High-corrosion resistance aluminum alloy filter and process thereof

An aluminum alloy, high corrosion resistance technology, applied in the field of high corrosion resistance aluminum alloy filter and its process, can solve the problems of poor corrosion resistance, limited application of ships and offshore drilling platforms, poor resistance and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

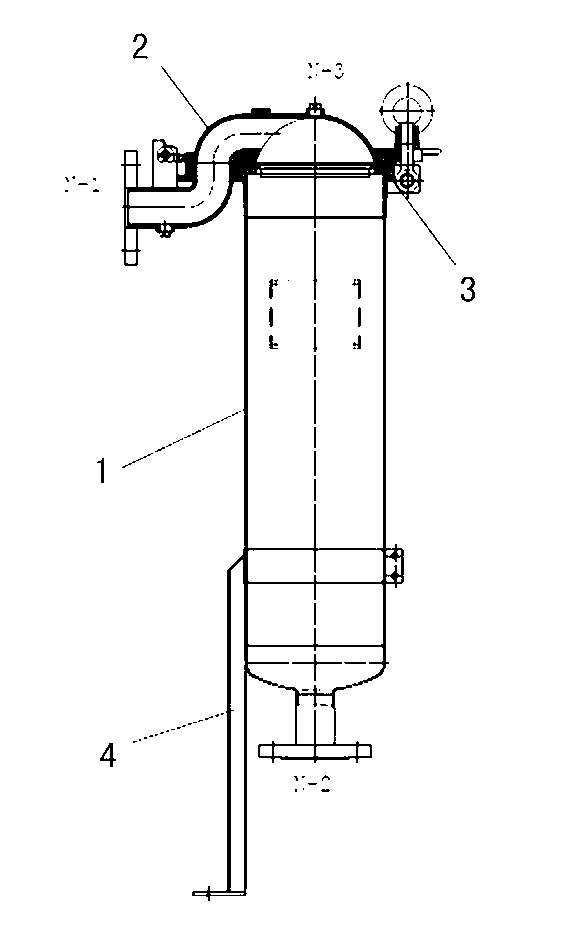

[0032] A high-corrosion-resistant aluminum alloy filter, including a shell composed of a cylinder body 1 and an upper cover 2, wherein:

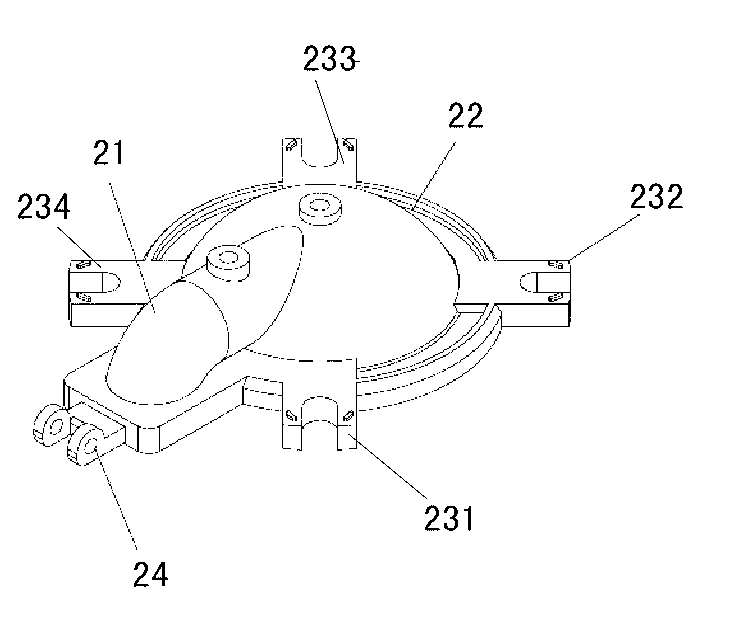

[0033] The upper cover 2 is an aluminum-magnesium-silicon alloy (Al2Mg2Si) casting, at least including an upper liquid inlet branch pipe 21, a round head 22, and bolt pressure plates 231, 232, 233, 234 evenly distributed around the round head 22;

[0034] The cylinder body 1 is a 5-series aluminum-magnesium alloy circular cylinder body, which is welded and formed by aluminum plate coils;

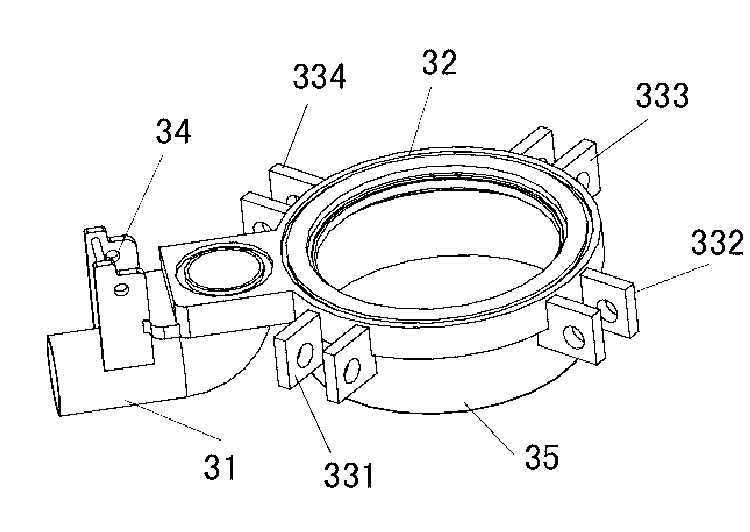

[0035] The connecting part of the cylinder 1 and the upper cover 2 is provided with a cylinder flange 3, wherein the cylinder flange 3 is a low-pressure precision casting, and a lower liquid inlet branch pipe 31 is arranged on it. The bolt fixing plates 331, 332, 333, 334 corresponding to the positions of the bolt pressing plates 231, 232, 233, 234 are arranged in the circumferential direction, O-ring grooves are arranged on the contact surface of the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com