Preparation method and application of Mannich base quaternary ammonium salt high-temperature resistant acidification corrosion inhibitor

一种酸化缓蚀剂、曼尼希碱的技术,应用在化学仪器和方法、有机化学、钻孔的组合物等方向,能够解决不利安全生产和环境保护、制备工艺要求高等问题,达到抑制腐蚀、吸附牢固、制备方法简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

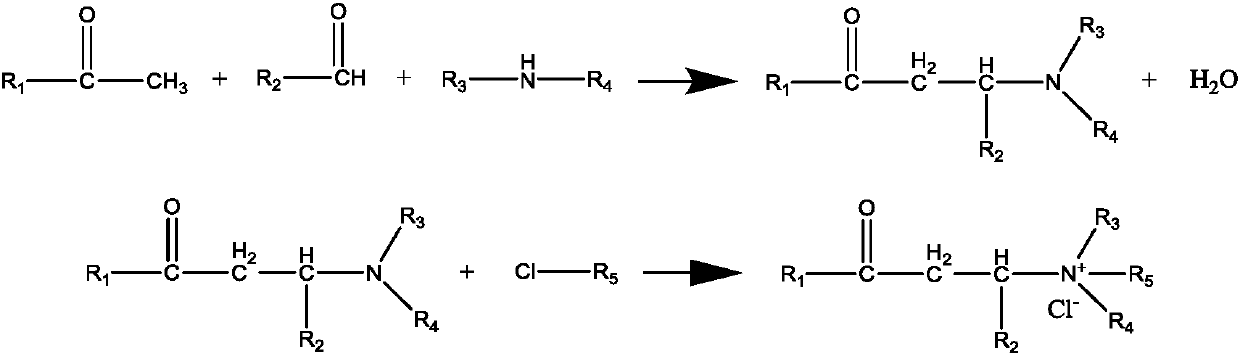

Method used

Image

Examples

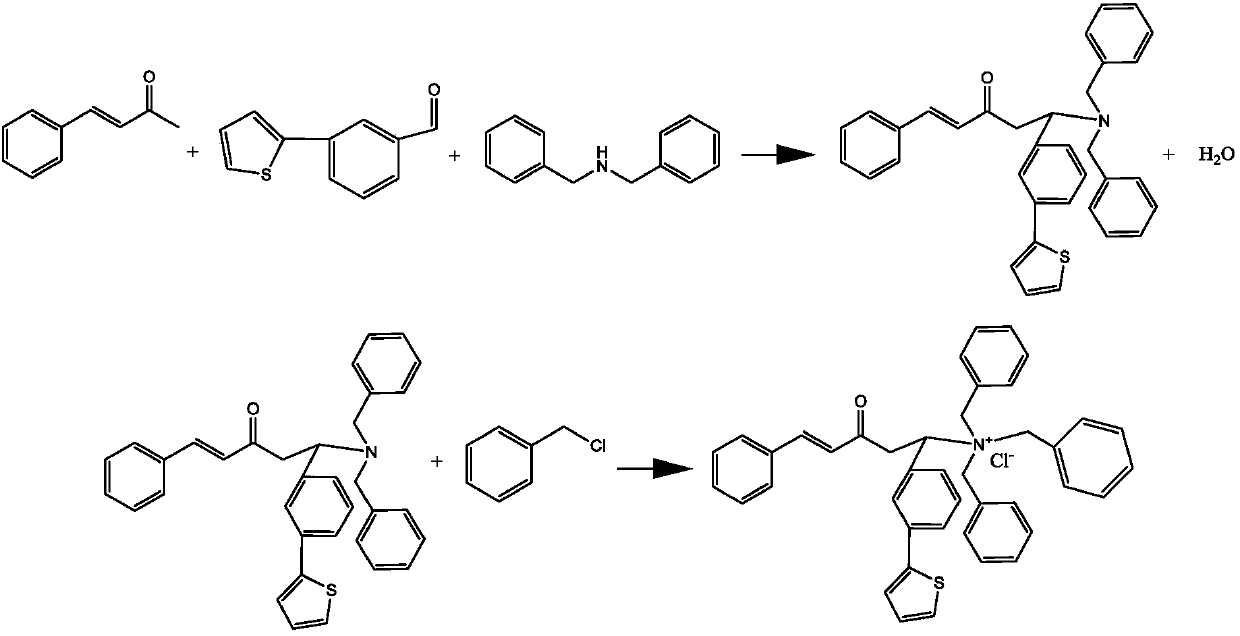

Embodiment 1

[0021] A preparation method of Mannich base quaternary ammonium salt high temperature acidification corrosion inhibitor, comprising the following steps:

[0022] (1) Add 1.97g of dibenzylamine into a 250mL three-necked flask, then slowly add 1.88g of 3-(2-thienyl)benzaldehyde, while adding 70mL of absolute ethanol as a solvent and stir evenly, and put the reaction system Put it into a constant temperature water bath, stir and react at 70°C for 1h;

[0023] (2) Add 1.46 g of benzylidene acetone to the flask, use hydrochloric acid solution to adjust the pH value of the reaction system to 4, react for 8 hours, and after cooling to room temperature, remove the solvent by distillation under reduced pressure to obtain the Mannich base;

[0024] (3) Add 5.13 g of the above-mentioned Mannich base product into a 250 mL three-necked flask, add 110 mL of absolute ethanol as a solvent and stir evenly, slowly add 1.27 g of benzyl chloride and stir evenly, stir and react at 80°C for 12 hour...

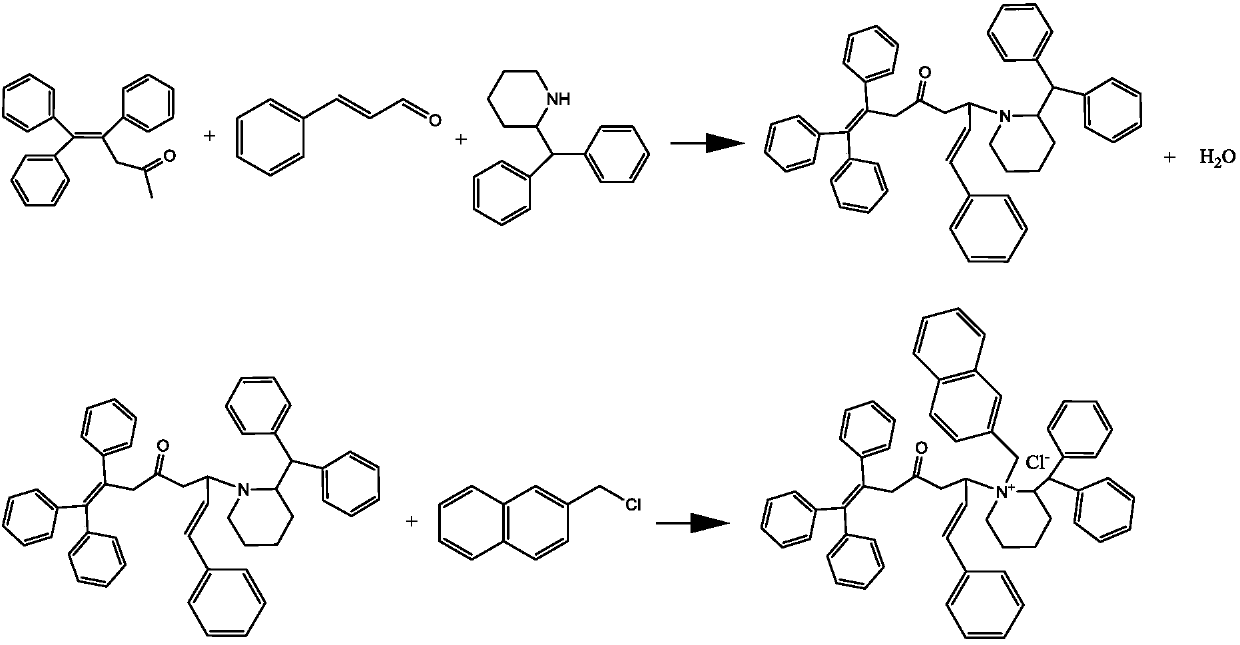

Embodiment 2

[0029] A preparation method of Mannich base quaternary ammonium salt high temperature acidification corrosion inhibitor, comprising the following steps:

[0030] (1) Add 2.51g of benzhydrylpiperidine into a 250mL three-necked flask, then slowly add 1.32g of cinnamaldehyde, and at the same time add 100mL of absolute ethanol as a solvent and stir evenly, and put the reaction system into a constant temperature water bath , stirred and reacted at 70°C for 1h;

[0031] (2) Add 3.12g stilbene acetone to the flask, use hydrochloric acid solution to adjust the pH value of the reaction system to 4, react for 8h, after cooling to room temperature, remove the solvent by distillation under reduced pressure to obtain the Mannich base;

[0032] (3) Add 6.77g of the above-mentioned Mannich base product into a 250mL three-necked flask, add 120mL of acetonitrile as a solvent and stir well, slowly add 1.76g of chloromethylnaphthalene and stir well, stir and react at 85°C for 12h, and cool to A...

Embodiment 3

[0035] A preparation method of Mannich base quaternary ammonium salt high temperature acidification corrosion inhibitor, comprising the following steps:

[0036] (1) Add 1.17g of indole to a 250mL three-necked flask, then slowly add 1.32g of cinnamaldehyde, and at the same time add 90mL of absolute ethanol as a solvent and stir evenly, and put the reaction system in a constant temperature water bath. Stir the reaction for 1h;

[0037] (2) Add 1.46 g of benzylidene acetone to the flask, use hydrochloric acid solution to adjust the pH value of the reaction system to 3, react for 9 hours, and after cooling to room temperature, remove the solvent by distillation under reduced pressure to obtain the Mannich base;

[0038] (3) Add 3.77g of the above-mentioned Mannich base product into a 250mL three-necked flask, add 110mL of absolute ethanol as a solvent and stir evenly, slowly add 2.78g of triphenylchloromethane and stir evenly, and stir and react at 80°C for 13h, After cooling to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com