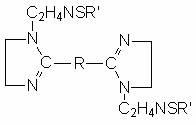

Sulfur-containing bis-imidazoline type carbon dioxide corrosion inhibitor and preparation method thereof

A technology of bis-imidazoline and carbon dioxide, applied in earthwork drilling, organic chemistry, wellbore/well parts, etc., can solve problems such as poor water solubility, layered precipitation, and influence on the use of chemicals, and achieve good water solubility and good protection The effect of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add sebacic acid and diethylenetriamine with a molar ratio of 1.0:1.5 into the reactor in a certain order, and raise the temperature to 110°C under stirring conditions. At this time, liquid separates and keeps reflux for 1h; then raise the temperature to 140°C, Reflux for 3 hours for amidation reaction; continue to heat up to 260°C and reflux for 3 hours for cyclization reaction to obtain a bis-imidazoline intermediate;

[0033] Lower the temperature of the reactant to 70°C, add thiourea according to the molar ratio of polyamine:thiourea=1.0:1.5, then raise the temperature to 100°C, and continue the reaction for 3 hours to obtain a brown-yellow uniform viscous liquid, which is the target product - sulfur-containing bis-imidazoline compounds.

[0034] The contents are: sulfur-containing bisimidazoline: 30% by weight, OP-10: 3% by weight, methanol: 62% by weight, propynyl alcohol: 5% by weight, mixed with each other, and stirred evenly.

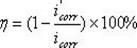

[0035]

Embodiment 2

[0037] Add adipic acid and triethylenetetramine with a molar ratio of 1.0:1.7 into the reactor in a certain order, and raise the temperature to 120°C under stirring conditions. At this time, liquid separates, and keep reflux for 1.4h; then raise the temperature to 160°C , reflux for 3h for amidation reaction; continue to heat up to 260°C and reflux for 4.5h for cyclization reaction to obtain a bis-imidazoline intermediate.

[0038] Reduce the temperature of the reactant to 85°C, add thiourea, then raise the temperature to 130°C, and continue the reaction for 4 hours to obtain a brown-yellow homogeneous viscous liquid, which is the target product-sulfur-containing bis-imidazoline compound.

[0039] The contents are: sulfur-containing bis-imidazoline: 35% by weight, OP-10: 1% by weight, methanol: 46% by weight, propynyl alcohol: 10% by weight, mixed with each other, and stirred evenly.

[0040]

Embodiment 3

[0042] Add sebacic acid and tetraethylenepentamine with a molar ratio of about 1.0:2.05 into the reactor in a certain order, and raise the temperature to 135°C under stirring conditions. At this time, liquid separates and keeps reflux for 1.8h; °C, reflux for 3 hours for amidation reaction; continue to heat up to 260 °C and reflux for 6 hours for cyclization reaction to obtain a bis-imidazoline intermediate.

[0043] Lower the temperature of the reactant to 90°C, add mercaptan according to the molar ratio of polyamine:thiol = 1.0:1.7, then raise the temperature to 145°C, and continue the reaction for 5 hours to obtain a brown-yellow uniform viscous liquid, which is the target product - sulfur-containing bis-imidazoline compounds.

[0044] The content is: sulfur-containing bisimidazoline: 20% by weight, OP-10: 3.5% by weight, methanol: 70% by weight, propynyl alcohol: 6.5% by weight, mixed with each other, and stirred evenly

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com