Carbon dioxide corrosion resistant pipeline steel and manufacturing method thereof

A technology of carbon dioxide and pipeline steel, which is applied in the field of steel production, can solve problems such as inability to connect and lay, inability to adapt and meet the needs of transmission pipelines, high carbon equivalent, etc., to achieve good carbon dioxide corrosion resistance, low carbon dioxide corrosion rate, and small anisotropy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiment of the present invention solves the problem of CO corrosion resistance of existing pipeline steel by providing a carbon dioxide corrosion-resistant pipeline steel and its manufacturing method. 2 Poor corrosion defects.

[0018] Under high temperature and high pressure environment, CO 2 The protection, formation rate and stability of the corrosion product film together determine the corrosion rate and type. The formation of corrosion product film is not only related to environmental factors such as temperature, pressure, flow rate, and medium solution, but also related to the composition and microstructure of the material itself. The embodiment of the present invention can effectively improve the protection of the corrosion product film and reduce the corrosion rate through targeted composition design and process control.

[0019] In order to solve the above problems, the main ideas of the embodiments of the present invention are:

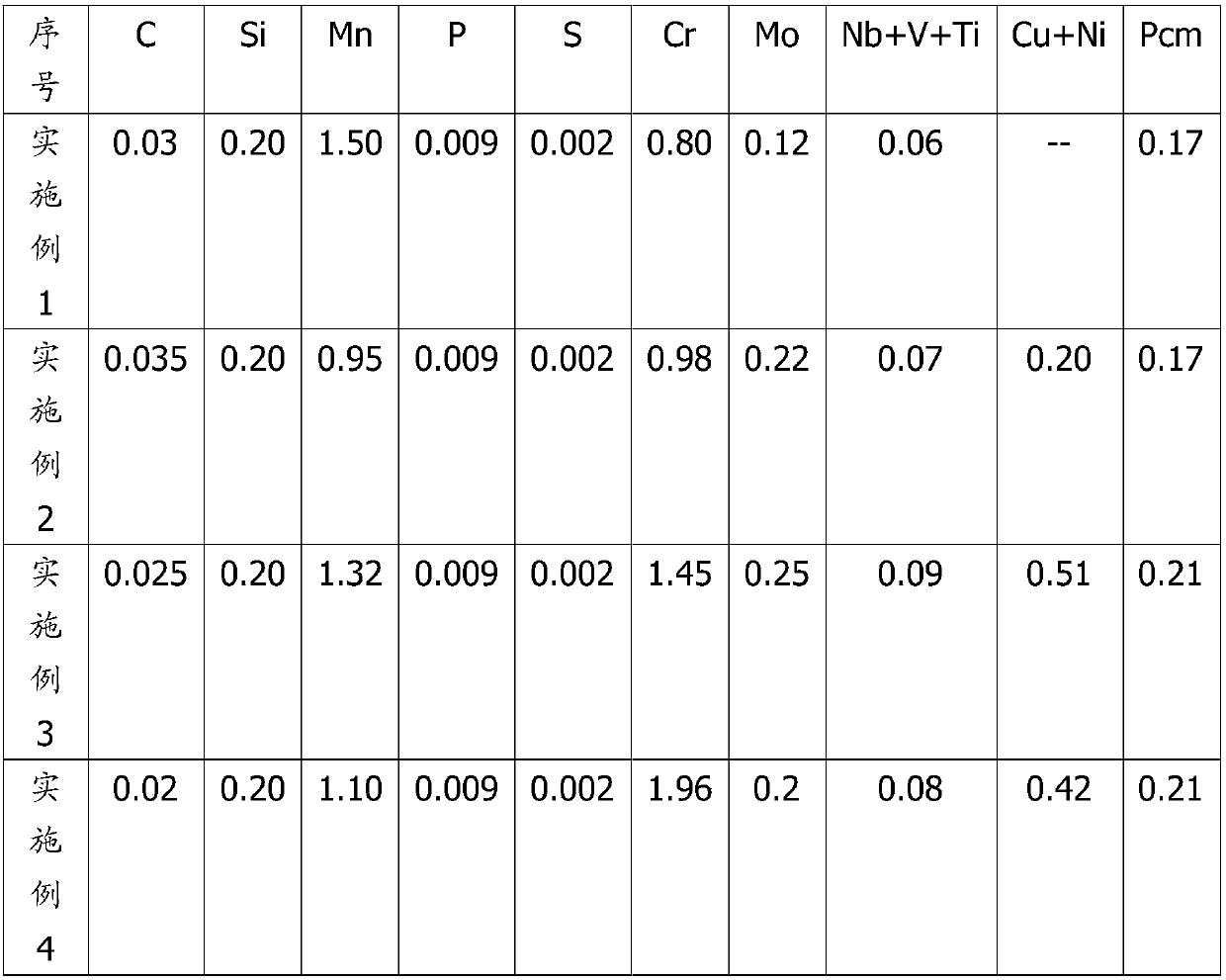

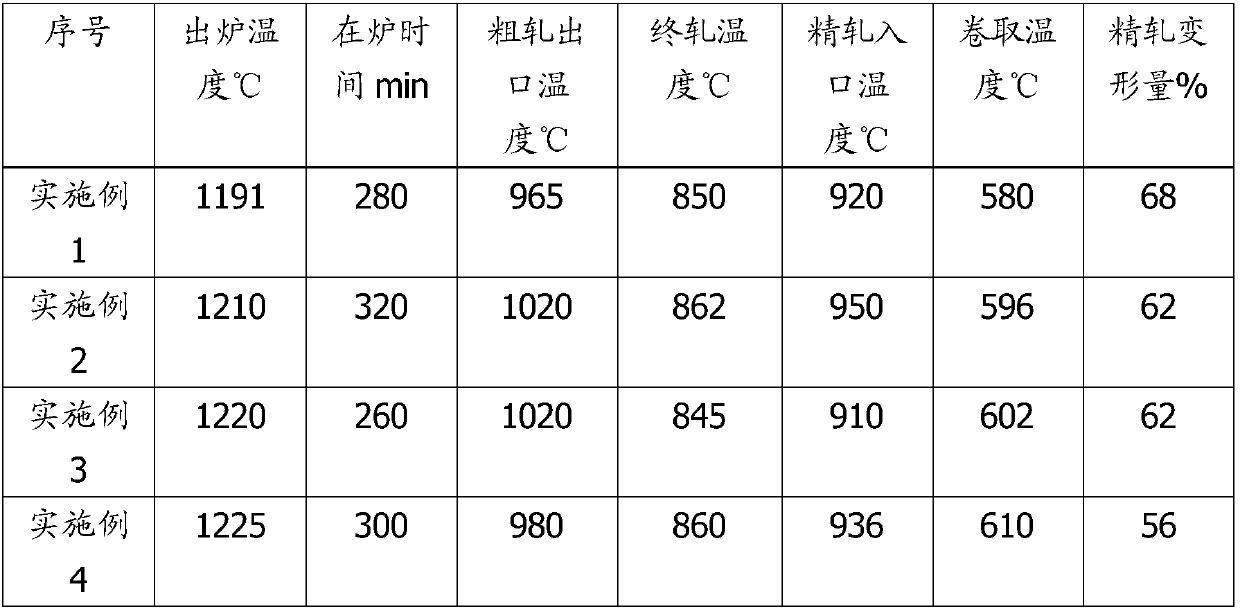

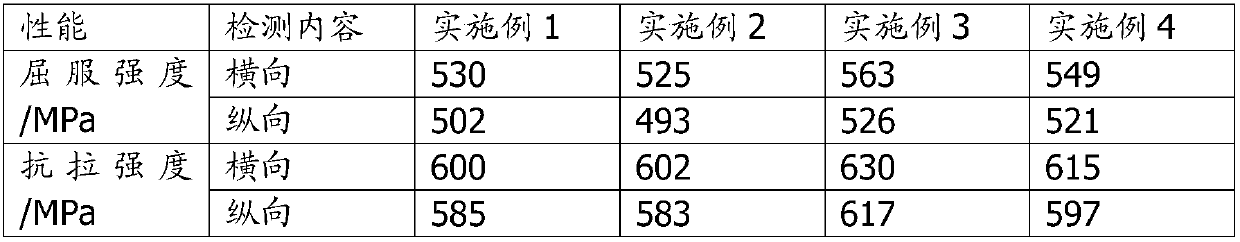

[0020] The carbon di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com