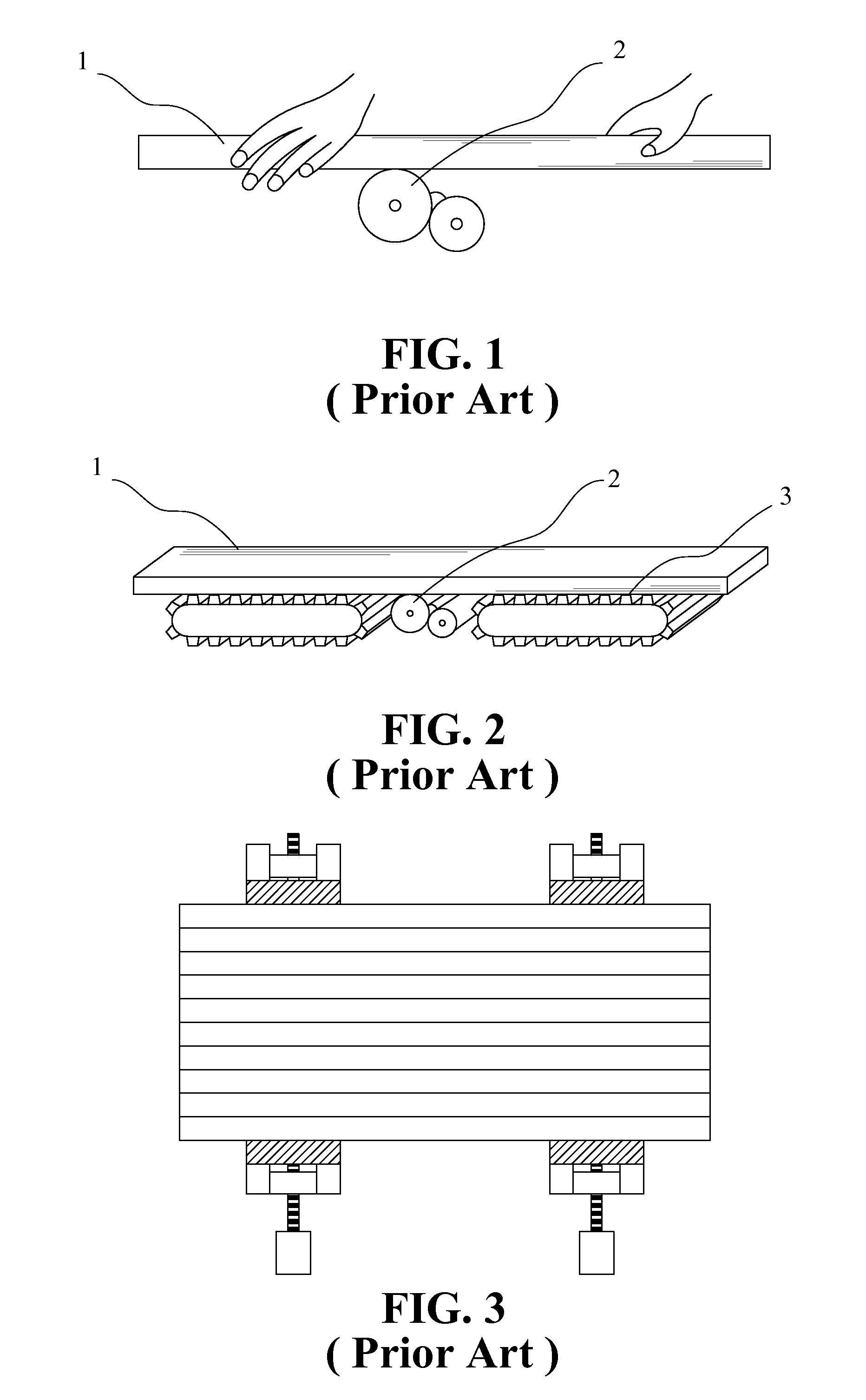

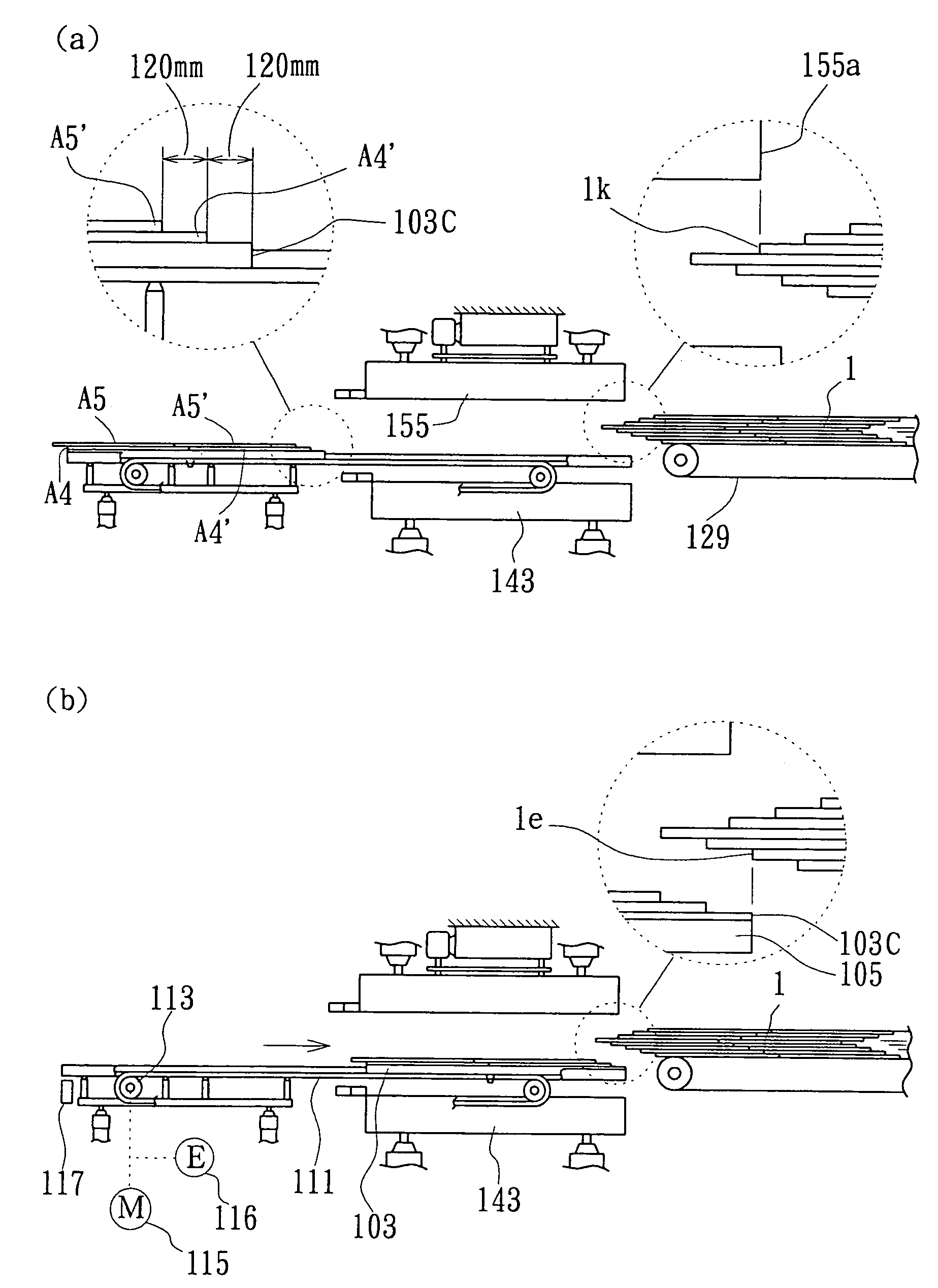

Method and apparatus of pressing in manufacturing glued laminated wood

A method and an apparatus of wood pressing usable in manufacturing glued laminated wood such as laminated veneer lumber (LVL) using a number of wood veneer sheets are disclosed. A hot press used for wood pressing includes a pair of heating plates which are disposed one above the other and have pressing surfaces facing each other. The paired heating plates are both movable toward and away from each other. In operation, firstly one of the heating plates is moved toward the other heating plate to a position where the pressing surface of the one heating plate is spaced from a surface to which a veneer sheet is to be glued by a distance corresponding to the thickness of the veneer sheet. Then, the other heating plate is moved toward the one heating plate until a desired pressure is produced pressing.

Owner:MEINAN MASCH WORKS INC

Engineered Wood Construction System for High Performance Structures

InactiveUS20130019545A1Avoiding and minimising structural damagePublic buildingsSpecial buildingAbsorbed energyRelative motion

A building includes a connection between an engineered wood load bearing element of the building such as a column, beam, or load bearing panel, and another load bearing element or a foundation of the building. At least one tendon ties the load bearing elements or the load bearing element and the foundation together. One or more energy dissipaters, replaceably connected between the load bearing element and / or the foundation, absorb energy when a loading event causes relative movement of the connection. The engineered wood element may be a laminated veneer lumber element, a parallel strand lumber element, or a glue laminated timber element, for example. Typically all of the load bearing elements of the building will be engineered wood elements. The building may be single or multi-storey. The building system enables lightweight low cost buildings, with energy dissipaters which may be replaced after extreme loading. The building may be prefabricated.

Owner:FPINNOVATIONS INC

Production method of starch-based non-formaldehyde adhesive for bamboo-wood glued laminated timber splice plates

InactiveCN103131361AHelps speed up the production processSpeed up the production processNon-macromolecular adhesive additivesGraft polymer adhesivesPotassium persulfateCross-link

The invention relates to a production method of a starch-based non-formaldehyde adhesive for bamboo-wood material. The production method comprises the following steps: by taking starch as a main material, further using styrene, a potassium persulfate water solution, sodium dodecylbenzenesulfonate, an ammonium persulfate water solution, vinyl acetate, methyl methacrylate, silicon sol, urea and tributyl phosphate as raw materials, by taking a NaOH water solution as a pH regulator, and performing four steps, namely preparation of an oxidized starch emulsion, acidification, grafting reaction of oxidized starch and cross-linking reaction to produce the starch-based non-formaldehyde adhesive. The starch-based non-formaldehyde adhesive is used as the adhesive for the bamboo-wood material, in particular to engineered wood; and the production method has the advantages of simple process, low cost, mild reaction conditions and easiness in control, and the produced adhesive has the advantages of no release of free formaldehyde, high storage stability, strong water resistance and high binding strength in comparison with a starch adhesive produced by the prior art.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Technology for manufacturing structural glued laminated timber by adopting fast-growing poplars

ActiveCN103302719AImprove anti-corrosion performanceImprove flame retardant performanceWood working apparatusDomestic articlesUltraviolet lightsVarnish

The invention provides a technology for manufacturing a structural glued laminated timber by adopting fast-growing poplars. The steps are as follows: firstly, selecting timber and cutting the timber into plates through an electric saw; secondly, coating a transparent water-based prime paint layer and a fire-retardant paint layer on the cut plates, and controlling the water content of the plates to range from 5% to 8% through fumigating; thirdly, planing the fumigated plates, and coating a ultraviolet light polymerization coating varnish layer and a water-based bright surface paint layer on the planed plates in sequence; fourthly, splicing the timber to form an assembly, and sending the assembly into a hot press to press the plates; fifthly, scissoring the pressed plates by using a cutting edge machine, mending, trimming and packing the plates, and then putting the plates into a warehouse. According to the invention, products have excellent corrosion resistance, snow and rain corrosion resistance, and water and oil resistance; the elastic modulus is 10000-12000 GPa, the bending strength reaches 12 MPa, the gloss is larger than or equal to 89, products have no yellow stains under the 100-110 DEG C / 1h condition, the inflaming retarding effect is excellent, and self-extinguish can be performed within 8 s; products are subjected to hard solidification under the irradiation of a high pressure mercury lamp of 500 W for 4-5 min, are ultraviolet light irradiation resistant, can be used widely, and can replace the conventional materials continuously.

Owner:江苏德鲁尼木业有限公司

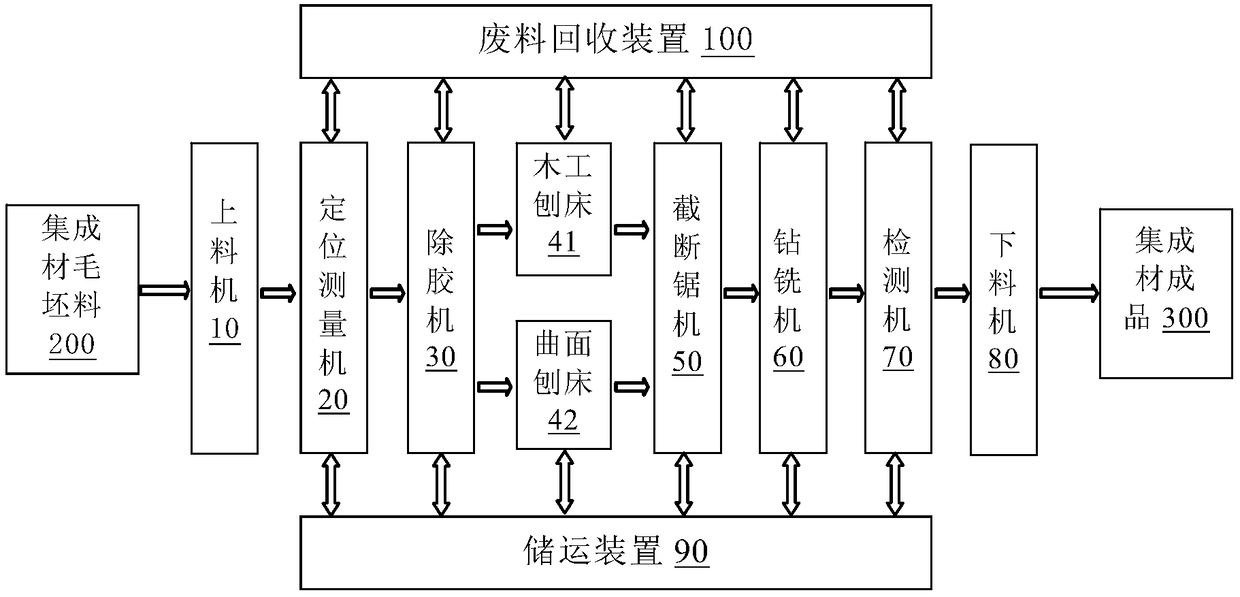

Wood-structure glued-laminated timber flexible machining production line and flexible machining method

ActiveCN108481467AIncrease profitReduce auxiliary timeMulti-purpose machinesProduction lineWork in process

The invention discloses a wood-structure glued-laminated timber flexible machining production line and a flexible machining method which is implemented on the basis of the production line. The production line comprises a feeding machine, a positioning measuring machine, a glue smearing machine, a planning machine, a cutting-off sawing machine, a drilling and milling machine, a detection machine and a discharging machine which are sequentially arranged according to the required sequence during production and connected end to end, wherein the planning machine comprises a woodworking planning machine and a curved surface planning machine which are arranged side by side; semi-finished product conveying openings of the positioning measuring machine, the glue smearing machine, the woodworking planning machine, the curved surface planning machine, the cutting-off sawing machine, the drilling and milling machine and the detection machine are connected with corresponding input and output openings formed in a storage transporting device; and waste output openings of the positioning measuring machine, the glue smearing machine, the woodworking planning machine, the curved surface planning machine, the cutting-off sawing machine, the drilling and milling machine and the detection machine are connected with corresponding input openings formed in a waste recovery device. According to the wood-structure laminated glued-laminated timber flexible machining production line and the flexible machining method, glued-laminated timber automatic batch production of glued-laminated timber blanks with different types is achieved through flexible machining.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

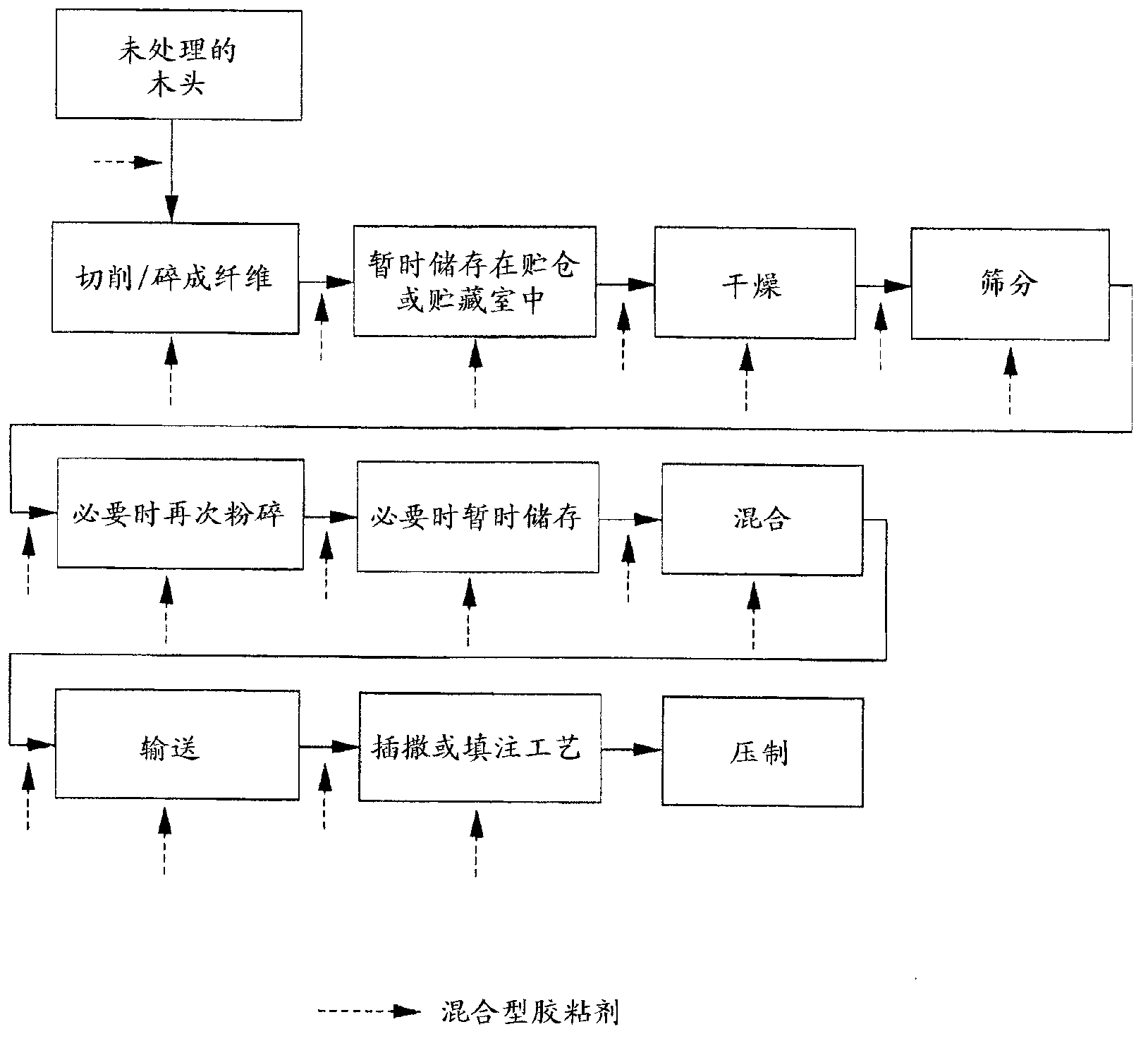

Hybrid adhesive and the use thereof in engineered wood boards

ActiveCN103210051AImprove usabilityEasy to operatePolyureas/polyurethane adhesivesAldehyde/ketone condensation polymer adhesivesFiberAdhesive

The present invention relates to a hybrid adhesive, in particular for use in the production of engineered wood such as particle boards, fiber boards, plywood or glued-laminated timber, comprising at least one polycondensation adhesive, at least one polyaddition adhesive, and at least one particle, in particular a nanoparticle smaller than 500 nm, wherein the at least one particle is modified with at least one compound of the general formula (I) RaSiX(4-a) (I), or the general formula (II) ObXc(OH)dReSiO(4-b-c-d-e) / 2 (II), where - X is H, OH or a hydrolyzable group selected from the group consisting of halogen, alkoxy, carboxy, amino, monoalkylamino or dialkylamino, aryloxy, acyloxy, alkylcarbonyl, - R is a non-hydrolyzable organic group R selected from the group consisting of substituted and non-substituted alkyl, substituted and non-substituted aryl, substituted and non-substituted alkenyl, substituted and non-substituted alkinyl, substituted and non-substituted cycloalkyl, which can be interrupted by -O- or -NH-, and where R comprises at least one functional group Q selected from a group consisting of an epoxy, hydroxy, ether, amino, monoalkylamino, dialkylamino, substituted and non-substituted anilino, amide, carboxy, alkinyl, acryl, acryloxy, methacryl, methacryloxy, mercapto, cyano, alkoxy, isocyanato, aldehyde, alkylcarbonyl, acid anhydride and / or phosphoric acid group, - R and X can be identical or different from each other, and - a = 1, 2, 3, in particular 1, - b, c, d = 0 or 1, and - e = 1, 2, 3. The present invention also relates to the use of the adhesive in engineered wood boards and to methods for the production thereof.

Owner:KRONOTEC

Method of manufacturing glued laminated wood

InactiveUS20040060634A1Tightly boundMechanical working/deformationPlywood pressesAdhesiveEngineering

A method of manufacturing glued laminated wood such as laminated veneer lumber (LVL) is disclosed. The glued laminated wood is made of a number of wood sheets such as veneer sheets which are laminated together by a hot press with a thermosetting adhesive into a continuous length of multiple-layered board wherein the end joints of the wood sheets are disposed in a staggered array. There is provided an initial base material having an end which is shaped in the form of a flight of steps including a series of alternate horizontal surface having a lengthwise dimension smaller than the length of the wood sheet and a vertical surface having a height corresponding to the wood sheet thickness, and the glued laminated wood board is formed extending from the end of such initial base material. The hot press includes a pair of heat plates each having an effective pressing area capable of covering the entire surface of the wood sheet. In hot pressing a wood sheet having on one surface thereof coated with adhesive, a board of the glued laminated wood in progress is placed and maintained for a predetermined length of time at a position where the entire top surface of the wood sheet is kept to be pressed from the top by one of the plates while the entire lower surface of the wood sheet is supported from the bottom by the other plate.

Owner:MEINAN MASCH WORKS INC

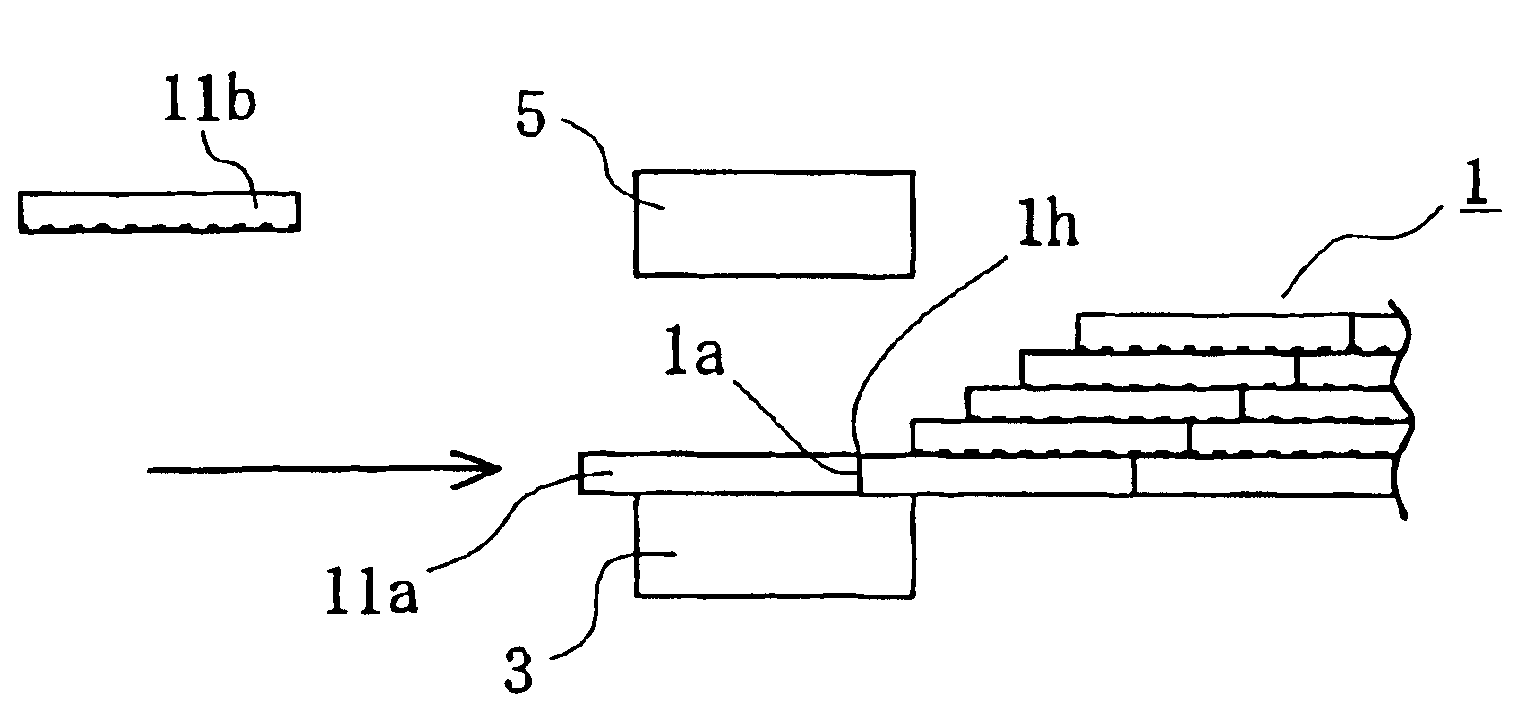

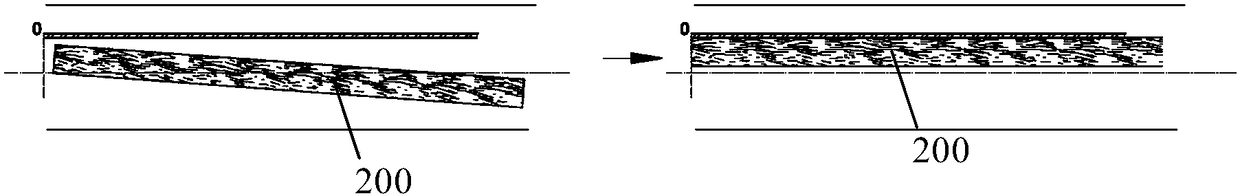

Method for producing infinitely-long glued laminated timber through conventional hot press

InactiveCN108145808AHigh strengthSuit one's needsWood veneer joiningFinger jointUltimate tensile strength

The invention relates to a method for producing infinitely-long glued laminated timber through a conventional hot press. The method comprises the steps of (1) drying, (2) slat finish planing and length determining, (3) slat end machining, (4) gluing, (5) assembling and joint reserving, (6) glued laminated timber main body solidifying and (7) joint hot-press extension. The method has the advantagesthat firstly, through staggered splicing of multiple slats, multiple pieces of glued laminated timber made in the existing conventional hot press can be connected into the infinitely-long glued laminated timber without bevel or finger joint face machining after glued laminated timber pressing; secondly, the joint strength is high, and the requirements of different transportation means, projects and buildings can be met; and thirdly, equipment is simple, tools are easy to obtain, operation is convenient, and the production efficiency is high.

Owner:NANJING FORESTRY UNIV

Method and apparatus of pressing in manufacturing glued laminated wood

A method and an apparatus of wood pressing usable in manufacturing glued laminated wood such as laminated veneer lumber (LVL) using a number of wood veneer sheets are disclosed. A hot press used for wood pressing includes a pair of heating plates which are disposed one above the other and have pressing surfaces facing each other. The paired heating plates are both movable toward and away from each other. In operation, firstly one of the heating plates is moved toward the other heating plate to a position where the pressing surface of the one heating plate is spaced from a surface to which a veneer sheet is to be glued by a distance corresponding to the thickness of the veneer sheet. Then, the other heating plate is moved toward the one heating plate until a desired pressure is produced pressing.

Owner:MEINAN MASCH WORKS INC

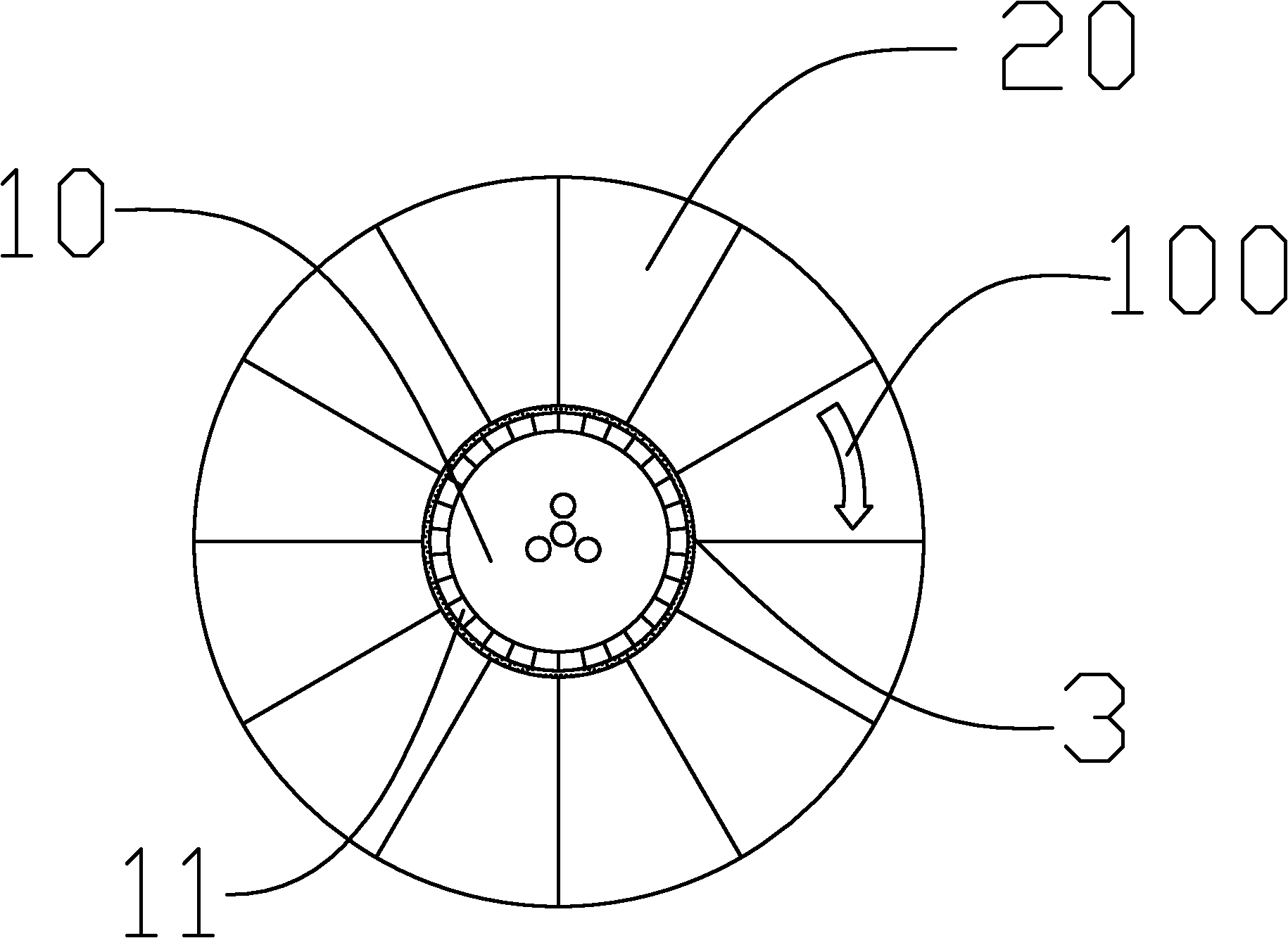

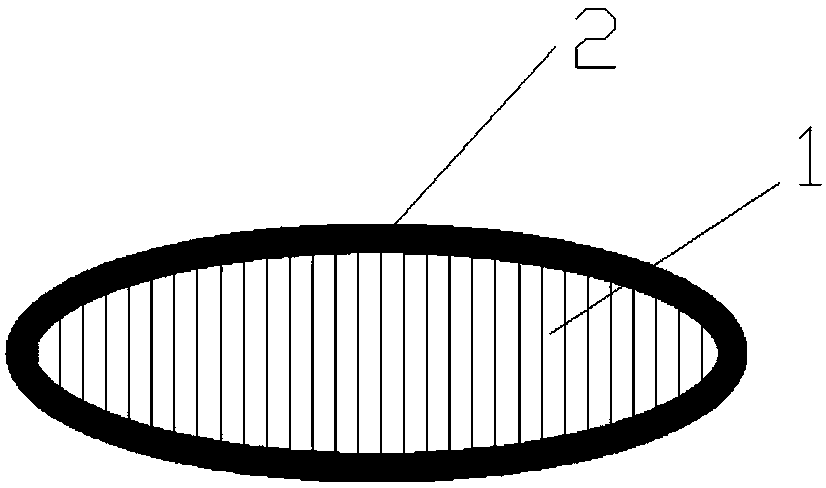

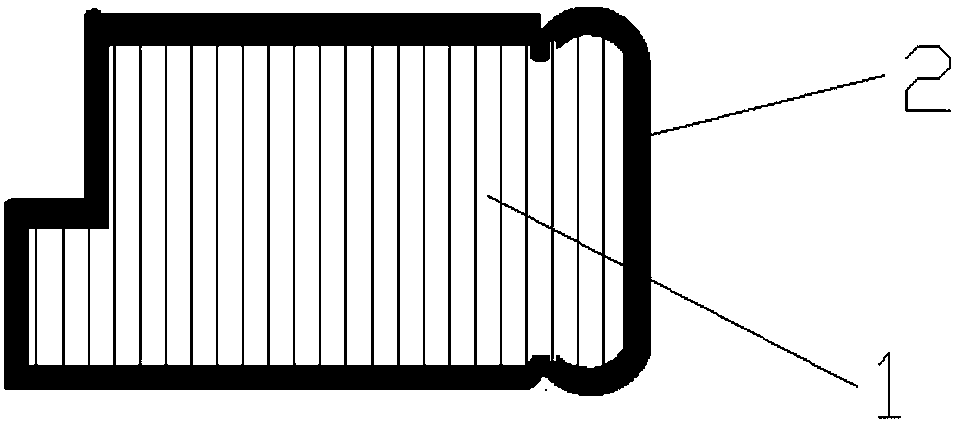

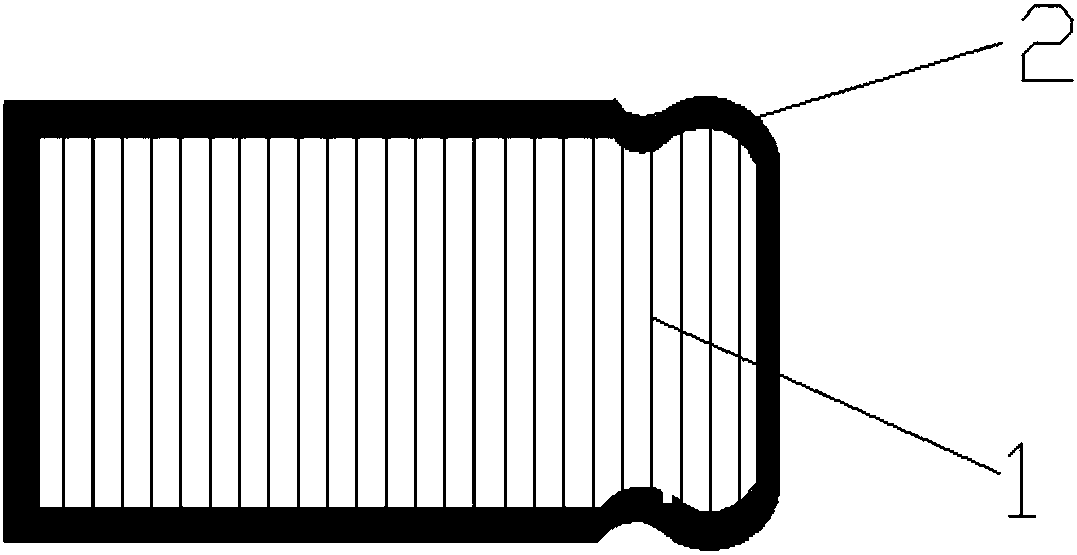

Glued laminated timber and production and utilization method thereof

InactiveCN102152376ASave resourcesAlleviating the lack of large-diameter logsWood working apparatusDomestic articlesFiberFlat joint

The invention provides a method for producing a large-diameter glued laminated timber from logs with short and small diameter and low quality, an obtained glued laminated timber and a utilization method thereof. The glued laminated timber can be produced into wide-width and whole continuous veneers by rotary-cut. The produced glued laminated timber is formed by bonding a central columned core body and a plurality of single annular glued laminated timber sheets which are sleeved on the core body, wherein the core body consists of a metal inner core with enclosed two ends and a wood structure layer closely laminated to the metal inner core, each glued laminated timber sheet is formed by aligning, splicing and bonding a plurality of sector blank boards with equal thickness, each sector blank board is formed by splicing, gluing and cutting a plurality of flat jointed boards equal in thickness, the sides of the jointed boards are perpendicular to one sloping sides of the sector blank boards, therefore, the obtained glued laminated timber is directional, and the better rotary-cut effect along the fiber can be achieved in the rotary-cut process.

Owner:唐光志

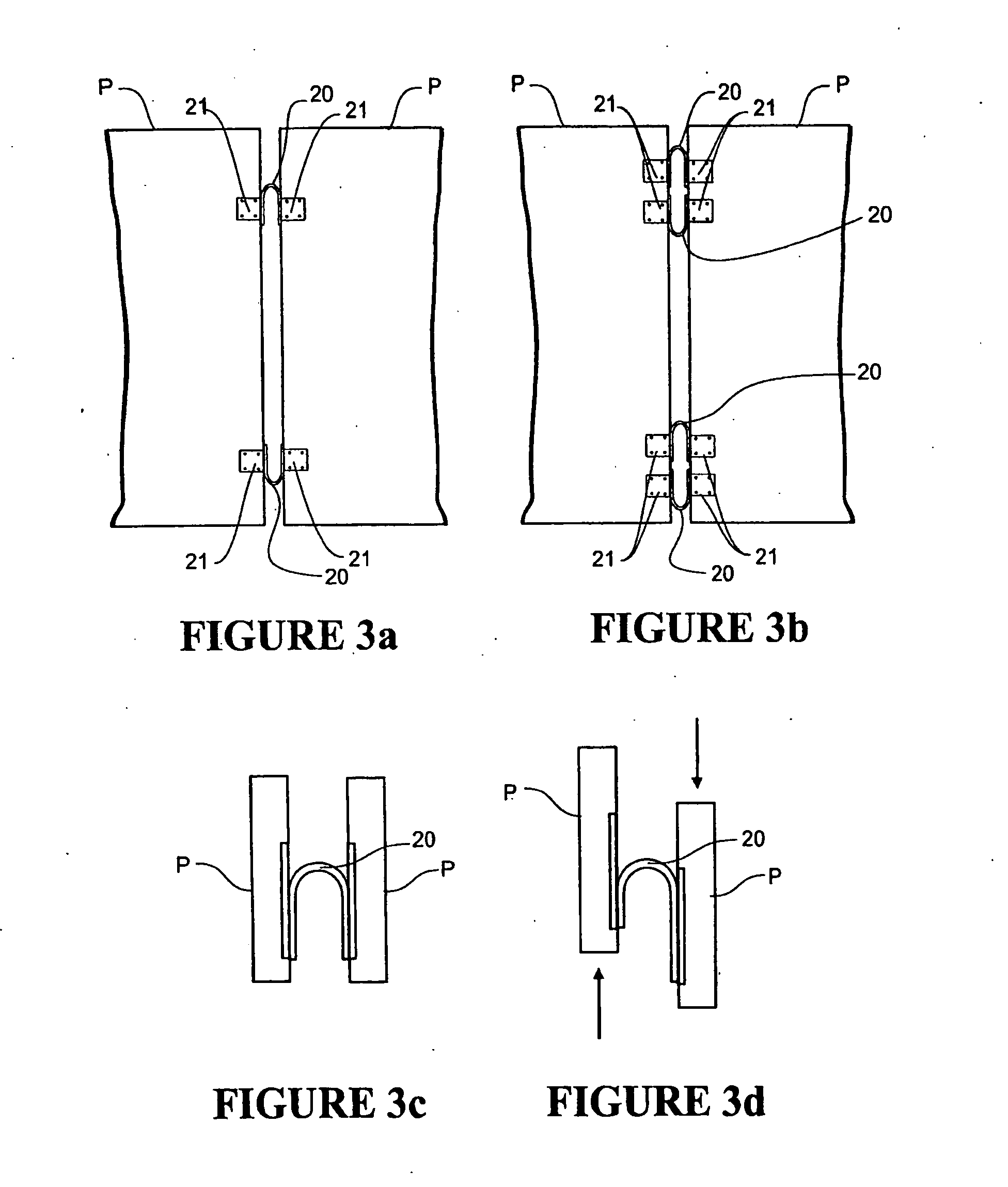

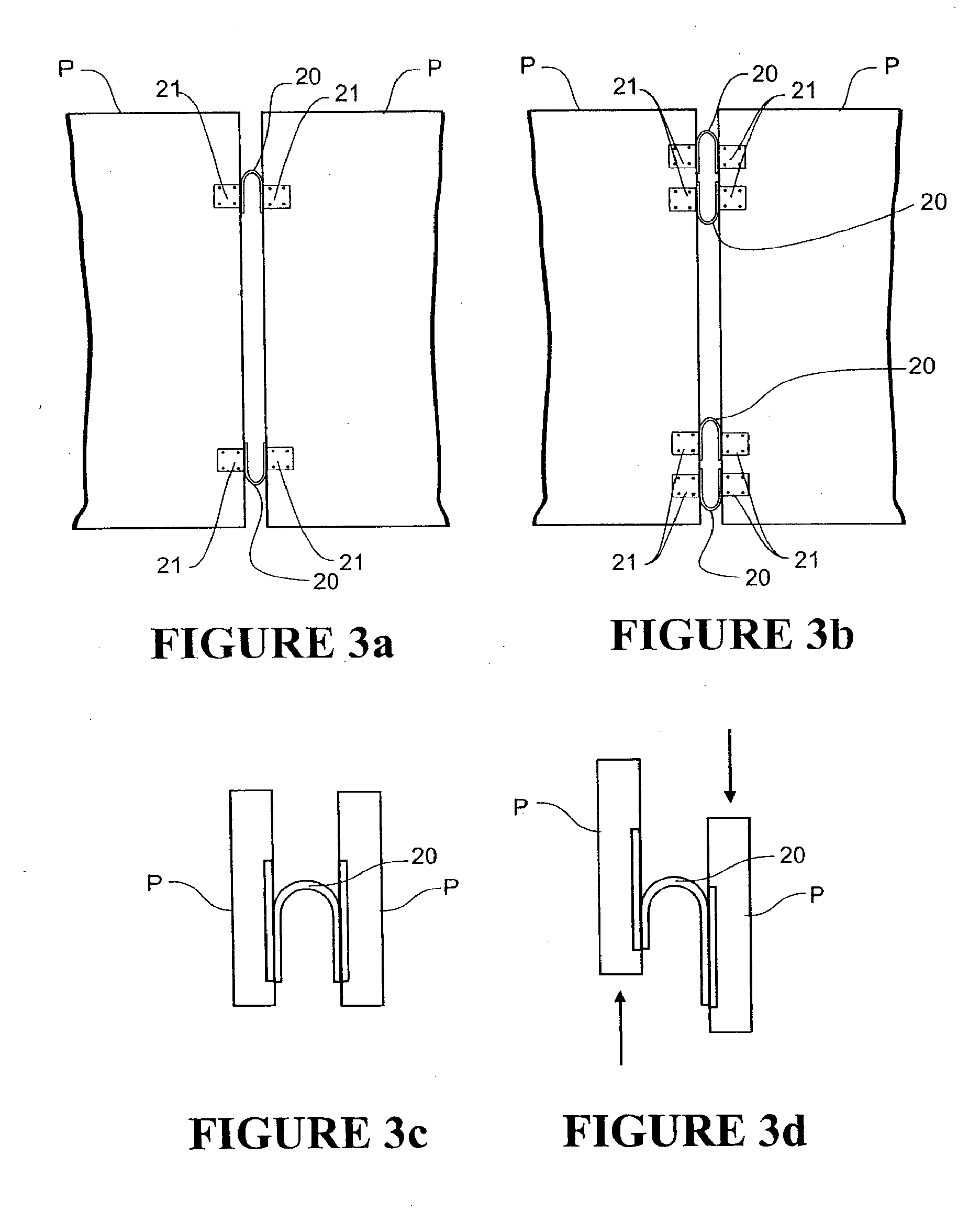

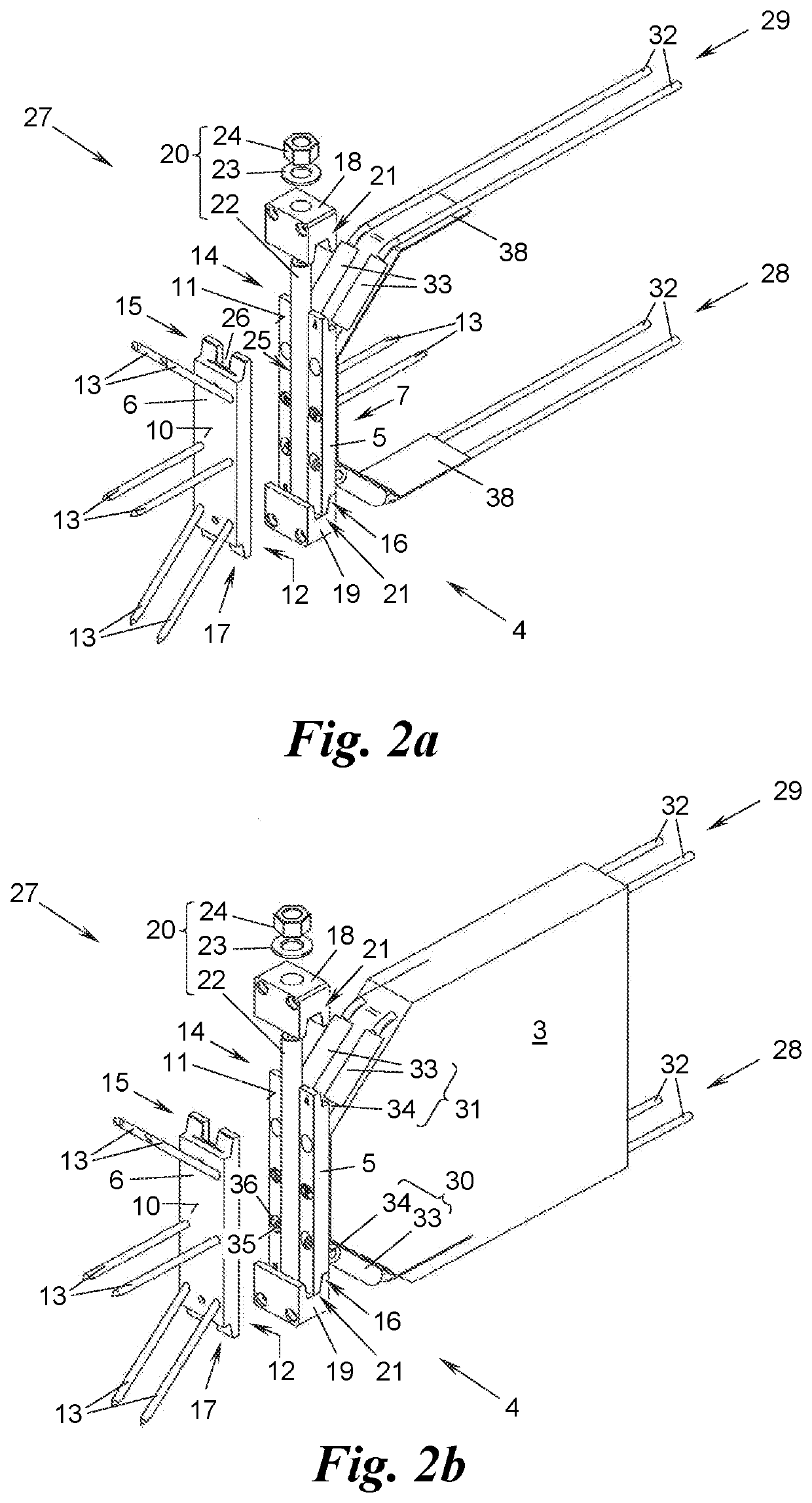

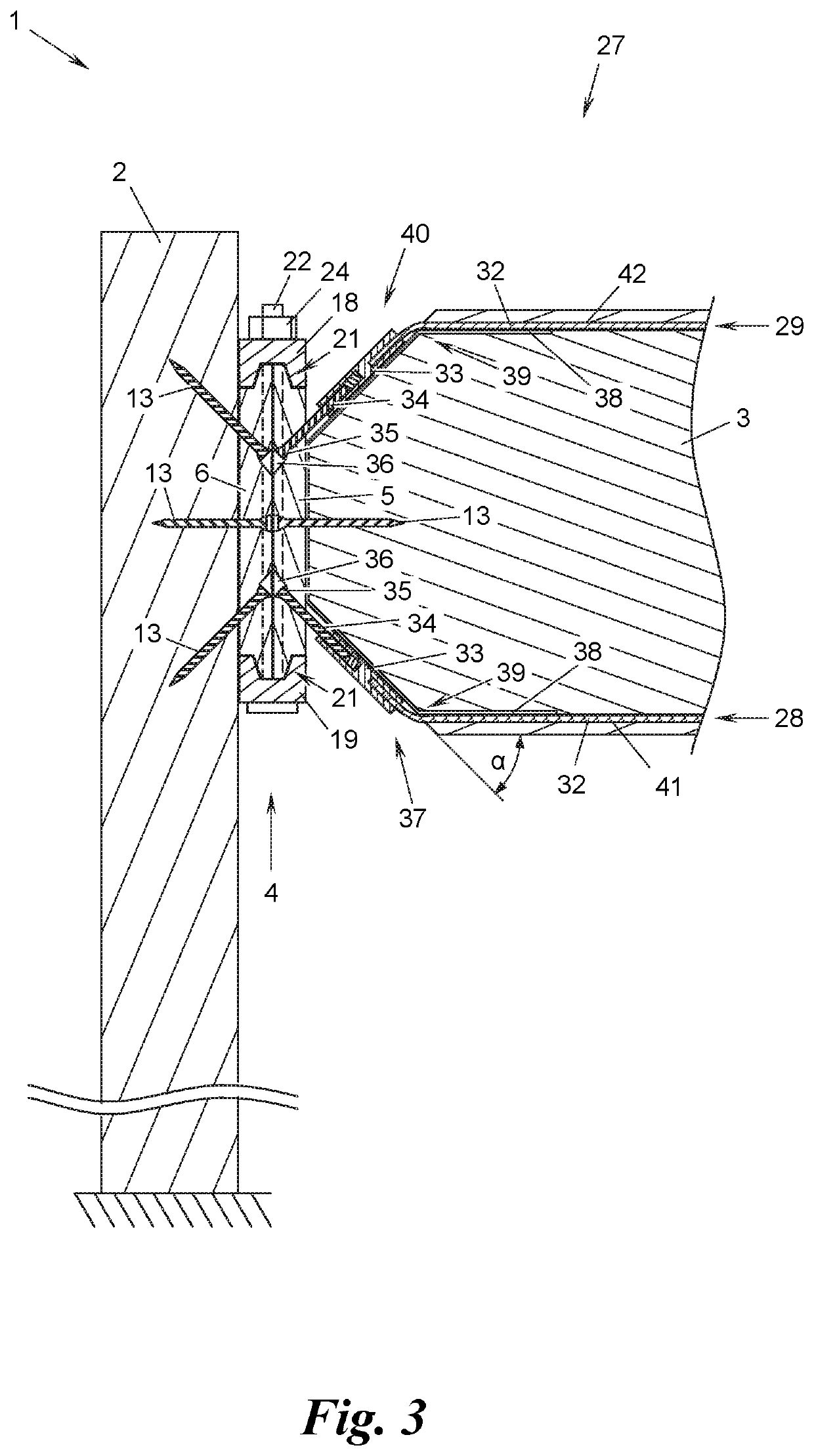

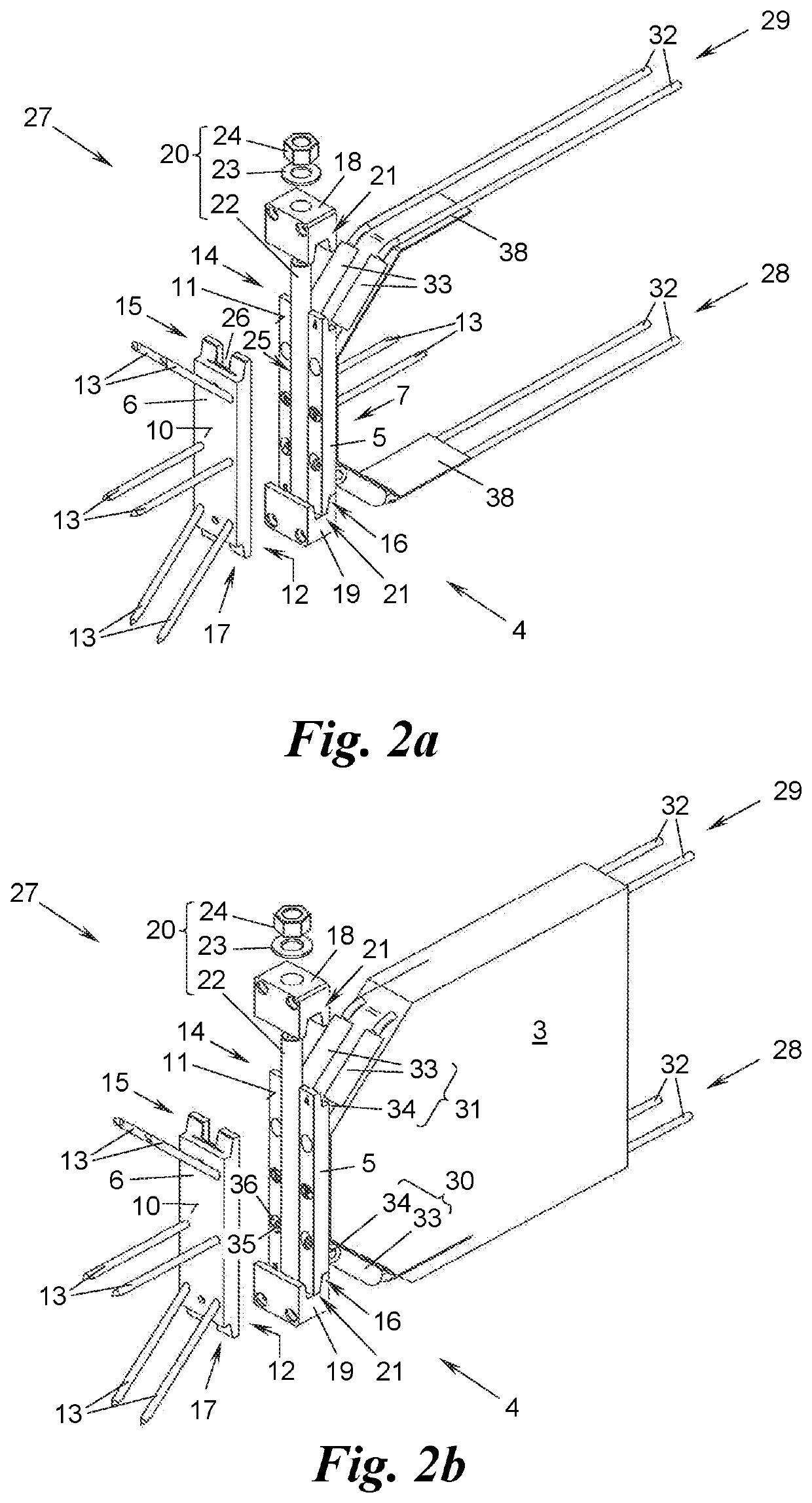

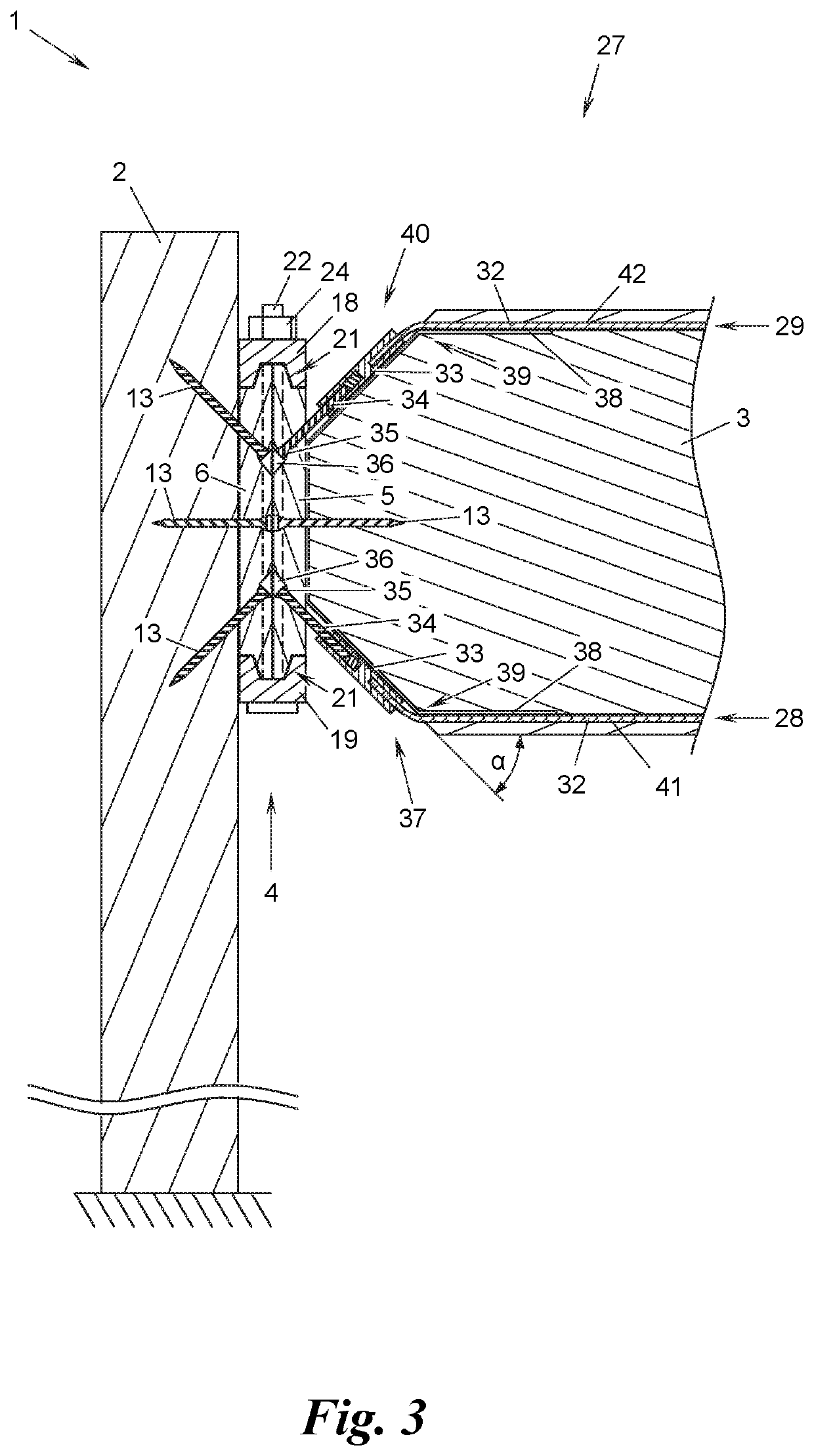

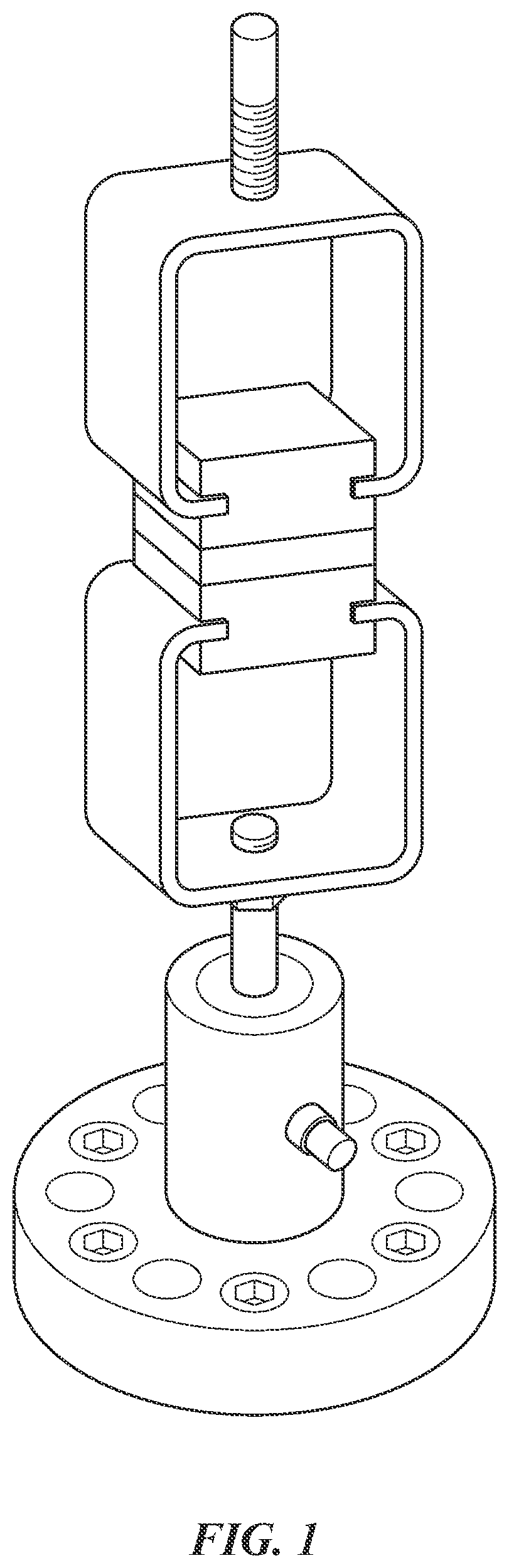

Device for coupling two vertical components

ActiveUS20190382997A1Simple designHigh load-bearing capability and durabilityGirdersJoistsSubject matterAbutment

The present subject matter relates to a device for coupling two vertical components, comprising a girder made of wood, in particular glued laminated timber, and a connector for each end face of the girder for connecting the end faces to one of the vertical components each. Each connector has two fittings, one of which is mounted via one side on the respective end face of the girder and the other of which can be mounted via one side on the associated vertical component and which fittings can be brought via their other sides into abutment against one another. Further, each connector has two tensioning jaws, which grasp the fittings at diametrical ends and can be tensioned against one another by means of at least one tensioning element running approximately parallel to said other sides. The girder has a bottom chord made of steel, which bottom chord is anchored at each end face of the girder to the fitting mounted thereon. At least one tensioning member is provided for tensioning the bottom chord.

Owner:KNAPP GMBH

Method for manufacturing glue laminated wood material and method for manufacturing luggage

Owner:QURZ

Manufacturing technology of notched glued laminated timber

InactiveCN108527590AHigh strengthAvoid crackingWood working apparatusGrinding machinesManufacturing technologyFinger joint

The invention discloses a manufacturing technology of notched glued laminated timber. The manufacturing technology comprises the following steps that a log is broken into plates to be dried through adrying kiln to reach the required moisture; the dried plates are manufactured into required specification plates; scars and cracks are cut off through a cutting saw; four-face dressing is conducted; then the specification plates are connected into the required length through a comb machine and a finger joint machine; then the finger joint plates are dressed through a four-face planer; and then thefinger joint plates are glued together according to the required thickness through a plate splicing machine and imported environment-friendly glue to be manufactured into the notched glued laminatedtimber. The manufacturing technology has the advantages that the notched glued laminated timber is manufactured through matching of the imported environment-friendly glue and the plate splicing machine, environmental protection and hygiene are achieved, the bonding effect is good, the glued laminated timber is processed through the technology that finger joint and splicing are combined, thus the glued laminated timber has the advantages of being high in strength and not liable to crack, an operator can manufacture the notched glued laminated timber of different sizes and shapes according to the specific using needs, the timber can be effectively saved, the cost is saved, and the environment is protected.

Owner:徐海林

Tanning agent myrica modified phenolic resin, and preparation method and application thereof

ActiveCN107964080AShort curing timeGood gluing propertiesMacromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesWorking lifeNational standard

The invention discloses a tanning agent myrica modified phenolic resin, and a preparation method and an application thereof. The tanning agent myrica modified phenolic resin is mainly prepared througha reaction of phenol, a formaldehyde solution, tanning agent myrica and a degrading agent, a mass ratio of the phenol to the formaldehyde solution is 1:(1.2-3.0), a mass ratio of the phenol to the tanning agent myrica is 1:(0.2-1.5), and a mass ratio of the tanning agent myrica to the degrading agent is 1:(0.1-0.4). The preparation method comprises: a primary reaction of the phenol and the formaldehyde solution, and a secondary reaction after the addition of the tanning agent myrica and the degrading agent. The tanning agent myrica modified phenolic resin is mixed with a curing agent and a filler to prepare a tanning agent myrica modified phenolic resin adhesive. The tanning agent myrica modified phenolic resin and its adhesive can reduce the use amount of the phenol, shorten the reactiontime, reduce the cost, shorten the curing time and prolong the working life of a glue solution on the premise of meeting national standards of Structural Glued Laminated Timber, and also have the advantages of low toxicity and environmental protection.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

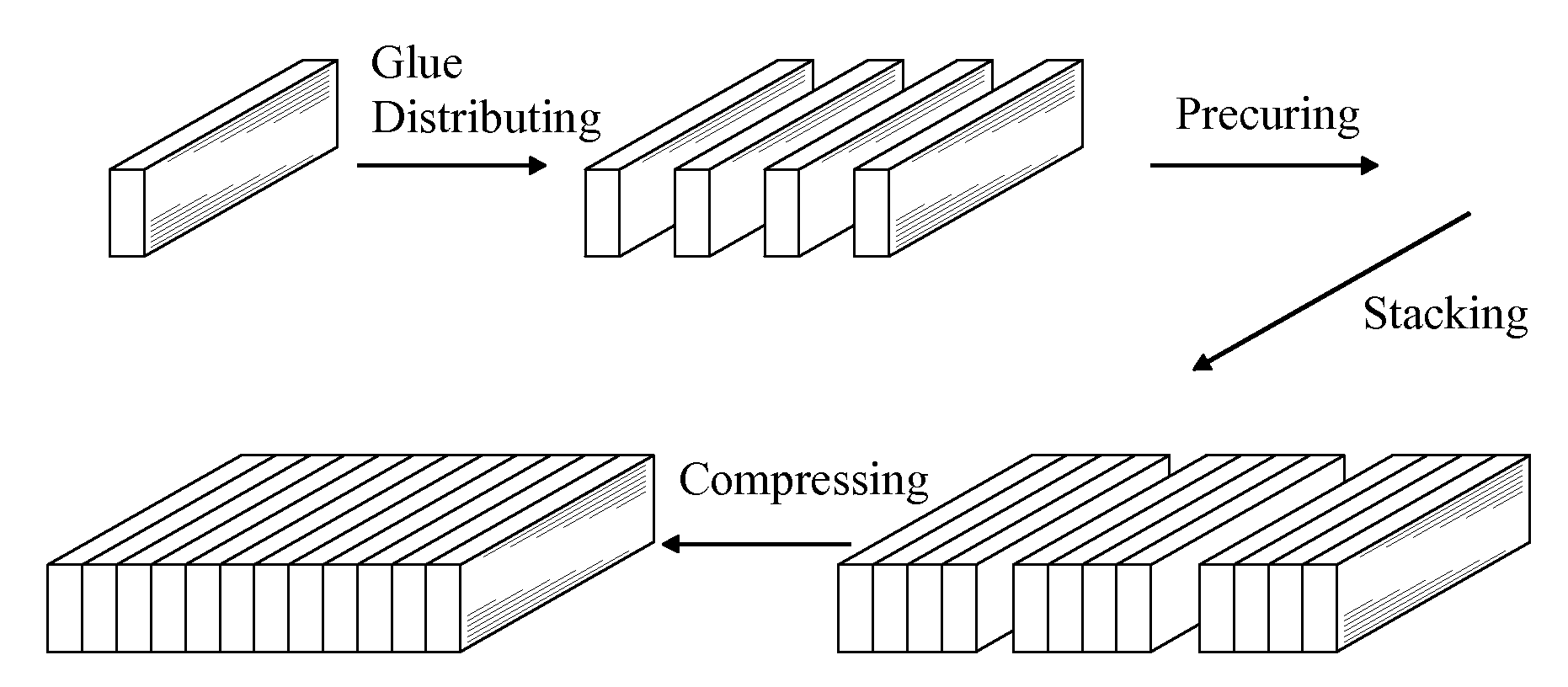

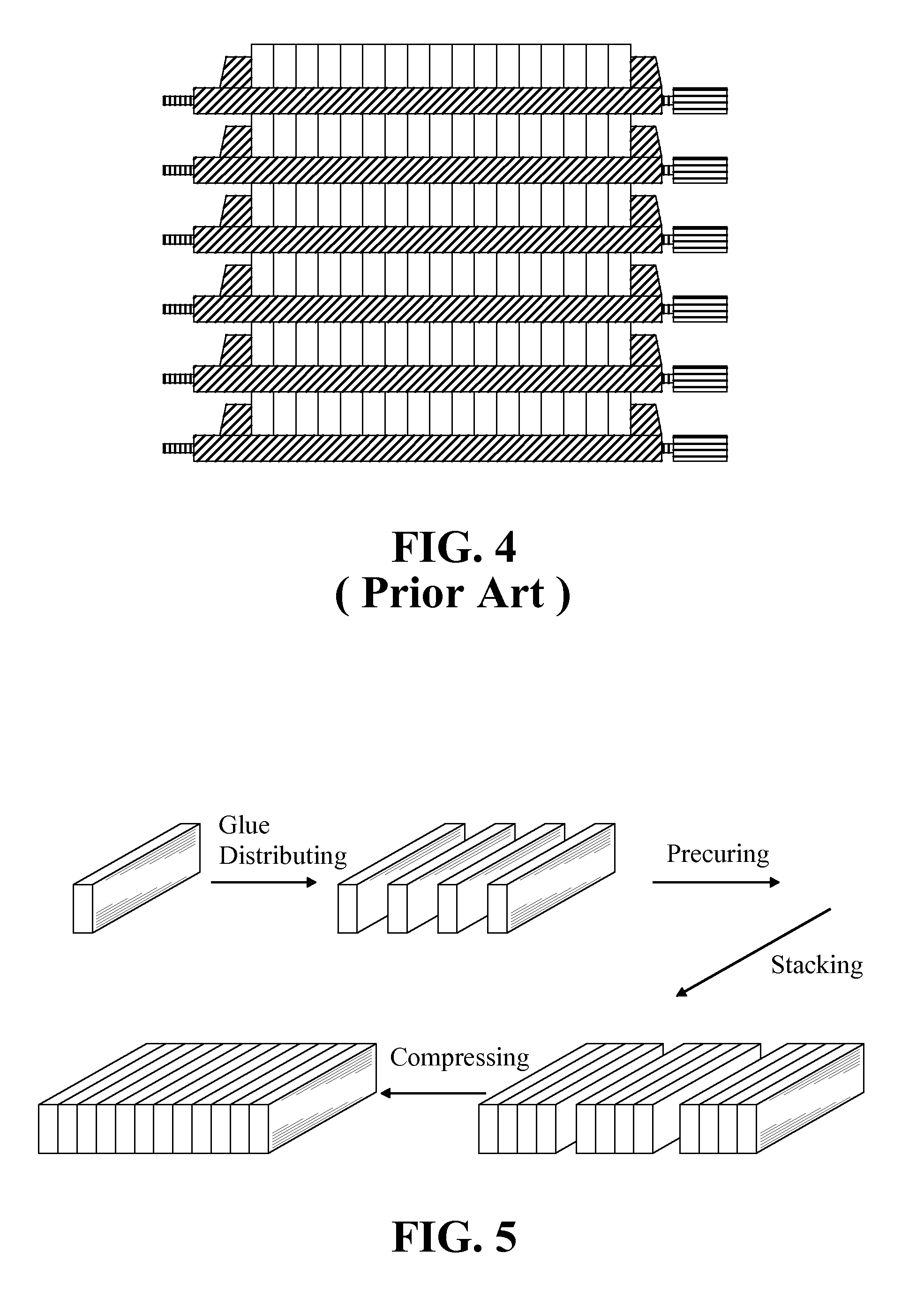

Method and system for fast fabricating glued laminated timber

InactiveUS20100319849A1Save consumptionQuality improvementWelding/cutting auxillary devicesLaminationEngineeringMechanical engineering

A method for fast fabricating a glued laminated timber is provided. The method includes the following steps: preparing a plurality of prelaminating pieces, each of the prelaminating pieces having at least two laminating surfaces, arranging the prelaminating pieces to position the laminating surfaces substantially perpendicular with a horizontal plane, and uniformly distributing glue onto the laminating surfaces of the prelaminating pieces; drying the prelaminating pieces having glue distributed thereon to precuring the glue distributed on the laminating surfaces; sequentially stacking the prelaminating pieces one on another to obtain a stack, wherein each of the prelaminating pieces is stacked to another with its laminating surfaces only; conducting a compression treatment to the stack and maintaining the compression treatment for a certain time to obtain a glued laminated timber preform; and conducting a drying treatment to the glued laminated timber preform to obtain the glued laminated timber.

Owner:LIN JAN DONG

Carbonization wood finger-joint glued-laminated timber and its manufacturing method

InactiveCN100500394CChange physical propertiesReduce hydrophilicityWood veneer joiningWood layered productsCarbonizationFinger joint

The invention relates to a carbonized figure jointed glulam lumber and a manufacturing method. The carbonized figure jointed glulam lumber is a one-layer integrated board, or one or several layers of lateral battens laying in the sandwich layer and the integrated board with more than two layers is glued in parallel in the direction of thickness. Each layer of the integrated board is made of standard battens formed by gluing many short battens through finger-jointing and tenoning, and then the standard width is formed by gelatinizing on the side of the batten and gluing and joining in parallel. The process of the method includes: log truncation, sawing, carbonization, chopping, finger-jointing, repairing, sanding and repairing; second glue jointing: gelatinizing; testing, warehousing. The advantages are that part of the chemical and physical properties of wood are changed permanently; hydrophilic property of the lumber is reduced and the inner stress is eliminated completely; the color of the wood is darkened and the wood texture is clear; the contained resin inside the wood is removed so that the wood can be glued and finished; the drying operation is substituted by the high temperature carbonization technique; the carbonized figure jointed glulam lumber is of stable size and shape, of no craze and resin and of clear texture and good durability.

Owner:NANJING FORESTRY UNIV +1

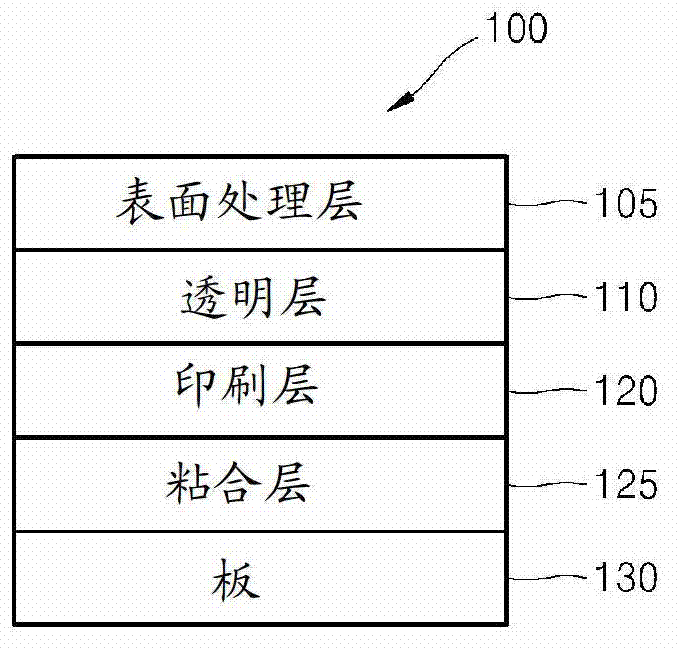

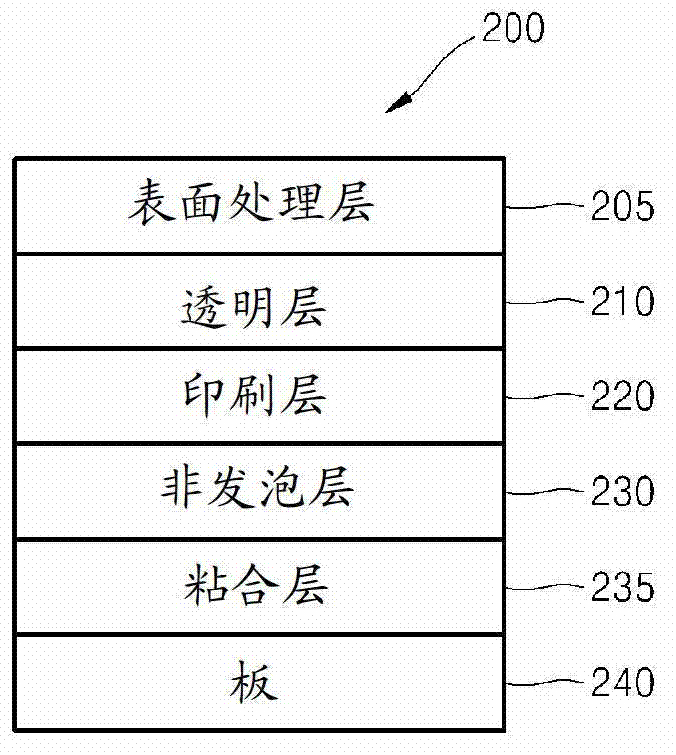

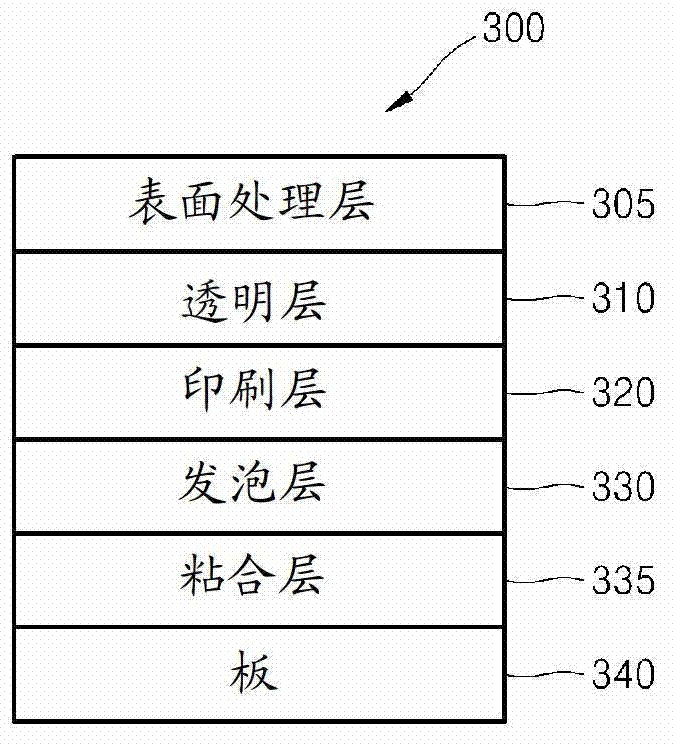

Board complex having a polylactic acid cover

InactiveCN102791482ASolve supply and demand problemsEliminate shortcomingsSynthetic resin layered productsConstructions elementsBrickCement board

The present invention relates to a board complex having a polylactic acid (PLA) cover. The board complex comprises: a cover member having at least one layer containing a PLA resin; and a board formed beneath the cover member, wherein the material for the board is selected from a medium-density fibreboard (MDF), plywood, an asbestos-free cellulose fiber reinforced cement board, a magnesium board, glued laminated timber, a high density fiberboard (HDF), a particle board, ceramic tile, porcelain tile, a ceramic board and a click-fastened board.

Owner:LG HAUSYS LTD

Wooden veneer-gluing ventilation window

InactiveCN107675999AMeet needsSimple structureShutters/ movable grillesVentilation arrangementEngineeringSoftwood

Owner:姜广学

Myrica tannin extract modified phenolic resin and its preparation method and application

ActiveCN107964080BShort curing timeGood gluing propertiesMacromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesPolymer scienceTannin

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

Device for coupling two vertical components

ActiveUS10822788B2Simple designHigh load-bearing capability and durabilityGirdersJoistsClassical mechanicsSubject matter

The present subject matter relates to a device for coupling two vertical components, comprising a girder made of wood, in particular glued laminated timber, and a connector for each end face of the girder for connecting the end faces to one of the vertical components each. Each connector has two fittings, one of which is mounted via one side on the respective end face of the girder and the other of which can be mounted via one side on the associated vertical component and which fittings can be brought via their other sides into abutment against one another. Further, each connector has two tensioning jaws, which grasp the fittings at diametrical ends and can be tensioned against one another by means of at least one tensioning element running approximately parallel to said other sides. The girder has a bottom chord made of steel, which bottom chord is anchored at each end face of the girder to the fitting mounted thereon. At least one tensioning member is provided for tensioning the bottom chord.

Owner:KNAPP GMBH

Deformation resistance manufacturing method of glued laminated timber board

InactiveCN107866874AImprove wear resistanceImprove deformation resistanceWood veneer joiningFiberCarbon fibers

The invention discloses an anti-deformation manufacturing method of glued laminated wood boards, comprising: an anti-deformation layer, a wear-resistant layer and a substrate, the wear-resistant layer is glued to the upper surface of the anti-deformation layer by an adhesive, and the substrate The lower surface of the anti-deformation layer is glued on the lower surface of the anti-deformation layer, the substrate is a wood fiber board, the wear-resistant layer is composed of copper oxide powder and quartz powder, and the content of the copper oxide powder accounts for 20-30%. The content of the quartz powder accounts for 70-80%, the anti-deformation layer is composed of carbon fiber and polyetherimide mixed, the content of the carbon fiber is 90-95%, and the content of the polyetherimide is 5‑10%, through the above method, the present invention can not only improve the wear resistance of the wood board, but also improve the overall rigidity and strength, so that the overall deformation resistance of the wood board can be greatly improved, and the use safety and service life can be improved.

Owner:宿州市徽睿木业有限公司

Technology for manufacturing structural glued laminated timber by adopting fast-growing poplars

ActiveCN103302719BImprove anti-corrosion performanceImprove flame retardant performanceWood working apparatusFlat articlesUltraviolet lightsVarnish

The invention provides a technology for manufacturing a structural glued laminated timber by adopting fast-growing poplars. The steps are as follows: firstly, selecting timber and cutting the timber into plates through an electric saw; secondly, coating a transparent water-based prime paint layer and a fire-retardant paint layer on the cut plates, and controlling the water content of the plates to range from 5% to 8% through fumigating; thirdly, planing the fumigated plates, and coating a ultraviolet light polymerization coating varnish layer and a water-based bright surface paint layer on the planed plates in sequence; fourthly, splicing the timber to form an assembly, and sending the assembly into a hot press to press the plates; fifthly, scissoring the pressed plates by using a cutting edge machine, mending, trimming and packing the plates, and then putting the plates into a warehouse. According to the invention, products have excellent corrosion resistance, snow and rain corrosion resistance, and water and oil resistance; the elastic modulus is 10000-12000 GPa, the bending strength reaches 12 MPa, the gloss is larger than or equal to 89, products have no yellow stains under the 100-110 DEG C / 1h condition, the inflaming retarding effect is excellent, and self-extinguish can be performed within 8 s; products are subjected to hard solidification under the irradiation of a high pressure mercury lamp of 500 W for 4-5 min, are ultraviolet light irradiation resistant, can be used widely, and can replace the conventional materials continuously.

Owner:江苏德鲁尼木业有限公司

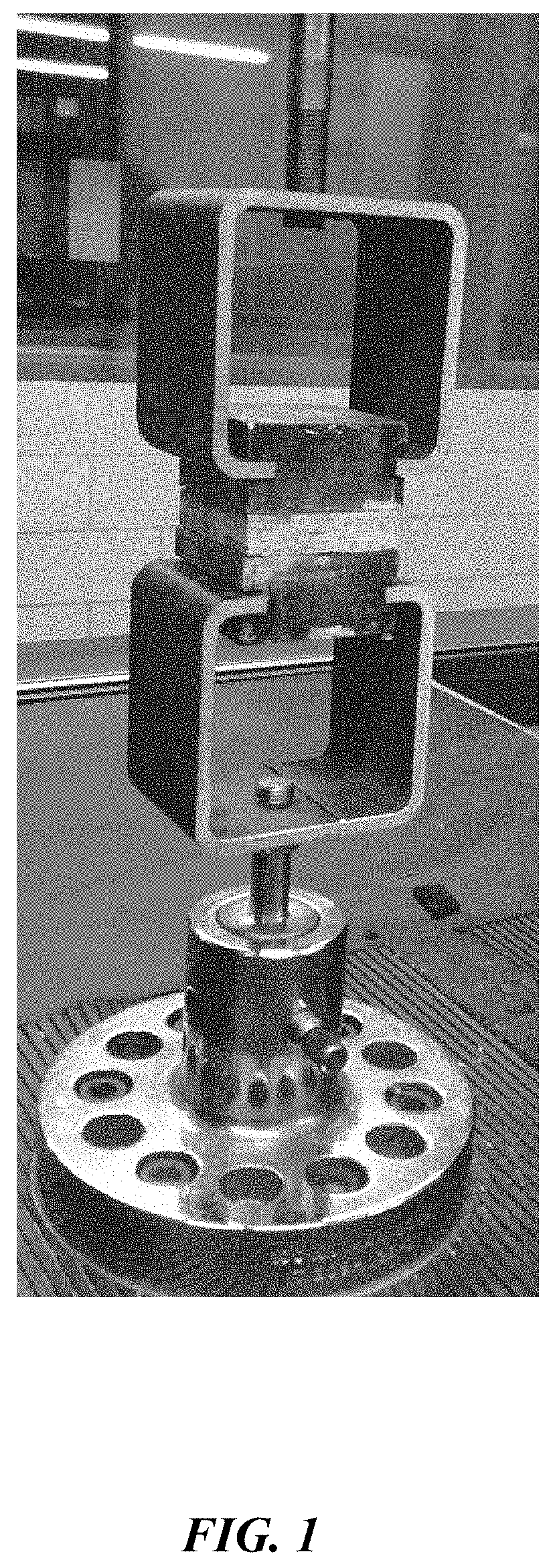

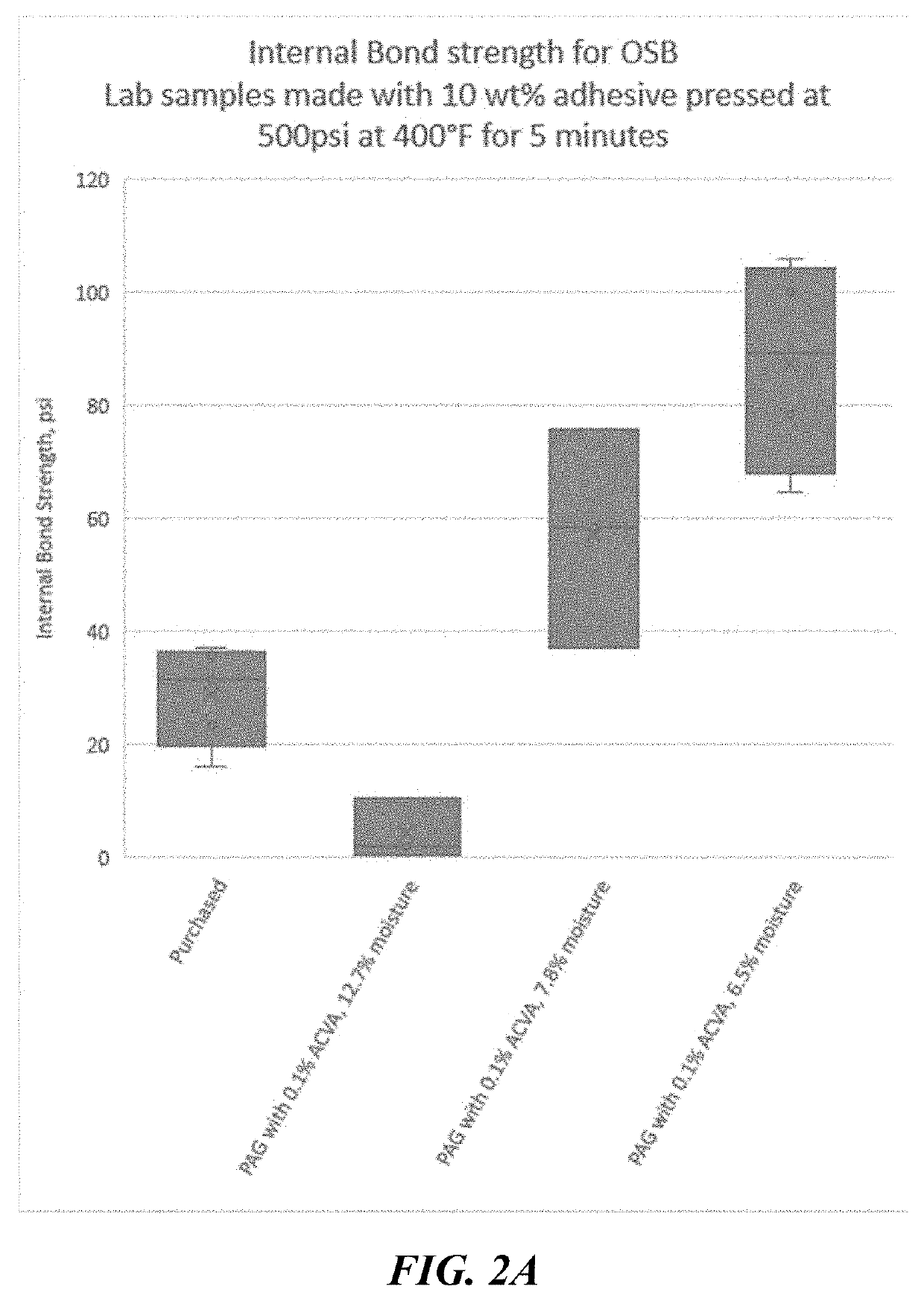

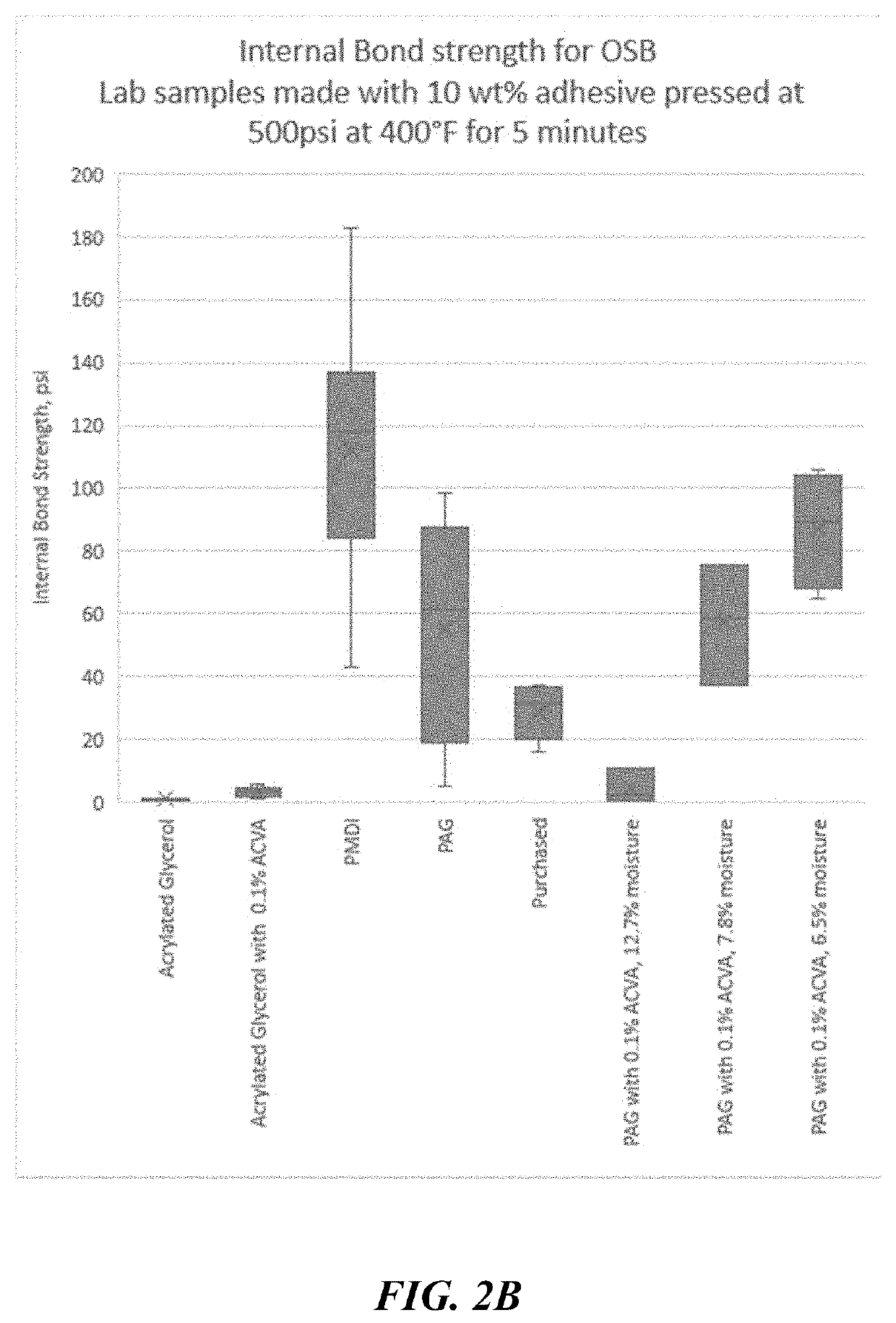

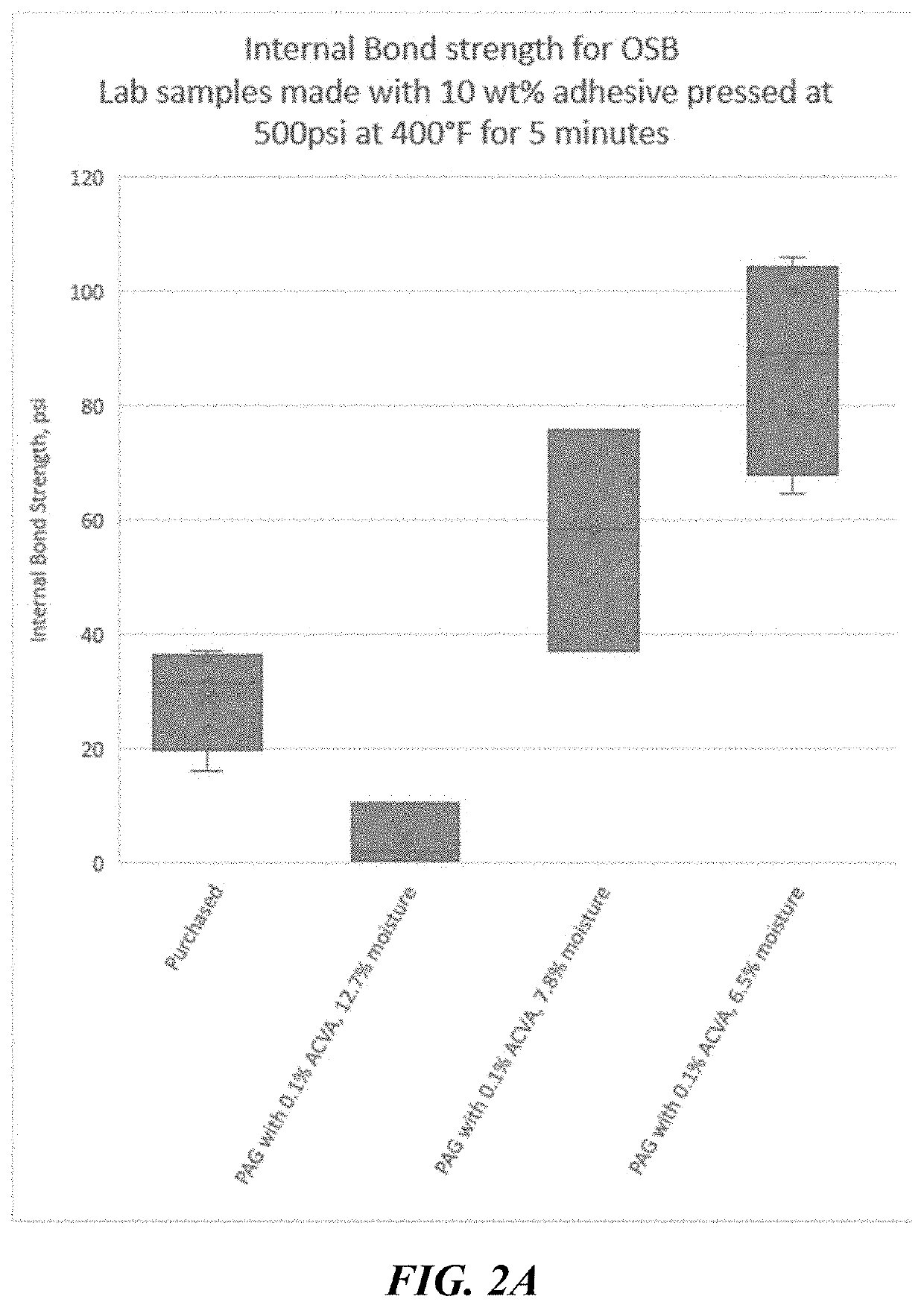

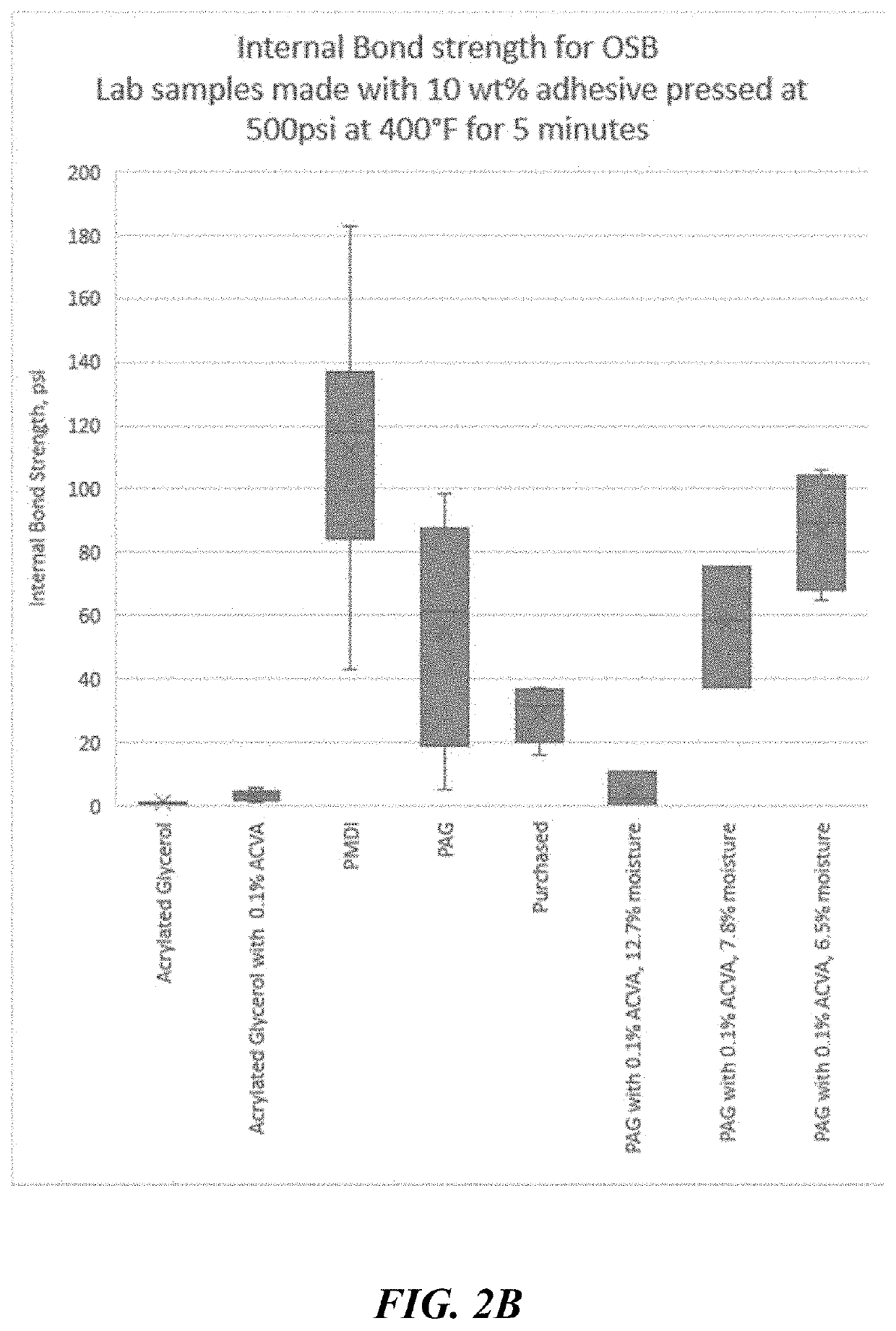

Thermoplastic poly acrylated glycerol adhesives useful in cellulosic products

ActiveUS20190345369A1Low costCleaner machined surfacesPolyureas/polyurethane adhesivesWood working apparatusThermoplasticCellulose

The present invention relates to an adhesive comprising a thermoplastic polyacrylated glycerol polymer, water, and a cross linker that is reactive with the polyacrylated glycerol polymer. This adhesive is useful in the formation of cellulosic products including oriented strand board (OSB), particle board, oriented structural straw board, chipboard, plywood, laminated veneer lumber (LVL), pressed wood, glued laminated timber (glulam), cross-laminated timber (CLT), and other wood products. Methods of producing the adhesive and cellulosic products are also disclosed.

Owner:IOWA STATE UNIV RES FOUND +1

Thermoplastic poly acrylated glycerol adhesives useful in cellulosic products

ActiveUS11214714B2Low costCleaner machined surfacesPolyureas/polyurethane adhesivesWood working apparatusThermoplasticCellulose

The present invention relates to an adhesive comprising a thermoplastic polyacrylated glycerol polymer, water, and a cross linker that is reactive with the polyacrylated glycerol polymer. This adhesive is useful in the formation of cellulosic products including oriented strand board (OSB), particle board, oriented structural straw board, chipboard, plywood, laminated veneer lumber (LVL), pressed wood, glued laminated timber (glulam), cross-laminated timber (CLT), and other wood products. Methods of producing the adhesive and cellulosic products are also disclosed.

Owner:IOWA STATE UNIV RES FOUND +1

Method and apparatus of manufacturing glued laminated wood

A method and apparatus of manufacturing glued laminated wood such as laminated veneer lumber (LVL) are disclosed. The glued laminated wood is made of a number of wood sheets such as veneer sheets which are laminated together by a hot press with a thermosetting adhesive into a continuous length of multiple-layered board of the glued laminated wood wherein wood sheets in each layer of the multiple-layered board are arranged in a staggered relation in the lengthwise direction of the board to wood sheets in an adjacent layer. The hot press has a pair of heating plates arranged substantially in facing relation to each other and an auxiliary heating plate disposed adjacent to one end of each heating plate. The auxiliary heating plate is adapted to press part of wood sheet which extends out beyond the above end of the heating plate.

Owner:MEINAN MASCH WORKS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com