Patents

Literature

62results about How to "Refine the weld grain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slag-free flux-cored wire

ActiveCN101780609AIncrease the combinationImprove toughnessWelding/cutting media/materialsSoldering mediaSlagFerrosilicon

The invention provides a novel process for a formula of a slag-free flux-cored wire, and relates to a welding material. The manufacturing method adds the combination of molybdenum powder, nickel powder and rare earth silicon to a formula of raw materials, eliminates mineral powder in a common formula, and optimizes the proportion of various types of metal powder in the formula. According to the formula, the welding material comprises the following components: 4 to 8 parts of micro carbon ferrochromium, 12 to 18 parts of low carbon ferromanganese, 56 to 67 parts of iron powder, 2 to 6 parts of molybdenum powder, 0.1 to 0.4 part of ferroboron, 2 to 5 parts of rare earth silicon, 1 to 3 parts of ferrosilicon, 2 to 3 parts of ferrotitanium, 2 to 3 parts of sodium fluoride, 3 to 7 parts of ferroaluminum, 1 to 3 parts of aluminum to magnesium powder and 4 to 8 parts of nickel powder. The invention improves the toughness, strength and anti-fatigue performance of welding seams and thins welding-seam grains by adding the combination of molybdenum powder, nickel powder and rare earth silicon into the raw materials of the formula, eliminating the mineral powder in the common formula, and optimizing the proportion of various types of metal powder in the formula. Meanwhile, slagging on the surfaces of the welding seams is avoided, and welding efficiency is raised by 20 percent compared with slag-type processes.

Owner:山东聚力焊接材料有限公司

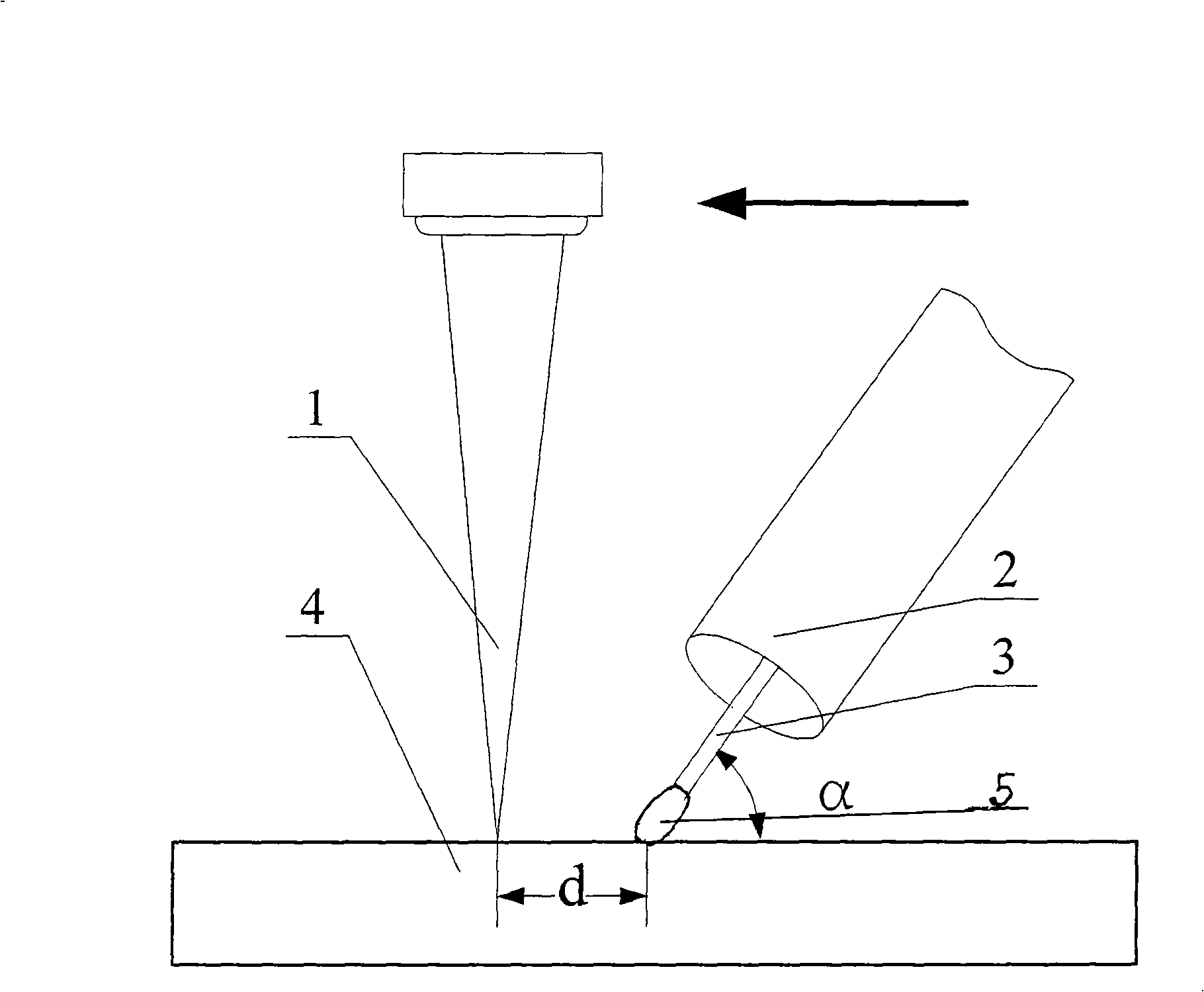

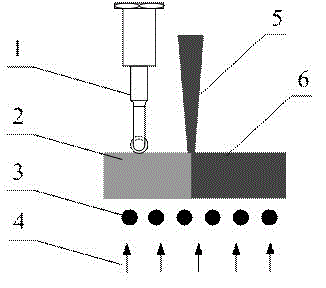

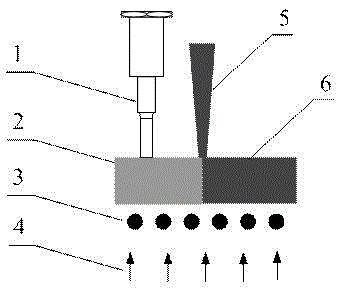

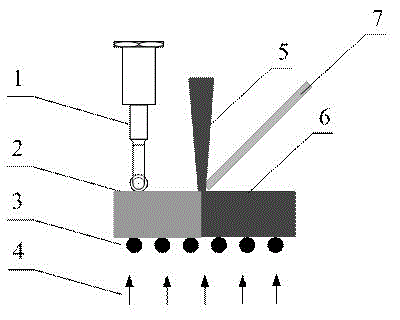

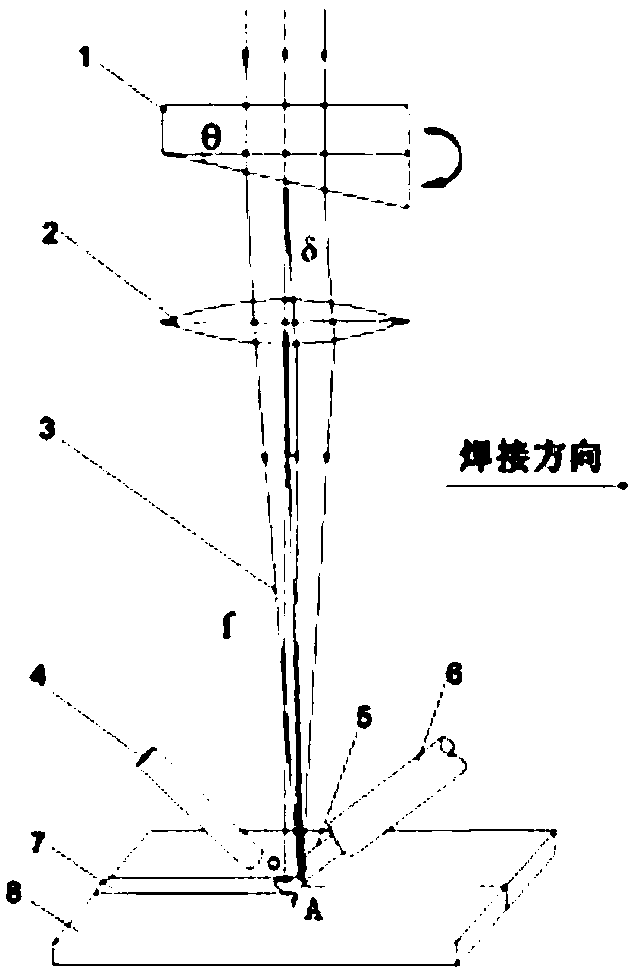

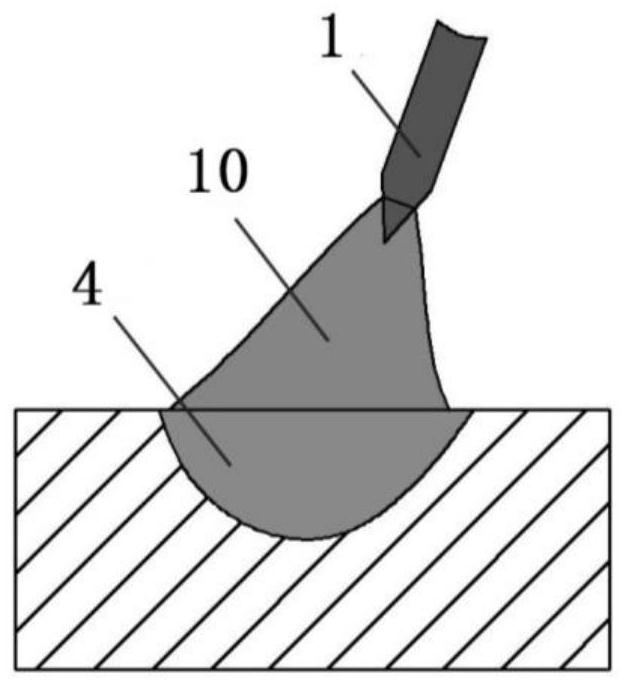

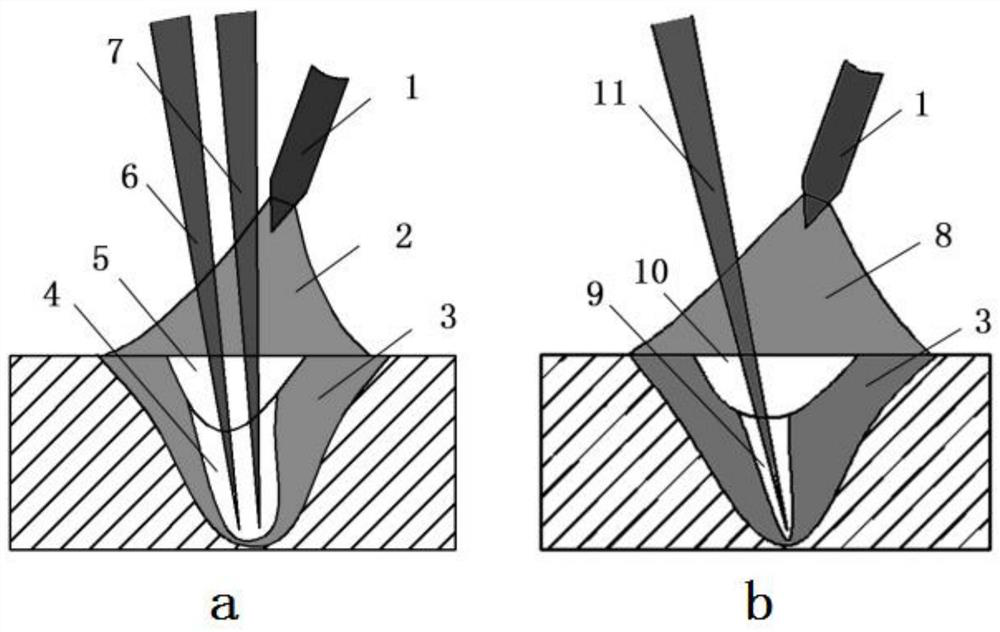

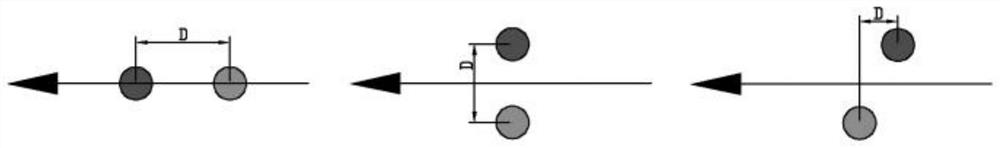

Laser-ultrasmall current GMA compound heat power supply welding method

InactiveCN101347870ASmall amount of deformationImprove mechanical propertiesLaser beam welding apparatusAverage currentLaser beams

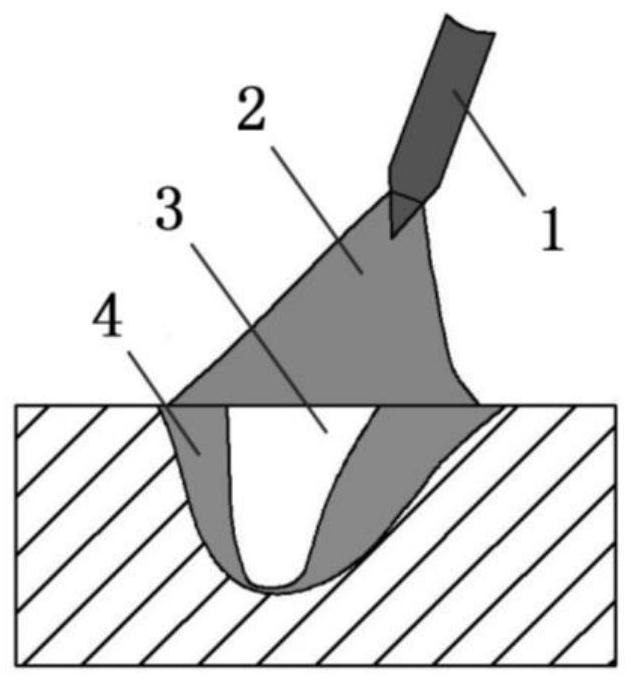

The invention discloses a welding method of a laser-ultra-small current GMA composite heat source; the welding method can solve the technical problem of large deformation when a metal thin plate is welded; the invention mainly comprises the following steps; in composite heat source welding, the adopted average current of a GMA arc (5) is 15A to 30A; when the steel material is welded, the power of the laser (1) is more than 800W, and when the aluminium alloy is welded, the power of the laser (1) is more than 1,600W; a laser beam (1) is at the front and the GMA arc is at the back; and the distance of chevilled silk is 0mm to 3mm and the two molten pools are connected together. The welding method is applicable to the welding of thin metal plates with the thickness to be 0.5mm to 4mm such as aluminium alloy, carbon steel, low alloy and more than two dissimilar metals.

Owner:HARBIN WELDING INST LTD

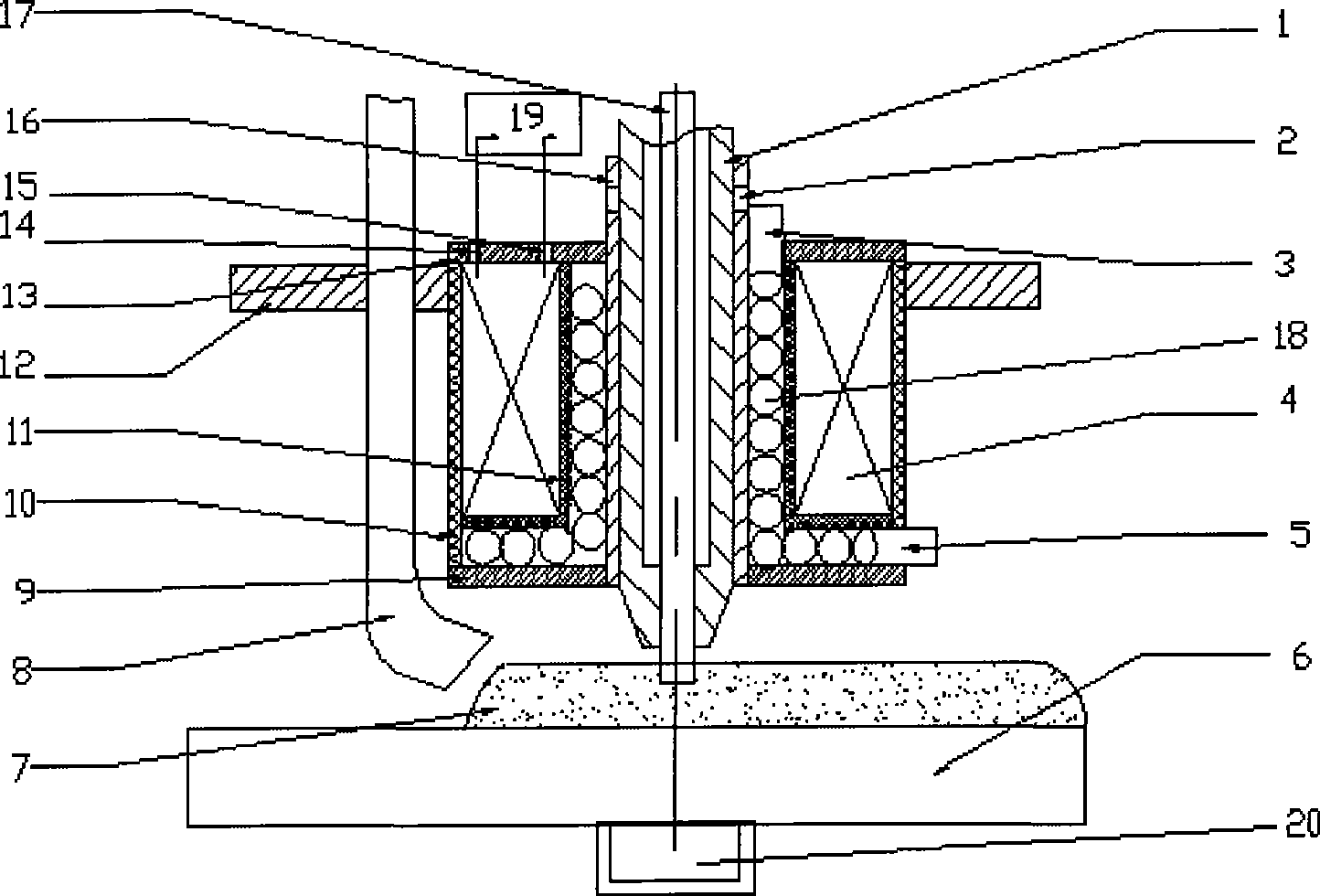

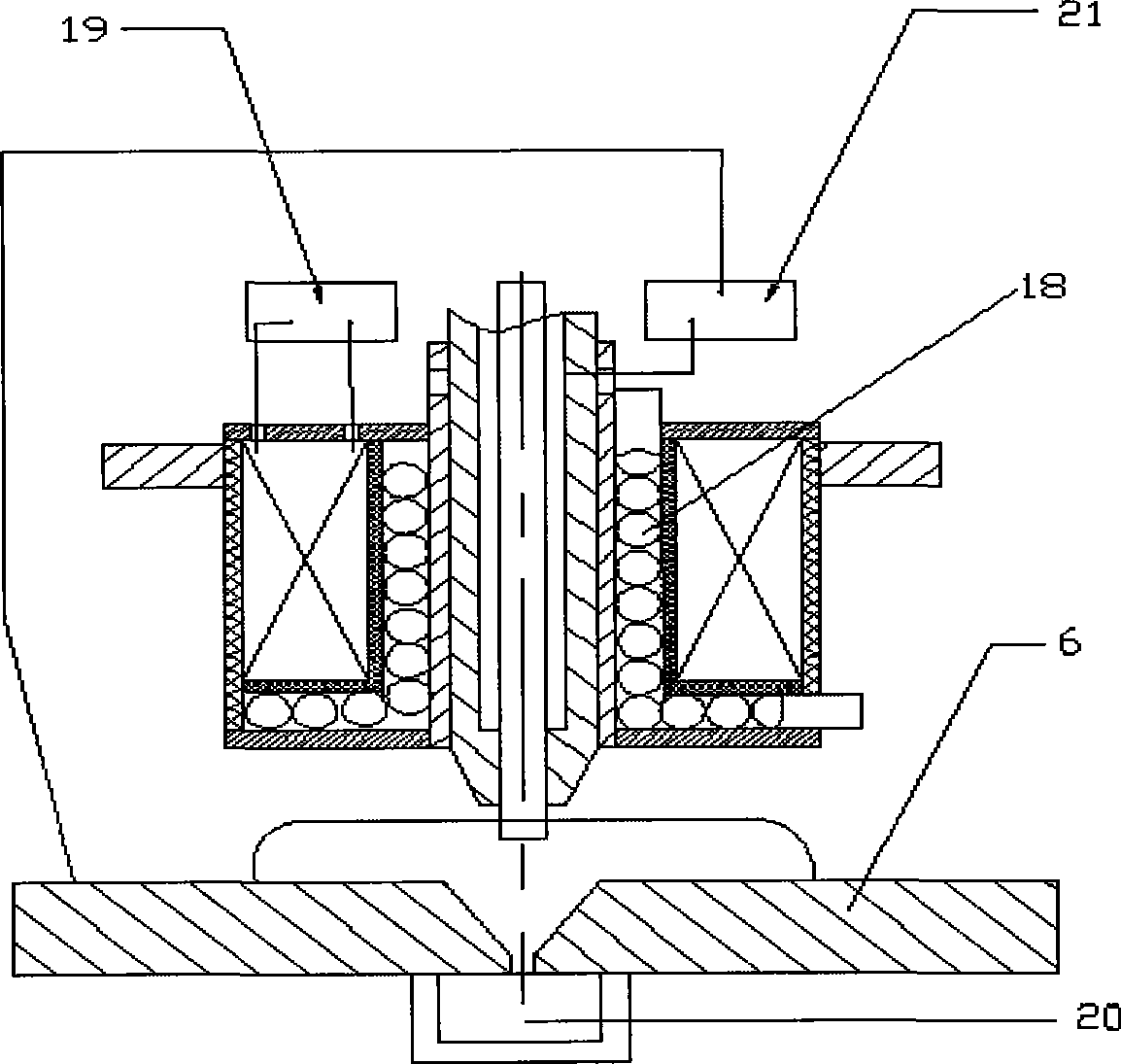

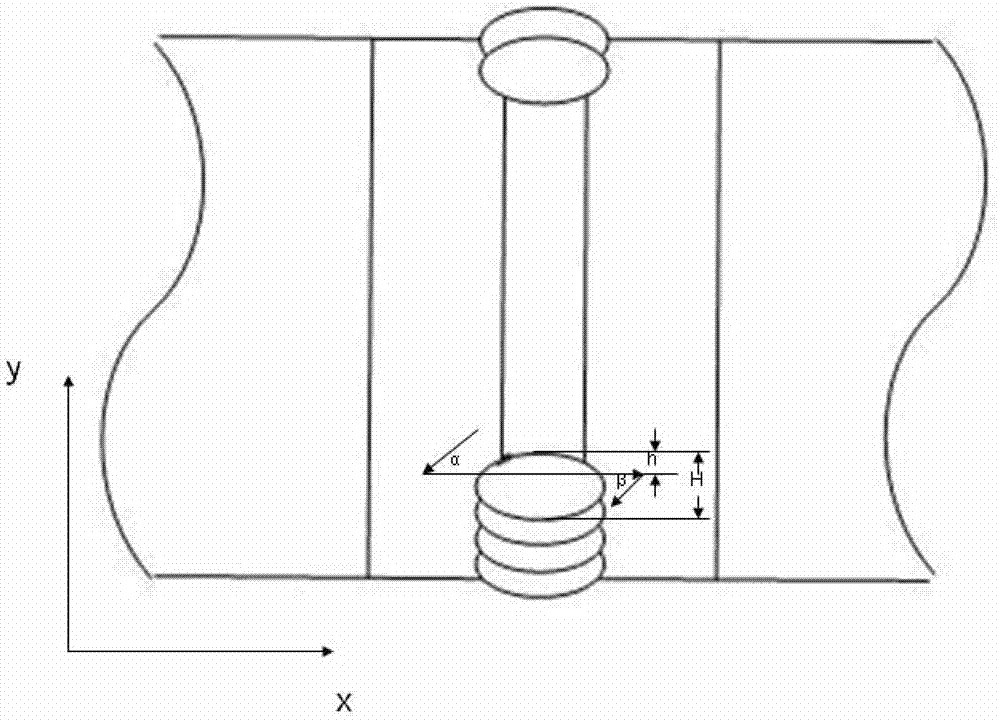

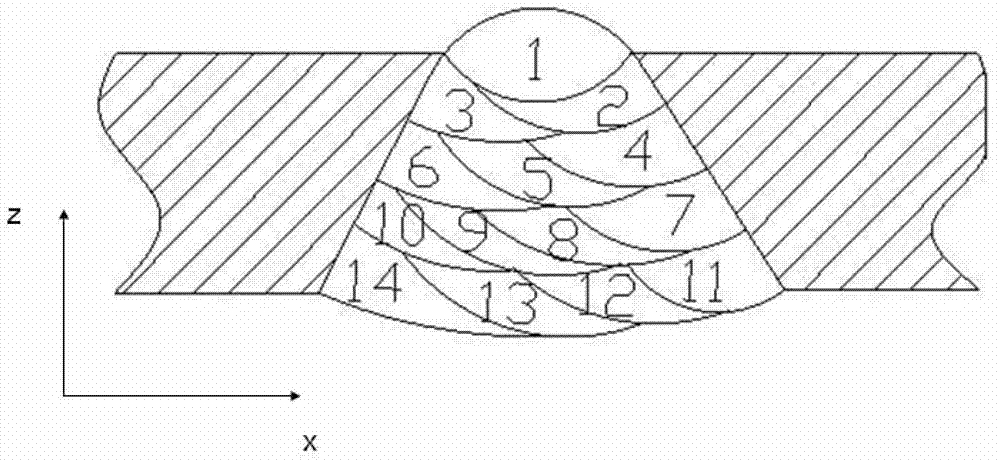

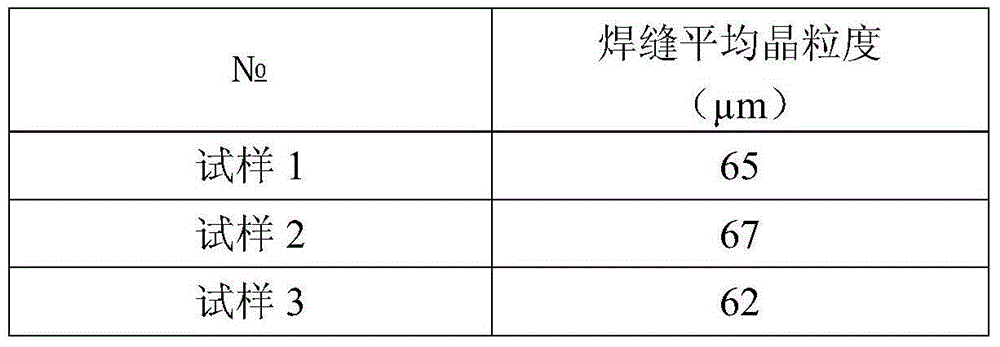

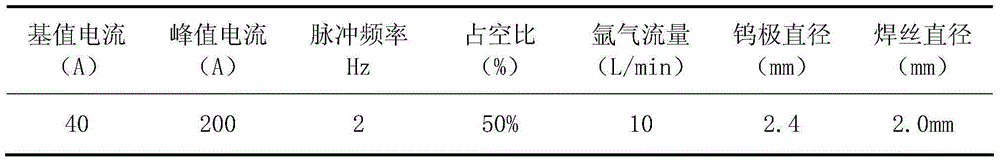

Method and equipment for electromagnetic composite double-face submerged arc welding of diphase stainless steel thick plate

InactiveCN101462196AImprove crystallizationReduce sensitivityArc welding apparatusChemical industryWelding power supply

The invention discloses a method for welding a dual-phase stainless steel and a device thereof. The method comprises: dual-side surfacing of heavy current submerged arc is controlled by an electromagnetic-composite field of the dual phase stainless steel of heavy plates without a grooveb; excitation current is provided by an excitation power supply to generate an additional longitudinal electromagnetic field; and a submerged arc welding process of the dual-phase stainless steel of the heavy plates without the groove is comprehensively controlled and realized by the electromagnetic field. The welding device is provided with the excitation power supply, a welding power supply, an excitation welding device, a device of an auxiliary electric field and a water cooling system. The excitation device consists of excitation coils, is fixed on a welding torch, and generates the additional longitudinal electromagnetic field which is coaxial with the welding torch, and the water cooling system is arranged in a bracket of the excitation coils. The device can realize the submerged arc welding of the dual-phase stainless steel of the heavy plates without the groove, with high efficiency, high quality and low cost through the electromagnetic-complex submerged arc welding; meanwhile, the device can be used for welding the dual-phase stainless steel of the heavy plates in industries, such as shipbuilding, chemical industry and so on.

Owner:CHONGQING UNIV

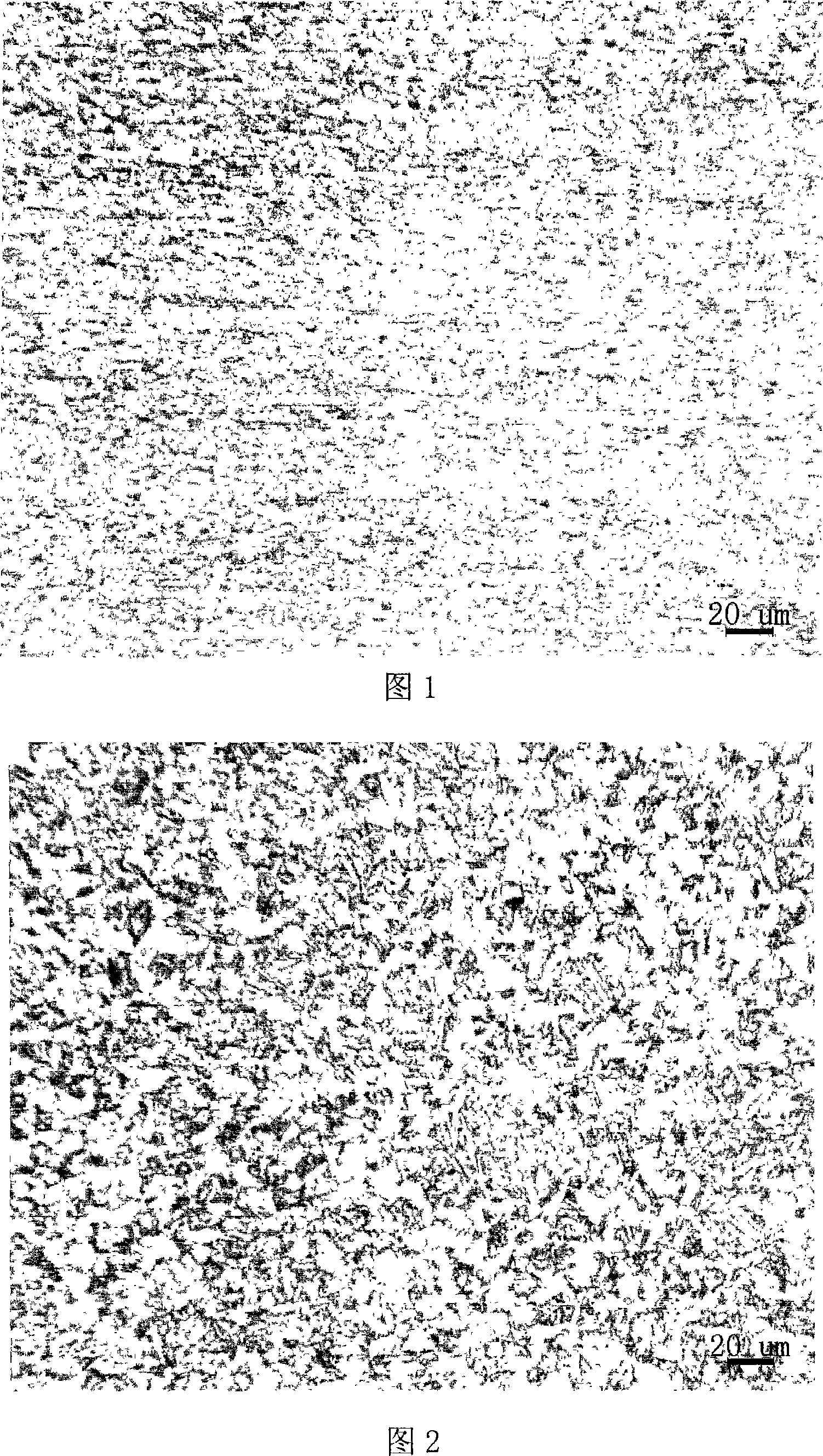

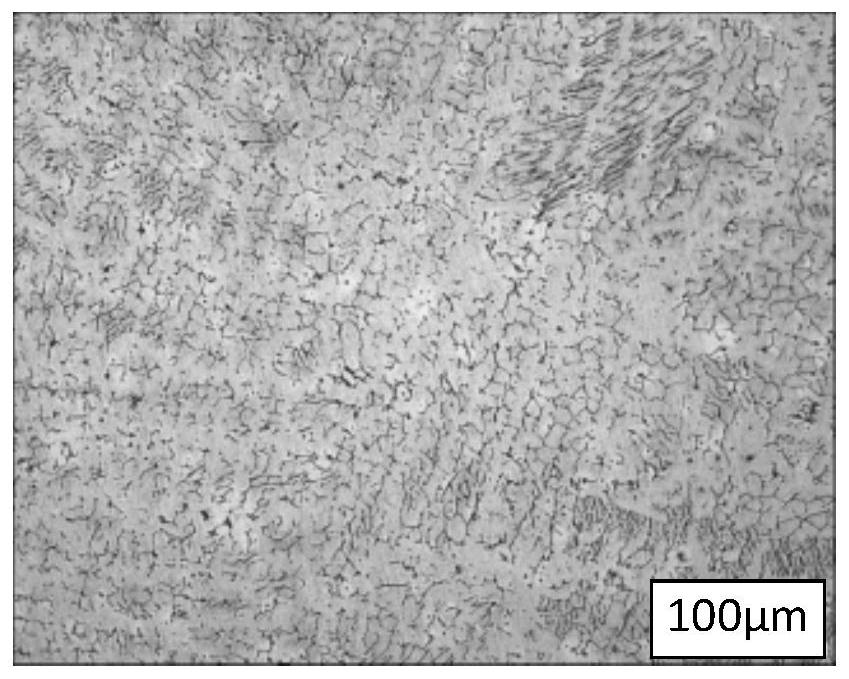

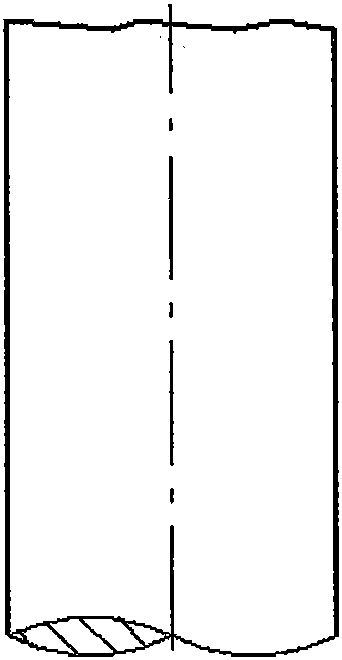

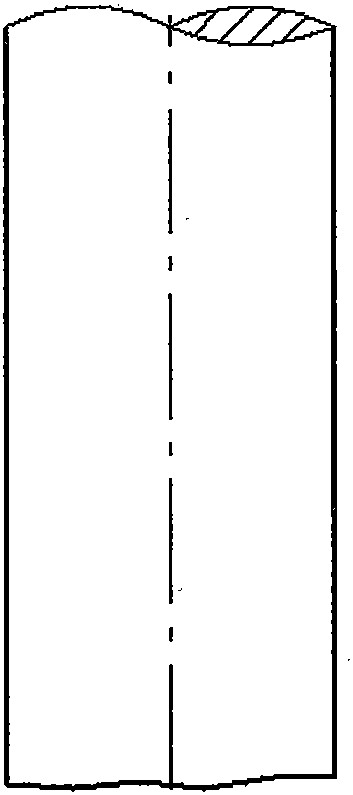

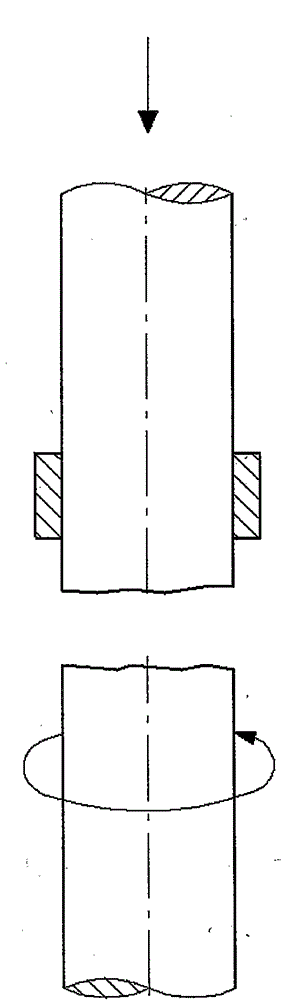

Deformation heat treatment method for modifying welding seam tissue capability

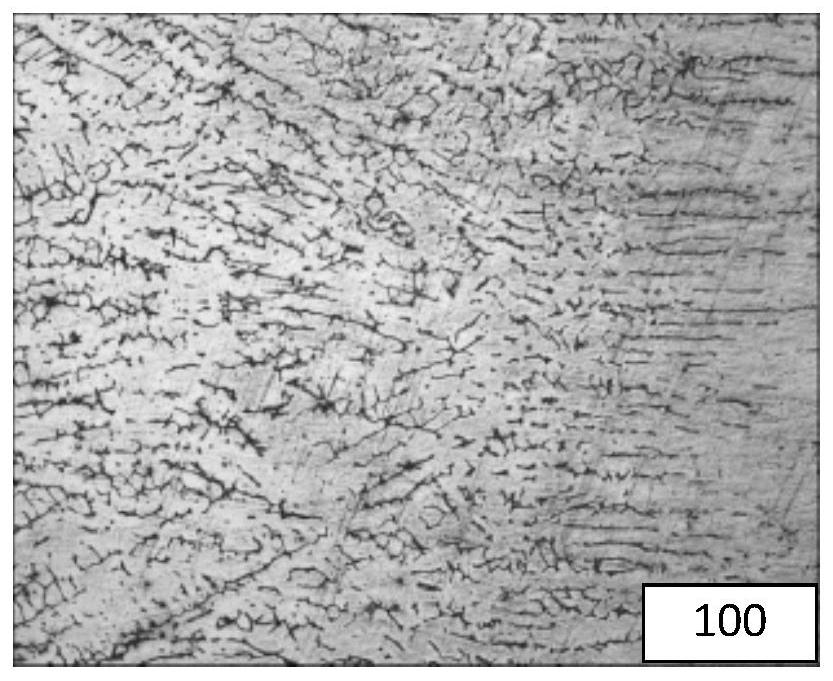

InactiveCN101215625AImprove performanceRefine the weld grainFurnace typesHeat treatment process controlButt jointPhase inversion

A thermo-mechanical treatment process can change welding seam structure property, which comprises heating up welding seam fast and evenly over phase inversion temperature through adopting medium-frequency induction heating way, rolling the welding seam rapidly under the temperature, refining butt-jointed seam grain under the effects of rolling force and temperature, thereby improving welding seam property, and reaching the basic uniform with base metal. The invention refines welding seam grain through heating and rolling welding seam according to certain technique conditions, eliminates residual stress of welding seam, increases ductibility and toughness of welding seam, and improves structure property of welding seam, thereby welding seam grain size number is improved to about 12 grades from the original zero grade which is approximate with the base metal, and welding seam obtains basic uniformed structure and mechanics property with the base metal.

Owner:BAOJI PETROLEUM STEEL PIPE

Manual arc welding bottoming layer Z-shaped arc extinction method and application thereof in Q460 high-strength steel horizontally-fixed steel pipe butt welding

ActiveCN102922085AFusion wellNo accumulationArc welding apparatusTubular articlesShielded metal arc weldingButt welding

The invention discloses a manual arc welding bottoming layer Z-shaped arc extinction method and application of the manual arc welding bottoming layer Z-shaped arc extinction method in Q460 high-strength steel horizontally-fixed steel pipe butt welding. An arcing point is located at a position of a root part of a groove 2 to 3mm close to a truncated edge, an electric arc is lightly led to an oblique rear part of a fusing tank along the groove after being struck and then transversely swung to the other side of the groove after a pause, act extinction is carried out towards the oblique rear part of an arcing point after fusing of the groove at the side is good through observation, and a running track of an end of a welding rod is Z-shaped. As the fusing tank can be well observed in a welding process, welding defects of a bottoming layer can be reduced and technical support is provided to ensure welding quality of the bottoming layer of a butt joint. With the adoption of the arc extinction method, shaping of the root part of a welding seam can be effectively controlled and a good welding seam structure can be obtained.

Owner:CHINA ENERGY ENG GRP TIANJIN ELECTRIC POWER CONSTR CO LTD

Double-physical-field-assisted single-face laminated metal composite plate manufacturing method

InactiveCN104438323AEffectively breakReduce pollutionMetal rolling arrangementsSide effectPhysical field

The invention provides a double-physical-field-assisted single-face laminated metal composite plate manufacturing method. The method includes the following steps that the surface of a base metal plate is cleaned through an acid pickling method, grease, stains and oxidation films are removed, and drying is conducted; the base metal plate is preheated under the atmospheric conditions or nitrogen or argon protection condition, the preheating temperature ranges from 150 DEG C to 1700 DEG C; rolling is conducted on the base metal plate or a base metal plate of preset low-melting-point filling materials through an inner-cooling type water cooling roller, meanwhile, ultrasonic waves and magnetic fields are applied continuously till a single-face laminated metal composite plate is manufactured. The double-physical-field-assisted single-face laminated metal composite plate manufacturing method has the advantages that the ultrasonic waves and the magnetic fields are applied, control over the interface reaction and intensifying of mass transfer process are facilitated, a composite welding seam for intensifying intermetallic compound particles is obtained, welding seam grain is refined, residual stress is lowered, the oxidation films are broken effectively, consumption of brazing flux is lowered or avoided, the toxic and side effect on staff and adverse effects on combined interfaces are reduced, energy saving is facilitated, and the environmental pollution is lowered.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Multi-physical-field auxiliary dissimilar metal material welding method

InactiveCN104400237AConducive to complete integrationImprove mechanical propertiesWelding/soldering/cutting articlesWelding apparatusArgon atmospherePhysical field

A multi-physical-field auxiliary dissimilar metal material welding method comprises the following steps of (1) removing dirt on to-be-welded surfaces of two different metal materials, cleaning and preheating after drying; (2) heating through an external heating source under the atmospheric environment, or nitrogen or argon atmosphere to enable a base metal or filling materials at a joint position to be melted into liquid metal, meanwhile applying double physical fields of ultrasonic waves and a magnetic field and obtaining a composite welding seam after the liquid metal at the joint position is cooled and solidified; (3) obtaining a particle reinforced welding seam after the liquid metal at the welding seam is solidified and cooled to be in the indoor temperature. The multi-physical-field auxiliary dissimilar metal material welding method has the advantages of effectively controlling interface reaction and intensifying flowing of the liquid metal by applying the ultrasonic waves and the magnetic field, obtaining the composite welding seam with intermetallic compound particles being enhanced, being beneficial to integral combination of a welded joint, improving mechanical property of the welded joint, refining welding seam crystal particles, reducing residual stress, reducing toxic and side effects to persons and harmful effects to an aluminum steel bonding interface from brazing flux and being beneficial to environmental protection.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

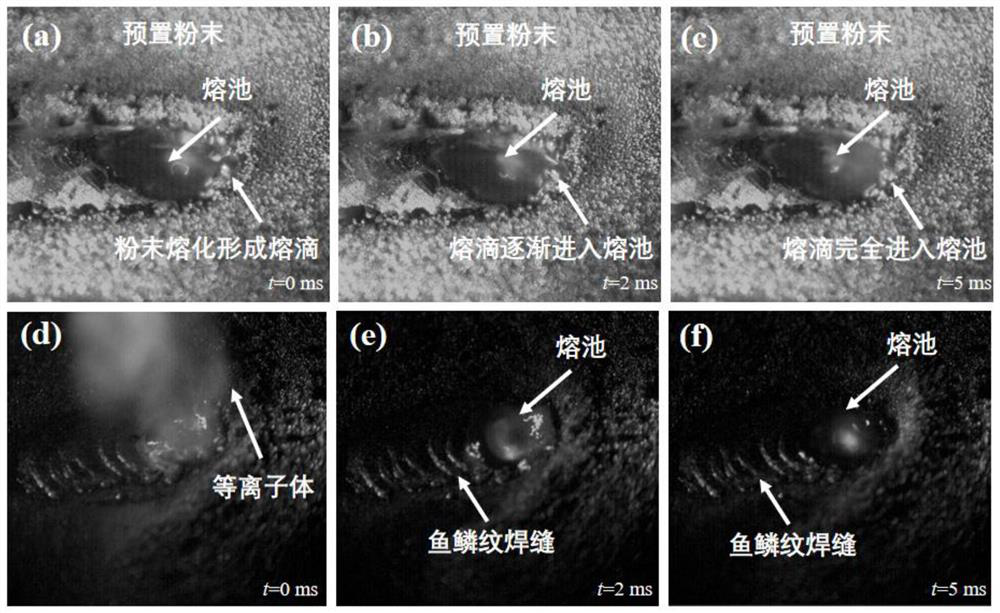

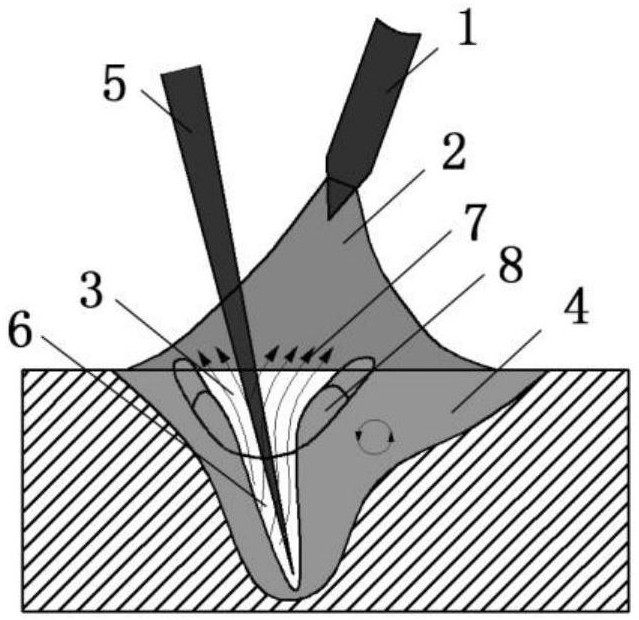

High-frequency laser pulse method applied to dissimilar metal composite heat source welding

ActiveCN112518109ASmooth appearanceRefine the weld grainLaser beam welding apparatusStress concentrationFlat joint

The invention discloses a high-frequency laser pulse method applied to dissimilar metal composite heat source welding. Through high-frequency pulse laser beam intervention, disturbance force in a molten pool can be increased, the Marangoni convection effect is enhanced, heat and mass transfer in the molten pool is accelerated, and uniform distribution of elements in the molten pool is achieved; aweld joint is shaped by directly or indirectly intervening a weld seam pool through a high-frequency pulse laser beam, weld seam grains can be refined, and a flat joint morphology which is symmetrically distributed along the center line of a weld seam is obtained; deformation maladjustment caused by difference of thermophysical performance parameters of dissimilar metal materials can be made up, so that the effect of intervening weldments in different time scales and space scales is achieved, and the reliability of dissimilar metal weld seam joints is improved; and the phenomenon of stress concentration induced by asymmetric distribution of pore and microcrack defects can be effectively prevented, and then the comprehensive mechanical property of the dissimilar metal weld seam joints is improved.

Owner:WUHAN UNIV

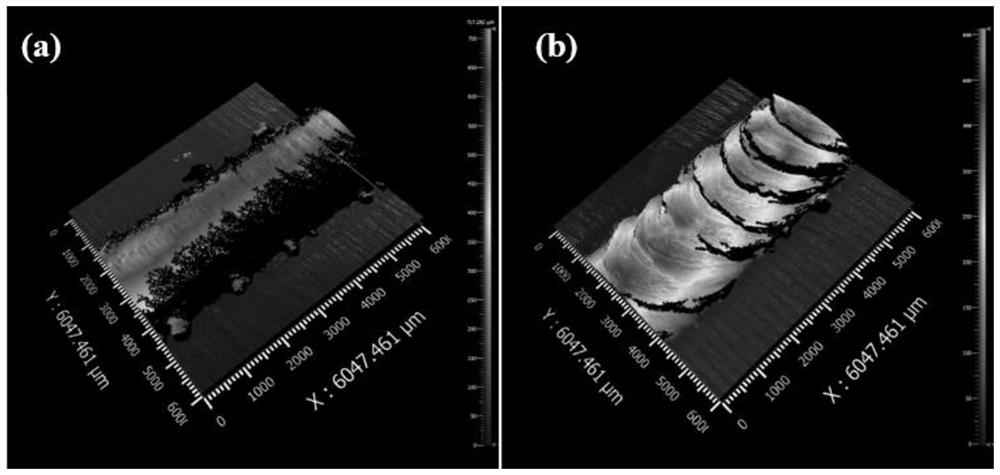

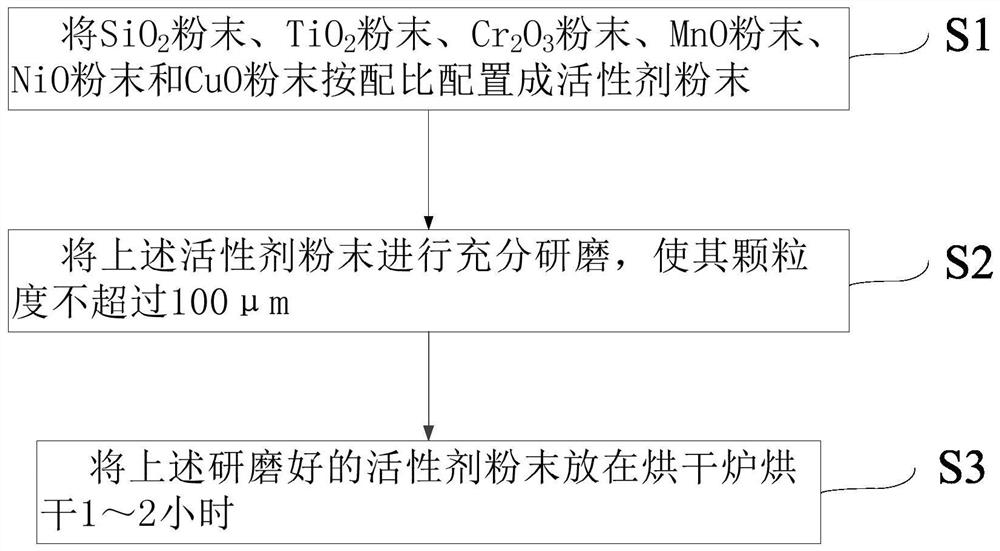

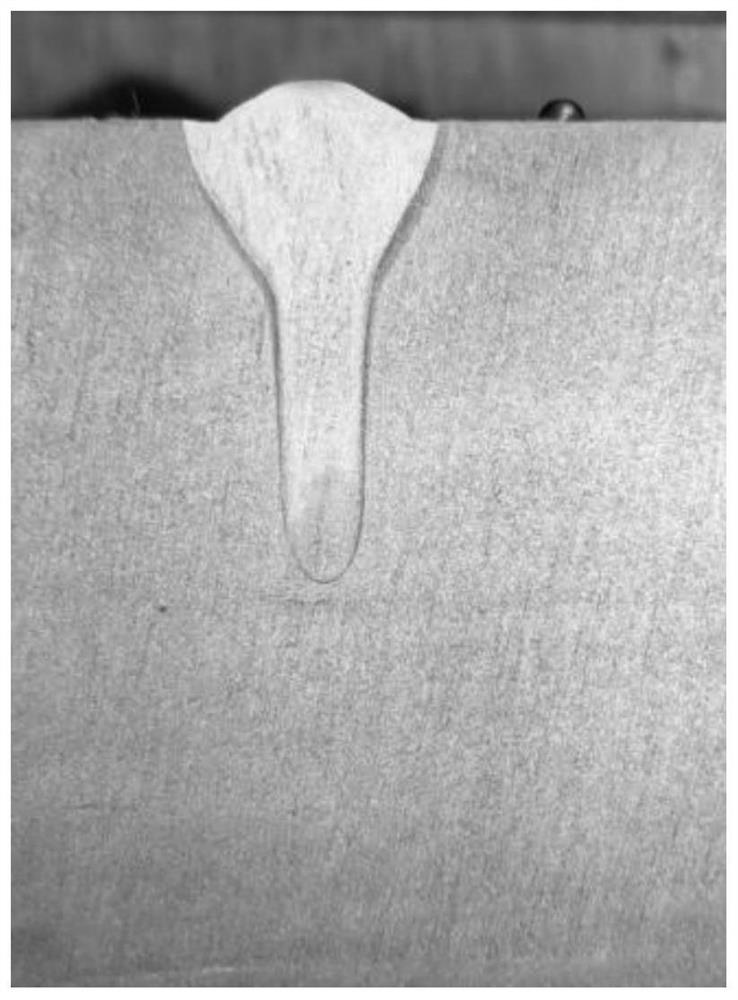

Stainless steel argon tungsten-arc welding active agent and preparation method and application thereof

InactiveCN111604618AQuality improvementLow costArc welding apparatusWelding/cutting media/materialsActive agentSS - Stainless steel

The invention belongs to the field of active agents for welding, and particularly relates to a stainless steel argon tungsten-arc welding active agent and a preparation method and application thereof.The stainless steel argon tungsten-arc welding active agent is prepared from the following components in percentage by weight: 35-45% of SiO2 powder, 20-25% TiO2 powder, 8-12% of Cr2O3 powder, 5-10%of MnO powder, 5-10% of NiO powder and 10-15% of CuO powder. The stainless steel argon tungsten-arc welding active agent does not contain precious metal, is low in cost, is non-poisonous and environmentally friendly, compared with methods such as general argon tungsten-arc welding, and the efficient active agent performs A-TIG welding on stainless steel and has the advantages of deep weld penetration, high production efficiency and reliable quality. The active agent is coated on the surface to be welded, the weld penetration is increased, the welding joint mechanical performance is obviously improved at the same parameter, 13mm welding by one side and molding by two sides can be realized, expensive welding equipment is not required, and good economic benefits and wide application prospectsare achieved.

Owner:JIUJIANG HAITIAN EQUIP MFG CO LTD

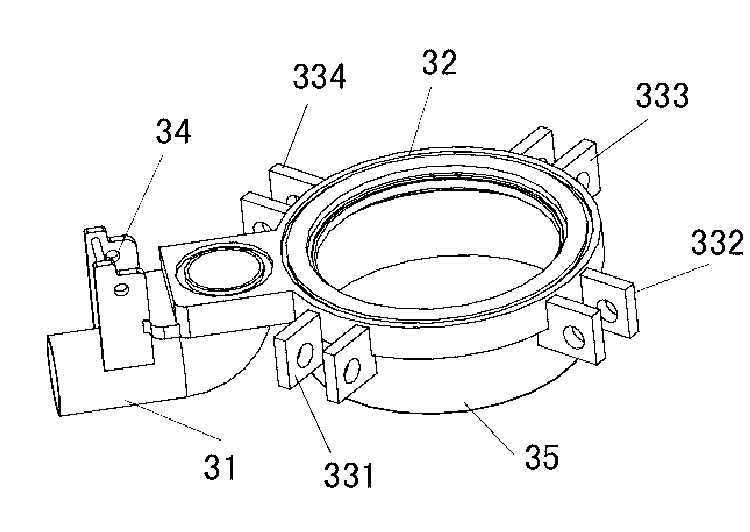

Ultrasonic arc laminating and rolling thin-wall steel tube welding device and welding method

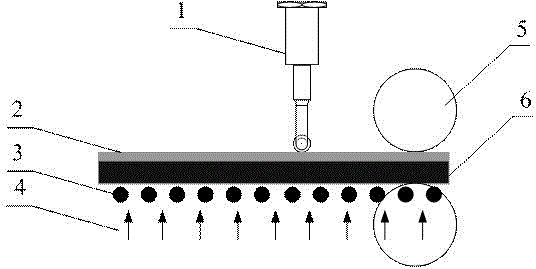

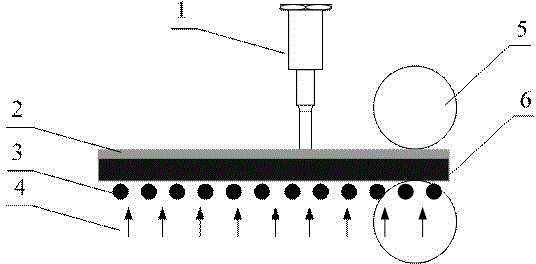

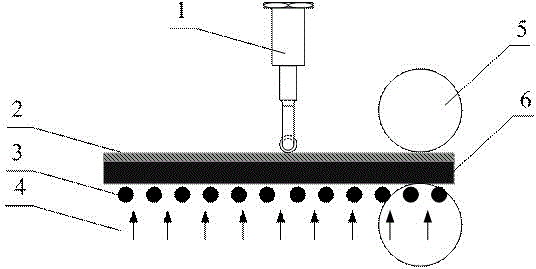

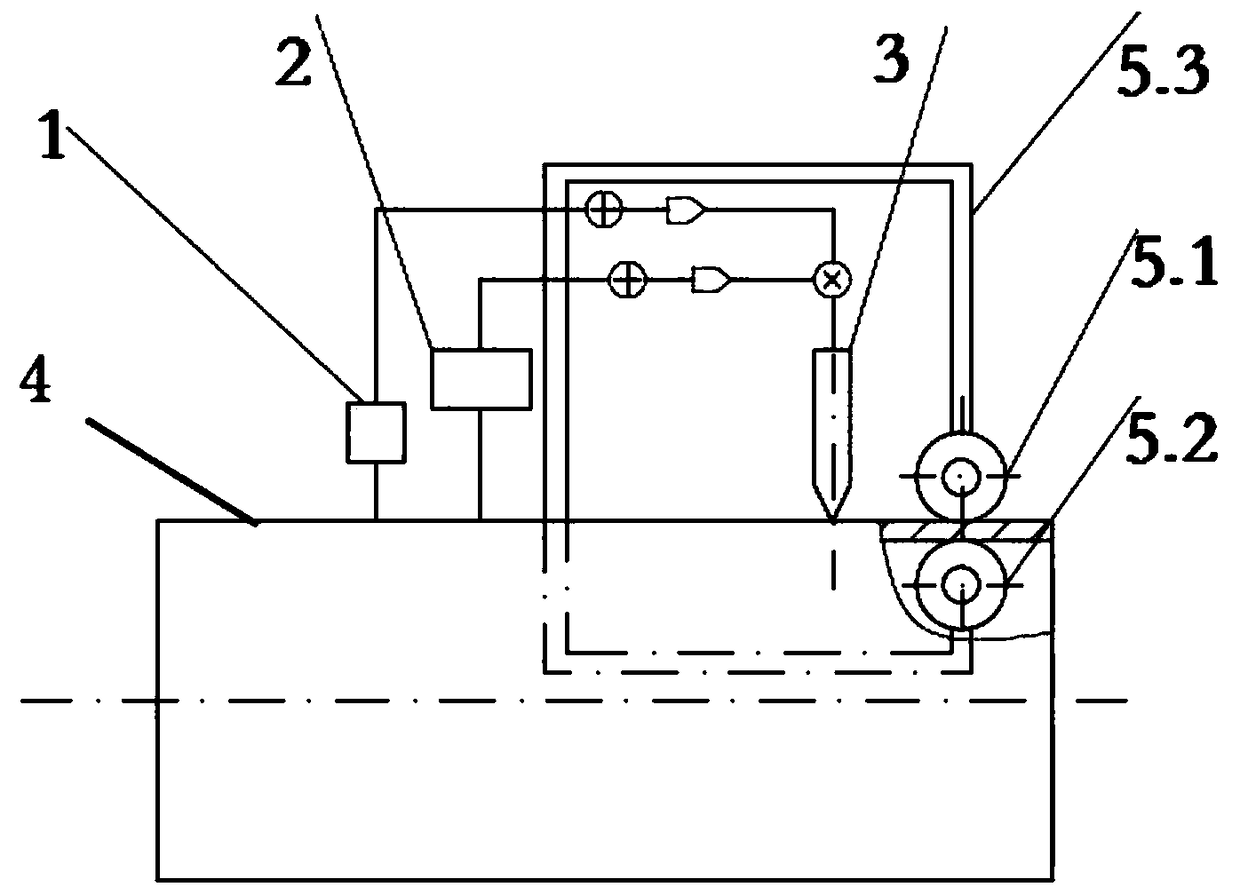

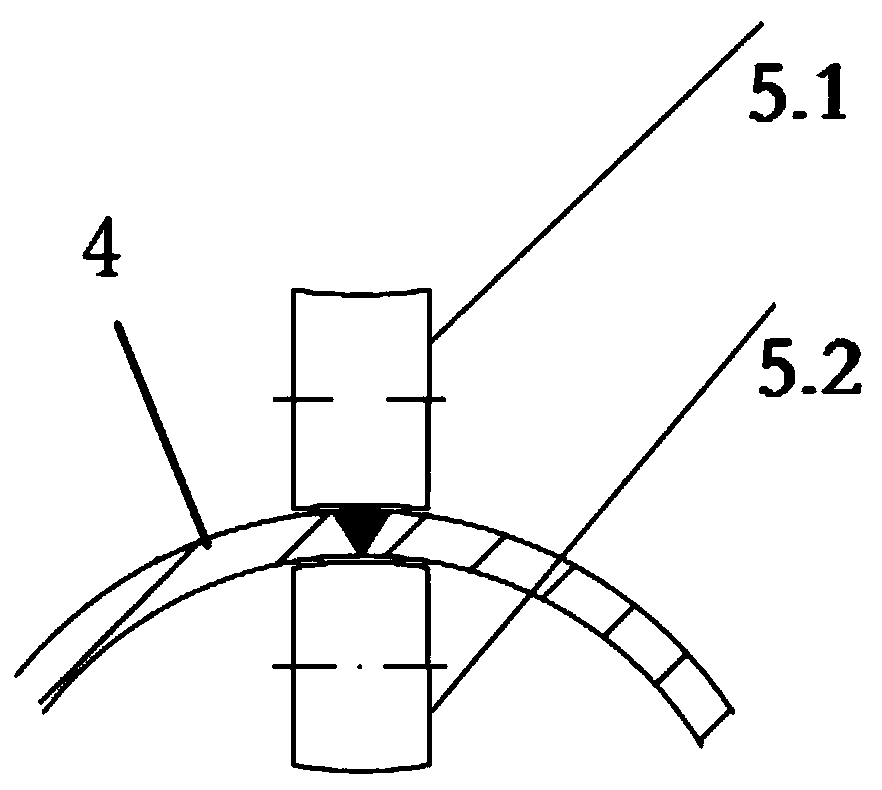

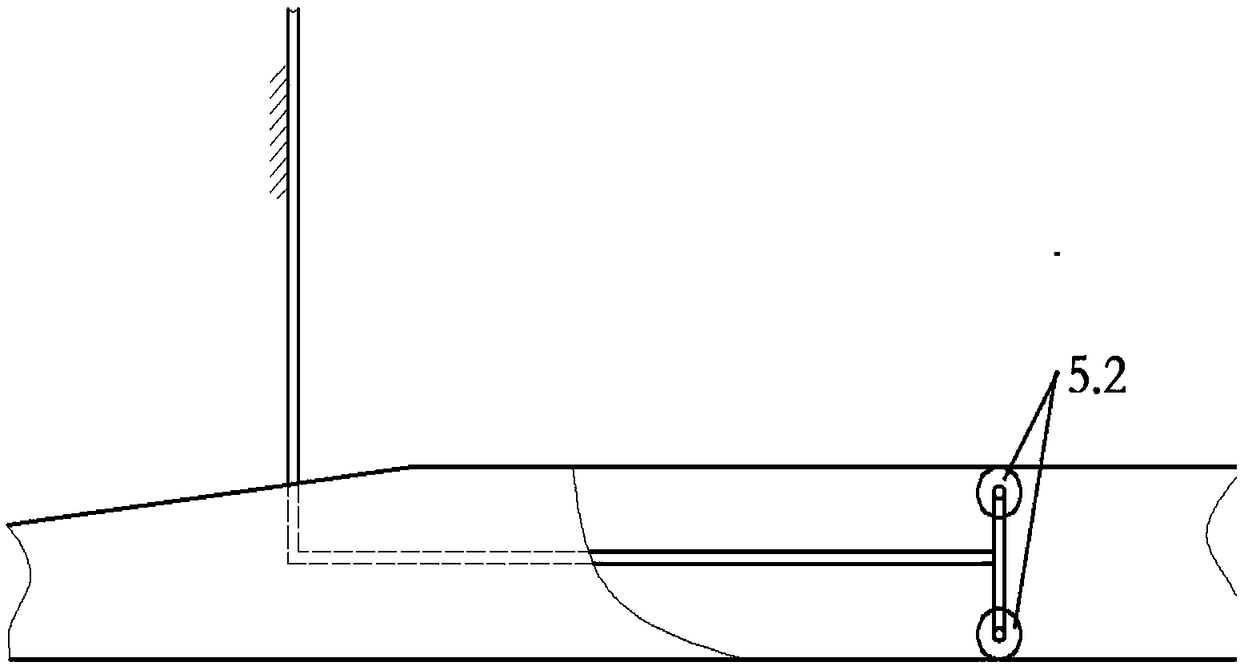

ActiveCN108817622AReduce residual stressRefine the weld grainTubular articlesWelding accessoriesSteel tubeCrystallite

The invention belongs to the field of welding processes and discloses an ultrasonic arc laminating and rolling thin-wall steel tube welding device and welding method. The device comprises an ultrasonic arc generating device and a rolling and laminating device. An upper rolling and laminating wheel (5.1) is laminated to the outer wall surface of the thin-walled steel tube with zero clearance, and the radian curvature of the upper rolling and laminating wheel (5.1) is matched with the diameter of the outer side of the thin-walled steel tube; a lower rolling and laminating wheel (5.2) is laminated to the inner wall surface of the thin-walled steel tube with zero clearance, and the radian curvature of the lower rolling and laminating wheel (5.2) is matched with the diameter of the inner side of the thin-walled steel tube; and the upper rolling and laminating wheel (5.1) and the lower rolling and laminating wheel (5.2) correspond in position. The ultrasonic arc generating device introducesultrasonic arcs into a weld pool. The upper and lower rolling and laminating wheels are laminated to the steel tube in a rolling manner without zero clearance, so that grains of a weld joint of the steel tube are refined, the ductility of the weld joint is improved, and the tearing tendency in a follow-up drawing process is reduced.

Owner:NANJING INST OF TECH

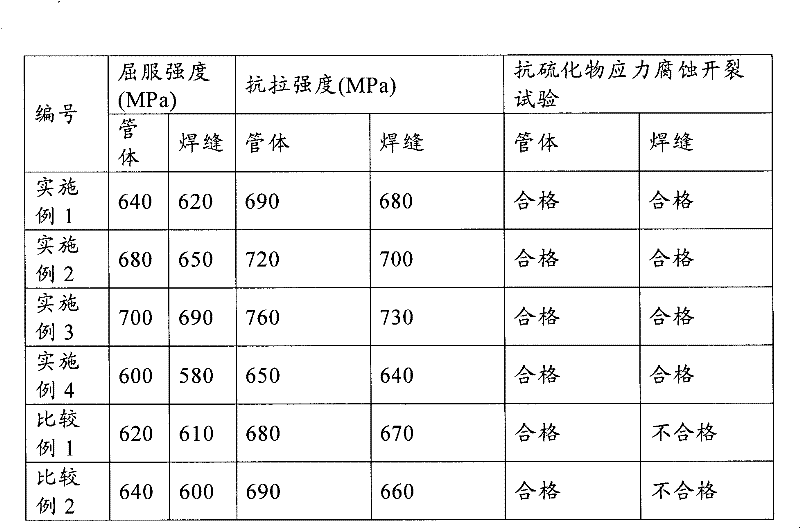

Steel for high-frequency resistance welding oil casing and its manufacturing method

ActiveCN102296233AIncrease productivityRefine the weld grainFurnace typesHeat treatment furnacesPetroleumGas protection

The invention relates to steel for a high-frequency electric resistance welding petroleum casing pipe used under a hydrogen sulfide environment. The steel comprises the following components in percentage by mass: 0.15 to 0.35 percent of C, 0.1 to 0.6 percent of Si, 0.3 to 1 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.003 percent of S, 0.1 to 0.5 percent of Mo, 0.03 to 0.2 percent of V, 0.01 to 0.05 percent of Nb, 0.01 to 0.05 percent of Ti, 0.01 to 0.08 percent of Al, 0.0005 to 0.005 percent of Ca, 0.001 to 0.003 percent of B, and the balance of Fe and inevitable impurities; and the carbon equivalent is less than or equal to 0.43. The provided steel for the petroleum casing pipe can be used for manufacturing the high-frequency electric resistance welding petroleum casing pipe of 80ksi steel level with good sulfide stress corrosion cracking resistance and can be applied to a CO2 gas protection welding process, and the subsequent production efficiency of the high-frequency electric resistance welding petroleum casing pipe is improved.

Owner:BAOSHAN IRON & STEEL CO LTD

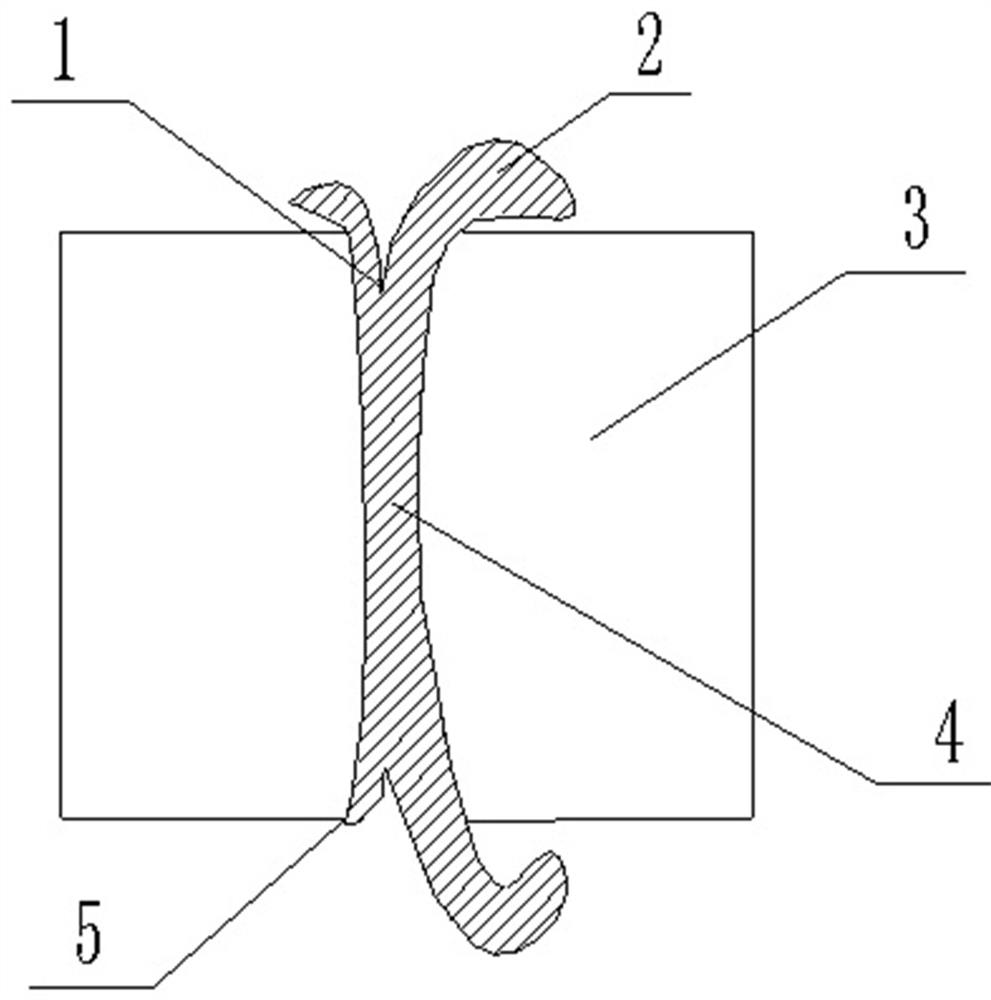

Sewage pump motor shaft friction welding method

InactiveCN104999174AIncrease productivityImprove pass rateNon-electric welding apparatusFriction weldingThree level

The invention discloses a sewage pump motor shaft friction welding method. Round steel 0Cr18Ni9Ti and round steel 42CrMo are sawn into sections through a sawing machine and the round steel 0Cr18Ni9Ti (1) is clamped in a rotation clamp of a friction welding machine; the outer circle of the round steel 42CrMo (2) is provided with a restraining sleeve (3), and the round steel 42CrMo is clamped in a moving clamp of the friction welding machine; the rotating speed is 1,110 rpm, the starting friction pressure ranges from 80 MPa to 90 MPa, friction welding is carried out for 1.2 seconds to 2.0 seconds, and the progressing speed is 1.5 mm / s; the rotating speed is 1,450 rpm, the progressing speed is 3.5 mm / s, the two-level friction pressure ranges from 160 MPa to 180 MPa, and the friction welding is carried out for 5 seconds to 7 seconds; the rotating speed is 1,300 rpm, the progressing speed is 3.5 mm / s, the three-level friction pressure ranges from 100 MPa to 120 MPa, and brake is started after friction welding is carried out for 7 seconds to 8 seconds; and at the same time, upsetting pressure of 240 MPa to 270 MPa is exerted, and the upsetting pressure is kept for 6 seconds to 8 seconds.

Owner:SHAANXI UNIV OF TECH

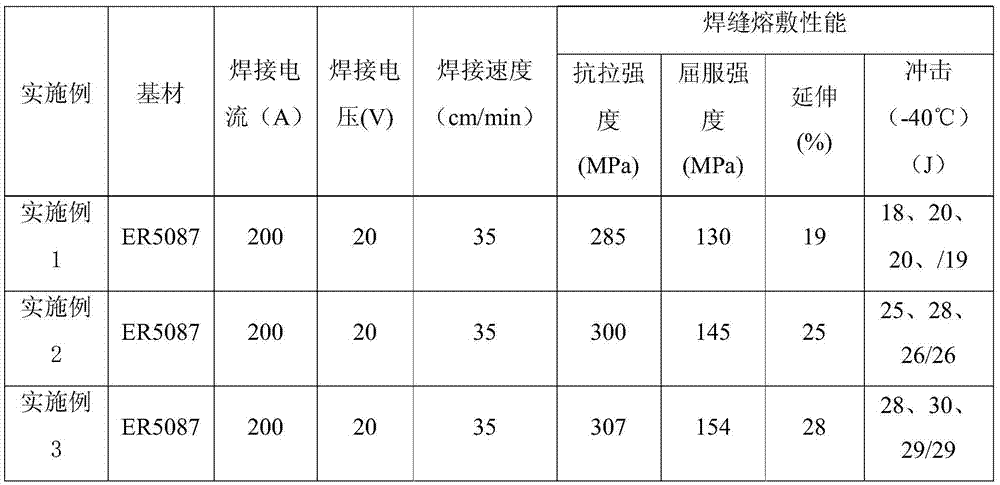

Aluminum-copper alloy grounding material welding wire and preparation method thereof

ActiveCN106862796AReduce compositional differencesGood resistance to soil corrosionWelding/cutting media/materialsSoldering mediaPotential differenceRare earth

The invention discloses an aluminum-copper alloy grounding material welding wire and a preparation method thereof. The aluminum-copper alloy grounding material welding wire comprises, by mass, 1%-3% of silicon, 1%-3% of copper, 0-0.3% of iron, 0.001%-0.05% of zirconium, 0.001%-0.5% of rare earth, and the balance aluminum. The aluminum-copper alloy grounding material welding wire can achieve welding of an aluminum-copper alloy grounding material, the structure of a weld zone is fine, the components are similar to those of parent metal, the potential difference is small, and the soil corrosion resistance is good.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

Plating aluminium welding wire for carbon dioxide arc welding and preparation method thereof

InactiveCN101633084AImprove rust resistanceReduce splashWelding/cutting media/materialsSoldering mediaTitaniumTitanium alloy

The invention discloses a plating aluminium welding wire for a carbon dioxide arc welding and a preparation method thereof; a magnesium titanium alloy layer is plated on the surface of the welding wire by a hot-dipping method. As the surface plating layer of the prepared welding wire contains metal elements such as aluminium, magnesium, titanium and the like, the welding wire can reduce splash and increases the welding quality in the premise of ensuring the electrical conductivity; in the preparation method, the hot-dipping method is adopted for cladding material and can avoid the pollution brought by about the traditional coppering technique.

Owner:TIANJIN UNIV

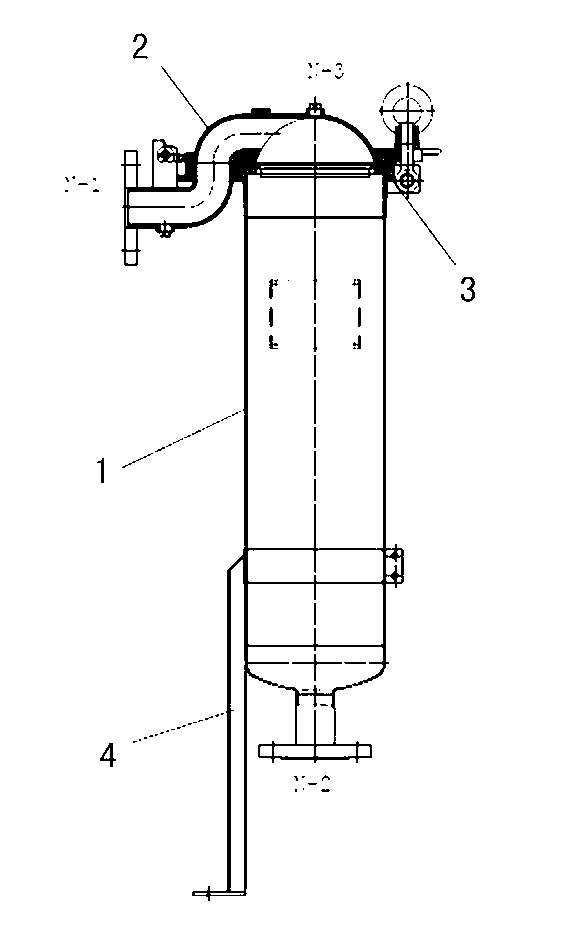

High-corrosion resistance aluminum alloy filter and process thereof

InactiveCN103230703AIncrease productivityStrong penetrating powerFiltration separationSilicon alloyFlange

The invention relates to a high-corrosion resistance aluminum alloy filter and a process thereof. The filter is used for seawater desalination in environments like a ship and an offshore drilling platform. The high-corrosion resistance aluminum alloy filter comprises a shell composed by a barrel and a top cover, wherein the top cover is an aluminum-magnesium-silicon alloy cast part and at least comprises an upper liquid inlet branch pipe, a round head and bolt pressing plates uniformly distributed around the round head, the barrel is a series-5 aluminum-magnesium alloy barrel, a barrel flange is arranged at an interconnecting part of the barrel and the top cover, the barrel flange is a low pressure precision cast part and is provided with a lower liquid inlet branch pipe, the circumference of the flange is provided with bolt fixing plates arranged relative to the bolt pressing plates, an O-shaped ring recess is arranged on a contact surface of the barrel flange and the top cover, the lower liquid inlet branch pipe is in butt joint with the upper liquid inlet branch pipe, the bolt pressing plates are in fixed connection with the bolt fixing plates. The invention also relates to a process for the high-corrosion resistance aluminum alloy filter. According to the invention, the filter provided by the invention can be used in a seawater corrosion environment, and production efficiency is improved by 2 to 3 times.

Owner:SHANGHAI FINETAC PRECISION TECH CO LTD

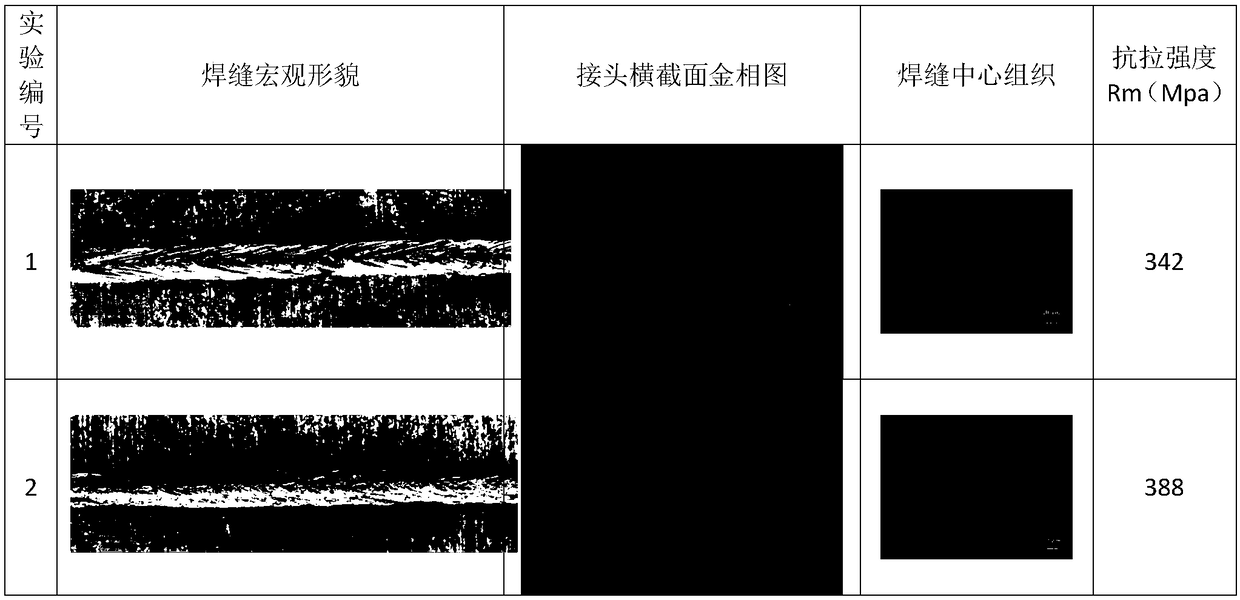

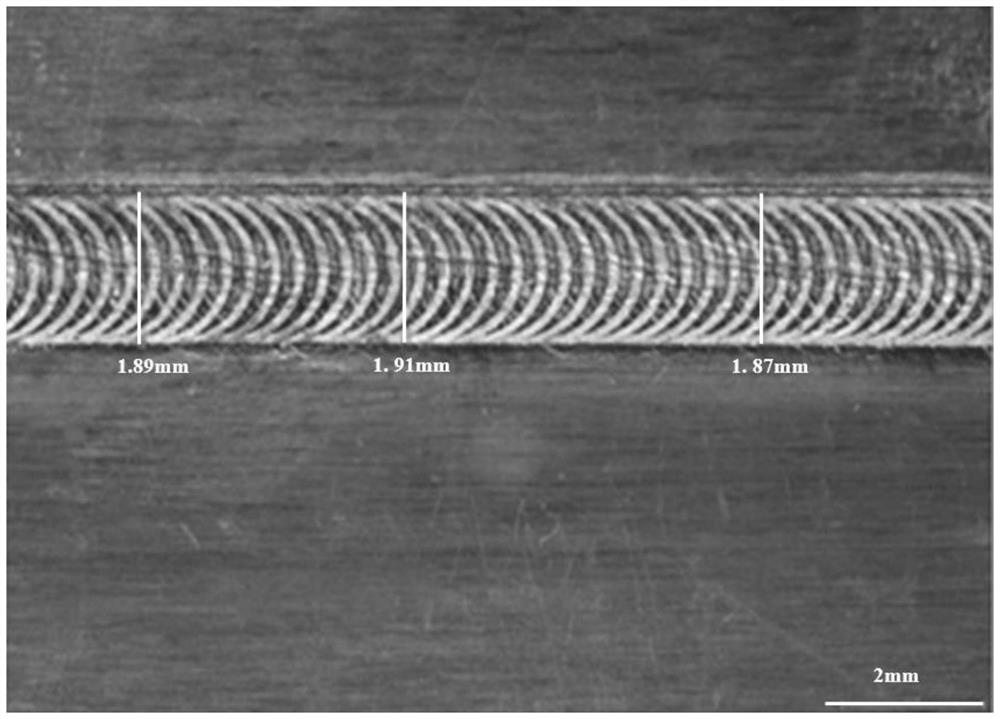

Aluminum alloy laser focus rotation wire-filling welding method

InactiveCN108213712AHigh strengthInhibit stomataWelding/soldering/cutting articlesLaser beam welding apparatusMolten bathWeld seam

The invention discloses an aluminum alloy laser focus rotation wire-filling welding method and belongs to the technical field of laser welding. The method is characterized in that a laser focus performs uniform circular motion on the surface of an aluminum alloy workpiece by a certain radius and at a certain frequency; and within each rotation cycle of the focus, laser can alternately acts on thetail end of a welding wire and the surface of the workpiece, and thus the effects that flow of a molten bath, the solidification behavior and fusion transitional behavior of the welding wire are adjusted and controlled actively are achieved. Compared with a traditional laser wire-filling welding method, the method has the beneficial effects that air holes are effectively inhibited, the form and appearance of a welding seam are improved, grains of the welding seam are refined, and the joint strength is improved.

Owner:BEIJING UNIV OF TECH

Brazing filler metal for 6 series aluminum alloy low-temperature vacuum brazing and preparation method thereof

InactiveCN107825002AGood spreadabilityImprove plasticityWelding/cutting media/materialsSoldering mediaCobaltFiller metal

The invention discloses brazing filler metal for 6 series aluminum alloy low-temperature vacuum brazing and a preparation method thereof, and relates to the technical field of aluminum alloy welding brazing filler metal preparation. The brazing filler metal is formed by smelting the following raw materials including, by mass, 6-7% of aluminum, 23-24% of tin, 9-10% of gallium, 7-8% of cobalt, 39-40% of bismuth, 12-13% of magnesium, and 4-5% of silicon. The brazing filler metal is formed by melting the multiple components, has good spreadability and plasticity and can be effectively matched with6 series aluminum alloy.

Owner:成都固联科技有限公司

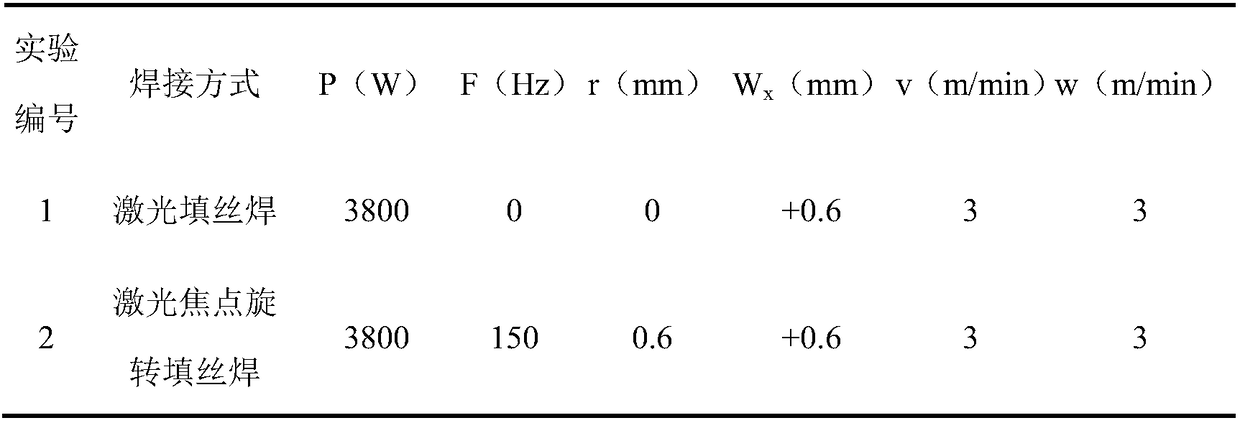

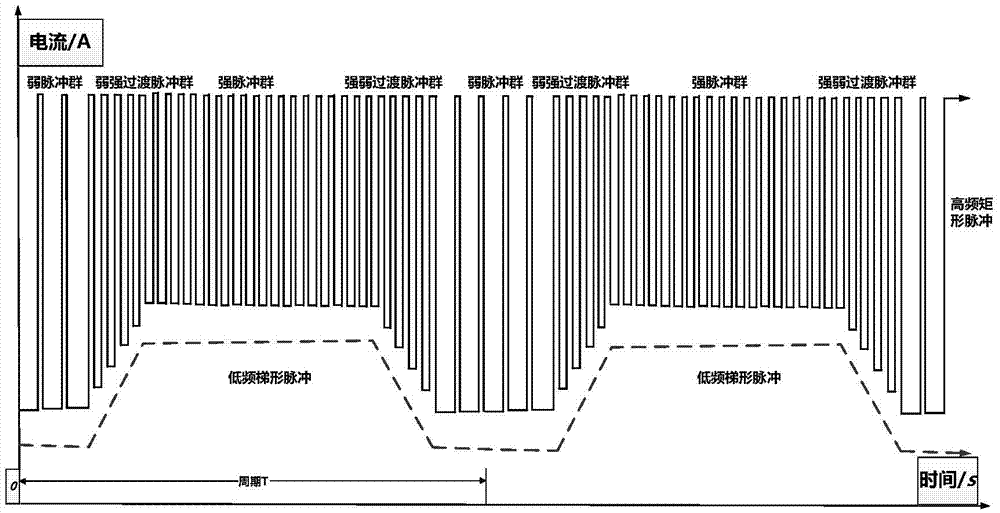

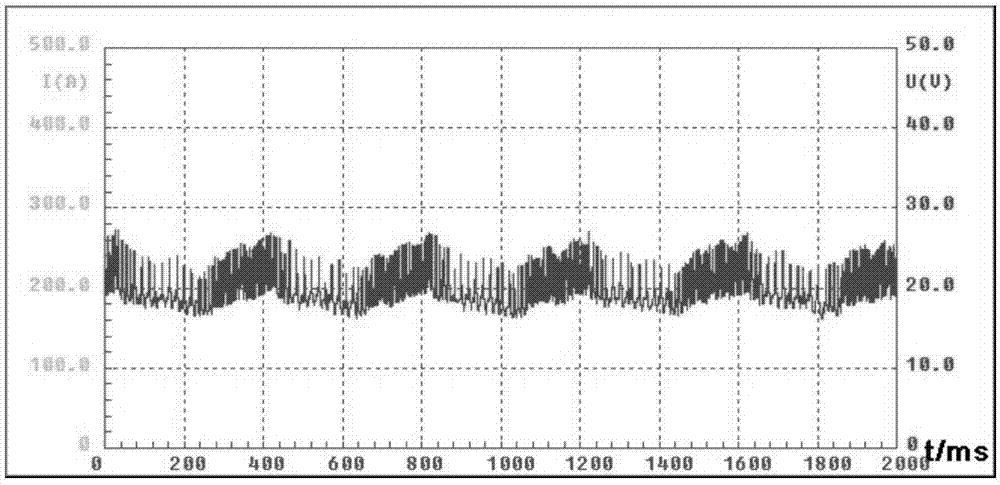

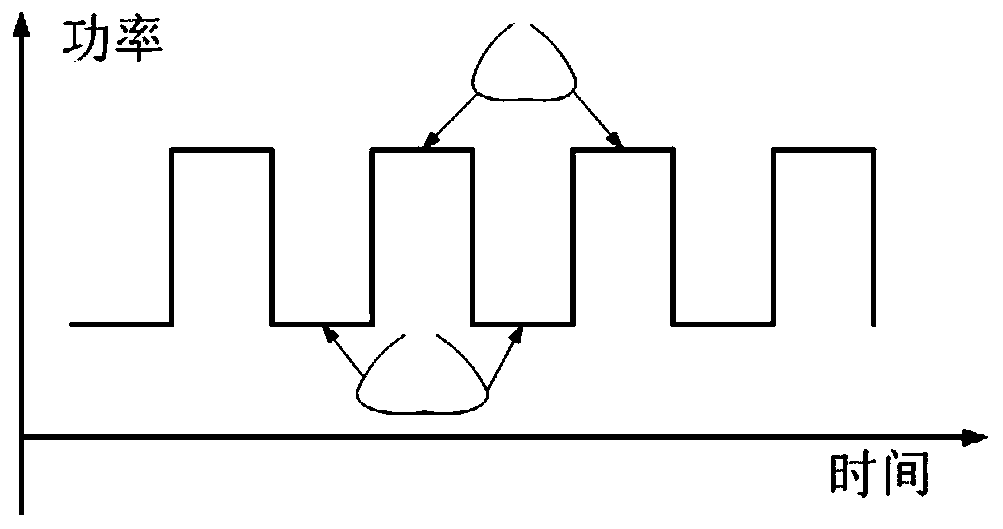

Trapezoidal wave modulation welding current waveform

InactiveCN105436666AReduce the incidence of stomataRefine the weld grainArc welding apparatusCurrent regulationStrong pulse

The invention discloses a trapezoidal wave modulation welding current waveform which is used for controlling welding current. Welding current waveform is in periodical cycle; within each welding current waveform period, the welding current waveform comprises a strong pulse packet, a strong-weak transition pulse packet, a weak pulse packet and a weak-strong transition pulse packet, which are sequentially connected to form a continuous modulation waveform. In the waveform, number of pulses in the strong-weak transition pulse packet is the same as the number of pulse in the weak-strong transition pulse packet; peak current values of all high-frequency rectangular pulses are the same; and peak current lasting time of all high-frequency rectangular pulses is the same. Base current and number of pulses in the weak pulse packet in the waveform are smaller than the base current and the number of pulses in the strong pulse packet, but the base value lasting time of the weak pulse packet in the waveform is greater than the base value lasting time of the strong pulse packet. The trapezoidal wave modulation welding current waveform can form attractive welding waves, and has a plurality of advantages of being very wide in current regulating range, reducing a pore occurrence rate and refining welding seam grains.

Owner:SOUTH CHINA UNIV OF TECH

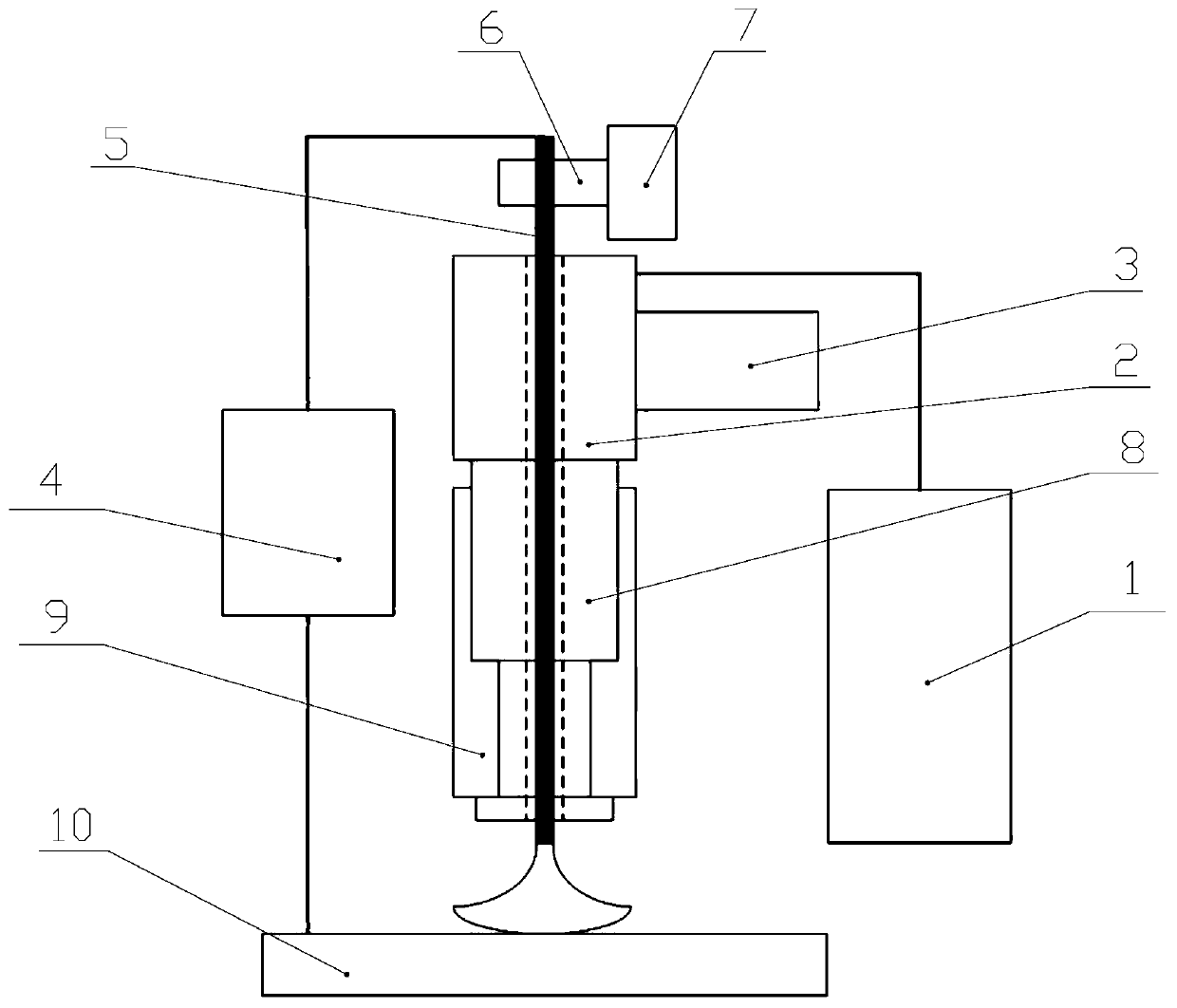

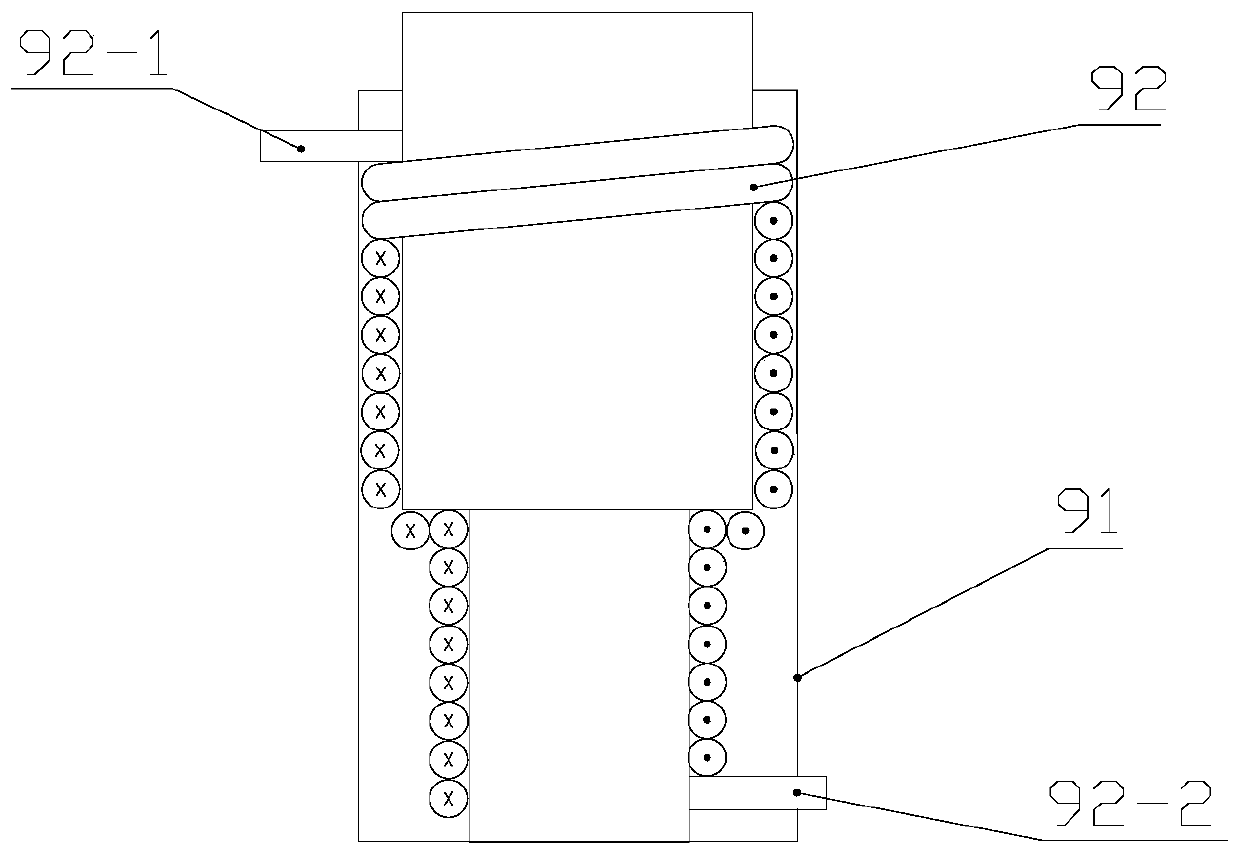

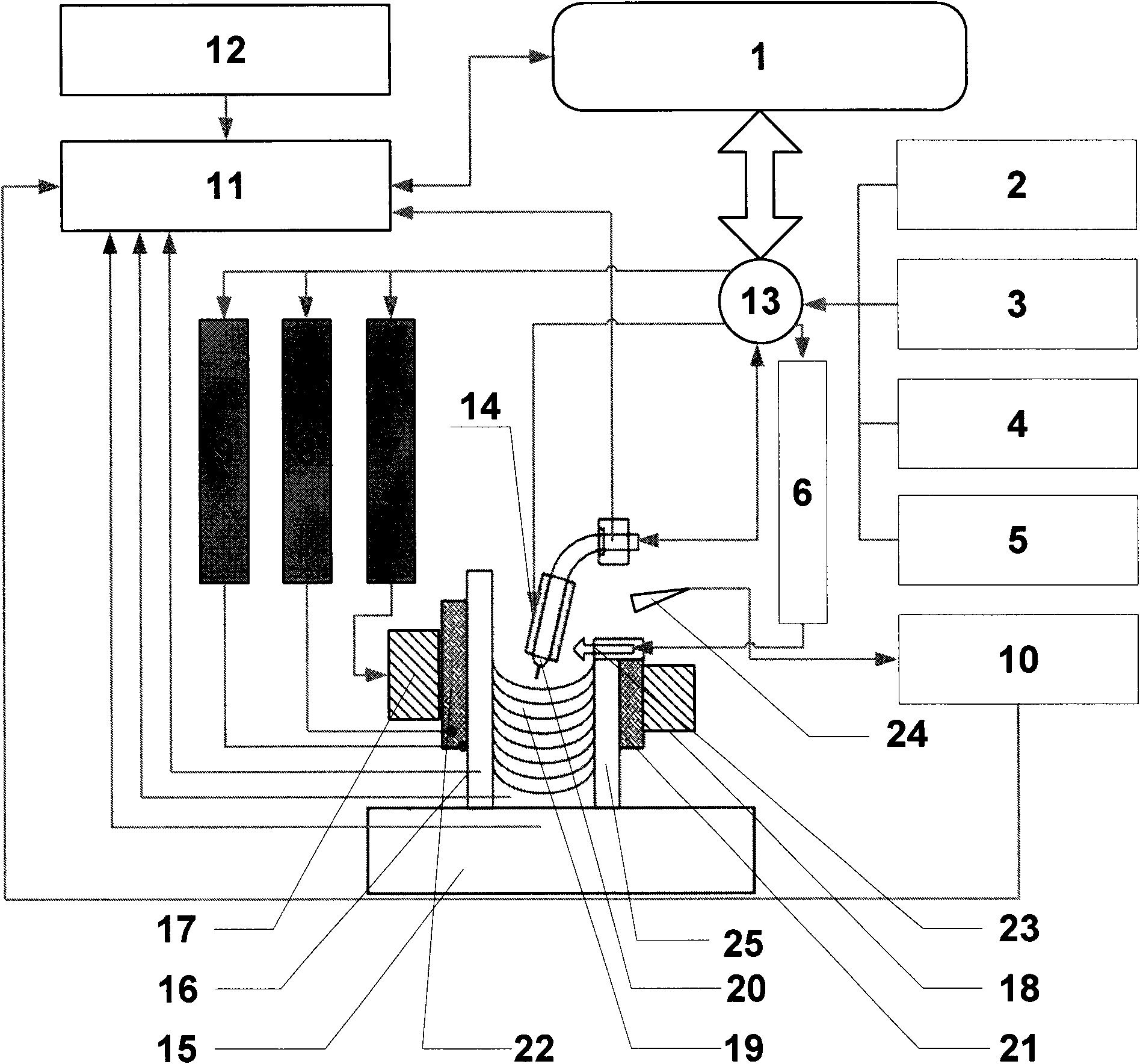

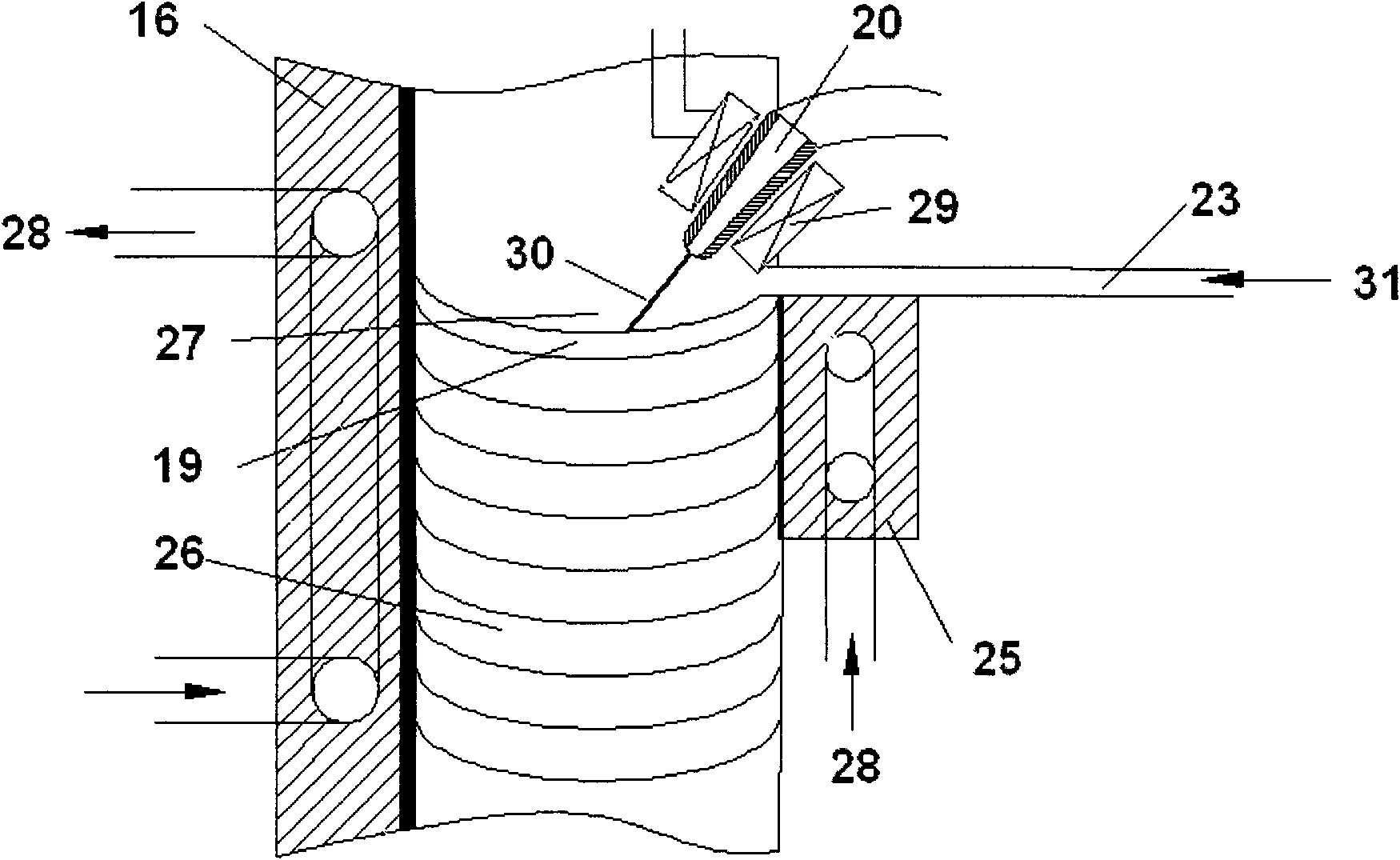

Novel pulse ultrasonic arc hybrid welding device and welding method thereof

ActiveCN110977216AExact matchAdjustable distanceWelding apparatusWelding power supplyControl ultrasound

The invention discloses a novel pulse ultrasonic electric arc hybrid welding device and a welding method thereof, and belongs to the technical field of electric arc welding and welding metallurgy. Theproblems that an existing pulse ultrasonic field is unstable in output, poor in heat dissipation of an energy converter, incapable of working for a long time, complex in equipment operation and highin precision requirement are solved. A transducer is connected with an amplitude-change pole, the amplitude-change pole is arranged in a water cooling system, displacement of an energy converter in the horizontal direction and the vertical direction is realized through an energy converter walking platform, an electrode is arranged in a center hole of the energy converter in a penetrating mode, theupper portion of the electrode is fixed to an electrode walking platform through an electrode clamp, displacement of the electrode in the horizontal direction and the vertical direction is achieved through the electrode walking platform, a welding power source is connected with the electrode through a wire, and an ultrasonic power source is connected with the energy converter through a wire. Theultrasonic power source is controlled to output according to certain frequency, pulse ultrasound is obtained, and the pulse peak value and the base value are adjustable.

Owner:HARBIN INST OF TECH

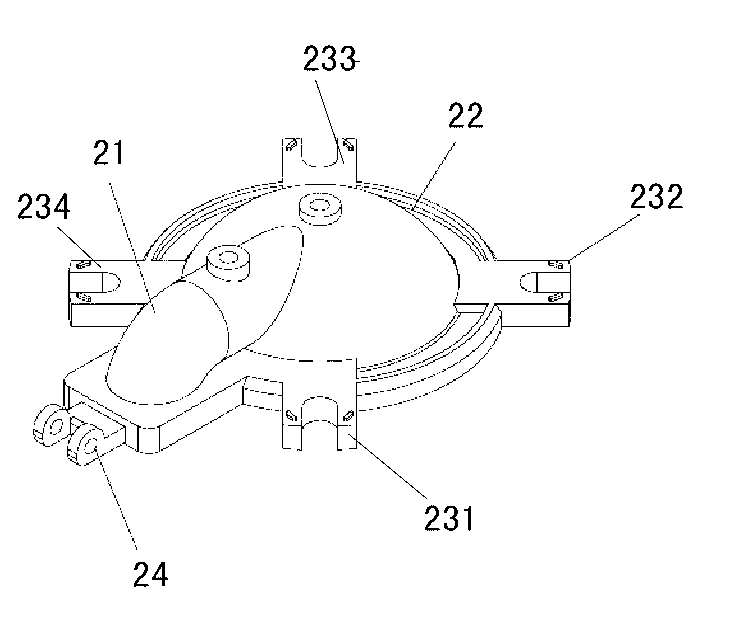

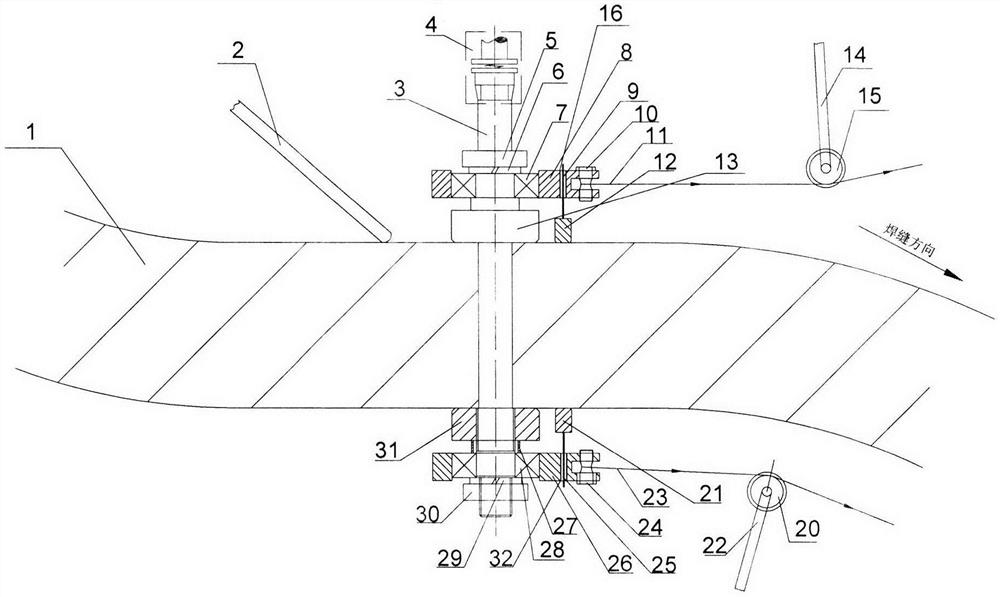

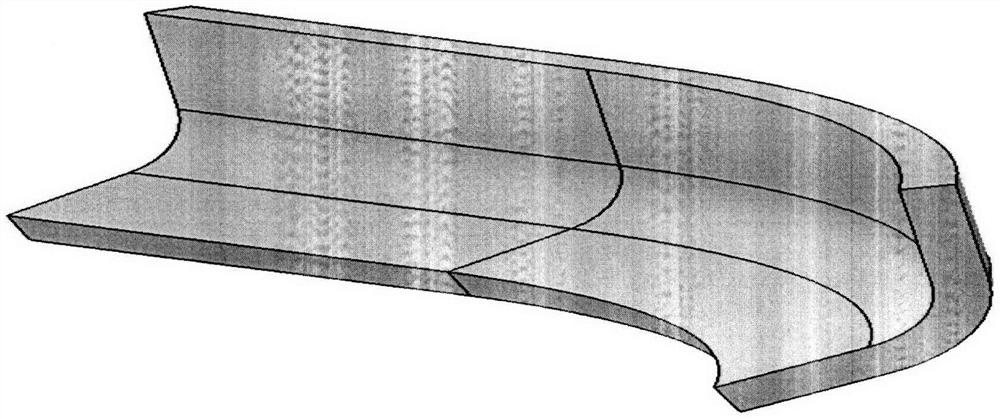

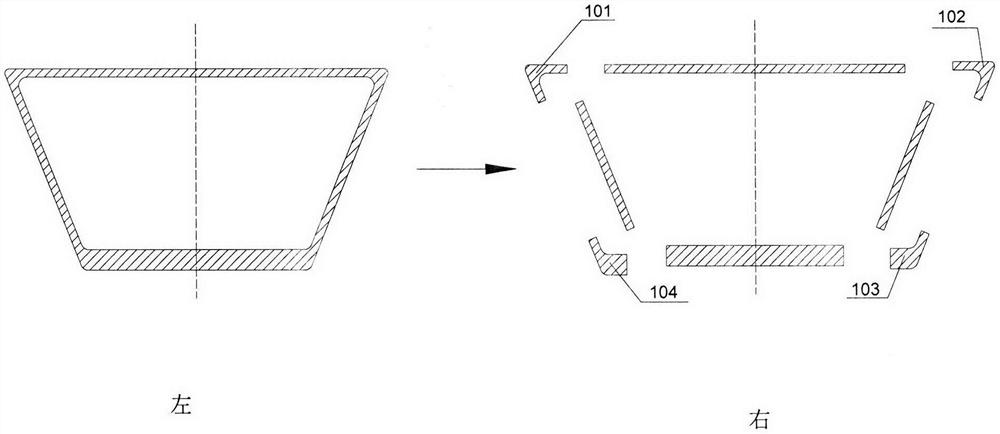

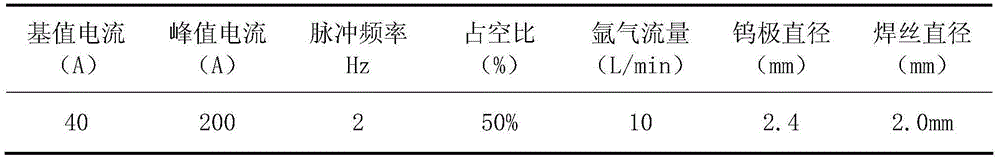

Double-shaft-shoulder friction stir welding stirring head with four sets of auxiliary devices and method for welding curve butt welds of medium-thickness steel parts through double-shaft-shoulder friction stir welding stirring head

ActiveCN112894120ARefine the weld grainImprove welding qualityProcess efficiency improvementNon-electric welding apparatusButt weldingCoupling

A double-shaft-shoulder friction stir welding stirring head with four sets of auxiliary devices comprises an auxiliary pull rope, a traction device, an auxiliary current heating device, a fixed pulley, an auxiliary multi-degree-of-freedom robot with a welding seam tracking device and a flexible coupler. With the four sets of auxiliary devices, the stress condition of the stirring head can be greatly improved, the service life of the stirring head is prolonged, and the welding length of the stirring head is increased. A slope is additionally arranged on an introduction plate, so that the reduction of the pre-tightening force between the two shaft shoulders after the pre-tightening force encounters softened metal in the working process is not reduced, and tunnel type welding defects can be reduced. Notches are formed in the corners and the positions with different thicknesses, so that the double-shaft-shoulder friction stir welding stirring head is particularly suitable for friction stir welding of plane and space curve butt welds, linear butt welds and segmented part transverse butt welds of medium-thickness steel parts and steel parts which are slightly staggered in height and are equal in thickness such as various ships, various warships including aircraft carriers, conventional submarines, nuclear submarines, deep diving submersibles, large cylinders, large platforms, large flat plates and large transporters. The invention also provides a corresponding welding method.

Owner:倪平涛

Quenching type pulsation welding method

InactiveCN104690401ASpeed up coolingReduce growth timeWelding/cutting auxillary devicesAuxillary welding devicesLiquid nitrogenFusion welding

The invention discloses a quenching type pulsation welding method, which comprises the following steps: a weldment is horizontally suspended and clamped in a welding fixture, a welder A begins to strike arc and weld with filler wires, after the needed melting quantity is achieved, the welder A stops wire filling, rapidly pulls a welding gun open, and guarantees that the electric arc is not extinguished; when the welder A pulls the welding gun open, a welder B rapidly sprays liquid nitrogen for 1-3s to the center of a molten pool on the front or the back of the weldment, and then moves away a nozzle of the liquid nitrogen; the welder A rapidly operates the welding gun back to the position near the last welding spot to continue performing fusion welding, and the steps are repeated until the welding is finished. As the welding molten pool can be quenched within the shortest period of time instead of being quenched before being about to solidify or is solidified, the refining effect of crystalline grains can be guaranteed, and the normal welding and melting process is not influenced.

Owner:TIANJIN UNIV

Method and equipment for manufacturing gradient functional structure

InactiveCN102240861BAvoid defectsMeet the needs of high-performance componentsWelding accessoriesNon-electric welding apparatusMelting tankGradient material

The invention relates to a method and equipment for manufacturing a gradient functional structure through arc welding and quick forming. By adopting the technology of outer-field compounding, molding, forcible temperature control, sequential growth, and whole welding forming, a double metal gradient material is subjected to in-situ alloying, and the gradient functional structure is manufactured in a near net way; and in the method, an electromagnetic stirring action, an electromagnetic metallurgical action and an ultrasonic welding action are adopted, the large-volume welding pool liquid metal solidification process is comprehensively controlled, and the gradient functional structure is manufactured by matching a high-speed wire feed system, a mould forcible temperature control system, a near net forcible sequential growth whole forming system, and an in-situ alloying gradient material. The equipment is formed by integrating and combining an electromagnetic welding system, an ultrasonic welding system, and an efficient welding system. By the method and the equipment for quickly manufacturing the gradient functional structure by a non-layered welding structure in a low-cost way, a manufacturing period is reduced, production efficiency is improved, and the high reliability and the long service life of the gradient functional structure are guaranteed.

Owner:CHONGQING UNIV

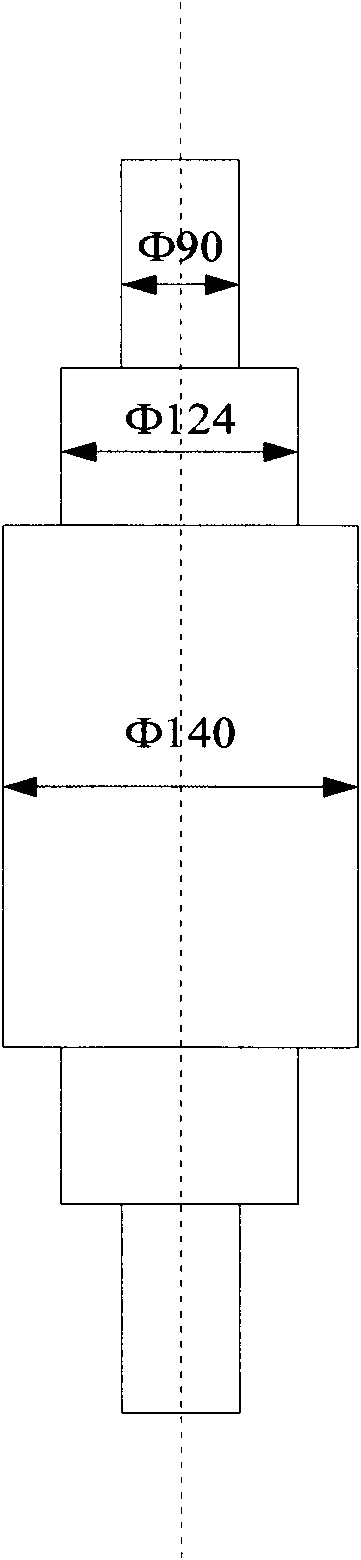

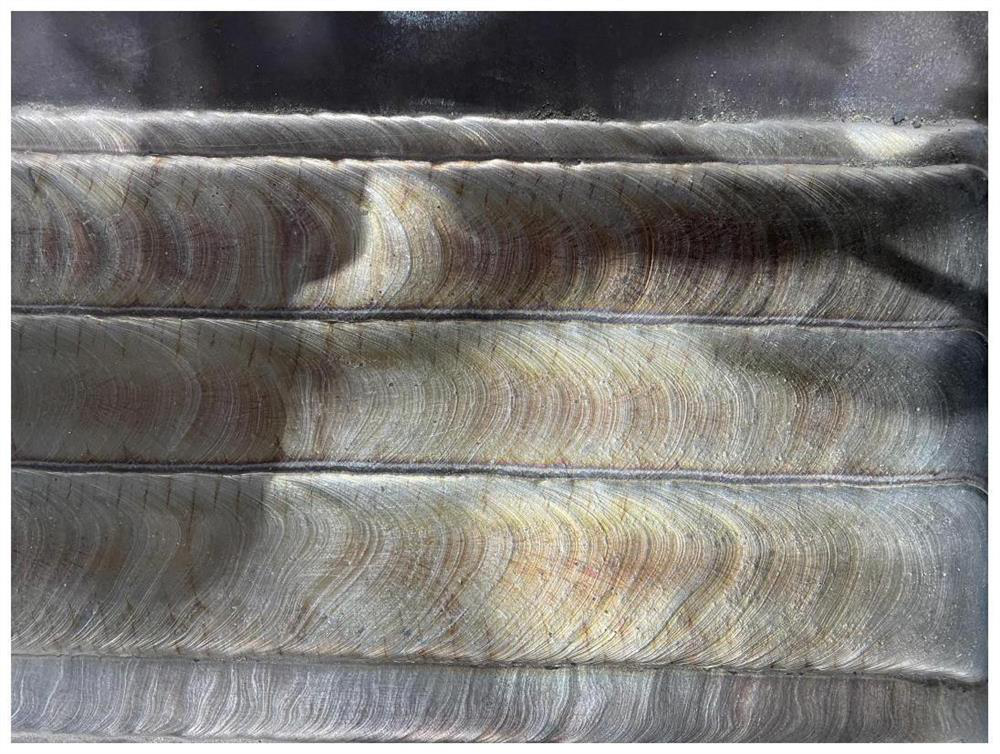

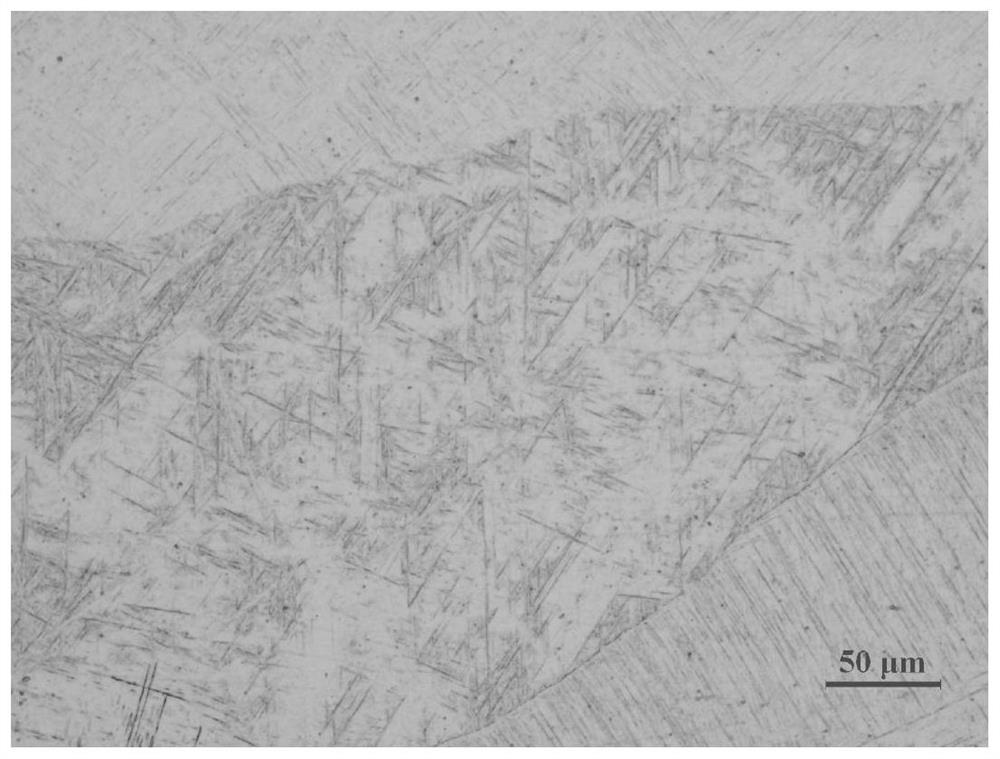

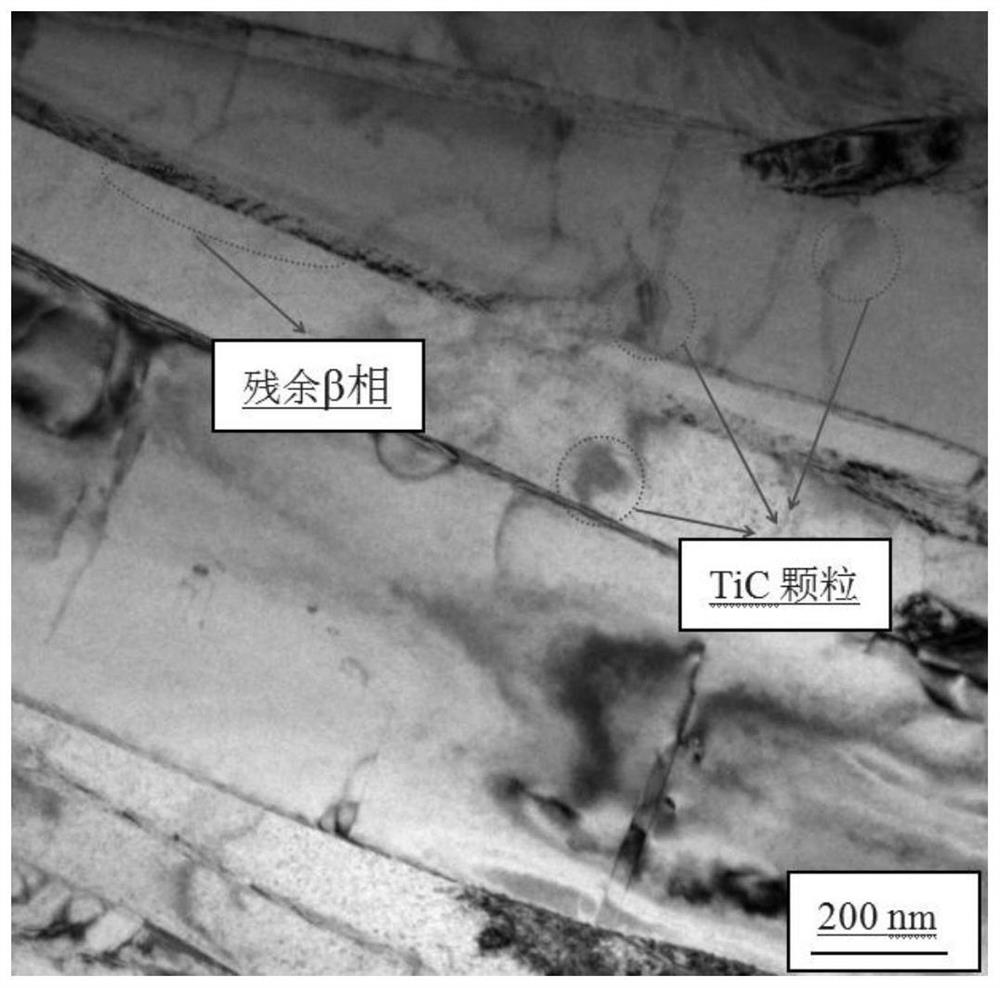

TC4 titanium alloy metal powder core flux-cored welding strip and preparation method thereof

ActiveCN114654128AIncreased residual beta contentImprove plastic toughnessWelding/cutting media/materialsSoldering mediaAl powderTitanium alloy

The invention discloses a TC4 titanium alloy metal powder core flux-cored welding strip and a preparation method thereof. The invention belongs to the technical field of welding material preparation. The titanium alloy solid welding strip aims at solving the technical problems that components of an existing titanium alloy solid welding strip for titanium alloy strip electrode submerged arc surfacing are not easy to regulate and control, and a surfacing cladding layer is difficult to meet comprehensive performance indexes such as strength, plasticity, toughness, abrasion resistance and corrosion resistance. The welding strip is composed of a Ti-9Mo-3Nb-3V titanium alloy skin and a metal powder core filled in the Ti-9Mo-3Nb-3V titanium alloy skin. The metal powder core is formed by mixing, by mass, 5%-7% of vanadium powder, 12%-17% of aluminum powder, 3%-5% of molybdenum powder, 3%-5% of iron powder, 1%-3% of silicon powder, 5%-8% of nickel powder and the balance titanium powder. By adding beneficial elements and supplementing burning elements in the welding process, the production cost is greatly reduced, the production efficiency is improved, a surfacing cladding layer has the advantages of being high in strength, good in plasticity and toughness and resistant to abrasion and corrosion, welding flux is not needed for molten pool protection and metallurgical regulation, and slag removal treatment is not needed after surfacing.

Owner:HARBIN WELDING INST LTD

Mixed active agent for activing flux tungsten inert gas arc welding of magnesium alloy

InactiveCN108032002AStrong penetrating powerAffect mechanical propertiesArc welding apparatusWelding/cutting media/materialsActive agentMolten bath

Provided is a mixed active agent for activing flux tungsten inert gas arc welding of a magnesium alloy. A method comprises the following steps that (1), the mixed active agent is formed by mixing MnCl2 with ZnO, wherein the mixed active agent comprises, by weight percentage, 65%-75% of MnCl2 and 25%-35% of ZnO; (2), according to a use method of the active agent, MnCl2 and ZnO active agent powder is fully ground, after even mixing, an appropriate amount of acetone is evenly added, and the mixture is made into a paste; (3), the upper surface of a sample is evenly coated with the pasty active agent with a flat hairbrush, the coating width is about 40 mm, and the average coating amount of the active agent is 6 mg.cm<-2>; (4), TIG is conducted after acetone is volatilized; and (5), after welding is completed, the morphology and the microstructure of a welding joint and a molten bath are observed, and representation of the mechanical property is conducted.

Owner:CHONGQING UNIV

Ultrahigh-power laser-deep penetration TIG composite welding method for thick plate

ActiveCN113941778ASuppression of spatter in ultra-high power laser weldingImprove welding qualityLaser beam welding apparatusHigh power lasersThick plate

The invention discloses an ultrahigh-power laser-deep penetration TIG composite welding method for a thick plate, and belongs to the technical field of thick plate ultra-high power laser welding. The problems that in an existing ultrahigh-power laser welding process of the thick plate, welding spatter and collapse are serious, so that the welding seam surface forming control difficulty is large, and the stability of the ultrahigh-power laser-traditional TIG composite welding process of the thick plate is poor are solved. According to the method, an ultra-high power laser is emitted into a deep penetration TIG electric arc key hole, an opening area of the ultra-high power laser key hole is forcibly enlarged by means of the high stiffness and the high penetrating power of a deep penetration TIG electric arc, meanwhile, a metal liquid column at an opening of the laser key hole is restrained from flying out of the surface of a molten pool, the purposes of restraining ultrahigh power laser welding splashing of the thick plate and improving the welding quality are achieved, the welding seam upper surface forming is improved, and the welding process stability is improved.

Owner:HARBIN WELDING INST LTD

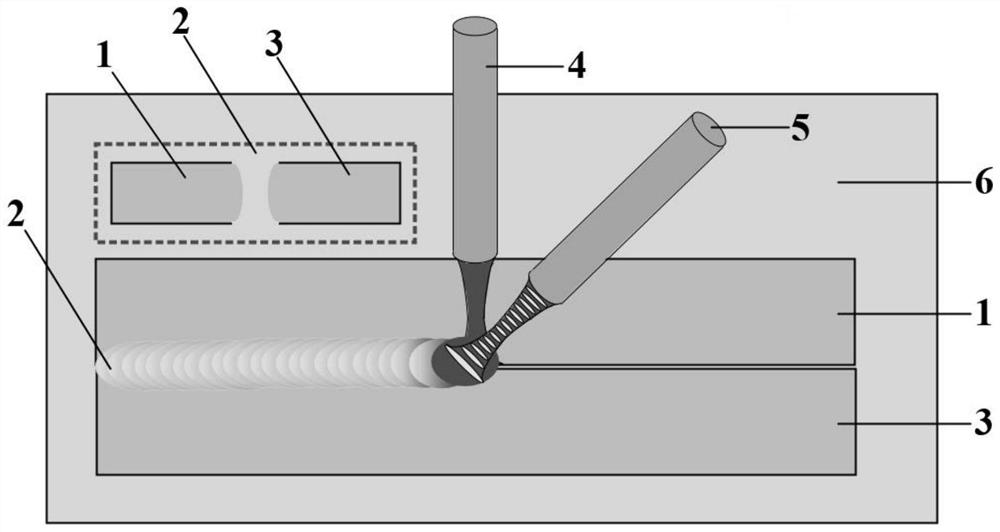

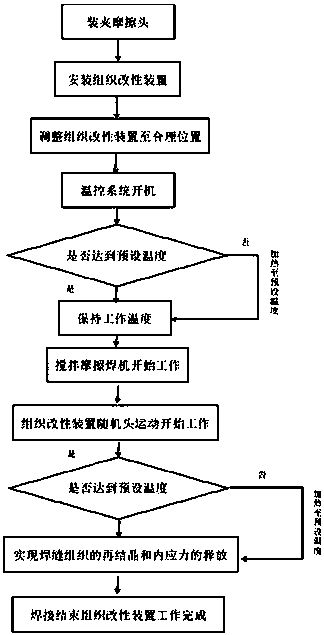

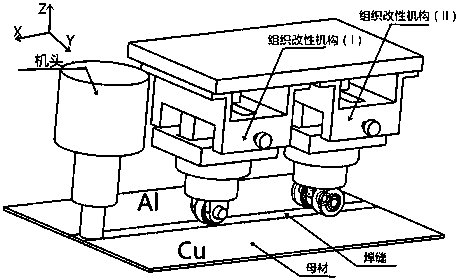

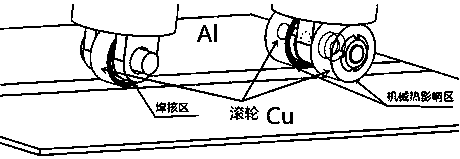

Follow-up Method for Improving Al/cu Friction Stir Welding Seam Microstructure

ActiveCN106181020BImprove mechanical propertiesImprove conductivityNon-electric welding apparatusTemperature controlWorking pressure

The invention discloses a method for improving a weld microstructure of Al / Cu friction stir welding in a follow-up manner. The method comprises the following steps: (1) adjusting the lowest working pressure, and adjusting the lowest pressing amounts of microstructure modification mechanisms; (2) adjusting the positions of the microstructure modification mechanisms by virtue of an adjustment-control mechanism, wherein two rolling wheels in a microstructure modification mechanism (II) with double rolling wheels correspond to the whole thermo-mechanical affected zone at an Al / Cu side as well as a part of a weld heat-affected zone and a part of a weld nugget zone; (3) starting up temperature control systems of the microstructure modification mechanisms, setting a modification temperature, setting a temperature T1 of the rolling wheels of a microstructure modification mechanism (I) to 290-315 DEG C, presetting a temperature T2 of the rolling wheels at an Al side of the microstructure modification mechanism (II) to 275-290 DEG C, setting a temperature T3 of the rolling wheels at a Cu side to 480-510 DEG C, heating the three rolling wheels to the modification temperature and then stopping heating; and (4) starting up a friction stir welding machine to start welding, enabling the microstructure modification mechanisms to start to work, and ensuring that the modification temperature set in the step (3) is achieved and stabilized until weld modification is ended during working by virtue of the temperature control systems of the microstructure modification mechanisms, wherein modification for the microstructure of the heat-affected zone can be realized after the end of the welding.

Owner:山东因泽智能设备有限公司

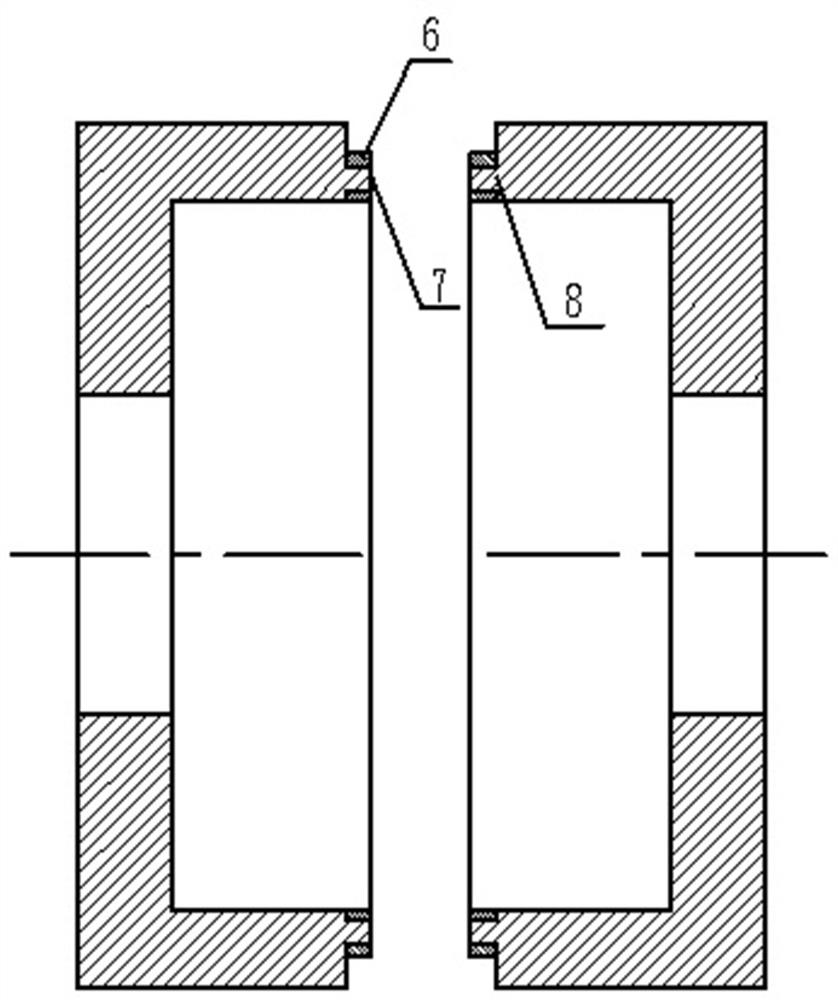

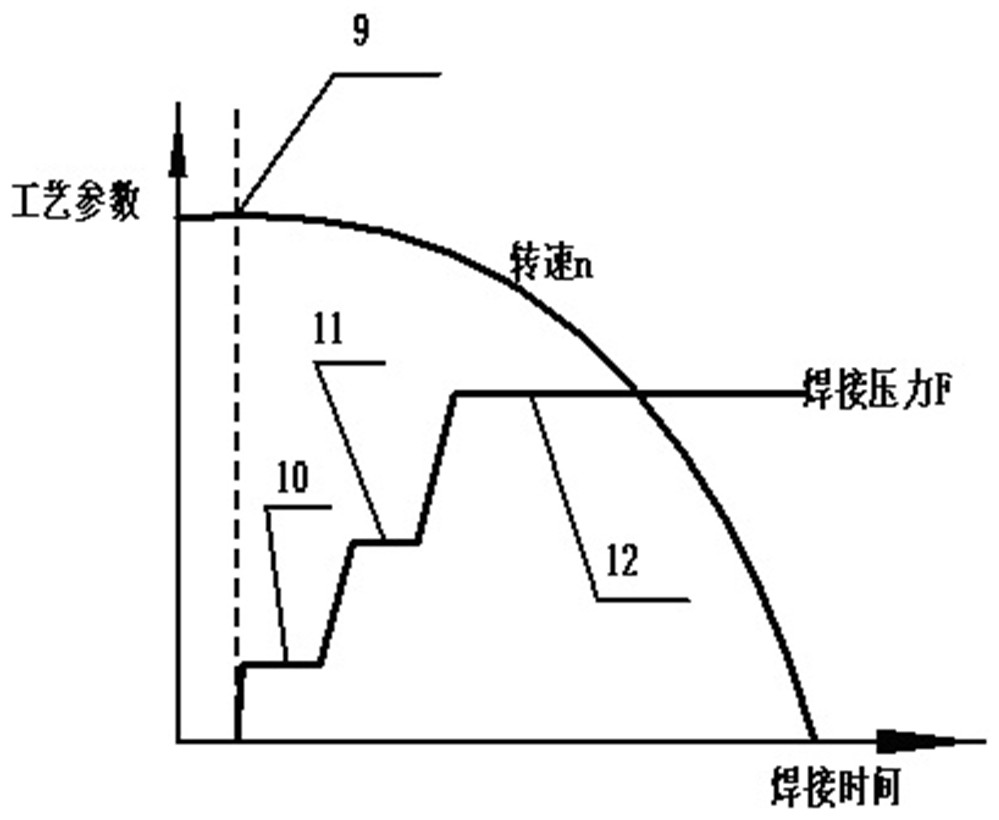

Process method for improving inertia friction welding weld joint quality of GH4151

ActiveCN113770508AHigh temperature capacityIncrease thrustAnalysing solids using sonic/ultrasonic/infrasonic wavesFluorescence/phosphorescenceFriction weldingStructural engineering

The invention relates to a process method for improving inertia friction welding weld joint quality of GH4151, and belongs to the technical field of welding of GH4151 alloy for aero-engine core rotor parts and plate-shaft type parts. According to the process method, an inertia friction welding three-stage pressure method is adopted, machining allowance is reserved on the inner face and the outer face of a boss relative to the final part size before welding, flash removal and heat treatment work are completed within limited time after welding is completed, and defect detection is conducted according to the sequence. By the adoption of the three-stage pressure process method, tip cracks of the welding flash do not go deep into a weld joint matrix, and the flash is continuous. Before welding, the machining allowance is reserved on the inner face and the outer face of the welding boss relative to the final part size, the possible flash tip defect can be thoroughly machined and removed, and the final weld joint quality of the part is guaranteed. Comprehensive quality detection is carried out on the surface, shallow surface and interior of the weld joint by using different detection sequences, so that the quality of the weld joint and the defect detection level are effectively improved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

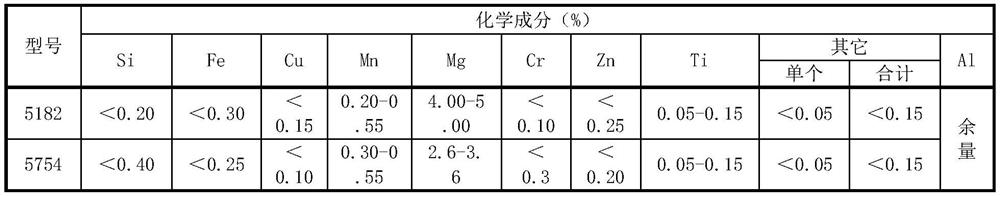

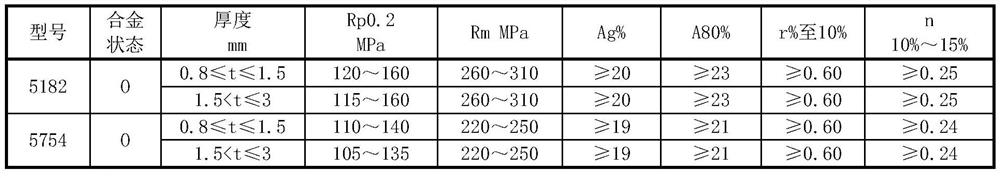

Aluminum alloy plate and preparation method

ActiveCN113275751AReduce cleaningRefine the weld grainWelding/soldering/cutting articlesLaser beam welding apparatusWeld strengthWelding defect

The invention provides an aluminum alloy plate and a preparation method. The preparation method of the aluminum alloy plate comprises the steps that a first 5000-series aluminum alloy mother plate and a second 5000-series aluminum alloy mother plate are welded through a laser stirring welding technology to obtain the aluminum alloy plate, wherein the surface of the first 5000-series aluminum alloy mother plate and the surface of the second 5000-series aluminum alloy mother plate each comprise a Ti / Zr film. According to the preparation method, the first 5000-series aluminum alloy mother plate and the second 5000-series aluminum alloy mother plate do not need to be specially cleaned before welding, additional filling of welding wires are not needed, the preparation cost is saved, and the aluminum alloy plate which is high in welding strength, equal to a base metal in strength and free of welding defects can be obtained.

Owner:宝能(广州)汽车研究院有限公司

Ultrahigh-power double-beam laser-high-frequency pulse deep penetration TIG composite welding method for thick plate

ActiveCN113941776AGood effectStrong penetrating powerLaser beam welding apparatusThick plateDual beam

The invention discloses an ultrahigh-power double-beam laser-high-frequency pulse deep penetration TIG composite welding method for a thick plate. The method belongs to the field of welding. The method aims to solve the technical problem of serious tendency of air holes and cracks in conventional ultrahigh-power laser-deep penetration TIG composite welding. The method comprises the steps that S1, a groove and a to-be-welded surface are polished or cleaned, and a butt joint is formed and fixed; S2, angles of a laser head and a TIG welding gun are set, and the distance between the tip end of a TIG welding gun tungsten electrode and a midpoint of a connecting line of centers of two laser spots on the surface of a to-be-welded thick plate is set; S3, parameters of the ultrahigh-power double-beam laser-high-frequency pulse penetration fusion TIG composite welding are set; S4, protective gas is set; and S5, the protective gas is introduced, and the ultrahigh-power double-beam laser-high-frequency pulse penetration fusion TIG composite welding is synchronously carried out. The method can inhibit weld pores and cracks and improve the welding quality.

Owner:HARBIN WELDING INST LTD

Titanizing technology for aluminum welding wire

ActiveCN105436747AIncrease the amount of platingFully fill surface imperfectionsWelding/cutting media/materialsSoldering mediaSurface conditionsTitanium

The invention belongs to the technical field of plating machining, and particularly relates to a titanizing technology method for the surface of an aluminum welding wire. A cotton thread containing titanium is wound on the surface of the aluminum welding wire, an assistant is dripped on the aluminum welding wire so that the assistant can be attached to the surface, with the cotton thread containing titanium, of the aluminum welding wire, after the cotton thread is completely pulled away from the aluminum welding wire and the assistant on the surface of the welding wire is completely volatized, the processed aluminum welding wire is polished, and the aluminum welding wire with the surface wrapped by titanium is obtained. According to the technology, titanium is evenly attached to the surface of the welding wire, pits and other unfavorable surface conditions generated in the pull-draw process can be comprehensively avoided, welding spatter is smaller during welding, weld joint grains can be refined through a trace of titanium, bubbles are avoided, the quality of a weld joint is improved, and the mechanical performance of the aluminum welding wire is improved.

Owner:哈焊所华通(常州)焊业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com