Patents

Literature

118 results about "Carbon dioxide corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon dioxide is usually the cause of corrosion in boiler systems, particularly in condensate systems. This is because the de-aeration of water eliminates carbon dioxide in boiled water. Alkaline water in this situation can generate high carbon dioxide levels. This extremely high level of carbon dioxide can result in a highly corrosive condensate.

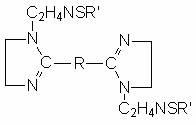

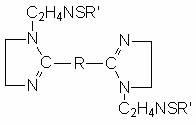

Sulfur-containing bis-imidazoline type carbon dioxide corrosion inhibitor and preparation method thereof

InactiveCN102321463AImprove protectionGood water solubilityOrganic chemistryBorehole/well accessoriesCarbon dioxide corrosionActive agent

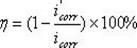

The invention discloses a sulfur-containing bis-imidazoline type carbon dioxide corrosion inhibitor and a preparation method thereof. The corrosion inhibitor comprises the following components in percentage by weight: 20-50 percent of sulfur-containing bis-imidazoline quaternary ammonium salt, 1-5 percent of nonionic surfactant, 40-70 percent of low molecular alcohol solvent and 5-10 percent of alkynol, wherein a sulfur-containing bis-imidazoline compound has a general formula of a structure which is shown in the specification; the number of carbon atoms in R of the formula is 5 or 8; the nonionic surfactant is fatty alcohol-polyoxyethylene ether or alkylphenol ethoxylate; the low molecular alcohol solvent is methanol, ethanol, isopropanol or ethylene glycol; and the alkynol is propargyl alcohol or hexynol. In the invention, the sulfur-containing bis-imidazoline compound which is generated through dehydration between dicarboxylic acid and polyamine molecule, dehydration reaction in the molecule and further reaction with the sulfur-containing compound is adopted; the molecule contains a plurality of active adsorption centers such as two diazo five-membered heterocyclic rings, a sulfur-containing group and the like; and a formed organic adsorption membrane has better protection effect on carbon steel.

Owner:UNIV OF SCI & TECH BEIJING

Inhibitor for controlling carbon dioxide corrosion and production thereof

InactiveCN1818138AOvercome the disadvantages of poor performanceGood corrosion control effectCarbon dioxide corrosionThiourea

An inhibitor which can control the corrosion of the CO2 is made up of the imidazoline oleate 1-70%; the thiourea 0.01-30%; the water 0-60%; polyoxyethylene ether 0-30%; the isopropanol 0-40%. It has the good effect of controlling the corrosion of the CO2.

Owner:YANGTZE UNIVERSITY

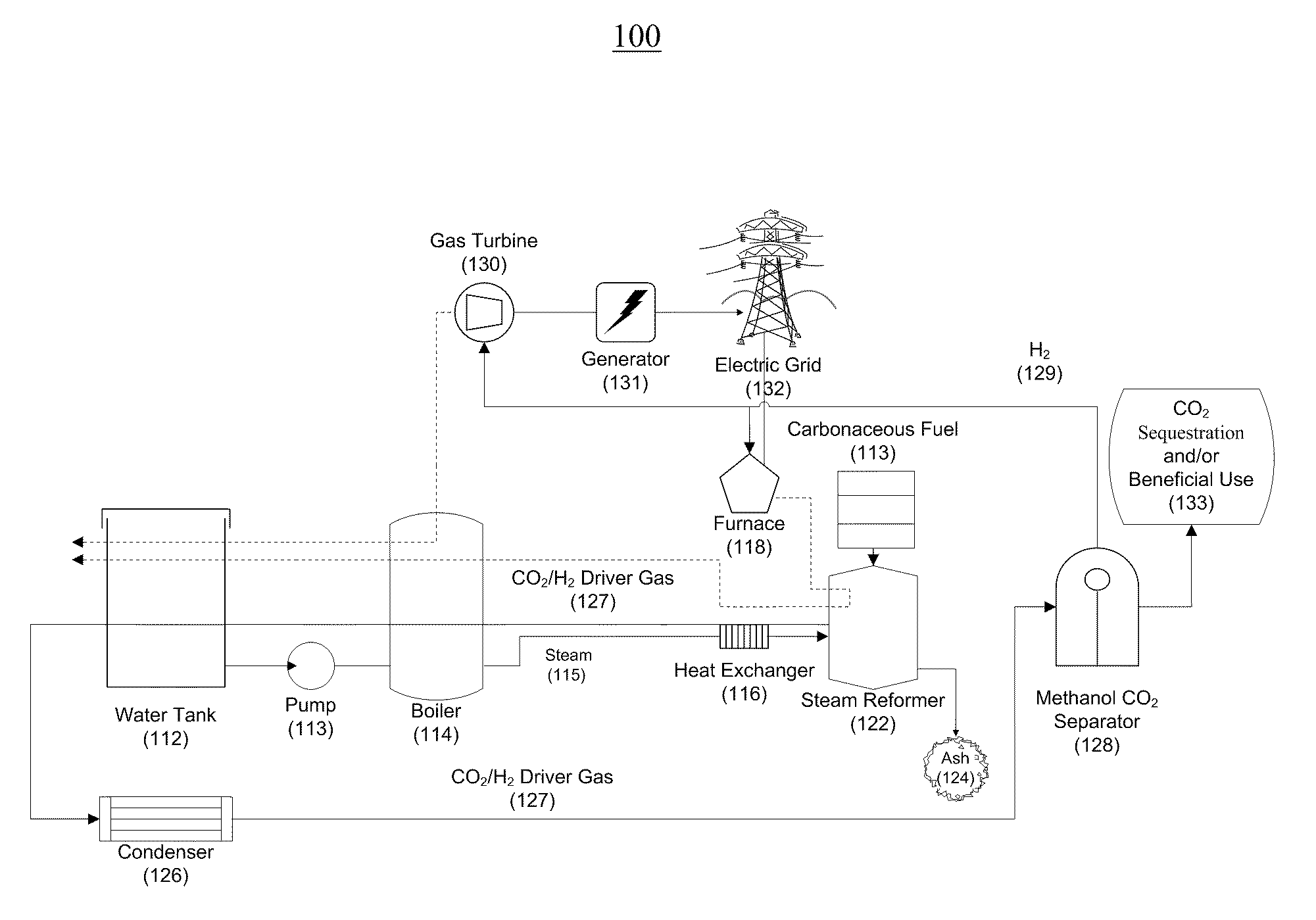

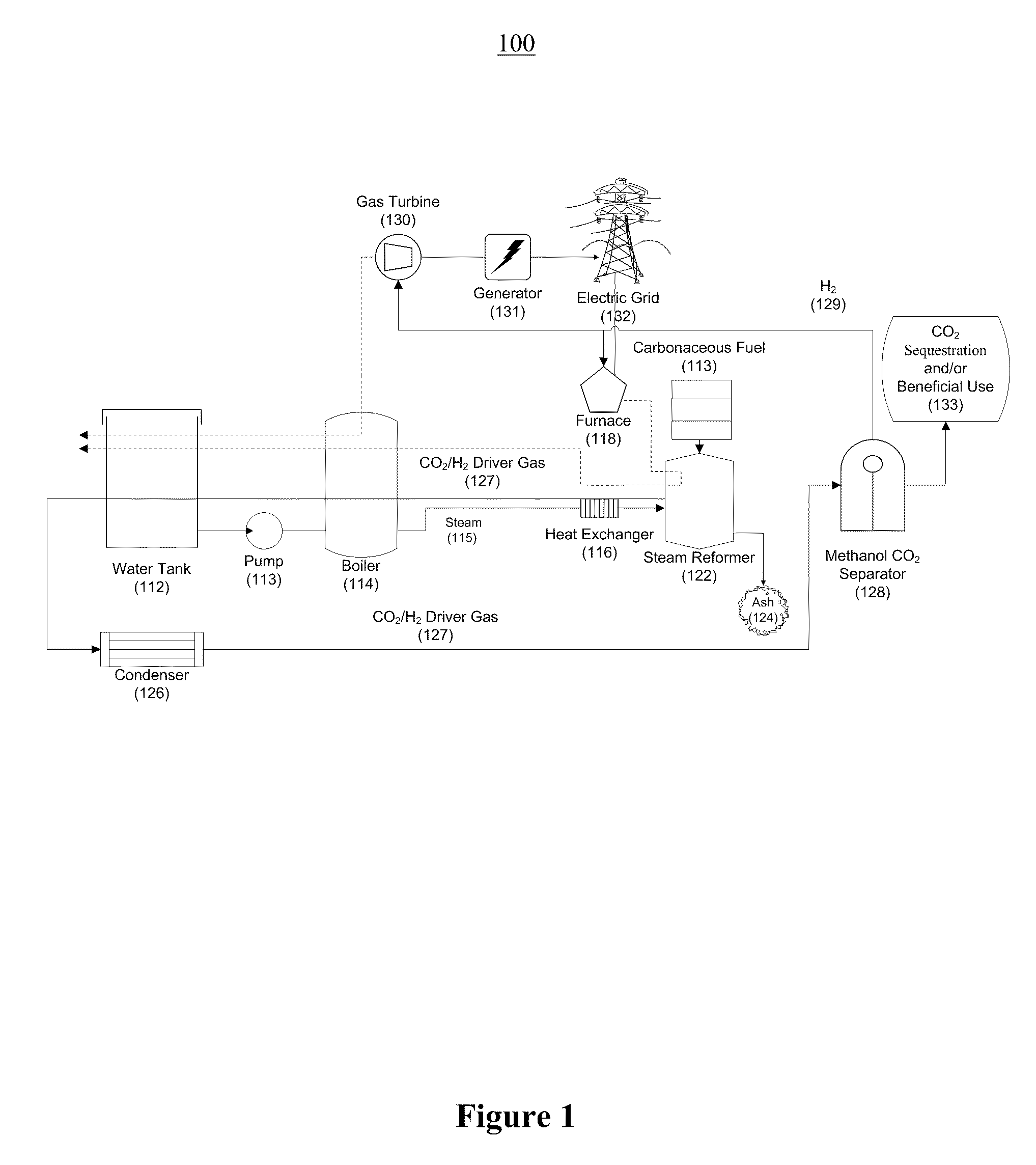

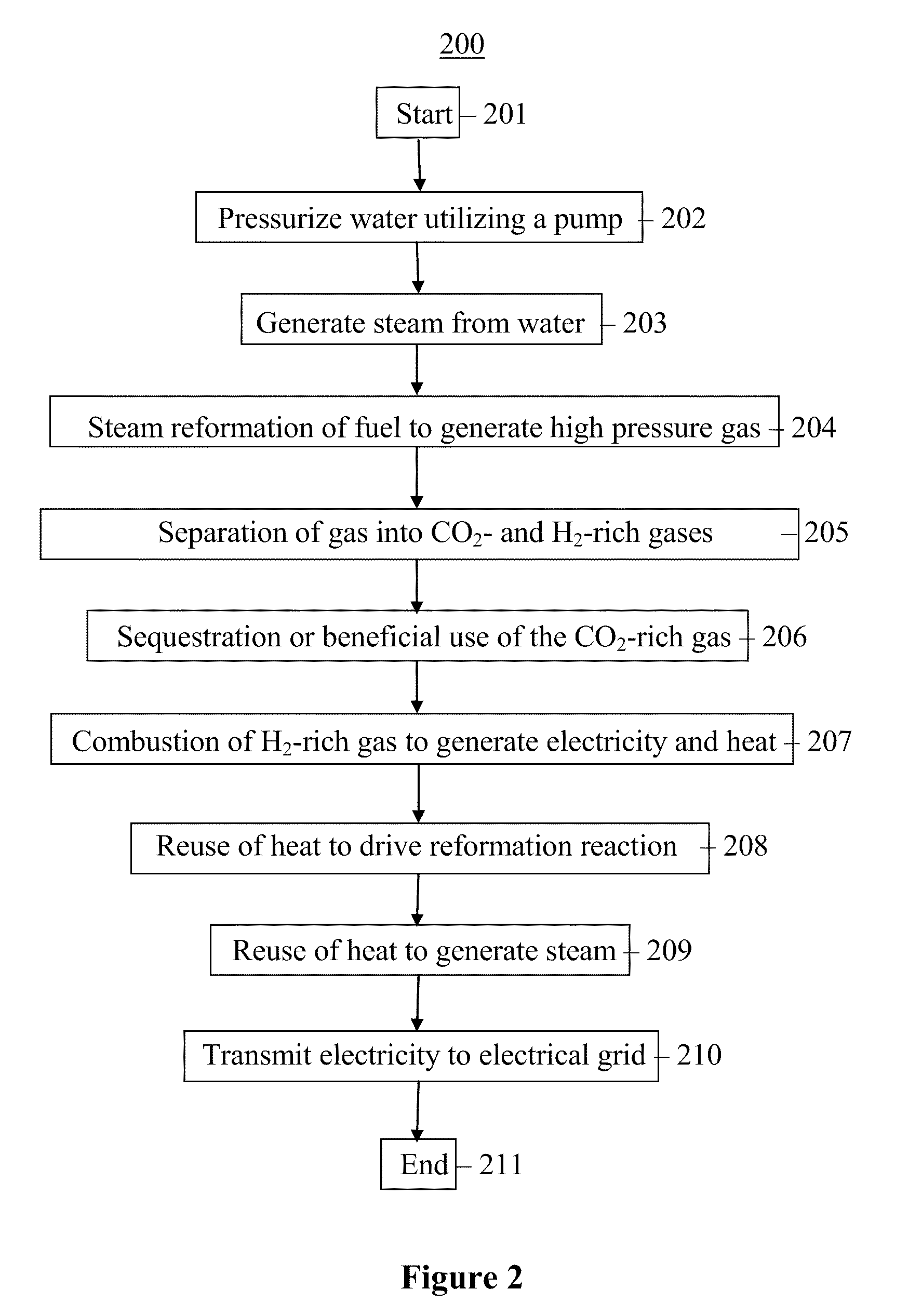

Systems and methods for generating electricity from carbonaceous material with substantially no carbon dioxide emissions

InactiveUS20110067410A1Little and no carbon dioxide emissionReduce carbon emissionsBiofuelsCombustion enginesCarbon dioxide corrosionMechanical energy

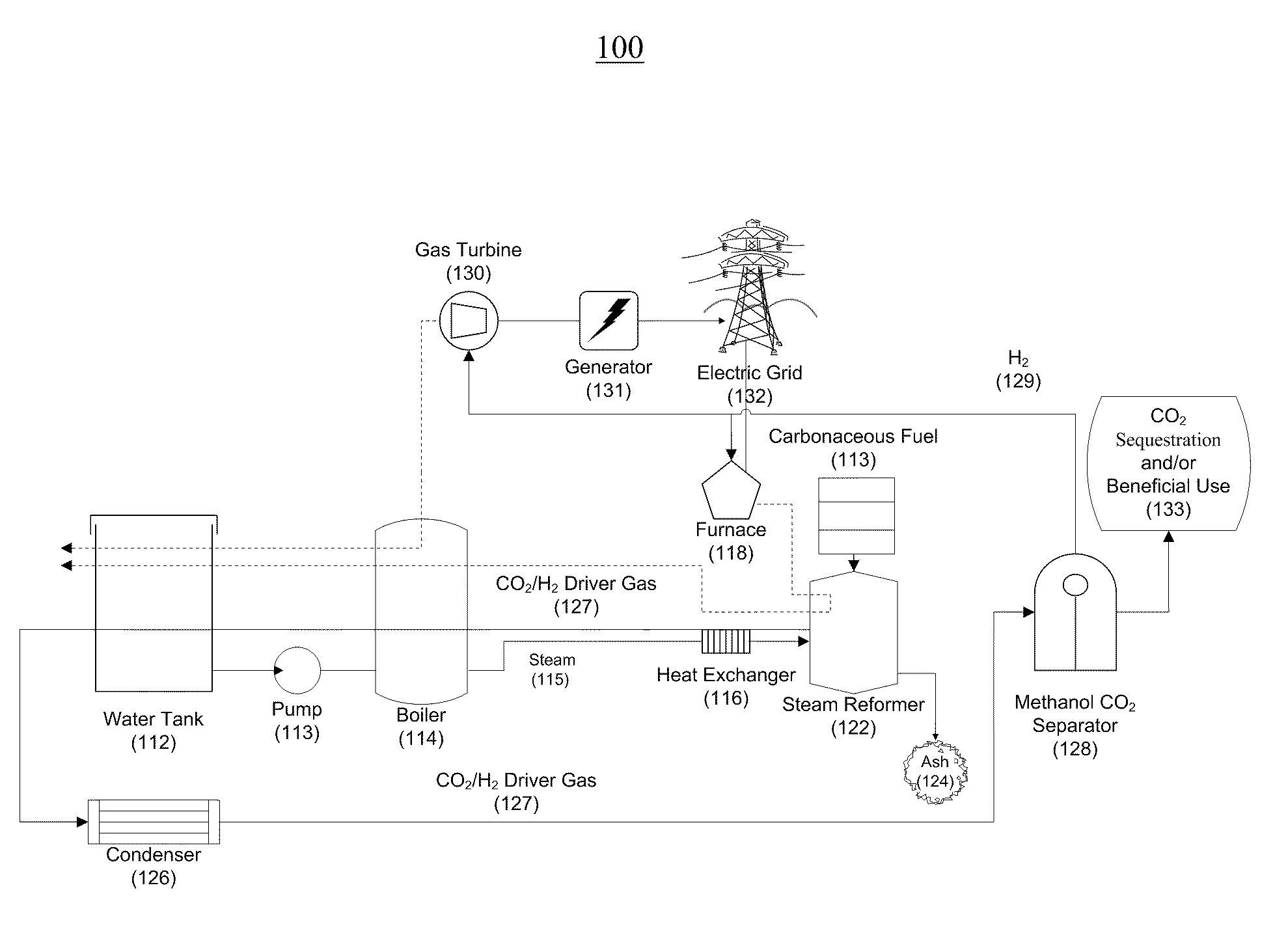

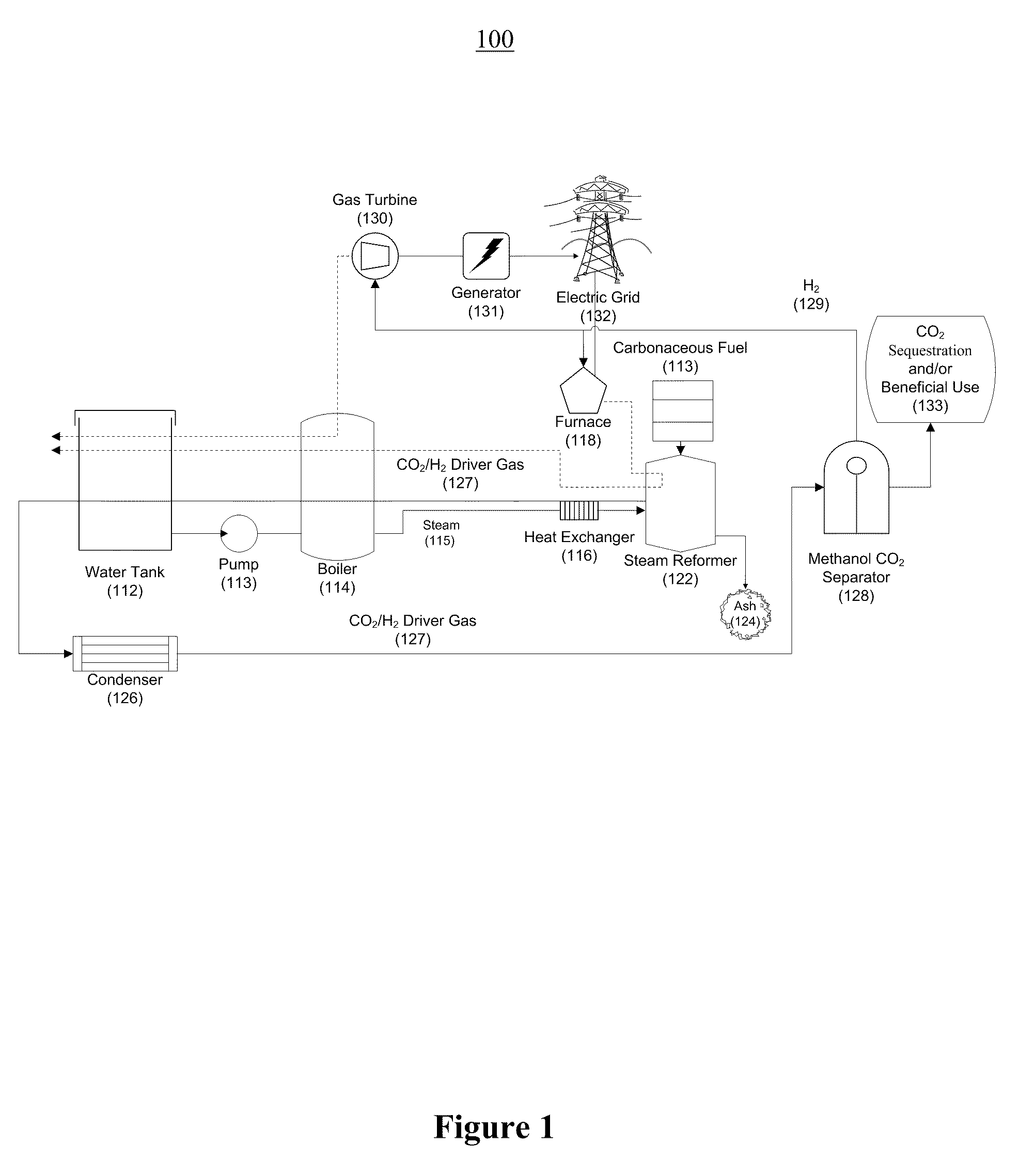

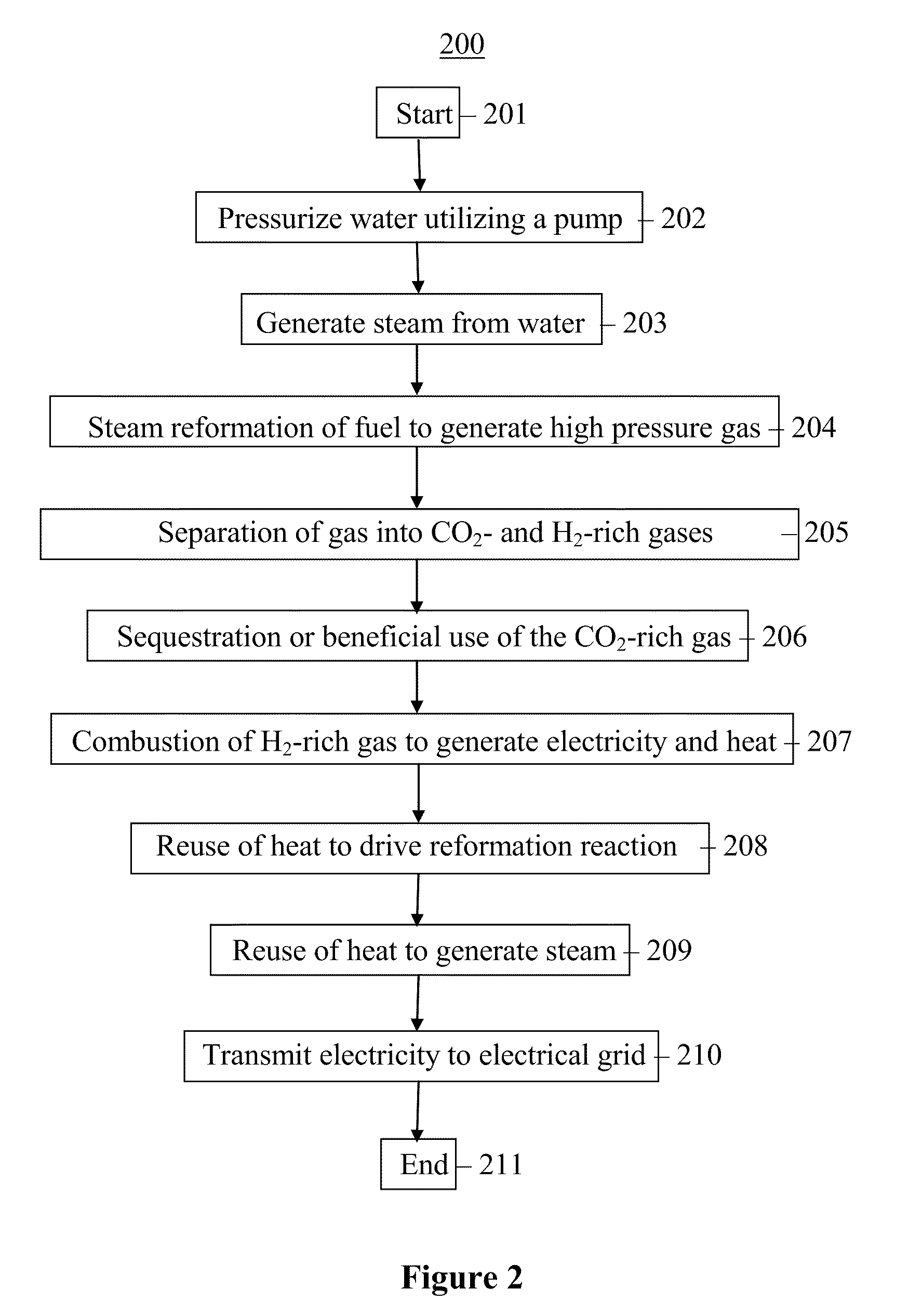

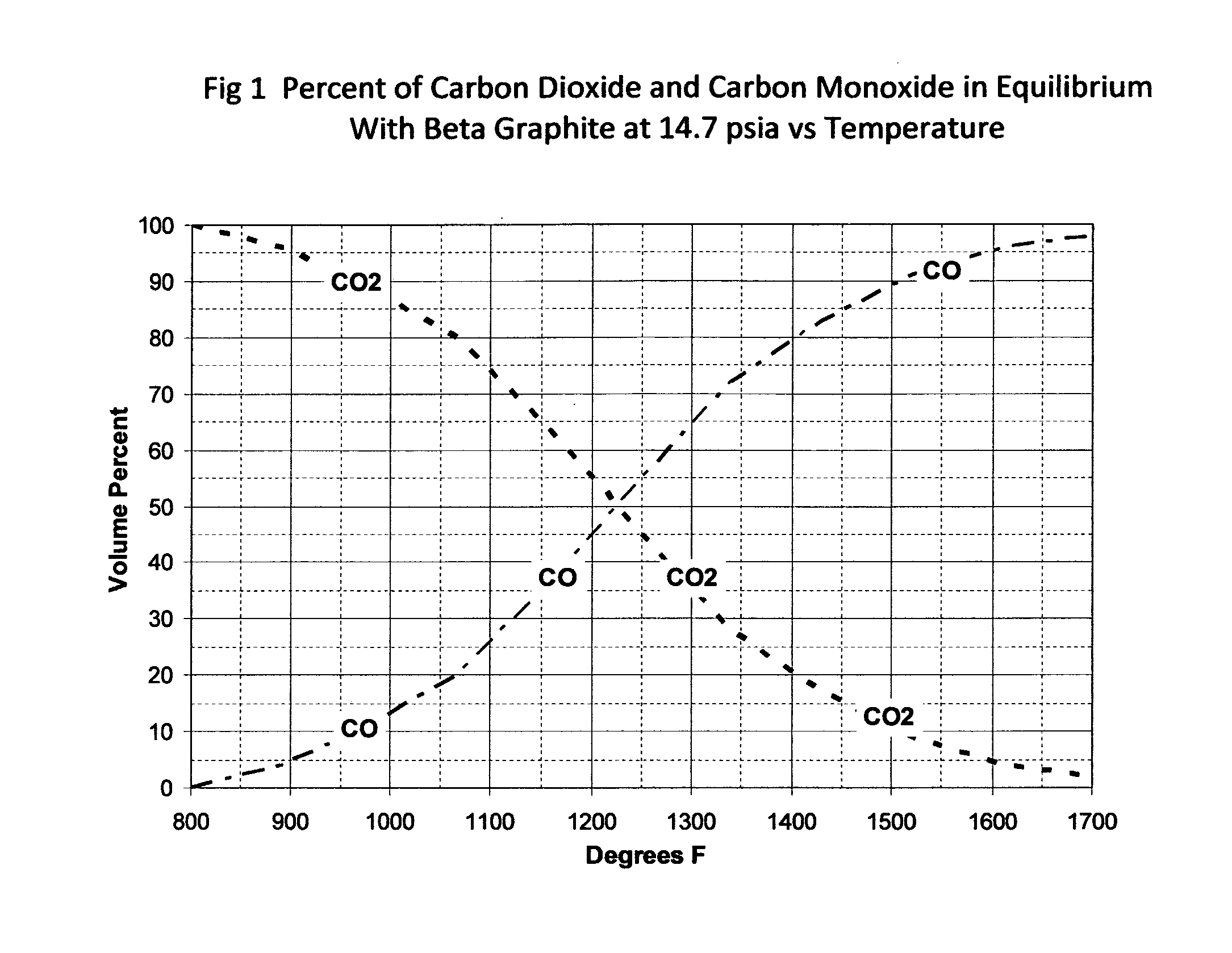

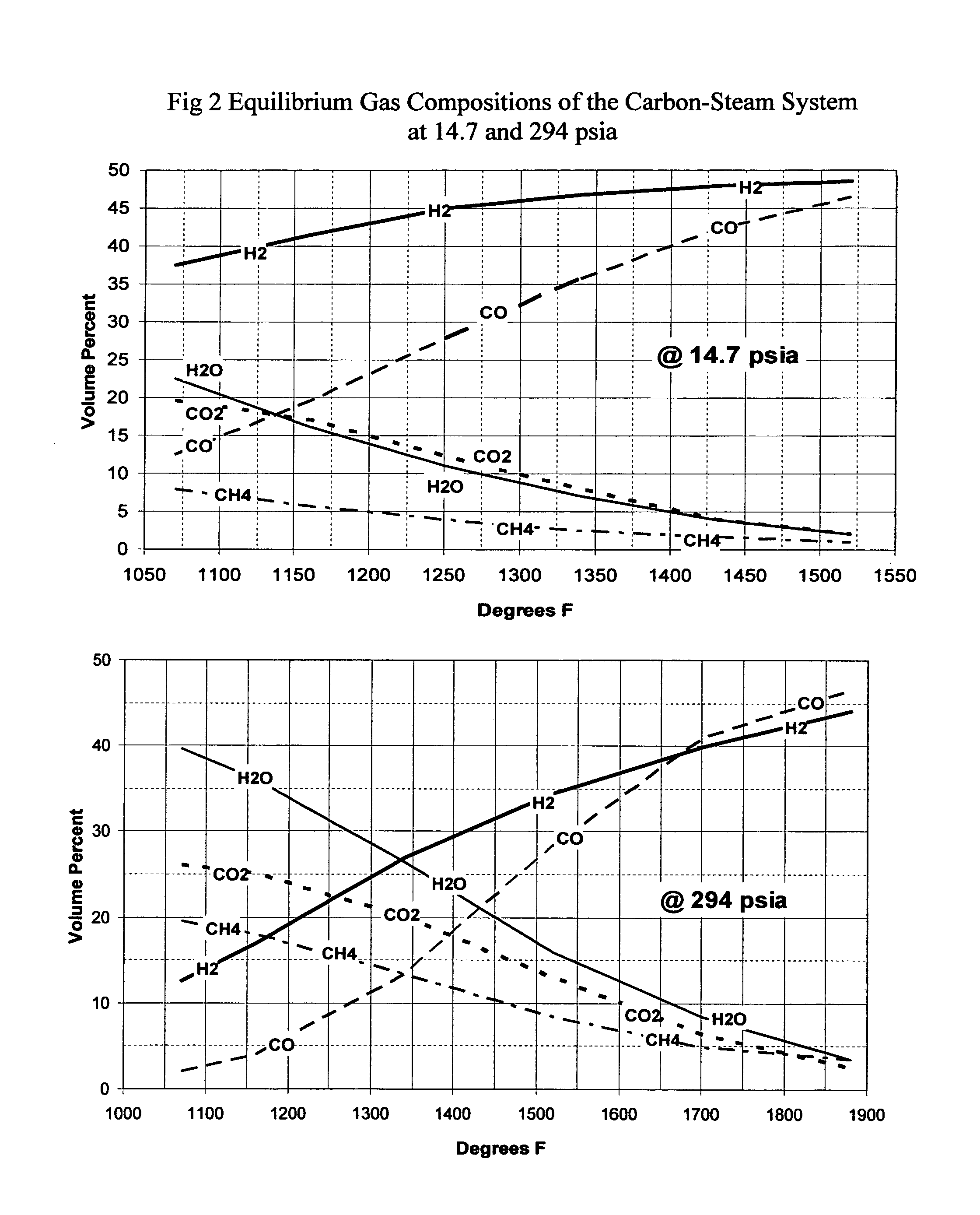

A reformation power plant generates clean electricity from carbonaceous material and high pressure CO2 which can be easily sequestered or utilized for a beneficial purpose, such as fuel production. The reformation power plant design utilizes a reformation process that reforms carbonaceous fuel with super-heated steam into a high-pressure gaseous mixture that is rich in carbon dioxide and hydrogen gas. This high-pressure gas exchanges excess heat with the incoming steam from a boiler and continues onward to a condenser. Once cooled, the high-pressure gas goes through a methanol separator, after which the CO2-rich gas is sequestered underground or beneficially re-used. The remaining hydrogen-rich gas is combusted through a gas turbine. The gas turbine provides power to a generator and also regenerative heat for the boiler. Finally, the generator converts mechanical energy into electricity, which is transferred to the electric grid. Therefore, carbon-free electricity is generated from coal, biomass, or other carbon-based feedstock.

Owner:PIONEER ENERGY

Systems and methods for generating electricity from carbonaceous material with substantially no carbon dioxide emissions

A reformation power plant generates clean electricity from carbonaceous material and high pressure CO2 which can be easily sequestered or utilized for a beneficial purpose, such as fuel production. The reformation power plant design utilizes a reformation process that reforms carbonaceous fuel with super-heated steam into a high-pressure gaseous mixture that is rich in carbon dioxide and hydrogen gas. This high-pressure gas exchanges excess heat with the incoming steam from a boiler and continues onward to a condenser. Once cooled, the high-pressure gas goes through a methanol separator, after which the CO2-rich gas is sequestered underground or beneficially re-used. The remaining hydrogen-rich gas is combusted through a gas turbine. The gas turbine provides power to a generator and also regenerative heat for the boiler. Finally, the generator converts mechanical energy into electricity, which is transferred to the electric grid. Therefore, carbon-free electricity is generated from coal, biomass, or other carbon-based feedstock.

Owner:PIONEER ENERGY

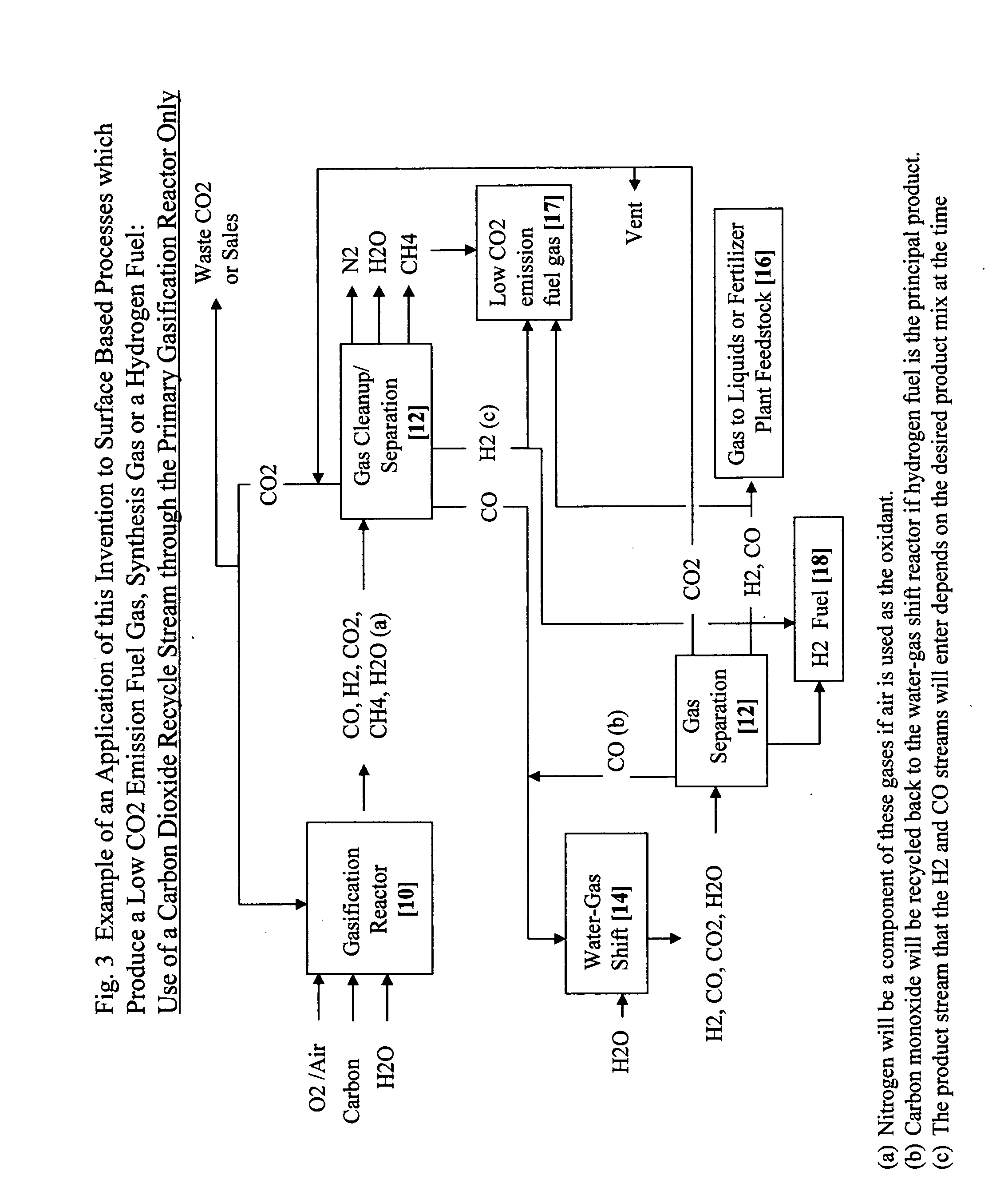

Method for reducing carbon dioxide emissions and water contamination potential while increasing product yields from carbon gasification and energy production processes

InactiveUS20090145843A1Water/sewage treatment by substance additionHydrogen/synthetic gas productionCarbon dioxide corrosionOxygen

Carbon dioxide from a process which oxidizes a carbon containing feed is separated and reduced to carbon monoxide using a carbon dioxide reduction reactor [22, 26] coupled to a water gas shift reactor [14], to simultaneously reduce carbon dioxide emissions and increase the product yield of clean fuels. In the preferred underground carbon gasification application, these reduction and shift reactions are substantially promoted by utilizing temporary [24] and permanent storage [28] of the carbon dioxide and carbon monoxide coupled with cyclic operational procedures. Additional advantages include carbon dioxide sequestration, removal of contaminants from the groundwater affected by the process and the ability to influence groundwater flow patterns to improve gasification efficiency and reduce potential environmental effects.

Owner:AHNER PAUL F

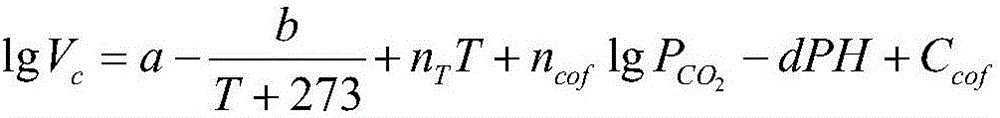

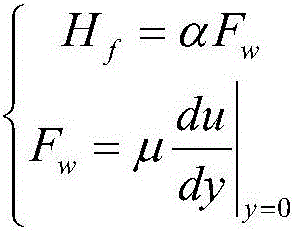

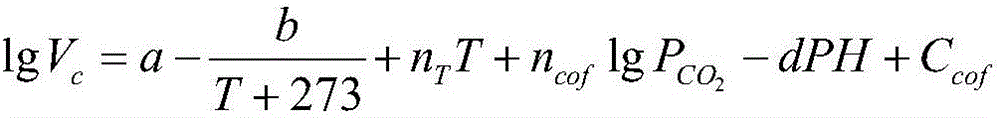

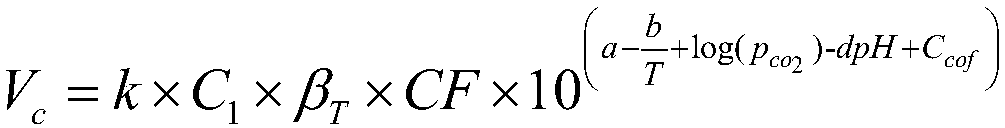

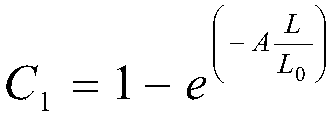

Method for determining corrosion rate of natural gas injection and production well pipe column under erosion-carbon dioxide corrosion coupling action

ActiveCN106021659ALow fluid fractionReduce flow rateDesign optimisation/simulationSpecial data processing applicationsCouplingLiquid water

The invention belongs to the technical field of oil field equipment and particularly provides a method for determining a corrosion rate of a natural gas injection and production well pipe column under an erosion-carbon dioxide corrosion coupling action. The method comprises the steps of 1) establishing a pipe column internal component heat transfer, flow and dispersion model; 2) establishing a pipe column wall surface carbon dioxide corrosion model and determining influence of a product layer on the corrosion rate in a carbon dioxide corrosion process; 3) establishing a model of wear of medium erosion on a pipe wall substrate and a corrosion layer; and 4) coupling the three models and determining the corrosion rate of the natural gas injection and production well pipe column. According to the method, a gas well pipe column corrosion rate prediction model is established through an erosion-electrochemical corrosion coupling action mechanism in the natural gas injection and production well pipe column, so that the corrosion rate of the natural gas injection and production well pipe column can be effectively predicted and a technical reference is provided for the security of the natural gas injection and production well pipe column carrying carbon dioxide and liquid water.

Owner:PETROCHINA CO LTD

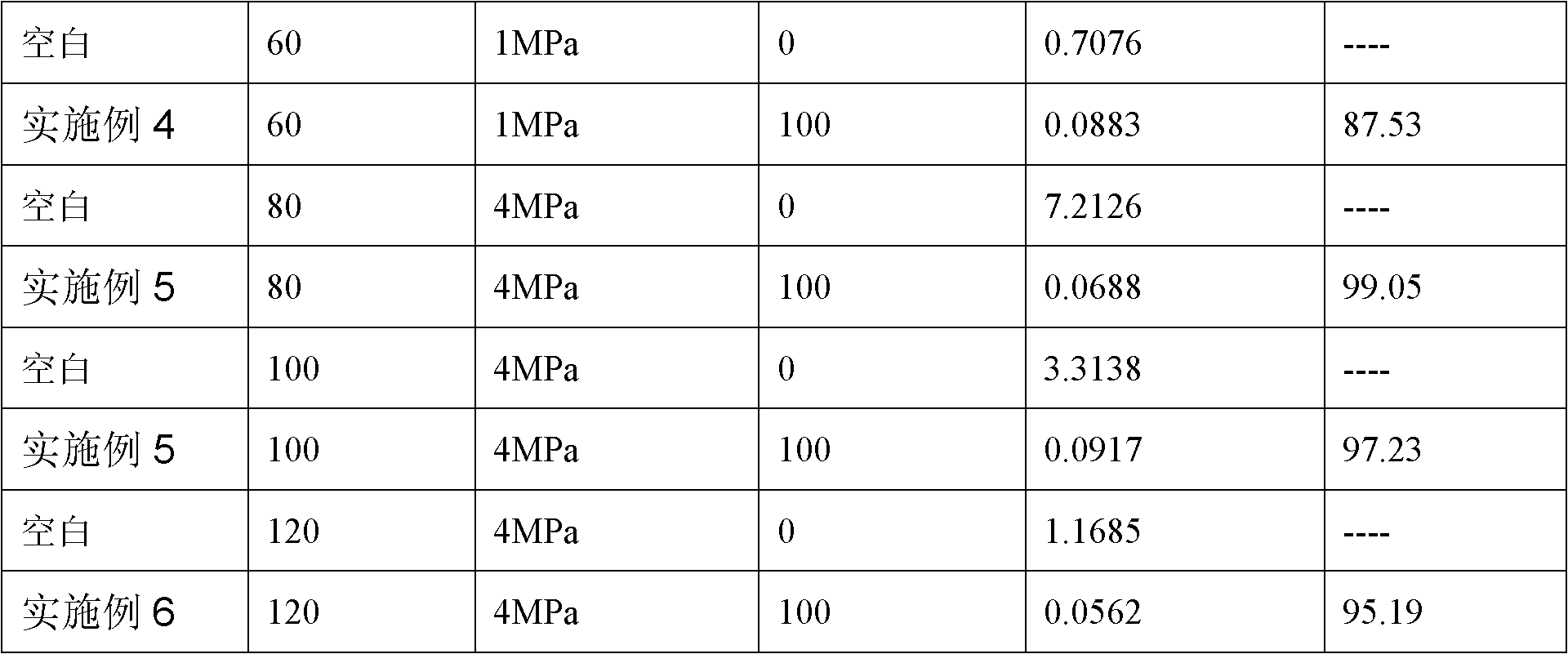

Corrosion inhibitor for inhibiting corrosion of high-temperature high-pressure carbon dioxide and preparation method thereof

The invention provides a corrosion inhibitor for inhibiting the corrosion of high-temperature high-pressure carbon dioxide and a preparation method thereof. The corrosion inhibitor comprises 1 to 80 weight percent of thioimidazolone derivative, 1 to 50 weight percent of quaternary alkylammonium salt, 0.01 to 20 weight percent of sulfur-containing low molecular weight organic matter, 0 to 70 weight percent of water, 0 to 30 weight percent of nonionic surfactant, 0 to 70 weight percent of solvent, and 1 to 20 weight percent of alkynol. The corrosion inhibitor has good effect of resisting the corrosion of the high-temperature high-pressure carbon dioxide, can form a layer of effective protective film on the surface of metal, prevent hypersalinity wastewater from corroding the metal at high temperature and high partial pressure of carbon dioxide, and can be used in oil wells with high temperature and high partial pressure of carbon dioxide.

Owner:HUAZHONG UNIV OF SCI & TECH +1

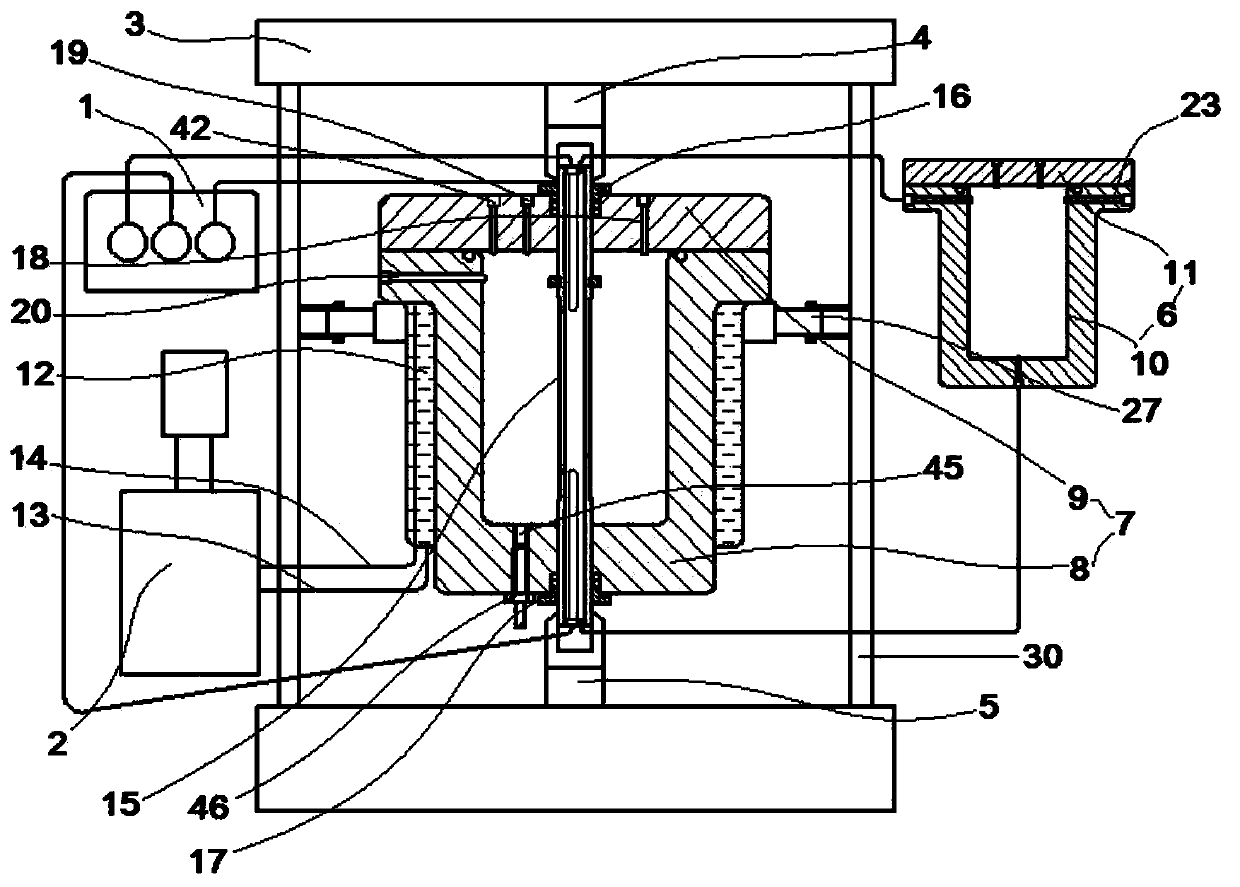

High temperature and high pressure corrosion hydrogen permeation testing device and method

ActiveCN104568727AReduce the amount of experimentsAvoid influenceWeather/light/corrosion resistanceFatigue loadingCarbon dioxide corrosion

The invention discloses a high temperature and high pressure corrosion hydrogen permeation testing device and method. When fatigue limit is measured, after hydrogen permeation current is stabilized under the given corrosion condition, step type fatigue loads are applied to a test sample material from a smaller one to a larger one, and when the hydrogen permeation current is increased along with increase of the load, dislocation movement inside the test sample material is caused by the load, and the load is considered as the fatigue limit of the test sample material in the environment. The device and the method disclosed by the invention have the characteristics that a quantitative relation between the fatigue load state and the hydrogen permeation amount can be measured in situ on line in a high-pressure carbon dioxide corrosion state, the internal relation between the stress and segregation diffusion of hydrogen can be intuitively reflected, and a mutual relation among multiple data is established.

Owner:ZHEJIANG UNIV OF TECH

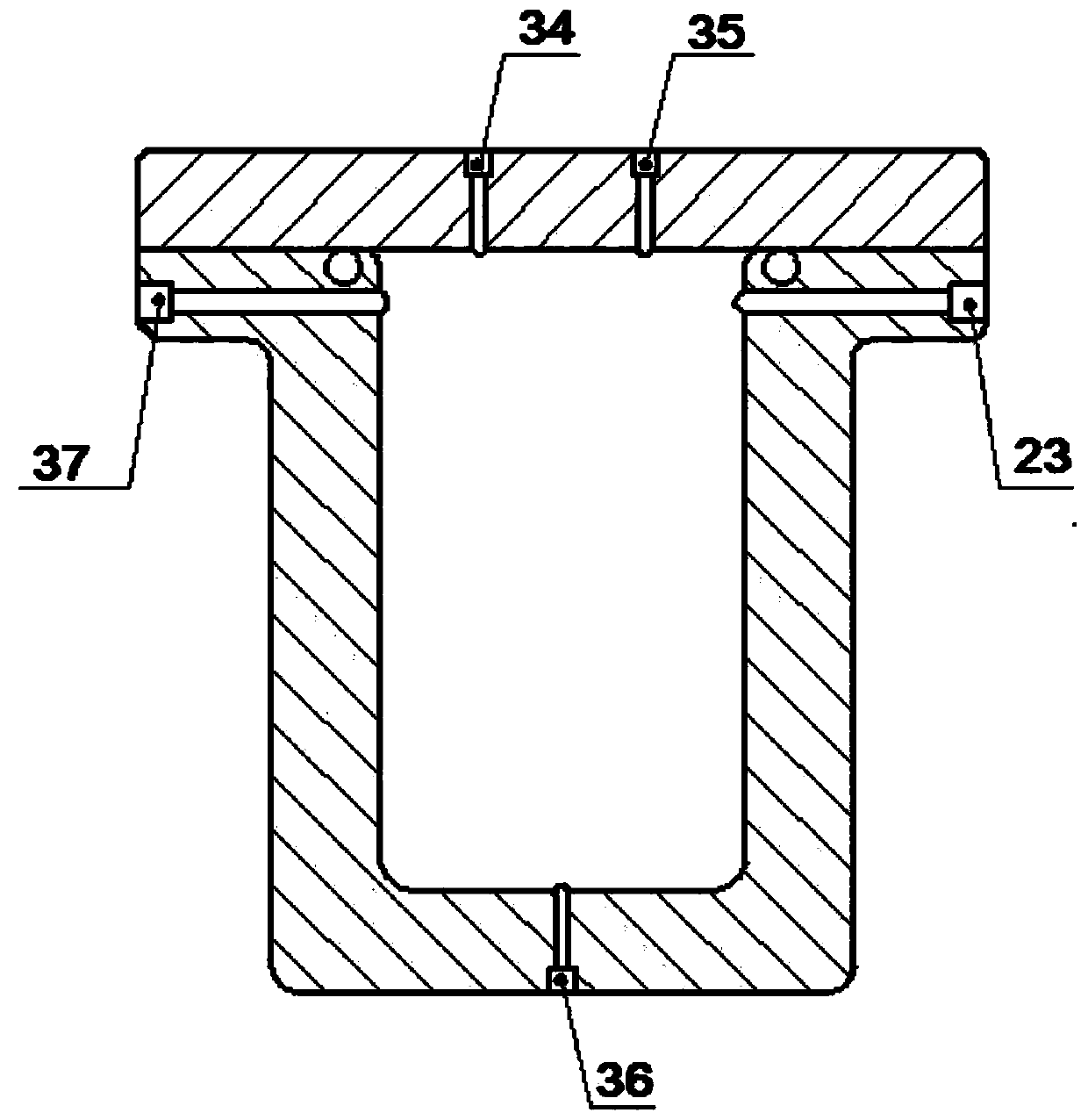

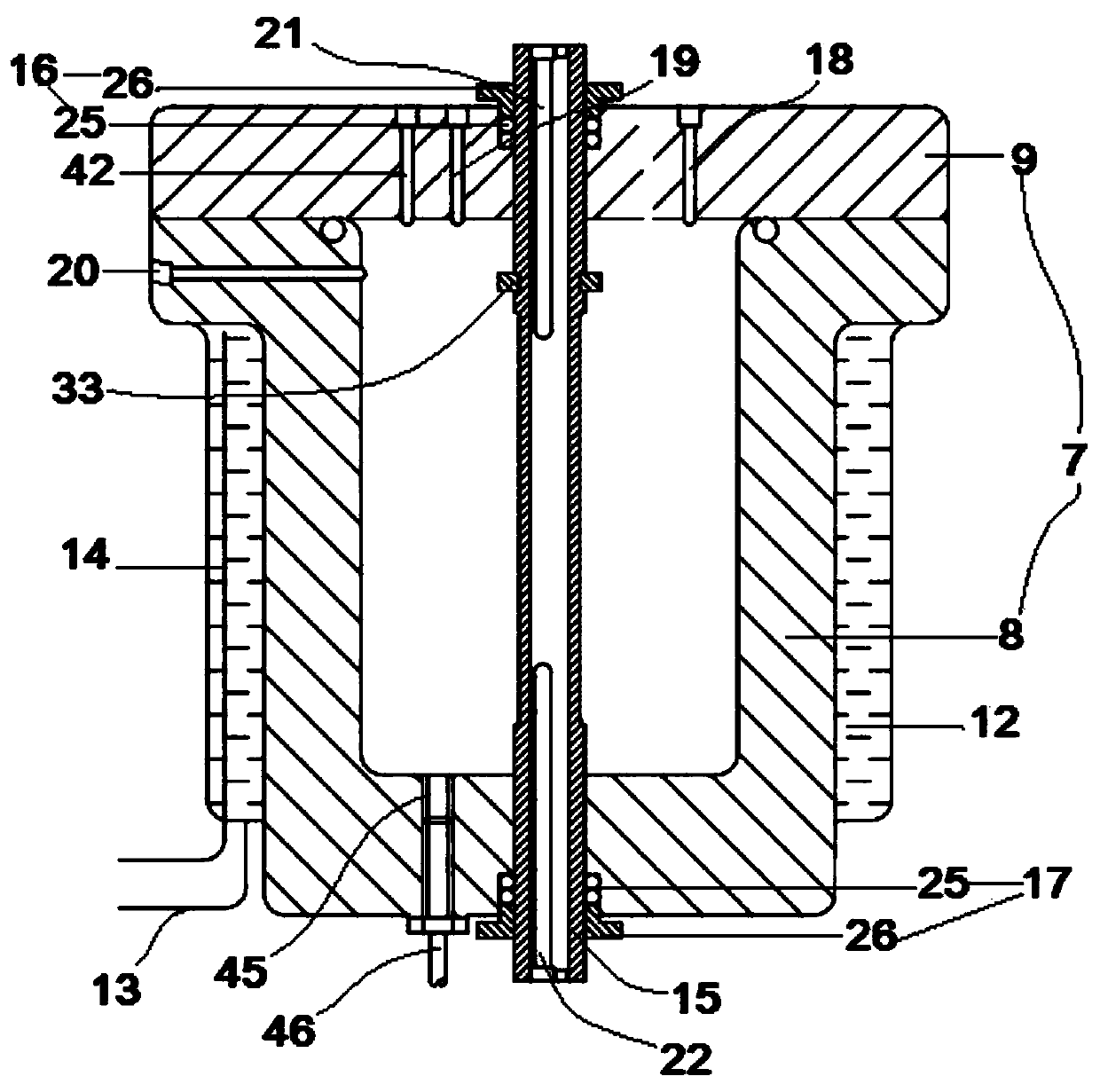

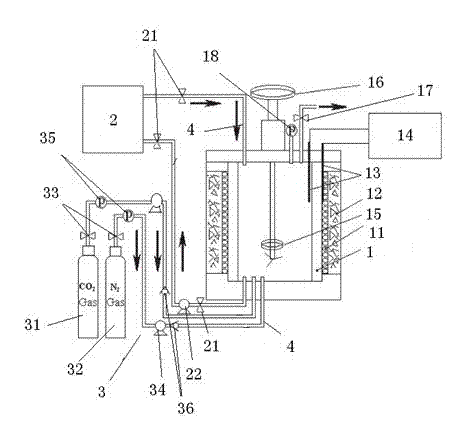

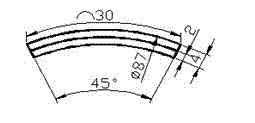

Contrast simulation testing device for carbon dioxide corrosion resistant performance of steel and testing method thereof

InactiveCN102854127ASatisfy Comparative Corrosion TestSimple structureWeather/light/corrosion resistancePreparing sample for investigationCarbon corrosionCarbon dioxide corrosion

The invention discloses a contrast simulation testing device for carbon dioxide corrosion resistant performance of steel and a testing method thereof. The device comprises a reaction kettle, a solution pond and a pressure adjusting device, wherein the solution tank is connected with the reaction kettle by a liquid control valve; a heating rod and a heat insulation material are wound on the outer wall of the reaction kettle; a thermal couple and a temperature adjuster are arranged in the reaction kettle; a sample clamp connected with a stirring device is arranged in the reaction kettle; and a pressure adjusting device comprises a CO2 gas tank and an N2 gas tank which are connected with the bottom of the reaction kettle. The method is used for contrasting and simulating a condition that a pipeline steel material is corroded by CO2 in crude oil so as to evaluate corrosion velocity of the steel material of which the temperature is between 90 and 120 DEG C, CO2 partial pressure is between 1 and 2.4MPa in the solution. The CO2 corrosion resistant performance of the steel with different materials, steel levels and thicknesses can be tested at the same time, and the test is convenient and easy. Corrosion simulation test of various oil fields is performed by adjusting the temperature, partial pressure and solution components.

Owner:NANJING IRON & STEEL CO LTD

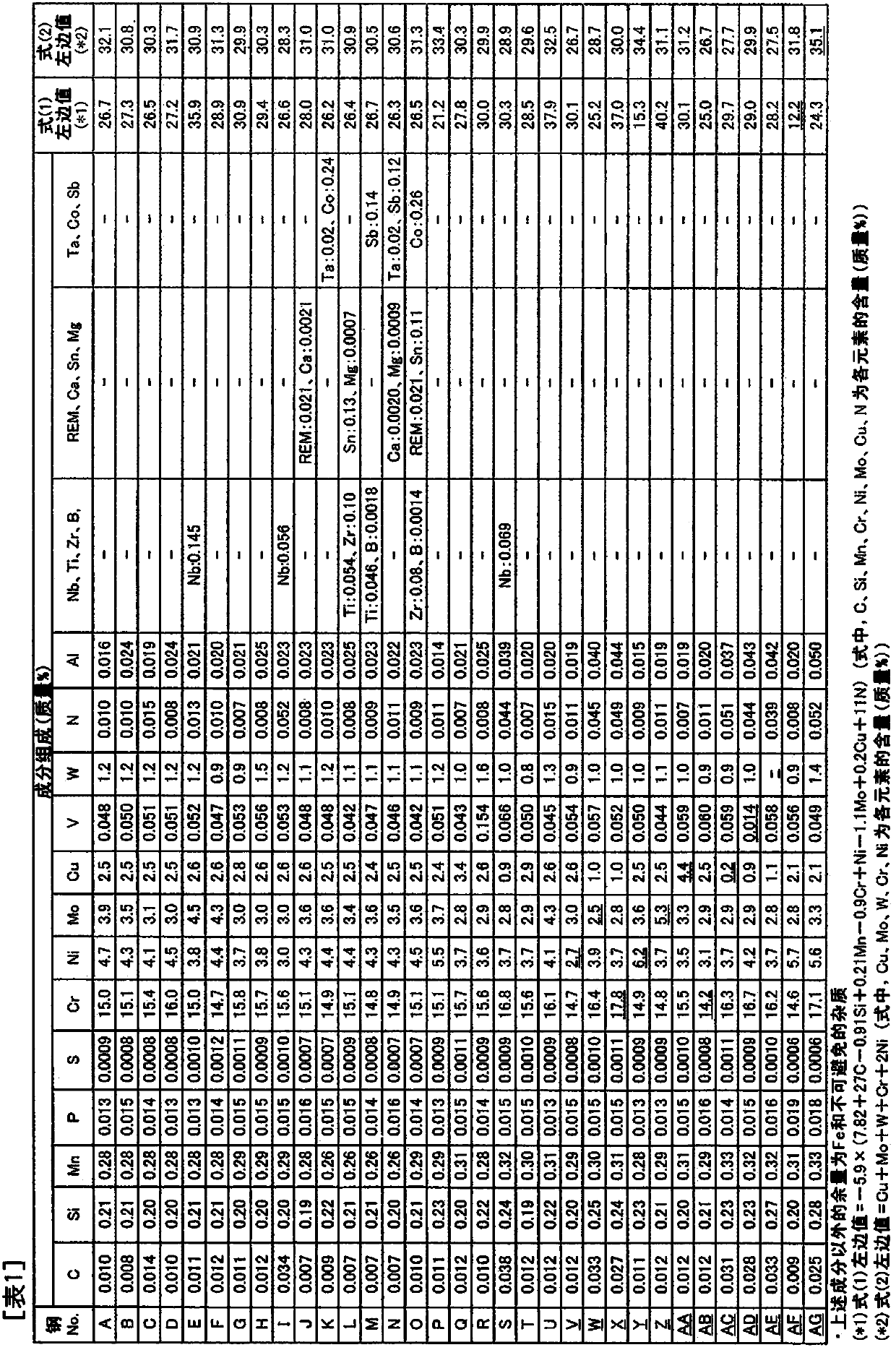

High strength seamless stainless steel pipe for oil wells and production method therefor

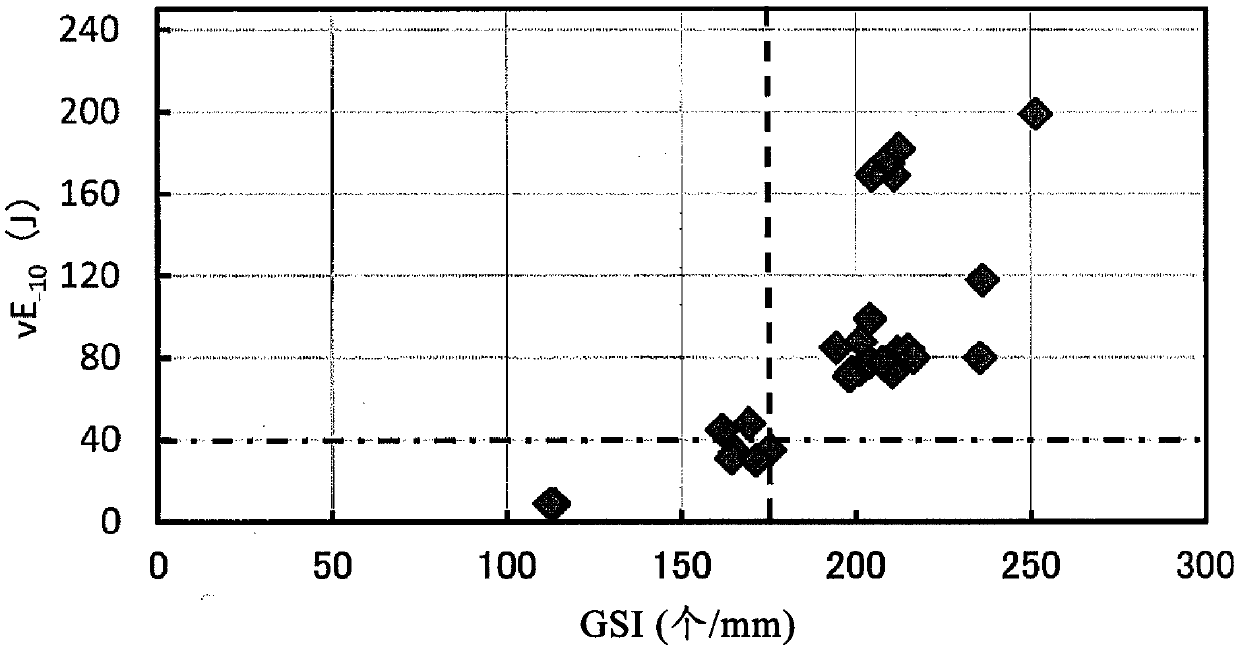

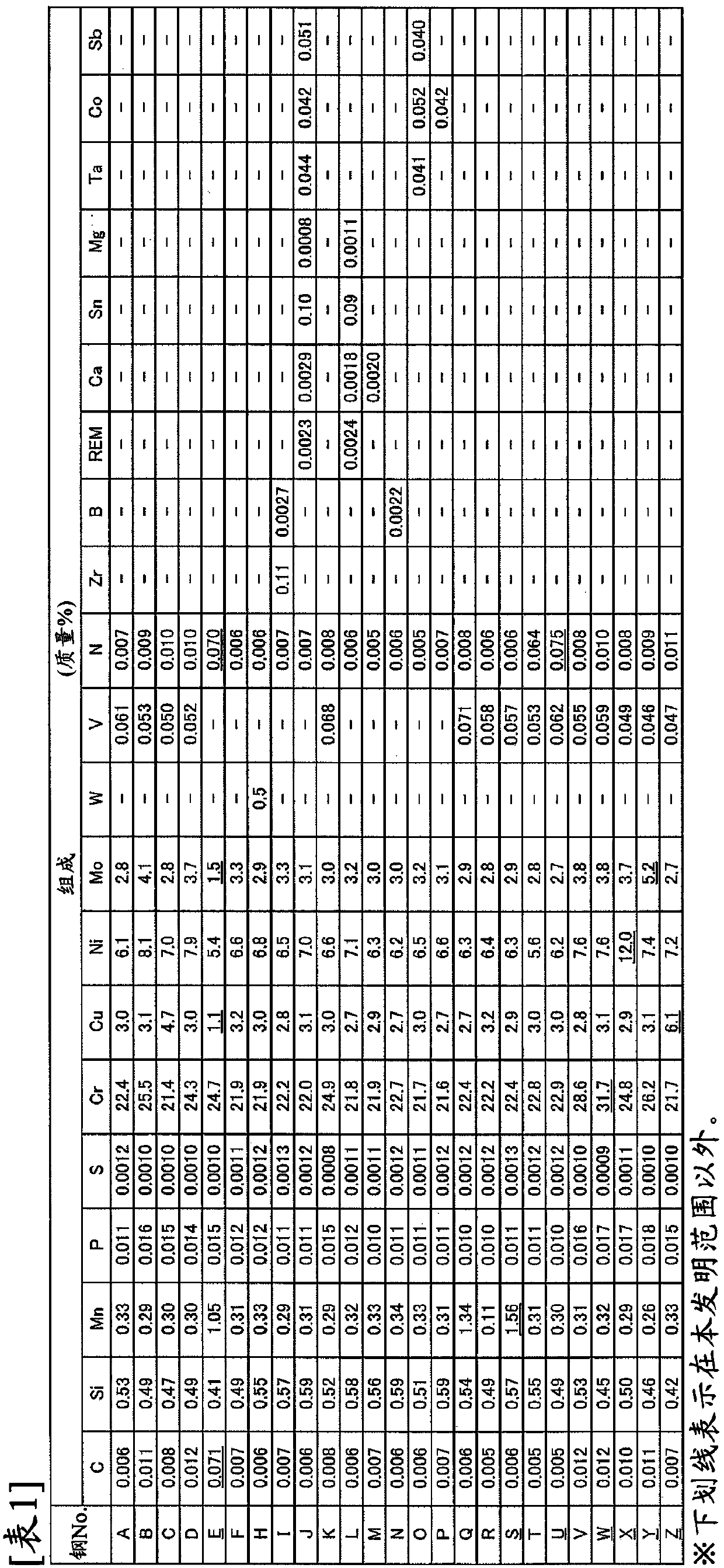

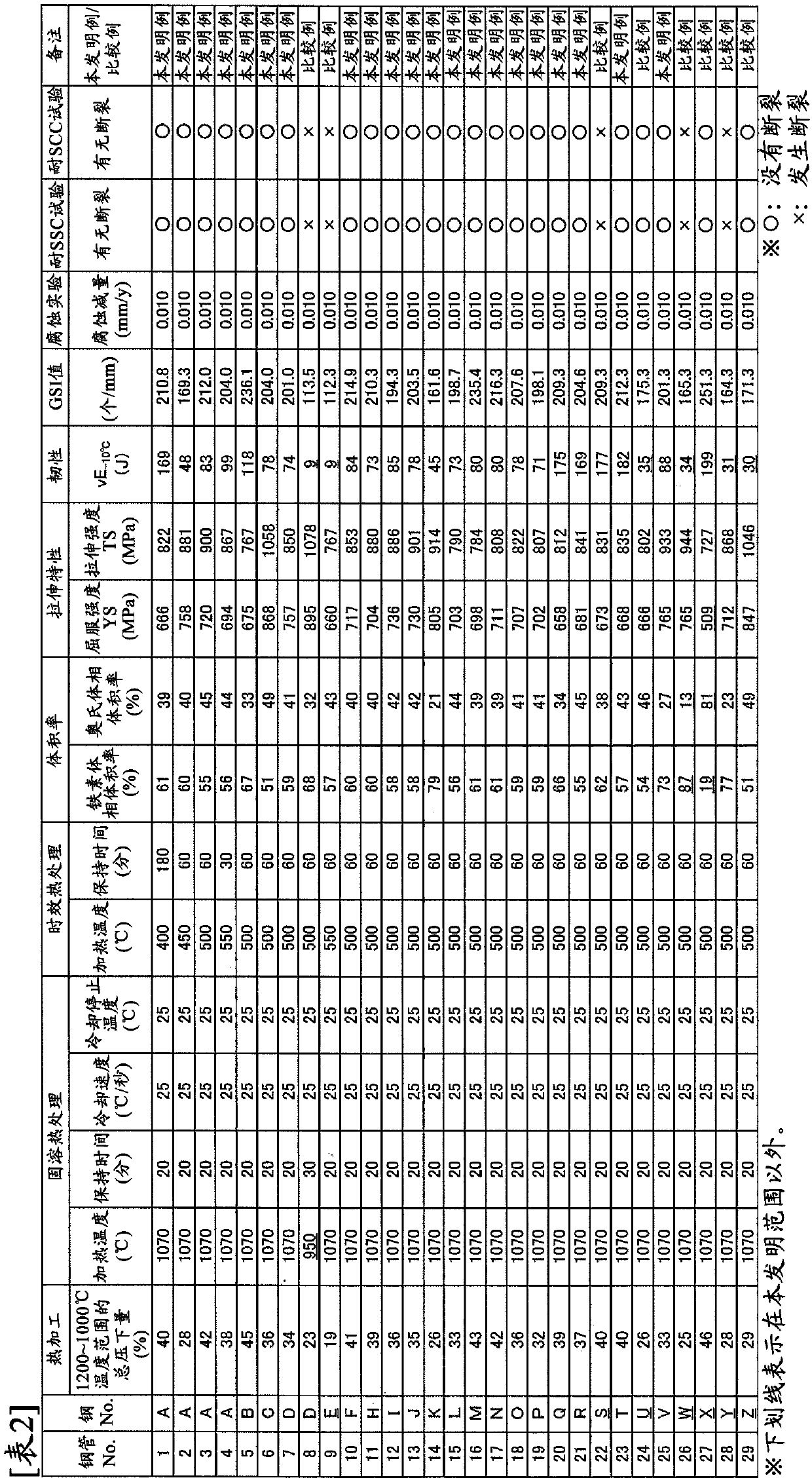

InactiveCN109563581AHigh strengthExcellent stress corrosion cracking resistanceFurnace typesHeat treatment furnacesCarbon dioxide corrosionSS - Stainless steel

Provided is a high strength seamless stainless steel pipe for oil wells with excellent low temperature toughness, carbon dioxide gas corrosion resistance, sulfide stress corrosion cracking resistance,and sulfide stress cracking resistance. The steel pipe contains, in mass%, C: 0.05% or less, Si: 0.5% or less, Mn: 0.15-1.0%, P: 0.030% or less, S: 0.005% or less, Cr: 14.5-17.5%, Ni: 3.0-6.0%, Mo: 2.7-5.0%, Cu: 0.3-4.0%, W: 0.1-2.5%, V: 0.02-0.20%, Al: 0.10% or less, and N: 0.15% or less, wherein C, Si, Mn, Cr, Ni, Mo, Cu and N satisfy a specified expression and Cu, Mo, W, Cr and Ni satisfy another specified expression, and the balance is made of Fe and unavoidable impurities. The steel pipe comprises martensite phase: greater than 45%, ferrite phase: 10-45%, and retained austenite phase: 30% or less. The total amount of deposited Cr, deposited Mo and deposited W is not more than 0.75 mass% and yield strength is at least 862 MPa.

Owner:JFE STEEL CORP

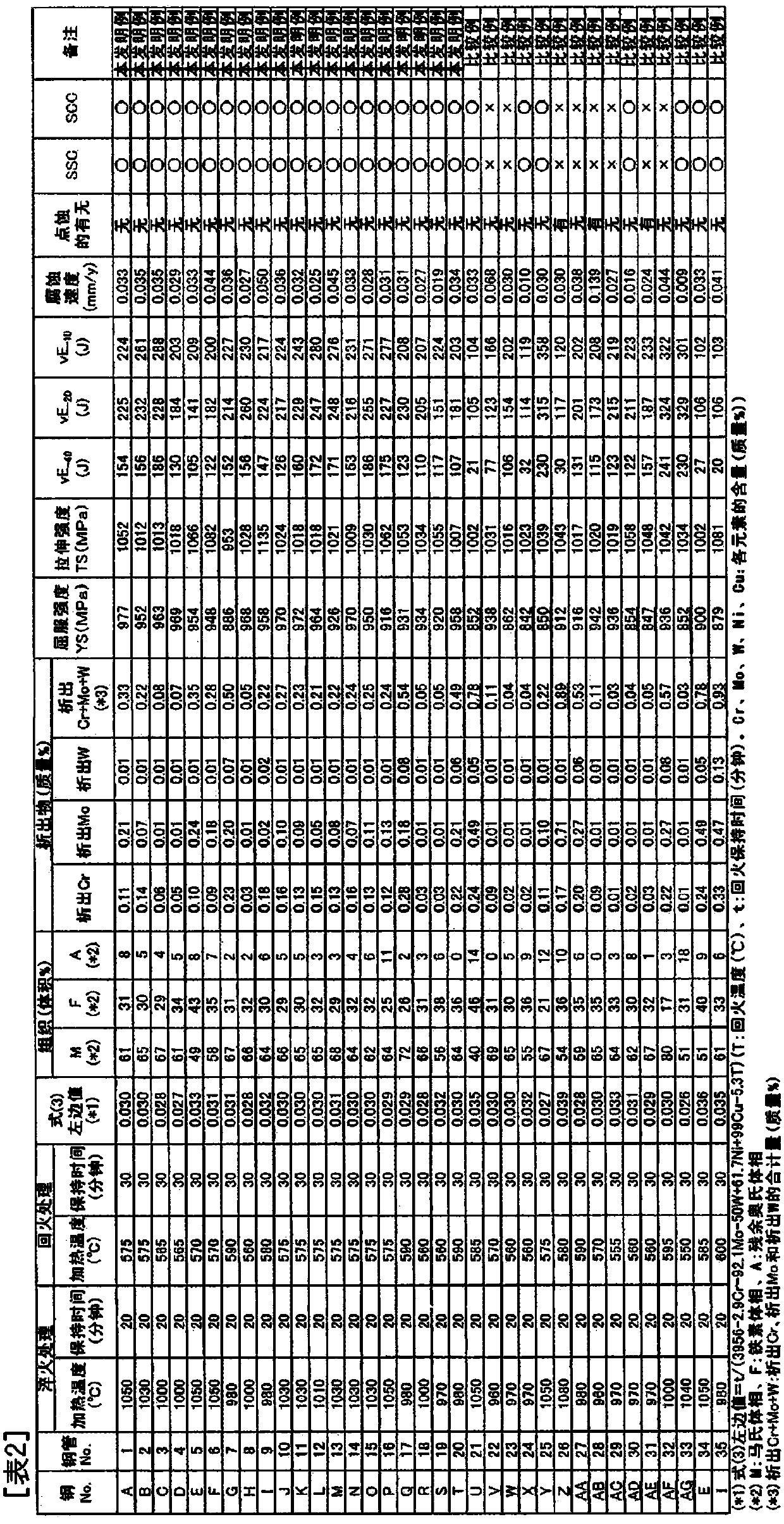

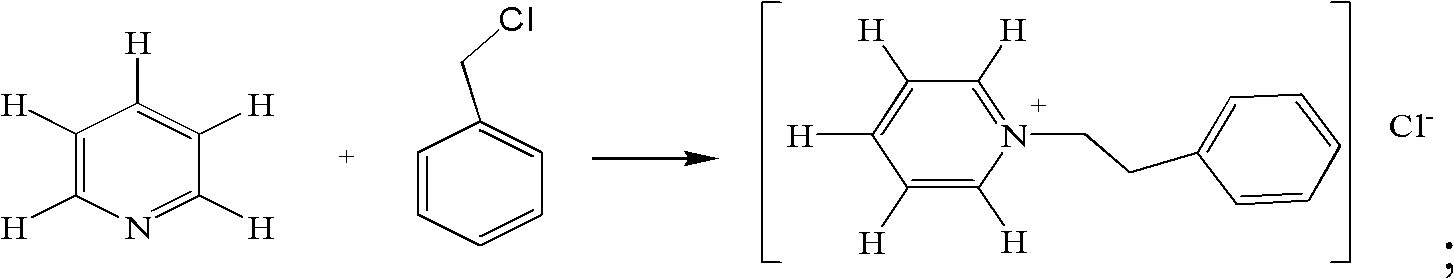

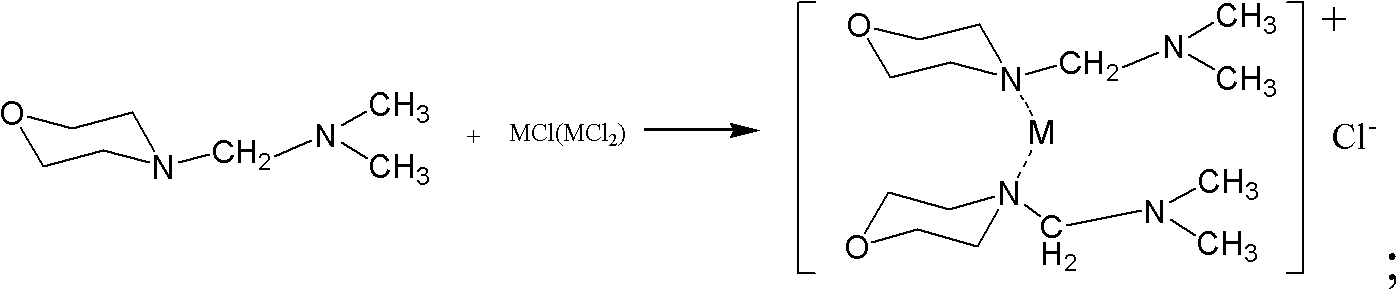

High-temperature O2/CO2 corrosion inhibitor for coiled tubing and preparation method of agent B of high-temperature O2/CO2 corrosion inhibitor

ActiveCN102627955AEnsure safe operationAvoid corrosionBorehole/well accessoriesSulfite saltMannich reaction

The invention discloses a high-temperature O2 / CO2 corrosion inhibitor for coiled tubing. The high-temperature O2 / CO2 corrosion inhibitor for the coiled tubing is used by matching an agent A mainly used for deoxidizing and an agent B mainly used for resisting corrosion of carbon dioxide, wherein the agent A is acetone oxime, D-ascorbic acid, sodium sulfite or ferrous sulphate; and the agent B is formed by mixing the components in percentage by weight: 20-30 percent of quaternary pyridine salt, 10-15 percent of mannich base chelate, 3-7 percent of surfactant and 48-67 percent of solvent. The quaternary pyridine salt is obtained by reacting pyridine with benzyl chloride; and the mannich base chelate is obtained by aldehyde ketone amine condensate generated by morpholine, trioxymethylene and dimethylamine through a mannich reaction with metal chloride. The corrosion inhibitor provided by the invention has use temperature up to 170DEG C, is suitable for a water-corrosive medium in which oxygen and carbon dioxde coexist and can be used for effectively inhibiting the corrosion of media such as the oxygen and the carbon dioxide and ensuring safe operation of the coiled tubing in the production process.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

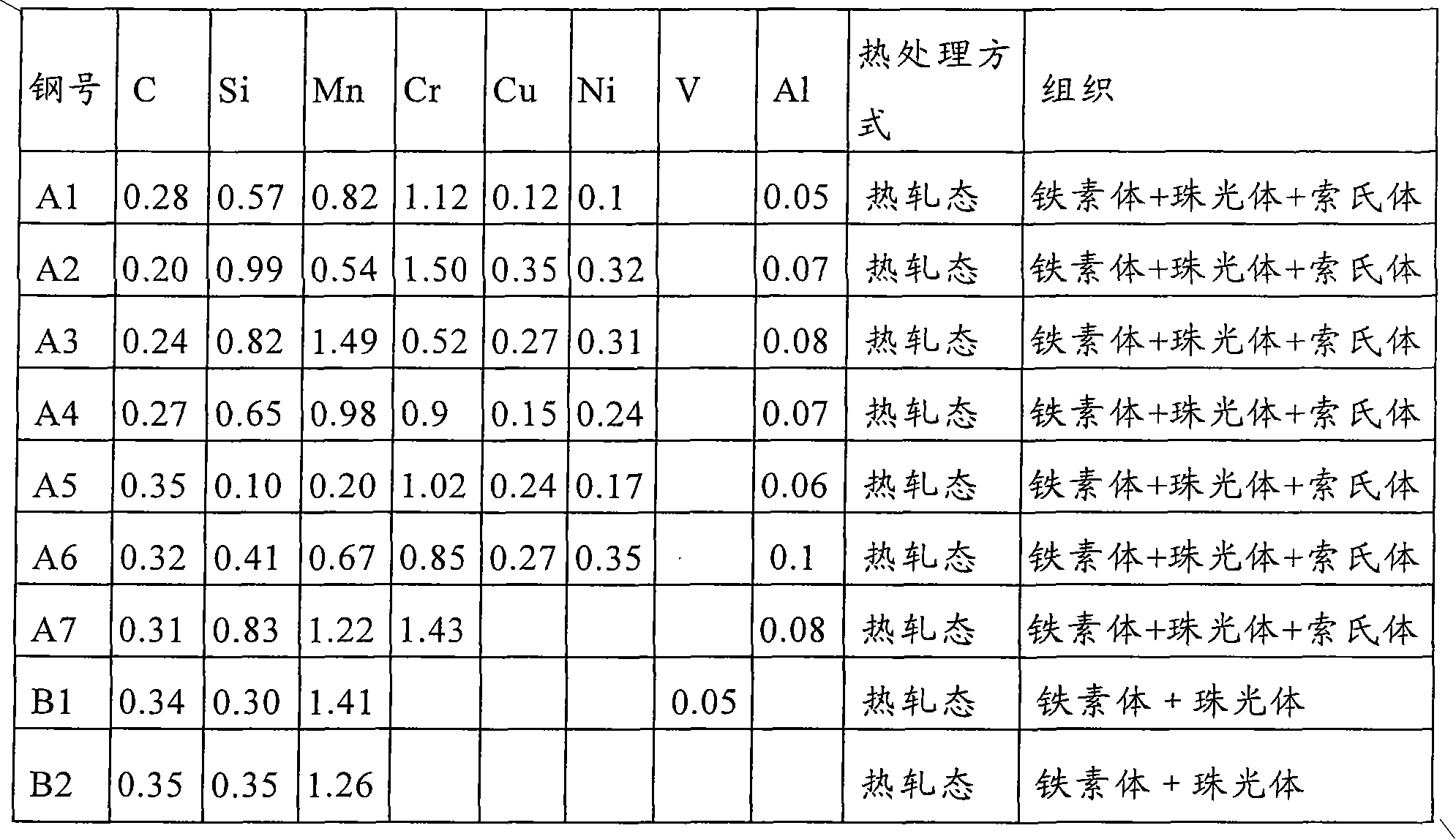

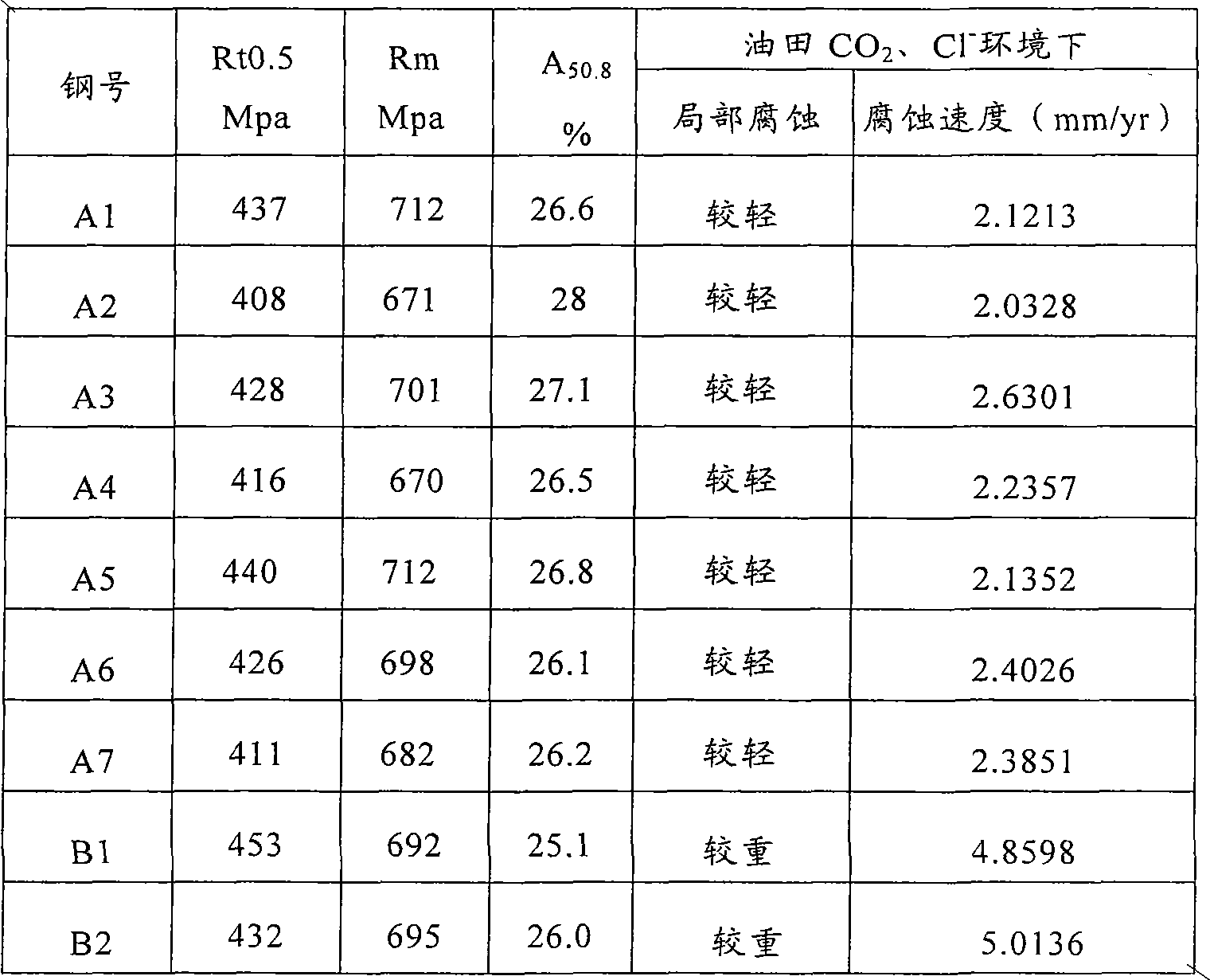

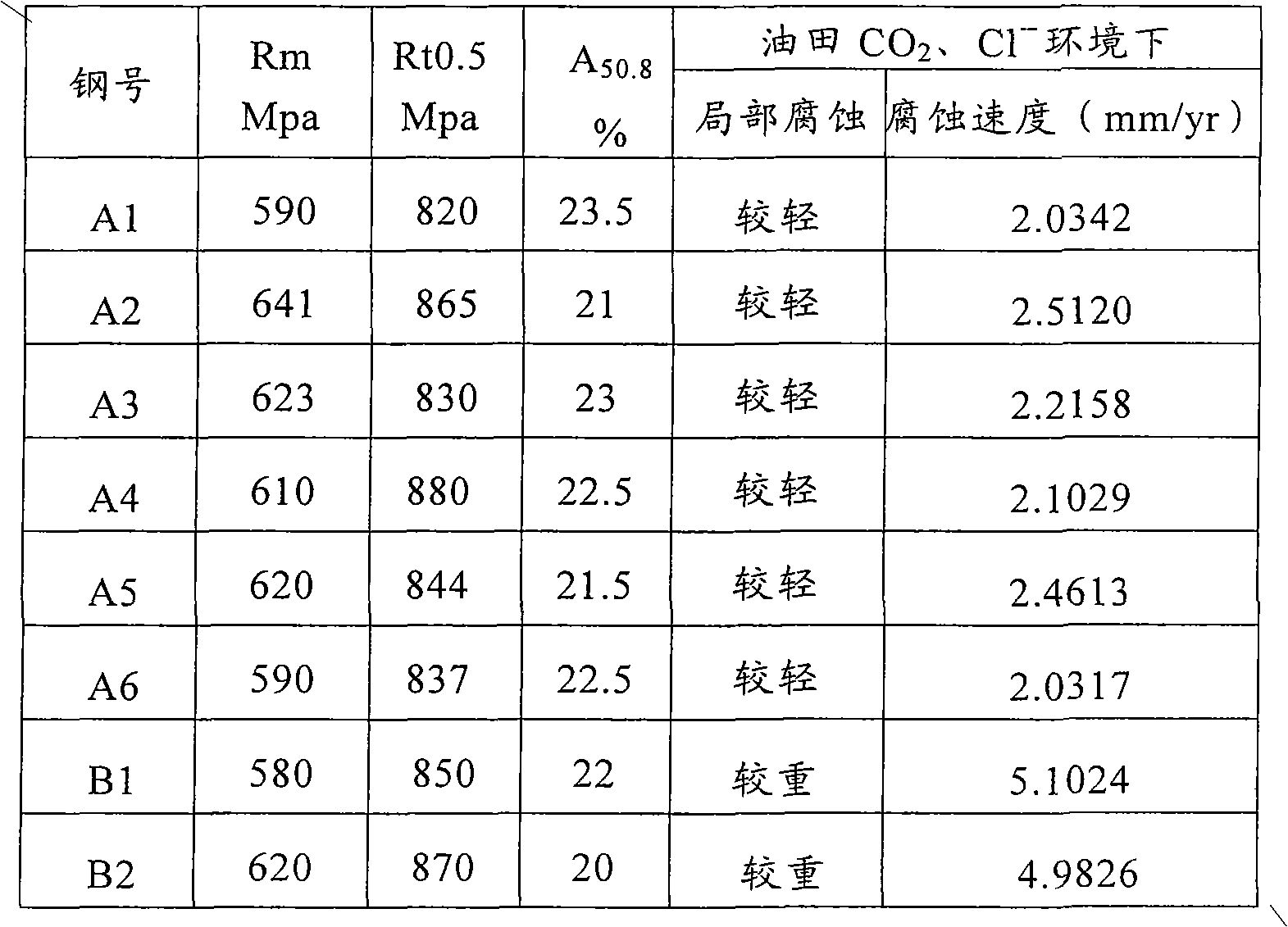

Low-alloy steel used for oil well pipe with carbon dioxide corrosion resistance and manufacturing method thereof

ActiveCN102400057ASub>goodAccelerated corrosionFurnace typesHeat treatment furnacesCarbon dioxide corrosionImpurity

The invention relates to a low-alloy steel used for an oil well pipe, and the low-alloy steel comprises the following chemical components in percentage by weight: 0.20-0.40% of C, 0.10-1.0% of Si, 0.50-2.0% of Mn, 0.5-1.5% of Cr, 0.02-0.2% of V, 0.01-0.10% of Al, 0.005-0.03% of N, 0.02-0.2% of Nb, less than or equal to 0.015% of P, less than or equal to 0.005% of S and the balance of Fe and inevitable impurities, wherein the total content of the impurity elements is less than 0.05wt. The invention also relates to a manufacturing method of the low-alloy steel. The manufacturing method comprises the following steps: performing steel making at the initial tapping temperature of 1600-1700 DEG C; performing continuous casting at the initial temperature of 1530-1570 DEG C, wherein in order to reduce the centre cracks and drawhole occurrence rates of a casting blank, the pulling rate of the continuous casting is controlled to be below 2.3m / min, and banding segregation is controlled to be within the level of 2.5; beginning performing perforation rolling at the temperature of 1180-1220 while performing hot rolling on the continuous casting blank; performing final stretch reducing until the temperature is 890-910 DEG C; and after hot rolling, air-cooling a steel tube to room temperature, thus obtaining the low-alloy steel used for the oil well pipe, wherein the low-alloy steel is provided with ferrite and pearlitic structures and has carbon dioxide and chloride ion corrosion resistance.

Owner:BAOSHAN IRON & STEEL CO LTD

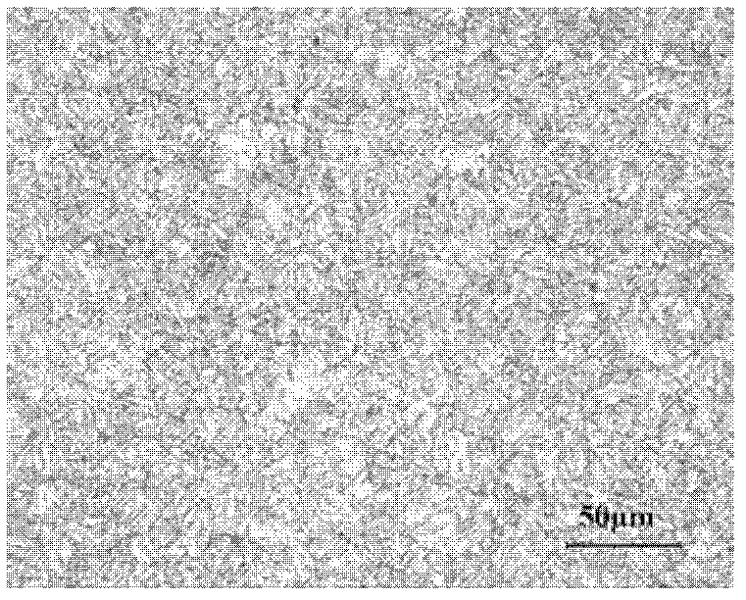

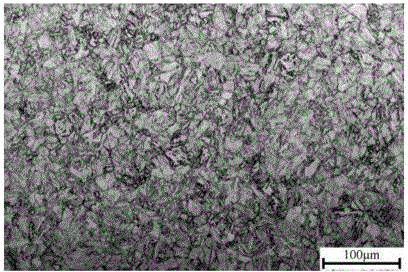

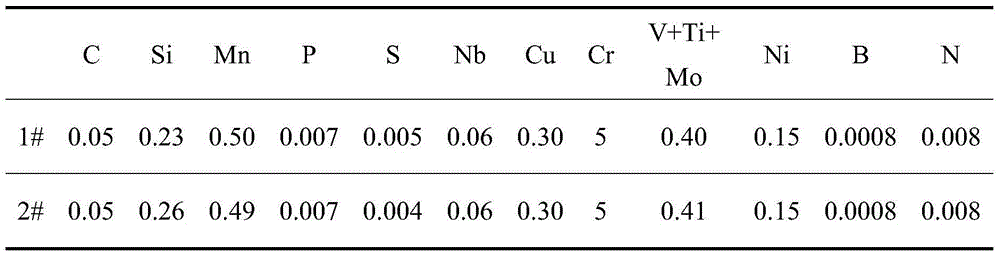

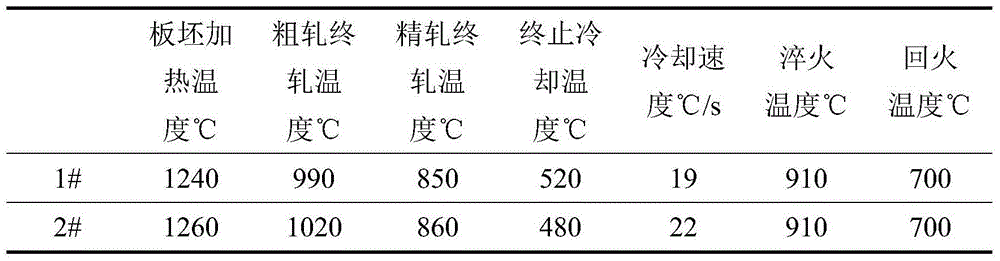

Pipeline steel resistant to carbon dioxide corrosion and preparation method thereof

ActiveCN104862607AImprove mechanical propertiesReduce contentCarbon dioxide corrosionCompound (substance)

The invention discloses pipeline steel resistant to carbon dioxide corrosion and a preparation method thereof, and belongs to the technical field of pipeline steel manufacturing. The pipeline steel comprises the following chemical components: not more than 0.05 percent of C, 0.2-0.3 percent of Si, 0.50-0.80 percent of Mn, not more than 0.020 percent of P, not more than 0.010 percent of S, 4.0-7.0 percent of Cr, not more than 0.080 percent of Nb, not more than 0.050 percent of Ti, not more than 0.080 percent of V, 0.2-0.50 percent of Mo, not more than 0.30 percent of Ni, not more than 0.5 percent of Cu, not more than 0.010 percent of N, not more than 0.0010 percent of B and the balance of Fe and impurities. A higher-toughness steel plate of the pipeline steel resistant to the carbon dioxide corrosion is obtained finally through the processes such as smelting, casting, forging and pressing, heating, rolling, cooling, quenching and tempering. The production process is simple, the operation is feasible, the production cost is low, the corrosion rate of the steel can be lowered to 0.0581 mm / a, the yield strength is greater than 500 MPa, the tensile strength is greater than 550 MPa, the elongation is greater than 25 percent, the impact energy at the temperature of minus 20 DEG C is greater than 150 J, and the DWTT mean value at the temperature of minus 20 DEG C is 100 percent.

Owner:UNIV OF SCI & TECH BEIJING

Anti-carbon dioxide corrosion inhibitor and preparation method thereof

The invention discloses a carbon dioxide corrosion inhibitor which consists of the following components in percentage by mass: 70-80% of clear water, 4-6% of dodecyl dimethyl benzyl ammonium chloride, 8-12% of imidazoline, 4-6% of alkyne-oxy methylamine and 4-6% of dodecyl trimethyl ammonium chloride. The preparation comprises the following steps: weighing the components according to the mass proportion and placing separately for later use; adding 70-80% of the clear water by mass into a mixer and starting stirring for 3-5min; adding the dodecyl dimethyl benzyl ammonium chloride into the mixer and starting stirring for 12-18min; adding the dodecyl trimethyl ammonium chloride into the mixer and starting stirring for 12-18min; adding the imidazoline into the mixer and starting stirring for 12-18min; and adding the alkyne-oxy methylamine into the mixer and the rest clear water, and starting stirring for at least 20min until the drug is uniformly mixed before stopping the stirring. The carbon dioxide corrosion inhibitor disclosed by the invention realizes a good corrosion inhibition effect on the sewage with high content of carbon dioxide in an oilfield, can effectively control the corrosion of sewage at low concentration and effectively saves the drug cost as well as the repair and maintenance cost of the oilfield water treatment equipment; and moreover, the preparation method is simple and fast, the production cost is low and the efficiency is high.

Owner:XIAN HUANUO ENVIRONMENTAL PROTECTION CO LTD

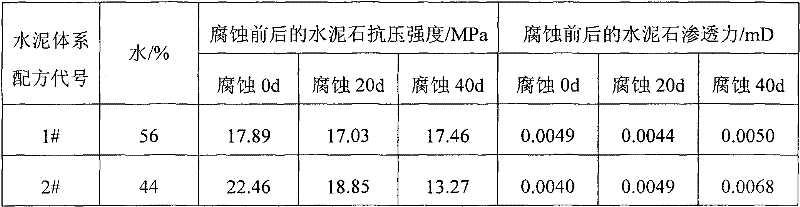

Carbon dioxide corrosion resisting cement system for oil-gas well cementation

InactiveCN102559161AExtend your lifeExcellent resistance to CO

<sub>2</sub>

corrosion performanceDrilling compositionHigh concentrationCarbon dioxide corrosion

The invention discloses a carbon dioxide corrosion resisting cement system for oil-gas well cementation, which comprises aluminate cement, soluble phosphate 10-20%, retarder 2-4.5% and fluid loss agent 3-10%, wherein the components are proportioned by mass with the aluminate cement as total weight. Cement stones of the cement system have excellent corrosion resistance under the conditions of high temperature, high pressure and high-concentration carbon dioxide, can meet the requirements for long-term cementation of an oil-gas well with high carbon dioxide content and provides guarantee for exploration, development, efficient production and environmental protection. The carbon dioxide corrosion resisting cement system for the oil-gas well cementation is suitable for the cementation of the oil-gas well with high temperature, high pressure and high carbon dioxide content.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

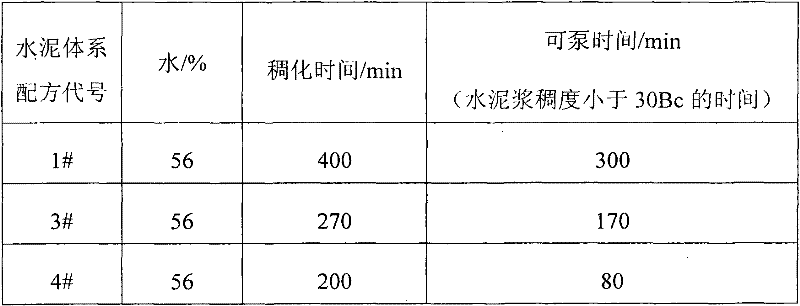

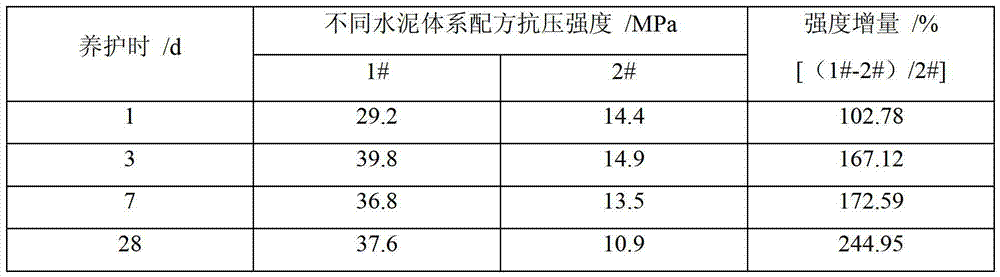

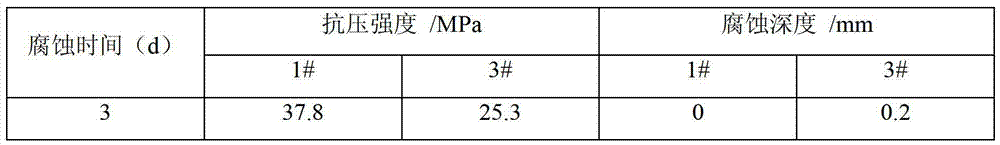

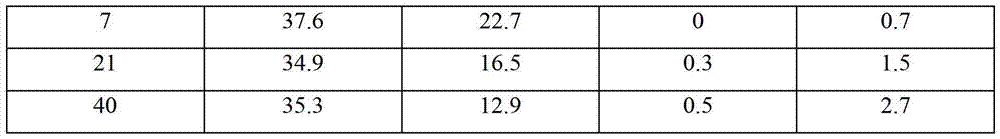

Aluminate cement-based carbon dioxide corrosion resistant cement system for cementing of well

ActiveCN103045215ASolve the problem of strength retractionReduce generationDrilling compositionHigh concentrationSodium phosphates

The invention relates to an aluminate cement-based carbon dioxide corrosion resistant cement system for cementing of a well. The aluminate cement-based carbon dioxide corrosion resistant cement system comprises the following components in parts by weight: 100 parts of aluminate cement, 40 parts of water, 8-12 parts of sodium phosphate, 0.4-0.6 part of oil well cement defoamer and 0-3.5 parts of retarder. The aluminate cement-based carbon dioxide corrosion resistant cement system disclosed by the invention has excellent CO2 corrosion resistance under the conditions of high temperature, high pressure and high-concentration CO2, and has good strength performance under high temperature. The compressive strength of the set cement 3d can reach 39.8 MPa, and the set cement can be used for an oil-gas well which is used for sealing high-concentration CO2 corrosion for a long time, thereby not only plugging a leakage zone to a certain extent, but also reducing the occurrence of gas channeling.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

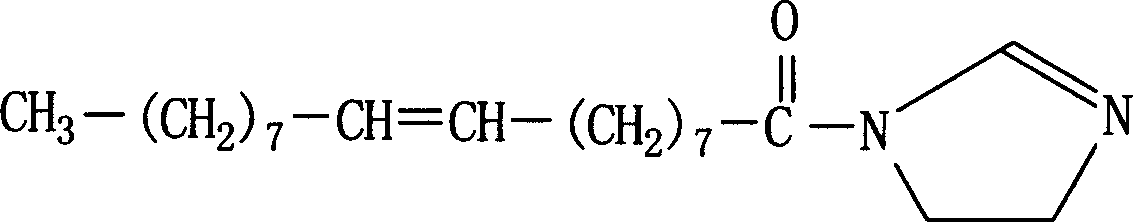

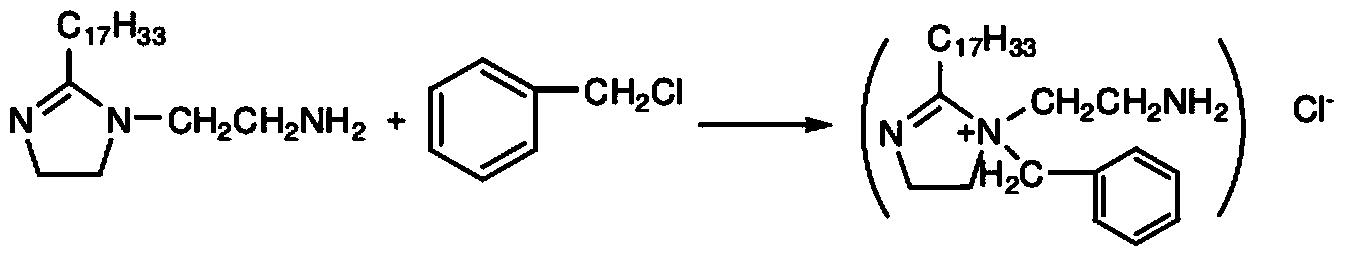

Preparation method of vegetable oil acid based imidazoline carbon dioxide corrosion inhibitor

The invention provides a preparation method of a vegetable oil acid based imidazoline carbon dioxide corrosion inhibitor. The vegetable oil acid based imidazoline carbon dioxide corrosion inhibitor is characterized by being prepared from the following components in percentage by weight: 20-22% of vegetable oil acid, 11%-12% of amine, 10%-15% of benzyl chloride, 5%-6% of dehydrant, 8% of thiourea, 4% of potassium iodide and 42%-33% of water. The corrosion inhibitor is mainly applied to inhibiting the corrosion of an oil pipe, a sleeve and the like caused by the carbon dioxide, and has the characteristics of low dosage, low corrosion rate, environmental friendliness and the like. The corrosion inhibitor is water-soluble, stable and easily soluble, compact in film forming, good in compatibility to other agents and strong in adsorptivity to metal surfaces. The corrosion inhibitor is applied to a produced liquid by 100mg / L vegetable oil acid based imidazoline carbon dioxide corrosion inhibitor so as to effectively inhibit metal corrosion, and the corrosion rate is smaller than 0.076mm / y.

Owner:CNPC SICHUAN GASOLINEEUM GEOPHYSICAL PROSPECTING ENG TECH RES INST

High Temperature Carbon Dioxide Corrosion Inhibitor

ActiveUS20150069301A1Improve coordinationImprove adsorption capacityOther chemical processesDrilling compositionCarbon dioxide corrosionPhysical chemistry

The present application relates to a high temperature carbon dioxide corrosion inhibitor comprising the following components by mass percent: amide compound 15˜50%, organic alkynol 10˜25%, mercaptan acid 5˜15%, piperidine 5˜25%, mercaptopyridine 5˜15%, and solvent 25˜60%. The corrosion inhibitor has excellent corrosion inhibition for CO2 corrosion of oil field water system at a high temperature (150˜250° C.).

Owner:CHINA NAT OFFSHORE OIL CORP +1

Method for predicting corrosion degree of natural gas pipeline under gas-liquid two-phase flow

ActiveCN108119761APipeline systemsDesign optimisation/simulationCarbon dioxide corrosionCollections data

The invention provides a method for predicting the corrosion degree of a natural gas pipeline under a gas-liquid two-phase flow. The method comprises firstly collecting and analyzing information on the working conditions of the natural gas pipeline; establishing a gas-liquid two-phase fluid model of the natural gas pipeline; performing numerical simulation of two-phase flow pattern and flow stateevolution based on the two-phase fluid model of the natural gas pipeline; finally establishing a carbon dioxide corrosion model, obtaining the carbon dioxide corrosion rate, calculating the pipeline corrosion rate by combination with the obtained pipeline corrosion damage probability Ptot, and predicting the pipeline service life. In the method, based on actual data collection on site, two-phase flow fluid calculation and carbon dioxide corrosion model are proposed, the effect of two-phase flow on carbon dioxide corrosion in the natural gas pipeline undergoes concentrated discussion, and computer numerical simulation is used to simulate the full set of carbon dioxide corrosion prediction of the natural gas pipeline under two-phase flow. Technical support is provided for the safety of the natural gas pipeline under gas-liquid two-phase flow.

Owner:PETROCHINA CO LTD

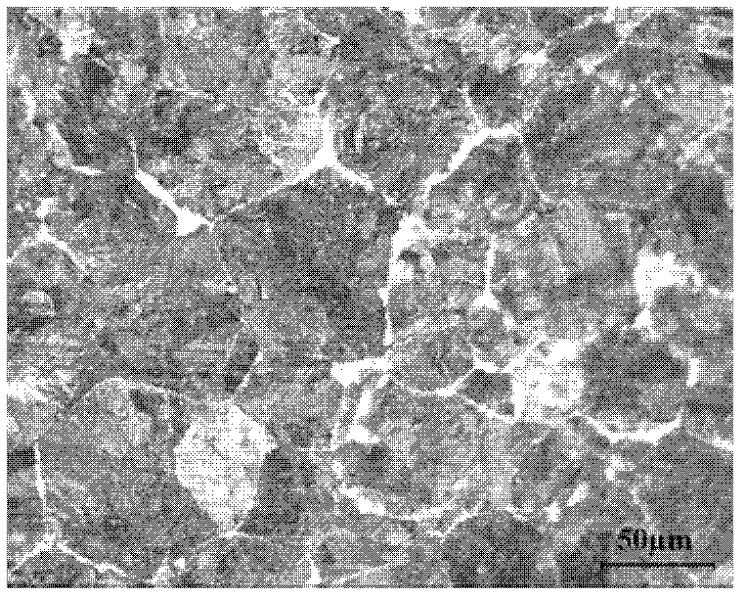

Low-alloy steel resistant to carbon dioxide corrosion

ActiveCN101928893ASimple preparation processOmit quenching and tempering heat treatment procedureDrilling rodsDrilling casingsChemical compositionCarbon dioxide corrosion

The invention relates to a low-alloy steel resistant to carbon dioxide corrosion, which comprises the following chemical components in percentage by weight: 0.20-0.35% of C, 0.10-1.0% of Si, 0.20-1.5% of Mn, 0.5-1.5% of Cr, being more than or equal to 0.35% of Ni, being more than or equal to 0.35% of Cu, 0.01-0.10% of Al, and the balance of Fe and inevitable impurities, wherein the total content of impurity elements is lower than 0.05 wt%. In manufacturing process of the alloy steel, heat treatment is not carried out after smelting, continuous casting, hot rolling and air cooling. The strength of the oil well pipe prepared by the alloy steel is 55 ksi, thus the oil well pipe prepared by the alloy steel is suitable for shallow wells resistant to carbon dioxide corrosion.

Owner:BAOSHAN IRON & STEEL CO LTD

Oil-well cement additive against carbon dioxide corrosion as well as preparation method and application thereof

ActiveCN102010702AAvoid erosionReduce penetrationBorehole/well accessoriesSlagCarbon dioxide corrosion

The invention provides an oil-well cement additive against carbon dioxide corrosion as well as a preparation method and application thereof, relating to the field of well cementation of oil-well cement. The oil-well cement additive mainly comprises the following raw materials in percentage by weight of: 20-65%wt of volcanic gray minerals, 2-25%wt of silica fume, 5-25%wt of aluminum salt mineral, 5-35%wt of organic paraffin material, 1-10%wt of methyl silanol sodium, and 3-25%wt of slag. When 15-60 parts of the oil-well cement additive is added into 100 parts of cement, the compactness of cement columns can be strengthened, with low gas permeability and strong resistance against carbon dioxide corrosion. The oil-well cement additive is suitable for different temperatures, and has wider application.

Owner:CHINA PETROLEUM & CHEM CORP +1

Compounded carbon dioxide corrosion inhibitor

ActiveCN103820789AReduce dosageGood corrosion inhibition effectBorehole/well accessoriesSimple Organic CompoundsCarbon dioxide corrosion

A compounded carbon dioxide corrosion inhibitor belongs to a corrosion inhibitor anticorrosion technology. The invention relates to a corrosion inhibitor anticorrosion technology of carbon steel materials in CO2 environment, and especially relates to an efficient corrosion inhibitor obtained through the compounding and the corrosion inhibition cooperation of organic compounds comprising an imidazoline corrosion inhibitor and its derivative, alicyclic amine and its derivative, rosin amine and the like with thiourea and sodium dodecanesulphonate, so the corrosion of the carbon steel materials in the CO2 system can be effectively inhibited. The efficient corrosion inhibitor can be obtained through the compounding and the corrosion inhibition cooperation of the organic compounds with thiourea and sodium dodecanesulphonate. The compounded corrosion inhibitor is compact on the adsorption layer of the surface of carbon steel, so the corrosion inhibition effect of the corrosion inhibitor on the carbon steel materials in the CO2 corrosion system is improved, and the consumption of the corrosion inhibitor is effectively reduced. The compounded carbon dioxide corrosion inhibitor is of important guidance significance for developing efficient composite corrosion inhibitors. The compounded carbon dioxide corrosion inhibitor can be used for preventing CO2 corrosion in oil and gas fields.

Owner:BEIJING UNIV OF CHEM TECH

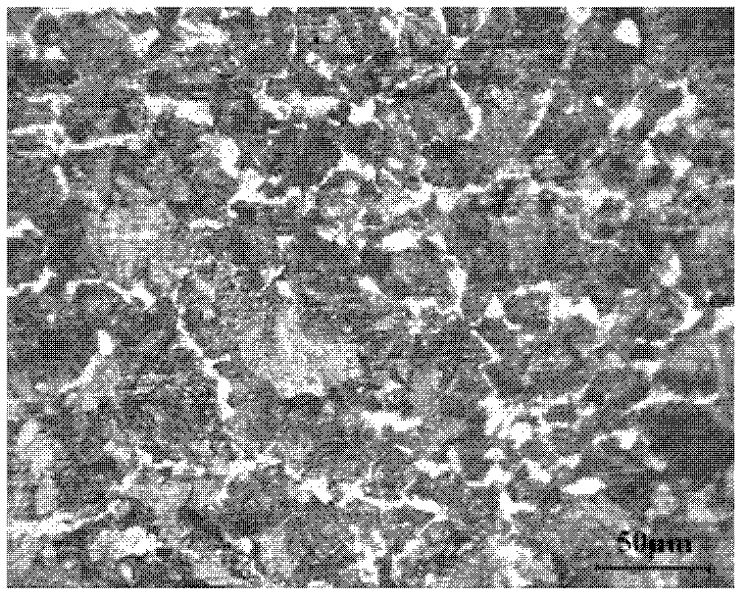

Low-alloy steel for resisting carbon dioxide corrosion and manufacturing method thereof

ActiveCN101928888AGood value for moneySimple preparation processDrilling rodsDrilling casingsChemical compositionCarbon dioxide corrosion

The invention discloses low-alloy steel for resisting carbon dioxide corrosion. The low-alloy steel comprises the following chemical components in percentage by weight: 0.20 to 0.35 percent of C, 0.10 to 1.0 percent of Si, 0.20 to 1.5 percent of Mn, 0.5 to 1.5 percent of Cr, 0.02 to 0.1 percent of V, 0.01 to 0.10 percent of Al and the balance of Fe and inevitable impurities, wherein the total amount of the impurity elements is lower than 0.05 weight percent. A manufacturing method for the low-alloy steel for resisting the carbon dioxide corrosion comprises steel making, continuous casting, hot rolling and normalizing in a two-phase area at the temperature of between 820 and 870 DEG C. The strength of the alloy steel reaches 80ksi level, the alloy steel has good CO2 corrosion resistance and low price, and an oil well pipe made of the alloy steel can be widely applied to an oil gas well with light CO2 corrosion resistance.

Owner:BAOSHAN IRON & STEEL CO LTD

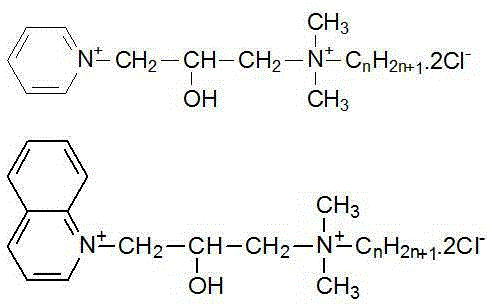

Dissymmetric bis-quaternary ammonium carbon dioxide corrosion inhibitor and preparation method thereof

InactiveCN105239076AImprove protectionGood water solubilityAmmonium compoundsCarbon dioxide corrosion

The invention relates to a dissymmetric bis-quaternary ammonium carbon dioxide corrosion inhibitor and a preparation method thereof, and belongs to the technical field of corrosion prevention for oil-gas gathering and transferring pipelines in offshore oil production. The corrosion inhibitor disclosed by the invention is composed of 40-60% of a dissymmetric bis-quaternary ammonium compound, and 40-60% of a low-molecular-weight alcohol solvent. The preparation method thereof comprises the following steps: adding a nitrogen heterocyclic ring compound and epoxy chloropropane with a molar ratio of 1.0: 1.05 in ethanol solution of a reactor, reacting for 3-5 hours under a condition of carrying out reflux at 85 DEG C, cooling to 55-65 DEG C, adding long-chain alkyl tertiary amine, continuing to react for 2-4 hours to obtain the dissymmetric bis-quaternary ammonium compound, then weighing the dissymmetric bis-quaternary ammonium compound and the low-molecular-weight alcohol solvent, and mutually mixing and uniformly stirring the dissymmetric bis-quaternary ammonium compound and the low-molecular-weight alcohol solvent to obtain the dissymmetric bis-quaternary ammonium carbon dioxide corrosion inhibitor. The corrosion inhibitor provided by the invention is capable of being used for corrosion prevention for oil-gas gathering and transferring pipelines in offshore oil production, high in compatibility with the medicaments of a demulsifier and the like, wide in adaptability, and capable of meeting the need of corrosion prevention under complex working conditions on site.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Duplex stainless steel and method for manufacturing same

ActiveCN109642282AHighly corrosiveImprove corrosion resistanceFurnace typesHeat treatment furnacesCarbon dioxide corrosionSS - Stainless steel

Provided is a duplex stainless steel having excellent corrosion resistance, in which excellent carbon dioxide corrosion resistance, excellent sulfide stress corrosion cracking resistance, and excellent sulfide stress cracking resistance are provided at the same time. The present invention has a composition containing, in terms of mass%, 0.03% or less of C, 1.0% or less of Si, 0.10-1.5% Mn, 0.030%or less of P, 0.005% or less of S, 20.0-30.0% Cr, 5.0-10.0% Ni, 2.0-5.0% Mo, 2.0-6.0% Cu, and less than 0.07% of N, the remainder comprising Fe and unavoidable impurities, and the metallographic structure of the present invention has an austenitic phase that is 20-70% by volume ratio and a ferritic phase that is 30-80% by volume ratio.

Owner:JFE STEEL CORP

Compositions and methods to prevent corrosion by co2 on cement compositions

ActiveUS20100018435A1Reduce corrosionHinders its propagationOther chemical processesAnti-corrosive paintsCarbon dioxide corrosionMaterials science

Methods and compositions that protect cement compositions from corrosion, particularly from wet carbon dioxide, are provided. A soluble salt additive is provided to react with reaction products generated during the reactions that occur when cement is exposed to wet carbon dioxide. The soluble salt reacts to form an insoluble salt that forms a protective layer on the surface of the cement that protects it from further corrosion from exposure to wet carbon dioxide.

Owner:BAKER HUGHES INC

Rod blockage prevention liquid for carbon dioxide huff-puff enhanced oil recovery and injection method thereof

ActiveCN102040992AEasy way to fillPrevent waxingCleaning apparatusDrilling compositionCarbon dioxide corrosionActive agent

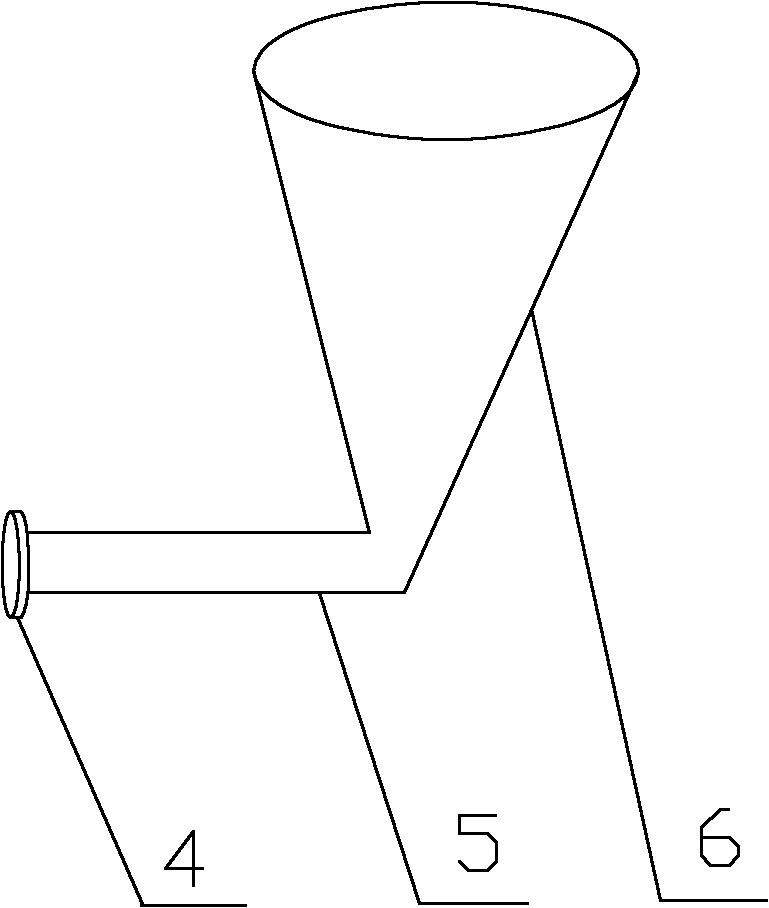

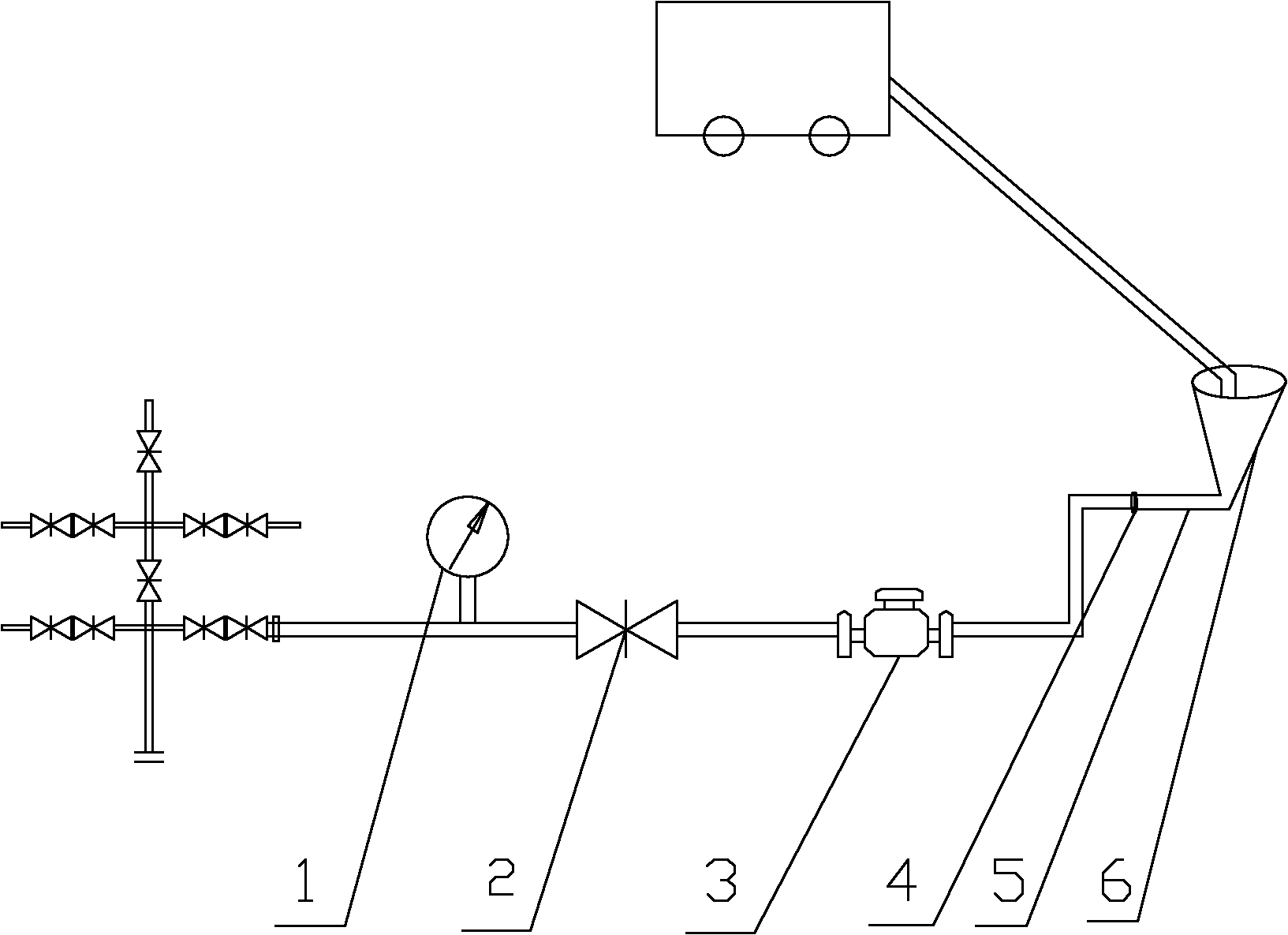

The invention discloses rod blockage prevention liquid for carbon dioxide huff-puff enhanced oil recovery and an injection method thereof, which mainly solve the problem of well blockage caused by a large quantity of paraffin deposits on the inner wall of an oil pipe during carbon dioxide huff-puff enhanced oil recovery operation. The rod blockage prevention liquid comprises the following components in percentage by mass: 40 to 50 percent of glycol, 3 to 5 percent of carbon dioxide corrosion inhibitor, 5 percent of anti-expanding agent, 2 percent of anti-scaling agent, 2 percent of surfactantand the balance of water. A pressure gauge (1), a one-way valve (2), a valve (3) and an agent feeder are arranged at the port of a well mouth casing; the rod blockage prevention liquid is injected into a well through the agent feeder; a pumping unit is not stopped during the injection of the agents; when a large amount of rod blockage prevention liquid occurs at the well mouth, the pumping unit is stopped at a lower dead point; and an agent injection device is disassembled and the port of the well mouth casing is closed well. The rod blockage prevention liquid can soften the paraffin depositsin the oil pipe and prevent well blockage; and the injection method of the rod blockage prevention liquid is simple, is easy to operate and is low in cost.

Owner:DAQING JINJUN PETROLEUM TECH DEV CO LTD

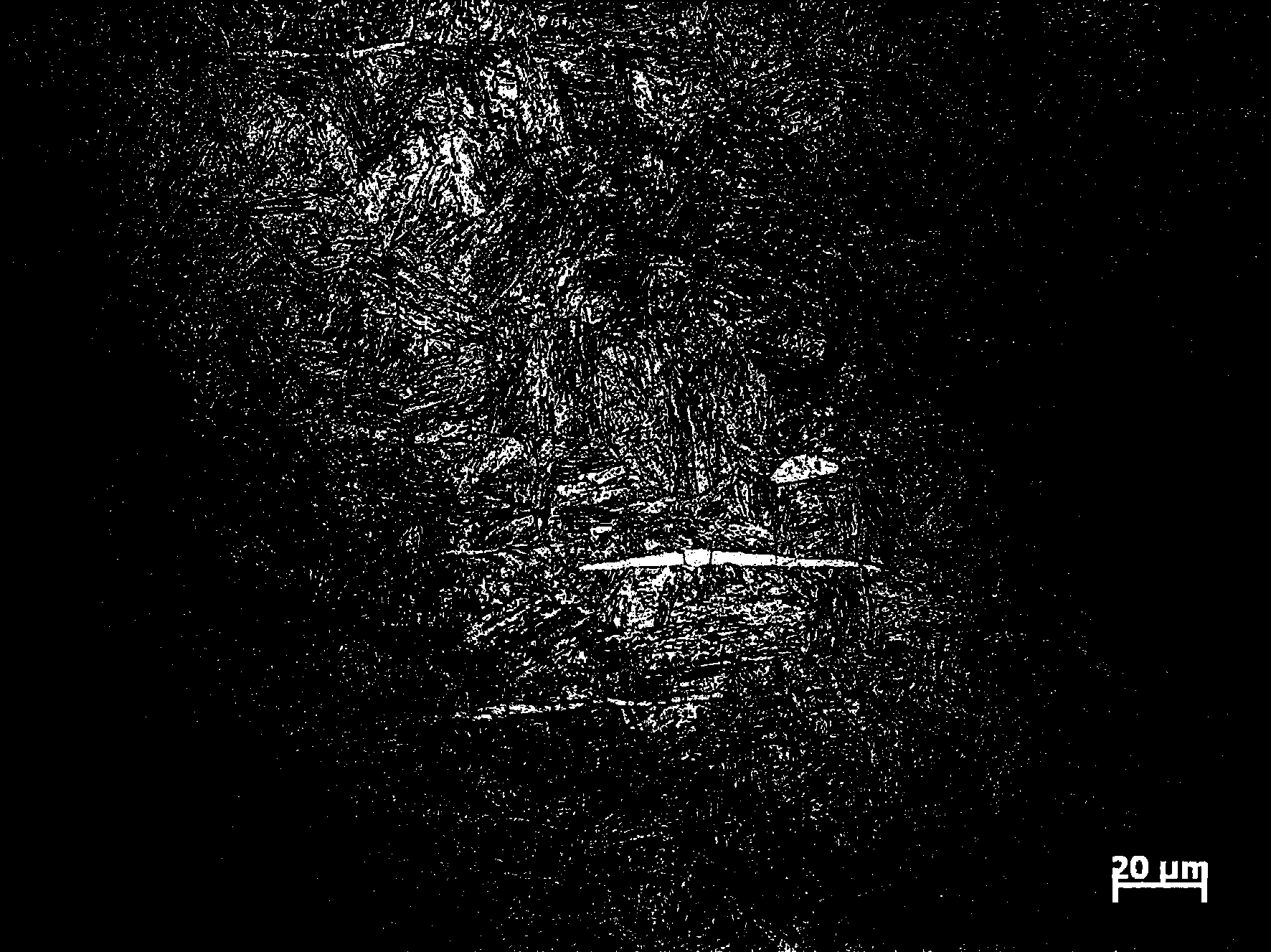

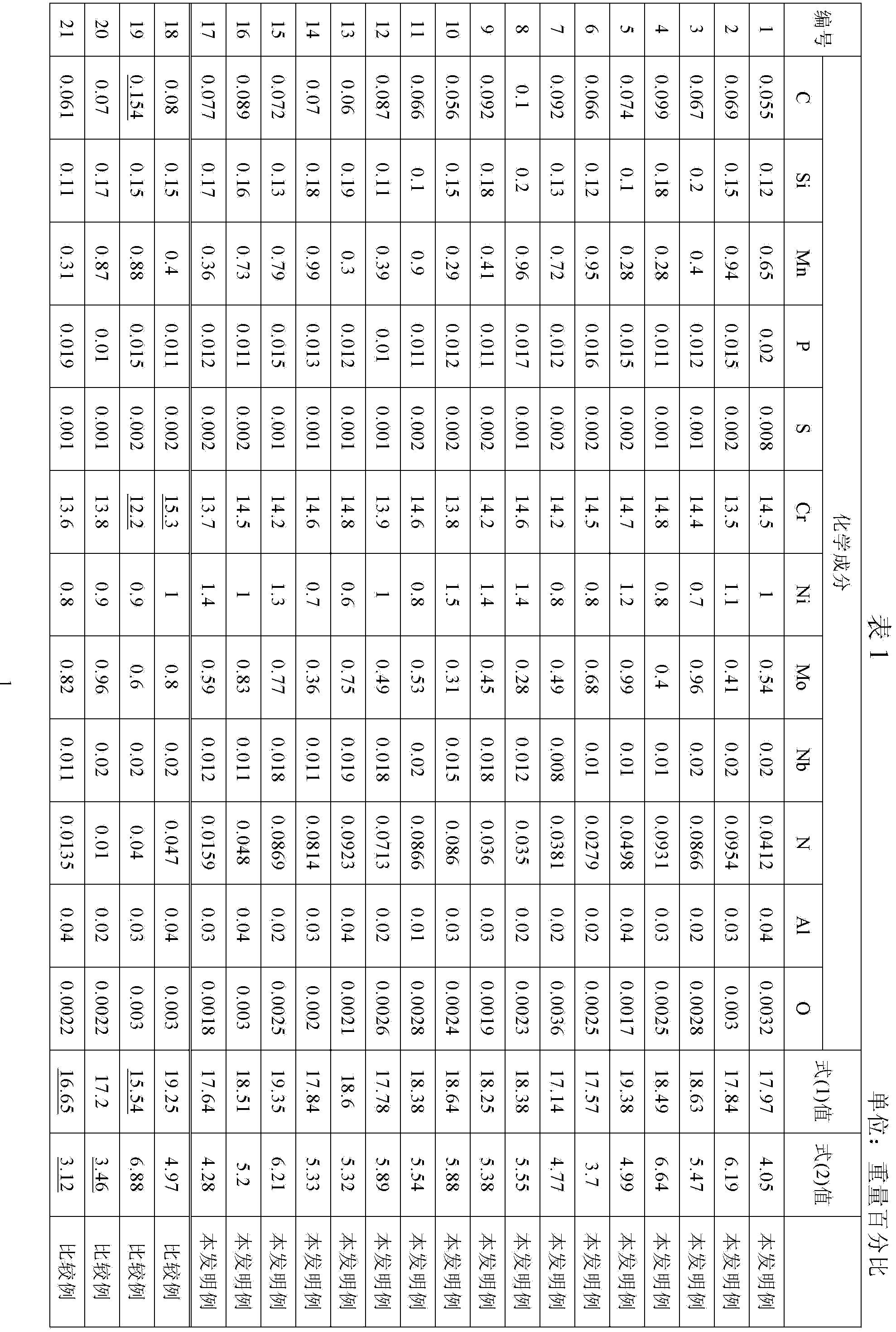

High-strength martensite ferrite two-phase stainless steel anti-corrosion oil casing pipe and manufacturing method thereof

ActiveCN103469097AImprove low temperature impact toughnessImprove toughnessCarbon dioxide corrosionHigh intensity

The invention provides a high-strength martensite and ferrite two-phase stainless steel anti-corrosion oil casing pipe and a manufacturing method of the high-strength martensite ferrite two-phase stainless steel anti-corrosion oil casing pipe. The high-strength martensite ferrite two-phase stainless steel anti-corrosion oil casing pipe comprises, by weight, 0.05% to 0.10% of C, 0.1% to 0.4% of Si, 0.20% to 1.0 % of Mn, less than 0.03% of P, less than 0.01% of S, 13.5% to 15.0% of Cr, 0.5% to 1.5% of Ni, 0.2% to 1.0% of Mo, 0.005% to 0.02% of Nb, 0.01% to 0.10% of N and less than 0.004% of O, wherein the compositions satisfies the inequality that Cr+1.5Mo+2Ni+16N>=17 and the inequality that Ni+30(C+N)+8Nb>=3.5, Cr, Ni, Mo, Si, Nb, Mn, C and N stand for the weight relative content of the elements, and the rest of the oil casing pipe comprises Fe and inevitable impurities. The oil casing pipe has good corrosion resistance performance, and the yield strength is more than 110ksi. The oil casing pipe is quenched and tempered, a martensite phase is used as the main body of a metallographic structure, and the metallographic structure contains 2% to 10% of ferrite phases. The steel pipe has good carbon dioxide corrosion resistance performance and low temperature impact toughness.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for testing carbon dioxide corrosion resistance of low-Cr pipeline steel

InactiveCN106442293AInspection is accurateEasy to prepareWeather/light/corrosion resistanceMaterial weighingCarbon dioxide corrosionErosion corrosion

The invention discloses a method for testing carbon dioxide corrosion resistance of low-Cr pipeline steel. The method comprises the following steps: firstly, processing the low-Cr pipeline steel into a plurality of samples, finely grinding and machining the surfaces of the samples till the roughness reaches Ra 0.8; measuring the length, width, thickness and weight w1 of each sample; then, placing parallel samples in a closed reaction kettle provided with a rotary sample rack; adding a test solution into the reaction kettle, heating the reaction kettle to 80 DEG C, feeding CO2 gas into the reaction kettle for 168 hours; designing partial pressure of CO2 as 1.5 MPa and flow velocity as 2 m / s; taking out the samples corroded by CO2 gas, removing a CO2 corrosion product film, and weighing to obtain w2; and calculating the CO2 corrosion rate R of each sample, and averaging to obtain the carbon dioxide corrosion resistance of low-Cr pipeline steel. The method provided by the invention can simulate the CO2 corrosive environment in an oil and gas transmission pipeline, and quickly and accurately test the carbon dioxide corrosion resistance of the low-Cr pipeline steel.

Owner:武汉钢铁有限公司

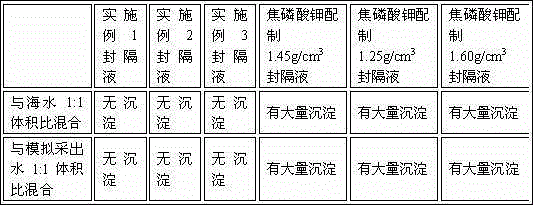

Packer liquid capable of reducing carbon dioxide corrosion at high temperature under high pressure and preparation method thereof

ActiveCN105131925AEase of well completionImprove thermal stabilityDrilling compositionBorehole/well accessoriesInorganic phosphateCarbon dioxide corrosion

The invention discloses a packer liquid capable of reducing the carbon dioxide corrosion at a high temperature under a high pressure and a preparation method thereof. The packer liquid is composed of the following components in parts by weight: 100 parts of fresh water, 0.20 to 0.50 part of NaOH, 0.10 to 0.30 part of deoxidant, 1 to 6 parts of corrosion inhibitor, and 10 to 200 parts of composite salt weighting agent; wherein the composite salt weighting agent is prepared by compounding inorganic phosphate and organic phosphonate. The packer liquid is a non-solid phase, and the density can reach 1.60 g / cm3 or more. The packer liquid can tolerate a temperature of 150 DEG C, and is capable of reducing the corrosion of carbon dioxide on tubing in the wells at a high temperature under a high pressure. Furthermore, compatibility between the packer liquid and seawater / stratum produced water is good, and thus the packer liquid can be applied to the well-completion practice on an oil gas well with a high carbon dioxide content at a high temperature under a high pressure.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com