Patents

Literature

196 results about "Diisopropanolamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

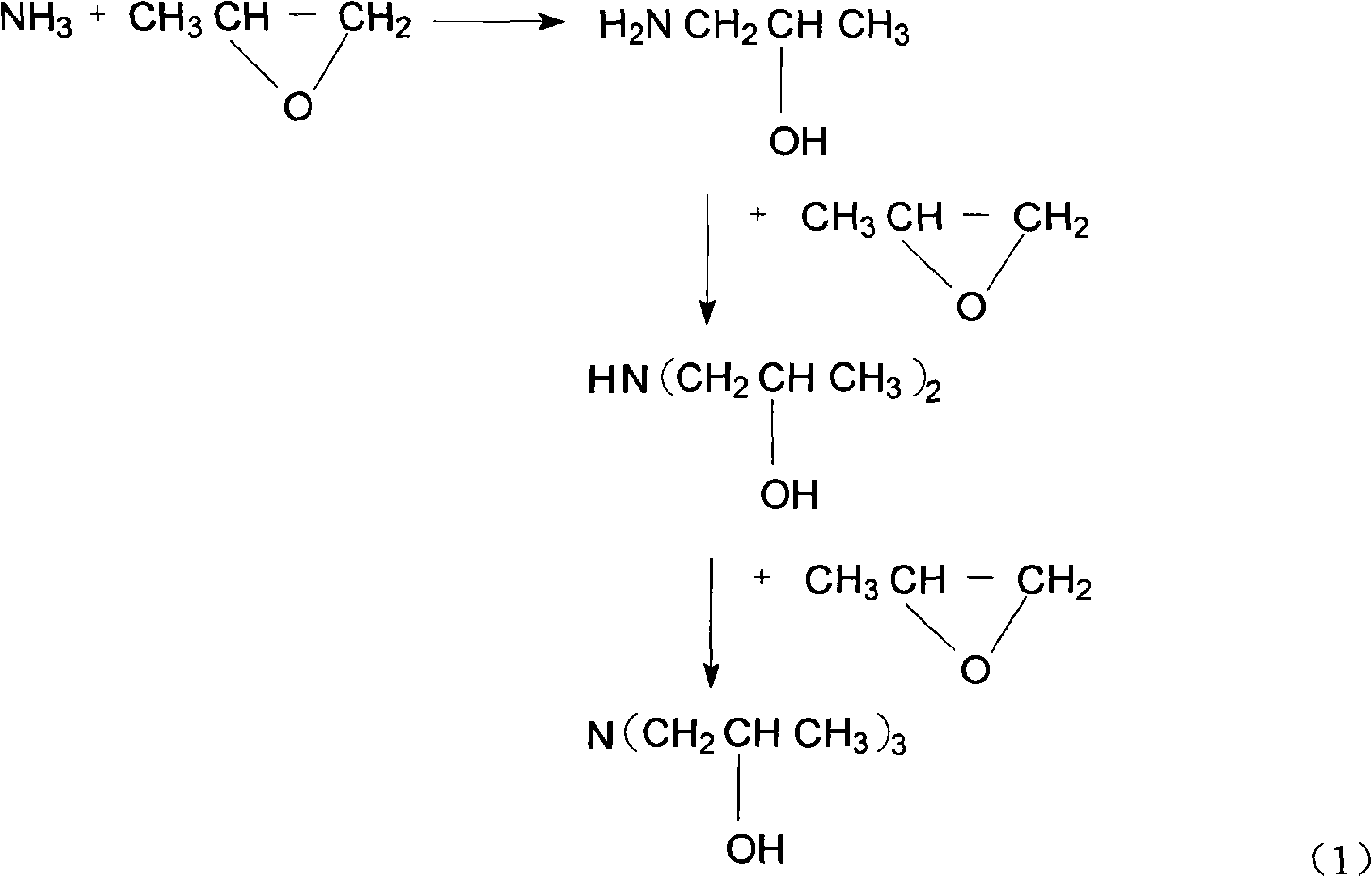

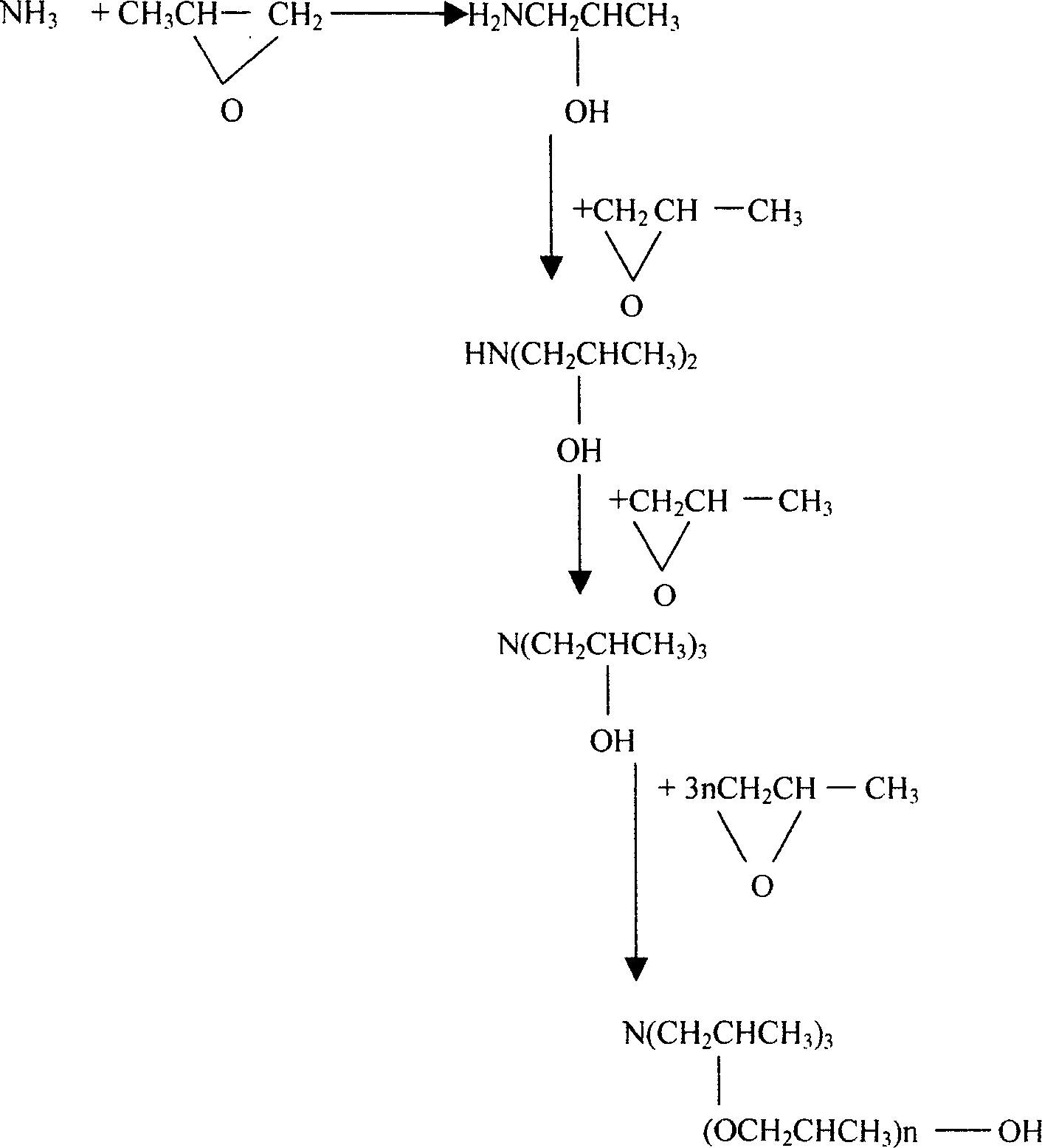

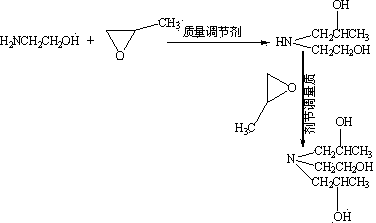

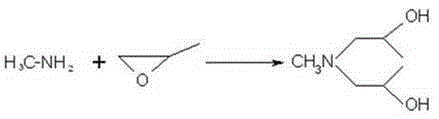

Diisopropanolamine is a chemical compound with the molecular formula used as an emulsifier, stabilizer, and chemical intermediate. Diisopropanolamine can be prepared by the reaction of isopropanolamine or ammonia with propylene oxide.

Sulfur removal agent suitable for production of oil-gas well

InactiveCN102698576ASimple recipeAffect normal productionDispersed particle separationPropanolAlcohol

The invention relates to a sulfur removal agent suitable for the production of an oil-gas well. The sulfur removal agent comprises the following components in percentage by mass: 10 to 25 percent of hexahydro-1,3,5-tris(hydroxyethyl)-s-triazine, 5 to 20 percent of alcohol amine, 5 to 20 percent of small molecular alcohol and the balance of water. The alcohol amine is one or a mixture of more thantwo of monoethanolamine, ethyleneglycol amine, diisopropanolamine, methyldiethanolamine and triethanolamine; and the small molecular alcohol is one or a mixture of more than two of methanol, ethanol and propanol. The sulfur removal agent has a simple formula, can be soluble with water, and can effectively reduce the content of hydrogen sulfide in crude oil or natural gas; simultaneously, productsgenerated by the sulfur removal agent and the hydrogen sulfide are water-soluble, and cannot block a mineshaft and influence the normal production of the oil-gas well; and the sulfur removal agent can achieve effects at the temperature of 30 to 120 DEG C and can be quickly reacted with the hydrogen sulfide.

Owner:SOUTHWEST PETROLEUM UNIV

Hyperbranched curing agent for two-component polyurethane waterproof coating and preparation method thereof

ActiveCN101709039AReduce manufacturing costLow costOrganic compound preparationCarboxylic acid amides preparationSolubilityDissolution

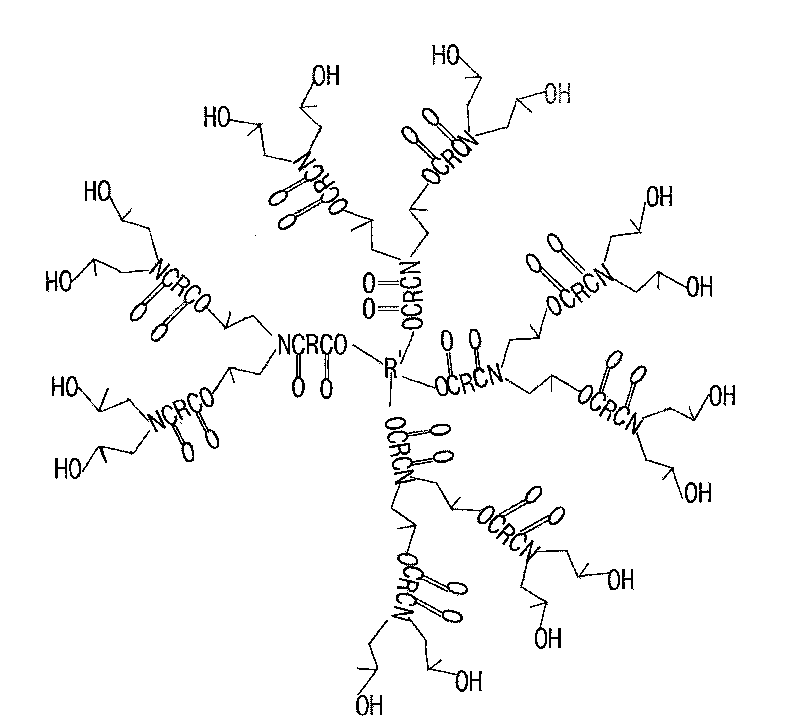

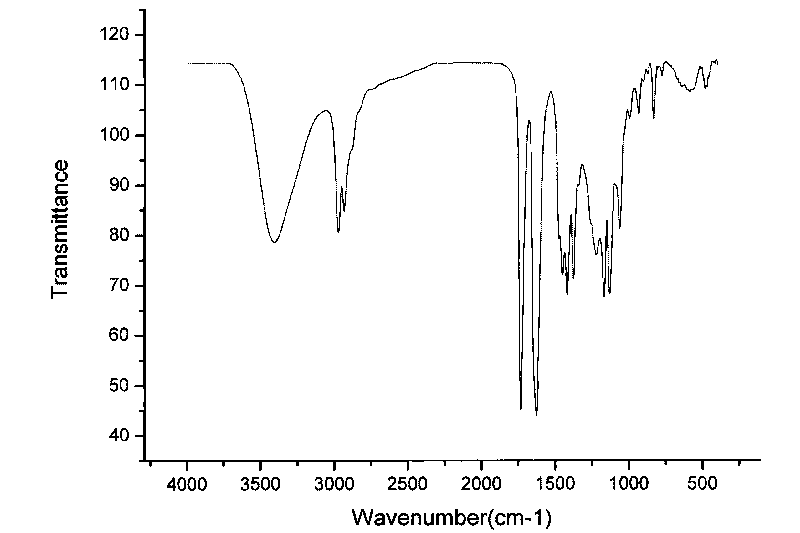

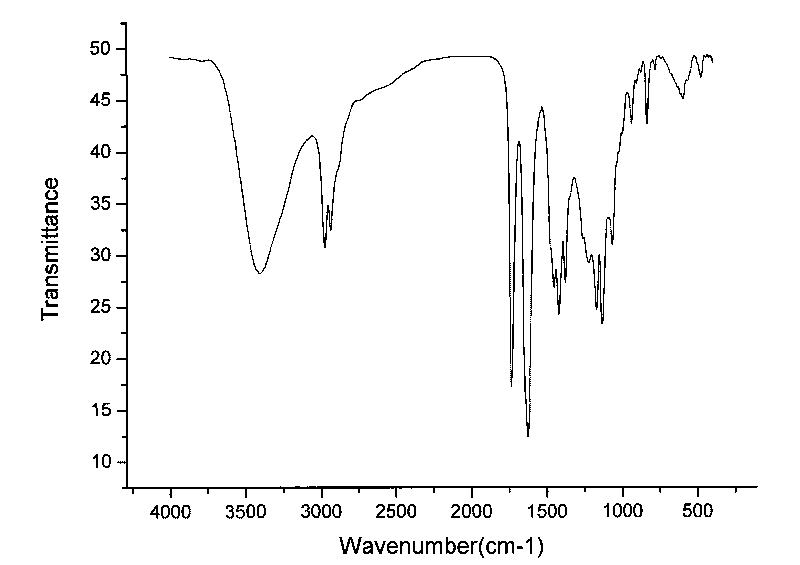

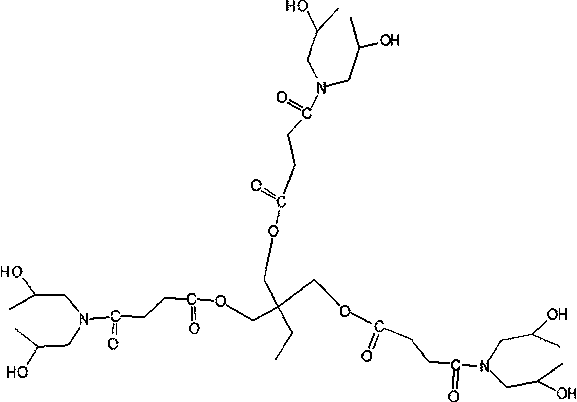

The invention relates to a hyperbranched curing agent for two-component polyurethane waterproof coating and a preparation method thereof. The preparation method comprises the following steps: (1) reacting equimolar anhydride with equimolar diisopropanolamine in the equal molar weight in an aprotic solvent at a temperature of between 0 and 40 DEG C for 1 to 6 hours, and removing the solvent through vacuum distillation to prepare an AB2-type monomer having a carboxyl redical and two hydroxyl redicals; and (2) dissolving the prepared AB2-type monomer into an aromatic solvent, adding nuclear molecules and a catalyst into the solvent for heating reflux, dehydrating reaction water, performing heat preservation to react for 4 to 10 hours, and stopping the reaction to prepare a target product through dissolution, sedimentation and drying. The structure of the hyperbranched curing agent is shown in the figure 1. The hyperbranched curing agent has the advantages of simple preparation process, lower production cost, and suitability for large-scale industrial production. The prepared hyperbranched curing agent has a large number of active end functional groups, has low viscosity, high solubility and less adulterating amount, has excellent intermiscibility with polyurethane prepolymer, can improve the crosslinking density of a polyurethane system greatly and integrally improve the tensile strength and tenacity of the polyurethane waterproof coating and the bond strength of the polyurethane waterproof coating with substrates.

Owner:江苏超力建材科技有限公司

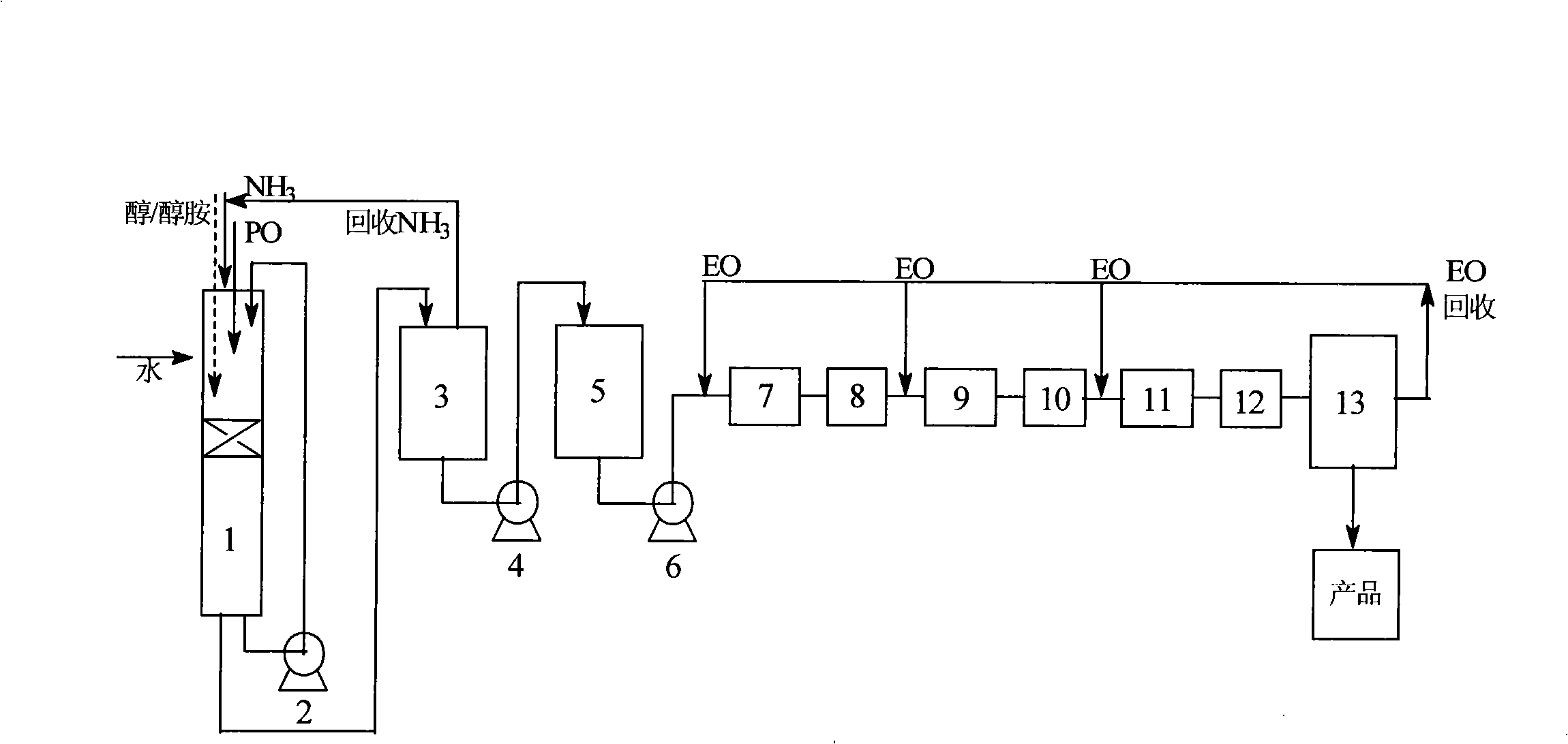

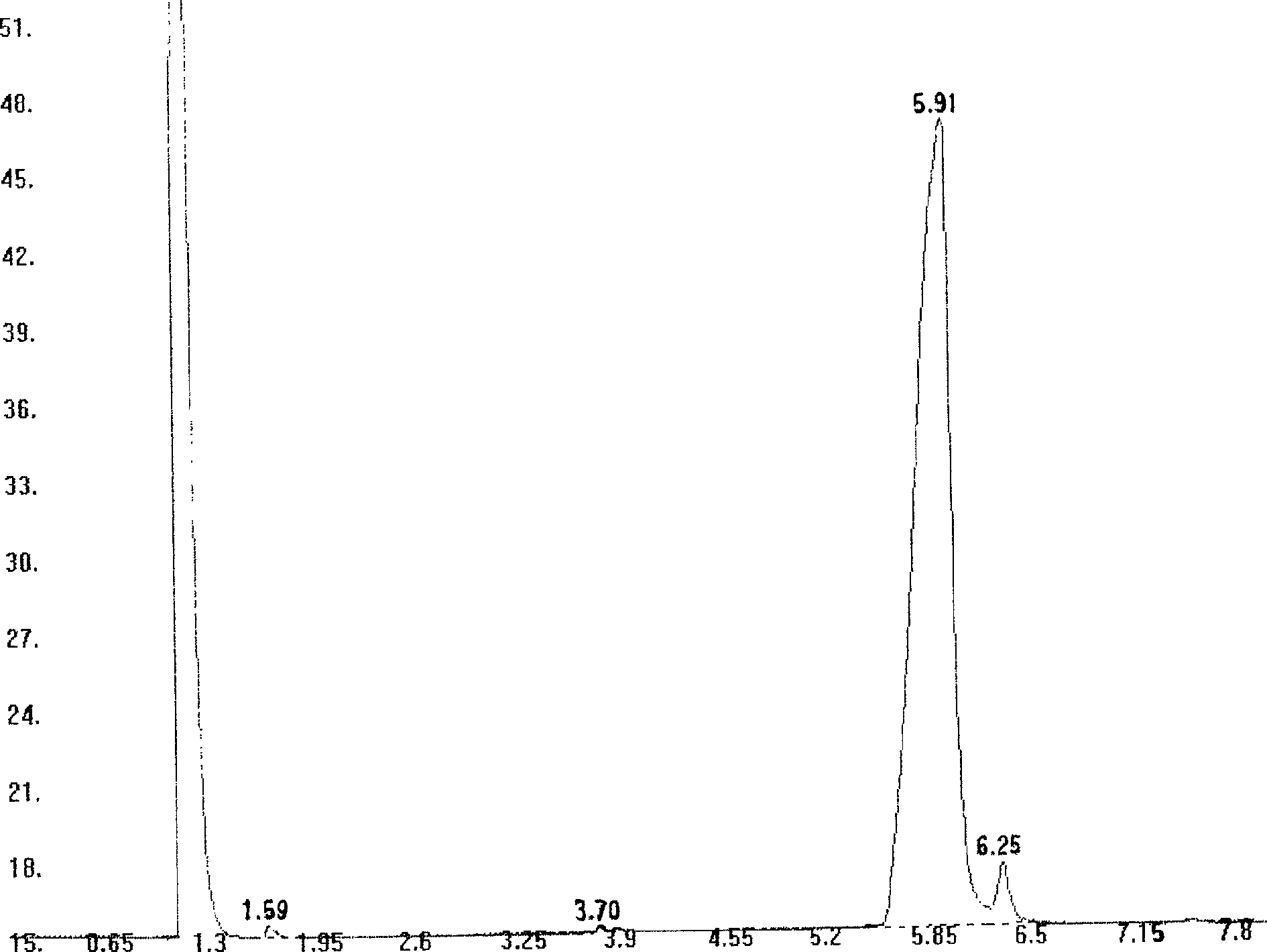

Method for continuously producing high-efficiency concrete grinding aid

InactiveCN101314533AReduce production energy consumptionReduce manufacturing costCement productionContinuous reactorMonoisopropanolamine

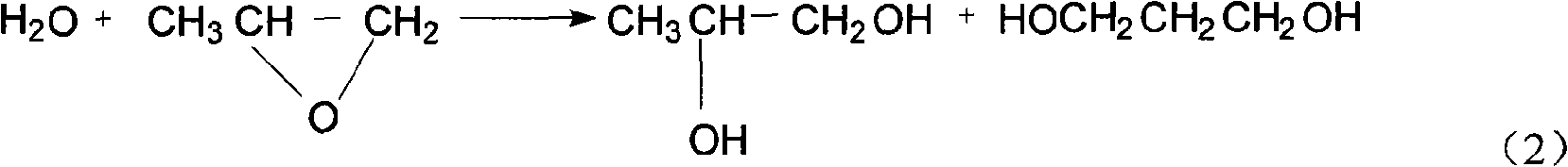

The invention provides a method for realizing simple and direct preparing of high-efficiency cement rubber additive. The method, which has lower cost and takes ammonia, propylene oxide (PO) and ethylene oxide (EO) as raw materials, comprises the following steps that: superfluous ammonia stream and PO stream are fed into a continuous reactor so as to continuously form a mixture containing isopropanolamine, diisopropanolamine and triisopropanolamine; liquid level inside the continuous reactor is maintained to ensure that the stream in the reactor undergoes outer circulation spraying through a circulating pump from the bottom to the top of the continuous reactor, and part of the stream is continuously fed into a flash tower so as to remove unreacted ammonia; then, the stream with ammonia removed is reacted with EO stream so as to continuously generate products. The method ensures that products do not need rectification separation and greatly reduce production energy consumption, thereby reducing the production cost of products.

Owner:HONGBAOLI GRP CO LTD

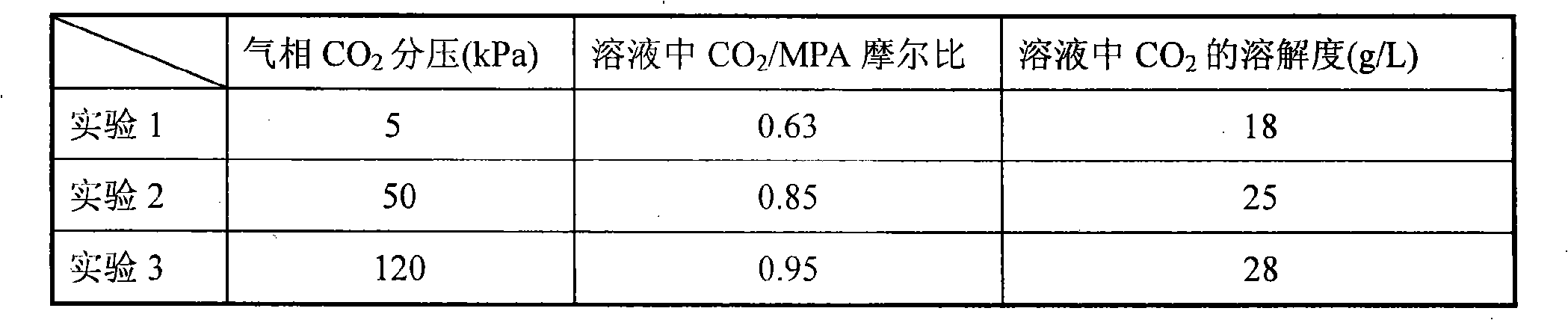

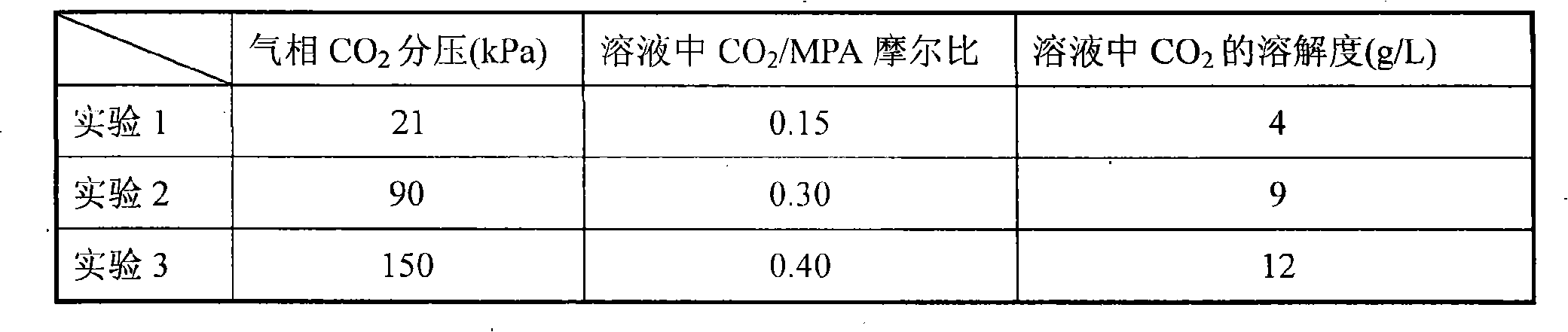

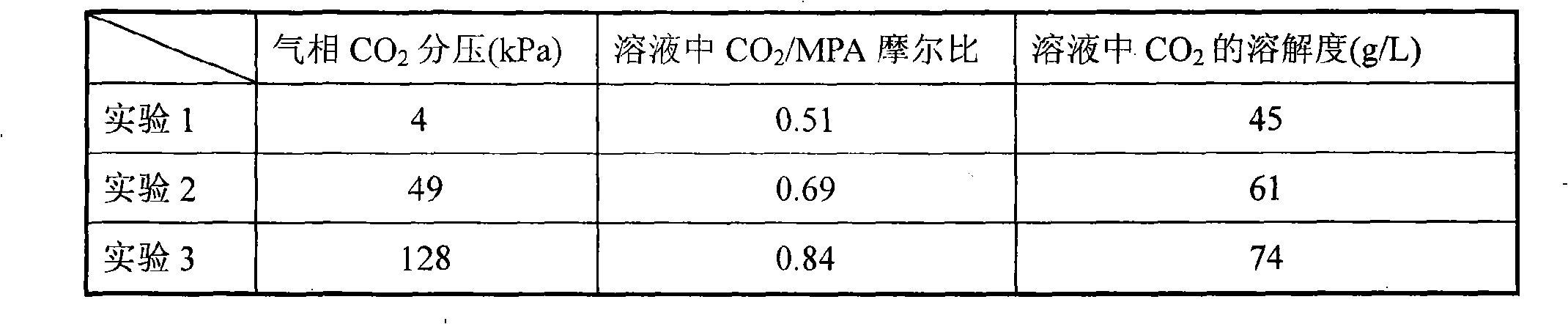

Absorbing solvent for capturing or separating carbon dioxide from gas mixture or liquid gas

The invention pertains to the field of chemical materials and in particular relates to a sorption solvent which catches or separates carbon dioxide from gaseous mixtures or liquefied gases. The solvent comprises n-propanolamine with a content range of 5-60wt% and other components with a total content range of 40-95wt%; other components comprise monoethanol amine, diethanolamine, methyl diethanolamine, diisopropanol amine, 2-amido-2-methyl-1-propyl alcohol, organic amine, water, physical solvent, inorganic salt and one or more accessory ingredients. The number of carbon atoms between the amidocyanogen and the hydroxide radical of the n-propanolamine is three; nitrogen atoms can form a hydrogen bond with the hydrogen atoms on oxygen atoms, or oxygen atoms can form a hydrogen bond with the hydrogen atoms on nitrogen atoms, thus forming a ring structure composed of six atoms; such molecular structure is similar to that of secondary amine, can reduce the formation of amino carbonates and improve the solubility and desorption degree of CO2; meanwhile, the formation of the six-element ring molecular structure increases the stability of molecular and can reduce the degradation loss of solvents in service process.

Owner:TSINGHUA UNIV

Environmentally friendly willow woven product water-based paint

The present invention discloses an environmentally friendly willow woven product water-based paint, and relates to the technical field of willow woven product water-based paints. The willow woven product water-based paint is made from the following materials by mass: 15-20% of methyl methacrylate, 3-5% of acrylic acid, 12- 16% of styrene, 10-15% of butyl acrylate, 0.5-1% of dibenzoyl peroxide, 0.2-0.5% of beta-thionaphthol, 4 -8% of 1-isopropoxy-2-propanol, 5-9% of diisopropanolamine, 0.5-1% of dioctyl phthalate, 3-5% of propylene glycol phenyl ether, 0.2-0.5% of Agitan 315, 0.1-0.2% of 2,4,5,6 -tetrachloro phthalonitrile, 0.8-1.2% of a polyurethane thickener, 1-3% of polyvinyl alcohol, 0.1-0 .3% of naphthenate, 0.5-1.5% of a dispersant, 0.2-0.5% of a leveling agent, 0.5-1% of an adhesion promoter, and 40-45% of water. The environmentally friendly willow woven product water-based paint may be applied to different willow woven product surfaces, and is delicate and fine in paint appearance, anti-mildew, anti-algae, strong in hiding power, and free of environment pollution.

Owner:赛诺(浙江)聚氨酯新材料有限公司

Composite cement grinding aid

The invention discloses a composite cement grinding aid, which is characterized by being prepared from the following components in percentage by weight: 5-15 percent of triethanolamine, 20-30 percent of diisopropanolamine, 15-20 percent of polymeric alkylol amine, 5-10 percent of sodium polyphosphate, 10-20 percent of lignosulfonate, 5-10 percent of syrup and the balance of water. By adopting the composite cement grinding aid, the grinding assisting effect of the conventional grinding aid is kept, the fluidity and dispersity of a material in a grinder can be enhanced remarkably, the bonding property of the material is reduced, the graduation of particles in the grinder is changed, the activity of the material is excited, the grinding efficiency is increased by 3-8 percent, the using amount of cement clinker is reduced by 4-10 percent, the hourly output of a cement grinding table is increased by 8-15 percent, the tensile strength of cement is enhanced by 4.1-5MPa within three days, the tensile strength of cement is enhanced by 6.7-7.9MPa within two days, the adaptability of an additive is enhanced, the cement production cost is reduced effectively, and a good energy-saving effect is achieved.

Owner:惠州市富力新技术有限公司

Method of synthesizing monoisopropanolamine

ActiveCN101265196AMeet high-end needsImprove qualityOrganic compound preparationAmino-hyroxy compound preparationTime rangeDistillation

The invention relates to a synthesis method of isopropanolamine. The synthesis method comprises the following steps: (1) liquid ammonia and water are mixed to form ammonia water which is mixed with propylene oxide; mixed solution is preheated until the temperature reaches 120 to 125 DEG C, and the inputting molar ratio of the ammonia and the propylene oxide is controlled within 10 to 15; (2) the materiel after preheating is delivered into a reactor, the reaction temperature ranges from 128 to 138 DEG C, the pressure ranges from 12.6 to 13.8MPa, and the reaction time ranges from 1.5 to 3 hours; (3) the surplus unreacted ammonia is separated from the obtained mixture after the reaction by using a flash distillation column, the pressure in the flash distillation column ranges from 0.6 to 1.6MPa, and the temperature of a column kettle ranges from 140 to 160 DEG C; (4) the mixture which is separated through the flash distillation column is delivered into a leading tower for rectification dehydration, the pressure in the leading tower ranges from minus 0.080 to minus 0.085MPa, the temperature at the top of the leading tower is 45 to 55 DEG C, and the temperature at the bottom in a tower kettle ranges from 110 to 130 DEG C; (5) the mixture after dehydration is delivered into a rectification column for rectification, the pressure in the rectification column ranges from minus 0.095 to minus 0.099MPa, the temperature in the column kettle ranges from 135 to 160 DEG C, the temperature at the top of the rectification column ranges from 60 to 70 DEG C, isopropanolamine products are obtained at the top of the rectification column, and the mixture composed of diisopropanolamine and triisopropanolamine is obtained in the column kettle. The synthesis method has simple production procedure, little equipment investment, and high product quality.

Owner:NANJING BAOCHUN CHEMICAL INDUSTRY CO LTD

Sweetening agent combination

ActiveCN101993751ANo emissionsRelieve pressureGaseous fuelsRefining with aqueous alkaline solutionsPhosphoniumSlag

The invention relates to a sweetening agent combination which comprises 0.1-50wt% of a first component, 0.1-98 wt% of a second component and balance of water, wherein the first component is one or a mixture of quaternary ammonium base and quaternary phosphonium base, and the second component is one or a mixture of monoethanol amine, diethanol amine, methyl diethanol amine, diglycol amine, diisopropanolamine, ethylene diamine, propane diamine, butanediamine, N-formylmorpholine, N-methylpyrrolidone, methanol, ethanol and glycol. The sweetening agent does not contain a sodium hydroxide solution, does not release base slag, and can be regenerated by steam stripping without oxidation. The sweetening agent combination can be used for producing non-corrosive ultra low-sulfur liquefied petroleum gas and light petrol (the boiling point is lower than 80 DEG C), and the total sulfur content of the liquefied petroleum gas and the light petrol can be decreased to 5 mu g.g<-1> or below.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

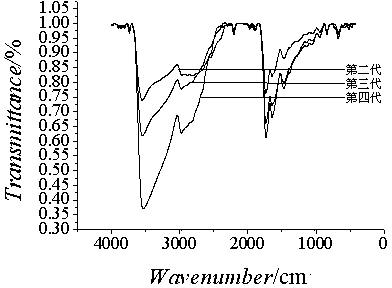

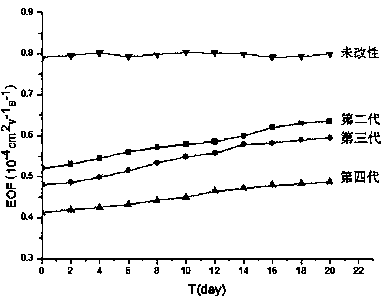

Hydroxyl-terminated hyperbranched polyurethane-ester polymer as well as modified micro-fluidic chip and application thereof

InactiveCN103755939AImprove hydrophilicityReduce dosageOrganic compound preparationLaboratory glasswaresPolymer modifiedPesticide residue

The invention relates to the technical field of pesticide residue detection, and in particular relates to a hydroxyl-terminated hyperbranched polyurethane-ester polymer. The hydroxyl-terminated hyperbranched polyurethane-ester polymer is prepared by the following steps: implementing reaction between diisopropanol amine and methyl acrylate which are equal in molar mass to obtain an AB2 monomer; and carrying out reaction among AB2 monomer, p-toluenesulfonic acid and triethanolamine to obtain the hydroxyl-terminated hyperbranched polyurethane-ester polymer. The invention further relates to a hyperbranched polymer modified polydimethyl siloxane (PDMS) micro-fluidic chip and application of the hyperbranched polymer in the technical field of pesticide residue detection. The prepared PDMS micro-fluidic chip disclosed by the invention has permanent hydrophilcity, and is capable of effectively improving stability of a polymer coating, free from use of expensive instrument and reasonable in price; and the coated capillary has the characteristics of small size, simple operation, low sample dosage, high separation efficiency and high analysis speed, and is capable of separating and detecting organic pesticide residue very well.

Owner:UNIV OF JINAN

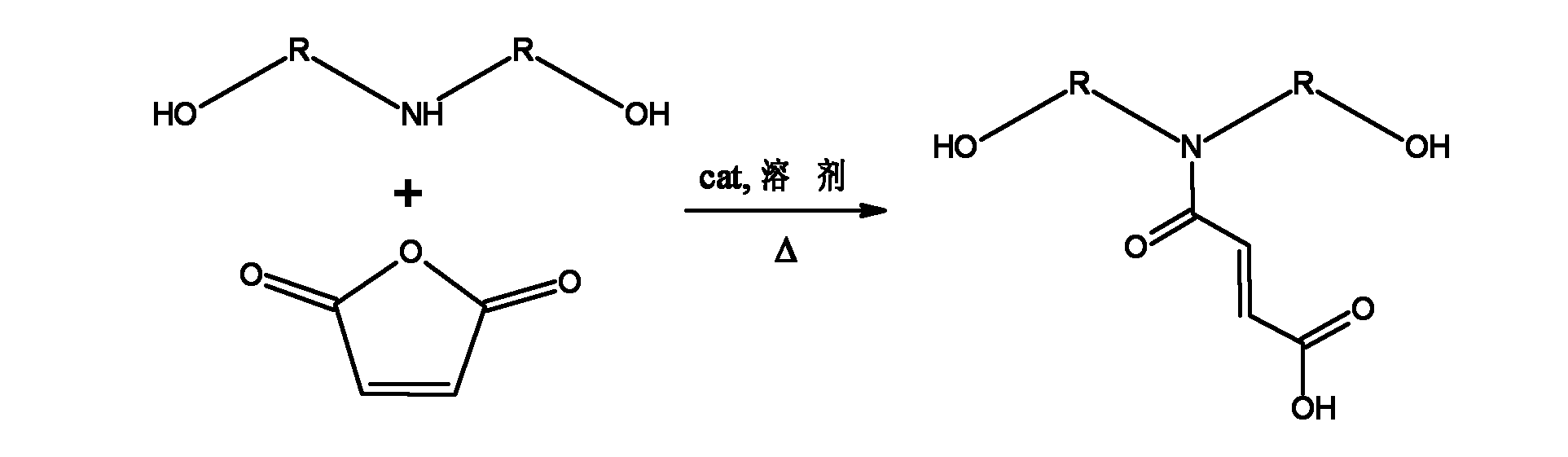

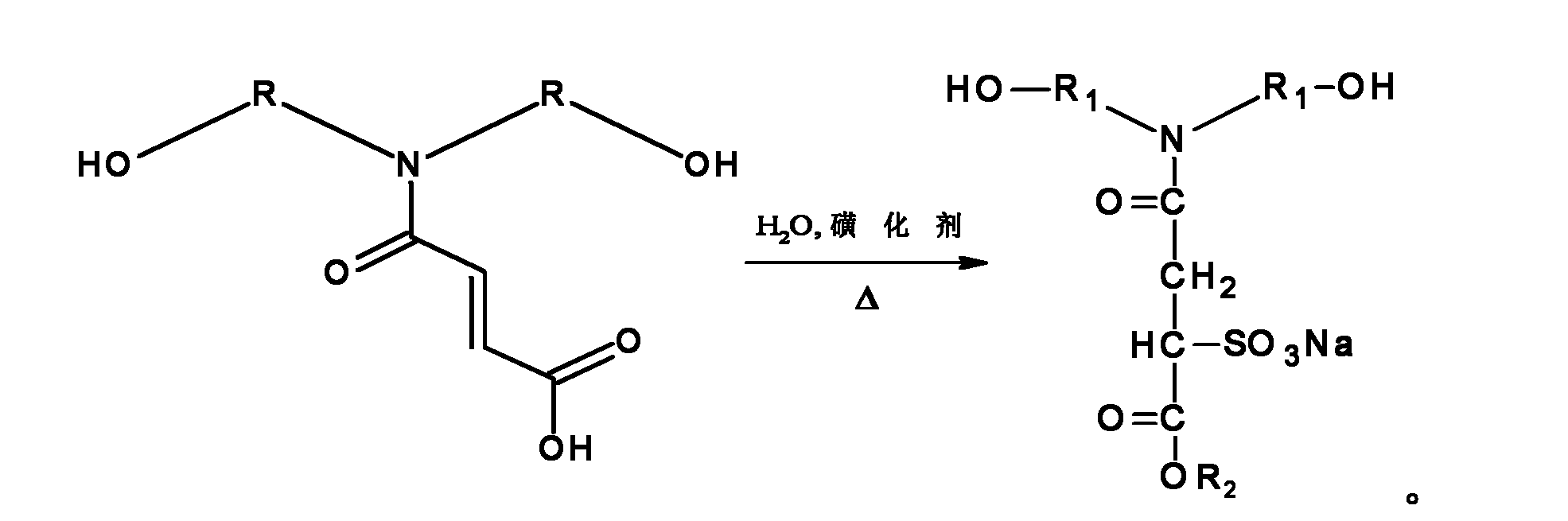

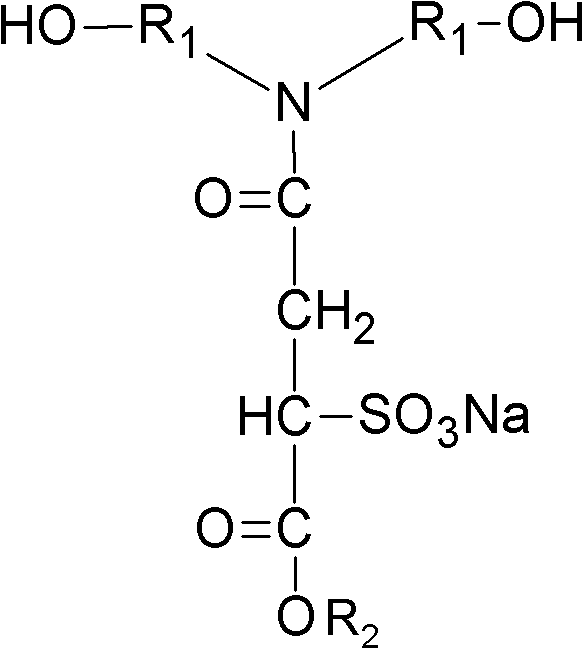

Sulfoacid/carboxylic acid type hydrophilic chain extender and preparation method thereof

InactiveCN102604023AInnovativeHave technical advantagesSulfonic acids salts preparationDistillationReaction intermediate

The invention discloses a sulfoacid / carboxylic acid type hydrophilic chain extender and a preparation method of the sulfoacid / carboxylic acid type hydrophilic chain extender. The preparation method comprises the following steps: dissolving maleic anhydride, diethanol amine or diisopropanolamine in a solvent, respectively; adding maleic anhydride solution into a reactor and slowly adding diethanol amine or diisopropanolamine solution to perform amidation reaction after the rise of the temperature; removing the solvent by means of reduced-pressure distillation after the mixture is fully reacted to obtain white powder; recrystallizing the white powder by using ethanol; filtering and drying a crystalline substance to obtain white powder which is an amidated reaction intermediate of the sulfoacid / carboxylic acid type hydrophilic chain extender; dissolving the white powder intermediate obtained by the amidation reaction and a sulfonating agent, adding the mixture into the reactor for fully stirring; performing sulfonation reaction at a risen temperature, reducing the temperature until the mixture is reacted fully; filtering and drying the solution to obtain white powder, i.e. the sulfoacid / carboxylic acid type hydrophilic chain extender.A molecular chain of the hydrophilic chain extender prepared by the method contains a sulfonic acid group and a carboxylic acid group.

Owner:SHAANXI UNIV OF SCI & TECH

Method for preparing high-activity aluminum oxide powder using aluminum ash

InactiveCN105731508ASolve pollutionAchieve sustainable useAluminium oxides/hydroxidesSlagPotassium hydroxide

The invention discloses a method for preparing high-activity aluminum oxide powder using aluminum ash, and belongs to the preparation field of aluminum oxide powder. The method comprises the following steps: by using aluminum ash as a raw material, floating in water to remove slag, adding sulfuric acid solution and diisopropanolamine to remove insoluble matters in the aluminum ash, and then removing other metal impurities soluble in potassium hydroxide under the effect of carbon disulfide assisted by titanium dioxide, adding polyethylene glycol and ammonia water, stirring, filtering to obtain jelly, washing, drying, calcinating, and crushing to obtain the high-activity aluminum oxide powder. The method disclosed by the invention has the beneficial effects that aluminum ash is sufficiently utilized to prepare the high activity aluminum oxide powder, not only the environment pollution problem is solved, but also the sustainable utilization of the resource is realized; the prepared aluminum oxide powder is small in grain, uniform in grain size distribution and hard to unite, and the activity is more than or equal to 18% higher than that of the aluminum oxide powder prepared by other methods.

Owner:CHANGZHOU DAAO NEW MATERIAL TECH CO LTD

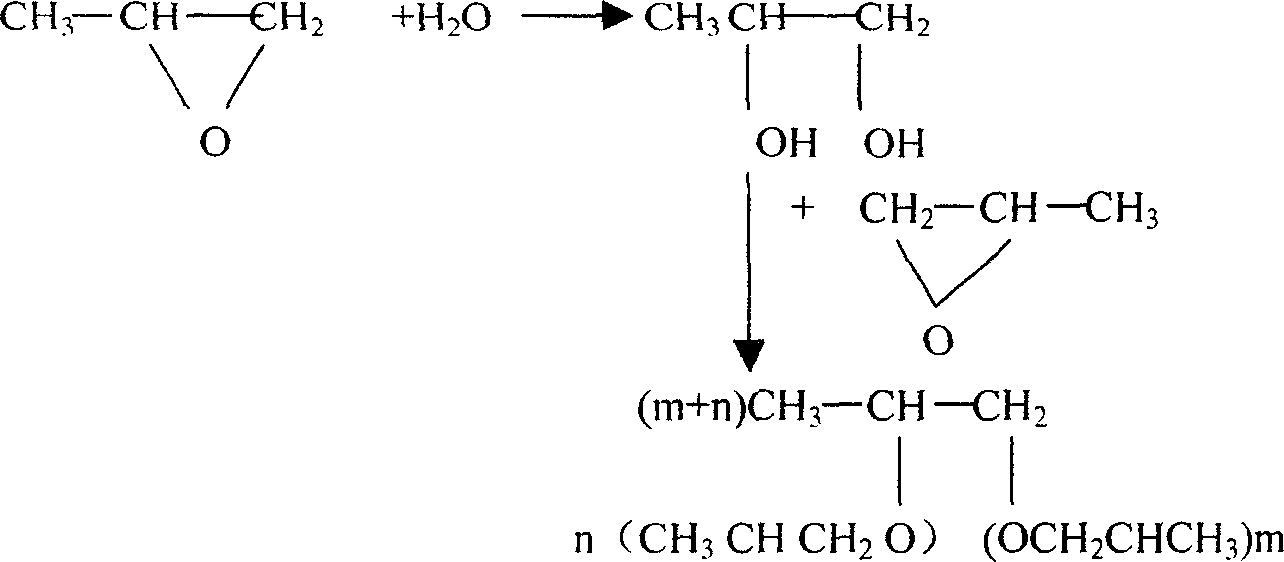

Process for synthesis of triisopropanolamine

ActiveCN1629134AIncrease moisture contentHigh purityOrganic compound preparationAmino-hyroxy compound preparationReaction temperatureMonoisopropanolamine

The invention provides a process for synthesis of triisopropanolamine by using liquid ammonia and trimethylene oxide as raw material, water as catalyst, stock preparing by the mol ratio of liquid ammonia : trimethylene oxide = 1 : 3.00 - 3.05, charging deionized water in one time, charging liquid ammonia and trimethylene oxide in two times, fully stirring, sustaining the pressure <0.5 MPa, sustaining reaction temperature between 20-75 deg. C for 1.0-3.0 hours, decompressing for dehydration till the water content is less than 5%.

Owner:HONGBAOLI GRP CO LTD

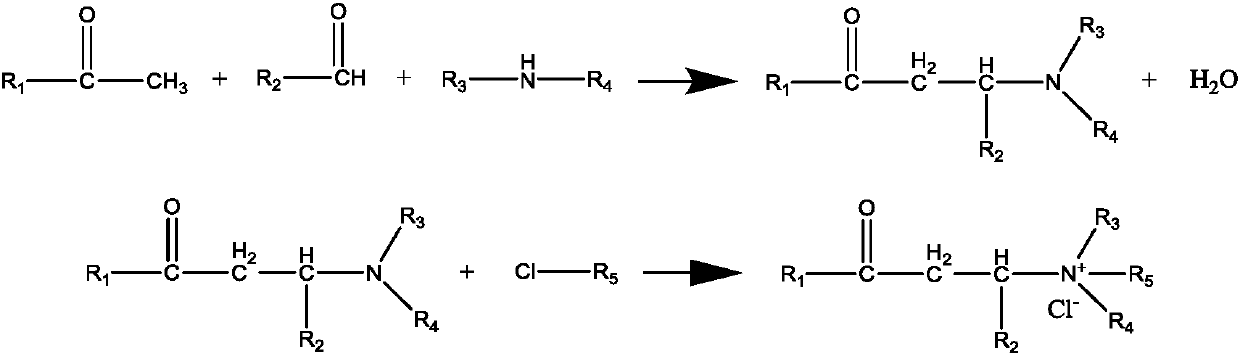

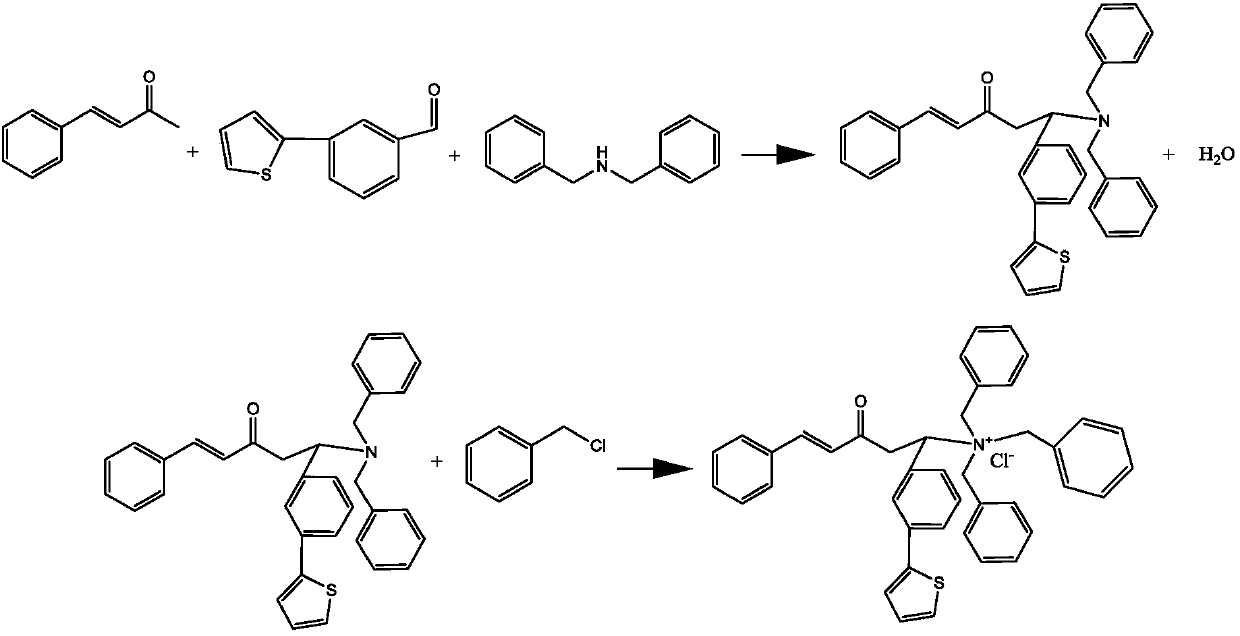

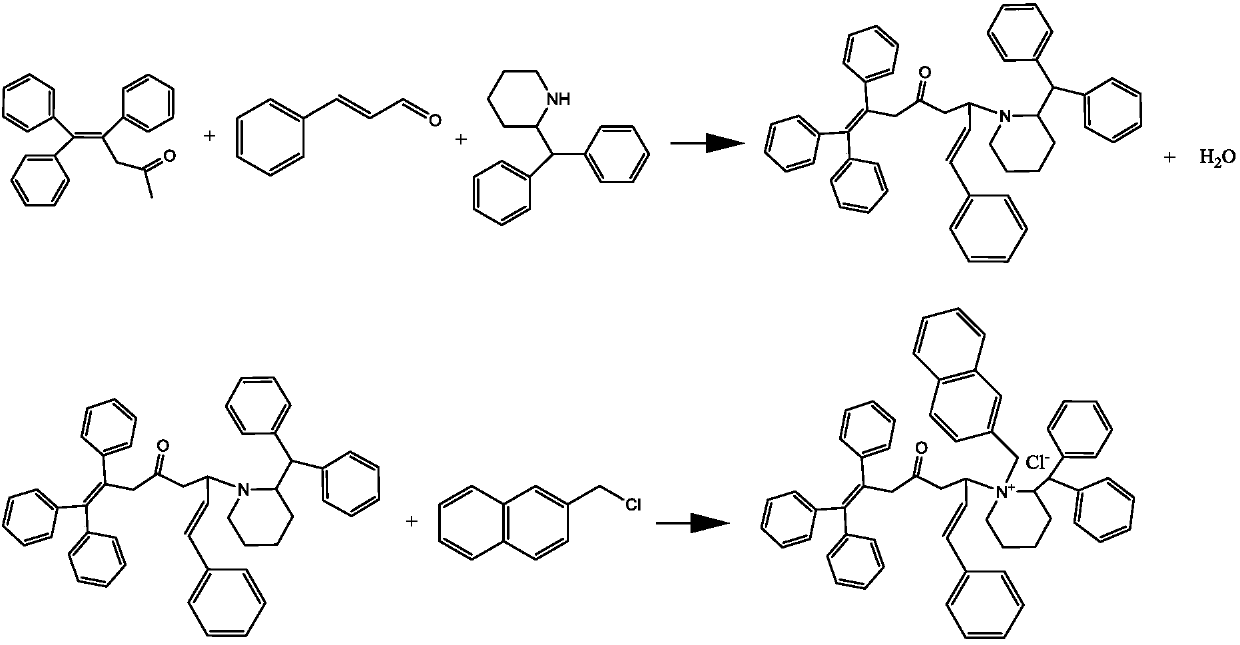

Preparation method and application of Mannich base quaternary ammonium salt high-temperature resistant acidification corrosion inhibitor

ActiveCN109810040AImprove adsorption capacityGood dispersionOrganic chemistryDrilling compositionWater bathsBenzaldehyde

Owner:SOUTHWEST PETROLEUM UNIV

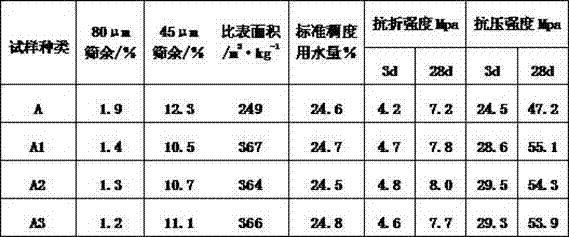

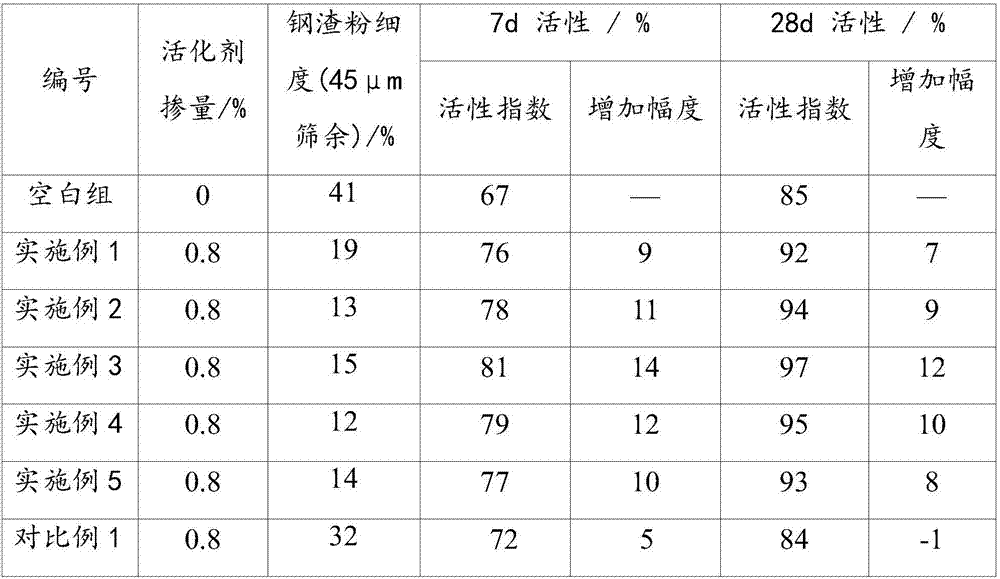

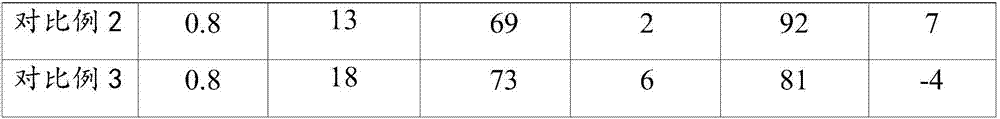

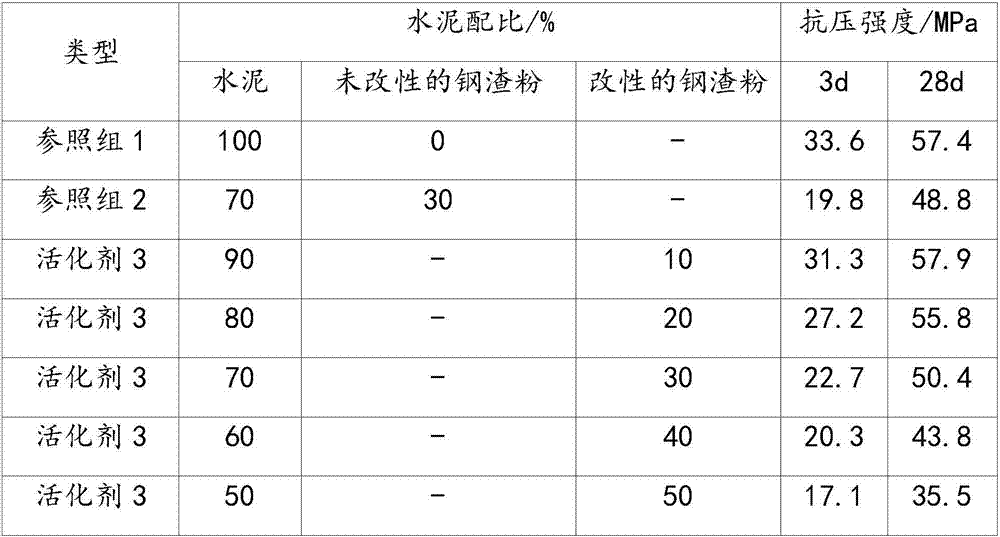

Activating agent for heat-stewing steel slag powder of converter as well as preparation method and application thereof

ActiveCN107244819AImprove early activityPromotes hydration and dissolutionEnvironmental resistanceSlag

The invention discloses an activating agent for a heat-stewing steel slag powder of a converter as well as a preparation method and application thereof, and belongs to the field of chemical additives in technical fields of resource utilization of industrial waste slag building materials. The activating agent is prepared from the following raw materials in parts by weight: 20 to 60 parts of alkaline residues, 15 to 40 parts of sulphoaluminate cement, 10 to 40 parts of water-quenched slag micropowder of blast furnace, 2 to 10 parts of calcium formate, 0.5 to 1 part of ammonium alcohol polyvinyl phosphate, 0.5 to 3 parts of diethanolisopropanolamine, and 0.01 to 0.05 part of defoaming agent. Compared with the alkaline excitation or common early strength agent or grinding additive, the activating agent has the advantages that the early and later activities of the heat-stewing steel slag of the converter are obviously improved, and the comprehensive effect breaks through the existing level; a large amount of chemical byproducts of alkaline slag is utilized, the activating effect is obvious, the cost is reduced, the green and environment-friendly effects are realized, and the purpose of treating wastes by wastes is certainly realized.

Owner:TSINGHUA UNIV +1

Additives capable of increasing slag activity

The invention relates to additives capable of increasing slag activity and belongs to the technical field of additives. The additives are characterized by mainly comprising ethylenediamine tetraacetic acid disodium calcium, diethanol isopropanolamine, monoethanol diisopropanolamine and water. The additives have the advantages that the additives have a good complexing effect in an alkaline environment and can promote the dissolving of compact mineral components on the surface layer of slag, the dissolving speed of the mineral components of the slag is increased continuously under the continuous complexing effect of polyhydric alcohol amine, the hydration speed of the slag can be increased, and the activity of slag of various ages can be increased; the adding amount of the additives is 0.005-0.012% of the weight of the slag, and 7-day activity and 28-day activity can be increased by 11-15%.

Owner:BEIJING UNIV OF TECH

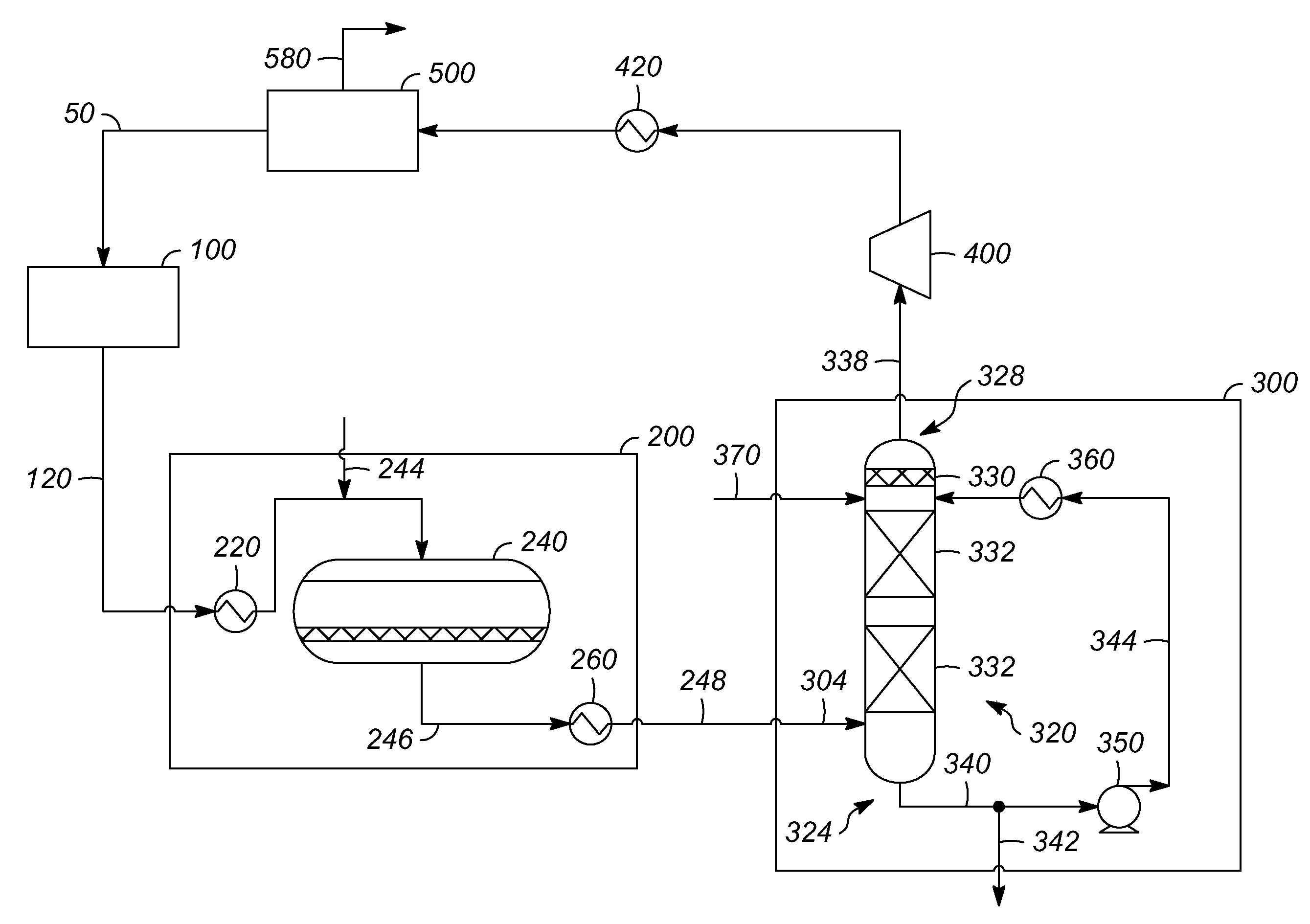

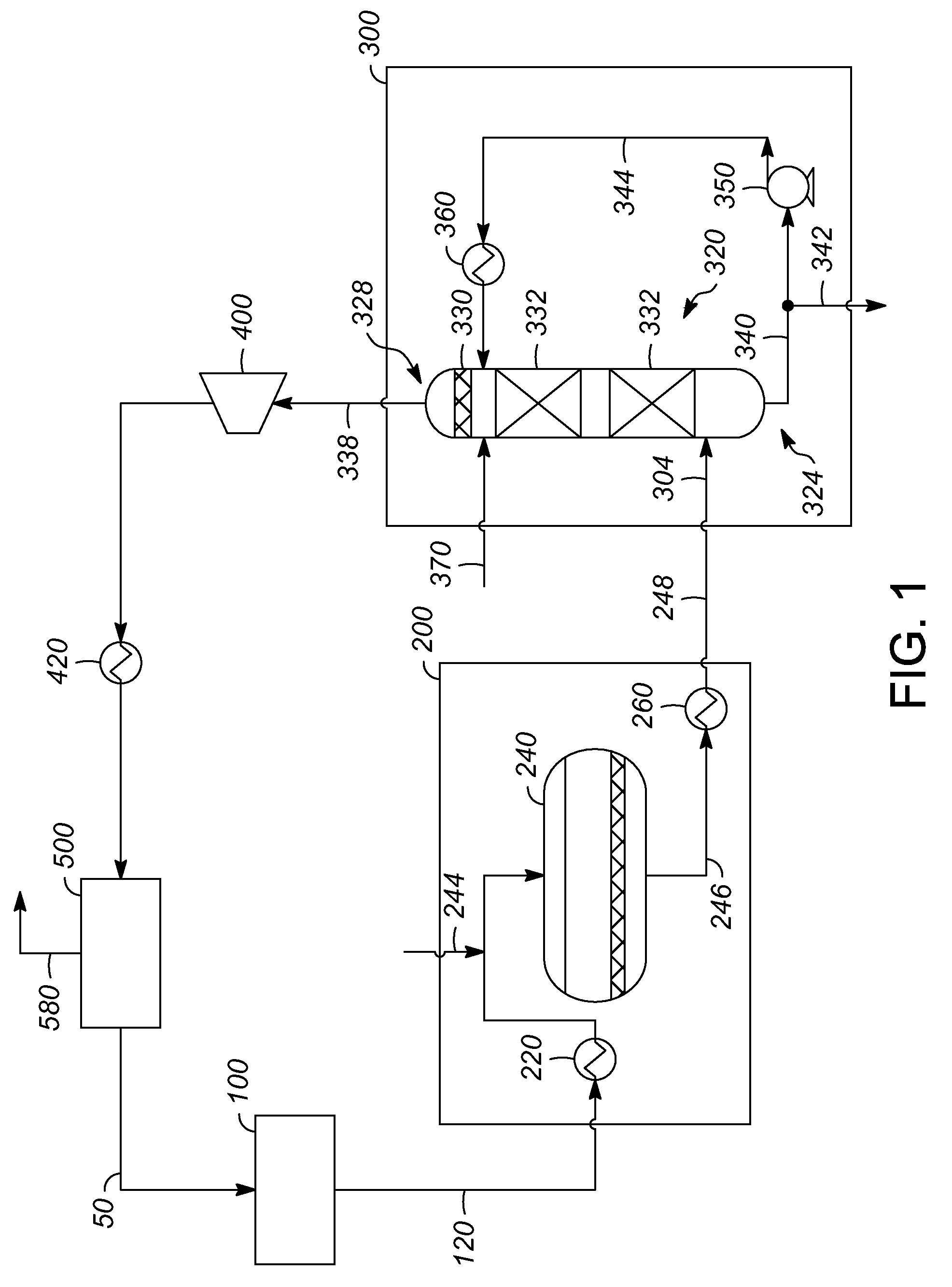

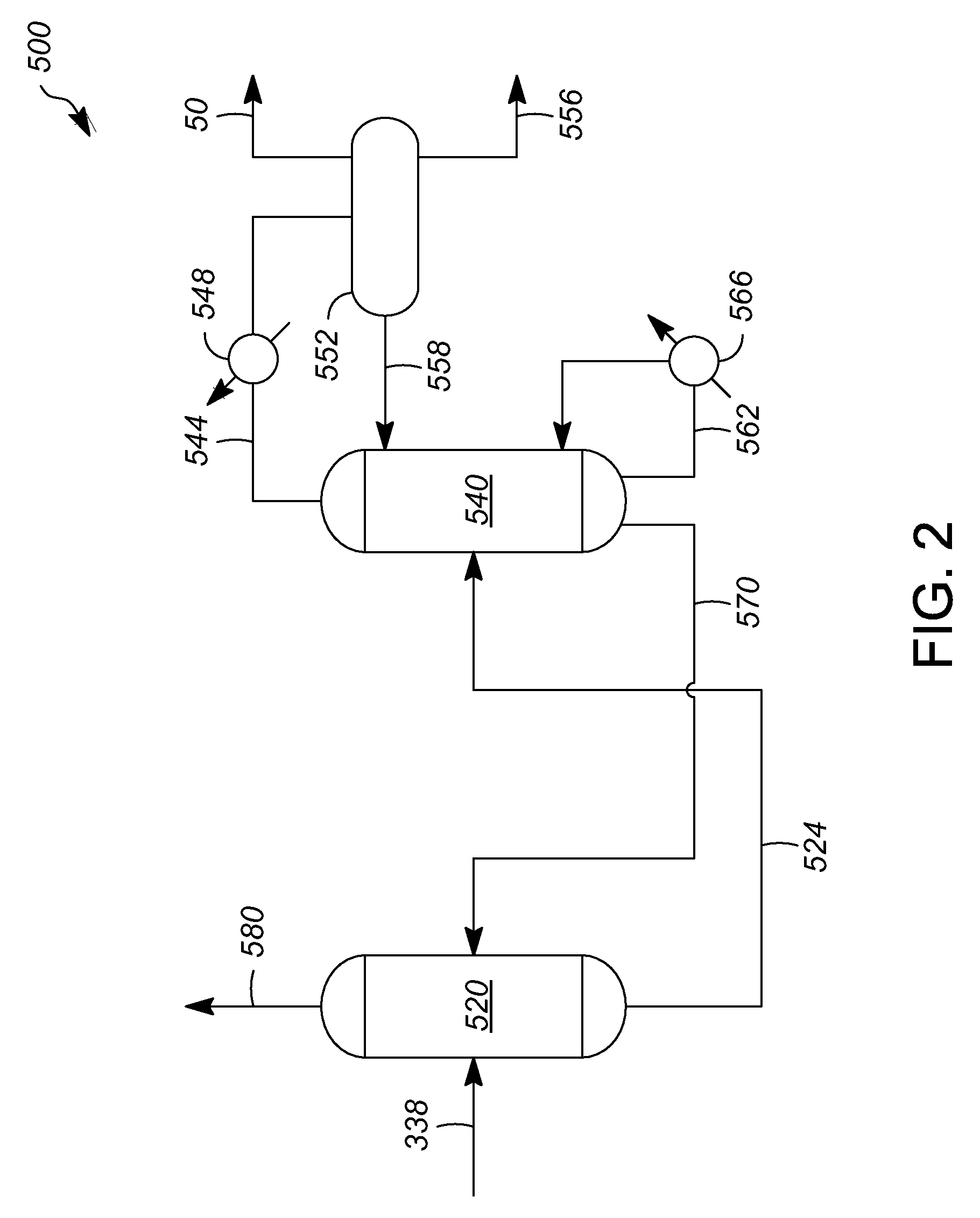

Process for treating a gas stream or effluent

InactiveUS20100303700A1Increase flexibilityProper disposalProductsGas treatmentMorpholinePolyethylene glycol

One exemplary embodiment can be a process for treating a tail gas stream from a sulfur recovery zone. Generally, the process includes passing the tail gas stream through, in sequence, a hydrogenation zone, a quench zone, and an acid gas removal zone using a solvent. The solvent can include at least one of a dimethyl ether of polyethylene glycol, a N-methyl pyrrolidone, a N-formyl morpholine, a N-acetyl morpholine, a tetrahydro-1,4-oxazine, and a mixture comprising diisopropanolamine and tetrahydrothiophene-1,1-dioxide.

Owner:UOP LLC

Novel preparation method for mono ethanol diisopropanolamine

ActiveCN103435499AReduce manufacturing costEasy ring opening polymerizationOrganic compound preparationAmino-hyroxy compound preparationEpoxyQuinone

Owner:UNIV OF JINAN

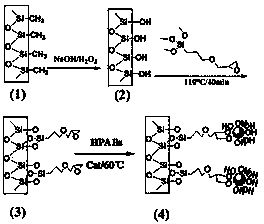

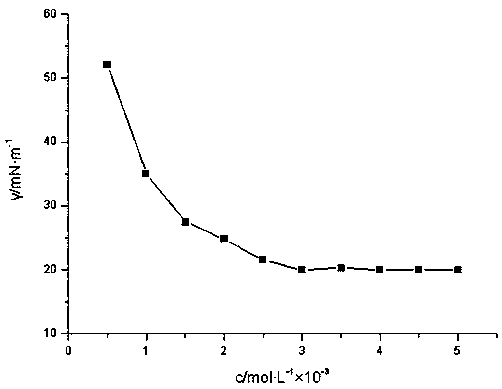

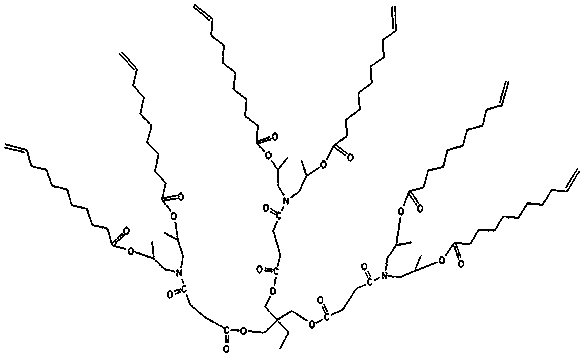

Synthesis and application of hyperbranched surfactant

InactiveCN108384021AOrganic compound preparationTransportation and packagingPolymer modifiedEmulsion

The invention relates to the technical field of research on the emulsifying property of coal pitch, particularly relates to a hyperbranched surfactant and also relates to a preparation method of the hyperbranched surfactant. The preparation method comprises the following steps: synthesizing a hydroxyl-terminated hyperbranched polymer, wherein the hydroxyl-terminated hyperbranched polymer is synthesized by the steps of performing reaction on succinic anhydride and diisopropanolamine which serve as raw materials to generate an AB2 monomer, and performing reaction on the AB2 monomer and trimethylolpropane according to a certain molar ratio to generate the hydroxyl-terminated hyperbranched polymer; and modifying the hydroxyl-terminated hyperbranched polymer, introducing sulfonic group at the tail end of the hydroxyl-terminated hyperbranched polymer to synthesize the hyperbranched surfactant. Compared with the traditional emulsifier, the hyperbranched surfactant has a large amount of activegroups and has high surface activity, high compatibility and excellent emulsifying property. When the hyperbranched surfactant is applied to research on the emulsifying property of the coal pitch, the coal pitch can be emulsified effectively and the obtained coal pitch emulsion has high stability.

Owner:UNIV OF JINAN

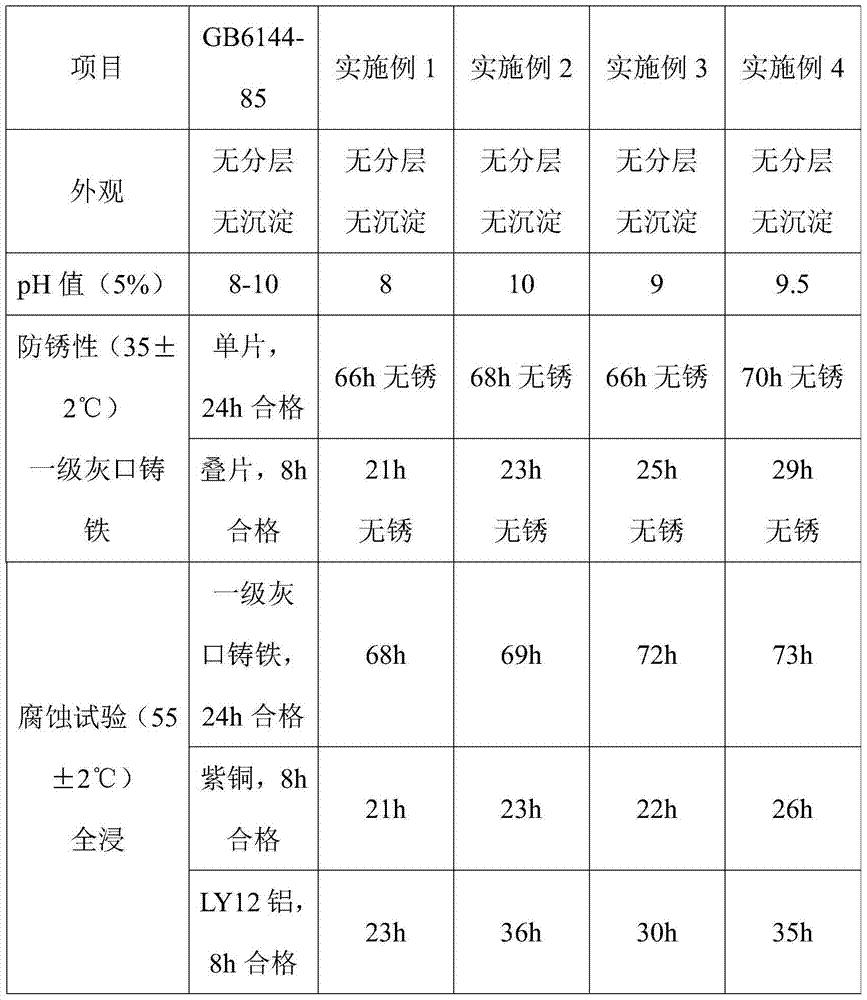

Microemulsion cutting fluid and preparation method thereof

The invention relates to a microemulsion cutting fluid and a preparation method thereof. The microemulsion cutting fluid is characterized by being prepared from the following raw materials in parts by weight: 3-4 parts of phenethyl naphthol polyoxyethylene ether, 1-2 parts of laurinol polyoxyethylene ether, 2-3 parts of chitosan, 1-2 parts of ricinoleic acid, 2-3 parts of sodium lauryl polyoxyethylene ether sulphate, 4-5 parts of chlorinated paraffin, 1-2 parts of diisopropanolamine, 5-6 parts of membrane auxiliary and 200 parts of water. The microemulsion cutting fluid is a semitransparent and transparent liquid, is easy in field operation and does not contain substances harmful to the environment and human health, such as nitrite; and the microemulsion cutting fluid has excellent processability and strong universality.

Owner:东莞市德士美润滑油科技有限公司

N-methyl diisopropanolamine preparation method

ActiveCN105237412ALess side effectsHigh purityOrganic compound preparationAmino-hyroxy compound preparationDepolymerizationPtru catalyst

The invention relates to a N-methyl diisopropanolamine preparation method, which comprises: (1) adding diisopropanolamine and paraformaldehyde to a reactor, heating, vacuumizing, and carrying out a stirring reaction to obtain an intermediate product; (2) cooling the intermediate product to a room temperature, and adding a solvent to dilute so as to obtain a diluted product; and (3) adding the diluted product to the reaction kettle, adding a catalyst and a tertiary amine inhibitor, replacing the air in the reaction kettle with hydrogen, heating, carrying out a stirring reaction, and filtering to obtain the N-methyl diisopropanolamine product. According to the present invention, diisopropanolamine and paraformaldehyde are adopted as raw materials, and diisopropanolamine is adopted as the paraformaldehyde depolymerization agent to reduce the side reaction at the intermediate product synthesis stage so as to produce the high purity intermediate product; and the tertiary amines inhibitor is added at the hydrogenation reduction reaction stage, such that the possible amine removing reaction during the reaction process is avoided, and the yield of the synthesis reaction is improved.

Owner:NANJING BAOCHUN CHEMICAL INDUSTRY CO LTD

Environmental-protection lubricating water-based cutting fluid

InactiveCN104327933AGood emulsification and dispersionGood dispersionLubricant compositionSolubilityWater based

The present invention discloses an environmental-protection lubricating water-based cutting fluid, which comprises the following raw materials by weight: 8-20 parts of sodium abietate, 15-25 parts of a rosin amine glucose ester surfactant, 5-10 parts of rosin amine polyoxyethylene ether, 12-18 parts of a polyaniline aqueous anti-corrosion agent, 5-15 parts of triethanolamine oleate, 3-8 parts of triethanolamine, 3-10 parts of diisopropanolamine, 10-15 parts of sodium carbonate, 5-15 parts of hydrophilic alcohol, 3-6 parts of a sterilization agent, 2-5 parts of a foaming agent, 3-10 parts of a stabilizer, and 80-100 parts of water. The environmental-protection lubricating water-based cutting fluid has functions of excellent cleaning, excellent lubrication, excellent corrosion resistance and excellent cooling, and further has characteristics of environmental protection, long service life, good water solubility, low cost, and high stability.

Owner:CHAOHU GUANGFENG METAL PROD

Method for synthesizing cis-2,6-dimethyl piperazine

The synthesis of cis-2,6-dimethyl piperazine is the reaction between diisopropanol amine (DIPA) and ammonia in the presence of catalyst inside the solvent water and / or ammonia water in a reactor. The weight ratio between ammonia and DIPA is 13-30 to 100, and that between the catalyst and DIPA is 1-40 to 100. The reaction conditions include: reaction temperature 100-250 deg.c, reaction pressure 2.0-8.0 MPa and constant temperatur time 1-5 hr. The product is separated through distillation and crystallization and the solvent for crystallization is aromatic compounded benzene, methyl benzene or xylene.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

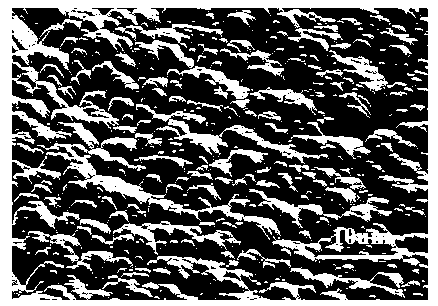

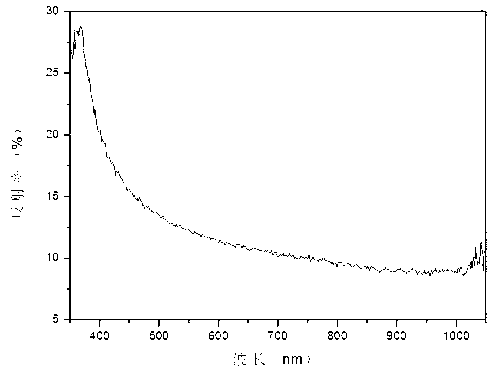

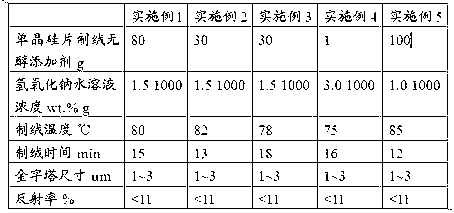

Mono-crystalline silicon piece texturing alcohol-free additives and using method thereof

ActiveCN102839427ASimple preparation processSimple to useAfter-treatment detailsAlcohol freeLiquid waste

The invention discloses mono-crystalline silicon piece texturing alcohol-free additives and a using method of the mono-crystalline silicon piece texturing alcohol-free additives. The mono-crystalline silicon piece texturing alcohol-free additives are composed of at least one of tri-isopropanol amine and di-isopropanol amine, sodium benzoate and water, the mass ratio of the three components is 10-40: 5-10: 100. According to the using method of the alcohol-free additives, the three components are added into sodium hydroxide aqueous solutions with the weight percentage of 1-3% according to the mass ration of 10-40: 5-10:100 to obtain alcohol-free texturing liquid, the mass ratio between the total weight of the three components and the sodium hydroxide aqueous solutions is 0.1-10:100, a mono-crystalline silicon piece is immersed into the alcohol-free texturing liquid for texturing, the texturing temperature is 75-85 DEG C, and the texturing temperature is 12-18 minutes. By means of the alcohol-free additives and the using method of the alcohol-free additives, the chemical oxygen demand (COD) value of the texturing liquid is reduced, liquid waste disposal cost is reduced, the size of pyramids of a texturing surface is thin and small and reaches 1-3 micrometers, the pyramids are distributed evenly, and reflectivity of the silicon piece is smaller than 11%.

Owner:广东中诚阳能科技有限公司

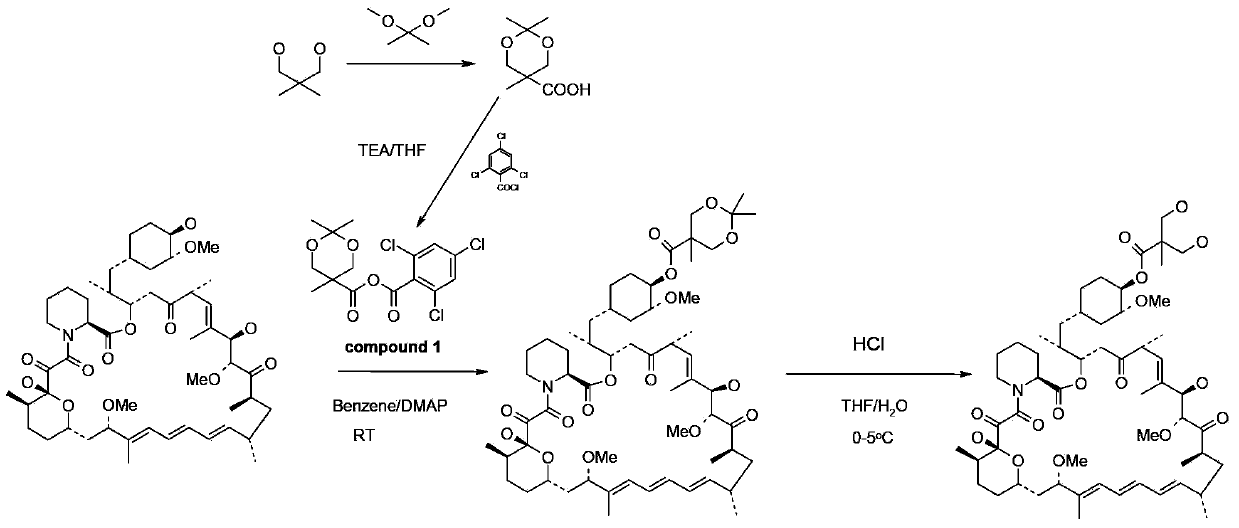

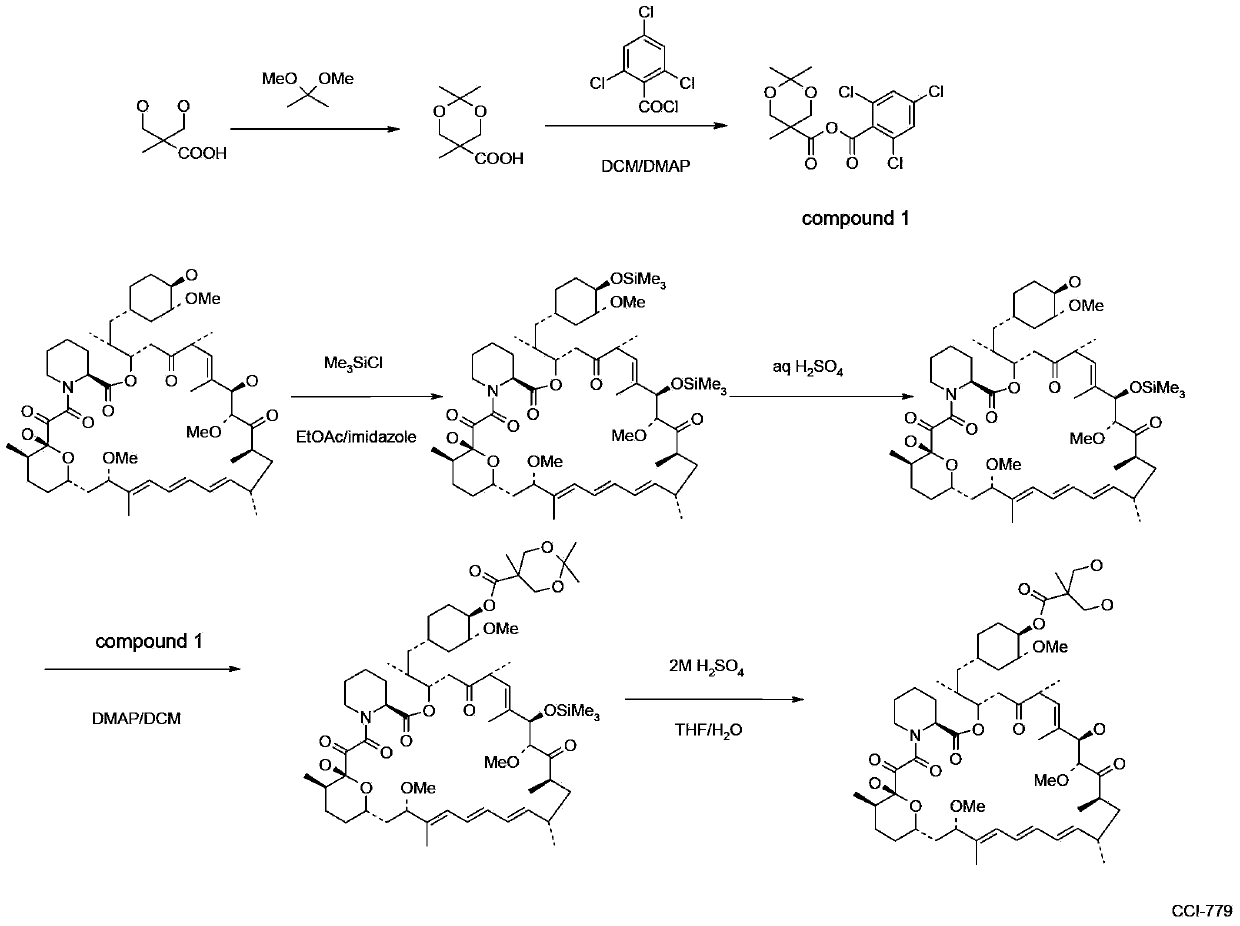

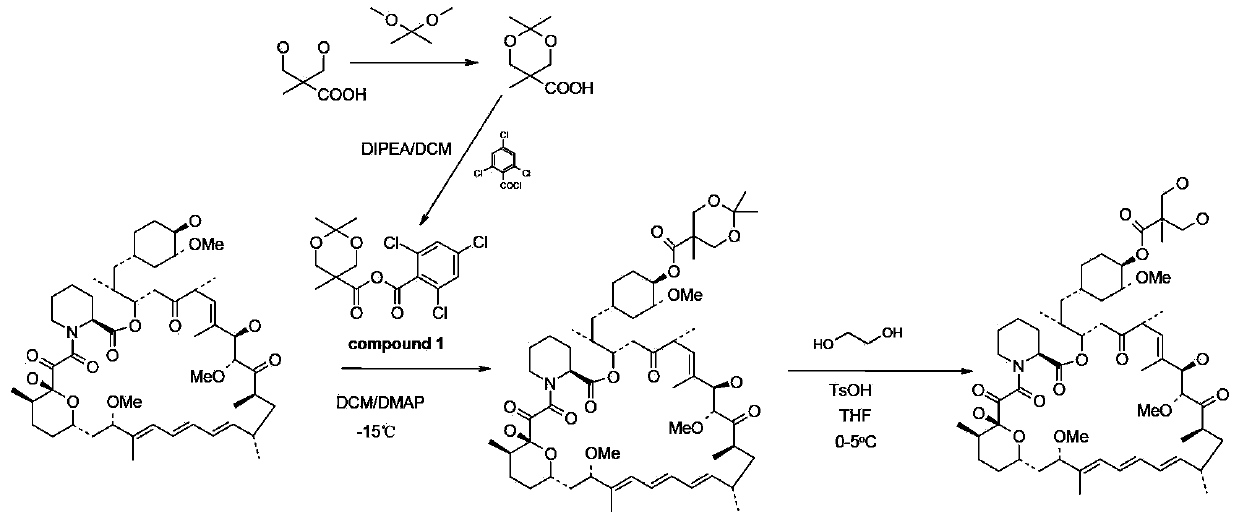

Synthesis process for temsirolimus

The invention provides a synthesis process for temsirolimus. The synthesis process comprises the following steps: step 1, preparing 2,2,5-trimethyl-5-carboxyl-1, 3-dioxane; step 2, preparing anhydride; step 3, carrying out esterification reaction; step 4, carrying out hydrolysis reaction and finally obtaining the target product, temsirolimus. According to the invention, in the reaction of the step 2, DIPEA (diisopropanolamine) is selected as alkali and methylene chloride is selected as solvent so that anhydride reaction liquid obtained directly can be directly used in the reaction in the step 3, and technological operation is reduced; the selectivity of the esterification reaction is directly achieved by lowering the temperature and controlling the usage amount of DMAP (dimethylaminopyridine) and the usage amount of anhydride, and the by-products of 31-esterification are reduced; esterification selectivity is improved greatly, and the reaction route is simplified; by selecting an ethylene-glycol, para-toluenesulfonic acid and tetrahydrofuran deprotection system, the reaction time is reduced greatly, and the productivity is improved.

Owner:FUJIAN INST OF MICROBIOLOGY

Method for preparing diisopropanolamine

ActiveCN101265197AMeet high-end needsLess operating costs for productionOrganic compound preparationAmino-hyroxy compound preparationMonoisopropanolaminePesticide

The invention relates to a method of manufacturing diisopropanolamine. Liquid ammonia and water are mixed to form ammonia water which is fully mixed with propylene oxide; the mixed solution is preheated until the temperature reach 140 to 145 DEG C and then is delivered into a reactor for reacting, the temperature is controlled within 148 to 155 DEG C when in reacting, the pressure is controlled within 16.0 to 18.0MPa, the inputting molar ratio of the ammonia and the propylene oxide is controlled within 5 to 8, and the reaction is fully performed for 1.5 to 3 hours; the mixture products obtained in the reaction are separated to obtain isopropanolamine products, diisopropanolamine products and triisopropanolamine products through flash evaporation and rectification in a stepwise way. In the diisopropanolamine products which are manufactured by adopting the method, the component of 1, 1<1>-nitrousalkyl-dipropyl-2-alcohol accounts for more than 99 percent (hereinafter referred to as mass percent), and the isomeride thereof is less than 1 percent. In addition, the cost of the production operation in the method is less, the production cost is low, the product quality is high, and the high-end requirement of products such as synthetic medicine, farm insecticide, etc. is satisfied.

Owner:NANJING BAOCHUN CHEMICAL INDUSTRY CO LTD

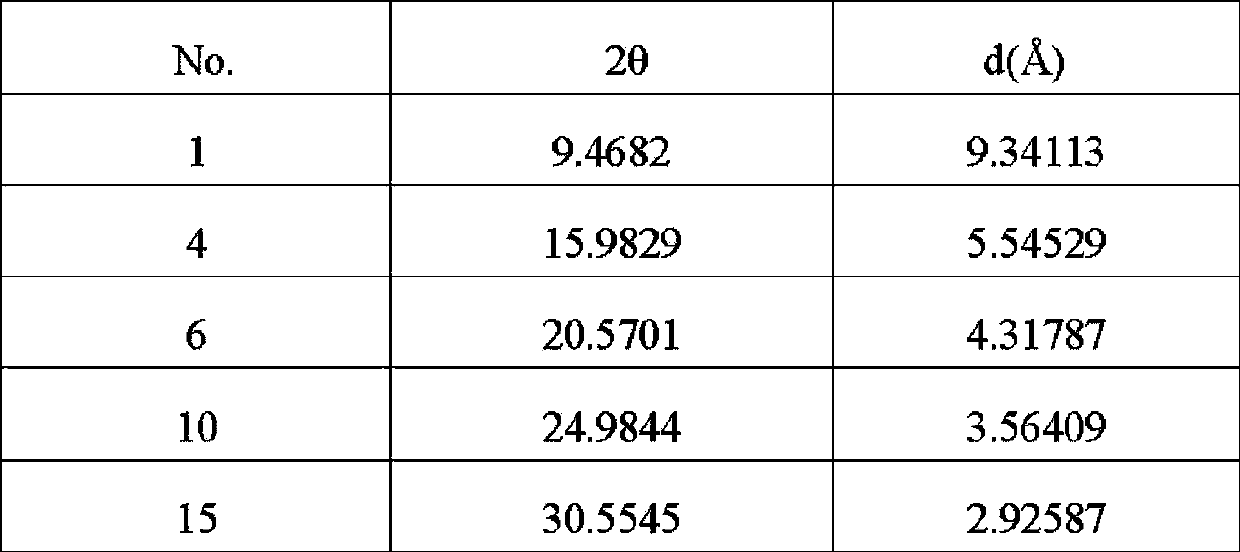

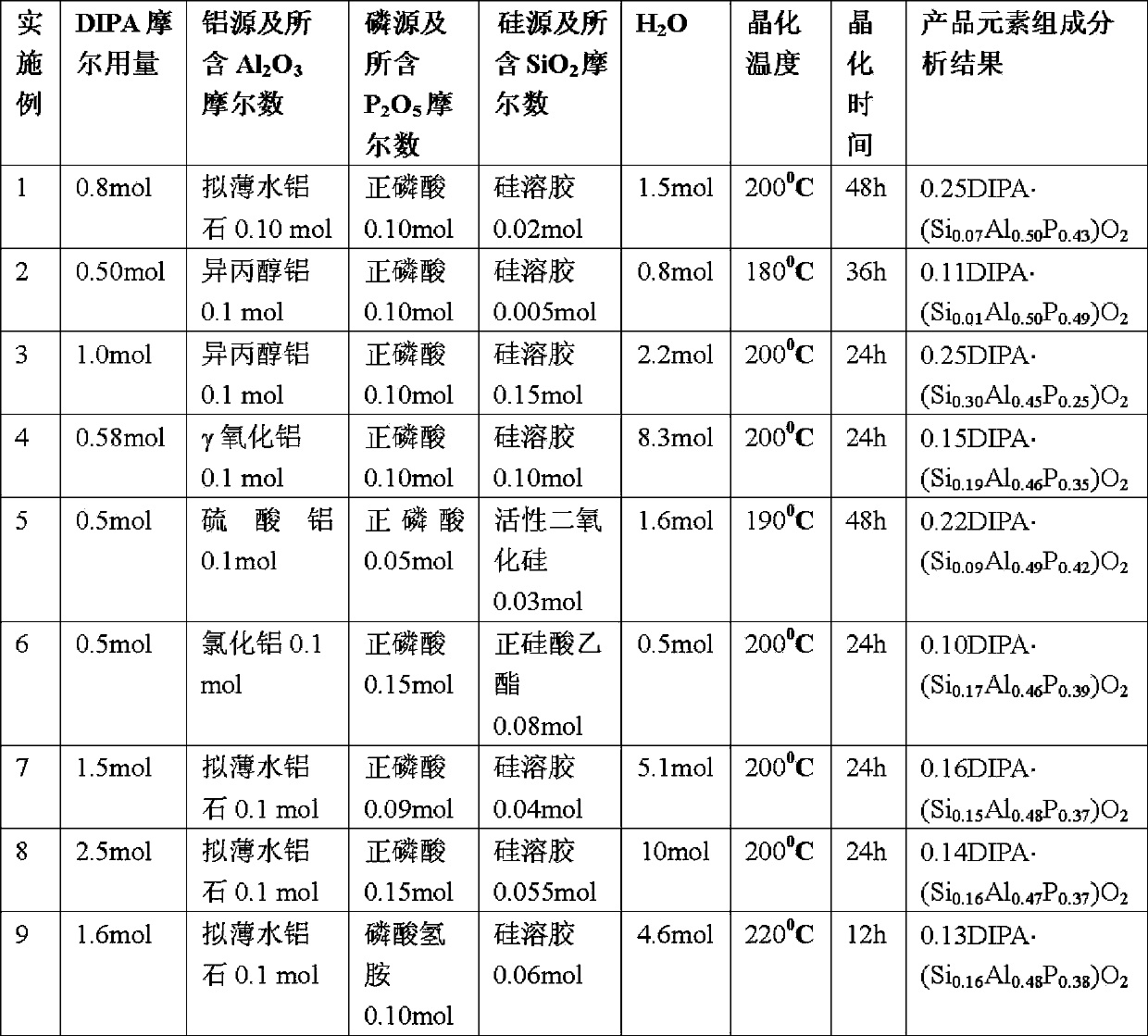

SAPO-34 molecular sieve with diisopropanolamine as template, and its synthetic method

ActiveCN103864095AImprove catalytic performanceGood choiceMolecular-sieve and base-exchange phosphatesMolecular-sieve silicoaluminophosphatesMolecular sieveChemical composition

The invention provides an SAPO-34 molecular sieve. The anhydrous chemical composition of the molecular sieve is mDIPA.(SixAlyPz)O2, wherein DIPA is N-methyldiethanolamine and is distributed in the cage and tunnels of a molecular sieve; m is the mole number of the diisopropanolamine template in each mole of (SixAlyPz)O2, and is in a range of 0.03-0.25; and x, y and z represent the mole fractions of Si, Al and P respectively, x is in a range of 0.01-0.30, y is in a range of 0.40-0.60, z is in a range of 0.25-0.49, and the value of x+y+z is 1. The above Si-P-Al molecular sieve SAPO-34 synthesized in the invention can be used as a catalyst for acid catalysis reactions, like a methanol-to-olefin reaction. The invention also relates to an application of the SAPO-34 molecular sieve in CH4 and CO2 adsorbing separation.

Owner:中科催化新技术(大连)股份有限公司

Cooling liquid for cutting solar silicon wafer through diamond wire

InactiveCN104087406AGuaranteed Surface PropertiesGood dispersionLubricant compositionEthylenediaminePolyethylene glycol

The invention discloses a cooling liquid for cutting a solar silicon wafer through a diamond wire. The cooling liquid consists of the following raw materials in parts by weight: 2-3 parts of triethanolamine, 2-4 parts of glycerin, 2-3 parts of methoxy polyethylene glycol, 3-5 parts of hydroxyethyl acrylate, 2-3 parts of fatty alcohol-polyoxyethylene ether, 3-4 parts of p-toluenesulfonic acid, 2-5 parts of fumaric acid, 1-2 parts of phthalic anhydride, 2-4 parts of maleinimide, 1-3 parts of cis-butenedioic acid, 2-4 parts of diisopropanolamine, 2-3 parts of n-butylamine, 1-2 parts of tri-isopropanolamine, 2-3 parts of potassium sorbate, 1-3 parts of phenoxyethanol, 2-3 parts of methylparaben, 2-3 parts of ethylenediamine tetraacetic acid, 2-5 parts of titanium dioxide, 2-4 parts of methyl methacrylate, 3-5 parts of acetone, and 50-70 parts of deionized water. The cooling liquid for cutting the solar silicon wafer through the diamond wire can be well applied to cutting with the diamond wire, is good in lubrication and cooling effects, low in cost and free of pollution, can effectively reduce the breakage rate, has a good dispersion function on silicon powder and iron impurities generated in the cutting process, and ensures the surface property of the silicon wafer.

Owner:梁胜光

Anti-corrosion concrete

The invention discloses anti-corrosion concrete. The anti-corrosion concrete is prepared from the following raw materials in parts by mass: 50 to 60 parts of cement, 5 to 9 parts of diisopropanolamine, 7 to 9 parts of calcium lignosulphonate, 6 to 8 parts of calcium nitrate, 15 to 20 parts of urea formaldehyde resin, 4 to 7 parts of monoethanolamine, 8 to 11 parts of acrylic emulsion, 7 to 12 parts of calcium carbonate, 8 to 10 parts of fiberglass, 6 to 8 parts of silicon dioxide powder, 3 to 6 parts of sodium perborate, 14 to 17 parts of pulverized fuel ash and 16 to 18 parts of haycite. The anti-corrosion concrete disclosed by the invention is strong in corrosion resistance, is capable of resisting corrosion of external corrosive articles, and is good in anti-freezing effect and small in cracking.

Owner:QINGDAO HONGYU ENVIRONMENTAL PROTECTION AIR CONDITIONING EQUIP

Carbon nanofiber dispersion liquid, coating compostion, and paste composition

ActiveUS20130221284A1Improve dispersion stabilityEasy to getNon-metal conductorsPigmenting treatmentOrganic acidMonoisopropanolamine

A carbon nanofiber dispersion liquid having an excellent dispersibility and dispersion stability. Also, coating paste compositions including the carbon nanofibers produced by using the dispersion liquid are provided. The carbon nanofiber dispersion liquid includes: a solvent; a carbon nanofiber; an alkanolamine; and a chelating agent. Preferably, in the carbon nanofiber dispersion liquid, the alkanolamine is at least one selected from a group consisting of monoisopropanolamine, diisopropanolamine, and triisopropanolamine. Also, in the carbon nanofiber dispersion liquid, the chelating agent is at least one selected from a group consisting of an aminocarboxylic acid chelating agent, a phosphonic acid chelating agent, a gluconic acid chelating agent, and an organic acid.

Owner:MITSUBISHI MATERIALS CORP

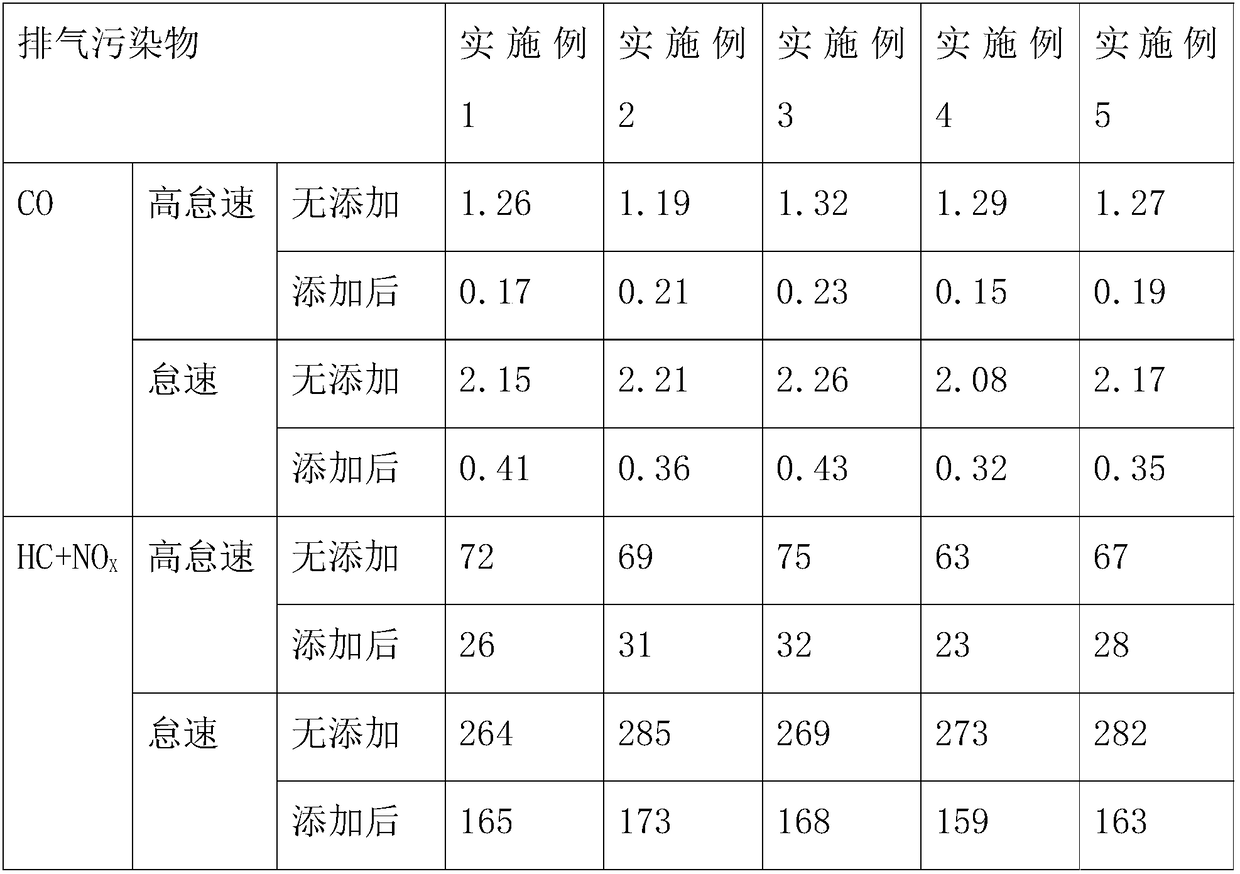

Automobile exhaust cleanser

InactiveCN108192676AReduce fuel consumptionIncrease motivationLiquid carbonaceous fuelsFuel additivesCombustion chamberCerium

The invention provides an automobile exhaust cleanser. The cleanser is prepared from raw materials in parts by weight as follows: 5-10 parts of ethanol, 10-15 parts of methanol, 1-3 parts of ethyl acetate, 1-5 parts of ethylene glycol, 1-3 parts of n-octane, 5-10 parts of fatty alcohol, 1-3 parts of lauryl alcohol, 1-3 parts of cyanuric acid, 3-5 parts of monoethanolamine, 1-3 parts of diglycolamine, 3-5 parts of diethanol amine, 1-3 parts of diisopropanol amine, 5-10 parts of triethanolamine, 1-3 parts of N-methyl-diethanol amine, 1-3 parts of dimethyl sulfoxide, 3-8 parts of zirconium dioxide, 1-5 parts of cerium dioxide, 1-5 parts of lanthanum oxide, 1-3 parts of palladium and 20-30 parts of activated carbon. The automobile exhaust cleanser enables oil mist to have enough oxygen for thorough burning while clearing automobile exhaust, oil consumption is reduced, oil mist sprayed into a combustor can explode instantly, and power is enhanced.

Owner:天津恩光科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com