Aluminum-copper alloy grounding material welding wire and preparation method thereof

A technology of aluminum-copper alloy and welding method, applied in welding equipment, welding/cutting medium/material, welding medium, etc., can solve the problem of large difference between joint composition and structure and base metal, threat to safe operation of power system, and poor corrosion resistance in joint area and other problems, to achieve the effects of excellent soil corrosion resistance, simple and easy preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

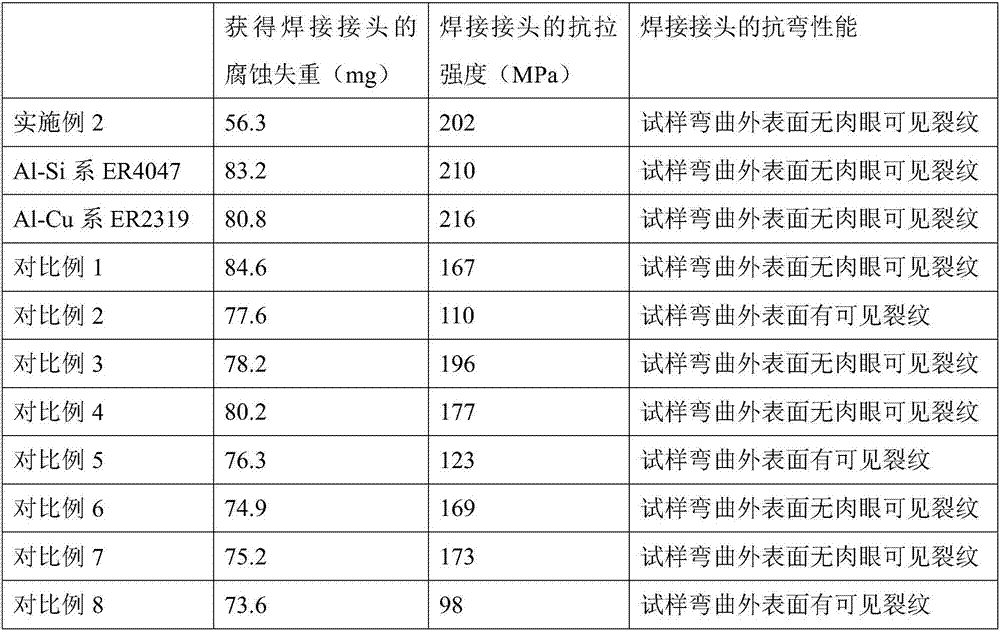

Examples

preparation example Construction

[0053] A second aspect of the present invention provides a method for preparing a welding wire for welding aluminum-copper alloy grounding materials, comprising the following steps:

[0054] Heat and melt the aluminum ingot, add the master alloy of other raw materials in proportion, when the raw material is fully melted in the molten pool, carry out slag removal and stirring, then take samples to test and adjust the composition, refining, and then cast into a rod-shaped aluminum alloy ingot;

[0055] The rod-shaped aluminum alloy ingot is extruded by the hot extrusion process, and processed into an aluminum alloy wire billet;

[0056] The aluminum alloy wire billet is drawn into a certain specification of aluminum-copper alloy grounding material welding wire by adopting a drawing process.

[0057] In the present invention, the pouring temperature is 680-730°C.

[0058] In the present invention, the heating temperature in the hot extrusion process is 440-460°C. Adopting this ...

Embodiment 1

[0070] A welding wire for welding aluminum-copper alloy grounding materials, the mass percentage of each component is: silicon 1%, copper 3%, iron 0.1%, zirconium 0.003%, rare earth 0.05%, and the balance is aluminum. Wherein, the rare earth is lanthanum.

[0071] The preparation method of the welding wire for welding the aluminum-copper alloy grounding material comprises the following steps:

[0072] Firstly, aluminum-copper rare-earth alloy ingots are smelted. Put the aluminum ingot into the furnace to heat. After the aluminum ingot is melted, add the master alloy of other raw materials according to the above ratio. When the furnace material is fully melted in the molten pool, carry out slag removal and stirring, then take samples to test and adjust the composition, refining, and pouring out of the furnace A rod-shaped aluminum-copper rare-earth alloy ingot with a diameter of 110mm is formed, and the pouring temperature is 690°C. Then, the rod-shaped aluminum-copper rare-e...

Embodiment 2

[0075] A welding wire for welding aluminum-copper alloy grounding materials, the mass percent of each component is: silicon 1.5%, copper 2.5%, iron 0.3%, zirconium 0.002%, rare earth 0.08%, and the balance is aluminum. Wherein, the rare earth is cerium.

[0076] The preparation method of the welding wire for welding the aluminum-copper alloy grounding material comprises the following steps:

[0077] Firstly, aluminum-copper rare-earth alloy ingots are smelted. Put the aluminum ingot into the furnace to heat. After the aluminum ingot is melted, add the master alloy of other raw materials according to the above ratio. When the furnace material is fully melted in the molten pool, carry out slag removal and stirring, then take samples to test and adjust the composition, refining, and pouring out of the furnace A rod-shaped aluminum alloy ingot with a diameter of 110mm is formed, and the pouring temperature is 690°C. Then the aluminum-copper rare-earth alloy ingot is hot-extruded i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com