Patents

Literature

38results about How to "Good corrosion performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacturing method of alloy tubular product

ActiveCN102527724AC, low content of NGuaranteed corrosion resistanceFurnace typesMetal rolling arrangementsChemical industrySolution treatment

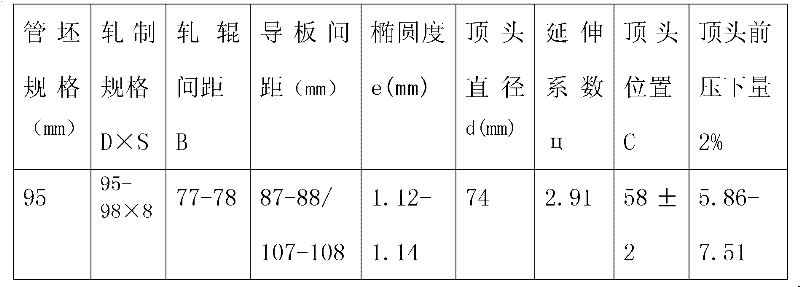

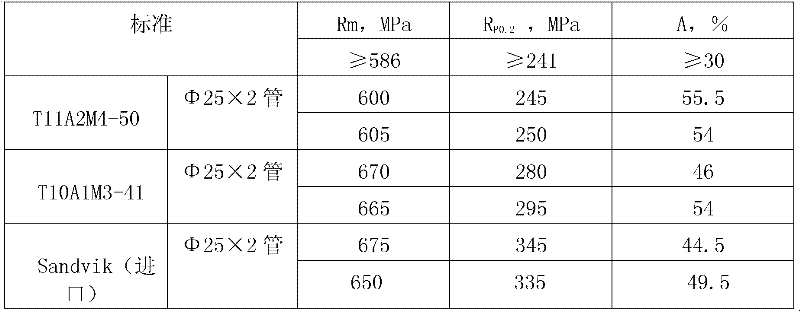

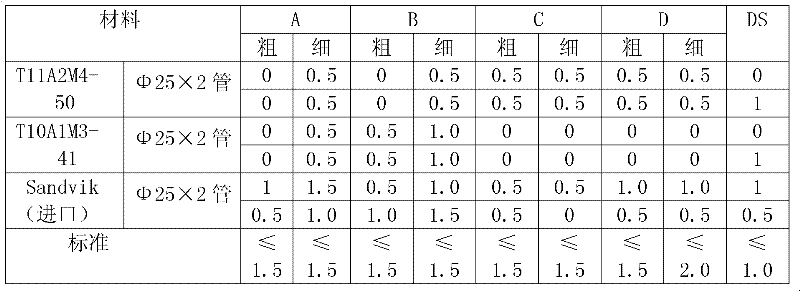

The invention discloses a manufacturing method of an alloy tubular product. The manufacturing method is characterized in that the method comprises the the steps of melting NS1402 alloy steel to be made into rods; sawing the rods into short cut materials, centering the short cut materials, and manufacturing the short cut materials into centering materials; heating the centering materials to the temperature being 950 DEG C, keeping the temperature for 20-30min, then heating the centering materials to the temperature being 1100 DEG C-1120 DEG C, and keeping the temperature for 15-20min, and subsequently, conducting hot punching on the centering materials to be manufactured into a tube blank; rolling the tube blank by 1 to 5 passes so as to manufacture the tube blank into a cold rolled tube; and conducting protective atmosphere solution treatment on the cold rolled tube to manufacture the alloy tubular product. Due to the adoption of the method, the production process is relatively simple, the yield is high, the production cost is low, the performance of the tubular product is good, and the produced alloy tubular product can be widely applied to the fields such as oil, chemical industry and the like.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

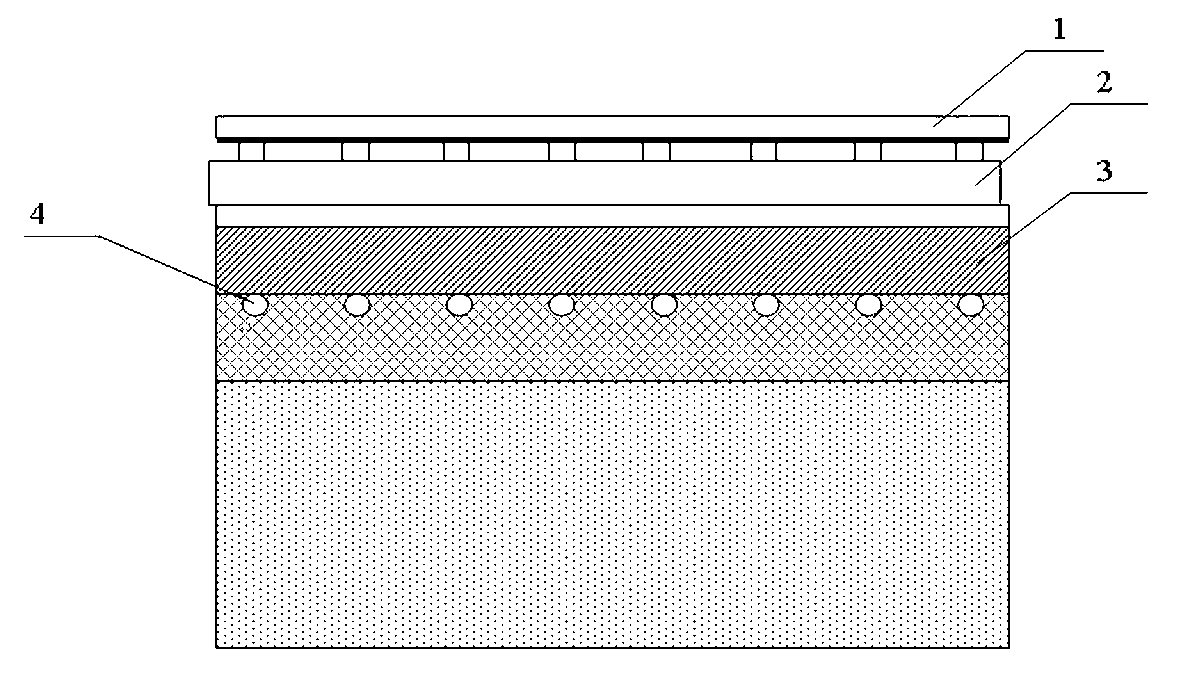

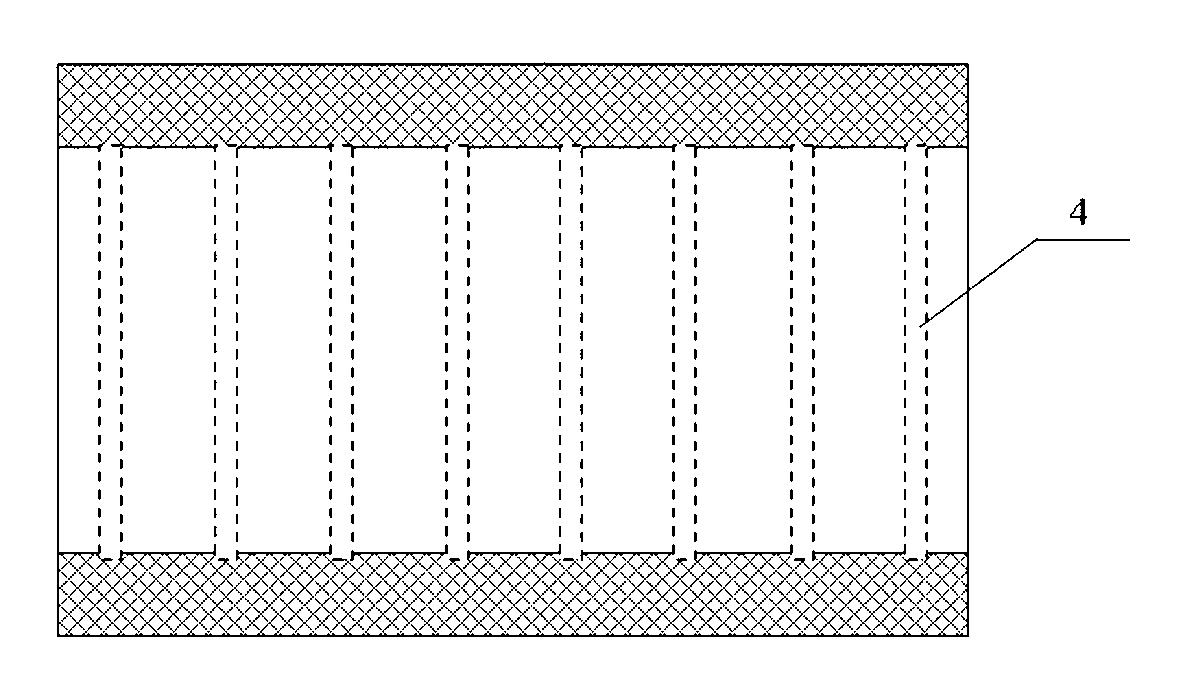

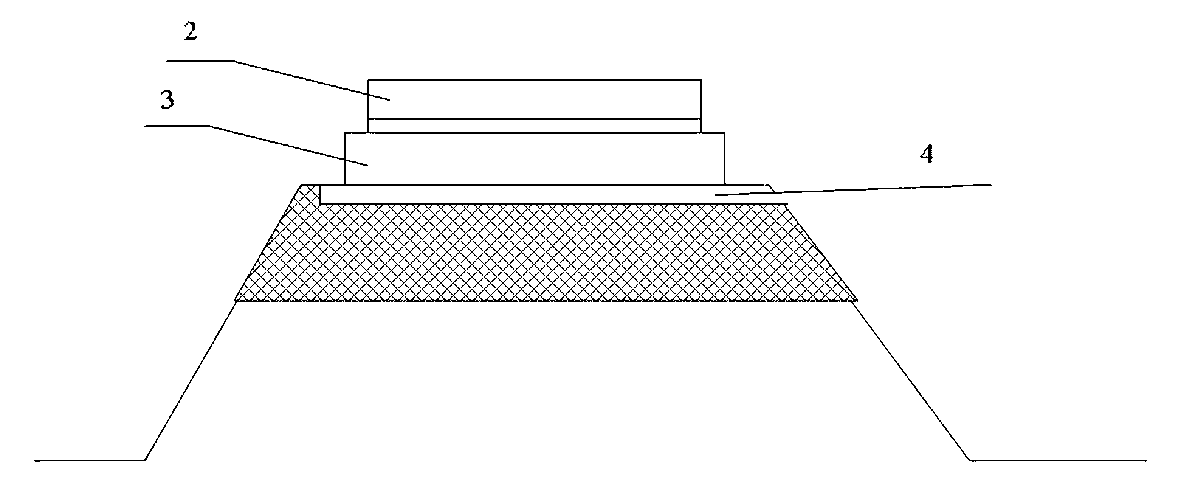

High polymer grouting method for lifting ballastless track of high speed railway

ActiveCN103215863AAchieve liftingGuaranteed smoothnessRailway track constructionSocial benefitsEngineering

The invention relates to a high polymer grouting method for lifting a ballastless track of a high speed railway. The method comprises the following steps that (1) grouting holes are drilled; (2) geotextile bags are manufactured, and in addition, the geotextile bags and grouting pipes are bound; (3) the geotextile bags are tied up; (4) the geotextile bags are placed; (5) the grouting is carried out in the geotextile bags; (6) the track is lifted; (7) the grouting is filled; and (8) the lifting quantity is monitored: a laser gradienter is used for monitoring the vertical lifting height in real time, and the grouting stops when the lifting requirement is reached. The method has the advantages of high speed, little damage, light weight, high tenacity, economy, endurance and the like, the lifting of the ballastless track of the high speed railway can be fast realized, and a novel, advanced, efficient, economic and practical method is provided for the subgrade settlement repair of a high-speed rail. The method is successfully applied to multiple ballastless track lifting projects, and huge economic and social benefits and wide development and application prospects are realized.

Owner:南方工程检测修复技术研究院

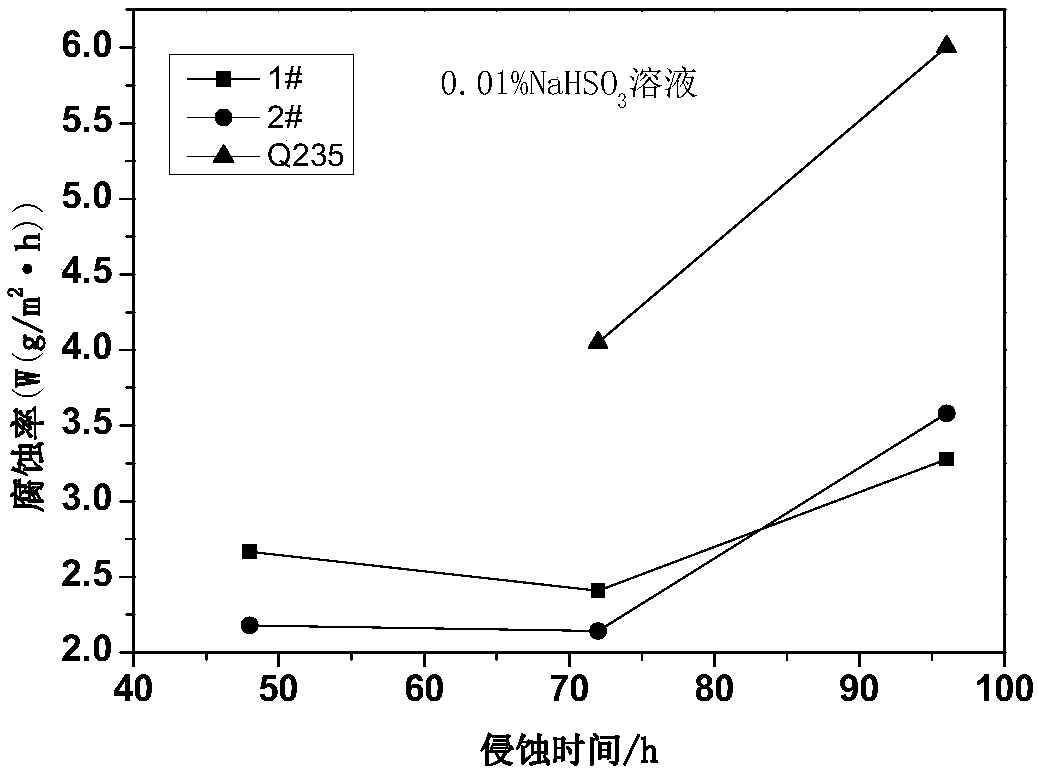

Industrial atmospheric corrosion resistant steel bar and preparation method thereof

The invention discloses an industrial atmospheric corrosion resistant steel bar and a preparation method thereof. The steel bar comprises, by mass, 0.15-0.20% of C, 0.40-0.60% of Si, 1.30-1.60% of Mn,0.070-0.130 of P, less than or equal to 0.030% of S, 0.40-0.55% of Cr, 0.25-0.35% of Cu, 0.40-0.60% of V, 0.15-0.25% of Ni, and 80-140 ppm of N. The steel bar can effectively prevent industrial atmospheric corrosion.

Owner:福建三宝钢铁有限公司

Low-alloy steel used for oil well pipe with carbon dioxide corrosion resistance and manufacturing method thereof

ActiveCN102400057ASub>goodAccelerated corrosionFurnace typesHeat treatment furnacesCarbon dioxide corrosionImpurity

The invention relates to a low-alloy steel used for an oil well pipe, and the low-alloy steel comprises the following chemical components in percentage by weight: 0.20-0.40% of C, 0.10-1.0% of Si, 0.50-2.0% of Mn, 0.5-1.5% of Cr, 0.02-0.2% of V, 0.01-0.10% of Al, 0.005-0.03% of N, 0.02-0.2% of Nb, less than or equal to 0.015% of P, less than or equal to 0.005% of S and the balance of Fe and inevitable impurities, wherein the total content of the impurity elements is less than 0.05wt. The invention also relates to a manufacturing method of the low-alloy steel. The manufacturing method comprises the following steps: performing steel making at the initial tapping temperature of 1600-1700 DEG C; performing continuous casting at the initial temperature of 1530-1570 DEG C, wherein in order to reduce the centre cracks and drawhole occurrence rates of a casting blank, the pulling rate of the continuous casting is controlled to be below 2.3m / min, and banding segregation is controlled to be within the level of 2.5; beginning performing perforation rolling at the temperature of 1180-1220 while performing hot rolling on the continuous casting blank; performing final stretch reducing until the temperature is 890-910 DEG C; and after hot rolling, air-cooling a steel tube to room temperature, thus obtaining the low-alloy steel used for the oil well pipe, wherein the low-alloy steel is provided with ferrite and pearlitic structures and has carbon dioxide and chloride ion corrosion resistance.

Owner:BAOSHAN IRON & STEEL CO LTD

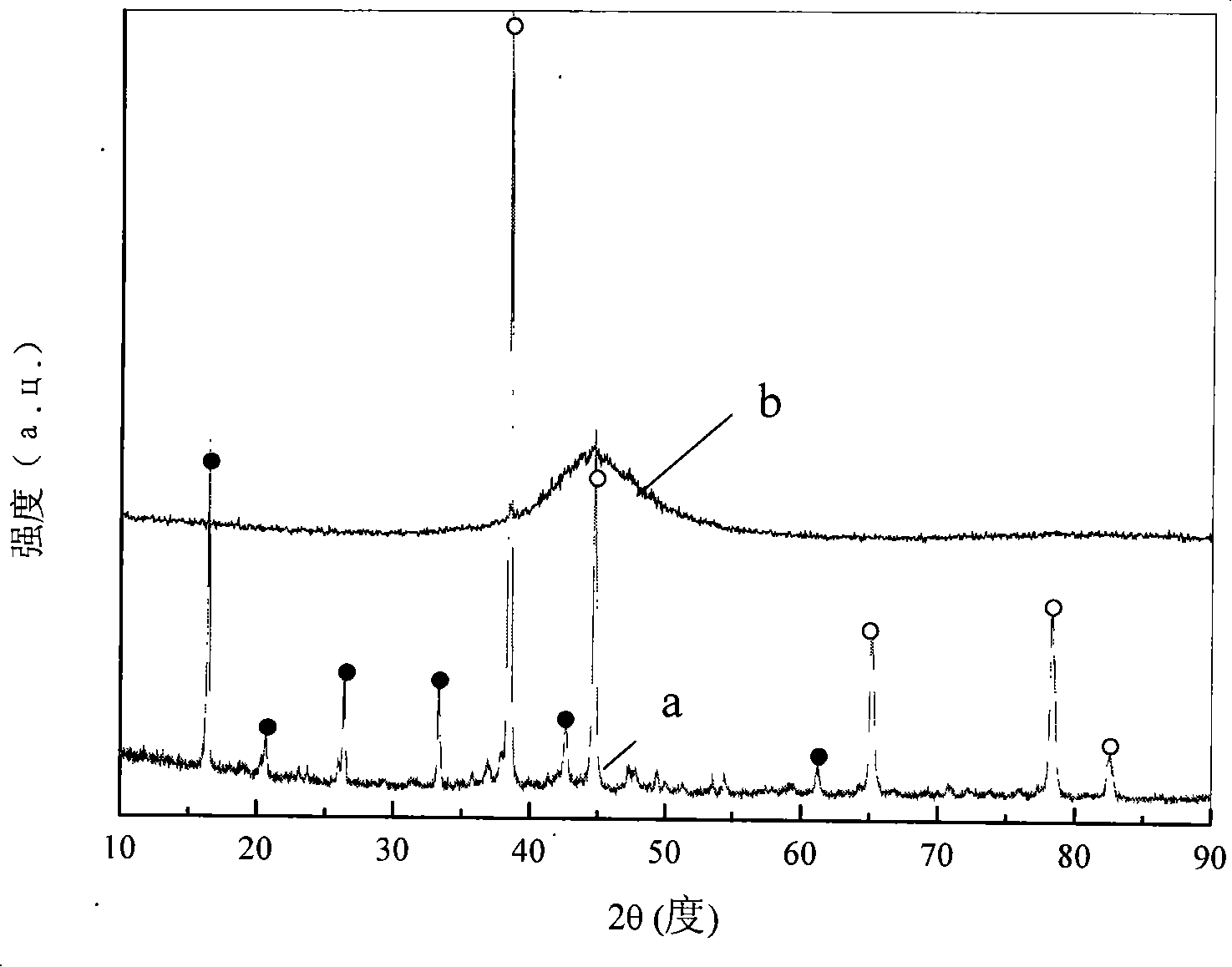

Degradable biomedical Mg-Zn-Zr-Nd alloy material and preparation method thereof

The invention discloses a degradable biomedical Mg-Zn-Zr-Nd alloy material and a preparation method thereof. Magnesium alloy comprises, by mass, 1-3% of Zn, 0.5-1% of Zr, 0.1-1.5% of Nd, and the balance Mg and inevitable impurities. The preparation method comprises the specific steps of raw material smelting, casting forming, homogenizing treatment, hot extrusion and artificial ageing treatment, and the biomedical magnesium alloy bar material meeting the service requirements under the biological fluid environment is obtained. According to the degradable biomedical Mg-Zn-Zr-Nd alloy material and the preparation method thereof, the alloy elements harmless to human bodies are added into the magnesium alloy, the alloy is non-poisonous to the human bodies after being degraded in the human bodies, is excellent in mechanical property, has good mechanical performance and machining performance, is good in corrosion resistance, can be completely degraded in the biological fluid environment and can also ensure the appropriate corrosion rate so that early failure can be avoided. The degradable biomedical Mg-Zn-Zr-Nd alloy material is simple in preparation method, low in production cost and suitable for being made into a cardiovascular stent, a bone nail and other medical materials.

Owner:UNIV OF SCI & TECH BEIJING

Pipeline paint resisting corrosion of sulfate reducing bacteria and its production process

ActiveCN101067065AEvenly distributedImprove adhesionCorrosion preventionAnti-corrosive paintsSulfate-reducing bacteriaGraphite

The present invention relates to one kind of paint for pipeline capable of resisting corrosion of sulfate reducing bacteria and its production process. The paint consists of two liquid components, including component A and component B, to be mixed in use. The component A is produced through adding modified phenol phenolic aldehyde type epoxy resin and bisphenol type epoxy resin into mixed solvent; adding chrome oxide green, precipitated barium sulfate, graphite and other seven kinds of material; mixing through stirring and grinding. The component B is produced through adding mannis added and modified polybasic amine into mixed solution. The paint is applied to the inner wall of oil field pipeline to prevent corrosion of sulfate reducing bacteria.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Low magnetism steel resisting sea water corrosion

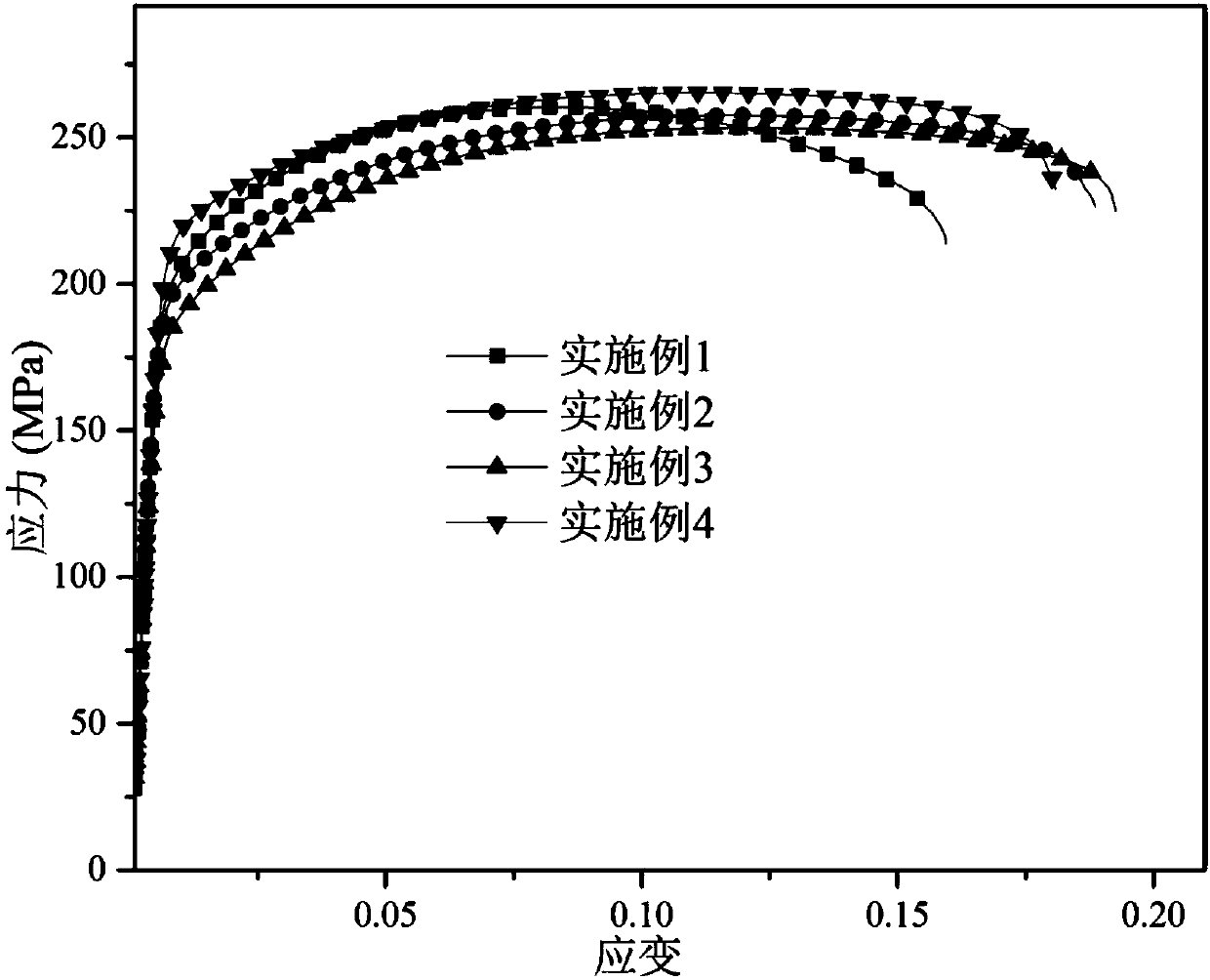

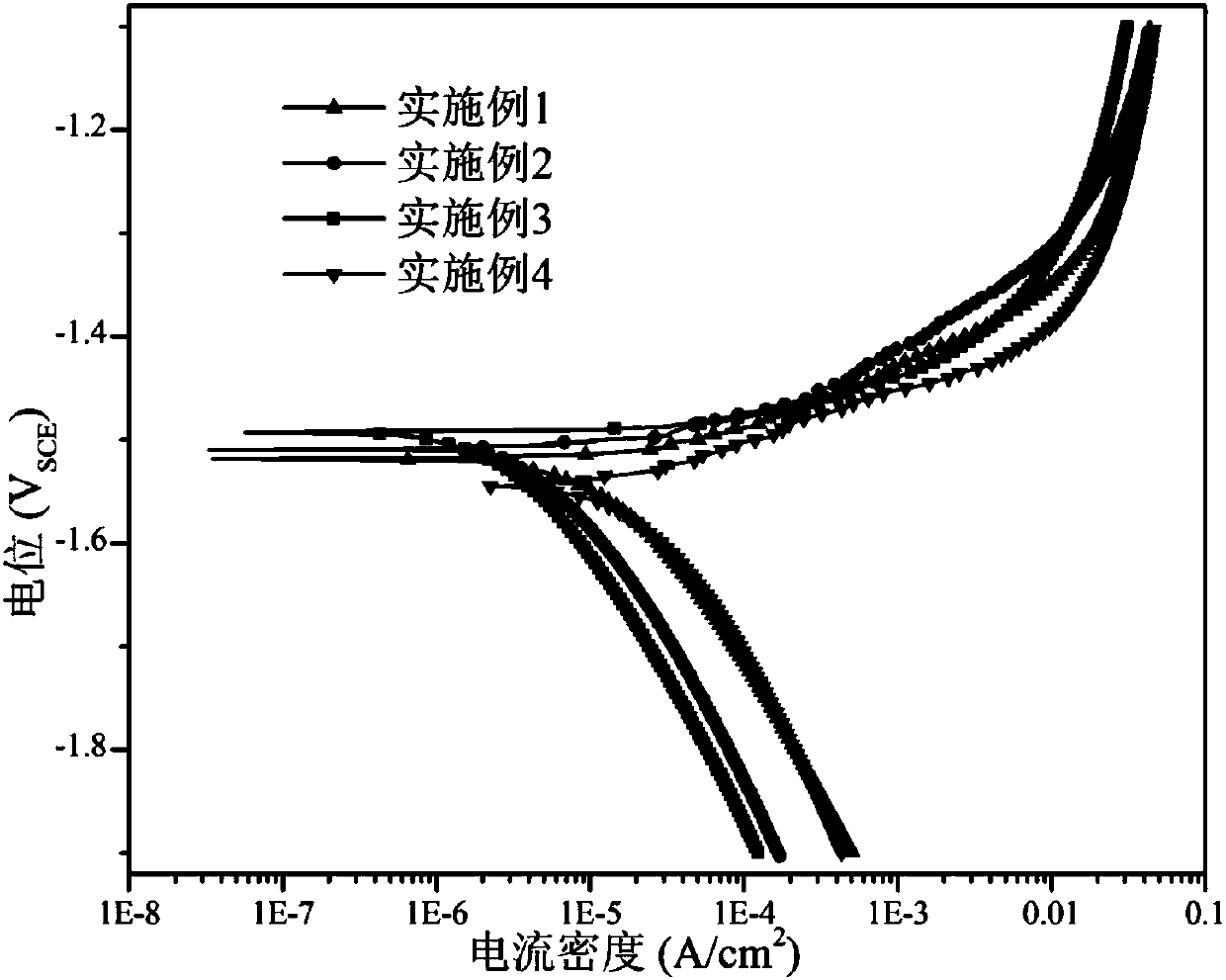

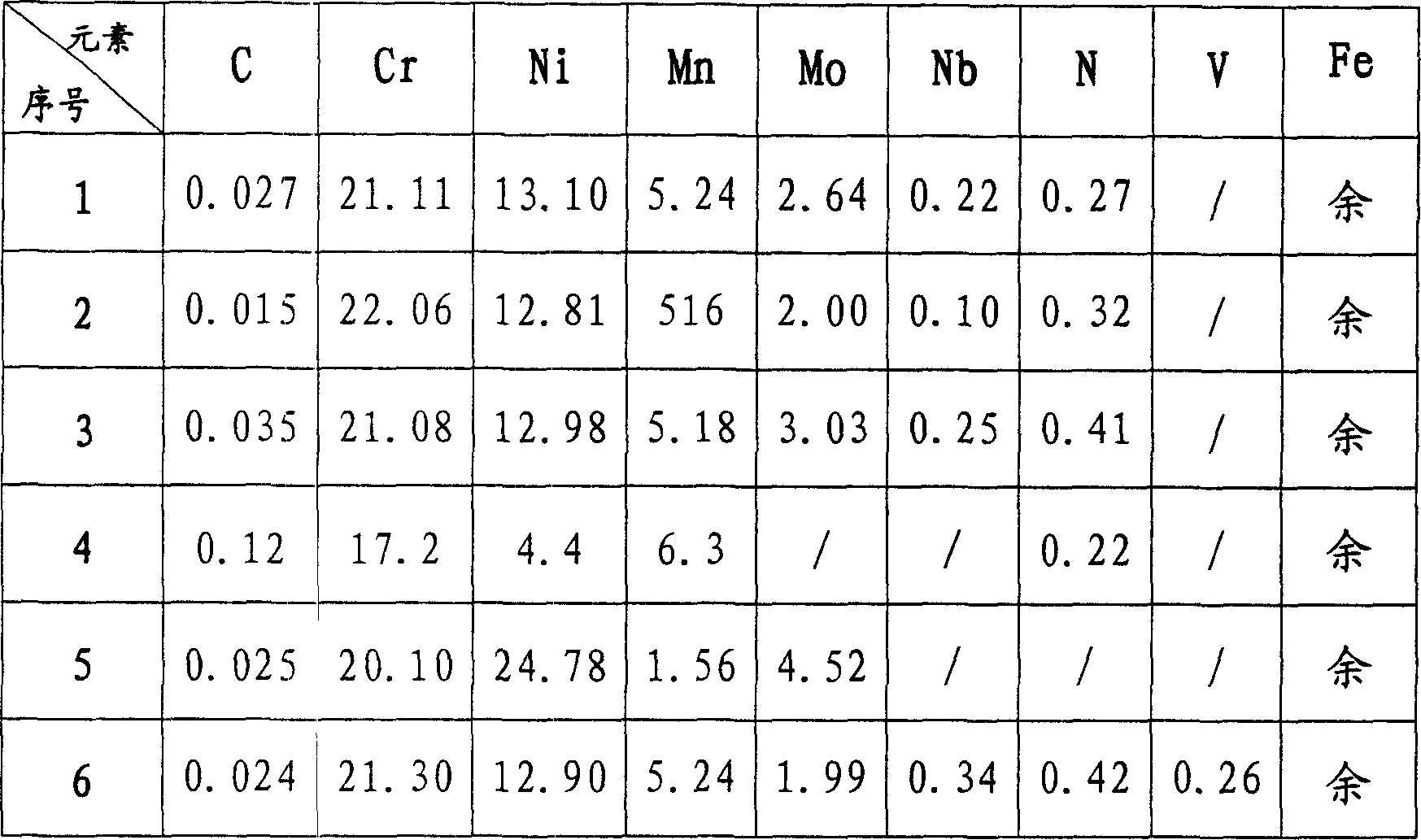

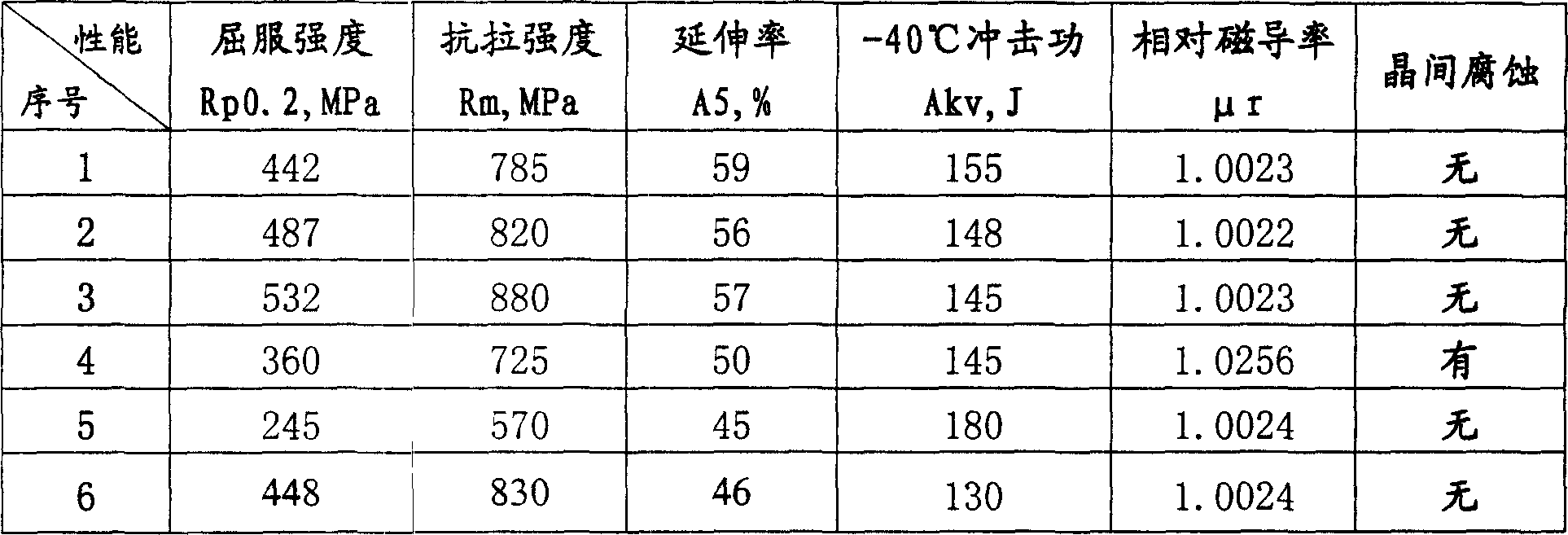

The present invention relates to alloy steel production, and is especially low magnetism stainless steel resisting sea water corrosion. The low magnetism stainless steel resisting sea water corrosion features its components including C not more than 0.04 wt%, N 0.2-0.5 wt%, Cr 21-23 wt%, Ni 12-14 wt%, Mo 2.0-3.5 wt%, Mn 4-6 wt%, Nb 0.05-0.25 wt%, S not more than 0.03 wt%, P not more than 0.035 wt%, and Fe and impurity. Compared with available technology, the material of the present invention has the advantages of high strength, high plasticity, high toughness, low magnetic conductivity, stable magnetic performance, excellent corrosion resistance, capacity of resisting sea water corrosion, low production cost, etc.

Owner:CENT IRON & STEEL RES INST

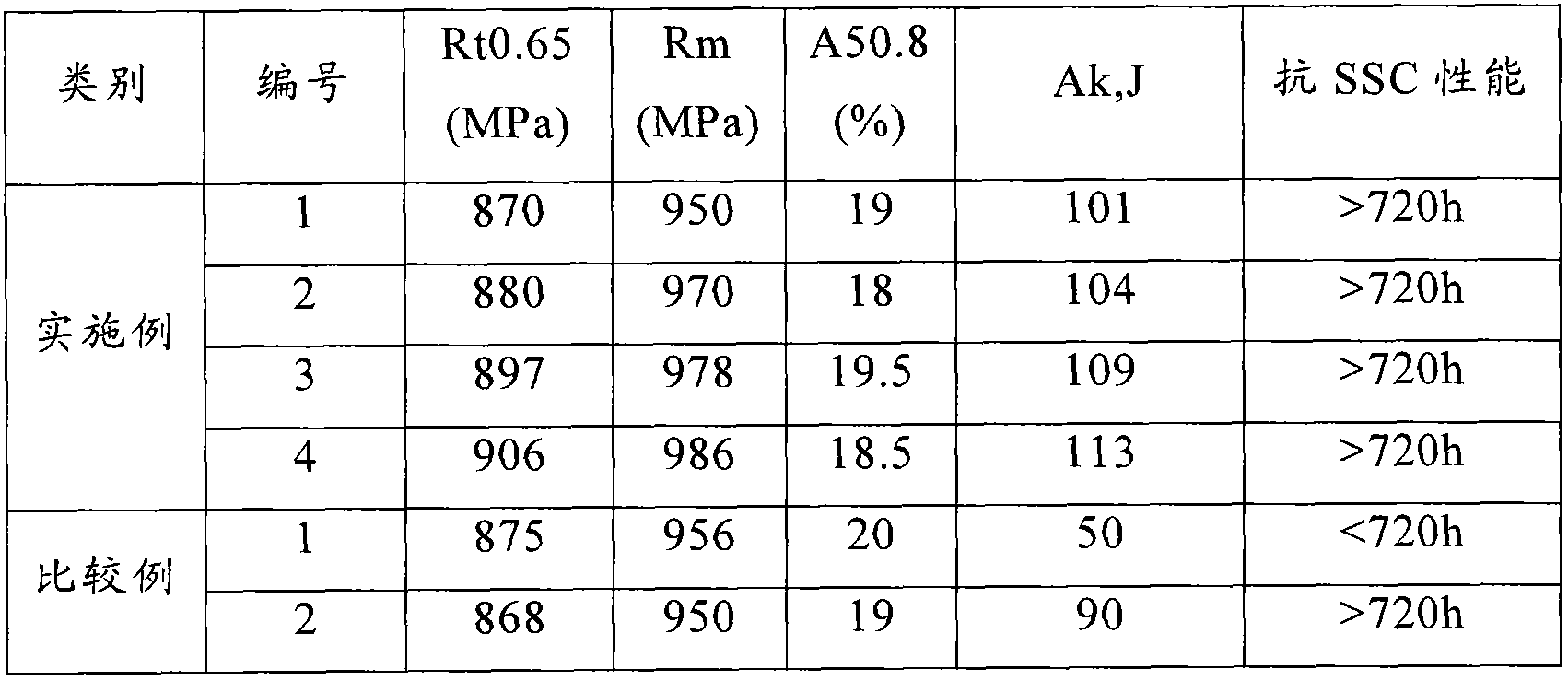

High strength sulfur resisting casing pipe and its heat treatment manufacturing method

ActiveCN102373374AImprove corrosion resistanceSolve the problem of materialsDrilling rodsFurnace typesSulfurThermal insulation

The invention relates to a high strength sulfur resisting casing pipe, which comprises the following chemical components: 0.25-0.35 wt% of C, 0.1-0.5 wt% of Si, 0.4-0.6 wt% of Mn, 0.1-0.6 wt% of Cr, 0.2-0.6 wt% of Mo, 0.03-0.15 wt% of V, less than 0.015 wt% of P, less than 0.010 wt% of S, and the balance Fe as well as inevitable impurity elements. In the invention, when a steel pipe is rolled, a quenching and tempering heat treatment is carried out twice. The quenching and tempering heat treatment comprises the steps of: during the first quenching and tempering heat treatment, keeping a heating temperature of 900DEG C-1000DEG C before quenching, conducting heat preservation for 45min-120min, then spraying water for quenching, and carrying out tempering at a temperature of 670DEG C-710DEG C, performing thermal insulation for 90min-150min, air cooling the pipe when taken out of a furnace; during the second tempering treatment, keeping a heating temperature of 850DEG C-950DEG C before quenching, conducting heat preservation for 45min-120min, then spraying water for quenching, and carrying out tempering at a temperature of 650DEG C-710DEG C, performing thermal insulation for 90min-150min, and air cooling the pipe when taken out of the furnace.

Owner:BAOSHAN IRON & STEEL CO LTD

Acid soil corrosion-resistant steel and preparation method thereof

InactiveCN106350732AGood corrosion performanceMeet the intensityUltimate tensile strengthCorrosion resistant

The invention relates to acid soil corrosion-resistant steel. The acid soil corrosion-resistant steel comprises the following components in percentage by weight: 0.174-0.182% of C, 0.51-0.55% of Si, 1.43-1.63% of Mn, smaller than or equal to 0.008% of P, smaller than or equal to 0.002% of S, 0.018-0.024% of Nb, 0.029-0.032% of Ti, 0.032-0.045% of V, 0.06-0.12% of W, 0.0081-0.0093% of Mg, 0.08-0.13% of Sn, smaller than or equal to 0.0016% of O and the balance of Fe and inevitable impurities. According to the acid soil corrosion-resistant steel and the preparation method thereof, provided by the invention, the acid soil corrosion-resistant steel meets the strength of building steel and has good acid soil corrosion resistance.

Owner:GUANGXI SHENGLONG METALLURGICAL CO LTD

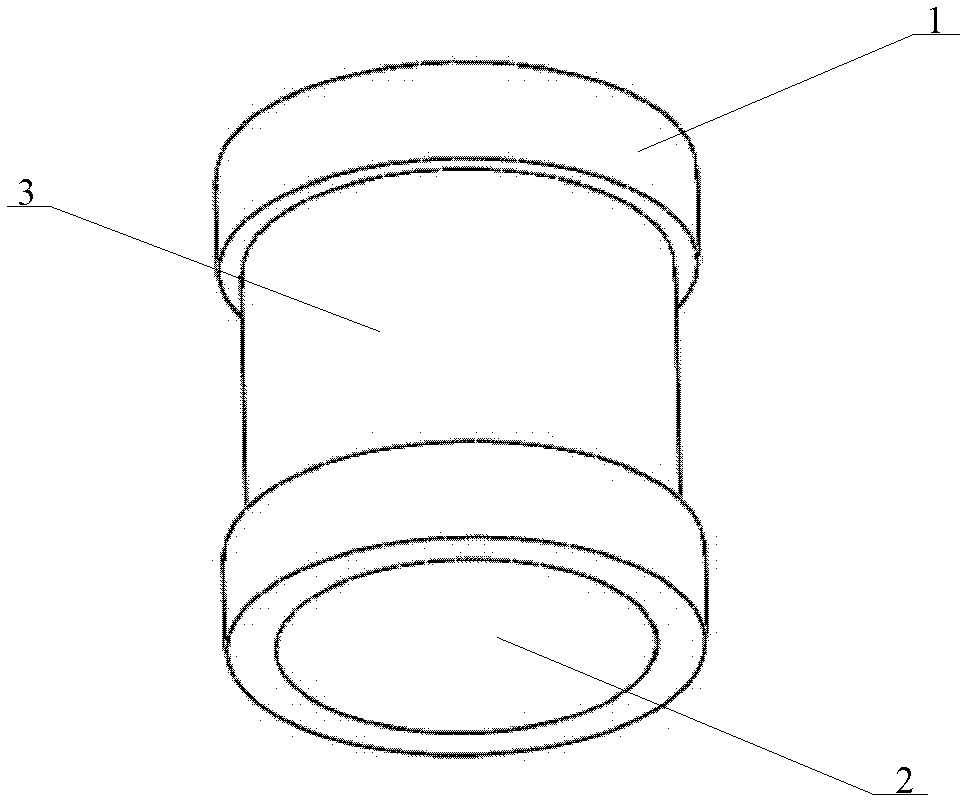

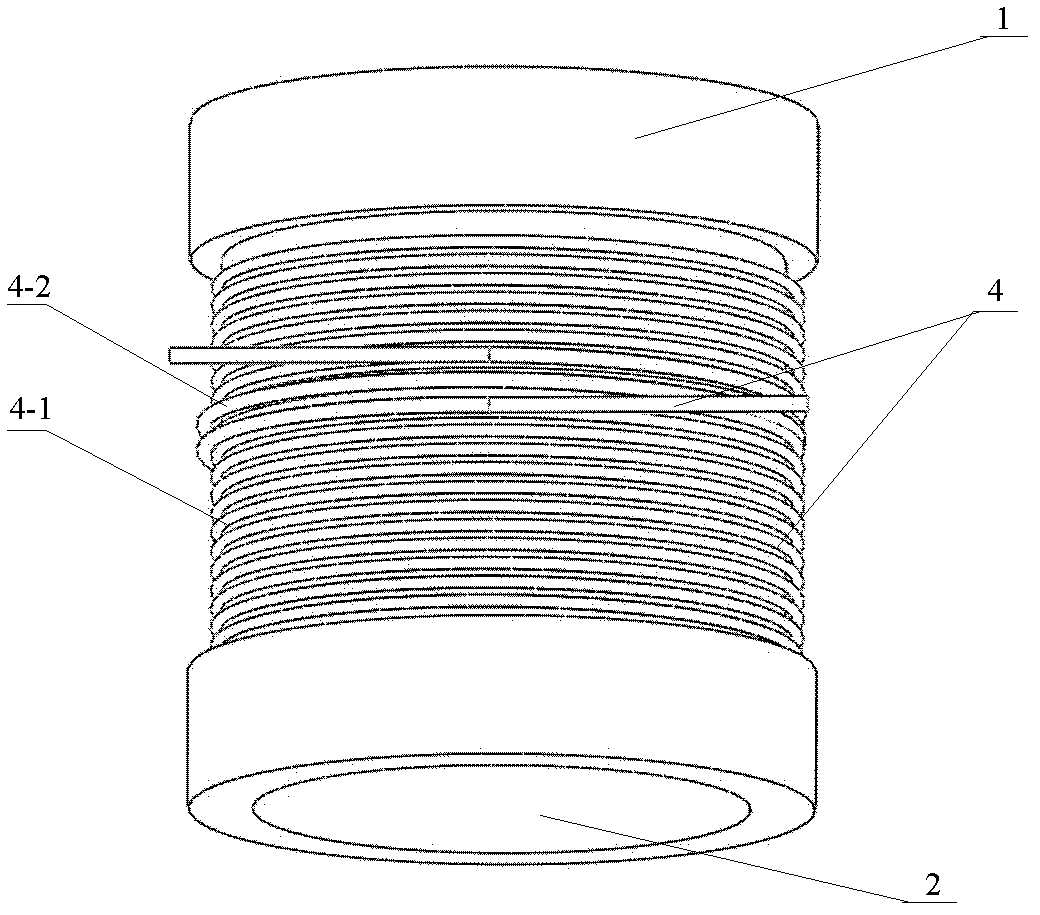

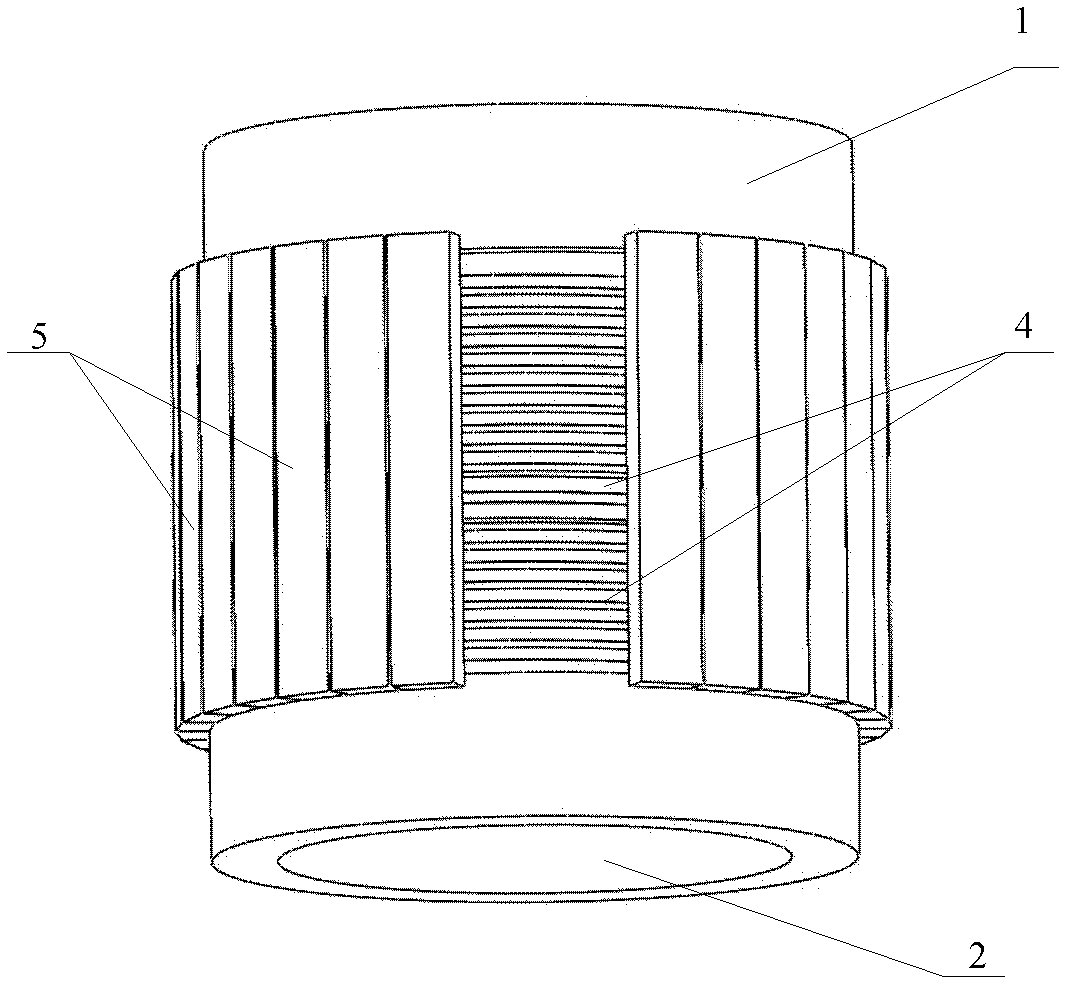

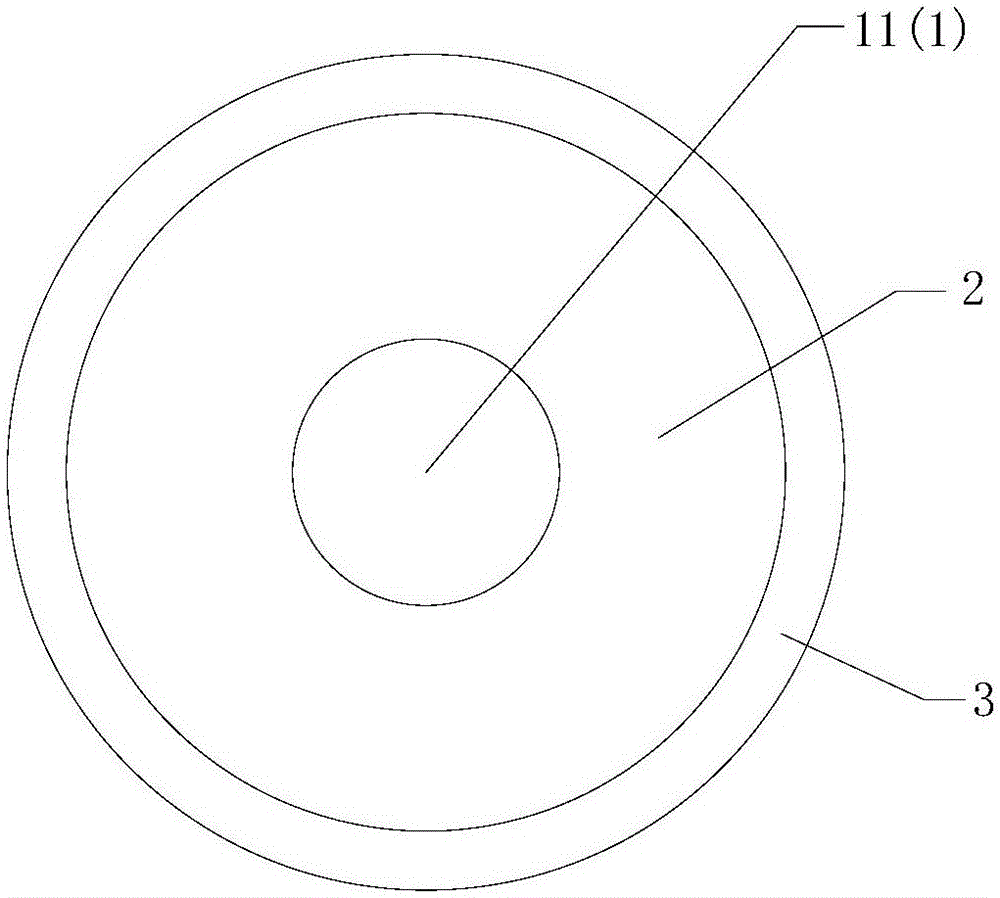

High-accuracy metal detection sensor device

InactiveCN103123400AStrong toughnessGood corrosion performanceElectric/magnetic detectionAcoustic wave reradiationInterference resistanceNonferrous metal

The invention discloses a high-accuracy metal detection sensor device which comprises an inner cylinder, a detection coil, a magnetic permeability layer and an electromagnetic shielding layer. A groove is arranged in the middle of the outer surface of the inner cylinder, and the detection coil is wound in the groove and comprises a primary coil and a secondary coil. The high-accuracy metal detection sensor device is characterized in that the primary coil is wound in the groove of the inner cylinder, the secondary coil is wound on the outer surface of the primary coil, the magnetic permeability layer is fixed on the outer surface of the inner cylinder, namely the outer surface of the detection coil, and the electromagnetic shielding layer is arranged outside the magnetic permeability layer. The high-accuracy metal detection sensor device is simple in structure, high in interference resistance, high in metal detection sensitivity, fine in stability, low in maintenance cost and applicable to various metal detection and separation devices, and can detect tiny ferrous and nonferrous metal particles such as copper, aluminum, stainless steel and alloy.

Owner:常州中科煜明科技有限公司 +1

400 Mpa-grade construction steel with excellent corrosion resistance and production method

InactiveCN106801188AMeet performance index requirementsGood corrosion performanceStrength designCorrosion resistant

The invention discloses 400 Mpa-grade construction steel with excellent corrosion resistance and a production method, and belongs to the field of production of construction corrosion steel. The steel comprises the following components by weight percent: 0.05% to 0.3% of C, 0.2% to 0.6% of Si, 1.2% to 1.6% of Mn, 0.03% or less of P, 0.02% or less of S, 0% to 1.9% of Cr, 0.25% to 1% of Cu, 0.4% to 1% of Ni, 0.1% to 0.5% of Mo and 0.01% to 0.02% of N, and the balance being Fe. The construction steel with excellent corrosion resistance is obtained through the adoption of a vacuum smelting-low temperature rolling-controlled rolling and controlled cooling production method, optimization of selected multi-group components, and optimization of technologies. The 400 Mpa-grade construction steel has the advantages that the steel has excellent corrosion resistance, so that the steel can be utilized in concrete structures with ultrahigh strength and ultrahigh strength design requirements in severe conditions like marine environment and marshland; and the innovation point is that optimal alloy elements like chromium are optimally selected, so that the 400 Mpa-grade construction steel has excellent corrosion resistance.

Owner:SHOUGANG CORPORATION

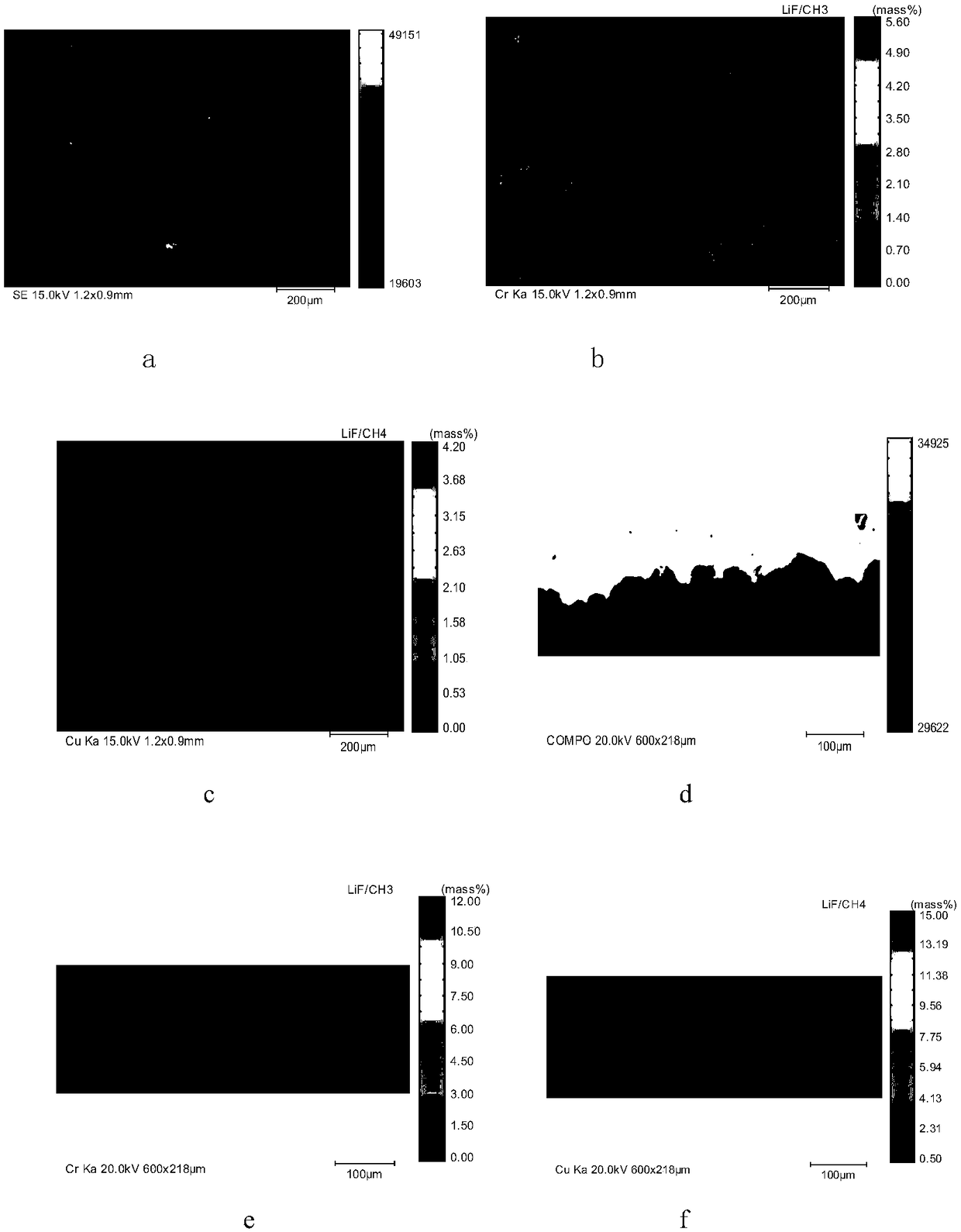

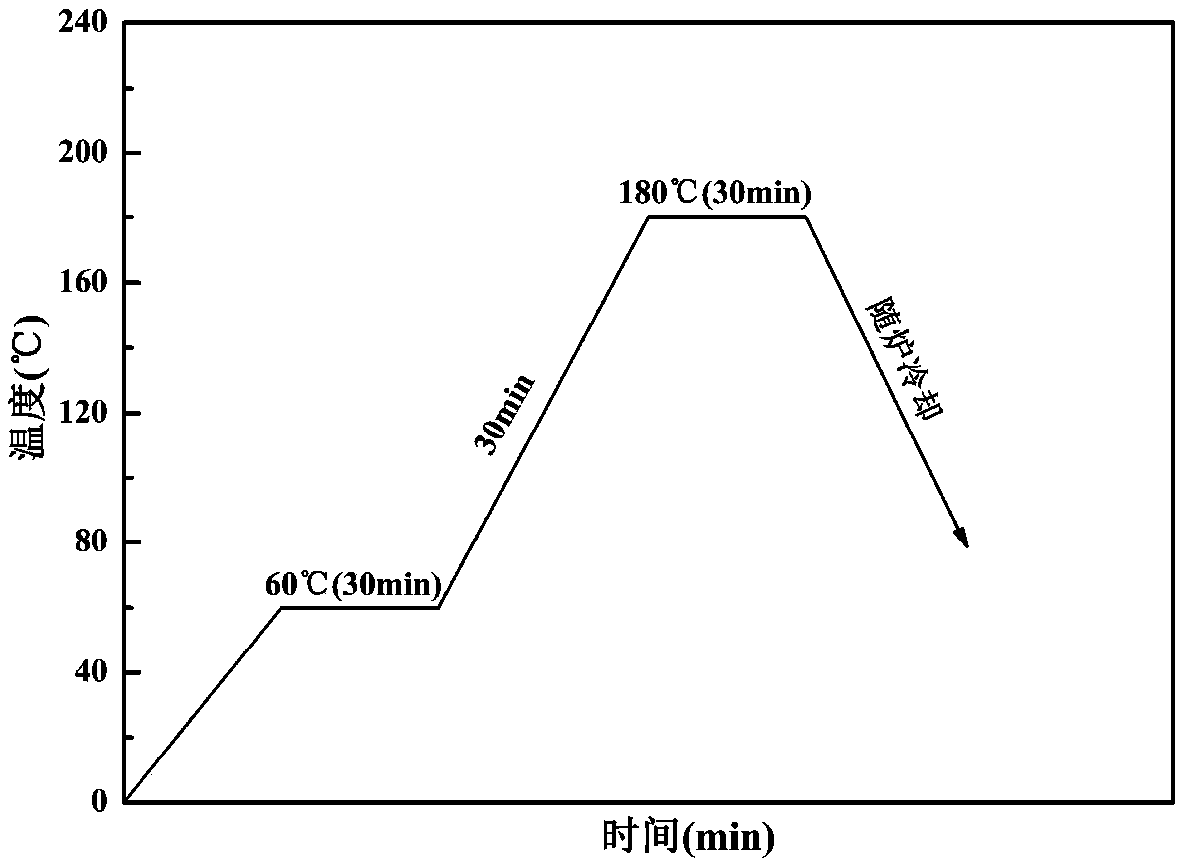

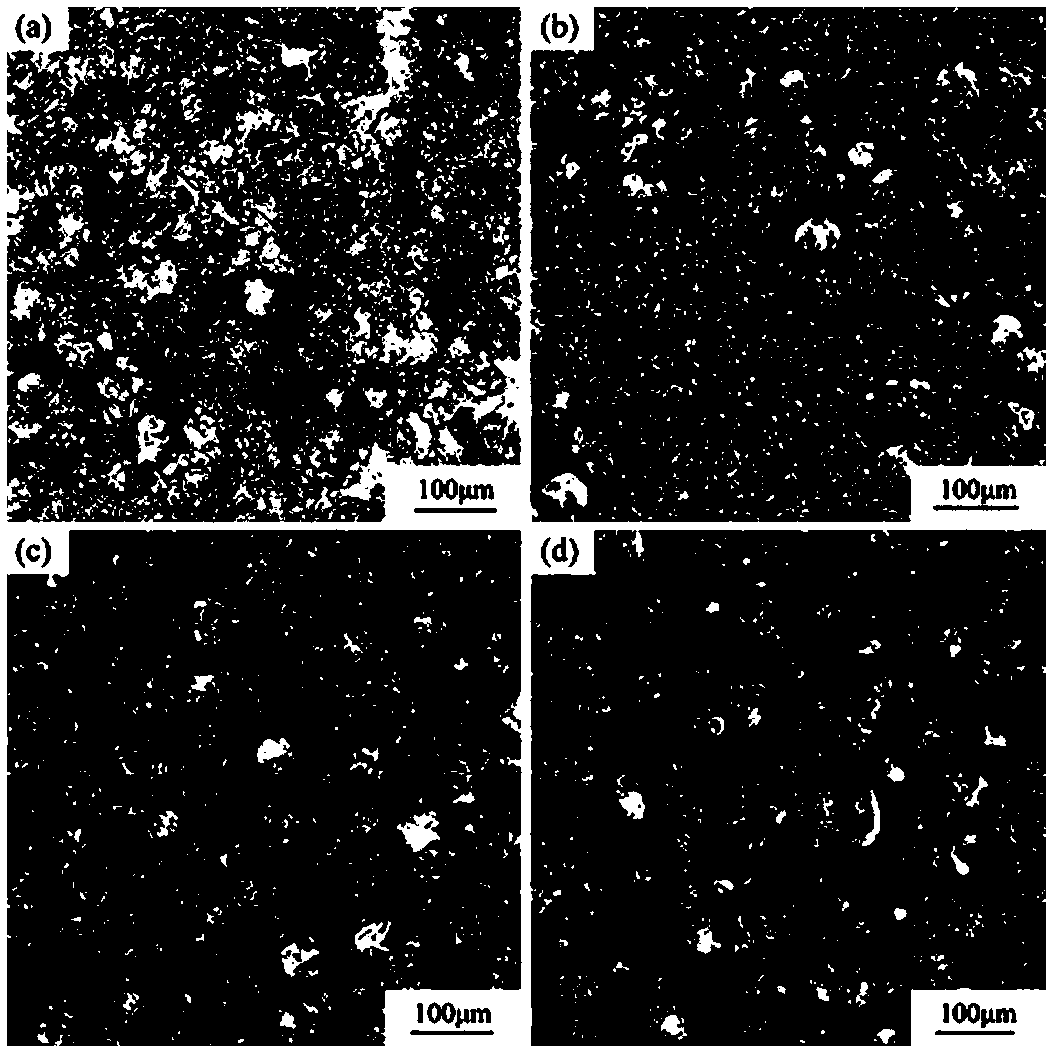

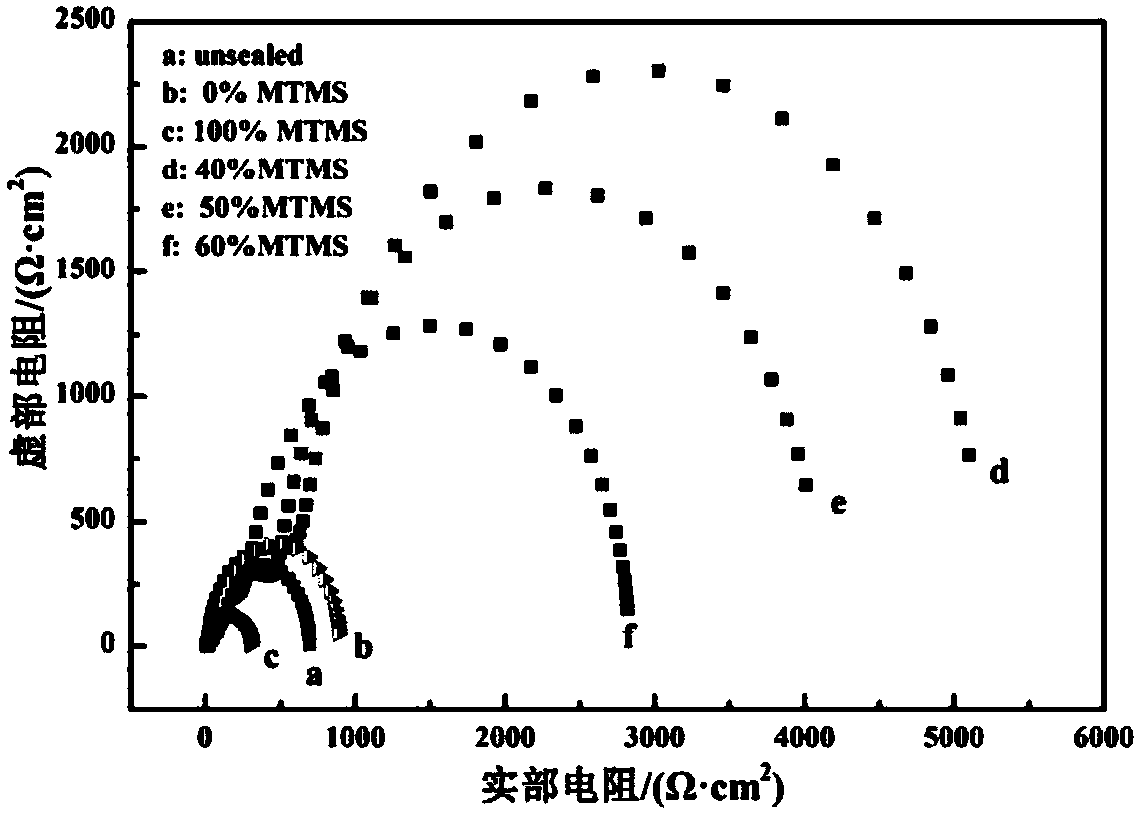

Preparation method of corrosion-resistant Cr3C2-NiCr-aluminum-silicon siloxane composite coating on surface of crystallizer copper plate

ActiveCN108070813AImprove corrosion resistanceAccelerated corrosionLiquid surface applicatorsMolten spray coatingSurface engineeringCopper

The invention discloses a preparation method of a corrosion-resistant Cr3C2-NiCr-aluminum-silicon siloxane composite coating on the surface of a crystallizer copper plate, and belongs to the technicalfield of metal surface engineering. The corrosion-resistant Cr3C2-NiCr-aluminum-silicon siloxane composite coating comprises a thermal-sprayed Cr3C2-NiCr coating and an aluminum-silicon siloxane coating. The preparation method comprises the step that the Cr3C2-NiCr coating which is hundreds of microns thick and the aluminum-silicon siloxane coating which is tens of microns thick are sequentiallysynthesized on the surface of the crystallizer copper plate. The corrosion-resistant Cr3C2-NiCr-aluminum-silicon siloxane composite coating prepared through the method has high compactness and good corrosion resistance, can be effectively used as a protective coating on the surface of the crystallizer copper plate, and effectively prolongs the service life of the crystallizer copper plate.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Paint for pattern-printed tableware and implementation method thereof

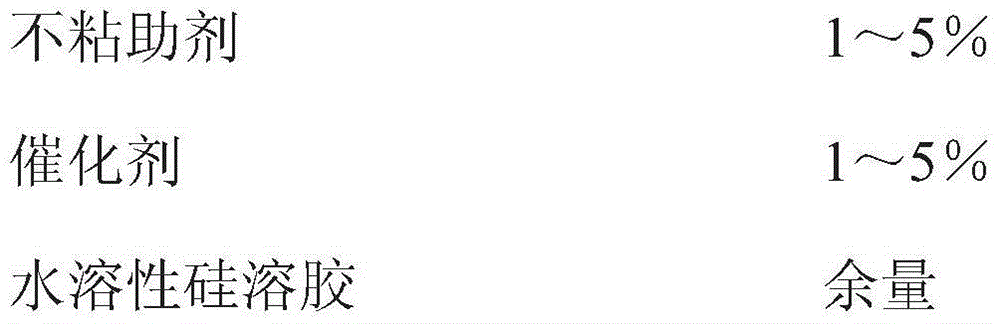

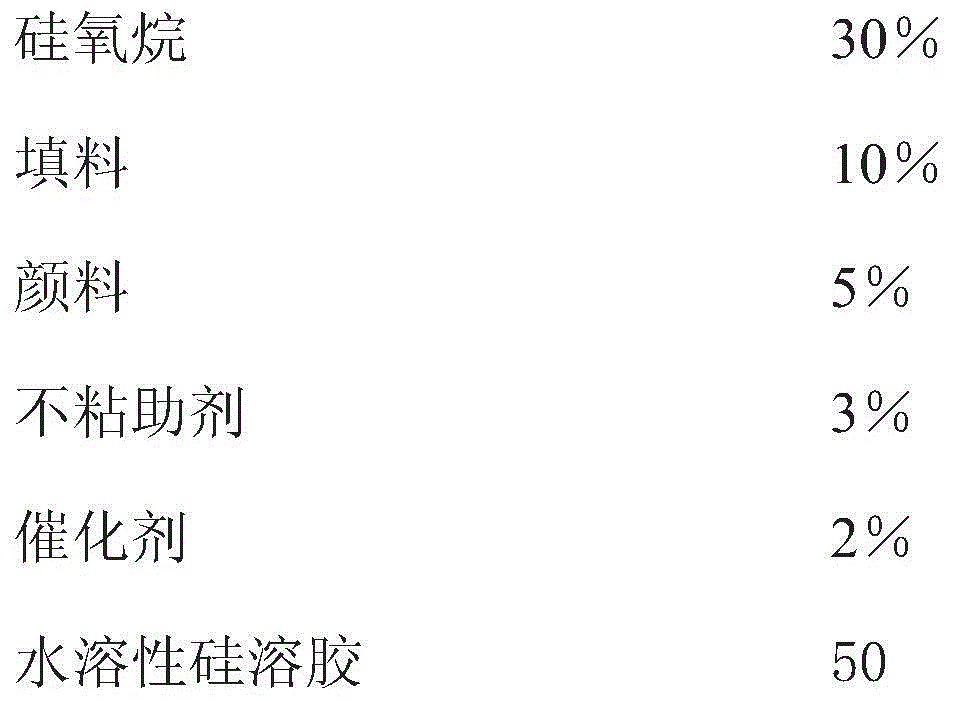

The invention relates to a paint for pattern-printed tableware and an implementation method thereof. The paint comprises the following components in percentage by mass: 10-35% of siloxane, 5-20% of filler, 1-10% of pigment, 1-5% of non-adhesive assistant, 1-5% of catalyst and the balance of water-soluble silica sol. The paint is simple to use, and has the advantages of low cost and favorable decorative effect; and the pattern can be customized to satisfy the market demands.

Owner:SHANGHAI EXCILON NEW MATERIALS +1

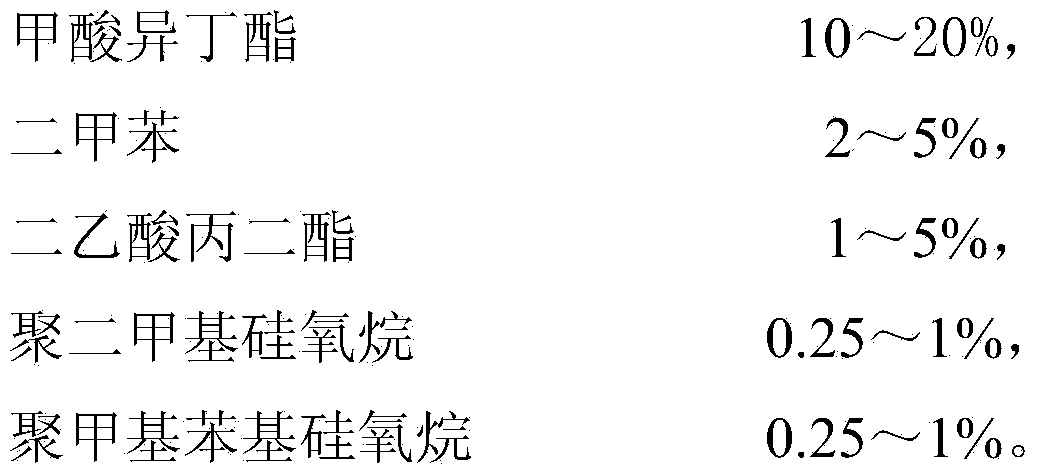

Conductive nano fluorocarbon coating

ActiveCN103468070AIncrease the amount of participationImprove conductivityAnti-corrosive paintsElectrically-conductive paintsFiberPolydimethyl siloxane

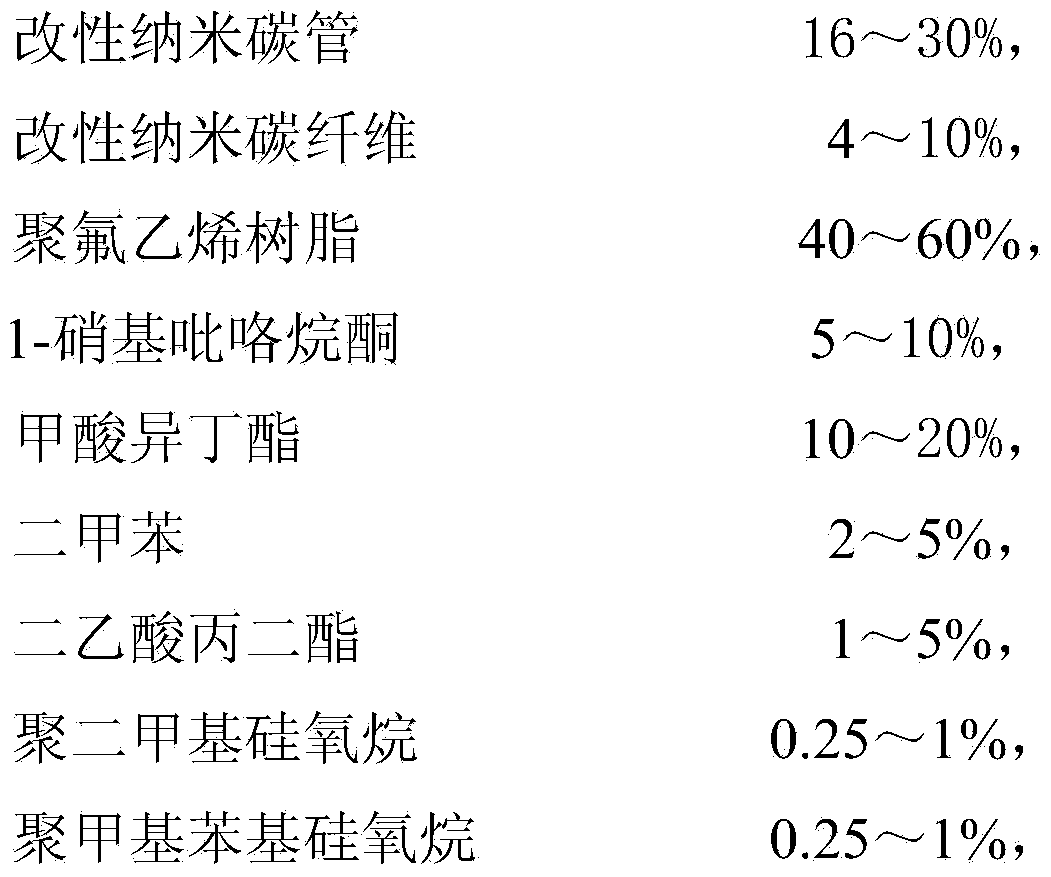

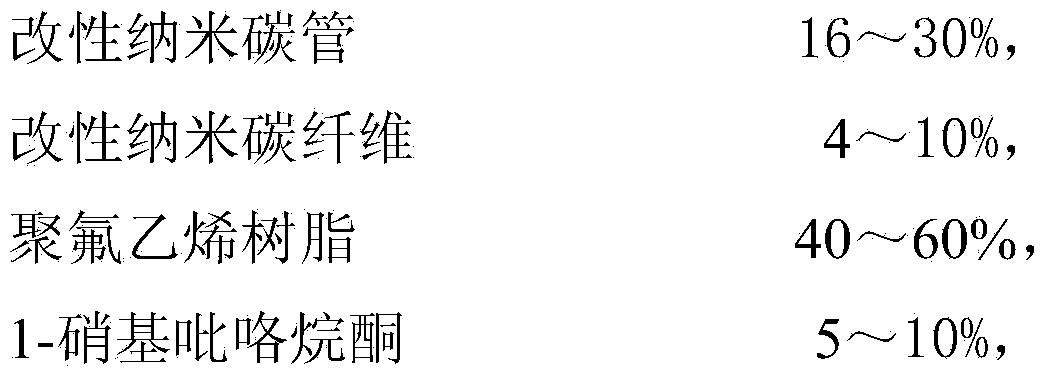

The invention discloses a conductive nano fluorocarbon coating which is prepared by mixing the raw materials by weight percent: 16-30% of modified nanocarbon tube, 4-10% of modified nanocarbon fiber, 40-60% of polyvinyl fluoride resin, 5-10% of 1-nitro-pyrrolidone, 10-20% of iso-butyl formate, 2-5% of dimethylbenzene, 1-5% of propylene diester diacetate, 0.25-1% of polydimethyl siloxane and 0.25-1% of polymethyl phenyl siloxane. The coating has the advantages that (1) the adding quantity of conductive filler reaches up to 40%, so that the adding quantity is greatly increased; (2) the high temperature resistance and the heat stability are greatly improved, so that the coating can endure large current shock; (3) the coating has excellent corrosion resistance and especially can resist the corrosion of acid soil, so that the service life of the coating reaches 20 years; (4) the coating is good in performances and high in cost performance; (5) the coating is widely applied to corrosion prevention of a grounding grid of a large transformer substation.

Owner:STATE GRID HUNAN ELECTRIC POWER +2

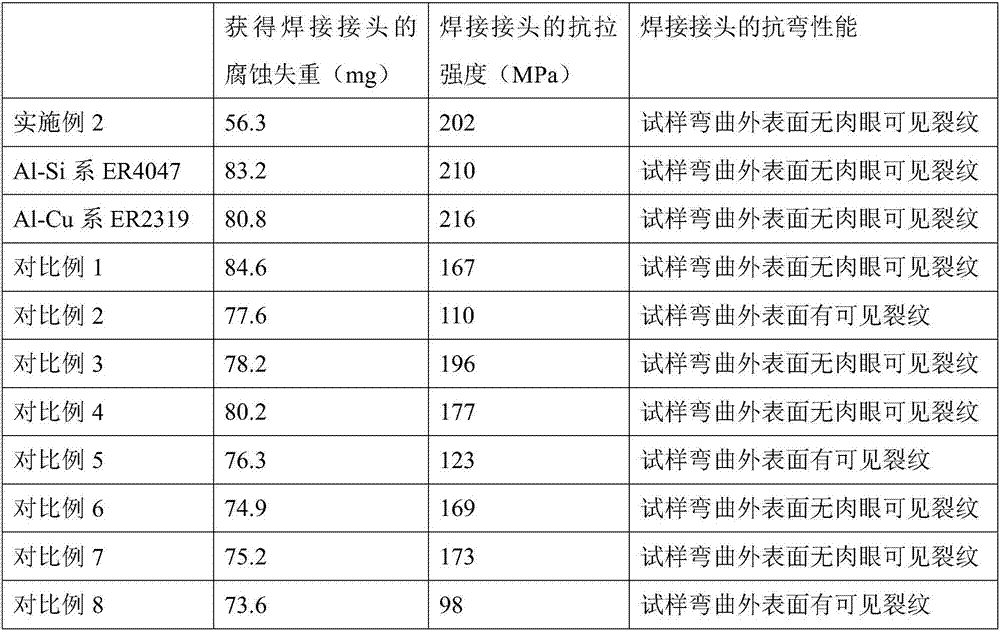

Aluminum-copper alloy grounding material welding wire and preparation method thereof

ActiveCN106862796AReduce compositional differencesGood resistance to soil corrosionWelding/cutting media/materialsSoldering mediaPotential differenceRare earth

The invention discloses an aluminum-copper alloy grounding material welding wire and a preparation method thereof. The aluminum-copper alloy grounding material welding wire comprises, by mass, 1%-3% of silicon, 1%-3% of copper, 0-0.3% of iron, 0.001%-0.05% of zirconium, 0.001%-0.5% of rare earth, and the balance aluminum. The aluminum-copper alloy grounding material welding wire can achieve welding of an aluminum-copper alloy grounding material, the structure of a weld zone is fine, the components are similar to those of parent metal, the potential difference is small, and the soil corrosion resistance is good.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

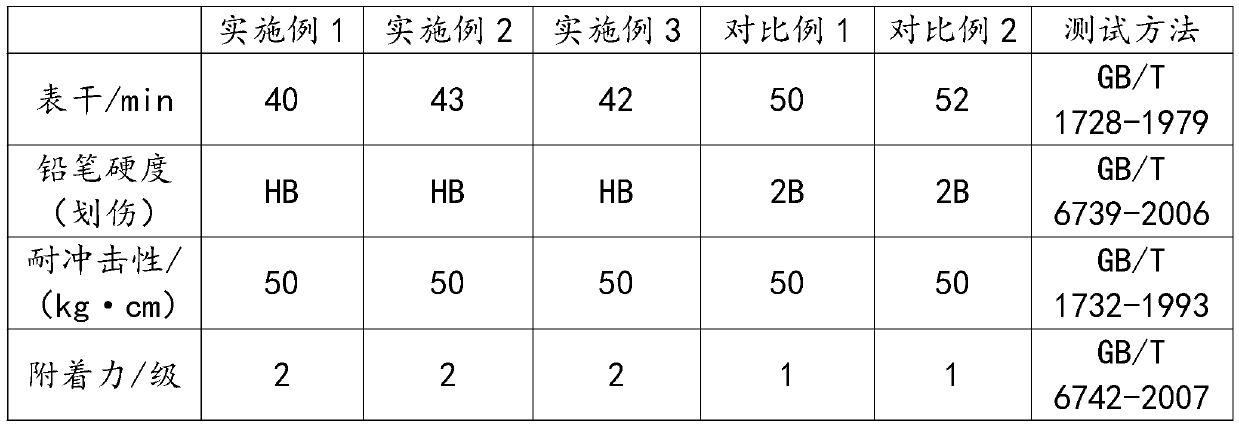

Rust-proof coating for ship deck and preparation process of coating

InactiveCN110054945AImprove stabilityGood redox propertiesLiquid surface applicatorsAnti-corrosive paintsDefoaming AgentsMaterials science

The invention discloses a rust-proof coating for a ship deck. The rust-proof coating is prepared from, by weight, 30-40 parts of silicone acrylic emulsion, 50-60 parts of acrylic emulsion, 2.5-3 partsof polyethylene wax emulsion, 28-34 parts of fluoro-silicon emulsion, 12-16 parts of anti-rust pigments, 3-5 parts of fillers, 2-3 parts of nano-silicon dioxide, 3-4 parts of corrosion inhibitors, 2-3 parts of dispersing agents, 2-3 parts of defoaming agents, 1.5-2 parts of waterborne leveling agents, 1.5-2 parts of waterborne wetting agents and 8-10 parts of ethanol water. The invention furtherdiscloses a preparation process of the rust-proof coating for the ship deck. According to the coating, the corrosion inhibitors and the anti-rust pigments are added, a bottom layer, a middle layer anda surface layer have different structures are matched each other, so that the prepared coating has good hydrophobicity, water resistance can reach 62d, acid and alkali resistance can reach 35d, saltfog performance can reach 38d, and the coating has good corrosion resistance.

Owner:谭运学

Carbon dioxide corrosion resistant pipeline steel and manufacturing method thereof

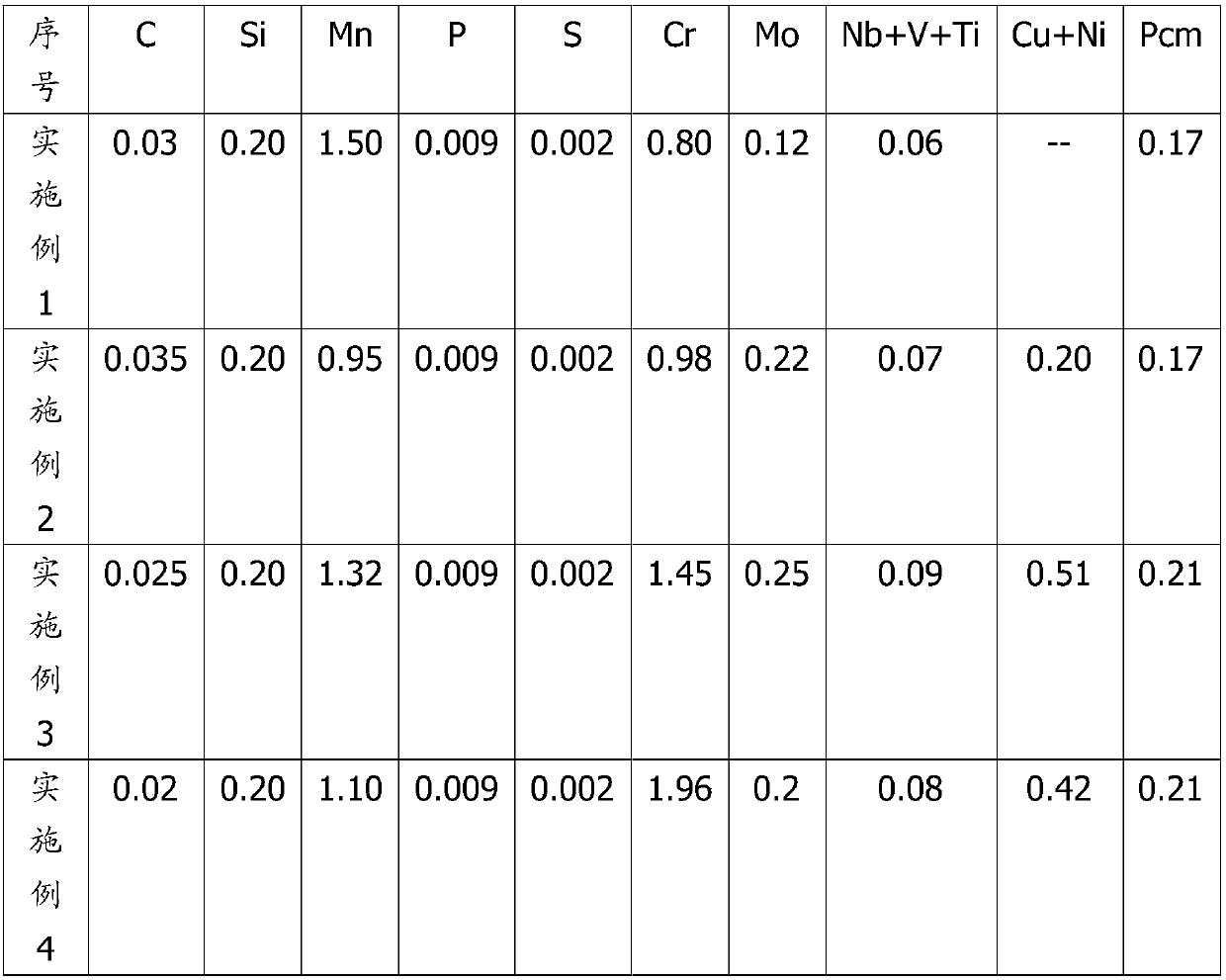

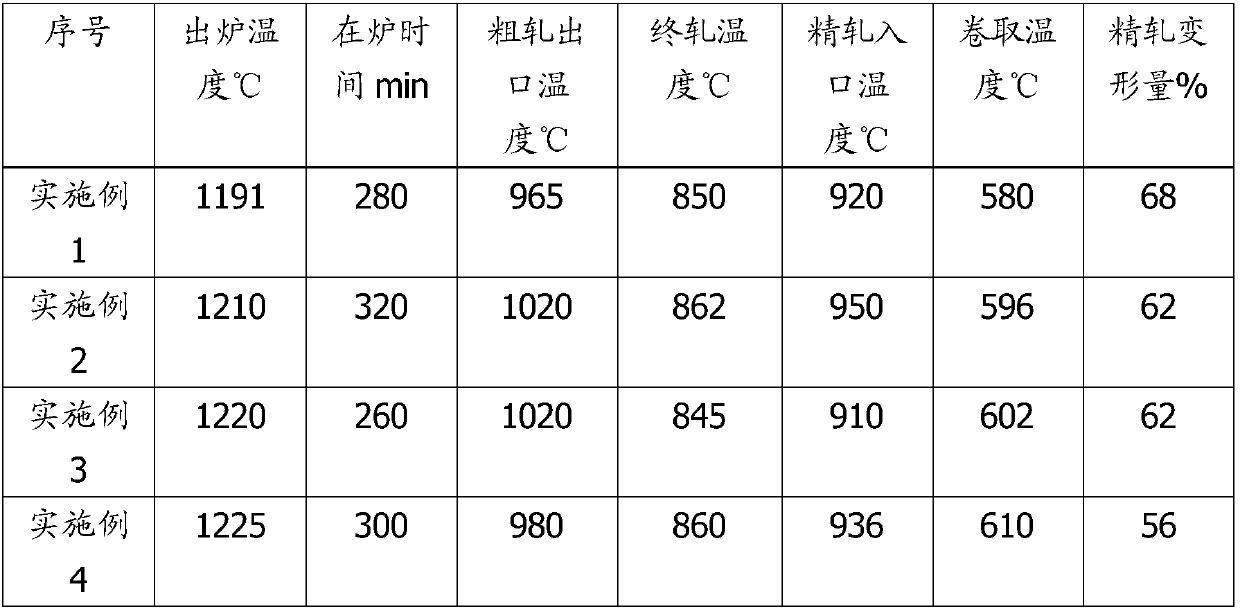

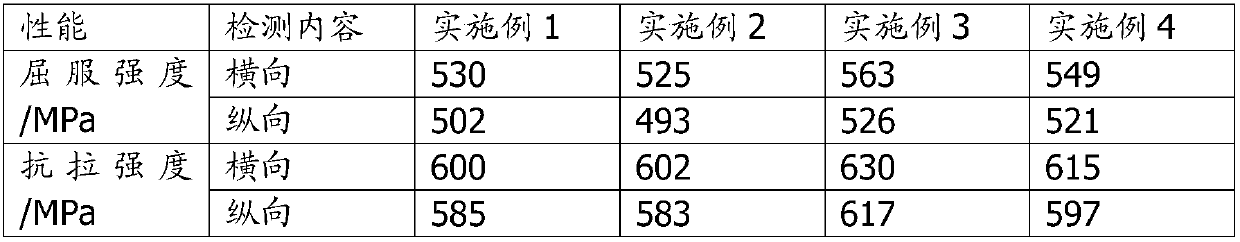

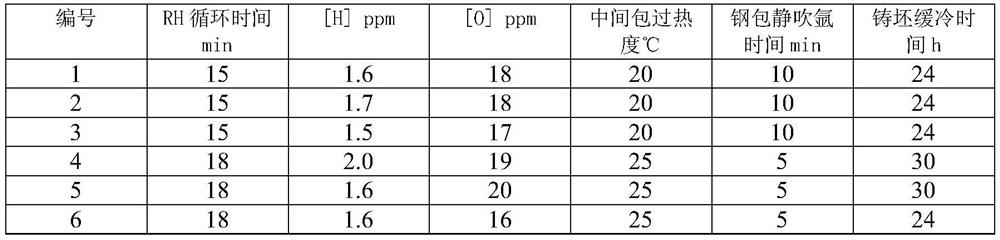

InactiveCN107904496AReduce anisotropyReduce corrosion rateChemical compositionCarbon dioxide corrosion

The invention provides carbon dioxide corrosion resistant pipeline steel and a manufacturing method thereof. The carbon dioxide corrosion resistant pipeline steel comprises the chemical components of,by mass, 0.02%-0.04% of C, 0.10%-0.50% of Si, 0.90%-1.65% of Mn, 0-0.015% of P, 0-0.003% of S, 0.5%-2.0% of Cr, 0.10%-0.50% of Mo, 0.03-0.08% of Nb, 0.01-0.05% of Ti, 0-0.06% of V, 0-0.50% of Cu, 0-0.50% of Ni, 0-0.22% of Pcm, and the balance Fe and unavoidable impurities. According to the carbon dioxide corrosion resistant pipeline steel and the manufacturing method thereof, the requirement of conventional pipeline steel for the Cr element is broken, the condition is matched with optimization design of other alloy elements at the same time, under the condition of little adding of microalloyelements, through corresponding control of smelting and rolling technology, the pipeline steel with good carbon dioxide corrosion resistance and small anisotropism is obtained, and compared with performance of common X65, the carbon dioxide corrosion rate is lowered by 40% or above.

Owner:SHOUGANG CORPORATION

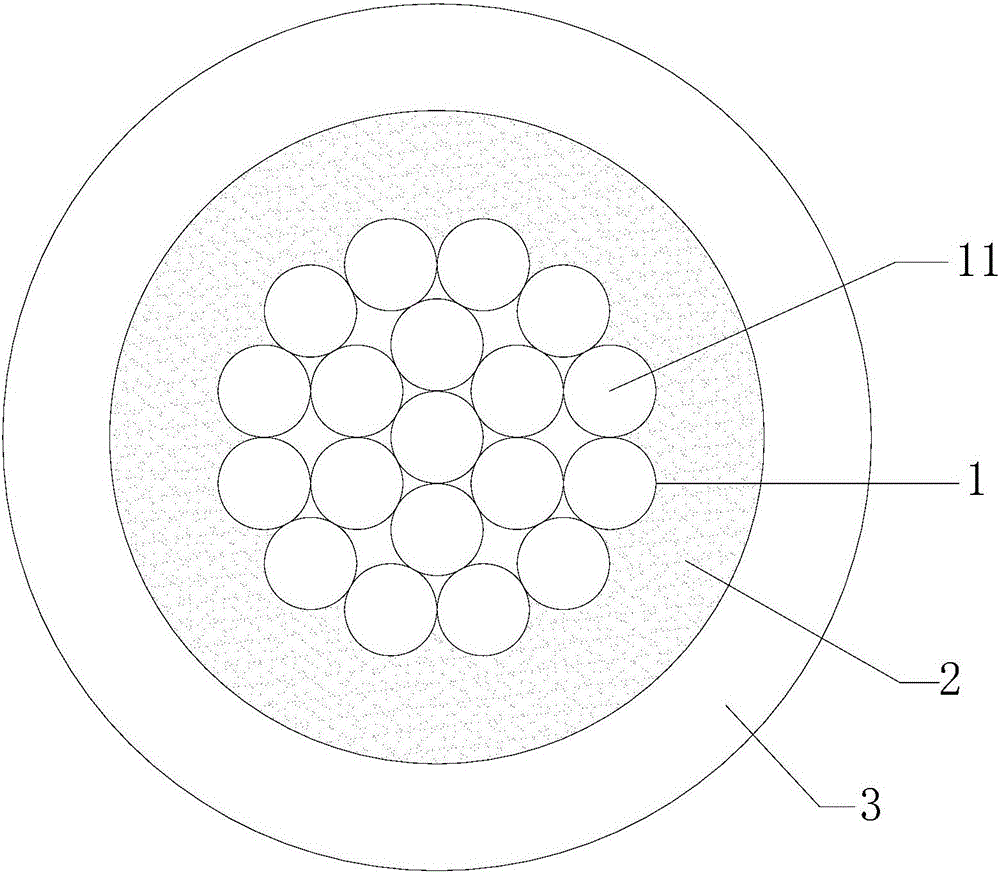

WDZB-BYN low-smoke halogen-free nylon power line and preparation method thereof

InactiveCN106098236AAvoid damageGood corrosion performanceInsulated cablesPower cablesElectrical conductorEngineering

The invention discloses a WDZB-BYN low-smoke halogen-free nylon power line which comprises a conductor, an insulating layer and a sheath. One or a plurality of conductor wires are stranded to form the conductor. The conductor formed by one or a plurality of conductor wires is externally covered by the insulating layer. The insulating layer is externally covered by the sheath. The insulating layer is a low-smoke halogen-free insulating layer. The sheath is a nylon sheath. The invention further provides a preparation method of the WDZB-BYN low-smoke halogen-free nylon power line. By means of conductor preparation, double-layer co-extrusion, printing processing and packaging storage, the WDZB-BYN low-smoke halogen-free nylon power line is obtained, the wearing resistance is good, and the risk of latent short accidents is effectively reduced; the oil resistance and the liquefied gas and gas corrosion resistance are good, and the reliability and the safety performance are effectively improved; the thermal stability and the thermal contraction resistance are good, the mechanical strength is relatively high, and the wearing resistance and other physical and chemical performance are good, and the service lifetime is relatively long; and the low-smoke halogen-free insulating layer and the nylon sheath meet Rosh standards, and the environment protection property is good.

Owner:ZHEJIANG QINSHAN CABLE

Modified epoxy acrylate and preparation method thereof

The invention discloses a modified epoxy acrylate and a preparation method thereof. Raw materials for synthesizing the modified epoxy acrylate comprise epoxy resin, dibasic acid or acid anhydride, hydroxyl acrylate, a catalyst comprising quaternary ammonium salt and an organometallic compound, a polymerization inhibitor and an antioxidant. The synthesis process is simple, and the quaternary ammonium salt and the organometallic compound are matched and are used as the catalyst, so the reaction time is shortened, and multiple performances of a paint film are improved; and the reaction temperature is properly improved, so the reaction time is shortened. The modified epoxy acrylate synthesized through the method has the characteristics of increased flexibility, fast light curing rate, high hardness after curing, large tensile strength, high film glossiness, and excellent chemical corrosion resistance.

Owner:KAMP PHARMA

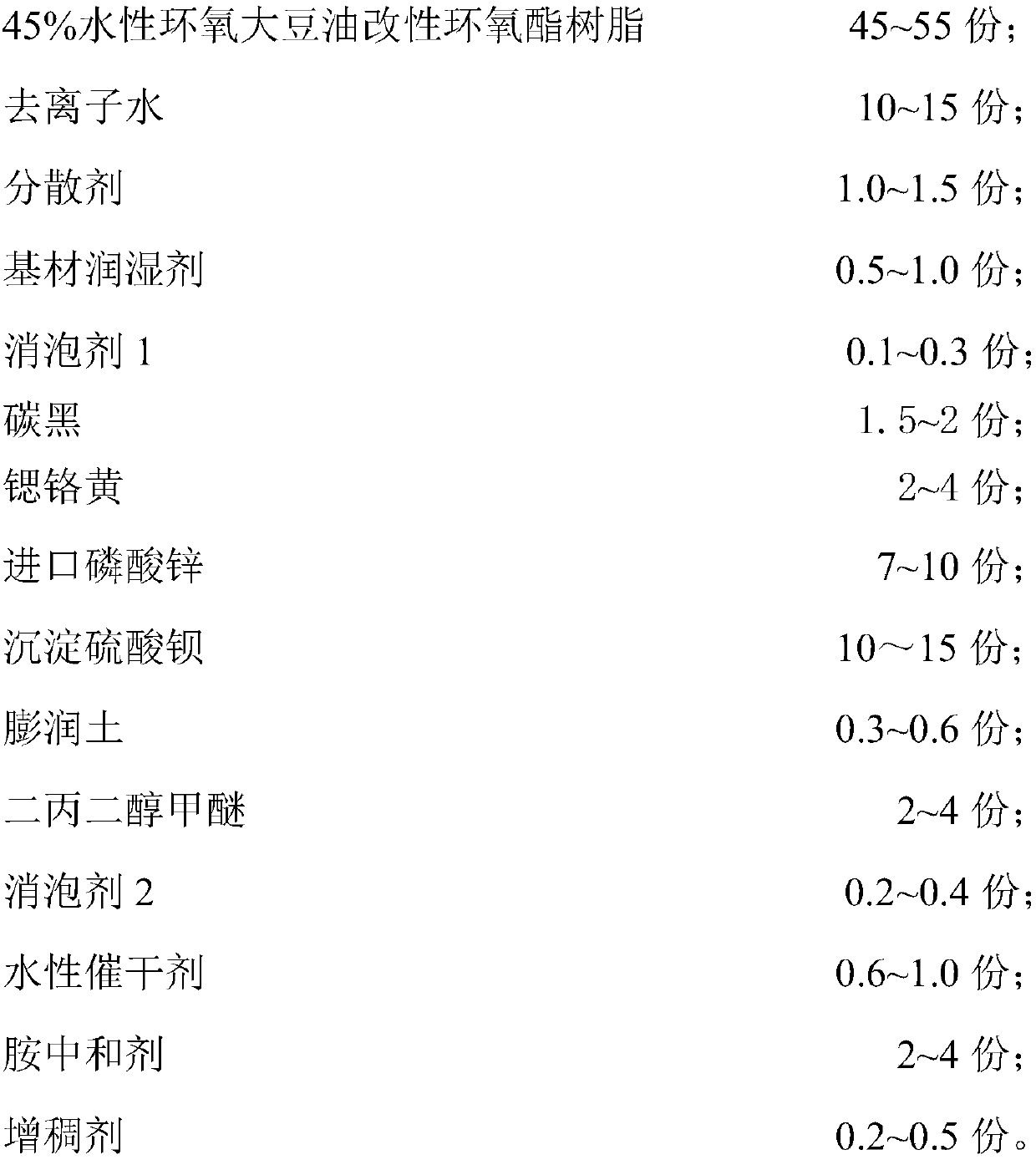

Preparation method of waterborne epoxy soybean oil modified epoxy-ester anticorrosive paint

InactiveCN107916049ASolve cleaningAddress riskAnti-corrosive paintsEpoxy resin coatingsEpoxyZinc phosphate

The invention discloses a waterborne epoxy soybean oil modified epoxy-ester anticorrosive paint and its preparation method. The paint is prepared by 1), preparing 45% of waterborne epoxy soybean oil modified epoxy-ester resin; 2), preparing resin-free mill the raw material comprises deionized water, wetting agent, dispersing agent, antifoaming agent 1, strontium yellow, imported zinc phosphate, carbon black, precipitated barium sulphate and waterborne bentonite; 3), paint mixing: the resin-free mill base, 45% of waterborne epoxy soybean oil modified epoxy-ester resin, drier, antifoamingagent 2, dimethylethanolamine, and thickening agent are mixed to obtain the waterborne epoxy soybean oil modified epoxy-ester anticorrosive paint. The product is excellent in salt-spray corrosion resistance, and can meet the use of an axle under the high salt-spray corrosion resistance environment; the product is good in dryness and can meet the requirement of the existing axle coating line; the thickness of a dry film of a primary film is up to 60 mu m, and the product is free from sagging and good in construction property; the paint is short in coating cycle, low in VOC emission, and is safeand environment-friendly waterborne heavy anti-corrosive paint.

Owner:陕西宝塔山油漆股份有限公司

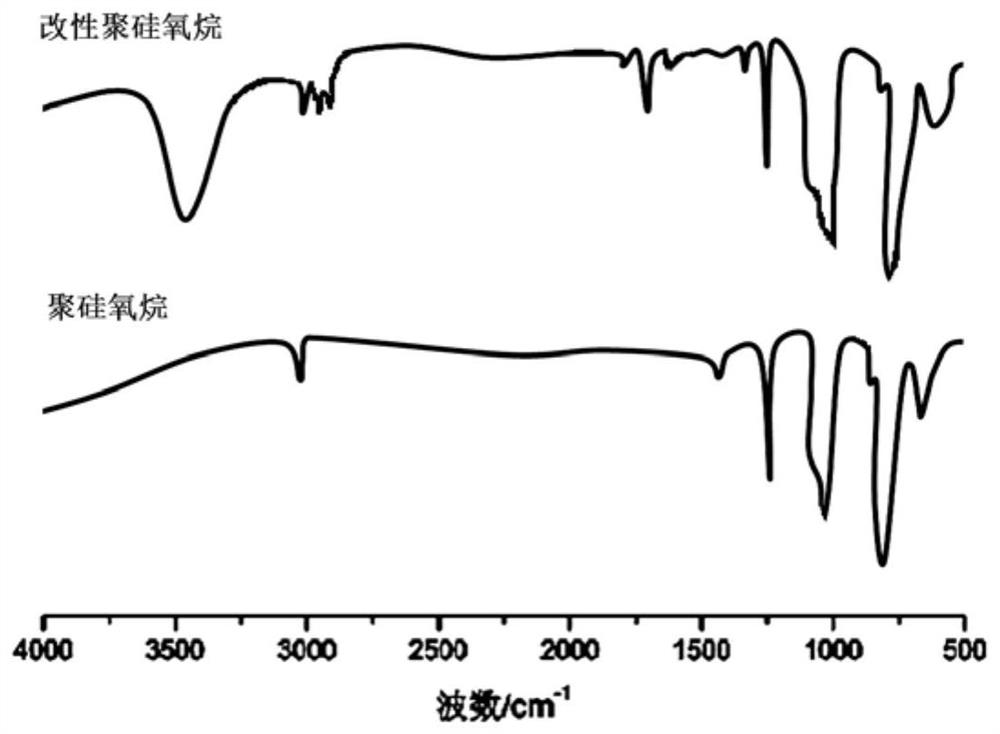

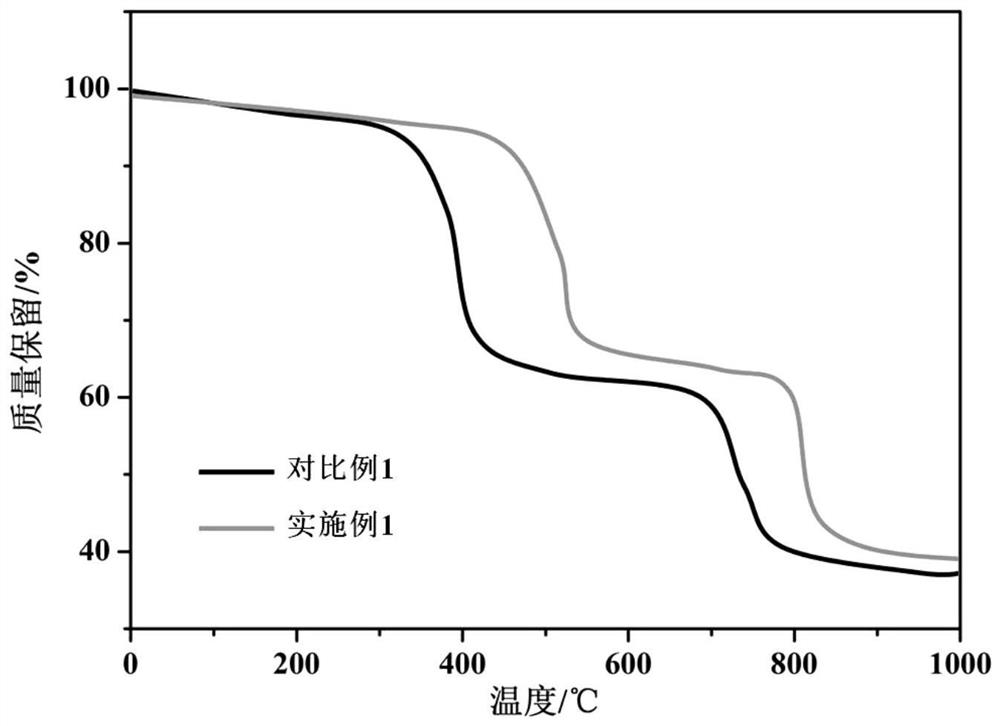

High-performance flame-retardant silane modified polyether sealant and preparation method thereof

ActiveCN112852381AImprove flame retardant performanceHigh tensile strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer sciencePtru catalyst

The invention discloses a high-performance flame-retardant silane modified polyether sealant and a preparation method thereof, and relates to the technical field of sealants. The preparation method of the sealant specifically comprises the following steps: S1, mixing the modified polysiloxane-terminated polyether, the plasticizer, the moisture scavenger, the calcium carbonate, the white carbon black and the flame-retardant filler to obtain a product A; s2, mixing the product A obtained in the step S1 with a tackifier, adding an organic chelated tin catalyst for reaction, and carrying out vacuum defoaming treatment, stirring, discharging and sealing to obtain the sealant. The sealant can maintain good mechanical properties while having excellent flame retardancy, has good elasticity, high adhesive property, good corrosion resistance, high curing speed, outstanding high temperature resistance and excellent product quality, and can be widely applied.

Owner:深圳市优力新材料科技有限公司

Oil well pipe for heavy oil thermal recovery well and manufacturing method

ActiveCN108588558ASolve the technical problems of comprehensive corrosionImprove high temperature resistanceSolid state diffusion coatingFurnace typesChemical compositionQuenching

The invention relates to an oil well pipe for a heavy oil thermal recovery well, and a manufacturing method. The oil well pipe comprises, by weight percent, 0.37 to 0.42% of C, 0.15 to 0.30% of Si, 0.60 to 0.80% of Mn, not larger than 0.02% of P, not larger than 0.01% of S, 0.8 to 1.5% of Cr, 0.04 to 0.06% of Nb, 0.04 to 0.06% of Ti and the balance Fe and inevitable impurities. The oil well pipe has the beneficial effects that the cost is low, the industrial batched production is easily achieved, through the heat treatment technology of subcritical quenching, superhigh temperature tempering and surface aluminizing, the structure of the steel pipe is fine and uniform, corrosion resistance is greatly improved, and the use needs of the current and future market for the oil well pipe with thehigh temperature resistance and corrosion resistance properties are met.

Owner:ANGANG STEEL CO LTD

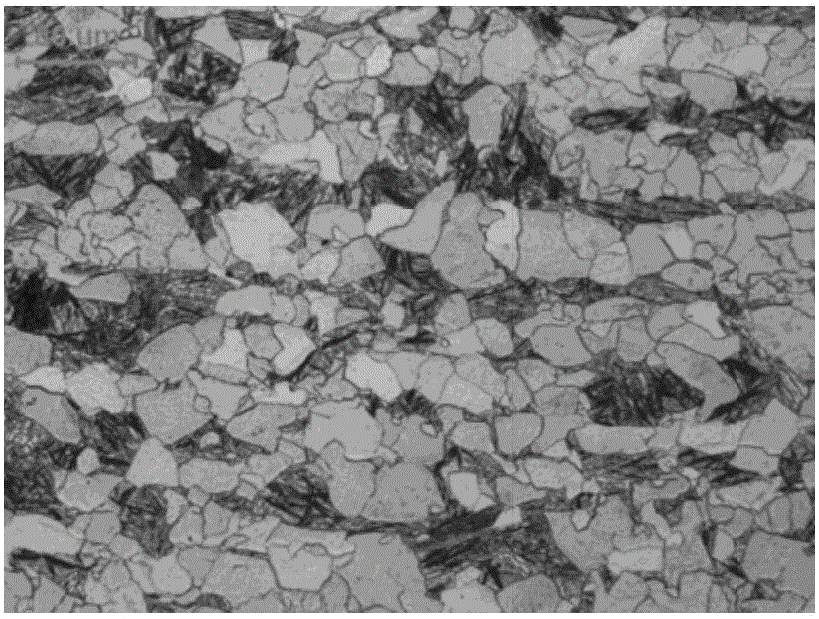

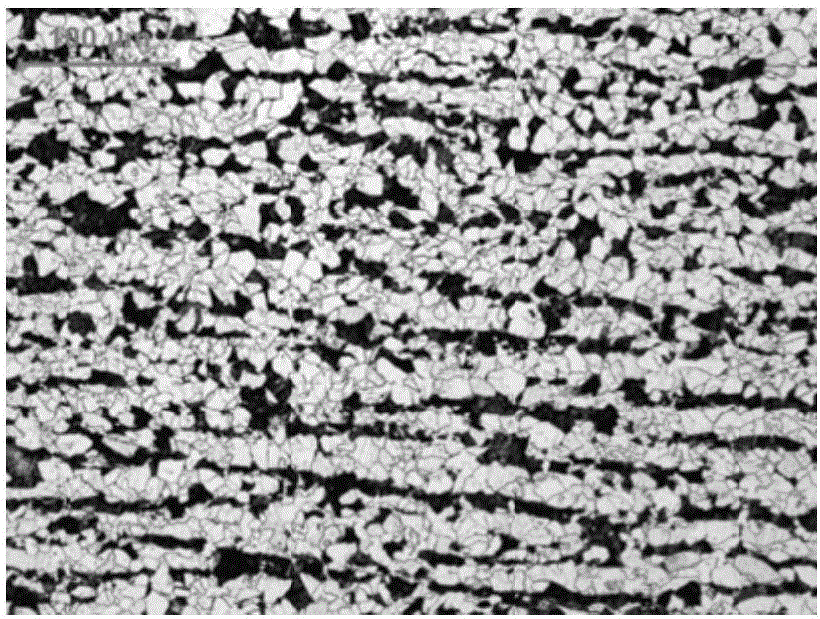

High-toughness titanium alloy and method for preparing bar by using titanium alloy

The invention discloses a high-toughness titanium alloy. The high-toughness titanium alloy comprises the following chemical components of, in percentage by mass, 4.0%-6.0% of Al, 1.0%-3.0% of Mo, 1.0%-3.0% of Zr, 0.5%-1.0% of Fe, 0.2%-0.5% of V and the balance Ti and inevitable impurities. The method for preparing the bar by using the high-toughness titanium alloy comprises the following steps that aluminum titanium, molybdenum titanium, iron nails, titanium-vanadium intermediate alloy, pure zirconium sponge and titanium sponge are correspondingly weighed, mixed and pressed into an electrode bar, and the electrode bar is smelted in a vacuum consumable electro-arc furnace for two times to obtain a titanium alloy cast ingot; the surface of the titanium alloy cast ingot is coated with a puretitanium plate with the thickness of 1.0-2.0 mm, an anti-oxidation coating is brushed on the surface of the pure titanium plate, and the titanium alloy cast ingot is aired for later use; the titaniumalloy cast ingot is placed in a heating furnace to be heated to 930-1150 DEG C, and heat preservation is conducted; and the ingot heated by a radial forging machine is forged to obtain a forging blank; and the forging blank is straightened by using a press machine by using waste heat, and finally machining is conducted to obtain the bar. According to the high-toughness titanium alloy and the method for preparing the bar by using the titanium alloy, the bar prepared from the titanium alloy is high in strength, high in plasticity, high in low-temperature impact toughness and good in corrosion resistance, and the application requirements of severe working conditions of oil and gas wells are met.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

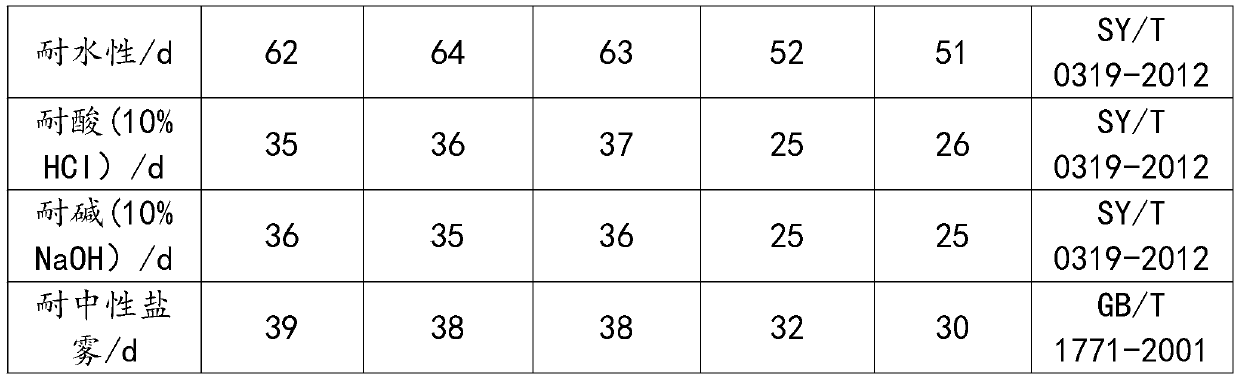

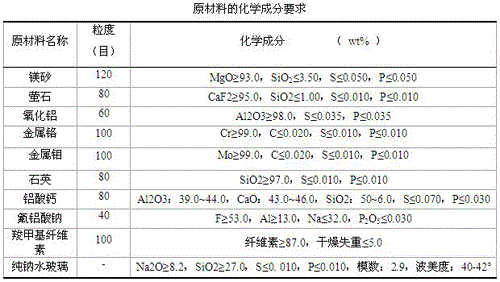

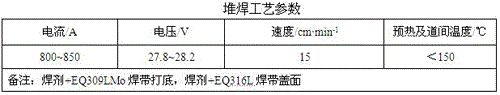

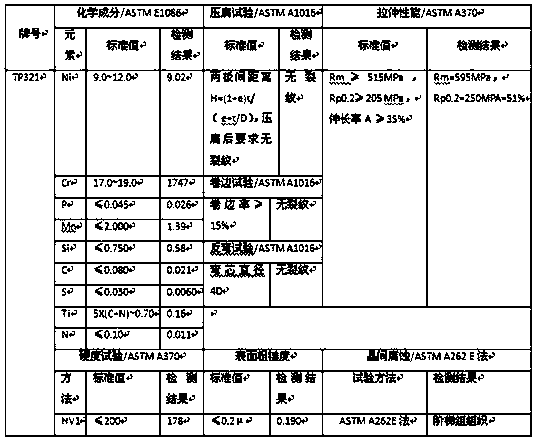

Stainless steel band electrode submerged arc surfacing flux allowing postweld heat treatment

ActiveCN106078005AExcellent lateral bending resistanceExcellent corrosion resistanceWelding/cutting media/materialsSoldering mediaAluminateSodium hexafluoroaluminate

The invention discloses stainless steel band electrode submerged arc surfacing flux allowing postweld heat treatment, and belongs to flux used in the metal welding field. The flux is formed by mixing, by weight ratio, 31-33% of magnesite, 3-6% of fluorite, 12-15% of aluminium oxide, 2-3% of metal chromium, 3-4% of metal molybdenum, 10-14% of quartz, 3-5% of sodium fluoroaluminate, 2-4% of calcium aluminate, 1-3% of carboxymethylcellulose and 21-24% of pure sodium silicate. When the flux is matched with an EQ309LMo and EQ316L solder strip, postweld heat treatment can be carried out, and the bending performance (especially lateral bending with t is equal to 3mm) and intergranular corrosion resistance are good, and the steel band electrode submerged arc surfacing flux allowing postweld heat treatment can be applied to inner wall surfacing welding of high-temperature containers such as hydrogenation reactors and coal gasifiers.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Manufacturing method of photo-thermal power generation and heat collection and absorption temperature-resistant special alloy welding pipe

InactiveCN108247293AGood appearance and dimensional accuracyGood mechanical propertiesSurface roughnessAlloy

The invention discloses a manufacturing method of a photo-thermal power generation and heat collection and absorption temperature-resistant special alloy welding pipe. The manufacturing method comprises the steps of plate rolling forming, welding, welding joint treatment, heat treatment, rounding and straightening, eddy current detection, water pressure testing, pickling and passivating, polishingand check of the external dimensions. The welding process is an argon arc welding, rough polishing and fine polishing combined process. The novel photo-thermal power generation and heat collection and absorption temperature-resistant special alloy welding pipe manufactured through the manufacturing method has good external dimensional accuracy, excellent mechanical property and excellent corrosion property, and the outer surface roughness of the photo-thermal power generation and heat collection and absorption temperature-resistant special alloy welding pipe meets the requirement for fine polishing.

Owner:ZHEJIANG JIULI HI TECH METALS

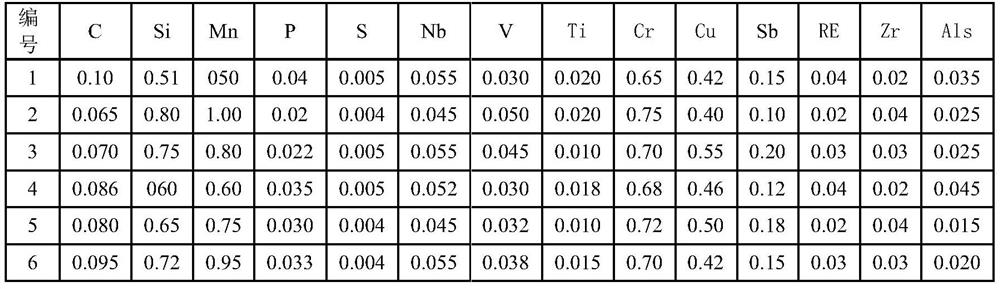

High-performance steel plate resistant to corrosion of marine total immersion zone and production method of high-performance steel plate

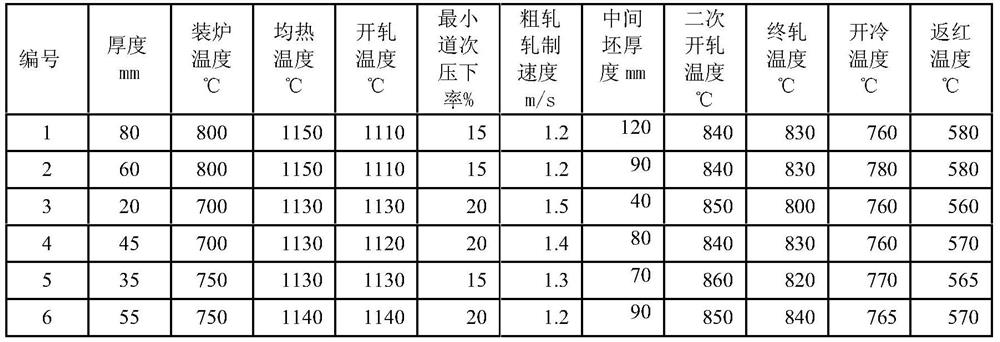

The invention discloses a high-performance steel plate resistant to corrosion of a marine total immersion zone and a production method of the high-performance steel plate. The steel plate comprises the following chemical components of, in percentage by weight, 0.065%-0.10% of C, 0.51%-0.80% of Si, 0.50%-1.00% of Mn, 0.02%-0.04% of P, S less than or equal to 0.005%, 0.045%-0.055% of Nb, 0.03%-0.05% of V, 0.01%-0.02% of Ti, 0.65%-0.75% of Cr, 0.40%-0.55% of Cu, 0.10%-0.20% of Sb, 0.020%-0.040% of RE, 0.02%-0.04% of Zr and 0.015%-0.045% of Als, the charging furnace temperature of a casting blank is 700-800 DEG C, the soaking temperature is 1130-1150 DEG C; the rough rolling starting temperature is 1100-1140 DEG C, the pass reduction rate is 15%-25%, the rough rolling speed is 1.2-1.5 m / s, the secondary rolling temperature is 840-860 DEG C, the finish rolling temperature is 800-840 DEG C, the initial cooling temperature is 760-780 DEG C, and the self-tempering temperature is 560-580 DEG C. The corrosion rate of the steel plate in the ocean total immersion area is smaller than 0.08 mm / a, the yield strength is 460-520 MPa, and the impact energy at the temperature of 60 DEG C below zero is larger than or equal to 200 J.

Owner:ANGANG STEEL CO LTD

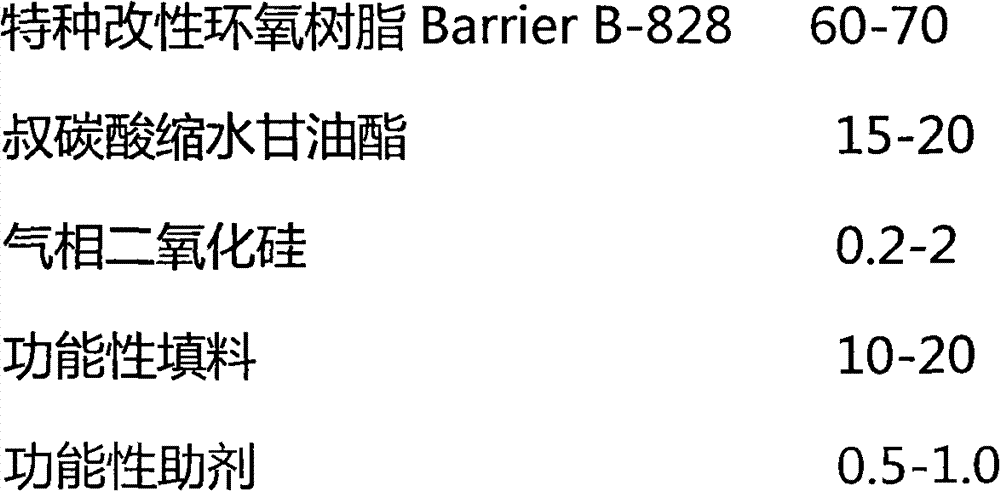

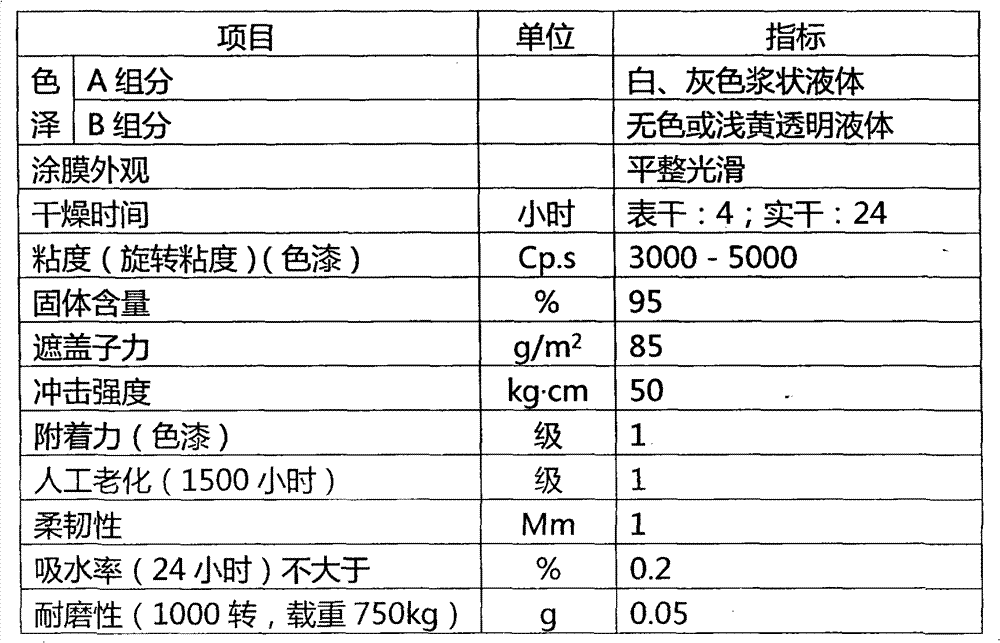

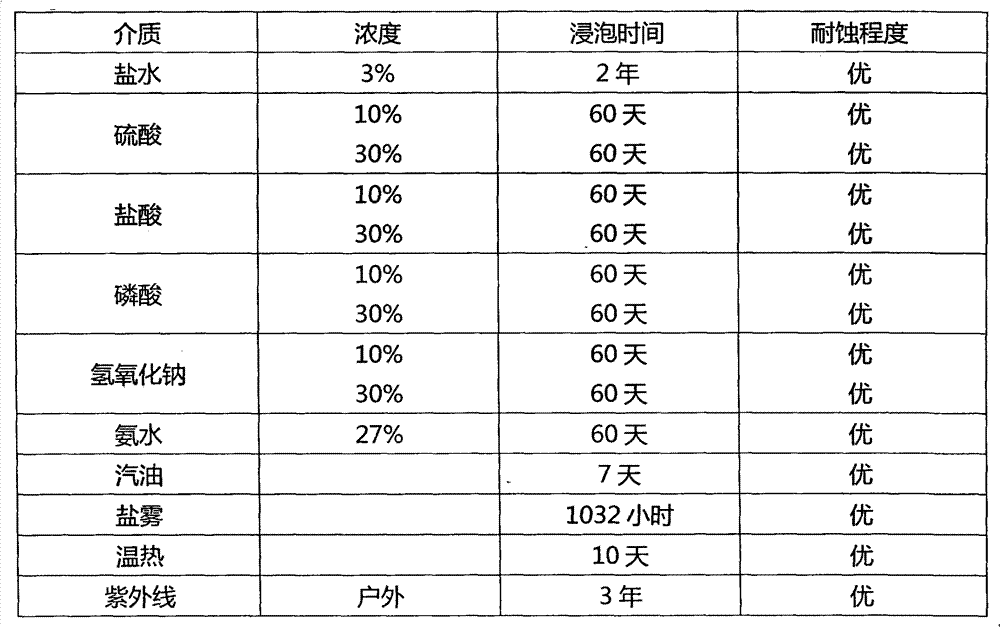

GZ-12 novel environmentally-friendly high-performance solvent-free epoxy coating and its preparation method

InactiveCN102952450AHigh environmental protection requirements cost-effectiveGood value for moneyAnti-corrosive paintsEpoxy resin coatingsEpoxyNon toxicity

The invention relates to a GZ-12 novel environmentally-friendly high-performance solvent-free epoxy coating and its preparation method, especially relates to a novel environmentally-friendly solvent-free epoxy coating and its preparation method, and belongs to the technical fields of a coating and its raw materials. The GZ-12 novel environmentally-friendly high-performance solvent-free epoxy coating is composed of a part A and a part B, wherein the part A comprises 60-70 parts by weight of a specific modified epoxy resin Barrier B-828, 15-20 parts by weight of Cardura E10P, 0.2-2 parts by weight of aerosil, 10-20 parts by weight of a functional filler, and 0.5-1.0 part of a functional assistant; the part B comprises 20-25 parts by weight of an alicyclic amine resin; and the weight ratio of the part A to the part B is 4-5:1. The GZ-12 novel environmentally-friendly high-performance solvent-free epoxy coating has the advantages of excellent resistances to the corrosion of acids, alkalis, salts, organic solvents and strong-oxidizability mediums, strong adhesion, good abrasion resistance, good flexibility, strong permeability, fast drying, simple construction, thick formed film, less application amount, non-toxicity, no benzene and the like, and is an ideal novel solvent-free epoxy anticorrosion coating which accords with environmental protection requirements and has a high cost performance.

Owner:许国良

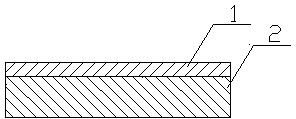

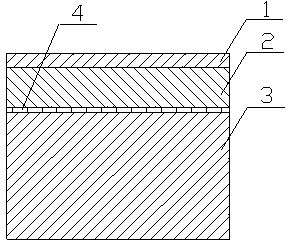

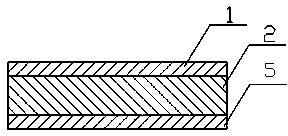

Method for employing copper-steel composite board to prevent adhesion corrosion of marine organisms and preparation method for copper-steel composite board

InactiveCN104085146AUniform corrosionGood weather resistanceLaminationLamination apparatusOil drillingComposite plate

The invention discloses a method for employing a copper-steel composite board to prevent adhesion corrosion of marine organisms and a preparation method for the copper-steel composite board. The corrosion-preventing method comprises: employing the copper-steel composite board or a copper-steel-copper composite board to coat the housing of a to-be protected apparatus, and attaching the steel layer to the to-be protected apparatus when the copper-steel composite board is employed. The preparation method of the composite board comprises the following steps: (1) performing surface texturing; (2) performing composite rolling; (3) performing diffusion heat processing; (4) performing beforehand finish rolling; (5) performing heat treatment for target performances; and (6) eliminating the yield ratio through flattening. By utilizing the bacteriostasis property of the surface copper of the copper-steel composite board, the copper-steel composite board is used to coat see-soaked bottom of a ship, a tension column of an offshore oil drilling platform and to-be protected parts of oceaneering facilities, and gives play to marine organism corrosion resistant effect on ship shells, the tension column of the offshore oil drilling platform and all oceaneering facilities wetted by seawater.

Owner:宁波宇能复合铜带有限公司

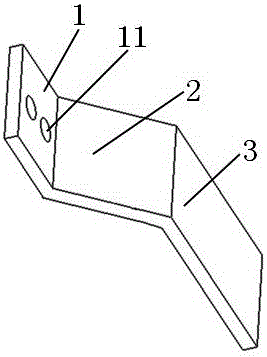

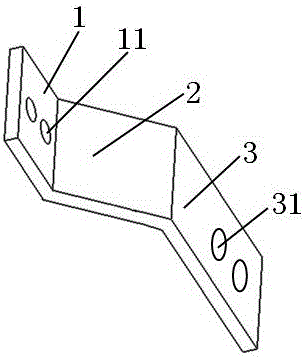

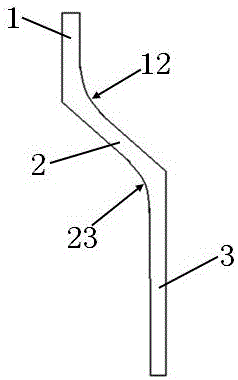

Electric power tower employing circular foundation ground wire

InactiveCN106129649AImprove acid resistanceImprove acid and alkali corrosion resistanceTowersConnection contact member materialElectrical conductorElectric power system

The invention relates to the technical field of electric power, in particular to an electric power tower employing a circular foundation ground wire. The electric power tower comprises an electric power tower body and the circular foundation ground wire; the electric power tower is characterized in that a grounding connection body is fixed on the outer surface of the lower part of the electric power tower body; a grounding gap is formed between the grounding connection body and the electric power tower body; the circular foundation ground wire has a special structure; a fixing component fixes a first connection segment and the grounding connection body into a whole; and the electric power tower body, the grounding connection body, the fixing component and the circular foundation ground wire all are electric conductors. The ground wire provided by the invention has the beneficial technical effects of being beautiful, easy to manufacture, more convenient to construct, more reliable in grounding and the like.

Owner:班戈设备系统(苏州)有限公司

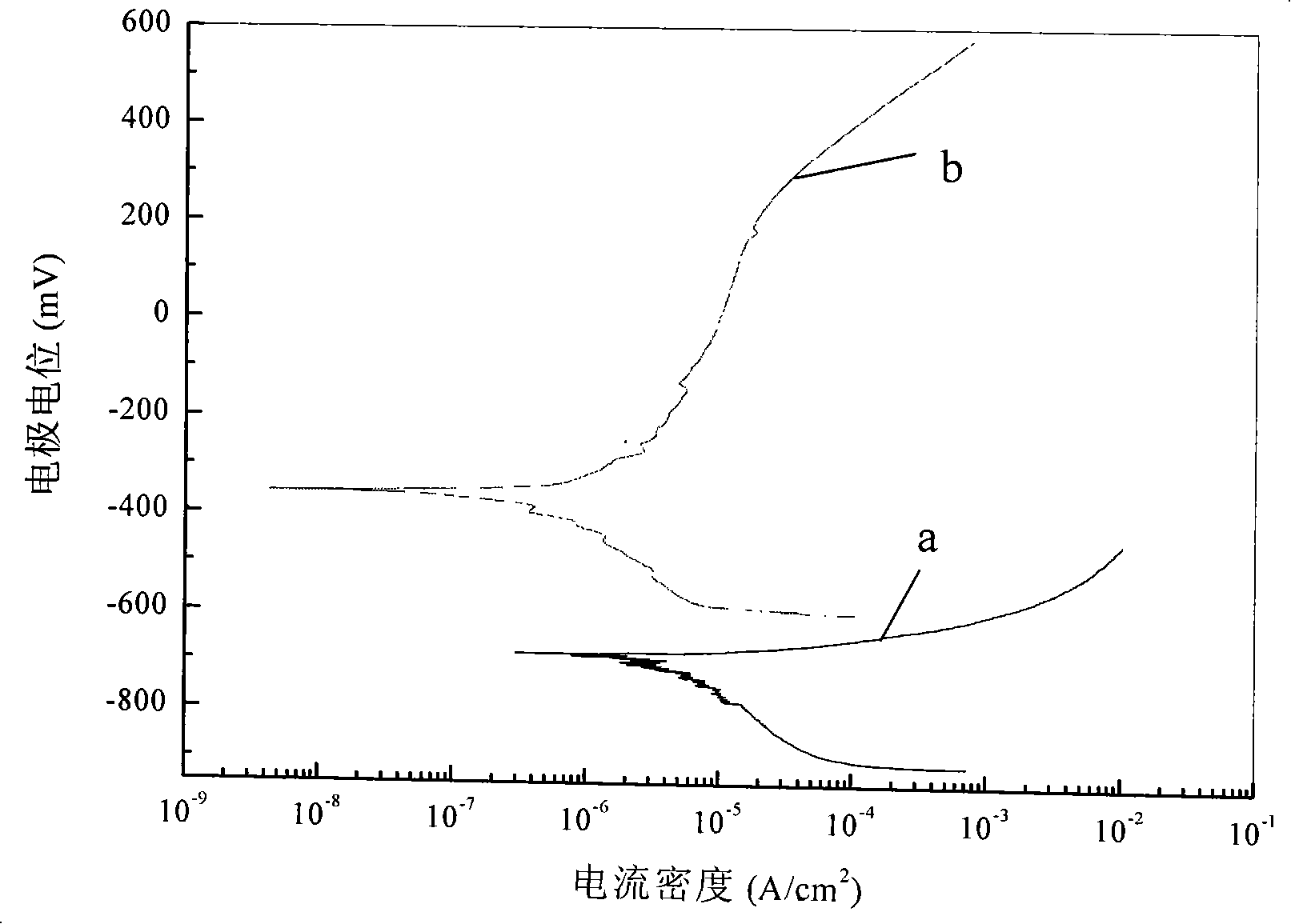

Nickeling liquid and nickeling method for metal-matrix composite

InactiveCN101250729APitting corrosion potential increasedImprove bindingPhosphoric acidMetal matrix composite

Nickel plating solution of metal matrix composites and a method for plating nickel relate to the nickel plating solution and the method for plating the nickel. The invention solves the problem that the anti-corrosion capacity of film which is formed on the surface of composite materials is little in an existing technique. The nickel plating solution of the invention has components of NiSO4.6H2O, NiCl2.6H2O, H3PO4, H3PO3 and C6H8O7.H2O. The method for plating the nickel comprises following steps: keeping the metal matrix composites in phosphoric acid for 30 seconds to 2 minutes after washing the metal matrix composites with ultrasound, then, putting the metal matrix composites in the nickel plating solution, and plating. The pit corrosion potential of the metal matrix composites which are processed through the method of the invention is increased by 300-900mV, the differential value between the pit corrosion potential and the corrosion potential is increased by 300-600mV, and the corrosion current density is lowered by 2-3 magnitudes.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com