Patents

Literature

88 results about "Flat joint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

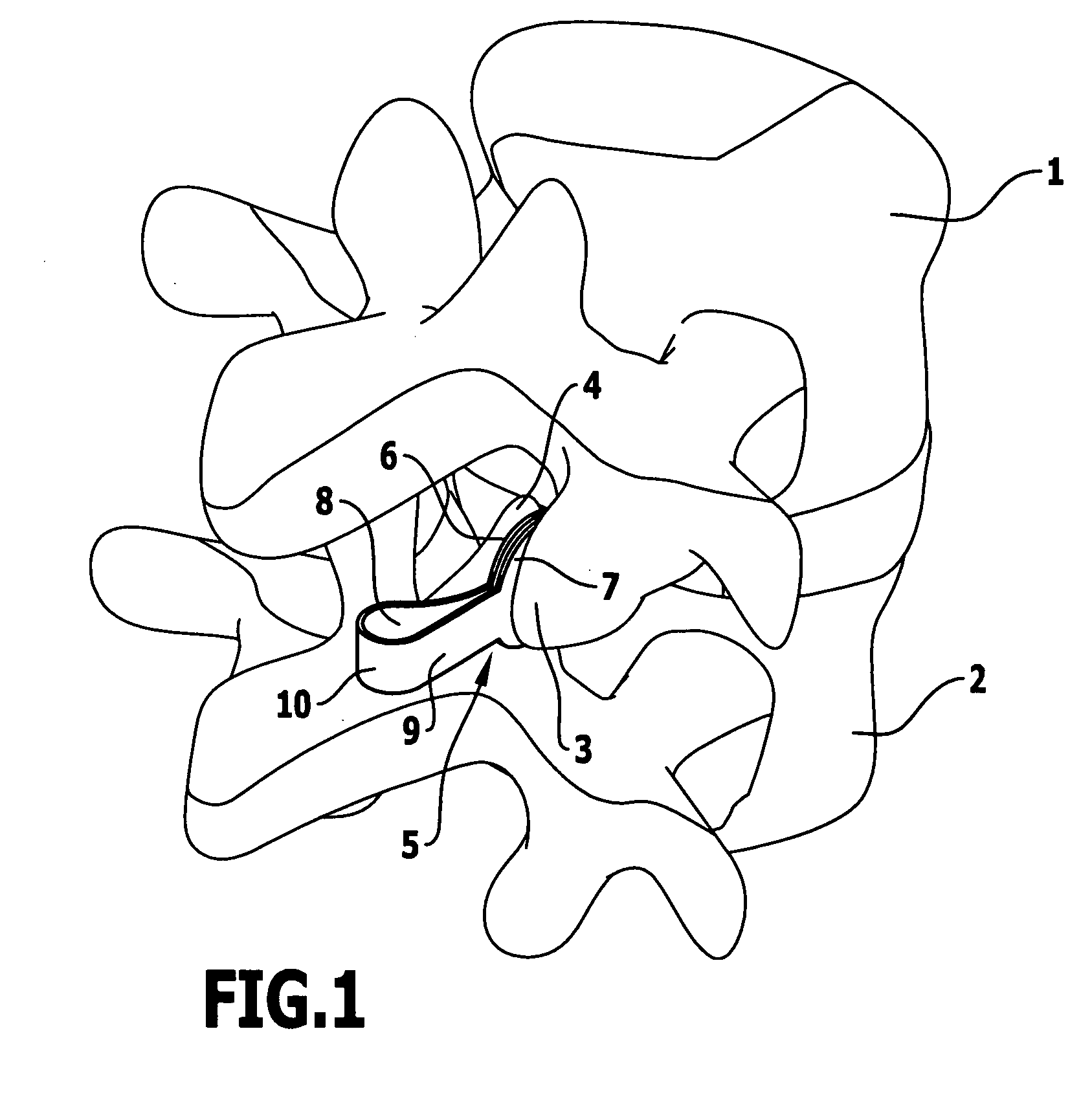

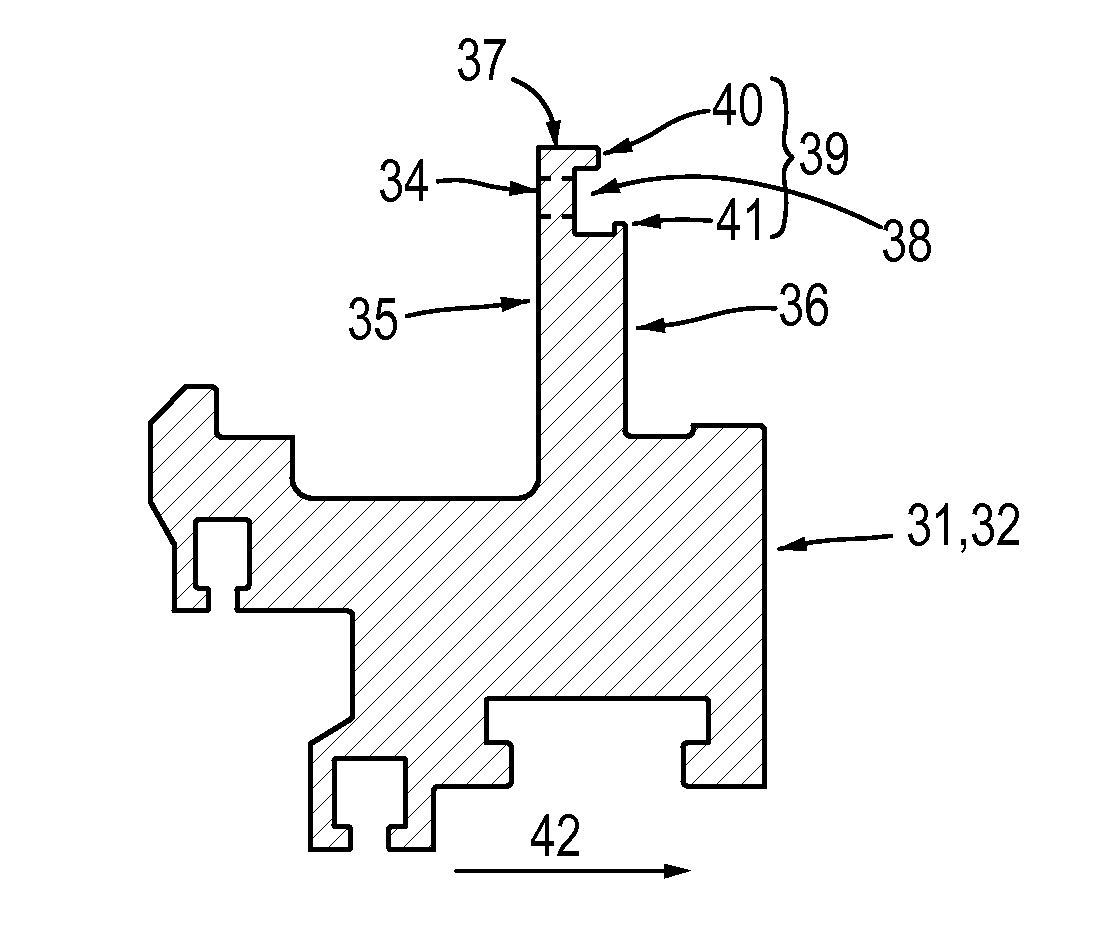

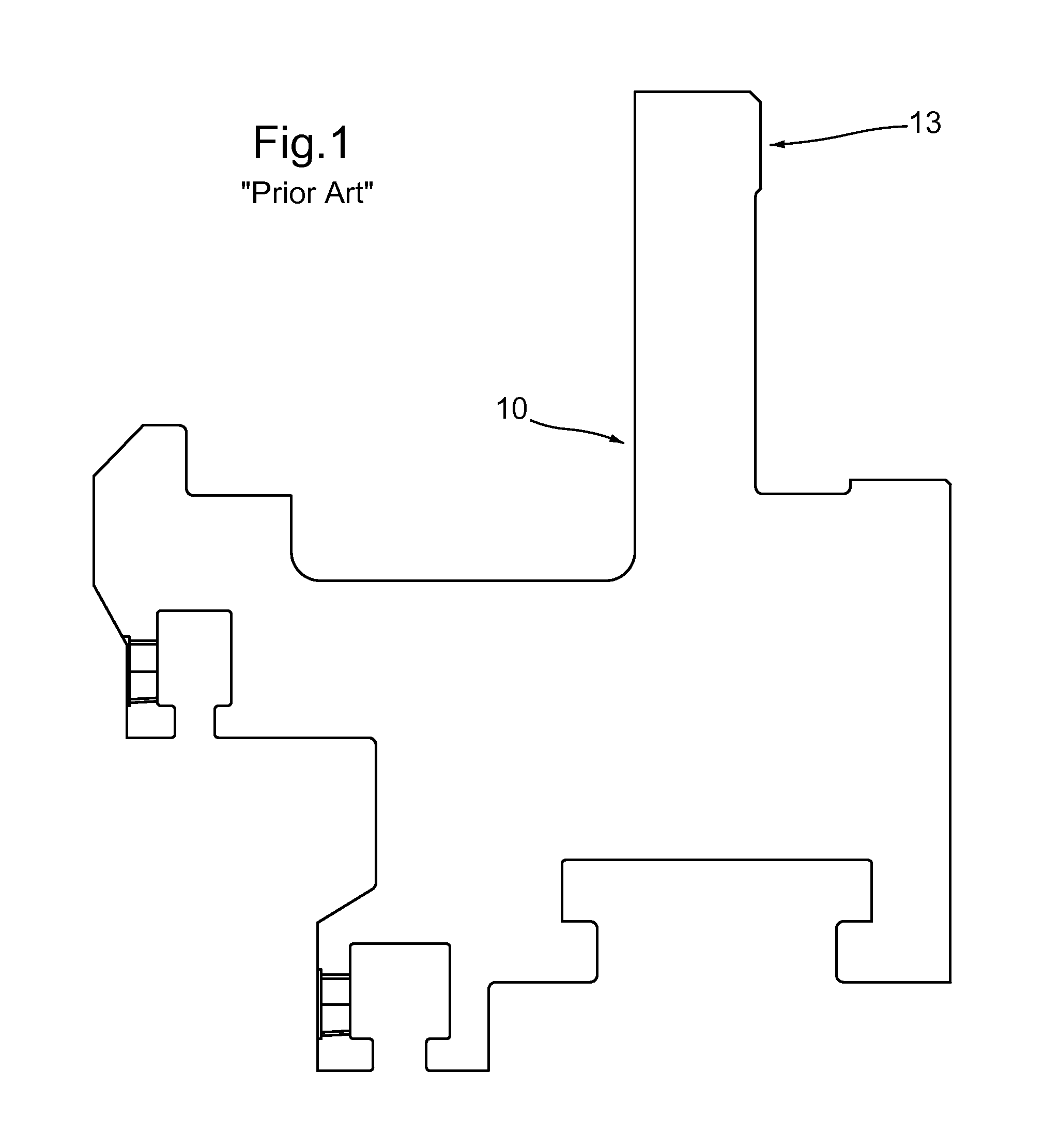

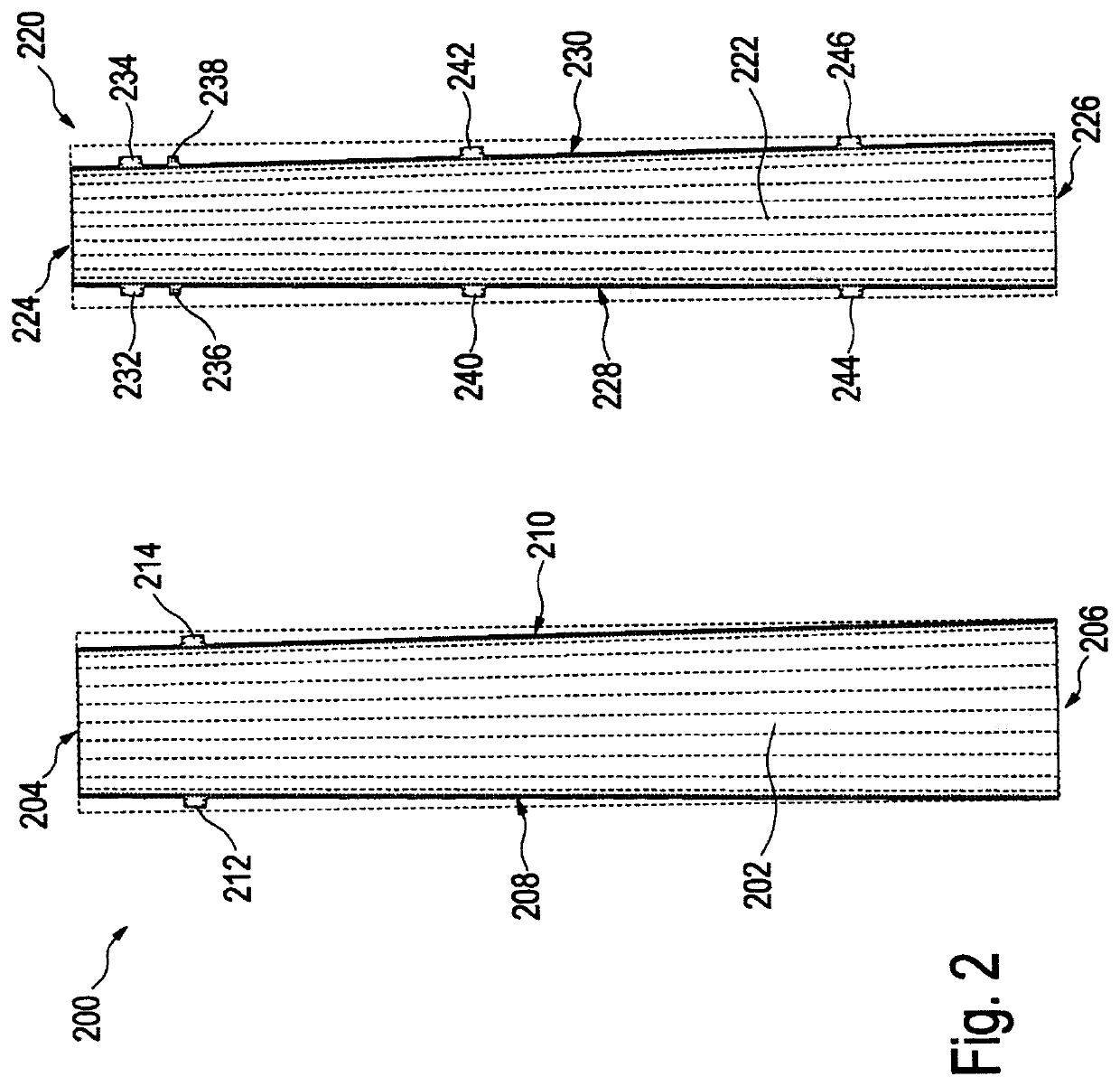

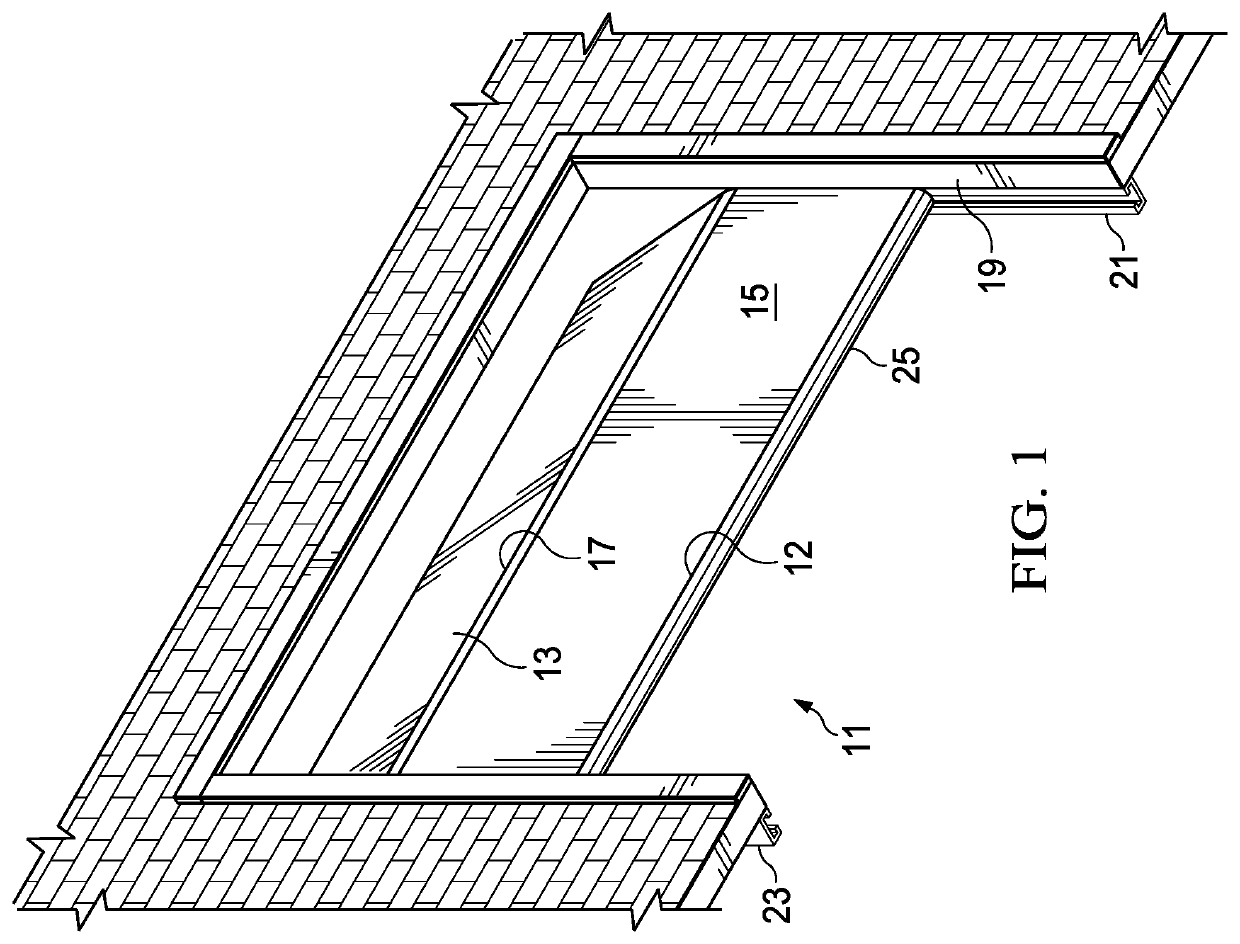

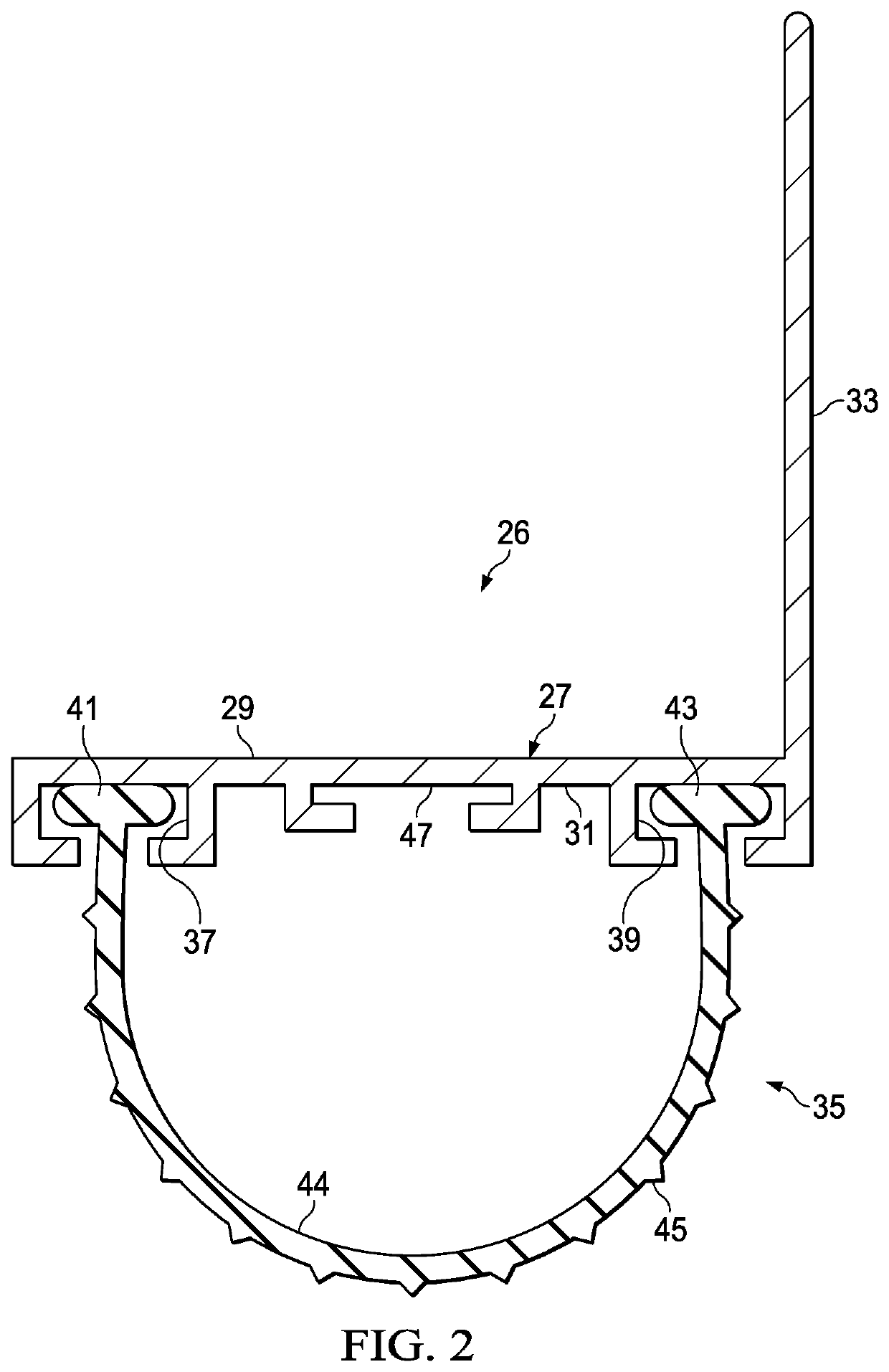

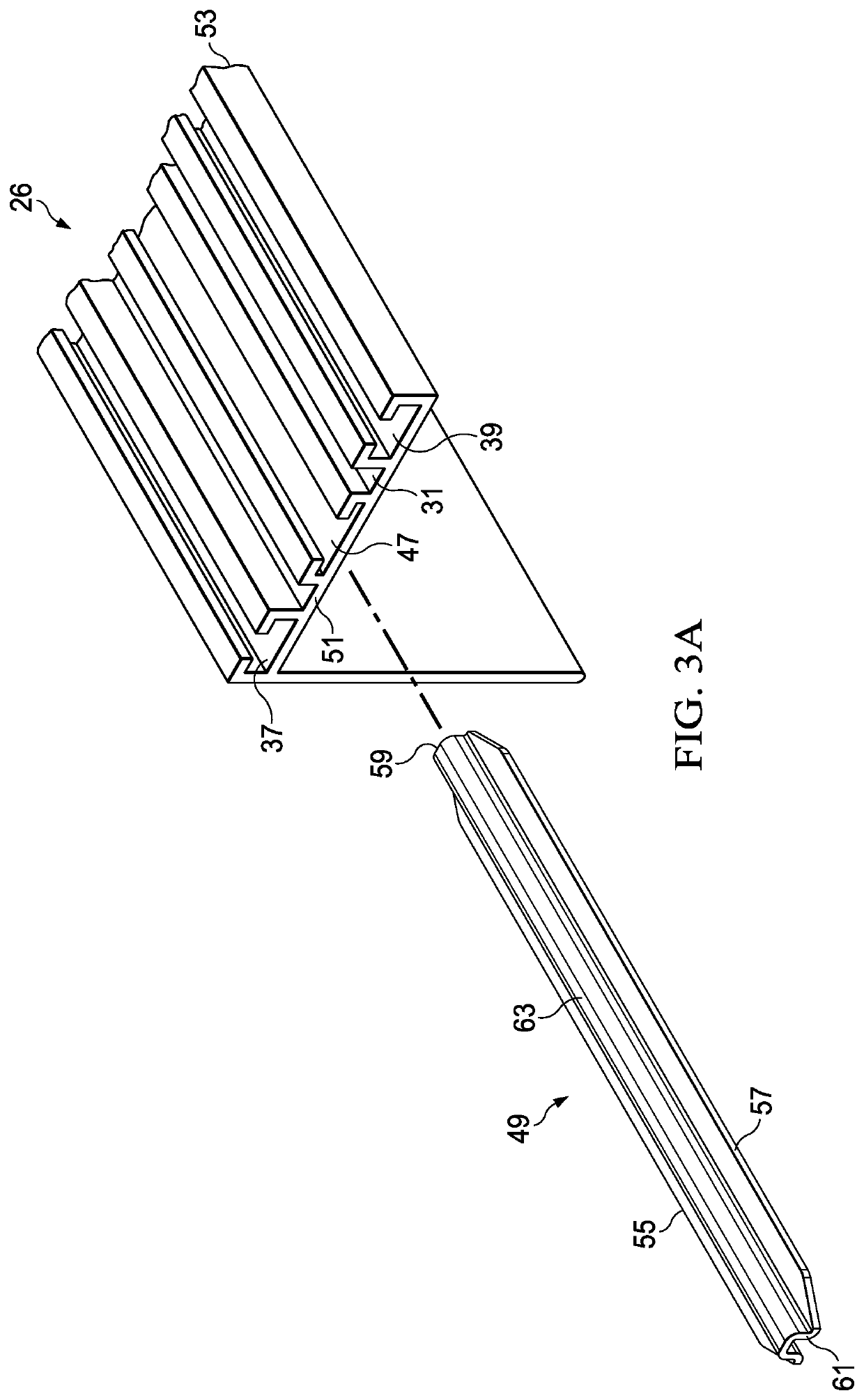

Locking system for mechanical joining of floorboards and method for production thereof

InactiveUS6898913B2High strengthFunction increaseCovering/liningsTongue/grooves making apparatusSurface layerEngineering

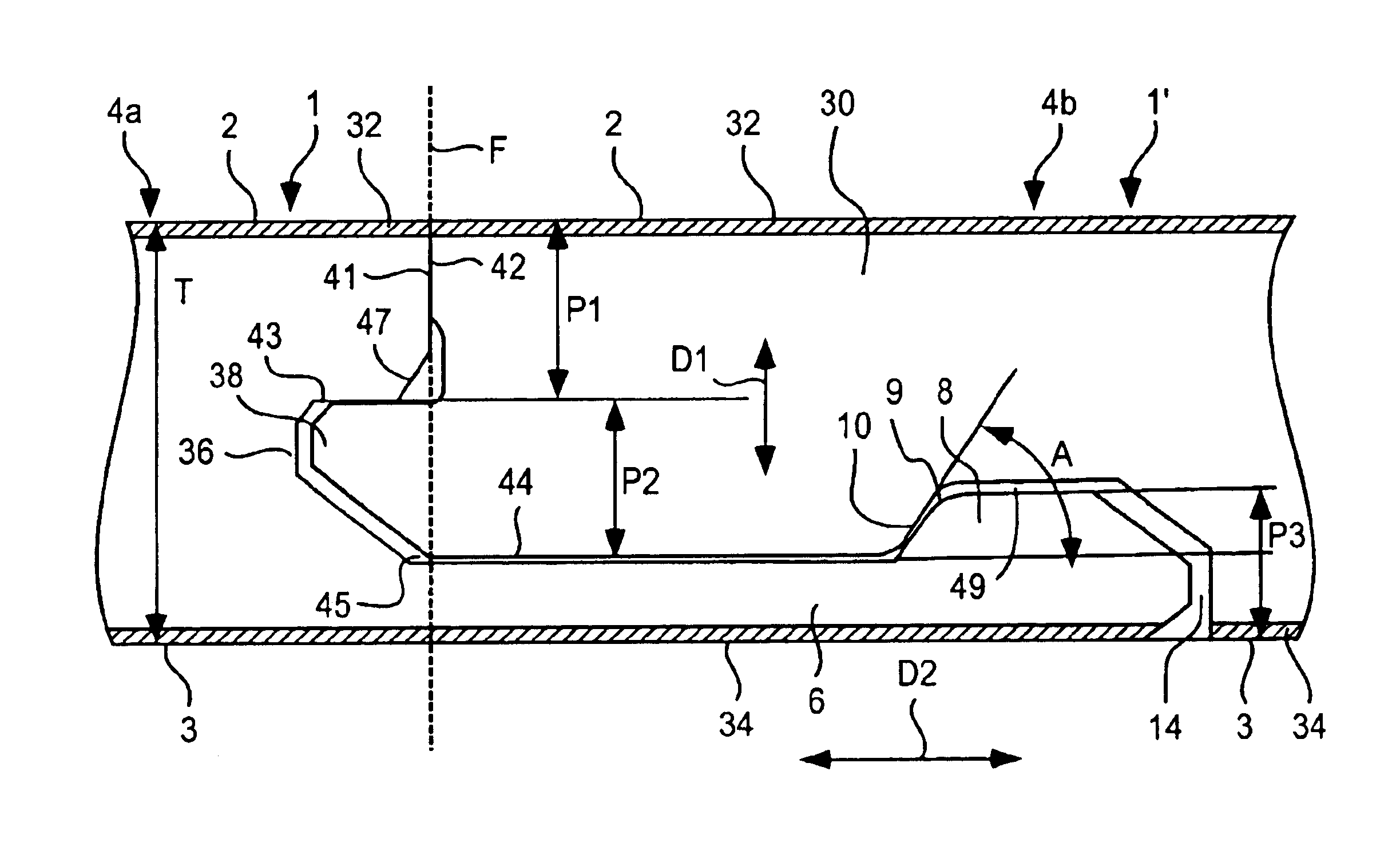

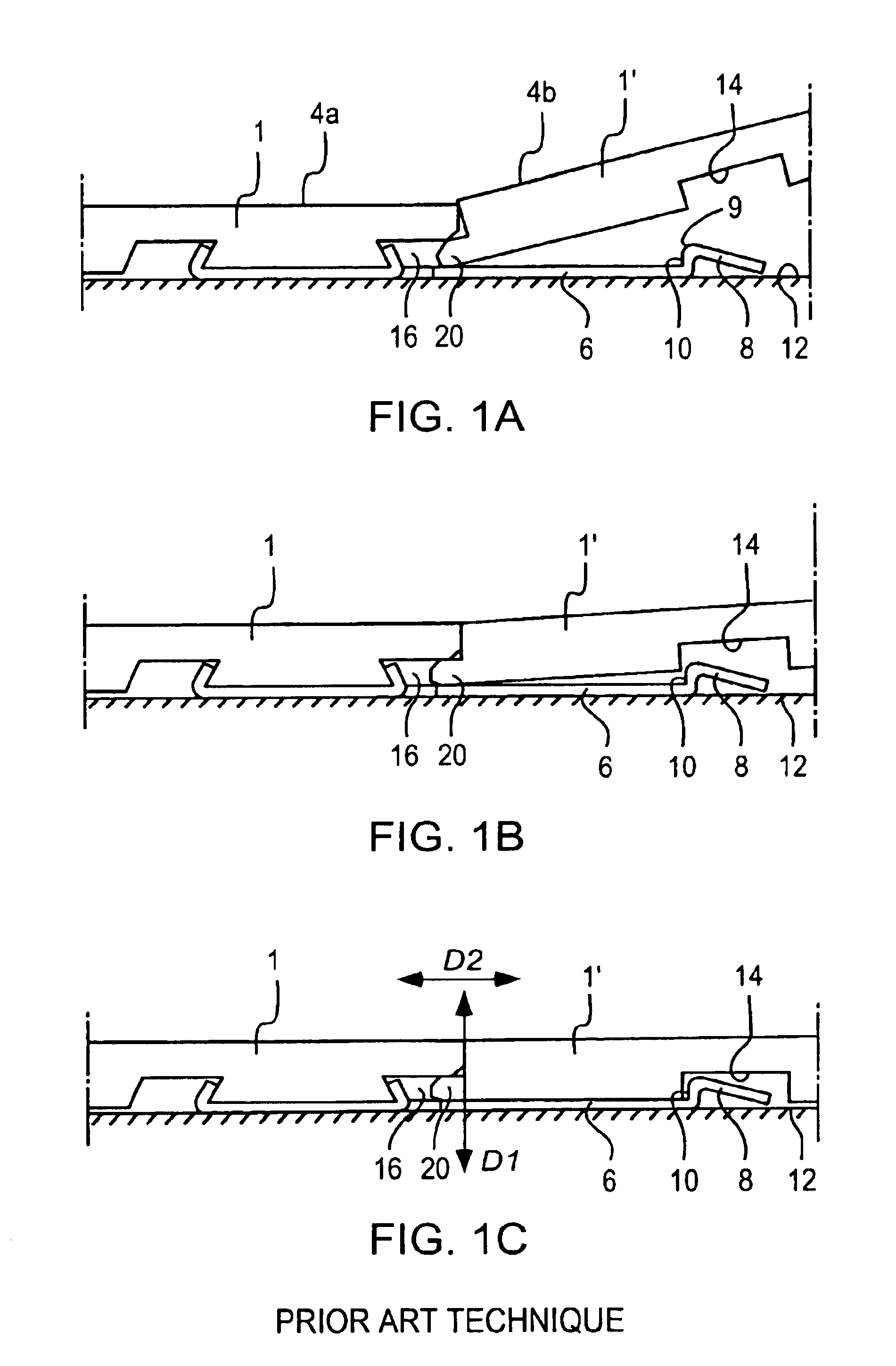

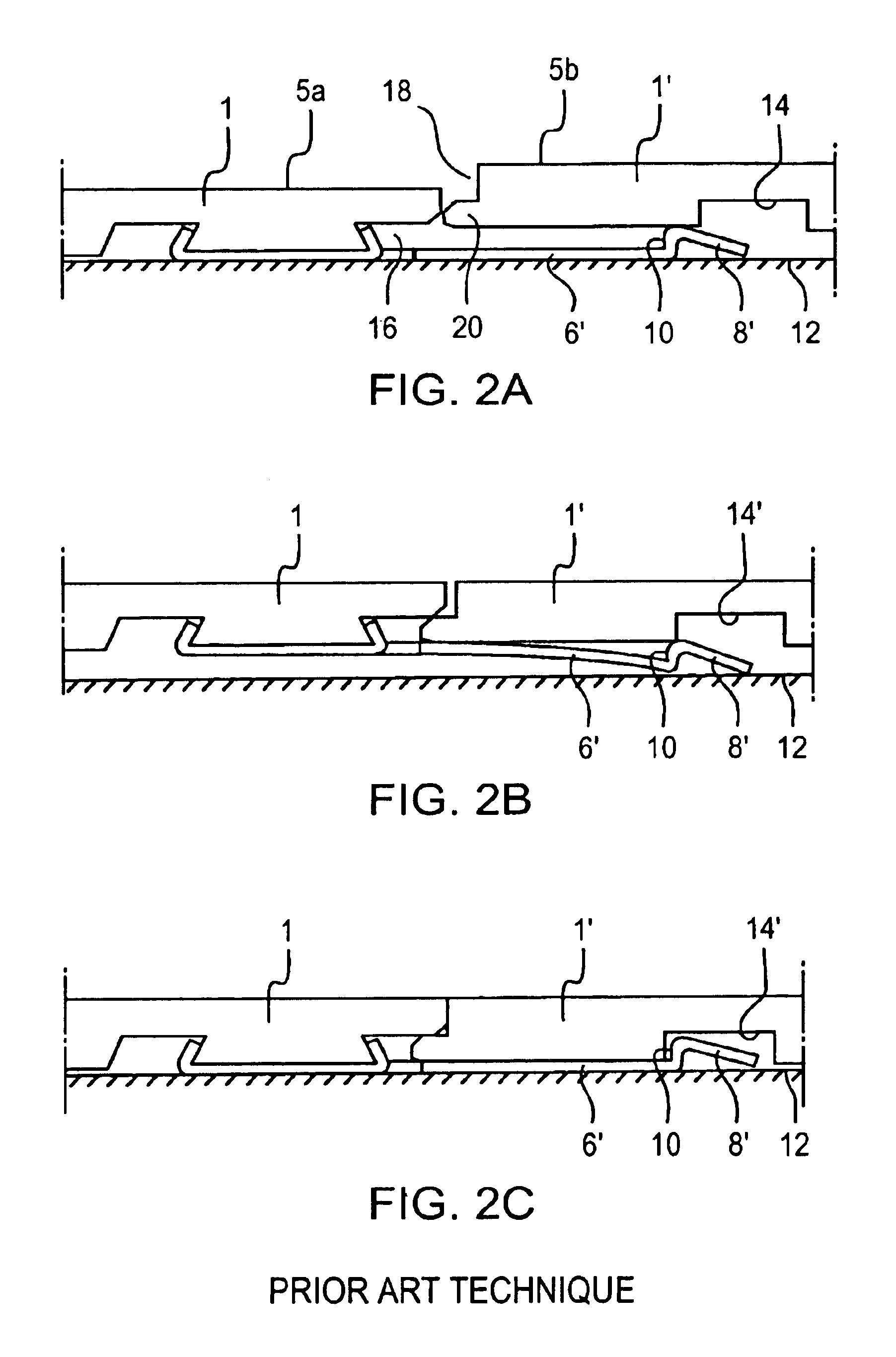

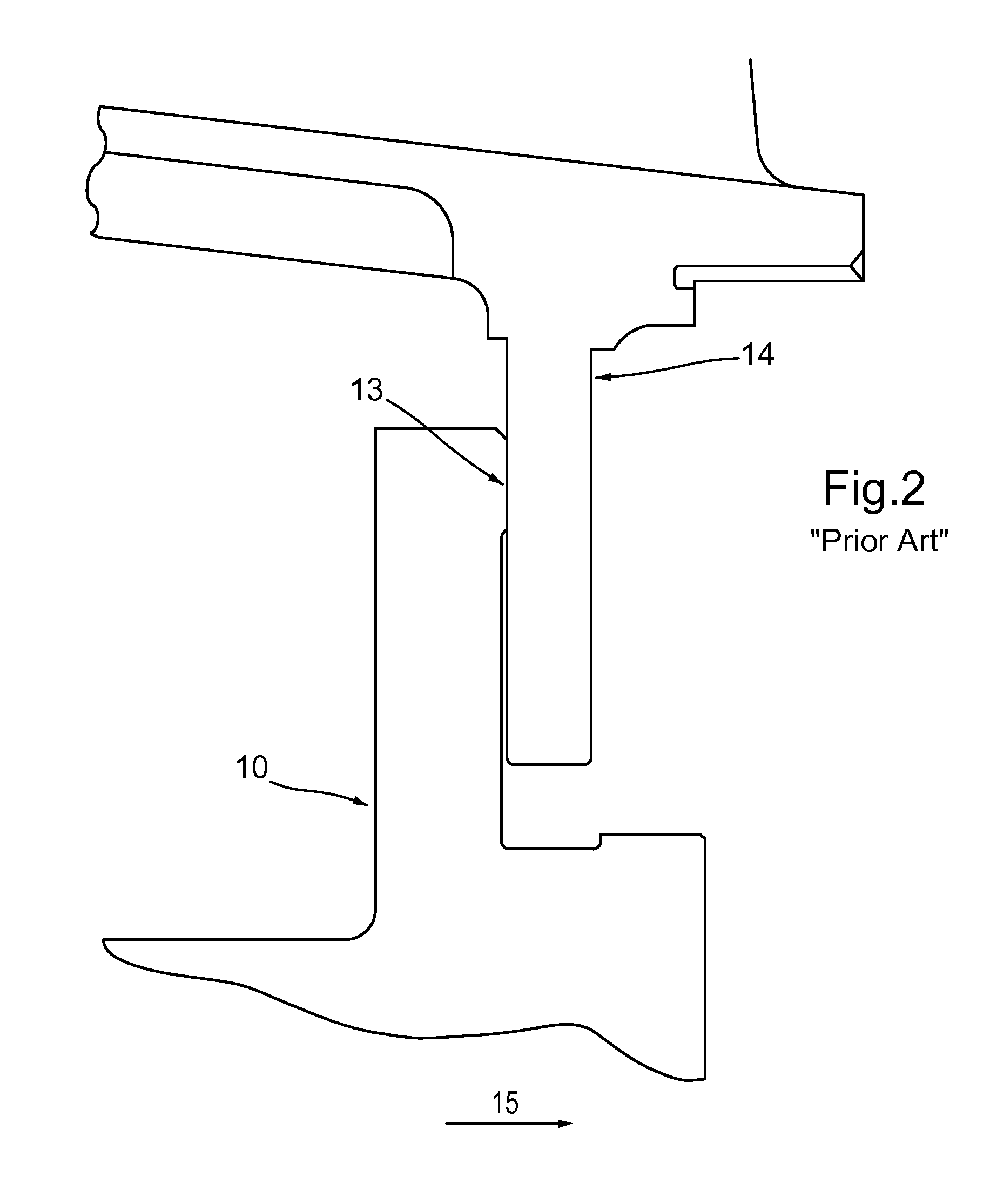

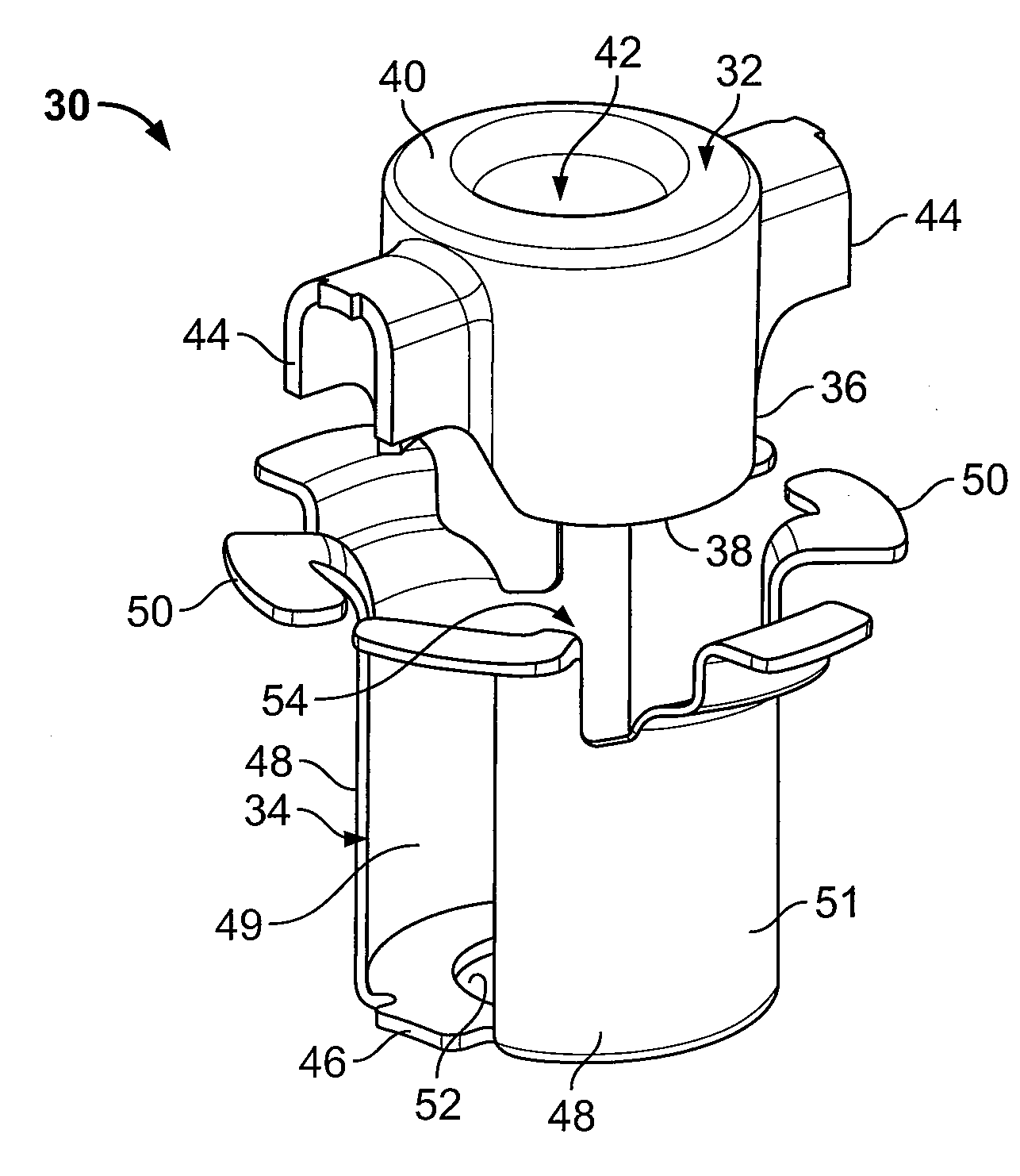

The invention relates to a locking system for mechanical joining of floorboards (1, 1′) which have a body (30), a lower balancing layer (34) and an upper surface layer (32). A strip (6) is integrally formed with the body (30) of the floorboard (1) and extends under an adjoining floorboard (1′). The strip (6) has a locking element (8), which engages a looking groove (14) in the underside of the adjoining floorboard (1′) and forms a horizontal joint. A tongue (38) and a tongue groove (36) form a vertical joint between upper and lower plane-parallel contact surfaces (43, 45) and are designed in such manner that the lower contact surfaces (45) are on a level between the upper side of the locking element (8) and a plane containing the underside (3) of the floorboard. The invention also relates to a floorboard having such a locking system, a floor made of such floorboards, as well as a method for making such a locking system.

Owner:VÄLINGE INNOVATION AB

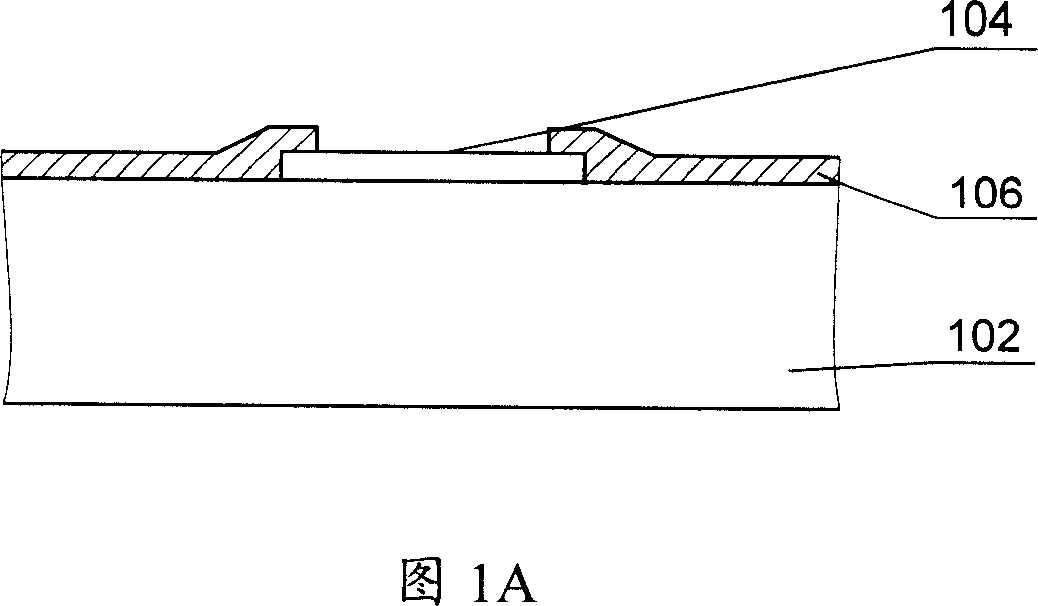

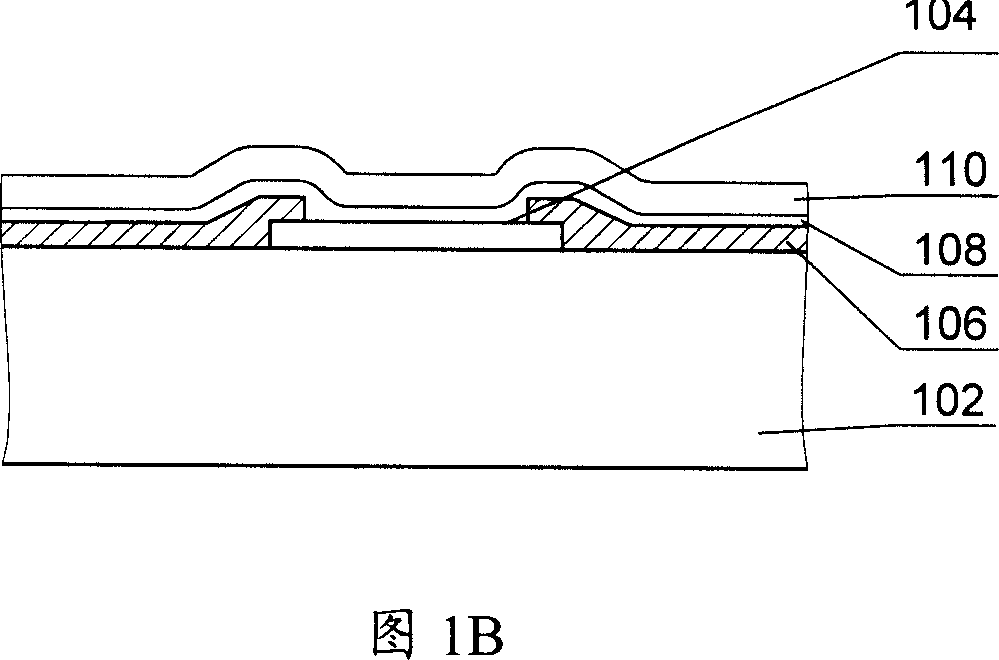

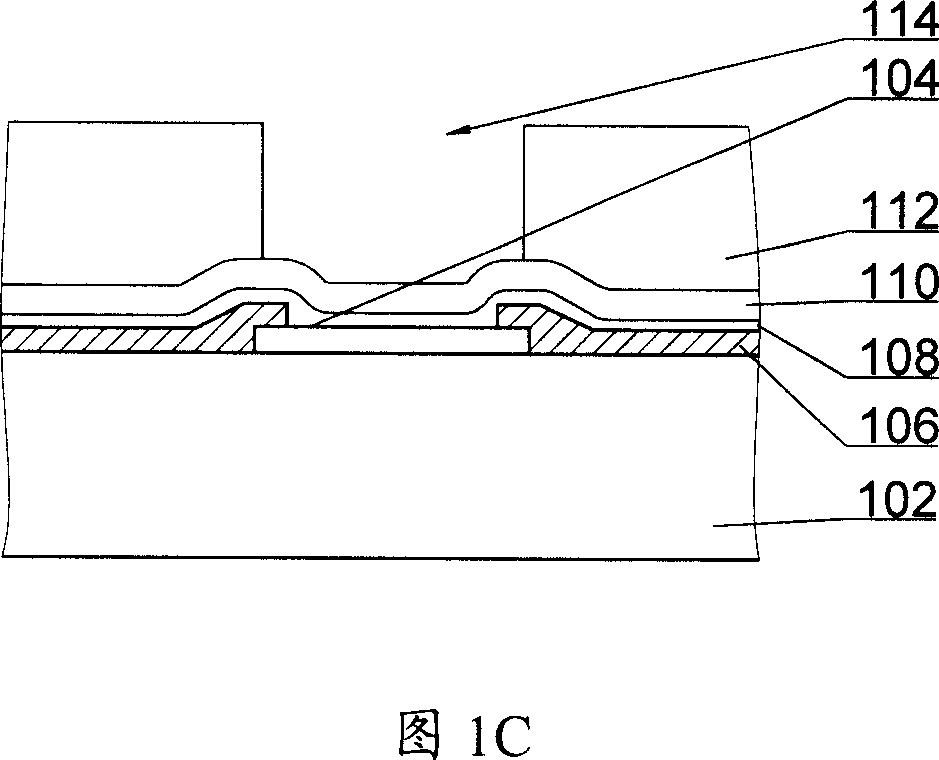

Semiconductor wafer welding material projected block structure and its production

ActiveCN101075595AQuality improvementReduce spacingSemiconductor/solid-state device detailsSolid-state devicesConvex structureFlat joint

This is a convex structure for semi-conducting wafer and its process method. Make a flat joint plate and passive layer on the surface of the underlay, then condensate a multi-layer metal coating to increase the refluence height of the electrode on the convex and volume coherence and purity.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

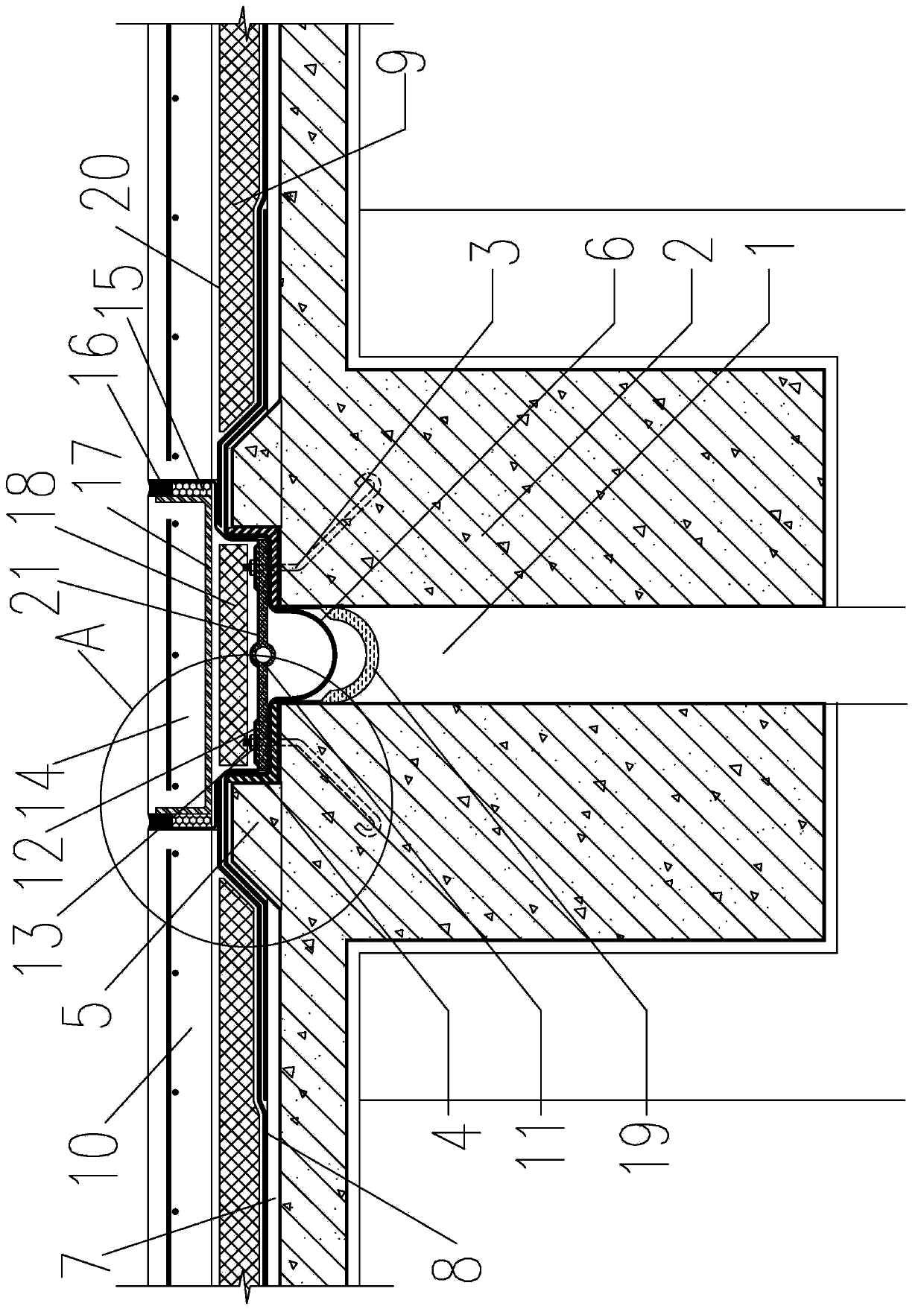

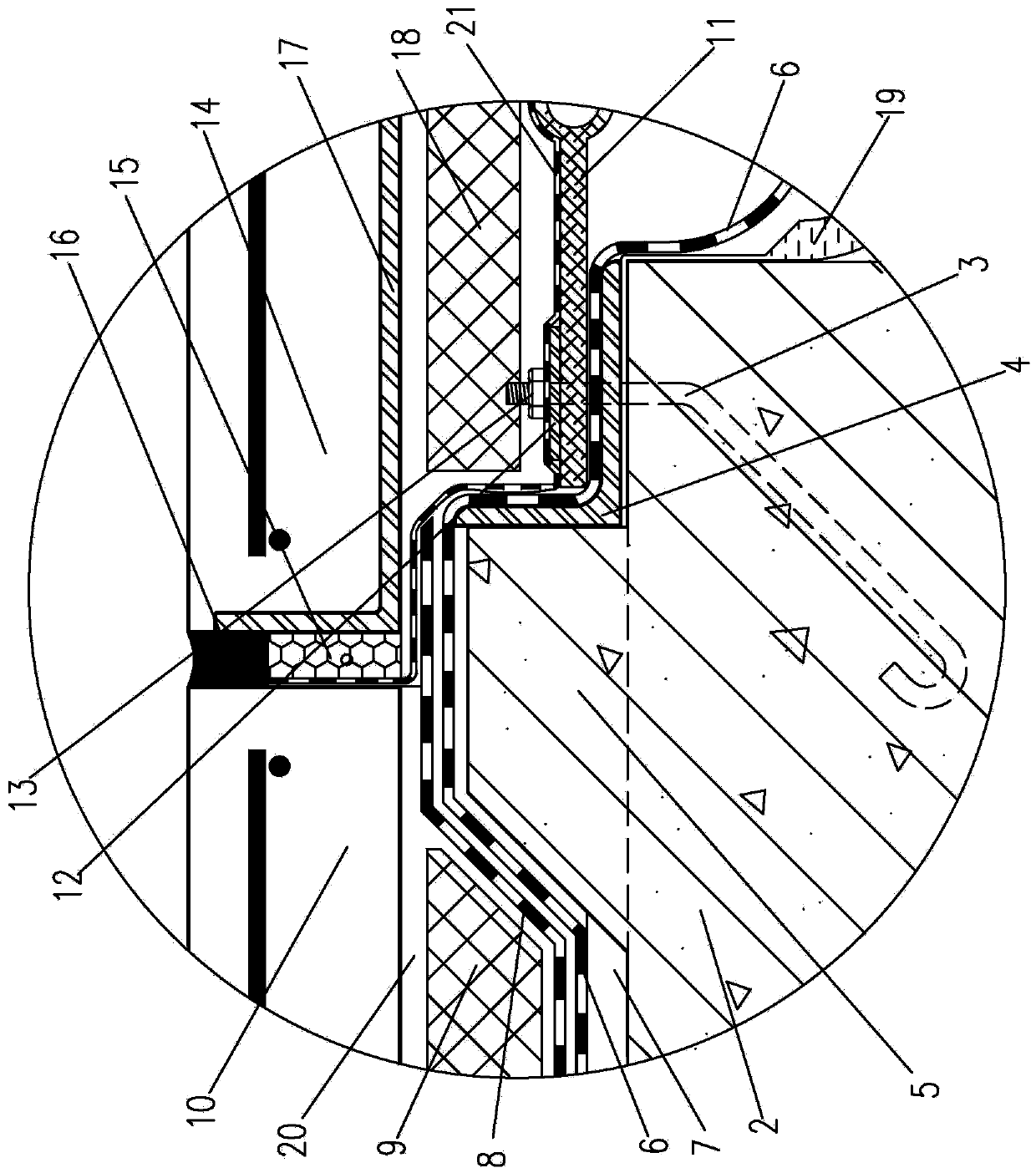

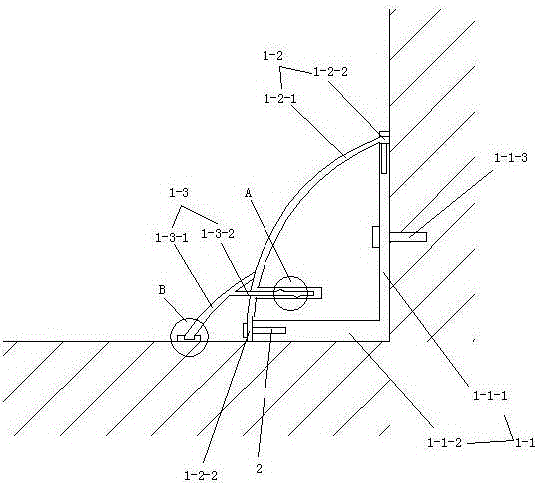

Flat-joint and detachable type roof deformation joint and construction method thereof

InactiveCN103469973AMeet the setup requirementsMeet the temperatureRoof covering using slabs/sheetsRoof covering insulationsFlat jointInsulation layer

The invention relates to a flat-joint and detachable type roof deformation joint and a construction method thereof, and belongs to the technical field of buildings. The deformation joint is characterized in that the interiors of reinforced concrete structure beams at the two sides of the deformation joint are embedded with round steel, each reinforced concrete structure beam is provided with an angle iron, the outer side of each angle iron is provided with a concrete retaining sill, each angle iron is provided with an additional waterproof layer, a detachable rubber water stop belt is arranged between the two angle irons above the deformation joint, and is provided with a steel plate pressing strip, the steel plate pressing strip, the detachable rubber water stop belt and the angle irons are screwed, fastened and connected through nuts and threads at one ends of the round steels, a roof waterproof layer is provided with a roof heat insulation layer, a leveling layer and a roof rigid protecting layer, a deformation joint heat insulation layer is arranged between the two angle irons, a cover plate is arranged in the roof rigid protective layers, a gap is formed between the cover plate and the roof rigid protective layer, a flexible plate strip is arranged in the gap, and the upper part of the flexible plate strip is fully embedded with sealant. The deformation joint has the advantages that the setting requirements of various deformation joints, such as earthquake-proof joints, telescopic joints and settlement joints, are met, the strength is high, the wear-resisting performance is good, and the maintenance is convenient.

Owner:YANGZHOU UNIV

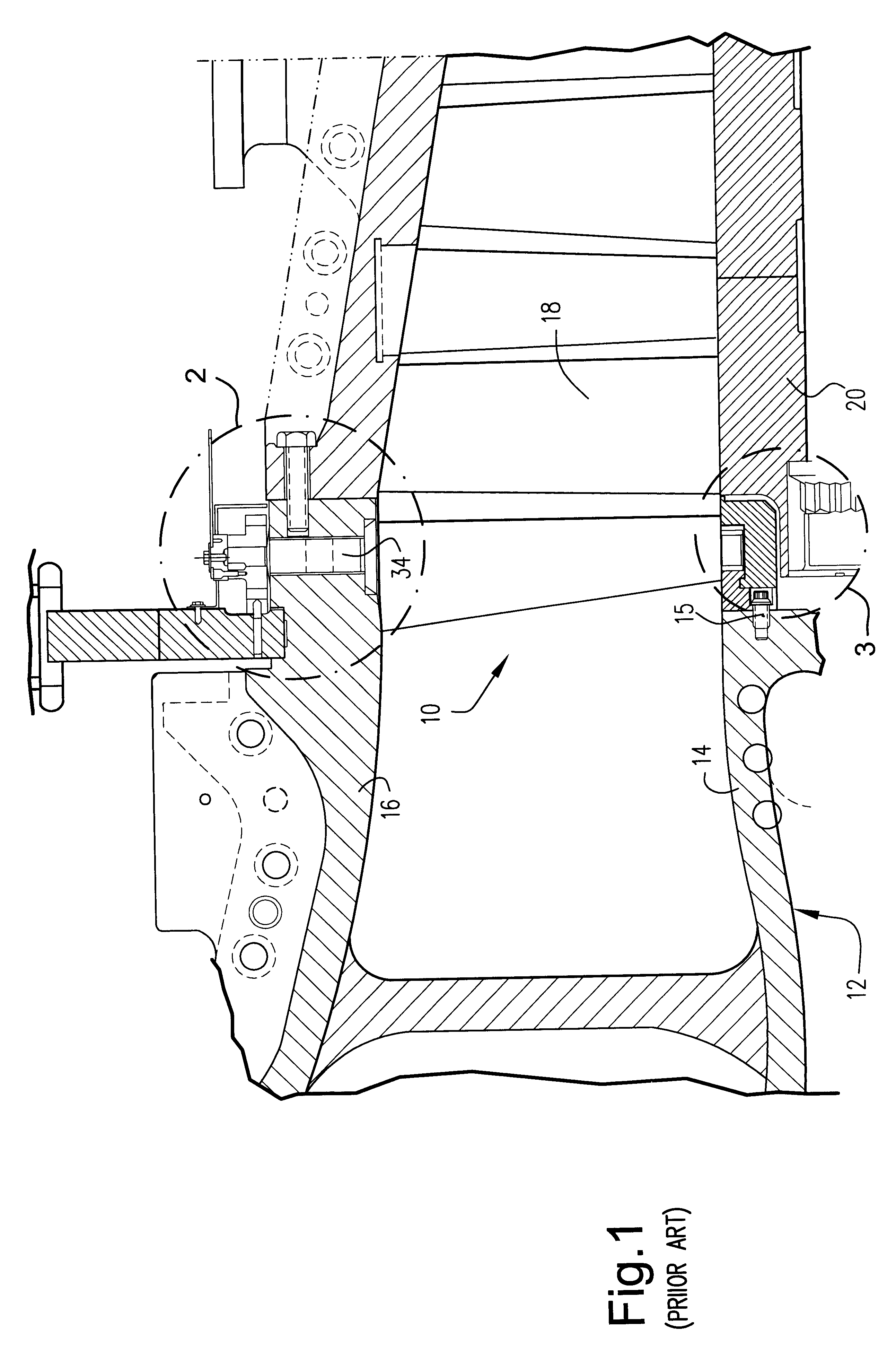

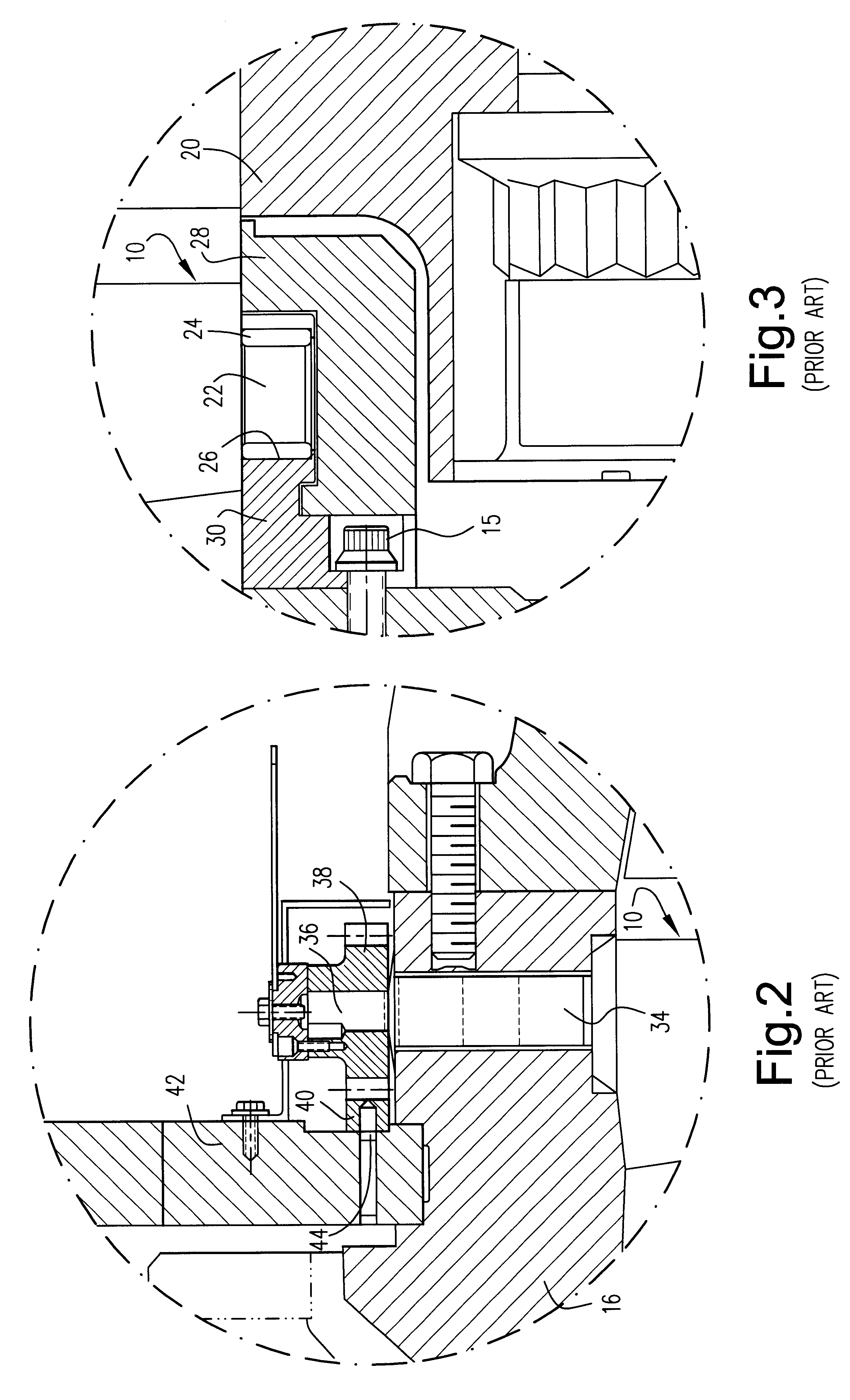

Replaceable variable stator vane for gas turbines

A method of replacing an inlet guide vane from a lower inlet casing of a compressor, the lower inlet casing adapted to be secured to an upper inlet casing at a horizontal joint, and after removal of the upper half of the inlet casing but with a rotor of the compressor remaining in place, wherein the inlet guide vane is supported between radially inner and outer walls of the lower inlet casing, and further wherein the inlet guide vane is formed with an integral stem that extends radially through the outer wall and supports a drive gear on its outer end that engages an annular gear rack, the method including a) removing the gear on the radially outer end of the integral stem of the inlet guide vane; b) shearing the inlet guide vane into two cut portions; c) removing the cut portions from inside the lower inlet casing; and d) replacing the inlet guide vane by a modified inlet guide vane having a two-piece stem assembly that enables installation without removal of the rotor. A new inlet guide vane assembly is provided for replacing the vane. The new assembly includes a vane having a cylindrical stub at a radially inner end thereof and a relatively short integral stem at a radially outer end thereof; a jack shaft adapted for connection at a radially inner end thereof to a radially outer end of the integral stem such that torque applied to the jack shaft is transmitted to the vane, a radially outer end of the jack shaft adapted to receive a drive gear. An outer stem piece is seated on the jack shaft and welded to the drive gear to complete a torque transmission path from the drive gear to complete a torque transmission path from the drive gear to the vane.

Owner:GENERAL ELECTRIC CO

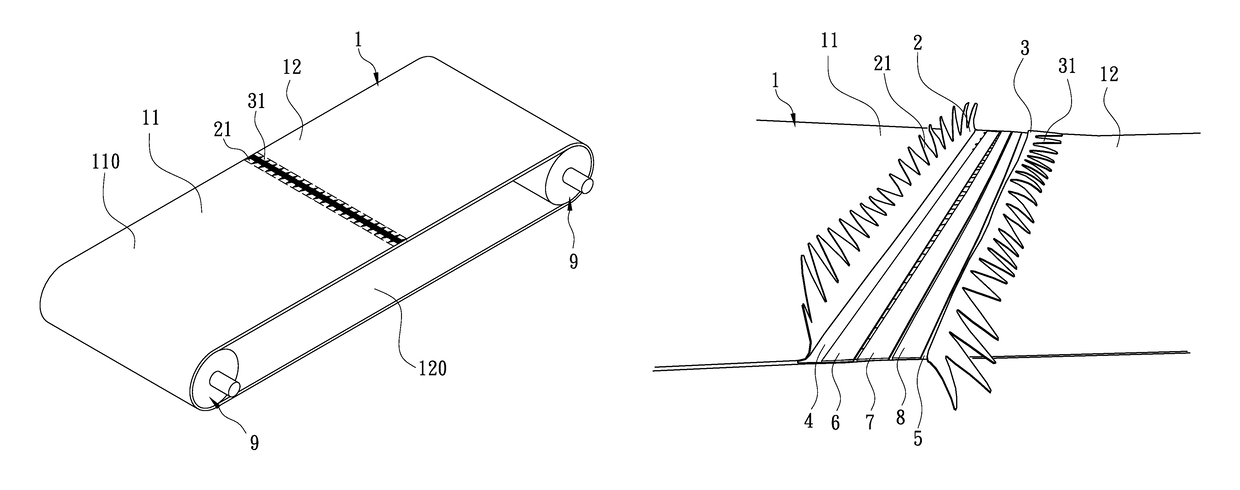

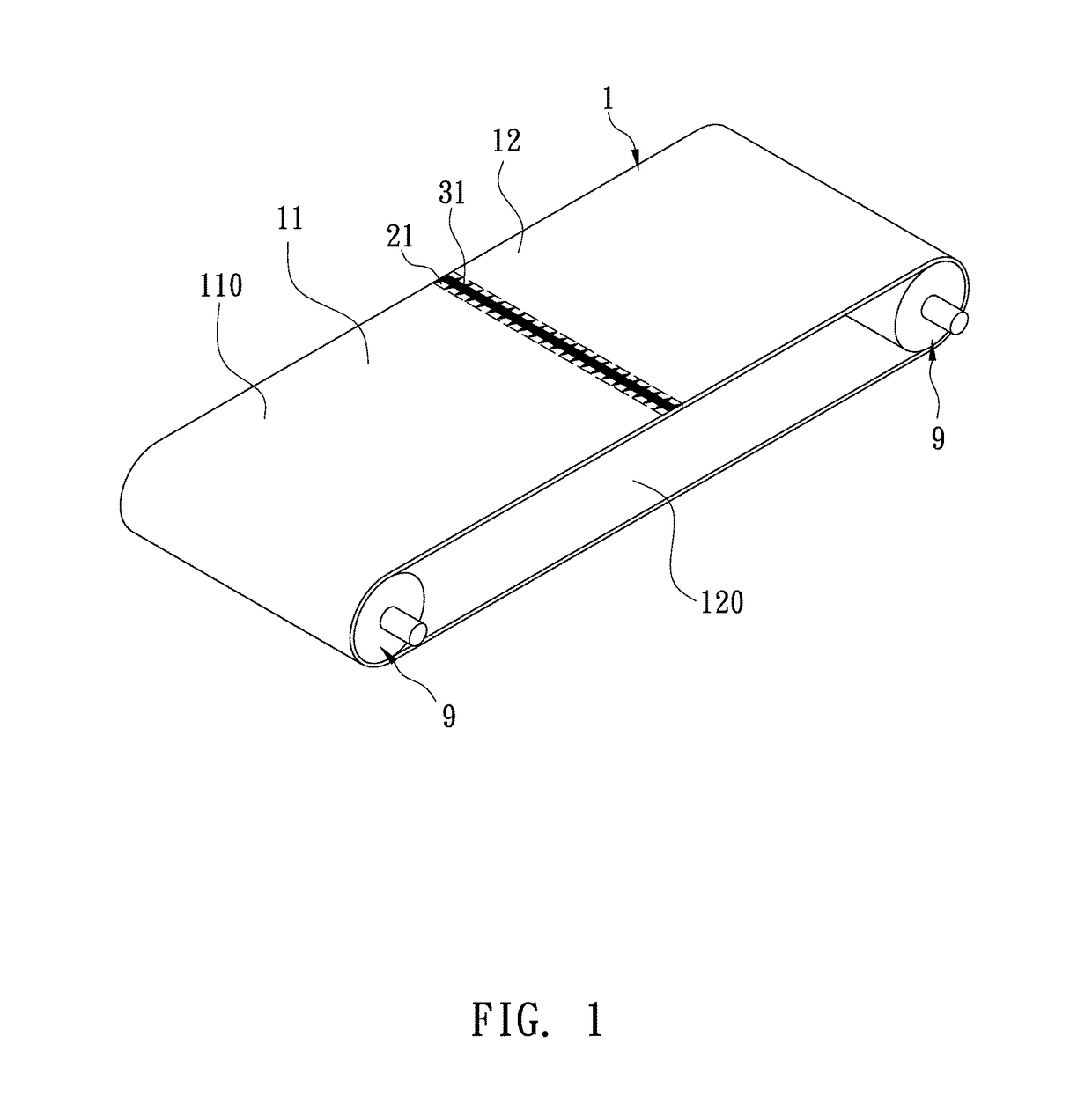

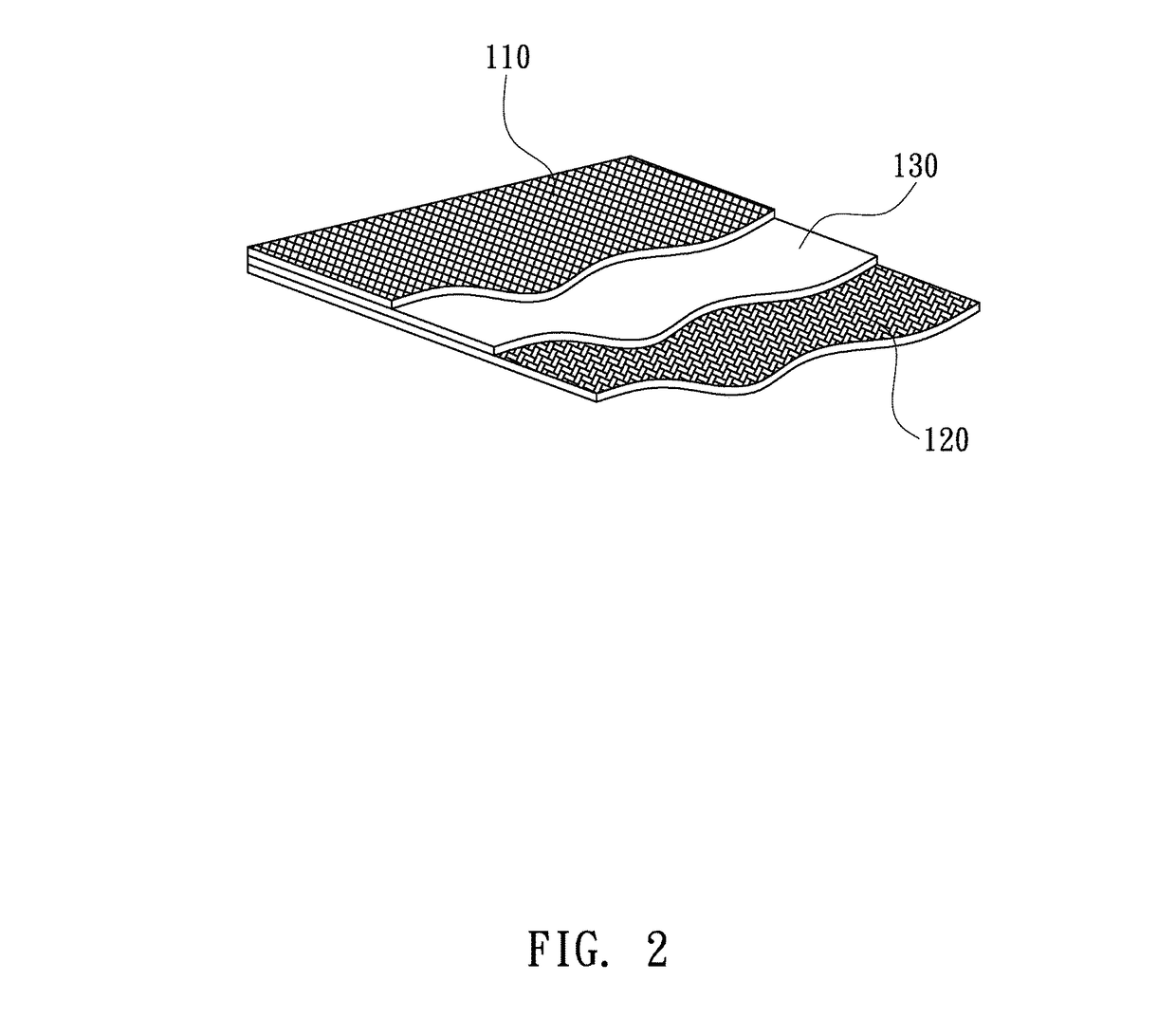

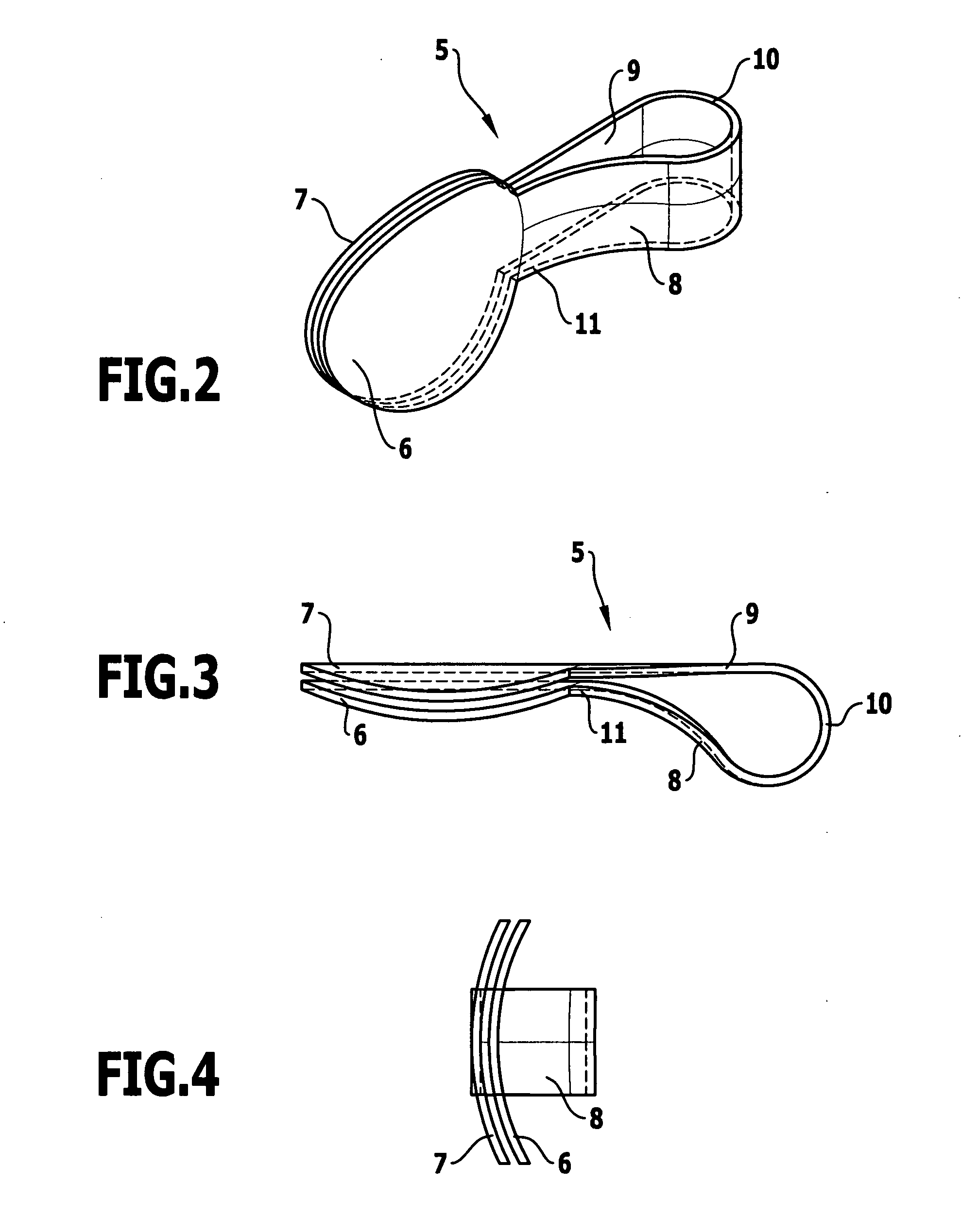

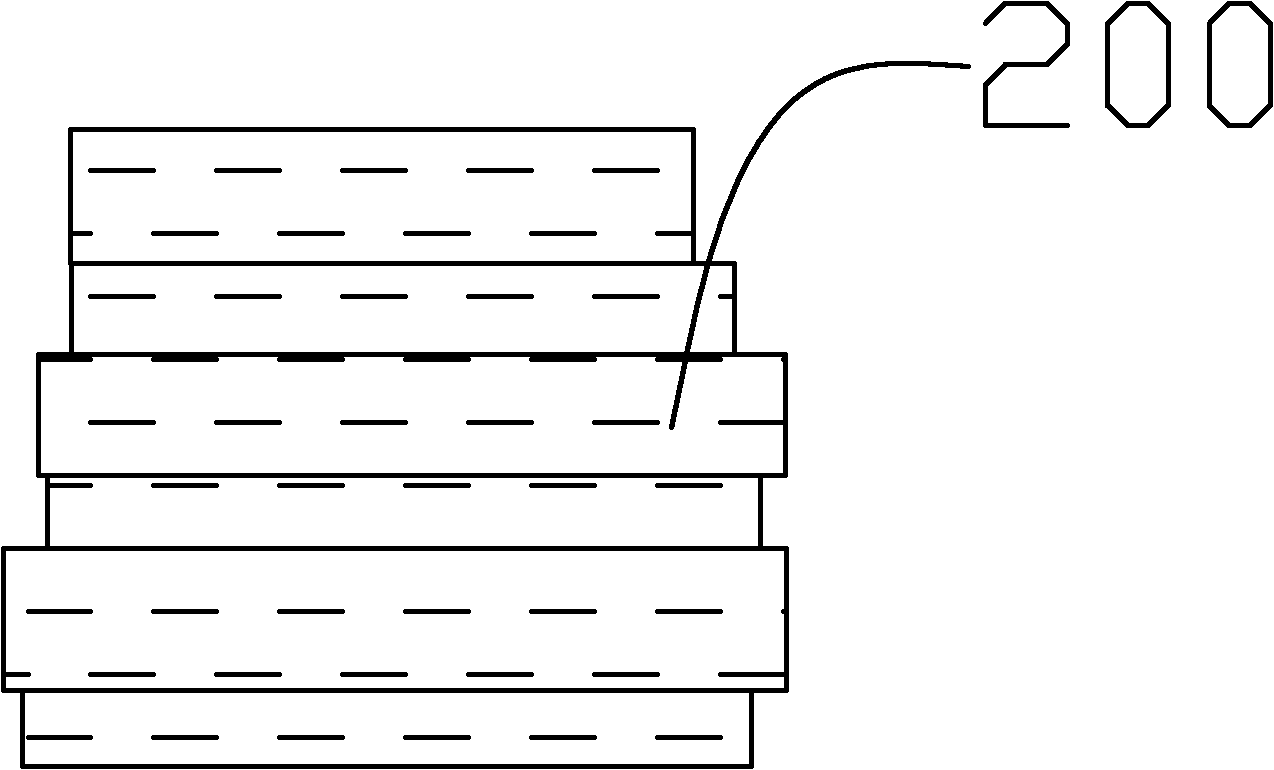

Joint structure of endless treadmill belt of treadmill

A joint structure of an endless treadmill belt of a treadmill is provided. The treadmill belt is a sandwich-type laminated rectangular treadmill belt. Two ends of the treadmill belt are cut to form serrations. Two ends of a bottom layer of the treadmill belt are meshed with each other. At least one plastic piece is placed on the joint of the two ends of the bottom layer. The serrations of two ends of a top layer of the treadmill belt are connected with each other in a cross-knitted manner, and the pointed portions of the serrations of the two ends of the top layer are inserted into and covered by the plastic piece and then the two ends of the treadmill belt are joined together by hot melting to form an integral flat joint of the treadmill belt.

Owner:SPORTS ART IND

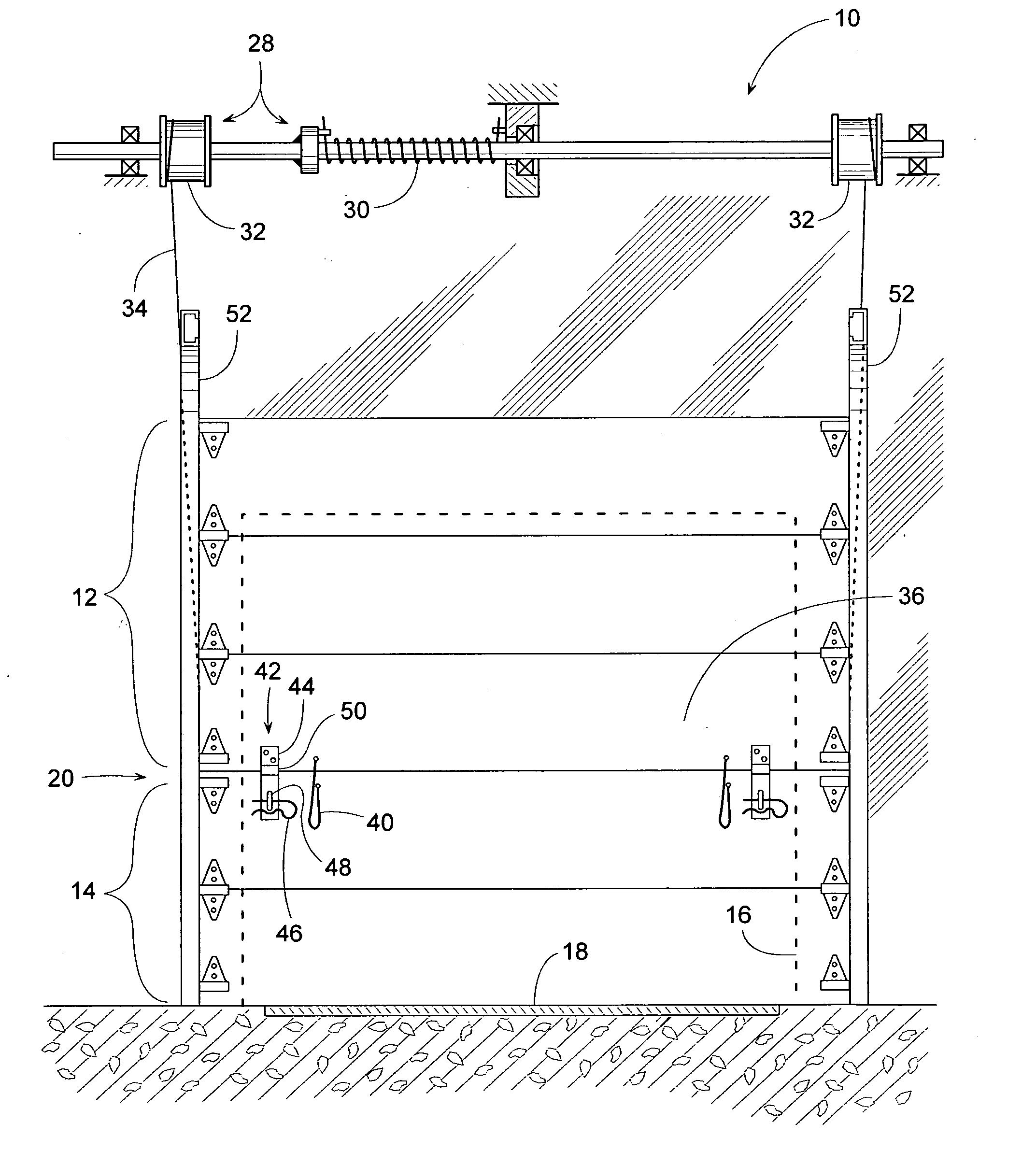

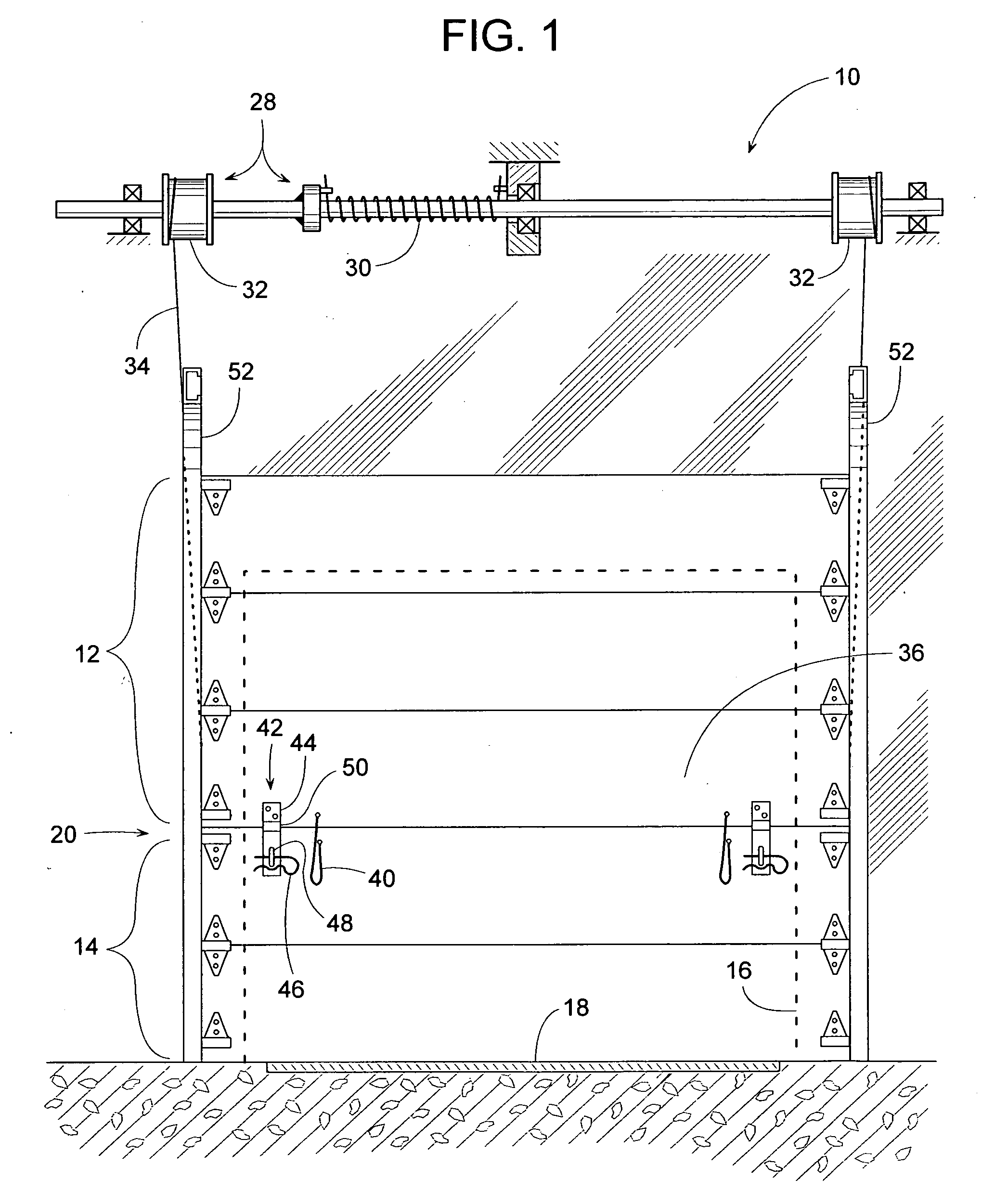

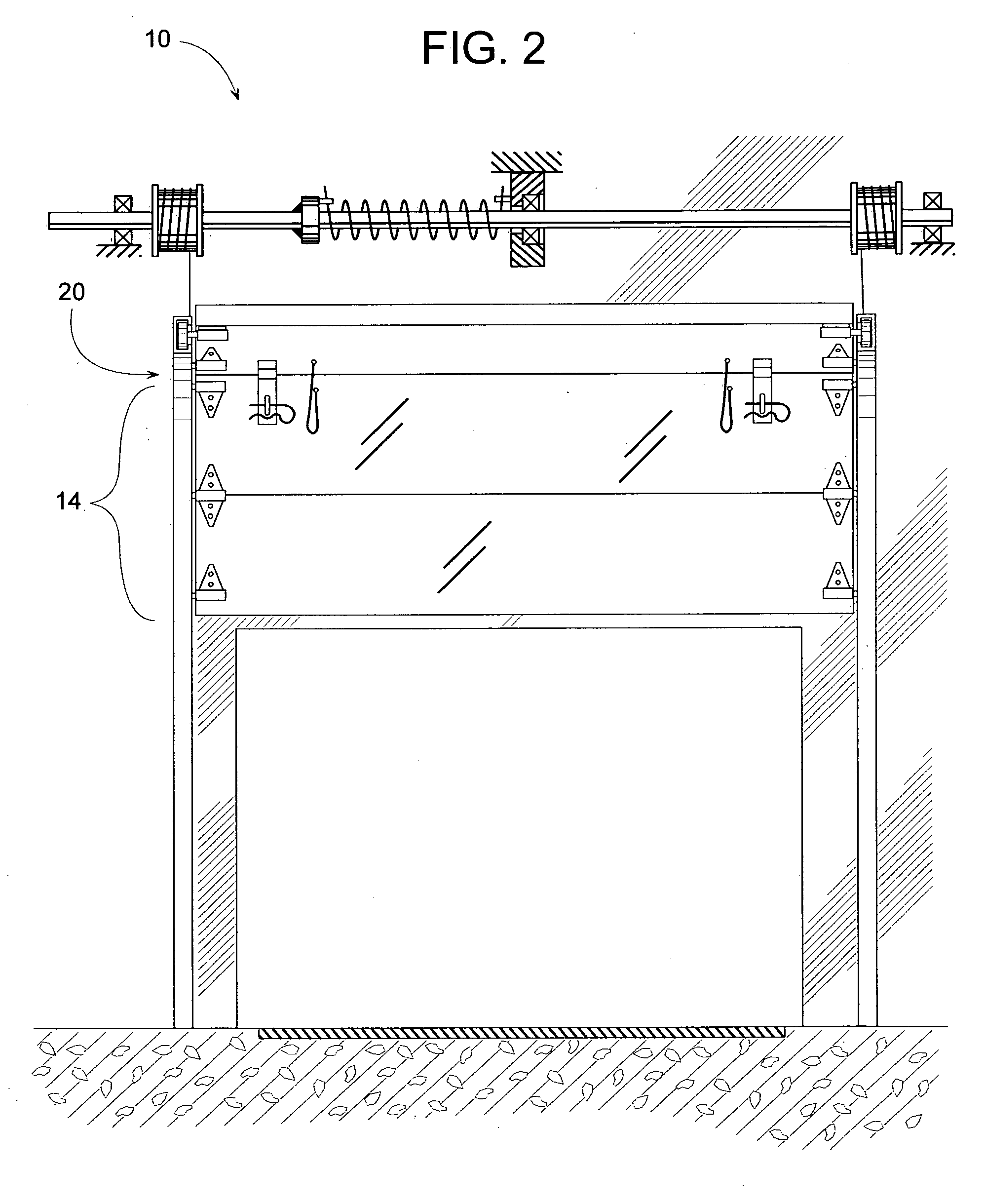

Vertically movable door with safety barrier

A vertically moving door of a truck loading dock includes a disconnectable horizontal joint that provides the door with a barrier position, wherein an upper section of the door can be separated from a lower section to create a ventilation area between the two. The ventilation area allows fresh outside air to enter the building, while the lower section remains at its lowermost position for safety and security. More specifically, the lower section serves as a barrier that helps prevent someone or something from accidentally falling through the doorway when a truck is not present at the dock. A lightweight, resilient strap can be attached to the lower section of the door to help protect that section from an otherwise damaging impact. A lattice of straps or a mesh can be installed across the ventilation area to help secure the building against theft.

Owner:RITE HITE HLDG CORP

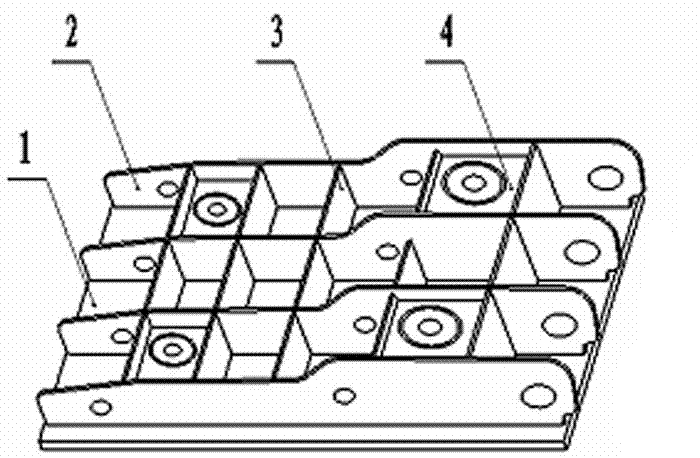

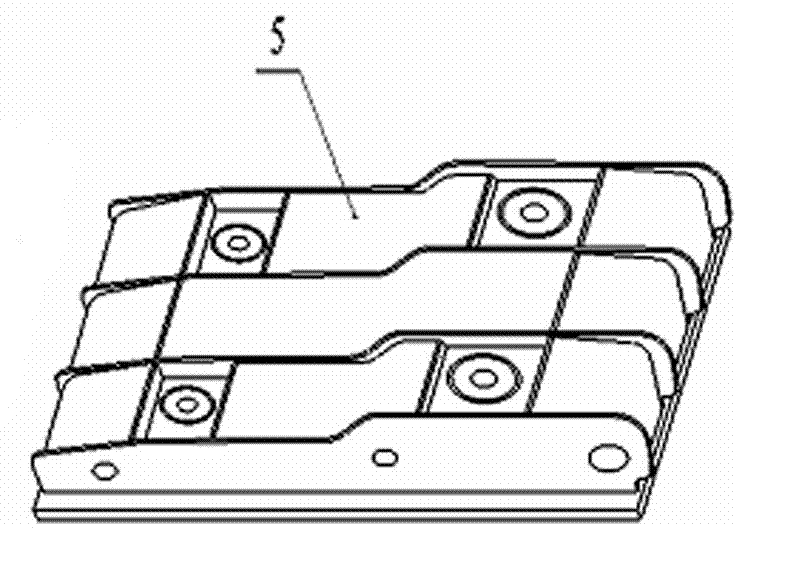

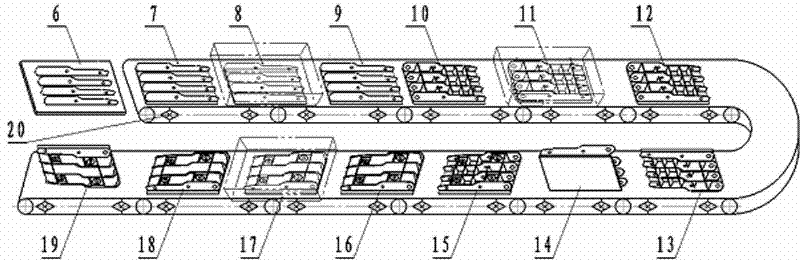

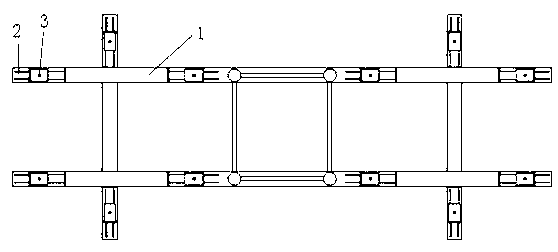

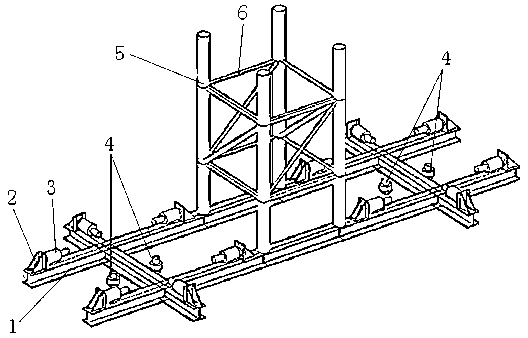

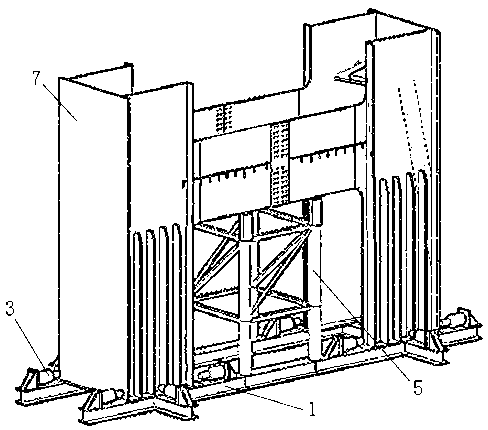

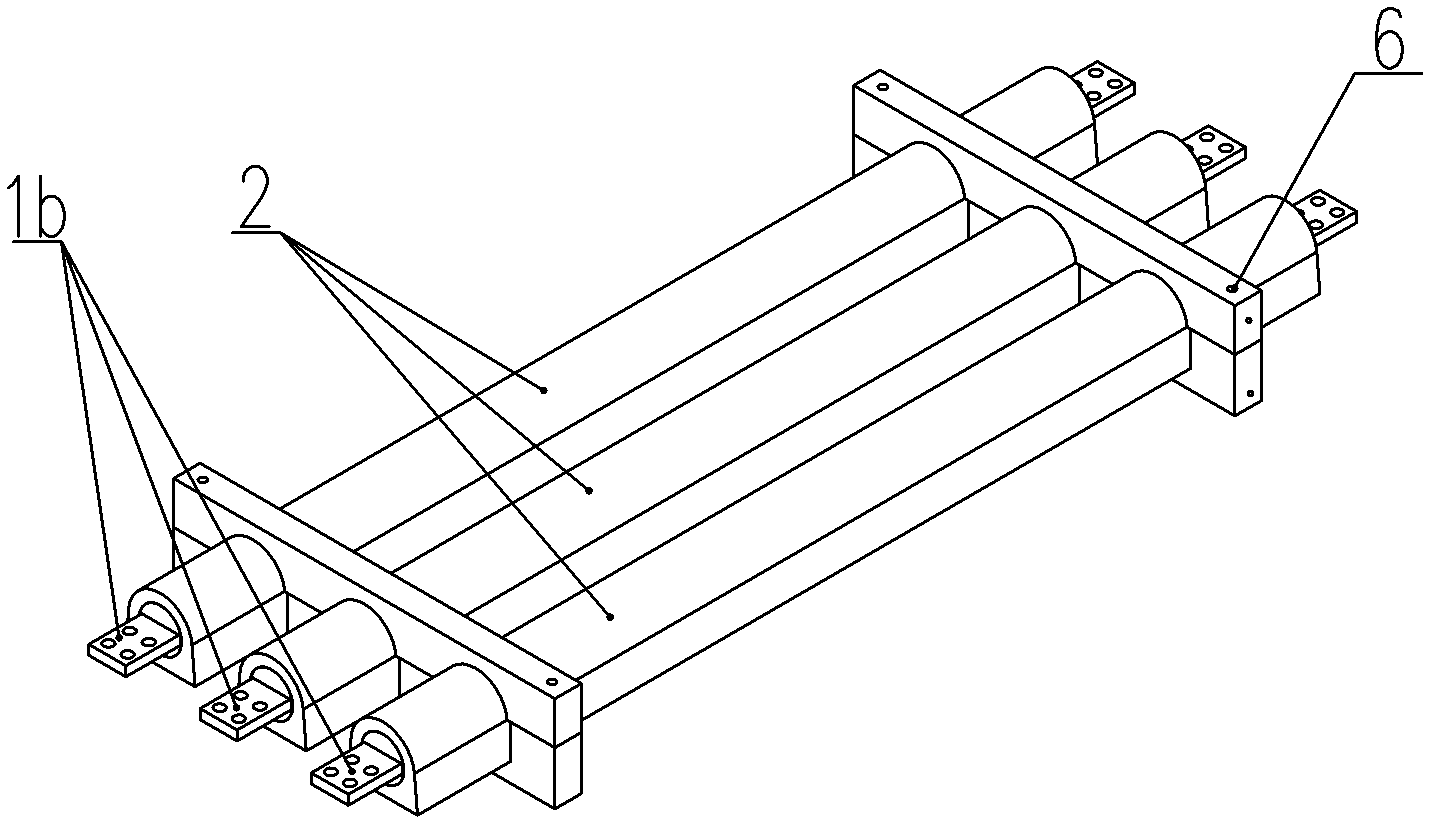

Automatic welding method of flow production line for hydraulic support grid box type structure members

ActiveCN102441720ASolve the deformationResolve integrityWelding accessoriesFlat jointProduction line

The invention relates to the field of welding fabrication of hydraulic support structure members, particularly to an automatic welding method of a flow production line for hydraulic support grid box type structure members, which solves the problem that the traditional manual welding method cannot guarantee the welding forming quality and workpieces cannot be completely and automatically welded due to deformation caused by a unit type automatic robot due to thick plate welding thermal cycle. The automatic welding method comprises the following concrete steps of: cutting and forming the grid box type structure members; automatically counting and assembling bottom plates and main rib plates; preheating the counted and assembled bottom plates and main rib plates; automatically welding the main rib plates; automatically counting and assembling separation plates; preheating the counted and assembled separation plates; automatically welding the flat joints of the separation plates; automatically welding the left vertical joints of the separation plates; automatically welding the right vertical joints of the separation plates; counting and assembling function parts; counting and assembling cover plates; automatically welding the flat joints of the cover plates; automatically welding the arc joints of the cover plates; and circulating the above steps. The method provided by the invention is reasonable and simple in process, strong in operability and high production efficiency, and can guarantee the welding quality.

Owner:SHANXI PINGYANG IND MACHINERY

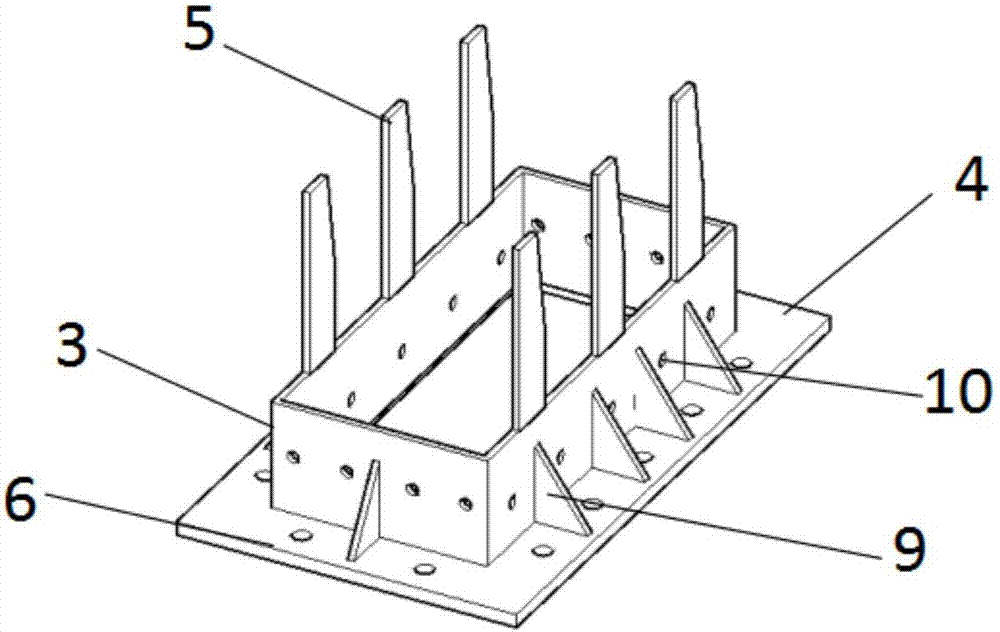

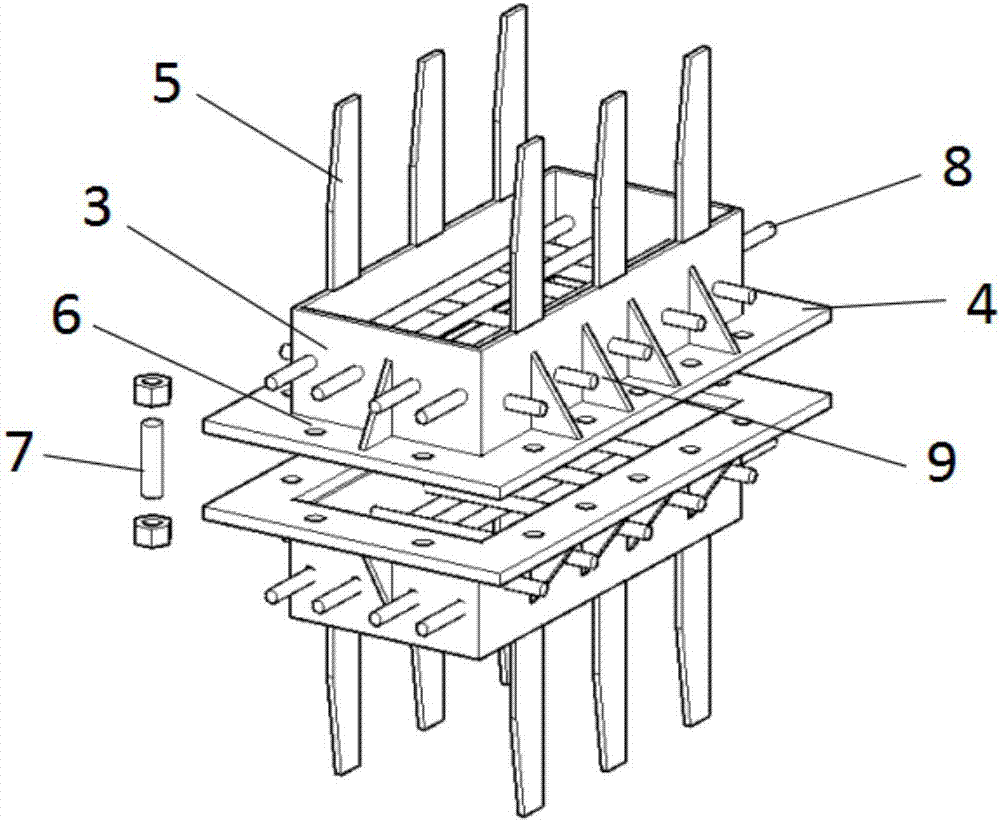

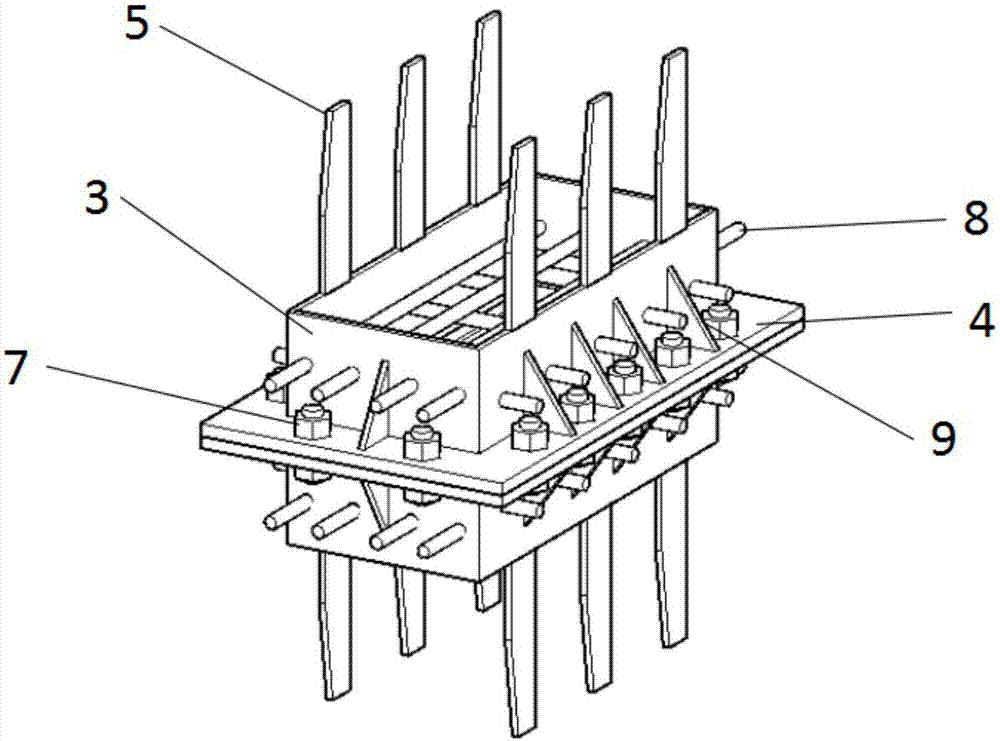

Positioning device for achieving embedded-sectional steel flat-joint bolt connection of concrete sectional prefabricated arch ribs and construction method of positioning device

ActiveCN107022947AIncrease stiffnessAvoid confictBridge structural detailsBridge erection/assemblyRear quarterFlat joint

The invention discloses a positioning device for achieving embedded-sectional steel flat-joint bolt connection of concrete sectional prefabricated arch ribs and a construction method of the positioning device. The positioning device is arranged at a junction of the concrete sectional prefabricated arch ribs, and comprises a pair of rectangular flanges adopting the same structure, wherein the two rectangular flanges are arranged at the centers of the prefabricated arch ribs respectively; each rectangular flange comprises a flange panel and a flange side plate; bolt connection holes are formed in the flange panels; the flange panels of the two rectangular flanges are fixedly connected through bolts; one end of each flange side plate is connected with the corresponding flange panel; spikes connected with concrete on the prefabricated arch ribs in an embedded manner are arranged at the other ends of the flange side plates. The positioning device is used for rapid positioning and connection of the sectional prefabricated arch ribs, shortens the construction period, improves the adjusting speed and the adjusting accuracy of arch axes of the sectional prefabricated arch ribs, reduces additional unfavorable eccentricity at a joint of the arch ribs, and improves the force performance of a wet joint of the arch ribs.

Owner:中交投资南京有限公司

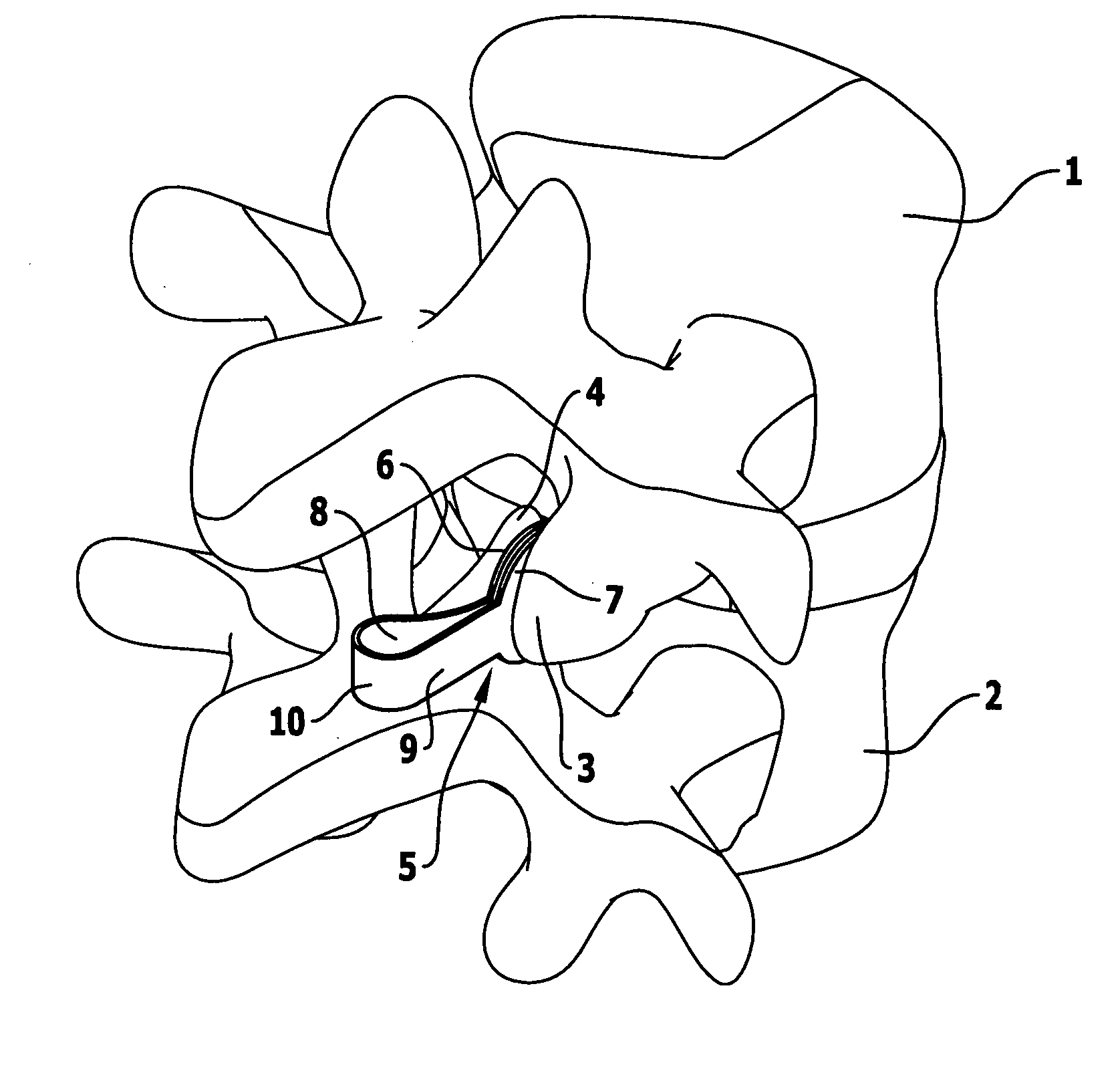

Facet joint implant

In order to improve the process of inserting a facet joint implant comprising two, flat joint surface replacement elements abutting each other face-to-face and in order to control the movement of the joint surface replacement elements relative to each other, it is proposed that both joint surface replacement elements should carry at least one arm which emerges in the plane of the joint surface replacement element from said element and projects therefrom, and in that in each case two arms of the two joint surface replacement elements which extend adjacent to one another in a pair are connected together at the end thereof remote from the joint surface replacement element.

Owner:AESCULAP AG

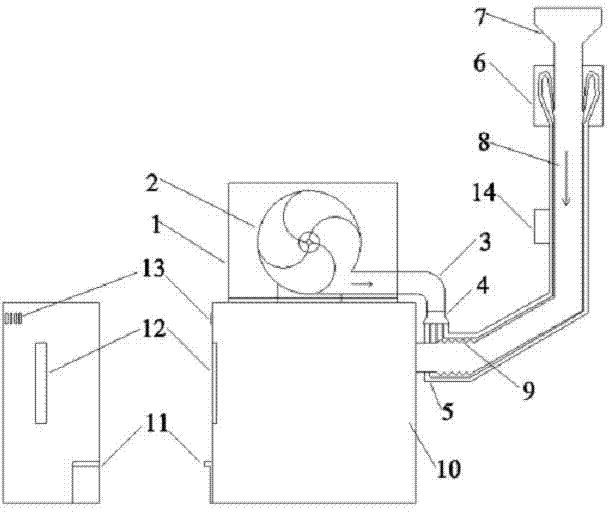

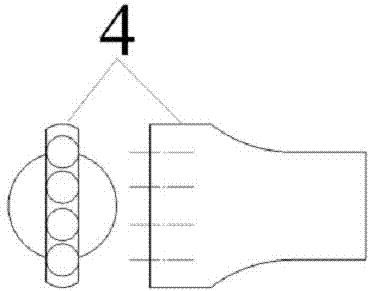

Sichuan pepper picker

The invention relates to a shoulder Sichuan pepper picker based on the jet principle, which comprises a gasoline engine, a fan, a collection box, a flat joint, thin hoses, a reversing joint, a nozzle and the like. The gasoline engine is connected with the fan through a coupling, the gasoline engine and the fan are disposed on the upper surface of the collection box, high-speed air from an outlet of the fan is led into the reversing joint through four thin hoses and blown into a rigid conveying tube, the nozzle is vacuumed, and accordingly, Sichuan pepper is sucked into the collection box. The shoulder Sichuan pepper picker has the advantages that firstly, the fan and the collection box are mounted independently, no mechanical sealing device is needed, and accordingly equipment cost is lowered; secondly, picking efficiency is high, labor intensity is greatly reduced, and efficiency is increased by about 25 times as compared with that of manual picking; and thirdly, the conveying hoses connected inside can be rotated at any angle, and accordingly fruits of Sichuan pepper at different positions can be collected conveniently.

Owner:JIANGSU UNIV

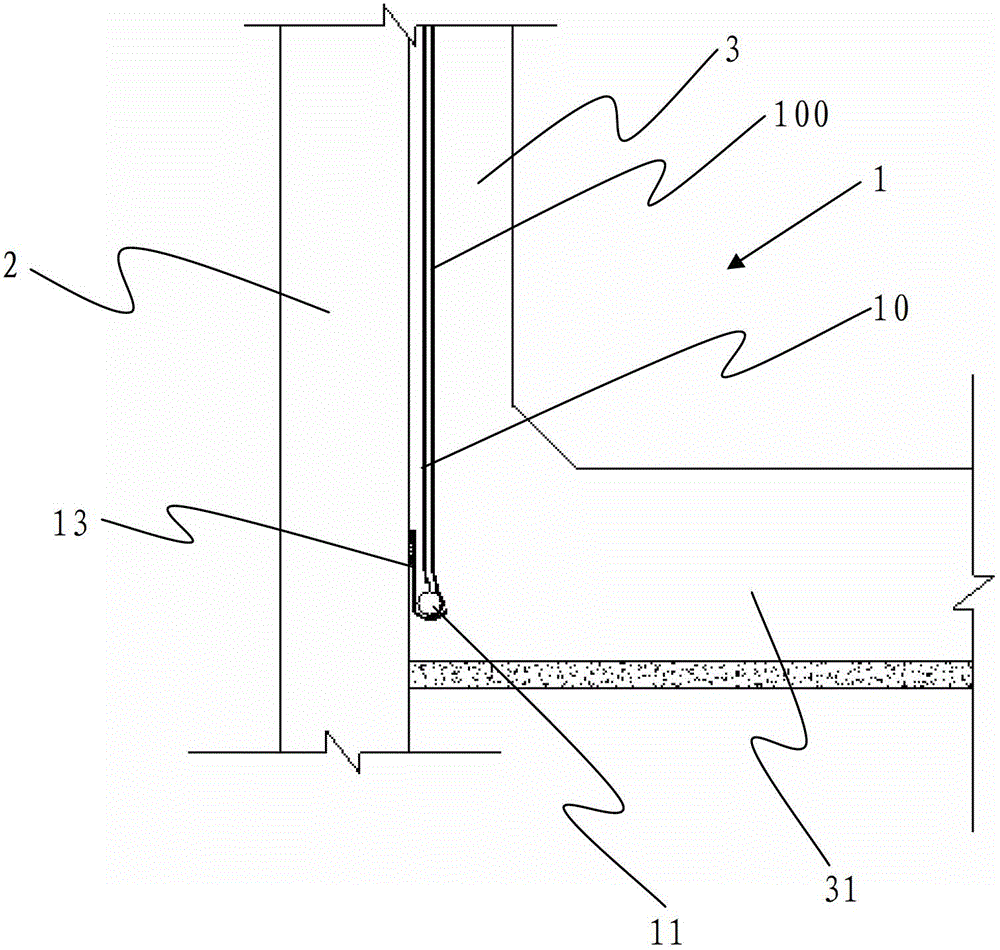

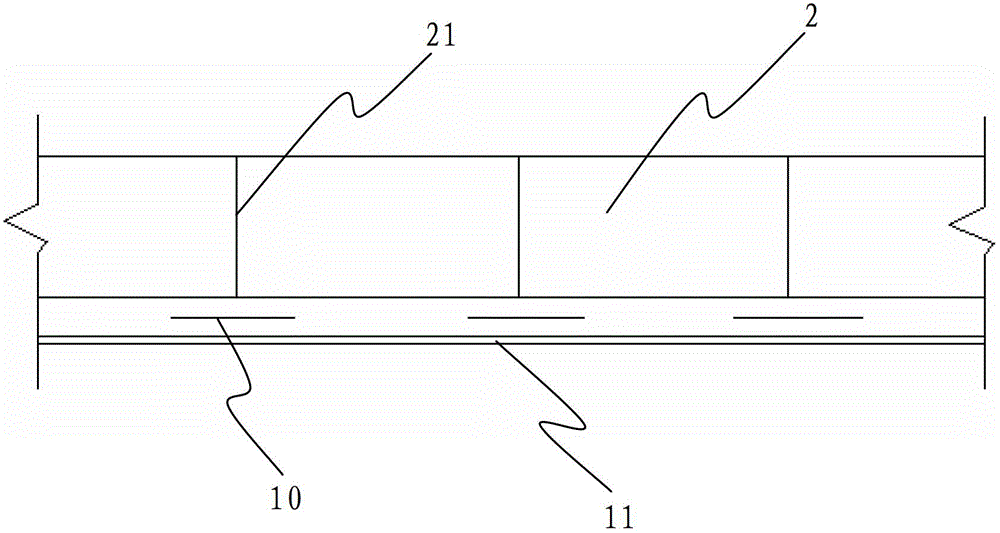

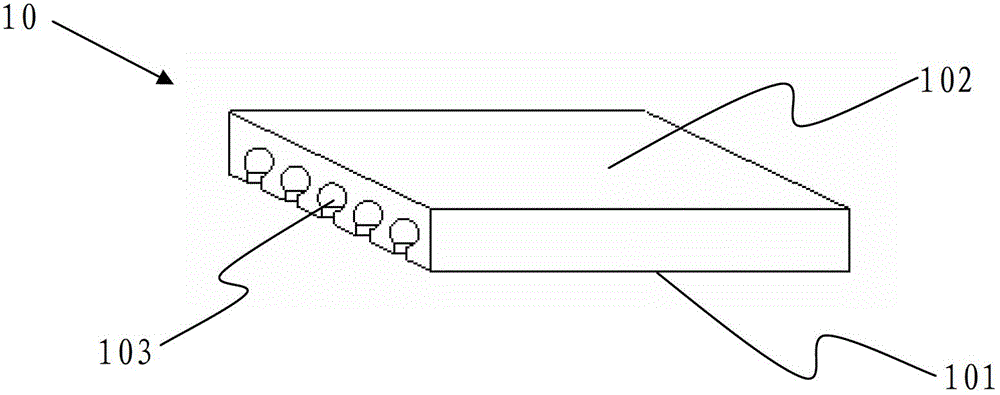

Method and structure for leakage seepage prevention construction for two-walls-in-one structure of deep-underground engineering

The invention discloses a method and a structure for leakage seepage prevention construction for a two-walls-in-one structure of a deep-underground engineering. The construction method comprises the following steps: processing and manufacturing a capillary drainage strip; foundation pit excavation, vertically chiselling a flat joint for allowing the capillary drainage strip to be accommodated in along a joint seam of an underground diaphragm wall; seizing a steel reinforced base plate (at the bottom of a lining wall) at the bottom of the foundation pit, horizontally arranging a plurality of water collecting pipes in the steel reinforced base plate along the underground diaphragm wall, and forming a slot opening in the position at the top of the water collecting pipe and corresponding to the end part of the capillary drainage strip; inserting the lower end of the capillary drainage strip in the slot opening, and sealing the joint between the capillary drainage strip and the water collecting pipe through spreading silicone glue onto the smooth surface of the capillary drainage strip; and laying the capillary drainage strip in the flat joint from the bottom to the top along the joint seam of the underground diaphragm wall, and allowing the grooving surface of the capillary drainage strip to face towards the underground diaphragm wall. The capillary drainage strip is used for cutting off water source for drainage redirection and dredge, so as to guide the water seepage between the underground diaphragm wall and the lining wall to enter the water collecting pipes for diversion.

Owner:SHANGHAI TUNNEL ENG CO LTD +1

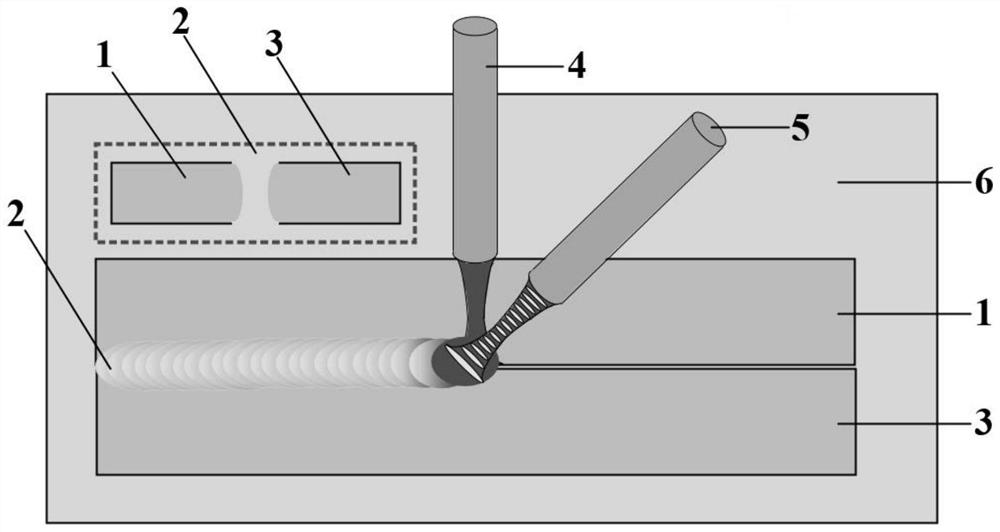

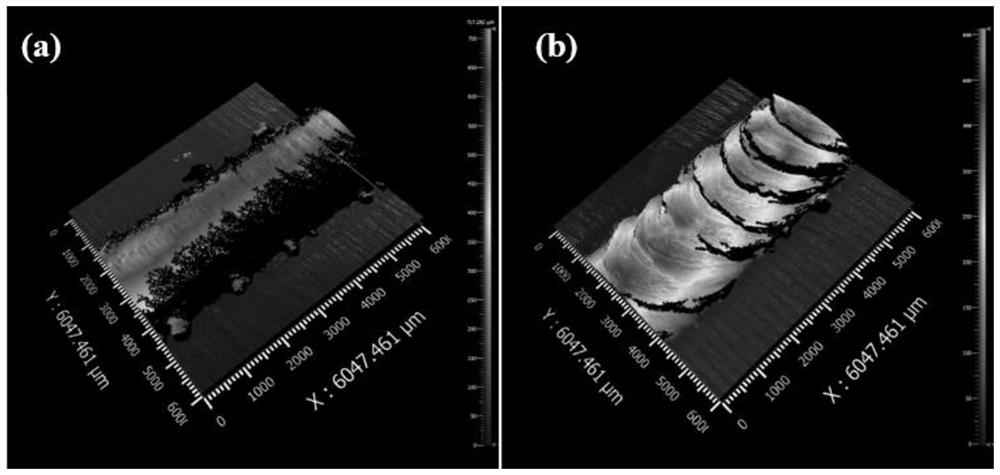

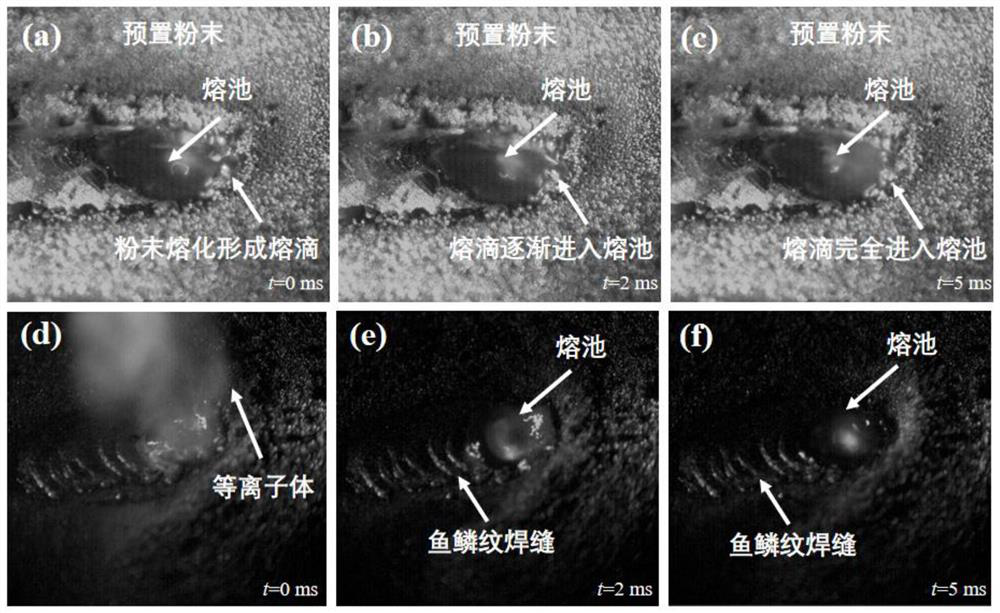

High-frequency laser pulse method applied to dissimilar metal composite heat source welding

ActiveCN112518109ASmooth appearanceRefine the weld grainLaser beam welding apparatusStress concentrationFlat joint

The invention discloses a high-frequency laser pulse method applied to dissimilar metal composite heat source welding. Through high-frequency pulse laser beam intervention, disturbance force in a molten pool can be increased, the Marangoni convection effect is enhanced, heat and mass transfer in the molten pool is accelerated, and uniform distribution of elements in the molten pool is achieved; aweld joint is shaped by directly or indirectly intervening a weld seam pool through a high-frequency pulse laser beam, weld seam grains can be refined, and a flat joint morphology which is symmetrically distributed along the center line of a weld seam is obtained; deformation maladjustment caused by difference of thermophysical performance parameters of dissimilar metal materials can be made up, so that the effect of intervening weldments in different time scales and space scales is achieved, and the reliability of dissimilar metal weld seam joints is improved; and the phenomenon of stress concentration induced by asymmetric distribution of pore and microcrack defects can be effectively prevented, and then the comprehensive mechanical property of the dissimilar metal weld seam joints is improved.

Owner:WUHAN UNIV

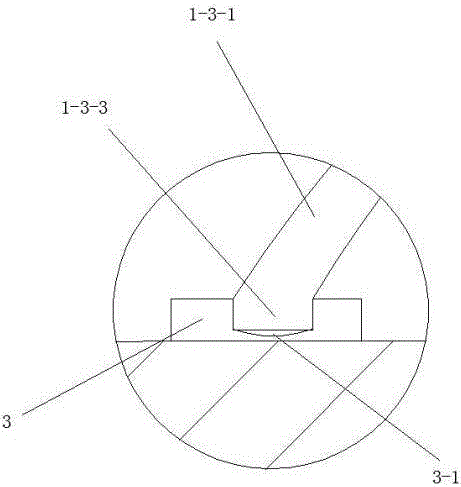

Three-way positioning device for base steel anchor box

ActiveCN103306204AImprove construction technologyEasy to operateBridge structural detailsFlat jointVertical edge

The invention discloses a three-way positioning device for a base steel anchor box. The three-way positioning device comprises a profile steel base, a steel pipe bracket system and a jack fine-adjustment system, wherein concrete embedded steel plates are welded at the bottom of the profile steel base and arranged in a # shape; the steel pipe bracket system comprises steel pipes and flat joints; the four steel pipes are vertical to the middle of the profile steel base respectively; the flat joints are arranged on the four steel pipes and divided into upper and lower layers; the jack fine-adjustment system comprises jacks and jack rear seats; the number of the jacks is 16; the 12 jacks are arranged on the jack rear seats welded on the profile steel base; the 8 jacks are arranged in an X-axis direction; the 4 jacks are arranged in a Y-axis direction; and the rest 4 jacks are flat jacks and are arranged at the two edges on the inner sides of the two vertical edges of the # shape of the profile steel base in a z-axis direction respectively and directly arranged on the bottom concrete surface. The three-way positioning device solves the problem of difficulty for positioning in the cable tower base steel anchor box, has the characteristics of simplicity for operation, convenience for construction, accuracy for positioning, high work efficiency and the like, lowers the construction difficulty and saves the construction cost.

Owner:THE SECOND CONSTR OF CTCE GROUP +2

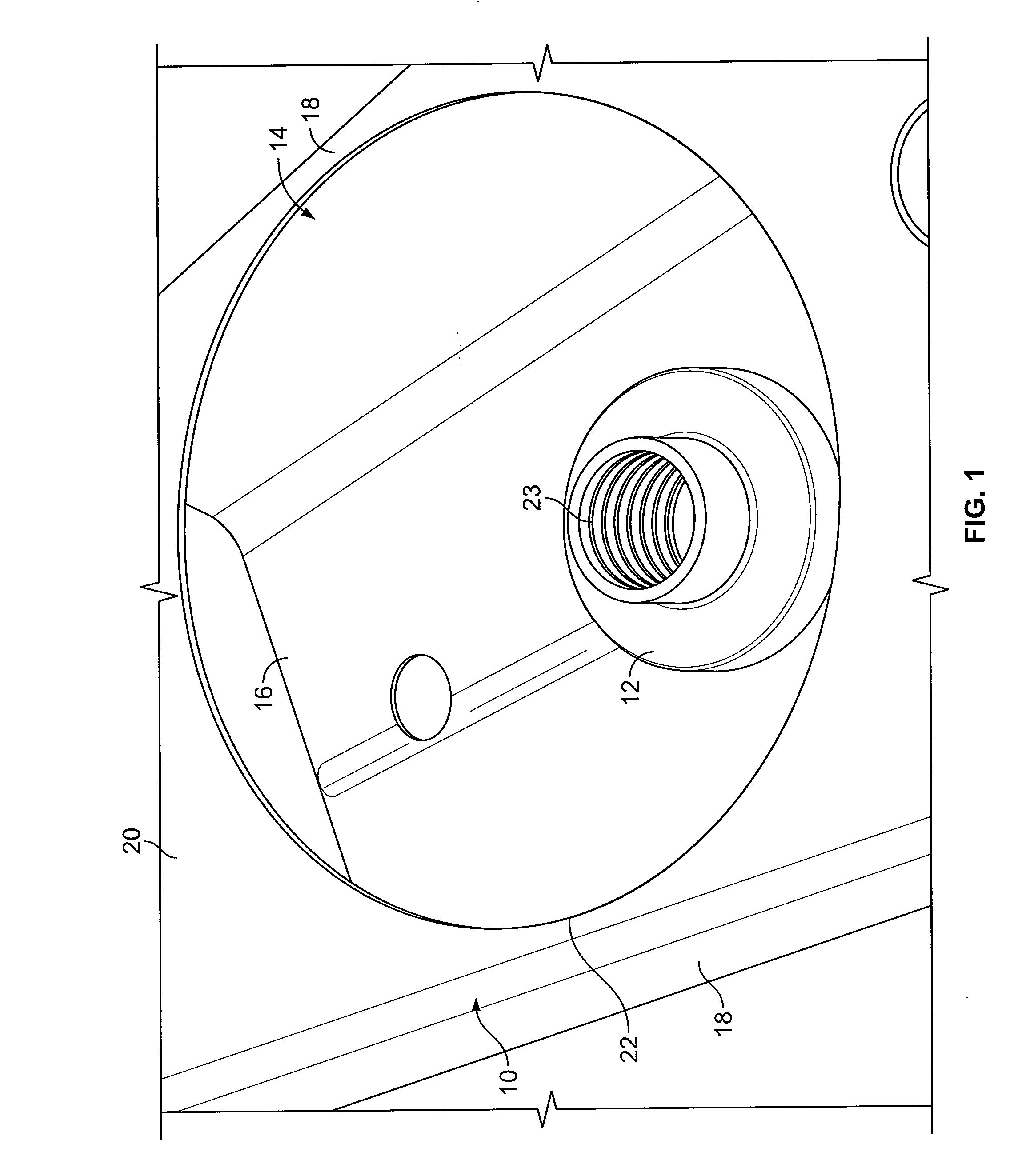

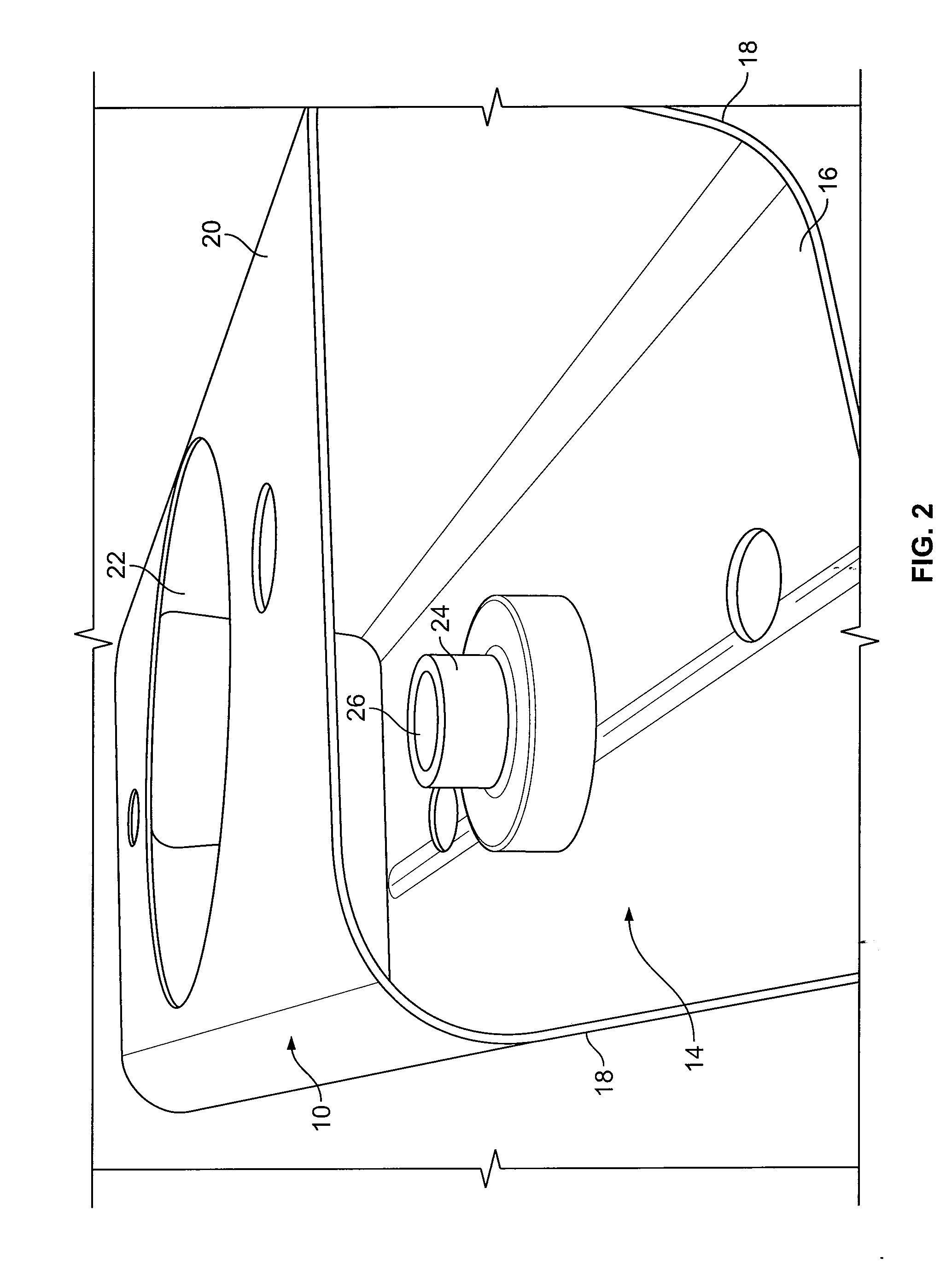

Inter stage seal housing having a replaceable wear strip

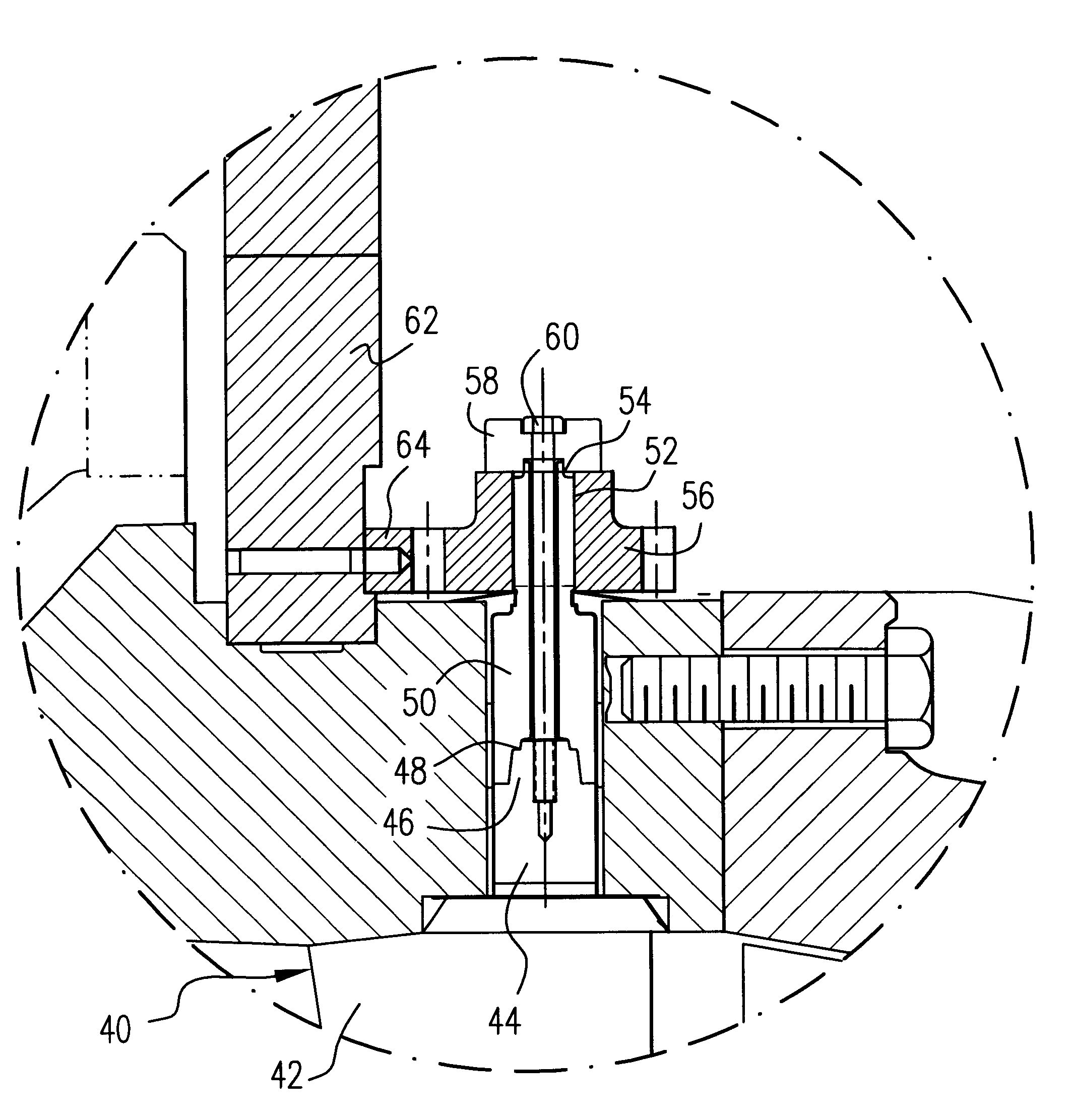

ActiveUS20120043724A1Prevent leakageUnwanted movementEngine sealsEngine manufactureEngineeringTurbine

An inter stage seal housing for a turbine engine having upper and lower half inter stage seal housings in which a contact sealing surface of the seal housing is restored after an interval of engine operation. The contact sealing surface is restored by fitting a replaceable wear strip on the downstream sealing surface of the seal housing. In order to fit the replaceable wear strip, a circumferential groove is machined along an outer peripheral edge of the seal housing. The groove is machined to include axial location and radial retention such that the wear strips can be slid into the upper half and lower half inter stage seal housing circumferentially from the horizontal joint. The groove includes through holes and the wear strips include corresponding threaded holes such that the wear strips can be fastened in the groove by fasteners and fastener retention hardware.

Owner:MITSUBISHI HITACHI POWER SYST AMERICAS

Cage nut fastening system

A cage-nut assembly is configured to securely clamp to at least one panel. The assembly includes a cage including an annular base integrally connected to beams having flat tabs extending from ends thereof. A nut chamber is defined between the annular base and the beams. A nut is positioned within the nut chamber, wherein at least one of the flat tabs prevents the nut from ejecting from the cage. The panel is configured to be clamped between the flat tabs and a portion of the nut.

Owner:ILLINOIS TOOL WORKS INC

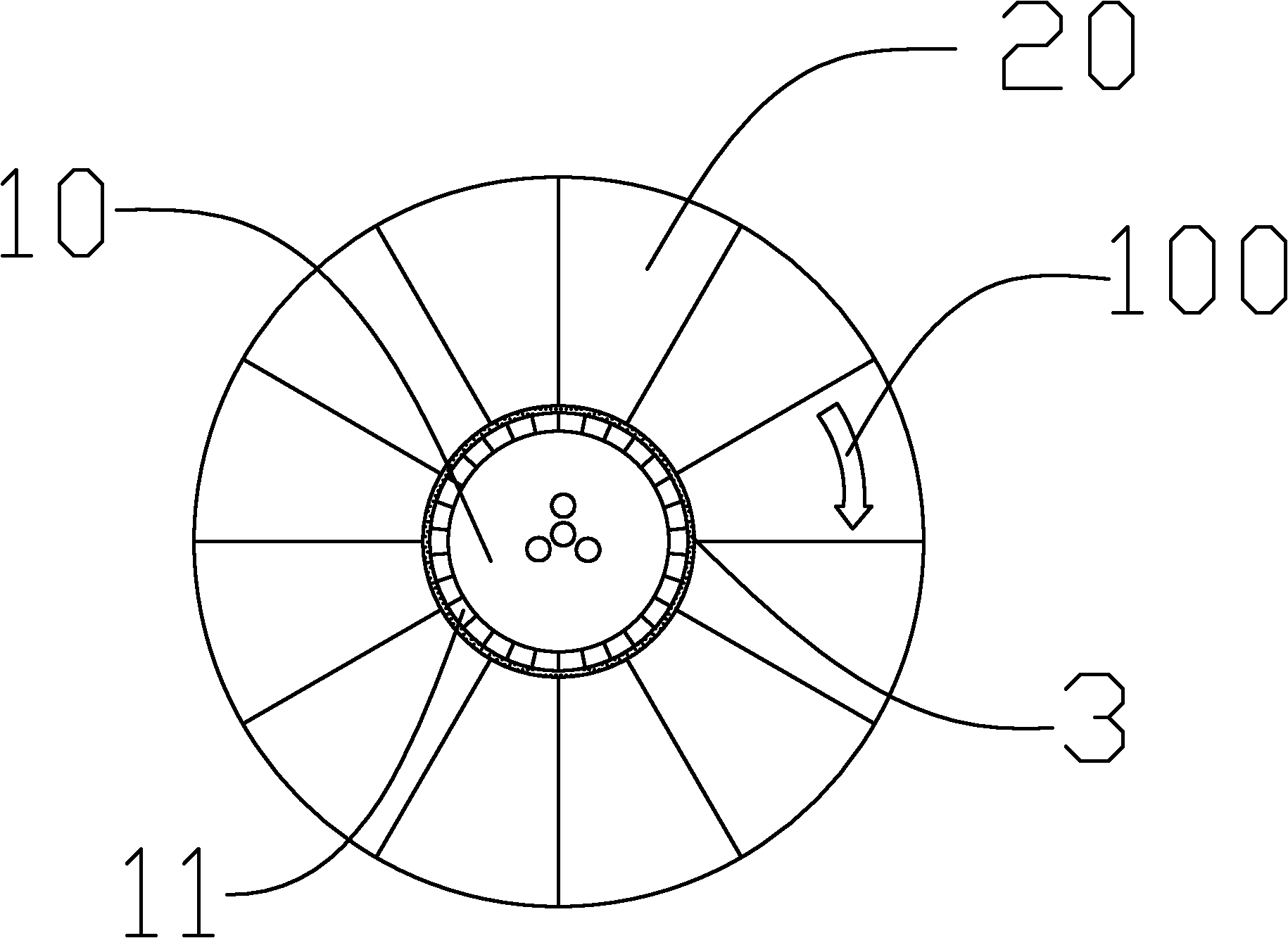

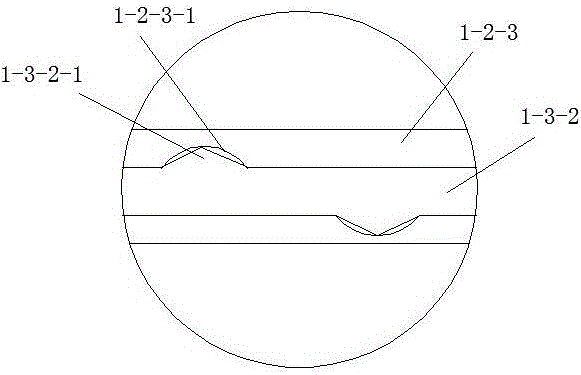

Playing ball with flat joint and manufacture method thereof

Then invention discloses a playing ball with flat joints and a manufacture method thereof. An outer layer of the playing ball with the flat joints is ball cover made of leather in a sewed mode, an aerated ball container is arranged inside the ball cover, the ball cover is sewed by a plurality of leather blocks, and each of the leather blocks is formed by at least two layers of materials in a composite mode. The playing ball with flat joints is characterized in that sewing areas are arranged on the edges around each of the leather blocks, each of the sewing areas is made of the outer layer material of the ball cover and is single-layer leather on the surface of the ball cover, or each of the sewing areas is formed by single layer leather and a bottom cloth in a composite mode, the middle part of an area defined by the sewing areas on the edges around each of the leather blocks is a composite layer area, wherein at least one layer of inner layer material is arranged on the lower face of the outer layer material in a composite mode, and thus a multi-layer composite material is formed. The thickness of sewing ridges of the playing ball with the flat joints is obviously smaller than the thicknesses of sewing ridges of all kinds of playing bolls in the prior art, and thus the circularity of the playing ball with the flat joints is higher than the circularity of the all kinds of playing bolls in the prior art, and the uniformity of the elasticity of all different positions of the playing ball with the flat joints is higher than the uniformity of the elasticity of all different positions of the all kinds of playing bolls in the prior art. The manufacture method of the playing ball with the flat joints is simple and practicable in process, and easy to implement.

Owner:南京绎霖国际贸易有限公司

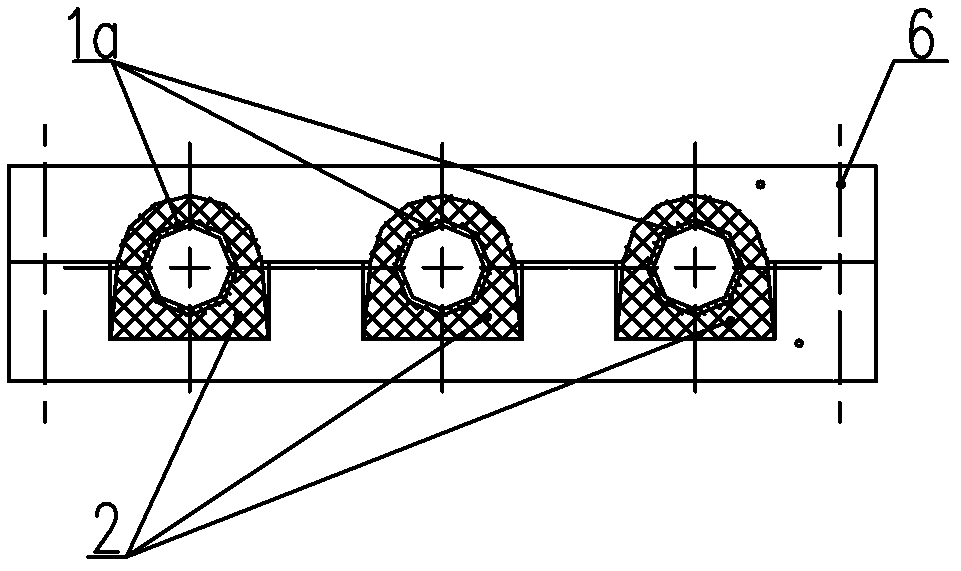

Phase isolated cast tubular bus and preparation method thereof

ActiveCN102426879AImprove rigidityReduce volumeContact member manufacturingInsulated cablesFlat jointForming gas

The invention relates to a phase isolated cast tubular bus and a preparation method thereof and belongs to the technical field of power transmission and distribution. The tubular bus is characterized in that flat joints are arranged at the two ends of a tubular bus main body; a resin insulating layer is cast outside the tubular bus main body; the section outline of the insulating layer is composed of a circular arc segment concentric with the tubular bus, extending line segments tangent with the two sides of the circular arc segment and a horizontal line segment intersecting with the two extending lines; the length of the horizontal line segment is greater than the diameter of the circular arc segment; and the circular arc segments are arranged above to form gas overflowing surfaces during casting and are arranged below to form positioning surfaces during installation. According to the invention, the convention is broken, thus an ideal casting effect can be achieved and the compact insulating casting layer can be formed, without the assistance of special equipment, thus solving the problem of insulating casting of the tubular bus; and the cast planes formed by opening casting become the ideal positioning surfaces during installation, thus achieving two aims at once.

Owner:WETOWN ELECTRIC GRP CO LTD

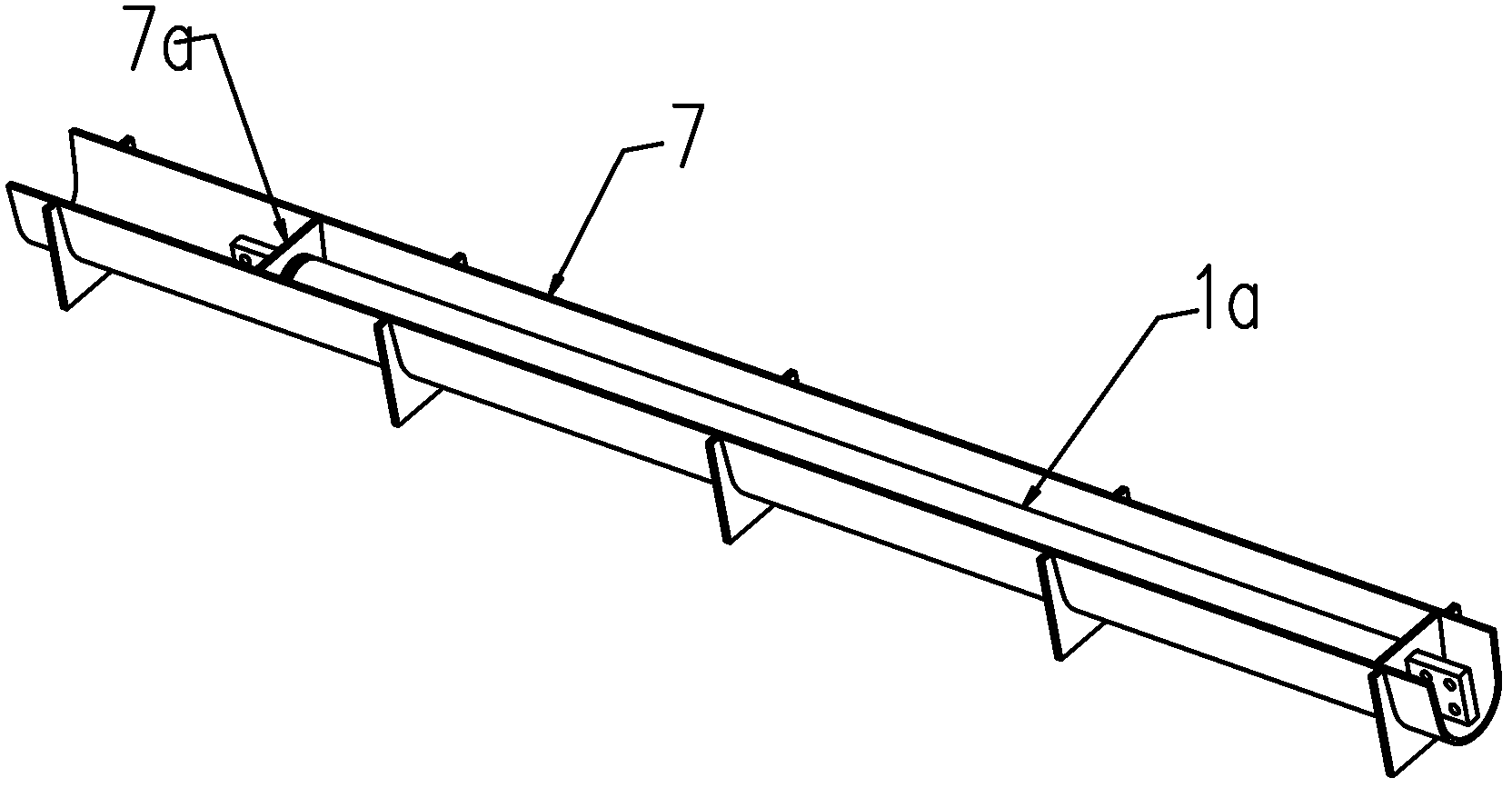

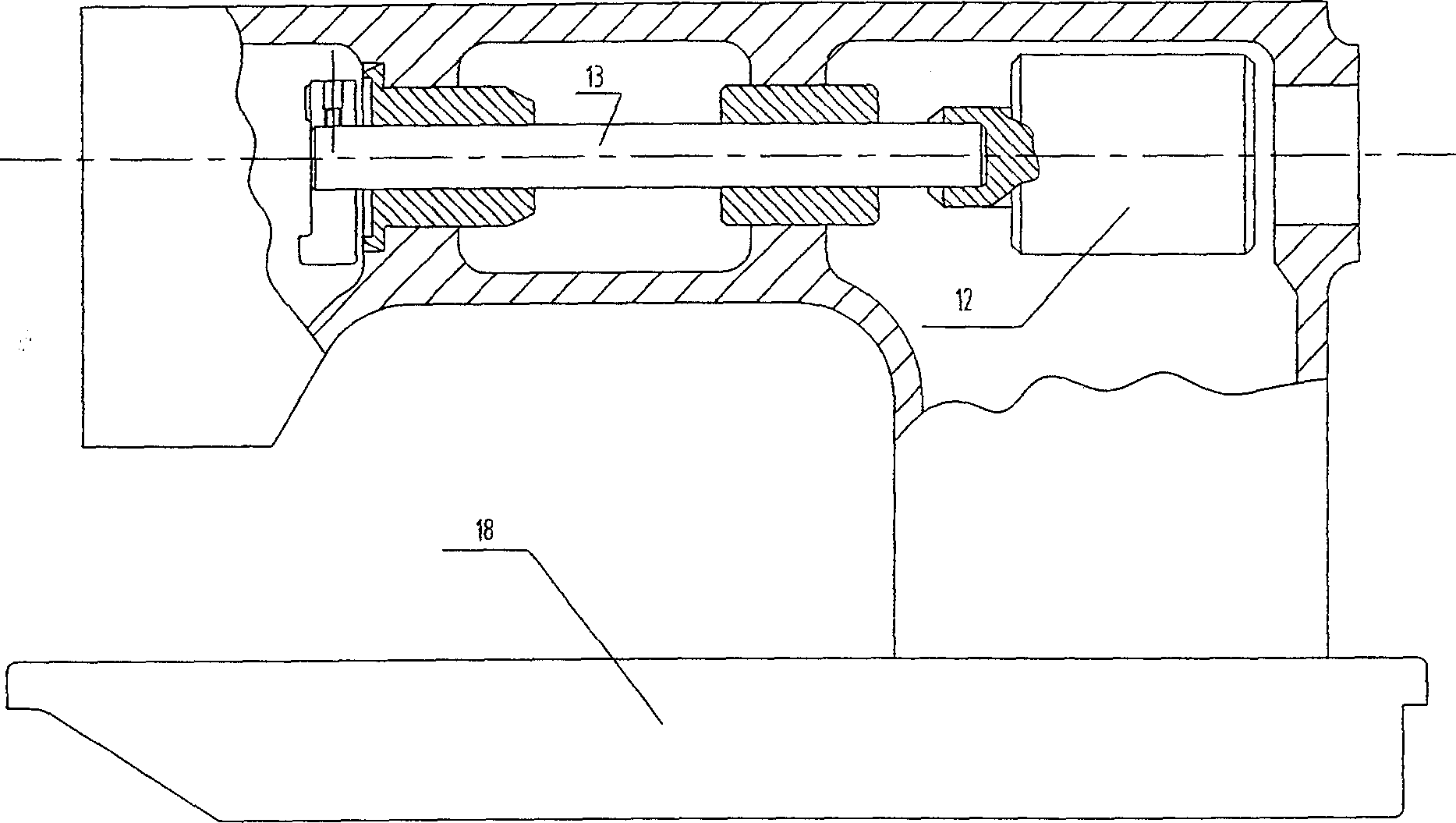

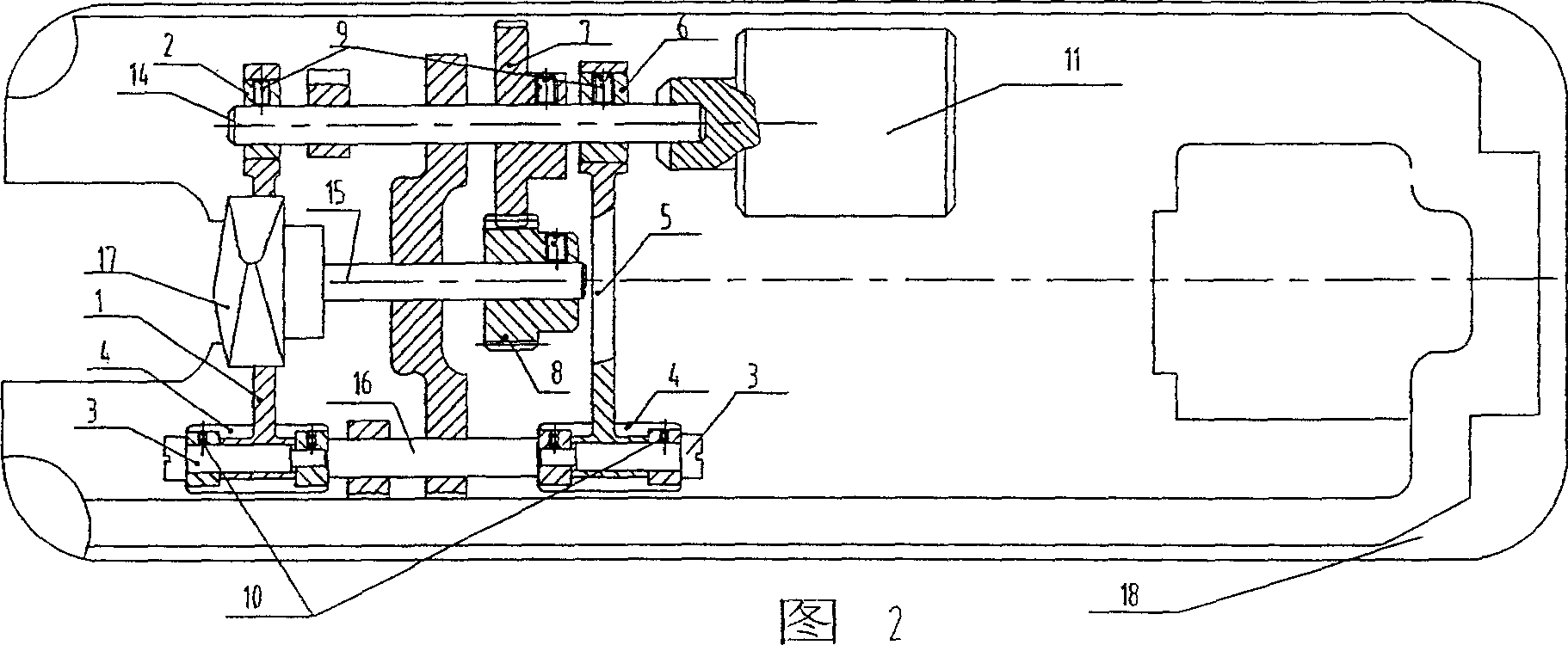

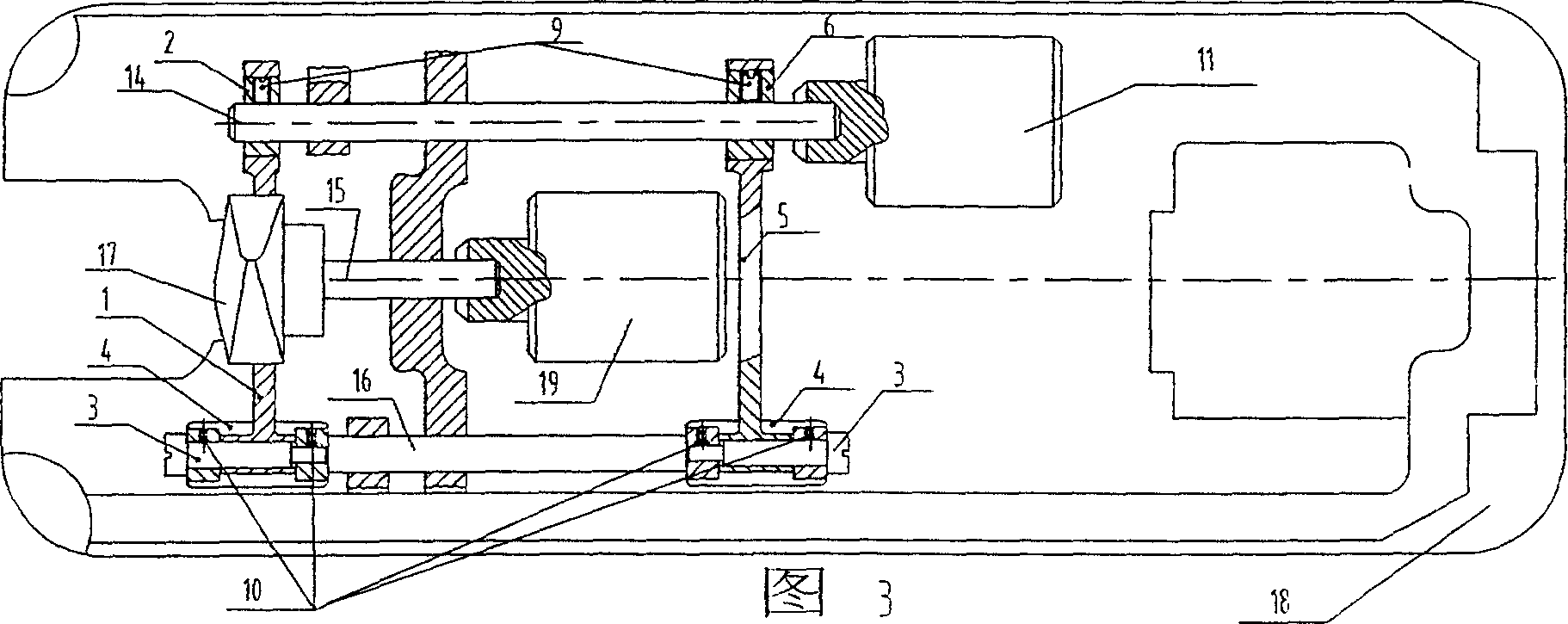

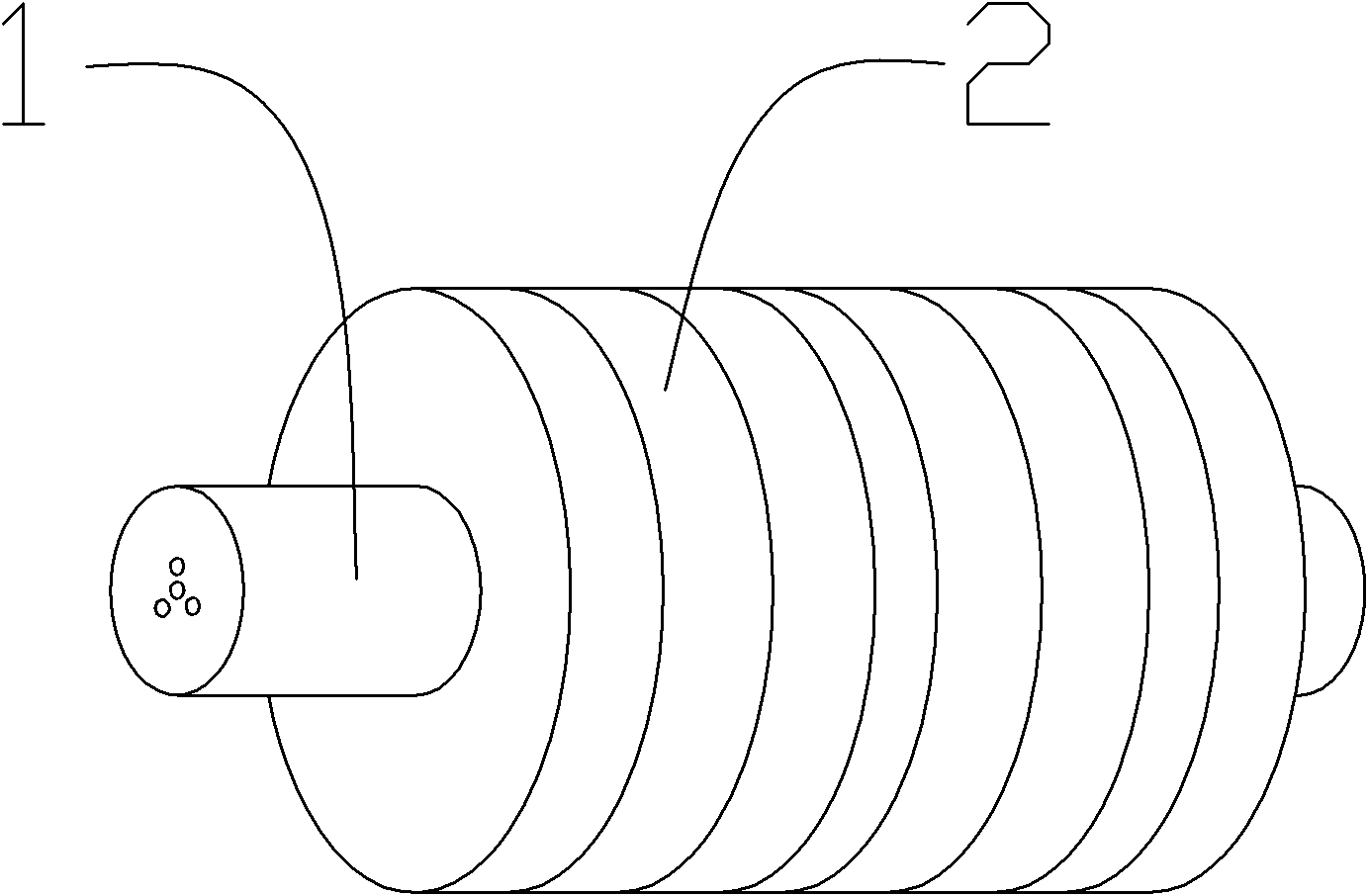

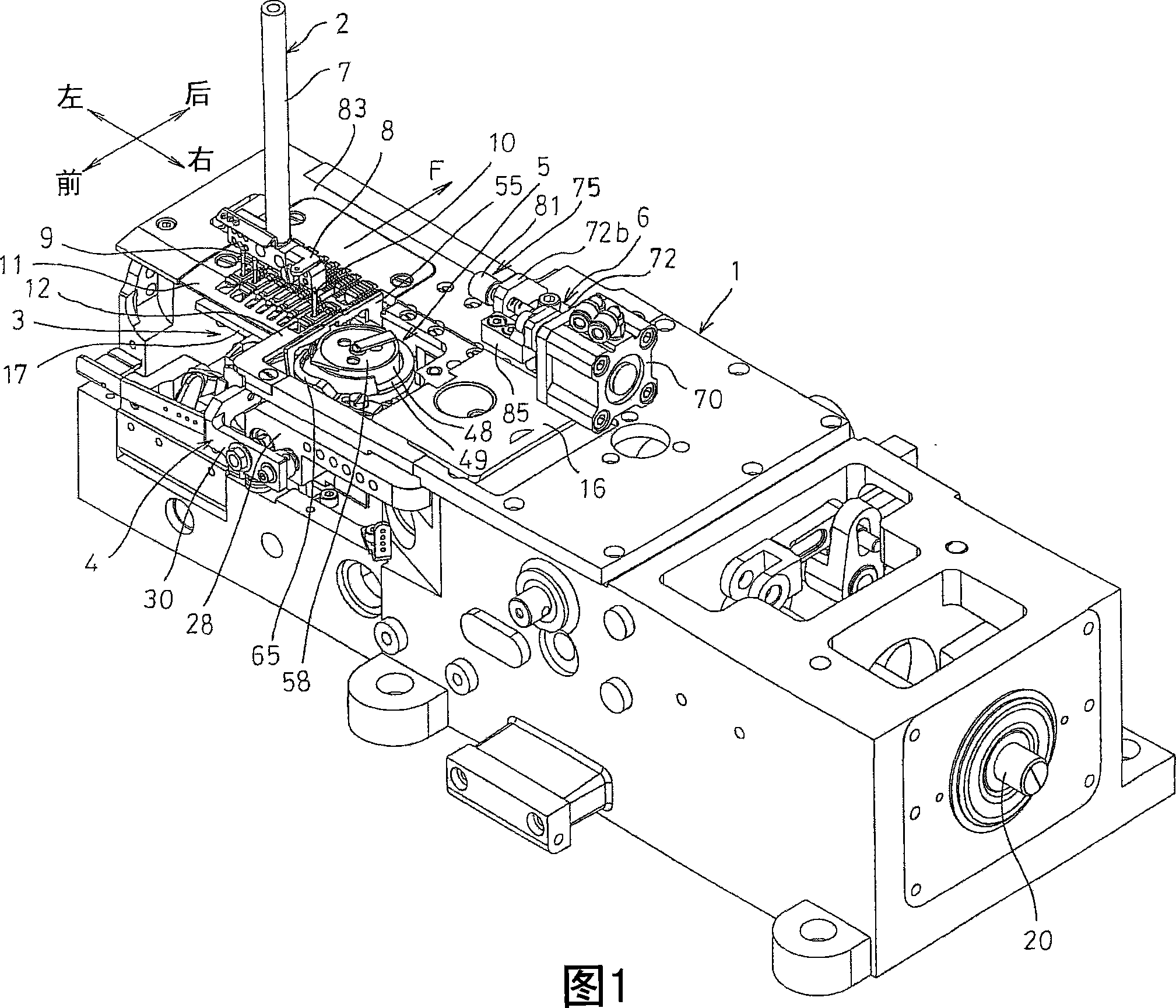

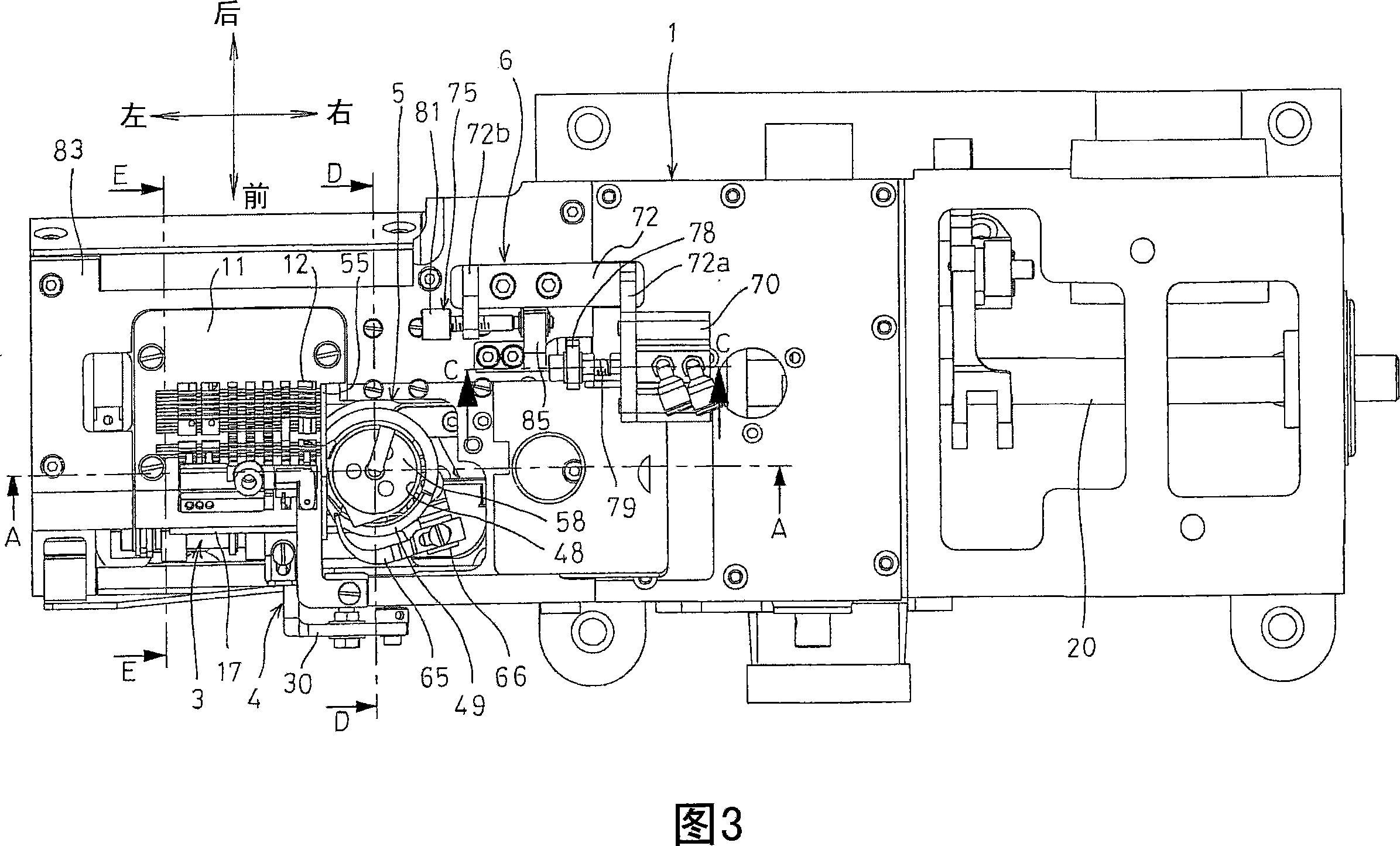

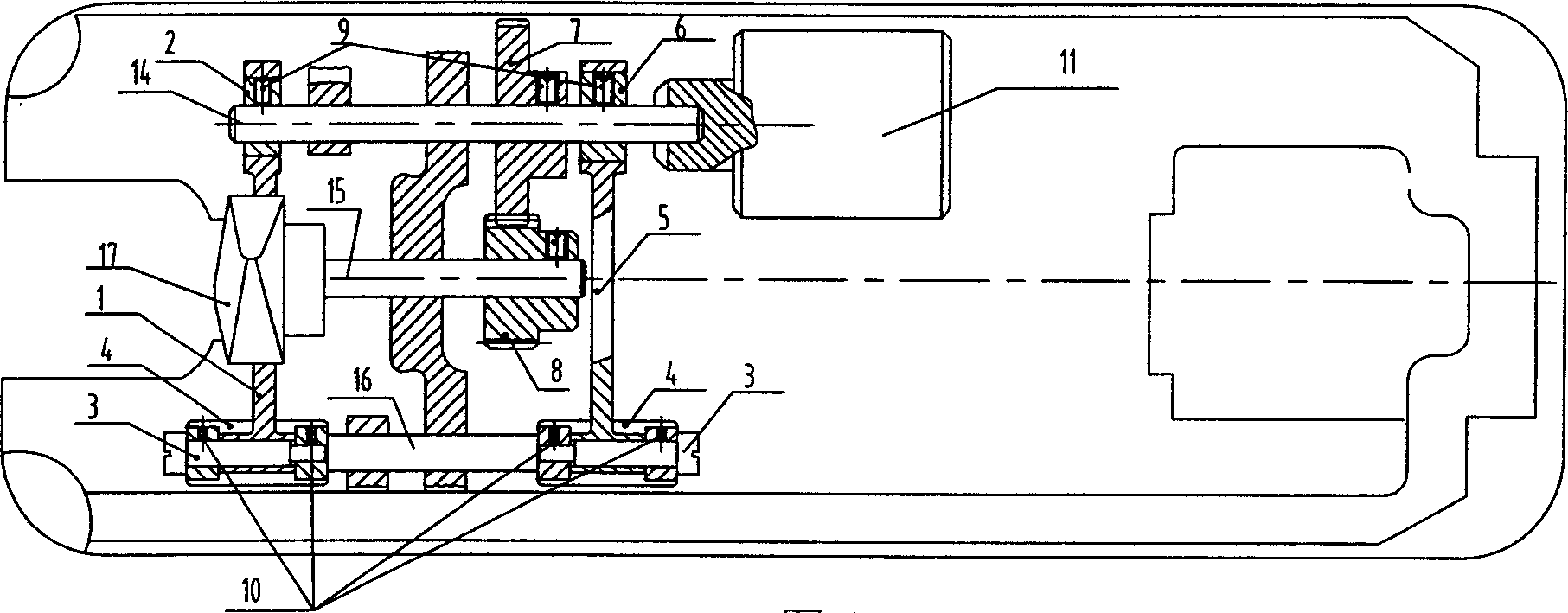

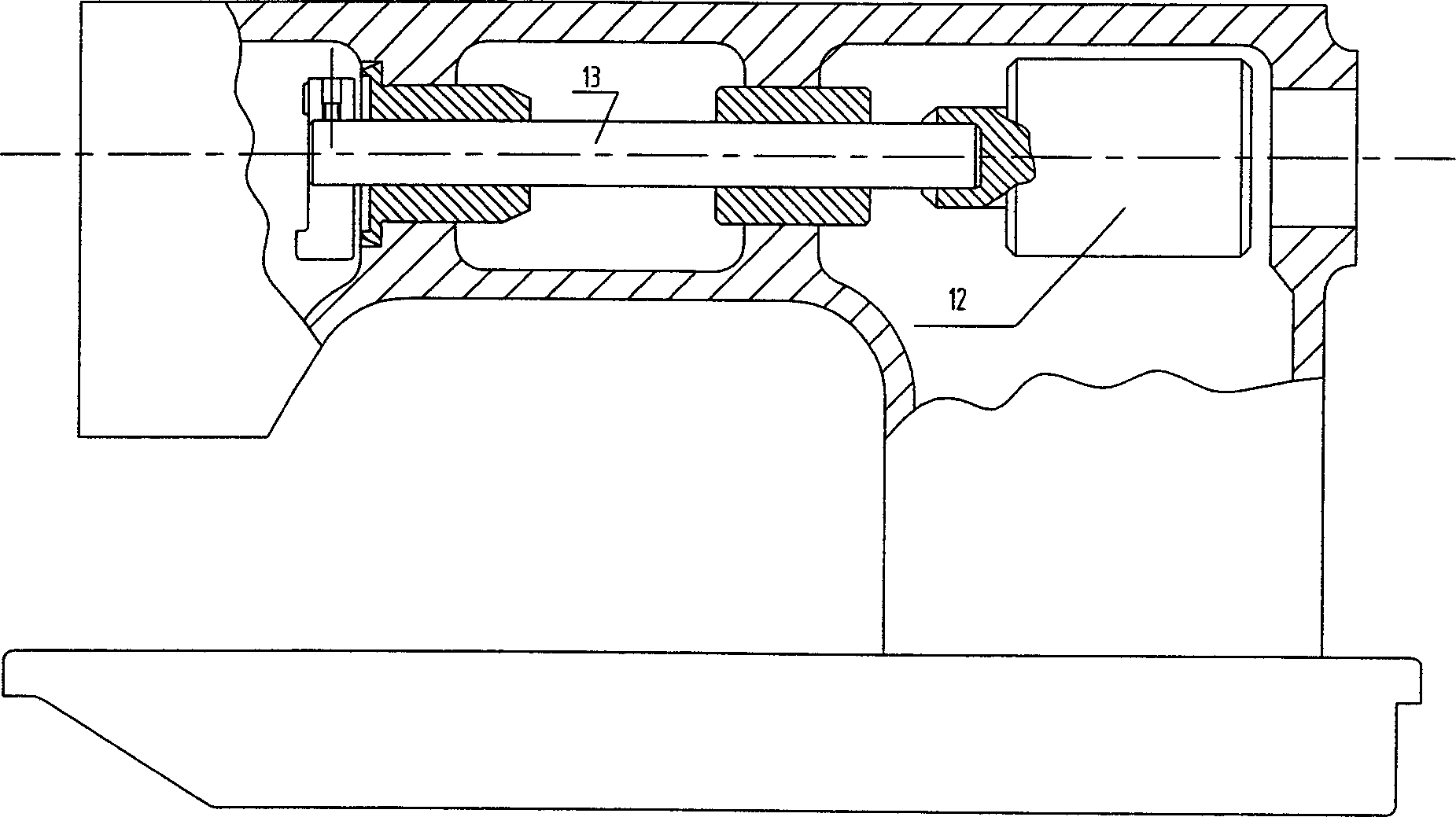

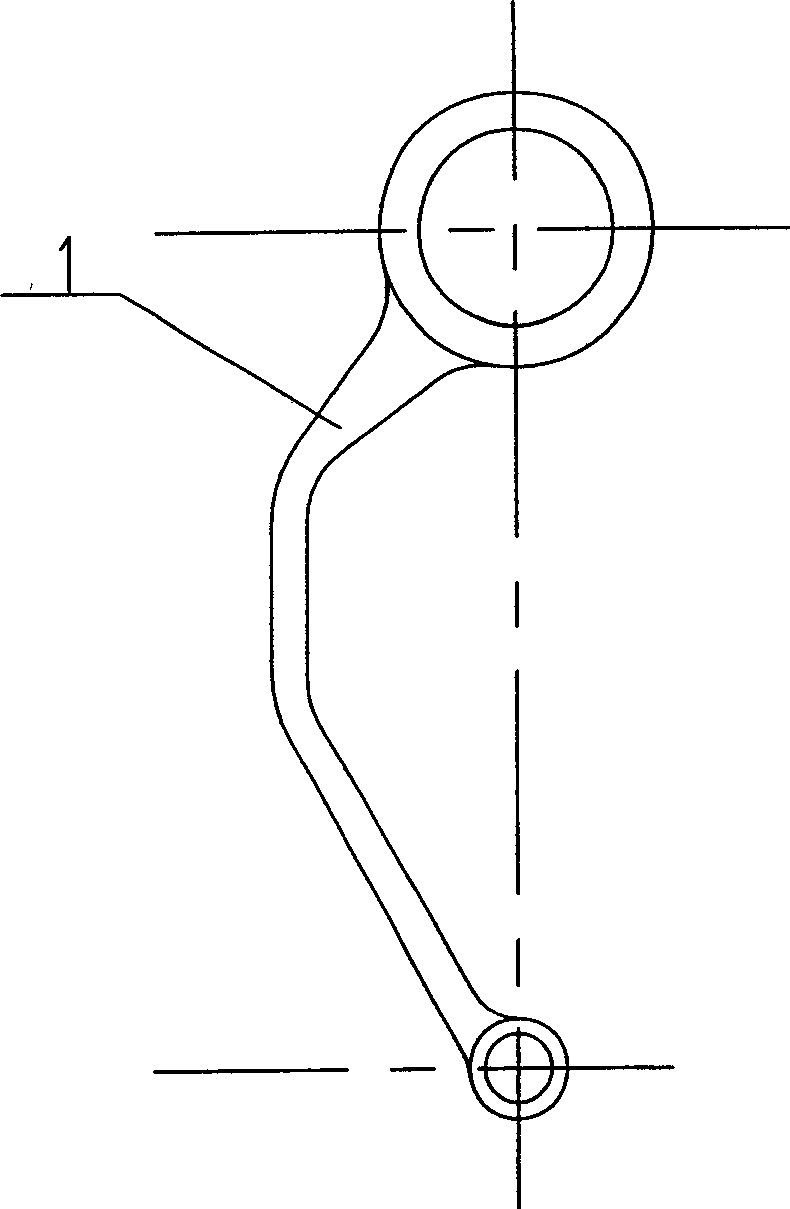

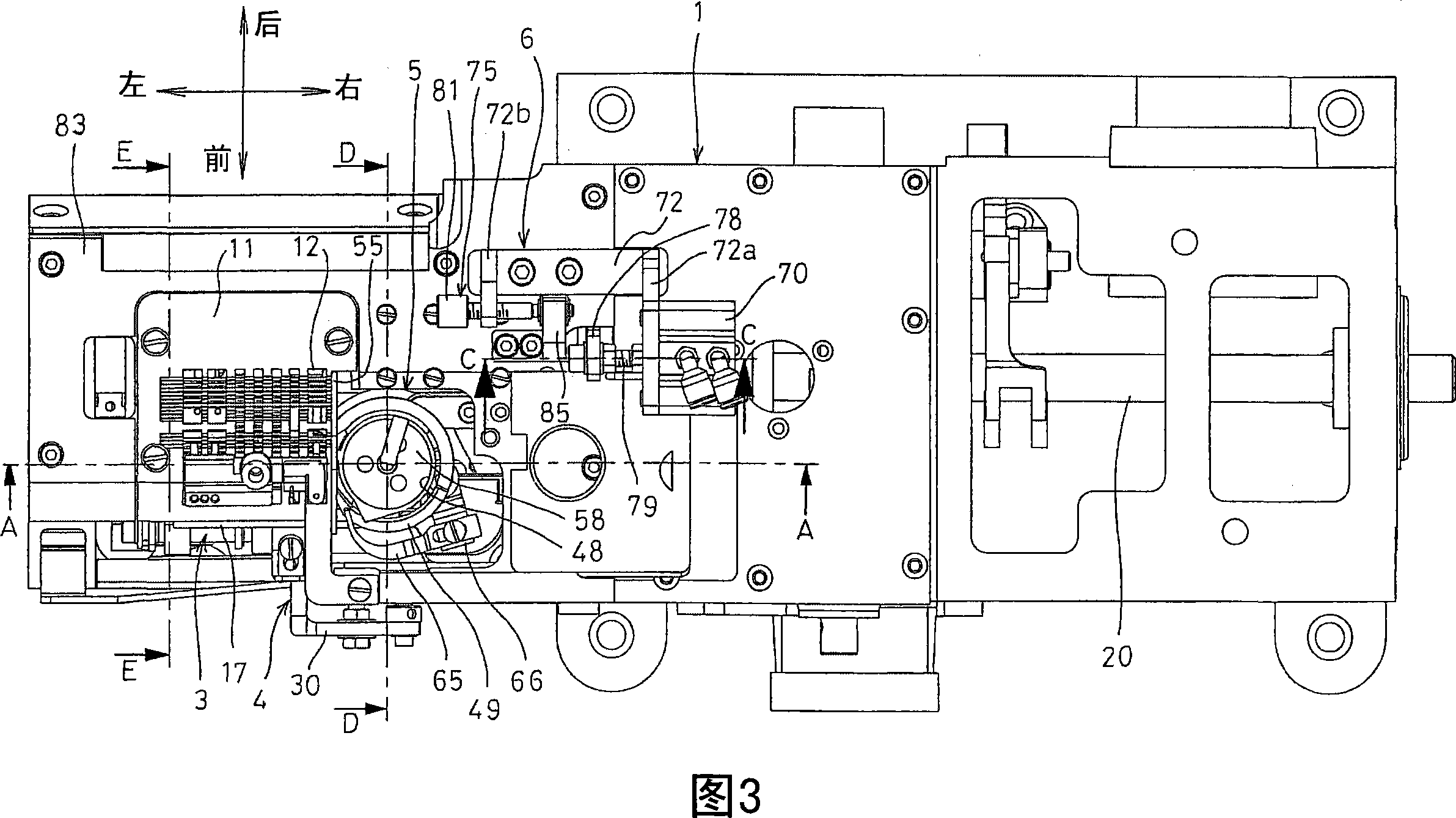

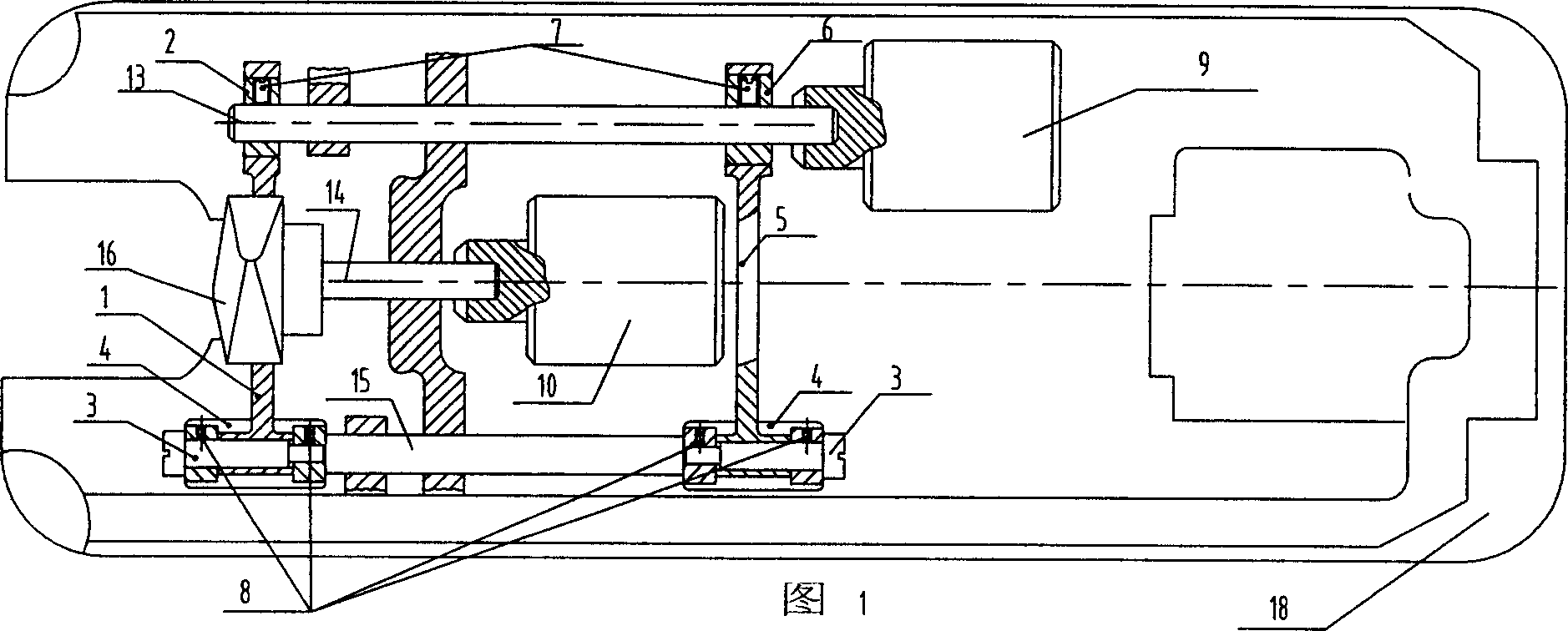

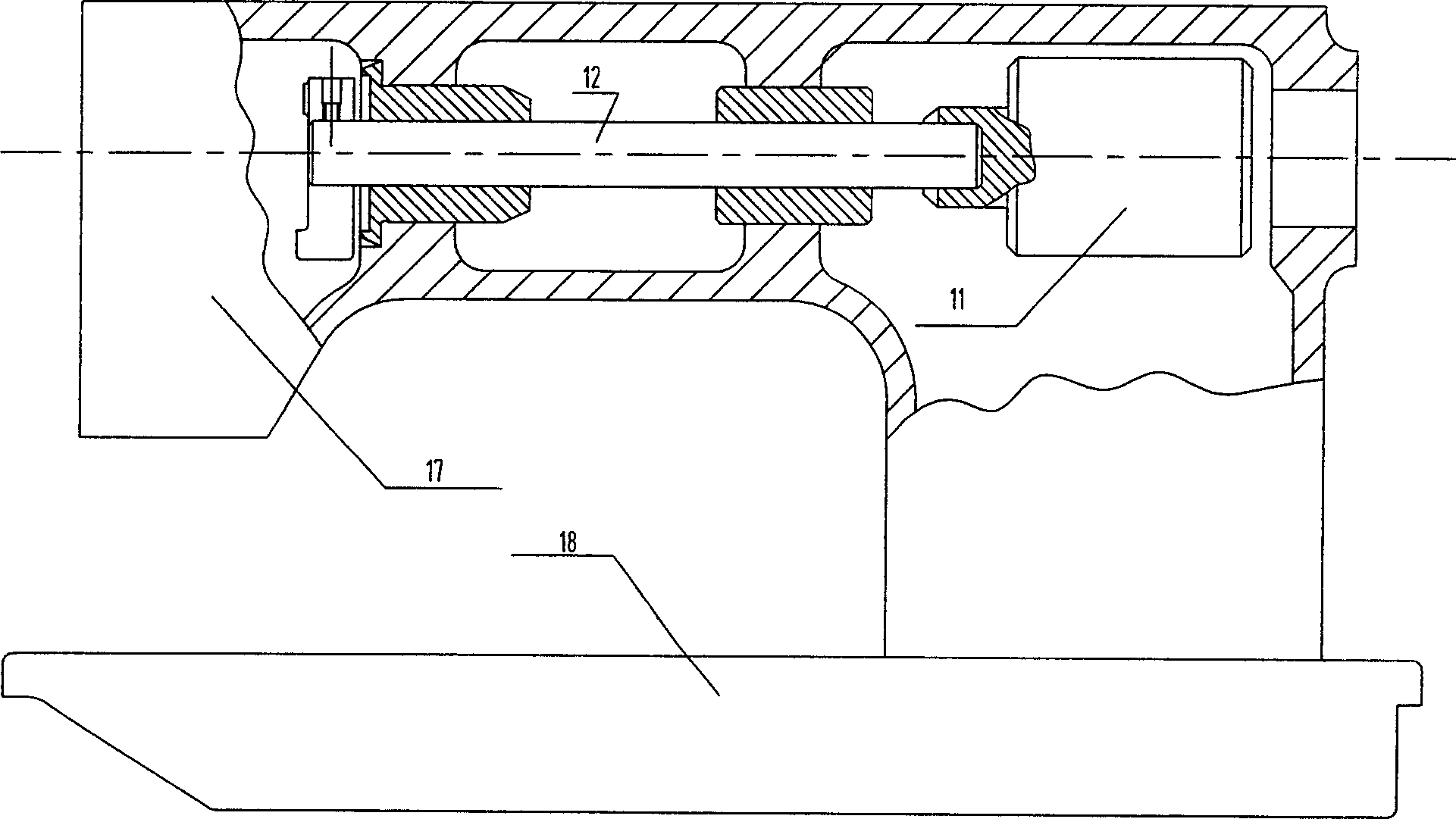

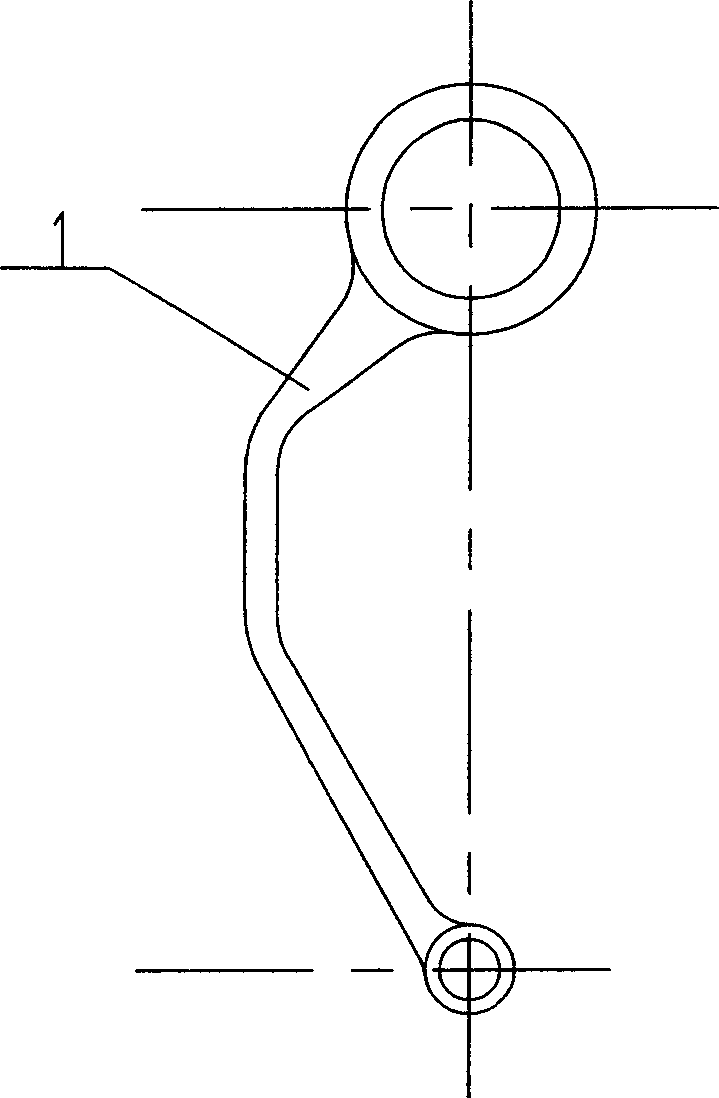

Servo drive mechanism of sewing machine

InactiveCN1804183AEasy to processOmit meshing transmission structureWork-feeding meansSewing-machine control devicesFlat jointGear drive

The servo drive mechanism for a flat joint machine comprises: a feed bar (1), a feed lifting cam (2), a pin shaft (3), a socket base (4), a feeding connecting rod (5), a feeding cam (6), a upper shaft (12) drove by a servo motor (11), a lower shaft (14) in platform (18) drove by a rotary-shuttle servo motor (10), and feed lifting shaft (13) drove by a feed lifting servo motor (9). This invention uses two or three servo motors to drive opposite shafts, eliminates a bevel gear structure or an engagement gear structure to reduce assembly difficulty and cost.

Owner:JACK SEWING MASCH CO LTD

Glued laminated timber and production and utilization method thereof

InactiveCN102152376ASave resourcesAlleviating the lack of large-diameter logsWood working apparatusDomestic articlesFiberFlat joint

The invention provides a method for producing a large-diameter glued laminated timber from logs with short and small diameter and low quality, an obtained glued laminated timber and a utilization method thereof. The glued laminated timber can be produced into wide-width and whole continuous veneers by rotary-cut. The produced glued laminated timber is formed by bonding a central columned core body and a plurality of single annular glued laminated timber sheets which are sleeved on the core body, wherein the core body consists of a metal inner core with enclosed two ends and a wood structure layer closely laminated to the metal inner core, each glued laminated timber sheet is formed by aligning, splicing and bonding a plurality of sector blank boards with equal thickness, each sector blank board is formed by splicing, gluing and cutting a plurality of flat jointed boards equal in thickness, the sides of the jointed boards are perpendicular to one sloping sides of the sector blank boards, therefore, the obtained glued laminated timber is directional, and the better rotary-cut effect along the fiber can be achieved in the rotary-cut process.

Owner:唐光志

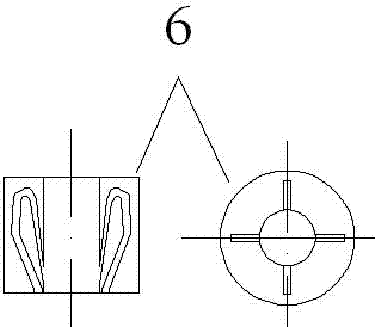

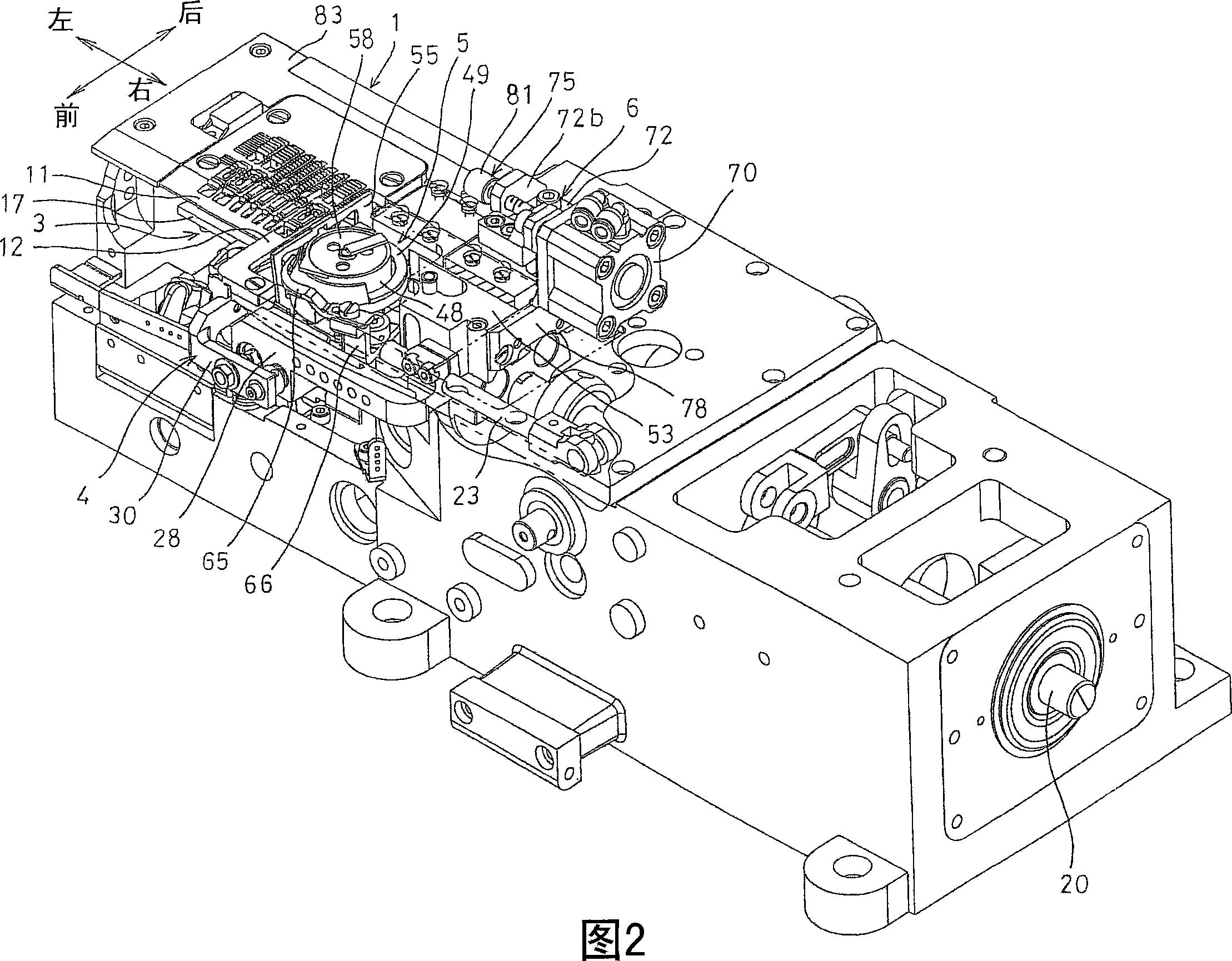

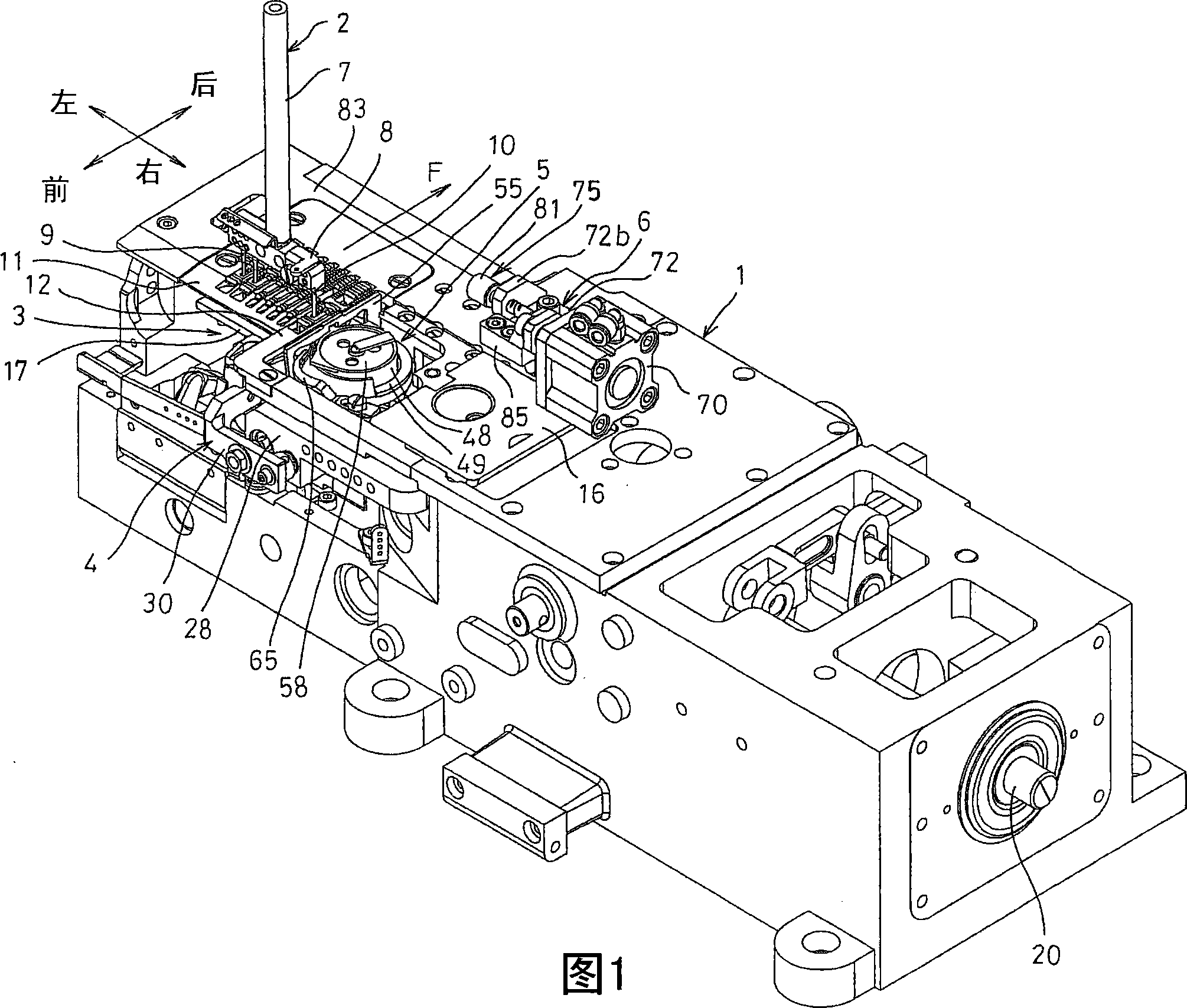

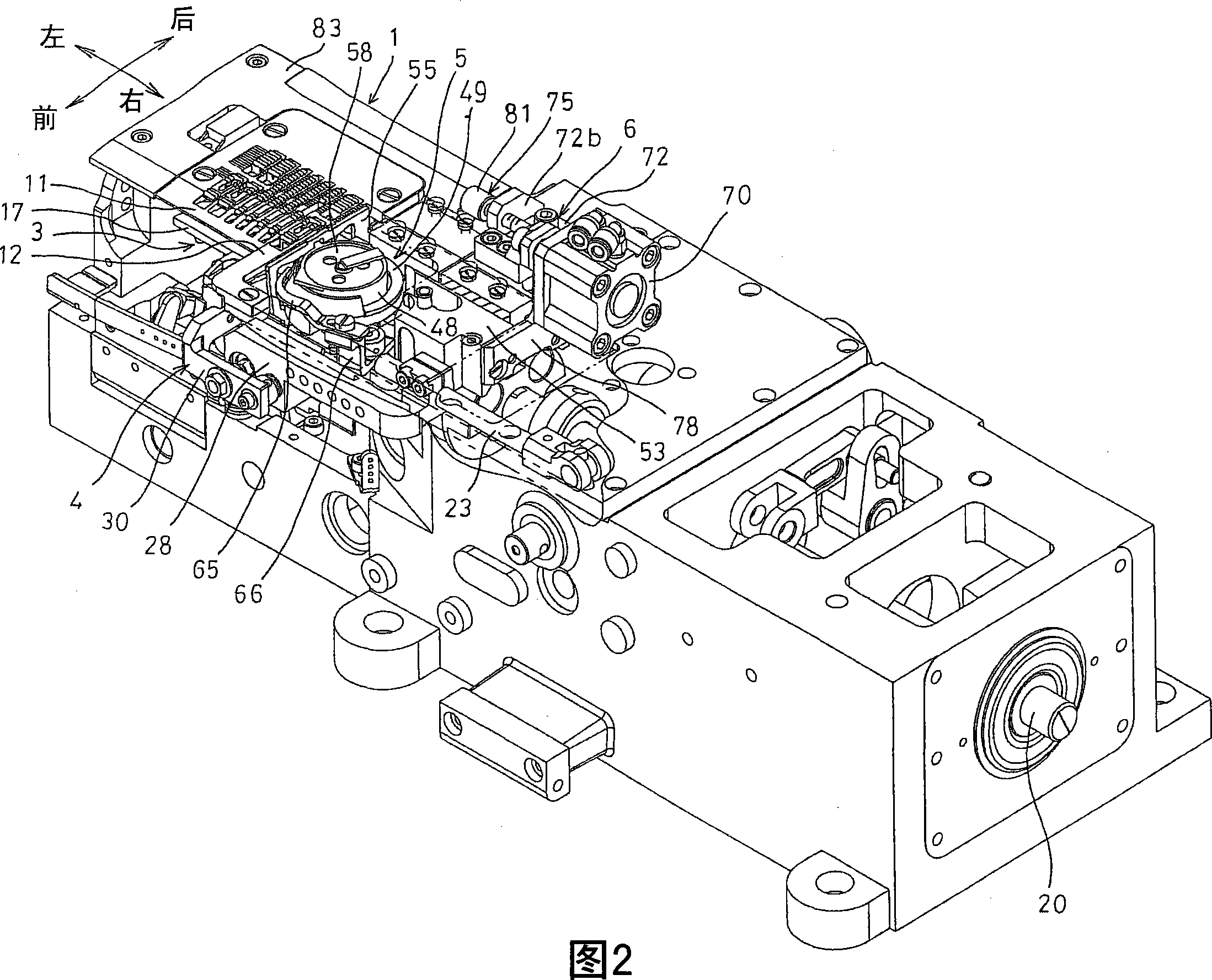

Sewing machine

InactiveCN101070664ACorrect and simple clearanceAvoid slackSewing-machine control devicesFlat jointBiomedical engineering

This invention relates to a sewing machine with skipped stitch mechanism of flat joint stitch. The said sewing machine comprises a needle bar mechanism (2), a needle cylinder mechanism (5) and a skipped stitch mechanism of flat joint stitch (6). The needle bar mechanism (2) seesaw needle bar (7), flat joint (10) held at the lower end of the needle bar. The needle cylinder mechanism (5) is composed of outer needle cylinder (49) and inner needle cylinder (48), and the flat joint stitch is formed along with seesaw movement of flat joint (10). The skipped stitch mechanism of flat joint stitch (6) makes the needle cylinder mechanism (5) move from the position of flat joint (10) to the position of moving away from the flat joint, and the stitches are skipped at the position of moving away from the flat joint.

Owner:MORIMOTO MFG

Double-color polyethylene film for disposal bed sheet of operating room

ActiveCN102432941AImprove puncture resistanceImprove mechanical propertiesLow-density polyethyleneMasterbatch

The invention relates to a double-color polyethylene film for a disposal bed sheet of an operating room. The double-color polyethylene film for the disposal bed sheet of the operating room is prepared by the following steps of: extruding a high-pressure low-density polyethylene resin, a metallocene linear polyethylene resin, masterbatch and an antifoaming agent from two screw extruders respectively and plasticizing, extruding by using a T-type flat joint die head to form a sheet, laminating and shaping by an embossing steel roller and a rubber roller, and then drawing and cutting ear sides. The aims of distinguishing front and reverse sides can be fulfilled under the condition of not adopting ink printing or an adhesive; when a double-color film is prepared by an ink printing process, equipment is added and solvent-based ink is needed to be used; when the double-film is prepared by bonding of the adhesive, two kinds of different films are needed to be produced, and then are bonded by the adhesive, and bonding equipment is high in manufacturing cost; compared with the two kinds of double-color films, the double-color polyethylene film for the disposable bed sheet of the operating room, which is prepared in the raw material proportion by a process has the advantages that the thickness is appropriate and is 0.05mm, and the double-color polyethylene film is excellent in puncture resistance performance, and mechanical property, and meets the using requirements of the disposable bed sheet of the operating room.

Owner:XINLE HUABAO MEDICAL SUPPLIES CO LTD

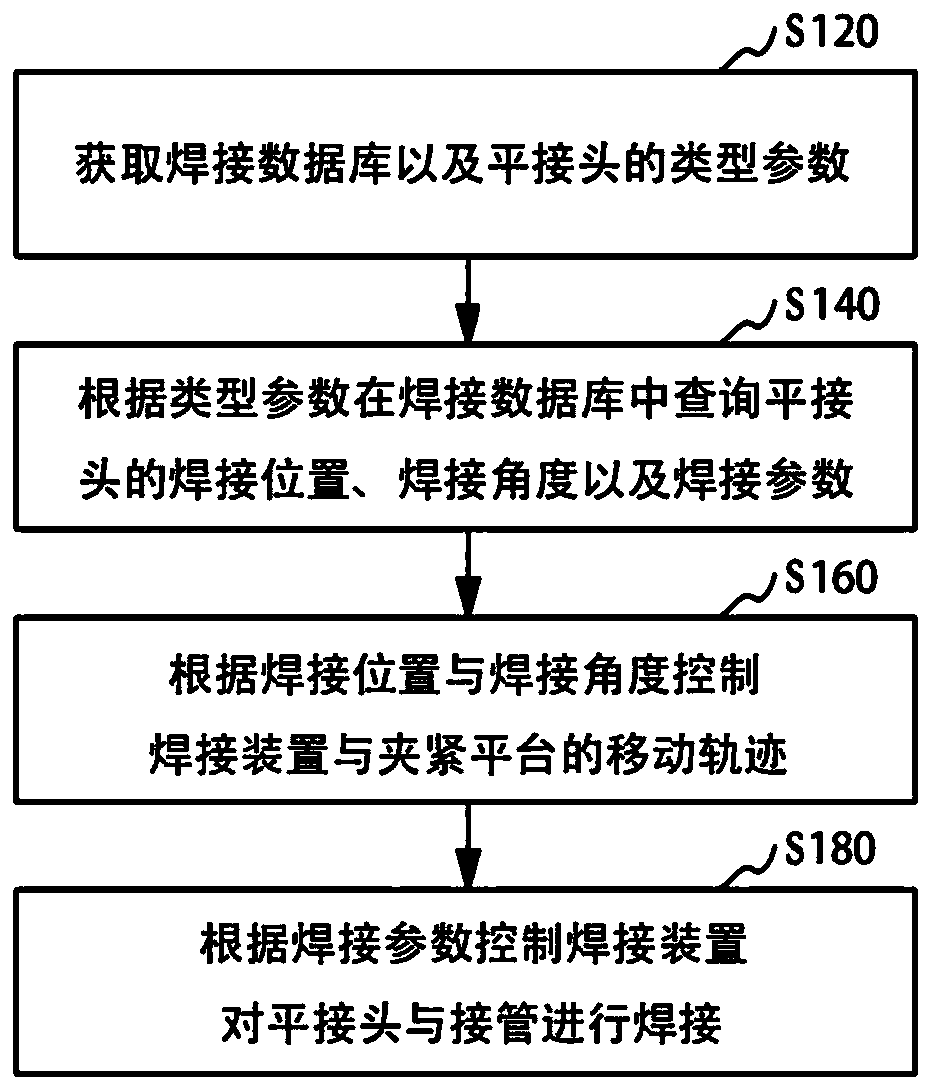

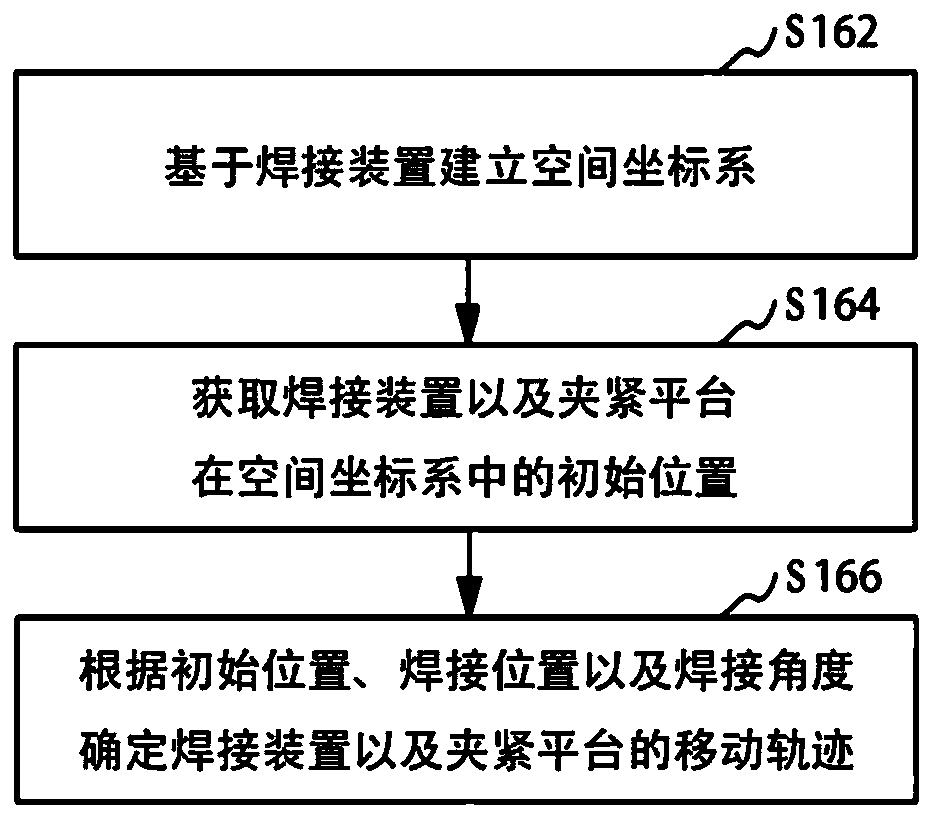

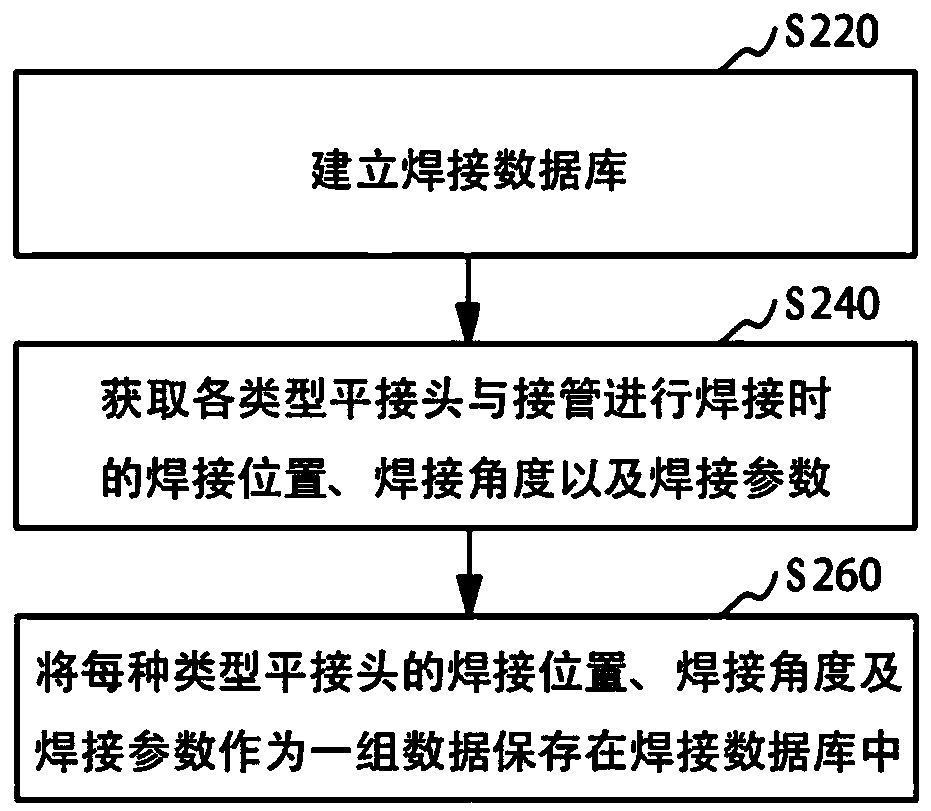

Flush joint welding method, device, system and computer readable storage medium

ActiveCN111037039AImprove welding efficiencyImprove accuracyDomestic vesselsMetal working apparatusData controlFlat joint

The invention discloses a flush joint welding system, a flush joint welding method, a flush joint welding device, computer equipment and a storage medium. The flush joint welding method is applied tothe flush joint welding system. The flush joint welding system comprises a welding device and a clamping platform used for fixing a flush joint and a connecting pipe. The method comprises the steps that: a welding database and the type parameters of the flush joint are obtained; the welding position, welding angle and welding parameters of the flush joint are queried in the welding database according to the type parameters; the moving tracks of the welding device and the clamping platform are controlled according to the welding position and the welding angle; and the welding device is controlled to weld the flush joint and the connecting pipe according to the welding parameters. According to the method, the data such as the welding position, the welding angle and the welding parameters canbe inquired in the pre-obtained welding database according to the type of the flush joint; the welding device and the clamping platform are controlled to move according to the data; the flush joint and the connecting pipe are automatically welded; and therefore, welding efficiency and accuracy are effectively improved.

Owner:SHANGHAI MORIMATSU PHARMA EQUIP ENG

Contamination accumulation preventing skirting line structure

A contamination accumulation preventing skirting line structure comprises a basic connecting plate, a skirting batten and a contamination accumulation preventing baffle. The basic connecting plate comprises a vertical plate and a base plate, the rear end of the base plate is fixedly connected with the bottom end of the vertical plate, the base plate is mutually and vertically connected with the vertical plate, and a fixing device for being connected with a wall is arranged on the vertical plate. The skirting batten comprises a body portion and fixing portions, wherein the fixing portions are arranged on two sides of the body portion, the upper surfaces of the fixing portions on two sides are mutually perpendicular, and the lower surfaces are also mutually perpendicular. The contamination accumulation preventing skirting line structure has the advantages of being simple in structure and convenient to mount and dismount, facilitating contamination removal, meanwhile remarkably decreasing contaminations at flat joints and reducing bug-begetting and mildewing rates.

Owner:昆明市建筑设计研究院股份有限公司

Servo drive device of lockstitch sewing machine

ActiveCN1804184AOmit the transmission structureEasy to processProgramme-controlled sewing machinesSewing-machine control devicesFlat jointGear drive

The servo drive mechanism for a flat joint machine comprises: a feed bar (1), a feed lifting cam (2), a pin shaft (3), a socket base (4), a feeding connecting rod (5), a feeding cam (6), feed lifting shaft gear (7), a upper shaft (13) drove by a servo motor (12), and a feed lifting shaft (14) or lower shaft (15 ) drove by a servo motor (11). This invention eliminates a bevel gear structure to reduce assembly difficulty and manufacture cost.

Owner:JACK SEWING MASCH CO LTD

Sewing machine

This invention relates to a sewing machine. In order to be corresponding with tailoring of the product of different tact system on the unner side and the outer side of the cestus blank patch, the sewing machine has skipped stitch mechanism of whipstitch and skipped stitch mechanism of flat joint stitch and with crimping and flat seaming function. The curved needle mechanism is composed of a curved needle and a dividing sinker device and a whipstitch formed along with seesaw movement of whipstitch of needle bar device. The whipstitch of skipped stitch mechanism is set to make the dividing sinker device move between the guiding yarn position and retreating position, and the stitch is skipped at the retreating position. The skipped stitch mechanism of whipstitch can make the needle cylinder mechanism move from position close to the flat joint needle to position apart from the flat joint needle, and the stitch is skipped at the position apart from the flat joint needle.

Owner:MORIMOTO MFG

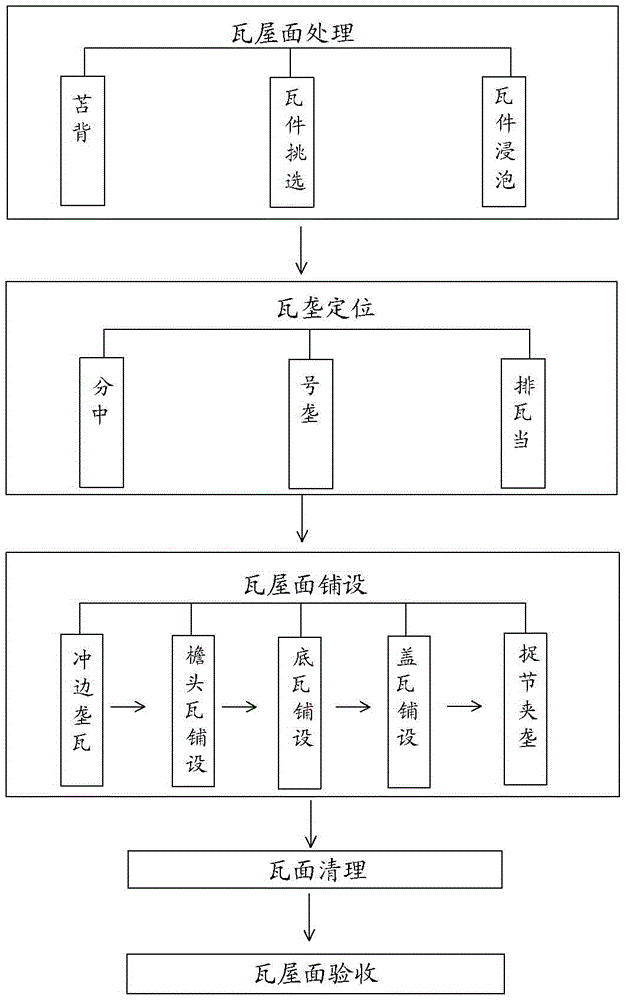

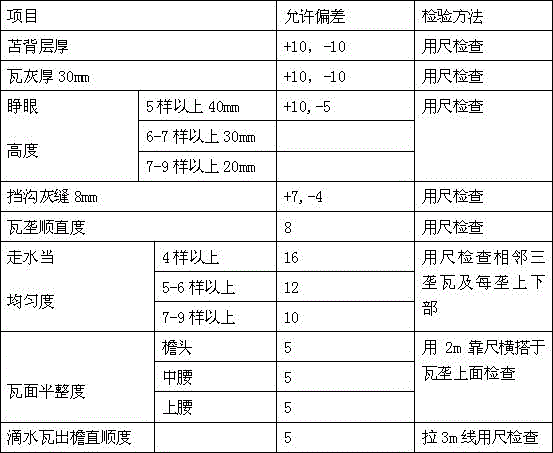

Construction method of tile roofing of ancient building

ActiveCN105625642ANo pollution in the processImprove construction efficiencyRoof covering using tiles/slatesSocial benefitsFlat joint

The invention relates to a construction method of a tile roofing of an ancient building, which can effectively solve the problems of difficultly realizing high efficiency and low cost and difficultly guaranteeing of restoration quality for the tile roofing of the ancient building. The construction method comprises the following steps of treatment of the tile roofing: cleaning a base layer of the tile roofing, and cleaning a plastered grey cement back; selecting and classifying tiles for the tile roofing, soaking, fetching out, and airing; centering a roof plane, forming a ridge, arranging eaves tiles, and performing planar positioning; tile paving at the roof: punching edge ridge tiles, paving eave edge tiles, tying tile ridge lines, paving bottom tiles, paving cover tiles, and tightly plastering and flatting joints; arranging a tile surface, cleaning a roof ridge, and preventing the pollution of cement mortar to a glaze surface, so as to maintain the cleanliness and brightness of the tiles. The construction method has the advantages that the construction efficiency is high, the cost is low, the overlapping of the tile roofing is tight and firm, lines and rows are regularly transverse and vertical, the protruding lengths of the eave head tiles are uniform, the slope of a tile surface is smooth and straight, and the visual effect is good; the waste caused by inaccurate size during cutting is avoided, the loss is reduced, the pollution to environment is avoided, and the huge economic and social benefits are realized.

Owner:ZHENGZHOU UNIV

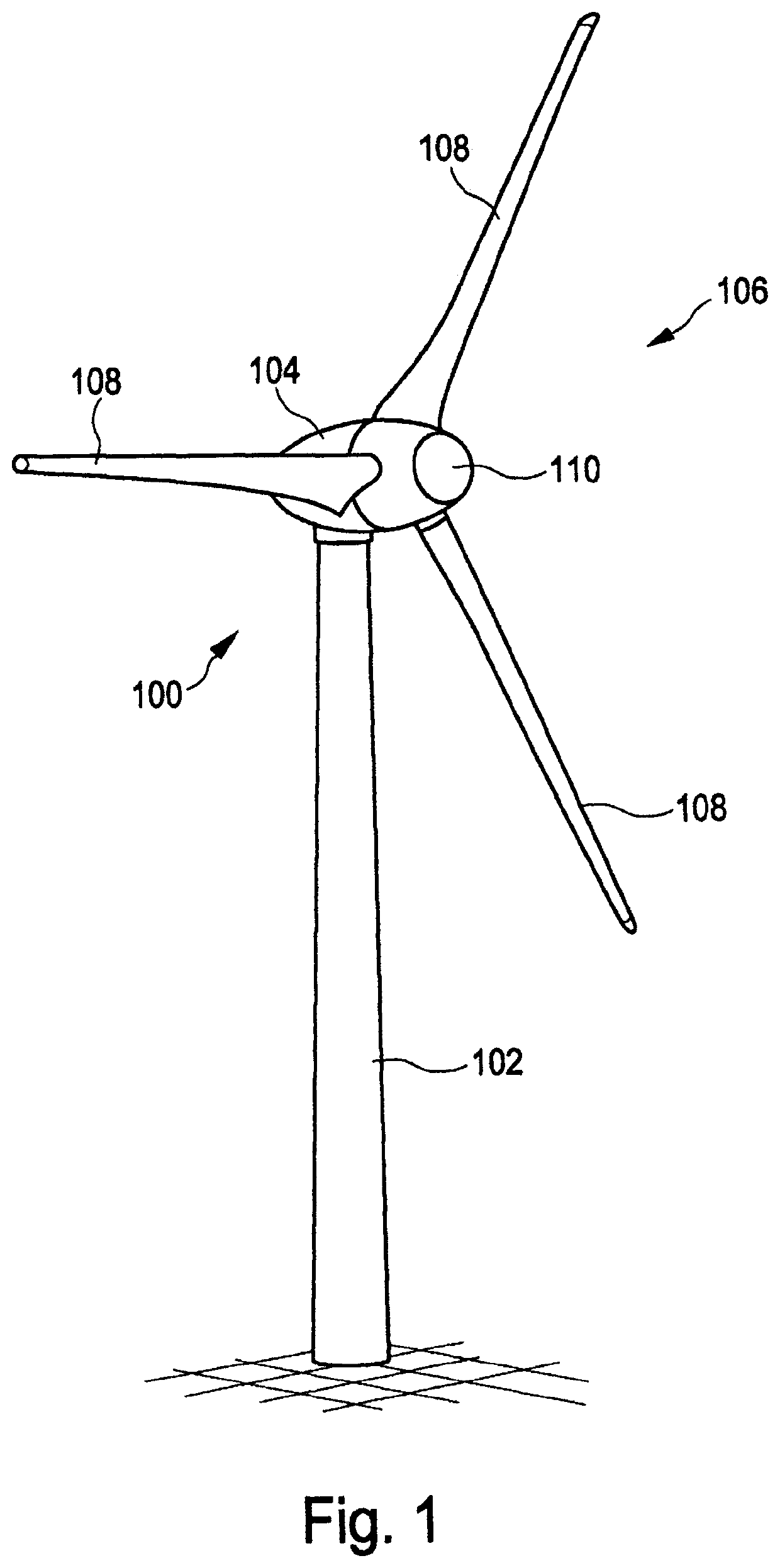

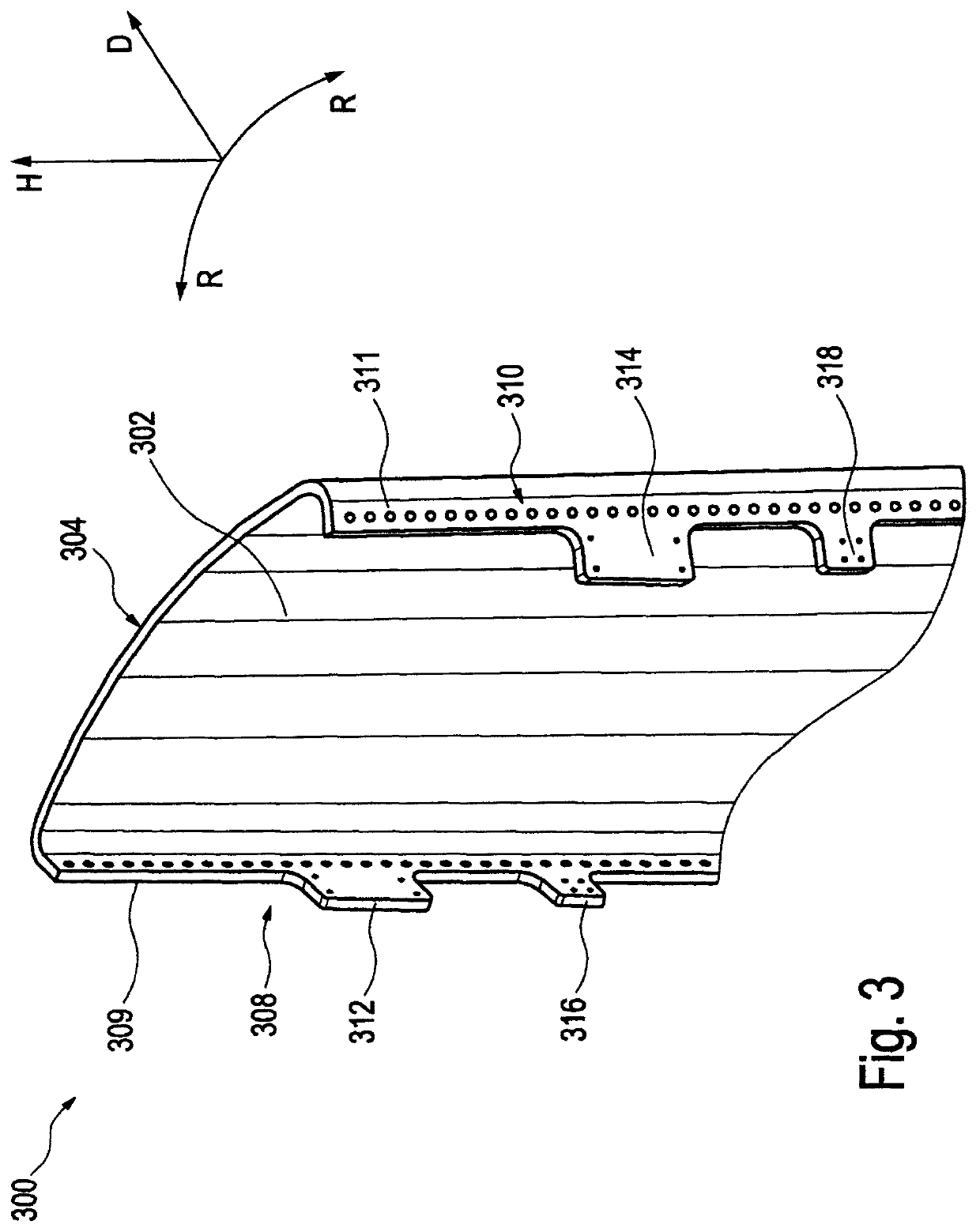

Wind turbine steel tower ring segment and method

ActiveUS11118371B2Low costAlleviate or eliminate one or more of the stated disadvantagesEngine manufactureWind motor assemblyFlat jointTurbine

A wind turbine steel tower ring segment, a wind turbine tower portion, a wind turbine tower, a wind turbine and a method for producing a wind turbine tower portion. A wind turbine steel tower ring segment for a wind turbine tower, comprising a shell segment with an extent in the direction of a segment height, of a segment ring direction and of a segment thickness and with a first horizontal joint side and a second horizontal joint side, a first vertical joint side and a second vertical joint side, wherein a first vertical flange is arranged at the first vertical joint side and / or a second vertical flange is arranged at the second vertical joint side, wherein the first vertical flange and / or the second vertical flange enclose(s) an angle with the shell segment, wherein at least one connection element for the arrangement of functional elements is formed on the first vertical flange and / or on the second vertical flange, wherein the connection element projects from the first vertical flange and / or the second vertical flange.

Owner:WOBBEN PROPERTIES GMBH

Servo drive mechanism of sewing machine

ActiveCN1804185AEasy to processSimple structureWork-feeding meansSewing-machine control devicesFlat jointGear drive

The servo drive mechanism for a flat joint machine comprises: a feed bar (1), a feed lifting cam (2), a pin shaft (3), a socket base (4), a feeding connecting rod (5), a feeding cam (6), a upper shaft (12) drove by a servo motor (11), a lower shaft in platform (18) drove by a rotary-shuttle servo motor (10), and feed lifting shaft drove by a feed lifting servo motor (9). This invention eliminates a bevel gear structure and an engagement gear structure to reduce assembly difficulty and cost.

Owner:JACK SEWING MASCH CO LTD

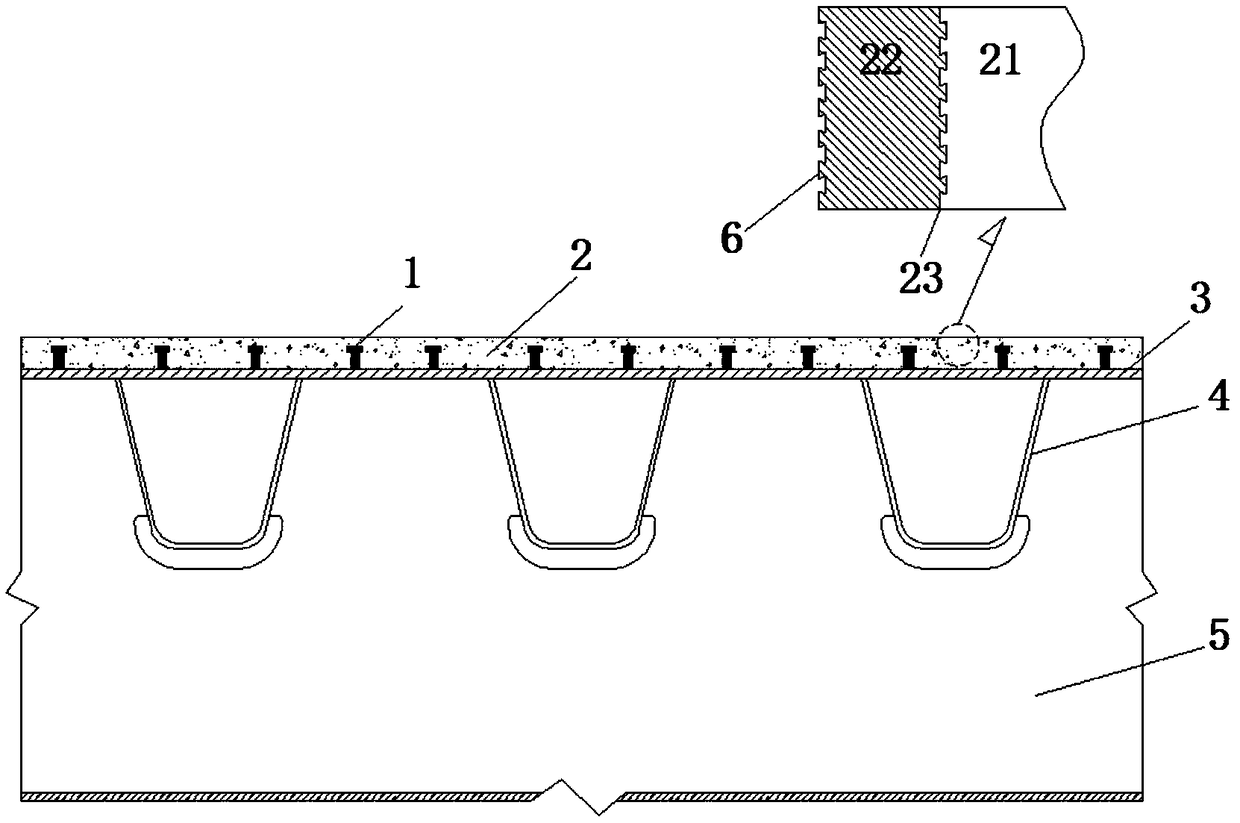

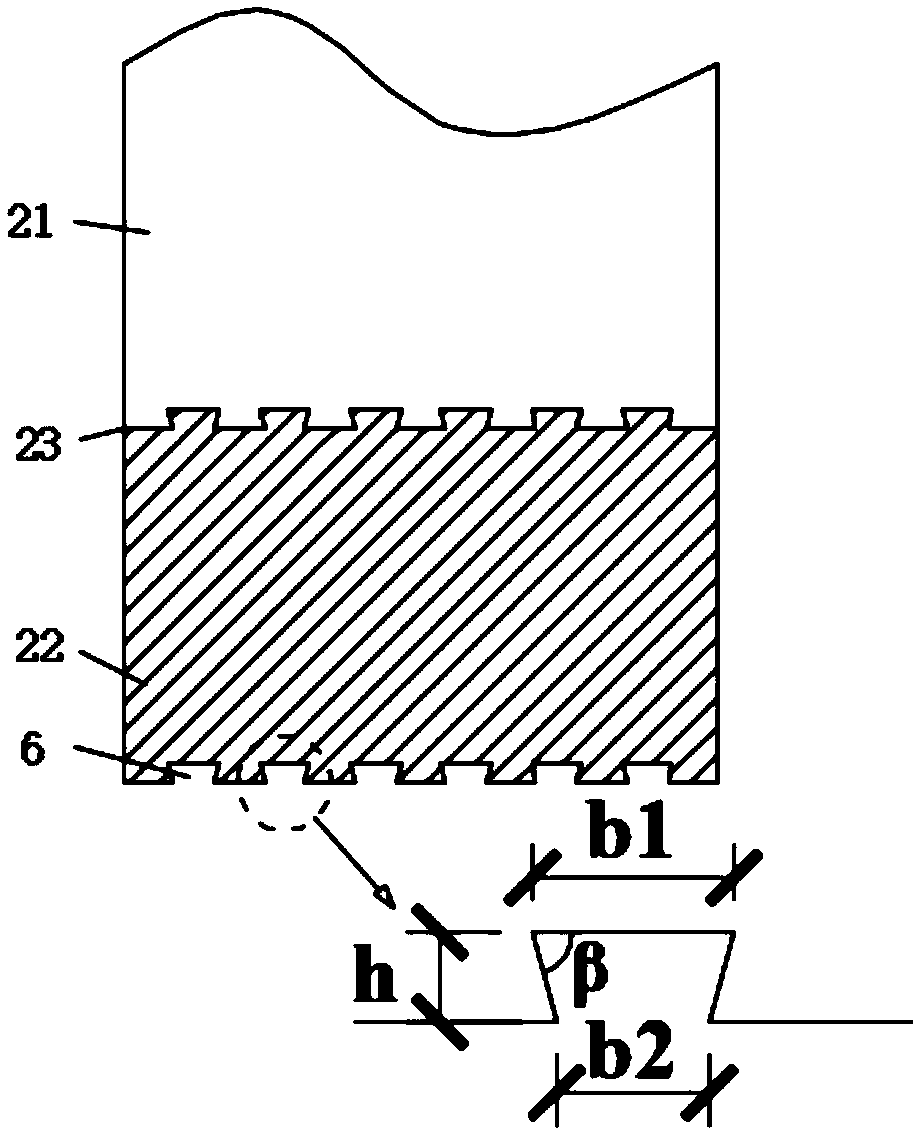

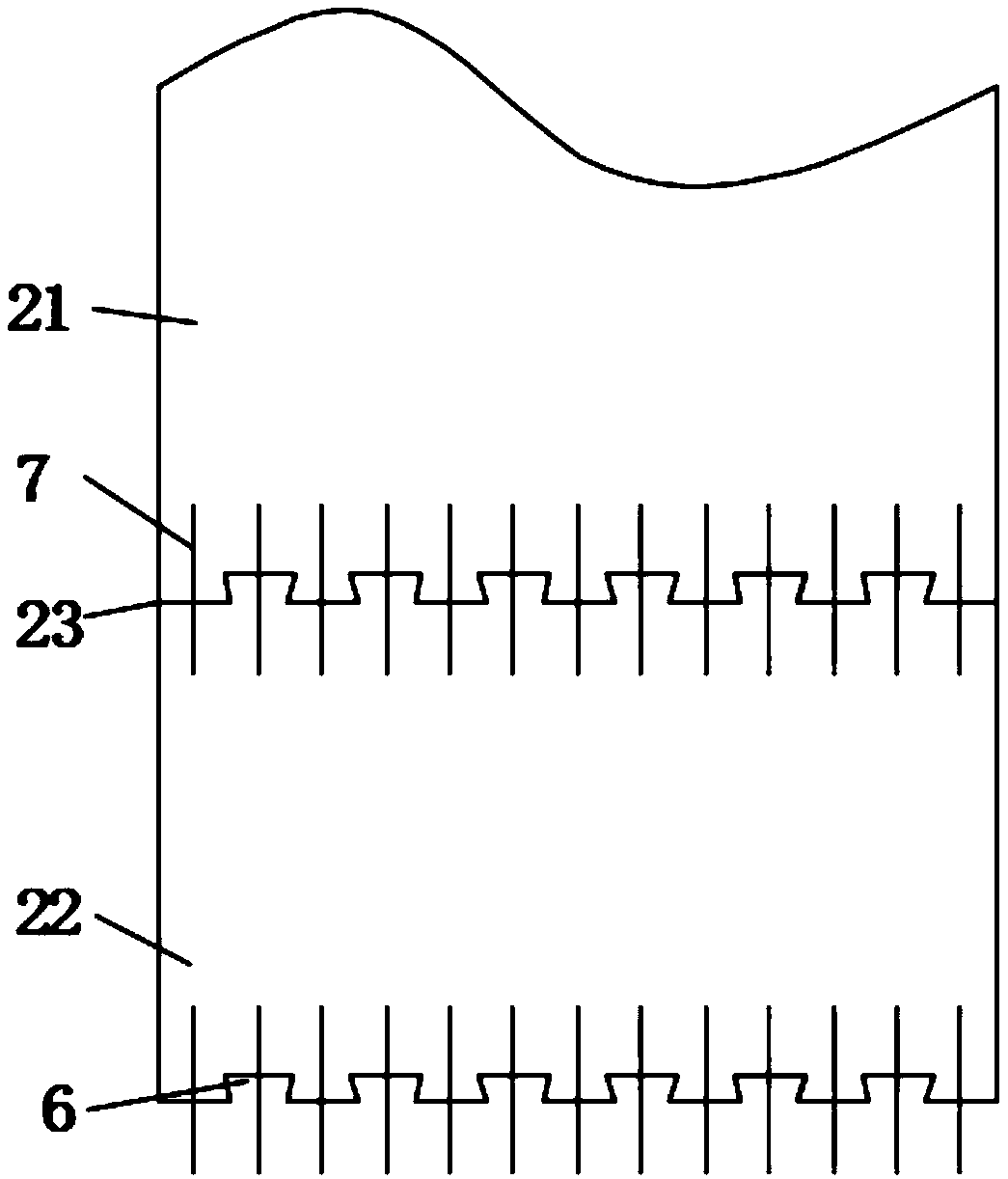

An unreinforced steel-UHPC composite bridge deck structure and a construction method thereof

PendingCN109208474ALow raw material costImprove carrying capacityBridge structural detailsBridge erection/assemblyFlat jointBridge deck

An unreinforced steel-UHPC composite deck structure comprises a UHPC bridge deck, an orthotropic steel bridge deck and a connecting bolt, and that main part of the UHPC bridge deck is not provided with stress reinforcement and structural reinforcement. When the UHPC bridge deck is cast in-situ in sections, the joint part adopts a keytooth bite joint or a flat joint with close reinforcement, and the keytooth bite joint is matched with a metal corrugated sleeve and a joint thread steel bar. The invention also discloses a construction method of the composite bridge deck structure. This steel-UHPCcomposite bridge deck structure is simple, which significantly reduces the raw material cost of composite bridge deck structure, reduces the construction human cost, and shortens the construction period, and the overall bearing capacity and fatigue resistance of bridge deck meet the stress requirements. the unreinforced steel-UHPC composite bridge deck structure is suitable for fatigue strengthening of orthotropic steel bridge deck and rigid deck paving of new steel bridge.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method of using and distributing a weather seal assembly for an overhead door

ActiveUS11391086B2Easy and less-expensive to shipConveniently providedWing accessoriesSealing arrangementsFlat jointWeather proofing

A knock-down seal assembly for an overhead-sectional door having horizontal joints between adjacent panels and a leading lateral edge that seals the lateral leading edge of the door as the door closes against the floor or traffic area. The seal assembly includes a pair of retainer rails which do not exceed about 6 feet in overall length. Each of the retainer rails has seal channels formed so as to extend from a bottom surface thereof for receiving a flexible weather seal strip. Each of the rails also has an extension channel formed so as to extend from the bottom surface thereof for receiving an elongate retainer clip. The retainer clip can be used to join the pair of retainer rails to form a single rail.

Owner:NAT DOOR INDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com