Patents

Literature

4372 results about "Isopropyl alcohol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Isopropyl alcohol (IUPAC name propan-2-ol; commonly called isopropanol or 2-propanol) is a colorless, flammable chemical compound (chemical formula CH₃CHOHCH₃) with a strong odor. As an isopropyl group linked to a hydroxyl group, it is the simplest example of a secondary alcohol, where the alcohol carbon atom is attached to two other carbon atoms. It is a structural isomer of 1-propanol and ethyl methyl ether.

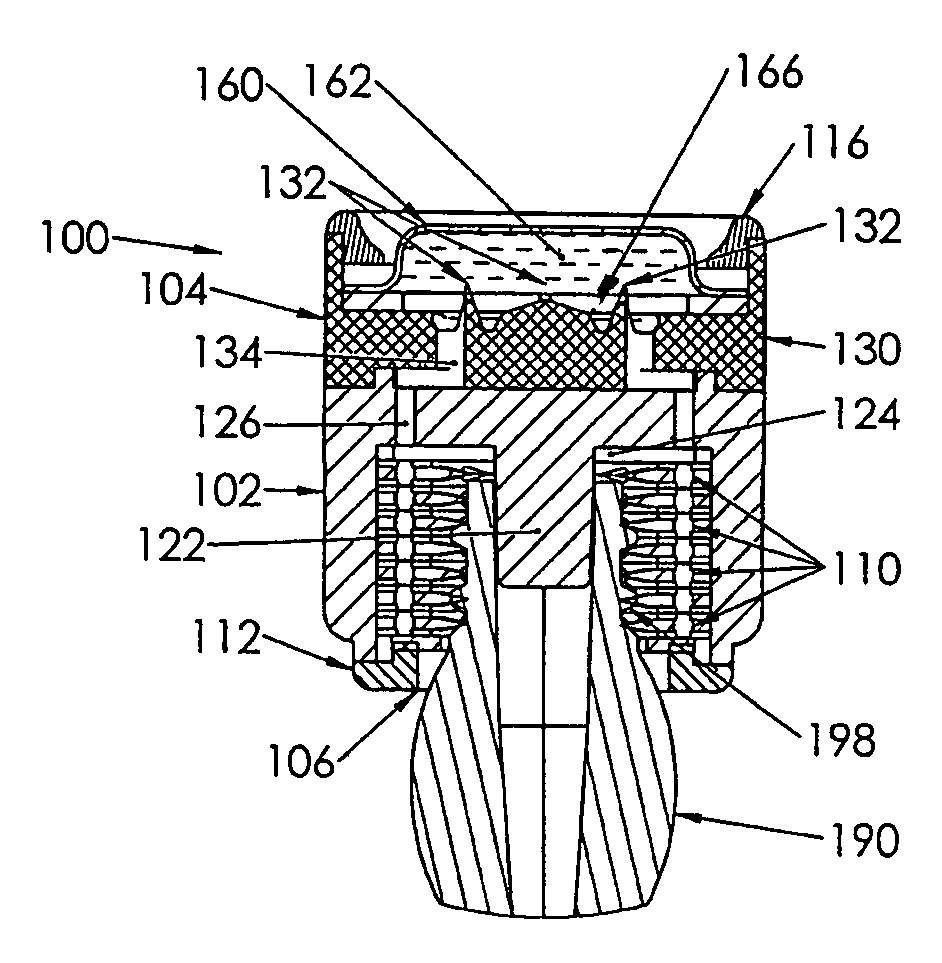

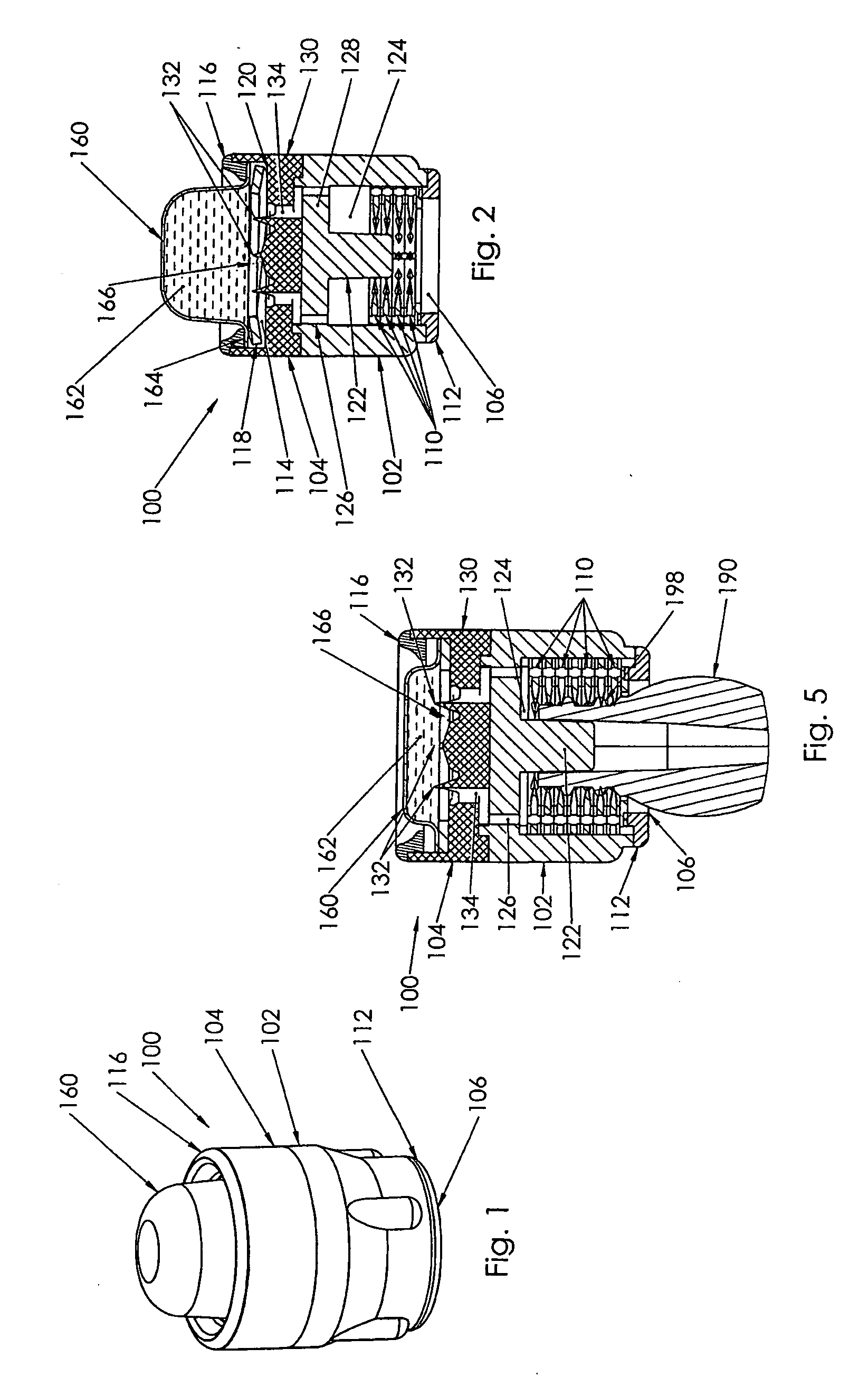

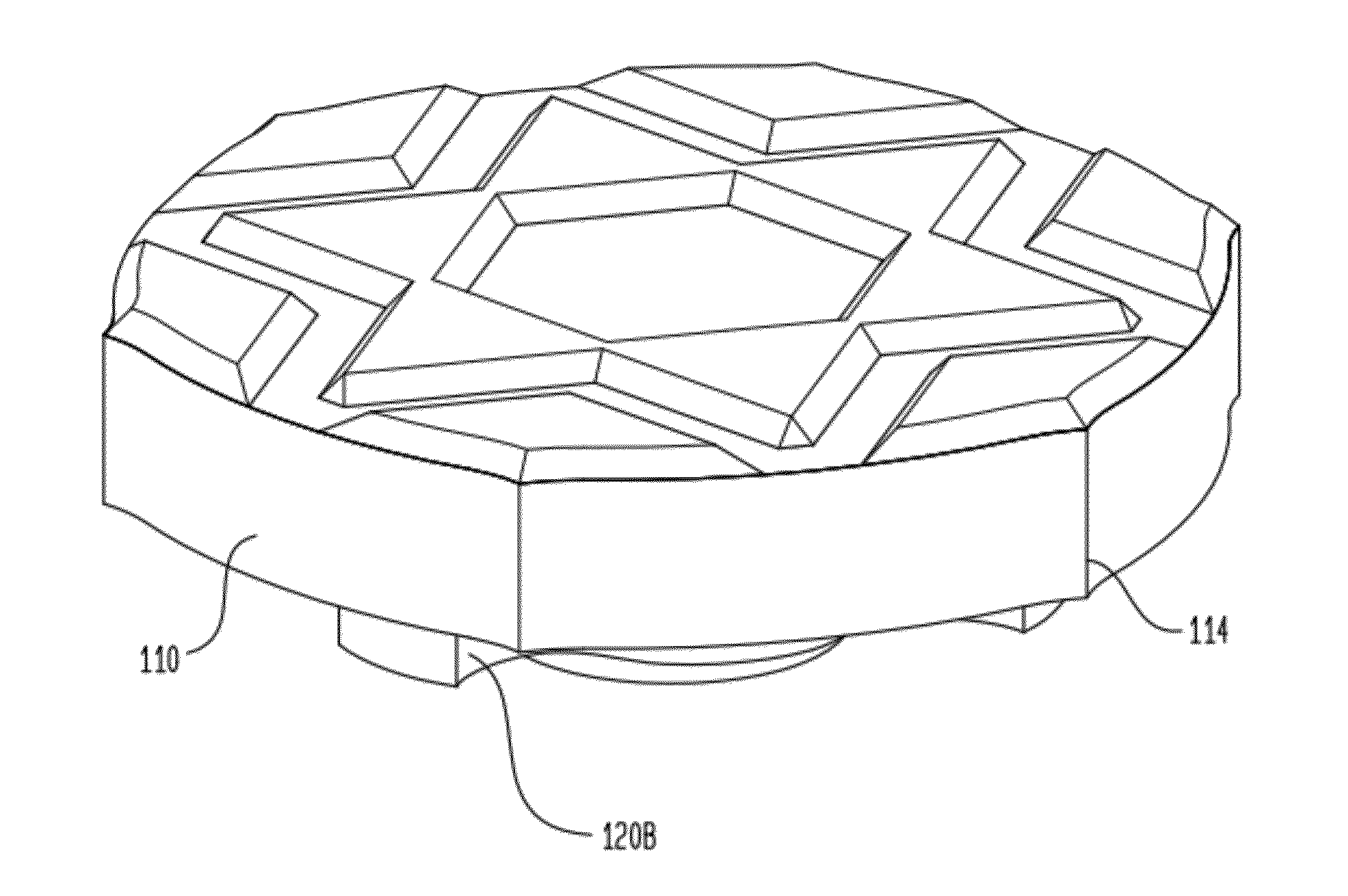

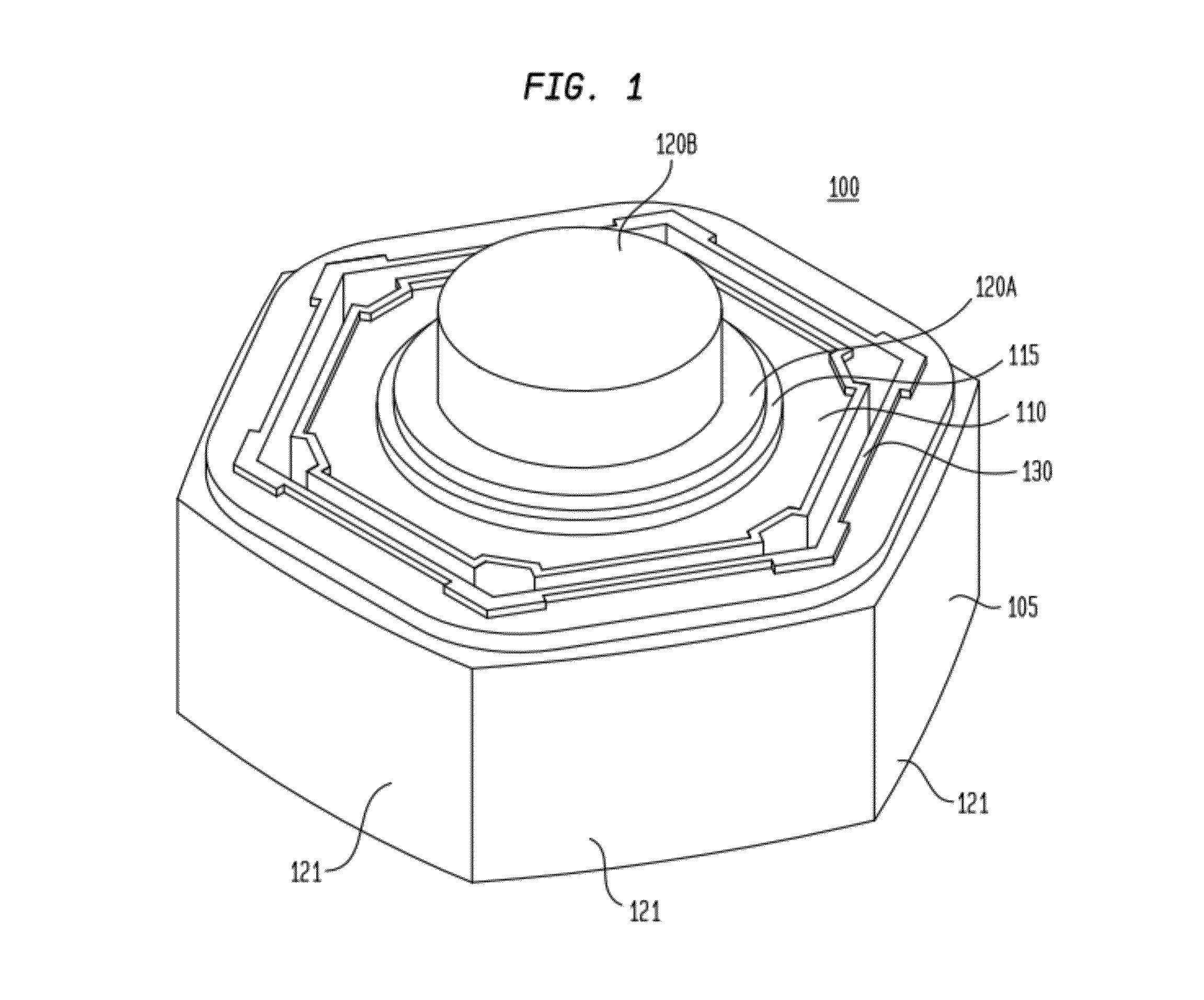

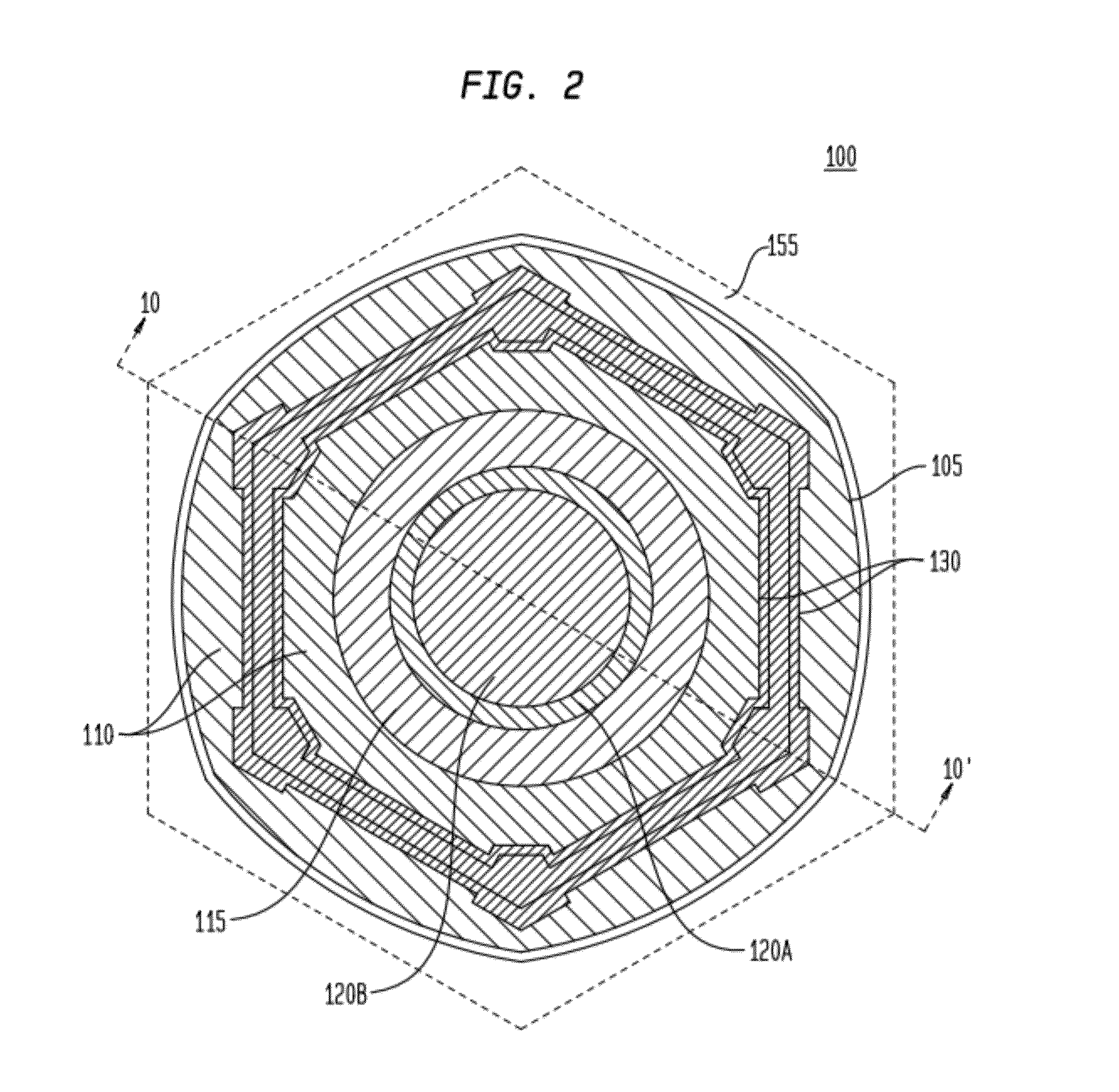

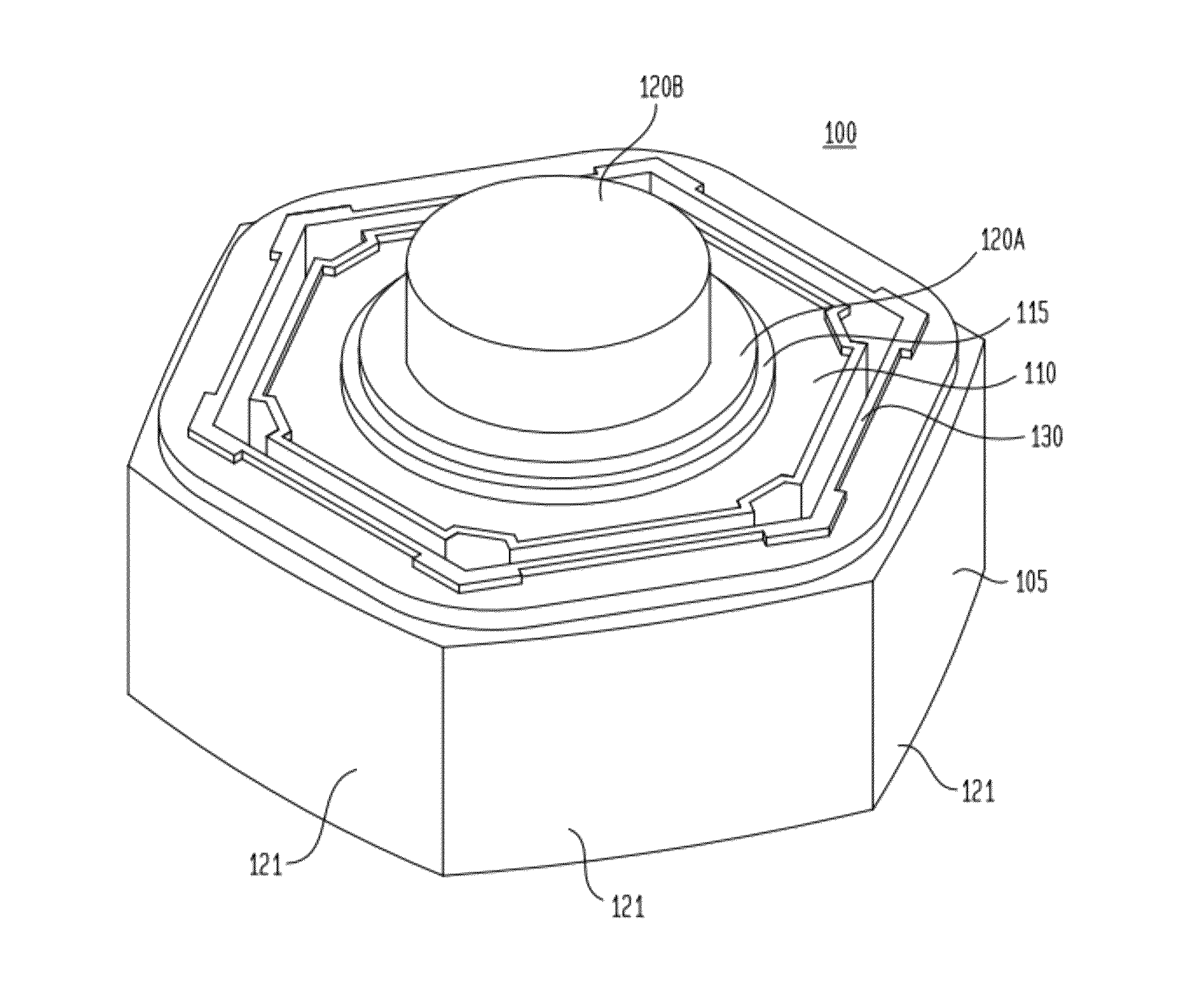

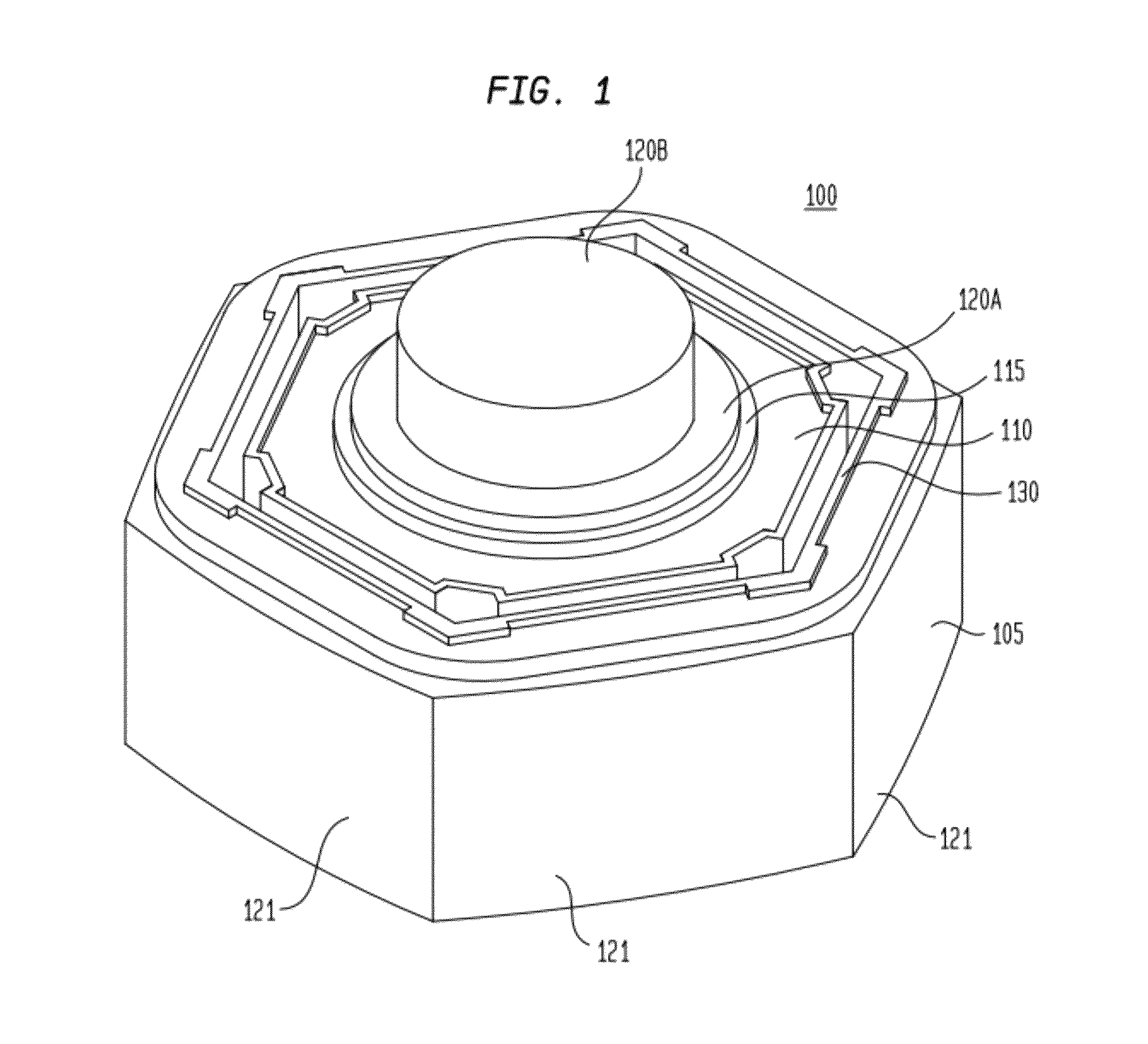

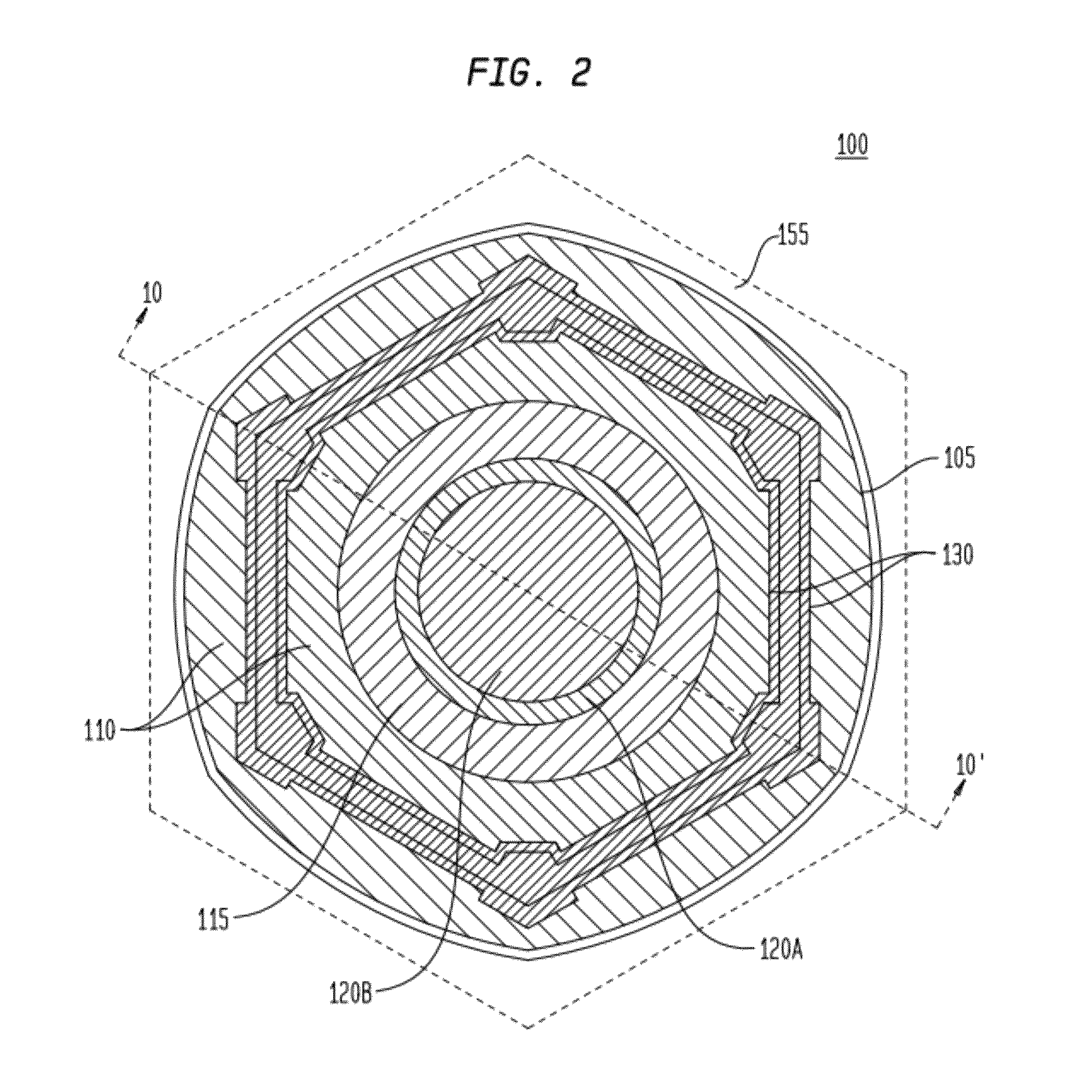

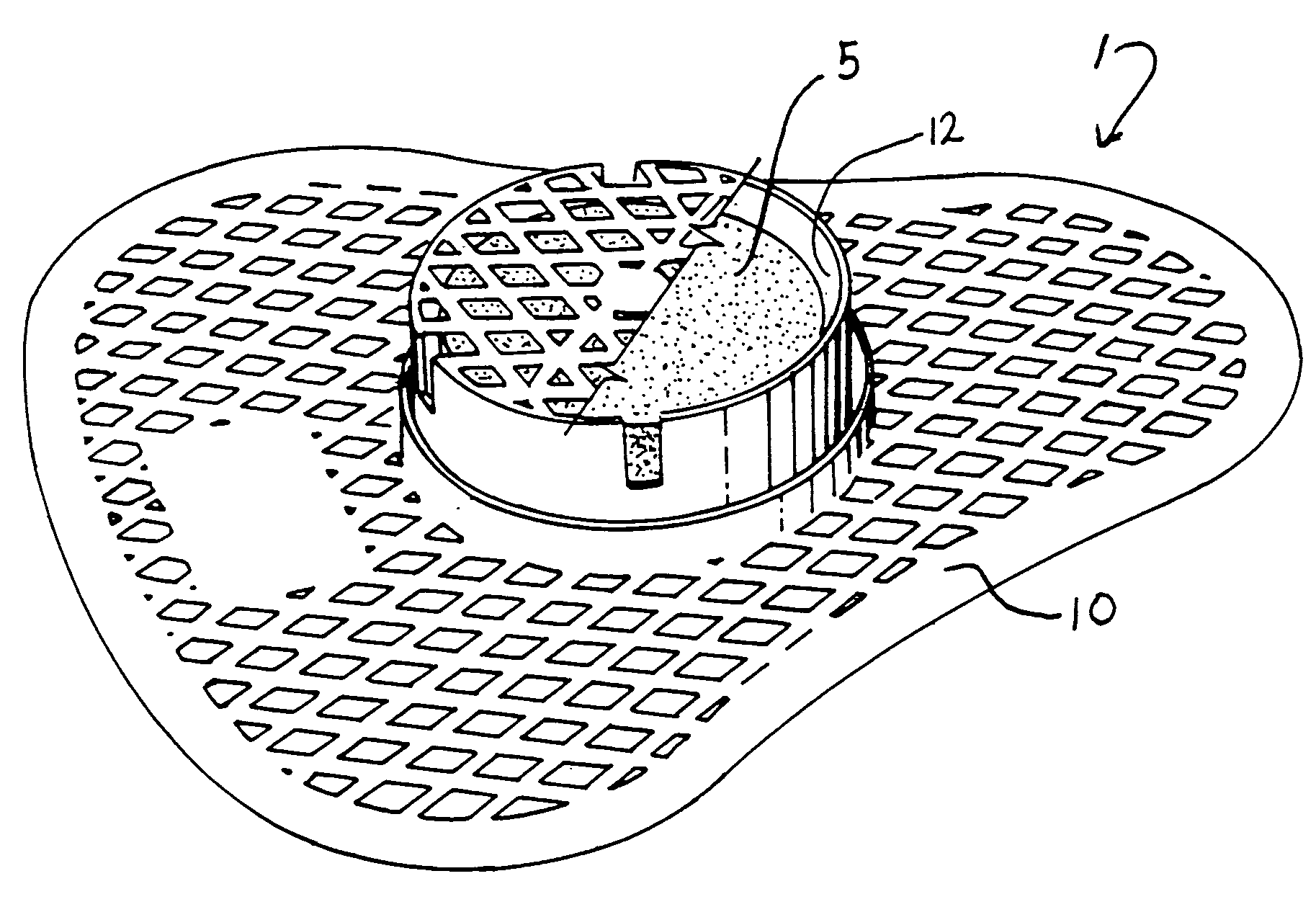

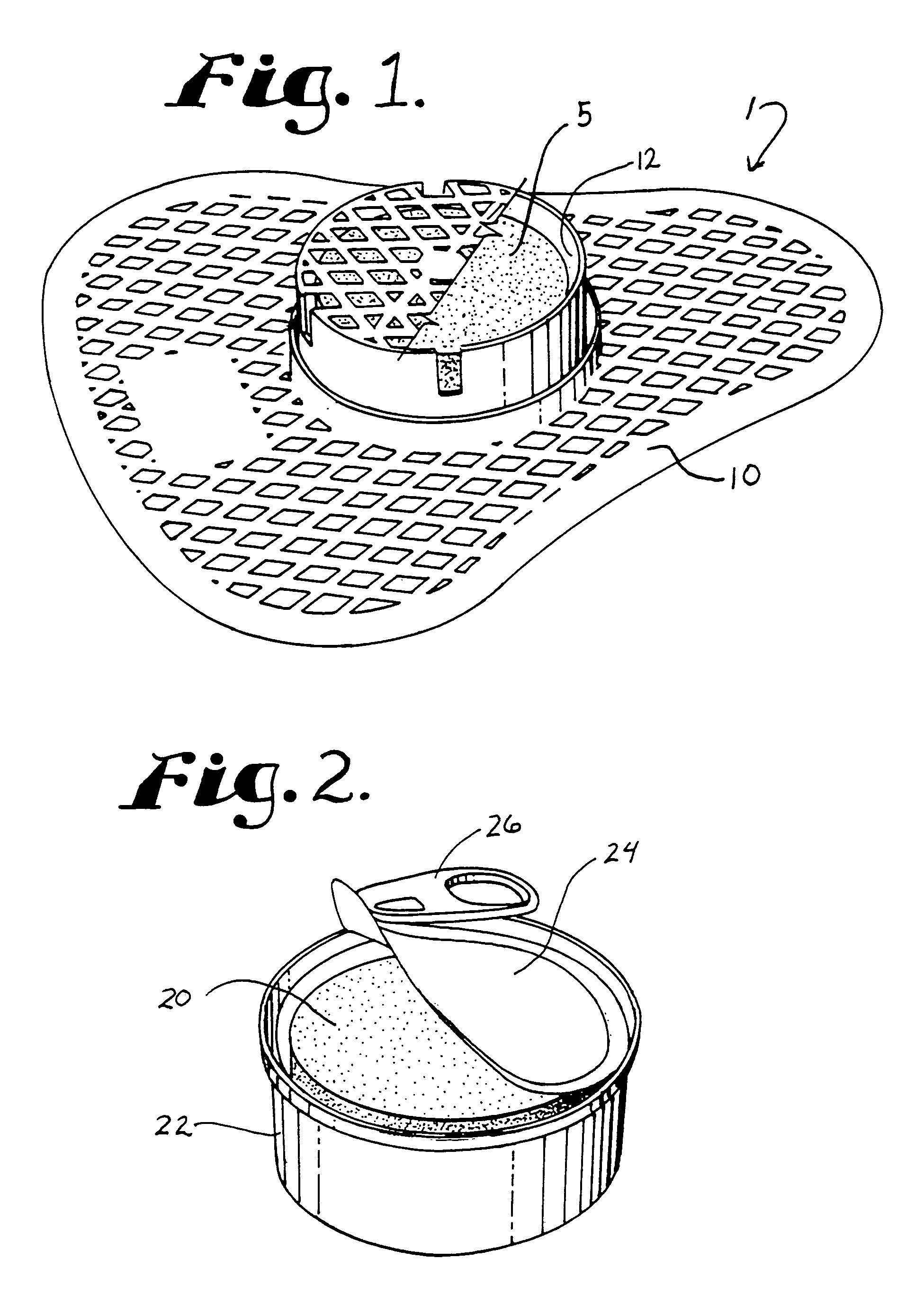

Luer Cleaner with Self-Puncturing Reservoir

A luer cleaner assembly (100) for cleaning luer fittings (190) secured to proximal ends of medical tubing. The luer cleaner (100) includes a luer-receiving cavity (124) within which are contained scrubbers (110) that scrub exposed outer surfaces of a luer fitting inserted thereinto through an open distal end (106) of the luer cleaner housing (102). The luer cleaner includes at a proximal end a fluid reservoir (160) containing a cleaning fluid (162) such as isopropyl alcohol. The assembly further includes a reservoir-penetrating array of sharp pointed projections (132), such that during luer cleaning the reservoir (160) is pressed distally toward the luer fitting in the cavity for the array of projections to penetrate a distal cover (166) of the reservoir to access the cleaning fluid (162) which then flows distally through passageways (134,126) into the luer-receiving cavity and onto the scrubbers (110) and the outer surfaces of the luer fitting (190).

Owner:MEDICAL COMPONENTS INC

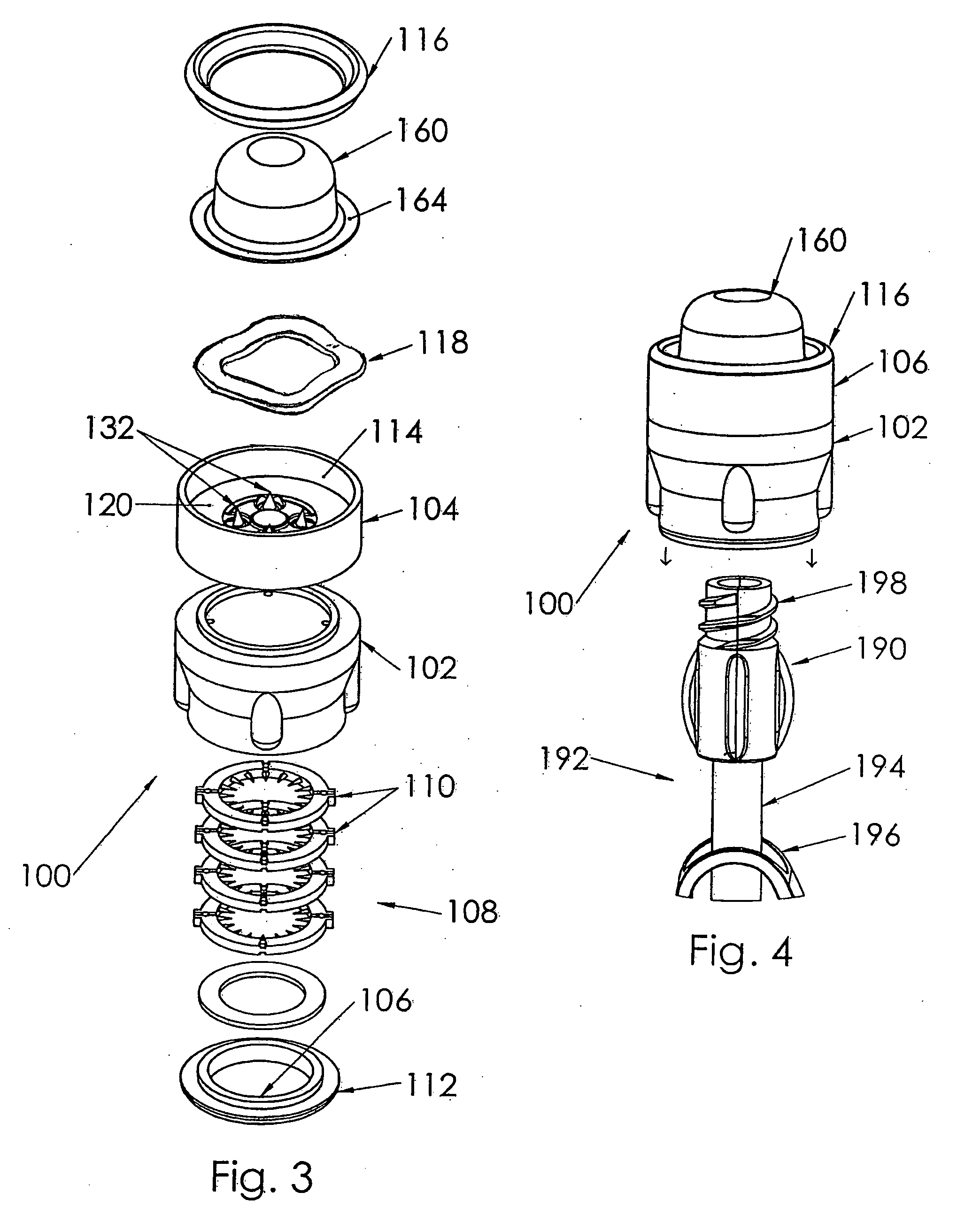

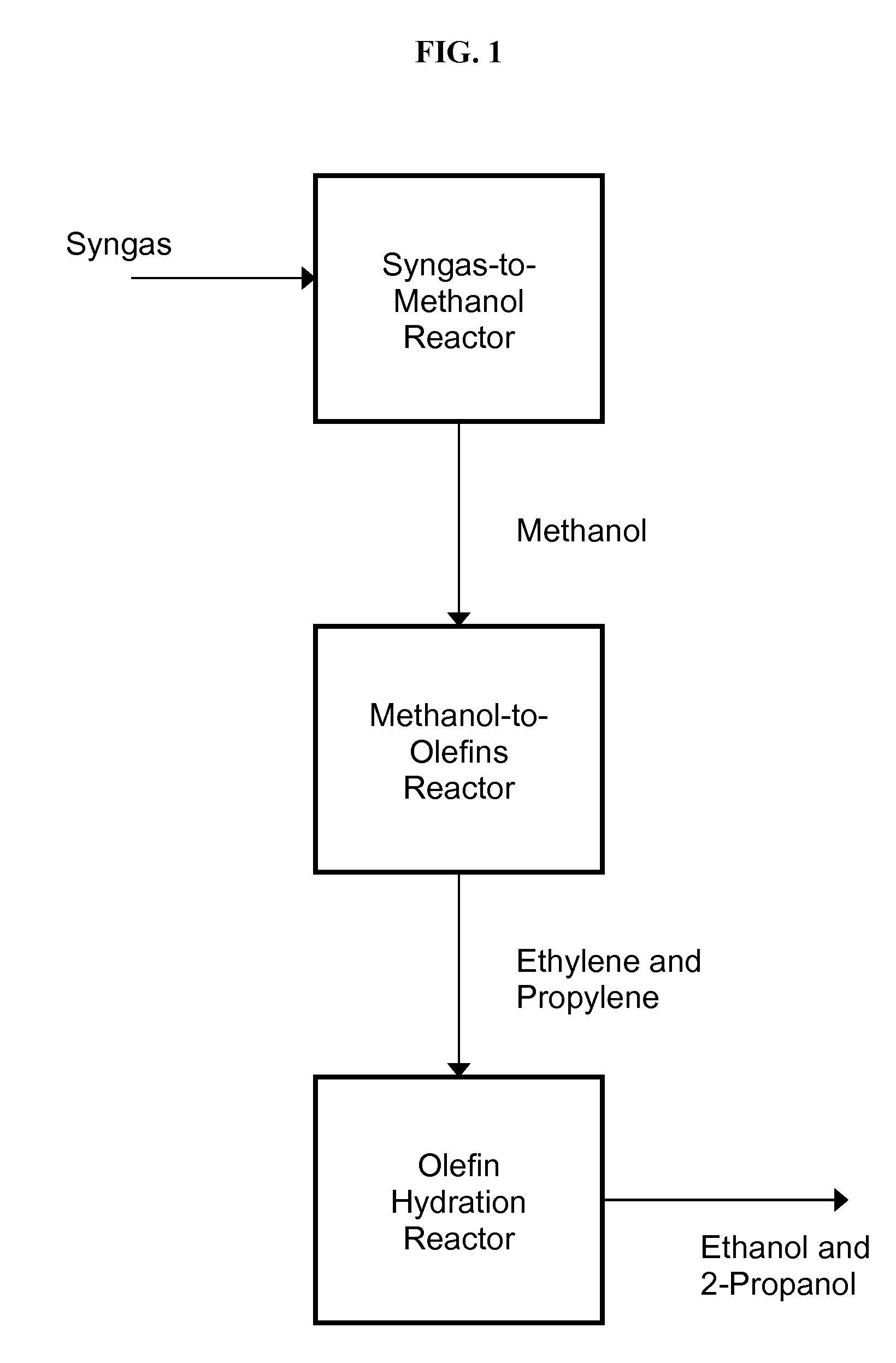

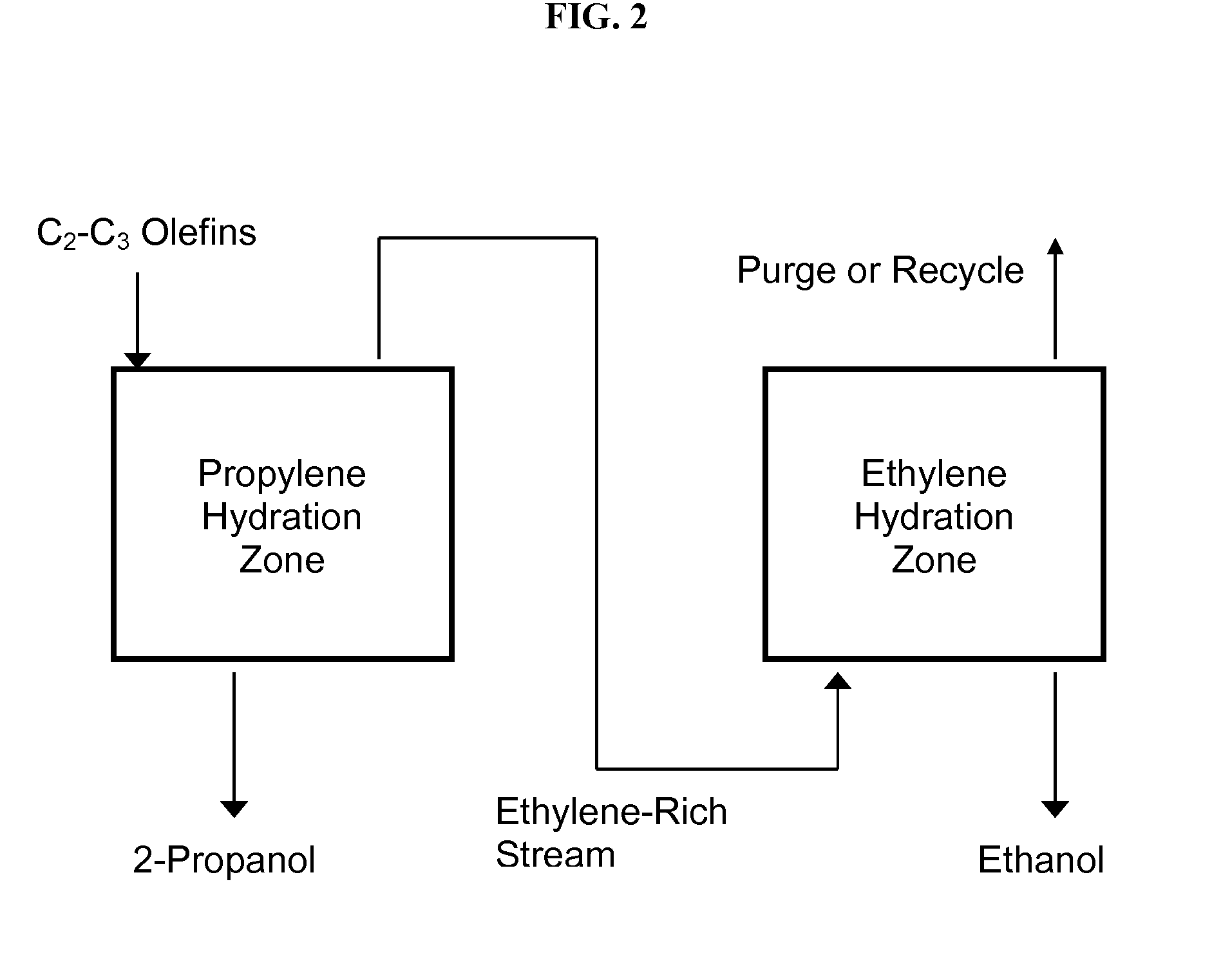

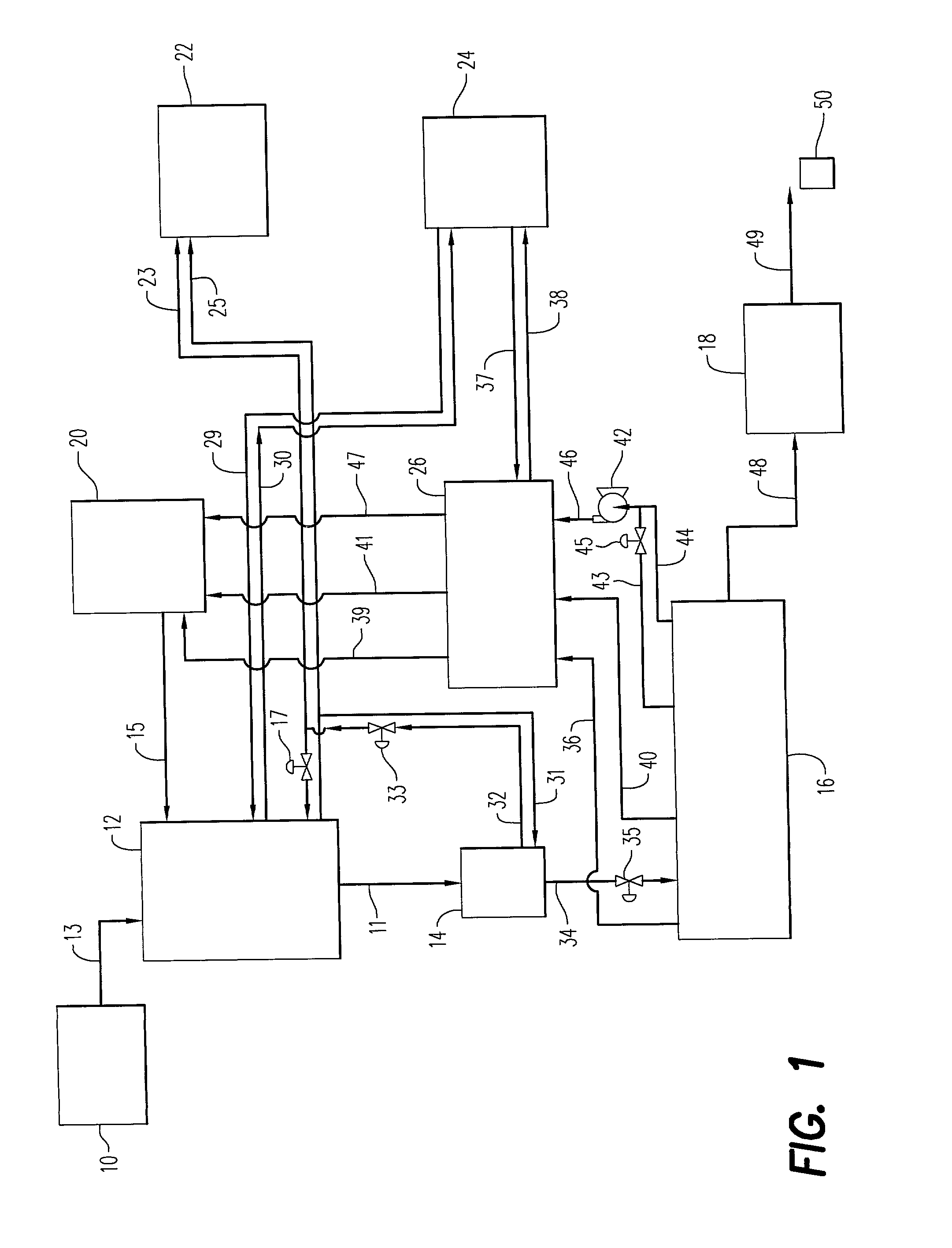

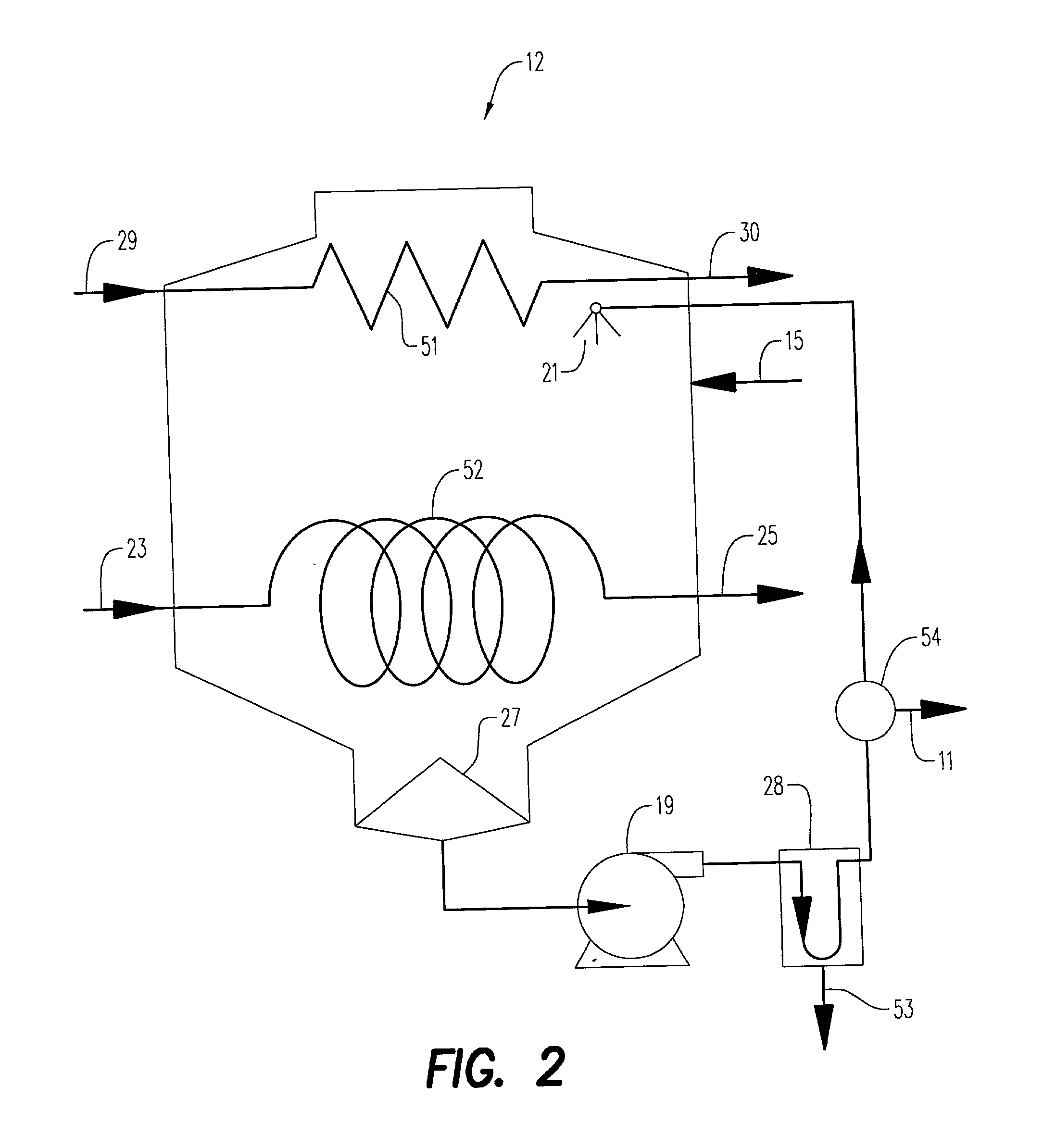

Methods and apparatus for synthesis of alcohols from syngas

This invention provides a method for producing ethanol and 2-propanol from syngas, the method comprising: (a) converting syngas into methanol using a methanol-synthesis catalyst; (b) converting methanol into ethylene and propylene using a methanol-to-olefins catalyst; and (c) hydrating ethylene into ethanol and propylene into 2-propanol. As taught herein, the combined yield of the ethanol and the 2-propanol from biomass can be at least 100 gallons per dry ton biomass. In certain embodiments, the yield of ethanol is at least 100 gallons per dry ton biomass. In some embodiments, the yield of 2-propanol is at least 50 gallons per dry ton biomass.

Owner:ALBEMARLE CORP +1

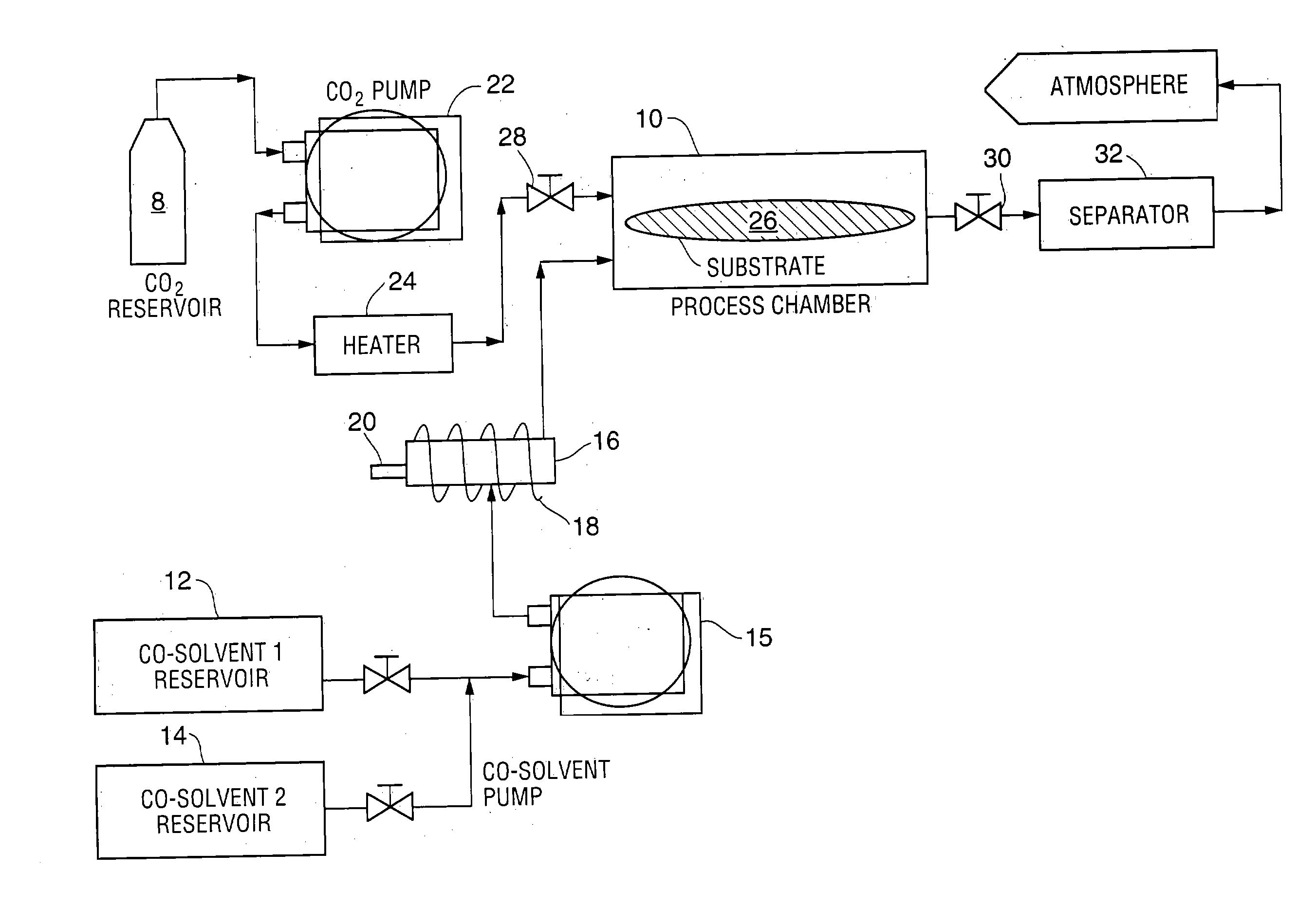

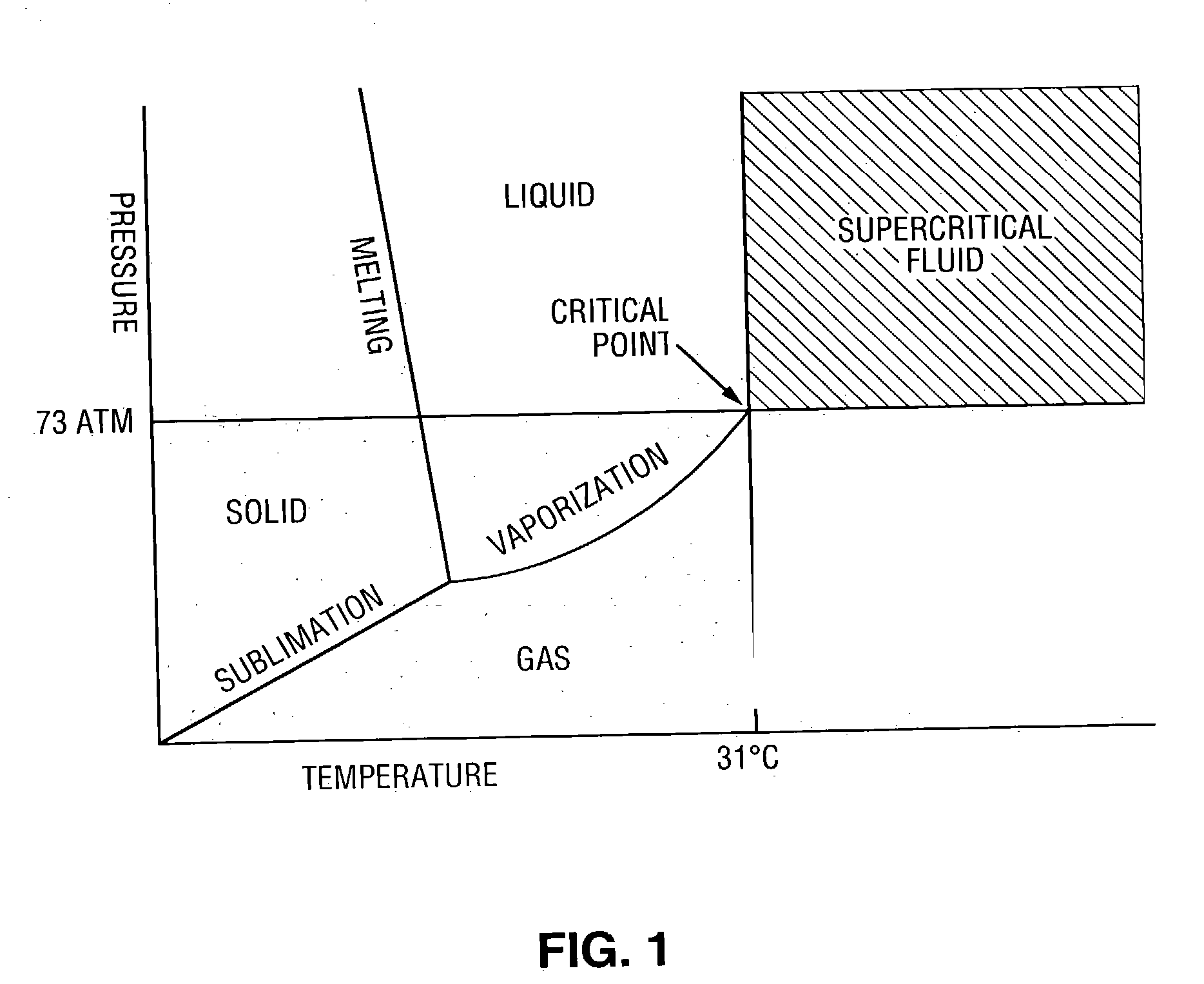

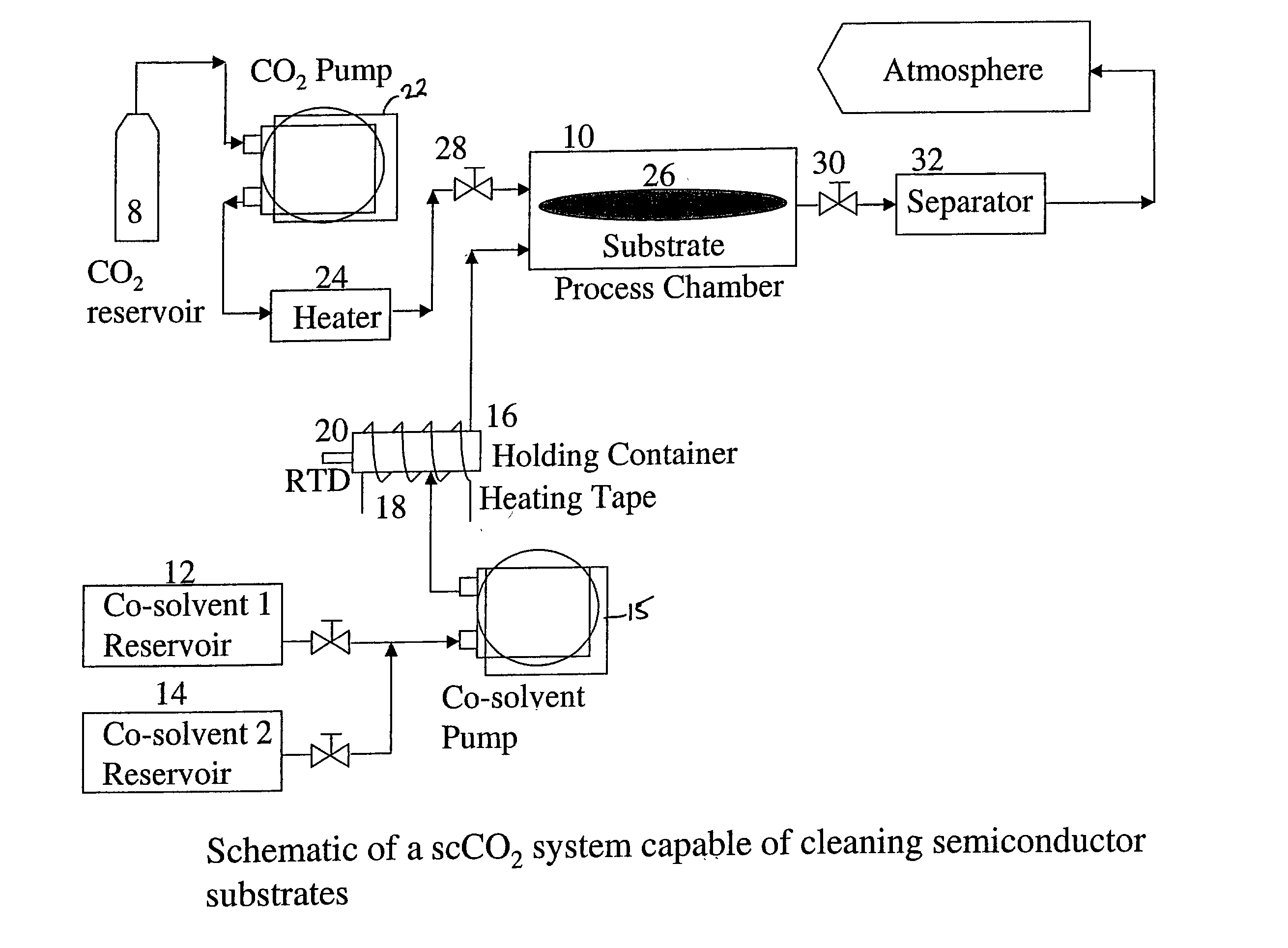

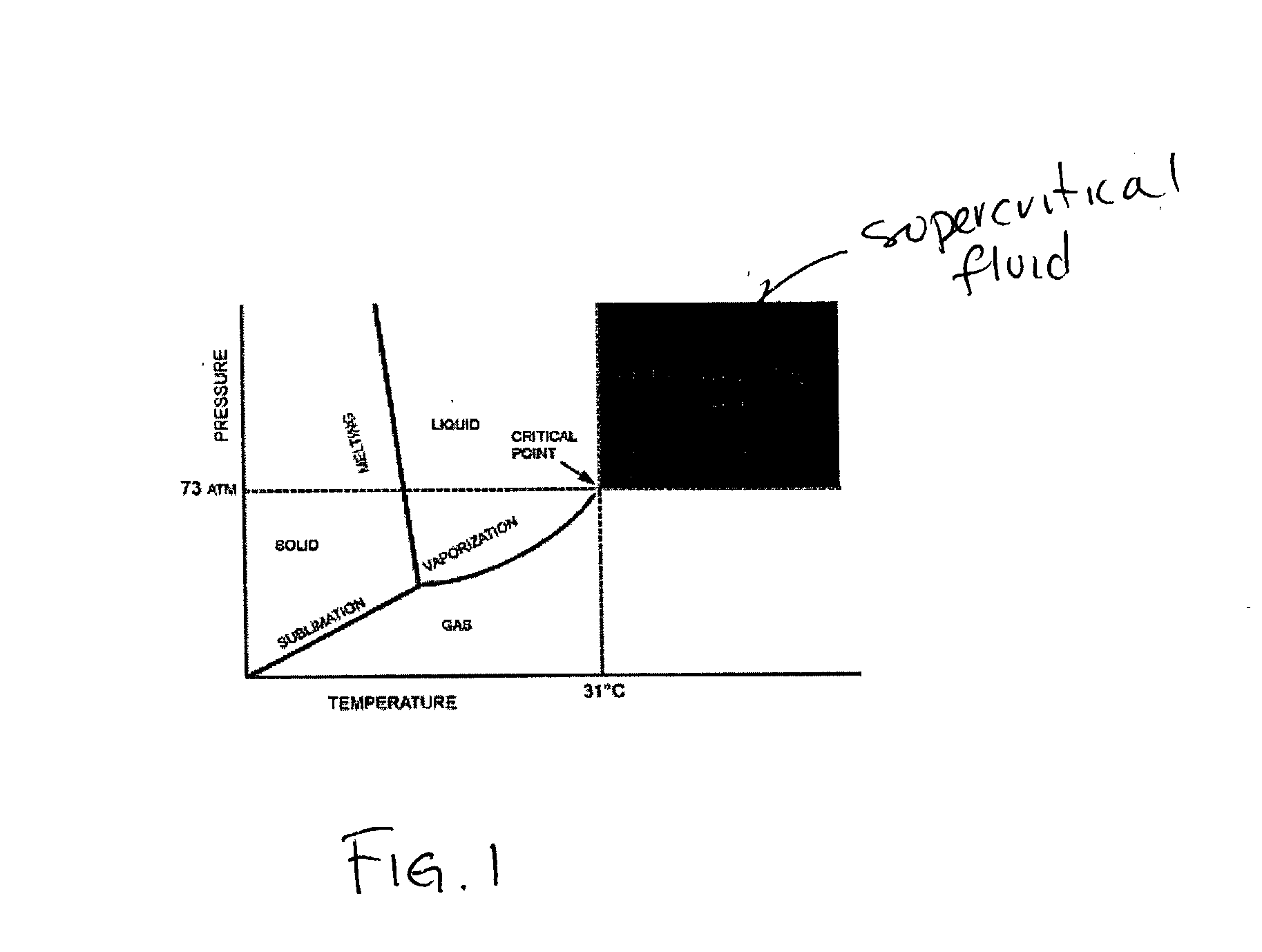

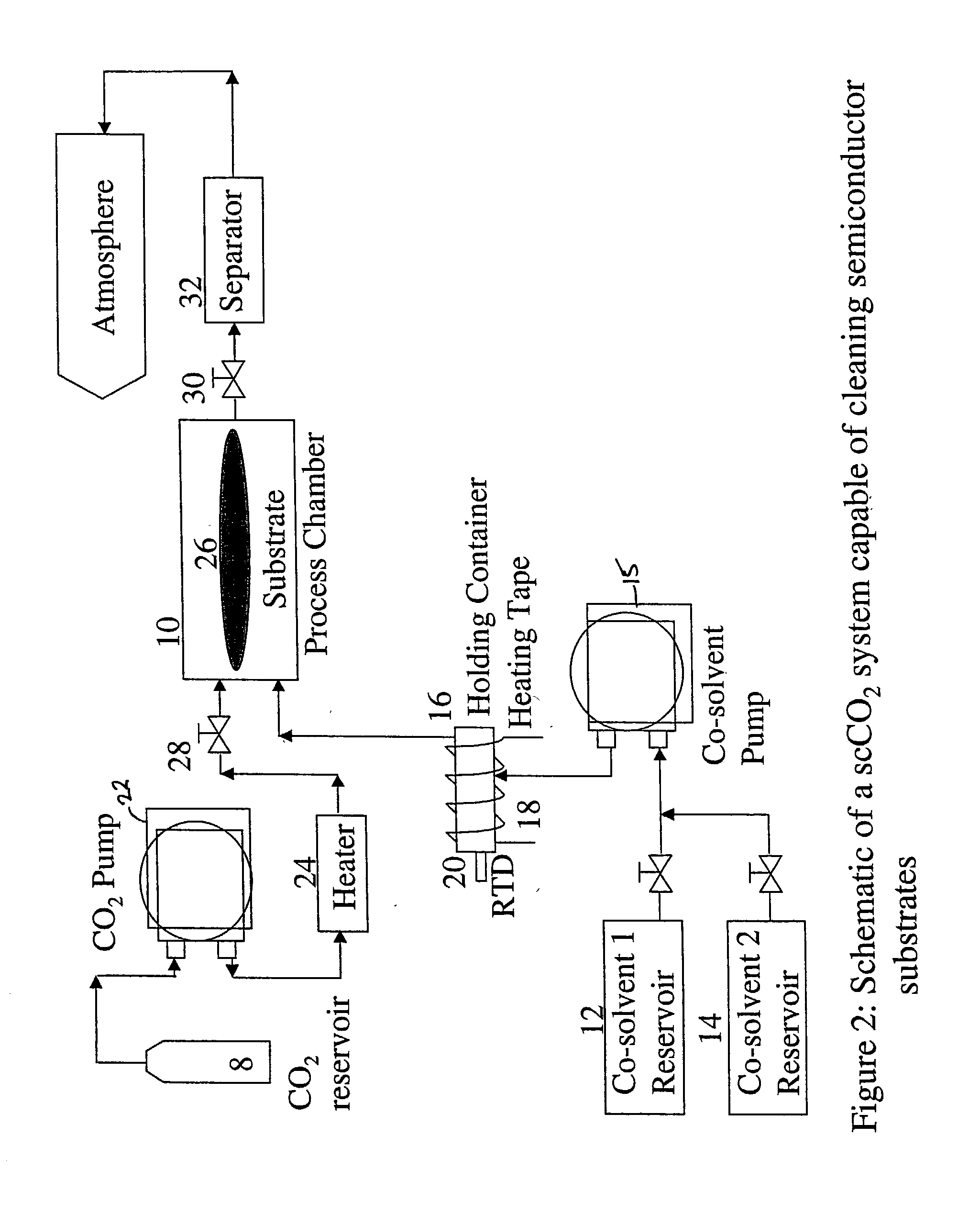

Compositions and method for removing photoresist and/or resist residue at pressures ranging from ambient to supercritical

InactiveUS20040050406A1Accelerate photoresist strippingImprove reaction kineticsNon-surface-active detergent compositionsSemiconductor/solid-state device manufacturingResistAlcohol

A method of enhancing removal of photoresist and / or resist residue from a substrate includes exposing the substrate to an environmentally friendly, non-hazardous co-solvent mixture comprising a carbonate, an oxidizer and an accelerator. The stripping process may be performed under ambient conditions, or in the presence of a supercritical fluid such as supercritical carbon dioxide with the supercritical cleaning step itself being a desirable "green" process. In one embodiment, the co-solvent mixture includes propylene carbonate, benzyl alcohol, hydrogen peroxide and an accelerator such as formic acid. If desired, supercritical carbon dioxide in combination with a second co-solvent mixture may be subsequently applied to the substrate to rinse and dry the substrate. In one embodiment, the second co-solvent mixture includes a lower alkyl alcohol such as isopropyl alcohol.

Owner:SCP GLOBAL TECH INC

Polyvinyl alcohol-containing compositions and methods for dermal delivery of drugs

InactiveUS20070196323A1Easily peelableEasily removablePharmaceutical non-active ingredientsSynthetic polymeric active ingredientsPropanolAlcohol

The present invention is drawn to adhesive solidifying formulations, and methods for dermal delivery of a drug. The formulation can include a drug, a solvent vehicle, and a polyvinyl alcohol. The solvent vehicle can include a volatile solvent system including water and an alcohol solvent, e.g., ethanol, propanol, and / or isopropanol, and a non-volatile solvent system including at least one non-volatile solvent which is compatible with polyvinyl alcohol. The formulation is formulated such that the water to polyvinyl alcohol weight ratio is in the range of from about 4:1 to about 1:1, and water to alcohol solvent weight ratio in the range of from about 0.33:1 to about 6:1.

Owner:ZARS INC

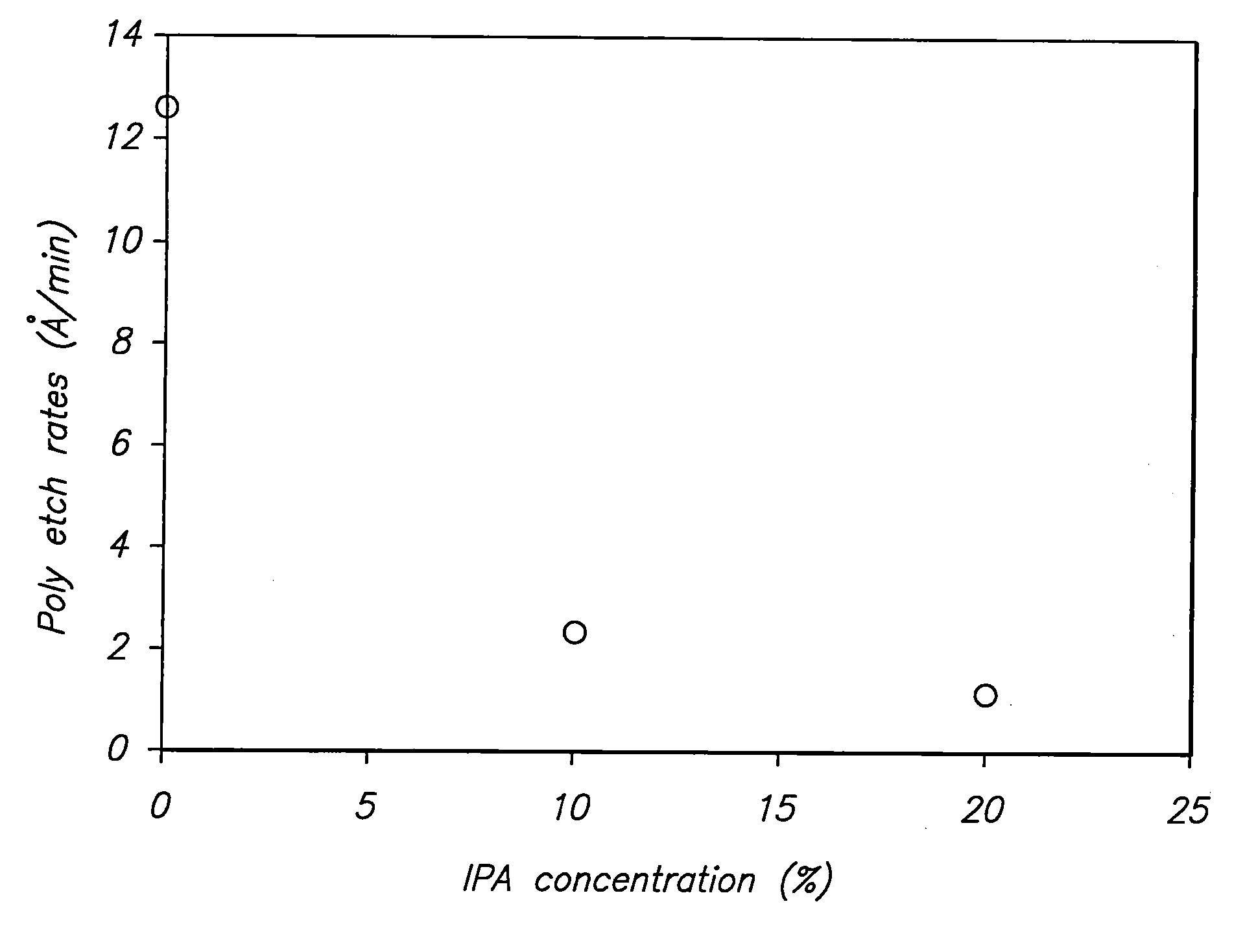

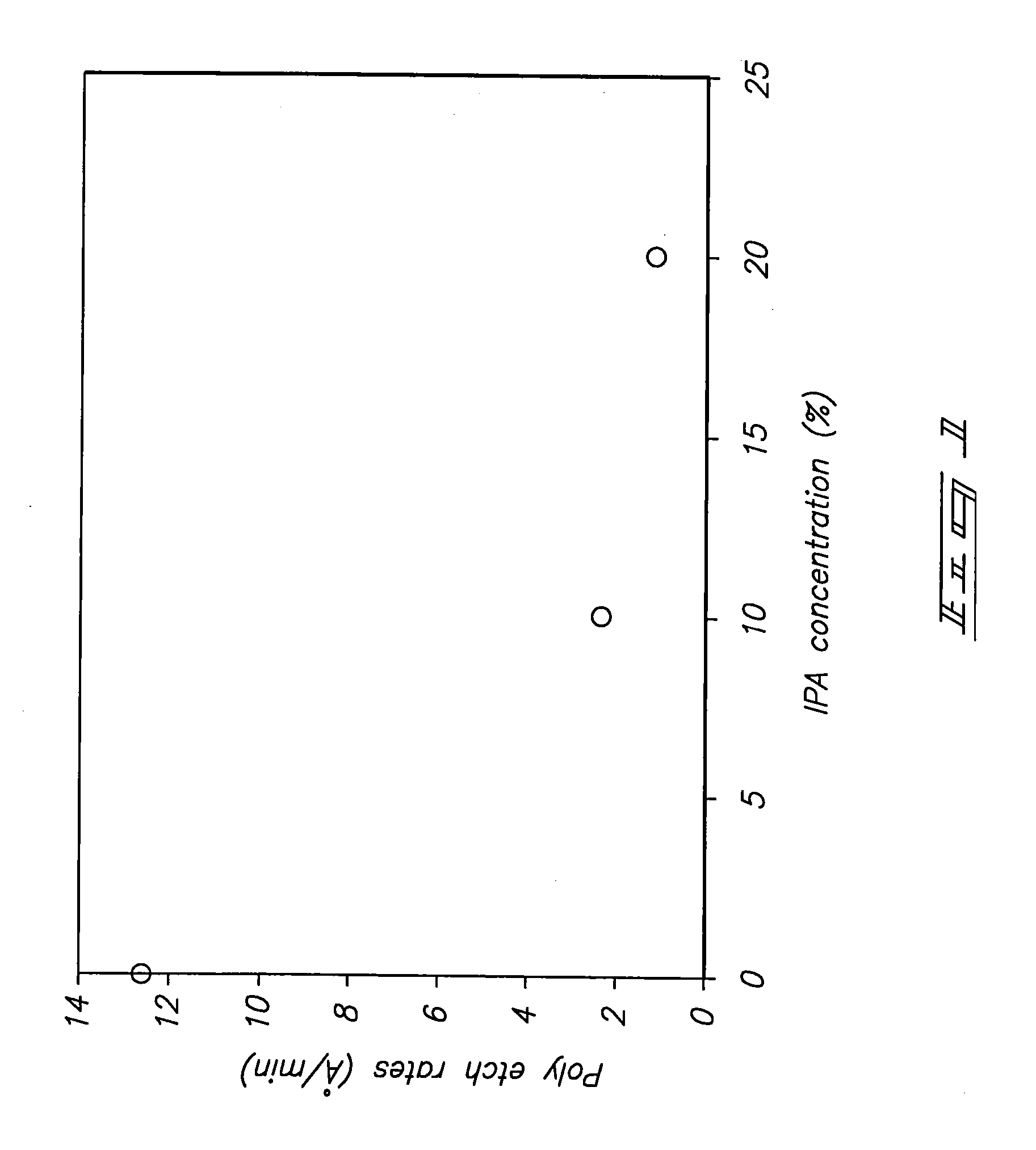

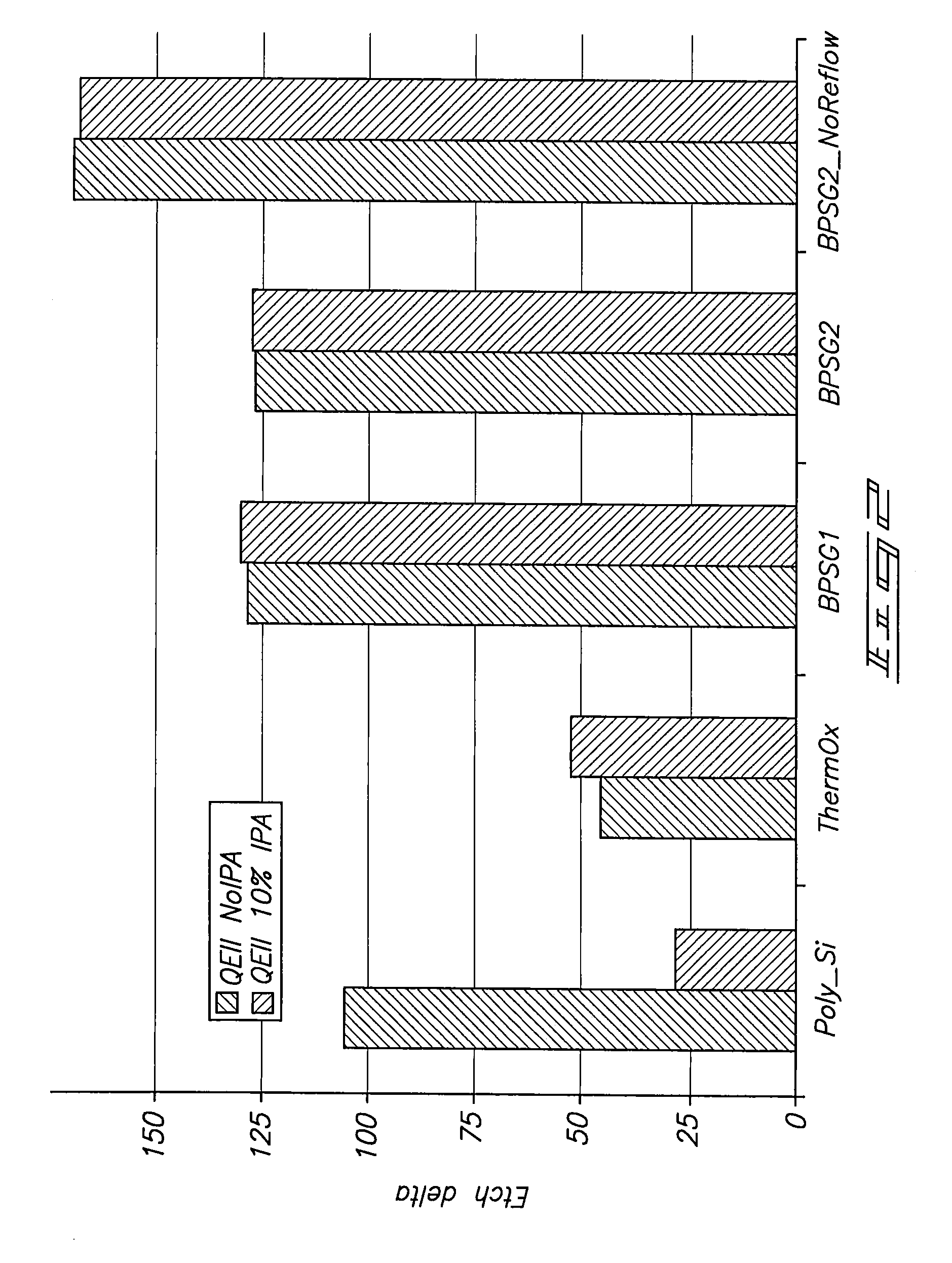

Etch Compositions and Methods of Processing a Substrate

InactiveUS20070145009A1Decorative surface effectsSemiconductor/solid-state device manufacturingChemistryIsotropic etching

The invention includes an etchant composition containing isopropyl alcohol and one or more of HF, NH4F and tetramethyl ammonium fluoride (TMAF). The invention encompasses a method of processing a substrate. A substrate is provided which has a first material containing at least one of polysilicon, monocrystalline silicon and amorphous silicon, and a second material. The substrate is exposed to an etch composition which comprises isopropyl alcohol and at least one of HF, NH4F and TMAF. The invention includes a method of processing a semiconductor construction including providing a construction which has a capacitor electrode material and an oxide material along at least a portion of the capacitor electrode material. At least some of the oxide material is removed by isotropic etching utilizing an etchant composition comprising isopropyl alcohol.

Owner:MICRON TECH INC

Carbonyl reductases, polynucleotides comprising DNA encoding the same, methods for producing the same, and methods for producing optically active alcohol utilizing the same

Owner:DAICEL CHEM IND LTD

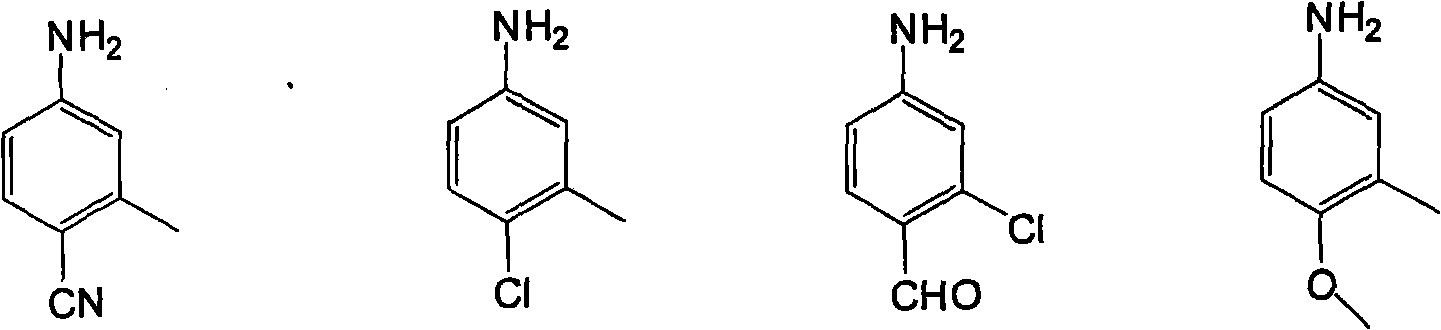

Method for preparing benzoxazine intermediate containing triazine structure

The invention provides a preparation method of triazine structure containing benzoxazine intermediate, which sequentially includes: (1) performing synthetic reaction of aldehyde compound and amine compound at a molar ratio of at least 1:1 which includes adding aldehyde compound and solvent of at least one of clean water, methanol, ethanol, isopropanol, and ethyl acetate into a reactor at the room temperature under the normal pressure to obtain mixed solution with aldehyde mass concentration of no greater than 95%, adding amine compound while stirring, and reacting at 0-100 DEG C under the normal pressure for at least 15 minutes to obtain the reactant liquor; (2) pouring into the cleaning solution, stirring and cleaning, and filtering to collect solid substance, or directly filtering the reactant liquor to collect the solid substance; and (3) drying the solid substance obtained in step (2) at 30-100 DEG C.

Owner:SICHUAN UNIV

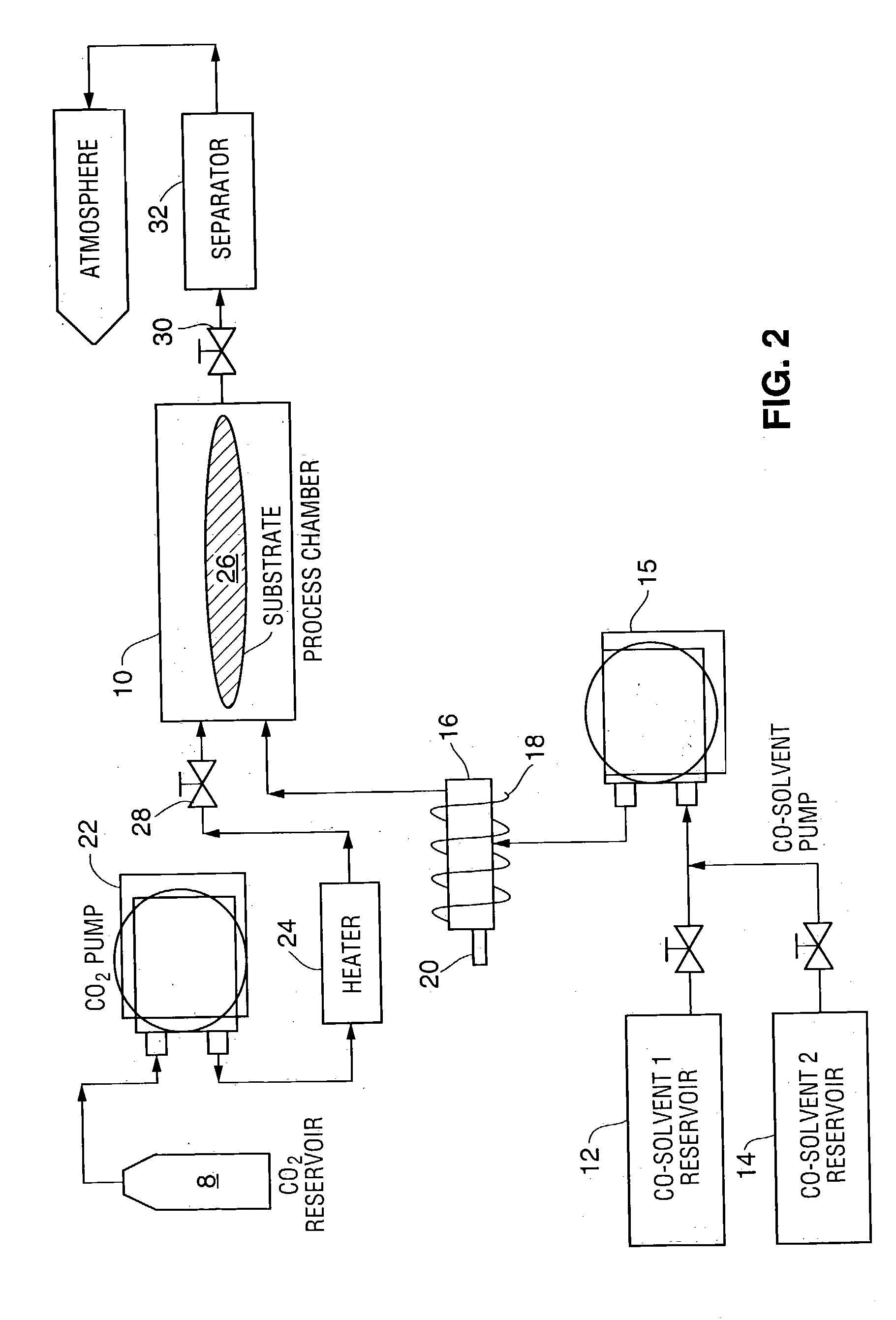

Composition and method for removing photoresist and/or resist residue using supercritical fluids

InactiveUS20040011386A1Non-surface-active detergent compositionsSemiconductor/solid-state device manufacturingResistOrganic solvent

A method of removing photoresist and / or resist residue from a substrate includes exposing the substrate to a supercritical fluid in combination with a co-solvent mixture comprising an organic solvent and an oxidizer. In one embodiment, the supercritical fluid is supercritical carbon dioxide and the co-solvent mixture includes 1,2-Butylene Carbonate, Dimethyl Sulfoxide and hydrogen peroxide. If desired, supercritical carbon dioxide in combination with a second co-solvent mixture may be subsequently applied to the substrate to rinse and dry the substrate. In one embodiment, the second co-solvent mixture includes isopropyl alcohol.

Owner:SCP GLOBAL TECH INC

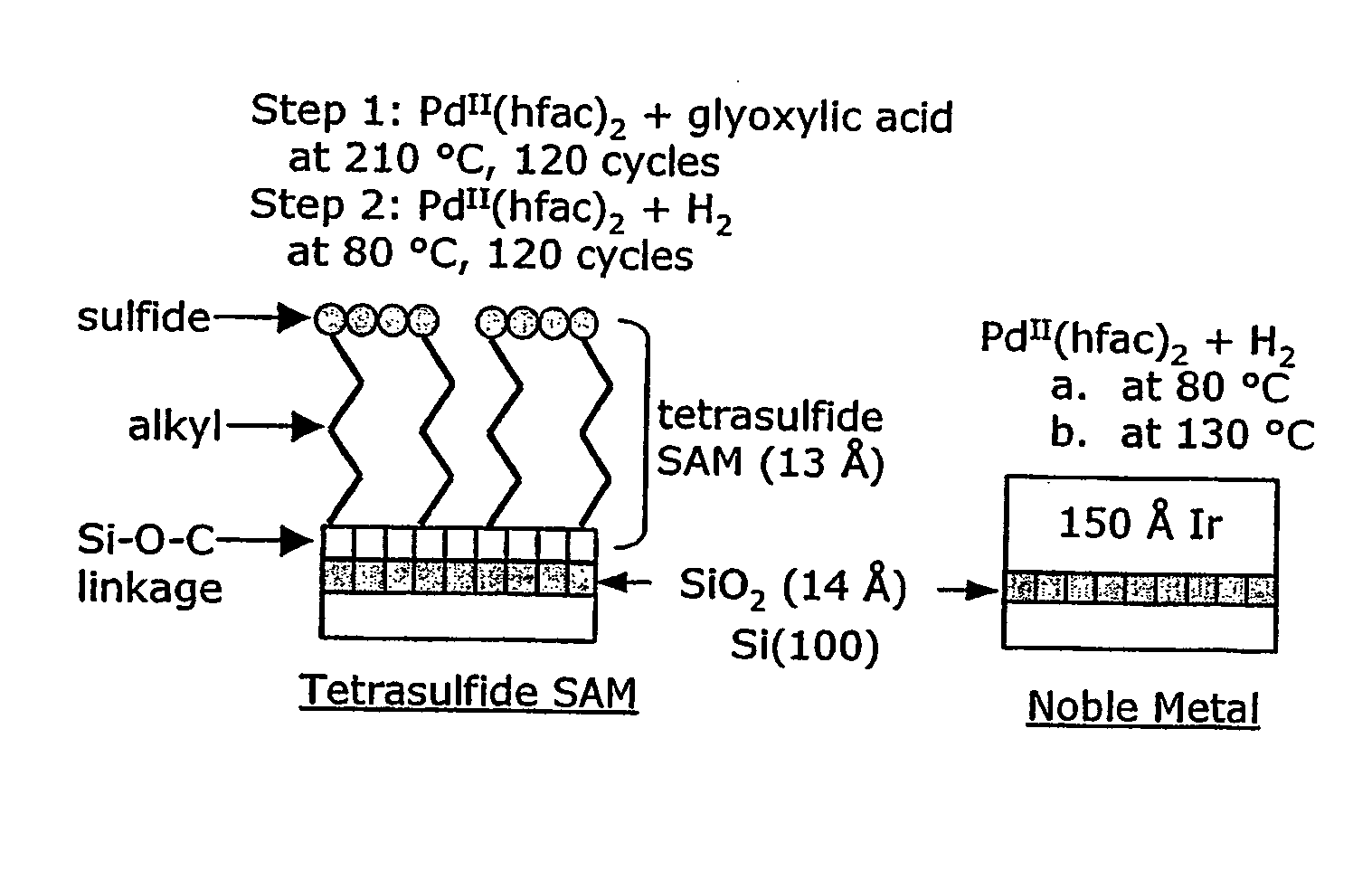

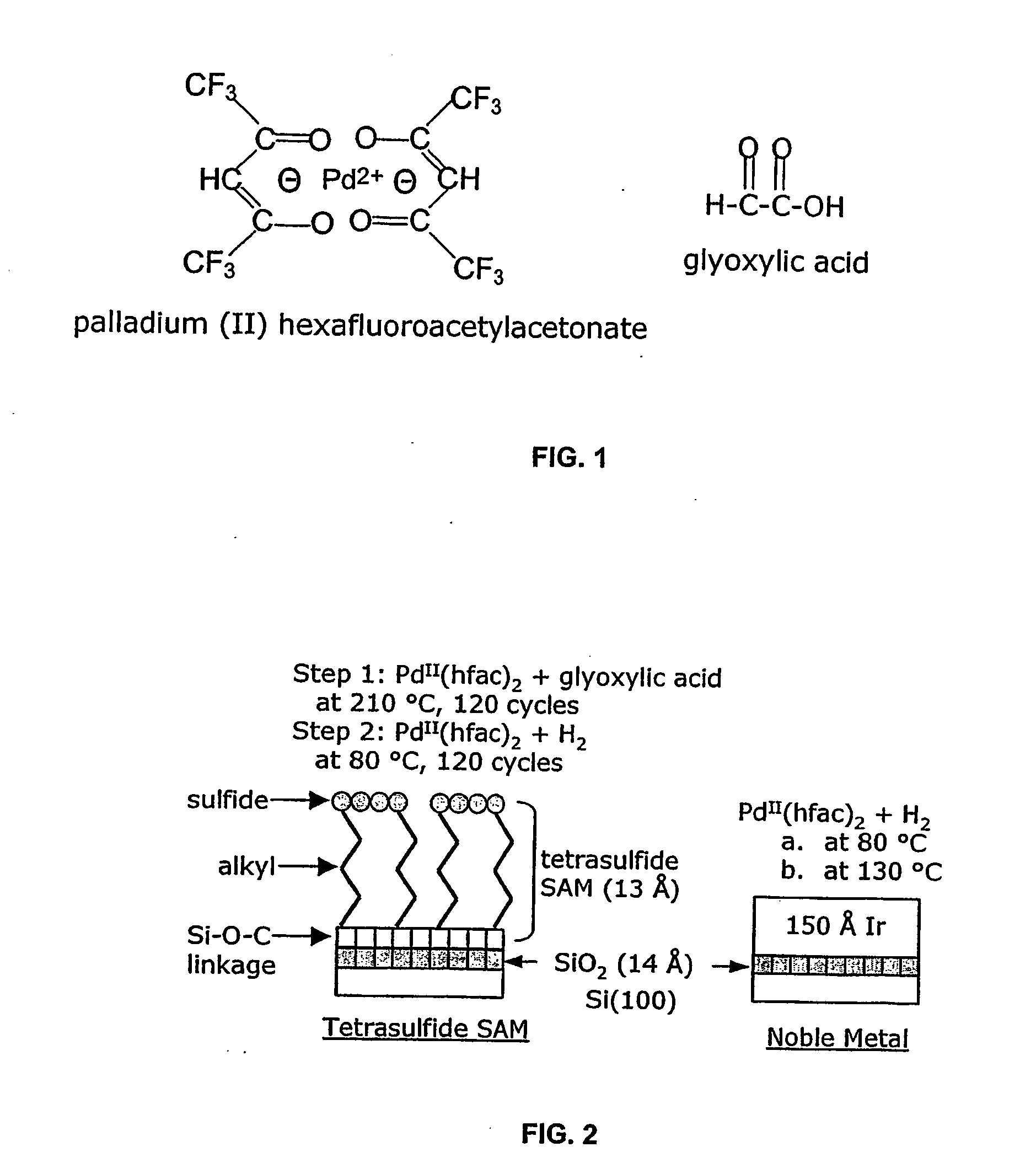

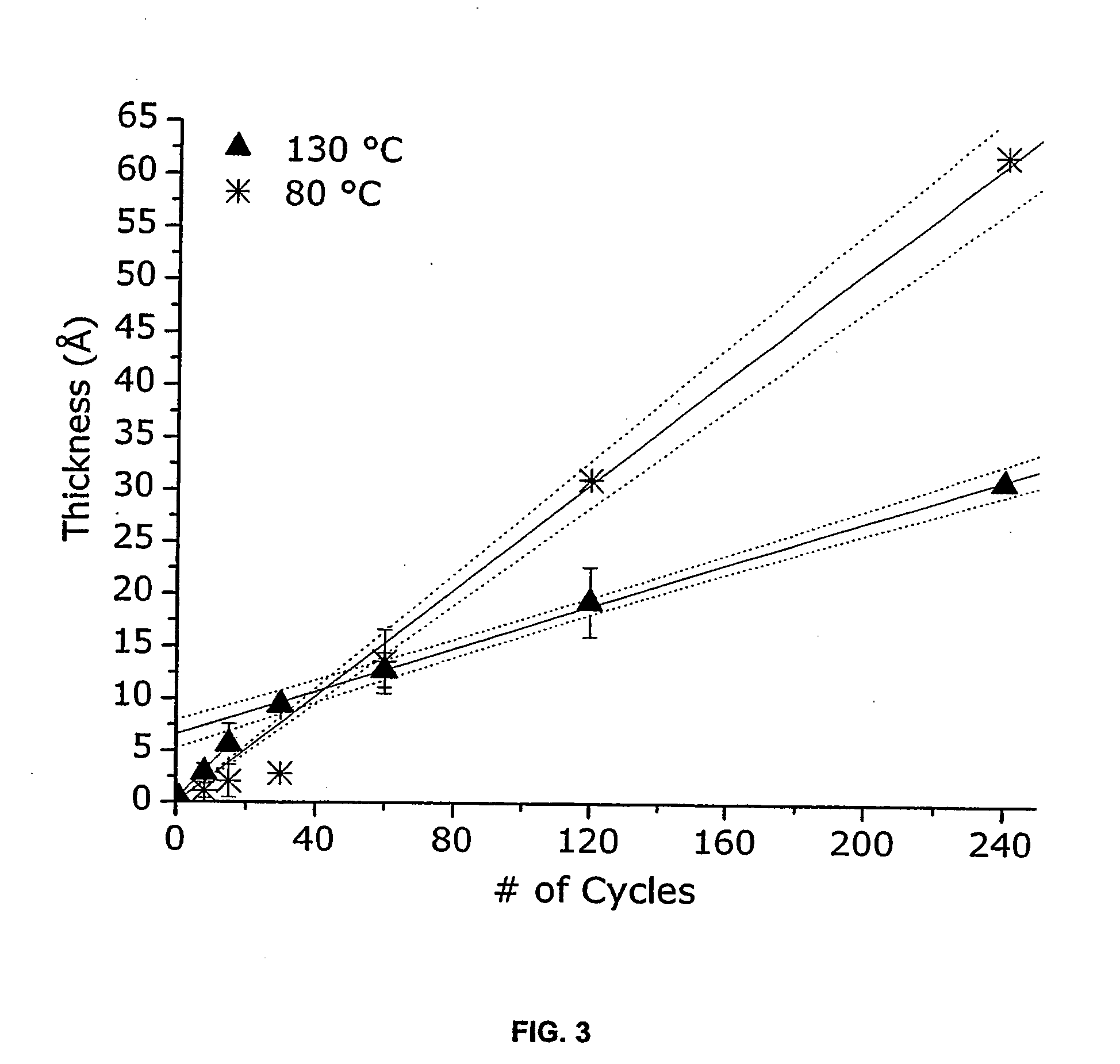

Atomic layer deposition of noble metals

The present invention relates to ALD processes for deposition of a metal selected from Pd, Rh, Ru, Pt and Ir wherein a layer including the metal is formed on a surface composed of a material selected from W, Ta, Cu, Ni, Co, Fe, Mn, Cr, V Nb, tungsten nitride, tantalum nitride, titanium nitride, dielectrics and activated dielectrics at a temperature ranging from >60° C. to <260° C. The layer is formed by sequentially pulsing into a chamber containing the surface a precursor for the metal and a reducing gas selected from hydrogen, glyoxylic acid, oxalic acid, formaldehyde, 2-propanol, imidazole and plasma-activated hydrogen.

Owner:SENKEVICH JOHN JOSEPH +1

Electrothermal film and manufacturing method thereof

ActiveCN101668359ASimple processEfficient processHeating element materialsResistors adapted for applying terminalsTitanium chlorideMetallurgy

The invention relates to an electrothermal film and a manufacturing method thereof, belonging to the technical field of semiconductor heating. The electrothermal film is mainly prepared by adopting stannic chloride, titanium tetrachloride, stannic chloride, titanium trichloride, ferric chloride, antimony trichloride, calcium chloride, potassium chloride, cadmium chloride, stannic dioxide, stannictetroxide, hydrofluoric acid, boric acid, ethanol, isopropyl alcohol and inorganic water. By adopting the above formula, the mixture is mixed, stirred and heated to prepare into electrothermal film treating fluid, a semi-finished product of the electrothermal film is obtained by spraying the electrothermal film treating fluid at negative pressure on the electrothermal film carrier, and then silveroxide slurry is coated on the semi-finished product of the electrothermal film for baking to form a finished product of the electrothermal film. The electrothermal film has reasonable proportion andsimple manufacturing process, can be manufactured into various electrothermal film heating devices, has a working temperature capable of being up to 500 DEG C, and has wider application range. The electrothermal film of the invention also has the function of far infrared radiation, can play a role of physical therapy and health care to human body, and can help improve the quality and output of agricultural products.

Owner:GUANGDONG HALLSMART INTELLIGENCE TECH CORP LTD

Alcohol-free fountain solution with high viscosity and low surface tension

InactiveCN103935150AHigh effective contentReduce pollutionPrinting pre-treatmentAlcohol freeAqueous alcohol

The invention discloses alcohol-free fountain solution with high viscosity and low surface tension. The alcohol free fountain solution with high viscosity and low surface tension comprises the following components by weight, 30-55 parts of alcohol solvents, 2-6 parts of buffer agents, 3-8 parts of wetting agents, 1-4 parts of surface active agents, 0.3-2.2 parts of antifoaming agents, 0.5-3 parts of thickening agents, 0.5-1.2 parts of anticorrosion and bactericidal agents, 1-3 parts of penetrating agents, 0-2 parts of electrolyte and 20-45 parts of viscosity modifier water. The fountain solution is free of volatile solvents containing alcohol and isopropyl alcohol and pollution to the environment, the surface tension ranges from 4*10-2N / m to 7*10-2N / m, pH ranges from 4.8 to 5.5, the heat conduction rate ranges from 800mus / cm to 1200mus / cm, and therefore, quality requirements of the fountain solution can be met better.

Owner:苏州禾川化学技术服务有限公司

Method for preparing aromatic hydrocarbon by carrying out catalytic hydrodeoxygenation on lignin

InactiveCN104744204AWide variety of sourcesRaw materials are renewableHydrocarbon from oxygen organic compoundsEthylene productionIridiumPtru catalyst

The invention relates to a method for preparing aromatic hydrocarbon by carrying out catalytic hydrodeoxygenation on lignin. A catalyst used in the method provided by the invention comprises two active components, namely an acid site being one or combination of more than one of transition metal elements niobium, tantalum, zirconium, molybdenum, tungsten and rhenium and a hydrogenation or hydrogen transfer active site being one or more than one of ruthenium, platinum, palladium, iridium, iron, cobalt, nickel and copper. According to the method provided by the invention, a phenol group, a guaiacol group, a syringa phenolic group compound, natural lignin and industrial lignin are taken as raw materials, water is taken as a solvent, high selectivity catalytic hydrodeoxygenation is carried out at the temperature of 180-350 DEG C and hydrogen pressure of 0.1-5MPa or with methyl alcohol, isopropyl alcohol and formic acid as hydrogen sources, so that C6-C9 aromatic hydrocarbon is obtained, the highest mass yield of aromatic hydrocarbon is 10%, and content of aromatic hydrocarbon in product oil can be up to more than 75%. The method provided by the invention has the advantages that reproducible natural biomass can be used as a raw material, and the raw material is cheap and available; the water is taken as the solvent, so that a reaction process is environment-friendly; and content of aromatic hydrocarbon in the product is high, and reaction conditions are mild.

Owner:EAST CHINA UNIV OF SCI & TECH

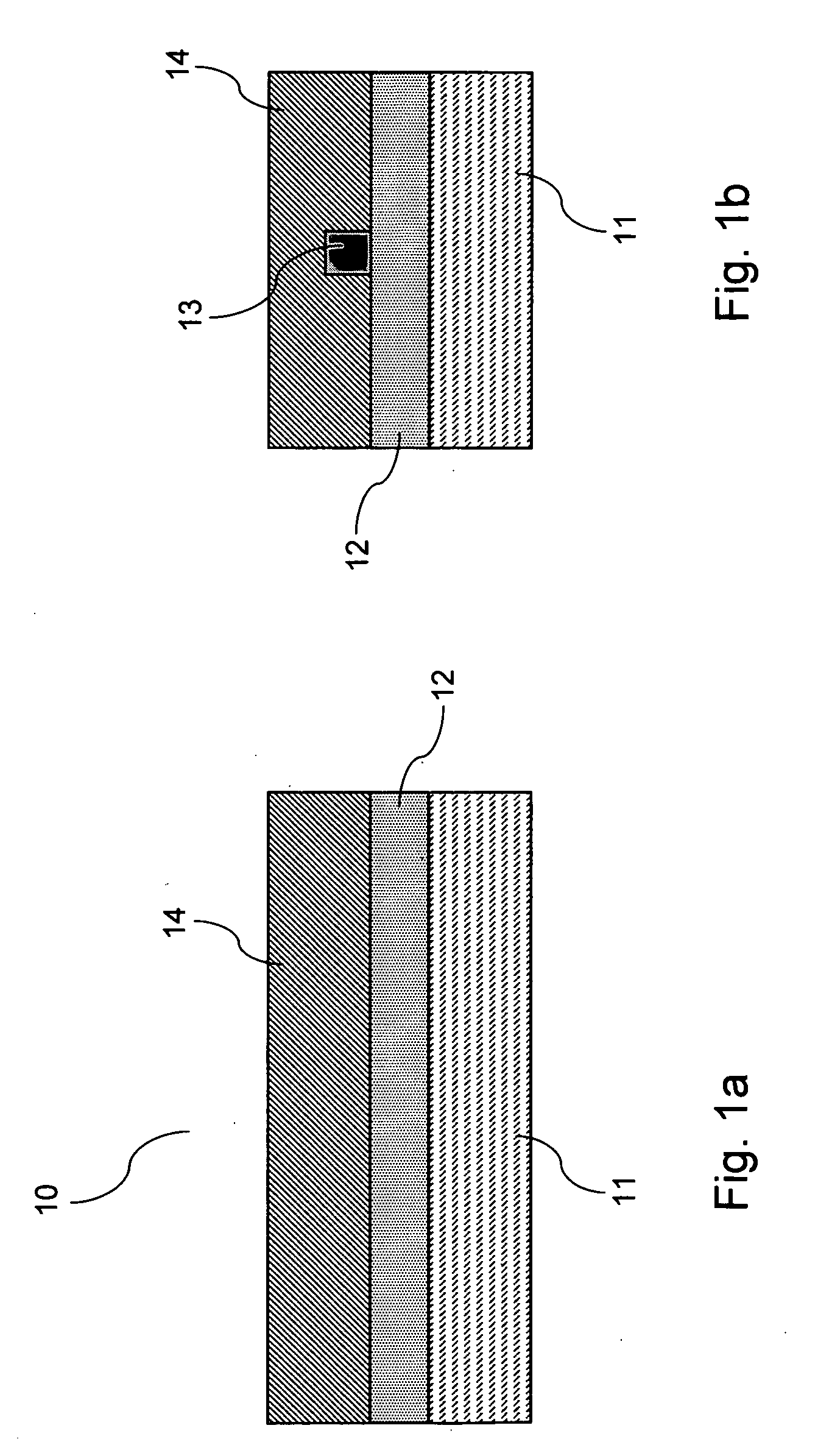

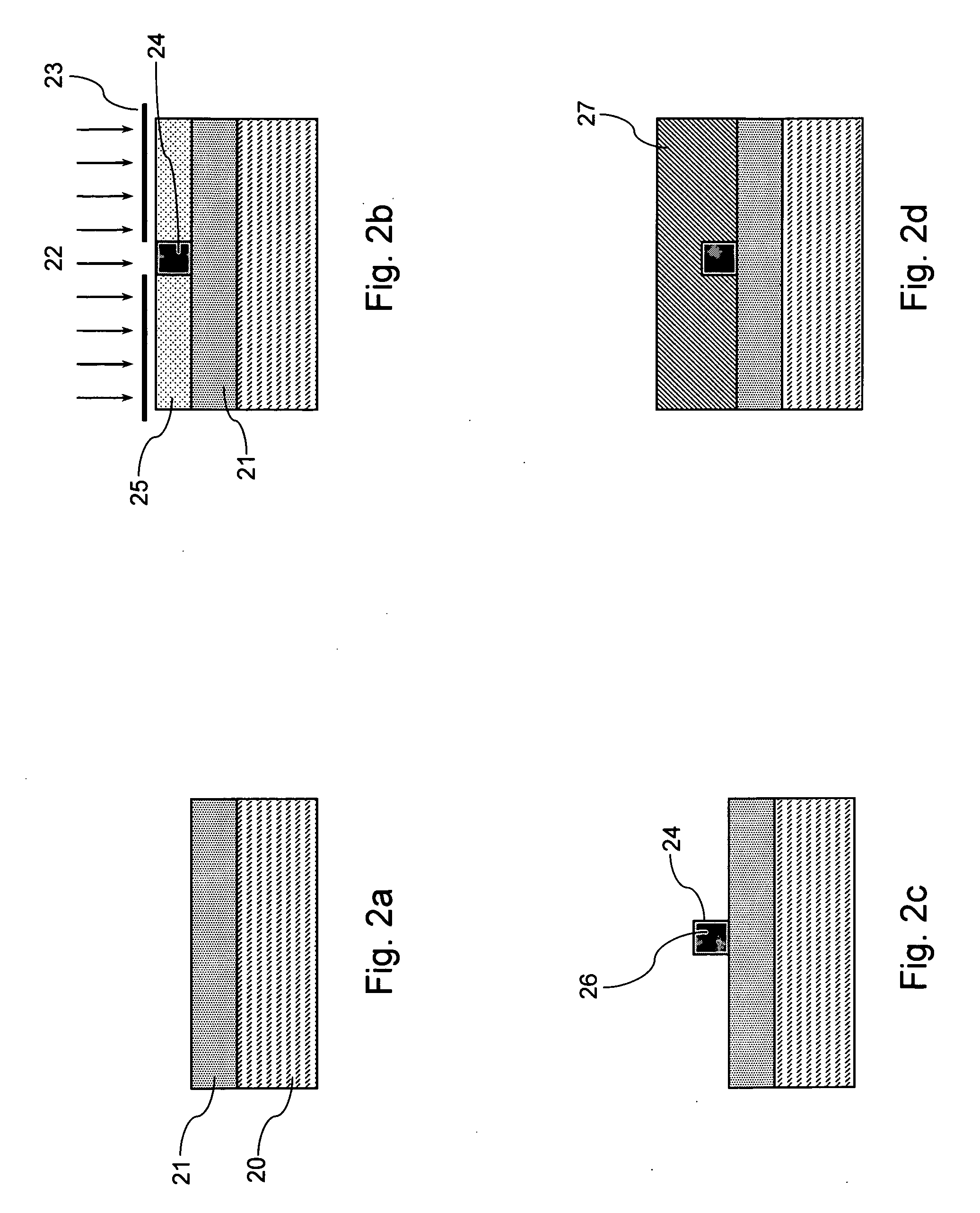

Printable Composition of a Liquid or Gel Suspension of Diodes

ActiveUS20120161195A1Solid-state devicesSemiconductor/solid-state device manufacturingOctanolSolvent

An exemplary printable composition of a liquid or gel suspension of diodes comprises a plurality of diodes, a first solvent and / or a viscosity modifier. In other exemplary embodiments a second solvent is also included, and the composition has a viscosity substantially between about 100 cps and about 25,000 cps at about 25° C. In an exemplary embodiment, a composition comprises: a plurality of diodes or other two-terminal integrated circuits; one or more solvents comprising about 15% to 99.9% of any of N-propanol, isopropanol, dipropylene glycol, diethylene glycol, propylene glycol, 1-methoxy-2-propanol, N-octanol, ethanol, tetrahydrofurfuryl alcohol, cyclohexanol, and mixtures thereof; a viscosity modifier comprising about 0.10% to 2.5% methoxy propyl methylcellulose resin or hydroxy propyl methylcellulose resin or mixtures thereof; and about 0.01% to 2.5% of a plurality of substantially optically transparent and chemically inert particles having a range of sizes between about 10 to about 50 microns.

Owner:NTHDEGREE TECH WORLDWIDE

Printable composition of a liquid or gel suspension of diodes

An exemplary printable composition of a liquid or gel suspension of diodes comprises a plurality of diodes, a first solvent and / or a viscosity modifier. In other exemplary embodiments a second solvent is also included, and the composition has a viscosity substantially between about 100 cps and about 25,000 cps at about 25° C. In an exemplary embodiment, a composition comprises: a plurality of diodes or other two-terminal integrated circuits; one or more solvents comprising about 15% to 99.9% of any of N-propanol, isopropanol, dipropylene glycol, diethylene glycol, propylene glycol, 1-methoxy-2-propanol, N-octanol, ethanol, tetrahydrofurfuryl alcohol, cyclohexanol, and mixtures thereof; a viscosity modifier comprising about 0.10% to 2.5% methoxy propyl methylcellulose resin or hydroxy propyl methylcellulose resin or mixtures thereof; and about 0.01% to 2.5% of a plurality of substantially optically transparent and chemically inert particles having a range of sizes between about 10 to about 50 microns.

Owner:NTHDEGREE TECH WORLDWIDE

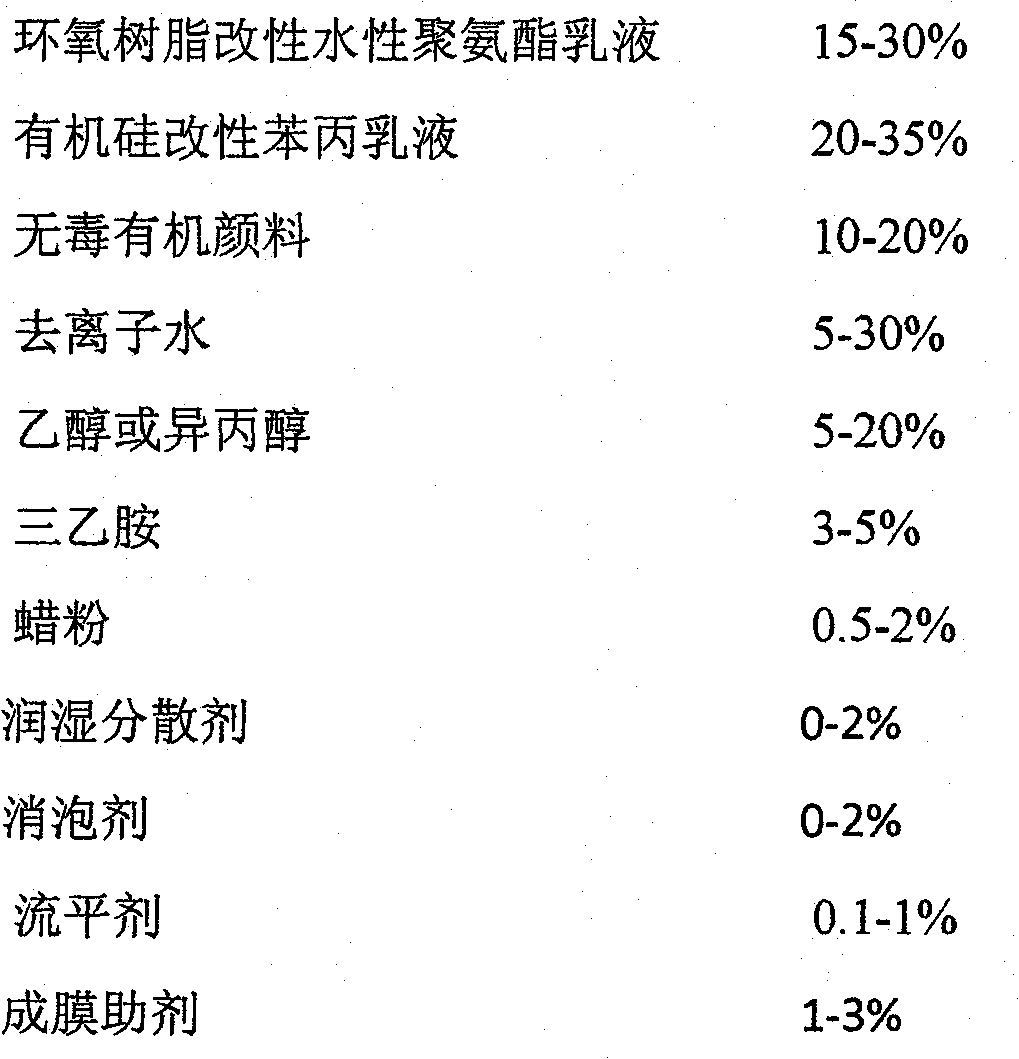

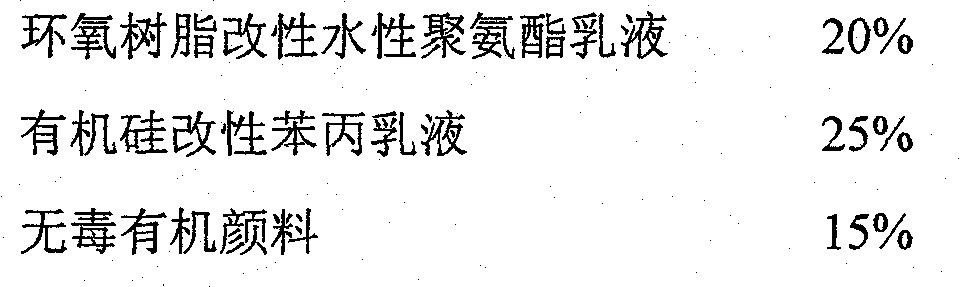

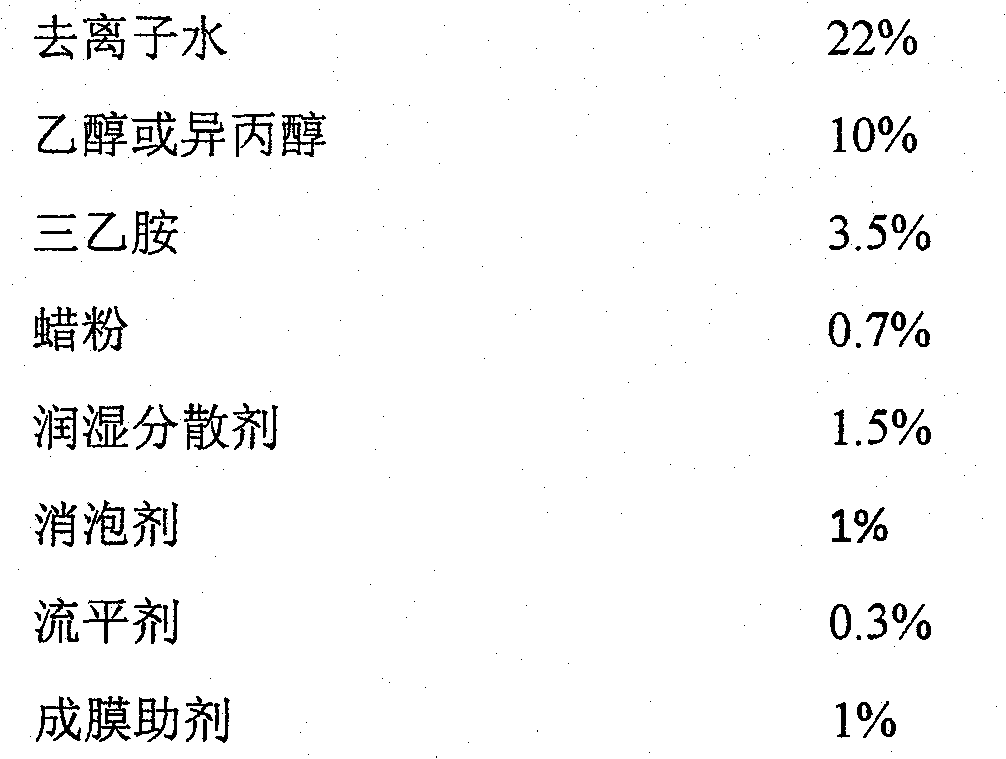

Water-based ink for plastic printing and preparation method thereof

The invention discloses a water-based ink for plastic printing and a preparation method thereof. The water-based ink is prepared by using epoxy resin modified water-based polyurethane emulsion and organic silicon modified styrene-acrylic emulsion as base materials and using deionized water and alcohol as solvents. The water-based ink comprises the following components by weight percent: 15-30% of epoxy resin modified water-based polyurethane emulsion, 20-35% of organic silicon modified styrene-acrylic emulsion, 10-20% of non-toxic organic pigment, 5-30% of deionized water, 5-20% of ethanol or isopropanol, 3-5% of triethylamine and 1.6-10% of additive. The water-based ink does not contain the volatile organic solvent, is incombustible, nonexplosible and non-toxic and has high attachment fastness on the plastic film and good printing effect; the ink has high chemical resistance, acid resistance and alkali resistance; and the ink has good water resistance, heat resistance, freezing resistance and oil resistance. The ink can be widely used in the packaging and printing of the industries such as grain, vegetables, alcohol and tobacco, and food; and the safety and non-toxicity of the ink can be ensured, and the ink is a green and environmentally-friendly product and has considerable market potential.

Owner:哈尔滨绿科科技有限公司

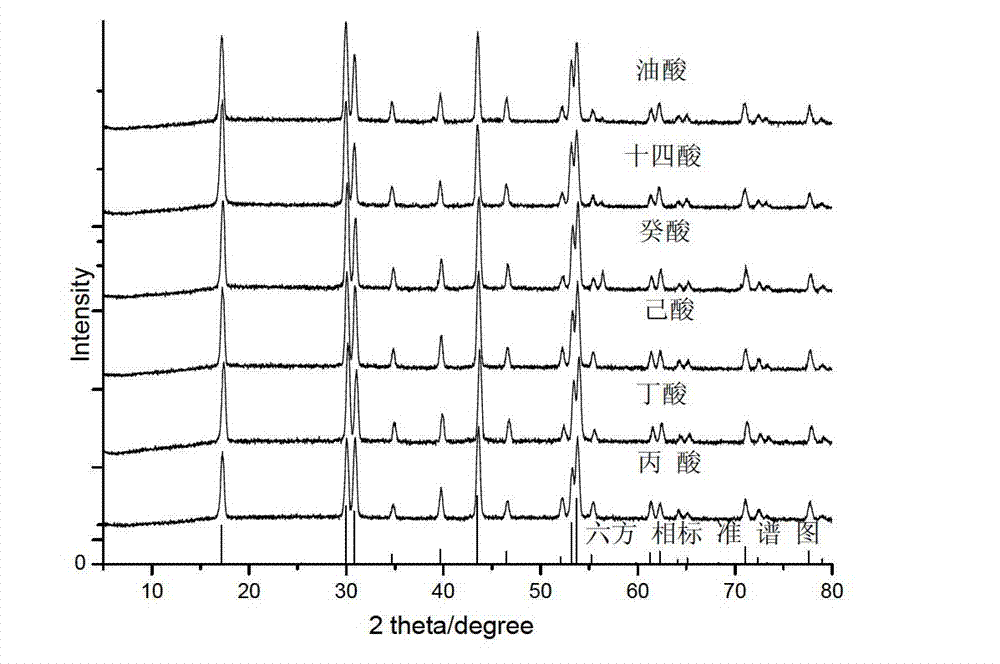

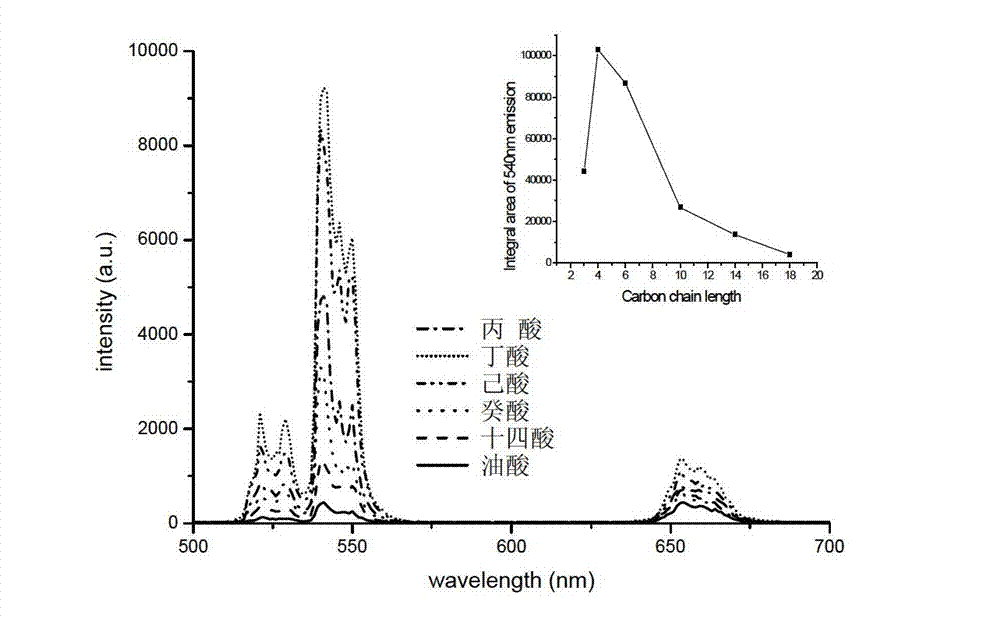

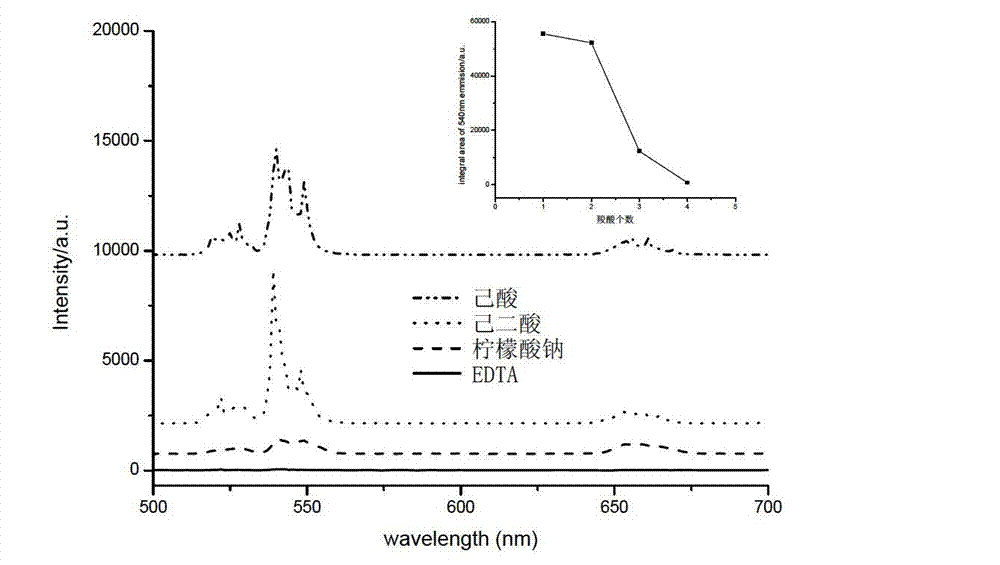

High-strength rare earth-doped up-conversion luminescence nanometer material and preparation method thereof

The invention provides a method of improving luminous efficiency of a rare earth-doped up-conversion luminescence nanometer material through changing the usage of a ligand. According to the method, the synthesis adopts a hydrothermal-solvothermal method, an organic ligand is an organic compound such as monocarboxylic acid, dicarboxylic acid or polycarboxylic acid, and amine, the molar ratio of rare earth ions to the ligand is 2:1-1:100, the molar ratio of NaOH to the ligand is 0:1-1:1, water / alcohol, water / n-propanol alcohol, water / isopropyl alcohol, water / n-butyl alcohol, water / acetone or water / ethylene glycol is used as a solvent, the temperature ranges from 180-240 DEG C, the reaction time is 2-24h, and the F<-> / Re value ranges from 4-12. With the method, the problems of selecting various ligands for synthesizing the up-conversion luminescence nanometer material, improving the luminous efficiency of the rare earth-doped up-conversion luminescence nanometer material, synthesizing the water-soluble up-conversion luminescence nanometer material, and the like can be mainly solved.

Owner:DALIAN UNIV OF TECH

Sulfur removal agent suitable for production of oil-gas well

InactiveCN102698576ASimple recipeAffect normal productionDispersed particle separationPropanolAlcohol

The invention relates to a sulfur removal agent suitable for the production of an oil-gas well. The sulfur removal agent comprises the following components in percentage by mass: 10 to 25 percent of hexahydro-1,3,5-tris(hydroxyethyl)-s-triazine, 5 to 20 percent of alcohol amine, 5 to 20 percent of small molecular alcohol and the balance of water. The alcohol amine is one or a mixture of more thantwo of monoethanolamine, ethyleneglycol amine, diisopropanolamine, methyldiethanolamine and triethanolamine; and the small molecular alcohol is one or a mixture of more than two of methanol, ethanol and propanol. The sulfur removal agent has a simple formula, can be soluble with water, and can effectively reduce the content of hydrogen sulfide in crude oil or natural gas; simultaneously, productsgenerated by the sulfur removal agent and the hydrogen sulfide are water-soluble, and cannot block a mineshaft and influence the normal production of the oil-gas well; and the sulfur removal agent can achieve effects at the temperature of 30 to 120 DEG C and can be quickly reacted with the hydrogen sulfide.

Owner:SOUTHWEST PETROLEUM UNIV

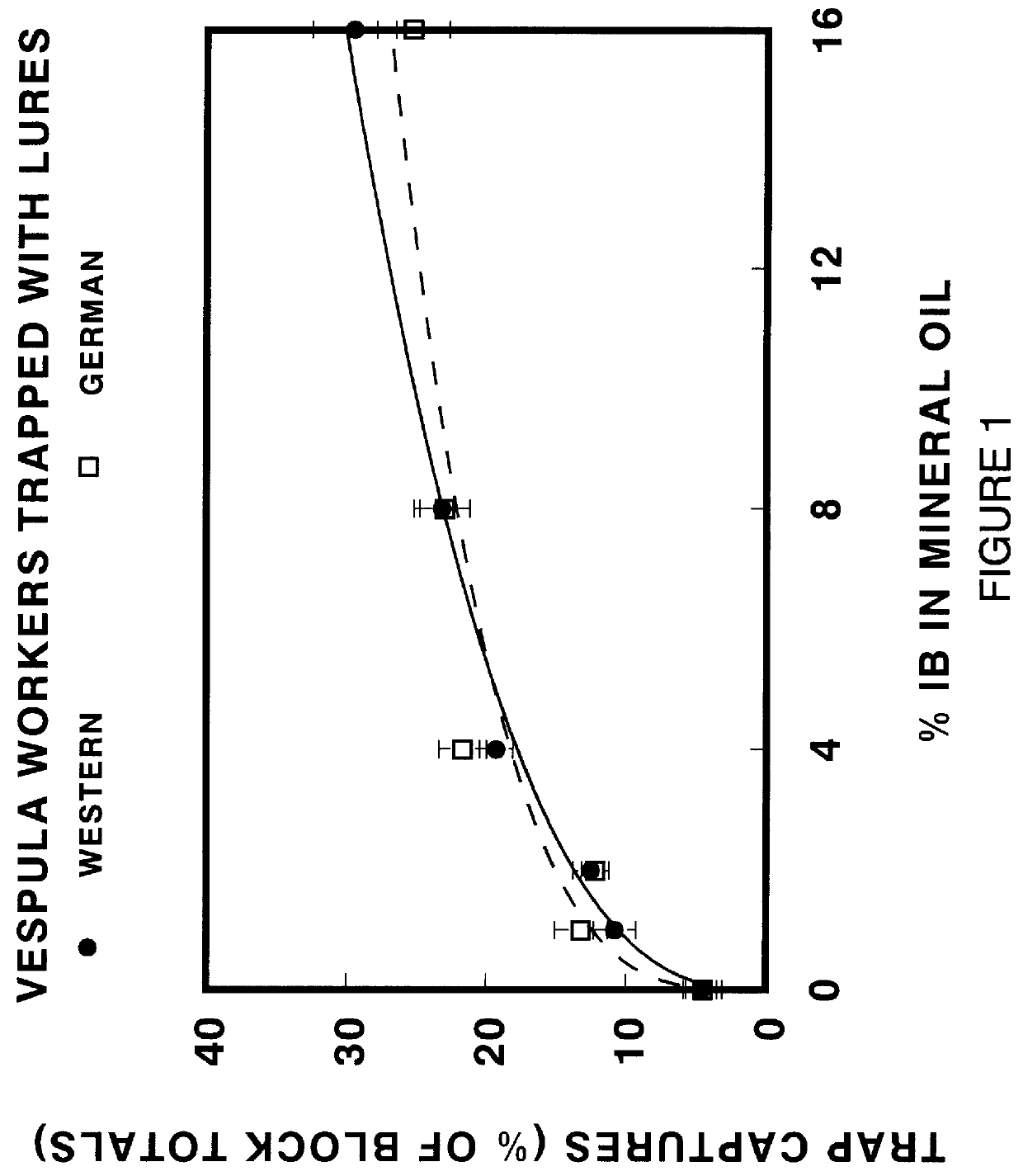

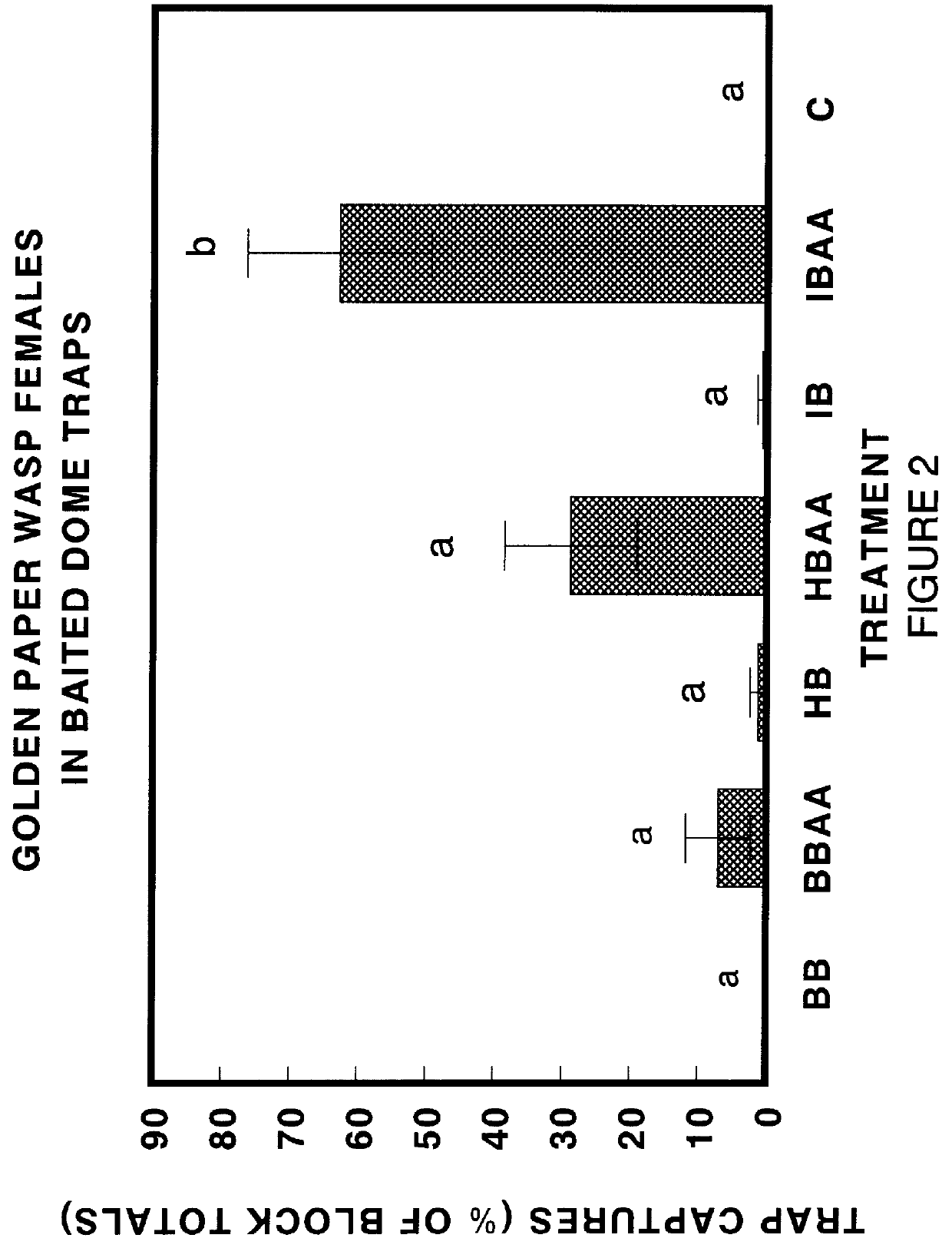

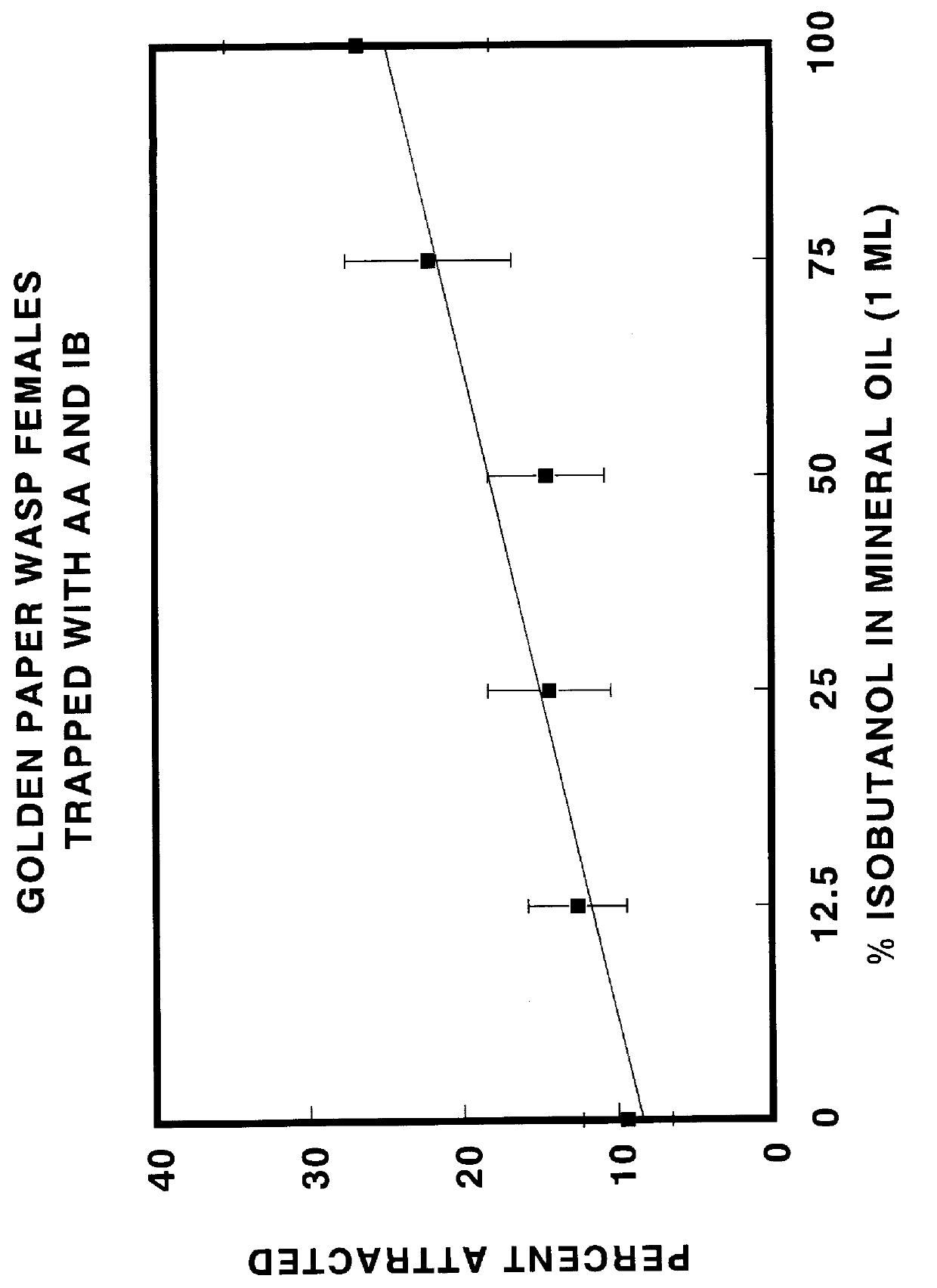

Chemical attractants for yellowjackets and paper wasps

InactiveUS6083498AEnhanced informationEfficient methodBiocidePeptide/protein ingredientsIsobutanolPropanol

Compositions and lures are described which provide vapor blends of acetic acid and one or more compounds selected from the group consisting of isobutanol, racemic 2-methyl-1-butanol, S-(-)-2-methyl-1-butanol, 2-methyl-2-propanol, heptyl butyrate, and butyl butyrate which function as highly effective attractants for yellowjacket wasps and paper wasps. By attracting wasps to traps or baits, the chemical attractants provide a means for detecting, surveying, monitoring, and controlling the wasps.

Owner:US SEC AGRI

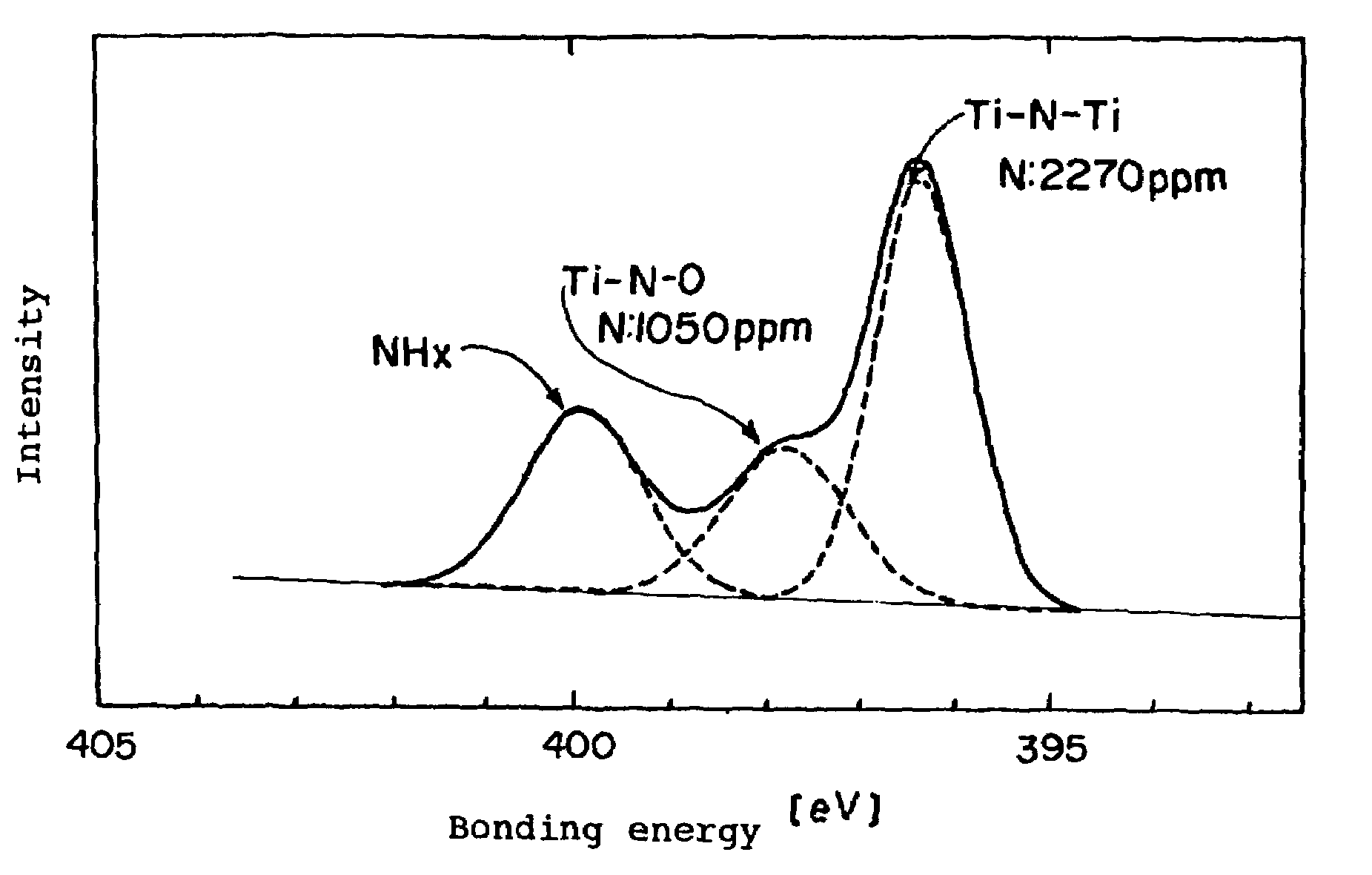

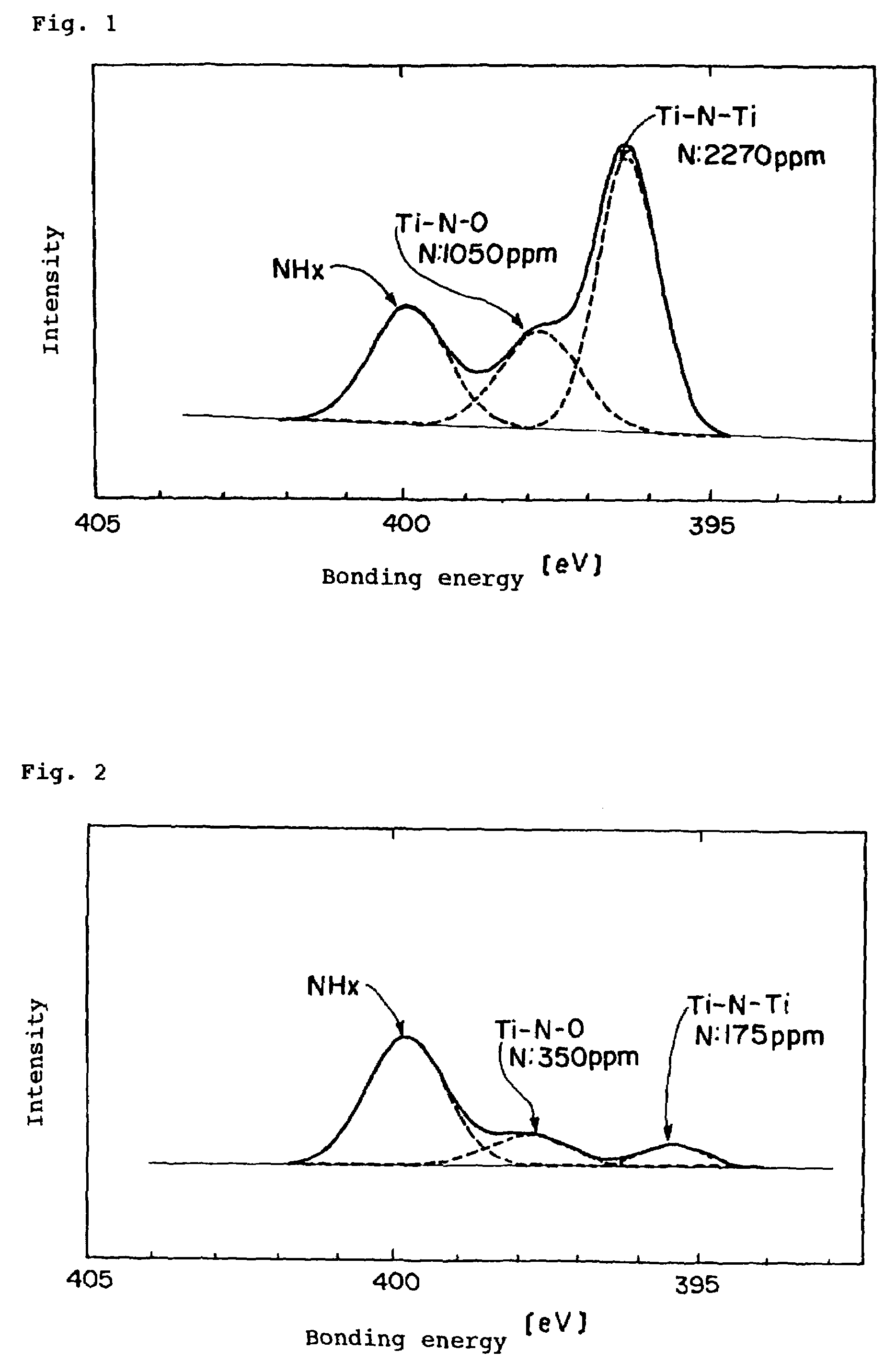

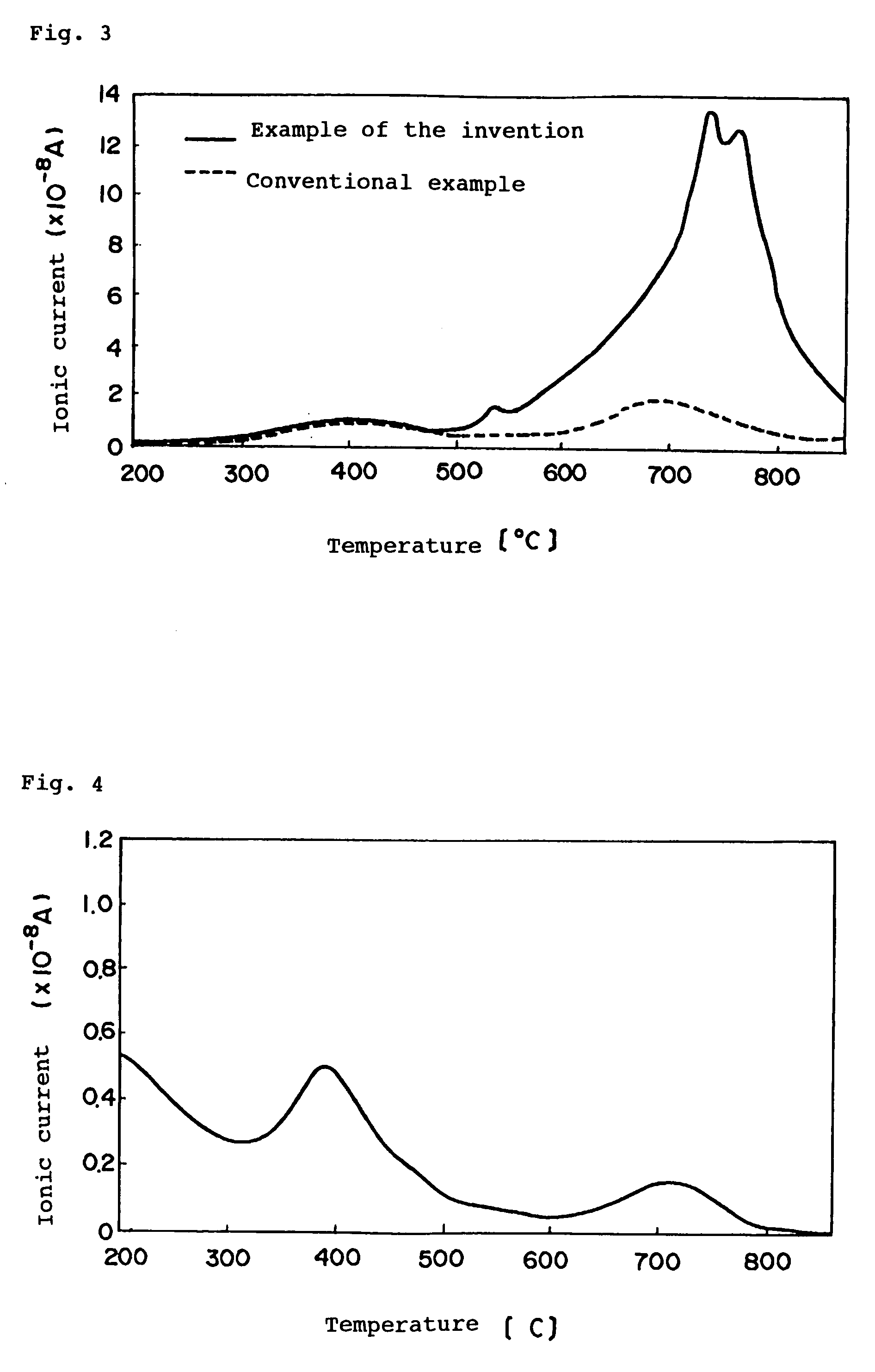

Titanium dioxide fine particles and method for producing the same, and method for producing visible light activatable photocatalyst

InactiveUS7175911B2Improve photocatalytic activityImprove stabilityMaterial nanotechnologySynthetic resin layered productsMicroparticlePhotochemistry

The invention provides titanium dioxide fine particles, wherein nitrogen and at least one element selected from carbon, hydrogen, sulfur doped in titanium dioxide by heat-treating fine particles of a material of titanium dioxide at 500° C. or more and 600° C. or less in a reducing gas atmosphere containing nitrogen. The titanium fine particles exhibit a high photocatalytic activity than in the conventional art by irradiating a visible light such that they exhibit an isopropanol oxidation activity induced by visible light irradiation with a wavelength of 400 nm or more and 600 nm or less with excellent stability and durability of the photocatalytic activity.

Owner:COVALENT MATERIALS CORP

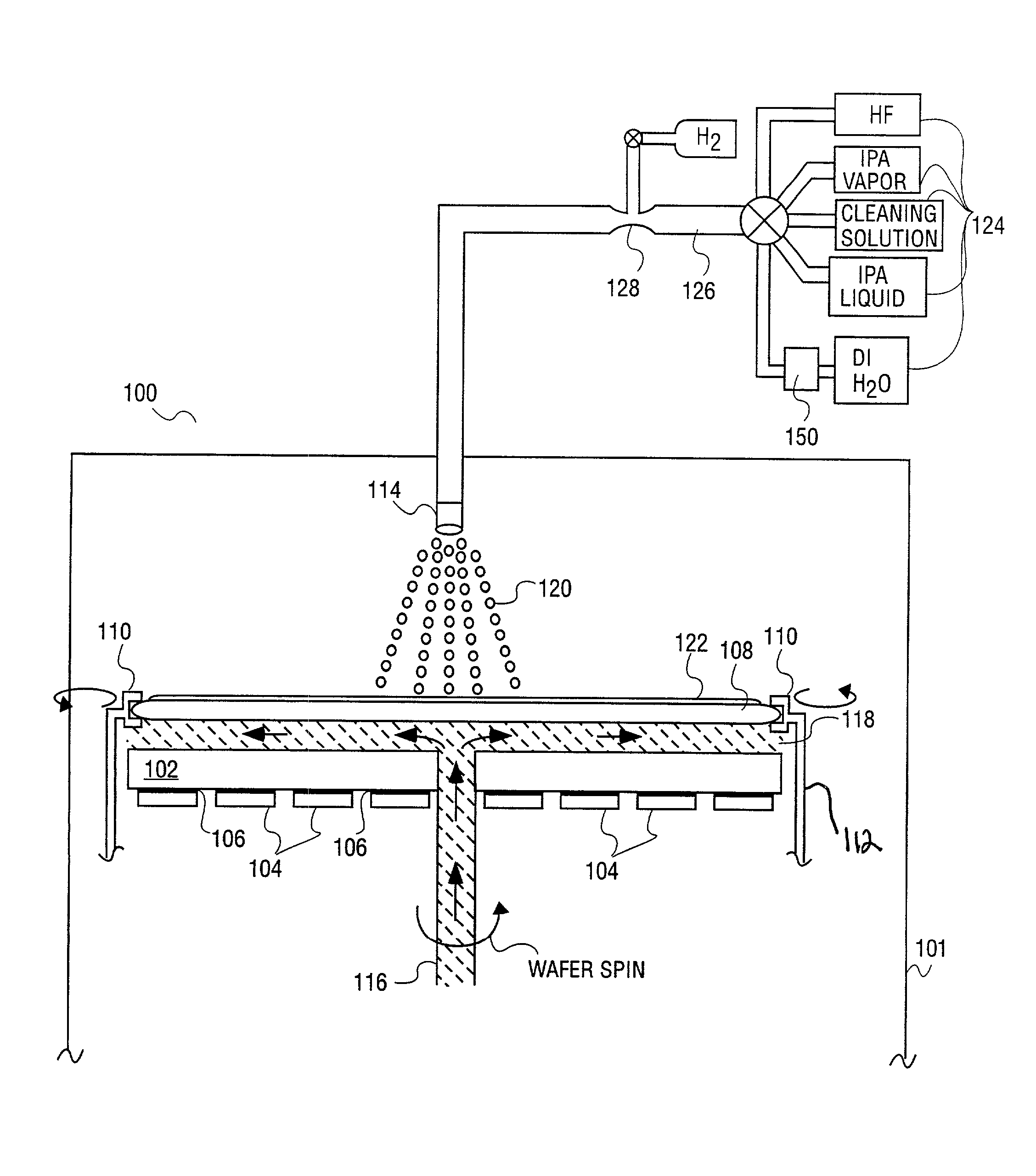

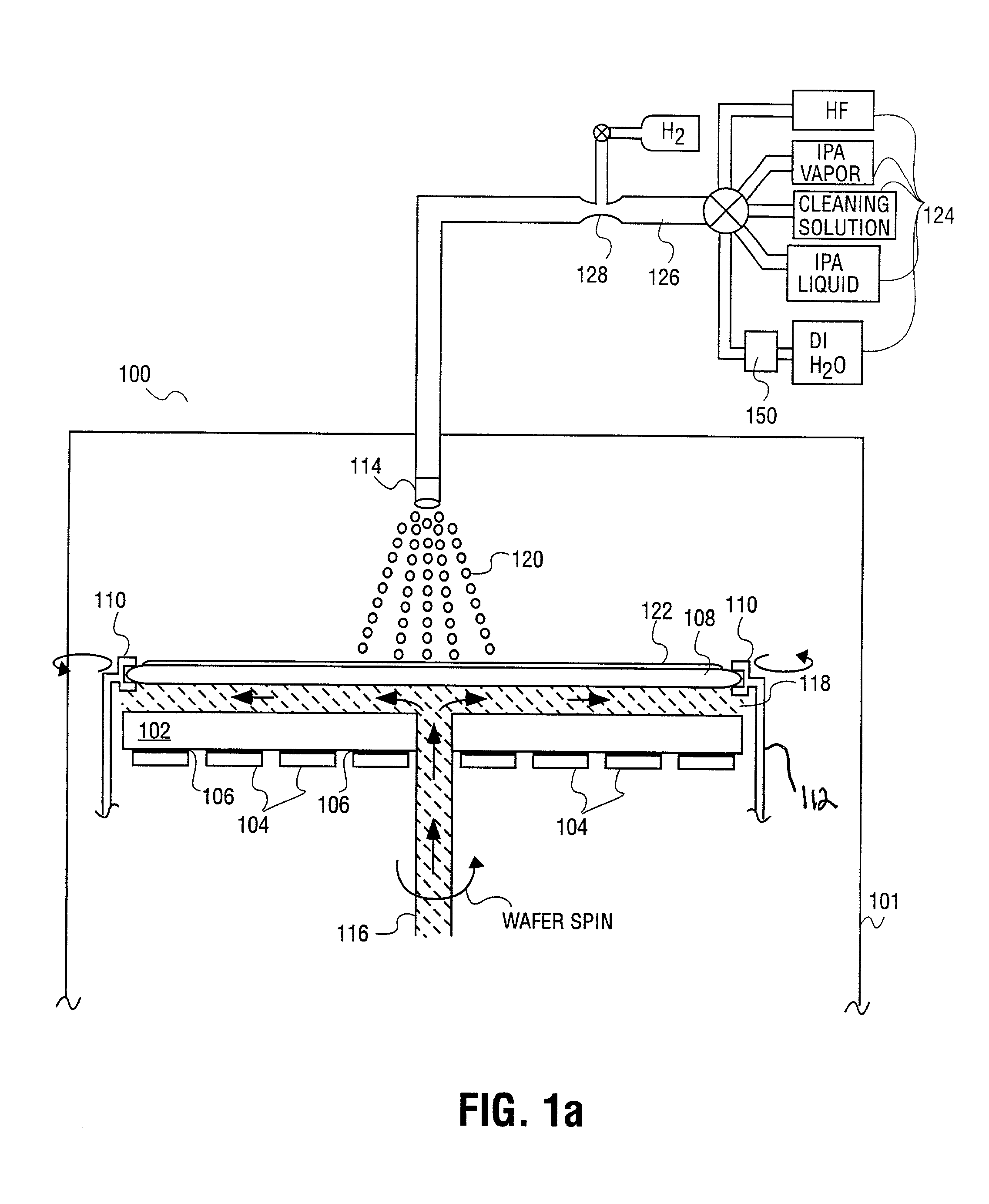

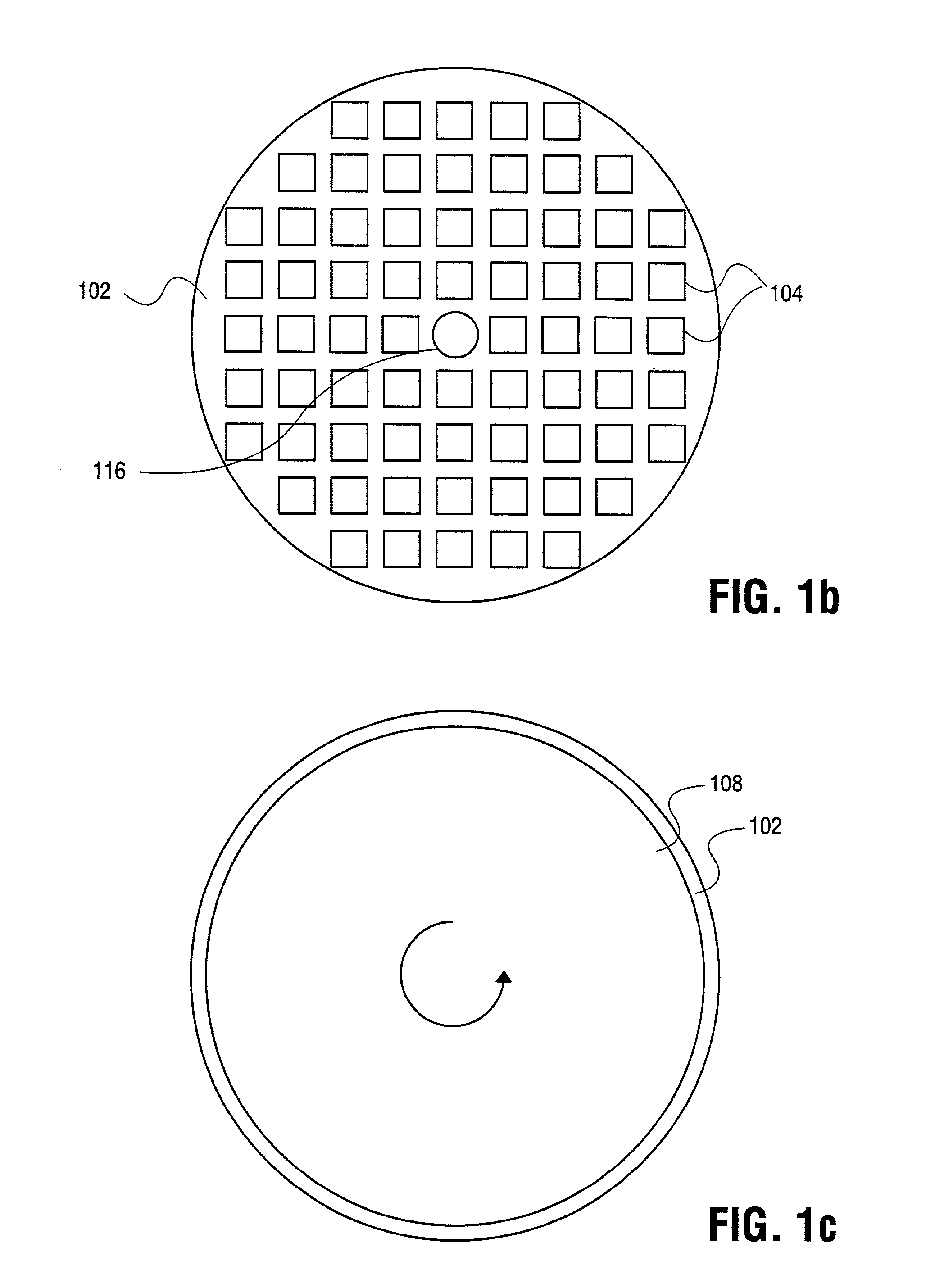

Assisted rinsing in a single wafer cleaning process

InactiveUS20020062840A1Small thicknessDecreases rinsingElectrostatic cleaningSemiconductor/solid-state device manufacturingRoom temperatureCentrifugal force

The present invention is a method of assisting the rinsing of a wafer in a single wafer cleaning apparatus. According to the present invention, after exposing a wafer to a cleaning and / or etching solution, the cleaning or etching solution is removed from the wafer by spinning the wafer and dispensing or spraying DI water onto the wafer as it is spun. The centrifugal force of the spinning wafer enhances the rinsing of the wafer. In order to enhance the rinsing of the wafer, in an embodiment of the present invention a solution having a lower surface tension than water, such as but not limited to isopropyl alcohol (IPA) is dispensed in liquid or vapor form onto the wafer after the DI water. In a specific embodiment of the present invention, the vapor of a solution with a lower surface tension than DI water, such as IPA vapor, is blown on the wafer in order to break up the DI water bulging up at the center of the spinning wafer. In another embodiment of the present invention, a gas such N2, is blown for a short period of time onto the center of the wafer to break up the DI water bulging up at the center of the spinning wafer. In yet another embodiment of the present invention, acoustic or sonic waves are applied to the wafer as it spins in order to help diffuse the DI water from the wafer. And in still yet another embodiment of the present invention, the DI water which is dispensed onto the spinning wafer is heated to a temperature above room temperature and preferably between 60-70° C. to enhance the diffusion of water from the wafer. The low surface tension liquid, acoustic application, gas blowing, and heated DI water can be used alone or in combination with one another into enhance the rinsing of a wafer and thereby decrease the rinsing time of a single wafer process to less than 20 seconds.

Owner:APPLIED MATERIALS INC

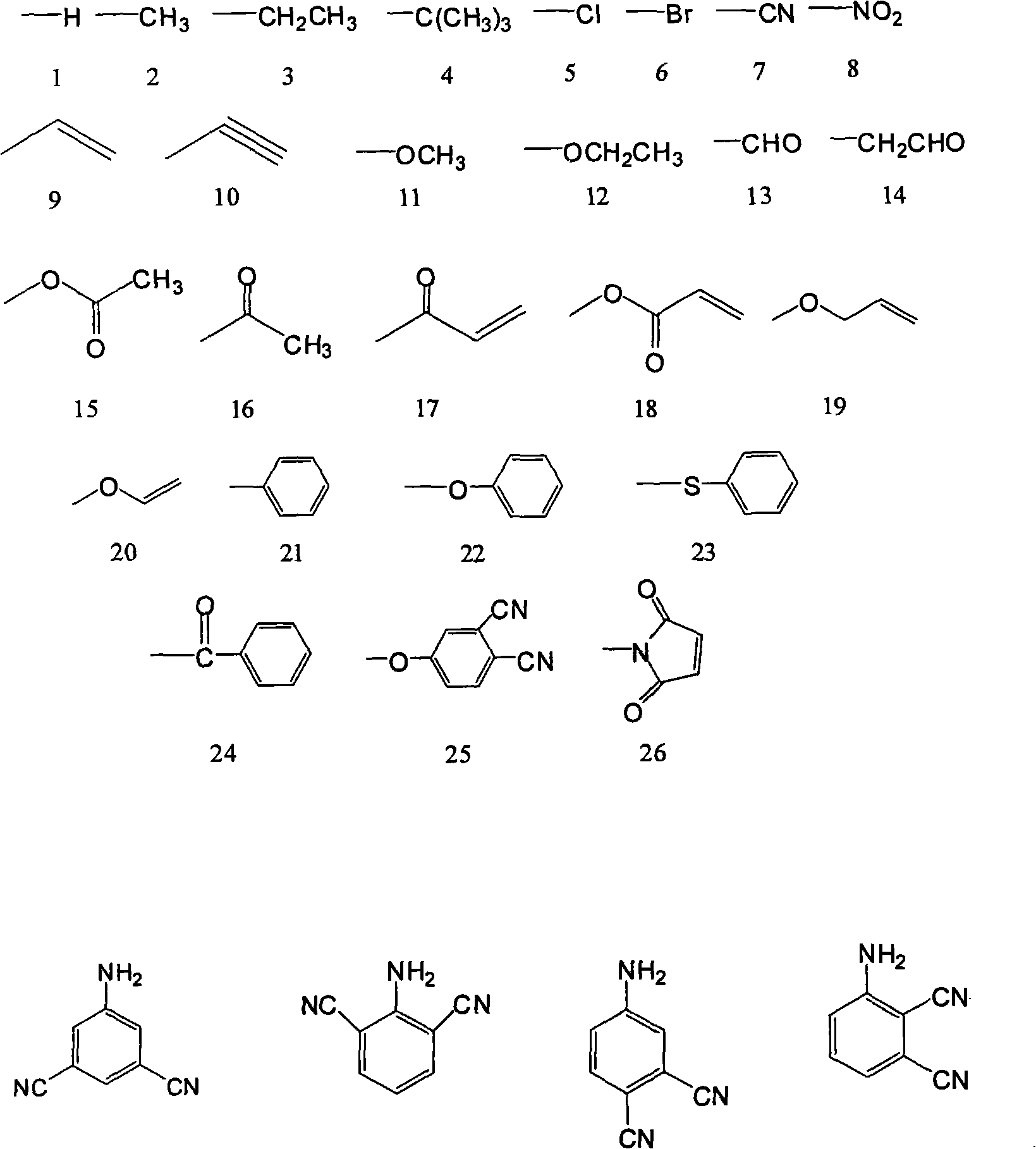

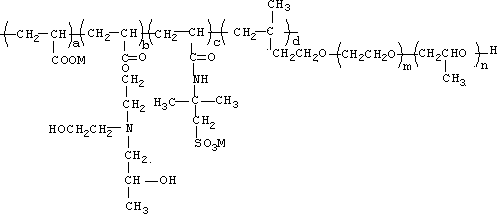

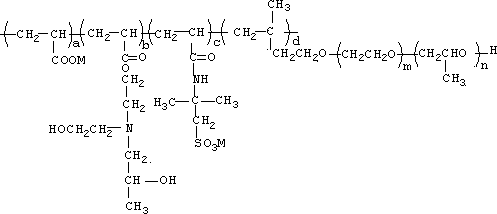

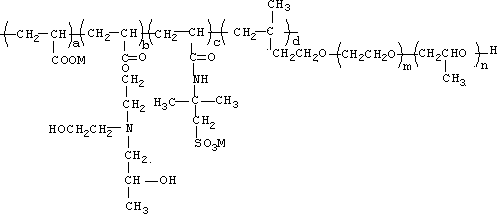

Ethers early strength type polycarboxylate water reducer and preparation method thereof

The invention discloses an ethers early strength type polycarboxylate water reducer and a preparation method thereof. The water reducer regards unsaturated esters, N,N-bis(2-hydroxyethyl)isopropanolamine (DIEPA), 2-acrylamide-2-methylpropanesulfonic acid (AMPS), methyl allyl polyoxyethylene polyoxypropylene ether (TPEG) and the like as main chemical synthesis raw materials, and the main chemical synthesis raw materials are subjected to amidation and copolymerization in certain conditions under the action of a catalyst, an initiator, a chain transfer agent and the like, so that a high-molecular polymer with an amphoteric structure is obtained. The molecular structure of the water reducer comprises hydrophilic hydroxyl, hydrophilic carboxyl, hydrophilic acylamino, hydrophilic sulfonyl, hydrophobic carbon chains and a polyoxyethylene polyoxypropylene ether long-chain structure with certain stereo-hindrance effects, wherein an N containing group can improve early strength of concrete obviously. Therefore, the ethers early strength type polycarboxylate water reducer is applicable to pre-cast concrete components which need improvement of early strength.

Owner:KZJ NEW MATERIALS GROUP CO LTD

Lost foam casting coating and preparation method thereof

The invention discloses a lost foam casting coating, which comprises fire-proof powder, phenolic resin, white latex, calcium bentonite and isopropyl alcohol, wherein the fire-proof powder includes bauxite and quartz powder. The bauxite is formed by uniformly mixing the following components: 80% of particles with the granularity ranging from -280 to -310, 14% of particles with the granularity ranging from -280 mesh to -190 mesh and 6% of particles with the granularity ranging from -90 mesh to -190 mesh. The preparation method of the lost foam casting coating is as follows: calcining selected bauxite ore at the temperature of 1510-1550 DEG C; grinding calcined clinkers to acquire the granularity particles with the granularities respectively; evenly mixing the particles according to the composition proportion; and mixing the mixed bauxite with quartz powder, phenolic resin, white latex, calcium bentonite and isopropyl alcohol. According to the invention, bauxite is distributed according to particle sizes, and bauxite particles of different sizes are alternately arranged after even mixing. As a result, the compactness is changed, the air permeability is strengthened, the cold shut phenomenon occurring between liquid metal and the coating is avoided, and finally the quality of the casting produced through lost foam casting is improved.

Owner:ANYUE COUNTY JINLONG MACHINERY MFG

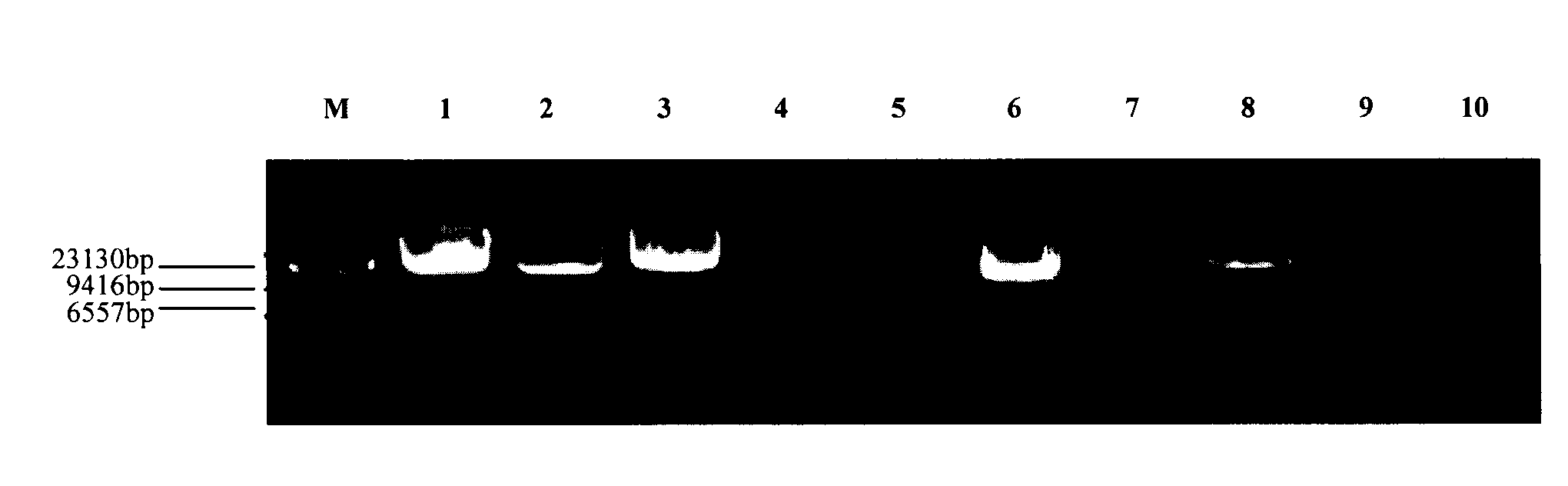

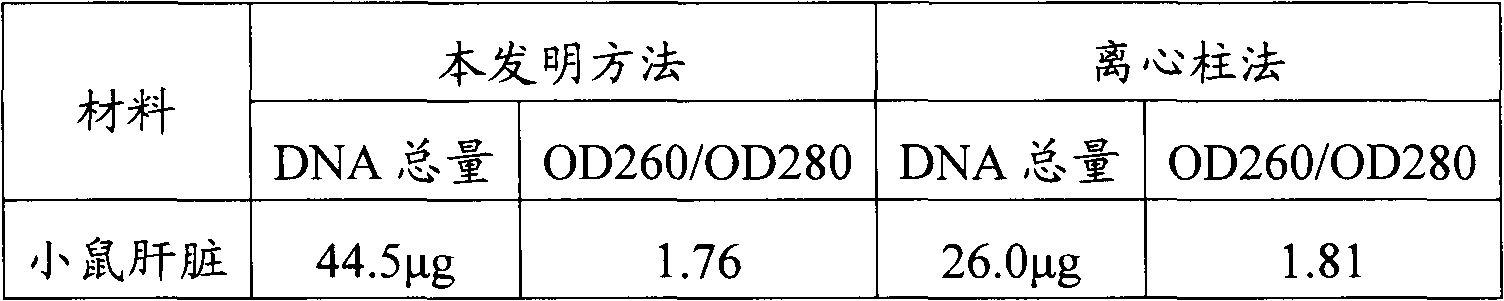

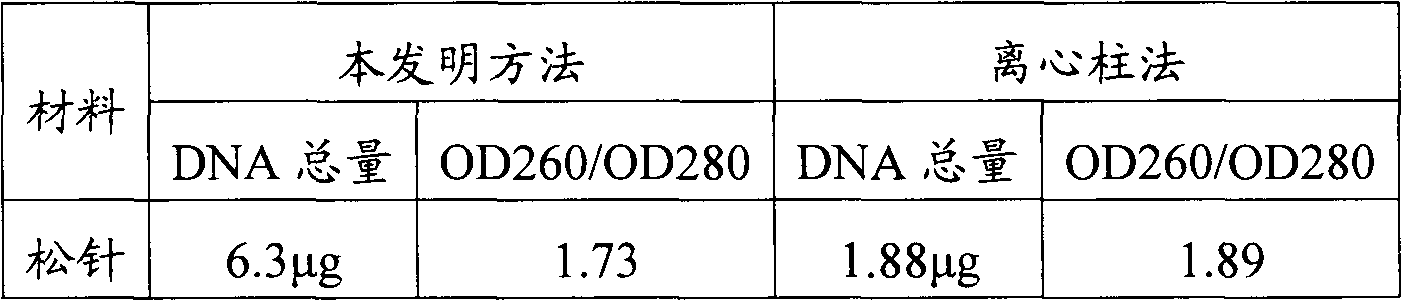

Kit for extracting DNA from histiocytes and method thereof

The invention relates to the field of molecular biology and discloses a kit and a method for extracting DNA from histiocytes. The kit comprises a binding solution, a regulating and binding solution and a deproteinization solution, wherein the binding solution comprises 3-5M of guanidinium isothiocyanate, 5-50mM of Tris-HCl with a pH value of 3.5-5.5, 5-25 percent by weight of Ttiton-X 100 and 5-20mM of Urea; the regulating and binding solution is isopropyl alcohol; and the deproteinization solution comprises 2-6M of guanidine hydrochloride, 5-50mM of Tris-HCl with a pH value of 6.5-8.0 and 5-50 percent by weight of absolute ethyl alcohol. The kit also comprises a pretreatment buffer solution, a splitting solution, a magnetic bead, a rinsing solution and an eluting solution. The DNA extracted by the kit and the method has the advantages of high content and high extraction speed, and the invention does not adopt toxic reagents and is suitable for extracting the DNA of various histiocytes.

Owner:中生方政生物技术股份有限公司

High content environmental protection alcohol ether fuel for vehicle

InactiveCN101100618AHigh calorific valueImprove thermal efficiencyLiquid carbonaceous fuelsIsobutanolNitromethane

A high-content environmental-protecting alcohol ether fuel for vehicle consists of additives and methanol or alcohol 75-87 proportion. The additives contain methanol, alcohol, isopropyl alcohol, isobutanol, dimethylcuprate, n-amyl alkyl, dipropyl, cyclopentane, nitro-methane, dimethyl benzene, pinecone oil, cyclopentadienyl, poly-isobutylene, propane diamine, carbomethoxy formate, dimethoxyester carbonate, natural gasoline, hydrocarbon solvent oil, diisopropyl ester, dimethoxy-methane, petroleum ether, methyl tert-amyl ether, tert-amyl tert-butyl ether, lauryl phenol poly-ethenoxy ether, anti-static agent, metal-corrosive inhibitor, rubber plastic swelling inhibitor and anti-oxidant. It's clean and universal; it has excellent burning stability, shock resistance and dynamic character and less oil consumption.

Owner:鲁家政

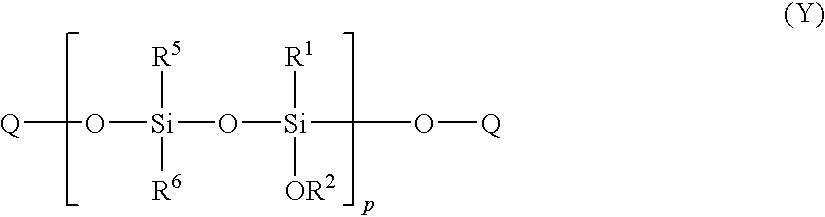

Process for producing polysiloxanes and use of the same

A process for the preparation of an organosilicon condensate which comprises reacting together a silicon containing compound having at least one silanol group and a silicon containing compound having at least one —OR group or at least one silanol group (or a compound having both groups) in the presence of strontium oxide, barium oxide, strontium hydroxide or barium hydroxide and optionally a solvent such as water, methanol, ethanol, 1-propanol, 2-propanol, 1-butanol and 2-butanol, acetone or toluene.

Owner:ZETTA RES & DEV LLC RPO SERIES

Polystyrene reclamation process

InactiveUS20020062054A1Avoid lostEasy to reuseHydrocarbon by hydrogenationPlastic recyclingPropyl bromideBoiling point

This disclosure concerns a process and apparatus for reclamation of waste polystyrene-type materials for reuse within the specification ranges of the input polystyrene-type material. The disclosed process and apparatus include dissolution of the waste polystyrene-type materials in a dissolve section utilizing a reusable solvent having a low boiling point and high vaporization rate, removal of solid contaminants in one or more filter sections, devolatilization of the dissolved polystyrene and recovery of the polystyrene-type material in a solid form in a recovery section. Preferably the process and apparatus provide a closed system and include recycling and reuse in the process of the vaporized solvent. The maximum temperature in the recovery section is 190° C. The reusable solvent is preferably environmentally safe and has a low boiling point and high vaporization rate. n-Propyl bromide, or environmentally safe mixtures thereof, including mixtures with isopropyl alcohol, is the preferred reusable solvent.

Owner:RESOURCE RECOVERY TECH

Pomegranate rind extraction and its preparation method

ActiveCN101057878ASimple production processShorten the production cycleAntibacterial agentsAntimycoticsAlcoholGuaijaverin

The invention discloses a pomegranate bark extract and the method for preparing the same. It takes pomegranate bark as raw material, extracts with low-carbon alcohol such as methanol, ethanol, propylic alcohol, isopropyl alcohol and butanol, condensing, column chromatography, condensing, drying and getting powder pomegranate bark extract. The invention extracts guaijaverin from pomegranate bark. The pomegranate bark extract is red or brunneus, powder, astringent taste and the guaijaverin weight proportion is 40% or above 98%.

Owner:GUILIN NATURAL INGREDIENTS CORP

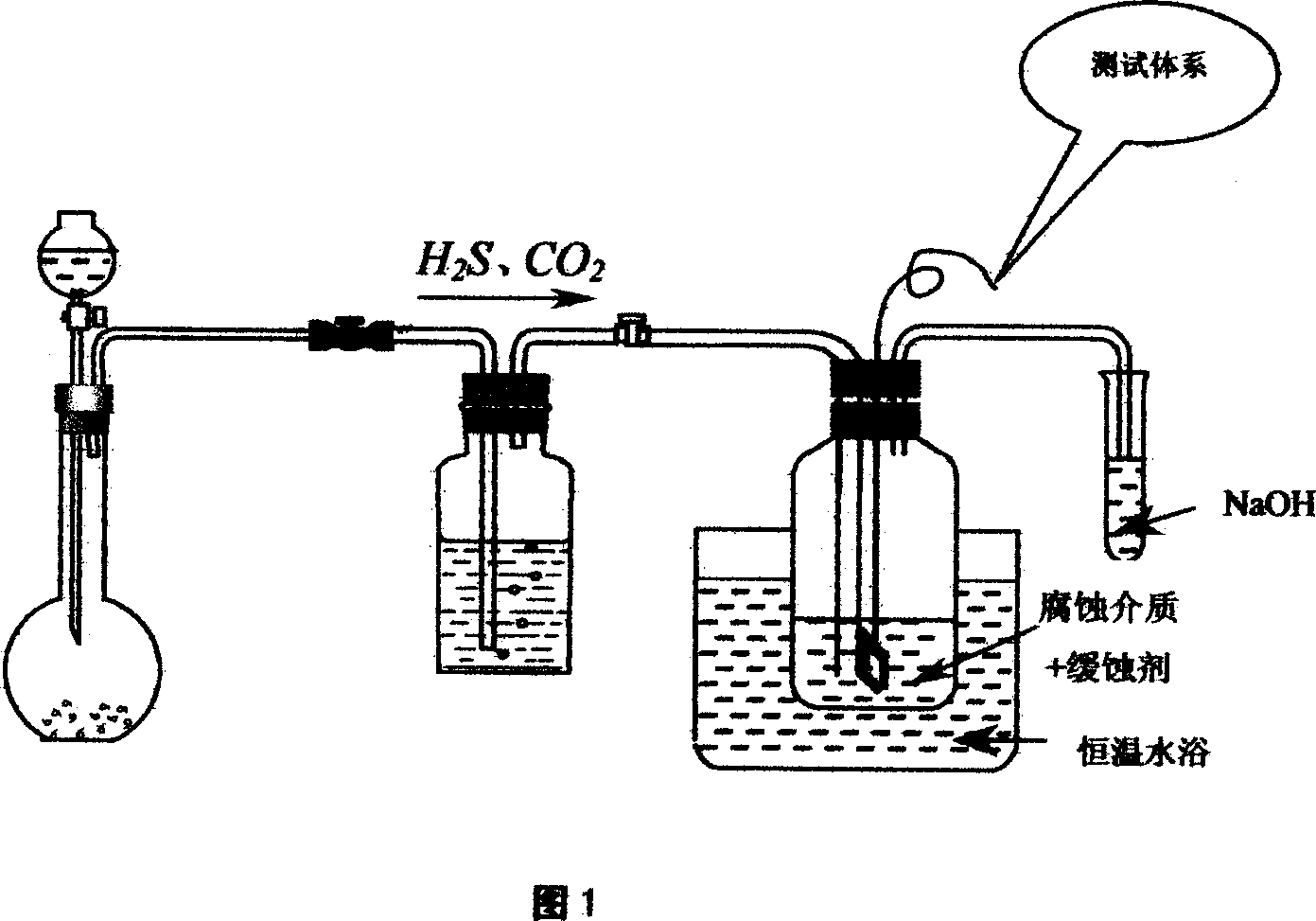

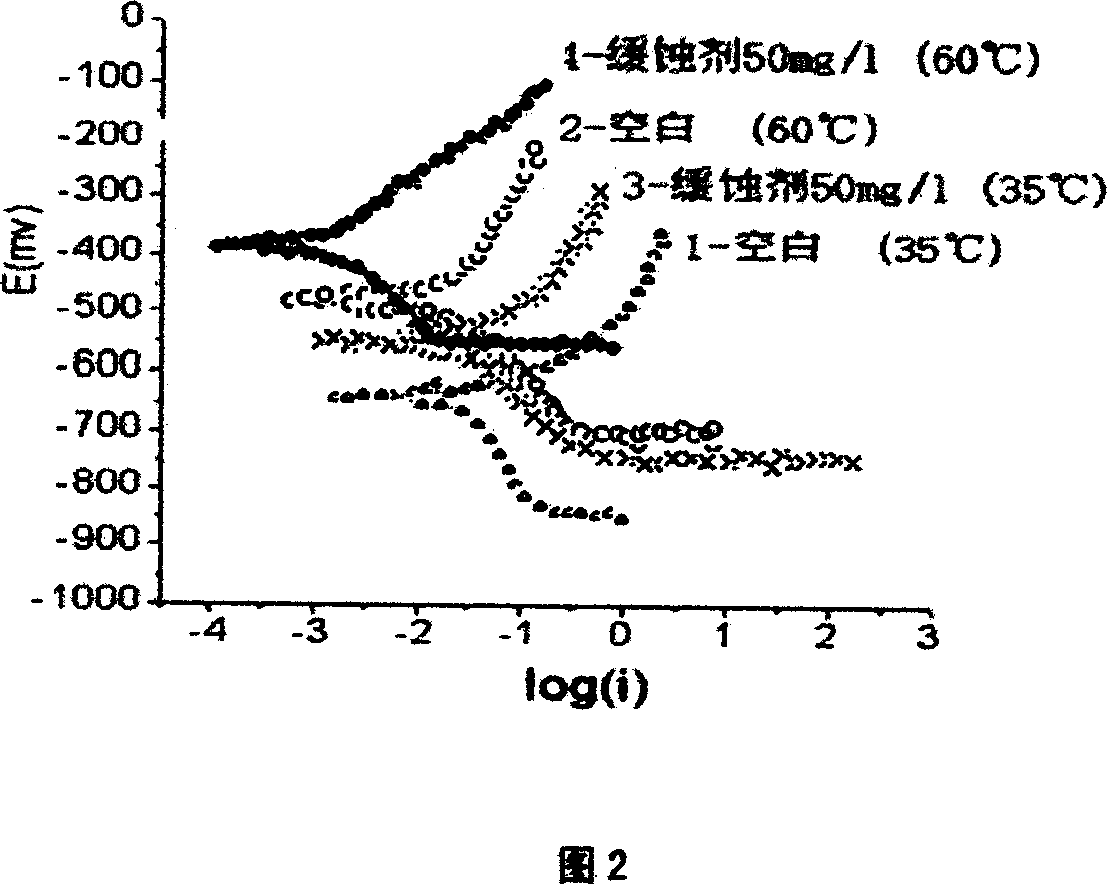

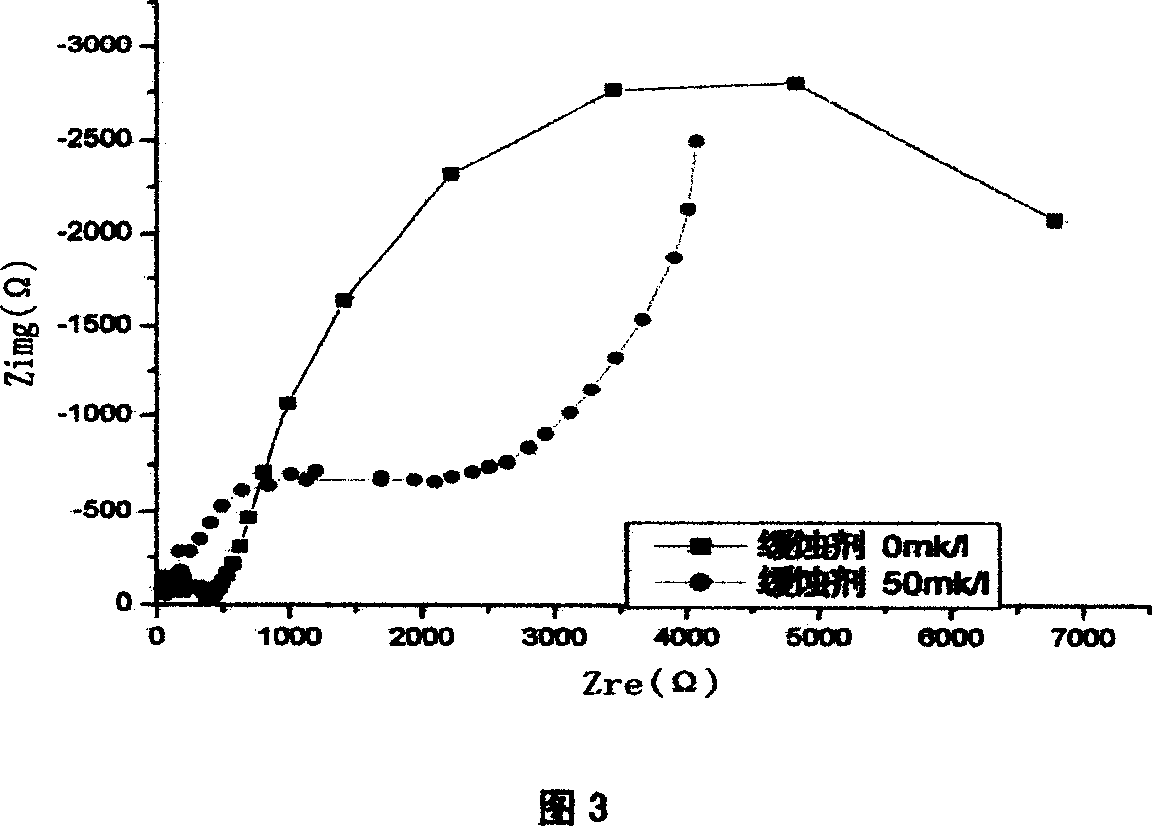

Corrosion inhibitor resistant to H2S and CO2

InactiveCN1966774ADoes not affect separation efficiencyGood corrosion inhibition effectBorehole/well accessoriesIsopropyl alcoholFatty alcohol

The invention relates the chemical engineering field, especially a H2 and CO2 inhibiter. H2 and CO2 are produced accompany to oil-gas field exploitation and transfusion process, and can corrode exploitation equipment. The inhibiter contains at least (by wt. %): isopropyl alcohol 10-30, fatty alcohol polyoxyethylene ether .1-0.5, and litol polyoxyethylene ether 0.1- 1.0. The inhibiter can be used in oil / water well with high temperature and pressure, and has the advantages of good corrosion resistance, low consumption, low cost and high efficiency.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

Multi-element co-polymerization oil well cement fluid loss additive and preparation method thereof

ActiveCN101397491ASimple preparation processDrilling compositionPotassium persulfateSodium hydroxide

The invention relates to a multicomponent copolymerization oil well cement fluid loss additive and a preparation method thereof. The method comprises: 10-120 portions of 2-acrylamide-2-methyl-1-AMPSA, 1-5 portions of acrylic acid and 15-50 portions of deionized water are added, stirred and then added with sodium hydroxide aqueous solution with the mass fraction of 5-10 percent for neutralizing to pH equal to 3-11; then 10 portions of acrylamide, 0.1-1 portion of complexing agent EDTA and 0.01-1 portion of chain transfer agent are added, the chain transfer agent is isopropyl alcohol or sodium benzoate, the temperature is controlled between 30 DEG C and 60 DEG C and N2 is introduced for 30 minutes; 2-10 portions of N-vinyl pyrrolidone and 0.01-0.5 portion of initiator are added, the initiator is potassium persulfate or ammonium persulfate, and the reaction is carried out for 4-12 hours. The solution keeps still for 5 hours at the temperature of 180 DEG C, and is cooled through flowing water after being taken out, without sedimentation or water separating; and the water loss is zero at the temperature of 180 DEG C according to the standards of drilling fluid, and the water loss is 48ml according to the standards of cement.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Fragrance emitting compositions and products

InactiveUS7202201B1Low production costReadily and easilyUrinalsCosmetic preparationsPotassium1-Hexene

Compositions and products for emitting fragrance include at least one fragrance, perlite, and sodium silicate or water glass. Compositions used to make urinal blocks and other products may further include at least one of: lime (calcium oxide), gypsum, enzymes and colorant agents. Chlorophyl and alfalfa may also be included, as well as calcium chloride, sodium chloride, potassium chloride, bicarbonate of soda, sodium sulfate, sodium talloate, nonionic surfactants, ethyl alcohol, hexylene glycol (1-hexene) ethylene glycol, propylene glycol and isopropyl alcohol.

Owner:UNITED LAB INT LLC +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com